FormNo.3435-863RevB

ZMaster

®

Professional6000

SeriesRidingMower

with60inor72inTURBOFORCE

DischargeMower

ModelNo.72960—SerialNo.406397883andUp

ModelNo.72961—SerialNo.400000000andUp

ModelNo.72967—SerialNo.400000000andUp

ModelNo.72968—SerialNo.400000000andUp

®

Side

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3435-863*B

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

GrossorNetTorque:Thegrossornettorque

ofthisenginewaslaboratoryratedbytheengine

manufacturerinaccordancewiththeSocietyof

AutomotiveEngineers(SAE)J1940orJ2723.As

conguredtomeetsafety,emission,andoperating

requirements,theactualenginetorqueonthisclass

ofmowerwillbesignicantlylower.Pleasereferto

theenginemanufacturer’sinformationincludedwith

themachine.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcode(ifequipped)ontheserial

numberdecaltoaccesswarranty,parts,andother

productinformation.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

g233771

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Introduction

Thisrotary-blade,ridinglawnmowerisintendedtobe

usedbyprofessional,hiredoperators.Itisdesigned

primarilyforcuttinggrassonwell-maintainedlawns

onresidentialorcommercialproperties.Usingthis

productforpurposesotherthanitsintendedusecould

provedangeroustoyouandbystanders.

©2019—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

SafetyAlertSymbol............................................4

GeneralSafety...................................................4

SlopeIndicator...................................................5

SafetyandInstructionalDecals..........................6

ProductOverview...................................................13

Controls...........................................................13

Specications..................................................15

Attachments/Accessories.................................15

BeforeOperation.................................................16

BeforeOperationSafety...................................16

AddingFuel......................................................17

PerformingDailyMaintenance..........................18

BreakinginaNewMachine..............................18

UsingtheRollover-ProtectionSystem

(ROPS).........................................................18

UsingtheSafety-InterlockSystem....................19

PositioningtheSeat..........................................20

UnlatchingtheSeat..........................................20

ChangingtheSeatSuspension.........................21

AdjustingtheRear-ShockAssemblies..............21

DuringOperation.................................................22

DuringOperationSafety...................................22

EnteringtheOperator’sPosition.......................25

OperatingtheParkingBrake.............................25

OperatingtheMowerBlade-ControlSwitch

(PTO)............................................................25

OperatingtheThrottle.......................................26

StartingtheEngine...........................................27

ShuttingOfftheEngine.....................................27

UsingtheMotion-ControlLevers.......................28

DrivingtheMachine..........................................28

UsingtheSideDischarge.................................29

AdjustingtheHeightofCut...............................30

AdjustingtheAnti-ScalpRollers........................31

AdjustingtheFlowBafeKnob.........................31

PositioningtheFlowBafe................................32

OperatingTips.................................................33

AfterOperation....................................................33

AfterOperationSafety......................................33

UsingtheFuel-ShutoffValve.............................34

UsingtheDrive-Wheel-ReleaseValves............34

TransportingtheMachine.................................35

Maintenance...........................................................37

MaintenanceSafety..........................................37

RecommendedMaintenanceSchedule(s)...........38

Lubrication..........................................................39

GreasingtheMachine.......................................39

LubricatingtheMowerDeck-LiftPivots.............39

GreasingtheMowerDeck................................40

GreasingtheCasterPivots...............................40

GreasingtheCaster-WheelHubs.....................41

EngineMaintenance...........................................42

EngineSafety...................................................42

ServicingtheAirCleaner..................................42

ServicingtheEngineOil....................................43

ServicingtheSparkPlug(s)..............................45

FuelSystemMaintenance...................................46

ReplacingtheFuelFilter...................................46

ServicingtheFuelT ank.....................................47

ElectricalSystemMaintenance...........................47

ElectricalSystemSafety...................................47

ServicingtheBattery.........................................47

ServicingtheFuses..........................................49

DriveSystemMaintenance..................................50

CheckingtheSeatBelt.....................................50

CheckingtheRoll-BarKnobs............................50

AdjustingtheTracking......................................51

CheckingtheTirePressure...............................51

CheckingtheWheelLugNuts...........................52

CheckingtheWheel-HubSlottedNut................52

AdjustingtheCaster-PivotBearing...................52

RemovingtheClutchShim...............................53

CoolingSystemMaintenance..............................54

CleaningtheEngineScreenandEngine-Oil

Cooler...........................................................54

CleaningtheEngine-CoolingFinsand

Shrouds........................................................55

CheckingandCleaningtheHydraulic-Unit

Shrouds........................................................55

BrakeMaintenance.............................................56

AdjustingtheParkingBrake..............................56

BeltMaintenance................................................57

InspectingtheBelts..........................................57

ReplacingtheMowerBelt.................................57

ReplacingtheHydraulicPump-Drive

Belt................................................................58

ControlsSystemMaintenance.............................59

AdjustingtheControl-HandlePosition..............59

AdjustingtheMotion-ControlLinkage...............60

AdjustingtheMotion-ControlDamper...............61

AdjustingtheMotion-ControlNeutral-Lock

Pivot..............................................................61

HydraulicSystemMaintenance...........................62

HydraulicSystemSafety...................................62

Hydraulic-FluidSpecications..........................62

CheckingtheHydraulicFluid............................62

ChangingtheHydraulicFluidand

Filters............................................................63

MowerDeckMaintenance....................................64

BladeSafety.....................................................64

ServicingtheCuttingBlades.............................64

LevelingtheMowerDeck..................................67

RemovingtheMowerDeck...............................69

ReplacingtheGrassDeector..........................71

Cleaning..............................................................71

CleaningundertheMowerDeck.......................71

CleaningtheSuspensionSystem.....................71

DisposingofWaste...........................................71

Storage...................................................................72

StorageSafety..................................................72

CleaningandStorage.......................................72

Troubleshooting......................................................73

Schematics.............................................................75

3

Safety

Thismachinehasbeendesignedinaccordancewith

ANSIstandardB71.4-2017.

SafetyAlertSymbol

ThisSafetyAlertSymbol(Figure2)isusedbothin

thismanualandonthemachinetoidentifyimportant

safetymessageswhichmustbefollowedtoavoid

accidents.

Thissymbolmeans:ATTENTION!BECOMEALERT!

YOURSAFETYISINVOL VED!

Figure2

SafetyAlertSymbol

GeneralSafety

Thismachineiscapableofamputatinghandsandfeet

andofthrowingobjects.T orodesignedandtested

thislawnmowertoofferreasonablysafeservice;

however,failuretocomplywithsafetyinstructions

mayresultininjuryordeath.

•Read,understand,andfollowallinstructionsand

warningsintheOperator’sManualandother

trainingmaterial,onthemachine,engine,and

attachments.Alloperatorsandmechanicsshould

betrained.Iftheoperator(s)ormechanic(s)can

notreadthismanual,itistheowner’sresponsibility

toexplainthismaterialtothem;otherlanguages

maybeavailableonourwebsite.

•Onlyallowtrained,responsible,andphysically

capableoperatorsthatarefamiliarwiththesafe

g000502

operation,operatorcontrols,andsafetysignsand

instructionstooperatethemachine.Neverlet

childrenoruntrainedpeopleoperateorservicethe

equipment.Localregulationsmayrestricttheage

oftheoperator.

Thesafetyalertsymbolappearsaboveinformation

whichalertsyoutounsafeactionsorsituationsand

willbefollowedbythewordDANGER,WARNING,or

CAUTION.

DANGER:Indicatesanimminentlyhazardous

situationwhich,ifnotavoided,Willresultindeathor

seriousinjury.

WARNING:Indicatesapotentiallyhazardoussituation

which,ifnotavoided,Couldresultindeathorserious

injury.

CAUTION:Indicatesapotentiallyhazardoussituation

which,ifnotavoided,Mayresultinminorormoderate

injury.

Thismanualusestwootherwordstohighlight

information.Importantcallsattentiontospecial

mechanicalinformationandNoteemphasizesgeneral

informationworthyofspecialattention.

•Alwayskeeptherollbarinthefullyraisedand

lockedpositionandusetheseatbelt.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,water,orotherhazards,or

onslopesgreaterthan15degrees.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

4

SlopeIndicator

Figure3

Youmaycopythispageforpersonaluse.

1.Themaximumslopeyoucanoperatethemachineonis15degrees.Usetheslopecharttodeterminethedegreeofslopeof

hillsbeforeoperating.Donotoperatethismachineonaslopegreaterthan15degrees.Foldalongtheappropriateline

tomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

5

g011841

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

decalbatterysymbols

1.Explosionhazard6.Keepbystandersaway

fromthebattery .

2.Nore,opename,or

smoking

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

3.Causticliquid/chemical

burnhazard

8.Batteryacidcancause

blindnessorsevereburns.

4.Weareyeprotection.9.Flusheyesimmediately

withwaterandgetmedical

helpfast.

5.ReadtheOperator's

Manual.

10.Containslead;donot

discard

Manufacturer'sMark

1.Thismarkindicatesthatthebladeisidentiedasapart

fromtheoriginalmachinemanufacturer.

decal99-8936

99-8936

1.Machinespeed4.Neutral

2.Fast5.Reverse

3.Slow

decaloemmarkt

decal106-2655

106-2655

1.Warning—donottouchorapproachmovingbelts;remove

thekeyandreadtheinstructionsbeforeservicingor

performingmaintenance.

decal58-6520

58-6520

1.Grease

106-5517

decal106-5517

1.Warning—donottouchthehotsurface.

6

decal107-3069

107-3069

1.Warning–thereisnorolloverprotectionwhentherollbaris

down.

2.Toavoidinjuryordeathfromarolloveraccident,keepthe

rollbarintheraisedandlockedpositionandweartheseat

belt.Lowertherollbaronlywhenabsolutelynecessary;do

notweartheseatbeltwhentherollbarisdown.

3.ReadtheOperator'sManual;driveslowlyandcarefully.

decal110-2067

110-2067

decal112-9028

112-9028

1.Warning—stayawayfrommovingparts;keepallguards

andshieldsinplace.

decal114-4466

114-4466

1.Main(25A)3.Charge(25A)

2.PTO(10A)4.Auxiliary(15A)

MachineswithMyRide™Only

107-3969

1.Warning—readtheOperator'sManual.

2.Crushinghazard,mower—engagetheparkingbrake,shut

offtheengine,andremovethekeybeforeworkingunder

themower .

decal107-3969

decal115-9625

115-9625

1.Parking

brake—disengaged

2.Parkingbrake—engaged

7

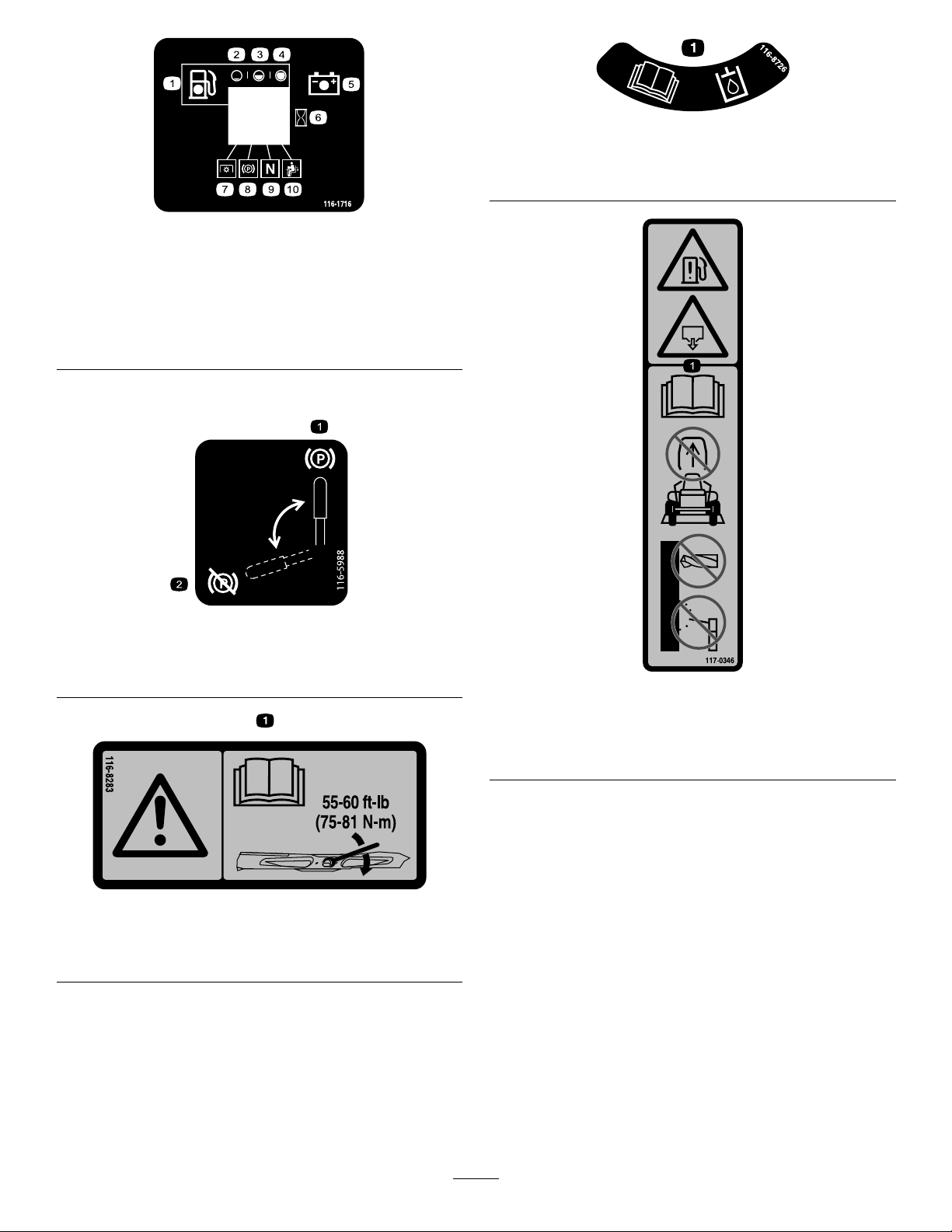

116-1716

1.Fuel6.Hourmeter

2.Empty

3.Half

4.Full9.Neutral

5.Battery

10.Operatorpresenceswitch

MachineswithoutMyRide™Only

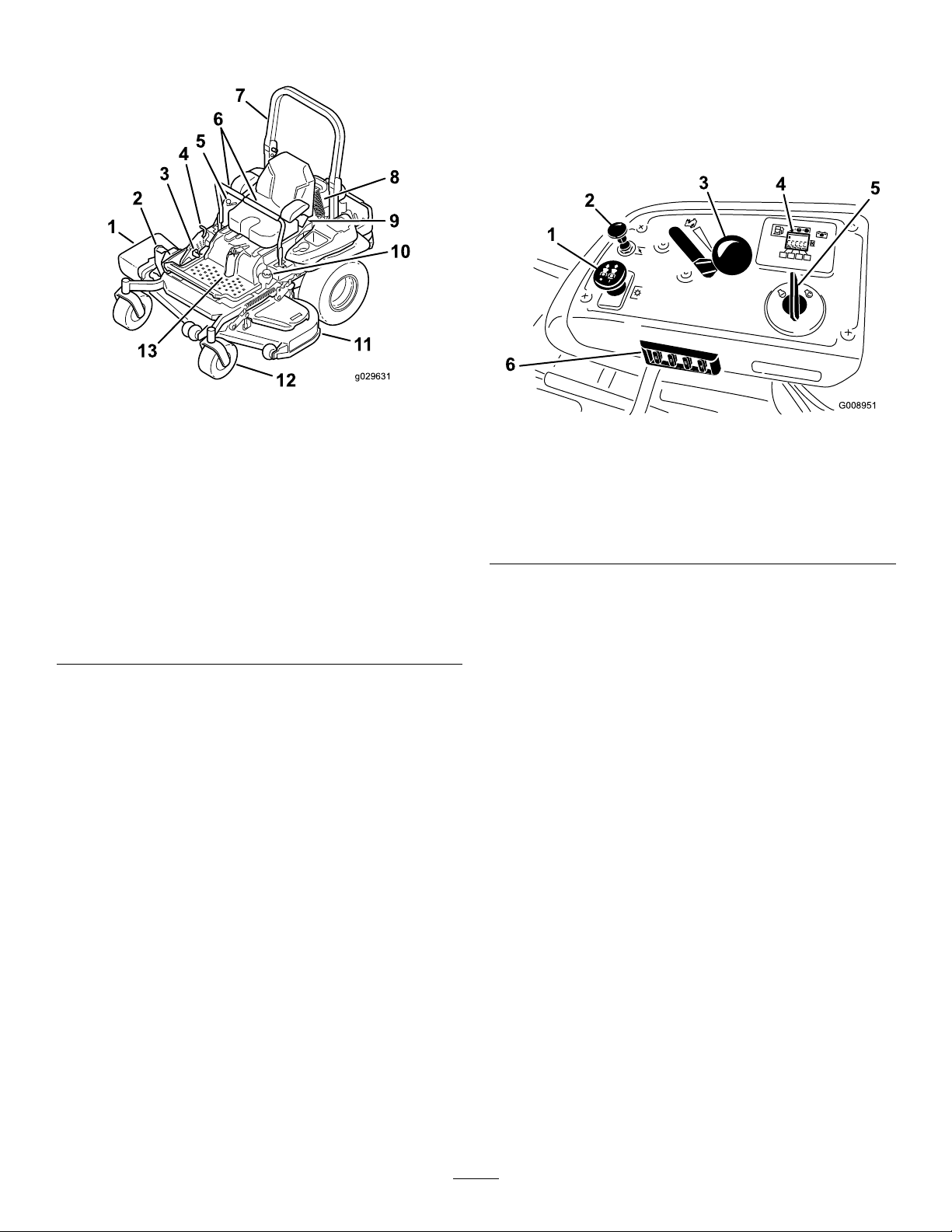

decal116-8726

116-8726

1.ReadtheOperator’sManualfortherecommendedhydraulic

uid.

decal116-1716

7.PTO

8.Parkingbrake

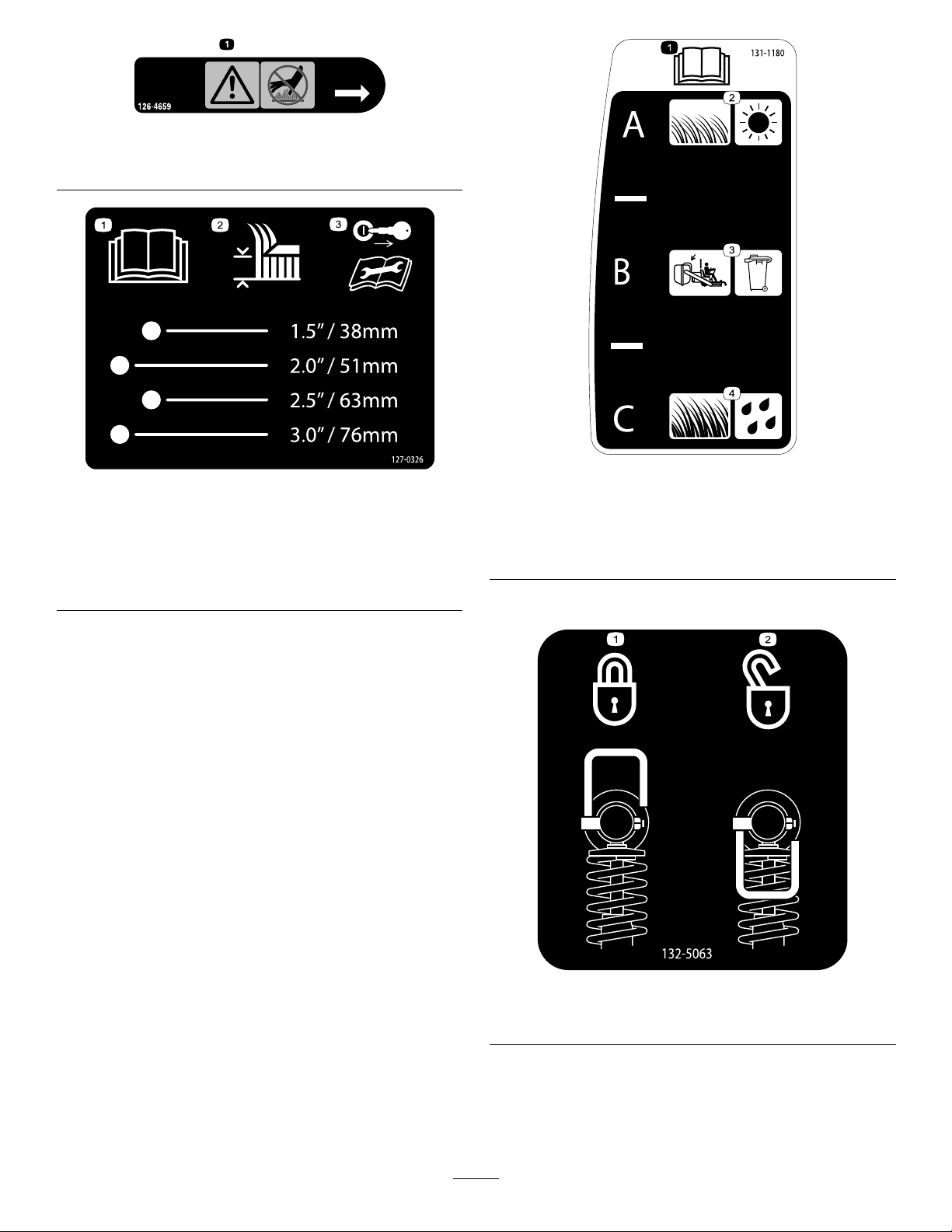

116-5988

1.Parkingbrake—engaged2.Parking

brake—disengaged

116-8283

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto75to81N∙m(55to60ft-lb).

decal116-5988

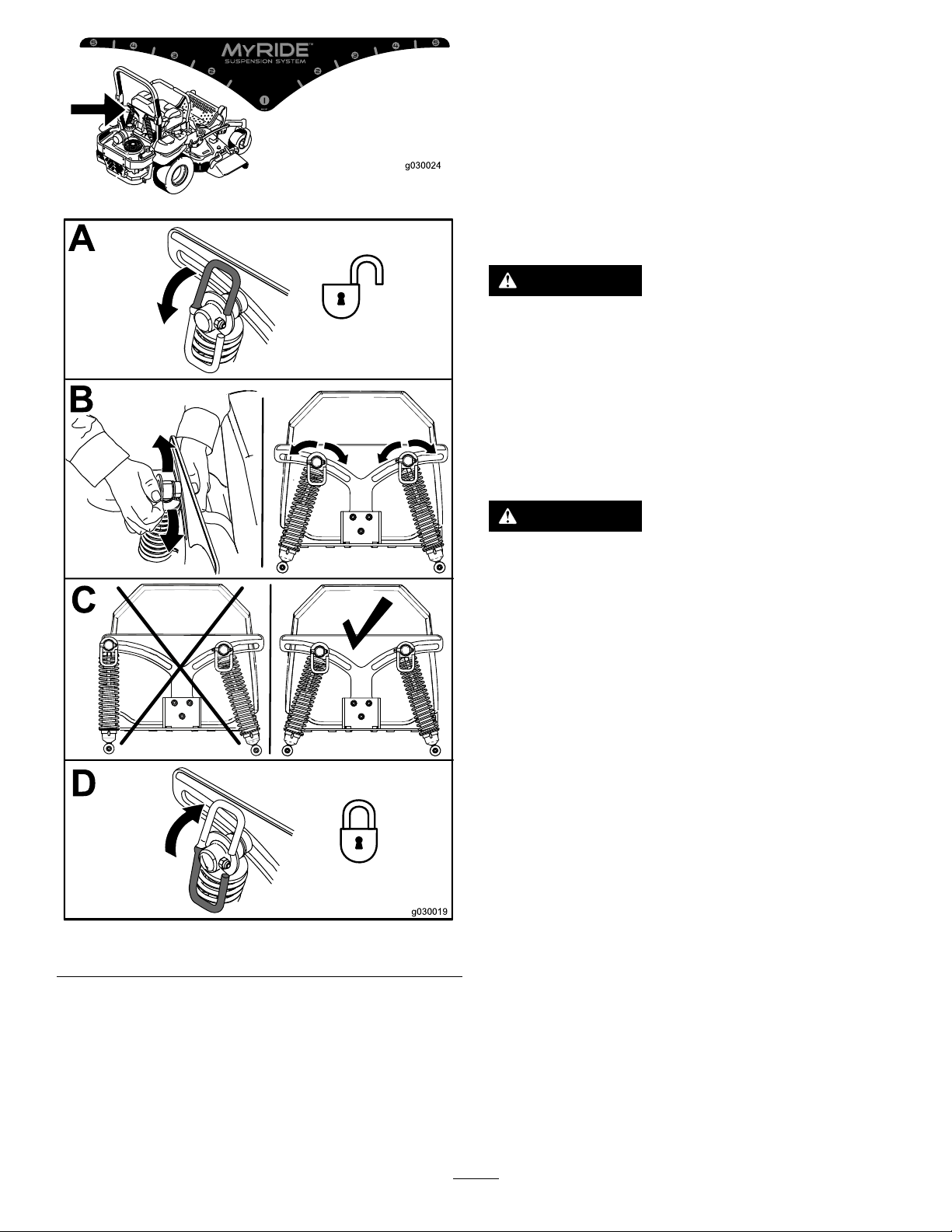

decal117-0346

117-0346

1.Fuelleakhazard—readtheOperator'sManual;donot

attempttoremovetherollbar;donotweld,drill,ormodify

therollbarinanyway.

decal116-8283

8

117-3848

1.Thrownobjecthazard—keepbystandersaway.

2.Thrownobjecthazard,raiseddeector—donotoperate

withoutthedeector ,dischargecover,orgrasscollection

systeminplace.

3.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts;keepallguardsand

shieldsinplace.

decal117-3848

120-5898

decal120-5898

1.Choke4.Slow

2.Fast

5.Powertake-off(PTO),

Bladecontrolswitch

3.Continuousvariable

setting

decal126-2055

126-2055

1.Wheellugnut—torqueto129N∙m(95ft-lb).

2.Wheelhubnut—torqueto319N∙m(235ft-lb).

3.ReadtheOperator’sManualbeforeperforming

maintenance;checkthetorqueaftertherst100hoursand

every500hoursafter.

120-5897

1.Choke4.Slow

2.Fast

3.Continuousvariable

setting

5.Powertake-off(PTO),

Bladecontrolswitch

decal120-5897

decal126-4398

126-4398

1.ReadtheOperator’s

Manual.

2.Lock

3.Unlock

9

126-4659

1.Warning—hotpulley;allowtocool.

decal126-4659

1.ReadtheOperator's

Manual.

2.Heightofcut

127-0326

3.Removethekeyand

readtheOperator's

Manualbeforeperforming

maintenance.

decal127-0326

1.ReadtheOperator's

131-1180

3.Baggingsetting

decal131-1180

Manual.

2.Short,lightgrass;dry

conditions

4.Tall,densegrass;wet

conditions

MachineswithMyRide™Only

1.Camlock2.Camunlock

10

decal132-5063

132-5063

decal133-8062

133-8062

decal136-5508

136-5508

1.Beltrouting

125-9383

1.Checkhydraulicuidevery50operatinghours.3.Checkthetirepressureevery50operatinghours.

2.ReadtheOperator’sManualforinformationonlubricating

themachine.

4.ReadtheOperator’sManualbeforeservicingorperforming

maintenance.

11

decal125-9383

MachineswithMyRide™Only

decal132-5067

132-5067

132-0871

Note:Thismachinecomplieswiththeindustrystandardstabilitytestinthestaticlateralandlongitudinaltestswiththemaximum

recommendedslopeindicatedonthedecal.ReviewtheinstructionsforoperatingthemachineonslopesintheOperator’sManualas

wellastheconditionsinwhichyouwouldoperatethemachinetodeterminewhetheryoucanoperatethemachineintheconditionson

thatdayandatthatsite.Changesintheterraincanresultinachangeinslopeoperationforthemachine.

1.Warning—readtheOperator’sManual;alloperatorsshould

betrainedbeforeoperatingthemachine;wearhearing

protection.

2.Cutting/dismembermenthazardofhand—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

3.Thrownobjecthazard—keepbystandersaway.

4.Tippinghazard—donotusedualrampswhenloadingontoa

trailer;use1rampwideenoughforthemachine;usearamp

withaslopelessthan15°;backuptheramp(inreverse)and

driveforwardofftheramp.

5.Runoverhazard—donotcarrypassengers;lookbehindyou

whenmovinginreverse.

6.Tippinghazard—donotusethemachineneardrop-offsor

onslopesgreaterthan15°;onlyoperateacrossslopesless

than15°.

decal132-0871

12

ProductOverview

Figure4

1.Side-dischargedeector

2.Height-of-cutdeck-lift

pedal

3.Parking-brakelever10.Fuelcap

4.Transportlock11.Mowerdeck

5.Controls12.Casterwheel

6.Motion-controllevers13.Front-shockassembly

7.Rollbar

8.Rear-shockassembly

9.Seatbelt

(machineswithMyRide™

only)

(machineswithMyRide™

only)

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

ControlPanel

g029631

g008951

Figure5

1.Blade-controlswitch

(powertakeoff)

2.Chokecontrol

3.Throttlecontrol6.Fuses

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andST ART.Referto

StartingtheEngine(page27).

4.Hour

meter/Safety-interlock

display

5.Keyswitch

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure5).

ChokeControl

Usethechokecontroltostartacoldengine.

Blade-ControlSwitch(Power

Takeoff)

Theblade-controlswitch,representedbya

power-takeoff(PTO)symbol,engagesand

disengagespowertothemowerblades(Figure5).

HourMeter

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

13

isrunning.Usethesetimesforschedulingregular

maintenance(Figure6).

Figure6

1.Fuelgauge(bars)4.Safety-interlocksymbols

2.Batterylight

3.Hourmeter

5.Lowfuelindicatorlight

FuelGauge

themachine(Figure25).Alwayspositionthe

motion-controlleversintotheNEUTRAL-LOCKposition

whenyoustopthemachineorleaveitunattended.

Parking-BrakeLever

Wheneveryoushutofftheengine,engagetheparking

braketopreventaccidentalmovementofthemachine.

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingor

storingthemachine;refertoUsingtheFuel-Shutoff

Valve(page34).

g008950

Thefuelgaugeislocatedwithinthehourmeter,and

thebarslightupwhenthekeyswitchisintheON

position(Figure6).

Theindicatorlightappearswhenthefuellevelislow

(approximately1gallonremaininginthefueltank).

Safety-InterlockIndicators

Therearesymbolsonthehourmeterthatindicate

withablacktrianglethattheinterlockcomponentis

positionedcorrectly(Figure6).

Battery-IndicatorLight

IfyouturnthekeyswitchtotheONpositionfora

fewseconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhenthekeyswitchis

turnedonandwhenthechargeisbelowthecorrect

operatinglevel(Figure6).

Motion-ControlLevers

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection(Figure4).

Neutral-LockPosition

Movethemotion-controlleversoutwardfromthe

centertotheNEUTRAL-LOCKpositionwhenexiting

14

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Width

Withoutthedeck

Deectorup

Deectordown

Length

Rollbarup

Rollbardown

Height

Rollbarup

Rollbardown

122cm(48-inch)Deck132cm(52-inch)Deck152cm(60-inch)Deck

116cm116cm135cm150cm

(46inches)(46inches)(53inches)(59inches)

137cm146cm157cm187cm

(54inches)(58inches)(62inches)(74inches)

161cm172cm192cm222cm

(64inches)(68inches)(76inches)(88inches)

122cm(48-inch)Deck132cm(52-inch)Deck152cm(60-inch)Deck

201cm201cm21 1cm219cm

(79inches)(79inches)(83inches)(86inches)

206cm206cm215cm223cm

(81inches)(81inches)(85inches)(88inches)

122cm(48-inch)Deck132cm(52-inch)Deck152cm(60-inch)Deck

179cm179cm179cm179cm

(71inches)(71inches)(71inches)(71inches)

119cm119cm119cm119cm

(47inches)(47inches)(47inches)(47inches)

72-inchDeck

72-inchDeck

72-inchDeck

Weight

ModelWeight

74960

74961

75967

75968

576kg(1,269lb)

612kg(1,349lb)

576kg(1,269lb)

612kg(1,349lb)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorauthorizedT orodistributororgoto

www.T oro.comforalistofallapprovedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafetycerticationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacementpartsandaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty .

15

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbyToro.

FuelSafety

Useextremecarewhenhandlingfuel.

DANGER

Incertainconditionsgasolineisextremely

ammableandvaporsareexplosive.

Areorexplosionfromgasolinecanburn

you,others,andcausepropertydamage.

•Fillthefueltankoutdoorsonlevelground,

inanopenarea,whentheengineiscold.

Wipeupanygasolinethatspills.

•Neverrellthefueltankordrainthe

machineindoorsorinsideanenclosed

trailer.

•Inspecttheareawheretheequipmentistobe

usedandremoveallrocks,toys,sticks,wires,

bones,andotherforeignobjects.Thesecan

bethrownorinterferewiththeoperationofthe

machineandmaycausepersonalinjurytothe

operatororbystanders.

•Wearappropriatepersonalprotectiveequipment

suchassafetyglasses,substantialslip-resistant

footwear,andhearingprotection.Tiebacklong

hairandavoidlooseclothingandloosejewelry

whichmaygettangledinmovingparts.

CAUTION

Thismachineproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperating

thismachine.

•Checkthattheoperatorpresencecontrols,

safetyswitches,andshieldsareattachedand

functioningproperly.Donotoperateunlessthey

arefunctioningproperly.

•DoNotllthefueltankcompletelyfull.

Fillthefueltanktothebottomoftheller

neck.Theemptyspaceinthetankallows

gasolinetoexpand.Overllingmayresult

infuelleakageordamagetotheengineor

emissionsystem.

•Neversmokewhenhandlinggasoline,and

stayawayfromanopenameorwhere

gasolinefumesmaybeignitedbyspark.

•Storegasolineinanapprovedcontainer

andkeepitoutofthereachofchildren.

•Addfuelbeforestartingtheengine.Never

removethecapofthefueltankoraddfuel

whenengineisrunningorwhentheengine

ishot.

•Iffuelisspilled,DoNotattempttostart

theengine.Moveawayfromtheareaof

thespillandavoidcreatinganysourceof

ignitionuntilfuelvaporshavedissipated.

•DoNotoperatewithoutentireexhaust

systeminplaceandinproperworking

condition.

•Donotoperatethemowerwhenpeople,especially

children,orpetsareinthearea.Stopthemachine

andattachment(s)ifanyoneentersthearea.

•Donotoperatethemachinewithouttheentire

grasscollectionsystem,dischargedeector,

orothersafetydevicesinplaceandinproper

workingcondition.Grasscatchercomponents

aresubjecttowear,damageanddeterioration,

whichcouldexposemovingpartsorallowobjects

tobethrown.Frequentlycheckforwornor

deterioratingcomponentsandreplacethemwith

themanufacturer’srecommendedpartswhen

necessary.

16

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingaspark

whichcanignitegasolinevapors.Areor

explosionfromgasolinecanburnyouand

othersandcausepropertydamage.

•Alwaysplacegasolinecontainersonthe

groundawayfromyourvehiclebefore

lling.

•DoNotllgasolinecontainersinsidea

vehicleoronatruckortrailerbedbecause

interiorcarpetsorplastictruckbedliners

mayinsulatethecontainerandslowthe

lossofanystaticcharge.

•Whenpractical,removegas-powered

equipmentfromthetruckortrailerand

refueltheequipmentwithitswheelsonthe

ground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfroma

portablecontainer,ratherthanfroma

gasolinedispensernozzle.

•Ifagasolinedispensernozzlemustbe

used,keepthenozzleincontactwiththe

rimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.DoNot

useanozzlelockopendevice.

WARNING

Gasolineisharmfulorfatalifswallowed.

Long-termexposuretovaporshascaused

cancerinlaboratoryanimals.Failuretouse

cautionmaycauseseriousinjuryorillness.

Tohelppreventres:

•Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulatein

theseareas.

•Cleanupoilandfuelspillsandremovefuelsoaked

debris.

•Allowthemachinetocoolbeforestoringthe

machineinanyenclosure.DoNotstorenear

ameoranyenclosedareawhereopenpilotlights

orheatappliancesarepresent.

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandgas

tank/containeropening.

•Keepawayfromeyesandskin.

•Neversiphonbymouth.

CAUTION

Fueltankventislocatedinsidetheroll

bartube.Removingormodifyingtheroll

barcouldresultinfuelleakageandviolate

emissionsregulations.

•DoNotremoverollbar.

•DoNotweld,drill,ormodifyrollbarinany

way.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

•Keepsfuelfreshlongerwhenusedasdirectedby

thefuel-stabilizermanufacturer

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuel

system,whichcauseshardstarting

Important:Donotusefueladditives

containingmethanolorethanol.

Addthecorrectamountoffuelstabilizer/conditioner

tothefuel.

Note:Afuelstabilizer/conditionerismost

effectivewhenmixedwithfreshfuel.T ominimize

17

thechanceofvarnishdepositsinthefuelsystem,

usefuelstabilizeratalltimes.

PerformingDaily

Maintenance

FillingtheFuelTank

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Cleanaroundthefuel-tankcap.

5.Fillthefueltanktothebottomofthellerneck

(Figure7).

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page37).

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

Usingthe

Rollover-ProtectionSystem

(ROPS)

WARNING

Toavoidinjuryordeathfromrollover,keep

therollbarinthefullyraised,lockedposition

andusetheseatbelt.

Figure7

Ensurethattheseatissecuredtothe

machine.

WARNING

Thereisnorolloverprotectionwhentheroll

barisinthedownposition.

•Lowertherollbaronlywhenabsolutely

necessary.

•Donotweartheseatbeltwhentherollbar

isinthedownposition.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Checkcarefullyforoverheadclearances

g027726

(i.e.,branches,doorways,electricalwires)

beforedrivingunderanyobjectsanddo

notcontactthem.

LoweringtheRollBar

Important:Lowertherollbaronlywhen

absolutelynecessary.

1.T olowertherollbar,applyforwardpressureto

theupperpartoftherollbar.

2.Pullbothknobsoutandrotatethem90degrees

sotheyarenotengaged(Figure8).

18

3.Lowertherollbartothedownposition(Figure

8).

UsingtheSafety-Interlock

System

WARNING

Ifthesafety-interlockswitchesare

disconnectedordamaged,themachinecould

operateunexpectedly,causingpersonal

injury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdailyandreplaceanydamaged

switchesbeforeoperatingthemachine.

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtopreventthe

enginefromstartingunlessthefollowingoccurs:

•Theparkingbrakeisengaged.

•Theblade-controlswitch(PTO)isdisengaged.

•Themotion-controlleversareintheNEUTRAL-LOCK

position.

Figure8

1.Rollbarintheupright

position

2.ROPSknobinthelatched

position

3.PulltheROPSknobout.6.Rollbarinthefolded

4.RotatetheROPSknob90

degrees.

5.ROPSknobinthe

unlatchedposition

position

RaisingtheRollBar

Important:Alwaysusetheseatbeltwiththeroll

barintheraisedposition.

1.Raisetherollbartotheoperatingpositionand

rotatetheknobsuntiltheymovepartiallyinto

thegrooves(Figure8).

2.Raisetherollbartothefulluprightpositionwhile

pushingontheupperrollbarsothatthepins

snapintopositionwhentheholesalignwiththe

pins(Figure8).

3.Pushontherollbarandensurethatbothpins

areengaged.

Thesafety-interlocksystemalsoisdesignedtoshut

offtheenginewhenthemotion-controlleversare

movedfromtheNEUTRAL-LOCKpositionwiththe

parkingbrakeengagedorifyourisefromtheseat

whenthePTOisengaged.

Thehourmeterhasindicatorstonotifytheuserwhen

g228804

theinterlockcomponentisinthecorrectposition.

Whenthecomponentisinthecorrectposition,an

indicatordisplaysonthescreen.

g009181

Figure9

1.Indicatorsdisplaywhentheinterlockcomponentsareinthe

correctposition

TestingtheSafety-Interlock

System

ServiceInterval:Beforeeachuseordaily

19

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.Ifthesafetysystemdoesnot

operateasdescribedbelow,haveanAuthorized

ServiceDealerrepairthesafetysystemimmediately .

1.Sitontheseat,engagetheparkingbrake,and

movetheblade-controlswitch(PTO)totheON

position.Trystartingtheengine;theengine

shouldnotstart.

2.Sitontheseat,engagetheparkingbrake,and

movetheblade-controlswitch(PTO)totheOFF

position.Moveeithermotion-controlleverout

oftheNEUTRAL-LOCKposition.Trystartingthe

engine;theengineshouldnotstart.Repeatfor

theothercontrollever.

3.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,disengage

theparkingbrake,engagetheblade-control

switch(PTO),andriseslightlyfromtheseat;the

engineshouldshutoff.

4.Sitontheseat,engagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Nowstartthe

engine.Whiletheengineisrunning,center

eithermotioncontrolandmove(forwardor

reverse);theengineshouldshutoff.Repeatfor

othermotioncontrol.

PositioningtheSeat

Theseatcanmoveforwardandbackward.Position

theseatwhereyouhavethebestcontrolofthe

machineandaremostcomfortable(Figure10).

g019754

Figure10

UnlatchingtheSeat

MachineswithMyRide™

SuspensionSystem

5.Sitontheseat,disengagetheparkingbrake,

movetheblade-controlswitch(PTO)totheOFF

position,andmovethemotion-controllevers

totheNEUTRAL-LOCKposition.Trystartingthe

engine;theengineshouldnotstart.

g204507

Figure11

20

MachineswithoutMyRide™

SuspensionSystem

Tounlatchtheseat,pushtheseatlatchforward

(Figure12).

Figure12

1.Seatlatch2.Seat

ChangingtheSeat

Suspension

AdjustingtheRear-Shock

Assemblies

MachineswithMyRide™

SuspensionSystemOnly

TheMyRide™suspensionsystemadjuststoprovide

asmoothandcomfortableride.Youcanadjustthe

rear2-shockassembliestoquicklyandeasilychange

thesuspensionsystem.Positionthesuspension

systemwhereyouaremostcomfortable.

Theslotsfortherear-shockassemblieshave

g008956

detentpositionsforreference.Youcanpositionthe

rear-shockassembliesanywhereintheslot,notjustin

thedetentpositions.Thefollowinggraphicshowsthe

positionforasoftorrmrideandthedifferentdetent

positions(Figure14).

MachineswithoutMyRide™

SuspensionSystemOnly

Theseatisadjustabletoprovideasmoothand

comfortableride.Positiontheseatwhereyouare

mostcomfortable.

Toadjustit,turntheknobinfronteitherdirectionto

providethebestcomfort(Figure13).

Figure13

1.Seat-suspensionknob

g030065

Figure14

1.Firmestposition3.Detentsintheslots

2.Softestposition

Note:Ensurethattheleftandrightrear-shock

assembliesarealwaysadjustedtothesamepositions.

Adjusttherear-shockassemblies(Figure15).

g024881

21

DuringOperation

DuringOperationSafety

GeneralSafety

g030024

Theoperatormustusetheirfullattentionwhen

operatingthemachine.DoNotengageinanyactivity

thatcausesdistractions;otherwise,injuryorproperty

damagemayoccur.

WARNING

Operatingengineparts,especiallythemufer,

becomeextremelyhot.Severeburnscan

occuroncontactanddebris,suchasleaves,

grass,brush,etc.cancatchre.

•Allowengineparts,especiallythemufer,

tocoolbeforetouching.

•Removeaccumulateddebrisfrommufer

andenginearea.

WARNING

Engineexhaustcontainscarbonmonoxide,

whichisanodorlessdeadlypoisonthatcan

killyou.

DoNotrunengineindoorsorinasmall

connedareawheredangerouscarbon

monoxidefumescancollect.

Figure15

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeopleorproperty .

•Thismowerwasdesignedforoneoperatoronly .

Donotcarrypassengersandkeepallothersaway

frommachineduringoperation.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Operateonlyindaylightorgoodarticiallight.

•Lightningcancausesevereinjuryordeath.If

lightningisseenorthunderisheardinthearea,

g030019

DoNotoperatethemachine;seekshelter.

•Useextracarewhileoperatingwithaccessoriesor

attachments,suchasgrasscollectionsystems.

Thesecanchangethestabilityofthemachine

andcausealossofcontrol.Followdirectionsfor

counterweightsifrequired.

•Keepawayfromholes,ruts,bumps,rocks,and

otherhiddenhazards.Usecarewhenapproaching

blindcorners,shrubs,trees,tallgrassorother

objectsthatmayhideobstaclesorobscurevision.

Uneventerraincouldoverturnthemachineor

causetheoperatortolosetheirbalanceorfooting.

22

•Besurealldrivesareinneutralandparkingbrake

isengagedbeforestartingengine.Useseatbelts

withtherollbarintheraisedandlockedposition.

•Starttheenginecarefullyaccordingtoinstructions

withfeetwellawayfromtheblades.

•Neveroperatethemowerwithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Keepclearofthedischargeopeningatalltimes.

Nevermowwiththedischargedoorraised,

removedoralteredunlessthereisagrass

collectionsystemormulchkitinplaceandworking

properly.

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.

WARNING

Hands,feet,hair,clothing,oraccessories

canbecomeentangledinrotatingparts.

Contactwiththerotatingpartscan

causetraumaticamputationorsevere

lacerations.

–DoNotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

–Keephands,feet,hair,jewelry,or

clothingawayfromrotatingparts.

–Beforeclearingblockages.

–Wheneveryouleavethemower.DoNotleave

arunningmachineunattended.

•Stopengine,waitforallmovingpartstostop:

–Beforerefueling.

–Beforedumpingthegrasscatcher.

–Beforemakingheightadjustments.

•Tragicaccidentscanoccuriftheoperatorisnot

alerttothepresenceofchildren.Childrenare

oftenattractedtothemachineandthemowing

activity.Neverassumethatchildrenwillremain

whereyoulastsawthem.

–Keepchildrenoutofthemowingareaand

underthewatchfulcareofanotherresponsible

adult,nottheoperator.

–Bealertandturnthemachineoffifchildren

enterthearea.

–Beforeandwhilebackingorchangingdirection,

lookbehind,down,andside-to-sideforsmall

children.

–Neverallowchildrentooperatethemachine.

–DoNotcarrychildren,evenwiththeblades

shutoff.Childrencouldfalloffandbeseriously

injuredorinterferewiththesafeoperationof

themachine.Childrenthathavebeengiven

ridesinthepastcouldsuddenlyappearinthe

workingareaforanotherrideandberunover

orbackedoverbythemachine.

•Neverraisethedeckwithbladesrunning.

•Beawareofthemowerdischargepathanddirect

dischargeawayfromothers.Avoiddischarging

materialagainstawallorobstructionasthe

materialmayricochetbacktowardtheoperator.

Stoptheblades,slowdown,andusecautionwhen

crossingsurfacesotherthangrassandwhen

transportingthemowertoandfromtheareatobe

mowed.

•Bealert,slowdownandusecautionwhen

makingturns.Lookbehindandtothesidebefore

changingdirections.DoNotmowinreverse

unlessabsolutelynecessary.

•DoNotchangetheenginegovernorsettingor

overspeedtheengine.

•Parkthemachineonlevelground.Stopengine,

waitforallmovingpartstostop,andremovethe

sparkplugwire(s).

–Beforechecking,cleaningorworkingonthe

mower.

–Afterstrikingaforeignobjectorabnormal

vibrationoccurs(inspectthemowerfor

damageandmakerepairsbeforerestarting

andoperatingthemower).

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Theoperatorisresponsiblefor

safeslopeoperation.Operatingthemachineon

anysloperequiresextracaution.Beforeusingthe

machineonaslope,theoperatormust:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

–Useanangleindicatortodeterminethe

approximateslopeangleofthearea.

–Neveroperateonslopesgreaterthan15

degrees.

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Identifyhazardsatthebaseoftheslope.Do

Notoperatethemachineneardropoffs,ditches,

embankments,waterorotherhazards.The

23

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalkbehind

machineorahandtrimmertomowthegrassin

theseareas.

Figure16

1.SafeZone-Usethemowerhereonslopeslessthan15

degrees

2.DangerZone-Useawalk-behindmowerand/orhand

trimmeronslopesgreaterthan15degrees

3.Water

4.W=widthofthemachine

5.Keepasafedistance(twicethewidthofthemachine)

betweenthemachineandanyhazard.

operatingonslopescancausethemachineto

becomeunstable.

RolloverProtectionSystem

(ROPS)Safety

ARolloverProtectionSystem(rollbar)isinstalledon

themachine.

WARNING

Thereisnorolloverprotectionwhentheroll

barisdown.Wheelsdroppingoveredges,

ditches,steepbanks,orwatercancause

rollovers,whichmayresultinseriousinjury,

deathordrowning.

•DoNotremovetheROPS.

•Keeptherollbarintheraisedandlocked

positionanduseseatbelt.

•Lowertherollbaronlywhenabsolutely

g221745

necessary.

•DoNotwearseatbeltwhentherollbaris

down.

•Driveslowlyandcarefully.

•Raisetherollbarassoonasclearance

permits.

•Becertainthattheseatbeltcanbereleased

quicklyintheeventofanemergency.

•Avoidstarting,stoppingorturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•DoNotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocksorotherhiddenhazards.T all

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Useextracarewhileoperatingwithaccessoriesor

attachments,suchasgrasscollectionsystems.

Thesecanchangethestabilityofthemachine

andcausealossofcontrol.Followdirectionsfor

counterweights.

•Ifpossible,keepthedeckloweredtotheground

whileoperatingonslopes.Raisingthedeckwhile

•Checkcarefullyforoverheadclearances(i.e.

branches,doorways,andelectricalwires)before

drivingunderanyobjectsandDoNotcontact

them.

•Intheeventofarollover,taketheunittoan

AuthorizedServiceDealertohavetheROPS

inspected.

•ReplaceadamagedROPS.DoNotrepairor

revise.

•Anyaccessories,alterations,orattachments

addedtotheROPSmustbeapprovedbyT oro.

24

EnteringtheOperator’s

Position

Usethemowerdeckasasteptogetintothe

operator’sposition(Figure17).

Figure17

1.Stephere.

DisengagingtheParkingBrake

g027335

Figure19

OperatingtheMower

Blade-ControlSwitch(PTO)

g029797

Theblade-controlswitch(PTO)startsandstopsthe

mowerbladesandanypoweredattachments.

OperatingtheParking

Brake

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.

EngagingtheParkingBrake

Parkthemachineonalevelsurface.

Figure18

EngagingtheBlade-Control

Switch(PTO)

Note:Engagingtheblade-controlswitch(PTO)with

thethrottlepositionathalforlesscausesexcessive

weartothedrivebelts.

g008945

Figure20

DisengagingtheBlade-Control

Switch(PTO)

g027334

g009174

Figure21

25

OperatingtheThrottle

YoucanmovethethrottlecontrolbetweenFASTand

SLOWpositions(Figure22).

AlwaysusetheFASTpositionwhenengagingthePTO.

Figure22

g008946

26

StartingtheEngine

Important:Donotengagestarterformorethan5

secondsatatime.Iftheenginefailstostart,wait

15secondsbetweenattempts.Failuretofollow

theseinstructionscanburnoutthestartermotor.

Note:Youmayneedmultipleattemptstostartthe

enginethersttimeafteraddingfueltoanemptyfuel

system.

ShuttingOfftheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

Figure23

g032328

g027337

Figure24

Important:Makesurethatthefuel-shutoffvalve

isclosedbeforetransportingorstoringthe

machine,asfuelleakagemayoccur.Engagethe

parkingbrakebeforetransporting.Makesurethat

youremovethekeyasthefuelpumpmayrunand

causethebatterytolosecharge.

27

UsingtheMotion-Control

WARNING

Levers

Themachinecanspinveryrapidly.You

maylosecontrolofthemachineandcause

personalinjuryordamagetothemachine.

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

DrivingForward

Note:Theengineshutsoffwhenyoumovethe

traction-controlwiththeparkingbrakeengaged.

Tostopthemachine,pullthemotion-controllevers

totheNEUTRALposition.

1.Disengagetheparkingbrake;referto

DisengagingtheParkingBrake(page25).

2.Movetheleverstothecenter,unlockedposition.

3.T ogoforward,slowlypushthemotion-control

leversforward(Figure26).

Figure25

1.Motion-control

lever—NEUTRAL-LOCK

position

2.Center,unlockedposition5.Frontofmachine

3.Forward

4.Backward

DrivingtheMachine

Thedrivewheelsturnindependently,poweredby

hydraulicmotorsoneachaxle.Youcanturn1side

inreversewhileyouturntheotherforward,causing

themachinetospinratherthanturn.Thisgreatly

improvesthemachinemaneuverabilitybutmay

requiresometimeforyoutoadapttohowitmoves.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.Alwaysoperateinthefullthrottle

positionwhenmowing.

g004532

g008952

Figure26

DrivingBackward

1.Movetheleverstothecenter,unlockedposition.

2.T ogobackward,slowlypullthemotion-control

leversrearward(Figure27).

28

Figure27

UsingtheSideDischarge

Themowerhasahingedgrassdeectorthat

dispersesclippingstothesideanddowntowardthe

turf.

DANGER

Withoutagrassdeector,dischargecover,or

acompletegrass-catcherassemblymounted

inplace,youandothersareexposedtoblade

contactandthrowndebris.Contactwith

rotatingmowerblade(s)andthrowndebris

willcauseinjuryordeath.

•Neverremovethegrassdeectorfromthe

mowerdeckbecausethegrassdeector

routesmaterialdowntowardtheturf.Ifthe

g008953

grassdeectoriseverdamaged,replaceit

immediately.

•Neverputyourhandsorfeetunderthe

mowerdeck.

•Nevertrytoclearthedischargearea

ormowerbladesunlessyoumovethe

blade-controlswitch(PTO)totheOFF

position,rotatethekeyswitchtotheOFF

position,andremovethekeyfromthekey

switch.

•Makesurethatthegrassdeectorisinthe

downposition.

29

AdjustingtheHeightofCut

UsingtheTransportLock

Thetransportlockhas2positions,andisusedwith

thedeck-liftpedal.ThereisaLOCKpositionand

anUNLOCKpositionforthetransportpositionofthe

mowerdeck(Figure28).

AdjustingtheHeight-of-CutPin

Theheight-of-cutisadjustedfrom25to140mm(1

to5-1/2inches)in6mm(1/4inch)incrementsby

relocatingtheclevispinintodifferentholelocations.

1.Movethetransportlocktothelockposition.

2.Pushonthedeck-liftpedalwithyourfoot,and

raisethemowerdecktothetransportposition

(alsothe140mm(5-1/2inch)cuttingheight

position)asshowninFigure29.

3.T oadjust,rotatethepin90degreesandremove

thepinfromtheheight-of-cutbracket(Figure

29).

4.Selectaholeintheheight-of-cutbracket

correspondingtotheheight-of-cutdesired,and

insertthepin(Figure29).

5.Pushonthedecklift,pullbackonthetransport

lock,andslowlylowerthemowerdeck.

Figure28

Transport-LockPositions

1.Transportlockknob3.UNLOCKposition—The

2.LOCKposition—The

mowerdecklocksintothe

transportposition.

mowerdeckdoesnotlock

intothetransportposition.

g027343

Figure29

1.Deck-liftpedal

2.Cut-of-heightpin

g229103

30

3.Transportlock

AdjustingtheAnti-Scalp

Rollers

Wheneveryouchangetheheight-of-cut,adjustthe

heightoftheanti-scalprollers.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Adjusttheanti-scalprollersasshowninFigure

30,Figure31,andFigure32.

Figure30

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

g029957

Figure32

1.Anti-scalproller4.Flangenut

2.Spacer

3.Bushing

5.Bolt

AdjustingtheFlowBafe

Knob

Thisprocedureappliesonlytomachineswiththe

owbafeknob.Certainmodelshavenutsandbolts

g029955

insteadoftheowbafeknobthatyoucanadjustthe

sameway.

Youcanadjustthemowerdischargeowfordifferent

typesofmowingconditions.Positiontheknoband

bafetogivethebestqualityofcut.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

Figure31

1.Anti-scalproller3.Flangenut

2.Bushing4.Bolt

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Loosentheknob.

4.Slidetheknobtothedesiredposition.

5.Tightentheknob.

g029956

31

PositioningtheFlowBafe

Thefollowingguresarerecommendationsonly.

Adjustmentsvarybygrasstype,moisturecontent,

andtheheightofthegrass.

Note:Iftheenginepowerdrawsdownandthe

mowergroundspeedisthesame,openthebafe.

PositionA

Thisisthefully-rearposition.Thesuggestedusefor

thispositionisasfollows:

•Short,lightgrassmowingconditions

•Dryconditions

•Smallergrassclippings

•Propelsgrassclippingsfartherawayfromthe

mower

g295811

Figure34

PositionC

PositionB

Thisisthefully-forwardposition.Thesuggesteduse

forthispositionisasfollows:

•Tall,densegrassmowingconditions

•Wetconditions

•Lowerstheengine-powerconsumption

•Allowsincreasedgroundspeedinheavyconditions

g295810

Figure33

Usethispositionwhenbagging.Alwaysalignitwith

thebloweropening.

g295812

Figure35

32

OperatingTips

UsingtheFastThrottleSetting

dropontoyourlawn.Toavoidthis,moveontoa

previouslycutareawiththebladesengagedoryou

candisengagethemowerdeckwhilemovingforward.

Forbestmowingandmaximumaircirculation,operate

theengineattheFASTposition.Airisrequiredto

thoroughlycutgrassclippings,sodonotsetthe

height-of-cutsolowastototallysurroundthemower

deckinuncutgrass.Alwaystrytohave1sideofthe

mowerdeckfreefromuncutgrass,whichallowsair

tobedrawnintothemowerdeck.

CuttingaLawnfortheFirstTime

Cutgrassslightlylongerthannormaltoensurethat

thecuttingheightofthemowerdeckdoesnotscalp

anyunevenground.However,thecuttingheight

usedinthepastisgenerallythebestonetouse.

Whencuttinggrasslongerthan15cm(6inches)tall,

youmaywanttocutthelawntwicetoensurean

acceptablequalityofcut.

CuttingaThirdoftheGrassBlade

Itisbesttocutonlyaboutathirdofthegrassblade.

Cuttingmorethanthatisnotrecommendedunless

grassissparse,oritislatefallwhengrassgrows

moreslowly.

KeepingtheUndersideofthe

MowerDeckClean

Cleanclippingsanddirtfromtheundersideofthe

mowerdeckaftereachuse.Ifgrassanddirtbuildup

insidethemowerdeck,cuttingqualitywilleventually

becomeunsatisfactory.

MaintainingtheBlade(s)

Maintainasharpbladethroughoutthecuttingseason

becauseasharpbladecutscleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.Checkthe

mowerbladesaftereachuseforsharpness,and

foranywearordamage.Filedownanynicksand

sharpenthebladesasnecessary .Ifabladeis

damagedorworn,replaceitimmediatelywitha

genuineT ororeplacementblade.

AfterOperation

AlternatingtheMowingDirection

Alternatethemowingdirectiontokeepthegrass

standingstraight.Thisalsohelpsdisperseclippings,

whichenhancesdecompositionandfertilization.

MowingatCorrectIntervals

Grassgrowsatdifferentratesatdifferenttimesof

theyear.Tomaintainthesamecuttingheight,mow

moreofteninearlyspring.Asthegrassgrowthrate

slowsinmidsummer,mowlessfrequently.Ifyou

cannotmowforanextendedperiod,rstmowata

highcuttingheight,thenmowagain2dayslaterata

lowerheightsetting.

UsingaSlowerCuttingSpeed

Toimprovecutquality,useaslowergroundspeed

incertainconditions.

AvoidingCuttingTooLow

Whenmowinguneventurf,raisethecuttingheight

toavoidscalpingtheturf.

AfterOperationSafety

GeneralSafety

•Parkmachineonlevelground,disengagedrives,

setparkingbrake,stopengine,removekeyor

disconnectsparkplugwire.Waitforallmovement

tostopandallowthemachinetocoolbefore

adjusting,cleaning,repairing,orstoring.Never

allowuntrainedpersonneltoservicemachine.

•CleanthemachineasstatedintheMaintenance

section.Keepengineandengineareafreefrom

accumulationofgrass,leaves,excessivegrease

oroil,andotherdebriswhichcanaccumulate

intheseareas.Thesematerialscanbecome

combustibleandmayresultinare.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.Tighten

loosehardware.

StoppingtheMachine

Ifyoumuststoptheforwardmotionofthemachine

whilemowing,aclumpofgrassclippingsmay

33

UsingtheFuel-Shutoff

Usingthe

Valve

Thefuel-shutoffvalveislocatedundertheseat.Move

theseatforwardtoaccessit.

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage.

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

Figure36

1.ONposition2.OFFposition

Drive-Wheel-Release

Valves

WARNING

Handsmaybecomeentangledintherotating

drivecomponentsbelowtheenginedeck,

whichcouldresultinseriousinjury.

Shutofftheengine,removethekey,andallow

allmovingpartstostopbeforeaccessingthe

drive-wheel-releasevalves.

WARNING

Theengineandhydraulic-driveunitscan

becomeveryhot.Touchingahotengineor

hydraulic-driveunitscancausesevereburns.

Allowtheengineandhydraulic-driveunits

tocoolcompletelybeforeaccessingthe

drive-wheel-releasevalves.

g008948

Thedrive-wheel-releasevalvesarelocatedinthe

backofeachhydraulic-driveunit,undertheseat.

Note:Makesurethatthereleasevalvesareinthe

fullyhorizontalpositionwhenoperatingthemachine;

otherwise,severedamagetothehydraulicsystem

canoccur.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Rotatetherelease-valveleversverticallytopush

themachine(Figure37).

Note:Thisallowshydraulicuidtobypassthe

pump,enablingthewheelstoturn.

4.Disengagetheparkingbrakebeforepushing

themachine.

34

Figure37

1.Verticaltopushthe

machine

5.Rotatethereleasevalvelevershorizontallyto

runthemachine(Figure37).

2.Horizontaltorunthe

machine

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure38).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Donotexceeda15-degreeanglebetween

therampandthegroundorbetweenthe

g015123

rampandthetrailerortruck.

•Ensurethatthelengthoftherampisat

least4timesaslongastheheightofthe

trailerortruckbedtotheground.This

ensuresthattherampangledoesnot

exceed15degreesonatground.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Useafull-widthramp.Ensurethatthetrailer

ortruckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyouorbystandersavoidinjury.Refertoyour

localordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

35

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakesand

lights.

3.Lowertheramp,ensuringthattheangle

betweentherampandthegrounddoesnot

exceed15degrees(Figure38).

4.Backthemachineuptheramp(Figure39).

Figure39

g028043

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

LoadingtheMachine

Figure38

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

1.Backthemachineupthe

ramp.

2.Drivethemachineforward

downtheramp.

5.Shutofftheengine,removethekey,andengage

theparkingbrake.

6.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumperwithstraps,chains,

cable,orropes(Figure40).Refertolocal

regulationsfortie-downrequirements.

g027996

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Backthemachineuptherampanddriveit

forwarddowntheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

g027338

Figure40

1.Tie-downloops

UnloadingtheMachine

1.Lowertheramp,ensuringthattheangle

betweentherampandthegrounddoesnot

exceed15degrees(Figure38).

2.Drivethemachineforwarddowntheramp

(Figure39).

36

Maintenance

MaintenanceSafety

WARNING

Whilemaintenanceoradjustmentsarebeing

made,someonecouldstarttheengine.

Accidentalstartingoftheenginecould

seriouslyinjureyouorotherbystanders.

Removethekeyfromtheignitionswitch,

engageparkingbrake,andpullthewire(s)

offthesparkplug(s)beforeyoudoany

maintenance.Alsopushthewire(s)asideso

itdoesnotaccidentallycontactthespark

plug(s).

WARNING

Theenginecanbecomeveryhot.Touchinga

hotenginecancausesevereburns.

Allowtheenginetocoolcompletelybefore

serviceormakingrepairsaroundtheengine

area.

•Parkmachineonlevelground,disengagedrives,

setparkingbrake,stopengine,removekeyor

disconnectsparkplugwire.Waitforallmovement

tostopandallowthemachinetocoolbefore

adjusting,cleaningorrepairing.Neverallow

untrainedpersonneltoservicemachine.

•Disconnectbatteryorremovesparkplugwire

beforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositivelast.

Reconnectpositiverstandnegativelast.

•Keepthemachine,guards,shieldsandall

safetydevicesinplaceandinsafeworking

condition.Frequentlycheckforwornor

deterioratingcomponentsandreplacethemwith

themanufacturer’srecommendedpartswhen

necessary.

WARNING

Removalormodicationoforiginal

equipment,partsand/oraccessories

mayalterthewarranty ,controllability,

andsafetyofthemachine.Unauthorized

modicationstotheoriginalequipmentor

failuretouseoriginalToropartscouldlead

toseriousinjuryordeath.Unauthorized

changestothemachine,engine,fuelor

ventingsystem,mayviolateapplicable

safetystandardssuchas:ANSI,OSHAand

NFPAand/orgovernmentregulationssuch

asEP AandCARB.

WARNING

Hydraulicuidescapingunderpressure

canpenetrateskinandcauseinjury.Fluid

accidentallyinjectedintotheskinmustbe

surgicallyremovedwithinafewhoursby

adoctorfamiliarwiththisformofinjuryor

gangrenemayresult.

–Ifequipped,makesureallhydraulic

uidhosesandlinesareingood

conditionandallhydraulicconnections

andttingsaretightbeforeapplying

pressuretohydraulicsystem.

–Keepbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

–Usecardboardorpaper,notyourhands,

tondhydraulicleaks.

–Safelyrelieveallpressureinthe

hydraulicsystembyplacingthemotion

controlleversinneutralandshuttingoff

theenginebeforeperforminganywork

onthehydraulicsystem.

WARNING

Fuelsystemcomponentsareunder

highpressure.Theuseofimproper

componentscanresultinsystemfailure,

gasolineleakageandpossibleexplosion.

Useonlyapprovedfuellinesandfuellters

forhighpressuresystems.

•Usecarewhencheckingblades.Wrapthe

blade(s)orweargloves,andusecautionwhen

servicingthem.Onlyreplacedamagedblades.

Neverstraightenorweldthem.

37

•Usejackstandstosupportthemachineand/or

componentswhenrequired.

CAUTION

Raisingthemachineforserviceor

maintenancerelyingsolelyonmechanical

orhydraulicjackscouldbedangerous.

Themechanicalorhydraulicjacksmaynot

beenoughsupportormaymalfunction

allowingthemachinetofall,whichcould

causeinjury.

Donotrelysolelyonmechanicalor

hydraulicjacksforsupport.Useadequate

jackstandsorequivalentsupport.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

RecommendedMaintenanceSchedule(s)

•Keephandsandfeetawayfrommovingparts.

Ifpossible,DoNotmakeadjustmentswiththe

enginerunning.Ifthemaintenanceoradjustment

procedurerequiretheenginetoberunningand

componentsmoving,useextremecaution.

WARNING

Contactwithmovingpartsorhotsurfaces

maycausepersonalinjury .

Keepyourngers,hands,andclothing

clearofrotatingcomponentsandhot

surfaces.

•Checkallboltsfrequentlytomaintainproper

tightness.

MaintenanceService

Interval

Aftertherst8hours

Aftertherst100hours

Aftertherst250hours

Beforeeachuseordaily

Every50hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthewheellug-nuttorque.

•Checkthewheel-hubslotted-nuttorque.

•Adjusttheparkingbrake.

•Changethehydraulicltersandhydraulicuid.

•Checkthesafety-interlocksystem.

•Checktheengine-oillevel.

•Checktheseatbelt.

•Checktherollbarknobs.

•Cleantheenginescreenandtheoilcooler.

•Checkandcleanthehydraulic-unitshrouds.

•Inspecttheblades.

•Cleanthemowerdeck.

•Cleanthesuspensionsystem.

•Checkthetirepressure

•Inspectthebeltsforcracksandwear.

•Checkthehydraulic-uidlevel.

•Lubricatethemowerdeck-liftpivots.

•Changetheengineoil(moreoftenindirtyordustyconditions).

•ForKawasakiengines—replaceorcleanandgapthesparkplug.

•Checkandcleanengine-coolingnsandshrouds.

Every200hours

Every250hours

Every400hours

•Changetheengine-oillter(moreoftenindirtyordustyconditions).

•Replacetheprimaryairlter(moreoftenindirtyordustyconditions).

•Checkthesafetyairlter(moreoftenindirtyordustyconditions).

•Aftertheinitialchange—changethehydraulic-systemltersanduidwhenusing

Mobil115W50uid.(Changeitmoreoftenunderdirtyordustyconditions)

•Greasethecasterpivots(moreoftenindirtyordustyconditions).

38

MaintenanceService

Every500hours

Interval

MaintenanceProcedure

•Replacethesafetyairlter(moreoftenindirtyordustyconditions).

•Replacethefuellter(moreoftenindusty ,dirtyconditions).

•Checkthewheellug-nuttorque.

•Checkthewheel-hubslotted-nuttorque.

•Adjustthecaster-pivotbearing.

•Adjusttheparkingbrake.

•Aftertheinitialchange—changethehydraulic-systemltersanduidwhenusing

Toro®HYPR-OIL™500uid.(Changeitmoreoftenunderdirtyordustyconditions)

Monthly

Yearly

Yearlyorbeforestorage

•Checkthebatterycharge.

•Greasethepump-belt-idlerarm.

•Repackthecaster-wheelbearings(moreoftenindirtyordustyconditions).

•Greasingthecaster-wheelhubs.

•Paintchippedsurfaces.

•Checkallmaintenanceprocedureslistedabovebeforestorage.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Shutofftheengineandremovethekeyfromtheswitchbeforeyouperformanymaintenance.

Lubrication

LubricatingtheMower

Deck-LiftPivots

GreasingtheMachine

Greasethemachinemoreoftenindirtyordusty

conditions.

GreaseType:No.2lithiumormolybdenumgrease

ServiceInterval:Every100hours

Uselightoilorspraylubricanttolubricatethedeck-lift

pivots.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.

Note:Scrapeanypaintoffthefrontofthe

tting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

g017028

Figure41

39

GreasingtheMowerDeck

ServiceInterval:Y early—Greasethepump-belt-idler

arm.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

Note:Keepthedustcapoffuntilgreasingis

done.

6.Removethehexplug.

7.Threadagreasettingintothehole.

8.Pumpgreaseintothettinguntilitoozesout

aroundthetopbearing.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Greasethemowerdeckidler-pulleypivotuntil

greasecomesoutthebottom(Figure42).

Figure42

9.Removethegreasettinginthehole.

10.Installthehexpluganddustcap(Figure44).

g027339

Figure44

11.Greasethecaster-wheelbearings(Figure44).

g295792

GreasingtheCasterPivots

4.Greasethedrive-belt-idlerarm(Figure43).

Figure43

5.Removethedustcapandadjustthecaster

pivots.

ServiceInterval:Every400hours/Yearly(whichever

comesrst)(moreoftenindirtyor

dustyconditions).

Yearly—Repackthecaster-wheelbearings

(moreoftenindirtyordustyconditions).

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethedustcapandadjustthecaster

pivotsandkeepthedustcapoffuntilgreasingis

done;refertoGreasingtheMowerDeck(page

40).

4.Removethehexplug.

g009030

5.Threadagreasettingintothehole.

6.Pumpgreaseintothettinguntilitoozesout

aroundthetopbearing.

7.Removethegreasettingfromthehole.Install

thehexplugandcap.

40

GreasingtheCaster-Wheel

Hubs

ServiceInterval:Yearly

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Raisethemowerforaccess.

4.Removethecasterwheelfromthecasterforks.

5.Removethesealguardsfromthewheelhub.

Figure45

13.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

general-purposegrease.

14.Insertthesecondbearingandnewsealintothe

wheel.

15.Applyathread-lockingcompoundtothesecond

spacernut,andthreaditontotheaxlewiththe

wrenchatsfacingoutward.

16.T orquethenutto8to9N∙m(75to80in-lb),

loosenthenut,thentorqueitto2to3N∙m(20

to25in-lb).

Note:Makesurethattheaxledoesnotextend

beyondeithernut.

17.Installthesealguardsoverthewheelhub,and

insertthewheelintothecasterfork.

18.Installthecasterboltandtightenthenutfully.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoften.Spinthe

castertire.Thetireshouldnotspinfreely(more

than1or2revolutions)orhaveanysideplay.If

thewheelspinsfreely,adjustthetorqueonthe

spacernutuntilthereisaslightamountofdrag.

Applyanotherlayerofthread-lockingcompound.

g006115

1.Sealguard2.Spacernutwithwrench

6.Removeaspacernutfromtheaxleassemblyin

thecasterwheel.

ats

Note:Thread-lockingcompoundhasbeen

appliedtolockthespacernutstotheaxle.

7.Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly.

8.Pryoutsealsandinspectbearingsforwearor

damageandreplaceifnecessary.

9.Packthebearingswithageneral-purpose

grease.

10.Insert1bearingand1newsealintothewheel.

11.Iftheaxleassemblyismissingbothspacernuts,

applyathread-lockingcompoundto1spacer

nutandthreaditontotheaxlewiththewrench

atsfacingoutward.

Note:Donotthreadthespacernutallof

thewayontotheendoftheaxle.Leave

approximately3mm(1/8inch)fromtheouter

surfaceofthespacernuttotheendoftheaxle

insidethenut.

12.Inserttheassemblednutandaxleintothewheel

onthesidewiththenewsealandbearing.

41

EngineMaintenance

EngineSafety

4.Cleantheinsideoftheair-cleanercoverwith

compressedair.

5.Gentlyslidetheprimarylteroutofthe

air-cleanerbody(Figure46).

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Keepyourhands,feet,face,clothing,andother

bodypartsawaythemuferandotherhotsurfaces.

ServicingtheAirCleaner

ServiceInterval:Every250hours—Replacethe

primaryairlter(moreoftenindirty

ordustyconditions).

Every250hours—Checkthesafetyairlter

(moreoftenindirtyordustyconditions).

Every500hours—Replacethesafetyairlter

(moreoftenindirtyordustyconditions).

Note:Servicetheaircleanermorefrequentlyif

operatingconditionsareextremelydustyorsandy .

RemovingtheFilters

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe

parkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

Note:Avoidknockingthelterintothesideof

thebody.

6.Removethesafetylteronlytoreplaceit.

InspectingtheFilters

1.Inspectthesafetylter.Ifitisdirty ,replaceboth

thesafetyandprimarylters.

Important:Donotattempttocleanthe

safetylter.Ifthesafetylterisdirty,then

theprimarylterisdamaged.

2.Inspecttheprimarylterfordamagebylooking

intothelterwhileshiningabrightlightonthe

outsideofthelter.Iftheprimarylterisdirty,

bent,ordamaged,replaceit.

Note:Holesinthelterappearasbrightspots.

Donotcleantheprimarylter.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandthe

coverinstalled.

1.Ifyouareinstallingnewlters,checkeachlter

forshippingdamage.

3.Releasethelatchesontheaircleanerandpull

theair-cleanercoverofftheair-cleanerbody

(Figure46).

Figure46

1.Air-cleanerbody4.Air-cleanercover

2.Primarylter5.Safetylter

3.Latch

Note:Donotuseadamagedlter.

2.Ifyouarereplacingtheinnerlter,carefullyslide

itintothelterbody(Figure46).

3.Carefullyslidetheprimarylteroverthesafety

lter(Figure46).

Note:Ensurethattheprimarylterisfully

seatedbypushingontheouterrimwhile

installingit.

Important:Donotpressonthesoft,inside

areaofthelter.

4.Installtheair-cleanercoverandsecurethe

latches(Figure46).

g001883

42

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily

Aftertherst8hours

Every100hours(moreoftenindirtyordusty

conditions).

Every200hours—Changetheengine-oillter

(moreoftenindirtyordustyconditions).

3.T okeepdirt,grassclippings,etc.,outofthe

engine,cleantheareaaroundtheoil-llcapand

dipstickbeforeremovingit(Figure48).

Engine-OilSpecications

OilType:Detergentoil(APIserviceSF,SG,SH,SJ,

orSL)

CrankcaseCapacity:1.9L(64oz)withalter

change;1.7L(57oz)withnolterchange

Viscosity:Seethetablebelow.

g008804

Figure47

Note:Useofmulti-gradeoils(5W-20,10W-30,or

10W-40)increasesoilconsumption.Checktheoil

levelmorefrequentlywhenusingthem.

CheckingtheEngine-OilLevel

Note:Checktheoilwhentheengineiscold.

Important:Ifyouoverllorunderlltheengine

crankcasewithoilandruntheengine,youmay

damagetheengine.

1.Parkthemachineonalevelsurface,disengage

theblade-controlswitch(PTO),andengagethe