FormNo.3443-227RevA

GrandStand

®

MowerWith122cmRearDischarge

TURBOFORCE

72542TE

GrandStand

®

RasenmäherMit122cmHeckauswurf

TURBOFORCE

72542TE

TondeuseGrandStand

FORCE

72542TE

GrandStand

®

de122cmàéjectionarrière

®

maaierMeteenTURBOFORCE

maai-eenheidvan122cmmetachteruitworp

72542TE

®

®

CuttingUnit

Mähwerk

®

avecunitédecoupeTURBO

®

www.T oro.com.

*3443-227*

FormNo.3443-215RevA

GrandStand

®

Mower

With122cmRearDischargeTURBOFORCE

CuttingUnit

ModelNo.72542TE—SerialNo.400000000andUp

®

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3443-215*

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ModelNo.

Pleaserefertotheenginemanufacturer’sinformation

includedwiththemachine.

Introduction

Thisrotary-blade,stand-onlawnmowerisintended

tobeusedbyprofessional,hiredoperators.Itis

designedprimarilyforcuttinggrassonwell-maintained

lawnsonresidentialorcommercialproperties.Using

thisproductforpurposesotherthanitsintendeduse

couldprovedangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

Visitwww.Toro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

Figure1

1.Locationofthemodelandserialnumbers

g235457

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

ProductOverview.....................................................8

Controls.............................................................8

Specications....................................................9

Attachments/Accessories...................................9

BeforeOperation.................................................10

BeforeOperationSafety...................................10

AddingFuel......................................................10

PerformingDailyMaintenance...........................11

BreakinginaNewMachine...............................11

UsingtheSafety-InterlockSystem.....................11

DuringOperation.................................................12

DuringOperationSafety...................................12

OperatingtheParkingBrake.............................14

OperatingtheMower-Blade-ControlSwitch

(PTO)............................................................14

OperatingtheThrottle.......................................15

OperatingtheChoke........................................15

OperatingtheIgnitionSwitch............................16

StartingtheEngine...........................................16

ShuttingOfftheEngine.....................................17

OperatingthePlatform......................................17

DrivingForwardorBackward............................18

AdjustingtheHeight-of-Cut...............................19

UsingWeights..................................................20

AfterOperation....................................................20

AfterOperationSafety......................................20

UsingtheFuel-ShutoffValve.............................21

PushingtheMachinebyHand..........................21

TransportingtheMachine.................................22

Maintenance...........................................................24

MaintenanceSafety..........................................24

RecommendedMaintenanceSchedule(s)...........24

Pre-MaintenanceProcedures..............................26

ReleasingtheCushionforRearAccess............26

OpeningtheEngineGuardandGuard

Extension......................................................26

ClosingtheEngineGuardandGuard

Extension......................................................27

RemovingtheLeftBeltCover...........................28

RemovingtheRightBeltCover.........................29

InstallingtheRightBeltCover...........................30

InstallingtheLeftBeltCover.............................31

Lubrication..........................................................32

GreasingtheMachine.......................................32

GreasingtheT orsionIdler.................................32

GreasingtheFrontCasterPivots......................33

GreasingtheCaster-WheelHubs.....................33

GreasingtheMotionControls...........................34

EngineMaintenance...........................................34

EngineSafety...................................................34

ServicingtheAirCleaner..................................34

ServicingtheEngineOil....................................35

ServicingtheSparkPlug...................................37

CheckingtheSparkArrester.............................38

FuelSystemMaintenance...................................39

DrainingtheFuelT ank......................................39

RemovingtheFuelT ank...................................39

ReplacingtheFuelFilter...................................40

ElectricalSystemMaintenance...........................40

ElectricalSystemSafety...................................40

ServicingtheBattery.........................................40

ServicingtheFuses..........................................42

DriveSystemMaintenance..................................43

AdjustingtheTracking......................................43

CheckingtheTirePressure...............................43

AdjustingtheCaster-PivotBearing...................44

ServicingtheCasterWheelsand

Bearings........................................................44

RemovingtheClutchShim...............................45

CheckingtheWheel-LugNuts..........................46

CoolingSystemMaintenance..............................47

CleaningtheAir-IntakeScreen.........................47

CleaningtheCoolingSystem............................47

BrakeMaintenance.............................................47

TestingtheParkingBrake.................................47

AdjustingtheBrakes.........................................47

BeltMaintenance................................................48

CheckingtheBelts............................................48

ReplacingtheMower-DeckBelt........................48

ReplacingtheTransmissionBelt......................49

ControlsSystemMaintenance.............................50

AdjustingtheMotion-ControlLevers.................50

HydraulicSystemMaintenance...........................51

HydraulicSystemSafety...................................51

HydraulicSystemSpecications.......................51

CheckingtheHydraulicFluid............................51

ReplacingtheHydraulicFluidand

Filters............................................................51

BleedingtheHydraulicSystem.........................52

MowerDeckMaintenance....................................53

BladeSafety.....................................................53

ServicingtheCuttingBlades.............................53

LevelingtheMowerDeck..................................55

AdjustingtheDeck-LiftSpring...........................57

Cleaning..............................................................58

CleaningundertheMowerDeck.......................58

CleaningtheRearWheelMotors......................58

DisposingofWaste...........................................58

Storage...................................................................58

StorageSafety..................................................58

CleaningandStorage.......................................58

Troubleshooting......................................................60

Schematics.............................................................62

3

Safety

Thismachinehasbeendesignedinconsideration

withENISO5395.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury .

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

functioningproperlyonthemachine.

•Keepclearofthedischargeopening.

SafetyandInstructionalDecals

•Keepbystandersandchildrenoutoftheoperating

area.Donotallowchildrentooperatethemachine.

Allowonlypeoplewhoareresponsible,trained,

familiarwiththeinstructions,andphysically

capabletooperatethemachine.

•Stopthemachine,shutofftheengine,andremove

theignitionkeybeforeservicing,fueling,or

uncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury ,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

,which

Safetydecalsandinstructionsareeasilyvisibleandarelocatednearareasofpotentialdanger.

Replaceeverydamagedormissingdecal.

decalbatterysymbols

BatterySymbols

Someorallofthesesymbolsareonyourbattery.

1.Explosionhazard6.Keepbystandersaway.

2.Nore,openames,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator’s

Manual.

7.Weareye

protection—explosive

gasescancauseblindness

andotherinjuries.

8.Batteryacidcancause

severeburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

decaloemmarkt

Manufacturer'sMark

1.Thismarkindicatesthatthebladeisidentiedasapart

fromtheoriginalmachinemanufacturer.

decal106-5517

106-5517

1.Warning—donottouchthehotsurface.

4

116-8283

131-3528

15A 15A 10A

7.5A

1.Warning—readtheOperator'sManualforinstructionson

torquingthebladebolt/nutto75to81N∙m(55to60ft-lb).

116-8775

decal116-8283

decal131-3521

131-3521

1.Heightofcut

decal116-8775

1.ReadtheOperator’s

Manual.

1.ReadtheOperator's

Manual.

2.Warning—lltothebottom

131-3507

2.Belttensioner

ofthellerneck;donot

overllthetank.

decal131-3524

131-3524

1.ReadtheOperator's

Manual.

2.Transmissionuid

decal131-3507

3.Colduidlevel

decal131-3528

131-3528

1.Keyswitch—15A

2.Accessoryport—15A

3.Powertakeoff(PTO)—10

A

4.Infocenter—7.5A

5

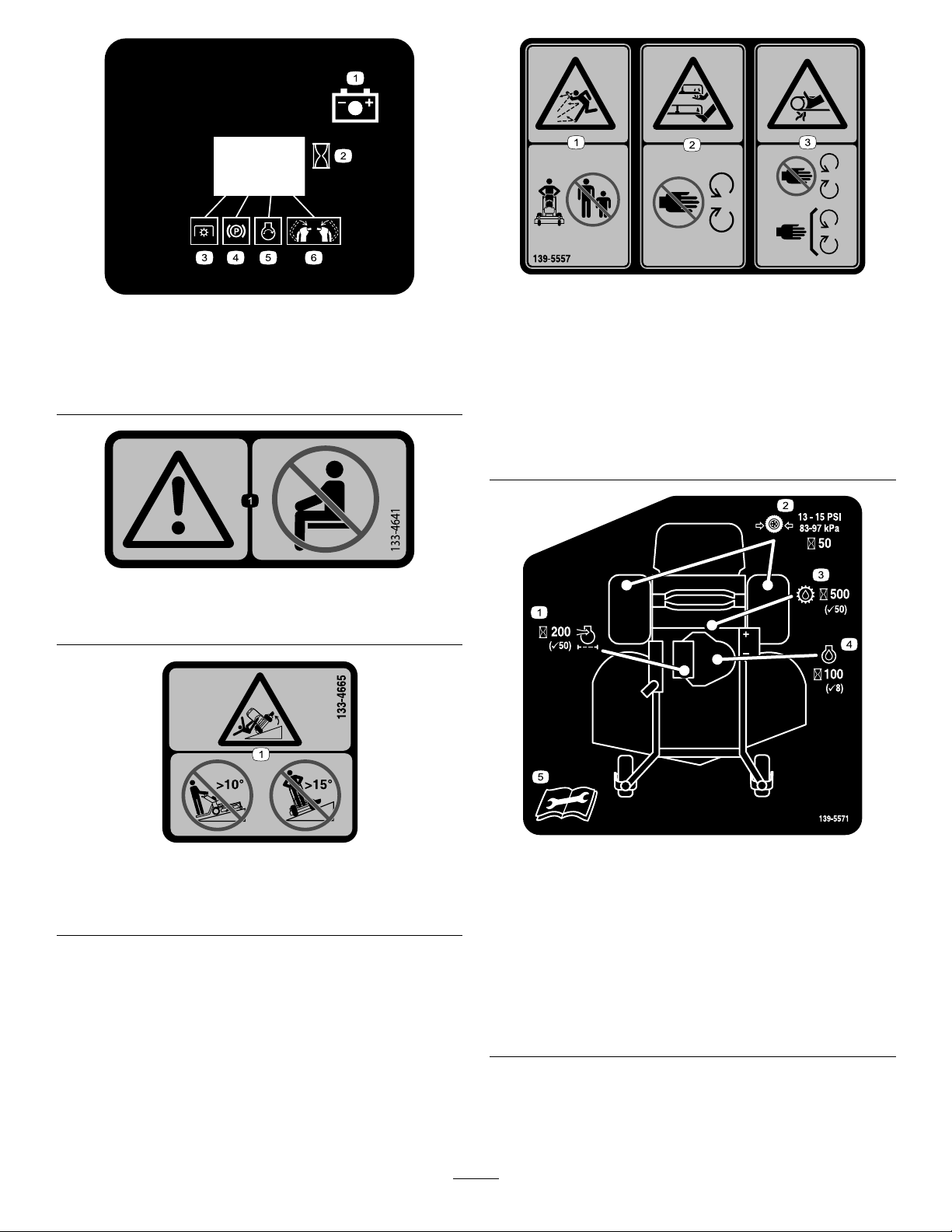

131-3536

1.Battery4.Parkingbrake

2.Time5.Engine—start

3.Powertakeoff(PTO)

6.Engagethehandlebars.

133-4641

1.Warning—donotcarrypassengers.

decal139-5557

decal131-3536

1.Thrownobject

hazard—keepbystanders

away.

139-5557

3.Entanglementhazard,

belt—stayawayfrom

movingparts;keepall

guardsandshieldsin

place.

2.Cutting/dismemberment

hazardofhandorfoot,

mowerblade—stayaway

frommovingparts.

decal133-4641

133-4665

1.Tippinghazard—donotoperateupslopesgreaterthan10°;

donotoperateacrossslopesgreaterthan15°.

decal133-4665

1.Engineairlter—Check

every50hours;Change

every200hours

2.TirePressure—Check

every50hours

139-5571

4.Engineoillter—Check

every8hours;Change

every100hours

5.ReadtheOperator’s

Manualbeforeperforming

decal139-5571

maintenance.

3.Transmission

uid—Checkevery50

hours;Changeevery500

hours

6

decal131-3526

131-3526

1.Powertakeoff(PTO)—disengaged

5.Reverse

2.Fast6.Tractiondrive

3.Slow

7.Engagethehandles.

4.Neutral

139-5556

1.Warning—readtheOperator’sManual.

2.Warning—donotoperatethemachineunlessyouaretrained.

3.Warning—wearhearingprotection.7.Tippinghazard—whenloadingontoatrailer,donotusedual

4.Cutting/dismembermenthazardofhandorfoot,mower

blade—stayawayfrommovingparts;keepallguardsand

shieldsinplace.

5.Thrownobjecthazard—keepbystandersaway.

6.Warning—engagetheparkingbrake,shutofftheengine,and

removethekeybeforeleavingthemachineorperforming

maintenance.

ramps;onlyuseasingularrampwideenoughforthemachine;

backuptheramp(inreverse)anddriveforwardofftheramp.

8.Tippinghazard—donotoperatethemachineneardrop-offsor

water;stayawayfromdrop-offs.

decal139-5556

decal140-4258

140-4258

1.Parkingbrake—disengaged

2.Parkingbrake—engaged

3.On

4.Off

5.Enginespeed—fast

6.Enginespeed—slow

7

ProductOverview

ControlPanel

g301785

Figure4

Figure3

1.Frontcasterwheel

2.Engine7.Fueltank

3.Controlpanel8.Platform(downposition)

4.Motion-controllevers9.Battery

5.Hydraulictank10.Mowerdeck

6.Operatorcushion

Controls

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethemachine.

g273599

1.Fuelcap7.Keyswitch

2.Chokecontrol

3.Parking-brakelever

4.Hydraulic-tankcap

5.Hourmeter11.Motion-controllever

6.Power-takeoffswitch

(PTO)

8.Throttlecontrol

9.Height-of-cutlever

10.Height-of-cutpin

12.Referencebar

Power-TakeoffSwitch(PTO)

Usethepower-takeoffswitch(PTO)toengageand

disengagemowerbladesorstartandstoppowered

attachments(Figure4);refertoOperatingthe

Mower-Blade-ControlSwitch(PTO)(page14).

8

HourMeter

Motion-ControlLevers

Thehourmeterrecordsthenumberofhoursthe

enginehasoperated.Itoperateswhentheengine

isrunning.Usethesetimesforschedulingregular

maintenance(Figure5).

Figure5

1.Safety-interlocksymbols

2.Batterylight

3.Hourmeter

Safety-InterlockIndicators

Usethemotion-controlleverstodrivethemachine

forward,reverse,andturneitherdirection(Figure4).

Fuel-ShutoffValve

Closethefuel-shutoffvalvewhentransportingor

storingthemachine;refertoUsingtheFuel-Shutoff

Valve(page21).

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

g216020

Cuttingwidth122cm(48inches)

Width

Lengthwithplatformdown191cm(75inches)

Lengthwithplatformup155cm(61inches)

Height

127cm(50inches)

122cm(48inches)

Symbolsonthehourmeterindicatewithablack

trianglethattheinterlockcomponentisinthecorrect

position(Figure5).

Battery-IndicatorLight

IfyouturnthekeytotheONpositionforafew

seconds,thebatteryvoltagedisplaysinthearea

wherethehoursarenormallydisplayed.

Thebatterylightturnsonwhenyouturnthekeytothe

ONpositionandwhenthechargeisbelowthecorrect

operatinglevel(Figure5).

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesettingfromtheSLOWtoFAST

position(Figure4).

ChokeControl

Usethechokecontroltostartacoldengine.Pullthe

chokecontroluptoengageit.Pushdownonthe

chokecontroltodisengageit.

Weight

415kg(915lb)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andSTART.Referto

StartingtheEngine(page16).

9

Operation

–Ifyouspillfuel,donotattempttostartthe

engine.Avoidcreatingasourceofignitionuntil

thefuelvaporshavedissipated.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopletooperate

themachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefor

trainingalloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeleavingthe

operator’sposition.Allowthemachinetocool

beforeservicing,adjusting,fueling,cleaning,or

storingit.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthatoperator-presencecontrols,safety

switches,andguardsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Evaluatetheterraintodeterminetheappropriate

equipmentandanyattachmentsoraccessories

requiredtooperatethemachineproperlyand

safely.

–Storefuelinanapprovedcontainerandkeep

itoutofthereachofchildren.

•Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

–Avoidprolongedbreathingofvapors.

–Keepyourhandsandfaceawayfromthe

nozzleandthefuel-tankopening.

–Keepfuelawayfromyoureyesandskin.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromyourvehicle

beforelling.

•Removetheequipmentfromthetruckortrailer

andrefuelitwhileitisontheground.Ifthisisnot

possible,thenrefuelfromaportablecontainer

ratherthanafuel-dispensernozzle.

•Donotoperatethemachinewithouttheentire

exhaustsysteminplaceandinproperworking

condition.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.Wipeupanyfuelthatspills.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

FuelSafety

•Fuelisextremelyammableandhighlyexplosive.

Areorexplosionfromfuelcanburnyouand

othersandcandamageproperty .

–Topreventastaticchargefromignitingthefuel,

placethecontainerand/ormachinedirectlyon

thegroundbeforelling,notinavehicleoron

anobject.

–Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuelthat

spills.

–Donothandlefuelwhensmokingoraroundan

openameorsparks.

–Donotremovethefuelcaporaddfueltothe

tankwhiletheengineisrunningorhot.

AddingFuel

RecommendedFuel

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol

(gasohol)or15%MTBE(methyltertiarybutyl

ether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.Gasolinewith15%

ethanol(E15)byvolumeisnotapprovedforuse.

Neverusegasolinethatcontainsmorethan

10%ethanolbyvolume,suchasE15(contains

15%ethanol),E20(contains20%ethanol),orE85

(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/or

10

enginedamagewhichmaynotbecoveredunder

warranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

PerformingDaily

Maintenance

Beforestartingthemachineeachday,performthe

EachUse/DailyprocedureslistedinMaintenance

(page24).

UsingStabilizer/Conditioner

Usefuelstabilizer/conditionerinthemachinetokeep

thefuelfreshlongerwhenusedasdirectedbythe

fuel-stabilizermanufacturer.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addtheamountoffuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizermanufacturer.

FillingtheFuelTank

1.Parkthemachineonalevelsurface,disengage

thePTO,movethemotion-controlleverstothe

NEUTRAL-LOCKposition,andengagetheparking

brake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundthefuel-tankcapandremovethe

cap.

4.Fillthefueltanktothebottomofthellerneck.

BreakinginaNewMachine

Newenginestaketimetodevelopfullpower.Mower

decksanddrivesystemshavehigherfrictionwhen

new,placingadditionalloadontheengine.Allow

40to50hoursofbreak-intimefornewmachinesto

developfullpowerandbestperformance.

UsingtheSafety-Interlock

System

WARNING

Ifsafety-interlockswitchesaredisconnected

ordamaged,themachinecouldoperate

unexpectedly,causingpersonalinjury.

•Donottamperwiththeinterlockswitches.

•Checktheoperationoftheinterlock

switchesdaily,andreplaceanydamaged

switchesbeforeoperatingthemachine.

Note:Donotllthefueltankcompletelyfull.

Theemptyspaceinthetankallowsthefuelto

expand.

5.Installthefuel-tankcapsecurely.Wipeupany

spilledfuel.

Figure6

Understandingthe

Safety-InterlockSystem

Thesafety-interlocksystemisdesignedtoprevent

PTOfromengagingunlessyoudo1ofthefollowing:

•Moveeithermotion-controllevertothecenter,

unlockedposition.

•PresstheONpositiononthePTOswitch.

Thesafety-interlocksystemisdesignedtostop

theblades/attachmentifyoumoveorrelease

bothmotion-controlleversintotheNEUTRAL-LOCK

position.

Thehourmeterhassymbolstonotifytheuser

wheneachinterlockcomponentisinthecorrect

position.Whenthecomponentisinthecorrect

position,atrianglelightsupinthecorresponding

square(Figure7).

g038312

11

Figure7

Note:Theclutchandblades/attachmentshould

engage.

9.PresstheOFFpositiononthePTOswitch.

Note:Theblades/attachmentshouldstop.

10.Withtheenginerunning,presstheONposition

onthePTOswitchwithoutholdingeither

motion-controllevertothecenter,unlocked

position.

Note:Theblades/attachmentshouldnot

g031282

engage.

1.Thetriangleslightupwhentheinterlockcomponentsare

inthecorrectposition.

TestingtheSafety-Interlock

System

ServiceInterval:Beforeeachuseordaily

Testthesafety-interlocksystembeforeyouusethe

machineeachtime.

Note:Ifthesafetysystemdoesnotoperateas

describedbelow,haveanAuthorizedServiceDealer

repairthesafetysystemimmediately.

1.Starttheengine;refertoStartingtheEngine

(page16).

2.Movethemotion-controlleverstothecenter,

unlockedposition.

Note:Theblades/attachmentshouldstopand

theengineshouldstoprunning.

3.Starttheengineanddisengagetheparking

brake.

4.Moveeithermotion-controllevertothecenter,

unlockedposition.

5.Continueholdingthemotion-controlleverin

thecenter,unlockedpositionandpresstheON

positiononthePTOswitch.

Note:Theclutchandblades/attachmentshould

engage.

6.Moveorreleasethemotion-controlleversinto

theNEUTRAL-LOCKposition.

Note:Theblades/attachmentshouldstopand

theengineshouldcontinuetorun.

7.PresstheOFFpositiononthePTOswitchand

moveeithermotion-controllevertothecenter,

unlockedposition.

8.Continueholdingthemotion-controlleverin

thecenter,unlockedpositionandpresstheON

positiononthePTOswitch.

DuringOperation

DuringOperationSafety

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

•Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.Avoidmowingin

wetconditions.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,theparkingbrakeisengaged,and

youareintheoperatingposition.

•Ensurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.

•Keepyourhandsandfeetawayfromthecutting

units.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Useextremecarewhenapproachingblind

corners,shrubs,trees,orotherobjectsthatmay

blockyourview.

12

•Stopthebladeswheneveryouarenotmowing.

•Stopthemachine,removetheignitionkey ,and

waitforallmovingpartstostopbeforeinspecting

themowerdeckorattachmentafterstrikingan

objectorifthereisanabnormalvibrationinthe

machine.Makeallnecessaryrepairsbefore

resumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Disengagethecuttingunitandshutofftheengine

beforeadjustingtheheightofcut(unlessyoucan

adjustitfromtheoperatingposition).

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,which

islethalifinhaled.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(including

toemptythecatchersortounclogthechute),do

thefollowing:

–Parkthemachineonalevelsurface.

–Disengagethepowertake-off.

–Engagetheparkingbrake.

–Shutofftheengineandremovetheignitionkey.

–Waitforallmovingpartstostop.

•Shutoffthemachineanddisengagethedriveto

thecuttingunitinthefollowingsituations:

–Beforefueling

–Beforeclearingblockages

–Beforechecking,cleaning,ormaintainingthe

cuttingunit

–Afterstrikingaforeignobjectorifanabnormal

vibrationoccurs.Inspectthecuttingunitfor

damageandmakerepairsbeforestartingand

operatingthemachine

–Beforeleavingtheoperatingposition

–Evaluatethesiteconditionsofthedayto

determineiftheslopeissafeformachine

operation.Usecommonsenseandgood

judgmentwhenperformingthisevaluation.

Changesintheterrain,suchasmoisture,can

quicklyaffecttheoperationofthemachineon

aslope.

•Operateacrossslopes,neverupanddown.Avoid

operationonexcessivelysteeporwetslopes.

•Identifyhazardsatthebaseoftheslope.Do

notoperatethemachineneardrop-offs,ditches,

embankments,water,orotherhazards.The

machinecouldsuddenlyrolloverifawheelgoes

overtheedgeortheedgecollapses.Keepasafe

distance(twicethewidthofthemachine)between

themachineandanyhazard.Useawalk-behind

machineorahandheldtooltooperateinthese

areas.

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction;turnslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steeringorstabilityisinquestion.

Beawarethatoperatingthemachineonwet

grass,acrossslopesordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.Themachinecanslideeven

ifthedrivewheelsarestopped.

•Removeormarkobstaclessuchasditches,holes,

ruts,bumps,rocks,orotherhiddenhazards.Tall

grasscanhideobstacles.Uneventerraincould

overturnthemachine.

•Useextracarewhileoperatingwithaccessoriesor

attachments.Thesecanchangethestabilityof

themachineandcausealossofcontrol.Follow

directionsforcounterweights.

•Ifyoulosecontrolofthemachine,stepoffand

awayfromthedirectionoftravelofthemachine.

•Donotusethemachineasatowingvehicle.

•Useonlyaccessoriesandattachmentsapproved

byTheT oro®Company.

SlopeSafety

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Youareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.Beforeusingthemachine

onaslope,dothefollowing:

–Reviewandunderstandtheslopeinstructions

inthemanualandonthemachine.

13

OperatingtheParking

Operatingthe

Brake

Alwaysengagetheparkingbrakewhenyoushutoff

themachineorleaveitunattended.Beforeeachuse,

checktheparkingbrakeforproperoperation.

Iftheparkingbrakedoesnotholdsecurely,adjustit;

refertoAdjustingtheBrakes(page47).

Pulltheparking-brakeleverrearwardtoengageit

(Figure8).

Pushtheparking-brakeleverforwardtodisengageit.

Figure8

1.Parkingbrake—engaged2.Parking

brake—disengaged

Mower-Blade-Control

Switch(PTO)

Usetheblade-controlswitch(PTO)inconjunctionwith

themotion-controlleverstoengageanddisengage

themowerblades.

EngagingtheMowerBlades(PTO)

g009465

Figure9

g301277

14

DisengagingtheMowerBlades

(PTO)

Figure10andFigure11show2waystodisengage

themowerblades.

Figure10

OperatingtheChoke

Usethechoketostartacoldengine.

1.Pullupthechokeknobtoengagethechoke

beforeusingthekeyswitch(Figure13).

2.Pushdownthechokeknobtodisengagethe

chokeaftertheenginehasstarted(Figure13).

g301401

Figure11

Note:Ifyoudisengagethemowerbladesby

releasingthemotion-controllevers,youcanengage

thebladesagainbypressingtheONpositionofthe

switch(Figure9)withoutpressingtheOFFposition

rst.

OperatingtheThrottle

YoucanmovethethrottlecontrolbetweenFASTand

SLOWpositions(Figure12).

AlwaysusetheFASTpositionwhenengagingthePTO.

g031593

g008959

Figure13

1.ONposition2.OFFposition

Figure12

g008946

15

OperatingtheIgnition

StartingtheEngine

Switch

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failure

tofollowtheseinstructionscanburnoutthe

startermotor.

Note:Y oumayneedtorepeatthecycleforstarting

theenginewhenyoustartitforthersttimeafteryou

havelledacompletelyemptyfuelsystemwithfuel.

Figure14

Important:Donotengagethestarterformore

than5secondsatatime.Iftheenginefailsto

start,wait15secondsbetweenattempts.Failure

tofollowtheseinstructionscanburnoutthe

startermotor.

Note:Y oumayneedtorepeatthecycleforstarting

theenginewhenyoustartitforthersttimeafteryou

havelledacompletelyemptyfuelsystemwithfuel.

g031239

Figure15

g031281

g339443

Figure16

16

ShuttingOfftheEngine

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingtheoperator’s

position.

OperatingthePlatform

Youcanusethemachinewiththeplatforminthe

upordownposition.Itisyourpreferenceonwhich

positiontouse.

WARNING

Theoperatorplatformisheavyandmaycause

injurywhenyouraiseorlowerit.Carefully

lowerorraisetheoperatorplatform,as

suddenlydroppingitcouldinjureyou.

Lettheengineidleatslowthrottle(turtle)for60

secondsbeforeturningthekeyswitchtotheOFF

position.

•Donotputyourhandsorngersinthe

platform-pivotareawhenloweringor

raisingtheoperatorplatform.

•Makesurethattheplatformissupported

whenyoupullthelatchpinout.

•Makesurethatthelatchsecuresthe

platformwhenfoldingitup.Pushittight

againstthecushionforthelatchpinto

lockintoplace.

•Keepbystandersawayfromthemachine

whenraisingorloweringtheplatform.

OperatingtheMachinewiththe

PlatformUp

Operatethemachinewiththeplatformupforthe

followingconditions:

•Usingthemachineneardrop-offs

•Usingthemachineinsmallareaswherethe

machineistoolarge

•Areaswithlow-hangingbranchesorobstacles

•Loadingthemachinefortransport

•Drivingupslopes

Figure17

Important:Makesurethatthefuel-shutoffvalve

isclosedbeforetransportingorstoringthe

machinetopreventafuelleak.Beforestoringthe

machine,disconnectthesparkplug(s)toprevent

thepossibilityofaccidentalstarting.

Toraisetheplatform,pullthebackoftheplatformup

g301288

sothatthelatchpinandknoblockitintoplace.Push

ittightagainstthecushionforthelatchpintolockit

intoplace.

OperatingtheMachinewiththe

PlatformDown

Operatethemachinewiththeplatformdownforthe

followingconditions:

•Usingthemachineinmostareas

•Drivingacrossslopes

•Drivingdownslopes

Tolowertheplatform,pushtheplatformforward

againstthecushiontoreleasepressureonthelatch

pin,thenpulltheknoboutandlowertheplatform

(Figure18).

17

Figure18

DrivingForward

1.Disengagetheparkingbrake;refertoOperating

theParkingBrake(page14).

2.Movethemotion-controlleverstothecenter,

unlockedposition.

g031026

1.Platformup

2.Platformdown

3.Pulltheknobouttorelease

theplatform.

DrivingForwardor

Backward

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Place

thethrottlecontrolintheFASTpositionforbest

performance.

Important:Backthemachineovercurbs,1wheel

atatime;drivingitforwardovercurbscould

damagethemachine.

CAUTION

Themachinecanspinveryrapidly,andyou

maylosecontrolofthemachine,causing

personalinjurytoyouanddamagetothe

machine.

Figure19

1.Frontreferencebar

2.Leftcontrollever

3.Rearreferencebar6.Leftcontrolleverinthe

4.Rightcontrollever

5.Rightcontrolleverinthe

NEUTRAL-LOCKposition

NEUTRAL-LOCKposition

3.Slowlypushthemotion-controlleversforward

(Figure20).

Note:Theengineshutsoffifyoumovea

motion-controlleverwhiletheparkingbrakeis

engaged.

Note:Thefartheryoumovethemotion-control

leversineitherdirection,thefasterthemachine

movesinthatdirection.

Note:T ostop,pullthemotion-controllevers

backtotheNEUTRALposition.

g030983

Slowdownthemachinebeforemakingsharp

turns.

18

Figure20

AdjustingtheHeight-of-Cut

Theheight-of-cutcanbeadjustedfrom38to127mm

(1-1/2to5inches)in6mm(1/4inch)increments.

Note:Usingaheight-of-cutunder51mm(2inches)

increasesthewearonthemower-deckbelt.Usea

height-of-cutthatisgreaterthan51mm(2inches)

wheneverpossible.

g273674

DrivingBackward

1.Movebothmotion-controlleverstothecenter,

unlockedposition.

2.Slowlypullthemotion-controlleversrearward

(Figure21).

Figure21

g273673

g267253

Figure22

19

UsingWeights

•Installweightstoimprovebalance.Youcanaddor

removeweightstocreateoptimizedperformance

underdifferentoperatingconditionsandforyour

preference.

AfterOperation

AfterOperationSafety

•Addorremoveweights1atatimeuntilyou

achievethedesiredhandlingandbalance.

•RefertotheOperator’sManualofattachmentsfor

recommendedweights.

Note:ContactanAuthorizedServiceDealertoorder

aweightkit.

WARNING

Excessiveweightchangescanaffectthe

handlingandoperationofthemachine.

Thiscouldcauseseriousinjurytoyouor

bystanders.

•Makeweightchangesinsmallincrements

only.

•Evaluatethemachineaftereachweight

changetoensurethatyoucanoperatethe

machinesafely.

GeneralSafety

•Alwaysshutoffthemachine,removetheignition

key,waitforallmovingpartstostop,andallow

themachinetocoolbeforeadjusting,servicing,

cleaning,orstoringit.

•Cleangrassanddebrisfromthecuttingunits,

mufers,andenginecompartmenttohelpprevent

res.Cleanupoilorfuelspills.

•Shutoffthefuelbeforestoringortransportingthe

machine.

•DisengagethePTOwheneveryouaretransporting

ornotusingthemachine.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Usefull-widthrampsforloadingthemachineinto

atrailerortruck.

•Tiethemachinedownsecurelyusingstraps,

chains,cable,orropes.Bothfrontandrearstraps

shouldbedirecteddownandoutwardfromthe

machine.

20

UsingtheFuel-Shutoff

PushingtheMachineby

Valve

Closethefuel-shutoffvalvefortransport,maintenance,

andstorage(Figure23).

Ensurethatthefuel-shutoffvalveisopenwhen

startingtheengine.

Hand

Thebypassvalvesallowyoutopushthemachineby

handwithouttheenginerunning.

Important:Alwayspushthemachinebyhand.

Donottowthemachine,becausehydraulic

damagemayoccur.

Important:Donotstartoroperatethemachine

withthebypassvalvesopen.Damagetosystem

mayoccur.

g273676

Figure23

1.ONposition2.OFFposition

g031238

g301290

Figure24

21

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Useafull-widthramp.Ensurethatthetrailer

ortruckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyouorbystandersavoidinjury.Refertoyour

localordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidents,causingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure25).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Ensurethatthelengthoframpisatleast4

timesaslongastheheightofthetraileror

truckbedtotheground.

Figure25

1.Full-widthrampinstowed

position

2.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

3.H=heightofthetraileror

truckbedtotheground

4.Trailer

LoadingtheMachine

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Backthemachineuptherampandwalkit

forwarddowntheramp.

g229507

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakesand

lights.

3.Lowertheramp(Figure25).

4.Raisetheplatform.

Important:Alwayskeeptheplatformup

whenloadingandunloadingthemachine.

5.Backthemachineuptheramp(Figure26).

22

Figure26

g031405

1.Backthemachineupthe

ramp.

2.Walkthemachinedown

theramp.

6.Shutofftheengine,removethekey,andengage

theparkingbrake.

7.Tiedownthemachinenearthefrontcaster

wheelsandtherearbumperwithstraps,chains,

cable,orropes(Figure27).Refertolocal

regulationsfortie-downrequirements.

1.Tie-downloops

g273707

Figure27

23

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

CAUTION

Ifyouleavetheignitionkeyintheswitch,someonecouldaccidentlystarttheengineand

seriousinjureyouorotherbystanders.

Removetheignitionkeyfromtheswitchbeforeyouperformanymaintenance.

MaintenanceSafety

•Beforeadjusting,cleaning,servicing,orleaving

themachine,dothefollowing:

–Parkthemachineonalevelsurface.

–Disengagethedrives.

–Engagetheparkingbrake.

–Shutofftheengineandremovetheignitionkey.

–Waitforallmovingpartstostop.

–Allowmachinecomponentstocoolbefore

performingmaintenance.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Checktheparkingbrakeoperationfrequently.

Adjustandservicethebrakeasneeded.

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Cleangrassanddebrisfromthecuttingunit,

drives,mufer,andenginetohelppreventres.

Cleanupoilorfuelspills.

•Checkthegrasscatchercomponentsfrequently

andreplacethemwhentheyarewornordamaged.

•Donotrelyonahydraulicsystemtosupportthe

machine;supportthemachinewithjackstands

wheneveryouraisethemachine.

•Keepallpartsingoodworkingconditionandall

hydraulicttingstight.Replaceallworn,damaged,

ormissingpartsanddecals.Keepallfasteners

tighttoensurethatthemachineisinsafeworking

condition.

•Toensureoptimumperformanceandcontinued

safetycerticationofthemachine,useonly

genuineT ororeplacementpartsandaccessories.

Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous,and

suchusecouldvoidtheproductwarranty.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Aftertherst100hours

Beforeeachuseordaily

Every50hours

MaintenanceProcedure

•Changetheengineoil.

•Checkthehydraulic-uidlevel.

•Changethehydraulicltersandhydraulicuid.

•Checkthewheel-lugnuts.

•Checkthesafety-interlocksystem.

•Checktheengine-oillevel.

•Cleantheair-intakescreen(moreoftenindirtyordustyconditions).

•Cleanthetransmissioncoolingfansandguards.

•T esttheparkingbrake.

•Inspecttheblades.

•Cleanunderthemowerdeck.

•Cleandebrisfromrearwheelmotors.

•Checkthesparkarrester(ifequipped).

•Checkthetirepressure.

•Checkthehydraulic-uidlevel.

24

MaintenanceService

Every100hours

Interval

MaintenanceProcedure

•Changetheengineoil.

•Check,cleanandgapthesparkplug.

•Checkthebattery.

•Checktheclutch.

•Checkandcleantheenginecoolingnsandshrouds(moreoftenindirtyordusty

conditions).

•Checkthemower-deckbelt(s).

Every200hours

Every250hours

Every300hours

Every500hours

Every800hours

Every1,000hours

Beforestorage

Yearly

•Changetheengine-oillter.

•Replacetheprimaryairlter(moreoftenindirtyordustyconditions).

•Checktheinnerairlter(moreoftenindirtyordustyconditions).

•Checkandadjustthevalveclearance.ContactanAuthorizedServiceDealer.

•Replacetheinnerairlter(moreoftenindirtyordustyconditions).

•Adjustthecaster-pivotbearing.

•Changethehydraulicltersandhydraulicuid.

•Replacethefuellter.

•Replacethetransmissionbelt.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Paintchippedsurfaces.

•Performallmaintenanceprocedureslistedabovebeforestorage.

•Greasethefrontcasterpivots(moreoftenindirtyordustyconditions).

•Greasethecaster-wheelhubs.

•Greasethemotioncontrols.

•Applyanti-seizecompoundtothecushionknobs.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

25

Pre-Maintenance

OpeningtheEngineGuard

Procedures

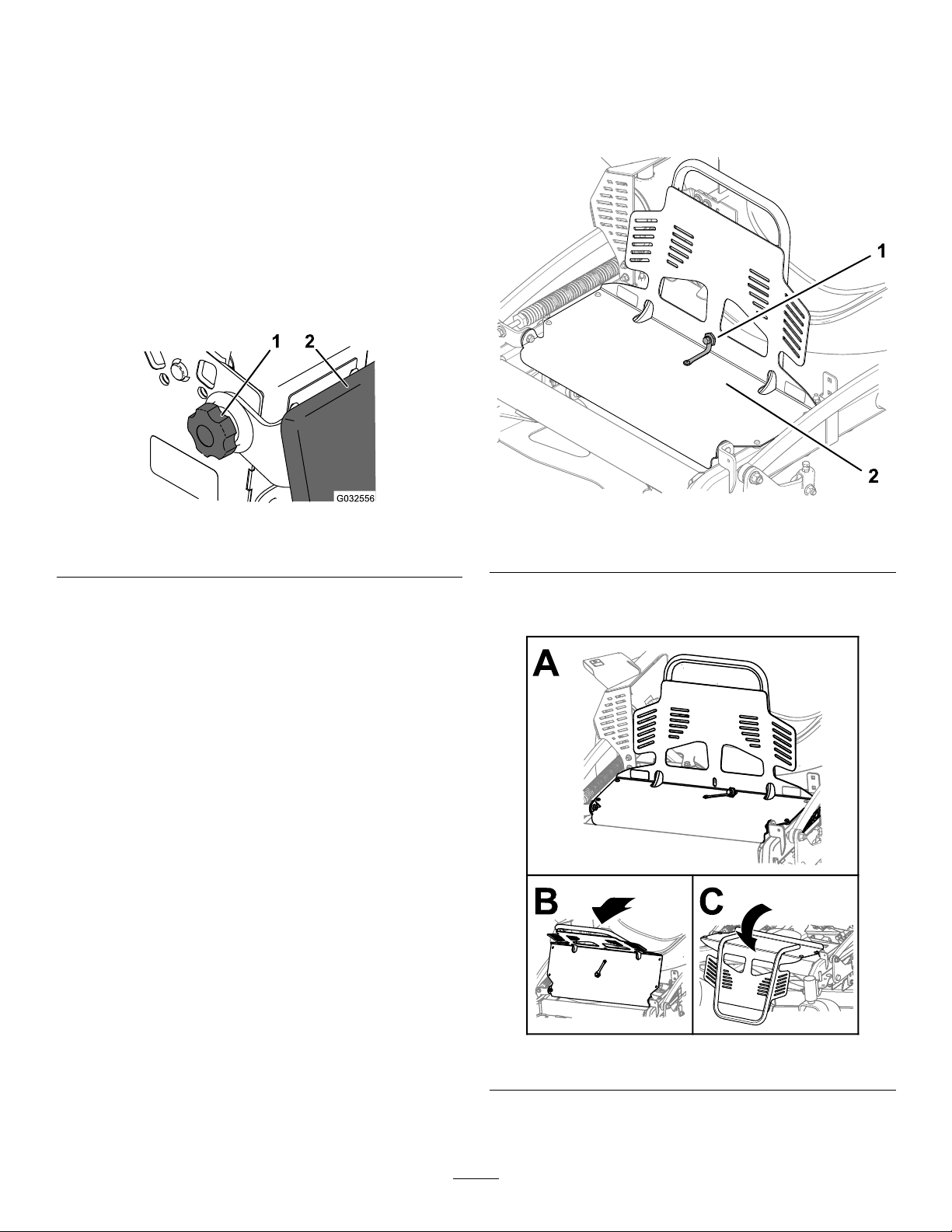

ReleasingtheCushionfor

RearAccess

Youcanreleasethecushionforrearaccesstothe

machineformaintenanceoradjustment.

1.Lowertheplatform.

2.Loosenthetwistknobsoneachsideofthe

machine(Figure28).

Figure28

1.Twistknob

2.Cushion

andGuardExtension

1.Removetheboltandshouldernutsecuringthe

engineguardtotheguardextension(Figure29).

g032556

1.Boltandshouldernut2.Engineguard

Figure29

g279539

3.Removethecushionandlowerittotheplatform.

4.Performanymaintenanceoradjustmentonthe

machine.

5.Raisethecushion,andslideitontothepinson

bothsidesofthemachine.

6.Tightenthetwistknobs.

2.Rotatetheengineguardforwardasshownin

Figure30.

g279542

Figure30

26

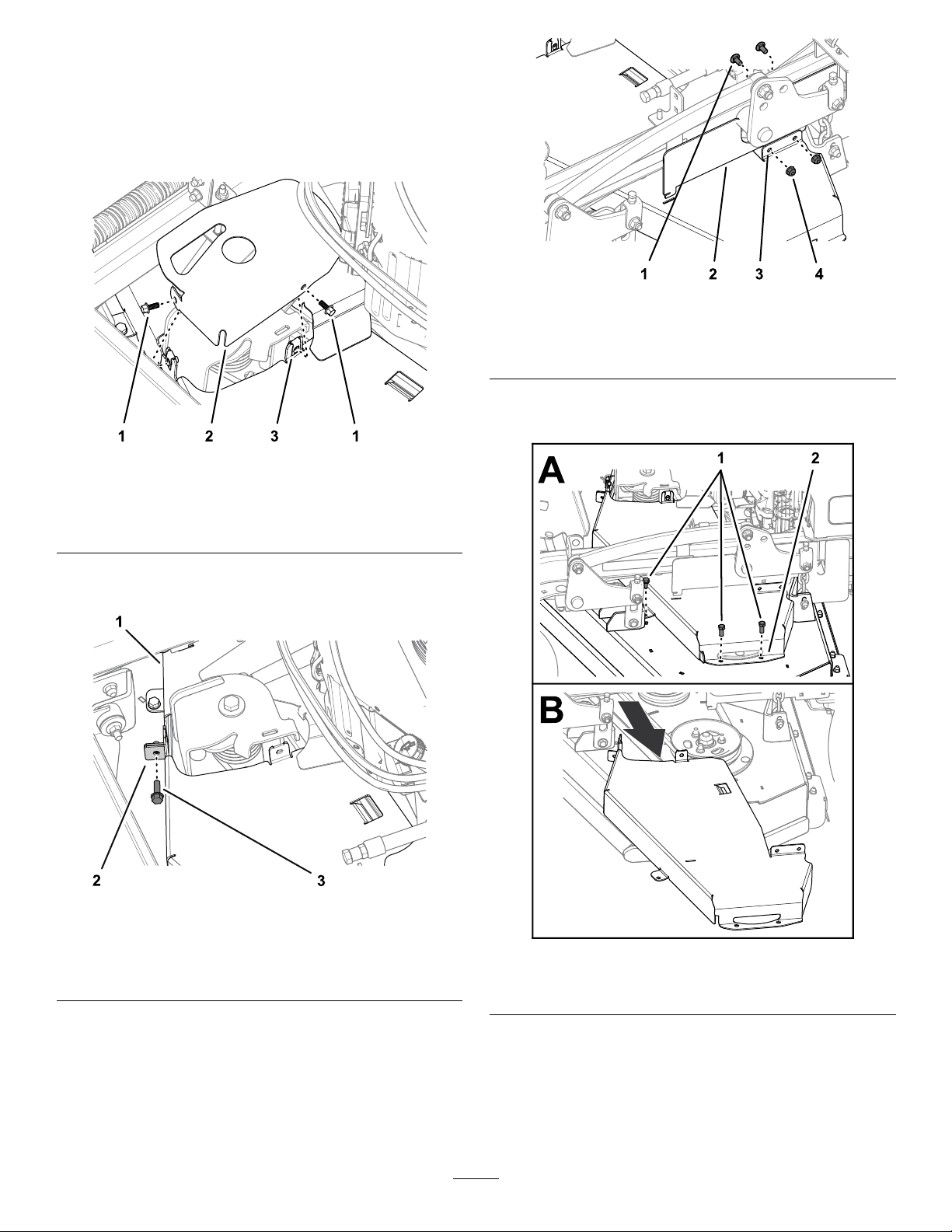

3.Removethe2bolts(5/16x1inch)andbelt

guard(Figure31).

Figure31

ClosingtheEngineGuard

andGuardExtension

1.InstalltheextensionguardasshowninFigure

32.T orquethenutsto20to25N∙m(15to18

ft-lb).

2.InstallthebeltguardasshowninFigure31.

Torquetheboltsto20to25N∙m(15to18ft-lb).

3.Rotatetheengineguardbackasshownin

Figure33.

g279540

1.Bolt—5/16x1inch(2)

2.Beltguard

4.Removethehexnut(5/16inch)nut(5/16inch)

securingtheguardextensiontothecarriage

bolts(Figure32).Removetheguardextension.

Figure32

1.Hexnut(5/16inch)3.Nut(5/16)

2.Guardextension4.Carriagebolt(5/16x4

inches)

g279543

Figure33

4.Securetheengineguardtotheextensionguard

usingtheboltandshouldernutasshownin

Figure29.

g279541

27

RemovingtheLeftBelt

Cover

1.Removethe2ange-headscrewsthatsecure

thetensionercovertotheleftbeltcover,and

removethetensionercover(Figure34).

Figure34

g270474

Figure36

1.Carriagebolt3.Leftbeltcover

2.LeftsideCEcover

4.Flangelocknut

4.Removethe3boltsthatsecuretheleftbeltcover

tothedeck,andremovethecover(Figure37).

g270487

1.Flange-headscrews(1/4

x5/8inch)

2.Tensionercover

3.Leftbeltcover

2.Removetheboltthatsecurethebeltcover

angesasshowninFigure35.

Figure35

1.Rightbeltcover

2.Flange(leftbeltcover)

3.Flange-headscrew(left

andrightbeltcover)

g270486

g270488

Figure37

1.Bolts

2.Leftbeltcover

3.Removethe2carriageboltsand2locknuts

thatsecuretheleftsideCEcovertotheleftbelt

cover(Figure36).

28

RemovingtheRightBelt

Cover

1.Removethe2carriageboltsand2locknutsthat

securetherightsideCEcovertotherightbelt

cover(Figure38).

Figure38

g270475

1.Flangelocknut

2.Rightbeltcover

3.RightsideCEcover

4.Carriagebolt

2.Removethe2boltsandange-headscrewthat

securetherightbeltcovertothedeck,and

removethecover(Figure39).

g270489

Figure39

1.Rightbeltcover3.Deck

2.Bolt4.Flange-headscrew

29

InstallingtheRightBelt

Cover

1.Assembletherightbeltcovertothedeck

(Figure40)withthe2boltsthatyouremovedin

RemovingtheLeftBeltCover(page28).

2.AssembletherightsideCEcovertotheright

beltcover(Figure41)withthe2carriagebolts

and2locknutsthatyouremovedinRemoving

theLeftBeltCover(page28).

g270475

Figure41

Figure40

1.Rightbeltcover3.Deck

2.Bolt4.Flange-headscrew

1.Flangelocknut

2.Rightbeltcover

g270504

3.RightsideCEcover

4.Carriagebolt

30

InstallingtheLeftBelt

Cover

1.Assembletheleftbeltcovertothedeck(Figure

42)withthe3boltsthatyouremovedin

RemovingtheLeftBeltCover(page28).

Figure43

1.Carriagebolt3.Leftbeltcover

2.LeftsideCEcover

4.Flangelocknut

3.Securethebeltcoverangeswiththe

ange-headscrew(Figure44)thatyouremoved

inRemovingtheLeftBeltCover(page28).

g270474

Figure42

1.Bolts

2.Leftbeltcover

2.AssembletheleftsideCEcovertotheleftbelt

cover(Figure43)withthe2carriageboltsand2

locknutsthatyouremovedinRemovingtheLeft

BeltCover(page28).

g270503

g270486

Figure44

1.Rightbeltcover

2.Flange(leftbeltcover)

3.Flange-headscrew(left

andrightbeltcover)

4.Assemblethetensionercovertotheleftbelt

coverwiththe2ange-headscrewsthatyou

removedinRemovingtheLeftBeltCover(page

28),asshowninFigure45.

31

1.Flange-headscrews(1/4

x5/8inch)

2.Tensionercover

Figure45

3.Leftbeltcover

Lubrication

GreasingtheMachine

GreasewithNo.2lithiumormolybdenumgrease.

1.DisengagethePTOandsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanthegreasettingswitharag.

Note:Makesuretoscrapeanypaintoffthe

g270487

frontofthetting(s).

4.Connectagreaseguntothetting.

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings.

6.Wipeupanyexcessgrease.

GreasingtheTorsionIdler

Important:Useonlyhigh-temperaturegrease.

Donotusegeneral-purposegrease.

1.Opentheengineguard;refertoOpeningthe

EngineGuardandGuardExtension(page26).

2.Removetheleftbeltcover;refertoRemoving

theLeftBeltCover(page28).

3.Greasethetorsionidleronthemowerdeck

usinghigh-temperaturegreaseatthegrease

ttingshowninFigure46.

Figure46

1.Greasetting

4.Installtheleftbeltcover;refertoInstallingthe

LeftBeltCover(page31).

5.Closetheengineguard;refertoClosingthe

EngineGuardandGuardExtension(page27).

32

g273838

GreasingtheFrontCaster

Pivots

ServiceInterval:Yearly

Greasetype:Lithiumormolybdenumgrease

Note:Thread-lockingadhesivehasbeen

appliedtolockthespacernutstotheaxle.

Removetheaxle(withtheotherspacernutstill

assembledtoit)fromthewheelassembly.

6.Pryouttheseals,inspectbearingsforwearor

damage,andreplacethemifnecessary .

1.Removethedustcapandadjustthecaster

pivots;refertoAdjustingtheCaster-Pivot

Bearing(page44).

Note:Keepthedustcapoffuntilyouhave

nishedgreasingthecasterpivots.

2.Removethehexplug.

3.Threadagreasetting(1/4inch–28taper

thread)intothehole.

4.Pumpgreaseintothettinguntilitoozesout

aroundthetopbearing.

5.Removethegreasettingfromthehole.

6.Installthehexpluganddustcap.

GreasingtheCaster-Wheel

Hubs

ServiceInterval:Yearly

Greasetype:Lithiumormolybdenumgrease

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

7.Packthebearingswithageneral-purpose

grease.

8.Insert1bearingand1newsealintothewheel.

Note:Y oumustreplacetheseals.

9.Ifbothspacernutsintheaxleassembly

havebeenremoved(orbrokenloose),apply

athread-lockingadhesiveto1spacernut,

threadingitontotheaxlewiththewrenchats

facingoutward.

Note:Donotthreadthespacernutallof

thewayontotheendoftheaxle.Leave

approximately3mm(1/8inch)fromtheouter

surfaceofthespacernuttotheendoftheaxle

insidethenut.

10.Inserttheassemblednutandaxleintothewheel

onthesideofthewheelwiththenewsealand

bearing.

11.Withtheopenendofthewheelfacingup,ll

theareainsidethewheelaroundtheaxlefullof

general-purposegrease.

12.Insertthesecondbearingandthenewsealinto

thewheel.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethecasterwheelfromthecasterforks.

4.Removethesealguardsfromthewheelhub

(Figure47).

Figure47

1.Sealguard2.Spacernutwithwrench

ats

5.Remove1spacernutfromtheaxleassemblyin

thecasterwheel.

13.Applyathread-lockingadhesivetothesecond

spacernut,threadingitontotheaxlewiththe

wrenchatsfacingoutward.

14.Torquethenutto8to9N∙m(71to80in-lb),

loosenit,thentorqueitto2to3N∙m(20to25

in-lb).

Note:Makesurethattheaxledoesnotextend

beyondeithernut.

15.Installthesealguardsoverthewheelhuband

insertthewheelintothecasterfork.

16.Installthecasterboltandtightenthenutfully.

Important:Topreventsealandbearingdamage,

checkthebearingadjustmentoftenbyspinning

thecasterwheel.Thewheelshouldnotspinfreely

(morethan1or2revolutions)orhaveanyside

g006115

play.Ifthewheelspinsfreely,adjustthetorque

onthespacernutuntilthereisaslightamountof

drag,andapplythread-lockingadhesive.

33

GreasingtheMotion

Controls

ServiceInterval:Yearly

Greasetheoperator-presence-controlballjointand

themotion-controlbushingforbothlevers.

Note:Useanoildripbetweentheleverbracketsto

greasethebushing,locatedinthepivottube.

EngineMaintenance

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Keepyourhands,feet,face,clothing,andother

bodypartsawayfromthemuferandotherhot

surfaces.

ServicingtheAirCleaner

Every250hours—Replacetheprimaryairlter

(moreoftenindirtyordustyconditions).

Every250hours—Checktheinnerairlter

(moreoftenindirtyordustyconditions).

Every500hours—Replacetheinnerairlter

(moreoftenindirtyordustyconditions).

RemovingtheFilters

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Opentheengineguard;refertoOpeningthe

EngineGuardandGuardExtension(page26).

4.Releasetheretainingclampsontheaircleaner

andpulltheair-cleanercoverofftheair-cleaner

body(Figure49).

1.Operator-presencecontrol

balljoint

Figure48

2.Pivottube

g228034

g026970

Figure49

1.Air-cleanerclamps

2.Air-cleanercover

5.Cleantheinsideoftheair-cleanercoverwith

compressedair.

6.Gentlyslidetheprimarylteroutofthe

air-cleanerbody(Figure49).

3.Primarylter

4.Innerlter

34

Note:Avoidknockingthelterintothesideof

thebody.

ServicingtheEngineOil

7.Removetheinnerlteronlytoreplaceit.

InspectingtheFilters

1.Inspectthesafetylter.Ifitisdirty,replaceboth

thesafetyandprimarylters.

Important:Donotattempttocleanthe

safetylter.Ifthesafetylterisdirty,then

theprimarylterisdamaged.

2.Inspecttheprimarylterfordamagebylooking

intothelterwhileshiningabrightlightonthe

outsideofthelter.Iftheprimarylterisdirty,

bent,ordamaged,replaceit.

Note:Holesinthelterappearasbrightspots.

Donotcleantheprimarylter.

InstallingtheFilters

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandthe

coverinstalled.

1.Ifyouareinstallingnewlters,checkeachlter

forshippingdamage.

Engine-OilSpecications

OilType:Detergentoil(APIserviceSJorhigher)

EngineOilCapacity:2.1L(71oz)withthelter;

1.8L(61oz)withoutthelter

Viscosity:Refertothetablebelow.

g004216

Figure50

Note:Donotuseadamagedlter.

2.Ifyouarereplacingtheinnerlter,carefullyslide

itintothelterbody(Figure49).

3.Carefullyslidetheprimarylteroverthesafety

lter(Figure49).

Note:Ensurethattheprimarylterisfully

seatedbypushingontheouterrimwhile

installingit.

Important:Donotpressonthesoft,inside

areaofthelter.

4.Installtheair-cleanercoverwiththebreathercap

down,androtatesothattheretainingclamps

lockthecoverinplace(Figure49).

5.Closetheengineguard;refertoClosingthe

EngineGuardandGuardExtension(page27).

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

Note:Checktheoilwhentheengineiscold.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keepyourhands,feet,face,clothingand

otherbodypartsawaythemuferandother

hotsurfaces.

Important:Donotoverllthecrankcasewithoil

becausedamagetotheenginemayresult.Donot

runenginewithoilbelowthelowmarkbecause

theenginemaybedamaged.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Checktheengine-oillevelasshownin(Figure

51).

35

ChangingtheEngineOil

ServiceInterval:Aftertherst8hours

Every100hours

Note:Disposeoftheusedoilatarecyclingcenter.

g273859

lowerthantheoppositesidetoassuretheoil

drainscompletely.

2.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

3.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

4.ChangetheengineoilasshowninFigure52.

g273859

1.Parkthemachinesothatthedrainsideisslightly

Figure51

g307458

g031447

Figure52

5.Slowlypourapproximately80%ofthespecied

oilintothellertubeandslowlyaddthe

additionaloiltobringittotheFullmark(Figure

53).

36

Figure53

6.Starttheengineanddrivetoaatarea.

7.Checktheoillevelagain.

g273859

g027477

ChangingtheEngine-OilFilter

ServiceInterval:Every200hours

Note:Changetheengine-oilltermorefrequently

whenoperatingconditionsareextremelydustyor

sandy.

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page36).

2.Changetheengine-oillter(Figure54).

g027477

Figure54

Note:Ensurethattheoil-ltergaskettouches

theengine,thenrotatethelteranextra3/4turn.

3.Fillthecrankcasewiththepropertypeofnew

oil;refertoEngine-OilSpecications(page35).

ServicingtheSparkPlug

ServiceInterval:Every100hours

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

Type:NGK®BPR4ESorequivalent

Airgap:0.75mm(0.03inch)

37

RemovingtheSparkPlug

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.RemovethesparkplugasshowninFigure55.

InstallingtheSparkPlug

Figure55

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty.

Setthegapto0.75mm(0.03inch).

g273860

Figure57

g027661

CheckingtheSpark

Arrester

g027478

ForMachineswithaSpark

Arrester

ServiceInterval:Every50hours

WARNING

Hotexhaust-systemcomponentsmayignite

fuelvaporsevenafteryoushutofftheengine.

Hotparticlesexhaustedduringengine

operationmayigniteammablematerials,

resultinginpersonalinjuryorproperty

damage.

Donotrefuelorruntheengineunlessthe

sparkarresterisinstalled.

Figure56

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Waitforthemufertocool.

g206628

4.Ifyouseeanybreaksinthescreenorwelds,

replacethearrester.

5.Ifthescreenisplugged,removethearrester,

shakelooseparticlesoutofthearrester,and

cleanthescreenwithawirebrush(soakthe

screeninsolventifnecessary).

6.Installthearresterontheexhaustoutlet.

38

FuelSystem

Maintenance

DrainingtheFuelTank

Youcandrainthefueltankbyremovingitandpouring

thefueloutofthellneck;refertoRemovingtheFuel

Tank(page39).Youcanalsodrainthefueltankby

usingasiphoninthefollowingprocedure.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

RemovingtheFuelTank

1.Lowertheplatform.

2.Releasethecushion;refertoReleasingthe

CushionforRearAccess(page26).

3.Removethecrossbracket.

•Drainfuelfromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanyfuelthatspills.

•Neversmokewhendrainingfuel,andstay

awayfromanopename,orwhereaspark

mayignitethefuelfumes.

1.DisengagethePTO,movethemotion-control

leverstotheNEUTRAL-LOCKposition,and

engagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Cleanaroundthefuelcaptopreventdebrisfrom

gettingintothefueltank(Figure58).

4.Removethefuelcap.

5.Insertasyphonpumpintothefueltank.

6.Usingthesyphonpump,drainthefuelintoafuel

container.

7.Wipeupanyspilledfuel.

Figure59

1.Fueltank

4.Removethefueltankandsetitontheoperator

platform.

2.Crossbracket

Note:Ifyouwanttomovethefueltankfurther

fromthemachine,removethefuelandvent

linesfromthetopofthetank.

g031413

1.Fuelcap

g273861

Figure58

39

ReplacingtheFuelFilter

ElectricalSystem

ServiceInterval:Every800hours/Yearly(whichever

comesrst)

Donotinstalladirtylterifitisremovedfromthefuel

line.

Note:Wipeupanyspilledfuel.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Closethefuel-shutoffvalve;refertoUsingthe

Fuel-ShutoffValve(page21).

4.ReplacethefuellterasshowninFigure60.

Maintenance

ElectricalSystemSafety

•Disconnectthebatteryorremovethespark-plug

wirebeforemakinganyrepairs.Disconnectthe

negativeterminalrstandthepositiveterminal

last.Connectthepositiveterminalrstand

negativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

ServicingtheBattery

ServiceInterval:Every100hours

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

fourpartswaterand1partbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoprevent

corrosion.

Figure60

Voltage:12V

RemovingtheBattery

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.RemovethebatteryasshowninFigure61.

g027518

40

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthat

canexplode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity)topreventbatterydamage

whenthetemperatureisbelow0°C(32°F).

1.Removethebatteryfromthechassis;referto

RemovingtheBattery(page40).

2.Checktheelectrolytelevel.

3.Ensurethatthellercapsareinstalledonthe

battery.

4.Chargethebatteryfor1hourat25to30Aor6

hoursat4to6A.

5.Whenthebatteryisfullycharged,unplugthe

chargerfromtheelectricaloutlet,anddisconnect

thechargerleadsfromthebatteryposts(Figure

62).

Figure61

6.Installthebatteryontothemachineandconnect

thebatterycables;refertoInstallingtheBattery

(page42).

Note:Donotrunthemachinewiththebattery

g030988

disconnected;electricaldamagemayoccur.

Figure62

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

g000538

41

InstallingtheBattery

InstallthebatteryasshowninFigure63.

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.It

requiresnomaintenance.Ifafuseblows,checkthe

componentorcircuitforamalfunctionorshort.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Releasetheoperatorcushionfromtherearof

themachine.

4.Ifyouneedtoaccessthechargefuse,remove

thefueltank;refertoRemovingtheFuelT ank

(page39).

5.Pulloutthefuseandreplaceit(Figure64).

Figure63

g031414

g030989

1.Keyswitchfuse(15A)4.Hourmeter(7.5A)

2.Accessoryport(15A)5.Chargefuse(30A)

3.Power-takeoff(PTO)fuse

(10A)

Figure64

6.Installthefueltank,ifremoved;referto

RemovingtheFuelTank(page39).

7.Installtheoperatorcushion.

42

DriveSystem

Maintenance

AdjustingtheTracking

Note:Ifyouareunabletoachieveproper

trackingbyadjustingtheleftcontrolrod,contact

yourAuthorizedServiceDealer.

6.Checkthatthemachinedoesnotcreepfrom

theneutralpositionwiththeparkbrakes

disengaged.

Ifyoupushbothmotion-controlleversforwardthe

samedistanceandthemachinepullsto1side,adjust

thetrackingasfollows.

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Releasethecushionfromtherearofthe

machine;refertoReleasingtheCushionfor

RearAccess(page26).

Note:Foreasieraccess,youcanalsoremove

thefueltank;refertoRemovingtheFuelT ank

(page39).

4.Rotatetheleftcontrolrodinquarter-turn

incrementsuntilthemachinetracksstraight

(Figure65).

Note:Ifthemachinepullstotheright,shorten

thecontrolrodbyrotatingittotheright.Ifthe

machinepullstotheleft,lengthentherodby

rotatingittotheleft.

7.Installthefueltank,ifyouremovedit.

8.Installthecushion.

CheckingtheTirePressure

ServiceInterval:Every50hours/Monthly(whichever

comesrst)

Maintaintheairpressureinthereartiresat83to97

kPa(12to14psi).

Important:Uneventirepressurecancausean

unevencut.

Note:Thefronttiresaresemi-pneumatictiresanddo

notrequireair-pressuremaintenance.

Note:Adjustonlytheleftcontrolrodtomatch

theleftwheelspeedtotherightwheelspeed.

Donotadjusttherightwheelspeed,asthis

positionstherightmotion-controlleveroutofthe

centerforthecontrolpanelneutral-lockslot.

Important:Donotrotatethecontrolrodtoo

far,asthismaycausethemachinetocreep

inneutral.

Figure65

1.Rotatelefttolengthenthe

rod.

2.Leftcontrolrod

3.Rotaterighttoshortenthe

rod.

g001055

Figure66

g031531

5.Checkforpropertracking,andadjusttherod

asnecessary.

43

AdjustingtheCaster-Pivot

ServicingtheCaster

Bearing

ServiceInterval:Every500hours/Yearly(whichever

comesrst)

1.Disengagetheblade-controlswitch(PTO),move

themotioncontrolleverstotheNEUTRAL-LOCK

position,andsettheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removethedustcapfromthecasterandtighten

thelocknut(Figure67).

4.Tightenthelocknutuntilthespringwashersare

at,andthenbackoffa1/4turntoproperlyset

thepreloadonthebearings(Figure67).

Important:Makesurethatthespring

washersareinstalledcorrectlyasshownin

Figure67.

5.Installthedustcap(Figure67).

WheelsandBearings

Thecasterwheelsrotateonarollerbearingsupported

byaspannerbushing.Ifthebearingiskeptwell

lubricated,wearwillbeminimal.Failuretokeepthe

bearingwelllubricatedcausesrapidwear.Awobbly

casterwheelusuallyindicatesawornbearing.

1.Removethelocknutandwheelboltholdingthe

casterwheeltothecasterfork(Figure68).

1.Springwashers

2.Locknut

Figure67

3.Dustcap

g009453

Figure68

1.Locknut4.Rollerbearing

2.Bushing

3.Spannerbushing

2.Remove1bushing,thenpullthespanner

bushingandrollerbearingoutofthewheelhub

(Figure68).

3.Removetheotherbushingfromthewheelhub

andcleananygreaseanddirtfromthewheel

g001297

hub(Figure68).

4.Inspecttherollerbearing,bushings,spanner

bushingandtheinsideofthewheelhubforwear.

5.Casterwheel

6.Wheelbolt

Note:Replaceanydamagedorwornparts

(Figure68).

5.Place1bushingintothewheelhub(Figure68).

6.Greasetherollerbearingandspannerbushing,

andslidethemintothewheelhub(Figure68).

7.Placethesecondbushingintothewheelhub

(Figure68).

8.Installthecasterwheelintothecasterforkand

secureitwiththewheelboltandlocknut(Figure

68).

44

9.Tightenthelocknutuntilthespannerbushing

bottomsagainsttheinsideofthecasterforks

(Figure68).

4.Checktheconditionofthewire-harnessleads,

connectors,andterminals.Cleanorrepairthem

asnecessary.

10.Greasethettingonthecasterwheel.

RemovingtheClutchShim

ServiceInterval:Every100hours

Whentheclutchbrakehasworntothepointwhere

theclutchnolongerengagesconsistently ,youcan

removetheshimtoextendtheclutchlife(Figure69).

Figure69

1.Armature5.Brakespacer

2.Fieldshell

3.Rotor7.Brakepole

4.Brake-mountingbolt

6.Shim.

5.Verifythat12Vispresentattheclutchconnector

whentheyouengagethePTOswitch.

6.Measurethegapbetweentherotorand

armature.Ifthegapisgreaterthan1mm(0.04

inch),proceedwiththefollowingsteps:

A.Loosenbothbrakemountingbolts1/2to1

fullturnasshowninFigure71.

Note:Donotremovethebrakepolefrom

theeldshell/armature.Thebrakepole

hasworntomatchthearmatureandneeds

tocontinuetomatchafteryouremovethe

shimtoensuretheproperbraketorque.

g302539

g302537

Figure71

1.Brake-mountingbolt

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Usinganaircompressor,blowoutanydebris

underthebrakepoleandaroundthebrake

spacers.

Figure70

B.Usingneedle-nosepliers,orbyhand,

removetheshim.

Note:Donotdiscardtheshimuntilyou

conrmthattheclutchfunctionsproperly.

g302538

Figure72

1.Shim

C.Usingapneumaticline,blowoutanydebris

g302534

underthebrakepoleandaroundthebrake

spacers.

D.Torqueeachbolt(M6x1)to12.3to13.7

N∙m(9.5to10.5ft-lb).

45

E.Usinga0.010inchthick-feelergauge,verify

thatagapispresentbetweentherotorand

armaturefaceonbothsidesofthebrake

poleasshowninFigure73andFigure74.

Note:Duetothewaytherotorand

armaturefaceswear(peaksandvalleys),it

issometimesdifculttomeasurethetrue

gap.

Figure73

1.Feelergauge

F.Performthefollowingsafetycheck:

i.Starttheenginefromtheoperator’s

position.

ii.Makesurethatthebladesdonot

engagewhenthePTOswitchisin

theOFFpositionandtheclutchis

disengaged.

Note:Iftheclutchdoesnot

disengage,installtheshim,andrefer

toTroubleshooting(page60).

iii.EngageanddisengagethePTO

switch10consecutivetimesto

ensurethattheclutchisfunctioning

properly.

Note:Iftheclutchdoesnotengage

g302536

properly,refertoTroubleshooting

(page60).

CheckingtheWheel-Lug

Nuts

1.Feelergauge

ServiceInterval:Aftertherst100hours—Checkthe

wheel-lugnuts.

Checkandtorquethewheel-lugnutsto115to142

N∙m(85to105ft-lb).

g302535

Figure74

•Ifthegapislessthan0.010inch,

theninstalltheshimandreferto

Troubleshooting(page60).

•Ifthegapissufcient,proceedtothe

safetycheckinstepF.

46

CoolingSystem

Maintenance

BrakeMaintenance

TestingtheParkingBrake

CleaningtheAir-Intake

Screen

ServiceInterval:Beforeeachuseordaily

Beforeeachuse,removeanybuildupofgrass,dirt,

orotherdebrisfromthecylinderandcylinder-head

coolingns,air-intakescreenontheywheelend,

andthecarburetor-governorleversandlinkage.This

helpsensureadequatecoolingoftheengineandthe

correctenginespeed,anditreducesthepossibilityof

overheatingormechanicaldamagetotheengine.

CleaningtheCooling

System

ServiceInterval:Every100hours—Checkand

cleantheenginecoolingnsand

shrouds(moreoftenindirtyordusty

conditions).

1.Parkthemachineonalevelsurface,disengage

thePTO,andengagetheparkingbrake.

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

ServiceInterval:Beforeeachuseordaily

Beforeeachuse,testtheparkingbrakeonbotha

levelsurfaceandslope.

Alwaysengagetheparkingbrakewhenyoustopthe

machineorleaveitunattended.Iftheparkingbrake

doesnotholdsecurely ,adjustit.

1.DisengagethePTOandengagetheparking

brake

2.Shutofftheengine,removethekey ,andwait

forallmovingpartstostopbeforeleavingthe

operatingposition.

3.Disengagetheparkingbrake.

4.Engagethebrakeleverandensurethatthe

machinedoesnotmove.

5.Adjustthebrakeifneeded.

AdjustingtheBrakes

1.Removethefueltank;refertoRemovingthe

FuelTank(page39).

2.Loosentheboltonthecableclampontheleft

sideofthemachine.

3.Removetheair-intakescreenandfanhousing

(Figure75).

4.Cleanthedebrisandgrassfromtheengine

parts.

5.Installtheair-intakescreenandfanhousing

(Figure75).

Figure75

1.Guardandengine

air-intakescreen

2.Fanhousing

g031396

Figure76

1.Cable

2.Cableclamp

g031343

3.Pulldownonthecablesuntiltheyaretaut.

4.Tightenthenut.

5.Installthefueltank,crossbracket,andcushion.

3.Boltandnut

47

BeltMaintenance

CheckingtheBelts

ServiceInterval:Every100hours—Checkthe

mower-deckbelt(s).

Checkbeltsforcracks,frayededges,burnmarks,

wear,signsofoverheating,oranyotherdamage.

Thesignsofawornmowerbeltaresquealingwhile

thebeltisrotating,bladesslippingwhileyouare

cuttinggrass,frayedbeltedges,burnmarks,and

cracks.Replacethemowerbeltifyoudetectanyof

thesesigns.

InstallingtheBelt

1.Assemblethebeltintothedeck(Figure78).

g270502

Figure78

ReplacingtheMower-Deck

Belt

RemovingtheBelt