Page 1

FORM NO. 3321-863

LAWN & GARDEN TRACTOR

MODEL NO. 72070–9900600 & UP

MODEL NO. 72105–9900600 & UP

MODEL NO. 72115–9900600 & UP

Loose Parts

Note: Use the chart below to identify parts for assembly.

DESCRIPTION QTY. USE

Front Wheel

Flat Washer-large OD

Shim Washer

Dust Cover

Cotter Pin

Hub Cap (optional on some models)

Rear Wheel

Wheel Bolt

Hub Cap (optional on some models)

2

2

4

2

2

2

2

10

2

Install front wheels.

Install rear wheels.

SET UP

INSTRUCTIONS

Steering Wheel

Lock Washer 1/2”

Nut 1/2”

Logo Cover

Seat

Spacer-small ID

Spacer-large ID

Shoulder Bolt

Knob

Flat Washer

Bolt 1/4–20 x 3/4”

Wing Nut-plastic 1/4”

Key 1 Use in ignition and “Key Choke” switches.

Operator’s Manual 1 Read manual before operating tractor.

1

1

Install steering wheel.

1

1

1

2

2

Install the seat.

2

2

2

2

Attach battery cables.

2

The Toro Company – 1998

Printed in USA

All Rights Reserved

Page 2

Set Up Instructions

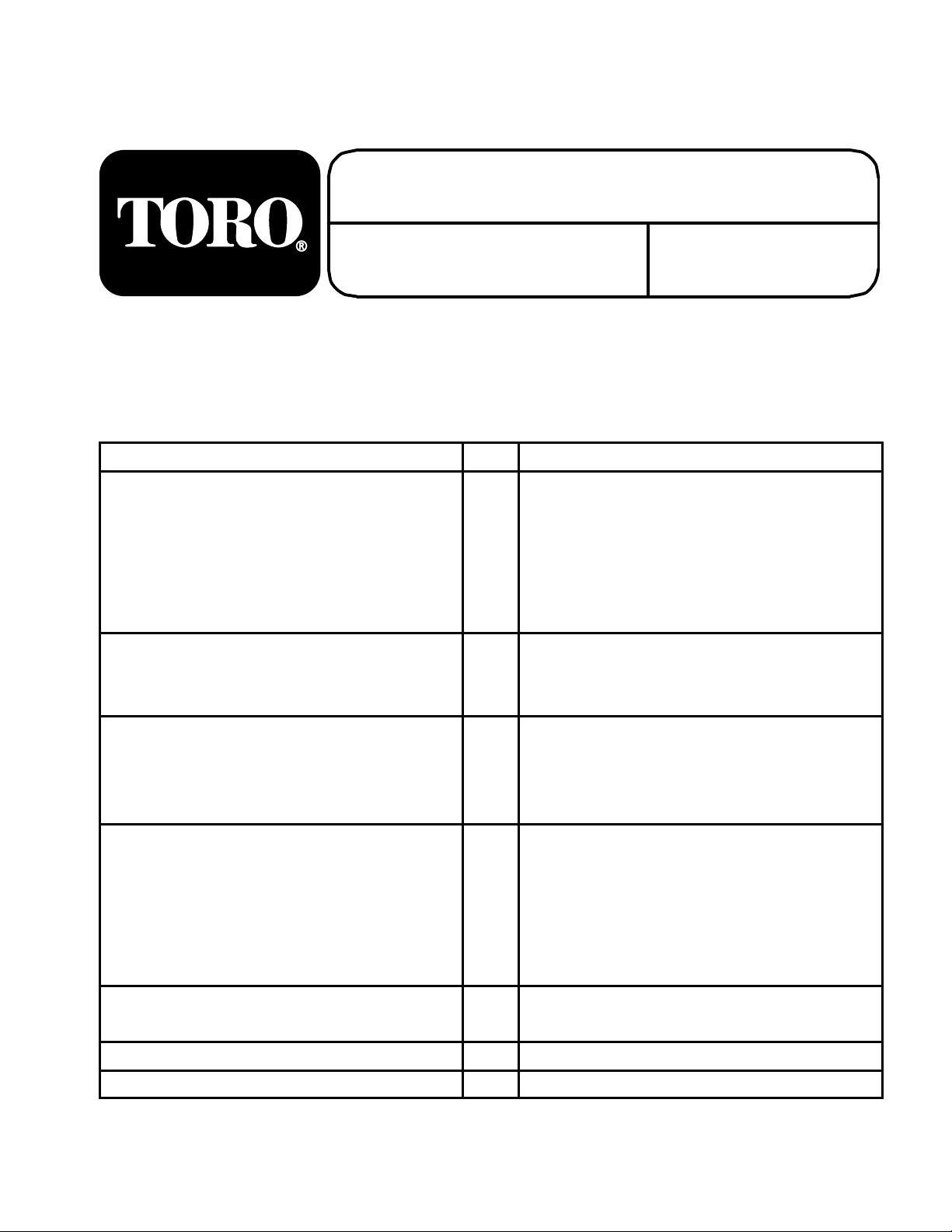

Install Front Wheels

Note: If wheels are already installed, refer to

Check Tire Pressure (below).

1. Slide wheel onto axle with valve stem in.

(Fig. 1).

2. Wheel end play should be 0-.015” (0-.4 mm).

Use shim washers (as required) and large OD flat

washer for spacing on the axle. Insert cotter pin

through the axle and bend the ends of the pin

open (Fig. 1).

3. Push the dust cover (Fig. 1) onto the end of the

axle so it snaps over washer.

1

2

4

Install Rear Wheels

1. Install wheel onto axle with valve stem to the

inside (Fig. 2).

2. Torque wheel bolts to 75-80 ft-lb (105-112 N.m).

3. Install hub caps, optional on some models.

1

1278 2

Figure 2

1. Wheel

2. Wheel bolts

3. Hub cap (optional)

3

1. Wheel

2. Shim washers (as

required)

3. Large OD flat washer

3

Figure 1

4. Cotter pin

5. Dust cover

6. Hub cap (optional)

5

4. Repeat steps 1–3 on opposite side.

5. Grease the wheel bearings.

6. Install hub caps, optional on some models.

6

Check Tire Pressure

Check front and rear tire pressure. See Operator’s

Manual for specification.

Pressure: 20 psi (138 kPa) front and rear.

2

Page 3

Set Up instructions

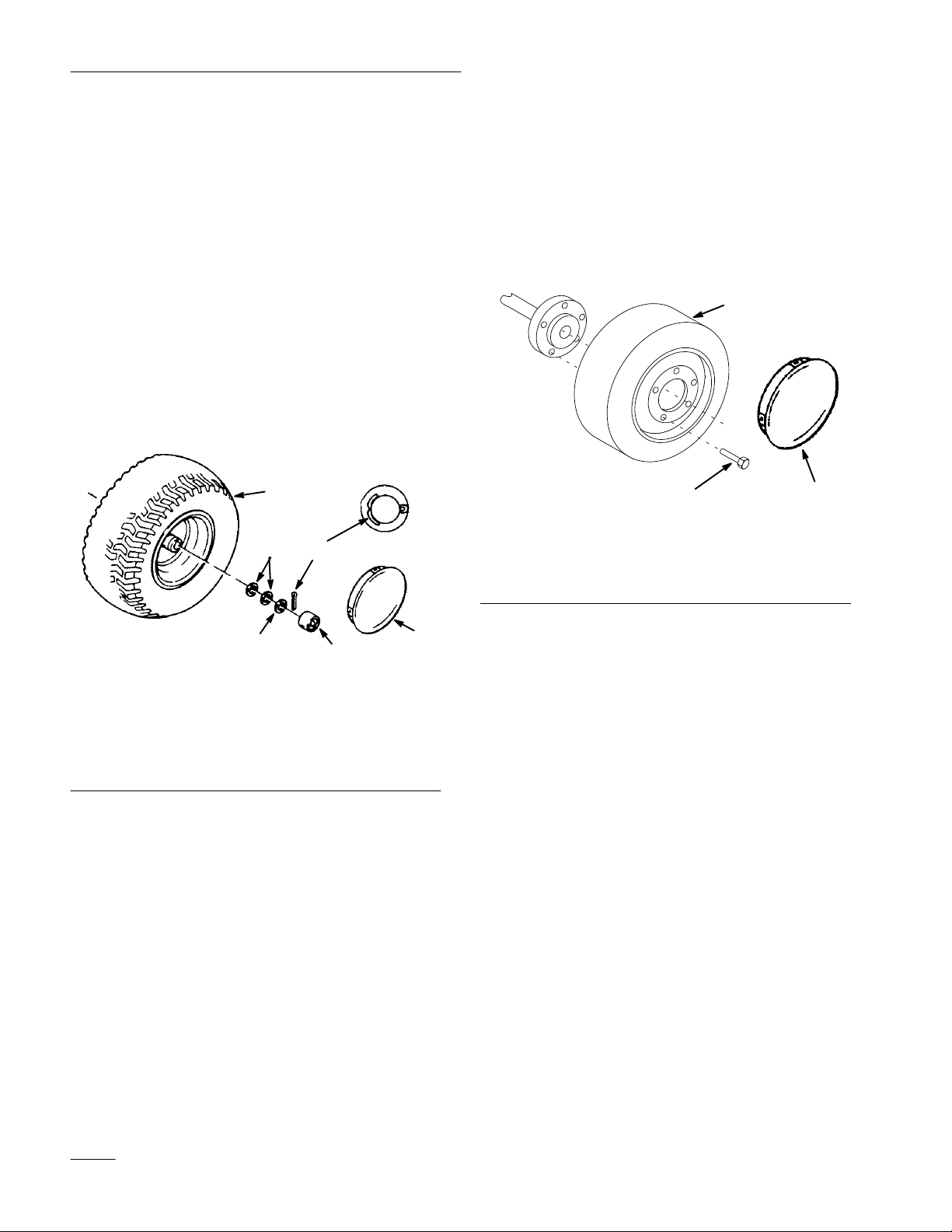

Install Steering Wheel

1. Position front wheels straight ahead.

2. Remove logo cover by releasing (3) latches from

back side with screwdriver.

3. Line up center spoke toward the seat and

position the steering wheel onto shaft spline

(Fig. 3).

4. Secure steering wheel with lockwasher and nut

(Fig. 3).

5. Torque steering wheel nut to 50 ft-lbs (37 N.m).

6. Snap logo cover into place (Fig. 3).

5

4

1

3

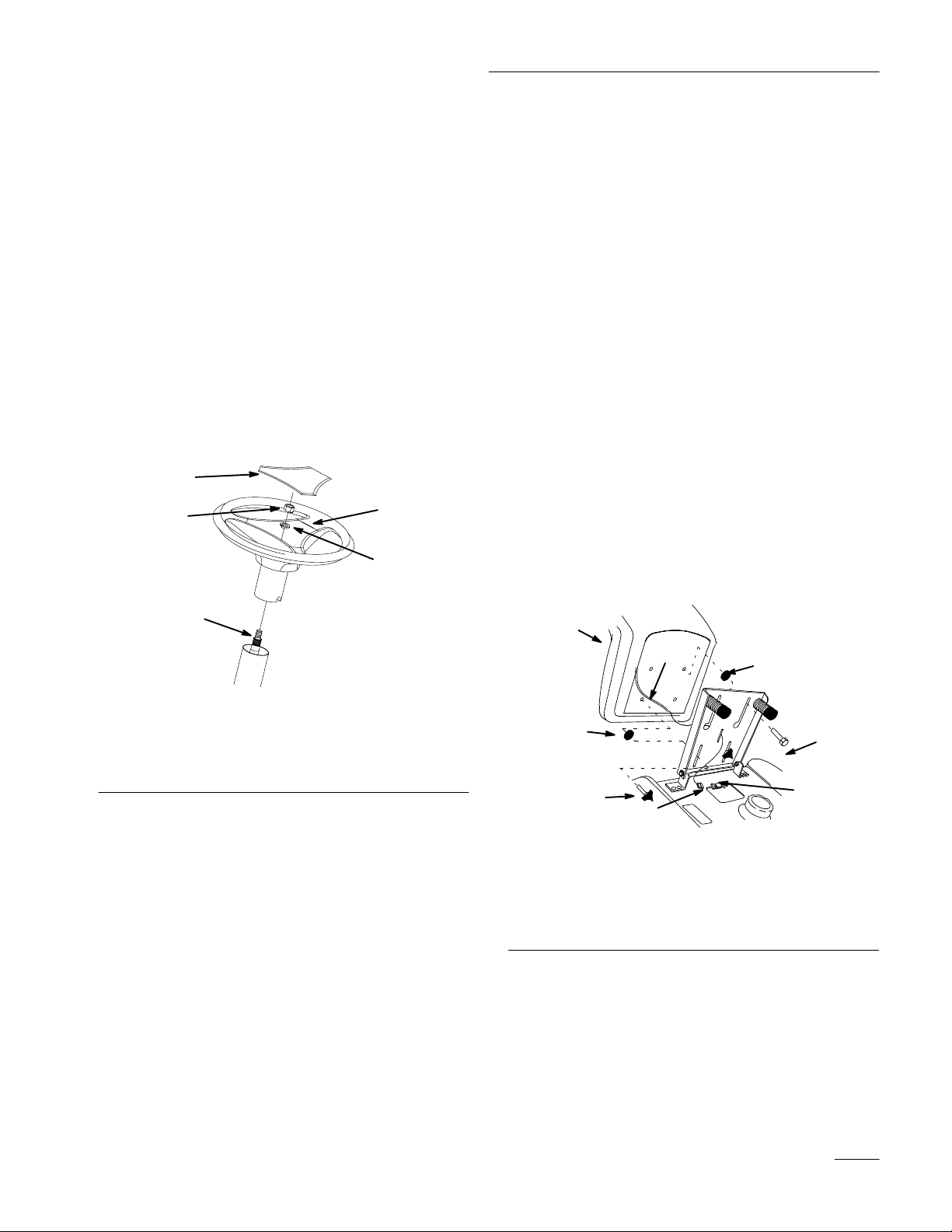

Install Seat

Note: If the seat is already installed, proceed

to Activate The Battery, page 4.

1. Install large ID spacer and shoulder bolts into

rear holes of seat (Fig. 4).

2. Position the seat onto the seat base by inserting

the two shoulder bolts through key hole

openings at the end of both slots (Fig. 4).

3. Locate small ID spacer between seat and seat

base, thread the knobs and flat washers into the

front holes in the seat (Fig. 4). Adjust the seat

and tighten the knobs.

4. Route seat switch wire and connector through

center opening in the seat base. Push the seat

switch connector fully into the wire harness

connector (Fig. 4).

5. Secure the seat switch wire cable to the fender

opening with wire clip (Fig. 4).

1. Center spoke

2. Shaft spline

3. Lock washer

2

2307

Figure 3

4. Nut

5. Logo cover

1. Seat

2. Spacer-small ID

3. Spacer-large ID

4. Bolt and flat washer

1

6

2

5

7

Figure 4

5. Knob and flat washer

6. Wire and connector

7. Wire harness connector

8. Wire clip

3

4

8

1271

3

Page 4

Set Up Instructions

Activate the Battery

Bulk electrolyte with 1.260 specific gravity must be

purchased from a local battery supply outlet.

1. Remove the battery from the tractor: refer to

Operator’s Manual, Removing the Battery.

IMPORTANT: Be careful not to damage the

long vent tube when removing the battery

box.

POTENTIAL HAZARD

• Battery electrolyte contains sulfuric acid

which is a deadly poison and it causes

severe burns.

WHAT CAN HAPPEN

• If you carelessly drink electrolyte you could

die or if it gets onto your skin you will be

burned.

1

3

Figure 5

1. Filler caps

2. Electrolyte

3. Lower part of the tube

3. Leave the covers off and connect a 3 to 4 amp

battery charger to the battery posts (Fig. 6).

Charge the battery at a rate of 4 amperes or less

for 4 hours (12 volts).

2

1262

HOW TO AVOID THE HAZARD

• Do not drink electrolyte and avoid contact

with skin, eyes or clothing. Wear safety

glasses to shield your eyes and rubber

gloves to protect your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

2. Remove filler caps from the battery. Slowly pour

electrolyte into each cell until the electrolyte

level is up to the lower part of the tube (Fig. 5).

1. Positive post

2. Negative post

4

2

3

1

1254

Figure 6

3. Charger red (+) wire

4. Charger black (–) wire

4

Page 5

Check Safety System

Set Up instructions

POTENTIAL HAZARD

• Charging battery produces gasses.

WHAT CAN HAPPEN

• Battery gasses can explode.

HOW TO AVOID THE HAZARD

• Keep cigarettes, sparks and flames away

from battery.

4. When the battery is fully charged, disconnect the

charger from the electrical outlet then from the

negative and positive battery posts (Fig. 6).

5. Slowly pour electrolyte into each cell until the

level is once again up to the “UPPER” line on

the battery case (Fig. 5) and install covers.

6. Install the battery in the tractor and connect

cables with (2) 1/4 x 3/4” bolts and (2) 1/4”

plastic wing nuts: refer to the Operator’s

Manual, Installing the Battery.

Refer to the Operator’s Manual, Checking Safety

System.

Electric Clutch Break-In

The electric clutch requires initial break-in to seat the

mating surfaces. Engage/disengage the clutch 10-20

cycles with the mower installed. Rotating the blades

provides load for break-in.

Adjust Electric Clutch

The electric clutch has three (3) adjustment nuts that

all must be adjusted the same (Fig. 7).

1. Insert a 0.010 inch (.25 mm) feeler gauge into

the slot (Fig. 7).

2. Turn the nut until light resistance is felt on the

gauge.

Crankcase Oil

Check the engine oil level, refer to the Operator’s

Manual, Engine Oi. If necessary, add only enough oil

to raise the level to the “FULL” mark on the dipstick.

Note: Slide the oil dipstick fully into the

filler tube, do not thread onto fill tube.

Lubricate the Tractor

Refer to the Operator’s Manual, Greasing and

Lubrication.

If equipped with Power Lift, check reservoir level, fill

with Dexron Type II.

3. Repeat for all three adjusting nuts.

1

3

2

Figure 7

1. Slot

2. 0.010” (25 mm) Feeler

gauge

3. Adjusting nut

Test Drive the Tractor

Make sure all electrical and mechanical systems are

operating properly.

1276

5

Page 6

Page 7

Page 8

Loading...

Loading...