Page 1

260 Series Tractor

Service

Manual

Page 2

ABOUT THIS MANUAL

This service manual was written expressly for Toro service technicians. The Toro Company

has made every effort to make the information in this manual complete and correct.

Basic shop safety knowledge and mechanical/electrical skills are assumed. The Table of

Contents lists the systems and the related topics covered in this manual.

For additional information on the electrical system, please refer to the Toro Electrical

Demystification Guide (492-4404). For service information on drive systems, please refer to

the appropriate service manual: Tuff Torq (492-0699), Hydro-Gear (492-0682), Peerless

(contact Tecumseh Products). For information specific to the engines used on this unit, refer

to the appropriate engine manufacturer’s service and repair instructions.

Tractor model years 1994 - 2002 are covered in this manual. The manual may also be

specified for use on later model products.

The hydrostatic transaxle is a sophisticated piece of machinery. Maintain strict cleanliness

control during all stages of service and repair. Cover or cap all hose ends and fittings

whenever they are exposed. Even a small amount of dirt or other contamination can

severely damage the system.

We are hopeful that you will find this manual a valuable addition to your service shop. If you

have questions or comments regarding this manual, please contact us at the following

address:

The Toro Company

Consumer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

The Toro Company reserves the right to change product specifications or this manual

without notice.

Copyright© All Rights Reserved

©2002 The Toro Company

Page 3

SPECIFICATIONS

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 1

Tecumseh Peerless Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Identification: Tecumseh Peerless Model 820-024 . . . . . . . . . . . . . . . . . . . . . . .1 - 2

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 2

Hydrostatic Transaxles . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

Identification: Tuff Torq Model K61A Transaxle . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 3

Identification: Hydro-Gear Model 322-3000 & 330-3000 Transaxle . . . . . . . . . .1 - 4

General Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 4

Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 5

Fastener Identification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 5

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series) . . . . . . . .1 - 6

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners) . . . . . . . . .1 - 7

Other Torque Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 8

SAE Grade 8 Steel Set Screws . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 8

Thread Cutting Screws (Zinc Plated Steel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 8

Conversion Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 8

Wheel Bolts and Lug Nuts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 8

Thread Cutting Screws (Zinc Plated Steel) . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 8

Equivalents and Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 9

Decimal and Millimeter Equivalents. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 9

U.S. to Metric Conversions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 - 10

TABLE OF CONTENTS

CHASSIS

Model and Serial Number Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Greasing and Lubrication . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 1

Front Wheel Toe-in . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 2

Front Wheel Toe-in Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Front Wheel and Spindle Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Front Axle Removal and Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 4

Steering Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Steering Backlash Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Steering Gear Shaft Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 7

Steering Gear Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 10

Sector Gear Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 11

Sector Gear Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 12

Tilt Steering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 12

Tilt Steering Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 13

Tilt Steering Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 14

Steering Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 15

Hood Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 16

Seat and Fender Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 16

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 3

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 6

Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2 - 12

260 Series Tractor Service Manual iii

Page 4

TABLE OF CONTENTS

Gas Tank Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 17

Lift Lever Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 18

Dial-A-Height Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 19

Lift Arm Linkage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 20

Adjustments . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Lift Height . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Leveling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Side to Side . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Power Lifts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Electrohydraulic Lift (2000 and Prior Models) . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Electric Lift (2001 and Later Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Removal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2 - 21

TUFF TORQ TRANSAXLE

Tuff Torq Hydrostatic Transaxle. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Internal Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Fluid Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Transaxle Removal – Tuff Torq . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 1

Installation - Tuff Torq Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 4

Belt Replacement – Tuff Torq Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 6

Belt Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 10

Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 13

Troubleshooting – Tuff Torq Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 14

Purging Procedures – Tuff Torq Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 15

Brake – Tuff Torq Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 15

Checking the Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 15

Adjusting the Brake – Tuff Torq Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 15

Foot Control Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 16

Neutral Adjustment – Tuff Torq Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3 - 17

iv 260 Series Tractor Service Manual

Page 5

HYDRO-GEAR TRANSAXLE

Hydro-Gear Hydrostatic Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Internal Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Fluid Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Transaxle Removal - Hydro-Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 1

Installation - Hydro-gear Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 4

Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 7

Purging Procedures – Hydro-Gear Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 8

Brake – Hydro-Gear Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Checking the Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Brake Adjustment – Hydro-Gear Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 9

Foot Control Adjustment Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 10

Troubleshooting Chart for the Hydro-Gear Transaxle . . . . . . . . . . . . . . . . . . . . . .4 - 11

Belt Replacement – Hydro-Gear Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 11

Belt Routing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 15

Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 16

Neutral Adjustment – Hydro-Gear Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4 - 17

GEAR DRIVE

Transaxle Removal – Gear Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 1

Installation – Gear Drive Transaxle . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 3

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 5

Internal Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 5

Symptom: Unit Jumps Out Of Gear . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 6

Symptom: Unit Can Not Be Shifted (or Difficult to Shift) . . . . . . . . . . . . . . . . . . . . .5 - 6

Symptom: Unit Does Not Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 6

Belt Replacement – Gear Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 7

Belt Routing Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 9

Belt Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 12

Proper Shifting Procedures - Gear Drive . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 13

Shift Linkage Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 13

Shift Detent Tension Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 14

Brakes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 14

Checking the Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 14

Adjusting the Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5 - 15

TABLE OF CONTENTS

260 Series Tractor Service Manual v

Page 6

TABLE OF CONTENTS

ELECTRICAL SYSTEMS

Gear Drive Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Hydrostatic Models . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Relay . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 1

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Solenoid . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 2

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 3

Ignition Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 4

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Low Voltage Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 5

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Electric (PTO) Clutch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Coil Resistance Measurement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 6

Measuring Clutch Current Draw . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 7

Setting the Air Gap on 1999 and Prior Model 260 Series Tractors . . . . . . . . . . . 6 - 8

Clutch Burnishing Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

PTO Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 8

Microswitches . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 9

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 10

Neutral Switch - Plunger Type (Used on 2000 and Later Hydrostatic Models) . . . 6 - 11

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 11

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 11

How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 11

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 12

vi 260 Series Tractor Service Manual

Page 7

TABLE OF CONTENTS

Brake Switch (Used on 2000 and Later Hydrostatic Models) . . . . . . . . . . . . . . . . .6 - 12

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 12

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 12

How it Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 12

Brake Switch Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 13

Seat Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 13

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 13

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 13

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 14

Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6 - 13

KeyChoice™ Reverse Operating System – Used on 1999 and Later Tractors. . . .6 - 14

Testing the Key Choice™ Reverse Operating System - Unactivated . . . . . . . .6 - 14

Testing the KeyChoice™ Operating System - Activated . . . . . . . . . . . . . . . . . .6 - 14

KeyChoice™ Reverse Operating System Switch . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

Reverse Switch (Hydrostatic Models) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 16

Reverse Switch (Gear Drive Tractors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 17

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 17

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 17

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 17

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 17

KeyChoice™ Reverse Operating System Module. . . . . . . . . . . . . . . . . . . . . . . . . .6 - 17

Purpose . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 17

Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 18

How It Works . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6 - 18

Testing - No Power to Circuit (With Module Out of Circuit) . . . . . . . . . . . . . . . . .6 - 19

Testing - Powered Circuit (With Module Out of Circuit). . . . . . . . . . . . . . . . . . . .6 - 19

260 Series Tractor Service Manual vii

Page 8

THIS PAGE INTENTIONALLY LEFT BLANK

viii 260 Series Tractor Service Manual

Page 9

SPECIFICATIONS

General Specifications

Item Specification

Engines All tractors since 1994 were manufactured with Kohler engines ranging from 14

to 20 Horsepower. For more information on servicing the engines, please

contact the Kohler Company.

Domestic Units High RPM Setting (no load) 3250 +/- 100 RPM

International Models High RPM Setting (no load) 2700 +/- 100 RPM

Fuel Capacity 3.9 Gallons (14.7 liter)

Wheel Base 49.5” (125.7cm)

Length 69.0” (175.2cm)

Width 35.5” (90.1cm) without the mower

Steering Sector and Pinion

Turning Radius 16 in. (40.6cm)

Electrical System 15 amp regulated DC alternator

Weight (Net Weight)

Model Weight

264-6 / 265-6 521 lbs. (236.3kg)

264-H / 265-H (Tuff Torq) 510 lbs. (231.3kg)

267-H / 268-H (Tuff Torq) 540 lbs. (244.9kg)

269-H / 270-H (Tuff Torq) 560 lbs. (254.0kg)

265-H/266-H (Hydro-Gear) 530 lbs. (240.4kg)

268-H (Hydro-Gear) 560 lbs. (254.0kg)

270-H (Hydro-Gear) 580 lbs. (263.0kg)

260 Series Tractor Service Manual 1 - 1

Page 10

SPECIFICATIONS

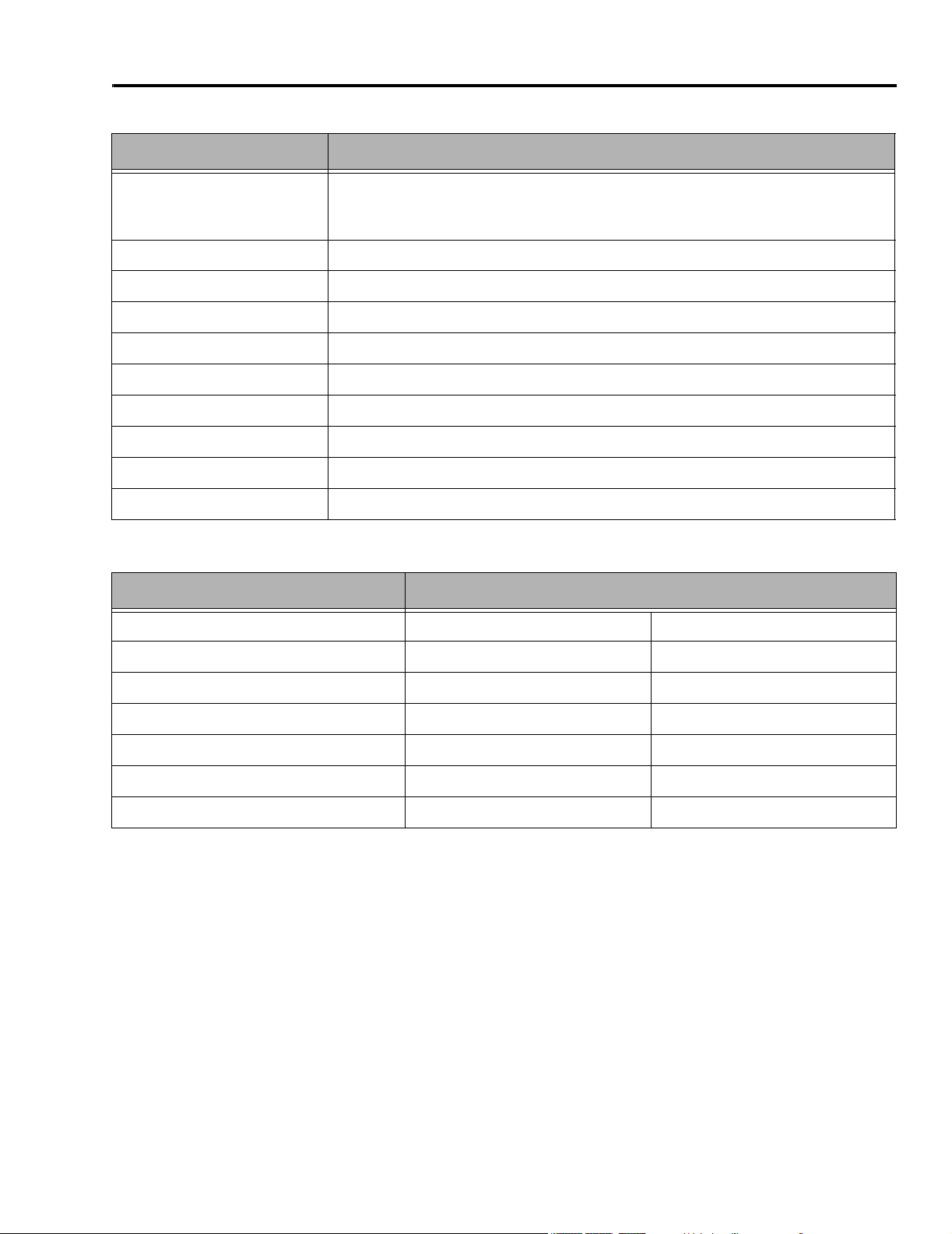

Tecumseh Peerless Transaxle

Identification:

Tecumseh Peerless Model 820-024

MVC-254X

General Specifications

Lubrication Bentonite grease (available through Tecumseh)

Ground Speed

st

Gear

1

nd

2

Gear

rd

Gear

3

th

4

Gear

th

Gear

5

th

6

Gear

Reverse 2.4 MPH (3.8km/h)

.7 MPH (1.1km/h)

1.4 MPH (2.2km/h)

2.2 MPH (3.5km/h)

3.3 MPH (5.3km/h)

4.2 MPH (6.7km/h)

5.3 MPH (8.5km/h)

1 - 2 260 Series Tractor Service Manual

Page 11

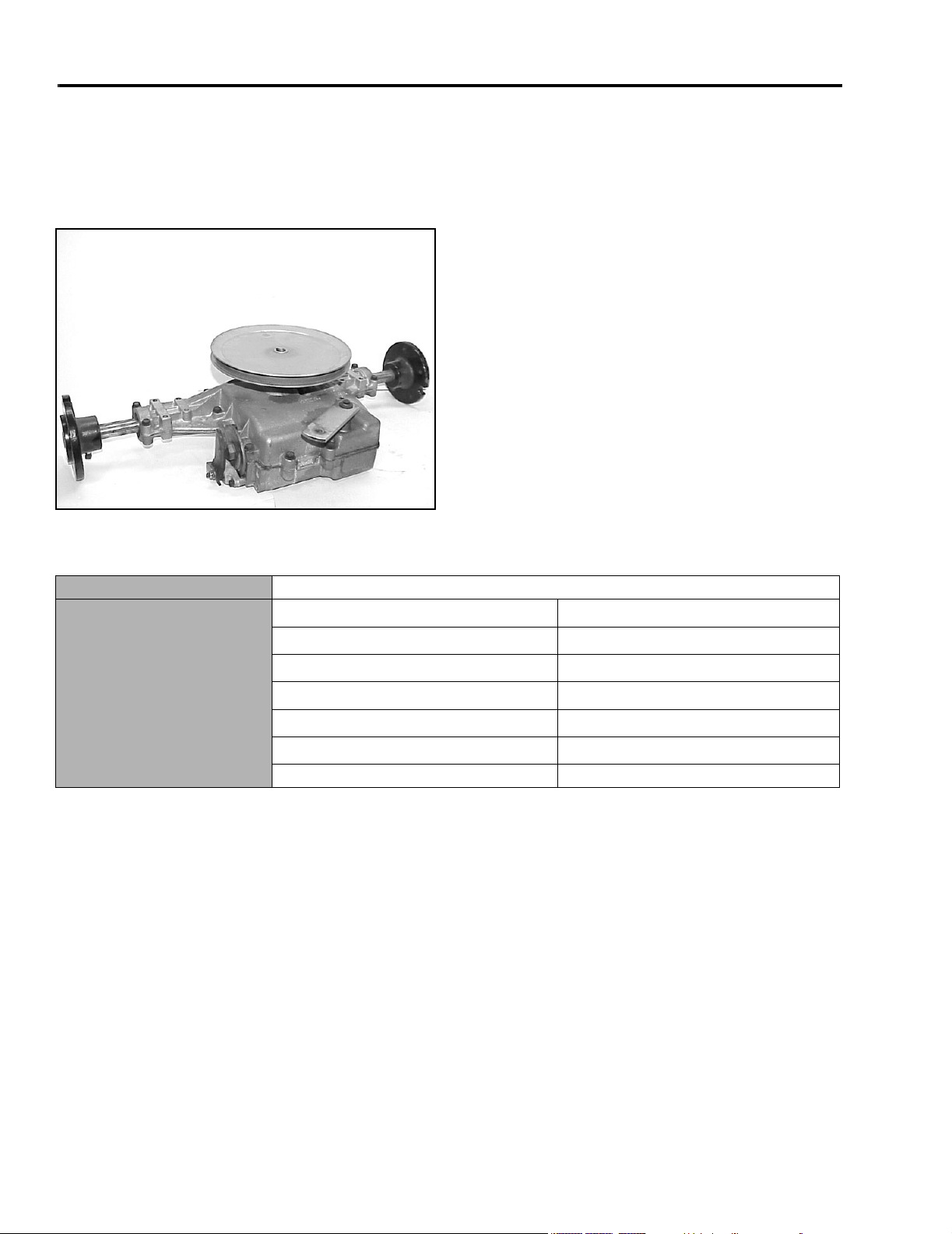

Hydrostatic Transaxles

Identification:

Tuff Torq Model K61A Transaxle

MVC-080X

SPECIFICATIONS

General Specifications

Used 1994 – 1999

Lubrication SAE 10W-30 API Service Classification SH or higher. Alternate oil: A

synthetic oil (5w50 or similar viscosity range) may be used in place of SAE 10w30. This will

permit an increase in the maximum operating temperature of approximately 18°F (10°C).

Oil Capacity 3.5 qt. (3.3 liter)

Oil Level Check when transaxle is cold. Oil should be checked at the reservoir cup, located under the

front hood, on the panel support; oil level should be at the cold mark.

Fluid Change The transaxle is factory filled and does not require regular oil changes.

Ground Speed Forward 0-5.2 MPH (0-8.3km/h)

Reverse 0-2.3 MPH (0-3.7km/h)

260 Series Tractor Service Manual 1 - 3

Page 12

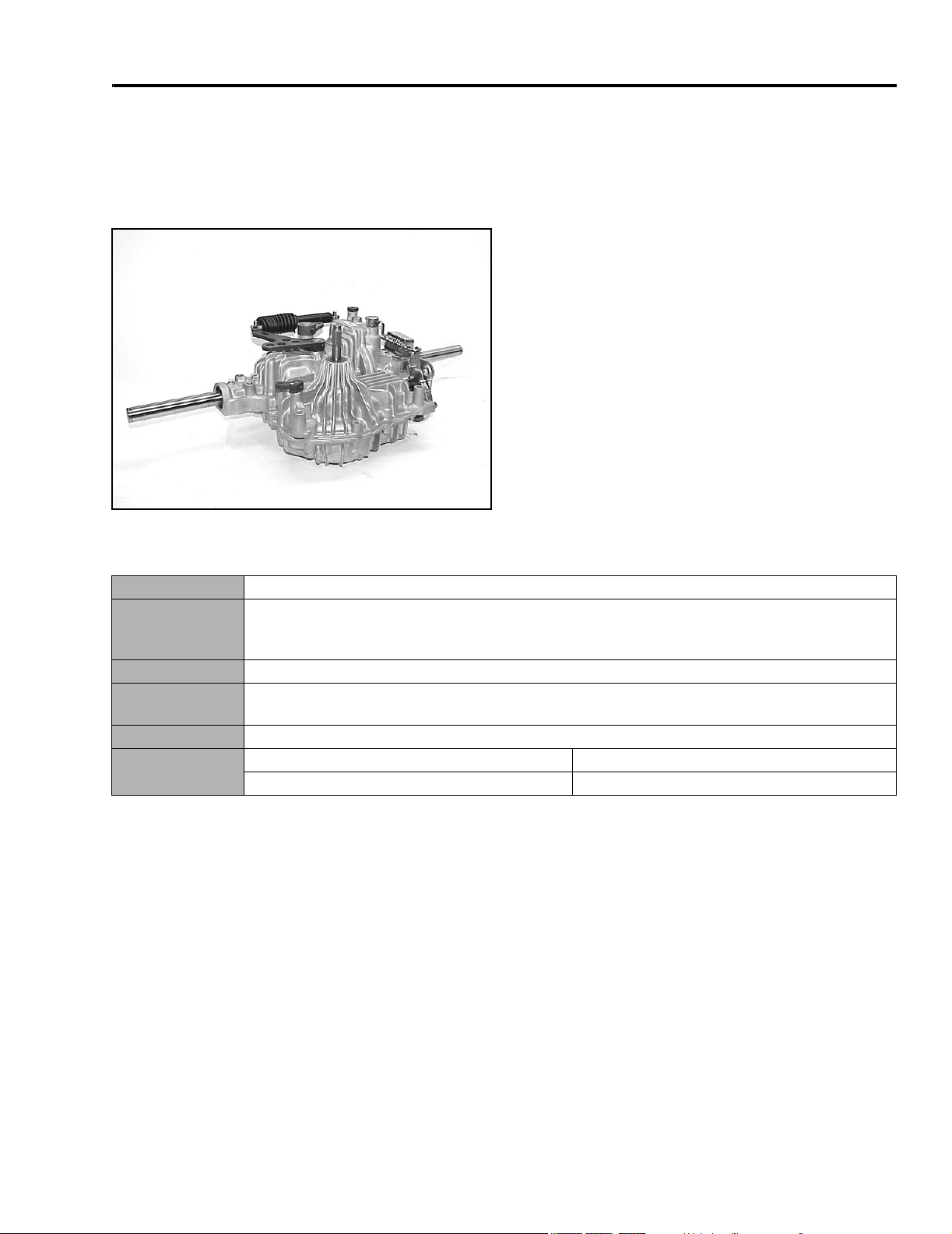

SPECIFICATIONS

Hydrostatic Transaxles

Identification:

Hydro-Gear Model 322-3000 & 330-3000 Transaxle

MVC-082X

General Specifications

Used 2000 to 2002

Lubrication SAE 20W-50 API Classification SH/CD

Oil Capacity 3.8 qt. (3.6liters)

Oil Level The transaxle is a sealed system and does not require periodic checking. If the oil needs to be

checked, IT CAN ONLY BE CHECKED COLD. There is a plug located on the right rear side

of the transaxle. Using a ¼ inch Allen wrench, slowly remove the plug. Oil level should be to

the bottom of the port.

F9260-09

General Specifications

Ground Speed Forward 0 – 6.3 MPH (10.1km/h)

Reverse 0 – 2.3 MPH (3.7km/h)

1 - 4 260 Series Tractor Service Manual

Page 13

SPECIFICATIONS

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as

determined by Toro, either the recommended torque or

a torque that is unique to the application is clearly

identified and specified in the service manual.

These torque specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in the

service manual. The following factors shall be

considered when applying torque: cleanliness of the

fastener, use of a thread sealant (Loctite), degree of

lubrication on the fastener, presence of a prevailing

torque feature, hardness of the surface underneath of

the fastener’s head, or similar condition which affects

the installation.

As noted in the following tables, torque values should

be reduced by 25% for lubricated fasteners to

achieve the similar stress as a dry fastener. Torque

values may also have to be reduced when the fastener

is threaded into aluminum or brass. The specific

torque value should be determined based on the

aluminum or brass material strength, fastener size,

length of thread engagement, etc.

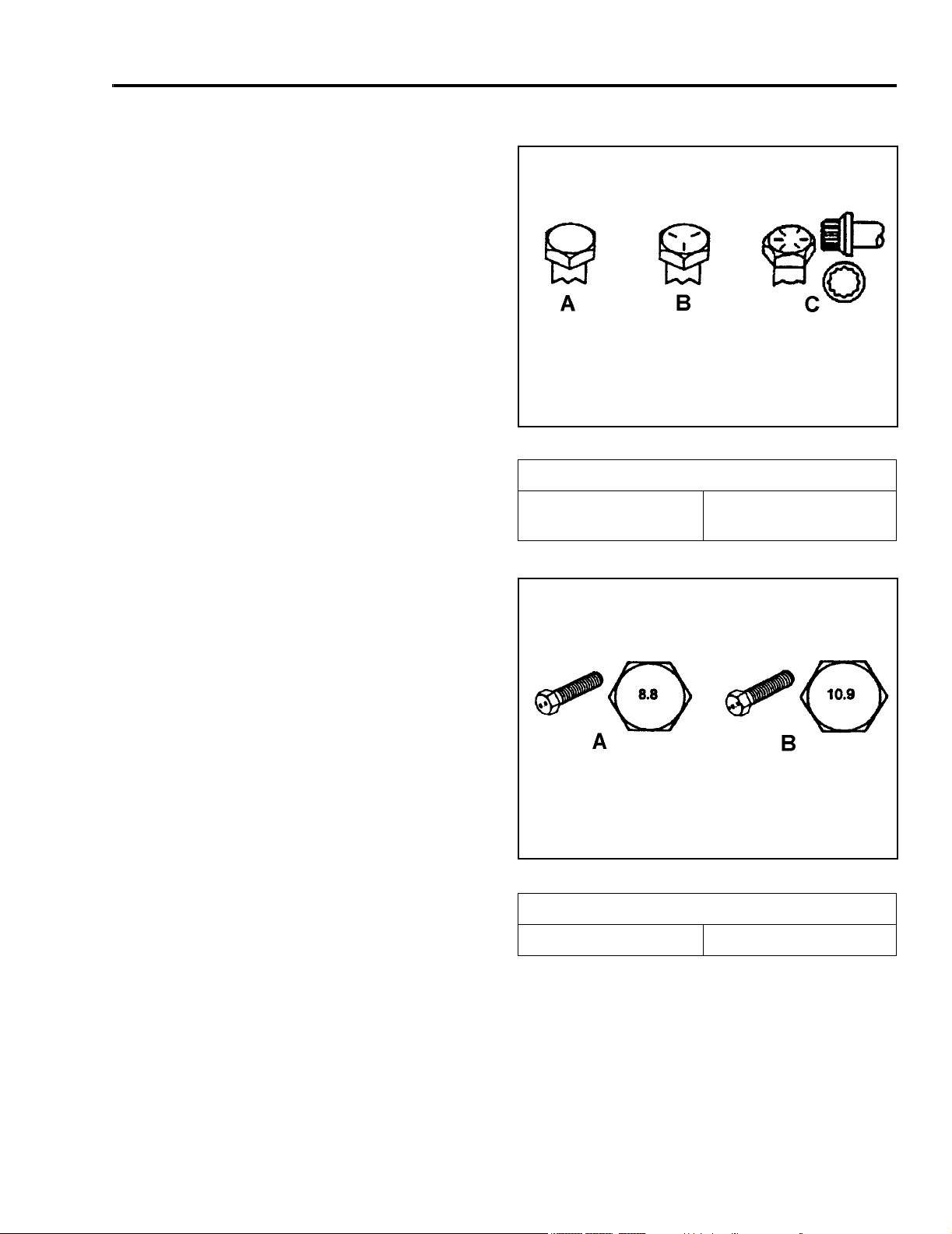

Fastener Identification

Inch Series Bolts and Screws

(A) Grade 1

(B) Grade 5

Figure 1

(C) Grade 8

The standard method of verifying torque shall be

performed by marking a line on the fastener (head or

nut) and mating part, then back off fastener 1/4 of a

turn. Measure the torque required to tighten the

fastener until the lines match up.

Figure 2

Metric Bolts and Screws

(A) Class 8.8 (B) Class 10.9

260 Series Tractor Service Manual 1 - 5

Page 14

SPECIFICATIONS

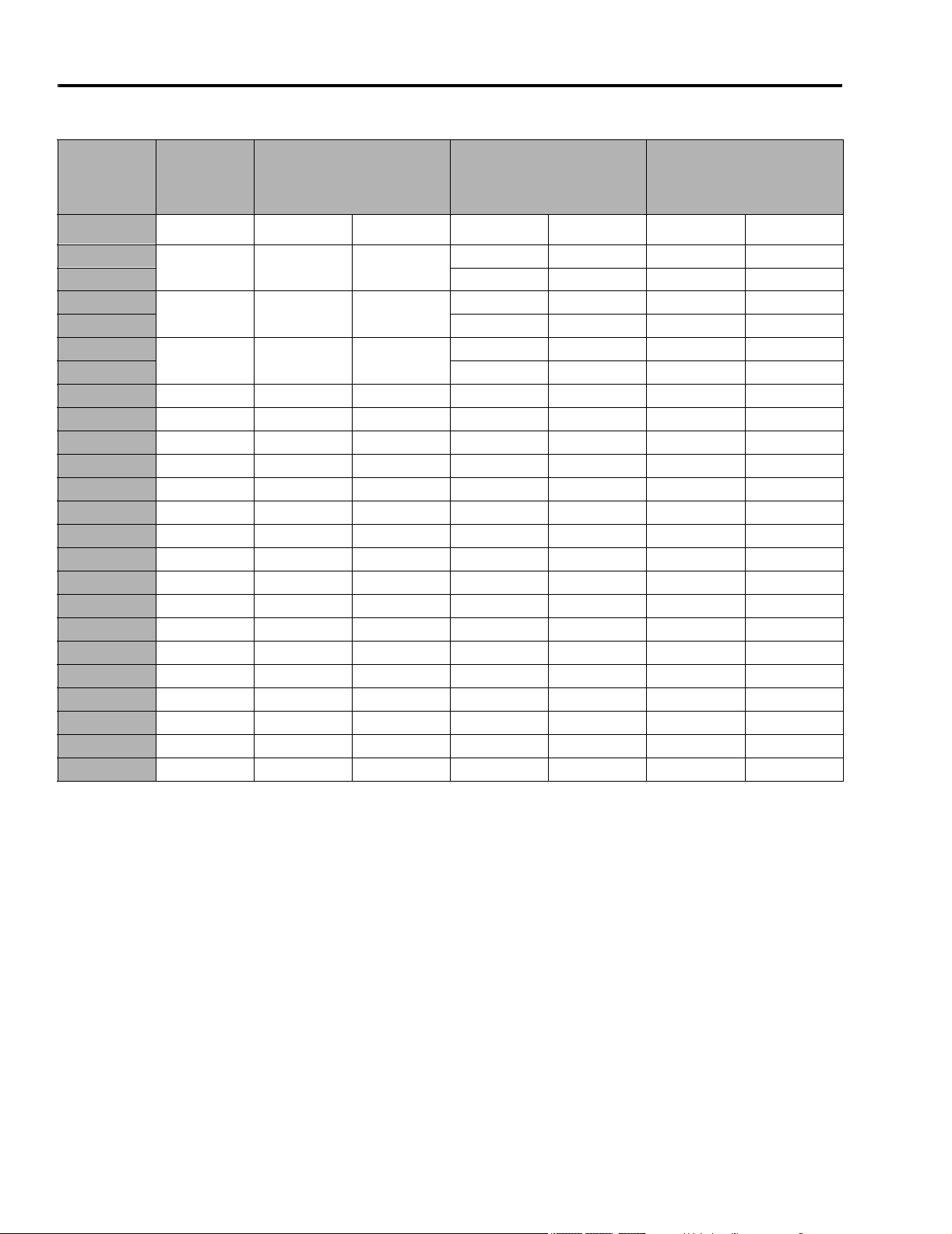

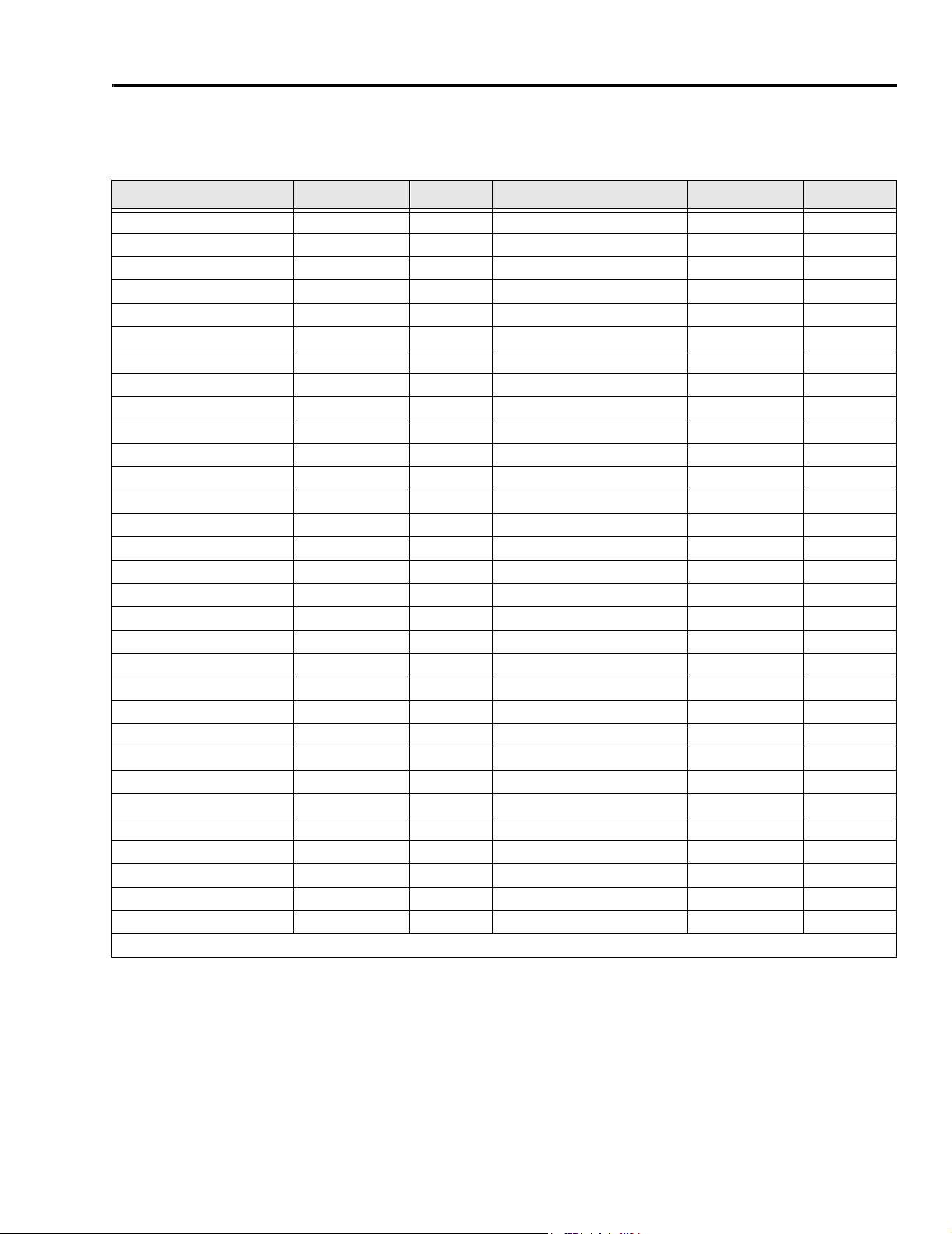

Standard Torque for Dry, Zinc Plated, and Steel Fasteners (Inch Series)

Grade 1, 5, &

Thread Size

# 6 - 32 UNC

# 6 - 40 UNF 17 ± 2 190 ± 20 25 ± 2 280 ± 20

# 8 - 32 UNC

# 8 - 36 UNF 31 ± 3 350 ± 30 43 ± 4 31 ± 3

# 10 - 24 UNC

#10 - 32 UNF 48 ± 4 540 ± 45 68 ± 6 765 ± 70

1/4 - 20 UNC 48 ± 7 53 ± 7 599 ± 79 100 ± 10 1125 ± 100 140 ± 15 1580 ± 170

1/4 - 28 UNF 53 ± 7 65 ± 10 734 ± 113 115 ± 10 1300 ± 100 160 ± 15 1800 ± 170

5/16 - 18 UNC 115 ± 15 105 ± 17 1186 ± 169 200 ± 25 2250 ± 280 300 ± 30 3390 ± 340

5/16 - 24 UNF 138 ± 17 128 ± 17 1446 ± 192 225 ± 25 2540 ± 280 325 ± 30 3670 ± 340

3/8 - 16 UNC 16 ± 2 16 ± 2 22 ± 3 30 ± 3 41 ± 4 43 ± 4 58 ± 5

3/8 - 24 UNF 17 ± 2 18 ± 2 24 ± 3 35 ± 3 47 ± 4 50 ± 4 68 ± 5

7/16 - 14 UNC 27 ± 3 27 ± 3 37 ± 4 50 ± 5 68 ± 7 70 ± 7 68 ± 9

7/16 - 20 UNF 29 ± 3 29 ± 3 39 ± 4 55 ± 5 75 ± 7 77 ± 7 104 ± 9

1/2 - 13 UNC 30 ± 3 48 ± 7 65 ± 9 75 ± 8 102 ± 11 105 ± 10 142 ± 14

1/2 - 20 UNF 32 ± 3 53 ± 7 72 ± 9 85 ± 8 115 ± 11 120 ± 10 163 ± 14

5/8 - 11 UNC 65 ± 10 88 ± 12 119 ± 16 150 ± 15 203 ± 20 210 ± 20 285 ± 27

5/8 - 18 UNF 75 ± 10 95 ± 15 129 ± 20 170 ± 15 230 ± 20 240 ± 20 325 ± 27

3/4 - 10 UNC 93 ± 12 140 ± 20 190 ± 27 265 ± 25 359 ± 34 374 ± 35 508 ± 47

3/4 - 16 UNF 115 ± 15 165 ± 25 224 ± 34 300 ± 25 407 ± 34 420 ± 35 569 ± 47

7/8 - 9 UNC 140 ± 20 225 ± 25 305 ± 34 430 ± 45 583 ± 61 600 ± 60 813 ± 81

7/8 - 14 UNF 155 ± 25 260 ± 30 353 ± 41 475 ± 45 644 ± 61 660 ± 60 895 ± 81

8 with Thin

Height Nuts

In-lb In-lb N-cm In-lb N-cm In-lb N-cm

10 ± 2 13 ± 2 147 ± 23

13 ± 2 25 ± 5 282 ± 30

18 ± 2 30 ± 5 339 ± 56

ft-lb ft-lb N-m ft-lb N-m ft-lb N-m

SAE Grade 1 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

15 ± 2 170 ± 20 23 ± 2 260 ± 20

29 ± 3 330 ± 30 41 ± 4 460 ± 45

42 ± 4 475 ± 45 60 ± 6 674 ± 70

SAE Grade 8 Bolts, Screws,

Studs, & Sems with Regular

Height Nuts (SAE J995

Grade 2 or Stronger Nuts)

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the

minimum proof load specified in SAE J429. The

tolerance is approximately

value. Thin height nuts include jam nuts.

± 10% of the nominal torque

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

1 - 6 260 Series Tractor Service Manual

Page 15

SPECIFICATIONS

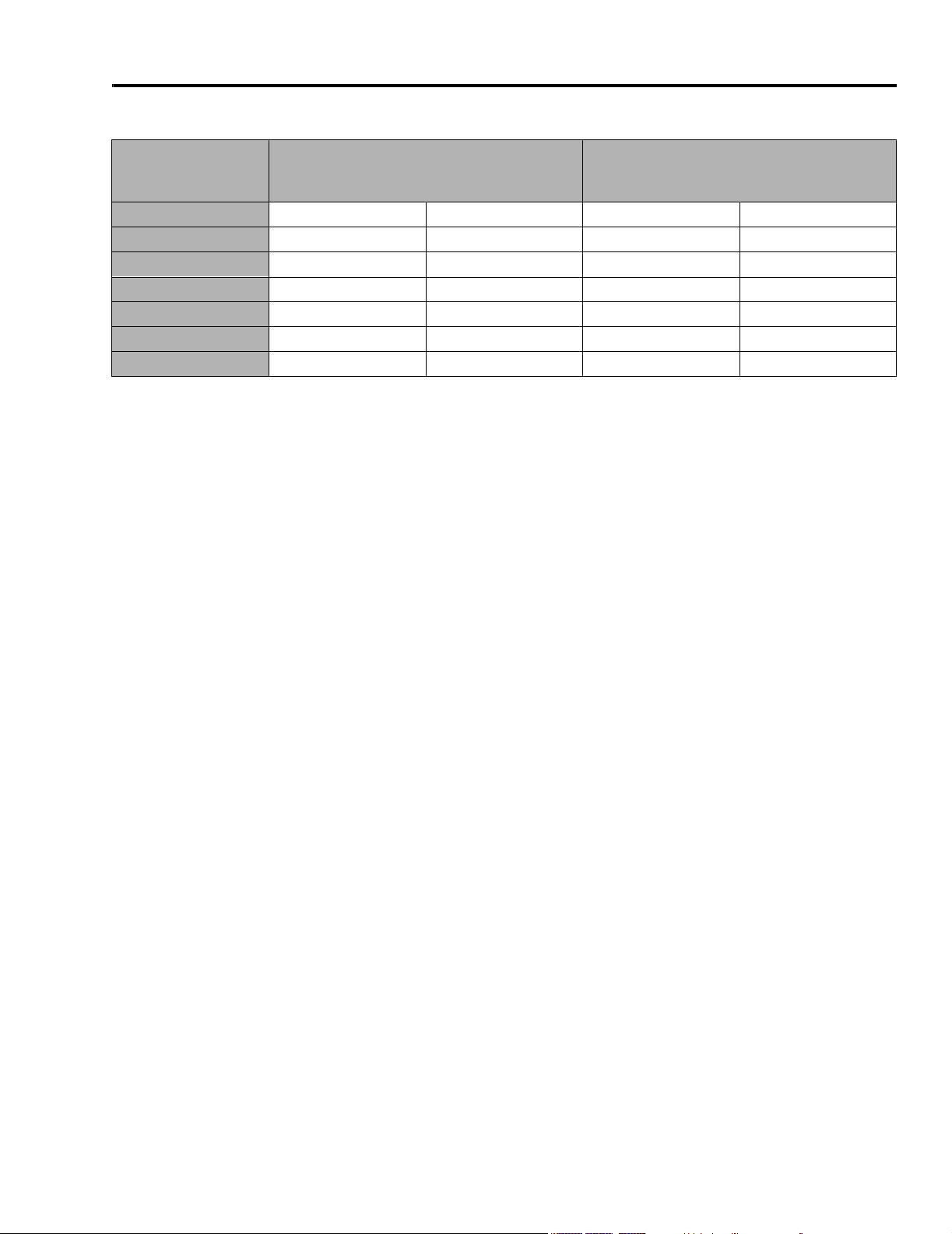

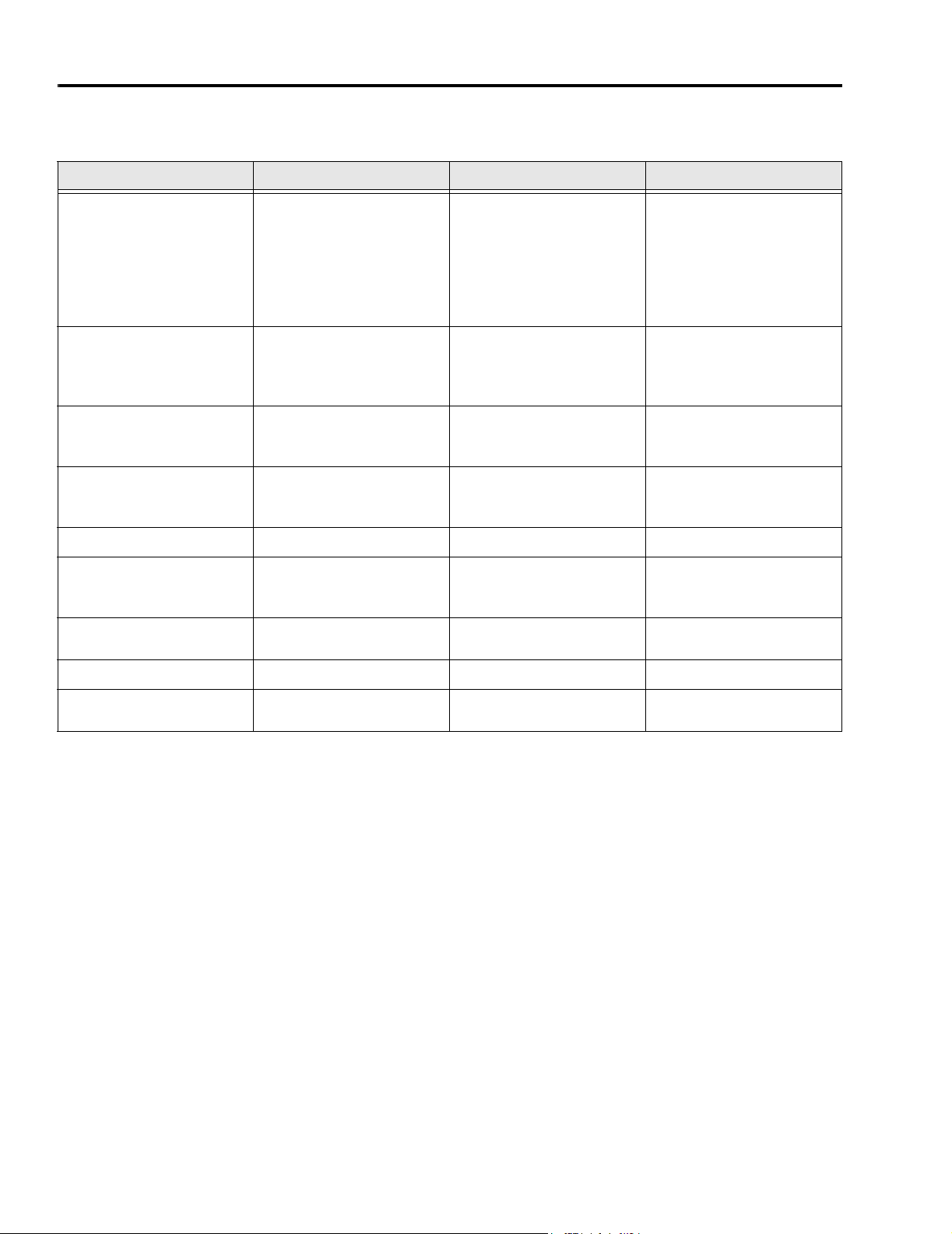

Standard Torque for Dry, Zinc, and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws, and Studs with

Thread Size

M5 X 0.8 57 ± 5 in-lb 640 ± 60 N-cm 78 ± 7 in-lb 885 ± 80 N-cm

M6 X 1.0 96 ± 9 in-lb 1018 ± 100 N-cm 133 ± 13 in-lb 1500 ± 150 N-cm

M8 X 1.25 19 ± 2 ft-lb 26 ± 3 N-m 27 ± 2 ft-lb 36 ± 3 N-m

M10 X 1.5 38 ± 4 ft-lb 52 ± 5 N-m 53 ± 5 ft-lb 72 ± 7 N-m

M12 X 1.75 66 ± 7 ft-lb 90 ± 10 N-m 92 ± 9 ft-lb 125 ± 12 N-m

M16 X 2.0 166 ± 15 ft-lb 225 ± 20 N-m 229 ± 22 ft-lb 310 ± 30 N-m

M20 X 2.5 325 ± 33 ft-lb 440 ± 45 N-m 450 ± 37 ft-lb 610 ± 50 N-m

Note: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

oil, graphite, or thread sealant such as Loctite.

Note: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Strong Nuts)

Note: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately

the nominal torque value. Thin height nuts include jam nuts.

Class 10.9 Bolts, Screws, and Studs with

Regular Height Nuts (

Class 10 or Strong Nuts)

± 10% of

260 Series Tractor Service Manual 1 - 7

Page 16

SPECIFICATIONS

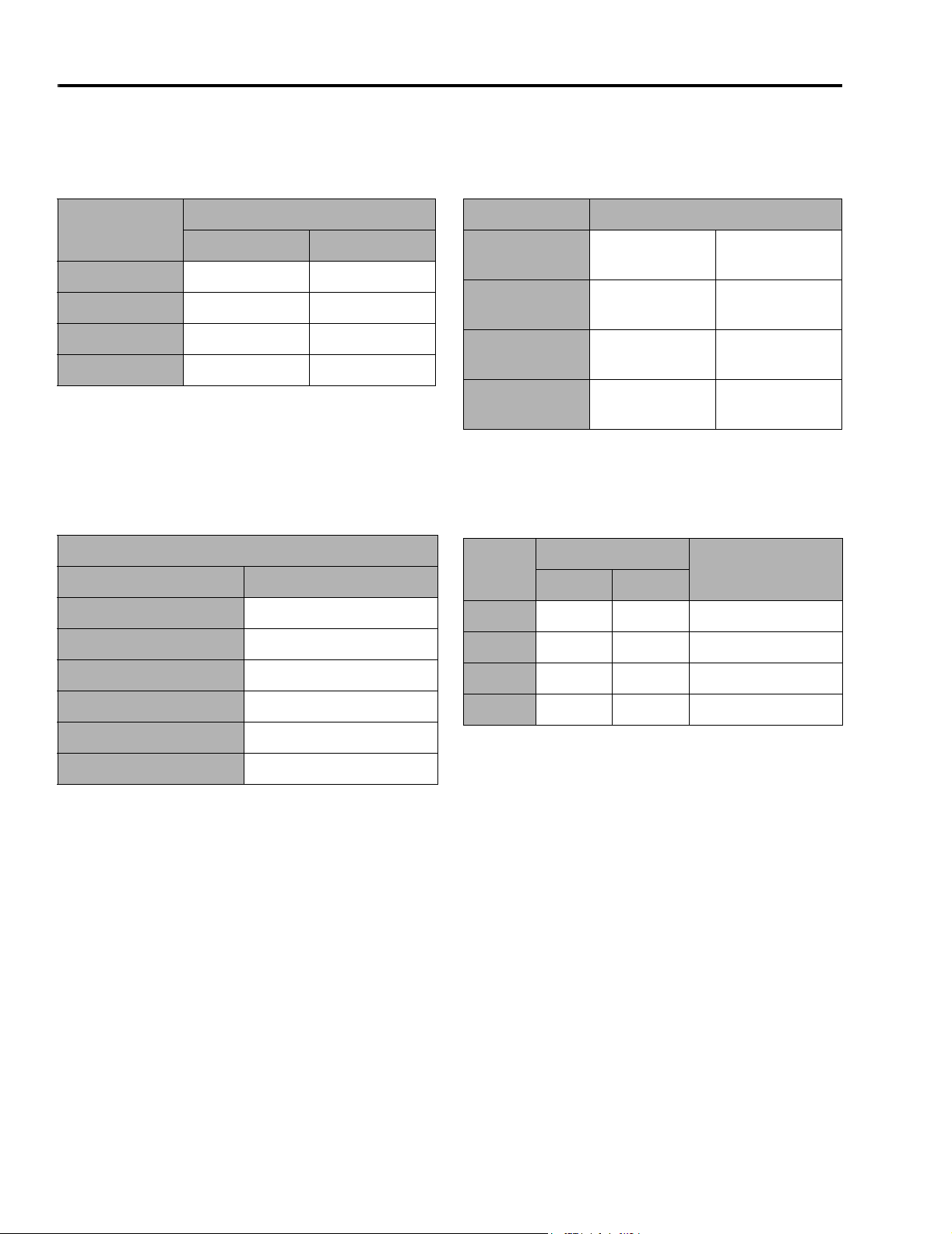

Other Torque Specifications

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 - 20 UNC 140 ± 20 in-lb 73 ± 12 in-lb

5/16 - 18 UNC 215 ± 35 in-lb 145 ± 20 in-lb

3/8 - 16 UNC 35 ± 10 ft-lb 18 ± 3 ft-lb

1/2 - 13 UNC 75 ± 15 ft-lb 50 ± 10 ft-lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23, or Type F

Thread Size Baseline Torque*

No. 6 - 32 UNC 20 ± 5 in-lb

Wheel Bolts and Lug Nuts

Thread Size Recommended Torque**

7/16 - 20 UNF

Grade 5

1/2 - 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non-lubricated fasteners.

Thread

Size

No. 6 18 20 20 ± 5 in-lb

Threads per Inch

Typ e A Type B

65 ± 10 ft-lb 88 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

80 ± 10 ft-lb 108 ± 14 N-m

Thread Cutting Screws

(Zinc Plated Steel)

Baseline Torque*

No. 8 - 32 UNC 30 ± 5 in-lb

No.10 - 24 UNC 38 ± 7 in-lb

1/4 - 20 UNC 85 ± 15 in-lb

5/16 - 18 UNC 110 ± 20 in-lb

3/8 - 16 UNC 200 ± 100 in-lb

Conversion Factors

in-lb X 11.2985 - N-cm

ft-lb X 1.3558 = N-m

No. 8 15 18 30 ± 5 in-lb

No. 10 12 16 38 ± 7 in-lb

No. 12 11 14 85 ± 15 in-lb

* Hole size, material strength, material thickness and

finish must be considered when determining specific

torque values. All torque values are based on nonlubricated fasteners.

N-cm X - 0.08851 = in-lb

N-cm X 0.73776 - ft-lb

1 - 8 260 Series Tractor Service Manual

Page 17

SPECIFICATIONS

Equivalents and Conversions

Decimal and Millimeter Equivalents

Fractions Decimals mm Fractions Decimals mm

1/64 0.015625 0.397 33/64 0.515625 13.097

1/32 0.03125 0.794 16/32 0.53125 13.484

3/64 0.046875 1.191 35/64 0.546875 13.891

1/16 0.0625 1.588 9/16 0.5625 14.288

5/64 0.078125 1.984 37/64 0.578125 14.684

3/32 0.9375 2.381 19/32 0.59375 15.081

1/8 0.1250 3.175 5/8 0.6250 15.875

9/64 0.140625 3.572 41/64 0.640625 16.272

5/32 0.15625 3.969 21/32 0.65625 16.669

11/64 0.171875 4.366 43/64 0.671875 17.066

3/16 0.1875 4.762 11/16 0.6875 17.462

13/64 0.203125 5.159 45/64 0.703125 17.859

7/32 0.21875 5.556 23/32 0.71875 18.256

15/64 0.234375 5.953 47/64 0.734375 18.653

1/4 0.2500 6.350 3/4 0.7500 19.050

17/64 0.265625 6.747 49/64 0.765625 19.447

9/32 0.28125 7.144 25/32 0.78125 19.844

19/64 0.296875 7.541 51/64 0.796875 20.241

5/16 0.3125 7.541 13/16 0.8125 20.638

21/64 0.328125 8.334 53/64 0.828125 21.034

11/32 0.34375 8.731 27/32 0.84375 21.431

23/64 0.359375 9.128 55/64 0.859375 21.828

3/8 0.3750 9.525 7/8 0.8750 22.225

25/64 0.390625 9.922 57/64 0.890625 22.622

13/32 0.40625 10.319 29/32 0.90625 23.019

27/64 0.421875 10.716 59/64 0.921875 23.416

7/16 0.4375 11.112 15/16 0.9375 23.812

29/64 0.453125 11.509 61/64 0.953125 24.209

15/32 0.46875 11.906 31/32 0.96875 24.606

31/64 0.484375 12.303 63/64 0.984375 25.003

1/2 0.5000 12.700 1 1.000 25.400

1 mm = 0.03937 in. 0.001 in. = 0.0254 mm

260 Series Tractor Service Manual 1 - 9

Page 18

SPECIFICATIONS

To Convert Into Multiply By

Miles

Yards

Linear

Measurement

Area

Volum e

Weight

Pressure

Feet

Feet

Inches

Inches

Inches

Square Miles

Square Feet

Square Inches

Acre

Cubic Yards

Cubic Feet

Cubic Inches

Tons (Short)

Pounds

Ounces (Abdp.)

Pounds/Sq. In. Kilopascal 6.895

U.S. to Metric Conversions

Kilometers

Meters

Meters

Centimeters

Meters

Centimeters

Millimeters

Square Kilometers

Square Meters

Square Centimeters

Hectare

Cubic Meters

Cubic Meters

Cubic Centimeters

Metric Tons

Kilograms

Grams

1.609

0.9144

0.3048

30.48

0.0254

2.54

25.4

2.59

0.0929

6.452

0.4047

0.7646

0.02832

16.39

0.9078

0.4536

28.3495

Work

Liquid Volume

Liquid Flos

Tempe r a ture

Foot-pounds

Foot-pounds

Inch-pounds

Quarts

Gallons

Gallons/Minute Liters/Minute 3.785

Fahrenheit Celsius 1. Subtract 32°

Newton-Meters

Kilogram-Meters

Kilogram-Centimeters

Liters

Liters

1.356

0.1383

1.152144

0.9463

3.785

2. Multiply by 5/9

1 - 10 260 Series Tractor Service Manual

Page 19

CHASSIS

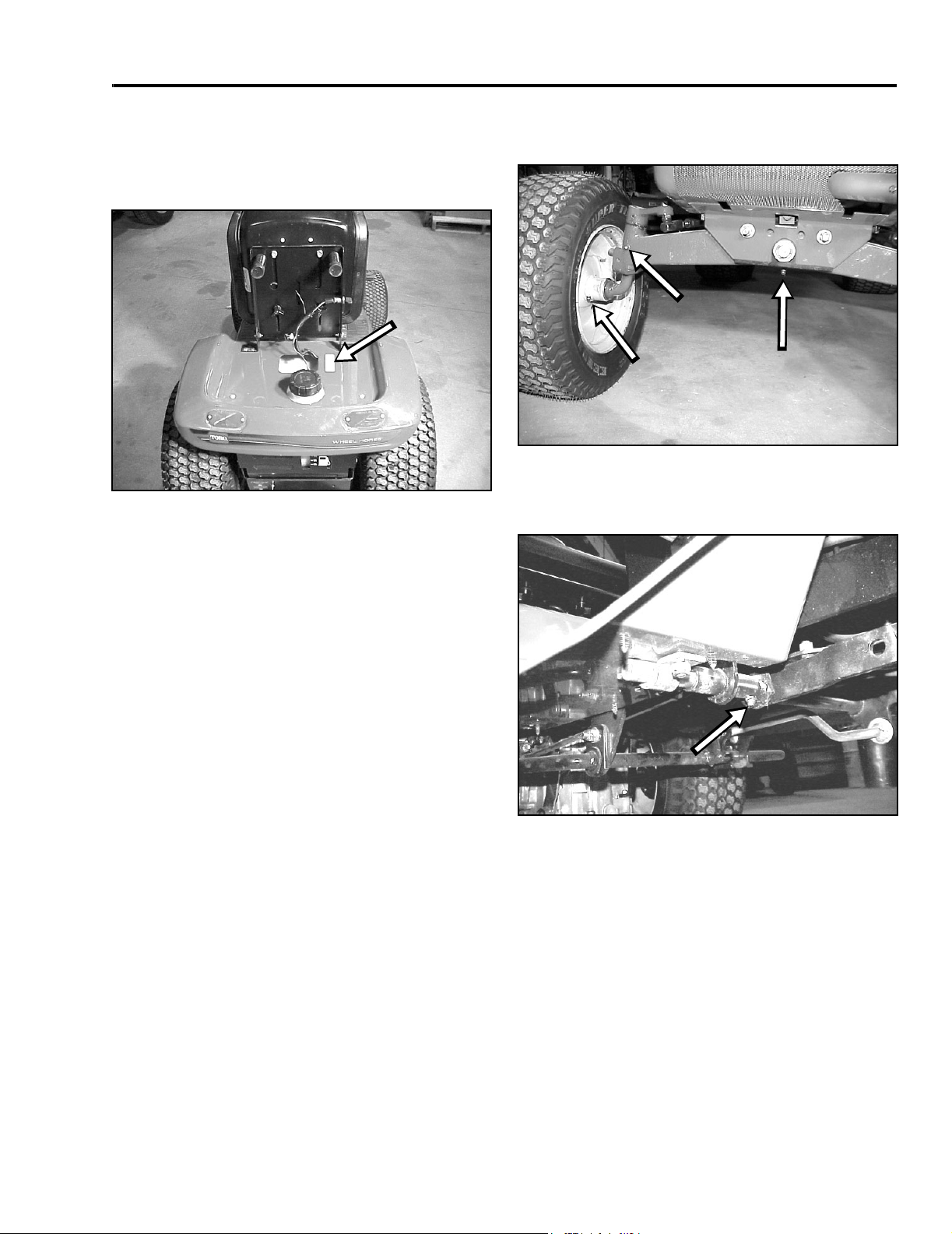

Model and Serial Number Location

The model and serial number plate location is under

the seat (Figure 3).

Figure 3

MVC-084X

Greasing and Lubrication

3. One located on the front axle pivot area (1 total)

(Figure 4).

Figure 4

Hydrostatic model tractors have one grease fitting on

the forward/reverse pedal (Figure 5).

MVC-085X

The machine should be greased every 50 hours or

yearly, whichever occurs first. You should grease

more frequently when operating conditions are

extremely dusty or sandy.

Grease Type: General-purpose grease.

There are 5 grease fittings located in the front axle

area:

1. One located on the inside of each wheel hub (2

total).

2. One located on each end of the front axle for the

spindles (2 total).

Figure 5

MVC-088X

260 Series Tractor Service Manual 2 - 1

Page 20

CHASSIS

On the gear drive tractors, there is a grease fitting

located on both the clutch and brake pedal (Figure 6).

Figure 6

MVC-089X

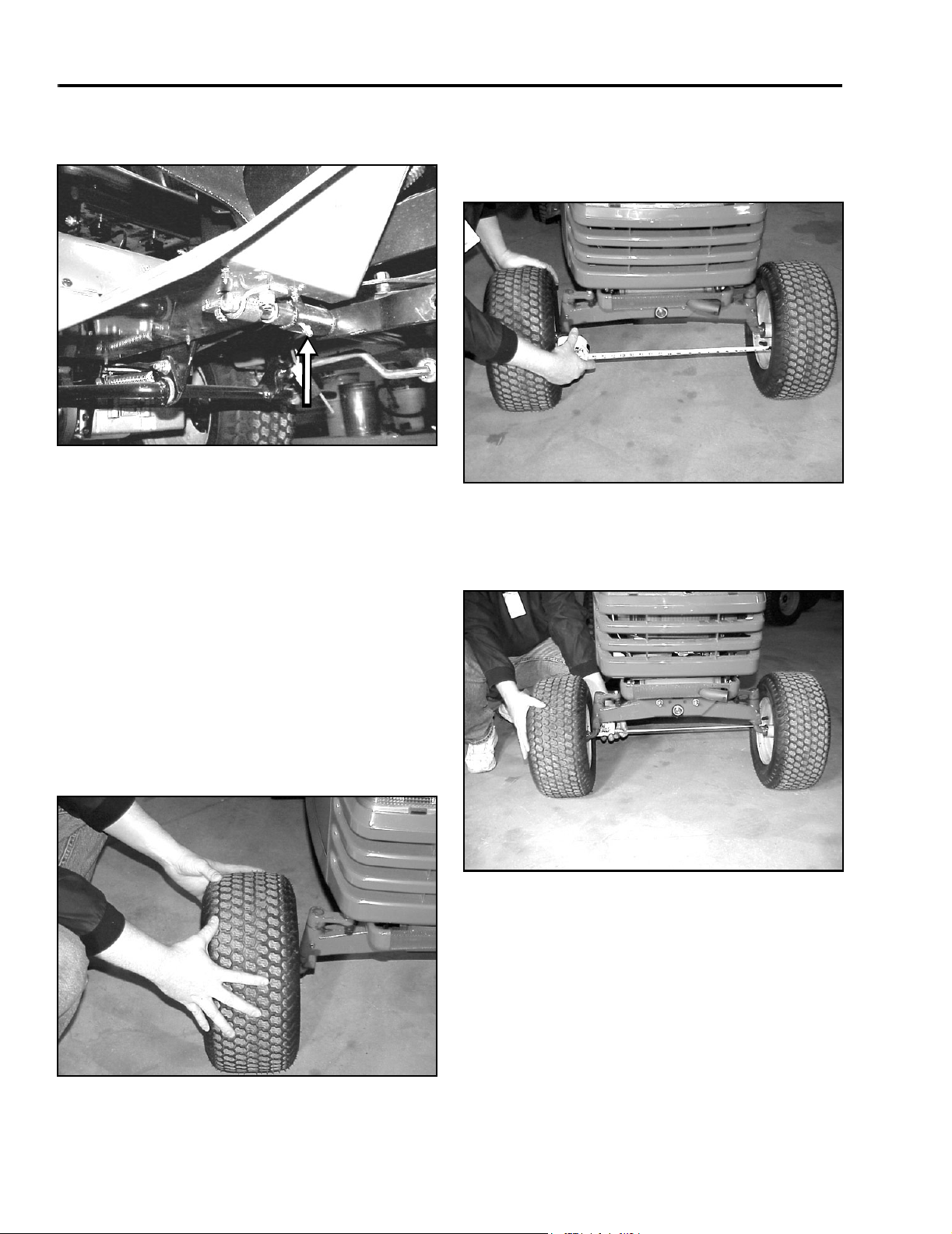

Front Wheel Toe-in

If there is uneven tire wear, lawn scuffing, or hard

steering, toe-in may need to be adjusted. The front

toe-in measurement should be 1/8” to ¼” (3 to 6mm).

This should be checked every 100 hours or once a

year, whichever occurs first.

3. Measure the distance between both the front rims

at spindle level, in front and rear of the wheels.

You can also measure between the tread mold

marks if the tires are new (Figure 8).

Figure 8

4. The front measurement should be 1/8” to ¼” (3 to

6mm) less than the rear measurement (Figure 9).

If needed, follow the adjustment procedure.

MVC-092X

MEASUREMENT:

1. Disengage the PTO, set the parking brake, and

turn the ignition key to OFF to stop the engine.

Remove the key.

2. Push the front of the tires out to remove normal

looseness in the linkage (Figure 7).

Figure 7

MVC-091X

Figure 9

MVC-094X

2 - 2 260 Series Tractor Service Manual

Page 21

CHASSIS

Front Wheel Toe-in Adjustment

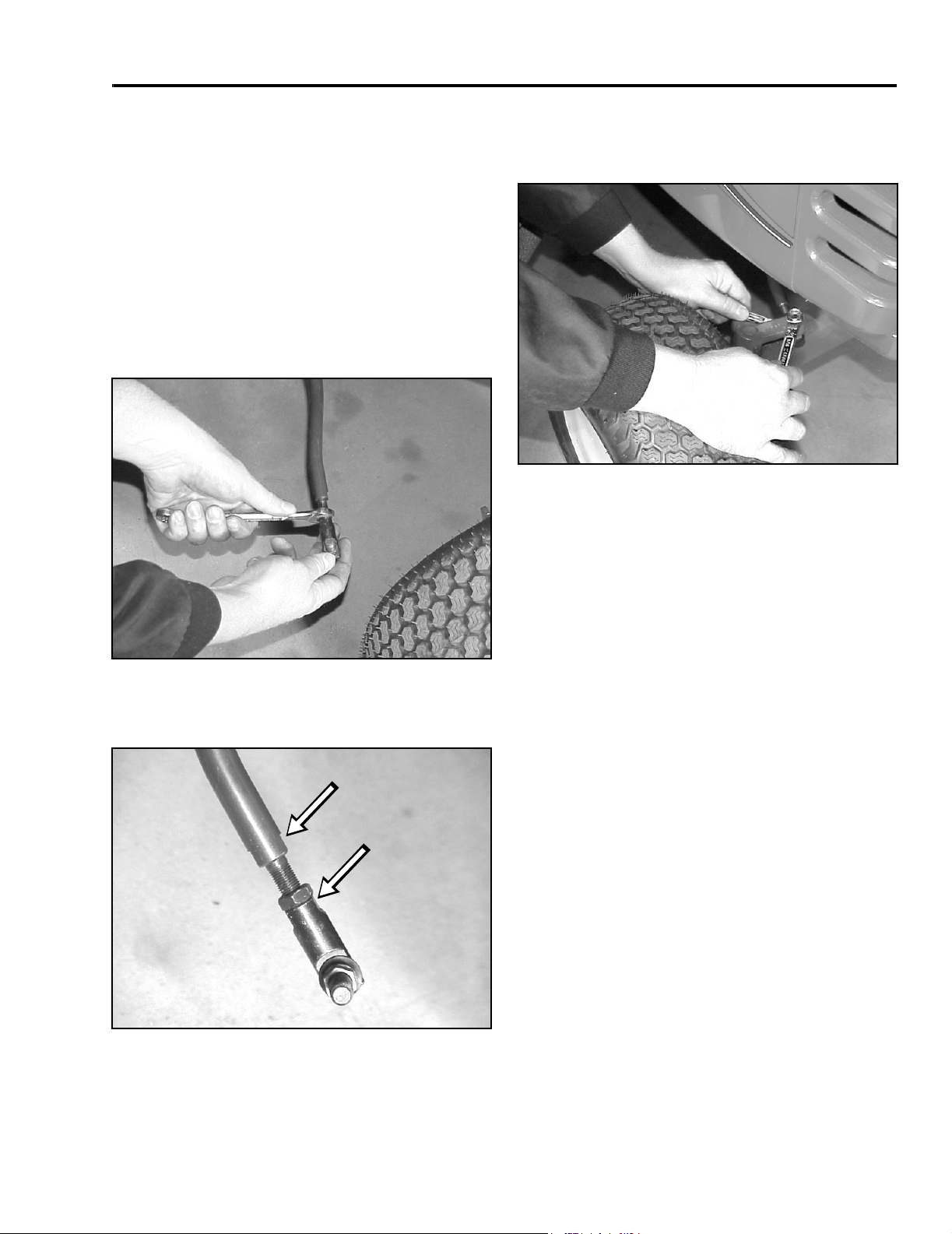

1. Remove the tie rod from one steering arm.

2. Loosen the jam nut securing the ball joint to the

steering rod. Rotate the ball joint one turn:

clockwise to increase toe-in; counterclockwise to

decrease toe-in (Figure 10).

IMPORTANT: If more than one turn is required

to meet specifications, alternate between the

right and left steering rods to maintain

steering wheel alignment.

4. Install the ball joint to the steering arm and check

the toe-in as described in the measurement

section (Figure 12).

Figure 12

MVC-099X

Front Wheel and Spindle Removal

and Installation

Figure 10

3. Hold flats on the ball joint to align with the flats on

the tie rod and tighten the jam nut (Figure 11).

Figure 11

MVC-095X

MVC-098X

Removal

1. Disengage the PTO. Set the parking brake, and

turn the ignition key to OFF to stop the engine.

Remove the key.

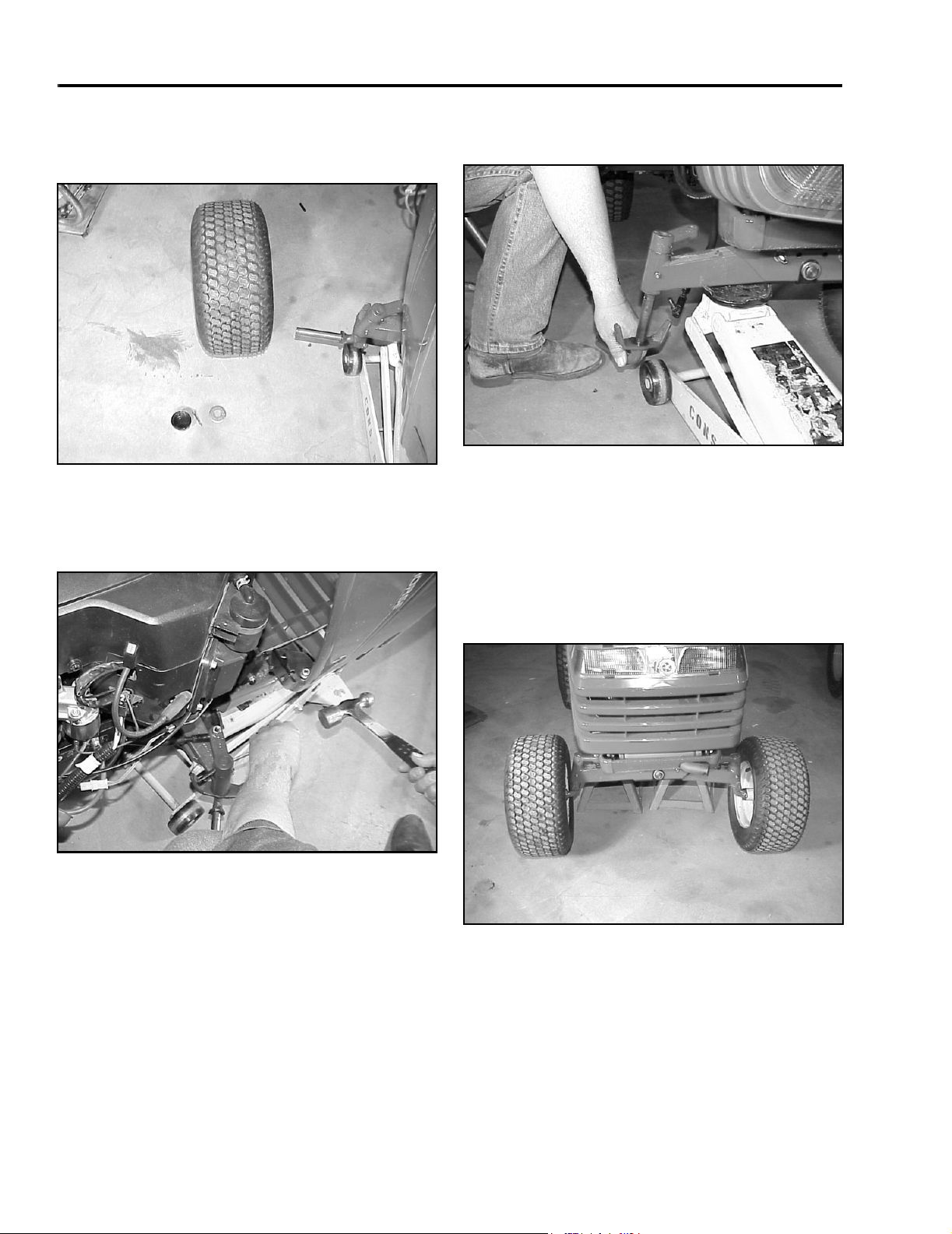

2. Raise the front axle by putting a jack under the

side you are removing the wheel or spindle from.

260 Series Tractor Service Manual 2 - 3

Page 22

CHASSIS

3. Remove the outer hub cap, cotter pin, washer,

and hub cap washer. Slide the wheel and tire off

the spindle (Figure 13).

Figure 13

4. Remove the tie rod from the front spindle arm.

With a drift punch and hammer, drive the roll pin

out of the front spindle arm (Figure 14).

MVC-100X

5. The spindle can now be removed out the bottom

of the front axle assembly (Figure 15).

Figure 15

6. Installation – reverse the order of removal.

MVC-102X

Front Axle Removal and Installation

Figure 14

MVC-101X

1. Jack-up the front of the tractor. Put jack stands

under the frame, just behind the front axle

assembly (Figure 16).

Figure 16

MVC-103X

2 - 4 260 Series Tractor Service Manual

Page 23

CHASSIS

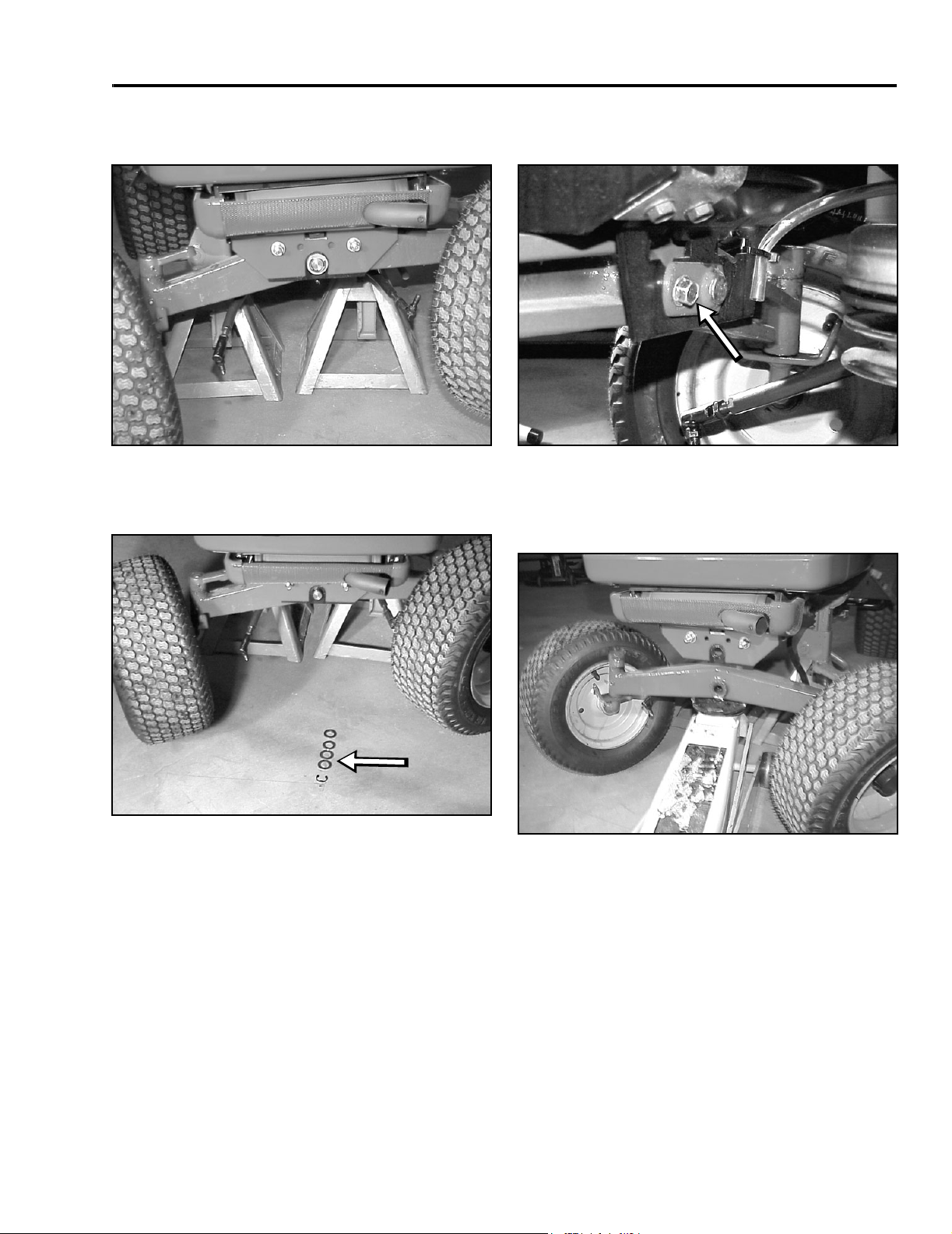

2. Remove right and left tie rods from the front

spindle arms (Figure 17).

Figure 17

3. On the front of the axle, in the center, remove the

E-ring and washers (Figure 18).

MVC-105X

5. On the back side of the axle, remove the bolt on

the axle pin (Figure 19).

Figure 19

6. Remove the axle pin; use a drift punch and

hammer to tap the axle pin out; if needed (Figure

20).

MVC-107X

Figure 18

4. Remove the electric PTO clutch from the engine

crankshaft.

260 Series Tractor Service Manual 2 - 5

MVC-106X

Figure 20

7. Installation – reverse the order of removal.

MVC-108X

Page 24

CHASSIS

Steering Gear

Description

The steering gear assembly is made up of a vertically

mounted steering shaft and a horizontal sector gear.

The sector gear is adjustable so that excessive

backlash play in steering gears can be removed

(Figure 21).

2. Position the steering wheel so the tie rods clear

the front axle and remove them from the steering

arms (Figure 22).

Figure 22

3. Loosen the locking nut on the eccentric (Figure

23). Position the steering wheel spokes so they

extend outward left to right.

MVC-263X

Figure 21

6-8

Steering Backlash Adjustment

Use the following procedure if there is excessive

steering backlash.

1. Remove battery and battery tray from the tractor.

Figure 23

MVC-110X

2 - 6 260 Series Tractor Service Manual

Page 25

CHASSIS

4. Tighten the nut until the eccentric turns with a

small amount of friction (Figure 21).

Figure 24

5. Using a punch, turn the eccentric clockwise until

zero clearance is obtained between the end of the

steering shaft gear and the steering sector (Figure

24).

MVC-113X

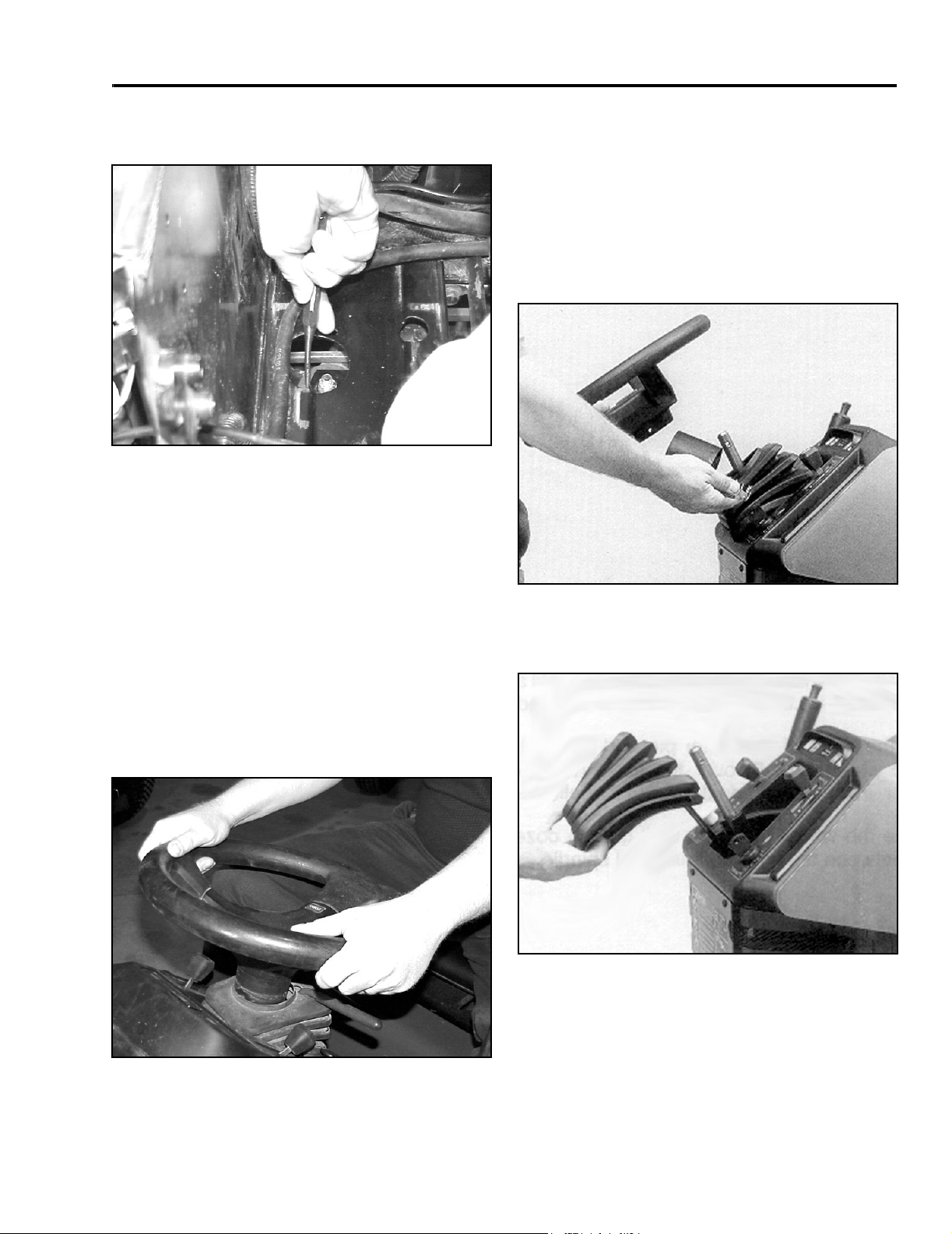

Steering Gear Shaft Disassembly

1. Disconnect the negative battery cable.

2. Remove the roll pin, steering wheel, spacer, and

spring from the top of the steering shaft (Figure

26). (Note: Some units use a retaining nut and

washer located under the center cover of the

steering wheel).

6. Tighten the nut to 25 – 35 ft lb (34 – 48 Nm). DO

NOT OVERTIGHTEN.

7. Apply some multipurpose grease to the steering

gear teeth.

8. Connect the tie rod ends to the steering arms.

9. Turn the wheels left and right. Recheck for zero

clearance (Figure 25).

Figure 26

3. Remove the rubber boot from the steering shaft

and console (Figure 27).

Figure 27

6-9

6-10

Figure 25

10. Reinstall the battery tray and battery.

260 Series Tractor Service Manual 2 - 7

MVC-115X

Page 26

CHASSIS

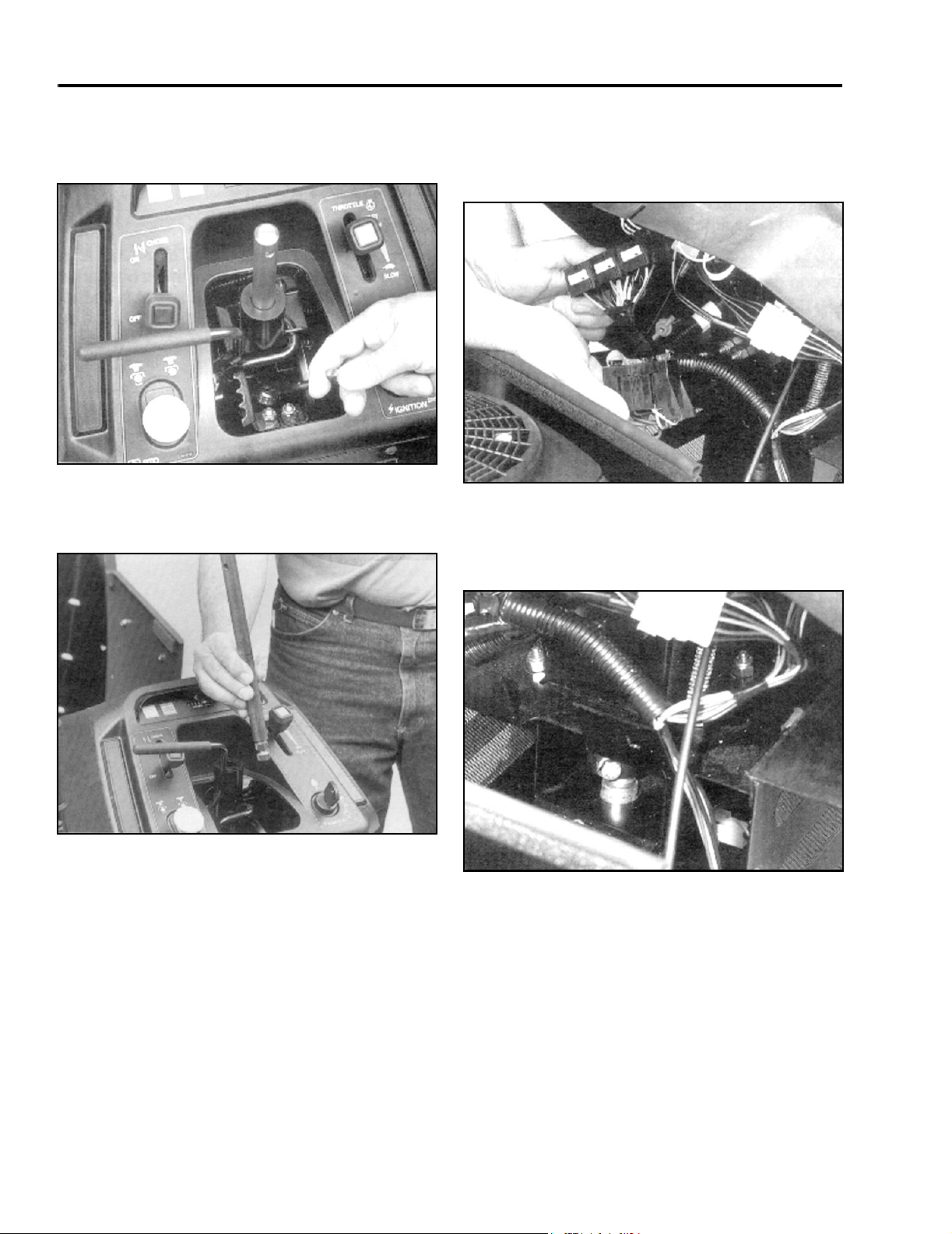

4. Rotate the steering shaft until the top bolt of the

universal joint faces the rear of the tractor.

Remove the bolt (Figure 28).

Figure 28

5. Pull the top shaft from the universal joint and

remove it from the top of the tractor (Figure 29).

6-11

6. Disconnect the relays from the mounting bracket

and remove the bracket from the tractor. Place

the wiring harness and fuse block to the side of

the console (Figure 30).

Figure 30

7. Rotate the steering gear shaft until the bottom bolt

of the universal joint faces the front of the tractor.

Remove the bolt (Figure 31).

6-13

Figure 29

2 - 8 260 Series Tractor Service Manual

6-12

Figure 31

6-14

Page 27

CHASSIS

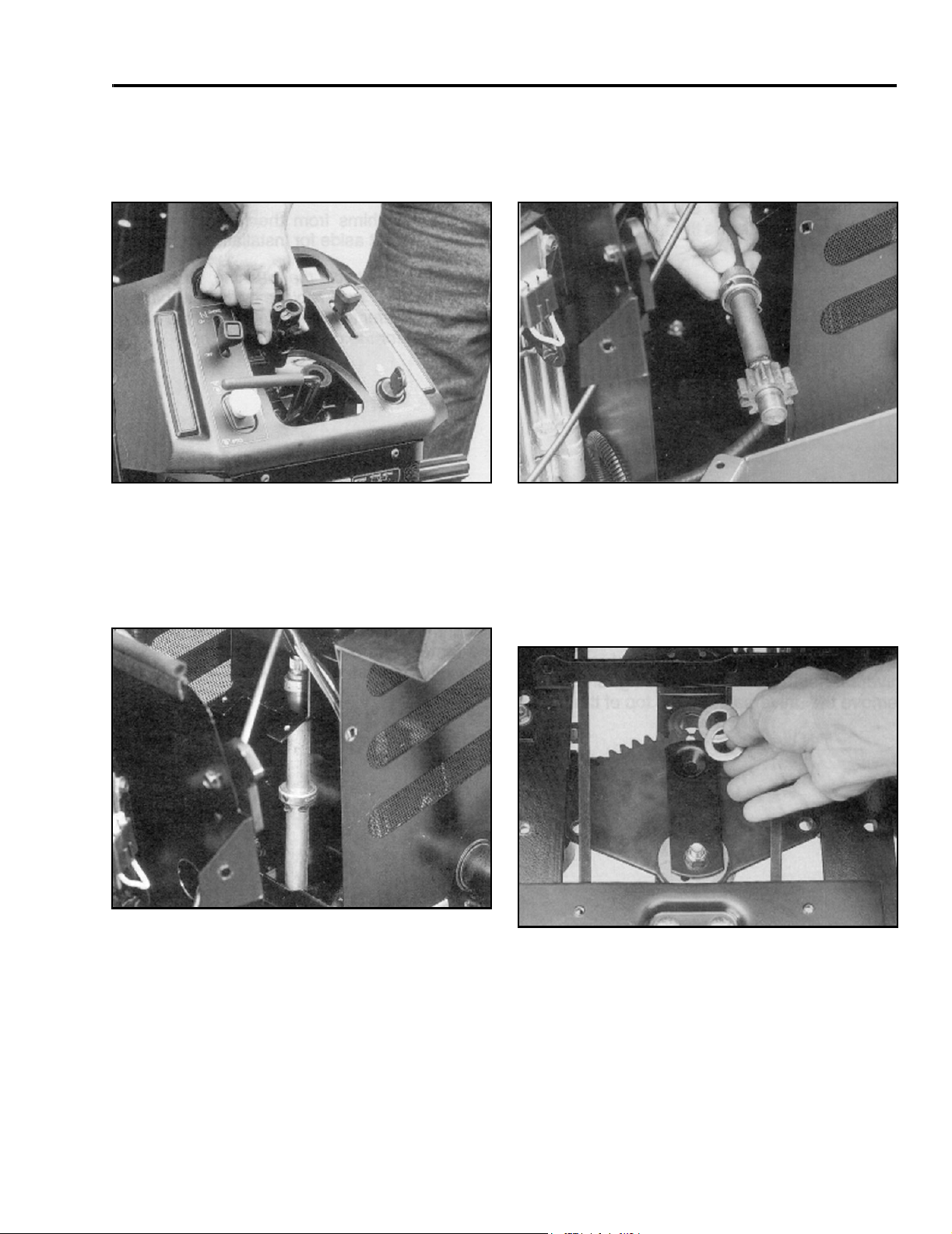

8. Tilt steering to the rear position and remove the

universal joint from the steering shaft gear.

Remove the universal joint from the top of the

tractor (Figure 32).

Figure 32

9. Expand the snap ring found on the steering gear

shaft and slide if halfway down the shaft. Loosen

the setscrew on the locking collar of the steering

gear shaft and move it until it meets the snap ring

(Figure 33).

6-15

10. Lift the steering shaft upwards, out of the lower

bushing and through the opening in the mounting

bracket. Tilt the shaft towards the front of the

tractor and remove it (Figure 34).

Figure 34

11. Remove the shims from the top of the lower

bushing and set aside for installation process

(Figure 35). Important: Check the bushing,

shaft, and gears for wear and replace with new

parts if necessary. Refer to “Steering

Specifications” on page 2 - 15.

6-17

Figure 33

260 Series Tractor Service Manual 2 - 9

6-16

Figure 35

6-18

Page 28

CHASSIS

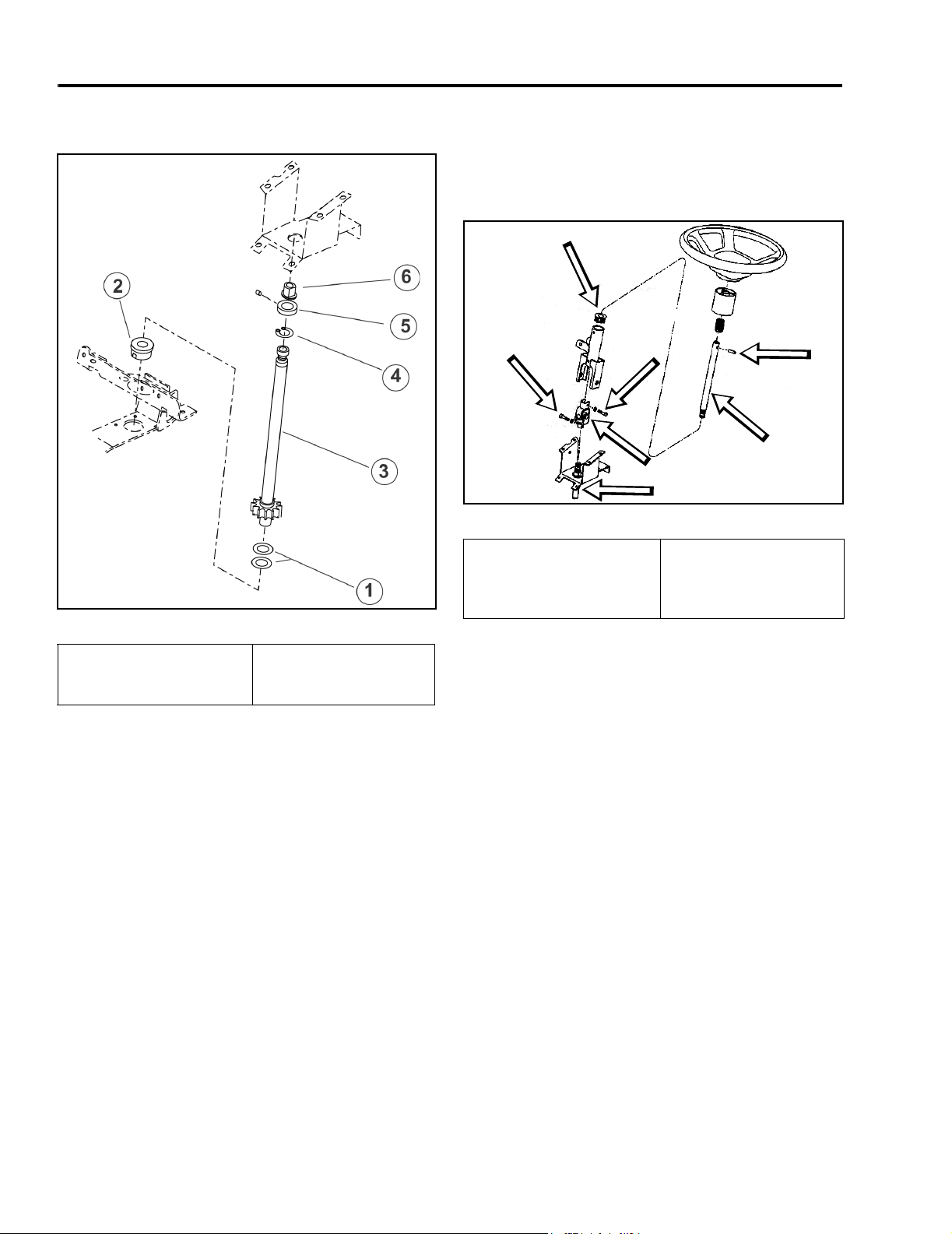

Steering Gear Assembly

Figure 36 6-19

5. Move the locking collar upward on the shaft until it

touches the column support mid bushing. Tighten

the collar set screw, then move the snap ring

upward on the shaft until it meets the bottom of

the locking collar (Figure 36).

6

3

3

4

5

1

2

Figure 37

(1) Universal Joint

(2) Lower Steering Gear

Shaft

(3) Retaining Bolts

(4) Roll Pin

(5) Upper Steering

Shaft

(6) Steering Bushing

6-22

(1) Shims

(2) Lower Bushing

(3) Steering Gear Shaft

1. Place two 0.05” (1.27mm) shims,1, between the

top of the bushing, 2, and the steering gear shaft,

3.

Note: Lubricate the bushing with never seize

lubricant during assembly.

2. Align the front wheels so that they face straight

ahead.

3. Install snap ring, 4; locking collar, 5; and upper

bushing, 6, onto the steering gear shaft.

4. Insert the steering gear shaft through the opening

in the mounting bracket and onto the lower

bushing.

Note: The shims must be in place.

(4) Snap Ring

(5) Locking Collar

(6) Mid Bushing

6. Tilt steering to the rear position and place the

universal joint,1, onto the top end of the lower

steering gear shaft, 2. Install the retaining bolt, 3,

of the universal joint through the joint and steering

gear shaft.

7. Place upper steering shaft, 5, onto the upper end

of the universal joint,1. Position the upper

steering shaft so that the roll pin hole runs

perpendicular (90°) to the tractor’s center line.

Install the retaining bolt, 3, through the upper end

of the universal joint and upper steering shaft.

Note: Ensure that electrical wiring can not come

into contact with upper steering shaft of universal

joint in any position.

2 - 10 260 Series Tractor Service Manual

Page 29

CHASSIS

8. Install the rubber boot over the steering shaft and

console (Figure 38).

Figure 38

9. Place the spring, spacer and steering wheel on

the steering shaft and install the roll pin. (Note:

Some steering wheels are secured with a

retaining nut and washer located under the center

cover of the steering wheel.) Install the relay

bracket, fuse block, battery tray, and battery.

Important: Ensure that all hardware is securely

fastened, that the steering wheel is centered when

the wheels are straight ahead, and that the

steering operates properly.

6-23

Sector Gear Disassembly

1. Remove the battery and plastic battery tray from

the tractor. Disconnect both steering tie rods from

the sector gear. Using the access hole in the

mounting bracket, remove the locknut and

carriage bolt holding the sector in place (Figure

39).

Figure 39

2. Remove the locking plate from the top of the

sector gear (Figure 40).

6-25

Note: Ensure that electrical wiring can not come

into contact with upper steering shaft of universal

joint in any position.

Figure 40

3. Remove the cam bushing, 3, from the sector gear.

Separate the sector gear, 2, from the mounting

bracket (Figure 41).

Important: Inspect the sector gear teeth and cam

bushing for wear and replace if necessary.

6-26

260 Series Tractor Service Manual 2 - 11

Page 30

CHASSIS

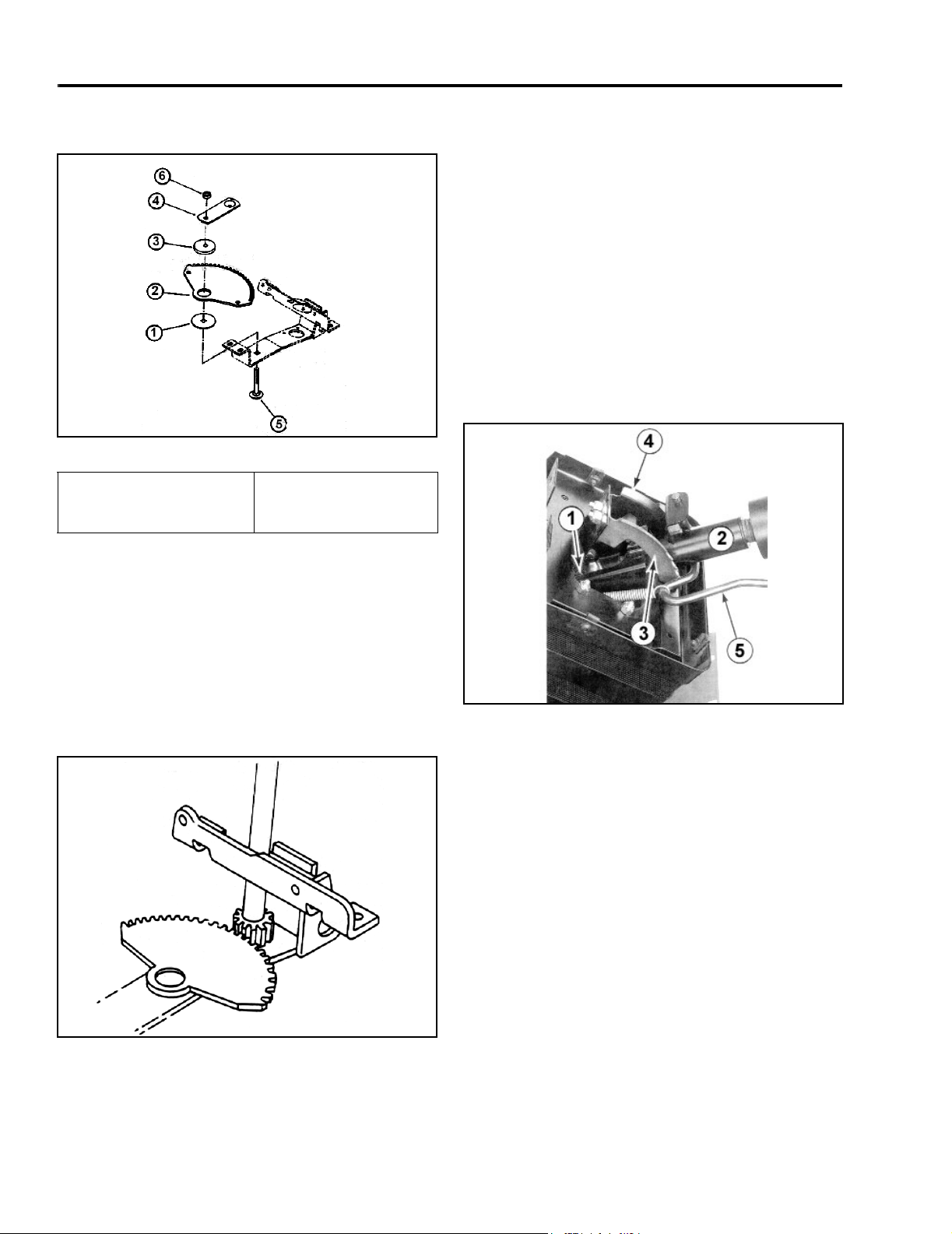

Sector Gear Assembly

Figure 41 6-28

(1) Washer Bearing

(2) Sector Gear

(3) Bushing

1. Install the bearing washer, 1, on the mounting

bracket (Figure 41).

(4) Locking Plate

(5) Carriage Bolt

(6) Locknut

5. Place the locking plate, 4, on the cam bushing

(Figure 41).

6. From the bottom, insert the carriage bolt, 5,

through the bearing washer, cam bushing, and the

locking plate. Secure the bolt with the locknut, 6

(Figure 41).

7. Adjust the steering gear, refer to “Steering

Backlash Adjustment” on page 2 - 6.

8. Fasten both steering arms onto the sector gear.

Check wheel alignment and toe-in.

Tilt Steering

2. Place the sector gear, 2, on top of the bearing

washer with the teeth facing the rear of the tractor

(Figure 41).

3. Center the steering shaft with the sector gear

(Figure 42). Make sure the steering wheel is

centered.

Figure 42

Figure 43 6-34

Description

The tilt steering assembly is made up of the following

components (Figure 43):

1. Universal joint.

2. Steering column (bushing mounted).

3. Detent bracket (left side).

4. Support bracket (right side).

5. Spring-loaded control handle.

6-8

4. Insert the cam bushing, 3, into the bore of the

sector gear (Figure 41).

2 - 12 260 Series Tractor Service Manual

Page 31

CHASSIS

(1) Retaining Bolt

(2) Universal Joint

(3) Retaining Bolt

(4) Upper Steering Shaft and Roll Pin

(Note: Some units have retaining nut and washer

located in the center steering wheel cover.)

Tilt Steering Disassembly

1. Remove the roll pin, steering wheel, spacer, and

spring from top of the steering shaft (Figure 45).

(Note: Some units use a retaining nut and washer

located under the center cover of the steering

wheel.)

Figure 44 6-35

(5) Spring Extension

(6) Bolts

(7) Nuts

(8) Detent Bracket

(9) Support Bracket

(10) Retaining Bolt

(11) Spacer-Yoke

(12) Column

(13) Tilt Lever

(14) Steering Bushing

Figure 45

260 Series Tractor Service Manual 2 - 13

6-9

Page 32

CHASSIS

2. Remove the rubber boot from the steering console

(Figure 46).

Figure 46

3. Remove the bottom retaining bolt, 1, from the

universal joint, 2 (Figure 44).

4. Remove the top retaining bolt, 3, from the

universal joint and disconnect the top steering

shaft, 4, from the tractor (Figure 44).

5. Tilt steering to the rear position and detach the

universal joint from the steering gear shaft. Take

the universal out of the tractor from the top side.

6-10

Tilt Steering Assembly

1. Place bushing, 14, on top of the steering column

(Figure 44).

2. Insert the tilt control handle, 13, into the steering

column bracket (Figure 44).

3. Secure the steering column to the mounting

bracket with pivot bolts, 10; spacers, 11; and

locknuts (Figure 44).

Note: The longer spacers should be positioned

on the left-hand side.

4. Install the left, 8, and right, 9, support brackets.

Fasten the notched bracket to the left side using

four bolts, 6, and nuts, 7. Adjust the brackets to

obtain minimal side play between the column and

brackets (Figure 44).

5. Attach the spring, 5, to the tilt handle and left pivot

spacers (Figure 44).

6. Tilt steering to its farthest rearward position and

place the universal joint, 2, on the steering gear

shaft. Pass the bottom bolt, 1, of the universal

joint through the universal and steering gear shaft

and secure (Figure 44).

6. Remove the spring, 5, from the left pivot spacer

and tilt control handle (Figure 44).

7. Remove the four bolts, 6, and nuts, 7, from the left

and right support brackets, 8, and 9, and remove

the brackets (Figure 44).

8. Remove the two side pivot bolts, 10, and spacers,

11, from the steering column. Lift the column, 12,

out of the tractor (Figure 44).

9. Slide the tilt control handle, 13, off the steering

column bracket (Figure 44).

10. Remove the bushing, 14, from the top of the

steering column (Figure 44).

Important: Inspect all bushings and pivot areas

for wear and replace as necessary. Refer to

“Steering Specifications” on page 2 - 15.

7. Insert the top steering shaft, 4, onto the upper end

of the universal joint. Check the front wheel

alignment, wheels should be straight ahead.

Position the steering shaft so that the roll pin hole,

(if the steering wheel is retained by a roll pin), runs

perpendicular (90º) to the tractor's center line.

Install the retaining bolt, 3, through the upper end

of the universal joint and steering shaft (Figure

44).

Note: Ensure electrical wiring can not come into

contact with upper steering shaft or universal joint

in any position.

2 - 14 260 Series Tractor Service Manual

Page 33

CHASSIS

8. Install the rubber boot over the steering shaft and

console (Figure 47).

Figure 47

6-10

Steering Specifications

9. Place the spring, spacer, and steering wheel on

the steering shaft. Secure the steering wheel with

a roll pin or with the washer and nut as applicable

(Figure 48).

Figure 48

6-9

Item Specification

Free Play – front axle pivot pin 0 – 0.015” (0 – 0.4mm)

End Play – wheel to spindle 0 – 0.015” (0 – 0.4mm)

Toe-In 1/8” – ¼” (3 – 6mm)

Steering Wheel Free Play 0.5” – 1.0” (13 – 25mm)

Steering Shaft Bushings (standard dimensions)

Top (Fiber) ID 0.752 – 0.756” (19.1 – 19.2mm)

OD 1.310 – 1.320” (33.3 – 33.5mm)

Mid (Metal) ID 0.755 – 0.760” (19.2 – 19.3mm)

OD 0.988 – 1.00” (25.3 – 25.4mm)

Bottom (Metal) ID 0.753 – 0.758” (19.1 – 19.2mm)

OD 1.380 – 1.385” (35.0 – 35.2mm)

260 Series Tractor Service Manual 2 - 15

Page 34

CHASSIS

Hood Removal

1. Disconnect the headlight wiring harness (Figure

49).

Figure 49

2. Remove the bolts and nuts located at the bottom

of the hood (Figure 50).

MVC-116X

Seat and Fender Removal

1. Unplug the seat switch, and if equipped with

KeyChoice™ Reverse operating system, unplug

the KeyChoice™ switch (Figure 51).

Figure 51

2. To make it easier to remove the fasteners for the

fender assembly, jack the tractor up in the rear

and remove both rear tires.

MVC-121X

Figure 50

3. Reinstall the hood in reverse order.

MVC-118X

3. Remove the two rear carriage bolts, washers, and

nuts located in the rear of the fender assembly

(Figure 52).

Figure 52

MVC-122X

2 - 16 260 Series Tractor Service Manual

Page 35

CHASSIS

4. Remove the four carriage bolts, washers, and

nuts, (two on the right and two on the left), that are

located between the footrest and fender (Figure

53).

Figure 53

5. Remove the seat and fender together as one

piece (Figure 54).

MVC-124X

2. Remove the two screws and spacers in the front

of the gas tank (Figure 55).

Figure 55

3. Lift the gas tank from the frame, close the gas

shut-off valve, and disconnect the gas line from

the shut-off valve (Figure 56).

MVC-129X

Figure 54

6. Installation - follow the removal procedure in

reverse.

MVC-126X

Figure 56

4. Carefully remove the gas tank.

5. Installation - reverse the order of removal.

MVC-130X

Gas Tank Removal

1. Follow the procedure for removing the rear fender

and seat.

260 Series Tractor Service Manual 2 - 17

Page 36

CHASSIS

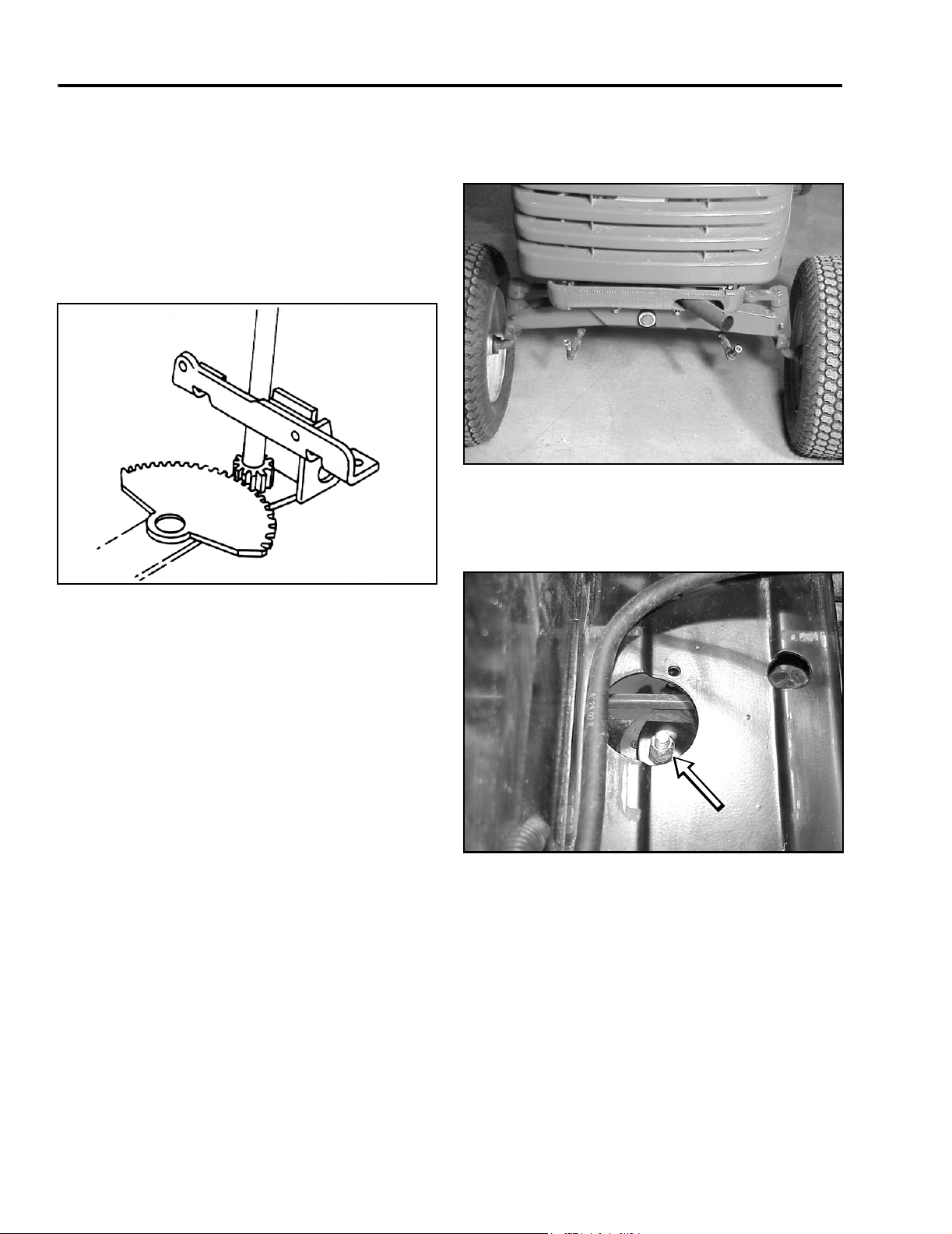

Lift Lever Linkage

Figure 57 7-1

(A) Lift Lever

(B) Lift Arm Cross-Shaft

(C) Mounting Bracket

(D) Control Arm

(E) Handle Grip

The main components of the lift lever weldment are

the:

•Lift Lever, A

• Lift Arm Cross-Shaft, B

• Mounting Brackets, C and H

• Control Arm, D

2 - 18 260 Series Tractor Service Manual

(F) Tip Rod Button

(G) Lift Lever Rod

(H) Pivot Linkage Bracket

(I) Lift Rod

The mounting brackets, C and H, secure the lift

weldment to the tractor frame and hold the lift arm

cross shaft, B, in place.

Handle Grip, E; spring-loaded button, F; and rod, G, is

released from its latching socket. This allows the lift

lever to rotate with the lift lever cross-shaft.

When the lift lever is returned to the latched position,

the spring tension pulls rod, G, back into the latching

socket, and the mower deck is secured in the raised

position.

Page 37

Dial-A-Height Linkage

CHASSIS

Figure 58 7-2

(J) Knob

(K) Trunnion

(L) Plate-HOC Gauge Bracket

(M) Rod-HOC Indicator Rod

(N) Lift Lever Weldment

The Dial-A-Height knob, J, is threaded through a

trunnion, K. A bracket, L, is attached to the trunnion

and the spring-loaded Dial-A-Height indicator rod, M.

The trunnion is also connected to the lift lever

weldment at point N.

As the Dial-A-Height knob, J, is adjusted through the

trunnion, K, the trunnion rotates the bracket, L. This

moves the Dial-A-Height rod, M.

260 Series Tractor Service Manual 2 - 19

Note: The Dial-A-Height rod is visible through the

center access plate between the fender and the hood

console.

At the same time, the trunnion rotates the cross shaft at

point, N, on the lift lever weldment, controlling the

distance the linkage will lower.

Page 38

CHASSIS

Lift Arm Linkage

Figure 59 7-3

(A) Rod

(B) Rear Lift Arm Assembly

(C) Front Lift Arm Assembly

The lift arm linkage is responsible for raising and

lowering the attachment and is made up of the

following main components:

•Lift rod

• Rear lift arm assembly

• Front lift arm assembly

• Leveling rod

• Cross shaft

• Gauge wheel lift link

• Mounting brackets

The lift rod, A, is connected to the lift lever weldment

and the rear lift arm assembly, B. The rear lift arm

assembly is attached to the front lift arm assembly, C,

by a leveling rod, D. It is also bolted to rear frame

hangers at the mounting brackets, F.

(D) Leveling Rod

(E) Cross Shaft

(F) Mounting Brackets

The front lift arm assembly, C, is secured to the tractor

by a cross shaft, E, which is mounted to the bottom of

the footrests. The mower gauge wheel lift link is

connected to the rear lift arm assembly at point G.

When the lift lever is moved, the lift rod, A, rotates the

rear lift arms, B, through the mounting brackets, F. The

gauge wheel lift link (connected to the rear lift arm

assembly at point G) raises and lowers with the lift

arms.

The front lift arms, C, rotate on the cross shaft, E.

Because the front lift arms are connected to the rear lift

arm assembly by a leveling rod, D. They also raise

and lower with the rear lift arms.

2 - 20 260 Series Tractor Service Manual

Page 39

CHASSIS

Adjustments

Lift Height

To obtain a positive latch when the lift handle is in the

full raised position, turn the ¾” nut on the lift rod, A, to

increase or decrease movement of the lift arm

assemblies, B and C.

Leveling

To position the two front lift arms parallel to the tractor

frame, disconnect the leveling rod, D, from the front lift

arms and turn the rod through the trunnion to alter its

length. This rotates the front lift arm assembly, C, on

the cross shaft, E.

Side to Side

When required, perform a side to side adjustment of

the rear lift arms by loosening and repositioning the

9/16” bolts found in the slots of the mounting brackets,

F.

Power Lifts

Electrohydraulic Lift (2000 and Prior Models)

Electric Lift (2001 and Later Models)

Figure 61 Electlift

(1) Actuator Bracket Assy.

(2) Clevis Pin

(3) E-Ring

(4) Pivot Bracket Linkage

(5) Flange Bearing

(6) Actuator

(7) Flat Washer

(8) Spacer

(9) Clevis Pin

(10) Lift Arm Assembly

(11) Flat Washer

(12) Battery Bracket

(13) Screw

Figure 60

For information on removal and repair of the

Electrohydraulic Lift, refer to Electrohydraulic Lift

Service Manual, Form Number 492-0704.

MVC-470X

Removal

1. Remove the hoodstand side panels to the battery

compartment.

2. Disconnect the negative and positive cables from

the battery.

3. Remove the screws, 13, from the battery bracket,

12, and remove the battery bracket.

4. Unplug the actuator, 6, from the wiring harness.

5. Remove the e-ring, 3, from the end of the clevis

pin, 9.

6. Remove the clevis pin, 9, washers, 7, and

spacers, 8.

7. Remove e-ring, 3, and remove clevis pin, 2.

8. Remove the actuator

Installation

Reverse the order of removal.

260 Series Tractor Service Manual 2 - 21

Page 40

THIS PAGE INTENTIONALLY LEFT BLANK

2 - 22 260 Series Tractor Service Manual

Page 41

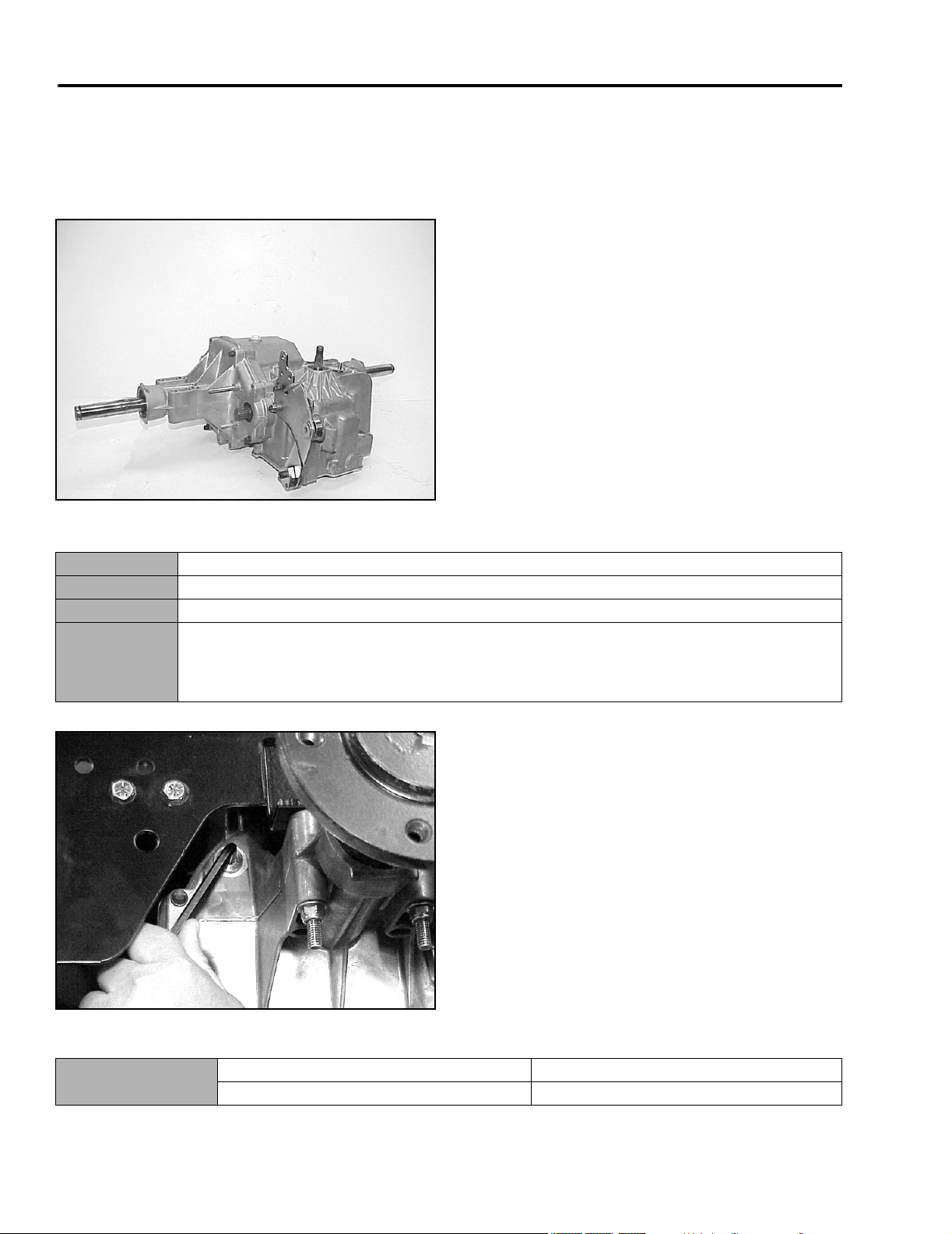

TUFF TORQ TRANSAXLE

Tuff Torq Hydrostatic Transaxle

Internal Service

Internal service information is contained in the Tuff

Torq KGIA Transaxle Service Manual, Form 492-0699.

Fluid Change

The Tuff Torq transaxle is factory filled, sealed, and

does not require oil changes. However, in the event of

oil contamination or degradation, oil replacement may

correct certain performance problems. Refer to the

Transaxle Service Manual.

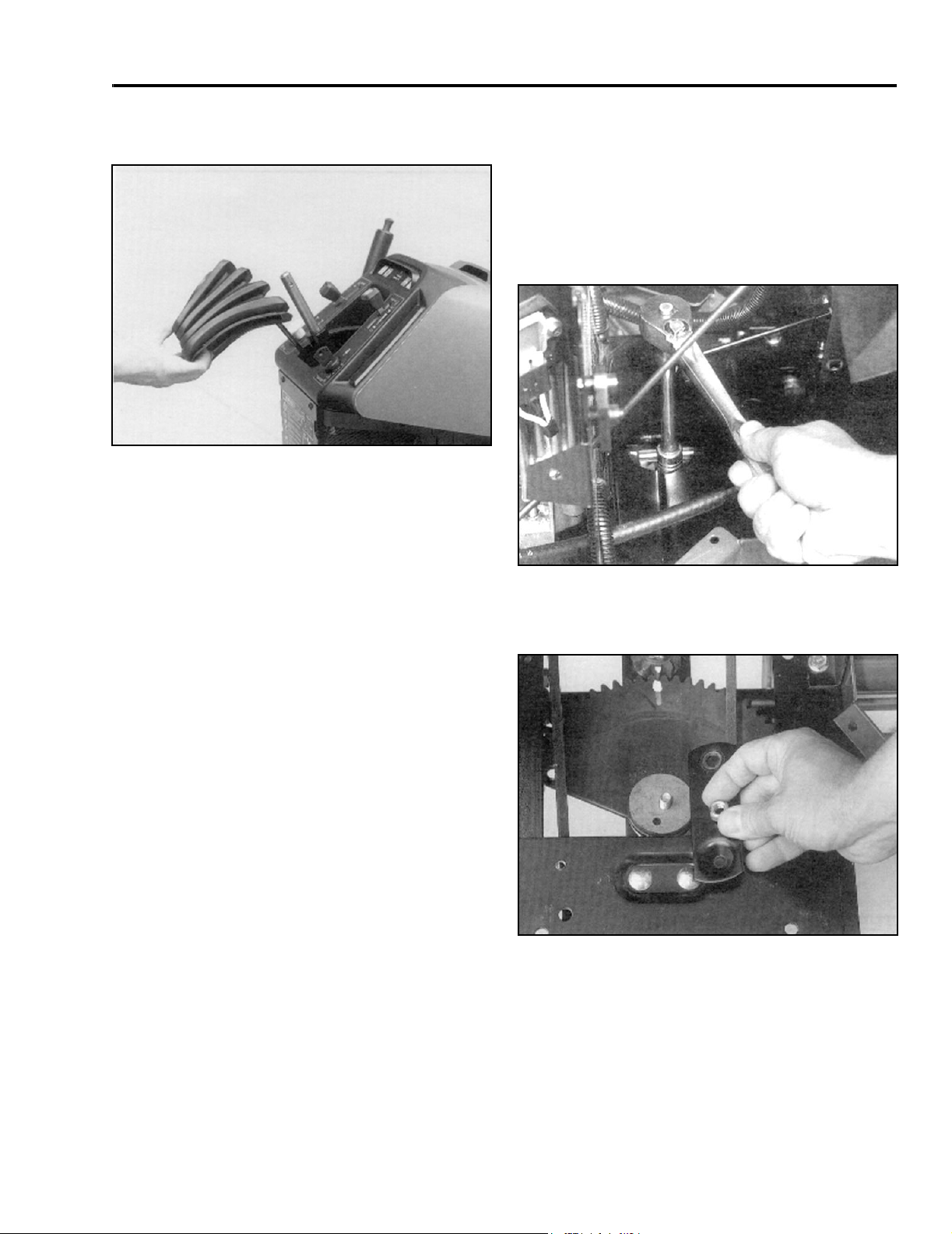

Transaxle Removal – Tuff Torq

1. Disconnect the negative battery cable from the

battery.

2. Raise the rear of the tractor and remove the right

and left rear tires. Support the rear frame, just in

front of the transaxle. Remove the fender, seat,

and gas tank. (Refer to the “Chassis” section on

page 2 - 16.) Remove the center access plate

between the fender and hoodstand (Figure 62).

3. Disconnect the cotter pin and the washer to the

brake rod (Figure 63).

Figure 63

4. Disconnect the cotter pin for the free wheeling

valve rod (Figure 64).

MVC-322X

Figure 64

Figure 62

260 Series Tractor Service Manual 3 - 1

MVC-321X

MVC-323X

Page 42

TUFF TORQ TRANSAXLE

5. Loosen the hose clamp around the reservoir hose

and remove from the top of the transaxle. Clean

the area from around the hose before removing

(Figure 65).

Figure 65

6. Unbolt the forward/reverse control rod. Note: This

tractor has cruise control and the forward/reverse

control rod is disconnected from the cruise plate

which is bolted to the control shaft assembly

(Figure 66).

MVC-324X

7. If the tractor is equipped with cruise control,

disconnect the plug and jack for the cruise control

magnet. Unbolt the cruise control magnet bracket

(Figure 67).

Figure 67

8. Unhook the idler spring at the bolt and spacer

located on the right side of the frame (Figure 68).

MVC-326X

Figure 68

Figure 66

3 - 2 260 Series Tractor Service Manual

MVC-325X

MVC-327X

Page 43

TUFF TORQ TRANSAXLE

9. Remove the 3 screws retaining the transaxle fan

to the input pulley; this will give you enough

clearance to remove the drive belt from the

transaxle input pulley (Figure 69).

Figure 69

10. Use a floor jack and put it under the transaxle to

help lower the transaxle from the frame (Figure

70).

MVC-328X

11. Located on the right front side of the transaxle is a

torque strap. Remove the bolt and nut (Figure

71).

Figure 71

12. Remove the 4 nuts from the U-bolts which hold

the two axle shafts to the frame (Figure 72).

MVC-330X

Figure 72

Figure 70

260 Series Tractor Service Manual 3 - 3

MVC-329X

lMVC-331X

Page 44

TUFF TORQ TRANSAXLE

13. Slowly lower the transaxle out of the frame (Figure

73).

Figure 73

MVC-333X

Installation - Tuff Torq Transaxle

1. Raise the transaxle up toward the frame (Figure

74).

2. Install the 4 washers and nuts to the U-bolts

retaining the two axle shafts to the frame and

tighten (Figure 75).

Figure 75

3. Install the bolt, washer, and nut for the torque

strap and tighten (Figure 76).

MVC-331X

Figure 76

Figure 74

3 - 4 260 Series Tractor Service Manual

MVC-334X

MVC-330X

Page 45

TUFF TORQ TRANSAXLE

4. Bolt the forward/reverse control rod to the control

shaft assembly (Figure 77).

Figure 77

5. Before installing the brake rod trunnion into the

brake control lever, make sure the brake control

lever is in its most rearward position and hold it

there. Adjust the trunnion on the brake rod until it

slips into the brake control lever. Secure with

washer and cotter pin (Figure 78).

MVC-325X

6. Attach the freewheeling rod to the lever with a

cotter pin (Figure 79).

Figure 79

7. Install the hose clamp and the reservoir hose to

the top of the transaxle. Add oil to the reservoir

cup located under the front hood to the cold mark,

located on the side of the cup (Figure 80).

MVC-323X

Figure 80

Figure 78

260 Series Tractor Service Manual 3 - 5

MVC-322X

MVC-337X

Page 46

TUFF TORQ TRANSAXLE

8. Install the drive belt around the transaxle pulley

and also install the transaxle cooling fan with the 3

retaining screws (Figure 81).

Figure 81

9. If the tractor has cruise control, reinstall the cruise

control magnet bracket and reconnect the plug

and jack wiring. Use a tie wrap to tie the wire to

the transaxle damper (Figure 82).

MVC-338X

10. Check the belt routing through the idler pulleys

and hook the idler spring at the bolt and spacer

located on the right side of the frame (Figure 83).

Figure 83

11. Purging of the transaxle is needed to remove

trapped air after repairs. Follow the “Purging

Procedures – Tuff Torq Transaxle” on page 3 - 15.

12. Check the neutral adjustment. If the unit needs to

be neutralized, follow the procedures, “Neutral

Adjustment – Tuff Torq Transaxle” on page 3 - 17).

MVC-327X

Figure 82

MVC-341X

13. Reconnect the battery negative cable and test

operate the tractor, making sure the safety circuits

and the tractor are operating properly.

14. Recheck the transaxle oil reservoir level; top off if

needed.

Belt Replacement – Tuff Torq

Transaxle

Note: Perform belt installation, routing, and inspection

procedures from beneath the tractor.

3 - 6 260 Series Tractor Service Manual

Page 47

TUFF TORQ TRANSAXLE

1. Disconnect the negative battery cable.

Disconnect the electric PTO clutch wire. There is

a tie strap through the frame of the tractor around

the clutch wire that needs to be cut to release the

clutch wire. Also, remove the battery drain tube

from the tie strap (Figure 84).

Figure 84

2. Remove the two steering tie rods from the

steering sector gear (Figure 85).

MVC-342X

4. Unhook the idler spring at the bolt and spacer

located on the right side of the frame (Figure 86).

Figure 86

5. Remove the cotter pin and washer on the brake

rod at the transaxle (Figure 87).

MVC-327X

3. Remove the fender, seat, and gas tank (refer to

the “Chassis” section on page 2 - 16

Figure 85

MVC-343X

Figure 87

MVC-322X

260 Series Tractor Service Manual 3 - 7

Page 48

TUFF TORQ TRANSAXLE

6. Remove the 3 screws retaining the transaxle fan

to the input pulley (Figure 88).

Figure 88

7. Unbolt the hydrostatic control rod from the

forward/reverse control pedal (Figure 89).

MVC-344X

8. Remove the 2 bolts holding the safety neutral

switch bracket (Figure 90).

Figure 90

9. Remove the 2 carriage bolts holding the righthand footrest to the frame (Figure 91).

MVC-346X

Figure 89

3 - 8 260 Series Tractor Service Manual

MVC-345X

Figure 91

MVC-350X

Page 49

TUFF TORQ TRANSAXLE

10. Loosen the left pedal pivot shaft clamp. Remove

the right pedal pivot shaft clamp (Figure 92).

Figure 92

11. Unhook the brake rod return spring, located under

the center access plate (Figure 93).

MVC-351X

12. Remove the roll pin holding the brake cross shaft

and slide the shaft out to clear the bushing (Figure

94).

Figure 94

13. Install the belt around and above the electric

clutch. Feed the belt above the steering sector

gear and over the brake shaft and pedal pivot

shaft (Figure 95).

MVC-353X

Figure 93

MVC-352X

C

(A) Brake Shaft

(B) Pedal Pivot Shaft

Figure 95

A

B

MVC-354X

(C) Steering Sector

Gear

260 Series Tractor Service Manual 3 - 9

Page 50

TUFF TORQ TRANSAXLE

Belt Routing

Figure 96

14. Install the belt around the transaxle input pulley

and then around the idler pulley assembly. Install

the id l er sp ri ng t o t he bo lt , spa c er, and was he r

located on the right side of the frame (Figure 97).

Beltroute

15. Slide the brake shaft back through the bushing

and install the roll pin. Raise the pedal pivot shaft

up to the footrest and install and tighten the

clamps (Figure 98).

Figure 98

16. Install the 2 bolts in the safety neutral bracket and

tighten the bolts (Figure 99).

MVC-357X

Figure 97

3 - 10 260 Series Tractor Service Manual

MVC-356X

Figure 99

MVC-346X

Page 51

TUFF TORQ TRANSAXLE

17. Reattach the brake rod return spring, located

under the center access plate (Figure 100).

Figure 100

18. Bolt the hydrostatic control rod to the forward/

reverse control pedal.

NOTE: Before tightening the bolt, check the pedal

adjustment (Figure 101). Refer to “Foot Control

Adjustment Procedure” on page 3 - 16.

MVC-352X

20. Reroute the PTO clutch wire through the frame

and tie strap the wire to the frame. Connect the

PTO clutch wire back into the plug. Install the

battery drain tube in the tie strap (Figure 102).

Figure 102

21. Reconnect the steering tie rods to the steering

sector gear (Figure 103).

MVC-361X

Figure 103

Figure 101

19. Check the belt tension. If adjustment is needed,

refer to “Belt Adjustment” on page 3 - 13.

260 Series Tractor Service Manual 3 - 11

MVC-345X

MVC-362X

Page 52

TUFF TORQ TRANSAXLE

22. Connect the brake rod to the brake lever on the

transaxle using a washer and cotter pin (Figure

104).

Figure 104

23. Install the fan on the transaxle input pulley (Figure

105).

MVC-322X

24. Check the routing of the drive belt (Figure 106 and

Figure 107).

Figure 106

Rear underside of tractor

MVC-368X

Figure 105

3 - 12 260 Series Tractor Service Manual

MVC-364X

Front underside of tractor

25. Reconnect battery negative cable. Reinstall

fender, seat, and gas tank.

26. Test the tractor, making sure all the safety devices

operate properly.

Figure 107 MVC-367X

Page 53

Belt Adjustment

TUFF TORQ TRANSAXLE

Figure 108

(A) Back Side Idler Pulley

(B) Idler Arm

(C) Eccentric

(D) Eccentric Mounted Idler Pulley

Remove the tunnel cover to check or adjust the belt tension. Loosen the back side idler pulley, A, and move it in

the slotted mounting hole on the idler arm, B. For additional adjustment, turn the eccentric C, on the eccentric

mounted idler pulley, D.

beltadjustment

260 Series Tractor Service Manual 3 - 13

Page 54

TUFF TORQ TRANSAXLE

Troubleshooting – Tuff Torq Transaxle

Problem Possible Cause

No Drive • Incorrect oil/oil level in unit.

• Drive belt has failed, is worn, or is out of adjustment.

• Push valve in push position.

• Parking brake engaged.

• Control pedal linkage worn, loose disconnected.

• Engine pulley or transmission pulley sheared/missing.

• Wheel hub key sheared/missing.

• Push valve stuck or spring broken.

• Damage to rotating groups or internal valving.

• Damaged pinion shaft or differential assembly.

No Drive – one direction • Control pedal bent or broken.

• Control pedal rod bent or binding.

• Control arm roll pin sheared.

• Directional valves sticking, broken springs, or need to be cleaned of debris.

Low Power – both directions • Incorrect oil/oil level in unit.

• Drive belt has failed, is worn, is out of position, at incorrect tension, or

engine. RPM is low.

• Push valve partially activated.

• Parking brake engaged or binding.

• Control pedal or linkage binding.

• Engine or transaxle drive pulleys loose, damaged, or worn.

• Directional valves sticking, need to be cleaned of debris, broken springs.

• Damage to rotating groups or valve body.

• Swash plate worn, damaged, not operating properly.

• Damaged output pinion or differential assembly.