Toro 71226, 71301 Setup Instructions

Wheel Horse Lawn Tractor

For T ractors with 32 and 38 Mowers

Loose Parts

Note: Use the chart below to verify that all parts have been shipped.

Description Qty. Use

Form No. 3328-648

Setup Instructions

Front wheels

Shim washers (as required)

Flat washers

Cotter pins

Hub caps

Steering wheel

Spirol pin

Seat

Knob

Flat washer

Wire clip (on seat pan)

Bolts—1/4-20 x 3/4 in.

Wing nuts

Spring hook 1 Installing the lift assist spring

Wheels

Wheel bolts

Locknuts—5/16 in.

2

2

2

2

2

1

1

1

1

1

1

2

2

2

2

2

Installing the front wheels

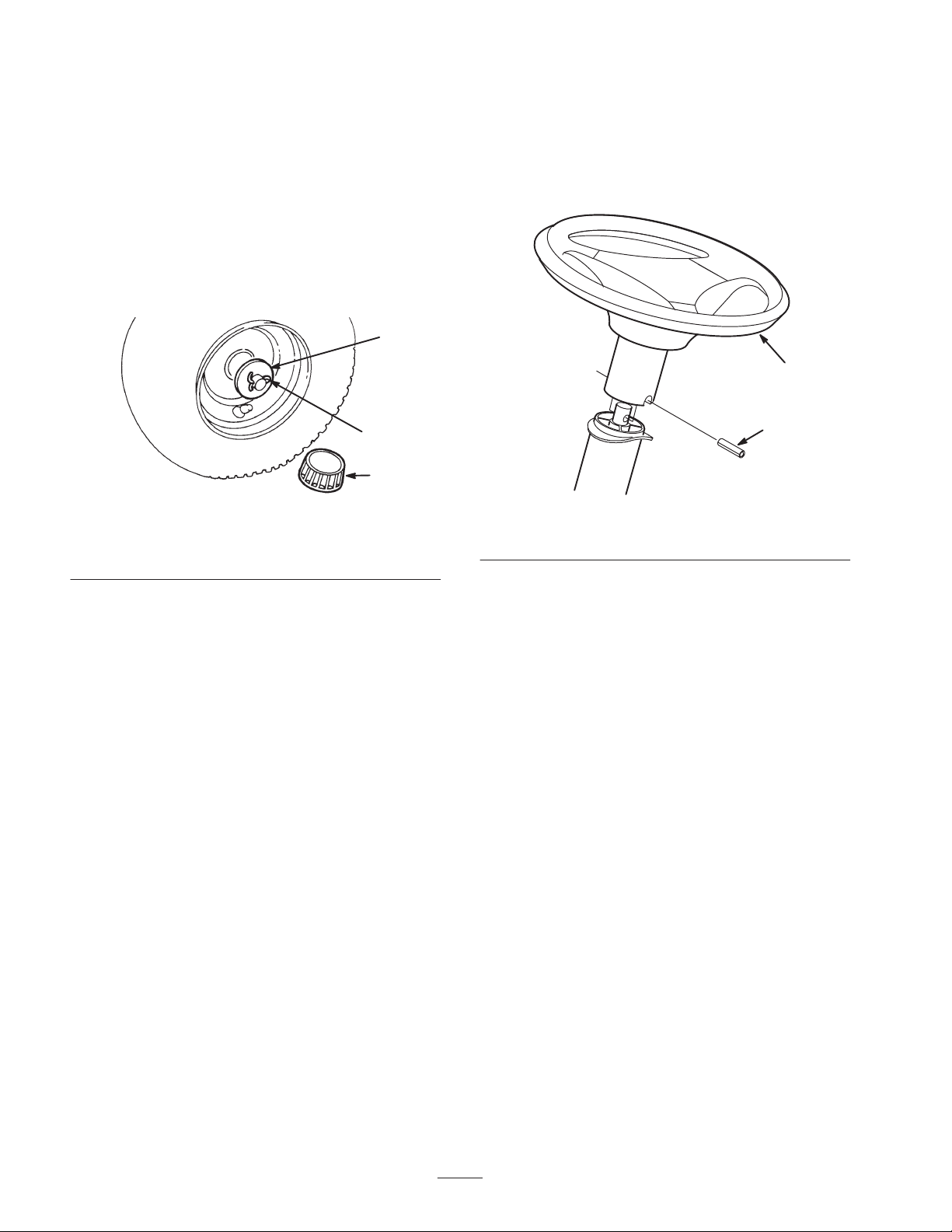

Installing the steering wheel

Installing the seat

Installing the battery cables

Installing the anti-scalp wheels

Keys 2 Using in the ignition and Key Choice switches

Operator’s Manual

Certificate of Conformance

Noise certificate

Registration Card 1 Filling out and mailing the card to Toro

2002 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

1

1

1

1

Reading before operating the tractor

All Rights Reserved

Printed in the USA

Installing the Front Wheels

Installing the Steering Wheel

Note: If the wheels are already installed, refer to

Checking the Tire Pressure below.

1. Install the shim washers onto the axle.

2. Install the wheel onto the axle with the valve stem

facing out.

3. Slide the flat washer onto the axle.

4. Insert the cotter pin through the axle and bend the ends

of the pin apart (Fig. 1).

1

2

3

m-1904

Figure 1

1. Flat washer

2. Cotter pin

3. Hub cap

1. Move the front wheels so that they face straight ahead.

2. Slide the steering wheel over the steering shaft and

line up the hole in the steering wheel with the hole in

the shaft (Fig. 2).

1

2

m-1905

Figure 2

1. Steering wheel 2. Spirol pin

Note: If the cotter pin does not fit, remove the shim

washer(s) as needed.

5. Push the hub cap (Fig. 1) onto the end of the axle.

6. Repeat steps 1 through 5 on the opposite side of the

tractor.

7. Grease the wheel bearings until the grease comes out

of the bearing seal area.

Checking the Tire Pressure

Check the tires to ensure that they are inflated to the

proper level. Refer to Checking the Tire Pressure section

in the Operator ’s Manual.

Note: From the seat you should be able to read the

brand logo on the steering wheel.

3. To align the holes, insert a punch or long nail partially

through the holes in the steering wheel and shaft. Then

insert the spirol pin into the hole on the opposite side.

4. Using a hammer, drive the spirol pin in until it is flush

with the outside of the steering wheel (Fig. 2).

2

Installing the Seat

Note: If the seat is already installed, go to Activating the

Battery below.

1. Insert the seat switch wire cable through the hole in

the seat base (Fig. 3).

Purchase bulk electrolyte with 1.260 specific gravity from

a local battery supply outlet.

Important Never fill the battery with electrolyte while

the battery is installed in the tractor. Electrolyte could be

spilled on other parts and corrode them.

1. Remove the battery and battery box from the tractor;

refer to Removing the Battery in the Operator ’s

Manual.

5

4

1

3

7

6

2

m-2364

Figure 3

1. Seat

2. Wire and connector

3. Shoulder bolts

4. Knob

5. Flat washer

6. Wire clip

7. Connectors

2. Position the seat onto the seat base by inserting

2 shoulder bolts through the key hole openings at the

end of both slots (Fig. 3).

3. Thread the knob and flat washer through the slot and

into the rear center hole in the seat (Fig. 3).

4. Adjust the seat and tighten the knob.

Danger

Battery electrolyte contains sulfuric acid, a deadly

poison that can severely burn you and others.

• Do not drink electrolyte and avoid contact with

skin, eyes, or clothing. Wear safety glasses to

shield your eyes and rubber gloves to protect

your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

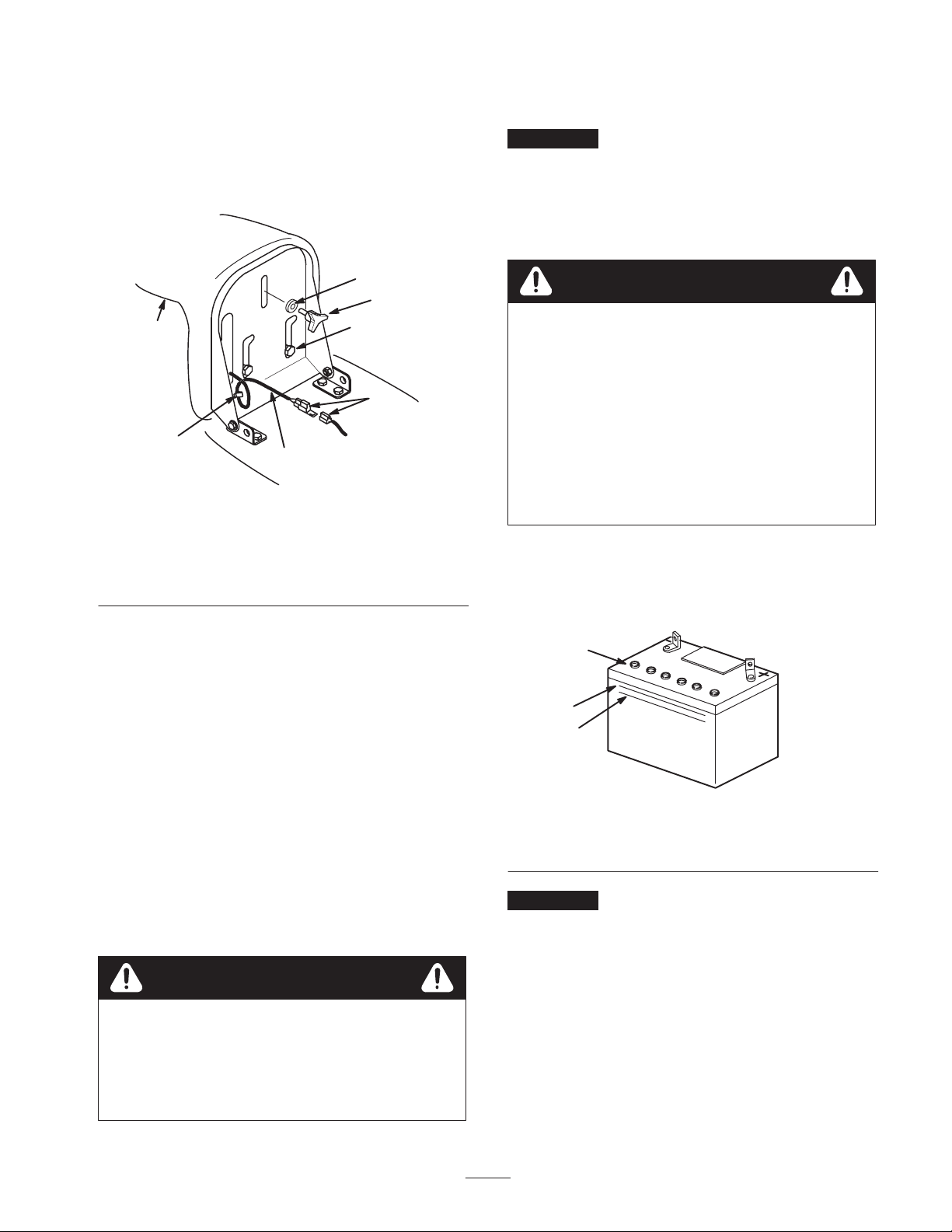

2. Remove the vent caps from the battery.

3. Slowly pour electrolyte into each battery cell until the

electrolyte level is up to the Upper line on the battery

case (Fig. 4).

1

2

3

5. Push the seat switch connector fully into the wire

harness connector (Fig. 3).

6. Secure the seat switch wire cable to the seat base with

the wire clip (Fig. 3).

Note: Check the seat switch wire routing. Ensure that the

wire is not pinched in the seat brackets.

Activating the Battery

Warning

Battery posts, terminals, and related accessories

contain lead and lead compounds, chemicals

known to the State of California to cause cancer

and reproductive harm. Wash hands after

handling.

Figure 4

1. Vent caps

2. Upper line

3. Lower line

Important Do not overfill the battery because

electrolyte (sulfuric acid) can severely corrode and

damage the chassis.

4. Wait 5 to 10 minutes after filling the battery cells.

5. Add electrolyte, if necessary, until the electrolyte level

is up to the Upper line (Fig. 4) on the battery case.

6. Install the battery vent caps.

3

m5004

Loading...

Loading...