Page 1

FORM NO. 3317–996GB

®

Wheel Horse

16–44 HXLE

Lawn Tractor

Model No. 71218 – 6900001 & Up

Operator’s Manual

IMPORTANT: Read this manual carefully. It contains information about your

safety and the safety of others. Also become familiar with the controls and

their proper use before you operate the product.

Page 2

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied

with your new product, so feel free to contact your

local Authorized Service Dealer for help with service,

genuine Toro replacement parts, or other information

you may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

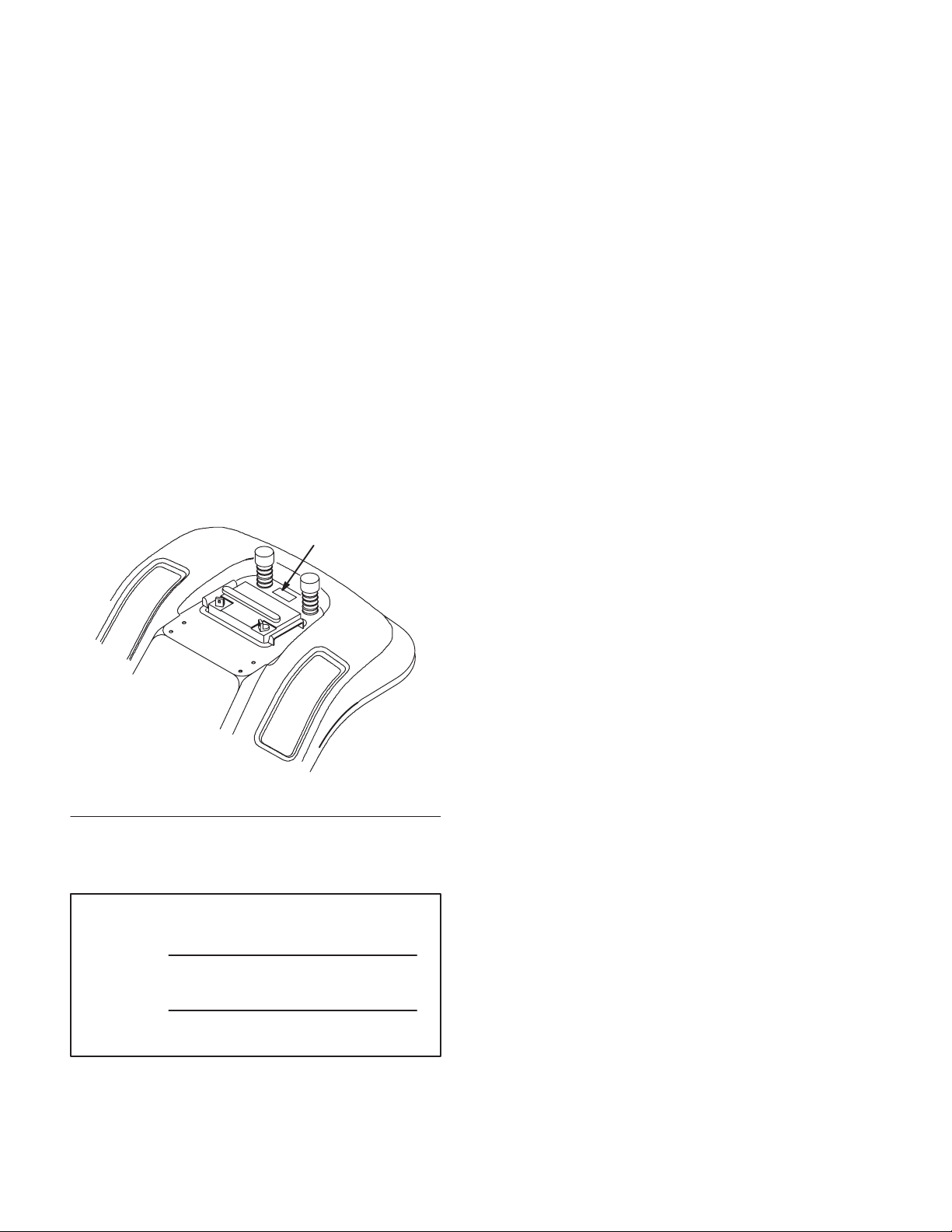

product. You will find the model and serial number

plate located in a unique place on the product as

shown below.

1

Read this manual carefully to learn how to operate

and maintain your product correctly. Reading this

manual will help you and others avoid personal injury

and damage to the product. Although Toro designs,

produces and markets safe, state-of-the-art products,

you are responsible for using the product properly

and safely. You are also responsible for training

persons who you allow to use the product about safe

operation.

The Toro warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

1. Model and Serial Number Plate (under the seat)

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

1856

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

The left and right side of the machine is determined

by sitting on the seat in the normal operator’s

position.

Printed in USA

EThe Toro Company – 1995

All Rights Reserved

Page 3

Contents

Safety 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operation Practices for Ride-on (riding)

Rotary Lawnmower Machines 2. . . . . . . . .

Slope Chart 5. . . . . . . . . . . . . . . . . . . . . . . . .

Symbols Glossary 6. . . . . . . . . . . . . . . . . . .

Gasoline and Oil 9. . . . . . . . . . . . . . . . . . . . . . . .

Recommended Gasoline 9. . . . . . . . . . . . . . .

Stabilizer/Conditioner 9. . . . . . . . . . . . . . . .

Filling the Fuel Tank 9. . . . . . . . . . . . . . . . .

Check Engine Oil Level 9. . . . . . . . . . . . . . .

Operation 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Think Safety First 10. . . . . . . . . . . . . . . . . . .

Controls 10. . . . . . . . . . . . . . . . . . . . . . . . . . .

Parking Brake 10. . . . . . . . . . . . . . . . . . . . . . .

Starting and Stopping the Engine 11. . . . . . .

Using the Blade Control (PTO) 12. . . . . . . . .

The Safety System 12. . . . . . . . . . . . . . . . . . .

Driving Forward or Backward 13. . . . . . . . . .

Stopping the Machine 13. . . . . . . . . . . . . . . .

Setting the Height-of-Cut 14. . . . . . . . . . . . . .

Page

Page

Positioning the Seat 14. . . . . . . . . . . . . . . . . .

Positioning the Tilt Steering Wheel 15. . . . . .

Headlights 15. . . . . . . . . . . . . . . . . . . . . . . . .

Pushing the Machine by Hand 15. . . . . . . . . .

Maintenance 16. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Service Interval Chart 16. . . . . . . . . . . . . . . .

Air Cleaner 17. . . . . . . . . . . . . . . . . . . . . . . . .

Engine Oil 19. . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug 21. . . . . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication 22. . . . . . . . . . . . . .

Tire Pressure 22. . . . . . . . . . . . . . . . . . . . . . . .

Brake 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Tank 24. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 24. . . . . . . . . . . . . . . . . . . . . . . . . .

Fuse 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Headlights 25. . . . . . . . . . . . . . . . . . . . . . . . .

Battery 26. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Wiring Diagram 28. . . . . . . . . . . . . . . . . . . . .

Storage 29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 30. . . . . . . . . . . . . . . . . . . . . . . . .

1

Page 4

Safety

Safe Operation Practices for

Ride-on (riding) Rotary

Lawnmower Machines

Training

1. Read the instructions carefully. Be familiar with

the controls and the proper use of the equipment.

2. Never allow children or people unfamiliar with

these instructions to use the lawnmower. Local

regulations may restrict the age of the operator.

3. Never mow while people, especially children, or

pets are nearby.

4. Keep in mind that the operator or user is

responsible for accidents or hazards occurring to

other people or their property.

5. Do not carry passengers.

6. All drivers should seek and obtain professional

and practical instruction. Such instruction should

emphasize:

Preparation

1. While mowing, always wear substantial

footwear and long trousers. Do not operate the

equipment when barefoot or wearing open

sandals.

2. Thoroughly inspect the area where the

equipment is to be used and remove all objects

which may be thrown by the machine.

3. WARNING – Petrol is highly flammable.

• Store fuel in containers specifically

designed for this purpose.

• Refuel outdoors only and do not smoke

while refuelling.

• Add fuel before starting the engine. Never

remove the cap of the fuel tank or add

petrol while the engine is running or when

the engine is hot.

• If petrol is spilled, do not attempt to start

the engine but move the machine away

from the are of spillage and avoid creating

any source of ignition until petrol vapors

have dissipated.

• the need for care and concentration when

working with ride-on machines;

• control of a ride-on machine sliding on a

slope will not be regained by the application

of the brake. The main reasons for loss of

control are:

insufficient wheel grip;

being driven too fast;

inadequate braking;

the type of machine is unsuitable for its

task;

lack of awareness of the effects of

ground conditions, especially slopes;

incorrect hitching and load distribution.

2

• Replace all fuel tanks and container caps

securely.

4. Replace faulty silencers.

5. Before using, always visually inspect to see that

the blades, blade bolts and cutter assembly are

not worn or damaged. Replace worn or damaged

blades and bolts in sets to preserve balance.

6. On multi–bladed machines, take care as rotating

one blade can cause other blades to rotate.

Page 5

Safety

Operation

1. Do not operate the engine in a confined space

where dangerous carbon monoxide fumes can

collect.

2. Mow only in daylight or in good artificial light.

3. Before attempting to start the engine, disengage

all blade attachment clutches and shift into

neutral.

4. Do not use on slopes of more than:

• Never mow side hills over 5_

• Never mow uphill over 10_

• Never mow downhill over 15_

Note: Slope angle is calculated as in

5.4.2.3.2.

5. Remember there is no such thing as a “safe”

slope. Travel on grass slopes requires particular

care. To guard against overturning:

• do not stop or start suddenly when going up

or downhill;

• engage clutch slowly, always keep machine

in gear, especially when travelling

downhill;

• machine speeds should be kept low on

slopes and during tight turns;

• stay alert for bumps and hollows and other

hidden hazards;

• never mow across the face of the slope,

unless the lawnmower is designed for this

purpose.

6. Use care when pulling loads or using heavy

equipment.

• Use only approved drawbar hitch points.

• Limit loads to those you can safely control.

• Do not turn sharply. Use care when

reversing.

7. Watch out for traffic when crossing or near

roadways.

8. Stop the blades rotating before crossing surfaces

other than grass.

9. When using any attachments, never direct

discharge of material toward bystanders nor

allow anyone near the machine while in

operation.

10. Never operate the lawnmower with defective

guards, shields or without safety protective

devices in place.

11. Do not change the engine governor settings or

overspeed the engine. Operating the engine at

excessive speeds may increase the hazard of

personal injury.

12. Before leaving the operator’s position:

• disengage the power take-off and lower the

attachments;

• change into neutral and set the parking

brake;

• stop the engine and remove the key.

13. Disengage drive to attachments, stop the engine,

and disconnect the spark plug wire(s) or remove

the ignition key

• before cleaning blockages or unclogging

chute;

• before checking, cleaning or working on the

lawnmower;

• after striking a foreign object. Inspect the

lawnmower for damage and make repairs

before restarting and operating the

equipment;

• if the machine starts to vibrate abnormally

(check immediately).

Disengage drive to attachments when

14.

transporting or not in use.

• Use counterweight(s) or wheel weights

when suggested in the instruction

handbook.

3

Page 6

Safety

15. Stop the engine and disengage drive to

attachment

• before refuelling;

• before removing the grass catcher;

• before making height adjustment unless

adjustment can be made from the operator’s

position.

16. Reduce the throttle setting during engine run-out

and, if the engine is provided with a shut-off

valve, turn the fuel off at the conclusion of

mowing.

Maintenance and storage

1. Keep all nuts, bolts and screws tight to be sure

the equipment is in safe working condition.

2. Never store the equipment with petrol in the tank

inside a building where fumes may reach an

open flame or spark.

Sound Pressure Level

This unit has an equivalent continuous A-weighted

sound pressure at the operator ear of: 100 dB(A),

based on measurements of identical machines per

ANSI B71.5-1984 procedures.

Sound Power Level

This unit has a sound power level of: 100 dB(A) /

1 pW, based on measurements of identical machines

per procedures outlined in Directive 79/113/EEC and

amendments. The test surface consisted of a surface

of coconut mat surrounded by 2” grass.

Vibration Level

This unit has a maximum hand-arm vibration level of

4.80 m/s2 and whole body vibration level of

0.30 m/s2, based on measurements of identical

machines per ISO 5349.

3. Allow the engine to cool before storing in any

enclosure.

4. To reduce the fire hazard, keep the engine,

silencer, battery compartment and petrol storage

area free of grass, leaves, or excessive grease.

5. Check the grass catcher frequently for wear or

deterioration.

6. Replace worn or damaged parts for safety.

7. If the fuel tank has to be drained, this should be

done outdoors.

8. On multi-bladed machines, take care as rotating

one blade can cause other blades to rotate.

9. When machine is to be parked, stored or left

unattended, lower the cutting means unless a

positive mechanical lock is used.

4

Page 7

Slope Chart

Read all safety instructions on pages 2–8.

Safety

5

Page 8

Safety

Symbols Glossary

Safety alert symbol

Safety alert symbol

Read operator’s manual

Consult Technical Manual for

proper service procedures

Thrown or flying objects–

Whole body exposure

Thrown or flying objects–

Rotary side-mounted mower.

Keep deflector shield in place

Dismemberment–Mower

in rearward motion

Stay a safe distance

from the machine

Stay a safe distance

from the mower

Keep children a safe distance

from machine

Machine rollover

side hill

Severing toes or foot–

mower blade

Severing fingers or hand–

mower blade

Rotating blade can cut off

toes or fingers. Stay clear

of blade as long as engine

is running

Do not open or

remove safety shields

while engine is running

6

Machine rollover

up hill

Machine rollover

down hill

Machine rollover

ROPS

Page 9

Symbols Glossary

Safety

Cutting element–

basic symbol

Cutting element–

height adjustment

Cutting unit–lower

Cutting unit-raised

Cutting or entanglement

of foot–Rotating auger

Severing of fingers or hand–

impeller blade

Keep a safe distance from

snowthrower

Riding on this machine is allowed

only on a passenger seat & only

if the driver’s view is not hindered

Crushing of fingers

or hands–Force applied

from side

Kickback or upward

motion–Stored energy

Shut off engine & remove key

before performing maintenance

or repair work

Machine travel direction–

combined

Stay a safe distance

from the snowthrower

Tractors must be equipped

with 45kg rear wheel weight

with this attachment installed

Machine rollover

ROPS snowthrower

Severing of hand–

Rotating knives

Severing of foot–

Rotating knives

Low

High

Reverse

Neutral

First gear

Second gear

Third gear up to

maximum # of

forward gears

7

Page 10

Safety

Symbols Glossary

Fast

Slow

Decreasing/Increasing

On/Run

Off/Stop

Engine

Engine start

Engine stop

Fuel

Fuel level

Volume empty

Volume full

Battery charging condition

Head lights–

Main/high beam

Brake system

Choke

Engine temperature

Engine lubricating

oil pressure

Engine lubricating oil level

Parking brake

Clutch

PTO (Power Take Off)

Engage

Disengage

Unlock

Lock

8

Page 11

Gasoline and Oil

Recommended Gasoline

Use fresh UNLEADED Regular Gasoline suitable for

automotive use (85 pump octane minimum). Leaded

regular gasoline may be used if unleaded regular is

not available.

IMPORTANT: Never use methanol, gasoline

containing methanol, or gasohol containing

more than 10% ethanol because the fuel

system could be damaged. Do not mix oil with

gasoline.

POTENTIAL HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AVOID THE HAZARD

• Use a funnel and fill the fuel tank outdoors,

in an open area, when the engine is cold.

Wipe up any gasoline that spills.

• Do not fill the fuel tank completely full.

Add gasoline to the fuel tank until the level

is 1/4” to 1/2” (6 mm to 13 mm) below the

bottom of the filler neck. This empty space

in the tank allows gasoline to expand.

• Never smoke when handling gasoline, and

stay away from an open flame or where

gasoline fumes may be ignited by a spark.

• Store gasoline in an approved container

and keep it out of the reach of children.

Never buy more than a 30-day supply of

gasoline.

Stabilizer/Conditioner

Toro Stabilizer/Conditioner

Add the correct amount of Toro Gas

Stabilizer/Conditioner to the gas. Using Toro

Stabilizer/Conditioner or an isopropyl-based

conditioner/stabilizer in the machine:

• Keeps gasoline fresh during storage

• Cleans the engine while it runs

• Eliminates gum-like buildup in the fuel system,

which causes hard starting

IMPORTANT: Never use fuel additives

containing methanol or ethanol.

Filling the Fuel Tank

1. Shut the engine off and open the hood.

2. Clean around the fuel tank cap and remove the

cap. Use a funnel and add unleaded regular

gasoline to the fuel tank, until the level is 1/4 to

1/2 inch (6 mm to 13 mm) below the bottom of

the filler neck. This space in the tank allows

gasoline to expand. Do not fill the fuel tank

completely full.

3. Install the fuel tank cap securely. Wipe up any

gasoline that may have spilled.

4. Close the hood.

Check Engine Oil Level

Before you start the engine and use the machine,

check the oil level in the engine crankcase; refer to

Checking Oil Level, page 19.

9

Page 12

Operation

Think Safety First

Please carefully read all the safety instructions.

Knowing this information could help you, your

family, pets or bystanders avoid injury.

Controls

Become familiar with all the controls (Fig. 1) before

you start the engine and operate the machine.

11

10

9

1

2

3

4

6

5

Parking Brake

Always set the parking brake when you stop the

machine or leave it unattended.

Setting the Parking Brake

1. Push the brake pedal (Fig. 2) down and hold it

in the depressed position.

2. Lift the parking brake lever (Fig. 2) up and

gradually take your foot off the brake pedal. The

brake pedal should stay in the depressed (locked)

position.

Releasing the Parking Brake

1. Push down on the brake pedal (Fig. 2). The

parking brake lever should release.

2. Gradually release the brake pedal.

8

7

1. Steering wheel

2. Light switch—on/off

(selected models)

3. Ignition switch

4. Brake pedal

5. Blade control (PTO)

6. Traction control pedal

Figure 1

7. Height-of-cut lever

(deck lift)

8. Parking brake lever

9. Tilt button (selected

models)

10. Throttle lever

11. Hood opening

1857

1

2

1852

3

1858

Figure 2

1. Brake pedal 2. Parking brake lever

10

Page 13

Operation

Starting and Stopping

the Engine

Starting

1. Sit down on the seat.

2. Set the parking brake; refer to Setting the

Parking Brake, page 10.

Note: The engine will not start unless you set

the parking brake or fully depress the

brake pedal.

3. Move the blade control (PTO) to

“DISENGAGED” (Fig. 3).

4. Move the throttle lever to “CHOKE” (Fig. 4).

Note: An engine that has been running and is

warm may not require step 4.

5. Turn the ignition key clockwise and hold it in

the “START” position (Fig. 5). When the engine

starts, release the key.

IMPORTANT: If the engine does not start

after 30 seconds of continuous cranking, turn

the ignition key to “OFF” and let the starter

motor cool; refer to Troubleshooting, page 30.

2

1

1852

Figure 3

1. Disengaged

2. Engaged

3. Blade control (PTO)

3

3

Figure 5

1. Start

2. On

3. Off

Figure 4

1. Choke

2. Fast

3. Slow

2

1

1

2

3

1859

1860

6. After the engine starts, slowly move the throttle

lever to “FAST” (Fig. 4). If the engine stalls or

hesitates, move the throttle lever back to

“CHOKE” for a few seconds. Then move the

throttle lever to “FAST.” Repeat this as required.

Stopping

1. Move the throttle lever to “SLOW” (Fig. 4).

2. Turn the ignition key to “OFF” (Fig. 5).

Note: If the engine has been working hard or

is hot, let it idle for a minute before

turning the ignition key “OFF.” This

helps cool the engine before it is

stopped. In an emergency, the engine

may be stopped by turning the ignition

key to “OFF.”

11

Page 14

Operation

Using the Blade Control (PTO)

The blade control (PTO) engages and disengages

power to the blade(s).

Engaging the Blade(s)

1. Depress the brake pedal to stop the machine.

2. Move the blade control (PTO) to “ENGAGED”

(Fig. 6).

2

1

1852

3

Figure 6

1. Disengaged

2. Engaged

Disengaging the Blade(s)

3. Blade control (PTO)

The Safety System

Understanding the Safety System

The safety system is designed to prevent the engine

from starting unless:

• You are sitting on the seat and

• The brake pedal is depressed and

• The blade control (PTO) is “DISENGAGED”

The safety system is designed to stop the engine if

you rise from the seat when the brake pedal is

released or the blade is “ENGAGED.”

Testing the Safety System

Test the safety system before you use the machine

each time. If the safety system does not operate as

described below, have an Authorized Service Dealer

repair the safety system immediately.

1. Set the parking brake. Move the blade control

(PTO) to “ENGAGED.” Now turn the ignition

key to “START”; the engine should not crank.

2. Move the blade control (PTO) to

“DISENGAGED” and release the parking brake.

Now turn the ignition key to “START”; the

engine should not crank.

1. Depress the brake pedal to stop the machine.

2. Move the blade control (PTO) to

“DISENGAGED” (Fig. 6).

12

3. Set the parking brake and move the blade control

(PTO) to “DISENGAGED.” Now start the

engine. While the engine is running, release the

parking brake and rise slightly from the seat; the

engine should stop.

Page 15

Operation

Driving Forward or Backward

The throttle control regulates the engine speed as

measured in rpm (revolutions per minute). Place the

throttle control in the “FAST” position for best

performance.

To go forward or backward, release the parking brake:

refer to Releasing the Parking Brake, page 10. Place

your foot on the traction control pedal and slowly

press on the top of the traction control pedal to move

forward or on the bottom of the traction control pedal

to move backward (Fig. 7). The farther you move the

traction control pedal in either direction, the faster the

machine will move in that direction.

To slow down release the pressure on the traction

control pedal.

IMPORTANT: To avoid transmission

damage, always release the parking brake

before moving the traction control pedal.

2

3

Stopping the Machine

To stop the machine, release the traction control

pedal, disengage the blade control (PTO), and turn

the ignition key to “OFF” to stop the engine. Also set

the parking brake if you leave the machine

unattended; refer to Setting the Parking Brake,

page 10. Remember to remove the key from the

ignition switch.

POTENTIAL HAZARD

• Someone could move or attempt to operate

the tractor while it is unattended.

WHAT CAN HAPPEN

• Children or bystanders may be injured if

they use the tractor.

HOW TO AVOID THE HAZARD

• Always remove the ignition key and set the

parking brake when leaving the machine

unattended, even if just for a few minutes.

1. Traction control pedal

2. Forward

1

1861

Figure 7

3. Backward

13

Page 16

Operation

Setting the Height-of-Cut

The height-of-cut lever (deck lift) is used to raise and

lower the mower to the desired cutting height.

1. The cutting height may be set in one of seven

positions from approximately 1 to 4 inches

(38 to 116 mm).

2. Pull on the height-of-cut lever (deck lift) and

move it to the desired position (Fig. 8).

Approximately

1

1853

Figure 8

1. Height-of-cut lever (deck lift)

1” (25 mm)

1–1/2” (38 mm)

2” (51 mm)

2–1/2” (64 mm)

3” (76 mm)

3–1/2” (89 mm)

4” (102 mm)

Positioning the Seat

The seat can move forward and backward. Position

the seat where you have the best control of the

machine and are most comfortable.

1. Raise the seat and loosen the adjustment knob

(Fig. 9).

2. Move the seat to the desired position and tighten

the knob.

1

1862

Figure 9

1. Adjustment knob

14

Page 17

Operation

Positioning the

Tilt Steering Wheel

On select models the steering wheel tilts up and

down. Position the steering wheel where you have the

best control of the machine and are most comfortable.

1. Push in on the tilt button (Fig. 10).

2. Move the steering wheel to any of three

positions; then release the button.

2

1863

1

Figure 10

1. Tilt button 2. Steering wheel

Pushing the Machine by Hand

IMPORTANT: Always push the machine by

hand. Never tow the machine because

transaxle damage may occur.

To Push the Machine

1. Disengage the blade control (PTO), and turn the

ignition key to “OFF” to stop the engine.

2. Hook the drive control in the “PUSH” position.

This disengages the drive system and allows the

wheels to turn freely (Fig. 11).

To Operate the Machine

1. MOVE the drive control to the “OPERATE”

position. This engages the drive system

(Fig. 11).

Note: The machine will not drive unless the

drive control is in the “OPERATE”

position.

Headlights

Headlights are optional on some models. A

dash-mounted “ON/OFF” switch (Fig. 1) controls the

headlights. The lights only shine while the engine is

running and the switch is “ON.”

Figure 11

1. Operate position 2. Push position

12

1791

15

Page 18

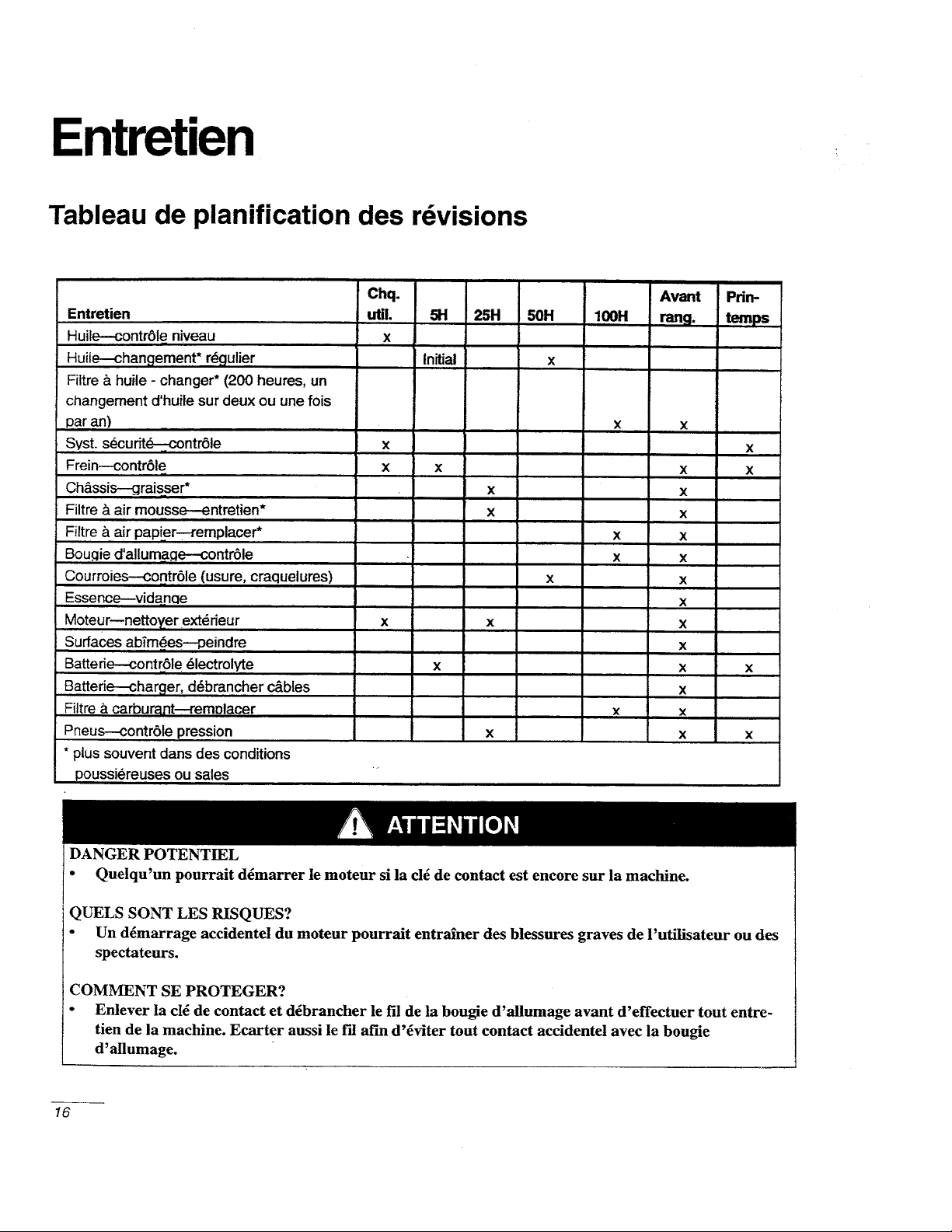

Maintenance

Service Interval Chart

Each

Service Operation

Oil—check level X

Oil—change* Initial X

Oil Filter—change* (100 hours or every

other oil change)

Safety System—check X X

Brake—check X X X X

Chassis—grease* X X

Foam Air Cleaner—service* X X

Paper Air Cleaner—replace* X X

Spark Plug(s)—replace X X

Belts—check for wear/cracks X X

Gasoline—drain X

Engine—clean outside X X X

Chipped Surfaces—paint X

Battery—check electrolyte X X X

Battery—charge, disconnect cables X

Fuel Filter—replace X X

Tires—check pressure X X X

Use5Hours25Hours50Hours

100

Hours

X X

Storage

Service

Spring

Service

* More often in dusty, dirty conditions

POTENTIAL HAZARD

• If you leave the key in the ignition switch, someone could start the engine.

WHAT CAN HAPPEN

• Accidental starting of the engine by someone else could seriously injure you or other

bystanders.

HOW TO AVOID THE HAZARD

• Remove the key from the ignition switch and pull the wire off the spark plug before

you do any maintenance. Also push the wire aside so it does not accidentally contact

the spark plug.

16

Page 19

Maintenance

Air Cleaner

Service Interval/Specification

Foam Element: Clean and re-oil after every 25

operating hours, or once a year, whichever occurs

first.

Paper Element: Replace after every 100 operating

hours or once a year, whichever occurs first.

Note: Service the air cleaner more frequently

(every few hours) if operating

conditions are extremely dusty or

sandy.

Removing the Foam and Paper Elements

1. Disengage the blade control (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine.

2. Open the hood.

3. Clean around the air cleaner to prevent dirt from

getting into the engine and causing damage.

Unscrew the knob and remove the air cleaner

cover (Fig. 12).

4. Carefully slide the foam element off the paper

element (Fig. 13).

1

2

1864

Figure 13

1. Foam element 2. Paper element

5. Unscrew the rubber nut and remove the paper

element (Fig. 14).

1

Figure 12

1. Knob 2. Air cleaner cover

1

1798

2

2

1865

Figure 14

1. Rubber nut 2. Paper element

17

Page 20

Maintenance

Cleaning the Foam and Paper Elements

1. Foam Element

A. Wash the foam element in liquid soap and

warm water. When the element is clean,

rinse it thoroughly.

B. Dry the element by squeezing it in a clean

cloth.

C. Put one or two ounces of oil on the element

(Fig. 15). Squeeze the element to distribute

the oil.

IMPORTANT: Replace the foam element if it

is torn or worn.

2

1

Figure 15

1. Foam element 2. Oil

2. Paper Element

A. Lightly tap the element on a flat surface to

remove dust and dirt (Fig. 16).

B. Inspect the element for tears, an oily film,

and damage to the rubber seal.

IMPORTANT: Never clean the paper element

with pressurized air or liquids, such as

solvent, gas, or kerosene. Replace the paper

element if it is damaged, defective, or cannot

be cleaned thoroughly.

1866

1

2

1867

Figure 16

1. Paper element 2. Rubber seal

Installing the Foam and Paper Elements

IMPORTANT: To prevent engine damage,

always operate the engine with the complete

foam and paper air cleaner assembly

installed.

1. Carefully slide the foam element onto the paper

air cleaner element (Fig. 13).

2. Slide the air cleaner assembly onto the long rod.

Now screw the rubber nut finger-tight against the

air cleaner (Fig. 14).

Note: Make sure the rubber seal is flat

against the air cleaner base.

3. Install the air cleaner cover and knob (Fig. 12).

Tighten the knob snugly.

4. Close the hood.

18

Page 21

Maintenance

Engine Oil

Service Interval/Specification

Change oil:

• After the first 5 operating hours.

• After every 50 operating hours.

Note: Change oil more frequently when

operating conditions are extremely

dusty or sandy.

Oil Type: Detergent oil (API service SC, SD, SE, SF

or SG)

Crankcase Capacity, with oil filter: 56 oz/1–3/4 qt

(1700 cc/1.7 l)

Viscosity: See table below

USE THESE SAE VISCOSITY OILS

Checking Oil Level

1. Park the machine on a level surface, disengage

the blade control (PTO), set the parking brake,

and turn the ignition key to “OFF” to stop the

engine.

2. Open the hood.

3. Clean around the oil dipstick (Fig. 17) so dirt

cannot fall into the filler hole and damage the

engine.

4. Unscrew the oil dipstick and wipe the metal end

clean (Fig. 17).

5. Screw the oil dipstick fully onto the filler tube

(Fig. 17). Unscrew the dipstick again and look at

the metal end. If oil level is low, slowly pour

only enough oil into the filler tube to raise the

level to the “FULL” mark.

IMPORTANT: Do not overfill the crankcase

with oil because the engine may be damaged.

–20 0 20 40 60 80 100

°

F

–30°–20 –10 0 10 20 30 40

C

1

3

1. Oil dipstick

2. Metal end

2

1868

Figure 17

3. Filler tube

19

Page 22

Maintenance

Changing/Draining Oil

1. Start the engine and let it run five minutes. This

warms the oil so it drains better.

2. Park the machine so that the right front side is

slightly lower than the left side to assure the oil

drains completely. Then disengage the blade

control (PTO), set the parking brake, and turn

the ignition key to “OFF” to stop the engine.

3. Open the hood.

4. Place a pan below the oil dipstick/fill tube and

remove the drain plug (Fig. 18).

5. When oil has drained completely, install the

drain plug.

Note: Dispose of the used oil at a certified

recycling center.

6. Slowly pour approximately 80% of the specified

amount of oil into the filler tube (Fig. 17). Now

check the oil level; refer to Checking Oil Level,

page 19, steps 4–5.

Change Oil Filter

Service Interval/Specification

Replace the oil filter every 100 hours or every other

oil change.

Note: Change oil filter more frequently when

operating conditions are extremely

dusty or sandy.

1. Drain the oil from the engine; refer to

Changing/Draining Oil, page 20.

2. Remove the old filter and wipe the filter adapter

(Fig. 19) gasket surface.

3. Apply a thin coat of new oil to the rubber gasket

on the replacement filter (Fig. 19).

3

2

2

1

1869

Figure 18

1. Oil drain plug 2. Oil dipstick/fill tube

1

Figure 19

1. Oil filter

2. Gasket

3. Adapter

4. Install the replacement oil filter to the filter

adapter. Turn the oil filter clockwise until the

rubber gasket contacts the filter adapter, then

tighten the filter an additional 1/2 turn (Fig. 19).

5. Fill the crankcase with the proper type of new

oil; refer to Changing/Draining Oil, page 20.

1256

20

Page 23

Maintenance

Spark Plug

Service Interval/Specification

Install a new spark plug after every 100 operating

hours. Make sure the air gap between the center and

side electrodes is correct before installing the spark

plug. Use a spark plug wrench for removing and

installing the spark plug and a gapping tool/feeler

gauge to check and adjust the air gap.

Type: Champion RC–12YC (or equivalent)

Air Gap: 0.030” (0.762 mm).

Removing the Spark Plug

1. Disengage the blade control (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine.

2. Open the hood.

3. Pull the wire off the spark plug (Fig. 20). Now

clean around the spark plug to prevent dirt from

falling into the engine and potentially causing

damage.

4. Remove the spark plug and metal washer.

Checking the Spark Plug

1. Look at the center of the spark plug (Fig. 21). If

you see light brown or gray on the insulator, the

engine is operating properly. A black coating on

the insulator usually means the air cleaner is

dirty.

IMPORTANT: Never clean the spark plug.

Always replace the spark plug when it has: a

black coating, worn electrodes, an oily film,

or cracks.

2. Check the gap between the center and side

electrodes (Fig. 21). Bend the side electrode

(Fig. 21) if the gap is not correct.

2

1

1. Center electrode insulator

2. Side electrode

Figure 21

3. Air gap (not to scale)

3

0.030”

(0.762 mm)

1870

1

2

Figure 20

1. Spark plug wire 2. Spark plug

Installing the Spark Plug

1. Install the spark plug and metal washer. Make

sure the air gap is set correctly.

2. Tighten the spark plug to 15 ft-lb (20.4 Nm).

1798

3. Push the wire onto the spark plug (Fig. 20).

4. Close the hood.

21

Page 24

Maintenance

Greasing and Lubrication

Service Interval/Specification

Grease the machine after every 25 operating hours or

once a year, whichever occurs first. Grease more

frequently when operating conditions are extremely

dusty or sandy.

Grease Type: General-purpose grease.

How to Grease

1. Disengage the blade control (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine.

2. Clean the grease fittings with a rag. Make sure to

scrape any paint off the front of the fitting(s).

3. Connect a grease gun to the fitting. Pump grease

into the fittings.

4. Wipe up any excess grease.

Tire Pressure

Service Interval/Specification

Maintain the air pressure in the front and rear tires as

specified. Check the pressure at the valve stem after

every 25 operating hours or yearly, whichever occurs

first (Fig. 23). Check the tires when they are cold to

get the most accurate pressure reading.

Pressure: 12 psi (.85 kPa) front and rear

1

1872

Figure 23

1. Valve stem

Where to Add Grease

1. Lubricate the front wheels and steering spindles

until grease begins to ooze out the bearings (Fig.

22).

2346

Figure 22

22

Page 25

Maintenance

Brake

The brake is on the right side of the rear axle, inside

the rear tire (Fig. 24). If the parking brake does not

hold securely, an adjustment is required.

Checking the Brake

1. Park the machine on a level surface, disengage

the blade control (PTO) and turn the ignition key

to “OFF” to stop the engine.

2. Move the drive control wire to the “PUSH”

position; refer to Pushing the Machine by Hand,

page 15.

3. If the rear wheels lock and skid when you push

the tractor forward, no adjustment is required.

An adjustment is required if the wheels turn and

do not lock; refer to Adjusting the Brake,

page 23.

IMPORTANT: With the parking brake

released, the rear wheels must rotate freely

when you push the mower. If the 0.020”

(5.08 mm) clearance and free wheel rotation

cannot be achieved contact your service

dealer immediately.

0.020” (5.08 mm)

Figure 24

1. Brake adjusting nut 2. Cotter pin

1 2

1674

Adjusting the Brake

(0.020” (5.08 mm) feeler gauge required)

1. Check the brake before you adjust it; refer to

Checking the Brake, page 23.

2. Release the parking brake; refer to Releasing the

Parking Brake, page 10.

3. To adjust the brake remove the cotter pin and

loosen the brake adjusting nut slightly (Fig. 24).

4. Carefully insert a 0.020” (5.08 mm) feeler gauge

between the two outer brake pads (Fig. 24).

5. Tighten the brake adjusting nut until slight

resistance is felt on the feeler gauge when sliding

it in and out. Install cotter pin.

6. Check the brake operation again; refer to

Checking the Brake, page 23.

23

Page 26

Maintenance

Fuel Tank

Draining The Fuel Tank

POTENTIAL HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AVOID THE HAZARD

• Drain gasoline from the fuel tank when the

engine is cold. Do this outdoors in an open

area. Wipe up any gasoline that spills.

• Never drain gasoline near an open flame or

where gasoline fumes may be ignited by a

spark.

• Never smoke a cigarette, cigar or pipe.

1. Park the machine so that the left front side is

slightly lower than the right side to assure fuel

tank drains completely. Then disengage the blade

control (PTO), set the parking brake, and turn

the ignition key to “OFF” to stop the engine.

2. Open the hood.

2

1873

1. Hose clamp

2. Fuel line

1

3

Figure 25

3. Filter

Fuel Filter

Service Interval/Specification

Replace the fuel filter after every 100 operating hours

or once a year, whichever occurs first.

Replacing the Fuel Filter

The best time to replace the fuel filter (Fig. 25) is

when the fuel tank is empty. Never install a dirty

filter if it is removed from the fuel line.

3. Squeeze the ends of the hose clamp together and

slide it up the fuel line toward the fuel tank

(Fig. 25).

4. Pull the fuel line off the filter (Fig. 25) and allow

gasoline to drain into a gas can or drain pan.

Note: Now is the best time to install a new

fuel filter because the fuel tank is

empty.

5. Install the fuel line onto the filter. Slide the hose

clamp close to the filter to secure the fuel line

and filter.

24

1. Disengage the blade control (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine.

2. Open the hood.

3. Squeeze the ends of the hose clamps together

and slide them away from the filter (Fig. 25).

4. Remove the filter from the fuel lines.

5. Install a new filter and move the hose clamps

close to the filter.

6. Close the hood.

Page 27

Fuse

Service Interval/Specification

The electrical system is protected by fuses. No

maintenance is required, however, if a fuse blows

check the circuit wiring for a short. To replace a fuse

pull up (Fig. 26) to remove from the socket. Push

down to insert.

Fuse: 10 amp, blade-type.

1

Maintenance

5

3

2

4

Figure 27

1. Bulb holder

2

2. Reflector

3. Tabs

4. Slots

5. Terminals

5

1

4

1874

Installing the Bulb

1672

Figure 26

1. Fuse (removed)

2. Socket

Headlights

Specification: Bulb # 1156, automotive type.

Removing the Bulb

1. Disengage the blade control (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine.

2. Open the hood. Pull wire connectors off both

bulb holder terminals.

3. Rotate the bulb holder 1/4 turn counterclockwise

and remove it from the reflector (Fig. 27).

4. Push and rotate the bulb counterclockwise until

it stops (approx. 1/4 turn) and remove bulb from

the bulb holder (Fig. 28).

1. The bulb has metal pins on the side of its base.

Align the pins with the slots in the bulb holder

and insert the base into the holder (Fig. 28).

Push and rotate the bulb clockwise until it stops.

1

1. Bulb

2. Metal pins

2

4

3

Figure 28

3. Bulb holder

4. Slots

2

4

1875

2. The bulb holder has two tabs (Fig. 27). Align the

tabs with the slots in the reflector, insert the bulb

holder into the reflector and rotate it 1/4 turn

clockwise until it stops.

3. Push the wire connectors onto the terminals on

the bulb holder.

25

Page 28

Maintenance

Battery

Service Interval/Specification

Check the electrolyte level in the battery after every 5

operating hours. Always keep the battery clean and

fully charged. Use a paper towel to clean the battery

and battery box. If the battery terminals are corroded,

clean them with a solution of four parts water and one

part baking soda. Apply a light coating of grease to

the battery terminals to prevent corrosion.

Voltage: 12 v, 160 Cold Cranking Amps

Removing the Battery

1. Disengage the blade control (PTO), set the

parking brake, and turn the ignition key to

“OFF” to stop the engine.

2. Tip the seat forward to see the battery.

3. Disconnect the negative (black) ground cable

from the battery post (Fig. 29).

Installing the Battery

1. Put the battery into the battery box and slide the

vent tube into the channel and through the slot in

the bottom of the box (Fig. 30).

IMPORTANT: Look down into the cut out

area where the battery box fits into the

chassis. Notice the holes at the end of the right

frame member (Fig. 30). Always install the

long battery vent tube through the holes to

prevent battery acid from corroding the

tractor and mower.

1

2

3

4

4. Slide the rubber cover up the positive (red)

cable. Disconnect the positive (red) cable from

the battery post (Fig. 29).

5. Remove the battery box, battery, and long vent

tube from the chassis (Fig. 30).

5

1

34

1. Negative cable (black)

2. Rubber cover

3. Positive cable (red)

Figure 29

4. Battery box

5. Bolt and wing nut

2

1876

5

2347

Figure 30

1. Battery

2. Battery box

3. Vent tube

4. Slot in battery box

5. Hole in frame

2. Install the battery box and battery into the

chassis (Fig. 30). Make sure to slide the end of

the vent tube through the hole in the frame

(Fig. 30).

3. Using the bolt and wing nut, connect the positive

(red) cable to the positive (+) battery post

(Fig. 29). Slide the rubber cover over the battery

post.

4. Using the bolt and wing nut, connect the

negative (black) cable to the negative (–) battery

post (Fig. 29).

26

Page 29

Maintenance

Checking Electrolyte Level

1. Tip the seat forward to see the battery.

2. Look at the side of the battery. The electrolyte

must be up to the “UPPER” line (Fig. 31). Do

not allow the electrolyte to get below the

“LOWER” line (Fig. 31).

3. If the electrolyte is low, add the required amount

of distilled water; refer to Adding Water to the

Battery, page 27.

2

3

Charging the Battery

IMPORTANT: Always keep the battery fully

charged (1.260 specific gravity). This is

especially important to prevent battery

damage when the temperature is below 32°F

(0°C).

1. Remove the battery from the chassis; refer to

Removing the Battery, page 26.

2. Check the electrolyte level; refer to Checking

Electrolyte Level, page 27, steps 2–3.

3. Remove the filler caps from the battery and

connect a 3 to 4 amp battery charger to the

battery posts. Charge the battery at a rate of 4

amperes or less for 4 hours (12 volts). Do not

overcharge the battery. Install the filler caps after

the battery is fully charged.

1

1. Filler caps

2. UPPER line

Figure 31

3. LOWER line

1878

Adding Water to the Battery

The best time to add distilled water to the battery is

just before you operate the machine. This lets the

water mix thoroughly with the electrolyte solution.

1. Clean the top of the battery with a paper towel.

2. Unscrew the filler caps (Fig. 31).

3. Slowly pour distilled water into each battery cell

until the level is up to the “UPPER” line

(Fig. 31) on the battery case.

IMPORTANT: Do not overfill the battery

because electrolyte (sulfuric acid) can cause

severe corrosion and damage to the chassis.

POTENTIAL HAZARD

• Charging the battery produces gasses.

WHAT CAN HAPPEN

• Battery gasses can explode.

HOW TO AVOID THE HAZARD

• Keep cigarettes, sparks and flames away

from battery.

4. Install the battery in the chassis; refer to

Installing the Battery, page 26.

4. Screw the filler caps onto the battery.

27

Page 30

Maintenance

Wiring Diagram

BLACK

GND

-+

C-2186

FUSE

10 A.

SAFETY RELAY

SOLENOID

RED

BLACK

RED/WHT

N.0.

N.C.

BATTERY

COM

RED

FUSE

FUSE

BLK/WHT

LIGHT BLUE

10 A.

10 A.

RED

GRAY

SEAT SWITCH

N.O.

RED

ENGINE

MAGNETO

RED

ALT.

LIGHT

RED

COIL

STARTER

SOLENOID

FUEL

(Some Models)

BLACK BLACK

28

N.O.

PTO SWITCH

LIGHTS N.O.

BROWN

BROWN

GREEN

WHITE

GRAY

DARK BLUE

YELLOW

B

YI

SX

A

YELLOW

KEY SWITCH

N.O.

NEUTRAL SWITCH

KEY SWITCH CIRCUIT LOGIC

LIGHTS CONNECTOR GND

NONE

NONE NONE

B+I+A X+Y

B+I+S

POSITION CIRCUIT "MAKE"

1. OFF

2. RUN

3. START

LIGHT HARNESS (NOT SHOWN)

Page 31

Maintenance

Storage

1. Clean dirt and chaff from the outside of the

engine’s cylinder head fins and blower housing.

Also remove grass clippings, dirt, and grime

from the external parts of the entire machine,

especially the engine, shrouding, and the top of

the mower.

2. Remove grass clippings, dirt, and grime from the

external parts of the machine, especially the

engine. Clean dirt and chaff from the outside of

the engine’s cylinder head fins and blower

housing.

IMPORTANT: You can wash the machine

with mild detergent and water. Do not

pressure wash the machine. Avoid excessive

use of water, especially near the control panel,

lights, engine, and the battery.

3. Check the brake; refer to Brake, page 22.

4. Service the air cleaner; refer to Air Cleaner,

page 17.

5. Grease the chassis; refer to Greasing and

Lubrication, page 22.

IMPORTANT: The battery must be fully

charged to prevent it from freezing and being

damaged at temperatures below 32°F (0°C). A

fully charged battery maintains its charge for

about 50 days at temperatures lower than

40°F (4°C). If the temperatures will be above

40°F (4°C), check the water level in the

battery and charge it every 30 days.

9. Check the tire pressure; refer to Tire Pressure,

page 22.

10. During long-term storage, either drain gasoline

from the fuel tank (step A) or add a fuel additive

to a full tank of gasoline (step B).

A. Drain gasoline from the fuel tank; refer to

Fuel Tank, page 24. After fuel is drained,

start the engine and let it idle until all

gasoline is consumed and the engine stops.

This eliminates gum-like buildup in the fuel

system, which causes hard starting. Try to

start the engine two more times to assure

that no gasoline is in the fuel system.

B. Add the correct amount of Toro

Stabilizer/Conditioner to a full tank of

gasoline.

6. Change the crankcase oil and oil filter; refer to

Engine Oil, page 19.

7. Remove the spark plug and check its condition;

refer to Spark Plug, page 21. With the spark plug

removed from the engine, pour two tablespoons

of engine oil into the spark plug hole. Now use

the electric starter to crank the engine and

distribute the oil inside the cylinder. Install the

spark plug and tighten it to 15 ft–lb (20.4 Nm).

Do not install the wire on the spark plug.

8. Remove the battery from the chassis, check the

electrolyte level, and charge it fully; refer to

Battery, page 26. Do not connect the battery

cables to the battery posts during storage.

Note: Stabilizer/conditioners normally

preserve gasoline for six to eight

months.

11. Check and tighten all bolts, nuts, and screws.

Repair or replace any part that is damaged or

defective.

12. Paint all scratched or bare metal surfaces. Paint

is available from you Authorized Service Dealer.

13. Store the machine in a clean, dry garage or

storage area. Remove the key from the ignition

switch and keep it in a memorable place. Cover

the machine to protect it and keep it clean.

29

Page 32

Troubleshooting

g,,

gp

PROBLEM POSSIBLE CAUSES CORRECTIVE ACTION

Starter does not engage.

Engine will not start, starts hard, or

fails to keep running.

1. Blade control (PTO) is

ENGAGED.

2. Parking brake is not on. 2. Set parking brake.

3. Battery is dead. 3. Charge the battery.

4. Electrical connections are

corroded or loose.

5. Fuse is blown. 5. Replace fuse.

6. Relay or switch is defective. 6. Contact Authorized Service

1. Operator is not seated. 1. Sit on the seat.

2. Fuel tank is empty. 2. Fill fuel tank with gasoline.

3. Air cleaner is dirty. 3. Clean or replace air cleaner

4. Spark plug wire is loose or

disconnected.

5. Spark plug is pitted, fouled, or

gap is incorrect.

6. Choke is not closing. 6. Check for choke operation.

7. Dirt in fuel filter. 7. Replace fuel filter.

1. Move blade control (PTO) to

DISENGAGED.

4. Check electrical connections

for good contact.

Dealer.

element.

4. Install wire on spark plug.

5. Install new, correctly gapped

spark plug.

Engine loses power.

8. Idle speed is too low or

mixture is incorrect.

9. Dirt, water, or stale fuel is in

fuel system.

1. Engine load is excessive. 1. Reduce ground speed.

2. Air cleaner is dirty. 2. Clean air cleaner element.

3. Oil level in crankcase is low. 3. Add oil to crankcase.

4. Cooling fins and air passages

under engine blower housing

are plugged.

5. Spark plug is pitted, fouled, or

gap is incorrect.

6. Vent hole in fuel cap is

plugged.

7. Dirt in fuel filter. 7. Replace fuel filter.

8. Dirt, water, or stale fuel is in

fuel system.

8. Contact Authorized Service

Dealer.

9. Contact Authorized Service

Dealer.

4. Remove obstruction from

cooling fins and air passages.

5. Install new, correctly gapped

spark plug.

6. Clean or replace the fuel cap.

8. Contact Authorized Service

Dealer.

30

Page 33

PROBLEM CORRECTIVE ACTIONPOSSIBLE CAUSES

g

Troubleshooting

Engine over heats.

Machine does not drive.

1. Engine load is excessive. 1. Reduce ground speed.

2. Oil level in crankcase is low. 2. Add oil to crankcase.

3. Cooling fins and air passages

under engine blower housing

are plugged.

1. Drive control is in “PUSH”

position.

2. Traction belt is worn, loose or

broken.

3. Traction belt is off pulley. 3. Contact Authorized Service

3. Remove obstruction from

cooling fins and air passages.

1. Move drive control to

“OPERATE” position.

2. Contact Authorized Service

Dealer.

Dealer.

31

Page 34

Page 35

FORM NO. 3317–996ES

®

Wheel Horse

16–44 HXLE

Tractor cortacésped

Modelo No 71218 – 6900001 y superiores

Manual del operador

IMPORTANTE : Lea detenidamente este manual. Contiene información

relativa a su seguridad y a la seguridad de otras personas. Familiarícese

con los controles y su correcta utilización antes de usar este producto.

Page 36

Introducción

Gracias por comprar un producto Toro.

Todo el personal de Toro queremos que esté

totalmente satisfecho con su nuevo producto. Por ello

le rogamos que se ponga en contacto con su

concesionario local autorizado, que dispone de piezas

de repuesto genuinas y le podrá ayudar con los

problemas técnicos y asistirle en todo momento.

Cuando se ponga en contacto con la fábrica o con su

concesionario local autorizado, mencione siempre el

modelo y el número de serie de su producto. Estos

números ayudarán al concesionario o al representante

técnico a proporcionarle información exacta sobre su

producto en particular. El modelo y el número de

serie se encuentran en una placa situada en un punto

determinado del producto, como se muestra a

continuación.

1

Lea este manual detenidamente para aprender a

utilizar y mantener correctamente su producto. La

lectura de este manual le ayudará a Vd. y a otros a

evitar lesiones corporales y daños a la máquina.

Aunque Toro diseña, fabrica y comercializa productos

seguros y de la más alta calidad, Vd. es el responsable

de utilizar el producto de forma segura y adecuada.

Vd. también es el responsable de instruir a las

personas a las que tiene intención de dejar utilizar la

máquina, para que la usen según las normas de

seguridad.

A lo largo de este manual, Toro ha incluido avisos

que identifican peligros potenciales y mensajes de

seguridad especiales que le ayudarán a Vd. y a otros a

evitar las lesiones corporales, incluso la muerte. Las

palabras utilizadas para indicar estos mensajes e

identificar el nivel de riesgo son PELIGRO,

ADVERTENCIA y CUIDADO. No obstante, sin

importar el nivel de riesgo, sea extremadamente

cuidadoso.

PELIGRO señala una situación extremadamente

arriesgada que causará lesiones graves, incluso la

muerte, si no se siguen las precauciones indicadas.

1856

1. Placa con el modelo y el número de serie

(debajo del asiento)

Para su comodidad, anote a continuación el modelo y

el número de serie de su producto.

Modelo No:

No. de serie :

EThe Toro Company – 1995

Printed in USA

All Rights Reserved

ADVERTENCIA señala un riesgo que puede causar

lesiones graves, incluso la muerte, si no se siguen las

instrucciones indicadas.

CUIDADO señala un riesgo que puede causar

lesiones leves o moderadas si no se siguen las

instrucciones indicadas.

También se utilizan otras dos palabras para resaltar

cierto tipo de información. “Importante” llama la

atención sobre informaciones técnicas especiales y

“Nota” hace hincapié sobre informaciones generales

que es conveniente resaltar.

Los lados izquierdo y derecho de la máquina se han

determinado desde la posición normal del usuario, de

pie, detrás del manillar.

Page 37

Contenido

Página

Seguridad 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Prácticas de funcionamiento seguro para las

máquinas cortadoras de césped, rotatorias,

con conductor 2. . . . . . . . . . . . . . . . . . . . .

Cuadro de pendientes 5. . . . . . . . . . . . . . . . .

Glosario de símbolos 6. . . . . . . . . . . . . . . . .

Gasolina y aceite 9. . . . . . . . . . . . . . . . . . . . . . . .

Gasolina recomendada 9. . . . . . . . . . . . . . . .

Estabilizador/acondicionador 10. . . . . . . . . . .

Llenado del depósito de combustible 10. . . . .

Comprobación del nivel de aceite motor 10. .

Operación 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Piense primero en la seguridad 11. . . . . . . . .

Controles 11. . . . . . . . . . . . . . . . . . . . . . . . . .

Freno de estacionamiento 12. . . . . . . . . . . . . .

Arranque y parada el motor 12. . . . . . . . . . . .

Utilización del control de la cuchilla (PTO) 14

El sistema de seguridad 14. . . . . . . . . . . . . . .

Conducción hacia adelante y hacia atrás 15. .

Parada de la máquina 15. . . . . . . . . . . . . . . . .

Ajuste de la altura de corte 16. . . . . . . . . . . . .

Página

Posición del asiento 16. . . . . . . . . . . . . . . . . .

Posición del volante inclinable 17. . . . . . . . .

Faros 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Empuje manual de la máquina 17. . . . . . . . .

Mantenimiento 19. . . . . . . . . . . . . . . . . . . . . . . . . .

Cuadro de intervalos de servicio 19. . . . . . . .

Depurador de aire 20. . . . . . . . . . . . . . . . . . . .

Aceite del motor 22. . . . . . . . . . . . . . . . . . . . .

Bujía 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Engrase y lubricación 26. . . . . . . . . . . . . . . .

Presión de los neumáticos 26. . . . . . . . . . . . .

Freno 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Depósito de combustible 28. . . . . . . . . . . . . .

Filtro de combustible 28. . . . . . . . . . . . . . . . .

Fusible 29. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Faros 30. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Batería 31. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Diagrama de cableado 34. . . . . . . . . . . . . . . .

Almacenamiento 35. . . . . . . . . . . . . . . . . . . .

Localización de averías 37. . . . . . . . . . . . . . . . . . .

1

Page 38

Seguridad

Prácticas de funcionamiento

seguro para las máquinas

cortadoras de césped,

rotatorias, con conductor

Entrenamiento

1. Lea cuidadosamente las instrucciones.

Familiarícese con los controles y con el uso

correcto del equipo.

2. No permita que los niños operen la cortadora ni

que lo hagan adultos que no estén familiarizados

con estas instrucciones. Es posible que existan

normativas locales restringiendo la edad del

operador.

3. Nunca utilice la cortadora mientras haya

personas, especialmente niños o animales

domésticos, en las proximidades.

4. Recuerde que el operador es responsable de los

accidentes o peligros a que están sometidas las

personas que se encuentren en su propiedad.

5. No transporte pasajeros.

6. Todos los conductores deben solicitar y obtener

instrucciones prácticas por parte de un

profesional. Dichas instrucciones deben

enfatizar:

• la necesidad de extremar el cuidado y la

concentración cuando se trabaja con

máquinas con conductor;

• el control de una máquina con conductor

que se desliza por una pendiente no se

puede recuperar mediante el uso de los

frenos. Las causas principales de la pérdida

de control son:

no se frena correctamente;

el tipo de máquina no es adecuado para

el tipo de tarea al que se la destina;

desconocimiento del efecto que tiene el

estado del terreno, especialmente las

pendientes;

enganche y distribución de la carga

incorrectos.

Preparación

1. Mientras corta el césped, use pantalones largos y

calzado fuerte. No opere la cortadora descalzo o

con sandalias.

2. Inspeccione cuidadosamente el área donde se va

a utilizar la cortadora y retire todos los objetos

que puedan ser arrojados por la máquina.

3. ADVERTENCIA – La gasolina es un líquido

altamente inflamable.

• Utilice recipientes especialmente diseñados

para su almacenamiento.

• Rellene el depósito en el exterior, nunca

fume mientras añade combustible.

• Añada el combustible antes de arrancar el

motor. Nunca retire la tapa del depósito de

combustible o añada gasolina mientras el

motor está en marcha o caliente.

• Si se derrama gasolina, no intente arrancar

el motor, retire la máquina de la zona donde

se ha vertido el combustible y evite la

presencia de fuentes de ignición hasta que

se hayan disipado los vapores de gasolina.

• Vuelva a colocar de forma segura las tapas

de todos los bidones y recipientes de

combustible.

4. Reemplace los silenciadores defectuosos.

la rueda no tiene suficiente agarre;

se conduce demasiado rápido;

2

Page 39

Seguridad

5. Antes de utilizar, compruebe visualmente que la

cuchilla, los pernos de la cuchilla y el sistema de

corte no están desgastados o dañados.

Reemplace la cuchilla y los pernos gastados o

dañados siempre en juegos, con el fin de

mantener el equilibrio.

6. Tenga cuidado con las máquinas provistas de

múltiples cuchillas, ya que la rotación de una de

ellas puede provocar el giro de otras cuchillas.

Operación

1. No haga funcionar el motor en recintos cerrados

donde se pueda acumular el monóxido de

carbono.

2. Corte el césped solamente con luz natural o con

una buena iluminación artificial.

3. Antes de arrancar el motor, desenganche todos

los embragues de accionamiento de la cuchilla, y

coloque la palanca en punto muerto.

4. No utilice la máquina en pendientes de más de:

• en las pendientes y durante los giros, se

debe mantener una marcha baja;

• manténgase alerta por si existen

protuberancias o agujeros en el terreno u

otros peligros ocultos;

• nunca corte el césped de las pendientes de

forma transversal, a no ser que la máquina

haya sido diseñada para ello.

6. Tenga cuidado cuando arrastre cargas o cuando

utilice maquinaria pesada.

• Utilice sólo puntos de enganche con barra

de tracción homologados.

• Limítese a las cargas que pueda controlar

con seguridad.

• No realice giros bruscos. Tenga cuidado

cuando vaya marcha atrás.

• Utilice contrapeso(s) o pesos en las ruedas

cuando así lo sugiera el manual de

instrucciones.

7. Tenga cuidado con el tráfico cuando cruce o esté

en las proximidades de una carretera.

• Nunca corte el césped lateralmente en

pendientes de más de 5_

• Nunca corte el césped cuesta arriba en

pendientes de más de 10_

• Nunca corte el césped cuesta abajo en

pendientes de más de 15_

Nota: En el apartado 5.4.2.3.2. se indica

cómo calcular el ángulo de la

pendiente.

5. Recuerde que no existe una pendiente ”segura”.

La conducción en pendientes cubiertas de hierba

requiere un cuidado especial. Para evitar que la

máquina vuelque:

• no pare o arranque de repente la máquina

cuando esté cuesta arriba o cuesta abajo;

• accione el embrague lentamente, y

mantenga siempre la máquina con la

marcha engranada, especialmente cuando

esté cuesta abajo;

8. Detenga las cuchillas rotatorias antes de cruzar

superficies que no esté cubiertas de hierba.

9. Cuando utilice alguno de los accesorios, nunca

dirija la descarga de material hacia los

espectadores ni permita que ninguna persona se

acerque a la máquina mientras está funcionando.

10. Nunca opere la cortadora con protecciones

deterioradas o sin los dispositivos de seguridad

necesarios.

11. No cambie los ajustes del regulador o

sobreacelere el motor. El funcionamiento del

motor a una velocidad excesiva puede aumentar

el riesgo de lesiones corporales.

12. Antes de abandonar la posición del operador:

• desengrane la toma de fuerza y baje los

accesorios;

• cambie a punto muerto y accione el freno de

estacionamiento;

• detenga el motor y saque la llave.

3

Page 40

Seguridad

13. Desconecte la transmisión a los accesorios,

detenga el motor y desconecte el(los) cable(s) de

la bujía o retire la llave del encendido

• antes de despejar las obstrucciones o

desatascar la canaleta de descarga;

• antes de inspeccionar, limpiar o reparar la

cortadora;

• después de golpear un objeto extraño.

Compruebe si la cortadora está dañada, en

cuyo caso efectúe las reparaciones

correspondientes antes de volver a operar la

máquina;

• si la cortadora comienza a vibrar de manera

anormal (comprobar inmediatamente).

14. Cuando transporte la máquina o no vaya a

utilizarla, desconecte la transmisión a los

accesorios.

15. Detenga el motor y desconecte la transmisión a

los accesorios

4. Para reducir el riesgo de incendio, mantenga el

motor, el silenciador, el compartimiento de la

batería y el área del depósito del combustible

libre de exceso de grasa, hierba y hojas.

5. Revise frecuentemente el saco recogedor de

hierba para asegurarse de que no está desgastado

o deteriorado.

6. Para mayor seguridad, reemplace las piezas

gastadas o deterioradas.

7. Si es necesario drenar el depósito de

combustible, hágalo al aire libre.

8. Tenga cuidado con las máquinas provistas de

múltiples cuchillas, ya que la rotación de una de

ellas puede provocar el giro de otras cuchillas.

9. Cuando se vaya a aparcar, almacenar o dejar

desatendida la máquina, baje los accesorios de

corte, a menos que se utilice un bloqueo positivo

mecánico.

• antes de repostar combustible;

• antes de desmontar el colector de hierba;

• antes de realizar los ajustes de altura, a no

ser que dichos ajustes se puedan realizar

desde la posición del operador.

16. Reduzca la aceleración antes de detener el motor

y, si el motor está equipado con una válvula de

cierre de combustible, ciérrela cuando finalice la

tarea.

Mantenimiento y almacenamiento

1. Mantenga apretados todos los pernos, tuercas y

tornillos y asegúrese de que todo el equipo está

en perfecto funcionamiento.

2. Nunca almacene el equipo con combustible en el

depósito dentro de un edificio donde una chispa

o una llama desnuda pueda inflamar sus vapores.

3. Espere a que se enfríe el motor antes de guardar

la cortadora en un recinto cerrado.

Nivel de presión de sonido

Esta unidad tiene una presión de sonido continua

A-ponderada en el oído del operador equivalente a

100 dB(A), basado en medidas realizadas en

máquinas idénticas de acuerdo con el procedimiento

ANSI B71.5-1984.

Nivel de potencia de sonido

Este aparato tiene una nivel de potencia de:

100 dB(A)/1pW, según medidas efectuadas en

máquinas idénticas de acuerdo con la Directiva

79/113/EEC y sus enmiendas. La superficie de prueba

consistió en una estera de coco rodeada de hierba de

5 cm de altura.

Nivel de vibración

Este aparato tiene un nivel de vibración máximo

afectando a las manos y al brazo de 4,80 m/s2 y un

nivel de vibración afectando a todo el cuerpo de

0,30 m/s

idénticas de acuerdo con los procedimientos

ISO 5349.

2

, según medidas efectuadas en máquinas

4

Page 41

Cuadro de pendientes

Lea todas las instrucciones de seguridad contenidas en las páginas 2–8.

ALINEE ESTE BORDE CON UNA SUPERFICIE VERTICAL

(ARBOL, EDIFICIO, VALLA, POSTE, ETC.)

Seguridad

EJEMPLO: COMPARE EL

BORDE PLEGADO CON

LA PENDIENTE

°

°

°

PLIEGUE POR LA LINEA APROPIADA

5

Page 42

Seguridad

Glosario de símbolos

Símbolo de alerta de seguridad

Símbolo de alerta de seguridad

Lea el manual del operador

Consulte en el manual técnico

los procedimientos de servicio

adecuados

Objetos voladores–Todo el cuerpo

está expuesto

Objetos proyectados o voladores –

Cortadora con dispositivo rotatorio

montado lateralmente. Mantenga la

protección deflectora en su lugar

Descuartizamiento–Cortadora

funcionando marcha atrás

Manténgase a una distancia

prudencial de la máquina

Manténgase a una distancia

prudencial de la cortadora

Mantenga a los niños a una

distancia prudencial de la

máquina

Volcado de la máquina en una

pendiente

Amputación de dedos de pies y

manos–cuchilla de la cortadora

Amputación de dedos de

pies y manos–cuchilla de

la cortadora

La cuchilla giratoria puede

amputar los dedos de los pies o

de las manos. Mantenerse alejado

de la cuchilla siempre que el

motor esté funcionando

No abra o retire las protecciones

de seguridad mientras el motor

esté en marcha

6

Volcado de la máquina cuesta

arriba

Volcado de la máquina cuesta

abajo

Estructura antivuelco ROPS

Page 43

Glosario de símbolos

Seguridad

Elemento de corte–símbolo básico

Elemento de corte–ajuste de la altura

Unidad de corte bajada

Unidad de corte alzada

Puede cortar o atrapar el

pie–taladro giratorio

Amputación de los dedos o

la mano–cuchilla impulsora

Se permite conducir esta máquina

sólo en el asiento del pasajero y

sólo si no se estorba la visión del

conductor

Puede aplastar los dedos o las

manos–Fuerza aplicada

lateralmente

Movimiento de reculado o

ascendente–energía almacenada

Apague el motor y retire la llave

antes de realizar cualquier

operación de mantenimiento o

ajuste

Manténgase a una distancia

prudencialdel quitanieves.

Manténgase a una distancia

prudencialdel quitanieves.

Los tractores deben estar

equipados con un peso de rueda

de 45 kg en la rueda trasera, con

su accesorio instalado

Sistema de protección contra

el vuelco del quitanieves

Amputación de las manos–

Cuchillas giratorias

Amputación de los pies–

Cuchillas giratorias

Dirección de avance de la máquina–

combinada

Baja

Alta

Marcha atrás

Punto muerto

Primera marcha

Segunda marcha

Tercera marcha hasta el máximo

número de marchas de avance

7

Page 44

Seguridad

Glosario de símbolos

Rápida

Lenta

Disminuyendo/aumentando

Encendido/funcionando

Apagado/aparado

Motor

El motor se pone en marcha

El motor se para

Combustible

El nivel de combustible

Tanque vacío

Tanque lleno

Estado de carga de la batería

Faros–Luces largas

Sistema de frenos

Estrangulador

Temperatura del motor

Presión del aceite

de lubricación del

motor

Nivel del aceite de lubricación

del motor

Freno de estacionamiento

Embrague

PTO (toma de fuerza)

Engranar

Desengranar

Destrabar

Trabar

8

Page 45

Gasolina y aceite

Gasolina recomendada

Utilice Gasolina regular fresca SIN PLOMO

adecuada para automóviles (de 85 octanos como

mínimo). Se puede utilizar gasolina normal con

plomo si la gasolina normal sin plomo no estuviera

disponible.

Importante: Nunca use metanol, gasolina que

contenga metanol o gasohol con más

de 10% etanol porque se podrían

producir daños en el sistema de

combustible del motor. No mezcle

aceite con la gasolina.

PELIGRO POTENCIAL

• En ciertas condiciones, la gasolina es

extremadamente inflamable y altamente

explosiva.

QUE PUEDE OCURRIR

• Un incendio o una explosión causados por

la gasolina puede causar quemaduras al

operador y a otras personas y causar daños

materiales.

COMO EVITAR EL PELIGRO

• Utilice un embudo y llene el depósito de

combustible en el exterior, en un área

abierta y con el motor frío. Limpie la

gasolina derramada.

• No llene completamente el depósito de

combustible. Añada gasolina hasta que el

nivel alcance de 6 mm a 13 mm (1/4 a

1/2 pulgada) por debajo de la parte inferior

del cuello de llenado. Este espacio vacío en

el depósito permitirá la dilatación de la

gasolina.

• No fume nunca mientras maneja gasolina y

manténgase alejado de llamas desnudas o

de lugares donde una chispa pudiera