Toro 68021HD Operator's Manual

FormNo.3404-698RevB

MM-858H-PMortarMixer

ModelNo.68021HD—SerialNo.316000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3404-698*B

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

YoumaycontactT orodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Writethenumbersinthespaceprovided.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Introduction

Thismachineisdesignedtomixmortar,plaster,reproong

material,grout,andothersmall-grainedPortlandcement

products.Avehicleequippedwithanappropriatepintlehitch

orballhitchcantowthemachine.

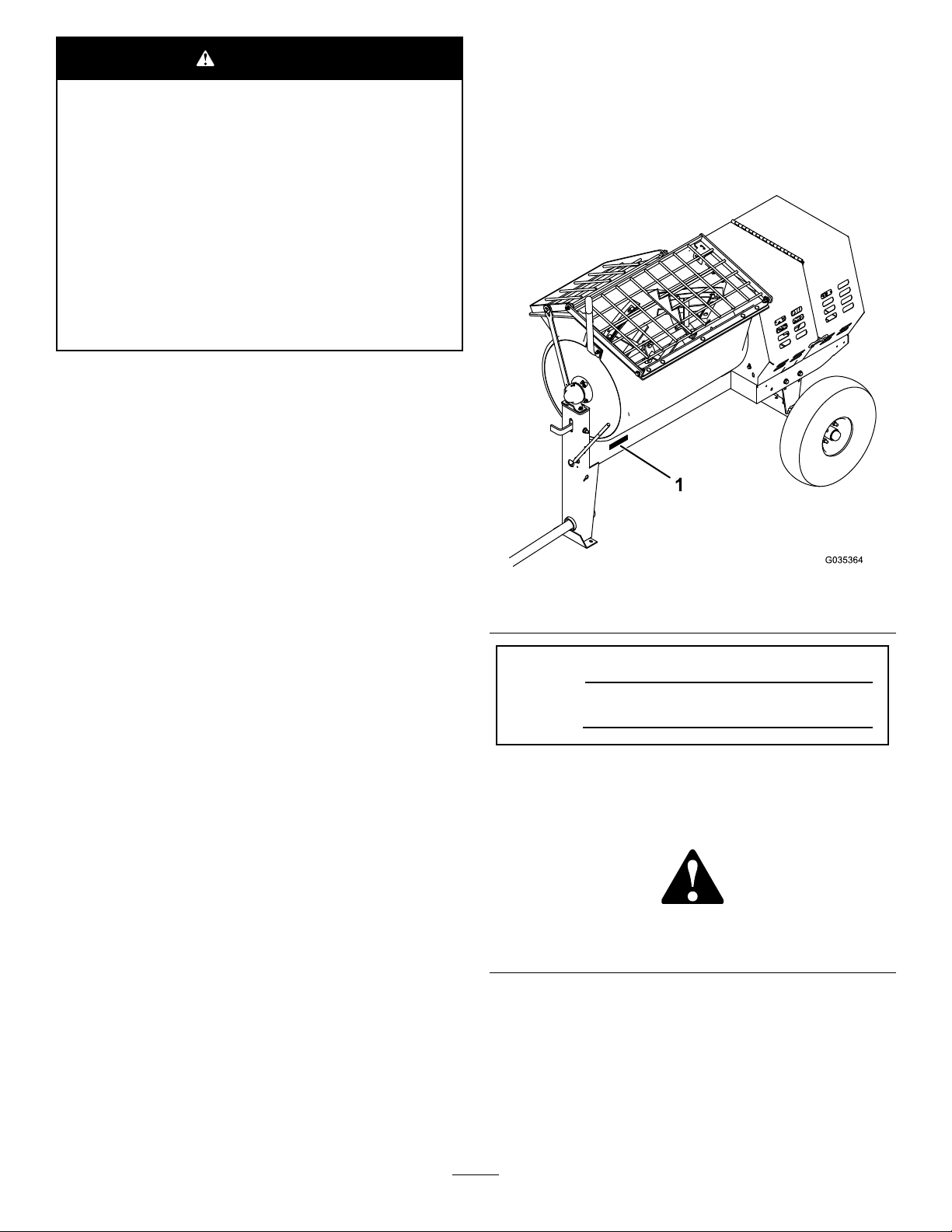

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

TireInformation

TheDOTtireinformationislocatedonthesideofeachtire.

Thisinformationgivesloadandspeedratings.Replacement

tiresshouldhavethesameorbetterratings.

Note:Thevariousmachinesinthismanualhavedifferent

weights;refertoSpecications(page13)toensurethatthe

tiresonyourmachinemeetorexceedtheweightrequirements

ofyourmachine.

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

SafetyandInstructionalDecals.................................7

Setup............................................................................9

1InstallingtheDumpHandle...................................9

2InstallingtheTowPole..........................................10

3InstallingtheSafetyChain.....................................10

ProductOverview.........................................................11

Controls...............................................................11

Specications........................................................13

Operation....................................................................13

PreparingtoT owtheMachine..................................13

ExtendingtheAxle.................................................17

TowingtheMachine...............................................18

PreparingtoUsetheMachine...................................18

OpeningandClosingtheCowl.................................18

AddingFuel...........................................................19

CheckingtheEngine-OilLevel.................................21

StartingandShuttingOfftheEngine.........................21

ControllingthePaddles...........................................22

MixingtheMaterial.................................................23

UsingtheDrum.....................................................24

AdjustingthePaddleBlades.....................................24

Maintenance.................................................................26

RecommendedMaintenanceSchedule(s)......................26

PremaintenanceProcedures........................................27

PreparingtheMachineforMaintenance.....................27

DisconnectingtheSpark-PlugWire...........................27

RemovingandInstallingtheDividerPlate..................27

Lubrication...............................................................28

LubricatingtheBearingsandSeals............................28

EngineMaintenance..................................................29

ServicingtheAirCleaner.........................................29

ServicingtheEngineOil..........................................30

ServicingtheSparkPlug..........................................31

ServicingtheSparkArrester.....................................33

RemovingandInstallingtheEngine..........................33

FuelSystemMaintenance...........................................35

CleaningtheFuel-SedimentCup...............................35

DrainingtheFuelTank...........................................35

BeltMaintenance......................................................36

ServicingtheBelts—Belt-driveModels......................36

ReplacingtheBelts—Belt-driveModels.....................37

AligningthePulleys................................................39

Cleaning...................................................................39

CleaningtheMachine..............................................39

Storage........................................................................40

StoringtheMachine................................................40

Troubleshooting...........................................................41

3

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safety-alertsymbol,whichmeans:

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

—personalsafetyinstruction.Failureto

Caution

,

W ar ning

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriestopeopleordamagetoproperty.

,

Towing

Checkwithyourlocalcountyorstatetowingsafetyregulations

beforetowingthemachine.

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Alwaysfollow

allsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Machiningorhandlingstone,masonry,concrete,

metal,andothermaterialscangeneratedust,mists,

andfumescontainingchemicals,suchassilica,

knowntocauseseriousorfatalinjuryorillness,

suchasrespiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthesource

wherepossible.Watershouldbeusedfordust

suppressionwhenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupationaland

tradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannotbe

eliminated,theoperatorandanybystanders

shouldweararespiratorapprovedbyOSHAfor

thematerialbeinghandled.

•Inordertoreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,makesurethat

thetowingvehicleismechanicallysoundandingood

operatingcondition.

•Shutdowntheenginebeforetransportingthemachine.

•Whentowingwithaballhitch,ensurethattheballhitch

youareusingisthepropersizeforthehitchcoupleron

themachine.

•Whentowingwithapintlehitch,ensurethattheeyeof

thetowpoleisthecorrectdimensionforthepintlehook.

•Inspectthehitchandcouplingforwear.Nevertowthe

machinewithdamagedordefectivehitches,couplings,

chains,orothercomponents.

•Checkthetireairpressureonthetowingvehicleandthe

machine.

•Checkthetiretreadandsidewallfordamageandwear.

•Properlyattachthesafetychainstothetowingvehicle.

•Ensurethatthedirectionalandbrakelightsareworking

properly(ifthemachineisequippedwiththelightkit).

•Ensurethatthedirectional,backup,andbrakelightsof

thetowvehicleareworkingproperly(ifthemachineis

equippedwiththelightkit).

•Beforetowing,checktomakecertainyourmachineis

correctlyandsecurelyattachedtothetowingvehicle.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Ensurethatthesafetychainsareproperlysecuredtothe

vehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhentowing.

•Avoidsuddenstopsandstarts.Thiscancauseskidding,

orjackkning.Smooth,gradualstartsandstopswill

improvetowing.

•Avoidsharpturnstopreventrolling.T owonlywitha

vehiclethathasahitchdesignedfortowing.Donot

attachtowedequipmentexceptatthehitchpoint.

•Donottowthemachinefasterthan88km/h(55mph).

•Usecautionwhenbackingup;useaspotteroutsidethe

vehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehiclebefore

usingit.

•Securethemachinefrommovementbeforeyoutowit.

4

Preparation

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Wearpersonalprotectiveequipmentandappropriate

clothing,includingthefollowing:

–Hardhat

–Respiratorordustmask

–Faceshield

–Hearingprotection

–Substantial,slip-resistantfootwear

–Longpants

–Shirtwithlongsleevesthataretightatthewrists

–Tight-ttinggloveswithoutdrawstringsorloosecuffs

•Securelooseclothing,tiebacklonghair,anddonotwear

jewelry.

•Operatingtheequipmentsafelyrequiresthefullattention

oftheoperator.Donotwearradioormusicheadphones

whileoperatingthemachine.

•Useextracarewhenhandlingfuels.Theyareammable

andthevaporsareexplosive.Usethefollowingpractices

whenhandlingfuel:

–Useonlyanapprovedfuelcontainer.

–Neverremovethefuelcaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neverrefuelordrainthemachineindoors.

–Replacethefuelcapandtightenitsecurely .

–Keepthecontainernozzleincontactwiththetank

duringlling.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Iffuelisspilled,wipeitofftheengineandequipment.

•Ensurethatthemachineisonalevelsurfacebefore

operatingthemachine.

•Securethemachinefrommovementbeforeyoubegin

toworkonit

•Beforeeveryuse,dothefollowing:

–Inspectthecoupler,ball,andhitch.

–Ensurethatalllightsarefunctioningproperly(ifthe

machineisequippedwithalightkit).

–Ensurethatthetiresareproperlyinatedas

recommended.

–Ensurethatthelugnutsaretightandtorqued

properly.

–Ensurethatthemachineisproperlysecured.

Operation

•Neverrunanengineinanenclosedorpoorlyventilated

area.

•Onlyoperatethemachineingoodlightingconditions.

•Beforestartingthemachine,makesurethatthereareno

personsorobstaclesnearorunderthemachine.

•Shutofftheenginebeforeleavingthemachineforany

reason.

Neverleavearunningmachineunattended.Always

shutofftheengineandverifythatallmovingpartshave

stopped.

•Avoidprolongedbreathingofexhaustfumes.Engine

exhaustfumescancausesicknessordeath.

•Keephandsawayfromanymovingparts.Keepfeetaway

fromthetiresandthefrontpost.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Ensurethattheareaisclearofotherpeopleorpetsbefore

operatingthemachine.Shutoffthemachineifanyone

entersthearea.

•Neverplaceyourhandsoranysolidobjectintothedrum

whenthemachineisinoperation.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Nevermovethemachinewhiletheengineisrunning.

•Keepthecowlclosedandlatchedduringoperation.

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperatingthemachine.

•Ifthemixingpaddlesstrikeaforeignobjectorifthe

machineshouldstartmakinganunusualnoiseor

vibration,shutofftheengineandemptythedrum.W ait

forallmovingpartstocometoacompletestopandcool.

Vibrationisgenerallyawarningoftrouble.Inspectfor

cloggingordamage.Cleanandrepairand/orreplace

damagedparts.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperatethe

machine;seekshelter.

5

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonlevelground.

–Shutofftheengine.W aitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

–Lettheenginecoolbeforeperformingmaintenance

orstoring.

–Disengageallpowerandoperationcontrols.

•Neverlubricate,service,repair,oradjustthemachine

whileitisrunning.

•Keepequipmentmaterialsclearfromthemuferand

enginetohelppreventres.Cleanupanyoilorfuel

spillage.

•Neverallowuntrainedpersonneltoservicethemachine.

•Keephands,feet,andclothingawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeanybuildupofgrease,oil,ordebrisfromthe

machine.

•Stopandinspectthemachineifaforeignobjectentersthe

drumorcausesanotherobstruction.Makeanynecessary

repairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Securethemachinefrommovementwhenstoringthe

machine.

•Keepallnuts,bolts,screws,andhoseclampssecurely

tightened.Keepequipmentingoodcondition.

•UseonlygenuineTororeplacementpartstoensurethat

theoriginalstandardsaremaintained.

6

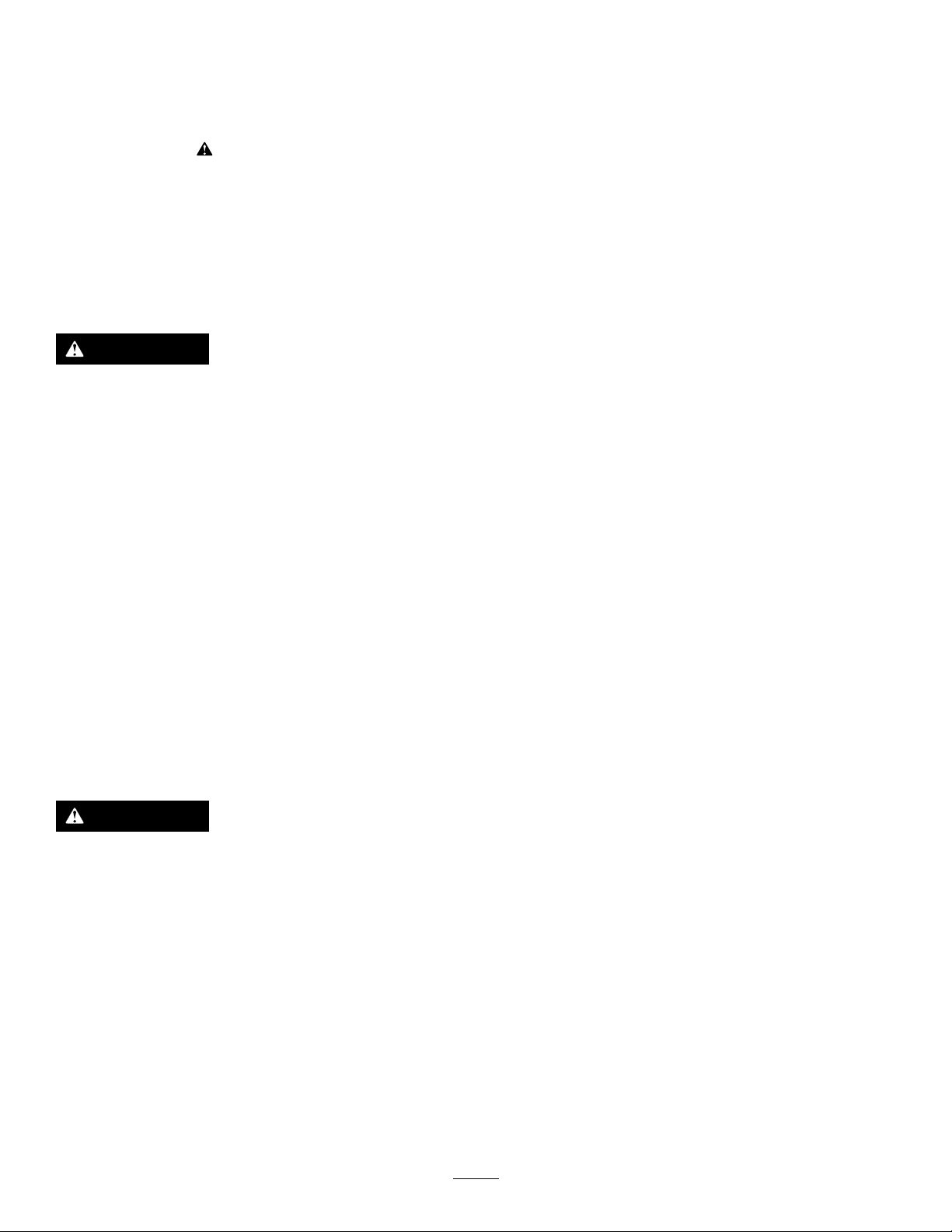

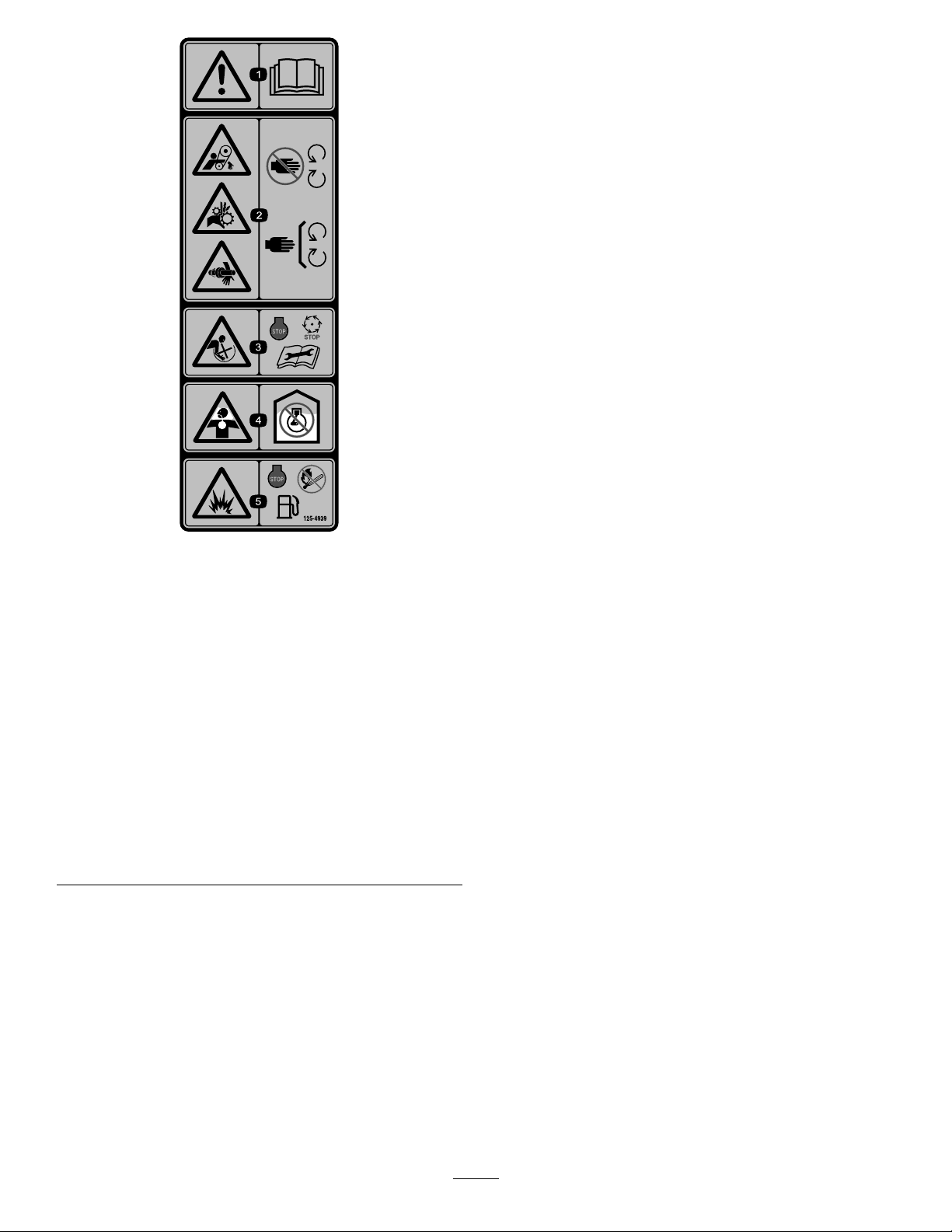

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117-2718

130-8322

125-8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

1.Onlyusefuelwithan

alcoholcontentbyvolume

under10%.

2.ReadtheOperator's

Manualformore

informationonfuel.

3.Donotusefuelwithan

alcoholcontentbyvolume

greaterthan10%.

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

125-8216

2.Warning—limittowing

speedtolessthan55mph

/88km/h.

7

125-4939

1.Warning—readthe

Operator’sManual.

2.Handandarm

entanglementatthe

beltdrive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keephandsaway

frommovingparts;keep

allguardsandshieldsin

place.

3.Entanglementhazard

atpaddles—shutoff

theengineandwait

forallmovingpartsto

stopbeforeperforming

maintenance.

4.Toxicgasinhalation

hazard—Don’trunthe

engineinanenclosed

space.

5.Explosionhazard—shut

offtheengineandkeep

awayfromameswhen

refueling.

8

Setup

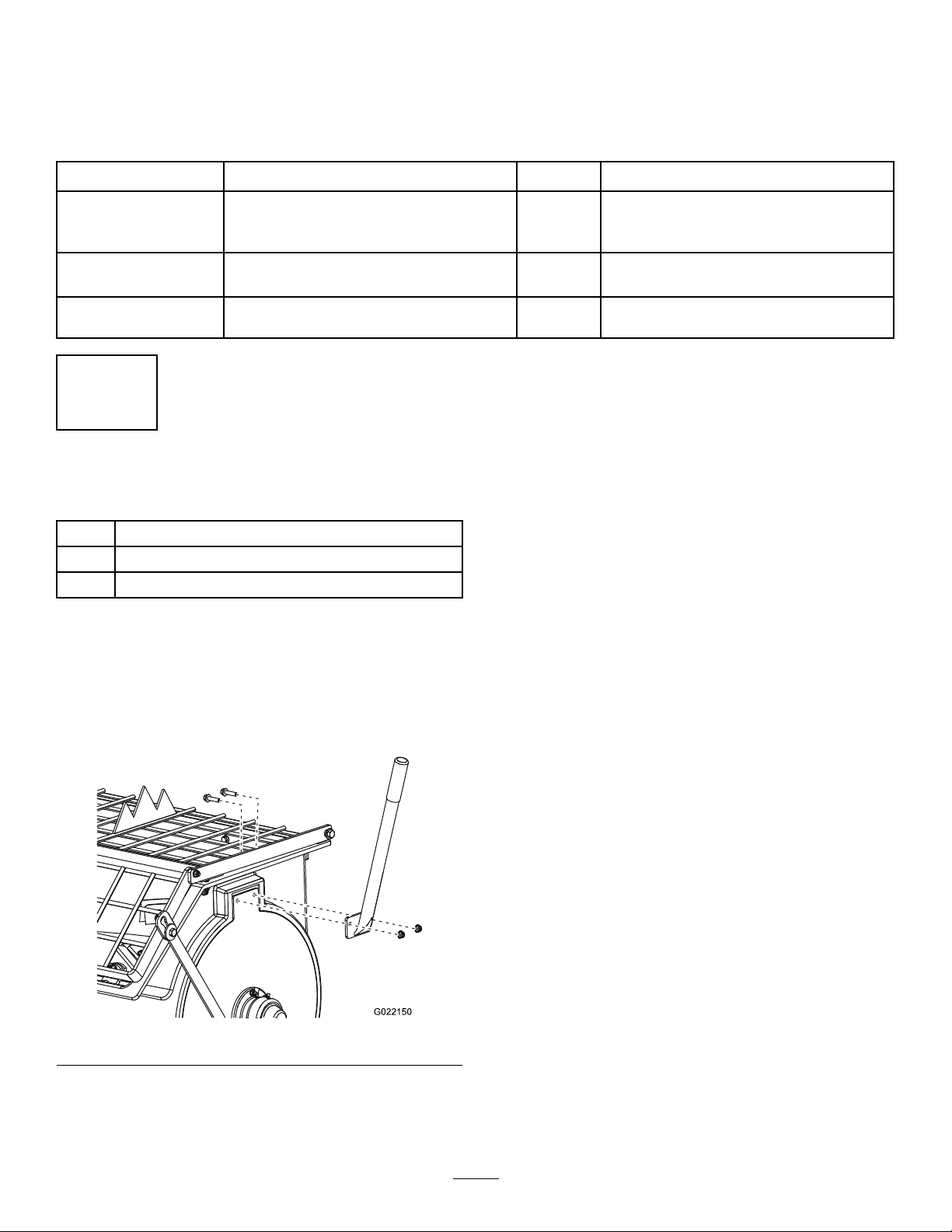

G022150

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

1

InstallingtheDumpHandle

Partsneededforthisprocedure:

1Dumphandle

2Bolt

2Nut

Dumphandle1

Bolt2

Nut2

Towpolekit(soldseparately)

Safetychain

Connectinglink

3.Insertthe2boltsthroughtheboltholesinthedump

handleandthedrum(Figure3).

4.Installanutontoeachbolt,andtightenthembyhand

topreventcross-threading.

5.Tightenthenutswithawrenchwhileusinganother

wrenchtokeeptheboltsfromspinning.

Qty.

Installthedumphandle.

1Installthetowpole.

1

2

Installthesafetychain.

Use

InstallingtheDumpHandletotheDrum

1.Cutthecabletiestoremovethedumphandlefrom

theundersideofthegrate.

2.Positionthedumphandlesothattheboltholesalign

withtheboltholesinthedrum(Figure3).

Figure3

9

2

5

1

2

4

6

3

G019804

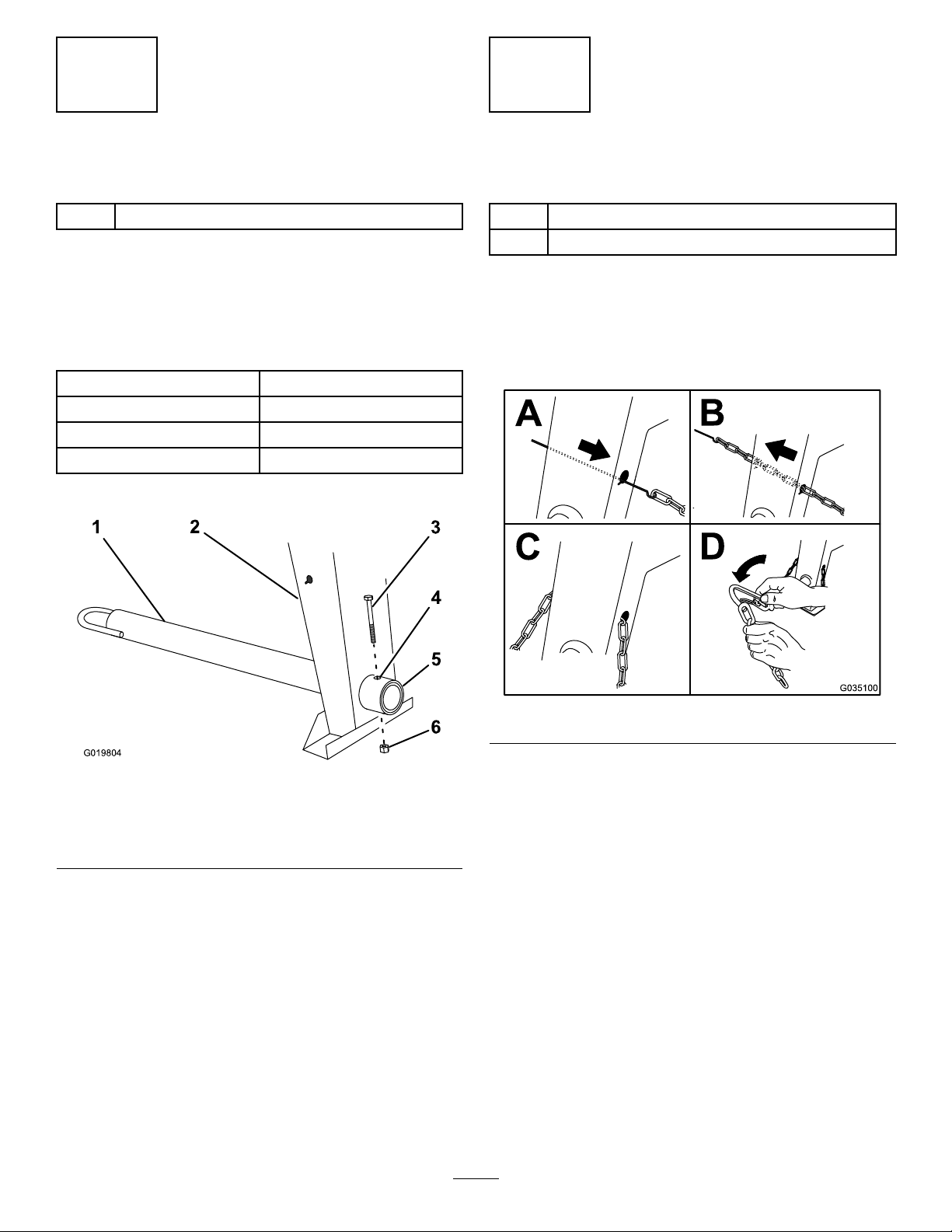

3

InstallingtheTowPole

Partsneededforthisprocedure:

1

Towpolekit(soldseparately)

Procedure

Note:Thetowpoleispurchasedseparatelyandincludesthe

nutandboltneededforinstallation.

Themachinehasthefollowingtowpoleoptions:

HitchT ypeLength

50mm(2inch)ball—stamped78.7cm(31inches)

50mm(2inch)ball—forged78.7cm(31inches)

Pintle

1.Removetheboltandnutfromthetowpole(Figure4).

78.7cm(31inches)

InstallingtheSafetyChain

Partsneededforthisprocedure:

1

Safetychain

2

Connectinglink

Procedure

Formahookontheendofabendablepieceofrodorstiff

wire,(notincluded),andinstallthesafetychainasshownin

Figure5.

Figure5

Figure4

1.Towpole4.Bolthole

2.Frontpost

3.Bolt6.Nut

2.Slidethetowpoleforwardandaligntheholeinthe

polewiththeholeintheframetting(Figure4).

3.Inserttheboltthroughtheholesinthettingandthe

pole(Figure4).

4.Threadthenutontotheboltandtightenthemuntil

theyaretightagainsttheframetting(Figure4).

Note:Iftheself-lockingnyloninsertinthelocknut

wearswithuse,replacethenutwithanewGrade5or

Grade8locknut.

5.Frametting

Note:Ensurethatapproximatelyequallengthsofsafety

chainextendfromeithersideofthefrontpost.

10

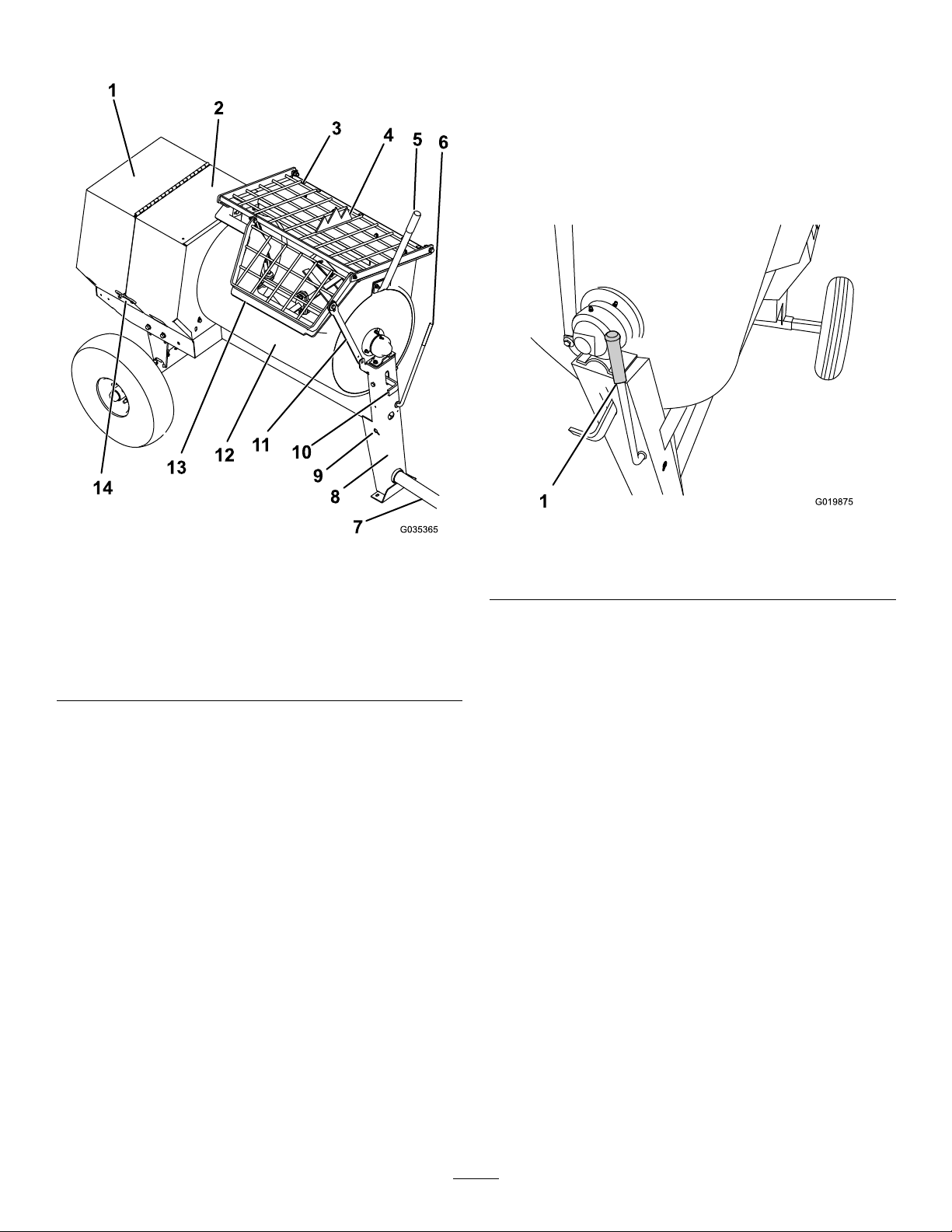

ProductOverview

G019875

1

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine.

ClutchLever

Theclutchleverengagesanddisengagesenginepowertothe

paddles(Figure7).

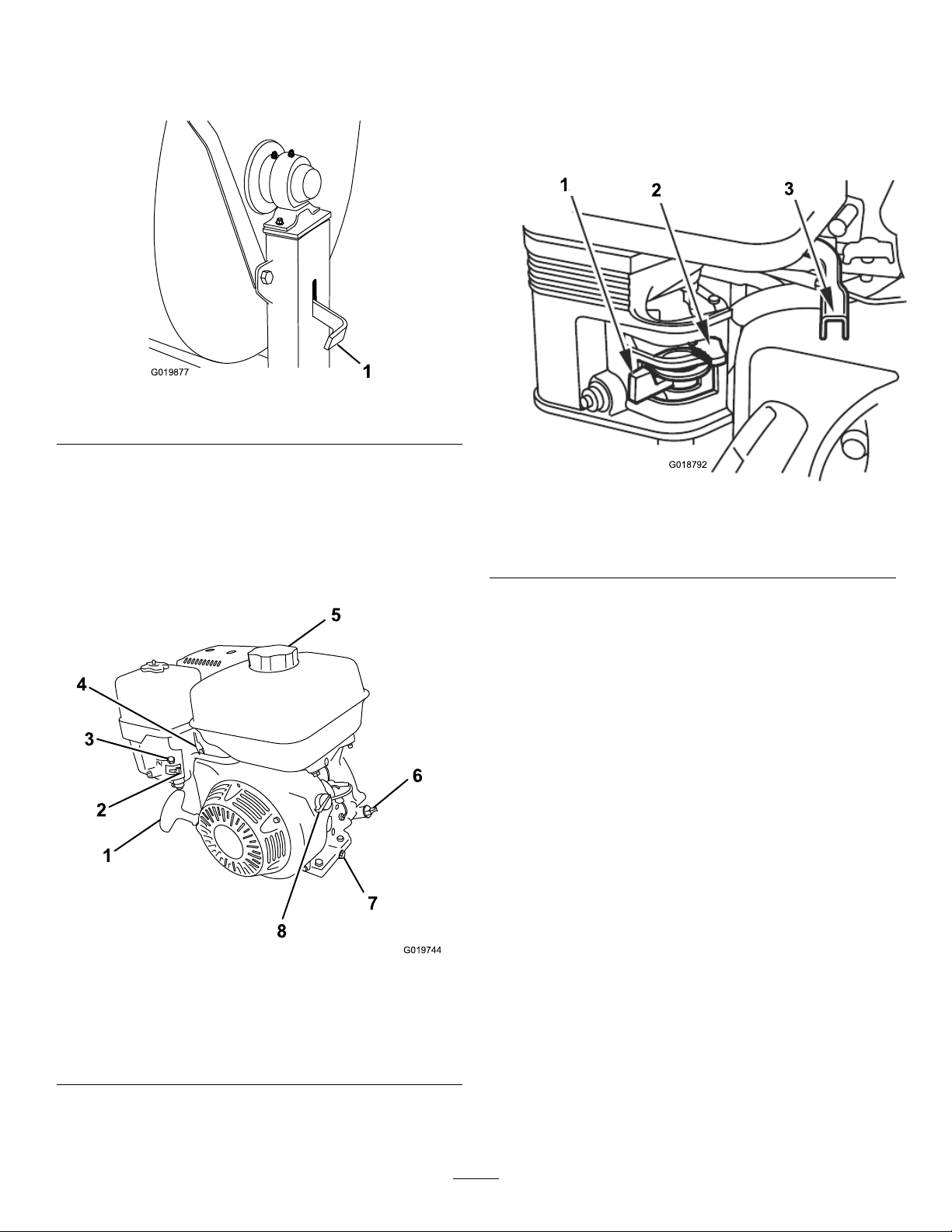

Figure6

1.Rearcowl

2.Frontcowl7.Towpole12.Drum

3.Grate

4.Bagsplitter

5.Dumphandle10.Drumlatch

6.Clutchlever11.Grateliftarm

8.Frontpost

9.Safety-chain

keyhole

Figure7

Belt-drivemodels

1.Clutchlever

13.Chute

14.Cowllatch

11

DrumLatch

1

G019877

1

2

3

4

5

6

7

8

G019744

1

2

3

G018792

FuelValve

Thedrumlatchsecuresthedrumtothemixposition(upright)

formixingoperationsandwhentransportingthemachine.

Figure8

1.Drumlatch

DumpHandle

Usethedumphandletorotatethedrumtothedumpposition

andtorotatethedrumtothemixposition(upright).

Thefuelvalve(Figure10)islocatedunderneaththechoke

lever.MovetheleverforthefuelvalvetotheONposition

beforeattemptingtostarttheengine.Whenyouhavenished

mixing,shutofftheengineandmovethefuelvalveleverto

theOFFposition.

Figure10

1.Fuelvalve3.Throttlelever

2.Chokelever

EngineControls

ChokeLever

Usethechokelever(Figure10)tostartacoldengine.Before

pullingtherecoil-starthandle,movethechokelevertothe

CLOSEDposition.Oncetheengineisrunning,movethe

chokelevertotheOPENposition.Donotusethechokeifthe

engineisalreadywarmeduporiftheairtemperatureishigh.

ThrottleLever

Thethrottlelever(Figure10)controlsthespeed(rpm)ofthe

engine.Itislocatednexttothechokelever.Itsetstheengine

speedandthereforecanincreaseanddecreasetherotation

speedofthemixingpaddles.Forbestperformance,setthis

1.Recoil-starthandle5.Fuelcap

2.Fuelvalve6.Dipstick

3.Chokelever7.Oil-drainplug

4.Throttlelever

Figure9

8.On/Offswitch

controltotheFASTpositionwhenmixingmaterial.

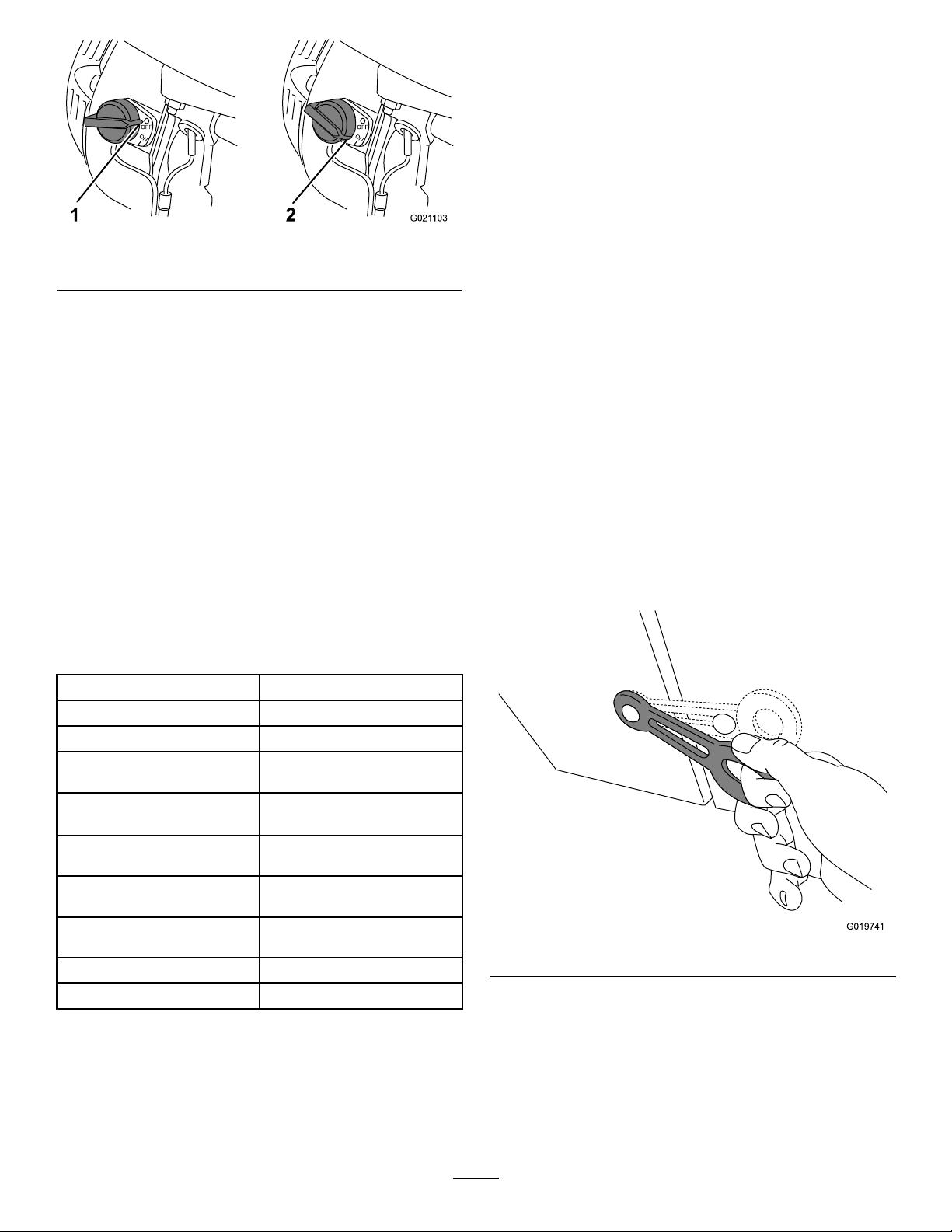

EngineOn/OffSwitch

UsetheOn/Offswitch(Figure11)tostartandshutoffthe

engine.Thisswitchislocatedonthefrontoftheengine.

RotatetheOn/OffswitchtotheONpositiontostartandrun

theengine.RotatetheOn/OffswitchtotheOFFposition

toshutofftheengine.

12

OFF

ON

1

OFF

ON

G021 103

2

Operation

G019741

PreparingtoTowtheMachine

Important:Ensurethatyourtowvehiclehastowing

capacityfortheweightofthemachine.

Important:UseaClass2orlargerreceiver.

Figure11

1.Offposition2.Onposition

Recoil-startHandle

Tostarttheengine,pulltherecoil-starthandle(Figure9)

quicklytoturntheengineover.Theenginecontrolsdescribed

abovemustallbesetcorrectlyfortheenginetostart.

Oil-levelSwitch

Theoil-levelswitchislocatedinsidetheengine,anditdoes

notallowtheenginetorunintheeventtheoillevelisbelow

thesafeoperatinglimit.

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

MachineSpecications

Note:Ensurethatyourtowvehiclehastheappropriatehitch

totowthemachine;optionsincludea50mm(2inch)ball

hitchorapintlehitch.

Note:Ifthemachineisequippedwithatrailer-lightkit,

ensurethattheelectricalconnectorofthetowvehicleis

compatiblewiththeelectricalconnectorofthemachine.The

machineusesastandard4-atplug.Ifyourtowvehiclehasa

differenttypeofplug,obtainanadapterfromanautomotive

partsstore.

1.Ensurethattheengineisshutoff,thefuelvalveisin

theOFFposition,andthedrumisempty.

2.Ifthedrumhasaccumulatedanywater,dumpthe

drum;refertoDumpingtheDrum(page24),steps1,

3,4,and5.

3.Usingthedumplever,positionthedrumsothatitisin

themixposition(upright)andlocked.

4.Closetheenginecowlandsecurethecowllatches

(Figure12).

BatchCapacity0.23m

TotalVolume

DrumMaterialPolyethylene

Length

(withouttowpole)

Width86cm

Height137cm

Weight266kg

Axle

Engine

DriveBelt

0.25m

193cm

(86inches)

(34inches)

(54inches)

(585lb)

86to117cm(34to46inches)

extendable

Honda

3

(8.0ft3)

3

(9.0ft3)

Figure12

®

GX240

5.Extendtheaxle;refertoExtendingtheAxle(page17).

13

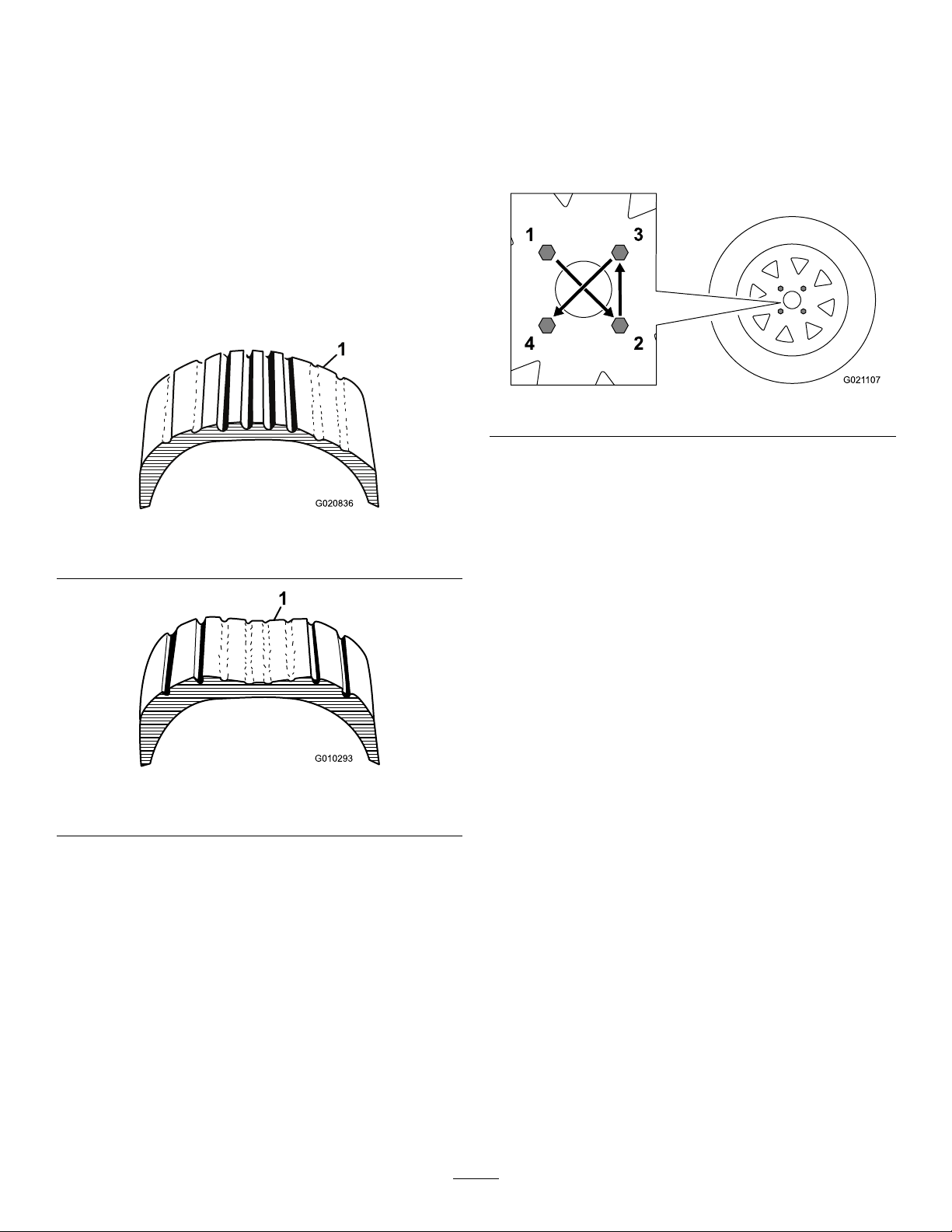

CheckingtheTiresandWheels

G020836

1

2

3

4

G021 107

ServiceInterval:Beforeeachuseordaily—Inspectthetires

andwheels.

TheDOTtireinformationislocatedontheside

ofeachtire.Thisinformationgivesloadandspeed

ratings.Replacementtiresshouldhavethesame

orbetterratings.Formoreinformationgoto

http://www.nhtsa.gov/Vehicle+Safety/Tires.

Note:RefertoSpecications(page13)toensurethatthe

tiresonyourmachinemeetorexceedtheweightrequirements

ofyourmachine.

1.Visuallyinspectthetiresfordamageandwear(Figure

13andFigure14).

3.Ensurethatthewheellugnutsaretorquedto108to

122N∙m(80to90ft-lb).

Note:Checkthetorqueofthewheellugnutsinitially

andaftertowing.

Note:Torquethelugnutsinthesequenceshownin

Figure15.

Figure15

Figure13

1.Exampleoftirewearcausedbyunderination

Figure14

1.Exampleoftirewearcausedbyoverination

2.Ensurethatthetiresareinatedtoamaximumof241

kPa(35psi).

Important:Alwayschecktheinformation

ontheactualtiresforthecorrectairpressure

requirement.

Important:Themostcommoncauseoftire

troubleisunderination.Maintainfullair

pressure.

14

Loading...

Loading...