Toro 68012C, 68018C, 68019C Operator's Manual

FormNo.3390-595RevA

G020896

MM-650E-SandMM-850E-S

MortarMixer

ModelNo.68012C—SerialNo.315000001andUp

ModelNo.68018C—SerialNo.315000001andUp

ModelNo.68019C—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3390-595*A

WARNING

1

G020900

2

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

Ifyoubelievethatyourmachinehasadefectwhichcould

causeacrashorcouldcauseinjuryordeath,youshould

immediatelyinformtheNationalHighwayTrafcSafety

Administration(NHTSA)ifyouliveintheUnitedStates,

orTransportCanadaifyouliveinCanada,inadditionto

notifyingTheToroCompany.

IfNHTSAorTransportCanadareceivessimilarcomplaints,

itmayopenaninvestigation,andifitndsthatasafetydefect

existsinagroupofmachines,itmayorderarecallandremedy

campaign.However,NHTSAorTransportCanadacannot

becomeinvolvedinindividualproblemsbetweenyou,your

dealer,orTheToroCompany.

YoumaycontactT orodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Writethenumbersinthespaceprovided.

•TocontactNHTSA,youmaycalltheV ehicle

SafetyHotlinetoll-freeat1-888-327-4236(TTY:

1-800-424-9153);gotohttp://www.safercar.gov;orwrite

to:Administrator,NHTSA,1200NewJerseyAvenue,

SEWestBuilding,Washington,DC20590.Youcanalso

obtainotherinformationaboutmotorvehiclesafetyfrom

http://www.safercar.gov.

•TocontactTransportCanada,youmaycall

1-800-333-0510or(819)994-3328;goto

http://www.tc.gc.ca/roadsafety/;writeto:Road

SafetyandMotorVehicleRegulationDirectorate,

TransportCanada,TowerC,PlacedeVille,330

SparksStreet,Ottawa,Ontario,K1A0N5;oremail

RoadSafety@tc.gc.ca.

Introduction

Thismachineisdesignedtomixmortar,plaster,reproong

material,grout,andothersmall-grainedcementproducts.A

vehicleequippedwithanappropriatepintlehitchorballhitch

cantowthemachine..

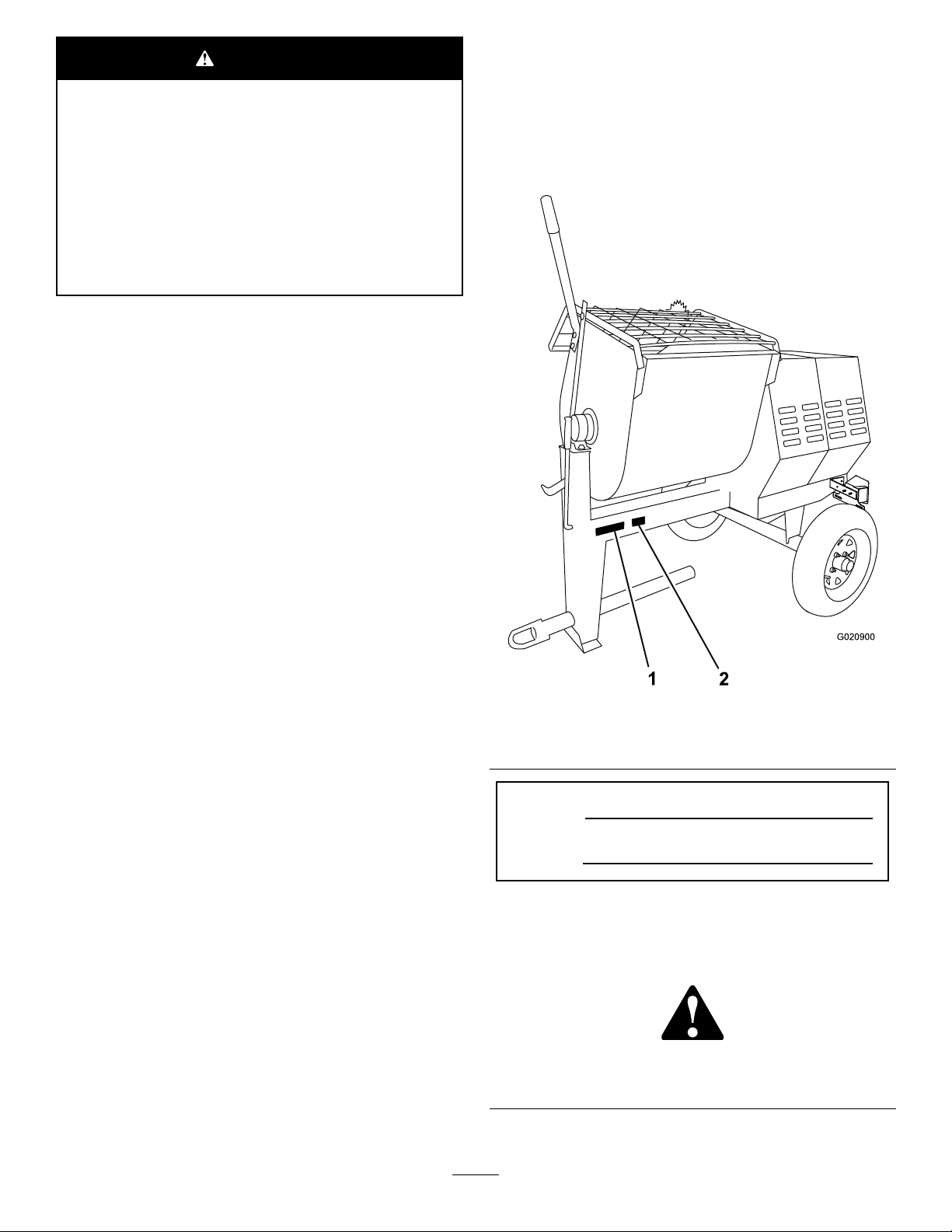

Figure1

1.Modelandserialnumber

location

ModelNo.

SerialNo.

2.Vehicleidentication

number(VIN)location

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

2

Figure2

1.Safetyalertsymbol

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

TheDOTtireinformationislocatedonthesideofeachtire.

Thisinformationgivesloadandspeedratings.Replacement

tiresshouldhavethesameorbetterratings.

Note:Thevariousmachinesinthismanualhavedifferent

weights;refertoSpecications(page13)toensurethatthe

tiresonyourmachinemeetorexceedtheweightrequirements

ofyourmachine.

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

SafetyandInstructionalDecals.................................7

Setup............................................................................8

1InstallingtheDumpHandle...................................8

2InstallingtheTowPole..........................................9

3InstallingtheSafetyChain......................................9

4InstallingtheLightAssembly.................................10

ProductOverview.........................................................12

Controls...............................................................12

Specications........................................................13

Operation....................................................................14

PreparingtoT owtheMachine..................................14

ExtendingtheAxle.................................................17

TowingtheMachine...............................................18

PreparingtoUsetheMachine...................................18

OpeningandClosingtheCowl.................................19

PoweringtheMachine.............................................19

StartingandStoppingtheMotor...............................20

ControllingthePaddles...........................................20

MixingtheMaterial.................................................21

UsingtheDrum.....................................................22

AdjustingthePaddleBlades.....................................22

Maintenance.................................................................24

RecommendedMaintenanceSchedule(s)......................24

PremaintenanceProcedures........................................24

PreparingtheMachineforMaintenance.....................24

RemovingandInstallingtheDividerPlate..................24

Lubrication...............................................................25

LubricatingtheBearingsandSeals............................25

LubricatingtheMotorBearings................................26

LubricatingtheDriveChain.....................................26

BeltMaintenance......................................................27

ServicingtheBelts..................................................27

ReplacingtheBelts.................................................28

AligningthePulleys................................................29

DriveChainMaintenance............................................30

CheckingandAdjustingtheDriveChain....................30

ReplacingtheLightBulbs............................................31

ReplacingtheRear-facingBulbs................................31

ReplacingtheSide-facingBulbs................................31

Cleaning...................................................................32

CleaningtheMachine..............................................32

Storage........................................................................33

StoringtheMachine................................................33

Troubleshooting...........................................................34

Schematics...................................................................35

3

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.Toreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans:

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

—personalsafetyinstruction.Failureto

SafeOperatingPractices

Thisproductiscapableofamputatinghands.Alwaysfollow

allsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Machiningorhandlingstone,masonry,concrete,

metal,andothermaterialscangeneratedust,mists,

andfumescontainingchemicals,suchassilica,

knowntocauseseriousorfatalinjuryorillness,

suchasrespiratorydisease,silicosis,cancer,birth

defects,orotherreproductiveharm.

•Controldust,mist,andfumesatthesource

wherepossible.Usewaterfordustsuppression,

whenfeasible.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufacturer

orsupplier,CCOHS,OSHA,andother

occupationalandtradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannotbe

eliminated,theoperatorandanybystanders

shouldweararespiratorapprovedbyCCOHSor

OSHAforthematerialbeinghandled.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriestopeopleordamagetoproperty.

Towing

Checkwithyourlocalcountyorstatetowingsafety

regulations,inadditiontomeetingTransportCanada(or

Caution

,

W ar ning

DepartmentofTransportationifintheU.S.)towingsafety

regulations,beforetowingthemachine.

•Inordertoreducethepossibilityofanaccidentwhile

transportingthemachineonpublicroads,makesure

thetowingvehicleismechanicallysoundandingood

,

operatingcondition.

•Shutdowntheenginebeforetransportingthemachine.

•Whentowingwithaballhitch,ensurethattheballhitch

youareusingisthepropersizeforthehitchcoupleron

themachine.

•Whentowingwithapintlehitch,ensurethattheeyeof

thetowpoleisthecorrectdimensionforthepintlehook.

•Inspectthehitchandcouplingforwear.Nevertowthe

machinewithdamagedordefectivehitches,couplings,

chains,orothercomponents.

•Checkthetireairpressureonthetowingvehicleandthe

machine.

•Checkthetiretreadandsidewallfordamageandwear.

•Properlyattachthesafetychainstothetowingvehicle.

•Ensurethatthedirectionalandbrakelightsareworking

properly.

•Ensurethatthedirectional,backup,andbrakelightsof

thetowvehicleareworkingproperly.

•Beforetowingchecktomakecertainyourmachineis

correctlyandsecurelyattachedtothetowingvehicle.

•Ensurethatthesafetychainsareproperlysecuredtothe

vehicle,andleaveenoughslackforturning.

•Donotcarryanymaterialinthemachinewhentowing.

•Avoidsuddenstopsandstarts.Thiscancauseskidding,

orjackkning.Smooth,gradualstartsandstopswill

improvetowing.

•Avoidsharpturnstopreventrolling.Towonlywitha

vehiclethathasahitchdesignedfortowing.Donot

attachtowedequipmentexceptatthehitchpoint.

•Donottowthemachinefasterthan88km/h(55mph).

•Usecautionwhenbackingup;useaspotteroutsidethe

vehicletoguideyou.

•Donotallowanyonetositorrideonthemachine.

•Disconnectthemachinefromthetowvehiclebefore

usingit.

•Placechockblocksunderneaththetirestopreventthem

fromrollingwhilethemachineisparked.

Preparation

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Wearpersonalprotectiveequipmentandappropriate

clothing,includingthefollowing:

4

–Hardhat

Operation

–Respiratorordustmask

–Faceshieldorsafetyglasses

–Hearingprotection

–Safetyshoes

–Longpants

–Shirtwithlongsleevesbuttonedatthewrists

–Tight-ttinggloveswithoutdrawstringsorloosecuffs

•Securelonghair,looseclothing,orjewelrythatmayget

tangledinmovingparts.

•Operatingtheequipmentsafelyrequiresthefullattention

oftheoperator.Donotwearradioormusicheadphones

whileoperatingthemachine.

•Ensurethatthemachineisonalevelsurfacebefore

operatingthemachine.

•Chockthetiresofthemachinetopreventunintended

movement.

•Beforeeveryuse,dothefollowing:

–Inspectthecoupler,ball,andhitch.

•Neverrunthemachineinapoorlyventilatedorenclosed

areawithoutproperrespiratoryprotection.Dustfrom

materialsbeingmixedcanbeveryharmfultooperators

andbystanders.

•Onlyoperatethemachineingoodlightingconditions.

•Beforestartingthemachine,makesurethatthereareno

personsorobstaclesnearorunderthemachine.

•Neverleavearunningmachineunattended.Alwaysstop

themotorandverifythatallmovingpartshavestopped.

•Chockthetiresofthemachineorkeepitattachedtothe

towingvehiclewhenitisnotinuse,topreventitfrom

rolling.

•Keephandsawayfromanymovingparts.Keepfeetaway

fromthetiresandthefrontpost.

•Donotoperatethemachineoutdoorsintherain.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Ensurethattheareaisclearofotherpeopleorpetsbefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

–Ensurethatalllightsarefunctioningproperly(if

equippedwithalightkit).

–Ensurethatthetiresareproperlyinatedas

recommended.

–Ensurethatthelugnutsaretightandtorqued

properly.

–Ensurethatthemachineisproperlysecured.

•Neverplaceyourhandsoranysolidobjectintothedrum

whenthemachineisinoperation.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Nevermovethemachinewhilethemotorisrunning.

•Keepthecowlclosedandlatchedduringoperation.

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperatingthemachine.

•EnsurethattheOn/OffswitchisintheOffposition

beforeconnectingthemachinetotheelectricalsource.

•Ifthemixingpaddlesstrikeaforeignobjectorifthe

machineshouldstartmakinganunusualnoiseor

vibration,stopthemotorandemptythedrum.Waitfor

allmovingpartstocometoacompletestopandcool.

Vibrationisgenerallyawarningoftrouble.Inspectfor

cloggingordamage.Cleanandrepairand/orreplace

damagedparts.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperatethe

machine;seekshelter.

5

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Parkthemachineonlevelground.

–Stopthemotor.W aitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

–Letthemotorcoolbeforeperformingmaintenance

orstoringthemachine.

–Unplugthemachinebeforemakinganyrepairs.

•Neverlubricate,service,repair,oradjustthemachine

whileitisrunning.

•Keepequipmentmaterialsclearfromthemotor.

•Neverallowuntrainedpersonneltoservicethemachine.

•Keephands,feet,andclothingawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththemotor

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeanybuildupofgrease,oil,ordebrisfromthe

machine.

•Donotmodifytheelectricalconnectorsorwiring.

•Donotconnectthegroundcircuitofthemachinetothe

energizedcircuitoftheelectricalsource.

•Donottamperwithsafetydevices.

•Chockthetireswhenstoringthemachine.

•Keepallnuts,bolts,screws,andhoseclampssecurely

tightened.Keepequipmentingoodcondition.

•UseonlygenuineTororeplacementpartstoensurethat

theoriginalstandardsaremaintained.

6

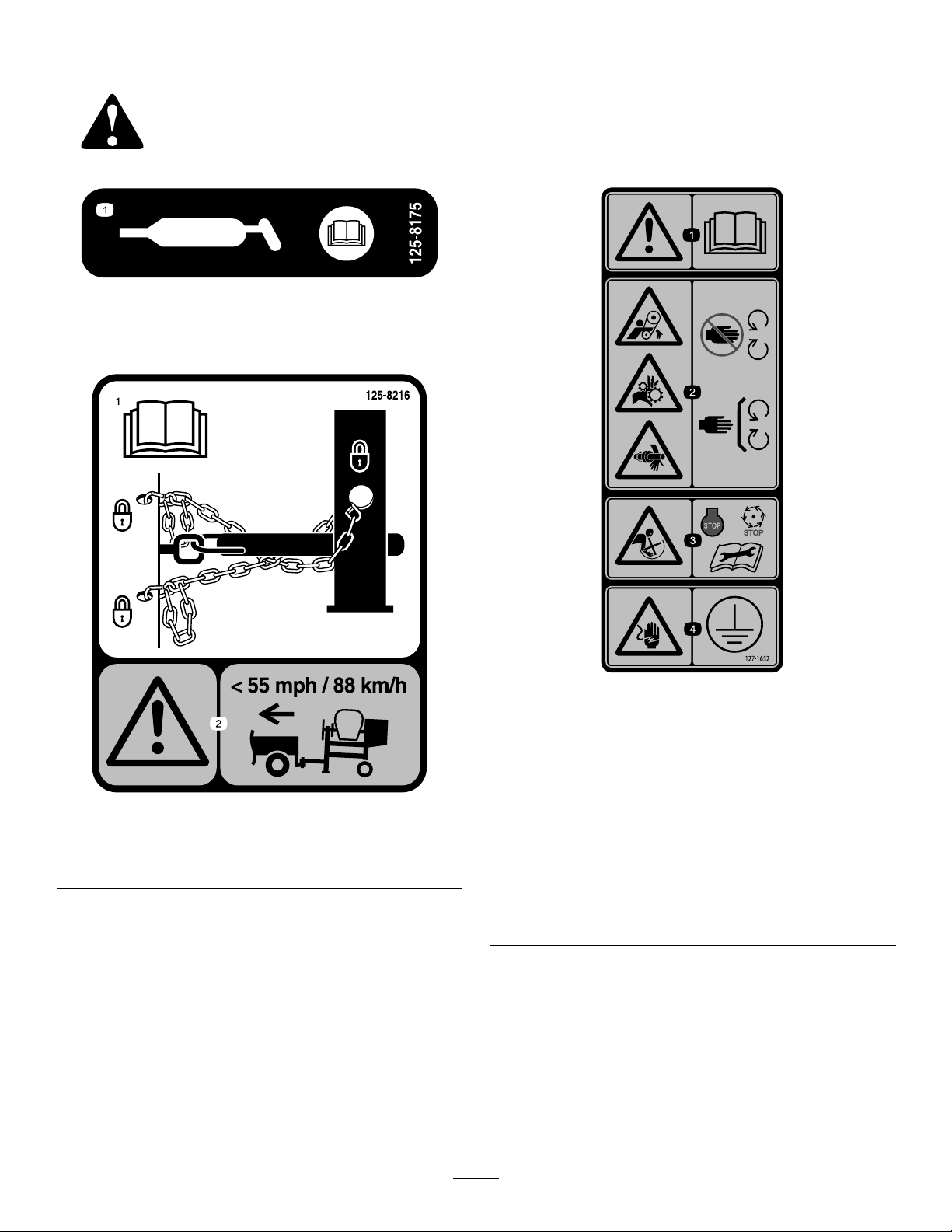

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

125–8175

1.ReadtheOperator’sManualforinformationongreasing

themachine.

1.ReadtheOperator’s

Manualforinformationon

howtotowthemachine.

125–8216

2.Warning—limittowing

speedtolessthan55mph

/88km/h.

1.Warning—readthe

Operator’sManual.

2.Handandarm

entanglementatthe

beltdrive;crushinghazard

ofhand;entanglement

hazardofhandatthe

shaft—keephandsaway

frommovingparts;keep

allguardsandsafetiesin

place.

127–1652

3.Entanglementhazardat

paddles—stopthemotor

andwaitforallmoving

partstostopbefore

servicingthemachine.

4.Shockhazard—makesure

themachineisgrounded

beforeoperation.

7

Setup

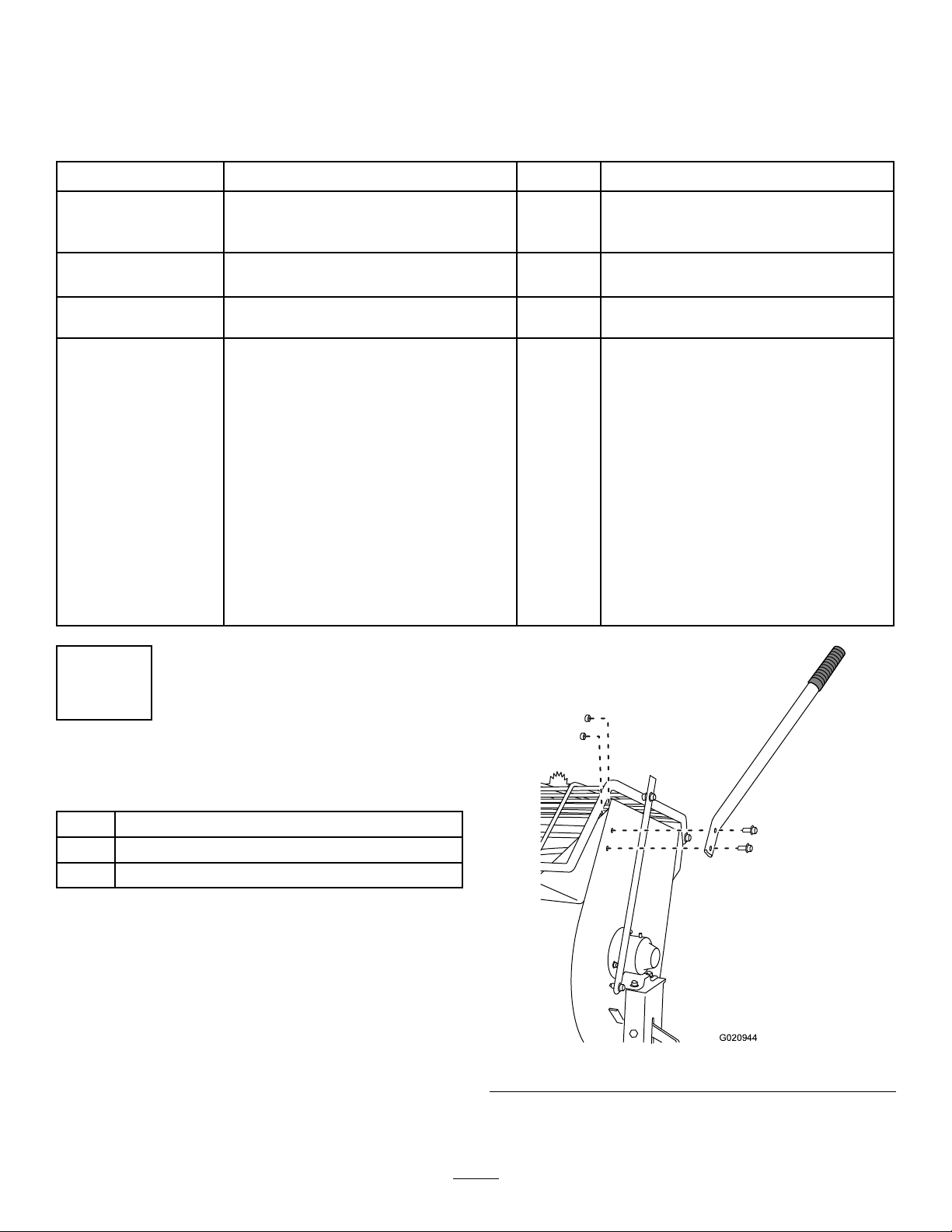

G020944

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Dumphandle1

Bolt2

Nut2

Towpolekit(soldseparately)

Safetychain

Connectinglink

Grommet

Firtreeclip1

Cableclamp

Bracket2

Licenseplateholder1

Leftlightassembly

Rigtlightassembly1

Frontlightassembly2

Nuts11

Bolts

Edgeclips4

Wiringharness1

Grommet,small

Cableties

Qty.

Installthedumphandle.

1Installthetowpole.

1

2

1

5

1

7

2

5

Installthesafetychain.

Installthelightassembly .

Use

1

InstallingtheDumpHandle

Partsneededforthisprocedure:

1Dumphandle

2Bolt

2Nut

InstallingtheDumpHandletotheDrum

1.Cutthecabletiestoremovethedumphandlefrom

theundersideofthegrate.

2.Positionthedumphandlesothattheboltholesalign

withtheboltholesinthedrum(Figure3).

Figure3

3.Insertthe2boltsthroughtheboltholesinthedump

handleandthedrum(Figure3).

8

4.Installanutontoeachbolt,andtightenthembyhand

5

1

2

4

6

3

G019804

A

B

D

g019883

2

3

4

3

1

topreventcross-threading.

5.Tightenthenutswithawrenchwhileusinganother

wrenchtokeeptheboltsfromspinning.

Note:Iftheself-lockingnyloninsertinthelocknut

wearswithuse,replacethenutwithanewGrade5or

Grade8locknut.

3

2

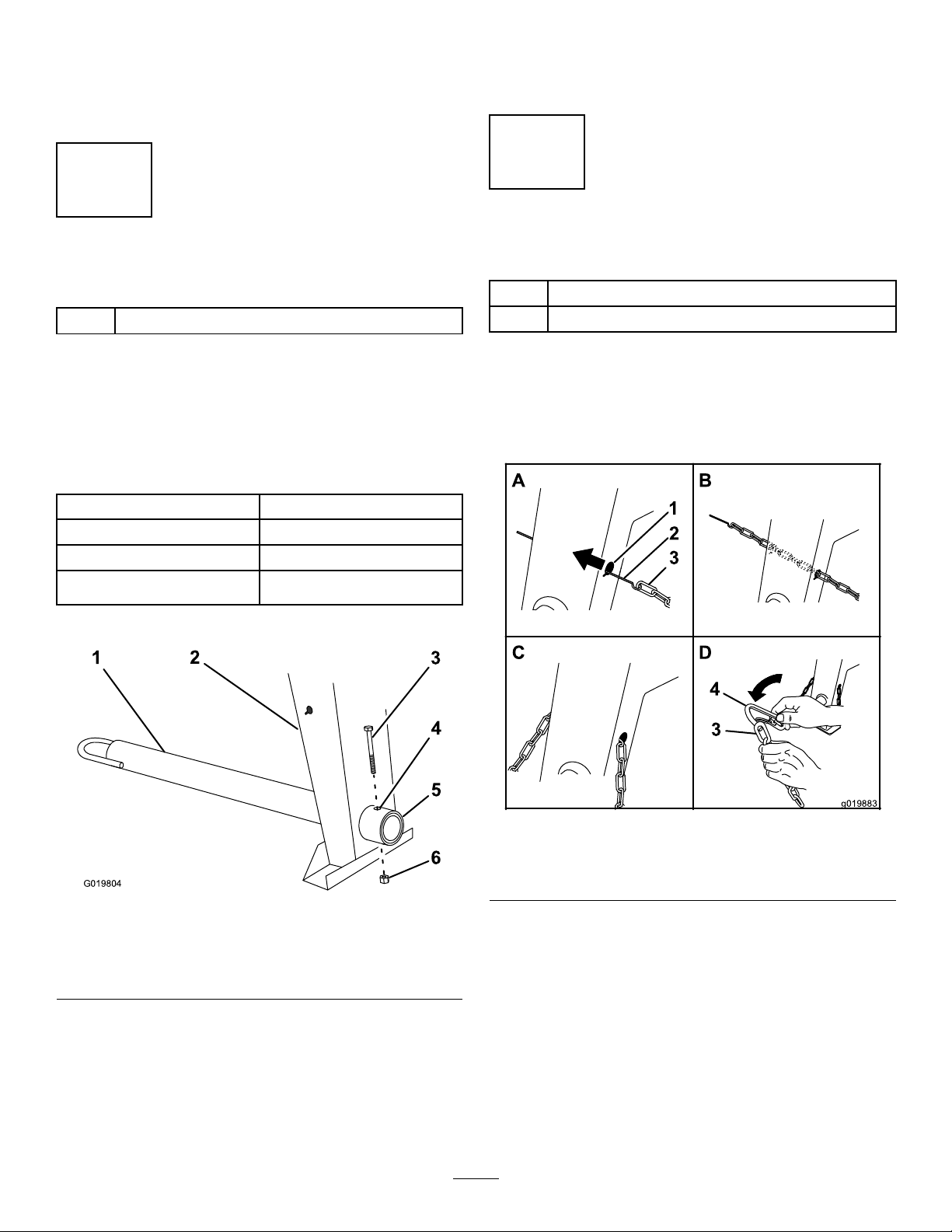

InstallingtheTowPole

Partsneededforthisprocedure:

1

Towpolekit(soldseparately)

InstallingtheTowPoletotheMachine

Note:Thetowpoleispurchasedseparatelyandincludesthe

nutandboltneededforinstallation.SeeaToroauthorized

dealerforthetowpoleforyourmachine.

Themachinehasthefollowingtowpoleoptions:

HitchTypeLength

50mm(2inch)ball—stamped79cm(31inches)

50mm(2inch)ball—forged79cm(31inches)

Pintle

1.Removetheboltandnutfromthetowpole(Figure4).

79cm(31inches)

InstallingtheSafetyChain

Partsneededforthisprocedure:

1

Safetychain

2

Connectinglink

InstallingtheSafetyChain

1.Formahookontheendofabendablepieceofrod

orstiffwire(notincluded),andinsertitthroughboth

keyholesinthefrontpostofthemachine(Figure5A).

Figure4

1.Towpole4.Bolthole

2.Frontpost

3.Bolt6.Nut

2.Slidethetowpoleforwardandaligntheholeinthe

polewiththeholeintheframetting(Figure4).

3.Inserttheboltthroughtheholesinthettingandthe

pole(Figure4).

4.Threadthenutontotheboltandtightenthemuntil

theyaretightagainsttheframetting(Figure4).

5.Frametting

Figure5

1.Keyhole

2.Rodorwire(notincluded)4.Connectinglink

2.Attachthesafetychaintothelengthofrodorwire

(Figure5A).

3.Pulltherod,orwire,andthesafetychainthroughboth

keyholes(Figure5B).

Note:Ensurethatapproximatelyequallengthsof

safetychainextendfromeithersideofthefrontpost.

3.Safetychain

InstallingtheConnectingLinks

1.Aligntheconnectinglinktothelastlinkinoneendof

thesafetychain(Figure5D).

9

2.Inserttheconnectinglinkthroughthechainlinkuntil

g0278 56

theconnectinglinksnapsclosed.

3.Repeatsteps1and2toinstalltheotherconnectinglink

intheotherendofthesafetychain.

4

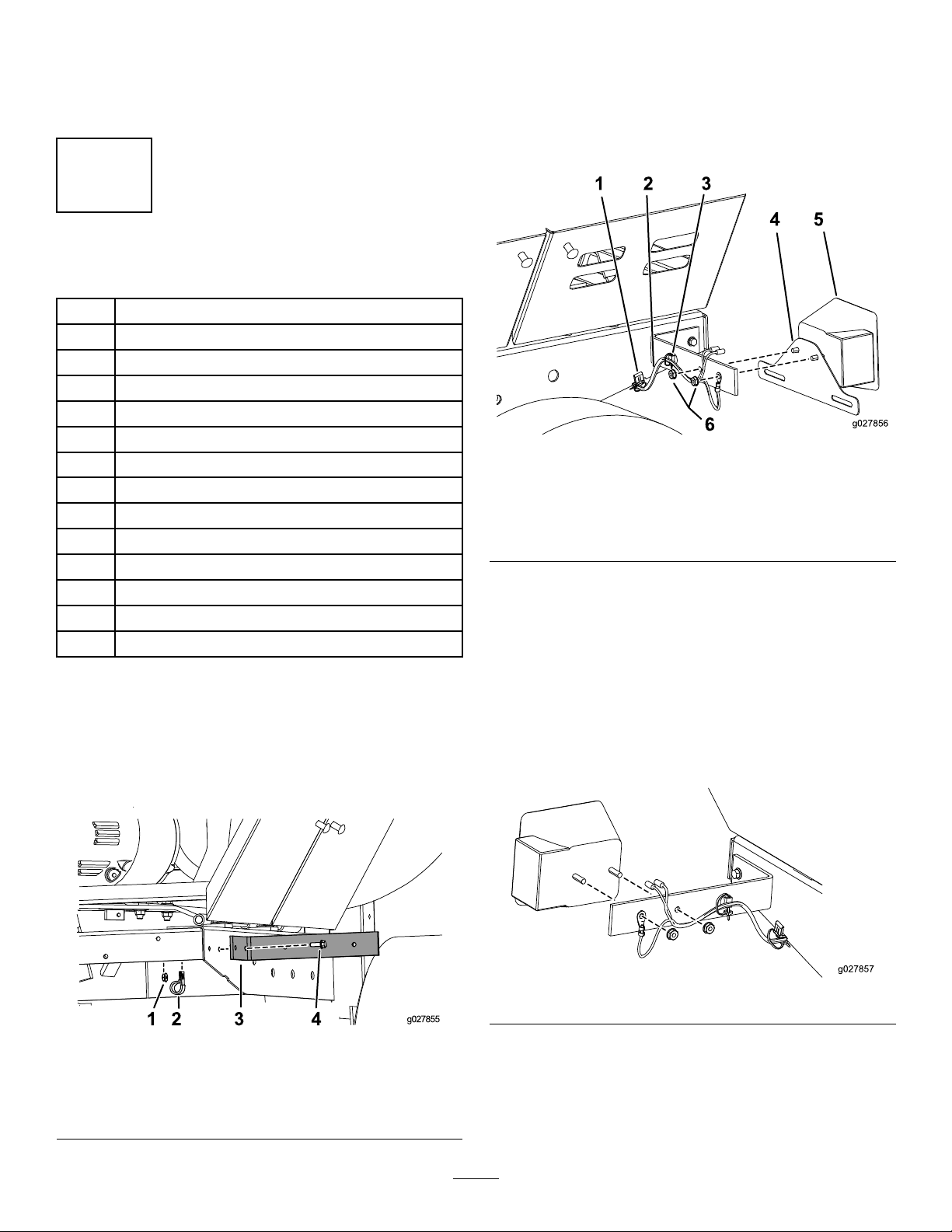

InstallingtheLightAssembly

Partsneededforthisprocedure:

1

Grommet

1Firtreeclip

5

Cableclamp

2Bracket

1Licenseplateholder

1

Leftlightassembly

1Rigtlightassembly

2Frontlightassembly

11Nuts

7

Bolts

4Edgeclips

1Wiringharness

2

Grommet,small

5

Cableties

2.Placethelicenseplateholderontotheleftlamp

assemblyandsecurethemtotheleftbracketusing2

nutsasshowninFigure7.

Note:Placetheterminalforthewiringharnessonthe

outsideprongofthewiringharnessbeforesecuringthe

nut(Figure7).

Figure7

1.Edgeclip4.Licenseplateholder

2.Wiringharness

3.Firtree(attachedtowiring

harness)

5.Leftlightassembly .

3.Insertthertreethatisattachedtothewiringharness

totheopenholeonthebracket(Figure7).

4.Securethewiringharnesstothesideofthemachine

usinganedgeclip(Figure7).

InstallingtheRearLightAssemblies

1.Installthebracketsontotheframeusing4bolts,2

cableclamps,and4nutsasshowninFigure6.

Note:Thecableclampsshouldbeinstalledonthe

boltsclosertothemiddleofthemachine.

Figure6

Rightbracketshown

1.Nut3.Bracket

2.Cableclamp

4.Bolt

5.Attachtherightlightassemblytotherightbracketas

showninFigure8using2nuts.

Note:Placetheterminalforthewiringharnessonthe

outsideprongofthewiringharnessbeforesecuringthe

nut(Figure8).

Figure8

6.Insertthertreethatisattachedtothewiringharness

totheopenholeonthebracket(Figure8).

7.Securethewiringharnesstothesideofthemachine

usinganedgeclip(Figure8).

10

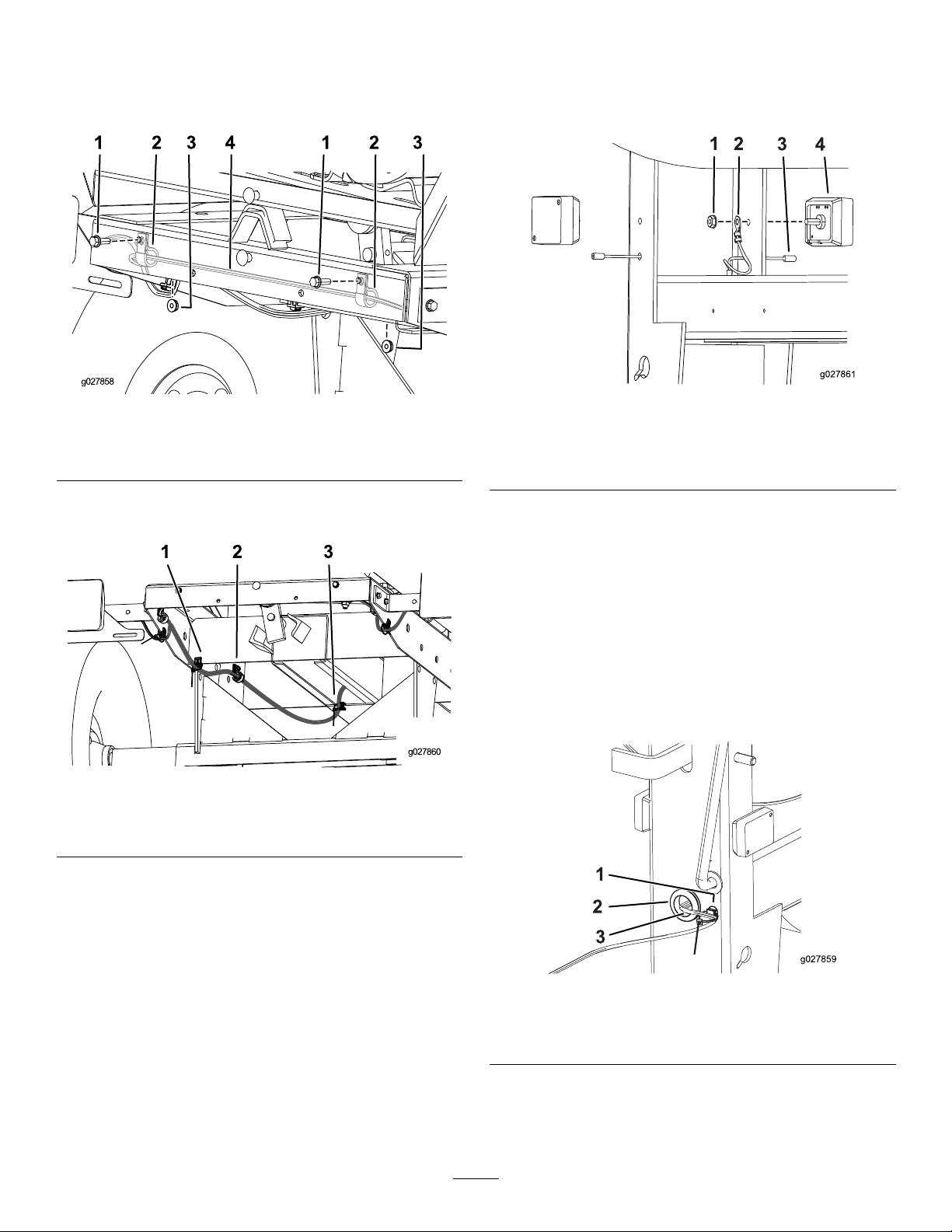

RoutingtheWiringHarness

1 2

3 4

g027861

1

2

3

g027859

InstallingtheFrontLightAssemblies

1.Securethewiringharnesstotherearofthemachine

using2cableclamps,2bolts,and2nutsasshownin

Figure9.

Figure9

1.Bolt3.Nut

2.Cableclamp

4.Wiringharness

2.Routethewiringharnessalongtheleftsideofthe

frameasshowninFigure10.

1.Feedthesmallersectionofthewiringharnessup

throughthehorizontalpostbelowthedrum,asshown

inFigure11.

Figure11

1.Nut(partofthefrontlight

assembly)

2.Wiringharness4.Lightassembly

3.Grommet,small

2.Placethesmallgrommetsoverthewiringharnessends

thatdonothavetheterminalsconnectedandpushthe

grommetsintothelowerhole(Figure11).

Figure10

1.Edgeclip3.Edgeclip

2.Cableclampassembly

3.Securethewiringharnesstotheleftsideoftheframe

using1edgeclipsecuredontothemiddlesupport

bracketasshowninFigure10;Callout1.

4.Securethewiringharnesstotheleftsideoftheframe

using1cableclamp,1bolt,and1nut(Figure10);

Callout2.

5.Securethewiringharnesstothefrontoftheunitwith

1edgeclipasshowninFigure10;Callout3.

6.Securetheexcessofthewiringharnesswiththe5zip

ties.

7.Routtheremainderofthewiringharnessthroughthe

horizontalpostunderneaththedrum.

3.Insertthelightassemblyintotheupperhole,through

thewiringharnessterminals,andsecurethelightswith

theboltsthatcameattachedtothelightassemblies

(Figure11).

4.Pulltherestofthewiringharnessoutthroughthehole

inthefrontpostofthemachine,throughthelarge

grommet,andinsertthelargegrommetinthehole

(Figure12).

Figure12

1.Firtree3.Wiringharness

2.Grommet,large

5.Insertthertreeintotheholenexttothegrommet

andsecurethewiringharnesstothisclip(Figure12).

11

Loading...

Loading...