Toro 58602 Operator's Manual

FrontTineTiller

58602

Motoazada

58602

Motoculteuràdentsavant

58602

FormNo.3445-372RevA

www.T oro.com.

*3445-372*

FormNo.3443-828RevA

FrontTineTiller

ModelNo.58602—SerialNo.321000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3443-828*

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Thistillerisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperatorsto

breakthroughhardsoilconditionsforplantingand

cultivatinggardens.Usingthisproductforpurposes

otherthanitsintendedusecouldprovedangerousto

youandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

g355851

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Visitwww.Toro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................6

1AssemblingtheTiller........................................6

2AddingOiltotheEngine...................................8

ProductOverview.....................................................9

Controls.............................................................9

Specications....................................................9

BeforeOperation.................................................10

BeforeOperationSafety...................................10

PerformingDailyMaintenance..........................10

ChangingtheTillingWidth................................10

DuringOperation..................................................11

DuringOperationSafety....................................11

StartingtheEngine...........................................12

ShuttingOfftheEngine.....................................12

AdjustingtheT ailMountPosition......................12

AdjustingtheDragStake..................................13

TillingSoil.........................................................13

AfterOperation....................................................13

AfterOperationSafety......................................13

Maintenance...........................................................14

MaintenanceSafety..........................................14

RecommendedMaintenanceSchedule(s)...........14

Pre-MaintenanceProcedures..............................15

PreparingforMaintenance...............................15

EngineMaintenance...........................................15

ServicingtheAirFilter.......................................15

ChangingtheEngineOil...................................16

ServicingtheSparkPlug...................................17

BeltMaintenance................................................18

CheckingandAdjustingtheBeltT ension...........18

ReplacingtheDriveBelt...................................19

Cleaning..............................................................21

CleaningtheTineAxleShaft.............................21

Storage...................................................................21

StorageSafety..................................................21

CleaningandStoringtheMachine....................21

Troubleshooting......................................................23

Thismachinehasbeendesignedinaccordancewith

ANSIB71.8-2016.

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811forthenationwide

markingservice).

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjuryordeath.

•Read,understand,andfollowtheinstructions

andwarningsinthisOperator’sManualandon

themachineandattachmentsbeforestartingthe

engine.

•Bethoroughlyfamiliarwiththecontrolsandthe

properuseoftheequipment.Knowhowtostop

themachineanddisengagethecontrolsquickly .

•Donotputyourhands,feet,otherbodyparts,or

clothingnearorundertherotatingtinesorother

movingpartsofthemachine.

•Donotoperatethemachinewithoutallproper

shields,guards,andothersafetyprotective

devicesinplaceandfunctioningproperlyonthe

machine.

•Keepbystanders,especiallysmallchildren,and

petsoutoftheoperatingarea.

•Donotallowchildrentooperatethemachine.

Allowonlypeoplewhoareresponsible,trained,

familiarwiththeinstructions,andphysically

capabletooperatethemachine.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

3

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

133-8062

144-4848

decal133-8062

decal144-4855

144-4855

1.Crushinghazardofhands—stayawayfrommovingparts.

decal144-4848

1.Squeezethethrottletoengagethetines.

144-4849

1.Transportposition

144-4853

1.Engine—shutoff

decal144-4849

2.Operatingposition

decal144-4853

144-4854

1.Tostartthemachine,movetheswitchtotheONposition,

releasethehandle(s),placeonehandonthemachineand

pulltherecoilhandle.

decal144-4854

4

decal148-4868

144-4856

1.Warning—readtheOperator’sManual.

2.Warning—alloperatorsshouldbetrainedbeforeoperating

themachine.

3.Warning—keepbystandersaway.

4.Warning—stayawayfrommovingparts;keepallguardsin

place.

5.Entanglementhazard,belt—stayawayfrommovingparts.

6.Warning—lookbehindyouwhenoperatingthemachinein

reverse.

7.Warning—donotoperateoverburiedlines.

8.Warning—keepfeetawayfrommovingparts.

9.Warning—shutofftheengineanddisconnectthespark

plugandreadtheOperator’sManualbeforeperforming

maintenance.

5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

1

Qty.

Wheel2

Tineshield1

Bolt(M8x20mm)

Hairpincotter2

Lockpin1

Washer(M8)

Bolt(M8x45mm)

Locknut(M8)

Washer(12mm)

Bolt(M6x16mm)

Locknut(M6)

Dragstakehandleassembly1

Axle1

Leftoutertine

Rightoutertine1

Engineoil1Addoiltotheengine.

4

4

2

6

2

4

4

1

Assemblethetiller.

Procedure

1.Installtheaxleandwheelstothelowertail

mount.

Use

AssemblingtheTiller

Partsneededforthisprocedure:

2Wheel

1Tineshield

4

Bolt(M8x20mm)

2Hairpincotter

1Lockpin

4

Washer(M8)

2

Bolt(M8x45mm)

6

Locknut(M8)

2

Washer(12mm)

4

Bolt(M6x16mm)

4

Locknut(M6)

1Dragstakehandleassembly

1Axle

1

Leftoutertine

1Rightoutertine

1.Axle

2.Lowertailmount

3.Wheel(2)

g356258

Figure3

4.Washer—12mm(2)

5.Hairpincotter(2)

6

2.Installthetineshield.Aligntheslotsonboth

sidesoftheshieldandinsertthefasteners

beforetighteningthem.

Important:Ensurethatthedirtshieldis

betweentheengine-mountdeckandtine

shield.

4.Installtheupperhandleassemblyontothelower

loopmount.

Note:Installtheboltswiththeheadfacing

outward.

Figure4

1.Bolt—M6(4)

2.Tineshield5.Dirtshield

3.Locknut—M6(4)

4.Enginemountdeck

3.Installthetinestothedesiredposition;referto

ChangingtheTillingWidth(page10).

g356256

g356424

Figure5

1.Bolt—M8x20mm(2)3.Locknut—M8(2)

2.Washer—M8(2)

5.Rotatethehandletothedesiredpositionand

installtheupperfasteners.

Note:Usethefrontholeforthehighestposition;

usetherearholeforthelowestposition.Install

theboltswiththeheadfacingoutwardasshown

inFigure7.

Figure6

1.Highposition4.Upperbolt

2.Middleposition5.Lowerbolt

3.Lowposition6.Lowerloopmount

7

g356255

Figure7

1.Bolt—M8x20mm(2)3.Locknut—M8(2)

2.Washer—M8(2)

2

AddingOiltotheEngine

g356257

Partsneededforthisprocedure:

1Engineoil

6.Insertthedragstakethroughthebottomopening

inthelowertailmountandsecureitwiththe

lockpin.

Figure8

1.Lockpin2.Dragstake

7.Installthedragstakehandleassemblytothe

dragstake.

Procedure

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,youmay

damagetheengine.

1.Movethemachinetoalevelsurface.

2.Carefullypourabout3/4oftheenginecapacity

ofoilintotheoil-lltube.

3.Wait3minutesfortheoiltosettleintheengine.

4.Wipethedipstickcleanwithacleancloth.

g356254

g334792

Figure10

1.Dipstick3.Add

2.Full

Figure9

5.Insertthedipstickintotheoil-lltube,then

removethedipstick.

6.Readtheoillevelonthedipstick(Figure10).

•Iftheoillevelonthedipstickistoolow,

carefullypourasmallamountofoilintothe

oil-lltube,wait3minutes,andrepeatsteps

g356436

4through6untiltheoillevelonthedipstick

iscorrect.

•Iftheoillevelonthedipstickistoohigh,

draintheexcessoiluntiltheoillevelonthe

dipstickiscorrect.

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,you

maydamagetheengine.

7.Installthedipstickintotheoil-lltubesecurely.

8.Recycletheusedoilproperly.

8

ProductOverview

Specications

Specicationsanddesignaresubjecttochange

withoutnotice.

Figure11

1.Drive-controllever7.Tineshield

2.Adjustablecable8.Hingedtailmount

3.Bumper9.Wheel

4.Drivebeltcover10.Handlebarheight

5.Tines11.Handgrip

6.Tinewidthadjustment

adjustment

12.Engineon/offswitch

Height

Length

Width

Weight

Tillingwidth

Tillingdepth

117.9cm(46.4inches)

122.2cm(48.1inches)

55.9cm(22.0inches)

46.7kg(103lb)

28to53cm(11to21inches)

Upto28cm(1 1inches)

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

g355853

Controls

Drive-ControlLever

Squeezethedrive-controllevertothehandgripto

engagethetines.Releaseittodisengagethetines.

EngineOn/OffSwitch

UsetheengineOn/Offswitchtoshuttheengineoff.

EnsurethattheswitchisintheONpositionbefore

startingtheengine.

9

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

•Donotoverllthefueltank.Replacethefuelcap

andtightenitsecurelyafterfueling.Cleanup

spilledfuelbeforestartingtheengine.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromthevehicle

beforelling.

•Removethemachinefromthetruckortrailer

beforellingthefueltank.Ifthisisnotpossible,

thenaddfuelfromaportablecontainerratherthan

fromafuel-dispensernozzle.

GeneralSafety

•Donotallowchildrenoruntrainedadultstooperate

orservicethemachine.Localregulationsmay

restricttheageoftheoperator.

•Usingthismachineisstrenuous.Youmustbein

goodphysicalconditionandmentallyalert.Ifyou

haveanyconditionthatmightbeaggravatedby

strenuouswork,checkwithyourdoctorbefore

operatingthemachine.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Checkthatallguardsandsafetydevices,suchas

deectors,areinplaceandfunctioningproperly.

Donotoperatethemachineunlesstheyare

functioningproperly.

•Knowhowtoshutofftheenginequickly.

•Keepbystanders,especiallysmallchildren,and

petsoutoftheoperatingarea.

•Thoroughlyinspecttheareawhereyouwilluse

themachineandremoveallobjectsthatcould

interferewiththeoperationofthemachineorthat

themachinecouldthrow.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

•Ifyouspillfuel,donotattempttostarttheengine;

movethemachineawayfromthespillandavoid

creatingasourceofignitionuntilthefuelvapors

havedissipated.

•Ifyoumustdrainthefueltank,doitoutdoors.

•Storefuelinafuelcontainerandkeepitoutofthe

reachofchildren.

•Donotstorethemachinewithfuelinthefueltank

orfuelcontainerwherethereisanopename,

spark,orpilotlight,suchasonawaterheateror

otherappliance.Allowtheenginetocoolbefore

storingthemachineinanyenclosure.

•Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

–Avoidprolongedbreathingofvapors.

–Keepyourhandsandfaceawayfromthe

nozzleandthefuel-tankopening.

–Keepfuelawayfromyoureyesandskin.

PerformingDaily

Maintenance

FuelSafety

•Useextremecareinhandlingfuel.Itisextremely

ammableanditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothetank

whiletheengineisrunningorhot.

•Allowtheenginetocoolbeforellingthefueltank.

•Donotllthefueltankindoors.

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page14).

ChangingtheTillingWidth

1.Movethemachinetoalevelsurface,shutoffthe

engine,andwaitforallmovingpartstostop.

2.Removethe2bolts(M8x45mm)and2locknuts

(M8)securingtheoutertinestothemachine.

3.Installtheoutertinestothedesiredposition.

10

Note:Thearrowonthetinesmustpoint

inthepointthedirectionofforwardrotation

(counterclockwise,whenviewedfromtheleft

side).

•Fora40.6cm(16inch)tillingwidth,install

theoutertineswiththeshortendofthetine

pipefacingtowardthecenterofthemachine.

Figure12

1.Boltandlocknut(2)

DuringOperation

DuringOperationSafety

GeneralSafety

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;hearingprotection;andgloves.Tieback

longhairanddonotwearlooseclothingorloose

jewelry.

•Keepyourhands,feet,otherbodyparts,and

clothingawayfromrotatingtinesandmovingparts

ofthemachine.Thetinesbeginrotatingwhen

youstarttheengineandmaycontinuetorotate

g356250

momentarilyafteryoushutofftheengine.

•Starttheenginecarefullyaccordingtoinstructions

inthisOperator’sManualandwithyourfeetwell

awayfromthetines.

•Fora53.3cm(21inch)tillingwidth,install

theoutertineswiththeshortendofthe

tinepipefacingtowardtheoutsideofthe

machine.

Figure13

1.Boltandlocknut(2)

•Useextremecautionwhenreversingorpulling

themachinetowardyou.T oavoidgettingpinned

againstastructure,allowenoughdistanceto

reversedirectionnearawallorfence.

•Keepbystandersoutoftheoperatingarea.Keep

smallchildrenoutoftheoperatingareaandunder

thewatchfulcareofaresponsibleadultwhois

notoperatingthemachine.Stopthemachineif

anyoneentersthearea.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutralandyouareintheoperatingposition.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

•Donotattempttoadjustthemachinewhilethe

engineisrunning.

•Ifthemachinestrikesanobjectorstartstovibrate

abnormally,immediatelyshutofftheengine,wait

forallmovingpartstostop,anddisconnectthe

wirefromthesparkplugbeforeexaminingthe

g356253

machinefordamage.Vibrationisoftenawarning

signoftrouble.Makeallnecessaryrepairsbefore

resumingoperation.

•Donotoperatethemachineathightransport

speedsonhardorslipperysurfaces.

4.Securetheoutertinesusingthe2boltsand2

locknuts.

•Lookbehindanddownandusecarewhen

reversing.

11

•Donotoverloadthemachinecapacityby

attemptingtotillorcultivatetoodeepandattoo

fastarate.

•Donotpickuporcarryamachinewhiletheengine

isrunning.

sharply.Allowtheropetoreturntothehandle

slowly.

Note:Ifthemachinedoesnotstartafterseveral

attempts,contactanAuthorizedServiceDealer.

•Exercisecautionandbesureofyourfooting,

especiallywhenbackingup,toavoidslippingor

falling.

•Becarefulwhenoperatingthemachineinhard

ground.Thetinescancatchinthegroundand

propelthemachineforward.Ifthisoccurs,letgo

ofthemachine;donottrytorestrainit.

•Exerciseextremecautionwhencrossinggravel

surfaces.Stayalertforhiddenhazardsortrafc.

•Donotleavearunningmachineunattended.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,whichis

anodorless,deadlypoison.

•Useonlyaccessoriesandattachmentsapproved

byTheT oro®Company.

ShuttingOfftheEngine

1.Releasethedrive-controllever.

2.Movetheengineon/offswitchtotheOFF

position.

3.Waitforallmovingpartstostopbeforeleaving

theoperatingposition.

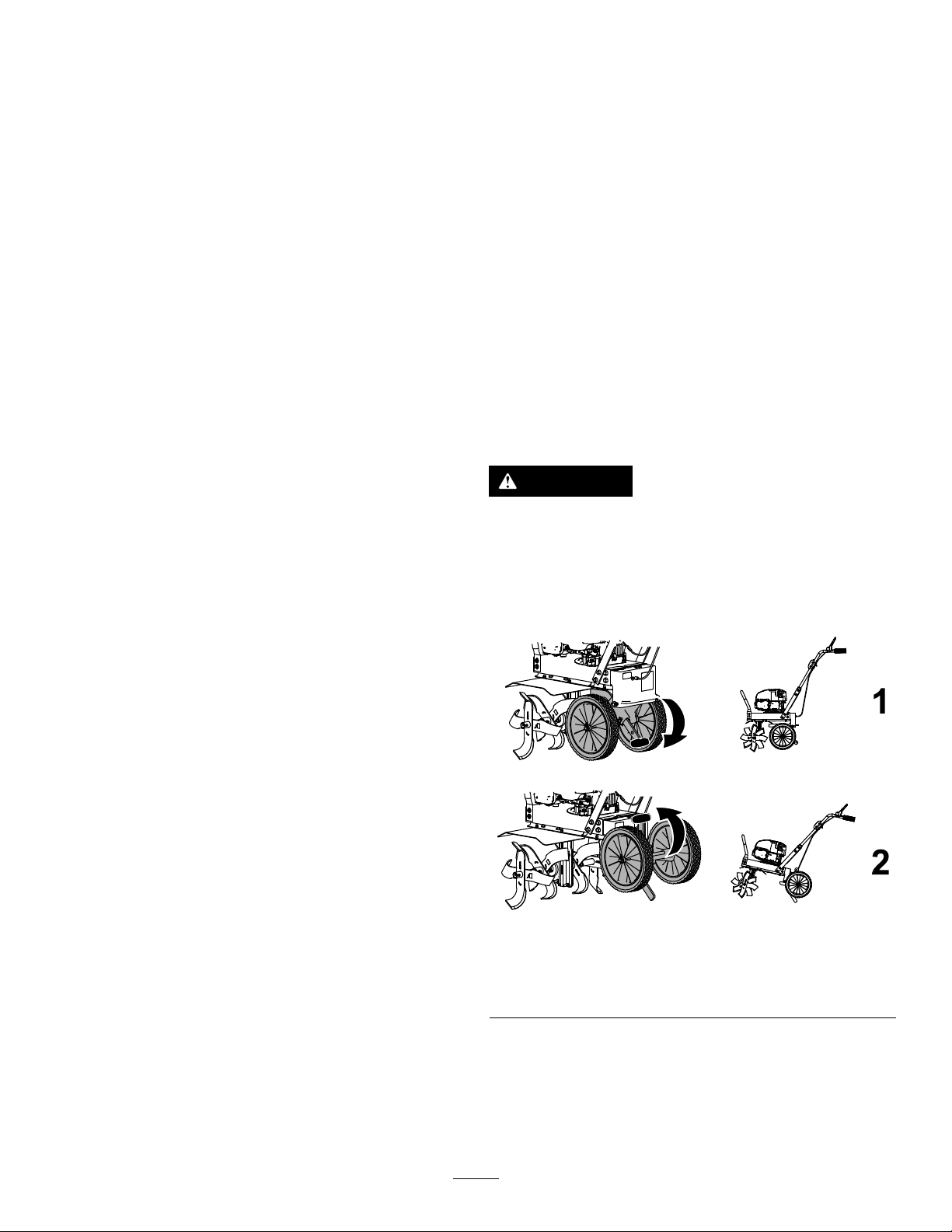

AdjustingtheTailMount

Position

Usethehandleonthedragstaketorotatethehinged

tailmounttotheTransportorOperatingpositions.

CAUTION

Rotatingthehingedtailmountcancreatea

pinchinghazardbetweentheupperandlower

portionsofthetailmount.

Keepawayfromthepivotpointswhen

adjustingthetailmountposition.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.

•Alwaysbesureofyourfooting;keeparmholdon

thehandleandwalk,neverrun.

•Allowthemuferandengineareatocoolbefore

touchingthem.

•Thetinesshouldnotrotatewhentheengineis

idling;iftheydorotate,contactyourAuthorized

ServiceDealer.

•Ifanobjectbecomeslodgedinthetines,shutoff

theengine,disconnectthewirefromthespark

plug,andallowtheenginetocoolbeforeremoving

theobject.

•Donotoperatethemachineonsteepslopes.T o

preventoverturning,operatethemachineupand

downtheslope.

StartingtheEngine

1.Settheengineon/offswitchtotheONposition.

2.Pulltherecoil-starthandle.

1.Transportposition—rotate

thehingedtailmount

downward

g356094

Figure14

2.Operatingposition—rotate

thehingedtailmount

upward

Note:Whenyoupulltherecoil-starthandle,

pullitlightlyuntilyoufeelresistance,thenpullit

12

AdjustingtheDragStake

Thedragstakehelpsregulatetillingdepthand

preventsthetillerfromjerkingforwardduring

operation.Setthedragstakeinthelowestposition

toincreaseresistancetoforwardmotionandtodig

deeper;raisethedragstakefortransport.

1.Movethemachinetoalevelsurface,shutoffthe

engine,andwaitforallmovingpartstostop.

2.Removethelockpin.

AfterOperation

AfterOperationSafety

GeneralSafety

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Cleandebrisfromthemachinetohelpprevent

res.Cleanupoilorfuelspills.

HaulingSafety

•Disconnectthewirefromthesparkplugbefore

loadingthemachineforhauling.

Figure15

1.Dragstake2.Lockpin

3.Positionthedragstaketothedesireddepth.

Note:Adjustthedragstake1holeatatimeand

testthetilleroperationaftereachadjustment.

Raisingthedragstaketoohighcanresultinloss

ofcontrolofthetiller.

4.Securethedragstakewiththelockpin.

TillingSoil

1.Adjustthedragstaketothedesireddepth;refer

toAdjustingtheDragStake(page13).

2.Squeezethedrive-controllevertoengagethe

tines.

3.Tillsoilasrequired.

4.Releasethedrive-controllevertodisengagethe

tines.

g356423

•Usecarewhenloadingorunloadingthemachine.

13

Maintenance

MaintenanceSafety

•Inspectthemachinefrequentlytoensurethatit

isinsafeworkingconditionandthatshearbolts,

engine-mountingbolts,andotherfastenersare

properlytightened.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Wearglovesandeyeprotectionwhenservicing

themachine.

RecommendedMaintenanceSchedule(s)

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Toensureoptimumperformanceofthemachine,

useonlygenuineT ororeplacementpartsand

accessories.Replacementpartsandaccessories

madebyothermanufacturerscouldbedangerous,

andsuchusecouldvoidtheproductwarranty.

•Replacetinesthatarebent,damaged,orloose;do

notrepairoralterthem.

•Keepthemachine,attachments,andaccessories

insafeworkingcondition.

•Donotattempttorepairthemachineunless

youhavethepropertoolsandinstructionsfor

disassembling,assembling,andrepairingthe

machine.

MaintenanceService

Interval

Beforeeachuseordaily

Every2hours

Every10hours

Every25hours

Every50hours

Every100hoursoryearly,

whichevercomesrst

Yearly

MaintenanceProcedure

•Checktheengine-oillevelandaddoilasneeded.

•Checkthebelttension.

•Cleandebrisfromcoolingns,airinletsandlinkages.

•Checkthebelttension.

•Cleanthetineaxleshaft.

•Servicetheairlter;serviceitmorefrequentlyindustyoperatingconditions.

•Replacethedrivebelt.

•Lubricatemovingpartsusing30-weightoil.

•Checkthesparkplug.

•Replacetheairlter;replaceitmorefrequentlyindustyoperatingconditions.

Important:Refertoyourenginemanualforadditionalmaintenanceprocedures

14

Pre-Maintenance

EngineMaintenance

Procedures

ServicingtheAirFilter

PreparingforMaintenance

1.Movethemachinetoalevelsurface,shutoffthe

engine,andwaitforallmovingpartstostop.

2.Disconnectthespark-plugwirefromthespark

plug.

Figure16

1.Spark-plugwire

3.Afterperformingthemaintenanceprocedure(s),

connectthespark-plugwiretothesparkplug.

Important:Beforetippingthemachine,

allowthefueltanktorundrythroughnormal

usage.Ifyoumusttipthemachinepriorto

runningoutoffuel,useahandfuelpumpto

removethefuel.

ServiceInterval:Every25hours

Yearly

1.Unclipthetopoftheair-ltercover.

g339525

g334791

Figure17

1.Clip3.Airlter

2.Air-ltercover

2.Removetheairlter.

3.Inspecttheairlter.

Note:Iftheairlterisexcessivelydirty,replace

itwithanewlter.Otherwise,gentlytaptheair

lteronahardsurfacetoloosendebris.

4.Installtheairlter.

5.Usethecliptoinstalltheair-ltercover.

15

ChangingtheEngineOil

Changingtheengineoilisnotrequired,butif

youwanttochangetheoil,usethefollowing

procedure.

Note:Runtheengineafewminutesbeforechanging

theoiltowarmit.Warmoilowsbetterandcarries

morecontaminants.

EngineOilSpecications

Engineoilcapacity

OilviscositySAE30orSAE10W-30

APIserviceclassicationSJorhigher

*Thereisresidualoilinthecrankcaseafteryoudrain

theoil.Donotpourtheentirecapacityofoilintothe

crankcase.Fillthecrankcasewithoilasdirectedin

thefollowingsteps.

0.44L(15oz)*

detergentoil

5.Afterdrainingtheusedoil,returnthemachineto

theoperatingposition.

6.Carefullypourabout3/4oftheenginecapacity

ofoilintotheoil-lltube.

7.Wait3minutesfortheoiltosettleintheengine.

8.Wipethedipstickcleanwithacleancloth.

9.Insertthedipstickintotheoil-lltube,then

removethedipstick.

10.Readtheoillevelonthedipstick.

•Iftheoillevelonthedipstickistoolow,

carefullypourasmallamountofoilintothe

oil-lltube,wait3minutes,andrepeatsteps

8through10untiltheoillevelonthedipstick

iscorrect.

•Iftheoillevelonthedipstickistoohigh,

draintheexcessoiluntiltheoillevelonthe

dipstickiscorrect.

1.Movethemachinetoalevelsurface.

2.RefertoPreparingforMaintenance(page15).

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

Figure18

1.Dipstick3.Add

2.Full

4.Tipthemachineontoitsside(sothattheairlter

isup)todraintheusedoilfromtheoil-lltube.

Important:Iftheoillevelintheengineistoo

lowortoohighandyouruntheengine,you

maydamagetheengine.

11.Installthedipstickintotheoil-lltubesecurely.

12.Recycletheusedoilproperly.

g334792

Figure19

g356437

16

ServicingtheSparkPlug

CheckingtheSparkPlug

ServiceInterval:Every100hoursoryearly,

whichevercomesrst

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

Type:ChampionRN9YCorequivalent

Airgap:0.75mm(0.03inch)

RemovingtheSparkPlug

1.Disconnectthespark-plugwirefromthespark

plug.

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.75mm(0.03inch).

g027479

Figure21

InstallingtheSparkPlug

Figure20

1.Spark-plugwire

2.Cleanaroundthesparkplugstopreventdirt

fromenteringtheengineandpotentiallycausing

damage.

3.Removethesparkplug.

g339525

g027480

Figure22

17

BeltMaintenance

CheckingandAdjustingthe

BeltTension

ServiceInterval:Beforeeachuseordaily

Every2hours

Thebelttensionmaydecreaseovertime.Y oumay

needtoadjustthebeltwithinthersthalfhourof

operation.

Important:Checkthebelttensionregularly.

Improperbelttensionmaycauseprematurebelt

wear.

Thebeltmayneedadjustmentifthereisaconstant

buzzingsoundwhilethetinesareengagedorifthere

isasquealingsoundwhenthetinesareengagedand

underload.

Note:Youmayhearashortbuzzingsoundafter

releasingthedrive-controlleverwhileusingthe

machine.Thisisnormalandiscausedbytheteethof

thecoggedbeltcontactingthewirebeltguidetostop

rotation.Youdonotneedtoadjustthebelttension

forthis.

1.Removethedirtshield.

2.Withthedrive-controlleverintheneutral

position,measurethelengthoftherelaxed

cablespring.

g356417

Figure24

1.Cablespring

3.Pulldownthedrive-controlleverandmeasure

thelengthoftheextendedcablespring.The

differenceshouldbe0.6cm(1/4inch).

4.Ifthebeltneedsadjustment,holdthelower

jamnutontheadjustablecableinplaceand

adjusttheupperjamnutin0.32cm(1/8inch)

increments.Checkthetensionagain,and

repeatasnecessary.

Figure23

1.Nut(4)3.Bolt(4)

2.Dirtshield

Note:Ifthetensionisincorrectandyoucannot

adjustthejamnutsfurther,movetheZ-bendend

ofthecabletothenextholeinthedrive-control

leverasshowninFigure26.Ifthetensionisstill

incorrect,replacethebelt.

g356421

Figure25

g356418

1.Upperjamnut2.Lowerjamnut

18

Figure26

ReplacingtheDriveBelt

ServiceInterval:Every50hours/Yearly(whichever

comesrst)

RemovingtheBelt

1.Removethedirtshield.

g361541

1.Z-bendendofcable

2.Movecabletothishole.

5.Installthedirtshield.

Figure27

1.Nut(4)3.Bolt(4)

2.Dirtshield

g356418

Figure28

1.Nut(4)3.Bolt(4)

2.Dirtshield

2.Removethedrivebeltcover.

g356418

Figure29

1.Bumper

2.Nut(4)

3.Washer(4)

4.Bolt(4)

5.Drivebeltcover

3.Gentlypulltheenginerecoilropetorotatethe

pulley.

19

g356422

4.Whilethepulleyturns,forcethebeltoffthe

V-groove.

5.Slidethebeltofftheenginepulley.

6.Pullthebeltdownandoutoftheway .

7.Pushthebeltforwardandoutthefrontofthe

machine.

InstallingtheBelt

1.Placebeltinthetransmissionpulleygroove.

2.Gentlypulltheenginerecoilropetorotatethe

enginepulleywhileforcingthebeltintothe

V-groove.

3.Installthedrivebeltcover.

4.Installthedirtshieldplate.

g356418

Figure31

1.Nut(4)3.Bolt(4)

2.Dirtshield

5.Checkthebelttension;adjustitasnecessary.

1.Bumper

2.Nut(4)

3.Washer(4)

g356422

Figure30

4.Bolt(4)

5.Drivebeltcover

20

Cleaning

Storage

CleaningtheTineAxle

Shaft

ServiceInterval:Every10hours

Removeallvegetation,string,wire,andothermaterial

thatmayhaveaccumulatedontheaxlebetweenthe

innertinesandthetransmissionhousing.

StorageSafety

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Runtheenginedryorremovethefuelwithahand

pump;neversiphonthefuel.Ifyoumustdrainthe

fueltank,doitoutdoors.

•FollowtheinstructionsinthisOperator’sManual

tosafelyunload,transport,andstorethemachine.

•Donotstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterandspaceheatersand

clothesdryers.Allowtheenginetocoolbefore

storingthemachineinanenclosure.

•AlwaysrefertotheOperator’sManualfor

importantdetailsifthemachineistobestoredfor

anextendedperiod.

CleaningandStoringthe

Machine

1.Parkthemachineonalevelsurface,shutoff

theengine,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

2.Removedebrisfromthetines,axle,transmission

housing,andengine.

Important:Youcanwashthemachine

withmilddetergentandwater.Donot

pressure-washthemachine.Avoid

excessiveuseofwater,especiallynearthe

engineandtransmission.

3.Coattheaxleslightlywithaxlegrease.

4.Servicetheairlter;refertoServicingtheAir

Filter(page15).

5.Preparethemachineforstorageforover

30daysasfollows:

A.Addfuelstabilizer/conditionertofreshfuel

inthetank.Followmixinginstructionsfrom

thefuelstabilizermanufacturer.Donot

useanalcohol-basedstabilizer(ethanolor

methanol).

B.Runtheenginetodistributeconditionedfuel

throughthefuelsystemfor5minutes.

C.Shutofftheengine,allowittocool,and

drainthefueltank.

D.Starttheengineandrunituntilitshutsoff.

21

E.Disposeoffuelproperly.Recyclethefuel

accordingtolocalcodes.

Important:Donotstorefuelcontaining

stabilizer/conditionerlongerthan

thedurationrecommendedbythe

fuel-stabilizermanufacturer.

6.Removeandchecktheconditionofthespark

plug;refertoCheckingtheSparkPlug(page17).

Withthesparkplugremovedfromtheengine,

pour15ml(1tablespoon)ofengineoilintothe

sparkplughole.Installthesparkplugandpull

therecoilrope3timestocoatthecylinderwith

oil.Donotinstallthewireonthesparkplug.

7.Checkandtightenallfasteners.Repairor

replaceanypartthatisdamaged.

8.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

9.Storethemachineinanuprightpositionina

clean,drygarageorstoragearea.Keepitout

ofreachofchildrenorotherunauthorizedusers.

Coverthemachinetoprotectitandkeepitclean.

22

Loading...

Loading...