10inCultivator

58601

Motoazadade25cm(10")

58601

Cultivateurde25cm(10po)

58601

FormNo.3445-371RevB

www.T oro.com.

*3445-371*

FormNo.3441-764RevD

10inCultivator

ModelNo.58601—SerialNo.321000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3441-764*

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

g342516

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Introduction

Thiscultivatorisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperatorsto

cultivateandlevelsoilaswellasblendlandscape

materials,compostandfertilizer.Usingthisproduct

forpurposesotherthanitsintendedusecouldprove

dangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comformoreinformation,including

safetytips,trainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................5

1AssemblingtheHandle....................................5

2RotatingtheDragStake...................................6

ProductOverview.....................................................7

Controls.............................................................7

Specications....................................................8

BeforeOperation...................................................8

BeforeOperationSafety.....................................8

AddingFuel........................................................9

PerformingDailyMaintenance..........................10

RemovingandInstallingtheTines....................10

DuringOperation..................................................11

DuringOperationSafety....................................11

StartingtheEngine...........................................12

ShuttingOfftheEngine.....................................12

AdjustingtheWheels........................................12

AdjustingtheDragStake..................................13

OperatingTips.................................................13

AfterOperation....................................................14

AfterOperationSafety......................................14

HaulingtheMachine.........................................14

Maintenance...........................................................15

MaintenanceSafety..........................................15

RecommendedMaintenanceSchedule(s)...........15

Pre-MaintenanceProcedures..............................15

PreparingforMaintenance...............................15

EngineMaintenance...........................................16

ServicingtheAirFilter.......................................16

ServicingtheSparkPlug...................................16

Storage...................................................................17

StorageSafety..................................................17

CleaningandStoringtheMachine....................17

Troubleshooting......................................................19

Thismachinehasbeendesignedinaccordancewith

ANSIB71.8-2016.

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjuryordeath.

•Read,understand,andfollowtheinstructions

andwarningsinthisOperator’sManualandon

themachineandattachmentsbeforestartingthe

engine.

•Bethoroughlyfamiliarwiththecontrolsandthe

properuseoftheequipment.Knowhowtostop

themachineanddisengagethecontrolsquickly .

•Donotputyourhands,feet,otherbodyparts,or

clothingnearorundertherotatingtinesorother

movingpartsofthemachine.

•Donotoperatethemachinewithoutallproper

shields,guards,andothersafetyprotective

devicesinplaceandfunctioningproperlyonthe

machine.

•Keepbystanders,especiallysmallchildren,and

petsoutoftheoperatingarea.

•Donotallowchildrentooperatethemachine.

Allowonlypeoplewhoareresponsible,trained,

familiarwiththeinstructions,andphysically

capabletooperatethemachine.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

3

,which

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

144-4726

decal144-4732

144-4732

1.Presstheprimer3times,pushthechokeleverdown,pull

therecoil-starthandle,andoncetheengineisrunningpull

thechokeleverup.

decal144-4726

1.Squeezethethrottletoengagethetines.

1.Warning—readtheOperator'sManual.

2.Warning—alloperatorsshouldbetrainedbeforeoperating

themachine.

3.Warning—keepbystandersaway.

4.Warning—stayawayfrommovingparts;keepallguardsand

shieldsinplace.

decal133-8062

133-8062

decal144-4727

144-4727

5.Warning—lookbehindyouwhenoperatingthemachinein

reverse.

6.Warning—donotoperateoverburiedlines.

7.Warning—keepfeetawayfrommovingparts.

8.Warning—shutofftheengineanddisconnectthespark

plugandreadtheOperator’sManualbeforeperforming

maintenance.

4

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

1

AssemblingtheHandle

Partsneededforthisprocedure:

4Knobnut

4

Curvedwasher

4

Saddlebolt

1Middlehandlebar

1

Upperlefthandlebar

1Upperrighthandlebar

Knobnut4

Curvedwasher

Saddlebolt

Middlehandlebar1

Upperlefthandlebar

Upperrighthandlebar1

Nopartsrequired

Qty.

Use

4

4

1

–

Assemblethehandle.

Rotatethedragstake.

Procedure

1.Parkthemachineonalevelsurface.

2.Setthewheelstothelowestposition;Adjusting

theWheels(page12).

3.Attachthemiddlehandlebartothelower

handlebar.

Note:Youcaninstallitintheupperorlower

holes,dependingonheightpreference.

Important:Donotovertightentheknob

nuts.

1.Middlehandle

2.Lowerhandle

3.Knobnut(2)

4.Attachtheupperrightandupperlefthandlebars

tothemiddlehandlebar.

Important:Donotovertightentheknob

nuts.

5

g334211

Figure3

4.Curvedwasher(2)

5.Saddlebolt(2)

Figure4

1.Knobnut(2)4.Leftupperhandle

2.Curvedwasher(2)

3.Saddlebolt(2)

5.Rightupperhandle

2

RotatingtheDragStake

NoPartsRequired

Procedure

1.Removethelockpin.

2.Rotatethedragstakesothatitpointsdownward,

facingtowardthetines.

3.Installthelockpin.

g334212

Figure5

1.Lockpin2.Dragstake

g334215

6

ProductOverview

Figure6

1.Engineon/offswitch

2.Chokelever

3.Throttlecontrol8.Tines

4.Handlebar-heightadjustment9.Primerbulb

5.Starterhandle

Controls

EngineOn/OffSwitch

UsetheengineOn/Offswitchtoshuttheengineoff.

EnsurethattheswitchisintheONpositionbefore

startingtheengine.

6.Engine

7.Fuelcap

10.Wheelverticalguide

ChokeLever

MovethechokeleverontheenginetotheCHOKE

positionwheninitiallystartingacoldengine,then

moveitintotheRUNpositiononcestarted.

ThrottleControl

Thethrottlecontrolstheenginespeed,andithasa

continuous-variablesetting.

g334228

Operatethemachineusingfullthrottleforbest

performance.

7

Specications

Specicationsanddesignaresubjecttochange

withoutnotice.

Height

Length

Width

Weight

Cultivatingwidth15to25cm(6to10inches)

CultivatingdepthUpto20cm(8inches)

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

97cm(38inches)

89cm(35inches)

46cm(18inches)

15kg(33lb)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Donotallowchildrenoruntrainedadultstooperate

orservicethemachine.Localregulationsmay

restricttheageoftheoperator.

•Usingthismachineisstrenuous.Youmustbein

goodphysicalconditionandmentallyalert.Ifyou

haveanyconditionthatmightbeaggravatedby

strenuouswork,checkwithyourdoctorbefore

operatingthemachine.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Checkthatallguardsandsafetydevices,suchas

deectors,areinplaceandfunctioningproperly.

Donotoperatethemachineunlesstheyare

functioningproperly.

•Knowhowtoshutofftheenginequickly.

•Keepbystanders,especiallysmallchildren,and

petsoutoftheoperatingarea.

•Thoroughlyinspecttheareawhereyouwilluse

themachineandremoveallobjectsthatcould

interferewiththeoperationofthemachineorthat

themachinecouldthrow.

FuelSafety

•Useextremecareinhandlingfuel.Itisextremely

ammableanditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporaddfueltothetank

whiletheengineisrunningorhot.

•Allowtheenginetocoolbeforellingthefueltank.

•Donotllthefueltankindoors.

8

•Donotoverllthefueltank.Replacethefuelcap

andtightenitsecurelyafterfueling.Cleanup

spilledfuelbeforestartingtheengine.

•Donotllcontainersinsideavehicleoronatruck

ortrailerbedwithaplasticliner.Alwaysplace

containersontheground,awayfromthevehicle

beforelling.

•Removethemachinefromthetruckortrailer

beforellingthefueltank.Ifthisisnotpossible,

thenaddfuelfromaportablecontainerratherthan

fromafuel-dispensernozzle.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Ifyouspillfuelonyourclothing,changeyour

clothingimmediately.

•Ifyouspillfuel,donotattempttostarttheengine;

movethemachineawayfromthespillandavoid

creatingasourceofignitionuntilthefuelvapors

havedissipated.

•Ifyoumustdrainthefueltank,doitoutdoors.

•Storefuelinafuelcontainerandkeepitoutofthe

reachofchildren.

•Donotstorethemachinewithfuelinthefueltank

orfuelcontainerwherethereisanopename,

spark,orpilotlight,suchasonawaterheateror

otherappliance.Allowtheenginetocoolbefore

storingthemachineinanyenclosure.

•Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

AddingFuel

RecommendedFuel

TypeUnleadedgasoline

Minimumoctanerating

Ethanol

MethanolNone

MTBE(methyltertiarybutyl

ether)

Oil

Useonlyclean,fresh(nomorethan30daysold),fuel

fromareputablesource.

MixingFuel

Thisproductispoweredbya2-cycleengineand

requirespre-mixingfueland2-cycleoil.Pre-mix

unleadedgasolineand2-cycleengineoilinaclean

containerapprovedforfuel.Donotmixquantities

largerthanusableina30-dayperiod.

Important:Topreventenginedamage,donotuse

automotiveoil(suchasSAE30or10W30)orfuel

mixedatthewrongfuel-to-oilratio.

50:1Fuel-to-OilRatioMixingChart

Fuel

3.8L(1USgallon)76ml(2.6oz)

7.6L(2USgallons)152ml(5.1oz)

19L(5USgallons)380ml(13oz)

87(US)or91(research

octane;outsidetheUS)

Nomorethan10%byvolume

Lessthan15%byvolume

2-cycleoil;mixedin50:1

fuel-to-oilratio

Oil

–Avoidprolongedbreathingofvapors.

–Keepyourhandsandfaceawayfromthe

nozzleandthefuel-tankopening.

–Keepfuelawayfromyoureyesandskin.

1.Pour1.9L(0.5USgallon)fresh,unleadedfuel

intoanapprovedfuelcontainer.

2.Add2-cycleoiltothefuelaccordingtothechart.

g001120

Figure7

3.Installthecaponthefuelcontainer.

4.Shakethecontainertomixthefuelandoil

thoroughly.

5.Slowlyremovethecapandaddtheremaining

amountoffuel.

9

Note:Donotmixfuelandoilinthefueltank.Oilat

roomtemperaturemixeseasierandmorethoroughly

thancoldoil.Oilbelow0°C(32°F)requiresadditional

mixing.

UsingStabilizer/Conditioner

Usefuelstabilizer/conditionerinthemachinetokeep

thefuelfreshlongerwhenusedasdirectedbythe

fuel-stabilizermanufacturer.

Important:Donotusefueladditivescontaining

methanolorethanol.

Addtheamountoffuelstabilizer/conditionertofresh

fuelasdirectedbythefuel-stabilizermanufacturer.

g334235

Figure9

1.Hairpincotter

FillingtheFuelTank

Fuel-tankcapacity:1.1L(36oz)

Refertoyourengineowner’smanualforadditional

information.

FillthefueltankasshowninFigure8.

Figure8

PerformingDaily

Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page15).

3.Slidethetinesofftheshaft.

4.Slidetheinnertines(“B”and“C”)ontheshaft.

Note:Thelettersarestampedonthetines.

Slidetine“B”ontheleftsideoftheshaft,and

slidetine“C”totherightsideoftheshaft.

g230458

g334237

Figure10

RemovingandInstalling

theTines

1.Parkthemachineonalevelsurface,shutoffthe

engine,andallowtheenginetocool.

2.Removethehairpincotterfromeachendofthe

tineshaft.

5.Slidetheoutertines(“A”and“D”)ontheshaft,

sothattheorderofthetinesis“A”,“B”,“C”,“D”,

whenviewedfromtheoperatingposition.

Note:Ensurethatthehubcollarsonboththe

leftandrightpairsoftinesfaceeachotherto

ensureadequatespacingbetweenthetine

blades.

10

Figure11

1.Hubcollar

6.Installahairpincotteroneachendofthetine

shaft.

Note:Todigmoreaggressively,reversetheorder

ofthetinessothatthetipsfaceforward(“D”,“C”,

“B”,“A”,whenviewedfromtheoperatingposition)as

showninFigure12.

Note:Foramorenarrowdiggingwidth,donotinstall

tines“A”and“D”instep5.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;hearingprotection;andgloves.Tieback

longhairanddonotwearlooseclothingorloose

jewelry.

•Keepyourhands,feet,otherbodyparts,and

clothingawayfromrotatingtinesandmovingparts

ofthemachine.Thetinesbeginrotatingwhen

youstarttheengineandmaycontinuetorotate

momentarilyafteryoushutofftheengine.

•Starttheenginecarefullyaccordingtoinstructions

inthisOperator’sManualandwithyourfeetwell

g334236

awayfromthetines.

•Useextremecautionwhenreversingorpulling

themachinetowardyou.T oavoidgettingpinned

againstastructure,allowenoughdistanceto

reversedirectionnearawallorfence.

•Keepbystandersoutoftheoperatingarea.Keep

smallchildrenoutoftheoperatingareaandunder

thewatchfulcareofaresponsibleadultwhois

notoperatingthemachine.Stopthemachineif

anyoneentersthearea.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutralandyouareintheoperatingposition.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

Figure12

Tineorderformoreaggressivedigging

DuringOperation

DuringOperationSafety

GeneralSafety

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Donotattempttoadjustthemachinewhilethe

engineisrunning.

•Ifthemachinestrikesanobjectorstartstovibrate

abnormally,immediatelyshutofftheengine,wait

forallmovingpartstostop,anddisconnectthe

wirefromthesparkplugbeforeexaminingthe

machinefordamage.Vibrationisoftenawarning

signoftrouble.Makeallnecessaryrepairsbefore

g334238

resumingoperation.

•Donotoperatethemachineathightransport

speedsonhardorslipperysurfaces.

•Lookbehindanddownandusecarewhen

reversing.

•Donotoverloadthemachinecapacityby

attemptingtotillorcultivatetoodeepandattoo

fastarate.

•Donotpickuporcarryamachinewhiletheengine

isrunning.

•Exercisecautionandbesureofyourfooting,

especiallywhenbackingup,toavoidslippingor

falling.

•Becarefulwhenoperatingthemachineinhard

ground.Thetinescancatchinthegroundand

propelthemachineforward.Ifthisoccurs,letgo

ofthemachine;donottrytorestrainit.

11

•Exerciseextremecautionwhencrossinggravel

surfaces.Stayalertforhiddenhazardsortrafc.

•Donotleavearunningmachineunattended.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Operatetheengineonlyinwell-ventilatedareas.

Exhaustgasescontaincarbonmonoxide,whichis

anodorless,deadlypoison.

•Useonlyaccessoriesandattachmentsapproved

byTheT oro®Company.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.

•Alwaysbesureofyourfooting;keeparmholdon

thehandleandwalk,neverrun.

•Allowthemuferandengineareatocoolbefore

touchingthem.

•Thetinesshouldnotrotatewhentheengineis

idling;iftheydorotate,contactyourAuthorized

ServiceDealer.

•Ifanobjectbecomeslodgedinthetines,shutoff

theengine,disconnectthewirefromthespark

plug,andallowtheenginetocoolbeforeremoving

theobject.

•Donotoperatethemachineonsteepslopes.T o

preventoverturning,operatethemachineupand

downtheslope.

6.Oncetheengineisrunning,movethechoke

levermidwaybetweentheCHOKEandRUN

positions.

7.Whentheenginerunssmoothly,movethechoke

levertotheRUNposition.

8.Squeezethethrottlelevertothedesiredspeed.

Note:Usefullthrottlewhenpossible.Donotlet

themachineidleforextendedperiodsoftime.

ShuttingOfftheEngine

1.Releasethethrottlelever.

2.Remainintheoperatingpositionandgrabthe

handlebarwith1hand.

3.MovetheengineOn/OffswitchtotheOFF

position.

4.Waitforallmovingpartstostopbeforeleaving

theoperatingposition.

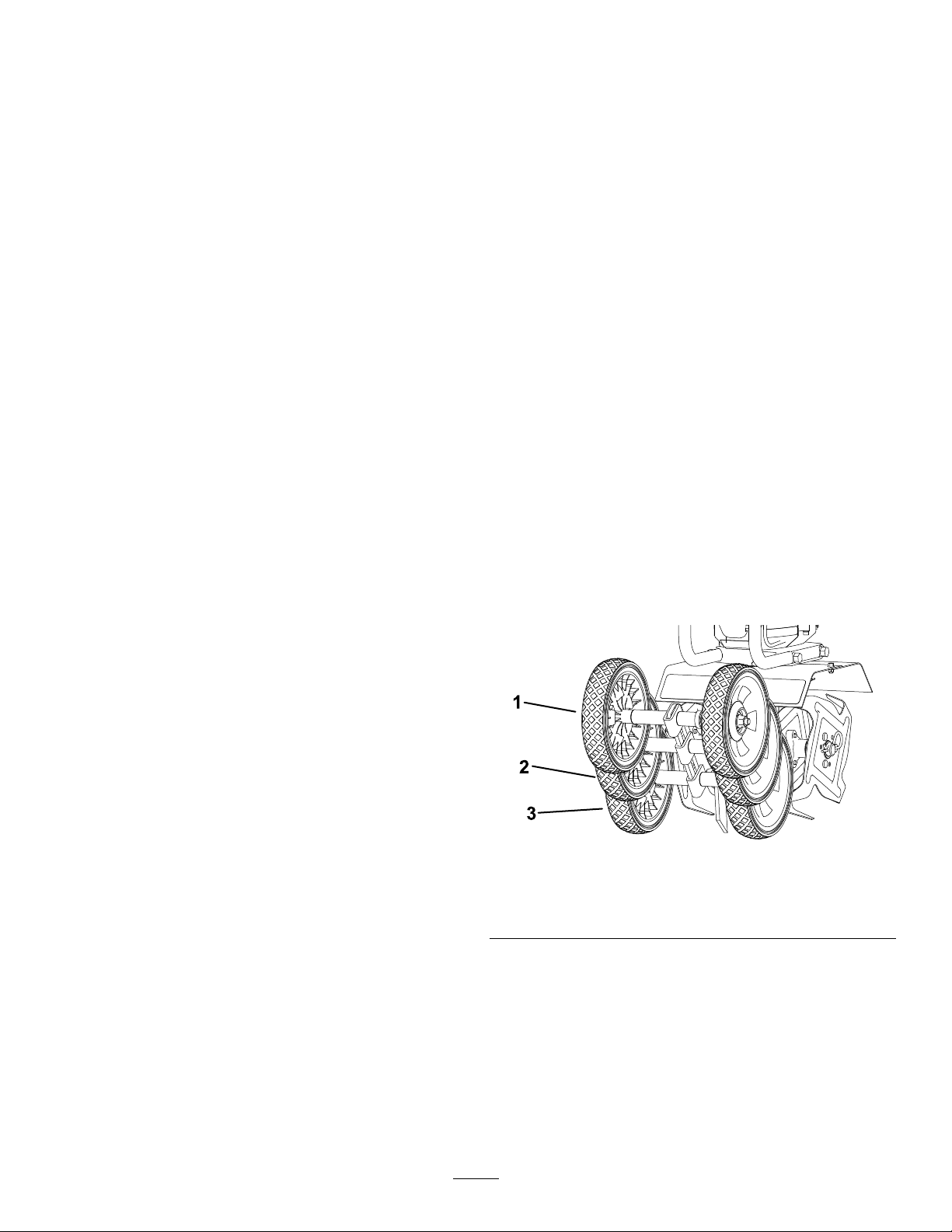

AdjustingtheWheels

Adjustthewheelsto1of3positions.Usethelow

positionwhentransportingthecultivatoroverlevel

surfaceswhiletheengineisoff.Usethemiddleand

highpositionstohelpstabilizethemachinewhen

cultivatingatdifferentdepths.

StartingtheEngine

1.Presstheprimerbulbuntiltheprimerhoseis

lledwithgas.

Note:Allowthebulbtoreturntoitsoriginal

positionbetweenpresses.

Note:Awarmorhotenginemaynotrequire

priming.

2.MovethechokelevertotheCHOKEposition.

Note:Awarmorhotenginemaynotrequire

choking.

3.PresstheengineOn/OffswitchtotheON

position.

4.Standintheoperatingpositionandgrabthe

handlebarwith1hand.

5.Withyourotherhand,pullthestarterhandle

lightlyuntilyoufeelresistance,thenpullthe

handlebriskly.Returnthestarterhandlegently.

Note:Iftheenginedoesnotstartafter5or6

pulls,presstheprimerbulbonceandpullthe

starterhandleagain.

g334240

Figure13

1.Highposition3.Lowposition

2.Middleposition

1.Movethemachinetoalevelsurface,shutoffthe

engine,andwaitforallmovingpartstostop.

2.Pullthelockingsleeveawayoutofthevertical

guidetotheunlockedposition(Figure14).

3.Slidethewheelstothedesiredposition.

4.Releasethelockingsleeveandensureitlocks

intoanotchintheverticalguide.

12

OperatingTips

•Inspecttheareawhereyouwillusethecultivator

andremoveallobjectssuchaslargerocks,

trash,andbranchesbeforecultivatingtoprevent

equipmentdamage.

•Theclutchtransfersmaximumpowerafterabout

2hoursofnormaloperation.Duringthisbreak-in

period,theclutchmayslip.Keeptheclutchfreeof

oilandothermoistureforefcientoperation.

•Alwaysbegincultivatingwiththeslowestground

speedpossible.Increasethespeedifconditions

permit.

Figure14

1.Lockingsleeve—locked

position

2.Lockingsleeve—unlocked

position

AdjustingtheDragStake

Thedragstakehelpsregulatecultivatingdepthand

preventsthecultivatorfromjerkingforwardduring

operation.Setthedragstakeinthelowestposition

toincreaseresistancetoforwardmotionandtodig

deeper.

1.Movethemachinetoalevelsurface,shutoffthe

engine,andwaitforallmovingpartstostop.

2.Removethelockpin.

3.Positionthedragstaketothedesireddepthwith

thetippointingdownward.

4.Securethedragstakewiththelockpin.

g334239

cultivator.Usetheweightofthemachineto

cultivatemoreefciently.

•Donotplaceexcessivebodyweightonthe

Figure15

1.Lockpin2.Dragstake

g334215

13

AfterOperation

AfterOperationSafety

GeneralSafety

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Cleandebrisfromthemachinetohelpprevent

res.Cleanupoilorfuelspills.

HaulingSafety

•Disconnectthewirefromthesparkplugbefore

loadingthemachineforhauling.

•Usecarewhenloadingorunloadingthemachine.

HaulingtheMachine

DANGER

Whentransportingthemachineinsidean

enclosedspaceinsideavehicle,fuelandfuel

vaporsmayigniteandcauseseriousinjury

ordeath.

Transportthemachineinanuprightposition

inanopenvehicleorremovefuelfromthe

machine.

Ensurethatthefuelcapistightandtransportthe

machineinanuprightpositioninanopenvehicle.

Securethemachinefrommovement.

Iffuelispresentinthefueltankandyoumusttransport

themachineinanenclosedvehicle,continueas

follows:

1.Drainthefuelintoanapprovedfuelcontainer.

2.Startthemachineandrunituntilitshutsoff.

3.Wipeawayanyfuelspillsandallowthemachine

todry .

4.Tightlyscrewonthefuelcap.

5.Securethemachinefrommovement.

14

Maintenance

MaintenanceSafety

•Inspectthemachinefrequentlytoensurethatit

isinsafeworkingconditionandthatshearbolts,

engine-mountingbolts,andotherfastenersare

properlytightened.

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Wearglovesandeyeprotectionwhenservicing

themachine.

RecommendedMaintenanceSchedule(s)

•Nevertamperwithsafetydevices.Checktheir

properoperationregularly.

•Toensureoptimumperformanceofthemachine,

useonlygenuineT ororeplacementpartsand

accessories.Replacementpartsandaccessories

madebyothermanufacturerscouldbedangerous,

andsuchusecouldvoidtheproductwarranty.

•Replacetinesthatarebent,damaged,orloose;do

notrepairoralterthem.

•Keepthemachine,attachments,andaccessories

insafeworkingcondition.

•Donotattempttorepairthemachineunless

youhavethepropertoolsandinstructionsfor

disassembling,assembling,andrepairingthe

machine.

MaintenanceService

Interval

Beforeeachuseordaily

Every20hours

Yearly

MaintenanceProcedure

•Checktheairlter.

•Cleandebrisfromcoolingns,airinletsandlinkages.

•Cleantheairlter.(Cleandailyinextremelydustyconditions.)

•Replacetheairlter .

•Check,clean,andgapthesparkplug.

•Replacetheairlter .

•Replacethesparkplug.

Pre-Maintenance

Procedures

PreparingforMaintenance

1.Movethemachinetoalevelsurface,shutoffthe

engine,andwaitforallmovingpartstostop.

2.Disconnectthespark-plugwirefromthespark

plug.

g335329

Figure16

1.Spark-plugwire

3.Afterperformingthemaintenanceprocedure(s),

connectthespark-plugwiretothesparkplug.

Important:Beforetippingthemachineto

replacetheblade,allowthefueltanktorun

drythroughnormalusage.Ifyoumusttip

themachinepriortorunningoutoffuel,use

ahandfuelpumptoremovethefuel.

15

EngineMaintenance

ServicingtheAirFilter

ServiceInterval:Beforeeachuseordaily—Check

theairlter.

Every20hours—Cleantheairlter.(Clean

dailyinextremelydustyconditions.)

Every20hours—Replacetheairlter.

Yearly—Replacetheairlter.

1.MovethechokelevertotheCHOKEposition.

2.Squeezethelatchtabsandrotatetheairlter

coveroffthemachine.

ServicingtheSparkPlug

ServiceInterval:Every20hours—Check,clean,and

gapthesparkplug.

Yearly—Replacethesparkplug.

Ensurethattheairgapbetweenthecenterandside

electrodesiscorrectbeforeinstallingthesparkplug.

Useasparkplugwrenchforremovingandinstalling

thesparkplug(s)andagappingtool/feelergaugeto

checkandadjusttheairgap.Installanewspark

plug(s)ifnecessary.

Type:T orchL7RTC,ChampionRCJ8Y,orequivalent

Airgap:0.71mm(0.028inch)

RemovingtheSparkPlug

1.Disconnectthespark-plugwirefromthespark

plug.

Figure17

1.Airltercover3.Filter-reinforcementplate

2.Foamlterelement4.Latchtab(2)

3.Removeandinspectthefoamlterelement.

Important:Replacethefoamelementifit

istornorworn.

4.Washthefoamelementinliquidsoapand

warmwater.Whentheelementisclean,rinse

itthoroughly.

Important:Donottwistthefoamelement

whilecleaningit.

5.Drytheelementbysqueezingitinacleancloth.

6.Dipthefoamelementincleanengineoil(30or

40weight),thensqueezeouttheexcessoil.

7.Installthelteroverthelter-reinforcement

plate.Pressthefoamlterevenlyovertheplate

toensureitisfullyseatedintoitssealedposition.

g335328

g335329

Figure18

1.Spark-plugwire

2.Cleanaroundthesparkplugstopreventdirt

fromenteringtheengineandpotentiallycausing

damage.

3.Removethesparkplug.

8.Installtheairltercover.Ensurethatitsnaps

intoplaceandissecuredbythelatchtabs.

16

CheckingtheSparkPlug

Important:Donotcleanthesparkplug(s).

Alwaysreplacethesparkplug(s)whenithasa

blackcoating,wornelectrodes,anoilylm,or

cracks.

Ifyouseelightbrownorgrayontheinsulator,the

engineisoperatingproperly.Ablackcoatingonthe

insulatorusuallymeanstheaircleanerisdirty .

Setthegapto0.71mm(0.028inch).

Figure19

InstallingtheSparkPlug

1.Threadthesparkplugclockwiseintothe

spark-plugholebyhand.

2.Rotatethesparkplugclockwiseusinga

spark-plugwrenchuntiltheplugandsealing

washerareseated.

3.Tightenthesparkplugasfollows:

•Wheninstallingtheoriginalsparkplug,

tightenthepluganadditional1/2turn.

•Wheninstallinganewsparkplug,tightenthe

pluganadditional1/8to1/4turn.

Important:Aloosesparkplugmaycause

thecylindertooverheat.Anover-tightspark

plugmaydamagethethreadsinthecylinder

head.

4.Connectthespark-plugwiretothesparkplug.

Storage

StorageSafety

•Shutoffthemachineandwaitforallmovingparts

tostopbeforeyouleavetheoperator’sposition.

Disconnectthespark-plugwire,keepitawayfrom

theplugtopreventaccidentalstarting,andallow

themachinetocoolbeforeadjusting,fueling,

unclogging,servicing,cleaning,orstoringthe

machine.

•Runtheenginedryorremovethefuelwithahand

pump;neversiphonthefuel.Ifyoumustdrainthe

fueltank,doitoutdoors.

•FollowtheinstructionsinthisOperator’sManual

tosafelyunload,transport,andstorethemachine.

•Donotstorethemachinewithfuelinthefuel

g027479

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterandspaceheatersand

clothesdryers.Allowtheenginetocoolbefore

storingthemachineinanenclosure.

•AlwaysrefertotheOperator’sManualfor

importantdetailsifthemachineistobestoredfor

anextendedperiod.

CleaningandStoringthe

Machine

1.Parkthemachineonalevelsurface,shutoff

theengine,andwaitforallmovingpartstostop

beforeleavingtheoperatingposition.

2.Removedebrisfromthecultivatortinesand

engine.

Important:Youcanwashthemachine

withmilddetergentandwater.Donot

pressure-washthemachine.Avoid

excessiveuseofwater,especiallynearthe

engineandtransmission.

3.Servicetheairlter;refertoServicingtheAir

Filter(page16).

4.Preparethemachineforstorageforover

30daysasfollows:

A.Addfuelstabilizer/conditionertofreshfuel

inthetank.Followmixinginstructionsfrom

thefuelstabilizermanufacturer.Donot

useanalcohol-basedstabilizer(ethanolor

methanol).

B.Runtheenginetodistributeconditionedfuel

throughthefuelsystemfor5minutes.

C.Shutofftheengine,allowittocool,and

drainthefueltank.

D.Starttheengineandrunituntilitshutsoff.

17

E.Disposeoffuelproperly.Recyclethefuel

accordingtolocalcodes.

Important:Donotstorefuelcontaining

stabilizer/conditionerlongerthan

thedurationrecommendedbythe

fuel-stabilizermanufacturer.

5.Removeandchecktheconditionofthespark

plug;refertoServicingtheSparkPlug(page16).

Withthesparkplugremovedfromtheengine,

pour15ml(1tablespoon)ofengineoilintothe

sparkplughole.Installthesparkplugandpull

therecoilrope3timestocoatthecylinderwith

oil.Donotinstallthewireonthesparkplug.

6.Checkandtightenallfasteners.Repairor

replaceanypartthatisdamaged.

7.Paintallscratchedorbaremetalsurfaces.Paint

isavailablefromyourAuthorizedServiceDealer.

8.Storethemachineinanuprightpositionina

clean,drygarageorstoragearea.Keepitout

ofreachofchildrenorotherunauthorizedusers.

Coverthemachinetoprotectitandkeepitclean.

18

Troubleshooting

Problem

Theenginedoesnotstart.

Theenginerunsroughoroodsduring

operation.

Theengineisdifculttostart.

Theenginedoesnotstart,startshard,or

failstokeeprunning.

PossibleCauseCorrectiveAction

1.TheengineswitchisintheOFF

position.

2.Thespark-plugwireislooseor

disconnected.

3.Thesparkplugiswet,pitted,fouled,or

thegapisincorrect.

4.Thefuel-linehoseisnotpositionedat

thebottomofthefueltank.

1.Theairlterisdirty.1.Cleanorreplacetheairlter.

2.Thechokeispartiallyengaged.2.MovethechokelevertotheRUN

3.Thecarburetorisoutofadjustment.3.ContactanAuthorizedServiceDealer

1.Stalefuelisinthefuelsystem.1.Drainthefueltankandaddfreshfuel.

2.Thespark-plugwireislooseor

disconnected.

3.Thecarburetorisdirty .

4.Thefuelisnotsufcientlyprimed.

1.Thefueltankisempty.1.Fillthefueltank.

2.Thechokeisnotengaged.

3.Theairlterisdirty.3.Cleanorreplacetheairlter.

4.Dirt,water,orstalefuelisinfuel

system.

5.Thereisincorrectfuelinthefueltank.

1.MovetheswitchtotheONposition.

2.Installthewireonthesparkplug.

3.Installanew,correctlygappedspark

plug.

4.Pushthefuel-linehoseintothefuelin

thefueltank.

position.

2.Installthewireonthesparkplug.

3.Cleanthecarburetor,usefuel

stabilizer,anduseanewfuelcan.

4.Presstheprimerbulb3times,thenpull

recoilhandle.

2.MovethechokelevertotheCHOKE

position.

4.ContactanAuthorizedServiceDealer.

5.Drainthetankandreplacethefuelwith

thepropertype.

Theenginemissesorlackspower.

Theenginerunsandthenstops.

Theenginespeedistoohigh.

1.Thefuellterisclogged.

2.Theaircleanerisdirtyordamaged.

3.Thecarburetorisoutofadjustment.3.ContactanAuthorizedServiceDealer

4.Thesparkplugiswet,pitted,fouled,or

thegapisincorrect.

1.Thegascapisnotventing.

2.Thefuellterisplugged.2.Cleanorreplacethefuellter.

3.Thecarburetorisoutofadjustment.3.ContactanAuthorizedServiceDealer

1.Thecarburetorisoutofadjustment.1.ContactanAuthorizedServiceDealer

1.Theidlespeedistoohigh.1.Lowertheidlespeed. Thetinesturnwhenthemachineidles.

2.Theclutchspringisbroken.2.Replacetheclutch.

1.Cleanthefueltankandreplacethe

fuellter .

2.Cleanorreplacetheair-cleaner

element.

4.Installanew,correctlygappedspark

plug.

1.Cleanorreplacethegascap;check

thevent.

19

Loading...

Loading...