Page 1

Specifications

• Body Style:

• AVB, 3/4" Female NPT (53763)

• AVB, 1" Female NPT (53764)

• Flow range (3/4"): 0.25–20 GPM

• Flow range (1"): 0.25–30 GPM

• Operating pressure: 10–150 PSI

• Solenoid:

24 V a.c., 60Hz (nominal)

19 V a.c., 60Hz (minimum)

Inrush: 0.40 amps, 11.50 VA @ 24 V a.c.

Holding: 0.20 amps, 5.75 VA @ 24 V a.c.

• Friction Loss:

GPM Flow 0.25 5 10 15 20 30

PSI Loss (3/4") 2.0 4.2 4.2 4.8 7.6 –

(1") 2.0 2.1 3.1 2.3 3.8 8.1

Installation Procedure

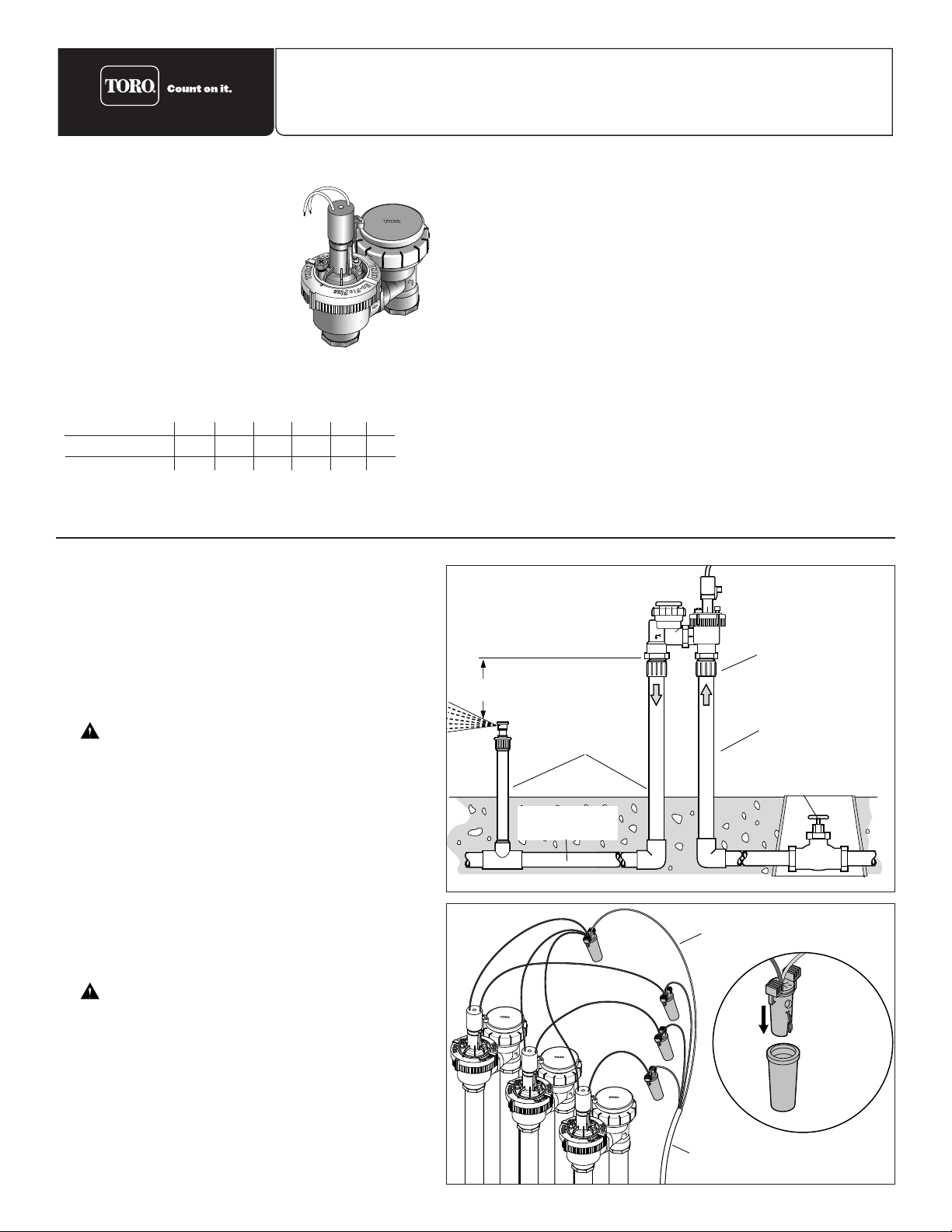

1. From the shut-off valve, route a supply pipe to the valve

installation site. For UV protection, use dark gray

Schedule 80 PVC on the inlet (pressurized) side of the

valve and all PVC pipe installed above ground. Use

Class 200 PVC on the underground sprinkler lines.

2. Flush the supply line thoroughly to remove all traces of

dirt and debris.

3. Prepare two 1" slip/male thread adapters with three to five

complete wraps of PTFE tape, evenly covering the threads.

CAUTION:

Use only PTFE tape on threaded valve

connections. Pipe dope will damage plastic threads.

4. Install the threaded adapters into the valve and tighten

securely. Using PVC primer and cement, install the valve to

the PVC pipe as shown in Figure 1.

5. Route a multi-wire, direct-burial sprinkler valve cable

from the sprinkler timer to the valve location. If the cable

run is less than 800', 18-gauge wire is sufficient. For distances from 800'–2000', 14-gauge wire is recommended.

6. Using wire splice connectors, attach either wire from

each valve solenoid to the white cable wire. This wire is

designated as the valve common wire. Connect the

remaining wire from the solenoid to one of the colorcoded cable wires. Ensure all wire connections are

secure and waterproof.

CAUTION: Use Toro Waterproof Wire Connectors

(Model # 53687) or grease caps on all wire splice

connections to prevent corrosion, connection failure

and short circuit.

7. At the sprinkler timer, connect the white common wire to

the output terminal labeled “C” or “COM.” Connect each

color-coded valve wire to the numbered output

terminals in the order you wish the valves to operate

during the automatic watering cycle.

8. Open the shut-off valve from the water source. Test valve

operation using the timer or manually at the valve.

6" (minimum)

SCH 80 PVC Pipe

From Water Source

Slip x Male Thread

PVC Adapters

Manual Shut-Off Valve

Use SCH 80 PVC

Above Ground

Class 200 PVC

Underground

Figure 1

Valve Installation Guidelines

Ensure the following requirements, in addition to all local code

requirements, are met when installing the Toro Jar Top Anti-Siphon Valve:

• The installed height, measured from the valve base, must not be less

than of 6" above the highest downstream outlet controlled by the valve.

• The anti-siphon valve must not be subject to standing water which can

rise to less than 6" from the base of the valve.

• The anti-siphon valve must not be installed indoors (some spillage may

occur) or in a valve box below ground level.

• The installation site must be accessible to allow inspection and servicing.

• Additional control valves must not be installed downstream of the antisiphon valve.

• The anti-siphon valve must be installed vertically with the top of the

anti-siphon cap level.

• The valve must not be operated continuously for more than 12 hours in

any 24-hour period.

• Installing a manual shut-off valve between the main water supply and

automatic valve or valve manifold is recommended for ease of valve

maintenance and sprinkler system winterization.

• Where local water pressure exceeds 70 psi, a pressure regulator should

be used. (See Uniform Plumbing Code, Sec. 1007 [b].) It is advisable to

use a regulator with any automatic valve to assure long life as well as

uniform and controllable operation.

Figure 2

Waterproof

Connector

Model #53687

Valve Common Wire

Multi-wire Cable from Timer

Jar Top Anti-siphon Valve Models 53763 & 53764

Installation and Operating Instructions

Page 2

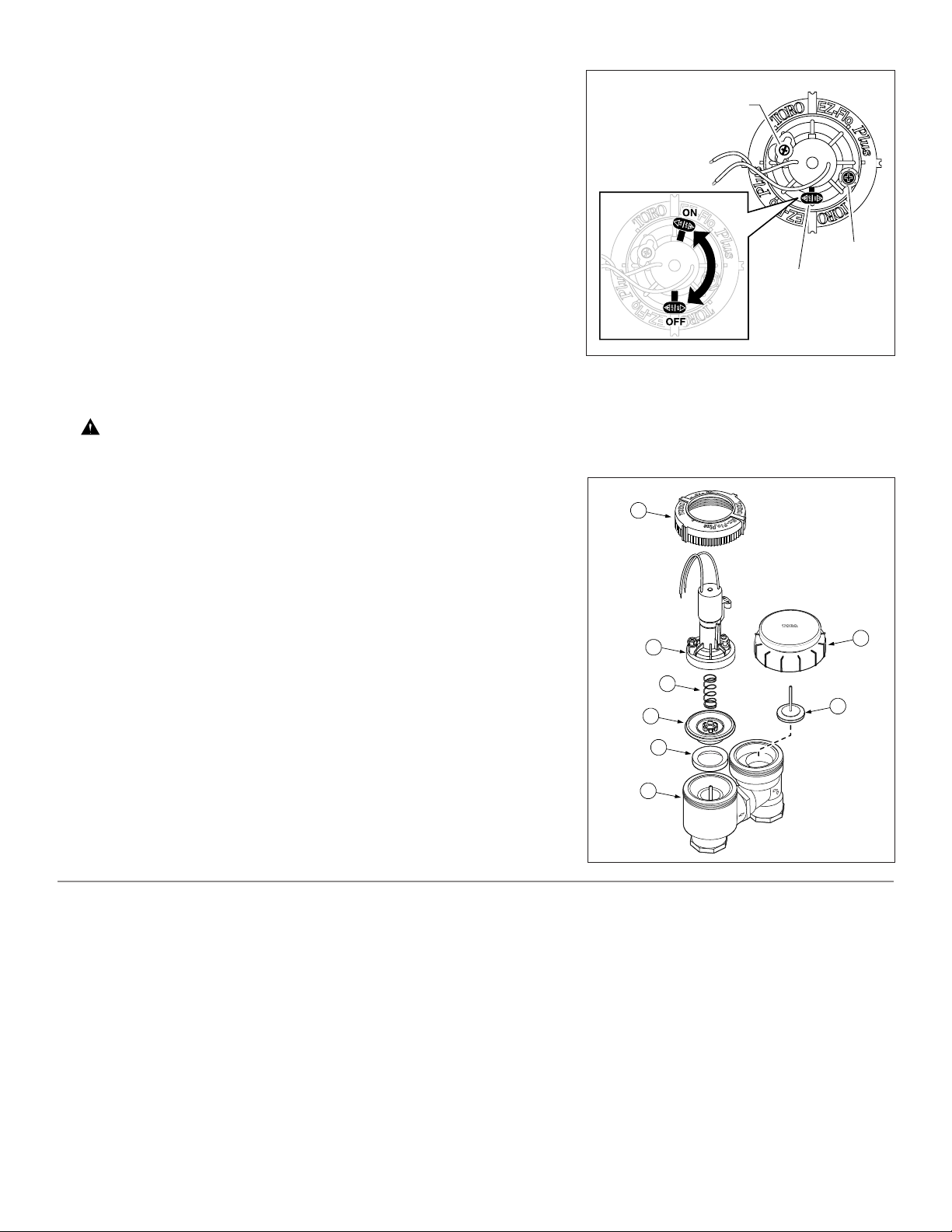

Manual Operation

Note: The valve can be manually operated using the external or internal bleed

controls. Refer to Figure 3.

Bleed Screw (external bleed): Turn the bleed screw counterclockwise one full

turn or until water begins discharging past the bleed screw threads.

Note: Removing the bleed screw is not required for manual operation, but can be

removed to help flush debris from the upper diaphragm area.

To close the valve, turn the bleed screw clockwise until it stops. Do not over-tighten!

Bleed Handle (internal bleed): To open the valve, move the bleed handle counterclockwise to the stop. The valve will open as discharge water is routed internally

downstream. To close the valve, move the handle clockwise until resistance is felt.

Do not over-tighten!

Flow Control Adjustment

The valve is set for maximum flow at the factory. If flow adjustment is required, use

the following procedure:

1. While the valve is operating, use a small screwdriver to turn the flow control

screw clockwise to decrease flow or counterclockwise to increase flow.

Note: The flow control screw requires approximately seven turns to adjust from maximum to minimum flow.

CAUTION: Do not use the flow control to shut off the valve. Do not force the flow control screw past the end of normal

adjustment travel. Damage to the flow control components can occur.

Maintenance Procedure

The Toro Jar Top valve series features a threaded cap nut which enables the valve

to be easily disassembled for maintenance. See Figure 4 for the following procedure.

1. Shut off the water supply and bleed pressure from the valve using the bleed screw.

2. Turn the cap nut (1) counterclockwise to remove.

3. Remove the cover assembly (2) by gripping the solenoid and gently rocking it

back and forth until the assembly is loose and lifts off.

4. Remove the spring (3), diaphragm (4), and divider (5).

5. Turn the anti-siphon cap (7) counterclockwise to remove.

6. Remove the stem assembly (8).

7. Inspect the valve body and internal parts for wear and debris.

8. Clean and reinstall parts into the valve body in reverse order.

Winterization

When winterizing the sprinkler system using compressed air, operate each valve

manually from the timer or at the valve for a minimum of one minute, enabling each

valve to be thoroughly drained.

The Toro Promise — Limited One-Year Warranty

The Toro Company and its affiliate, Toro Warranty Company, pursuant to an agreement between them, jointly warrants, to the owner against defects in material and workmanship

for a period of one year from the date of purchase.

Neither The Toro Company nor Toro Warranty Company is liable for failure of products not manufactured by them even though such products may be sold or used in conjunction

with Toro products.

During such warranty period, we will repair or replace, at our option, any part found to be defective.

Return the defective part to the place of purchase.

Our liability is limited solely to the replacement or repair of defective parts. There are no other express warranties.

This warranty does not apply where equipment is used, or installation is performed, in any manner contrary to Toro’s specifications and instructions, nor where equipment is altered

or modified.

NEITHER THE TORO COMPANY NOR TORO WARRANTY COMPANY IS LIABLE FOR INDIRECT, INCIDENTAL OR CONSEQUENTIAL DAMAGES IN CONNECTION WITH

THE USE OF EQUIPMENT, INCLUDING BUT NOT LIMITED TO: VEGETATION LOSS, THE COST OF SUBSTITUTE EQUIPMENT OR SERVICES REQUIRED DURING

PERIODS OF MALFUNCTION OR RESULTING NON-USE, PROPERTY DAMAGE OR PERSONAL INJURY RESULTING FROM INSTALLER’S NEGLIGENCE.

Some states do not allow the exclusion or limitation of incidental or consequential damages, so the above limitation or exclusion may not apply to you.

ALL IMPLIED WARRANTIES, INCLUDING THOSE OF MERCHANTABILITY AND FITNESS FOR USE, ARE LIMITED TO THE DURATION OF THIS EXPRESS WARRANTY.

Some states do not allow limitations of how long an implied warranty lasts, so the above limitation may not apply to you.

This warranty gives you specific legal rights and you may have other rights which vary from state to state.

Figure 3

1

3

2

4

5

6

7

8

Figure 4

© 2007 The Toro Company, Consumer Division

An ISO 9000-certified Company • Toro HelpLine - 800-367-8676 • www.toro.com Form Number 373-0309 Rev. B

Bleed Screw

Bleed Handle

Flow Control Screw

Loading...

Loading...