Toro 53020, 53021 Operator's Manual

ProLine Brushcutter

Model No. 53020 — 895001 & Up

Model No. 53021 — 895001 & Up

16” & 18” Gas

Modèle No. 51903 — 790000001 et suivants

Modèle No. 51904 — 790000001 et suivants

Modèle No. 51906 — 790000001 et suivants

Modèle No. 51907 — 790000001 et suivants

FORM NO. 3322-369

16” & 18” Gas

Modelos N. 51903 — 790000001 y siguientes

Modelos N. 51904 — 790000001 y siguientes

Modelos N. 51906 — 790000001 y siguientes

Modelos N. 51907 — 790000001 y siguientes

Operator’s Manual

Manuel de l’Utilisateur

Manual del Usuario

Contents

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Brushcutter Safety 3. . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power Brushcutter Operating Safety 4. . . . . . . . . . .

Safety and Instruction Decals 5. . . . . . . . . . . . . . . . . . .

Assembly 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Bullhorn Handle Installation 6. . . . . . . . . . . . . . . . .

Installing Shield 6. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Brushcutter Blade 7. . . . . . . . . . . . . . . . . .

Attaching Strap 8. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Brushcutter Blade Cover 8. . . . . . . . . . . .

Before Operation 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil and Fuel 9. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mixing Gasoline And Oil 10. . . . . . . . . . . . . . . . . . . .

Starting And Stopping 11. . . . . . . . . . . . . . . . . . . . . .

Hot Restart 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Page

Page

Operation 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Position 12. . . . . . . . . . . . . . . . . . . . . . . . .

Cutting Direction 13. . . . . . . . . . . . . . . . . . . . . . . . . .

Cutting Blades 13. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maintenance 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Filter 14. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Spark Plug 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Idle Speed Adjustment 16. . . . . . . . . . . . . . . . . . . . . .

Cylinder Cooling Fins 16. . . . . . . . . . . . . . . . . . . . . .

Spark Arrester 17. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Exhaust Muffler 17. . . . . . . . . . . . . . . . . . . . . . . . . . .

Gearcase Maintenance 18. . . . . . . . . . . . . . . . . . . . . .

General Cleaning and Tightening 18. . . . . . . . . . . . .

Blade Sharpening 18. . . . . . . . . . . . . . . . . . . . . . . . . .

Storage 19. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 20. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Federal and California Emission Control

Warranty Statement 23. . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING:

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects,

or other reproductive harm.

The Toro Company – 1998

All Rights Reserved

1

Introduction

Thank you for purchasing a T oro product.

All of us at T oro want you to be completely satisfied with

your new product, so feel free to contact your local

Authorized Service Dealer for help with service, genuine

T oro parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory, always know the model and serial numbers of

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. You will find the model and serial

number decal located in a unique place on the product

(Fig. 1).

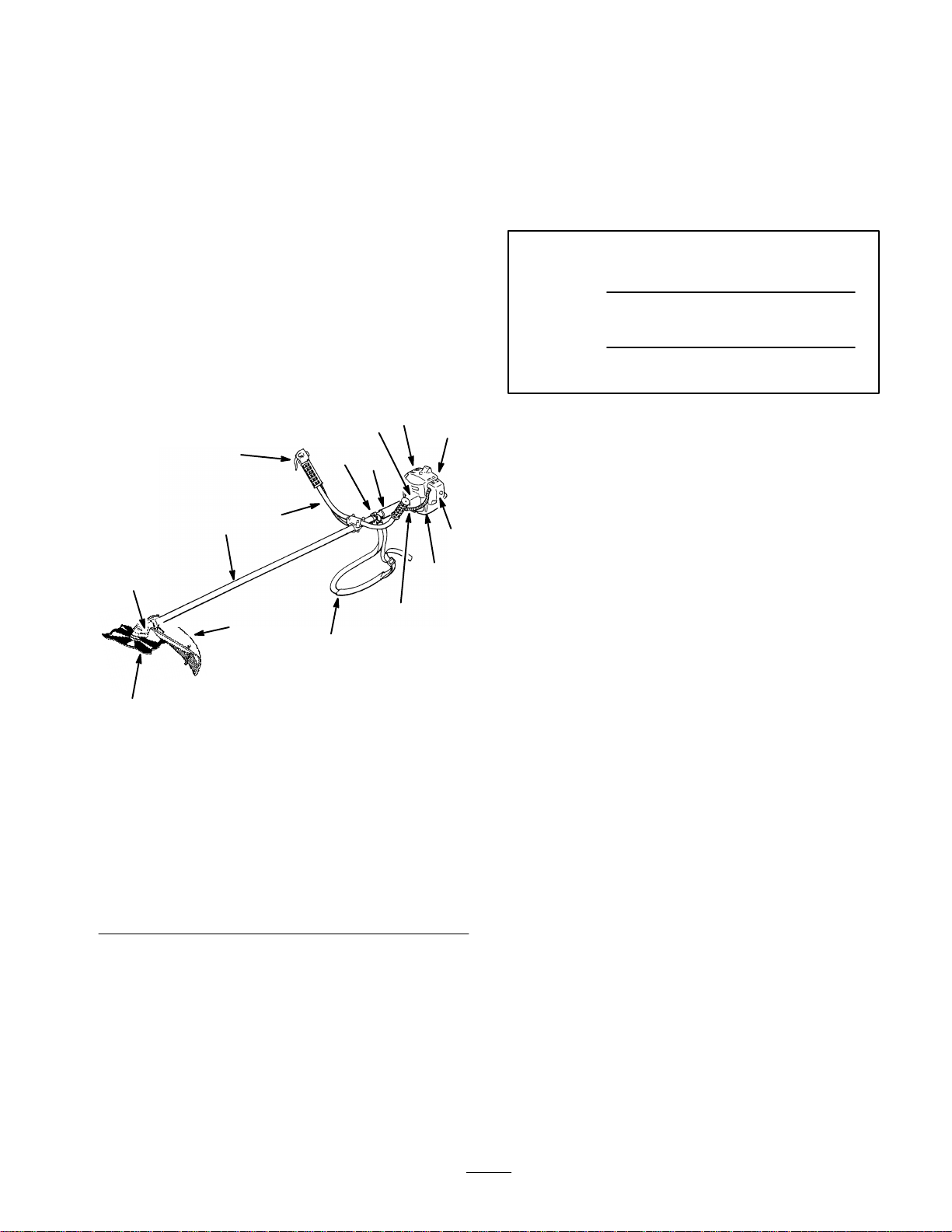

Figure 1

1. Gearcase

2. Shaft Assembly

3. Throttle Trigger and Stop

Switch

4. Bullhorn Handle

5. Shoulder Harness

Attachment

6. Shaft Grip

7. Clutch Drum Housing

8. Engine

9. Model and Serial Number

Decal (on rear of engine

stand)

10. Brushcutter Blade

11. Blade Shield

12. Strap

13. Throttle Cable and Stop

Switch Wires

14. Fuel Tank

15. Air Filter

For your convenience, write the product model and serial

numbers in the space below.

Model No.

Serial No.

Read this manual carefully to learn how to operate and

maintain your product correctly. Reading this manual will

help you and others avoid personal injury and damage to

the product. Although T oro designs, produces and markets

safe, state-of-the-art products, you are responsible for

using the product properly and safely. You are also

responsible for training persons who you allow to use the

product about safe operation.

The Toro warning system in this manual identifies

potential hazards and has special safety messages that help

you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal words

used to identify the level of hazard. However, regardless

of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended precautions

are not followed.

WARNING signals a hazard that may cause serious injury

or death if the recommended precautions are not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are not

followed. T wo other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes general

information worthy of special attention.

2

Safety

Operator Safety

1. Read and understand this Operator’s Manual before

using this product. Be thoroughly familiar with the

proper use of this product.

2. Never allow children to operate the Brushcutter. It is

not a toy. Never allow adults to operate the unit

without first reading the Operator’s Manual.

3. Always wear eye protection that complies with ANSI

(American National Standards Institute) Z87–1.

4. Always wear hearing protection.

Brushcutter Safety

1. Make sure the Brushcutter is assembled correctly and

that the Brushcutter blade is correctly installed and

securely fastened as instructed in the Assembly

section.

2. Inspect the Brushcutter before each use. Replace

damaged parts. Check for fuel leaks. Make sure all

fasteners are in place and tightened securely. Follow

the maintenance instructions beginning on page 14.

3. Make sure the Brushcutter blade does not rotate at

engine idle speed. Refer to Idle Speed Adjustment,

page 16.

4. Inspect the Brushcutter cutting blade and replace any

parts that are cracked, chipped or damaged before

using the Brushcutter.

5. Make sure the blade shield is installed and positioned

correctly before using the Brushcutter.

6. Never use a cutting blade or replacement parts that are

not approved by T oro.

7. Maintain the Brushcutter according to the

recommended maintenance intervals and procedures in

the Maintenance section on page 14.

5. Always wear heavy, long pants, a long sleeved shirt,

boots and gloves. Do not wear loose clothing, jewelry,

short pants, sandals, or go barefoot. Secure hair so it is

above shoulder length.

6. Never operate this Brushcutter when you are tired, ill,

or under the influence of alcohol, drugs or medication.

7. Never start or run the engine inside a closed room or

building. Breathing exhaust fumes can cause death.

8. Keep handles clean of oil, fuel and dirt.

8. Shut off the engine and be certain the cutting blade has

completely stopped rotating before inverting the

Brushcutter, performing maintenance on or working on

the machine.

9. If running problems or excessive vibration occur, stop

immediately and inspect the unit for the cause. If the

cause cannot be determined or is beyond your ability

to correct, return the Brushcutter to your servicing

dealer for repair.

Fuel Safety

1. Gasoline is highly flammable and must be handled and

stored carefully . Use a container approved for fuel for

storing gasoline and/or fuel/oil mixture.

2. Mix and pour fuel outdoors and where there are no

sparks or flames.

3. Do not smoke near fuel or Brushcutter, or while using

the Brushcutter.

4. Do not overfill the fuel tank. Stop filling 1/4–1/2 inch

(6mm–13mm) from the top of the tank.

5. Wipe up any spilled fuel before starting the engine.

3

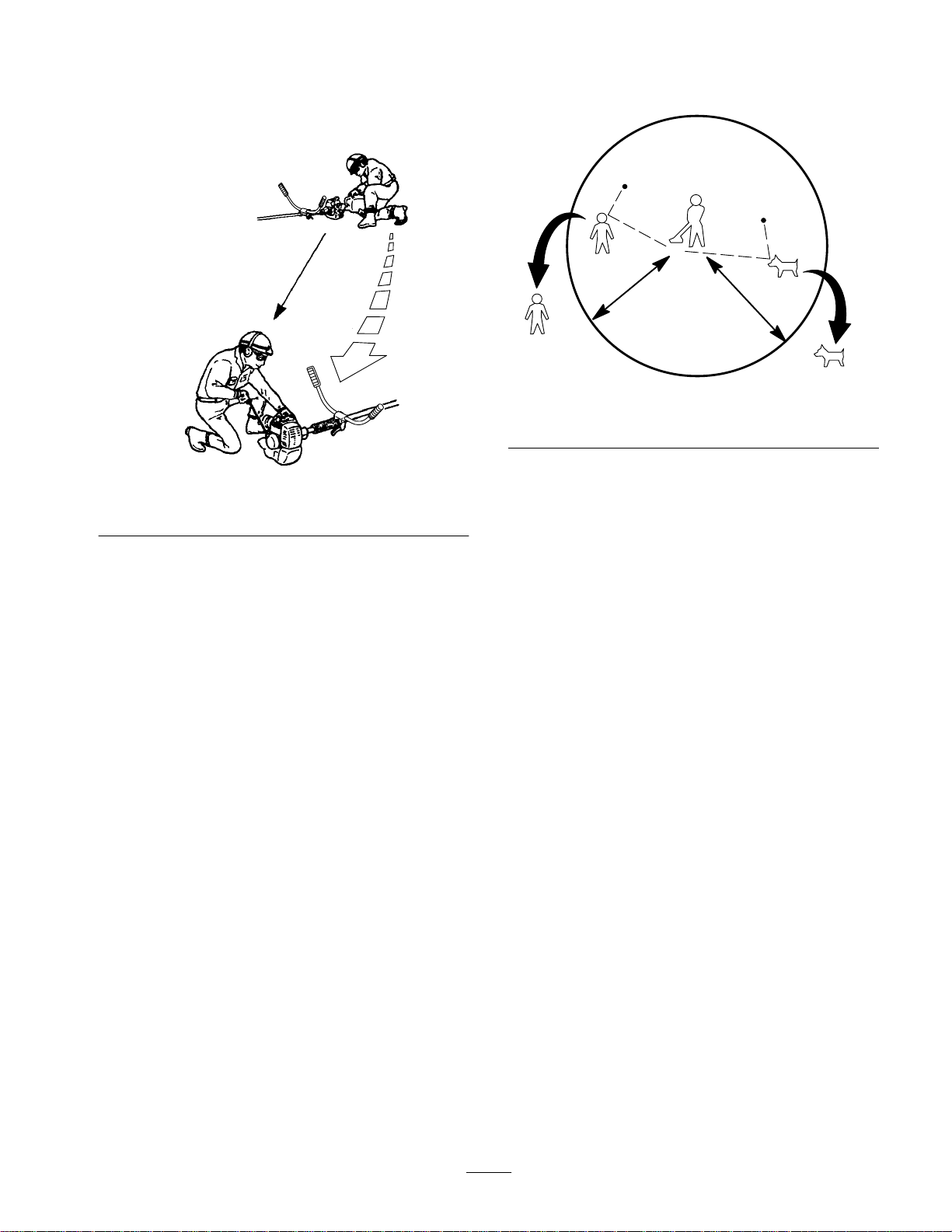

6. Move the Brushcutter at least 10 feet (3 m) away from

the fueling location before starting the engine (Fig. 2).

m-3021

Figure 2

1. 10 feet (3m) Minimum

7. Do not remove the Brushcutter fuel tank cap while the

engine is running, or right after stopping the engine.

8. Allow the engine to cool before refueling.

9. Drain the tank and run the engine dry before storing

the unit.

10.Store fuel and Brushcutter away from open flame,

sparks and excessive heat. Make sure fuel vapors

cannot reach sparks or open flames from water heaters,

furnaces, electric motors, etc.

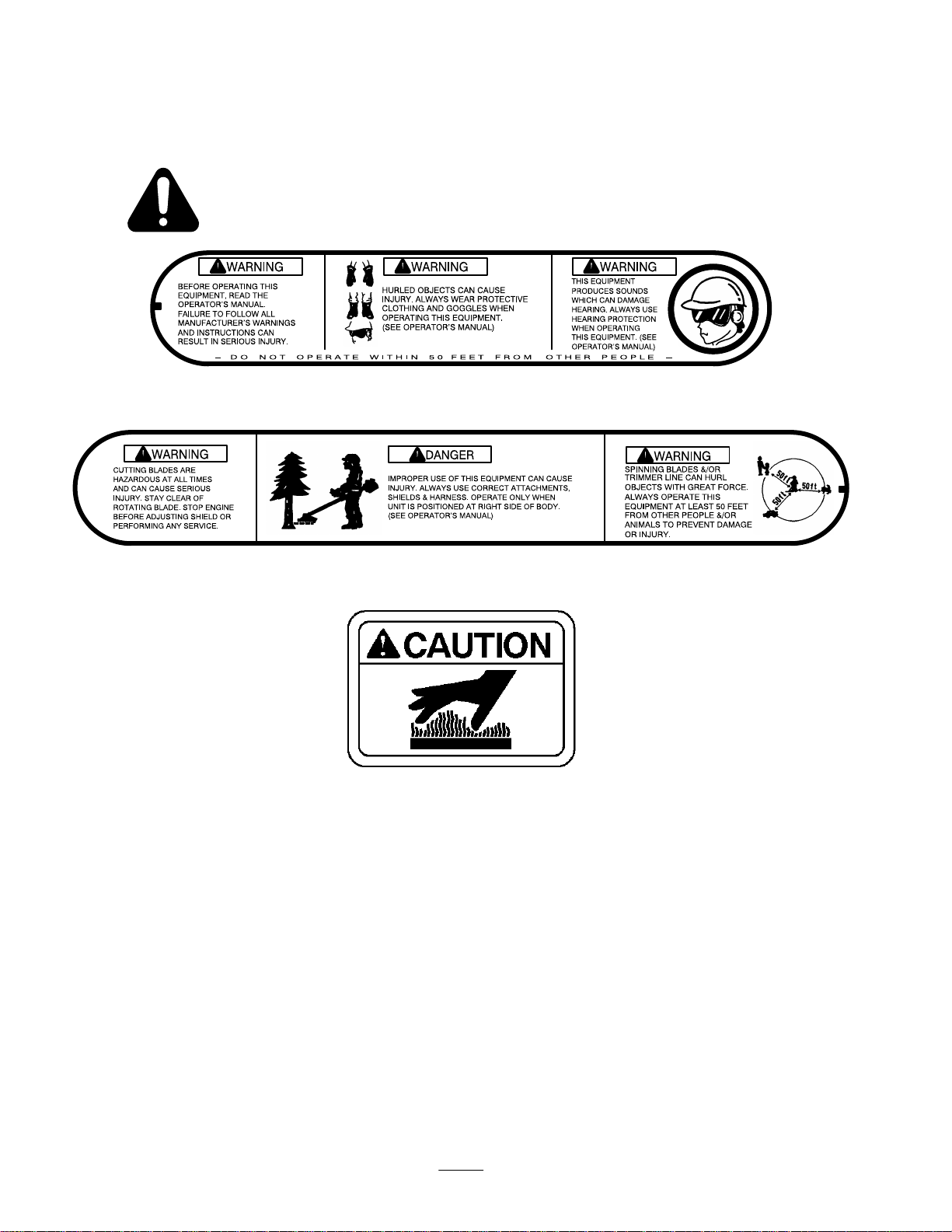

Figure 3

1. 50 ft. (15 m) Minimum

5. If you are approached while operating the Brushcutter,

stop the engine and Brushcutter blade rotation.

6. Use the Brushcutter only in daylight or good artificial

light.

7. Never operate the Brushcutter without proper guards

or other protective safety devices in place.

8. Do not put hands or feet near or under any rotating

parts. Keep clear at all times. Keep all parts of your

body away from the rotating Brushcutter blade and hot

surfaces such as the muffler .

9. When cutting heavy brush or small trees, always swing

the Brushcutter from right to left to prevent kick-back

(Figs 12 and 13).

m-2967

Power Brushcutter Operating

Safety

1. THIS BRUSHCUTTER CAN CAUSE SERIOUS

INJURIES. Read the instructions carefully. Be familiar

with all controls and the proper use of the Brushcutter.

2. Make sure the 3mm hex wrench has been removed

from the gearcase and boss adapter before you start the

engine (Fig 6).

3. Avoid using the Brushcutter near rocks, gravel, stones

and similar material that would cause harmful

missiles.

4. Keep children, bystanders and animals outside a 50 ft.

(15 m) radius from the operator and Brushcutter

(Fig. 3).

10.Keep firm footing and balance. Do not overreach.

11. Use the right tool for the job. Do not use the

Brushcutter for any job that is not recommended by

T oro.

4

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any

area of potential danger. Replace any decal that is damaged or lost.

ON SHAFT

(Part No. M221501)

ON SHAFT

(Part No. M221502)

ON ENGINE

(Part No. M266291)

5

Assembly

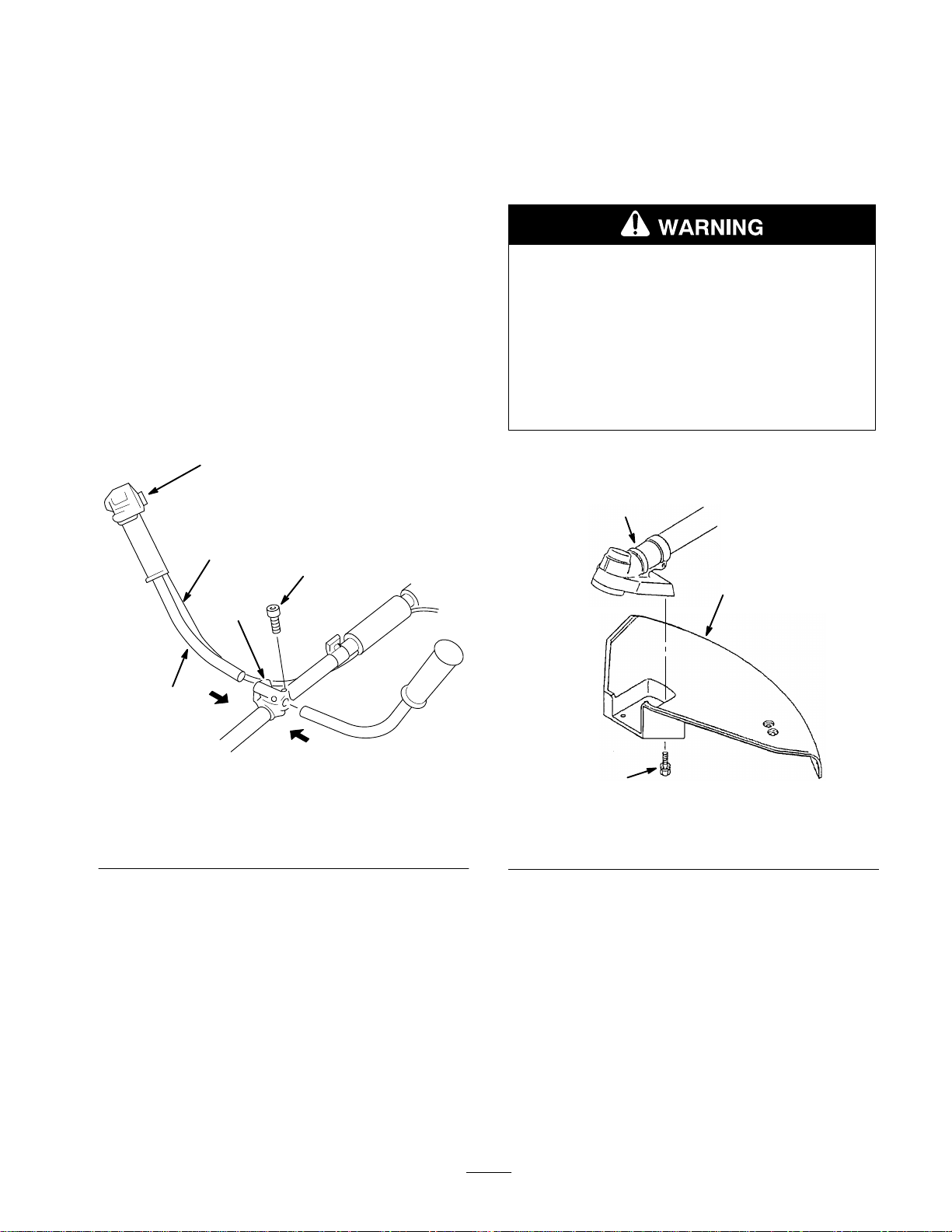

Bullhorn Handle Installation

IMPORTANT: Be careful not to damage the throttle

cable and stop switch wires when you remove the

bullhorn handles from the shipping carton.

1. Loosen the four Phillips hex head screws on the top of

the clamp bracket (Fig. 4).

2. Insert the left and right bullhorn handles into the

clamp bracket. Note that the bullhorn handle with the

throttle trigger and stop switch goes on the right-hand

side of the Brushcutter (Fig. 4).

3. Adjust the bullhorn handles to the desired position,

then tighten the four Phillips hex head screws (Fig. 4).

Installing Shield

POTENTIAL HAZARD

• Foreign objects can be thrown by Brushcutter.

WHAT CAN HAPPEN

• Contact with thrown objects can cause personal

injury.

HOW TO AVOID THE HAZARD

• Never operate the Brushcutter without the

blade shield in place.

1. Install the blade shield onto the gearcase (Fig. 5).

2. Install and tighten the four M5 x 12 screws (Fig. 5).

1. Throttle Trigger/Stop

Switch

2. Stop Switch Wires/Throttle

Cable

Figure 4

3. Clamp Bracket

4. Screw (4)

5. Bullhorn Handle (2)

m-3022

1. Gearcase

2. Blade Shield

m-2990

Figure 5

3. M5 x 12 Screw (4)

6

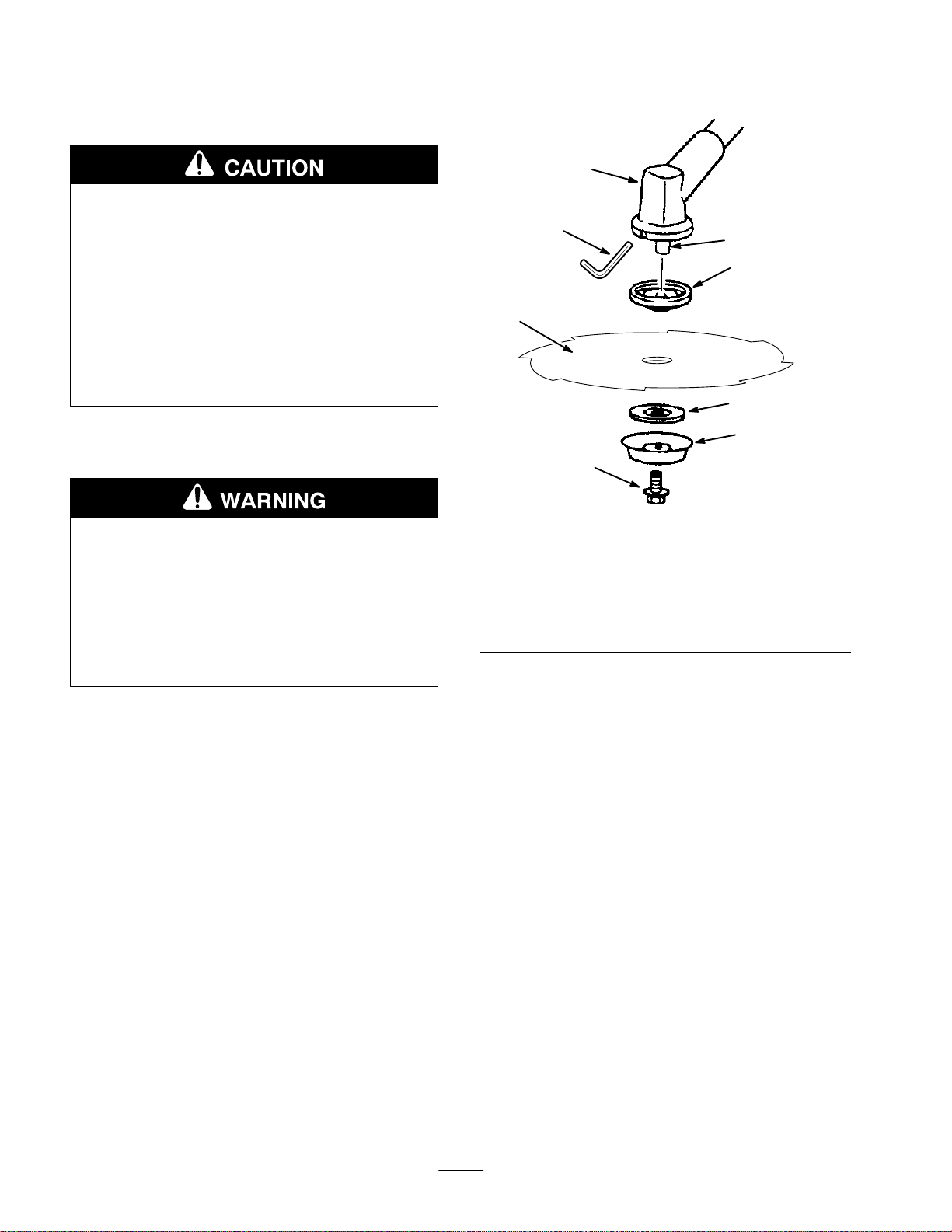

Installing Brushcutter Blade

POTENTIAL HAZARD

• If the Brushcutter blade is not adequately

tightened, it can come loose from the

Brushcutter during use.

WHAT CAN HAPPEN

• This may cause damage to property or personal

injury.

HOW TO AVOID THE HAZARD

• Make sure the Brushcutter blade is securely

fastened to the splined shaft in the gearcase.

1. Remove the blade bolt, stabilizer and clamping washer

from the splined shaft out of the gearcase (Fig. 6).

Note: The blade bolt has left-hand threads.

POTENTIAL HAZARD

• Brushcutter blade is sharp.

WHAT CAN HAPPEN

• Contact with sharp blade can cause serious

personal injury.

HOW TO AVOID THE HAZARD

• Wear gloves when you handle the blade.

1. Gearcase

2. 3mm Hex Wrench

3. Splined Shaft

4. Boss Adapter

5. Edger Blade (eight-tooth)

m-2984

Figure 6

6. Clamping Washer

7. Stabilizer

8. Blade Bolt (left-hand

thread)

2. Install the brushcutter blade onto the boss adapter, then

reinstall the clamping washer, stabilizer and blade bolt

(Fig. 6).

3. Align the hole in the boss adapter with the hole in the

gearcase (Fig. 6).

4. Insert a 3mm hex wrench or other suitable tool into the

holes in the boss adapter and gearcase to lock the

splined shaft (Fig. 6).

5. Tighten blade bolt to 100 in.-lbs. (11.3 NSM) (Fig. 6).

6. Remove the 3mm hex wrench from the boss adapter

and gearcase (Fig. 6).

7

Loading...

Loading...