Page 1

ProLine Trimmers

Model No. 53002 — 895001 & Up

Model No. 53003 — 895001 & Up

Model No. 53010 — 895001 & Up

Model No. 53011 — 895001 & Up

16” & 18” Gas

Modèle No. 51903 — 790000001 et suivants

Modèle No. 51904 — 790000001 et suivants

Modèle No. 51906 — 790000001 et suivants

Modèle No. 51907 — 790000001 et suivants

FORM NO. 3322-364

16” & 18” Gas

Modelos N. 51903 — 790000001 y siguientes

Modelos N. 51904 — 790000001 y siguientes

Modelos N. 51906 — 790000001 y siguientes

Modelos N. 51907 — 790000001 y siguientes

Operator’s Manual

Manuel de l’Utilisateur

Manual del Usuario

Page 2

Contents

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operator Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . .

String Trimmer Safety 3. . . . . . . . . . . . . . . . . . . . . .

Fuel Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Power String Trimmer Operating Safety 4. . . . . . . .

Safety and Instruction Decals 5. . . . . . . . . . . . . . . . .

Assembly 6. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing Trimmer Head Shield 6. . . . . . . . . . . . . . .

Installing Trimmer Head 7. . . . . . . . . . . . . . . . . . . .

Before Operation 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Oil and Fuel 7. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Mixing Gasoline And Oil 8. . . . . . . . . . . . . . . . . . . .

Starting And Stopping 9. . . . . . . . . . . . . . . . . . . . . .

Hot Restart 1 1. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 11. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Position 11. . . . . . . . . . . . . . . . . . . . . . . . .

Cutting with Nylon Trimmer Line 12. . . . . . . . . . . . .

Rewinding the Trimmer Spool 13. . . . . . . . . . . . . . . .

Page

Page

Maintenance 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Air Filter 15. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Fuel Filter 16. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Idle Speed Adjustment 16. . . . . . . . . . . . . . . . . . . . . .

Spark Plug 17. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Cylinder Cooling Fins 19. . . . . . . . . . . . . . . . . . . . . .

Spark Arrester 19. . . . . . . . . . . . . . . . . . . . . . . . . . . .

Gearcase Maintenance 21. . . . . . . . . . . . . . . . . . . . . .

General Cleaning and Tightening 21. . . . . . . . . . . . .

Storage 21. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Accessories 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 22. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 23. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

53010/Commercial 23. . . . . . . . . . . . . . . . . . . . . . . . .

53011/Commercial 23. . . . . . . . . . . . . . . . . . . . . . . . .

53002/Industrial 23. . . . . . . . . . . . . . . . . . . . . . . . . . .

53003/Industrial 23. . . . . . . . . . . . . . . . . . . . . . . . . . .

Federal and California Emission Control

Warranty Statement 24. . . . . . . . . . . . . . . . . . . . . . . . . .

Warranty 27. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

WARNING:

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects,

or other reproductive harm.

1

Page 3

Introduction

Thank you for purchasing a T oro product.

All of us at T oro want you to be completely satisfied with

your new product, so feel free to contact your local

Authorized Service Dealer for help with service, genuine

T oro parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory, always know the model and serial numbers of

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. You will find the model and serial

number decal located in a unique place on the product

(Fig. 1).

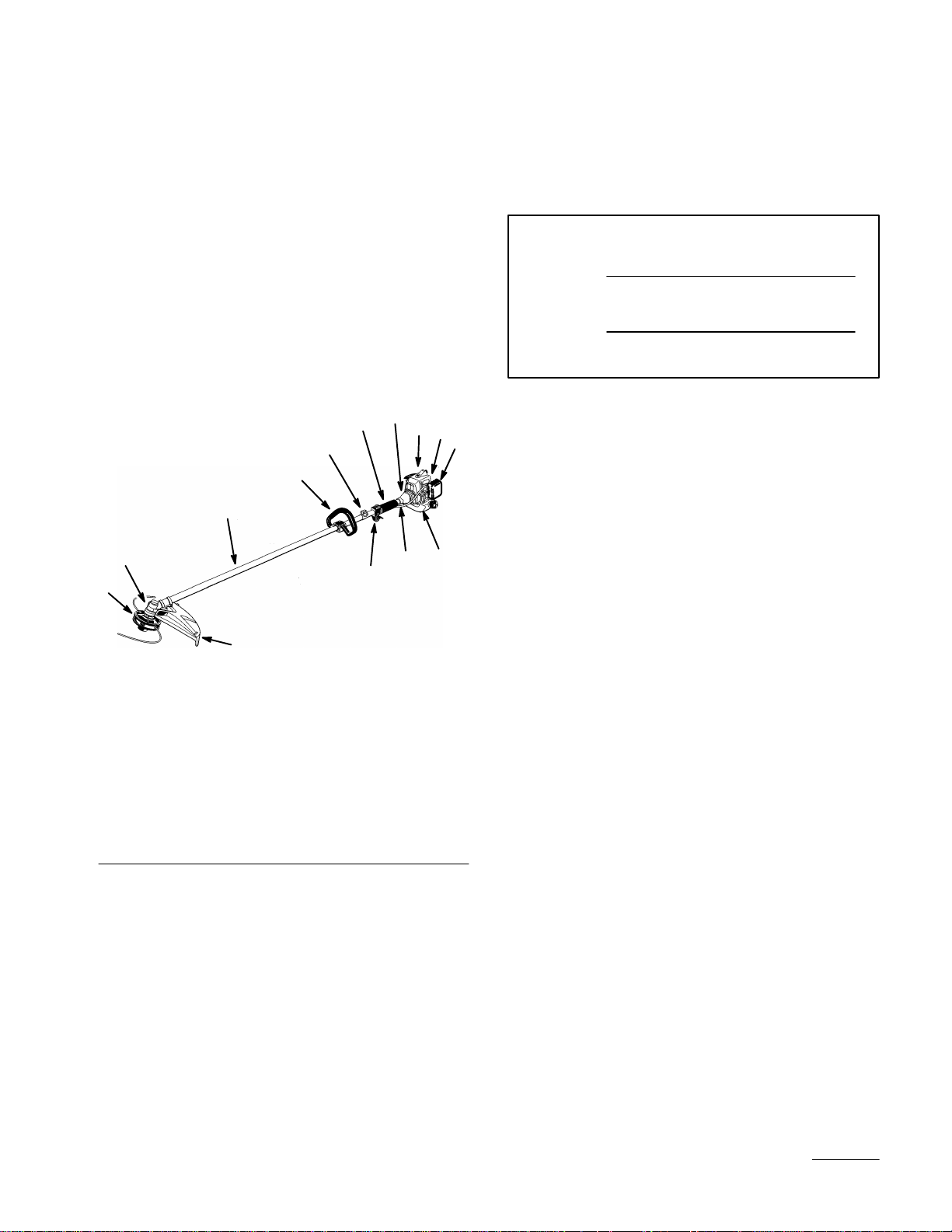

Figure 1

1. Trimmer Head

2. Gearcase

3. Shaft Assembly

4. Loop Handle

5. Attachment Ring for

Shoulder Harness

6. Shaft Grip

7. Clutch Drum Housing

8. Engine

9. Model and Serial Number

Decal (on rear of engine

stand)

10. Air Filter

11. Trimmer Head Shield

12. Throttle Trigger and Stop

Switch

13. Throttle Cable and Stop

Switch Wire

14. Fuel Tank

For your convenience, write the product model and serial

numbers in the space below.

Model No.

Serial No.

Read this manual carefully to learn how to operate and

maintain your product correctly. Reading this manual will

help you and others avoid personal injury and damage to

the product. Although T oro designs, produces and markets

safe, state-of-the-art products, you are responsible for

using the product properly and safely. You are also

responsible for training persons who you allow to use the

product about safe operation.

The Toro warning system in this manual identifies

potential hazards and has special safety messages that help

you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal words

used to identify the level of hazard. However, regardless

of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended precautions

are not followed.

WARNING signals a hazard that may cause serious injury

or death if the recommended precautions are not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are not

followed. T wo other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes general

information worthy of special attention.

2

Page 4

Safety

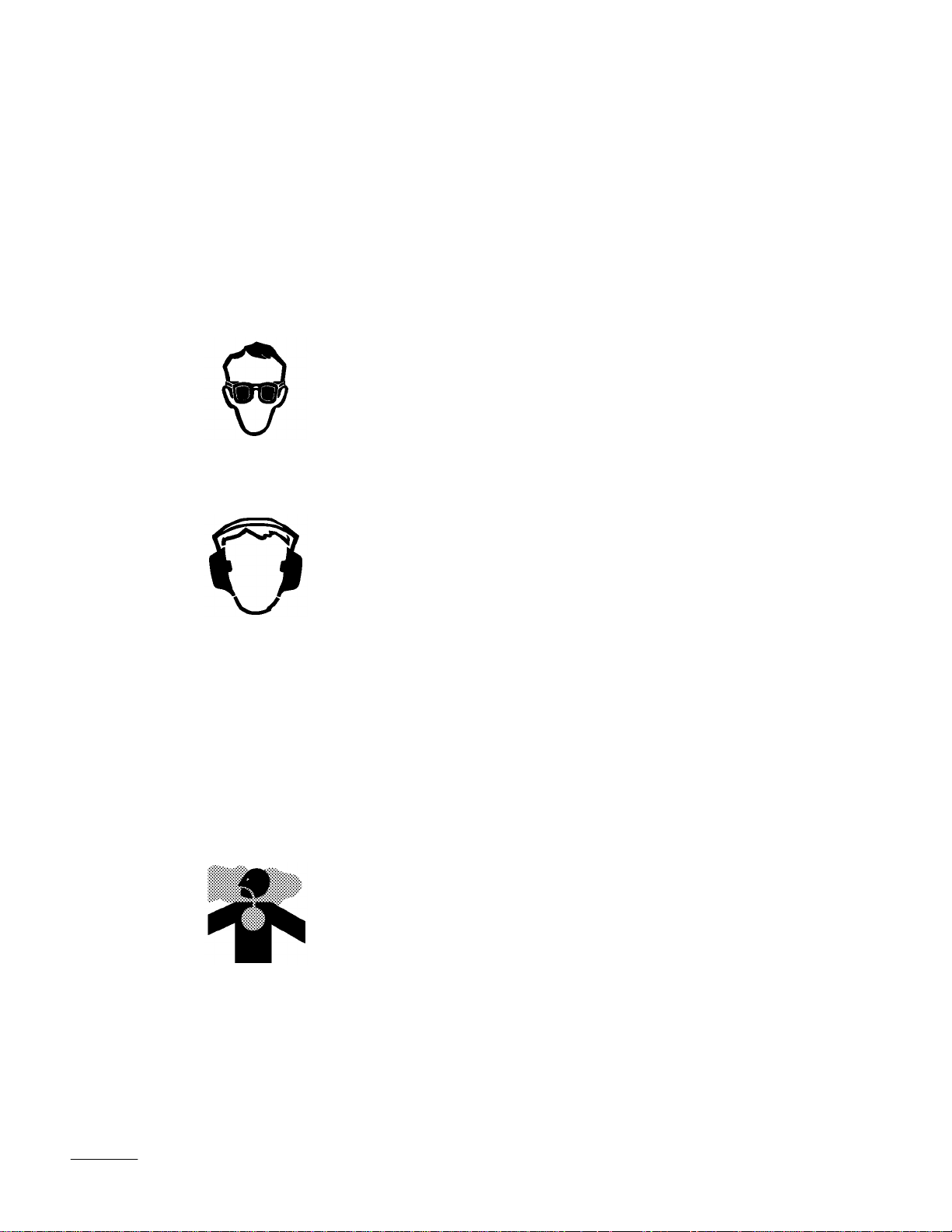

Operator Safety

1. Read and understand this Operator’s Manual before

using this product. Be thoroughly familiar with the

proper use of this product.

2. Always wear eye protection that complies with ANSI

(American National Standards Institute) Z87–1.

3. Always wear hearing protection.

4. Always wear heavy, long pants, boots and gloves. Do

not wear loose clothing, jewelry, short pants, sandals,

or go barefoot. Secure hair so it is above shoulder

length.

5. Never operate this String Trimmer when you are tired,

ill, or under the influence of alcohol, drugs or

medication.

2. Inspect the String Trimmer before each use. Replace

damaged parts. Check for fuel leaks. Make sure all

fasteners are in place and tightened securely. Follow

the maintenance instructions beginning on page 15.

3. Make sure the trimmer head does not rotate at engine

idle speed. Refer to Idle Speed Adjustment, page 16.

4. Inspect the String Trimmer cutting head and replace

any parts that are cracked, chipped or damaged before

using the Trimmer.

5. Install the required shield before using the Trimmer.

6. Use only flexible, non–metallic, monofilament cutting

line of the correct diameter. Never use wire, rope,

string, etc.

7. Never use a cutting head or replacement parts that are

not approved by T oro.

8. Maintain the String Trimmer according to the

recommended maintenance intervals and procedures in

the Maintenance section on page 15.

9. Shut off the engine and wait until the trimmer head has

completely stopped moving before checking,

performing maintenance on or working on the String

Trimmer.

10.If running problems or excessive vibration occur, stop

immediately and inspect the unit for the cause. If the

cause cannot be determined or is beyond your ability

to correct, return the String Trimmer to your servicing

dealer for repair.

6. Never start or run the engine inside a closed room or

building. Breathing exhaust fumes can cause death.

7. Keep handles clean of oil, fuel and dirt.

String Trimmer Safety

1. Make sure the Trimmer is assembled correctly and that

the trimmer head is correctly installed and securely

fastened as instructed in the Assembly section.

3

Fuel Safety

1. Gasoline is highly flammable and must be handled and

stored carefully . Use a container approved for fuel for

storing gasoline and/or fuel/oil mixture.

2. Mix and pour fuel outdoors and where there are no

sparks or flames.

3. Do not smoke near fuel or String Trimmer, or while

using the String Trimmer.

4. Do not overfill the fuel tank. Stop filling 1/4–1/2 inch

(6mm–13mm) from the top of the tank.

5. Wipe up any spilled fuel before starting the engine.

6. Move the Trimmer at least 10 feet (3 m) away from

the fueling location before starting the engine (Fig. 2).

Page 5

m-2966

Figure 2

1. 10 feet (3m) Minimum

7. Do not remove the Trimmer fuel tank cap while the

engine is running, or right after stopping the engine.

8. Allow the engine to cool before refueling.

9. Drain the tank and run the engine dry before storing

the unit.

10.Store fuel and String Trimmer away from open flame,

sparks and excessive heat. Make sure fuel vapors

cannot reach sparks or open flames from water heaters,

furnaces, electric motors, etc.

m-2967

Figure 3

1. 50 ft. (15 m) Minimum

4. If you are approached while operating the Trimmer,

stop the engine and trimmer head rotation.

5. Never allow children to operate the Trimmer.

6. Use the Trimmer only in daylight or good artificial

light.

7. Never operate the Trimmer without proper guards or

other protective safety devices in place.

8. Always keep the Trimmer on the right side of your

body (Fig. 4).

Power String Trimmer

Operating Safety

1. THIS STRING TRIMMER CAN CAUSE SERIOUS

INJURIES. Read the instructions carefully. Be familiar

with all controls and the proper use of the String

Trimmer.

2. Inspect your work area before you begin. Remove

objects such as broken glass, nails, wire and rocks

which can become dangerous projectiles if thrown by

the Trimmer. Remove string, rope or similar materials

which can become entangled in the trimmer head.

3. This Trimmer will throw objects and cut. Keep

children, bystanders and animals outside a 50 ft. (15

m) radius from the operator and Trimmer (Fig. 3).

Beyond the 50 ft. (15 m) there still may be a risk of

injury to bystanders from thrown objects. It is

recommended that bystanders wear eye protection. A

thrown object can ricochet.

m-2968

Figure 4

9. Do not raise the trimmer head above waist level.

10.Keep all parts of your body away from the rotating

trimmer head and hot surfaces such as the muffler.

11. Keep firm footing and balance. Do not overreach.

12.Use the right tool for the job. Do not use the Trimmer

for any job that is not recommended by T oro.

4

Page 6

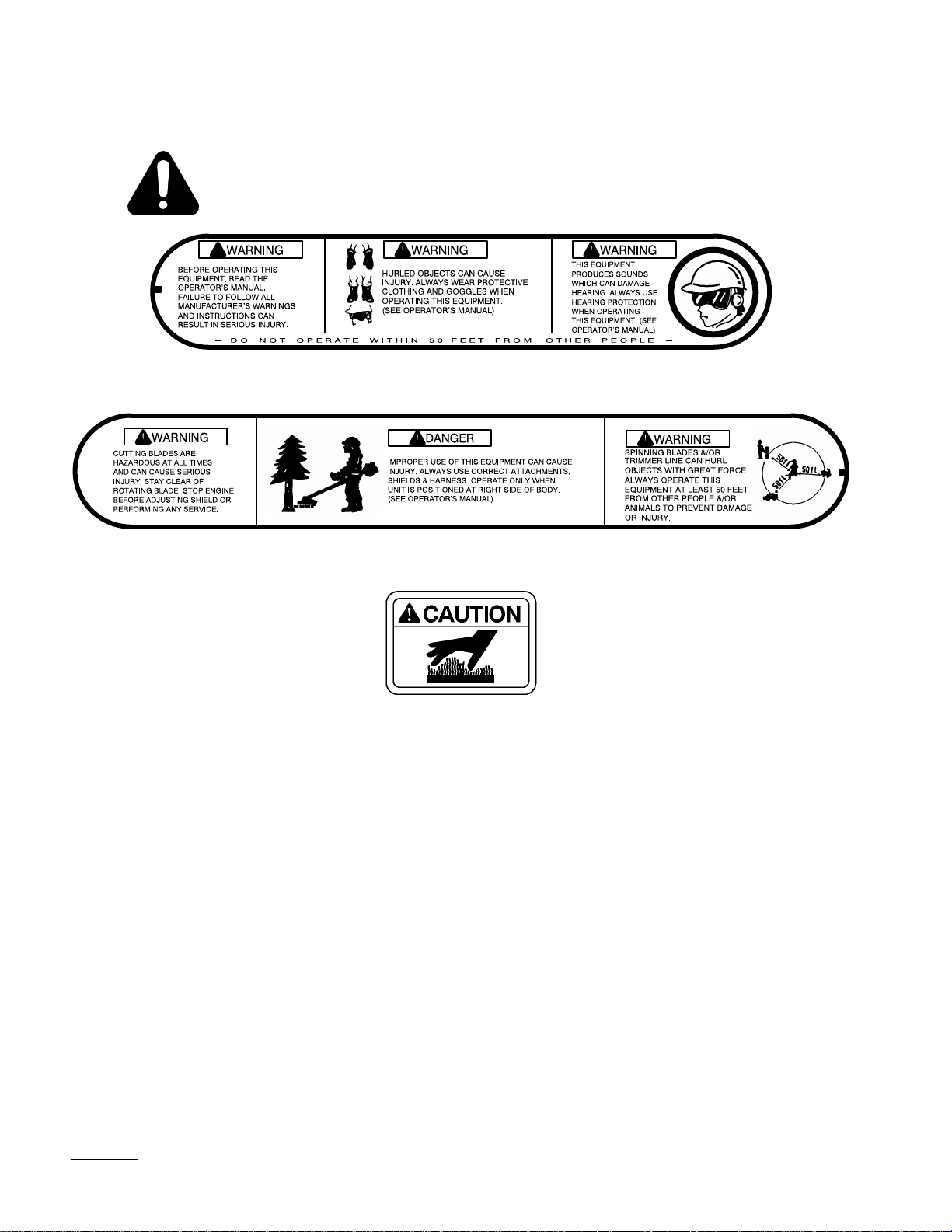

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any

area of potential danger. Replace any decal that is damaged or lost.

(Part No. M221501)

(Part No. M221502)

ON SHAFT

ON SHAFT

ON ENGINE

(Part No. M266291)

5

Page 7

Assembly

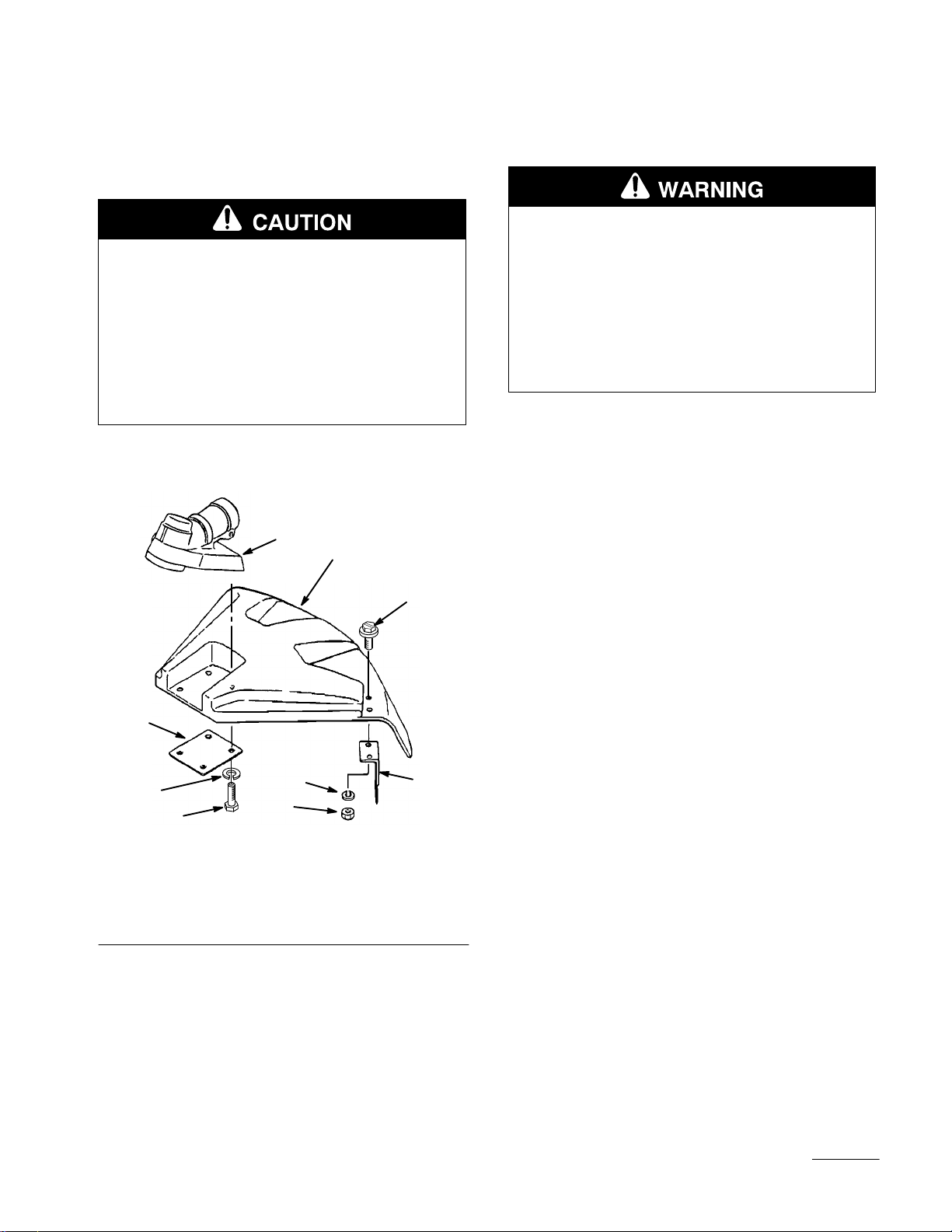

Installing Trimmer Head Shield

POTENTIAL HAZARD

• The cutoff blade is sharp.

WHAT CAN HAPPEN

• Contact with cutoff blade could cause serious

cuts or personal injury.

HOW TO AVOID THE HAZARD

• Keep hands, feet and clothing away from cutoff

blade.

1. Fasten the string cutoff blade to the trimmer head

shield with two M5 x 25 screws, lock washers and hex

nuts as shown (Fig 5).

POTENTIAL HAZARD

• Foreign objects can be thrown by Trimmer.

WHAT CAN HAPPEN

• Contact with thrown objects can cause personal

injury.

HOW TO AVOID THE HAZARD

• Never operate the Trimmer without the

trimmer head shield in place.

2. Attach the trimmer head shield to the gearcase with

the four M5 x 12 screws and lock washers as shown

(Fig 5).

1. Gearcase

2. Trimmer Head Shield

3. M5 x 25 Screw (2)

4. Plate

Figure 5

m-2975

5. Lock Washer

6. M5 x 12 Screw (4)

7. Hex Nut

8. String Cutoff Blade

6

Page 8

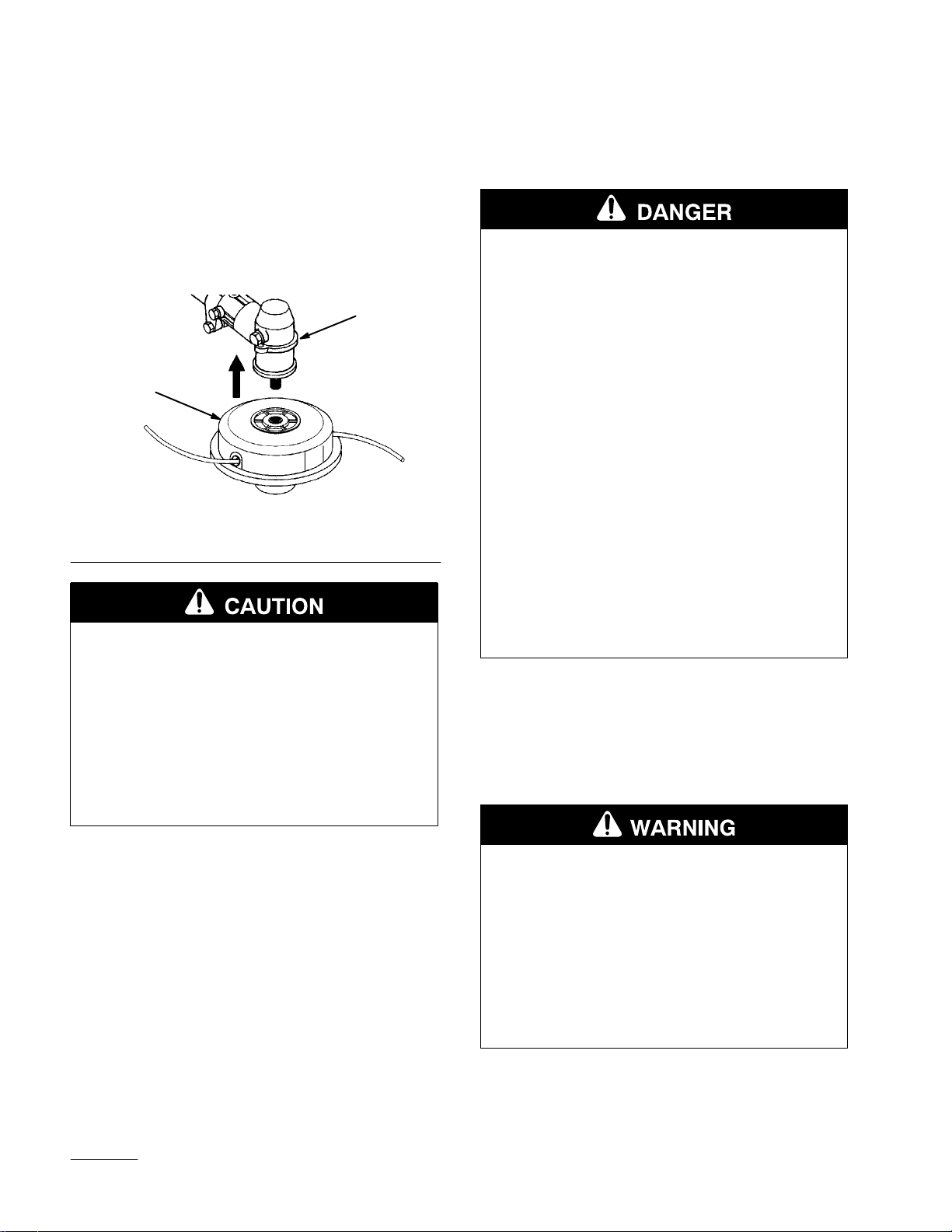

Installing Trimmer Head

IMPORTANT: Make sure the trimmer head is for

LEFT-HAND ROTATION (counterclockwise) as

viewed from the operator’s position, and that the

trimmer head adapter is a male, M8 x 1.25 left-hand

thread.

Before Operation

Oil and Fuel

1. Thread the trimmer head into the gearcase, tighten

trimmer head firmly by hand (Fig. 6).

1

2

Figure 6

1. Gearcase 2. Trimmer Head

POTENTIAL HAZARD

• If the trimmer head is not adequately tightened,

it can come loose from the Trimmer during use.

WHAT CAN HAPPEN

• This may cause damage to property or personal

injury.

HOW TO AVOID THE HAZARD

• Make sure the trimmer head is securely

fastened to the splined shaft in the gearcase.

POTENTIAL HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn you,

others, and cause property damage.

HOW TO AVOID THE HAZARD

• Use a funnel and fill the fuel tank outdoors, in

an open area, when the engine is cold. Wipe up

any gasoline that spills.

• Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1/4” to

1/2” (6 mm to 13 mm) below the bottom of the

filler neck. This empty space in the tank allows

gasoline to expand.

• Never smoke when handling gasoline, and stay

away from an open flame or where gasoline

fumes may be ignited by a spark.

• Store gasoline in an approved container and

keep it out of the reach of children.

• Never buy more than a 30-day supply of

gasoline.

1. Do not smoke near fuel.

2. Mix and pour fuel outdoors and where there are no

sparks or flames.

3. Always shut off the engine before refueling. Never

remove the String Trimmer fuel tank cap while the

engine is running or right after just stopping the

engine.

POTENTIAL HAZARD

• Gasoline contains gasses that can build up

pressure inside a gas tank.

WHAT CAN HAPPEN

• Fuel can be sprayed on you when removing gas

cap.

HOW TO AVOID THE HAZARD

• Remove fuel cap slowly to avoid injury from

fuel spray.

7

Page 9

4. Always open the fuel tank cap slowly to release any

possible overpressure inside the tank.

5. Do not overfill the fuel tank. Stop filling 1/4–1/2 inch

(6mm–13mm) from the top of the tank.

6. Tighten the tank fuel cap carefully but firmly after

refilling.

7. Wipe up any spilled fuel before starting the engine.

8. Move the String Trimmer at least 10 feet (3 m) away

from the fueling location and fuel storage container

before starting the engine (Fig. 2).

Recommended Oil Type

Only use a two-cycle engine oil formulated for use in

high-performance, air-cooled two-cycle engines. Toro

brand 2-cycle oil is formulated for use in

high-performance, air-cooled two-cycle engines.

IMPORTANT: Do not use National Marine

Manufacturer’s Association (NMMA) or BIA certified

oils. This type of 2–cycle engine oil does not have the

proper additives for air-cooled, 2–cycle engines and

can cause engine damage.

Do not use automotive motor oil. This type of

oil does not have the proper additives for

air-cooled, 2–cycle engines and can cause

engine damage.

DO NOT USE FUEL ADDITIVES OTHER

THAN THOSE MANUFACTURED FOR

FUEL STABILIZATION DURING

STORAGE SUCH AS TORO’S

STABILIZER/CONDITIONER OR A

SIMILAR PRODUCT. TORO’S

STABILIZER/CONDITIONER IS A

PETROLEUM DISTILLA TE BASED

CONDITIONER/STABILIZER.

TORO DOES NOT RECOMMEND

STABILIZERS WITH AN ALCOHOL BASE

SUCH AS ETHANOL, METHANOL OR

ISOPROPYL. ADDITIVES SHOULD NOT

BE USED TO TRY TO ENHANCE THE

POWER OR PERFORMANCE OF

MACHINE.

Mixing Gasoline And Oil

IMPORTANT: The engine used on this String Trimmer

is of a 2–cycle design. The internal moving parts of the

engine, i.e., crankshaft bearings, piston pin bearings

and piston to cylinder wall contact surfaces, require oil

mixed with the gasoline for lubrication.

Failure to add oil to the gasoline or failure to

mix oil with the gasoline at the appropriate

ratio will cause major engine damage which

will void your warranty.

Recommended Fuel Type

Use clean, fresh lead-free gasoline, including oxygenated

or reformulated gasoline, with an octane rating of 85 or

higher. To ensure freshness, purchase only the quantity of

gasoline that can be used in 30 days. Use of lead-free

gasoline results in fewer combustion chamber deposits

and longer spark plug life. Use of premium grade fuel is

not necessary or recommended.

Use Of Fuel Additives

IMPORTANT: NEVER USE METHANOL,

GASOLINE CONTAINING METHANOL,

GASOHOL CONTAINING MORE THAN

10% ETHANOL, PREMIUM GASOLINE,

OR WHITE GAS BECAUSE ENGINE

FUEL SYSTEM DAMAGE COULD

RESULT.

For your fuel premix, only use a quality oil

designed for 2–cycle air cooled engines. Toro

50:1 2–Cycle Oil is formulated to meet the

requirements of high-performance, air-cooled

two-cycle engines.

Fuel Mixture

The fuel:oil ratio is 50 parts gasoline to 1 part oil or 50:1.

Note: Never use a mixing ratio less than 50:1

regardless of the oil package mixing instructions.

Ratios less the 50:1, (for example, 60:1, 80:1, 100:1),

reduce the amount of lubrication to the internal

moving parts of the engine and can cause damage.

8

Page 10

Fuel Mixture Chart

Starting And Stopping

Before Starting The Engine

Gasoline 50:1 2-cycle oil

1 gallon 2.6 oz.

2 gallons 5.2 oz.

5 gallons 12.8 oz.

Mixing Instructions

IMPORTANT: Never mix gasoline and oil directly in

the String Trimmer fuel tank.

1. Always mix fuel and oil in a clean container approved

for gasoline.

2. Mark the container to identify it as fuel mix for the

String Trimmer.

3. Use regular unleaded gasoline and fill the container

with half the required amount of gasoline.

4. Pour the correct amount of oil into the container then

add the remaining amount of gasoline.

1. Fill the fuel tank as instructed in the Before Operation

section of this manual.

2. Rest the String Trimmer on the ground.

3. Make sure the trimmer head is clear of any broken

glass, nails, wire, rocks or other debris.

4. Keep all bystanders, children and animals away from

the working area.

Cold Starting Procedure

The carburetors on T oro engines contain a choke system.

T o start a “cold” engine properly, perform the following

procedure:

1. Pump the primer bulb at the bottom of the carburetor

until fuel can be seen flowing through the fuel return

line to the fuel tank (Figs. 7 and 8). (Flowing fuel

should be almost clear, not foamy or full of bubbles.)

5. Close the container tightly and shake it momentarily to

evenly mix the oil and the gasoline before filling the

fuel tank on the String Trimmer.

6. When refilling the String Trimmer fuel tank, clean

around the fuel tank cap to prevent dirt and debris

from entering the tank during cap removal.

7. Always shake the premix fuel container momentarily

before filling the fuel tank

8. Always use a spout or funnel when fueling to reduce

fuel spillage.

9. Fill the tank only to within 1/4–1/2 inch (6mm–13mm)

from the top of the tank. Avoid filling to the top of the

tank filler neck.

1

Model 53002 & 53003

Figure 7

1. Primer Bulb 2. Fuel Return Line

1

2

m-2978

9

Page 11

1

1

2

Model 53010 & 53011

m-3040

Figure 8

1. Primer Bulb 2. Fuel Return Line

2. Move the choke lever to the closed ( ) position and

move the stop switch to the “ON” position (Figs. 9).

1

2

3

4

Figure 10

1. Stop Switch

2. Fast-idle Lock

3. Throttle Trigger (in

fast-idle start position)

4. Throttle Trigger (in idle

position)

4. After the engine starts, move the choke lever to the

open (

) position, then squeeze and release the

throttle trigger to allow it to return to the idle position

(Figs. 10).

If the engine stops running before you move the choke

lever to the open (

) position:

A. Go ahead and open the choke (Fig. 9).

B. Make sure the throttle trigger is set to the fast-idle

start position (Fig. 10).

C. Pull the starter handle until the engine starts

(Fig. 9).

m-2939

2

m-2938

Figure 9

1. Starter Handle 2. Choke Lever (typical)

3. Lock the throttle trigger in the fast-idle start position,

then pull the starter handle (Figs. 10).

10

Page 12

Hot Restart

T o start an engine that is already warmed up (hot restart),

or if the ambient temperature exceeds 68F (20C):

1. Pump the primer bulb at the bottom of the carburetor

until fuel can be seen flowing through the fuel return

line to the fuel tank (Figs. 7 and 8).

2. Move the choke lever to the open (

move the stop switch to the “ON” position (Figs. 9 and

10).

3. Leave the throttle trigger in the idle position and pull

the starter handle (Figs. 9 and 10).

4. If the engine fails to start after three to four pulls,

follow the instructions in the Cold Starting Procedure

section above.

If the engine fails to start after you follow the above

procedures, contact an authorized T oro dealer.

) position and

To Stop The Engine:

1. Release the throttle trigger (Fig. 10).

1. Hearing Protection

2. Eye Protection

3. Right Arm Slightly Bent

4. Left Arm Fully Extended,

Hand Holding Loop

Handle

1. The Trimmer should be on the operator’s right side.

m-2968

Figure 11

5. Hand Holding Throttle

Grip, Fingers on Throttle

Trigger

6. Trimmer Head Near and

Parallel to Ground

2. Slide the stop switch to the “STOP”

position (Fig. 10).

Operation

• Read the Safety instructions on page 3

concerning proper use of the String Trimmer.

Operating Position

Before using the Trimmer, check the following (Fig. 11):

2. The operator’s right hand should be holding the shaft

grip, with his or her fingers on the throttle trigger. The

right arm should be slightly bent.

3. The left hand should be holding the loop handle with

the fingers and thumb fully enclosed around the grip.

The left arm should be extended. Reposition the loop

handle up or down the driveshaft if necessary for a

comfortable position.

4. The Trimmer weight should be evenly distributed

between the arms. The trimmer head should be near

and parallel to the ground.

5. Accelerate and hold the engine at cutting speed before

entering the material to be cut.

6. Always release the throttle trigger and allow the

engine to return to idle speed when not cutting.

7. Stop the Trimmer engine when moving between work

sites.

11

Page 13

• Always wear gloves and protective clothing

when operating the String Trimmer.

• If the trimmer head becomes jammed, stop the engine

immediately.

• Make certain all moving parts have stopped and

disconnect the spark plug before inspecting the

equipment for damage.

• Never use a String Trimmer that has chipped, cracked

or broken trimmer head.

Cutting with Nylon Trimmer

Line

Figure 13

m-2980

• The tip of the line does the cutting. The line should

stay extended while cutting (Fig. 12).

m-2979

Figure 12

1. Three inches (7.6 cm) Above Ground

• Do not force the line into the material. Forcing the line

will cause it to slap against the material, increasing

line usage and causing poor cutting results (Fig. 13).

Trimming

Hold the bottom of the trimmer head about 3 in. (7.6 cm)

above the ground and at an angle. Allow only the tip of

the line to make contact (Figs. 14).

m-2981

Figure 14

1. Three inches (7.6 cm) Above Ground

12

Page 14

Scaling

T o remove unwanted vegetation, hold the trimmer head

about 3 in. (7.6 cm) above the ground and at an angle.

Allow the tip of the line to strike the ground cutting the

vegetation off at the surface (Fig. 15).

m-2982

Figure 15

Mowing

Rewinding the Trimmer Spool

POTENTIAL HAZARD

• Use of improper line could cause line to break

and be thrown in operator’s or bystander’s

direction.

WHAT CAN HAPPEN

• Use of improper line could result in serious

personal injury.

HOW TO AVOID THE HAZARD

• Use only good quality, commercial grade, weld

resistant trimmer line with a diameter of .095

inches (2.413 mm).

• Do not use any type of wire or other string-like

substance. Do not use metal-reinforced line.

1. Push in on one side of the head where it says to “push

open” then pull on bottom (Figs. 17).

Keep the line parallel to the ground and use a gentle

side-to-side motion (Fig. 16).

Figure 16

m-2983

1

Figure 17

1. Push here

2. Remove the empty spool from the head (Fig. 18).

13

Page 15

1

1

1

Figure 20

1. Groves

Figure 18

1. Spool

3. Clean the dirt from the inside of the spool parts if

required.

4. Cut two (2) new lines (10’–15’) of equal length.

5. Place ends of line in holes on inside of spool

(Figs. 19).

6. Place the two (2) lines through the slits and wind the

line in even, tight layers onto the spool in the direction

indicated on the spool (Figs. 19).

3

1

2

2

8. Thread the two ends of the line through the eyelets,

place spool into head and pull line to release from

grooves (Figs. 21).

1

1

Figure 21

1. Eyelets

9. Align the eyelet projections andsnap the cover and

head together (Figs. 22).

3

Figure 19

1. Holes

2. Slits

3. Wind direction arrow

7. Snap the two (2) ends in the grooves as indicated,

leaving 3-4 inches of line to be placed through eyelets

(Figs. 20).

14

Page 16

Figure 22

Maintenance

NOTICE:Maintenance, replacement or repair of the

emission control devices and systems may be

performed by any non-road engine repair

establishment or individual. However, to obtain no

charge repairs under the terms and provisions of the

Toro warranty statement, any service or emission

control part repair or replacement must be performed

by an Authorized Toro Service Dealer.

Air Filter

Maintenance Interval

• The air filter should be cleaned daily, or more often

when working in extremely dusty conditions.

• Replace after every 100 hours of operation.

Air Filter Cleaning

Figure 23

1. Air Filter Cover 2. Foam Filter

Model 53002 & 53003

1. Loosen the knob and remove the air filter cover

(Fig. 24).

2. Remove the foam ring and filter screen from the air

filter cover (Fig. 24).

3. Clean the foam ring and filter screen with warm, soapy

water. Let the screen and ring dry completely.

4. Apply a light coat of SAE 30 motor oil to the foam

ring and squeeze out all excess oil.

5. Reassemble the filter screen and foam ring to the air

filter cover (Fig. 24).

m-2930

Model 53010 & 53011

1. Unsnap the air filter cover (Fig. 23).

2. Remove the foam filter (Fig. 23).

3. Clean the filter with warm, soapy water. Let the filter

completely dry.

4. Apply a light coat of SAE 30 motor oil to the foam

filter and squeeze out all excess oil.

5. Reassemble the filter and filter cover (Fig. 23).

15

1. Air Filter Cover

2. FIlter Screen

m-2997

Figure 24

3. Foam Ring

Page 17

IMPORTANT: The air filter screen is designed to fit

into the air filter cover ONE WAY ONLY . Make sure

the cutouts in the screen fit onto the matching plastic

posts in the air filter cover. The fit should be snug

(Fig. 25).

5. While still holding on to the fuel hose, attach the new

fuel filter.

6. Drop the new fuel filter back into the fuel tank.

7. Make sure that the fuel filter is not stuck in a corner of

the tank, and that the fuel hose is not doubled over

(kinked) before refueling.

Figure 25

1. Filter Screen

2. Cutout (typical)

3. Air Filter Cover

4. Plastic Post (typical)

6. Reinstall the air filter cover and tighten the knob

(Fig. 24).

Fuel Filter

m-3010

m-2931

Figure 26

1. Wire

2. Fuel Pick-up Hose

3. Fuel Filter

Idle Speed Adjustment

This String Trimmer is equipped with non-adjustable fuel

mixture carburetor. The engine idle speed is the only

adjustment for the operator.

Maintenance Interval

The fuel filter should be replaced after every 100 hours of

operation.

Fuel Filter Replacement

The fuel filter is attached to the end of the fuel pick-up

hose inside the fuel tank (Fig. 26).

T o replace the fuel filter:

1. Make sure the fuel tank is empty.

2. Remove the fuel cap.

3. Using a wire hook, gently pull the fuel filter out

through the fuel filler opening (Fig. 26).

4. Grasp the fuel hose next to the fuel filter fitting and

remove the filter, but do not release the hose.

POTENTIAL HAZARD

• Engine must be running to make some

carburetor adjustments.

• When engine is running, trimmer head is

rotating and other parts are moving.

WHAT CAN HAPPEN

• Contact with rotating trimmer head or other

moving parts could cause serious personal

injury or death.

HOW TO AVOID THE HAZARD

• Keep hands, feet and clothing away from

trimmer head and other moving parts.

• Keep all bystanders and pets away from unit

while making carburetor adjustments.

The trimmer head may be rotating during idle speed

adjustment. Wear the recommended personal protective

equipment and observe all safety instructions. Keep hands

and body away from the trimmer head.

16

Page 18

When the throttle trigger is released, the engine should

return to an idle speed between 2400 and 2800 RPM, or

just below the clutch engagement speed. The trimmer

head must not rotate and the engine should not stall (stop

running) at engine idle speed (Fig. 27).

m-2974

Figure 28

1. Idle Speed Adjustment Screw

m-2968

Figure 27

1. Throttle Trigger in Idle

Position

2. No Trimmer Head

Rotation

T o adjust the engine idle speed, rotate the idle speed

adjustment screw on the carburetor (Fig. 28).

• Turn the idle speed screw in (clockwise) to increase

the engine idle speed.

• Turn the screw out (counterclockwise) to decrease the

engine idle speed.

Spark Plug

Maintenance Interval

• The spark plug should be removed from the engine

and checked after each 25 hours of operation.

• Replace the spark plug (NGK BPM6Y) after every 100

hours of operation.

Spark Plug Maintenance

Model 53010 & 53011

1. With the engine at ambient (room) temperature,

remove the socket head screw holding the muffler

cover, then remove the muffler cover (Fig. 30).

2. Loosen the cylinder cover screw and lift off the

cylinder cover (Fig. 29).

If idle speed adjustment is necessary, and after

adjustment the trimmer head rotates or the engine

stalls, stop using the String Trimmer immediately!

Contact your local authorized T oro Dealer for assistance

and servicing.

17

m-2934

Figure 29

1. Screw 2. Cylinder Cover

Page 19

3. T wist the high tension lead boot on the spark plug back

and forth a couple of times to loosen the boot, then

pull the boot off of the spark plug.

4. Remove the spark plug.

5. Clean the electrodes with a stiff brush (Fig. 32).

6. Adjust the electrode air gap to .024–.028 in.

(0.6–0.7mm) (Fig. 32).

m-2997

7. Replace the spark plug if it is oil-fouled, damaged, or

if the electrodes are worn down.

8. Do not overtighten the spark plug when installing. The

tightening torque is 95–148 in. lbs. (10.7–16.6 NSm).

9. Reinstall the cylinder and muffler covers

(Figs. 29 and 30).

m-2927

Figure 31

1. Air Filter Cover

2. FIlter Screen

3. Foam Ring

3. T wist the high tension lead boot on the spark plug back

and forth a couple of times to loosen the boot, then

pull the boot off of the spark plug.

4. Remove the spark plug.

5. Clean the electrodes with a stiff brush (Fig. 32).

6. Adjust the electrode air gap to .024–.028 in.

(0.6–0.7mm) (Fig. 32).

7. Replace the spark plug if it is oil-fouled, damaged, or

if the electrodes are worn down.

8. Do not overtighten the spark plug when installing. The

tightening torque is 95–148 in. lbs. (10.7–16.6 NSm).

9. Reinstall the cylinder and air cleaner covers (Fig. 31).

Figure 30

1. Muffler Cover 2. Socket Head Screw

Model 53002 & 53003

1. With the engine at ambient (room) temperature, loosen

the knob and remove the air cleaner cover (Fig. 31).

2. Loosen the knob and lift off the cylinder cover

(Fig. 31).

m-2932

Figure 32

1. .024”–.028” (0.6–0.7 mm)

18

Page 20

Cylinder Cooling Fins

Maintenance Interval

The cylinder cooling fins should be cleaned after every 25

hours of operation, or once a week, whichever comes first.

Air must flow freely around and through the cylinder

cooling fins to prevent engine overheating. Leaves, grass,

dirt and debris buildup on the fins will increase the

operating temperature of the engine, which can reduce

engine performance and shorten engine life.

Cooling Fin Cleaning

Model 53010 & 53011

1. With the engine cool (ambient or room temperature),

remove the socket head screw holding the muffler

cover, then remove the muffler cover (Fig. 30).

2. Loosen the cylinder cover screw and remove the

cylinder cover (Fig. 29).

Figure 33

1. Air Filter Cover

2. FIlter Screen

Spark Arrester

m-3041

3. Foam Ring

3. Clean all dirt and debris from the cooling fins and

from around the cylinder base.

4. Reinstall the cylinder cover and the muffler cover

(Figs 30 and 29).

Model 53002 & 53003

1. With the engine at ambient (room) temperature, loosen

the knob and remove the air cleaner cover (Fig. 33).

2. Loosen the knob and lift off the cylinder cover

(Fig. 33).

3. Clean all dirt and debris from the cooling fins and

from around the cylinder base.

4. Reinstall the cylinder and air cleaner covers (Fig. 33).

POTENTIAL HAZARD

• Muffler surface becomes hot when Trimmer is

in operation and remains hot for some time

after the engine is shut off.

WHAT CAN HAPPEN

• Contact with hot muffler surfaces could cause a

burn.

HOW TO AVOID THE HAZARD

• Make sure the muffler is cool before inspecting

and cleaning the spark arrester.

Maintenance Interval

• The spark arrester should be inspected and cleaned

after every 25 hours of use.

• Replace the screen if it cannot be thoroughly cleaned,

or if it is damaged.

19

Page 21

Spark Arrester Maintenance

Model 53010 & 53011

1. With the engine at ambient (room) temperature,

remove the socket head screw holding the muffler

cover, then remove the muffler cover (Fig. 30).

2. Remove the four socket head screws holding the spark

arrester assembly to the muffler (Fig. 34).

3. Remove and clean the tail, screen, gasket and plate

with a safety solvent and a stiff brush. If any part

cannot be thoroughly cleaned, it must be replaced.

4. Reinstall the plate, gasket, screen and tail onto the

muffler, then reinstall and tighten the four socket head

screws (Fig. 34).

5. Reinstall the spark arrester, gasket and tail onto the

muffler, then reinstall and tighten the two socket head

screws (Fig. 35).

m-3042

Figure 35

1. Socket Head Screw (2)

2. Tail

3. Gasket

4. Spark Arrester

5. Muffler

m-3043

Figure 34

1. Socket Head Screw (4)

2. Tail

3. Screen

4. Gasket

5. Plate

6. Muffler

5. Reinstall the muffler cover (Fig. 30).

Model 53002 & 53003

1. With the engine at ambient (room) temperature, loosen

the knob and remove the air cleaner cover (Fig. 33).

2. Loosen the knob and lift off the cylinder cover

(Fig. 33).

3. Remove the two socket head screws holding the spark

arrester assembly to the muffler (Fig. 35).

4. Remove and clean the tail, gasket and spark arrester

with a safety solvent and a stiff brush. If any part

cannot be thoroughly cleaned, it must be replaced.

6. Reinstall the cylinder and air cleaner covers (Fig. 33).

20

Page 22

Gearcase Maintenance

The gearcase is a sealed unit which has been greased at

the factory. No gearcase maintenance or lubrication is

required or recommended.

General Cleaning and

Tightening

POTENTIAL HAZARD

• When engine is running, cutting head is

rotating and other parts are moving.

WHAT CAN HAPPEN

• Contact with rotating cutting head or other

moving parts could cause serious personal

injury or death.

HOW TO AVOID THE HAZARD

• Always turn off your Trimmer before you clean

or perform any maintenance on it.

5. Remove the spark plug and squirt a very small amount

of oil into the cylinder (Fig. 36).

Figure 36

The T oro String Trimmer will provide maximum

performance for many, many hours if it is maintained

properly. Good maintenance includes regular checking of

all fasteners for correct tightness, and cleaning the entire

machine.

Storage

For long-term storage of the String Trimmer:

1. Empty the fuel tank into a suitable fuel storage

container.

2. Pump the primer bulb on the carburetor until all fuel is

discharged through the clear fuel return hose.

3. Run the engine to remove any fuel that may remain in

the carburetor.

4. Perform all regular maintenance procedures and any

needed repairs.

POTENTIAL HAZARD

• Oil may squirt out of the spark plug opening

when you pull the starter handle.

WHAT CAN HAPPEN

• Oil can cause eye injuries.

HOW TO AVOID THE HAZARD

• Protect your eyes and keep your face away

from the spark plug opening.

6. Pull the starter handle once.

7. Slowly pull the starter handle to bring the piston to the

top of the cylinder (TDC).

8. Reinstall the spark plug.

9. Store the String Trimmer in a dry place away from

excessive heat, sparks or open flame.

21

Page 23

Accessories

The following accessories may be purchased at your local

authorized TORO Service Dealer .

1. Single Strap Harness, Model No. 46–2951 and

Deluxe Strap Harness, Model No. 46–2961—safety

release straps made out of durable nylon webbing

(Fig. 37).

POTENTIAL HAZARD

• Without the Brushcutter blade shield installed

on the String Trimmer, the Brushcutter blade

can throw foreign objects.

• Without the correct blade shield, handles and

strap installed on the String Trimmer, the

Brushcutter can produce side thrust which can

expose the operator and bystanders to blade

contact.

WHAT CAN HAPPEN

• Contact with the Brushcutter blade or thrown

objects can cause severe personal injury .

HOW TO AVOID THE HAZARD

• Never install only a Brushcutter blade onto a

String Trimmer.

• To convert a String Trimmer to a Brushcutter,

you must purchase and install the entire

Brushcutter Accessory Kit.

2. Brushcutter Accessory Kit, Model No.

53050—allows you to convert the String Trimmer to a

Brushcutter; available for Industrial Models (53002

and 53003) only.

1. Red Band

2. Strap

Figure 37

3. Ring

Troubleshooting

Problem Cause Action

Engine Will Not Start

Engine Will Not Idle Idle speed set incorrectly Set idle speed

Engine Lacks Power or Stalls When

Cutting

STOP switch set to off position

Empty fuel tank

Primer bulb wasn’t pushed enough Press primer bulb until fuel flows

Engine flooded Use warm engine starting

Throttle wire has come loose Tighten throttle wire

Dirty air filter Clean or replace air filter

Move switch to on position

Fill fuel tank

through fuel return line

procedure

If further assistance is required, contact your local authorized Toro service dealer.

22

Page 24

Specifications

Note: All models are CARB approved.

53010/Commercial

Engine Displacement 23cc

Shaft Straight (59”/150 cm)

steel with 5 ball

bearings, 5 bushings

Anti Vibration Dual Isolation – grip and

engine mount

Carburetor Walbro – Choke Type

Ignition System Solid State

Fuel Tank Capacity 0.63 qts. (0.6 liter)

Gas to Oil Ratio 50:1

Cutting Head 4” Semiautomatic

Weight 12.6 lbs. (5.7 kg)

Spark Plug NGK BPM6Y

Spark Plug Gap .024–.028 in

(0.6–0.7mm)

53002/Industrial

Engine Displacement 26cc

Shaft Straight (59”/150 cm)

steel with 6 ball

bearings, 5 bushings

Anti Vibration Dual Isolation – grip and

engine mount

Carburetor Walbro – Choke Type

Ignition System Solid State

Fuel Tank Capacity 0.85 qts. (0.8 liter)

Gas to Oil Ratio 50:1

Cutting Head 5” Semiautomatic

Weight 14.8 lbs. (6.7 kg)

Spark Plug NGK BPM6Y

Spark Plug Gap .024–.028 in

(0.6–0.7mm)

53011/Commercial

Engine Displacement 26cc

Shaft Straight (59”/150 cm)

steel with 6 ball

bearings, 5 bushings

Anti Vibration Dual Isolation – grip and

engine mount

Carburetor Walbro – Choke Type

Ignition System Solid State

Fuel Tank Capacity 0.74 qts. (0.7 liter)

Gas to Oil Ratio 50:1

Cutting Head 4” Semiautomatic

Weight 13.3 lbs. (6 kg)

Spark Plug NGK BPM6Y

Spark Plug Gap .024–.028 in

(0.6–0.7mm)

53003/Industrial

Engine Displacement 32cc

Shaft Straight (59”/150 cm)

steel with 6 ball

bearings, 5 bushings

Anti Vibration Dual Isolation – grip and

engine mount

Carburetor Walbro – Choke Type

Ignition System Solid State

Fuel Tank Capacity 1.05 qts. (1 liter)

Gas to Oil Ratio 50:1

Cutting Head 5” Semiautomatic

Weight 15.3 lbs. (6.9 kg)

Spark Plug NGK BPM6Y

Spark Plug Gap .024–.028 in

(0.6–0.7mm)

23

Page 25

Federal and California Emission Control Warranty Statement

A Two Year Limited Warranty

Your Warranty Rights and Obligations

The U.S. Environmental Protection Agency (EPA), the California Air Resources Board (CARB) and Toro

are pleased to explain the emission control system warranty on your 1995 and later utility/lawn/garden

equipment engine. In California, new utility/lawn/garden equipment engines must be designed, built and

equipped to meet the State’s stringent anti–smog standards. In other states, new 1997 and later model

year utility/lawn/garden equipment engines must be designed, built and equipped, at the time of sale, to

meet the U.S. EPA regulations for small nonroad engines. The equipment engine must be free from

defects in materials and workmanship which cause it to fail to conform with U.S. EPA standards for the

first two years of engine use from the date of sale to the ultimate purchaser. Toro must warrant the

emission control system on your utility/lawn/garden equipment engine for the period of time listed above

provided there has been no abuse, neglect or improper maintenance of your utility/lawn/garden

equipment engine.

Your emission control system may include parts such as the carburetor or fuel injection system, the

ignition system, and catalytic converter. Also included may be hoses, belts, and connectors and other

emission related assemblies.

Where a warrantable condition exists, Toro will repair your engine at no cost to you including diagnosis,

parts and labor.

Manufacturer’s Warranty Coverage:

Utility/Lawn/Garden equipment engines are warranted for two years from the date of delivery. If any

emission–related part on your engine is defective in materials or workmanship, the part will be repaired or

replaced by T oro free of charge.

Owner’s Warranty Responsibilities:

• As the engine owner, you are responsible for the performance of the required maintenance listed

in your owner’s manual. Toro recommends that you retain all receipts covering maintenance on

your equipment, but Toro cannot deny warranty solely for the lack of receipts or for your failure

to ensure the performance of all scheduled maintenance.

• Any replacement part or service that is equivalent in performance and durability may be used in

non–warranty maintenance or repairs, and shall not reduce the warranty obligations of the

engine manufacturer.

• As the engine owner, you should, however, be aware that Toro may deny you warranty

coverage if your engine or a part has failed due to abuse, neglect, improper maintenance or

unapproved modifications or parts.

• You are responsible for presenting your equipment engine to a TORO Service Dealer as soon as

a problem exists. The warranty repairs should be completed in a reasonable amount of time,

not to exceed 30 days.

• If you have any questions regarding your warranty rights and responsibilities or if you need a

referral to a TORO Service Dealer, please feel free to contact us at the following address:

Toro Customer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420–1196

612–888–8801

800–348–2424

Warranted Parts:

The warranty period begins on the date the engine or equipment is delivered to a retail purchaser. The

manufacturer warrants to the initial owner and each subsequent purchaser that the engine is free from

defects in materials and workmanship which cause the engine to fail to conform with applicable regulations

for a period of two years.

Rev. 10/29/97

Page 26

Failures caused by abuse, neglect, or improper maintenance are not covered. The use of add–on or

modified parts can be grounds for disallowing a warranty claim. The manufacturer is not liable to cover

failures of warranted parts caused by the use of add–on or modified parts. T oro is liable for damages to

other engine components caused by the failure of a warranted part still under warranty. The owner is

responsible for the performance of the required maintenance, as defined by the manufacturer in the written

instructions.

Any warranted part which is not scheduled for replacement as required maintenance, or which is scheduled

only for regular inspection to the effect of ”repair or replace as necessary” shall be warranted for the

warranty period. Any warranted part which is scheduled for replacement as required maintenance shall be

warranted for the period of time up to the first scheduled replacement point for that part. Coverage under

this warranty extends only to the parts listed below (the emissions system parts) to the extent that these

parts were present on the engine when purchased.

– Fuel Metering System

• Cold start enrichment system including the choke mechanism or priming system

• Fuel pump

• Air fuel ratio feed back system

• Carburetor and internal parts

• Fuel injection system

– Air Induction System

• Air cleaner

• Reed intake system

• Intake manifold

• Controlled hot air intake system

– Ignition System

• Spark plug(s)

• Ignition coils and electronics

• Advance/retard mechanisms

– Catalytic Converter/Thermal Reactor System

• Catalytic converter

• Thermal reactor

• Exhaust manifold

– Air Injection System

• Air injection system or pulse valve

• Valves affecting distribution of air

– Exhaust Gas Recirculation (EGR) System

• EGR valve body and piping system connecting to the intake side of the engine

• EGR control system

– Particulate Controls

• Traps filters, precipators and any other device used to capture particulate emissions

– Miscellaneous Items Used in the Above Systems

• Vacuum, temperature, and time sensitive valves and switches

• Electronic controls

• Hoses, connectors, and assemblies of same

How to Get Warranty Service:

Should you feel your TORO Product requires warranty service, contact the dealer who sold you the product

or any Authorized TORO Service Dealer or TORO Master Service Dealer. The Yellow Pages of your

telephone directory is a good reference source. The dealer will either arrange service at his/her dealership

or recommend another Authorized Service Dealer who may be more convenient. You may need proof of

purchase (copy of registration card, sales receipt, etc.) for warranty validation. The owner shall not be

charged for diagnostic labor which leads to the determination that a warranted part is defective, if the

diagnostic work is performed at a warranty station.

Page 27

The Toro Company is not liable for indirect, incidental or consequential damages in connection

with the use of the TORO Products covered by this warranty, except for damages to other engine

components caused by the failure of a warranted part still under warranty. Some states do not

allow exclusions of incidental or consequential damages, so the above exclusion may not apply to

you.

This warranty gives you specific legal rights, and you may also have other rights which vary from

state to state.

Page 28

LCG

THE TORO TOTAL COVERAGE

GUARANTEE

A OneĆYear Limited Warranty

(A TwoĆYear Full Warranty for Residential Use)

What Is Covered By This Express Warranty?

The Toro Company promises to repair any TORO Product

used for commercial, institutional, or rental purposes if defective in materials or workmanship for a period of one year from

the date of purchase. The cost of parts and labor are included, but the customer pays the transportation cost. Transportation within a 15-mile radius of a TORO ProLine Service

Dealer is covered under this warranty for Riding Products,

Mid-size Mowers and Turf Maintenance Equipment.

What Products Are Covered By This Warranty?

The following products and their attachments are covered by

this warranty:

S Z-Master Zero Radius Tractors

S ProLine Mid-size Mowers

S Groundsmaster Riding Mowers

S ProLine Hand-held Gas Products

S Backpack Blowers

S Commercial WPM

S Turf Maintenance Equipment

S Debris Management Equipment

How About Residential Use?

TORO Products used for residential use are covered by a full

two-year warranty.

How Do You Get Warranty Service?

Should you feel your TORO Product contains a defect in materials or workmanship, contact the dealer who sold you the

product or any TORO ProLine Service Dealer. The Yellow

Pages of your telephone directory is a good reference

source; look under TORO Commercial Service Dealers. The

Service Dealer will either arrange service at his/her dealership or recommend another authorized Service Dealer who

may be more convenient. You may need proof of purchase

(copy of registration card, sales receipt, etc.) for warranty

validation.

If for any reason you are dissatisfied with a Service Dealer ’s

analysis of the defect in materials or workmanship or if you

need a referral to a TORO ProLine Service Dealer, please feel

free to contact us at the following address:

What Must You Do To Keep The Warranty In Effect?

You must maintain your TORO Product by following the maintenance procedures described in the operator’s manual. Such

routine maintenance, whether performed by a dealer or by

you, is at your expense.

What Does This Warranty Not Cover?

and

How Does Your State Law Relate To This Warranty?

There is no other express warranty except for special emission system coverage on some products and as described

above. This express warranty does not cover:

S Cost of regular maintenance service or parts, such as

filters, fuel, lubricants, tune-up parts, blade sharpening,

brake and clutch adjustments.

S Any product or part which has been altered or misused or

required replacement or repair due to normal wear, accidents, or lack of proper maintenance.

S Repairs necessary due to improper fuel, contaminants in

the fuel system, or failure to properly prepare the fuel system prior to any period of non-use over three months.

S Pickup and delivery charges for distances beyond a

15-mile radius from a TORO ProLine Service Dealer.

All repairs covered by this warranty must be performed by a

TORO Service Dealer using T o ro approved replacement parts.

The Toro Company is not liable for indirect or consequential damages in connection with the use of the TORO

Products covered by this warranty, including any cost or

expense of providing substitute equipment or service during reasonable periods of malfunction or non-use pending completion of repairs under this warranty. Some

states do not allow exclusions of incidental or consequential damages, so the above exclusion may not apply

to you.

This warranty gives you specific legal rights, and you may

also have other rights which vary from state to state.

Toro Customer Service Department

81 11 Lyndale Avenue South

Bloomington, MN 55420–1196

612–888–8801 or 800–348–2424

COUNTRIES OTHER THAN THE UNITED STATES OR CANADA

Customers who have purchased TORO products exported from the United States or Canada should contact their TORO DisĆ

tributor (Dealer) to obtain guarantee policies for your country, province, or state. If for any reason you are dissatisfied with

your Distributor's service or have difficulty obtaining guarantee information, contact the TORO importer. If all other remedies

fail, you may contact us at The Toro Company.

Rev 6/18/97

Loading...

Loading...