ELECTRIC TRIMMER/WEEDER SERVICE MANUAL

Table of Contents – Page 1 of 4

TRIMMER/WEEDER MODELS

FOREWORD

TOOL REQUIREMENTS

AUTOMATIC LIN E FEED ASSEMBLY

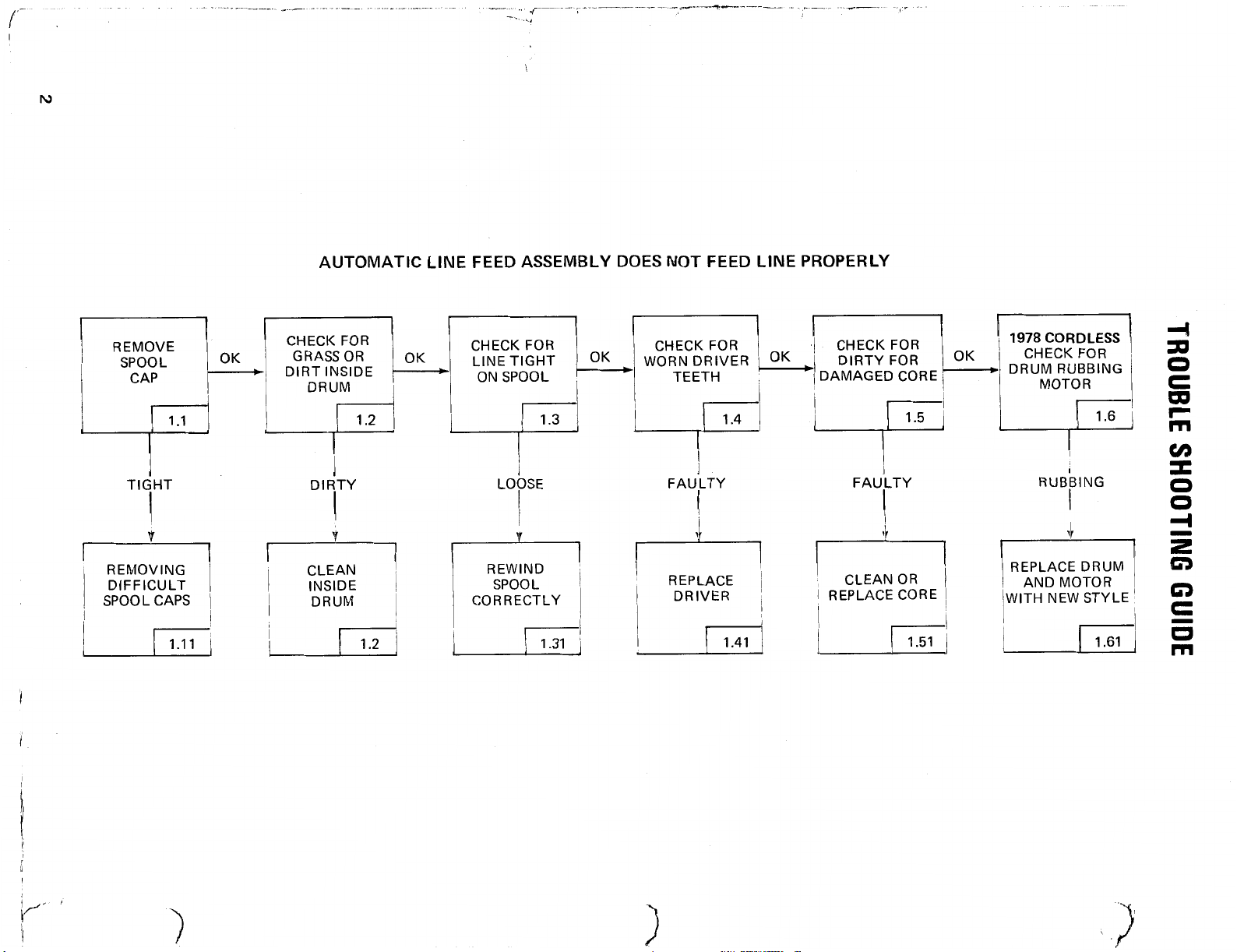

TROUBLE SHOOTING GUIDE

AUTOMATIC LINE FEED ASSEMBLY SERVICE INSTRUCTIONS

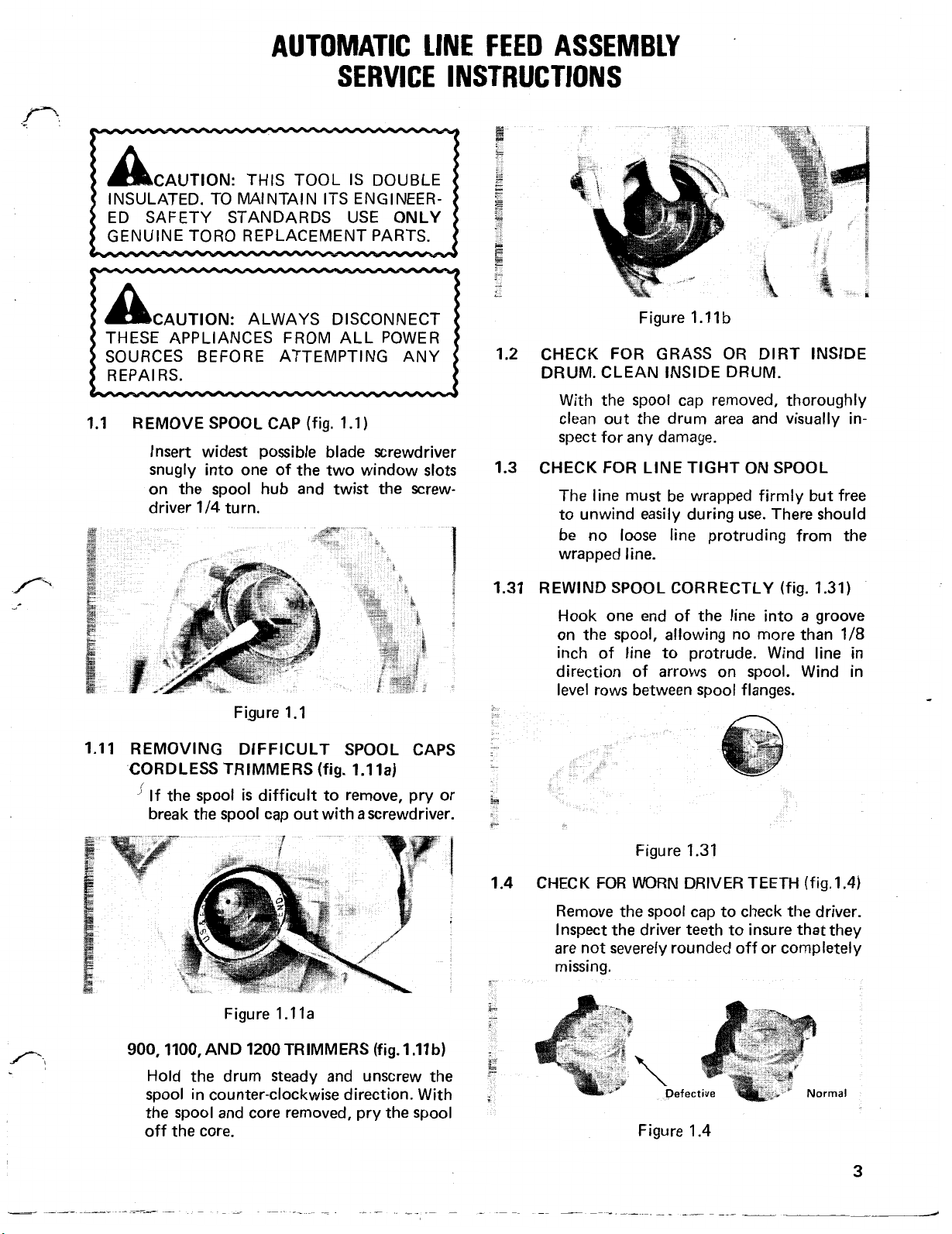

1.1 REMOVE SPOOL CAP (FIG. 1.1)

1.11 REMOVING DIFFICULT SPOOL CAPS CORDLESS TRIMMERS (FIG 1.11A).

900, 1100, AND 1200 TRIMMERS (FIG. 1.11B)

1.2 CHECK FOR GRASS OR DIRT INSIDE DRUM. CLEAN INSIDE DRUM

1.3 CHECK FOR LINE TIGHT ON SPOOL

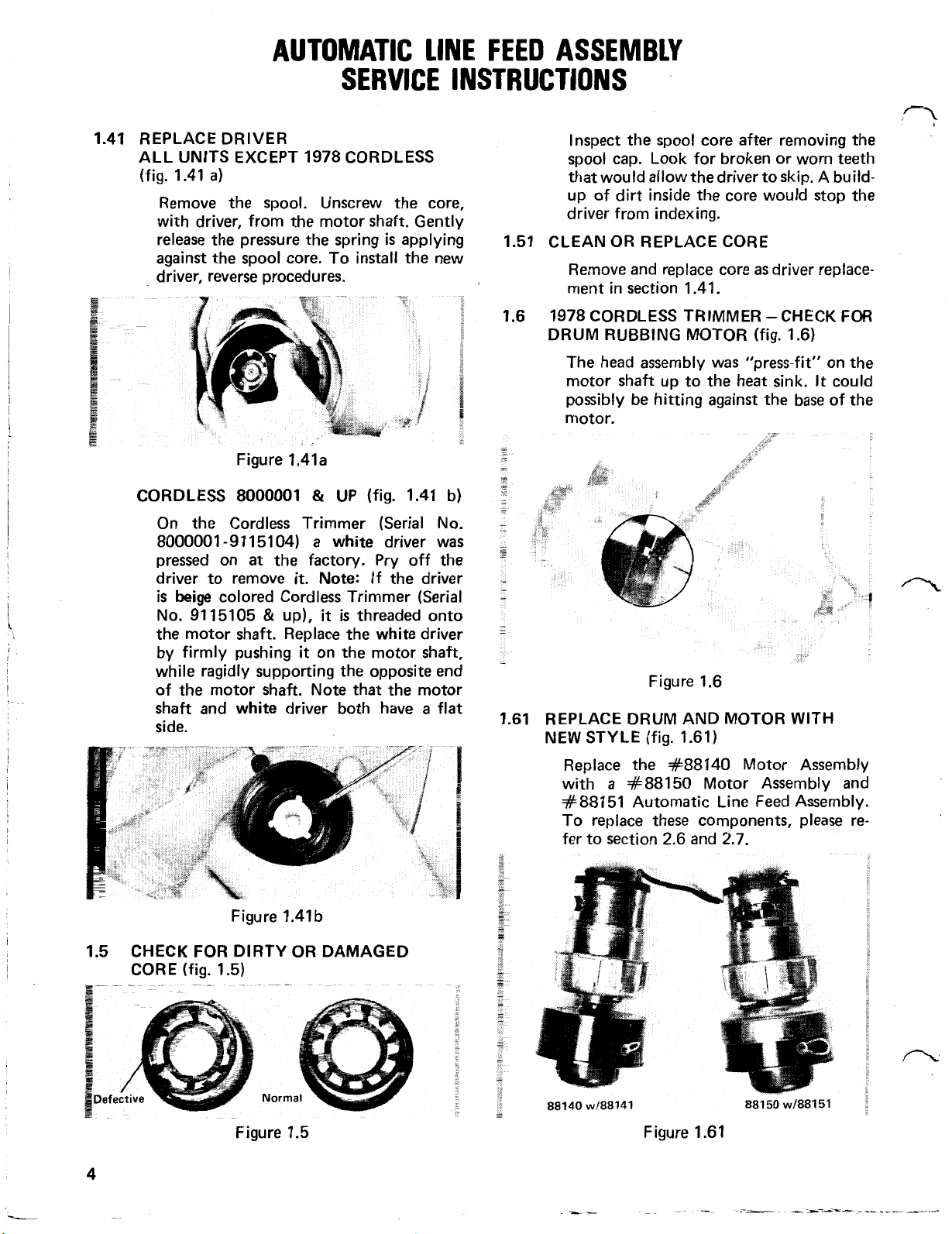

1.31 REWIND SPOOL CORRECTLY (FIG. 1.31)

1.4 CHECK FOR WORN DRIVER TEETH (FIG. 1.4)

1.41 REPLACE DRIVER ALL UNITS EXCEPT 1978 CORDLESS (FIG. 1.41A)

1.5 CHECK FOR DIRTY OR DAMAGED CORE (FIG. 1.5)

1.51 CLEAN OR REPLACE CORE

1.6 1978 CORDLESS TRIMMER -CHECK FOR DRUM RUBBING MOTOR (FIG.

1.61 REPLACE DRUM AND MOTOR WITH NEW STYLE (FIG. 1.61)

900 AND 1100 TRIMMERS

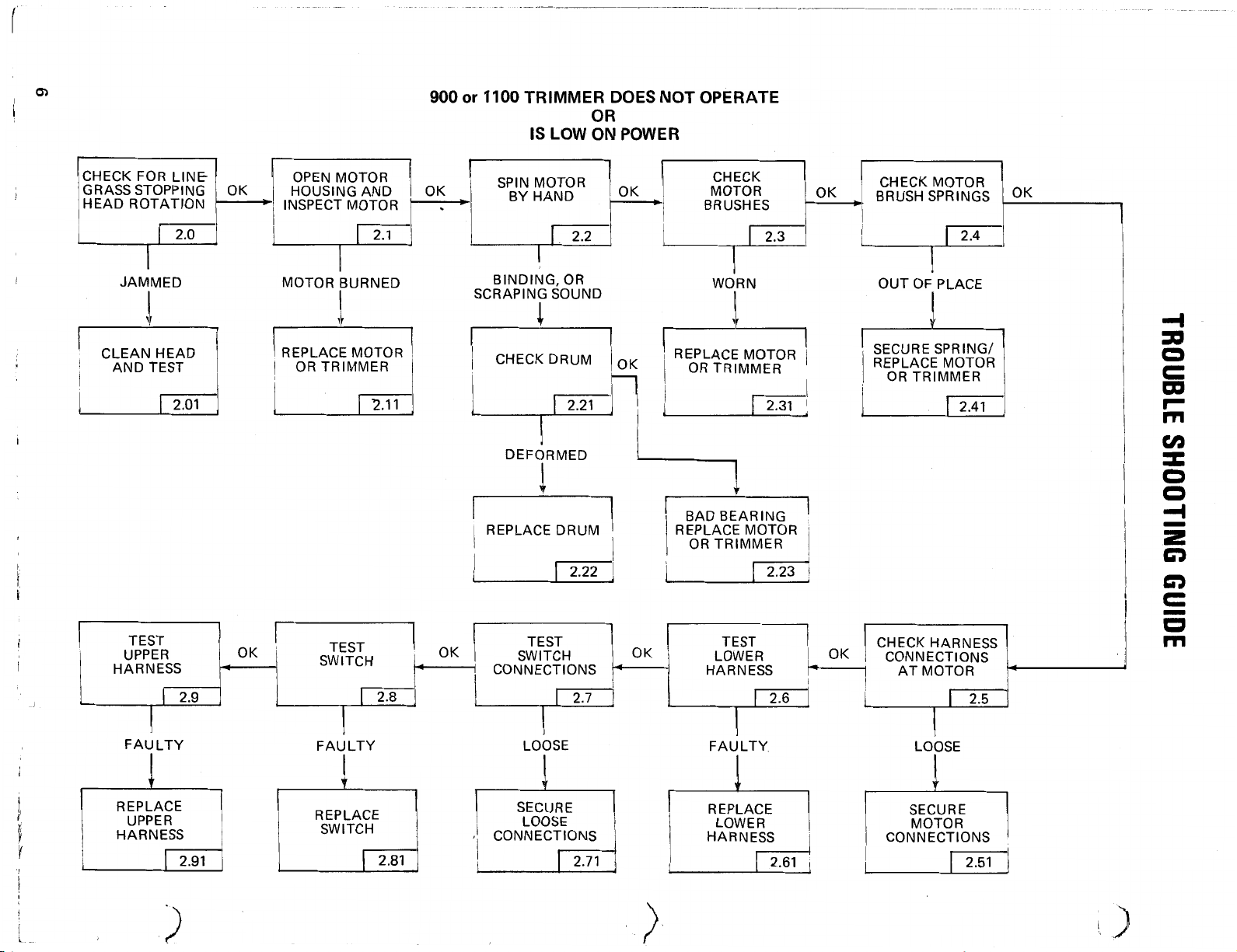

TROUBLE SHOOTING GUIDE

WIRING DIAGRAM

SERVICE INSTRUCTIONS

2.0 CHECK FOR LINE/GRASS STOPPING HEAD ROTATION (FIG. 2.0)

2.01 CLEAN HEAD AND TEST (FIG. 2.01)

2.1 OPEN MOTOR HOUSING AND INSPECT MOTOR (FIG. 2.1)

2.11 REPLACE MOTOR (FIGS. 2.11A, 2.11B)

2.2 SPIN MOTOR BY HAND

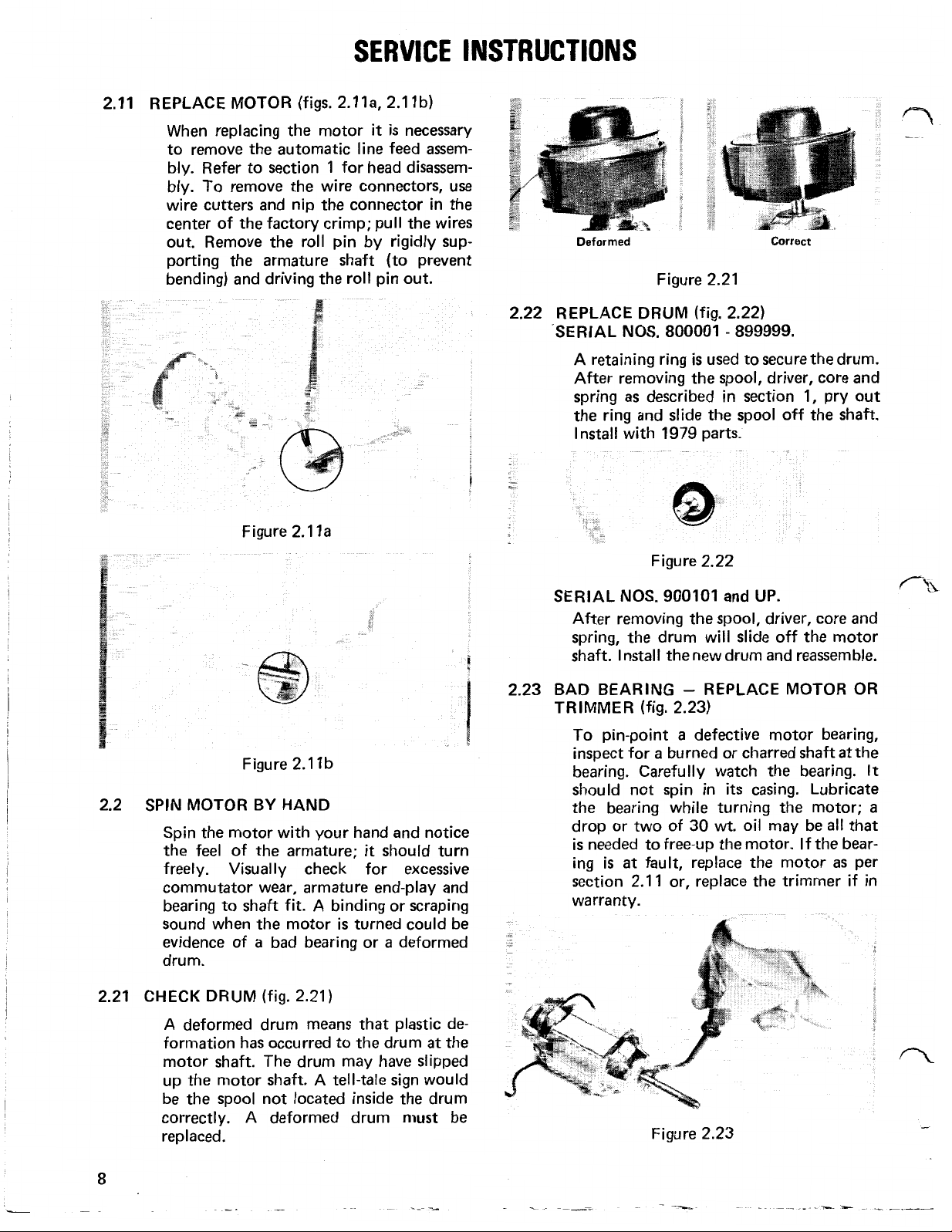

2.21 CHECK DRUM (FIG. 2.21)

2.22 REPLACE DRUM (FIG. 2.22) SERIAL NOS. 800001-899999

2.23 BAD BEARING - REPLACE MOTOR OR TRIMMER (FIG. 2.23)

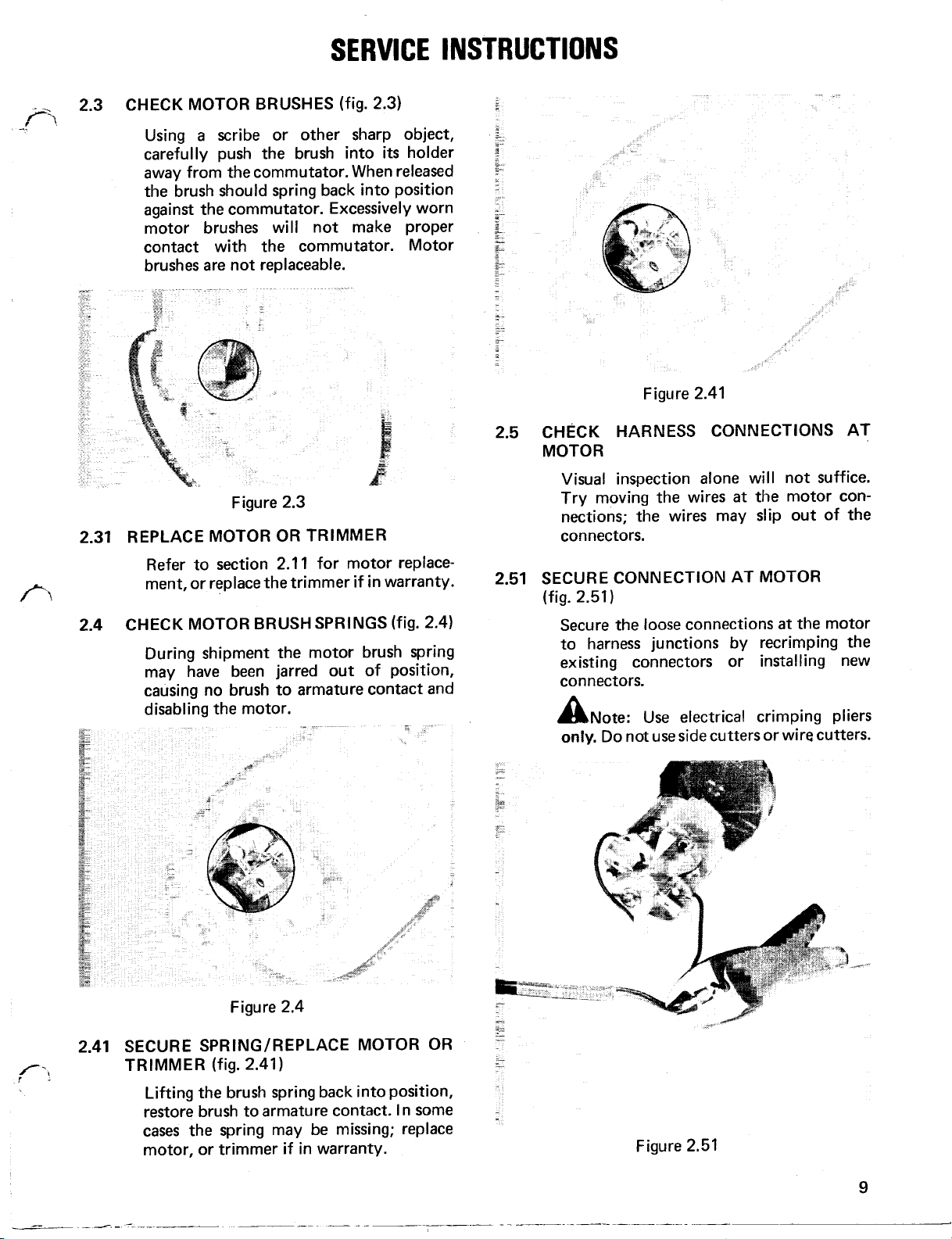

2.3 CHECK MOTOR BRUSHES (FIG. 2.3)

2.31 REPLACE MOTOR OR TRIMMER

2.4 CHECK MOTOR BRUSH SPRINGS (FIG. 2.4)

2.41 SECURE SPRING/REPLACE MOTOR OR TRIMMER (FIG. 2.41)

2.5 CHECK HARNESS CONNECTIONS AT MOTOR

2.51 SECURE CONNECTION AT MOTOR (FIG. 2.51)

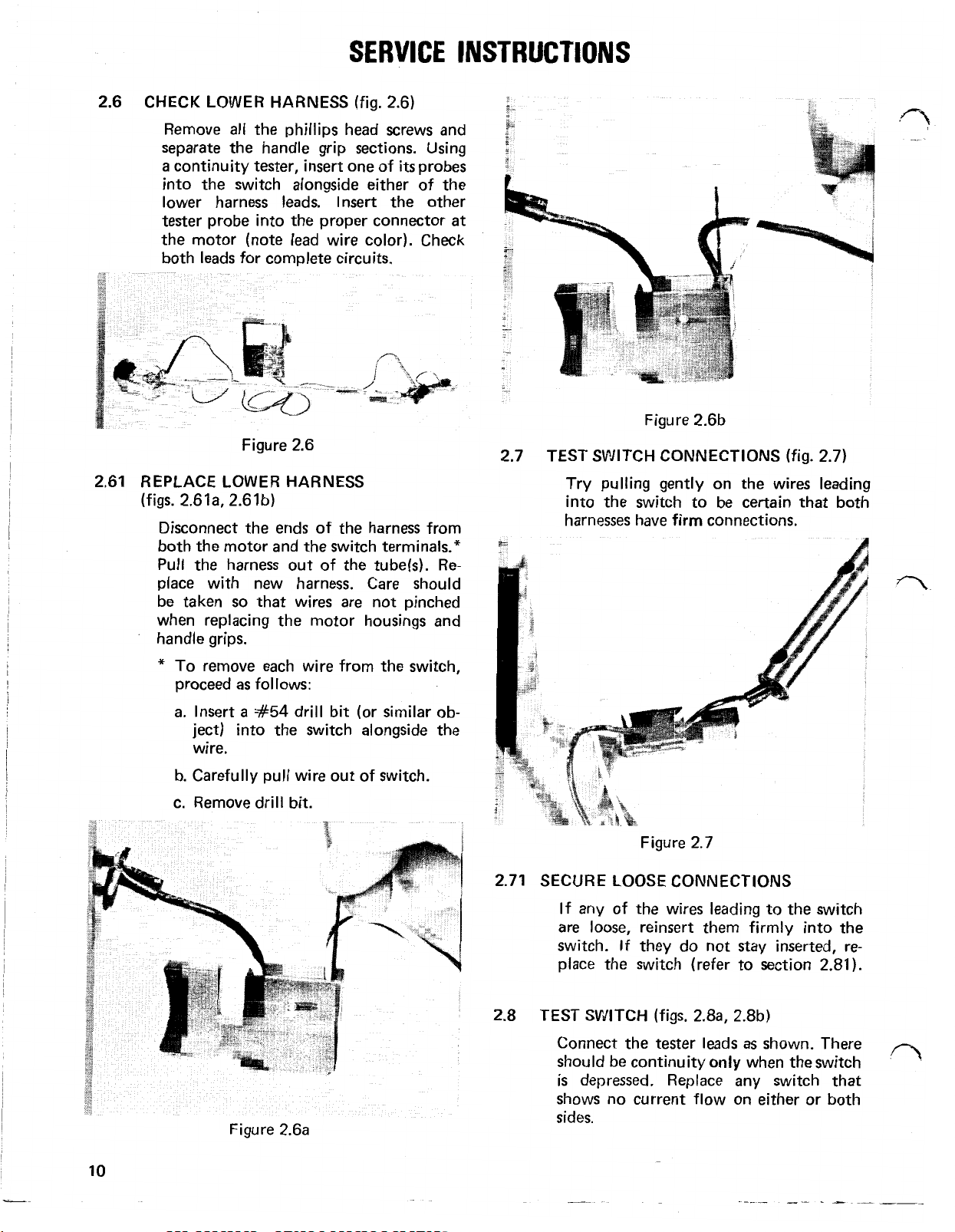

2.6 CHECK LOWER HARNESS (FIG. 2.6)

2.61 REPLACE LOWER HARNESS (FIGS. 2.61A, 2.61B)

2.7 TEST SWITCH CONNECTIONS (FIG. 2.7)

ELECTRIC TRIMMER/WEEDER SERVICE MANUAL

Table of Contents – Page 2 of 4

SERVICE INSTRUCTIONS - continued

2.71 SECURE LOOSE CONNECTIONS

2.8 TEST SWITCH (FIGS. 2.8A, 2.8B)

2.81 REPLACE SWITCH (FIG. 2.81)

2.9 TEST UPPER HARNESS (FIG. 2.9)

2.91 REPLACE UPPER HARNESS

1200 TRIMMER

TROUBLE SHOOTING

WIRING DIAGRAM

SERVICE INSTRUCTIONS

3.0 CHECK FOR LINE/GRASS STOPPING HEAD ROTATION (FIG. 3.0)

3.01 CLEAN HEAD AND TEST (FIG. 3.01)

3.1 OPEN MOTOR HOUSING AND INSPECT MOTOR (FIG. 3.1)

3.11 REPLACE MOTOR (FIG. 3.11A, 3.11B)

3.2 SPIN MOTOR BY HAND

3.21 CHECK DRUM (FIG. 3.21)

3.22 REPLACE DRUM (FIG. 3.22) SERIAL NOS. 800001-899999.

3.23 BAD BEARING -- REPLACE MOTOR OR TRIMMER (FIG. 3.23)

3.3 CHECK MOTOR BRUSHES (FIG. 3.3)

3.31 REPLACE MOTOR OR TRIMMER

3.4 CHECK MOTOR BRUSH SPRINGS (FIG. 3.4)

3.41 SECURE SPRING/REPLACE MOTOR OR TRIMMER (FIG. 3.41)

3.5 TEST BRIDGE RECTIFIER (FIG. 3.5A, 3.5B)

3.51 REPLACE BRIDGE RECTIFIER

3.6 CHECK HARNESS CONNECTIONS AT RECTIFIER

3.61 SECURE CONNECTION AT RECTIFIER

3.7 CHECK LOWER HARNESS (FIG. 3.7)

3.71 REPLACE LOWER HARNESS

3.8 TEST SWITCH CONNECTIONS (FIG. 3.8)

3.81 SECURE LOOSE CONNECTIONS

3.9 TEST SWITCH (FIG. 3.9A, 3.9B)

3.91 REPLACE SWITCH (FIG. 3.91)

4.0 TEST UPPER HARNESS (FIG. 4.0)

4.01 REPLACE UPPER HARNESS

CORDLESS TRIMMER

TROUBLE SHOOTING GUIDE

WIRING DIAGRAM

ELECTRIC TRIMMER/WEEDER SERVICE MANUAL

Table of Contents – Page 3 of 4

SERVICE INSTRUCTIONS

5.0 CHECK FOR LINE/GRASS STOPPING HEAD ROTATION (FIG. 5.0)

5.01 CLEAN HEAD AND TEST (FIG. 5.01)

5.1 INSPECT UPPER TO LOWER HARNESS CONNECTION (FIG. 5.1)

5.11 SECURE UPPER TO LOWER HARNESS CONNECTION (FIG. 5.11)

5.2 CHECK BATTERY CONNECTIONS (FIG. 5.2)

5.21 SECURE BATTERY CONNECTIONS

5.3 TEST OUTPUT VOLTAGE OF BATTERY CHARGER (FIG. 5.3)

5.31 REPLACE BATTERY CHARGER

5.4 CHECK CHARGER OUTPUT AT BATTERY CONNECTIONS (FIG. 5.4)

5.41 REPLACE UPPER WIRING HARNESS

5.5 CHARGE BATTERY FOR 48 HOURS AND TEST (FIG. 5.5)

5.51 REPLACE BATTERY AND CHARGE FOR 48 HOURS

5.6 INSPECT MOTOR

5.61 REPLACE MOTOR (FIG. 5.61)

5.7 SPIN MOTOR BY HAND

5.71 CHECK DRUM (FIG. 5.71)

5.72 REPLACE DRUM SERIAL NOS. 800001-9115104

5.73 BAD BEARING - REPLACE MOTOR OR TRIMMER

5.8 CHECK HARNESS CONNECTIONS AT MOTOR

5.81 SECURE MOTOR CONNECTIONS (FIG. 5.81)

5.9 TEST LOWER HARNESS (FIG. 5.9)

5.91 REPLACE LOWER HARNESS

6.0 TEST SWITCH CONNECTIONS

6.01 SECURE LOOSE CONNECTIONS

6.1 TEST SWITCH (FIGS. 6.1A, 6.1B)

6.11 REPLACE SWITCH

6.2 TEST UPPER HARNESS (FIGS. 6.2A, 6.2B)

6.21 REPLACE UPPER HARNESS

6.3 REPLACE MOTOR

PARTS CATALOG

TORO TRIMMER 900 HANDLE ASSEMBLY

PARTS

TORO TRIMMER 900 MOTOR AND HOUSING ASSEMBLY

PARTS

TORO TRIMMER 900 HANDLE ASSEMBLY

PARTS

TORO TRIMMER 900 MOTOR AND HOUSING ASSEMBLY

PARTS

TORO TRIMMER 1100 HANDLE ASSEMBLY

PARTS

ELECTRIC TRIMMER/WEEDER SERVICE MANUAL

Table of Contents – Page 4 of 4

TORO TRIMMER 1100 MOTOR AND HOUSING ASSEMBLY

PARTS

TORO TRIMMER 1100 HANDLE ASSEMBLY

PARTS

TORO TRIMMER 1100 MOTOR AND HOUSING ASSEMBLY

PARTS

TORO TRIMMER 1200 HANDLE ASSEMBLY

PARTS

TORO TRIMMER 1200 MOTOR AND HOUSING ASSEMBLY

PARTS

TORO TRIMMER 1200 HANDLE ASSEMBLY

PARTS

TORO TRIMMER 1200MOTOR AND HOUSING ASSEMBLY

PARTS

TORO CORDLESS TRIMMER UPPER CASE ASSEMBLY

PARTS

TORO CORDLESS TRIMMER MOTOR HOUSING ASSEMBLY

PARTS

TORO CORDLESS TRIMMER UPPER CASE ASSEMBLY

PARTS

TORO CORDLESS TRIMMER MOTOR HOUSING ASSEMBLY

PARTS

OUTDOOR

APPLIANCE

DIVISION

--

Electric

.

I

Trimmer/

SERVICE

Weeder

MANUAL

CORDLESS TRIMMER/WEEDER

900

HOME DUTY TRIMMER/WEEDER

..

.

Model Number 51550

L

Model Numbers 51200

and 51225

1100 HEAVY DUTY TRIMMER/WEEDER

Model Numbers 51300

MARCH

1979

This service repair manual

Complete Trouble Shooting Guides, Wiring Diagrams and Service Instructions are included.

is

The manual

line feeding devices used in the four different trimmers. The second section deals with the

900 and 1100 Trimmers, the third with the 1200 and the fourth with the Cordless. The fifth

section contains an illustrated

The Trouble Shooting Guides

pattern which will enable you to find

Shooting Guide

need only refer to this same number in the service section for complete repair instructions.

divided into five sections. The first section concerns

is

numbered in the lower right hand corner. After finding the problem, you

is

written for use by Authorized Toro Appliance Service Dealers.

itself

with the automatic

Parts

Catalog for each model.

at

the beginning of the first four sections follow a systematic

a

problem quickly. Each section of the Trouble

TABLE

Automatic Line Feed Assembly

Trouble Shooting Guide

Service Instructions.

900

&1100

Trouble Shooting Guide

Wiring Diagram

Service

1200

Trouble Shooting Guide

Wiring Diagram

Service Instructions.

Cordless Trimmer 21-30

Trouble Shooting Guide

Wiring Diagram

Service Instructions.

Parts Catalog

900 Trimmer Model No. 51 200 8000001 9000100. 32-33

900 Trimmer Model No. 51 225

1100 Trimmer/Model No. 51300

1100 Trimmer/Model No. 51325

..

1200 Trimmer/Model No. 51400 . 8000001 . 9000100..

1200 Trimmer

Cordless Trimmer/Model No. 51550

Cordless Trimmer/Model No. 51550

Trimmers

I

Instructions

Trimmer

.......................................................

....................................................

........................................................

/

.................................................

..................................................

.......................................................

................................................

......................................................

...............................................

......................................................

...............................................

Model No. 51425 . 9000101 & Up.

...........................................

................................................

................................................

...............................................

............................................

OF

CONTENTS

. .

.

9000101 & Up.

.

8000001 . 9000100..

.

9000101 & Up.

.

8000001 . 9115104

.

91 15105 & Up

....................

........................

..................

.......................

..................

.......................

..........

.....

.....................

1-4

3-4

5-11

7 . 1 1

13-19

14

15

15-19

22-23

24

24-30

31-47

34-35

36-37

38-39

40-41

42-43

44-45

46-47

2

6

7

No. 2 Phillips Screwdriver

Small Standard Screwdriver

Medium Standard Screwdriver

Large Standard Screwdriver

Long Nose Pliers

Diagonal Cutting Pliers

Electrical Terminal Crimping Pliers

Scribe or Awl

TOOL REQUIREMENTS

No. 54 Drill Bit (or object similar in size and hardness)

VOM Multimeter

Continuity Tester (or use mulitimeter)

1/8" Pin Punch

Small Hammer

(or

similar support system)

1979

-

U.S.A.

COPYRIGHT

The

"US.

Toro

&

Foreign Patents Pending"

MINNEAPOLIS, MN

Vise

Extension Cord

110 Volt A.C. Power Source

ALL

RIGHTS RESERVED

Company

-

55420

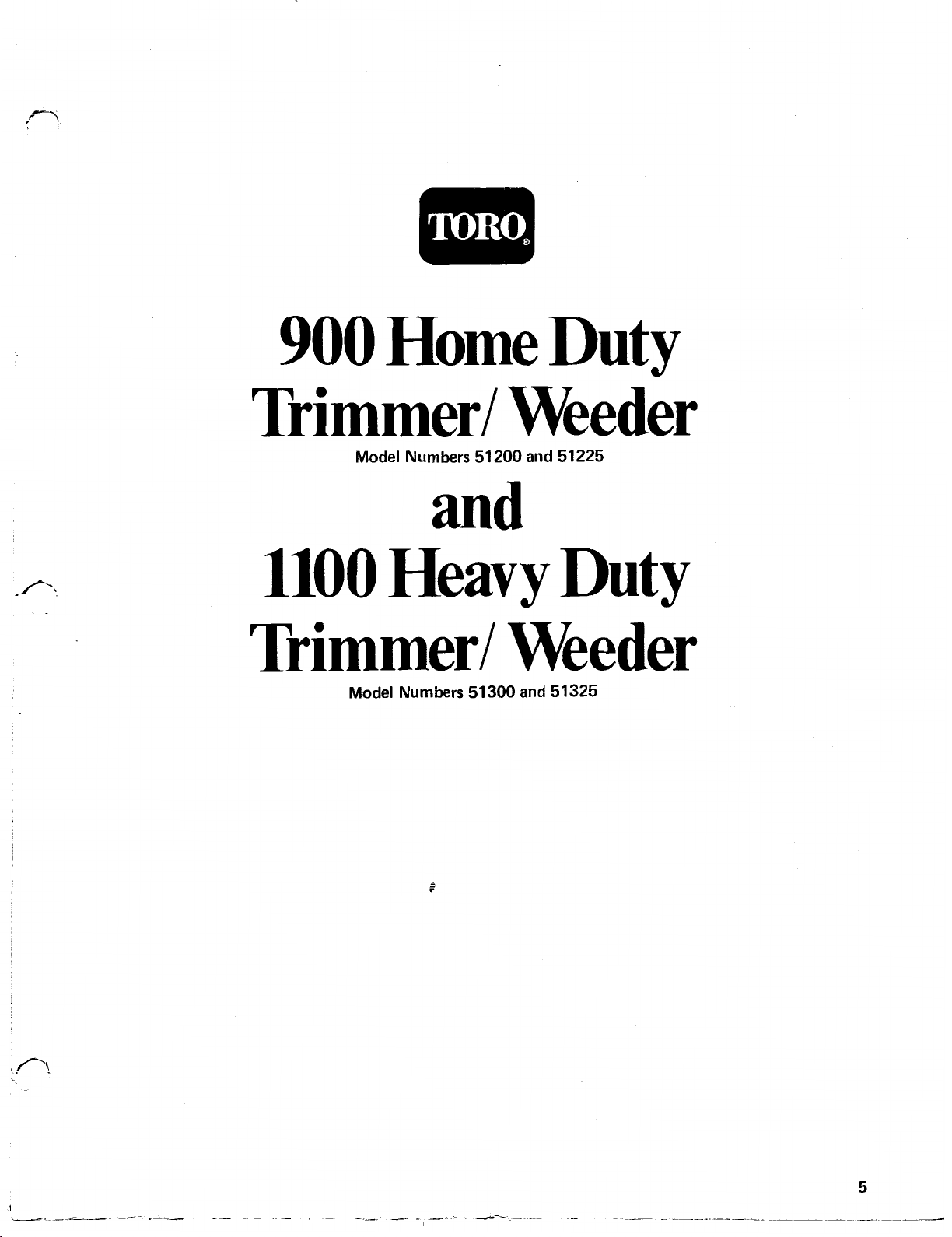

AUTOMATIC LINE FEED ASSEMBLY

900

Home Duty

Trimmer/Weeder

Model Numbers 51 200 and

1100

Heavy

Trimmer/ Weeder

Model Numbers 51300 and 51325

1200

Professional

51

225

Duty

Trimmer/Weeder

Model Numbers 51400 and 51425

Cordless

Trimmer/

Model Number 51550

Weeder

1

2

I-

.g-

I-

i

-I

0

I---

--

'

-1

.I

0

0

TROUBLE

SHOOTING

t

>

I-

I-

r

GUIDE

lr'

AUTOMATIC LINE

FEED ASSEMBLY

SERVICE

CAUTION: THIS TOOL

INSULATED. TO MAINTAIN ITS ENGINEERED SAFETY STANDARDS USE ONLY

GENUINE TORO REPLACEMENT PARTS.

THESE APPLIANCES FROM ALL POWER

SOURCES BEFORE ATTEMPTING ANY

REPAlRS.

1.1

REMOVE SPOOL CAP (fig. 1.1)

Insert widest possible blade screwdriver

snugly into one of the two window slots

on the spool hub and twist the screwdriver 1 /4 turn.

IS

DOUBLE

INSTRUCTIONS

I

Figure 1.1 1

CHECK FOR GRASS

1.2

DRUM. CLEAN INSIDE DRUM.

With the spool cap removed, thoroughly

out

clean

spect for any damage.

1.3

CHECK FOR LINE TIGHT ON SPOOL

The line must be wrapped firmly but free

to unwind easily during use. There should

be no loose line protruding from the

wrapped line.

the drum area and visually in-

b

OR

DIRT INSIDE

Figure 1.1

1.11

REMOVING DIFFICULT SPOOL CAPS

.CORDLESS TRIMMERS (fig.

If

the spool

break the spool cap out with

is

difficult to remove, pry or

Figure 1.1

la

l.lla)

a

screwdriver.

1.31

1.4

*-

REWIND SPOOL CORRECTLY (fig. 1.31)

a

Hook one end of the line into

on the spool, allowing no more than 1/8

of

inch

direction of arrows on spool. Wind in

level rows between spool flanges.

CHECK

Remove the spool cap to check the driver.

Inspect the driver teeth to insure that they

are not severely rounded off or completely

missing.

line to protrude. Wind line in

Figure 1.31

FOR

WORN

DRIVER TEETH (fig.l.4)

groove

900,1100,

Hold the drum steady and unscrew the

spool in counter-clockwise direction. With

the spool and core removed, pry the spool

off the core.

AND

1200

TRIMMERS

(fig.

1.11

b)

Figure 1.4

3

1.41 REPLACE DRIVER

ALL UNITS EXCEPT 1978 CORDLESS

(fig. 1.41

Remove the spool. Unscrew the core,

with driver, from the motor shaft. Gently

release the pressure the spring

against the spool core. To install the new

driver, reverse procedures.

a)

SERVICE

is

applying

INSTRUCTIONS

Inspect the spool core after removing the

spool cap. Look for broken or worn teeth

that would allow the driver to skip. A build-

of

up

driver from indexing.

dirt inside the core would stop the

1.51 CLEAN OR REPLACE CORE

Remove and replace core

ment in section 1.41.

as

driver replace-

1.6 1978 CORDLESS TRIMMER -CHECK FOR

DRUM RUBBING MOTOR

The head assembly was "press-fit" on the

motor shaft up to the heat sink.

possibly be hitting against the base of the

motor.

(fig.

.

1.6)

It

could

,-

Figure 1.41

CORDLESS 8000001 & UP

On the Cordless Trimmer (Serial No.

8000001-9115104)

pressed on

driver to remove

is

beige colored Cordless Trimmer (Serial

No. 9115105

the motor shaft. Replace the white driver

by firmly pushing

while rigidly supporting the opposite end

of the motor shaft. Note that the motor

shaft and white driver both have

side.

at

&

a

(fig.

1.41

a

white driver was

the factory. Pry off the

it.

Note: If the driver

up),

it

is

threaded onto

it

on the motor shaft,

a

b)

flat

Figure

1.6

1.61 REPLACE DRUM AND MOTOR WITH

(fig.

NEW STYLE

Replace the

a

with

# 88151 Automatic Line Feed Assembly.

To replace these components, please refer to section

# 88150 Motor Assembly and

1.61)

# 88140

2.6

and

Motor Assembly

2.7.

Figure 1.41 b

1.5 CHECK FOR DIRTY OR DAMAGED

(fig.

CORE

1.5)

Figure 1.5

4

88140~188141 88150w/88151

Figure

1.6

1

900

Home

Duty

Trimmer/ Weeder

Model Numbers 51200 and 51225

and

1100

Heavy

Duty

Trimmer/ Weeder

Model Numbers 51300 and 51325

I-

TROUBLE SHOOTING GUIDE

WIRING

-

WIRING HARNESS

UPPER

SWfTCH -SINGLE SPEED

.

SERVICE INSTRUCTIONS

INSULATED. TO MAINTAIN ITS ENGINEERED SAFETY STANDARDS USE

GENUINE TORO REPLACEMENT PARTS.

ONLY

DIAGRAM

IRING HARNESS - LOWER

CONNECTOR

CONNECTOR

I

THESE APPLIANCES FROM ALL POWER

SOURCES BEFORE ATTEMPTING ANY

2.0 CHECK

HEAD ROTATION

2.01 CLEAN HEAD AND TEST

assembly. While cleaning the head assembly,

drum and the motor for build-up. Refer

to section 1 for further details on the

automatic line feed assembly.

2.1 OPEN MOTOR HOUSING AND INSPECT

MOTOR

FOR

LINE/GRASS STOPPING

(fig. 2.0)

Depending on the environmental condi-

the

tions and

dures during trimmer use, the head assem-

bly could jam with debris, thus stopping

the head from turning or slowing

Remove any debris from about the head

be sure to check the

(fig. 2.1)

customer’s operating proce-

it

down.

(fig. 2.01)

area

between the

Figure 2.0

Figure 2.0 1

Remove the decal on the motor housing.

all

Remove

ings together. Gently separate the

halves and inspect the motor for charred

or broken wires, etc.

the screws that hold the hous-

two

7

2.1

REPLACE

MOTOR

(figs. 2.1

SERVICE

la,

2.1lb)

INSTRUCTIONS

When replacing the motor

to remove the automatic line feed assembly. Refer to section 1 for head disassem-

To

bly.

wire cutters and nip the connector in the

center of the factory crimp; pull the wires

out. Remove the roll pin by rigidly supporting the armature shaft (to prevent

bending) and driving the roll pin out.

remove the wire connectors, use

Figure 2.11a

it

is

necessary

2.22

Deformed

Figure 2.21

REPLACE DRUM

SERIAL

A

After removing the spool, driver, core and

spring

the ring and slide the spool off the shaft.

Install with 1979 parts.

SERIAL

After removing the

spring, the drum will slide off the motor

shaft. Install the new drum and reassemble.

NOS.

retaining ring

as

described in section 1, pry out

NOS.

(fig.2.22)

800001

is

used to secure the drum.

Figure 2.22

900101

spool,

and

Correct

-

899999.

UP.

driver, core and

CYA

Figure 2.1 1 b

2.2 SPIN MOTOR BY HAND

Spin the motor with your hand and notice

the feel of the armature;

freely. Visually check for excessive

commutator wear, armature end-play and

bearing to shaft fit. A binding or scraping

sound when the motor

a

evidence of

drum.

2.21 CHECK DRUM

A deformed drum means that plastic deformation has occurred to the drum

motor shaft. The drum may have slipped

up the motor shaft. A

be the spool not located inside the drum

correctly. A deformed drum must be

replaced.

bad bearing or a deformed

(fig. 2.21)

it

should turn

is

turned could be

tell-tale

sign would

at

the

2.23 BAD BEARING

TRIMMER

To pin-point

inspect for

bearing. Carefully watch the bearing.

should not spin in

the bearing while turning the motor;

drop or two of 30 wt. oil may be

is

needed to free-up the motor. If the bearing

section 2.1

warranty.

is

at

(fig. 2.23)

-

REPLACE MOTOR OR

a

defective motor bearing,

a

burned or charred shaft

its

casing. Lubricate

fault, replace the motor

1

or, replace the trimmer if in

Figure 2.23

at

all

as

the

It

a

that

per

8

SERVICE INSTRUCTIONS

2.3

CHECK MOTOR BRUSHES

Using

carefully push the brush into

away from the commutator. When released

the brush should spring back into position

against the commutator. Excessively worn

motor brushes will not make proper

contact with the commutator. Motor

brushes are not replaceable.

2.31 REPLACE MOTOR OR TRIMMER

a

scribe or other sharp object,

Figure 2.3

(fig. 2.3)

its

holder

Figure 2.41

2.5 CHECK HARNESS CONNECTIONS AT

MOTOR

Visual inspection alone will not suffice.

at

Try moving the wires

nections; the wires may slip out of the

connectors.

the motor con-

Refer to section 2.1 1 for motor replace-

ment, or replace the trimmer if in warranty.

2.4 CHECK MOTOR BRUSH SPRINGS

During shipment the motor brush spring

may have been jarred out of position,

causing no brush to armature contact and

disabling the motor.

Figure

2.4

(fig. 2.4)

2.51 SECURE CONNECTION AT MOTOR

(fig. 2.51)

Secure the loose connections

to harness junctions by recrimping the

existing connectors or installing new

connectors.

Note:Use

! A

only,

Do not use side cutters or wire cutters.

electrical crimping pliers

at

the motor

2.41 SECURESPRING / REPLACEMOTOR OR

TRIMMER

Lifting the brush spring back into position,

restore brush to armature contact. In some

cases

motor, or trimmer if in warranty.

(fig.

2.41)

the spring may be missing; replace

Figure 2.51

9

2.6

CHECK LOWER HARNESS

SERVICE

(fig. 2.6)

INSTRUCTIONS

2.61

Remove

separate the handle grip sections. Using

a

continuity tester, insert one of

into the switch alongside either of the

lower harness leads. Insert the other

tester probe into the proper connector

the motor (note lead wire color). Check

both leads for complete circuits.

all

the Phillips head screws and

Figure 2.6

its

probes

REPLACE LOWER HARNESS

(figs. 2.61 a, 2.61b)

Disconnect the ends

both the motor and the switch terminals.*

Pull the harness out of the tube(s).

place with new harness. Care should

so

be taken

when replacing the motor housings and

handle grips.

that wires are not pinched

of

the harness from

at

Re-

Figure 2.6b

2.7

TEST SWITCH CONNECTIONS

Try pulling gently on the

into the switch to be certain that both

(fig.

2.7)

w

wires leading

*

To remove each wire from the switch,

proceed

a.

b. Carefully pull wire out of switch.

c.

as

follows:

Insert

ject) into the switch alongside the

wire.

Remove drill bit.

a

#54

drill bit (or similar ob-

Figure 2.6a

2.71

2.8

Figure 2.7

SECURE LOOSE CONNECTIONS

If any of the wires leading to the switch

are loose, reinsert them firmly into the

switch. If they do not stay inserted, replace the switch (refer to section 2.81).

TEST SWITCH

Connect the tester leads

should be continuity

is

depressed. Replace any switch that

shows no current flow on either or both

sides.

(figs. 2.8 a, 2.8b)

as

only

when the switch

shown. There

10

SERVICE

INSTRUCTIONS

WARNING: FORCING

SWITCH MAY CAUSE INTERNAL DAMAGE.

DO NOT INSERT OBJECTS LARGER THAN

1/32 INCH DIAMETER INTO SWITCH.

Figure

PROBES

2.8a

INTO THE

2.9

TEST UPPER HARNESS

Insert one probe of

into the switch alongside either harness

lead. Connect the other terminal of the

tester to the proper spade of the harness.

Test both leads for complete circuits.

Figure 2.8 1

(fig.

2.9)

a

continuity tester

2.81

Figure 2.8b

REPLACE SWITCH (fig. 2.81)

Install the new switch after replacing the

wires in their proper terminals (refer

the trimmer wiring schematic). Correctly

position the switch in the handle grip.

as

Care should be taken

wires when securing the handle grips.

not to pinch any

to

2.91

Figure 2.91

REPLACE UPPER HARNESS

After removing the wires from the switch

(see

*

in section 2.611, install the new up-

per wiring harness by replacing the wires

in the proper terminals of the switch.

Position the harness in the handle grips.

so

Caution should be taken

are not pinched when securing the handle

grips.

that the wires

1200

Professional

Trimmer/ Weeder

Model

Numbers

51400

and

51425

'I

0

,!-I

0

I-

O

5

a

k

5

2

3-

>

1

0

3

-u4

a

0

I-

J

I

'I--

0

TROUBLE

--f

'ri

n

a

w

SHOOTING

9

'

LL

a

3-

5

t

4

s

-

0-

v)

w

WIRING DIAGRAM

WIRING HARNESS - UPPER

SWITCH-TWOSPEED

MOTOR

R

BRIDGE

WIRING HARNESS - LOWER

SERVICE INSTRUCTIONS

INSULATED. TO MAINTAIN ITS ENGINEER-

ED SAFETY STANDARDS USE

THESE APPLIANCES FROM ALL

SOURCES

3.0

CHECK

HEAD ROTATION

BEFORE

FOR

ATTEMPTING ANY

LINE/GRASS STOPPING

(fig.

3.0)

POWER

RECTIFIER

ONLY

Figure

3.0

Depending on the environmental conditions and the customer‘s operating procedures during trimmer use, the head

assembly could jam with debris, thus

stopping the head from turning or slowing

it

down.

3.01 CLEAN HEAD AND TEST

Remove any debris from about the head

While

assembly.

be sure to check the area between the drum

and the motor for build-up. Refer to

section 1 for further details on the automatic line feed assembly.

cleaning the head assembly,

(fig.

3.01)

3.1 OPEN MOTOR HOUSING AND INSPECT

MOTOR

Remove the decal on the motor housing.

Remove

ings together. Gently separate the two

halves and inspect the motor for charred

or broken wires,

(fig.

all

the screws that hold the hous-

etc.

.

Figure

Figure

3.01

3.1

15

SERVICE INSTRUCTIONS

3.11

REPLACE MOTOR

When replacing the motor

to remove the automatic line feed assembly.

Refer to section

To

remove the wire connectors, use wire

cutters and nip the connector in the center

of the factory crimp; pull the wires out.

Remove the roll pin by rigidly supporting

the armature shaft (to prevent bending)

and driving the roll pin out.

Figure 3.1

(fig. 3.1

1

la,

3.1 1b)

it

is

necessary

for head disassembly.

la

3.22

REPLACE DRUM

SERIAL NOS.

-

Deformed

Figure 3.21

(fig. 3.22)

800001 -899999.

is

A retaining ring

After removing the spool, driver, core and

as

spring

the ring and slide the spool off the shaft.

Install with 1979 parts.

described in section 1, pry out

used to secure the drum.

Correct

3.2

SPIN MOTOR

Spin the motor with your hand and notice

the feel of the armature;

freely. Visually check for excessive commutator wear, armature end-play and bearing to shaft

when the motor

of

CHECK DRUM

3.21

A deformed drum means that plastic de-

formation has occurred to the drum

motor shaft. The drum may have slipped

up the motor shaft. A

be the spool not located inside the drum

correctly. A deformed drum must be

replaced.

Figure 3.1 1 b

BY

HAND

it

should turn

fit.

A binding or scraping sound

is

turned could be evidence

a

bad bearing or a deformed drum.

(fig. 3.21)

tell-tale

sign would

at

the

Figure 3.22

SERIAL NOS.

After removing the spool, driver, core and

spring, the drum will slide off the motor

shaft. Install the new drum and reassemble.

BAD BEARING - REPLACE MOTOR

3.23

TRIMMER

To pin-point

inspect for

the bearing. Carefully watch the bearing;

it

should not spin in

the bearing while turning the motor;

drop or two of 30 wt. oil may be

is

needed to free-up the motor.

bearing

section 2.1

in warranty.

900101 and

(fig.

3.23)

a

defective motor bearing,

a

burned or charred shaft at

its

is

at

fault, replace the motor

1

or, replace the trimmer if

Figure 3.23

UP.

OR

casing. Lubricate

all

that

If

the

as

per

a

16

3.3

SERVICE

CHECK MOTOR BRUSHES

a

Using

carefully push the brush into

away from the commutator. When re-

leased the brush should spring back into

position against the commutator. Excessively worn motor brushes will not make

proper contact with the commutator.

Motor brushes

scribe or other sharp object,

are

not replaceable.

(fig.

3.3)

its

INSTRUCTIONS

3.41

SECURE SPRING/

TRIMMER

holder

3.5

Lifting the brush spring back into position,

restore brush to armature contact.

cases the spring may be missing; replace

motor or, trimmer

TEST BRIDGE RECTIFIER

REPLACE

(fig. 3.41)

Figure 3.41

if

in

MOTOR OR

warranty.

(fig. 3.5a, 3.5b)

In

some

Figure 3.3

3.31 REPLACE MOTOR

Refer to section 2.1 1 for motor replace-

ment, or replace the trimmer

3.4

CHECK MOTOR BRUSH

During shipment the motor brush spring

may have been jarred out of position,

causing no brush to armature contact

and disabling the motor.

OR

TRIMMER

SPRINGS

if

in warranty.

(fig.

3.4)

The readings obtained during the following

test

will vary depending on the

ment and settings used.

adjacent terminals on the rectifier

combinations will be tested), connect

the

tester

Reverse the leads. Again, note the reading.

Continue this

terminals have been checked (4

after any

2nd reading, the rectifier

must be replaced.

to them and note the reading.

test

process until

test

the 1st reading equals the

test

Select

is

faulty and

equip-

any

two

(all

all

the

tests).

If

Figure 3.4

Figure 3.5a

17

SERVICE

INSTRUCTIONS

3.51

3.6

Figure 3.5b

REPLACE BRIDGE RECTIFIER

Careful attention must be paid to replacing

the wires in the proper position.

schematic. Trimmers with serial number

9000101

harness replaced.

CHECK HARNESS CONNECTIONS AT

RECTIFIER

Visual inspection alone will not suffice.

Try moving the wires

connections; the wires may slip out of the

terminals.

and up must have the lower wire

at

See

wiring

the rectifier

Figure

3.71 REPLACE LOWER HARNESS

Disconnect the ends of the harness from

both the rectifier and the switch terminals

(see

sections

ness out of the tubes. Replace with new

harness. Caution should be taken

wires are not pinched when replacing the

motor housings and handle grips.

3.8

TEST SWITCH CONNECTIONS

Try pulling gently on the wires leading into the switch to be certain that both har-

3.1

1

3.7

and

2.61).

Pull the har-

so

that

(fig.

3.8)

SECURE CONNECTION AT RECTIFIER

3.61

Secure the loose connections

rectifier or replace the lower harness.

! Note: Use electrical crimping pliers

Do

only.

CHECK LOWER HARNESS

3.7

Remove

separate the handle grip sections. Using

a

probes into the switch along either of the

lower harness leads.

probe onto the proper terminal

rectifier (note lead wire color). Check both

leads for complete circuits.

not use side cutters or wire cutters.

all

continuity tester, insert one of

at

(fig.

3.7)

the phillips head screws and

Place

the other tester

at

the

its

the

Figure

3.81 SECURE LOOSE CONNECTIONS

If any of the wires leading to the switch

are loose, reinsert them firmly into the

switch.

place the switch (refer to section

If

they do not stay inserted, re-

3.8

2.81

).

SERVICE

DO

NOT INSERT OBJECTS LARGER THAN

1/32 INCH DIAMETER INTO SWITCH.

3.9

TEST SWITCH

(figs.

3.9 a, 3.9b)

INSTRUCTIONS

wires in their proper terminals (refer

to the trimmer wiring schematic). Correctly position the switch in the handle

grip. Care should be taken

pinch any wires when securing the handle

grips.

as

not to

THE

SPEED SWITCH. Disconnect

the switch

the tester leads

continuity

pressed. Replace any switch that shows

no current flow on either or both sides.

1200

NOTE:

pending on

other

does not have

replace the switch.

tests

TRIMMER USES A TWO

all

(see

*

in section 2.61). Connect

as

shown. There should be

only

when the switch

The

test

readings may vary de-

test

equipment used. If

are good and the trimmer

a

high and low speed,

lines to

is

de-

all

Figure 3.91

TEST UPPER HARNESS

Insert one probe of a continuity tester

into the switch alongside either harness

lead. Connect the other terminal of the

tester to the proper spade of the harness.

Test both leads for complete circuits.

(fig.

4.0)

3.91

Figure 3.9b

REPLACE SWITCH

Install the new switch by replacing the

(fig. 3.91)

4.01

Figure

4.0

REPLACE UPPER HARNESS

After removing the wires from the switch

(see

*

in section 2.61), install the new up-

per wiring harness by placing the wires in

the proper terminals of the switch. Position

the harness in the handle grips. Caution

so

should be taken

pinched when securing the handle grips.

that the wires are not

19

Cordless

Trimmer/ Weeder

Model

Number

51550

22

-t

0

8

I-

l-

CT

W

a

W

--

-L

0

TROUBLE SHOOTING GUIDE

L

,-.

.

-

I

r

n

K

TROUBLE SHOOTING GUIDE

yI

0

z

3

23

I

E

W

n

L

W

n

I

a

W

WIRING

DIAGRAM

.

UPPER

WIRING

HARNESS

SERVICE

CAUTION:

INSULATED. TO MAINTAIN ITS ENGINEERED SAFETY STANDARDS USE

THIS TOOL

IS

DOUBLE

ONLY

MOTOR

.

INSTRUCTIONS

CAUTION:

THESE APPLIANCES FROM ALL

I

SOURCES

CHECK FOR LINE/GRASS STOPPING

5.0

HEAD ROTATION

CLEAN HEAD AND TEST

5.01

5.1

INSPECT UPPER TO LOWER HARNESS

CONNECTION

assembly. While cleaning the head assemdrum and the motor for build-up. Refer

to section 1 for further details on the

automatic line feed assembly.

BEFORE

Depending on the environmental conditions and the customer's operating procedures during trimmer use, the head

assembly could jam with debris, thus

stopping the head from turning or slow-

it

down.

ing

Remove any debris from about the head

bly, be sure to check the area between the

ALWAYS DISCONNECT

ATTEMPTING ANY

(fig. 5.0)

(fig. 5.1)

POWER

(fig. 5.01)

Figure 5.0

Figure 5.01

24

Remove red cover from power pack

by inserting a wide blade screw driver

between the black handle and red cover

as

on both sides

Lift cover forward, then up. The upper to

lower harness connection should be secure.

shown and twist gently.

case

Figure 5.1

SERVICE

INSTRUCTIONS

5.11 SECURE UPPER

\

CONNECTION

Check that the connection

or corrosion. If reconnecting had no

effect, unplug the connector, clean the

terminals and retest the trimmer. If any

of the wires or connectors are damaged,

refer to section 5.41 for upper wire harness replacement.

TO

(fig. 5.1

Figure 5.1

LOWER HARNESS

1

)

1

5.2 CHECK BATTERY CONNECTIONS

The battery connections should be free of Figure 5.3

dirt and corrosion. Insure that each bat-

is

tery lead wire

proper battery terminal.

NOTE:

(red wire).

The largest terminal

firmly in place on the

is

free of dirt

(fig.

5-2)

5.31 REPLACE BATTERY CHARGER

a

Replace

is

positive TORO charger, part # 33-6730.

5.4

CHECKCHARGER OUTPUT ATBATTERY

CONNECTIONS

faulty charger with a genuine

(fig. 5.4)

Figure

5.2

5.21 SECURE BATTERY CONNECTIONS

Plug each battery lead wire

place on the appropriate battery ter-

minal.

NOTE:

(red wire). If securing them did not repair

the trimmer, clean the battery terminals

and retest the trimmer. In the event that

any of the wires or connectors are damaged,

refer to section 5.41 for upper wire harness replacement.

The largest terminal

5.3 TEST OUTPUT VOLTAGE

CHARGER

Test the charger with a voltmeter.

tester for

voltmeter leads to the charger wires

shown. Plug the charger into

outlet (make sure switched outlets are on)

and read the charger output on the voltmeter scale.

least

(fig. 5.3)

a

10

V.D.C.

A

good charger will show

5.0

volts D.C. output.

OF

test.

firmly

is

BATTERY

Connect the

a

110

in

positive

Set

the

as

volt

at

Disconnect battery leads from battery.

Plug the battery charger into the receptacle

on the bottom of the battery case and into

a

110 volt outlet (make sure switched

a

outlets are turned on). Using

set

meter

the negative voltmeter lead to the small

battery terminal. The charger output indicated on the voltmeter

ceed

for a 10 V.D.C.

5.0

volts.

Figure 5.4

test,

scale

volt-

connect

must ex-

25

SERVICE

INSTRUCTIONS

E.

Remove

5.41 d).

the

battery pack

(fig.

SERVICE

H.

Replace the wiring harness (fig.

5.41f).

INSTRUCTIONS

c.

Insert the short end of the

spring into the hole in the

trigger release. The coil of

the spring must

plastic boss in the case (fig.

5.41i).

fit

over the

Figure 5.41f

To

save

I.

be tested

tion

To replace the trigger release, trigger

J.

and spring, proceed

a.

time later, the switch should

at

this point. Refer to

2.8

for procedures.

as

follows:

Note that on the inside of the

trigger release there

hole. This hole accepts the short

end of the spring (fig. 5.419g).

Figure 5.41g

is

a

sec-

small

Figure 5.41

d.

Place

end of the spring. Put the trig-

boss

ger

case.

ger in this position and

the spring and trigger release

(Fig. 5.41 j ) .

Figure 5.41

e.

Place the remaining half of the

battery case over the trigger

mechanism, assuring the charging receptacle

the case halves

i

the trigger over the long

into the hole in the

Carefully hold the trig-

j

is

in place. Secure

(fig.

5.41 k).

let

go of

b. Lay

the

left half of the battery

case

on a work bench in a steady

position and install the trigger

release in position

Figure 5.41 h

(fig.

5.41h).

Figure 5.41

k

27

SERVICE

INSTRUCTIONS

5.5 CHARGE BATTERY FOR 48 HOURS AND

TEST

(fig. 5.5)

To

test

the Power Pack, the battery must

be in place and connected inside the trim-

a

mer. Connect

V.D.C.

large terminal

With the trimmer cutting head in

position, squeeze the trigger and read the

voltmeter

means that the battery

should be replaced.

test)

scale.

voltmeter

to the battery wiring harness;

is

positive, small

A reading below 6 volts

(set

for a 10

is

negative.

is

defective and

a

safe

Figure 5.61

5.7 SPIN MOTOR BY HAND

Spin the motor with your hand and notice

the feel of the armature;

freely. Visually check for excessive commutator wear, armature end-play and bearing to shaft fit. A binding or scraping sound

is

when the motor

idence of a bad bearing or a deformed

drum.

turned could be

it

should turn

ev-

I

Figure 5.5

5.51 REPLACE BATTERY AND CHARGE FOR

48 HOURS

After removing the battery

section 5.41 (steps A,

the new battery in reverse order.

DON’T FORGET:

for

48

hours before putting

5.6 INSPECT MOTOR

Remove

ings together. Gently separate the two

halves and inspect the motor for charred

or broken wires,

all

the screws that hold the hous-

5.61 REPLACE MOTOR

When replacing the motor

to remove the automatic line feed assem-

bly. Refer to section

To

bly.

wire cutters and nip the connector in the

center of the factory crimp; now pull the

wires out.

remove the wire connectors, use

Charge the new battery

etc.

(fig. 5.61)

as

outlined in

C,

D,

E),

it

to use!

it

is

necessary

1

for head disassem-

install

5.71 CHECK DRUM

A deformed drum means that plastic deformation has occurred to the drum

motor shaft. The drum may have slipped

up the motor shaft.

be the

correctly. When the drum

it

must be replaced.

(fig. 5.71)

spool

not located inside the drum

Figure 5.71

5.72 REPLACE DRUM

SERIAL NOS. 800001-91 15104

After removing the spool, driver, core and

as

spring

spool off the shaft. Note that the motor

shaft has

drum.

described in section

a

flat side to line up inside the

A

tell-tale

at

sign would

is

deformed

1,

pry the

--

the

28

SERVICE INSTRUCTIONS

SERIAL NOS. 9115105 & UP

After removing the spool, driver, core and

spring, the drum will slide off the motor

shaft. Install the new drum and reassemble.

5.73

5.8

5.81

BAD BEARING - REPLACE MOTOR OR

TRIMMER

To pin-point a defective bearing, inspect

a

burned or charred shaft

for

Carefully watch the bearing;

spin in

while turning the motor;

oil

the motor.

place the motor

replace the trimmer if in warranty.

CHECK HARNESS CONNECTIONS AT

MOTOR

Visual inspection alone will not suffice.

Try moving the wires

tions; the wires may slip out of the con-

nectors.

SECURE MOTOR CONNECTIONS

(fig. 5.81)

Secure the loose connections

by recrimping the existing connectors or

installing new ones.

! Note:

only.

its

casing. Lubricate the bearing

may

be

all

that

is

If

the bearing

as

per section 2.1 1, or

at

use

electrical crimping pliers

Do not use side cutters or wire cutters.

at

the bearing.

it

should not

a

drop of

needed to free-up

is

the motor connec-

at

30

at

fault, re-

the motor

wt.

Figure 5.9

REPLACE LOWER HARNESS

To replace lower harness, disconnect the

upper to lower harness. Cut the motor

at

terminals

wires out. Pull the harness out of the tube.

Install the new harness. Caution should be

taken

replacing the motor housings.

TEST SWITCH CONNECTIONS

Pull gently on the wires leading into the

switch to be certain of firm connections.

SECURE LOOSE CONNECTIONS

If

any of the wires leading to the switch

are loose, re-install them firmly onto the

switch. If they do not stay

squeeze the wire terminals with pliers

to close the ears of the terminal.

TEST SWITCH

Open the battery

tion 5.41. Disconnect the wires on the

switch. Connect the -tester leads

and activate the switch. There should be

continuity only when the switch

pressed.

the factory crimp and pull the

so

that wires are not pinched when

on,

carefully

(figs. 6.1a, 6.1b)

case

as

described in sec-

as

shown

is

de-

Figure 5.81

5.9 TEST LOWER HARNESS

With the battery cover off, unplug the

upper to lower harness. Insert one of the

probes of a continuity tester into either

of the lower harness leads. Insert the

other tester probe into the proper con-

at

nector

color). Check both leads for complete

circuits.

the motor (note lead wire to

(fig. 5.9)

Figure 6.1a

SERVICE

INSTRUCTIONS

h

Figure 6.2a

Figure 6.1 b

6.11 REPLACE SWITCH

Install the new switch by replacing the

wires on the terminals (refer to the trim-

mer wiring schematic). Correctly position

the switch in the handle grip. Care should

as

be taken

securing the handle grips.

5.41 for case assembly.

6.2 TEST UPPER HARNESS

Remove the battery cover. Disconnect both

battery terminals and the upper to lower

harness connection.

(Test 1) Using

a

probe into the upper harness connector

(red wire). Connect the other lead

tester to the red wire battery terminal.

Activate the switch. The tester should

show continuity.

not to pinch any wires when

a

continuity tester, insert

(figs.

See

section

6.2a, 6.2b)

of

the

6.21

6.3

(Test 2) Connect one

black wire battery terminal and the other

to the upper harness connector (black

test

wire). The

REPLACE UPPER HARNESS

See

section 5.41 for proper instructions.

REPLACE MOTOR

Refer to section 2.11 for motor replace-

ment.

should show continuity.

Figure 6.2b

tester

lead to the

900 Trimmer/ Model

900 Trimmer/Model

1100 Trimmer/Model

1100 Trimmer/Model

1200 Trimmer

1200 Trimmer/Model

Cordless

Cordless Trimmer/ Model

/

Trimmer / Model

Model

No .

No.

No . 51300 . 8000001 . 9000100

No

No

No

51

200

.

8000001 . 9000100

.

51225 . 9000101 & Up

.

51325 . 9000101 & Up

.

51400 . 8000001 . 9000100

.

51425 . 9000101 & Up

No

.

51550

No . 51550 . 91

.

8000001 . 9115104

15105

.........................

&

.....................

....................

........................

....................

........................

.................

Up

.....................

32-33

34-35

36-37

38-39

40-41

42-43

44-45

46-47

31

......

.

........

.......

...

........

TORO

TRIMMER

900

HANDLE ASSEMBLY

MODEL

NO.

51200 - 8000001

&

UP

32

4 5 6 7

Part

No.

29-8290

29-7220

29-7660

29-8270

29-7400

29-8300

32104-121

Description

Left Hand Grip

Upper Wiring Harness

Single Speed Switch

Main Wiring Harness

Caution Decal

Tu

be

Screw

PARTS

No.

Used

1

1

1

1

1

1

2

Ref.

No.

-7 Description

8

9

10

11

12

13

32 104-1 19

29-8280

29-7270

29-7280

29-8340

Screw

Right Hand Grip

Screw 32104-1 18

Extension Cord Wire Clamp

Extension Cord Retainer

Serial Number

Plate

No.

Used

1

1

2

1

1

1

TORO

TRIMMER

900

MODEL

MOTOR AND

NO.

51200

-

8000001 & UP

HOUSING

ASSEMBLY

Part

No.

29-81 70

2 18-496

50

29-81

29-8 180

32121-88

29-82 10

33-5870

29-8230

29-8 120

3290-4 18

Description

Right Motor Housing

Wire Connector

Motor

Left Motor Housing

Roll

Pin

Fan Hub with Eyelet

Toro 900 Decal

Compression Spring

Spool Core

Retaining Ring

PARTS

No.

11

12

13

14

1

1

1

15

16

17

Part

No.

29-81 30

29-81 10

88002

88004

0

29-831

32104-120

I

Description

Driver

Empty Spool

50', .040" Cutting Line

in Coil

50', .040" Cutting Line

prewound on Spool

Shield with Cut-off Blade

Screws

Screws

4 2

33

TORO

TRIMMER

900

HANDLE ASSEMBLY

MODEL

8

NO.

51225

-

9000101 & UP

34

4

Part

No.

33-8570

33-8520

29-7660

338560

Description

Pigtail

Plug

Left Hand Grip

Switch

Wiring Harness

PARTS

No

used

1

1

1

1

5 33-8550

6 338600

7

8 338510

32104-121

Description

Tube

Decal (UL)

Screw

Right Hand Grip

No.

Used

1

1

5

1

TORO

TRIMMER

900

MOTOR AND

HOUSING

ASSEMBLY

MODEL

NO.

51225 9OOO101

&

UP

;d

SWUZ

G15~iji

Prewound Spool

Empty Spool

50'

Coil - .040" Cutting Line

Roll

Pin

PARTS

17 29-8230

I:I I

18 33-8680

19 33-8630 Right Hand Housing

20

21 33-8710

I

32104-121

Spring

Drum with Eyelet

Screw

Grommet

TORO

TRIMMER

1100

HANDLE

ASSEMBLY

MODEL

NO.

51300 - 8000001

&

UP

9

10

Part

No.

32104-1 19

29-7250

32104-1 18

29-7280

29-7270

29-7260

29-7220

29-7660

29-7650

3296-1 2

Description

Screws

Right Hand Grip

Screws

Extension Cord Retainer

Extension Cord Wire Clamp

Left Hand Grip

Upper Wiring Harness

Single Speed Switch

Main Wiring Harness

Locknut

PARTS

Ref.

No.

11

12

13

14

15

16

17

1

2

18

19

20

Part

No.

33-61 40

29-7440

29-7680

29-7690

29-7670

321 7-5

1

3250-1

33-61 30

29-7400

29-7730

WIRING

Lower Tubing

Screws

Cam Adjustment Lever

Spacer

Support Handle

Nut

Screw

Upper Tubing

Caution Decal

Serial Number

DIAGRAM

Description

Plate

36

TORO

I

TRIMMER

1100

MOTOR

MODEL NO.

51300

AND

-

8000001

HOUSING

&

UP

ASSEMBLY

-6

7

8

9

Part

No.

32104-120

32121-88

29-7610

2 18-496

33-5860

29-7590

29-7620

3290-41

29-7 130

8

Description

Screws

Roll

Pin

Motor

Wire Connector

Toro 1100 Decal

Left Motor Housing

Fan Hub with Eyelet

Retaining Ring

Compression Spring

I

PARTS

No.

Used

6

1

1

2

1

1

1

1

1

Part

No.

3256-42

29-7 150

29-7 140

29-7380

88003

88005

29-7370

29-7600

12

13

Description

Washer

Spool

Core

Driver

Empty Spool

50',

.065"

Cutting Line

in Coil

50',

.065" Cutting Line

prewound on

Shield with Cut Off Blade

Right Motor Housing

Spool

No.

Used

1

1

1

1

1

1

1

1

37

TOR0

TRIMMER

1100

HANDLE

ASSEMBLY

MODEL

NO.

51325 - 9000101 & UP

Ref.

No.

1

2

3

4

5

6

7

Part

No.

33-8570

33-881

29-7660

33-8870

33-8900

33-5790

3296-1 2

0

Description

Power Cord

-

Left Hand

Grip

Switch

Tube

-

Lower

Wiring Harness

Carriage

Locknut

Bolt

PARTS

12

13

No.

Part

33-8950

33-880

33-8890

19-4050

321 04-121

33-8810

Description

Machine Screw

Tube

-

Adjustable Handle

Knob

Screw

Grip

-

Right Hand

_I_-

Upper

TOR0

TRIMMER

1100

MOTOR

AND

HOUSING

ASSEMBLY

29

28

27

MODEL

NO.

51325 - 9000101

&

UP

26

Ref.

Part

No.

15

16

17

18

19

20

21

No.

33-8910

218-496

33-8920

33-8850

321 21 -88

88-00F

29-7380

88003

33-8940

Description

Motor

Wire Connectors

1100

Decal

Housing

Roll

Prewound Spool

Empty

50’

Saddle Clip

Pin

Coil

-

Left Hand

Spool

-

.065”

Cutting Line

PARTS

4

1

Description

Driver

Core

Spring

Drum with Eyelet

Screw

Shield

Screw

-

Housing

Right Hand

No.

Used

1

1

1

1

2

4

1

39

TOR0

TRIMMER

1200

HANDLE ASSEMBLY

MODEL

NO.

51400

-

8000001

&

UP

UPPER

WIRING HARNESS

1 32104-119

2 29-7250

3 32104-118

4 29-7280

5 29-7270

6 29-7260

7 29-7220

8 29-7360

9

29-7210

10 3296-12

11 29-7290

Description

Screws

Right Hand Grip

Screws

Extension Cord Retainer

Extension Cord Wire Clamp

Left Hand Grip

Upper Wiring Harness

Two Speed Switch

Main Wiring Harness

Locknut

Cord Bracket Assembly

PARTS

No.

Used

3

1

2

2

1

1

1

1

1

2

2

Ref.

No.

12

13

14

15

16

17

18

19

20

21

22

\

II

Part

No.

32144-28

29-7230

29-7340

33-5790

29-7440

29-7320

29-7470

19-4050

29-7240

29-7400

29-7480

RECTIFIER

LOWER

WIRING HARNESS

WIRING DIAGRAM

Description

Self Tapping Screw

Lower Tubing

Handle Bracket

Carriage Bolt

Screws

Tee Handle

Rubber Insert

Handle

Upper Tubing

Caution Decal

Serial Number

Release

Knob

Plate

MOTOR

No.

Used

2

1

2

1

2

1

4

1

1

1

1

40

Ref.

No.

1

2

3

4

5

6

7

8

9

10

11

Part No.

32 104-120

32121-88

1

10

29-7

3255-1 7

3219-14

29-7080

33-5850

29-7050

29-7090

3290-41 8

29-71 30

Description

Screws

Roll

Pin

Bridge Rectifier Assembly

Lockwasher

Jam Nut

Motor

Tor0 1200 Decal

Left Motor Housing

Fan Hub with Eyelets

Retaining Ring

Compression Spring

PARTS

No.

Used

6

1

1

1

1

--

Ref.

No.

13

14

15

16

1

1

17

1

1

1

18

19

1

12

Part No.

3256-42

29-7 150

29-7 140

29-7380

88003

88006

29-7370

29-7060

Description

Washer

Spool

Core

Driver

Empty

50'.

.065" Cutting Line

in Coil

50'. .65" Cutting Line

Prewound on

Shield with Cut-Off Blade

Right Motor Housing

.

Spool

Spool

No.

Used

1

1

1

1

1

1

1

1

41

TOR0

TRIMMER

1200

HANDLE

ASSEMBLY

MODEL NO.

51425

-

9000101

&

UP

ref.

No.

1

2

3

4

5

6

7

8

9

Part

No.

33-8570

33-8811

29-7360

29-7440

33-91 30

3296-12

33-9210

33-91 50

33-5790

Description

Power Cord

Left

Hand Grip

Two Speed Switch

Hex H.D. Screw

Wiring Harness

Locknut

Decal

Bracket

Carriage Bolt

Motor

PARTS

No.

Used

1

1

1

1

1

1

1

2

1

PartNo.

33-9180

19-4050

29-7470

321 04-121

33-8821

Tubing Sleeve

Upper Tube

Tee

Knob

Rubber Insert

Screw

Right Hand Grip

Description

Lower Tube

Handle

I

42

TOR0

TRIMMER

1200

MOTOR

AND HOUSING ASSEMBLY

31

30

29

MODEL

NO.

51425 - 9000101

&

UP

Ref.

No.

--

18

19

20

21

22

23

24

25

Part

No.

29-7081

218-496

33-91 70

29-7052

33-9240

29-7 1 30

33-6230

29-7 140

Description

.

Motor

Wire Connectors

Decal 1200

Left Hand Housing

Drum with Eyelets

Spring

Core

Driver

PARTS

~-

No.

Usded

1

2

1

1

1

1

1

1

Ref:

No.

Part

No.

26 33-8940

27

88006

29-7380

88003

32121 -88

28

33-9110

29

32104-120

30

29-7062

31

.~__I_.-

Description

Saddle Clip

Prewound Spool

Empty Spool

50’ Coil

Roll Pin

Shield with Cut Off Blade

Screw

Right Hand Housing

-

.065”

Cutting Line

No.

Used

!

43

TOR0

CORDLESS TRlMMER

UPPER

CASE ASSEMBLY

MODEL

NO.

51550

-

8000001 & UP

Ref.

Not

44

No.

1

2

3

4

5

6

7

8

9

No.

Part

33-6630

33-6620

33-6670

33-661

0

33-671

0

33-6700

32104-121

33-6650

33-6540

Illustrated

Description

Trigger

Trigger Lock

Spring

Switch

Upper Wiring Harness

Handle and Battery

Left Hand

Screw

Battery

Control Panel

Case

PARTS

1

1

1

1

1

-

1

6

1

1

c-

Ref.

No.

10

11

12

13

14

15

*

Part

No.

33-6770

33-6780

33-6550

321 44-30

33-6600

32104-1 18

33-6730

33-6830

Description

Decal, Control Panel

Toro Decal

Cover

Screw

Handle and Battery

Right Hand

Screw

Charger

Foam Pad

Case

No.

Used

1

2

1

4

-

1

2

1

1

TOR0

CORDLESS

TRIMMER

MOTOR

HOUSING

ASSEMBLY

IS

MODEL

NO.

51550

-

8000001

&

UP

32144-31

33-6530

88014

Description

Lower Wiring Harness

Tubing

Left Motor Housing

Screw

.040" Cutting Line in Coil

Empty Spool

20", .040" Cutting Line

prewound on spool

Driver

PARTS

I

1 1

29-8 120

33-6840

33-6750

33-6580

13

33-6590

14

2 18-496

33-6760

15

16

32 104-1 23

Part

No.

Spool Core

Compression Spring

Drum (including eyelet)

Heat Sink Casting

Motor

Wire Connectors

Rt.Motor

Cut off Blade

Screw

I

Description

Housing including

No.

Used

1

1

1

1

1

2

1

4

45

TORO

CORDLESS

TRIMMER

UPPER

CASE

MODEL NO. 51550-911510581 & UP

ASSEMBLY

33-6620

2

33-6670

3

33-6610

4

33-9660

5

33-6700

6

321 04-121

7

32144-30

8

Description

_--

Trigger

Trigger

Spring

Switch

Wiring Harness

Left

Screws

Self Tapping Screws

Release

Handle and Battery

Case

PARTS

1

1

4

33-6540

10

Description

~-

Battery

Foam Pad

Control Panel

Control Panel Decal

Cover

Right Handle and Battery

Screws

Case

46

TOR0

CORDLESS

TRIMMER

MOTOR

HOUSING

ASSEMBLY

MODEL

NO.

51550 - 9115105

&

UP

Part

No.

33-9750

33-6660

33-6720

33-6560

3250-18

88014

33-6530

88002

33-9720

Description

Motor

Tube

Lower Wiring Harness

Left Hand Housing

Screws

Prewound

Empty

50'

Driver

Coil

Spool

Spool

-

.040"

Cutting Line

PARTS

Ref,

No.

23

1

1

1

2

1

1

1

1

24

25

26

27

28

29

30

PartNo.

29-8120

33-6840

33-9760

33-9730

33-9740

21 8-496

32104-123

33-6760

Description

Core

Spring

Drum with Eyelet

Drum Cup

Heat Sink Casting

Wire Connectors

Screws

Right Hand Motor Housing

with Cut

Off

Blade

No.

I

Used

Form

No.

3710-139

PRINTED

INUSA.

Loading...

Loading...