Toro 41199, Multi-Pro 1200 Operator's Manual

FormNo.3377-127RevA

Multi-Pro

ModelNo.41199—SerialNo.313000001andUp

®

1200TurfSprayer

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3377-127*A

TheMulti-Pro®turfsprayerisadedicatedturfspray

G002182

1

applicationvehicleandisintendedtobeusedbyprofessional,

hiredoperatorsincommercialapplications.Itisprimarily

designedforsprayingonwell-maintainedlawnsinparks,golf

courses,sportselds,andoncommercialgrounds.

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

Important:Thisengineisnotequippedwithaspark

arrestermufer.ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

land.Otherstatesorfederalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Introduction

Readthismanualcarefullytolearnhowtooperateand

maintainyourproductproperly.Theinformationinthis

manualcanhelpyouandothersavoidinjuryandproduct

damage.AlthoughT orodesignsandproducessafeproducts,

youareresponsibleforoperatingtheproductproperlyand

safely.Y oumaycontactTorodirectlyatwww.Toro.comfor

productandaccessoryinformation,helpndingadealer,or

toregisteryourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.

modelandserialnumbersontheproduct.

Figure1illustratesthelocationofthe

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol.

Thismanualusestwootherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

ChemicalSafety.......................................................4

BeforeOperating....................................................4

WhileOperating......................................................5

Maintenance...........................................................6

SoundPower..........................................................7

SoundPressure.......................................................7

Hand-ArmVibration...............................................7

WholeBodyVibration.............................................7

SafetyandInstructionalDecals.................................8

Setup...........................................................................13

1InstallingtheAnti-siphonFillReceptacle.................13

2InstallingtheSprayProMonitor.............................14

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

3CheckingtheBoomHingeSprings.........................15

4AdjustingtheBoomstoLevel................................16

5CompletingtheSetup:Learningmoreaboutyour

product..............................................................16

ProductOverview.........................................................17

Controls...............................................................18

Specications........................................................23

Attachments/Accessories........................................23

Operation....................................................................24

ThinkSafetyFirst...................................................24

BeforeDrivingtheSprayerfortheFirst

Time.................................................................24

Pre-StartingChecks................................................25

DrivingtheSprayer.................................................25

NewSprayerBreak-In.............................................26

OperatingtheSprayer.............................................26

FillingtheFreshWaterTank....................................26

FillingtheSprayTank..............................................27

OperatingtheBooms..............................................27

Spraying................................................................28

SprayingTips.........................................................28

CleaningtheSprayer...............................................28

CalibratingtheSprayProMonitor.............................31

CalibratingtheBoomBypassValves..........................33

Pump....................................................................33

TransportingtheSprayer.........................................34

TowingtheSprayer.................................................34

Maintenance.................................................................35

RecommendedMaintenanceSchedule(s)......................35

DailyMaintenanceChecklist....................................36

NotationforAreasofConcern.................................37

PremaintenanceProcedures........................................38

JackingtheSprayer.................................................38

Lubrication...............................................................38

GreasingtheSprayer...............................................38

GreasingtheBoomHinges......................................40

GreasingtheActuatorRodBearings..........................40

EngineMaintenance..................................................42

CheckingtheAirIntakeScreen.................................42

ServicingtheAirCleaner.........................................42

ServicingtheEngineOil..........................................43

ChangingtheSparkPlugs........................................44

FuelSystemMaintenance...........................................45

ReplacingtheFuelFilter..........................................45

DrainingtheFuelTank...........................................45

ElectricalSystemMaintenance....................................46

ReplacingtheFuses................................................46

ServicingtheBattery...............................................46

DriveSystemMaintenance.........................................49

InspectingtheWheels/Tires....................................49

AdjustingtheFrontWheelToe-In............................49

BrakeMaintenance....................................................50

CheckingtheBrakeFluid.........................................50

InspectingtheBrakes..............................................50

AdjustingtheParkingBrake.....................................50

BeltMaintenance......................................................51

ServicingtheDriveBelt...........................................51

AdjustingtheSteeringPumpBelt..............................51

HydraulicSystemMaintenance....................................52

CheckingtheTransaxle/HydraulicFluid....................52

ChangingTransaxle/HydraulicFluid.........................52

ReplacingtheHydraulicFilter..................................53

SpraySystemMaintenance..........................................53

InspectingtheHoses..............................................53

PumpMaintenance.................................................54

AdjustingtheBoomActuator...................................54

EmergencyManualOperationoftheBoom

Actuators...........................................................55

InspectingtheNylonPivotBushings.........................55

Cleaning...................................................................56

CleaningtheFlowmeter..........................................56

CleaningtheSuctionStrainer...................................57

Storage........................................................................57

Troubleshooting...........................................................59

Schematics...................................................................63

3

Safety

ChemicalSafety

Improperuseormaintenancebytheoperatororownercan

resultininjury.Toreducethepotentialforinjury,comply

withthesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeansCAUTION,W ARNING,

orDANGER-personalsafetyinstruction.Failuretocomply

withtheinstructionmayresultinpersonalinjuryordeath.

Supervisors,operators,andservicepersonsshouldbefamiliar

withthefollowingstandardsandpublications:(Thematerial

maybeobtainedfromtheaddressshown).

•FlammableandCombustibleLiquidsCode:

ANSI/NFPA30

•NationalFireProtectionAssociation:

ANSI/NFPA#505;PoweredIndustrialTrucks

NationalFirePreventionAssociation

BarrymarchPark

Quincy,Massachusetts02269U.S.A.

•SAEJ2258LightUtilityVehiclesSocietyof

AutomotiveEngineers

SAEWorldHeadquarters400CommonwealthDrive

Warrendale,PA15096-0001

•ANSI/UL558;InternalCombustion

EnginePoweredIndustrialTrucks

AmericanNationalStandardsInstitute,Inc.

1430BroadwayNewYork,NewYork10018U .S.A.

or

UnderwritersLaboratories

333PngstenRoad

Northbrook,Illinois60062U.S.A.

SafeOperatingPractices

WARNING

Thesprayerisanoff-highwayvehicleonlyandis

notdesigned,equipped,ormanufacturedforuseon

publicstreets,roads,orhighways.

Supervisor'sResponsibilities

•Makesurethatoperatorsarethoroughlytrainedand

familiarwiththeOperator'sManual,EngineManual,andall

labelsonthesprayer.

•Establishyourownspecialproceduresandworkrules

forunusualoperatingconditions(e.g.slopestoosteep

forsprayeroperation).

WARNING

Chemical substances used in the spray system may

be hazardous and to xic to y ou, bystander s, animals,

plants, soils or other pr oper ty .

•Carefullyreadandfollowthechemical

warninglabelsandMaterialSafetyData

Sheets(MSDS)forallchemicalsusedand

protectyourselfaccordingtothechemical

manufacturer'srecommendations.Forexample,

useappropriatePersonalProtectiveEquipment

(PPE)includingfaceandeyeprotection,gloves,

orotherequipmenttoguardagainstpersonal

contactwiththechemical.

•Keepinmindthattheremaybemorethanone

chemicalusedandinformationoneachshould

beassessed.

R efuse to operate or w or k on the spray er if this

•

inf or mation is not a v aila ble!

•Beforeworkingonaspraysystemmakesurethe

systemhasbeentriplerinsedandneutralized

accordingtotherecommendationsofthe

chemicalmanufacturer(s).

•Verifythereisanadequatesupplyofcleanwater

andsoapnearby,andimmediatelywashoffany

chemicalsthatcontactyou.

•Obtainpropertrainingbeforeusingorhandling

chemicals.

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer'sinstructionsforthe

safeapplicationofthechemical.

•Handlechemicalsinawellventilatedarea.

•Weargogglesandotherprotectiveequipmentas

instructedbythechemicalmanufacturer.Ensurethatas

littleskinaspossibleisexposedwhileusingchemicals.

•Havecleanwateravailableespeciallywhenllingthe

spraytank.

•Donoteat,drink,orsmokewhileworkingwithchemicals.

•Alwayswashyourhandsandotherexposedareasassoon

aspossibleafternishingthework.

•Properlydisposeofunusedchemicalsandchemical

containersasinstructedbythechemicalmanufacturer

andyourlocalcodes.

•Chemicalsandfumesinthetanksaredangerous;never

enterthetankorplaceyourheadoverorintheopening.

BeforeOperating

•Operatethemachineonlyafterreadingandunderstanding

thecontentsofthismanual.

4

•Neverallowchildrentooperatethesprayer.

•Neverallowotheradultstooperatethesprayerwithout

rstreadingandunderstandingtheOperator'sManual.

Onlytrainedandauthorizedpersonsshouldoperatethis

sprayer.Makesurethatalloperatorsarephysicallyand

mentallycapableofoperatingthesprayer.

•Thissprayerisdesignedtocarryonlyyou,theoperator.

Nevercarryanypassengersonthesprayer.

•Neveroperatethesprayerwhenundertheinuence

ofdrugsoralcohol.Evenprescriptiondrugsandcold

medicinescancausedrowsiness.

•Donotdrivethesprayerwhenyouaretired.Besureto

takeoccasionalbreaks.Itisveryimportantthatyoustay

alertatalltimes.

•Becomefamiliarwiththecontrolsandknowhowtostop

theenginequickly.

•Keepallshields,safetydevices,anddecalsinplace.Ifa

shield,safetydevice,ordecalismalfunctioning,illegible,

ordamaged,repairorreplaceitbeforeoperatingthe

machine.

•Alwayswearsubstantialshoes.Donotoperatethe

machinewhilewearingsandals,tennisshoes,orsneakers.

Donotwearloosettingclothingorjewelrywhichcould

getcaughtinmovingpartsandcausepersonalinjury.

•Wearingsafetyglasses,safetyshoes,longpants,anda

helmetisadvisableandrequiredbysomelocalsafetyand

insuranceregulations.

•Avoiddrivingwhenitisdark,especiallyinunfamiliar

areas.Ifyoumustdrivewhenitisdark,besuretodrive

cautiously,usetheheadlights,andevenconsideradding

additionallights.

•Beextremelycarefulwhenoperatingaroundpeople.

Alwaysbeawareofwherebystandersmightbeandkeep

themawayfromtheworkarea.

•Beforeoperatingthesprayer,alwayscheckthedesignated

areasofthesprayerthatarestatedinthePre-Starting

ChecksintheOperationsection.Ifthemachinedoes

notfunctioncorrectlyorisdamagedinanyway ,donot

usethesprayer.Makesurethattheproblemiscorrected

beforethesprayerorattachmentisoperated.

•Ensurethatalluidlineconnectorsaretightandallhoses

areingoodconditionbeforeapplyingpressuretothe

system.

•Sincegasolineishighlyammable,handleitcarefully.

–Useanapprovedgasolinecontainer.

–Donotremovethecapfromthefueltankwhenthe

engineishotorrunning.

–Donotsmokewhilehandlinggasoline.

–Fillthefueltankoutdoors,andllittoabout1inch

(25mm)belowthetopofthetank(thebottomofthe

llerneck).Donotoverllit.

–Wipeupanyspilledgasoline.

WhileOperating

WARNING

Engineexhaustcontainscarbonmonoxide,which

isanodorless,deadlypoisonthatcankillyou.

Donotrunengineindoorsorinanenclosedarea.

•Theoperatorshouldremainseatedwheneverthesprayer

isinmotion.Theoperatorshouldkeepbothhandson

thesteeringwheelwheneverpossible.Keepyourarms

andlegswithinthesprayerbodyatalltimes.

•Alwayswatchoutforandavoidlowoverhangssuchas

treelimbs,doorjambs,andoverheadwalkways.Make

surethereisenoughroomoverheadtoeasilyclearthe

sprayerandyourhead.

•Failuretooperatethesprayersafelymayresultinan

accident,tipoverofthesprayer,andseriousinjuryor

death.Drivecarefully.Topreventtippingorlossof

control:

–Useextremecaution,reducespeed,andmaintain

asafedistancearoundsandtraps,ditches,creeks,

ramps,unfamiliarareas,oranyareasthathaveabrupt

changesingroundconditionsorelevation.

–Watchforholesorotherhiddenhazards.

–Useextracautionwhenoperatingthesprayeronwet

surfaces,inadverseweatherconditions,athigher

speeds,orwithafullload.Stoppingtimeanddistance

willincreasewithafullload.

–Avoidsuddenstopsandstarts.Donotgofrom

reversetoforwardorforwardtoreversewithoutrst

comingtoacompletestop.

–Slowdownbeforeturning.Donotattemptsharp

turnsorabruptmaneuversorotherunsafedriving

actionsthatmaycausealossofsprayercontrol.

–Beforebackingup,looktotherearandensurethat

nooneisbehindyou.Backupslowly.

–Watchoutfortrafcwhenyouarenearorcrossing

roads.Alwaysyieldtherightofwaytopedestrians

andothervehicles.Thissprayerisnotdesignedfor

useonstreetsorhighways.Alwayssignalyourturns

orstopearlyenoughsothatotherpeopleknowwhat

youplantodo.Obeyalltrafcrulesandregulations.

–Theelectricalandexhaustsystemsofthesprayercan

producesparkscapableofignitingexplosivematerials.

Neveroperatethesprayerinornearanareawhere

thereisdustorfumesintheairwhichareexplosive.

–Ifyouareeverunsureaboutsafeoperation,stop

workandaskyoursupervisor.

•Donottouchtheengineormuferwhiletheengineis

runningorsoonafterithasstopped.Theseareasmaybe

hotenoughtocauseburns.

5

•Ifthemachineevervibratesabnormally,stopimmediately,

waitforallmotiontostop,andinspectthesprayerfor

damage.Repairalldamagebeforeresumingoperation.

•Beforegettingoffoftheseat:

1.Stopthemovementofthemachine.

2.PlacetherangeselectorinNeutralandsetthe

parkingbrake.

3.TurntheignitionkeytoOff.

4.Removetheignitionkey .

Important:Donotparkthemachineonan

incline.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

onlevelground.Ifthesprayermustbestopped,avoid

suddenspeedchanges,whichmayinitiatetippingor

rollingofthesprayer.Donotslamonthebrakes

whenrollingbackward,asthismaycausethesprayerto

overturn.

•Usetheseatbeltwhenoperatingthemachineandbe

certainthatitcanbereleasedquicklyintheeventofan

emergency.

•Donotremoveoraltertherolloverprotectionsystem

(ROPS).

•Reducespeedandloadwhenoperatingonroughterrain,

unevenground,andnearcurbs,holes,andothersudden

changesinterrain.Loadsmayshift,causingthesprayer

tobecomeunstable.

WARNING

Braking

•Slowdownbeforeyouapproachanobstacle.Thisgives

youextratimetostoporturnaway .Hittinganobstacle

candamagethesprayeranditscontents.Moreimportant,

itcaninjureyou.

•GrossVehicleWeight(GVW)hasamajorimpactonyour

abilitytostopand/orturn.Heavyloadsandattachments

makeasprayerhardertostoporturn.Theheavierthe

load,thelongerittakestostop.

•Turfandpavementaremuchmoreslipperywhenthey

arewet.Itcantake2to4timesaslongtostoponwet

surfacesasondrysurfaces.Ifyoudrivethroughstanding

waterdeepenoughtogetthebrakeswet,theywillnot

workwelluntiltheyaredry.Afterdrivingthroughwater,

youshouldtestthebrakestomakesuretheywork

properly.Iftheydonot,driveslowlywhileputtinglight

pressureonthebrakepedal.Thiswilldrythebrakesout.

OperatingonHillsandRoughTerrain

Operatingthesprayeronahillmaycausetippingorrolling

ofthesprayer,ortheenginemaystallandyoucouldlose

headwayonthehill.Thiscouldresultinpersonalinjury.

•Donotacceleratequicklyorslamonthebrakeswhen

backingdownahill,especiallywithaload.

•Neverdriveacrossasteephill;alwaysdrivestraightupor

downorgoaroundthehill.

•Iftheenginestallsoryoubegintoloseheadwaywhile

climbingahill,graduallyapplythebrakesandslowlyback

straightdownthehill.

•Turningwhiletravelingupordownhillscanbe

dangerous.Ifyouhavetoturnwhileonahill,doitslowly

andcautiously.Nevermakesharporfastturns.

•Heavyloadsaffectstability.Reducetheweightoftheload

andyourspeedwhenoperatingonhills.

•Avoidstoppingonhills,especiallywithaload.Stopping

whilegoingdownahillwilltakelongerthanstopping

Suddenchangesinterrainmaycauseabrupt

steeringwheelmovement,possiblyresultingin

handandarminjuries.

•Reduceyourspeedwhenoperatingonroughterrainand

nearcurbs.

•Gripthesteeringwheellooselyaroundtheperimeter.

Keepyourhandsclearofthesteeringwheelspokes.

Loading

Theweightofthecargocanchangethesprayercenterof

gravityandsprayerhandling.Toavoidlossofcontroland

personalinjury,followtheseguidelines:

•Reducetheweightoftheloadwhenoperatingonhills

androughterraintoavoidtippingoroverturningofthe

sprayer.

•Liquidloadscanshift.Thisshiftinghappensmostoften

whileturning,goingupordownhills,suddenlychanging

speeds,orwhiledrivingoverroughsurfaces.Shifting

loadscancausethesprayertotipover.

•Whenoperatingwithaheavyload,reduceyourspeedand

allowforsufcientbrakingdistance.Donotsuddenly

applythebrakes.Useextracautiononslopes.

•Beawarethatheavyloadsincreaseyourstoppingdistance

andreduceyourabilitytoturnquicklywithouttipping

over.

Maintenance

•Onlypermitqualiedandauthorizedpersonnelto

maintain,repair,adjust,orinspectthesprayer.

•Beforeservicingormakingadjustmentstothemachine,

stoptheengine,settheparkingbrake,andremovethekey

fromtheignitiontopreventsomeonefromaccidentally

startingtheengine.

•Tomakesurethattheentiremachineisingoodcondition,

keepallnuts,bolts,andscrewsproperlytightened.

6

•Toreducethepotentialforre,keeptheengineareafree

ofexcessivegrease,grass,leaves,andaccumulationofdirt.

•Neveruseanopenametocheckthelevelorleakageof

fuelorbatteryelectrolyte.

•Iftheenginemustberunningtoperformamaintenance

adjustment,keepyourhands,feet,clothing,andanyparts

ofyourbodyawayfromtheengineandanymovingparts.

Keepeveryoneaway .

•Donotuseopenpansoffuelorammablecleaning

uidswhencleaningparts.

•Donotadjustthegroundspeedgovernor.Toensure

safetyandaccuracy,haveanAuthorizedToroDistributor

checkthegroundspeed.

•Keepyourbodyandhandsawayfrompinholeleaksor

nozzlesthatejecthighpressureuid.Usecardboardor

papertondleaks.Fluidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

•Ifmajorrepairsareeverneededorassistanceisrequired,

contactanAuthorizedToroDistributor.

•Tobesureofoptimumperformanceandsafety ,

alwayspurchasegenuineTororeplacementpartsand

accessories.Replacementpartsandaccessoriesmadeby

othermanufacturerscouldbedangerous.Alteringthis

sprayerinanymannerthatmayaffectsprayeroperation,

performance,durability,oritsuse,mayresultininjuryor

death.Suchusecouldvoidtheproductwarranty.

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

SoundPower

Thisunithasaguaranteedsoundpowerlevelofof98dBA,

whichincludesanUncertaintyValue(K)of1dBA.

Soundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

SoundPressure

Thisunithasasoundpressurelevelattheoperator’searof83

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinENISO11201.

Hand-ArmVibration

Measuredvibrationlevelforrighthand=1.00m/s

Measuredvibrationlevelforlefthand=0.90m/s

UncertaintyValue(K)=0.5m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinEN1032.

2

2

2

WholeBodyVibration

Measuredvibrationlevel=0.2m/s

2

7

SafetyandInstructional

Decals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

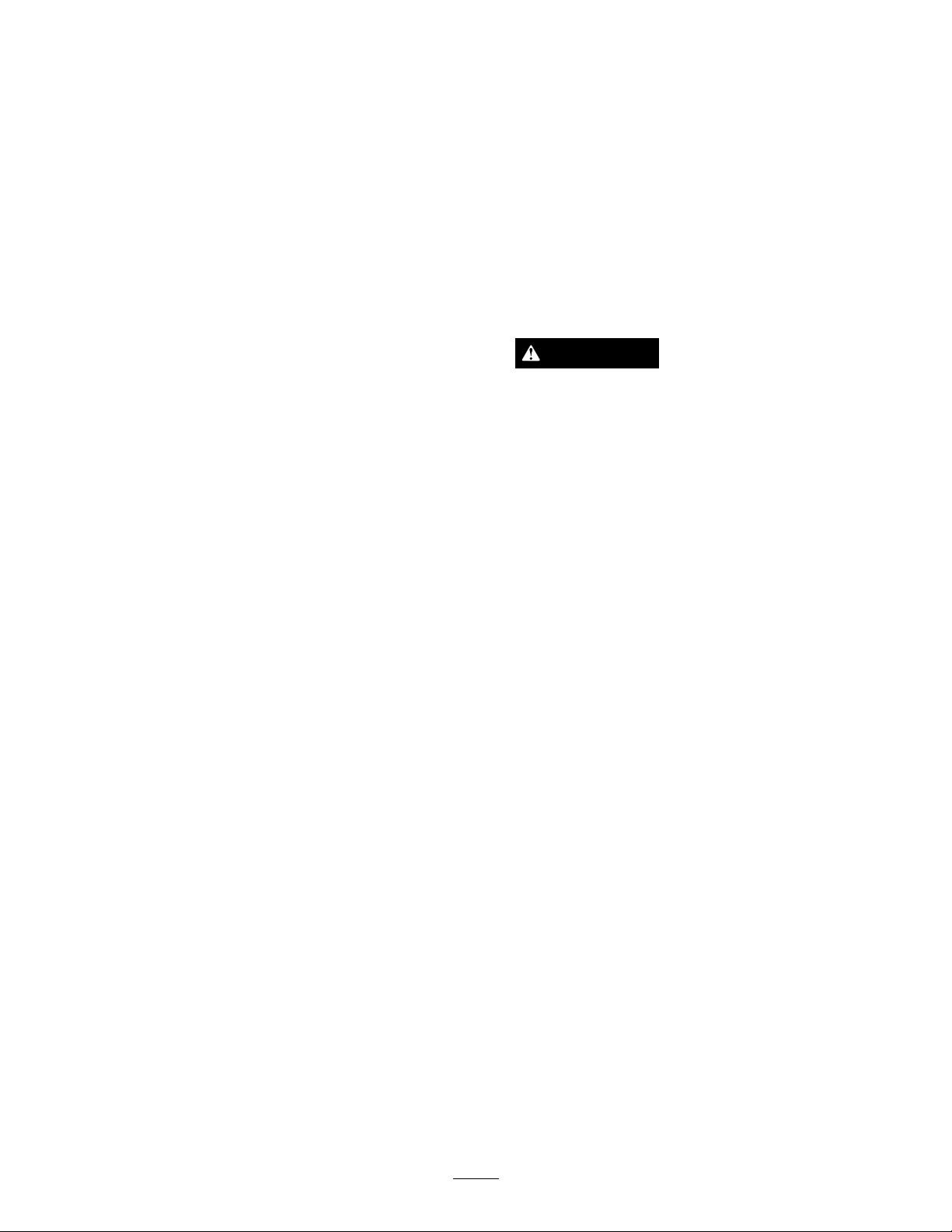

100-8454

1.ReadtheOperator'sManualforinformationonthe

transmission.

2.Tostarttheengine,sitontheoperator'sseat,pressthe

brake,settherangeselectortoNeutral,turntheignition

keytoEngine-start,settherangeselectortothedesired

gear,releasethebrakeandparkingbrake,andpressthe

acceleratorpedaltothedesiredspeed.

3.Tostoptheengine,pressthebrake,settherangeselector

toNeutral,settheparkingbrake,andturntheignitionkey

toEngine-stop.

4.Rangeselectorgearpattern

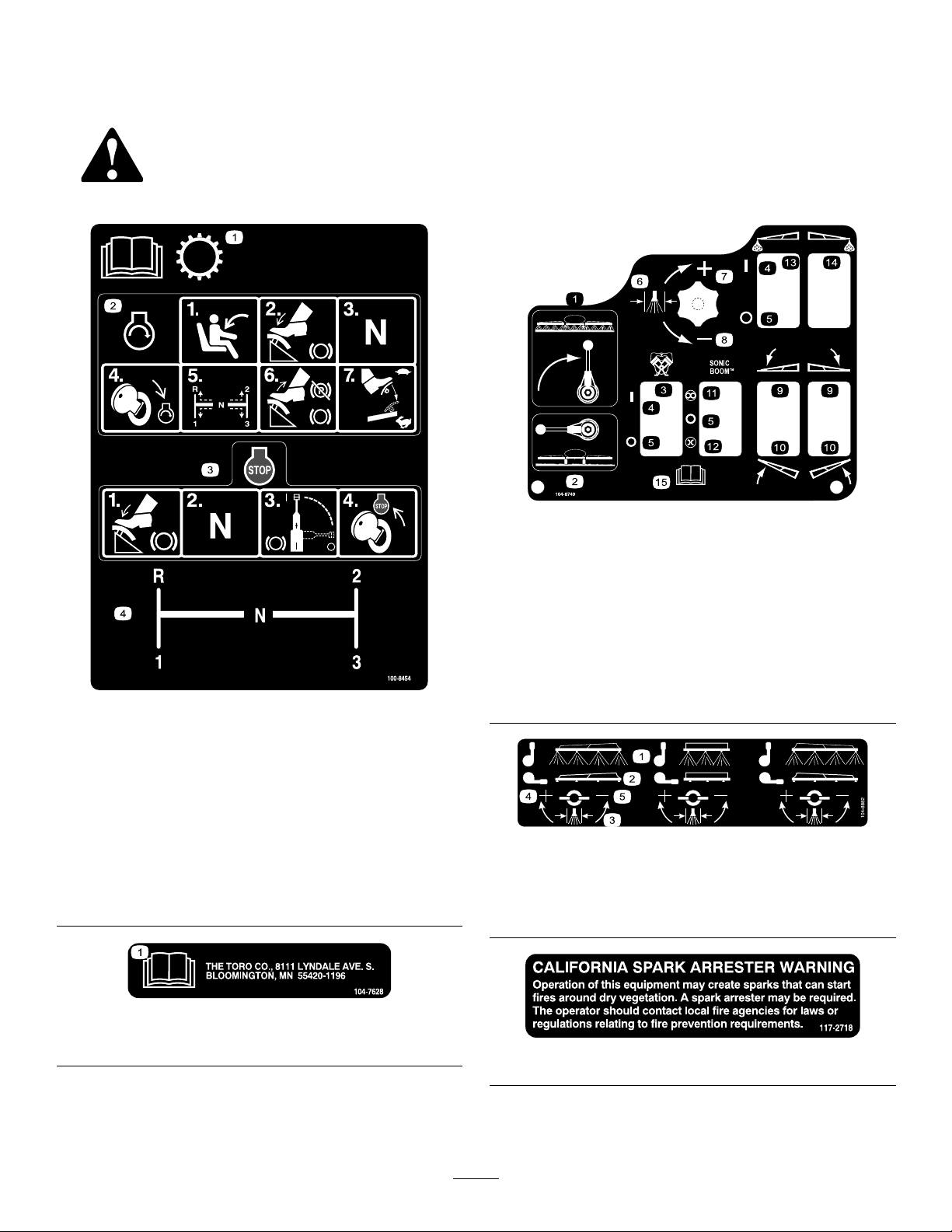

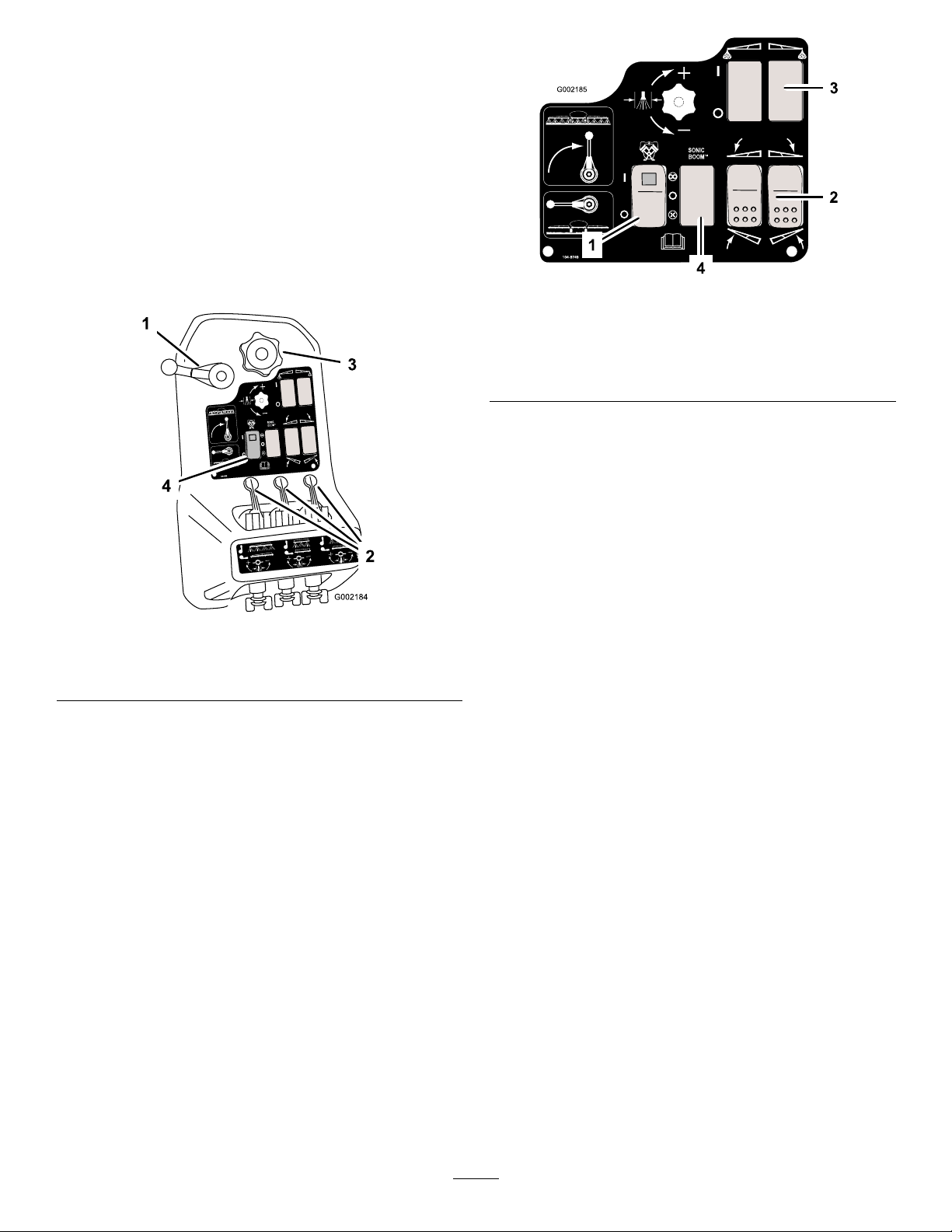

104-8749

1.Sprayon

2.Sprayoff

3.Pump11.Automatic

4.On

5.Off13.Leftboomfoammarker

6.Spraypressure14.Rightboomfoammarker

7.Increase

8.Decrease

9.Lowertheboom.

10.Raisetheboom.

12.Manual

15.ReadtheOperator's

Manual.

104-8882

1.Sprayon

2.Sprayoff

3.Spraypressure

4.Increase

5.Decrease

1.ReadtheOperator'sManual.

104-7628

117–2718

8

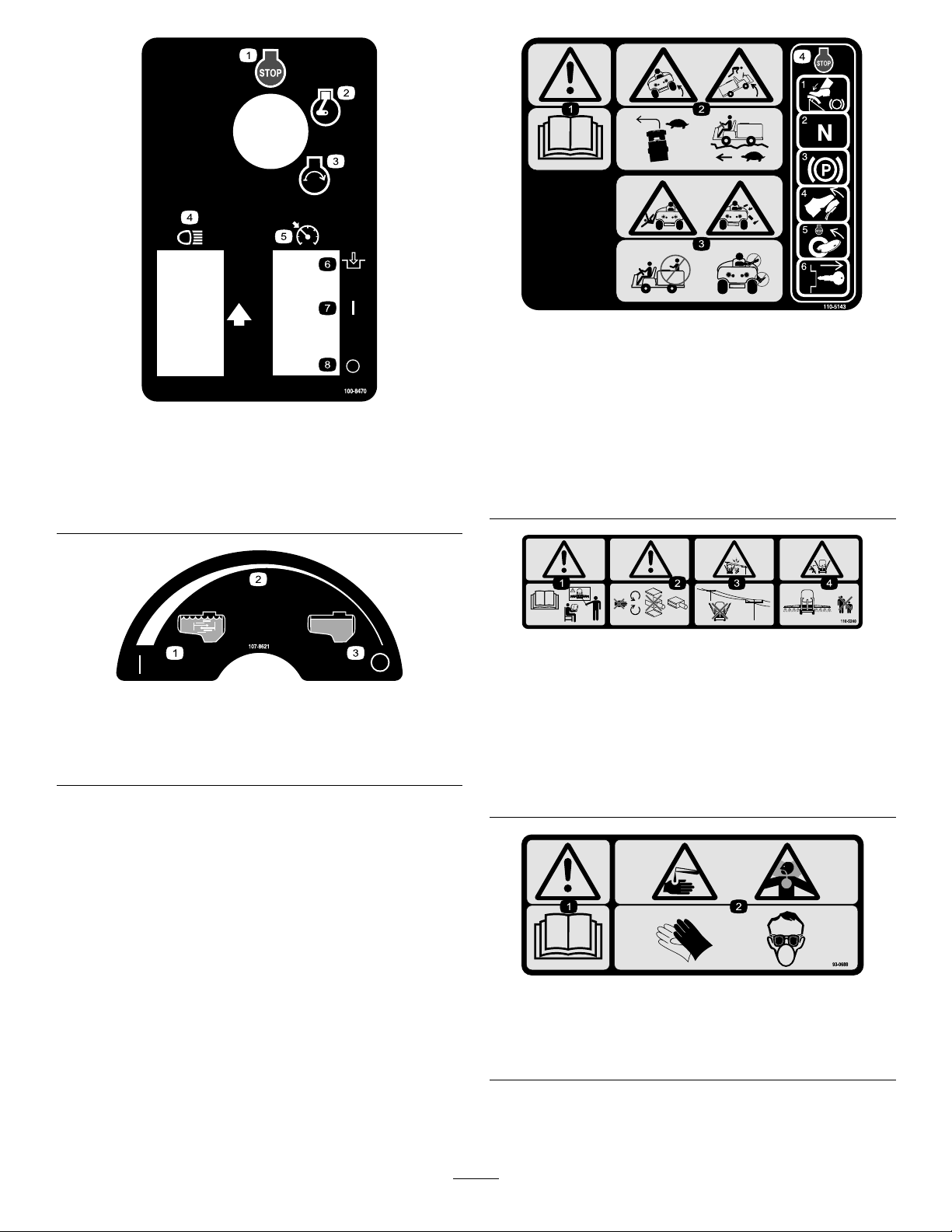

100-8470

1.Engine—stop5.Neutralenginespeedlock

2.Engine—run6.Engage

3.Engine—start

4.Headlights

7.On

8.Off

107-8621

1.Agitationon

2.Continuousvariable

setting

3.Agitationoff

110-5143

1.Warning—readtheOperator'sManual.

2.TippingHazard—driveslowlyoverroughterrainandwhen

turning.

3.Fallingandarm/leginjuryhazards—donotcarrypassengers

andkeeparmsandlegsinsideofthevehicleatalltimes.

4.Tostoptheengine,pressthebrake,movetherange

selectortoNeutral,settheparkingbrake,releasethebrake

pedal,turntheignitionkeytoEngine-stop,andremovethe

key.

110-5240

1.Warning—readtheOperator'sManualandreceivetraining

beforeoperating.

2.Warning—stayawayfrommovingparts,donotoperate

withcoversremoved.

3.Electricshockhazard,overheadpowerlines—stayaway

fromoverheadpowerlines.

4.Crushinghazard,boom—keepbystandersasafedistance

fromthemachine.

93-0688

1.Warning—readtheOperator'sManual.

2.Causticliquid/chemicalburnandtoxicgasinhalation

hazards—wearhand,skin,eye,andrespiratoryprotection.

9

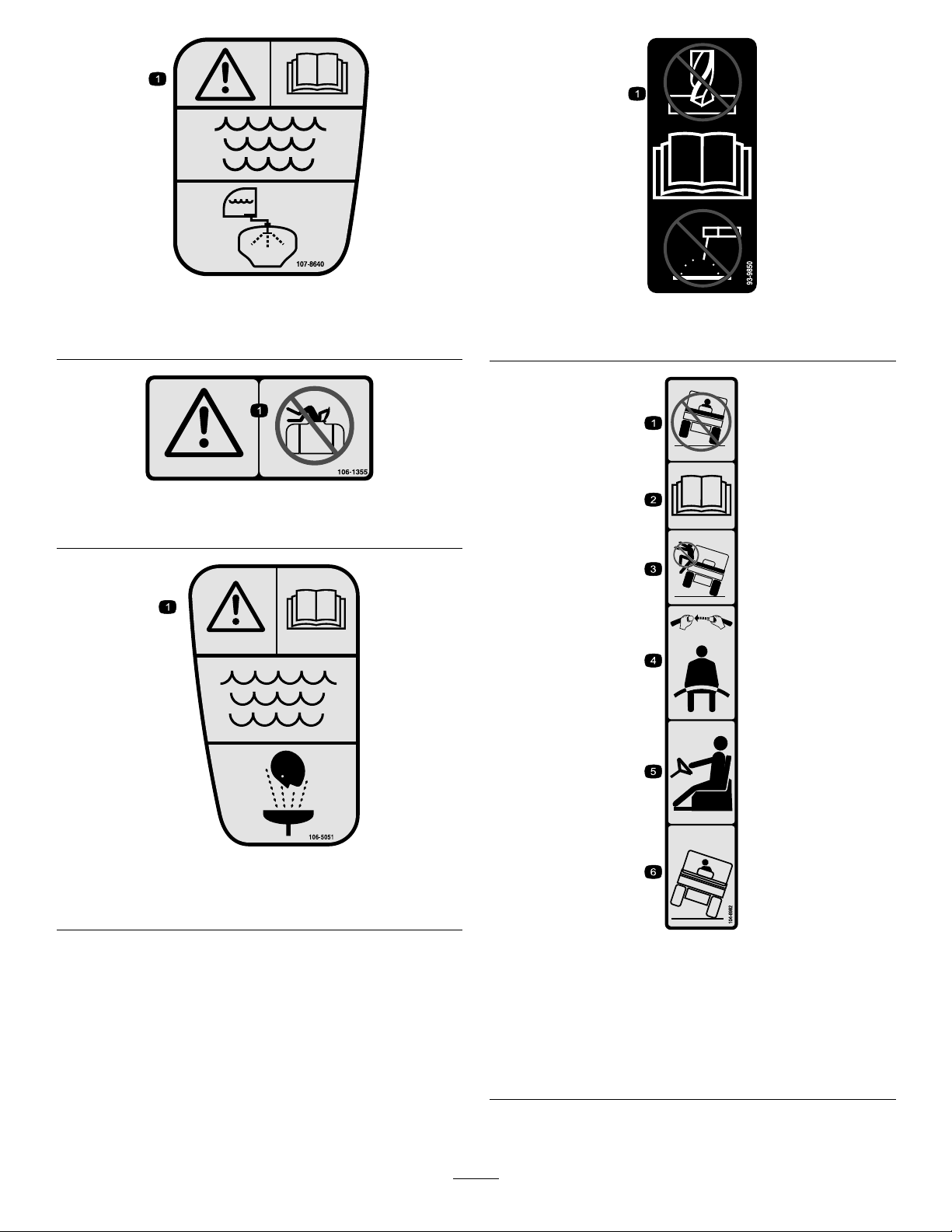

107-8640

1.Warning—readtheOperator'sManual;usefresh,clean

waterforrinsingthetank.

106-1355

1.Warning—donotenterthetank.

93-9850

1.Donotrepairorrevise—readtheOperator'sManual.

106-5051

1.Warning—readtheOperator'sManual;usefresh,clean

waterforrst-aidwashing.

104–8982

1.Avoidtippingthemachine.4.Alwaysweartheseatbelt.

2.ReadtheOperator’s

Manual.

3.Donotexitthemachine

whenitistipping.

5.Ifthemachinetips,hold

tightandbracewithyour

feet.

6.Ifthemachinebeginsto

tip,leanawayfromthe

directionitistipping.

10

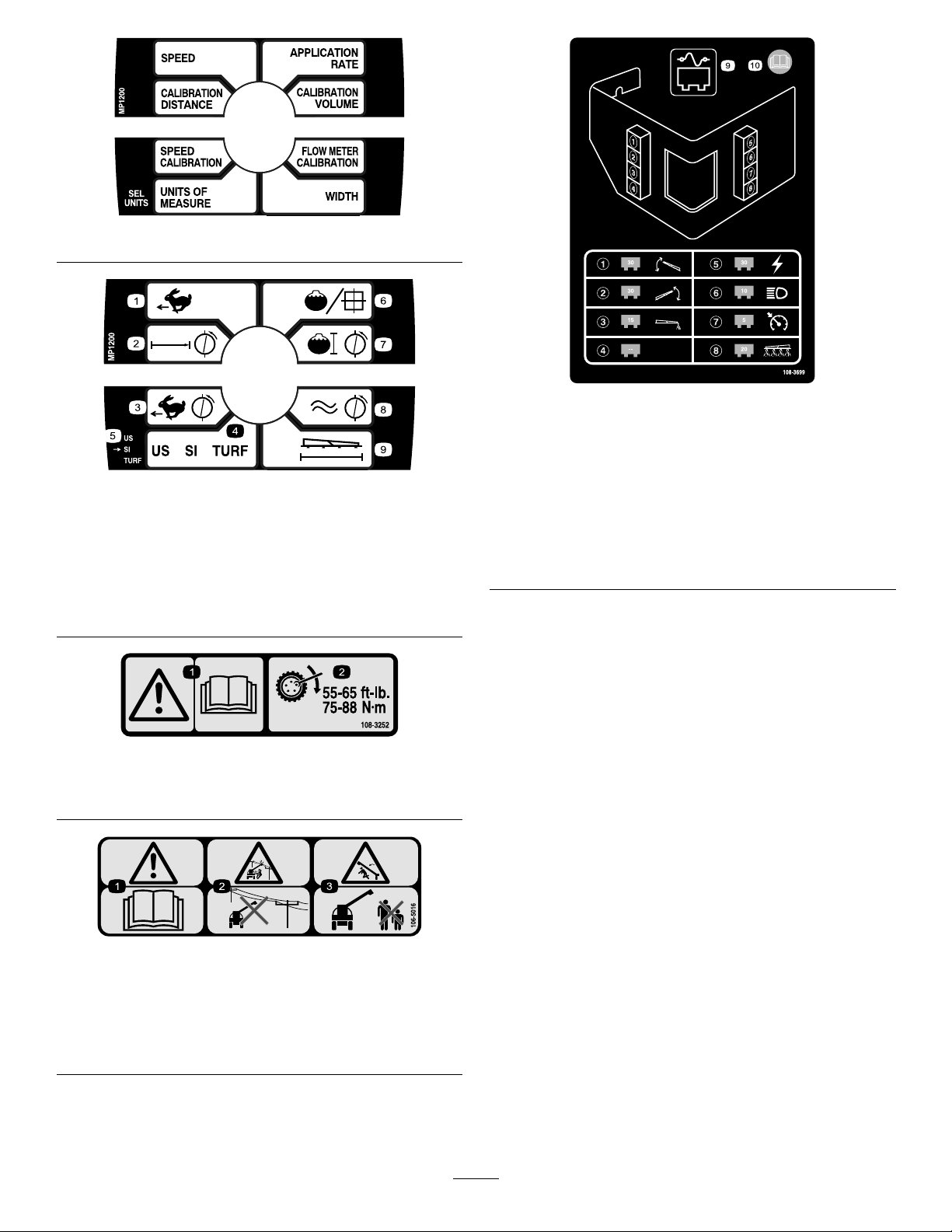

108-3306

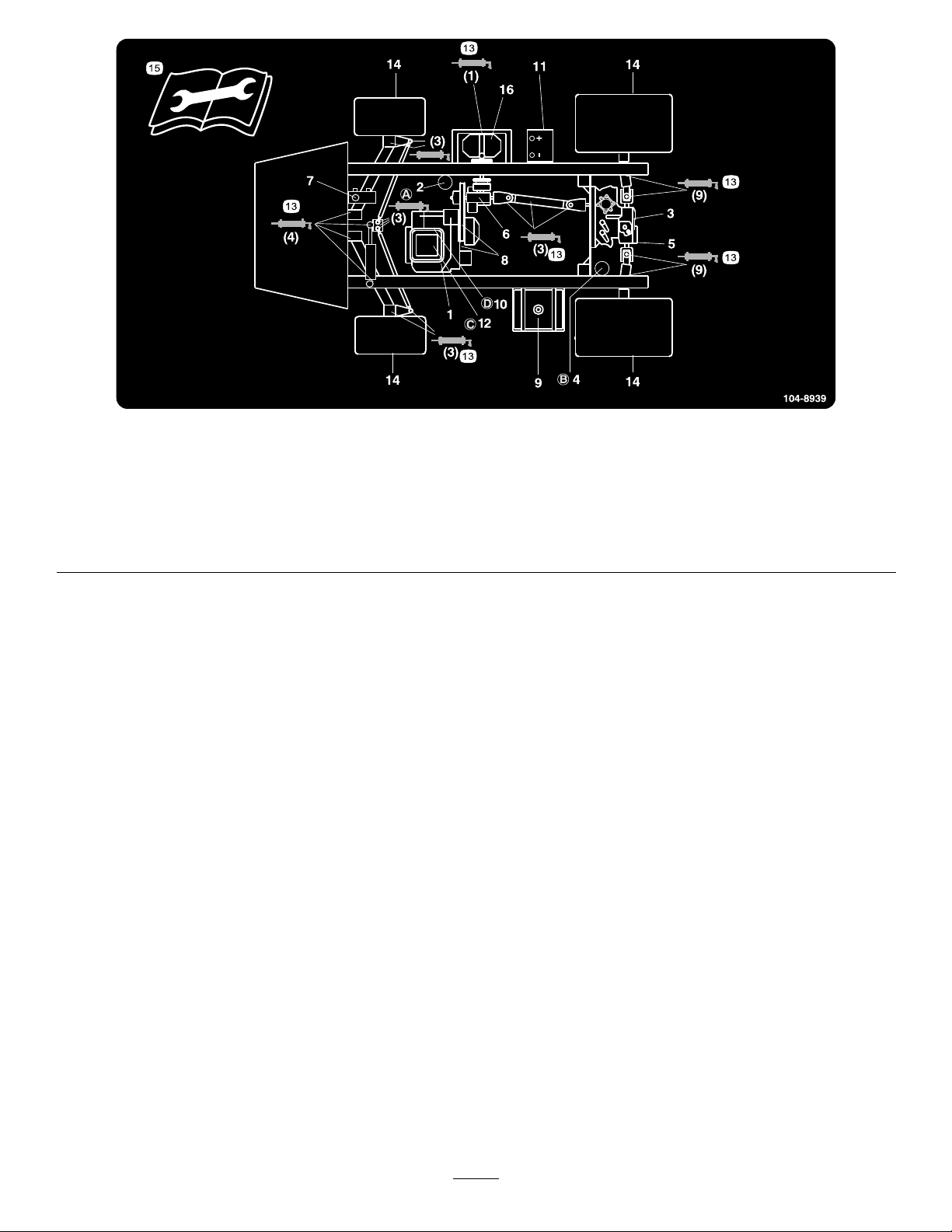

108-3699

108-3308

CEUnitsOnly

1.Speed

2.Calibrationdistance7.Calibrationvolume

3.Speedcalibration

4.Unitsofmeasure

5.Selectunits

6.Applicationrate

8.Flowmetercalibration

9.Width

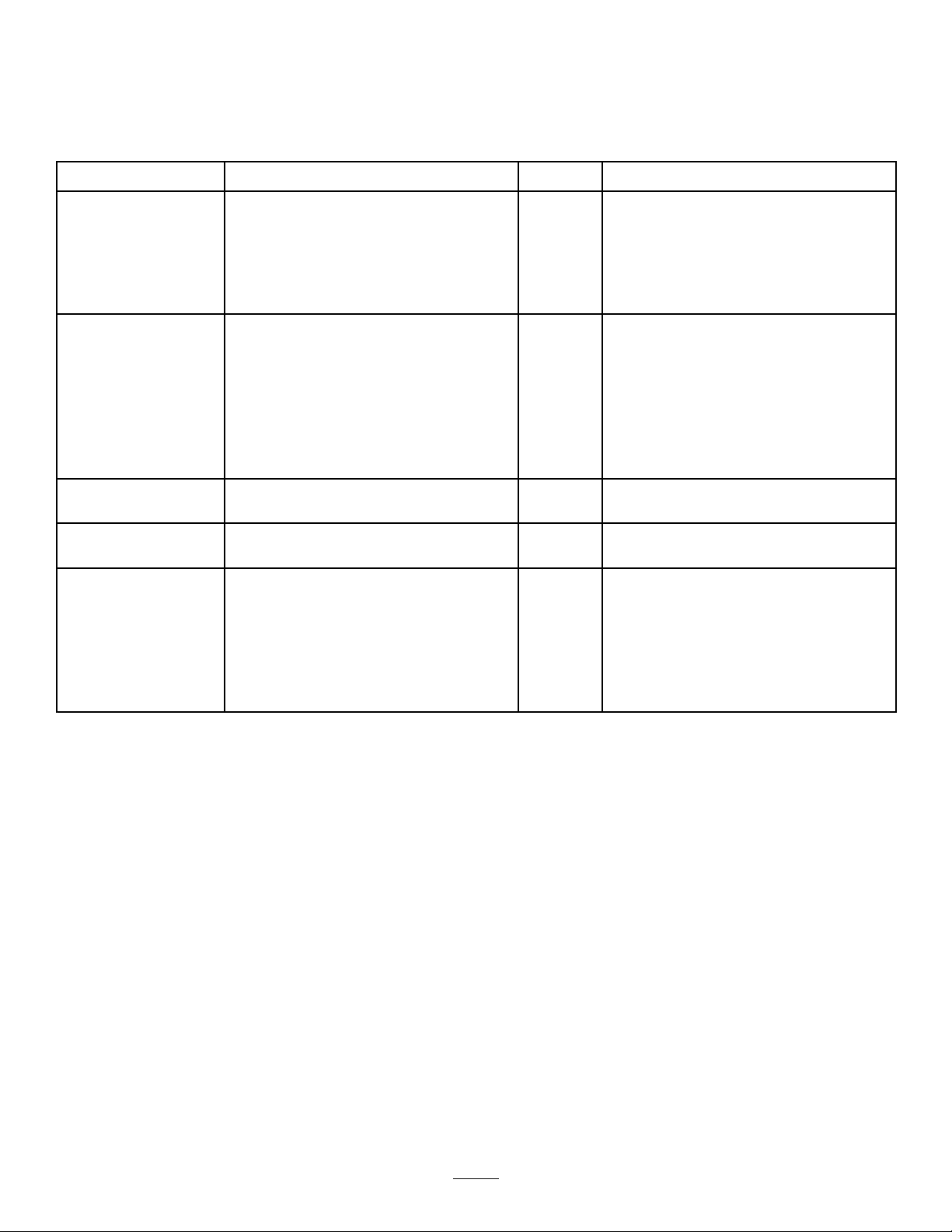

108-3252

1.Warning—readthe

Operator'sManual.

2.Torquelugnutsto55-65

ft-lb(75-88N·m).

1.30ampfuse,leftboom

actuator

2.30ampfuse,rightboom

actuator

3.15ampfuse,foammarker8.20ampfuse,spraysystem

4.Empty9.Fusepanel

5.30ampfuse,power10.ReadtheOperator's

6.10ampfuse,headlights

7.5ampfuse,cruisecontrol

Manualformore

information.

106-5016

1.Warning—readtheOperator'sManual.

2.Electricshockhazard,overheadpowerlines—stayaway

fromoverheadpowerlines.

3.Crushinghazard,boom—keepbystandersasafedistance

fromthemachine.

11

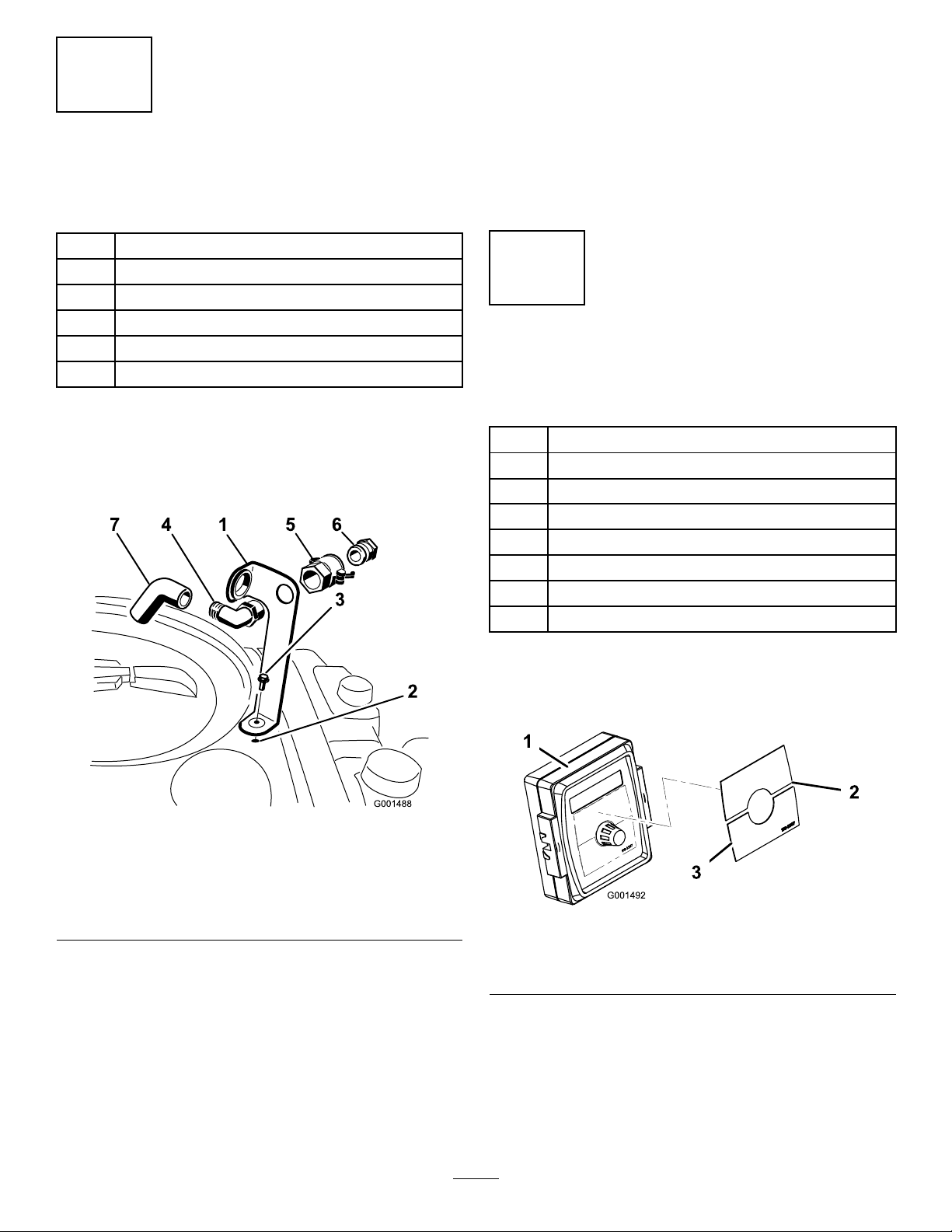

104-8939

1.Engineoillevel(dipstick)

2.Engineoillter6.Gearboxuidlevel10.Fuellter

3.Transaxle/hydraulicuid

level(dipstick)

4.Transaxlehydrauliclter

5.Hydraulicstrainer9.Fuel,unleadedonly

7.Brakeuid

8.Belts,steeringanddrive12.Aircleaner16.Pump

11.Battery15.Readtheinstructions

13.Grease

14.Tirepressure

beforeservicingor

performingmaintenance.

12

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

90degreetting

Quickcoupler

Hoseadapter1

Fillreceptaclebracket1

Flange-headbolt,5/16x3/4inch

Anti-siphonhose1

SprayProMonitor

SprayProDecal

Bracket1

Flange-headbolt,3/4inch

Flangenut,1/4inch

Knob2

Washer2

Carriagebolt

Nopartsrequired

Nopartsrequired

Ignitionkey1

Operator'sManual

EngineOperator'sManual

PartsCatalog

OperatorTrainingMaterial

RegistrationCard

Pre-deliveryInspectionSheet

Qty.

Use

1

1

Installtheanti-siphonllreceptacle.

1

1

1

2

2

2

–

–

1

1

1

1

1

1

InstalltheSpray-Promonitor.

Checktheboomhingesprings.

Adjusttheboomstolevel.

Readthemanualsandviewthetraining

materialbeforeoperatingthemachine.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

13

1

InstallingtheAnti-siphonFill

Receptacle

Partsneededforthisprocedure:

1

90degreetting

1

Quickcoupler

1Hoseadapter

1Fillreceptaclebracket

1

Flange-headbolt,5/16x3/4inch

1Anti-siphonhose

Procedure

1.Placethellreceptaclebracketoverthethreaded

holeinthetankandsecureitwithaange-headbolt

(5/16x3/4inch)(

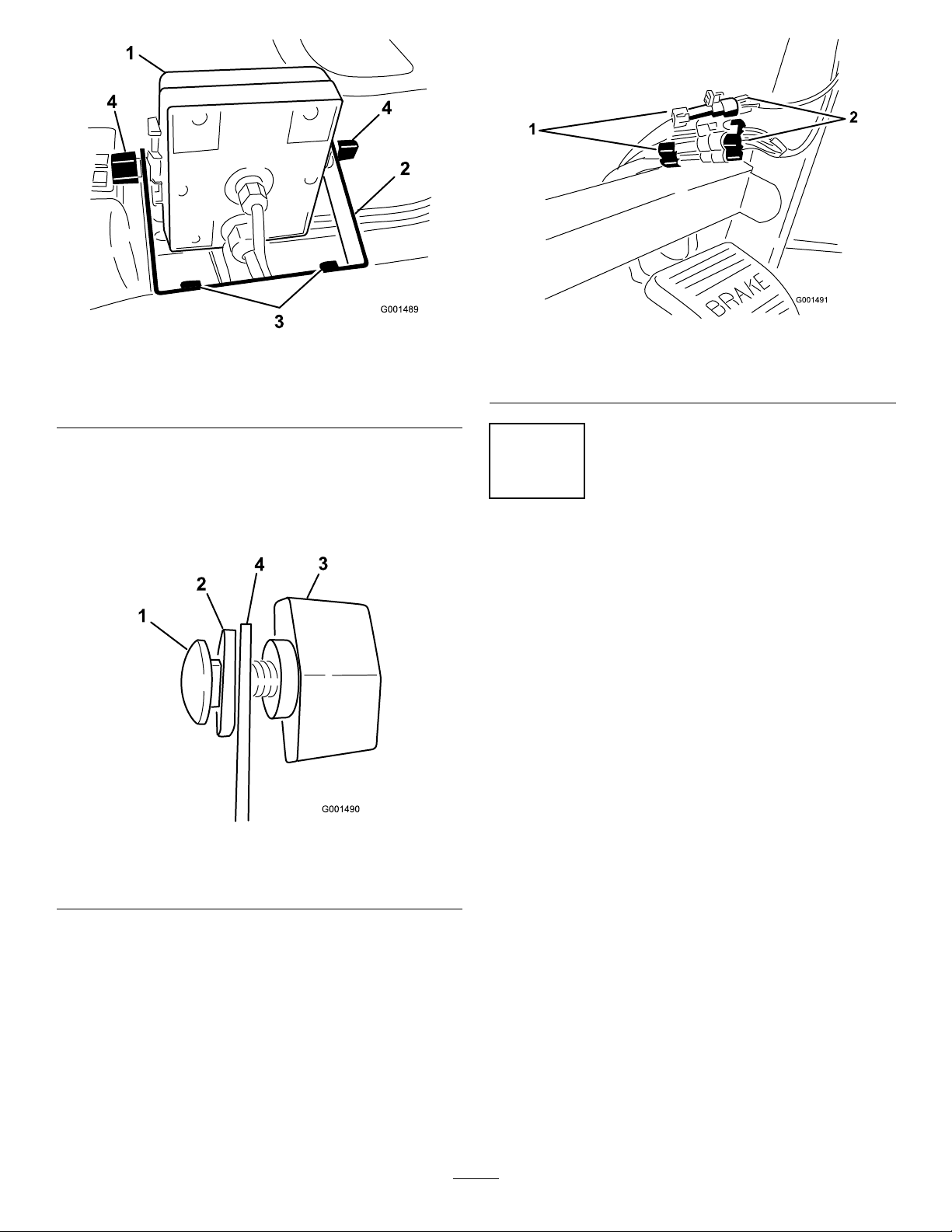

Figure3).

4.Locktheadapterintoplacebyswingingthelevers

towardtheadapterandthensecurethemwiththe

hairpincotters(Figure3).

5.Installtheanti-siphonhosethroughthelargeopening

onthebracketandontothebarbedendofthe90

degreeelbowtting(Figure3).

Important:Donotlengthenthehosetoallow

contactwiththetankuids.

2

InstallingtheSprayPro Monitor

Partsneededforthisprocedure:

1

SprayProMonitor

1

SprayProDecal

1Bracket

2

Flange-headbolt,3/4inch

2

Flangenut,1/4inch

2Knob

2Washer

2

Carriagebolt

Figure3

1.Fillreceptaclebracket

2.Threadedholeinthetank6.Hoseadapter

3.Flangebolt,5/16x3/4inch

4.90degreeelbowtting

2.Placethethreadedendofthe90degreeelbowtting

throughthebracketandthreadthequickcoupleronto

it,securingittothebracket(Figure3).

Note:Installthettingwiththeopenendpointing

towardthelargeopeninginthebracketandtowardthe

tankopeningsothewaterwillarcintothetankwhen

youllit.

3.Installthehoseadapterintothequickcoupler

(Figure3).

5.Quickcoupler

7.Anti-siphonhose

Procedure

1.InstalltheSprayProDecaltothemonitor(Figure4).

Figure4

1.Spraypromonitor3.Decal,Lowerhalf

2.Decal,Upperhalf

Note:Besuretoorientthedecalasshownin

Figure19.

2.Installthemonitorbracketonthedash(Figure5)using

2ange-headbolts(1/4x3/4inch)and2angenuts

(1/4inch).

14

Figure5

1.SprayPromonitor

2.Bracket4.Knob

3.Looselyinstallthe2carriagebolts,rubber

washers,andknobsonthebracketasillustratedin

FigureFigure5andFigure6.

3.Flange-headbolts,

1/4x3/4inch

1.Connectorsfromthe

sprayer

3

Figure7

2.Connectorsfromthe

monitor

Note:Installthecarriageboltsandrubberwashers

insideofthebracketandtheknobsontheoutside.

Figure6

1.Carriagebolt

2.Rubberwasher4.Bracket

4.Removethelargegrommetfromtheholeinthedash

andthreadthecablesonthemonitorthroughthe

grommetandthedash.

5.Installthegrommetintothedash.

6.InstalltheSprayPromonitoroverthecarriagebolt

heads(

7.ConnecttheSprayProwireconnectorstothewire

connectorslocatedunderthedash(Figure7).

Figure5)andtightentheknobstosecureit.

3.Knob

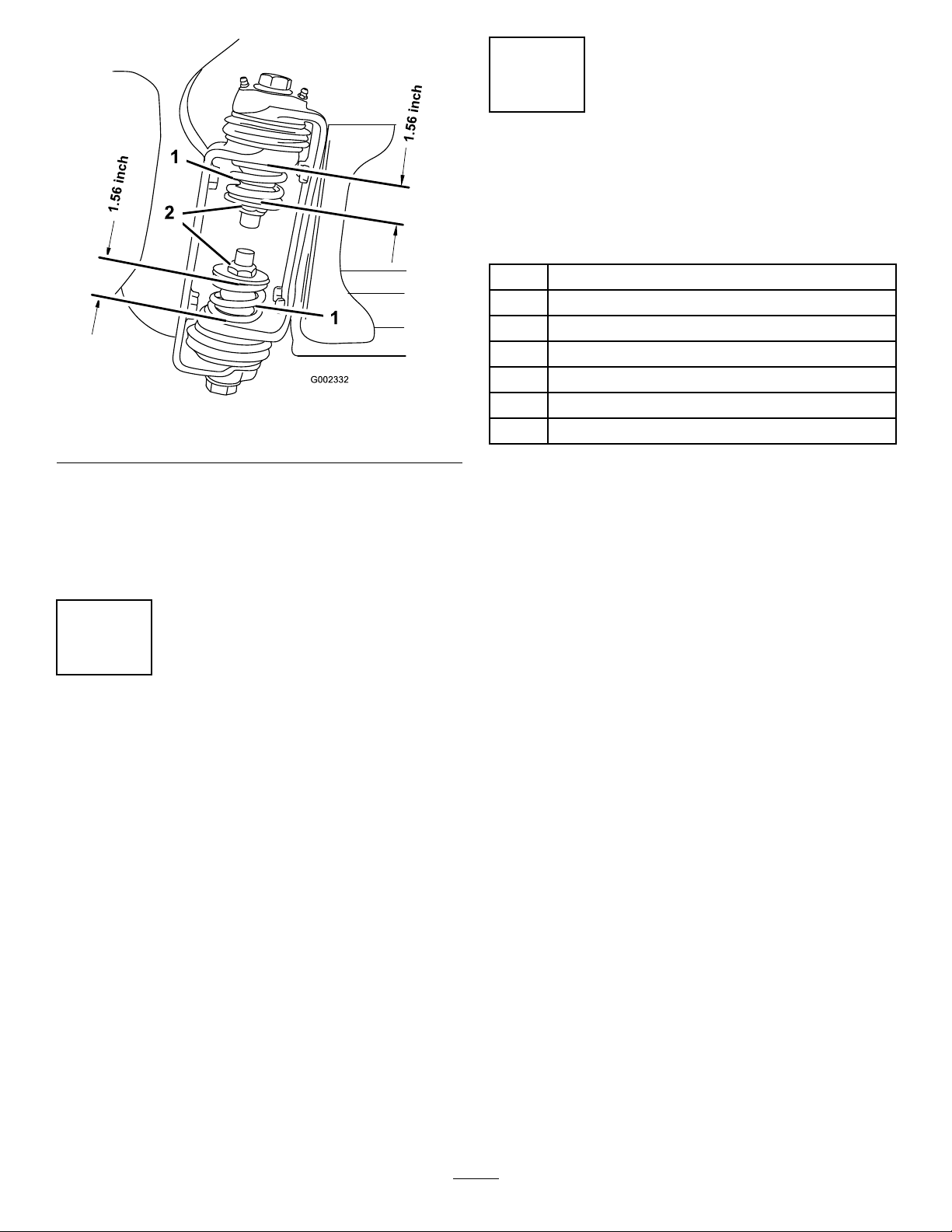

CheckingtheBoomHinge Springs

NoPartsRequired

Procedure

Important:Operatingthespraysystemwiththeboom

hingespringsundertheincorrectcompressioncould

damagetheboomassembly.Measurethespringsand

usethejamnuttocompressthespringsto1.56inches

ifnecessary.

Thesprayerisshippedwiththeboomextensionsswung

forwardtofacilitatepackagingofthemachine.Thesprings

arenotfullytightenedatthetimeofmanufacturetoallowthe

boomstobeinthispositionfortransit.Beforeoperating

themachine,thespringsmustbeadjustedtothecorrect

compression.

1.Ifnecessary,removethepackingcomponentsthat

securetherightandleftextensionboomsduring

shipping.

2.Supporttheboomswhiletheyareextendedtothe

sprayposition.

3.Attheboomhinge,measurethecompressionofthe

upperandlowerspringswhiletheboomsareintheir

extendedposition(

A.Allspringsmustbecompresseduntilthey

measure1.56inches.

B.Usethejamnuttocompressanyspringthat

measuregreaterthan1.56inches.

Figure8).

15

Figure8

1.Boomhingespring2.Jamnut

5

CompletingtheSetup: Learningmoreaboutyour product.

Partsneededforthisprocedure:

1Ignitionkey

1

Operator'sManual

1

EngineOperator'sManual

1

PartsCatalog

1

OperatorTrainingMaterial

1

RegistrationCard

1

Pre-deliveryInspectionSheet

4.Repeattheprocedureforeachspringonbothboom

hinges.

5.Movetheboomsintothetransport“X”position.See

OperatingtheBoomsintheOperationsectionfor

moreinformation.

4

AdjustingtheBoomstoLevel

NoPartsRequired

Procedure

1.Attheoperator'sposition,turntheignitionkeytoOn

toenergizethesystem.

2.Movetheboomsintopositionsothattheyarelevel

withtheground.

3.Removethekeyandexittheoperator'sposition.

Procedure

1.Readthemanuals.

2.ViewtheOperatortrainingmaterial.

3.CompletetheregistrationcardandreturntoToro.

4.Storethedocumentationinasafeplace.

4.Atthehinge,adjustthepositionofthebumperssothe

boomcannotmovepastlevelwiththeground.Take

caretomakesurethebumperislevel.

5.Tightentheboltandnuttolockthebumpersintothe

adjustedposition.Torquethefastenersto135-165

ft-lbs(183-223N-m).

Note:Thebumpermayexperiencesomecompressionover

time.Iftheboomsdropbelowlevel,usethisprocedureto

readjustthebumperpositionneeded.

16

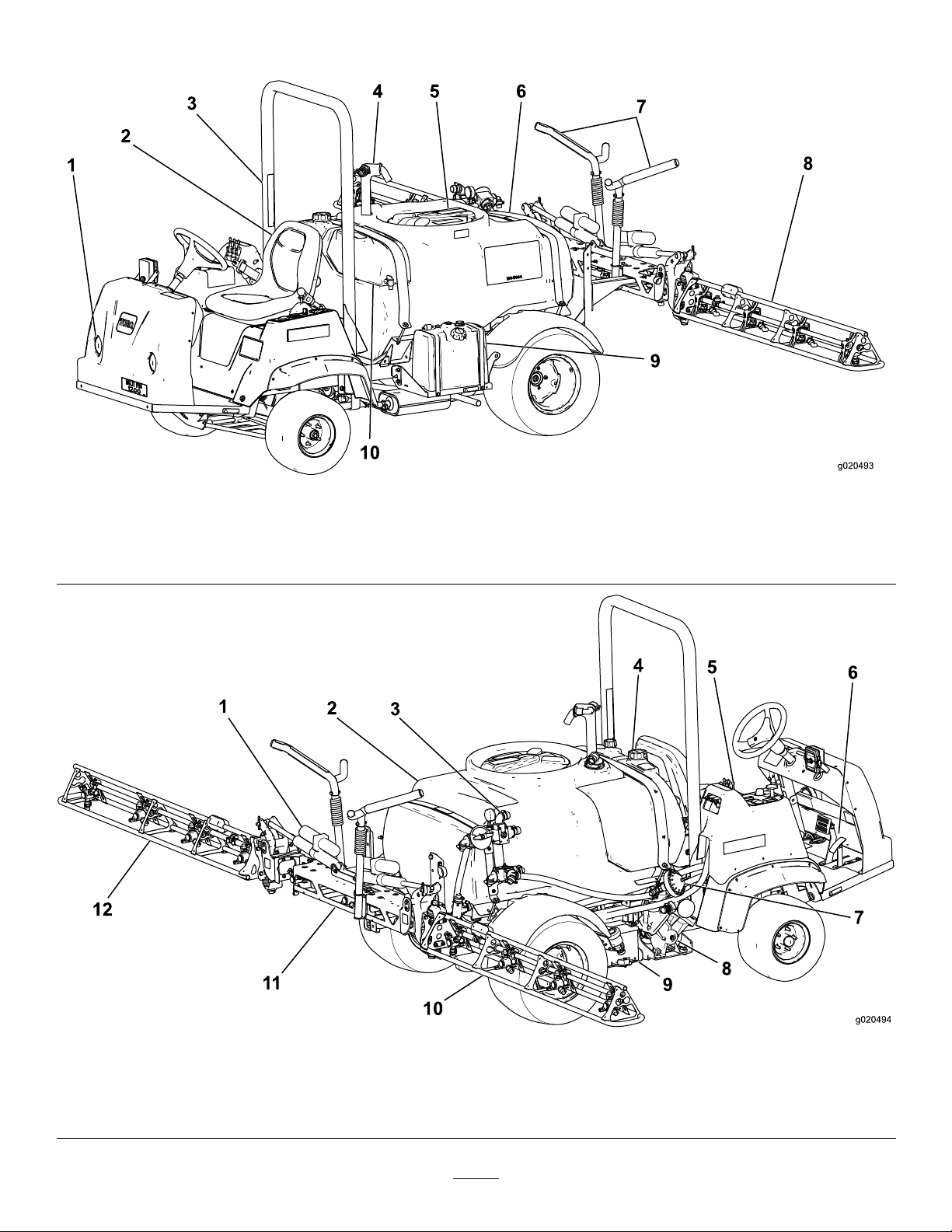

ProductOverview

Figure9

1.Headlight

2.Operator'sseat

3.Rolloverbar

4.Anti-SiphonReceptacle

5.Tanklid8.Boom

6.Chemicaltank

7.Boomtransportcradle10.Freshwatertank

9.Fueltank

Figure10

1.Boomcontrolcylinder4.Rinsetank7.Pumppressuredampener10.Rightboom

2.Chemicaltank5.Spraycontrolpanel

3.Agitationcontrolvalve6.Pedals9.Battery

8.Pump

17

11.Centerboom

12.Leftboom

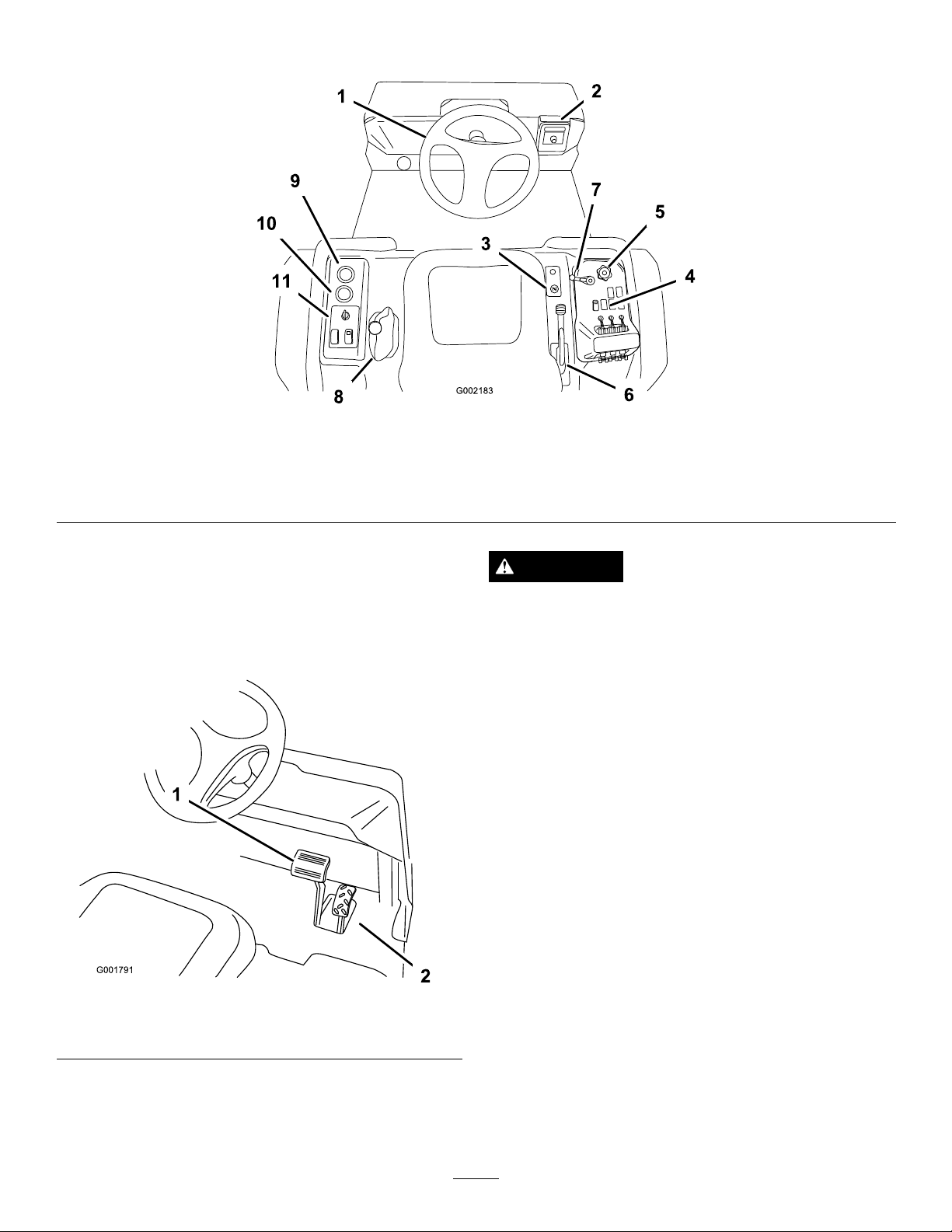

Controls

Figure11

1.Steeringwheel4.Sprayercontrols

2.Spray-Promonitor

3.Choke

5.Applicationrateknob

6.Parkingbrake9.Voltmeter

AcceleratorPedal

Theacceleratorpedal(Figure12)givesyoutheabilitytovary

groundspeedofthesprayer.Pressingthepedalincreases

groundspeed.Releasingthepedalwillslowthesprayerand

theenginewillidle.

7.Masterspraylever10.Hourmeter

8.RangeSelector

11.V ehiclecontrols

CAUTION

Brakescanbecomewornorcanbeadjusted

incorrectlyresultinginpersonalinjury.

Ifbrakepedaltravelstowithin1inch(2.5cm)ofthe

sprayeroorboard,thebrakesmustbeadjusted

orrepaired.

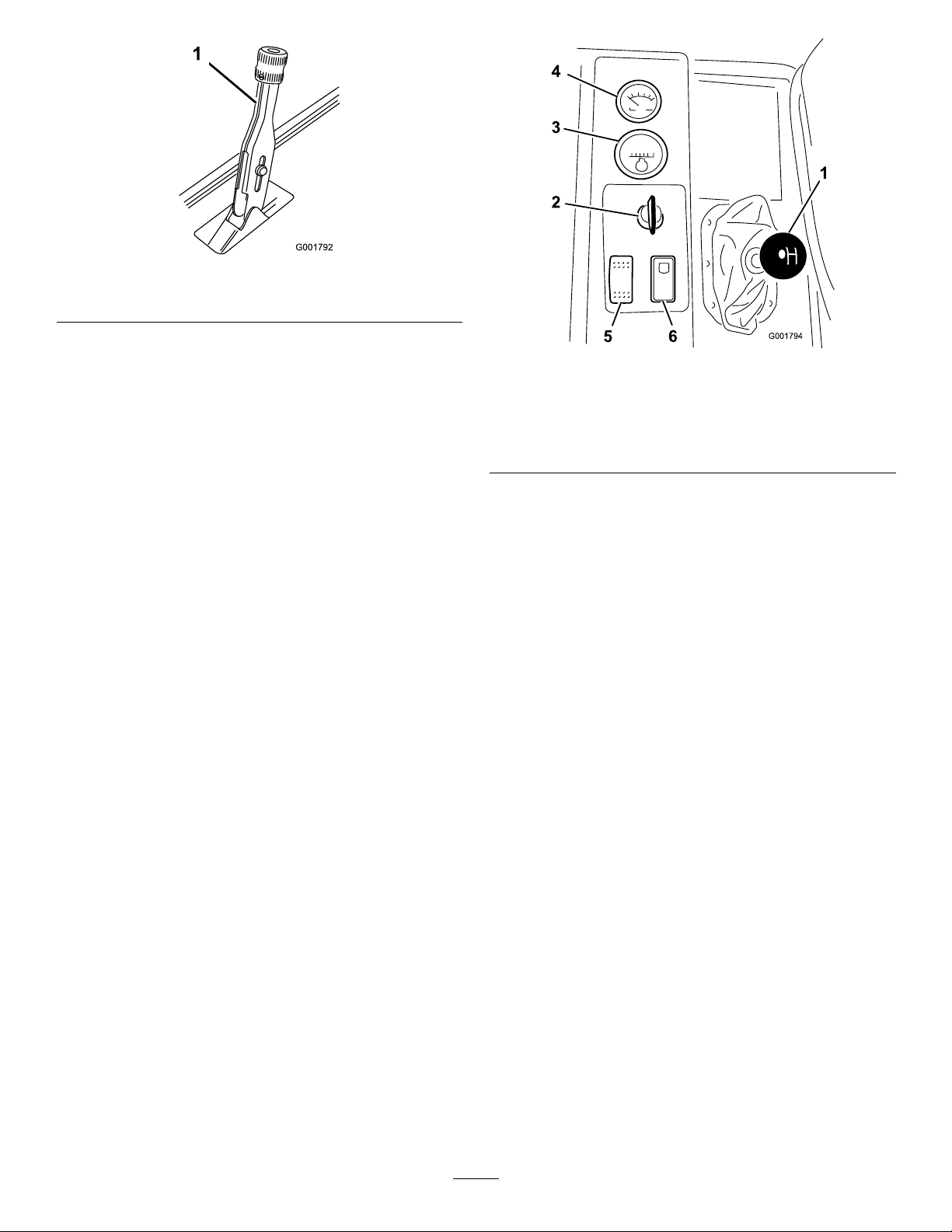

ParkingBrake

Theparkingbrakeisalargelevertotherightoftheseat.

(Figure13).Engagetheparkingbrakewheneveryouplan

onleavingtheseattopreventaccidentalmovementofthe

sprayer.Toengagetheparkingbrake,pullupandbackonthe

lever.Todisengage,pushitforwardanddown.Ifthesprayer

isparkedonasteepgrade,applytheparkingbrakeandplace

blocksatthedownhillsideofthewheels.

Figure12

1.Brakepedal2.Acceleratorpedal

BrakePedal

Usethebrakepedaltostoporslowthesprayer(Figure12).

18

1.Parkingbrakelever

Figure13

ChokeControl

Thechokecontrolisasmallknobtotherightoftheseat.

Tostartacoldengine,pullthechokecontrolup.Afterthe

enginestarts,regulatethechoketokeeptheenginerunning

smoothly.Assoonaspossible,pushthecontroldowntothe

Offposition.Awarmenginerequireslittleornochoking.

RangeSelector

Therangeselector,locatedtotheleftoftheseat,has5

positions:3forwardspeeds,Neutral,andReverse(Figure14).

Theenginewillstartonlywhentherangeselectorisinthe

Neutralposition.Youmustalsofullypressthebrakewith

thesprayerstoppedtochangeranges.

Important:Donotshiftoutoforchangeranges

whilethevehicleismoving.Attemptingtochange

rangeswhilethevehicleismovingcandamagethe

transmission.Onlystoppingthesprayercompletely,

andfullyengagingthebrakewillsafelydisengagethe

lockingpinandallowtherangestobechanged.

Figure14

1.RangeSelector

2.Ignitionswitch5.Headlightswitch

3.Hourmeter6.Neutralenginespeedlock

4.Voltmeter

switch

IgnitionSwitch

Theignitionswitch(Figure14),usedtostartandstopthe

engine,has3positions:Stop,Run,andStart.Rotatethekey

clockwisetotheStartpositiontostarttheengineandrelease

ittotheRunpositionwhenstarted.Rotatethekeytothe

Stoppositiontostoptheengine.

HourMeter

Thehourmeter(Figure14)indicatesthetotalnumberof

hourstheenginehasrun.Thehourmeterstartstofunction

wheneverthekeyisturnedtotheRunposition.

Voltmeter

Thevoltmeter(Figure14)indicatesthelevelofchargein

thebattery.Whenthebatteryisfullycharged,thevoltmeter

willreadinthecenterofthedialwhenthekeyisintheRun

positionwiththeengineoff.Whentheengineisrunningthe

voltmeterneedleshouldbetotheright.

HeadlightSwitch

Toggletheswitchtooperatetheheadlights(Figure14).Push

itforwardtoturnthelightsonandrearwardtoturnthemoff.

NeutralEngineSpeedLockSwitch

WhentherangeselectorisintheNeutralposition,youcan

usetheacceleratorpedaltospeeduptheengine,thenpush

thisswitchforwardtosettheengineatthatspeed.Thisis

necessarytorunthechemicalagitationwhilestationaryor

operatingattachmentssuchasthehandsprayer(

19

Figure14).

Important:Therangeselectormustbeintheneutral

positionfortheswitchtowork.

FuelGauge

Thefuelgaugeislocatedontopofthefueltank,ontheright

sideofthemachineandshowstheamountoffuelinthetank.

MasterSprayLever

Themastersprayleverallowsyoutostartorstopthespray

operation.Rotatetheleverforwardtoenablethespraysystem

andrearwardtodisableit(Figure15).Whenthemasterspray

leverisintheOffposition,theSprayProscreenreads“Hold.”

Figure16

Figure15

1.Masterspraylever3.Applicationrateknob

2.Boomlevers4.Pumpswitch

BoomLevers

Theboomleversarelocatedattherearofthecontrolpanel

totherightoftheseat(Figure15).Pusheachleverdown

toturnthecorrespondingboomsectiononanduptoturn

themoff.Theseleverswillonlyaffectthespraysystemwhen

themastersprayleverison.

ApplicationRateKnob

Theapplicationrateknobislocatedonthecontrolpanelto

therightoftheseat(Figure15).Rotatetheknobclockwise

toincreasethespraysystempressureorcounterclockwiseto

decreasepressure.

1.Pumpswitch

2.Boomliftswitch,leftand

right

3.Foammarkerswitch,left

andright

4.Sonicboomswitch

BoomLift

Theboomliftswitchesareusedtoraisetheleftandright

boomrespectively(

Figure16).

FoamMarkerSwitchLocations

(Optional)

Ifyouinstalltheelectricboomlift,sonicboom,andfoam

markerkit,youwilladdswitchestothecontrolpanelfor

controllingtheiroperation.Thesprayercomeswithplastic

plugsintheselocations.

SonicBoom(Optional)

TheSonicBoomswitchisarockerswitchusedtooperatethe

SonicBoom.Toggleswitchforwardforautomatic,rearward

formanualandcenterforOff.

ApplicationRateControlValve

Thisvalvecontrolstheamountofuidthatisroutedtothe

boomsbydirectinguidowtotheboomsorthebypass

hosetothetank(Figure17).Tocontrolthisvalve,rotate

theapplicationrateknobontopofthevalvetoobtainthe

desiredpressure.

PumpSwitch

Thepumpswitchislocatedonthecontrolpaneltotheright

oftheseat(Figure16).Togglethisswitchforwardtorunthe

pumporrearwardtostopthepump.

Important:Onlyengagethepumpswitchwhenthe

engineisatlowidletoavoiddamagingthepumpdrive.

20

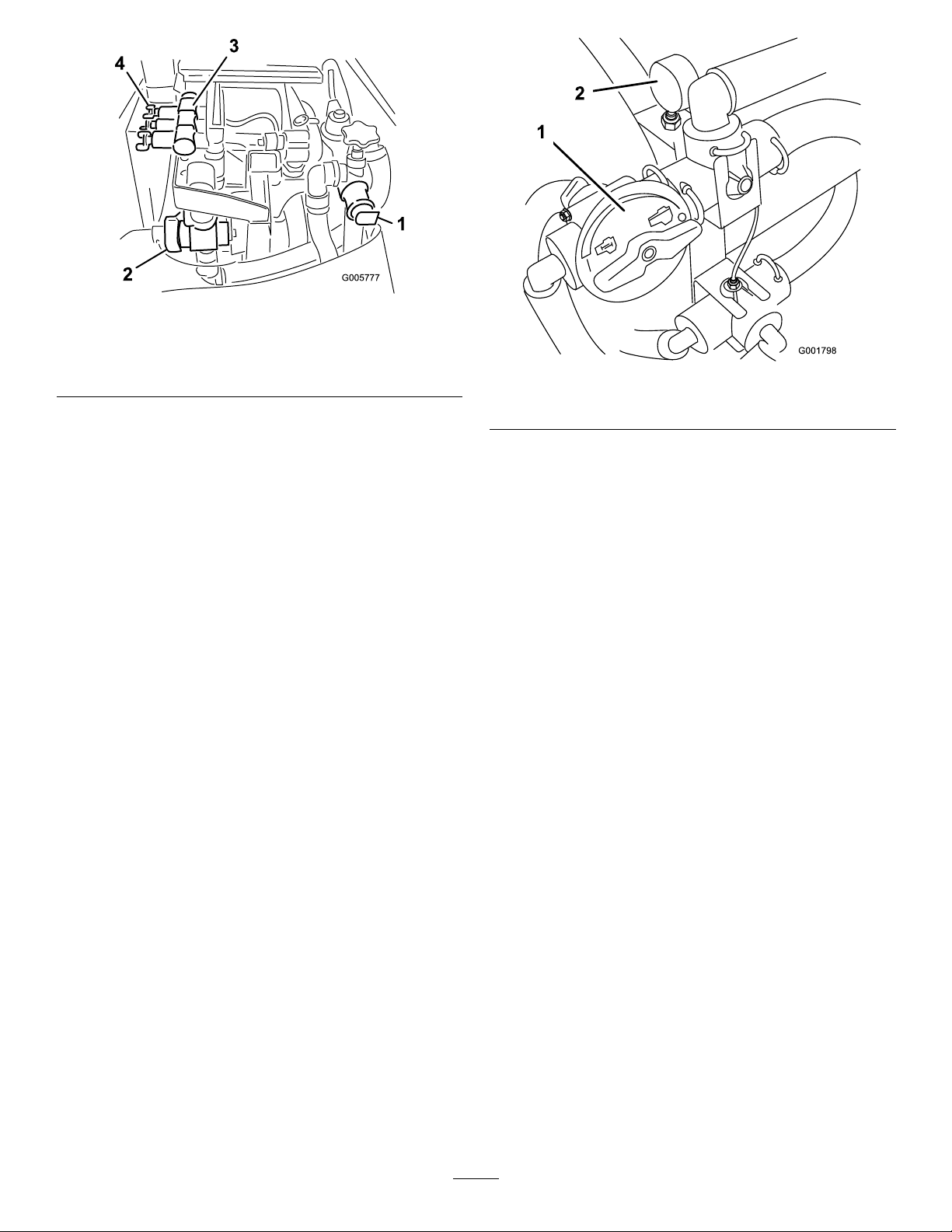

Figure17

1.Applicationratecontrol

valve

2.Flowmeter4.Boomby-passvalves

3.Boomvalves(3)

Flowmeter

Theowmetermeasurestheowrateoftheuidforuseby

theSprayPro™system(Figure17).

BoomValves

Thesevalvesturnthethreeboomsonoroff(Figure17).

BoomBypassValves

Theboombypassvalvesredirecttheuidowforaboom

tothetankwhenyouturnofftheboomsection.Y oucan

adjustthesevalvestoensurethattheboompressureremains

constantnomatterhowmanyboomsareon.Referto

CalibratingtheBoomBypassValves,intheOperationsection.

AgitationControlValve

Thisvalveislocatedontherightsideofthetank(Figure18).

Turntheknobonthevalvetothe9o'clockpositiontoturn

onthetankagitationandtothe3o'clockpositiontoturn

offthetankagitation.

Figure18

1.Agitationcontrolvalve2.Pressuregauge

Note:Foragitationtowork,thepumpmustbeonandthe

enginemustberunningaboveanidle.Ifyoustopthesprayer

andneedagitationon,placetherangeselectorintheNeutral

position,settheparkingbrake,presstheacceleratorpedal

totheoor,turnthepumpOnandturntheneutralengine

speedlockOn.

PressureGauge

Thepressuregaugeislocatedtotherightofthetank

(Figure18).Thisgaugeshowsthepressureoftheuidinthe

systeminpsiandkPa.Usethegaugetoadjusttheby-pass

valveswheneveryouchangenozzles.

Anti-siphonFillReceptacle

Tothefrontofthetankcoverisahosereceptaclewitha

threadedtting,a90degreebarbedtting,andashorthose

whichyoucandirecttowardthetankopening.Thisreceptacle

allowsyoutoconnectawaterhosetoitandllthetankwith

waterwithoutcontaminatingthehosewiththechemicalsin

thetank.

Important:Donotlengthenthehosetoallowcontact

withthetankuids.

21

Loading...

Loading...