Page 1

Form No. 3326-372 Rev B

824 Power Throw

Snowthrower

Model No. 38078—220000001 and Up

Operator ’s Manual

Domestic English (EN)

Page 2

Warning

The engine exhaust from this product contains

chemicals known to the State of California to cause

cancer, birth defects, or other reproductive harm.

Important This engine is not equipped with a spark

arrester muffler. It is a violation of California Public

Resource Code Section 4442 to use or operate this engine

on any forest–covered, brush–covered or grass–covered

land. Other states or federal areas may have similar laws.

This spark ignition system complies with Canadian

ICES-002.

Ce système d’allumage par étincelle de véhicule est

conforme à la norme NMB-002 du Canada.

The enclosed Engine Owner’s Manual is supplied for

information regarding The U.S. Environmental

Protection Agency (EPA) and the California Emission

Control Regulation of emission systems, maintenance

and warranty.

Keep this engine Owner’s Manual with your unit.

Should this engine Owner’s Manual become damaged

or illegible, replace immediately. Replacements may be

ordered through the engine manufacturer.

Contents

Page

Introduction 2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safety 3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 3. . . . . . . . . . . . . . . . . . . .

Toro Snowthrower Safety 4. . . . . . . . . . . . . . . . . . .

Safety and Instruction Decals 6. . . . . . . . . . . . . . . .

Assembly 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 8. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Handle Assembly 9. . . . . . . . . . . . . .

Installing the Speed Selector Rod 9. . . . . . . . . . . . .

Installing the Traction Rod 10. . . . . . . . . . . . . . . . . .

Installing the Auger/Impeller Drive Control

Linkage 10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Installing the Chute Control Rod 11. . . . . . . . . . . . .

Before Starting 12. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Filling the Engine Crankcase with Oil 12. . . . . . . . .

Filling the Fuel Tank with Gasoline 12. . . . . . . . . . .

Checking the Tire Pressure 13. . . . . . . . . . . . . . . . . .

Reviewing the Maintenance Schedule 13. . . . . . . . .

Operation 13. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating Controls 13. . . . . . . . . . . . . . . . . . . . . . . .

Removing the Carburetor Heater Box 14. . . . . . . . .

Page

Installing the Carburetor Heater Box 15. . . . . . . . . .

Starting the Engine 15. . . . . . . . . . . . . . . . . . . . . . . .

Stopping the Engine 16. . . . . . . . . . . . . . . . . . . . . . .

Freewheeling or Self-propel Drive 16. . . . . . . . . . . .

Snowthrowing Tips 16. . . . . . . . . . . . . . . . . . . . . . .

Maintenance 18. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Recommended Maintenance Schedule 18. . . . . . . . .

Checking the Engine Oil Level 19. . . . . . . . . . . . . .

Checking the Auger Gearbox Grease 19. . . . . . . . . .

Adjusting the Skids and the Scraper 19. . . . . . . . . . .

Adjusting the Speed Selector 20. . . . . . . . . . . . . . . .

Adjusting the Traction Drive Belt 20. . . . . . . . . . . .

Replacing the Traction Drive Belt 20. . . . . . . . . . . .

Adjusting the Auger/Impeller Drive Belt 22. . . . . . .

Replacing the Auger/Impeller Drive Belt 22. . . . . . .

Lubricating the Snowthrower 23. . . . . . . . . . . . . . . .

Changing the Engine Oil 24. . . . . . . . . . . . . . . . . . .

Replacing the Spark Plug 24. . . . . . . . . . . . . . . . . . .

Emptying the Fuel Tank 24. . . . . . . . . . . . . . . . . . . .

Storage 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Preparing the Fuel System 25. . . . . . . . . . . . . . . . . .

Preparing the Engine 25. . . . . . . . . . . . . . . . . . . . . .

Preparing the Snowthrower 25. . . . . . . . . . . . . . . . .

Accessories 25. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Troubleshooting 26. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

The Toro Total Coverage Guarantee 28. . . . . . . . . . . . .

Introduction

Read this manual carefully to learn how to operate and

maintain your product properly. The information in this

manual can help you and others avoid injury and product

damage. Although Toro designs and produces safe

products, you are responsible for operating the product

properly and safely.

Whenever you need service, genuine Toro parts, or

additional information, contact an Authorized Service

Dealer or Toro Customer Service and have the model and

serial numbers of your product ready. Figure 1 illustrates

the location of the model and serial numbers on the

product.

1

Figure 1

1. Location of the model and serial numbers

2001 by The Toro Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

All Rights Reserved

Printed in the USA

2

Page 3

Write the product model and serial numbers in the space

below:

Model No.

Training

• Read the operator’s manual carefully. Be thoroughly

familiar with the controls and the proper use of the

equipment. Know how to stop the unit and disengage

the controls quickly.

Serial No.

This manual identifies potential hazards and has special

safety messages that help you and others avoid personal

injury and even death. Danger, Warning, and Caution are

signal words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

Danger signals an extreme hazard that will cause serious

injury or death if you do not follow the recommended

precautions.

Warning signals a hazard that may cause serious injury or

death if you do not follow the recommended precautions.

Caution signals a hazard that may cause minor or moderate

injury if you do not follow the recommended precautions.

This manual uses 2 other words to highlight information.

Important calls attention to special mechanical

information and Note: emphasizes general information

worthy of special attention.

Safety

This 2-stage snowthrower meets or exceeds the B71.3

specifications of the American National Standards

Institute in effect at the time of production.

To ensure maximum safety and best performance, and

to gain knowledge of the product, it is essential that you

and any other operator of the snowthrower read and

understand the contents of this manual before the

engine is ever started.

This is the safety alert symbol. It is used to alert you

to potential personal injury hazards. Obey all safety

messages that follow this symbol to avoid possible

injury or death.

Improperly using or maintaining this snowthrower

could result in injury or death. To reduce this potential,

comply with the following safety instructions.

• Never allow children to operate the snowthrower. Never

allow adults to operate the snowthrower without proper

instruction.

• Keep the area of operation clear of all persons

(particularly small children) and pets.

• Exercise caution to avoid slipping or falling, especially

when operating the snowthrower in reverse.

Preparation

• Thoroughly inspect the area where you will use the

snowthrower. Remove all doormats, sleds, boards,

wires, and other foreign objects.

• Before starting the engine, disengage all clutches. For

Power Shift models, shift the snowthrower into

neutral as well.

• Do not operate the snowthrower without wearing

adequate winter garments. Wear footwear that will

improve your footing on slippery surfaces.

• Handle fuel with care; it is highly flammable.

– Use an approved fuel container.

– Never add fuel to a running or hot engine.

– Fill the fuel tank outdoors with extreme care. Never

fill the fuel tank indoors.

– Replace the fuel tank cap securely and wipe up any

spilled fuel.

• Use only the power cord supplied with the snowthrower

and a receptacle appropriate for use with the power cord

for electric-starting motors.

• Adjust the auger housing height to clear gravel or

crushed rock surface.

• Never attempt to make any adjustments while the

engine is running, except where specifically

recommended by Toro.

• Let the engine and the snowthrower adjust to the

outdoor temperature before starting to clear snow.

Safe Operating Practices

The following instructions have been adapted from the

ANSI/OPEI B71.3–1995 standard and the ISO 8437:1989

standard. Information or terminology specific to Toro

snowthrowers is enclosed in parenthesis.

• Operating any powered machine can result in foreign

objects being thrown into the eyes. Always wear safety

glasses or eye shields while operating, adjusting, or

repairing the snowthrower.

3

Page 4

Operation

• Do not put hands or feet near or under rotating parts.

Keep clear of the discharge opening at all times.

• Never operate the snowthrower without good visibility

or light. Always be sure of your footing, and keep a

firm hold on the handle. Walk; never run.

• Exercise extreme caution when operating on or crossing

gravel drives, walks, or roads. Stay alert for hidden

hazards or traffic.

• After striking a foreign object, stop the engine, remove

the wire from the spark plug, thoroughly inspect the

snowthrower for any damage, and repair the damage

before operating the snowthrower.

• If the unit should start to vibrate abnormally, stop the

engine and check immediately for the cause. Vibration

is generally a warning of trouble.

• Stop the engine whenever you leave the operating

position, before unclogging the auger/impeller housing

or discharge chute, and when making any repairs,

adjustments, or inspections.

• When cleaning, repairing, or inspecting, make certain

that the auger/impeller and all moving parts have

stopped. Disconnect the spark-plug wire, and keep the

wire away from the spark plug to prevent someone from

accidentally starting the engine.

• Do not run the engine indoors, except when starting it

and for moving the snowthrower in or out of the

building. Open the outside doors; exhaust fumes are

dangerous.

• Do not clear snow across the face of slopes. Exercise

extreme caution when changing direction on slopes. Do

not attempt to clear steep slopes.

• Never operate the snowthrower without proper guards

or other safety devices in place.

• Never operate the snowthrower near glass enclosures,

automobiles, window wells, and drop-offs without

properly adjusting the snow discharge angle. Keep

children and pets away.

• Do not overload the machine capacity by attempting to

clear snow at too fast a rate.

• Never operate the machine at high transport speeds on

slippery surfaces. Look behind and use care when

moving in reverse.

• Never direct the discharge at bystanders or allow

anyone in front of the unit.

• Disengage the power to the auger/impeller when the

snowthrower is being transported or when not in use.

• Use only attachments and accessories approved by

Toro, such as wheel weights, counterweights, and cabs.

(Contact your Authorized Service Dealer for

accessories available for your snowthrower.)

Maintenance and Storage

• Check all fasteners at frequent intervals for proper

tightness to be sure that the equipment is in safe

working condition.

• Never store the machine with fuel in the fuel tank inside

a building where ignition sources are present, such as

hot water and space heaters and clothes dryers. Allow

the engine to cool before storing in any enclosure.

• Always refer to this operator’s manual for important

details if the snowthrower is to be stored for an

extended period.

• Maintain or replace safety and instruction labels when

necessary.

• Run the engine run for a few minutes after clearing the

snow to prevent the auger/impeller from freezing.

Toro Snowthrower Safety

The following list contains safety information specific to

Toro products or other safety information that you must

know.

• Rotating auger/impeller can cut off or injure fingers or

hands. Stay behind the handles and away from the

discharge opening while operating the snowthrower.

Keep your face, hands, feet, and any other part of your

body or clothing away from moving or rotating parts.

• Before adjusting, cleaning, repairing, and inspecting the

snowthrower, and before unclogging the discharge

chute, stop the engine, remove the key, and wait for all

moving parts to stop. Also, disconnect the wire from the

spark plug and keep it away from the spark plug to

prevent someone from accidentally starting the engine.

• Use a stick, not your hands, to remove obstructions

from the discharge chute.

• Before leaving the operating position, stop the engine,

remove the key, and wait for all moving parts to stop.

• Do not wear loose-fitting clothing that could get caught

in moving parts.

• If a shield, safety device, or decal is damaged, illegible,

or lost, repair or replace it before beginning operation.

Also, tighten any loose fasteners.

• Do not smoke while handling gasoline.

• When operating the snowthrower on slopes, use the

lower gear. For Power Shift snowthrowers, use the

rear wheel position.

4

Page 5

• Do not use the snowthrower on a roof.

• Do not touch the engine while it is running or soon after

it has stopped because the engine may be hot enough to

cause a burn. Do not add oil or check the oil level in the

crankcase while the engine is running.

• Perform only those maintenance instructions described

in this manual. Before performing any maintenance,

service, or adjustment, stop the engine, remove the key

and disconnect the wire from the spark plug. Keeping

the wire away from the spark plug to prevent someone

from accidentally starting the engine. If major repairs

are ever needed, contact your Authorized Service

Dealer.

• Do not change the governor settings on the engine.

• When storing the snowthrower for more than 30 days,

drain the fuel from the fuel tank to prevent a potential

hazard. Store fuel in an approved fuel container.

Remove the key from the ignition switch before storing

the snowthrower.

• To ensure the best performance and safety, purchase

only genuine Toro replacement parts and accessories.

Before Operating

Read and understand the contents of this manual

before operating the snowthrower. Become familiar

with all controls and know how to stop the engine

quickly.

Operator's

Position

472

Caution: Improper use may result

in loss of fingers, hands, or feet.

There is a highspeed

impeller within two inches

of the opening.

1508

The lowspeed auger

has a moving pinch

point close to the

opening.

5

Page 6

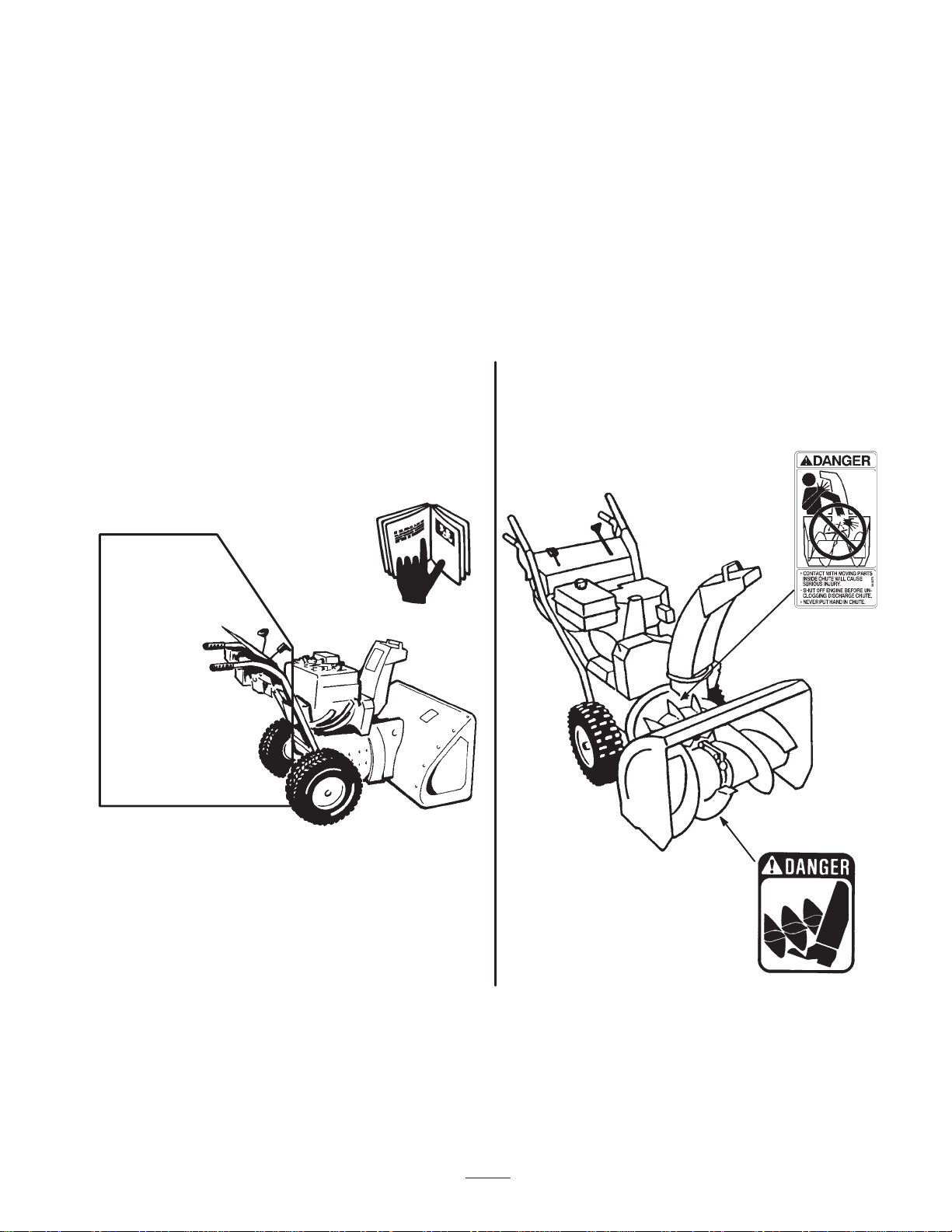

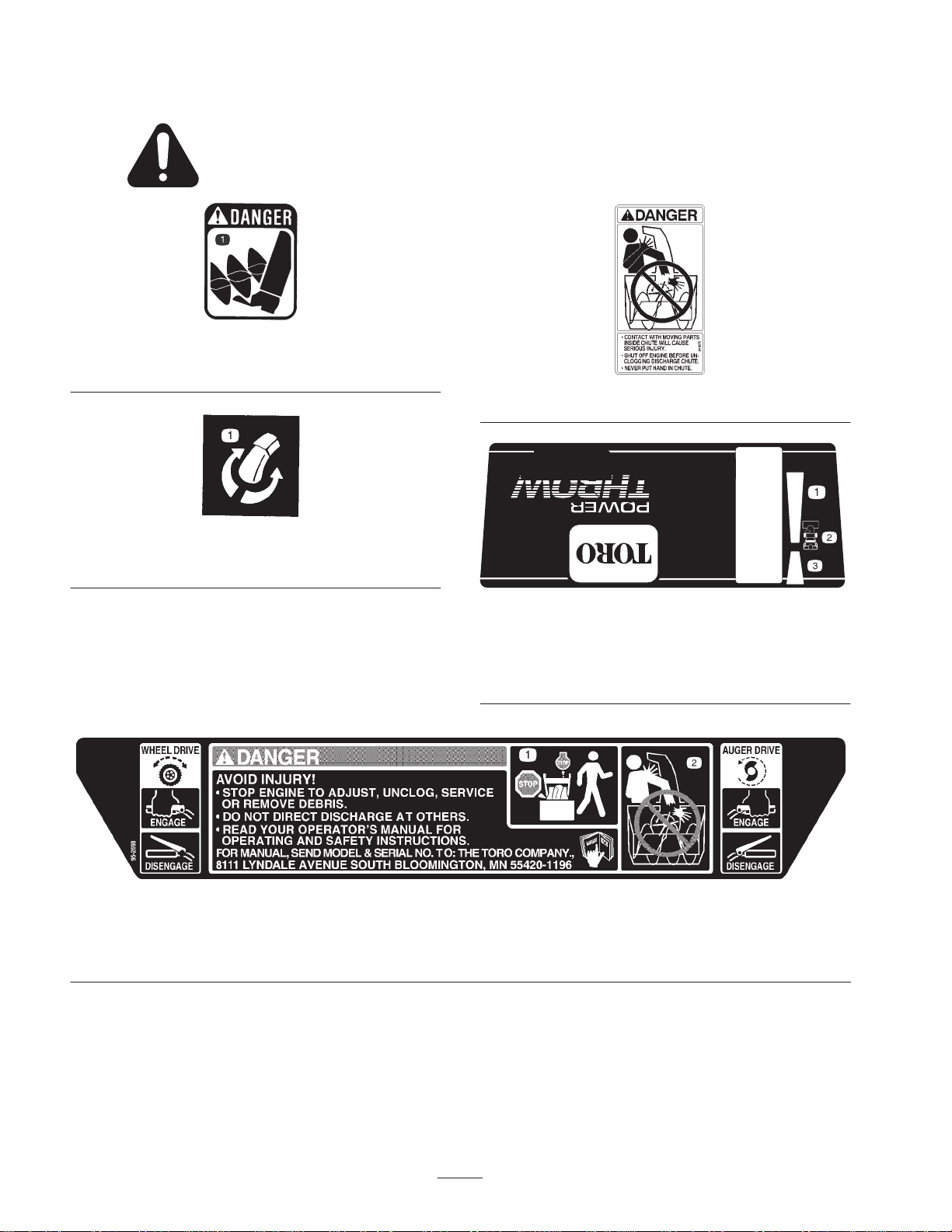

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near any area

of potential danger. Replace any decal that is damaged or lost.

53-7670

1. Cutting/dismemberment hazard in auger

94-8079

2. Chute direction control

63-3510

TM

1. Forward drive speed

settings

2. Speed selector

8 HP 24”

100-3341

Electric Start

5

824

3. Reverse drive speed

settings

4

3

2

1

R

1

R

2

GRAPHIC #

100-3412

1. Stop the engine before leaving the machine

2. Contact with the moving parts within the chute will cause serious injury; never put your hand into the chute

6

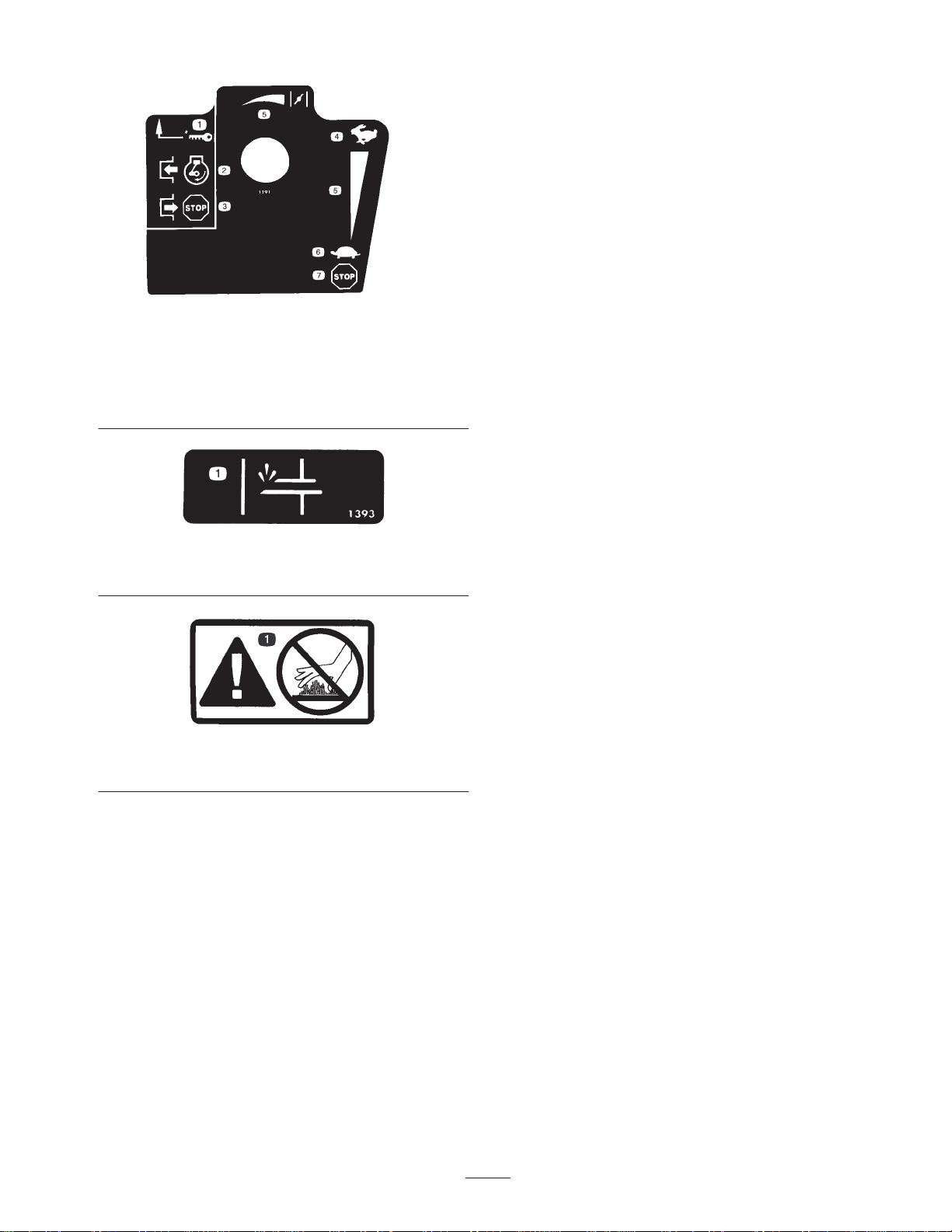

Page 7

T ecumseh Part No. 35077

1. Key ignition

2. Engage to start the

engine

3. Disengage to stop the

engine

4. Fast

5. Increasing scale

6. Slow

7. Stop the engine

T ecumseh Part No. 36501

1. Primer

T ecumseh Part No. 37119

1. Warning—hot surface; do not touch

7

Page 8

Assembly

gy

g

Note: Determine the left and right sides of the machine from the normal operating position.

Loose Parts

DESCRIPTION QTY. USE

Handle assembly 1

Bolts 4

Curved washers 4

Speed selector rod 1

Cotter pin 1

Flat washer 1

Spring 1

Flange locknut 1

Lower link 1

Flange nut 1 Installing the auger/impeller drive control

Flange locknut 1

Discharge chute 1 Installing the discharge chute

Chute control rod assembly (Rod and bracket,

worm gear, and bracket)

Bolt, pyramidal washer, and locknut 1 Installing the chute control rod

Bolt 1

Locknut 1

1

Installing the handle assembly

Installing the speed selector rod

Installing the traction rod

linkage

Power cord 1 Starting the engine

Ignition key 1 Starting and stopping the engine

8

Page 9

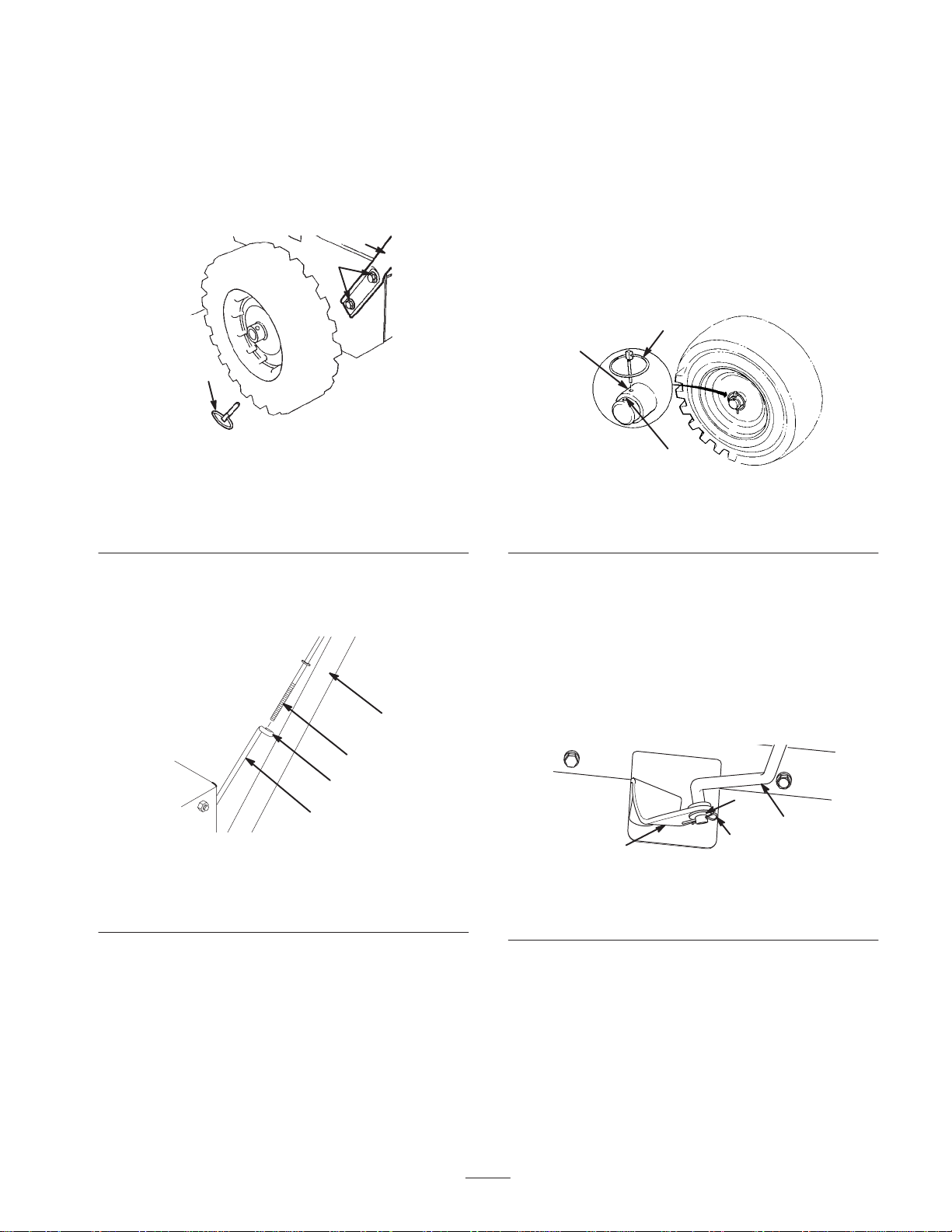

Installing the Handle Assembly

1. Remove the tie straps that secure the control rods to the

handle assembly.

2. Remove the axle pins from both wheels (Fig. 2) and

slide the wheels outward on the axle approximately one

inch (2.5 centimeters).

3

2

1

653

Figure 2

1. Axle pin (2)

2. Bolts and curved

washers (4)

3. Handle assembly

5. Position the right side of the handle assembly against

the right side of the snowthrower, align the handle

mount holes with the holes in the side plate, and secure

the right side of the handle assembly with 2 bolts and

curved washers until they are finger tight.

6. Ensure that both sides of the handle assembly are in line

with each other and then tighten the bolts that hold the

handle assembly.

7. Slide the wheels inward and insert each axle pin

through the hole in each wheel hub and through the

inner hole of the axle (Fig. 4).

3

1

2 473

Figure 4

1. Inner axle hole and wheel

hub

2. Outer axle hole

3. Axle pin

3. Hold the handle assembly in the installation position

and insert the upper traction rod through the loop in the

lower traction rod (Fig. 3).

4

3

2

1

m-4039

Figure 3

1. Lower traction rod

2. Loop

3. Upper traction rod

4. Left side of handle

assembly

4. Position the left side of the handle assembly against the

left side of the snowthrower, align the handle mount

holes with the holes in the side plate, and secure the left

side of the handle assembly with 2 bolts and curved

washers until they are finger tight (Fig. 2).

Note: The concave side of the curved washer goes

against the outside of the handle.

Note: To use tire chains (optional), install the axle pins

through the outer axle holes.

Installing the Speed Selector

Rod

1. Pull the speed selector arm (Fig. 5) to the most outward

position.

3

4

1

2

Figure 5

1. Speed selector arm

2. Cotter pin

3. Flat washer

4. Speed selector rod

2. Move the speed selector (Fig. 14) on the control panel

to the R2 (Reverse) position.

3. Rotate the speed selector rod in the trunnion (Fig. 6)

until the bottom end of the rod can slip into the hole in

the speed selector arm (Fig. 5).

m-2672

9

Page 10

2

1

1

2

m-2670

Figure 6

1. Trunnion 2. Speed selector rod

4. Install the speed selector rod into the selector arm, add

one flat washer on the rod, and secure it with a cotter

pin (Fig. 5).

Note: If the speed selector does not move into fifth gear or

does not meet your speed requirements, adjust the speed

selector. Refer to Adjusting the Speed Selector on page 20.

Installing the Traction Rod

1. Slide the spring over the bottom of the upper traction

rod (Fig. 7).

3

4

3

4

m-2628

Figure 8

1. Traction control lever

2. Approximately 5 inches

(12.7 centimeters)

3. Three to 4 inches (7.6 to

10.2 centimeters)

4. Handgrip

4. Move the speed selector (Fig. 14) into fifth gear.

5. Slowly pull the snowthrower backward while slowly

pressing the traction control lever toward the handgrip.

Note: The adjustment is correct when the wheels stop

rolling backward and the distance between the top of

the handgrip and the bottom of the traction control lever

is 3 to 4 inches (7.6 to 10.2 centimeters) as shown in

Figure 8.

6. Adjust the flange locknut, if necessary, to obtain the

proper distance between the top of the handgrip and the

bottom of the traction control lever.

2

1

m-4039a

Figure 7

1. Flange locknut

2. Spring

3. Lower traction rod

4. Upper traction rod

2. Thread a flange locknut (flange side up) onto the

bottom of the upper traction rod below the spring

(Fig. 7).

3. Adjust the flange locknut up or down on the upper

traction rod until the distance between the top of the

handgrip and the bottom of the traction control lever is

approximately 5 inches (12.7 centimeters) as shown in

Figure 8.

Installing the Auger/Impeller

Drive Control Linkage

1. Thread a flange nut (flange side down) onto the upper

control rod located on the right side of the handle

assembly (Fig. 9).

2

3

4

1

5

m-2676

Figure 9

1. Lower control rod

2. Upper control rod

3. Flange nut

4. Flange locknut

5. Lower link

10

Page 11

2. Install the lower link through the outer hole in the lower

control rod as shown in Figure 9.

3. Insert the upper control rod through the loop in the

lower link (Fig. 9).

4. Thread a flange locknut (flange side up) onto the

bottom of the upper control rod below the loop in the

lower link (Fig. 9).

5. Check the distance between the top of the handgrip and

the bottom of the auger/impeller drive control lever.

The distance should be approximately 4 inches

(10.2 centimeters) as shown in Figure 10.

Installing the Chute Control

Rod

1. Assemble the chute control bracket and rod to the left

side of the handle assembly with the bolt and the

locknut as shown in Figure 11.

Note: Leave the locknut loose.

2

3

4

2

1

m-2628

Figure 10

1. Handgrip

2. Two inches

(5 centimeters)

3. Approximately 4 inches

(10.2 centimeters)

4. Auger/impeller drive

control lever

6. Press the auger/impeller drive control lever slowly

toward the handgrip.

Note: The amount of force needed to compress the

lever increases noticeably when you remove the slack

from the auger/impeller drive belt (approximately

one-half of the lever movement). The adjustment is

correct when the force begins to increase and the

distance between the top of the handgrip and the bottom

of the auger/impeller drive control lever is 2 inches

(5 centimeters) as shown in Figure 10.

Note: If the force does not noticeably increase, remove

the belt cover (refer to steps 1 and 2 of Replacing the

Auger/Impeller Drive Belt on page 22) and measure

2 inches (5 centimeters) above the handgrip at the point

where you remove the slack from the auger/impeller

drive belt.

7. Adjust the flange nut and the flange locknut (Fig. 9), if

necessary, to obtain the proper dimension between the

top of the handgrip and the bottom of the auger/impeller

drive control lever.

1

886

Figure 11

1. Chute control bracket and

rod

2. Bolt and locknut

2. Apply No. 2 general purpose grease to the worm gear

(Fig. 12).

1

2

4

3

658

Figure 12

1. Worm gear

2. Bracket

3. Bolt, pyramidal washer,

and locknut

4. Mounting flange

3. Loosely mount the worm gear and the bracket to the

mounting flange with a bolt, a pyramidal washer, and a

locknut as shown in Figure 12.

4. Slide the worm gear into the teeth of the chute retaining

ring and tighten the locknut (Fig. 12).

5. Tighten the locknut that secures the chute control

bracket (Fig. 11).

6. Check the operation of the chute control rod, and move

the worm gear slightly outward if it binds.

8. Tighten the nuts securely.

11

Page 12

Before Starting

Filling the Engine Crankcase

with Oil

The engine comes from the factory with only a few ounces

of oil in the crankcase. Before starting the engine, add oil.

The crankcase holds 26 ounces (0.77 liters) of oil; however,

because there is some oil in the crankcase, do not add the

full amount at one time. Use only a high-quality, SAE

5W–30 or SAE 10 weight detergent oil that has the

American Petroleum Institute (API) service classification

SF, SG, SH, or SJ. For extremely cold conditions (below

0°F or –18°C), use 0W–30 weight detergent oil that has the

American Petroleum Institute (API) service classification

SF, SG, SH, or SJ.

To add oil:

1. Move the snowthrower to a level surface to ensure an

accurate oil level reading.

2. Clean around the dipstick (Fig. 13).

2

Important Do not overfill the crankcase with oil and

run the engine; engine damage will result. Drain the excess

oil until the oil level on the dipstick reads Full.

9. Insert the dipstick into the filler neck and rotate the cap

clockwise until it is tight.

Filling the Fuel Tank with

Gasoline

For best results, use clean, fresh, lead-free gasoline,

including oxygenated or reformulated gasoline, with an

octane rating of 87 or higher. To ensure freshness, purchase

only the quantity of gasoline that you expect to use in 30

days. Using unleaded gasoline results in fewer combustion

deposits and longer engine life. You may use leaded

gasoline if unleaded gasoline is not available.

Important Do not add oil to the gasoline.

Important Do not use methanol, gasoline containing

methanol, gasohol containing more than 10% ethanol,

premium gasoline, or white gas. Using these fuels can

damage the engine’s fuel system.

Important Do not use gasoline that is more than 30

days old.

1

m-2673

Figure 13

1. Dipstick 2. Fuel tank cap

3. Remove the dipstick by rotating the cap

counterclockwise and pulling it out (Fig. 13).

4. Slowly pour about 3/4 of the crankcase capacity of oil

into the crankcase.

5. Wipe the dipstick clean with a clean cloth.

6. Install the dipstick into the filler neck, then remove it.

Note: To ensure an accurate oil level reading, you must

fully install the dipstick.

7. Read the oil level on the dipstick.

8. If the oil level is below the Add mark on the dipstick,

slowly pour only enough oil into the filler hole to raise

the oil level to the Full mark on the dipstick.

Danger

In certain conditions, gasoline is extremely

flammable and highly explosive. A fire or

explosion from gasoline can burn you and others

and can damage property.

• Fill the fuel tank outdoors, in an open area, and

when the engine is cold. Wipe up any gasoline

that spills.

• Do not fill the fuel tank completely full. Add

gasoline to the fuel tank until the level is 1/4 to

1/2 in. (6 to 13 mm) below the bottom of the

filler neck. This empty space in the tank allows

the gasoline to expand.

• Never smoke when handling gasoline, and stay

away from an open flame or where a spark may

ignite the gasoline fumes.

• Store gasoline in an approved fuel container and

keep it out of the reach of children.

• Never buy more than a 30-day supply of

gasoline.

12

Page 13

Danger

When fueling, under certain circumstances, a

static charge can develop, igniting the gasoline. A

fire or explosion from gasoline can burn you and

others and damage property.

• Always place gasoline containers on the ground

and away from your vehicle before filling.

• Do not fill gasoline containers inside a vehicle or

on a truck or trailer bed because interior

carpets or plastic truck bed liners may insulate

the container and slow the loss of any static

charge.

• When practical, remove gasoline-powered

equipment from the truck or trailer and refuel

the equipment with its wheels on the ground.

• If this is not possible, then refuel such

equipment on a truck or trailer from a portable

container, not from a gasoline dispenser nozzle.

• If you must use a gasoline dispenser nozzle, keep

the nozzle in contact with the rim of the fuel

tank or container opening at all times until

fueling is complete.

Reviewing the Maintenance

Schedule

Review the Recommended Maintenance Schedule on

page 18. You may need to perform one or more additional

procedures before or soon after you begin operating the

snowthrower.

Operation

Note: Determine the left and right sides of the machine

from the normal operating position.

Operating Controls

• Auger/Impeller Drive Control Lever (Fig. 14)—To

engage both the auger and impeller, press the lever

against the right handgrip. To disengage, release the

lever.

1

3

2

Use a fuel stabilizer/conditioner regularly during operation

and storage. A stabilizer/conditioner cleans the engine

during operation and prevents gum-like varnish deposits

from forming in the engine during periods of storage.

Important Do not use fuel additives other than a fuel

stabilizer/conditioner. Do not use fuel stabilizers with an

alcohol base such as ethanol, methanol, or isopropanol.

1. Clean around the fuel tank cap (Fig. 13).

2. Remove the fuel tank cap.

3. Fill the fuel tank with unleaded to within 1/4 to 1/2 inch

(6 to 13 millimeters) from the top of the tank. Do not

fill into the filler neck.

Important Do not fill the fuel tank more than 1/4 inch

(6 millimeters) from the top of the tank because the

gasoline must have room to expand.

4. Install the fuel tank cap and wipe up any spilled

gasoline.

Checking the Tire Pressure

Check the pressure of the tires because they are

overinflated at the factory for shipping. Reduce the

pressure equally in both tires to between 12 and 15 psi

(82 and 103 kPa).

4

5

6

879

Figure 14

1. Auger/impeller drive

control lever

2. Traction control lever

3. Speed selector

• Traction Control Lever (Fig. 14)—To engage the

traction (wheel drive), press the lever against the left

handgrip. To stop the traction, release the lever.

• Speed Selector (Fig. 14)—This control has 7 positions:

5 forward and 2 reverse gears. To change speeds, move

the speed selector to the desired position. The lever

locks in a notch at each speed selection. The speed

selector may shift with difficulty in heavy load

conditions.

Note: Before shifting gears into or out of reverse, you

must release the traction control lever. You may shift

between any of the forward speeds without releasing the

traction control lever.

4. Discharge chute control

5. Chute deflector handle

6. Fuel shutoff valve

13

Page 14

• Discharge Chute Control (Fig. 14)—Rotate the

discharge chute control clockwise to move the

discharge chute to the left; counterclockwise to move

the chute to the right.

• Chute Deflector Handle (Fig. 14)—Move the deflector

handle forward to move the snow stream down; move it

rearward to move the snow stream up.

• Fuel Shutoff Valve (Fig. 14)—Close the valve by

rotating it clockwise. Open the valve by rotating it

counterclockwise. Close the valve when you do not use

the snowthrower.

1

1. Electric starter

2. Starter button

2

3

4

m–4516

Figure 17

3. Receptacle

4. Power cord

• Ignition Switch (Fig. 15)—Insert the key before

starting the engine. To stop the engine, remove the key.

4

2

1

3

m–4034

Figure 15

1. Ignition switch

2. Choke

3. Throttle

4. Primer

• Choke (Fig. 15)—Rotate the choke clockwise to the On

position to start a cold engine. As engine warms up,

gradually rotate the choke counterclockwise to the Off

position.

• Throttle (Fig. 15)—Move the throttle upward to

increase the engine speed; move it downward to

decrease the engine speed. Move the throttle to the Stop

position to stop the engine.

• Primer (Fig. 15)—Press the primer to pump a small

amount of gasoline into the engine for improved

cold-weather starting.

• Recoil Starter (Fig. 16)—The recoil starter is on the

back side of the engine. Pull the recoil starter to start the

engine.

• Power Cord (Fig. 17)—Connect the power cord to the

electric starter and to an electrical outlet when starting

the engine.

Removing the Carburetor

Heater Box

If you operate the engine when the air temperature is above

40F (4C), remove the carburetor heater box (Fig. 18).

2

3

4

1

5

m-2675

Figure 18

1. Screw and lock washer

2. Spark-plug wire

3. Bolt

1. Disconnect the wire from the spark plug and ensure that

the wire does not contact the plug (Fig. 18).

2. Remove the key from the ignition switch (Fig. 15).

4. Carburetor heater box

5. Screws

1

934

Figure 16

1. Recoil starter

• Electric Starter (Fig. 17)—Push the starter button to

start the engine.

3. Pull the choke knob off (Fig. 15).

4. Remove 2 screws, 2 bolts, and one lock washer that

secure the carburetor heater box (Fig. 18).

Note: Install these fasteners in their holes for safe

keeping.

5. Lift the carburetor heater box up and away from the

engine.

6. Disconnect the green ground wire clip under the throttle

(Fig. 19).

14

Page 15

1

m4947

Figure 19

1. Green ground wire clip

7. Install the choke knob.

8. Insert the ignition key.

9. Connect the wire to the spark plug.

Important Use the carburetor heater box as a reference

for the choke and throttle positions.

Installing the Carburetor

6. Insert the ignition key (Fig. 15).

Important Do not use the primer or the choke if the

engine has been running and is hot. Excessive priming may

flood the engine and prevent it from starting.

7. Cover the hole in the center of the primer (Fig. 15) with

your thumb and push in the primer 3 times, pausing a

moment between pushes.

8. For the recoil starter:

A. Grasp the recoil starter handle (Fig. 16) and pull it

out slowly until positive engagement results; then

pull the handle vigorously to start the engine.

B. Keep a firm grip on the starter handle and return the

rope slowly.

For the electric starter:

A. Connect the power cord to the snowthrower

(Fig. 17) and to a standard household power outlet.

Heater Box

To install the carburetor heater box, reverse steps 1 through

9 of Removing the Carburetor Heater Box on page 14.

Remove the fasteners from their holes before installing the

carburetor heater box.

Starting the Engine

Important Ensure that there are no obstructions in the

auger/impeller and the discharge chute before you operate

the snowthrower. Use a stick, not your hand, to remove an

obstruction from the auger/impeller or the discharge chute.

1. Connect the wire to the spark plug.

2. Move the throttle to the Fast position.

3. Release the auger/impeller drive control lever and the

traction control lever (Fig. 14).

4. Open the fuel shutoff valve below the fuel tank

(Fig. 20).

Caution

If you leave the snowthrower plugged into a power

outlet, someone can inadvertently start the

snowthrower and injure people or damage

property.

Unplug the power cord whenever you do are not

starting the snowthrower.

B. Push the starter button.

Note: Run the electric starter no more than 10 times at

intervals of 5 seconds on, then 5 seconds off.

Important Running the electric starter extensively can

overheat and damage the starter.

Note: If the engine does not start after this series of

attempts, wait at least 40 minutes to allow the starter to

cool before attempting to start it again.

Note: If the engine does not start after the second series

of attempts, take the snowthrower to an Authorized

Service Dealer for service.

C. When the engine starts, disconnect the power cord

from the snowthrower and the outlet.

3

1

2

Figure 20

1. Fuel line

2. Hose clamp

5. Rotate the choke (Fig. 15) to the On position.

3. Fuel shutoff valve

726

Note: If engine does not start or if the air temperature is

–10F (–23C) or below, the engine may need additional

priming. After pushing in the primer, try to start the engine

before priming again.

9. After the engine starts, immediately rotate the choke

(Fig. 15) to the 3/4 position. As the engine warms up,

rotate the choke to the 1/2 position. When the engine

warms up sufficiently, rotate the choke to the Off

position.

15

Page 16

10.Move the speed selector (Fig. 14) to first gear, squeeze

the traction control lever to the handgrip, and then

release the traction control lever. If the snowthrower

moves forward before engaging the traction drive

control lever or after releasing the lever, see Adjusting

the Traction Drive Belt on page 20.

Important Do not operate the snowthrower if the auger

and impeller rotate when you disengage the auger/impeller

drive control lever.

Stopping the Engine

1. Engage the auger to clear any remaining snow from

inside the housing.

2. Run the engine for a few minutes to dry off any

accumulated moisture.

3. Release the auger/impeller drive control lever and the

traction control lever (Fig. 14).

4. Stop the engine by doing one of the following:

D. Move the throttle to the Slow position and remove

the ignition key.

E. Move the throttle to the Stop position.

5. Close the fuel shutoff valve (Fig. 20).

Snowthrowing Tips

Danger

When the snowthrower is in operation, the

impeller and auger can be rotating and cut off or

injure hands and feet.

• Before adjusting, cleaning, repairing and

inspecting the snowthrower, and before

unclogging the discharge chute, stop the engine

and wait for all moving parts to stop. Disconnect

the wire from the spark plug and keep it away

from the plug to prevent someone from

accidentally starting the engine.

• Use a stick, not your hands, to remove an

obstruction from the discharge chute.

• Stay behind the handles and away from the

discharge opening while operating the

snowthrower.

• Keep face, hands, feet, and any other part of

your body or clothing away from concealed,

moving, or rotating parts.

Warning

6. Pull the recoil starter with a rapid, continuous, full-arm

stroke 3 or 4 times. This helps prevent the recoil starter

from freezing up.

7. Wait for all moving parts to stop before leaving the

operating position.

Freewheeling or Self-propel

Drive

You can operate the snowthrower with the self-propel

feature engaged or disengaged (freewheeling). When you

insert the axle pins through the outer axle holes and not

through the wheel hubs (Fig. 4), the snowthrower

freewheels. When you insert the axle pins through the holes

in the wheel hubs and the inner axle holes (Fig. 4) and

engage the traction control lever, the snowthrower propels

itself.

The auger/impeller may pick up and throw stones,

toys, and other foreign objects, causing serious

personal injury to the operator or to bystanders.

• Keep the area to be cleared free of all objects

that could be picked up and thrown by the

auger/impeller.

• Keep all children and pets away from area of

operation.

• Adjust the skids to match the type of surface being

cleaned. Refer to Adjusting the Skids and the Scraper

on page 19.

• In snowy and cold conditions, some controls and

moving parts may freeze. Do not use excessive force

when trying to operate frozen controls. If you have

difficulty operating any control or part, start the engine

and let it run for a few minutes.

• Remove snow as soon as possible after it falls. This

produces the best snow removal results.

• Always use the Fast throttle position when throwing

snow.

• Overlap each swath to ensure complete snow removal.

• Discharge the snow downwind whenever possible.

• Do not overload the snowthrower by clearing snow at

too fast a rate. If the engine slows down, shift the

snowthrower into a lower gear to reduce the forward

speed.

16

Page 17

• In wet or slushy conditions, maintain maximum engine

speed, and do not overload the engine to prevent

clogging the discharge chute.

• If the front of the snowthrower tends to ride up, reduce

the forward speed by shifting the snowthrower into a

lower gear. If the front still tends to ride up, lift up on

both handgrips to hold down the front of snowthrower.

• If the wheels slip, shift the snowthrower into a lower

gear to reduce the forward speed.

• After clearing the snow, let the engine run for a few

minutes to prevent moving parts from freezing. Engage

the auger/impeller to clear any remaining snow from

inside the housing. Shut off the engine, wait for all

moving parts to stop, and remove all ice and snow from

the snowthrower.

• With the engine shut off, pull the recoil starter handle

several times to prevent the recoil starter from freezing

up.

• When you are not using the snowthrower, close the fuel

shutoff valve and remove the key.

17

Page 18

Maintenance

Note: Determine the left and right sides of the machine from the normal operating position.

Recommended Maintenance Schedule

Maintenance Service

Interval

Maintenance Procedure

• Check the engine oil level.1 Refer to Checking the Engine Oil Level on page 19.

• Check the auger gearbox grease and add grease if necessary. Refer to

Initially

Checking the Auger Gearbox Grease on page 19.

• Adjust the skids and the scraper.2 Refer to Adjusting the Skids and the Scraper

on page 19.

• Adjust the speed selector.

3

Refer to Adjusting the Speed Selector on page 20.

• Inspect and adjust the traction drive belt. Refer to Adjusting the Traction Drive

1 Hour

Belt on page 20.

• Inspect and adjust the auger/impeller drive belt. Refer to Adjusting the

Auger/Impeller Drive Belt on page 22.

2 Hours • Change the engine oil. Refer to Changing the Engine Oil on page 24.

• Inspect and adjust or replace the traction drive belt if necessary. Refer to

Adjusting the Traction Drive Belt on page 20, or to Replacing the Traction Drive

5 Hours

Belt on page 20.

• Inspect and adjust or replace the auger/impeller drive belt if necessary. Refer to

Adjusting the Auger/Impeller Drive Belt on page 22, or to Replacing the

Auger/Impeller Drive Belt on page 22.

10 Hours

15 Hours

• Check the auger gearbox grease and add grease if necessary. Refer to

Checking the Auger Gearbox Grease on page 19.

• Oil and grease the internal moving parts. Refer to Lubricating the Snowthrower

on page 23.

25 Hours • Change the engine oil. Refer to Changing the Engine Oil on page 24.

100 Hours

• Inspect and gap the spark plug. Replace it if necessary. Refer to Replacing the

Spark Plug on page 24.

• Check the auger gearbox grease after removing the snowthrower from storage

and add grease if necessary. Refer to Checking the Auger Gearbox Grease on

page 19.

• Change the engine oil at the end of the snowthrowing season. Refer to Changing

Annually

the Engine Oil on page 24.

• Oil and grease the internal moving parts at the end of the snowthrowing season.

Refer to Lubricating the Snowthrower on page 23.

• Drain the gasoline and run the engine to dry out the fuel tank and the carburetor

at the end of the snowthrowing season. Refer to Emptying the Fuel Tank on

page 24.

1

Check the engine oil level

2

Adjust the skids and the scraper as needed.

3

Adjust the speed selector as needed.

before each use

and add oil if necessary.

Important Refer to your engine operator’s manual for additional maintenance procedures.

18

Page 19

Caution

If you leave the wire on the spark plug, someone could accidently start the engine and seriously

injure you or other bystanders.

Disconnect the wire from the spark plug before you do any maintenance. Set the wire aside so

that it does not accidentally contact the spark plug.

Checking the Engine Oil Level

Every time you use the snowthrower, first ensure that the

oil level is between the Add and the Full marks on the

dipstick.

1. Stop the engine and wait for all moving parts to stop.

2. Move the snowthrower to a level surface to ensure an

accurate oil level reading.

3. Clean around the dipstick (Fig. 13).

4. Remove the dipstick by rotating the cap

counterclockwise and pulling it out (Fig. 13).

5. Wipe the dipstick clean with a clean cloth.

6. Install the dipstick into the filler neck, then remove it.

Note: To ensure an accurate oil level reading, you must

fully install the dipstick.

7. Read the oil level on the dipstick.

8. If the oil level is below the Add mark on the dipstick,

slowly pour only enough oil into the filler hole to raise

the oil level to the Full mark on the dipstick.

Note: Use only a high-quality, SAE 5W–30 or SAE 10

weight detergent oil that has the American Petroleum

Institute (API) service classification SF, SG, SH, or SJ.

For extremely cold conditions (below 0°F or –18°C),

use 0W–30 weight detergent oil that has the American

Petroleum Institute (API) service classification SF, SG,

SH, or SJ.

3. Disconnect the wire from the spark plug and ensure that

the wire does not contact the spark plug (Fig. 18).

4. Clean the area around the pipe plug (Fig. 21).

6521

Figure 21

1. Pipe plug

5. Remove the pipe plug from the gearbox (Fig. 21).

6. Check the level of grease in the gearbox. The grease

should be visible through the opening.

7. If the level of grease is low, add Lubriplate MAG-1

grease (a low-temperature, high-pressure grease) to the

gearbox until the point of overflow.

8. Install the pipe plug in the gearbox.

9. Connect the wire to the spark plug.

Adjusting the Skids and the

Scraper

Important Do not overfill the crankcase with oil and

run the engine; engine damage will result. Drain the excess

oil until the oil level on the dipstick reads Full.

9. Insert the dipstick into the filler neck and rotate the cap

clockwise until it is tight.

Checking the Auger Gearbox

Grease

Check the auger gearbox initially, after every 10 operating

hours, and when you remove the snowthrower from annual

storage.

1. Stop the engine and wait for all moving parts to stop.

2. Move the snowthrower to a level surface.

Adjust the skids and the scraper initially and then as needed

to ensure that the auger does not contact the paved or gravel

surface. Also, adjust them as needed to compensate for

wear.

1. Stop the engine and wait for all moving parts to stop.

2. Move the snowthrower to a level surface.

3. Disconnect the wire from the spark plug and ensure that

the wire does not contact the plug (Fig. 18).

4. Check the tire pressure in the tires. Refer to Checking

the Tire Pressure on page 13.

5. Loosen the 4 flange nuts that secure both skids to the

auger side plates (Fig. 22) until the skids slide up and

down easily.

19

Page 20

1. Skid (2)

2. Flange nuts (4)

1

2

Figure 22

3. Auger side plate (2)

Adjusting the Speed Selector

Adjust the speed selector linkage initially and when the

snowthrower is slow, first gear has no speed, or the speed

selector does not move into fifth gear.

3

651

1. Stop the engine and wait for all moving parts to stop.

2. Disconnect the wire from the spark plug and ensure that

the wire does not contact the plug (Fig. 18).

3. Move the speed selector (Fig. 14) on the control panel

to the R2 (Reverse) position.

6. Support the auger blades so that they are 1/8 inch

(3 millimeters) off the ground (Fig. 23).

3

2

1

Figure 23

1. Scraper

2. Mounting screws

7. Check the scraper adjustment. The scraper should be

1/8 inch (3 millimeters) above and parallel to a level

surface.

For Concrete and Asphalt Surfaces:

If the snowthrower does not clear the snow close enough to

the pavement, adjust the skids to lower the scraper; if the

pavement surfaces are cracked, rough, or uneven, adjust the

skids to raise the scraper.

For Gravel Surfaces:

Support the auger blades a few inches (centimeters) above

the ground, and adjust the skids to prevent the snowthrower

from picking up rocks.

8. To adjust the scraper, loosen the 5 mounting screws

(Fig. 23), level the scraper, and tighten the mounting

screws.

2

652

3. Auger blades

4. Remove the cotter pin and the flat washer (Fig. 5).

5. Pull the speed selector rod out of the hole in the speed

selector arm (Fig. 5).

6. Adjust the forward speed by rotating the speed selector

rod in the trunnion (Fig. 6).

Note: Lengthening the rod makes the forward speed

faster; shortening the rod makes the forward speed

slower.

7. Insert the speed selector rod into the speed selector arm

and secure it with the flat washer and cotter pin.

8. Connect the wire to the spark plug.

Adjusting the Traction Drive

Belt

Check the traction drive belt for the proper tension after the

first operating hour, after every 5 operating hours

thereafter, and when the speed selector shifts properly but

the snowthrower does not drive in the forward or reverse

speeds. Adjust the belt when necessary.

1. Stop the engine and wait for all moving parts to stop.

2. Disconnect the wire from the spark plug and ensure that

the wire does not contact the plug (Fig. 18).

3. Check the adjustment according to steps 3 through 6 of

Installing the Traction Rod on page 10. Make any

needed adjustments.

4. If the linkage is properly adjusted and the problem

persists, contact an Authorized Service Dealer.

5. Connect the wire to the spark plug.

9. Move the skids down as far as possible.

10.Tighten the 4 flange nuts that secure both skids to the

auger side plates (Fig. 22).

11. Connect the wire to the spark plug.

Replacing the Traction Drive

Belt

If the traction drive belt becomes worn, oil-soaked, or

otherwise damaged, replace the belt.

1. Stop the engine and wait for all moving parts to stop.

20

Page 21

2. Disconnect the wire from the spark plug and ensure that

the wire does not contact the plug (Fig. 18).

3. Remove the 3 bolts that hold the belt cover in place and

set the cover aside (Fig. 24).

3

4

5

6

7

1

2

m-4040

Figure 24

1. Upper belt cover 2. Bolt (3)

4. Loosen the auger brake arm assembly by loosening the

rearmost screw and removing the front screw (Fig. 25).

1

2

3

4

m-2678

Figure 25

1. Rearmost screw

2. Front screw

3. Idler pulley spring

4. Auger brake arm

1

2

11

10

8

9

m-3331

Figure 26

1. Traction idler pulley

2. Idler pulley

3. Bolt, washer, and lock

washer

4. Traction drive belt

5. Engine pulley

6. Auger/impeller drive belt

7. Belt guide

8. Engine pulley sheave

9. Engine crankshaft bolt,

lock washer, and washer

10. Large auger/impeller

pulley

11. Traction pulley

7. Remove the engine crankshaft bolt, lock washer, and

washer (Fig. 26).

8. Separate and remove the engine pulley sheave (Fig. 26).

9. Remove the auger/impeller drive belt, leaving it looped

around the large auger/impeller pulley.

10.Remove the engine pulley (Fig. 26).

11. Remove the traction drive belt from the traction pulley

and the engine crankshaft (Fig. 26).

12.Pull the traction idler pulley outward and install a new

traction drive belt (Fig. 26).

13.Install the engine pulley.

Note: Do not to pinch the traction drive belt (Fig. 27).

5. Remove the idler pulley spring (Fig. 25). Let the brake

arm assembly hang free but out of the way.

6. Remove 2 bolts, 2 washers, and 2 lock washers that

secure the belt guide (Fig. 26).

2

1

3

Figure 27

1. Traction drive belt

2. Engine pulley

3. Indexing rib in indexing

notch

4. Engine pulley sheave

5. Auger/impeller drive belt

14.Pull the idler pulley outward and loop the

auger/impeller drive belt in front of the engine pulley,

ensuring that the belt is on the inside of the idler pulley

(Fig. 26).

21

4

5

m-2677

Page 22

15.Install the engine pulley sheave, ensuring that the

indexing rib in the engine pulley sheave aligns with the

indexing notch in the engine pulley (Fig. 27).

16.Install the washer, lock washer, and crankshaft bolt that

secures the engine pulley sheave (Fig. 27).

Note: Do not to pinch the auger/impeller drive belt

(Fig. 27).

17.Ensure that the brake pad is properly installed on the

brake arm. Position the angled cutoff on the brake pad

as shown in Figure 28.

1

2

Important Do not operate the snowthrower if the auger

and the impeller rotate when you disengage the

auger/impeller drive control lever.

Adjusting the Auger/Impeller

Drive Belt

Operating the snowthrower with an auger/impeller drive

belt that slips decreases the snowthrowing performance and

damages the belt. Check the auger/impeller drive belt for

the proper tension after the first operating hour, after every

5 operating hours thereafter. Adjust the belt when

necessary.

Danger

3

Figure 28

View from left side of unit

1. Brake pad

2. Angled cutoff

18.Install the 2 screws that secure the auger brake arm

assembly. Ensure that the tabs fit into the holes in the

left side of the snowthrower (Fig. 29).

1

Figure 29

1. Tabs in holes

19.Have someone squeeze the auger/impeller drive control

lever (Fig. 14) against the handgrip, and install the belt

guide using 2 bolts, 2 washers, and 2 lock washers.

20.Check and adjust the belt guide, and ensure that it does

not contact any part of the engine pulley.

21.Check and adjust the auger/impeller drive control

linkage. Refer to steps 5 through 7 of Installing the

Auger/Impeller Drive Control Linkage on page 10.

4

m-2681

3. Auger/impeller drive belt

4. Traction drive belt

m-2678

Improperly adjusting the auger/impeller may

cause it to turn when disengaged. A rotating auger

or impeller can cut off or injure fingers, hands, or

feet.

• Keep your face, hands, feet, and any other part

of your body or clothing away from concealed,

moving, or rotating parts.

• Ensure that the impeller brake arm clearance is

maintained.

• Do not adjust the auger/impeller drive belt too

tight because it may cause the auger/impeller to

turn when the control lever is in the Disengaged

position. If this occurs, decrease the belt tension.

1. Stop the engine and wait for all moving parts to stop.

2. Disconnect the wire from the spark plug and ensure that

the wire does not contact the plug (Fig. 18).

3. Check the adjustment according to steps 5 through 7 of

Installing the Auger/Impeller Drive Control Linkage on

page 10. Make any needed adjustments.

4. Connect the wire to the spark plug.

5. Check the belt tension by operating the auger.

6. If the belt still slips, replace it. Refer to Replacing the

Auger/Impeller Drive Belt on page 22.

Important Do not operate the snowthrower if the auger

and the impeller rotate when you disengage the

auger/impeller drive control lever.

Replacing the Auger/Impeller

22.Install the idler pulley spring.

23.Install the belt cover with the 3 bolts.

24.Connect the wire to the spark plug.

Drive Belt

If the auger/impeller drive belt becomes worn, oil-soaked,

or otherwise damaged, replace the belt.

1. Stop the engine and wait for all moving parts to stop.

22

Page 23

2. Disconnect the wire from the spark plug and ensure that

the wire does not contact the plug (Fig. 18).

3. Remove the 3 bolts that hold the belt cover in place and

set the cover aside (Fig. 24).

4. Loosen the auger brake arm assembly by loosening the

rear screw and removing the front screw that fasten the

auger brake arm assembly to the frame (Fig. 25).

5. Remove the idler pulley spring (Fig. 25). Let the brake

arm assembly to hang free but out of the way.

6. Remove the 2 bolts, 2 washers, and 2 lock washers that

secure the belt guide (Fig. 26).

7. Remove the engine crankshaft bolt, lock washer, and

washer (Fig. 26).

8. Separate and remove the engine pulley sheave (Fig. 26).

9. Remove the auger/impeller drive belt (Fig. 26).

10.Pull the idler pulley outward and install a new belt

around the large auger/impeller pulley (Fig. 26).

11. Loop the belt in front of the engine pulley, and ensure

that the belt is on the inside of the idler pulley (Fig. 26).

12.Install the engine pulley sheave, the washer, the lock

washer, and the engine crankshaft bolt.

Lubricating the Snowthrower

Lightly lubricate all moving parts of the snowthrower after

every 15 operating hours and at the end of the

snowthrowing season.

Important Do not get oil or grease on the rubber wheel

or friction drive plate because the wheel will slip and the

rubber may deteriorate.

1. Stop the engine and wait for all moving parts to stop.

2. Disconnect the wire from the spark plug and ensure that

the wire does not contact the plug (Fig. 18).

3. Drain the gasoline from the fuel tank; refer to Emptying

the Fuel Tank on page 24.

4. Tip the snowthrower forward onto its auger housing and

block it so that it cannot fall.

5. Remove the 8 bolts that hold the back and the bottom

covers in place and remove the covers (Fig. 30).

1

1

Note: Ensure that the indexing rib in the engine pulley

sheave aligns with the indexing notch in the center

engine pulley. Do not pinch the belt (Fig. 27).

13.Ensure that the brake pad is properly installed on the

brake arm. Position the angled cutoff on the brake pad

as shown in Figure 28.

14.Install the 2 screws that secure the auger brake arm

assembly. Ensure that the tabs fit into the holes in the

right side of the snowthrower (Fig. 29).

15.Have someone squeeze the auger/impeller drive control

lever against the handgrip, and install the belt guide

using the 2 bolts, 2 washers, and 2 lock washers.

16.Check and adjust the belt guide. Ensure that the belt

guide is about 1/8 inch (0.3 centimeters) from the belt

or the engine pulley.

17.Check and adjust the auger/impeller drive control

linkage. Refer to steps 5 through 7 of Installing the

Auger/Impeller Drive Control Linkage on page 10.

18.Install the idler pulley spring.

19.Install the belt cover with the 3 bolts.

20.Connect the wire to the spark plug.

Important Do not operate the snowthrower if the auger

and the impeller rotate when you disengage the

auger/impeller drive control lever.

1

2

1

m-2682

3

Figure 30

1. Bolts

2. Back cover

3. Bottom cover

6. Lightly lubricate the snowthrower with light oil as

shown in Figures 31 and 32.

1

m-2679

Figure 31

1. Axle gear

23

Page 24

m-3331

Figure 32

7. Wipe up any excess oil.

8. Lightly grease the axle gear (Fig. 31).

9. Wipe up any excess grease.

10.Install the back and the bottom covers.

11. Return the snowthrower to its upright position.

12.Connect the wire to the spark plug.

Changing the Engine Oil

Change the engine oil after the first 2 operating hours, after

every 25 operating hours, and at the end of the

snowthrowing season. If possible, run the engine just

before changing the oil because warm oil flows better and

carries more contaminants.

1. Stop the engine and wait for all moving parts to stop.

2. Disconnect the wire from the spark plug and ensure that

the wire does not contact the spark plug (Fig. 18).

3. Clean the area around the oil drain plug (Fig. 33).

Replacing the Spark Plug

Use a Champion RJ-19LM or equivalent spark plug. Install

a new plug after every 100 operating hours.

1. Stop the engine and wait for all moving parts to stop.

2. Clean any debris from around the base of the spark

plug.

3. Disconnect the wire from the spark plug (Fig. 18).

4. Remove the spark plug.

5. Examine the spark plug and replace it if it is cracked,

fouled, dirty, or if the electrodes are worn.

Important Do not clean the electrodes because grit

could enter the cylinder and damage the engine.

6. Set the gap between the electrodes on the spark plug at

0.030 in. (0.76 mm) as shown in Figure 34.

1

110

Figure 34

1. 0.030 in. (0.76 mm)

7. Install the spark plug by hand and then torque it to

15 ft-lb (20.4 Nm). If you do not have a torque wrench,

tighten the plug firmly.

8. Connect the wire to the spark plug.

2

1

m-4036

Figure 33

1. Oil drain plug 2. Drain extension

4. Slide an oil drain pan under the drain extension and

remove the oil drain plug.

5. Drain the oil.

6. Install the oil drain plug.

7. Fill the crankcase with oil. Refer to Filling the Engine

Crankcase with Oil on page 12.

8. Wipe up any spilled oil.

9. Connect the wire to the spark plug.

Emptying the Fuel Tank

1. Stop the engine and wait for all moving parts to stop.

2. Disconnect the wire from the spark plug (Fig. 18)

3. Close the fuel shutoff valve (Fig. 20).

Danger

Gasoline is highly flammable; it can ignite and

cause serious personal injury.

• Drain gasoline outdoors.

• Drain gasoline from a cold engine only.

• Wipe up any gasoline that may have spilled.

• Do not drain gasoline near any open flame or

where gasoline fumes may be ignited by a spark.

• Do not smoke a cigar, a cigarette, or a pipe when

handling gasoline.

4. Place a clean drain pan under the fuel shutoff valve.

24

Page 25

5. Loosen the hose clamp that secures the fuel line to the

valve and slide the fuel line off the fuel shutoff valve

(Fig. 20).

6. Open the fuel shutoff valve and allow the fuel to drain

out of the fuel tank into the drain pan.

7. Install the fuel line onto the fuel shutoff valve and

secure it with a hose clamp.

8. Connect the wire to the spark plug.

3. Use an oil can to squirt 2 teaspoons of oil into the spark

plug hole.

4. Install the spark plug by hand and then torque it to

15 ft-lb (20.4 Nm). If you do not have a torque wrench,

tighten the plug firmly. Do not connect the wire to the

plug.

5. Pull the recoil starter slowly to distribute the oil on the

inside of the cylinder.

9. Start the snowthrower and run the engine until it stops.

Repeat this step 2 more times to ensure that the fuel

tank and the carburetor are empty.

Storage

Warning

Gasoline fumes are highly flammable, explosive,

and dangerous if inhaled. If the product is stored

in an area with an open flame, the gasoline fumes

may ignite and cause an explosion.

Do not store the snowthrower in a house (living

area), basement, or any other area where ignition

sources may be present, such as hot water and

space heaters, clothes dryers, furnaces, and other

like appliances.

Preparing the Fuel System

1. Add stabilizer/conditioner to the fuel in the fuel tank as

directed.

2. Run the engine for 10 minutes to distribute conditioned

fuel through the fuel system.

3. Stop the engine, allow it to cool, and drain the fuel tank

or run the engine until it stops. Refer to Emptying the

Fuel Tank on page 24.

Preparing the Snowthrower

1. Lubricate the snowthrower. Refer to Lubricating the

Snowthrower on page 23.

2. Clean the snowthrower.

3. Touch up chipped surfaces with paint available from an

Authorized Service Dealer. Sand affected areas before

painting, and use a rust preventative to prevent the

metal parts from rusting.

4. Tighten any loose fasteners. Repair or replace any

damaged parts.

5. Cover the snowthrower and store it in a clean, dry place

out of the reach of children. Allow the engine to cool

before storing it in any enclosure.

Accessories

You can obtain the following snowthrower accessories

from an Authorized Service Dealer:

• Tire Chain Kit

• Drift Breaker Kit

• Snow Cab Kit

• Light Kit

4. Start the engine and run it until it stops.

5. Choke or prime the engine, start it a third time, and run

the engine until it will not start.

6. Dispose of unused fuel properly. Recycle it according to

local codes, or use it in your automobile.

Note: Do not store stabilized gasoline for more than 90

days.

Preparing the Engine

1. While the engine is still warm, change the engine oil.

Refer to Changing the Engine Oil on page 24.

2. Remove the spark plug.

25

Page 26

Troubleshooting

Engine does not start or starts

1.The key is not in the ignition or

1.Insert the key into the ignition

Toro designed and built your snowthrower for trouble-free operation. Check the following components and items carefully,

and refer to Maintenance on page 18 for more information. If a problem continues, see an Authorized Service Dealer.

Problem Possible Causes Corrective Action

Electric starter does not turn

(electric-start models only)

Engine does not start or starts 1. The key is not in the ignition or 1. Insert the key into the ignition

hard

1. The power cord is

disconnected at the outlet or

the snowthrower.

2. The power cord is worn,

corroded, or damaged.

3. The power outlet is not

energized.

is in the

2. The choke is in the

and the primer has not been

pressed.

3. The fuel shutoff valve is not

open.

4. The throttle is not in the

position.

5. The fuel tank is empty or the

fuel system contains stale fuel.

6. The spark plug wire is loose or

disconnected.

Off

position.

Off

position

Fast

1. Connect the power cord to the

outlet and/or the snowthrower.

2. Replace the power cord.

3. Have a qualified electrician

energize the power outlet.

and turn it to the On position.

2. Move the choke to the

position and press the primer 3

times.

3. Open the fuel shutoff valve.

4. Move the throttle to the

position.

5. Drain and/or fill the fuel tank

with fresh gasoline (not more

than 30 days old). If the

problem persists, contact your

Authorized Service Dealer.

6. Connect the wire to the spark

plug.

On

Fast

7. The spark plug is pitted, fouled,

or the gap is incorrect.

8. The fuel cap vent is restricted. 8. Remove the vent restriction or

9. The engine oil level in the

engine crankcase is too low or

too high.

10.The air temperature is above

40°F (4°C) and the carburetor

heater box is on the

snowthrower.

Engine runs rough 1. The choke is in the On position. 1. Move the choke to the

2. The fuel shutoff valve is not

completely open.

7. Check the spark plug and

adjust the gap if necessary.

Replace the spark plug if it is

pitted, fouled, or cracked.

replace the fuel cap.

9. Add or drain oil to adjust the oil

level in engine crankcase to the

Full

mark on the dipstick.

10.Remove the carburetor heater

box.

position.

2. Open the fuel shutoff valve.

Off

26

Page 27

Problem Corrective ActionPossible Causes

Engine runs, but the snowthrower

discharges snow poorly or not at

all

3. The fuel tank is nearly empty or

contains stale fuel.

4. The spark plug wire is loose. 4. Connect the wire to the spark

5. The spark plug is pitted, fouled,

or the gap is incorrect.

6. The engine oil level in the

engine crankcase is too low or

too high.

7. The air temperature is above

40°F (4°C) and the carburetor

heater box is on the

snowthrower.

1. The throttle is not in the

position when throwing snow.

2. The snowthrower is moving too

fast to clear the snow.

Fast

3. Drain and fill the fuel tank with

fresh gasoline (not more than

30 days old). If the problem

persists, contact an Authorized

Service Dealer.

plug.

5. Check the spark plug and

adjust the gap if necessary.

Replace the spark plug if it is

pitted, fouled, or cracked.

6. Add or drain the oil level in the

engine crankcase to the

mark on the dipstick.

7. Remove the carburetor heater

box.

1. Move the throttle to the

position.

2. Shift the snowthrower into a

lower gear.

Full

Fast

Snowthrower does not properly

clear the snow off the surface

3. You are trying to remove too

much snow per swath.

4. You are trying to remove

extremely heavy or wet snow.

5. The discharge chute is

plugged.

6. The auger/impeller drive belt is

loose or is off the pulley.

7. The auger/impeller drive belt is

worn or broken.

1. The tire pressure is low. 1. Check the pressure in the tires

2. The skids and/or the scraper is

not properly adjusted.

3. Reduce the amount of snow

removed for per swath.

4. Don’t overload the snowthrower

with extremely heavy or wet

snow.

5. Stop the engine, wait for all

moving parts to stop, and use a

stick to remove the snow from

the discharge chute.

6. Install and/or adjust the

auger/impeller drive belt.

7. Replace the auger/impeller

drive belt.

and adjust it if necessary.

2. Adjust the skids and the

scraper.

27

Page 28

Gas Powered

Snow Products

The Toro Total Coverage Guarantee

A Two-Year Full Warranty

(Limited Warranty for Commercial Use)

Conditions and Products Covered

The Toro Company and its affiliate, Toro Warranty Company,

pursuant to an agreement between them, jointly promise to repair

any Toro Product used for normal residential purposes* if defective

in materials or workmanship for a period of two years from the date

of purchase.

This warranty includes the cost of parts and labor, but you must

pay transportation costs. Transportation within a fifteen mile radius

of the servicing dealer is covered under this warranty for two-stage

snowthrowers only.

This warranty applies to all gasoline powered snow products.

* Normal residential purposes means use of the product on the

same lot as your home. Use at more than one location is

considered commercial use, and the commercial use warranty

would apply.

Limited Warranty for Commercial Use

Toro Consumer Products used for commercial, institutional, or

rental use are warranted against defects in materials or workmanship for 45 days from the date of purchase.

Instructions for Obtaining Warranty Service

If you think that your T oro Product contains a defect in materials or

workmanship, follow this procedure:

1. Contact any Toro Authorized or Master Service Dealer to

arrange service at their dealership. To locate a dealer

convenient to you, refer to the Y ellow Pages of your telephone

directory (look under “Lawn Mowers”) or access our website at

www.Toro.com. U.S. Customers may also call 800-421-9684

to use our 24-hour Toro dealer locator system.

2. Bring the product and your proof of purchase (sales receipt) to

the Service Dealer.

If for any reason you are dissatisfied with the Service Dealer’s

analysis or with the assistance provided, contact us at:

Customer Care Department, Consumer Division

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

800-348-2424 (U.S. customers)

877-484-9255 (Canada customers)

You must maintain your Toro Product by following the maintenance

procedures described in the operator’s manual. Such routine

maintenance, whether performed by a dealer or by you, is at your

expense.

There is no other express warranty except for special emission

system coverage on some products and the Toro Starting

Guarantee on GTS engines. This express warranty does not

cover:

• Cost of regular maintenance service or parts, such as filters,

fuel, lubricants, tune-up parts, blade sharpening, brake and

clutch adjustments

• Any product or part which has been altered or misused or

required replacement or repair due to normal wear, accidents,

or lack of proper maintenance

• Repairs necessary due to improper fuel, contaminants in the