Page 1

TORO/LAWN-BOY TWO STAGE SNOWTHROWER DRIVE SYSTEMS MANUAL

Table of Contents – Page 1 of 2

AUGER GEARBOX SERVICE

GENERAL INFORMATION

AUGER GEARBOX LUBRICANT

GEARBOX REMOVAL

PRIMARY METHOD — MINIMUM DISASSEMBLY

SECONDARY METHOD — TRACTION AND AUGER HOUSINGS SEPARATED:

TORO MODELS 38065 AND 38080

ALL OTHER MODELS

INSTALLATION

AUGER GEARBOX DISASSEMBLY / SERVICE

FAILURE ANALYSIS

GEARBOX ASSEMBLY

BELTS, CONTROLS AND LINKAGES

INTRODUCTION

REPLACING THE AUGER/IMPELLER DRIVE BELT

REPLACING THE TRACTION BELT

REPLACING THE TRACTION BELT

TORO MODELS 38065, 38080, 38085

LAWN-BOY MODELS 28230, 28231

TORO MODELS 38051, 38052, 38054, 38056, 38062, 38063, 38064, 38072, 38073

LAWN-BOY MODEL 28232

TORO MODELS 38053, 38066, 38078, 38083, 38084, 38086

CONTROL AND LINKAGE ADJUSTMENT

AUGER CONTROL ADJUSTMENT — TORO MODELS 38065, 38080, 38085

INSTALL AUGER DRIVE CONTROL ROD

ADJUSTING AUGER/IMPELLER DRIVE BELT

AUGER/IMPELLER DRIVE CONTROL LINKAGE — ALL OTHER MODELS

ADJUSTING TRACTION CONTROL

ADJUSTING THE TRACTION CONTROL

TORO MODELS 38065, 38080, 38085

824XL (TORO MODELS 38066, 38078, 38083, 38084, 38086

LAWN-BOY MODEL 28232

ADJUSTING THE TRACTION ROD

LAWN-BOY MODELS 28230, 28231

TORO MODELS 38051, 38052, 38054, 38056, 38062, 38063, 38064

ADJUSTING THE SPEED SELECTOR

TRACTION DRIVE SYSTEMS

INTRODUCTION

TROUBLESHOOTING THE TRACTION DRIVE — ALL MODELS

DISASSEMBLY

TORO MODELS 38065, 38080, 38085

ASSEMBLY

TORO MODELS 38065, 38080, 38085

PREPARATION

ASSEMBLY

Page 2

TORO/LAWN-BOY TWO STAGE SNOWTHROWER DRIVE SYSTEMS MANUAL

Table of Contents – Page 2 of 2

TRACTION DRIVE SYSTEMS - CONTINUED

DISASSEMBLY

LAWN-BOY MODELS 28230, 23231

TORO MODELS 38051, 38052, 38054, 38056, 38062, 38063, 38064, 38072, 38073

ASSEMBLY

LAWN-BOY MODELS 28230, 23231

TORO MODELS 38051, 38052, 38054, 38056, 38062, 38063, 38064, 38072, 38073

ASSEMBLY TIPS

ASSEMBLY STEPS

DISASSEMBLY

TORO MODELS 38066, 38078, 38083, 38084, 38086

ASSEMBLY

TORO MODELS 38066, 38078, 38083, 38084, 38086

SUB ASSEMBLY REPAIR

TORO MODELS 38066, 38078, 38083, 38084, 38086

TRACTION SHAFT/FRICTION WHEEL DISASSEMBLY

ASSEMBLY

AXLE AND FRICTION PLATE DISASSEMBLY

AXLE AND FRICTION PLATE ASSEMBLY

Page 3

2-Stage Snowthrower

Drive Systems

Service Manual

Page 4

About This Manual

This manual was written expressly for the Toro and Lawn-Boy servicing dealer. The Toro

Company has made every effort to make the information in this manual complete and

correct.

This manual was written with assumption that the reader has basic mechanical knowledge

and skills. This book contains material covering the Toro and Lawn-Boy brand 2-Stage

Snowthrowers produced from 1990 to 2002, and may be specified for use on products built

before 1990 or after 2002 that are similar in design.

We hope that you find this manual a valuable addition to your service shop. If you have

questions or comments regarding this manual, please contact us at the following address:

The Toro Company

Consumer Service Department

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

The Toro Company reserves the right to change product specifications or this manual

without notice.

Copyright© - All Rights Reserved

The Toro Company - 2001

Bloomington, MN 55420 - U.S.A.

Page 5

Contents

AUGER GEARBOX SERVICE . . . . . . . . . . . . . 1-1

GENERAL INFORMATION . . . . . . . . . . . . . . . . 1-1

AUGER GEARBOX LUBRICANT . . . . . . . . . . . 1-1

GEARBOX REMOVAL . . . . . . . . . . . . . . . . . . . 1-1

Primary Method — Minimum

Disassembly . . . . . . . . . . . . . . . . . . . . . . 1-2

Secondary Method — Traction and Auger

Housings Separated: Toro Models

38065 and 38080 . . . . . . . . . . . . . . . . . . 1-4

Secondary Method — Traction and

Auger Housings Separated:

All Other Models . . . . . . . . . . . . . . . . . . . 1-5

INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

AUGER GEARBOX

DISASSEMBLY / SERVICE . . . . . . . . . . . . . . 1-7

Failure Analysis . . . . . . . . . . . . . . . . . . . . . 1-9

GEARBOX ASSEMBLY . . . . . . . . . . . . . . . . . . 1-9

BELTS, CONTROLS AND LINKAGES . . . . . . 2-1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . 2-1

REPLACING THE AUGER/IMPELLER

DRIVE BELT . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

REPLACING THE TRACTION BELT . . . . . . . . 2-2

Replacing the Traction Belt — Toro Models

38065, 38080, 38085 . . . . . . . . . . . . . . . 2-2

Replacing the Traction Belt —

Lawn-Boy Models 28230, 28231 and

Toro Models 38051, 38052, 38054, 38056,

38062, 38063, 38064, 38072, 38073 . . . 2-3

Replacing the Traction Belt —

Lawn-Boy Model 28232 and

Toro Models 38053, 38066,

38078, 38083, 38084, 38086 . . . . . . . . . 2-4

CONTROL AND LINKAGE ADJUSTMENT. . . . 2-7

Auger Control Adjustment —

Toro Models 38065, 38080, 38085 . . . . . 2-7

Install Auger Drive Control Rod . . . . . 2-7

Adjusting Auger/Impeller Drive Belt . . 2-7

Auger/Impeller Drive Control Linkage —

All Other Models . . . . . . . . . . . . . . . . . . . 2-8

ADJUSTING TRACTION CONTROL . . . . . . . . 2-9

Adjusting the Traction Control —

Toro Models 38065, 38080, 38085 . . . . . 2-9

Adjusting the Traction Control —

824XL (Toro Models 38066, 38078,

38083, 38084, 38086 and

Lawn-Boy Model 28232) . . . . . . . . . . . . . 2-10

ADJUSTING THE TRACTION ROD —

LAWN-BOY MODELS 28230, 28231 AND

TORO MODELS 38051, 38052, 38054,

38056, 38062, 38063, 38064 . . . . . . . . . . . . 2-11

ADJUSTING THE SPEED SELECTOR . . . . . 2-12

TRACTION DRIVE SYSTEMS . . . . . . . . . . . . 3-1

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . 3-1

TROUBLESHOOTING THE TRACTION

DRIVE — ALL MODELS . . . . . . . . . . . . . . . . 3-2

DISASSEMBLY — TORO MODELS 38065,

38080, 38085 . . . . . . . . . . . . . . . . . . . . . . . . 3-2

ASSEMBLY — TORO MODELS 38065,

38080, 38085 . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Preparation . . . . . . . . . . . . . . . . . . . . . . . 3-4

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

DISASSEMBLY — LAWN-BOY MODELS 28230,

23231 AND TORO MODELS 38051, 38052,

38054, 38056, 38062, 38063, 38064, 38072,

38073 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-7

ASSEMBLY — LAWN-BOY MODELS 28230,

23231 AND TORO MODELS 38051, 38052,

38054, 38056, 38062, 38063, 38064, 38072,

38073 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-10

Assembly Tips . . . . . . . . . . . . . . . . . . . . . 3-10

Assembly Steps . . . . . . . . . . . . . . . . . . . . 3-10

DISASSEMBLY — TORO MODELS 38066,

38078, 38083, 38084, 38086 . . . . . . . . . . . . 3-14

ASSEMBLY — TORO MODELS 38066, 38078,

38083, 38084, 38086 . . . . . . . . . . . . . . . . . . 3-16

SUB ASSEMBLY REPAIR —

TORO MODELS 38066, 38078, 38083, 38084,

38086 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-17

Traction Shaft/Friction

Wheel Disassembly . . . . . . . . . . . . . . . . 3-17

Assembly . . . . . . . . . . . . . . . . . . . . . . . . . 3-18

Axle and Friction Plate Disassembly . . . . 3-18

Axle and Friction Plate Assembly . . . . . . 3-19

Two Stage Snowthrower Drive Systems Manual

Page 6

THIS PAGE INTENTIONALLY LEFT BLANK

Two Stage Snowthrower Drive Systems Manual

Page 7

Introduction

This manual will cover service to the auger and traction drive systems on small and intermediate frame 2 stage

snowthrowers. Service information for Power Shift snowthrowers is contained in manual 492-0354.

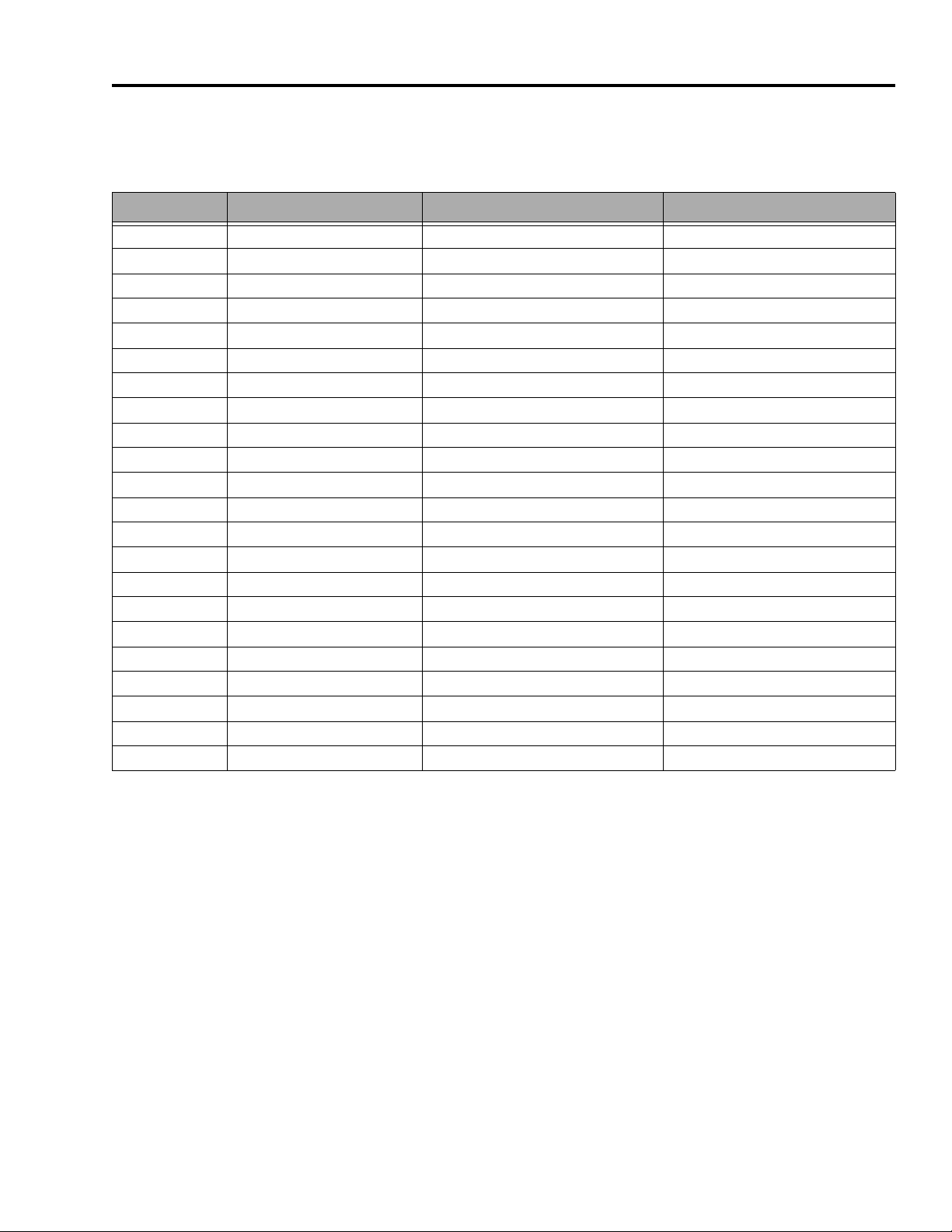

The models covered are as follows*:

Model Model Name Year Auger Gearbox Lubricant

28230 522R 1997-2000 MAG 1

28231 522R 1997 MAG 1

28232 824E 1999-2000 MAG 1

38051 522 2000-2001 MAG 1

38052 521 1990-1996 MAG 1

38053 824 2000-2002 MAG 1

38054 521 1990-1996 MAG 1

38056 521 1990-1991 MAG 1

38056C 521 1990 MAG 1

38062 622 1997-1999 MAG 1

38063 622 1997-2002 MAG 1

38064 622 2000-2002 MAG 1

38065 624 1990 90 wt.

38066 824XL 2000-2002 90 wt.

38072 724 1993-2000 MAG 1

38073 724 1993-2000 MAG 1

38078 824 2000-2002 MAG 1

38080 824 1990-1993 90 wt.

38083 824XL 1997-1999 90 wt.

38084 824XL 1997-1999 90 wt.

38085 824 1990 90 wt.

38086 824XL 2000-2002 90 wt.

Model numbers 28XXX are Lawn-Boy.

Model numbers 38XXX are Toro.

Engines: All of the models in the table were

manufactured with engines from the Tecumseh

Products Company. Refer to their service manual for

engine information.

Note:

Maximum RPM for all models is 3300 ± 150 RPM.

* This manual may be specified for products produced

before 1990 or after 2002 in addition to the models

above.

Two Stage Snowthrower Drive Systems Manual Introduction - 1

Page 8

THIS PAGE INTENTIONALLY LEFT BLANK

Introduction - 2 Two Stage Snowthrower Drive Systems Manual

Page 9

Chapter 1 — Auger Gearbox Service

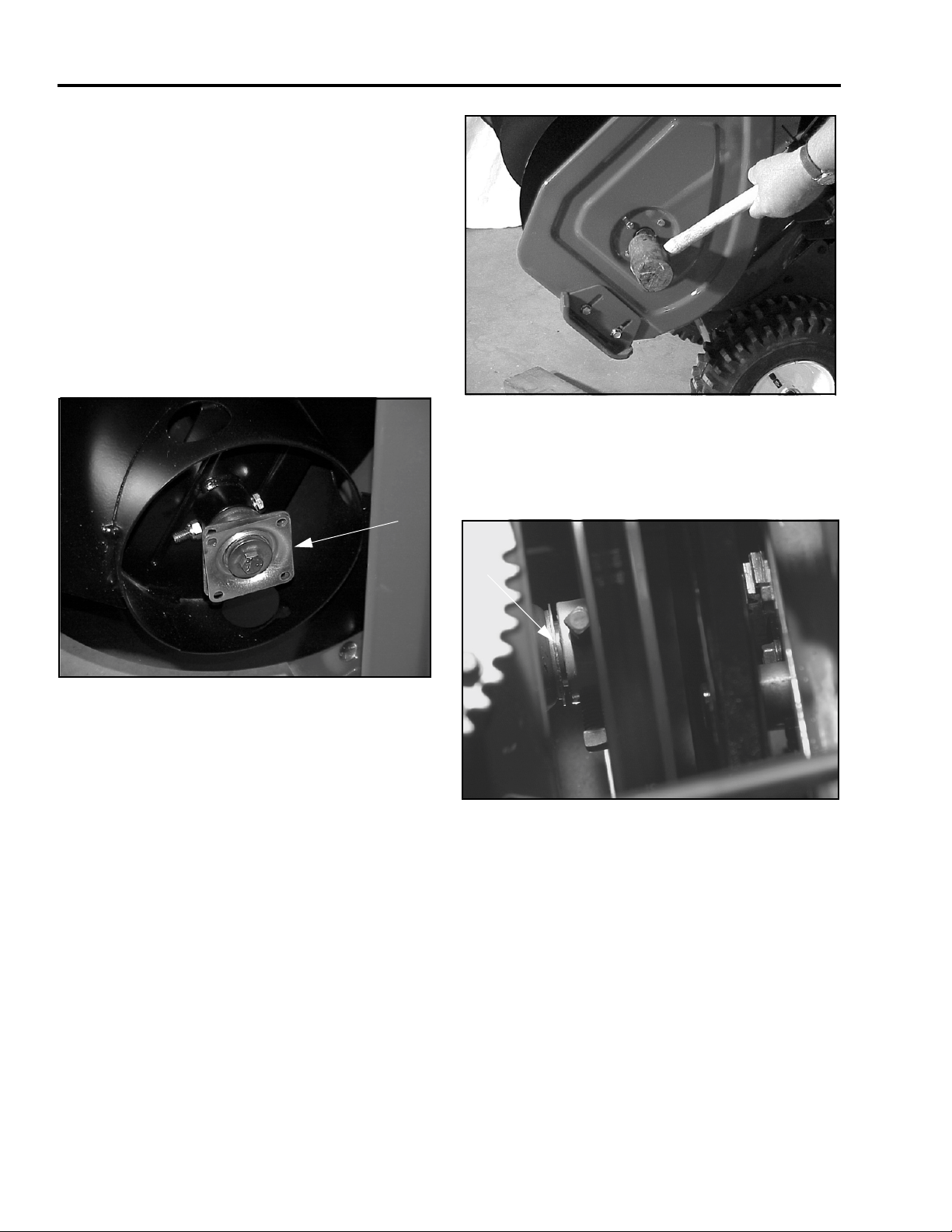

1.Check/fill pl

GENERAL INFORMATION

The manual takes a systems approach. There are two

versions of the auger gearbox and three versions of the

traction drive system used among the various 2-stage

models.

For information on the auger drive or linkage

adjustments see the section titled Belts, Controls and

Linkages.

The lubricant level in a gearbox should be checked

prior to each season.

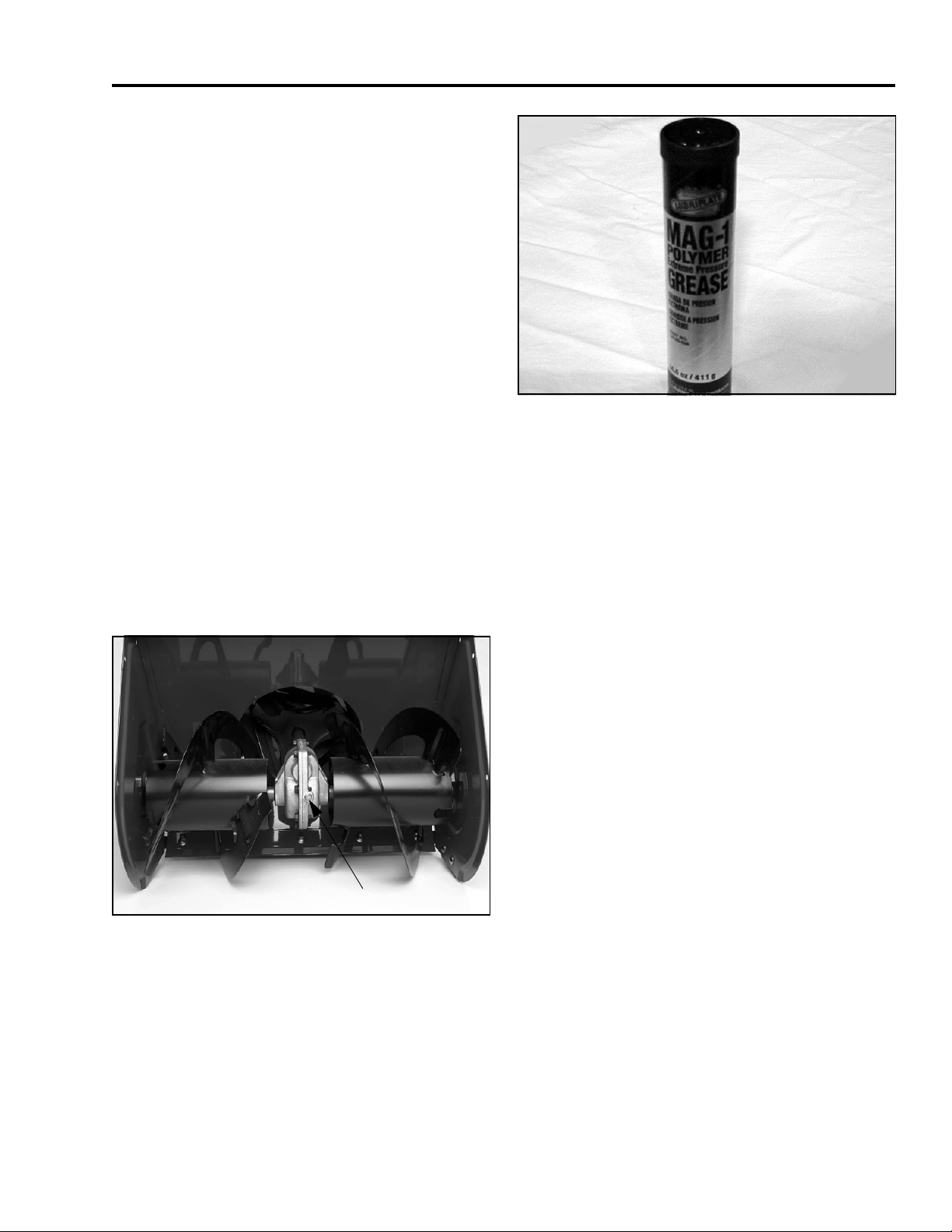

AUGER GEARBOX LUBRICANT

Two different lubricants are used in the various models.

They are NOT interchangeable. Use the lubricant

specified in the model chart.

90 wt. indicates a 90-weight gear oil. A multi weight

such as 85-120 is acceptable as long as it

encompasses the 90 weight. The oil used must also

have an extreme pressure (EP) rating of GL5 or higher.

Fill until it runs out of the fill check plug (Figure 1).

Figure 2

Should you see an oil leak, disassembly is required.

Lubriplate MAG 1 is thick so it will normally not leak out

even with a failed seal. The bearings used in all

applications are oil impregnated, so they do not require

regular maintenance. Internal gearbox repair will

require removal from the chassis.

MVC-458

GEARBOX REMOVAL

There are two methods commonly used to remove the

auger gearbox:

• The primary method is to remove the auger

assembly without separating the traction assembly

from the auger housing.

• The secondary method is to separate the auger

and traction assemblies. Separating the auger and

traction assemblies improves access if the auger is

difficult to remove.

1

Figure 1

ug

MAG 1 is a special low temperature grease made by

Lubriplate™. Use 1/3 tube of MAG 1 per gearbox.

Obtain from your area Lubriplate Distributor or from

your Toro parts supplier (Toro Part Number 505-101)

(Figure 2).

Two Stage Snowthrower Drive Systems Manual 1 - 1

DSC-0168

Page 10

Auger Gearbox Service

Primary Method — Minimum Disassembly

The following steps apply to all models.

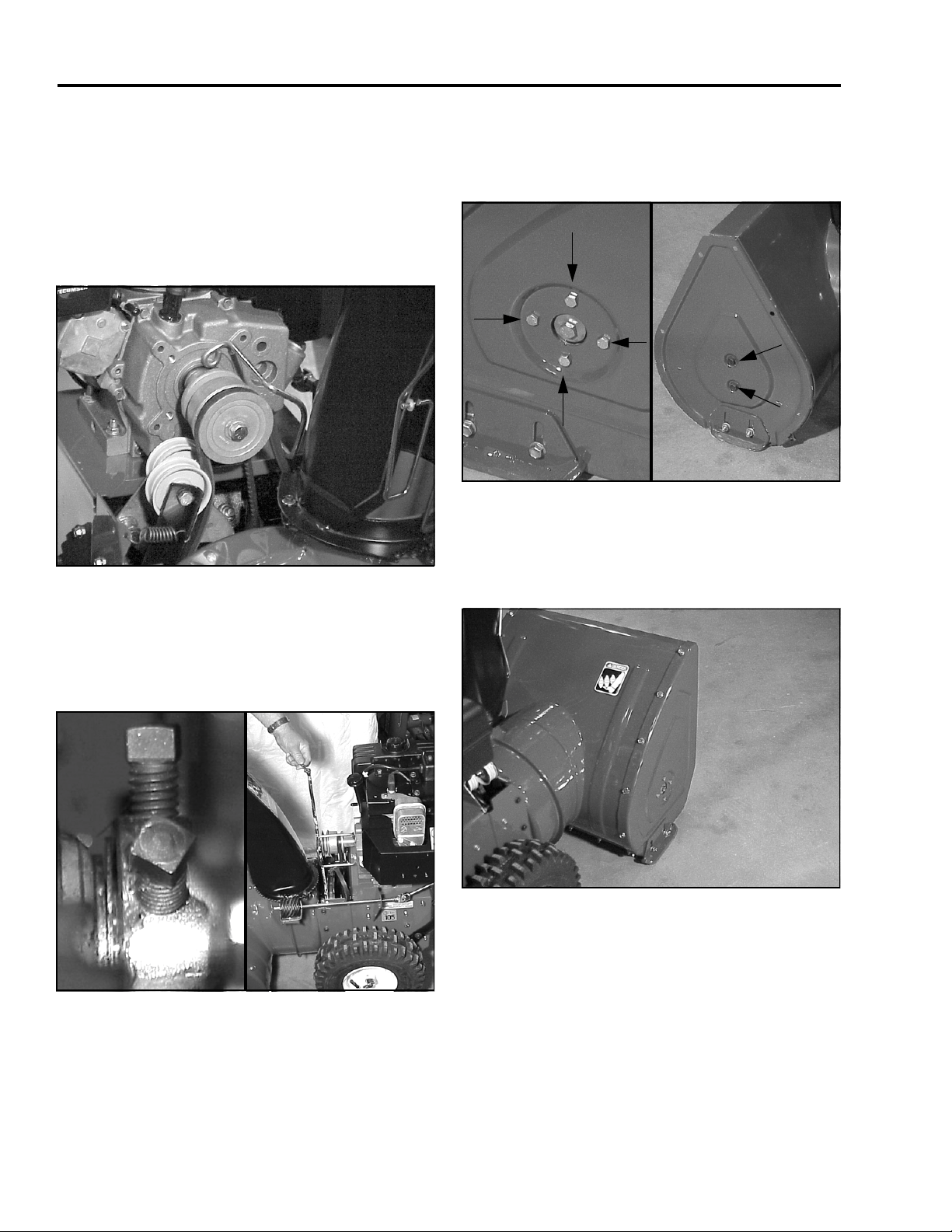

1. Remove the belt cover. Loosen the belt guide on

the engine crankshaft and remove the auger belt.

DO NOT bend the belt guide out of the way

(Figure 3).

Figure 3

MVC-526

3. In the center of each side plate are either two or

four cap screws (depending on the model). These

go into the bearing that supports each side of the

auger. Remove the cap screws (Figure 5).

Figure 5

4. Many models have side plates that are attached

by cap screws and lock nuts. Removing or at least

loosening one side plate will ease removal of the

auger assembly (Figure 6).

MVC-529/MVC-531

2. On the forward side of the auger pulley is 1 or 2

set screws, depending on the model, which must

be loosened. Use the square end of a 3/8” socket

extention. Note: The pulley is keyed to the shaft

and will be removed later (Figure 4).

Figure 4

MVC-527/MVC-536

Figure 6

MVC-530

1 - 2 Two Stage Snowthrower Drive Systems Manual

Page 11

5. Loosen the rear and remove the front capscrew

1.L

2.R

1.Pull

2.A

1.Sid

3.S

securing the idler arm to the chassis.

1

Auger Gearbox Service

1

2

2

M-3331

oosen

Figure 7

emove

6. Begin to pull the auger assembly out to the front.

Note: The auger pulley and key have not yet been

removed. However, if you pull the auger slightly

forward, it will make it easier to slide the pulley off

the end of the impeller shaft. Once the pulley is

out of the way, remove the key (Figure 8 and

Figure 9).

ey

Figure 9

uger housing

2768-023

7. Model 38065 and 38080 only — Disconnect the

(2) scraper springs from either the slot in the side

plates or from the scraper. Also there are two

bolts, sleeves, and bumpers that limit the scraper

travel, one through the side plate on each side,

into the scraper. Both must be removed

(Figure 10).

4

1

3

2

e plate

2. Bumper

Figure 10

craper

4. Spring mount

2768-029

Figure 8

2768-022

8. The auger assembly can now be pulled

completely from the auger housing.

Two Stage Snowthrower Drive Systems Manual 1 - 3

Page 12

Auger Gearbox Service

1.A

9. The auger flighting is attached to the auger shaft

with one bolt and locknut. Reach through the

holes in the drum augers to access. On models

without drum augers, the bolts are easily

accessible (Figure 11).

1

Figure 11

ccess hole

The auger assembly can be separated from the

traction assembly. However, it is generally not

necessary to work on the auger. Should the auger

pulley be rusted on the shaft, it might be easier to

remove the pulley with the traction assembly out of the

way.

MVC-533

2. Drain the fuel and oil and stand the machine up on

its auger. Support or brace to prevent tipping

(Figure 13).

Figure 13

3. Disconnect the chute crank rod at the auger

(Figure 14).

2768-027

Secondary Method — Traction and Auger

Housings Separated: Toro Models 38065

and 38080

1. Remove the belt cover. Loosen the belt guide and

remove the auger belt (Figure 12).

Figure 12

2768-021

Figure 14

4. Remove the lower cover from the traction

assembly.

MVC-534

1 - 4 Two Stage Snowthrower Drive Systems Manual

Page 13

5. There are 4 locknuts in the forward part of the

1.Locknut

housing. These are on studs from the auger.

Remove the locknuts. The traction assembly will

now lift straight up off the auger assembly

(Figure 15).

Auger Gearbox Service

1

Figure 15

6. Now perform steps 1 - 9 under “GEARBOX

REMOVAL” on page 1 - 1.

2768-025

Secondary Method — Traction and Auger

Housings Separated: All Other Models

1. Remove the belt cover, loosen the belt guide, and

remove the traction belt (Figure 16).

Figure 17

3. Place a block of wood under BOTH the auger and

traction assembly to support them when the

connecting cap screws are removed. Remove the

6 cap screws, 3 on each side, that connect the

auger to the traction assembly and separate the

two (Figure 18).

Figure 18

MVC-534

MVC-535

4. Now perform steps 1 - 8 under “GEARBOX

REMOVAL” on page 1 - 1.

Figure 16

2. Disconnect the chute crank rod at the auger

(Figure 17).

Two Stage Snowthrower Drive Systems Manual 1 - 5

MVC-526

Page 14

Auger Gearbox Service

1.B

1.U

INSTALLATION

Installation of the auger assembly into the auger

housing can be done whether the auger housing and

traction assemblies are connected or not. There is no

significant time savings to either sequence.

1. All self-aligning bearings (sometimes called the

flange bearings) MUST be installed loosely. All

models have one next to the auger drive pulley

and some use 2 more supporting the auger output

shafts. In all cases, these bearings must be a little

loose to assure the bearing can align itself with the

shaft before it is secured (Figure 19).

1

Figure 19

earing and flange

MVC-540

2. Make sure all the parts are installed on the auger

assembly. All spacers, thrust washers, and auger

bearings need to be hanging on the shafts.

(Including the scraper for models 38065 and

38080.)

3. Slide the assembly into the housing, directing the

input shaft into the rear bearing.

Figure 20

MVC-542

6. All models — Rotate the impeller back and forth.

One direction will push the impeller shaft to the

rear. Rotate it in that direction to force the shaft as

far to the rear as possible (Figure 21).

1

Figure 21

se pulley to remove gap

2773-012

7. Secure the 4 cap screws on the self-aligning

bearing. Install the thrust washer and key.

4. Start the cap screws from the side plates into the

bearings that support the auger output shafts.

Some models have 2 cap screws into a fixed

bearing; others have 4 cap screws into a selfaligning bearing.

8. Holding the shaft to the rear, install the pulley on

the shaft. Push the pulley forward, hold and

secure. The pulley is used to limit the front to back

movement of the impeller (Figure 21).

5. Models using four bolt bearings ONLY - Strike the

side plate and bearing area with a rubber mallet

three or four times, then secure the bearings. The

jolt aligns the bearings (Figure 20).

1 - 6 Two Stage Snowthrower Drive Systems Manual

Page 15

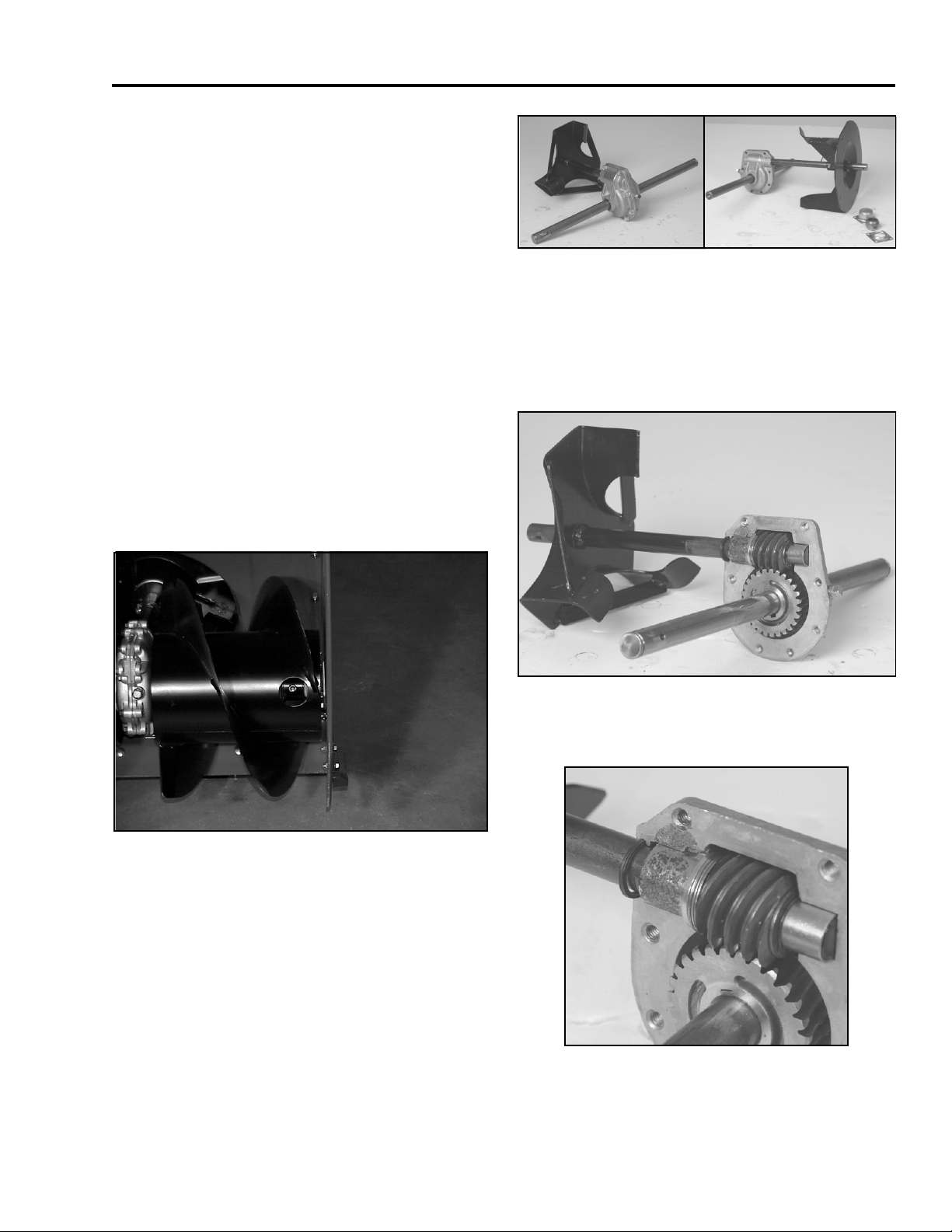

AUGER GEARBOX DISASSEMBLY /

SERVICE

Once the auger gearbox assembly is removed from the

housing the repair process is the same for all models.

The only variables are what type of lubricant is used

(see the chart on Introduction page 1), whether the

impeller is removable from the shaft (on some models

the impeller is welded to the shaft) and how the

gearbox case halves are sealed.

Auger gearbox disassembly:

1. With the gearbox assembly removed from the

housing the first step is to slide the bearings off

the output shafts. (Model 38080 & 38065, also

slide the scraper off).

2. All models use a cap screw, lock nut, and spacer

to connect the auger to the shaft (Figure 22).

Remove the cap screw, nut and spacer and slide

both augers from the shaft.

Auger Gearbox Service

Figure 23

4. Remove the 8 or 9 self-tapping screws that hold

the gearbox halves together. Note: On a model

that uses 90 weight gear oil, you may want to

place the gearbox over a pan when the screws are

removed. Then separate the gearbox halves

(Figure 24).

2773-055/2773-066

Figure 22

3. Some models have the impeller welded to the

impeller shaft. Others use a combination of bolts,

set screws, and a key. If you see bolt(s) through

the impeller hub, remove them. Some may have

set screws, which only require being loosened.

The models with the setscrews also have a key

between the hub and shaft. Once the visible

retainers are removed, slide the impeller away

from the gearbox, the key will be uncovered.

Remove the key (Figure 23).

MVC-533

Figure 24

5. The impeller shaft can now be removed

(Figure 25).

Figure 25

2773-060

2773-061

Two Stage Snowthrower Drive Systems Manual 1 - 7

Page 16

Auger Gearbox Service

1

LH

ASM

5:1.A

ASM, RH

12.Bushi

t

6. Clean the output shaft and slide the case halves

off. Remove the seals from the case halves and

discard the seals.

7. Clean and inspect the bushings in the case

halves. If they are damaged or worn, press them

out of the case halves at this time.

8. Slide the worm gear off the shaft. Depending on

the model, there will be one or two woodruff keys

between the gear and the shaft. Refer to the parts

manual for your specific machine.

9. Returning to the impeller shaft, the 824XL models

have a worm that is actually rolled into the impeller

shaft. All other models use an individually

replaceable gear. Remove all the bushings,

bearings and spacers from the impeller shaft

(Figure 26).

10. Now inspect the worm and worm gear. If either

gear is damaged, replace them both. When gears

run together, they develop wear patterns unique to

the two of them. Replacing only one gear will

result in early failure.

Figure 26

.

1:1. Auger gearcase ASM, LH

1:1:1. Bushing

1:1:2. Seal-oil

2. Bearing-thrust

4. Gear-helical

5. RH auger gearcase ASM

auger gearcase

uger gearcase

5:1:1. Bushing

5:1:2. Seal-oil

6. Shaft-auger, 24”

9. Key-woodruff

10. Impeller shaft

11. Seal-oil

13. Bushing-worm

14. Washer-thrust

15. Bearing-thrust

16. Ring-retaining, Ext.

17. Screw-HWH

18. Plug-SQH pipe

ng-inpu

1577-028

1 - 8 Two Stage Snowthrower Drive Systems Manual

Page 17

Auger Gearbox Service

1.Wi

1.Flush

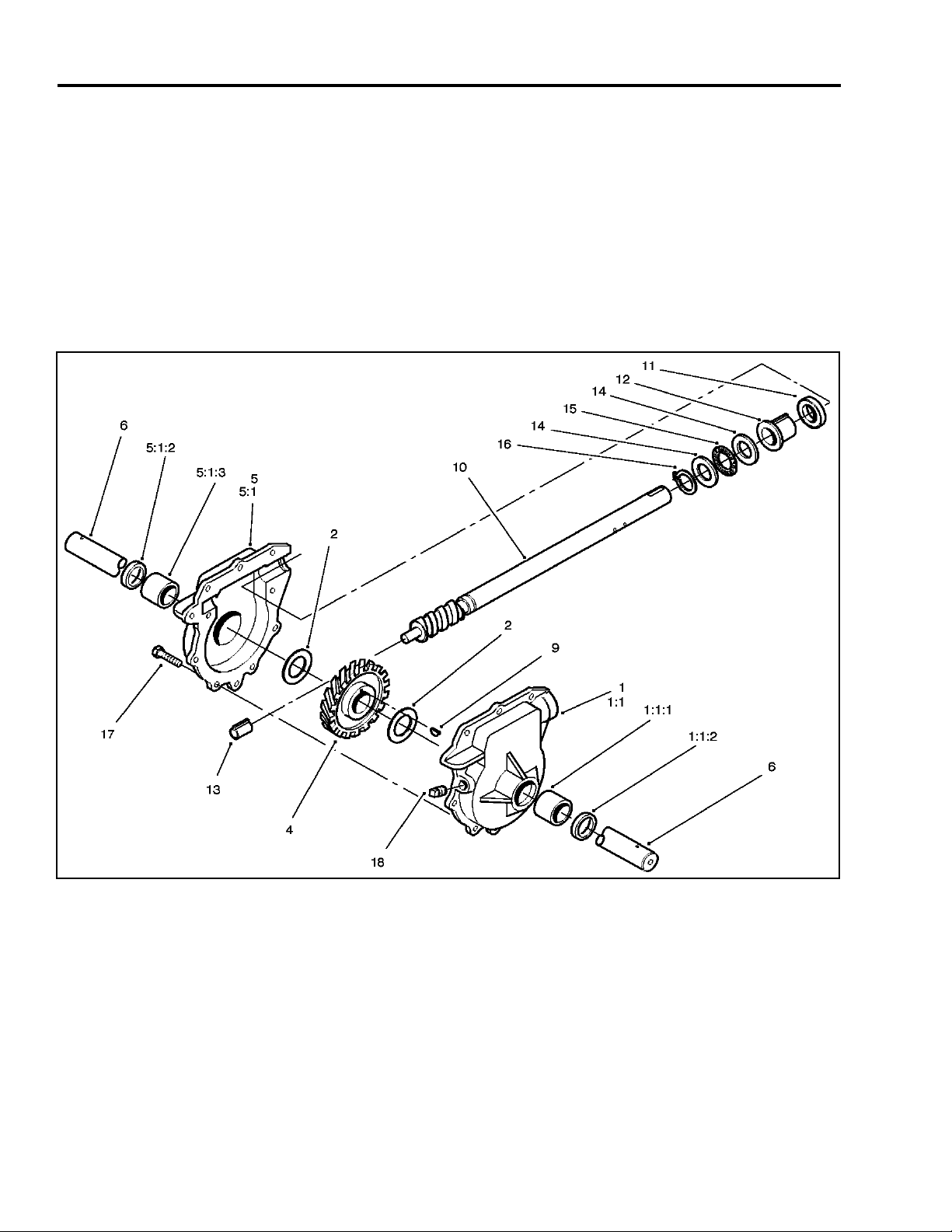

Failure Analysis

There are some misconceptions regarding these

gearboxes that result in incorrectly identifying the

causes of failure.

The square cut ring on the impeller shaft is not really a

seal. It is a wiper ring that has a tendency to pull down

to the shaft when the shaft begins to turn. The bushing

next to the ring really deflects most of the oil that is

thrown towards that area. The loose fit provides a vent

for the case (Figure 27). Occasionally a drop or two of

oil will get between the bushing and ring. When the

auger drive is disengaged, the ring will relax and that

oil might drip into the auger housing. At this rate, the

machine can be used for several years without any

significant oil loss. The yearly oil level check is more

than adequate to compensate for this.

1

Figure 27

per ring

If there is a significant amount of oil coming out of this

area, it would indicate that the gearbox has been at a

severe operating angle or the bushing is badly worn.

2773-061

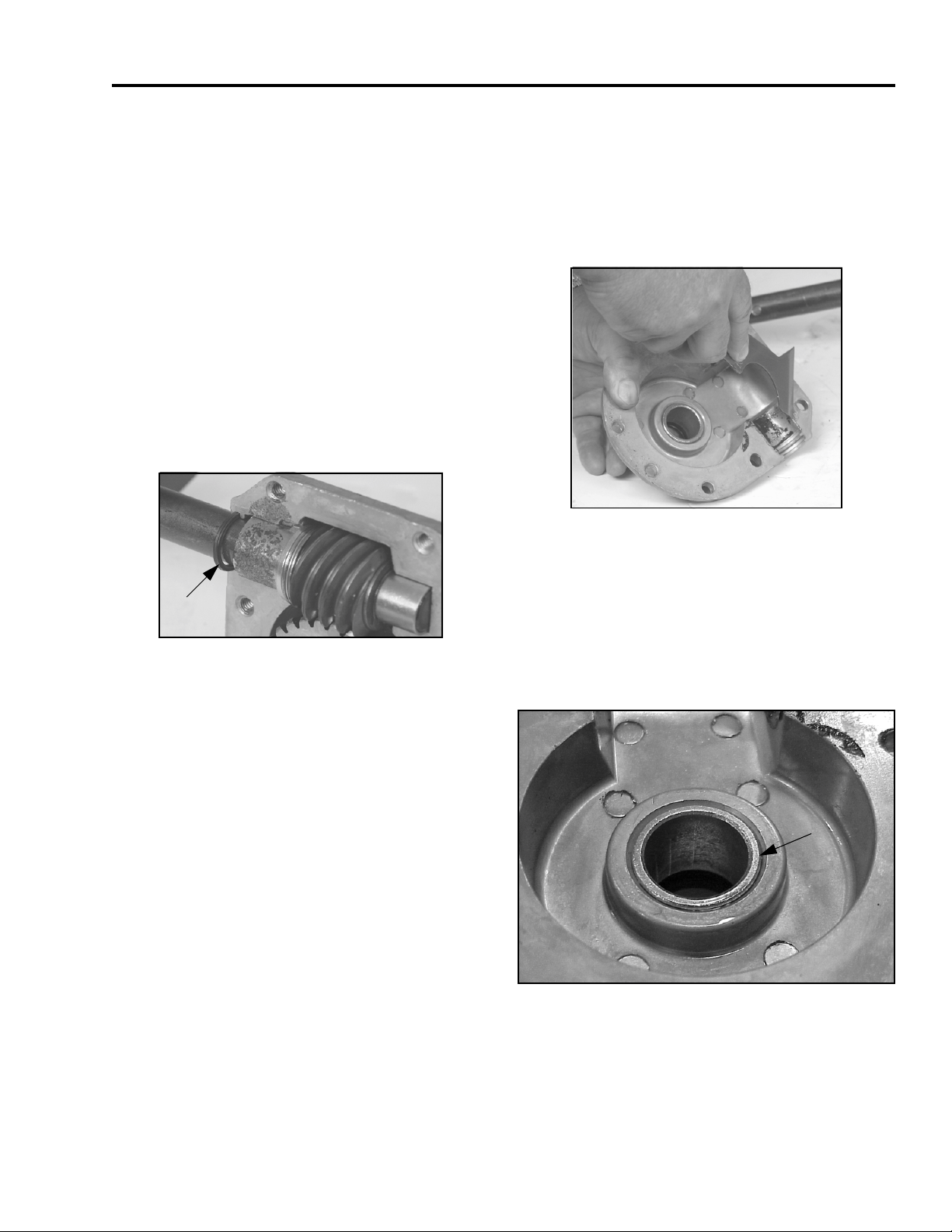

GEARBOX ASSEMBLY

1. Use a wire brush or sandpaper to clean the auger

shaft. A clean, smooth shaft will help avoid

damage when installing new bushings and seals.

Clean the old gasket material from the case

mating surfaces (Figure 28).

Figure 28

2. If new bushings are to be installed in the gear

case halves, now is the time. Apply a thin coat of

Loctite™ Blue #242 or equivalent to the OUTSIDE

of the bushing and press in flush with the INSIDE

of the case (Figure 29). This will allow space for

the seal on the outside. Wipe up any Loctite™ that

is visible. The Loctite™ must not get into the gear

or seal area.

2773-067

Oil on the bottom of the gearbox can result from a leak

at any part of the case. As there is no internal pressure,

any leaking oil runs down the side of the case and

collects on the bottom until there is enough to drip off.

1

The source of the oil leak oil can be difficult to see.

Sprinkling some powder on the outside of the gearbox

will usually show the oil trail. The type of powder used

is not important. Just something that will stick to the oil.

When you open a gearbox that has had the gears fail,

the remaining oil will likely appear as a small puddle of

very thick grease in the bottom. Worm gears normally

create a large amount of friction due to the sliding

Figure 29

MVC-710

action. When something goes wrong, not enough oil,

poor quality oil, a problem with the gears, or just a gear

or bearing wearing out, the friction becomes

abnormally high. The remaining oil is cooked down to a

very thick residue. This can be the result of failures, not

the cause.

Two Stage Snowthrower Drive Systems Manual 1 - 9

Page 18

Auger Gearbox Service

1.Lett

“R”

1.Bushi

7.Wash

t

1.I

ft

4.Bushi

t

3. Insert the keys into the shaft and slide the large

worm gear into place. Note: There is a large letter

“R” and an arrow on one side of the gear. This

gear MUST be installed such that the R and the

arrow are on the right hand side and the arrow is

pointing forward (Figure 30). This is a two piece

gear that is bonded together. If it is installed

backwards, the forces try to separate the gear and

can result in failure.

Figure 31

ng

2. Ring-snap

3. Washer-thrust

4. Gear

5. Washer-thrust

6. Bearing-thrust

8. Bushing-input

er-thrus

9. Ring-quad

10. Key-woodruff

11. Shaft-impeller

37-6962

On models with worm integral with the

impeller shaft — This version is assembled

1

starting on the end opposite the worm. Start with

the snap ring (sharp edge towards the rear), thrust

washer, thrust bearing, thrust washer, bushing

and seal. There is also a bushing on the worm end

of the shaft (Figure 32).

Figure 30

er

and arrow

30

4. Install the thrust washers and slide the case

halves on. Note the direction to keep the markings

on the gear on the right side.

5. There are two versions of the impeller shaft. One

has the worm separate and the other has the

worm as part of the impeller shaft.

Figure 32

mpeller sha

2. Seal-oil

3. Bushing-input

5. Bearing-thrust

ng-thrus

6. Ring-snap

38086-01

6. On models with worm separate from the

impeller shaft — Assemble the parts on the

impeller shaft. From the inside out, the order is as

follows: seal, bushing, thrust washer, thrust

bearing, thrust washer, key, worm, thrust washer,

retaining ring (sharp edge towards the front) and

bushing (Figure 31).

1 - 10 Two Stage Snowthrower Drive Systems Manual

Page 19

Auger Gearbox Service

7. Apply a VERY light coat of Loctite™ Blue #242 or

quivalent to the outer diameter of the bearing.

Loctite™ should not squeeze out when everything

is tightened (Figure 33).

Figure 33

8. Some models use a gasket and some do not. For

those with a gasket use a small amount of grease

to stick the open ends of the gasket in place

during assembly. Otherwise this gasket is

intended to seal to a clean dry surface.

2773-059

10. All models. Apply a light coat of oil or anti-seize to

the gear case screws. Tighten them in an X

pattern to 120 in/lbs. (15kg/m) (Figure 34).

Note: Some models have 8 gear case screws;

others have 9.

9

3

1

8

6

Figure 34

11. Fill the gearbox with lubricant. See the chart on

Introduction page 1 for the proper lubricant for

your model.

5

2

7

4

MVC-709

9. The 824XL seals in a different manner. The

mating surfaces must be clean and dry. Then a

thin coat of Hylomar (Toro PN 505-129) is applied

to BOTH halves. Allow it to cure until it is dull and

tacky, 15 minutes or so, then assemble.

Two Stage Snowthrower Drive Systems Manual 1 - 11

Page 20

THIS PAGE INTENTIONALLY LEFT BLANK

1 - 12 Two Stage Snowthrower Drive Systems Manual

Page 21

Chapter 2 — Belts, Controls and Linkages

1.U

2.S

(3)

1.Engi

5.Idl

1.R

3.Idl

INTRODUCTION

All models use two belts. One to drive the auger and a

second to drive the traction system. The auger drive

uses a combination idler and brake to engage the belt

for driving and to disengage the belt and apply the

brake for stopping.

The traction drive uses a constantly tensioned belt. The

clutching and shifting are done through the drive plate

and friction disc.

REPLACING THE AUGER/IMPELLER

DRIVE BELT

When the auger/impeller drive belt becomes worn,

stretched, oil-soaked, or otherwise damaged, replace

the belt.

1. Turn the engine off and disengage all controls.

Figure 36

ne crankshaft

screw, lock washer

and washer

2. Engine pulley sheave

3. Auger/impeller drive

belt

4. Large auger/impeller

pulley

M-3331

er pulley

6. Center engine pulley

7. Belt guide

8. Traction belt

9. Traction pulley

10. Traction idler pulley

11. Screw, washer, lock

washer

2. Pull the wire off of the spark plug and ensure the

wire does not contact the spark plug.

3. Remove the two screws that hold the belt cover in

place and set the cover aside (Figure 35).

Figure 35

pper belt cover

crew

M-2671

4. Remove the belt guide; do not bend (Figure 36).

5. Slip the auger belt off the pulleys. Note: On some

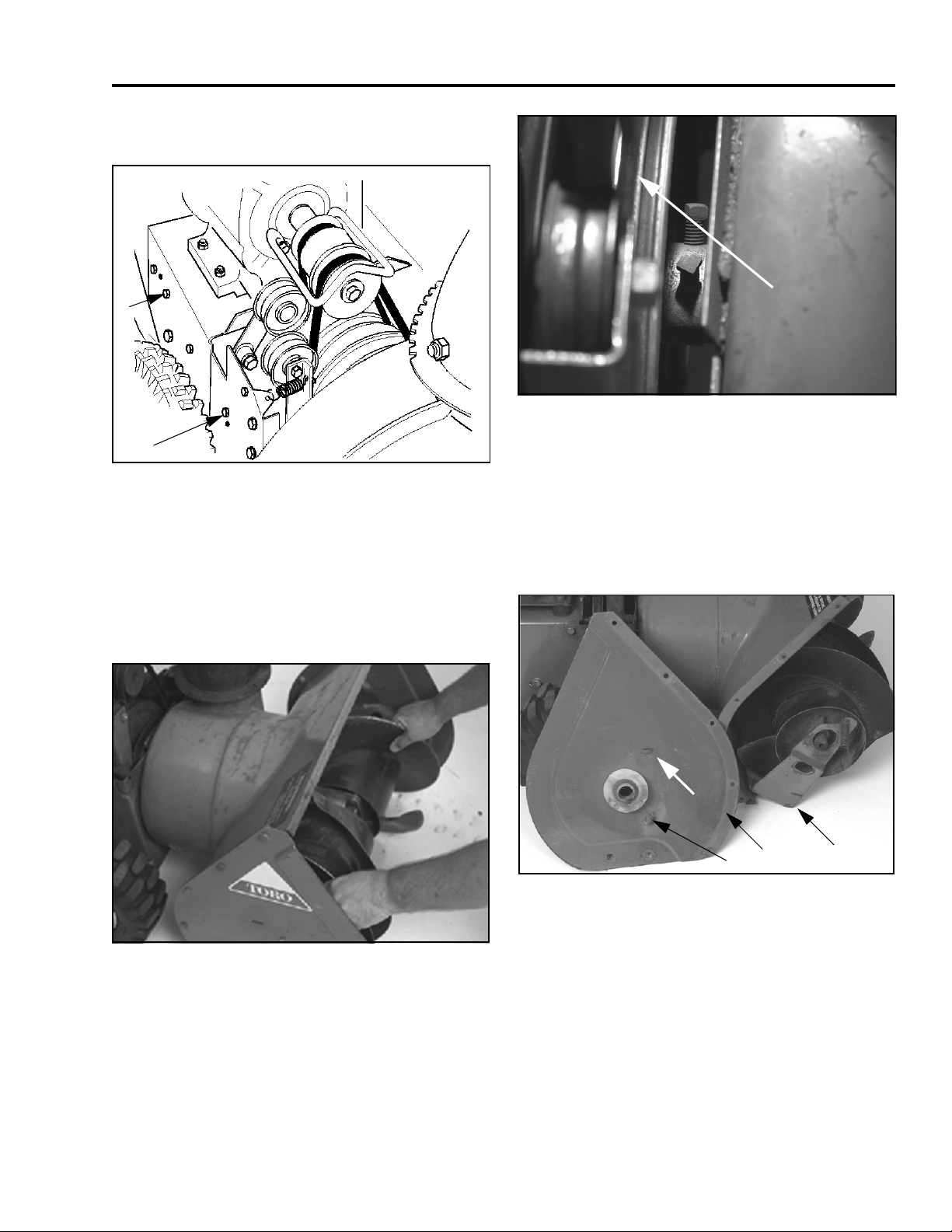

models (typically the 824 and the 824XL) the

auger belt brake will not back off far enough to

remove the belt. Remove the front screws and

loosen the rear screw that fastens the brake arm

assembly to the chassis (Figure 37).

ear screw

2. Front screw

Figure 37

er pulley spring

M-2678

6. Slip the new belt over the pulleys. Install any parts

that were removed.

Two Stage Snowthrower Drive Systems Manual 2 - 1

Page 22

Belts, Controls and Linkages

1.T

lt

4.C

7. The belt guide must be checked and adjusted.

With the engine off, engage both the auger and

traction controls. Adjust the belt guide so that

there is approximately 1/8 inch (.3 cm) clearance

between the belt guide and the belt.

Check auger belt adjustment. See “CONTROL AND

LINKAGE ADJUSTMENT” on page 2 - 7 for the linkage

adjustment procedures.

REPLACING THE TRACTION BELT

The models covered in this manual use three different

methods of tensioning the traction belt. As the

tensioning method affects the belt replacement

process, they are separated by model number.

Replacing the Traction Belt — Toro

Models 38065, 38080, 38085

When traction drive belt (Figure 38) becomes worn,

stretched, oil-soaked, or otherwise damaged, replace

the belt.

3. Move auger drive control to DISENGAGE and

wheel drive control to N, neutral. Next, remove

auger drive belt from engine pulley and large

auger/impeller pulley.

4. Loosen two capscrews (securing traction idler arm

to front of engine. Next, remove traction drive belt

from engine pulley and large traction pulley.

5. Install new belt around large traction pulley. Next,

loop belt over engine pulley, making sure that belt

is on inside of traction idler pulley and wire belt

guide.

6. Reinstall auger belt around large auger/impeller

pulley. Next, loop belt over engine pulley, making

sure that belt is on inside of auger/impeller, idler

pulley and wire belt retainer. Slide idler arm and

pulley assembly against belt to remove belt slack

and tighten capscrews.

Note: Tension belt only enough to remove slack.

Do not over-tension.

7. With the engine off, engage the auger lever.

Adjust the belt guide so it is within 1/8 inch (.3 cm)

of the belt.

Figure 38

raction drive be

2. Auger/impeller drive

belt

3. Auger/impeller pulley

and idler

apscrews, traction

idler

5. Traction idler pulley

6. Traction pulley

7. Belt guide

13299-32

1. Pull high tension wire off spark plug and make

sure it does not contact the plug accidentally.

2. Remove two thread forming screws holding belt

cover in place, and set belt guard aside.

8. Install belt cover with two thread forming screws.

9. Install high tension lead and test operate unit to

check traction. If little or no traction is evident,

proceed to step 10. If traction operation is

satisfactory, proceed to operate machine.

10. Remove high tension lead from spark plug and

remove belt guard. Loosen two capscrews

securing traction idler arm and slide idler arm and

pulley assembly further against belt. Move

assembly a minimal amount to assure belt is not

over tensioned.

2 - 2 Two Stage Snowthrower Drive Systems Manual

Page 23

Belts, Controls and Linkages

1.Belt

2.S

(2)

1.T

lt

4.Idl

1.S

1.Spri

3.L

Replacing the Traction Belt — Lawn-Boy

Models 28230, 28231 and Toro Models

38051, 38052, 38054, 38056, 38062, 38063,

38064, 38072, 38073

When the traction drive belt becomes worn, stretched,

oil-soaked, or otherwise damaged, replace the belt.

1. Pull the wire off of the spark plug and ensure that

the wire does not contact the plug.

2. Drain the gasoline from fuel tank.

3. Remove the two screws that hold the belt cover in

place and set the cover aside (Figure 39).

5. Tip the snowthrower forward and block it so it

cannot fall.

6. Remove the four screws that secure the bottom

cover to the frame and remove the cover

(Figure 41).

Figure 41

crews

M-2592

7. Disconnect the spring from the notch in the bottom

edge of the side plate (Figure 42).

Figure 39

cover

crew

4. Remove the auger/impeller drive belt from the

engine pulley and the large auger/impeller pulley

(Figure 40).

Figure 40

raction drive be

2. Auger/impeller

drive belt

3. Belt guide

er pulley

5. Large auger/

impeller pulley

6. Engine pulley

661

664

Figure 42

2. Notch in side plate

! !

ng

CAUTION

arge traction

pulley

POTENTIAL HAZARD: The spring is under

heavy tension.

WHAT CAN HAPPEN: The spring could be

thrown in operator’s or bystander’s direction.

HOW TO AVOID THE HAZARD: Use caution

when removing the spring.

8. Set the snowthrower upright.

9. Loosen the belt guide (Figure 40).

10. Remove the traction drive belt from the engine

pulley and the large traction pulley (Figure 40).

650

Two Stage Snowthrower Drive Systems Manual 2 - 3

Page 24

Belts, Controls and Linkages

1.Engi

5.Idl

1.U

2.S

(3)

11. Install a new belt around the large traction pulley.

12. Loop the belt over the engine pulley, ensuring that

the belt is on the inside of the belt guide

(Figure 40).

13. Tip the snowthrower forward and block it so that it

cannot fall.

14. Hook the spring into the notch in the bottom edge

of the side plate (Figure 42).

15. Replace the bottom cover with the four screws.

16. Set the snowthrower upright.

17. Install the auger/impeller drive belt around the

large auger/impeller pulley and engine pulley,

ensuring that the belt is on the inside of the idler

pulley and belt guide (Figure 40).

18. Adjust the belt guide so that there is 1/8 in. (0.3

cm) of clearance between the belt and the guide,

and secure the belt guide.

19. Install the belt cover.

Replacing the Traction Belt —

Lawn-Boy Model 28232 and Toro Models

38053, 38066, 38078, 38083, 38084, 38086

When traction belt (Figure 43) becomes worn, oil–

soaked or otherwise damaged, belt replacement is

required.

Figure 43

ne crankshaft

screw, lock washer

and washer

2. Engine pulley sheave

3. Auger/impeller drive

belt

4. Large auger/impeller

pulley

er pulley

6. Center engine pulley

7. Belt guide

8. Traction belt

9. Traction pulley

10. Traction idler pulley

11. Screw, washer, lock

washer

M-3331

1. Pull wire off spark plug and make sure it does not

contact the plug accidentally.

2. Remove (3) screws holding belt cover in place

and set cover aside (Figure 44).

Figure 44

pper belt cover

crew

M-2671

2 - 4 Two Stage Snowthrower Drive Systems Manual

Page 25

Belts, Controls and Linkages

1.R

3.Idl

1.Indexi

2.Engi

Vi

it

3. Loosen auger brake arm assembly by loosening

rear screw and removing front screw (Figure 45).

M-2678

ear screw

2. Front screw

Figure 45

er pulley spring

4. Remove idler pulley spring (Figure 45). Let brake

arm assembly hang free but out of the way.

5. Remove (2) screws, (2) washers, and (2) lock

washers securing belt guide (Figure 43). If the belt

will not slip off, the engine pulley can be removed.

13. Reinstall engine pulley sheave, washer, lock

washer, and crankshaft screw. Make sure the

indexing rib in the engine pulley sheave is aligned

with the indexing notch in the center engine pulley

(Figure 46).

ng rib in indexing

notch

Figure 46

ne pulley sheave

3. Center engine pulley

M-2677

14. Make sure brake pad is properly installed on brake

arm. Angled cut-off on brake pad must be

positioned as shown in Figure 47.

6. Remove engine crankshaft screw, lock washer

and washer (Figure 43).

7. Separate and remove engine pulley sheaves

(Figure 43).

8. Remove auger/impeller drive belt from center

engine pulley, leaving belt looped around large

auger/impeller pulley. Remove center engine

pulley (Figure 43).

9. Remove traction belt from traction pulley and

engine crankshaft (Figure 43).

10. Pull traction idler pulley outward and install new

traction belt (Figure 43).

11. Reinstall center engine pulley.

12. Pull idler pulley outward and loop auger/impeller

drive belt in front of center engine pulley, making

sure that belt is on inside of idler pulley and belt

guide (Figure 43).

ew from left side of un

1. Brake pad

2. Angled cut-off

Figure 47

3. Auger/impeller drive

4. Traction drive belt

M-2681

belt

Two Stage Snowthrower Drive Systems Manual 2 - 5

Page 26

Belts, Controls and Linkages

1.Tabs in hol

1.A

3.S

1.L

d

15. Reinstall (2) screws that secure auger brake arm

assembly. Make sure tabs fit into holes in left side

of machine (Figure 48).

Figure 48

es

M-2678

16. While someone squeezes the auger/impeller

control lever (Figure 49) against the handgrip,

reinstall belt guide using (2) screws, (2) washers,

and (2) lock washers removed previously. Check

and readjust belt guide, making sure it does not

contact any part of the engine pulley.

17. Check and adjust auger drive linkage. Refer to

steps 5–7 of "Auger/Impeller Drive Control

Linkage — All Other Models" on page 2 - 8.

18. Reinstall idler pulley spring.

19. Reinstall belt cover with (3) screws.

20. Make sure that auger and impeller are not rotating

when auger/impeller control lever is disengaged.

While standing in the operator position behind the

handles, look around to the side of the auger

housing. If the auger and impeller are rotating, a

large screw head on the side of the auger housing

will be rotating (Figure 50). If the auger and

impeller are rotating when the engine is

running and the auger/impeller control lever is

not engaged, immediately stop the unit. Refer

to "Adjusting Auger/Impeller Drive Belt" on

page 2 - 7.

IMPORTANT: Do not operate unit if auger and

impeller rotate when auger/impeller control lever

is not engaged.

Figure 50

arge screw hea

Figure 49

uger/impeller

control lever

2. Traction control lever

peed selector

4. Discharge chute

control

M-4035

2 - 6 Two Stage Snowthrower Drive Systems Manual

M-2680

Page 27

Belts, Controls and Linkages

1.Clevi

3.Bent

d

1.J

t

3.Clevi

CONTROL AND LINKAGE ADJUSTMENT

Note: Before making any control adjustments, verify

that the handles are secured to the traction frame. If

the handles move at all, the linkages will not maintain

adjustment.

Auger Control Adjustment — Toro Models

38065, 38080, 38085

Install Auger Drive Control Rod

1. Move auger drive control backward to

DISENGAGE and hold it in that position.

2. Rotate clevis at end of auger drive control rod until

holes in clevis line up with hole in bent rod

(Figure 51). Next, secure clevis and bent rod

together with clevis pin and cotter pin.

Adjusting Auger/Impeller Drive Belt

If auger slips, which means the auger drive belt is

slipping, an adjustment is required. When a new auger/

impeller drive belt is installed, an adjustment may also

be required.

1. Loosen jam nut from clevis at bottom of auger

drive control rod (Figure 52). Next, remove cotter

pin and clevis pin holding clevis to bent rod.

am nu

2. Clevis

Figure 52

s pin and

cotter pin

4. Bent rod

13299-33

Figure 51

s

2. Clevis pin and

cotter pin

4. Jam nut

ro

13299-4

3. Tighten the jam nut firmly against top of clevis.

Note: Move auger drive control forward to

ENGAGE. If excessive force is required to move

the control, adjust the auger drive control: refer to

Adjusting Auger/Impeller Drive Belt (below).

2. Rotate clevis counterclockwise — out — to

increase belt tension. By contrast, rotate clevis

clockwise — in — to decrease belt tension.

3. Connect clevis to bent rod with clevis pin and

cotter pin. Next, tighten jam nut against top of

clevis.

4. Check tension of belt by operating the auger. If

belt still slips, or if the auger does not stop when

disengaged, adjust clevis again.

IMPORTANT: Do not adjust belt too tight because

the belt will wear out quickly or possibly cause

damage to the snowthrower.

Two Stage Snowthrower Drive Systems Manual 2 - 7

Page 28

Belts, Controls and Linkages

1.T

d

4.Fl

t

1.T

3.4 3/8 i

(11

)

1.J

t

4.L

d

Auger/Impeller Drive Control Linkage —

All Other Models

There are two adjustment mechanisms used. One has

a clevis with a jam nut. The other has a rod going

through a loop with a flange nut on either side.

1. Thread a hex flange nut (flange side down) onto

upper control rod located on right handle

(Figure 53).

raction ro

2. Loop

3. Lower traction rod

Figure 53

ange nu

5. Locking flange nut

654

6. Remove the belt cover (refer to "REPLACING

THE AUGER/IMPELLER DRIVE BELT",

page 2 - 1, steps 1-2). Compress the auger/

impeller control lever and check that the slack is

removed from the auger drive belt when the lever

is 1-2 inches (2.5-5 cm) above the handgrip

(Figure 54).

7. Adjust the clevis or two flange nuts to obtain this

dimension, then tighten the two nuts or jam nut

securely (Figure 55).

2. Install lower link through outer hole in lower

control rod.

3. Insert upper control rod through loop in lower link

control rod.

4. Thread a flange lock nut (flange side up) onto

bottom of upper control rod below loop in lower

link.

5. Check the distance between the top of the

handgrip and the bottom of the auger/impeller

control lever (Figure 54). This is a preliminary

setting only.

Figure 55

am nu

2. Clevis

3. Upper control rod

ower control ro

5. Clevis pin

6. Cotter pin

8. The auger must stop when the handgrip is

released. If it does not stop, adjust the clevis or

flange units on the auger rod.

649

raction control

lever

2. Handgrip

Figure 54

4. 1 to 2 in. (2.5 to

5 cm)

n.

cm

665

2 - 8 Two Stage Snowthrower Drive Systems Manual

Page 29

Belts, Controls and Linkages

1.L

d

6.Clevi

ADJUSTING TRACTION CONTROL

Adjusting the Traction Control —

Toro Models 38065, 38080, 38085

1. Move wheel drive control into No. 1, 1st gear.

Position control lever so its front surface is 1/4 of

an inch (6mm) from bottom of slot (Figure 56);

then hold lever in this position.

(6 mm)

Figure 56

2. While holding wheel drive control lever in position,

push up on long rod and rotate clevis until holes in

clevis line up with hole in link arm (Figure 57).

Next, secure clevis and link arm together with

clevis pin and cotter pin (Figure 57).

13299-5

3. Move wheel drive control lever onto the hump

between N and 1 (Figure 58). Hold wheel drive

control lever in this position — on hump.

Note: Lever must be held against the hump, not in

the N or 1 position.

Figure 58

13299-7

4. Move shift arm fully to the left (Figure 57). Next,

rotate clevis at end of short rod until holes in clevis

line up with hole in shift arm (Figure 57). Secure

clevis and shift arm together with clevis pin and

cotter pin (Figure 57).

5

4

3

Figure 57

ong ro

2. Clevis

3. Link arm

4. Clevis pin and

cotter pin

5. Shift arm

5. Tighten the jam nut against top of both clevises

(Figure 57).

1

2

13299-6

s

7. Short rod

8. Clevis pin and

cotter pin

9. Jam nut

Two Stage Snowthrower Drive Systems Manual 2 - 9

Page 30

Belts, Controls and Linkages

1.T

d

3.Fl

t

1.A

3.S

1.T

3.A

Adjusting the Traction Control — 824XL

(Toro Models 38066, 38078, 38083, 38084,

38086 and Lawn-Boy Model 28232)

1. Slide spring onto bottom of traction control rod

(Figure 59).

M-2665

raction control ro

2. Spring

Figure 59

ange lock nu

2. Thread a flange lock nut (flange side up) onto

bottom of traction control rod below spring.

3. Adjust flange locknut up or down on traction

control rod until the distance between the top of

the handgrip and the bottom of the traction control

lever (Figure 60) is approximately five inches

(13 cm) (Figure 61). This is a preliminary setting

only.

raction control lever

2. Handgrip

Figure 61

pproximately

5 inches (13 cm)

4. 3-4 inches (8-10 cm)

M-2628

4. Move speed selector (Figure 60) into fifth gear.

5. Slowly pull machine backward while slowly

depressing traction control lever toward handle.

Adjustment is correct when wheels stop turning

and the distance between the top of the handgrip

and the bottom of the traction control lever is three

to four inches (Figure 61). Readjust flange

locknut, if necessary, to obtain this dimension and

then tighten flange locknut securely.

uger/impeller control

lever

2. Traction control lever

Figure 60

peed selector

4. Discharge chute control

M-4035

2 - 10 Two Stage Snowthrower Drive Systems Manual

Page 31

Belts, Controls and Linkages

1.T

d

4.Fl

t

1.T

3.4 3/8 i

(11

)

1.A

3.S

ADJUSTING THE TRACTION ROD —

LAWN-BOY MODELS 28230, 28231 AND

TORO MODELS 38051, 38052, 38054,

38056, 38062, 38063, 38064

1. Thread the locking flange nut (flange side up) onto

the bottom of the traction control rod, below the

loop in the lower traction rod (Figure 62).

Figure 62

raction ro

2. Loop

3. Lower traction rod

ange nu

5. Locking flange nut

2. Adjust the two flange nuts up or down on the

traction control rod until the distance between the

top of the handgrip and the bottom of the traction

control lever (Figure 63) is approximately

4-3/8 in. (11 cm).

654

3. Tighten the two flange nuts finger tight.

4. Move the speed selector (Figure 64) into third

gear.

Note: If the speed selector does not move into

third gear, adjust the speed selector before

continuing. See “ADJUSTING THE SPEED

SELECTOR” on page 2 - 12.

Figure 64

uger/impeller control

lever

2. Traction control lever

peed selector

4. Speed selector rod

5. Slowly pull the snowthrower backward while

slowly pressing the traction control lever toward

the handle. The adjustment is correct when the

wheels stop rolling backwards and the distance

between the top of the handgrip and the bottom of

the traction control lever is one to two inches

(2.5 to 5 cm) (Figure 63).

879

raction control lever

2. Handgrip

Figure 63

4. 1-2 in. (2.5-5 cm)

n.

6. Adjust the two flange nuts, if necessary, to obtain

this dimension.

7. Tighten the flange nuts securely.

665

cm

Two Stage Snowthrower Drive Systems Manual 2 - 11

Page 32

Belts, Controls and Linkages

1.S

2.Fl

1.Roll pi

2.Dri

ADJUSTING THE SPEED SELECTOR

If the snowthrower is slow, the No.1 speed selection

has no speed, or the speed selector does not move

into the No. 3 speed selection, adjust the speed

selector linkage.

1. Disconnect the wire from the spark plug and make

sure that the wire does not contact the spark plug.

2. Tip the snowthrower forward and block it so that it

cannot fall.

3. Remove the four screws that secure the bottom

cover to the frame and remove the cover.

4. Loosen the flange nuts that secure the selector

plate to the control panel (Figure 65).

Figure 65

peed selector plate

ange nuts

5. Shift the speed selector to third gear and push

down on the speed selector plate to move the

drive assembly to the right.

Note: The drive assembly should be 1/8 inch

(3mm) from the roll pin; if not, slide the selector

plate (Figure 65) until the gap is 1/8 inch (3mm)

(Figure 66).

659

n

Figure 66

ve assembly

650/913

6. With the drive assembly 1/8 inch (3mm) from the

roll pin, tighten the flange nuts that secure the

speed selector plate.

7. Shift the speed selector to the R (Reverse)

position and back to third gear to check the

adjustment.

8. If the space between the roll pin and the drive

assembly is more than 3/16 inch (5 mm), repeat

steps 4 through 7.

9. Install the bottom cover and return the

snowthrower to the upright position.

2 - 12 Two Stage Snowthrower Drive Systems Manual

Page 33

Chapter 3 — Traction Drive Systems

1.G

INTRODUCTION

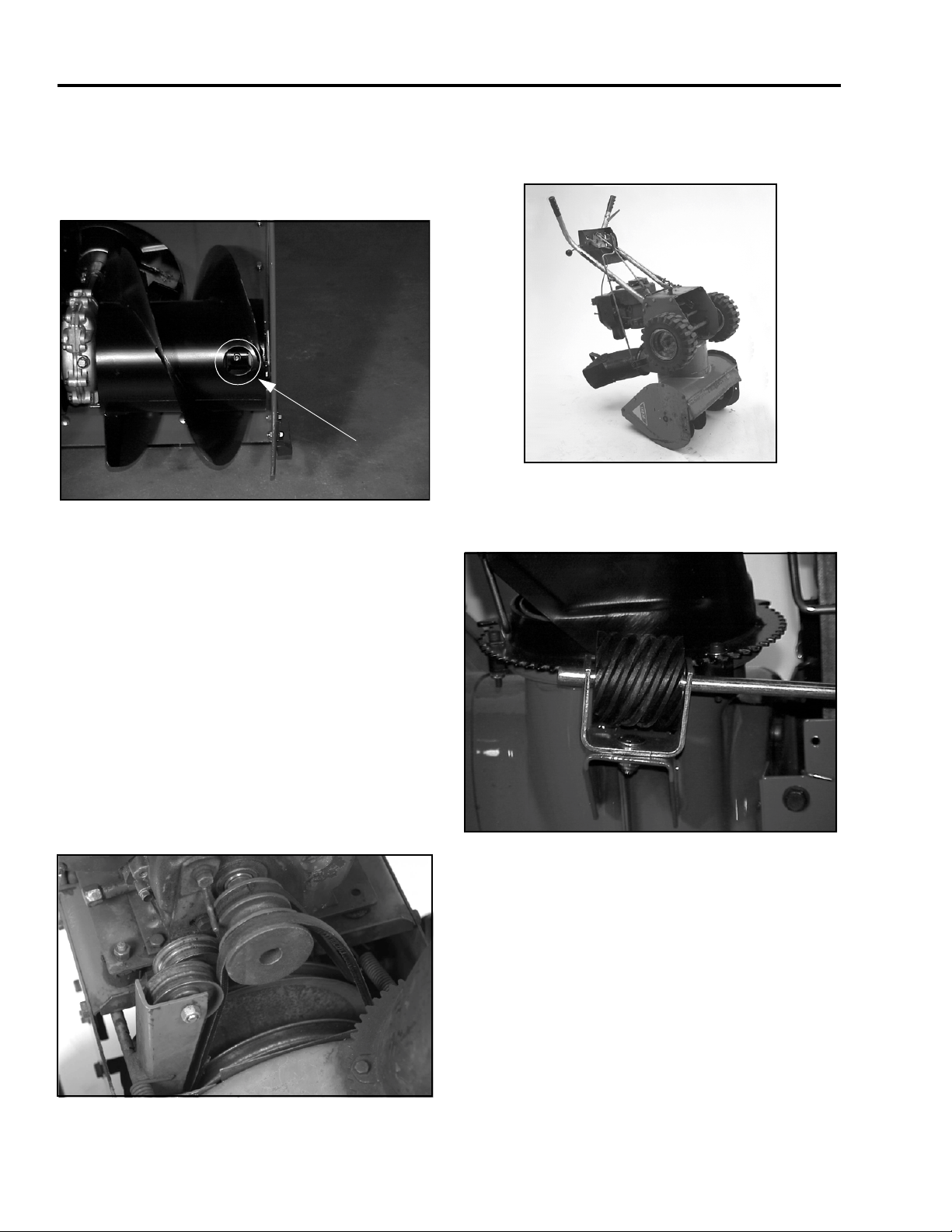

All models use some variation of a friction drive. The

engine drives a belt, which causes a drive plate(s) to

rotate. As this belt is constantly tensioned, the belt and

drive plate turn whenever the engine is running

(Figure 67).

1

Figure 67

2773-014

Clutching and speed control is accomplished by

moving the friction wheel. When declutched the friction

wheel is not contacting the drive plate (Figure 68).

When the drive is engaged, the friction wheel is moved

into contact with the right side of the drive plate (Figure

69). As the friction wheel begins to turn, it drives gears,

or sprockets and chains, which provide the speed

reduction for the axle. Ground speed is determined by

the point on the drive plate where the friction wheel

makes contact. The further from center, the faster the

friction wheel will turn. Moving the friction wheel to the

left side of the plate changes direction of rotation

(Figure 70).

Figure 68

ap

Figure 69

1. Forward

2768-018

1

2773-073

1

Figure 70

1. Reverse

2768-015

Two Stage Snowthrower Drive Systems Manual 3 - 1

Page 34

Traction Drive Systems

1.R

5.Rubb

1.B

TROUBLESHOOTING THE TRACTION

DRIVE — ALL MODELS

Drive slipping:

1. Verify adjustment of traction drive linkage.

2. Make sure the engagement spring and idler spring

are in place and undamaged.

3. Verify that the drive plate and friction wheel are

clean and free of grease or oil. Clean with alcohol

or something that does not leave a residue.

4. Replace the friction wheel if worn.

DISASSEMBLY — TORO MODELS 38065,

38080, 38085

These models work as previously described in the

Introduction, except there is a separate drive plate for

reverse. When the shift lever is pulled into reverse, the

friction wheel is pulled to the rear until it contacts the

small reverse plate. The drive will then operate in

reverse (Figure 71).

The most convenient method of working on the traction

drive is to stand the machine up on the auger.

1. Drain both fuel and oil from the engine.

2. Stand the machine up on its auger and secure to

prevent tipping (Figure 72).

Figure 72

2768-027

3. Remove 4 self-tapping screws securing the lower

shield.

4. Remove the klik pins and both wheels.

1

2

3

2. Friction wheel

3. Forward plate

4. Rubber wheel

everse plate

up = reverse

Figure 71

6. Rubber wheel

4

R

N

6

F

er wheel in

middle = neutral

down = forward

5

2768-024

5. Each end of the axle is supported by a bearing

which is attached to the chassis by two thread

forming screws. At minimum, the screws must be

removed from the bearing on the left side in order

to remove the axle. The right side axle bearing

can also be removed (Figure 73).

Figure 73

earing

2768-026

1

3 - 2 Two Stage Snowthrower Drive Systems Manual

Page 35

Traction Drive Systems

1.Fl

lt

1.Should

lt

1.H

6. The axle can now be removed from the chassis.

Inspect the gear, the roll pin, and the areas where

the bearings contact the axle for damage or

severe wear. Remove the thrust washers from

either end of the axle. The purpose of the roll pin

and thrust washers is to limit the side to side

movement of the axle.

7. Disconnect the two clevis pins on the shift linkage

rods.

8. Next to the friction wheel is a large eyebolt, which

is connected to the shift linkage (Figure 74).

Remove the flange nut and washer from the end

of the eyebolt. Note the location and type of

washers. You should be able to slip the linkage off

of the eyebolt. If not, loosen the shoulder screw

that the linkage pivots on.

1

10. The pivot shaft, which contains the friction wheel,

is retained by two shoulder bolts. They pass

through the side plate, into the ends of the shaft.

Remove these two bolts and the pivot assembly

will slide out of the chassis (Figure 76).

1

Figure 76

er bo

2768-033

11. To disassemble the pivot assembly, proceed as

follows (Figure 77):

Figure 74

ange nut/eyebo

2768-32A

9. There is a spring connected between the left front

corner of the pivot shaft (that contains the friction

wheel) forward to a tab on the chassis. Unhook

one end of this spring (Figure 75).

Figure 75

2768-32B

1

Figure 77

ex shaft bearing

2768-036

A. The drive chain contains a master link.

Separate that and remove the chain.

B. To remove the friction wheel, remove four cap

screws securing the hex shaft bearings. Slide

the bearings off the ends of the hex shaft.

C. The hex shaft can now be removed from the

pivot assembly.

D. If the friction wheel is to be replaced, remove

the four screws and lock nuts connecting it to

the traction drive hub.

Two Stage Snowthrower Drive Systems Manual 3 - 3

Page 36

Traction Drive Systems

1.Eyebolt

3.S

1.F

2.R

E. If the eyebolt, or traction drive hub is to be

replaced, remove the snap ring on the hub

(Figure 78).

5

2

4

3

Figure 78

2. Rubber wheel

and hub

1

2768-040

nap ring

4. Spacers

5. Hex shaft

F. The small sprocket is retained to the hex shaft

with a key and set screw.

G. The large sprocket just rotates on the bearings,

so it will slide off the shaft.

ASSEMBLY — TORO MODELS 38065,

38080, 38085

Preparation

14. Before assembling something with a new bushing,

wipe the bushing with a clean shop towel. This

should remove any debris that might have gotten

into the bushing during shipping and storage.

15. These are oil-impregnated bearings. However,

before installing them on a shaft, wipe the bearing

surface with a clean shop towel. Then apply a light

coat of engine oil to the bearing surface.

16. Apply oil sparingly in this drive system. Excess oil

will be thrown around during operation and can

cause the friction wheel to slip.

17. Wipe the drive plate and friction wheel with

alcohol to make sure they are clean, to prevent

slippage.

12. The drive shaft assembly is held in place by a

front pillow block bearing and a bearing on the

rear with spacers to locate everything front to rear.

Remove two cap screws holding each bearing in

place. Remove the shaft assembly (Figure 79).

2

1

ront bearing

Figure 79

ear bearing

2768-043

13. Note the location of the thrust washers and

spacers. Drive the roll pin out of the end of the

drive shaft and remove the bolt securing the

reverse drive plate. All the parts will slide off the

drive shaft.

3 - 4 Two Stage Snowthrower Drive Systems Manual

Page 37

Assembly

1.Pill

4.R

1. Slide the pillow block bearing, reverse plate (with

the hub side away from the pulley), thrust washer,

bearing (hub side facing the reverse plate), thrust

washer, and spacer onto the drive shaft. Drive the

roll pin through the spacer and shaft. Secure the

reverse plate with the cap screw and locknut

(Figure 80).

Traction Drive Systems

3

Figure 80

ow block bearing

2. Reverse plate

3. Pulley/forward plate

1

2

6

ear bearing

5. Spacer

6. Thrust washer

5

4

2768-046

2. Install the pillow block bearing loosely. Secure the

rear bearing to the center frame.

3. The shaft should be parallel to the sides of the

chassis (Figure 81). The pillow block bearing has

slotted mounting holes to provide adjustment.

Tighten the cap screws on the pillow block

bearing. While rotating the pulley, strike the pillow

block bearing with a rubber mallet (Figure 82).

This helps the bearing align itself with the shaft. If

the shaft turns with difficulty, loosen the cap

screws on the pillow block bearing and rotate the

pulley. Then secure the cap screws.

Figure 81

1

Figure 82

1. Pillow block bearing

2768-041

2768-047

Two Stage Snowthrower Drive Systems Manual 3 - 5

Page 38

Traction Drive Systems

1.Eyebolt 2.H

ft

1.Should

lt

4. If the pivot assembly was repaired, now is the time

to assemble it.

A. Secure the friction wheel to the hub with four

cap screws and locknuts. If the locknuts are

worn, apply a drop of Loctite™ Red #271 or

equivalent to the threads.

B. Slip a slider ring on either side of the eyebolt

and slide it on the hub. Install the spacer and

snap ring. Note the snap ring must be installed

with the sharp edge facing outward (away from

the friction plate) (Figure 83).

2

1

Figure 83

ex sha

2773-049

C. If the hex shaft is rusty, now is the time to clean

it with a wire brush or emery cloth. Apply a very

light coat of engine oil to the shaft. A thin coat

will prevent rust, but too much will be flung

around the drive system during operation. A

very thin coat of Lubriplate™ MAG-1 could be

use here as an alternative to oil. Ordinary

grease will thicken in cold weather and cause a

hard shifting problem.

D. To assemble the pivot shaft assembly, hold the

shaft with the flat bar that the linkage attaches

to pointing towards you.

F. Hook the long end of the spring in the hole in

the left front corner of the frame (Figure 84).

Figure 84

2773-051

G. Slide the spacer on the right hand side. Clean

the bushings and install them in the sprocket

with a light coat of oil. Lightly oil the inside of

the bushing and slide the sprocket on with the

gear to the outside.

H. Now insert the key into the keyway and slide

the small sprocket on. Align the sprockets and

tighten the setscrew in the small sprocket.

Install the chain. Lubricate the chain with chain

oil. If you use engine oil, use a very light coat,

as it will be thrown around the drive system

(Figure 84).

5. The pivot assembly is installed by first feeding the

flat arm through the slot in the center frame. Align

the pivot assembly with the holes in the side

plates. Note that there are special shoulder bolts.

The shoulder must pass through the side plate

and bottom on the end of the shaft (Figure 85).

After securing the bolts, check to be sure the pivot

assembly can rotate. If not, check the pivot bolts

to see if the side plate was pinched between the

bolt and pivot shaft.

E. The hub and friction wheel goes inside the

frame with the hub to your left. Insert the hex

shaft into the hub with the keyway on the left.

Slide the bearings on the hex shaft (Figure 83).

Note the hub on both bearings should face to

the left. Secure both bearings with self-tapping

screws. The friction wheel should spin without

binding.

Figure 85

er bo

1

2768-033

3 - 6 Two Stage Snowthrower Drive Systems Manual

Page 39

Traction Drive Systems

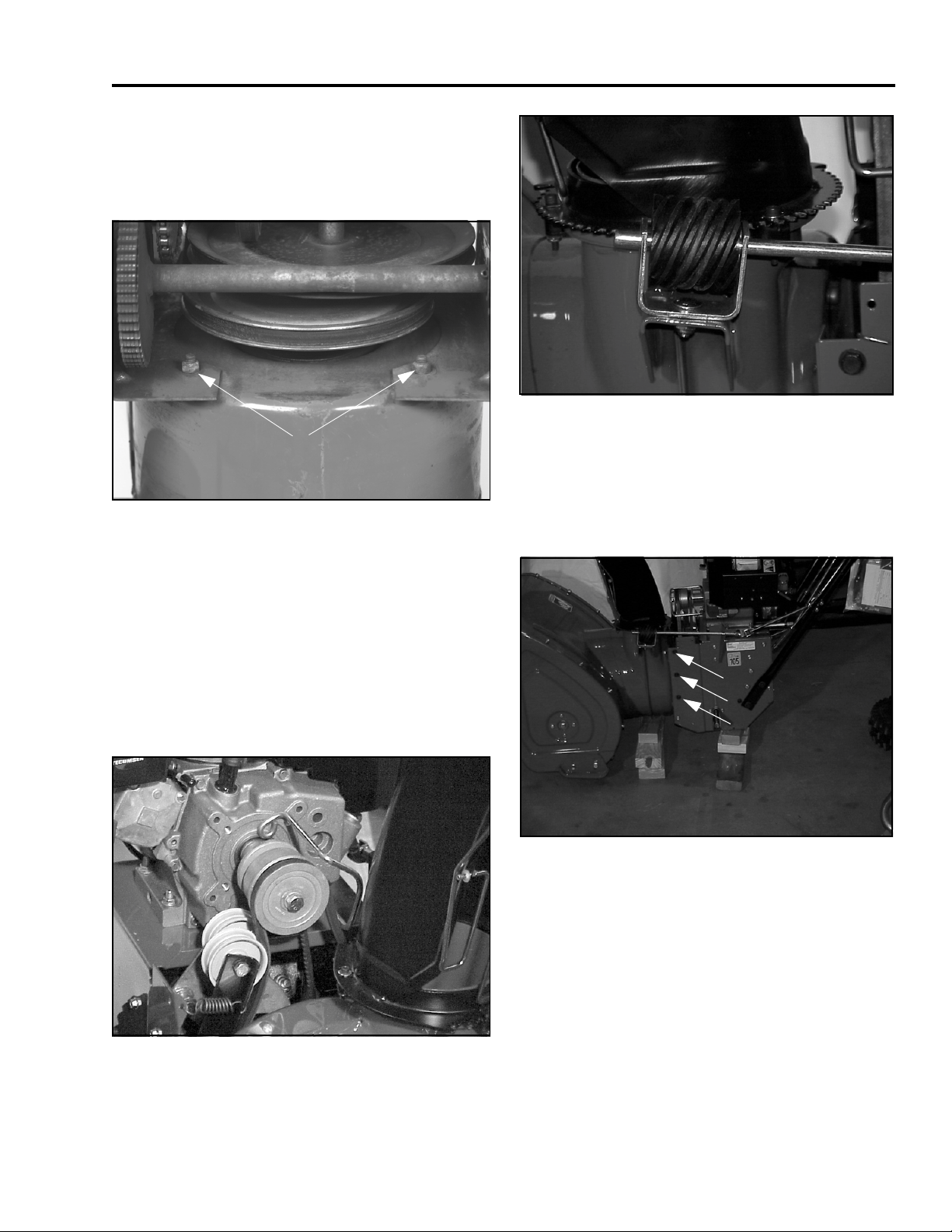

1.Belt

6. Next, tension the pivot assembly. With the unit

upright, use a screwdriver to stretch the traction

spring and hook it into the hole provided

(Figure 86).

Figure 86

7. Slip one thrust washer on each end of the axle

and insert it into the chassis. Lightly oil the inside

of the bearings and slip one on each end, with the

hub pointing inward. Secure each bearing with two

thread forming screws (Figure 87).

MVC-714

DISASSEMBLY — LAWN-BOY MODELS

28230, 23231 AND TORO MODELS 38051,

38052, 38054, 38056, 38062, 38063, 38064,

38072, 38073

1. Drain the gasoline and oil.

2. Remove the belt cover. Loosen the belt guide, do

not bend. Remove the auger and traction belts

(Figure 88).

1

Figure 87

8. Coat the end of the axles with anti-seize or a

water repellent grease and install the wheels with

the click pins.

9. Lower the machine to the ground, check the

linkage adjustments, fill with fuel and oil, and test

run.

2768-026

Figure 88

guide

3. Stand the unit up on its auger and secure to

prevent tipping.

4. Remove the bottom cover.

5. Remove the klik pins and slide both wheels off the

axle.

2773-014

Two Stage Snowthrower Drive Systems Manual 3 - 7

Page 40

Traction Drive Systems

1.G

t2.Slidi

t

6. Remove 4 self-tapping screws that secure the

axle bearings to the traction frame. Lift the axle

and bearings out (Figure 89). Slide the bearings

and thrust washers off the axle.

Figure 89

2773-074

7. Disconnect the shift rod and traction drive rod.

8. If the friction plate frame spring (traction belt

tension) did not unhook when the belt was

removed, unhook it now (Figure 90).

9. To remove the traction engagement assembly,

remove the retaining ring on the left side of the

frame. Note: Some older models use a cap screw

through the side plate into the end of the shaft.

Slide the shaft to the side and it will disengage

from the chassis (Figure 91).

Figure 91

2773-079

10. To remove the friction wheel and bracket

assembly, remove the bolt that goes through the

side plate into each end of the shaft. The gear

quadrant fingers should disengage themselves

from the sliding bracket that contains the friction

wheel (Figure 92).

Figure 90

2773-077

ear quadran

Figure 92

1

2

2773-081

ng bracke

3 - 8 Two Stage Snowthrower Drive Systems Manual

Page 41

Traction Drive Systems

1.Self-t

1.Dri

2.Hub

11. If it is necessary to remove the gear quadrant, it is

best to just remove the two self-tapping screws

that secure the gear quadrant mount to the

traction frame. The gear quadrant and gear

quadrant frame can then be separated easily

(Figure 93).

1

Figure 93

apping screws

2773-082

12. To disassemble the gear quadrant, hold the hex

shaft with an open-end wrench. Remove the

locknut on the end of the hex shaft (Figure 94).

16. To remove the front frame, pulley, and drive plate

assembly, remove the two shoulder bolts that the

frame pivots on. The assembly will then lift out of

the chassis (Figure 95).

Figure 95

2773-001

17. To service the drive plate, pulley, and hub, hold

the pulley and unscrew the drive plate. It is left

hand thread so rotate the plate clockwise to

remove (Figure 96).

3

2

Figure 94

2773-085

13. The friction wheel and hub will slide off the shaft.

Remove 4 screws to separate the hub and wheel.

14. Now the two bearings that support the hex shaft

can be removed.

15. To remove the pivot shaft, drive out the roll pins on

either side of the double gear. The shaft will then

slide out of the gear and bracket.

1

Figure 96

ve plate

— LH thread

3. Front frame

2773-005

18. The hub contains one ball bearing and one

bushing.

19. The hub can be separated from the front frame by

removing 4 screws.

Two Stage Snowthrower Drive Systems Manual 3 - 9

Page 42

Traction Drive Systems

ASSEMBLY — LAWN-BOY MODELS 28230,

23231 AND TORO MODELS 38051, 38052,

38054, 38056, 38062, 38063, 38064, 38072,

38073

Assembly Tips

1. Before assembling something with a new bushing,

wipe the bushing with a clean shop towel. This

should remove any debris that might have gotten

into the bushing during shipping and storage

(Figure 97).

Assembly Steps

1. Assemble the hub to the front frame using 4

screws.

2. Install the snap ring onto the pulley and shaft.

Assure the sharp edge of the snap ring faces

towards the pulley (Figure 98).

Figure 98

3. Install the pulley in the hub and install the drive

plate (left hand thread). Tighten firmly.

2773-006

Figure 97

2. Add a drop or two of 30 weight engine oil before

assembly. This will ensure good lubrication upon

start up.

3. It is important to minimize oil in this area. Too

much oil will be thrown about when running. Oil on

the drive plate or friction wheel will result in drive

slippage.

4. Wipe the drive plate and friction wheel with

alcohol to make sure they are clean, to prevent

slippage.

5. Do not use general-purpose grease to lubricate

drive components. In cold temperatures, it will

stiffen and can prevent shifting.

2773-008

4. Install the front frame into the chassis using two

shoulder bolts. Tighten firmly (Figure 99).

Figure 99

2773-001

3 - 10 Two Stage Snowthrower Drive Systems Manual

Page 43

Traction Drive Systems

5. Install the friction plate spring into the front frame

assembly. Note some models just have a hole in

the frame. Others have a tab bent outward to hook

the spring into (Figure 100). Hook the lower end of

the spring into the notch in the traction frame.

Figure 100

2773-078

6. Begin assembly of the friction wheel and sliding

bracket by installing the right side (opposite the

friction wheel) bearing (Figure 101).

7. Lightly oil the hex shaft. Insert the hex shaft from

the left side, non-threaded end first. Slip the shaft

through the left side of the sliding bracket

(Figure 102).

Figure 102

MVC-864

8. Place the pinion gear on the hex shaft (larger OD

to the left). Add the thrust washer, then insert the

shaft into the previously mounted bearing.

9. Install a thrust washer and the second bearing.

Tighten the bearing mounting bolts securely.

Figure 101

MVC-862

10. Assemble the friction wheel and hub using 4 selftapping screws. Note the hub mounts to the flat

side of the friction wheel (Figure 103).

Figure 103

MVC-718

Two Stage Snowthrower Drive Systems Manual 3 - 11

Page 44

Traction Drive Systems

1.R

11. Slide the wheel and hub on the hex shaft with the

friction wheel closest to the sliding bracket. Install

the locknut, holding the hex shaft with an openend wrench (Figure 104).

1

Figure 104

MVC-720

12. If the receiver cam has been removed, install it

now.

1

Figure 105

eceiver cam

MVC-865

Figure 106

MVC-866

15. Connect spring to hole in front of pivot assembly

(Figure 107).

Figure 107

2773-084

16. Assemble the gear quadrant and the mounting

bracket. (Figure 108).

13. Insert the pivot shaft through the cam receiver

then the washer, double gear, another washer,

then through the other end of the sliding bracket

(Figure 105).

14. Line up the gears using the holes in the pivot

shaft. The longer end of the shaft must be on the

side with the friction wheel. Secure with two roll

pins (Figure 106).

Figure 108

MVC-719

3 - 12 Two Stage Snowthrower Drive Systems Manual

Page 45

Traction Drive Systems

1.G

t2.Slidi

t

1.S

2.Retaini

17. Install the friction wheel and sliding bracket. The

friction wheel should be on your left (Figure 109).

1

2

2773-081

ear quadran

Figure 109

ng bracke

The gear quadrant must be free to pivot. The first

tooth on the quadrant should go into the hole in

the right side as shown in Figure 110.

19. Install a thrust washer and bearing on each end of

the axle. Locate the holes and secure the axle

bearings to the frame (Figure 111).

Figure 111

773-074

20. Slip the spacer on the end of the traction

engagement assembly. Slide the assembly into

the holes in the frame and secure the left end of

the shaft with a retaining ring (Figure 112).

Figure 110

MVC-716

Secure with 2 shoulder bolts. One through each

side of the frame into the shaft. Assure the shaft is

free to pivot. If not, loosen the shoulder bolts and

relieve the binding (Figure 109).

18. Clean the axle so dirt or rust does not damage the

bearing during installation.

2

pacer

1

Figure 112

2773-079

ng ring

Two Stage Snowthrower Drive Systems Manual 3 - 13

Page 46

Traction Drive Systems

1.T

21. If the lower traction rod was removed, reinstall it

now. Slide the end through the traction bracket

then install the spring and locknut. Turn the

locknut on until the spring is compressed to

approximately 2 ¼” (5.7 cm) long (Figure 113).

1

1

Figure 113

22. Install the bottom cover and reconnect any

additional linkage that may have been removed.

23. See "Auger/Impeller Drive Control Linkage — All

Other Models" on page 2 - 8 and "ADJUSTING

THE TRACTION ROD — LAWN-BOY MODELS

28230, 28231 AND TORO MODELS 38051,

38052, 38054, 38056, 38062, 38063, 38064" on

page 2 - 11 to make all final linkage adjustments.

2773-010

DISASSEMBLY — TORO MODELS 38066,

38078, 38083, 38084, 38086

Figure 114

raction shaft bearings

4. To remove the upper traction shaft and friction

wheel assembly, disconnect the master link in the

chain. Remove the two bolts securing the

bearings on each side and slide the assembly out

of the frame (Figure 115).

Figure 115

0054-007

0054-008

1. Drain the fuel and oil. Stand the machine up on its

auger and secure to prevent tipping.

2. Remove the klik pins and remove both wheels.

3. Remove 8 self-tapping screws securing the lower

cover and rear plate (Figure 114).

3 - 14 Two Stage Snowthrower Drive Systems Manual

5. For service of the traction shaft assembly, refer to

"SUB ASSEMBLY REPAIR — TORO MODELS

38066, 38078, 38083, 38084, 38086" on

page 3 - 17.

Page 47

Traction Drive Systems

1.Spri

1.Spri

3.Bell

k

6. To remove the intermediate shaft, loosen the

retaining bolts and remove the chain. Loctite™

Red #271 is used to secure these bolts. Remove

the shaft (Figure 116).

Figure 116

0054-009

7. To remove the axle and friction plate assembly,

disconnect the traction idler spring (shown just

below the right side axle bearing) (Figure 117).

8. Disconnect the friction plate disengagement

spring (in the upper left corner of the traction

housing) (Figure 118).

2

3

1

2. Traction

ng

engagement rod

Figure 118

cran

0054-011

9. At this point the traction belt must be removed.

Refer to "Replacing the Traction Belt — Lawn-Boy

Model 28232 and Toro Models 38053, 38066,

38078, 38083, 38084, 38086" on page 2 - 4.

Figure 117

ng

1

0054-010

10. Disconnect the traction engagement rod (left front

corner) from the bell crank (Figure 118).

11. Remove the retaining bolts from the axle bearings

and the friction plate and axle will slide out of the

chassis.

12. For servicing, refer to "Axle and Friction Plate

Assembly" on page 3 - 19.

Two Stage Snowthrower Drive Systems Manual 3 - 15

Page 48

Traction Drive Systems

1.Shift

2.Slid

ASSEMBLY — TORO MODELS 38066,

38078, 38083, 38084, 38086