Page 1

1800 Power Curve® Snowthrower

Model No. 38026 —Serial No. 270000001 and Up

Form No. 3354-207 Rev A

Operator's Manual

Introduction

R ead this infor mation carefully to lear n ho w to operate and

maintain y our product properly and to a v oid injur y and

product damag e . Y ou are responsible for operating the

product properly and safely .

Y ou ma y contact T oro directly at www .T oro .com for

product and accessor y infor mation, help finding a dealer ,

or to register y our product.

W henev er y ou need ser vice , g en uine T oro par ts , or

additional infor mation, contact an A uthorized Ser vice

Dealer or T oro Customer Ser vice and ha v e the model and

serial n umbers of y our product ready . Figure 1 identifies the

location of the model and serial n umbers on the product.

W rite the n umbers in the space pro vided.

T his man ual uses 2 other w ords to highlight infor mation.

Impor tant calls attention to special mec hanical infor mation

and Note emphasizes g eneral infor mation w or th y of special

attention.

Safety

T his sno wthr o w er meets or ex ceeds the ISO standard

8437 in ef fect at the time of pr oduction.

R ead and under stand the contents of this man ual

bef or e the engine is ev er star ted.

T his is the safety aler t symbol. It is used to aler t y ou

to potential per sonal injur y hazards. Obey all safety

messa ges that f ollo w this symbol to a v oid possible

injur y or death.

Impr oper l y using or maintaining this sno wthr o w er

could r esult in injur y or death. T o r educe this potential,

compl y with the f ollo wing safety instr uctions.

T he follo wing instr uctions ha v e been adapted from the

ANSI/OPEI standard B71.3-1995, the ISO 8437:1989

standard, and European Standard EN 786:1996 and EN

60335-2-91:2002.

Figure 1

1. Model and serial number location

Model No.

Serial No.

T his man ual identifies potential hazards and has safety

messag es identified b y the safety aler t symbol ( Figure 2 ),

whic h signals a hazard that ma y cause serious injur y or

death if y ou do not follo w the recommended precautions .

Figure 2

1. Safety alert symbol

© 2006—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Register at www.Toro.com. Original Instructions (EN)

Training

• R ead the operator’ s man ual carefully . Be thoroughly

familiar with the controls and the proper use of the

equipment. Kno w ho w to stop the unit and diseng ag e

the controls quic kly .

• Nev er allo w c hildren to operate the sno wthro w er .

Nev er allo w adults to operate the sno wthro w er without

proper instr uction.

• K ee p the area of operation clear of all persons

(par ticularly small c hildren) and pets .

• Ex ercise caution to a v oid slipping or falling .

Preparation

• T horoughly inspect the area where y ou will use the

sno wthro w er . R emo v e all door mats , sleds , boards ,

wires , and other foreign objects .

• R elease the control bar to diseng ag e the rotor blades

before star ting the engine .

Printed in the USA.

All Rights Reserved

Page 2

• Do not operate the sno wthro w er without w earing

adequate winter g ar ments . W ear footw ear that will

impro v e y our footing on slipper y surfaces .

• Nev er attempt to mak e any adjustments while the motor

is r unning, ex ce pt where specifically recommended b y

T oro .

• Let the motor and the sno wthro w er adjust to the

outdoor temperature before star ting to clear sno w .

• Operating any po w ered mac hine can result in foreign

objects being thro wn into the eyes . Alw a ys w ear safety

glasses or eye shields while operating, adjusting, or

re pairing the sno wthro w er .

• Alw a ys ensure that the v entilation openings are k e pt

clear of debris .

• Before use , c hec k the supply and extension cord for

signs of damag e or aging .

• Nev er operate the sno wthro w er without proper guards ,

plates , or other safety protecti v e devices in place .

• Nev er operate the sno wthro w er near glass enclosures ,

automobiles , windo w w ells , and drop-offs without

properly adjusting the sno w disc harg e angle . K ee p

c hildren and pets a w a y .

• Do not o v erload the mac hine capacity b y attempting to

clear sno w at too fast a rate .

• Look behind and use care when bac king up with the

sno wthro w er .

• Nev er direct the disc harg e at b ystanders or allo w any one

in front of the unit.

• Nev er operate the sno wthro w er without g ood visibility

or light. Alw a ys be sure of y our footing, and k ee p a fir m

hold on the handle . W alk; nev er r un.

Operation

• Do not put hands or feet near or under rotating par ts .

K ee p clear of the disc harg e opening at all times .

• Disconnect the mac hine from the po w er source before

c hec king, cleaning, or w orking on the mac hine and

when it is not in use .

• If the cord becomes damag ed during use , disconnect

the cord from the po w er supply immediately . Do not

touc h the cord before disconnecting the po w er supply .

• Do not use the mac hine if the cord is damag ed or w or n.

• K ee p extension cords a w a y from the rotor blades .

• T he po w er supply used with the appliance should be a

residential cur rent device (R CD) with a tripping cur rent

of not more than 30 mA.

• Ex ercise extreme caution when crossing g ra v el dri v es ,

w alks , or roads . Sta y aler t for hidden hazards or traffic .

• Do not attempt to clear sno w from a cr ushed-roc k or

g ra v el surface . T his product is intended for use only on

pa v ed surfaces .

• After striking a foreign object, stop the motor ,

thoroughly inspect the sno wthro w er for any

damag e , and re pair the damag e before operating the

sno wthro w er .

• If the unit should star t to vibrate abnor mally , stop the

motor and c hec k immediately for the cause . Vibration

is g enerally a w ar ning of trouble .

• Stop the motor whenev er y ou lea v e the operating

position, before unclog ging the disc harg e c hute , and

when making any re pairs , adjustments , or inspections .

• W hen cleaning, re pairing, or inspecting, mak e cer tain

that the rotor blades and all mo ving par ts ha v e stopped.

• Do not clear sno w across the face of slopes . Ex ercise

extreme caution when c hanging direction on slopes . Do

not attempt to clear stee p slopes .

Maintenance and Storage

• Chec k all fasteners at frequent inter v als for proper

tightness to be sure that the equipment is in safe

w orking condition.

• Alw a ys refer to this operator’ s man ual for impor tant

details if the sno wthro w er is to be stored for an

extended period.

• Maintain or re place safety and instr uction labels when

necessar y .

Toro Snowthrower Safety

T he follo wing list contains safety infor mation specific to

T oro products or other safety infor mation that y ou m ust

kno w .

• R otating rotor blades can injure fing ers or hands .

Sta y behind the handles and a w a y from the disc harg e

opening while operating the sno wthro w er . K ee p y our

face , hands , feet, and any other par t of y our body or

clothing a w a y from mo ving or rotating par ts .

• Before adjusting, cleaning, re pairing, and inspecting

the sno wthro w er , and before unclog ging the disc harg e

c hute , stop the motor and w ait for all mo ving par ts to

stop .

• Use a stic k, not y our hands , to remo v e obstr uctions

from the disc harg e c hute .

• Before lea ving the operating position, stop the motor

and w ait for all mo ving par ts to stop .

• Do not w ear loose-fitting clothing that could g et caught

in mo ving par ts .

• If a shield, safety device , or decal is damag ed, illegible ,

or lost, re pair or re place it before beginning operation.

Also , tighten any loose fasteners .

• Do not use the sno wthro w er on a roof .

2

Page 3

• P erfor m only those maintenance instr uctions described

Sound Power

in this man ual. Before perfor ming any maintenance ,

ser vice , or adjustment, stop the motor and disconnect

the po w er cord from the po w er source . If major re pairs

T his unit has a guaranteed sound po w er lev el of 104 dB A,

based on measurements of identical mac hines per EN 3744.

are ev er needed, contact y our A uthorized Ser vice

Dealer .

Vibration

• Purc hase only g en uine T oro re placement par ts and

accessories .

T his unit does not ex ceed a hand/ar m vibration lev el of

2.3 m/s

2

, based on measurements of identical mac hines

per EN 1033.

Sound Pressure

T his unit has a maxim um sound pressure lev el at the

operator’ s ear of 89 dB A, based on measurements of

identical mac hines per EN 11201.

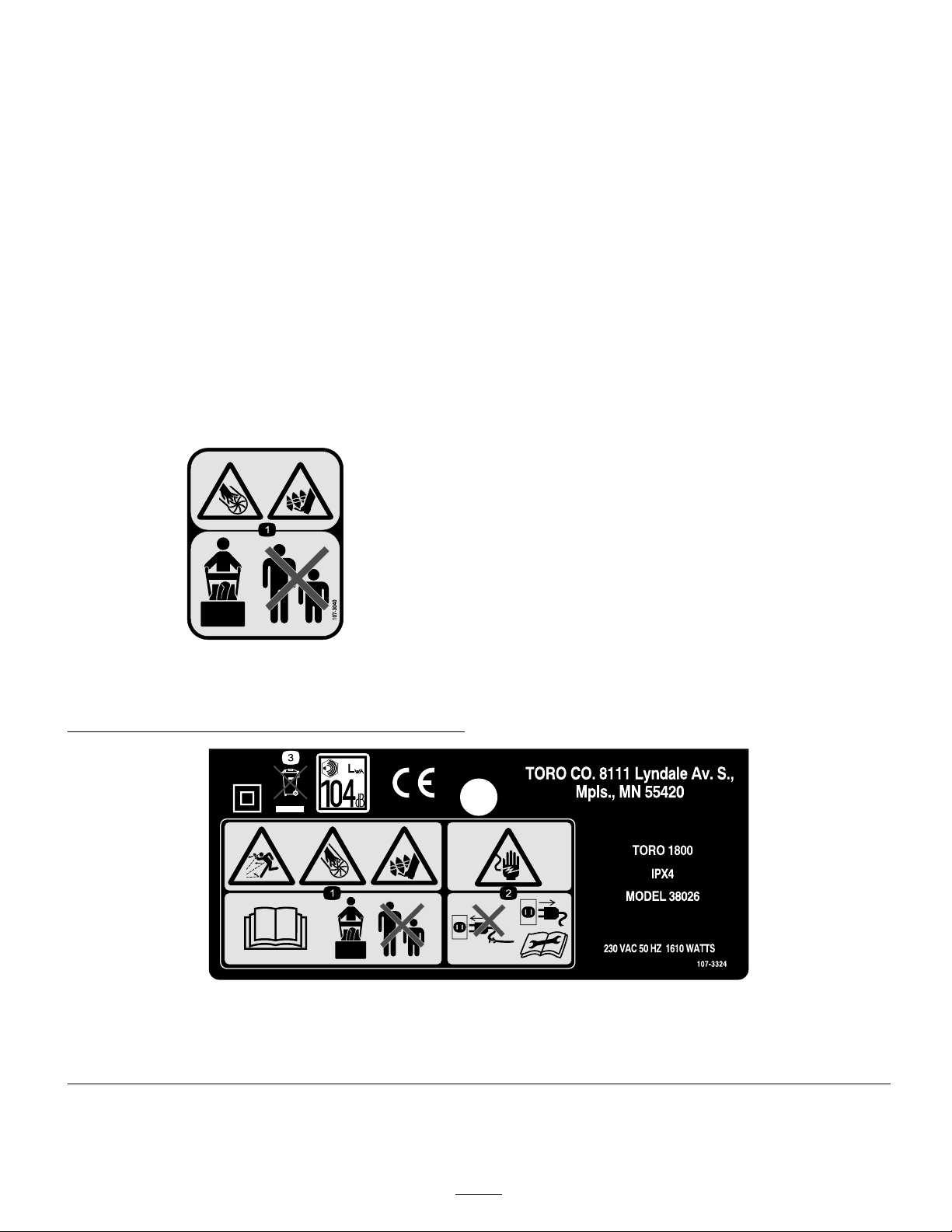

Safety and Instructional Decals

Important: Safety and instr uction decals ar e located near ar eas of potential danger . R eplace dama ged decals.

107-3040

1. Cutting dismemberment, impeller and cutting dismemberment,

auger hazards—keep bystanders a safe distance from the

snowthrower.

107-3324

1. Thrown object hazard; cutting/dismemberment hazard, impeller and auger—read the Operator’s Manual, keep bystanders a safe distance from

the machine.

2. Electric shock hazard—disconnect the machine from the power outlet and read the instructions before servicing or performing maintenance.

3. Contains recyclable materials, do not discard.

3

Page 4

Setup

Loose Parts

Use the chart below to verify that all parts have been shipped.

Step

Mounting plate

Chute crank

1.

2.

Note: Deter mine the left and right sides of the mac hine from the nor mal operating position.

Machine screw

Locknut

Chute deector

Rubber washer

Carriage bolt

Metal washer

Locknut

Description

Qty.

1

1

2

2

1

2

2

2

2

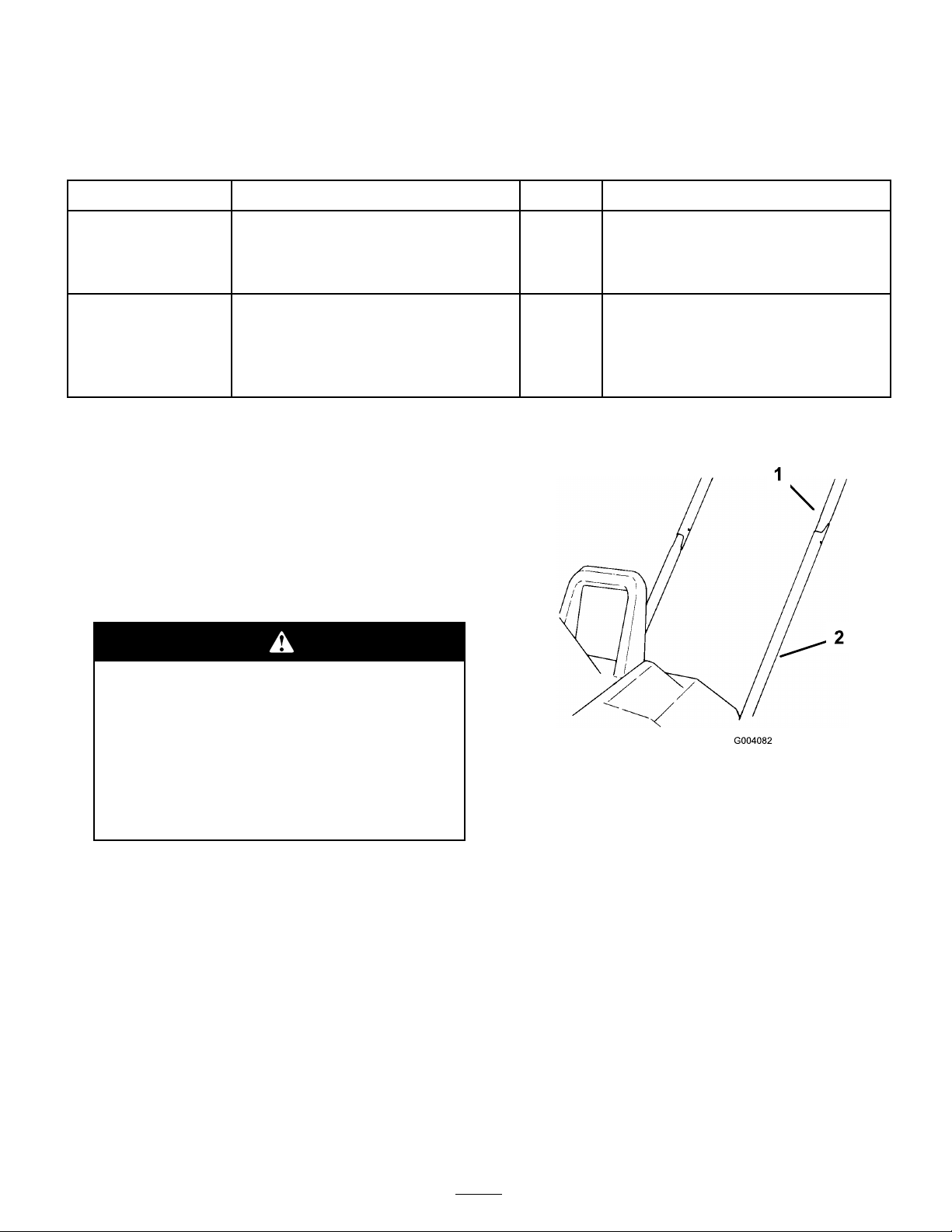

1. Installing the Upper Handle

and Chute Crank

1. Stand the sno wthro w er on its wheels and position the

upper handle .

2. Inspect the open inter nal wiring; if it is damag ed, do not

assemble . Contact an A uthorized Ser vice Dealer .

Use

Install the upper handle and chute

crank.

Install the discharge chute.

T he inter nal wiring could be dama ged during

assembl y , causing serious per sonal injur y when

operating the sno wthr o w er .

• Car efull y assemble the sno wthr o w er so that

y ou will not dama ge the electrical wiring .

• If the wiring is dama ged, do not assemble the

sno wthr o w er . Contact an Authoriz ed Ser vice

Dealer .

3. Carefully inser t the right side of the upper tubing o v er

the end of the lo w er right side tubing ( Figure 3 ).

Figure 3

1. Upper tubing 2. Lower tubing

4. Carefully inser t the left side of the upper tubing into the

end of the lo w er left side tubing ( ).

5. Squeeze the upper tubes tog ether , and wig gle the upper

tubes do wn until the mounting holes in the upper and

lo w er tubing line up ( Figure 3 ).

6. Place the mounting plate o v er the tubes ( Figure 4 ).

4

Page 5

Figure 4

1. Mounting plate 3. Chute crank

2. Shroud

4. Gear

7. Align the mounting plate holes with the upper and

lo w er tubing holes .

8. Inser t the end of the c hute crank through the hole in

the shroud.

9. T ur n the c hute crank rod slo wly until the flattened end

drops into the slot in the g ear , then fir mly push the

c hute crank into the g ear until it snaps into place ( Figure

4 and Figure 5 ).

Figure 5

1. Chute crank 2. Chute crank gear

Figure 6

1. Chute deector

2. Discharge chute

3. Rubber washer (2) 6. Locknut (2)

4. Carriage bolt (2)

5. Metal washer (2)

2. Inser t a r ubber w asher betw een the c hute deflector and

the disc harg e c hute on eac h side while maintaining the

hole alignment ( Figure 6 ).

3. Secure the deflector to the disc harg e c hute with 2

car riag e bolts , 2 metal w ashers , and 2 loc kn uts .

Note: Ensure that the square shoulders on the car riag e

bolts align with the inside square on the disc harg e c hute .

P osition the metal w ashers to the outside of the c hute

deflector as sho wn in Figure 6 . Do not o v er tighten the

bolts .

Product Overview

10. Secure the upper and lo w er tubing and the mounting

plate tog ether with 2 mac hine screws and 2 loc kn uts .

Note: P osition the screw heads on the outside of the

mounting plate . Be careful not to damag e the inter nal

electrical wiring when y ou inser t the screws . If the

wiring bloc ks the hole , use a blunt 1/8 inc h punc h

to carefully route the electrical wiring a w a y from the

aligned holes .

2. Installing the Discharge

Chute

1. P osition the c hute deflector onto the disc harg e c hute

and align the mounting holes ( Figure 6 ).

Figure 7

1. Control bar 5. Discharge chute

2. Chute crank 6. Chute deector

3. Belt cover 7. Secondary handle

4. Rotor

5

Page 6

Operation

Before Starting

F or safe and efficient use of y our appliance , use only an

extension cord recommended for outdoor use . Use only a

2.5 mm extension cord up to 25 m long .

Contact with w ater while operating the sno wthr o w er

can cause electric shock, r esulting in per sonal injur y

or death.

Don’ t handle the plug or the appliance with w et

hands or while standing in w ater .

Starting and Stopping

1. T o star t the rotor , squeeze the control bar ( Figure 9 ).

Figure 9

1. Control bar

2. T o stop the rotor , release the control bar .

Note: T o prev ent the extension cord from disconnecting

during operation, tie it to the loop in the upper handle

before y ou connect it to the sno wthro w er ( Figure 8 ).

Figure 8

1. Extension cord

T he electrical cord can get dama ged, causing a

shock or fir e.

T hor oughl y inspect the electrical cord bef or e using

the sno wthr o w er . If the cord is dama ged, do not

operate the sno wthr o w er . R epair or r eplace the

dama ged cord immediatel y . Contact an Authoriz ed

Ser vice Dealer f or assistance.

2. Loop

Operating Tips

If sno wthr o w er hits an object while in operation, the

object could be thr o wn in operator’ s or bystander’ s

dir ection. T hr o wn objects could cause serious

per sonal injur y .

K eep the ar ea to be clear ed fr ee of all objects which

may be pick ed up and thr o wn by the r otor blades.

• Chec k the condition of the sno wthro w er before

operating it to ensure that the rotor tur ns freely .

• Alw a ys k ee p c hildren and pets a w a y from the area of

operation.

• K ee p the area to be cleared free of stones , to ys , or other

objects whic h the rotor blades can thro w . Suc h items

could be co v ered b y sno wfall and g o unnoticed. If the

sno wthro w er strik es an object during operation, stop the

sno wthro w er , unplug the extension cord, remo v e the

obstr uction, and c hec k the sno wthro w er for damag e .

• T o adjust the disc harg e c hute , rotate the c hute crank

cloc kwise to mo v e the disc harg e c hute to the left;

countercloc kwise to mo v e it to the right.

Note: T he c hute crank mak es a noise as y ou tur n the

crank. T his is nor mal.

• T o adjust the height of the sno w stream, raise or lo w er

the c hute deflector handle ( Figure 10 ).

6

Page 7

Figure 10

1. Chute deector handle

A gap betw een the discharge chute and the chute

deflector may allo w the sno wthr o w er to thr o w

sno w and objects in the dir ection of the operator .

T hr o wn objects could cause serious per sonal

injur y .

Figure 11

1. Primary handle 2. Secondary handle

• W hen clearing ste ps , hold the sno wthro w er b y the

primar y and secondar y handles and use a swinging or

sw ee ping motion.

– Do not f orce the chute deflector too f ar

f orw ard so that a gap appear s betw een the

discharge chute and chute deflector .

– Do not o v er tighten the lockn uts that hold the

chute deflector in place.

• Begin remo ving sno w near the electrical outlet and

w ork outw ard. Blo w bac k and for th, not a w a y from

and to w ard the outlet.

• W hen tur ning at the end of a sw ath, ste p o v er the cord

and tur n the sno wthro w er .

• Alw a ys o v erlap eac h sw ath and disc harg e the sno w

do wnwind when possible .

• T o sha v e do wn larg e banks of sno w , lift the sno wthro w er

b y the primar y and secondar y handles ( Figure 11 )

and place the sno wthro w er on the bank. Let the

w eight of the sno wthro w er sha v e do wn the bank in a

bac k-and-for th motion.

W hen using the secondar y handle, nev er dir ect

the sno w discharge chute at the operator or

bystander s. T he sno wthr o w er can thr o w objects

and cause serious per sonal injur y .

W hen using the secondar y handle, al w ays tur n

the discharge chute in the opposite dir ection

fr om wher e y ou or bystander s ar e standing .

• K ee p the extension cord clear of obstr uctions , shar p

objects , and all mo ving par ts . Do not pull shar ply on

cord or abuse it in any manner . F requently inspect the

extension cord for damag e that ma y result in an electric

shoc k. If the extension cord becomes damag ed, re place

it.

• In cold and sno wy w eather conditions , some controls

and mo ving par ts ma y freeze . T herefore , when any

control becomes difficult to operate , stop the motor ,

disconnect the extension cord, and c hec k for frozen

par ts . Do not use ex cessi v e force when tr ying to operate

frozen controls . F ree all the controls and mo ving par ts

before operating .

• W hen operating the sno wthro w er , k ee p the wheels

1 inc h (2.5 cm) off the pa v ement b y tipping the

sno wthro w er forw ard. T his helps prev ent the sno w

from building up on the wheels .

• After clearing the sno w , let the motor r un for a few

min utes so that mo ving par ts don ’ t freeze . T hen shut

off the motor , w ait for all mo ving par ts to stop , and

wipe the ice and sno w off the sno wthro w er . R otate the

c hute crank sev eral times to remo v e the sno w .

7

Page 8

Maintenance

Important: All electrical r epair s should be

perf or med onl y by an Authoriz ed Ser vice Dealer .

Note: Deter mine the left and right sides of the mac hine

from the nor mal operating position.

If the extension cord is plug ged into the

sno wthr o w er , someone could accidentall y operate

sno wthr o w er while y ou ar e perf or ming maintenance

on it, causing serious per sonal injur y .

Disconnect the extension cord bef or e y ou perf or m

an y maintenance.

Lubricating the Snowthrower

Y ou do not need to lubricate the sno wthro w er; all the

bearings w ere lubricated at the factor y for the life of the

sno wthro w er .

Replacing the Scraper

T he scraper is located at the bottom of the rotor housing

as sho wn in Figure 12 .

Figure 13

1. Right side cover 3. Skid

2. Screw

2. Use a 5/16 inc h Allen wrenc h to tur n the rotor shaft

cloc kwise (left-hand thread) while holding the rotor

( Figure 14 ).

Figure 14

1. Rotor shaft

2. Rotor

Note: Y ou ma y need to tap the Allen wrenc h with a

hammer to loosen the rotor shaft. W edg e a stic k or a

hammer handle in the rotor to prev ent it from rotating .

Figure 12

1. Scraper

2. Screw (2)

1. R emo v e the 2 screws that secure the scraper to the

sno wthro w er ( Figure 12 ).

2. Install the new scraper and fasten it securely with 2

screws .

Replacing the Rotor

1. R emo v e the 3 screws that secure the right side co v er

and the skid to the sno wthro w er frame ( Figure 13 ).

Note: If y ou cannot remo v e the rotor shaft b y holding

the rotor , remo v e the left side co v er and the skid ( Figure

15 ).

Figure 15

1. Left side cover 2. Skid

3. Hold the hex n ut with a 7/8 inc h wrenc h while

unscrewing the rotor shaft ( Figure 16 ).

Figure 16

1. Hex nut

8

Page 9

4. Hold the rotor and pull out the rotor shaft.

5. R emo v e the rotor .

6. Align the left side of the new rotor with the coupler .

Note: T he 3 bosses on the rotor end m ust align with

the slots on the coupler ( Figure 17 ).

Figure 17

1. Coupler 3. Slot

2. Boss

4. Drive hex

Note: W hen mounting the coupler to the dri v e hex,

align the coupler tabs to the inside .

Figure 18

1. Idler spring 2. Idler arm

4. R otate the rotor with y our left hand while sliding the

belt off the larg e pulley with y our right hand ( Figure 19 ).

7. Slide the right side of the rotor into the mounting

position.

8. Inser t the rotor shaft through the rotor and ensure that

the shaft fits into the bearing on the right side .

9. T or que it to at least 10 ft-lb (14 N ⋅ m).

10. Install the co v er and the skid.

Replacing the Large Belt

1. R emo v e the 3 screws that secure the left side plate to

the sno wthro w er frame ( Figure 15 ).

2. R emo v e the side plate and the skid.

T he idler spring could fly in y our f ace while y ou

r emo v e it, causing per sonal injur y .

W ear safety go g g les when w or king with the idler

spring .

3. R emo v e the idler spring from the idler ar m ( Figure 18 ).

Figure 19

1. Large pulley 2. Belt

5. Slip the new belt o v er the small pulley ( Figure 20 ).

Figure 20

1. Idler arm 3. Small pulley

2. Idler pulley

6. Lift up the idler ar m and slip the belt under the idler

pulley ( Figure 20 ).

7. R otate the rotor with y our left hand while sliding the

belt onto the larg e pulley with y our right hand ( Figure

21 ).

9

Page 10

Note: T he bolt, the bolt head, and the w ashers m ust

be flush ag ainst the small pulley .

11. Slip the larg e belt o v er the small pulley ( Figure 22 ).

R efer to R e placing the Larg e Belt.

Storage

Figure 21

8. Assemble the idler spring ( Figure 18 ), ensuring that the

idler pulley rides on the belt.

9. Install the left side co v er and the skid with the 3 screws .

Replacing the Small Belt

1. R emo v e the screws that secure the left side plate and

the skid to the sno wthro w er frame ( Figure 15 ).

2. R emo v e the side plate and the skid.

3. R emo v e the larg e belt b y slo wly sliding it off the small

pulley (Fig . Figure 19 ).

Note: R efer to ste ps 2 and 3 of R e placing the Larg e

Belt.

4. R emo v e the small pulley bolt (left hand thread) b y

tur ning the bolt cloc kwise .

5. R emo v e the 2 w ashers and the small pulley ( Figure 22 ).

1. R un the sno wthro w er for a few min utes to melt a w a y

any sno w on the sno wthro w er .

2. Disconnect the extension cord from the sno wthro w er .

3. Examine the extension cord thoroughly for signs of

w ear or damag e . R e place it if it is w or n or damag ed.

4. Examine the sno wthro w er thoroughly for w or n, loose ,

or damag ed par ts . T o re pair or re place par ts , contact an

local A uthorized Ser vice Dealer for assistance .

5. Store the extension cord with the sno wthro w er .

6. Store the sno wthro w er in a clean, dr y place .

Figure 22

1. Bolt (left-hand thread)

2. Washers 5. Motor shaft pulley

3. Small pulley

6. R emo v e and discard the small belt ( Figure 22 ).

7. Slide 2 w ashers onto the bolt and inser t the bolt through

the small pulley .

Note: T he bolt m ust ride on the bearings in the small

pulley .

8. Place the new belt on the small pulley .

9. Slide the belt o v er the motor shaft pulley ( Figure 22 ).

10. T or que the bolt to 25 to 30 in-lb (2.8 to 3.4 N∙m). Do

not o v er tighten the bolt.

4. Small belt

10

Page 11

International Distributor List—Consumer Products

Distributor:

Atlantis Su ve Sulama Sisstemleri Lt Turkey

Balama Prima Engineering Equip

B-Ray Corporation

Casco Sales Company

Ceres S.A

CSSC Turf Equipment (pvt) Ltd

Cyril Johnston & Co Nothern Ireland

Equiver Mexico

Femco S.A.

G.Y.K. Company ltd.

Geomechaniki of Athens

Guandong Golden Star China

Hako Gorund and Garden Sweden

Hydroturf Int. Co Dubai United Arab Emirates

Hydroturf Egypt LLC

Ibea S.p.A. Italy

Irriamc

Jean Heybroek b.v. Netherlands

Lely (U.K. ) Limited

Maquiver S.A.

Maruyama Mfg. Co. Inc.

Metra Kft

Mounteld a.s. Czech Republic

Munditol S.A.

Oslinger Turf Equipment SA Ecuador

Oy Hako Ground and Garden Ab Finland

Parkland Products Ltd New Zealand

Prochaska & Cie

RT Cohen 2004 Ltd Israel

Riversa Spain

Roth Motorgerate GmBh & Co

Sc Svend Carlsen A/S Denmark

Solvert S.A.S

Spypros Stavrinides Limited

Surge Systems India Limited India

T-Markt Logistics Ltd

Toro Australia Australia

Toro Europe BVBA

Country:

Hong Kong 852 2155 2163

Korea 82 32 551 2076

Puerto Rico

Costa Rica

Sri Lanka

Guatemala

Japan

Greece 30 10 935 0054

Egypt

Portugal

United Kingdom

Columbia

Japan

Hungary

Argentina

Austria

Germany 49 7144 2050

France

Cyprus 357 22 434131

Hungary

Belgium

Phone Number:

90 216 344 86 74

787 788 8383

506 239 1138

94 11 2746100

44 2890 813 121

52 55 539 95444

502 442 3277

81 726 325 861

86 20 876 51338

46 35 10 0000

97 14 347 9479

202 519 4308

39 0331 853611

351 21 238 8260

31 30 639 4611

44 1480 226 800

57 1 236 4079

81 3 3252 2285

36 1 326 3880

420 255 704 220

54 11 4 821 9999

593 4 239 6970

358 987 00733

64 3 34 93760

43 1 278 5100

972 986 17979

34 9 52 83 7500

45 66 109 200

33 1 30 81 77 00

91 1 292299901

36 26 525 500

61 3 9580 7355

32 14 562 960

374-0102 Rev A

Page 12

The Toro Warranty

Conditions and Products Covered

The Toro® Company and its afliate, Toro Warranty Company, pursuant to

an agreement between them, jointly promises to the original purchaser* to

repair any Toro Product used for normal residential purposes* if defective in

materials or workmanship. The following time periods apply from the date

of original purchase:

Products

Walk Power Mowers

Rear Engine Riders 2-year limited warranty

Lawn & Garden Tractors

Electric Hand Held Products

Snowthrowers

Consumer Zero Turn

* “Original purchaser” means use the person who originally purchased Toro

products.

* “Normal residential purposes” means use of the product on the same lot as

your home. Use at more than one location is considered commercial use, and

the commercial use warranty would apply.

Warranty Period

2-year limited warranty

2-year limited warranty

2-year limited warranty

2-year limited warranty

2-year limited warranty

Limited Warranty for Commercial Use

Toro Consumer Products and attachments used for commercial, institutional,

or rental use are warranted against defects in materials or workmanship for the

following time periods from the date of original purchase:

Products

Walk Power Mowers

Rear Engine Riders 90 day warranty

Lawn & Garden Tractors

Electric Hand Held Products

Snowthrowers

Consumer Zero Turn

Warranty Period

90 day warranty

90 day warranty

90 day warranty

90 day warranty

45 day warranty

Instructions for Obtaining Warranty Service

If you think that your Toro Product contains a defect in materials or

workmanship, follow this procedure:

1. Contact your seller to arrange service of the product. If for any reason

it is impossible for you to contact your seller, you may contact any Toro

Authorized Distributor to arrange service.

2. Bring the product and your proof of purchase (sales receipt) to your seller

or the Service Dealer.

If for any reason you are dissatised with the Service Dealer’s analysis or with the

assistance provided, contact the Toro importer or contact us at:

Customer Care Department, Consumer Division

Toro Warranty Company

8111 Lyndale Avenue South

Bloomington, MN 55420-1196

Manager: Technical Product Support: 001-952-887-8248

See attached Distributor List

Owner Responsibilities

You must maintain your Toro Product by following the maintenance procedures

described in the operator’s manual. Such routine maintenance, whether

performed by a dealer or by you, is at your expense.

Items and Conditions Not Covered

This express warranty does not cover:

• Cost of regular maintenance service or parts, such as lters, fuel, lubricants,

tune-up parts, blade sharpening, brake and clutch adjustments.

• Any product or part which has been altered or misused or required

replacement or repair due to normal wear, accidents, or lack of proper

maintenance.

• Repairs necessary due to improper fuel, contaminants in the fuel system, or

failure to properly prepare the fuel system prior to any period of non-use

over three months.

• Engine and transmission. These are covered by the appropriate

manufacturer’s guarantees with separate terms and conditions.

All repairs covered by this warranty must be performed by an Authorized Toro

Service Dealer using Toro approved replacement parts.

General Conditions

The purchaser is covered by the national laws of each country. The rights to

which the purchaser is entitled with the support of these laws are not restricted

by this warranty.

374-0101 Rev A

Loading...

Loading...