Page 1

PowerMax826OTESnowthrower

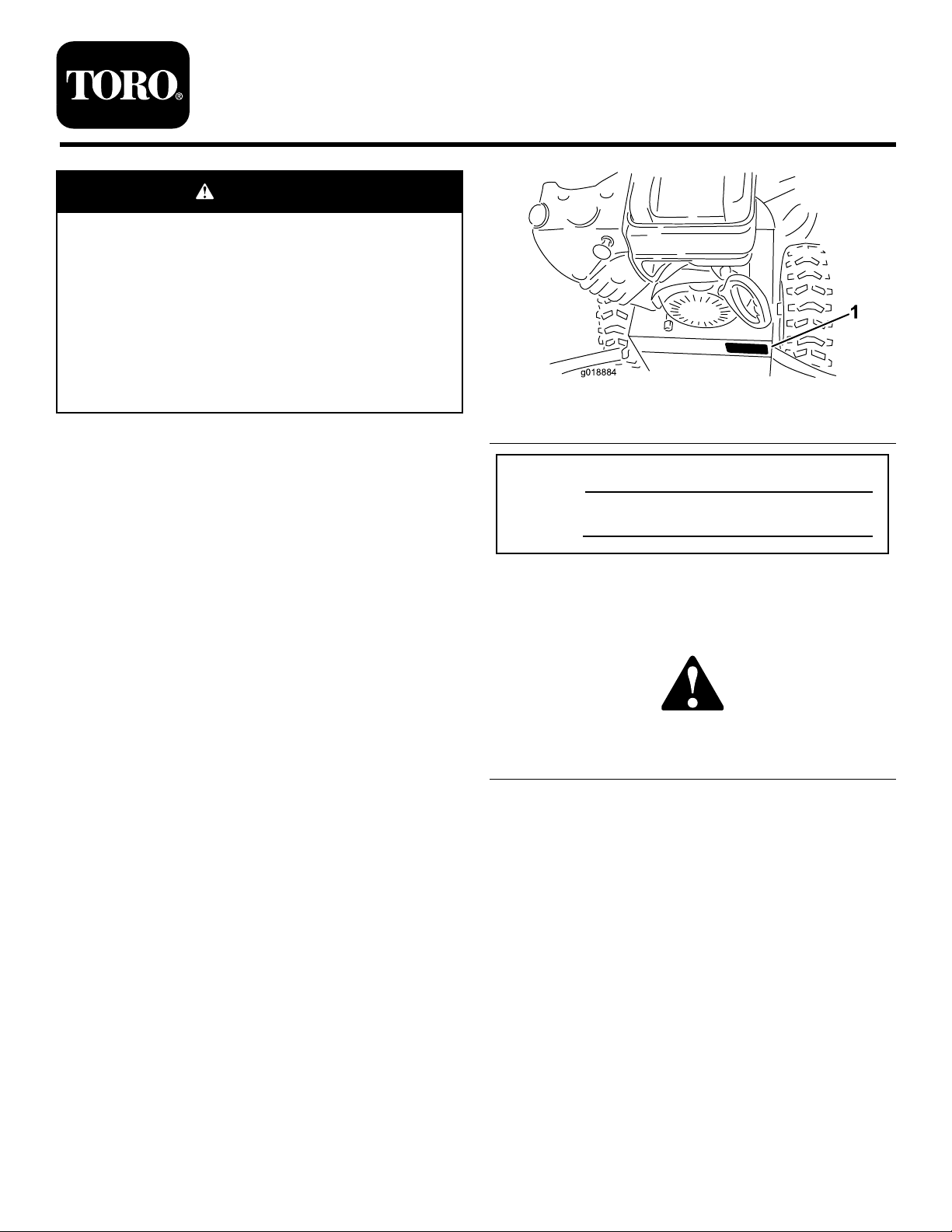

g018884

ModelNo.37777—SerialNo.315000001andUp

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

FormNo.3385-232RevA

Operator'sManual

Figure1

1.Modelandserialnumberlocation

Introduction

Thismachineisintendedtobeusedbyresidential

homeownersorprofessional,hiredoperators.Itis

designedforremovingsnowfrompavedsurfaces,such

asdrivewaysandsidewalks,andothersurfacesfor

trafconresidentialorcommercialproperties.Itisnot

designedforremovingmaterialsotherthansnow,noris

amodelwithapivotingscraperdesignedforclearingoff

gravelsurfaces.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourmachineproperlyandtoavoidinjuryand

machinedamage.Youareresponsibleforoperatingthe

machineproperlyandsafely.

YoumaycontactTorodirectlyatwww.Toro.comformachine

andaccessoryinformation,helpndingadealer,ortoregister

yourmachine.

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourmachineready.Figure1identiesthelocationofthe

modelandserialnumbersonthemachine.Writethenumbers

inthespaceprovided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

©2014—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

Introduction..................................................................1

Safety...........................................................................2

Training.................................................................3

Preparation.............................................................3

Operation...............................................................3

ClearingaCloggedDischargeChute..........................4

MaintenanceandStorage..........................................4

ToroSnowthrowerSafety.........................................4

SafetyandInstructionalDecals.................................5

Setup............................................................................7

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3385-232*A

Page 2

1InstallingtheUpperHandle....................................7

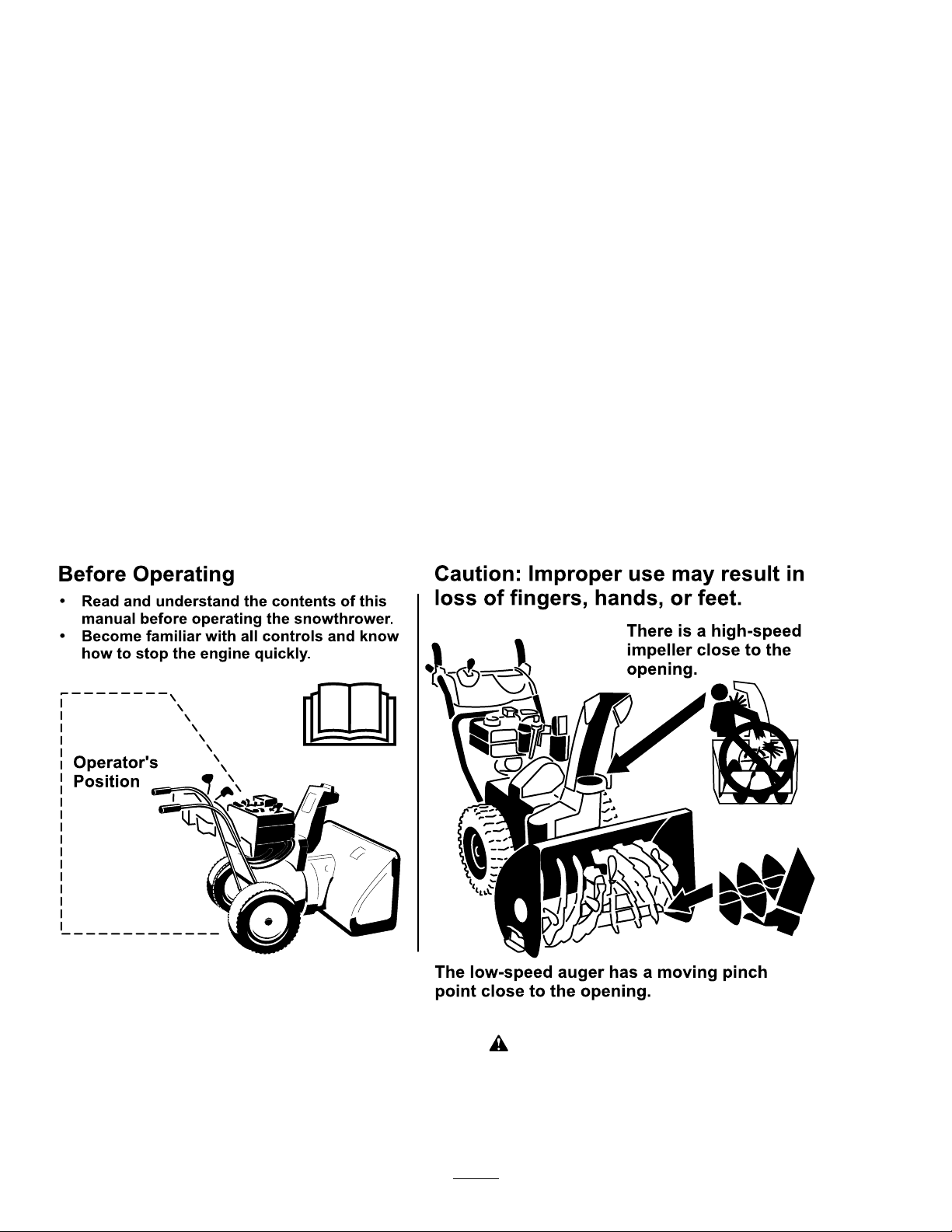

BeforeOperating

?

?

Readandunderstandthecontentsofthis

manualbeforeoperatingthesnowthrower .

Becomefamiliarwithallcontrolsandknow

howtostoptheenginequickly .

Operator 's

Position

Thelow-speedaugerhasamovingpinch

pointclosetotheopening.

Caution:Improperusemayresultin

lossoffingers,hands,orfeet.

Thereisahigh-speed

impellerclosetothe

opening.

2InstallingtheTractionControlLinkage....................8

3InstallingtheChute...............................................9

4InstallingtheChuteControlRod............................10

5ConnectingtheWiretotheHeadlight......................10

6CheckingtheEngineOilLevel...............................11

7CheckingtheTirePressure....................................11

8CheckingtheSkidsandScraper..............................12

9CheckingtheTractionDriveOperation...................12

ProductOverview.........................................................13

Operation....................................................................13

FreewheelingorUsingtheSelf-propelDrive...............13

FillingtheFuelTank...............................................13

StartingtheEngine.................................................15

StoppingtheEngine...............................................16

OperatingtheTractionDrive...................................16

OperatingtheSpeedSelector...................................17

OperatingtheAuger/ImpellerDrive.........................17

OperatingtheQuickStick™....................................17

UncloggingtheDischargeChute..............................18

PreventingFreeze-up..............................................18

OperatingTips......................................................19

Maintenance.................................................................19

RecommendedMaintenanceSchedule(s)......................19

............................................................................20

PreparingforMaintenance.......................................20

CheckingtheEngineOilLevel.................................20

CheckingandAdjustingtheSkidsand

Scraper..............................................................20

CheckingandAdjustingtheTractionCable................21

CheckingandAdjustingtheAuger/Impeller

Cable................................................................21

CheckingtheAugerGearboxOilLevel......................22

ChangingtheEngineOil.........................................22

LubricatingtheHexShaft........................................23

ReplacingtheSparkPlug.........................................23

AdjustingtheDischargeChuteLatch........................24

ReplacingtheDriveBelts.........................................24

ReplacingtheHeadlightBulb...................................24

Storage........................................................................26

PreparingtheMachineforStorage............................26

RemovingtheMachinefromStorage.........................26

Troubleshooting...........................................................27

Safety

ThismachinemeetsorexceedstheB71.3specications

oftheAmericanNationalStandardsInstituteineffect

atthetimeofproduction.

Readandunderstandthecontentsofthismanualbefore

theengineiseverstarted.

Thisisthesafetyalertsymbol.Itisusedtoalertyou

topotentialpersonalinjuryhazards.Obeyallsafety

messagesthatfollowthissymboltoavoidpossibleinjury

ordeath.

2

Page 3

Improperlyusingormaintainingthismachinecould

resultininjuryordeath.Toreducethispotential,

complywiththefollowingsafetyinstructions.

Training

•Read,understandandfollowallinstructionsonthe

machineandinthemanual(s)beforeoperatingthis

machine.Bethoroughlyfamiliarwiththecontrolsand

theproperuseofthemachine.Knowhowtostopthe

machineanddisengagethecontrolsquickly.

•Neverallowchildrentooperatethemachine.Neverallow

adultstooperatethemachinewithoutproperinstruction.

•Keeptheareaofoperationclearofallpersons,particularly

smallchildren.

•Exercisecautiontoavoidslippingorfalling,especially

whenoperatingthemachineinreverse.

Preparation

•Thoroughlyinspecttheareawherethemachineistobe

usedandremovealldoormats,sleds,boards,wires,and

otherforeignobjects.

•Disengageallclutchesandshiftintoneutralbefore

startingtheengine.

•Donotoperatethemachinewithoutwearingadequate

wintergarments.Avoidloosettingclothingthatcanget

caughtinmovingparts.Wearfootwearthatwillimprove

footingonslipperysurfaces.

•Handlefuelwithcare;itishighlyammable.

–Useanapprovedfuelcontainer.

–Neveraddfueltoarunningengineorhotengine.

–Fillfueltankoutdoorswithextremecare.Neverll

fueltankindoors.

–Neverllcontainersinsideavehicleoronatruckor

trailerbedwithaplasticliner.Alwaysplacecontainers

ontheground,awayfromyourvehicle,beforelling.

–Whenpractical,removegas-poweredmachineryfrom

thetruckortrailerandrefuelitontheground.If

thisisnotpossible,thenrefuelsuchmachineryona

trailerwithaportablecontainer,ratherthanfroma

gasolinedispensernozzle.

–Keepthenozzleincontactwiththerimofthefuel

tankorcontaineropeningatalltimes,untilrefueling

iscomplete.Donotuseanozzlelock-opendevice.

–Replacegasolinecapsecurelyandwipeupspilledfuel.

–Iffuelisspilledonclothing,changeclothing

immediately.

•Useextensioncordsandreceptaclesasspeciedby

themanufacturerforallmachineswithelectricstarting

motors.

•Adjustthecollectorhousingtocleargravelorcrushed

rocksurface.

•Neverattempttomakeanyadjustmentswhiletheengine

isrunning(exceptwhenspecicallyrecommendedby

manufacturer).

•Alwayswearsafetyglassesoreyeshieldsduringoperation

orwhileperforminganadjustmentorrepairtoprotect

eyesfromforeignobjectsthatmaybethrownfromthe

machine.

Operation

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Exerciseextremecautionwhenoperatingonorcrossing

graveldrives,walks,orroads.Stayalertforhidden

hazardsortrafc.

•Afterstrikingaforeignobject,stoptheengine,remove

theignitionkey ,thoroughlyinspectthemachineforany

damage,andrepairthedamagebeforerestartingand

operatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,stopthe

engineandcheckimmediatelyforthecause.Vibrationis

generallyawarningoftrouble.

•Stoptheenginewheneveryouleavetheoperating

position,beforeuncloggingtheauger/impellerhousing

ordischargechute,andwhenmakinganyrepairs,

adjustmentsorinspections.

•Whencleaning,repairingorinspectingthemachine,stop

theengineandmakecertaintheauger/impellerandall

movingpartshavestopped.Disconnectthesparkplug

wireandkeepthewireawayfromtheplugtoprevent

someonefromaccidentallystartingtheengine.

•Donotruntheengineindoors,exceptwhenstarting

theengineandfortransportingthemachineinorout

ofthebuilding.Opentheoutsidedoors;exhaustfumes

aredangerous.

•Exerciseextremecautionwhenoperatingonslopes.

•Neveroperatethemachinewithoutproperguards,and

othersafetyprotectivedevicesinplaceandworking.

•Neverdirectthedischargetowardpeopleorareaswhere

propertydamagecanoccur.Keepchildrenandothers

away.

•Donotoverloadthemachinecapacitybyattemptingto

clearsnowattoofastarate.

•Neveroperatethemachineathightransportspeeds

onslipperysurfaces.Lookbehindandusecarewhen

operatinginreverse.

•Disengagepowertotheauger/impellerwhenmachineis

transportedornotinuse.

•Useonlyattachmentsandaccessoriesapprovedbythe

manufacturerofthemachine(suchaswheelweights,

counterweights,orcabs).

3

Page 4

•Neveroperatethemachinewithoutgoodvisibilityor

light.Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

•Nevertouchahotengineormufer.

ClearingaCloggedDischarge Chute

WARNING

Handcontactwiththerotatingrotorbladesinside

thedischargechuteisthemostcommoncauseof

injuryassociatedwithmachines.Neveruseyour

handtocleanoutthedischargechute.

Toclearthechute:

•Shuttheengineoff!

•Wait10secondstobesuretherotorbladeshavestopped

rotating.

•Alwaysusethecleanouttoolmountedonthe

snowthrower,notyourhands.

•Beforeleavingtheoperatingposition,stoptheengine,

removethekey,andwaitforallmovingpartstostop.

•Tounclogthedischargechute,stayintheoperating

positionandreleasethelefthand(traction)lever.While

runningtheauger/impeller,pushdownonthehandlesto

raisethefrontofthemachineafewinches(centimeters)

offthepavement.Thenliftthehandlesquicklytobump

thefrontofthemachineonthepavement.Repeatif

necessaryuntilastreamofsnowcomesoutthedischarge

chute.

•Ifyoucannotunclogthedischargechutebybumping

thefrontofthemachine,stoptheengine,waitfor

allmovingpartstostop,andusethecleanouttool;

neveruseyourhand.

•Ifashield,safetydevice,ordecalisdamaged,illegible,or

lost,repairorreplaceitbeforebeginningoperation.

•Donotsmokewhilehandlinggasoline.

•Donotusethemachineonaroof.

•Donottouchtheenginewhileitisrunningorsoonafter

ithasstoppedbecausetheenginemaybehotenoughto

causeaburn.

MaintenanceandStorage

•Checkallfastenersatfrequentintervalsforproper

tightnesstobesurethemachineisinsafeworking

condition.

•Neverstorethemachinewithfuelinthefueltankinsidea

buildingwhereignitionsourcesarepresentsuchashot

waterheaters,spaceheaters,orclothesdryers.Allowthe

enginetocoolbeforestoringinanyenclosure.

•AlwaysrefertotheOperator’ sManualforimportantdetails

ifthemachineistobestoredforanextendedperiod.

•Maintainorreplacesafetyandinstructionlabels,as

necessary.

•Runthemachineafewminutesafterthrowingsnowto

preventfreeze-upoftherotorblades.

ToroSnowthrowerSafety

ThefollowinglistcontainssafetyinformationspecictoToro

machinesorothersafetyinformationthatyoumustknow .

•Rotatingauger/impellercanamputateorinjure

ngersorhands.Staybehindthehandlesandawayfrom

thedischargeopeningwhileoperatingthemachine.Keep

yourface,hands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingorrotatingparts.

•Beforeadjusting,cleaning,inspecting,troubleshooting,or

repairingthemachine,stoptheengine,removethekey,

andwaitforallmovingpartstostop.Disconnect

thewirefromthesparkplugandkeepitawayfrom

thesparkplugtopreventsomeonefromaccidentally

startingtheengine.

•Performonlythosemaintenanceinstructionsdescribedin

thismanual.Beforeperforminganymaintenance,service,

oradjustment,stoptheengine,removethekey,and

disconnectthewirefromthesparkplug.Ifmajorrepairs

areeverneeded,contactyourAuthorizedServiceDealer.

•Donotchangethegovernorsettingsontheengine.

•Whenstoringthemachineformorethan30days,drain

thefuelfromthefueltanktopreventapotentialhazard.

Storefuelinanapprovedfuelcontainer.Removethekey

fromtheignitionswitchbeforestoringthemachine.

•PurchaseonlygenuineTororeplacementpartsand

accessories.

4

Page 5

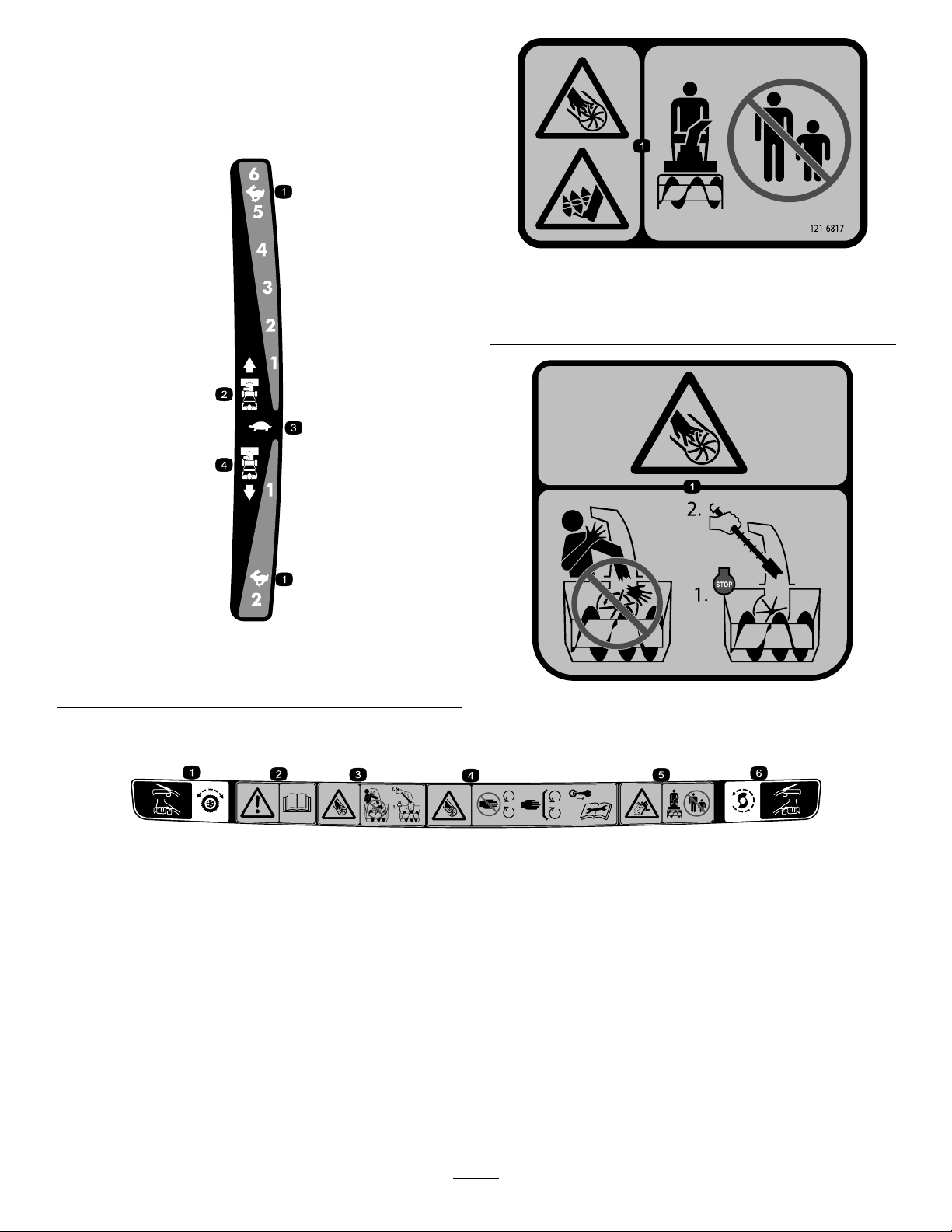

SafetyandInstructional

Decals

Important:Safetyandinstructiondecalsarelocated

nearareasofpotentialdanger.Replacedamageddecals.

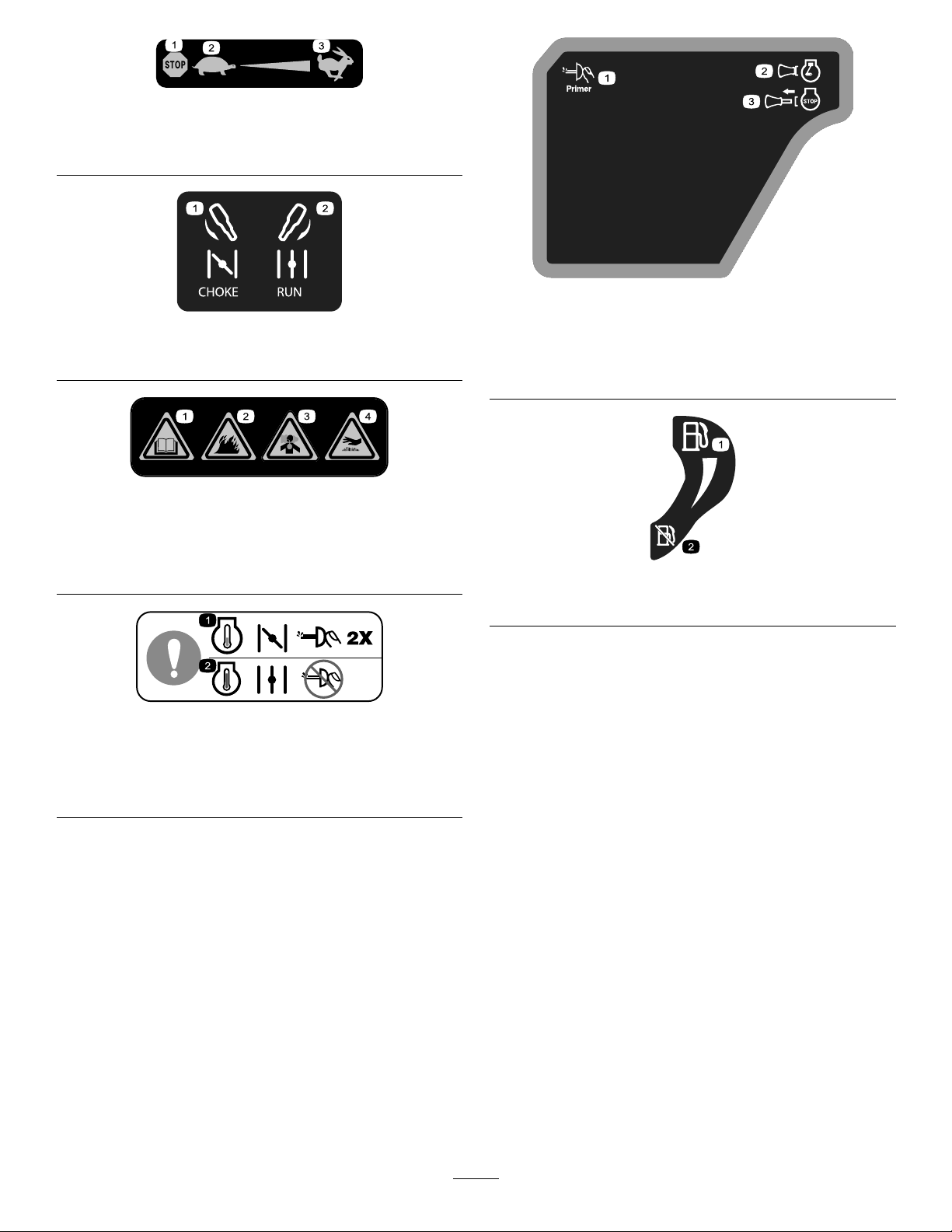

121–6817

1.Cuttingdismemberment,impellerandcutting

dismemberment,augerhazards—keepbystandersasafe

distancefromthesnowthrower.

121–6823

1.Fast

2.Forwardspeeds4.Reversespeeds

1.Tractiondrive—squeezethelevertoengage;releasethe

levertodisengage.

2.Warning—readtheOperator’sManual.5.Thrownobjecthazard—keepbystandersasafedistancefrom

3.Cutting/dismembermenthazard,impeller—donotplace

yourhandinthechute;stoptheenginebeforeleavingthe

operatingposition,usethetooltoclearthechute.

3.Slow

121–1239

Reorderpartno.121–1215

121–1240

Reorderpartno.120–7194

4.Cuttingdismembermenthazard,impeller—keepaway

frommovingparts;removetheignitionkeyandreadthe

instructionsbeforeservicingorperformingmaintenance.

thesnowthrower.

6.Auger/impellerdrive—squeezethelevertoengage;release

thelevertodisengage.

5

Page 6

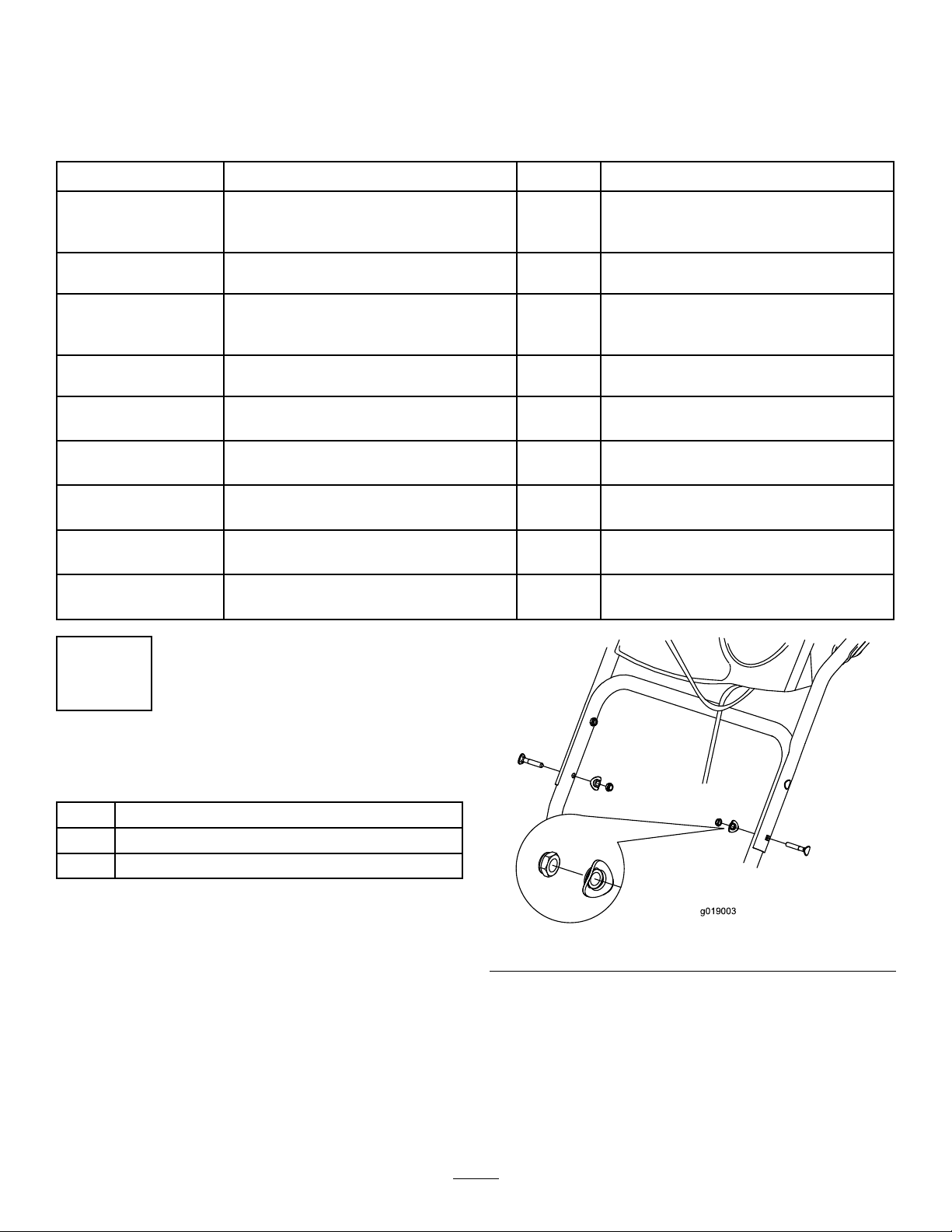

Briggs&StrattonPartNo.273676

1.Stop

2.Slow

3.Fast

Briggs&StrattonPartNo.275949

1.Chokeon(Choke)2.Chokeoff(Run)

Briggs&StrattonPartNo.276925

1.Warning—readthe

Operator'sManual.

2.Warning—rehazard.

3.Warning—toxicgas

inhalationhazard.

4.Warning—hot

surface/burnhazard.

Briggs&StrattonPartNo.277588

1.Primer3.Ignitionkeyout

(Engine—Stop)

2.Ignitionkeyin

(Engine—Run)

Briggs&StrattonPartNo.278866

Briggs&StrattonPartNo.277566

1.Whenstartingacold

engine,closethechoke

andpresstheprimertwo

times.

1.Fuel—On2.Fuel—Off

2.Whenstartingawarm

engine,openthechoke

anddonotpressthe

primer.

6

Page 7

Setup

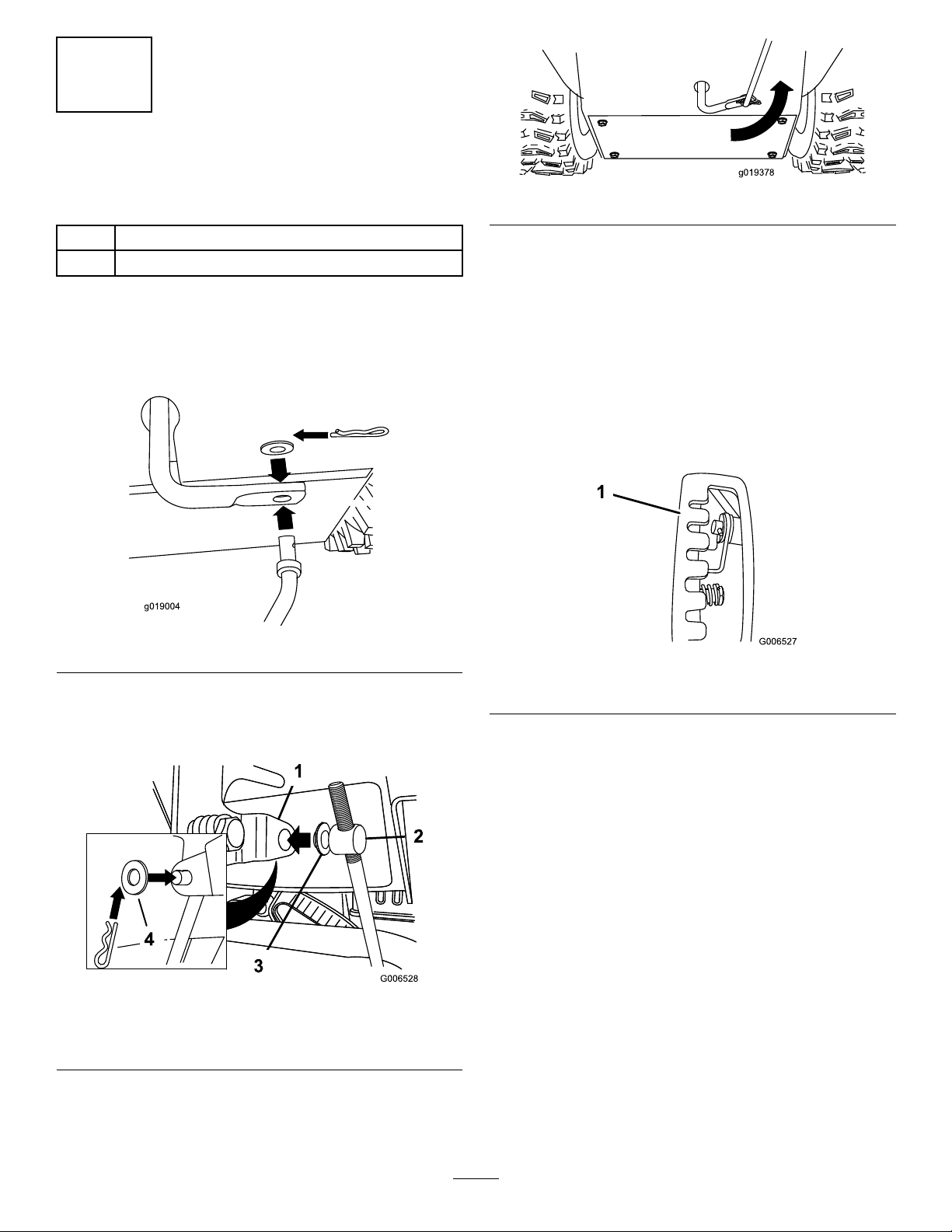

g019003

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

8

9

Handlebolts2

Curvedwashers

Locknuts2

Hairpincotter2

Flatwasher3

Nut2

Carriagebolt

Flatwasher2

Carriagebolts

Locknuts2

Cabletie

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

Use

2

2

2

1

–

–

–

–

Installtheupperhandle.

Installthetractioncontrollinkage.

Installthechute.

Installthechutecontrolrod.

Connectthewiretotheheadlight.

Checktheengineoillevel.

Checkthetirepressure.

Checktheskidsandscraper.

Checktheoperationofthetractiondrive.

1

InstallingtheUpperHandle

Partsneededforthisprocedure:

2Handlebolts

2

Curvedwashers

2Locknuts

Procedure

1.Liftandrotatetheupperhandleandpositionitover

thelowerhandle(Figure3).

2.Install2handlebolts,2curvedwashers,and2locknuts

inthelowerhandleholes(Figure3).

Figure3

7

Page 8

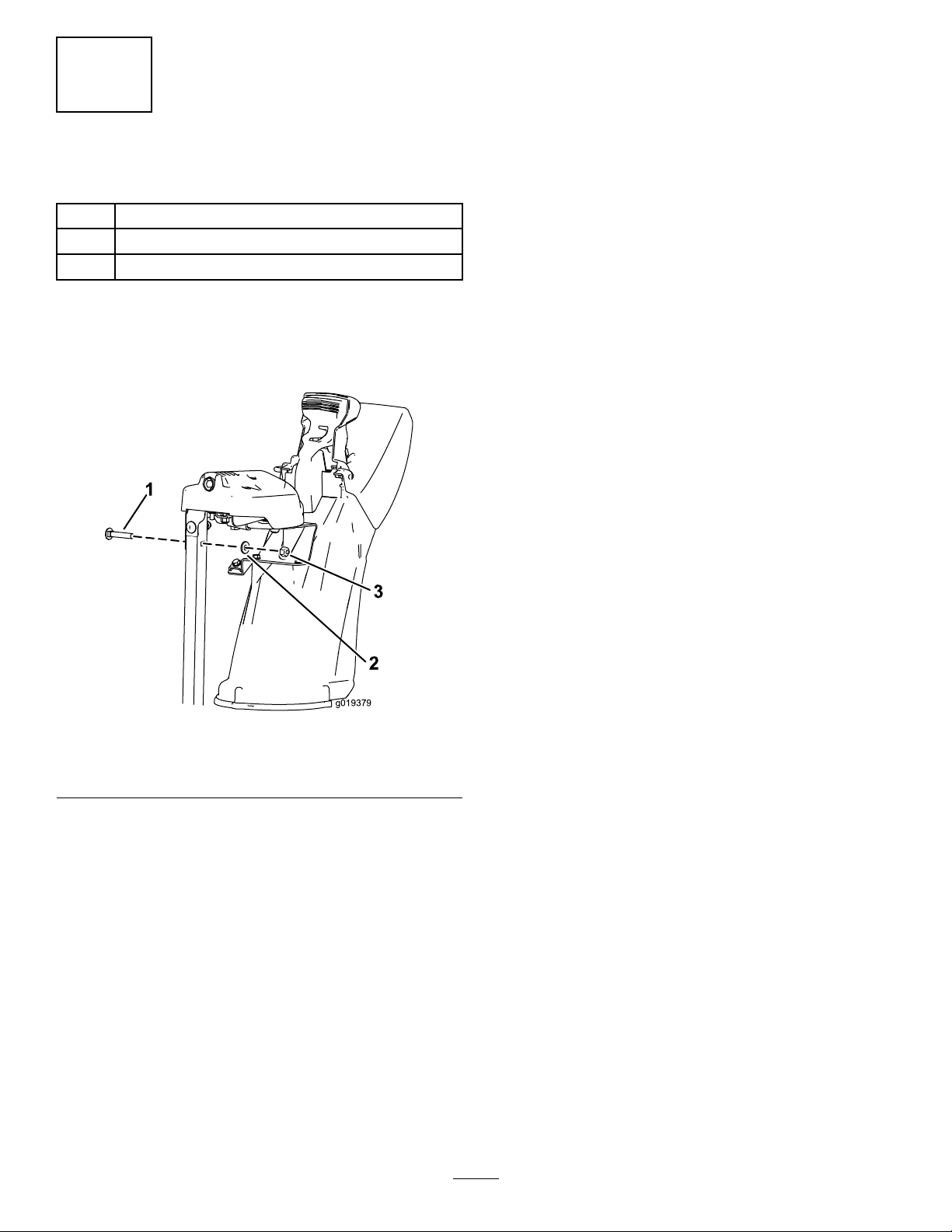

2

g019004

g019378

InstallingtheTractionControl Linkage

Partsneededforthisprocedure:

Figure6

2Hairpincotter

3Flatwasher

Procedure

1.Insertthelowerendoftherodintothelowerlinkarm

sothatthebentendofthespeedcontrolrodfaces

rearward(Figure4).

Figure4

2.Securethelowerendofthespeedcontrolrodwitha

atwasherandahairpincotter(Figure4).

3.Placeaatwasheronthetrunnion(Figure5).

6.Pulluponthespeedcontrolrodandinsertthetrunnion

intotheholeinthespeedselectorlever(Figure5).

Note:Ifthetrunniondoesnottintothehole

whenyouliftuponthespeedcontrolrod,rotatethe

trunnionupwardordownwardonthespeedcontrol

roduntilitts.

7.Securethetrunnionandupperendofthespeedcontrol

rodwithawasherandahairpincotter.

Note:Foreasierinstallation,lookdownthroughthe

openinginthespeedselector(Figure7).

Figure7

1.Speedselector

Figure5

1.Speedselectorlever

2.Trunnion

4.ShiftthespeedselectorleverintoPositionR2.

5.Rotatethelowerlinkarmfullyupward

(counterclockwise)(Figure6).

3.Innerwasher

4.Outerwasher

8

Page 9

3

3

1

2

g019379

InstallingtheChute

Partsneededforthisprocedure:

2Nut

2

Carriagebolt

2Flatwasher

Procedure

1.Placethechuteontheframeandthealignthedischarge

chutemounttothechutesupport.

Figure8

1.Carriagebolt

2.Flatwasher

2.Securethedischargechutemountusing2bolts,2nuts,

and2atwashers.

3.Nut

9

Page 10

4

g018885

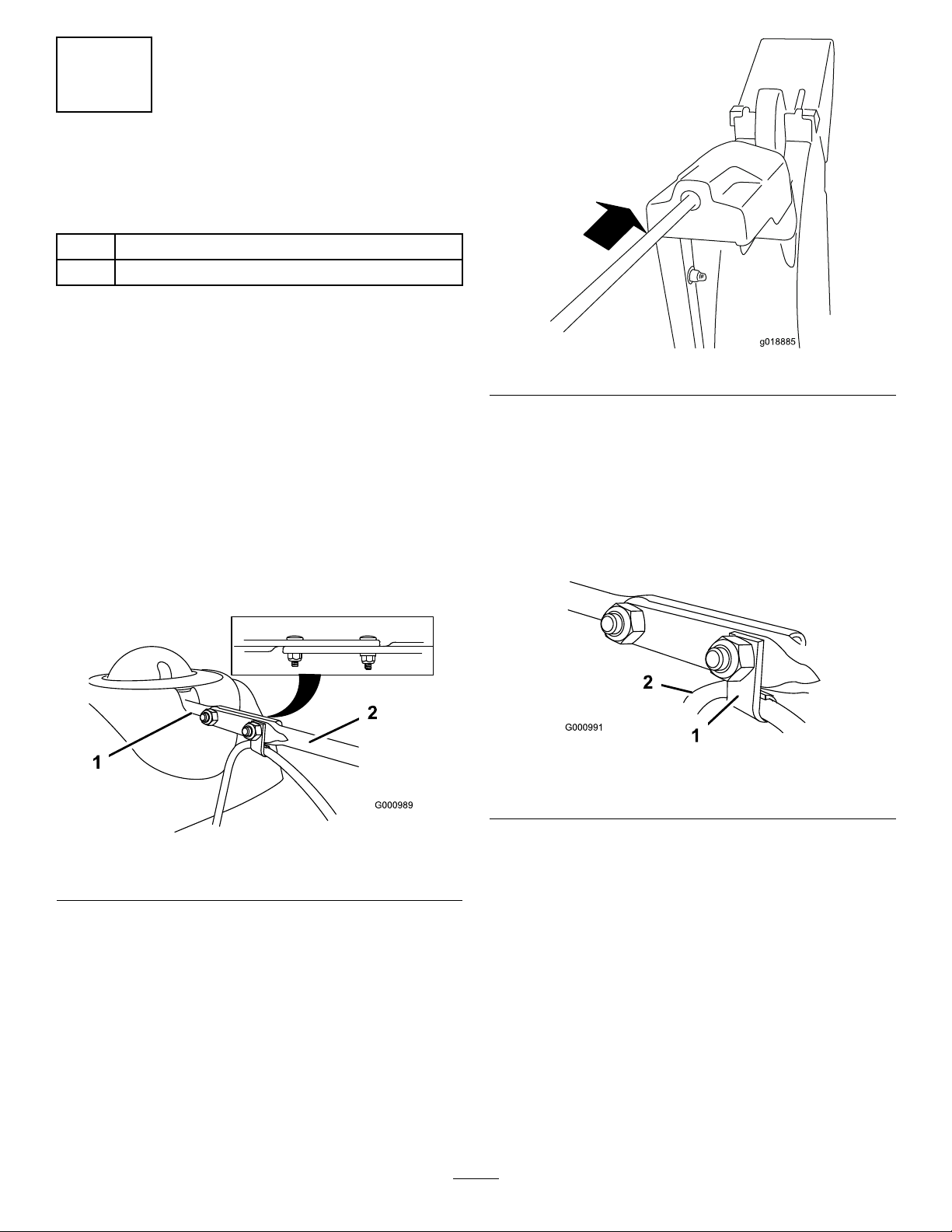

InstallingtheChuteControl Rod

Partsneededforthisprocedure:

2

Carriagebolts

2Locknuts

Procedure

1.UnwraptheQuickStickandrotateitsothatitis

uprightandinthecenter.

2.Holdthebluetriggercapdownandpulltheleverfully

rearward.

Note:Thedischargechuteanddeectorshouldface

forward.Iftheydonot,holdthebluetriggercap

down(butdonotmovetheQuickStick)androtatethe

dischargechuteuntiltheydo.

3.Aligntheattenedbackendofthelongchutecontrol

rodwiththeattenedfrontendoftheshortrod

thatextendsfromthecontrolpanelsothattheynest

together(Figure9).

Figure10

5.Aligntheholesinthenestedendsoftherodsand

insert2carriagebolts(intheloosepartsbag)through

theshortrodfromtheleftsideofthemachine(from

theoperatingposition).

6.Insertthecableclipthatsupportsthedeectorcable

ontotheforwardcarriagebolt,andsecurethecarriage

boltswithlocknutsfromtheloosepartsbag(Figure

11).

Figure11

1.Cableclip2.Deectorcable

Figure9

1.Shortrod

4.Insertthefrontendoftherodintotheopeningin

thebackofthechutegearcoveruntilitslidesintothe

chutegear(Figure10).

2.Longchutecontrolrod

7.HoldthebluetriggercapdownandrotatetheQuick

Stickinacircletoensurethatthechuteanddeector

operatesmoothly.

10

Page 11

1

2

3

G016761

Note:Beforestartingtheengine,checktheoilleveland

g019049

g018886

addoilifnecessary.

5

ConnectingtheWiretothe

Headlight

Partsneededforthisprocedure:

1

Cabletie

Procedure

Allmodelsexcept38614

1.Insertthewireconnectoronthelooseendofthewire

straightintothebackoftheheadlightuntilitissecurely

inplace(Figure12).

UseautomotivedetergentoilwithanAPIserviceclassication

ofSF ,SG,SH,SJ,SL,orhigher.Refertoyourengineowner's

manual.

UseFigure13belowtoselectthebestoilviscosityforthe

outdoortemperaturerangeexpected:

Figure13

EngineOilCapacities

Figure12

1.Plasticcliponwire

connector

2.U-bolt

Note:Ensurethattheplasticcliponthewire

connectorisonthebottom(Figure12).

2.Secureacabletie(fromtheloosepartsbag)aroundthe

wireandthehandleaboutaninch(2.5cm)belowthe

U-bolt(Figure12).

3.Cabletie

6

CheckingtheEngineOilLevel

Model

37777

1.Removethedipstickandslowlypouroilintotheoil

lltubetoraisetheoilleveltotheFullmarkonthe

dipstick.Donotoverll.(Figure14).

2.Installthedipsticksecurely.

EngineOilCapacity

18to20oz.(0.53to0.59l)

Figure14

NoPartsRequired

Procedure

Yourmachinecomeswithoilintheenginecrankcase.

Note:Donotspilloilaroundtheoillltube;oilcould

leakontotractionpartsandcausethetractiontoslip.

11

Page 12

7

CheckingtheTirePressure

NoPartsRequired

Procedure

Thetiresareoverinatedatthefactoryforshipping.Reduce

thepressureequallyinbothtirestobetween17and20psi

(116and137kPa).

1.Starttheengine;refertoStartingtheEngine.

2.MovethespeedselectortoPositionR1;referto

OperatingtheSpeedSelector.

3.Squeezethelefthand(traction)levertothehand-grip

(Figure15).

Figure15

8

CheckingtheSkidsand Scraper

NoPartsRequired

Procedure

RefertoCheckingandAdjustingtheSkidsandScraperin

Maintenance.

9

CheckingtheTractionDrive Operation

NoPartsRequired

Themachineshouldmoverearward.Ifthemachine

doesnotmoveormovesforward,completethe

following:

A.Releasethetractionleverandstoptheengine.

B.Disconnectthetrunnionfromthespeedselector

lever(Figure5).

C.Turnthetrunniondownward(clockwise)onthe

speedcontrolrod(Figure5).

D.Connectthetrunniontothespeedselectorlever

(Figure5).

4.Releasethetractionlever.

5.MovethespeedselectortothePosition1;referto

OperatingtheSpeedSelector.

6.Squeezethelefthand(traction)levertothehand-grip

(Figure15).

Themachineshouldmoveforward.Ifthemachine

doesnotmoveormovesrearward,completethe

following:

A.Releasethetractionleverandstoptheengine.

Procedure

CAUTION

Ifthetractiondriveisnotproperlyadjusted,the

machinemaymoveinthedirectionoppositeof

whatyouintended,causinginjuryand/orproperty

damage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary.

Note:Tocheckthetractiondriveoperation,theself-propel

featuremustbeengagedbyensuringthewheelsarepinned

intheaxle.Referto(page).

B.Disconnectthetrunnionfromthespeedselector

lever(Figure5).

C.Turnthetrunnionupward(counterclockwise)on

thespeedcontrolrod(Figure5).

D.Connectthetrunniontothespeedselectorlever

(Figure5).

7.Ifyoumadeanyadjustments,repeatthisprocedure

untilnoadjustmentsarerequired.

Important:Ifthemachinemoveswhenthetraction

leverisinthereleasedposition,checkthetractioncable

(refertoCheckingandAdjustingtheTractionCable)or

takethemachinetoanAuthorizedServiceDealerfor

service.

12

Page 13

ProductOverview

g018887

g018888

g019015

g019014

Figure18

1.Snowcleanouttool(attachedtothehandle)

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

FreewheelingorUsingthe Self-propelDrive

Youcanoperatethesnowthrowerwiththeself-propelfeature

engagedordisengaged(freewheeling).

Figure16

1.Hand-grip(2)

2.Auger/impellerlever10.Scraper

3.Speedselectorlever

4.QuickStick™discharge

chutecontrol

5.Tractionlever13.Electricstarterbutton

6.Fueltankcap14.Electricstarterplug-in

7.Engineoillltube/dipstick15.Snowcleanouttool

8.Chutedeector

9.Dischargechute

11.Auger

12.Skid(2)

Tofreewheel,slidethewheelsinwardandinserttheaxle

pinsthroughtheaxleholes,butnotthroughthewheelhubs

(Figure19).

Figure19

Toself-propel,axlepinthroughtheholesinthewheelhubs

andtheinneraxleholes(Figure20).

Figure20

1.Choke

2.Ignitionswitch

3.Fuelshutoffvalve

4.Throttle

Figure17

5.Recoilstarter

6.Oildrainplug

7.Primer

FillingtheFuelTank

RecommendedFuel:

•Forbestresults,useonlyclean,fresh(lessthan30days

old),unleadedgasolinewithanoctaneratingof87or

higher((R+M)/2ratingmethod).

•Ethanol:Gasolinewithupto10%ethanol(gasohol)

or15%MTBE(methyltertiarybutylether)byvolume

isacceptable.EthanolandMTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeisnot

13

Page 14

approvedforuse.Neverusegasolinethatcontains

g018889

morethan10%ethanolbyvolume,suchasE15

(contains15%ethanol),E20(contains20%ethanol),or

E85(containsupto85%ethanol).Usingunapproved

gasolinemaycauseperformanceproblemsand/orengine

damagewhichmaynotbecoveredunderwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•Donotaddoiltogasoline.

Important:Toreducestartingproblems,addfuel

stabilizertothefuelallseason,mixingitwithgasoline

lessthan30daysold;runthemachinedrybeforestoring

itformorethan30days.

Donotusefueladditivesotherthanafuel

stabilizer/conditioner.Donotusefuelstabilizers

withanalcoholbasesuchasethanol,methanol,or

isopropanol.

DANGER

Figure21

1.1-1/2inch(3.8cm)

Gasolineisextremelyammableandexplosive.A

reorexplosionfromgasolinecanburnyouand

others.

•Topreventastaticchargefromignitingthe

gasoline,placethecontainerand/ormachine

directlyonthegroundbeforelling,notina

vehicleoronanobject.

•Fillthetankoutdoorswhentheengineiscold.

Wipeupspills.

•Donothandlegasolinewhensmokingoraround

anopenameorsparks.

•Storegasolineinanapprovedfuelcontainer,out

ofthereachofchildren.

14

Page 15

StartingtheEngine

g018890

g018891

g018892

1.Checktheengineoillevel.RefertoCheckingthe

EngineOilLevelinMaintenance.

2.Turnthefuelshutoffvalve1/4turncounterclockwise

toopenit(Figure22).

Figure22

3.Inserttheignitionkey(Figure23).

Figure23

1.Ignitionkey

Figure24

5.RotatethechoketotheChokeposition(Figure25).

Figure25

6.MovethethrottletotheFastposition(Figure26).

4.Firmlypushintheprimerwithyourthumb2times

(15°For-9°Corabove)or4times(below15°For

-9°C),holdingtheprimerinforasecondbefore

releasingiteachtime(Figure24).

Figure26

7.Startthemachinepullingtherecoilstarterorpressing

theelectric-starterbutton(Figure27).

15

Page 16

g018893

Figure27

1.Electric-starterbutton3.Recoilstarter

2.Electricstarterplug-in

StoppingtheEngine

1.MovethethrottletotheSlowposition,andthentothe

Stopposition(Figure28).

Figure28

Note:Tousetheelectricstarter,connectapower

cordtotheelectricstarterplug-inrstandthentoa

poweroutlet.UseonlyaUL-listed,16-gaugeextension

cordrecommendedforoutdoorusethatisnotlonger

than50feet(15m).

WARNING

Theelectricalcordcanbecomedamaged,

causingashockorre.

Thoroughlyinspecttheelectricalcordbefore

usingthemachine.Ifthecordisdamaged,

donotoperatethemachine.Replaceorrepair

thedamagedcordimmediately.Contactan

AuthorizedServiceDealerforassistance.

Important:Topreventdamagingtheelectric

starter,runitinshortcycles(5secondsmaximum,

thenwaitoneminutebeforetryingtostartit

again).Iftheenginestilldoesnotstart,take

themachinetoanAuthorizedServiceDealerfor

service.

8.Disconnectthepowercordfromthepoweroutletrst

andthenfromthemachine(electricstartonly).

2.Waitforallmovingpartstostopbeforeleavingthe

operatingposition.

3.Removetheignitionkey.

4.Closethefuelshutoffvalvebyrotatingitclockwise

(Figure29).

Figure29

5.Pulltherecoilstarter3or4times.Thishelpsprevent

therecoilstarterfromfreezingup.

OperatingtheTractionDrive

9.Allowtheenginetowarmupforseveralminutes,move

thechoketowardtheRunposition.Waitfortheengine

torunsmoothlybeforeeachchokeadjustment.

CAUTION

Ifyouleavethemachinepluggedintoa

poweroutlet,someonecaninadvertentlystart

themachineandinjurepeopleordamage

property.

Unplugthepowercordwheneveryouarenot

startingthemachine.

CAUTION

Ifthetractiondriveisnotproperlyadjusted,the

machinemaymoveinthedirectionoppositeof

whatyouintended,causinginjuryand/orproperty

damage.

Carefullycheckthetractiondriveandadjustit

properly,ifnecessary;refertoCheckingtheTraction

DriveOperationinSetupformoreinformation.

Important:Ifthemachinemoveswhenthetraction

leverisinthereleasedposition,checkthetractioncable

16

Page 17

(refertoCheckingandAdjustingtheTractionCable)or

takethemachinetoanAuthorizedServiceDealerfor

service.

Important:T ooperatethetractiondrive,youmust

operatethemachinewiththeself-propelfeature

engaged.RefertoFreewheelingorUsingtheSelf-propel

Drive.

1.Toengagethetractiondrive,squeezethelefthand

(traction)levertothehandgrip(Figure30).

Figure30

2.Tostopthetractiondrive,releasethetractionlever.

OperatingtheSpeedSelector

Thespeedselectorhas6forwardand2reversegears.To

changespeeds,releasethetractionleverandshiftthespeed

selectorlevertothedesiredposition(Figure31).Thelever

locksinanotchateachspeedselection.

Figure32

2.Tostoptheaugerandimpeller,releasetherighthand

lever.

Important:Whenyouengageboththe

auger/impellerleverandthetractionlever,the

tractionleverlockstheauger/impellerleverdown,

freeingyourrighthand.Toreleasebothlevers,

simplyreleasethelefthand(traction)lever.

3.Iftheaugerandimpellercontinuetorotatewhenyou

releasetheauger/impellerlever,donotoperatethe

machine.Checktheauger/impellercable(referto

CheckingandAdjustingtheAuger/ImpellerCable)

andadjustitifnecessary.Otherwise,takethemachine

toanAuthorizedDealerforservice.

WARNING

Iftheaugerandimpellercontinuetorotate

whenyoureleasetheauger/impellerlever,

donotoperatethemachine,asyoucould

seriouslyinjureyourselforothers.

Figure31

OperatingtheAuger/Impeller Drive

1.Toengagetheauger/impellerdrive,squeezetheright

hand(auger/impeller)levertothehandgrip(Figure

32).

TakeittoanAuthorizedServiceDealerfor

service.

OperatingtheQuickStick™

HoldthebluetriggercapdowntousetheQuickStickto

movethedischargechuteandthechutedeector.Releasethe

triggercaptolockthedischargechuteandchutedeector

intoposition(Figure33).

Figure33

17

Page 18

MovingtheDischargeChute

g018894

UncloggingtheDischarge

HoldthebluetriggercapdownandmovetheQuickStick

tothelefttomovethedischargechutetotheleft;movethe

QuickSticktotherighttomovethedischargechutetothe

right(Figure34).

Figure34

Chute

WARNING

Iftheauger/impellerisrunningbutthereisno

snowcomingoutofthedischargechute,the

dischargechutemaybeclogged.

Neveruseyourhandstoclearacloggeddischarge

chute.Thiscouldresultinpersonalinjury.

•Tounclogthedischargechute,stayintheoperating

positionandreleasethelefthand(traction)lever.While

runningtheauger/impeller,pushdownonthehandlesto

raisethefrontofthemachineafewinches(centimeters)

offthepavement.Thenliftthehandlesquicklytobump

thefrontofthemachineonthepavement.Repeatif

necessaryuntilastreamofsnowcomesoutthedischarge

chute.

•Ifyoucannotunclogthedischargechutebybumping

thefrontofthemachine,stoptheengine,waitforall

movingpartstostop,andusethesnowcleanouttool;

neveruseyourhand.

•Ifthechutedoesnotmove,refertoAdjustingthe

DischargeChuteLatch.

•Ifthechutedoesnotturnasfartotheleftasitdoesto

theright,ensurethatthecableisroutedtotheinsideof

thehandles.RefertoInstallingtheUpperHandle.

•Ifthechutedoesnotlockintoplacewhenyoureleasethe

triggercap,refertoAdjustingtheDischargeChuteLatch.

MovingtheChuteDeector

HoldthebluetriggercapdownandmovetheQuickStick

forwardtolowerthechutedeector;moveitrearwardtoraise

thechutedeector(Figure35).

Important:Uncloggingthedischargechuteby

bumpingthefrontofthemachineonthepavement

maycausetheskidstomove.Adjusttheskidsand

tightentheskidboltssecurely.

PreventingFreeze-up

•Insnowyandcoldconditions,somecontrolsandmoving

partsmayfreeze.Donotuseexcessiveforcewhen

tryingtooperatefrozencontrols.Ifyouhavedifculty

operatinganycontrolorpart,starttheengineandletit

runforafewminutes.

•Afterusingthemachine,lettheenginerunforafew

minutestopreventmovingpartsfromfreezing.Engage

theauger/impellertoclearanyremainingsnowfrom

insidethehousing.RotatetheQuickSticktopreventit

fromfreezing.Stoptheengine,waitforallmovingparts

tostop,andremovealliceandsnowfromthemachine.

•Withtheengineoff,pulltherecoilstarterhandleseveral

timesandpushtheelectric-starterbuttononcetoprevent

therecoilandelectricstartersfromfreezingup.

Figure35

18

Page 19

OperatingTips

DANGER

Whenthemachineisinoperation,theimpellerand

augerrotateandcaninjureoramputatehandsor

feet.

•Beforeadjusting,cleaning,inspecting,

troubleshooting,orrepairingthemachine,stop

theengineandwaitforallmovingpartstostop.

Disconnectthewirefromthesparkplugand

keepitawayfromtheplugtopreventsomeone

fromaccidentallystartingtheengine.

•Removeanobstructionfromthedischarge

chute;refertoUncloggingtheDischargeChute.

Ifnecessary,usethesnowcleanouttool,not

yourhands,toremoveanobstructionfromthe

dischargechute.

•Staybehindthehandlesandawayfromthe

dischargeopeningwhileoperatingthemachine.

•Keepface,hands,feet,andanyotherpartof

yourbodyorclothingawayfromconcealed,

moving,orrotatingparts.

WARNING

Theimpellercanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonalinjuryto

theoperatorortobystanders.

•Keeptheareatobeclearedfreeofallobjects

thattheaugercouldpickupandthrow.

•Keepallchildrenandpetsawayfromthearea

ofoperation.

•AlwayssetthethrottletotheFastpositionwhenthrowing

snow .

•Iftheengineslowsdownunderaloadorthewheelsslip,

shiftthemachineintoalowergear.

•Ifthefrontofthemachineridesup,shiftthemachine

intoalowergear.Ifthefrontcontinuestorideup,liftup

onthehandles.

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst2hours

Aftertherst5hours

Beforeeachuseordaily

Yearly

Yearlyorbeforestorage

MaintenanceProcedure

•Inspectthetractioncableandadjustitifnecessary.

•Inspecttheauger/impellercableandadjustitifnecessary.

•Changetheengineoil.

•

•Checktheengineoillevelandaddoilifnecessary.

•Checktheskidsandthescraperandadjustthemifnecessary.

•Inspectthetractioncableandadjustorreplaceitifnecessary.

•Inspecttheauger/impellercableandadjustorreplaceitifnecessary.

•Checktheaugergearboxoilandaddoilifnecessary.

•Changetheengineoil.

•Lubricatethehexshaft.

•Replacethesparkplug.

•Checktheairpressureinthetiresandinatethemto17–20psi(116–137kPa).

•Drainthegasolineandruntheenginetodryoutthefueltankandthecarburetorat

theendoftheseason.

•HaveanAuthorizedServiceDealerinspectandreplacethetractiondrivebeltand/or

theauger/impellerdrivebelt,ifnecessary.

Important:Youcanndmoreinformationaboutmaintainingandservicingyourmachineatwww.T oro.com.

19

Page 20

Important:Refertoyourengineoperator'smanualforadditionalmaintenanceprocedures.Forengineadjustments,

g018886

g019046

1

repairs,orwarrantyservicenotcoveredinthismanual,contactanAuthorizedBriggs&StrattonServicingDealer.

ServiceInterval:Beforeeachuseordaily

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthesparkplugwire.RefertoReplacing

theSparkPlug.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily—Checktheengine

oillevelandaddoilifnecessary.

1.Removethedipstick,wipeitclean,thenfullyinstall

thedipstick.

2.Removethedipstickandchecktheoillevel(Figure36).

IftheoillevelisbelowtheAddmarkonthedipstick,

addoil.RefertoFillingtheEnginewithOil.

CheckingandAdjustingthe SkidsandScraper

ServiceInterval:Yearly—Checktheskidsandthescraper

andadjustthemifnecessary.

Checktheskidsandthescrapertoensurethattheaugerdoes

notcontactthepavedorgravelsurface.Adjusttheskidsand

thescraperasneededtocompensateforwear.

1.Checkthetirepressure.RefertoCheckingtheTire

Pressure.

2.Loosenthenutsthatsecurebothskidstotheauger

sidesuntiltheskidsslideupanddowneasily.

Figure36

Figure37

1.1/8inch(3mm)

Important:Theaugerbladesmustbesupported

abovethegroundbytheskids.

3.Ensurethatthescraperis1/8inch(3mm)aboveand

paralleltoalevelsurface.

Note:Ifthepavementiscracked,rough,oruneven,

adjusttheskidstoraisethescraper.Forgravelsurfaces,

adjusttheskidsfurtherdowntopreventthemachine

frompickinguprocks.

4.Movetheskidsdownuntiltheyareevenwiththe

ground.

5.Firmlytightenthenutsthatsecurebothskidstothe

augersides.

Note:Toquicklyadjusttheskidsiftheyloosen,

supportthescraper1/8inch(3mm)offthepavement,

thenadjusttheskidsdowntothepavement.

Note:Iftheskidsbecomeexcessivelyworn,youcan

turnthemoverandsettheunusedsidetowardthe

pavement.

20

Page 21

CheckingandAdjustingthe

3

g019048

4

2

1

3

g019047

4

TractionCable

ServiceInterval:Aftertherst2hours—Inspectthe

tractioncableandadjustitifnecessary.

4.Tightenthejamnut(Figure39),ensuringthereisslight

tensiononthecable.

5.Ifthetractioncableisproperlyadjustedbutaproblem

remains,contactanAuthorizedServiceDealer.

Yearly—Inspectthetractioncableandadjustor

replaceitifnecessary.

Ifthemachinedoesnotdriveintheforwardorreversespeeds

oritdriveswhenyoureleasethetractionlever,adjustthe

tractioncable.

Ifthelefthand(traction)cableisnotproperlyadjusted,do

thefollowingsteps:

1.Loosenthejamnut.

2.Engagethetractionleverandholditinplace(Figure

38).

Figure38

CheckingandAdjustingthe Auger/ImpellerCable

ServiceInterval:Aftertherst2hours—Inspectthe

auger/impellercableandadjustitif

necessary.

Yearly—Inspecttheauger/impellercableandadjust

orreplaceitifnecessary.

1.Loosenthejamnut.

2.Engagetheauger/impellerleverandholditinplace

(Figure40).

Figure40

3.Loosenortightentheturnbuckletoadjustspring

lengthto2.18inches(5.5cm)(Figure39).

1.Jamnut

2.Turnbuckle

Figure39

3.Spring

4.2.18inches(5.5cm)

3.Loosenortightentheturnbuckletoadjustthespring

lengthto2.75inches(7cm)(Figure41)

Figure41

1.Jamnut

2.Turnbuckle

4.Tightenthejamnut(Figure41),ensuringthereisslight

tensiononthecable.

3.Spring

4.2.75inches(7cm)

21

Page 22

5.Iftheauger/impellercableisproperlyadjustedbut

g019049

aproblemremains,contactanAuthorizedService

Dealer.

ChangingtheEngineOil

ServiceInterval:Aftertherst5hours—Changetheengine

oil.

CheckingtheAugerGearbox OilLevel

ServiceInterval:Yearly—Checktheaugergearboxoiland

addoilifnecessary.

1.Movethemachinetoalevelsurface.

2.Cleantheareaaroundthepipeplug(Figure42).

Figure42

3.Removethepipeplugfromthegearbox.

4.Checktheoillevelinthegearbox.Theoilshouldbe

3/8inch(9.5mm)belowthelleropening.

Yearly—Changetheengineoil.

Ifpossible,runtheenginejustbeforechangingtheoilbecause

warmoilowsbetterandcarriesmorecontaminants.

UseautomotivedetergentoilwithanAPIserviceclassication

ofSF ,SG,SH,SJ,SL,orhigher.Refertoyourengineowner's

manual.

UseFigure43belowtoselectthebestoilviscosityforthe

outdoortemperaturerangeexpected:

Figure43

5.Iftheoillevelislow ,addGL-5orGL-6,SAE80-90

EPgearoillubricanttothegearboxuntiltheoillevel

is3/8inchbelowthelleropening.

Note:Donotusesyntheticoil.

6.Installthepipepluginthegearbox.

EngineOilCapacities

Model

37777

1.Cleantheareaaroundtheoildraincap(Figure44).

1.Oildraincap

2.Slideanoildrainpanunderthedrainextensionand

removetheoildraincap.

3.Draintheoil.

Note:Disposeoftheusedoilproperlyatalocal

recyclingcenter.

4.Installtheoildraincap.

EngineOilCapacity

18to20oz.(0.53to0.59l)

Figure44

5.Fillthecrankcasewithoil.RefertoFillingtheEngine

CrankcasewithOil.

22

Page 23

LubricatingtheHexShaft

g019018

g019019

1

ServiceInterval:Y early—Lubricatethehexshaft.

9.Installthebackcoverandreturnthemachinetothe

operatingposition.

Lightlylubricatethehexshaftyearlywithautomotiveengine

oil(Figure45).

Figure45

1.Hexshaft

2.Steelfrictionpulley

3.Rubberwheel

Important:Donotgetoilontherubberwheelorthe

steelfrictionpulleybecausethetractiondrivewillslip

(Figure45).

1.Drainthegasolinefromthefueltank.

2.Tipthemachineforwardontoitsaugerhousingand

blockitsothatitcannotfall.

ReplacingtheSparkPlug

ServiceInterval:Y early—Replacethesparkplug.

UseaChampionQC12YCorequivalentsparkplug.

Note:Toaccessthesparkplug,youmustrstremovethe

uppersnowhood(Figure47).

Figure47

1.Chokeknob

2.Uppersnowhood

3.Ignitionkey

4.Screw(2)

3.Removethebackcover(Figure46).

Figure46

1.Screws

4.MovethespeedselectorlevertoPositionR2.

5.Dipyourngerinautomotiveengineoilandlightly

lubricatehexshaft.

6.MovethespeedselectorlevertoPosition6.

1.Removethechokeknobandtheignitionkey(Figure

47).

2.Removethe2screwsthatsecuretheuppersnowhood

tothemachine(Figure47).

3.Slowlyremovetheuppersnowhood,ensuringthat

theprimerbulbhoseandtheignitionwireremain

connected.

4.Removethebracketthumbscrewandthebracket

(Figure48).

7.Lubricatetheotherendofthehexshaft.

8.Movethespeedselectorleverforwardandrearward

afewtimes.

23

Page 24

Figure48

g019021

1

2

3

AdjustingtheDischargeChute Latch

Ifthedischargechutedoesnotlockintothedesiredposition

ordoesnotunlocksothatyoucanmoveittoanother

position,adjustthedischargechutelatch.

1.Loosentheclampfasteneronthechutesupportplate

untilthecableisfree.

1.Spark-plugwire

2.Bracket

5.Cleanaroundthebaseofthesparkplug(Figure48).

6.Removeanddiscardtheoldsparkplug.

Note:Y ouwillneedaratchetwrenchextensionto

removethesparkplug.

7.Setthegapbetweentheelectrodesonanewsparkplug

at0.030inch(0.76mm)(Figure49).

1.0.030inch(0.76mm)

8.Installthenewsparkplug,tightenitrmly,andattach

theignitionwiretothesparkplug.

9.Installthebracketwiththethumbscrewthatyou

removedinstep4.

10.Ensurethattheprimerbulbhoseandtheignitionwire

areconnectedandclearofthecarburetorbracket.

11.Securetheuppersnowhoodtothemachinewiththe2

screwsthatyoupreviouslyremoved.

3.Thumbscrew

Figure49

Figure50

1.Cableconduit3.Clampfastener

2.Cableclamp

2.Removeanyslackinthecablebypullingthecable

conduitrearward.

3.Tightentheclampfastenerwhileholdingthecablein

place.

ReplacingtheDriveBelts

Iftheauger/impellerdrivebeltorthetractiondrivebelt

becomesworn,oil-soaked,orotherwisedamaged,havean

AuthorizedServiceDealerreplacethebelt.

ReplacingtheHeadlightBulb

UseaGE89216Whalogenlightbulb.Donottouchthe

bulbwithyourhandsorallowdirtormoisturetocomeinto

contactwiththebulb.

1.Removethewireconnectorfromthebackofthe

headlight(Figure51).

12.Alignthetabonthechokecontrolknobwiththeslot

ontheuppersnowhood.

13.Connectthechokecontrolknobtothechokeshafton

thecarburetor.

24

Page 25

Figure51

2.Turnthebaseofthebulbcounterclockwiseuntilit

stops(Figure52).

Figure52

3.Removethebulbstraightoutfromthebackofthe

headlight(Figure53).

Figure55

6.Insertthewireconnectorstraightintothebackofthe

headlightuntilitissecurelyinplace(Figure56).

Figure56

Figure53

4.Insertanewbulbintothebackoftheheadlight(Figure

54).

Figure54

5.Turnthebaseofthebulbclockwiseuntilitissnug

(Figure55).

25

Page 26

Storage

WARNING

•Gasolinevaporscanexplode.

•Donotstoregasolinemorethan30days.

•Donotstorethemachineinanenclosurenear

anopename.

•Allowtheenginetocoolbeforestoringit.

PreparingtheMachinefor Storage

1.Onthelastrefuelingoftheyear,addfuelstabilizerto

freshfuelasdirectedbytheenginemanufacturer.

Note:Fuelshouldnotbestoredlongerthansuggested

bythefuelstabilizermanufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Runthemachineuntiltheenginerunsoutoffuel.

4.Primetheengineandstartitagain.

5.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

6.Stoptheengineandallowittocool.

7.Removetheignitionkey.

8.Cleanthemachinethoroughly.

9.Touchupchippedsurfaceswithpaintavailablefroman

AuthorizedServiceDealer.Sandaffectedareasbefore

painting,andusearustpreventativetopreventthe

metalpartsfromrusting.

10.Tightenallloosescrews,bolts,andlocknuts.Repairor

replaceanydamagedparts.

11.Coverthemachineandstoreitinaclean,dryplaceout

ofthereachofchildren.

RemovingtheMachinefrom Storage

1.Removethesparkplugandspintheenginerapidly

usingthestartertoblowtheexcessoilfromthe

cylinder.

2.Installthesparkplugandtightenitrmly.

3.Connectthesparkplugwire.

4.Performtheannualmaintenanceproceduresasgiven

intheRecommendedMaintenanceSchedule.

26

Page 27

Troubleshooting

Problem

Electricstarterdoesnotturn(electric-start

modelsonly)

Enginedoesnotstartorstartshard

PossibleCauseCorrectiveAction

1.Thepowercordisdisconnectedatthe

outletorthemachine.

2.Thepowercordisworn,corroded,or

damaged.

3.Thepoweroutletisnotenergized.

1.Thekeyisnotintheignitionorisinthe

Stopposition.

2.ThechokeisintheOffpositionandthe

primerhasnotbeenpressed.

3.Thefuelshutoffvalveisnotopen.3.Openthefuelshutoffvalve.

4.ThethrottleisnotintheFastposition.4.MovethethrottletotheFastposition.

5.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

6.Thesparkplugwireislooseor

disconnected.

7.Thesparkplugispitted,fouled,orthe

gapisincorrect.

8.Thefuelventcapisrestricted.

9.Theengineoillevelintheengine

crankcaseistoolowortoohigh.

1.Connectthepowercordtotheoutlet

and/orthemachine.

2.Replacethepowercord.

3.Haveaqualiedelectricianenergize

theoutlet.

1.Insertthekeyintotheignitionandturn

ittotheOnposition.

2.MovethechoketotheOnpositionand

presstheprimer3times.

5.Drainand/orllthefueltankwithfresh

gasoline(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

6.Connectthewiretothesparkplug.

7.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

8.Removetheventrestrictionorreplace

thefuelcap.

9.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

Enginerunsrough

1.ThechokeisintheOnposition.1.MovethechoketotheOffposition.

2.Thefuelshutoffvalveisnotcompletely

open.

3.Thefueltankisnearlyemptyor

containsstalefuel.

4.Thesparkplugwireisloose.

5.Thesparkplugispitted,fouled,orthe

gapisincorrect.

6.Theengineoillevelintheengine

crankcaseistoolowortoohigh.

2.Openthefuelshutoffvalve.

3.Drainandllthefueltankwithfresh

gasoline(notmorethan30daysold).

Iftheproblempersists,contactan

AuthorizedServiceDealer.

4.Connectthewiretothesparkplug.

5.Checkthesparkplugandadjustthe

gapifnecessary .Replacethespark

plugifitispitted,fouled,orcracked.

6.Addordrainoiltoadjusttheoillevelin

theenginecrankcasetotheFullmark

onthedipstick.

27

Page 28

Problem

PossibleCauseCorrectiveAction

Engineruns,butthemachinedischarges

snowpoorlyornotatall

Dischargechuteeitherdoesnotlockinto

placeordoesnotmove

Themachinedoesnotproperlyclearthe

snowoffthesurface

1.ThethrottleisnotintheFastposition

whenthrowingsnow .

2.Themachineismovingtoofasttoclear

thesnow.

3.Youaretryingtoremovetoomuch

snowperswath.

4.Youaretryingtoremoveextremely

heavyorwetsnow.

5.Thedischargechuteisplugged.5.Unclogthedischargechute.

6.Theauger/impellerdrivebeltisloose

orisoffthepulley .

7.Theauger/impellerdrivebeltisworn

orbroken.

1.Thedischargechutelatchisnot

properlyadjusted.

1.Theskidsand/orscraperarenot

properlyadjusted.

2.Thepressureinthetiresisnotequal.

1.MovethethrottletotheFastposition.

2.Shiftthemachineintoalowergear.

3.Reducetheamountofsnowremoved

perswath.

4.Don'toverloadthemachinewith

extremelyheavyorwetsnow.

6.Installand/oradjusttheauger/impeller

drivebelt;refertowww.T oro.com

forservicinginformationortakethe

machinetoanAuthorizedService

Dealer.

7.Replacetheauger/impellerdrivebelt;

refertowww.T oro.comforservicing

informationortakethemachinetoan

AuthorizedServiceDealer.

1.Adjustthedischargechutelatch.

1.Adjusttheskidsand/orthescraper .

2.Checkandadjustthepressureinone

orbothtires.

28

Page 29

Notes:

29

Page 30

EmissionControlWarrantyStatement

FortheUnitedStates,California,andCanada

YourWarrantyRightsandObligations

TheCaliforniaAirResourcesBoard(CARB),theU.S.EnvironmentalProtectionAgency(EPA),andTheT oroCompany,arepleasedtoexplainthe

emissioncontrolsystemwarrantyonyour2015–2016smalloff-roadengine/equipment.InCaliforniaandtheUnitedStates,newsmalloff-road

engines/equipmentmustbedesigned,built,andcertiedtomeetstringentanti-smogstandards.TheToroCompanywarrantstheemissioncontrol

systemonyoursmalloff-roadengine/equipmentfortheperiodoftimelistedbelow,providedtherehasbeennoabuse,neglect,orimpropermaintenance

ofyoursmalloff-roadengine/equipment.

Youremissioncontrolsystemmayincludepartssuchasthecarburetor,fuel-injectionsystem,theignitionsystem,catalyticconverter,fueltanks,fuellines,

fuelcaps,valves,canisters,lters,vaporhoses,clamps,connectors,andotherassociatedemission-relatedcomponents.

Whereawarrantableconditionexists,TheT oroCompanywillrepairyoursmalloff-roadengine/equipmentatnocosttoyouincludingdiagnosis,

partsandlabor.

Manufacturer’sWarrantyCoverage

Thisemissioncontrolsystemiswarrantedfortwoyears.Ifanyemission-relatedpartonyourengine/equipmentisdefective,thepartwillberepairedor

replacedbyTheT oroCompany.

OwnerResponsibilities

Asthesmalloff-roadengineowner,youareresponsiblefortheperformanceoftherequiredmaintenancelistedinyourOperator'sManual.Werecommend

thatyouretainallreceiptscoveringmaintenanceonyoursmalloff-roadengine/equipment,butwecannotdenywarrantysolelyforthelackofreceipts.

Asthesmalloff-roadengine/equipmentowner ,youshouldhoweverbeawarethatwemaydenyyouwarrantycoverageifyoursmalloff-road

engine/equipmentoraparthasfailedduetoabuse,neglect,impropermaintenanceorunapprovedmodications.

Youareresponsibleforpresentingyoursmalloff-roadengine/equipmenttoaT oroDistributionCenterorServiceCenterassoonasaproblemexists.The

warrantyrepairsshouldbecompletedinareasonableamountoftime,nottoexceedthirty(30)days.

Ifyouhaveanyquestionsregardingyourwarrantycoverage,contactusat:

CustomerCareDepartment,ConsumerDivision

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

1–952–948–4027(U.S.andCanadiancustomers)

emailCustomerSupportat:www.toro.com

*374-0299*

GeneralEmissionsWarrantyCoverage

TheT oroCompanywarrantstotheultimatepurchaserandeachsubsequentpurchaserthatthesmalloff-roadengine/equipmentis:

•Designed,built,andcertiedtoconformwithallapplicableemissionsregulations;and

•Freefromdefectsinmaterialsandworkmanshipthatcouldcausethefailureofawarrantedpart;and

•Identicalinallmaterialrespectstothepartsasdescribedintheapplicationforcertication.

Thewarrantyperiodbeginsonthedatethesmalloff-roadengine/equipmentisdeliveredtoanultimatepurchaser .Thewarrantedperiodistwoyears.

Subjecttocertainconditionsandexclusionsasstatedbelow,thewarrantyonevaporativeemissions-relatedpartsisasfollows:

1.Anywarrantedpartthatisnotscheduledforreplacementasrequiredmaintenanceinthewritteninstructionssupplied,iswarranted

forthewarrantyperiodstatedabove.Ifthepartfailsduringtheperiodofwarrantycoverage,thepartwillberepairedorreplacedby

TheT oroCompany .Anysuchpartrepairedorreplacedunderwarrantywillbewarrantedfortheremainderofthewarrantyperiod.

2.Anywarrantedpartthatisscheduledonlyforregularinspectioninthewritteninstructionssuppliediswarrantedforthewarranty

periodstatedabove.Anysuchpartrepairedorreplacedunderthewarrantywillbewarrantedfortheremainderofthewarrantyperiod.

3.Anywarrantedpartthatisscheduledforreplacementasrequiredmaintenanceinthewritteninstructionssuppliedis

warrantedfortheperiodoftimebeforetherstscheduledreplacementdateforthatpart.Ifthepartfailsbeforetherst

scheduledreplacement,thepartwillberepairedorreplacedbyTheToroCompany .Anysuchpartrepairedorreplaced

underwarrantywillbewarrantedfortheremainderoftheperiodpriortotherstscheduledreplacementpointforthepart.

4.Repairorreplacementofanywarrantedpartunderthewarrantyprovisionshereinmustbeperformedatan

AuthorizedServiceDealeratnochargetotheowner.

5.WarrantyservicesorrepairswillbeprovidedatallServiceDealersauthorizedtoservicethesubjectenginesorequipment.

6.Thesmalloff-roadengine/equipmentownerwillnotbechargedfordiagnosticlaborthatisdirectlyassociatedwithdiagnosis

ofadefective,emission-relatedwarrantedpart,providedthatsuchdiagnosticworkisperformedatanAuthorizedServiceDealer.

7.TheToroCompanyisliablefordamagestootherengine/equipmentcomponentscausedbyafailureunderwarrantyofanywarrantedpart.

8.Throughoutthesmalloff-roadengine/equipmentwarrantyperiodstatedabove,TheToroCompanywillmaintainasupply

ofwarrantedpartssufcienttomeettheexpecteddemandforsuchparts.

9.Manufacturerapprovedreplacementpartsmaybeusedintheperformanceofanywarrantymaintenanceorrepairsand

mustbeprovidedwithoutchargetotheowner.SuchusewillnotreducethewarrantyobligationsofTheT oroCompany .

10.Add-onormodiedpartsthatarenotapprovedbyTheT oroCompanymaynotbeused.Theuseofanon-approvedadd-onormodiedpartsby

thepurchaserwillbegroundsfordisallowingawarrantyclaim.TheT oroCompanywillnotbeliabletowarrantfailuresofwarrantedpartscausedby

theuseofannon-approvedadd-onormodiedparts.

WarrantedParts

Thefollowingemissionwarrantypartsarecovered,totheextentthesepartswerepresentontheT oroengine/equipmentand/orT orosuppliedfuelsystem:

374-0299RevA

Page 31

1.FuelSystemParts

•Carburetorandinternalparts

•Coldstartingenrichment(primerorchoke)

•Fuelpump

•Fuelline,ttings,andclamps

•Fueltank,cap,andtether

•Carboncanister

2.AirInductionSystem

•Aircleaner

•Intakemanifold

•Crankcaseventandline(s)

•Purgelineandttings

3.IgnitionSystem

•Sparkplug(s)andwire(s)

•Magnetoignitionsystem

4.CatalyticExhaustSystem

•Catalyticconverter

•Exhaustmanifold

•Airinjectorsystemandvalve(s)

5.MiscellaneousItemsUsedinEmissionControlSystem

•Valves,switches,andlinkages

•Connectors,ttings,andbrackets

374-0299RevA

Page 32

AThree-Y earLimitedWarranty(45DayLimitedWarrantyforCommercialUse)

TheT oroT otalCoverageGuarantee

PowerMaxHDand

PowerMax

Two-StageSnowthrowers

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlypromisetorepairtheT oroProduct

listedbelowifusedforresidentialpurposes*,ifdefectiveinmaterialsor

workmanshiporifitstopsfunctioningduetothefailureofacomponent

fortheperiodlistedbelow.

Thiswarrantycoversthecostofpartsandlabor,butyoumustpay

transportationcosts.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod`

PowerMaxHDandPowerMaxSnowthrowers

andAttachments

—PowerMaxHDandPowerMaxChuteGuaranteedforLife

—PowerMaxHDandPowerMaxDeectorGuaranteedforLife

—PowerMaxHDandPowerMax

Anti-CloggingSystem

(PlasticImpellerHousingcover)

3years

Warranty(originalowner

only)

Warranty(originalowner

only)

GuaranteedforLife

Warranty(originalowner

only)

LimitedWarrantyforCommercialUse

Gas-poweredT oroProductsusedforcommercial,institutional,orrental

use,arewarrantedfor45daysagainstdefectsinmaterialsorworkmanship.

Componentsfailingduetonormalweararenotcoveredbythiswarranty .

InstructionsforObtainingWarrantyService

IfyouthinkthatyourToroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.ContactanyAuthorizedToroServiceDealertoarrangeserviceattheir

dealership.Tolocateadealerconvenienttoyou,refertotheYellow

Pagesofyourtelephonedirectory(lookunder“LawnMowers”)or

accessourwebsiteatwww.Toro.com.Youmayalsocallthenumbers

listedinitem#3tousethe24-hourToroDealerlocatorsystem.

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.Thedealerwilldiagnosetheproblemanddetermineif

itiscoveredunderwarranty.

3.IfforanyreasonyouaredissatisedwiththeServiceDealer’s

analysisorwiththeassistanceprovided,contactusat:

CustomerCareDepartment,ConsumerDivision

TheT oroCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Tollfreeat866-336-5205(U.S.customers)

Tollfreeat866-854–9033(Canadiancustomers)

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator'sManual.Suchroutinemaintenance,

whetherperformedbyadealerorbyyou,isatyourexpense.

ItemsandConditionsNotCovered

Thereisnootherexpresswarrantyexceptforspecialemissionsystem

coverageandenginewarrantycoverageonsomeproducts.Thisexpress

warrantydoesnotcoverthefollowing:

•Costofregularmaintenanceserviceorreplacementofwearparts,

suchasrotorblades(paddles),scraperblades,belts,fuel,lubricants,

oilchanges,sparkplugs,cable/linkageorbrakeadjustments

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetofailuretousefreshfuel(lessthanone

monthold),orfailuretoproperlypreparetheunitpriortoanyperiodof

non-useoveronemonth

•Pickupanddeliverycharges

•Operationalmisuse,neglect,oraccidents

•RepairsorattemptedrepairsbyanyoneotherthananAuthorizedToro

ServiceDealer

GeneralConditions

AllrepairscoveredbythesewarrantiesmustbeperformedbyanAuthorized

ToroServiceDealerusingToroapprovedreplacementparts.Repairbyan

AuthorizedToroServiceDealerisyoursoleremedyunderthiswarranty .

NeitherTheToroCompanynorToroW arrantyCompanyisliablefor

indirect,incidental,orconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythesewarranties,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletionof

repairsunderthesewarranties.

Allimpliedwarrantiesofmerchantability(thattheproductistforordinary

use)andtnessforuse(thattheproductistforaparticularpurpose)are

limitedtothedurationoftheexpressedwarranty .

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsmaynotapplytoyou.

Thiswarrantygivesyouspeciclegalrights,andyoumayalsohaveother

rightswhichvaryfromstatetostate.

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheToroimporter.Ifallotherremediesfail,youmaycontactusatToroWarrantyCompany.

AustralianConsumerLaw

AustraliancustomerswillnddetailsrelatingtotheAustralianConsumerLaweitherinsidetheboxoratyourlocalT oroDealer.

*Residentialpurposesmeansuseoftheproductonthesamelotasyourhome.Useatmorethanonelocation,orinstitutionalorrentaluse,isconsidered

commercialuse,andthecommercialusewarrantywouldapply.

374-0251RevD

Loading...

Loading...