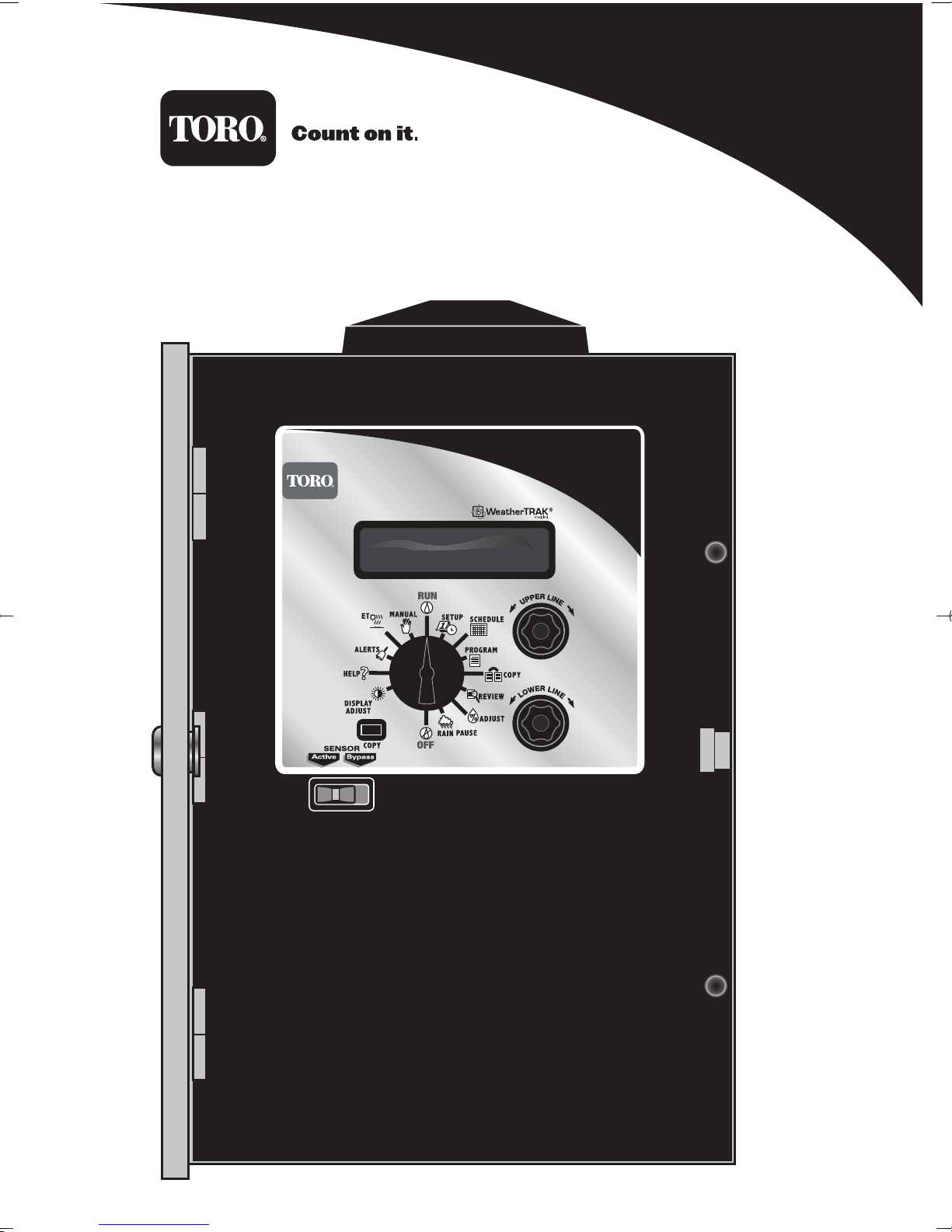

Page 1

Intelli-Sense

User’s Guide

Professional Controllers

12-, 24-, 36-, and 48-Station Models

TIS-PRO

Page 2

ii

The Toro Company

Technical Support

(877) 345-8676

WeatherTRAK

®

ET Everywhere Subscription & Technical Support

(800) 362-8774

Page 3

iii

Table of Contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Chapter 1 - Getting Started . . . . . . . . . . . . . . . . . 3

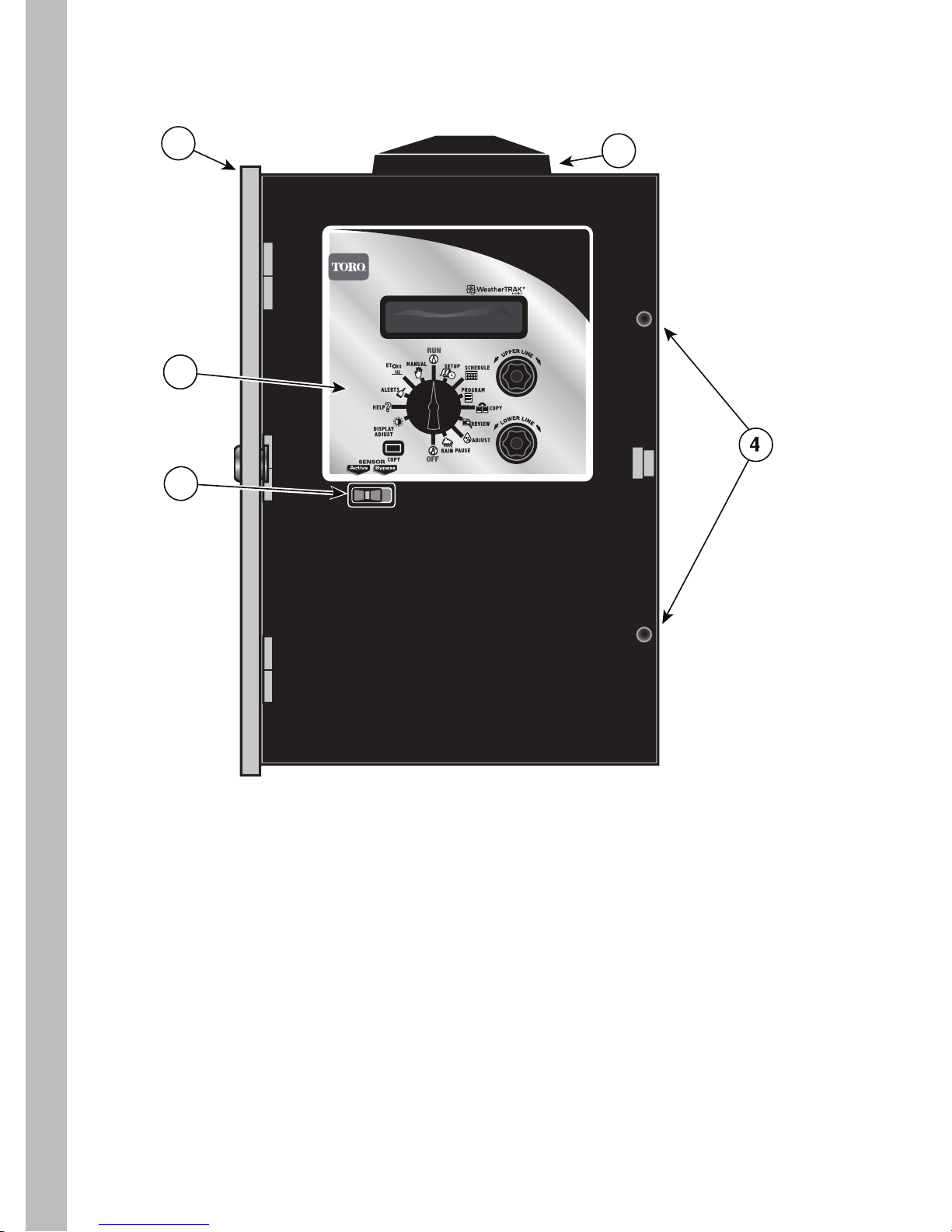

Controller Hardware Overview . . . . . . . . . . . . . . . . . . . . . . . . 4

Control Module Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

Chapter 2 - Controller Setup. . . . . . . . . . . . . . . . . 9

Adjust Display Contrast . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Set Controller Date and Time . . . . . . . . . . . . . . . . . . . . . . . . . 10

Select Time Zone . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Select Auto Daylight Savings Option. . . . . . . . . . . . . . . . . . . . 11

Set Maximum Active Station Count. . . . . . . . . . . . . . . . . . . . . 12

Select Stack or Overlap Option . . . . . . . . . . . . . . . . . . . . . . . . 13

Select Master Valve/Pump Start Option . . . . . . . . . . . . . . . . . 14

Select Run Time Valve Test Option . . . . . . . . . . . . . . . . . . . . 15

Set Maximum Backup ET . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Chapter 3 - Set Program Schedule . . . . . . . . . . . . . 17

Select Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Set Program Start Times and Water Windows . . . . . . . . . . . . 18

Set High ET Start / Water Window . . . . . . . . . . . . . . . . . . . . . 19

Set Program Water Day Mode . . . . . . . . . . . . . . . . . . . . . . . . 20

Chapter 4 - Station Data Setup . . . . . . . . . . . . . . 23

Station Setup Mode: Automated by WeatherTRAK . . . . . . 24

Select Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Select Station Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Select Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Select Water Window Option . . . . . . . . . . . . . . . . . . . . . . . . . 25

Select Usable Rainfall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Select Sprinkler Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Set Precipitation Rate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Set Sprinkler Efficiency . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Assign Pump Start Outpt. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Page 4

IV

Chapter 4 (continued)

Select Soil Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Select Plant Type . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Set Root Depth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Set Microclimate . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Select Slope Factor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Select Sprinkler Location. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Completing Station Setup . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Station Setup Modes: User Defined. . . . . . . . . . . . . . . . . . . 32

Select Station . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Select Station Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Select Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 33

Select Water Window Option . . . . . . . . . . . . . . . . . . . . . . . . . 33

Select Usable Rainfall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Set Station Runtime. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

Select Number of Cycles. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Set Soak Time. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

Set Reference ET Value . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Set Reference Month . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

Using the Review Function. . . . . . . . . . . . . . . . . . . . . . . . . . 38

Review Station Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Review Flow Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 39

Using the Copy Function . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Restoring Station Default Settings . . . . . . . . . . . . . . . . . . . . . 41

Restoring Program Settings . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Restoring Setup Default Settings . . . . . . . . . . . . . . . . . . . . . . 43

Using the % Adjust Function . . . . . . . . . . . . . . . . . . . . . . . . 44

% Adjust by Water Amount . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

% Adjust by Day Frequency/ Max. Allowable Depletion . . . . . 45

Using the Alerts Function. . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Using the Flow Monitor Function. . . . . . . . . . . . . . . . . . . . . 47

Set Station Exclusion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 48

Edit Flow Sensor K Value and Offset . . . . . . . . . . . . . . . . . . . 49

Set Threshold and Delay Values. . . . . . . . . . . . . . . . . . . . . . . 50

Setting the High Flow Threshold . . . . . . . . . . . . . . . . . . . . . . . 50

Setting the No Flow Threshold . . . . . . . . . . . . . . . . . . . . . . . . 51

Setting the Leak Detection Threshold . . . . . . . . . . . . . . . . . . . 52

Copy Station Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Chapter 5 - Support Functions. . . . . . . . . . . . . . . . . 37

Page 5

v

Using the Reports Function . . . . . . . . . . . . . . . . . . . . . . . . . 53

Weekly Stations Report. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Monthly Station Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Flow Report . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Using the ET Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Edit Custom Plant Kc Value . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Edit Custom Turf Kc Value . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Set Weekly ET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Using the Help / ET Function . . . . . . . . . . . . . . . . . . . . . . . . 59

Rain Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

View Group Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Days Since Last ET. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Current Depletion . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Run Valve Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 61

Using the Manual Watering Function . . . . . . . . . . . . . . . . . 62

Manually Operate Specific Stations . . . . . . . . . . . . . . . . . . . . 62

Manually Operate All Stations . . . . . . . . . . . . . . . . . . . . . . . . . 63

The Run Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

The Off Function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Using the Maintenance Timeout Function 55

Using the Rain Pause Function . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

55

Appendix A - Troubleshooting Guide . . . . . . . . . 65

Appendix B - Glossary of Terms . . . . . . . . . . . . 69

Appendix C - Installation Procedures. . . . . . . . . 71

Selecting the Installation Site . . . . . . . . . . . . . . . . . . . . . . . . . 71

Mounting the Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Connecting the Power Wires. . . . . . . . . . . . . . . . . . . . . . . . . . 73

Connecting an Earth Ground Source . . . . . . . . . . . . . . . . . . . 73

Connecting the Station Wires (includes Pump Relay). . . . . . . 74

Toro Rain Sensor Connection . . . . . . . . . . . . . . . . . . . . . . . . . 76

Flow Sensor Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Toro TMR-1 Handheld Remote Connection . . . . . . . . . . . . . . 78

Fuse Replacement. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Warranty Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 81

FCC Compliance Information . . . . . . . . . . . . . . . . . . . . . . . . 82

Page 6

vi

Notes:

Page 7

• Reliable Toro-built irrigation controller.

• WeatherTRAK’s exclusive irrigation scheduleing software.

•

• Four independent irrigation programs

• Integrated flow management and reporting utilities with

flow sensing and leak detection at station and system

level.

• User alerts relating to flow, valves, communications,

scheduling and more.

• Station-specific programming of watering days, run times,

start times and cycle/soak periods.

• Automatic syringe irrigation for high ET-rate conditions.

• Toro Handheld Remote and Rain/Freeze Sensor ready.

• Large, easy-to-read liquid crystal display.

• Built-in surge protection.

• Non-volatile memory.

• Weather and vandal-resistant heavy-gauge steel cabinet.

• Weather-proof external antenna.

1

Introduction

Congratulations on selectingToro, the proven leader in smart

irrigation. Twenty public agency studies and thousands of

customers make it clear— the Toro Intelli-Sense Commercial

controllers with WeatherTRAK technology are #1 in saving

water, protecting landscapes, reducing runoff, and satisfying

customers. The Toro Intelli-Sense Professional controller series,

available in 12, 24, 36 and 48 station-count models, dynamically

adjust irrigation based on current ET (evapotranspiration)

conditions, received each day via radio transmission from

the WeatherTRAK ET Everywhere®subscription service.

Some Key Features of the TIS-PRO Controllers

The flexibility of 12, 24, 36 and 48 station-counts models

to meet a wide variety of irrigation system needs.

Page 8

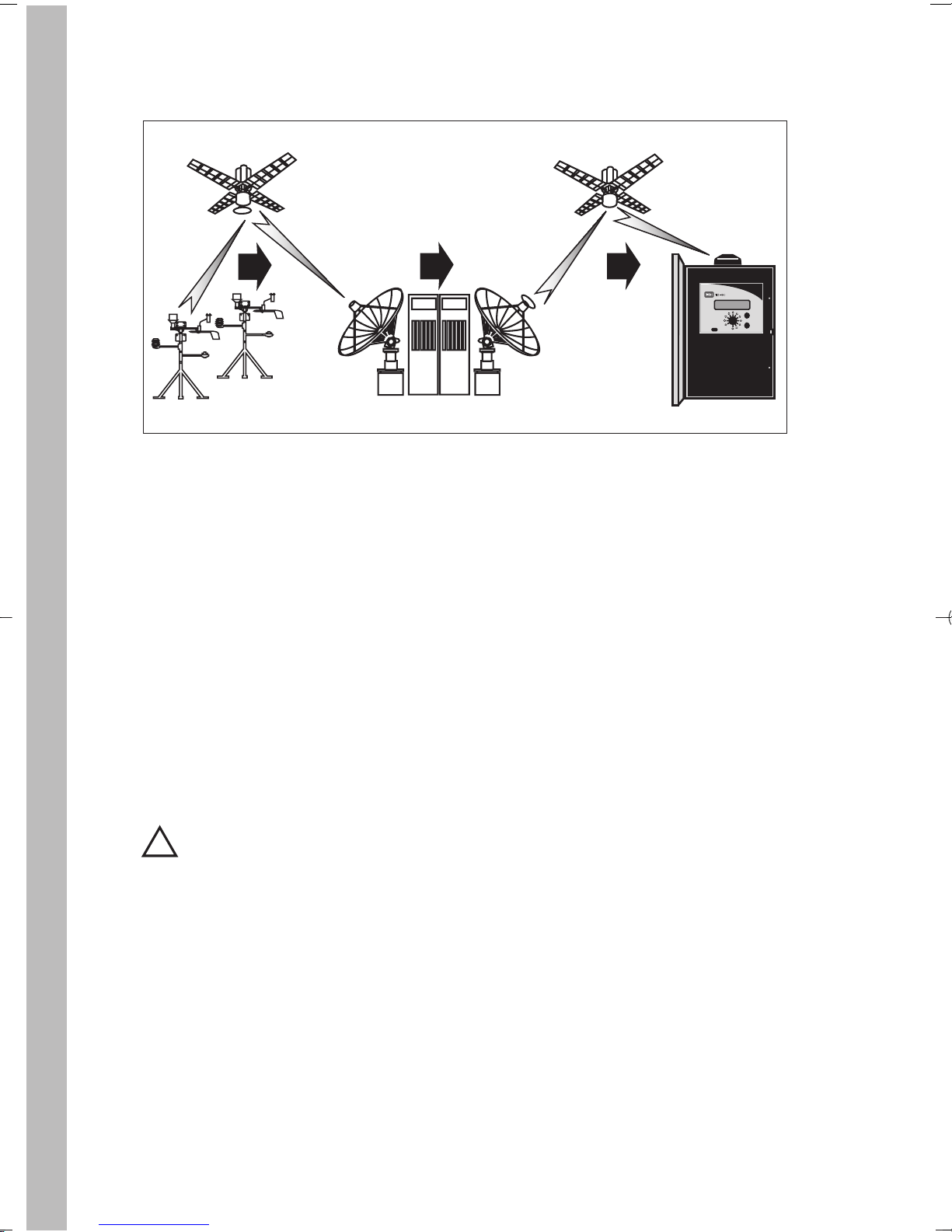

How the ET Everywhere Service Works

2 - Proven scientific modeling techniques are then used to

calculate and validate specific ET data down to one square

kilometer.

3 - The ET data is uploaded to a communications satellite

where it received nightly by the intelli-Sense controller to

automatically recalculate station-specific irrigation

parameters for the next scheduled watering day.

32

1

2

1 - The WeatherTRAK ET Everywhere service collects data

from over 25,000 monitoring stations including the National

Oceanic and Atmospheric Administration (NOAA) network,

state and county networks, and private weather stations.

Important: The ET Everywhere subsciption service is

!

not included with the purchase of the Intelli-Sense controller.

For service subscription information, contact WeatherTRAK

customer service at 1-800-362-8774 during normal business

hours.

Page 9

The following checklist provides the basic steps required for

Intelli-Sense Professional Controller installation, setup,

programming and operation.

Install per the provided intallation instructions. (See Installation

Instructions beginning on page 69).

Fill out the Intelli-Sense Control System Profile spreadsheet with

as much accurate detail as possible. Have the spreadsheet on

hand when performing the controller setup and programming

procedures.

Program the controller. This manual provides step-by-step

instructions for programming the controller based on the infor-

mation captured on the System Profile spreadsheet.

3

Chapter 1

Getting Started

Thoroughly inspect the irrigation system for proper design,

installation and operating condition, leaks, as well as broken

heads and pipes. The performance of your new controller

depends on the integrity of the irrigation system design and

installation. You will maximize the performance of your

controller when the irrigation system is well maintained.

Activate the WeatherTrak ET Everywhere subscription service.

This necessary and important step enables the Intelli-Sense to

receive daily ET updates.

Page 10

TIS-PRO

Controller Hardware Overview

1 - Intelli-Sense Control Module - (See page 6 for details.)

3 - Weatherproof External Anatenna - Provides exceptional

reception in most locations.

4 - Hinged Access Panel Fasteners - Thumbscrew fasteners

secure hinged control panel for ease of access without

tools.

5 - Rain Sensor Control Switch - Slide switch provides

manual override control of auxiliary rain sensor.

4

3

2

1

5

2 - Enclosure - Weather- and vandel- resistant heavy-gauge

steel cabinet with locking cover.

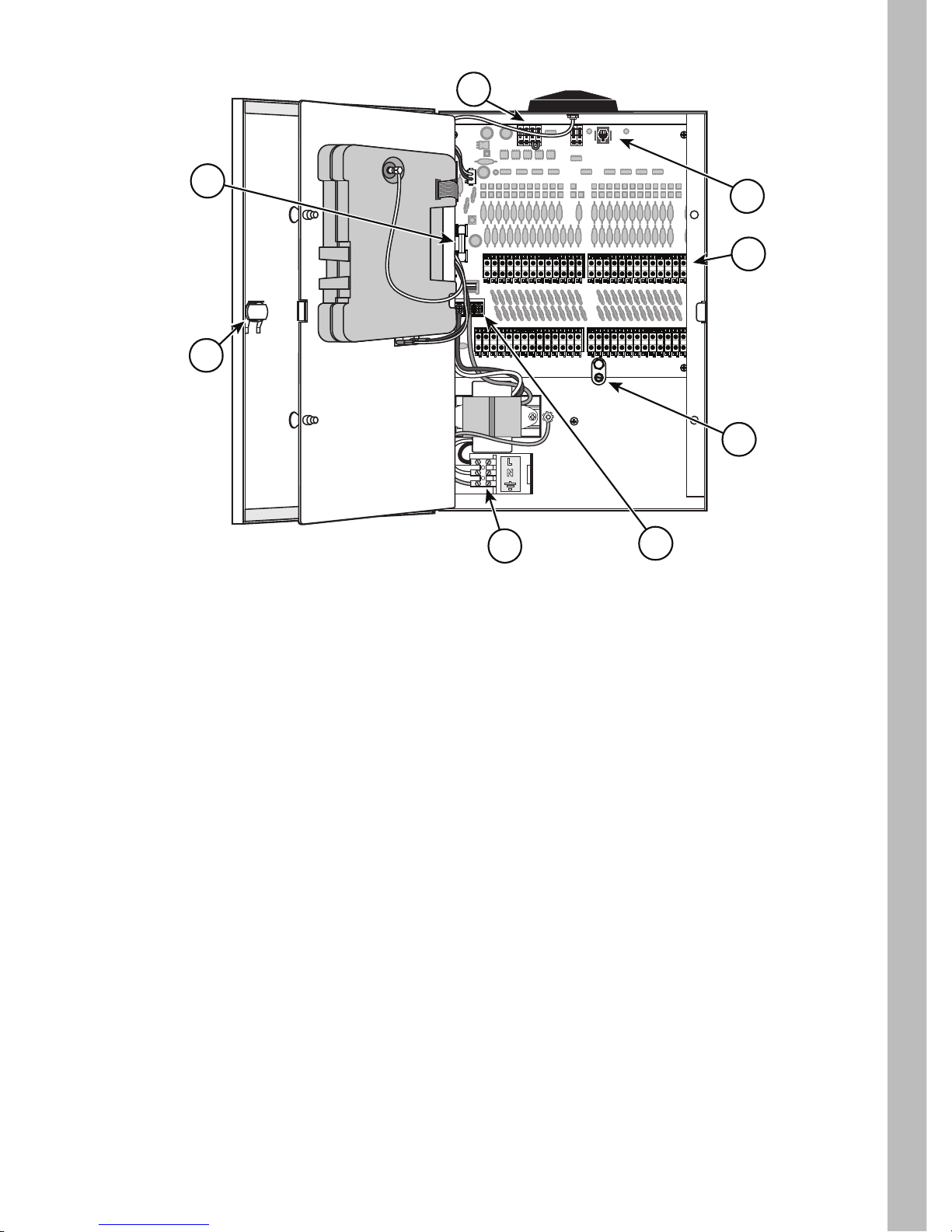

Page 11

MV/

PUMP

1 2 3 4 5 6 7 8 9 10 11 12

MV/

PUMP

1 2 3 4 5 6 7 8 9 10 11 12

VC/

COM

VC/

COM

13 14 15 16 17 18 19 20 21 22 23 24

VC/

COM

37 38 39 40 41 42 43 44 45 46 47 48

37 38 39 40 41 42 43 44 45 46 47 48

25 26 27 28 29 30 31 32 33 34 35 36

25 26 27 28 29 30 31 32 33 34 35 36

VC/

COM

VC/

COM

VC/

COM

VC/

COM

13 14 15 16 17 18 19 20 21 22 23 24

VC/

COM

5

6

7

10

11

12

13

8

9

6 - Control Module Latch - Enables control module

to be

easily removed without disturbing controller installation.

7 - Fuse - 2A Slo-Blo fuse provides short-circuit protection

on the 24 VAC output circuit.

- Flow and Rain Sensor Connection Terminal Block

Quick release wire terminals for easy, secure connections.

- TMR-1 Handheld Remote Connections - Provides

RJ-11 plug receptacle and 24 VAC power source for

TMR-1 handheld remote reciever connection.

- Valve Wire Connection Terminal Blocks - Screwless,

quick release control wire terminals for easy installation.

11 - Earth-ground Lug -

Heavy-duty ground lug accepts

10 AWG solid-copper wire from earth ground device.

12 - Hot Post - Provides a constant 24 VAC power sou

rce

to assist in valve identification for initial installation,

system service and troublshooting procedures.

13 - Main Power Connection Terminal Block - Screw

terminals for 120 VAC input power wires.

8

10

9

Page 12

6

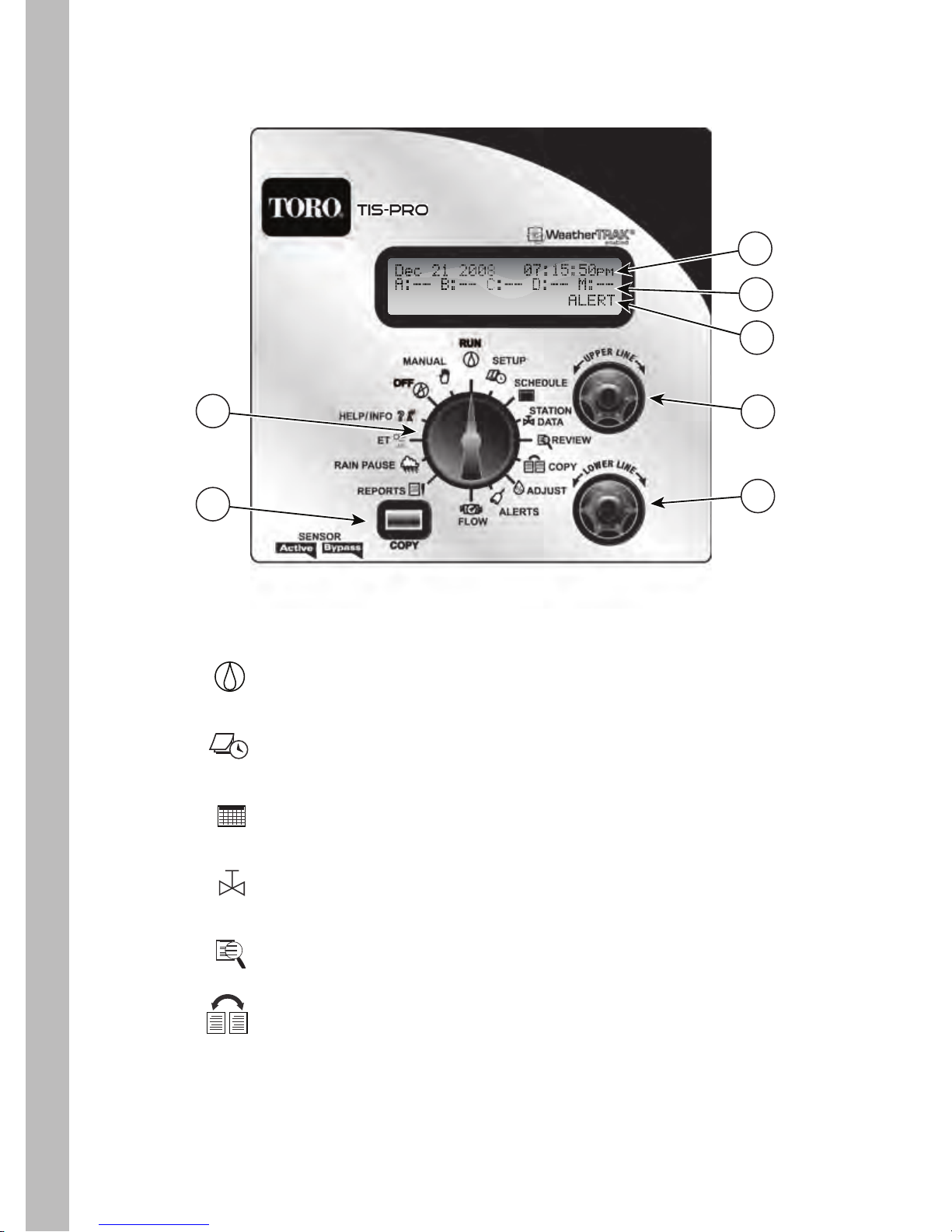

Control Module Overview

16a

17

16

15

14

18

17a

14 - Function dial - Turn this dial in either direction to select

controller setup and operational functions:

RUN - The normal position for automatic operation.

Current time/date and controller activity is displayed.

SETUP - Select and define specific controller setup

and operating parameters.

SCHEDULE - Set up and adjust start times/water

windows and watering day schedules.

STATION DATA - Select and define specific station

setup and operating parameters.

REVIEW - Review current program information

for each station, and flow sensor setup and data log.

COPY - Transfer station or program information

from one station or program to another. Also used

reset station, setup and program default settings.

1

to

Page 13

7

ALERTS - Display system problems and

operationalconflicts.

FLOW - Set flow meter attributes and operational

partameters.

REPORTS - Access and review station run time

and

flow data by day, week or month time periods.

RAIN PAUSE - Suspend automatic watering for a

period of 1 to 14 days.

ET - Display current daily and average weekly ET

values. Set custom Kc and weekly ET values.

HELP/INFO -

OFF - Terminate and suspend all watering activity.

MANUAL - Access manual watering operations.

15 -

16 - Lower Line knob - This knob is used to select and/or

adjust data viewed on the lower line of the display

(16a).

17 - Upper Line knob - This knob is used to select setup and

program control options shown on the upper line of the

display (17a ).

18 - Information Line - The third line of the display provides

supplemental information including the Alert prompt.

Access various controller activation

setup data, operational preferences, and status

information.

Copy button – The Copy button is used in various

operations including copying and transferring station

and program data, restoring default settings and

reviewing various setup, station, and flow data.

ADJUST - Adjust station watering by 5% increase or

decrease of run time and/or watering days.

o

Page 14

8

Notes

Page 15

Controller Setup

•

• Set Time Zone

• Set Auto Daylight Savings option

• Set Maximum Active Stations

• Select Stack or Overlap option

• Set Master Valve Type/Pump Start option

• Select Runtime Valve Test

• Set Maximum Backup ET

ADJUST DISPLAY CONTRAST

224

Set Controller Clock

•

Adjust Display Contrast

9

About Controller Input

As you begin the controller setup procedures, you will find that

virtually all user-defined input is accomplished in the same

manner using the Function dial, Upper Line knob, and Lower

Line knob. For example, when you turn the Function dial to the

SETUP position, the first screen in the Setup menu will be

displayed. In this case, Adjust Display Contrast will be displayed

on the upper line and the default contrast value of 224 will be

displayed on the lower line.

The contrast value is underscorred and flashing, indicating that

it is selected and can be changed or edited by turning the Lower

Line knob. The information displayed on the screen when the

Upper Line knob or Function dial is turned in either direction,

enters the information into the controller memory.

Chapter 2

The SETUP function menu consists of 10 screens listed in

the following order:

Page 16

Set Controller Clock

2. Turn the Lower Line knob to set the current year.

4. Turn the Lower Line knob to set the current month.

DATE (YEAR)

Feb 24 2008

DATE (MONTH)

Feb 24 2008

5. Turn the Upper Line knob right to select

6. Turn the Lower Line knob to set the current day.

Date (Day).

7. Turn the Upper Line knob right to select

8. Turn the Lower Line knob to set the current hour (am or pm).

Time (Hour).

9. Turn the Upper Line knob right to select

10. Turn the Lower Line knob to set the current minute.

Time (Minute).

10

1. With the Function dial in the SETUP position, turn the Upper Line

knob to select the following display:

3. Turn the Upper Line knob right to select the next menu item,

Date (Month).

Note: Leave the Function dial in the SETUP position to continue

selecting and setting the remaining Setup menu items.

Page 17

11

1. Within the Setup menu, turn the Upper Line knob to view the

following display:

2. Turn the Lower Line knob to select your time zone from the

following choices:

• Pacific (default setting)

• Alaska

• Hawaii

• Atlantic

• Eastern

• Central

• Mountain

Select Auto Daylight Savings Option

1. W

The default selection is Yes which enables the controller to

automatically compensate for Daylight Savings time. To disable

this option, turn the Lower Line knob to display No.

ithin the Setup menu , turn the Upper Line knob to view the

following display:

2.

AUTO DAYLIGHT SAVINGS

Yes

TIME ZONE

Pacific

Set Time Zone

Page 18

1.

2.

Within the Setup menu, turn the Upper Line knob to view the

following display:

Note: The active station count entered in this step will also determine the

number of stations that can be accessed within the Programming, Review

and Copy function procedures.

MAX ACTIVE STATIONS

01 (User Defined)

Set Maximum Active Station Count

The actual number of stations being used for irrigation must be entered

to enable accurate automatic scheduleing.

12

To change the number of active stations, turn the Lower Line knob.

STA CONFIG FOUND ACIVE

36 36 36

Note: To review the current station configuration, press the Copy button

when SETUP function is selected.

!

Note: The abbreviated display information indicates the following:

STA CONFIG = Controller model configuration of 36 or 48 stations

FOUND = Actual number of stations recognized by controller

ACTIVE = Maximum active station count selected.

Important: The Intelli-Sense Professional controller firmware

provides for the scheduling of 48 stations regardless of controller

output configuration. If the actual number of active stations is not

set accurately and/or set according to controller output configuration, alert errors and reuced controller performace will result. For

example, setting the active station count higher than actual will

result in an alert error or will add unnecessary time to the Water

Window. Setting the station count lower than actual will cause

some stations to be skipped.

Page 19

1. Within the Setup menu, turn the Upper Line knob to view the

following display:

STACK OR OVERLAP

Stack

Select Stack or Overlap Option

When the Stacking option is selected, the controller will be

constrained to operate one station at a time. The Water Window

start time and duration selected for Automatic Schedule A will

also be assigned to Automatic Schedule B, C and D.

When the Overlap option is selected, the constraint is removed,

allowing multiple programs to run simultaneously.

When Overlap is selected, Start time and Water Window options

are available in all schedules.

13

2.

The Stack option isseleted by default. To select the Overlapoption,

turn the Lower Line knob to displayOverlap.

Important: Prior to selecting the Overlap option,

confirm that the irrigation system hydraulic capacity and

the controller’s maximum current draw capacity (2.0A) will

not be exceeded if four stations and master valve circuit are

operated concurrently.

!

Important: When the STACK option is selected within the

Setup menu, the start time and water window parameters

defined for Program A will apply to all progams, and can not

be edited by individual program.

If the OVERLAP option is selected, separate start time and

water window parameters can be defined for each program.

!

Page 20

1. Within the Setup menu, turn the Upper Line knob to view the

following display:

2. Turn the Lower Line knob to select the preferred option.

Note: If a pump station is in use but no master valve is required,

use the Normally Closed/Pump On option.

MASTER VALVE/PUMP START

Normally Closed/Pump On

ASSIGN PUMP START OUTPUT

NOT ASSIGNED

Set Master Valve/Pump Start Option

14

• Normally Closed/Pump On (default)

• Normally Open/Pump Off

• None

Assign Pump Start Output

The controller features a dedicated master valve/pump start output

as a standard feature. The master valve is used to isolate the

mainline or a portion of the mainline when programmed as part of

flow monitoring. It enables the controller to troubleshoot and isolate

pipe malfunctions or other problems. Three choices provided are:

The controller allows the user to assign a pump start to a station output,

effectively decreasing the controller station count by 1. The assigned

station will be active with all stations. This feature is typically used in

combination with a normally-open (NO) type master valve to enable the

pump to operate while the NO master valve remains de-engerized (open).

1. Within the setup Menu, turn the Upper Line knob to view the

following display:

2. Turn the Lower Line knob to select the station number to be designated as the pump start output.

Page 21

Set Maximum Backup ET

1. Within the Setup menu, turn the Upper Line knob to view the

following display:

Turn the Lower Line knob to adjust the decimal number value.

MAX BACKUP ET Part 1

2.00

The Maximum Backup ET value is a failsafe measure used by the

controller to calculate daily watering requirments in the event that

current ET Everywhere data is not recieved for an extended period.

2.

The Maximum Backup ET default value of 2.00 is automatically

entered to help compensate for seasonal weather changes.

The whole number of the Maximum Backup ET value is selected

by default. To adjust the value from 1 – 3, turn the Lower Line

knob.

Note: The Maximum Backup ET is adjustable from 0.50 – 3.99.

The whole number is only adjustable to 0 when the decimal

number value is .50 or higher.

4.

Turn the Upper Line knob right one stop to select the decimal

number.

3.

15

The controller features a Valve Test feature that will test each station

for a short-circuit condition each time it is activated. If a fault is detected,

an Alert will be posted, enabling identification and repairs to be made.

1. Within the Setup menu, turn the Upper Line knob to view the

following display:

2. Turn the Lower Line knob to select Yes or No as preferred.

RUNTIME VALVE TEST

No (Check Fuse Often)

Set Runtime Valve Test Option

Page 22

Notes

16

Page 23

Chapter 3

Set Program Schedule

1. Turn the Function dial SCHEDULE to view the following

display:

Program A is selected by default. The current watering day

schedule, start time and water window information is shown

for Program A.

SELECT PROGRAM

A (Optm S12:00am W16:00)

17

Select Program

2. To change the program selection, turn the Lower Line knob to

select program B, C or D.

Note: The abbreviated display information indicates the following:

Optm = Watering day schedule is Optimized by WeatherTRAK

S12:00am = Start Time is 12:00 a.m.

W16:00 = Water window duration is 16 hours.

Important: When the STACK option is selected within the

Setup menu, the start time and water window parameters

defined for Program A will apply to all progams, and can not

be edited by individual program.

If the OVERLAP option is selected, separate start time and

water window parameters can be defined for each program.

!

The Intelli-Sense Professional Controller enables four independent

program schedules (A, B, C and D) to be defined by one or two start

times with associated water window and a specific watering day

schedule. Each station is then assigned to one of the programs in

the Station Data function.

Page 24

18

SET STARTS/WINDOWS PRG A

Skip (Button to View)

Set Program Start Start Time and Water Window

1. Within the Schedule menu, turn the Upper Line knob to select

the following display:

2. Skip is selected by default. To edit the selected program, turn the

Lower Line knob to select Edit.

SET STARTS/WINDOWS PRG A

Edit (Button to View)

(Button to View)

3. Turn the Upper Line knob to select the following display:

4. The start time hour is underlined and flashing, indicating that it

can be edited. Turn the Lower Line knob to set the start time

hour, or turn the Upper Line knob right to select next element

of the screen to be edited.

1st Start/Window PRG A

Start 12:00am Win 16:00

START 1 S12:00am W16:00

Off

Note: To review the current start time/water window settings,

Start 1 = 12:00 a.m., water window is 16 hours in duration,

and Start Time 2 is turned off.

press the Copy button. The abbreviated information will be

displayed as shown in the example below.

Page 25

Repeat the editing procedure used to enter the 1st start time

andwater window.

8.

19

(Button to View)

5. Turn the Upper Line knob right to select water window duration.

1st Start/Window PRG A

Start 12:00am Win 16:00

(Button to View)

2nd Start/Window PRG A

Start 07:00pm Win 05:00

7. Turn the Upper Line knob right to select the 2nd Start Type screen.

The High ET start time option is Off by defualt. To program, turn the

Upper Line knob right to display the following setup screen.

Note: Water window is the duration of time allotted for all stations,

assigned to the program to complete their programmed watering

cycle(s). The water window duration is adjustable from 1 hour to

23 hours and 59 minutes. The controller provides the water window

end time by factoring the selected start time and duration.

6. Turn the Lower Line knob to adjust number of hours, or turn the

Upper Line knob right to select minutes and edit as preferred.

Note: A second program start time/water window is provided for

automatic syringe watering where compensation for higher than

normal ET is desired. Labeled High ET start, the controller

automatically reduces the total station watering amount during this

syringe operation to 25% of normal.

To prevent operational conflicts due to overlapping watering

cycles, the following setup criteria must be considered:

• The 2nd start time cannot occur within the 1st start time cycle

• The combined water window duration cannot exceed 23 hours

and 59 minutes.

If an Overlap condition alert is posted, the source of the conflict

must be resolved. If not corrected, the 2nd start time will default to

the Off mode. Press the Copy button to compare settings. Also

refer to the Alerts function on page 44 for additional information.

Page 26

20

WATER DAY MODE PRG A

Optimized by WeatherTRAK

WATER DAY MODE PRG A

Odd/Even

1. With the Function dial in the SCHEDULE position, turn the

Upper Line dial to view the following display:

Set Program Water Day Mode

Each program can be assigned to unique water day schedule using

one of the following options:

• Optimized by WeatherTRAK - Water day schedule selected

automatically by the Intelli-Sense scheduling engine.

• Odd/Even - Odd or Even numbered calendar days.

• Interval - Water days set by frequency ranging from 1 to 30 days.

• Days of Week - Specific days of the week (same all months)

• Days of Week by Month - Specific days of the week for each month.

• Off - Turn program off.

3. Turn the

that enables a weekday to be excluded from operation.

Upper Line knob to select the Day Exclusion feature

4. Turn the Lower Line

knob to display the day name or None.

1. Turn the Lower Line knob to select Odd/Even.

2. Turn the Upper Line knob to display Odd.

3. Turn the Lower Line

knob to select Even.

2. Optimized by WeatherTRAK is selected by default.

To use this mode, continue at step 3. To use an alternate

mode, continue at the appropriate following section.

Odd/Even

Page 27

Days of Week

By default, every day is an active watering day. To remove days

from the schedule, turn the Upper Line knob to select the day

indicator, then turn the Lower Line knob to replace the indicator

with a dash (as shown in the following example).

WATER DAY INTERVAL PGM A

01 (Everyday)

WATER DAY MODE PGM A

Days of Week

OK TO WATER ON PGM A

S M T W T F S

1. Turn the Lower Line knob to select Interval.

1. Turn the Lower Line knob to select Days of Week.

2.3.Turn the Upper Line knob to view the following display:

Interval

2. The default Interval is 01 which schedules every day as active.

To select an Interval from 02 – 30, turn the Lower Line knob.

:etoN The current day is the first active day of the Interval

schedule. For example, if today is Saturday and a 02 interval

(water every-other-day) is set, today will be active. The next

active watering day will be Monday.

21

OK TO WATER ON PGM A

S M - W T - S

Page 28

22

Days of Week by Month

WATER DAY MODE PGM A

Days of Week by Month

Jan OK TO WATER ON PGM A

S M T W T F S

1. Turn the Lower Line knob to select Days of Week by Month.

Water Day Mode Off

WATER DAY MODE PGM A

Off

1. Turn the Lower Line knob to select Off. .

2.3.Turn the Upper Line knob to view the following display:

By default, every day of every month is an active watering day.

To omit specific days from specific months, turn the Upper Line

knob to select the month.

4.

Jan OK TO WATER ON PGM A

S M - W T - S

To omit specific days, turn the

Selecting the Off water day mode effectively prevents the program from

running automatically. To reinstate a program to automatic operation,

simply choose an alternate watering day mode.

Upper Line knob to select the day

indicator, then turn the Lower Line knob to replace the indicator

with a dash (as shown in the following example).

Page 29

Chapter 4

Station Data Setup

23

The Station Data function menu consists of several station setup

parameters required for automatic operation.

Four station operating mode options provide the control flexability to

program each station for optimum irrigation control.

The station operating mode selections are:

• Automated by WeatherTRAK

• User - With ET (user-defined setup parameters with ET control)

• User - No ET (user-defined setup parameters without ET control)

• Off (station disabled)

Within each operating mode are the following required setup

parameters:

Automated By WeatherTRAK:

• Select Program

• Select Program

• Select Station

• Water Window option

• Select Station

• Select Station Mode • Select Station Mode

• Usable Rainfall

• Sprinkler Type

• Precipitation Rate*

• Sprinkler Efficiency*

• Soil Type

• Plant Type

• Root Depth*

• Microclimate

• Slope Factor

• Sprinkler Location (on slope)

User Defined:

• Water Window option

• Usable Rainfall

• Run Time

• Number of Cycles

• Soak Time

• Reference ET

(applies to

• Reference Month (applies to

User - With ET mode and

watering days by month only)

As you can see by the extent of these lists, many factors are required

to formulate an accurate baseline watering schedule. To simplify

this procedure, Intelli-Sense will select default values based on your entries.

You can adjust these values if needed. The items listed with an asterisk (*) will

have default values based on the selection made in preceding setup parameter.

User - With ET mode only)

Note: To begin the setup process, select Automated by WeatherTRAK

mode on page 24, or User-defined modes starting on page 33.

Page 30

Select Station

Station Setup Mode: Automated by WeatherTRAK

SELECT STATION

01

Select Station Mode

STATION MODE STA 01

Automated by WeatherTRAK

Select Program

SELECT PROGRAM STA 01

A (Optm S12:00am W16:00)

24

2. Automated by WeatherTRAK mode is selected by default.

If it is not displayed, turn the Lower Line knob to select.

2. Program A is selected by default. To change the program selection,

turn the Lower Line knob.

1. Turn the Upper Line knob to display Station Mode.

1. Turn the Upper Line knob to display Select Program.

Note: The Maximum Active Station number defined in Setup,

determines station number access.

1. Turn the Function dial to the STATION DATA position.

The Select Station menu item is displayed by default.

2. Station 01 is selected by default. To change the station number,

turn the Lower Line knob.

Page 31

25

Select Water Window Option

Use Water Window STA 01

Yes (end time 04:00pm)

Select Sprinkler Type

SPKLR TYPE

Spray Head

2. Spray Head is selected by default. To choose from the menu of

listed sprinker types, turn the Lower Line knob.

1. Turn the Upper Line knob to display Sprinkler Type

Select Usable Rainfall

USABLE RAINFALL

100%

2. 100% is selected by default. To decrease the value, turn the

Lower Line knob right.

1. Turn the Upper Line knob to display Usable Rainfall.

1. Turn the Upper Line knob to display Use Water Window.

The current water window end time is automatically calculated

and displayed for the selected program.

2. Yes is selected by default. To disable the water window for the

selected station, turn the Lower Line knob to select No.

Note: By selecting No, the station will run until irrigation is

complete, regardless of the water window established for

the program.

The Usable Rainfall setting defines the percentage of the station’s

watering area exposed to rainfall. This setting is adjustable from

None (no rain contact) to 100% (full rain contact) in 25% increments.

For example, about 25% of the station zone is covered by a roof

overhang. The usable rainfall value for this station would be 75%.

Page 32

Set Precipitation Rate

2. The default PR value will be displayed for the sprinkler type

selected. The whole number is selected in Part 1. Turn the

Lower Line knob to adjust the value from 0 – 9.

PRECIP PART 1 STA 01

1.70 Inches/Hr (default)

PRECIP PART 2 STA 01

1.70 Inches/Hr (default)

3. Turn the Upper Line knob right one stop to select the decimal

number (Part 2).

26

Note: The PR value is adjustable from 0.10 – 9.99 Inches/Hour.

The whole number value is adjustable to 0 only when the

decimal number value is ≥ 10. Conversely, the decimal number

is adjustable to 0 when the whole number is ≥ 1.

4. Turn the Lower Line knob to adjust the decimal number value

from 00–99.

1. Turn the Upper Line knob to display Precip Part 1.

Important:The sprinkler precipitation rate (PR) is a key

factor in the calculation of an automatic watering program.

If you know the actual PR value, enter it at this time. If you do

not have this information, the baseline PR of the sprinkler

type (entered in the previous step) will be entered.

!

Page 33

The default efficiency value is displayed for the sprinkler type

selected. To change the value, turn the Lower Line knob to

adjust the value from 10 – 95%.

2.

SPKLR EFFICIENCY

STA 01

70 Percent (default)

27

Set Sprinkler Efficiency

Select Soil Type

Like the sprinkler PR value, the Sprinkler Efficiency value is a key

factor used by the Intelli-Sense to calculate an efficient watering

program for each station. The controller will automatically enter an

efficiency value based on the type of sprinkler selected for the station.

Changing the efficiency value will alter overall station watering

operation as follows:

▲ Increasing sprinkler efficiency (sprinkler performs above average),

decreases overall watering.

▼ Decreasing sprinkler efficiency (sprinkler performs below average),

increases overall watering.

1. Turn the Upper Line knob to display Spklr Efficiency.

The soil type displayed is the default for the sprinkler type

selected. To change the soil type, turn the Lower Line knob

to select one the following options:

• Sandy

• Sandy Loam - Higher percentage of sand than clay

• Loam - Equal percentage of sand and clay

• Clay Loam - Higher percentage of clay than sand

• Clay.

2.

SOIL TYPE

STA 01

Sandy

1. Turn the Upper Line knob to display Soil Type.

Page 34

Select Plant Type

Within the Program menu, turn the Upper Line knob to select

Plant Type.

PLANT TYPE STA 01

Cool Season Turf (default)

2.

1.

The default Plant Type will be displayed, Cool Season Turf.

To select an alternate Plant Type, turn the Lower Line knob.

3.

Plant factors corresponding to the custom types can be set

in the ET menu.

Select from the following Plant Type selections that best matches

the plant material in the station:

• Cool Season Turf

• Warm Season Turf

• Combined Turf

• Annuals

• Ground Cover

• Trees

• Shrubs – High Water Use

• Shrubs – Medium Water Use

• Shrubs – Low Water Use

• Mixed – High Water Use

• Mixed – Medium Water Use

• Mixed – Low Water Use

• Native Shrubs/Trees

• Native Grasses

• Custom Plant A

• Custom Plant B

• Custom Turf

28

Page 35

29

Notes

Page 36

Set Root Depth

Within the Program menu, turn the Upper Line knob to select

Set Root Depth.

SET ROOT DEPTH STA 01

06 Inches (default)

2.

1.

2.

1.

The default root depth will be displayed for the soil type and

plant type previously selected. To change the depth, turn the

Lower Line knob to adjust from 2 – 36 inches.

•

SET MICROCLIMATE STA 01

Sunny All Day

Select Microclimate

Sunny All Day = Sun for 7 to 8 hours per day – no change to

the calculated ET rate.

•

Sunny Most of the Day = Sun for 4 to 6 hours per day –

decreases watering by 10% of calculated ET rate.

•

Shady Most of the Day = Shady for 4 to 6 hours per day –

decreases watering by 20% of calculatd ET rate.

•

Shady All Day = Shady for 7 to 8 hours per day – decreases

watering by 30% of calculated ET rate.

30

Note:

▲ Increasing the Root Depth value (root depth greater than average),

increases overall watering.

▼ Decreasing the Root Depth value (root depth less than average),

decreases overall watering.

The station Microclimate value is the average exposure to sunlight and

shade throughout the day. One of following four Microclimate options

is selected that best describes the average conditions for the station:

Turn the Upper Line knob to select Set Microclimate.

Sunny All Day is selected by default. To select an alternate

microclimate, turn the Lower Line knob.

Page 37

Select Slope Factor

2.

• 6 – 8% Grade

• Mild 9 – 12% Grade

Gentle

• 0 – 5% Grade

None/Slight

• Moderate 13 – 20% Grade

• Steep >20% Grade.

SET SLOPE FACTOR STA 01

None/Slight 0-5% Grade

None/ Slight (0 –5%) grade is selected by default. To select

an alternate Slope Factor, turn the Lower Line knob.

Select Sprinkler Location

• All Parts of Slope (default if Slope Factor is other than None)

• Top of Slope

• Middle of Slope

• Bottom of Slope.

SPRINKLR LOCATION STA 01

None, No Slope Set

None, No Slope Set is selected by default. To choose an

alternate Sprinkler Location, turn the Lower Line knob

to select one of the following options:

31 9

The SlopeFactor is an important component used in the automatic

watering program calculation to determine the amount of run time and

number of repeat cycles required per watering day.

The Slope Factor options are as follows:

1. Turn the Upper Line knob to select Set Slope Factor.

1.2.Turn the Upper Line knob to select Sprinklr Location.

Note: To prevent runnoff, selecting any slop factor other than

None/Slight will result in a decrease in station run time per

cycle and an increase in the watering cycle frequency.

Note: If a Slope Factor of None/Slight is selected, Sprinkler Location

setting is not enabled.

Page 38

Completing Station Setup

1.2.Turn the Upper Line knob to select Station (01) Complete.

STATION 01 COMPLETE

32

The next station number in sequence will be selected. To select

a different station, turn the Lower Line knob. Turn the Upper Line

knob to continue with the station setup procedure.

!

Important: To set up additional stations with the same

or similar operating parameters, use the COPY function to

transfer station setup data from one station to another or to

all stations at the same time. Minor adjustments to individual

stations can then be made quickly and easily. See Using the

Copy Function on page 38 for details.

Within the User-defined station mode are two format options:

User - With ET and User - No ET. Both formats require the same basic

setup process, with the exception that User - With ET mode enables a

Reference ET and (optional) Reference Month value to be selected.

A User-defined watering program is established for the station with the

setup parameters in the following menu order:

• Select Water Window option

• Select Station

• Select Program

• Set Usable Rainfall

• Set Run Time

• Select Number of Cycles

• Set Soak Time

• Set Reference ET (User - With ET format only)

• Set Reference Month (optional)

When the User - With ET option is used, the station’s baseline watering

progam is updated daily by the ET Everywhere service and adjusted

automatically to suit current ET conditions.

When the User - No ET option is used, the station’s watering progam

remains constant, without regard to changes in ET.

Station Setup Modes: User Defined

Page 39

33

Select Station

SELECT STATION

01

Note: The Maximum Active Station number defined in Setup,

determines station number access.

1. Withthe Function dial in the Station Data position, turn the

Upper Line knob to display Select Station.

2. Station 01 is selected by default. To change the station number,

turn the Lower Line knob.

Select Station Mode

STATION MODE STA 01

User - With ET

Select Program

SELECT PROGRAM STA 01

A (Optm S12:00am W16:00)

2. Turn the Lower Line knob to select Use - With ET or User - No ET.

2. Program A is selected by default. To change the program selection,

turn the Lower Line knob.

1. Turn the Upper Line knob to display Station Mode.

1. Turn the Upper Line knob to display Select Program.

Select Water Window Option

Use Water Window STA 01

Yes (end time 04:00pm)

1. Turn the Upper Line knob to display Use Water Window.

2. Yes is selected by default. To enable the station to ignore a water

window constraint, turn the Lower Line knob to select No.

Page 40

34

Select Usable Rainfall

USABLE RAINFALL

100%

2. 100% is selected by default. To decrease the value, turn the

Lower Line knob right.

1. Turn the Upper Line knob to display Usable Rainfall.

The Usable Rainfall setting defines the percentage of the station’s

watering area exposed to rainfall. This setting is adjustable from

None (no rain contact) to 100% (full rain contact) in 25% increments.

For example, about 25% of the station zone is covered by a roof

overhang. The usable rainfall value for this station would be 75%.

Set Station Run Time

The station run time defines how long the station will operate during

the watering cycle. The run time is adjustable from 1 to 99. 9 minutes.

RUNTIME PART 1 STA 01

05.0 Minutes

1. Turn the Upper Line knob to display Runtime Part 1.

2. Turn the Lower Line knob to adjust the whole number value

from 01 to 99.

3. Turn the Upper Line knob right to select the decimal value

(Runtime Part 2).

4. Turn the Lower Line knob to adjust the decimel number value

from 0 to 9.

Page 41

35

NUMBER OF CYCLES STA 1

01 Cycles/Operating Day

Select Number of Cycles

Note: Selecting 0 cycles will prevent the station from operating

during automatic watering operations.

2. The number of watering cycles per watering day is set to 1 by

default. To adjust the number between 0 – 20 cycles per operating

day, turn the Lower Line knob.

1. Turn the Upper Line knob to select Number of Cycles.

Set Soak Time

SET SOAK TIME STA 01

30 Minutes

Soak Time is an adjustable delay period that occurs between station

watering cycles to help promote deeper rooting, and to avoid pooling,

runoff and soil erosion. Soak Time is adjustable from 0–480 minutes in

10-minute increments.

2. The default Soak Time is 30 minutes. To adjust the soak time,

turn the Lower Line knob (00–480 minutes).

1. Turn the Upper Line knob to select Set Soak Time.

Note: The Soak Time is actually the minimum delay that can

occur before the station can run again. The actual delay period

may be longer due to the programming variables of other stations

assigned to the same watering program.

Page 42

36

1.

Set Reference [weekly] ET Value (applies to User With ET mode only)

Turn the Upper Line knob to view the following display:

The Reference ET is the weekly ET set in the User – With ET mode that

your runtimes correspond to. Runtimes will be adjusted up or down

automatically depending on whether the actual weekly ET is higher or lower

than the Reference ET. The default Reference ET is 1.00 (0.14 inches per day).

It is recommended that you set runtimes and the Reference ET value based

on the highest weekly ET demand period of the year.

REF. ET PART 1 STA 01

1.00 (Weekly ET 1.00)

5. Turn the Upper Line knob to view the following display:

REFERENCE MONTH STA 01

Jul (If Days by Month)

6. Turn the Lower Line knob to select the preferred month.

2. The whole number of the Reference ET value is selected by default.

To adjust the value from 1 – 3, turn the Lower Line knob.

4.

Turn the Lower Line knob to adjust the decimal number value.

3. Turn the Upper Line knob right to select the decimal

number.

Note: TheReference ET value is adjustable from 0.50 – 3.99.

The whole number is only adjustable to 0 when the decimal

number value is .50 or higher.

Note: If the station uses the Days of Week by Month,

watering day mode, the Reference Month screen will be

displayed as shown below. To adjust this setting, continue at

step 5. If not applicable, the Program Complete screen will

be shown.

Page 43

Support Functions

Function Page

REVIEW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

COPY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

% ADJUST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ALERTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

FLOW . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

REPORTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

ET . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

HELP/INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. 59

RUN/OFF . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

MANUAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

RAIN PAUSE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

MAINTENANCE TIMEOUT 56

37

The Setup, Schedule and Station Data functions enable you to set up

an automatic watering schedule designed specifically or each watering

zone of the landscape.

The support functions provide enhanced control capabilities of your

irrigation system; enabling you to perform various operations such as:

program data copy, review, fine-tuning to resolving actual and

potential irrigation problems, as well as providing a means of manually

operating the irrigation system.

Within this chapter you will find detailed instructions provided for

each of the support functions on the following pages:

Chapter 5

Page 44

Using the Review Function

(1) Station number 1 is assigned to watering Schedule A.

(2) The station will water for 11.9 minutes, one cycle per day.

(3 Automated by WeathTRAK is the assigned station mode.

If the station mode is User-No ET, User will be displayed.

UwET indicates station is assigned to User with ET mode.

(4) The active watering day schedule for Week 1 is Thursday.

(5) The % Adjust factor is +00%.

(6) Soak time is set for 30 minutes.

ST01 A 11.9 MIN 01X AUTO

Wk1:-––T-– +00% Soak 30

3.

Station 1 will be selected by default. To select a differ ent station

to review, turn the Upper Line knob.

1 2 3

4 5 6

REVIEW MODE

Station Data

38

1. Turn the Function dial to the REVIEW position. Review Mode will

be displayed.

2. Station Data is selected by default. To select Flow Data, turn the

Lower Line knob. (Refer to Flow Data Review on page 37.)

The Review function provides a convenient, at-a-glance overview

of all relavent station and flow monitro setup information.

Note: Additional review information can be acquired for each station

by pressing the Copy button when the Fucntion dial is in the

STATION DATA position.

The review information is displayed in an abbrevieated format that

allows the information to viewed in one screen as shown in the

example below.

Note: The remainder of the 8-week watering day schedule can be

viewed by turning the Lower Line knob.

Page 45

39

Flow Data Review

REVIEW MODE

Flow Data

VIEW EXCLUDED STATIONS

View (No Flow Only)

01 02 03 04 05 06 07 08

N N N N N N Y Y

1. With the Function dial in the REVIEW position, turn the Lower

Line knob to display Flow Data.

2. Turning the Upper Line knob right displays the Flow Data review

screens in the following sequence:

• Master Valve Status

• View Excluded Stations

• Flow Meter Status/Size

• Flow Meter K and Offset Value

• Flow Thresholds (GPM)

• Flow Delay (Minutes)

3. All Flow Review screens are self explanitory, with the exception of

View Excluded Stations. The initial screen provides a Skip/View

option. To review the stations excluded from flow monitoring, turn

the Lower Line knob to select View.

4. Turn the Upper Line knob right to display the first 8 stations.

Continue turning the knob right to display additional stations.

In the example above, station 7 and 8 are excluded from the flow

monitoring function.

Page 46

Using the Copy Function

Copying Station Information

1. Turn the Function dial to COPY to view the following

display:

2. Turn the Upper Line knob to select the source station number.

3. Turn the Lower Line knob to select the destination station number.

To select All Stations, turn the Lower Line knob one stop past the

highest station number, as shown in the following display:

COPY FROM STA 01 TO

STA 02 (Press Button)

The Copy function provides a convenient method of transferring

all watering program information from one station to another or to

all active stations simultaniously. Minor changes can then be made to

each station as needed, greatly simplifying the process of programming

several stations with similar watering progam attributes.

The Copy function also serves as a means of quickly resetting all userdefined Setup, Schedule and Program settings back to the factory-default

values. The default values can be reapplied to selected stations or all

stations simultaniously as needed.

4. Press and hold the Copy button. Release the button when

Copying... Done! is displayed.

COPY FROM STA 01 TO

ALL STA’s (Press COPY)

COPYING...DONE!

Note: The number of active stations defined in the Setup function,

determines the number of stations that can be selected.

40

Page 47

Restoring STATION Default Settings

2. Turn the Upper Line knob to select Copy Station Defaults

as shown in the following example:

3. Turn the Lower Line knob to select the station number to be

restored. Or, to restore defaults to all stations , turn the

Lower Line knob to select All Stations.

COPY FROM STA 01

To STA 02 (Press COPY)

4.

Press and hold the Copy button. Release the button when

Copying Done is displayed.

COPY STATION DEFAULTS TO

To STA 02 (Press Button)

COPY STATION DEFAULTS TO

ALL STA’s (Press BUTTON)

COPYING...DONE!

41

1. Turn the Function dial to the COPY position.

Soil Type -

Sandy

Plant Type - Cool Season Turf

Root Depth - 6 Inches

Microclimate - Sunny All Day

Slope Factor - None/Slight

Sprinkler Location - None

Station Mode -

Automated By WT

Program Mode - A

Use Water Window - Yes

Usable Rainfall - 100%

Sprinkler Type - Spray Head

Precipitation Rate - 1.70 In/Hr

Sprinkler Efficiency - 70%

Important: Restoring the STATION defaults erases

and resets all user settings for all stations as follows:

!

Page 48

Restoring PROGRAM Default Settings

42

Important: Restoring the default Program settings erases

and resets all user-defined settings for all programs as follows:

1st Start Time - 12:00am

Water Window - 16:00

2nd Start Type - High ET

2nd Start Time - 07:00 pm

Water Window - 05:00

Water Day Mode - Optimized by WT

Day Excusion - None

2. Turn the Upper Line knob to select Copy Program Defaults

as shown in the following example:

3.

COPY FROM STA 01 TO

STA 02 (Press BUTTON)

4.

Press and hold the Copy button. Release the button when

Copying Done is displayed.

COPY PROGRAM DEFAULTS TO

PGM A (Press Button)

COPY PROGRAM DEFAULTS TO

ALL PGM (Press Button)

COPYING...DONE!

1. Turn the Function dial to the COPY position.

Turn the Lower Line knob to select the program A, B, C or D) to

be restored. Or, to restore defaults to all programs simultaneously,

turn the Lower Line knob to select All Pgm.

!

Page 49

Restoring SETUP Default Settings

43

2. Turn the Upper Line knob to select Copy Setup Defaults.

COPY FROM STA 01 TO

STA 02 (Press BUTTON)

3.

Press and hold the Copy button. Release the button when

Copying Done is displayed.

COPY SETUP DEFAULTS

(Press Button)

COPYING...DONE!

1. Turn the Function dial to the COPYposition.

Adjust Display - 224

Date - No change

Time - No change

Time Zone - No change

Auto Daylight Savings - Yes

Active Stations - No Change

Stack or Overlap - Stack

Master Valve - Normally Closed

Pump Start - Pump On

Run Time Valve Test - No

Max. Backup ET - 2.00

Flow Meter Mode - Off

Important: Restoring the SETUP defaults erases

and resets all user-defined settings as follows:

!

Copy Station Mode

If the controller is initially programmed in the field using the

Auto Station mode, but is left running in the User No ET mode,

e.g., for landscape establishment, the Auto Station settings are stored

in the controller memory. The Copy Station feature allows stations in

User No ET mode to be quickly copied to the Auto Station mode.

Page 50

44

Using the % Adjust Function

ADJ WATER AMOUNT STA 01

0% = No Change

ADJ WATER AMOUNT STA 01

+05% = More Water

ADJUST

Water Amount

1. Turn the Function dial to % ADJUST. The Water Amount

adjustment option is selected by default.

1. Turn the Upper Line knob to select the station number.

% Adjust by Water Amount

2. The unadjusted water amount value is 0%. Turn the Lower Line knob

right to increase, or left to decrease the value in 5% increments.

Maximum adjustment range is +25 to –50%.

The % Adjust function allows you to make minor changes in overall

station irrigation rate by increasing or decreasing the watering program

values proportionally by percentage. Adjustments can be made in

5% increments by Water Amount (station run time and cycles per day),

and by Day Frequency/Maximum Allowable Depletion (MAD).

Note: Both adjustment methods can be applied to each active station,

however, DF/MAD is only available to stations operating in the

Automated by WeatherTRAK mode.

Important: A small percentage adjustment can result in

a significant change in irrigation rate. Always adjust in 5 or 10%

increments, then monitor the condition of the landscape for

7 to 10 days prior to making additional adjustments.

!

2. To adjust by Water Amount factors, continue below. To adjust by

Day Frequency/MAD, continue on page 43.

Page 51

Turn the Lower Line knob to select Day Frequency/Depletion

adjustment option.

ADJUST DAYS (MAD) STA 01

+05% = More Often (45%)

ADJUST DAYS (MAD) STA 01

0% = No Change (50%)

ADJUST DAYS (MAD) STA 06

Non-Adjustable Mode

1.

Day Frequency/Depletion

ADJUST

45

% Adjust by Day Frequency/Maximum Allowable Depletion

Note: If the selected station number is assigned to a User-defined

station mode, the following display will be shown:

3. Turn the Lower Line knob right to increase or left to decrease

the percent value. Maximum adjustment range is +30% to -30%.

2. Turn the Upper Line knob to select the station number.

Stations assigned to the Automated by WeatherTRAK station mode

can be % adjusted by watering Day Frequency/Maximum Allowable

Depletion. For example, when establishing new turf, total water

application can be increased while decreasing the possibility of

runoff. Day Frequency is adjustable from -30% to +30% in 5%

increments. The equivalent MAD value will be displayed ranging

from 20% to 80% (with 50% being the standard depletion rate).

Note: In the following example, the watering day frequency for

station 1 has been increased by 5%, which decreased the MAD

value to 45%. This change translates to irrigation being permitted

when soil moisture content drops to 45% instead of the standard

50% MAD value.

Page 52

Using the Alerts Function

FL - Flow Status

VL - Valve Status

CM - Communication Status

WD - Water Window Status

DY - Water Day Status

HW - Hardware Status

SB - Subscription (ET) Status

01 02 03 04 05 06 07 08

SH=Short NC=NoConnect

FL VL CM WD DY HW SB

——=Ok ER=Error

-- ER -- -- —— —— ––

-- -- SH -- —— —— —— ––

VIEW VALVE STATUS

Skip Short

Example: Valve Status Alert

46

Note: When the condition has been resolved, the Alert display

prompt will be removed.

1. Turn the Function dial to the ALERT position.

2. Turn the Upper Line knob to select the function to review.

The current status will be displayed, and if additional data is

available, a Skip/View option will be provided.

3. To view the additional data, turn the Lower Line knob to select

View. Turn the Upper Line knob to display the data.

If a problem, confilict or error occurs with one of the essential

Intelli-Sense functions, an Alert prompt will be immediately posted.

Selecting Alerts function provides a quick overview of the monitored

functions, and flags the source of the alert condition.

From the initial Alert display screen, the specific function causing

the alert condition will be identified as follows:

1. With the ALERTS function selected, turn the Upper Line knob

right to select View Valve Status.

2. Turn the Lower Line knob to select View.

3. Turn the Upper Line knob right as needed to display the affected

station number(s).

Page 53

MEASURED FLOW (GPM)

FM1: 000.0

FLOW METER MODE

Off

FLOW METER MODE

1

47

Using the Flow Monitor Function

1. Turn the Function dial to the FLOW position. The Measured

Flow review screen is displayed by default and provides the

current system GPM flow rate.

Note: Pressing the Copy button while the Flow function is

selected will prompt the Measured Flow screen to display the

current flow rate.

2. Turn the Upper Line knob right to select Flow Meter Mode.

3. By default, the flow monitor function is Off. To turn the

monitor function On, turn the Lower Line knob to select 1.

The Intell-Sense Professional Controller incorporates a precision

flow monitorfunction to display and record flow data provided by

a compatible Toro TFS Series or Data Industrial IR Series flow

sensor. (See flow sensor installation details on page 75.) With the

flow sensor properly installed and configured for operation,the

Intelli-Sense will continually monitor flow sensor input to record

and respond to specific flow conditions including: High-flow,

Non-flow, and Leakage. Each flow parameter has an adjustable

alert threshold and response delay period. During system operation, any monitored flow condition detected outside the threshold

will initiate anAlertresponse. The controller will automatically

turn off any affected station(s) or the entire irrigation system as

warranted by the monitored condition.

Page 54

48

EDIT EXCLUDED STATIONS

Skip (No Flow Only)

01 02 03 04 05 06 07 08

N N N N N N N N

2. Turn the Lower Line knob to change Skip to Edit.

2. Turn the Lower Line knob to select the actual flow sensor size from

the following options: 1.00”, 1.25”, 1.50”, 2.00”, 3.00”, 4.00” and

Insert Type (sizes < 1” or > 4”).

Set Station Exclusion

The station exlusion feature enables individual stations to be omitted

from the Flow Monitor operations.

3. Turn the Upper Line knob to display the first eight station numbers

in sequence.

1. With the the Function dial in FLOW position, turn the Upper Line

knob right to select Edit Excluded Stations.

SET FLOW METER SIZE

1.00”

Set Flow Meter Size

1. With the the Function dial in FLOW position, turn the Upper Line

knob right to select Set Flow Meter Size

4. By default, no stations are excluded (indicated by N) and station

01 is selected. To exclude the selected station, turn the Lower Line

knob to change N to Y (Yes). To select another station number, turn

the Upper Line knob. Repeat as needed for all station numbers.

Page 55

49

A default flow sensor K value, based on the flow sensor size, is

automatically entered. Refer to the manufacturer’s recommended

K value and edit accordingly.

Edit Flow Sensor K Value and Offset

EDIT K VALUE FOR 1:00”

Skip 00.397368 (default)

EDIT K VALUE FOR 1:00”

EDIT 00.397368 (default)

EDIT K VALUE FOR 1:00”

00.397368 (default)

3. Turn the Lower Line knob to select the edit screen. The first digit

in sequence will be selected. To adjust the digit, turn the

Lower Line knob. To advance to the next digit, turn the

Upper Line knob. Repeat this process for the remaining digits

to be edited.

4. Turn the Upper Line knob right to select Edit Flow Offset.

EDIT FLOW OFFSET 1.00”

Skip +00.261768 (default)

5. Edit the Flow Offset value in the same manner as K Value.

1. With the the Function dial in FLOW position, turn the Upper Line

knob right to select Edit K Value.

2. Turn the Lower Line knob to change Skip to Edit.

Page 56

50

HIGH FLOW THRESHOLD

050 GPM 3 Minutes

Set Threshold and Delay Values

Setting the High Flow Threshold

The threshold value is the defined limit for maximum, minimum and

no-flow conditions. If monitored flow exceeds a threshold, an Alert is

posted, and all remaining watering operations suspended or modified untl

the alert is cleared or problem resolved.

The delay period provides a 1- to 6-minute buffer between an exceeded

threshold and the controller response. Increasing the delay period,

decreases controller sensitivity to temporary or minor fluctuations.

1. With the the Function dial in FLOW position, turn the Upper Line

knob right to select High Flow Threshold.

Note: The High Flow threshold should be set approximately 10–15%

higher than the expected flow in any program configuration to prevent a

false alert response.

2. The default threshold will be displayed. To adjust, turn the Lower

Line knob. The value is adjustable from Off –30 in one-GPM

increments, or 30–995 in five-GPM increments.

Controller Response: Controller response to an exceeded threshold

is based on the selected operating mode as follows:

Stack Mode – The operating station will turn of f, and the next station in

sequence will turn on. If the condition persists, all irrigation will be

terminated and an alert posted. If the flow normalizes, the controller will

continue the watering cycle. Bypassed stations will be indicated and

given first priority in the next schedueld watering cycle.

Overlap Mode – The system will shut down. After a short delay , the

master valve will be opened and flow measured. If the condition

persistes, all irrigation will be terminated and an alert posted. If flow

normalizes, watering will resume one station at a time. Each station will

be flow monitored and bypassed if the threshold is exceeded. Bypassed

stations will be indicated and given first priority in the next schedueld

watering cycle.

Page 57

51

HIGH FLOW DELAY

050 GPM 3 Minutes

NO FLOW THRESHOLD

005 GPM 3 Minutes

3. Turn the Upper Line knob (right) to select High Flow Delay.

1. Turn the Upper Line knob (right) to select No Flow Threshold.

NO FLOW DELAY

005 GPM 3 Minutes

3. Turn the Upper Line knob (right) to select No Flow Delay.

4. Turn the Lower Line knob to adjust the delay minutes (1–6).

4. Turn the Lower Line knob to adjust the delay period (1–6 minutes).

Setting the No Flow Threshold

Note: To prevent a false alert response, the No Flow threshold should be

set 10–15% lower than the expected flow in any program configuration.

2. The default threshold will be displayed. To adjust, turn the Lower

Line knob. The value is adjustable from Off –30 in one-GPM

increments, or 30–995 in five-GPM increments.

Page 58

52

LEAK DETECT THRESHOLD

015 GPM 3 Minutes

1. Turn the Upper Line knob (right) to select Leak Detect Threshold.

Setting the Leak Detection Threshold

Note: Flow is monitored during non-irrigation periods (outside of scheduled

irrigation or during soak periods) to detect leaks. If flow is monitored above

the Leak Detect threshold, the master valve will be shut off and an alert

will be posted. The alert condition must be cleared to resume operation.

Note: If Manual Irrigation or Quick Couplers are used, the Leak Detect should

be set above the expected flow for these operations.

LEAK DETECT DELAY

015 GPM 3 Minutes

3. Turn the Upper Line knob (right) to select Leak Detect Delay.

4. Turn the Lower Line knob to adjust the delay period (1–6 minutes).

2. The default threshold will be displayed. To adjust, turn the Lower

Line knob. The value is adjustable from Off –30 in one-GPM

increments, or 30–995 in five-GPM increments.

Page 59

53

REPORTS TYPE

Weekly Stations

WEEKLY RUNTIME STA 01

000Hrs 00Mins Since Sun

Using the Reports Function

The Reports function provides cumulative station run time and flow data,

selectable within the following specified reference formats:

Weekly Stations - Run time in hours and minutes per station per week.

Monthly Stations – Run time in hours and minutes per station per month.

Flow – Total flow in gallons per day, week, month, specific day range and

specific prior date.

1. Turn the Function dial to the REPORTS position.

2. Weekly Stations is selected by default.

Weekly Stations Report

Monthly Stations Report

3. Turn the Upper Line knob right on stop to display cumulative

run time for station 1. To change the station number, turn the

Upper Line knob to the right.

REPORTS TYPE

Monthly Stations

1. Turn the Lower Line knob to select Monthly Stations.

Page 60

54

1. Turn the Lower Line knob to select the Flow report option.

Flow Report

2. Turn the Upper Line knob right on stop to display Todays Usage.

3. Turn the Upper Line knob one stop to select Weekly Usage.

4. Week 1 is selected by default. Turn the Lower Line knob right to

review usage for weeks

Note: Week 1 is the current week starting Sunday at Midnight (12:00am).

2–8.

5.

Turn the Upper Line knob to advance the report option to

MONTHLY USAGE and USAGE FOR LAST XX Days.

The Lower Line knob will select the Month (MONTHLY USAGE) or

the range of days (USAGE FOR LAST XX Days) to review.

MONTHLY RUNTIME STA 01

Jan 000HRS 00MINS

REPORTS TYPE

Flow

TODAYS USAGE

0000 Gals/Day

WEEKLY USAGE

Wk1: 000000 Gals/Week

3. Turn the Upper Line knob right on stop to display Monthly Runtime

for station 01 in January.

4. Turn the Lower Line knob right to change the month to review.

Turn the Upper Line knob to change the day to review.

Page 61

55

RAIN PAUSE ALL STATIONS

00 Days to Resume

Feb 26 2010 10:15:45am

Rain Pause M:

Using the Rain Pause Function

The Rain Pause function enables all automatic watering operations

to be easily suspended from 1 to 200 days. At the end of the selected

delay period, the controller resumes automatic operation. All other

functions, including programming, manual operations and ET

updates are available while the Rain Pause mode is active.

1. Turn the Function dial to select Rain Pause.

2. Turn the Lower Line knob to select the number of days to

pause operation.

3. Turn the Function dial to the Run position.

4. The display will indicate Rain Pause until automatic

operation resumes at the end of the delay period.

To terminate the Rain Pause mode at any time, turn the

Function dial to select Rain Pause.

5. Turn the Lower Line knob to select 00 days to resume.

6. Turn the Function dial back to the Run position.

Page 62

56

1. Turn the Function dial to the blank position, located

between Flow and Reports.