Page 1

SnowMaster724ZXRSnowthrower

ModelNo.36001—SerialNo.402082000andUp

Introduction

Thismachineisintendedtobeusedbyresidential

homeowners.Itisdesignedprimarilyforremoving

snowfrompavedsurfaces,suchasdrivewaysand

sidewalks,andothersurfacesfortrafconresidential

orcommercialproperties.Itisnotdesignedfor

removingmaterialsotherthansnow,norisitdesigned

forclearinggravelsurfaces.

Note:Themachinemayleaverubbermarkson

newbrushedorlight-coloredconcrete.T estonan

inconspicuouslocationbeforeuse.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

FormNo.3415-639RevA

Operator'sManual

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

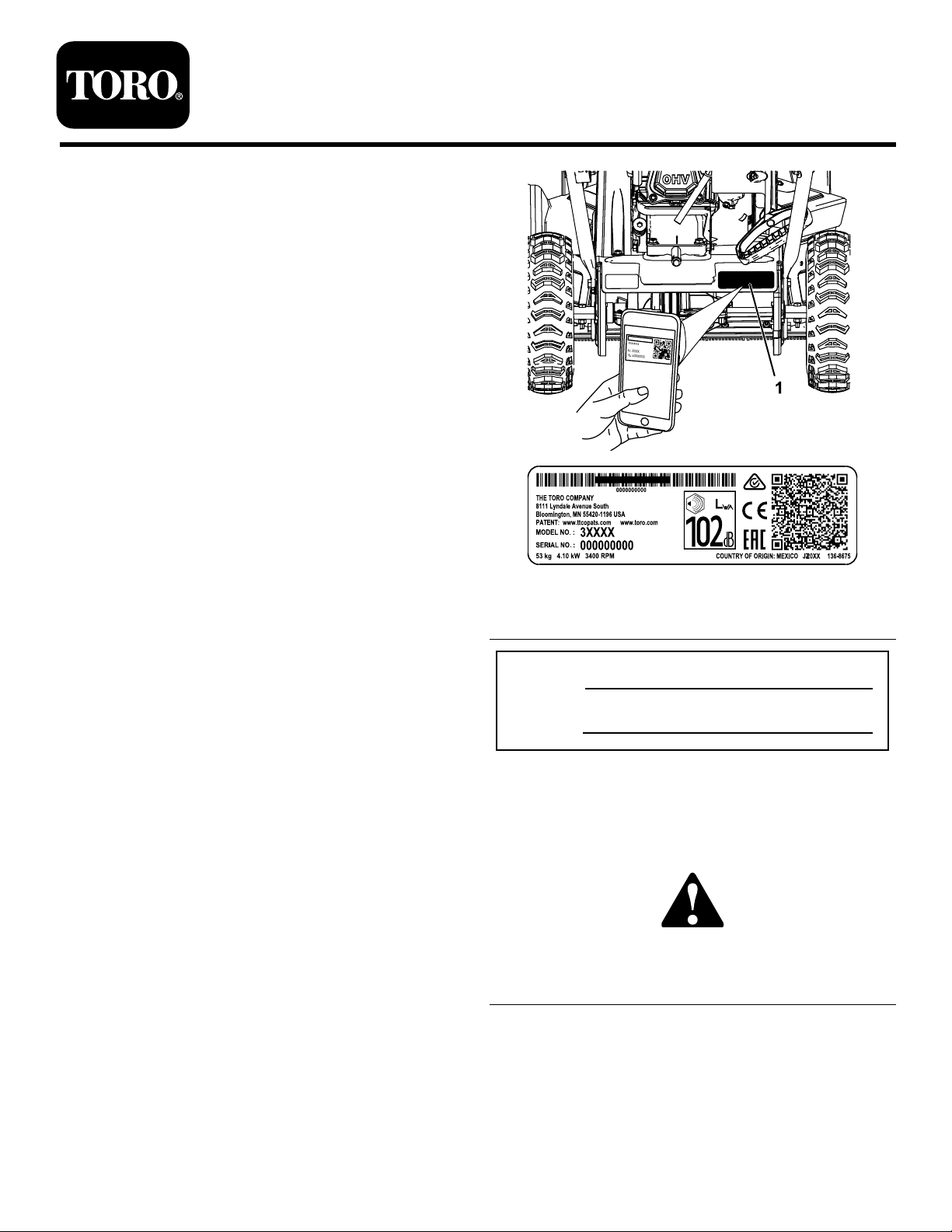

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyoursmartphoneortablet,scan

theQRcodeontheserialnumberdecaltoaccess

warranty,parts,andotherproductinformation.

g217476

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

©2017—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

OriginalInstructions(EN)

PrintedinMexico

AllRightsReserved

*3415-639*A

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Ifyouareusingthismachineabove

1500m(5,000ft)foracontinuousperiod,ensure

thattheHighAltitudeKithasbeeninstalled

sothattheenginemeetsCARB/EPAemission

regulations.TheHighAltitudeKitincreases

engineperformancewhilepreventingspark-plug

fouling,hardstarting,andincreasedemissions.

Onceyouhaveinstalledthekit,attachthe

high-altitudelabelnexttotheserialdecalonthe

machine.ContactanyAuthorizedToroService

DealertoobtaintheproperHighAltitudeKitand

high-altitudelabelforyourmachine.T olocate

adealerconvenienttoyou,accessourwebsite

atwww.Toro.comorcontactourToroCustomer

CareDepartmentatthenumber(s)listedinyour

EmissionControlWarrantyStatement.Remove

thekitfromtheengineandrestoretheengineto

itsoriginalfactorycongurationwhenrunningthe

engineunder1500m(5,000ft).Donotoperatean

enginethathasbeenconvertedforhigh-altitude

useatloweraltitudes;otherwise,youcould

overheatanddamagetheengine.

Ifyouareunsurewhetherornotyourmachinehas

beenconvertedforhigh-altitudeuse,lookforthe

followinglabel(Figure3).

Contents

Introduction...............................................................1

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................5

UnfoldingtheHandle..........................................5

InstallingtheDischargeChute............................5

CheckingtheEngine-OilLevel............................6

CheckingtheTirePressure.................................6

ProductOverview.....................................................6

Operation..................................................................7

BeforeOperation...................................................7

BeforeOperationSafety.....................................7

FillingtheFuelT ank............................................7

DuringOperation...................................................8

DuringOperationSafety.....................................8

StartingtheEngine.............................................8

EngagingtheAuger............................................9

DisengagingtheAuger.......................................9

Self-PropellingtheMachine................................9

ShuttingOfftheEngine.......................................9

AdjustingtheDischargeChuteandChute

Deector.........................................................9

ClearingaCloggedDischargeChute..................9

OperatingTips.................................................10

AfterOperation....................................................10

AfterOperationSafety......................................10

PreventingFreeze-upafterUse........................10

Maintenance............................................................11

RecommendedMaintenanceSchedule(s)............11

MaintenanceSafety...........................................11

CheckingtheEngine-OilLevel..........................12

CheckingandAdjustingtheSkids.....................12

InspectingtheThrowingEdges.........................13

ChangingtheEngineOil...................................13

ReplacingtheSparkPlug.................................14

AdjustingtheAugerCable................................15

AdjustingtheTransmissionCable.....................15

CheckingtheTirePressure...............................15

Storage...................................................................16

StoringtheMachine..........................................16

Figure3

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

decal127-9363

2

Page 3

Safety

GeneralSafety

ThismachinecomplieswithANSIB71.3specications.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeyoustarttheengine.

Ensurethateveryoneusingthisproductknows

howtousetheproductandunderstandsthe

warnings.

•Donotputyourhandsorfeetnearmoving

componentsonthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersasafedistanceawayfromthe

machine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Shutofftheenginebeforeunclogging,servicing,

orfuelingthemachine.

Youcanndadditionalitemsofsafetyinformationin

theirrespectivesectionsthroughoutthismanual.

3

Page 4

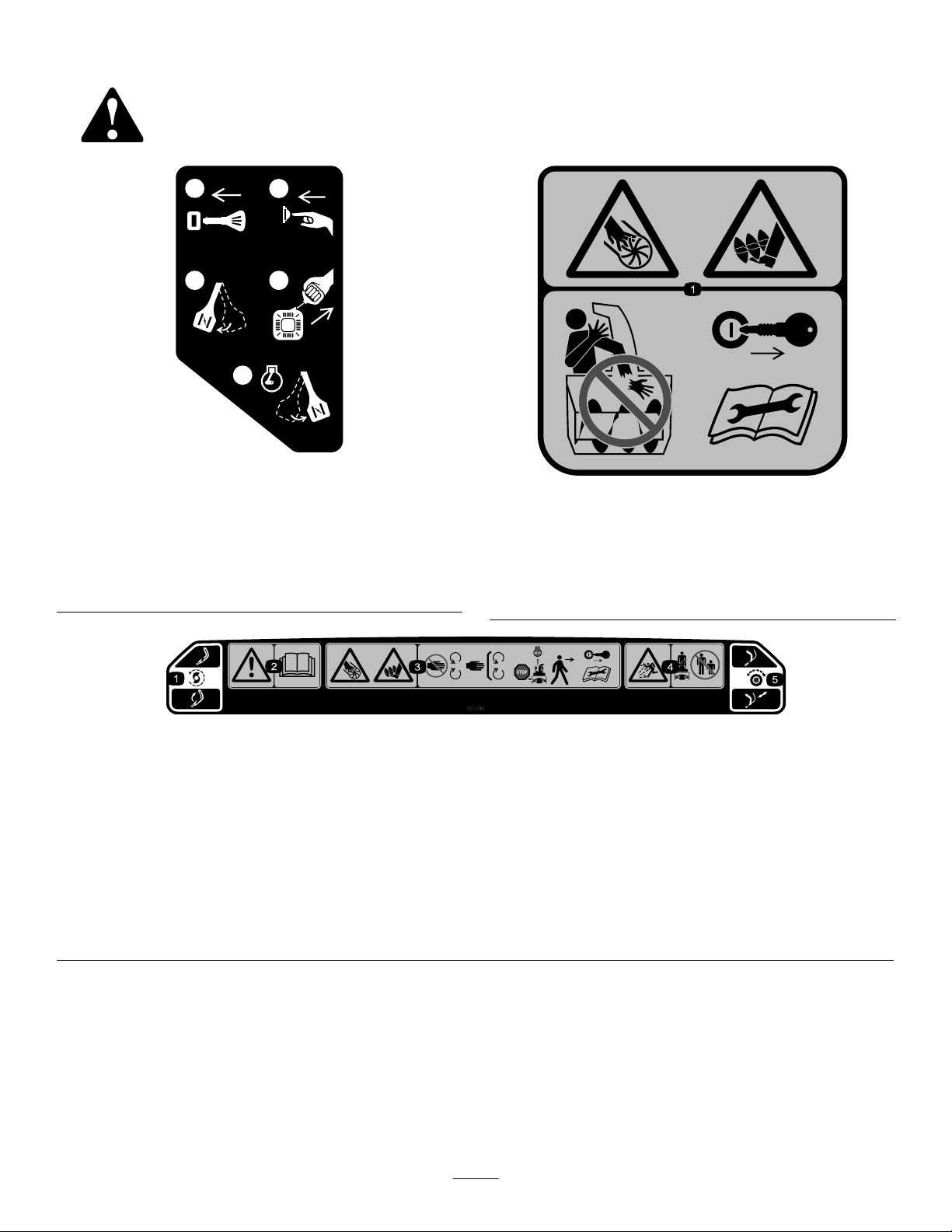

SafetyandInstructionalDecals

x 3

1

2

3

4

5

120-9805

Safetyanddecalsandinstructionsareeasilyvisibletotheoperatorandarelocated

nearanyareaofpotentialdanger.Replaceanydecalthatisdamagedormissing.

120-9805

1.Insertthekey.

2.Primetheengine3times.

3.Engagethechoke.

4.Pullthestartercord.

5.Oncetheengineisrunning,disengagethechoke.

decal120-9805

decal131-5914

131-5914

OrderPartNo.131-5916

1.Cutting/dismembermenthazardsofhandorfoot,impeller

andauger—donotplaceyourhandinthechute;remove

theignitionkeyandreadtheinstructionsbeforeservicing

orperformingmaintenance.

decal131-1785

131-1785

OrderPartNo.131-5921

1.Augerdrive—squeezethelevertoengage;releasethelever

todisengage.

2.Warning—readtheOperator'sManual.5.Self-propeldrive—pushdownonthehandletoengagethe

3.Cutting/dismembermenthazardsofhandorfoot,impeller

andauger—stayawayfrommovingparts;keepallguards

andshieldsinplace;shutofftheengineandwaitforthe

augertostopbeforeleavingthemachine;removetheignition

keyandreadtheinstructionsbeforeservicingorperforming

maintenance.

4.Thrownobjecthazard—keepbystandersasafedistance

awayfromthemachine.

self-propeldrive.

4

Page 5

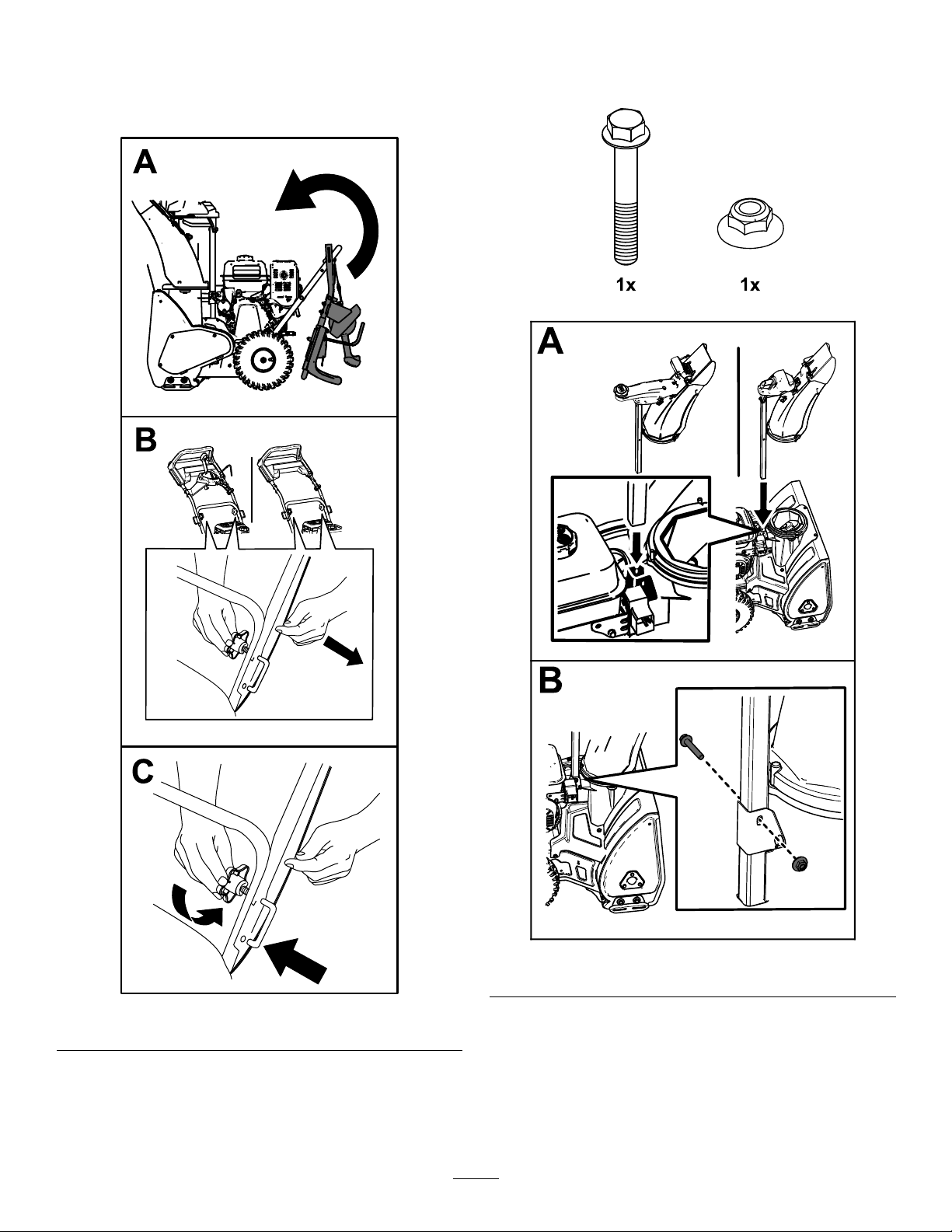

Setup

UnfoldingtheHandle

InstallingtheDischarge

Chute

Figure4

g217148

Figure5

g217126

5

Page 6

CheckingtheEngine-Oil

Level

Note:Yourmachinecomeswithoilintheengine

crankcase.Beforestartingtheengine,checktheoil

levelandaddoilifnecessary.

RefertoCheckingtheEngine-OilLevel(page12).

CheckingtheTirePressure

Thetiresareoverinatedatthefactoryforshipping.

Reducethetirepressureequallyinbothtiresto

between103and137kPa(15and20psi).

ProductOverview

Figure6

1.Augerlever7.Dischargechute

2.Fuel-tankcap

3.Dipstick

4.Skid(2)

5.Auger11.Upperhandle

6.Scraper

8.Chutedeector

9.Chute-deectorcontrol

10.Discharge-chutecontrol

g030450

Figure7

1.Fuel-tankcap

2.Primer5.Recoil-starthandle

3.Ignitionkey

6

g030451

4.Choke

Page 7

Operation

BeforeOperation

BeforeOperationSafety

•Forelectric-startmodelsonly:Useextension

cordsandreceptaclesasspeciedinthemanual.

Thoroughlyinspecttheelectricalcordbefore

pluggingitintoapowersource.Ifthecordis

damaged,donotuseit.Replacethedamaged

cord.Unplugthepowercordwheneveryouare

notstartingthemachine.

•Wearadequatewintergarmentswhenever

youoperatethemachine.Wearsubstantial,

slip-resistantfootwearthatimprovesfootingon

slipperysurfaces.Avoidloose-ttingclothingthat

cangetcaughtinmovingparts.

•Alwaysweareyeprotectionduringoperationor

whileperforminganadjustmentorrepairtoprotect

youreyesfromforeignobjectsthatthemachine

maythrow.

FillingtheFuelTank

•Forbestresults,useonlyclean,fresh(lessthan

30daysold),unleadedgasolinewithanoctane

ratingof87orhigher((R+M)/2ratingmethod).

•Oxygenatedfuelwithupto10%ethanolor15%

MTBEbyvolumeisacceptable.

•Donotuseethanolblendsofgasoline(such

asE15orE85)withmorethan10%ethanolby

volume.Performanceproblemsand/orengine

damagemayresultwhichmaynotbecovered

underwarranty.

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Donotllabovethebottomofthefueltank(Figure8).

•Thoroughlyinspecttheareawhereyouwillusethe

machine,andremovealldoormats,sleds,boards,

wires,andotherforeignobjects.

•Ifashield,safetydevice,ordecalisdamaged,

illegible,ormissing,repairorreplaceitbefore

beginningoperation.Also,tightenanyloose

fasteners.

DANGER

Fuelisextremelyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

others.

•Topreventastaticchargefromignitingthe

fuel,placethecontainerand/ormachineon

thegroundbeforelling,notinavehicle

oronanobject.

•Fillthetankoutdoorswhentheengineis

cold.Wipeupspills.

•Donothandlefuelwhensmokingor

aroundanopenameorsparks.

g217208

Figure8

Note:Forbestresults,purchaseonlythequantity

offuelthatyouexpecttousein30days.Otherwise,

youmayaddfuelstabilizertonewlypurchasedfuelto

keepitfreshforupto6months.

•Storefuelinanapprovedfuelcontainer,

outofthereachofchildren.

•Donottipthemachineeitherforward

orbackwardwithfuelinthefueltank;

otherwise,fuelmayleakoutofthe

machine.

7

Page 8

DuringOperation

DuringOperationSafety

•Shutofftheenginebeforeuncloggingthe

machineandalwaysuseastickorthe

snow-cleanouttool(ifprovided).

•Arotatingaugercaninjurehandsorfeet.Stay

behindthehandlesandawayfromthedischarge

openingwhileoperatingthemachine.Keepyour

face,hands,feet,andanyotherpartofyour

bodyorclothingawayfrommovingorrotating

parts.

•Neverdirectthedischargetowardpeopleorareas

wherepropertydamagecanoccur.

•Exercisecautiontoavoidslippingorfalling.

Alwaysbesureofyourfooting,andkeeparm

holdonthehandles.Walk;neverrun.

•Exerciseextremecautionwhenoperatingon

slopes.

•Neveroperatethemachinewithoutgoodvisibility

orlight.

StartingtheEngine

Note:Fullyinsertthekey;insertingthekeytothe

middlepositiondoesnotallowyoutostarttheengine.

g218596

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Lookbehindandusecarewhenbackingupwith

themachine.

•Whennotactivelyclearingsnow,disengagepower

totheauger.

•Exerciseextremecautionwhenoperatingonor

crossinggraveldrives,walks,orroads.Stayalert

forhiddenhazardsortrafc.

•Neverattempttomakeanyadjustmentswhilethe

engineisrunning.

•Afterstrikingaforeignobject,shutofftheengine,

removetheignitionkey(electric-startmodels

only),thoroughlyinspectthemachineforany

damage,andrepairthedamagebeforestarting

andoperatingthemachine.

•Ifthemachineshouldstarttovibrateabnormally,

shutofftheengineandcheckforthecause.

•Donotruntheengineindoorsunlessthereis

adequateventilation(e.g.,leavingtheoutsidedoor

open);exhaustfumesaredangerous.

g037395

Figure9

•Donotoverloadthemachinecapacityby

attemptingtoclearsnowattoofastarate.

•Nevertouchahotengineormufer.

Note:Primetheengine(refertoBofFigure9)

accordingtothefollowingtable:

Temperature

-23°C(-10°F)andabove

Below-23°C(-10°F)

8

SuggestedNumberofPrimes

3

6

Page 9

EngagingtheAuger

Figure10

DisengagingtheAuger

Todisengagetheauger,releasetheaugerlever.

Self-PropellingtheMachine

AdjustingtheDischarge

ChuteandChuteDeector

Toraiseorlowertheangleofthechutedeector,

pressthetriggeronthechutedeectorandmovethe

chutedeectorupordown.

Toadjustthedischargechute,movethechutehandle.

Note:Disengagetheaugerbeforeadjustingthe

chuteorchutedeector.

g030453

Tooperatetheself-propeldrive,simplywalkwithyour

handsontheupperhandleandyourelbowsatyour

sides,andthemachinewillautomaticallykeeppace

withyou(Figure11).

Note:Youcanself-propelthemachinewiththeauger

engagedordisengaged.

Figure11

g030530

Figure12

1.Trigger

2.Chutehandle

ClearingaClogged DischargeChute

WARNING

Iftheauger/impellerisrunningbutthereisno

snowcomingoutofthedischargechute,the

dischargechutemaybeclogged.

Neveruseyourhandstoclearaclogged

dischargechute.Thiscouldresultinpersonal

injury.

g030528

1.Whileremainingintheoperatingposition,

releasetheself-propelhandle.

ShuttingOfftheEngine

Toshutofftheengine,removethekeyfromthe

ignitionormovethekeytothemiddleposition.

2.Engagetheauger.

3.Pushdownonthehandletoraisethefrontof

themachineafewcentimeters(inches)offthe

pavement,thenliftthehandlesquicklytobump

thefrontofthemachineontothepavement.

9

Page 10

4.Disengagetheauger.

5.Repeatsteps1through4,ifnecessary,until

astreamofsnowcomesoutofthedischarge

chute.

AfterOperation

AfterOperationSafety

Important:Ifyoucannotunclogthedischarge

chutebybumpingthefrontofthemachine,shut

offtheengine,waitforallmovingpartstostop,

anduseasnow-cleanouttool(notincluded).

Important:Uncloggingthedischargechute

bybumpingthefrontofthemachineonthe

pavementmaycausetheskidstomove.Adjust

theskidsandtightentheskidboltssecurely;refer

toCheckingandAdjustingtheSkids(page12).

OperatingTips

WARNING

Theaugercanthrowstones,toys,andother

foreignobjectsandcauseseriouspersonal

injurytoyouorbystanders.

•Keeptheareatobeclearedfreeofall

objectsthattherotorbladescouldpickup

andthrow.

•Keepallchildrenandpetsawayfromthe

areaofoperation.

•Removethesnowassoonaspossibleafteritfalls.

•Overlapeachswathtoensurecompletesnow

removal.

•Dischargethesnowdownwindwheneverpossible.

•Ifthemachinedoesnotpropelitselfforwardon

slipperysurfacesorinheavysnow,pushforward

onthehandle,butallowthemachinetoworkat

itsownpace.

•Neverstorethemachinewithfuelinthefuel

tankinsideabuildingwhereignitionsourcesare

present,suchashotwaterheaters,spaceheaters,

orclothesdryers.Allowtheenginetocoolbefore

storinginanyenclosure.

•Whenstoringthemachineformorethan30days,

refertoStorage(page16)forimportantdetails.

PreventingFreeze-upafter Use

•Lettheenginerunforafewminutestoprevent

movingpartsfromfreezing.Shutofftheengine,

waitforallmovingpartstostop,andremoveice

andsnowfromthemachine.

•Cleanoffanysnowandicefromthebaseofthe

chute.Alwaysuseatooltocleansnowoutofa

chute,neveruseyourhand.

•Rotatethedischargechuteleftandrighttofree

itfromanyicebuildup.

•WiththeignitionkeyintheOFFposition,pullthe

recoil-starthandleseveraltimesorconnectthe

electricalcordtoapowersourceandthemachine

andpushtheelectric-startbuttononcetoprevent

therecoilstarterand/ortheelectricstarterfrom

freezingup(electric-startmodelsonly).

•Insnowyandcoldconditions,somecontrolsand

movingpartsmayfreeze.Donotuseexcessive

forcewhentryingtooperatefrozencontrols.Ifyou

havedifcultyoperatinganycontrolorpart,start

theengineandletitrunforafewminutes.

•Donotusethechutecontroltoattempttomovea

frozendischargechute.Holddowntheblueknob

anduseyourhandstorotatethechute.

•Transportingthemachineinanopentraileror

vehiclecancausethecontrolsordischargechute

tofreeze.

10

Page 11

Maintenance

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Afterthersthour

Aftertherst2hours

Beforeeachuseordaily

Every100hours

Yearly

Yearlyorbeforestorage

MaintenanceSafety

MaintenanceProcedure

•Checkforloosefastenersandtightenthemifnecessary.

•Changetheengineoil.

•Inspecttheaugercableandadjustitifnecessary.

•Inspectthetransmissioncableandadjustitifnecessary .

•Checktheengine-oillevelandaddoilifnecessary.

•Replacethesparkplug.

•Checktheskidsandadjustthemifnecessary .

•InspectthethrowingedgesandhaveanAuthorizedServiceDealerreplacethe

throwingedgesandscraperifnecessary.

•Changetheengineoil.

•Inspecttheaugercableandadjustitifnecessary.

•Inspectthetransmissioncableandadjustitifnecessary .

•Checkthetirepressure.

•Checkforloosefastenersandtightenthemifnecessary.

•HaveanAuthorizedServiceDealerinspectthedrivebeltandreplaceitifnecessary.

•Preparethemachineforstorage.

Readthefollowingsafetyprecautionsbefore

performinganymaintenanceonthemachine:

•Beforeperforminganymaintenance,service,or

adjustment,shutofftheengineandremovethe

key.Ifmajorrepairsareeverneeded,contactan

AuthorizedServiceDealer.

•Checkallfastenersatfrequentintervalsforproper

tightnesstoensurethatthemachineisinsafe

workingcondition.

•Donotchangethegovernorsettingsontheengine.

•PurchaseonlygenuineTororeplacementparts

andaccessories.

11

Page 12

CheckingtheEngine-Oil

CheckingandAdjustingthe

Level

ServiceInterval:Beforeeachuseordaily

Skids

ServiceInterval:Yearly

Checktheskidstoensurethattheaugerdoesnot

contactthepavedsurface.Adjusttheskidsasneeded

tocompensateforwear(Figure14).

1.Loosentheskidbolts.

2.Slidea5mm(3/16inch)boardunderneaththe

scraper.

Note:Usingathinnerboardresultsinamore

aggressivescraper;usingathickerboardresults

inalessaggressivescraper.

3.Lowertheskidstotheground.

Note:Ensurethattheskidsareatonthe

ground.

4.Tightentheskidbolts.

Figure13

g218004

g217249

g037704

Figure14

12

Page 13

InspectingtheThrowing

ChangingtheEngineOil

Edges

ServiceInterval:Yearly—Inspectthethrowingedges

andhaveanAuthorizedService

Dealerreplacethethrowingedges

andscraperifnecessary .

Beforeeachsession,inspectthethrowingedges

forwear.Whenathrowingedgehasworndownto

thewear-indicatorhole,haveanAuthorizedService

Dealerreplacethethrowingedges(Figure15).

ServiceInterval:Aftertherst2hours

Yearly

Ifpossible,runtheengineforafewminutesbefore

changingtheoilbecausewarmoilowsbetterand

carriesmorecontaminants.

EngineOilSpecications

Engineoilcapacity

OilviscosityRefertoFigure16.

APIserviceclassicationSJorhigher

UseFigure16toselectthebestoilviscosityforthe

outdoortemperaturerangeexpected:

0.50L(17oz)

1.Thewear-indicatorhole

isintact;youdonotneed

toreplacethethrowing

edges.

Figure15

2.Thewear-indicatorhole

isexposed;replaceboth

throwingedges.

g030128

Figure16

g011606

1.Movethemachinetoalevelsurface.

2.Placeanoil-drainpanundertheoil-drainplug,

removetheoil-drainplug,andtipthemachine

backwardanddraintheusedoilintheoil-drain

pan(Figure17).

g030122

Figure17

13

1.Oil-drainplug

Page 14

3.Afterdrainingtheusedoil,returnthemachineto

theoperatingposition.

4.Installtheoil-drainplugandtightenitsecurely.

5.Cleanaroundtheoil-llcap.

ReplacingtheSparkPlug

ServiceInterval:Every100hours—Replacethe

sparkplug.

6.Fillthecrankcasewithoil(Figure18).

WARNING

Replacingthesparkplugwhiletheengineis

hotcanresultinburns.

Waituntiltheengineiscooltoreplacethe

sparkplug.

UseaT orosparkplugorequivalent(Champion®

RN9YCorNGKBPR6ES).

1.Removetheboot(Figure19).

Figure18

g030123

Figure19

1.Spark-plugboot

2.Cleanaroundthebaseofthesparkplug.

3.Removeanddiscardtheoldsparkplug.

Note:Youwillneedaratchetwrenchextension

toremovethesparkplug.

4.Setthegapbetweentheelectrodesonanew

sparkplugat0.76mm(0.030inch)asshown

inFigure20.

g217249

g001029

Figure20

1.0.76mm(0.030inch)

14

Page 15

AdjustingtheAugerCable

AdjustingtheTransmission

ServiceInterval:Aftertherst2hours

Yearly

Ifthedrivebeltslipsorsquealsunderaheavyload,

adjusttheaugercable.

1.Loosenthenutonthelowercableclamp,butdo

notremoveit(Figure21).

Cable

ServiceInterval:Aftertherst2hours

Yearly

Ifthewheelseasilystallout,orifthewheelsdrive

withoutengagingtheself-propelhandle,adjustthe

transmissioncable.

1.Loosenthenutontheuppercableclamp,butdo

notremoveit(Figure22).

Figure21

1.Nut

2.Cable4.Spring

2.Pullthecableuptoremovesomeslack(Figure

21).

3.Connector

Important:Donotremovealltheslack

fromthecable.Removingalltheslackfrom

thecablepreventstheaugerfromstopping

properly.

3.Holdthecableinplaceandtightenthenut

(Figure21).

g030444

g030446

Figure22

1.Nut

2.Pullthecabledowntoremovemostoftheslack

inthecable(Figure22).

2.Cable

Important:Donotremovealltheslack

fromthecable.Removingalltheslackfrom

thecablemaycausethewheelstoengage

withoutengagingtheself-propelhandle.

3.Tightenthenut(Figure22).

CheckingtheTirePressure

ServiceInterval:Yearly

Checktheairpressureinthetiresandinatethemto

103to137kPa(15to20psi).

15

Page 16

Storage

StoringtheMachine

WARNING

Fuelfumesarehighlyammable,explosive,

anddangerousifinhaled.Ifyoustorethe

productinanareawithanopename,thefuel

fumesmayigniteandcauseanexplosion.

•Donotstorethemachineinahouse(living

area),basement,oranyotherareawhere

ignitionsourcesmaybepresent,such

ashotwaterandspaceheaters,clothes

dryers,furnaces,andotherappliances.

•Donottipthemachineeitherforward

orbackwardwithfuelinthefueltank;

otherwise,fuelmayleakoutofthe

machine.

•Donotstorethemachinewithitshandle

tippeddownontotheground;otherwise,

oilleaksintotheenginecylinderandonto

theground,andtheenginedoesnotstart

orrun.

12.WiththeignitionkeyintheOFFposition,pullthe

recoil-starthandleslowlytodistributetheoilon

theinsideofthecylinder.

13.Cleanthemachine.

14.Touchupchippedsurfaceswithpaintavailable

fromanAuthorizedServiceDealer.Sand

affectedareasbeforepainting,andusearust

preventativetopreventthemetalpartsfrom

rusting.

15.Tightenanyloosefasteners.Repairorreplace

anydamagedparts.

16.Coverthemachineandstoreitinaclean,dry

placeoutofthereachofchildren.Allowthe

enginetocoolbeforestoringthemachineinany

enclosure.

1.Onthelastrefuelingoftheseason,addfuel

stabilizertofreshfuelasdirectedbythe

fuel–stabilizermanufacturer.

Important:Donotstorefuellonger

thansuggestedbythefuel-stabilizer

manufacturer.

2.Runtheenginefor10minutestodistributethe

conditionedfuelthroughthefuelsystem.

3.Shutofftheengine,allowittocool,andsiphon

thefueltankorruntheengineuntilitshutsoff.

4.Starttheengineandrunituntilitshutsoff.

5.Chokeorprimetheengine,startitathirdtime,

andruntheengineuntilitdoesnotstart.

6.Drainthefuelinthecarburetorthroughthe

carburetor-drainboltintoanapprovedgasoline

container.

7.Disposeofunusedfuelproperly.Recycleit

accordingtolocalcodes,oruseitinyour

automobile.

8.Whiletheengineisstillwarm,changetheengine

oil.RefertoChangingtheEngineOil(page13).

9.Removethesparkplug.

10.Squirt10ml(2tsp)ofoilintothespark-plughole.

11.Installthesparkplugbyhandandthentorqueit

to27to30N∙m(20to22ft-lb).

16

Loading...

Loading...