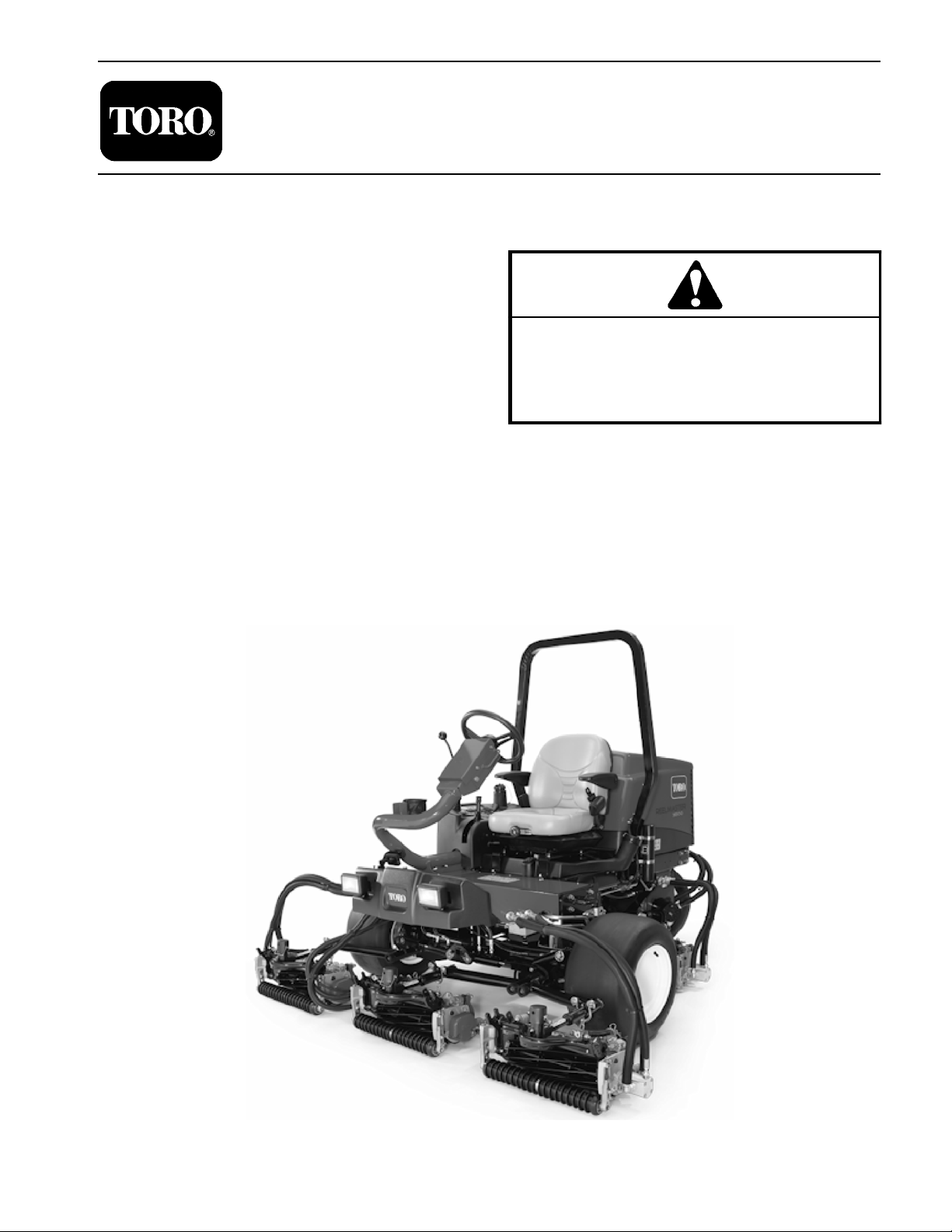

Page 1

Part No. 15213SL

Service Manual

Preface

The purpose of this publication is to provide the service

technician with service information for service and

repair of major systems and components on the

Reelmaster 3550- D.

REFER TO THE TRACTION UNIT AND CUTTING

UNIT OPERATOR’S MANUALS FOR OPERATING,

MAINTENANCE AND ADJUSTMENT INSTRUCTIONS. Copies of the Operator’s Manuals and Parts

Catalog are available on the internet at www.Toro.com.

The ToroCompany reserves the right to changeproduct

specifications or this publication without notice.

Reelmaster

This safety symbol means DANGER, WARNING

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing or repair of the machine.

IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the

machine.

3550- D

R

EThe Toro Company - 2015

Page 2

This page is intentionally blank.

Reelmaster 3550- D

Page 3

Table Of Contents

Chapter 1 - Safety

General Safety Instructions 1 - 2..................

Jacking Instructions 1 - 4.........................

Safety and Instruction Decals 1 - 5................

Chapter 2 - Product Records and Maintenance

Product Records 2 - 1...........................

Maintenance 2 - 1...............................

Equivalents and Conversions 2 - 2................

Torque Specifications 2 - 3.......................

Chapter 3 - Kubota Diesel Engine

Specifications 3 - 3..............................

General Information 3 - 4........................

Service and Repairs 3 - 6........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

05 SERIES

Chapter 4 - Hydraulic System

Specifications 4 - 2..............................

General Information 4 - 3........................

Special Tools 4 - 8..............................

Hydraulic Schematic 4 - 14.......................

Hydraulic Flow Diagrams 4 - 16...................

Troubleshooting 4 - 26...........................

Testing 4 - 31...................................

Adjustments 4 - 62..............................

Service and Repairs 4 - 63.......................

EATON MEDIUM DUTY PISTON PUMP REPAIR

INFORMATION MODEL 70160 VARIABLE

DISPLACEMENT PISTON PUMP

PARKER TORQMOTOR

(TC, TB, TE, TJ, TF, TG, TH AND TL SERIES)

SAUER- DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

TM

SERVICE PROCEDURE

Chapter 5 - Electrical System

General Information 5 - 2........................

Electrical Schematic 5 - 3........................

Special Tools 5 - 4..............................

Troubleshooting 5 - 6............................

Electrical System Quick Checks 5 - 18.............

Component Testing 5 - 20........................

Service and Repairs 5 - 47.......................

Chapter 6 - Chassis

Specifications 6 - 2..............................

Special Tools 6 - 2..............................

Adjustments 6 - 3...............................

Service and Repairs 6 - 4........................

Chapter 7 - DPA Cutting Units

Specifications 7 - 2..............................

General Information 7 - 3........................

Special Tools 7 - 5..............................

Factors That Can Affect Cutting Performance 7 - 9..

Set Up and Adjustments 7 - 13....................

Service and Repairs 7 - 15.......................

Chapter 8 - Groomer (Optional)

Grooming Performance 8 - 2.....................

Troubleshooting 8 - 3............................

Service and Repairs 8 - 4........................

Chapter 9 - Foldout Drawings

Electrical Drawing Designations 9 - 2..............

Hydraulic Schematic 9 - 3........................

Electrical Schematic 9 - 4........................

Wire Harness Diagram 9 - 5......................

Wire Harness Drawing 9 - 6......................

SafetyProduct Records

and Maintenance

Kubota

Diesel Engine

System

Hydraulic

System

Electrical

Reelmaster 3550- D

Units

DPA Cutting Chassis

Groomer

Foldout

Drawings

Page 4

This page is intentionally blank.

Reelmaster 3550−D

Page 5

Table of Contents

GENERAL SAFETY INSTRUCTIONS 2............

Before Operating 2............................

While Operating 2............................

Maintenance and Service 3....................

JACKING INSTRUCTIONS 4.....................

SAFETY AND INSTRUCTION DECALS 5..........

Chapter 1

Safety

Safety

Reelmaster 3550−D Page 1 − 1 Safety

Page 6

General Safety Instructions

The Reelmaster 3550−D has been tested and certified

by Toro for compliance with existing safety standards

and specifications. Although hazard control and accident prevention partially are dependent upon the design

and configuration of the machine, these factors are also

dependent upon the awareness, concern and proper

training of the personnel involved in the operation, transport, maintenance and storage of the machine. Improper use or maintenance of the machine can result in injury

or death. To reduce the potential for injury or death, comply with the following safety instructions.

Before Operating

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

1. Review and understand the contents of the Operator’s Manuals and Operator’s DVD before starting and

operating the vehicle. Become familiar with the controls

and know how to stop the vehicle and engine quickly.

Additional copies of the Operator’s Manual are available

on the internet at www.Toro.com.

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible or

damaged, repair or replace it before operating the machine. Also tighten any loose nuts, bolts or screws to ensure machine is in safe operating condition.

3. Assure interlock switches are adjusted correctly so

engine cannot be started unless traction pedal is in

NEUTRAL and cutting units are DISENGAGED.

While Operating

1. Sit on the seat when starting and operating the machine.

2. Before starting the engine:

A. Engage the parking brake.

4. Since diesel fuel is flammable, handle it carefully:

A. Use an approved fuel container.

B. Do not remove fuel tank cap while engine is hot or

running.

C. Do not smoke while handling fuel.

D. Fill fuel tank outdoors and only to within an inch of

the top of the tank, not the filler neck. Do not overfill.

E. Wipe up any spilled fuel.

4. Do not touch engine, exhaust system components or

radiator while engine is running or soon after it is

stopped. These areas could be hot enough to cause

burns.

5. Before getting off the seat:

B. Make sure traction pedal is in neutral and the

PTO switch is OFF (disengaged).

C. After engine is started, release parking brake and

keep foot off traction pedal. Machine must not move.

If movement is evident, the traction pedal linkage

may be adjusted incorrectly; therefore, shut engine

off and adjust traction pedal linkage until machine

does not move when traction pedal is released.

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

A. Ensure that traction pedal is in neutral.

B. Engage parking brake.

C. Disengage PTO and wait for cutting unit reels to

stop rotating.

D. Stop engine and remove key from ignition switch.

E. Toro recommends that anytime the machine is

parked (short or long term), the cutting units should

be lowered to the ground. This relieves pressure

from the lift circuit and eliminates the risk of cutting

units accidentally lowering to the ground.

F. Do not park on slopes unless wheels are chocked

or blocked.

Reelmaster 3550−DPage 1 − 2Safety

Page 7

Maintenance and Service

1. The T raction Unit and Cutting Unit Operator’s Manuals provide information regarding the operation, general

maintenance and maintenance intervals for your Reelmaster machine. Refer to these publications for additional information when servicing the machine.

2. Before servicing or making adjustments, lower cutting units, stop engine, set parking brake and remove

key from the ignition switch.

3. Make sure machine is in safe operating condition by

keeping all nuts, bolts and screws tight.

4. Never store the machine or fuel container inside

where there is an open flame, such as near a water heater or furnace.

5. Make sure all hydraulic line connectors are tight and

all hydraulic hoses and lines are in good condition before applying pressure to the hydraulic system.

6. Keep body and hands away from pin hole leaks in hydraulic lines that eject high pressure hydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury. Fluid accidentally injected into the skin

must be surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result.

7. Before disconnecting or performing any work on the

hydraulic system, all pressure in system must be relieved by stopping engine and lowering cutting units to

the ground.

8. If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor.

9. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt. Clean

protective screen on machine frequently.

10.If engine must be running to perform maintenance or

an adjustment, keep hands, feet, clothing and other

parts of the body away from cutting units and other moving parts. Keep bystanders away.

11.To assure safety and accuracy , check maximum engine speed.

12.Shut engine off before checking or adding oil to the

engine crankcase.

13.Disconnect battery before servicing the machine.

Disconnect negative battery cable first and positive

cable last. If battery voltage is required for troubleshooting or test procedures, temporarily connect the battery.

Reconnect positive battery cable first and negative

cable last.

14.Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes and clothing. Protect your

face, eyes and clothing when working with a battery.

15.Battery gases can explode. Keep cigarettes, sparks

and flames away from the battery.

16.When welding on machine, disconnect both battery

cables to prevent damage to machine electronic equipment. Disconnect negative battery cable first and positive cable last. Also, disconnect the wire harness

connector from th e m achine TEC controller and disconnect the terminal connector from the alternator.

17.At the time of manufacture, the machine conformed

to the safety standards for riding mowers. To assure optimum performance and continued safety certification of

the machine, use genuine Toro replacement parts and

accessories. Replacement parts and accessories made

by other manufacturers may result in non-conformance

with the safety standards and the warranty may be

voided.

18.When changing attachments, tires or performing

other service, use correct jacks, hoists and jack stands.

Make sure machine is parked on a solid level surface

such as a concrete floor. Prior to raising the machine, remove any attachments that may interfere with the safe

and proper raising of the machine. Always chock or

block wheels. Use appropriate jack stands to support

the raised machine. If the machine is not properly supported by jack stands, the machine may move or fall,

which may result in personal injury (see Jacking Instructions in this chapter).

19.Make sure to dispose of potentially harmful waste

(e.g. fuel, oil, engine coolant, filters, battery) in an environmentally safe manner . Follow all local codes and regulations when recycling or disposing of waste.

Safety

Reelmaster 3550−D Page 1 − 3 Safety

Page 8

Jacking Instructions

Jacking the Rear End

CAUTION

When changing attachments, tires or performing other service, use correct jacks and supports. Make sure machine is parked on a solid,

level surface such as a concrete floor. Prior to

raising machine, remove any attachments that

may interfere with the safe and proper raising of

the machine. Always chock or block wheels. Use

jack stands to support the raised machine. If the

machine is not properly supported by jack

stands, the machine may move or fall, which

may result in personal injury.

Jacking the Front End

1. If the front wheel or wheel motor is to be removed,

position jack securely under the round tube of the lower

frame as closely to the side plate as possible.

2. Use appropriate jack stands under the round tube to

support the machine.

1. Chock both front wheels.

IMPORTANT: Make sure jack is as close to the rear

fork as possible when raising the machine.

2. Place jac k s e c u r e l y u n d e r the rear lift arm support as

close to the fork as possible. Raise rear tire off the

ground.

3. Use appropriate jack stands under the frame to sup-

port the machine.

Reelmaster 3550−DPage 1 − 4Safety

Page 9

Safety and Instruction Decals

Numerous safety and instruction decals are affixed to

the Reelmaster 3550−D. If any decal becomes illegible

or damaged, install a new decal. Decal part numbers are

listed in your Parts Catalog.

Safety

Reelmaster 3550−D Page 1 − 5 Safety

Page 10

This page is intentionally blank.

Reelmaster 3550−DPage 1 − 6Safety

Page 11

Product Records and Maintenance

Table of Contents

PRODUCT RECORDS 1.........................

MAINTENANCE 1..............................

EQUIVALENTS AND CONVERSIONS 2...........

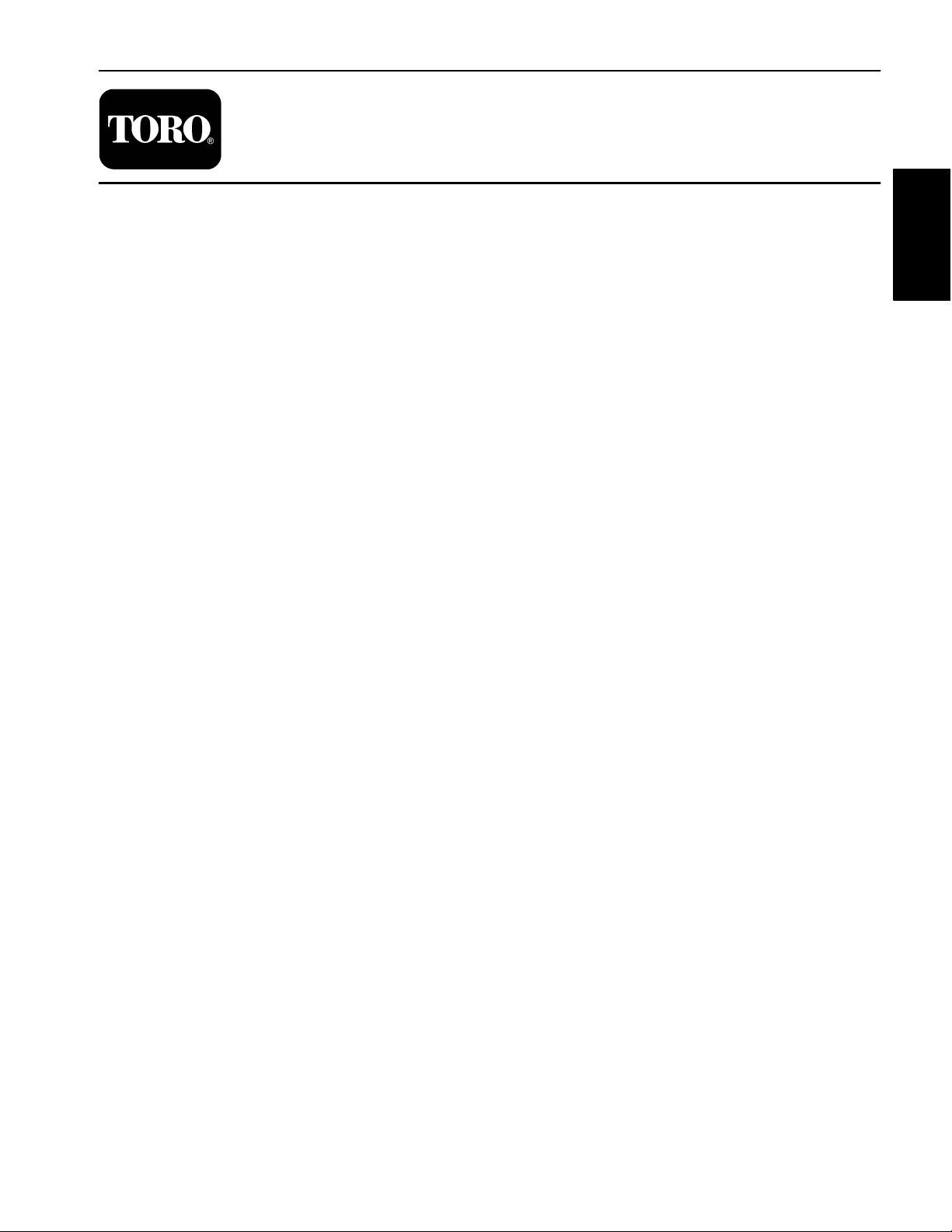

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3...................

Fastener Identification 3.......................

Using a Torque Wrench with an Offset Wrench 3..

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Inch Series) 4...............

Standard Torque for Dry, Zinc Plated and

Steel Fasteners (Metric Fasteners) 5..........

Other Torque Specifications 6..................

Conversion Factors 6.........................

Product Records

Chapter 2

Product Records

and Maintenance

Insert Operator’s Manuals and Parts Catalog for your

Reelmaster at the end of this chapter. Additionally, insert

Installation Instructions, Operator’s Manuals and Parts

Catalogs for any accessories that have been installed

on your Reelmaster at the end of this section.

Maintenance

Maintenance procedures and recommended service intervals for your Reelmaster are covered in the Traction

Unit and Cutting Unit Operator’s Manuals. Refer to

those publications when performing regular equipment

maintenance. Several maintenance procedures have

break−in intervals identified in the Operator’s Manuals.

Refer to the Engine Operator’s Manual for additional engine specific maintenance procedures.

Reelmaster 3550−D Page 2 − 1 Product Records and Maintenance

Page 12

Equivalents and Conversions

0.09375

Reelmaster 3550−DPage 2 − 2Product Records and Maintenance

Page 13

Torque Specifications

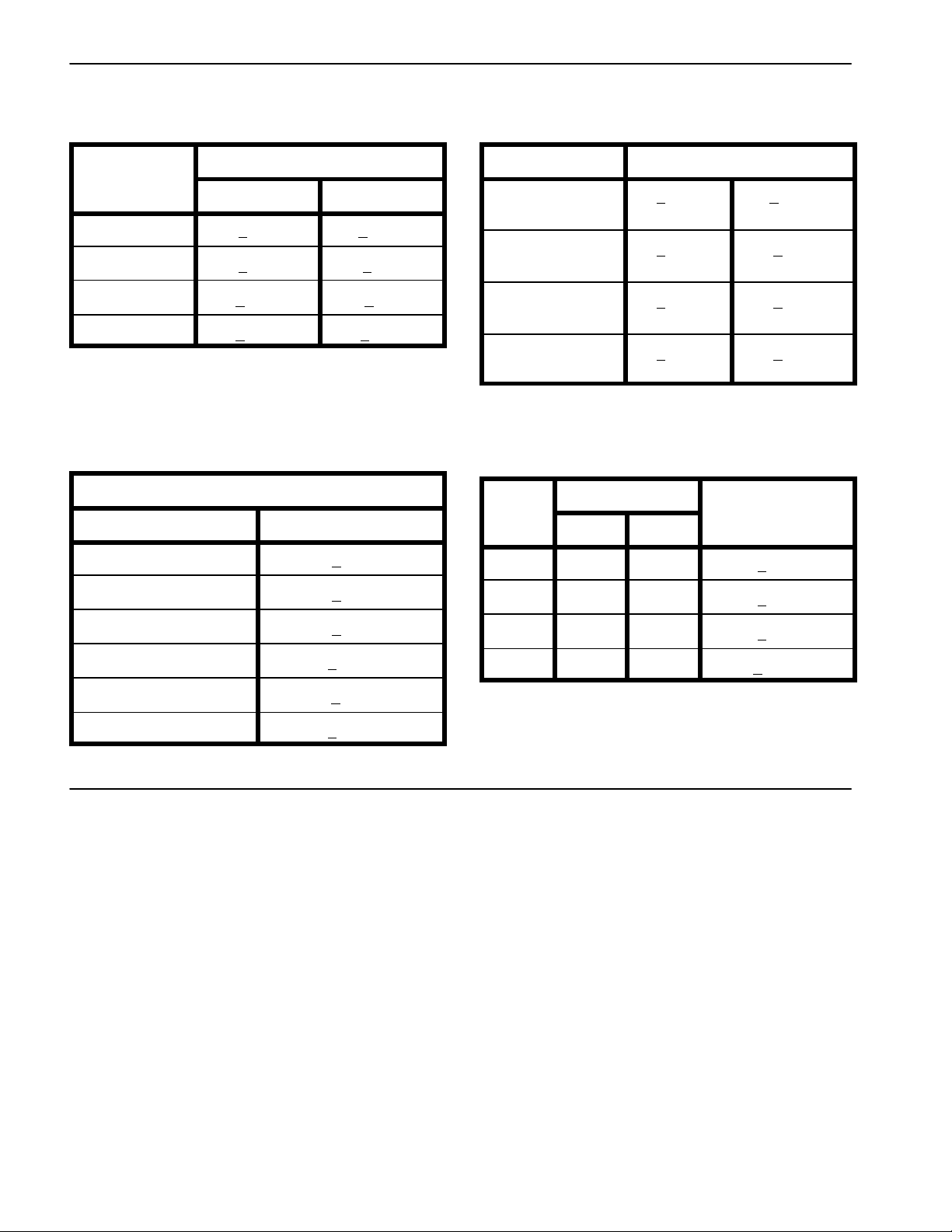

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque that

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a specific requirement identified in this Service Manual. The following factors shall be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torque feature

(e.g. Nylock nut), hardness of the surface underneath

the fastener’s head or similar condition which affects t h e

installation.

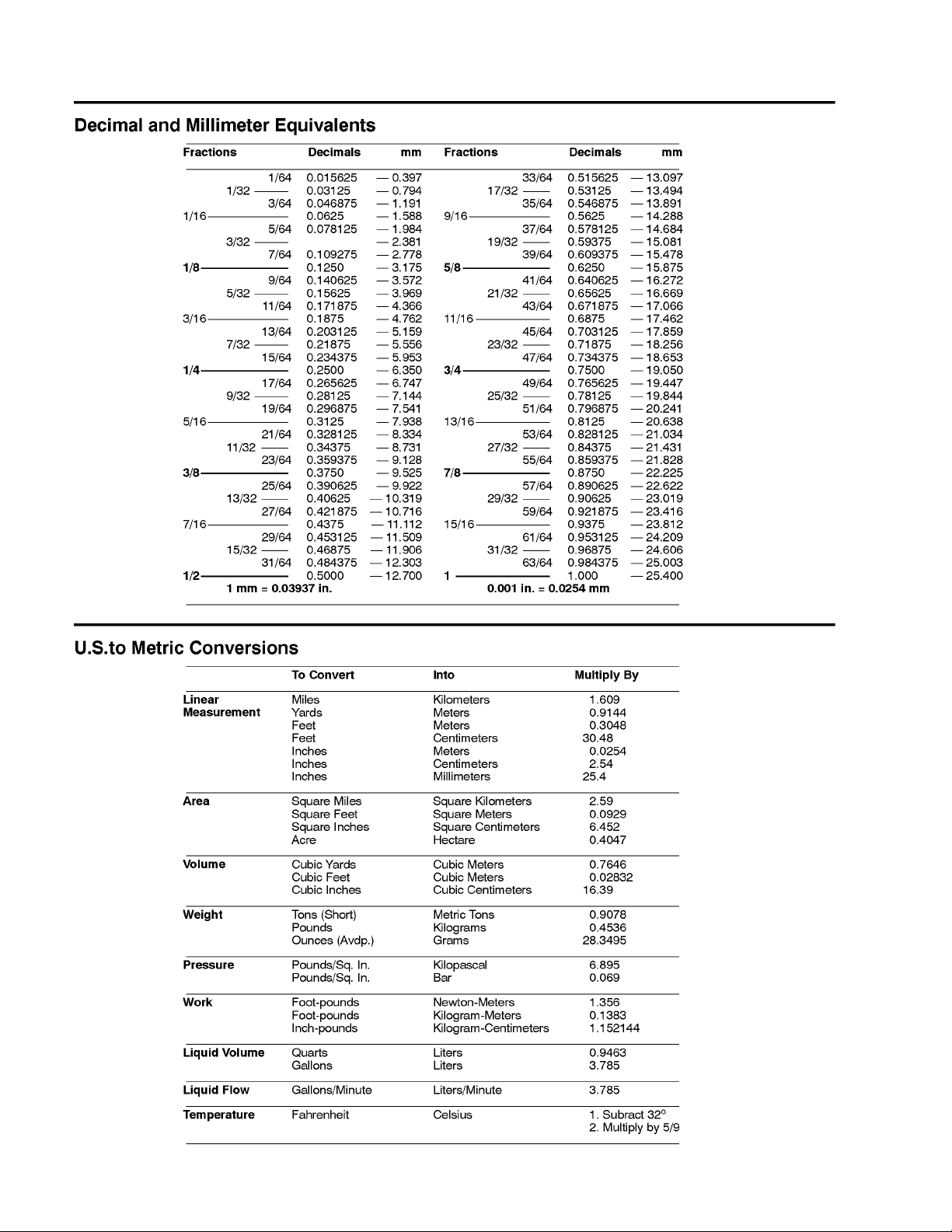

Fastener Identification

As noted in the following tables, torque values should be

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

the lines match up.

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

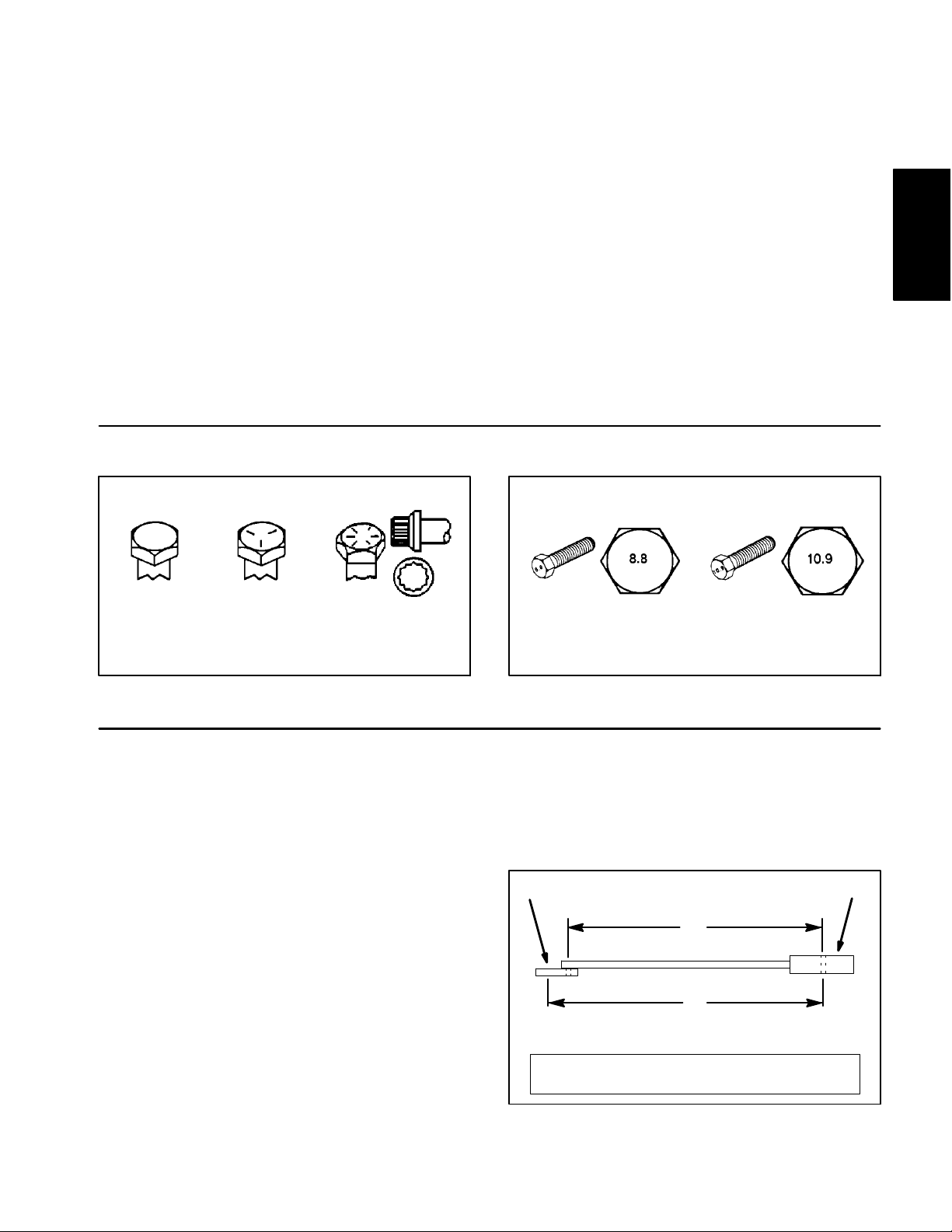

Using a Torque Wrench with an Offset Wrench

Use of an offset wrench (e.g. crowfoot wrench) will affect

torque wrench calibration due to the effective change of

torque wrench length. When using a torque wrench with

an offset wrench, multiply the listed torque recommendation by the calculated torque conversion factor (Fig.

3) to determine proper tightening torque. Tightening

torque when using a torque wrench with an offset

wrench will be lower than the listed torque recommendation.

Example: The measured effective length of the torque

wrench (distance from the center of the handle to the

center of the square drive) is 18”.

The measured effective length of the torque wrench with

the offset wrench installed (distance from the center of

the handle to the center of the offset wrench) is 19”.

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

If the listed torque recommendation for a fastener is

from 76 to 94 ft−lb, the proper torque when using this

torque wrench with an offset wrench would be from 72

to 89 ft−lb.

(effective length of

torque wrench)

A

B

(effective length of torque

wrench + offset wrench)

TORQUE CONVERSION FACTOR = A / B

Torque wrenchOffset wrench

The calculated torque conversion factor for this torque

wrench with this offset wrench would be 18 / 19 = 0.947.

Reelmaster 3550−D Page 2 − 3 Product Records and Maintenance

Figure 3

Page 14

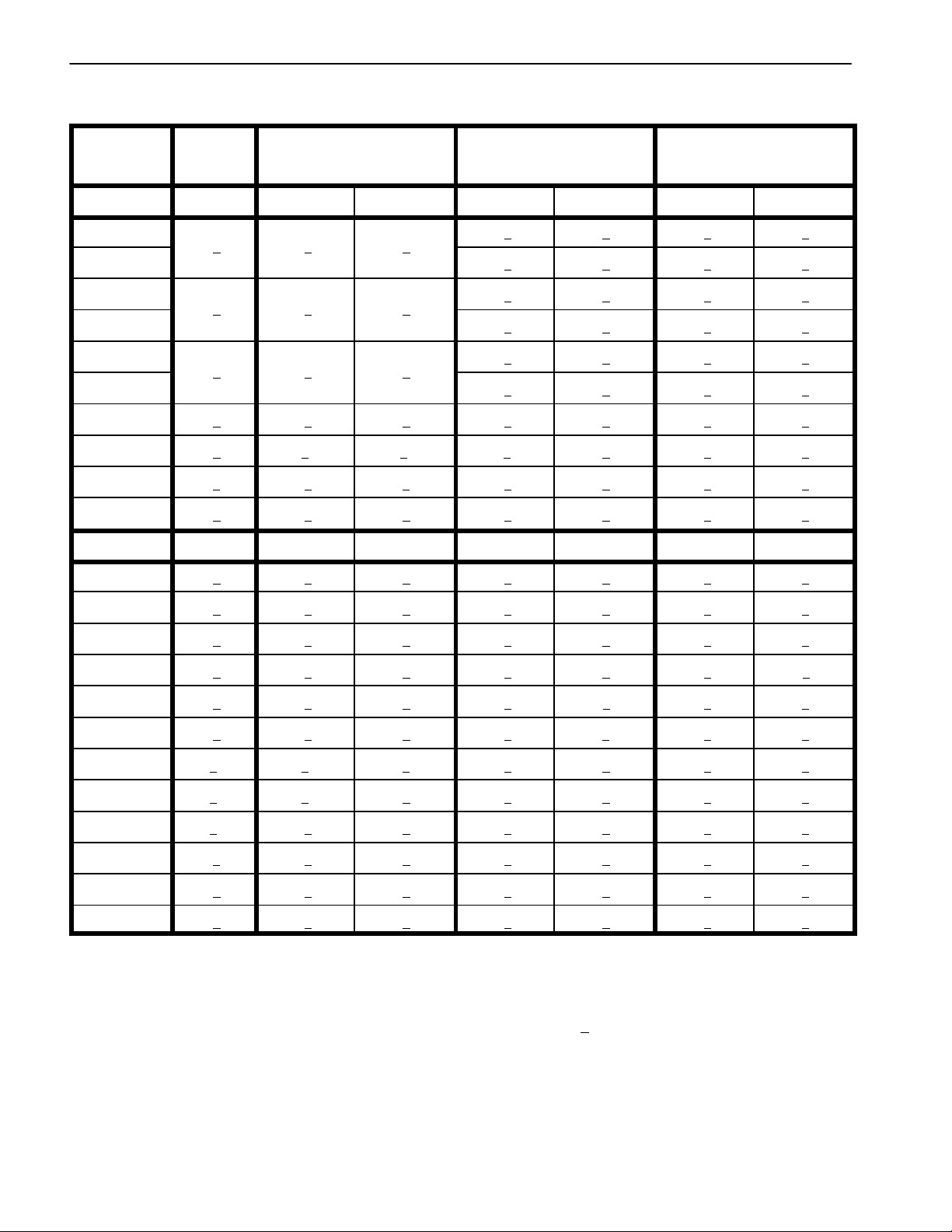

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 − 32 UNC

# 6 − 40 UNF 17 + 2 192 + 23 25 + 3 282 + 34

# 8 − 32 UNC

# 8 − 36 UNF 31 + 4 350 + 45 43 + 5 486 + 56

# 10 − 24 UNC

# 10 − 32 UNF 48 + 5 542 + 56 68 + 7 768 + 79

1/4 − 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130 + 113 140 + 15 1582 + 169

1/4 − 28 UNF 53 + 7 65 + 10 734 + 113 115 + 12 1299 + 136 160 + 17 1808 + 192

5/16 − 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 − 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 − 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8 with Thin

Height Nuts

in−lb in−lb N−cm in−lb N−cm in−lb N−cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft−lb ft−lb N−m ft−lb N−m ft−lb N−m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

29 + 3 328 + 34 41 + 5 463 + 56

42 + 5 475 + 56 60 + 6 678 + 68

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 − 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 − 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 − 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 − 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 − 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 − 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 − 18 UNF 75 + 10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 − 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 − 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 − 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 − 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimum proof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Reelmaster 3550−DPage 2 − 4Product Records and Maintenance

Page 15

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Series)

Class 8.8 Bolts, Screws and Studs with

Thread Size

M5 X 0.8 57 + 6 in−lb 644 + 68 N−cm 78 + 8 in−lb 881 + 90 N−cm

M6 X 1.0 96 + 10 in−lb 1085 + 113 N−cm 133 + 14 in−lb 1503 + 158 N−cm

M8 X 1.25 19 + 2 ft−lb 26 + 3 N−m 28 + 3 ft−lb 38 + 4 N−m

M10 X 1.5 38 + 4 ft−lb 52 + 5 N−m 54 + 6 ft−lb 73 + 8 N−m

M12 X 1.75 66 + 7 ft−lb 90 + 10 N−m 93 + 10 ft−lb 126 + 14 N−m

M16 X 2.0 166 + 17 ft−lb 225 + 23 N−m 229 + 23 ft−lb 310 + 31 N−m

M20 X 2.5 325 + 33 ft−lb 440 + 45 N−m 450 + 46 ft−lb 610 + 62 N−m

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

Regular Height Nuts

(Class 8 or Stronger Nuts)

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199. The tolerance is approximately +

nominal torque value.

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

10% of the

Product Records

and Maintenance

Reelmaster 3550−D Page 2 − 5 Product Records and Maintenance

Page 16

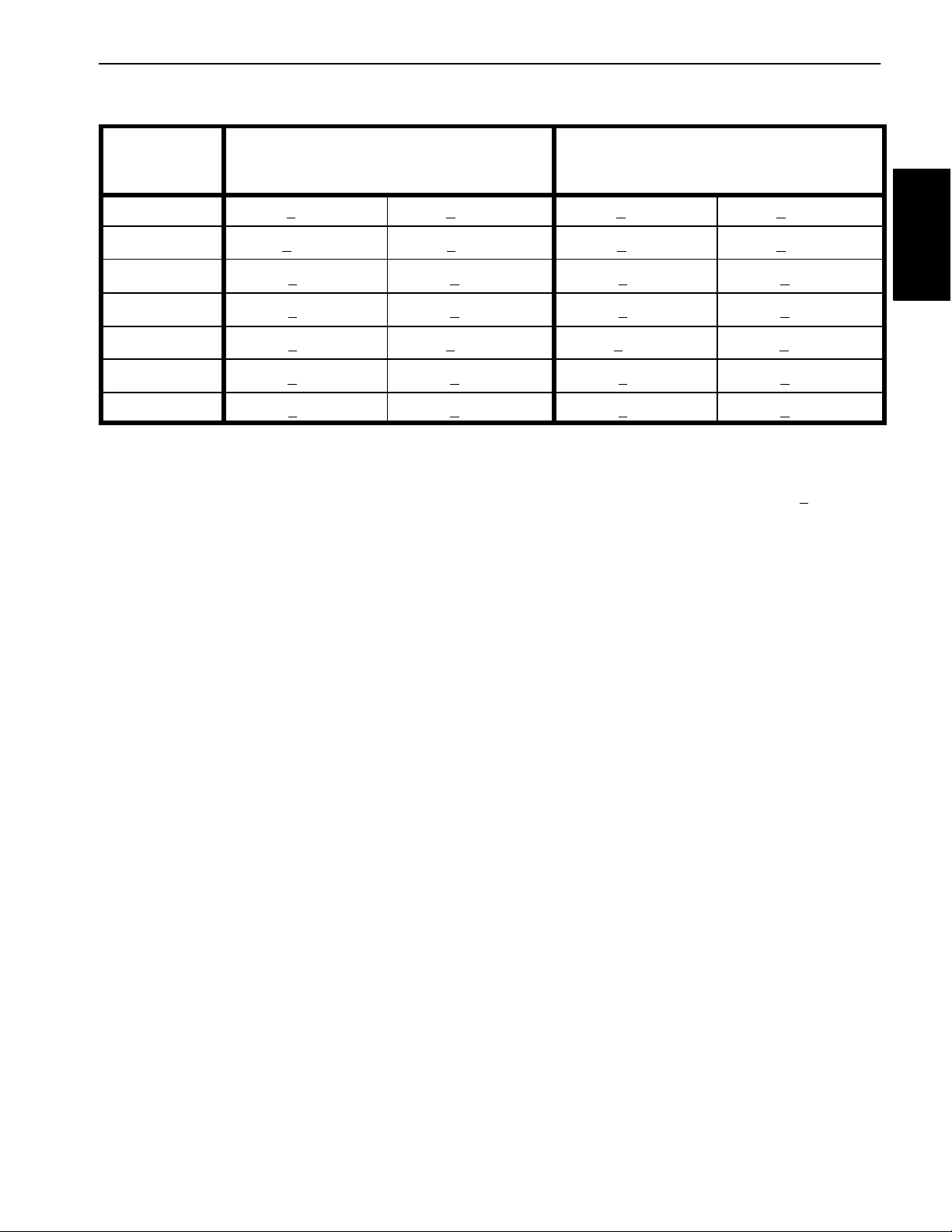

Other Torque Specifications

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 − 20 UNC 140 + 20 in−lb 73 + 12 in−lb

5/16 − 18 UNC 215 + 35 in−lb 145 + 20 in−lb

3/8 − 16 UNC 35 + 10 ft−lb 18 + 3 ft−lb

1/2 − 13 UNC 75 + 15 ft−lb 50 + 10 ft−lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 − 32 UNC 20 + 5 in−lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 − 20 UNF

Grade 5

1/2 − 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non−lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5 in−lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft−lb 88 + 14 N−m

80 + 10 ft−lb 108 + 14 N−m

80 + 10 ft−lb 108 + 14 N−m

80 + 10 ft−lb 108 + 14 N−m

Baseline Torque*

No. 8 − 32 UNC 30 + 5 in−lb

No. 10 − 24 UNC 38 + 7 in−lb

1/4 − 20 UNC 85 + 15 in−lb

5/16 − 18 UNC 110 + 20 in−lb

3/8 − 16 UNC 200 + 100 in−lb

Conversion Factors

in−lb X 11.2985 = N−cm N−cm X 0.08851 = in−lb

ft−lb X 1.3558 = N−m N−m X 0.7376 = ft−lb

No. 8 15 18 30 + 5 in−lb

No. 10 12 16 38 + 7 in−lb

No. 12 11 14 85 + 15 in−lb

* Hole size, material strength, material thickness and finish must be considered when determining specific

torque values. All torque values are based on non−lubricated fasteners.

Reelmaster 3550−DPage 2 − 6Product Records and Maintenance

Page 17

Table of Contents

SPECIFICATIONS 3............................

GENERAL INFORMATION 4.....................

Operator’s Manual 4..........................

Kubota Workshop Manual 4....................

Kubota Diesel Engine 4........................

SERVICE and REPAIRS 6.......................

Air Cleaner and Muffler 6......................

Fuel System 8................................

Radiator and Oil Cooler Assembly 10............

Engine 12....................................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

05 SERIES

Chapter 3

Kubota Diesel Engine

Kubota

Diesel Engine

Reelmaster 3550- D Page 3 - 1 Kubota Diesel Engine

Page 18

This page is intentionally blank.

Reelmaster 3550−DPage 3 − 2Kubota Diesel Engine

Page 19

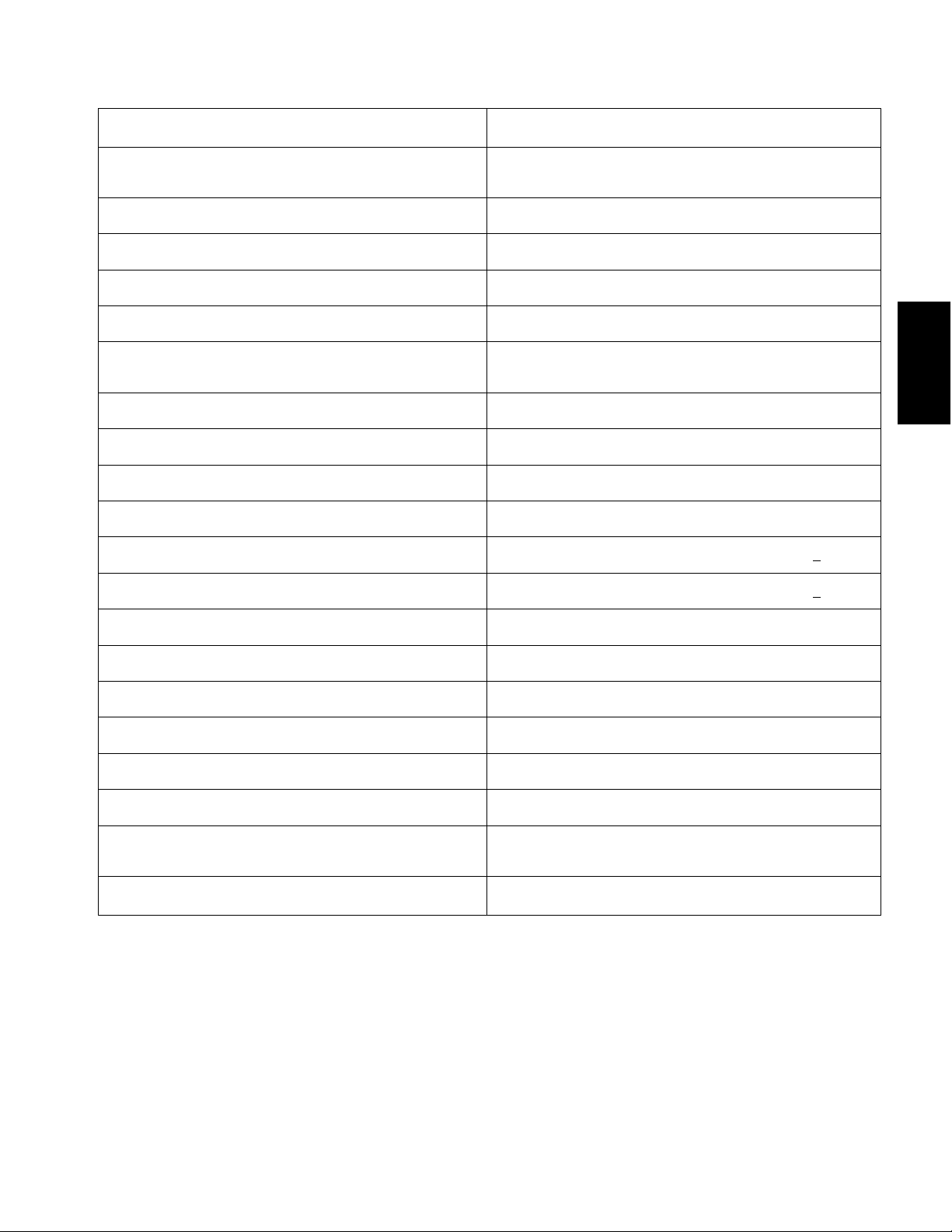

Specifications

Item Description

Make / Designation Kubota D1105- E3B or D1105- E4B

4- Cycle, 3 Cylinder, Liquid Cooled, Diesel Engine

Bore x Stroke 3.07” x 3.09” (78 mm x 78.4 mm)

Total Displacement 68.5 in3(1123 cc)

Firing Order 1 (fan end) - 2 - 3 (flywheel end)

Direction of Rotation Counterclockwise (viewed from flywheel)

Fuel Diesel or Biodiesel (up to B20) Fuel with Low or Ultra Low

Sulfur Content

Fuel Capacity 7.5 U.S. gallons (28.4 liters)

Fuel Injection Pump Bosch MD Type Mini

Injection Nozzle Mini Nozzle (DNOPD)

Governor Centrifugal Mechanical

Low Idle (no load) 1400 + 50 RPM

High Idle (no load) 3220 + 50 RPM

Kubota

Diesel Engine

Engine Oil API CH- 4, CI- 4 or higher

Engine Oil Viscosity See Traction Unit Operator’s Manual

Crankcase Oil Capacity 4 U.S. Quarts (3.8 Liters) with Filter

Oil Pump Trochoid Type

Coolant Capacity 6 U.S. Quarts (5.7 Liters)

Starter 12 VDC 1.4 KW

Alternator/Regulator 12 VDC

Alternator Output 40 amp

Engine Dry Weight 205 lb. (93 kg)

Reelmaster 3550- D Page 3 - 3 Kubota Diesel Engine

Page 20

General Information

This Chapter gives information about specifications and

repair of the diesel engine used in the Reelmaster

3550- D.

General maintenance procedures are described in your

Traction Unit Operator’s Manual. Information on engine

troubleshooting, testing, disassembly and assembly is

identified in the Kubota Workshop Manual: 05 Series

Diesel Engine.

Most repairs and adjustments require tools which are

commonly available in many service shops. Special

Operator’s Manual

The Traction Unit Operator’s Manual provides information regarding the operation, general maintenance and

maintenance intervals for the Kubota diesel engine that

powers your Reelmaster 3550- D. Refer to this publication for additional information when servicing the machine.

Kubota Workshop Manual

tools are described in the Kubota Workshop Manual: 05

Series Diesel Engine. The use of some specialized test

equipment is explained. However, the cost of the test

equipment and the specialized nature of some repairs

may dictate that the work be done at an engine repair facility.

Service and repair parts for the Kubota engine in your

Reelmaster are available from your Authorized Toro

Distributor. If no parts list is available, be prepared to

provide your distributor with the Toro model and serial

number.

The engine that powers your Reelmaster machine is a

Kubota model D1105. The Kubota Workshop Manual is

available for these engines. Make sure that the correct

engine manual is used when servicing the engine on

your Reelmaster 3550- D.

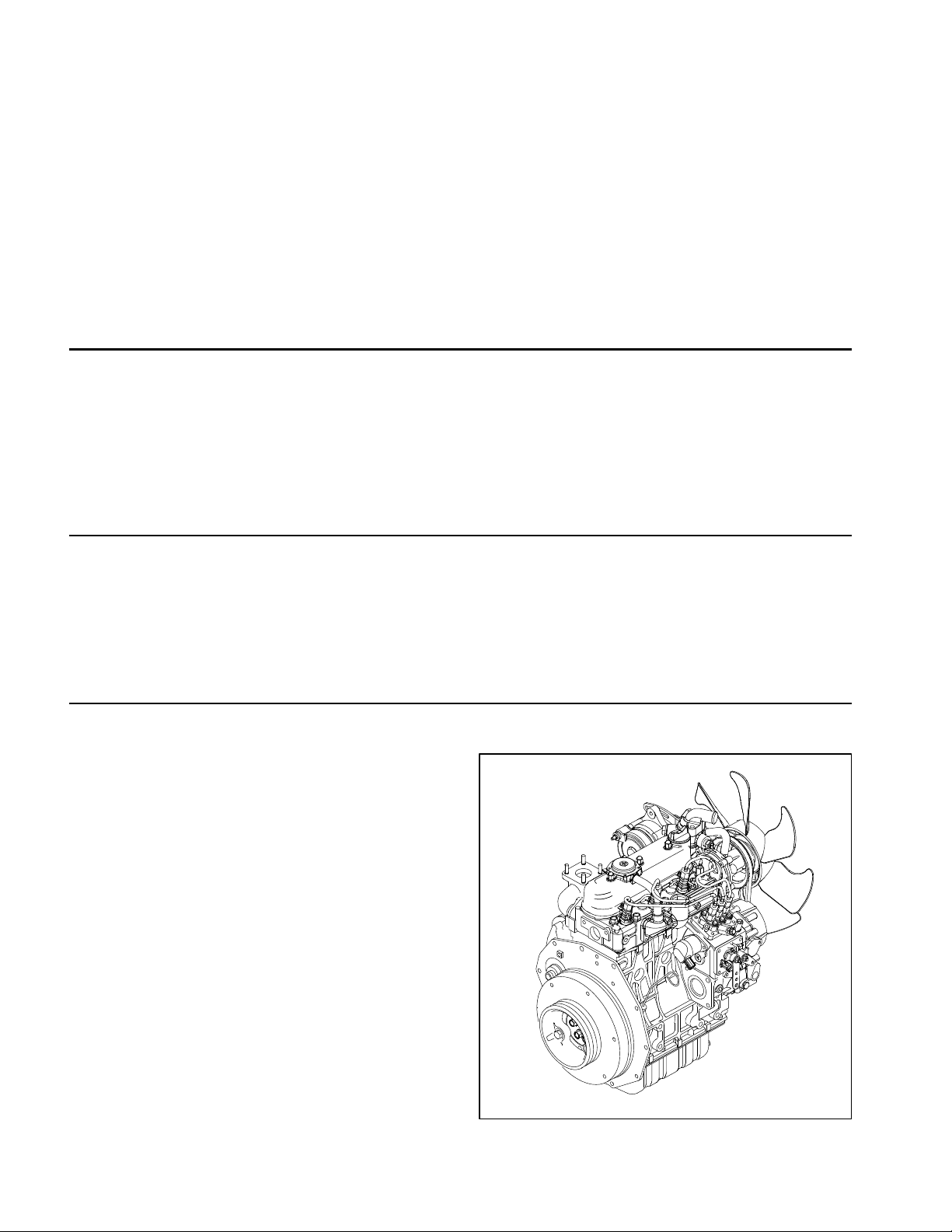

Kubota Diesel Engine

The Kubota D1105 engine used in your Reelmaster

3550- D is a naturally aspirated engine that complies

with either EPA emission regulations Tier 4i (model

D1105- E3B) or Tier 4 (model D1105- E4B) depending

on manufacture date. The engine includes a Bosch inline injection pump.

Figure 1

Reelmaster 3550- DPage 3 - 4Kubota Diesel Engine

Page 21

This page is intentionally left blank.

Kubota

Diesel Engine

Reelmaster 3550−D Page 3 − 5 Kubota Diesel Engine

Page 22

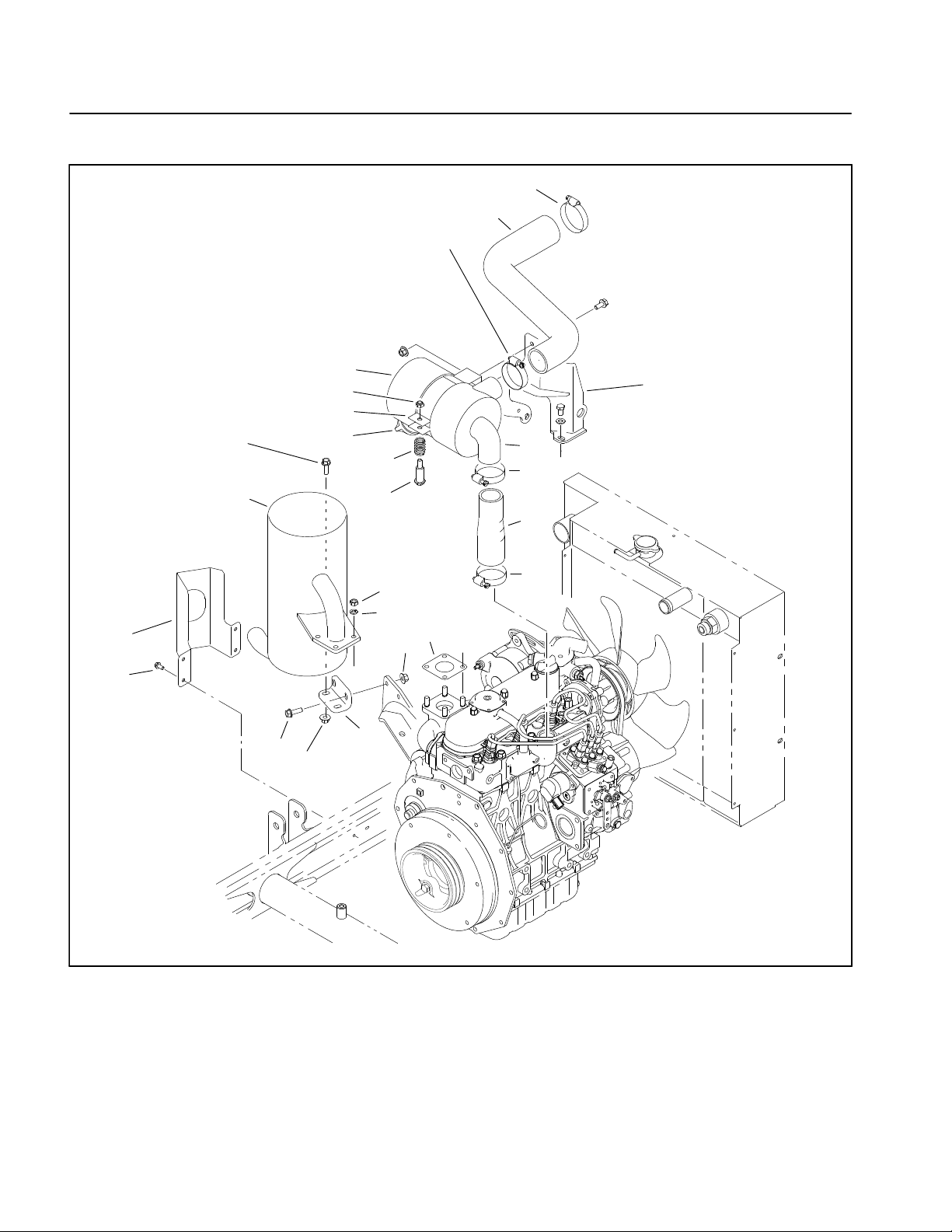

Service and Repairs

Air Cleaner and Muffler

10

11

12

14

19

21

16

4

3

15

18

17

13

12

20

12

7

8

1

9

5

2

6

4

5

1. Exhaust guard

2. Cap screw

3. Muffler

4. Flange head screw

5. Flange nut

6. Muffler bracket

7. Hex nut

Figure 2

8. Lock washer

9. Exhaust gasket

10. Hose clamp

11. Air inlet hose (upper)

12. Hose clamp

13. Air cleaner body

14. Filter cover

15. Burp (Actuator) valve

16. Mounting band assembly

17. Shoulder bolt

18. Compression spring

19. Lock nut

20. Air inlet hose (lower)

21. Air filter mount

Reelmaster 3550−DPage 3 − 6Kubota Diesel Engine

Page 23

Check Air Filter, Dust Cup, & Burp Valve

The air cleaner body , air filter, dust cup, and burp valve

should be checked daily, prior to operation.

IMPORTANT: Any leaks in the air cleaner system

will cause serious engine damage. Make sure that

all air cleaner components are in good condition

and are properly secured during operation.

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch. Unlatch and raise hood.

2. Check air cleaner body for damage that could cause

possible air leaks. Make sure dust cup seals completely

to the air cleaner body (Fig. 3).

3. Check burp valve and dust cup for damage.

4. Make sure air hoses connecting the air cleaner to the

engine and radiator are secured tightly and free of possible air leaks.

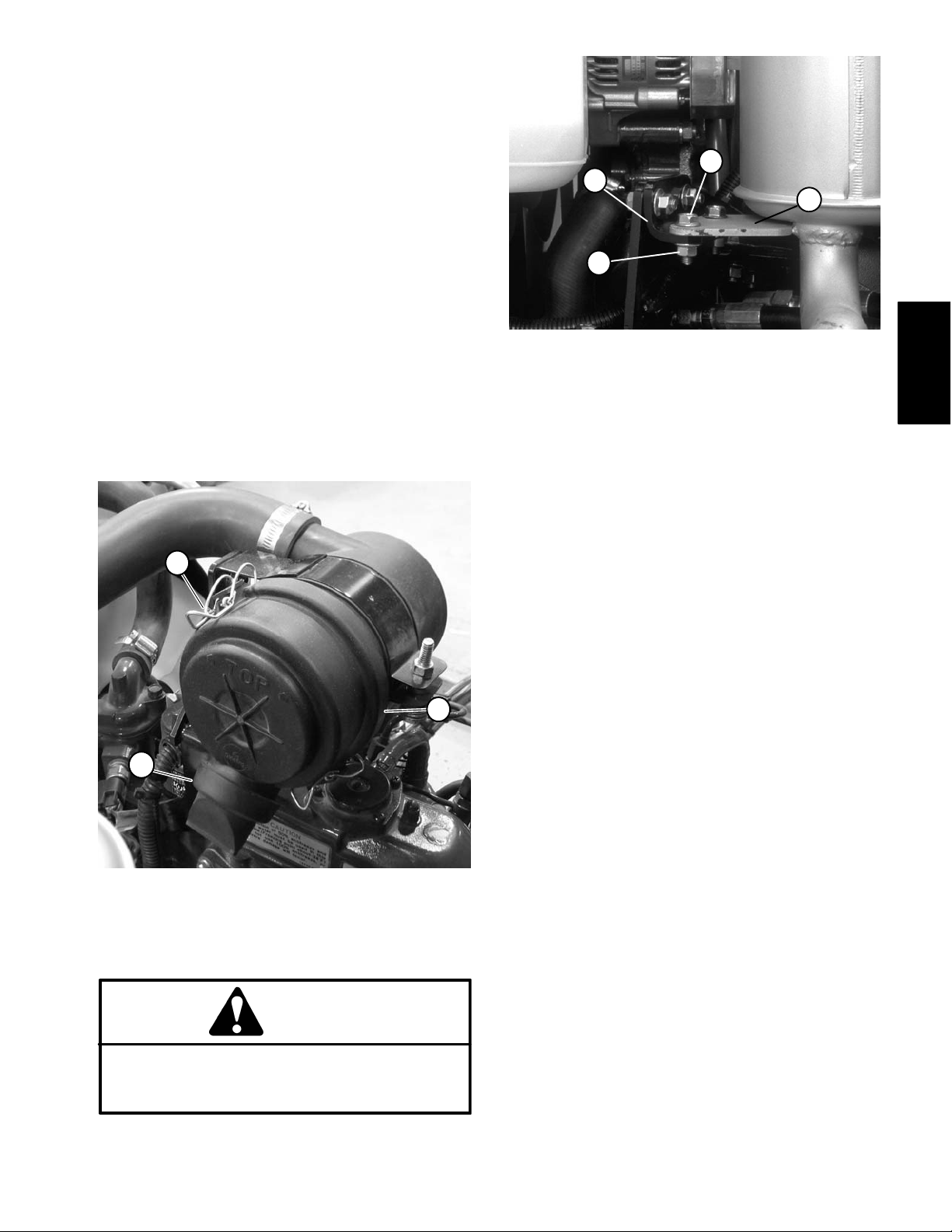

1

2

4

3

1

Figure 4

1. Flange head nut

2. Flange head screw

3. Muffler plate

4. Muffler bracket

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

2. Open engine hood to gain access to engine.

3. Remove exhaust guard.

4. Remove both flange head nuts and screws securing

the muffler plate to the muffler bracket (Fig. 4).

Kubota

Diesel Engine

3

Figure 3

1. Latch

2. Dust cup

3. Burp valve

Muffler Removal

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the engine and exhaust system to cool before working on the muffler.

5. Remove four hex nuts and lock washers from the exhaust manifold studs. Separate muffler flange from the

exhaust manifold. Remove muffler from the machine.

6. Remove exhaust gasket. Replace gasket if damaged or torn.

2

Muffler Installation

NOTE: Make sure muffler flange and exhaust manifold

sealing surfaces are free of debris or damage that may

prevent a tight seal.

1. Place exhaust gasket on the exhaust manifold.

IMPORTANT: Finger tighten all fasteners before securing the muffler plate to the muffler bracket so

there is no preload on the exhaust manifold.

2. Position muffler flange to the exhaust manifold with

four lock washers and hex nuts.

3. Position mu ffler plate to the muffler bracket with both

flange head screws and nuts (Fig. 4).

4. Tighten muffler flange hex nuts and then muffler

plate screws and nuts.

5. Install exhaust guard.

6. Close and latch engine hood.

Reelmaster 3550−D Page 3 − 7 Kubota Diesel Engine

Page 24

Fuel System

6

5

4

TO

PUMP

6

12

7

10

8

11

9

3

8

13

14

2

16

15

17

18

19

20

Thread

Sealant

(typical)

11

21

22

11

38

11

33

34

29

27

28

27

1

30

31

32

Thread

Sealant

(typical)

RIGHT

TO

TANK

39

35

37

36

23

24

25

26

11

7

40

FRONT

16

41

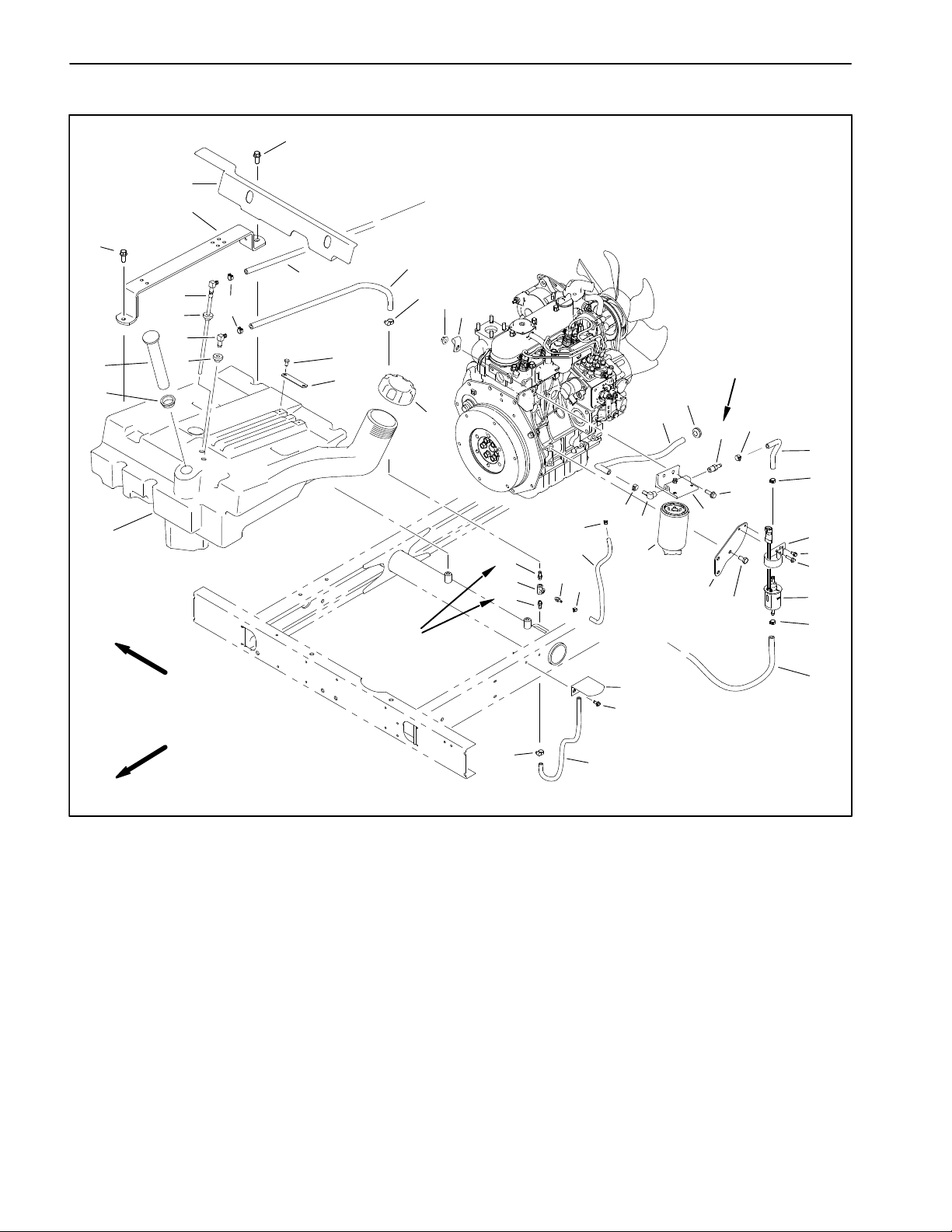

1. Fuel tank

2. Grommet

3. Fuel gauge

4. Seat support strap (2)

5. Heat shield

6. Washer head screw (4)

7. Fuel hose (tank to pump)

8. Bushing (2)

9. Elbow fitting

10. Stand pipe

11. Hose clamp (7)

12. Fuel hose (tee to tank)

13. Cap screw (2)

14. Fuel hose strap

Figure 5

15. Fuel cap

16. Hose clamp (2)

17. Flange nut (2)

18. R−Clamp

19. Fuel hose (filter to engine)

20. Grommet

21. Barbed fitting

22. Fuel hose (pump to filter)

23. Clamp

24. Washer head screw

25. Washer head screw

26. Fuel pump

27. Hose clamp (2)

28. Fuel hose (engine return to tee)

29. Barbed fitting

30. Barbed fitting

31. Tee fitting

32. Barbed fitting

33. Elbow fitting

34. Fuel/water separator element

35. Pump mount plate

36. Cap screw (3)

37. Fuel/water separator head

38. Flange head screw (2)

39. Tank support

40. Flange head screw (2)

41. Fuel hose (tee to vent tube)

Reelmaster 3550−DPage 3 − 8Kubota Diesel Engine

Page 25

DANGER

3

Because diesel fuel is flammable, use caution

when storing or handling it. Do not smoke while

filling the fuel tank. Do not fill fuel tank while engine is running, hot or when machine is in an enclosed area. Always fill fuel tank outside and

wipe up any s p i l l e d diesel fuel before starting the

engine. Store fuel in a clean, safety−approved

container and keep cap in place. Use diesel fuel

for the engine only; not for any other purpose.

Fuel Tank Removal (Fig. 5)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch. Unlatch and raise hood.

IMPORTANT: Follow all local codes and regulations

when recycling or disposing waste fuel.

2. Drain fuel from the tank into a suitable container. If

necessary.

3. Disconnect seat switch from the electrical harness.

Remove seat and seat support straps from the frame.

4. Remove fuel hose strap and both fuel hoses from the

fuel tank (Fig 6). Remove fuel tank from the machine.

Clean Fuel Tank

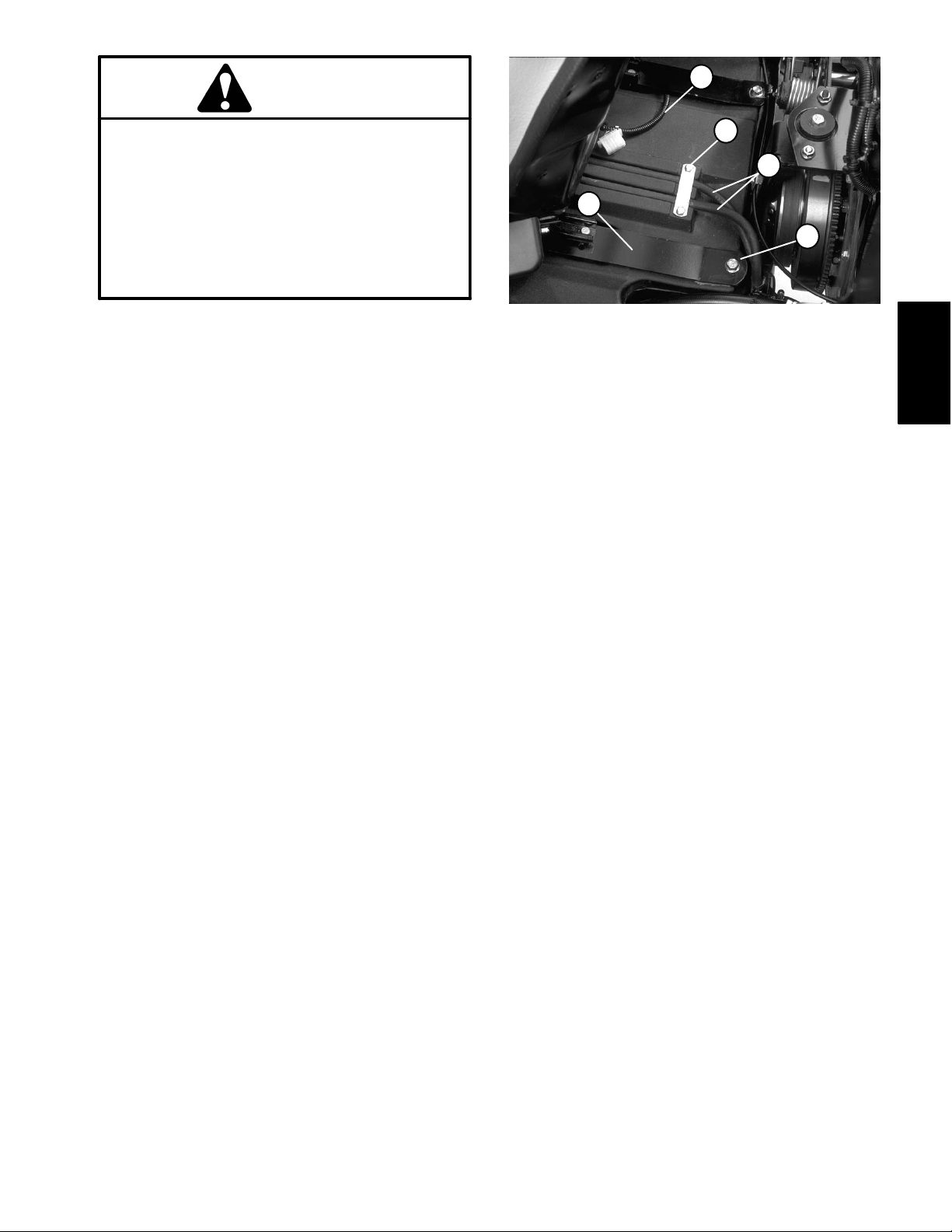

4

5

1

2

Figure 6

1. Seat support strap

2. Hex flange head screw

3. Electrical harness

4. Fuel hose strap

5. Fuel hose

4. Connect wire harness connector to the seat switch.

Route seat switch wire under seat support strap. Secure

seat support straps and seat to the frame (see Operator

Seat in Chapter 6 − Chassis in this manual).

5. Check that fuel tank support contacts the bottom of

the fuel tank but does not raise tank from machine

frame. Adjust location of support if necessary.

6. Check for correct seat operation. Also check that

seat switch wires and connector are not pinched and do

not contact any moving parts.

7. Fill fuel tank.

Kubota

Diesel Engine

Clean the fuel tank every 2 years. Also, clean the fuel

tank if the fuel system becomes contaminated or if the

machine is to be stored for an extended period.

1. Remove fuel tank from the machine (see Fuel Tank

Removal).

2. Flush fuel tank out with clean diesel fuel. Make sure

tank is free of contaminates and debris.

3. Install fuel tank to the machine (see Fuel Tank Installation).

Fuel Tank Installation (Fig. 5)

1. Position fuel tank to the machine.

2. Connect both fuel hoses to the tank and secure with

hose clamps.

3. Install fuel hose strap to top of tank making sure that

fuel lines are properly positioned in grooves in tank.

Reelmaster 3550−D Page 3 − 9 Kubota Diesel Engine

Page 26

Radiator and Oil Cooler Assembly

21

2

27

19

21

18

9

20

9

10

22

25

10

5

8

16

11

14

3

4

12

24

13

21

33

23

34

Thread

Sealant

26

2

RIGHT

30

29

28

15

16

1

33

31

7

2

17

FRONT

32

6

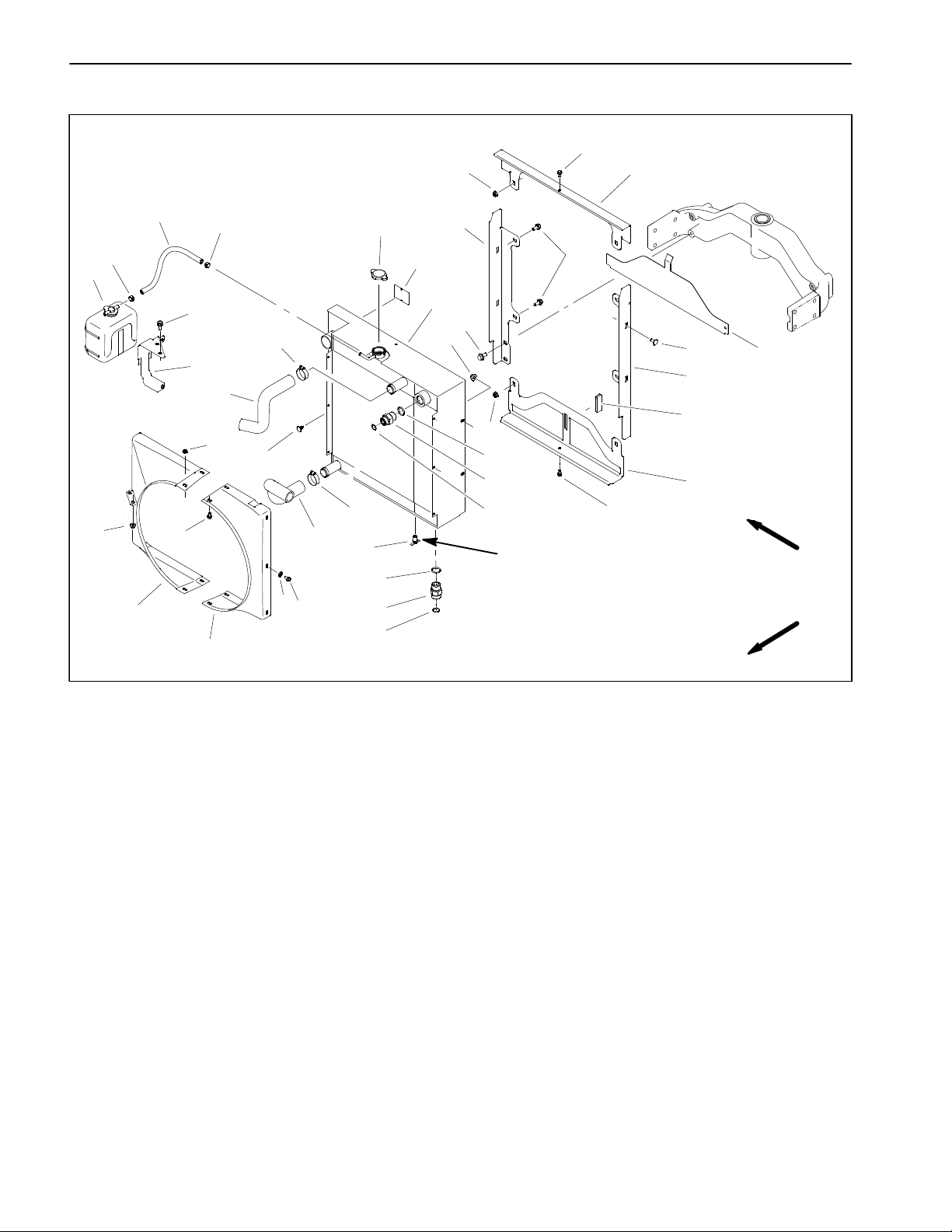

1. Draincock valve

2. Flange head screw (8)

3. Flange nut (4)

4. Carriage bolt (4)

5. Radiator/oil cooler assembly

6. LH fan shroud

7. RH fan shroud

8. Flange head screw (4)

9. Hose clamp (2)

10. Flange head screw (6)

11. Overflow bottle bracket

12. Radiator lower shield

Figure 7

13. Magnet

14. Radiator hose (upper)

15. Radiator hose (lower)

16. Hose clamp (2)

17. Straight hydraulic fitting

18. Hose

19. Coolant expansion tank

20. Radiator cap

21. Flange nut (6)

22. Foam seal (2)

23. Adapter

24. LH radiator bracket

25. RH radiator bracket

26. Bottom radiator bracket

27. Top radiator bracket

28. Plastic plug (2)

29. Flange nut (4)

30. Flange head screw (4)

31. Flat washer (4)

32. O−ring

33. O−ring

34. O−ring

Reelmaster 3550−DPage 3 − 10Kubota Diesel Engine

Page 27

Removal (Fig. 7)

Installation (Fig. 7)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Open and remove hood from the machine.

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns.

Ethylene- glycol antifreeze is poisonous. Dispose of coolant properly or store it in a properly

labeled container away from children and pets.

IMPORTANT: Follow all local codes and regulations

when recycling or disposing engine coolant.

3. Drain radiator into a suitable container either by using the draincock near the lower left side corner of the

radiator or by removing the lower radiator hose from the

radiator.

4. Disconnect radiator hoses from the radiator.

1. Inspect seals around radiator location for wear or

damage. Replace seals if necessary.

2. If hydraulic fittings were removed from oil cooler, lubricate and place new O- rings onto fittings. Install fittings into port openings and tighten fittings (see

Hydraulic Fitting Installation in the General Information

section of Chapter 4 - Hydraulic System in this manual).

3. If draincock valve was removed from radiator, apply

thread sealant to draincock threads before installing it

into radiator.

4. Remove all plugs placed in radiator and hose openings during the removal procedure.

5. Carefully position radiator to the radiator brackets.

6. Secure radiator to the side radiator brackets with four

(4) carriage bolts and flange nuts. Secure top and bottom of radiator to brackets with flange head screws.

7. Connect hydraulic lines to fittings in oil cooler ports

(see Hydraulic Hose and Tube Installation in the General Information section of Chapter 4 - Hydraulic System

in this manual).

Kubota

Diesel Engine

5. Remove air cleaner inlet hose from radiator opening.

6. Read the General Precautions for Removing and

Installing Hydraulic System Components in the Service

and Repairs section of Chapter 4 - Hydraulic System in

this manual.

7. Thoroughly clean hydraulic lines at oil cooler ports.

Disconnect hydraulic lines and put caps or plugs on lines

to prevent contamination. Label disconnected hydraulic

lines for proper installation.

8. Remove coolant expansion tank and bracket from

machine.

9. Remove fan shrouds from machine.

10.Remove fasteners that secure radiator to the upper,

lower and side radiator brackets.

1 1 .Carefully separate radiator/oil cooler assembly from

brackets and remove from the machine.

12.If necessary, remove hydraulic fittings from oil cooler

and discard O- rings.

8. Position fan shrouds to radiator and secure with removed fasteners.

9. Secure coolant expansion tank and bracket to machine.

10.Connect radiator hoses to the radiator and secure

with hose clamps.

11. Install and secure air cleaner inlet hose.

12.Make sure radiator draincock valve is closed. Fill radiator with coolant.

13.Install hood to the machine. Close and latch hood.

14.Fill the hydraulic fluid tank.

15.Start the unit and run engine to normal operating

temperature. Use all of the hydraulic controls while the

engine is running to d istribute the hydraulic fluid

throughout the system.

16.Stop the engine and check the hydraulic fluid and

coolant levels. Adjust as necessary.

13.Plug all r adiator and hose openings to prevent contamination.

Reelmaster 3550- D Page 3 - 11 Kubota Diesel Engine

Page 28

Engine

44

43

45

42

46

1

2

3

5

6

7

8

Thread Sealant

9

6

10

13

12

11

4

26

15

14

31

41

38

40

37

32

30

36

34

35

26

16

17

18

19

20

23

24

25

27

21

22

30

28

29

4

31

32

39

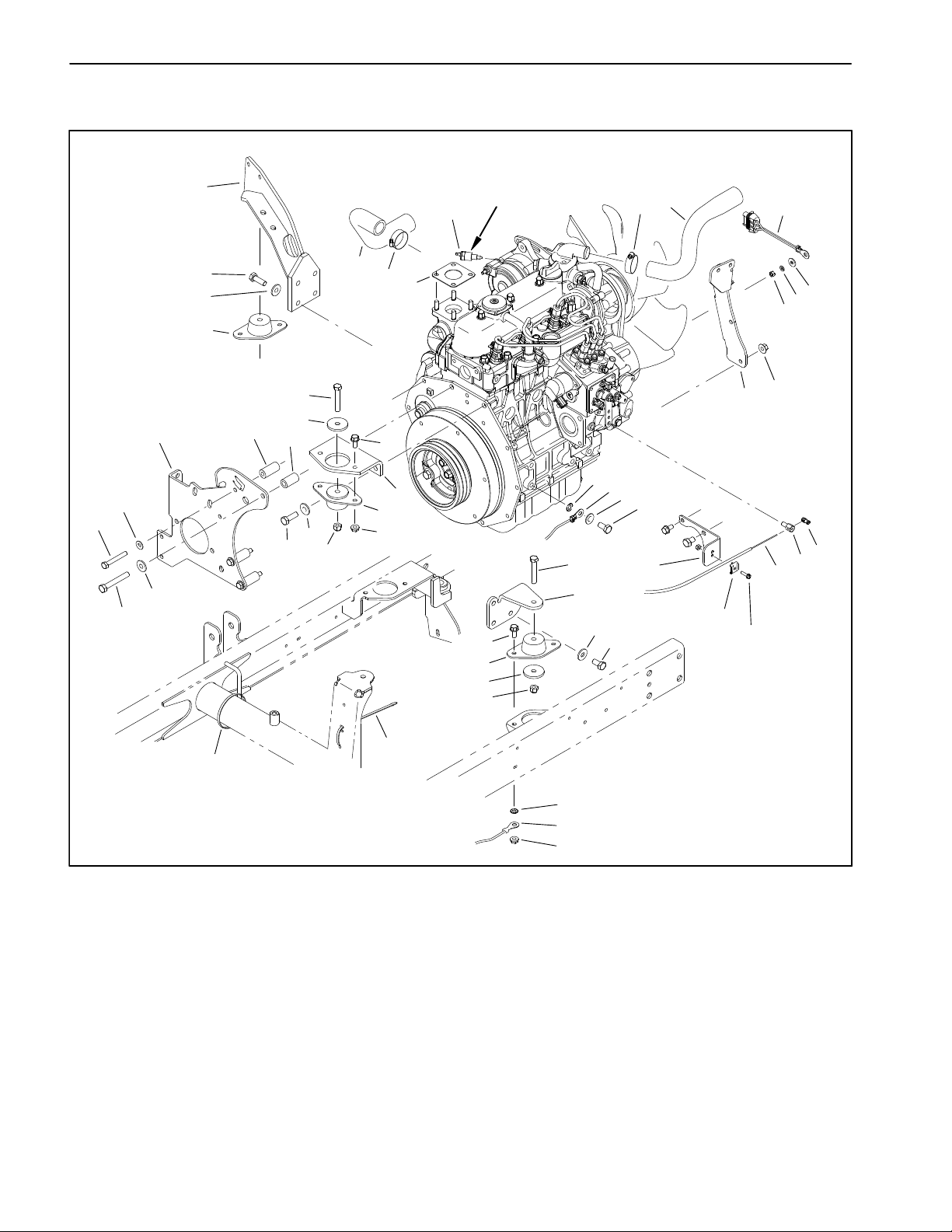

1. Engine mount bracket − RH

2. Cap screw

3. Hardened washer

4. Engine mount

5. Lower radiator hose

6. Hose clamp

7. Exhaust flange gasket

8. Coolant temperature switch

9. Upper radiator hose

10. Wire Harness − fusible link

11. Flat washer

12. Lock washer

13. Hex nut

14. Flange nut

15. Fuel filter bracket

16. External tooth lock washer

39

Figure 8

17. Engine ground wire

18. Flat washer

19. Cap screw

20. Throttle cable bracket

21. Cable clamp

22. Cap screw

23. Throttle cable

24. Swivel clamp

25. Cable stop

26. Cap screw

27. Engine mount bracket − LH

28. Hardened washer

29. Cap screw

30. Flange head screw

31. Hardened washer

32. Hex nut

33

17

34

33. Lock washer

34. Flange nut

35. Engine mount bracket − front

36. Engine mount

37. Hardened washer

38. Cap screw

39. Cable tie

40. Spacer (1)

41. Spacer (4)

42. Pump mount plate

43. Hardened washer

44. Cap screw

45. Cap screw

46. Hardened washer

Reelmaster 3550−DPage 3 − 12Kubota Diesel Engine

Page 29

Removal (Fig. 8)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake, and remove key

from the ignition switch.

2. Open and remove engine hood from the machine.

Slide seat all the way forward.

3. Disconnect air hose from the air cleaner and radiator.

Remove air cleaner assembly from the engine.

4. Disconnect both battery cables at the battery (see

Battery Service in Chapter 5 − Electrical System).

5. Remove muffler from the e x h a u s t manifold and muffler bracket (see Muffler Removal in this Chapter).

6. Drain radiator from the drain cock valve into a suitable container (see Radiator Removal in this Chapter).

Disconnect coolant hoses from the water pump and engine block.

7. Remove coolant expansion tank and bracket from

the top fan shroud. Remove top fan shroud from the radiator (see Radiator Removal in this Chapter).

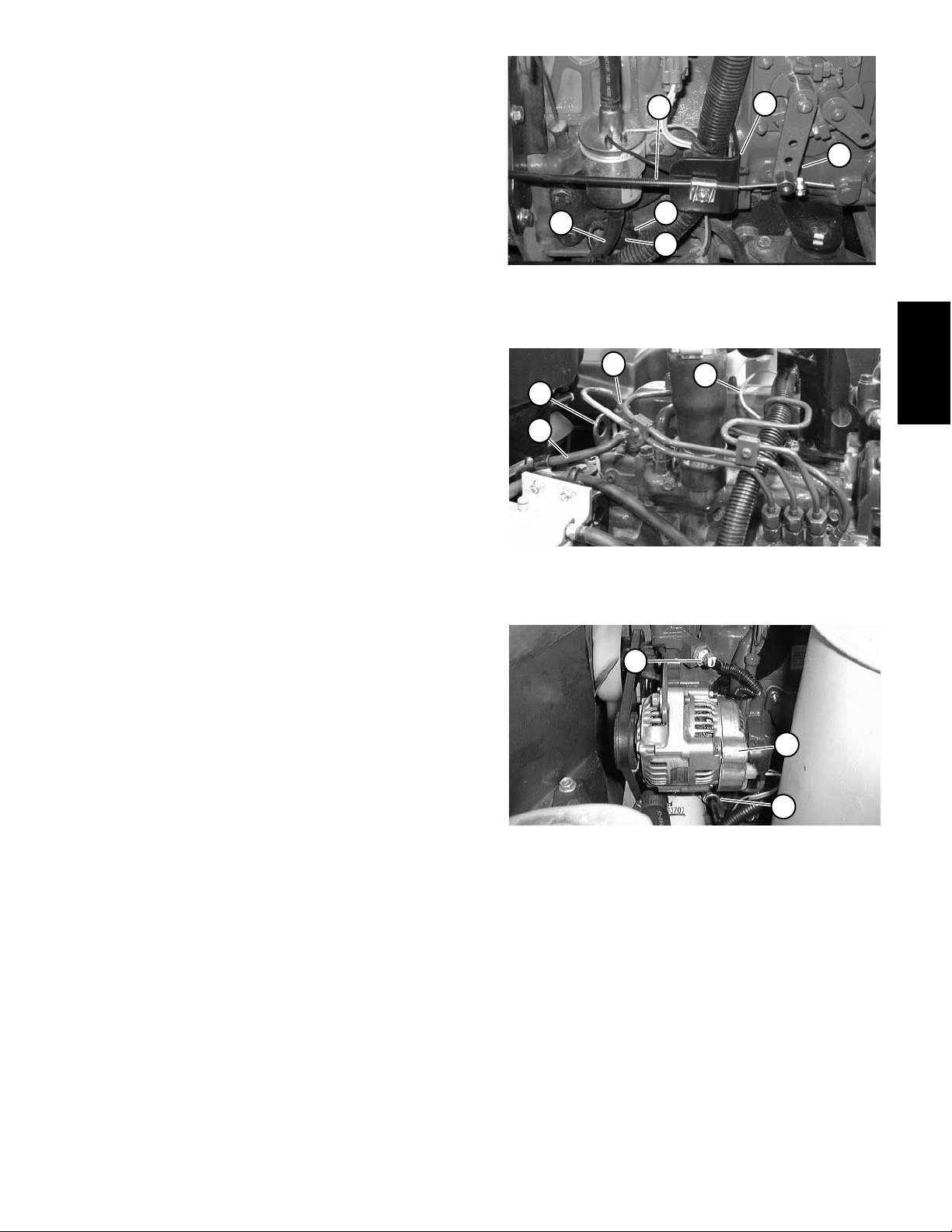

8. Disconnect wire harness and electrical wires from

the following:

A. Battery, wire harness and engine grounds

(Fig. 9).

6

1. Battery ground cable

2. Wire harness ground

3. Throttle cable

2

4

3

1. Glow plug wire

2. Rear injector nozzle

3

2

1

Figure 9

1

Figure 10

4

5

4. Support bracket

5. Speed control lever

6. Fuel hose

Kubota

Diesel Engine

3. Fuel hose

4. Lift tab

B. Glow plug bus (Fig. 10) and fuel stop solenoid.

C. Engine temperature sensor, alternator, and low

oil pressure switch (Fig. 11).

9. Disconnect throttle cable from the support and swivel on the speed control lever (Fig. 9).

10.Disconnect fuel hose from the fuel pump (Fig. 9) and

front injector nozzle.

11.Remove traction control cable from the neutral arm

assembly on the piston pump. Remove all hydraulic

hoses from the piston and gear pumps (see Piston

Pump Removal in Chapter 4− Hydraulic System).

12.Remove cable ties securing the wire harness to the

front lift tab and other engine parts. Connect hoist or lift

to the front and rear lift tabs (Fig. 10).

1

1. Engine temp. sensor

2. Alternator

2

3

Figure 11

3. Oil pressure switch

Reelmaster 3550−D Page 3 − 13 Kubota Diesel Engine

Page 30

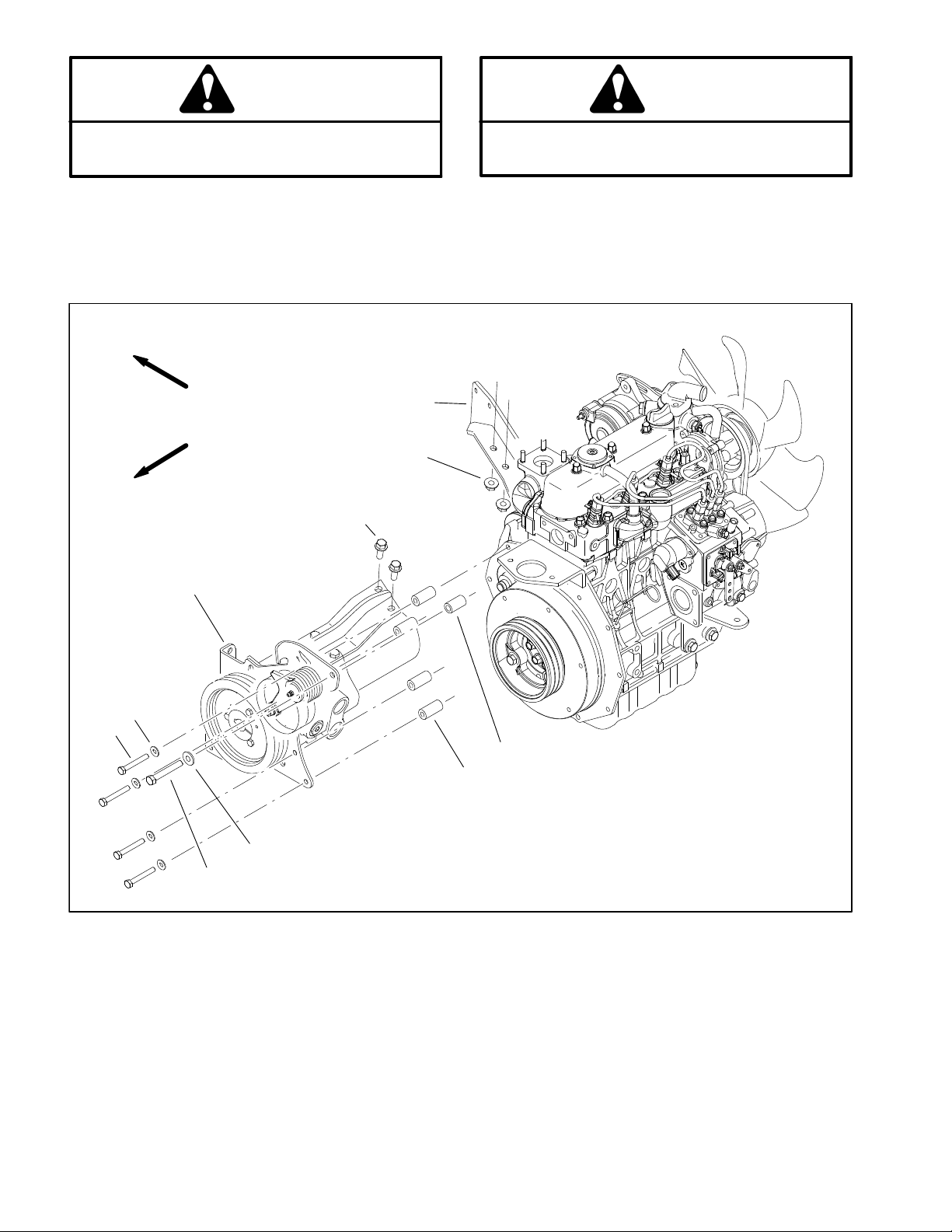

CAUTION

CAUTION

Make sure lift or hoist can support the total

weight of the engine before removing the cap

screws from the engine and engine brackets.

13.Remove hex nuts, cap screws, and washers from the

center of the three engine mounts.

RIGHT

1

FRONT

2

3

One person should operate lift or hoist while the

other person guides the engine out of the machine.

IMPORTANT: Make sure not to damage the engine,

fuel and hydraulic lines, electrical harness, or other

parts while removing the engine.

14.Remove engine slowly from the machine.

4

5

6

7

1. Engine mount bracket

2. Flange nut

3. Flange screw

4. Pump mount plate

10

9

8

Figure 12

5. Hardened washer

6. 10 mm cap screw (4)

7. 8 mm cap screw (1)

8. Hardened washer

9. Long spacer (4)

10. Short spacer (1)

Reelmaster 3550−DPage 3 − 14Kubota Diesel Engine

Page 31

15.Separate hydrostat and pump assembly from the engine as follows (Fig. 12):

A. Remove traction belt from the engine flywheel

and hydrostat pulleys.

B. Remove five cap screws, washers, and spacers

securing the pump mount plate to the engine.

tion in Chapter 4− Hydraulic System).

8. Connect fuel hose to the fuel pump (Fig. 9) and front

injector nozzle.

9. Install top fan shroud to the radiator. Install expansion tank and bracket to the top fan shroud (see Radiator

Installation in this Chapter).

C. Remove two cap screws and flange nuts securing the pump support to the engine mount bracket

and remove the hydrostat and pump assembly from

the engine.

16.As necessary, remove engine mounts, front engine

mounting bracket, throttle support bracket and left engine mounting bracket.

Installation (Fig. 8)

1. If removed, install engine mounts, front engine

mounting bracket, throttle support bracket and left engine mounting bracket. Also, make sure that all switches

and sensors are installed on engine.

2. Install hydrostat and pump assembly to the engine

as follows (Fig. 12):

A. Secure the pump support to the engine mount

bracket with two flange nuts and cap screws.

B. Secure pump mount plate to the engine with five

spacers, washers, and cap screws.

C. Install traction belt to the engine flywheel and hydrostat pulleys.

3. Connect hoist or lift to the front and rear engine lift

tabs (Fig. 10).

10.Connect wire harness and electrical wires to the following:

A. Engine grounds to the battery and wire harness

(Fig. 9).

B. Glow plug bus (Fig. 10) and fuel stop solenoid.

C. Engine temperature sensor, alternator, and low

oil pressure switch (Fig. 11).

11.Secure wire harness to engine with cable ties at lo cations noted during engine removal.

12.Connect coolant hoses to the water pump and engine block. Make sure drain cock valve is closed. Fill radiator with coolant.

13.Install muffler to the exhaust manifold and muffler

bracket (see Muffler Installation in this Chapter).

14.Connect throttle cable to the support and swivel on

the speed control lever (Fig. 9).

15.Connect both battery cables at the battery (see Battery Service in Chapter 6 − Electrical system).

16.Install air cleaner to the engine. Connect air hose to

air cleaner and radiator.

17.Adjust throttle cable.

Kubota

Diesel Engine

18.Bleed air from the fuel system.

CAUTION

19.Install engine hood to the machine. Close and latch

One person should operate lift or hoist while the

other person guides the engine into the machine.

IMPORTANT: Make sure not to damage the engine,

fuel and hydraulic lines, electrical harness, or other

parts while installing the engine.

4. Position engine slowly into the machine.

5. Secure all three engine mounts to the engine mounting brackets with cap screws, washers, and hex nuts.

6. Secure wire harness to the front lift tab and the engine with cable ties.

7. Install all hydraulic hoses to the piston and gear

pumps. Install traction control cable to the neutral arm

assembly on the piston pump (see Piston Pump Installa-

Reelmaster 3550−D Page 3 − 15 Kubota Diesel Engine

hood.

20.Fill the hydraulic fluid tank.

21.Start the unit and run engine to normal operating

temperature. Use all of the hydraulic controls while the

engine is running to distribute the hydraulic fluid

throughout the system.

22.Stop the engine and check the hydraulic fluid and

coolant levels. Adjust as necessary.

23.Adjust traction drive for neutral.

Page 32

This page is intentionally blank.

Reelmaster 3550−DPage 3 − 16Kubota Diesel Engine

Page 33

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS 2............................

GENERAL INFORMATION 3.....................

Operator’s Manual 3..........................

Relieving Hydraulic System Pressure 3..........

Traction Circuit Component Failure 3............

Hydraulic Hoses 4............................

Hydraulic Hose and Tube Installation 5..........

Hydraulic Fitting Installation 6..................

SPECIAL TOOLS 8.............................

HYDRAULIC SCHEMATIC 14....................

HYDRAULIC FLOW DIAGRAMS 16...............

Traction Circuit 16............................

Cutting Unit Circuit 18.........................

Lift Circuit: Lower 20..........................

Lift Circuit: Raise 22...........................

Steering Circuit 24............................

TROUBLESHOOTING 26........................

General Hydraulic System Problems 26..........

Traction Circuit Problems 27...................

Lift Circuit Problems 28........................

Steering Circuit Problems 29...................

Mow Circuit Problems 30......................

TESTING 31...................................

Traction Circuit Testing

Charge Pressure Test 34....................

Wheel Motor Efficiency Tests 36..............

Piston Pump/Hydrostat Flow and

Relief Pressure Test 40....................

Cutting Unit Circuit Testing

Pressure Test 44...........................

Reel Motor Efficiency/Case Drain Test 46......

Proportional Relief Valve (PRV)

Pressure Test 48..........................

Mow Control Manifold Relief Valve (RV)

Pressure Test 50..........................

Gear Pump (P1) Flow Test 52................

Steering/Lift Circuit Testing

Gear Pump (P2) Flow Test 54................

Relief Valve Pressure Test 58................

Steering Control Valve and

Steering Cylinder Test 60..................

ADJUSTMENTS 62.............................

Adjust Control Manifold Relief Valves 62.........

SERVICE AND REPAIRS 63.....................

General Precautions for Removing and

Installing Hydraulic System Components 63....

Check Hydraulic Lines and Hoses 64............

Priming Hydraulic Pumps 64...................

Flush Hydraulic System 65.....................

Filtering Closed- Loop Traction Circuit 66........

Charge Hydraulic System 67...................

Hydraulic Tank 68.............................

Radiator and Oil Cooler Assembly 70............

Hydraulic Pump Assembly 72..................

Piston Pump/Hydrostat 76.

Piston Pump/Hydrostat Service 80..............

Gear Pump 83................................

Gear Pump Service 86........................

Front Wheel Motors 88........................

Rear Wheel Motor 90..........................

Wheel Motor Service 92.......................

Cutting Unit Reel Motor 94.....................

Cutting Unit Reel Motor Service 96..............

Mow Control Manifold 100.....................

Mow Control Manifold Service 102..............

Lift Control Manifold 106.......................

Lift Control Manifold Service 108................

Control Manifold Cartridge Valve Service 110.....

Steering Control Valve 112.....................

Steering Control Valve Service 114..............

Steering Cylinder 116.........................

Steering Cylinder Service 118..................

Front Lift Cylinders 120........................

Rear Lift Cylinders 122........................

Lift Cylinder Service 124.......................

EATON MEDIUM DUTY PISTON PUMP REPAIR IN-

FORMATION MODEL 70160 VARIABLE DISPLACEMENT PISTON PUMP

PARKER TORQMOTORt TC, TB, TE, TJ, TF, TG,

TH and TL SERIES SERVICE PROCEDURE

SAUER/DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

....................

System

Hydraulic

Reelmaster 3550- D Hydraulic SystemPage 4 - 1

Page 34

Specifications

Item Description

Piston Pump (Hydrostat) Variable displacement piston pump

Charge Pressure Specification:100 to 150 PSI (6.9 to 10.3 bar)

Maximum Displacement 1.44 in

Traction Circuit Relief Pressure (Forward Only) 3500 PSI (241 bar)

Tested: 150 to 200 PSI (10.3 to 13.8 bar)

3

/rev (23.6 cc/rev)

Tandem Gear Pump 2 section positive displacement gear type pump

Maximum Displacement Section 1 (P1 − mow) 0.58 in

Maximum Displacement Section 2 (P2 − steering & lift) 0.33 in

Wheel Motors (see note) Orbital geroller motor

Front Wheel Motor Displacement 12.0 in

Rear Wheel Motor Displacement 24.7 in

Mow Circuit Relief Pressures

Front Cutting Units (PRV) 3000 PSI (207 bar)

Rear Cutting Units (RV) 1500 PSI (103 bar)

Lift Circuit Relief Pressure (RV1) Lower: 500 PSI (34.5 bar)

Cutting Unit Motors Gear motor

Displacement 0.73 in

Steering Control Valve Distributor valve with rotary meter

Displacement 6.1 in

Relief Valve Pressure 1000 PSI (69 bar)

Hydraulic Filters 10 Micron, spin−on cartridge type

In−line Suction Strainer 100 mesh (in tank)

Hydraulic Tank Capacity 6 U.S. Gallons (22.6 Liters)

Hydraulic Fluid See Traction Unit Operator’s Manual

3

/rev (9.45 cc/rev)

3

/rev (5.34 cc/rev)

3

/rev (195 cc/rev)

3

(405 cc)

Raise: 1000 PSI (69 bar)

3

/rev (11.96 cc/rev)

3

/rev (100 cc/rev)

NOTE: The three wheel motors are similar in construction with only minor differences. The right front wheel motor and rear wheel motor have a

reverse timed manifold, and the front left wheel motor does not. The end cover of the rear motor has a check valve consisting of a ball and spring,

and both front motors lack this feature.

Reelmaster 3550−DHydraulic System Page 4 − 2

Page 35

General Information

Operator’s Manual

The Traction Unit and Cutting Unit Operator’s Manuals

provide information regarding the operation, general

maintenance and maintenance intervals for your Reelmaster machine. Refer to these publications for additional information when servicing the machine.

Relieving Hydraulic System Pressure

Before disconnecting or performing any work on the hydraulic system, all pressure in the hydraulic system

must be relieved. Park machine on a level surface, lower

cutting units fully, stop engine and apply parking brake.

To relieve hydraulic pressure in traction circuit, move

traction pedal to both forward and reverse directions. To

relieve hydraulic pressure in steering circuit, rotate

steering wheel in both directions.

System pressure in mow circuit is relieved when the cutting units are disengaged (reel enable/disable switch in

DISENGAGE position).

Traction Circuit Component Failure

The traction circuit on Reelmaster 3550−D machines is

a closed loop system that includes the piston (traction)

pump, two (2) front wheel motors and the rear wheel motor. If a component in the traction circuit should fail, debris and contamination from the failed component will

circulate throughout the traction circuit. This contamination can damage other components in the circuit so it

must be removed to prevent additional component failure.

The recommended method of removing traction circuit

contamination would be to temporarily install the Toro

high flow hydraulic filter (see Special Tools in this chapter) into the circuit. This filter should be used when connecting hydraulic test gauges in order to test traction

circuit components or after replacing a failed traction circuit component (e.g. traction (piston) pump or wheel

motor). The filter will ensure that contaminates are removed from the closed loop and thus, do not cause additional component damage.

Once the Toro high flow hydraulic filter kit has been

placed in the c i r c ui t , r a i s e a n d s u p port the machine with

To relieve hydraulic pressure in lift circuit, fully lower the

cutting units to the ground. Turn ignition switch to OFF.

NOTE: Moving steering wheel with engine off may unseat implement relief valve. If steering or lift circuits appear weak or inoperative after machine is returned to

service, repeat relieving hydraulic system pressure procedure.

all drive wheels off the ground. Then, operate the traction circuit to allow oil flow throughout the circuit. The filter will remove contamination from the traction circuit

during operation. Because the Toro high flow filter is bi−

directional, the traction circuit can be operated in both

the forward and reverse direction. The filter should be

removed from the machine after contamination has

been removed from the traction circuit. See Filtering

Closed−Loop T raction Circuit in the Service and Repairs

section of this chapter for additional information on using the Toro high flow hydraulic filter.

The alternative to using the Toro high flow hydraulic filter

kit after a traction circuit component failure would be to

disassemble, drain and thoroughly clean all components, tubes and hoses in the traction circuit. If any debris remains in the traction circuit and the machine is

operated, the debris can cause additional circuit component failure.

NOTE: If traction circuit contamination exists, the traction pump case drain could allow contaminates to enter

other hydraulic circuits on the machine.

System

Hydraulic

Reelmaster 3550−D Hydraulic SystemPage 4 − 3

Page 36

Hydraulic Hoses

r

r

-

r

Hydraulic hoses are subject to extreme conditions such

as pressure differentials during operation and exposure

to weather, sun, chemicals, very warm storage conditions or mishandling during operation and maintenance.

These conditions can cause hose damage and deterioration. Some hoses are more susceptible to these

conditions than others. Inspect all machine hydraulic

hoses frequently for signs of deterioration or damage:

WARNING

Before disconnecting or performing any work on

hydraulic system, relieve all pressure in system

(see Relieving Hydraulic System Pressure in this

section of this chapter).

Hard, cracked, cut, abraded, charred, leaking or

otherwise damaged hose.

Kinked, crushed, flattened or twisted hose.

Blistered, soft, degraded or loose hose cover.

Cracked, damaged or badly corroded hose fittings.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint (layline) on

the hose. Use two wrenches; hold the hose straight with

one wrench and tighten the hose swivel nut onto the fitting with the other wrench (See Hydraulic Hose and

Tube Installation in this section in this chapter). If the

hose has an elbow at one end, tighten the swivel nut on

that end before tightening the nut on the straight end of

the hose.

For additional hydraulic hose information, refer to Toro

Service Training Book, Hydraulic Hose Servicing (Part

Number 94813SL).

Keep body and hands away from pin hole leaks o

nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, not hands, to

search for leaks. Hydraulic fluid escaping unde

pressure can have sufficient force to penetrate

the skin and cause serious injury. If fluid is in

jected into the skin, it must be surgically re

moved within a few hours by a doctor familia

with this type of injury. Gangrene may result from

such an injury.

Reelmaster 3550−DHydraulic System Page 4 − 4

Page 37

Hydraulic Hose and Tube Installation (O−Ring Face Seal Fitting)

1. Make sure threads and sealing surfaces of the hose/

tube and the fitting are free of burrs, nicks, scratches or

any foreign material.

2. As a preventative measure against leakage, it is recommended that the face seal O−ring be replaced any

time the connection is opened. Make sure the O−ring is

installed and properly seated in the fitting groove. Lightly

lubricate the O−ring with clean hydraulic oil.

3. Place the hose/tube against the fitting body so that

the flat face of the hose/tube sleeve fully contacts the O−

ring in the fitting.

4. Thread the swivel nut onto the fitting by hand. While

holding the hose/tube with a wrench, use a torque

wrench to tighten the swivel nut to the recommended

installation torque (Fig. 3). This tightening process will

require the use of an offset wrench (e.g. crowfoot

wrench). Use of an offset wrench will affect torque

wrench calibration due to the effective length change of

the torque wrench. Tightening torque when using a

torque wrench with an offset wrench will be lower than

the listed installation torque (see Using a Torque

Wrench with an Offset Wrench in the Torque Specifications section of Chapter 2 − Product Records and Maintenance).

C. Use a second wrench to tighten the nut to the correct Flats From Wrench Resistance (F.F.W.R.). The

markings on the nut and fitting body will verify that the

connection has been properly tightened.

Size F.F.W.R.

4 (1/4 in. nominal hose or tubing) 1/2 to 3/4

6 (3/8 in.) 1/2 to 3/4

8 (1/2 in.) 1/2 to 3/4

10 (5/8 in.) 1/2 to 3/4

12 (3/4 in.) 1/3 to 1/2

16 (1 in.) 1/3 to 1/2

Swivel Nut

Tube or Hose

O−ring

Fitting Body

Figure 1

System

Hydraulic

5. If a torque wrench is not available or if space at the

swivel nut prevents use of a torque wrench, an alternate

method of assembly is the Flats From Wrench Resist-

Mark Nut

and Fitting

Body

Final

Position

ance (F.F.W.R.) method (Fig. 2).

A. Using a wrench, tighten the swivel nut onto the fitting until light wrench resistance is reached (approximately 30 in−lb).

B. Mark the swivel nut and fitting body. Hold the

hose/tube with a wrench to prevent it from turning.

AT WRENCH RESISTANCE

Extend Line

Figure 2

Fitting Dash Size Hose/Tube Side Thread Size Installation Torque

4 9/16 − 18 18 to 22 ft−lb (25 to 29 N−m)

6 11/16 − 16 27 to 33 ft−lb (37 to 44 N−m)

8 13/16 − 16 37 to 47 ft−lb (51 to 63 N−m)

10 1 − 14 60 to 74 ft−lb (82 to 100 N−m)

12 1 3/16 − 12 85 to 105 ft−lb (116 to 142 N−m)

16 1 7/16 − 12 110 to 136 ft−lb (150 to 184 N−m)

Initial

Position

AFTER TIGHTENING

20 1 11/16 − 12 140 to 172 ft−lb (190 to 233 N−m)

Figure 3

Reelmaster 3550−D Hydraulic SystemPage 4 − 5

Page 38

Hydraulic Fitting Installation (SAE Straight Thread O−Ring Fitting into Component Port)

Non−Adjustable Fitting (Fig. 4)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. As a preventative measure against leakage, it is recommended that the O−ring be replaced any time the

connection is opened.

3. Lightly lubricate the O−ring with clean hydraulic oil.

Fitting threads should be clean with no lubricant applied.

IMPORTANT: Before installing fitting into port, determine port material. If fitting is to be installed into

an aluminum port, installation torque is reduced.

4. Install the fitting into the port. Then, use a torque

wrench and socket to tighten the fitting to the recommended installation torque (Fig. 5).

NOTE: Use of an offset wrench (e.g. crowfoot wrench)

will affect torque wrench calibration due to the effective

length change of the torque wrench. Tightening torque

when using a torque wrench with an offset wrench will

be less than the recommended installation torque. See

Using a Torque Wrench with an Offset Wrench in the

Torque Specifications section of Chapter 2 − Product

Records and Maintenance to determine necessary conversion information.

5. If a torque wrench is not available, or if space at the

port prevents use of a torque wrench, an alternate method of assembly is the Flats From Finger Tight (F.F.F.T.)

method.

A. Install the fitting into the port and tighten it down

full length until finger tight.

B. If port material is steel, tighten the fitting to the

listed F.F.F.T. If port material is aluminum, tighten fitting to 60% of listed F.F.F.T.

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6 (3/8 in.) 1.50 + 0.25

8 (1/2 in.) 1.50 +

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 + 0.25

Fitting

O−ring

0.25

0.25

0.25

0.25

Figure 4

Fitting

Dash Size

Fitting Port Side

Thread Size

Installation Torque Into

Steel Port

Installation Torque Into

Aluminum Port

4 7/16 − 20 15 to 19 ft−lb (21 to 25 N−m) 9 to 11 ft−lb (13 to 15 N−m)

5 1/2 − 20 18 to 22 ft−lb (25 to 29 N−m) 11 to 15 ft−lb (15 to 20 N−m)

6 9/16 − 18 34 to 42 ft−lb (47 to 56 N−m) 20 to 26 ft−lb (28 to 35 N−m)

8 3/4 − 16 58 to 72 ft−lb (79 to 97 N−m) 35 to 43 ft−lb (48 to 58 N−m)

10 7/8 − 14 99 to 121 ft−lb (135 to 164 N−m) 60 to 74 ft−lb (82 to 100 N−m)

12 1 1/16 − 12 134 to 164 ft−lb (182 to 222 N−m) 81 to 99 ft−lb (110 to 134 N−m)

14 1 3/16 − 12 160 to 196 ft−lb (217 to 265 N−m) 96 to 118 ft−lb (131 to 160 N−m)

16 1 5/16 − 12 202 to 248 ft−lb (274 to 336 N−m) 121 to 149 ft−lb (165 to 202 N−m)

20 1 5/8 − 12 247 to 303 ft−lb (335 to 410 N−m) 149 to 183 ft−lb (202 to 248 N−m)

Figure 5

Reelmaster 3550−DHydraulic System Page 4 − 6

Page 39

Adjustable Fitting (Fig. 6)

1. Make sure all threads and sealing surfaces of fitting

and component port are free of burrs, nicks, scratches

or any foreign material.

2. As a preventative measure against leakage, it is recommended that the O−ring be replaced any time the

connection is opened.

3. Lightly lubricate the O−ring with clean hydraulic oil.

Fitting threads should be clean with no lubricant applied.

4. Turn back the lock nut as far as possible. Make sure

the back up washer is not loose and is pushed up as far

as possible (Step 1 Fig. 7).

IMPORTANT: Before installing fitting into port, determine port material. If fitting is to be installed into

an aluminum port, installation torque is reduced.

Lock Nut

Back−up Washer

O−ring

Figure 6

5. Install the fitting into the port and tighten finger tight

until the washer contacts the face of the port (Step 2).

6. T o put the fitting in the desired position, unscrew it by

the required amount, but no more than one full turn

(Step 3).

7. Hold the fitting in the desired position with a wrench

and use a torque wrench to tighten the fitting to the recommended installation torque (Fig. 5). This tightening

process will require the use of an offset wrench (e.g.

crowfoot wrench). Use of an offset wrench will affect

torque wrench calibration due to the effective length

change of the torque wrench. Tightening torque when

using a torque wrench with an offset wrench will be lower

than the listed installation torque (see Using a Torque

Wrench with an Offset Wrench in the Torque Specifications section of Chapter 2 − Product Records and Maintenance).

8. If a torque wrench is not available, or if space at the

port prevents use of a torque wrench, an alternate method of assembly is the Flats From Finger Tight (F.F.F.T.)

method. Hold the fitting in the desired position with a

wrench and, if port material is steel, tighten the lock nut

with a second wrench to the listed F.F.F.T (Step 4). If port

material is aluminum, tighten fitting to 60% of listed

F.F.F.T.

Step 3Step 1

Step 2 Step 4

Figure 7

System

Hydraulic

Size F.F.F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6 (3/8 in.) 1.50 + 0.25

8 (1/2 in.) 1.50 +

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

0.25

0.25

0.25

0.25

0.25

Reelmaster 3550−D Hydraulic SystemPage 4 − 7

Page 40

Special Tools

Order the following special tools from your Toro Distributor.

Hydraulic Pressure Test Kit

Use to take various pressure readings for diagnostic

tests. Quick disconnect fittings provided attach directly

to mating fittings on machine test ports without tools. A

high pressure hose is provided for remote readings.

Contains one each: 1000 PSI (70 Bar), 5000 PSI (350

Bar) and 10000 PSI (700 Bar) gauges. Use gauges as

recommended in Testing section of this chapter.

Toro Part Number: TOR47009

Hydraulic Tester (Pressure and Flow)

Figure 8

Use to test hydraulic circuits and components for flow

and pressure capacities as recommended in the Testing

section of this chapter. This tester includes the following:

1. INLET HOSE: Hose connected from the system circuit to the inlet side of the hydraulic tester.

2. LOAD VALVE: A simulated working load is created

in the circuit by turning the valve to restrict flow.

3. PRESSURE GAUGE: Glycerine filled 0 to 5000 PSI

gauge to provide operating circuit pressure.

4. FLOW METER: This meter measures actual oil flow

in the operating circuit with a gauge rated from 1 to 15

GPM (5 to 55 LPM).

5. OUTLET HOSE: A hose from the outlet side of the

hydraulic tester connects to the hydraulic system circuit.

6. FITTINGS: An assortment of hydraulic fittings are included with this kit.

Toro Part Number: TOR214678

Figure 9

Reelmaster 3550−DHydraulic System Page 4 − 8

Page 41

40 GPM Hydraulic Tester (Pressure and Flow)

Use to test hydraulic circuits and components for flow

and pressure capacities as recommended in the Testing

section of this chapter. This tester includes the following:

1. LOAD VALVE: A simulated working load is created

in the circuit by turning the valve to restrict flow.

2. PRESSURE GAUGE: Glycerine filled 0 to 5000 PSI

gauge to provide operating circuit pressure.

3. FLOW METER: This meter measures actual oil flow

in the operating circuit with a gauge rated from 4 to 40

GPM (20 to 150 LPM).

Toro Part Number: AT40002

NOTE: This tester does not include hydraulic hoses

(see Hydraulic Hose Kit TOR6007 below).

Hydraulic Hose Kit

This kit includes hydraulic fittings and hoses needed to

connect 40 GPM hydraulic tester (AT40002) or high flow

hydraulic filter kit (TOR6011) to machine hydraulic traction system components.

Toro Part Number: TOR6007

Figure 10

Figure 11

System

Hydraulic

Reelmaster 3550−D Hydraulic SystemPage 4 − 9

Page 42

High Flow Hydraulic Filter Kit

The high flow hydraulic filter kit is designed with large

flow (40 GPM/150 LPM) and high pressure (5000

PSI/345 bar) capabilities. This kit provides for bi−directional filtration which prevents filtered debris from being

allowed back into the circuit regardless of flow direction.

If a component failure occurs in the closed loop traction

circuit, contamination from the failed part will remain in

the circuit until removed. When connecting hydraulic

test gauges in order to test traction circuit components

or after replacing a failed traction circuit component (e.g.

piston (traction) pump or wheel motor), the high flow hydraulic filter can be installed in the traction circuit. The

filter will ensure that contaminates are removed from the

closed loop and thus, do not cause additional component damage.

Toro Part Number: TOR6011

NOTE: This kit does not include hydraulic hoses (see

Hydraulic Hose Kit TOR6007 above).

NOTE: Replacement filter element is Toro part number

TOR6012. Filter element canister tightening torque is 25

ft−lb (34 N−m).

Figure 12

Hydraulic Test Fitting Kit

This kit includes a variety of O−ring Face Seal fittings to

enable you to connect test gauges into the system.

The kit includes: tee’s, unions, reducers, plugs, caps

and male test fittings.

Toro Part Number: TOR4079

Figure 13

Reelmaster 3550−DHydraulic System Page 4 − 10

Page 43

Measuring Container

Use this container for doing hydraulic motor efficiency