Page 1

PART NO. 05145SL (Rev. B)

Service Manual

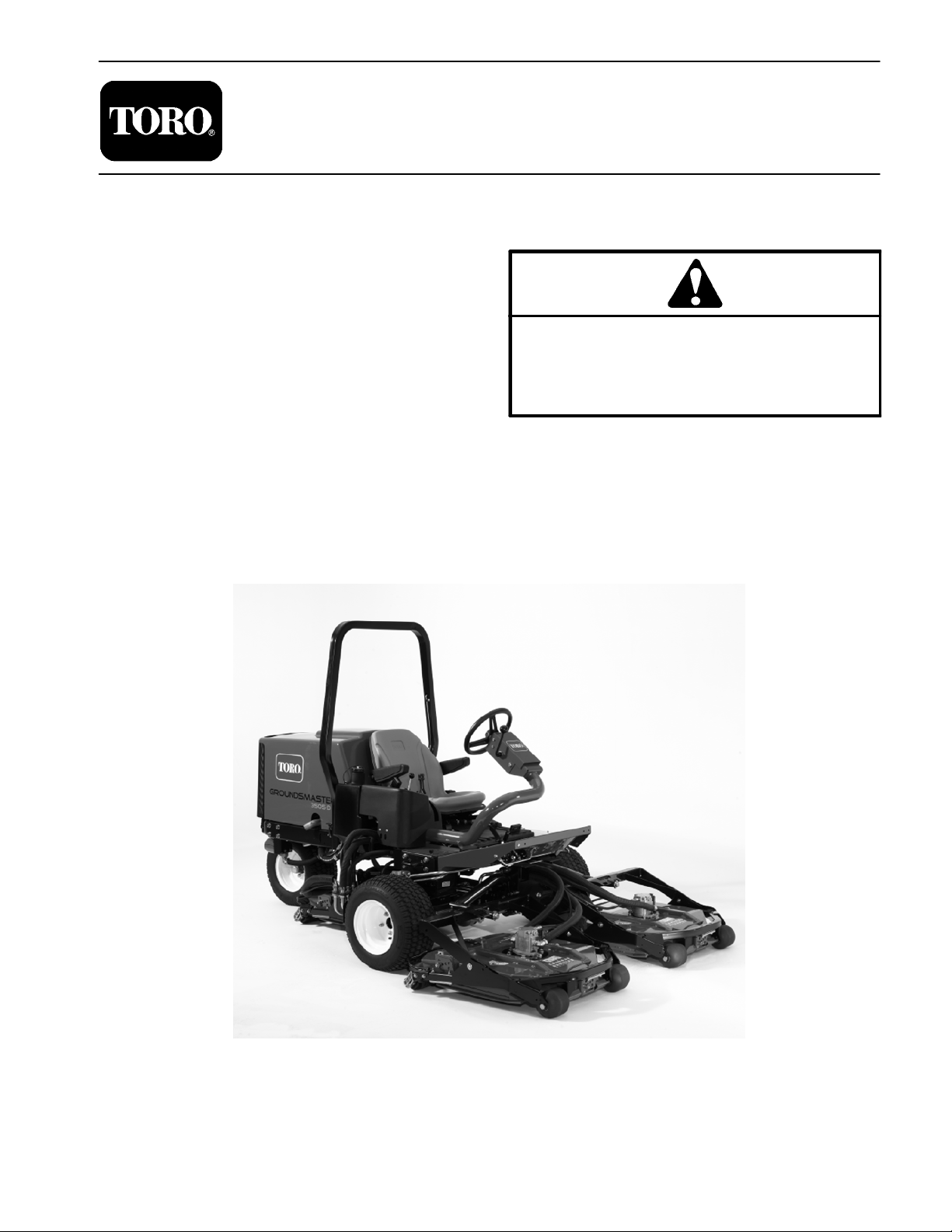

Groundsmaster

Preface

The purpose of this publication is to provide the service

technician with information for troubleshooting, testing,

and repair of major systems and components on the

Groundsmaster 3505--D.

REFER TO THE OPERATOR’S MANUAL FOR OPERATING, MAINTENANCE AND ADJUSTMENT

INSTRUCTIONS. For reference, insert a copy of the

Operator’s Manual and Parts Catalog for your machine

into Chapter 2 of this service manual. Additional copies

of the Operator’s Manual and Parts Catalog are available on the internet at www.Toro.com.

The Toro Company reserves the right to change product

specifications or this publication without notice.

R

3505--D

This safety symbol means DANGER, WARNING

or CAUTION, PERSONAL SAFETY INSTRUCTION. When you see this symbol, carefully read

the instructions that follow. Failure to obey the

instructions may result in personal injury.

NOTE: A NOTE will give general information about the

correct operation, maintenance, service, testing or

repair of the machine.

IMPORTANT: The IMPORTANT notice will give important instructions which must be followed to prevent damage to systems or components on the

machine.

E The Toro Company -- 2005, 2007, 2009

Page 2

This page is intentionally blank.

Groundsmaster 3505--D

Page 3

Table Of Contents

Chapter 1 -- Safety

General Safety Instructions 1 -- 1..................

Jacking Instructions 1 -- 4.........................

Chapter 2 -- Product Records and Maintenance

Product Records 2 -- 1...........................

Maintenance 2 -- 1...............................

Equivalents and Conversions 2 -- 2................

Torque Specifications 2 -- 3.......................

Chapter 3 -- Kubota Diesel Engine

Introduction 3 -- 2................................

Specifications 3 -- 3..............................

Service and Repairs 3 -- 4........................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

05 SERIES

Chapter 4 -- Hydraulic System

Specifications 4 -- 2..............................

General Information 4 -- 3........................

Hydraulic Schematic 4 -- 7........................

Hydraulic Flow Diagrams 4 -- 8....................

Special Tools 4 -- 18.............................

Troubleshooting 4 -- 22...........................

Testing 4 - - 25...................................

Adjustments 4 -- 50..............................

Service and Repairs 4 -- 51.......................

ROSS TORQMOTOR

RIES SERVICE PROCEDURE

EATON MEDIUM DUTY PISTON PUMP REPAIR IN-

FORMATION MODEL 70160 VARIABLE DISPLACEMENT PISTON PUMP

SAUER/DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

TM

MG, MF, ME, AND MJ SE-

Chapter 5 -- Electrical System

Electrical Schematics and Diagrams 5 -- 1..........

Special Tools 5 -- 2..............................

Troubleshooting 5 -- 4............................

Electrical System Quick Checks 5 -- 7..............

Component Testing 5 -- 9.........................

Service and Repairs 5 -- 22.......................

Chapter 6 -- Chassis

Specifications 6 -- 2..............................

Special Tools 6 -- 3..............................

Adjustments 6 -- 4...............................

Service and Repairs 6 -- 6........................

Chapter 7 -- Cutting Units

Specifications 7 -- 2..............................

Special Tools 7 -- 3..............................

Troubleshooting 7 -- 4............................

Adjustments 7 -- 5...............................

Service and Repairs 7 -- 6........................

Chapter 8 -- Electrical Diagrams

Electrical Schematic 8 -- 3........................

Circuit Diagrams 8 -- 4...........................

Wire Harness Drawings 8 -- 8.....................

SafetyProduct Records

Kubota

Hydraulic

Electrical

ChassisCutting

and Maintenance

Diesel Engine

System

System

Groundsmaster 3505--D

Electrical

Units

Diagrams

Page 4

This page is intentionally blank.

Groundsmaster 3505--D

Page 5

Table of Contents

GENERAL SAFETY INSTRUCTIONS 1............

Supervisor’s Responsibilities 1.................

Before Operating 1............................

While Operating 2.............................

Maintenance and Service 3....................

JACKING INSTRUCTIONS 4.....................

General Safety Instructions

The GROUNDSMASTER 3505--D was tested and certified by TORO for compliance with existing standards

and specifications as identified in the Operator’s Manual. Although hazard control and accident prevention are

dependent partially upon the design and configuration

of the machine, these factors are also dependent upon

the awareness, concern and proper training of the personnel involved in the operation, transport, maintenance and storage of the machine. Improper use or

maintenance by the operator or owner of the machine

can result in injury. To reduce the potential for any injury,

comply with the following safety instructions.

Chapter 1

Safety

Safety

WARNING

To reduce the potential for injury or death,

comply with the following safety instructions.

Supervisor’s Responsibilities

1. Make sure operators are thoroughly trained and familiar with the Operator’s Manual, Operator’s Video and

all the operating and safety decals on the machine.

2. Be sure to establish your own special procedures

and work rules for unusual operating conditions (e.g.

slopes too steep for machine operation). Survey mow-

ing site completely to determine which hills can be

Before Operating

1. Read and understand the contents of the Operator’s

Manual before starting and operating the machine. Become familiar with the controls and know how to stop the

machine and engine quickly. Copies of the Operator’s

Manual are available on the internet at www.Toro.com.

2. Keep all shields, safety devices and decals in place.

If a shield, safety device or decal is defective, illegible or

damaged, repair or replace it before operating the machine. Also tighten any loose nuts, bolts or screws to ensure machine is in safe operating condition.

operated on safely. When performing this site survey,

always use common sense and take into consideration

the turf condition and the rollover risk. To perform a site

survey, follow the procedure outlined in the Traction Unit

Operator’s Manual. THE MAXIMUM SIDE HILL

ANGLE SHOULD NOT BE GREATER THAN 15 DEGREES.

3. Assure that operator’s presence controls, safety

switches and shields are attached and functioning properly. Do not operate the machine unless these items are

functioning properly.

Groundsmaster 3505--D Page 1 -- 1 Safety

Rev. B

Page 6

4. Since fuel is highly flammable, handle it carefully:

A. Store fuel in containers specifically designed for

this purpose.

B. Do not remove machine fuel tank cap while engine is hot or running.

C. Do not smoke while handling fuel.

While Operating

D. Fill fuel tank outdoors and only to within an inch of

the top of the tank, not the filler neck. Do not overfill.

E. Replace fuel tank and fuel container caps securely after refueling machine.

F. If fuel is spilled, do not attempt to start the engine

but move the machine away from the area of the spillage. Avoid creating any source of ignition until fuel

vapors have dissipated. Clean up any spilled fuel.

1. Sit on the seat when starting and operating the machine.

2. Before starting the engine:

A. Engage the parking brake.

B. Make sure traction pedal is in neutral and the

P.T.O. switch is OFF (disengaged).

C. After engine is started, release parking brake and

keep foot off traction pedal. Machine must not move.

If movement is evident, the traction pedal linkage is

adjusted incorrectly; therefore, shut engine off and

adjust traction pedal linkage until machine does not

move when traction pedal is released (see Traction

Unit Operator’s Manual).

3. Do not run engine in a confined area without adequate ventilation. Exhaust fumes are hazardous and

could possibly be deadly.

4. The slope angle at which the machine will tip is dependent on many factors. Among these are mowing

conditions such as wet or undulating turf, speed (especially in turns), tire pressure and operator experience. At

side hill angles of 10 degrees or less, the risk of a rollover

is low. As the slope angle increases to a recommended

maximum limit of 15 degrees, the risk of a rollover increases to a moderate level. DO NOT EXCEED A 15

DEGREE SIDE HILL ANGLE BECAUSE THE RISK OF

A ROLLOVER AND SERIOUS INJURY OR DEATH IS

VERY HIGH.

5. Do not touch engine, radiator or exhaust system

while engine is running or soon after it is stopped. These

areas could be hot enough to cause burns.

6. Before getting off the seat:

A. Ensure that traction pedal is in neutral.

B. Lower and disengage cutting decks and wait for

all movement to stop.

C. Set parking brake.

D. Stop engine and remove key from ignition switch.

7. Anytime the machine is parked (short or long term),

the cutting decks should be lowered to the ground. This

relieves pressure from the lift circuit and eliminates the

risk of a cutting deck accidentally lowering to the ground.

8. Do not park on slopes unless wheels are chocked or

blocked.

Groundsmaster 3505--DPage 1 -- 2Safety

Page 7

Maintenance and Service

1. Before servicing or making adjustments, lower cutting decks, stop engine, set parking brake and remove

key from the switch.

2. Make sure machine is in safe operating condition by

keeping all nuts, bolts and screws tight.

3. Never store the machine or fuel container inside

where there is an open flame, such as near a water heater or furnace.

4. Make sure all hydraulic line c onnectors are tight, and

all hydraulic hoses and lines are in good condition before applying pressure to the hydraulic system.

5. Keep body and hands away from pin hole leaks in hydraulic lines that eject high pressure hydraulic fluid. Use

cardboard or paper to find hydraulic leaks. Hydraulic

fluid escaping under pressure can penetrate skin and

cause injury. Fluid accidentally injected into the skin

must be surgically removed within a few hours by a doctor familiar with this form of injury or gangrene may result.

6. Before disconnecting or performing any work on the

hydraulic system, all pressure in the system must be relieved by lowering the cutting decks to the ground, stopping the engine and then using all of the hydraulic

controls (depressing the traction pedal, turning the

steering wheel in both directions and energizing the

deck solenoid with the engine not running).

7. If major repairs are ever needed or assistance is desired, contact an Authorized Toro Distributor.

8. Use care when checking or servicing the cutting

deck. Wear gloves and use caution when servicing it.

9. To reduce potential fire hazard, keep engine area

free of excessive grease, grass, leaves and dirt. Clean

protective screen on machine frequently.

10.If engine must be running to perform maintenance or

to make an adjustment, keep hands, feet, clothing and

other parts of the body away from the cutting decks and

other moving parts. Keep bystanders away.

11. Do not overspeed the engine by changing governor

setting. To assure safety and accuracy,check maximum

engine speed with a tachometer.

12.Shut engine off before checking or adding oil to the

crankcase.

13.Disconnect battery before servicing the machine.

Disconnect negative battery cable first and positive

cable last. If battery voltage is required for troubleshooting or test procedures, temporarily connect the battery.

Reconnect positive cable first and negative cable last.

14.Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes and clothing. Protect your

face, eyes and clothing when working with a battery.

15.Battery gases can explode. Keep cigarettes, sparks

and flames away from the battery.

16.If welding on the machine is necessary, disconnect

the negative battery cable to prevent electrical system

damage.

17.At the time of manufacture, the machine conformed

to the safety standards for riding mowers. To assure optimum performance and continued safety certification of

the machine, use genuine Toro replacement parts and

accessories. Replacement parts and accessories made

by other manufacturers may result in non-conformance

with the safety standards, and the warranty may be

voided.

18.When changing attachments, tires or performing

other service, use correct blocks, hoists and jacks.

Make sure machine is parked on a solid level floor such

as a concrete floor. Prior to raising the machine, remove

any attachments that may interfere with the safe and

proper raising of the machine. Always chock or block

wheels. Use jack stands or solid wood blocks to support

the raised machine. If the machine is not properly supported by blocks or jack stands, the machine may move

or fall, which may result in personal injury (see Jacking

Instructions in this chapter).

Safety

Groundsmaster 3505--D Page 1 -- 3 Safety

Page 8

Jacking Instructions

CAUTION

When changing attachments, tires or performing

other service, use correct blocks, hoists and

jacks. Make sure machine is parked on a solid level floor such as a concrete floor. Prior to raising

machine, remove any attachments thatmay interfere with the safe and proper raising of the machine. Always chock or block wheels. Use jack

stands or solid wood blocks to support the raised

machine. If the machine is not properly supported by blocks or jack stands, the machine may

move or fall, which may result in personal injury.

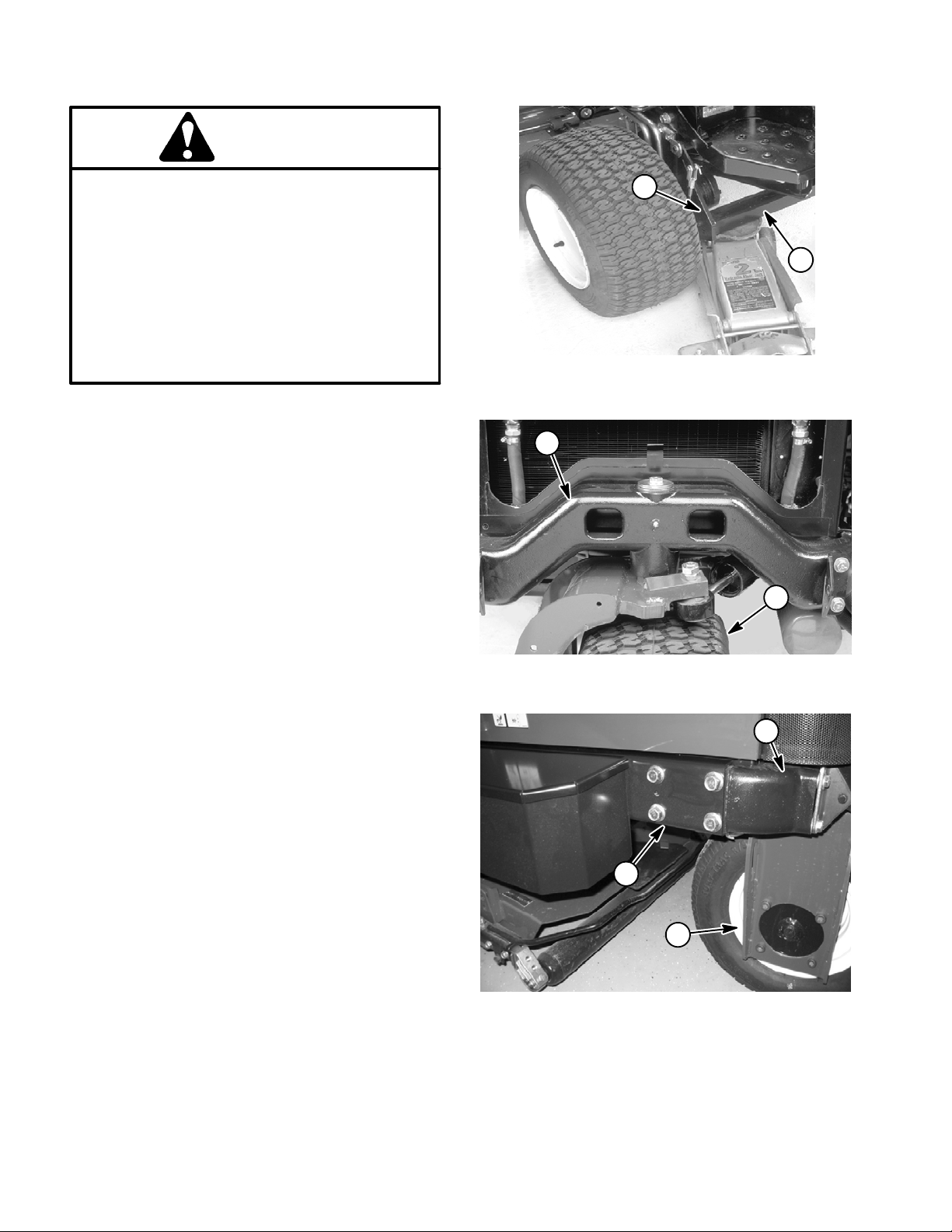

Jacking the Front End

1. If the front wheel motor is to be removed, position

jack securely under the square tube of the lower frame

as closely to the side plate as possible (Fig. 1).

2. If the front tire is to be removed, position the jack securely under the front wheel motor.

3. Use jack stands or hardwood blocks under the

square tube or wheel motors to support the machine.

Jacking the Rear End

2

1

Figure 1

1. Square tube 2. Side plate

2

1

1. The preferred method for removing the rear fork or

the rear wheel is to lift the rear end of the machine from

above:

A. Secure a chain fall or hoist to the rear casting (Fig

2).

B. Chock both front tires. Lift rear tire off the ground.

C. Use jack stands or hardwood blocks under the

frame to support the machine (Fig. 3).

2. If the rear of the machine cannot be lifted from above:

A. Chock both front tires.

IMPORTANT: Make sure jack is as close to the

rear fork as possible when jacking the machine.

B. Place jack s ecurely under the rear casting as

close to the fork as possible (Fig. 3). Jack rear tire off

the g round.

C. Use jack stands or blocks under the frame to support the machine.

Figure 2

1. Rear tire 2. Rear casting

1

3

Figure 3

1. Frame

2. Rear casting

3. Rear fork

2

Groundsmaster 3505--DPage 1 -- 4Safety

Page 9

Product Records and Maintenance

Table of Contents

Chapter 2

PRODUCT RECORDS 1.........................

MAINTENANCE 1...............................

EQUIVALENTS AND CONVERSIONS 2...........

Decimal and Millimeter Equivalents 2............

U.S. to Metric Conversions 2...................

TORQUE SPECIFICATIONS 3....................

Fastener Identification 3.......................

Product Records

Insert a copy of the Operator’s Manual and Parts Catalog for your Groundsmaster 3505--D at the end of this

chapter. Additionally, if any optional equipment or accessories have been installed to your Groundsmaster,

insert the Installation Instructions, Operator’s Manuals

and Parts Catalogs for those options at the end of this

chapter.

Maintenance

Maintenance procedures and recommended service intervals for the Groundsmaster 3505--D are covered in

the Operator’s Manual. Refer to that publication when

performing regular equipment maintenance.

Standard Torque for Dry, Zinc Plated and Steel Fas-

teners (Inch Series) 4........................

Standard Torque for Dry, Zinc Plated and Steel Fas-

teners (Metric Fasteners) 5...................

Other Torque Specifications 6..................

Conversion Factors 6..........................

Product Records

and Maintenance

Groundsmaster 3505--D Page 2 -- 1 Product Records and Maintenance

Page 10

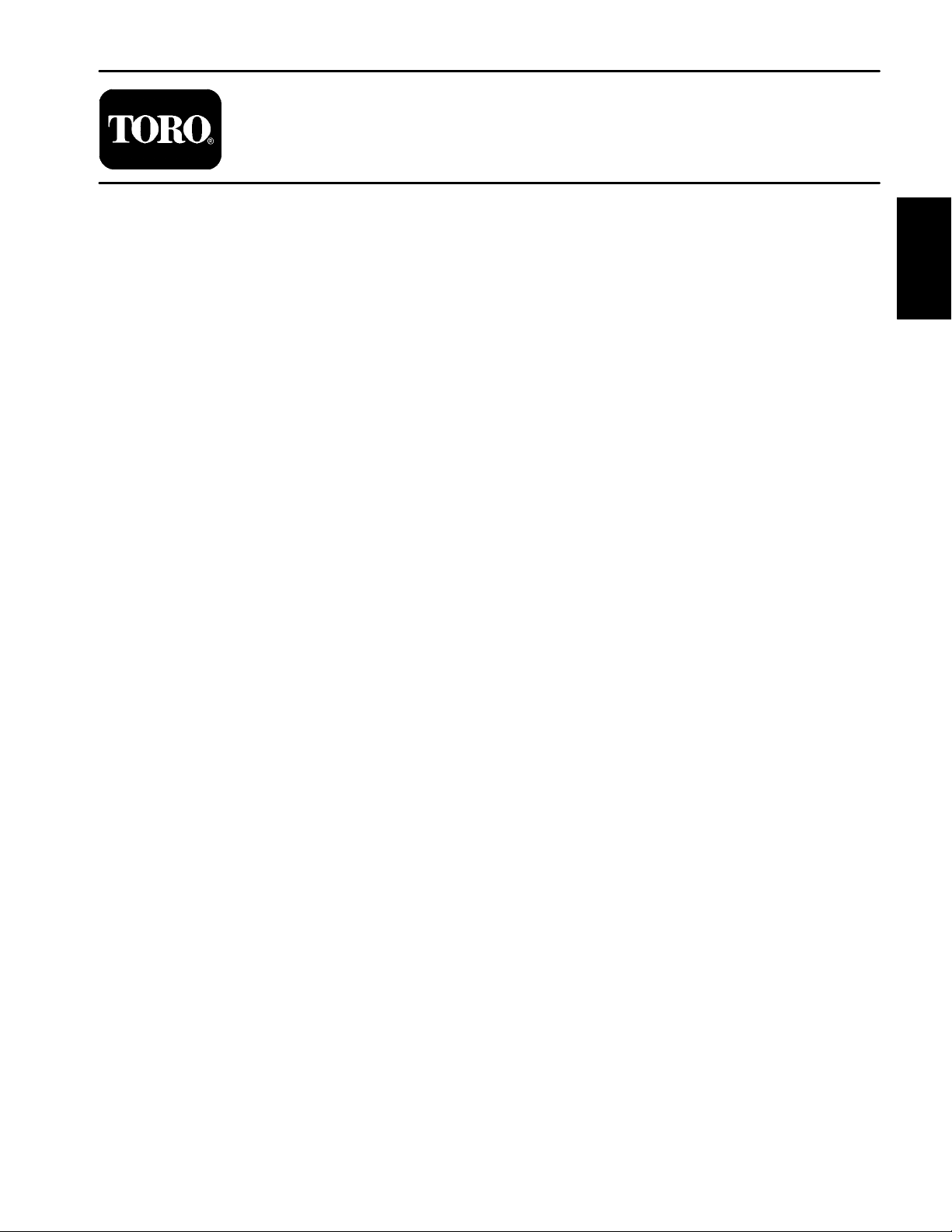

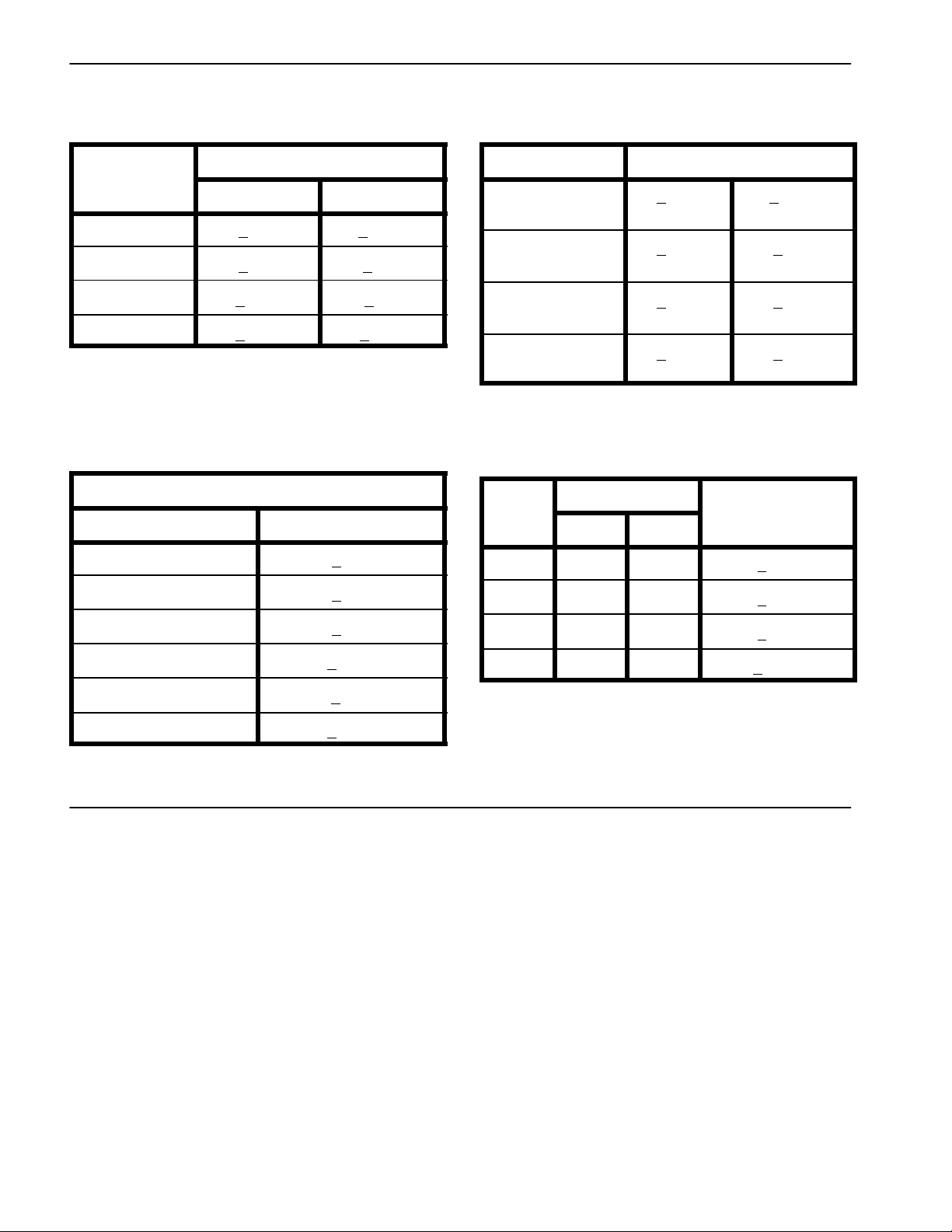

Equivalents and Conversions

0.09375

Rev. A

Groundsmaster 3505--DPage 2 -- 2Product Records and Maintenance

Page 11

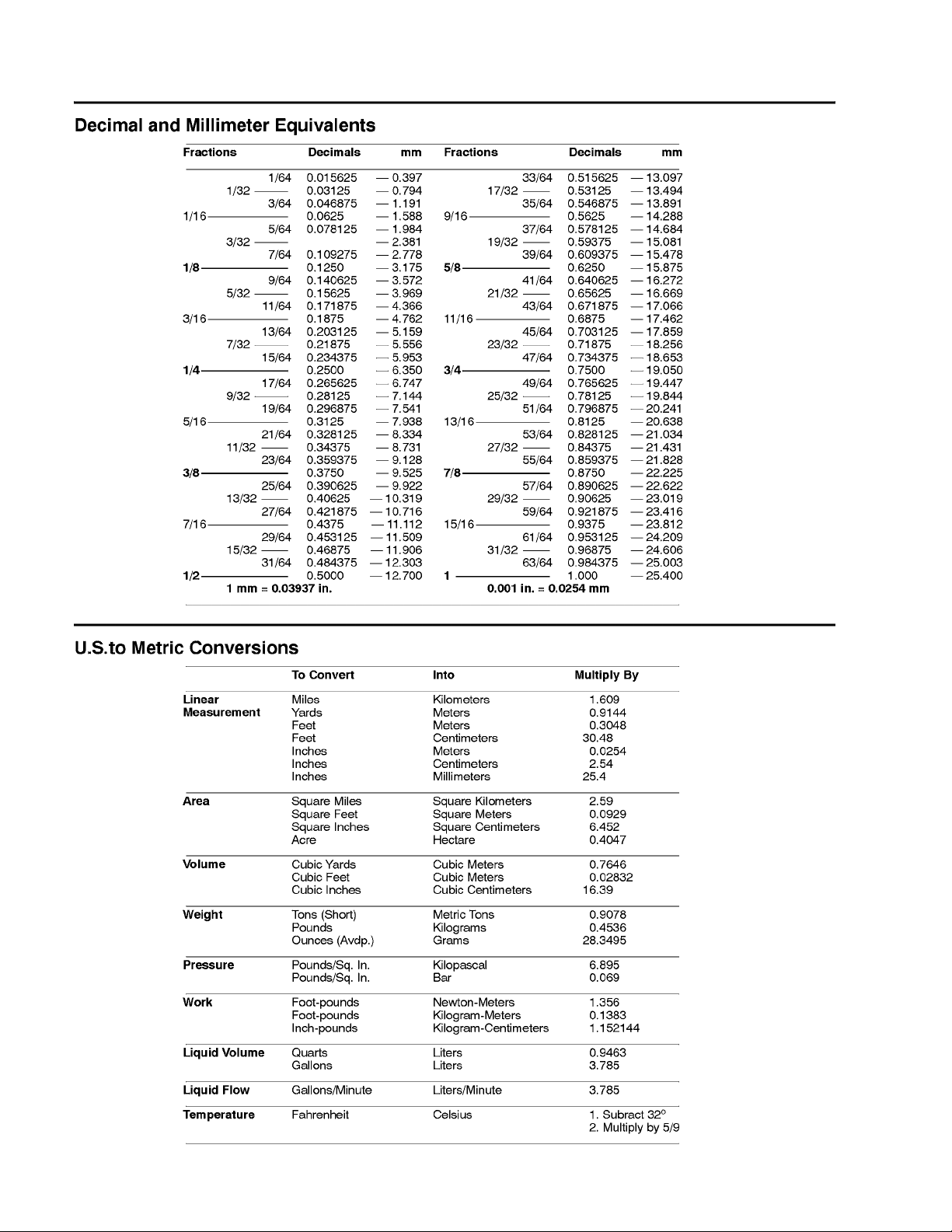

Torque Specifications

Recommended fastener torque values are listed in the

following tables. For critical applications, as determined

by Toro, either the recommended torque or a torque that

is unique to the application is clearly identified and specified in this Service Manual.

These Torque Specifications for the installation and

tightening of fasteners shall apply to all fasteners which

do not have a s pecific requirement identified in this Service Manual. The following factors should be considered

when applying torque: cleanliness of the fastener, use

of a thread sealant (e.g. Loctite), degree of lubrication

on the fastener, presence of a prevailing torque feature

(e.g. Nylock nut), hardness of the surface underneath

the fastener’shead or similar condition which affects the

installation.

Fastener Identification

As noted in the following tables, torque values should be

reduced by 25% for lubricated fasteners to achieve

the similar stress as a dry fastener. Torque values may

also have to be reduced when the fastener is threaded

into aluminum or brass. The specific torque value

should be determined based on the aluminum or brass

material strength, fastener size, length of thread engagement, etc.

The standard method of verifying torque shall be performed by marking a line on the fastener (head or nut)

and mating part, then back off fastener 1/4 of a turn.

Measure the torque required to tighten the fastener until

the lines match up.

Product Records

and Maintenance

Grade 1 Grade 5 Grade 8

Inch Series Bolts and Screws

Figure 1

Class 8.8 Class 10.9

Metric Bolts and Screws

Figure 2

Groundsmaster 3505--D Page 2 -- 3 Product Records and Maintenance

Page 12

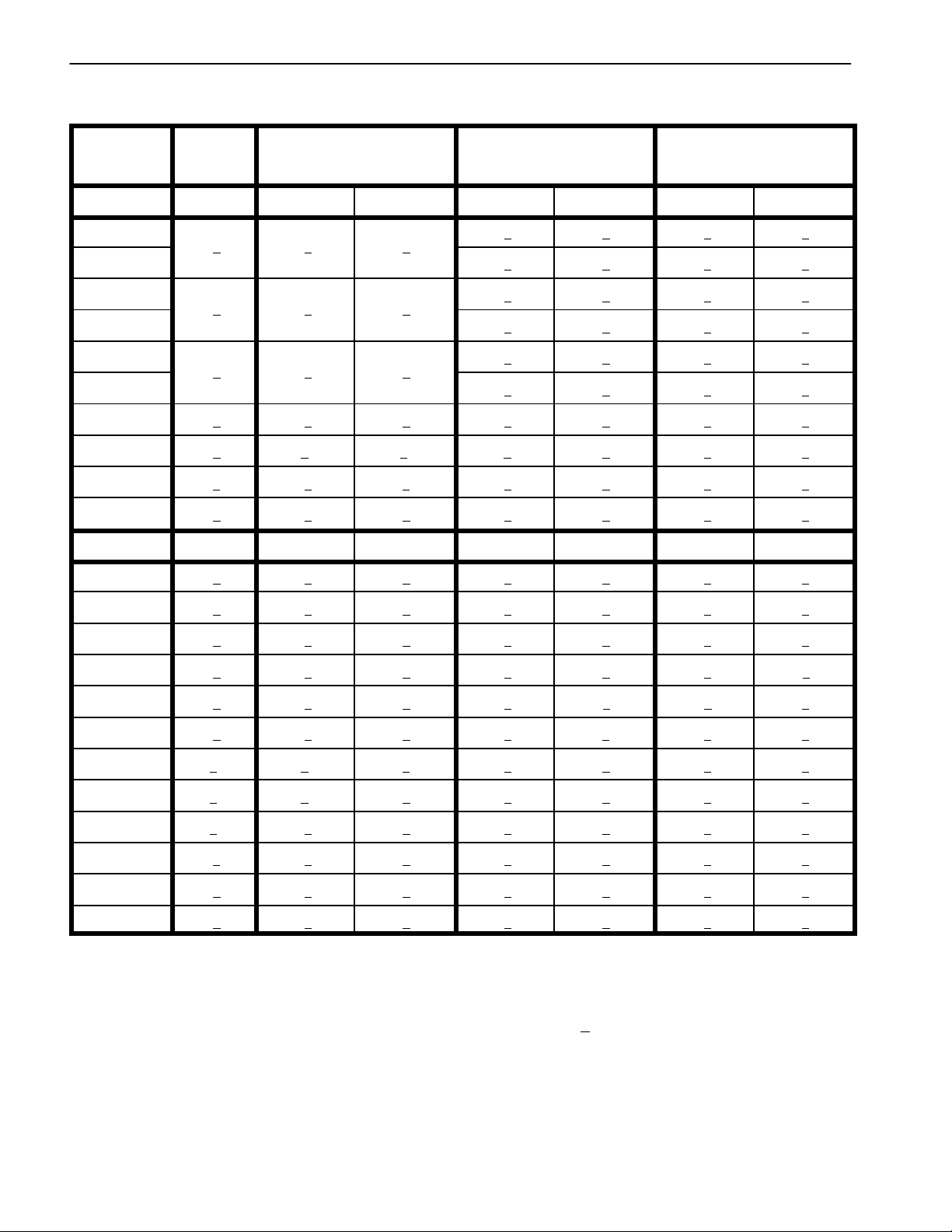

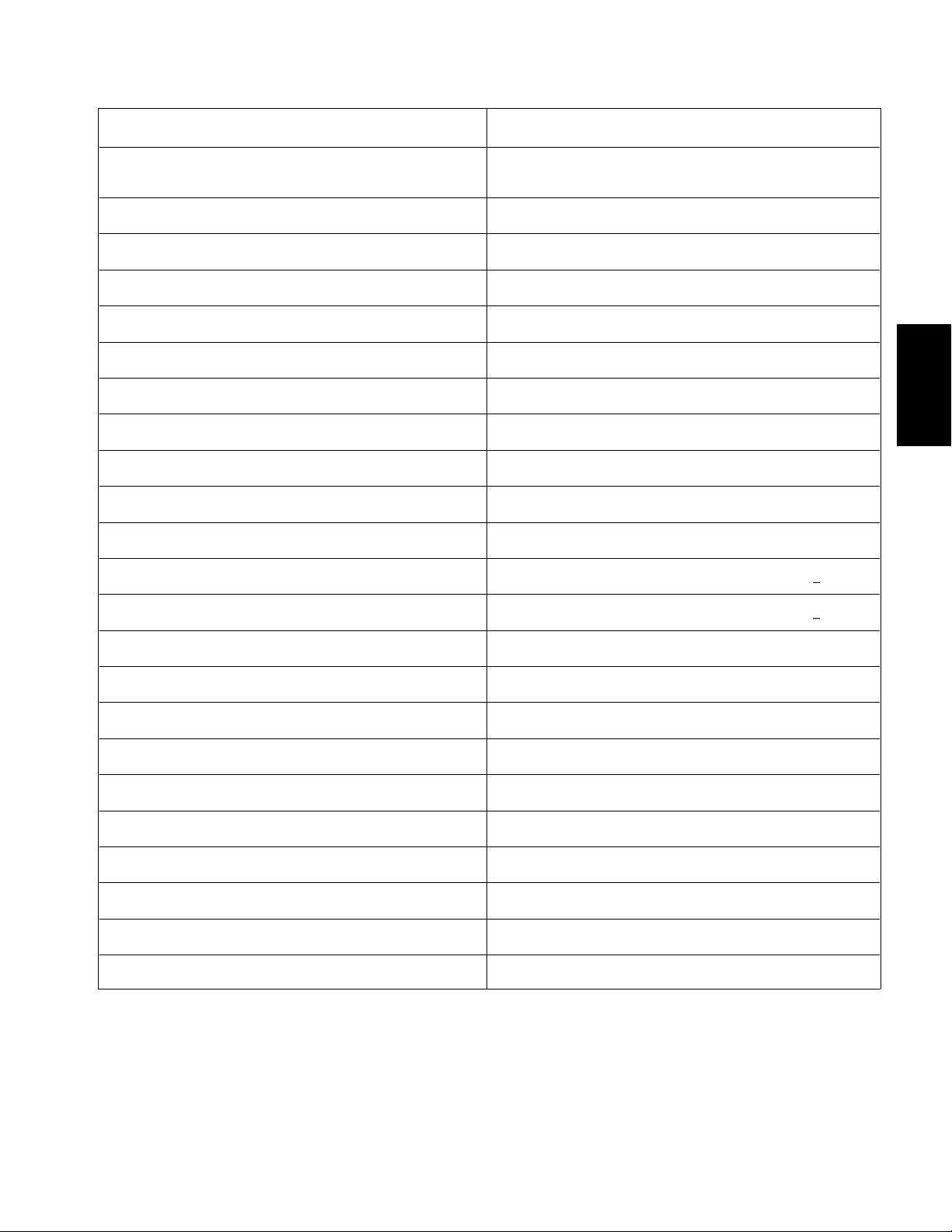

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Inch Series)

Thread Size

# 6 -- 32 UNC

# 6 -- 40 UNF

# 8 -- 32 UNC

# 8 -- 36 UNF

#10--24UNC

#10--32UNF

1/4 -- 20 UNC 48 + 7 53 + 7 599 + 79 100 + 10 1130 + 11 3 140 + 15 1582 + 169

1/4 -- 28 UNF 53 + 7 65 + 10 734 + 113 115 + 12 1299 + 136 160 + 17 1808 + 192

5/16 -- 18 UNC 115 + 15 105 + 15 1186 + 169 200 + 25 2260 + 282 300 + 30 3390 + 339

5/16 -- 24 UNF 138 + 17 128 + 17 1446 + 192 225 + 25 2542 + 282 325 + 33 3672 + 373

3/8 -- 16 UNC 16 + 2 16 + 2 22 + 3 30 + 3 41 + 4 43 + 5 58 + 7

Grade 1, 5 &

8withThin

Height Nuts

in--lb in--lb N--cm in --lb N--cm in --lb N--cm

10 + 2 13 + 2 147 + 23

13 + 2 25 + 5 282 + 30

18 + 2 30 + 5 339 + 56

ft--lb ft--lb N--m ft--lb N--m ft--lb N-- m

SAE Grade 1 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

SAE Grade 5 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 2 or Stronger Nuts)

15 + 2 169 + 23 23 + 3 262 + 34

17 + 2 192 + 23 25 + 3 282 + 34

29 + 3 328 + 34 41 + 5 463 + 56

31 + 4 350 + 45 43 + 5 486 + 56

42 + 5 475 + 56 60 + 6 678 + 68

48 + 5 542 + 56 68 + 7 768 + 79

SAE Grade 8 Bolts, Screws, Studs &

Sems with Regular Height Nuts

(SAE J995 Grade 5 or Stronger Nuts)

3/8 -- 24 UNF 17 + 2 18 + 2 24 + 3 35 + 4 47 + 5 50 + 6 68 + 8

7/16 -- 14 UNC 27 + 3 27 + 3 37 + 4 50 + 5 68 + 7 70 + 7 95 + 9

7/16 -- 20 UNF 29 + 3 29 + 3 39 + 4 55 + 6 75 + 8 77 + 8 104 + 11

1/2 -- 13 UNC 30 + 3 48 + 7 65 + 9 75 + 8 102 + 11 105 + 11 142 + 15

1/2 -- 20 UNF 32 + 4 53 + 7 72 + 9 85 + 9 115 + 12 120 + 12 163 + 16

5/8 -- 11 UNC 65 + 10 88 + 12 119 + 16 150 + 15 203 + 20 210 + 21 285 + 28

5/8 -- 18 UNF 75 + 10 95 + 15 129 + 20 170 + 18 230 + 24 240 + 24 325 + 33

3/4 -- 10 UNC 93 + 12 140 + 20 190 + 27 265 + 27 359 + 37 375 + 38 508 + 52

3/4 -- 16 UNF 115 + 15 165 + 25 224 + 34 300 + 30 407 + 41 420 + 43 569 + 58

7/8 -- 9 UNC 140 + 20 225 + 25 305 + 34 430 + 45 583 + 61 600 + 60 813 + 81

7/8 -- 14 UNF 155 + 25 260 + 30 353 + 41 475 + 48 644 + 65 667 + 66 904 + 89

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

NOTE: The nominal torque values listed above for

Grade 5 and 8 fasteners are based on 75% of the minimum proof load specified in SAE J429. The tolerance is

approximately +

10% of the nominal torque value. Thin

height nuts include jam nuts.

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

Groundsmaster 3505--DPage 2 -- 4Product Records and Maintenance

Rev. B

Page 13

Standard Torque for Dry, Zinc Plated and Steel Fasteners (Metric Fasteners)

Class 8.8 Bolts, Screws and Studs with

Thread Size Regular Height Nuts

(Class 8 or Stronger Nuts)

M5 X 0.8 57 + 6in--lb 644 + 68 N--cm 78 + 8in--lb 881 + 90 N--cm

M6 X 1.0 96 + 10 in--lb 1085 + 11 3 N - -cm 133 + 14 in--lb 1503 + 158 N--cm

M8 X 1.25 19 + 2ft--lb 26 + 3N--m 28 + 3ft--lb 38 + 4N--m

M10 X 1.5 38 + 4ft--lb 52 + 5N--m 54 + 6ft--lb 73 + 8N--m

M12 X 1.75 66 + 7ft--lb 90 + 10 N--m 93 + 10 ft--lb 126 + 14 N--m

M16 X 2.0 166 + 17 ft--lb 225 + 23 N--m 229 + 23 ft--lb 310 + 31 N--m

M20 X 2.5 325 + 33 ft--lb 440 + 45 N--m 450 + 46 ft--lb 610 + 62 N--m

NOTE: Torque values may have to be reduced when

installing fasteners into threaded aluminum or brass.

The specific torque value should be determined based

on the fastener size, the aluminum or base material

strength, length of thread engagement, etc.

NOTE: The nominal torque values listed above are

based on 75% of the minimum proof load specified in

SAE J1199.The tolerance is approximately +

nominal torque value.

10% of the

NOTE: Reduce torque values listed in the table above

by 25% for lubricated fasteners. Lubricated fasteners

are defined as threads coated with a lubricant such as

engine oil or thread sealant such as Loctite.

Class 10.9 Bolts, Screws and Studs with

Regular Height Nuts

(Class 10 or Stronger Nuts)

Product Records

and Maintenance

Groundsmaster 3505--D Page 2 -- 5 Product Records and Maintenance

Page 14

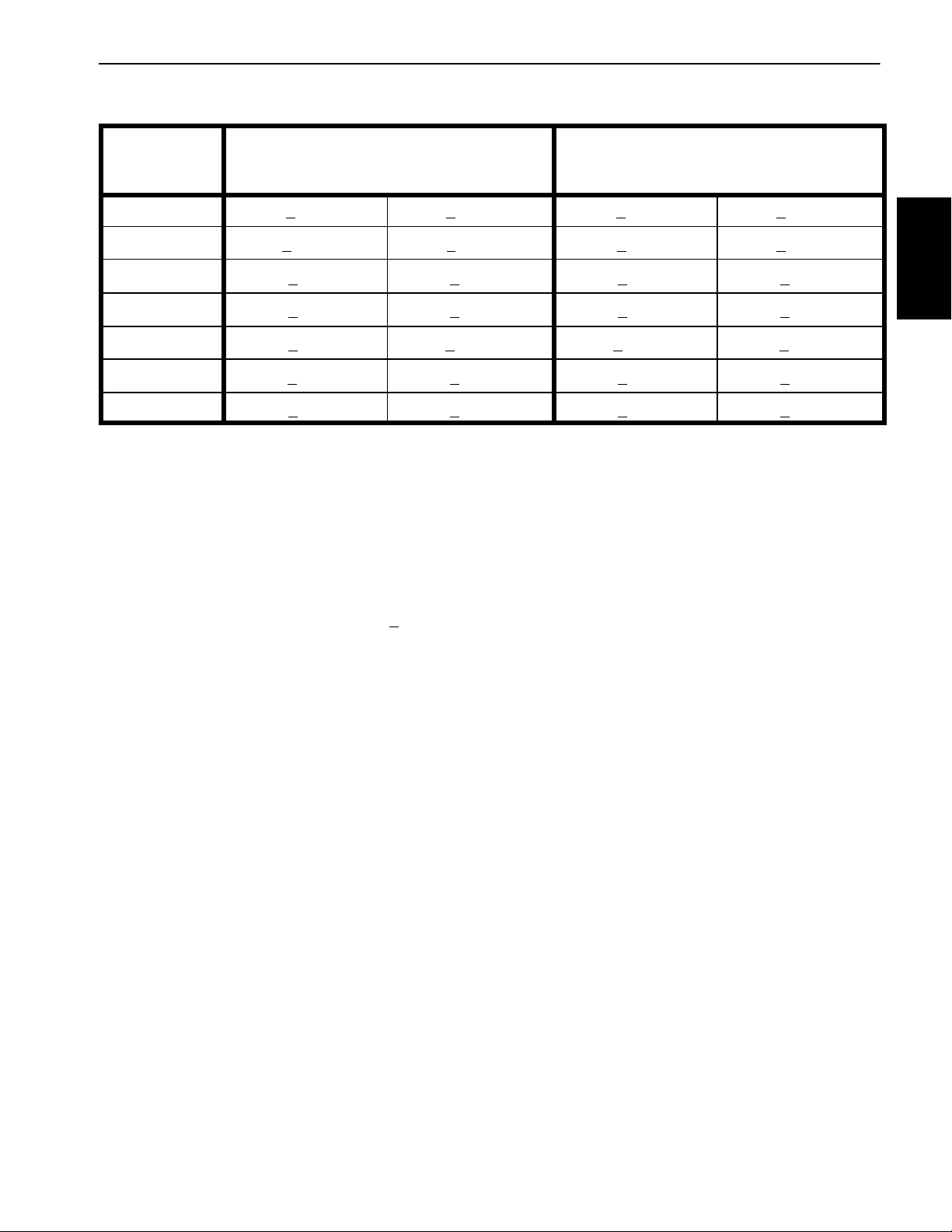

Other Torque Specifications

*

SAE Grade 8 Steel Set Screws

Recommended Torque

Thread Size

Square Head Hex Socket

1/4 -- 20 UNC 140 + 20 in--lb 73 + 12 in--lb

5/16 -- 18 UNC 215 + 35 in--lb 145 + 20 in--lb

3/8 -- 16 UNC 35 + 10 ft--lb 18 + 3ft--lb

1/2 -- 13 UNC 75 + 15 ft--lb 50 + 10 ft--lb

Thread Cutting Screws

(Zinc Plated Steel)

Type 1, Type 23 or Type F

Thread Size Baseline Torque*

No. 6 -- 32 UNC 20 + 5in--lb

Wheel Bolts and Lug Nuts

Thread Size

7/16 -- 20 UNF

Grade 5

1/2 -- 20 UNF

Grade 5

M12 X 1.25

Class 8.8

M12 X 1.5

Class 8.8

** For steel wheels and non--lubricated fasteners.

Thread Cutting Screws

(Zinc Plated Steel)

Thread

Size

No. 6 18 20 20 + 5in--lb

Threads per Inch

Type A Type B

Recommended Torque**

65 + 10 ft--lb 88 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

80 + 10 ft--lb 108 + 14 N--m

Baseline Torque

No. 8 -- 32 UNC 30 + 5in--lb

No. 10 -- 24 UNC 38 + 7in--lb

1/4 -- 20 UNC 85 + 15 in--lb

5/16 -- 18 UNC 110 + 20 in--lb

3/8 -- 16 UNC 200 + 100 in--lb

Conversion Factors

in--lb X 11.2985 = N--cm N-- cm X 0.08851 = in--lb

ft--lb X 1.3558 = N--m N--m X 0.7376 = ft--lb

No. 8 15 18 30 + 5in--lb

No. 10 12 16 38 + 7in--lb

No. 12 11 14 85 + 15 in--lb

* Hole size, material strength, material thickness & finish

must be considered when determining specific torque

values. All torque values are based on non--lubricated

fasteners.

Groundsmaster 3505--DPage 2 -- 6Product Records and Maintenance

Page 15

Table of Contents

INTRODUCTION 2..............................

SPECIFICATIONS 3.............................

SERVICE AND REPAIRS 4......................

Muffler and Air Cleaner Assembly 4.............

Muffler Removal 5...........................

Muffler Installation 5.........................

Air Cleaner Assembly Removal 6..............

Air Cleaner Assembly Installation 6............

Fuel System 8................................

Check Fuel Lines and Connections 9...........

Fuel Tank Removal 9........................

Drain and Clean Fuel Tank 9..................

Fuel Tank Installation 9.......................

Chapter 3

Kubota Diesel Engine

Radiator 10..................................

Removal 11.................................

Installation 11...............................

Engine 12....................................

Removal 12.................................

Installation 14...............................

KUBOTA WORKSHOP MANUAL, DIESEL ENGINE,

05 SERIES

Kubota

Diesel Engine

Groundsmaster 3505--D Page 3 -- 1 Kubota Diesel Engine

Page 16

Introduction

This Chapter gives information about specifications,

troubleshooting, testing and repair of the Kubota

D1105T diesel engine used in the Groundsmaster

3505--D. Refer to the Traction Unit Operator’s Manual

for engine maintenance information.

Most repairs and adjustments require tools which are

commonly available in many service shops. Special

tools are described in the Kubota Workshop Manual,

Diesel Engine, 05 Series included at the end of this

chapter. The use of some specialized test equipment is

explained. However, the cost of the test equipment and

the specialized nature of some repairs may dictate that

the work be done at an engine repair facility.

Service and repair parts for Kubota engines are supplied through your Authorized Toro Distributor. If no

parts list is available, be prepared to provide yourdistributor with the Toro equipment model and serial numbers

as well as the Kubota engine model and serial numbers.

Groundsmaster 3505--DPage 3 -- 2Kubota Diesel Engine

Page 17

Specifications

Item Description

Make / Designation Kubota D1105T, 3 Cylinder, Liquid Cooled,

Turbocharged, Diesel Engine

Horse Power 32 HP @ 2800 RPM

Bore mm (in.) 78.0 (3.07)

Stroke mm (in.) 78.4 (3.09)

Total Displacement cc (cu. in.) 1123 (68.53)

Firing Order 1--2--3

Combustion Chamber Spherical Type

Fuel No. 2 Diesel Fuel (ASTM D975)

Fuel Capacity liters (gallons) 41.6 (11)

Fuel Injection Pump Bosch MD Type Mini Pump

Governor Centrifugal Mechanical

Low Idle (no load) 1400 + 50 RPM

High Idle (no load) 3050 + 50 RPM

Kubota

Diesel Engine

Direction of Rotation Counterclockwise (Viewed from Flywheel)

Compression Ratio 23:1

Injection Nozzles Mini Nozzle (DNOPD)

Engine Oil See Traction Unit Operator’s Manual

Oil Pump Trochoid Type

Crankcase Oil Capacity liters (U.S. qt.) 3.8 (4.0) with Filter

Starter 12 VDC, 1.4 KW

Alternator/Regulator 12 VDC, 40 AMP

Dry Weight kilograms (U.S. lbs) 98.0 (216.0)

Coolant Capacity liters (U.S. qt.) 5.7 (6.0) with 0.9 (1.0) Reservoir

Groundsmaster 3505--D Page 3 -- 3 Kubota Diesel Engine

Page 18

Service and Repairs

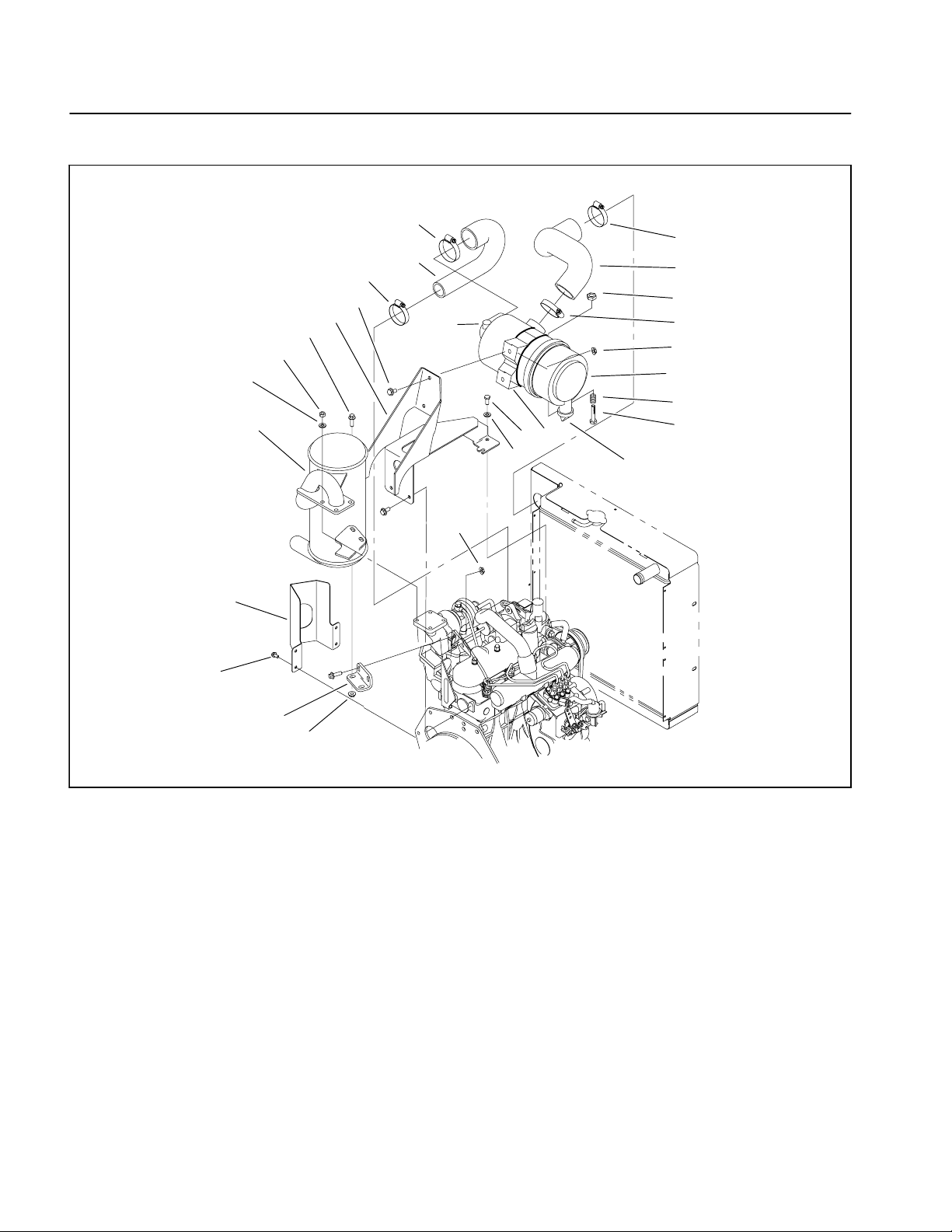

Muffler and Air Cleaner Assembly

18

16

17

12

14

11

10

2

8

4

7

19

1

20

18

3

9

21

18

13

6

5

23

22

3

1. Air inlet hose (upper)

2. Air inlet hose (lower)

3. Flange nut

4. Flange head screw

5. Flat washer

6. Cap screw

7. Air filter mount

8. Hose clamp

15

3

Figure 1

9. Air cleaner assembly

10. Flange head screw

11. Hex nut (4 used)

12. Lock washer (4 used)

13. Mounting band assembly

14. Muffler

15. Muffler bracket

16. Cap screw (4 used)

17. Exhaust guard (if used)

18. Hose clamp

19. Plug

20. Lock nut

21. Compression spring

22. Bolt

23. Vacuator valve

Groundsmaster 3505--DPage 3 -- 4Kubota Diesel Engine

Page 19

Muffler Removal (Fig. 1)

CAUTION

The muffler and exhaust pipe may be hot. To

avoid possible burns, allow the engine and exhaust system to cool before working on the muffler.

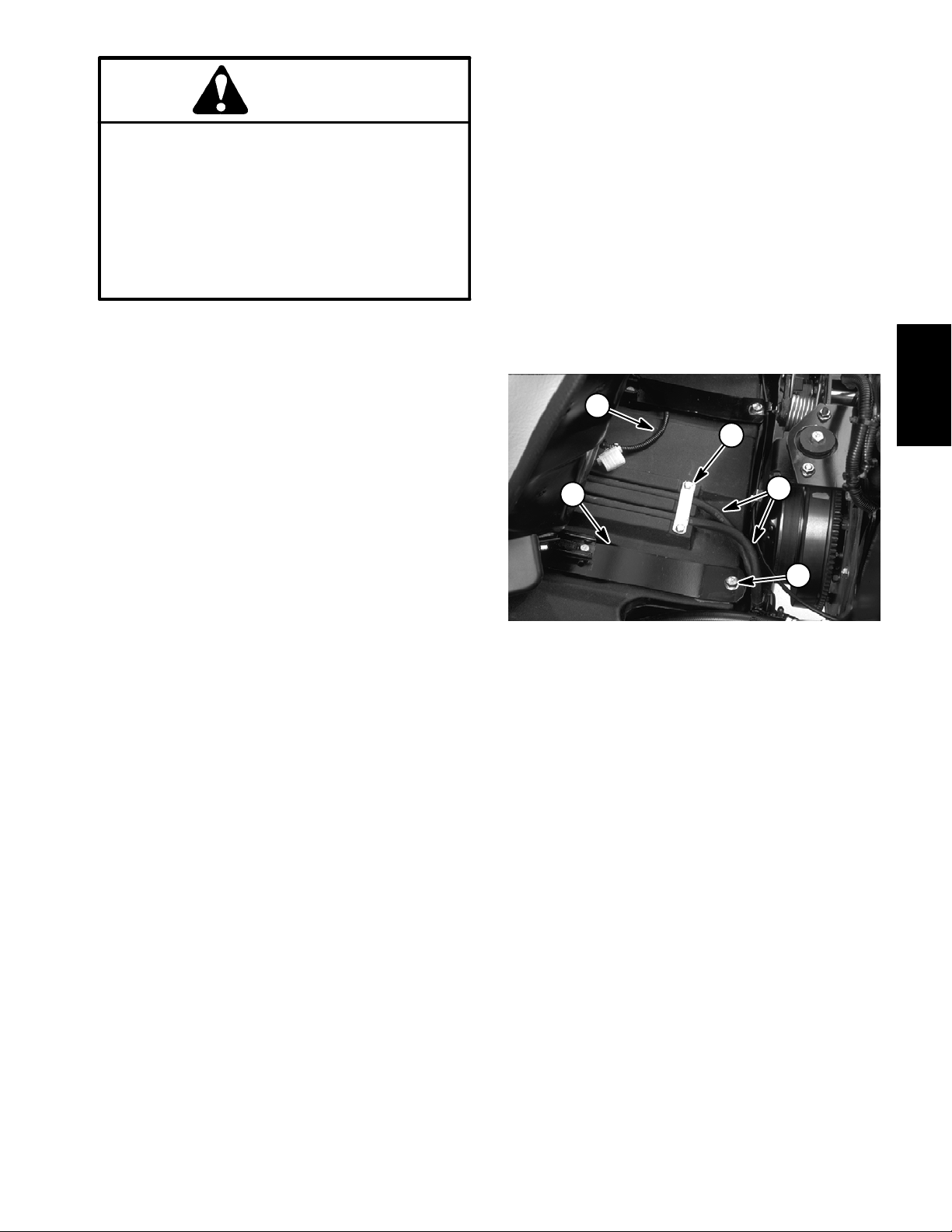

4

3

2

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Open hood to gain access to engine.

3. Remove exhaust guard (if equipped) from frame.

4. Remove both flange head nuts and screws securing

the muffler plate to the muffler bracket (Fig. 2).

5. Remove four hex nuts and lock washers from the exhaust manifold studs. Separate muffler flange from the

exhaust manifold. Remove muffler from the machine.

6. Remove exhaust gasket. Replace gasket if damaged or torn.

Muffler Installation (Fig. 1)

NOTE: Make sure muffler flange and exhaust manifold

sealing surfaces are free of debris or damage that may

prevent a tight seal.

1. Place exhaust gasket on the exhaust manifold.

1

1. Flange head nut

2. Flange head screw

Figure 2

3. Muffler plate

4. Muffler bracket

Kubota

Diesel Engine

IMPORTANT: Finger tighten all fasteners before securing the muffler plate to the muffler bracket so

there is no preload on the exhaust manifold.

2. Position muffler flange to the exhaust manifold with

four lock washers and hex nuts.

3. Position muffler plate to the muffler bracket with both

flange head screws and nuts (Fig. 2).

4. Tighten muffler flange hex nuts and then muffler

plate screws and nuts.

5. If equipped, install exhaust guard to frame.

6. Close and latch hood.

Groundsmaster 3505--D Page 3 -- 5 Kubota Diesel Engine

Page 20

Air Cleaner Assembly Removal (Fig. 1)

NOTE: See Traction Unit Operator’s Manual for air

cleaner maintenance procedures and intervals.

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch. Unlatch and raise hood.

2. Remove air cleaner components as needed using

Figure 1 as a guide.

3. Check air cleaner body for damage that could cause

possible air leaks. Make sure that dust cup seals completely to the air cleaner body.

Air Cleaner Assembly Installation (Fig. 1)

IMPORTANT: Any leaks in the air filter system will

allow dirt into engine and will cause serious engine

damage. Make sure that all air cleaner components

are in good condition and are properly secured during assembly.

1. Assemble air cleaner system using Figure 1 as a

guide. Make sure that vacuator valve is pointed down after assembly (Fig. 3).

1

3

1. Latch

2. Dust cup

2

Figure 3

3. Vacuator valve

2. Close and latch hood.

Groundsmaster 3505--DPage 3 -- 6Kubota Diesel Engine

Page 21

This page is intentionally blank.

Kubota

Diesel Engine

Groundsmaster 3505--D Page 3 -- 7 Kubota Diesel Engine

Page 22

Fuel System

22

10

28

29

42

7

8

31

20

30

22

9

1

3

32

15

27

22

5

33

2

41

37

38

22

40

26

25

21

18

14

16

22

24

22

17

44

12

19

13

36

22

23

11

43

22

34

39

35

22

6

4

1. Cap screw (2 used)

2. Fuel tank

3. Fuel hose strap

4. Cap screw

5. Fuel cap

6. Tank support

7. Fuel gauge

8. Grommet

9. Connector fitting

10. Stand pipe

11. R--clamp

12. Barb fitting

13. Cap screw (2 used)

14. Flange hex nut (2 used)

15. Heat shield

Figure 4

16. Flat washer (2 used)

17. Tee fitting

18. Barb fitting

19. Barb fitting

20. Bushing

21. Spacer (2 used)

22. Hose clamp

23. Fuel prefilter

24. Fuel/water separator

25. Fuel fitting

26. Flange head screw (2 used)

27. Flange nut (2 used)

28. Seat support strap (2 used)

29. Foam (2 used)

30. Hex flange head screw (2 used)

31. Flat washer (2 used)

32. Fuel hose

33. Fuel hose

34. Fuel hose

35. Fuel hose

36. Fuel hose

37. Fuel hose

38. Fuel hose

39. R--clamp

40. Fuel pump

41. Spacer (2 used)

42. Cap screw (2 used)

43. Crossover fuel hose

44. Hose clamp

Groundsmaster 3505--DPage 3 -- 8Kubota Diesel Engine

Page 23

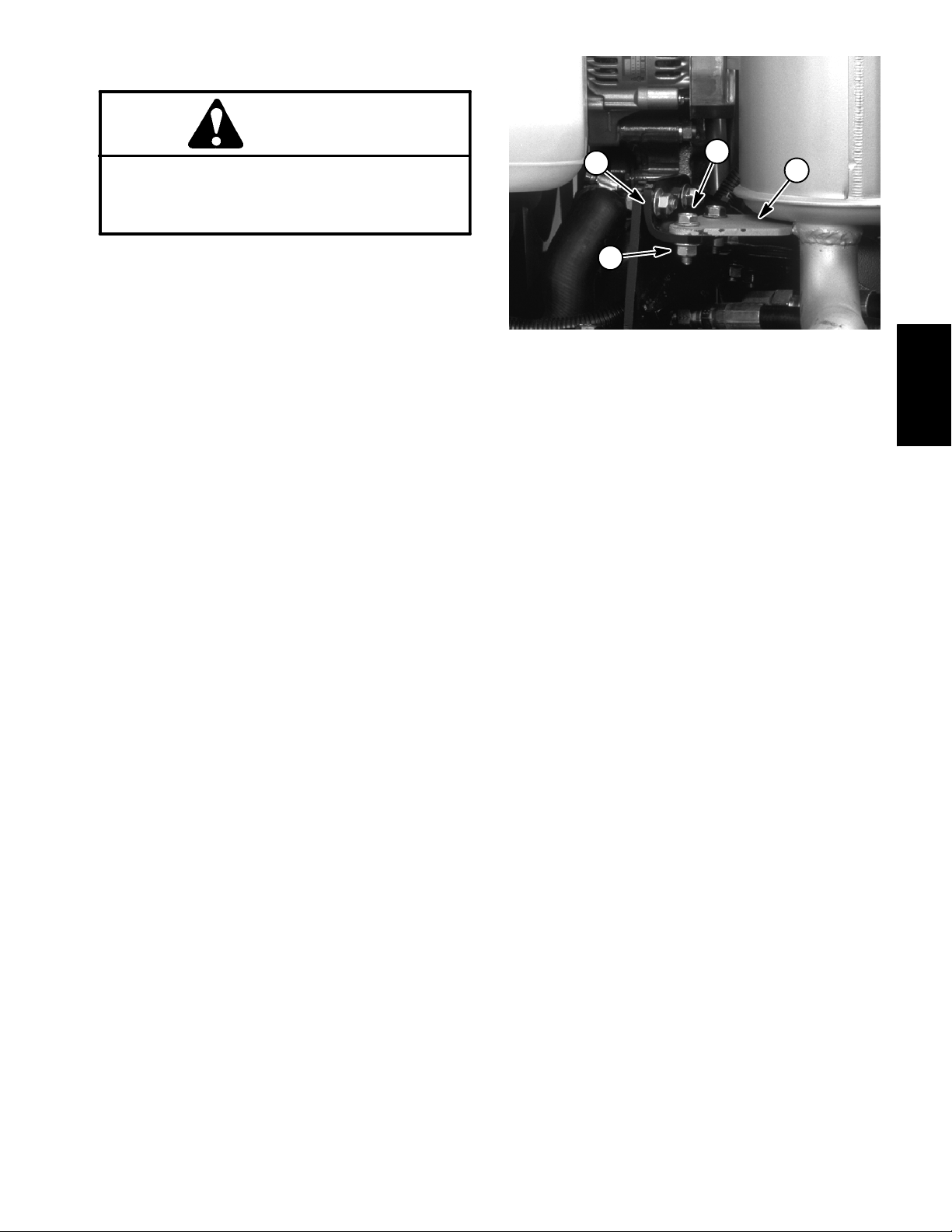

Fuel Tank Installation (Fig. 4)

DANGER

Because diesel fuel is highly flammable, use caution when storing or handling it. Do not smoke

while filling the fuel tank. Do not fill fuel tank

while engine is running or hot or when machine

is in an enclosed area. Always fill fuel tank outside and clean up any spilled diesel fuel before

starting the engine. Store fuel in a clean, safety-approved container and keep cap in place. Use

diesel fuel for the engine only; not for any other

purpose.

Check Fuel Lines and Connections

Check fuel lines and connections every 400 hours or

yearly, whichever comes first.

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch. Unlatch and raise hood.

2. Check fuel lines for deterioration, damage, leaks or

loose connections. Replace hoses, clamps and connections as necessary.

1. Position fuel tank to the machine.

2. Connect both fuel hoses to the tank and secure with

hose clamps and fuel hose strap.

3. Connect seat switch to the electrical harness. Route

seat switch wire under seat support strap. Secure seat

support straps and seat to the frame (see Operator Seat

Installation in Chapter 6 -- Chassis).

4. Check for correct seat operation and also that seat

switch wires and connector are not pinched and do not

contact any moving parts.

5. Fill fuel tank (see Traction Unit Operator’s Manual).

3

4

1

5

Kubota

Diesel Engine

Fuel Tank Removal (Fig. 4)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch. Unlatch and raise hood.

2. Remove fuel from the tank into a suitable container.

Crossover fuel hose (item 44) removal may assist to

drain tank completely.

3. Remove seat and seat support straps from the frame

(see Operator Seat Removal in Chapter 6 -- Chassis).

Note location of spacers under front of seat support

straps. Disconnect seat switch from the electrical harness (Fig. 5).

4. Remove fuel hose strap and both fuel hoses from the

fuel tank. Pull tank from the machine (Fig. 5).

Drain and Clean Fuel Tank

Drain and clean the fuel tank every 2 years. Also, drain

and clean the fuel tank if the fuel system becomes contaminated or if the machine is to be stored for an extended period.

1. Seat support strap

2. Hex flange head screw

3. Electrical harness

2

Figure 5

4. Fuel hose strap

5. Fuel hose

1. Remove fuel tank from the machine (see Fuel Tank

Removal).

2. Flush fuel tank out with clean diesel fuel. Make sure

that tank is free of all contaminates and debris.

3. Install fuel tank to the machine (see Fuel Tank Installation).

Groundsmaster 3505--D Page 3 -- 9 Kubota Diesel Engine

Page 24

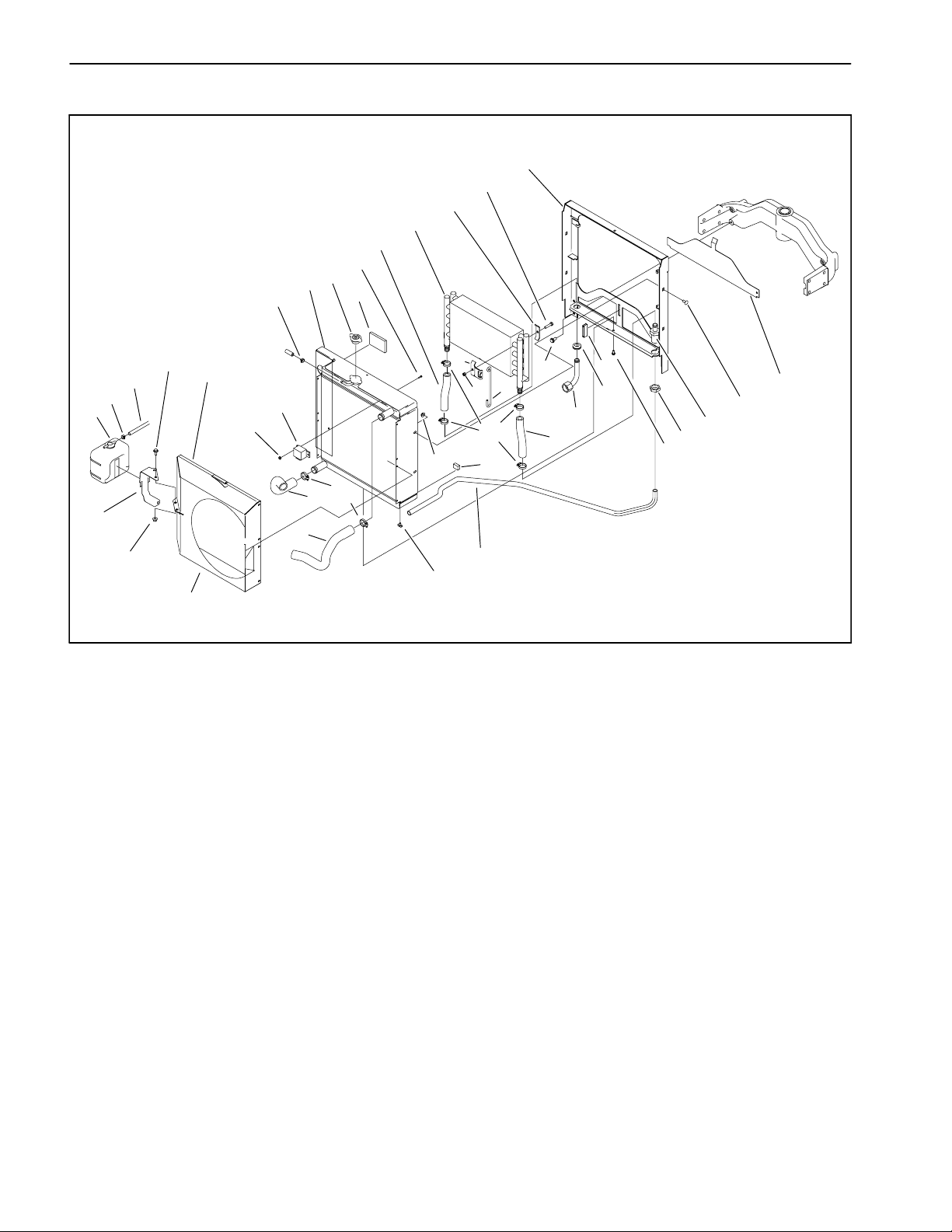

Radiator

10

18

17

22

28

34

11

5

9

30

13

31

9

32

14

38

1. Draincock valve

2. Flange head screw (11 used)

3. Flange nut (4 used)

4. Carriage bolt (4 used)

5. Radiator

6. Upper fan shroud

7. Lower fan shroud

8. Flange head screw (4 used)

9. Hose clamp

10. Radiator frame

11. Radiator cap

12. Radiator foam seal

13. Flange head screw (2 used)

6

35

7

33

23

24

16

3

25

1

Figure 6

14. Reservoir bracket

15. Wire form latch (2 used)

16. Oil cooler bracket (2 used)

17. Bracket clamp (2 used)

18. Screw (2 used)

19. Lock nut (2 used)

20. Radiator shield (lower)

21. Magnetic catch

22. Oil cooler

23. Radiator hose (upper)

24. Radiator hose (lower)

25. Hose clamp

26. Hydraulic tube

19

37

25

12

15

26

21

29

36

2

27. Hydraulic tube

28. Oil cooler hose

29. Grommet

30. Foam seal

31. Expansion tank hose

32. Expansion tank

33. Glow plug relay

34. Thread forming screw

35. Flange lock nut

36. Bulkhead nut

37. Tube assembly

38. Flange nut (2 used)

20

4

27

8

28

Groundsmaster 3505--DPage 3 -- 10Kubota Diesel Engine

Page 25

Removal (Fig. 6)

Installation (Fig. 6)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Open and remove hood from the machine (see Traction Unit Operator’s Manual).

CAUTION

Do not open radiator cap or drain coolant if the

radiator or engine is hot. Pressurized, hot coolant can escape and cause burns. Ethylene--glycol antifreeze is poisonous. Dispose of coolant

properly or store it in a properly labeled container away from children and pets.

3. Place a suitable container under the radiator to collect the coolant. Open draincock valve and completely

drain the radiator.

4. Remove glow plug relay from the radiator assembly.

Position relay away from the radiator.

5. Disconnect following hoses from the radiator:

1. Remove any plugs placed in radiator and coolant

hose openings during the removal procedure.

2. Carefully position radiator to the radiator frame.

3. Secure radiator to the radiator frame with four (4)

carriage bolts and flange nuts. Secure top and bottom

of radiator to frame with flange head screws.

4. Secure lower and upper fan shrouds to the radiator

assembly with flange head screws.

5. Secure expansion tank bracket and tank to the top

fan shroud with flange head screws and flange nuts.

6. Connect following hoses to the radiator:

A. Upper radiator hose to the water pump.

B. Lower radiator hose to the engine block.

C. Coolant hose to the expansion tank.

D. Air hose to the air cleaner.

7. Secure glow plug relay to the radiator assembly.

Kubota

Diesel Engine

A. Upper radiator hose to the water pump.

B. Lower radiator hose to the engine block.

C. Coolant hose to the expansion tank.

D. Air hose to the air cleaner.

6. Remove expansion tank and bracket from the top fan

shroud.

7. Remove upper and lower fan shrouds from radiator

assembly.

8. Remove flange head screws securing the top and

bottom of the radiator frame to the radiator.Remove four

(4) carriage bolts and flange nuts securing the radiator

to the radiator frame.

9. Carefully pull radiator from the radiator frame.

10.Plug radiator and hose openings to prevent contamination.

8. Make sure radiator draincock valve is closed. Fill radiator with coolant (see Traction Unit Operator’s Manual).

9. Install hood to the machine (see Traction Unit Operator’s Manual). Close and latch hood.

Groundsmaster 3505--D Page 3 -- 11 Kubota Diesel Engine

Page 26

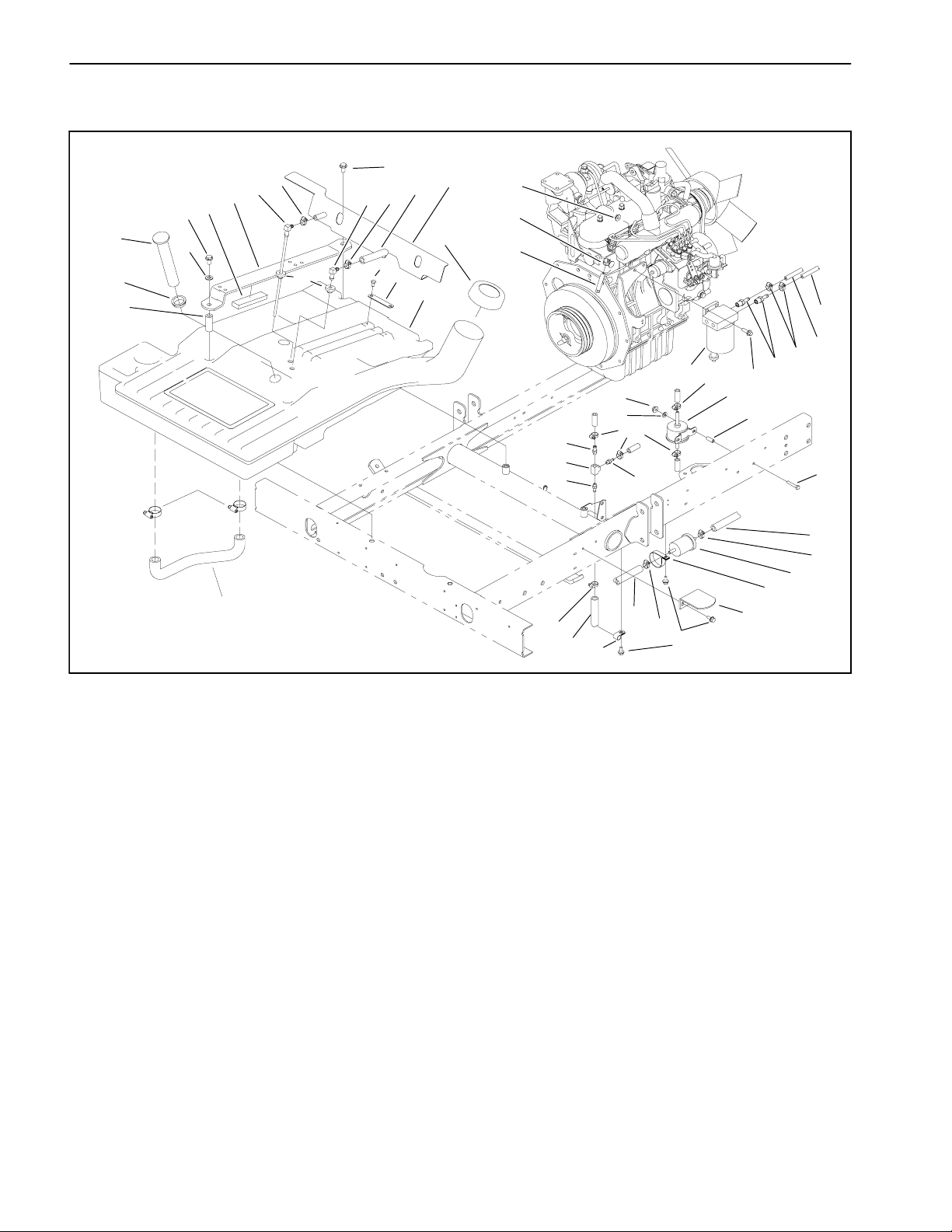

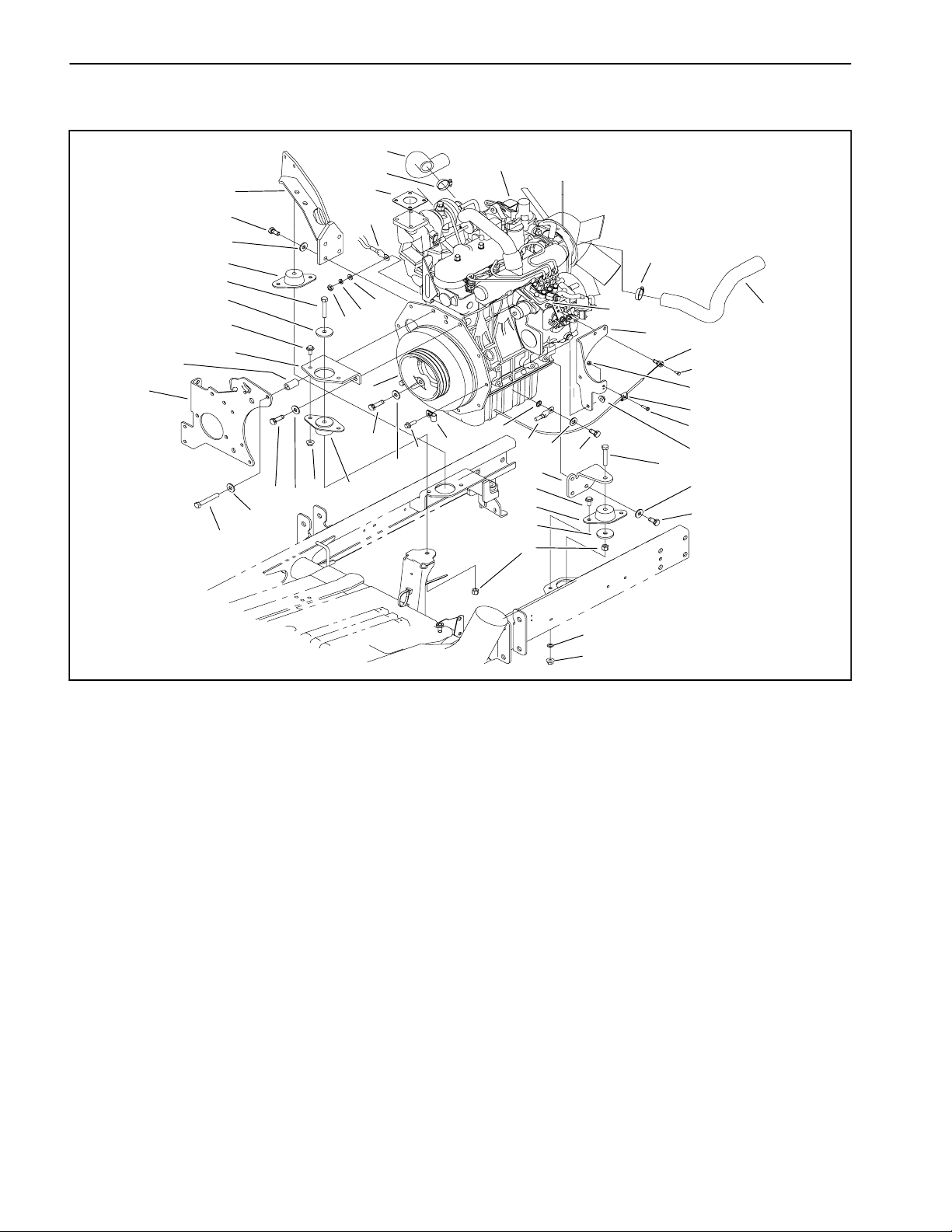

Engine

40

41

12

13

15

11

2

5

9

10

27

1

37

21

36

37

32

6

35

34

23

42

38

22

24

17

28

25

26

19

5

11

16

11

12

11

18

20

3

4

31

33

39

14

6

30

16

2

9

29

8

1. Kubota engine

2. Engine mount (2 used)

3. Engine mount

4. Flange nut (6 used)

5. Cap screw (3 used)

6. Flange head screw (6 used)

7. External lock washer

8. Lock nut (3 used)

9. Hardened washer (3 used)

10. Machine screw

11. Hardened washer (11 used)

12. Cap screw (5 used)

13. Engine mounting bracket (front)

14. Engine mounting bracket (LH)

15. Engine mounting bracket (RH)

16. Cap screw (4 used)

17. Pulley

18. Bolt (3 used)

19. Flange nut (2 used)

20. Flat washer (3 used)

21. Exhaust gasket

22. Throttle swivel

23. Lock nut

24. Slotted hex head screw

25. Throttle cable clamp

26. Cap screw

27. Radiator hose (lower)

28. Lock nut

Removal (Fig. 7)

1. Park machine on a level surface, lower cutting units,

stop engine, engage parking brake and remove key

from the ignition switch.

2. Open and remove hood from the machine (see Traction Unit Operator’s Manual). Slide operator seat all the

way forward.

3. Disconnect air hose from the air cleaner and radiator.

Remove air cleaner from the engine (see Air Cleaner

Assembly Removal in this section).

7

4

Figure 7

29. Lock washer

30. Flat washer

31. Flange head screw (2 used)

32. Flat washer

33. R--clamp

34. Lock washer

35. Hex nut

36. Wire harness

37. Hose clamp

38. Radiator hose (upper)

39. Wire harness ground

40. Pump mount plate

41. Spacer

42. Throttle support bracket

4. Disconnect both battery cables at the battery (see

Battery Service in Chapter 5 -- Electrical System).

5. Remove muffler from the exhaust manifold and muffler bracket (see Muffler Removal in this section).

6. Drain coolant from the radiator into a suitable container (see Radiator Removal in this section). Disconnect r adiator hoses from the water pump and engine

block.

Groundsmaster 3505--DPage 3 -- 12Kubota Diesel Engine

Page 27

7. Remove coolant expansion tank and bracket from

the upper fan shroud. Remove upper fan shroud from

the radiator (see Radiator Removal in this section).

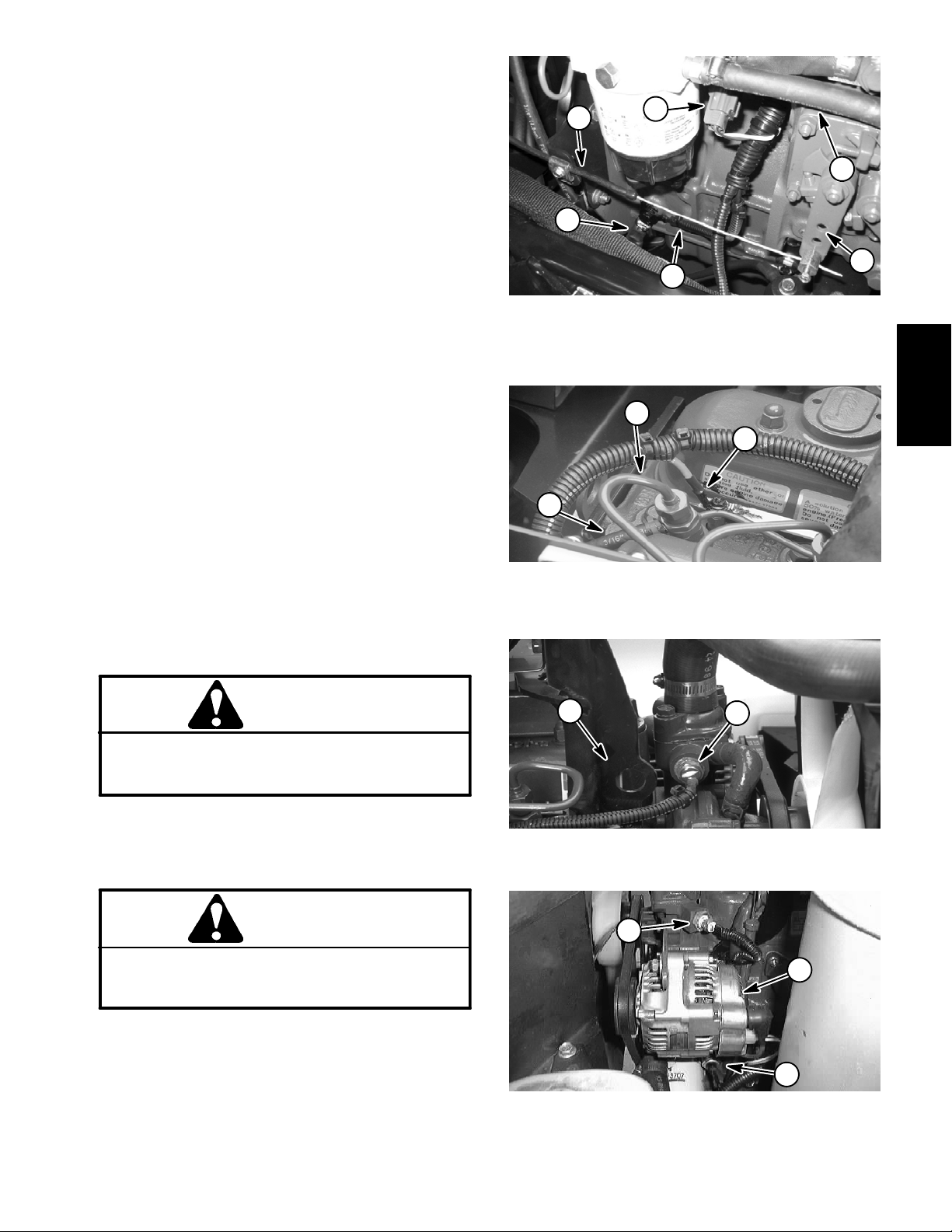

8. Disconnect electrical wires from engine:

4

3

A. Negative battery cable, wire harness ground and

fuel stop solenoid (Fig. 8).

B. Glow plug bus (Fig. 9).

C. High temperature w arning switch (Fig. 10).

D. High temperature shutdown switch, alternator

and oil pressure switch (Fig. 11).

9. Disconnect throttle cable from the throttle support

bracket and swivel on the speed control lever (Fig. 8).

10.Disconnect fuel hoses from the fuel/water separator

(Fig. 8). Position disconnected hose from fuel pump to

prevent fuel leakage.

11. Remove traction control cable from the neutral arm

assembly on the piston pump. Remove all hydraulic

hoses from the piston and gear pumps (see Piston

Pump Removal in the Service and Repairs section of

Chapter 4-- Hydraulic System).

12.Note location of cable ties securing the wire harness

to engine. Remove cable ties.

13.Attach a suitable lift or hoist to lift tabs on front (Fig.

10) and rear (on air filter mount) of engine.

1

1. Negative battery cable

2. Wire harness ground

3. Fuel stop solenoid

2

3

1. Glow plug wire

2. Rear injector nozzle

6

5

2

Figure 8

4. Throttle cable

5. Speed control lever

6. Fuel hose

Kubota

Diesel Engine

1

Figure 9

3. Fuel hose

CAUTION

Make sure lift or hoist can support the total

weight of the engine before removing the cap

screws from the engine and engine brackets.

14.Remove flange nuts (item 4), flange head screws

(item 6) and lock washer (item 7) s ecuring three engine

mounts to the engine mounting brackets.

CAUTION

One person should operate lift or hoist while a

second person guides the engine out of the machine.

IMPORTANT: Make sure not to damage the engine,

fuel hoses, hydraulic lines, electrical harness or

other parts while removing the engine.

15.Slowly remove engine from the machine.

2

1

Figure 10

1. Temp. warning switch 2. Front lift tab

1

3

Figure 11

1. Temp. shutdown switch

2. Alternator

3. Oil pressure switch

2

Groundsmaster 3505--D Page 3 -- 13 Kubota Diesel Engine

Page 28

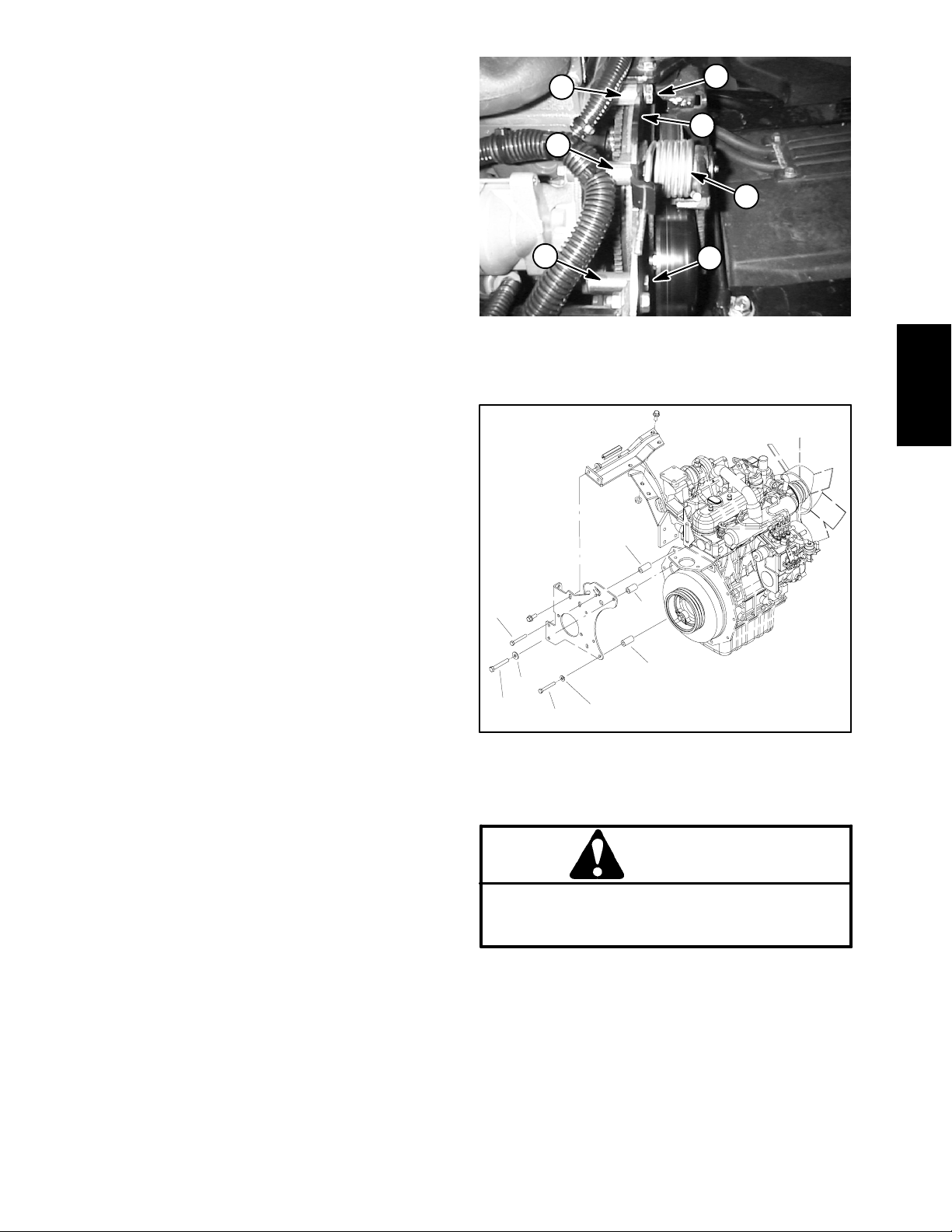

16.Separate hydrostat and pump mount plate from the

engine as follows:

2

1

A. Remove traction belt from the engine flywheel

and hydrostat pulleys (see Traction Unit Operator’s

Manual).

B. Support hydraulic pump assembly to prevent it

from falling during removal.

C. Remove five (5) cap screws, four (4) washers and

five (5) spacers securing the pump mount plate to the

engine (Fig. 12 and 13). Note location of spacers,

washers and cap screws during removal.

D. Remove four (4) cap screws (item 12) and hardened washers (item 11) securing the right engine

mounting bracket to the engine.

E. Remove hydrostat, pump mount plate and

mounting brackets from engine.

17.As necessary, remove engine mounts (item 3), front

engine mounting bracket (item 13), throttle support

bracket (item 42) and left engine mounting bracket (item

14).

Installation (Fig. 7)

6

6

1. Cap screw (10 mm)

2. Short spacer

3. Torsion spring

4

3

5

Figure 12

4. Pump mount plate

5. Cap screw (8 mm)

6. Long spacer (4 used)

Kubota

Diesel Engine

1

1. If removed, install engine mounts ( item 3), front engine mounting bracket (item 13), throttle support bracket

(item 42) and left engine mounting bracket (item 14).

Also, make sure that all switches and sensors are

installed on engine.

2. Install h ydrostat, pump mount plate and mounting

brackets to the engine as follows:

A. Position hydrostat, pump mount plate and mounting brackets to engine.

B. Secure right engine mounting bracket (with hydrostat attached) to the engine with four (4) hardened washers and cap screws.

NOTE: To prevent the torsion spring from binding,

do not install flat washer on cap screw near the

spring.

C. Using locations noted during engine removal, secure pump mount plate to the engine with five (5)

spacers, four (4) washers and five (5) cap screws

(Fig. 12 and 13).

D. Install traction belt to the engine flywheel and hydrostat pulleys (see Traction Unit Operator’s Manual).

3. Connect hoist or lift to the front and rear engine lift

tabs (Fig. 9 and 10).

3

4

5

3

6

1

2

Figure 13

1. Long spacer (4 used)

2. Flat washer (3 used)

3. 8 mm cap screw (4 used)

4. Hardened washer

5. 10 mm cap screw

6. Short spacer

CAUTION

One person should operate lift or hoist while a

second person guides the engine into the machine.

IMPORTANT: Make sure not to damage the engine,

fuel or hydraulic lines, electrical harness or other

parts while installing the engine.

4. Carefully lower engine into the machine.

5. Secure three (3) engine mounts to the engine mounting brackets with cap screws, washers and flange nuts.

Groundsmaster 3505--DPage 3 -- 14Kubota Diesel Engine

Page 29

6. Secure wire harness to the front lift tab and the engine with cable ties.

7. Install all hydraulic hoses to the piston and gear

pumps. Install traction control cable to the neutral arm

assembly on the piston pump (see Piston Pump Installation in Chapter 4-- Hydraulic System).

8. Connect fuel hose to the fuel/water separator (Fig. 8)

and front injector nozzle.

9. Install top fan shroud to the radiator. Install expansion tank and bracket to the top fan shroud (see Radiator

Installation in this section).

10.Connect electrical wires to engine:

12.Connect coolant hoses to the water pump and engine block. Close radiator drain cock valve. Fill radiator

with coolant (see Traction Unit Operator’s Manual).

13.Install muffler to the exhaust manifold and muffler

bracket (see Muffler Installation in this section).

14.Connect throttle cable to the support bracket and

swivel on the speed control lever (Fig. 8).

15.Connect both battery cables to the battery (see Battery Service in Chapter 5 -- Electrical system).

16.Install air cleaner to the engine (see Air Cleaner Assembly Installation in this section). Connect air hose to

air cleaner and radiator.

A. Negative battery cable and wire harness ground

(Fig. 8).

B. Glow plug bus (Fig. 9) and fuel stop solenoid.

C. High temperature w arning switch (Fig. 10).

D. High temperature shutdown switch, alternator

and oil pressure switch (Fig. 11).

11. Secure wire harness to engine with cable ties at locations noted during engine removal.

17.Adjust throttle cable (see Adjust Throttle Cable).

18.Bleed fuel system (see Traction Unit Operator’s

Manual).

19.Install hood to the machine (see TractionUnit Operator’s Manual). Close and latch hood.

20.Check hydraulic oil level (see Traction Unit Operator’s Manual). Adjust as needed.

21.Check traction drive for neutral (see Traction Unit

Operator’s Manual). Adjust as needed.

Groundsmaster 3505--D Page 3 -- 15 Kubota Diesel Engine

Page 30

This page is intentionally blank.

Groundsmaster 3505--DPage 3 -- 16Kubota Diesel Engine

Page 31

Table of Contents

Chapter 4

Hydraulic System

SPECIFICATIONS 2.............................

GENERAL INFORMATION 3.....................

Hydraulic Hoses 3.............................

Hydraulic Fitting Installation 3...................

Towing Traction Unit 5..........................

Relieving Hydraulic System Pressure 5...........

Traction Circuit (Closed Loop) Component Failure 6

HYDRAULIC SCHEMATIC 7.....................

HYDRAULIC FLOW DIAGRAMS 8................

Traction Circuits 8.............................

Cutting Unit Circuit 10..........................

Lift Circuit (Raise) 12...........................

Lift Circuit (Lower) 14..........................

Steering Circuit 16.............................

SPECIAL TOOLS 18............................

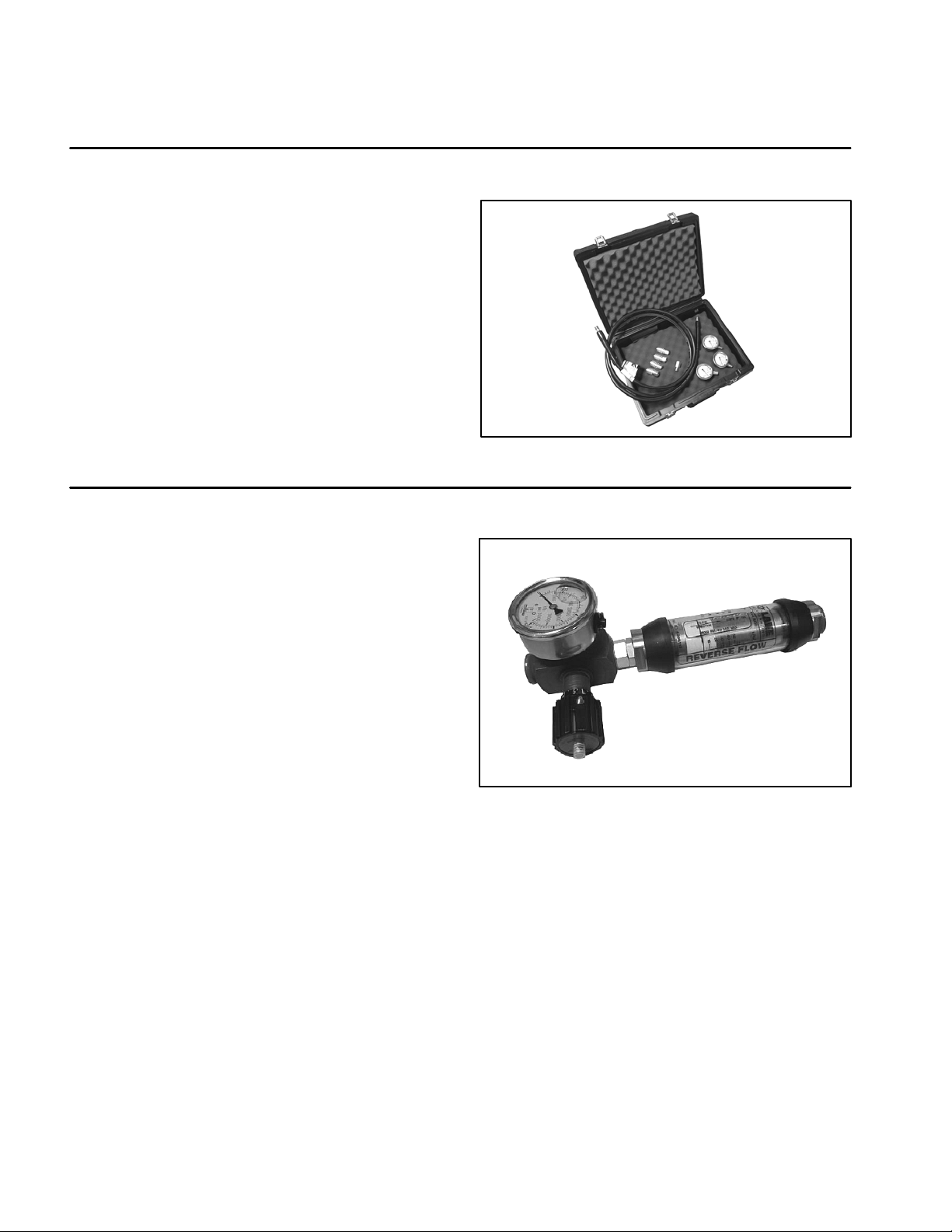

Hydraulic Pressure Test Kit 18...................

Hydraulic Tester (Pressure and Flow) 18..........

Hydraulic Test Fitting Kit 19.....................

Measuring Container 19........................

O--Ring Kit 20.................................

Wheel Hub Puller 20...........................

High Pressure Hydraulic Oil Filter 20.............

TROUBLESHOOTING 22........................

TESTING 25...................................

Traction Circuit Working Pressure Test 26.........

Charge Relief Valve Pressure Test 28............

Piston Pump (P3) Flow & Traction Relief

Pressure Test 30.............................

Wheel Motor Efficiency Test 32..................

Cutting Deck Circuit Pressure Test 34............

Manifold Relief Valve (R1) Pressure Test 36.......

Logic (Counterbalance) Valve (LC1)

Pressure Test 38.............................

Gear Pump (P1) Flow Test 40...................

Deck Motor Efficiency -- Case Drain Test 42.......

Steering and Lift Relief Pressure Test 44..........

Gear Pump (P2) Flow Test 46...................

Steering C ontrol Valve Test 48...................

ADJUSTMENTS 50.............................

Braking Valve Adjustment 50....................

SERVICE AND REPAIRS 51.....................

General Precautions for Removing and

Installing Hydraulic System Components 51.....

Check Hydraulic Lines and Hoses 51.............

Flush Hydraulic System 52......................

Charge Hydraulic System 53....................

Hydraulic Tank 54..............................

Oil C ooler 56..................................

Wheel Motors 58..............................

Wheel Motor Service 60........................

Cutting Deck Motors 62.........................

Cutting Deck Motor Service 64..................

Hydraulic Manifold 68

Hydraulic Manifold Service 70...................

Lift Control Valve 72............................

Lift Control Valve Service 74....................

Neutral Arm Assembly 78.......................

Piston Pump 80...............................

Piston Pump Service 84........................

Gear Pump 86................................

Gear Pump Service (Serial Number Below

260000400) 88...............................

Gear Pump Service (Serial Number Above

260000400) 91.1.............................

Steering Control Valve 92.......................

Steering Control Valve Service 94................

Front Lift Cylinder 96...........................

Rear Lift Cylinder 98...........................

Lift Cylinder Service 100........................

Steering Cylinder 102..........................

Steering Cylinder Service 104...................

ROSS TORQMOTOR

RIES SERVICE PROCEDURE

EATON MEDIUM DUTY PISTON PUMP REPAIR IN-

FORMATION MODEL 70160 VARIABLE DISPLACEMENT PISTON PUMP

SAUER/DANFOSS STEERING UNIT TYPE OSPM

SERVICE MANUAL

..........................

TM

MG, MF, ME AND MJ SE-

System

Hydraulic

Groundsmaster 3505--D Hydraulic SystemPage 4 -- 1

Rev. B

Page 32

Specifications

Item Description

Piston Pump (Hydrostat) (P3) Variable displacement piston pump

Charge Pressure 100 to 150 PSI (6.9 to 10.3 bar)

Traction Circuit Relief Pressure (Forward Only) 3000 PSI (207 bar)

Gear Pump (P1 and P2) Dual section, positive displacement, gear pump

Section P1 Displacement .946 in

Section P2 Displacement .31 in

Counterbalance Pressure (LC1) 250 PSI (17.2 bar)

Hydraulic Manifold Relief Pressure (R1) 3200 PSI (221 bar)

Cutting Unit Motor Gear motor

Cross--over Relief Pressure 1813 PSI (125 bar)

Wheel Motors Orbital rotor motor

Steering Control Valve Sauer Danfoss S teering Unit, Type OSPM

Implement (Steering and Lift) Relief Valve Pressure 1000 PSI (69 bar)

Hydraulic Reservoir Capacity 6 Gal. U.S. (22.7 L)

Hydraulic Filter 10 Micron (nominal), spin--on cartridge type

Hydraulic Oil See Traction Unit Operator’s Manual

3

/rev. (15.5 cm3/rev.)

3

/rev. (5 cm3/rev.)

Groundsmaster 3505--DHydraulic System Page 4 -- 2

Page 33

General Information

Hydraulic Hoses

Hydraulic hoses are s ubject to extreme conditions such

as pressure differentials during operation and exposure

to weather, sun, chemicals, very warm storage conditions or mishandling during operation or maintenance.

These conditions can cause damage or premature deterioration. Some hoses are more susceptible to these

conditions than others. Inspect the hoses frequently for

signs of deterioration or damage.

When replacing a hydraulic hose, be sure that the hose

is straight (not twisted) before tightening the fittings.

This can be done by observing the imprint on the hose.

Use two wrenches; hold the hose in position with one

wrench and tighten the hose swivel nut onto the fitting

with the second wrench.

WARNING

Before disconnecting or performing any work

on hydraulic system, relieve all pressure in

system (see Relieving Hydraulic System Pressure). Stop engine; lower or support cutting

units and/or other attachment(s).

Keep body and hands away from pin hole leaks

or nozzles that eject hydraulic fluid under high

pressure. Use paper or cardboard, not hands,

to search for leaks. Hydraulic fluid escaping

under pressure can have sufficient force to

penetrate the skin and cause serious injury. If

fluid is injected into the skin, it must be surgically removed within a few hours by a doctor

familiar with this type of injury. Gangrene may

result from such an injury.

System

Hydraulic

Hydraulic Fitting Installation

O--Ring Face Seal

1. Make sure both threads and sealing surfaces are

free of burrs, nicks, scratches or any foreign material.

2. Make sure the o--ring is installed and properly seated

in the groove. It is recommended that the o--ring be replaced any time the connection is opened.

3. Lubricate the o--r ing with a light coating of oil.

4. Put the tube and nut squarely into position on the

face seal end of the fitting and tighten the nut until finger

tight.

5. Mark the nut and fitting body. Hold the body with a

wrench. Use a second wrench to tighten the nut to the

correct Flats From Finger Tight (F.F.F.T.). The markings

on the nut and fitting body will verify that the connection

has been tightened.

Siz e F. F. F.T.

4 (1/4 in. nominal hose or tubing) 0.75 +

6(3/8in.) 0.75+

8(1/2in.) 0.75+

10 (5/8 in.) 1.00 +

12 (3/4 in.) 0.75 +

16 (1 in.) 0.75 +

0.25

0.25

0.25

0.25

0.25

0.25

Nut

Sleeve

Seal

Body

Figure 1

Final

Position

Mark Nut

and Body

Extend Line

Initial

Position

Finger Tight After Proper Tightening

Figure 2

Groundsmaster 3505--D Hydraulic SystemPage 4 -- 3

Page 34

SAE Straight Thread O--Ring Port -- Non--adjustable

1. Make sure both threads and sealing surfaces are

free of burrs, nicks, scratches or any foreign material.

2. Always replace the o--ring seal when this type of fitting shows signs of leakage.

3. Lubricate the o--r ing with a light coating of oil.

O--Ring

4. Install the fitting into the port and tighten it down full

length until finger tight.

5. Tighten the fitting to the correct flats from finger tight

(F.F.F.T.).

Siz e F. F. F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

0.25

0.25

0.25

0.25

0.25

0.25

SAE Straight Thread O-- Ring Port -- Adjustable

1. Make sure both threads and sealing surfaces are

free of burrs, nicks, scratches or any foreign material.

2. Always replace the o--ring seal when this type of fitting shows signs of leakage.

3. Lubricate the o--r ing with a light coating of oil.

4. Turn back the jam nut as far as possible. Make sure

the back up washer is not loose and is pushed up as far

as possible (Step 1).

Figure 3

Lock Nut

Back--up Washer

O--Ring

5. Install the fitting into the port and tighten finger tight

until the washer contacts the face of the port (Step 2).

6. To put the fitting in the desired position, unscrew it by

the required amount, but no more than one full turn

(Step 3 ).

7. Hold the fitting in the desired position with a wrench

and turn the jam nut with a second wrench to the correct

Flats From Finger Tight (F.F.F.T.) (Step 4).

Siz e F. F. F.T.

4 (1/4 in. nominal hose or tubing) 1.00 +

6(3/8in.) 1.50+

8(1/2in.) 1.50+

10 (5/8 in.) 1.50 +

12 (3/4 in.) 1.50 +

16 (1 in.) 1.50 +

0.25

0.25

0.25

0.25

0.25

0.25

Figure 4

Step 3Step 1

Step 2 Step 4

Figure 5

Groundsmaster 3505--DHydraulic System Page 4 -- 4

Page 35

Towing Traction Unit

In case of emergency, the Groundsmaster 3505--D can

be towed (or pushed) for a very short distance. However, Toro does not recommend this as a standard procedure.

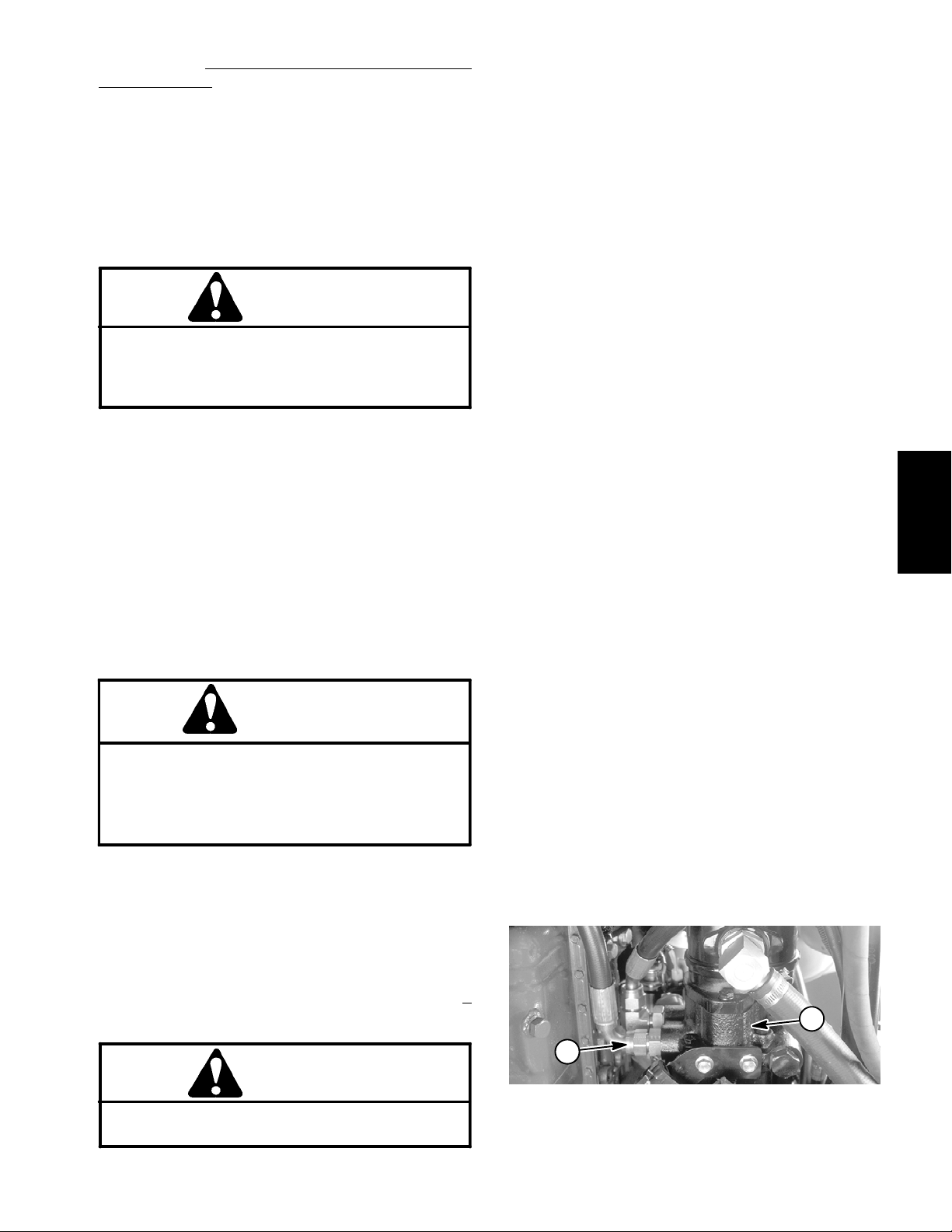

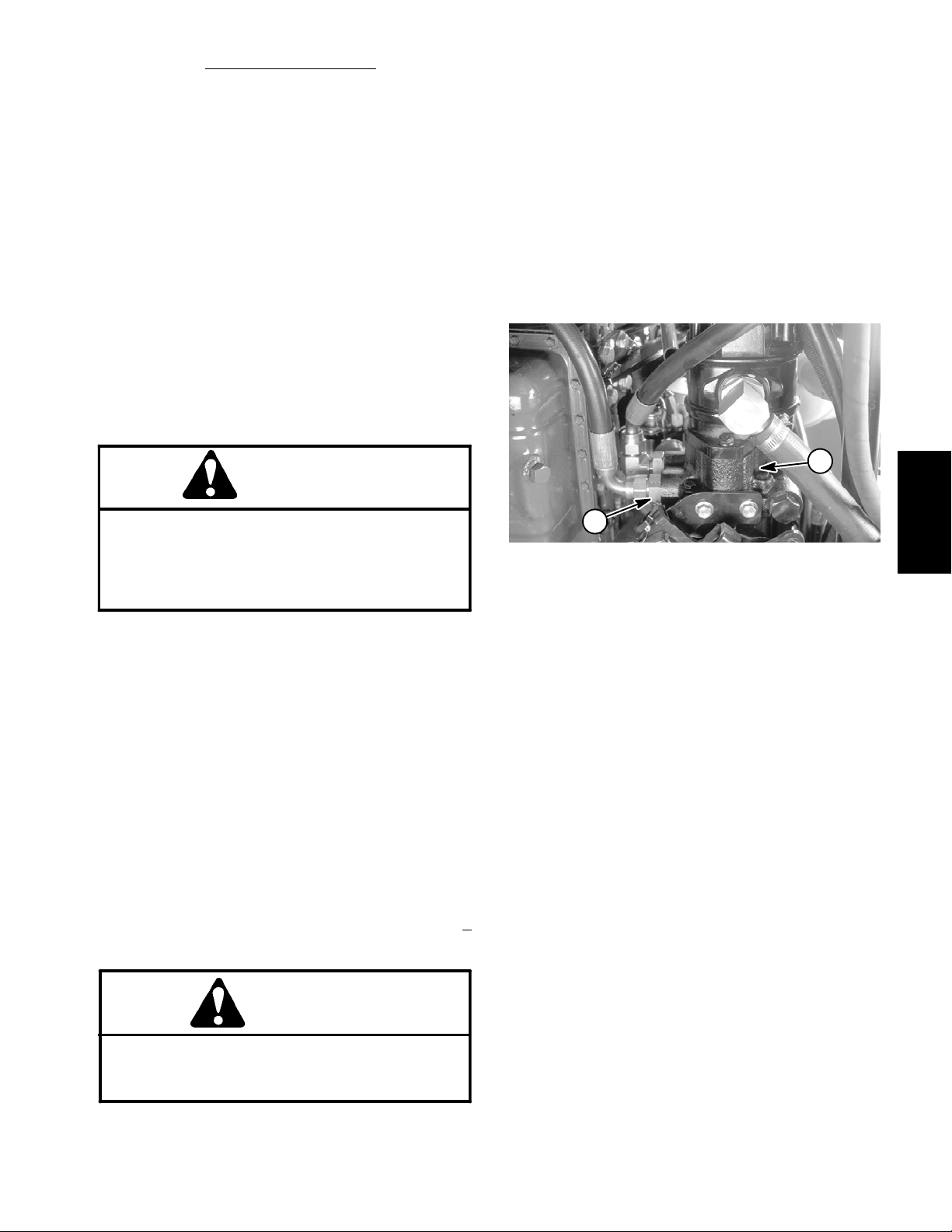

1. Locate by--pass valve on hydrostat pump (Fig. 6)

and rotate it 90

o

to open the by--pass valve. This open

position should be horizontal (Fig. 7).

IMPORTANT: Do not tow (or push) the machine fast er than 2 to 3 mph because the drive system may be

damaged. If machine must be moved a considerable

distance (more than a few feet), transport it on a

truck or trailer.

2. Slowly tow (or push) machine.

3. Before starting engine, close by--pass valve by rotating it 90

o

. This closed position should be vertical (Fig. 7).

Do not start engine when by--pass valve is open.

2

Figure 6

1. Hydrostat pump 2. By--pass valve

1

2

Figure 7

1. Valve closed position 2 . Valve open position

1

System

Hydraulic

Relieving Hydraulic System Pressure

Before disconnecting or performing any work on the

Groundsmaster 3505--D hydraulic system, all pressure

in the hydraulic system must be relieved. Park machine

on a level surface with the cutting units lowered and off.

Turn key switch to OFF and allow engine to stop.

To relieve hydraulic pressure in traction circuit, move

traction lever to both forward and reverse directions. To

relieve hydraulic pressure in steering and lift circuits, rotate steering wheel in both directions.

To relieve cutting unit system pressure, turn key switch

to ON (engine not running). Move PTO switch to engage

which will energize the solenoid valve on hydraulic manifold to relieve circuit pressure. Move PTO switch to disengage, return key switch to OFF and remove key from

the ignition switch.

NOTE: Moving steering wheel with engine off may unseat implement relief v alve. If steering or lift circuits appear weak or inoperative after machine is returned to

service, repeat relieving hydraulic system pressure procedure.

Groundsmaster 3505--D Hydraulic SystemPage 4 -- 5

Page 36

Traction Circuit (Closed Loop) Component Failure

The Groundsmaster 3505--D traction circuit is a closed

loop system that includes the hydrostat and two (2)

wheel motors. If a component in the traction circuit

should fail, debris and contamination from the failed

component will circulate throughout the traction circuit.

This contamination can damage other components in

the circuit so it must be removed to prevent additional

component failure.

If a component failure occurs in the traction circuit, it is

critical that the entire traction circuit be disassembled,

drained and thoroughly cleaned to ensure that all contamination is removed from the circuit. If any debris remains in the traction circuit and the machine is operated,

the debris can cause additional component failure.

An additional step for removing all traction circuit contamination would be to temporarily install a high pressure hydraulic oil filter (see Special Tools)into the circuit.

The filter could be used when connecting hydraulic test

gauges in order to test traction circuit components or after replacing a failed traction circuit component (e.g. hydrostat or wheel motor). The filter will ensure that

contaminates are removed from the closed loop and

thus, do not cause additional component damage.

Once the filter has been placed in the traction circuit,

place the machine on jack stands and operate the traction circuit to allow oil flow through the circuit. With the

machine raised off the ground, the traction circuit will

have maximum oil flow at minimum pressure to minimize damage from any remaining contamination. The

filter will remove contamination from the closed loop

traction circuit during operation. Remove the filter from

the machine after contamination has been removed

from the traction circuit.

IMPORTANT: When operating the traction system with

the high pressure filter installed, make sure that flow is

always directed through the filter (e.g. do not press the

traction pedal in the reverse direction if the filter is placed

for forward direction flow). If flow is reversed, debris

from the filter will re--enter the traction circuit.

Groundsmaster 3505--DHydraulic System Page 4 -- 6

Page 37

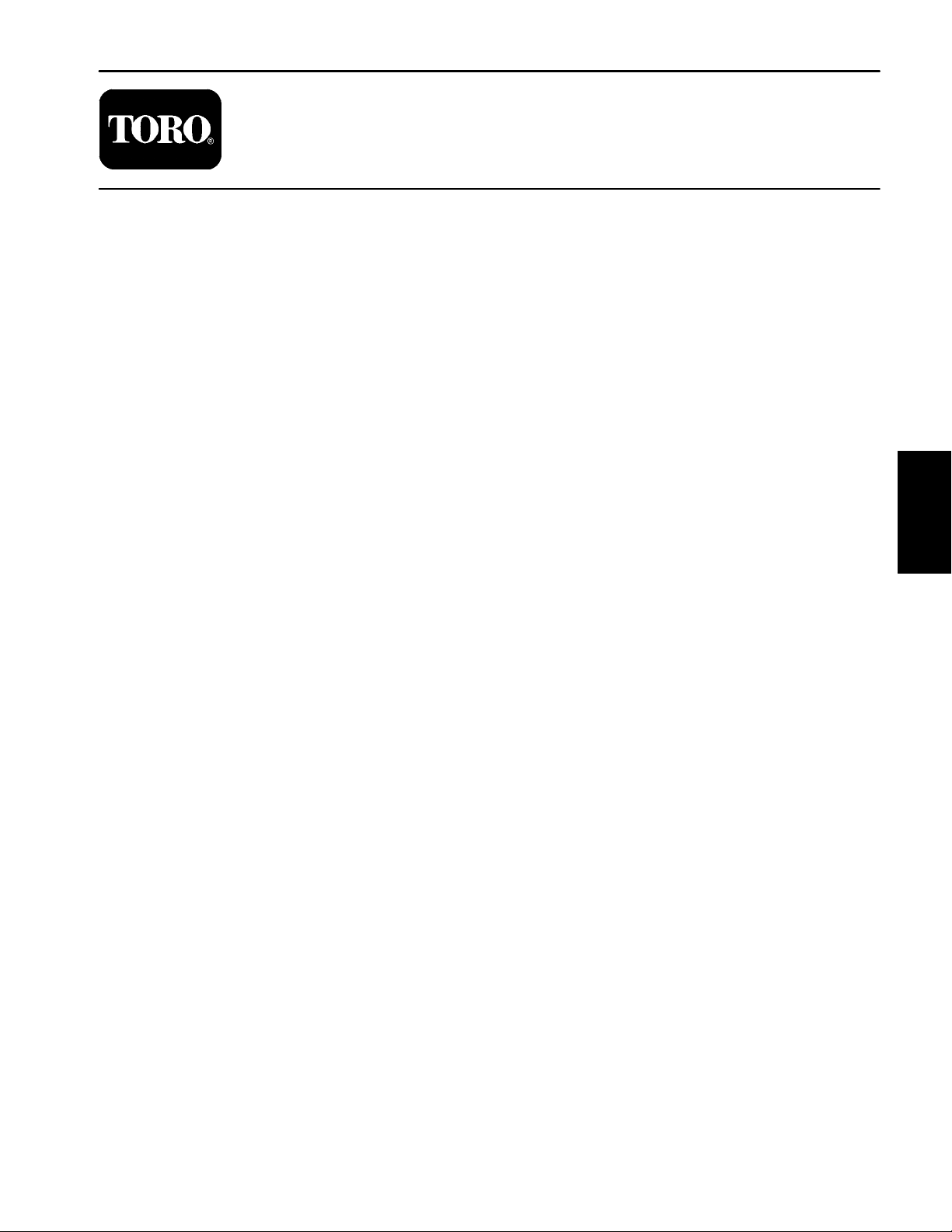

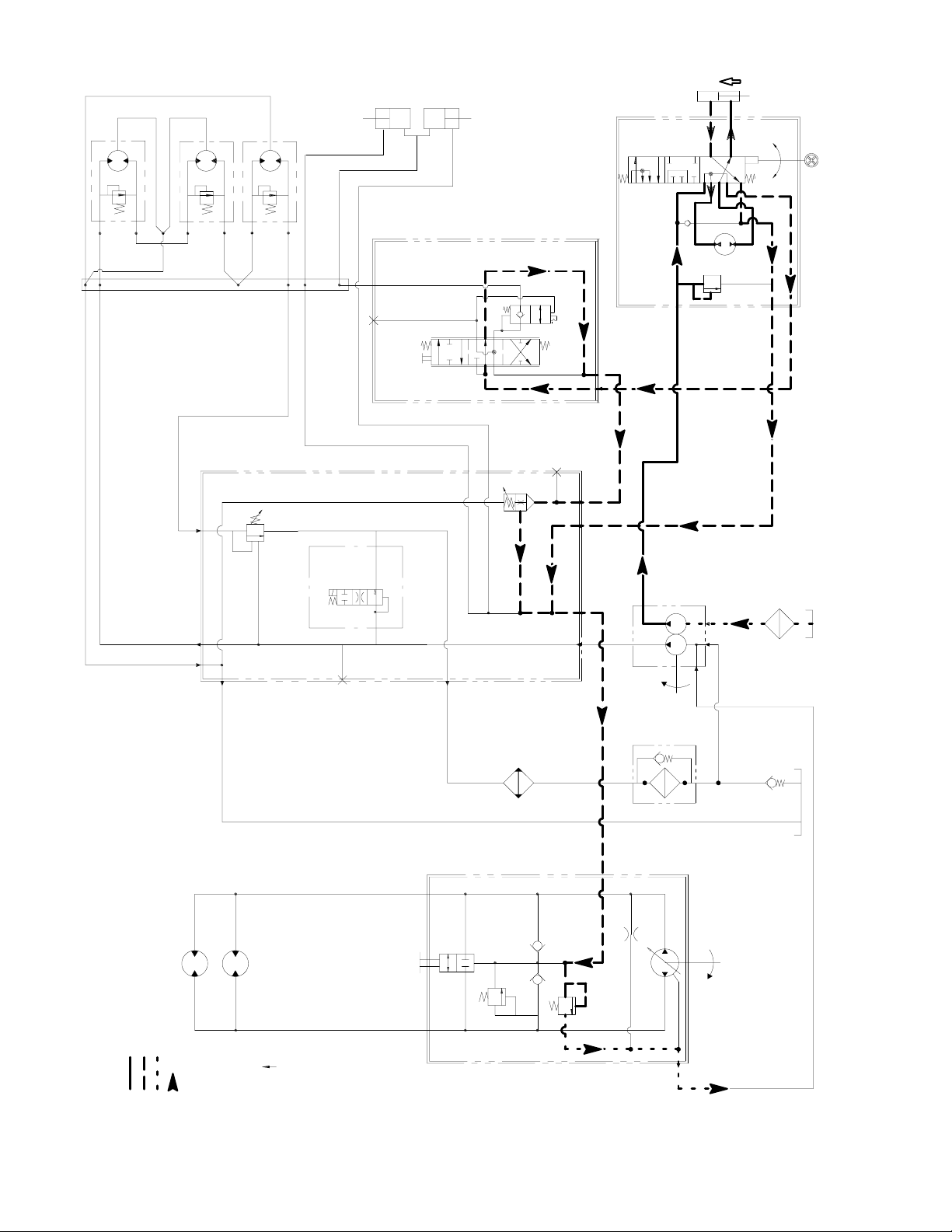

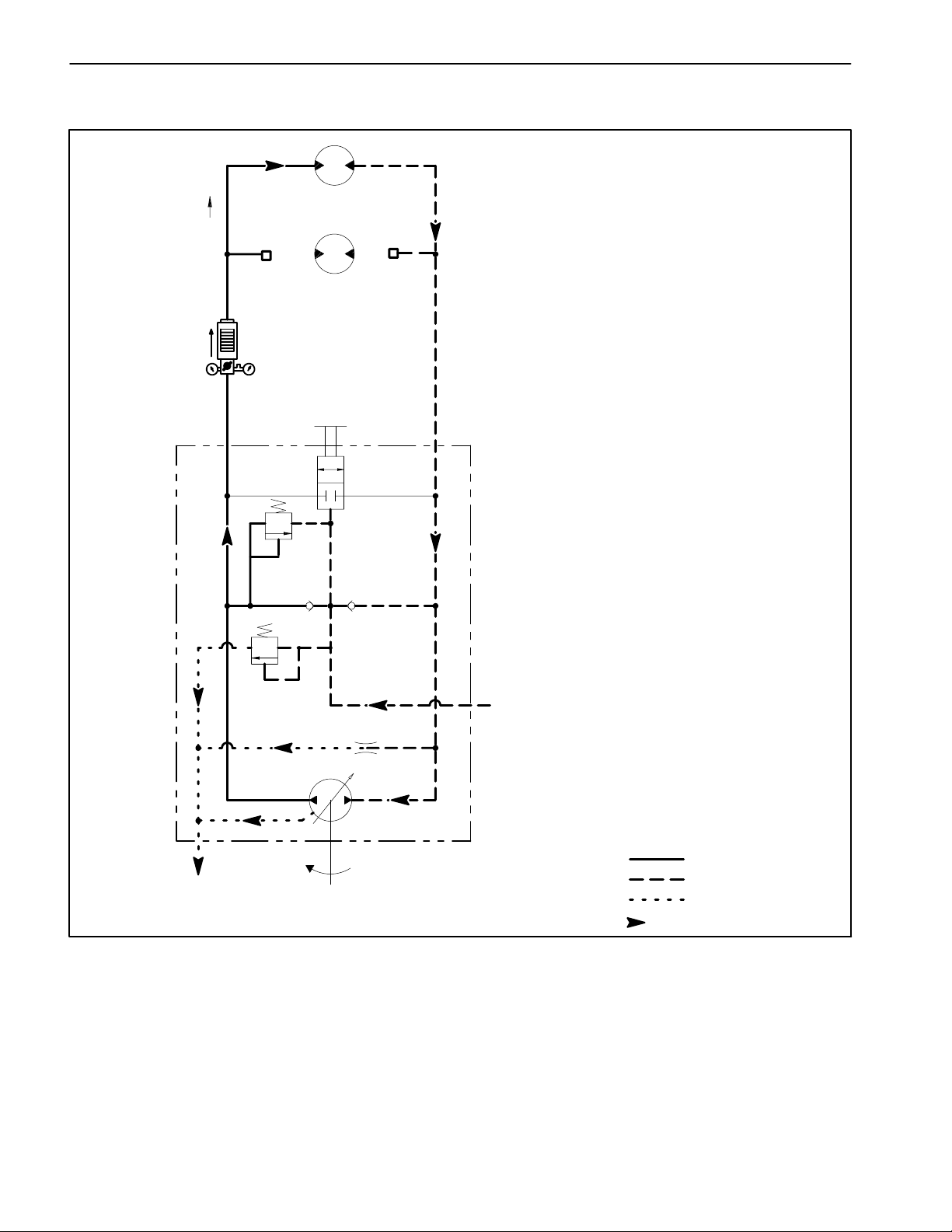

Hydraulic Schematic

IN (P)

OUT (T)

AUX (E)

System

Hydraulic

de--energized

All solenoids are shown as

Hydraulic Schematic

Groundsmaster 3505--D

Groundsmaster 3505--D Hydraulic SystemPage 4 -- 7

Page 38

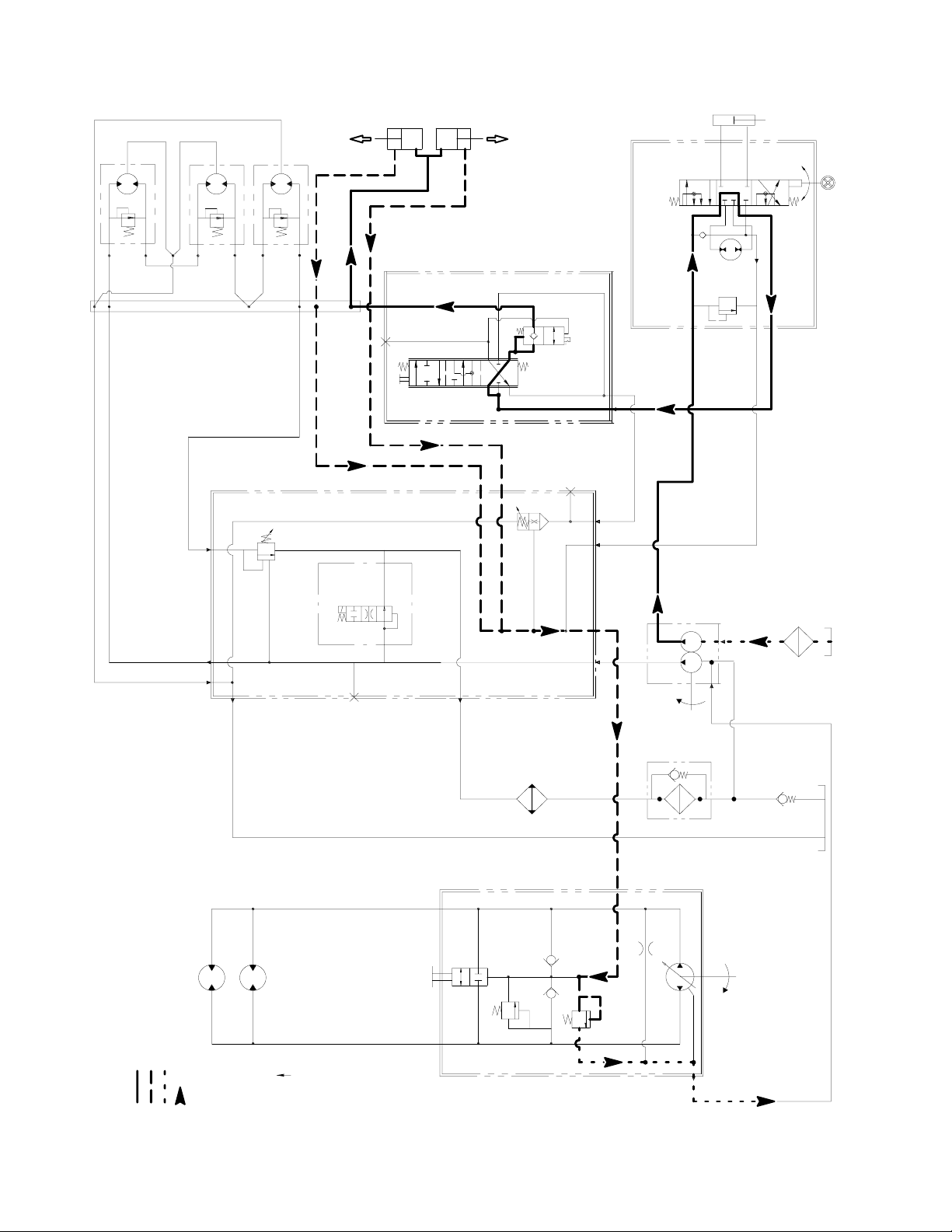

Hydraulic Flow Diagrams

M3

REAR

DECK

LEFT

DECK

M1

M2

DECK

RIGHT

FRONT

LIFT

CYLINDER

REAR

LIFT

CYLINDER

CYLINDER

STEERING

L

R

POWER

STEERING

VALV E

V1

M2

M1

D1

BULKHEAD

OIL

FILTER

1000 psi

OUT (T)

AUX (E)

GEAR PUMP

P2

P1

STRAINER

B

PLATE

A

CR

CF

BV

1500 psi

DECK

ON-- OFF

T2

G1

R1

3200 psi

BLOCK

MANIFOLD

T1

LC1

OIL

G2

COOLER

LIFT VALVE

OUT

IN

LV

ST

CHG

P1

IN (P)

250 psi BACKPRESSURE

Traction Circuits (Forward)

Groundmaster 3505--D

Working Pressure

Low Pressure (Charge)

Return or Suction

Flow

M5

M4

TRACTION WHEEL

MOTORS

FORWARD

UPPER

DUMP

VALV E

LOWER

PORT

HYDROSTAT

P3

3000 psi

100-- 150 psi

PORT

INTERNAL CASE DRAIN

Groundsmaster 3505--DHydraulic System Page 4 -- 8

Page 39

Traction Circuits

Forward

The traction circuit of the hydraulic system consists of a

hydrostat connected in a closed loop circuit to two orbital

rotor wheel motors.

The engine drives traction pump (P3) indirectly through

pulleys and a V--belt.The traction pump is a variable displacement piston pump. The traction pedal connects

through a cable to the trunnion shaft and swash plate of

the pump. With the engine running and the traction pedal in the neutral position, traction pump (P3) supplies no

flow to the wheel motors. When the traction pedal is

pressed to the forward position, the cable from the pedal

positions the swash plate in the traction pump so oil

flows out of the lower port. Oil flow out of the lower port

goes to the wheel motors and turns them in the forward

direction. Oil flowing out of the wheel motors returns to

the upper port of the hydrostat and is continuously

pumped out of the lower port.

As the load increases, forward traction circuit pressure

can increase to the relief valve setting of 3000 PSI (207

bar). If pressure exceeds the relief setting, oil flows

through the relief valve in the hydrostat to the low pressure side of the closed loop traction circuit.

The traction pump uses a small amount of hydraulic fluid

for internal lubrication. Fluid is designed to leak across

pump parts into the case drain. This leakage results in

the loss of hydraulic fluid from the closed loop traction

circuit that must be replenished.

A two section gear pump is directly coupled to the the hydrostat. Gear pump section (P2) supplies hydraulic flow

for maintaining 100 to 150 PSI (6.9 to 10.3 bar) to the low

pressure side of the traction circuit (charge), raising and

lowering the cutting units and operating the steering

system. The pump replenishes the closed loop traction

circuit with fluid from the hydraulic tank. The charge relief valve in the hydrostat maintains sufficient pressure

so that pump flow is guided to the low pressure side of

the traction circuit through one of two check valves.

Pump flow in excess of replenishment requirements is

relieved through the charge relief valve back to gear

pump (P1) inlet.

Reverse

The traction circuit operates essentially the same in reverse as it does in forward. However, there are a few differences in operation.

When the reverse traction pedal is depressed, the cable

from the pedal positions the swash plate in the traction

pump (P3) so oil flows out of the upper port. Oil flow out

of the upper port goes to the wheel motors and turns

them in the reverse direction. Oil flowing out of the wheel

motors returns to the lower port of the hydrostat and is

continuously pumped out of the upper port.

System

Hydraulic

Groundsmaster 3505--D Hydraulic SystemPage 4 -- 9

Page 40

LEFT

DECK

RIGHT

DECK

REAR

DECK

FRONT

LIFT

CYLINDER

REAR

LIFT

STEERING

CYLINDER

CYLINDER

L

R

POWER

STEERING

VALV E

M1

BULKHEAD

M2

PLATE

M2

M1

D1

M3

FILTER

V1

1000 PSI

OUT (T)

AUX (E)

P2

P1

STRAINER

LIFT VALVE

BA

IN (P)

OUT

IN

OIL

COOLER

G2

LV

ST

CHG

P1

250 psi BACKPRESSURE

GEAR PUMP

OIL

CR

CF

BV

1500 psi

DECK

ON-- OFF

T2

G1

R1

3200 psi

T1

BLOCK

MANIFOLD

LC1

Groundmaster 3505--D

Working Pressure

Low Pressure (Charge)

Cutting Unit Circuit

Return or Suction

Flow

M5

M4

TRACTION WHEEL

MOTORS

FORWARD

BI-- PASS

UPPER

PORT

VALV E

PORT

LOWER

HYDROSTAT

P3

3000 psi

100 to 150 psi

INTERNAL CASE DRAIN

Groundsmaster 3505--DHydraulic System Page 4 -- 10

Page 41

Cutting Unit Circuit

Mow

A two section gear pump is directly coupled to the the hydrostat which is driven by the engine. Gear pump section (P1) supplies oil flow to the cutting unit circuit

through the manifold block and to the cutting unit motors.

Solenoid valve (R1) in the manifold block is de--energized when either the PTO switch is in DISENGAGE or

the transport/mow slide is in TRANSPORT. When de-energized, solenoid valve (R1) by--passes flow from the

cutting unit motors. Flow returns to gear pump (P1) inlet.

Solenoid valve (R1) is energized when the PTO switch

is in ENGAGE and the transport/mow slide is in MOW.

When energized, solenoid valve (R1) allows gear pump

(P1) flow out manifold block port M1 to the cutting unit

motors. When solenoid v alve (R1) is energized, brake

relief cartridge (BV) is shifted (opens) to allow oil return

from the cutting unit motors.

Oil flows through the left, right and then rear cutting unit

motors as it turns the motors. The oil then returns

through manifold block port (M2), the oil cooler, the oil

filter and to gear pump (P1) inlet.

Cutting Unit Blade Braking

When the solenoid valve (R1) is de--energized as the

PTO switch is DISENGAGED, brake relief cartridge

(BV) shifts to its closed position, blocking return flow

from the deck motors and slowing the cutting blades

The inertia of the rotating cutting blades, however,effectively turns the deck motors into pumps causing an increase in pressure as the flow from the motors comes

up against the closed brake relief cartridge (BV). When

this pressure builds to approximately 1500 PSI (103

bar), brake relief c artridge (BV) opens which allows hydraulic flow to return to tank and reduces return pressure. When return pressure drops below 1500 PSI (103

bar), brake relief cartridge (BV) reseats to further slow

the cutting blades. This action repeats several times in

a very short time frame as the blades finally come to a

stop. Once the blades have stopped, brake relief cartridge (BV) remains seated to keep the deck motors

from rotating.

System

Hydraulic

If cutting unit circuit pressure exceeds relief pressure of

3200 PSI (221 bar), solenoid valve (R1) shifts to allow

circuit pressure relief.

Groundsmaster 3505--D Hydraulic SystemPage 4 -- 11

Rev. B

Page 42

LEFT

DECK

DECK

RIGHT

REAR

DECK

FRONT

LIFT

CYLINDER

REAR

LIFT

CYLINDER

CYLINDER

STEERING

L

R

POWER

STEERING

VALV E

M1

BULKHEAD

M2

M1

D1

M2

PLATE

M3

LIFT VALVE

(MOVED TO RAISE)

BA

OUT

IN

OIL

COOLER

G2

LV

ST

CHG

P1

250 psi BACKPRESSURE

GEAR PUMP

OIL

CR

CF

BV

1500 psi

DECK

ON-- OFF

T2

G1

R1

3200 psi

T1

BLOCK

MANIFOLD

LC1

V1

1000 PSI

IN (P)

P2

P1

FILTER

OUT (T)

AUX (E)

STRAINER

Groundmaster 3505--D

Working Pressure

Low Pressure (Charge)

Lift Circuit (Raise)

Return or Suction

Flow

M5

M4

TRACTION WHEEL

MOTORS

FORWARD

BI-- PASS

UPPER

PORT

VALV E

PORT

LOWER

HYDROSTAT

P3

3000 psi

100 to 150 psi

INTERNAL CASE DRAIN

Groundsmaster 3505--DHydraulic System Page 4 -- 12

Page 43

Lift Circuit (Raise)

A two section gear pump is directly coupled to the the hydrostat which is driven by the engine. Gear pump section (P2) supplies hydraulic flow for raising and lowering

the cutting units, operating the steering system and

maintaining 100 to 150 PSI (6.9 to 10.3 bar) to the low

pressure side of the traction circuit (charge). The pump

section (P2) takes its suction from the hydraulic reservoir.

During conditions of not lifting or lowering cutting units,

flow from the gear pump (P2) is by--passed through the