Page 1

FormNo.3424-696RevA

Stand-OnSpreader/Sprayer

ModelNo.34215—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3424-696*A

Page 2

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

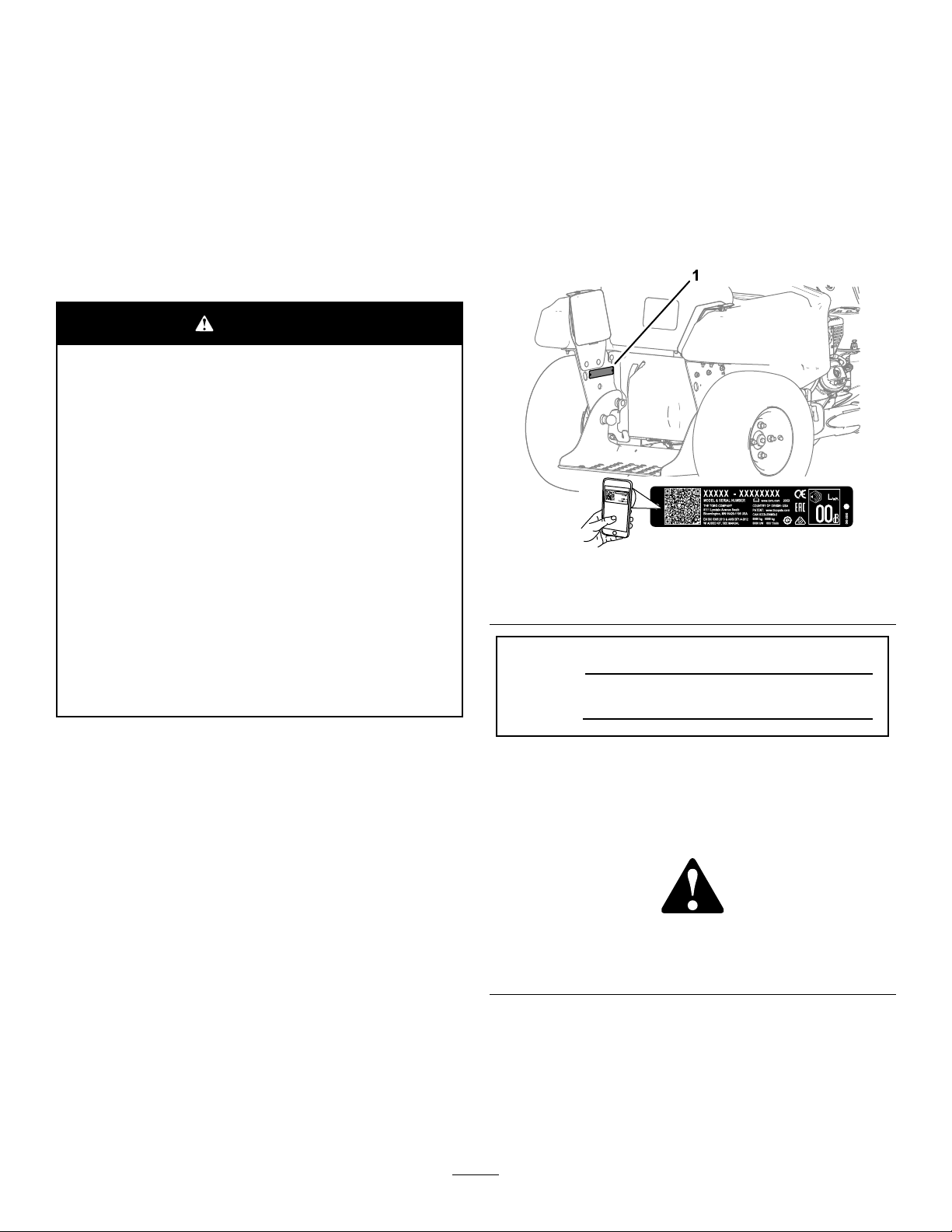

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g248806

Figure1

1.Locationofthemodelandserialnumbers

ModelNo.

Introduction

Thisstand-onspreadersprayerisintendedforuse

bytrainedoperatorsinresidentialandcommercial

applications.Themachineisprimarilydesignedfor

chemicaldistributionusedforturfcareorsnow/ice

removalatresidentialgrounds,parks,sportselds,

andoncommercialgrounds.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contactusatwww.Toro.com.

2

g000502

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................9

1CheckingtheTireAirPressure.........................9

2CheckingtheEngine-OilLevel.........................9

3CheckingtheTransaxle-FluidLevel.................9

4ConnectingtheBattery..................................10

ProductOverview...................................................10

Controls............................................................11

MachineControls...........................................11

SpreaderControls.........................................13

SprayerControls...........................................14

Specications..................................................16

BeforeOperation.................................................16

BeforeOperationSafety...................................16

PerformingDailyMaintenance..........................17

CheckingtheSafetyInterlockSystem...............17

FuelSpecication.............................................18

UsingStabilizer/Conditioner.............................18

FillingtheFuelTank..........................................18

DuringOperation.................................................19

DuringOperationSafety...................................19

OperatingtheMachine.....................................21

OperatingtheSpreader....................................23

OperatingtheSprayer......................................34

AfterOperation....................................................43

AfterOperationSafety......................................43

CleaningandLubricatingtheSpreader.............43

CleaningtheSprayer........................................44

TransportingtheMachine.................................46

Maintenance...........................................................48

MaintenanceSafety..........................................48

RecommendedMaintenanceSchedule(s)...........49

NotationforAreasofConcern...........................49

Pre-MaintenanceProcedures..............................50

PreparingtheMachine......................................50

Lubrication..........................................................51

LubricatingtheGreaseFittings.........................51

EngineMaintenance...........................................51

ServicingtheAirCleaner..................................51

EngineOilSpecication....................................52

CheckingtheEngine-OilLevel..........................52

ChangingtheEngineOil...................................53

ServicingtheSparkPlug...................................54

ServicingtheSparkArrester.............................55

FuelSystemMaintenance...................................57

CleaningtheFuelSedimentCup......................57

ServicingtheFuelStrainer................................57

ElectricalSystemMaintenance...........................59

ServicingtheBattery.........................................59

RemovingandInstallingtheBattery..................61

Jump-StartingtheMachine...............................62

ServicingtheFuses..........................................62

DriveSystemMaintenance..................................63

CheckingtheAirPressureintheTires...............63

TorquingtheAxleBolts.....................................63

AligningtheFrontWheels.................................64

ServicingtheTransaxle....................................65

ControlsSystemMaintenance.............................66

AdjustingthePatternControlCableforthe

Spreader......................................................66

MaintainingtheChassis.......................................67

CheckingtheMachineforLoose

Hardware......................................................67

MaintainingtheSprayerSystem...........................67

CheckingSprayerSystem................................67

Cleaning..............................................................68

CleaningtheEngineandtheExhaust

SystemArea.................................................68

CleaningtheDebrisfromtheMachine...............68

RemovingtheEngineShroudandCleaning

theCoolingFins............................................68

WasteDisposal.................................................68

Storage...................................................................69

PreparingtheMachineforExtendedor

WinterStorage..............................................69

Troubleshooting......................................................71

Schematics.............................................................75

3

Page 4

Safety

ThefollowinginstructionsarefromANSIstandard

B71.4-2017.

GeneralSafety

Thisproductiscapableofcausingpersonalinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforestartingtheengine.

•Useappropriatepersonalprotectiveequipment

(PPE)toguardagainstcontactwithchemicals.

Chemicalsubstancesusedinthesprayersystem

maybehazardousandtoxic.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeareaofthesprayer

nozzlesandspraydrift.Keepbystandersandpets

asafedistanceawayfromthemachine.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforelling,emptying,servicing,or

uncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

Also,gotowww.Toro.comforevenmoresafe

operatingpractices,includingsafetytipsandtraining

materials.

Notalltheattachmentsthatadapttothismachine

arecoveredinthismanual.Refertotheoperator’s

manualprovidedwitheachattachmentforadditional

safetyinstructions.

,which

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

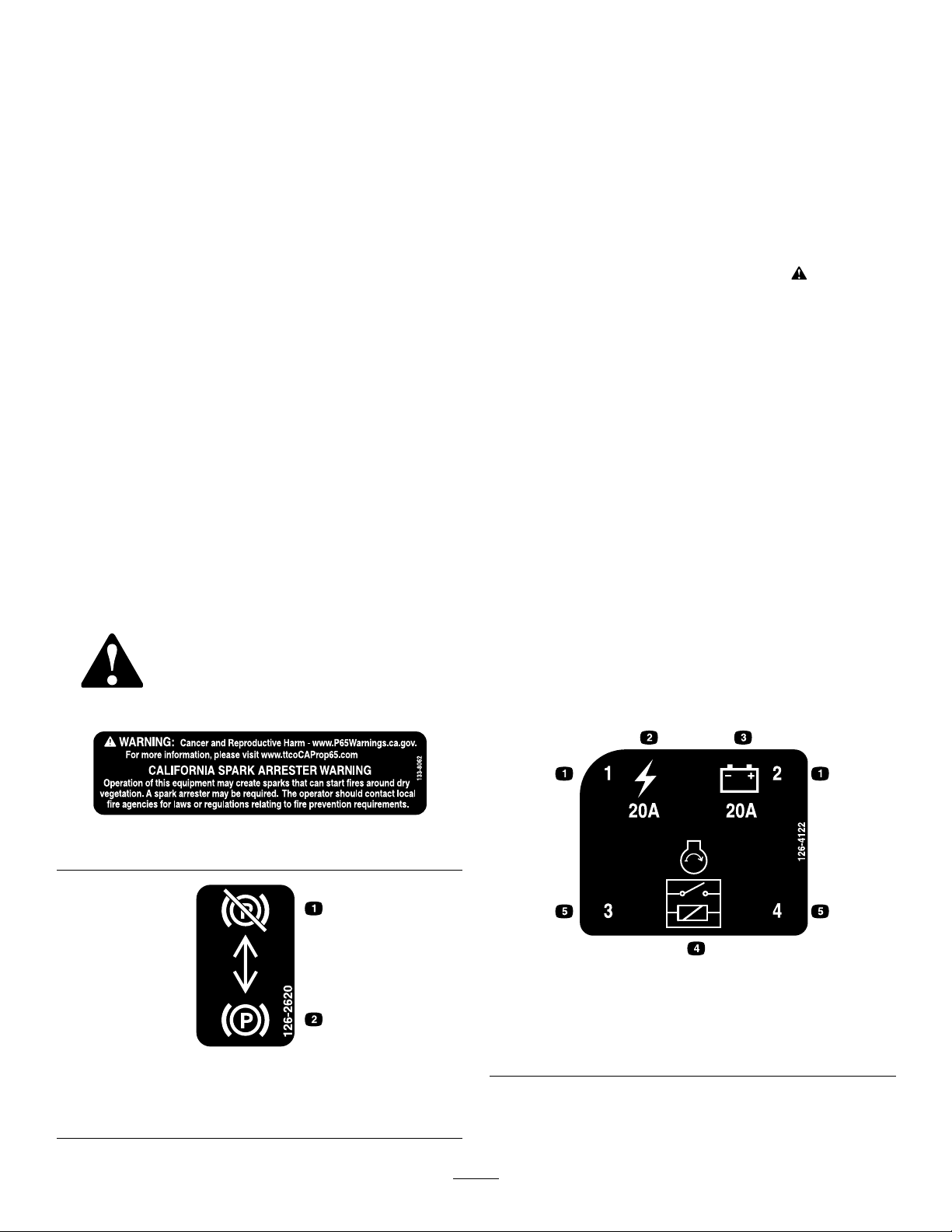

133-8062

126-2620

decal133-8062

decal126-4122

126-4122

1.Fuselocation

2.Main,20A5.Relaylocation

decal126-2620

3.Regulator,20A

4.Startrelay

1.Pullleveruptodisengage

thebrake.

2.Pushleverdownto

engagethebrake.

4

Page 5

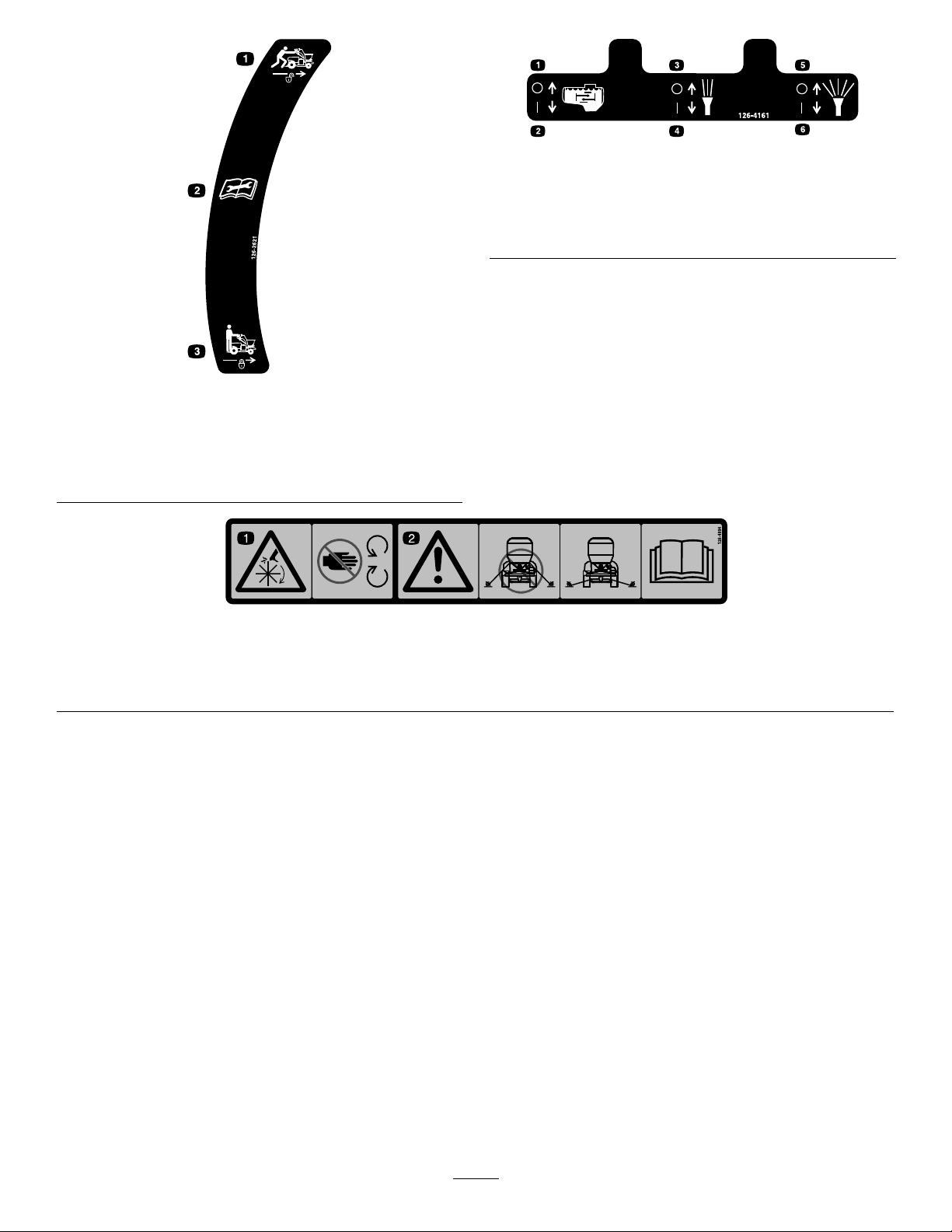

126-2621

1.Unlocktopushmachine.3.Locktodrivemachine.

2.Readtheinstructions

beforeservicingor

performingmaintenance.

decal126-4161

126-4161

1.Agitation-Off4.Narrowspray-On

2.Agitation-On5.Widespray-Off

3.Narrowspray-Off6.Widespray-On

decal126-2621

1.Cutting/dismembermenthazard—keepawayfrommoving

parts.

decal126-4994

126-4994

2.Warning—donotusetheupperfrontlocationsastiedown

points,onlyusethespeciedtie-downpoints;seethe

Operator’sManualforlocation.

5

Page 6

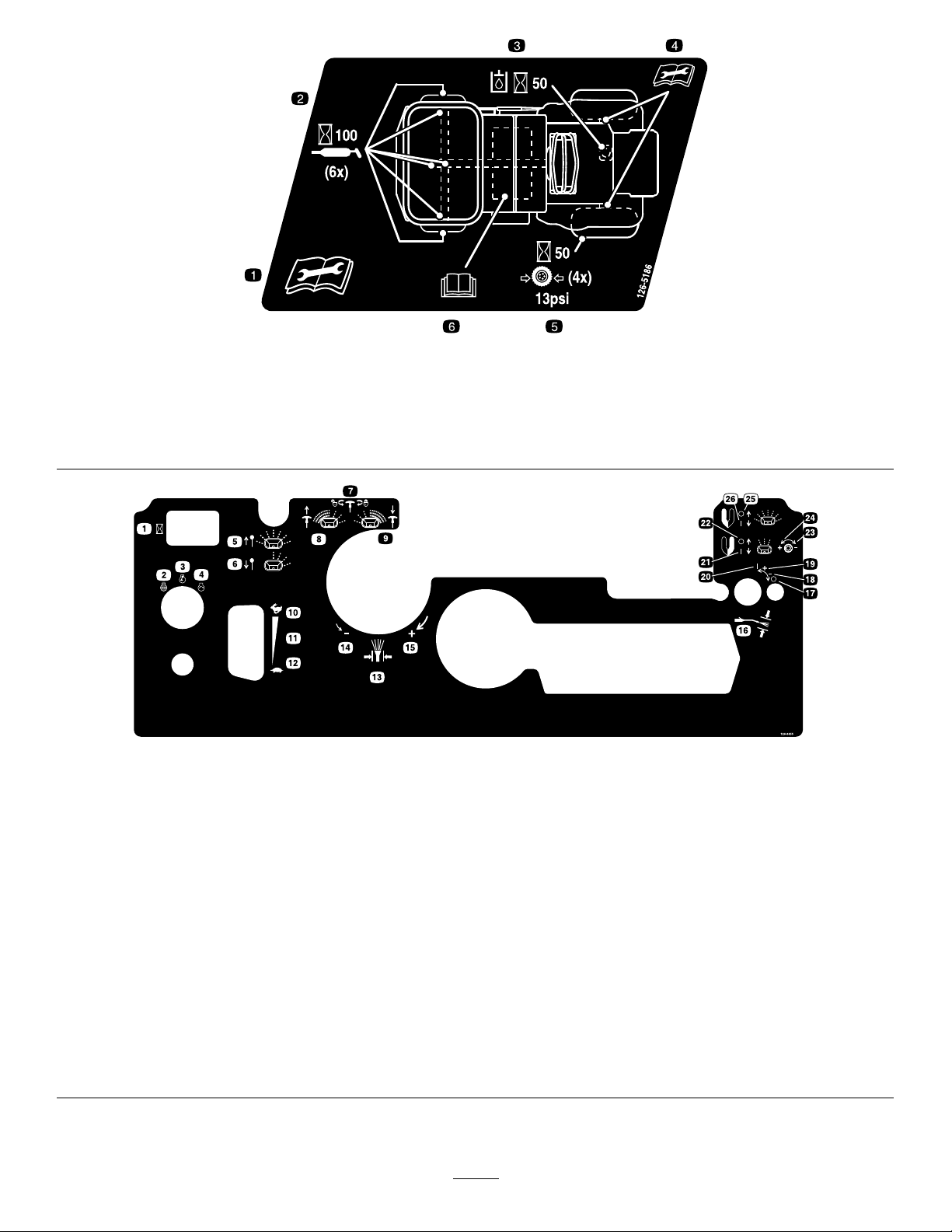

decal126-5186

126-5186

1.ReadtheOperator'sManualbeforeservicingthemachine

orperformingmaintenance.

4.Formoreinformationonservicingtherearaxleshafts,read

theOperator'sManual.

2.Greasethesteeringpivotsevery100hours.5.Checkthetirepressure—90kPa(13psi)every50hours.

3.Checkthehydraulicuidlevelevery50hours.6.ReadtheOperator'sManual.

126-9655

1.Hourmeter

2.Engine—off15.Spraypressure—increase

3.Engine—on

4.Engine—start

5.Deector—pullknobuptoopen18.Spray-wand-pressurecontrol—decrease

6.Deector—pushknobdowntoclose19.Spray-wandpressurecontrol—increase

7.Spreaderpatterncontrol—rotatecounterclockwisetounlock;

rotateclockwisetolock.

8.Spreadpatterncontrol—pullhandleupifheavyonleftside21.Granular-spinnerlever—narrowdistribution-on

9.Spreadpatterncontrol—pushhandledownifheavyonright

side

10.Throttle—fast23.Granular-spinnerknob—narrowdistribution-decrease

11.Continuous-variablesetting24.Granular-spinnerknob—narrowdistribution-increase

12.Throttle-slow

13.Spray-pressurecontrol26.Granular-spinnerlever—widedistribution-on

14.Spraypressure—decrease

16.Spray-wand-pressurecontrol

17.Spray-wand-pressurecontrol—off

20.Spray-wandpressurecontrol—on

22.Granular-spinnerlever—narrowdistribution-off

25.Granular-spinnerlever—widedistribution-off

decal126-9655

6

Page 7

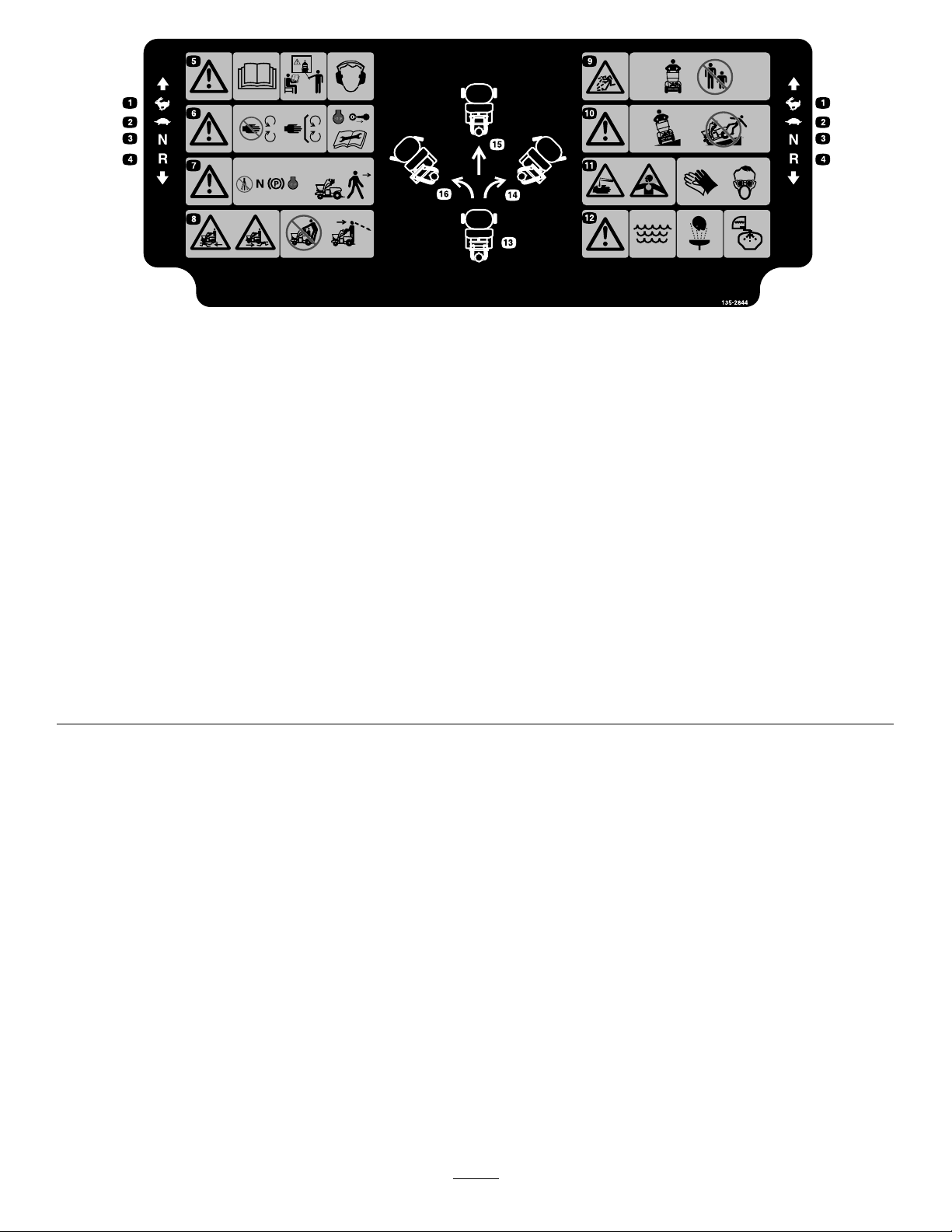

135-2844

1.Fast

2.Slow

3.Neutral

4.Reverse

5.Warning—readtheOperator’sManual;donotoperatethismachineunlessyouaretrained;wearearprotection.

6.Warning—stayawayfrommovingparts;keepallguardsandshieldsinplace;shutofftheengineandremovethekeybefore

performingmaintenance.

7.Warning—shutoffthesprayercontrols,putthemachineinNeutral,engagetheparkingbrake,andshutofftheenginebefore

leavingthemachine.

8.Runover/backoverhazard—donotcarrypassengers;lookbehindyouwhenmovinginreverse.

9.Thrownobjecthazard—keepbystandersaway .

10.Warning—operateacrossslopes,notupanddown;youcanfallifoperatingdownslopes.

11.Causticliquid/chemicalburnandtoxicgasinhalationhazard—wearhandandskinprotection;weareyeandrespiratoryprotection.

12.Warning—usefresh,cleanwaterforrst-aidwashingandrinsingthetank.

13.Neutral

14.Movethesteeringcontrolrighttoturnright.

15.Movethesteeringcontroltothecentertogostraight.

16.Movethesteeringcontrollefttoturnleft.

decal135-2844

7

Page 8

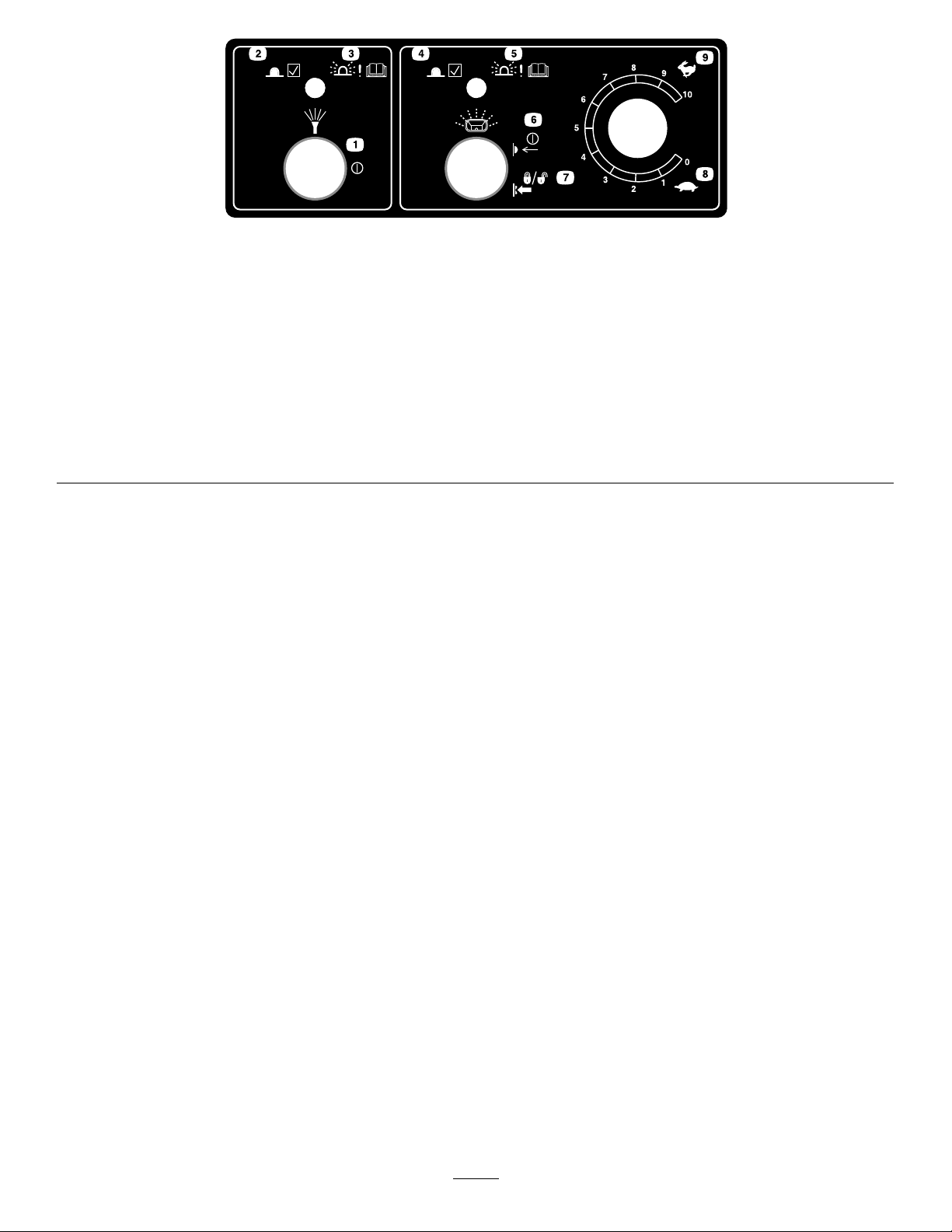

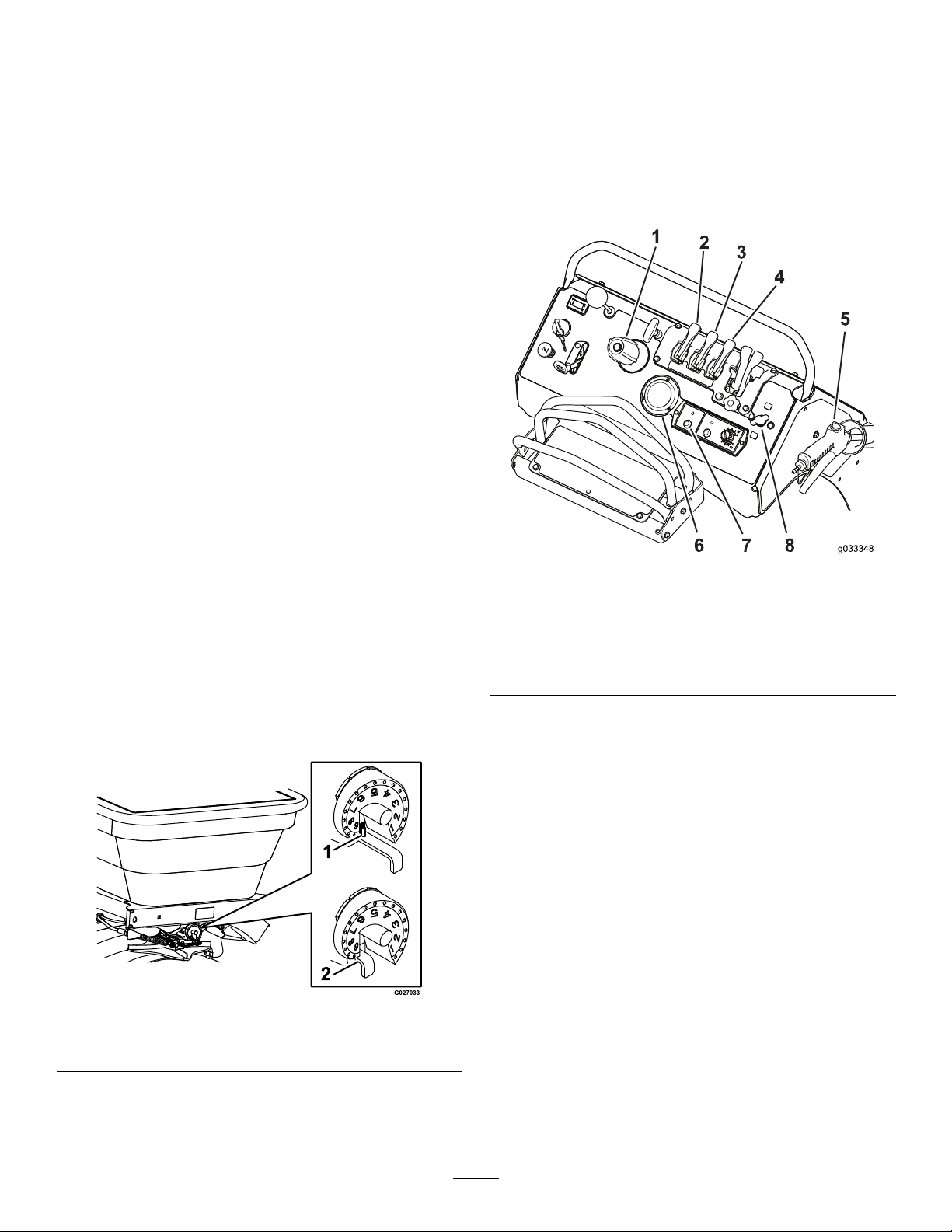

SpreaderSprayerControl

1.Spraypumpswitch—On/Off

2.Solidlight-normalpumpoperation

3.Fastashinglight-pumpmalfunction;seeOperator’smanual.

4.Solidlight-normaloperationofspreadermotorandspeedcontrol.

5.Fastashinglight-spreadermotorand/orspeedcontrolmalfunction;seeOperator’smanual.

Constantslowashinglight-spreadermotorspeedsettinglocked.

6.Granularimpellermotorandspeedcontrol—On/Off;presspushbuttonfast.

7.Granularspeedcontrollock/unlock-On/Off;pressandholdbutton.

8.Speedcontrol—slow

9.Speedcontrol—fast

decalspreadspraycontrol

8

Page 9

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

4

MediaandAdditionalParts

Description

Operator'sManual

Key2

Nopartsrequired

1

CheckingtheTireAir Pressure

NoPartsRequired

Qty.

Qty.

–

1

Readbeforeoperatingthemachine.

Startthemachine.

Connectthebattery.

Use

Use

3

Checkingthe Transaxle-FluidLevel

NoPartsRequired

Procedure

Checktheairpressureinthefrontandreartires,and

ifnecessary,addairtotheappropriatepressure;refer

toCheckingtheAirPressureintheTires(page63).

2

CheckingtheEngine-Oil Level

NoPartsRequired

Procedure

Theenginecomeswithoil;checktheengine-oillevel

and,ifnecessary,addtotheappropriatelevel;referto

EngineOilSpecication(page52)andCheckingthe

Engine-OilLevel(page52).

Procedure

Thetransaxlecomeswithuid;checktransaxle-uid

levelintheexpansiontank,andifnecessary,addto

theappropriatelevel;refertoServicingtheTransaxle

(page65).

9

Page 10

4

ConnectingtheBattery

NoPartsRequired

Procedure

1.Removethebatterycoverfromthebatterybox

(Figure3).

ProductOverview

g033350

Figure4

Figure3

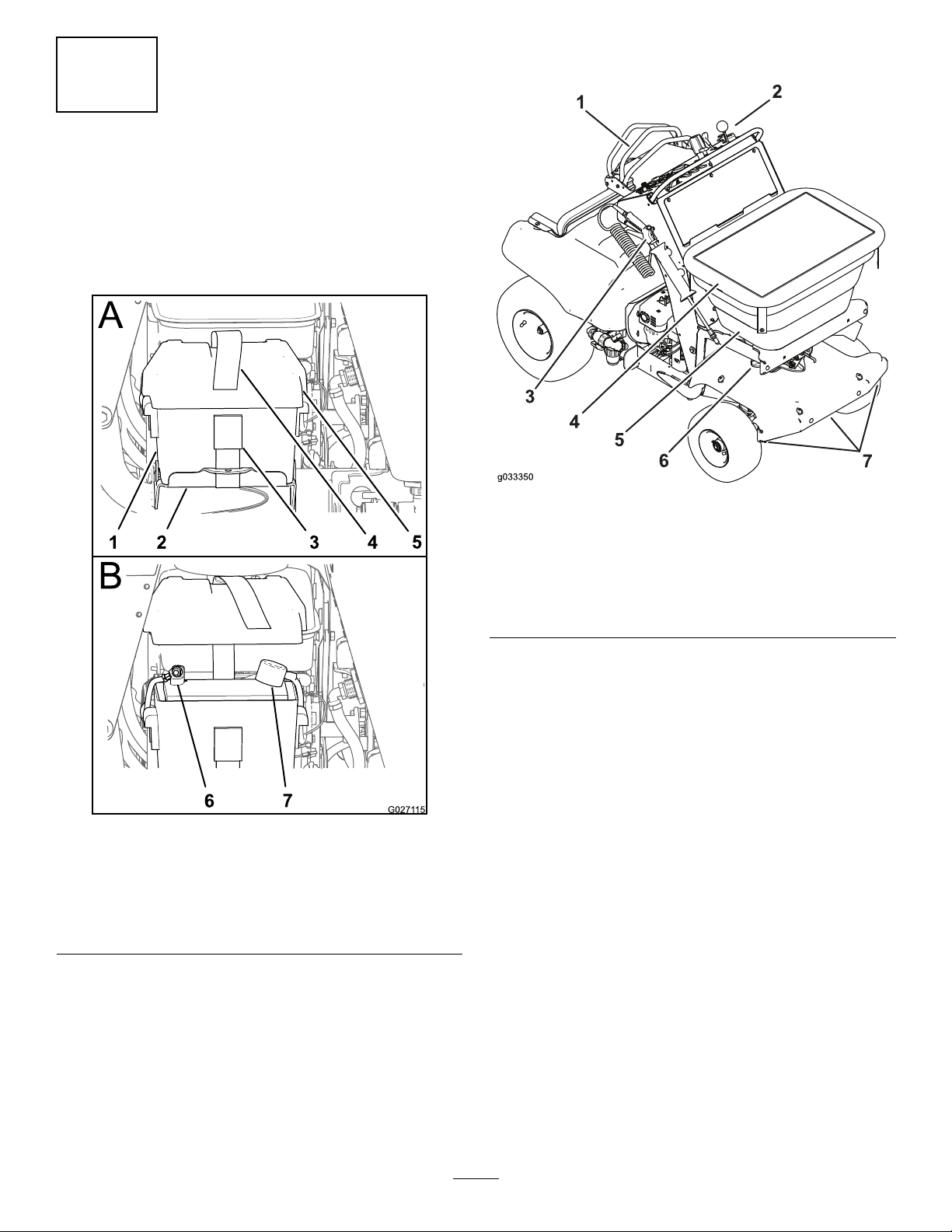

1.Batterybox5.Batterycover

2.Batterysupport6.Negativeterminal

3.Buckle7.Positiveterminal

4.Batterystrap

2.Installthepositive-batterycabletothepositive

(+)batteryterminalwithaangedboltand

angednut(Figure3).

3.Installthenegative-batterycabletothenegative

(–)batteryterminalwithaangedboltand

angednut(Figure3).

4.Installthecoveronthebatteryboxandsecure

thecoverandboxtothebatterytraywiththe

batterystrap(Figure3).

1.Motion/steeringcontrol

2.Engine/spreader—sprayer

controls

3.Spraywand7.Sprayernozzles

4.Hoppercover

g027115

5.Hopper

6.Impeller

10

Page 11

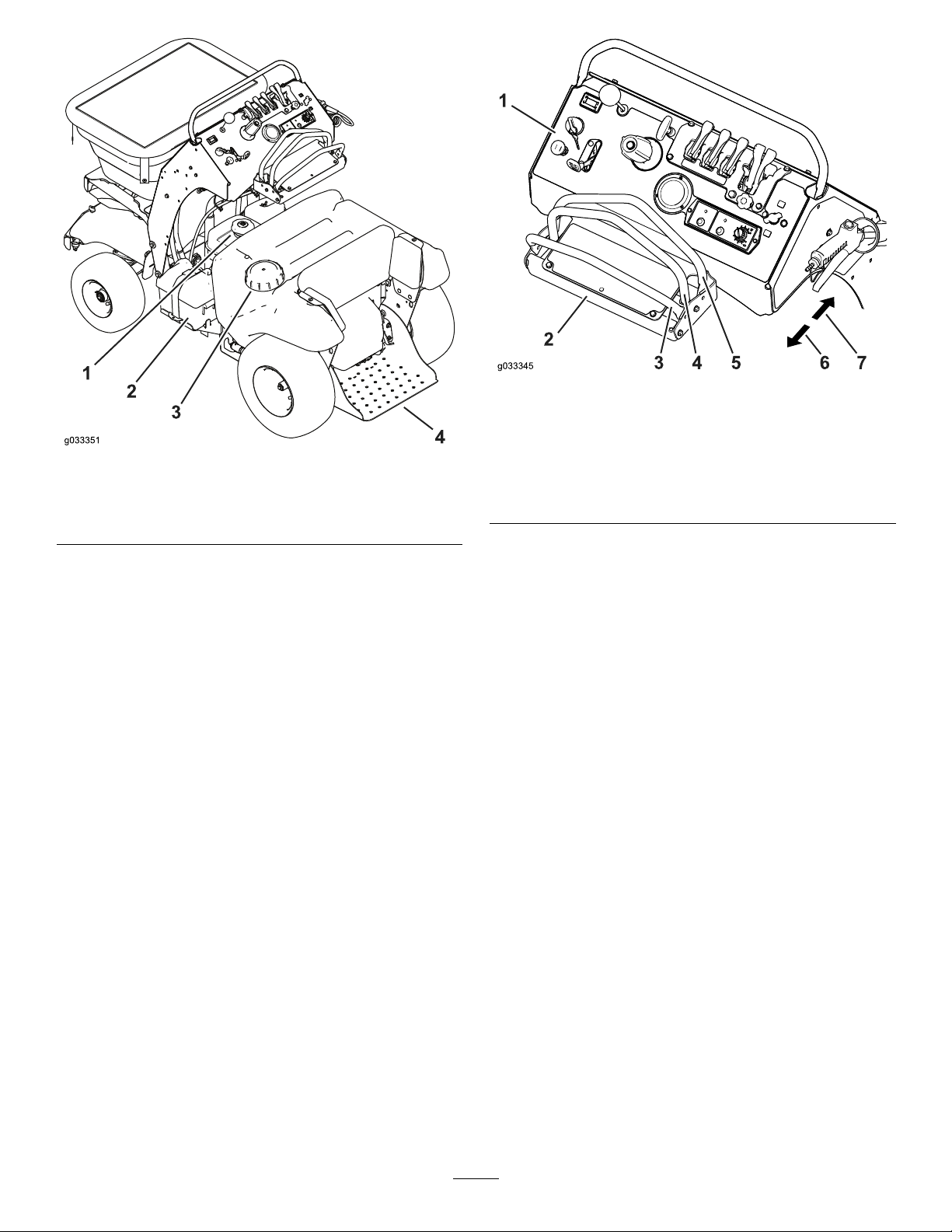

1.Fuel-tankcap

2.Battery

Figure5

3.Sprayer-tankcap

4.Platform

g033345

Figure6

1.Controlconsole5.Frontreferencebar

g033351

2.Steeringcontrol

3.Rearreferencebar

4.Motion-controllever

(Neutralposition)

Motion-ControlLever

6.Reverse

7.Forward

Controls

MachineControls

SteeringControl

Thesteeringcontrolislocatedbehindthecontrol

console(seeFigure6).

•Movethesteeringcontroltotherightorleftto

steerthemachinetotherightorleftrespectively.

•Movingthesteeringcontroltothecenterallows

themachinetosteerstraight.

Themotion-controllever,locatedinthecenterofthe

steeringcontrol,controlstheforwardandreverse

motionofthemachine(seeFigure6).

•Movethemotion-controlleverforwardorbackward

todrivethemachinerespectively.

Note:Themachinespeedisproportionaltothe

amountthatyoumovethemotion-controllever.

•Whenyoumovethemotion-controllevertothe

centerposition,themachineshouldstop.

Note:Whenyoureleasethemotion-controllever,

itshouldreturntotheNEUTRALposition.

Important:Ifthemotion-controlleverdoes

notreturntotheNEUTRALpositionwhenyou

releaseit,contactanAuthorizedService

Dealer.

11

Page 12

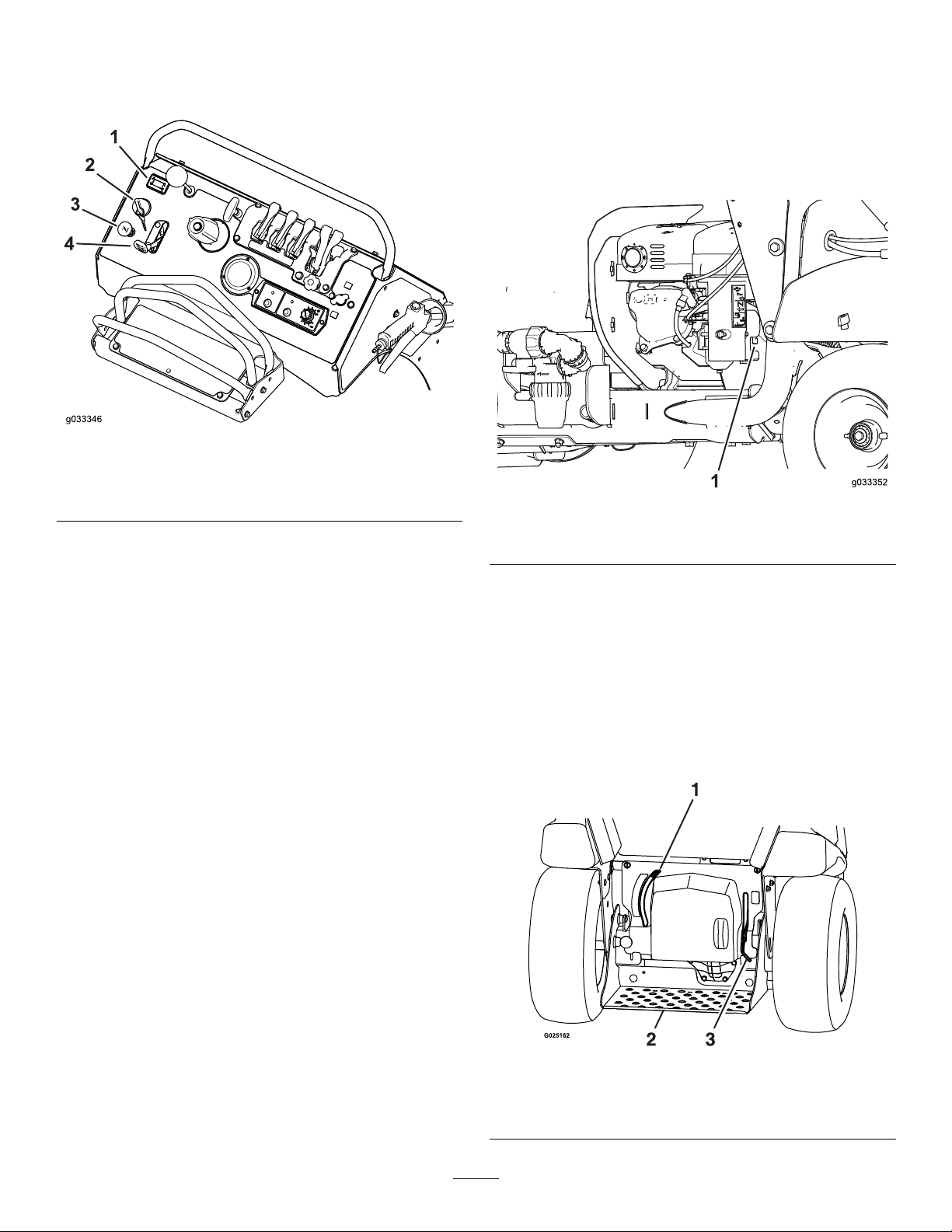

ThrottleControl

Fuel-Shut-OffValve

Thethrottlecontrol(theredlever)islocatedattheleft

sideofthecontrolconsole(Figure7).

Figure7

1.Hourmeter

2.Ignitionswitch4.Throttle

3.Choke

Thefuel-shut-offvalveislocatedatthefront,rightside

oftheenginebelowthefueltank(Figure8).

Note:Closethefuel-shut-offvalvewhenthemachine

isnotusedforafewdays,duringtransporttoand

fromthejobsite,orwhenthemachineisparked

insideabuilding.

g033346

g033352

Figure8

ChokeControl

Thechokecontrolislocatedattheleftsideofthe

controlconsole;youuseittohelpstartacoldengine

(Figure7).

Note:Donotstartorrunawarmenginewiththe

chokeintheONposition.

•Pulluponthechokecontroltosetthechoketo

theONposition.

•Pushdownonthechokecontroltosetthechoke

totheOFFposition.

IgnitionSwitch

Theignitionswitchislocatedattheleftsideofthe

controlconsole(Figure7).

Usetheignitionswitchtostartandshutofftheengine.

Theignitionswitchhasthreepositions,OFF,ONand

START.

Note:Youmustengagetheparkingbraketostart

theengine.

1.Fuel-shut-offvalve(rightsideoftheengine)

Parking-BrakeLever

Theparking-brakeleverislocatedabovetheplatform

ontherightside(Figure9).

•Toengagetheparkingbrake,pushthe

parking-brakeleverdown.

Note:Thebrakeleverengagesaparkingbrake

inthetransaxle.

•Toreleasetheparkingbrake,pulltheleverup.

HourMeter

Thehourmeterislocatedabovetheignitionswitchat

theleftsideofthecontrolconsole(Figure7).

Thehourmeterrecordsthenumberofhoursthatthe

machinehasoperated.

g025162

Figure9

1.Drive-wheel-releaselever3.Park-brakelever

2.Platform

12

Page 13

Note:Whenparkingonasteepslope,chockorblock

thewheelsinadditiontoengagingtheparkingbrake.

Whentransportingthemachine,engagetheparking

brakeandbindthemachinetothetransportvehicle.

Drive-Wheel-ReleaseLever

Thedrive-wheel-releaseleverislocatedabovethe

platformontheleftside(Figure9).

Usethedrive-wheel-releaselevertodisengagethe

hydrostatic-drivesystemtomovethemachineby

hand.

•Topushorpullthemachine,movethe

drive-wheel-releaseleverup.

•Tooperatethemachine,movethe

drive-wheel-releaseleverdown.

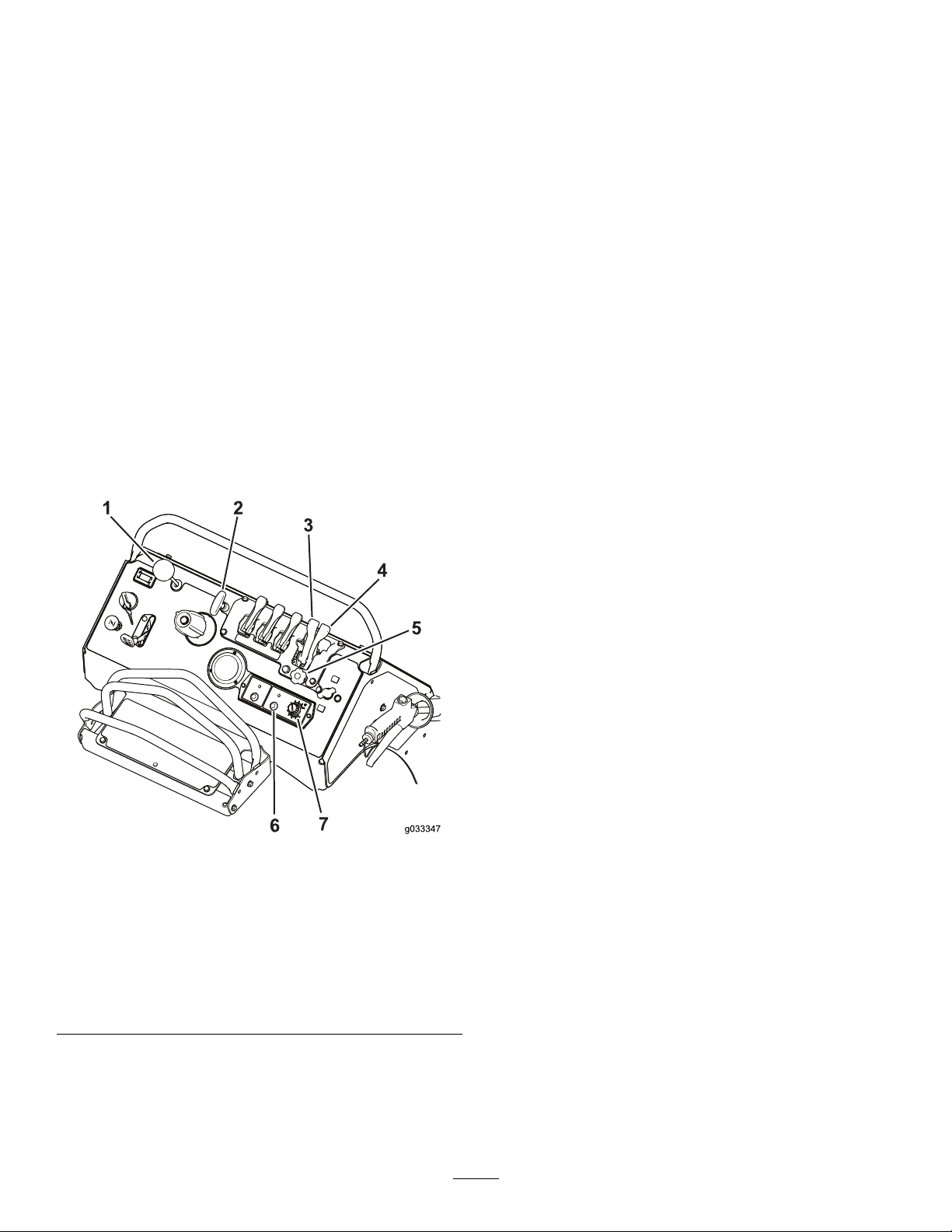

SpreaderControls

DeectorGateControl

Thedeector-gatecontrolislocatedtotherightofthe

hourmeteronthecontrolconsole(Figure10).

•Pushtheknobforthedeector-gatecontroldown

toclosethegateandtemporarilydeectthe

granularmaterials.

•Pulltheknobuptoopenthedeectorgateforfull

granularbroadcasting.

Spreader-PatternControl

Thespreader-patterncontrolislocatedtotheright

ofthedeector-gatecontrolatthecontrolconsole

(Figure10).

Usethespreader-patterncontroltobroadcasta

heavierpatternofgranularmaterialtotheleftorright

sideofthemachine.

•Tobroadcastaheavierpatterntotheleft,unlock

thespreader-patterncontrol,pullthecontrolup

slightly,andlockthecontrol.

•Tobroadcastaheavierpatterntotheright,unlock

thespreader-patterncontrol,pushthecontrol

downslightly,andlockthecontrol.

Wide-distributionImpeller-GateLever

Thewide-distributionimpeller-gateleveristhefourth

leverlocatedatthetopcenterofthecontrolconsole

(Figure10).

•Tobroadcastawidepatternofgranularmaterial,

pullthewide-distributionimpeller-gatelever

rearwardfullytothefullopenposition.

•Toclosetheimpellergate,pushthe

wide-distributionimpeller-gateleverforwardfull

closedposition.

Figure10

1.Deector-gatecontrol

2.Spreader-patterncontrol6.ImpellerOn/Offswitch

3.Wide-distribution

impeller-gatelever

4.Narrow-distribution

impeller-gatelever

5.Narrow-spreader

distributionow-rate

knob

7.Impeller-speedcontrol

Usethedeector-gatecontroltotemporarilystop

thedischargeofgranularmaterialsfromtheleftside

ofthespreader.Closethedeectorgatewiththe

controlwhenitisnotdesirabletobroadcastgranular

materialsontosidewalks,parkinglots,orpatios.

Narrow-distributionImpeller-GateLever

Thenarrow-distributionimpeller-gateleveristhefth

leverlocatedatthetopcenterofthecontrolconsole

(Figure10).

•Tobroadcastanarrowpatternofgranularmaterial,

pullthenarrow-distributionimpeller-gatelever

rearwardfullytothelimitedOPENposition.

g033347

•Toclosetheimpellergate,pushthe

wide-distributionimpeller-gateleverforwardfully.

Note:Onlythewide-distributionimpeller-gate

leverclosestheimpellergate.Pushingthe

wide-distributionimpeller-gateleverforwardalso

resetsthenarrow-distributionimpeller-gatelever

totheforwardposition.

Narrow-SpreaderDistributionFlow-RateKnob

Thenarrow-spreaderdistributionow-rateknobis

locatedbelowthewide-andnarrow-impeller-gate

levers(Figure10).

Usethenarrow-spreaderdistribution-ow-rateknobto

controlthedischargerateofgranularmaterialfromthe

hopperontotheimpellerwhenthenarrow-distribution

impeller-gateleverisintheOPENposition(limited).

13

Page 14

•Rotatethenarrow-spreaderdistribution-ow-rate

knobclockwisetodecreasethedischargerateof

granularmaterialfromthehopper.

•Rotatethedistributionow-rate-knob

counterclockwisetoincreasethedischargerateof

granularmaterialfromthehopper.

ImpellerOn/OffSwitch

TheimpellerOn/Offswitchislocatedbelowthe

impeller-distributionow-rateknobatthebottomof

thecontrolconsole(Figure10).

UsetheimpellerOn/Offswitchtoruntheelectric

motorthatdrivestheimpeller.

•PresstheimpellerOn/Offswitchuptorunthe

impeller.

•PresstheimpellerOn/Offswitchdowntostopthe

impeller.

Impeller-speedControl

Theimpeller-speedcontrolislocatedtotherightof

theimpellerOn/Offswitchatthebottomofthecontrol

console(Figure10).

Theslotinthecam,aftersetting9onthecam,allows

theimpellergatetobeopenedtothemaximum

position.Thissettingcanbeusedfordrysand,ice

melt,orothermaterialsthataredifculttospread.

Note:Usecamsetting9maywhenyouarecleaning

outthehopper.

SprayerControls

Usetheimpeller-speedcontroltoadjusttherotational

speedoftheimpeller.

•Rotatetheimpeller-speedcontrolcounterclockwise

todecreasetherotationalspeedoftheimpeller.

•Rotatetheimpeller-speedcontrolclockwiseto

increasetheimpellerspeed.

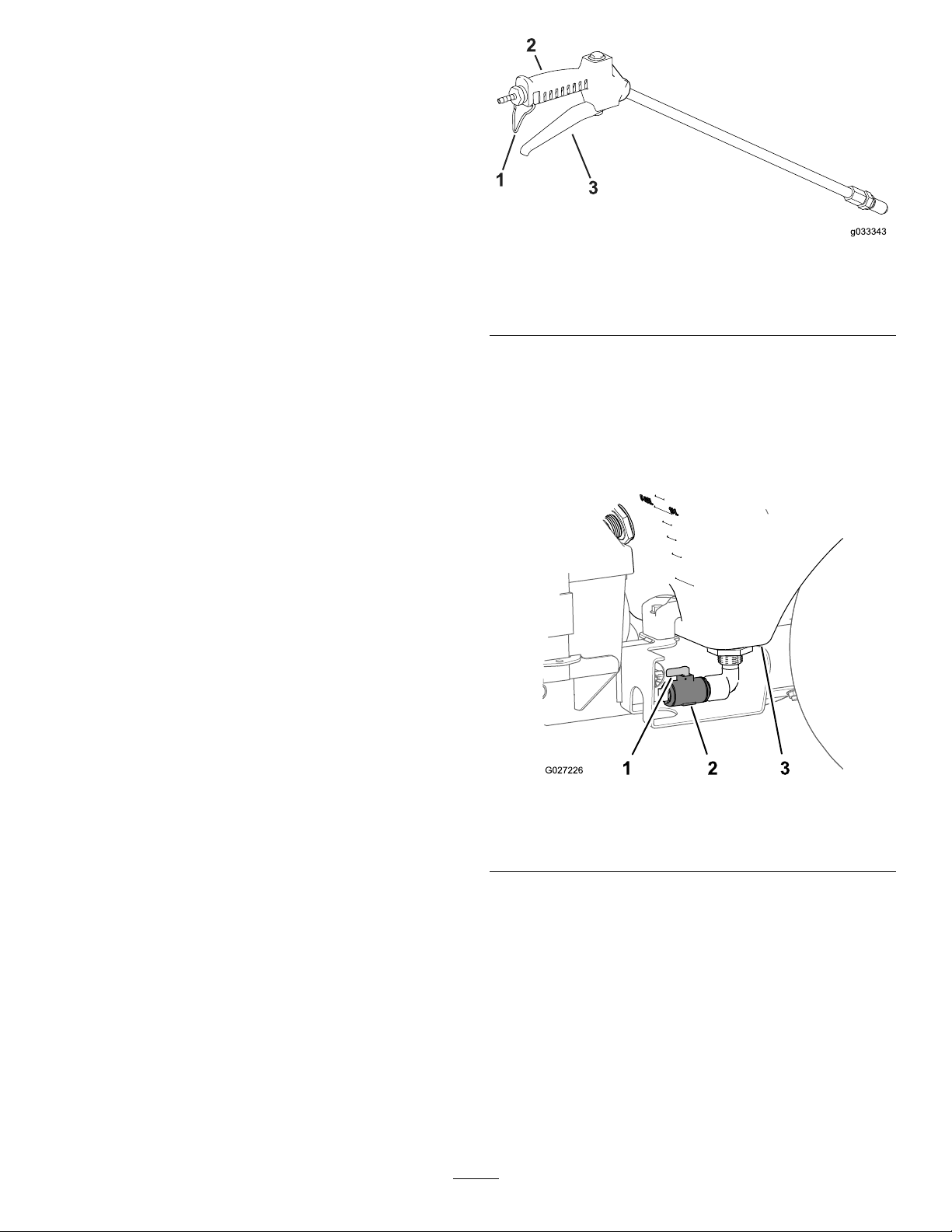

Drop-rateCamandLinkage

Thedrop-ratecamandlinkagearelocatedatthefront

ofthemachineandbelowthehopperonthespreader

(Figure11).

Figure12

1.Sprayer-pressurecontrol5.Sprayerwand

2.Tank-agitationlever

3.Narrow-spraypatternlever

4.Wide-spraypatternlever8.Wandpressurecontrol

SprayerPressureControl

6.Sprayer-pressuregauge

7.Sprayer-pumpswitch

Thesprayer-pressurecontrolislocatedonthecontrol

console(Figure12).

•Rotatethesprayer-pressurecontrolclockwiseto

increasethepressuretothesprayernozzles

•Rotatethepressure-controlcounterclockwiseto

thedecreasenozzlepressure.

TankAgitationLever

Thetank-agitationleverislocatedonthecontrol

console(Figure12).

g033348

Figure11

1.Slot–maximumposition

2.Linkage

Usethedrop-ratecamtosetthemaximumamountof

materialtobedispensedthroughtheimpellergate

andontotheimpeller.

g027033

Settingthetank-agitationlevertotheONposition

allowsthesprayerpumptocirculatethecontentinthe

spraytanktokeepthechemicalsolutionmixed.

•Pullthetank-agitationleverrearwardtocirculate

thecontentinthespraytank.

•Pushtheleverforwardtostopcirculatingthe

contentinthespraytank.

14

Page 15

Note:Donotuseagitationwhilespraying.Shut

offthetankagitationtoensureproperspray

distribution.

Note:Runtheenginespeedaboveidleandrunthe

sprayerpumpforthetankagitationtoworkeffectively.

Narrow-SprayPatternLever

Thenarrow-spraypatternleverislocatedonthe

controlconsole(Figure12).

•ToturnONthesprayerinanarrow-spraypattern

(thecenternozzleonly),pullthenarrow-spray

patternlevertowardyou.

•ToturnOFFthesprayer,pushthenarrow-spray

patternleverawayfromyou.

g033343

Figure13

1.Triggerlock3.Trigger

2.Spray-wandhandle

Wide-SprayPatternLever

Thewide-spraypatternleverislocatedonthecontrol

console(Figure12).

•ToturnONthesprayerinawide-spraypattern(the

rightandleftnozzles),pullthewide-spraypattern

levertowardyou.

•ToturnOFFthesprayer,pushthewide-spray

patternleverawayfromyou.

Sprayer-PressureGauge

Thesprayer-pressuregaugeislocatedonthecontrol

console(Figure12).

Usethepressuregaugetoseetheuidpressurein

thesprayersystem.

Sprayer-PumpSwitch

Thesprayer-pumpswitchislocatedonthecontrol

console(Figure12).

Usethesprayer-pumpswitchtostartandstopthe

pumpwhensprayingorcirculatingtheuidinthe

sprayertank(tank-agitation).

•Tostartthepump,pushdownonthetopofthe

sprayer-pumpswitch.

•Tostopthepump,pushdownonthebottomof

theswitch.

Spray-WandTriggerandTriggerLock

Thespray-wandtriggerandtriggerlockarelocated

onthebottomofthespray-wandhandle(Figure12

andFigure13).

•Tousethespraywand,holdthehandleofthe

wandsqueezethetrigger.

•TolockthetriggertotheONposition,fullysqueeze

thetriggeragainstthehandleandthenlatchthe

triggerlockoverthetrigger;tounlockthetrigger,

unlatchthetriggerlockfromthetrigger.

•Releasethetriggertostopthespray.

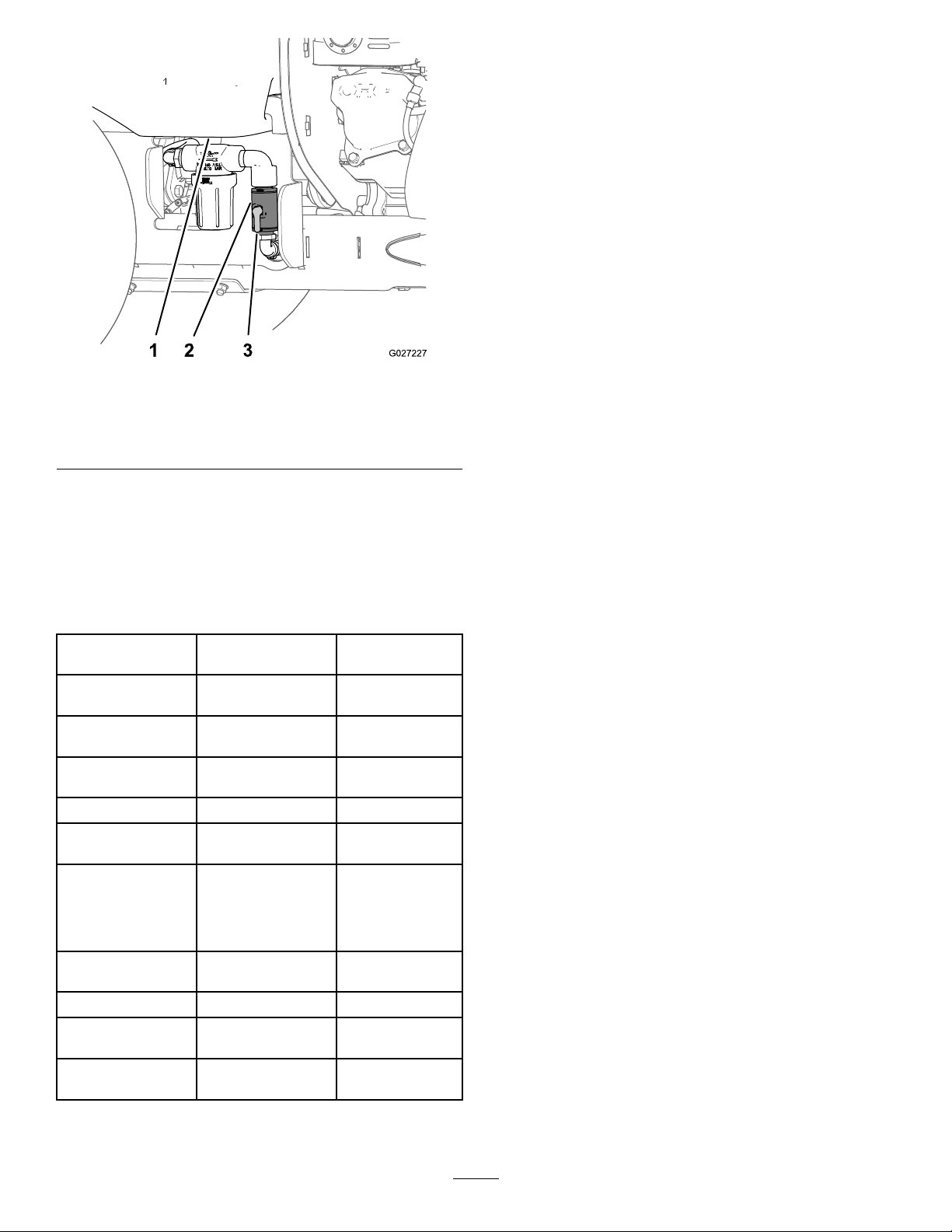

TankDrainValve

Thetankdrainvalveislocatedattheleftsideand

underthesprayertank(Figure15).

Usethetankdrainvalvetoemptythesprayertank

ofliquidchemicals.

g027226

Figure14

1.Handle(openposition)3.Sprayertank

2.Tankdrainvalve

•Toopenthevalve,rotatethehandleofthetank

drainvalve90°clockwise(leverin-linewithvalve).

•Toclosethevalve,rotatethehandle90°

counterclockwise.

Sprayer-Pump-SupplyValve

Thesprayer-pump-supplyvalveislocatedatthe

rightsideofthemachineandunderthesprayertank

(Figure15).

Usethesprayer-pump-supplyvalvetoshutoffthe

owofliquidchemicalstothepump.

15

Page 16

Figure15

1.Sprayertank3.Handle(openposition)

2.Sprayer-pump-supply

valve

•Toopenthevalve,rotatethehandlevalve90°

clockwise(leverin-linewithvalve).

•Toclosethevalve,rotatethehandle90°

counterclockwise.

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Parkthemachineonalevelsurface;shutoffthe

engine;engagetheparkingbrake;removethe

g027227

key;waitforallmovementtostop;andallow

themachinetocoolbeforeadjusting,cleaning,

storing,orservicingit.

•Neverallowchildrenoruntrainedpeopletooperate

themachine.Localregulationsmayrestrictthe

ageoftheoperator.Theownerisresponsiblefor

trainingalloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

Specications

Overallwidth90cm(35.5

Overalllength171cm(67.5

Overallheight131cm(51.5

Weightsprayertankand

Maximum

machineweight

Hoppercapacity

Sprayertank

capacity

Maximumground

speed

hopperempty

onlyhopperfull307kg(676lb)

onlysprayertank

full

sprayertankand

hopperemptyand

1extrabagof

granularmaterial

inthetank

loadedmachine+

operator

forward9kph(5.5mph)

inches)

inches)

inches)

227kg(500lb)

309kg(682lb)

412kg(909lb)

≤513kg(1130lb)

79kg(175lb)

76L(20US

gallon)

•Checkthatoperator-presencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Ifthemachinedoesnotfunctioncorrectlyoris

damagedinanyway,donotusethemachine.

Correcttheproblembeforeyouoperatethe

machineorattachment.

•Ensurethattheoperatorareaiscleanandfree

fromchemicalresidueanddebrisbuildup.

•Ensurethatalluidlineconnectorsaretightand

thatallhosesareingoodconditionbeforeapplying

pressuretothesystem.

ChemicalSafety

Chemicalsubstancesusedinthesprayersystem

maybehazardousandtoxictoyou,bystanders,and

animals,andtheymaydamageplants,soil,andother

property.

Ifyouwillusemorethan1chemical,readthe

informationoneachchemical.Refusetooperateor

workonthesprayerifthisinformationisnotavailable.

Beforeworkingonasprayersystem,ensurethatit

hasbeenneutralizedandtriplerinsedaccordingto

therecommendationsofthechemicalmanufacturer(s)

andthatallthevalveshavebeencycled3times.

16

Page 17

Verifythatthereisanadequatesupplyofcleanwater

andsoapnearby ,andimmediatelywashoffany

chemicalsthatcontactyou.

•Carefullyreadandfollowthechemicalwarning

labelsandmaterialsafetydatasheets(MSDS)for

allchemicalsused,andprotectyourselfaccording

tothechemicalmanufacturer'srecommendations.

•Alwaysprotectyourbodywhileusingchemicals.

Usetheappropriatepersonalprotectiveequipment

(PPE)toguardagainstcontactwithchemicals,

suchasthefollowing:

–safetyglasses,goggles,and/orfaceshield

–achemicalsuit

–arespiratororltermask

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainthefuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

–chemical-resistantgloves

–rubberbootsorothersubstantialfootwear

–acleanchangeofclothes,soap,and

disposabletowelsforcleanup

•Obtainpropertrainingbeforeusingorhandling

chemicals.

•Usethecorrectchemicalforthejob.

•Followthechemicalmanufacturer'sinstructionsfor

thesafelyapplyingthechemical.Donotexceed

therecommendedsystemapplicationpressure.

•Donotll,calibrate,orcleanthemachinewhile

people,especiallychildren,orpetsareinthearea.

•Handlechemicalsinawell-ventilatedarea.

•Havecleanwateravailable,especiallywhenlling

thespraytank.

•Donoteat,drink,orsmokewhileworkingnear

chemicals.

•Donotcleanspraynozzlesbyblowingthrough

themorplacingtheminyourmouth.

•Alwayswashyourhandsandotherexposedareas

assoonaspossibleafterworkingwithchemicals.

•Keepchemicalsintheiroriginalpackagesand

storedinasafelocation.

•Properlydisposeofunusedchemicalsand

chemicalcontainersasinstructedbythechemical

manufacturerandyourlocalcodes.

•Chemicalsandfumesaredangerous;neverenter

thetankorplaceyourheadoverorintheopening

ofatank.

•Followalllocal,state,andfederalregulationsfor

spreadingorsprayingchemicals.

PerformingDaily Maintenance

Beforestartingthemachineeachday ,performthe

followingdaily-checkprocedures:

•CheckingtheEngine-OilLevel(page52)

•CheckingtheSafetyInterlockSystem(page17)

•CheckingtheMachineforLooseHardware(page

67)

CheckingtheSafety InterlockSystem

ServiceInterval:Beforeeachuseordaily

CAUTION

Ifinterlockswitchisdisconnectedordamaged

themachinecouldoperateunexpectedly

causingpersonalinjury.

•Donottamperwiththeinterlockswitch.

•Checktheoperationoftheinterlockswitch

dailyandreplacedamagedswitchbefore

operatingthemachine.

Important:Ensurethatthesafetymechanisms

onyourmachineareconnectedandinproper

operatingconditionpriortooperatingyour

machine.

Thesafetyinterlocksystemisdesignedtopreventthe

enginefromstartingunlessyouengagetheparking

brake.

FuelSafety

•Useextremecareinhandlingfuel.Itisammable

anditsvaporsareexplosive.

17

Page 18

TestingtheStarterInterlock

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Chockthewheelsofthemachine.

3.Disconnectthespark-plugwires.

4.Releasetheparkingbrake.

5.Withthemotion-controlleverintheNEUTRAL

positionturnthekeytotheSTARTposition.

Note:Thestartermustnotrotatetheengine.

•Ifthestarterrotatestheengineofyour

machine—themachinedoesnotpass

thistest,donotoperateit.Contactyour

authorizedT orodistributor.

•Ifthestarterdoesnotrotatetheengine—the

machinedoespassthetest:engagethe

parkingbrake,connectthespark-plugwire

tothesparkplug,andremovethechock(s)

fromthewheels.

Addthecorrectamountoffuelstabilizer/conditioner

tothegasoline.

Note:Afuelstabilizer/conditionerismosteffective

whenmixedwithfreshgasoline.T ominimizethe

chanceofvarnishdepositsinthefuelsystem,usefuel

stabilizeratalltimes.

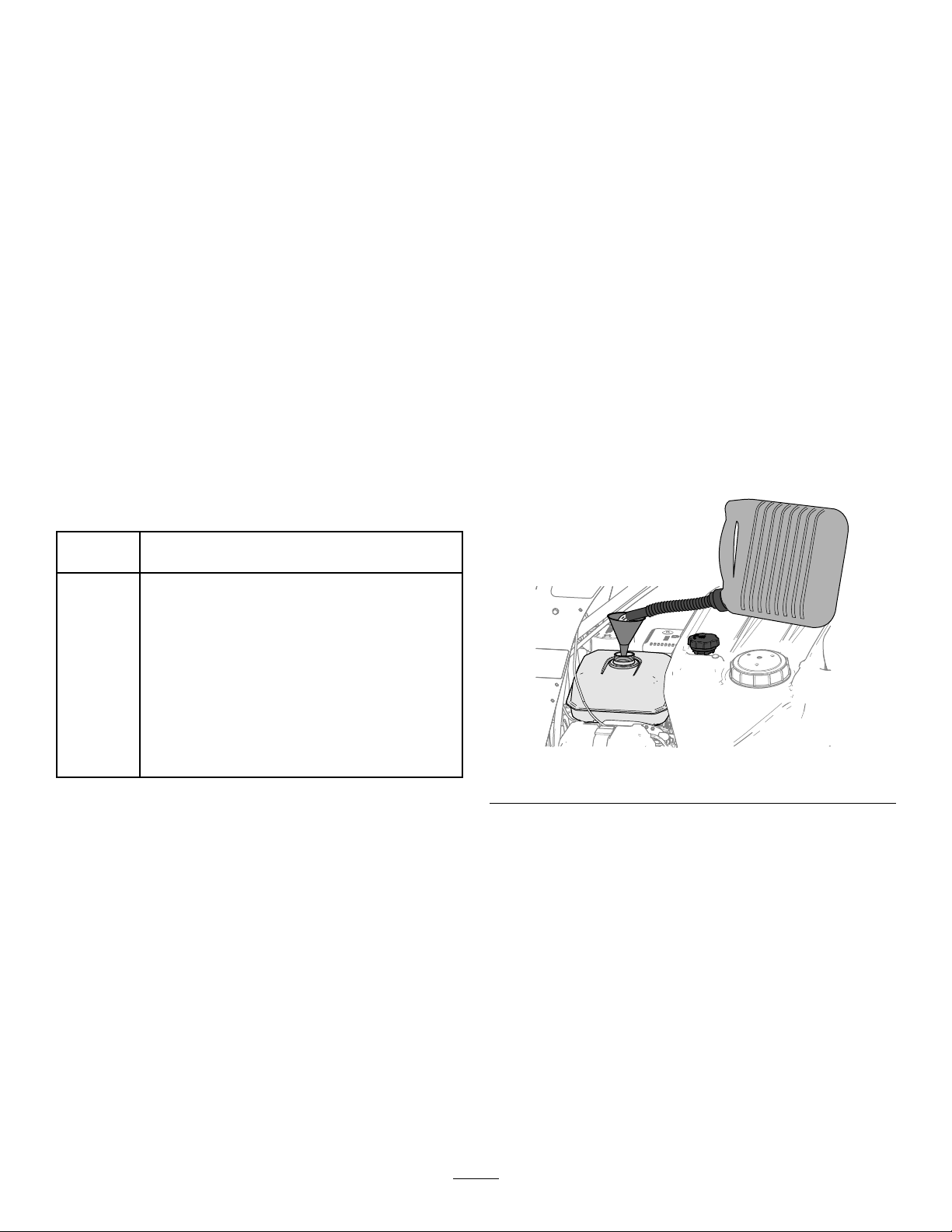

FillingtheFuelTank

Fueltankcapacity:6.1L(1.6USgallons)

Note:Refuelingtheengineisdifcultwhenusinga

largerrefuelingcontainersuchasacontainerwitha

19L(5USgal)capacity .

Tomakefuelingthemachineeasier,usea4to8L(1

to2USgal)fuelcontainerandafunnel.

1.Parkthemachineonalevelsurfaceandshut

offtheengine.

2.Allowtheenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit

(Figure16).

FuelSpecication

Petroleum

fuel

Ethanol

blended

fuel

Important:Forbestresults,useonlyclean,fresh

fuel(lessthan30daysold).

•Donotusegasolinecontainingmethanol.

•Donotstorefueleitherinthefueltankorfuel

containersoverthewinterunlessyouuseafuel

stabilizer.

•Donotaddoiltogasoline.

Useunleadedgasolinewithanoctaneratingof87

orhigher((R+M)/2ratingmethod).

Useanunleaded-gasolineblendwithupto10%

ethanol(gasohol)or15%MTBE(methyltertiary

butylether)byvolumeisacceptable.Ethanoland

MTBEarenotthesame.

Gasolinewith15%ethanol(E15)byvolumeis

notapprovedforuse.Neverusegasolinethat

containsmorethan10%ethanolbyvolume,such

asE15(contains15%ethanol),E20(contains

20%ethanol),orE85(containsupto85%

ethanol).Usingunapprovedgasolinemaycause

performanceproblemsand/orenginedamage

whichmaynotbecoveredunderwarranty.

g249048

Figure16

4.Fillthetankwithfuel(Figure16)towithin6to13

mm(1/4to1/2inch)fromthetopofthetank.Do

notllintothellerneckofthetank.

Important:Donotllthetankmorethan

6mm(1/4inch)fromthetopofthetank

becausethefuelneedsroomtoexpand.

5.Installthefuel-tankcapsecurely.

Using Stabilizer/Conditioner

Useafuelstabilizer/conditionerinthemachineto

providethefollowingbenets:

Important:Donotusefueladditivescontaining

methanolorethanol.

6.Wipeupanyspilledfuel.

18

Page 19

DuringOperation

DuringOperationSafety

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

GeneralSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hair,securelooseclothing,anddonotwearloose

jewelry.

•Wearappropriatepersonalprotectiveequipment

asdirectedinChemicalSafety(page16).

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemachineandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Donottrytostabilizethemachinebyputting

yourfootontheground.Ifyoulosecontrolofthe

machine,stepofftheplatformandawayfromthe

machine.

•Donotplaceyourfeetundertheplatform.

•Donotmovethemachineunlessyouarestanding

withbothfeetontheplatformandyourhandsare

holdingontothereferencebars.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Beforeyoustarttheengine,ensurethatyouare

intheoperatingposition,thetransmissionisin

neutral,andtheparkingbrakeisengaged.

•Beforeyoustarttheengine,ensurethatyouare

intheoperatingposition,thetransmissionisin

neutral,andtheparkingbrakeisengaged.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•Ensurethatyouhavegoodfootingwhileusingthis

machine,especiallywhenbackingup.

•Keepclearofanydischargeareaofthesprayer

nozzlesandspraydrift.Keepbystandersandpets

asafedistanceawayfromthemachine.

•Donotoperatethemachineneardrop-offs,

ditches,orembankments.Themachinecould

suddenlyrolloverifawheelgoesovertheedge

oriftheedgegivesway.

•Reducethespeedandloadwhenoperatingon

roughterrain,unevenground,andnearcurbs,

holes,andothersuddenchangesinterrain.

Loadsmayshift,causingthemachinetobecome

unstable.

•Stopthemachine,shutofftheengine,remove

thekey,engagetheparkingbrake,andinspect

fordamageafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Useextracautionwhenoperatingthemachineon

wetsurfaces,inadverseweatherconditions,at

higherspeeds,orwithafullload.Stoppingtime

anddistanceincreaseintheseconditions.

•Neverrunanengineinanenclosedareawhere

exhaustgassescancollect.

•Neverleavearunningmachineunattended.

•Donottouchtheengineormuferwhiletheengine

isrunningorsoonafterithasshutoff.These

areasmaybehotenoughtocauseburns.

•Beforeleavingtheoperatingposition,dothe

following:

–Stopthemachineonlevelground.

–Shutthewide-distributionimpeller-gateforthe

spreaderandshutoffthesprayer-pumpswitch.

–Shutofftheengineandremovethekey.

–Engagetheparkingbrake.

–Waitforallmovingpartstostop.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Donotusethemachineasatowingvehicle.

•Donotchangethegovernorspeedoroverspeed

theengine.

•Useaccessoriesandattachmentsapprovedby

Toroonly .

•Neversprayorspreadchemicalswhilepeople,

especiallychildren,orpetsarenearby .

19

Page 20

SprayerandSpreaderOperation Safety

•Thespraywandtrapsliquidsunderhighpressure,

evenwhenengineisoff.High-pressurespray

couldcauseseriousinjuryordeath.

–Keepclearofnozzleanddonotdirectspray

orstreamatpeople,pets,ornon-workarea

property.

–Donotdirectsprayonornearelectrical-power

componentsorsource.

–Donotattachhosesorothercomponentsto

theendofthespray-wandnozzle.

–Donotattempttodisconnectthespray

wandfromthemachinewhilethesystemis

pressurized.

–Donotusespraywandiftriggerlockis

damagedormissing.

–Rotatethespray-wandlocktotheOFFposition

whenjobiscomplete.

•Donottouchtheimpellerforthespreaderwhile

theimpellerisrotating.

•Stopspreading/sprayingwhenmakingtightturns

tominimizechemicaldrift.

•Chemicalsmaydriftandcauseinjurytopeople

andanimals;itmayalsodamageplants,soil,or

otherproperty.

•Liquidloadsandgranularmaterialscanshift.This

shiftinghappensmostoftenwhileturning,going

upordownhills,suddenlychangingspeeds,or

whiledrivingoverroughsurfaces.Shiftingloads

cancausethemachinetotipover.

•Safelyrelievepressurefromspraywandevery

timetheengineisshutoff.

•Whendrainingorrelievingsystem,donotlet

anyonestandinfrontofnozzlesanddonotdrain

onaperson’sfeet.

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Avoidstarting,stopping,orturningthemachine

onslopes.Travelupanddownonslopes.Avoid

makingsuddenchangesinspeedordirection.

Ifyoumustturnthemachine,turnitslowlyand

graduallydownhill,ifpossible.Usecarewhen

reversingthemachine.

•Donotoperateamachinewhenyouareuncertain

aboutthetraction,steering,orstability .

•Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhiddenhazards.

Tallgrasscanhideobstructions.Uneventerrain

couldoverturnthemachine.

•Beawarethatoperatingthemachineonwet

surfaces,acrossslopes,ordownhillmaycause

themachinetolosetraction.Lossoftractiontothe

wheelsmayresultinslidingandalossofbraking

andsteering.

•Useextremecautionwhenoperatingthemachine

neardrop-offs,ditches,embankments,water

hazards,orotherhazards.Themachinecould

suddenlyrolloverifawheelgoesovertheedge

ortheedgecavesin.Establishasafetyarea

betweenthemachineandanyhazard.

•Useextracarewhileoperatingthemachinewith

attachments;theycanaffectthestabilityofthe

machine.

•Iftheenginestallsoryoubegintolosemomentum

whileclimbingahill,graduallyapplythebrakes

andslowlybackstraightdownthehill.

•Alwayskeepthetransmissioningear(ifapplicable)

whenyoudrivethemachinedownaslope.

•Donotparkthemachineonanincline.

•Theweightofthematerialinthetankcanchange

thehandlingofthemachine.Toavoidlossof

controlandpersonalinjury,followtheseguidelines:

SlopeSafety

Slopesareamajorfactorrelatedtolossofcontroland

rolloveraccidents,whichcanresultinsevereinjuryor

death.Y ouareresponsibleforsafeslopeoperation.

Operatingthemachineonanysloperequiresextra

caution.

•Reviewtheslopeinstructionslistedbelowfor

operatingthemachineonslopesandtodetermine

whetheryoucanoperatethemachineinthe

conditionsonthatdayandatthatjobsite.

Changesintheterraincanresultinachangein

slopeoperationforthemachine.

•Determineiftheslopeissafeformachine

operation,includingsurveyingthesite.Always

–Whenoperatingwithaheavyload,reduceyour

speedandallowforsufcientbrakingdistance.

Donotsuddenlyapplythebrakes.Useextra

cautiononslopes.

–Liquidloadsshift,especiallywhileturning,

goingupordownslopes,suddenlychanging

speeds,orwhiledrivingoverroughsurfaces.

Shiftingloadscancausethemachinetotip

over.

20

Page 21

OperatingtheMachine

OpeningandClosingthe Fuel-Shut-OffValve

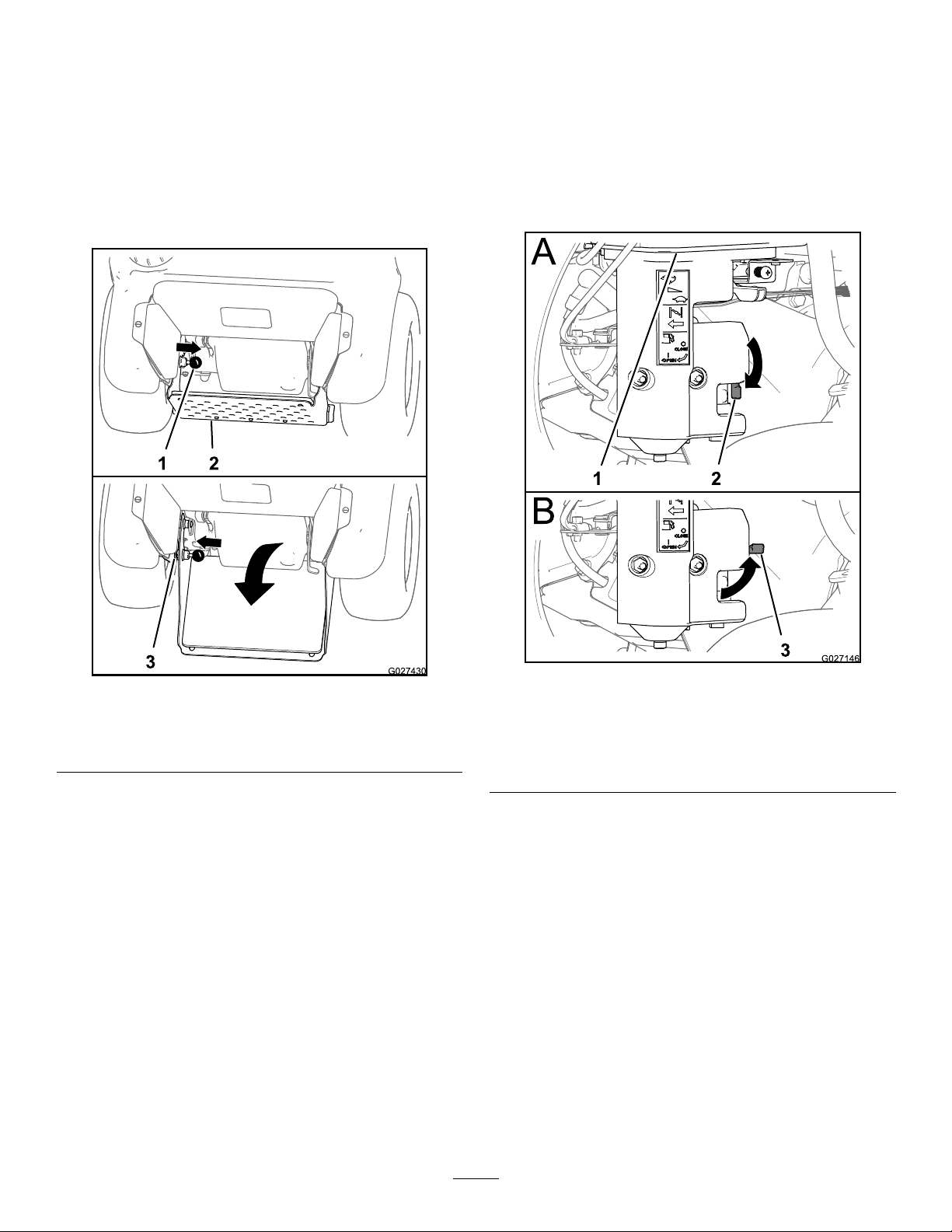

ExtendingandRetractingthe Operator’sPlatform

ExtendingtheOperator’sPlatform

1.Pulltheplatform-lockknobinwarduntilthepinof

clearstheupperholeinthechassis(Figure17).

Controlfuelowtotheenginewiththefuel-shut-off

valveasfollows:

•Rotatethehandleforthefuel-shut-offvalve90

degreesclockwisetotheopenthevalve.

•Rotatefuel-shut-offvalvehandle90degrees

counterclockwisetoclosethevalve.

Figure17

1.Platform-lockknob

2.Operator’splatform

2.Rotatetheoperator’splatformdownuntilthepin

oftheplatformlockalignswiththelowerholein

thechassis(Figure17).

3.Movetheplatform-lockknoboutwarduntilthe

pinprotrudesthroughthelowerhole(Figure17).

3.Lowerchassishole

RetractingtheOperator’sPlatform

1.Pulltheplatform-lockknobinwarduntilthepin

clearstheupperholeinthechassis(Figure17).

2.Rotatetheoperator’splatformupuntilthepinof

theplatformlockalignswiththeupperholein

thechassis(Figure17).

3.Movetheplatform-lockknoboutwarduntilthe

pinprotrudesthroughtheupperhole(Figure17).

g027430

1.Fueltank

2.Fuel-shutoffvalve(open

position)

Figure18

3.Fuel-shutoffvalve(closed

position)

g027146

StartingtheEngine

1.Ensurethatthefuel-shutoffvalveisopen;refer

toOpeningandClosingtheFuel-Shut-OffV alve

(page21).

2.Movethesteering-control/motion-control

leverinNEUTRALpositionandengagethe

parkingbrake;refertoSteeringControl(page

11),Motion-ControlLever(page11),and

Parking-BrakeLever(page12).

Note:T ostarttheengine,youmustengagethe

parkingbrake.(Y oucanstarttheenginewhile

youareofftheplatform.)

3.Movethethrottlelevermidwaybetweenthe

SLOWandFASTpositions;refertoThrottle

Control(page12).

21

Page 22

4.Iftheengineiscold,pullupthechokecontrolto

theONposition;refertoChokeControl(page

12).

Important:Ifthemotion-controlleverdoesnot

returntotheNEUTRALpositionwhenyourelease

it,contactanAuthorizedServiceDealer.

Note:Iftheengineiswarm,pushdownthe

chokelevertotheOFFposition.

5.RotatetheignitionswitchtotheSTARTposition;

refertoIgnitionSwitch(page12).

Note:Whentheenginestarts,releasethe

switch.

Important:Donotcranktheengine

continuouslyformorethan10secondsata

time.Iftheenginedoesnotstart,allowa60

secondcool-downperiodbetweenstarting

attempts.Failuretofollowtheseguidelines

canoverheatthestartermotor

6.IfthechokecontrolisintheONposition,

graduallymovetheleverdown,towardtheOFF

positionastheenginewarmsup.

ShuttingOfftheEngine

1.Movethesteering-control/motion-controllever

totheNEUTRALpositionandbringthemachine

toafullstop;refertoSteeringControl(page1 1)

andMotion-ControlLever(page11).

2.Placethethrottleinthemidwaybetweenthe

SLOWandFASTpositions;refertoThrottle

Control(page12).

3.Runtheengineforaminimumof15seconds,

thenturntheignitionswitchtotheOFFposition;

refertoIgnitionSwitch(page12).

4.Engagetheparkingbrake;refertoParking-Brake

Lever(page12).

5.Removethekey;refertoIgnitionSwitch(page

12).

6.Closethefuel-shutoffvalvewhenyouare

notusingthemachineforafewdays,when

transportingit,orwhenitisparkedinsidea

building;refertoOpeningandClosingthe

Fuel-Shut-OffValve(page21).

Important:Tobeginmovingthemachine

(forwardorbackward),theparking-brakelever

mustbereleased(pulledup)beforeyoumovethe

motion-controllever.

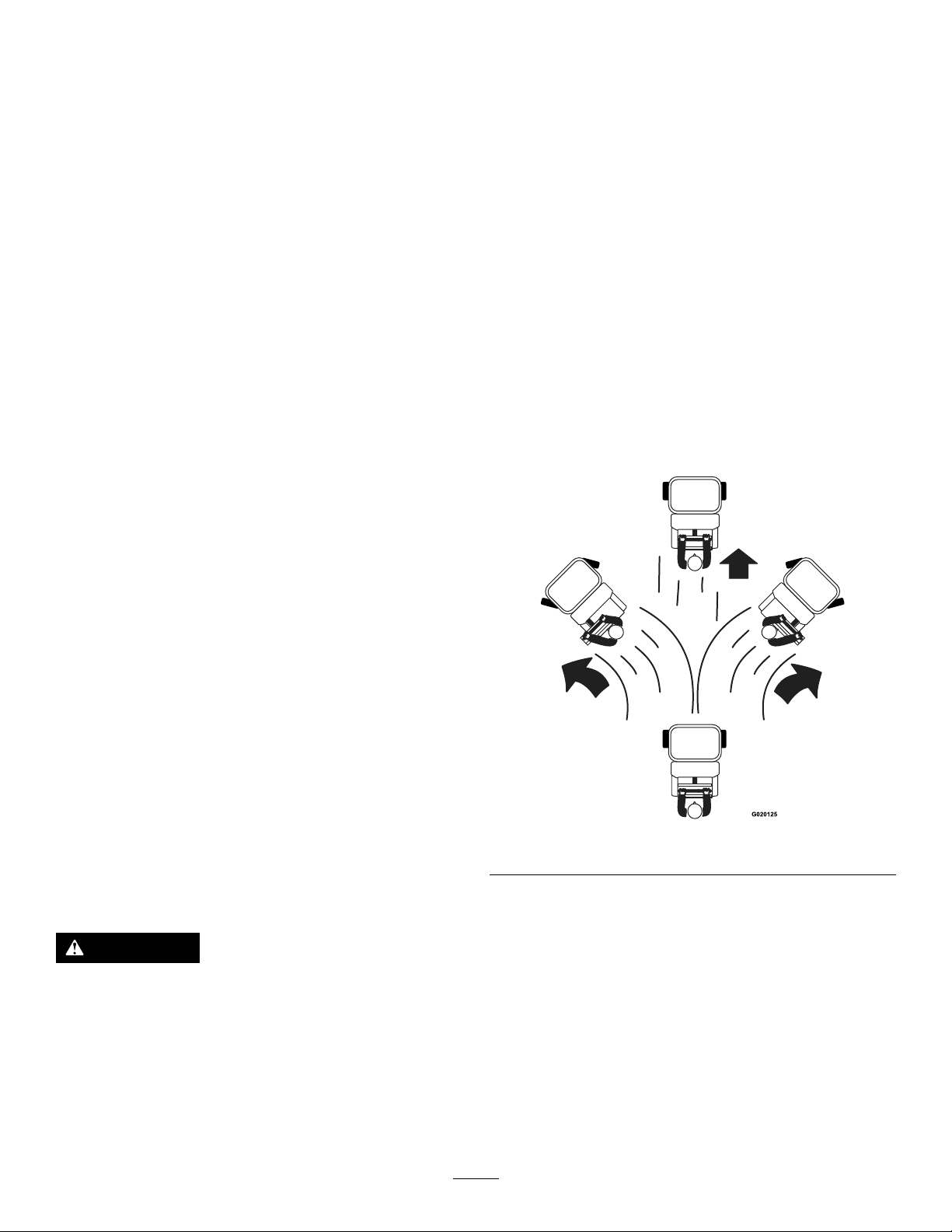

DrivingtheMachineForward

1.Movethemotion-controllevertotheNEUTRAL

position.

2.Releasetheparkingbrake.

3.Todrivethemachine,performthefollowing:

•Tomovethemachineforwardinastraight

line,centerthesteeringcontrolandmove

themotion-controlleverforward.

Note:Themachinemovesfasterthefarther

youmovethemotion-controlleverawayfrom

theNEUTRALposition.

g020125

Figure19

DrivingtheMachine

CAUTION

Machinecanturnrapidlybymovingthe

steeringcontroltothefarrightorleft.

Operatormaylosecontrolofthemachine,

whichmaycausedamagetothemachineor

injury.

•Usecautionwhenmakingturns.

•Slowdownthemachinebeforemaking

sharpturns.

•Toturnleftorright,movethesteeringcontrol

towardthedesiredturndirection.

•Tostopthemachine,movethemotion-control

leverintheNEUTRALposition.

Note:Stoppingdistancemayvary

dependingonthespreader-sprayerload.

Note:Whenyoureleasethemotion-control

lever,itautomaticallyreturnstotheNEUTRAL

position.

22

Page 23

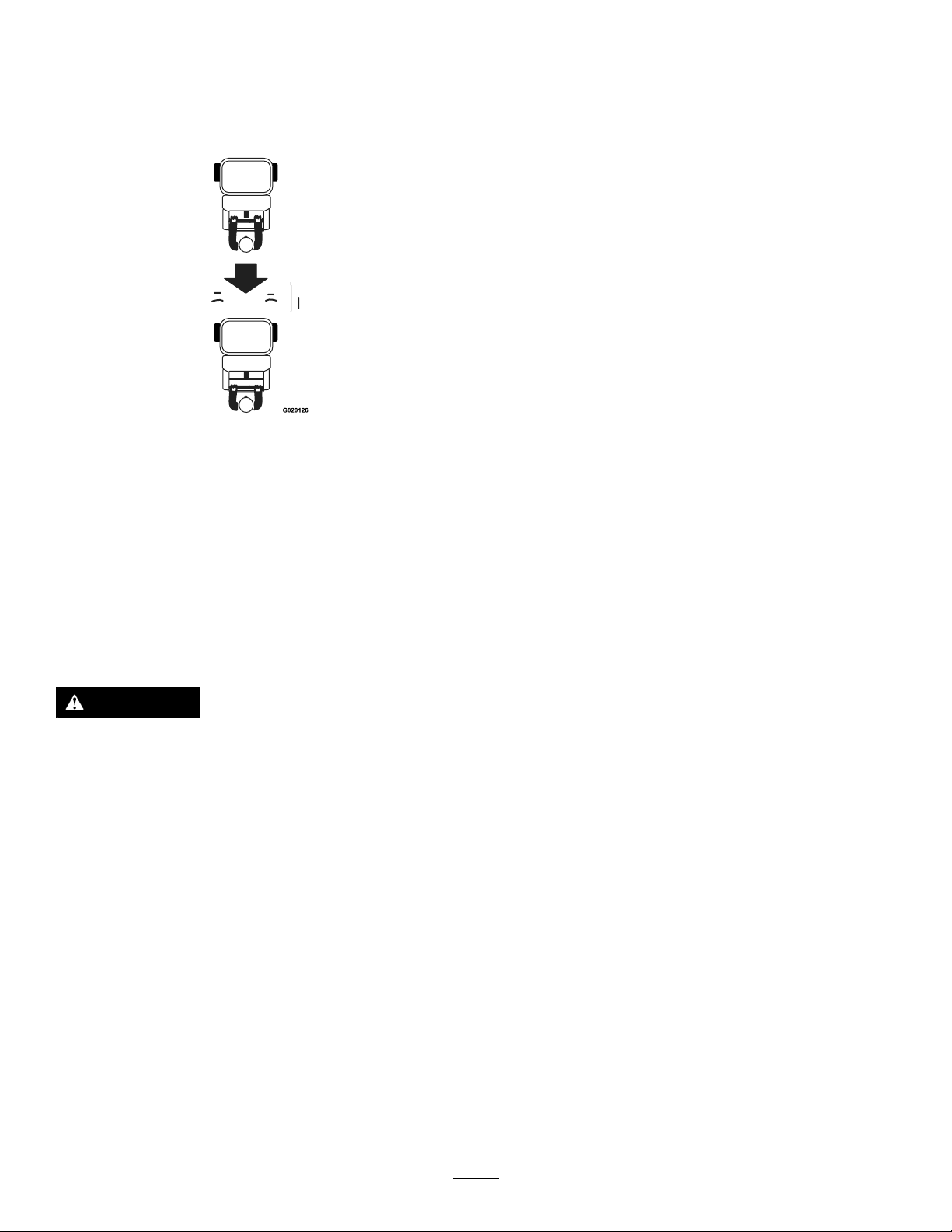

DrivingtheMachineinReverse

1.Movethemotion-controllevertotheNEUTRAL

position.

2.Tomovethemachinerearwardinastraightline,

slowlymovethemotion-controlleverrearward.

Figure20

BeforeOperatingtheSpreader

Beforeyoustartusingthespreader,calibratethe

spreaderforthematerialthatyouwilldisperse;refer

toCalibratingtheSpreader(page23).

Important:Priortollingthehopper,verifythat

youhavesettheproperspreader-applicationrate.

CalibratingtheSpreader

Calibratethespreadereachtimeyouuseanew

material.Thespreaderbroadcastsmaterialina

pattern1.5to6.7m(5to22ft)widedependingonthe

materialparticlesize,volume/density ,rateoftravel,

andwindconditions.

UsetheSpreadingCharts(page29)alongwith

informationfromDeterminingtheDistributionPattern

(page24),DeterminingtheEffectiveSpreadingWidth

g020126

(page25),andCalculatingtheApplicationRate(page

25)whencalibratingthespreader.

Toturnleftorright,movethesteeringcontrol

towardthedesiredturndirection.

3.Tostopthemachine,movethemotion-control

levertotheNEUTRALposition.

Note:Stoppingdistancemayvarydepending

onthespreader-sprayerload.

OperatingtheSpreader

CAUTION

Chemicalsarehazardousandcancause

personalinjury.

•Readthechemicalmanufacture’s

directionsonthelabelbeforehandling

thechemicals;followallmanufacturer

recommendationsandprecautions.

•Keepchemicalsawayfromyourskin.

Shouldcontactoccur,washtheaffected

areathoroughlywithsoapandcleanwater.

PreparingtheTestSiteandMachine

Operatorsuppliedequipment:15shallowcollection

pansand15graduatedmeasuringcylinders

Note:Themostaccuratemethodtomeasure

thedistributionusesshallowcollectionpansand

graduatedmeasuringcylinders.Intheexamplebelow,

the15shallowcollectionpansapproximately30cm

(12inches)wide,91cm(36inches)long,and5cm

(2inches)tall.

1.Placeonepaninthecenterofthedrivepath.

Arrangethenexttwopans,oneoneachside,

farenoughaparttoallowadequateroomforthe

drivetiresofthemachinetopassaroundthe

centerpan.

2.Placetheremainingpansinastraightlineas

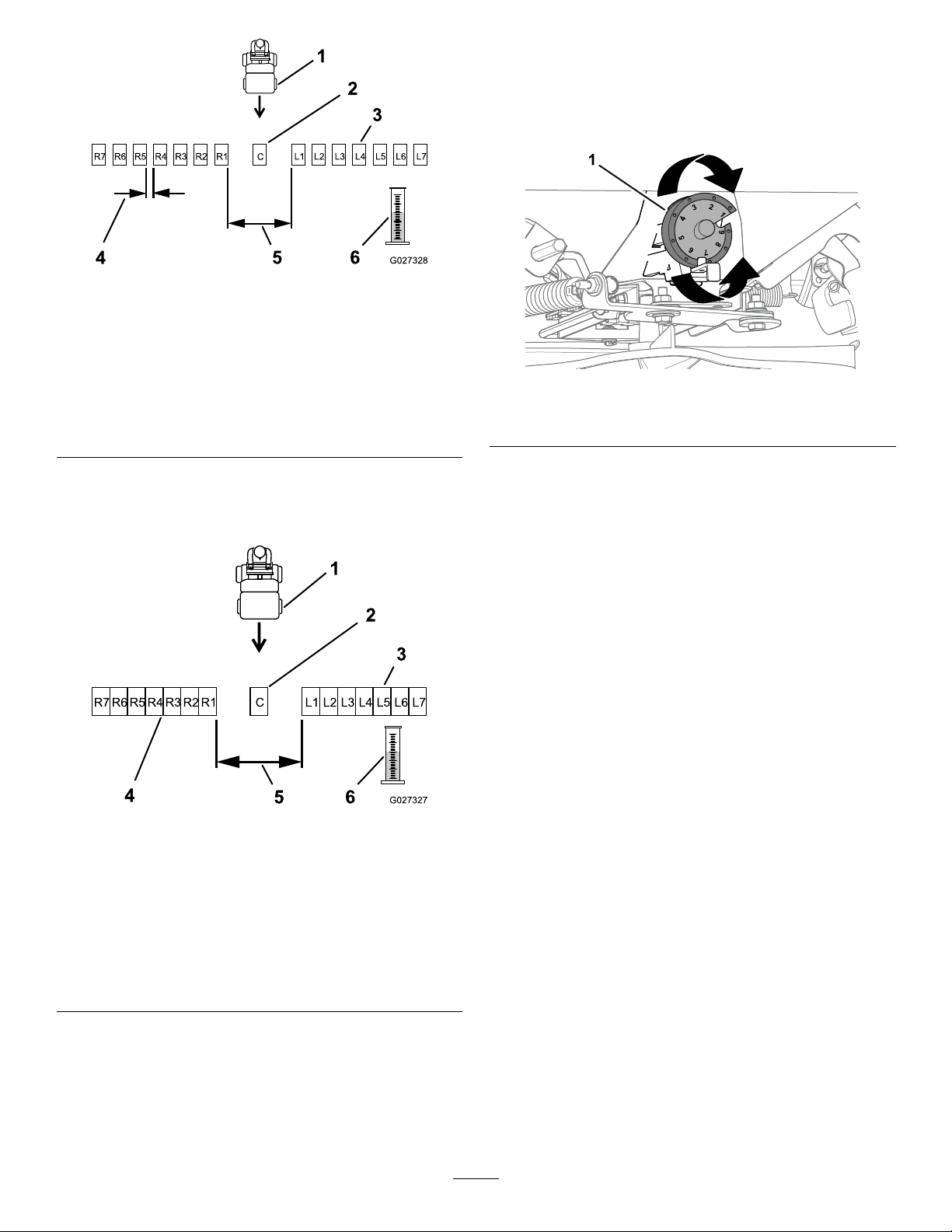

showninFigure21orFigure22.

•Forlargergranulematerials:

Space6additionalpans,oneachside,12

inches(30cm)apart(Figure21).

•Weareyeprotection,gloves,andanyother

protectiveequipmentrecommendedbythe

chemicalmanufacturer.

Usethespreadertodispersesfree-owinggranular

substancessuchasgrassseed,fertilizer,icemelt,

etc.Whenyouusethespreader,rstllthegranular

hopper,thenapplythegranularmaterialstothework

site,andnallycleanthehopper.

Important:Whenyouuseyourspreader,

thoroughlycleanitattheendoftheday.

23

Page 24

Figure21

Panspacingforlargergranulematerials

4.Determinetheapplicationrateandtherelated

drop-ratecamsetting;refertoSpreadingCharts

(page29).

5.Rotatethedropratecam(Figure23)tothecam

settingyoudeterminedinstep4.

g027328

1.Spreadermovingtoward

pans

2.Centerpan5.30cm(12inch)gap

3.Collectionpans(gap

betweeneach)

4.L1andR1collectionpan

gap(spreadaparttoallow

machinetopassthrough)

6.Graduatedmeasuring

cylinder

•Forsmallgranulematerials:

Place6additionalpans,oneachside,with

nogapinbetweeneachpan(Figure22).

Figure22

Panspacingforsmallgranulematerials

1.Spreadermovingtoward

pans

2.Centercollectionpan

3.Lestcollectionpans(no

gapbetweeneach)

3.Movethemachinefarenoughawayfromthe

testarea(wherethecollectionpansarelocated)

toensurethatthemachinetravelsatthedesired

spreadingspeedbeforereachingthesite.

4.Rightcollectionpans(no

gapbetweeneach)

5.L1andR1collectionpan

gap(spreadaparttoallow

machinetopassthrough)

6.Graduatedmeasuring

cylinder

g259776

Figure23

1.Dropratecam

6.Fillthehopperapproximatelyhalf-fullwiththe

desiredmaterial;refertoFillingtheSpreader

Hopper(page26).

DeterminingtheDistributionPattern

1.Setthespreaderpatterncontroltothemiddleof

itstravel;referto.

2.Settheimpellerspeedtotheappropriate

broadcastingrate.

3.Drivethemachinetowardthetestsiteatthe

appropriatespeed.

4.Asyouapproachthecenterpan,pullthewide

distributiongranulargatecontroltotheopen

position,anddriveoverthecenterpan.

5.Closethegatecontrol,movemotion-control

g027327

levertotheNEUTRALposition,shutoffthe

engine,waitforallmovingpartstostop,remove

key,andengageparkingbrake.

6.Labeleachgraduatedmeasuringcylinderto

correspondwiththedistributionpans(suchas

L2,L1,Center,R1,R2);refertoFigure21and

Figure22.

7.Oneatatime,takeacollectionpananddump

thecontentsintothecorrespondinggraduated

cylinder.Recordtheamountofmaterial

collectedandreturnthepantoitslocation.

Repeatthisuntilallpancontentshavebeen

emptied.

Note:Repeatbroadcastingoverthetestsite

severaltimes,movinginthesamedirection

eachtime,untilenoughmaterialisdispensedto

thecollectionpantohalfllagraduatedcylinder.

24

Page 25

8.Withthegraduatedmeasuringcylinderinthe

samestraightlineasthepans,evaluatethe

volumeofmaterialineachcylindertodetermine

thequalityofthedistributionfromthespreader.

9.Toadjustthespreaderpattern,refertothe

AdjustingtheSpreaderPattern(page30).

10.Fillthehopperhalf-fullofthedesiredmaterial

andrepeatsteps1through9untilyouachieve

auniformpattern.

DeterminingtheEffectiveSpreadingWidth

Usetheeffectivewidthtodeterminetheuniform

distributionofthematerial.

Note:Thespreadingwidthrangeis6to8m(20to

25ft).

1.Afterthespreaderpatterniscorrectlyadjusted,

evaluatetheamountofmaterialinthecenter

graduatedmeasuringcylinder.

2.Locatethe2graduatedcylinder,oneeachside

ofcenter,thatcontain1/2themeasuredamount

ofthematerialthatyouobservedinthecenter

graduatedcylinder.

3.Gotothetwocorrespondingpans.Startingfrom

theouteredge,measurethedistancebetween

leftpan,acrossthecenterpan,totheouteredge

oftherightpan,andrecordthemeasurement.

Recordtheeffectivespreadingwidth

here:

.

CalculatingtheApplicationRate

1.Determinetheareaandamountofmaterialthat

youareapplyingtothejobsiteandrecordthose

amountsintheareaandmaterialsworksheet.

Recordthejobsitearea

here:

.

Recordtheamountofjobsitematerial

here:.

2.Initially,usetherecommendedapplicationrate

indicatedintheSpreadingCharts(page29)

sectionorusetheraterecommendedlistedon

theproductmanufacturer’slabelasaguideto

helpdeterminetheamountofmaterialthatyou

wouldspreadovera93m

2

(1,000ft2)area.

Note:Inthisexamplethecalibrationcourseis

1.8m(6ft)by51m(167ft).

3.Settheappropriatedrop-ratecamsetting;refer

totheSpreadingCharts(page29)asastarting

point.

4.Addmaterialtothehopper.

Note:Inthisexampleweadded11.3kg(25

lb)ofmaterial.

5.Drivethespreaderoverthecalibrationcourse

whileapplyingthematerial.

6.Emptytheremainingmaterialofthehopperinto

acleanbucket;refertoEmptyingtheSpreader

(page26).

PreparingtheCalibrationCoursefor

CalculatingtheApplicationRate

1.Determineacourselengthbydividing93m

(1,000ft2)bytheeffectivespreadwidththat

youdeterminedinDeterminingtheEffective

SpreadingWidth(page25);usethecourse

lengthformula.Recordthecourselength

here:

.

CalibrationCourseLengthFormula

93m2(1,000ft2)

Formula

Example

/Effectivewidth

measurement

93m2(1,000ft2)

/1.8m(6ft)

=

=

Calibrationcourse

51m(167ft)

Note:Inthisexampletheeffectivewidth

measures1.8m(6ft).

2.Measureandvisiblymarkthecourselength.

Ensurethatyouallowenoughdistancebefore

thestartingmarkersothatthespreadermoving

forwardatfullspeedwhencrossingtherst

markofthecourse.

7.Weighthebucketcontainingthematerialand

recordtheweight.Pourthecontentsback

intothehopperandthenweightheempty

2

bucket.Calculatetheremainingmaterialweight

usingtheremainingmaterialweightformula.

Recordtheremainingmaterialweight

here:

.

RemainingMaterialWeightFormula

(Remaining

materialand

Formula

length

Example

bucketweight)-

(Bucketweight)

10kg(22lb)—

1kg(2lb)

Remainingmaterial

=

=

weight

9kg(20lb)

Note:Inthisexample,9kg(20lb)ofmaterial

remaininthehopperafterapplyingthematerial

tothetestcourse.

8.Calculateappliesmaterialweighusing

theappliedmaterialformulathatfollows.

Recordtheappliedmaterialweight

here:

.

25

Page 26

AppliedMaterialWeightFormula

(Original

materialweight)

Formula

Example

-(Remaining

materialweight)

11.3kg(25lb)

—9kg(20lb)

3

=

=

Note:Thiscalculationmeansthat2.3kg(5lb)

ofmaterialwasappliedtothe93m

testcourse.

9.Ifnecessary,adjustthedrop-ratecamtoachieve

therecommendedapplicationrate.Onceyou

achievethecorrectapplicationrate,repeat

thisprocedureanadditionaltimetoverifyyour

results.

Important:Designateanewcalibration

courseeachtime,sothattheturfisnot

damagedbyexcessiveapplicationof

material.

FillingtheSpreaderHopper

Appliedmaterial

2.3kg(5lb)

weight

2

(1,000ft2)

g027326

Figure24

1.Cover

2.Hopper

3.Drop-ratecam

Maximumhopperweightcapacity:79kg(175lb)

1.Drivethemachinetotheworksite.

2.Movethemachinetoalevelsurface,move

motion-controllevertotheNEUTRALposition,

shutofftheengine,waitforallmovingpartsto

stop,removekey,andengageparkingbrake.

3.Ensurethatthewide-distributionimpeller-gate

leverisinthefullyforward(closed)position;

refertoWide-distributionImpeller-GateLever

(page13).

4.UsetheSpreadingCharts(page29)to

determinethesettingforthedrop-ratecam

(Figure24).

Note:Ifthesettingisnotlistedforthetypeof

materialthatyouareusing,setthecamtothe

settingwithalowervaluethenadjustasneeded.

5.Removethecoverfromthehopper,addthe

materialthatyouarespreading,andinstallthe

coverontothehopper(Figure24).

Note:Donotoverloadthehopper;the

maximumweightcapacityofthehopperis79

kg(175lb).

Note:Youmayplace1extrabagofgranular

productontopofthesprayertankifnecessary .

EmptyingtheSpreader

RemovingtheImpeller

1.Movethemachinetoalevelsurface,move

motion-controllevertotheNEUTRALposition,

shutofftheengine,waitforallmovingpartsto

stop,removekey,andengageparkingbrake.

2.Emptythehopperbyscoopingoutasmuchof

thematerialaspossible.

3.Removethe4thumbscrewsthatsecurethefront

cover(belowtheimpeller)tothechassis,and

removethecover(Figure25).

26

Page 27

Figure25

1.Forwardcover3.Thumbscrew

2.Clipnut

g033530

4.Removethedrivepinthatsecuretheimpellerto

theshaftoftheimpellermotor,andremovethe

impellerfromtheshaft(Figure26andFigure

27).

Figure26

g027325

Figure27

5.Placeashallowpanundertheshaftofthe

impellermotor(Figure27).

DisconnectingtheRate-GateLinkage

1.Pushthelockingsleeveforthegatecable

rearwardandliftthecableupfromtheballstud

oftherate-gatelinkage(Figure28).

g027324

1.Drivepin3.Impeller

2.Shaft

27

Page 28

ConnectingtheRate-GateLinkage

1.Pullthelinkageoutuntilitclearsthedrop-rate

cam(Figure28).

2.Movethewide-distributionimpeller-gatelever

forward.

3.Attachingthecabletotheballstudatthegate

lever(Figure28).

AssemblingtheImpeller

1.Assembleimpellerontotheimpellershaftand

securetheimpellerwiththedrivepin.

2.Aligntheholesinthefrontcoverwiththeclip

nutsinthechassisandsecurethecoverwith

the4thumbscrewsthatyouremovedinstep3

ofRemovingtheImpeller(page26).

Figure28

1.Lockingsleeve4.Drop-ratecam

2.Gatecable

3.Ballstud

5.Rate-gatelinkage

2.Pullthecableofftheballstud(Figure28).

3.Rotatethedrop-ratecampastposition-9so

thattheslotinthecamalignswiththelinkage

(Figure28).

4.Fullypushtherate-gatelinkagerearward(Figure

28).

5.Ifthereismaterialinthehopperallowthe

materialtopourintoashallowpan;whenthe

hopperisempty ,removethepan.

g027304

28

Page 29

UsingtheSpreader

SpreadingCharts

Note:Thecamsettingtablesforpelletmaterialandthegrassseedareprovidedwithpermissionfromthe

Brinly-HardyCompany;referencetheBrinly-HardyCompanywebsiteformoreinformation.

Usethesechartsasanapproximateguidelineonly .Otherfactors,suchasweatherconditions,spreader

operation,andtheconditionofmaterialaffectsspreaderperformance.

CamSettingsforPelletMaterialApplication

Type

FinePellets

MixedFinePellets

SmallPellets

NitrogenPelletsMediumSize

MediumPelletsandGranules

LargeHeavyPellets

kgper93m

2

(lbper1,000ft2)CamSetting—OnePassCamSetting—T woPasses

0.5(1)

0.9(2)

1.4(3)

0.9(2)

1.8(4)

2.7(6)

0.9(2)

1.8(4)

2.7(6)

0.5(1)

0.9(2)

1.4(3)

0.9(2)

1.8(4)

2.7(6)

0.9(2)

1.8(4)

2.7(6)

3.63.1

4.03.5

4.23.7

3.73.2

4.74.1

5.24.5

32.2

4.23.7

4.54

3.53

4.23.7

4.74

3.53

4.23.8

5.24.5

3.83.3

4.94.1

5.94.9

Usethechartbelowforreferenceonly.Whensprayingandspreadingatthesametime,setthespreadpattern

totwicethewidthofthespray;thiswillhelpavoidstripingandstreaking.Forexample,standardspraywidth=

2.7m(9ft)andspreadwidth=5.4m(18ft).

CamSettingsforGrassSeedApplication

2

TypeBagWeight

BlueGrassorRed

Top

Park,Merion,

Delta,orKentucky

Bluegrass

HulledBermuda

Coverage-m

0.23kg(0.5lb)93(1,000)

0.45kg(1lb)93(1,000)

0.9kg(2lb)93(1,000)

2.27kg(.5lb)93(1,000)

0.45kg(1lb)93(1,000)

0.9kg(2lb)93(1,000)

0.9kg(2lb)93(1,000)

1.36kg(3lb)93(1,000)

1.81kg(4lb)93(1,000)

2

(ft

)CamSetting–

FullRate

29

CamSetting–

HalfRate

1.254

2.0

2.54

2.5

3.04

3.5

2.752.256

3.02.56

3.252.756

SpreaderWidth

4

4

4

Page 30

CamSettingsforGrassSeedApplication(cont'd.)

TypeBagWeight

MixturesIncluding

CoarseSeeds

RyeGrassesorTall

Fescue

Dichondra

PensacolaBahia

0.9kg(2lb)93(1,000)

1.81kg(4lb)93(1,000)

2.72kg(6lb)93(1,000)

0.9kg(2lb)93(1,000)

1.81kg(4lb)93(1,000)

2.72kg(6lb)93(1,000)

113kg(4oz)93(1,000)

227g(8oz)93(1,000)

340g(12oz)93(1,000)

1.81kg(4lb)93(1,000)

2.27kg(.5lb)93(1,000)

2.72kg(6lb)93(1,000)

AdjustingtheSpreaderPattern

Coverage-m

2

2

(ft

)CamSetting–

FullRate

6.06

7.06

7.06

6.06

7.06

7.75

1.98

2.18

2.58

4.53.75

4.754.0

5.04.25

CamSetting–

HalfRate

SpreaderWidth

6

7

7

7

Ifthespreadercastsmaterialunequallyside-to

side—toolight/heavytooneside—(seeFigure29and

Figure30),adjustthespreader-pattern.

Figure29

1.Heavytoleftside

2.Moveramppatternto

shadedposition

3.Heavytorightside

Note:Donotadjusttherampsthatsplittheproduct

ow.Adjustonlythefrontorrearramppositions.

1.Unlockthespreader-patterncontrolbyturning

thehandlecounterclockwise90°asshownin2

ofFigure30.

g025543

1.Spreader-patterncontrol4.Startnotchifpatternis

2.Rotatecounterclockwise

tounlock

3.Startnotchifpatternis

heavytoleftside

Figure30

heavytorightside

5.Rotateclockwisetolock

g027035

2.Adjustthespreaderpatternasfollows:

•Ifthematerialisbroadcasttooheavy

attheleftsideofthemachine,pullthe

spreader-patterncontrolupslightly;referto

3ofFigure30.

•Ifthematerialisbroadcasttooheavyat

therightsideofthemachine,pushthe

spreader-patterncontroldownslightly;refer

to4ofFigure30.

30

Page 31

3.Lockthespreader-patterncontrolbyturningthe

handleclockwise90°;referto5ofFigure30.

UsingtheDeectorGate

Usethedeector-gatecontroltotemporarilystopor

deectgranularmaterialawayfromsidewalks,parking

lots,patios,oranywherethegranularchemicalsare

notdesired.

Note:Thedeectorgatechangesthedischargedof

materialsfromtheleftsideofthespreaderonly.

•Pushtheknobforthedeector-gatecontroldown

tolowerthedeectorandtemporarilyblockthe

granularmaterial.

•Pulltheknobtoraisethedeectortocastmaterials

normallyattheleftsideofthemachine.

SpreadingMaterial

1.Starttheengineandplacethethrottlemidway

betweentheSLOWandtheFASTpositions.

2.Settheimpeller-speedcontroltoappropriate

broadcastrateandthenpresstheimpeller

On/OffswitchtotheONposition(Figure32).

g027483

Figure32

1.Indicatorlight4.Impeller-speedcontrol

2.ImpellerOn/Offswitch5.Spreader-motorand

sprayer-motorcontroller

3.Icon—pressandholdthe

impellerOn/Offbutton5

seconds

•Tolocktheimpellerspeedcontrol,pressand

holdtheimpellerOn/Offswitchfor5seconds

(Figure32).

Note:Theindicatorlightabovetheimpeller

On/Offswitchwillashataconstantrate.

g027373

Figure31

1.Fence

2.Flowers

3.Deectorgatelowered

Iftheimpeller-speedcontrolislocked

(indicatedbytheashingindicatorlight),the

impellermotorwillstartandrunatthelast

lockedspeed.

•Tounlocktheimpeller-speedcontrol,start

theimpellermotorandthenpressand

holdpressandholdtheOn/Offswitchfor

5seconds(theindicatorlightwillilluminate

steadily).

31

Page 32

Figure33

g027123

1.Deector-gatecontrol

2.Spreader-patterncontrol6.ImpellerOn/Offswitch

3.Wide-distribution

impeller-gatelever

4.Narrow-distribution

impeller-gatelever

5.Narrow-spreader

distributionow-rate

knob

7.Impeller-speedcontrol

3.MovethethrottletotheFASTpositionanddrive

themachineforward.

4.Opentheeitherthenarroworwideimpeller-gate

levertobeginspreading(Figure34).

Note:Usethenarrow-spreaderdistribution

ow-rateknobtocontrolthedischargerate

ofthegranularmaterialfromthehopperonto

theimpellerwhenthenarrow-distribution

impeller-gateleverisintheOPENposition.

Figure34

1.Widespreader

pattern—variableeffective

widthto6.7m(22ft)

maximum

2.Narrowspreader

pattern—variableeffective

widthfrom1.5m(5ft)

minimum

5.Evaluatethespreadpattern.

Note:Ifyouneedtoadjustmentthespreading

pattern,refertoAdjustingtheSpreaderPattern

(page30).

6.Whenyouarenishedspreading,closethe

wide-distributionimpeller-gatelever.

Note:Onlythewide-distributionimpeller-gate

leverclosestheimpellergate.Pushingthe

wide-distributionimpeller-gateleverforwardalso

resetsthenarrow-distributionimpeller-gatelever

totheforwardposition.

7.Cleanthehopperaftereachspreadingsession;

refertoCleaningandLubricatingtheSpreader

(page43).

g027497

Important:Alwaysemptyandcleanthe

spreaderimmediatelyaftereachuse.Failure

todosomaycausethechemicalstocorrode

thespreaderandothercomponents.

32

Page 33

SpreadingTips

Important:Ensurethatyoucalibratethespreader

beforeyoustartusingit.

Figure35

Spreaderpathexample

1.Narrowdistribution-sidedeectorlowered5.Endofspreadingjob

2.Forward

3.Effectivespreadingwidth—variable1.5to6.7m(5to22ft)

4.Donotspreadwhenturning180°

6.Propertyfence

7.Gate

•Toensureuniformapplication,broadcastthe

materialinanoverlappingpatternasshownin

Figure35.

Note:Thehighestamountofmaterialwill

dispensefromthefrontofthehopperandless

materialfromeachside.Youcanadjustthe

distributionpatterntoachievethedesiredresults.

•Watchforchangesinthedistributionpattern;

unequaldistributionmayleadtostriping.

g027374

33

Page 34

OperatingtheSprayer

CAUTION

Chemicalsarehazardousandcancause

personalinjury.

•Readthechemicalmanufacture’s

directionsonthelabelbeforehandling

thechemicals;followallmanufacturer

recommendationsandprecautions.

•Keepchemicalsawayfromyourskin.

Shouldcontactoccur,washtheaffected

areathoroughlywithsoapandcleanwater.

•Weareyeprotection,gloves,andanyother

protectiveequipmentrecommendedbythe

chemicalmanufacturer.

Usethesprayertodisperseliquidherbicides,

pesticides,fertilizers,andothersubstances.Before

usingthesprayerensurethatyouhavecleaned

thetank,plumbing,andnozzlesbeforeaddingany

chemicals.Whenyouusethesprayer,yourstllthe

spraytank,thenapplythechemicalsolutiontothe

worksite,andthenwhenyouarenishedspraying,

cleanthetank.Itisimportanttocompleteall3of

thesestepstoavoiddamagingthesprayer.For

example,Donotmixandaddchemicalsinthespray

tankthenightbeforeandthensprayinthemorning.

Thiscouldleadtoseparationofthechemicalsand

possiblecausedamagetocomponentsofthesprayer.

Important:Whenyouuseyoursprayer,

thoroughlycleanitattheendoftheday.

CalibratingtheSprayer

1.Measureandvisiblymarkacourselengthused

tocalculatetheaveragegroundspeed.Record

thecourselengthhere:

Note:Inthisexamplethecourselengthis45.7

m(150ft).

2.Addcleanwaterintothespraytankuntilitis1/2

full;refertoFillingtheSprayT ank(page38).

3.Drivethemachinetoanareafarenoughaway

fromthecoursesothatwhenyouaredriving

itintothecourse,themachinetravelsatthe

desiredgroundspeedbeforereachingtherst

marker.

4.Useastopwatchtomeasurethetime(in

seconds)thatittakesthemachinetotravelthe

markedcourse(45.7m(150ft)inthisexample)

whilemaintainingthedesiredgroundspeed.

Recordyourcoursetimeinthecoursetime

worksheet.

CourseTimeWorksheet

Time

Test1seconds

Test2seconds

Test3seconds

5.Repeatsteps2through4anadditional2times.

6.Movethesprayertoalevelsurface,movethe

motion-controlleverintheNEUTRALposition,

shutofftheengine,waitforallmovingpartsto

stop,removekey,andengageparkingbrake.

7.Averagethe3testruntimes(inseconds);

usetheaveragecoursetimeformula.

Recordtheaveragecoursespeed

here:

.

.

Note:Beforeyouusethesprayerforthersttime

orchangethenozzlesorwhenthesprayerisoutof

adjustment—calibratethesprayerforgroundspeed

andowrate.

Note:Theleftandrightsprayerboomnozzlesare

widepattern(white)nozzlesandthecenternozzleis

anarrowpattern(red)nozzle.

Note:Refertothechemicalproductlabelfor

applicationraterecommendations.

Themethodtocalibratethesprayerowinvolves

drivingapresetdistance,recordingthetime,andthen

measuringtheamountofliquidappliedduringthat

time.

CalculatingtheGroundSpeed

Operatorsuppliedequipment:Stopwatchcapable

ofmeasuring±1/10second.

AverageCourseTimeFormula

Formula

Example21.6+19.1+

8.Calculatetheaveragegroundspeed;usethe

groundspeedformula.Recordtheaverage

groundspeedhere:

(time1)+(time

2)+(time3)

18.4seconds

seconds

3

3

=

=

Note:1kph=16.6m/minute(1mph=88

ft/minute)

34

Theaveragetimeto

drivethecourse

19.7seconds

.

Page 35

GroundSpeedFormula

Formula

Example45.7m(150ft)x60seconds

19.7secondsx16.6m/minute

Courselength

m(ft)x60seconds

Coursetime(seconds)x

16.7m/minute(88ft/minute)

(88ft/minute)

Groundspeed

=

kph(mph)

8.4kph

=

(5.2mph)

UnderstandingtheEffectiveSprayPattern

Width

Note:Sprayerpressureregulator:2.8bar(40psi).

•Thenarrow-spraypattern(Figure36)onthe

machineis122cm(48inches)wide.

Figure37

Topviewofthewide-pattern-spraynozzles

1.Spraywidth=274cm(108

inches)

2.Nozzle5.Distancebetweenspray

3.Sprayangle=120°6.Frontofthemachine

4.Spraydistance=61cm

(24inches)

nozzles=66cm(26

inches)

g027415

Figure36

Topviewofthenarrow-pattern-spraynozzle

1.Spraywidth=122cm(48

inches)

2.Nozzle

3.Sprayangle=120°

4.Spraydistance=36cm

(14inches)

5.Frontofthemachine

•Thewide-spraypattern(Figure37)onthismachine

is274cm(108inches)wide.

TestingtheSprayerNozzleDischarge

Operatorsuppliedequipment:Stopwatchcapable

ofmeasuring±1/10secondandacontainergraduated

in50ml(1oz)increments.

Note:Ensurethatthespraysystemiscleanand

g027414

thereis1/2tankofcleanwater.

1.Engagetheparkingbrakeandstarttheengine.

2.Setthepump/tankagitationswitchtotheON

position.

3.Pulltheagitationleverrearwardtostartthetank

agitation.

4.PlacethethrottletotheFASTposition.

5.PushtheagitationcontrolleverdowntotheOFF

position.

Note:Shutofftheagitationtoensureproper

spraypressureanddistribution.

6.Usethespray-pressurecontroltoadjustthe

sprayer-systempressureto40psi(2.8bar).

Note:Theredandwhitenozzlesinstalledon

thissprayerhaveanormaloperatingpressure

of40psi(2.8bar).

7.Alignthegraduatedcontainerundereachnozzle

for19.7seconds.

35

Page 36

Note:Recordtheamountofwatercollected

fromeachnozzleinthecollectionworksheet.

1.Graduatedcontainer

CollectionWorksheet

Figure38

2.Personalprotective

equipment—chemical

resistantgloves

•Centernozzle—recordthe

averagedischargequantity

here:.

•Leftnozzle—recordtheaveragedischarge

quantityhere:.

ConvertingtheTimeandCollectionResults

toFlowRate

1.Convertthemilliliters(uidounce)quantities

thatyoucalculatedinstep10ofT estingthe

SprayerNozzleDischarge(page35)toliters(US

gallons)usingthequantityconversionformula.

Note:1L=1000ml

1USgallon=128oz

QuantityConversionFormula

g027502

FormulaResult(X)ml(oz)

0.1L(128oz)

Example

center

nozzle—narrow

pattern(red)

490ml(16.75oz)

0.1L(128oz)

=

=

(X)L(USgallon)

0.49L(0.13US

gallon)

Leftsprayer

nozzle

Test

1

Test

2

Test

3

ml(oz)ml(oz)ml(oz)

ml(oz)ml(oz)ml(oz)

ml(oz)ml(oz)ml(oz)

Centersprayer

nozzle

8.Repeatteststep7foreachnozzleanadditional

2times.

9.Turnoffthepump/tankagitationswitch.

10.Calculatetheaveragequantityofwater

dischargedforeachnozzle;useaverage

dischargeformula.

AverageDischargeFormula

Formula

Example

center

nozzle—narrow

pattern(red)

test1+test2

+test3

3

475ml(16.05

oz)+507ml

(17.15oz)+504

ml(17.05oz)

3

=

=

•Rightnozzle—recordthe

averagedischargequantity

here:

Rightsprayer

nozzle

Theaveragespray

nozzledischargein

19.7seconds

0.49L(16.75oz)

.

A.Rightnozzle—recordthe

convertedcollected-waterquantity

here:

.

B.Centernozzle—recordthe