Page 1

FormNo.3420-986RevB

SpreaderAttachment

Stand-onAerator

ModelNo.33525—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3420-986*B

Page 2

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Introduction

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcode(ifequipped)ontheserial

numberdecaltoaccesswarranty,parts,andother

productinformation.

Figure1

1.Locationofthemodelandserialnumbers

Contents

Safety.......................................................................3

SafeOperatingPractices....................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................5

1PreparingtheMachine.....................................6

2InstallingtheFlowControlPanel......................6

3InstallingtheHopperAssembly........................6

4InstallingtheCable-MountBracket...................7

5InstallingtheControlCable..............................7

6InstallingtheWireHarness..............................9

7InstallingtheCover........................................10

ProductOverview....................................................11

Specications...................................................11

Operation.................................................................11

Controls.............................................................11

Pre-Start...........................................................12

OperatingInstructions......................................13

OperatingtheSpreaderAccessory...................13

OperatingTips..................................................16

RemovingtheSpreaderAttachment.................16

Maintenance...........................................................17

RecommendedMaintenanceSchedule(s)...........17

.............................................................................17

CheckforLooseHardware...............................17

SpreaderPatternControlCable

Adjustment....................................................17

g253435

AdjustingtheGateClosure...............................18

Cleaning..............................................................18

CleanDebrisFromMachine.............................18

Troubleshooting......................................................19

Schematics.............................................................20

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury ,complywiththesesafetyinstructions,

andpayattentiontothesafetyalertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeinstructions

mayresultinpersonalinjuryordeath.

SafeOperatingPractices

CAUTION

Themachinethatthespreaderaccessory

attachestoproducessoundlevelsin

excessof85dBAattheoperator’searand

cancausehearinglossthroughextended

periodsofexposure.

Wearhearingprotectionwhenoperating

thismachine.

•Inspecttheareawhereyouwillusetheequipment

andremoveallobjectsfromtheareabeforeusing

themachine.

Training

•ReadtheOperator'sManualforthemachineand

thisaccessoryandothertrainingmaterial.

Note:Iftheoperator(s)ormechanic(s)cannot

readthemanuallanguage,itistheowner's

responsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.

Theownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.

Note:Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsible

foraccidentsorinjuriesoccurringtohimselfor

herself,otherpeople,ordamagetoproperty.

Preparation

•Donotmodifytheaccessory.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Useonlyaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludingsafetyglasses,

substantialfootwear,andhearingprotection.Tie

backlonghair,securelooseclothing,anddonot

wearloosejewelry.

Operation

WARNING

Hands,feet,hair,clothing,oraccessoriescan

becomeentangledinrotatingparts.Contact

withtherotatingpartscancausetraumatic

amputationorseverelacerations.

•Donotoperatethemachinewithout

guards,shields,andsafetydevicesin

placeandworkingproperly.

•Keephands,feet,hair,jewelry,orclothing

awayfromrotatingparts.

•Operatethemachineonlyingoodvisibilityand

appropriateweatherconditions.Donotoperate

themachinewhenthereistheriskoflightning.

•Operatethemachineonlyinwell-litareas,keeping

awayfromholesandhiddenhazards.

•Beawareofweatherconditionsandcheckthat

spreaderpatternsandvolumearesuitable.

•Neveroperatethemachinewithdamagedguards,

shields,orcovers.Alwayshavesafetyshields,

guards,switchesandotherdevicesinplaceandin

properworkingcondition.

•Stoponlevelground,disengagedrives,engage

theparkingbrake(ifprovided),shutofftheengine,

andremovethekeybeforeleavingtheoperator's

positionforanyreason.

•Stopspreadingwhenmakingtightturnsto

minimizeunevendistributionpatternand

applicationrate.

•Reducetheweightoftheloadwhenoperating

onhillsandroughterraintoavoidtippingor

overturningthemachine.

•Materialloadscanshift.Thisshiftinghappens

mostoftenwhileturning,goingupordownhills,

suddenlychangingspeeds,orwhiledrivingover

roughsurfaces.Shiftingloadscancausethe

machinetotipover.

3

Page 4

•Whenoperatingwithaheavyload,reduceyour

speedandallowforsufcientstoppingdistance.

Useextracautiononslopes.

•Reducespeedandloadwhenoperatingonrough

terrain,unevenground,andnearcurbs,holes,and

othersuddenchangesinterrain.Loadsmayshift,

causingthemachinetobecomeunstable.

•Heavyloadsaffectstability.Reducetheweightof

theloadandyourspeedwhenoperatingonhills.

tostopbeforeadjusting,cleaningorrepairingthe

machine.

•Emptythehopperbeforetiltingthemachinefor

maintenanceandbeforestoring.

•Keepyourhandsandfeetawayfrommoving

parts.Ifpossible,donotmakeadjustmentswith

theengineand/ortheimpellerrunning.

•Keepallguards,shields,andsafetydevicesin

placeandinsafeworkingcondition.

MaintenanceandStorage

•Closethespreadergate,engagetheparking

brake,shutofftheengine,andremovethekeyor

disconnectsparkplugwire.Waitforallmovement

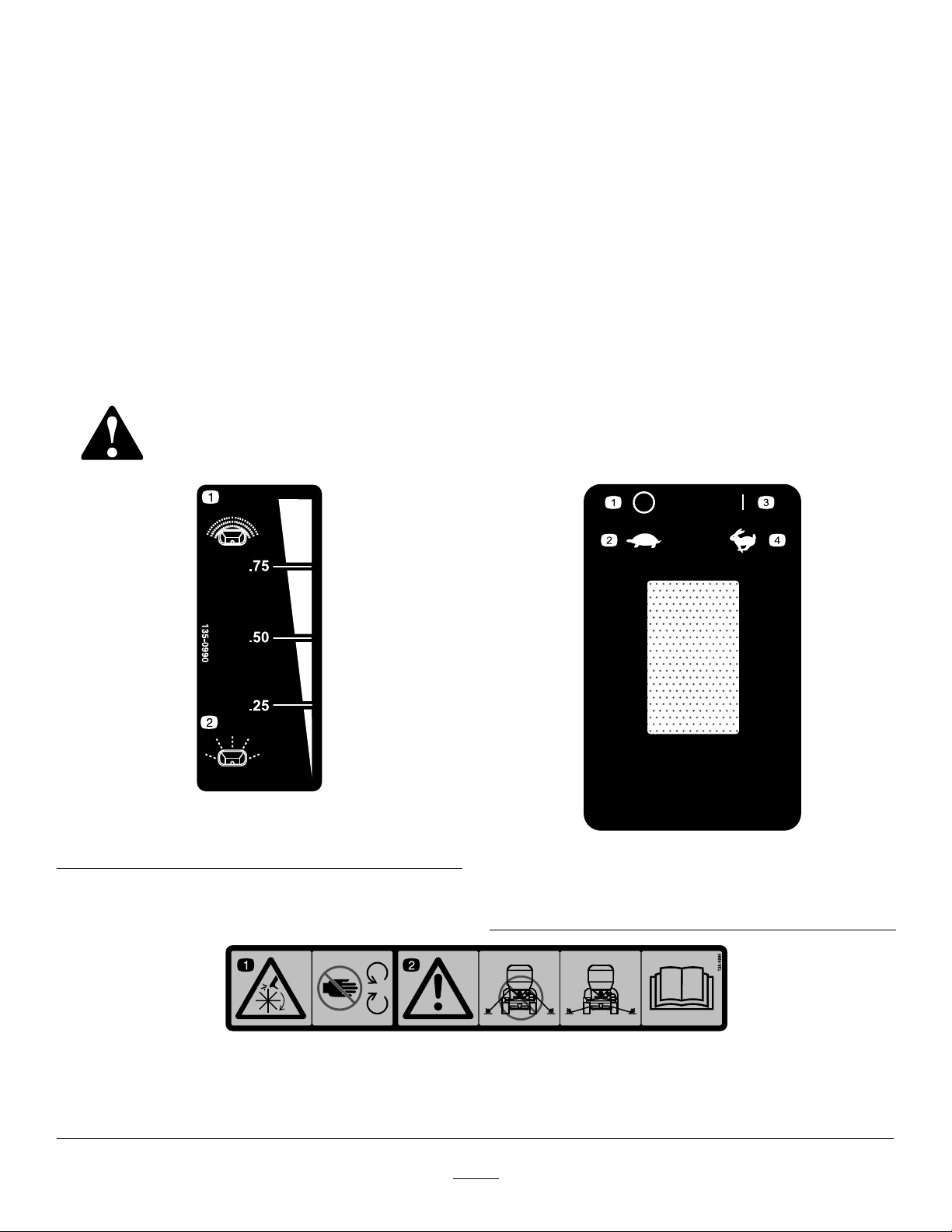

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

•Checkallboltsfrequentlytomaintainproper

tightness.

•Frequentlycheckforwornordeteriorating

componentsthatcouldcreateahazard.

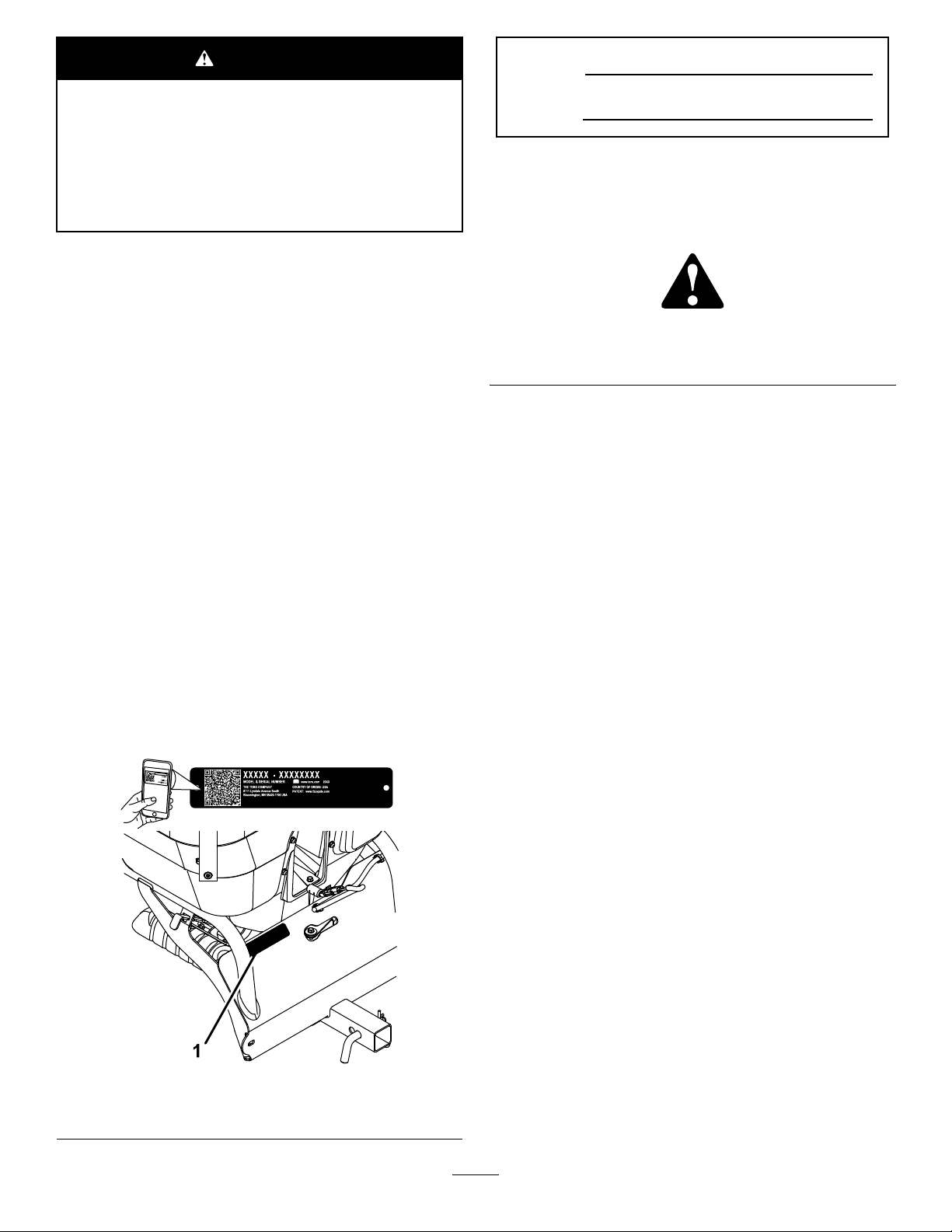

135-0990

1.Spreadpattern-heavy2.Spreadpattern-light

1.Cutting/dismembermenthazard—keepawayfrommoving

parts.

decal135-0990

decal135-0739

135-0739

1.Impeller—off

2.Impeller—slow

126-4994

2.Warning—donotusetheupperfrontlocationsastiedown

points,onlyusethespeciedtie-downpoints;seethe

Operator’sManualforlocation.

4

3.Impeller—on

4.Impeller—fast

decal126-4994

Page 5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

7

Nopartsrequired

Bolt(3/8x1-1/4inches)—30-inch

machinesonly

Locknut(1/4inch)—30-inchmachines

only

Bolt(1/4x5/8inch)—30-inchmachines

only

Bolt(5/16x3/4inch)—24-inchmachines

only

Locknut(5/16inch)—24-inchmachines

only

Hopperassembly1

Hairpincotter1

Hitchpin1

Cable-mountbracketfor24-inch

machines

Cable-mountbracketfor30-inch

machines

Carriagebolt(5/16x1inch)—24-inch

machinesonly

Carriagebolt(1/4x1inch)—24-inch

machinesonly

Locknut(1/4inch)—24-inchmachines

only

Locknut(1/4inch)—30-inchmachines

only

Bolt(1/4x5/8inch)—30-inchmachines

only

Controlcable

Locknut(1/4inch)

Washer2

Wireharness1

Cabletie

Cover

Washer4

Locknut(1/4inch)

Bolt(1/4x3/4inch)

Qty.

10

Use

–

1

1

1

3

3

1

1

1

1

1

2

2

1

2

1

4

4

Preparethemachine.

Installtheowcontrolpanel.

Installthehopperassembly .

Installthecable-mountbracket.

Installthecontrolcable.

Installtheharness.

InstallingtheCover

5

Page 6

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Engagetheparkingbrake.

3.Shutofftheengineandremovethekey.

4.Disconnectthenegative(black)batterycable

fromthenegative(-)batteryterminal.

2

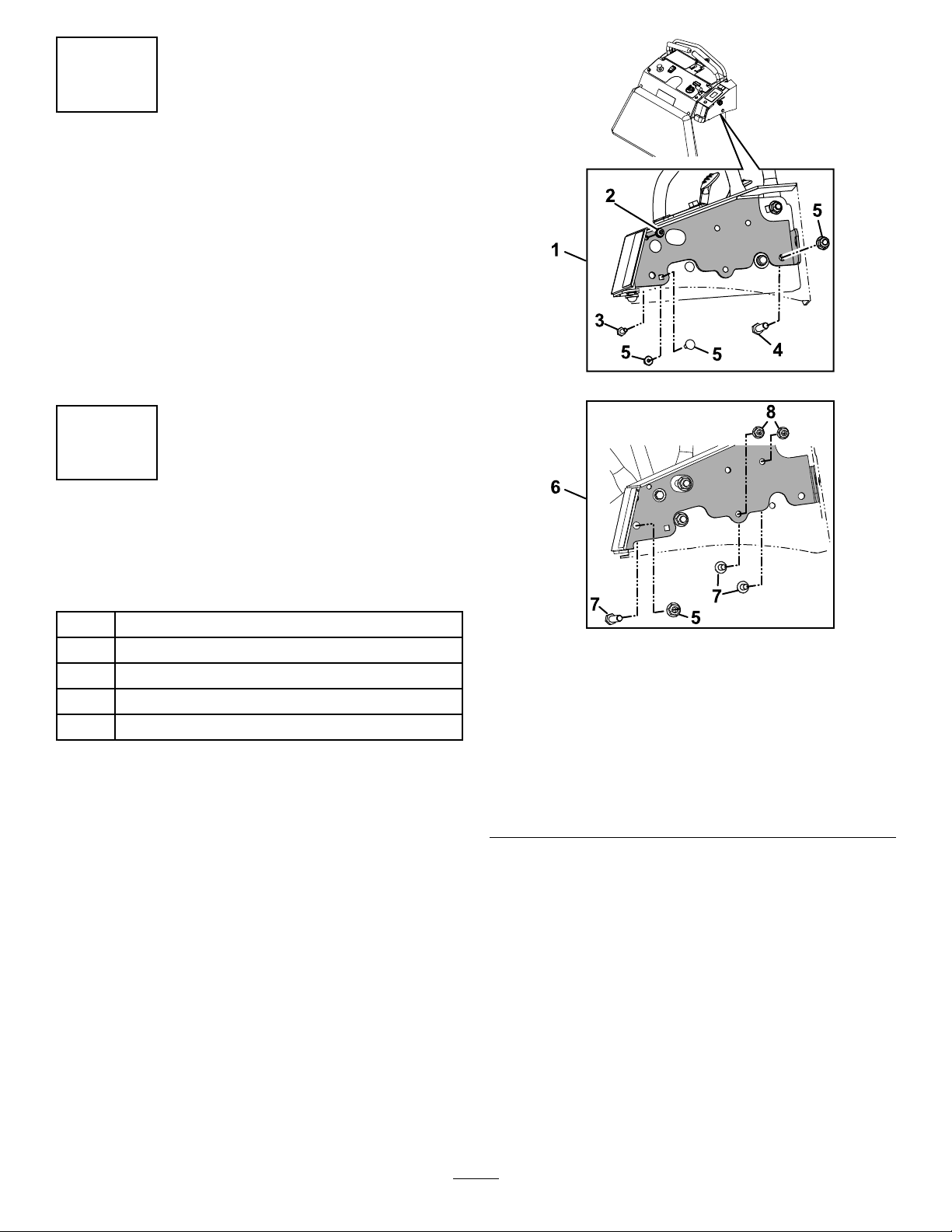

InstallingtheFlowControl Panel

Partsneededforthisprocedure:

1

Bolt(3/8x1-1/4inches)—30-inchmachinesonly

1

Locknut(1/4inch)—30-inchmachinesonly

1

Bolt(1/4x5/8inch)—30-inchmachinesonly

3

Bolt(5/16x3/4inch)—24-inchmachinesonly

3

Locknut(5/16inch)—24-inchmachinesonly

Procedure

1.Holdtheowcontrolpanelagainsttheright

sideofthemachinetodeterminethemounting

holeconguration.Removeandretainthe

mountinghardwarefromwherethebracketwill

beinstalledonthemachine.

Figure3

Outercoverhiddenforclarity

1.Installationfor30-inch

machine

2.Locknut(1/4inch)6.Installationfor24-inch

3.Bolt(1/4x5/8inch)7.Hex-headbolt(5/16x3/4

4.Bolt(3/8x1-1/4inches)8.Locknut(5/16inch)

2.Placetheowcontrolpanelontothemachine

andsecureitusingthehardwareshownin

Figure3.

Note:Additionalhardwareisshippedwiththe

spreaderiftheretainedhardwareisnotlong

enoughtomountthecontrolpanel.

5.Reuseretainedhardware

machine

inch)

g238611

6

Page 7

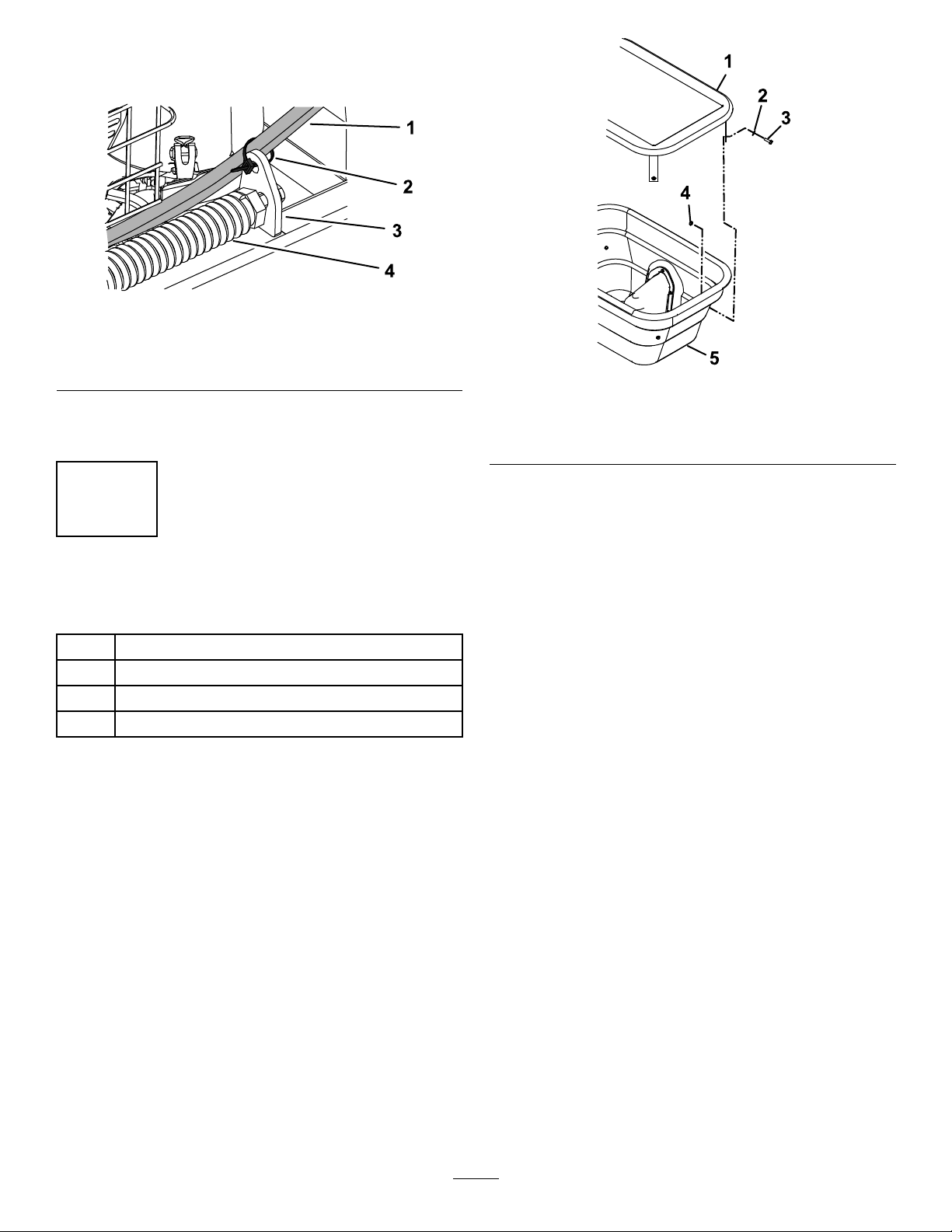

3

4

InstallingtheHopper

Assembly

Partsneededforthisprocedure:

1Hopperassembly

1Hairpincotter

1Hitchpin

Procedure

1.Insertthehopperhitchtubeintothereceiveron

themachine.

InstallingtheCable-Mount Bracket

Partsneededforthisprocedure:

1

Cable-mountbracketfor24-inchmachines

1

Cable-mountbracketfor30-inchmachines

1

Carriagebolt(5/16x1inch)—24-inchmachinesonly

1

Carriagebolt(1/4x1inch)—24-inchmachinesonly

1

Locknut(1/4inch)—24-inchmachinesonly

2

Locknut(1/4inch)—30-inchmachinesonly

2

Bolt(1/4x5/8inch)—30-inchmachinesonly

Procedure

Choosetheappropriatecable-mountbracketby

matchingtheholestotherightsideofthemachine.

UsethehardwareshowninFigure5toinstallthe

bracket.

Figure4

1.Hopperhitchtube

2.Hitchpin

2.Usethehitchpinandhairpincottertosecurethe

hopperassemblytotheaerator.

3.Cotterpin

g213510

g213563

Figure5

1.Bracketfor30-inchaerator5.Carriagebolt(5/16x1

2.Bolt(1/4x5/8inch)

3.Locknut(1/4inch)7.Carriagebolt(1/4x1inch)

4.Bracketfor24-inchaerator8.Locknut(1/4inch)

inch)

6.Removeandusethisnut

tomountthebracket.

7

Page 8

5

InstallingtheControlCable

Partsneededforthisprocedure:

1

Controlcable

2

Locknut(1/4inch)

2Washer

Procedure

1.Ensuringthatthecableballjointissecurely

attachedtothecable,connecttheballjointto

thecontrolarmandsecureitwithawasherand

locknut(1/4inch)asshowninFigure6.

Figure6

g213569

Figure7

1.Locknut(1/4inch)4.Cableend

2.Washer5.Hopperbracket

3.Gatearm

4.Insertthecableendintotheholeofthegate

arm;securethecableendwithawasherand

locknut(1/4inch);seeFigure7.

5.Loosenthenutsoneachsideofthecontrolcable

andslideitintothenotchofthehopperbracket.

Tightenthenutsoneachsideofthebracket.

6.Movetheowcontrolleverforwardand

rearward,makingsurethatthegatearmfully

opensandcloses.Ifitdoesnotclose,loosen

theknoband/ornutstoadjustthecableuntilthe

gatecanbefullyclosed;tightenallcomponents.

Makesurethatthejamnuthasbeensecurely

tightenedagainstthecableballjointafterall

adjustmentshavebeenmade(seeFigure6).

g221603

1.Cableballjoint

2.Controllever

3.Locknut(1/4inch)

4.Cable-mountbracket

2.Loosentheknobandslidethecontrolcableinto

thenotchofthemountbracketandtightenthe

knob.

3.Routetheotherendofthecontrolcabletothe

gatearm.

5.Knob

6.Washer

7.Jamnut

8

Page 9

6

InstallingtheWireHarness

Partsneededforthisprocedure:

bracketandhoppertube.Connectthespreader

harnesstothespreadermotorasshownin

Figure8.Insertthe3harnesstieclipsintothe

holesofthehoppermainframetosecurethe

harness.

4.Removethecapfromtheaccessorywireon

themainharnessandplugintothespreader

accessoryharnessasshowninFigure9.

1Wireharness

10

Cabletie

Procedure

Important:Besurethemachineisnotrunning

andthekeyhasbeenremovedfromtheignition

switchpriortoproceedingwiththeharness

installation.

1.Disconnectthebattery;refertoyourOperator’s

Manual.

2.PlugthehourmeterandON/OFFconnectorson

thespreaderharnessintotheswitchesonow

controlpanel(seeFigure8).

24InchModelsOnly:Removetheadaptor

plugfromthemainaccessoryharness.

Figure8

1.Harness

2.Hourmeterconnector4.Motorconnector

3.Routetheharnessalongtherightsideofthe

machine,followingthecontrolcable.Placethe

harnessontopofthecontrolcableandslideit

intothenotchofthehopperbracket.Continue

toroutetheharnessbetweentherighthopper

3.On/offswitch

g213882

Figure9

1.Spreaderharness

2.Accessoryplug

3.Battery

4.Positivebatteryterminal

5.Spreaderharnesspositivebatteryconnection

6.Spreaderharnessnegativebatteryconnection

7.Negativebatteryterminal

g213636

5.Removeandretainthenutandscrewfrom

thepositiveterminalonthebattery.Installthe

accessoryharnesspositivecable(secondtolast

terminalring—seeFigure9)andthepositive

cableofthemainharnesstothefrontofthe

positivebatteryterminalandsecurewiththenut

andscrew.Repeatfornegativebatterycable.

6.Usetheedgecliptosecuretheharnesstothe

rightaeratorpanel.

9

Page 10

7.For24-inchmachines,use1cabletietosecure

thecableandharnesstothespringorspring

mount.

Figure10

1.Cableandharness3.Springmount

2.Cabletie4.Spring

g253434

g221638

Figure11

8.Usetheremainingcabletiestosecurethe

harnesstotheframeand/orcontrolcable.

7

InstallingtheCover

Partsneededforthisprocedure:

1

Cover

4Washer

4

Locknut(1/4inch)

4

Bolt(1/4x3/4inch)

Procedure

1.Attachthecovertothehopperin2placesby

insertingabolt(1/4x3/4inch)andwasher

throughthecovertabgrommetandhopperas

showninFigure11.

1.Cover3.Bolt(1/4x3/4inch)

2.Washer

2.Securewithalocknut(1/4inch).

3.Plugtheother2holesinthehopperwith

remaininghardware.

4.Locknut(1/4inch)

10

Page 11

ProductOverview

Figure12

1.Controls

Specications

Width

Length

Height

Weight

Maximumhoppercapacity

Spreadingwidth1.2to6.7m(4to22ft)

2.Hopper

69cm(27inches)

81cm(32inches)

71cm(28inches)

32kg(70lb)

36kg(80lb)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Important:Theintendeduseofthisspreader

attachmentisfordispersinggrassseed.Thisis

nottobeusedforfertilizeroranyotherchemical

applications.

Controls

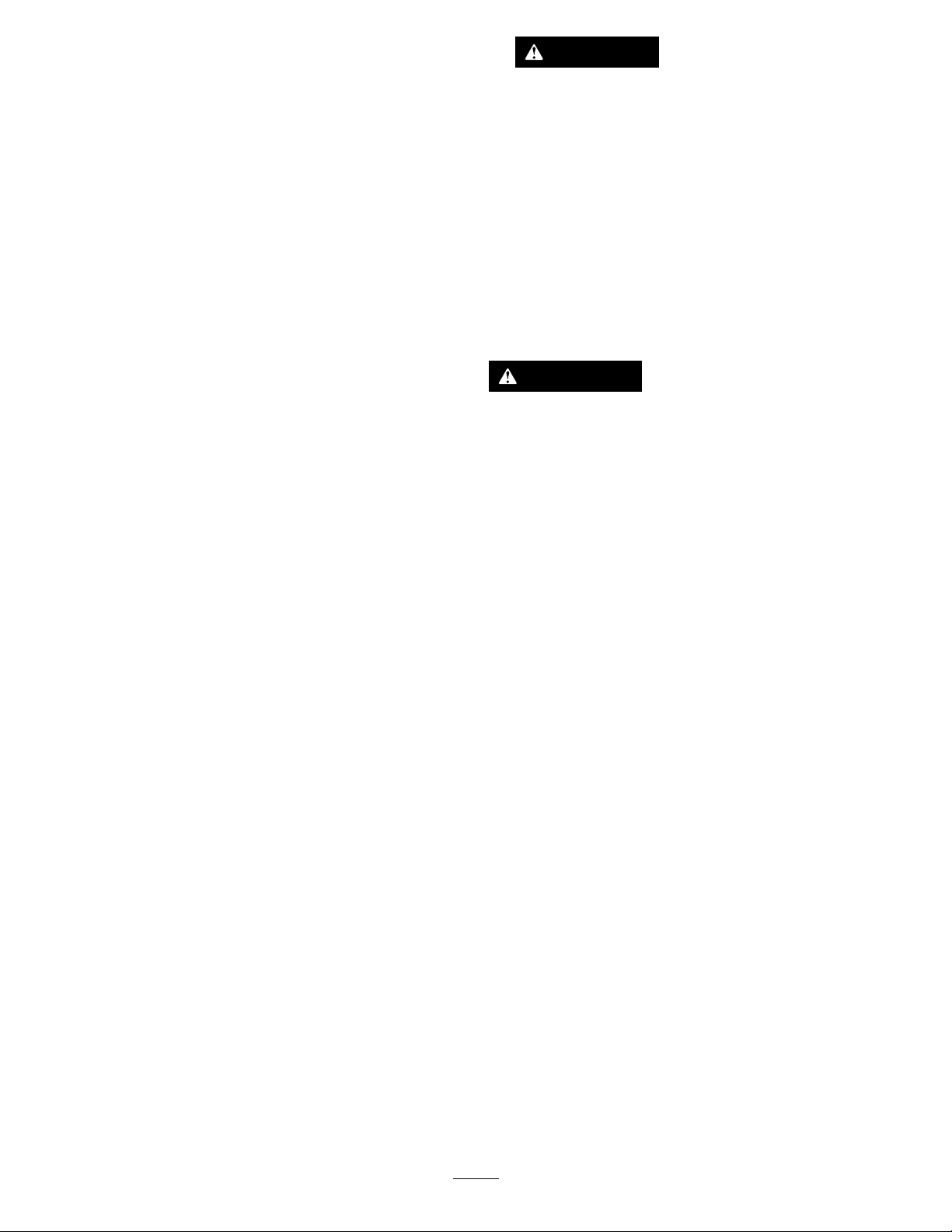

ImpellerSpeedControl

Locatedatthetopofthespreaderaccessorycontrol

g228584

panel(seeFigure13).

Pushdownontherightsideoftheswitch1timeto

turnthespreader“ON”;continuetotaptherightside

toincreasetheimpellerspeed.

Taptheleftsideofthecontroltodecreasethespeed;

pushandholdtheleftsideoftheswitchtoturnit

“OFF”.

Note:Theimpellerspeedcontrolcanbeturnedoff

atanyspeedrate.Itisnotnecessarytodecreasethe

speeduntilitturnsoff.Thelastsetspeeddisplays

whenthecontrolispoweredbackon.

Figure13

1.Impellerspeedcontrol3.Distributionlimitlockknob

2.Impellerspeeddisplay4.Flowcontrollever

ImpellerSpeedDisplay

Locatedbelowtheimpellerspeedcontrol.

Thisdisplayshowsthespeedsettingnumberfrom1

to10(1istheslowestspeedand10isthefastest).A

circledisplayswhenthecontrolhasbeenturnedoff.

11

g207672

Page 12

FlowControlLever

Locatedtotherightofthemaincontrols.

Lifttheleverupwardtostarttheowandcontinue

liftingittoincreasethedistributionrate.Pullthelever

downwardtodecreaseorstopthedistributionrate.

DistributionLimitLockKnob

Locatedontherightpanelofthespreaderaccessory

controlpanel.

Thisknobisusedtolimitthemaximumamount

ofgrassseedbeingdispensedtohelpmaintain

consistentdistribution.

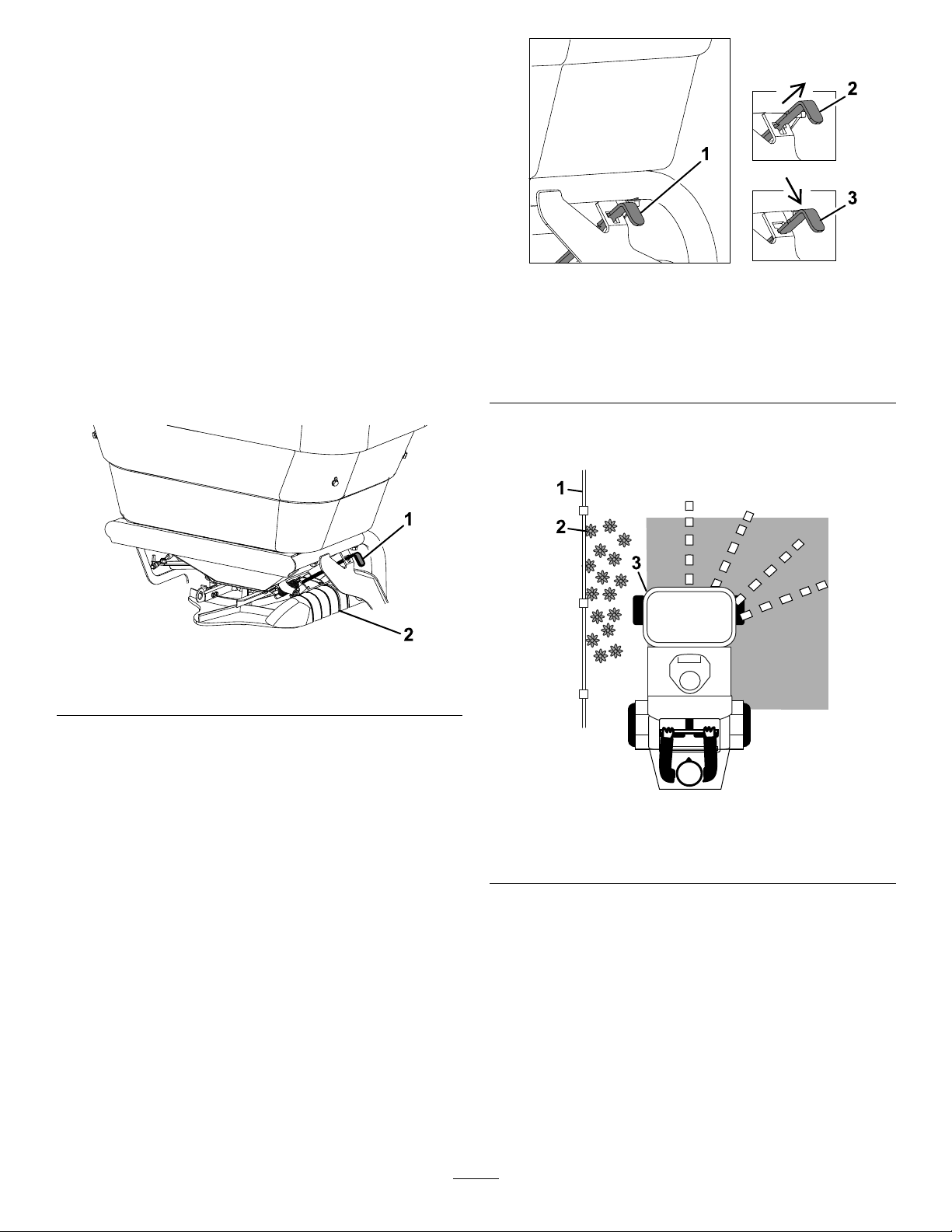

SideDeectorControlLever

Locatedontheleftsideofthehopper(seeFigure14).

g208735

Figure15

LeverPositions

1.Sidedeectorraises

2.Pullleveroutward

3.Pushdown—sidedeectorlowers

Toraisethedeector,lifttheleverintothewideportion

oftheslotandpushtheleverinwarduntilitstops.

Figure14

1.Sidedeectorcontrollever2.Sidedeector

Usethesidedeectorcontroltotemporarilystopor

deectgrassseedawayfromsidewalks,parkinglots,

patios,oranywheregrassseedisnotdesiredtobe

dischargedfromtheleftsideofthespreader.

Totemporarilydeectthegrassseed,lifttheleverup

andpulloutwarduntilthenotchcanbeseatedinto

thelowernarrowportionofthebracket;sidedeector

lowers(seeFigure15).

g207876

g207826

Figure16

1.Fence

2.Flowers

3.Sidedeectorlowered

Pre-Start

Ensurethatyouunderstandthecontrols,their

locations,theirfunctions,andtheirsafety

requirements.

Ensurethatthehopperanditscomponentsarein

goodcondition,properlyattached,andlatched.

12

Page 13

OperatingInstructions

CAUTION

Machinecanspinveryrapidlybypositioning

1levertoomuchaheadoftheother.Operator

maylosecontrolofthemachine,whichmay

causedamagetothemachineorinjury .

•Usecautionwhenmakingturns.

•Slowthemachinedownbeforemaking

sharpturns.

Note:Thestoppingdistancemayvarydependingon

thespreaderload.

OperatingtheSpreader Accessory

Thespreaderaccessoryisdesignedtodispersegrass

seed.

BeforeOperatingtheSpreader

Ensurethatthespreaderhasbeencalibratedforthe

correctapplicationrateofthegrassseedtobespread

beforestarting(seeCalculatingtheApplication

Ratesection).

FillingtheSpreaderHopper

Important:Verifythattheproperapplicationrate

hasbeensetpriortollingthehopper.

1.Parkthemachineonalevelsurface,movethe

motion-controllevertotheneutralposition,shut

offtheengine,removethekey,andengagethe

parkingbrake.

2.Ensurethatthespreadergateisclosed.

3.Removethecoverfromthehopper,addthe

grassseedtobespread,andreplacethecover.

Note:Donotoverloadthehopper;the

maximumweightcapacityofthehopperis36

kg(80lb).

CalculatingtheApplicationRate

1.Determinethekg(lb)per93m

producttobeapplied.

2.Determinethecalibrationcourse:

2

(1,000ft2)of

A.Determinetheamountofproducttobe

spreadper93m

recommendedratefromtheSpreading

Chartsectionortheproductmanufacturer’s

labelasaguide.

B.Determineacourselengthbydividing93

2

m

(1,000ft2)bytheeffectivespreadwidth.

Forexample,iftheeffectivewidthis1.8

m(6ft),thenthecalibrationcourselength

equals51m(167ft).

2

(1,000ft2).Usethe

CourseLength

93m2(1,000ft2)

1.8m(6ft)

C.Thecalibrationcourseis1.8m(6ft)by51

m(167ft).

D.Measureandvisiblymarkthecourselength.

Makesuretoallowampledistancebefore

thestartingmarkertoensurethespreader

isatfullspeedwhencrossingtherstmark

ofthecourse.

3.Settheappropriategatesetting(referencethe

SpreadingChartsectionasastartingpoint).

4.Addgrassseedtothehopper(forexample,11.3

kg(25lb)wasadded).

5.Drivethespreaderoverthecalibrationcourse

whileapplyingthegrassseed.

6.Emptytheremaininggrassseedofthehopper

intoacleanbucket.

7.Weighthebucketcontainingthegrassseedand

recordtheweight.Pourthecontentsbackinto

thehopperandthenweightheemptybucket.

Subtractthese2amountstodeterminethe

amountofgrassseedremaininginthehopper

(forexample,9kg(20lb)remains).

8.Subtracttheamountremaininginthehopper

(step7)fromtheamountoriginallyadded(step

4);theresultistheamountappliedtothecourse.

=

51m(167ft)

AmountApplied

11.3kg–9kg(25lb–20lb)

Forthisexample,2.3kg(5lb)wasappliedto

2

93m

9.Ifnecessary ,adjusttheratelevertoachievethe

recommendedamounttobeappliedandrepeat

theprocedure.Oncethecorrectapplicationrate

isachieved,repeatthisprocedureanadditional

timetoverifytheresults.

(1,000ft2).

=

5lb(2.3kg)

SpreadingChart

Thechartbelowisforreferenceonly.

13

Page 14

GrassSeedApplicationatMaximumGroundSpeed

Type

BlueGrassorRedT op0.9kg(2lb)

Park,Merion,Delta,orKentucky

Bluegrass

HulledBermuda

MixturesIncludingCoarseSeeds2.7kg(6lb)

RyeGrassesorTallFescue2.7kg(6lb)

Dichondra

PensacolaBahia

kg(lb)/93m

(Coverage93m

0.2kg(0.5lb)

0.9kg(2lb)

0.3kg(0.75lb)

2.7kg(6lb)

2

(1,000ft2)GateOpeningSpreadWidth

2

or1,000ft2)

.25

.25

.75

.75

.75tomaximumopen

.25

.50

1.2m(4ft)

1.2m(4ft)

1.8m(6ft)

1.8m(6ft)

1.8m(6ft)

2.4m(8ft)

2.1m(7ft)

Spreading

SpreadingTips:

•Toensureuniformapplication,besuretooverlapthegrassseeddistribution.Thehighestamountof

seeddispensesfromthefrontofthehopperandlessfromeachside.Adjustthedistributionpatternto

achievedesiredresults.

•Watchforchangesinthedistributionpattern;unequaldistributionmayleadtostriping.

Figure17

1.Narrowdistribution-sidedeectorlowered5.Endofspreadingjob

2.Forward

3.Effectivespreadingwidth—variable1.2to6.7m(4to22ft)7.Gate

4.Donotspreadwhenturning180degrees

6.Propertyfence

1.StarttheengineandplacethethrottlemidwaybetweentheSLOWandFASTpositions.

2.Turnontheimpellerspeedcontrol.

3.Settheimpellerspeedtotheappropriatesetting.

14

g207791

Page 15

4.MovethethrottletotheFASTpositionanddriveforward.

5.Openthehoppergateandbeginspreading.

1.Effectivespreadingwidth—variable1.2to6.7m(4to22ft)

g207728

Figure18

6.Evaluatethespreadpattern.IfadjustmentsareneededseetheSpreaderPatternAdjustmentsection.

7.Whennishedspreading,closethehoppergate.

15

Page 16

SpreaderPatternAdjustment

Ifthespreadpatternisskewedordispensingtoo

light/heavyto1side(Figure19),adjustthegateas

follows:

OperatingTips

Overseeding

Important:Donotputdownmoreseedthan

recommendedbytheseedcompany.Overseeding

cancausethegrasstobetoothickandcauseitto

besusceptibletofungus.

Note:Themachineseedsatthesamerategoing

bothforwardandrearward.

Note:Ifthereisexcessivethatch,itmaybe

necessarytoremovethethatchpriortoseeding.

Figure19

1.Heavytoleftside

2.Moveramppatternto

shadedposition

3.Heavytorightside

Note:Donotadjusttherampstosplitproductow.

Useonlythefrontorrearramppositionsasshown.

1.Unlockthespreaderpatterncontrolknobby

turningitcounterclockwise90degrees.

g025543

RemovingtheSpreader Attachment

1.Shutofftheengine,removethekey,waitforall

movingpartstostop,engagetheparkingbrake,

andremovethekey.

2.Unplugthespreaderaccessoryharness

(referenceFigure9).

3.Disconnectthecableballjointfromthecontrol

lever(referenceFigure6).Loosentheknobon

thecablemountbracket.

4.Removeandretainthehitchpinfromthe

receiver(referenceFigure4)

5.Removethehopperassembly,controlcable,

andaccessoryharness.

Note:Allotherspreaderattachment

componentsmaystaymountedonthemachine.

Makesurecomponentsaresecureandaway

frommovingparts.

Figure20

1.Spreaderpatterncontrol

knob

Toadjustwhenthegrassseedpatternisheavy:

2.Controlhandle

•Totheleftside,slightlypullthecontrolhandle

rearward.

•Totherightside,slightlypushthecontrol

handleforward.

2.Lockthespreaderpatterncontrolbyturningthe

controlknobclockwise90degrees.

g207877

16

Page 17

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

WARNING

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitch,engageparkingbrake,andpullthewire(s)offthespark

plug(s)beforeyoudoanymaintenancetothemachineorattachment.Alsopushthewire(s)

asidesoitdoesnotaccidentallycontactthesparkplug(s).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Beforeeachuseordaily

MaintenanceProcedure

•Checkforloosehardware.

•Cleanthedebrisbuildupfromthemachine.

CheckforLooseHardware

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey.Engagetheparking

brake.

2.Visuallyinspectthemachineforanyloose

hardwareoranyotherpossibleproblem.Tighten

anyloosehardwareorcorrecttheproblem

beforeoperatingthemachine.

SpreaderPatternControl CableAdjustment

Toadjustthespreaderpatterncontrolcable:

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey.Engagetheparking

brake.

2.Closethegranulargate.

3.Ensurethatthespreadpatterncontrolhandleis

pusheddownandlockedatthecontrolpanel.

4.Loosenthejamnutattheendofthecable.

g027205

Figure21

1.Jamnut

2.Linkagerod

3.Impellershaft

4.3.2mm(1/8inch)gapbetweenramptoothandimpeller

shaft

5.Ramptooth

5.Pullthelinkageroduntilthereis3.2mm(1/8

inch)gapbetweentheramptoothandthe

impellershaft.

6.Tightenthejamnut.

17

Page 18

AdjustingtheGateClosure

1.Ifthegatearmisnotfullyclosing,adjustthe

controlcable:

•Knoblocatedonthecablemountbracket

•Nutslocatedoneithersideofthehopper

bracket

2.Continuetoadjustuntilthegatecanbefully

closed;tightenallcomponents.

Cleaning

CleanDebrisFromMachine

ServiceInterval:Beforeeachuseordaily

1.Shutofftheengine,waitforallmovingpartsto

stop,andremovethekey.Engagetheparking

brake.

2.Cleanoffanydebrisorbuilduponthemachine,

especiallytheimpeller.

18

Page 19

Troubleshooting

Thefollowingtablelistssomeofthecommoncausesoftrouble.Ifaproblemcontinues,contactanAuthorized

ServiceDealer.

Problem

Messagedisplays“STALLED(02)”1.Controllerhasdetectedanexcessive

Messagedisplays“WIREFAULT(04)”

Messagedisplays“WIREFAULT(05)”1.Oneoftwooutputsarenotproviding

Messagedisplays“WIREFAULT(06)”

Thecontrollerdoesnotpoweron.

Thecontrollerfailstokeeprunning.

electricalcurrenttotheimpellermotor.

1.Thecontrollerisunabletodetectmotor

feedbackvoltage.

powertotheimpellermotor.

1.Thecontrollerisunabletodetect

connectiontotheimpellermotor .

1.Afuseisblown.1.Replacetheblownfuse.

2.Thereareimproperelectrical

connections.

3.Thecontrollermoduleisfaulty.

1.Electricalconnectionsarecorroded,

loose,orfaulty.

PossibleCauseCorrectiveAction

1.Checktheimpellerandhopperfor

obstructionsthatmayaddanexcessive

loadtotheimpellermotor.Checkthe

electricalconnectionstotheimpeller

motortoensuretheyarenotshorted.

Pressthe“ON”switchtoretry.

1.Checkpins18onthecontroller

connectorforproperpinseatingand

locking.

1.Checkpins6and8onthecontroller

connectorforproperpinseatingand

locking.

1.Powerofftheimpellerandcheckthe

electricalconnectionstotheimpeller

motor.

2.Checktheelectricalconnectionsat

theaccessorypowerconnectorand

batteryringterminalsandensureboth

havepower .

3.Replacethecontrollermodule.

1.Checktheelectricalconnections

forgoodcontact.Cleanconnector

terminalsthoroughlywithelectrical

contactcleaner,applydielectricgrease

andreconnect.

Aswitchisunresponsive.

1.Theswitchconnectormaybeloose.1.Ensurethattheswitchconnectoris

2.Pinsmaynotbeinsertedintothe

correctterminals.

connectedtotherockerswitch.

2.Checkforincorrectpinpositions.

19

Page 20

Schematics

M

BT01

TERMINAL +

TERMINAL -

BATTERY

DIS01

CONTROLLER - MOTOR DRIVE

B+

NC

NCSW PWR

NC

NC

OUTPUT ENABLE

NC

NC

MOTOR IN

NC

MOTOR OUT 1

MOTOR OUT 2

UP SW

NC

DOWN SW

NC

GND

CAN LO

CAN HI

P04

121420

5

6

8

1

18

17

15

P04

3

4

7

16

111319

2

9

10

Motor+

Motor-

SPREADER MOTOR

M01

P07

A

B

NC

CAN HI

CAN LO

SW PWR

FUSED PWR

GND

CAP03

DUST CAP

P02

12345

6

D01

DIODE

P05

B

P05

A

J02

F01 20A

Motor Power

RED RED/GREEN

BLACK

BLACK

BLACK

BLACK

BROWN/WHITE

VIOLET/RED

BLACK

VIOLET/BLACK VIOLET

WHITE/BLACK

WHITE/TAN

BLACK

BLACK

BLACK

BLACK

ORANGE

RED/WHITE

RED/WHITE

GREEN

GREEN

YELLOW

YELLOW

RED/GREEN

RED/GREEN

RED/WHITE

PINK

BLACK

VIOLET/WHITE

SP01

SP02

SP03

SP04

SP05

SP06

SP07

MINI FUSE HOLDER CAP

P03P03

BA

P08

A

B

P09

A

B

BLACK

VIOLET/RED

P01

ACC CONNECTOR

A

B

C

ACC PWR ADAPTER

GND

SW PWR

A

B

S01

DOWN

(ON)-OFF-(ON)

UP

P06

1

3

4

6

8

P06

2

5

7

J01

g212875

ElectricalSchematic(Rev .A)

20

Loading...

Loading...