FormNo.3421-778RevA

Groundsmaster

®

1200SeriesPull

BehindRotaryMower

ModelNo.31905—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3421-778*A

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Thismachinehasbeendesignedinaccordancewith

ANSIB71.4-2012.

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

g249978

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Introduction

Thismachineisintendedforusebyprofessional,

hiredoperatorsincommercialapplications.Itis

designedformowinggrassonwell-maintained

lawnsinparks,golfcourses,sportselds,andon

commercialgrounds.

Important:Readthisinformationcarefullyto

learnhowtooperateandmaintainyourproduct

properlyandtoavoidinjuryandproductdamage.

Youareresponsibleforoperatingtheproduct

properlyandsafely.

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserial-numberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety

Safety.......................................................................3

GeneralSafety...................................................3

SafetyandInstructionalDecals..........................4

Setup........................................................................6

1ApplyingtheEntanglementDecal....................6

2InstallingtheDeckCoverKnobs.......................7

3AdjustingtheDrawbarPositionoftheT ow

Vehicle............................................................7

4AdjustingtheT owBaroftheMower..................7

5ConvertingthePinT owBartoaPintleTow

Bar..................................................................8

6RoutingtheDeck-LockRopeatthe

Mower.............................................................8

ProductOverview...................................................10

Specications...................................................11

Attachments/Accessories..................................11

BeforeOperation..................................................11

BeforeOperationSafety....................................11

TractorControls................................................12

OutcrossTractionUnitControls........................12

PTOSpeed.......................................................12

TrainingPeriod.................................................12

CheckingtheTireAirPressure..........................12

CheckingthePTOandDriveShaft

Guards..........................................................13

UsingtheT owBarJack.....................................14

AssemblingtheMowertotheT ow

Vehicle..........................................................15

DuringOperation.................................................19

DuringOperationSafety...................................19

SlopeSafety.....................................................20

LoweringtheMowerDecksfromthe

TransportPosition.........................................20

RaisingtheMowerDeckswhileCutting

Grass............................................................21

RaisingtheMowerDeckstotheTransport

Position.........................................................21

AdjustingtheHeight-of-Cut...............................22

MakingaSharpTurn........................................23

AfterOperation....................................................24

AfterOperationSafety......................................24

CleanandInspect.............................................24

Tie-DownPoints...............................................24

TransportingtheMachine.................................24

Maintenance...........................................................25

RecommendedMaintenanceSchedule(s)...........25

LiftingtheMower..............................................26

AccessingtheMowerDecks.............................26

Lubrication........................................................27

ServicingtheGearboxes..................................30

CheckingtheMowerBelts................................33

ReplacingtheMowerBelts...............................33

ServicingtheBlades.........................................35

AdjustingtheMowerPitch................................39

Storage...................................................................41

StoringtheMachine..........................................41

GeneralSafety

Thisproductiscapableofamputatinghandsand

feetandofthrowingobjects.Alwaysfollowallsafety

instructionstoavoidseriouspersonalinjury.

Usingthisproductforpurposesotherthanitsintended

usecouldprovedangeroustoyouandbystanders.

•Readandunderstandthecontentsofthis

Operator’sManualbeforeusingthemower.

•Useyourfullattentionwhileoperatingthetow

vehicleandmower.Donotengageinanyactivity

thatcausesdistractions;otherwise,injuryor

propertydamagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemowerwithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepclearofanydischargeopening.Keep

bystandersandpetsasafedistanceawayfrom

themower.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethetowvehicleorthe

mower.

•Stopthemachine,engagetheparkingbrake,

shutofftheengine,removethekey,andwait

forallmovingpartstostopbeforeservicingor

uncloggingthemower.

Improperlyusingormaintainingthismowercanresult

ininjury .T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattention

tothesafety-alertsymbol

Warning,orDanger—personalsafetyinstruction.

Failuretocomplywiththeseinstructionsmayresultin

personalinjuryordeath.

,whichmeansCaution,

3

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

110-4668

1.Entanglementhazard,shaft—stayawayfrommovingparts.

2.PTOspeedandinputdirection.

3.Usecliptosecurelashcablewhennotinuse.Uselash

cabletosupportthepowertake-offwhenthemachineis

disconnectedfromtractor.

decal110-4668

117-4979

1.Entanglementhazard,belt—keepawayfrommovingparts;

keepallguardsandshieldsinplace.

119-6807

1.Warning—nostep

120-0625

1.Pinchpoint,hand—keephandsaway.

decal117-4979

decal120-6604

120-6604

1.Thrownobjecthazard—keepbystandersawayfromthe

machine.

2.Cutting/dismembermenthazardofhand,mower

blade—stayawayfrommovingparts;keepallguardsand

shieldsinplace.

3.Cutting/dismembermenthazardoffoot,mowerblade—stay

awayfrommovingparts;keepallguardsandshieldsin

place.

decal119-6807

decal120-0625

decal125-6110

125-6110

1.Crushinghazard—donotstandunderanypartofthe

machine.

decal133-8061

133-8061

4

decal138-3078

138-3078

1.Beltrouting

decal138-3087

138-3087

5

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

6

MediaandAdditionalParts

Description

Operator'sManual

Qty.

CEentanglementdecal

Knob6Installthedeckcoverknobs.

Nopartsrequired

Nopartsrequired

Nopartsrequired

Nopartsrequired

Qty.

1

Readthismanualbeforeusingthepullbehindrotary

mower.

1

–

–

–

–

Applytheentanglementdecal—CE

mowers

Adjustthedrawbarpositionofthe

machine.

Adjustthetowbarofthemower

Convertthepintowbartoapintletow

bar.

Routethedecklatchropeatthemower.

Use

Use

1

ApplyingtheEntanglement Decal

CEMowers

Partsneededforthisprocedure:

1

CEentanglementdecal

Procedure

Important:ThisprocedureisrequiredforallCE

countriesandanywhereEnglishiscommonly

spoken.

1.RotatethePTOshaftguardtoaccessthe

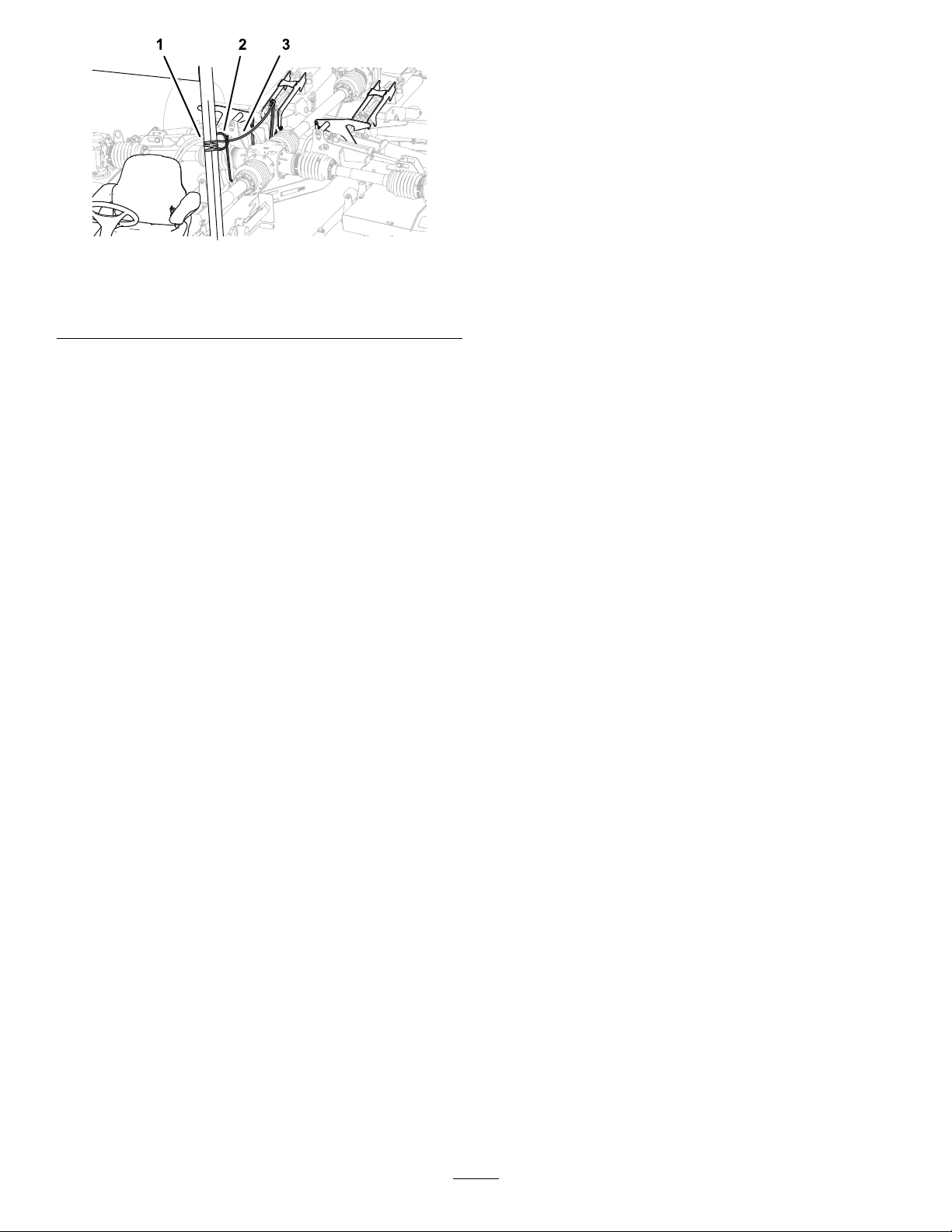

existingentanglementdecal(Figure3).

g262546

Figure3

1.Existingentanglement

decal

2.CEentanglementdecal

6

2.Cleantheexistingentanglementdecalandthe

guardareasurroundingthedecal.

3.RemovethebackingfromtheCEentanglement

decal.

4.PlacetheCEentanglementdecaloverthe

existingentanglementdecal(Figure3).

2

InstallingtheDeckCover Knobs

Non-CEMowers

Partsneededforthisprocedure:

6Knob

Procedure

1.Removethemowerdeckcovers;referto

RemovingtheDeckCovers(page26).

2.Removethepush-nutthatsecurestheboltto

thedeckcoverandremovetheboltfromthe

cover(Figure4).

3

AdjustingtheDrawbar PositionoftheTowVehicle

NoPartsRequired

Procedure

Adjustthedrawbar(Figure5)ofthetowvehicleto

theextendedposition;refertotheOperator’sManual

foryourtowvehicle.

g250235

Figure5

1.Drawbar(extendedposition)

Figure4

1.Bolt3.Push-nut

2.Deckcover

3.Installthemowerdeckcoverwiththeknob;refer

toInstallingtheDeckCovers(page27).

4.Repeatsteps1through3fortheremainingdeck

covers,

4

AdjustingtheTowBarof theMower

NoPartsRequired

g264078

AssessingtheJobSite

Considerthefollowingjobsiteconditionstodetermine

thetowbarpositionofthemower:

•Turfwithhillsanddipsinthecontour—setthetow

bartoashorterlength.

•Turfthatisprimarilyat—setthetowbartoa

longerlength.

Note:Youmayneedtotryanintermediateposition

tow-barlengthwhenjobsitehasamixtureofatand

hillyareas.

7

AdjustingtheTow-BarLength

Note:Thetowbarofthemowerhas5tow-bar

positionsallowingyoutoadjustthelength20cm(8

inches).

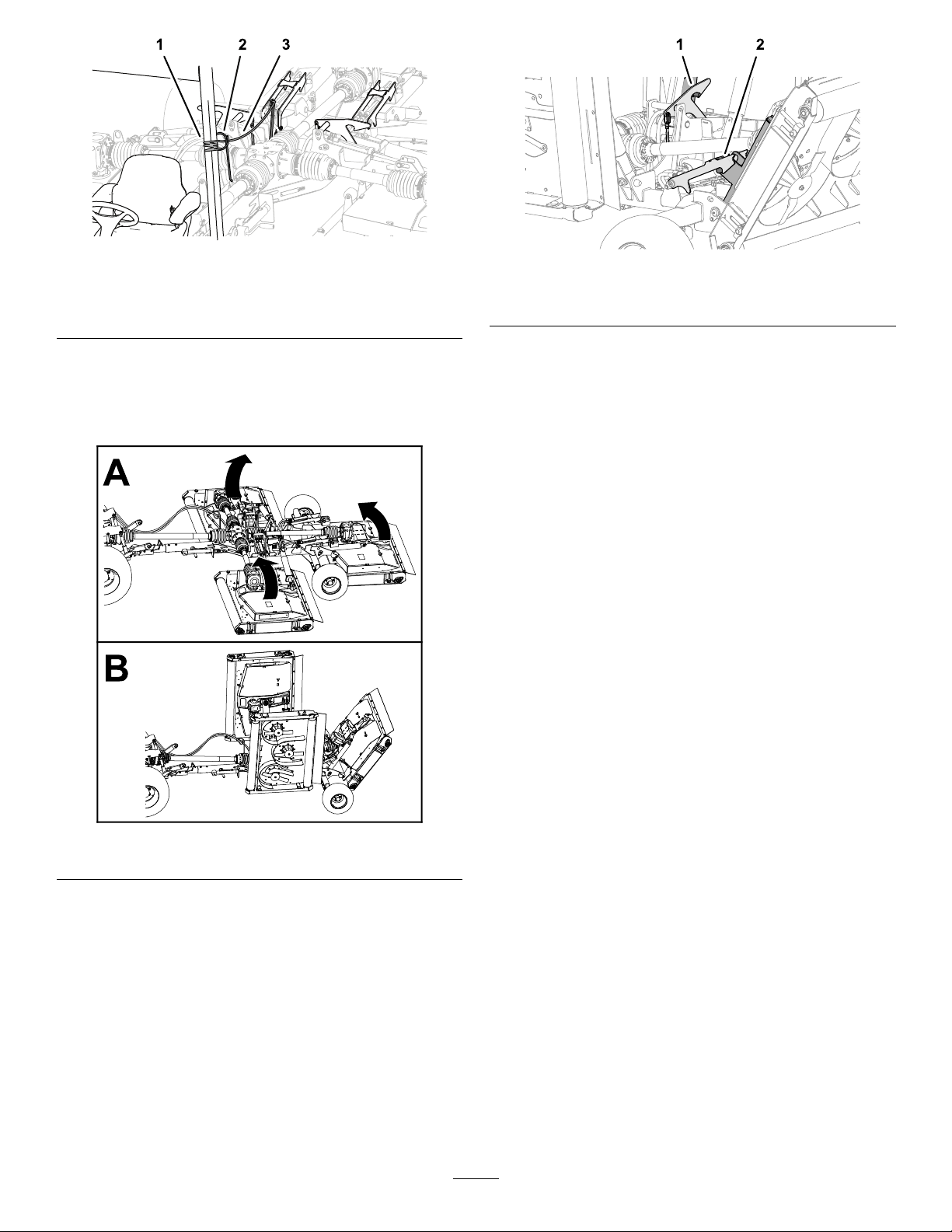

1.Removethe2angelocknuts,2capscrews,

and2washersthatsecurethehitchtubetothe

receivertube(Figure6).

Figure6

1.Hitchtube4.Flangenut

2.Capscrew

3.Washer

5.Receivertube

5

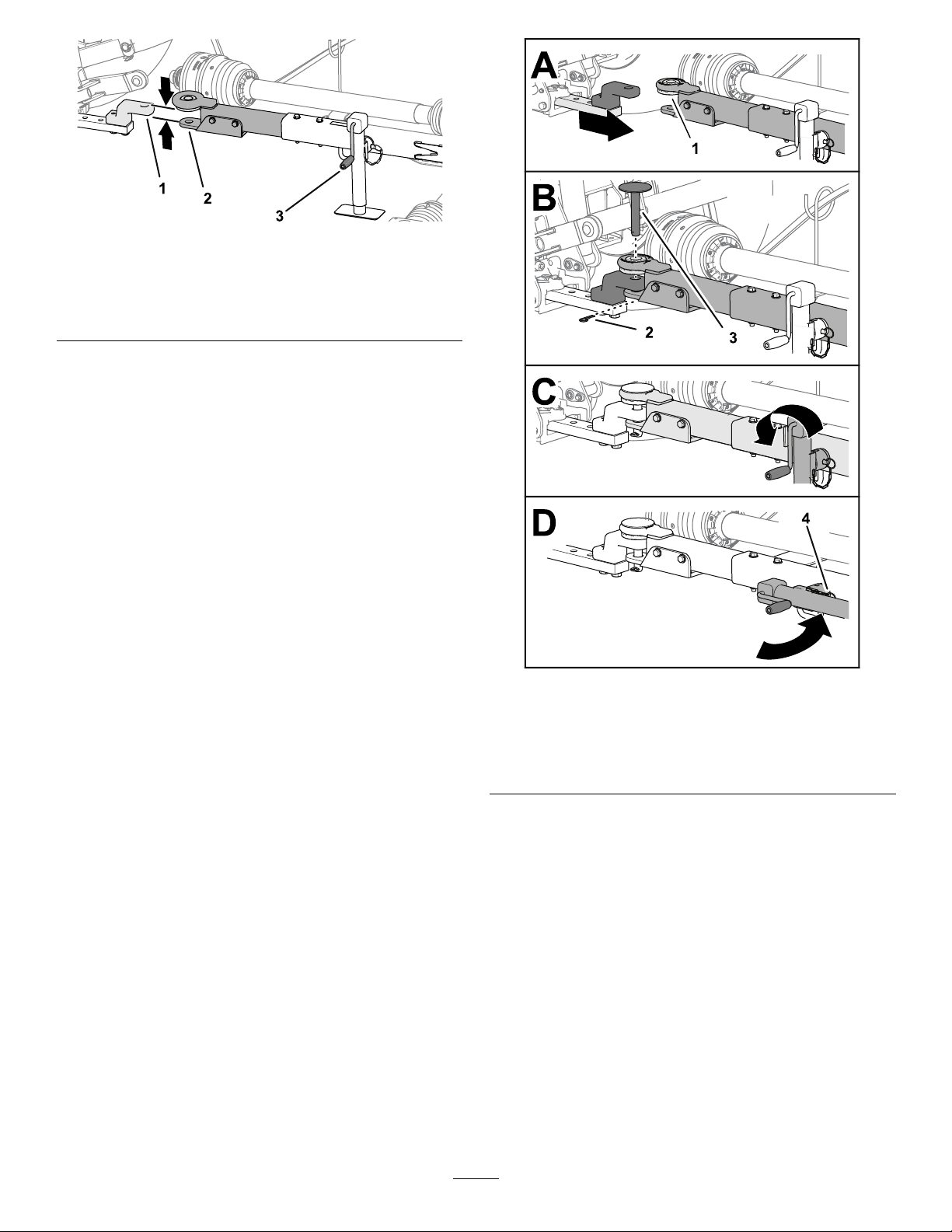

ConvertingthePinTowBar toaPintleTowBar

NoPartsRequired

Procedure

1.Removethehairpinthatsecuresthehitchpinto

thetowbar,andremovethehitchpin(Figure7).

g250236

2.Adjustthepositionofthehitchtubeinthe

receivertubeaccordingtothepositionthatyou

determinedinAssessingtheJobSite(page7).

3.Assemblethehitchtubetothereceivertubewith

theangelocknuts,capscrews,andwashers

thatyouremovedinstep1.

4.Torquethenutsandcapscrewsto91to113N∙m

(67to83ft-lb).

Figure7

1.Hitchpin5.Flangelocknut

2.Hairpin

3.Pintleeye

4.Flangebushing

2.Removetheangebushingfromthepintleeye

(Figure7).

6.Clevisbracket

7.Capscrew

g250399

3.Removethe2angelocknutsand2capscrews

thatsecuretheclevisbrackettothetowbar,and

removetheclevisbracket(Figure7).

Note:Retainthehairpin,hitchpin,ange

locknuts,capscrews,andclevisbracketto

convertthepintletowbartoapintowbar.

8

6

RoutingtheDeck-Lock

RopeattheMower

NoPartsRequired

Procedure

Routethefreeendofthedeck-lockropefromthelock

leverthroughthe2hoseguides(Figure8).

Figure8

1.Deck-lockrope

2.Locklever4.Hoseguide

3.Knottedendofthe

g260004

deck-lockrope

9

ProductOverview

g262052

Figure9

1.Rearmowerdeck

2.Decklock

3.Locklever

4.Outermowerdeck7.Quick-connectcoupling(PTOdrive

5.Guard(PTOdriveshaft)

6.Hoseguideanddriveshaftrest

shaft)

8.Hydraulichoses

Figure10

g262053

1.Deck-lockrope

2.Jack4.Roller

3.Guard(deckdriveshaft)5.Height-of-cutadjuster

10

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

TowVehicleSpecication

MinimumPTOoutput-power

rating

RecommendedPTOspeed

PTORotationClockwise(viewedfrom

PTOspindle34.8mm(1-3/8inch)

Minimumhydraulicpressure

Towsystem

MowerSpecication

Weight

Tongueweight

26Kw(35hp)

540rpm

behindthetowvehicle)

diameter,6-spline

13790Kpa(2000psi)

Drawbarandpin—25mm

(1inch)diameter

Pintle

1354kg(2984lb)

313kg(691lb)

MowerSpecication(cont'd.)

WidthMow

HeightMow

Length

Widthofcut365cm(144inches)

Cutheight13to102mm(1/2to4.0

CuttingCapacity9.7km/h(6

MaximumTransport

Speed

position

Transport

position—13

mm(1/2

inch)HOC

position

Transport

position

Hitchfully

extend

mph)

381cm(150inches)

218cm(86inches)

78cm(31inches)

193cm(76inches)

371cm(146inches)

inches)

3.5hectar/hr(8.7acres

/hr)

30kph(19mph)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesisavailableforusewiththemachinetoenhance

andexpanditscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww.Toro.comfora

listofallapprovedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafetycerticationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacementpartsandaccessoriesmadebyothermanufacturerscouldbe

dangerous,andsuchusecouldvoidtheproductwarranty.

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageoftheoperator.Theowner

isresponsiblefortrainingalloperatorsand

mechanics.

•Keepyourhandsclearofthejointpivotareas

whenhandlingthePTOdriveshaft.

•Donotstepon,overorunderthePTOordrive

shafts.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•DonotusePTOsplineadaptersorextensions.

•Useonlyatowvehiclewiththemowerthathasa

maximumPTOspeedof540rpm(9rotationsper

second).

•Ensurethattheguardsandshieldsareproperly

installedandmaintained.Replacemissing,

damaged,orwornguardsandshieldsbeforeusing

themachine.

•EnsurethatthePTOdriveshaftdoesnotcontact

thedrawbar

•Beforemowing,alwaysinspectthemachineto

ensurethattheblades,bladebolts,andcutting

assembliesareingoodworkingcondition.

Replacewornordamagedbladesandboltsinsets

topreservebalance.

11

•Inspecttheareawhereyouwillusethemachine

andremoveallobjectsthatthemachinecould

throw.

•Ensurethatyourtowvehicleissuitableforuse

withamowerofthisweightbycheckingwithyour

towvehiclesupplierormanufacturer.

TractorControls

Becomefamiliarwithoperatingthefollowingtractor

controlsbeforeyouoperatethemower:

CAUTION

Arunningattachmentcancausepersonal

injury.

Toavoidpersonalinjury,donotleavethe

operator’sseatwithoutrstdisengaging

thePTOdrive,engagingtheparkingbrake,

shuttingofftheengine,andremovingthekey.

Ensurethatallsafetydevicesaresecuredin

theirproperplacebeforeresumingoperation.

•PTOengagement

•Engine/PTOspeed

•Therearattachmentcontrol(raise/lower)

•Auxiliaryvalveoperation

•Clutch

•Throttle

•Gearselection

•Parkingbrake

Important:RefertothetractorOperator's

Manualforoperatinginstructions.

OutcrossTractionUnit Controls

RefertotheOutcrosstractionunitOperator’sManual

forinformationoncontrolsandoperation,aswellas

additionalinformationonsettingupthevehicleforthis

attachment.

CheckingtheTireAir Pressure

ServiceInterval:Beforeeachuseordaily

DANGER

Lowtirepressuredecreasesmowerstability

whentransportingit.Thiscouldcausea

rollover,whichmayresultinpersonalinjury

ordeath.

Donotoperatethemowerwithunderinated

tires.

1.Checkthetireairpressuredaily.

Youshouldmeasure207kPa(30psi).

PTOSpeed

ThemowerisdesignedtooperatewithaPTOspeed

ofupto540rpm.Mosttowvehiclesindicatea540

PTOrpmpositiononthetachometer.

TrainingPeriod

Beforeusingthemower,ndaclearareaandpractice

usingtheit.Operatethetowvehicleatrecommended

gearsettingsandPTOdrivespeedsandbecome

thoroughlyfamiliarwithdrivingcharacteristicsofthe

towvehicleandthemower.Practiceraisingand

loweringmowerdecks,stopping,andstartingthe

PTOdrive,andaligningthemachinewithprevious

passes.Practicesessionsincreasecondenceinthe

operatingthemowerandhelpsensureuseofproper

techniquescuttinggrass.

g001055

Figure11

2.Ifthetireairpressureisnot30psi,addairtoor

removeairfromthetires.

12

CheckingthePTOand DriveShaftGuards

ServiceInterval:Beforeeachuseordaily

1.Ifinstalledtothetowvehicle,removethedrive

shaft.

2.RotatetheforwardhalfofthePTOshaftguarda

fullrotation(Figure12).

Note:Cleanorreplacetheshaftguardifitdoes

notrotatefreely.

g264215

Figure13

Figure12

1.PTOshaftguard(forwardhalf)

3.MovetheforwardhalfofthePTOshaftguard

togetherandaparttoensurethattheytelescope

freely(Figure12).

Note:Cleanorreplacetheshaftguardisit

doesnottelescopefreely .

4.Ifremovedfromthetowvehicle,installthedrive

shaft;refertoConnectingtheDriveShafttothe

PTO(page17).

5.Checkthattherestraintchainisinstalled

betweentheforwardPTOshaftguardanda

stationarypartonthetowvehicle(Figure13).

1.PTO-shaftguard(forward

half)

g262236

2.Restraintchain

6.Checkthattherestraintchainisconnectedto

therearPTOshaftguard,driveshaftguards,

andtheframeofthemower(Figure14and

Figure15).

Figure14

LeftDeck,RightDeck,andPTODrive-ShaftGuards

1.Restraintchain

2.Driveshaftguard

13

g262208

3.PTOshaftguard

Figure15

CenterDeckDrive-ShaftGuard

g262209

1.Driveshaftguard(center

deck)

2.Restraintchain

7.Checkthatthe7hoseclampsrmlysecurethe

drive-shaftguardstothecenteranddeckgear

boxes(Figure16).

Figure16

1.Hoseclamps

g250413

Figure17

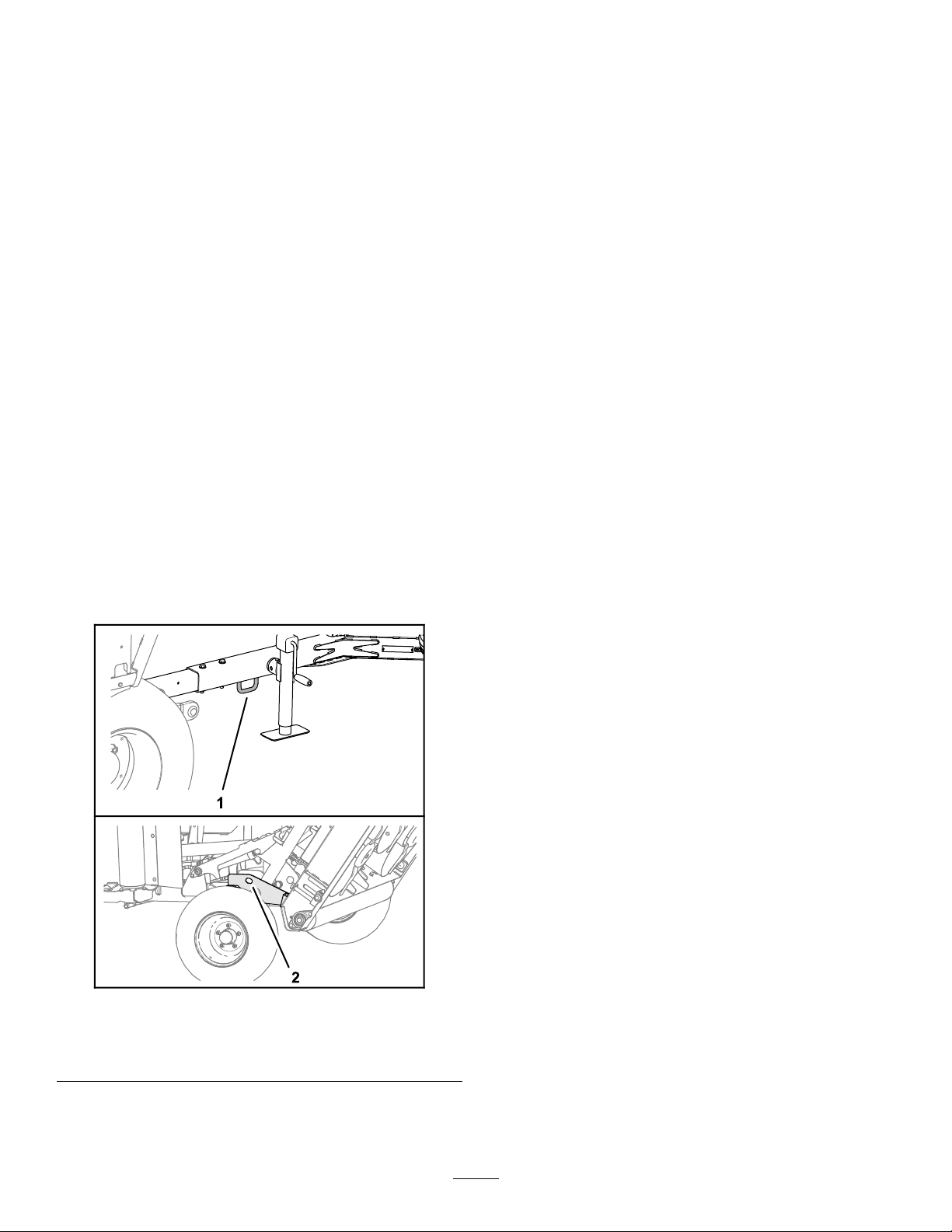

1.Pin3.Jackpad

2.Tow-barjack4.Jackhandle

4.Aligntheholeinthetowbarwiththeholeinthe

jack(Figure17).

5.Insertthepinthroughtheholesinthetowbar

andjack(Figure17).

g264297

6.Rotatethejackhandleuntilthejackfully

supportstheweightofthemower.

7.Chockbothtiresofthemower(Figure18).

UsingtheTowBarJack

SupportingtheMowerwiththe Jack

1.Parkthemachineonalevelsurface,movethe

shiftlevertotheNEUTRALposition.

2.Engagetheparkingbrake,shutofftheengine,

removethekey,andwaitforallmovingparts

tostop.

3.Removethepinandrotatethetow-barjack

vertical(Figure17).

g256133

Figure18

1.Wheelchocks

14

8.DisconnectthehydraulichosesandthePTO

driveshaftfromthetowvehicle.

9.Disconnectthehitchfromthetowbar.

10.Drivethetowvehicleinastraightlineawayfrom

themower.

StowingtheJack

1.Ensurethatthemowerissecurelyattachedto

thetowvehicle.

2.Rotatethejackhandletofullyraisethejackpad;

refertoFigure17inSupportingtheMowerwith

theJack(page14).

3.Removethepinandrotatethetowbarjack

horizontal.

4.Aligntheholeinthetowbarwiththeholeinthe

jack.

5.Insertthepinthroughtheholesinthetowbar

andjack.

AssemblingtheMowerto

g264148

Figure20

5.Ifyourmowerhasapintowbar,removethe

hairpinandhitchpinfromthetowbar.

6.Ifyourtowvehiclehasapintlehitch,openthe

hitch.

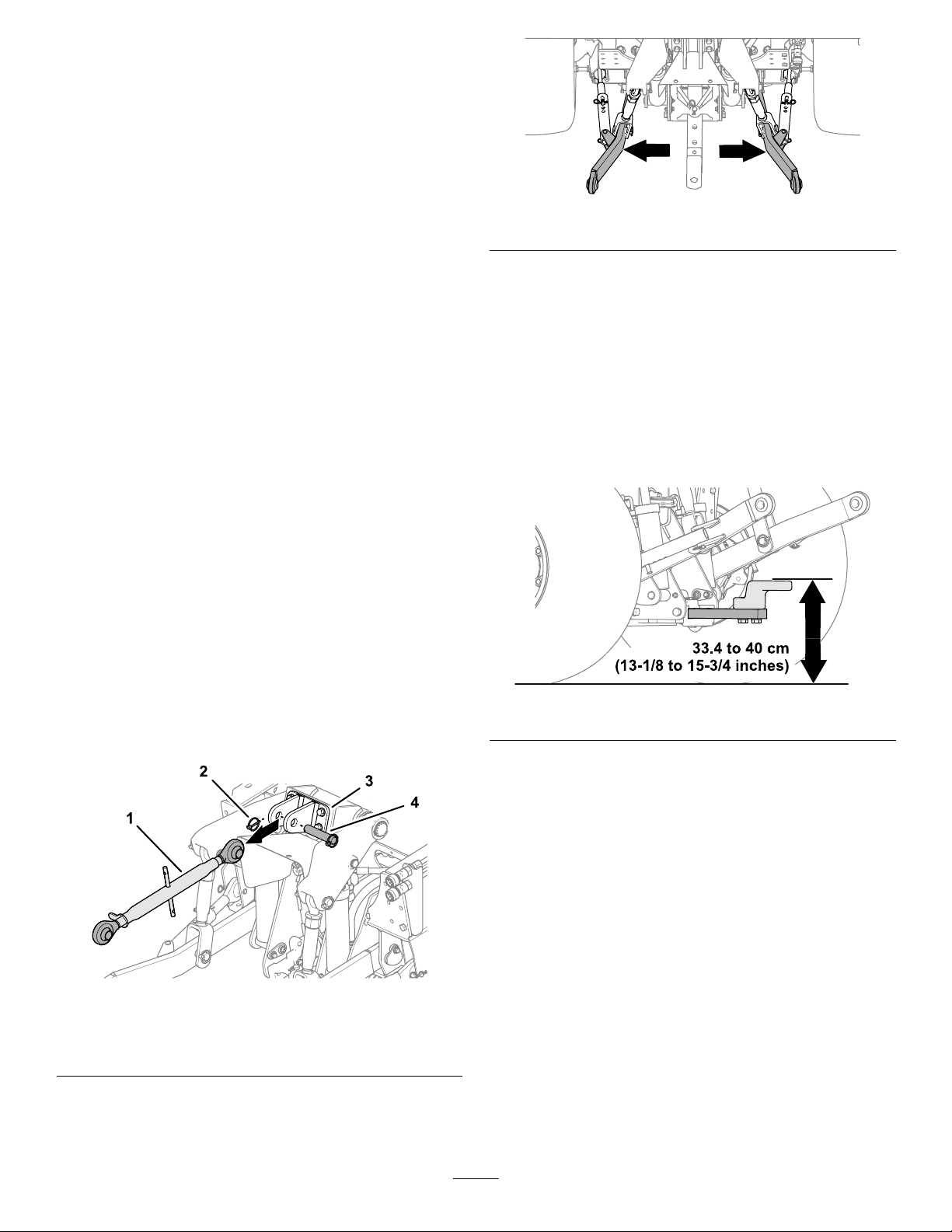

SelectingaDrawbarfortheMower

•Hitchpin-holediameter:31.75mm(1-1/4inches).

•Workingheight:33.4to40cm(13-1/8to15-3/4

inches);refertoFigure21.

theTowVehicle

PreparingtheTowVehicleand Mower

1.Ensurethatthemowerissupportedwiththe

tow-barjack;refertoSupportingtheMowerwith

theJack(page14).

2.Lowerthe3-pointhitch;refertotheOperator’s

Manualforyourtowvehicle.

3.Ifinstalled,removethelynchpin,clevispin,and

upper3-pointlinkfromtheupper-linkbracket

(Figure19).

g250512

Figure21

•Ensurethatyourdrawbardoesnotinterfereswith

thePTOdriveshaft.

ConnectingtheMowertotheTow Vehicle

1.Usejackhandletoraiseorlowerthetowbar

jackandalignthetowbartothedrawbaror

pintlehitch(Figure22).

Figure19

1.Upper3-pointlink3.Upper-linkbracket

2.Lynchpin

4.Adjustthestabilizerarms(Figure20)outward

fully;refertotheOperator’sManualsforthetow

machine.

4.Clevispin

g250419

15

Figure22

Pintowbarshown

1.Drawbar3.Jackhandle

2.Towbar

2.Fullyraisethe3-pointhitch;refertothe

Operator’sManualforyourtowvehicle.

Note:Whenequipped,lockthe3-pointhitch.

3.Alignthedrawbarorpintlehitchofthetow

vehiclewiththetowbarofthemower(Figure

22).

4.MovetheshiftlevertotheNEUTRALposition,

engagetheparkingbrake,shutofftheengine

removethe,andwaitforallmovingpartstostop.

5.Securethetowbarasfollows:

•Ifyourmowerhasapintowbar,insertthe

hitchpinthroughtheholesinthetowbarand

drawbarandsecurethepinwiththehairpin

(Figure23).

g250416

g250418

Figure23

Pintowbarshown

1.Flangebushing3.Hitchpin

2.Hairpin4.Pin

•Ifyourtowvehiclehasapintlehitch,close

andsecurethehitch.

6.Fullyraisethejack(Figure23).

7.Removethepinthatsecuresthejacktothetow

bar,rotatethejackhorizontal,andsecurethe

hacktothetowbarwiththepin(Figure23).

16

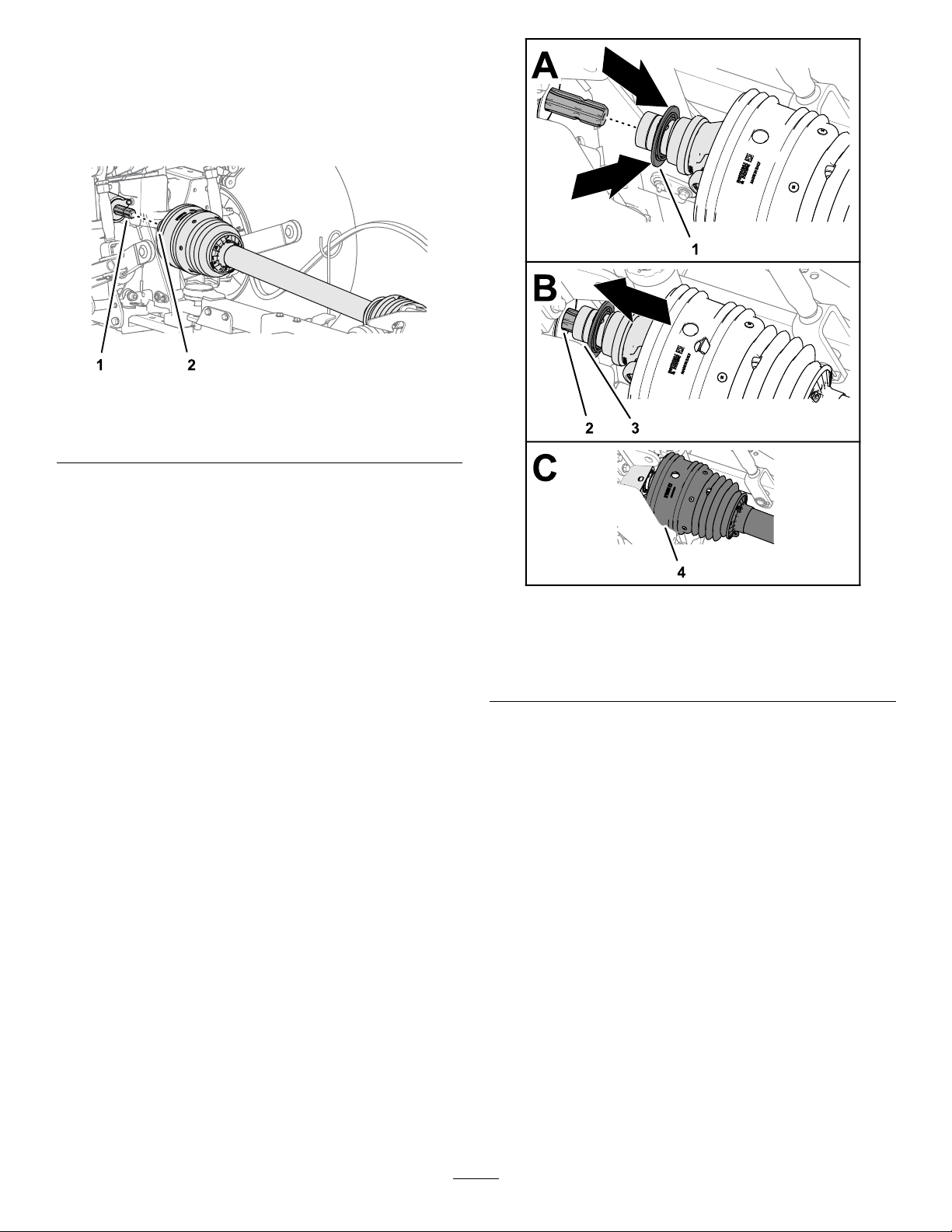

ConnectingtheDriveShafttothe PTO

1.Alignthequick-connectcouplingofthePTO

driveshaftwiththeoutputshaftofthePTO

(Figure24).

Figure24

g250417

1.PTOoutputshaft

(machine)

2.Pullbackthelockcollarofthequick-connect

coupling(Figure25).

2.Quick-connectcoupling

(PTOdriveshaft)

Figure25

1.Lockcollar(quick-connect

coupling)

2.Splines(PTOoutputshaft)4.Shield

3.Driveshaftyoke

3.Whilepullingbackthelockcollar,pullthePTO

drive-shaftyokeforwardandslipthesocketof

thecouplingoverthesplinesofthePTOoutput

shaft(Figure25).

4.Ensurethatthelockatthequick-connect

couplingsnapsintothegrooveofthePTO

outputshaftsecurely.

g250500

5.Ensurethattheshieldispositionedoverthe

driveshaftyoke(Figure25).

6.Attachtherestraintchaintoaxedpartofthe

towvehicle(Figure26).

Important:Ensurethatthereisenough

slackintherestraintchainsothatyoucan

turnthemachineinbothdirections.

17

Figure26

g264215

1.PTO-shaftguard(forward

half)

2.Restraintchain

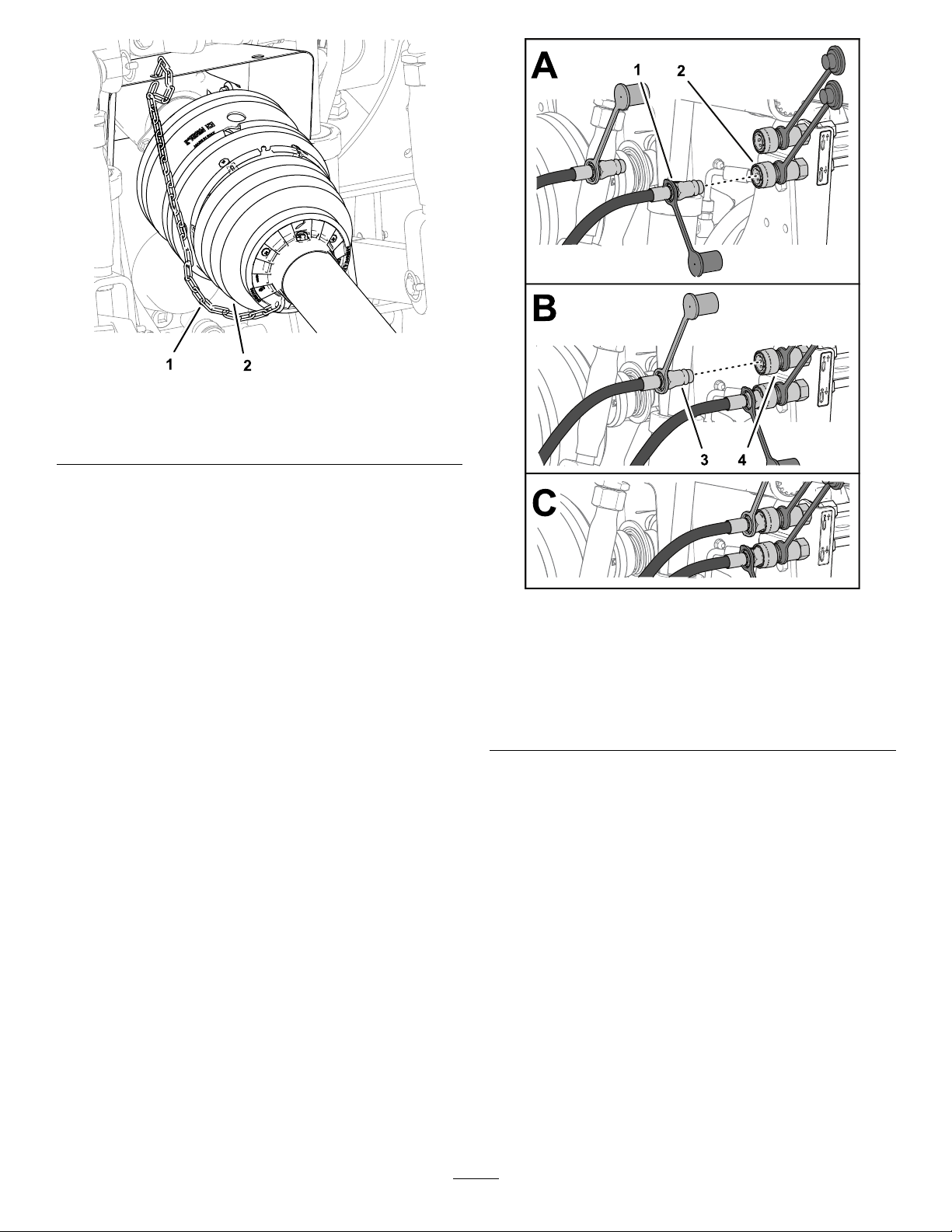

ConnectingtheHydraulicHoses

1.Identifythequick-disconnectttingsfortherear

attachment-liftandlowercircuitsforthetow

vehicle.

2.Removethedustcoversfromthe

quick-disconnectttingsofthetowvehicle.

3.Removetheblackdustcoverfromthe

quick-disconnectttingofthecylinder-extend

hoseofthemower

4.Connectthequick-connectttingcylinder

extendhosetothequick-disconnectcoupling

rear-attachment-lowercircuit(Figure27).

Figure27

1.Quick-connecttting

withblackdustcap

(cylinder-extendhose)

2.Quick-connectcoupling

(rearattachment-lower

circuit)

3.Quick-connecttting

withreddustcap

(cylinder-retracthose)

4.Quick-connectcoupling

(rearattachment-raise

circuit)

5.Removethereddustcoverfromthe

quick-disconnectttingofthecylinder-retract

hoseofthemower

6.Connectthequick-disconnectttingofthe

cylinderretracthosetothequick-disconnect

couplingrear-attachment-raisecircuit.

g250538

RoutingtheDeck-LockRopeto theMachine

1.Routethedeck-lockropefromthehoseguide

towardtheoperator’sseat(Figure28).

Important:Ensurethatyouallowslackin

theropesothatthemowercanfullyturn

rightandleftbehindthetowvehiclewithout

addingtensiontotherope,butitdoesnot

contactthePTOdriveshaft.

18

Figure28

1.Fixed-chassiscomponent3.Deck-lockrope

2.Hoseguide

2.Tietheropetothexed-chassiscomponentof

thetowvehiclesuchastheROPStube(Figure

28).

Important:Donottiethedeck-lockrope

totheseat,steeringwheel,orthehandleof

acontrol.

3.Removethechocksfromthemowertires.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscureyour

vision.

•DonotrunthePTOwiththedecksraisedabove

thepartialup-stopposition.

•Stopthemowerwheneveryouarenotcutting

grass.

•Stopthemachine,engagetheparkingbrake,

shutofftheengine,removethekey ,andwaitfor

g250665

allmovingpartstostopbeforeinspectingthe

attachmentafterstrikinganobjectorifthereis

anabnormalvibrationinthemachine.Makeall

necessaryrepairsbeforeresumingoperation.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalkswiththe

machine.Alwaysyieldtheright-of-way.

•Reducespeedonroughroadsandsurfaces

•Themowerisheavy.Whenattachedtoatow

vehicle,andintheraisedposition,theweightof

themoweraffectsstability,brakingandsteering.

Exercisecautionwhentransportingbetween

workingareas.

DuringOperation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

DuringOperationSafety

•Theowner/operatorcanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothing,includingeye

protection;longpants;substantial,slip-resistant

footwear;andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotoperatethemachinewhileill,tired,or

undertheinuenceofalcoholordrugs.

•Nevercarrypassengersonthemowerandkeep

bystandersandpetsawayfromthemachine

duringoperation.

•Operatethemachineonlyingoodvisibilitytoavoid

holesorhiddenhazards.

•Beforeyoustarttheengine,ensurethatalldrives

areinneutral,thePTOisdisengaged,theparking

brakeisengaged,andyouareintheoperating

position.

•Keepyourhandsandfeetawayfromrotating

parts.Keepclearofthedischargeopeningatall

times.

•Lookbehindanddownbeforebackinguptobe

sureofaclearpath.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition(including

adjustingtheheightofcut)dothefollowing:

–EnsurethatthePTOisdisengaged.

–Parkthemachineonalevelsurface.

–Engagetheparkingbrake.

–Lowerthemowerdecks.

–Shutofftheengineandremovethekey.

–Waitforallmovingpartstostopbeforeleaving

themachine.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Useaccessories,attachments,andreplacement

partsapprovedbyTheT oro®Companyonly.

•FordisassemblyorrepairofallsteelPTO

drive-shaftparts(tubes,bearings,joints,etc.),

contactyourauthorizedTorodistributor.Removal

ofcomponentsforrepairsandreassemblymay

damagesomepartsifnotperformedwithspecial

toolsbytrainedtechnicians.

•DonotoperatethemowerifthePTOordriveshaft

guardsaremissing.

•Becarefulwhenturningthemachinesothatthe

towvehicletiresdonotcontactthePTOdrive

shaft.

•Securehydraulichoses,electricalwiring,ropes,

andotheritemstokeepthemfromcontactingthe

PTOdrive-shaftguard.

19

SlopeSafety

LoweringtheMowerDecks

•Slopesareamajorfactorrelatedtolossofcontrol

androlloveraccidents,whichcanresultinsevere

injuryordeath.Y ouareresponsibleforsafeslope

operation.Operatingthemachineonanyslope

requiresextracaution.

•Reviewandunderstandtheslopeinstructionsin

themanualandonthetowvehicle.

•Evaluatethesiteconditionstodetermineifthe

slopeissafeformachineoperation,including

surveyingthesite.Alwaysusecommonsense

andgoodjudgmentwhenperformingthissurvey .

•Reviewtheslopeinstructionslistedbelowfor

operatingthemachineonslopesandtodetermine

whetheryoucanoperatethemachineinthe

conditionsonthatdayandatthatsite.Changes

intheterraincanresultinachangeinslope

operationforthemachine.

•Avoidstarting,stopping,orturningthemachineon

slopes.Avoidmakingsuddenchangesinspeedor

direction.Maketurnsslowlyandgradually.

•Donotoperateamachineunderanyconditions

wheretraction,steering,orstabilityareinquestion.

fromtheTransportPosition

1.EnsurethatthePTOisintheOFFposition;refer

totheOperator’sManualforyourtowvehicle.

2.Movethemowertoaatareathatislarge

enoughtosupportthemowerdecks.

3.Ensurethattherearenobystandersnearby .

4.Movethecontrolfortherearattachment-circuit

totheLIFTposition;refertotheOperator’s

Manualforyourtowvehicle.

Themowerdecksmayraiseslightlyand

pressureonthedecklocksreduces.

5.Pullandholdthedeck-lockrope(Figure29).

Thedecklocksrelease.

•Removeormarkobstructionssuchasditches,

holes,ruts,bumps,rocks,orotherhiddenhazards.

Tallgrasscanhideobstructions.Uneventerrain

couldoverturnthemachine.

•Beawarethatoperatingthemachineonwet

grass,acrossslopes,ordownhillmaycausethe

machinetolosetraction.Lossoftractiontothe

drivewheelsmayresultinslidingandalossof

brakingandsteering.

•Useextremecautionwhenoperatingthemachine

neardrop-offs,ditches,embankments,water

hazards,orotherhazards.Themachinecould

suddenlyrolloverifawheelgoesovertheedge

ortheedgecavesin.Establishasafetyarea

betweenthemachineandanyhazard.

•Identifyhazardsatthebaseoftheslope.If

therearehazards,mowtheslopewithapower

walk-behindmower.

•Ifpossible,keepthecuttingunit(s)loweredtothe

groundwhileoperatingonslopes.Raisingthe

cuttingunit(s)whileoperatingonslopescancause

themachinetobecomeunstable.

g250665

Figure29

1.Deck-lockrope3.Lockarm

2.Hoseguide

6.Movethecontrolfortherearattachment-circuit

totheLOWERposition;refertotheOperator’s

Manualforyourtowvehicle.

Themowerdeckslowertotheground(Figure

30).

•Useextremecautionwithotherattachments.

Thesecanchangethestabilityofthemachineand

causealossofcontrol.Alwayskeepthemachine

ingearwhengoingdownslopes.Donotcoast

downhill(applicableonlytogear-driveunits).

20

Figure30

7.Whenthedecksfullylowertotheground,

releasetheropeandattachmentcontrol.

8.Movethecontrolfortherearattachment-circuit

totheFLOATposition;refertotheOperator’s

Manualforyourtowvehicle.

g250716

g250705

g250715

Figure31

1.Decklocks2.Deckpins

RaisingtheMowerDecks whileCuttingGrass

Usethisproceduretoraisethemowerdecksslightly

whenturningthemachinesaroundattheendofa

cuttingpass.

Forinstructiononusingtherearattachmentcontrol,

refertotheOperator’sManualforyourtowvehicle.

1.Movethecontrolfortherearattachment-circuit

totheLIFTposition.

Thedecksraise,andtheliftpinscontactthe

partialup-stopportionofthedecklocks.

Note:Donotpullthedeck-lockrope.

2.Turnthetowvehicleandalignitforthenext

cuttingpass.

3.Movethecontrolfortherearattachment-circuit

totheLOWERposition.

4.EngagethePTO.

RaisingtheMowerDecks totheTransportPosition

ForinstructiononusingthePTOandrearattachment

control,refertotheOperator’sManualforyourtow

vehicle.

1.Movethemowertoaatarea.

2.ShutoffthePTO.

3.Pullandholdthedeck-lockrope(Figure32).

21

Figure32

1.Deck-lockrope3.Lockarm

2.Hoseguide

g250665

Figure34

1.Rightdecklock

2.Centerdecklock

g250714

4.Movethecontrolfortherearattachment-circuit

totheRAISEposition.

ThemowerdecksraisetotheTRANSPORT

position(Figure33).

6.Movethecontrolfortherearattachment-circuit

totheLOWERpositionuntilthedecklocks

supporttheweightofthedecks.

AdjustingtheHeight-of-Cut

1.Ifthemowerisinstalledtothetowvehicle,

performthefollowing:

A.EnsurethatthePTOisdisengaged.

B.Ifthemowerdecksareinthetransport

position,lowerthedecks;refertoLowering

theMowerDecksfromtheTransport

Position(page20).

C.Engagetheparkingbrake,shutoffthe

engine,removethekey ,andwaitforall

movingpartstostop.

2.Determinetheheightthatyouwanttocutthe

grass.

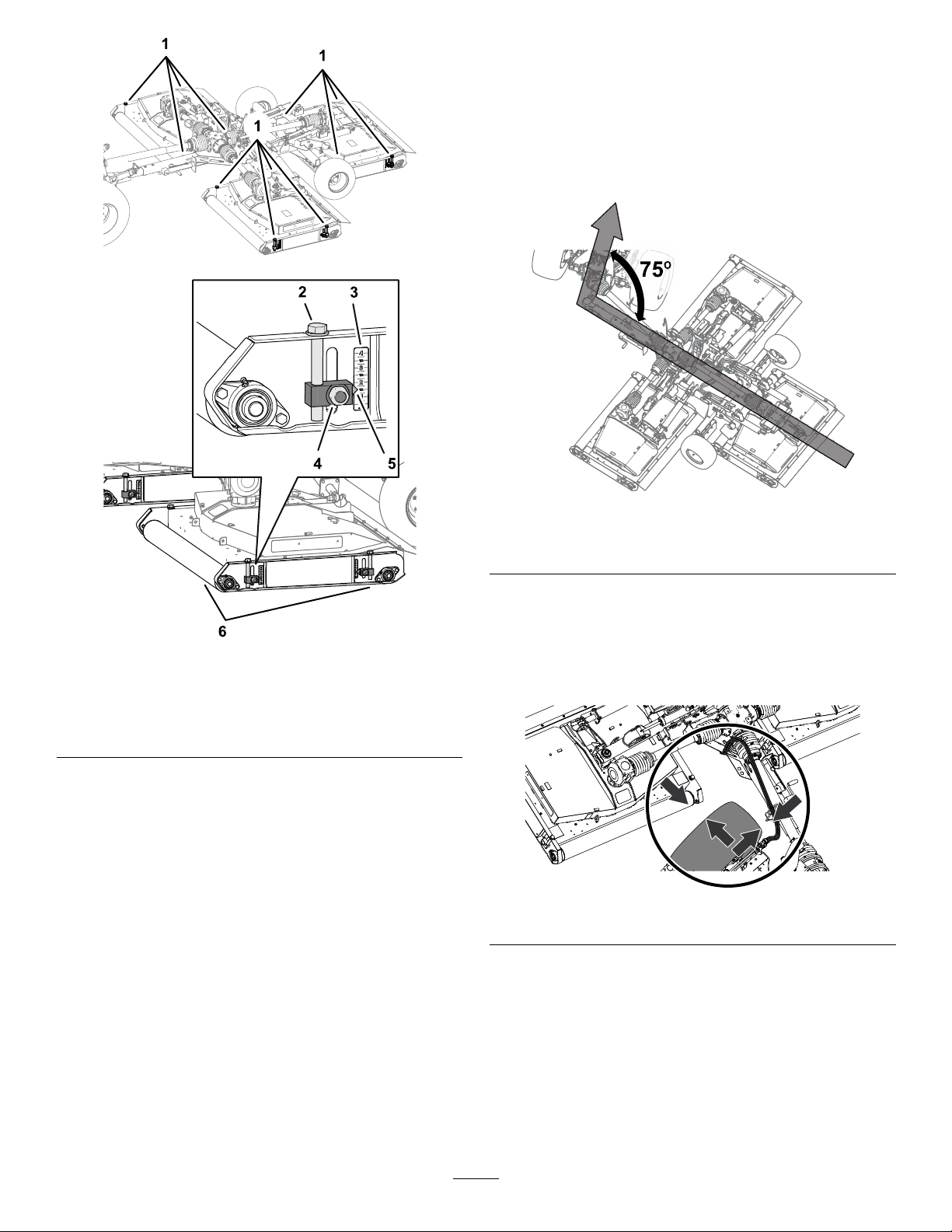

3.Loosenthe4locknutsthatsecurethe4

height-of-cutadjusters(Figure35)ofthemower

deck.

Figure33

5.Whenthedecksfullyraised,releasetherope

andattachmentcontrol.

Thedecklocksengagethedeckpins(Figure

34).

g250706

22

MakingaSharpTurn

1.ShiftthetowvehicletoLOWGEARorLOWRANGE.

2.Drivingthemachineslowly,steertomakethe

sharpturn.

Important:Donotexceedthe75°maximum

towvehicletomowerangle.

g250931

g264251

Figure36

75°MaximumT owVehicletoMowerAngle

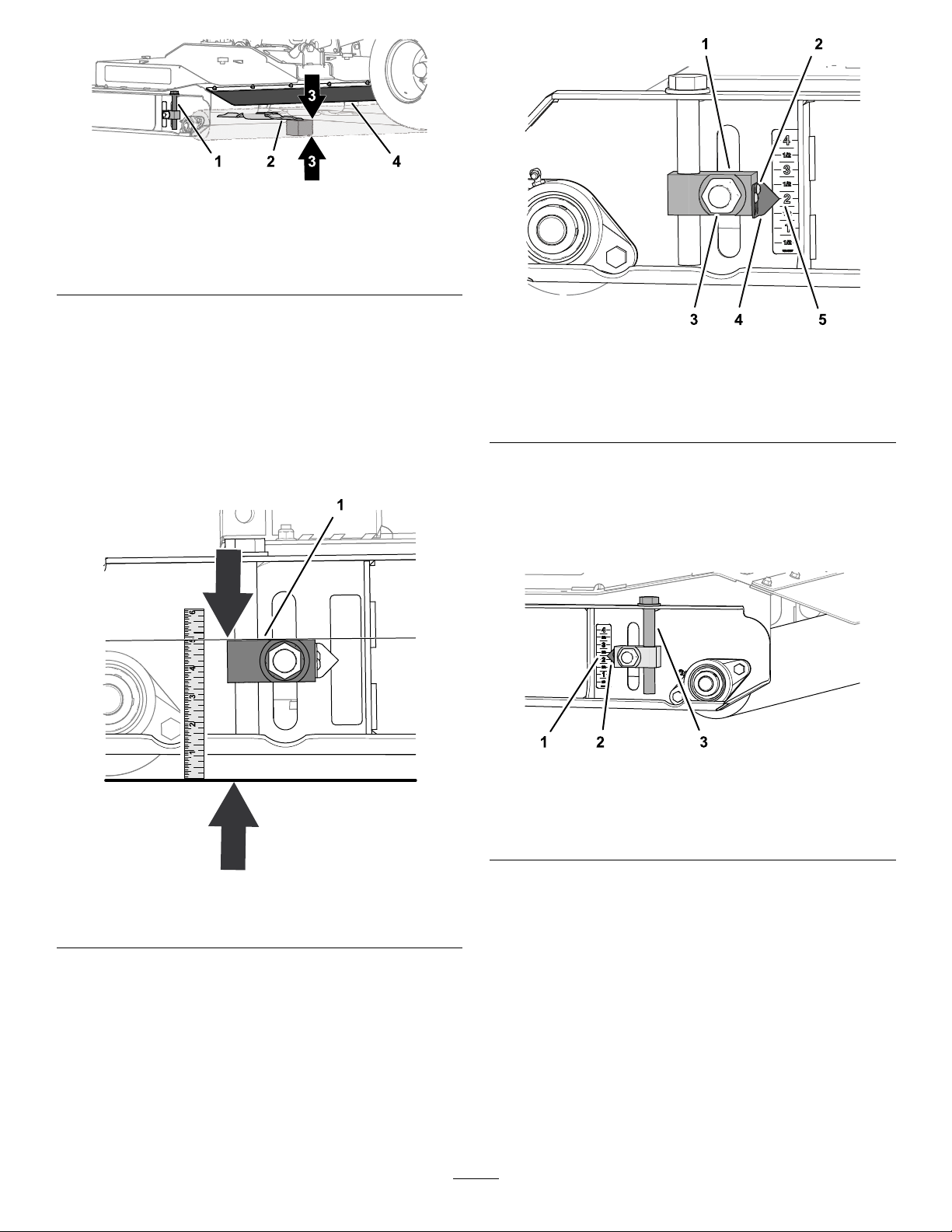

Figure35

1.Height-of-cutadjusters

2.Adjustercapscrew

3.Cut-heightscale

4.Locknut

5.Pointer

6.Rollers

4.Workingat1ofthedeckrollers,turntheadjuster

capscrewtoraiseorlowerthemoweruntilthe

pointeralignswiththegrasscutheightthatyou

determinedinstep2.

5.Tightenthelocknutsfor2height-of-cutadjusters.

6.Repeatsteps4and5fortheheight-of-cut

adjustersattheotherroller.

7.Repeatsteps3through6fortheotherdecks.

3.Asyouturn,checktoensureclearancebetween

thetireofthetowvehicleandthepartsofthe

g250930

mower(Figure37).

Note:Ifthetireistooclosetothemower,turn

moregradually.

g264252

Figure37

23

AfterOperation

AfterOperationSafety

•Parkthemachineonalevelsurface;engagethe

parkingbrake;shutofftheengine;removethekey;

andwaitforallmovementtostopbeforeleaving

themachine.

TransportingtheMachine

Important:Raiseandlatchthedecksbefore

loadingthemowerontoorofffromthetrailer.

•Usecarewhenloadingorunloadingthemachine

intoatraileroratruck.

•Usefull-widthrampsforloadingthemachineinto

atraileroratruck.

•Donotstepon,overorunderthedriveshaft.

•DonotusetherestrainchainofthePTO-shaft

guardtosupporttheshaftwhentransportingor

storingthemower.

•DonotrestthePTOshaftontheground.

•DonotallowthePTO-shaftguardstopullapart.

•Keepallpartsofthemachineingoodworking

conditionandallhardwaretightened.

•Replaceallworn,damaged,ormissingdecals.

CleanandInspect

ServiceInterval:Aftereachuse

Raisethemowerdecksandthoroughlywashthem.

Tie-DownPoints

RefertoOperator’sManualforyourtowchassisand

towvehiclethetie-downlocationsofthemachine.

1.Drivethetowvehicleuptheramp.

2.Shutofftheengine,removethekey,andengage

theparkingbrake.

3.Lowerthejack.

4.Tiedownthemachinenearthewheelswith

straps,chains,orcables.

Note:Refertolocalregulationsfortie-down

requirements.

5.Secureblocksatthewheelsofthemachineto

thebedofthetrailerortruck.

6.EnsurethatthePTOdriveshaftiscoupledto

atowvehicleorsecuredtothetowbarofthe

mower.

Figure38

1.Forwardtie-downpoint2.Forwardtie-downpoint

(leftandrightsides)

g264216

24

Maintenance

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

WARNING

Ifthemowerdecksareraisedbutnotlatched,thedeckscouldlowerunexpectedlyand

seriouslyinjureyouorotherbystanders.

Fullyraisealldecksandensurethepinsonallliftarmsengagethelatches.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst50hours

Beforeeachuseordaily

Aftereachuse

Every50hours

Every500hours

Beforestorage

MaintenanceProcedure

•Changethecentergearlubricant.

•Changethecentergearlubricant.

•Checkthemowerbelts.

•Checkthetireairpressure.

•CheckthePTOanddriveshaftguards.

•GreasetheconstantvelocityjointforthePTOdriveshaft.

•Checkthemowerblades.

•Cleanandinspectthemower.

•Greasethetelescopingdrive-shaftjoints.

•GreasethedriveshaftU-joints.

•Greasethedriveshaftguard-slipjoints.

•Greasetheliftarms,hydrauliccylinders,latches,andimpactstruts(also,lubricate

themowerimmediatelyaftereverywashing).

•Greasethespindles.

•Greasethebelttensioner.

•Greasethedeckrollers(also,lubricatetherollersimmediatelyaftereverywashing).

•Checkthegearboxuidlevel.

•Inspectgearboxandspindlebearings.

•Performall50-hourmaintenanceprocedures.

•Removealldebris.

•Inspecttherollerbearings.

•Paintanychippedsurfaces.

•Changethecentergearlubricant.

Yearly

•Changethecentergearlubricant.

•InspectthePTO-shaftsplinesforsignsofwear.

25

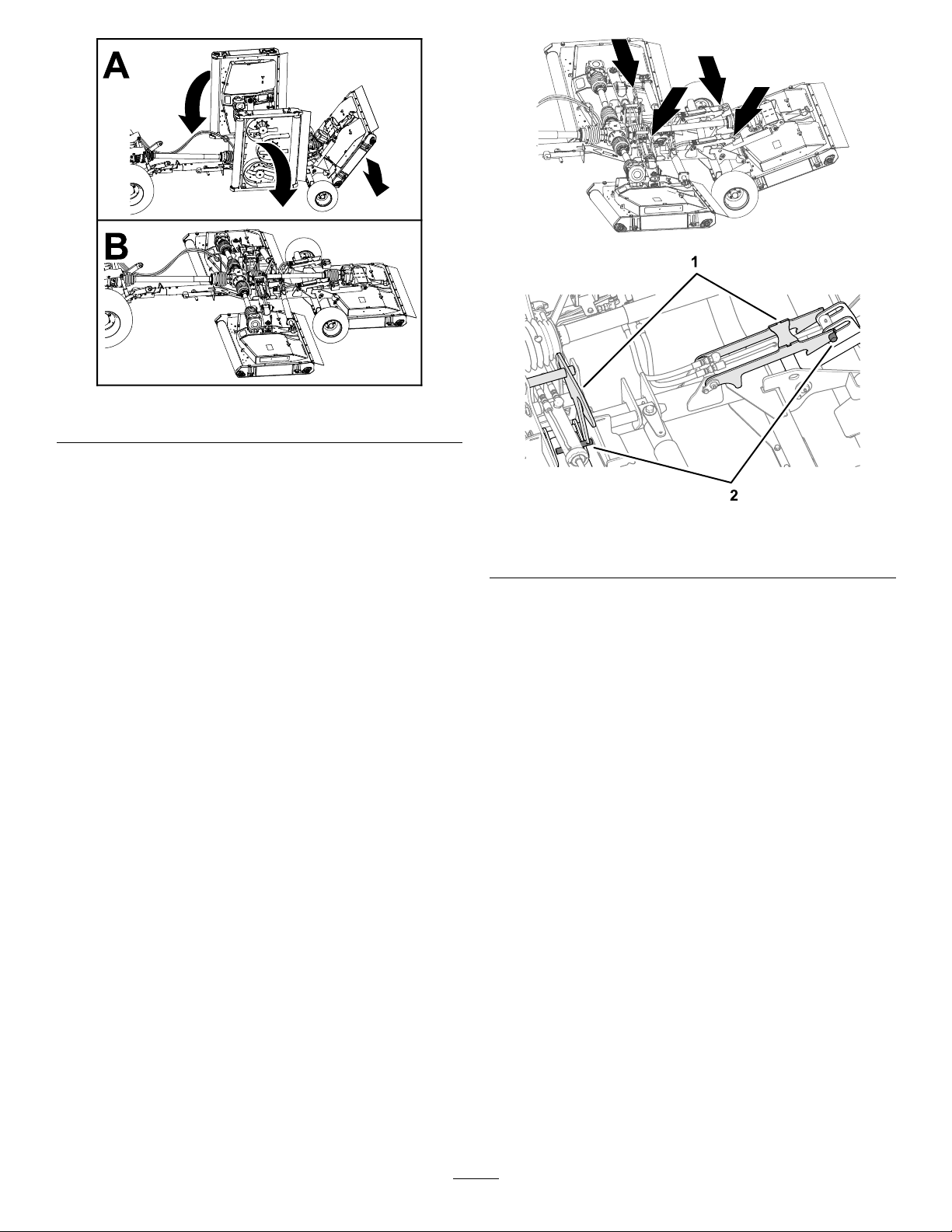

LiftingtheMower

1.Liftthemowerattheaxlehalvesasshownin

Figure39.

Figure39

1.Axlehalves

2.Usejackstandstosupportthemower.

AccessingtheMower Decks

RemovingtheDeckCovers

g264176

1.Releasethe3latchesthatsecurethecoverof

themowerdeck(Figure40).

Figure40

1.Knob(deck

cover—non-CEmowers)

2.Latch(mower-deckcover)4.Knob(non-CEmowers)or

2.Loosentheknoborbolt(CEmowerdeck)that

securesthecoverofthemowerdecktothe

mowerdeck(Figure40).

3.Liftandremovethecoverfromthedeck.

4.Repeatsteps1and2fortheothercover(Figure

40).

3.Bolt(deckcover—CE

mowers)

bolt(CEmowers)

g251061

26

InstallingtheDeckCovers

1.Alignthelatchesofthemower-deckcoverwith

theholesinthemowerdeck(Figure41).

Lubrication

GreaseSpecication

No.2lithiumbasegrease

GreasingthePTOShaftConstant VelocityJoint

ServiceInterval:Beforeeachuseordaily

Applythespeciedgreasetothe3greasettingsat

theforwardendofthePTOdriveshaft(Figure42).

Figure41

1.Latch(mower-deckcover)3.Knob(deck

2.Knob(non-CEmowers)or

bolt(CEmowers)

cover—non-CEmowers)

4.Bolt(deckcover—CE

mowers)

2.Assemblethedeckcovertothemowerdeck

(Figure41).

3.Securethecover(Figure41)asfollows:

•Non-CEmowers:threadtheknobthrough

thecoverandintothemowerdeck,and

tightentheknob.

•CEmowers:threadtheboltintothemower

deck,andtightenthebolt.

4.Securethe3latchesofthecovertothemower

deck(Figure41).

g255325

g254821

g255326

Figure42

5.Repeatsteps1through4fortheothercovers

thatyouremoved(Figure41).

27

GreasingtheTelescoping Drive-ShaftJoints

ServiceInterval:Every50hours

1.PartiallyextendthePTOdriveshafttoaccess

thegreasettingnearthemiddleoftheinboard

drive-shaftguard(Figure43).

g255328

g264299

Figure43

2.Applygreasetothe4greasettingsforthe

telescopingdrive-shaftjointsasshowninFigure

43.

GreasingtheDriveshaftU-Joints

ServiceInterval:Every50hours

Applythespeciedgreasetothe7ttingforthedrive

shaftU-jointsasshowninFigure44.

g264298

Figure44

g255327

28

GreasingtheDriveShaft Guard-SlipJoints

ServiceInterval:Every50hours

Applythespeciedgreasetothe6greasettingsfor

thedriveshaftguard-slipjointsasshowninFigure45.

g264214

g251060

Figure46

LeftorRightMowerDeck

1.Outboard

•Applygreasetheliftarmsandhydrauliccylinders,

andimpactstrutsofthecentermowerdeck(Figure

47).

Figure45

GreasingtheLiftArms,Hydraulic Cylinders,Latches,andImpact Struts

ServiceInterval:Every50hours(also,lubricate

themowerimmediatelyafterevery

washing).

•Applythespeciedgreasetotheliftarms,

hydrauliccylinders,andimpactstrutsoftheleft

andrightmowerdecks(Figure46).

g251059

Figure47

CenterMowerDeck

g264213

1.Backofthemower

GreasingtheSpindles

ServiceInterval:Every50hours

Applythespeciedgreasetothegreasettingatthe

3spindlesateachmowerdeck(Figure47).

g251062

Figure48

Leftdeckshown.Rightandcenterdecksaresimilar.

29

GreasingtheBeltTensioners

ServiceInterval:Every50hours

Applythespeciedgreasetothegreasettingsatthe

2belttensionersofeachmowerdeck.

2.Greasethedeckrollerbearingsattherightside

ofthedeck(Figure50).

3.Repeatsteps1and2forthedeckrollersatthe

otherdecks.

ServicingtheGearboxes

Customersuppliedmaterial:PTFEthreadsealant

andasmallhandpump.

GearboxFluidSpecication

•ToroPremiumTractoruid

•Mobiluid™424tractorhydraulicuid

CheckingtheGearboxFluidLevel

Figure49

GreasingtheDeckRollers

ServiceInterval:Every50hours(also,lubricate

therollersimmediatelyafterevery

washing).

1.Applythespeciedgreasethedeckroller

bearingsattheleftsideofthedeck(Figure50).

g264169

ServiceInterval:Every50hours

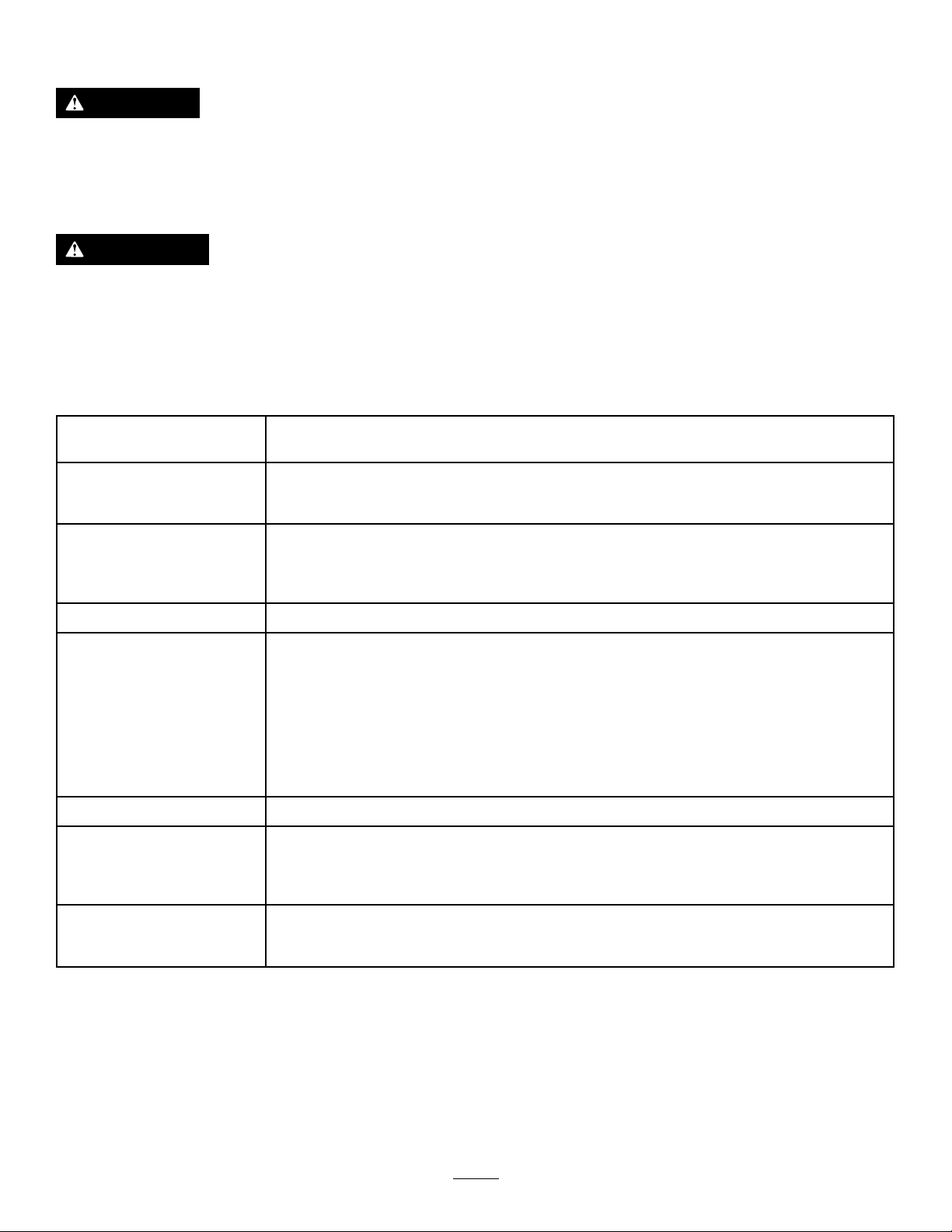

1.Removethedipstickfromthedipstickportatthe

topofthecentergearbox(Figure51orFigure

52).

1.Leftsideofthemachine

g255251

Figure51

CenterGearbox

1.Dipstick3.Fulldipstickmark

2.Dipstickport4.Adddipstickmark

g254862

Figure50

30

Figure52

DeckGearbox

1.Dipstick3.Fulldipstickmark

2.Dipstickport4.Adddipstickmark

ChangingtheCenterGearBox Lubricant

ServiceInterval:Aftertherst50hours

Yearly

DrainingtheCenterGearbox

g255263

g255203

Figure53

CenterGearboxDrainLocation

2.Checktheuidlevelindicatedonthedipstick

(Figure51orFigure52).

Theuidlevelshouldindicatebetweenthefull

andaddmarksofthedipstick.

Note:Addlubricantasneededtoraisethe

levelbetweenthefullandaddmarks;referto

FillingtheCenterGearbox(page32)orFilling

theDeckGearbox(page32).

3.Cleanthethreadsofthedipstickandllplugand

applyPTFEthreadsealanttothethreads.

4.Threadthedipstickintothellportandtighten

thedipstick(Figure51orFigure52).

5.Repeatsteps1through4forthedeck

gearboxes.

1.Workingthroughtheaccessholeatthe

bottom-frameplateofthemower,alignadrain

panunderthehole(Figure54).

Figure54

1.Socket-drainplug

2.Drainport(center

grearbox)

3.Accesshole

(bottom-frame

plate—mower)

g255204

2.Removethesocket-drainplugfromthedrain

portofthecentergearboxandallowthelubricant

todraincompletely(Figure54).

3.Cleanthethreadsofthedrainplugandapply

PTFEthreadsealanttothethreads.

4.Assemblethedrainplugintothedrainportand

tightentheplug.

31

FillingtheCenterGearbox

ChangingtheDeckGearbox

Centergearboxuidcapacity:1,774mL(60oz)

1.Removethedipstickfromthedipstickportatthe

topofthecentergearboxandwipecleanthe

dipstick(Figure55).

Lubricant

ServiceInterval:Aftertherst50hours

Yearly

EmptyingtheDeckGearbox

1.Removethedipstickfromthetopofthegearbox

(Figure56).

Figure55

CenterGearbox

1.Dipstick4.Fillport

2.Fillplug5.Fulldipstickmark

3.Dipstickport6.Adddipstickmark

2.Removethellplugfromthellportatthetopof

thegearbox(Figure55).

3.Add1,774mL(60oz)ofthespeciedgear

lubricanttothegearboxthroughthellport

(Figure55).

4.Threadthedipstickintotheport,removethe

dipstick,andcheckthatthelubricantlevel

(Figure55).

Theuidlevelshouldindicatebetweenthefull

andaddmarksofthedipstick.

Note:Addlubricantasneededtoraisethelevel

betweenthefullandaddmarks.

5.Cleanthethreadsofthedipstickandllplugand

applyPTFEthreadsealanttothethreads.

g255252

g255295

Figure56

1.Dipstick2.Dipstickport

2.Throughthedipstickport,useasuctionpumpto

removetheuidfromthegearbox(Figure56).

3.Repeatsteps1and2fortheotherdeck

gearboxes.

FillingtheDeckGearbox

Deckgearboxuidcapacity:1,064mL(36oz)

1.Add1,064mL(36oz)ofthespeciedgear

lubricanttothegearboxthroughthedipstickport

(Figure57).

6.Threadthedipstickintothellportandtighten

thedipstick(Figure55).

7.Assemblethellplugintothellportandtighten

theplug(Figure55).

32

Figure57

1.Dipstick3.Fulldipstickmark

2.Dipstickport4.Adddipstickmark

g251058

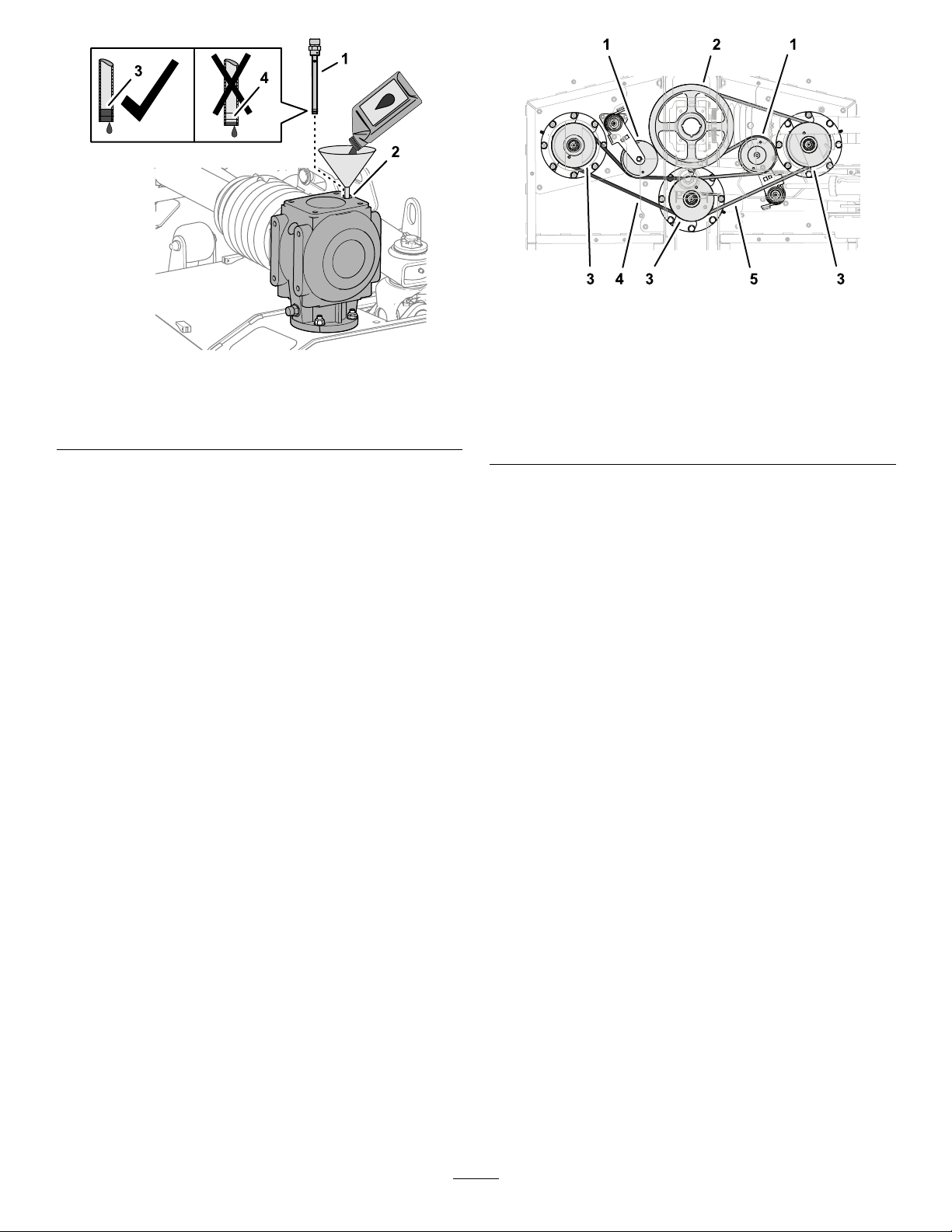

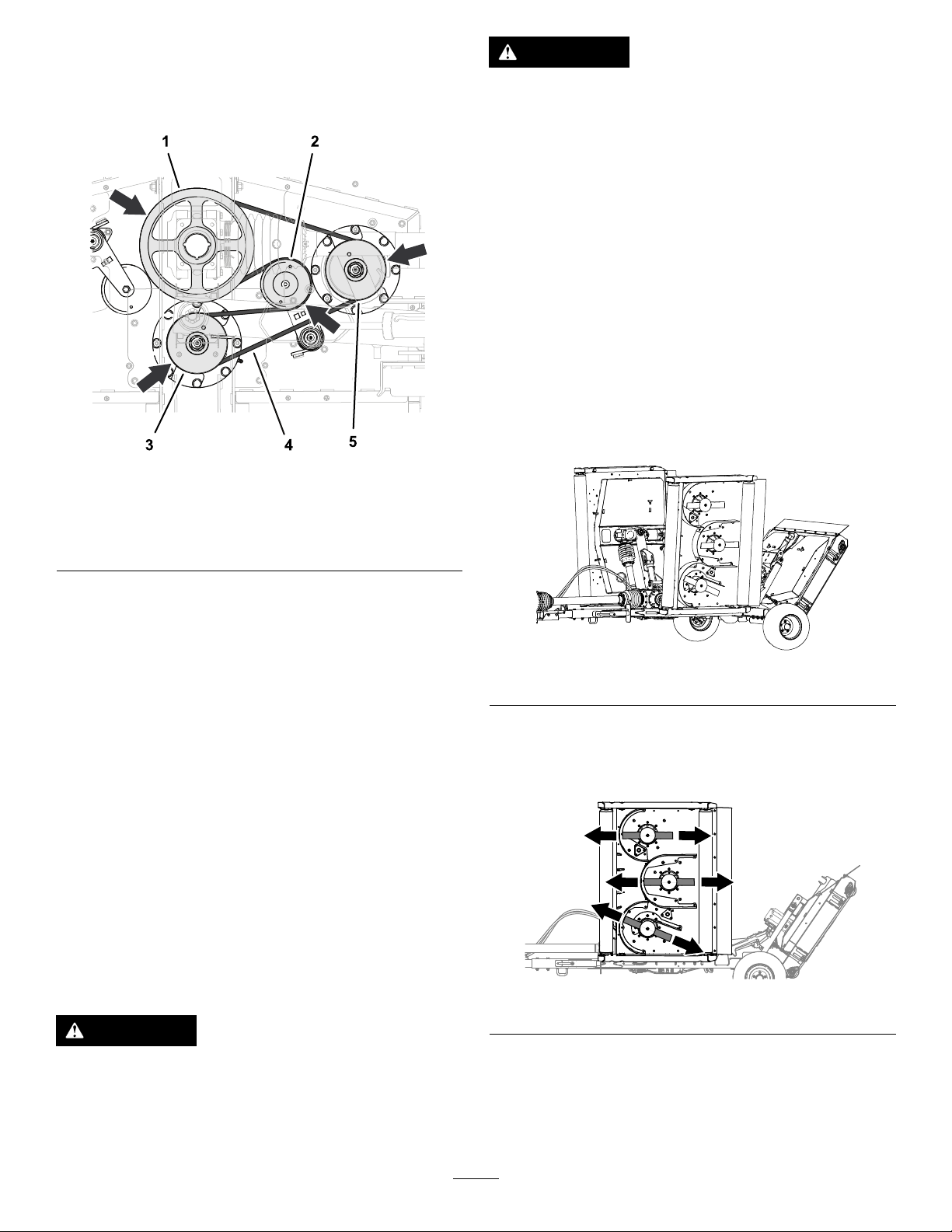

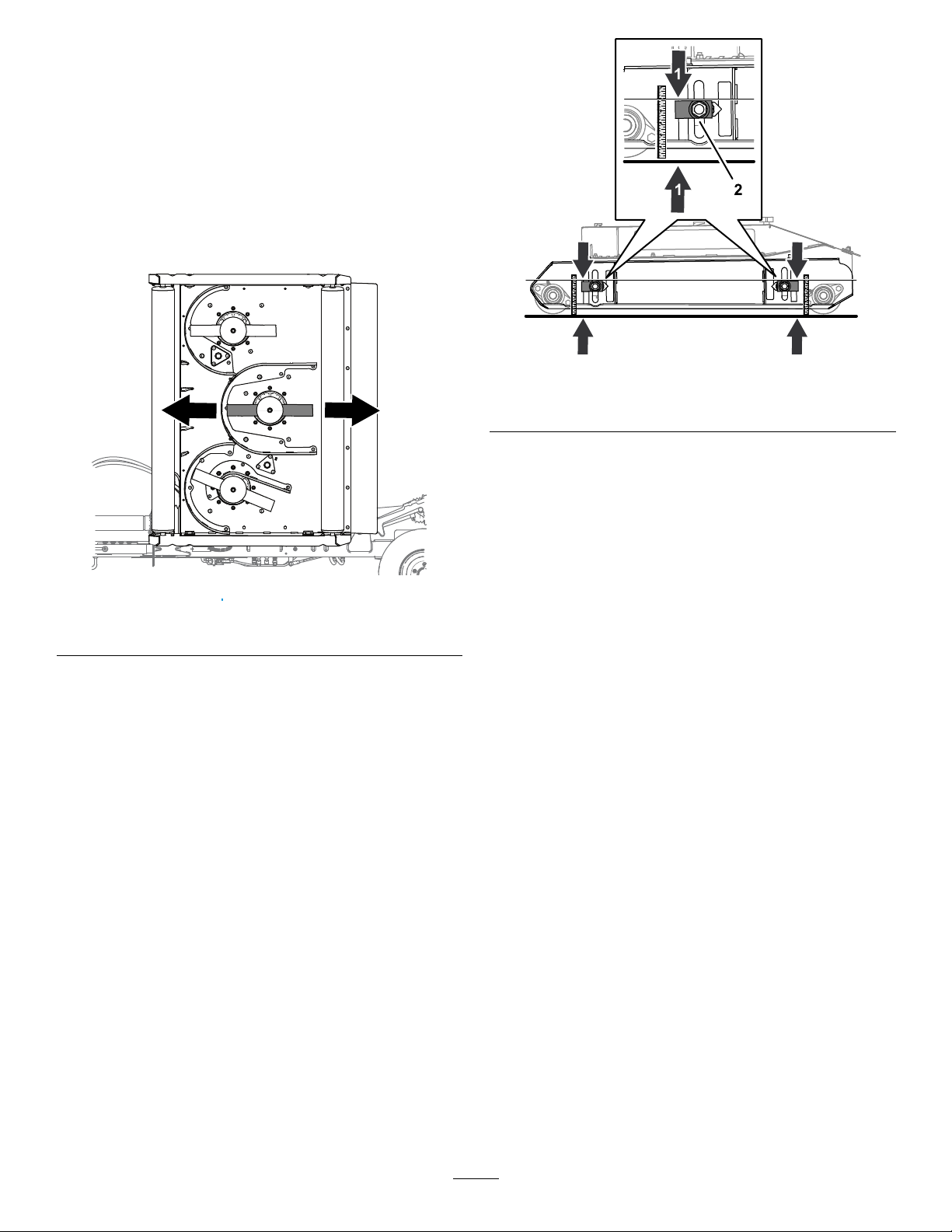

Figure58

Thebeltsfortheleftdeckareshown.Thebeltsrightand

g255294

1.Tensionerpulleys

2.Drivepulleys

3.Spindlepulleys(left,

center,andright)

centerdecksaresimilar.

4.Shortbelt(left)

5.Longbelt(right)

2.Threadthedipstickintotheport,removethe

dipstick,andcheckthatthelubricantlevel

(Figure57).

Theuidlevelshouldindicatebetweenthefull

andaddmarksofthedipstick.

Note:Addlubricantasneededtoraisethelevel

betweenthefullandaddmarks.

3.Cleanthethreadsofthedipstickandapply

PTFEthreadsealanttothethreads.

4.Threadthedipstickintothellportandtighten

thedipstick(Figure57).

5.Repeatstepsand1through4fortheotherdeck

gearboxes.

CheckingtheMowerBelts

ServiceInterval:Aftertherst50hours

Thebladedrivebelts,tensionedbythespringloaded

idlerpulleys,aredurable.However,aftermanyhours

ofuse,thebeltswillshowsignsofwear.Signsofa

wornbeltinclude:squealingwhenbeltisrotating,the

mowerbladesslipwhencuttinggrass,thebelthas

frayededges,thebelthasburnmarksandcracks,

andpoorqualityofcut.Replacethebeltsifyounotice

anyoftheseconditions.

1.Removethedeckcovers;refertoRemovingthe

DeckCovers(page26).

2.Checktheshortandlongbeltforsignsof

damageorexcessivewear.

Replacedamagedorwornbelts;referto

ReplacingtheMowerBelts(page33).

3.Installthedeckcovers;refertoInstallingthe

DeckCovers(page27).

ReplacingtheMowerBelts

Note:Youmustremovethelongbelttoreplacethe

shortbelt.

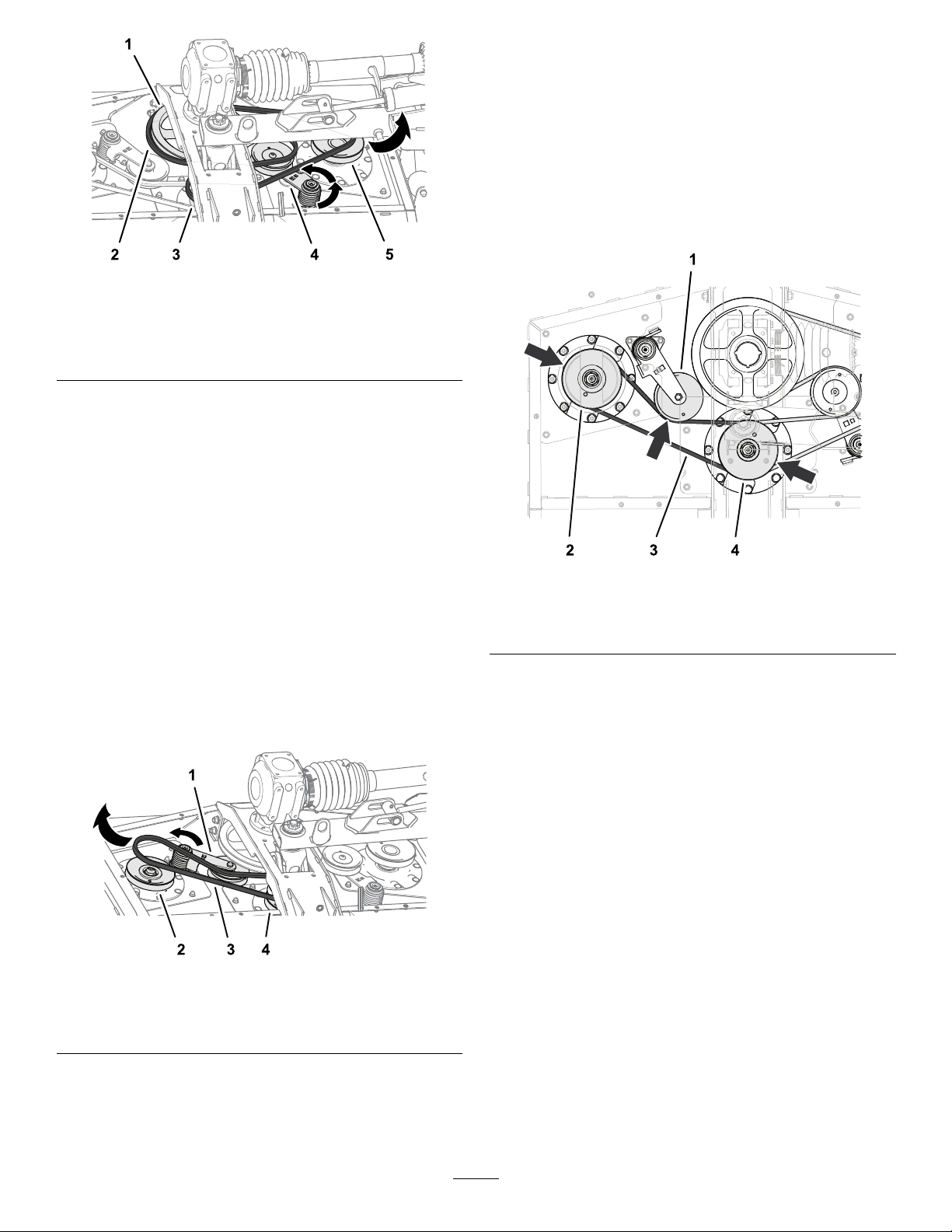

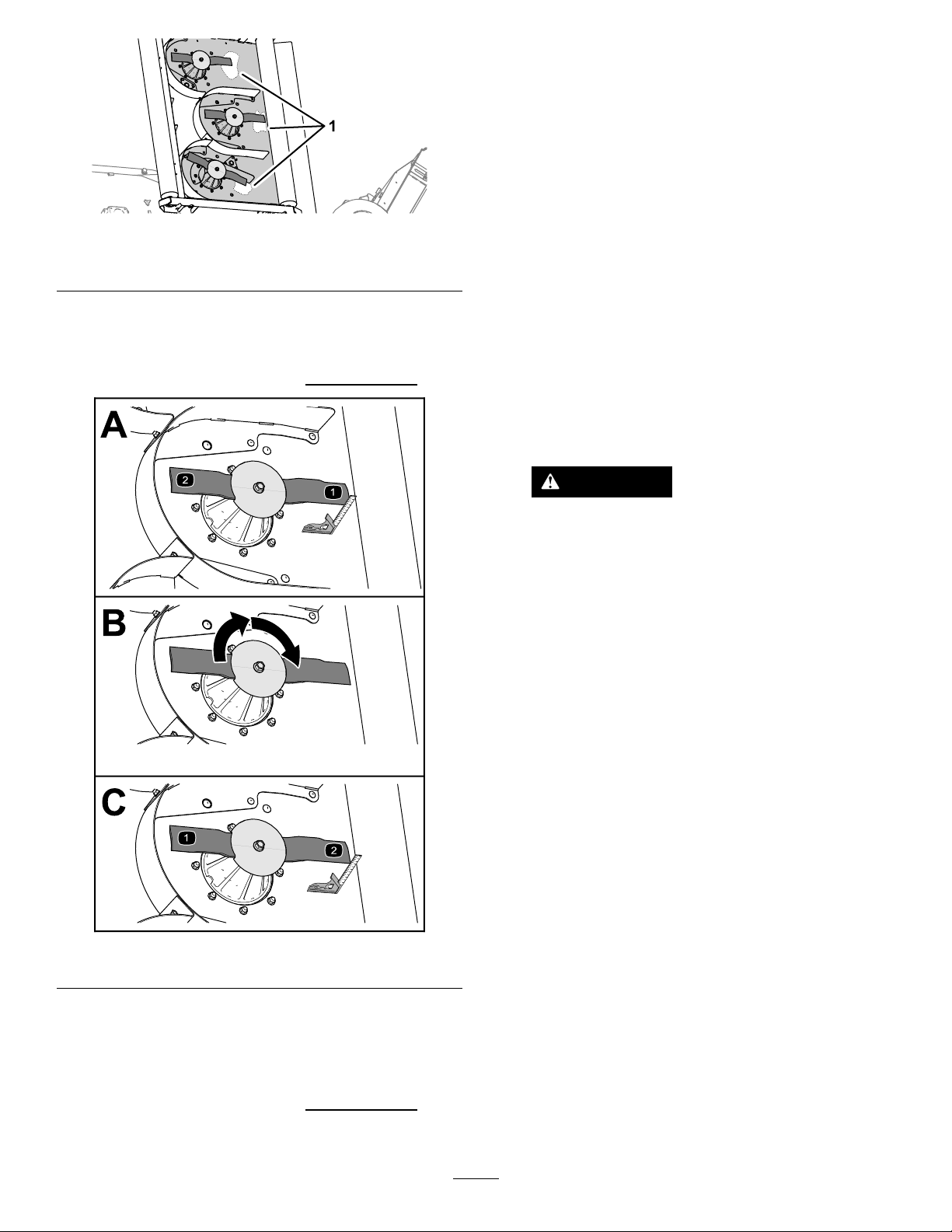

RemovingtheLongBelt

1.Removethebeltcovers;refertoRemovingthe

DeckCovers(page26)

2.Useabreakerbarorsimilartooltorotatethebelt

tensionerforthelongbeltcounterclockwiseand

slipthebeltoffthetensionerpulley(Figure59).

33

Figure59

1.Drivepulley4.Tensionerandpulley

2.Longbelt5.Right-spindlepulley

3.Center-spindlepulley

3.Slipthelongbeltoffthedrivepulley,

center-spindlepulley,andright-spindlepulley

(Figure59).

4.Removethebeltfromthemower.

Note:Youmayneedtorotatethebeltwhile

removingitfromthecenter-spindlepulley.

InstallingtheShortBelt

1.Installthelongbelt;refertoInstallingtheLong

Belt(page35).

2.Routethelongbeltaroundtheleft-spindlepulley

andthelowergrooveofthecenter-spindlepulley

(Figure61).

g255022

Note:Youmayneedtorotatethebeltwhile

removingitfromthecenter-spindlepulley.

RemovingtheShortBelt

1.Removethebeltcovers;refertoRemovingthe

DeckCovers(page26).

2.Ifinstalled,removethelongbelt;referto

RemovingtheLongBelt(page33).

3.Useabreakerbarorsimilartooltorotatethebelt

tensionerfortheshortbeltcounterclockwiseand

slipthebeltoffthetensionerpulley(Figure60).

Figure61

1.Tensionerandpulley

2.Left-spindlepulley4.Center-spindlepulley

3.Shortbelt

3.Useabreakerbarorsimilartooltorotatethe

belttensionercounterclockwiseandslipthebelt

overthetensionerpulley(Figure61).

g255021

Figure60

1.Tensionerandpulley

2.Left-spindlepulley4.Center-spindlepulley

3.Shortbelt

4.Slipthelongbeltoffthedrivepulley,

center-spindlepulley,andright-spindlepulley

5.Removethebeltfromthemower.

g255020

34

InstallingtheLongBelt

1.Routethelongbeltaroundthedrivepulley,

uppergrooveofthecenter-spindlepulley,and

right-spindlepulley(Figure62).

Figure62

1.Drivepulley4.Longbelt

2.Tensionerandpulley5.Right-spindlepulley

3.Center-spindlepulley

DANGER

Awornordamagedbladecanbreak,anda

pieceofthebladecouldbethrowntowardyou

orabystander,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

PreparingtoServicetheMower Blades

Note:Y ouneedthemowerinstalledtothetow

vehiclewhenservicingthemowerblades.

1.DisengagethePTO,movethemachinetoa

levelsurface,andengagetheparkingbrake.

2.Raiseandlatchthemowerdecks,shutoffthe

g255023

engine,andremovethekey(Figure63).

2.Useabreakerbarorsimilartooltorotatethe

belttensionercounterclockwiseandslipthebelt

overthetensionerpulley(Figure62).

3.Ifyouareonlyreplacingthelongbelt,installthe

deckcovers;refertoInstallingtheDeckCovers

(page27).

4.Installthedeckcovers;refertoInstallingthe

DeckCovers(page27).

ServicingtheBlades

Maintainsharpbladesthroughoutthecuttingseason

becausesharpbladescutcleanlywithouttearingor

shreddingthegrassblades.Tearingandshredding

turnsgrassbrownattheedges,whichslowsgrowth

andincreasesthechanceofdisease.

Checkthebladesdailyforsharpness,andforany

wearordamage.Sharpenthebladesasnecessary.

Ifabladeisdamagedorworn,replaceitimmediately

withagenuineTororeplacementblade.

DANGER

Themowerbladesaresharpandcaninjure

you.

Wearheavyleatherorcutresistantgloves

whenservicingwiththeblades.

g255457

Figure63

CheckingforBentMowerBlades

1.AlignthemowerbladeasshowninFigure64.

g256136

Figure64

2.Cleanthebottomofthemowerdeckatthearea

adjacenttothecuttingedgeattherearofthe

blade(Figure65).

35

Figure65

1.Cleanarea(bottomofthemowerdeck)

Thedifferencebetweenmeasurementsthatyou

observedinsteps4and6exceed3mm(1/8

inch),thebladeisbent,andyoumustreplace

theit;refertoRemovingtheBlades(page37)

andInstallingtheBlades(page38)

6.Repeatsteps3through5fortheotherblades

ofthemowerdeckorsteps1through6forthe

otherdecks.

g255531

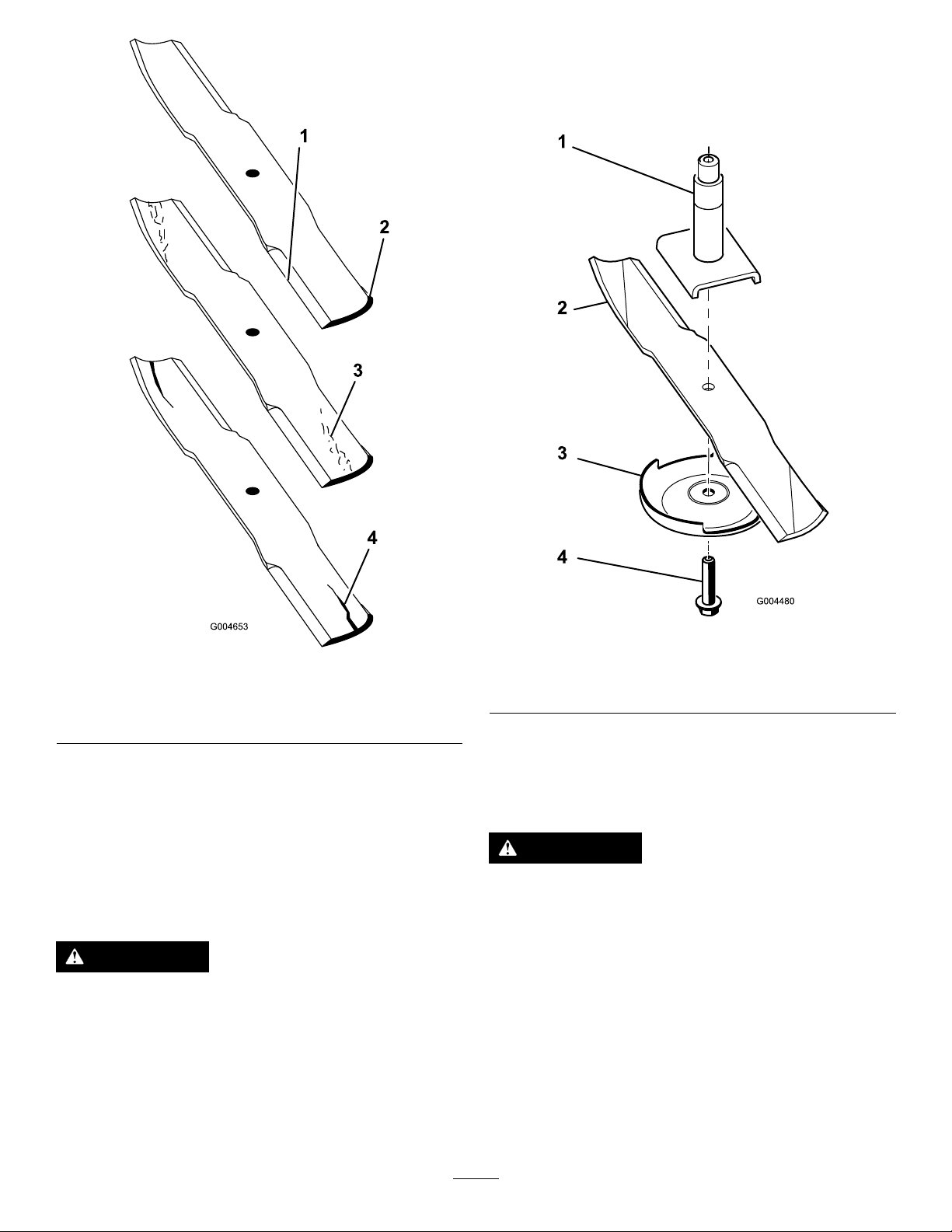

InspectingtheBlades

ServiceInterval:Beforeeachuseordaily

3.Useacombinationsquaretomeasurethe

distancebetweenthecleanareaofthedeckand

thetipofthecuttingedge(Figure66).

Recordyourmeasurement.

1.Inspectthecuttingedges(Figure67).Ifthe

edgesarenotsharporhavenicks,removeand

sharpentheblades.RefertoSharpeningthe

Blades(page37).

2.Inspecttheblades,especiallythesailarea

(Figure67).Ifyounoticeanydamage,wear,ora

slotforminginthisarea(Figure67),immediately

installanewblade.

DANGER

Ifyouallowthebladetowear,aslotwill

formbetweenthesailandatpartofthe

blade.Eventuallyapieceoftheblade

maybreakoffandbethrownfromunder

thehousing,possiblyresultinginserious

injuryordeathtoyouorbystanders.

•Inspectthebladeperiodicallyforwear

ordamage.

•Nevertrytostraightenabladethat

isbentorweldabrokenorcracked

blade.

Figure66

4.Rotatetheblade180°(Figure66).

5.Measurethedistancebetweenthecleanarea

onthedeckandthetipofthecuttingedge

(Figure66).

Recordyourmeasurement

•Replaceawornordamagedblade.

g255530

.

36

2.Rotatethebladeboltclockwisetoremovethe

bolt(Figure68).

Important:Thebladeboltshaveleft-hand

threads

Figure67

1.Cuttingedge3.Wear/slotforming

2.Sailarea4.Crack

RemovingtheBlades

Bladesmustbereplacedifasolidobjectishit,ifthe

bladeisoutofbalanceorisbent.T oensureoptimum

performanceandcontinuedsafetyconformanceof

themachine,usegenuineTororeplacementblades.

Replacementbladesmadebyothermanufacturers

mayresultinnon-conformancewithsafetystandards.

WARNING

Contactwithasharpbladecancauseserious

injury.

Wearglovesorwrapsharpedgesoftheblade

witharag.

1.Holdthebladeendusingaragorthickly-padded

glove.

g004480

g004653

1.Spindle

2.Sailareaofblade

Figure68

3.Anti-scalpplate

4.Bladebolt

3.Removetheanti-scalpplateandbladefromthe

spindleshaft(Figure68).

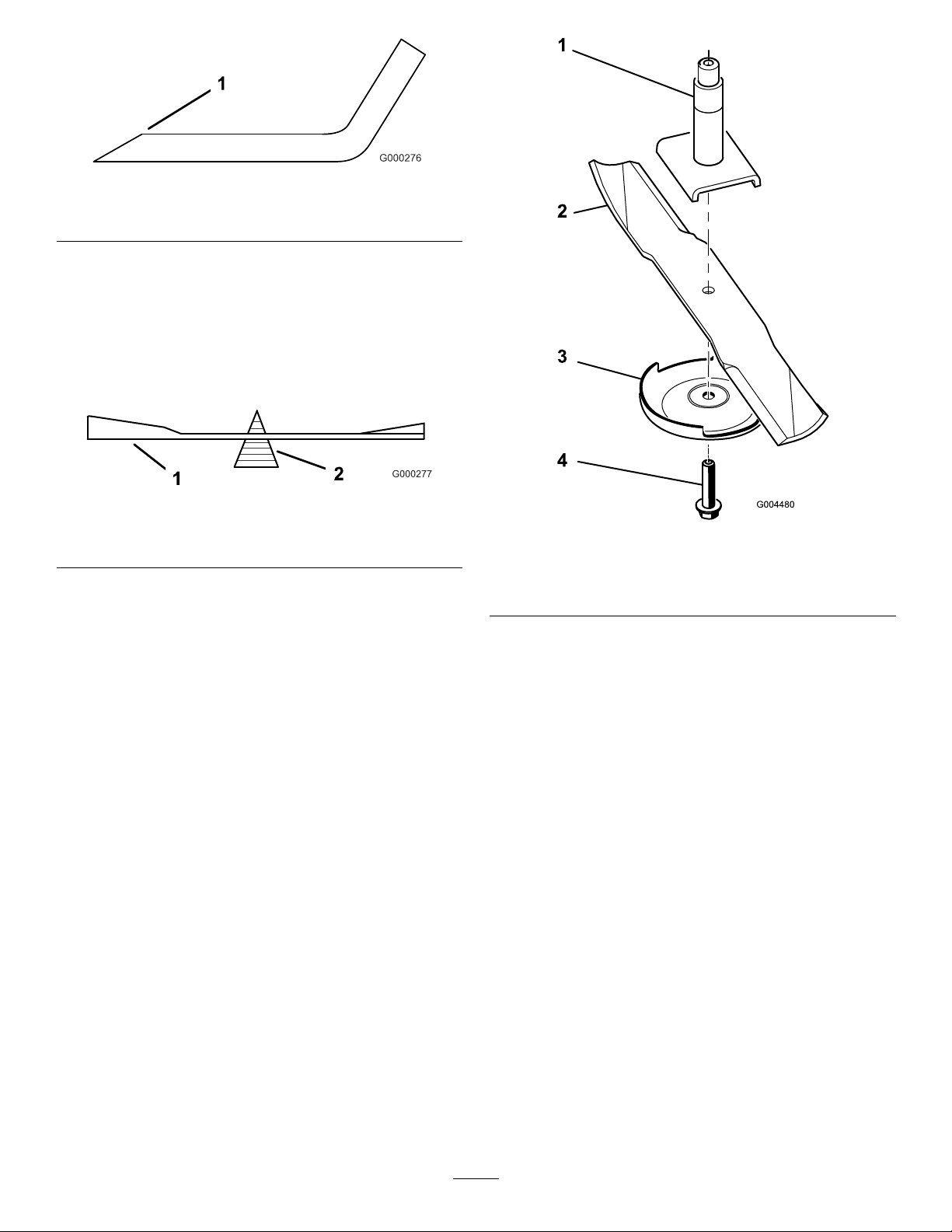

SharpeningtheBlades

WARNING

Whensharpeningblade,piecesofbladecould

bethrownandcauseseriousinjury.

Wearpropereyeprotectionwhensharpening

blades.

1.Sharpenthecuttingedgeatbothendsofthe

blade(Figure69).

Note:Maintaintheoriginalangle.Theblade

retainsitsbalanceifthesameamountof

materialisremovedfrombothcuttingedges.

37

Figure69

1.Sharpenatoriginalangle

2.Checkthebalanceofthebladebyputtingitona

bladebalancer(Figure70).

Note:Ifthebladestaysinahorizontalposition,

thebladeisbalancedandcanbeused.Ifthe

bladeisnotbalanced,lesomemetaloffthe

endofthesailareaonly(Figure71).Repeatthis

procedureuntilthebladeisbalanced.

Figure70

1.Blade2.Balancer

g000276

g000277

g004480

Figure71

1.Spindle

2.Sailareaofblade

3.Anti-scalpplate

4.Bladebolt

InstallingtheBlades

1.Installthebladeontothespindleshaft(Figure

71).

Important:Thecurvedpartoftheblade

mustbepointingupwardtowardtheinside

ofthemowertoensurepropercutting.

2.Installtheanti-scalpplateandbladebolt(Figure

71).

Important:Thebladeboltshaveleft-hand

threads.

3.Torquethebladeboltto115to150N∙m(85to

110ft-lb).

38

AdjustingtheMowerPitch

Thefactorypresetsthepitchofthemowerdeckso

thatbackofthedeckishigherthanthefront.

PreparingtheAdjustMowerPitch

Customerprovidedmaterial:awoodblock51mm

(2inch)

1.Foreachmowerdeckthatyouareadjusting

mowerpitch,alignthecentermowerblade

showninFigure72.

g256062

Figure73

1.4-7/8inchmeasurement2.Height-of-cutadjuster

2.Movetheheight-of-cutadjusterupordownuntil

youmeasure124mm(4-7/8inches)fromthe

topofadjusterblocktotheground(Figure73).

Figure72

2.Lowerthemowerdeckstotheground.

LevelingtheDeck

1.Loosenthenutthatsecurestheheight-of-cut

adjusterblock(Figure73).

3.Repeatsteps1and2attheotherheight-of-cut

adjusters.

SettingtheDeckPitch

g255552

Customerprovidedmaterial:woodspacerblock51

mm(2inches)

1.Workingatthebackofthemowerdeck,lift

therearapandalignthewoodblock51mm

(2inches)betweentherearendofthecenter

mowerbladeandtheground(Figure74).

Youshouldfeelslightdragasyousliptheblock

betweenthebladeandtheground.

•Ifthereistoomuchclearancebetweenthe

bladeandtheground,usethe4height-of-cut

adjusterstolowerthedeck.

•Ifyoucannotslipthewoodblockbetweenthe

bladeandtheground,usethe4height-of-cut

adjusterstoraisethedeck.

39

Figure74

g256063

1.Height-of-cutadjuster

2.Centermowerblade4.Rearap

3.Woodspacerblock51mm

(2inches)

2.Measurethedistancebetweentopofadjuster

blocktotheground(Figure75).

Rotatetheheight-of-cutadjusteruntilyou

achievethefollowingresults:

•Theheight-of-cutblocktotheground

measurementthesameatall4locations.

•Thewoodblockisasliptbetweenthe

centermowerbladeandtheground.

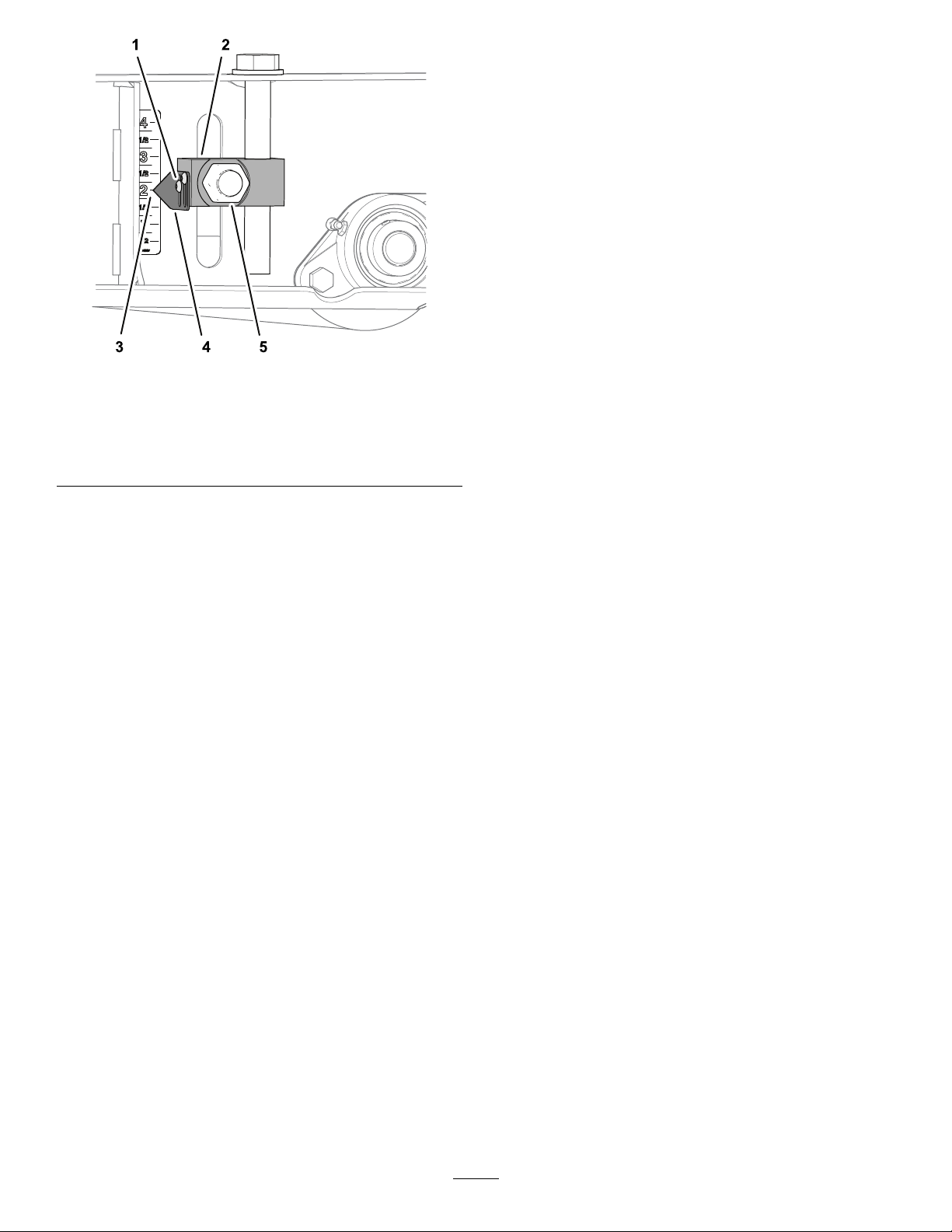

Figure76

1.Height-of-cutadjuster

2.Socket-headscrew5.2inchmark(decal)

3.Nut

4.Pointer

4.Repeatstep3attheotherheight-of-cut

adjusters.

5.Attherearroller,raisetheleftandrightheight

ofcutadjusterstothe2-1/4inchmarkonthe

decal(Figure77).

g256085

Figure75

1.Topoftheheight-of-cutadjuster

3.Loosenthe2socket-headscrewsthatsecure

thepointertotheheight-of-cutadjusterblock,

alignthepointertothe2inchmarkonthedecal,

andtightenthescrews(Figure76).

g256086

Figure77

1.2-1/4inchmark(decal)3.Height-of-cutadjuster

2.Pointer

g256087

6.Loosenthesocket-headscrewsthatsecurethe

(rearroller)

2pointerstotheheight-of-cutadjusterblock,

alignthepointerstothe2inchmarkonthe

decal,andtightenthescrews(Figure78).

40

Figure78

1.Socket-headscrew

2.Height-of-cutadjuster

(rearroller)

3.2inchmark(decal)

7.Torquethe4nutsthatsecurethe4height-of-cut

adjusterblocks(Figure76andFigure78)forthe

frontandrearrollersto322to396N∙m(238to

292ft-lb).

4.Pointer

5.Nut

Storage

StoringtheMachine

Attheendofthemowingseasonorwhenthemoweris

storedforanextendedperiod,carryoutthefollowing

preventativemaintenance:

1.Parkthemachineonalevelsurface;engagethe

parkingbrake;shutofftheengine;removethe

key;andwaitforallmovementtostopbefore

leavingthemachine.

2.Cleanoffanydirtorgreasethatmayhave

accumulatedonthemachineoranyofthe

movingparts.

g256116

3.Lubricateallgreasettings.

4.Touchuppaintanyotherscratchesonthe

paintedsurfaces.

5.Replaceanymissingordamageddecals.

6.Whenpossible,storethemowerinsidea

dry,securebuilding.Ifinsidestorageisnot

available,coverthemachinewithaheavysheet

ortarpaulinandsecureittightly.

41

Notes:

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally ,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromToroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,TorohaselectedtoprovidetheProp65warnings.Moreover,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

TheToroWarranty

ATwo-YearLimitedWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,T oroWarrantyCompany,pursuant

toanagreementbetweenthem,jointlywarrantyourT oroCommercial

product(“Product”)tobefreefromdefectsinmaterialsorworkmanship

fortwoyearsor1500operationalhours*,whicheveroccursrst.This

warrantyisapplicabletoallproductswiththeexceptionofAerators

(refertoseparatewarrantystatementsfortheseproducts).Wherea

warrantableconditionexists,wewillrepairtheProductatnocosttoyou

includingdiagnostics,labor,parts,andtransportation.Thiswarranty

beginsonthedatetheProductisdeliveredtotheoriginalretailpurchaser.

*Productequippedwithanhourmeter.

InstructionsforObtainingWarrantyService

YouareresponsiblefornotifyingtheCommercialProductsDistributoror

AuthorizedCommercialProductsDealerfromwhomyoupurchasedthe

Productassoonasyoubelieveawarrantableconditionexists.Ifyouneed

helplocatingaCommercialProductsDistributororAuthorizedDealer,or

ifyouhavequestionsregardingyourwarrantyrightsorresponsibilities,

youmaycontactusat:

ToroCommercialProductsServiceDepartment

ToroWarrantyCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

952–888–8801or800–952–2740

E-mail:commercial.warranty@toro.com

OwnerResponsibilities

AstheProductowner,youareresponsibleforrequiredmaintenanceand

adjustmentsstatedinyourOperator'sManual.Failuretoperformrequired

maintenanceandadjustmentscanbegroundsfordisallowingawarranty

claim.

ItemsandConditionsNotCovered

Notallproductfailuresormalfunctionsthatoccurduringthewarranty

periodaredefectsinmaterialsorworkmanship.Thiswarrantydoesnot

coverthefollowing:

•Productfailureswhichresultfromtheuseofnon-Tororeplacement

parts,orfrominstallationanduseofadd-on,ormodiednon-Toro

brandedaccessoriesandproducts.Aseparatewarrantymaybe

providedbythemanufactureroftheseitems.

•Productfailureswhichresultfromfailuretoperformrecommended

maintenanceand/oradjustments.Failuretoproperlymaintainyour

ToroproductpertheRecommendedMaintenancelistedinthe

Operator’sManualcanresultinclaimsforwarrantybeingdenied.

•ProductfailureswhichresultfromoperatingtheProductinanabusive,

negligent,orrecklessmanner.

•Partssubjecttoconsumptionthroughuseunlessfoundtobedefective.

Examplesofpartswhichareconsumed,orusedup,duringnormal

Productoperationinclude,butarenotlimitedto,brakepadsand

linings,clutchlinings,blades,reels,rollersandbearings(sealedor

greasable),bedknives,sparkplugs,castorwheelsandbearings,tires,

lters,belts,andcertainsprayercomponentssuchasdiaphragms,

nozzles,andcheckvalves,etc.

•Failurescausedbyoutsideinuence.Conditionsconsideredtobe

outsideinuenceinclude,butarenotlimitedto,weather,storage

practices,contamination,useofunapprovedfuels,coolants,lubricants,

additives,fertilizers,water,orchemicals,etc.

•Failureorperformanceissuesduetotheuseoffuels(e.g.gasoline,

diesel,orbiodiesel)thatdonotconformtotheirrespectiveindustry

standards.

•Normalnoise,vibration,wearandtear,anddeterioration.

•Normal“wearandtear”includes,butisnotlimitedto,damagetoseats

duetowearorabrasion,wornpaintedsurfaces,scratcheddecalsor

windows,etc.

Parts

Partsscheduledforreplacementasrequiredmaintenancearewarranted

fortheperiodoftimeuptothescheduledreplacementtimeforthatpart.

Partsreplacedunderthiswarrantyarecoveredforthedurationofthe

originalproductwarrantyandbecomethepropertyofT oro.T orowillmake

thenaldecisionwhethertorepairanyexistingpartorassemblyorreplace

it.T oromayuseremanufacturedpartsforwarrantyrepairs.

DeepCycleandLithium-IonBatteryWarranty:

DeepcycleandLithium-Ionbatterieshaveaspeciedtotalnumberof

kilowatt-hourstheycandeliverduringtheirlifetime.Operating,recharging,

andmaintenancetechniquescanextendorreducetotalbatterylife.Asthe

batteriesinthisproductareconsumed,theamountofusefulworkbetween

chargingintervalswillslowlydecreaseuntilthebatteryiscompletelyworn

out.Replacementofwornoutbatteries,duetonormalconsumption,

istheresponsibilityoftheproductowner.Batteryreplacementmaybe

requiredduringthenormalproductwarrantyperiodatowner’sexpense.

Note:(Lithium-Ionbatteryonly):ALithium-Ionbatteryhasapartonly

proratedwarrantybeginningyear3throughyear5basedonthetime

inserviceandkilowatthoursused.RefertotheOperator'sManualfor

additionalinformation.

MaintenanceisatOwner’sExpense

Enginetune-up,lubrication,cleaningandpolishing,replacementoflters,

coolant,andcompletingrecommendedmaintenancearesomeofthe

normalservicesT oroproductsrequirethatareattheowner’sexpense.

GeneralConditions

RepairbyanAuthorizedToroDistributororDealerisyoursoleremedy

underthiswarranty.

NeitherTheToroCompanynorToroWarrantyCompanyisliablefor

indirect,incidentalorconsequentialdamagesinconnectionwiththe

useoftheToroProductscoveredbythiswarranty,includingany

costorexpenseofprovidingsubstituteequipmentorserviceduring

reasonableperiodsofmalfunctionornon-usependingcompletion

ofrepairsunderthiswarranty.ExceptfortheEmissionswarranty

referencedbelow,ifapplicable,thereisnootherexpresswarranty .All

impliedwarrantiesofmerchantabilityandtnessforusearelimitedto

thedurationofthisexpresswarranty.

Somestatesdonotallowexclusionsofincidentalorconsequential

damages,orlimitationsonhowlonganimpliedwarrantylasts,sotheabove

exclusionsandlimitationsmaynotapplytoyou.Thiswarrantygivesyou

speciclegalrights,andyoumayalsohaveotherrightswhichvaryfrom

statetostate.

Noteregardingenginewarranty:

TheEmissionsControlSystemonyourProductmaybecoveredby

aseparatewarrantymeetingrequirementsestablishedbytheU.S.

EnvironmentalProtectionAgency(EP A)and/ortheCaliforniaAirResources

Board(CARB).Thehourlimitationssetforthabovedonotapplytothe

EmissionsControlSystemWarranty.RefertotheEngineEmissionControl

WarrantyStatementsuppliedwithyourproductorcontainedintheengine

manufacturer’sdocumentationfordetails

CountriesOtherthantheUnitedStatesorCanada

CustomerswhohavepurchasedT oroproductsexportedfromtheUnitedStatesorCanadashouldcontacttheirT oroDistributor(Dealer)toobtain

guaranteepoliciesforyourcountry ,province,orstate.IfforanyreasonyouaredissatisedwithyourDistributor'sserviceorhavedifcultyobtaining

guaranteeinformation,contacttheT oroimporter.

374-0253RevD

Loading...

Loading...