Toro 23890 Operator's Manual

FormNo.3383-875RevA

G023981

Gas-PoweredFM330FluidMixer

ModelNo.23890—SerialNo.313000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3383-875*A

ThisproductcomplieswithallrelevantEuropeandirectives.

1

G023835

Fordetails,pleaseseetheseparateproduct-specic

DeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Useofthisproductmaycauseexposureto

chemicalsknowntotheStateofCalifornia

tocausecancer,birthdefects,orother

reproductiveharm.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Writethenumbersinthespaceprovided.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

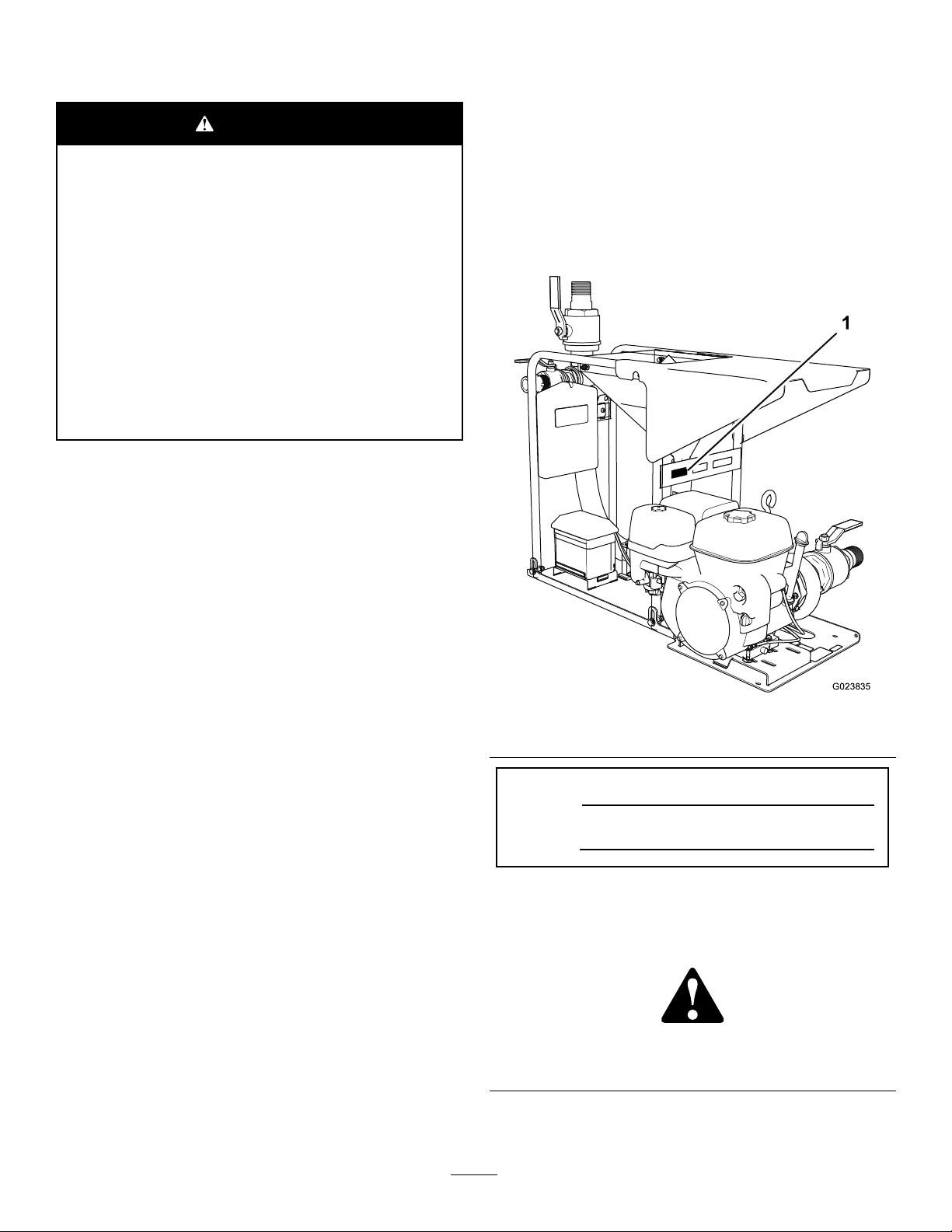

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Introduction

Thismachineisdesignedtomixdrilling-uidproductswith

cleanwater.Youcanmountthemachineontoasuitable

trailerandconnectthemachinetoasuitablehorizontal

directionaldrill.Readandunderstandthedirectionaldrill

Operator’sManual.

©2014—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safetyalertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................3

SafeOperatingPractices...........................................3

SoundPowerLevel..................................................5

SoundPressureLevel...............................................5

SafetyandInstructionalDecals.................................6

Setup............................................................................7

ConnectingtheBattery.............................................7

ConnectingthePumptotheTank..............................8

ProductOverview..........................................................9

Controls................................................................9

Specications........................................................11

Operation....................................................................11

PreparingtoUsetheMachine...................................11

GroundingtheMixerandtheTank...........................11

AdjustingtheValves...............................................11

AddingFuel...........................................................11

CheckingtheEngine-oilLevel..................................13

StartingandStoppingtheEngine..............................14

MixingtheFluid.....................................................15

PumpingtheFluidtotheDrill..................................16

DrainingtheTank..................................................16

ProtectingtheMachinefromFreezing.......................16

OperatingTips......................................................17

Maintenance.................................................................18

RecommendedMaintenanceSchedule(s)......................18

PremaintenanceProcedures........................................19

PreparingtheMachineforMaintenance.....................19

DisconnectingtheSpark-plugWire...........................19

Lubrication...............................................................19

LubricatingthePump.............................................19

EngineMaintenance..................................................20

ServicingtheAirCleaner.........................................20

ChangingtheEngineOil.........................................21

ServicingtheSparkPlug..........................................22

ServicingtheSparkArrester.....................................23

FuelSystemMaintenance...........................................24

ServicingtheFuelSystem........................................24

ElectricalSystemMaintenance....................................25

InspectingandReplacingtheFuse............................25

ChargingtheBattery...............................................26

ReplacingtheBattery..............................................26

CheckingandCleaningtheBattery............................27

Cleaning...................................................................27

CleaningtheMachine..............................................27

Storage........................................................................28

StoringtheMachine................................................28

Troubleshooting...........................................................29

Safety

Improperlyusingormaintainingthemachinecanresult

ininjury.T oreducethepotentialforinjury,complywith

thesesafetyinstructionsandalwayspayattentiontothe

safetyalertsymbol,whichmeans:

or

Danger

complywiththeinstructionmayresultinpersonalinjury

ordeath.

—personalsafetyinstruction.Failureto

SafeOperatingPractices

Alwaysfollowallsafetyinstructionstoavoidseriousinjury

ordeath.

WARNING

Handlingvariousdrilling-uidmaterialscan

generatedustandfumescontainingchemicals,

suchassilica,knowntocauseseriousorfatalinjury

orillness,suchasrespiratorydisease,silicosis,

cancer,birthdefects,orotherreproductiveharm.

•Usegoodworkpracticesandfollowthe

recommendationsofthemanufactureror

suppliers,OSHA,andotheroccupationaland

tradeassociations.

•Alwaysfollowrespiratoryprecautions.

•Whenthehazardsfrominhalationcannotbe

eliminated,theoperatorandanybystanders

shouldweararespiratorapprovedbyOSHAfor

thematerialbeinghandled.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadorunderstand

theinformation,itistheowner'sresponsibilitytoexplain

thismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriestopeopleordamagetoproperty.

Caution

,

W ar ning

,

3

Preparation

Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Useonlyaccessoriesandattachmentsapprovedbythe

manufacturer.

•Weararespiratororadustmask.

•Operatingtheequipmentsafelyrequiresthefullattention

oftheoperator.Donotwearradioormusicheadphones

whileoperatingthemachine.

•Useextracarewhenhandlingfuels.Theyareammable,

andthevaporsareexplosive.Usethefollowingpractices

whenhandlingfuel:

–Useonlyanapprovedfuelcontainer.

–Neverremovethefuelcaporaddfuelwiththeengine

running.

–Allowtheenginetocoolbeforerefueling.

–Donotsmoke.

–Neveraddfuelordrainthemachineindoors.

–Replacethefuelcapandtightenitsecurely .

–Keepthecontainernozzleincontactwiththetank

duringlling.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Iffuelisspilled,wipeitofftheengineandequipment.

•Ensurethatthemachineisonalevelsurfacebefore

operatingthemachine.

•Beforeeveryuse,ensurethatthemachineisproperly

secured.

Operation

•Neverrunanengineinanenclosedorpoorlyventilated

area.

•Onlyoperatethemachineingoodlightingconditions.

•Beforestartingthemachine,makesurethatthereareno

personsorobstaclesnearorunderthemachine.

•Stoptheenginebeforeleavingthemachineforany

reason.

Neverleavearunningmachineunattended.Alwaysstop

theengineandverifythatallmovingpartshavestopped.

•Avoidprolongedbreathingofexhaustfumes.Engine

exhaustfumescancausesicknessordeath.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Ensurethattheareaisclearofotherpeopleorpetsbefore

operatingthemachine.Stopthemachineifanyoneenters

thearea.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Nevermovethemachinewhiletheengineisrunning.

•Ensurethatalltheguardsandshieldsaresecurelyinplace

beforeoperatingthemachine.

•Ifthemachineshouldstartmakinganunusualnoiseor

vibration,stoptheengine.Waitforallmovingpartsto

cometoacompletestopandcool.Vibrationisgenerally

awarningoftrouble.Inspectforcloggingordamage.

Cleanandrepairand/orreplacedamagedparts.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Lightningcancausesevereinjuryordeath.Ifyousee

lightningorhearthunderinthearea,donotoperatethe

machine;seekshelter.

MaintenanceandStorage

•Beforeperformingmaintenance,dothefollowing:

–Ensurethatthemachineisonlevelground.

–Stoptheengine.Waitforallmovementtostopbefore

adjusting,cleaning,orrepairing.

–Lettheenginecoolbeforeperformingmaintenance

orstoring.

–Disengageallpowerandoperationcontrols.

•Neverlubricate,service,repair,oradjustthemachine

whileitisrunning.

•Keepequipmentmaterialsclearfromthemuferand

enginetohelppreventres.Cleanupanyoilorfuel

spillage.

•Neverallowuntrainedpersonneltoservicethemachine.

•Keephands,feet,andclothingawayfrommovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Removeanybuildupofgrease,oil,ordebrisfromthe

machine.

•Stopandinspectthemachineifaforeignobjectenters

thehopperorcausesanotherobstruction.Makeany

necessaryrepairsbeforestartingthemachine.

•Donottamperwithsafetydevices.

•Keepallnuts,bolts,screws,andhoseclampssecurely

tightened.Keepequipmentingoodcondition.

•Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonToro

genuineparts.Whenitcomestoreliability ,Torodelivers

replacementpartsdesignedtotheexactengineering

specicationsofourequipment.Forpeaceofmind,insist

onTorogenuineparts.

4

Hauling

1

G024269

4

2

3

•Ensurethatthetransportvehiclehasacarryingcapacity

tohandletheweightofthemachineandafulltankof

uid—inadditiontoanyothermachinesormaterials

thatthetransportvehiclemayneedtocarry.Themixing

systemalonerequiresacarryingcapacityofatleast2,268

kg(5,000lb)forasystemthatusesasingle1,893L

(500-gallon)tank,upto9,072kg(20,000lb)forasystem

thatusestwo3,785L(1000-gallon)tanks.

•Usecarewhenloadingorunloadingthemachineontoa

trailerortruck.

•Ensurethatthetankisemptybeforeloadingthemachine

ontoatrailerortruck.

•Securethemachineusingadequateboltsthroughallthe

mountingholesofboththemixerframeandthetank

frame.

SoundPowerLevel

Thisunithasasoundpowerlevelof103dBA,whichincludes

anUncertaintyValue(K)of1dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinEN/ISO3744.

SoundPressureLevel

Thisunithasasoundpressurelevelattheoperator’ searof90

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Asthisproductdoesnothaveadedicatedoperator’sposition,

thesoundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedintheMachinerySafetyDirective

2006/42/EC.

Measurementsweretakenonall4sidesofthemachinewith

themicrophonepositionedalongthecenterlineofthearea

facingthemicrophone.Ineachcase,themicrophonewas

locatedataheightof1.6mfromthegroundandadistance

of1mfromthesurfaceareaofthemachine.Forthismodel,

theloudesttestedpointisshowninFigure3.

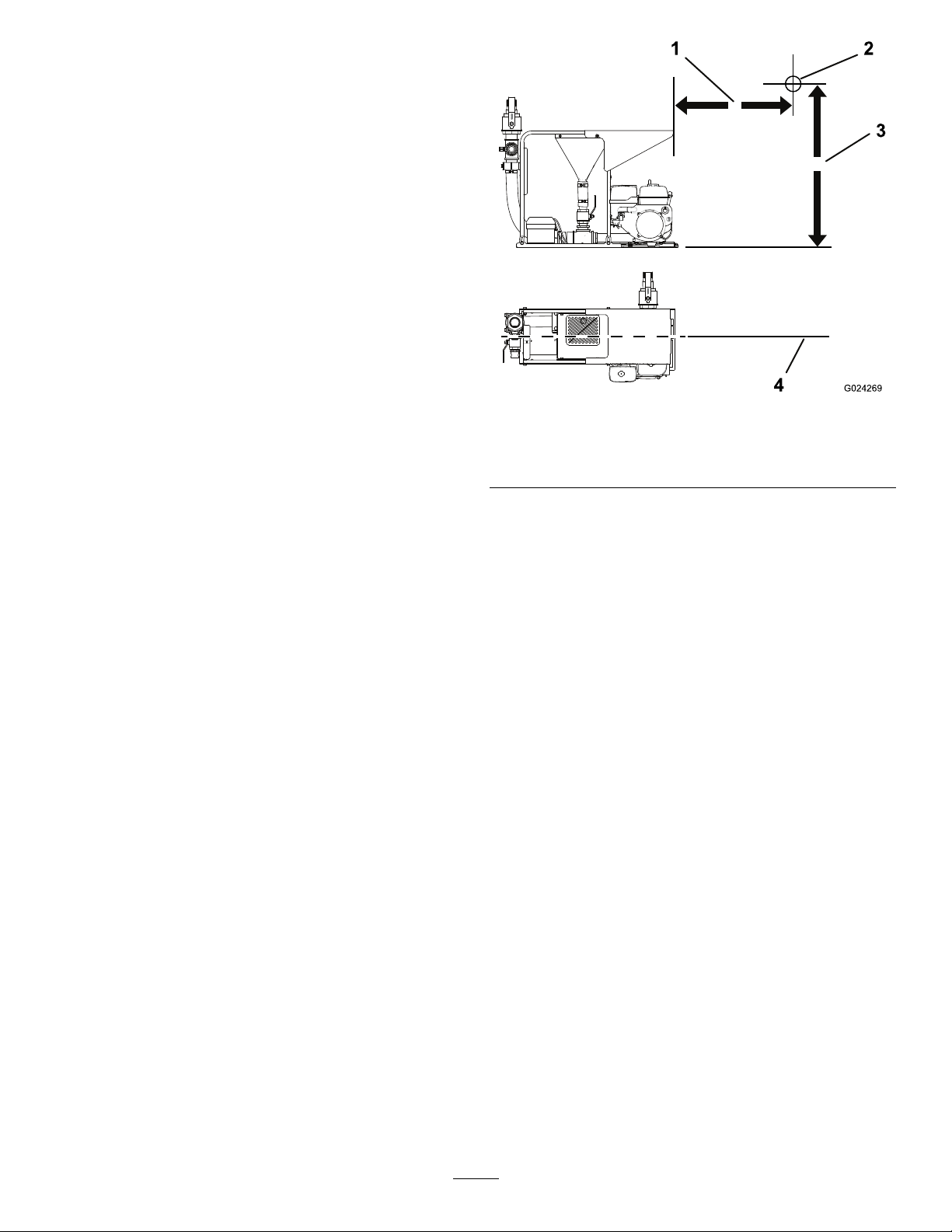

Figure3

1.1m(39inches)3.1.6m(63inches)

2.Measurementpoint

4.Centerlineofthemachine

5

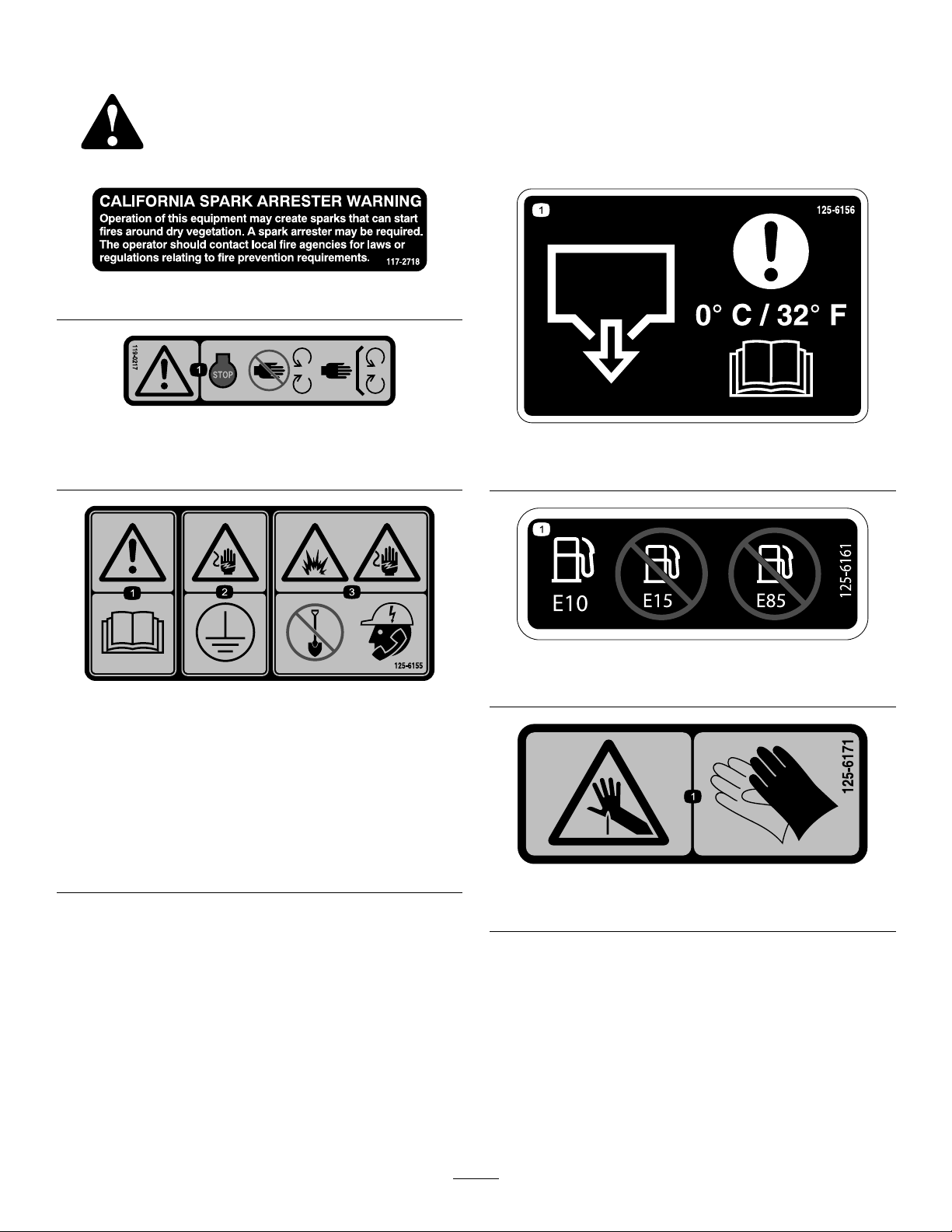

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

117-2718

119–0217

1.Warning—stoptheengine;keepawayfrommovingparts;

keepallguardsandshieldsinplace.

125–6156

1.Tankdrain—readtheOperator’sManual.

1.Warning—readthe

Operator’sManual.

2.Electricalshock

hazard—ensurethe

equipmentisgrounded

beforestartingdrill

operation.

125–6161

125–6155

3.Explosionhazard;

electricalshock

hazard—Calllocal

utilitiesbeforedigging

underground.

1.UseE10fuel;donotuseE15orE85fuel.

125-6171

1.Piercinghazard—wearhandprotection.

6

Setup

A B

C D

1 2

3

4

G024037

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

Description

Bolt(5/16x3/4inch)

Nut(5/16inch)

Circulationhose

Hoseclamp3

MediaandAdditionalParts

Description

Transferhose

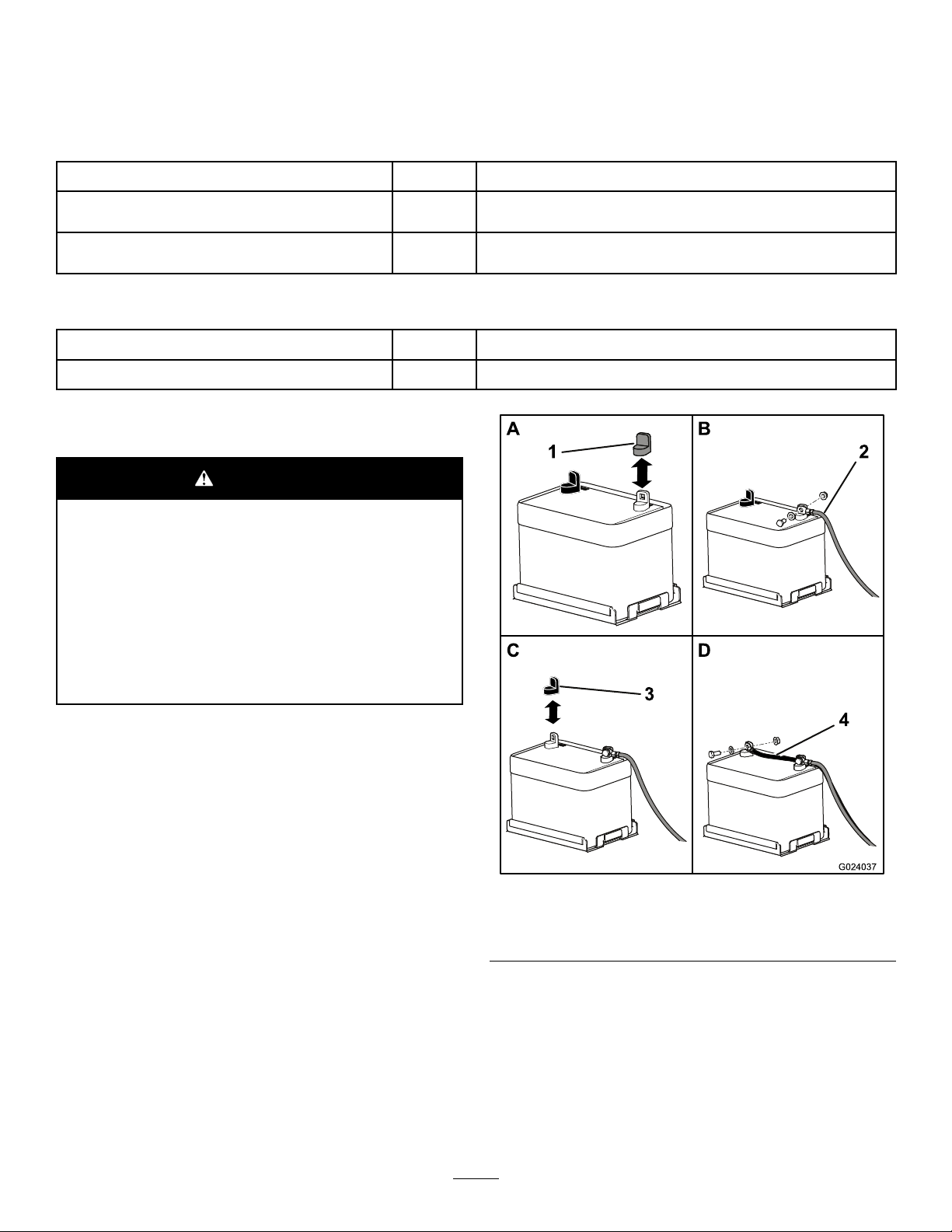

ConnectingtheBattery

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Qty.

Qty.

Use

2

2

1

1

Connectthebattery.

Connectthepumptothetank.

Use

Connectthemixertothedrill.

1.Removetheredplasticcoverfromthepositivebattery

terminal(

Figure4).

Figure4

1.Redcover3.Blackcover

2.Positivecable4.Negativecable

2.Useabolt(5/16x3/4inch)andanut(5/16inch)

tomountthepositivecabletothepositivebattery

terminal.

3.Removetheblackplasticcoverfromthenegative

batteryterminal.

4.Useabolt(5/16x3/4inch)andanut(5/16inch)

tomountthenegativecabletothenegativebattery

terminal.

7

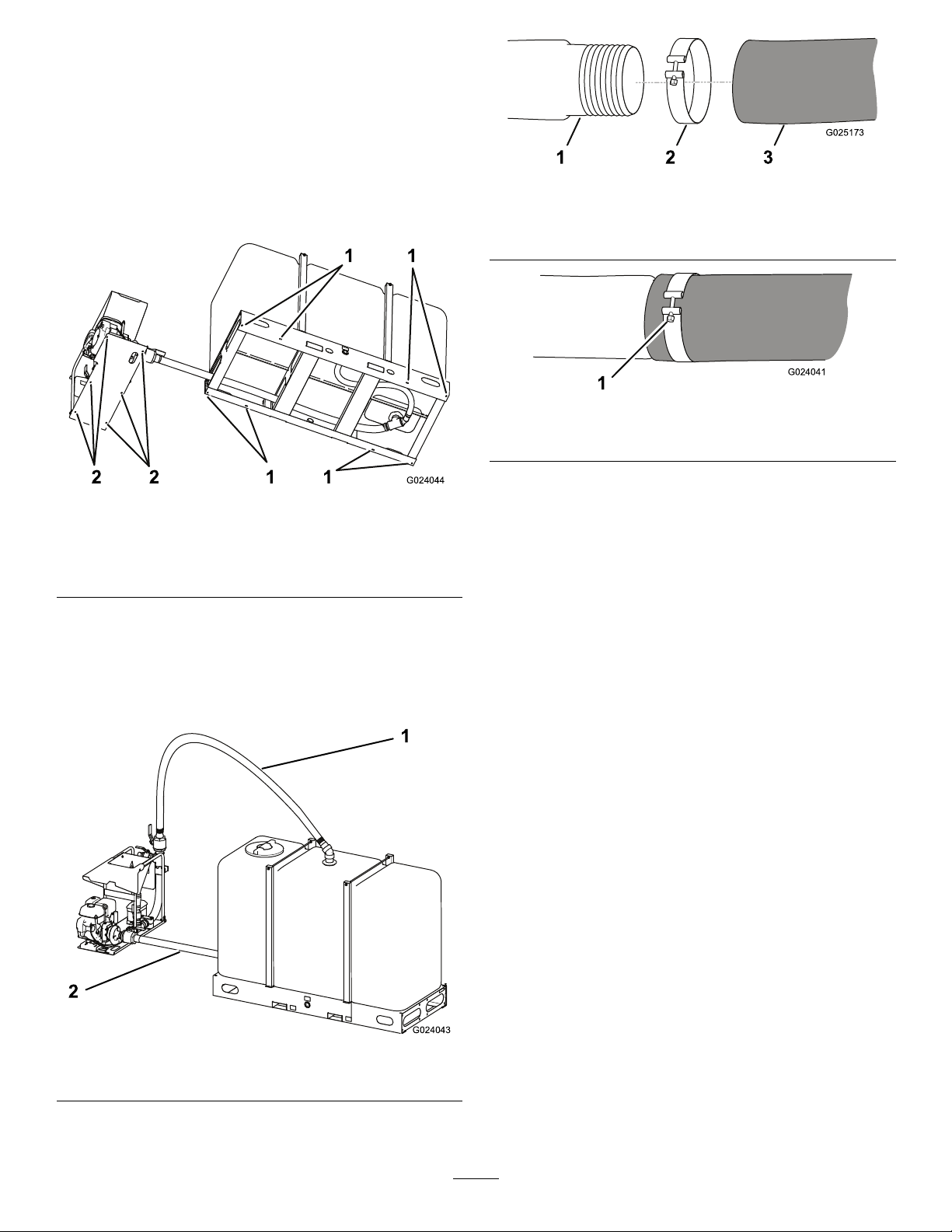

ConnectingthePumptothe

2

G024044

11

1

1

2

G024043

1

2

G025173

1 2 3

1

G024041

Tank

Ensurethattheframeoftheuidmixerandtheframeofthe

tankaresecuredtoastrongsurface,withanadequatefastener

througheachmountinghole(Figure5).

Note:Ensurethatthemixerandthetankareinaposition

thatallowsthehosestoconnectthemwithoutstretchingor

kinking.

Figure5

Undersideshown

1.Mountingholesintank

frame

2.Mountingholesinmixer

frame

1.Locatethesuctionhoseconnectedtothebottomofthe

tank,andpullthelooseendoutfromunderthetank.

Figure7

1.Fitting3.Hose

2.Hoseclamp

Figure8

1.Locknut

3.Tightenthehoseclampbytighteningthelocknut.

4.Use2hoseclamps(provided)toconnecttheother

hosetothetopofthetankandthetopofthemixeras

showninFigure6,Figure7,andFigure8.

5.Tightenthehoseclampsbytighteningthelocknuts.

2.Useahoseclamp(provided)toconnectthelooseend

ofthehosetothepumpinletonthemixerasshown

inFigure6,Figure7,andFigure8.

Figure6

1.Circulationhose2.Suctionhose

8

ProductOverview

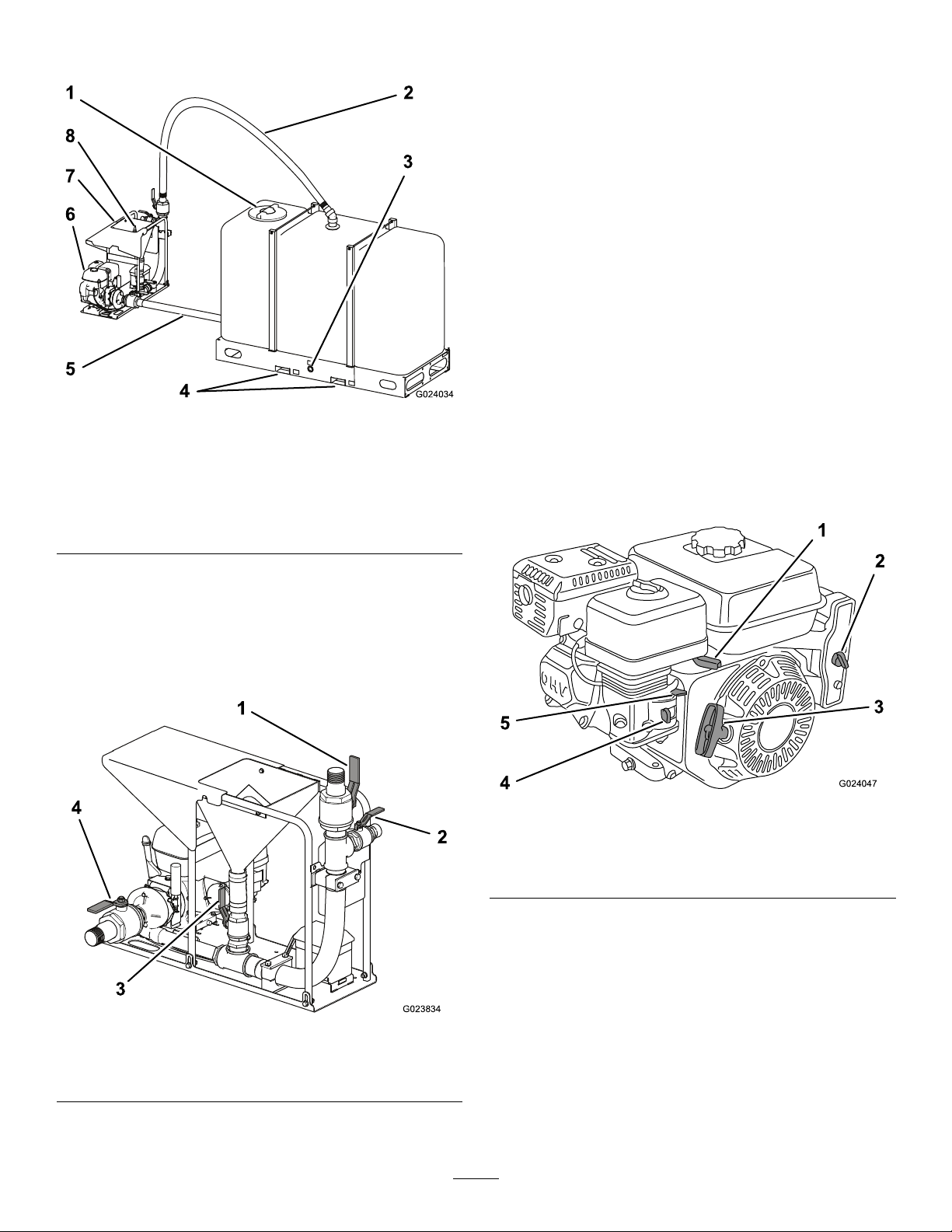

G024034

1

6

7

8

2

3

4

5

1

2

3

4

G023834

1

2

3

4

G024047

5

1.Accesshatch

2.Circulation

hose

3.Tankdrainplug6.Engine

Figure9

Tanksoldseparately

4.Forkliftpockets

5.Suctionhose8.Grate

CirculationValve

Thecirculationvalve(Figure10)controlstheowfromthe

pumptothetank.

SuctionValve

Thesuctionvalve(Figure10)controlstheowfromthetank

tothepump.

HopperValve

Thehoppervalve(Figure10)controlstheowfromthe

hopperintothemixingsystem.Thehoppervalveismost

effectivewhenitisjustslightlyopen,astheuidthen

createsavacuumeffectanddrawsthebentoniteandother

componentsintotheow .

TransferValve

Thetransfervalve(Figure10)controlstheowfromthe

mixingsystemtothedrill.

7.Hopper

EngineControls

Controls

Becomefamiliarwithallthecontrolsbeforeyoustartthe

engineandoperatethemachine.

Figure11

1.Throttlelever4.Fuelvalve

2.Electric-startswitch

3.Recoil-starthandle

FuelValve

Figure10

1.Circulationvalve

2.Transfervalve4.Suctionvalve

3.Hoppervalve

Thefuelvalve(Figure12)islocatedunderneaththechoke

lever.MovetheleverforthefuelvalvetotheOnposition

beforeattemptingtostarttheengine.Whenyouhavenished

mixing,stoptheengineandmovethefuelvalvelevertothe

Offposition.

5.Chokelever

9

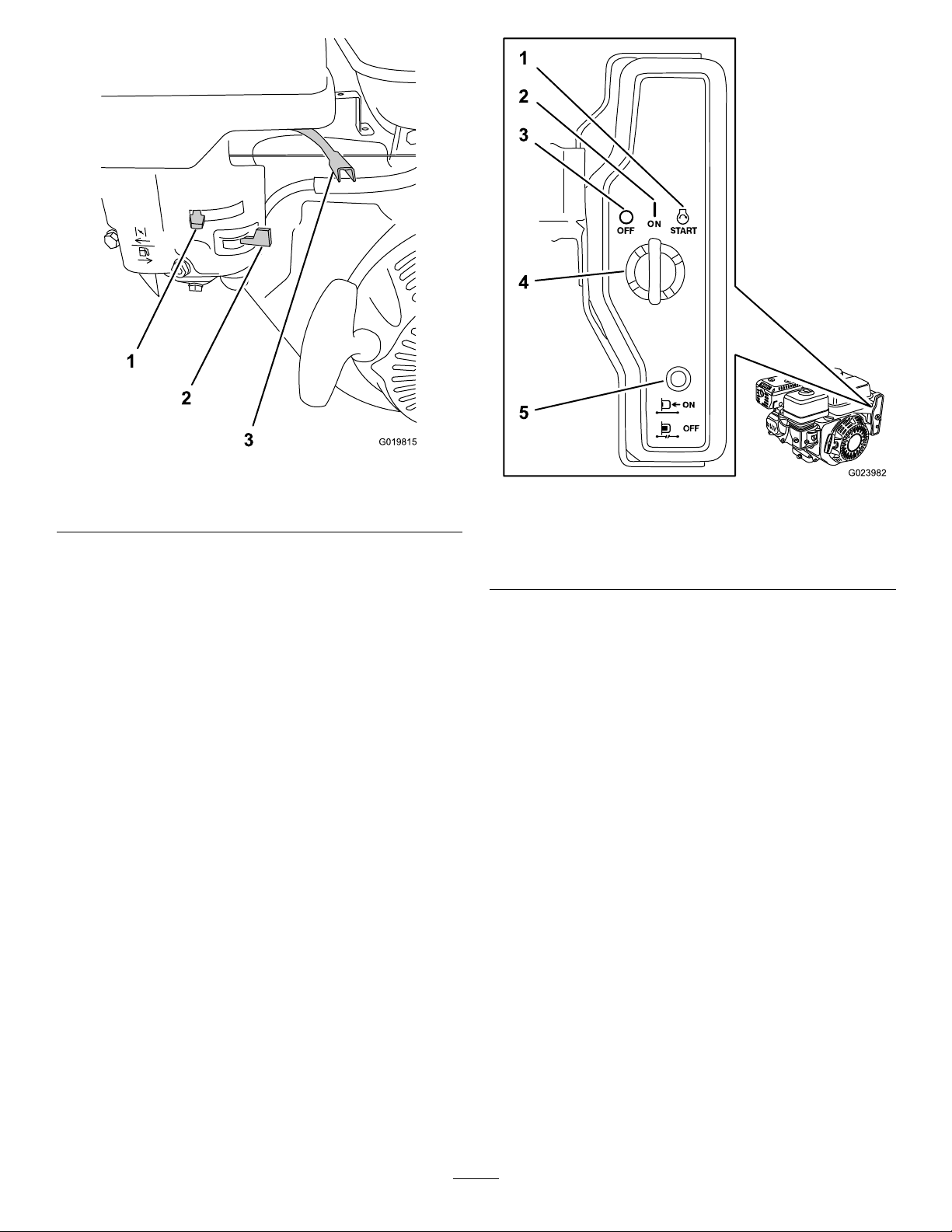

G019815

1

2

3

Figure12

1

2

3

4

G023982

5

1.Chokelever

2.Fuelvalve

3.Throttlelever

ChokeLever

Usethechokelever(Figure12)tostartacoldengine.Before

pullingtherecoil-starthandle,movethechokelevertothe

closedposition.Oncetheengineisrunning,movethechoke

levertotheopenposition.Donotusethechokeiftheengine

isalreadywarmeduportheairtemperatureishigh.

ThrottleLever

Thethrottlelever(Figure12)controlsthespeed(rpm)ofthe

engine.Itislocatednexttothechokelever.Itsetstheengine

speedandthereforecanincreaseanddecreasethespeedof

thepump.

Electric-startSwitch

Theelectric-startswitch(Figure13)allowstheoperatorofthe

machinetostartandstoptheengine.Thisswitchislocated

onthefrontoftheengine.RotatetheOn/Offswitchtothe

Startpositiontostarttheengine.RotatetheOn/Offswitch

totheOnpositiontoallowtheenginetorun.Rotatethe

On/OffswitchtotheOffpositiontostoptheengine.

Figure13

1.Startposition

2.Onposition5.Circuit-protectorbutton

3.Offposition

4.Ignitionswitch

Circuit-protectorButton

Theenginehasacircuitprotectorthatisdesignedtoprotect

thebattery-chargingcircuit.Ashortcircuit,orabatterywith

reversepolarity,willtripthecircuitprotector.Ifthegreen

indicatorpopsout,thatindicatesthatthecircuitprotector

hasswitchedoff.Ifthisoccurs,determinethecauseofthe

problem,andcorrectitbeforeresettingthecircuitprotector.

Toresetthecircuitprotector,pushthebutton(Figure13).

Recoil-startHandle

Ifthebatteryisnotcharged,youcanstarttheenginewiththe

recoil-starthandle.T ostarttheengine,pulltherecoil-start

handle(Figure11)quicklytoturntheengineover.The

enginecontrolsdescribedabovemustallbesetcorrectlyfor

theenginetostart.

Oil-levelSwitch

Theoil-levelswitchislocatedinsidetheengine;itprevents

theenginefromrunningiftheoillevelfallsbelowthesafe

operatinglimit.

10

Loading...

Loading...