Trailer

TRXTrencherorSTXStumpGrinder

ModelNo.22979

ModelNo.22979HD

FormNo.3432-587RevA

SetupInstructions

Safety

Readandunderstandthefollowingbeforeusingthe

trailer.

•Beforeeveryuse:

–Inspectthecoupler,ball,andhitch.

–Alwaysusesafetychains.

–Verifythatalllightsarefunctioningproperly.

–Verifythatthetiresareproperlyinatedas

recommendedontires.

–Verifythatthelugnutsaretightandtorqued

properly.

–Verifythatthatthemachineisproperlysecured.

•Knowhowtoproperlycontrolyourtowing

vehicle/trailercombinationonthehighwayunder

SafetyandInstructionalDecals

allconditions.Rememberthattheloadedweight

ofthetrailerincreasesyourbrakingandstopping

distances.

•Youareresponsiblefordeterminingthetowing

capacityofyourvehicle.

•Cleanoffthemachinespriortoloadingthem

ontothetrailer.Keepthetrailercleanofloose

debristhatcouldfalloffduringtransport,causinga

hazard.

•Useproperloadingandunloadingprocedures

andsequences.Readallmanualsandfollowthe

instructionsprovided.

•Inspectthetrailerandmachineoftenduring

transport.

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

140-1123

1.Warning—readtheOperator’sManual;maximumweight

of676kg(1,492lb).

©2019—TheT oro®Company

8111LyndaleA venueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

decal140-1123

133-8061

OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved

decal133-8061

*3432-587*A

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

5

Trailerbed1

Wheel2

Lugnuts10

Tongue1

Bolt(5/8x3inches)

Nut(5/8inch)

Mountingstrap2

Jack1

Bolt4

Locknut4

Chain

Ramp1

Bolt(1/2x1-1/2inches)

Nut(1/2inch)

Rampstrap2

Cotterpin(1-1/4inch)

Nopartsrequired

Qty.

Use

Installthewheels.

2

2

1

2

2

2

–

Attachthetongue.

Installthetrailerjack.

Installtheramp.

Testthewireharness.

1

InstallingtheWheels

Partsneededforthisprocedure:

1Trailerbed

2Wheel

10Lugnuts

Procedure

1.Usingahoistormechanicaljack,raisethetrailer

bed.

2.Installthewheelsontothehubwiththevalve

stemfacingouttoallowaccess(Figure1).

g008362

Figure1

1.Lugnut4.Hub

2.Wheel5.Posts

3.Valvestem

3.Secureeachwheeltothehubusing5lugnuts.

Torquethenutsto68-102N∙m(50-75ft-lb).

4.Whilethebedisstillraised,removethefasteners

securingthepackingstandstothetrailerbed.

5.Lowerthebedtothegroundandverifythecold

pressureofthewheelsisatamaximumof551

kPa(80psi).

2

2

AttachingtheTongue

Partsneededforthisprocedure:

1Tongue

2

Bolt(5/8x3inches)

2

Nut(5/8inch)

Procedure

1.Laythetongueoutinfrontofthetrailerand

locateaexiblewirelongerthanthetongue.

2.Feedthewirethroughthelengthofthetongue

soaportionofthewireisvisibleatbothends

(Figure2).

g008364

Figure3

1.Tongue3.Wireharness

2.Opening4.Wire(securedtoharness)

5.Usingajackorhoist,raisethefrontendofthe

trailerbedtoallowtheinstallationofthetongue

(Figure4).

g008365

Figure4

Figure2

1.Tongue

2.Opening5.Harness(fromtrailer)

3.Wire

3.Removethefastenersecuringthehitchwiring

bundledtothetrailerbed.

4.Securethewireinthetonguetothewiring

harnessonthetrailerandpullthewiringharness

throughthelengthofthetongueusingthewire

(Figure3).Removethewirefromtheharness.

4.Tongue(trailerside)

1.Jack2.Trailer

6.Movethetongueintopositionunderthetrailer

bedandraiseittoaligntherearholesinthe

trailerbedwiththerearholesintongue.

g008363

7.Withthehelpofanotherperson,installabolt

(5/8x3inches)throughtheholes.Raisethe

frontendofthetonguetoalignthefrontholes

anduseabolt(5/8x3inches)toholdthetongue

inplace(Figure5).

3

3

InstallingtheTrailerJack

(Model22979)

Partsneededforthisprocedure:

Figure5

1.Trailer(underside)

2.Tongue

3.Boltholes

8.Atthefrontendofthetongue,pullthewire

harnessforwardtoremoveallslackinthe

harnessbeforecontinuingtheinstallation.

4.Wireharness

5.Bolt(5/8x3inches)

Important:Ensurethatthewireharnessis

notbeingpinchedorimpingedduringthe

installation.Damagedwirescancausethe

taillightstomalfunction.

9.Securetheboltswith2nuts(5/8inch)(Figure6).

Torquethenutsto103-135N∙m(76-100ft-lb).

g008366

2Mountingstrap

1Jack

4Bolt

4Locknut

Procedure

1.Placethejackagainstthetongue(Figure7).

Figure6

1.Trailerandtongue

2.Bolt(5/8x3inches)

10.Lowerthefrontendofthetrailer.

3.Nut(5/8inch)

g022032

Figure7

g008367

1.Locknuts(4)3.Bolts(4)

2.Mountingstraps

2.Positionthe2mountingstrapsontheotherside

ofthetongue(Figure7).

3.Securethejackandthe2mountingstrapstothe

tongueusing4boltsand4locknuts(Figure7).

4.Torquethelocknutsto33.9N∙m(25ft-lb).

4

4

InstallingtheRamp

Partsneededforthisprocedure:

1

Chain

1Ramp

2

Bolt(1/2x1-1/2inches)

2

Nut(1/2inch)

2Rampstrap

2

Cotterpin(1-1/4inch)

Procedure

1.Installtheretainingchainfromthebedofthe

trailertotheretainingpin(Figure8).

Figure8

1.Trailerbed4.Retainingpin

2.Loop

3.Chain

5.Keeper(attached)

2.Withthehelpofanotherperson,placetheramp

intopositionattheendofthetrailerbed.Usea

bolt(1/2x1-1/2inches)andanut(1/2inch)at

eachhingetoattachtheramptothetrailerbed

(Figure9).

g008369

Figure9

1.Trailerbed

2.Ramp

3.Bolt(1/2x1-1/2inches)

g008368

3.Tightentheboltuntilthereisapproximatelya

4.Nut(1/2inch)

5.0.16cm(1/16inch)gap

0.16cm(1/16inch)gapbetweenthebedand

ramphinges.Thisallowstheramptomove

freelywhilesecurelyfastenedtothetrailer.

Important:Donotovertightentheramp

pivotboltsorbindingwilloccur,causing

damagetothetrailer.

4.Installarampstraptoeachsideofthetraileras

showninFigure10.Installacotterpinandbend

backtheendstosecurethestrapstothetrailer.

5

Figure10

1.Lynchpin4.Ramp

2.Postonramp5.Postonbed

3.Rampstrap

5.Raisetherampandusethestrapsandlynch

pinstosecureitinthetransportposition(Figure

10).

6.Cotterpin

5

TestingtheWireHarness

NoPartsRequired

Procedure

g008372

g008371

1.Tongue3.Wiringharness

2.Holster

Figure11

Operation

OperatingtheJack

Turnthecrankclockwisetolowerthejack(Figure12).

1.Locatethewhitegroundwireonthewiring

harnessandgroundboltonthefrontofthe

tongue.Securethegroundwiretothetongueat

thegroundbolt.Donotovertightenthebolt.

2.Plugtheatconnectortoasuitablevehiclefor

testing.Checktomakesurethebrakelights

illuminateproperlywiththebrakepedalapplied

andthetaillightsashwhentheturningsignals

areuse.

3.Disconnectthewireconnectorandbundleitto

thetrailer.Storetheatconnectortotheholster

onthetongue(Figure1 1).

g022033

Figure12

Turnthecrankcounterclockwisetoraisethejack

(Figure13).

6

Figure13

Pulloutonthehandletorotatethejack(Figure14).

AttachingtheTrailer

Thistrailerusescouplersthatrequirea2inchball

forthehitch.

1.Rotatethejackintotheverticalposition(Figure

14).

2.Raisethetrailertoabovetheballhitch.

3.Liftthehandleonthetongue.

4.Lowerthetongueballsocketovertheballhitch

(Figure15).

g022034

g008373

Figure15

1.Tongue4.Auxiliarychains

2.Ballsocket

3.Handle,lockedposition

5.Lockingpin(notincluded

withthetrailer)

5.Closethehandle,makingsureitissecurely

locked.

6.Installapin(notincludedwiththetrailer)tolock

thehandle.

7.Attachthechainstoholesonthevehiclehitch.

Connectthewiringharnesstotheatconnector

onthehitch.

8.Raisethejackoffofthegroundandrotatethe

jackintothehorizontalposition.

g02211 1

Figure14

1.Handle

7

LoadingtheTrencher

CAUTION

Attemptingtoloadorunloadthemachine

fromatrailerthatisnotsecurelyhitchedto

asuitablevehiclecouldcausethetrailerto

becomeunstable,andtipcausinginjuryto

youorbystanders.

Makesurethetrailerissecurelyhitchedto

asuitablevehicleparkedonalevelsurface

beforeattemptingtoloadorunloadthe

machine.

1.Removetheretainingstrapsandlowertheramp

totheground.

2.Removethetiedownbarpinandslidethebars

apart(Figure16).

Important:Allowthepinandchaintolayon

thecenterofthebedtoavoidrunningoverit

withthemachineanddamagingit.

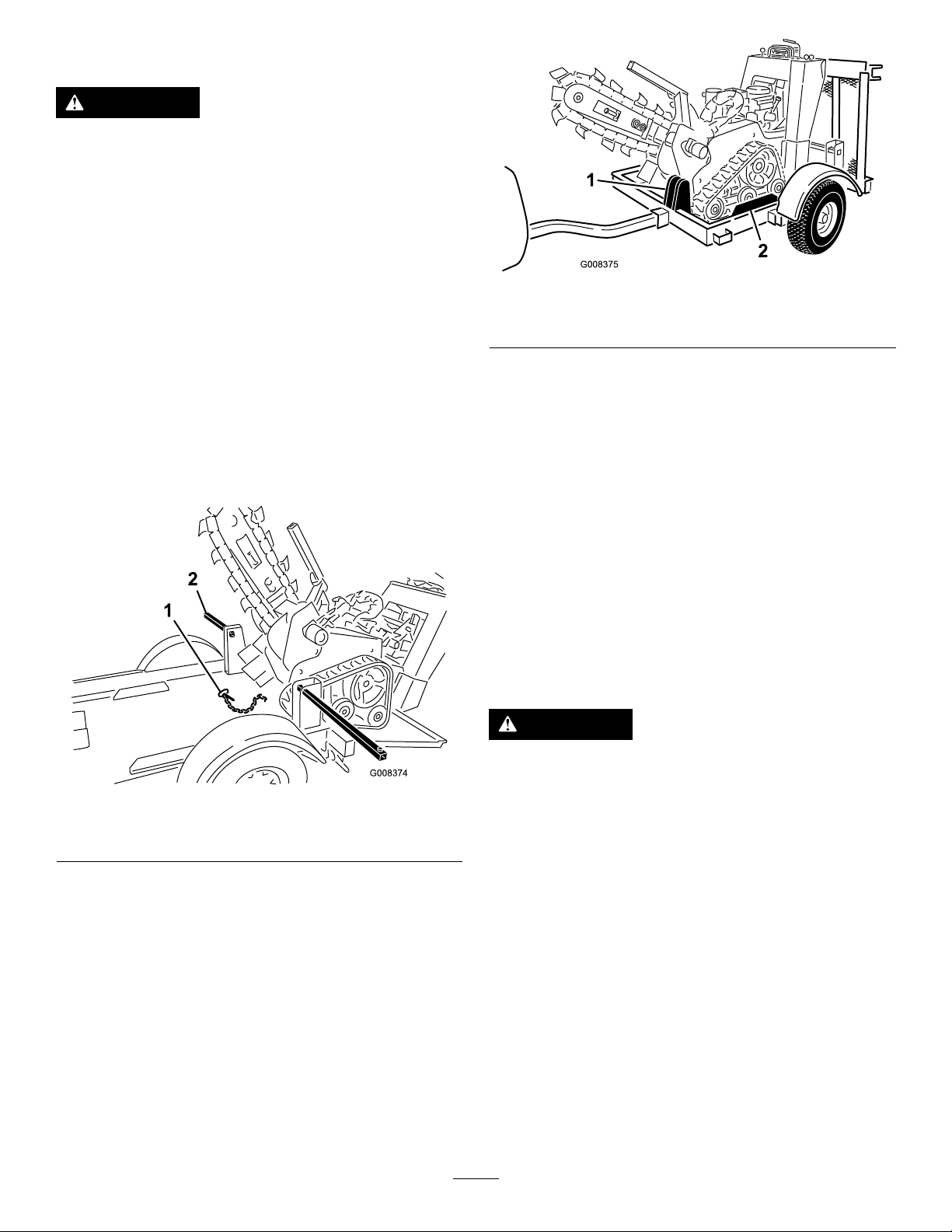

Figure17

1.Forwardstop

7.Turnthemachineoffandengagetheparking

brake.

8.Lowerthetrencherarmuntilitrestsonthefront

stop.

2.Guiderails

Note:Makesurethefrontcrosstubeofthe

trencherisfullyengagedtothefrontstopon

thetrailer.

g008375

Figure16

1.Tiedownbar2.Retainingpin

3.Startthetrencheraccordingtothedirectionsin

theOperator'sManualandruntheengineat

lowspeed.

4.Withthetrencherarmraisedinthetransport

positiondrivethemachineuptherampontothe

trailerbed.

5.Takecaretoloadthetrencherwiththetracks

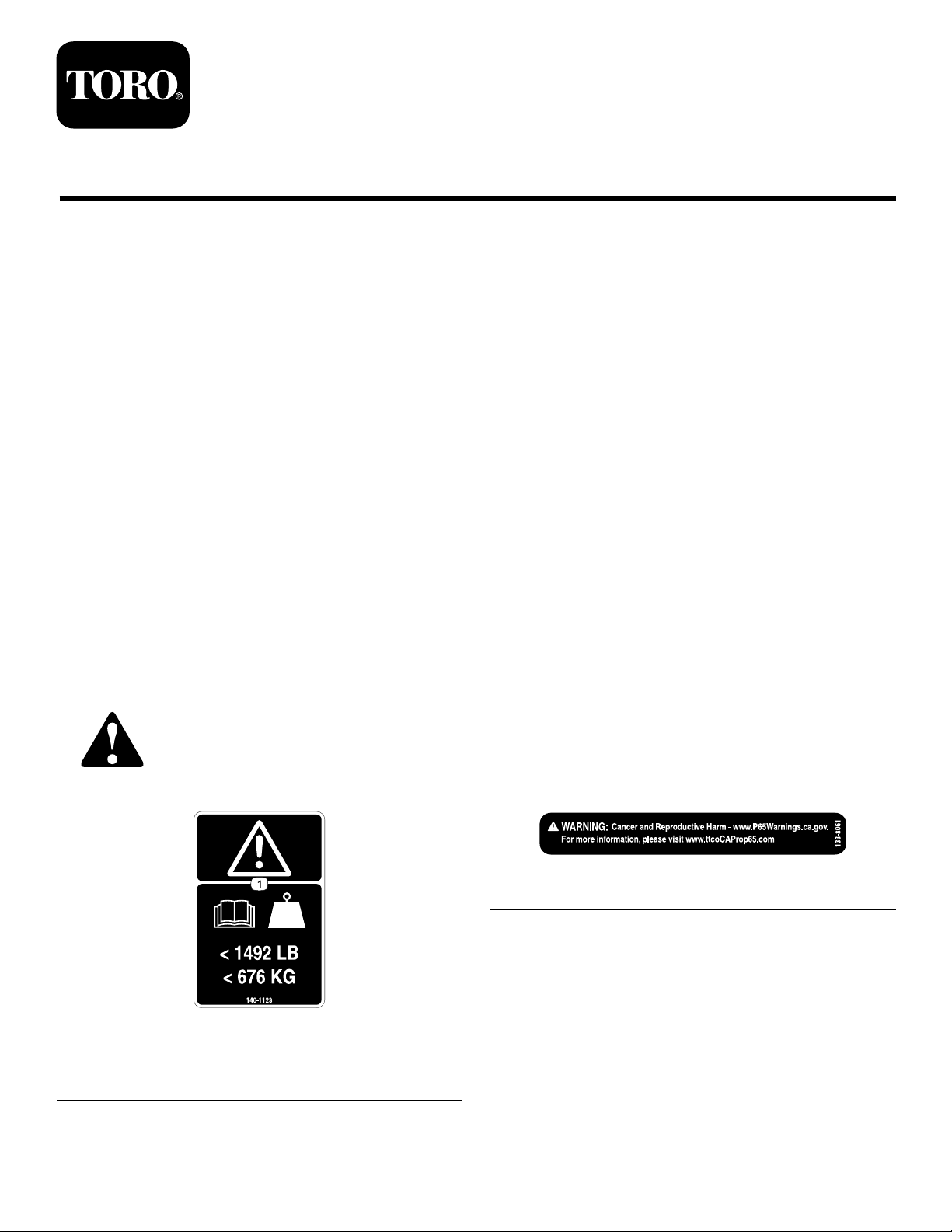

betweenguiderailsonthetrailerbed(Figure

17).

9.Slidethetiedownbarstogetherthroughtherear

tiedownloops,aligningtheholestoallowfor

theretainingpin.Installthepin.

10.Raisetherampandusethestrapsandlynch

pinstosecureitinthetransportposition.

UnloadingtheTrencher

CAUTION

Attemptingtoloadorunloadthemachine

g008374

fromatrailerthatisnotsecurelyhitchedto

asuitablevehiclecouldcausethetrailerto

becomeunstable,andtipcausinginjuryto

youorbystanders.

Makesurethetrailerissecurelyhitchedto

asuitablevehicleparkedonalevelsurface

beforeattemptingtoloadorunloadthe

machine.

1.Removelynchpinssecuringtherampstraps.

Removethestrapsandslowlylowertheramp

totheground.

6.Movethetrencherforwardslowlyuntilthefront

ofthemachinemeetstheforwardstoponthe

trailerbed.

8

DANGER

Therampinthetransportposition

representsastoredenergyhazardand

ifnotsecuredcanfall;injuringyouor

bystanders.

Holdtherampinplacewhenremoving

strapsandusecaretolowertheramp

carefullytotheground.

2.Removethepinontheholddownbarandlay

thechainandpinonthecenterofthetrailerbed.

Slidetheholddownbarsapart.

3.StartthemachineaccordingtotheOperator's

Manualanddisengagetheparkingbrake.

4.Raisethetrencherarmintothetransport

position.

5.Slowly,whilelookingbehindyouanddown,

movethemachinedownandofftheramp.

RemovingtheTrailerHitch

1.Parkthemachineandtraileronalevelsurface.

2.Rotatethejackintotheverticalposition.

3.Disconnectthewiringharnessfromtheelectrical

connectoronthehitch.Placetheconnectorinto

theholsteronthetongue.

4.Removethechainsretainingthetonguetothe

hitch.

5.Removethepinandliftthehandleontopofthe

hitch.

6.WiththetonguehandleraisedCHECK.

7.Raisethetongueabovethehitchandlowerthe

handle

8.Installapin(notincluded)tolockthehandle.

9.Chockthetrailerwheels.

Maintenance

CheckingLugNuts

ServiceInterval:Aftertherst10hours/Monthly

(whichevercomesrst)

Torquethenutsto68-102N∙m(50-75ft-lb).

9

Notes:

Notes:

Loading...

Loading...