Page 1

Form No. 3323-258

Hydraulic

Blade

Sitework Systems Attachment

Model No. 22414—890001 & Up

Operator’s Manual

English (CE)

Page 2

Contents

Page

Introduction 2.

Safety 2

Safety Decals3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 3

Stability Ratings3. . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 3

T

ips for Using the Blade4. . . . . . . . . . . . . . . . . . . .

Blade Operation and Controls4. . . . . . . . . . . . . . . .

Maintenance 4

Service Interval Chart4. . . . . . . . . . . . . . . . . . . . . .

Checking the Blade Cutting Edge4. . . . . . . . . . . . .

Storage 4

Troubleshooting 5

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

W

e want you to be completely satisfied with your new

product, so feel free to contact your local Authorized

Service Dealer for help with service, genuine replacement

parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. Y

number on a plate located on the blade pivot frame.

For your convenience, write the product model and serial

numbers in the space below

, always know the model and serial numbers of

ou will find the model and serial

.

Model No:

DANGER

serious injury or death if the recommended precautions

are not followed.

WARNING

or death if the recommended precautions are not followed.

CAUTION

moderate injury if the recommended precautions are not

followed.

wo other words are also used to highlight information.

T

“Important” calls attention to special mechanical

information and “Note” emphasizes general information

worthy of special attention.

The left and right side of the machine is determined by

standing in the normal operator’s position.

signals an extreme hazard that will cause

signals a hazard that may cause serious injury

signals a hazard that may cause minor or

Safety

Impr

oper use or maintenance by the operator or owner

can r

esult in injury

comply with the safety instructions in the traction unit

Operator’

safety alert

W

ARNING, or DANGER—“personal safety

instruction.” Failur

may r

POTENTIAL HAZARD

• Ther

WHA

•

HOW T

•

s Manual and always pay attention to the

esult in personal injury or death.

e may be buried power

telephone lines in the work ar

T CAN HAPPEN

Shock or explosion may occur

O AVOID THE HAZARD

Have the pr

buried lines and do not dig in marked ar

. T

o r

educe the potential for injury

symbol, which means CAUTION,

e to comply with the instruction

, gas, and/or

ea.

.

operty or work ar

ea marked for

eas.

,

Serial No.

The

warning system in this manual identifies potential

hazards and has special safety messages that help you and

others avoid personal injury

W

ARNING and CAUTION are signal words used to

identify the level of hazard. However

hazard, be extremely careful.

, even death. DANGER,

, regardless of the

The Toro Company – 1999

8111 Lyndale Ave. South

Bloomington, MN 55420–1196

2

All Rights Reserved

Printed in the USA

Page 3

POTENTIAL HAZARD

•

When the engine is off, attachments in the

raised position can gradually lower

WHA

T CAN HAPPEN

•

Someone nearby may be pinned or injur

the attachment as it lowers.

HOW T

•

O AVOID THE HAZARD

Always lower the attachment lift each time you

shut off the traction unit.

.

ed by

table, then find the degree of slope for the same rating and

hill position in the Stability Data section of the traction

unit operator’s manual.

Orientation

Front Uphill

Stability Rating

D

Rear Uphill

C

Safety

1. Pinching/crushing

hazard—hand

2. Pinching/crushing

hazard—foot

Decals

1

3

#

100–4650

Figure 1

3. Keep

Specifications

Note:

Specifications and design are subject to change

without notice.

Width 47.75

Length

Height

inches (121.3 cm)

25 inches (63.5 cm)

21 inches (53 cm)

2

3

bystanders away

Side Uphill

B

Note:

On traction units with a rear operator platform, the

blade is rated for use without the counterweight. If you

use the counterweight with the blade, the traction unit will

be less stable in the front and side uphill positions.

WARNING

POTENTIAL HAZARD

•

Exceeding the maximum r

can cause the traction unit to tip.

WHA

T CAN HAPPEN

•

If the traction unit tips, you or bystanders could

be crushed.

HOW T

•

O AVOID THE HAZARD

Do not drive the traction unit on a slope steeper

than the maximum r

determined in the pr

traction unit operator’s manual.

ecommended slope

ecommended slope, as

evious table and the

Weight

Stability

To

determine the degree of slope you can traverse with the

blade installed on a traction unit, find the stability rating

for the hill position you want to travel in the following

Ratings

212 lbs (96.2 Kg)

Operation

Note:

Refer to your traction unit operator’s manual for

complete instructions on installing/removing attachments

onto/from the traction unit and connecting/disconnecting

hydraulic hoses.

Note:

Always use the traction unit to lift and move the

attachment.

3

Page 4

Tips

for Using the Blade

Blade

Operation and Controls

• Clean

•

•

•

•

the area of trash, branches and rocks before

beginning work to prevent equipment damage.

Always begin with the slowest ground speed possible.

Increase speed if conditions permit.

Always use full throttle (maximum engine speed).

Never transport the blade with the loader arms raised.

Keep the arms lowered and the blade tilted up.

When scraping, leveling, and surface stripping, lower

the blade to the ground, ensuring that the cutting edge

makes contact. The blade will bite into the soil as you

move forward.

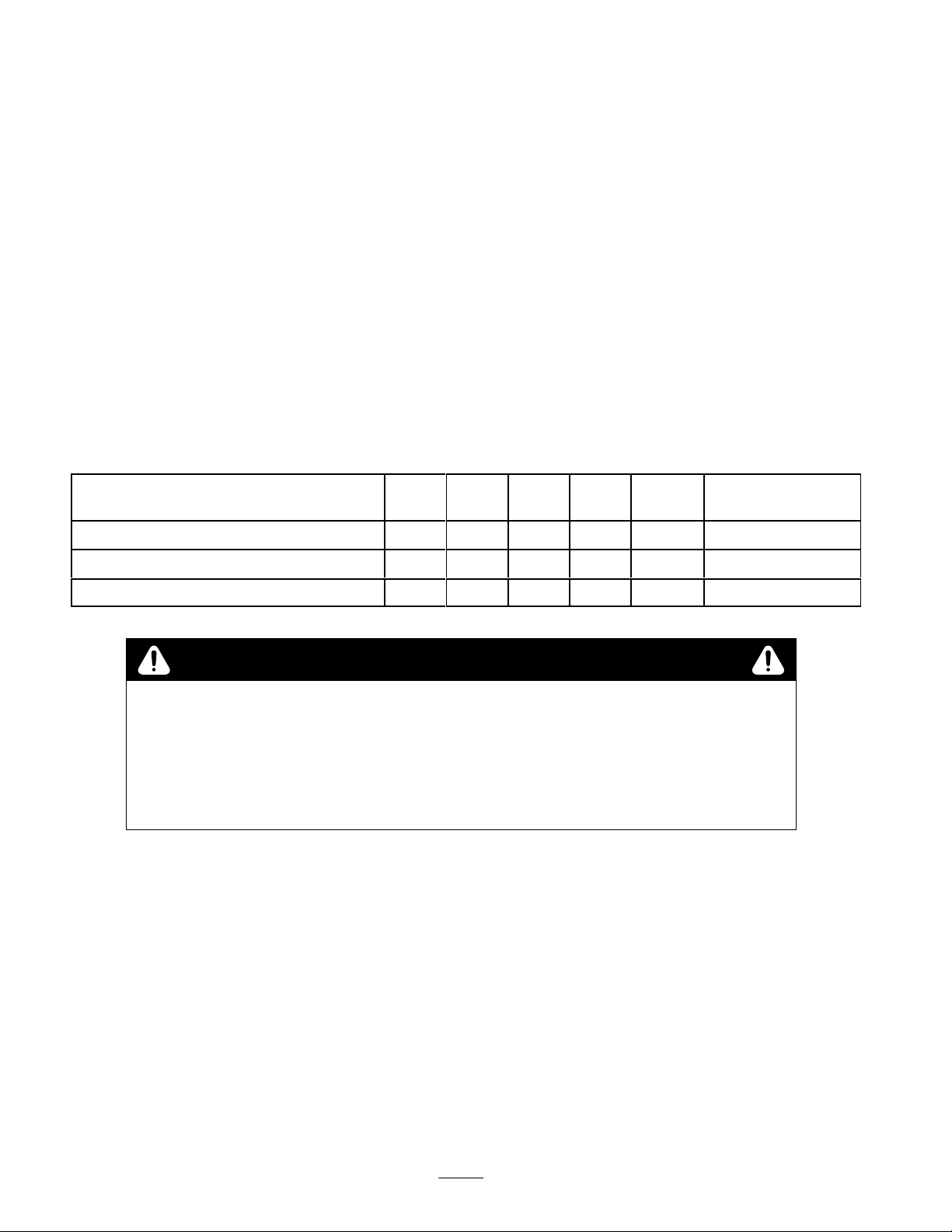

Maintenance

Service

Service

Blade cutting edge—check

Hydraulic hoses—inspect

Interval Chart

Operation

1. If

your traction unit has a speed selector

fast (rabbit) position.

2.

Pull the auxiliary hydraulics valve to the operator grip

to angle the blade to the right.

3.

Push the auxiliary hydraulics valve away from the

operator grip to angle the blade to the left.

Each

Use5Hours25Hours

200

Hours

X X

Storage

Service

X

, move it to the

Notes

Replace if damaged

Chipped surfaces—paint

POTENTIAL

•

If you leave the key in the ignition switch, someone could start the engine.

WHA

•

Accidental starting of the engine could seriously injur

HOW T

•

Remove the key fr

Checking

T CAN HAPPEN

the Blade Cutting

HAZARD

O AVOID THE HAZARD

om the ignition switch befor

Edge

Check

the blade cutting edge once a year for wear

blade is badly worn, complete the following procedure:

1.

Remove the pins securing the blade to the frame and

hydraulic cylinder and remove the blade.

2. T

urn the blade 180 degrees so the worn edge is on top,

then install it back on the mounting frame and

hydraulic cylinder

.

. If the

CAUTION

e you do any maintenance.

Storage

1.

2.

3.

4.

X

e you or other bystanders.

Before long term storage, wash the attachment with

mild deter

Check the condition of the cutting edge. Remove and

rotate the blade 180 degrees so the worn edge is on

top, if it is badly worn.

Check and tighten all bolts, nuts, and screws. Repair or

replace any part that is damaged or worn.

Ensure that all hydraulic couplers are connected

together to prevent contamination of the hydraulic

system.

gent and water to remove dirt and grime.

Paint all scratched or bare metal surfaces. Paint is

5.

available from your Authorized Service Dealer

4

.

Page 5

6.

Store the attachment in a clean, dry garage or storage

area. Cover it to protect it and keep it clean.

Troubleshooting

PROBLEM POSSIBLE

Blade will not change angle.

CAUSES

1.

Hydraulic coupler not

completely connected

2.

Defective hydraulic coupler

3.

An obstruction in a hydraulic

hose

4.

Auxiliary valve on the traction

unit is not opening.

5.

Defective hydraulic cylinder

CORRECTIVE ACTION

1.

Check and tighten all couplers.

2.

Check couplers and replace

any that are defective.

3.

Find and remove the

obstruction.

4.

Repair the valve.

5.

Replace or repair defective

cylinder.

5

Page 6

Page 7

Page 8

Loading...

Loading...