Page 1

Backhoe

Sitework Systems Attachment

Model No. 22412—990001 & Up

Form No. 3321-518

Operator’s Manual

English (CE)

Page 2

Contents

Page

Introduction 2.

Safety 2

Safety Decals3. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 4

Stability Ratings4. . . . . . . . . . . . . . . . . . . . . . . . . . .

Installation 5

Loose Parts5. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Initial Assembly5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Greasing the Backhoe6. . . . . . . . . . . . . . . . . . . . . .

Installing the Backhoe on the T

Installing a Bucket7. . . . . . . . . . . . . . . . . . . . . . . . .

Adjusting the Seat8. . . . . . . . . . . . . . . . . . . . . . . . .

Removing the Backhoe from the T

Operation 9

Operation Checklist9. . . . . . . . . . . . . . . . . . . . . . . .

Backhoe Overview10. . . . . . . . . . . . . . . . . . . . . . . . .

Controls 10

Operating the Backhoe10. . . . . . . . . . . . . . . . . . . . . .

Maintenance 12

Service Interval Chart13. . . . . . . . . . . . . . . . . . . . . .

Greasing and Lubrication13. . . . . . . . . . . . . . . . . . . .

Changing the Bucket Orientation13. . . . . . . . . . . . . .

Changing the Boom Speed14. . . . . . . . . . . . . . . . . . .

Storage 14

Troubleshooting 15

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

raction Unit6. . . . .

raction Unit8. . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

For your convenience, write the product model and serial

numbers in the space below

Model No:

Serial No.

The

warning system in this manual identifies potential

hazards and has special safety messages that help you and

others avoid personal injury

W

ARNING and CAUTION are signal words used to

identify the level of hazard. However

hazard, be extremely careful.

DANGER

serious injury or death if the recommended precautions

are not followed.

WARNING

or death if the recommended precautions are not followed.

CAUTION

moderate injury if the recommended precautions are not

followed.

wo other words are also used to highlight information.

T

“Important” calls attention to special mechanical

information and “Note” emphasizes general information

worthy of special attention.

The left and right side of the machine is determined by

standing in the normal operator’s position.

signals an extreme hazard that will cause

signals a hazard that may cause serious injury

signals a hazard that may cause minor or

.

, even death. DANGER,

, regardless of the

W

e want you to be completely satisfied with your new

product, so feel free to contact your local Authorized

Service Dealer for help with service, genuine replacement

parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. Y

number on a plate located on the product.

, always know the model and serial numbers of

ou will find the model and serial

The Toro Company – 1999

8111 Lyndale Ave. South

Bloomington, MN 55420–1196

Safety

Impr

oper use or maintenance by the operator or owner

can r

esult in injury

comply with the safety instructions in the traction unit

operator’

safety alert

W

ARNING, or DANGER—“personal safety

instruction.” Failur

may r

2

s manual and always pay attention to the

esult in personal injury or death.

. T

o r

educe the potential for injury

symbol, which means CAUTION,

e to comply with the instruction

All Rights Reserved

Printed in the USA

,

Page 3

DANGER

WARNING

POTENTIAL HAZARD

• Ther

WHA

•

HOW T

•

e may be buried power

telephone lines in the work ar

, gas, and/or

ea.

T CAN HAPPEN

Electric shock, death, or explosion may occur

O AVOID THE HAZARD

Have the pr

operty or work ar

ea marked for

buried lines and do not dig in marked ar

DANGER

POTENTIAL HAZARD

• Ther

WHA

•

HOW T

•

e may be overhead power lines in the work

area.

T CAN HAPPEN

Electric shock or death may occur if a power

line is touched by the backhoe.

O AVOID THE HAZARD

Survey and mark the ar

ea wher

e ther

e ar

overhead power lines, and dig with caution

under power lines, to ensur

e that you do not

touch them with the backhoe.

eas.

e

POTENTIAL HAZARD

•

When going up or down hill, the machine could

overturn if the heavy end is toward the

downhill side.

.

WHA

T CAN HAPPEN

•

Someone may be pinned or seriously injured by

the machine if it overturns.

HOW T

•

O AVOID THE HAZARD

Operate up and down slopes with the backhoe

uphill.

CAUTION

POTENTIAL HAZARD

•

The tir

es of the traction unit can be slippery

WHA

T CAN HAPPEN

•

If the tir

es ar

e used as a step to climb on to or

off of the backhoe, the operator could slip and

fall, causing injury

HOW T

•

O AVOID THE HAZARD

Use the step pr

.

ovided when climbing on to or

off of the backhoe and not the traction unit

tires.

.

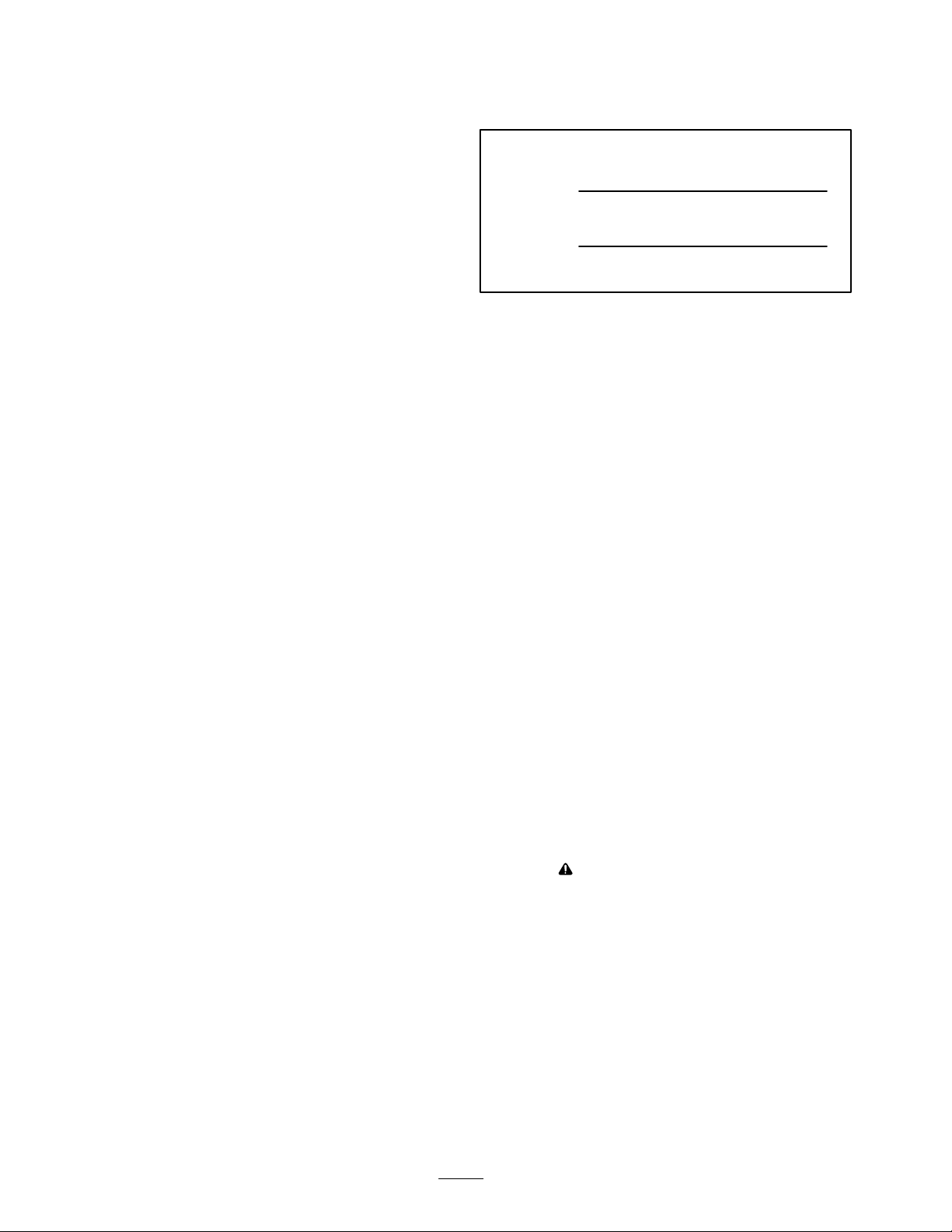

Safety

1

9

1. Crushing

body

2.

Keep bystanders away

3.

Safety alert symbol

4.

Read the operator’s manual

5.

Explosive hazard

Decals

# 100–4132

10

hazard—whole

2

1

11

6.

Electric shock hazard

7.

Do not dig in areas with

underground utilities

8.

Do not allow the backhoe to

contact

overhead power lines

9. Crushing

hazard—foot

12

3

4

5 6

7

8

16

15

Figure

13

# 100–4133# 100–4136

1

10.

Crushing hazard—hand

11.

Keep hands and feet away

from moving stabilizers

12.

Secure the boom before

leaving the machine

13. T

ipping hazard

14.

15.

16.

14

Do not move the traction unit

while seated on the backhoe

Lower the stabilizers before

beginning work

Use the counterweight

3

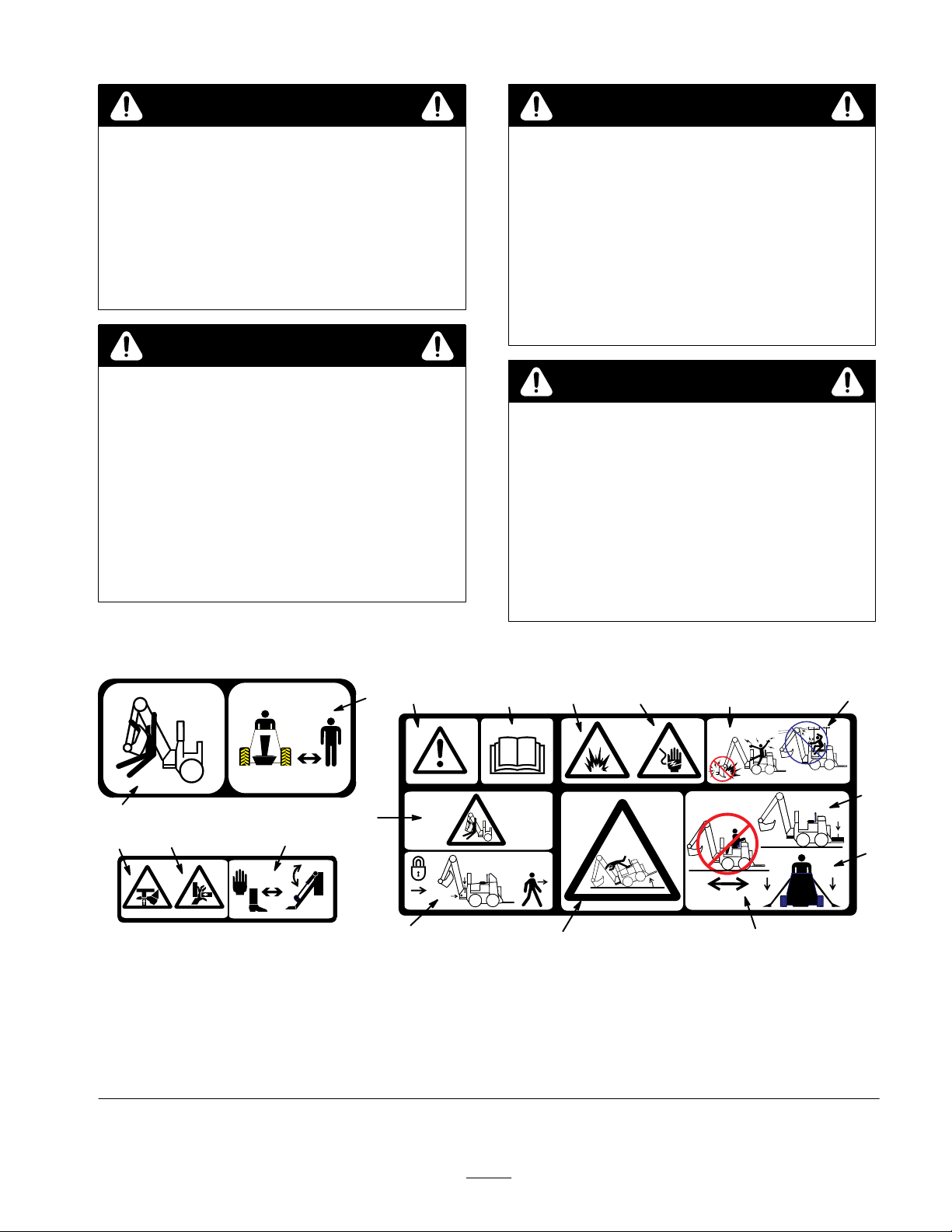

Page 4

1

2

3

# 100–4137# 100–4134 # 100–4135

4

Figure

1. Secure

the boom before

transporting the backhoe

2.

Install and secure the side

bars before operating the

backhoe

3. T

Specifications

Note:

Specifications and design are subject to change without notice.

Width 34.5

Length 1

T

ransport height

Fully raised height

Weight

Digging depth (maximum) 79 inches (200.6 cm)

Bucket rotation

Swing arc

Stabilizer spread (working)

inches (87.6 cm)

12.5 inches (286 cm)

84 inches (213 cm)

1

15 inches (292 cm)

710 lbs (322 Kg)

135 degrees

151 degrees

130 inches (330 cm)

2

ipping hazard

4.

Do not move the traction unit

while seated on the backhoe

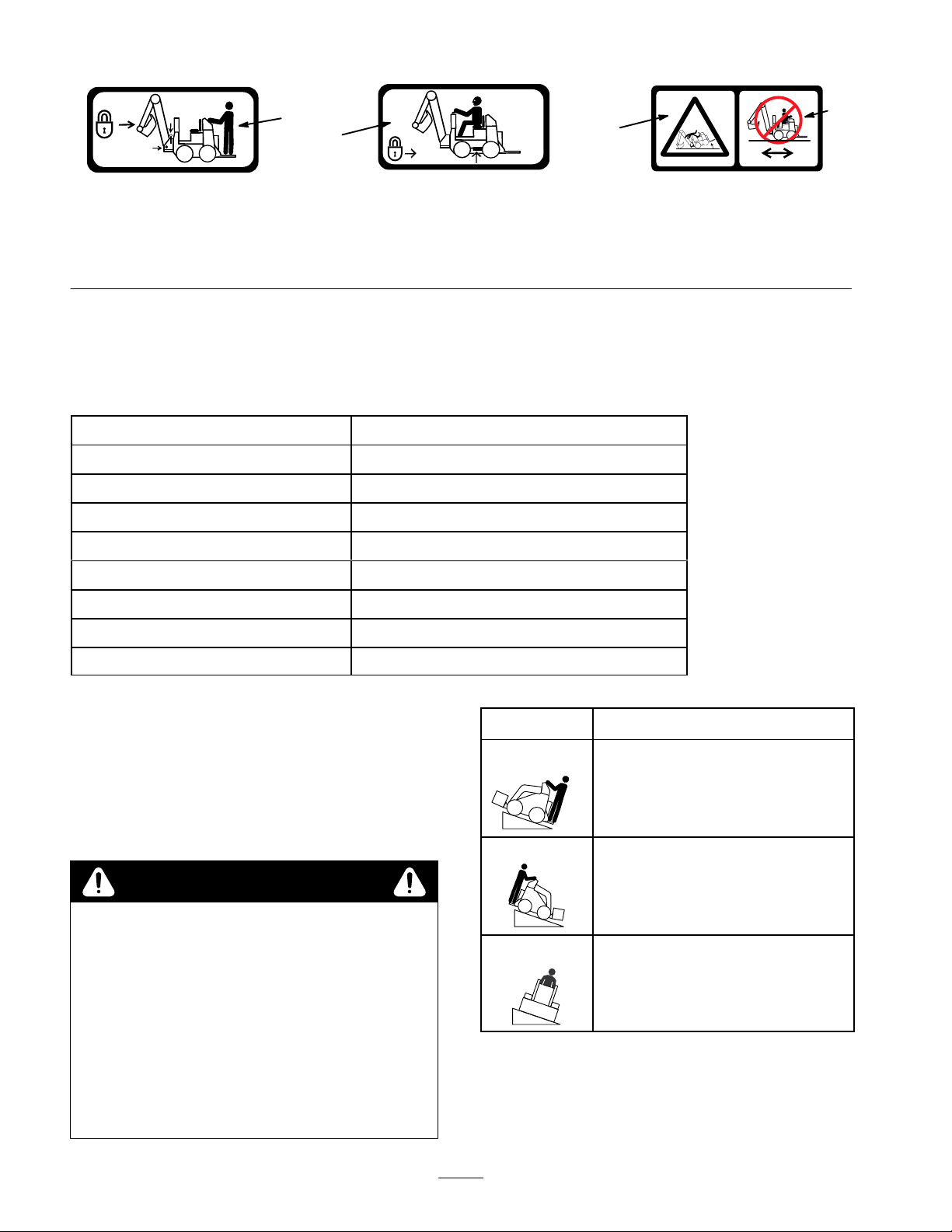

Stability

To

determine the degree of slope you can traverse with the

backhoe installed on a traction unit, find the stability

rating for the hill position you want to travel in the

following table, then find the degree of slope for the same

rating and hill position in the Stability Data section of the

traction unit operator’s manual.

Ratings

WARNING

POTENTIAL HAZARD

•

Exceeding the maximum r

can cause the traction unit to tip.

WHA

T CAN HAPPEN

•

If the traction unit tips, you or bystanders could

be crushed.

HOW T

•

O AVOID THE HAZARD

Do not drive the traction unit on a slope steeper

than the maximum r

determined in the following table and the

traction unit operator’s manual.

ecommended slope

ecommended slope, as

Orientation

Front Uphill

Stability Rating

C

Rear Uphill

D

Side Uphill

C

IMPORTANT:

operator’

on the platform while using the backhoe, or the

traction unit will become unstable.

If your traction unit has a r

s platform, the counterweight must be used

ear

4

Page 5

Installation

Loose

Note:

DESCRIPTION

Side

Back-plate

Bolt

Nut

Side bar

Long tilt cylinder pin

Cotter pin

Linch pin

Link

Bucket, 9, 12, or 16 inch (23, 30, or 41 cm)

Initial

Parts

Use the chart below to identify parts for assembly

bar bracket

Assembly

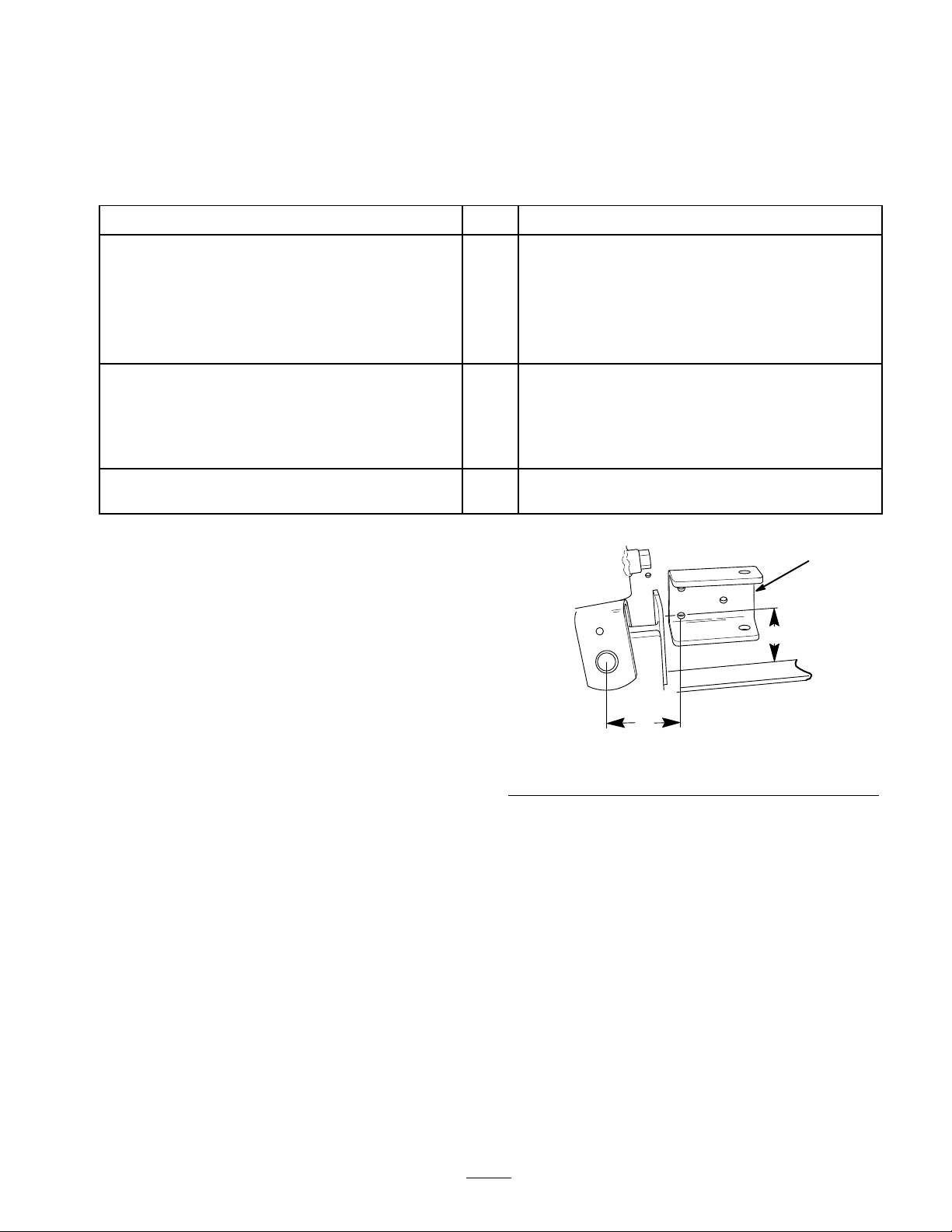

Installing the Side Bar Bracket

.

QTY. USE

2

2

6

6

2

1

2

2

2

1

Install the side bar brackets and attach to the

backhoe.

Replace the tilt cylinder pin and connect to the

backhoe.

Install on the backhoe. Must be purchased

separately.

1

1. Remove

under the control panel (models 22305 and 22305TE

only).

Remove the battery from the traction unit. Refer to

2.

your traction unit operator’s manual.

Note:

you do not need to remove the battery; however

need to remove the loader arm cylinder and exhaust cover

plate on the right side of the machine. To remove the

loader arm cylinder

install the cylinder lock on the left side before removing

the right cylinder

finished installing the side bar bracket.

3.

Line up the side bar bracket as illustrated in Figure 3

and mark the centers of the three holes.

the traction unit manual holder and relocate it

If you have a four

-wheel drive, diesel traction unit,

, you need to raise the loader arms and

. Replace the cylinder and plate when

, you do

3.5 in. (8.9 cm)

m–4560

1. Side

4. Drill

5.

bar bracket

three, 0.568 in. (1.43 cm) diameter holes through

the side of the traction unit at the marked locations.

Secure the side bar bracket to the side of the traction

unit using the back-plate, three carriage bolts, and

three nuts.

3.2 in. (8.1 cm)

Figure

3

2.

3.2 in. (8.1 cm)

5

Page 6

3

2

Greasing

Before

using the backhoe for the first time, grease all of

the fittings; refer to Greasing and Lubrication, page 13.

the Backhoe

4

1

Figure

1. Side

bar bracket

2. Back-plate

6. Torque

7.

the nuts to 75 ft-lbs (102 N·m).

Repeat steps 3–6 for the other side of the traction unit.

4

Carriage bolt

3.

4. Nut

Changing the Tilt Cylinder Pin

1. Remove

(Fig. 5).

2.

Using a hammer and punch, remove the tilt cylinder

pin.

the bolt securing the upper tilt cylinder pin

2

3

m–4586

Installing

T

raction Unit

IMPORTANT:

the traction unit, ensur

the Backhoe on the

Befor

e connecting any attachments to

e that the mount plates ar

e fr

of any dirt or debris.

1.

Start the engine.

2. T

ilt the attachment mount plate forward.

3.

Drive forward, positioning the mount plate into the

upper lip of the receiver plate (Fig. 7).

IMPORTANT

r

eceiver plate so that the gaps on the sides are equal. If

: Y

ou must center the mount plate in the

you do not center the plates, you may not be able to

install the side bars.

1

2

ee

1

m–4562

Figure

1. Tilt

cylinder

2. T

ilt cylinder pin

3. Apply

4.

a generous coating of grease to the new pin.

Install the new pin into position and secure it with two

5

3. Bolt

cotter pins (Fig. 6).

Note:

Leave the new pin installed, even when the backhoe

is removed.

1

2

m–4563

1. New

Figure

tilt cylinder pin

6

2.

Cotter pin

Figure

1. Mount

4. Tilt

plate

the mount plate back until the receiver plate

7

2.

contacts the mount plate

5.

Engage the attachment lock pins (Fig. 8).

1

Figure

1. Attachment

6. Tilt

lock pins (shown in engaged position)

the backhoe part of the way back.

8

m–4055

Receiver plate

m–4056

6

Page 7

7.

Stop the engine.

8.

Move the auxiliary hydraulic lever forward, backward,

and back to the neutral position to relieve hydraulic

pressure at the hydraulic couplers.

IMPORTANT

cleaned fr

: Ensur

e that all for

eign matter is

om hydraulic connections befor

e making

connections.

Remove protective covers from hydraulic couplers on

9.

the traction unit. Connect covers together to prevent

contamination during operation.

10.

Slide the collars back on the hydraulic couplers and

connect the attachment couplers to the machine

couplers.

Note: You may need to move the attachment tilt lever to

line up the holes in the links with the pins.

4

4

1

2

1. Tilt

cylinder pin

2.

Backhoe link pin

3

Figure

9

3. Link

4.

Linch pin

m–4130

WARNING

POTENTIAL HAZARD

•

Hydraulic fluid escaping under pr

penetrate skin and cause injury

WHA

T CAN HAPPEN

•

Fluid accidentally injected into the skin must be

surgically r

emoved within a few hours by a

.

essur

e can

doctor familiar with this form of injury or

gangr

ene may r

HOW T

•

O AVOID THE HAZARD

Keep body and hands away from pin hole leaks

or nozzles that eject high pr

esult.

essur

e hydraulic

fluid.

Use cardboard or paper to find hydraulic leaks,

•

never use your hands.

11.

Confirm that the connection is secure by pulling on the

hoses.

Start the engine.

12.

13.T

ilt the backhoe all the way back.

CAUTION

15.Install

the side bars on each side as illustrated in

Figure 10.

16.

If the bars do not fit snuggly

, remove them, loosen the

jam nut, and thread the compound side bar together or

apart as needed to ensure that they fit as tight as

possible (Fig. 10). T

Note:

If you have a four

ighten the jam nut when finished.

-wheel drive, diesel traction unit,

you may need to loosen the hood and slide it up in the

mounting slots to ensure that the hood does not interfere

with the side bars.

2

4

3

1. Side

2. Pin

bar

Figure

10

Hairpin cotter

3.

4.

Jam nut

1

m–4561

POTENTIAL HAZARD

• T

ilting the backhoe can can pinch hands.

WHA

T CAN HAPPEN

• Y

ou could pinch and/or crush your hand when

adjusting the seat.

HOW T

•

O AVOID THE HAZARD

Keep away fr

om the moving backhoe when

tilting.

14.

Slide the two links on each end of the tilt cylinder pin

and the backhoe link pin and secure them with two

linch pins (Fig. 9).

Installing

The

backhoe does not come with a bucket installed

a Bucket

because several sizes of buckets are available for you to

choose from. Install your bucket as follows:

1.

Install the backhoe onto the traction unit and raise the

dipperstick above the ground.

2.

Remove the bolts and nuts securing each of the two

bucket pins to the dipperstick (Fig. 1

Remove the pins.

3.

1).

7

Page 8

4.

Align the pin holes in the bucket with the mounting

holes in the dipperstick (Fig. 1

Secure the bucket with the pins, bolts, and nuts

5.

removed previously (Fig. 1

1

4

1).

1).

4

2

1

3

Figure 11

1. Dipperstick

2. Bucket

pin

Adjusting

the Seat

3. Bolt

4. Nut

CAUTION

POTENTIAL

•

The seat mounting bracket has several pinch

points.

WHA

T CAN HAPPEN

• Y

ou could pinch and/or cut your fingers when

adjusting the seat.

HOW T

• T

ake car

seat mounting bracket when moving the seat up

and down and when lowering the seat into

position.

HAZARD

O AVOID THE HAZARD

e to keep your fingers away fr

2

m–4589

om the

3

Figure

1. Seat

2. Knobs

5. When

Removing

the T

1. With

2.

3.

you have the proper height, install the pin and

hairpin cotter to secure the seat.

the Backhoe from

raction Unit

the backhoe secured in the transport position

(refer to Preparing for T

backhoe to a level storage area and stop the engine.

Remove the hairpin cotters and pins securing the side

bars and remove the side bars.

Pin the side bars in the storage positions as illustrated

in Figure 13.

12

3. Pin

and hairpin cotter

ransport, page 12), move the

m–4547

1.

Stop the engine.

2. T

ilt the seat forward.

3.

Loosen the knobs on the bottom of the seat (Fig. 12)

and slide the seat forward or back as needed.

4. T

o adjust the seat height, remove the hairpin cotter and

pin from the seat stand (Fig. 12) and raise or lower the

seat as required.

Figure

4. Start

5.

Note: You may need to adjust the tilt lever slightly to

loosen the links.

the engine.

Remove the linch pins securing the links and remove

the links.

13

8

m–4590

Page 9

6.

Secure the links and two linch pins for storage on the

pins on the backhoe and the other two linch pins on the

traction unit tilt cylinder pin.

7. T

ilt the backhoe forward slowly until the storage

supports on the backhoe receiver plate and the bucket

contact the ground.

CAUTION

POTENTIAL HAZARD

•

If the backhoe is r

unit without a bucket installed on the

dipperstick, the backhoe will be unstable.

WHA

T CAN HAPPEN

•

The backhoe could tip over injuring you or

other bystanders and damaging the backhoe.

HOW T

•

8.

9.

O AVOID THE HAZARD

Do not remove the backhoe fr

unit without first installing a bucket onto the

backhoe.

Stop the engine.

Move the auxiliary hydraulic lever forward, backward,

and back to the neutral position to relieve hydraulic

pressure at the hydraulic couplers.

emoved fr

om the traction

om the traction

Operation

Note:

Always use the traction unit to lift and move the

attachment.

Operation

To

ensure safe, ef

you complete the following activities before, during, and

after operating the backhoe:

Note:

For detailed descriptions of these procedures, refer

to Installing the Backhoe on the T

and Operating the Backhoe (page 10).

Befor

e Operation:

•

Locate and mark under

•

Install the counterweight on the traction unit.

•

Install the links between the backhoe and the tilt

cylinder pin on the traction unit.

•

Install the side bars between the backhoe and the

traction unit frame.

•

Install the hydraulics lever clamp over the traction unit

controls.

Lower the stabilizer arms before digging.

•

Checklist

fective use of the backhoe, ensure that

raction Unit (page 6)

ground utilities.

10.

Slide the collar back on hydraulic couplers and

disconnect them.

11.

Install protective covers onto the hydraulic couplers on

the traction unit.

12.

Connect the attachment hoses together to prevent

hydraulic system contamination during storage.

13.

Disengage the attachment lock pins by turning them to

the outside.

14.

Start the engine.

15.T

ilt the mount plate forward and back the traction unit

away from the backhoe.

During Operation:

Only operate the backhoe from the backhoe seat.

Only move the traction unit from the traction unit

operator’

After Operation:

Install the pins securing the boom from moving up and

down and side to side (Figs. 17 and 18) before leaving the

backhoe unattended.

s position and not from the seat of the backhoe.

9

Page 10

Backhoe

Figure

14 illustrates the backhoe. Familiarize yourself

Overview

with all of the components listed in Figure 14.

Y

ou can also move the boom control lever into an

intermediate position (i.e., forward and left, forward and

right, rearward and left, or rearward and right) to swing

the boom at the same time as you raise or lower it.

2

3

1

7

6

Figure

1. Seat

2. Controls

3. Boom

4. Dipperstick

14

5. Bucket

6. Stabilizer

7. Speed

Controls

Familiarize

Figure 15 before you operate the backhoe.

yourself with all of the controls listed in

4

5

m–4587

adjustment valve

Dipperstick/Bucket Control Lever

Move

the dipperstick/bucket control lever forward to

extend the dipperstick and rearward to retract the

dipperstick. Move the dipperstick/bucket control lever to

the right to dump the bucket and move it left to load the

bucket.

ou can also move the dipperstick/bucket control lever

Y

into an intermediate position (i.e., forward and left,

forward and right, rearward and left, or rearward and

right) to extend or retract the dipperstick at the same time

as you load or dump the bucket.

Operating

the Backhoe

Preparing the Backhoe

1. Drive

2.

3.

to the work location.

If your traction unit has a parking brake, engage it.

Pull the auxiliary hydraulics lever to the operator grip

and install the hydraulics lever clamp by pushing it

over the hand grip and sliding it right so that the pin

through the clamp slides under the right hand grip

(Fig. 16).

1

1. Stabilizer

2.

Boom control lever

2

control levers

Figure

15

3.

Dipperstick/bucket control

lever

3

m–4546

Stabilizer Control Levers

Move

the stabilizer control levers forward to lower the

stabilizers and rearward to raise the stabilizers.

Boom Control Lever

Move

the boom control lever forward to lower the boom

and rearward to raise the boom. Move the boom control

lever to the right to swing the boom to the right and move

it left to swing the boom to the left.

1

2

1. Hydraulics

2. Pin

4. Push

the stabilizer control levers forward to lower both

Figure

lever clamp

16

Auxiliary hydraulics lever

3.

stabilizers until they touch the ground and the front

wheels of the traction unit come of

f of the ground

slightly.

Remove the two pins locking the boom in place (Figs.

5.

17 and 18) and place them in the storage positions

(Fig. 19).

Note:

One pin prevents the boom from swinging side to

side (Fig. 17) and the other prevents the boom from

moving up and down (Fig. 18).

3

m–4641

10

Page 11

1

A

2

m–4548

Figure

1. Pin 2. Linch

17

1

Figure

1. Pin 2. Linch

18

pin

pin

1

2

m–4550

B

C

m–4554/4555/4556

Figure

To

empty the bucket you swing it to the left or right and

20

extend the dipperstick and uncurl bucket, dumping the

load (Fig. 21).

A

B

m–4557/4558

2

m–4549

Figure

1. Pin 2. Linch

19

pin

Digging a Hole

Using

a backhoe with precision and proficiency takes time

and practice. In general you dig a hole by extending the

dipperstick and bucket, lowering them into the ground,

and then pullback on the dipperstick while raising the

boom and curling the bucket rearwards (Fig. 20).

Figure

The

distance you extend the dipperstick and bucket and

21

the size of bite you take will vary greatly with the soil

type, moisture content of the soil, and obstructions in the

soil, such as tree roots and rocks.

Spend some time practicing with the backhoe to get the

feel for how it operates and how to best use it in the

conditions in which you work. Please read and use the

following tips when operating the backhoe:

11

Page 12

•

Do not dig too close to the backhoe body or stabilizers.

The backhoe could undercut the stabilizers or traction

unit causing the machine to fall into the hole.

WARNING

POTENTIAL HAZARD

•

If you dig too close to the backhoe, the backhoe

could fall into the hole.

WHA

T CAN HAPPEN

•

The backhoe and traction unit could tip on top

of you into the hole causing sever

HOW T

• Ensur

•

•

•

•

O AVOID THE HAZARD

e that you do not dig within thr

the backhoe or stabilizers.

Do not take lar

bucket through the soil using the swinging motion of

the dipperstick a few inches deep at a time.

If the bucket catches in the soil, uncurl the bucket,

raise the boom slightly

If your traction unit has a speed selector

fast position (rabbit) while you are learning how to

operate the backhoe (this will slow the backhoe down).

Set it to the slow position (turtle) once you feel you

have mastered the use of the backhoe.

If your traction unit has a flow divider

o’clock position.

ge bites of soil. Instead, sweep the

, and continue digging.

Preparing for Transport

1. Fully

2.

3.

raise the boom, retract the dipperstick, and curl

the bucket rearward (Fig. 14). Ensure that you center

the boom locking pin holes as much as possible.

Pull the stabilizer levers rearward until the stabilizers

are fully raised.

Stop the engine and remove the key

e injury

.

.

ee feet of

, set it to the

, set it to the 1

CAUTION

POTENTIAL HAZARD

•

If you do not secur

lower during transport.

WHA

T CAN HAPPEN

•

The traction unit could become unstable

causing loss of contr

could be injur

HOW T

•

5.

6.

1

1. Pin

2. Clamp

7. Slowly

O AVOID THE HAZARD

Always secur

the traction unit of on a trailer

Remove the hydraulics lever clamp (Fig. 16).

Secure the clamp under the backhoe seat by inserting

the end of the pin in the clamp into the hole in the seat

support (Fig. 22).

transport the backhoe as needed.

e the boom, it could swing or

ol and you or bystanders

ed.

e the boom befor

Figure

e transport with

.

3

22

3. Hole

in seat support

2

1

m–4644

Maintenance

Secure the boom using the two pins removed prior to

4.

operation (Figs. 17 and 18).

POTENTIAL HAZARD

•

If you leave the key in the ignition switch,

someone could start the engine.

WHA

T CAN HAPPEN

•

Accidental starting of the engine could seriously

injur

e you or other bystanders.

HOW T

•

O AVOID THE HAZARD

Remove the key fr

you do any maintenance.

12

CAUTION

om the ignition switch befor

e

Page 13

Service

Service

Operation

Interval Chart

Hours

8

Storage

Service

Grease fittings

Chipped surfaces–paint

Greasing

and Lubrication

X X

X

Service Interval/Specification

Grease

all fittings every 8 operating hours (Fig. 23). Note

that in most cases the grease fittings are located in the

center of every pivot pin. Grease all fittings immediately

after every washing.

Grease Type: General-purpose grease

How to Grease

1. Stop

2.

3.

4.

the engine and remove the key

Clean the grease fittings with a rag.

Connect a grease gun to each fitting.

Pump grease into the fittings until grease begins to

ooze out of the bearings.

.

m–4587

m–4552

5. W

ipe up any excess grease.

Changing

Figure

the Bucket

23

Orientation

You

can change the angle that the bucket is mounted on

the dipperstick to a position that allows you to dig more

vertically

foundation, or dig a square sided hole. T

orientation, complete the following procedure:

1.

2.

3.

4.

. This will allow you to dig very close to a

o change the

Remove the bolts and nuts securing the upper bucket

pin (Fig. 24).

Remove the pin.

Swing the bucket up, aligning the second set of holes

with the mounting holes on the dipperstick (Fig. 24).

Secure the bucket with the pin, bolt, and nut removed

previously.

13

Page 14

1

m–4589

4

4

The

two valves that control the left and right swing of the

boom are located inside of the controls access panel

(Fig. 26). T

the panel. Adjust both valves equally

o access these valves, remove six locknuts and

. Replace the access

panel when finished.

5

1

2

3

Figure

1. Dipperstick

2. Upper

3. Bolt

Changing

You

bucket pin

the Boom Speed

can change the speed that the boom moves up and

24

4. Nut

5.

Second set of holes

down and left and right by changing the setting of three

speed adjustment valves. The valve that controls the up

and down movement is located on top of the boom (Fig.

14).

3

1

4

5

2

1. Speed

2. Knob

3.

Set screw

Figure

adjustment valve

25

4. Slow

5. Fast

m–4551

Figure

1. Controls

To

adjust the valves, complete the following procedure

access panel

26

and refer to Figure 25.

1.

Loosen the set screw located on the side of the knob

on the valve.

2. T

o increase the speed of the boom, turn the knob

counter-clockwise.

o decrease the speed of the boom, turn the knob

3. T

clockwise.

ighten the set screw

4. T

.

Storage

1.

Before long term storage wash the attachment with

mild deter

2.

Apply grease to all grease fittings.

3.

Check and tighten all bolts, nuts, and screws. Repair or

replace any part that are damaged or worn.

4.

Paint all scratched or bare metal surfaces. Paint is

available from your Authorized Service Dealer

gent and water to remove dirt and grime.

m–4587

.

14

Store the attachment in a clean, dry garage or storage

5.

area. Cover it to protect it and keep it clean.

Page 15

Troubleshooting

p(

yg

PROBLEM POSSIBLE

Backhoe does not operate

CAUSES

1.

Hydraulic coupler not

completely connected

2.

Auxiliary hydraulics valve on

the traction unit is not fully

engaged.

3. T

ransport pins were not

removed.

4.

Hydraulic fluid level is low

5.

Damaged hydraulic coupler

6.

Obstructed hydraulic hose

7.

Pinched hydraulic hose

8.

Auxiliary hydraulic valve on the

traction unit is not opening.

9.

Hydraulic coupler not

completely connected

10.

Bent piston rod

1.

2.

3.

. 4.

5.

6.

7.

8.

9.

10.

CORRECTIVE ACTION

Check and tighten all couplers.

Engage the valve.

Remove the pins.

Fill the traction unit hydraulic

tank.

Check couplers and replace

any that are defective.

Find and remove the

obstruction.

Replace the hose.

Repair the valve.

Check and tighten all couplers.

Contact your Authorized T

Dealer.

oro

Backhoe is operating slowly

Backhoe fails to hold up a load (all

loads will normally settle down

over a long period of time)

Hydraulic oil leakage

1.

Hydraulic oil is cold.

2.

Engine speed is too slow

3.

Speed adjustment valve is set

too slow

4.

Pinched hydraulic hose

5.

Speed adjustment valve is

leaking oil.

6.

Damaged cylinder

7.

Damaged hydraulic pump

1.

Damaged hydraulic hose

2.

Damaged cylinder

3.

Damaged control valve

1.

Damaged hydraulic hose

.

1.

. 2.

3.

4.

5.

6.

7.

1.

2.

3.

1.

Allow the engine to warm the

oil before operating.

Increase the throttle speed of

the traction unit.

Adjust the speed adjustment

valve to obtain the desired

speed.

Replace the hose.

Contact your Authorized T

Dealer.

Contact your Authorized T

Dealer.

Contact your Authorized T

Dealer.

Replace the hose.

Contact your Authorized T

Dealer.

Contact your Authorized T

Dealer.

Replace the hose.

oro

oro

oro

oro

oro

2.

Damaged hydraulic system

15

2.

Contact your Authorized T

Dealer.

oro

Page 16

PROBLEM

gg

jy

POSSIBLE CAUSES

CORRECTIVE ACTION

Swing cylinder malfunctioning

Control valve sticking or working

hard

Backhoe operation is spongy or

jerky

1.

Damaged cylinders, swing

restrictors, or cross-over relief

valve

1.

Dirty hydraulic oil

2.

Damaged or dirty valve

3.

Damaged cylinder

1.

Hydraulic fluid level is low

2.

Air in the hydraulic system

3.

Hydraulic oil is cold.

4.

Pinched hydraulic hose

1.

1.

2.

3.

. 1.

2.

3.

4.

Contact your Authorized T

Dealer.

Change the hydraulic oil.

Contact your Authorized T

Dealer.

Contact your Authorized T

Dealer.

Fill the traction unit hydraulic

tank.

Extend the cylinders as far as

possible and hold them in an

extended position for several

seconds.

Allow the engine to warm the

oil before operating.

Replace the hose.

oro

oro

oro

16

Loading...

Loading...