Page 1

4

in 1 Bucket

Sitework Systems Attachment

Model No. 22411—890001 & Up

Form No. 3323-253

Operator’s Manual

English (CE)

Page 2

Contents

WARNING

or death if the recommended precautions are not followed.

signals a hazard that may cause serious injury

Page

Introduction 2.

Safety 2

Safety Decal3. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Specifications 4

Maximum Material Density at Capacity4. . . . . . . .

Stability Ratings5. . . . . . . . . . . . . . . . . . . . . . . . . . .

Operation 6

Modes of Operation6. . . . . . . . . . . . . . . . . . . . . . . .

Bucket Operation and Controls7. . . . . . . . . . . . . . .

Maintenance 7

Service Interval Chart7. . . . . . . . . . . . . . . . . . . . . .

Storage 7

Troubleshooting 7

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Introduction

W

e want you to be completely satisfied with your new

product, so feel free to contact your local Authorized

Service Dealer for help with service, genuine replacement

parts, or other information you may require.

Whenever you contact your Authorized Service Dealer or

the factory

your product. These numbers will help the Service Dealer

or Service Representative provide exact information about

your specific product. Y

number on a plate located on the back of the bucket.

For your convenience, write the product model and serial

numbers in the space below

, always know the model and serial numbers of

ou will find the model and serial

.

CAUTION

moderate injury if the recommended precautions are not

followed.

wo other words are also used to highlight information.

T

“Important” calls attention to special mechanical

information and “Note” emphasizes general information

worthy of special attention.

The left and right side of the machine is determined by

standing in the normal operator’s position.

signals a hazard that may cause minor or

Safety

Impr

oper use or maintenance by the operator or owner

can r

esult in injury

comply with these safety instructions and those in the

traction unit operator’s manual. Always pay attention

to the safety alert

W

ARNING, or DANGER—“personal safety

instruction.” Failur

may r

esult in personal injury or death.

POTENTIAL HAZARD

• Ther

WHA

•

HOW T

•

e may be buried power

telephone lines in the work ar

T CAN HAPPEN

Shock or explosion may occur

O AVOID THE HAZARD

Have the pr

buried lines and don’t dig in marked ar

. T

o r

educe the potential for injury

symbol, which means CAUTION,

e to comply with the instruction

DANGER

, gas, and/or

ea.

.

operty or work ar

ea marked for

eas.

,

Model No:

Serial No.

The

warning system in this manual identifies potential

hazards and has special safety messages that help you and

others avoid personal injury

W

ARNING and CAUTION are signal words used to

identify the level of hazard. However

hazard, be extremely careful.

DANGER

serious injury or death if the recommended precautions

are not followed.

signals an extreme hazard that will cause

, even death. DANGER,

, regardless of the

The Toro Company – 1999

8111 Lyndale Ave. South

Bloomington, MN 55420–1196

POTENTIAL HAZARD

• Ther

WHA

•

HOW T

•

2

e may be overhead power lines in the work

area.

T CAN HAPPEN

Shock may occur if a power line is touched by a

tr

ee or other object that is being transported.

O AVOID THE HAZARD

Survey and mark the ar

overhead power lines, and do not transport

tr

ees or tall objects under the power lines.

DANGER

ea wher

e ther

e ar

e

All Rights Reserved

Printed in the USA

Page 3

WARNING

CAUTION

POTENTIAL HAZARD

•

When the engine is off, attachments in the

raised position can gradually lower

WHA

T CAN HAPPEN

•

Someone nearby may be pinned or injur

.

ed by

the attachment as it lowers.

HOW T

•

O AVOID THE HAZARD

Always lower the attachment lift each time you

shut off the traction unit.

WARNING

POTENTIAL HAZARD

•

When going up or down hill, the machine could

overturn if the heavy end is toward the

downhill side.

WHA

T CAN HAPPEN

•

Someone may be pinned or seriously injured by

the machine if it overturns.

HOW T

•

O AVOID THE HAZARD

Operate up and down slopes with the heavy end

of the machine uphill. An empty bucket will

make the r

make the fr

ear end heavy and a full bucket will

ont end heavy

.

POTENTIAL HAZARD

•

If the bucket is not kept level while lifting, the

load could be inadvertently dumped on the

operator.

WHA

T CAN HAPPEN

•

The operator could be injur

ed when the load is

dumped.

HOW T

•

Safety

O AVOID THE HAZARD

When lifting the bucket, tilt it forward to keep

it level and pr

event it fr

om spilling backwards.

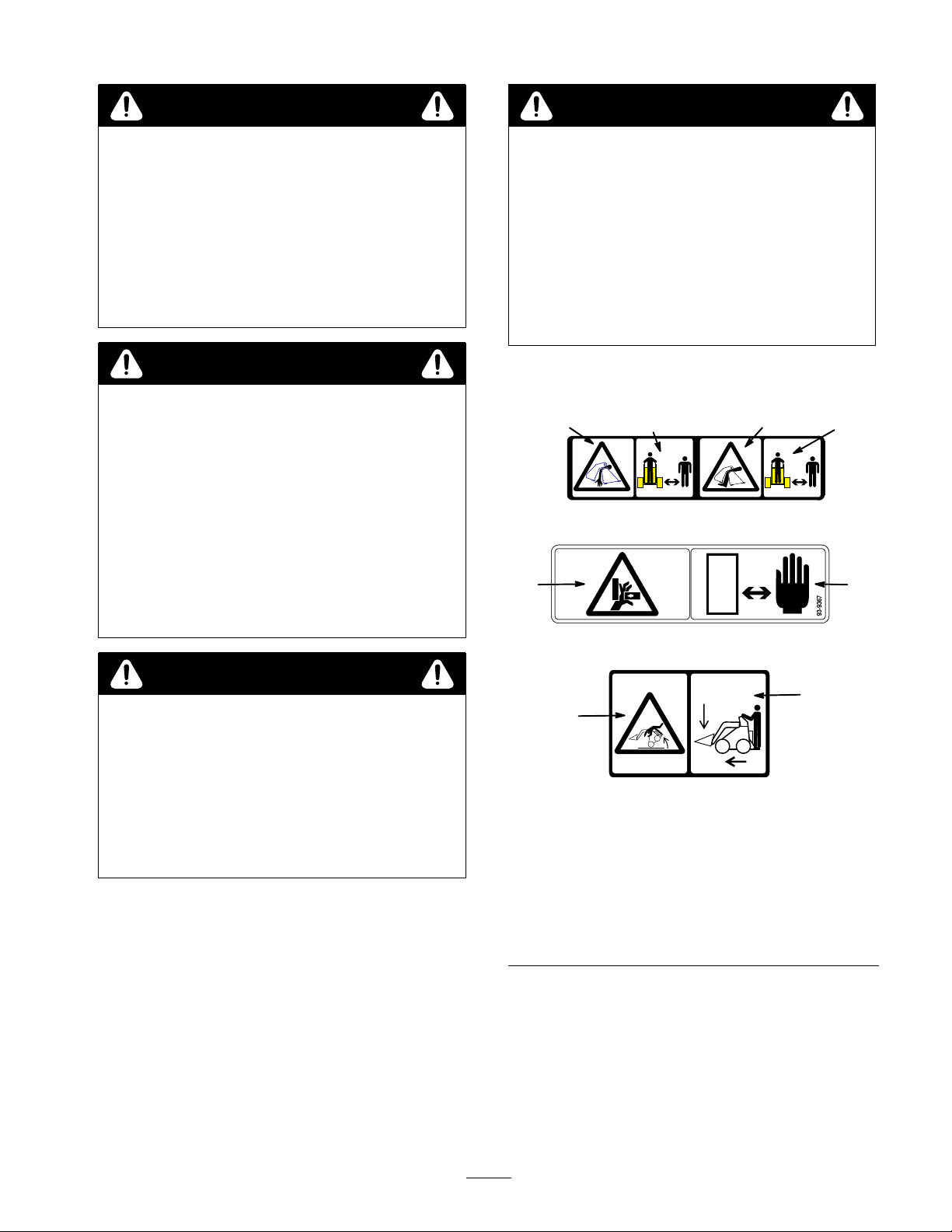

Decal

12

#

100–4648

3

4

2

5

CAUTION

POTENTIAL HAZARD

•

If you step off of the platform with the load

raised, the machine could tip forward.

WHA

T CAN HAPPEN

•

Someone nearby may be pinned or injur

HOW T

•

O AVOID THE HAZARD

Lower the bucket befor

platform.

e stepping off or the

ed.

6

1. Crushing

bucket—hand/arm

2.

Keep bystanders away

3.

Crushing hazard in

bucket—foot/leg

4. Pinching/crushing

hazard—hand

hazard in

# 93–9367

172 Kg

380 lbs

# 100–4689

Figure

1

5.

6.

7.

7

Keep hands away

Machine rollover–

exceeding rated load

capacity can cause

instability

Maximum load capacity

3

Page 4

Specifications

Note:

Specifications and design are subject to change

without notice.

Overall

Overall length

Overall height

Weight

Capacity

(SAE struck capacity)

width

41 inches (105.4 cm)

30.5 inches (77.5 cm)

20 inches (50.8 cm)

271 lbs (123 Kg)

4.3 ft3 (0.12 m3)

Maximum

Material Density at

Capacity

The

density of materials being moved by the bucket varies

and therefore so will the amount of a given material that

can be carried by the bucket before the maximum load

rating is reached. The first table lists the density of

material that can be carried, both heaped and struck (i.e.,

leveled off), in the bucket. Following that is a table

listing common materials and their densities.

T

o move materials with densities greater than the

maximum allowed for the bucket, reduce the volume of

material placed in the bucket.

Hydraulic cylinders (2):

Rod diameter

Stroke

Bore Diameter

1.25 inches (3.175 cm)

4.72 inches (12 cm)

2 inches (51.3 cm)

Material Density Chart

Material Density (Loose)

Caliche

Clay:

Natural bed

Dry

Wet

With gravel, dry 89 lb/ft3 (1420 kg/m3)

With gravel, wet

Coal:

Anthracite, broken 69 lb/ft3 (1

78lb/ft3 (1250 kg/m3)

104 lb/ft3 (1600 kg/m3)

93 lb/ft3 (1480 kg/m3)

104 lb/ft3 (1660 kg/m

96 lb/ft3 (1540 kg/m3)

100 kg/m3)

Maximum Density for Capacity Chart

Bucket

Bucket, heaped

Bucket, struck

Material Density (Loose)

Gravel:

3)

Limestone, broken or

crushed

Sand:

Capacity

Dry

Pit run (graveled sand)

Dry 1/2

(13–51mm)

W

(13–51mm)

et 1/2

I–2I

I–2I

Maximum Density

70 lb/ft3 (11

88 lb/ft3 (1403 kg/m3)

94 lb/ft3 (1510 kg/m3)

120 lb/ft3 (1930 kg/m3)

106 lb/ft3 (1690 kg/m

126 lb/ft3 (2020 kg/m

96 lb/ft3 (1540 kg/m

10 kg/m3)

3)

3)

3)

Bituminous, broken

Earth:

, packed

Dry

et, packed

W

Loam

opsoil, pulverized

T

Granite, broken or

large crushed

*Actual material density will vary from these typical values.

52 lb/ft3

94 lb/ft3 (1510 kg/m3)

100 lb/ft3 (1600 kg/m3)

78 lb/ft3 (1250 kg/m3)

59 lb/ft3 (950 kg/m

104 lb/ft3 (1660 kg/m3)

(830 kg/m3)

3)

4

Dry

Wet 1

With gravel, dry

With gravel, wet

Sandstone, broken

Shale

Slag, broken

Stone, crushed

89 lb/ft3 (1420 kg/m3)

15 lb/ft3 (1840 kg/m3)

107 lb/ft3 (1720 kg/m

126 lb/ft3 (2020 kg/m

94 lb/ft3 (1510 kg/m

78 lb/ft3 (1250 kg/m

109 lb/ft3 (1750 kg/m

100 lb/ft3 (1600 kg/m

3)

3)

3)

3)

3)

3)

Page 5

Stability

To

determine the degree of slope you can traverse with the

bucket installed on a traction unit, find the stability rating

for the hill position you want to travel in the appropriate

table in the section, then find the degree of slope for the

same rating and hill position in the Stability Data section

of the traction unit operator’s manual.

The bucket may be used when loaded or unloaded and, if

you have a traction unit with a rear operator’s platform,

with or without the counterweight on the traction unit.

The following tables reflect the dif

these various conditions.

Note:

If your traction unit does not have rear operator

platform, refer to your traction unit operator’s manual for

more information of counterweights and stability

Ratings

ferences in stability of

’s

.

Stability With a Loaded Bucket Without

the Counterweight

Orientation

Front Uphill

Stability Rating

B

Rear Uphill

D

Side Uphill

WARNING

POTENTIAL HAZARD

•

Exceeding the maximum r

can cause the traction unit to tip.

WHA

T CAN HAPPEN

•

If the traction unit tips, you or bystanders could

be crushed.

HOW T

•

O AVOID THE HAZARD

Do not drive the traction unit on a slope steeper

than the maximum r

determined in the following tables and the

traction unit operator’s manual.

ecommended slope

ecommended slope, as

B

Stability With an Unloaded Bucket

Without the Counterweight

Orientation

Front Uphill

Stability Rating

C

Rear Uphill

C

Side Uphill

B

5

Page 6

Stability With a Loaded Bucket with the

Counterweight

Orientation

Front Uphill

Stability Rating

B

Rear Uphill

D

Side Uphill

B

Stability With an Unloaded Bucket with

the Counterweight

Orientation

Stability Rating

Modes

The

4 in 1 bucket can be used in 4 dif

modes, as follows:

• Bucket

• Blade

Grapple bucket

•

• Leveler

Bucket Operation

With

the jaws together

standard loader bucket. However, by opening the bucket

jaws with a full load, the bucket can dump into a higher

truck, spill out a sticky load, or dribble its contents better

than a standard bucket.

When loading material into the front of the bucket, always

have the bucket level with the ground, moving forward

into the material to be lifted. When the bucket is full, tilt

it gently rearwards to decrease the lifting resistance when

you lift the load.

When transporting a load, keep the bucket as close to the

ground as possible.

of Operation

ferent operating

, this attachment can be used as a

Front Uphill

D

Rear Uphill

B

Side Uphill

B

Operation

Note:

Refer to your traction unit operator’s manual for

complete instructions on installing/removing attachments

onto/from the traction unit and connecting/disconnecting

hydraulic hoses.

Note:

Always use the traction unit to lift and move the

attachment.

Blade Operation

With

the jaws completely open, you can use the back of

the bucket as a blade to push material. Y

partially close the jaws using the bottom of the front

bucket to knock the top off of clumps and grade with the

rear blade.

When scraping, leveling, and surface stripping, lower the

blade to the ground, ensuring that the cutting edge makes

contact. The blade will bite into the soil as you move

forward.

Grapple Bucket Operation

The

jaws can also be used for picking up material by

closing them over the objects or materials to be

transported. This is especially useful for picking the

remnants of a pile of dirt or rocks.

T

ake care when using this method that you don’

object that you are picking up between the jaws. Also,

when grabbing an object of uneven dimensions or one of

center in the bucket, do not apply excessive force or you

may damage the bucket.

Leveler Operation

With

the jaws partially open and the bucket tipped slightly

forward, you can use the bucket as a leveler by moving

the cutting edges back and forth across the surface of the

ground.

ou can also

t crush an

f

6

Page 7

Bucket

1. If

your traction unit has a speed selector and a flow

divider

(rabbit) position and the flow divider to the 10 to 1

o’clock position.

Operation and Controls

, move the speed selector valve to the fast

Maintenance

2.

Pull the auxiliary hydraulics valve to the operator grip

to close the bucket.

3.

Push the auxiliary hydraulics valve away from the

1

operator grip to open the bucket.

Service

Service

Hydraulic hoses—inspect

Chipped surfaces—paint

Interval Chart

Operation

POTENTIAL

•

If you leave the key in the ignition switch, someone could start the engine.

WHA

T CAN HAPPEN

•

Accidental starting of the engine could seriously injur

HOW T

•

Remove the key fr

HAZARD

O AVOID THE HAZARD

om the ignition switch befor

Storage

1.

Before long term storage, wash the attachment with

mild deter

2.

Check and tighten all bolts, nuts, and screws. Repair or

replace any part that is damaged or worn.

gent and water to remove dirt and grime.

Each

Use5Hours25Hours

CAUTION

e you or other bystanders.

e you do any maintenance.

3.

Ensure that all hydraulic couplers are connected

together to prevent contamination of the hydraulic

system.

Paint all scratched or bare metal surfaces. Paint is

4.

available from your Authorized Service Dealer

Store the attachment in a clean, dry garage or storage

5.

area. Cover it to protect it and keep it clean.

200

Hours

X X

Storage

Service

X

Notes

Replace if damaged

.

Troubleshooting

PROBLEM POSSIBLE

Bucket does not open and close.

1.

2.

3.

4.

5.

CAUSES

Hydraulic coupler not

completely connected

Defective hydraulic coupler

An obstruction in a hydraulic

hose

Auxiliary valve on the traction

unit is not opening.

Defective hydraulic cylinder(s)

7

CORRECTIVE ACTION

1.

Check and tighten all couplers.

2.

Check couplers and replace

any that are defective.

3.

Find and remove the

obstruction.

4.

Repair the valve.

5.

Replace or repair any defective

cylinders.

Page 8

Loading...

Loading...