TX1300CompactToolCarrier

22370

KompakterWerkzeugträgerTX1300

22370

Porte-outilcompactTX1300

22370

TX1300compactewerktuigdrager

22370

FormNo.3446-257RevA

www.T oro.com.

*3446-257*

FormNo.3438-963RevA

TX1300CompactToolCarrier

ModelNo.22370—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3438-963*

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

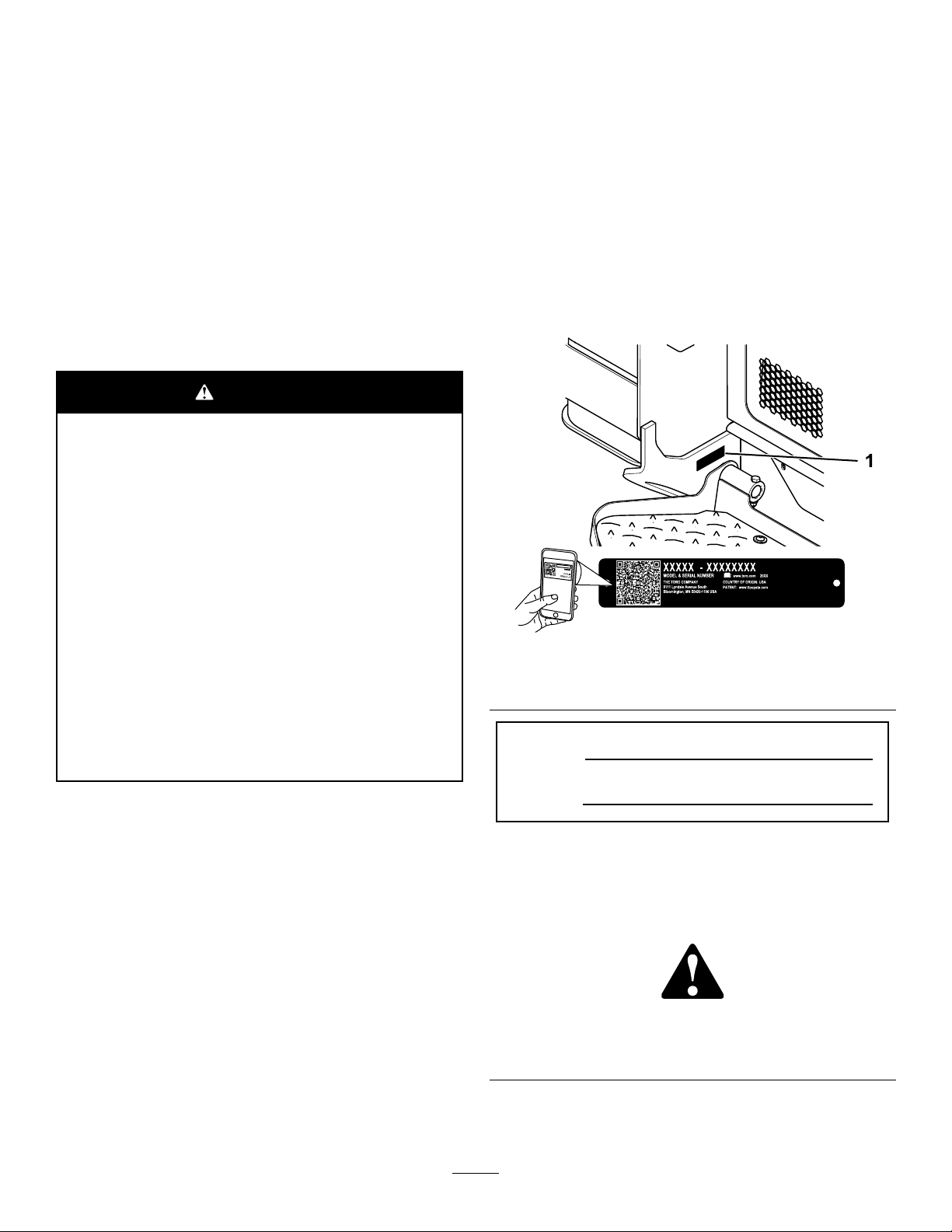

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g362307

Figure1

1.Modelandserialnumberlocation

ModelNo.

Introduction

Thismachineisacompacttoolcarrierintendedfor

useinvariousearthandmaterialsmovingactivitiesfor

landscapingandconstructionwork.Itisdesignedto

operateawidevarietyofattachmentseachofwhich

performaspecializedfunction.Usingthisproduct

forpurposesotherthanitsintendedusecouldprove

dangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

Safety-alertsymbol

Contactusatwww.Toro.com.

2

g000502

PrintedintheUSA

AllRightsReserved

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

ProductOverview....................................................11

Controls...........................................................12

InfoCenterDisplay........................................15

Specications..................................................18

Attachments/Accessories.................................18

BeforeOperation.................................................19

BeforeOperationSafety...................................19

AddingFuel......................................................19

PerformingDailyMaintenance..........................20

DuringOperation.................................................20

DuringOperationSafety...................................20

StartingtheEngine...........................................22

DrivingtheMachine..........................................22

ShuttingOfftheEngine.....................................23

UsingAttachments...........................................23

UnderstandingtheSmartLoadSystem.............25

DieselParticulateFilter(DPF)

Regeneration................................................26

AfterOperation....................................................36

AfterOperationSafety......................................36

RetrievingaStuckMachine..............................36

MovingaNon-FunctioningMachine..................36

HaulingtheMachine.........................................37

LiftingtheMachine...........................................39

Maintenance...........................................................40

MaintenanceSafety..........................................40

RecommendedMaintenanceSchedule(s)...........40

Pre-MaintenanceProcedures..............................42

UsingtheCylinderLocks..................................42

AccessingInternalComponents.......................43

RemovingtheFrontCover................................44

RemovingtheFrontCoverAssembly................45

RemovingtheSideScreens.............................45

Lubrication..........................................................45

GreasingtheMachine.......................................45

EngineMaintenance...........................................46

EngineSafety...................................................46

ServicingtheAirCleaner..................................46

ServicingtheEngineOil....................................47

ServicingtheDiesel-OxidationCatalyst

(DOC)andtheSootFilter..............................49

FuelSystemMaintenance...................................49

DrainingtheWaterSeparator...........................49

ReplacingtheWaterSeparatorFilter................50

CheckingtheFuelLinesand

Connections..................................................50

BleedingtheFuelSystem.................................50

DrainingtheFuelT ank(s)..................................50

ElectricalSystemMaintenance...........................51

ElectricalSystemSafety...................................51

UsingtheBattery-DisconnectSwitch................51

ServicingtheBattery.........................................51

Jump-StartingtheMachine...............................53

ServicingtheFuses..........................................55

DriveSystemMaintenance..................................56

ServicingtheTracks.........................................56

CoolingSystemMaintenance..............................59

CoolingSystemSafety.....................................59

ServicingtheCoolingSystem...........................59

ChangingtheEngineCoolant...........................60

BeltMaintenance................................................60

CheckingtheAlternator-BeltTension................60

ControlsSystemMaintenance.............................61

AdjustingtheControls.......................................61

HydraulicSystemMaintenance...........................61

HydraulicSystemSafety...................................61

RelievingHydraulicPressure............................61

Hydraulic-FluidSpecications..........................62

CheckingtheHydraulic-FluidLevel...................62

ReplacingtheHydraulicFilters.........................63

ChangingtheHydraulicFluid............................63

LoaderMaintenance............................................64

TorquingtheLoaderArmAdjustment

Screws..........................................................64

Cleaning..............................................................64

RemovingDebris..............................................64

WashingtheMachine.......................................64

CleaningtheChassis........................................65

Storage...................................................................65

StorageSafety..................................................65

Storage.............................................................65

Troubleshooting......................................................66

3

Safety

componentsandattachments.

•Keepyourhandsandfeetawayfromthemoving

Thismachinehasbeendesignedinaccordancewith

ISO20474-15:2019.

GeneralSafety

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

•Donotexceedtheratedoperatingcapacity,asthe

machinemaybecomeunstable,whichmayresult

inlossofcontrol.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsawayfromthemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury .T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

,which

•Donottransportaloadwiththearmsraisedor

extended;alwaystransportloadsclosetothe

ground,withtheloaderarmsretracted.

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Operatethemachineupanddownslopes

withtheheavyendofthemachineuphilland

theloadclosetothegroundandtheloader

armsretracted.Weightdistributionchangeswith

attachments.Anemptyload-bearingattachment

makestherearofthemachinetheheavyend,

andafullload-bearingattachmentmakesthe

frontofthemachinetheheavyend.Mostother

attachmentsmakethefrontofthemachinethe

heavyend.

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

4

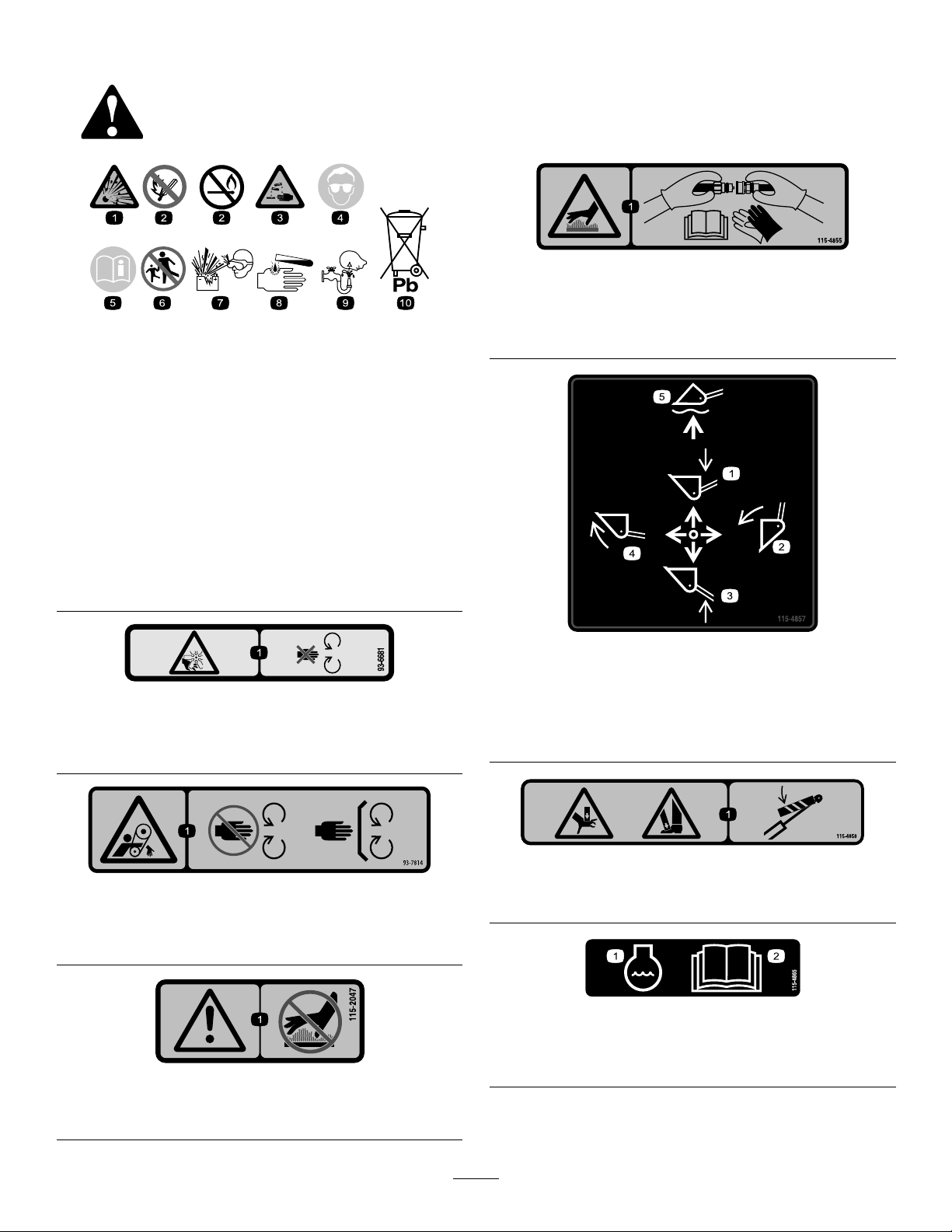

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal115-4855

115-4855

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard6.Keepbystandersaway

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

fromthebattery .

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

93-6681

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts.

decalbatterysymbols

handlingthehydrauliccouplersandreadtheOperator's

Manualforinformationonhandlinghydrauliccomponents.

1.Hotsurface/burnhazard—wearprotectivegloveswhen

decal115-4857

115-4857

decal93-6681

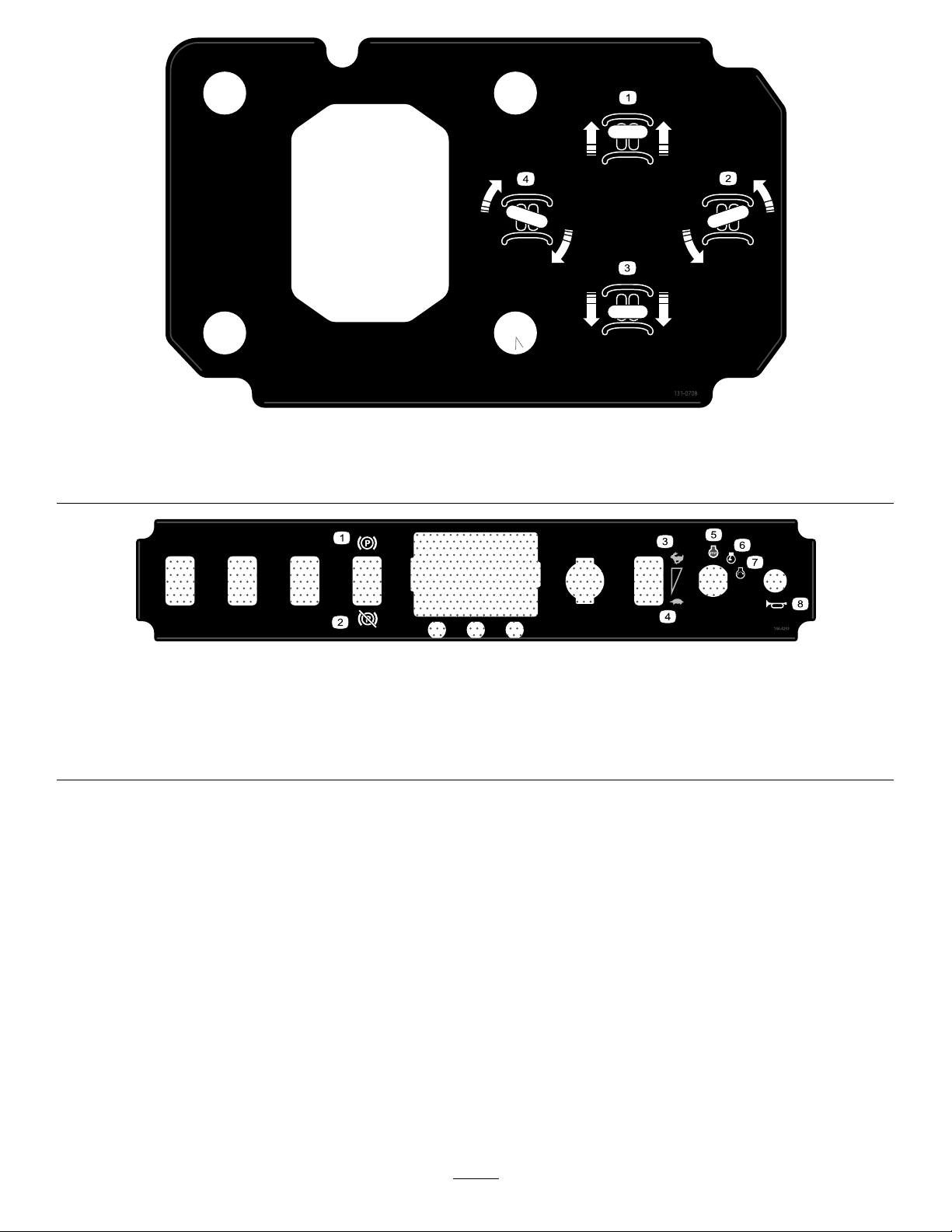

1.Lowertheloaderarms.

2.Dumpthebucket.5.Floatthebucketonthe

3.Raisetheloaderarms.

4.Curlthebucket.

ground.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts;

keepallguardsandshieldsinplace.

115-2047

1.Warning—donottouchthehotsurface.

decal115-4858

decal93-7814

115-4858

1.Crushinghazardofhandsorfeet—installthecylinderlock.

decal115-4865

115-4865

1.Enginecoolant

decal115-2047

2.ReadtheOperator's

Manual.

5

decal117-3276

117-3276

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

120-0625

1.Pinchpoint,hand—keephandsaway.

122-1925

1.Torqueto2.82to3.16N∙m(25to28in-lb)

decal125-6694

125–6694

1.Tiedownlocation

decal120-0625

decal125-8483

125-8483

1.Hydraulicuid;readtheOperator’sManual.

decal122-1925

1.Liftpoint

decal125-4967

125-4967

6

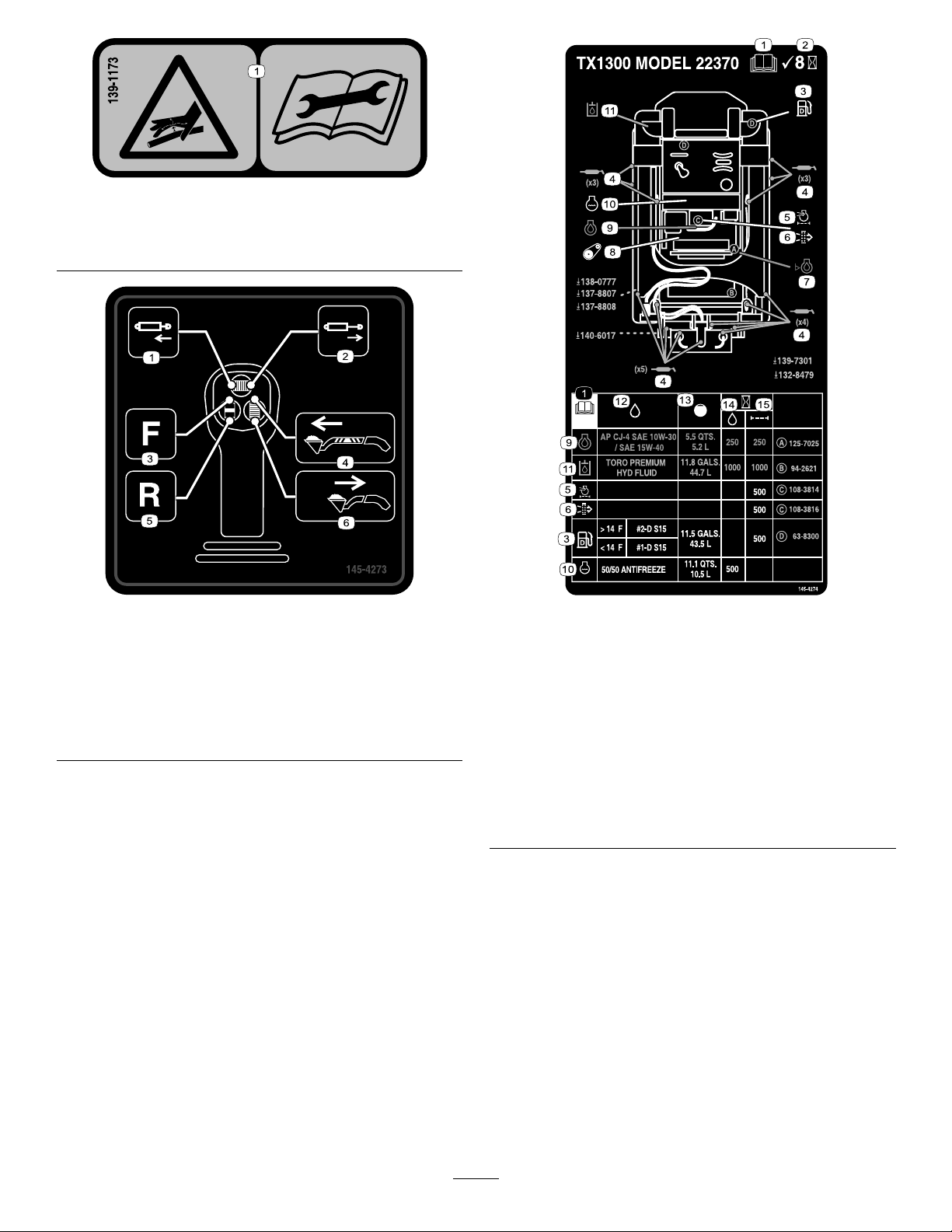

139-1159

1.Warning—keepbystandersaway.

decal139-1159

131-8026

1.Battery

power—disconnect

2.Off4.ReadtheOperator's

3.On

133-8062

137-5409

Manual.

decal131-8026

decal139-1162

139-1162

1.Warning—readthe

Operator’sManualfor

thebucketmaximum

weightlimit.

decal133-8062

decal137-5409

2.Tippinghazard—donot

drivethemachinewiththe

loadraisedorthearms

extended;carrytheload

closetothegroundwith

thearmsretractedwhen

driving.

139-1158

1.Crushinghazard,fromabove,andpinchinghazard—stay

awayfromthebucketandloadingarms.

decal139-1158

decal139-1164

139-1164

1.Crushinghazardfromabove,fallingload—ensurethatthe

quick-attachleversarelocked.

7

139-1173

1.High-pressureuidhazard,injectionintothebody—read

theOperator’sManualbeforeperformingmaintenance.

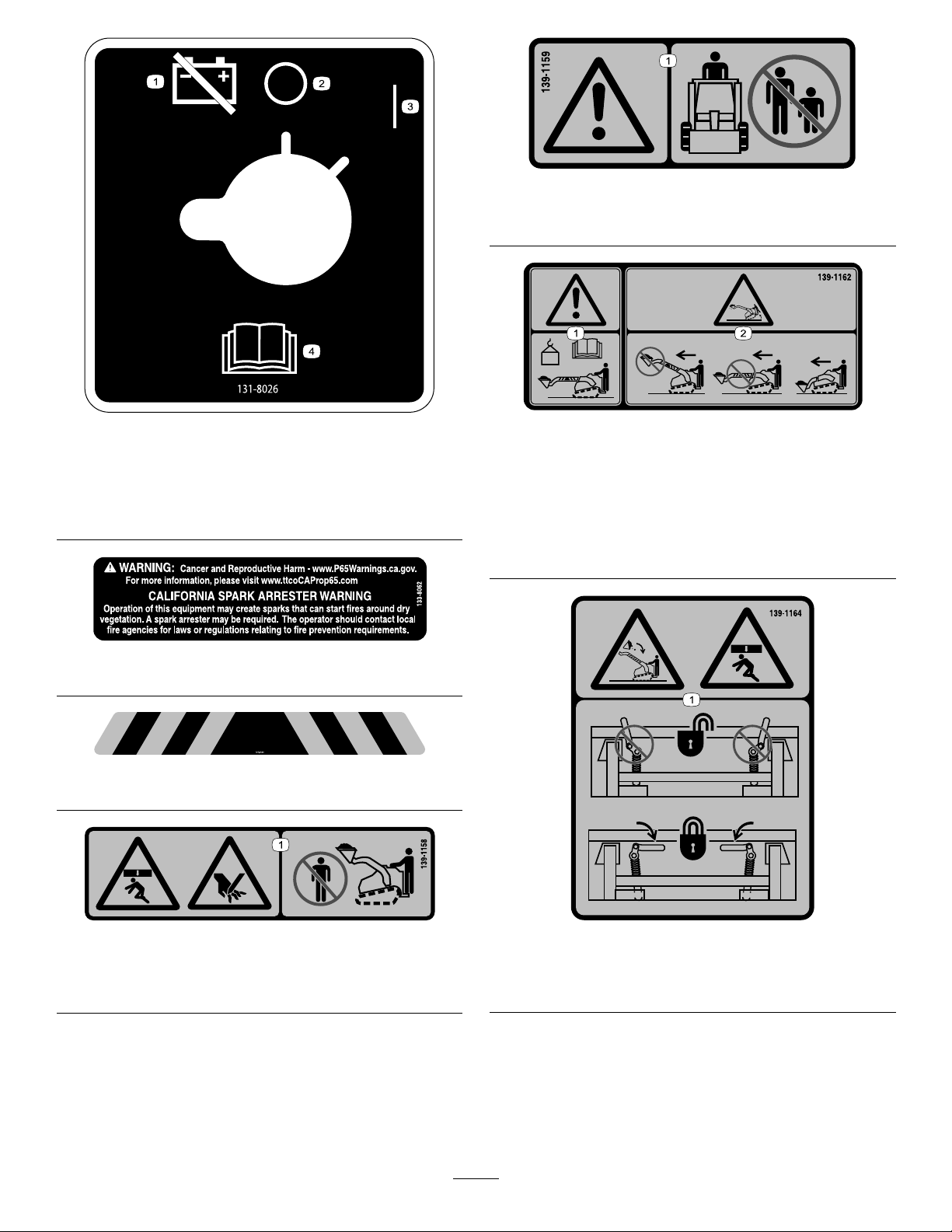

decal139-1173

1.Retractthehydraulic

cylinder(optional)

2.Extendthehydraulic

cylinder(optional)

3.Attachmentow—Forward

145-4273

4.Extendthearms

(telescopingmodelonly)

5.Attachment

ow—Reverse

6.Retractthearms

(telescopingmodelonly)

decal145-4273

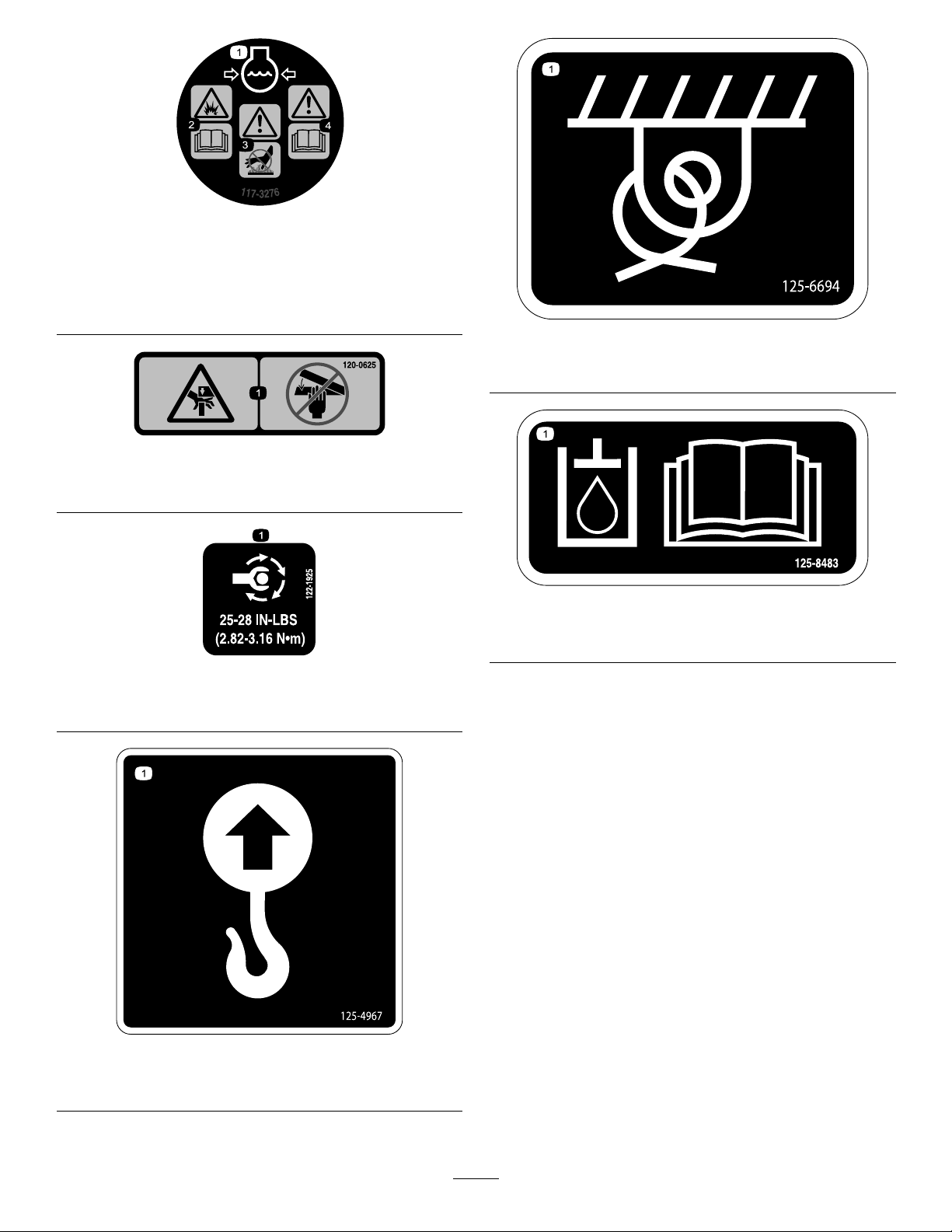

decal145-4274

145-4274

1.ReadtheOperator’s

Manualbeforeperforming

maintenance.

2.Checkevery8hours

3.Fuel

4.Greasepoints

5.Engineairlter13.Capacity

6.Safetyairlter14.Fluidinterval(hours)

7.Engineoillevel

8.Belttension

9.Engineoil

10.Enginecoolant

11.Hydraulicuid

12.Fluids

15.Filterinterval(hours)

8

decal131-0708

131-0708

1.Moveforward

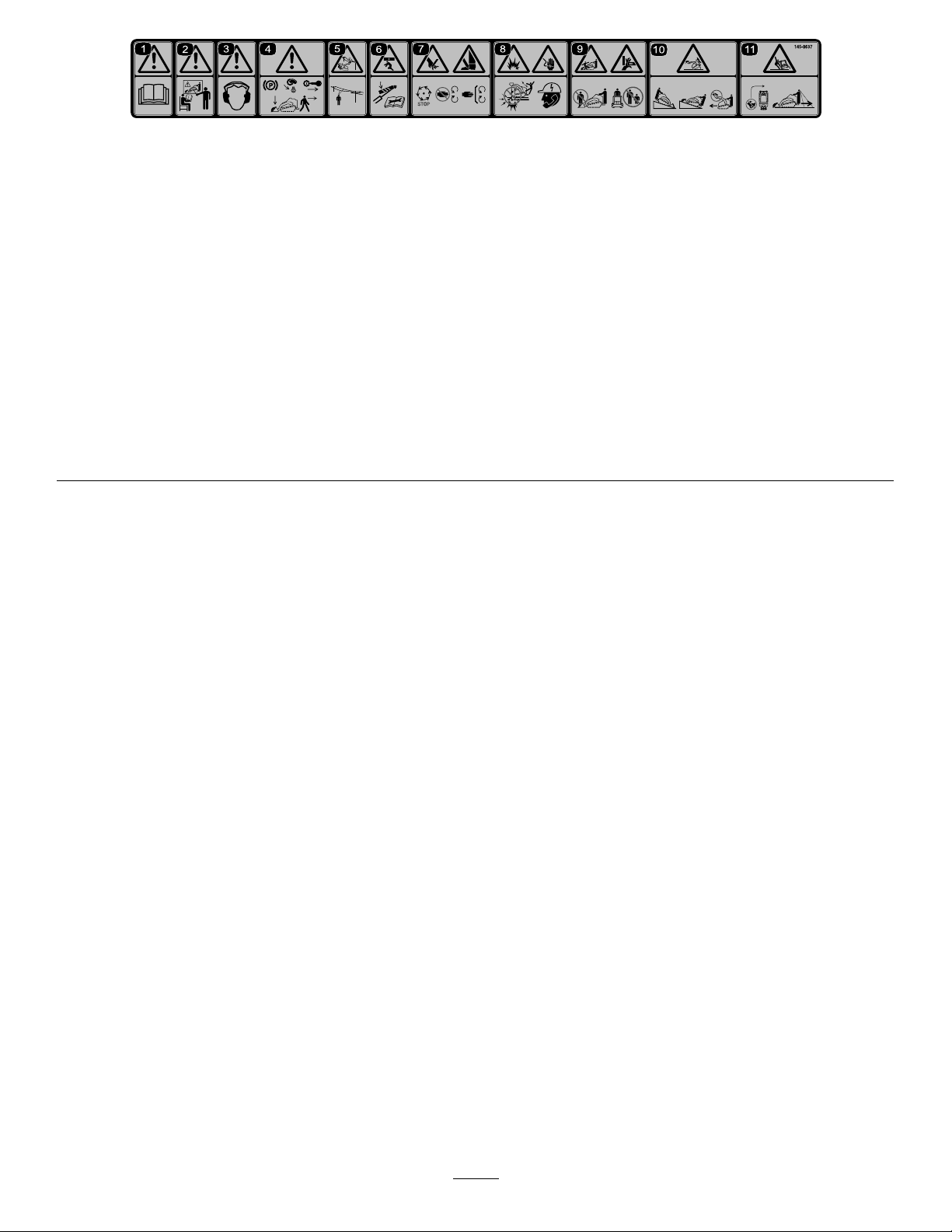

2.Turnleft

1.Parkingbrake—engaged5.Engine—stop

2.Parkingbrake—disengaged6.Engine—run

3.Fast7.Engine—start

4.Slow

3.Moverearward

4.Turnright

decal144-4253

144-4253

8.Horn

9

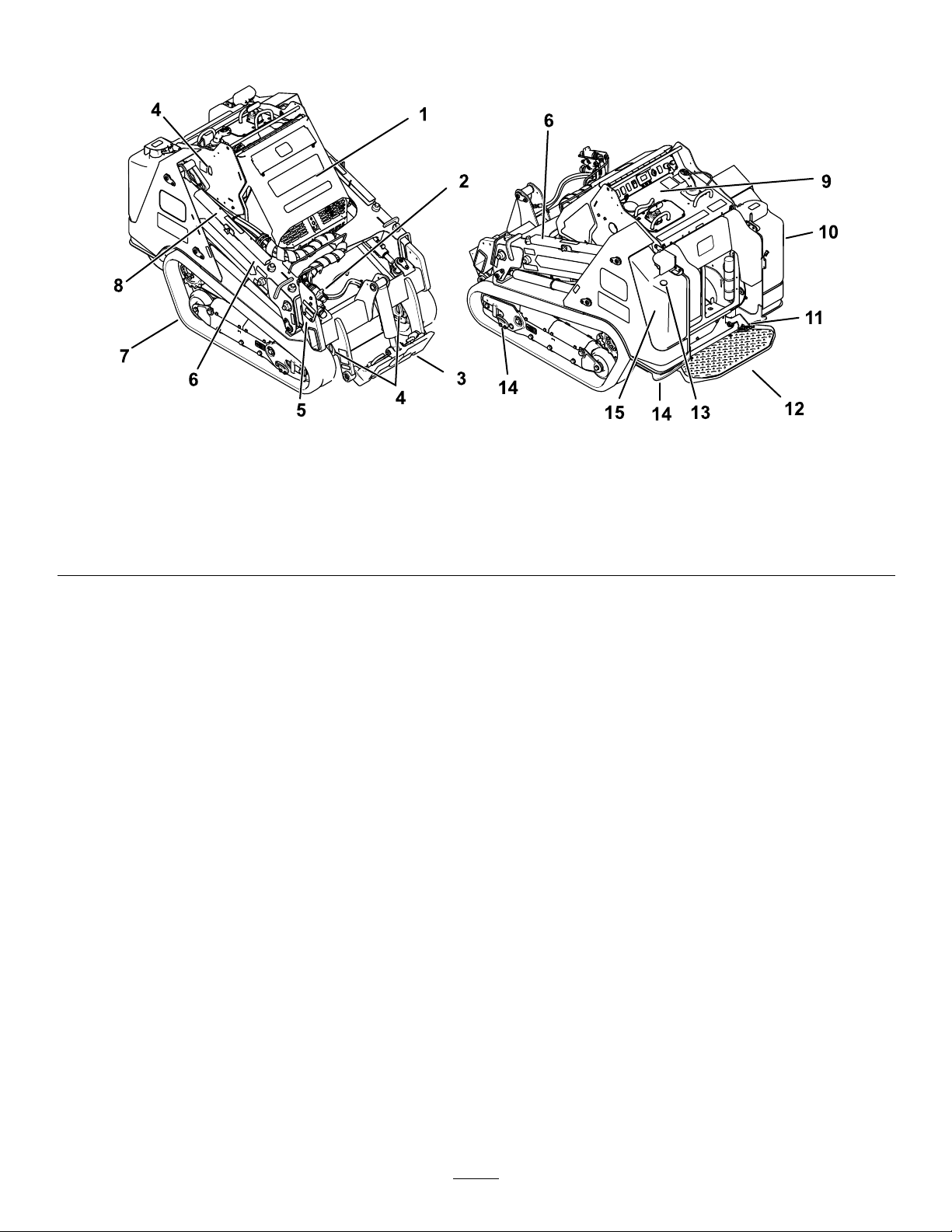

decal145-0637

145-0637

1.Warning—readtheOperator'sManual.7.Cutting/severinghazardofhandorfoot—waitforallmoving

partstostopbeforeservicing;keepawayfrommovingparts;

keepallguardsandshieldsinplace.

2.Warning—receivetrainingbeforeoperatingthemachine.

8.Explosionhazard;electrocutionhazard—callthelocalutilities

hotlinebeforebeginningworkinanarea.

3.Warning—wearhearingprotection.

9.Crushinghazard—keepawayfromtheattachmentwhen

operatingthemachine;keepbystandersawayfromthe

machine.

4.Warning—engagetheparkingbrake,lowertheattachmentto

theground,shutofftheengine,andremovethekeyfromthe

ignitionbeforeleavingthemachine.

10.Tippinghazard—alwaysmoveupordownslopeswith

theattachmentlowered;neverdriveonaslopewiththe

attachmentraised;alwaysoperatewiththeheavyenduphill;

alwayscarryloadslow;neverjerkthecontrollevers;use

asteady,evenmotion.

5.Electrocutionhazard,powerlines—checkforpowerlinesin

theareabeforeusingthemachine.

11.Tippinghazard—donotmakefastturns;alwayscheckbehind

youbeforereversingthemachine.

6.Crushinghazard—keepawayfrompinchpoints;read

theOperator'sManualbeforeservicingorperforming

maintenance.

10

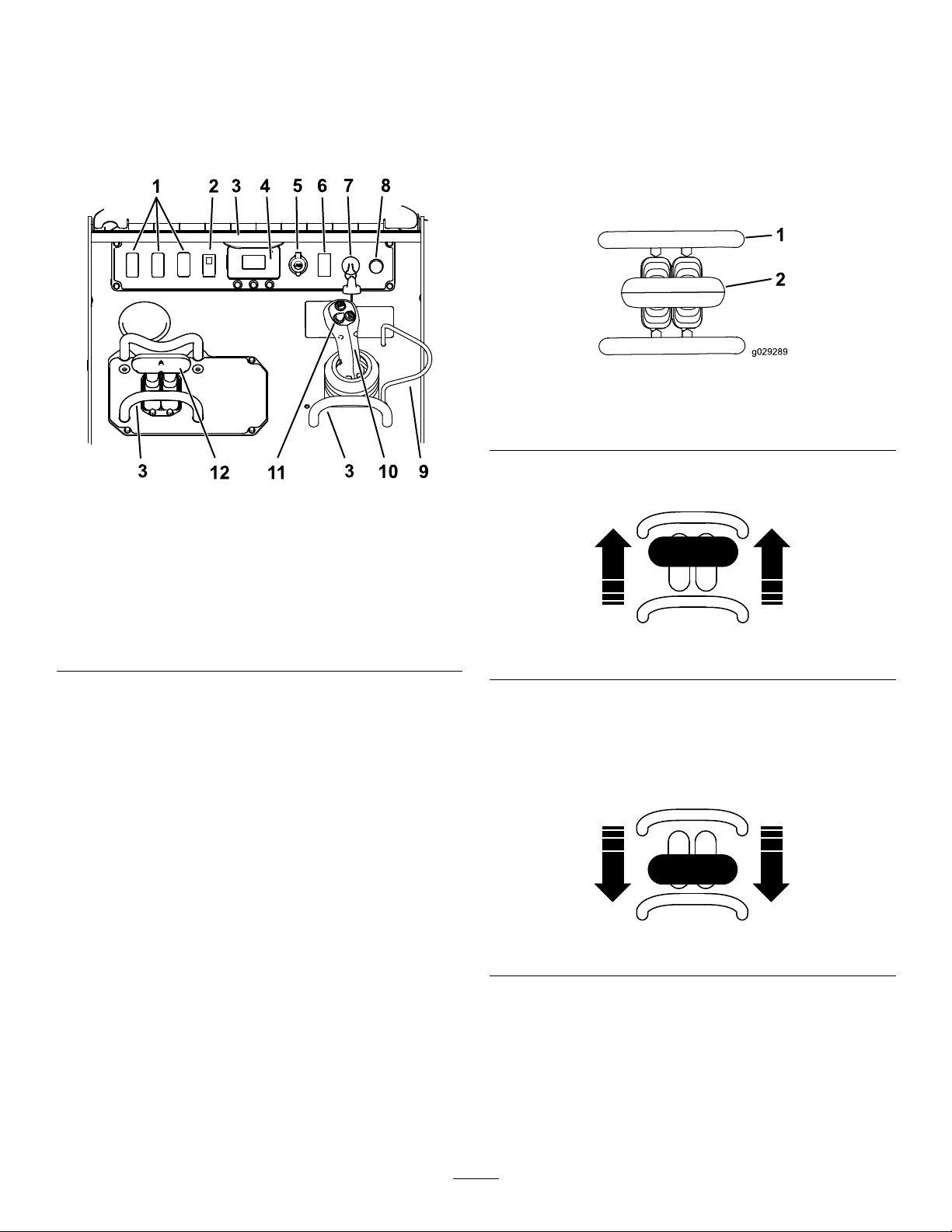

ProductOverview

g318043

Figure3

1.Hood5.Lowerloaderarm

2.Auxiliaryhydrauliccouplers6.Upperloaderarm10.Hydraulictank14.Tie-downpoint

3.Mountplate7.Track11.Auxiliaryhydraulicslock

4.Liftpoint8.Cylinderlock12.Operatorplatform

9.Controlpanel

switch

13.Fuelgauge

15.Fueltank

11

Controls

ControlPanel

Becomefamiliarwithallthecontrolsbeforeyoustart

theengineandoperatethetractionunit.

ReferenceBar

Whendrivingthetractionunit,usethereferencebar

asahandleandaleveragepointforcontrollingthe

tractioncontrolandthejoysticklever.T oensure

smooth,controlledoperation,donottakeyourhands

offthereferencebarswhileoperatingthemachine.

TractionControl

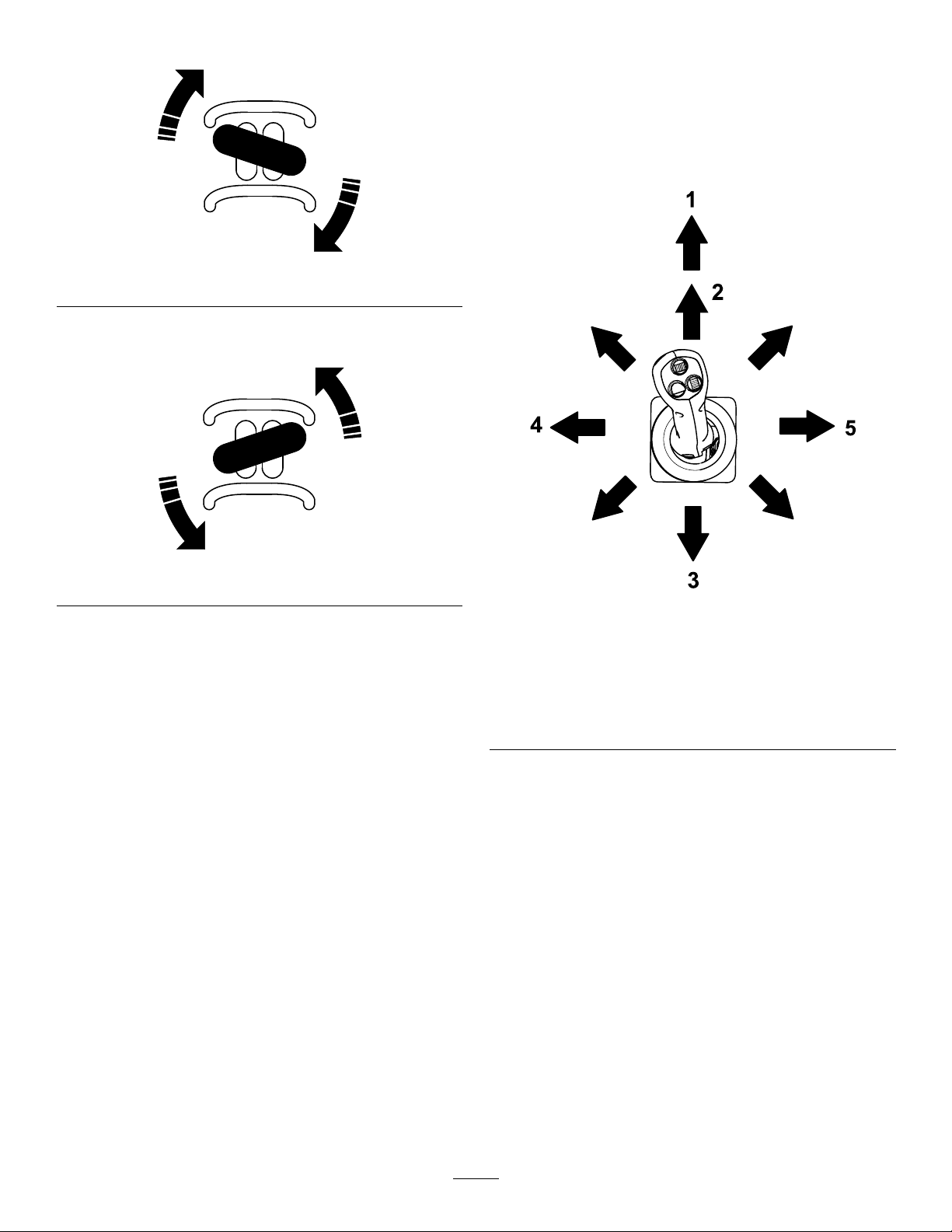

g029289

Figure5

1.Referencebar

2.Tractioncontrol

Figure4

1.Plugforoptionalkit

2.Parkingbrakeswitch

3.Referencebar

4.InfoCenterDisplay10.Loaderarm/attachment-tilt

5.Powersocket1 1.Joystickcontrols

6.Throttleswitch12.Tractioncontrol

7.Keyswitch

8.Horn

9.Loader-valvelock

lever

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andSTART.

Parking-BrakeSwitch

Presstheparking-brakeswitchtoengageand

disengagetheparkingbrake.Theparkingbrakealso

engagesautomaticallywhenyoushutoffthemachine.

ThrottleSwitch

g318044

•Tomoveforward,movethetractioncontrol

forward.

g264830

Figure6

•Tomoverearward,movethetractioncontrol

rearward.

Important:Whenreversing,lookbehindyou

forobstructionsandkeepyourhandsonthe

referencebar.

g264831

Figure7

Holdtheswitchforwardfor2ormoresecondstoset

thethrottleatHIGHIDLE;holdtheswitchrearwardfor

2ormoresecondstosetthethrottleatLOWIDLE;

ormomentarilypresstheswitchineitherdirectionto

increaseordecreasetheenginespeedinsmaller

increments.

12

•Toturnright,rotatethetractioncontrolclockwise.

Figure8

•Toturnleft,rotatethetractioncontrol

counterclockwise.

LoaderArm/Attachment-TiltLever

Slowlymovethelevertooperatetheloaderarmsand

tilttheattachment.

Note:Thedetent(oat)positionallowsattachments

suchasthelevelerandthehydraulicbladetofollow

thecontoursoftheground(i.e.,oat)whengrading.

g264833

Figure9

•Tostopthemachine,releasethetractioncontrol.

Note:Thefartheryoumovethetractioncontrolin

anydirection,thefasterthemachinemovesinthat

direction.

g264832

g358629

Figure10

1.Detent(oat)

position—pushthelever

fullyforward.

2.Lowertheloaderarms.5.Tilttheattachment

3.Raisetheloaderarms.

4.Tilttheattachment

rearward.

forward.

Bymovingthelevertoanintermediateposition(e.g.,

forwardandleft),youcanmovetheloaderarmsand

tilttheattachmentatthesametime.

13

Loader-ValveLock

Theloader-valvelocksecurestheloader

arm/attachment-tiltleversothatyoucannotpushit

forward.Thishelpstoensurethatnooneaccidentally

lowerstheloaderarmsduringmaintenance.Secure

theloadervalvewiththelock,inadditiontothe

cylinderlocks,anytimeyouneedtoshutoffthe

machinewiththeloaderarmsraised.RefertoUsing

theCylinderLocks(page42).

Tosetthelock,liftitsothatitclearstheholeinthe

controlpanelandswinginfrontoftheloader-arm

lever.Pushitdownintothelockedposition.

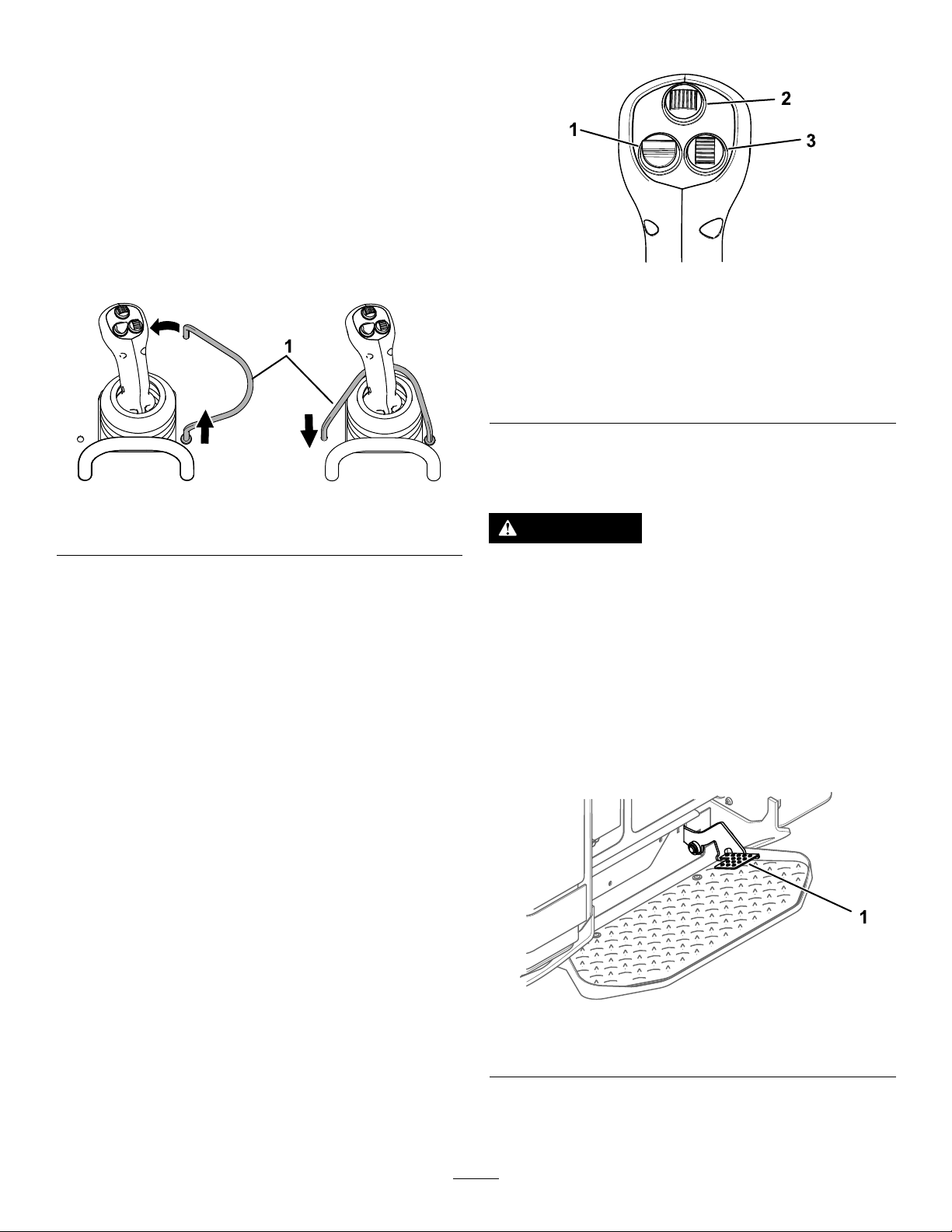

JoystickControls

g318281

Figure12

1.Loader-valvelock

Figure11

1.Attachmentprimary

function(hydraulic

attachmentsonly)

2.Attachmentsecondary

function(certain

attachmentsonly)

3.Extendandretractthe

loaderarms

Note:Theloaderarmsmaynotextendwhenthey

arefullyraisedduetotrappedpressure;lowerthe

g358630

armsslightlytorelievepressureandextendthem.

WARNING

Movingthemachinewhiletheloaderarms

areextendedmayaffectthestabilityofthe

machine.

Minimizemachinemovementwhiletheloader

armsareextended.

Auxiliary-HydraulicsLockSwitch

Engagetheforwardorreversehydraulics,thenuse

yourrightfoottopressthelockswitchtocontinuethe

owandfreeyourhandforothercontrols.

1.Auxiliary-hydraulicslockswitch

14

g358628

Figure13

FuelGauge

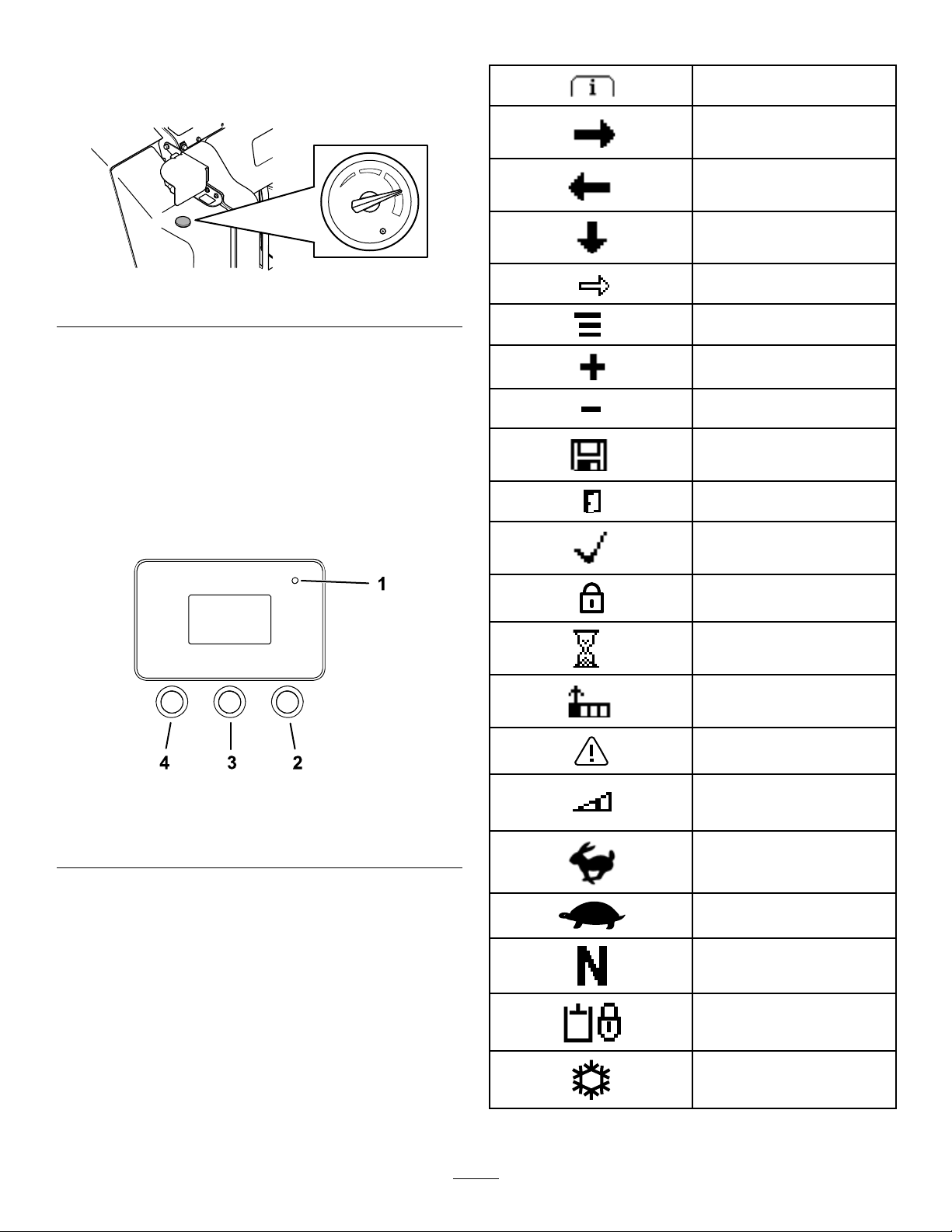

InfoCenterIconDescriptions

Thisgaugemeasurestheamountoffuelinthefuel

tank(s).

Figure14

InfoCenterDisplay

TheInfoCenterLCDdisplayshowsinformationabout

yourmachine,suchastheoperatingstatus,various

diagnosticsandotherinformationaboutthemachine.

Thereisasplashscreenandmaininformationscreen

oftheInfoCenter.Y oucanswitchbetweenthesplash

screenandmaininformationscreenatanytimeby

pressinganyoftheInfoCenterbuttonsandthen

selectingtheappropriatedirectionalarrow.

Menuaccess

Next

Previous

Scrolldown

g371278

Enter

Changethenextvalueinthe

list

Increase

Decrease

Savevalue

Exitmenu

Accept

Figure15

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•LeftButton,MenuAccess/BackButton—pressthis

buttontoaccesstheInfoCentermenus.Youcan

useittoexitanymenuthatyouarecurrentlyusing.

•MiddleButton—usethisbuttontoscrolldown

menus.

•RightButton—usethisbuttontoopenamenu

wherearightarrowindicatesadditionalcontent.

Theoptionislocked.

Hourmeter

Adjustdigit

Warning

g264015

Transport-speedscreen

access

Fast

Slow

Neutral

Auxiliarylock

Note:Thepurposeofeachbuttonmaychange

dependingonwhatisrequiredatthetime.Each

buttonislabeledwithanicondisplayingitscurrent

function.

Coldstart

15

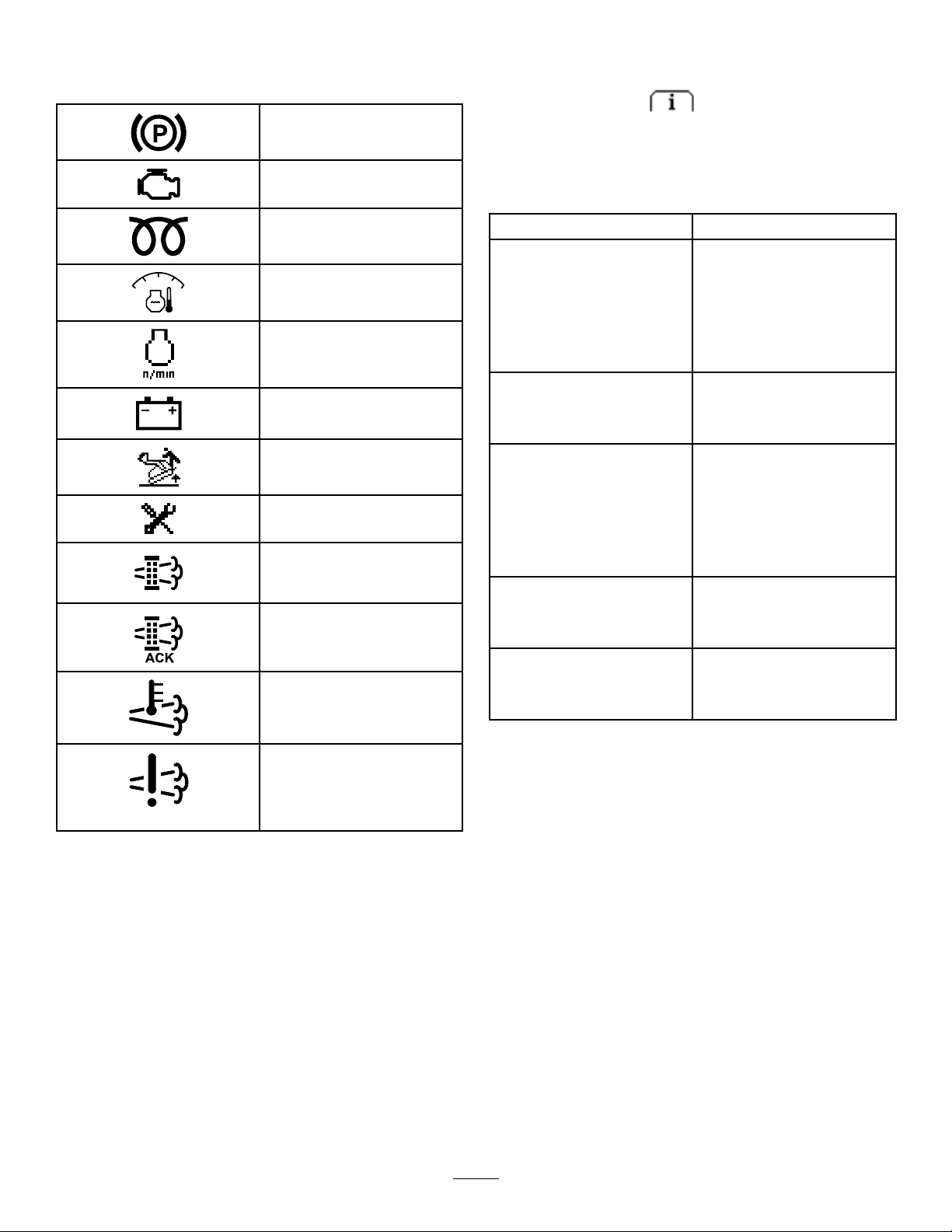

InfoCenterIconDescriptions(cont'd.)

UsingtheMenus

ToaccesstheInfoCentermenusystem,pressthe

Parkingbrake

Engine

Glowplugs

Engine-coolanttemperature

Enginespeed

Batteryvoltage

SmartLoadisactive.

Indicateswhenscheduled

serviceshouldbeperformed

DPFregenerationisrequired.

Aparkedorrecovery

regenerationisprocessing.

Highexhausttemperature

menuaccessbuttonwhileatthemainscreen.

Thiswillbringyoutothemainmenu.Refertothe

followingtablesforasynopsisoftheoptionsavailable

fromthemenus:

MainMenu

MenuItemDescription

FaultsTheFaultsmenucontains

alistoftherecentmachine

andenginefaults.Referto

theServiceManualoryour

AuthorizedServiceDealerfor

moreinformationontheFaults

menuandtheinformation

containedthere.

ServiceTheServicemenucontains

informationonthemachine

suchashoursofuseandother

similarnumbers.

DiagnosticsTheDiagnosticsmenu

displaysthestateofeach

machineswitch,sensorand

controloutput.Y oucanuse

thistotroubleshootcertain

issuesasitwillquicklytellyou

whichmachinecontrolsareon

andwhichareoff.

SettingsTheSettingsmenuallows

youtocustomizeandmodify

congurationvariablesonthe

InfoCenterdisplay.

AboutTheAboutmenuliststhe

modelnumber,serialnumber,

andsoftwareversionofyour

machine.

NOxcontroldiagnosis

malfunction;drivethemachine

backtotheshopandcontact

yourAuthorizedService

Dealer.

16

Service

Settings

MenuItemDescription

Hours

CountsListsthenumberofstartsthat

DPFRegenerationTheDPFregenerationoption

InhibitRegenUsetocontrolreset

ParkedRegenUsetoinitiateaparked

LastRegenListsthenumberhourssince

RecoverRegenUsetoinitiatearecovery

Liststhetotalnumberofhours

thatthemachine,engine,and

auxiliaryhydraulicshavebeen

on,aswellasthenumberof

hoursforengineserviceand

hydraulicservice.

themachinehasexperienced,

thenumberoftimesthe

machinehaswarnedthatthe

enginetemperatureistoo

high,andthenumberoftimes

theenginehasshutoffdueto

hightemperatures.

andDPFsubmenus.

regeneration.

regeneration.

thelastreset,parked,or

recoveryregeneration.

regeneration.

Diagnostics

MenuItemDescription

Units

Language

Brightness

ContrastControlsthecontrastofthe

ProtectedMenus

ProtectSettingsChangeswhetherapinis

Controlstheunitsusedonthe

InfoCenter;themenuchoices

areImperialorMetric.

Controlsthelanguageused

ontheInfoCenter.

Controlsthebrightnessofthe

LCDdisplay.

LCDdisplay.

Grantsaccesstoprotected

menus.

requiredinProtectedMenus.

About

MenuItemDescription

Model

SerialListstheserialnumberofthe

SoftwareListsthesystemsoftware

Display

Liststhemodelnumberofthe

machine

machine

revisionofthemachine.

Liststhedisplaysoftware

revisionoftheInfoCenter.

MenuItemDescription

TractionIndicatestheinputsand

outputsfordrivingthe

machine.

AuxiliaryIndicatestheinputsand

outputsforengagingauxiliary

hydraulics.

EngineIndicatestheinputsand

outputsforstartingtheengine.

BoomIndicatestheinputsand

outputsforextendingand

retractingthetelescoping

arms.

AccessingProtectedMenus

Note:ThefactorydefaultPINcodeforyoumachine

iseither0000or1234.

IfyouchangedthePINcodeandforgotthecode,

contactyourAuthorizedServiceDealerforassistance.

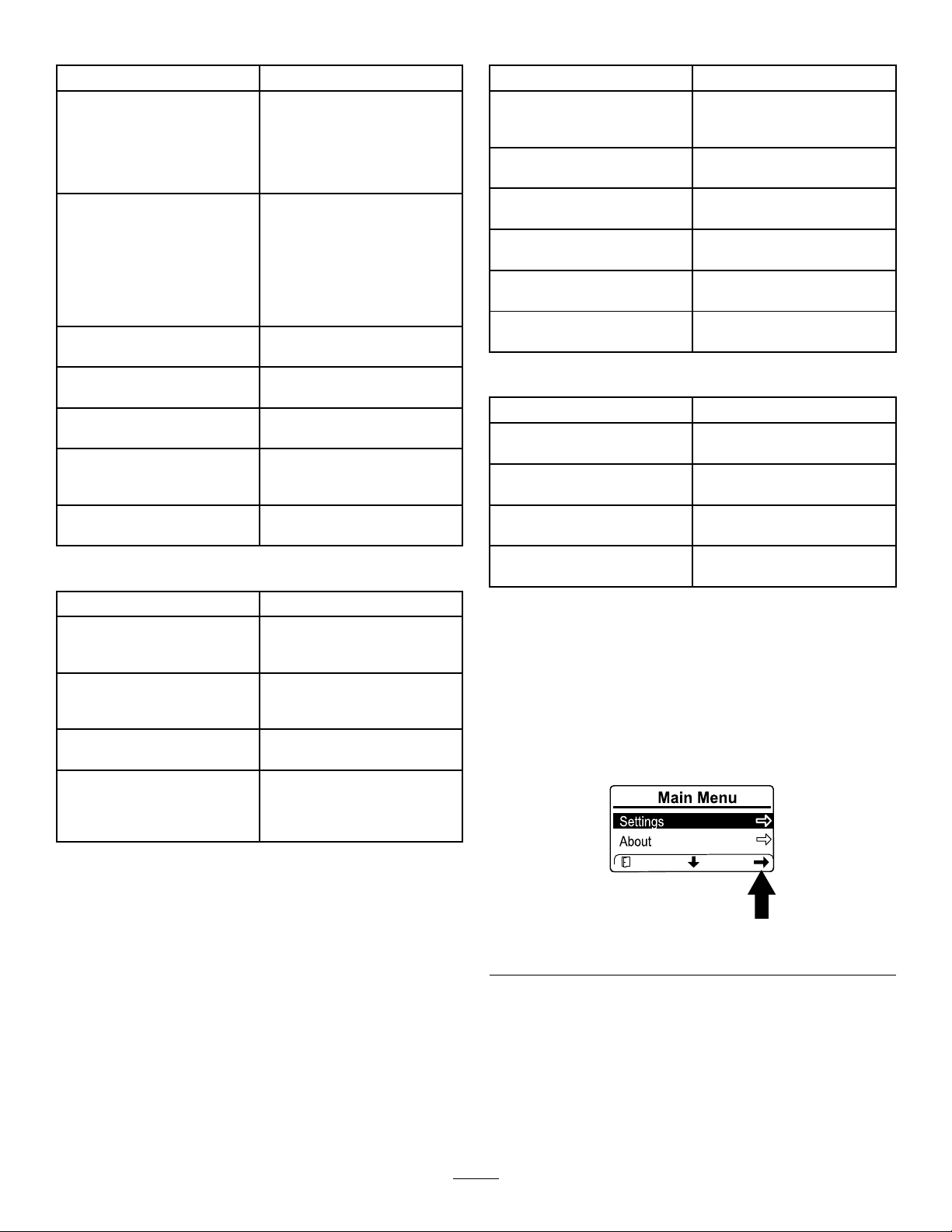

1.FromtheMAINMENU,scrolldowntothe

SETTINGSMENUandpresstherightbutton.

g364600

Figure16

17

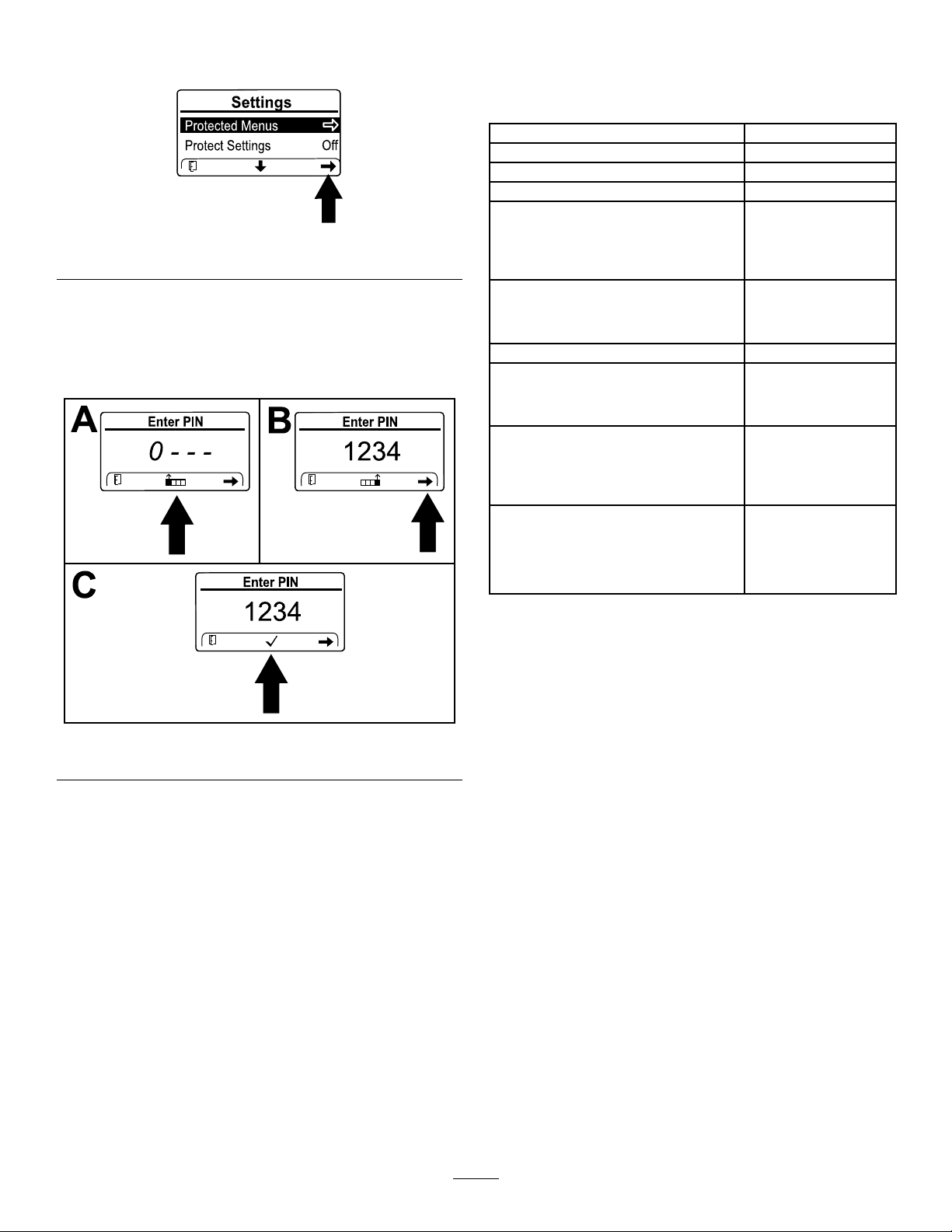

2.IntheSETTINGSMENU,scrolldowntothe

PROTECTEDMENUandpresstherightbutton.

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Figure17

3.ToenterthePINcode,pressthecenterbutton

untilthecorrectrstdigitappears,thenpress

therightbuttontomoveontothenextdigit.

Repeatthisstepuntilthelastdigitisenteredand

presstherightbuttononcemore.

Width

Length

Height

Weight

Operatingcapacity(35%oftipping

g364601

capacity

1

)

•Armsretracted

•Armsextended

Tippingcapacity

1

•Armsretracted

•Armsextended

Wheelbase

Dumpheight(withstandardbucket)

•Armsretracted

•Armsextended

Reach—fullyraised(withstandard

bucket)

•Armsretracted

•Armsextended

Heighttohingepin(withstandard

bucketinhighestposition)

•Armsretracted

•Armsextended

116.8cm(46.0inches)

215.6cm(84.9inches)

143.5cm(56.5inches)

1750kg(3858lb)

589.7kg(1300lb)

280kg(618lb)

1685kg(3714lb)

792kg(1746lb)

99.1cm(39.0inches)

180.1cm(70.9inches)

230.3cm(90.7inches)

33.5cm(13.2inches)

67.8cm(26.7inches)

227.1cm(89.4inches)

277.3cm(109.2

inches)

Figure18

4.PressthemiddlebuttontoconrmthePINcode.

Note:IftheInfoCenteracceptsthePINcode

andtheprotectedmenuisunlocked,theword

“PIN”displaysintheupperrightcornerofthe

screen.

Youcanviewandchangethesettingsinthe

PROTECTEDMENU.OnceyouaccessthePROTECTED

MENU,scrolldowntoPROTECTSETTINGSoption.

Usetherightbuttontochangethesetting.Setting

theProtectSettingstoOFFallowsyoutoviewand

changethesettingsinthePROTECTEDMENUwithout

enteringthePINcode.SettingtheProtectSettings

toONhidestheprotectedoptionsandrequiresyou

toenterthePINcodetochangethesettinginthe

PROTECTEDMENU.

1.Theoperatingcapacityiscalculatedas35%ofthetippingcapacitywith

astandardbucketand75kg(165lb)operator,perISO14397-1.Other

attachmentswillhavedifferentoperatingcapacities;refertotheOperator’s

Manualorloadcapacitydecalfortheattachment.

g364599

Attachments/Accessories

AselectionofT oro-manufacturedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

Toro-manufacturedattachmentsandaccessories.

Toensureoptimumperformance,usegenuineT oro

replacementpartsandaccessories.Toroaccepts

noliabilityformachinedamageorpersonalinjury

thatresultsfromtheuseofothermanufacturer

attachments.Theuseracceptstheburdenofthese

risks.

18

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageorrequirecertiedtrainingof

theoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetydecals.

•Alwaysengagetheparkingbrake(ifequipped),

shutofftheengine,removethekey,waitforall

movingpartstostop,andallowthemachine

tocoolbeforeadjusting,servicing,cleaning,or

storingthemachine.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

FuelSafety

•Useextremecarewhenhandlingfuel.Itis

ammableanditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

•Topreventastaticchargefromignitingthefuel,

removethemachinefromthetruckortrailerand

refuelitontheground,awayfromallvehicles.If

thisisnotpossible,placeaportablefuelcontainer

ontheground,awayfromallvehicles,andllit;

thenrefuelthemachinefromthefuelcontainer

ratherthanfromafuel-dispensernozzle.

•Keepthefuel-dispensernozzleincontactwith

therimofthefueltankorcontaineropeningat

alltimesuntilfuelingiscomplete.Donotusea

nozzlelock-opendevice.

•Checkthatthesafetyswitches,andshieldsare

attachedandfunctioningproperly.Donotoperate

themachineunlesstheyarefunctioningproperly .

•Locatethepinch-pointareasmarkedonthe

machineandattachments;keepyourhandsand

feetawayfromtheseareas.

•Beforeoperatingthemachinewithanattachment,

ensurethattheattachmentisproperlyinstalled.

Readalltheattachmentmanuals.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsyouneedtoproperlyandsafely

performthejob.

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas;notethelocationofunmarkedobjectsand

structures,suchasundergroundstoragetanks,

wells,andsepticsystems.

•Inspecttheareawhereyouwillusetheequipment

forunevensurfacesandhiddenhazards.

•Ensurethattheareaisclearofbystandersbefore

operatingthemachine.Stopthemachineifa

bystanderentersthearea.

AddingFuel

RecommendedFuel

Useonlyclean,freshdieselfuelorbiodieselfuels

withultralow(<15ppm)sulfurcontent.Theminimum

cetaneratingshouldbe45.Acetaneratinggreater

than50ispreferred,especiallyattemperaturesbelow

-20°C(-4°F)oratelevationsabove1500m(5000ft).

Purchasefuelinquantitiesthatyoucanusewithin

180daystoensurefuelfreshness.

Usingnon-ultralowsulfurfuelwilldamagetheengine

emissionssystem.

Usesummer-gradedieselfuel(No.2-DorNo.

2-DS15)attemperaturesabove-10°C(14°F)and

wintergrade(No.1-DorNo.1-DS15)below

thattemperature.Usingwinter-gradefuelatlower

temperaturesprovideslowerashpointandcoldow

characteristics,whicheasesstartingandreducesfuel

lterplugging.

Usingsummer-gradefuelabove-10°C(14°F)

contributestowardlongerfuelpumplifeandincreased

powercomparedtowinter-gradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

19

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB5(5%biodiesel,95%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

PerformingDaily

Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedintheMaintenance

(page40).

Important:Checkthehydraulic-uidlevel

andbleedthefuelsystembeforestartingthe

engineforthersttime;refertoCheckingthe

Hydraulic-FluidLevel(page62)andBleedingthe

FuelSystem(page50).

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaydegradeovertime.

•Fuellterpluggingmayoccurforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorformoreinformationon

biodiesel.

FillingtheFuelTank

Fueltankcapacity:42L(11.1USgallons)

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

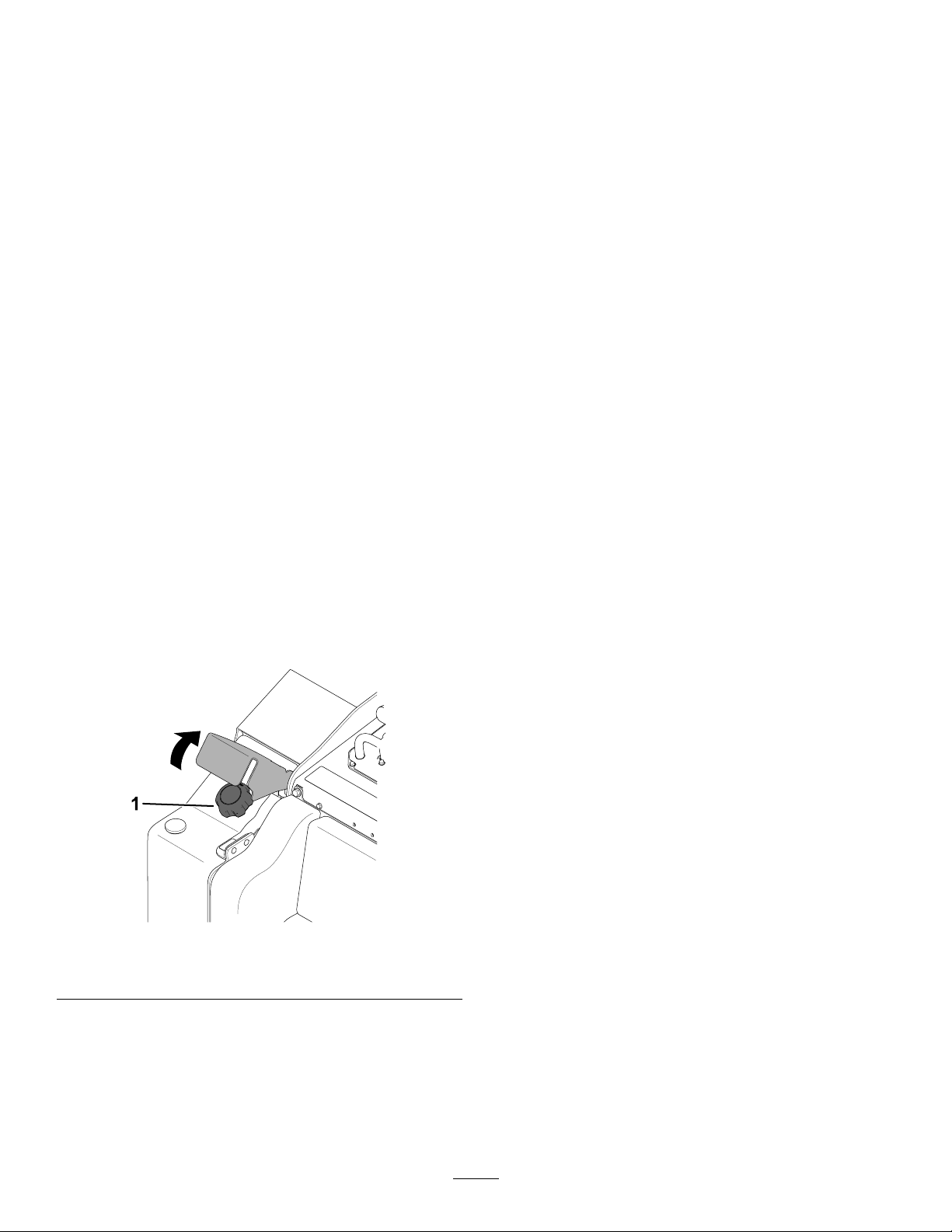

3.Raisethebracket.

Figure19

1.Fuelcap

4.Removethefuelcap.

5.Fillthetankwithfueluptothellerneck.

6.Installthecap.

7.Lowerthebracket.

DuringOperation

DuringOperationSafety

GeneralSafety

•Donotexceedtheratedoperatingcapacity ,as

themachinemaybecomeunstable,whichmay

resultinlossofcontrol.Theoperatingcapacity

isreducedifyouextendtheloaderarmstothe

pointwhereyoucanseethestripeddecalinside

thearms.

•Donottransportanattachment/loadwiththe

armsraisedorextended;alwaystransportthe

attachments/loadclosetotheground,withthe

loaderarmsretracted.

•Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthemachine.

•Formachineswithaplatform:

–Lowertheloaderarmsbeforesteppingoffthe

platform.

–Donottrytostabilizethemachinebyputting

yourfootontheground.Ifyoulosecontrolof

themachine,stepofftheplatformandaway

fromthemachine.

–Donotplaceyourfeetundertheplatform.

–Donotmovethemachineunlessyouare

standingwithbothfeetontheplatformand

yourhandsareholdingontothereferencebars

g362590

•Useyourfullattentionwhileoperatingthe

•Lookbehindanddownbeforebackingupto

•Neverjerkthecontrols;useasteadymotion.

•Theowner/usercanpreventandisresponsible

ortheloadercontrol.

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

ensurethatthepathisclear.

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

20

•Wearappropriateclothingincludingeyeprotection,

longpants,substantialslip-resistantfootwear,and

hearingprotection;alsoweararespiratorordust

maskindustyconditions.Tiebacklonghairand

donotwearlooseclothingorloosejewelry .

•Donotoperatethemachinewhenyouaretired,ill,

orundertheinuenceofalcoholordrugs.

•Nevercarrypassengersandkeeppetsand

bystandersawayfromthemachine.

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

•Ensurethatallthedrivesareinneutralbefore

startingtheengine.Starttheengineonlyfromthe

operator'spositionontheplatform.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Watchfor

trafc.

•Stoptheattachmentwhenyouarenotworking.

•Stopthemachine,shutofftheengine,remove

thekey,andinspectthemachineifyoustrike

anobject.Makeanynecessaryrepairsbefore

resumingoperation.

•Neverrunanengineinanenclosedarea.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowertheloaderarmsanddisengagethe

auxiliaryhydraulics.

–Engagetheparkingbrake.

–Shutofftheengineandremovethekey.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Operatethemachineonlyinareaswherethereis

sufcientclearanceforyoutosafelymaneuver.

Beawareofobstaclesincloseproximitytoyou.

Failuretomaintainadequatedistancefromtrees,

walls,andotherbarriersmayresultininjuryasthe

machinebacksupduringoperationifyouarenot

attentivetothesurroundings.

•Checkforoverheadclearance(i.e.,electrical

wires,branches,anddoorways)beforedriving

underanyobjectsanddonotcontactthem.

•Donotoverlltheattachmentandalwayskeepthe

loadlevelwhenraisingtheloaderarms.Itemsin

theattachmentcouldfallandcauseinjury.

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.Anempty

load-bearingattachmentmakestherearofthe

machinetheheavyend,andafullload-bearing

attachmentmakesthefrontofthemachinethe

heavyend.Mostotherattachmentsmakethefront

ofmachinetheheavyend.

•Raisingorextendingtheloaderarmsonaslope

affectsthestabilityofthemachine.Keepthe

loaderarmsintheloweredandretractedposition

whenonslopes.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.Tallgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Evaluatetheareatoensurethatthegroundis

stableenoughtosupportthemachine.

•Usecautionwhenoperatingthemachinenearthe

following:

–Drop-offs

–Ditches

–Embankments

–Bodiesofwater

21

Themachinecouldsuddenlyrolloverifatrack

goesovertheedgeortheedgecavesin.Maintain

asafedistancebetweenthemachineandany

hazard.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

UtilityLineSafety

•Ifyoustrikeautilityline,dothefollowing:

–Shutoffthemachineandremovethekey.

–Removeallindividualsfromtheworkarea.

–Immediatelycontacttheproperemergencyand

utilityauthoritiestosecurethearea.

–Ifyoudamageaber-opticcable,donotlook

intotheexposedlight.

•Donotleavetheoperator’splatformifthemachine

ischargedwithelectricity.Y ouwillbesafeaslong

asyoudonotleavetheplatform.

–T ouchinganypartofthemachinemayground

you.

–Donotallowanotherindividualtotouchor

approachthemachinewhencharged.

–Alwaysassumethemachineischargedifyou

strikeanelectricalorcommunicationline.Do

notattempttoleavethemachine.

•Leakinggasisbothammableandexplosiveand

maycauseseriousinjuryordeath.Donotsmoke

whileoperatingthemachine.

StartingtheEngine

1.Ensurethatthebattery-disconnectswitch

isintheONposition;refertoUsingthe

Battery-DisconnectSwitch(page51).

2.Ensurethatthetraction-controlisintheNEUTRAL

position.

3.Insertthekeyintothekeyswitchandturnitto

theONposition.

4.TurnthekeytotheST ARTposition.Whenthe

enginesstarts,releasethekey .

Important:Donotengagethestarterfor

morethan10secondsatatime.Iftheengine

failstostart,wait30secondsforthestarter

tocooldownbetweenattempts.Failureto

followtheseinstructionscouldburnoutthe

startermotor.

StartinginColdWeather

Iftheoutdoortemperatureisbelowfreezing,storethe

machineinagaragetokeepitwarmerandtoaidin

starting.

Themachinesoftwaremayautomaticallylimitthe

enginerpmifthecoolantisextremelycold.After

startingtheengine,waituntilthesnowakeicon

andcoldhydraulicuidwarningdisappearfromthe

Infocenterbeforeincreasingthethrottleandengaging

theauxiliaryhydraulics.

Important:Runningtheengineathighspeeds

whenthehydraulicsystemiscold(i.e.,whenthe

airtemperatureisatorbelowfreezing)could

damagethehydraulicsystem.

DrivingtheMachine

Usethetractioncontrolstomovethemachine.The

fartheryoumovethetractioncontrolsinanydirection,

thefasterthemachinemovesinthatdirection.

Releasethetractioncontrolstostopthemachine.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Runthe

engineathighthrottleforbestperformance.

22

ShuttingOfftheEngine

1.Parkthemachineonalevelsurfaceandlower

theloaderarms.

2.Disengagetheauxiliaryhydraulics.

3.Setthethrottletolowidle.

4.Iftheenginehasbeenworkinghardorishot,let

itidlefor5minutesbeforeturningthekeyswitch

totheOFFposition.

Note:Thishelpstocooltheenginebeforeyou

shutitoff.Inanemergency,youcanshutoff

theengineimmediately.

5.TurnthekeyswitchtotheOFFpositionand

removethekey.

CAUTION

Achildoruntrainedbystandercouldattempt

tooperatethetractionunitandbeinjured.

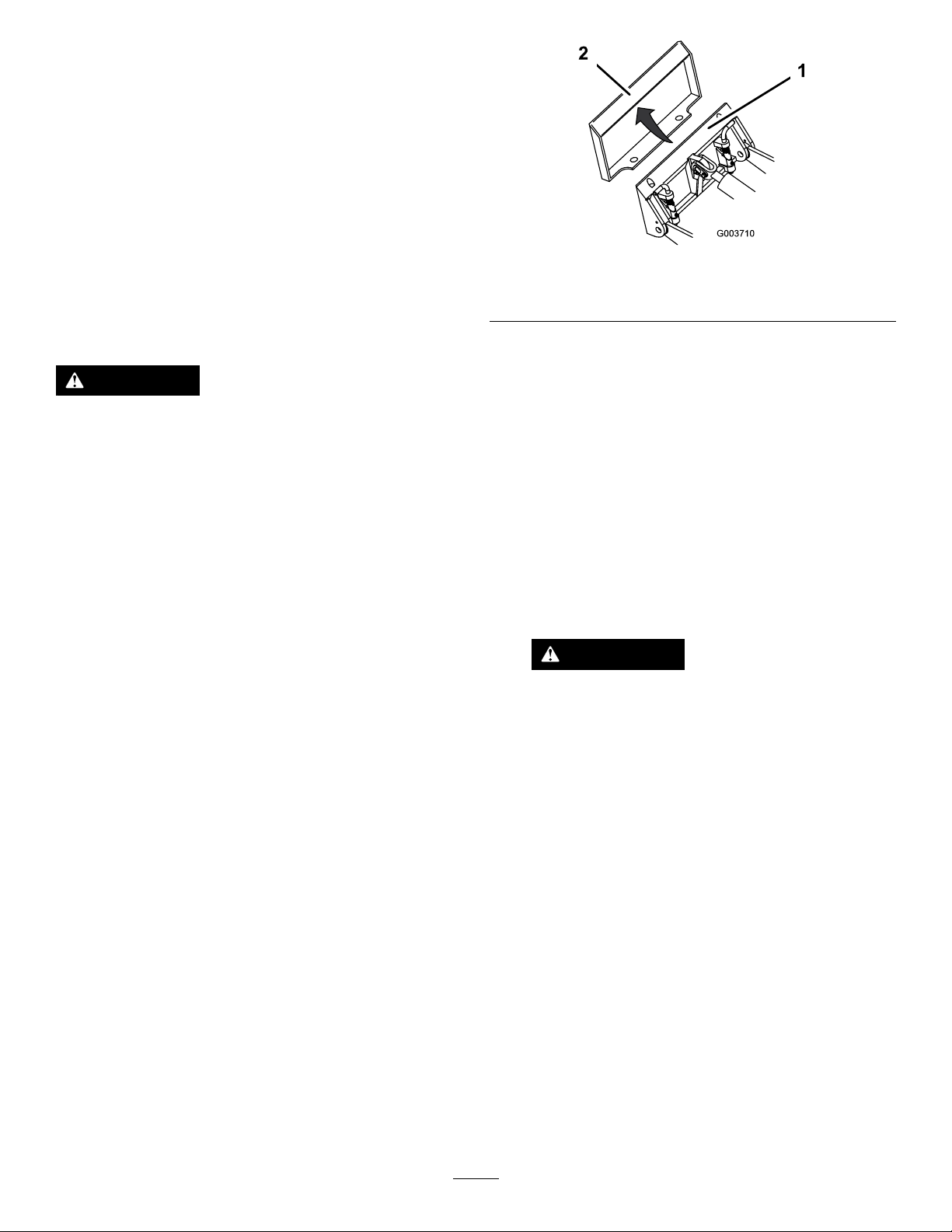

g003710

Figure20

1.Mountplate2.Receiverplate

5.Raisetheloaderarmswhiletiltingbackthe

mountplateatthesametime.

Important:Raisetheattachmentenoughto

clearthegroundandtiltthemountplateall

thewayback.

Removethekeyfromthekeyswitchwhen

leavingthetractionunit,evenifjustforafew

seconds.

UsingAttachments

InstallinganAttachment

Important:UseonlyT oro-approvedattachments.

Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthemachine.The

warrantyofthemachinemaybevoidedifyouuse

themachinewithunapprovedattachments.

Important:Beforeinstallingtheattachment,

ensurethatthemountplatesarefreeofanydirtor

debrisandthatthepinsrotatefreely.Ifthepins

donotrotatefreely,greasethem.

1.Positiontheattachmentonalevelsurfacewith

enoughspacebehindittoaccommodatethe

machine.

2.Starttheengine.

6.Shutofftheengineandremovethekey.

7.Engagethequick-attachpins,ensuringthatthey

arefullyseatedinthemountplate.

Important:Ifthepinsdonotrotatetothe

engagedposition,themountplateisnot

fullyalignedwiththeholesintheattachment

receiverplate.Checkthereceiverplateand

cleanitifnecessary.

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

3.Tilttheattachmentmountplateforward.

4.Positionthemountplateintotheupperlipofthe

attachmentreceiverplate.

23

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponents,youmaybeburned.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

Iftheattachmentrequireshydraulicsforoperation,

connectthehydraulichosesasfollows:

1.Shutofftheengineandremovethekey.

2.Removetheprotectivecoversfromthehydraulic

connectorsonthemachine.

3.Ensurethatallforeignmatteriscleanedfrom

thehydraulicconnectors.

Figure21

1.Quick-attachpins

(engagedposition)

2.Disengagedposition

3.Engagedposition

ConnectingtheHydraulicHoses

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

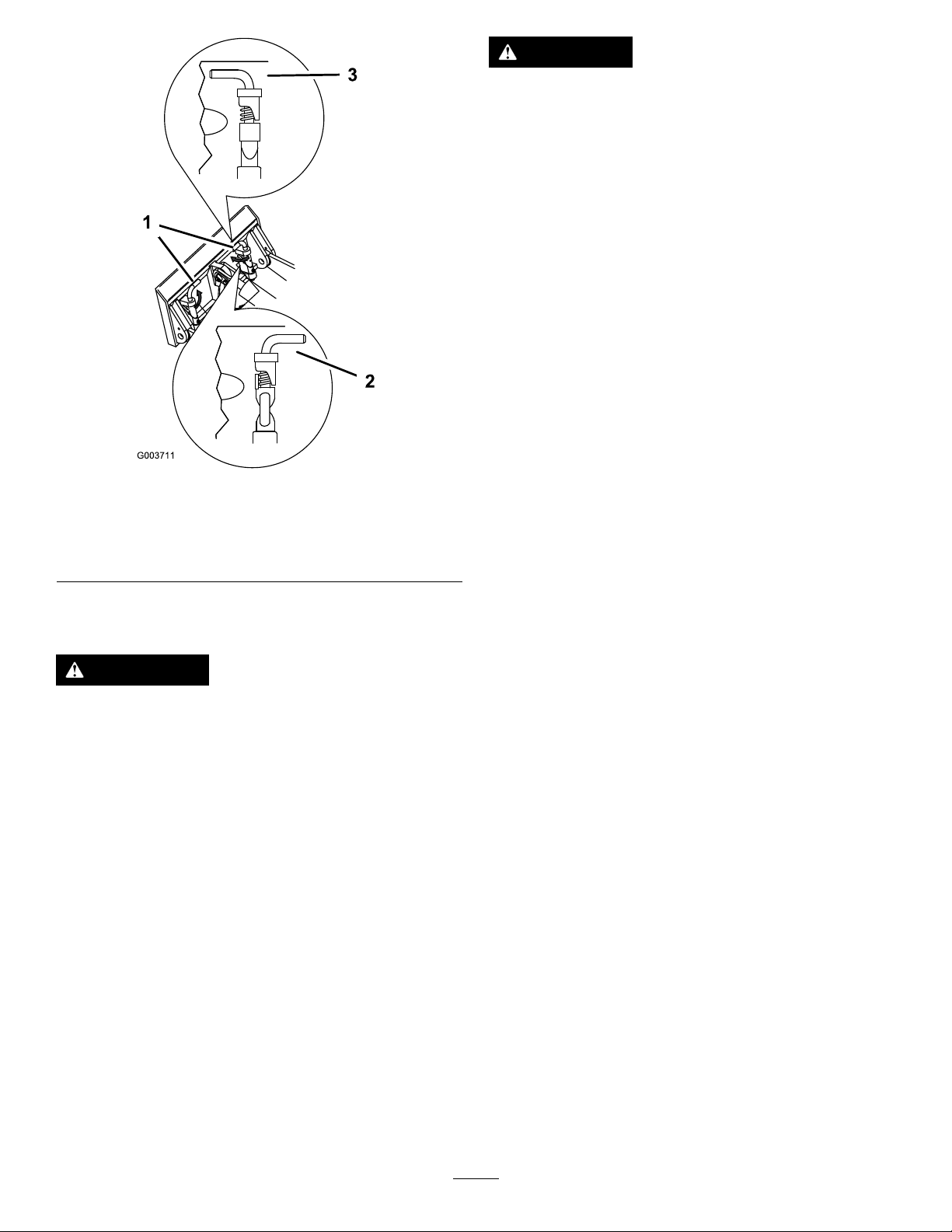

g003711

4.Pushtheattachmentmaleconnectorintothe

femaleconnectoronthemachine.

Note:Whenyouconnecttheattachmentmale

connectorrst,yourelieveanypressurebuilt

upintheattachment.

5.Pushtheattachmentfemaleconnectorontothe

maleconnectoronthemachine.

6.Conrmthattheconnectionissecurebypulling

onthehoses.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

24

RemovinganAttachment

1.Parkthemachineonalevelsurface.

2.Lowertheattachmenttotheground.

3.Shutofftheengineandremovethekey.

4.Disengagethequick-attachpinsbyturningthem

totheoutside.

UnderstandingtheSmart

LoadSystem

TheSmartLoadsystemalsomeasuresthehydraulic

pressureintheloaderarmcylinderstodeterminethe

maximumreach.

Whenyouextendtheloaderarmstothemaximum

reachforthearmheightandloadweight,the

InfoCenterwilldisplaytheSmartLoadiconandash

theindicatorlight,analarmwillbeep,andthearms

willstopextending.

Toextendtheloaderarmsfurther,lightentheload.

g270732

Figure23

Figure22

1.Quick-attachpins

(engagedposition)

2.Disengagedposition

5.Iftheattachmentuseshydraulics,slidethe

collarsbackonthehydrauliccouplersand

disconnectthem.

3.Engagedposition

Important:Connecttheattachmenthoses

togethertopreventhydraulicsystem

contaminationduringstorage.

6.Installtheprotectivecoversontothehydraulic

couplersonthemachine.

7.Starttheengine,tiltthemountplateforward,and

backthemachineawayfromtheattachment.

g003711

25

DieselParticulateFilter

(DPF)Regeneration

UnderstandingDPFRegeneration

Thedieselparticulatelter(DPF)ispartoftheexhaust

system.Thediesel-oxidationcatalystoftheDPF

reducesharmfulgasses,andthesootlterremoves

sootfromtheengineexhaust.

TheDPFregenerationprocessusesheatfromthe

engineexhausttoincineratethesootaccumulatedon

thesootlter,convertingthesoottoash,andclears

thechannelsofthesootltersothatlteredengine

exhaustowsouttheDPF .

Theenginecomputermonitorstheaccumulationof

sootbymeasuringthebackpressureintheDPF.If

thebackpressureistoohigh,sootisnotincinerating

inthesootlterthroughnormalengineoperation.T o

keeptheDPFclearofsoot,rememberthefollowing:

•Passiveregenerationoccurscontinuouslywhile

theengineisrunning—runtheengineatfull

enginespeedwhenpossibletopromoteDPF

regeneration.

•IfthebackpressureintheDPFistoohighora

resetregenerationhasnotoccurredfor100hours,

theenginecomputersignalsyouthroughthe

InfoCenterwhenresetregenerationisrunning.

•Allowtheresetregenerationprocesstocomplete

beforeshuttingofftheengine.

Operateandmaintainyourmachinewiththefunction

oftheDPFinmind.Engineloadathighidle(full

throttle)enginespeedgenerallyproducesadequate

exhausttemperatureforDPFregeneration.

Important:Minimizetheamountoftimethatyou

idletheengineoroperatetheengineatlow-engine

speedtohelpreducetheaccumulationofsootin

thesootlter.

26

DPFSootAccumulation

•Overtime,thedieselparticulatelteraccumulatessootinthesootlter.Thecomputerfortheengine

monitorsthesootlevelintheDPF .

•Whenenoughsootaccumulates,thecomputerinformsyouthatitistimetoregeneratetheDPF .

•DPFregenerationisaprocessthatheatstheDPFtoconvertthesoottoash.

•Inadditiontothewarningmessages,thecomputerreducesthepowerproducedbytheengineatdifferent

soot-accumulationlevels.

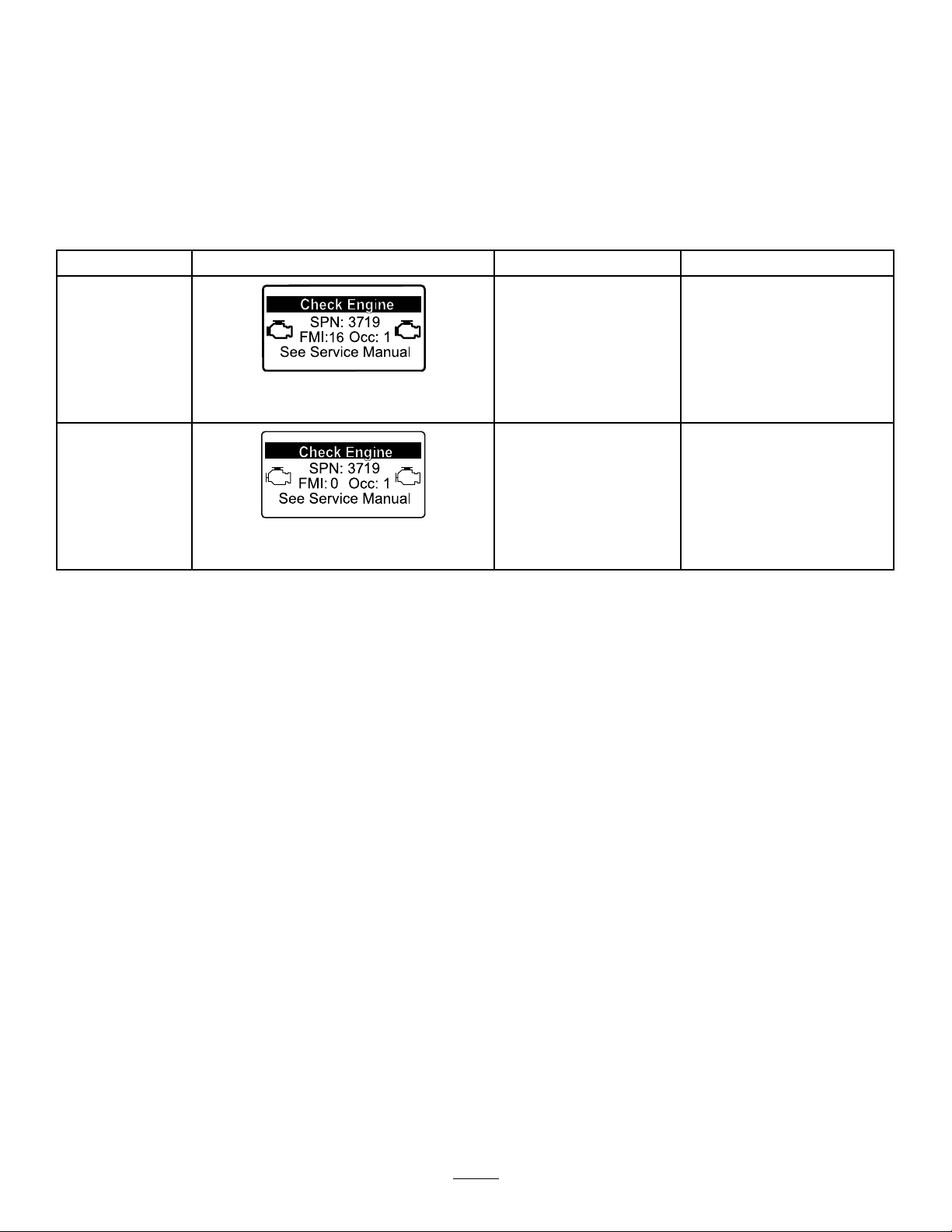

EngineWarningMessages—SootAccumulation

IndicationLevel

Level1:Engine

Level2:Engine

FaultCode

Warning

CheckEngine

SPN3719,FMI16

Warning

CheckEngine

SPN3719,FMI0

EnginePowerRatingRecommendedAction

Performaparkedregeneration

Thecomputerde-ratesthe

enginepowerto85%.

Thecomputerde-ratesthe

enginepowerto50%.

assoonaspossible;refer

toPerformingaParked

orRecoveryRegeneration

Performarecoveryregeneration

assoonaspossible;referto

PerformingaParkedor

RecoveryRegeneration

(page33).

(page33).

27

DPFAshAccumulation

•Thelighterashisdischargedthroughtheexhaustsystem;theheavierashcollectsinthesootlter.

•Ashisaresidueoftheregenerationprocess.Overtime,thedieselparticulatelteraccumulatesash

thatdoesnotdischargewiththeengineexhaust.

•ThecomputerfortheenginecalculatestheamountofashaccumulatedintheDPF .

•Whenenoughashaccumulates,theenginecomputersendsinformationtotheInfoCenterintheformofan

enginefaulttoindicatetheaccumulationofashintheDPF .

•ThefaultmessagesindicatethatitistimetoservicetheDPF.

•Inadditiontothewarnings,thecomputerreducesthepowerproducedbytheengineatdifferent

ash-accumulationlevels.

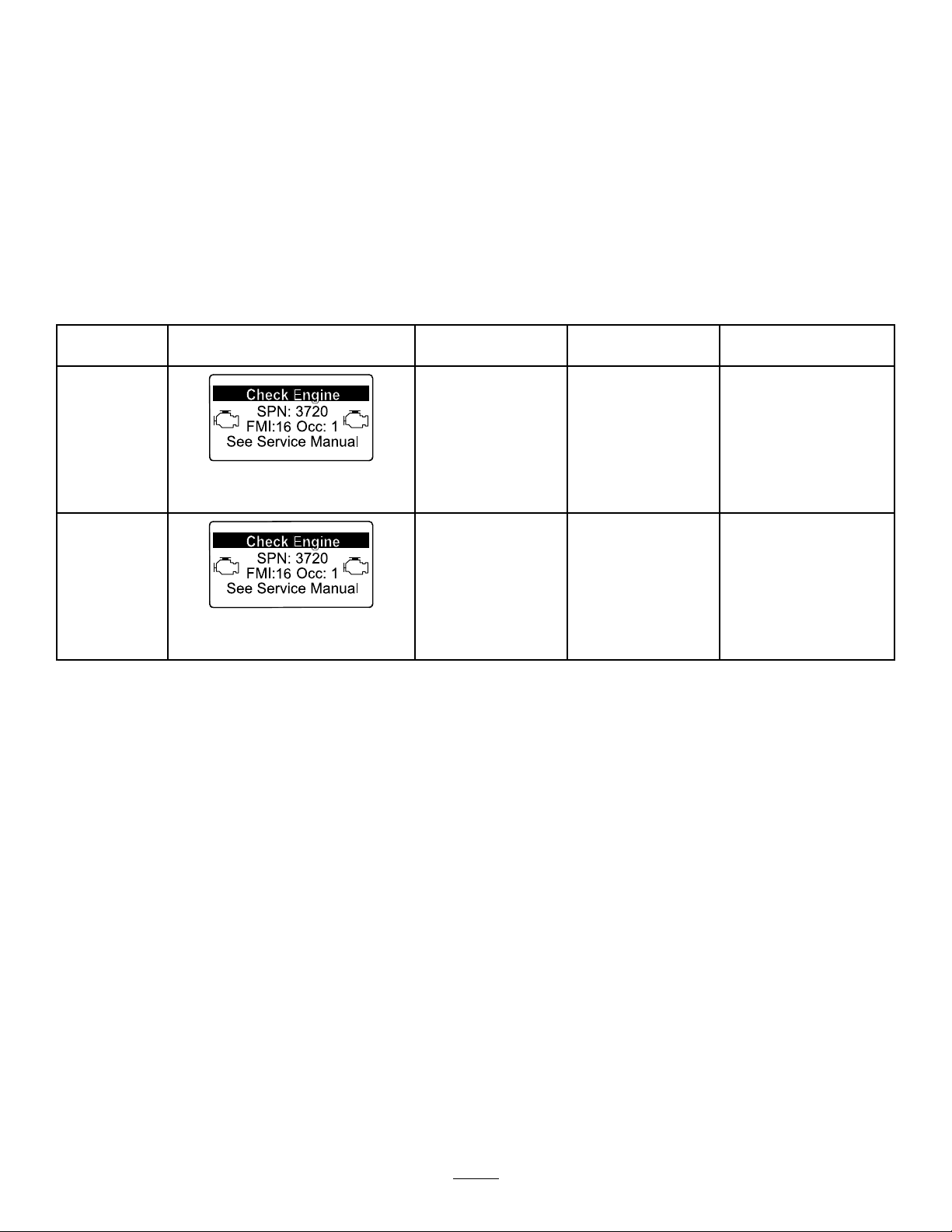

InfoCenterAdvisoryandEngineWarningMessages—AshAccumulation

Indication

Level1:

Engine

Warning

Level2:

Engine

Warning

Level

FaultCode

CheckEngine

SPN3720,FMI16

CheckEngine

SPN3720,FMI0

EngineSpeed

Reduction

None

None

EnginePowerRatingRecommendedAction

Thecomputer

de-ratestheengine

powerto85%.

Thecomputer

de-ratestheengine

powerto50%.

ServicetheDPF;refer

toParkedorRecovery

Regeneration(page33)

ServicetheDPF;refer

toParkedorRecovery

Regeneration(page33)

28

TypesofDPFRegeneration

TypesofDPFregenerationthatareperformedwhilethemachineisoperating:

TypeofRegenerationConditionsthatcauseDPFregenerationDPFdescriptionofoperation

Passive

Assist

Reset

Occursduringnormaloperationofthemachineat

high-enginespeedorhigh-engineload

Occursbecauseoflow-enginespeed,low-engine

load,orafterthecomputerdetectstheDPFis

becomingobstructedwithsoot

Occursevery100hours

Alsooccursafterassistregenerationonlyifthe

computerdetectsthatassistregenerationdidnot

sufcientlyreducethesootlevel

•TheInfoCenterdoesnotdisplayanicon

indicatingpassiveregeneration.

•Duringpassiveregeneration,theDPF

processeshigh-heatexhaustgasses,oxidizing

harmfulemissions,andburningsoottoash.

RefertoPassiveDPFRegeneration(page31)

.

•TheInfoCenterdoesnotdisplayanicon

indicatingassistregeneration.

•Duringassistregeneration,theengine

computeradjuststheenginesettingstoraise

theexhausttemperature.

RefertoAssistDPFRegeneration(page31).

•Whenthehighexhaust-temperatureicon

isdisplayedintheInfoCenter,aregeneration

isinprogress.

•Duringresetregeneration,theenginecomputer

adjuststheenginesettingstoraisetheexhaust

temperature.

RefertoResetRegeneration(page31).

TypesofDPFregenerationthatrequireyoutoparkthemachine:

TypeofRegenerationConditionsthatcauseDPFregenerationDPFdescriptionofoperation

Parked

Occursbecausethecomputerdetectsback

pressureintheDPFduetosootbuildup

Alsooccursbecausetheoperatorinitiatesaparked

regeneration

MayoccurbecauseyousettheInfoCentertoinhibit

resetregenerationandcontinuedoperatingthe

machine,addingmoresootwhentheDPFalready

needsaresetregeneration

Mayresultfromusingtheincorrectfuelorengineoil

•Whenthereset-standby/parkedorrecovery

regenerationicon

displaysintheInfoCenter,aregenerationis

requested.

•Performtheparkedregenerationassoon

aspossibletoavoidneedingarecovery

regeneration.

•Aparkedregenerationrequires30to60

minutestocomplete.

•Youmusthaveatleasta1/4tankoffuelinthe

tank.

•Youmustparkthemachinetoperformaparked

regeneration.

RefertoPerformingaParkedorRecovery

Regeneration(page33).

orADVISORY#188

29

TypesofDPFregenerationthatrequireyoutoparkthemachine:(cont'd.)

TypeofRegenerationConditionsthatcauseDPFregenerationDPFdescriptionofoperation

Recovery

Occursbecausetheoperatorignoredrequestsfor

aparkedregenerationandcontinuedoperatingthe

machine,addingmoresoottotheDPF

•Whenthereset-standby/parkedorrecovery

regenerationicon

displaysintheInfoCenter,arecovery

regenerationisrequested.

•Arecoveryregenerationrequiresupto3hours

tocomplete.

•Youmusthaveatleasta1/2tankoffuelinthe

machine.

•Youmustparkthemachinetoperforma

recoveryregeneration.

RefertoPerformingaParkedorRecovery

Regeneration(page33).

orADVISORY#190

DPFRegenerationMenu

AccessingtheDPFRegenerationMenu

1.AccesstheServicemenuandscrolldownto

DPFREGENERATION.

Figure24

2.PresstherightbuttontoaccesstheDPF

Regenerationmenu.

TimeSinceLastRegeneration

AccesstheDPFRegenerationmenuandscrolldown

totheLASTREGENeld.

TechnicianMenu

Important:Foroperatingconvenience,you

maydecidetoperformaparkedregeneration

beforethesootloadreaches100%,provided

theenginehasrunmorethan50hourssince

thelastsuccessfulreset,parked,orrecovery

regeneration.

Usethetechnicianmenutoviewthecurrentstateof

engineregenerationcontrolandviewthereported

sootlevel.

g362603

AccesstheDPFRegenerationmenu,thenscrolldown

andaccesstheTECHNICIANmenu.

g362719

Figure26

UsetheLASTREGENeldtodeterminehowmany

hoursyouhaveruntheenginesincethelastreset,

parked,orrecoveryregeneration.

Figure25

•UsetheDPFOperationTabletounderstandthe

currentstateofDPFoperation.

g362604

30

Figure27

g362718

DPFOperationTable

PassiveDPFRegeneration

State

NormalTheDPFisinnormal-operating

AssistRegen

ResetStby

ResetRegenTheenginecomputerisrunningareset

ParkedStby

ParkedRegenYouinitiatedaparkedregeneration

Recov.Stby

Recov.RegenY ouinitiatedarecoveryregeneration

Description

mode—passiveregeneration.

Theenginecomputerisperformingan

assistregeneration.

Theengine

computeristrying

torunareset

regeneration,but

1ofthefollowing

conditionsprevents

regeneration:

regeneration.

Theenginecomputerisrequestingthat

yourunaparkedregeneration.

requestandtheenginecomputeris

processingtheregeneration.

Theenginecomputerisrequestingthat

yourunarecoveryregeneration.

requestandtheenginecomputeris

processingtheregeneration.

Theregeninhibit

settingissettoON.

Theexhaust

temperature

istoolowfor

regeneration.

•Thesootloadismeasuredasthepercentageof

sootintheDPF;refertothesoot-loadtable.

Note:Thesootloadvaluevariesasthemachine

isoperatedandDPFregenerationoccurs.

•Passiveregenerationoccursaspartofnormal

engineoperation.

•Whileoperatingthemachine,runtheengineat

full-enginespeedandhighloadwhenpossibleto

promoteDPFregeneration.

AssistDPFRegeneration

•Theenginecomputeradjustsenginesettingsto

raisetheexhausttemperature.

•Whileoperatingthemachine,runtheengineat

fullenginespeedandhighloadwhenpossibleto

promoteDPFregeneration.

ResetRegeneration

CAUTION

Theexhausttemperatureishot(approximately

600°C(1,112°F)duringDPFregeneration.Hot

exhaustgascanharmyouorotherpeople.

•Neveroperatetheengineinanenclosed

area.

•Makesurethattherearenoammable

materialsaroundtheexhaustsystem.

•Nevertouchahotexhaustsystem

component.

Figure28

Soot-LoadTable

ImportantSootLoadValuesRegenerationState

0%to5%

78%Theenginecomputerperforms

100%

122%

Minimumsootloadrange

anassistregeneration.

Theenginecomputer

automaticallyrequestsa

parkedregeneration.

Theenginecomputer

automaticallyrequestsa

recoveryregeneration.

•Neverstandnearoraroundtheexhaust

pipeofthemachine.

•Thehighexhaust-temperatureicon

g365225

intheInfoCenterwhiletheresetregenerationis

processing.

displays

•Theenginecomputeradjustsenginesettingsto

raisetheexhausttemperature.

Important:Thehighexhaust-temperature

iconindicatesthattheexhausttemperature

dischargedfromofyourmachinemaybe

hotterthanduringregularoperation.

•Whileoperatingthemachine,runtheengineat

fullenginespeedandhighloadwhenpossibleto

promoteDPFregeneration.

•Wheneverpossible,donotshutofftheengineor

reduceenginespeedwhiletheresetregeneration

isprocessing.

Important:Wheneverpossible,allowthe

machinetocompletetheresetregeneration

processbeforeshuttingofftheengine.

31

PeriodicResetRegeneration

AllowingaResetRegeneration

IftheenginehasnotcompletedasuccessfulReset,

Parked,orRecoveryregenerationintheprevious100

hoursofengineoperation,theenginecomputerwill

attempttoperformaresetregeneration.

SettingtheInhibitRegen

ResetRegenerationOnly

Aresetregenerationproducestheelevatedengine

exhausttemperatures.Ifyouareoperatingthe

machinearoundtrees,brush,tallgrass,orother

temperature-sensitiveplantsormaterials,youcan

usetheInhibitRegensettingtopreventtheengine

computerfromperformingaresetregeneration.

Important:Whenyoushutofftheengineand

startitagain,theInhibitRegensettingdefaults

toOFF.

Note:IfyousettheInfoCentertoinhibitregeneration,

theInfoCenterdisplaysADVISORY#185every

15minuteswhiletheenginerequestsareset

regeneration.

TheInfoCenterdisplaysthehighexhaust-temperature

iconwhentheresetregenerationisinprocess.

Note:IfInhibitRegenissettoON,theInfoCenter

displaysADVISORY#185.Presstherightbuttontoset

inhibitregenerationsettingtoOFFandcontinuewith

theresetregeneration.

g362746

Figure32

Note:IftheInfoCenterdisplaysADVISORY#186,set

theenginetofullthrottle(highidle)toallowthereset

regenerationtocontinue.

Figure29

1.AccesstheDPFRegenerationmenuandscroll

downtoINHIBITREGEN.

Figure30

2.Presstherightbuttontochangetheinhibit

regenerationsettingtoONorOFF.

Figure31

g224692

g224395

Figure33

Note:Whentheresetregenerationcompletes,the

highexhaust-temperatureicon

theInfoCenterscreen.

g362745

g365224

disappearsfrom

32

ParkedorRecoveryRegeneration

•Whentheenginecomputerrequestseithera

parkedregenerationorarecoveryregeneration,

theregenerationrequesticondisplaysinthe

InfoCenter.

•Themachinedoesnotautomaticallyperforma

parkedregenerationorarecoveryregeneration,

youmustruntheregenerationthroughthe

InfoCenter.

ParkedRegenerationMessages

DPFStatus-Limitation

•Iftheenginecomputerrequestsaparked

regenerationorisprocessingaparked

regeneration,thePARKEDREGENoptionlocksand

thelockiconappearsonthescreen.

Whentheenginecomputerrequestsaparked

regeneration,thefollowingmessagesdisplayinthe

InfoCenter:

•EnginewarningSPN3720,FMI16

Figure34

•ADVISORY#188Parkedregenerationrequired

Note:Advisory#188displaysevery15minutes.

Figure35

g224625

Figure37

•Iftheenginecomputerrequestsarecovery

regenerationorisprocessingarecovery

regeneration,theRECOVERYREGENoptionlocks

andthelockiconappearsonthescreen.

g213863

g224628

Figure38

g224397

PerformingaParkedorRecovery

Regeneration

RecoveryRegenerationMessages

Whentheenginecomputerrequestsarecovery

regeneration,thefollowingmessagesdisplayinthe

InfoCenter:

EnginewarningSPN3719,FMI0

RefertotheServiceManualoryourAuthorized

ServiceDealerfordetails.

Figure36

CAUTION

Theexhausttemperatureishot(approximately

600°C(1,112°F)duringDPFregeneration.Hot

exhaustgascanharmyouorotherpeople.

•Neveroperatetheengineinanenclosed

area.

•Makesurethattherearenoammable

materialsaroundtheexhaustsystem.

•Nevertouchahotexhaustsystem

component.

•Neverstandnearoraroundtheexhaust

pipeofthemachine.

g213867

Important:Thecomputerofthemachinecancels

DPFregenerationifyouincreasetheenginespeed

fromlowidleorreleasetheparkingbrake.

33

1.Ensurethatthemachinehasatleastthe

speciedamountfuelinthetankforthetypeof

regenerationyouareperforming:

•ParkedRegeneration:1/4tankoffuel

•RecoveryRegeneration:1/2tankoffuel

2.Parkthemachineonalevelsurface,inanarea

outsideawayfromcombustiblematerials.

3.Engagetheparkingbrakeandlowertheloader

arms.

4.SetthethrottletothelowIDLEposition.

8.AttheINITIATEDPFREGENscreen,pressthe

rightbuttontocontinue.

g224630

Figure42

RecoveryRegenerationscreenshown.

5.IntheDPFRegenerationmenu,scrolltoPARKED

REGENSTARTorRECOVERYREGENSTART.Press

therightbuttontostarttheregeneration.

Figure39

6.Whenprompted,verifythatyouhavethatthe

fuellevelissufcient,asindicatedinstep1.

Presstherightbuttontocontinue.

Figure40

RecoveryRegenerationscreenshown.

9.TheInfoCenterdisplaystheINITIA TINGDPF

REGENmessage.

g227681

g362809

RecoveryRegenerationscreenshown.

Figure43

10.TheInfoCenterdisplaysthetimetocomplete

message.

•Parkedregenerationrequiresupto30

minutestocomplete.

•Recoveryregenerationrequiresupto3

hourstocomplete.

Note:Ifyoumustcanceltheregenerationafter

g227678

itisinitiated,refertoCancelingaParkedor

RecoveryRegeneration(page35).

7.AttheDPFchecklistscreen,verifythatthe

parkingbrakeisengagedandtheenginespeed

issettolowidle.Presstherightbuttonto

continue

Figure41

RecoveryRegenerationscreenshown.

g224406

g224416

g227679

34

Figure44

11.Theenginecomputercheckstheenginestate

andfaultinformation.TheInfoCentermay

displaythefollowingmessages:

CheckMessageandCorrectiveActionT able

Message

CorrectiveAction

Exittheregeneration

menuandrunthemachine

untilthetimesincelast

regenerationisgreater

than50hours;refertoTime

SinceLastRegeneration

(page30).

Troubleshoottheengine

faultandretryDPF

regeneration.

13.Whentheenginecomputercompletesa

parkedorrecoveryregeneration,theInfoCenter

displaysADVISORY#183;ifitfails,theInfoCenter

displaysADVISORY#184.Presstheleftbuttonto

exittothehomescreen.

g362807

Figure45

Startandruntheengine.

Runtheenginetowarm

thecoolanttemperatureto

60°C(140°F).

Changetheenginespeed

tolowidle.

Troubleshoottheengine

computerconditionand

retryDPFregeneration.

12.TheInfoCenterdisplaysthehomescreenand

CancelingaParkedorRecoveryRegeneration

1.IntheDPFRegenerationmenu,scrolltoPARKED

REGENCANCELorRECOVERYREGENCANCEL.

g362918

Figure46

2.Presstherightbuttontocanceltheregeneration.

theregenerationacknowledgeicon

inthelowerrightcornerofthescreenasthe

regenerationprocesses.

Note:WhiletheDPFregeneration

runs,theInfoCenterdisplaysthehigh

exhaust-temperatureicon

.

appears

35

AfterOperation

MovingaNon-Functioning

Machine

AfterOperationSafety

GeneralSafety

•Engagetheparkingbrake(ifequipped),lower

theloaderarms,shutofftheengine,removethe

key,waitforallmovementtostop,andallowthe

machinetocoolbeforeadjusting,cleaning,storing,

orservicingit.

•Cleandebrisfromtheattachments,drives,

mufers,andenginetohelppreventres.Clean

upoilorfuelspills.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

RetrievingaStuckMachine

Important:Donottoworpullthemachine

withoutrstopeningthetowvalves,oryouwill

damagethehydraulicsystem.

1.Shutofftheengineandremovethekey .

2.Removethebottomplate;refertoRemovingthe

BottomPlate(page44).

3.Foreachdrivemotor,removethecap.

Ifthemachinebecomesstuck(e.g.,inmuddy

conditions),pullthemachinebackintoastable

positionusingeitherbothfrontliftpointsorbothrear

tie-downpointssimultaneously.

Important:Donotusethefronttie-downpoints

topullthemachine.

Figure47

1.Frontliftpoints

2.Reartie-downpoints

g362932

Figure48

1.Drivemotorcap

4.Lubricateawasher(M12)withoilonbothsides.

5.Threadanut(M12)ontoascrew(M12),then

installthescrewthroughthewasherandbypass

toolintothebrakepiston.Donotovertighten.

g371330

Figure49

1.Bypasstool3.Nut

2.Washer

4.Screw

g370287

36

6.Tightenthenuttoreleasethebrake.

Figure50

youorbystandersavoidinjury.Refertoyourlocal

ordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidentscausingpersonal

injury.

Donotdrivethemachineonapublicstreet

g370392

orroadway.

SelectingaTrailer

7.Removethefrontcover;RemovingtheFront

Cover(page44).

8.Turnthetowvalvesunderthehydraulicpumps

twicecounterclockwise.

Figure51

1.Towvalve

9.Towthemachineasrequiredusingthepoints

describedinRetrievingaStuckMachine(page

36).

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure52).

•Useonlyfull-widthramps.

•Ensurethatthelengthoframpisatleast4

timesaslongastheheightofthetraileror

truckbedtotheground.Thisensuresthat

rampangledoesnotexceed15degreeson

atground.

g362931

10.Afterrepairingthemachine,closethetowvalves

beforeoperatingit.

11.Installthefrontcover.

12.Removethefastenersandbypasstoolfrom

eachdrivemotorandinstallthecap.

13.Installthebottomplate.

HaulingtheMachine

Useaheavy-dutytrailerortrucktohaulthemachine.

Useafull-widthramp.Ensurethatthetrailerortruck

hasallthenecessarybrakes,lighting,andmarkingas

requiredbylaw.Pleasecarefullyreadallthesafety

instructions.Knowingthisinformationcouldhelp

1.Full-widthramp(s)in

stowedposition

2.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

37

g229507

Figure52

3.H=heightofthetraileror

truckbedtotheground

4.Trailer

LoadingtheMachine

WARNING

Loadingorunloadingamachineontoatrailer

ortruckincreasesthepossibilityoftip-over

andcouldcauseseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Loadandunloadthemachinewiththe

heavyenduptheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

Important:Donotusethetie-downloopsto

liftthemachine.

g318338

Figure54

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Lowertheramp(s).

4.Lowertheloaderarms.

5.Loadthemachineontothetrailerwiththeheavy

enduptheramp,carryingloadslow.

•Ifthemachinehasafullload-bearing

attachment(e.g.,bucket)ora

non-load-bearingattachment(e.g.,

trencher),drivethemachineforwardupthe

ramp.

•Ifthemachinehasanemptyload-bearing

attachmentornoattachment,backthe

machineuptheramp.

Figure53

1.Machinewithfull

attachmentor

non-load-bearing

attachment—drivethe

machineforwardupthe

ramp(s).

2.Machinewithemptyor

noattachment—backthe

machineuptheramp(s).

1.Tie-downloops

UnloadingtheMachine

1.Lowertheramp(s).

2.Unloadthemachinefromthetrailerwiththe

heavyenduptheramp,carryingloadslow.

•Ifthemachinehasafullload-bearing

attachment(e.g.,bucket)ora

non-load-bearingattachment(e.g.,

trencher),backitdowntheramp.

•Ifthemachinehasanemptyload-bearing

attachmentornoattachment,driveitforward

downtheramp.

g204457

1.Machinewithfull

attachmentor

non-load-bearing

attachment—backthe

machinedownthe

ramp(s).

Figure55

2.Machinewithemptyor

noattachment—drivethe

machineforwarddownthe

ramp(s).

g204458

6.Lowertheloaderarmsallthewaydown.

7.Engagetheparkingbrake,shutofftheengine,

andremovethekey.

8.Usethemetaltie-downloopsonthemachine

tosecurelyfastenthemachinetothetraileror

truckwithstraps,chains,cable,orropes.Refer

tolocalregulationsfortie-downrequirements.

38

LiftingtheMachine

Removeanyattachmentsandliftthemachineusing

the4liftpoints.

Donotexceeda30-degreeanglewhenliftingthe

machine;usetheminimumchainlengthsprovided

below.

Figure56

1.Chainlengthforrearliftpoint(2)—143.0cm(56.3inches)

2.Chainlengthforfrontliftpoint(2)—223.2cm(87.9inches)

g371939

39

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

MaintenanceSafety

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

•Parkthemachineonalevelsurface,disengage

theauxiliaryhydraulics,lowertheattachment,

engagetheparkingbrake(ifequipped),shut

offtheengine,andremovethekey .Waitforall

movementtostopandallowthemachinetocool

beforeadjusting,cleaning,storing,orrepairingit.

•Cleanupoilorfuelspills.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthecomponentswhen

required.

•Carefullyreleasepressurefromcomponents

withstoredenergy;refertoRelievingHydraulic

Pressure(page61).

•Disconnectthebatterybeforemakinganyrepairs;

refertoUsingtheBattery-DisconnectSwitch(page

51).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

•Keepyourhandsandfeetawayfromthemoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Donottamperwiththesafetydevices.

•Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthemachine.

•UseonlygenuineT ororeplacementparts.

•Ifanymaintenanceorrepairrequirestheloader

armstobeintheraisedposition,securethearms

intheraisedpositionwiththehydraulic-cylinder

lock(s).

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every50hours

•Checkandadjustthetracktension.

•Changetheengineoilandlter.

•Checkandadjustthetracktension.

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checktheair-lter-serviceindicator.

•Checktheengine-oillevel.

•Cleanthetracksandcheckforexcessivewearandpropertension.

•Cleanthescreen,oilcooler,andfrontoftheradiator(moreoftenindirtyordusty

conditions).

•Checkandcleantheradiatorscreen

•Checkthecoolantlevelintheexpansiontank.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

•Checkthehydraulic-uidlevel.

•Torquetheloaderarmadjustmentscrews.

•Drainwaterandothercontaminantsfromthewaterseparator.

•Checkthebatterycondition.

•Checkandadjustthetracktension.

40

MaintenanceService

Every100hours

Interval

MaintenanceProcedure

•Removetheair-cleanercoverandcleanoutdebris.(Cleanmoreoftenindirtyor

dustyconditions.)

•Checkthecoolingsystemhoses.

•Checkthealternator-belttension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather ,andchemicaldeterioration.

•Checkfordirtbuildupinthechassis.(Moreoftenindirtyconditions.)

•Checkthealternator/fanbelttension.

Every250hours

Every400hours

Every500hours

Every800hours

Every1,000hours

Every1,500hours

Every3,000hours

Yearlyorbeforestorage

Every2years

•Changetheengineoilandlter.

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Replacethehydraulicoilandlters(ifnotusingT orouid).

•Servicetheaircleaner.(Servicemorefrequentlyinextremelydustyordirty

conditions).

•Replacingthewaterseparatorlter.

•Drainandcleanthefueltank(s)—AuthorizedServiceDealeronly .

•Replacethealternator/fanbelt(refertotheengineowner’smanualforinstructions).

•Changetheenginecoolant.

•Replacethehydraulicoilandlters(ifusingTorouid).

•Replaceallmovinghydraulichoses.

•Disassemble,clean,andassemblethesootlteroftheDPForifenginefaultsSPN

3251FMI0,SPN3720FMI0,orSPN3720FMI16displayintheInfoCenter.

•Checkandadjustthetracktension.

•Touchupchippedpaint.

•Replaceallmovinghydraulichoses.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

41

Pre-Maintenance

Procedures

UsingtheCylinderLocks

WARNING

Theloaderarmsmaylowerwhenintheraised

position,crushinganyoneunderthem.

Installthecylinderlock(s)beforeperforming

maintenancethatrequiresraisedloaderarms.

5.Slidethecylinderlockoverthelift-cylinderrod.

InstallingtheCylinderLocks

1.Removetheattachment.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengineandremovethekey .

4.Loosentheknobsecuringthecylinderlockto

theloaderarm.

Figure57

1.Pin3.Handknob

2.Cylinderlock

g267536

Figure58

1.Cylinderlock3.Pin(2)

2.Lift-cylinderrod

6.Repeatstep4and5fortheothersideofthe

machine.

7.Slowlylowertheloaderarmsuntilthecylinder

lockscontactthecylinderbodiesandrodends.

8.Securetheloader-valvelock;referto

Loader-ValveLock(page14).

g359013

42

RemovingandStoringthe

CylinderLocks

Important:Removethecylinderlocksfromthe

rodsandfullysecuretheminthestorageposition

beforeoperatingthemachine.

1.Starttheengine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengineandremovethekey .

4.Removethepinssecuringthecylinderlocks.

5.Removethecylinderlocksfromthelift-cylinder

rods.

6.Insertthepinsintothelocks.

AccessingInternal

Components

WARNING

Openingorremovingcovers,hoods,and

screenswhiletheengineisrunningcould

allowyoutocontactmovingparts,seriously

injuringyou.

Beforeopeninganyofthecovers,hoods,and

screens,shutofftheengine,removethekey

fromthekeyswitch,andallowtheengineto

cool.

7.Placethecylinderlocksontheloaderarms,with