Page 1

FormNo.3422-426RevA

CEKit

Dingo

ModelNo.22366

®

323CompactToolCarrier

InstallationInstructions

Safety

SafetyandInstructional

Decals

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

100-1692

1.Brakeengaged3.Brakedisengaged

2.Parkingbrake

Installation

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

2

3

4

Nopartsrequired

Nopartsrequired

Brakebar2

Brake-barbracket2

Flange-headbolt2

Brake-cablebracket2

Parking-brakecable1

Lockingcollarwithsetscrew2

Largespring1

Convolutedcabletube

Bolt(5/16x1inch)

Locknut(5/16inch)

decal100-1692

Qty.

–

–

1

4

4

Preparethemachine.

Removetherear-wheelhubs.

Assembletheparking-brakelocking

mechanism.

Installtheparking-brakelocking

mechanism.

Use

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.T oro.com.

OriginalInstructions(EN)

PrintedintheUSA

AllRightsReserved

*3422-426*A

Page 2

ProcedureDescription

5

6

Parking-brakeleverassembly1

Clevispin(3/4inch)

Cotterpin(3/4inch)

Wheel-hubassembly2

Hublocknut2

Qty.

Use

1

1

Installtheparking-brakelever.

Installtherear-wheelhubs.

7

8

9

Nopartsrequired

Loader-valvelockassembly1

Self-tappingbolts(1/4x5/8inch)

Bolt(1/4x2inches)

Spacer

CE-informationdecal

1

PreparingtheMachine

NoPartsRequired

Procedure

1.Parkthemachineonalevelsurface.

2.Lowertheloaderarms.

3.Engagetheparkingbrake.

4.Shutofftheengineandremovethekey.

5.Raisethemachineoffthegroundandsupportit

usingjackstands.

Note:Usejackstandsratedforyourmachine.

RefertotheOperator’sManualforyourmachine

todeterminetheweight.

–

2

1

1

1

Adjusttheparkingbrake.

Installtheloader-valvelock.

InstalltheCE-informationdecal.

2

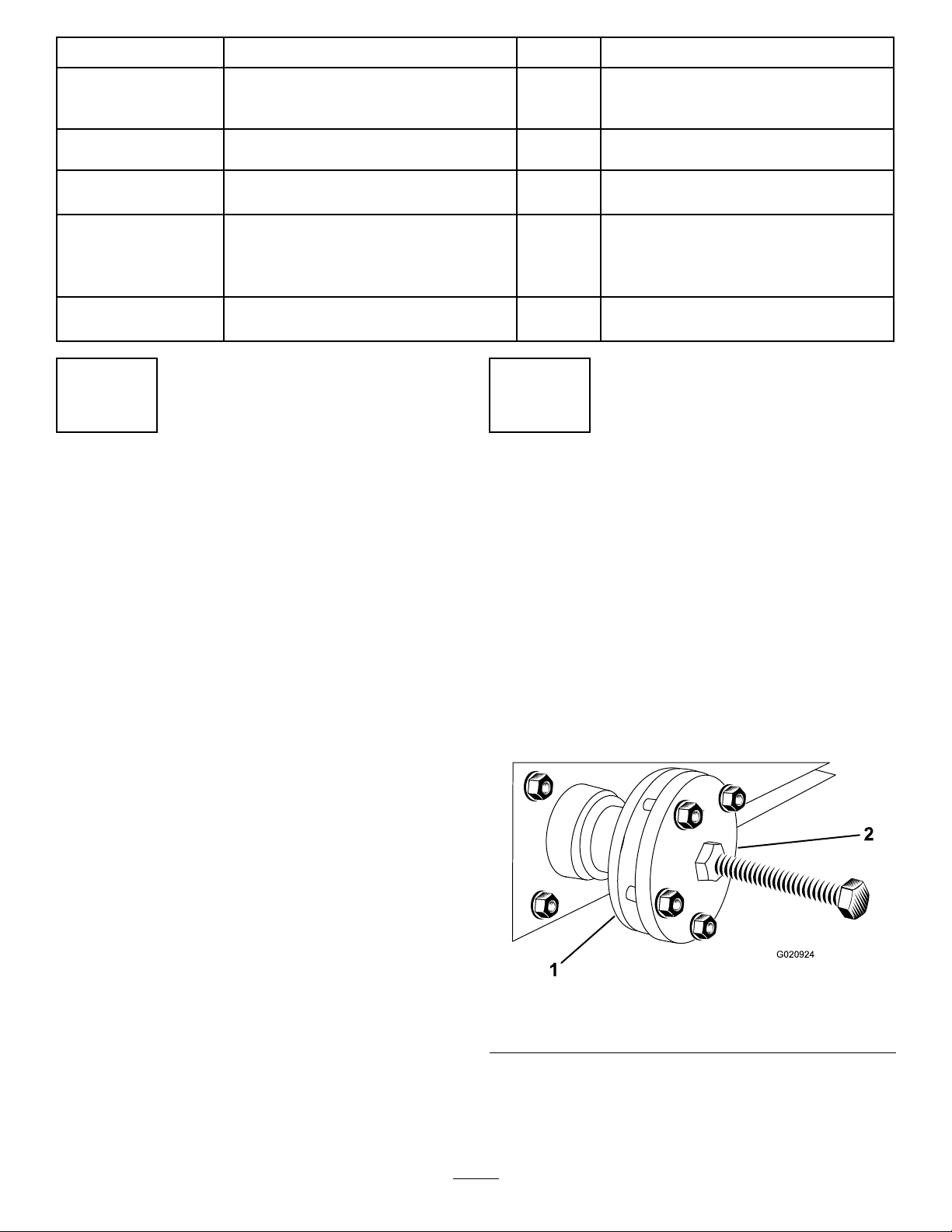

RemovingtheRear-Wheel Hubs

NoPartsRequired

Procedure

1.Removetherearwheels.

2.Removeanddiscardthelocknutssecuringthe

rear-wheelhubs.

3.Usingahubpuller(K-LineSpecialServiceT ools,

partnumberTOR4096),removetherear-wheel

hubs(Figure1).

1.Hub2.Hubpuller

4.Savethekeyfromeachshaft.

2

g020924

Figure1

Page 3

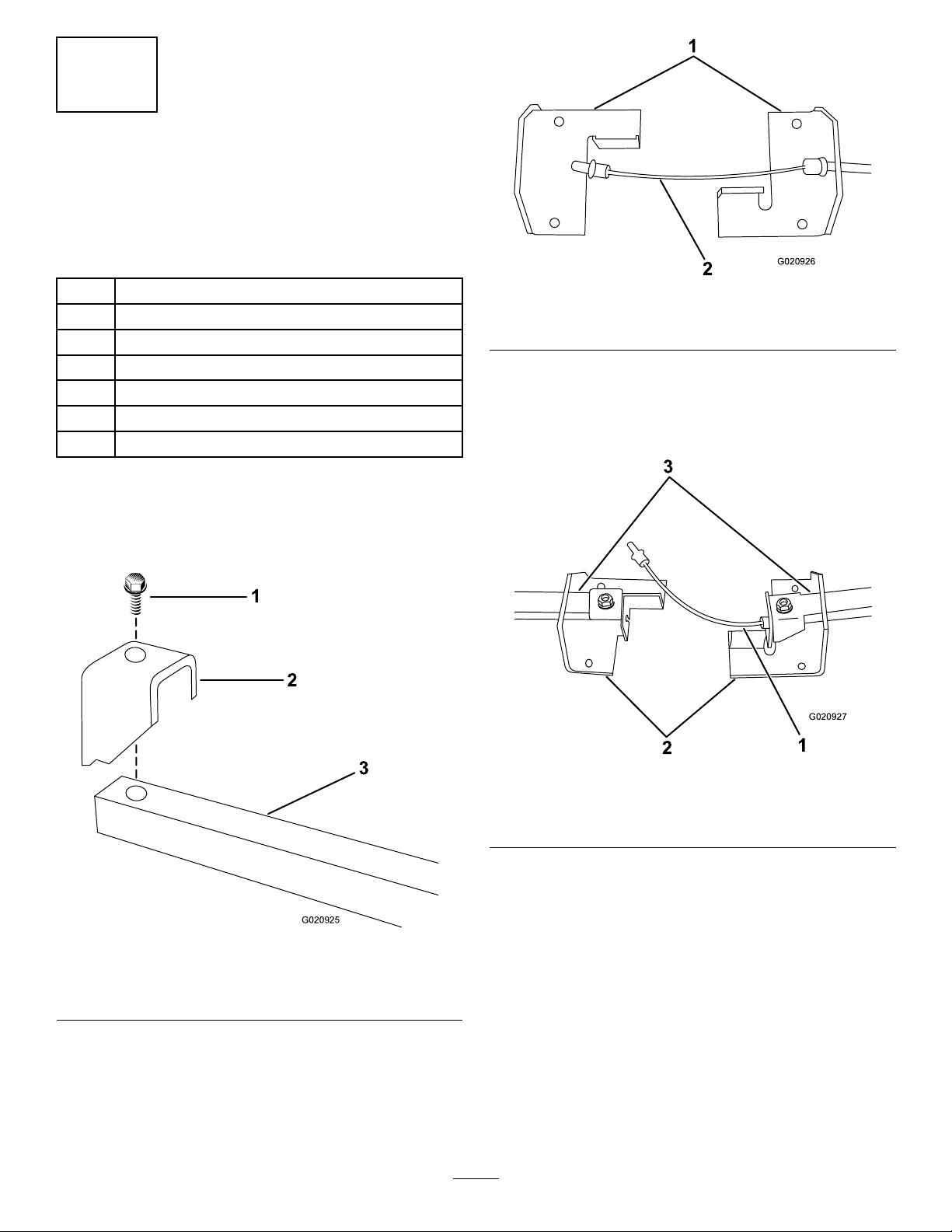

3

Assemblingthe

Parking-BrakeLocking

Mechanism

Partsneededforthisprocedure:

2Brakebar

2Brake-barbracket

2Flange-headbolt

2Brake-cablebracket

1Parking-brakecable

2Lockingcollarwithsetscrew

1Largespring

Procedure

1.Fastenthebrake-barbracketstothebrakebars

using2bolts(Figure2).

g020926

Figure3

1.Brake-cablebracket2.Brakecable

3.Insertthecablethroughtherightbrake-cable

bracket(Figure3).

4.Slidethebrake-cablebarsthroughtheopenings

inthebrake-cablebrackets(Figure4).

Figure2

1.Bolt3.Brakebar

2.Brake-barbracket

2.Arrangethebrakecablebracketsonaat

surface(Figure3).

g020927

Figure4

1.Brakecable3.Brake-cablebar

2.Brake-cablebracket

5.Setthecableintotherightbrake-barbracket,

andsecureitrmlyinplacewithalockingcollar

andsetscrewassembly(Figure5).

g020925

3

Note:Thecablemustbesecurelyheldinthe

bracketwithnomovement.

Page 4

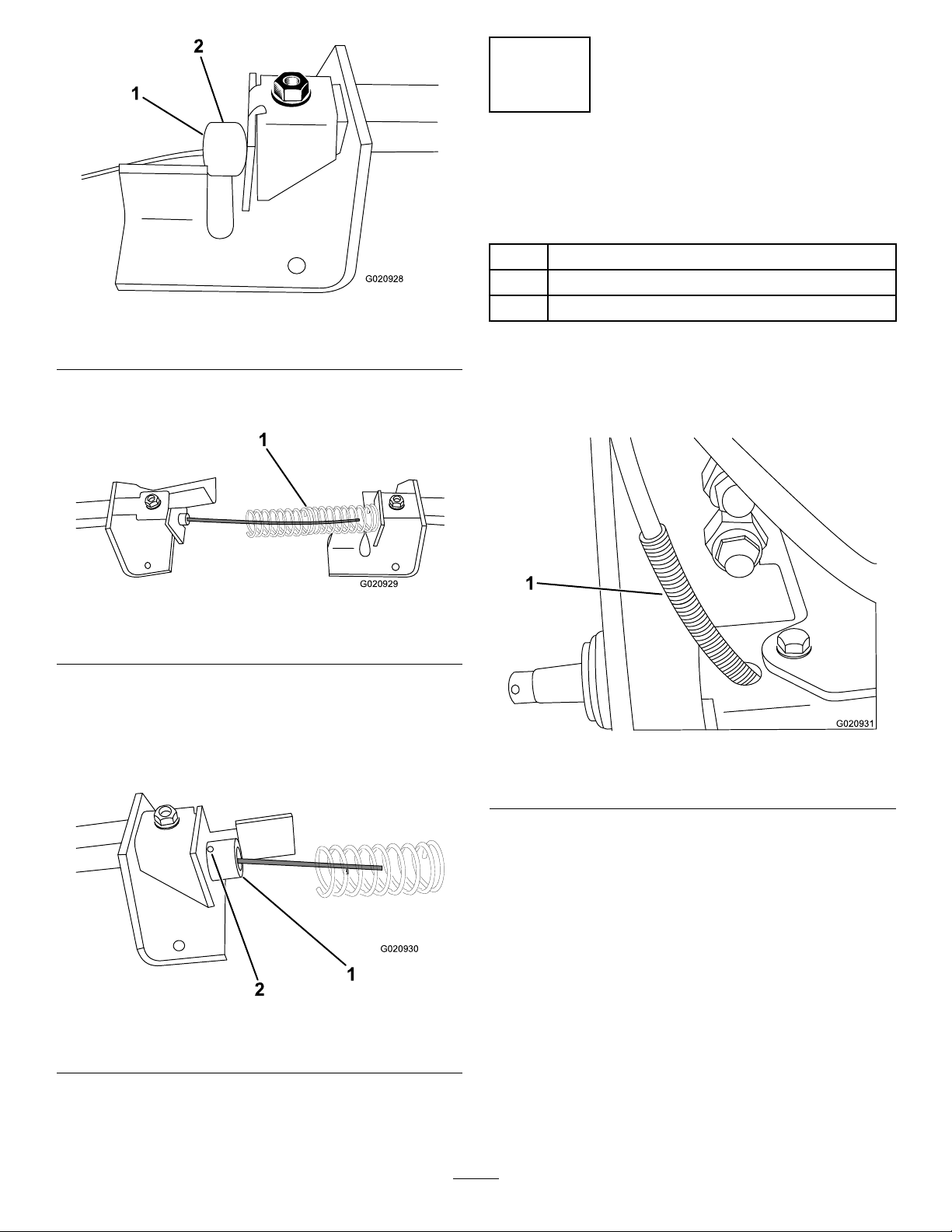

Figure5

4

InstallingtheParking-Brake LockingMechanism

Partsneededforthisprocedure:

1

Convolutedcabletube

4

g020928

4

Bolt(5/16x1inch)

Locknut(5/16inch)

1.Lockingcollar

6.Positionthelargespringoverthecable(Figure

6).

1.Largespring

7.Setthecableintotheleftbrake-barbracket,and

secureitwithalockingcollarandasetscrew

assembly(Figure7).

2.Setscrew

Figure6

Note:Thecablemustbesecurelyheldinthe

bracketwithnomovement.

Procedure

1.Slidetheconvolutedcabletubeoverthebrake

cable(Figure8).

g020929

g020931

Figure8

1.Parkingbrakecablewiththeconvolutedtube

1.Lockingcollar

Figure7

2.Setscrewassembly

2.Fromunderthemachine,routetheendofthe

cablethroughtheframeinthelower-leftcorner

oftheframe(Figure8).

Note:Ensurethatconvolutedcabletube

protrudesatleast10to15cm(4to6inches)

throughthehole.

3.Positionthebrakeassemblyunderthemachine

againstthebackoftheframewiththebrake

g020930

4

barsthroughtheholesinthesideoftheframe,

locatedinfrontofthewheelmotors(Figure9).

Page 5

5

InstallingtheParking-Brake Lever

Partsneededforthisprocedure:

1Parking-brakeleverassembly

1

Clevispin(3/4inch)

1

Cotterpin(3/4inch)

Procedure

Figure9

1.Rearwheelmotors

4.Securethebrakeassemblytotheframewiththe

4bolts(5/16x1inch)and4locknuts(5/16inch)

asshowninFigure9.

2.Bolts(5/16x1inch)

andlocknuts(5/16

inch)—fourthboltand

locknutnotvisible

Note:Y oumustpushtheboltsthroughthe

frameandthebrakecablebracketsfromthe

rearofthemachine.

g020932

1.Routethecableacrosstheparking-brakelever

assembly(Figure10).

Figure10

1.Parking-brakecable2.Parking-brakelever

assembly

2.Securethecabletotheleverwiththeclevispin

(3/4inch)andthecotterpin(3/4inch)asshown

inFigure11.

5

g020933

Page 6

Figure12

g020935

Figure11

1.Parking-brakelever3.Parking-brakecable

2.Clevispin(3/4inch)and

cotterpin(3/4inch)

3.Lightlytightenthenutsontheadjustmentcollar

aroundthebracketontheleverplate(Figure12).

1.Cablewithadjustment

nuts

g020934

4.Loosenthenutssecuringtheaircleanertothe

2.Bracketonthe

parking-brakelever

assembly

frame(Figure13).

Figure13

1.Air-cleanernuts2.Aircleaner

5.Slidetheboltsintheleverassemblyoverthe

air-cleanerboltsbetweentheframeandthe

air-cleanermounting-bracketasshowninFigure

14andFigure15.

6

g020936

Page 7

Figure15

g020938

Figure14

1.Leverassembly2.Lever-assemblyslots

1.Leverassembly3.Air-cleaner

mounting-bracket

g020937

2.Air-cleanerbolts

6.Withtheslotsintheplatepositionedoverthe

air-cleanerbolts,tightentheair-cleanernuts.

7

Page 8

6

InstallingtheRear-Wheel Hubs

Partsneededforthisprocedure:

2Wheel-hubassembly

2Hublocknut

Procedure

1.Cleantherear-driveshaftsandtheinsideofthe

taperedboreofthewheelhubswithalcoholora

degreaser(Figure16).

g020940

Figure17

1.Wheelhub(leftside)

5.Securethehubswithnewhublocknuts.

Figure16

1.Rear-driveshaft(leftside)

2.Disengagetheparking-brakelever.

3.Placethepreviously-removedkeysintotheslots

inthedriveshafts.

4.Placethenewwheelhubsontothedriveshafts

(Figure17).

6.Torquethenutsto406to474N∙m(300to350

ft-lb).

7.Installtherearwheels.

8.Torquethewheellugnutsto68N∙m(50ft-lb).

g020939

8

Page 9

7

AdjustingtheParking Brake

NoPartsRequired

Procedure

1.Pushtheparking-brakeleverupandforwardto

disengageit.

2.Checkthebrakebarsprotrudingfromeitherside

ofthemachine.

Note:Thebarsshouldbeabout3mm(1/8

inch)fromthewheelhubandneitherbarshould

beabletomovesidetoside.

3.Pulltheparking-brakeleverdowntoengageit.

Note:Thebarsshouldslideintothenotches

inthewheelhub.

4.Ifthebrakebarsmove,aretooclosetothe

wheelwhendisengaged,ordonotfullyengage

theslotsinthewheelhubwhenengaged,

correctitbyadjustingthe2adjustmentnutson

thecable(Figure12).

Figure18

1.Loader-valvelock

2.Removetheboltsecuringtheleftleverand

replaceitwiththebolt(1/4x2inches)andthe

spacer(Figure19).

2.Self-tappingbolts(1/4x

5/8inch)

g003566

8

InstallingtheLoader-Valve Lock

Partsneededforthisprocedure:

1Loader-valvelockassembly

2

Self-tappingbolts(1/4x5/8inch)

1

Bolt(1/4x2inches)

1

Spacer

Procedure

1.Using2self-tappingbolts(1/4x5/8inch),

looselyinstalltheloader-valvelockbehindthe

controllevers(Figure18).

Note:Theloadervalvelockshouldbeableto

slideforwardandbackwardintheslots.

g003597

Figure19

1.Bolt(1/4x2inches)2.Spacer

9

Page 10

3.Rotatetheloader-valvelockrearwardasshown

inFigure20.

Figure20

1.Loader-valvelock

4.Slidetheloader-valvelockrearwarduntilit

contactstheloaderarmandattachment-tilt

levers.

5.Tightentheself-tappingbolts(1/4x5/8inch)to

securetheloadervalvelock.

6.Pushforwardontheloaderarmand

attachment-tiltlevers.

9

InstallingtheCE-Compliant Decals

Partsneededforthisprocedure:

1

CE-informationdecal

Procedure

Installthedecalsontheleftsideofthemachine,near

g020941

thereartire.

1.Cleantheareawhereyouwillinstallthedecal.

2.Dampentheareawithwaterormildly-soapy

water.

3.Peelthedecalfromthebackingandinstallitin

place.

4.Squeegeeacrossthesurfaceofthedecal,

startingatthecenterofthedecalandworking

towardtheedgesusingoverlappingstrokes.

Note:Theyshouldnotmoveforwardatall.

Note:Iftheydo,loosentheself-tappingbolts

(1/4x5/8inch)andrepeatsteps4through6.

Important:Youwillneedtomovethe

leversrearwardtoengageordisengagethe

loader-valvelock.Theloader-valvelock

musttouchtheleverswhenitisdownand

theleversarereleased.

g249999

Figure21

1.CE-informationdecal

10

Page 11

Notes:

Page 12

Loading...

Loading...