CE Kit

For Dingo® 320-D Compact Utility Loaders with

260000001 and Higher Serial Numbers

Model No. 22365

Loose Parts

Use the chart below to verify that all parts have been shipped.

Form No. 3354-736 Rev C

Installation Instructions

Step

1

2

3

4

5

6

7

8

No parts required

No parts required

Brake bar

Brake bar bracket

Flange-head bolt

Brake bracket

Parking brake cable

Locking collar with set screw

Large spring

Convoluted cable tube

Bolt (5/16 x 1 inch)

Locknut (5/16 inch)

Parking brake lever assembly

Clevis pin (3/4 inch)

Cotter pin

Wheel hub assembly

Hub locknut

No parts required

Loader valve lock assembly

Self-tapping screws (1/4 x 5/8 inch)

Bolt (1/4 x 2 inches)

Spacer

Description

Qty.

–

–

2

2

2

2

1

2

1

1

4

4

1

1

3/4 inch

2

2

–

1

2

1

1

Prepare the traction unit.

Remove the rear wheel hubs.

Assemble the parking brake locking

mechanism.

Install the parking brake locking

mechanism.

Install the parking brake lever.

Install the rear wheel hubs.

Adjust the parking brake.

Install the loader valve lock.

Use

© 2006—The Toro® Company

8111 Lyndale Avenue South

Bloomington, MN 55420

Register at www.Toro.com. Original Instructions (EN)

Printed in the USA.

All Rights Reserved

Step

Auxiliary hydraulics lever gate

Spacer 2

Lever mount block

Thick washer

Lock washer (5/16 inch)

Flange-head bolt (8 x 20 mm)

Auxiliary hydraulics lever

9

10

Carriage bolt (1/4 x 2 inches)

Locknut (1/4 inch)

Torsion spring

Self-tapping screw (1/4 x 1-3/8

inches)

Lock washer (1/4 inch)

Nut (1/4 inch)

No parts required

Description

Qty.

1

1

1

1

1

1

2

2

1

1

1

1

–

Install the auxiliary hydraulics lever

gate.

Adjust the high-speed throttle

setting to 3200 rpm.

Use

11

12

13

Self-tapping screw (5/16 x 3/4 inch)

CE information decal, 108-9738

European noise decal, 108-4725

Danger decal, 100-1701

Caution decal, 100-1702

Speed limiter decal, 100-1703

Control panel decal, 108-9733

Pinch decal, 100-8821

No rider decal, 100-8822

Hydraulic oil decal, 93-6686

Radiator cap decal, 106-5976

Delaration of Conformity

Step

1

Preparing the Traction Unit

1

1

1

1

1

1

1

4

2

1

1

1

Secure the rear access cover.

Install the CE compliant decals.

Obtain an Operator’s Manual.

Step

2

Removing the Rear Wheel

No Parts Required

Procedure

1. Stop the engine , lo w er the loader ar ms , and

remo v e the k ey .

2. Hoist the rear of the traction unit off of the

g round and secure it with jac k stands under the

frame so that y ou can safely w ork under it and

remo v e the rear wheels .

Hubs

No Parts Required

Procedure

1. R emo v e the rear wheels .

2. R emo v e and discard the loc kn uts securing the

rear wheel hubs .

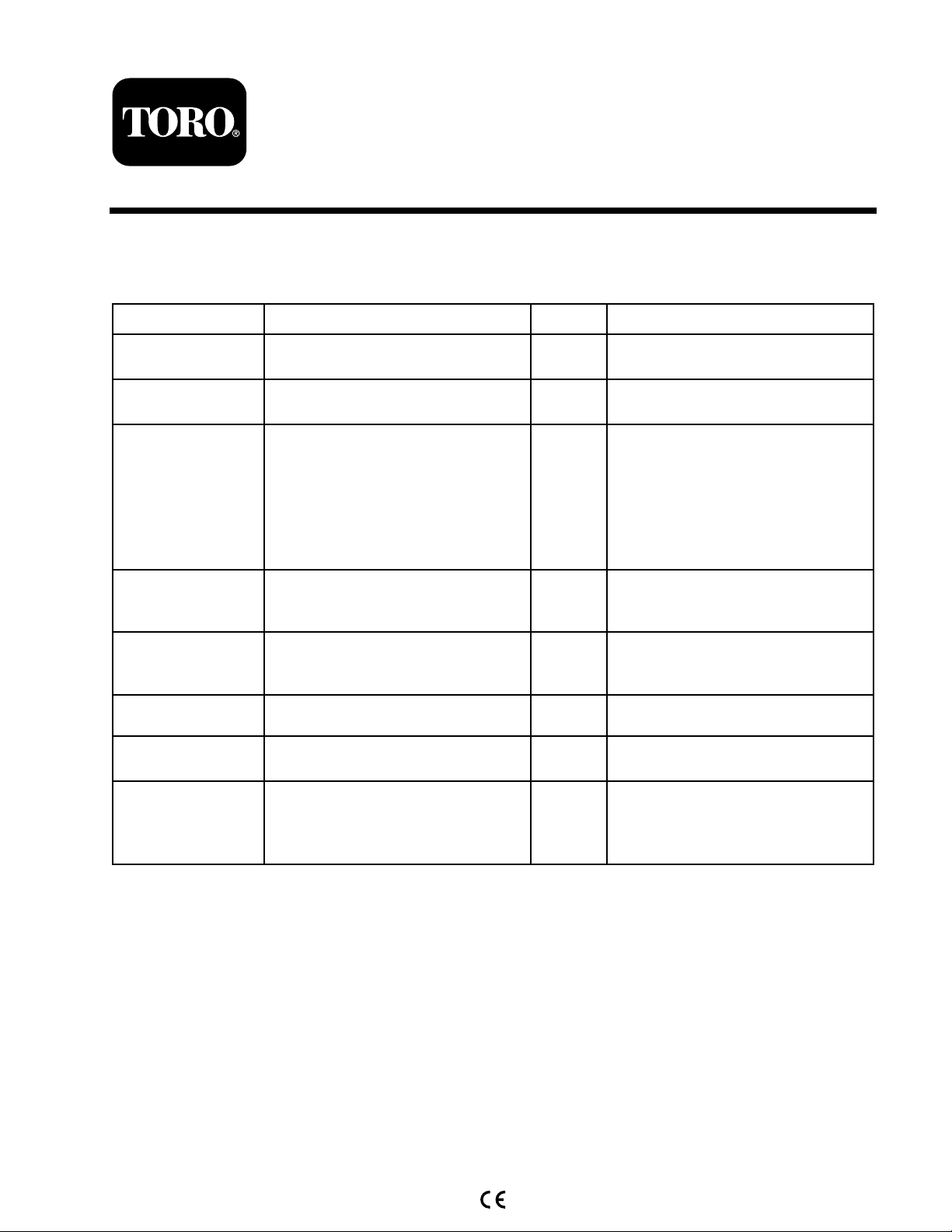

3. Using a hub puller (Ow atonna T ool Company

(OTC) par t n umber TOR4096), remo v e the

rear wheel hubs ( Figure 1 ).

2

Note: Y ou can contact OTC at

www .OTCtools .com .

Figure 1

1. Hub 2. Hub puller

4. Sa v e the k ey from eac h shaft.

Step

3

Assembling the Parking

Brake Locking Mechanism

Parts needed for this step:

2

Brake bar

2

Brake bar bracket

2

Flange-head bolt

2

Brake bracket

1

Parking brake cable

2

Locking collar with set screw

1

Large spring

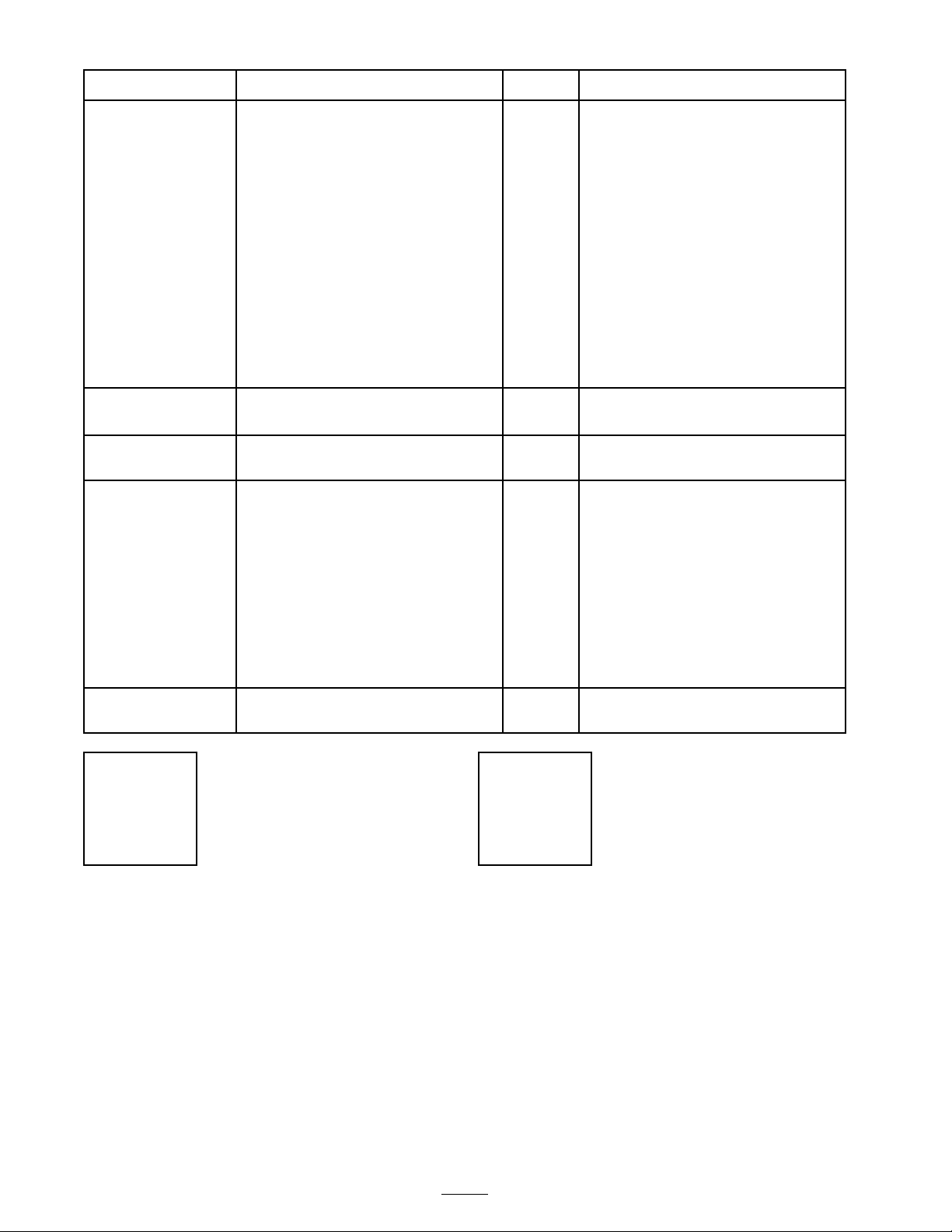

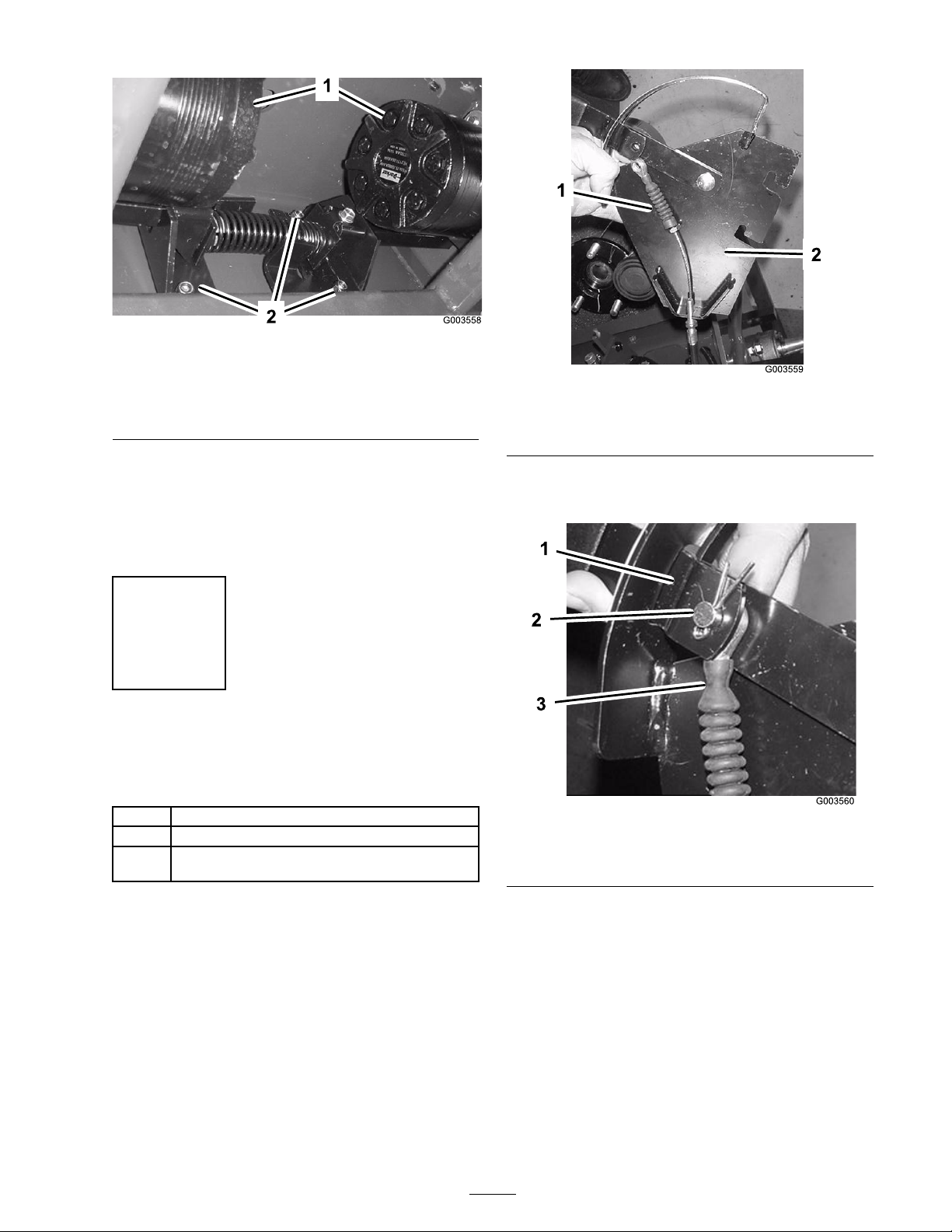

Figure 2

1. Brake bar 3. Flange-head bolt

2. Brake bar bracket

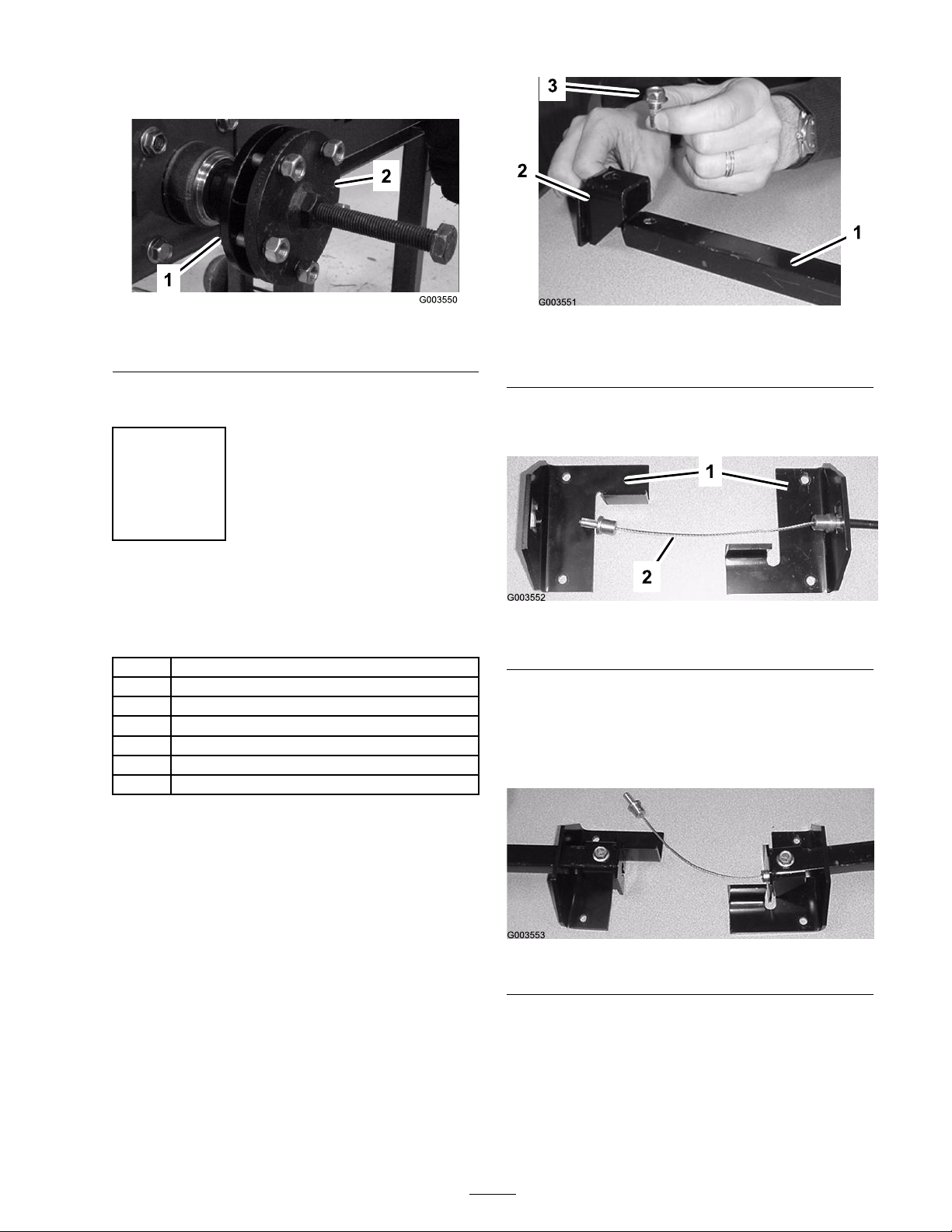

2. Ar rang e the brak e brac k ets on a table as sho wn

in Figure 3 .

Figure 3

1. Brake brackets 2. Brake cable

3. Inser t the cable through the right brak e brac k et

as sho wn in Figure 3 .

4. Slide the bars through the openings in the

brak e brac k ets as sho wn in Figure 4 .

Procedure

1. F asten the brak e bar brac k ets to the brak e bars

using 2 flang e-head bolts ( Figure 2 ).

Figure 4

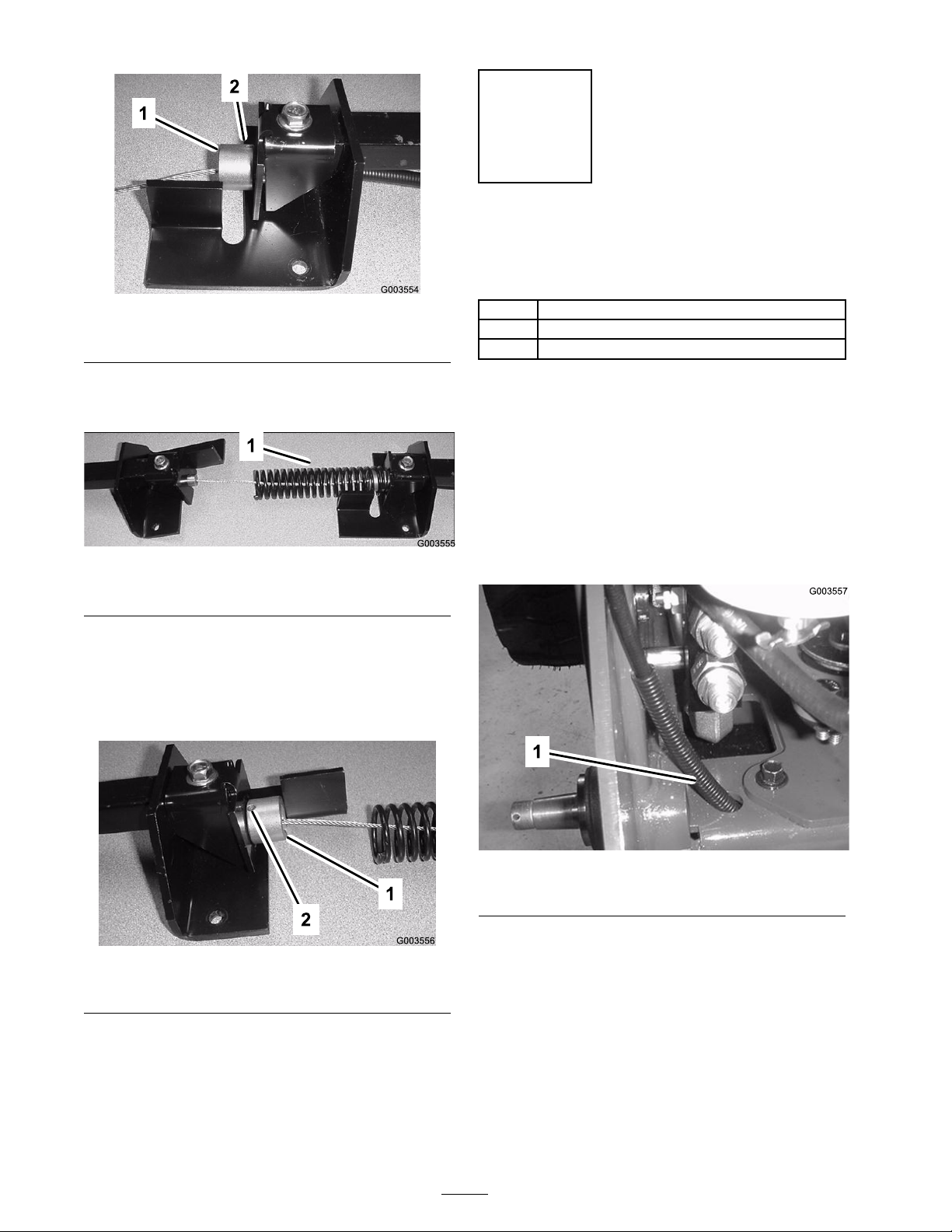

5. Set the cable into the right brak e bar brac k et,

and secure it fir mly in place with a loc king

collar and set screw assembly ( Figure 5 ). T he

cable m ust be securely held in the brac k et with

no mo v ement at all.

3

Step

4

Installing the Parking Brake

Locking Mechanism

Parts needed for this step:

Figure 5

1. Locking collar

2. Set screw

6. P osition the larg e spring o v er the cable ( Figure

6 ).

Figure 6

1. Large spring

7. Set the cable into the left brak e bar brac k et,

and secure it fir mly in place with a loc king

collar and set screw assembly ( Figure 7 ). T he

cable m ust be securely held in the brac k et with

no mo v ement at all.

1

Convoluted cable tube

4

Bolt (5/16 x 1 inch)

4

Locknut (5/16 inch)

Procedure

1. Slide the con v oluted tube o v er the brak e cable

( Figure 8 ).

2. F rom under the mac hine , route the end of

the cable through the frame in the lo w er left

cor ner of the frame ( Figure 8 ). Ensure that the

con v oluted tube protr udes at least 4 to 6 in.

(10 to 15 cm) through the hole .

1. Locking collar

Figure 7

Figure 8

1. Parking brake cable with the convoluted tube

3. P osition the brak e assembly under the traction

unit ag ainst the bac k w all of the frame with

2. Set screw

the brak e bars through the rectangular holes in

the sides of the frame , located in front of the

wheel motors ( Figure 9 ).

4

Figure 9

1. Rear wheel motors

2. Bolts (5/16 x 1 inch)

and locknuts (5/16 inch)

(fourth bolt and locknut

not visible)

4. Secure the brak e assembly to the frame with

4 bolts (5/16 x 1 in.) and loc kn uts (5/16

in.) ( Figure 9 ). T he bolts should be pushed

through the frame and brak e brac k ets from the

rear of the mac hine .

Step

5

Installing the Parking Brake

Lever

Parts needed for this step:

Figure 10

1. Parking brake cable 2. Parking brake lever

assembly

2. Secure the cable to the lev er with a clevis pin

and cotter pin (3/4 in.) ( Figure 11 ).

1

Parking brake lever assembly

1

Clevis pin (3/4 inch)

3/4

inch

Cotter pin

Procedure

1. R oute the cable across the parking brak e lev er

assembly ( Figure 10 ).

Figure 11

1. Parking brake lever 3. Parking brake cable

2. Clevis pin and cotter pin

3. Lightly tighten the n uts on the adjustment

collar around the brac k et on the lev er plate

( Figure 12 ).

5

Loading...

Loading...