FormNo.3430-855RevB

AdjustableForks

TX1000CompactToolCarriers

ModelNo.22341—SerialNo.404797000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3430-855*B

WARNING

CALIFORNIA

Proposition65Warning

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Introduction

Theadjustableforksattachmentisaload-bearing

attachmentintendedtobeusedonaTorotoolcarrier.

Itisdesignedprimarilyformovingmaterialsuchas

posts,rocks,trees,pallets,etc.Usingthisproduct

forpurposesotherthanitsintendedusecouldprove

dangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.Toro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

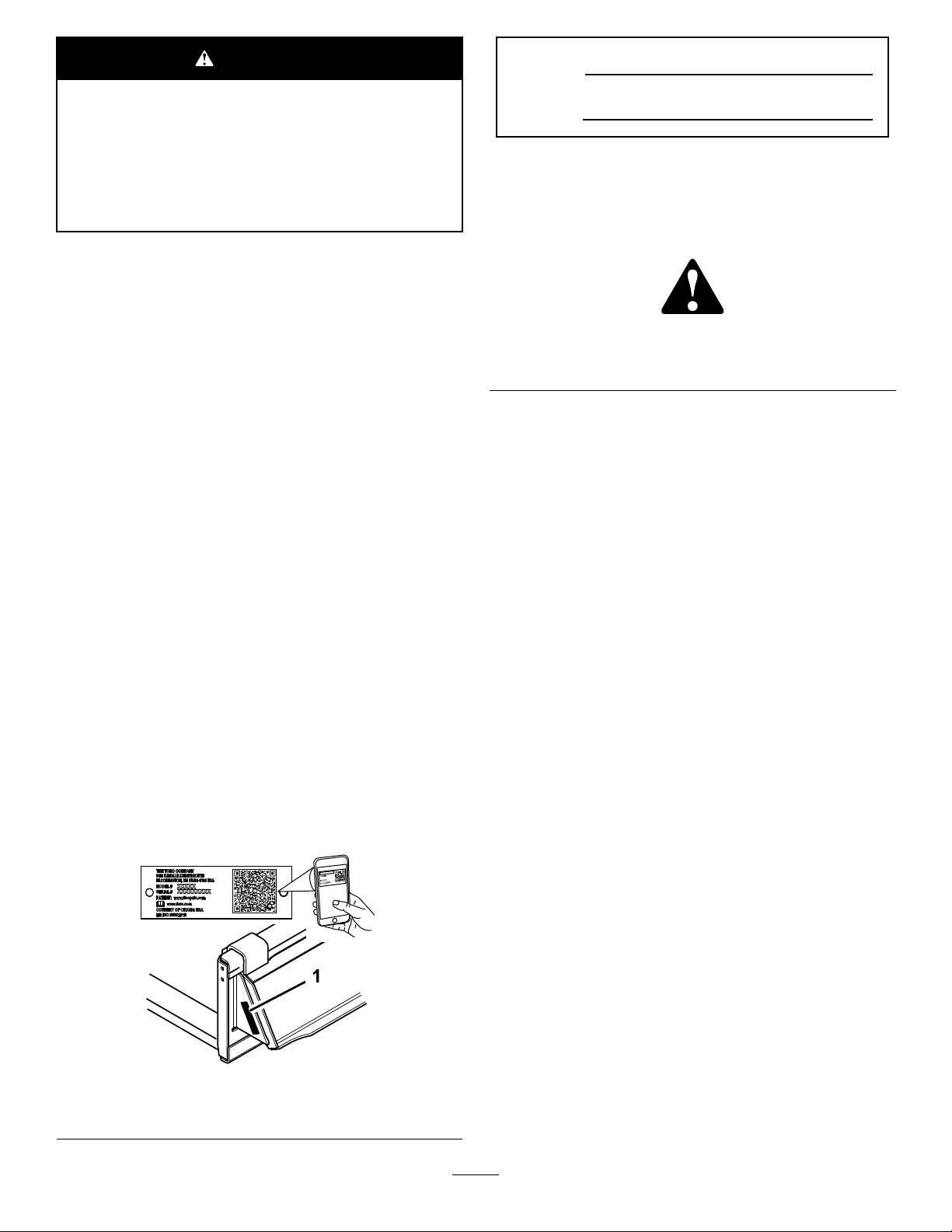

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g000502

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................3

GeneralSafety...................................................3

SlopeSafety.......................................................3

ForksSafety.......................................................3

MaintenanceandStorageSafety........................4

SafetyandInstructionalDecals..........................4

Setup........................................................................5

1AssemblingtheForks......................................5

ProductOverview.....................................................6

Specications....................................................6

Operation..................................................................6

InstallingandRemovingtheAttachment.............6

TransportPosition..............................................6

OperatingTips...................................................7

Storage.....................................................................7

1.Modelandserialnumberlocation

©2020—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure1

g242361

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Safety

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

•Donottransportanattachmentwiththearms

raised.Alwaystransporttheattachmentcloseto

theground;refertoTransportPosition(page6).

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsawayfromthemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.Anempty

load-bearingattachmentmakestherearofthe

machinetheheavyend,andafullload-bearing

attachmentmakesthefrontofthemachinethe

heavyend.Mostotherattachmentsmakethefront

ofmachinetheheavyend.

•Keeptheattachmentintheloweredposition

whenonslopes.Raisingtheattachmentona

slopeaffectsthestabilityofthemachine.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

,which

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.T allgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Evaluatetheareatoensurethatthegroundis

stableenoughtosupportthemachine.

•Usecautionwhenoperatingthemachinenearthe

following:

–Drop-offs

–Ditches

–Embankments

–Bodiesofwater

Themachinecouldsuddenlyrolloverifatrack

goesovertheedgeortheedgecavesin.Maintain

asafedistancebetweenthemachineandany

hazard.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

ForksSafety

•Alwayslowertheattachmentandshutoffthe

machineeachtimeyouleavetheoperating

position.

•Cleananydirtordebristhatmayhinderconnecting

theattachmenttothemachine.Ensurethatthe

attachment-lockingpinsarefullyseatedinthe

holesoftheattachment-mountplate.Refertothe

Operator’sManualforthemachinefordetailed

informationonsafelyconnectinganattachmentto

yourmachine.

3

•Whenliftingtheattachmentkeepitleveland

preventtheloadfromspillingbackward.

•Inspecttheforksfordamageaftereachuse.

MaintenanceandStorage

Safety

•Checkfastenersatfrequentintervalsforproper

tightnesstoensurethattheequipmentisinsafe

operatingcondition.

•RefertotheOperator’sManualforimportant

detailsifyoustoretheattachmentforanextended

periodoftime

•Maintainorreplacesafetyandinstructionlabels,

asnecessary.

SafetyandInstructional

Decals

Safetydecalsandinstructionsare

easilyvisibletotheoperatorandare

locatednearanyareaofpotential

danger.Replaceanydecalthatis

damagedormissing.

decal133-0219

133-0219

1.Tippinghazard—readtheOperator'sManual;fortheTX

1000donotexceedloadsof272kg(600lb);forother

modelsdonotexceedloadsof91kg(220lb).

133-0220

1.Tippinghazard—readtheOperator'sManual;fortheTX

1000donotexceedloadsof272kg(600lb);forother

modelsdonotexceedloadsof91kg(220lb).

133-8061

decal133-0220

decal133-8061

4

Setup

LooseParts

Usethechartbelowtoverifythatallpartshavebeenshipped.

ProcedureDescription

1

1

AssemblingtheForks

Partsneededforthisprocedure:

1

Adjustable-forksframe

2Fork

1

Upperforkframe

7

Bolt(3/8x1inch)

7

Locknut(3/8inch)

Adjustable-forksframe

Fork2

Upperforkframe

Bolt(3/8x1inch)

Locknut(3/8inch)

Qty.

Use

1

1

7

7

Assembletheforks.

Procedure

1.Installtheforksovertheadjustable-forksframe

asshowninFigure3,andsecureeachforkwith

abolt(3/8x1inch)andlocknut(3/8inch).

Figure3

1.Fork

2.Forkframe

3.Upperforkframe

2.Installtheupperforkframeovertheassembly

asshowninFigure3,andsecuretheupper

frameusing5bolts(3/8x1inch)and5locknuts

(3/8inch).

3.Tightenallfastenerssecurely.

4.Bolt(3/8x1inch)

5.Locknut

g001353

5

ProductOverview

1.Fork

2.Adjustable-forksframe

Figure4

3.Upperframe

Operation

InstallingandRemoving

theAttachment

RefertotheOperator’sManualforthetractionunitfor

theinstallationandremovalprocedure.

Important:Beforeinstallingtheattachment,

positionthemachineonalevelsurface,ensure

thatthemountplatesarefreeofanydirtordebris,

andensurethatthepinsrotatefreely .Ifthepins

donotrotatefreely,greasethem.

Note:Alwaysusethetractionunittoliftandmove

theattachment.

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

g001354

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Overallwidth80cm(31inches)

Overalllength115cm(45inches)

Overallheight69cm(27inches)

Weight

Forklength

Forkcross-sectionsize

Forkwithadjustmentrange

(outsidetooutsidedimensions)

Loadratingcapacity(perSAE

J1197)

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

103kg(226lb)

91cm(36inches)

10.2x3.2cm(4.0x1inches)

23to76cm(9to30inches)

272kg(600lb)

TransportPosition

Whentransportingaload,keeptheattachmentas

closetothegroundaspossible,nomorethan15cm

(6inches)abovetheground.Tiltitrearwardtokeep

theloadlevel.

Figure5

1.Nomorethan15cm(6

inches)abovetheground

2.Tilttheloadrearward

g242374

6

OperatingTips

•Toadjusttheforks,slidethemalongtheframeto

thedesiredwidth.Adjusttheforkstothewidest

possiblesettingtoensurethattheloadisasstable

aspossible.

•Whentransportingaload,keeptheforksasclose

tothegroundaspossible.

•Neverusetheforksforpryingasdamagemay

occur.

•Neverattempttoliftmorethantheratedlift

capacityofthetractionunit.

Storage

1.Beforelong-termstorage,washtheattachment

withmilddetergentandwatertoremovedirtand

grime.

2.Paintallscratchedorbaremetalsurfaces.

Note:PaintisavailablefromyourAuthorized

ServiceDealer.

3.Storetheattachmentinaclean,drygarageor

storagearea.Coverittoprotectitandkeepit

clean.

7

CaliforniaProposition65WarningInformation

Whatisthiswarning?

Youmayseeaproductforsalethathasawarninglabellikethefollowing:

WARNING:CancerandReproductiveHarm—www.p65Warnings.ca.gov.

WhatisProp65?

Prop65appliestoanycompanyoperatinginCalifornia,sellingproductsinCalifornia,ormanufacturingproductsthatmaybesoldinorbroughtinto

California.ItmandatesthattheGovernorofCaliforniamaintainandpublishalistofchemicalsknowntocausecancer,birthdefects,and/orother

reproductiveharm.Thelist,whichisupdatedannually,includeshundredsofchemicalsfoundinmanyeverydayitems.ThepurposeofProp65isto

informthepublicaboutexposuretothesechemicals.

Prop65doesnotbanthesaleofproductscontainingthesechemicalsbutinsteadrequireswarningsonanyproduct,productpackaging,orliteraturewith

theproduct.Moreover,aProp65warningdoesnotmeanthataproductisinviolationofanyproductsafetystandardsorrequirements.Infact,the

CaliforniagovernmenthasclariedthataProp65warning“isnotthesameasaregulatorydecisionthataproductis‘safe’or‘unsafe.’”Manyofthese

chemicalshavebeenusedineverydayproductsforyearswithoutdocumentedharm.Formoreinformation,gotohttps://oag.ca.gov/prop65/faqs-view-all

AProp65warningmeansthatacompanyhaseither(1)evaluatedtheexposureandhasconcludedthatitexceedsthe“nosignicantrisklevel”;or(2)

haschosentoprovideawarningbasedonitsunderstandingaboutthepresenceofalistedchemicalwithoutattemptingtoevaluatetheexposure.

Doesthislawapplyeverywhere?

Prop65warningsarerequiredunderCalifornialawonly.ThesewarningsareseenthroughoutCaliforniainawiderangeofsettings,includingbutnot

limitedtorestaurants,grocerystores,hotels,schools,andhospitals,andonawidevarietyofproducts.Additionally ,someonlineandmailorder

retailersprovideProp65warningsontheirwebsitesorincatalogs.

.

HowdotheCaliforniawarningscomparetofederallimits?

Prop65standardsareoftenmorestringentthanfederalandinternationalstandards.TherearevarioussubstancesthatrequireaProp65warning

atlevelsthatarefarlowerthanfederalactionlimits.Forexample,theProp65standardforwarningsforleadis0.5μg/day,whichiswellbelow

thefederalandinternationalstandards.

Whydon’tallsimilarproductscarrythewarning?

•ProductssoldinCaliforniarequireProp65labellingwhilesimilarproductssoldelsewheredonot.

•AcompanyinvolvedinaProp65lawsuitreachingasettlementmayberequiredtouseProp65warningsforitsproducts,butothercompanies

makingsimilarproductsmayhavenosuchrequirement.

•TheenforcementofProp65isinconsistent.

•CompaniesmayelectnottoprovidewarningsbecausetheyconcludethattheyarenotrequiredtodosounderProp65;alackofwarningsfora

productdoesnotmeanthattheproductisfreeoflistedchemicalsatsimilarlevels.

WhydoesToroincludethiswarning?

Torohaschosentoprovideconsumerswithasmuchinformationaspossiblesothattheycanmakeinformeddecisionsabouttheproductstheybuyand

use.T oroprovideswarningsincertaincasesbasedonitsknowledgeofthepresenceofoneormorelistedchemicalswithoutevaluatingthelevelof

exposure,asnotallthelistedchemicalsprovideexposurelimitrequirements.WhiletheexposurefromT oroproductsmaybenegligibleorwellwithinthe

“nosignicantrisk”range,outofanabundanceofcaution,T orohaselectedtoprovidetheProp65warnings.Moreover ,ifTorodoesnotprovidethese

warnings,itcouldbesuedbytheStateofCaliforniaorbyprivatepartiesseekingtoenforceProp65andsubjecttosubstantialpenalties.

RevA

Loading...

Loading...