FormNo.3422-276RevA

320-DCompactToolCarrier

ModelNo.22337CP—SerialNo.401350000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3422-276*A

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

WARNING

CALIFORNIA

Proposition65Warning

Dieselengineexhaustandsomeofits

constituentsareknowntotheStateof

Californiatocausecancer,birthdefects,

andotherreproductiveharm.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

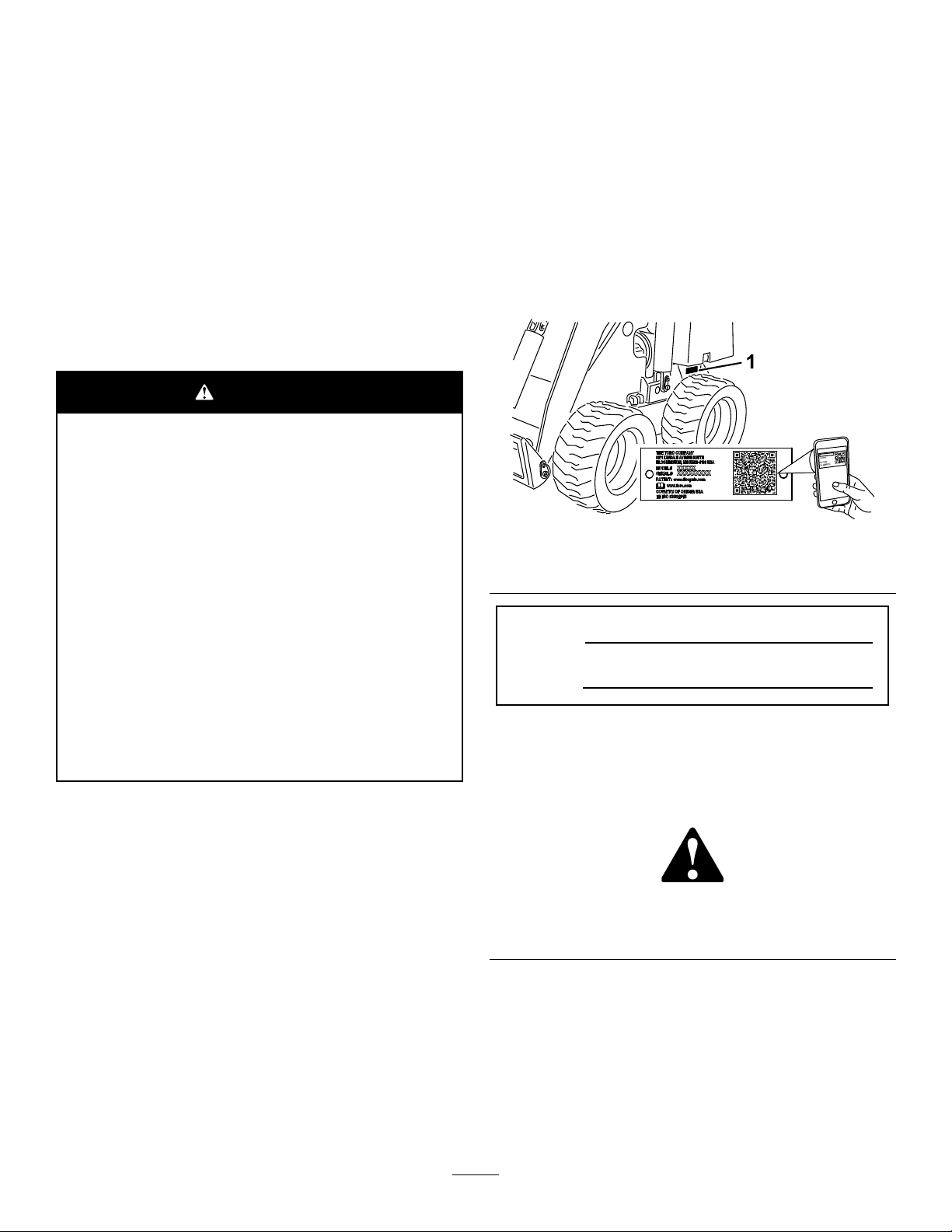

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

g237186

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Introduction

Thismachineisacompacttoolcarrierintendedfor

useinvariousearthandmaterialsmovingactivitiesfor

landscapingandconstructionwork.Itisdesignedto

operateawidevarietyofattachmentseachofwhich

performaspecializedfunction.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely.

YoumaycontactT orodirectlyatwww.T oro.com

forproductsafetyandoperationtrainingmaterials,

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

2

g000502

Contactusatwww.Toro.com.

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

Setup........................................................................9

1InstallingtheSpeed-SelectorLever..................9

2CheckingtheFluidLevelsandTire

Pressure.........................................................9

3ChargingtheBattery......................................10

4SettingtheEngineSpeed..............................10

ProductOverview....................................................11

Controls...........................................................12

Specications..................................................14

Attachments/Accessories.................................14

BeforeOperation.................................................15

BeforeOperationSafety...................................15

AddingFuel......................................................15

PerformingDailyMaintenance..........................16

AdjustingtheThighSupport..............................16

DuringOperation.................................................17

DuringOperationSafety...................................17

StartingtheEngine...........................................18

DrivingtheMachine..........................................18

ShuttingOfftheEngine.....................................18

UsingAttachments...........................................19

AfterOperation....................................................21

AfterOperationSafety......................................21

MovingaNon-FunctioningMachine..................21

TransportingtheMachine.................................21

LiftingtheMachine...........................................23

Maintenance...........................................................24

RecommendedMaintenanceSchedule(s)...........24

Pre-MaintenanceProcedures..............................25

MaintenanceSafety..........................................25

UsingtheCylinderLocks..................................25

AccessingInternalComponents.......................26

Lubrication..........................................................27

GreasingtheMachine.......................................27

EngineMaintenance...........................................27

EngineSafety...................................................27

ServicingtheAirCleaner..................................27

ServicingtheEngineOil....................................28

FuelSystemMaintenance...................................30

DrainingWaterfromtheFuelFilter....................30

ChangingtheFuelFilter....................................30

BleedingtheFuelSystem.................................31

DrainingtheFuelT ank......................................31

ElectricalSystemMaintenance...........................32

ElectricalSystemSafety...................................32

ServicingtheBattery.........................................32

DriveSystemMaintenance..................................34

CheckingtheTirePressure...............................34

CheckingtheWheel-LugNuts..........................34

CoolingSystemMaintenance..............................34

CoolingSystemSafety.....................................34

CleaningtheRadiatorScreen...........................34

CheckingtheEngine-CoolantLevel..................34

ChangingtheEngineCoolant...........................35

BrakeMaintenance.............................................35

TestingtheParkingBrake.................................35

HydraulicSystemMaintenance...........................36

HydraulicSystemSafety...................................36

HydraulicFluidSpecications...........................36

CheckingtheHydraulic-FluidLevel...................36

ReplacingtheHydraulicFilter...........................37

ChangingtheHydraulicFluid............................37

Cleaning..............................................................38

RemovingDebris..............................................38

Storage...................................................................38

StorageSafety..................................................38

Storage.............................................................38

Troubleshooting......................................................39

Schematics.............................................................43

3

Safety

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.Usingthisproductforpurposesother

thanitsintendedusecouldprovedangeroustoyou

andbystanders.

•Donotcarryaloadwiththearmsraised;always

carryloadsclosetotheground.

•Keepbystandersandpetsasafedistanceaway

fromthemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury .Toreducethepotentialforinjury ,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphillandtheload

closetotheground.Weightdistributionchanges

withattachments.Anemptybucketmakesthe

rearofthemachinetheheavyend,andafull

bucketmakesthefrontofthemachinetheheavy

end.Mostotherattachmentsmakethefrontofthe

machinetheheavyend.

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

4

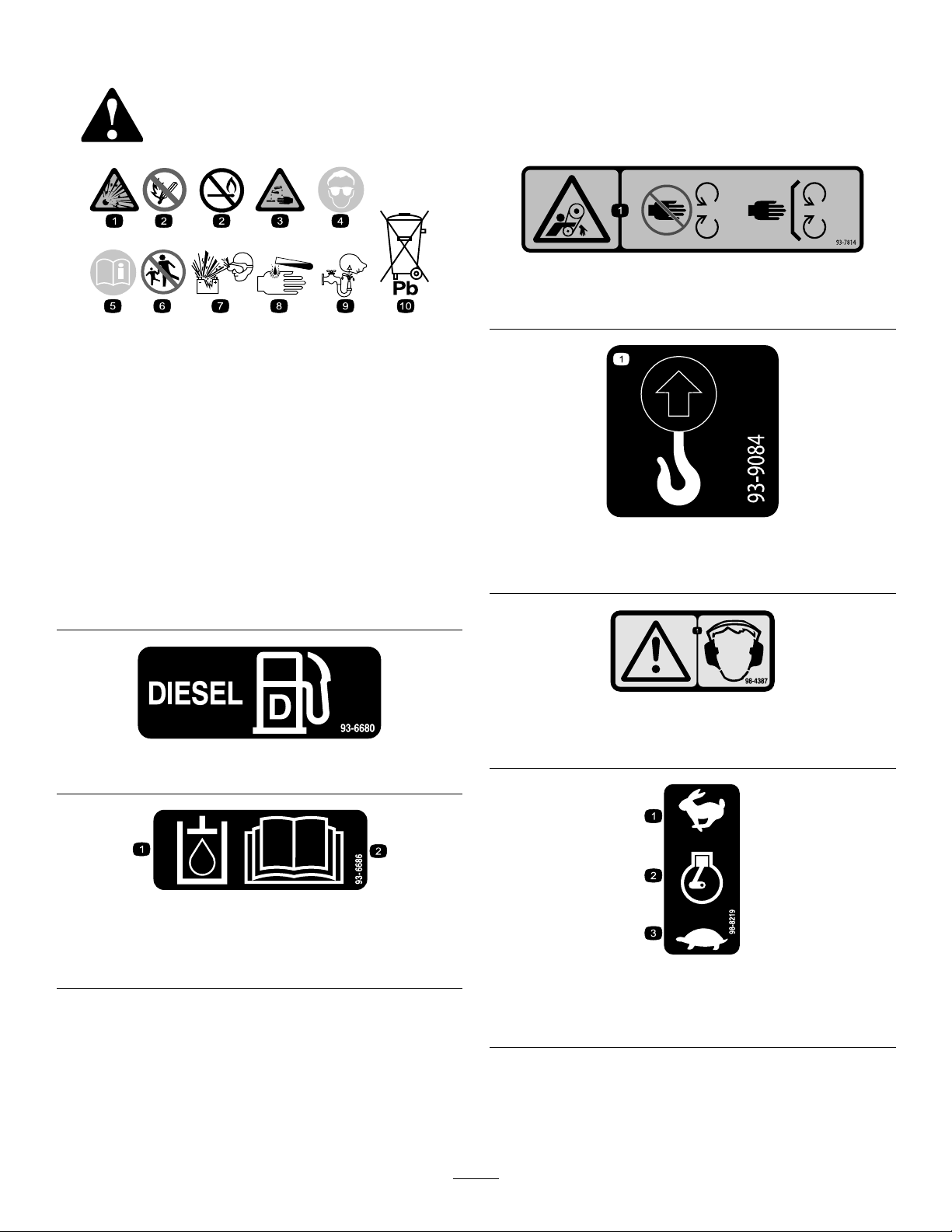

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

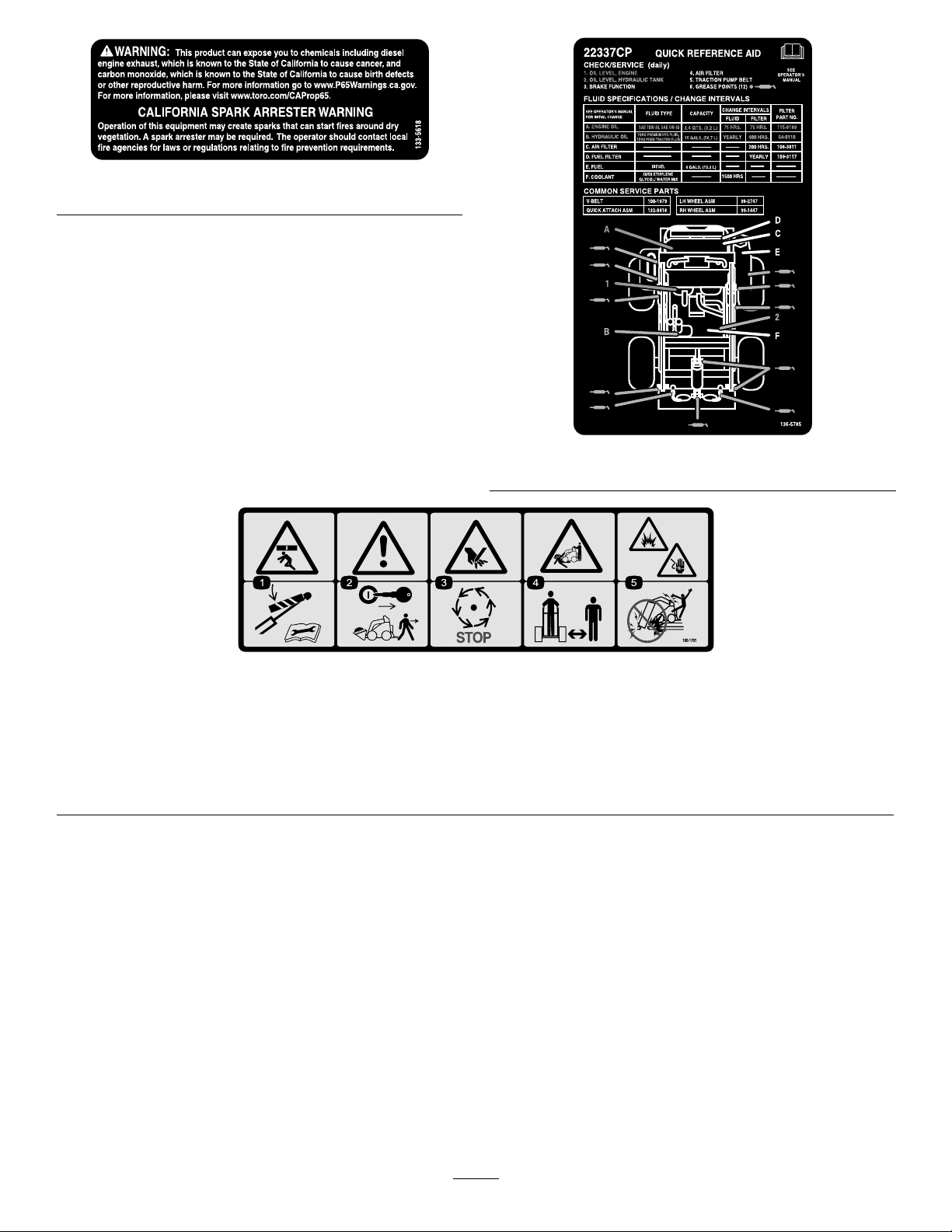

decal93-7814

93-7814

BatterySymbols

Someorallofthesesymbolsareonyourbattery.

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distanceawayfromthe

battery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

93-6680

decalbatterysymbols

decal93-9084

93-9084

1.Entanglementhazard,belt—stayawayfrommovingparts.

1.Liftpoint/Tie-downpoint

decal98-4387

98-4387

decal93-6680

1.Warning—wearhearingprotection.

1.Hydraulicuid

2.ReadtheOperator'sManual.

decal93-6686

93-6686

decal98-8219

98-8219

1.Fast

2.Throttle

3.Slow

5

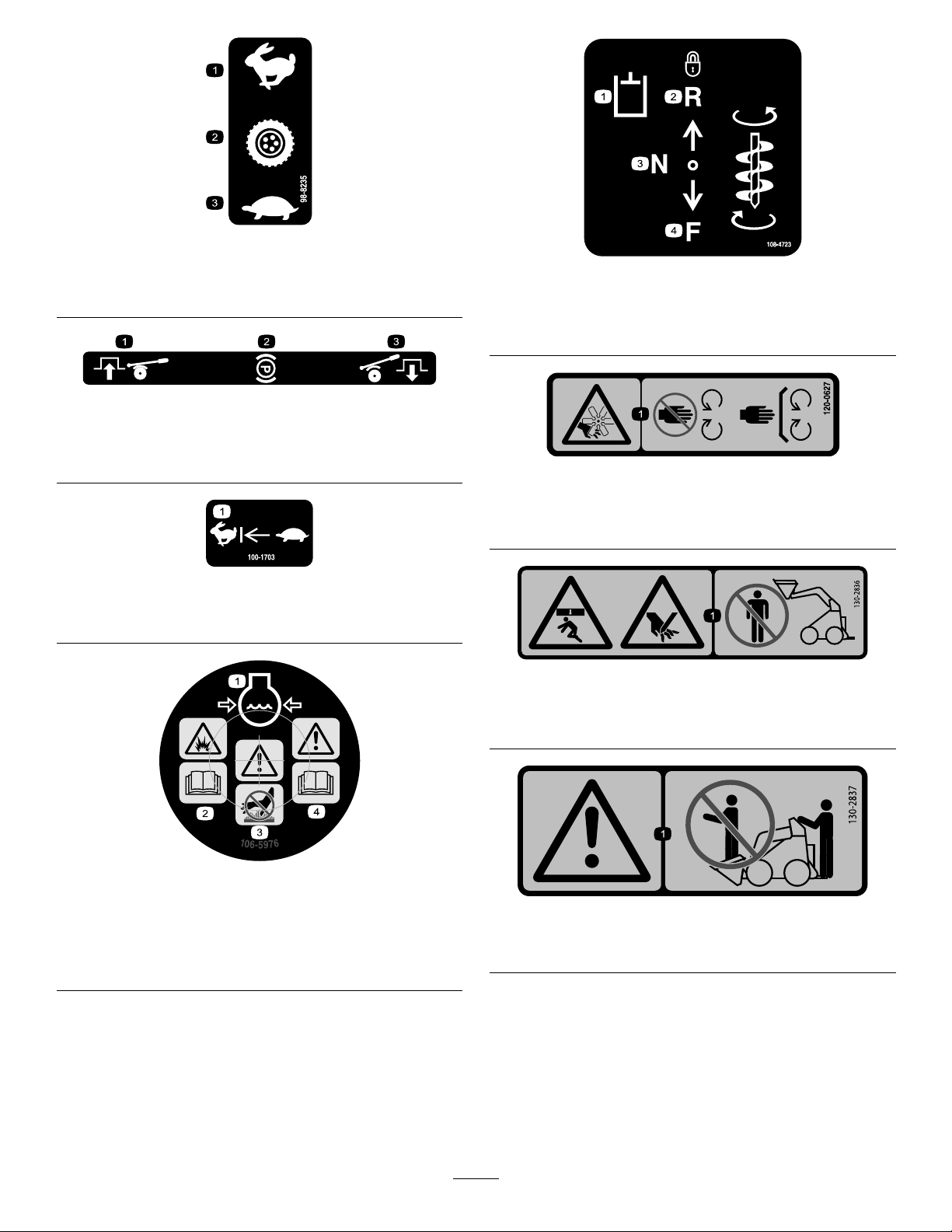

98-8235

1.Fast

2.Tractiondrive

100-1692

1.Brakeengaged3.Brakedisengaged

2.Parkingbrake

100-1703

1.Speedselector

decal98-8235

3.Slow

1.Auxiliaryhydraulics

2.Lockedreverse(detent)

decal100-1692

108-4723

3.Neutral(off)

4.Forward

decal108-4723

decal120-0627

120-0627

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts;keepallguardsandshieldsinplace.

decal100-1703

decal130-2836

130-2836

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator’sManual.

106-5976

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator’sManual.

1.Crushinghazard;cuttinghazard—keepawayfromthe

bucketandtheliftarm.

decal106-5976

decal130-2837

130-2837

1.Warning—donotcarrypassengersontheattachment.

6

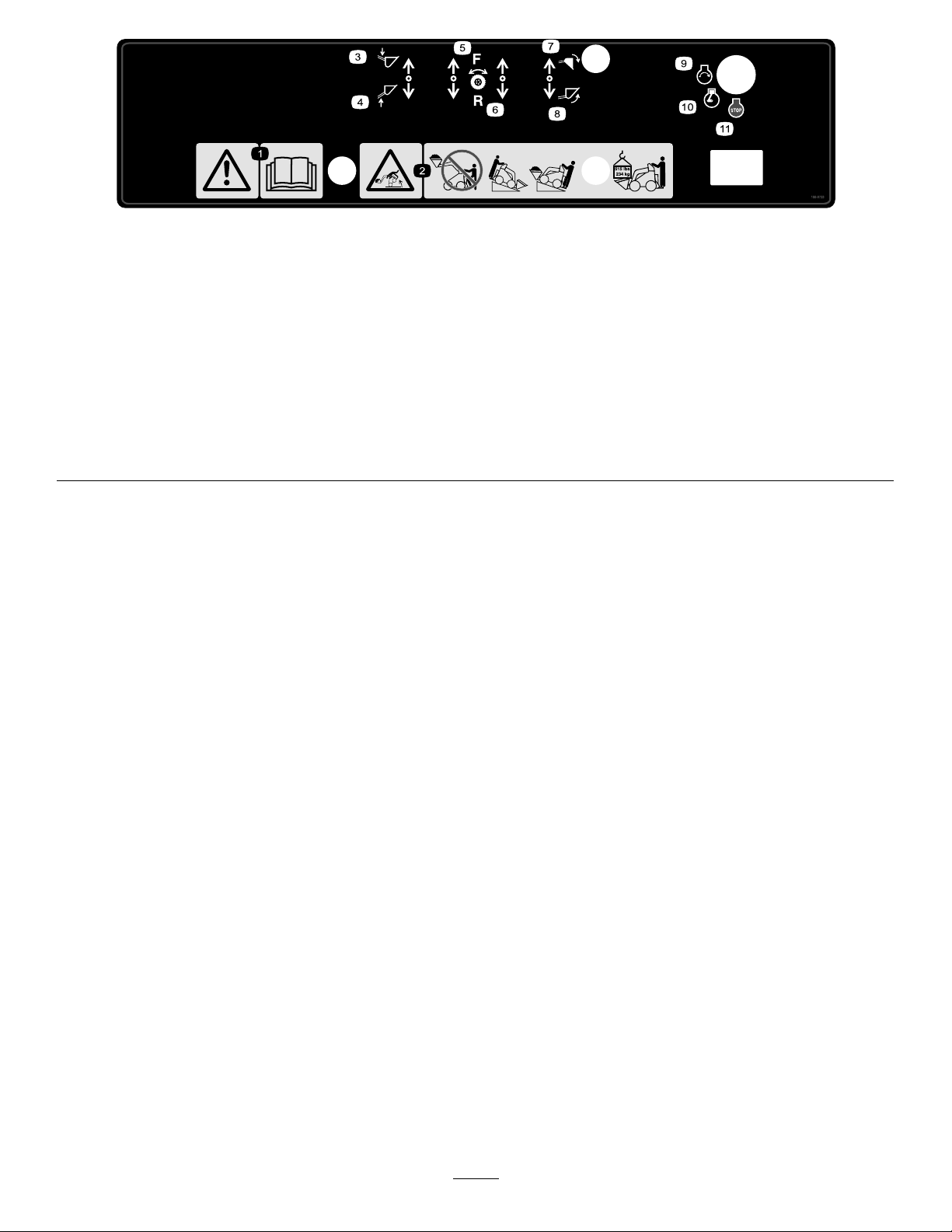

decal133-5618

133-5618

decal136-5785

136-5785

100-1701

1.Crushinghazard—installthecylinderlockandreadtheinstructionsbeforeservicingorperformingmaintenance.

2.Warning—removethekeyandlowertheloaderarmsbeforeleavingthemachine.

3.Cuttinghazardofhand—waitformovingpartstostop.

4.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistanceawayfromthemachine.

5.Explosionandelectricalshockhazards—donotdiginareaswithburiedgasorelectricallines.

decal100-1701

7

decal108-9733

108-9733

1.Warning—readthe

Operator'sManual.

2.Tippinghazard—donot

stepoffoperatorplatform

withloadraised;always

operatewiththeheavyend

ofthemachinepointed

uphill;carryloadslow;

neverjerkthecontrols;

useasteady,evenmotion;

maximumloadis234kg

(515lb).

3.Armlift—down

4.Armlift—up

5.Wheeldrive—forward

6.Wheeldrive—reverse9.Engine—start

7.Buckettilt—down10.Engine—run

8.Buckettilt—up11.Engine—stop

8

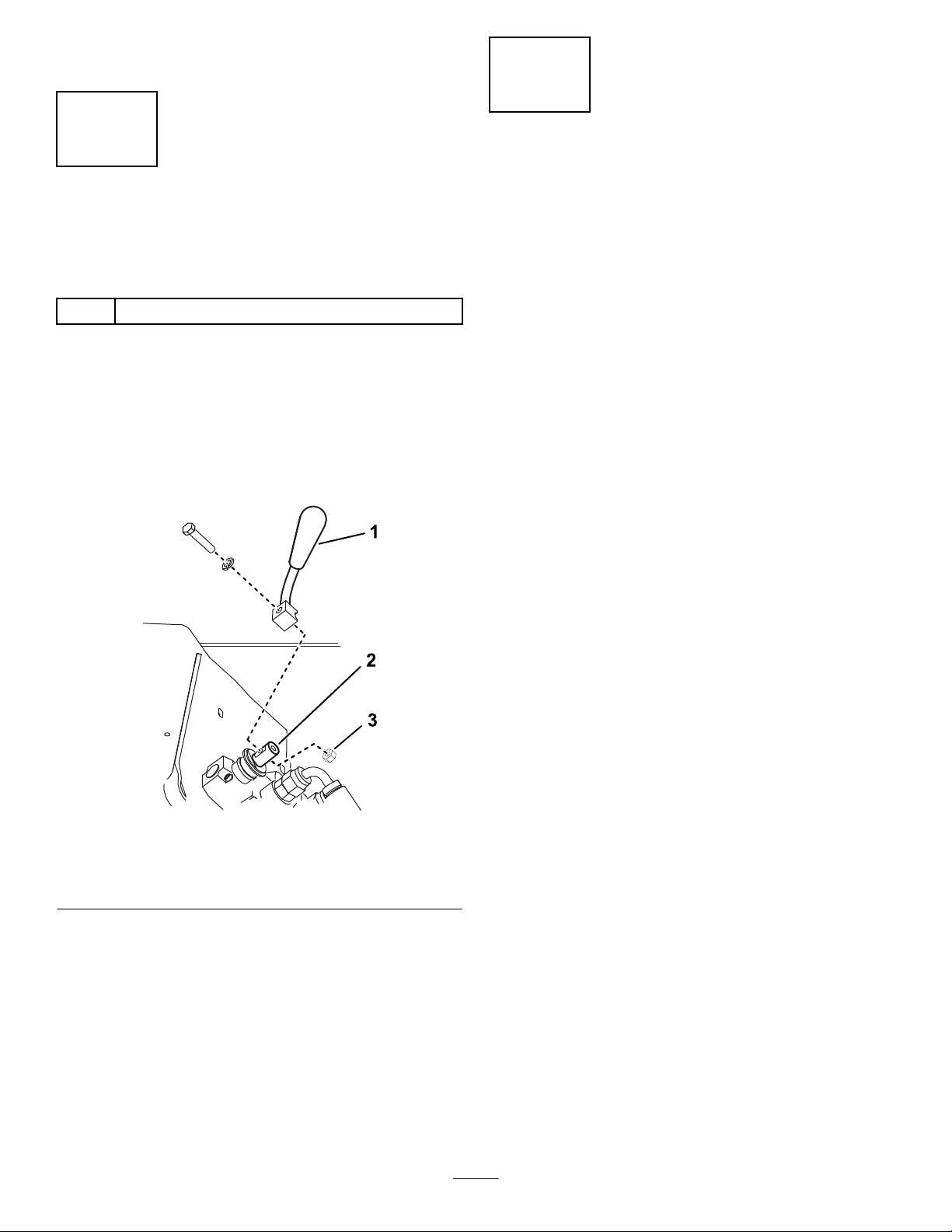

Setup

2

1

Installingthe Speed-SelectorLever

Partsneededforthisprocedure:

1

Speed-selectorlever

Procedure

1.Removeanddiscardthenutsecuringthebolt

andlockwashertothespeed-selectorlever.

2.Securethelevertothespeed-selectorvalve

usingthebolt,lockwasher,andnutasillustrated

inFigure3.

CheckingtheFluidLevels andTirePressure

NoPartsRequired

Procedure

Beforestartingtheengineforthersttime,checkthe

engine-oillevel,hydraulic-uidlevel,engine-coolant

level,andthetirepressure.Refertothefollowing

sectionsformoreinformation:

•CheckingtheEngine-OilLevel(page28)

•CheckingtheHydraulic-FluidLevel(page36)

•CheckingtheEngine-CoolantLevel(page34)

•CheckingtheTirePressure(page34)

1.Speed-selectorlever

2.Speed-selectorvalve

g230938

Figure3

3.Nut

9

3

ChargingtheBattery

NoPartsRequired

Procedure

Chargeandinstallthebattery;refertoChargingthe

Battery(page33).

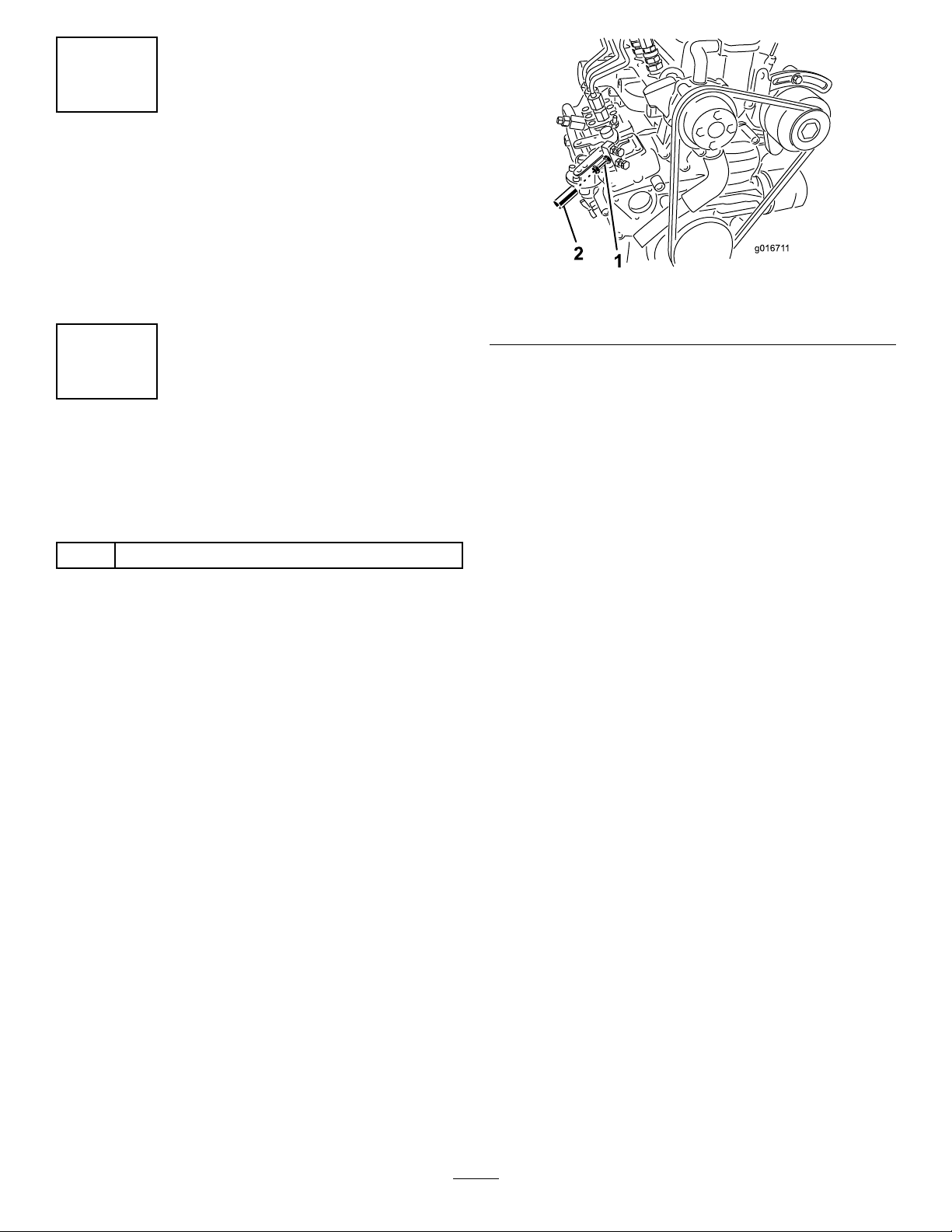

4

SettingtheEngineSpeed

CEMachinesOnly

Partsneededforthisprocedure:

1Aluminumtube

Procedure

Ifyouaresettingupthismachineforuseinthe

EuropeanCommunity(CE),youmustpermanently

adjusttheenginespeedsothatitisnomorethan

3,200rpm,asfollows:

g016711

Figure4

1.Throttle-adjustmentscrew2.Aluminumtube

4.Shutofftheengine.

5.Slideanaluminumtubeoverthe

throttle-adjustmentscrewandjamnut

(Figure4)andcrimpitdownoverthescrewso

thatthescrewcannotbeadjustedagain.

Important:Thetubemustbefullyoverthe

jamnuttopreventaccesstoit.

6.Closetherear-accesscoverandsecureitwith

thelanyardfastener.

1.Starttheengineandrunitathalfthrottlefor5to

10minutestowarmitup.

Important:Theenginemustbewarmbefore

makingthisadjustment.

2.MovethethrottletotheFASTposition.

3.Usingatachometerandthethrottle-adjustment

screwontheengine(Figure4),settheengine

speedto3,200rpmmaximum,thentightenthe

jamnutontheadjustingscrew.

Important:Iftheenginespeedexceeds

3,200rpm,theengineisnotincompliance

withCEregulationsandcannotbelegally

soldorusedintheEuropeanCommunity.

10

ProductOverview

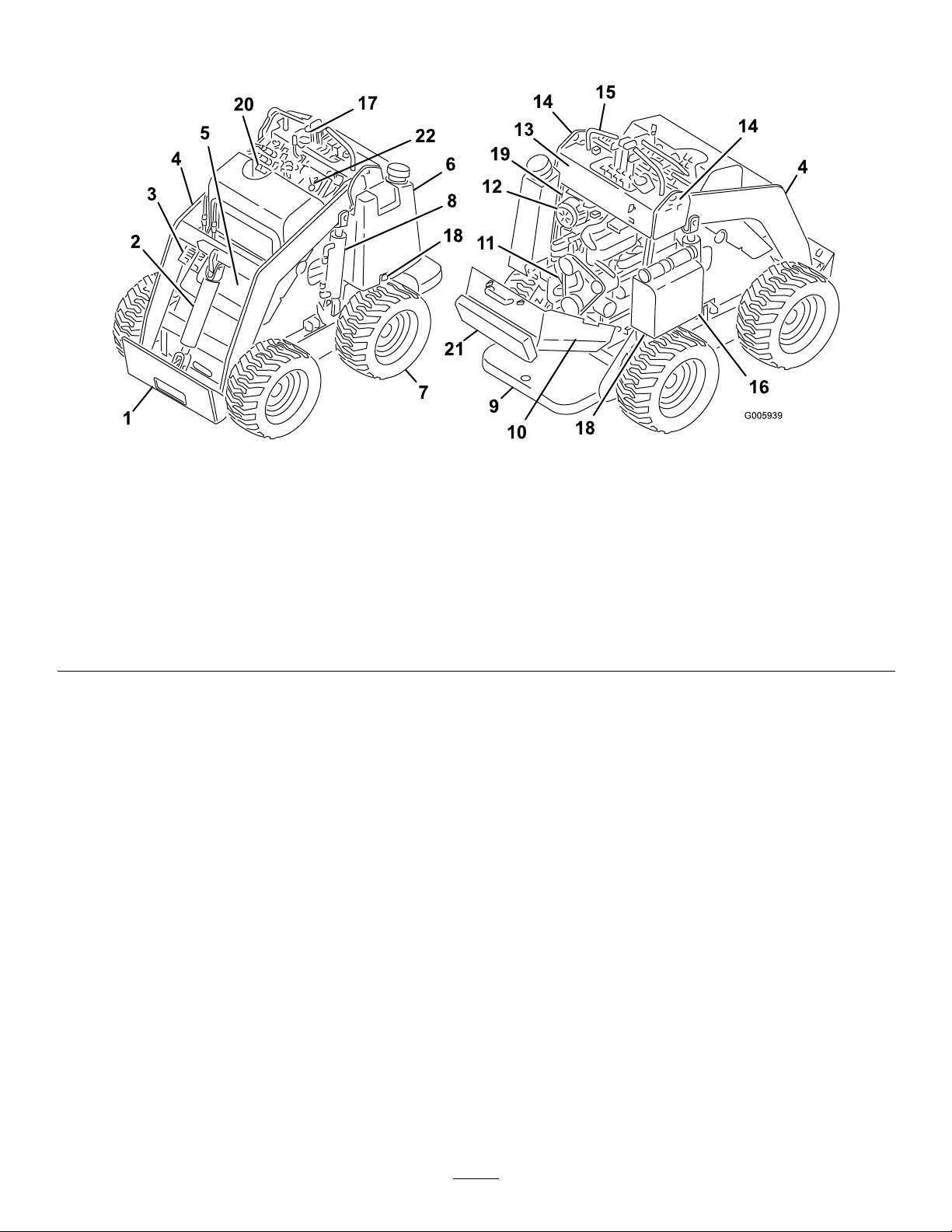

g005939

Figure5

1.Mountplate7.Wheel

2.Tiltcylinder

3.Auxiliary-hydrauliccouplers

4.Loaderarms

5.Front-accesscover11.Engine17.Indicatorlights

6.Fueltank

8.Liftcylinder14.Liftpoints20.Radiator-llcap

9.Operatorplatform

(removablecounterweight

notshown)

10.Rear-accesscover(open)

12.Airlter18.Towvalves(underfueltank

13.Controlpanel

15.Handle21.Thighsupport

16.Battery22.Flow-dividercontrol

andbattery)

19.Parking-brakelever

11

Controls

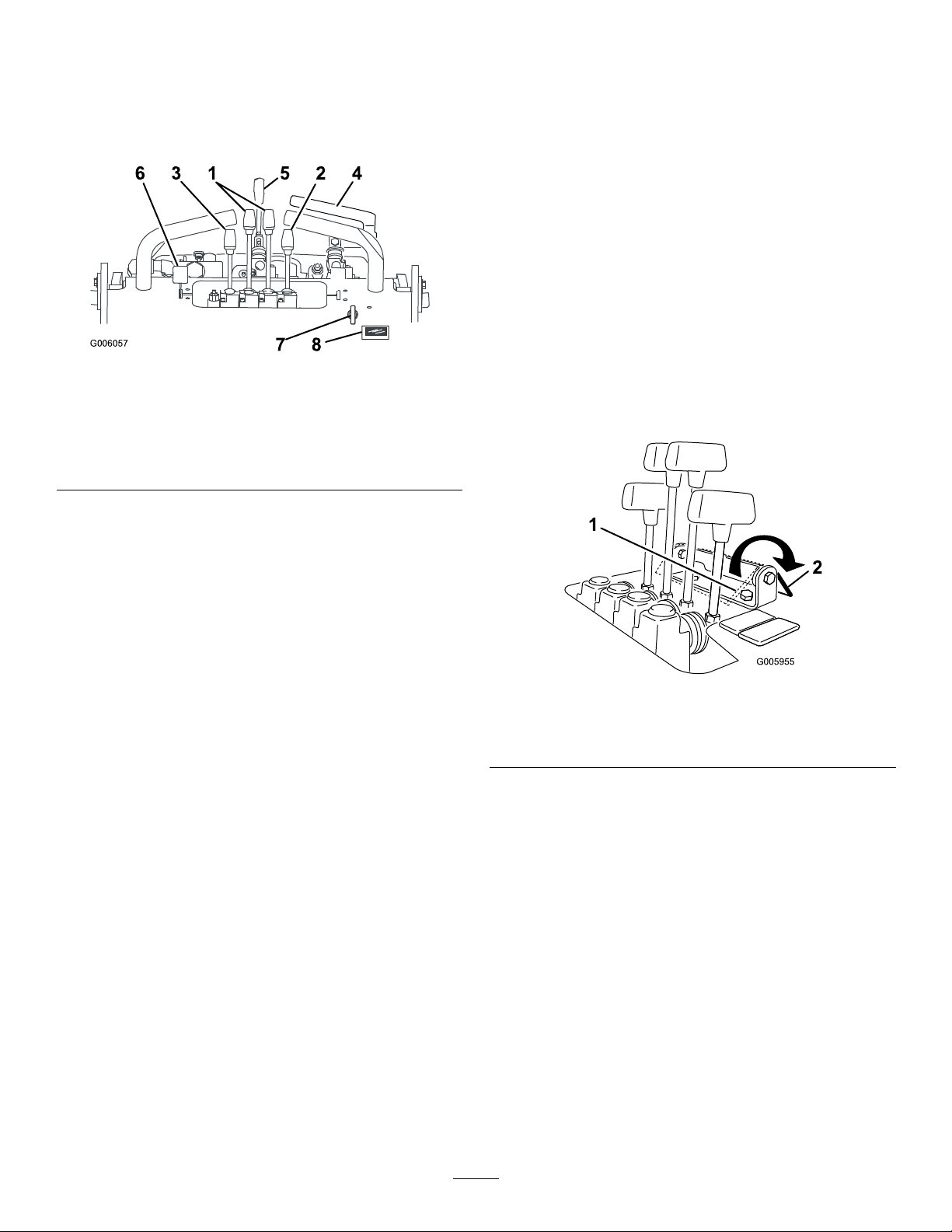

Becomefamiliarwithallthecontrols(Figure6)before

youstarttheengineandoperatethemachine.

ControlPanel

Loader-ArmLever

•Tolowertheloaderarms,slowlypushthe

loader-armleverforward.

•Toraisetheloaderarms,slowlypulltheloader-arm

leverrearward.

Loader-ValveLock

Theloader-valvelocksecurestheloader-armand

attachment-tiltleverssothatyoucannotpushthem

forward.Thishelpstoensurethatnooneaccidentally

lowerstheloaderarmsduringmaintenance.Secure

theloaderarmswiththelockanytimeyouneedto

shutoffthemachinewiththeloaderarmsraised.

Figure6

1.Traction-controllevers

2.Attachment-tiltlever6.Throttlelever

3.Loader-armlever7.Keyswitch

4.Auxiliary-hydraulicslever8.Hourmeter

5.Speed-selectorlever

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andSTART.Referto

StartingtheEngine(page18).

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeed

andrearwardtodecreasespeed.

Traction-ControlLevers

•Tomoveforward,movethetraction-controllevers

forward.

•Tomoverearward,movethetraction-controllevers

rearward.

•Toturn,movetheleverlocatedonthesideyou

wanttoturnbacktowardtheNEUTRALposition

whilekeepingtheotherleverengaged.

Note:Thefartheryoumovethetraction-control

leversineitherdirection,thefasterthemachine

movesinthatdirection.

•Tosloworstop,movethetraction-controllevers

totheNEUTRALposition.

g006057

Tosetthelock,pullitbackandallthewaydown

againstthelevers(Figure7).

Note:Y oumustmovetheleversrearwardtoengage

ordisengagetheloader-valvelock.

g005955

Figure7

1.Loader-valvelock

(engaged)

2.Loader-valvelock

(disengaged)

Auxiliary-HydraulicsLever

•Tooperateahydraulicattachmentintheforward

direction,slowlypulltheauxiliary-hydraulicslever

upwardandthenrearward.

•Tooperateahydraulicattachmentinthereverse

direction,slowlypulltheauxiliary-hydraulicslever

upwardandthenpushitforward.Thisisalso

calledtheDETENTpositionbecauseitdoesnot

requireoperatorpresence.

Attachment-TiltLever

•Totilttheattachmentforward,slowlypushthe

attachment-tiltleverforward.

•Totilttheattachmentrearward,slowlypullthe

attachment-tiltleverrearward.

12

Speed-SelectorLever

Flow-DividerControl

•Tosetthetractiondrive,loaderarms,and

attachmenttilttohighspeedandtheauxiliary

hydraulicstolowspeed,movethespeed-selector

levertotheFORWARDposition.

•Tosettheauxiliaryhydraulicstohighspeedand

thetractiondrive,loaderarms,andattachmenttilt

tolowspeed,movethespeed-selectorleverto

theREARWARDposition.

WARNING

Ifyoumovethespeed-selectorleverwhilethe

machineisinmotion,themachinewilleither

stopsuddenlyoracceleratequickly .Ifyou

operatethemachinewiththespeed-selector

leverinanintermediateposition,themachine

willoperateerraticallyandmaybedamaged.

Youcouldlosecontrolofthemachineand

injurebystandersoryourself.

•Donotmovethespeed-selectorleverwhen

themachineisinmotion.

•Donotoperatethemachinewhenthe

speedselectorisinanyintermediate

position(i.e.,anypositionotherthanfully

forwardorfullyrearward).

HourMeter

Thehourmeterdisplaysthenumberofhoursof

operationloggedonthemachine.

After50hoursandevery75hoursthereafter(i.e.,50,

125,200,etc.)thehourmeterdisplaysSVConthe

lowerleftsideofthescreentoremindyoutochange

theengineoilandperformtherequiredmaintenance.

Afterevery400hours(i.e.,400,800,1200,etc.),

thehourmeterdisplaysSVConthelowerright

sideofthescreentoremindyoutoperformthe

othermaintenanceproceduresbasedona400-hour

schedule.

Note:Thesereminderscomeonstarting3hours

priortotheserviceintervaltimeandashatregular

intervalsfor6hours.

Thetractionunithydraulics(i.e.,thetractiondrive,

loaderarms,andattachmenttilt)workonaseparate

hydrauliccircuitfromtheauxiliaryhydraulicsfor

poweringattachments;however,the2systemsshare

thesamehydraulicpumps.Usingtheow-divider

control(Figure8),youcanvarythespeedofthe

tractionunithydraulicsbydivertinghydraulicowto

theauxiliary-hydraulicscircuit.Therefore,themore

hydraulicowyoudiverttotheauxiliaryhydraulics,

theslowerthetractionunithydraulicsmove.

g005940

Figure8

1.Flow-dividercontrol4.10to11o'clockposition

2.Knob5.9o'clockposition

3.12o'clockposition

•Movetheow-dividercontroltothe12o'clock

positiontoprovidemaximumspeedtothetraction

unithydraulics.

Usethissettingforfastoperationofthetraction

unit.

•Movetheow-dividercontrolbetweenthe12

o'clockand9o'clockpositionstoslowthetraction

unithydraulicsandne-tunethespeed.

Useasettinginthisrangewithattachments

withhydraulicswhereyouneedtobothrunthe

attachmentandmovethetractionunithydraulics,

suchastheauger,boringunit,hydraulicblade,

andtiller.

•Movethecontroltothe9o'clockpositionto

transferallhydraulicowtotheauxiliaryhydraulics

oftheattachment.

Inthissetting,thetractionunithydraulicsdonot

work.Usethissettingwithhydraulicattachments

thatdonotrequirethetractionunithydraulics.

Thetrencherworksbestifyousetitcloseto9

o'clocksothatthetractionunitcreepsslowlywhen

trenching.

Note:Theow-dividercontrolcanbexedinplace

byturningtheknobonthecontrolclockwiseuntilit

contactsthedial(Figure8).

13

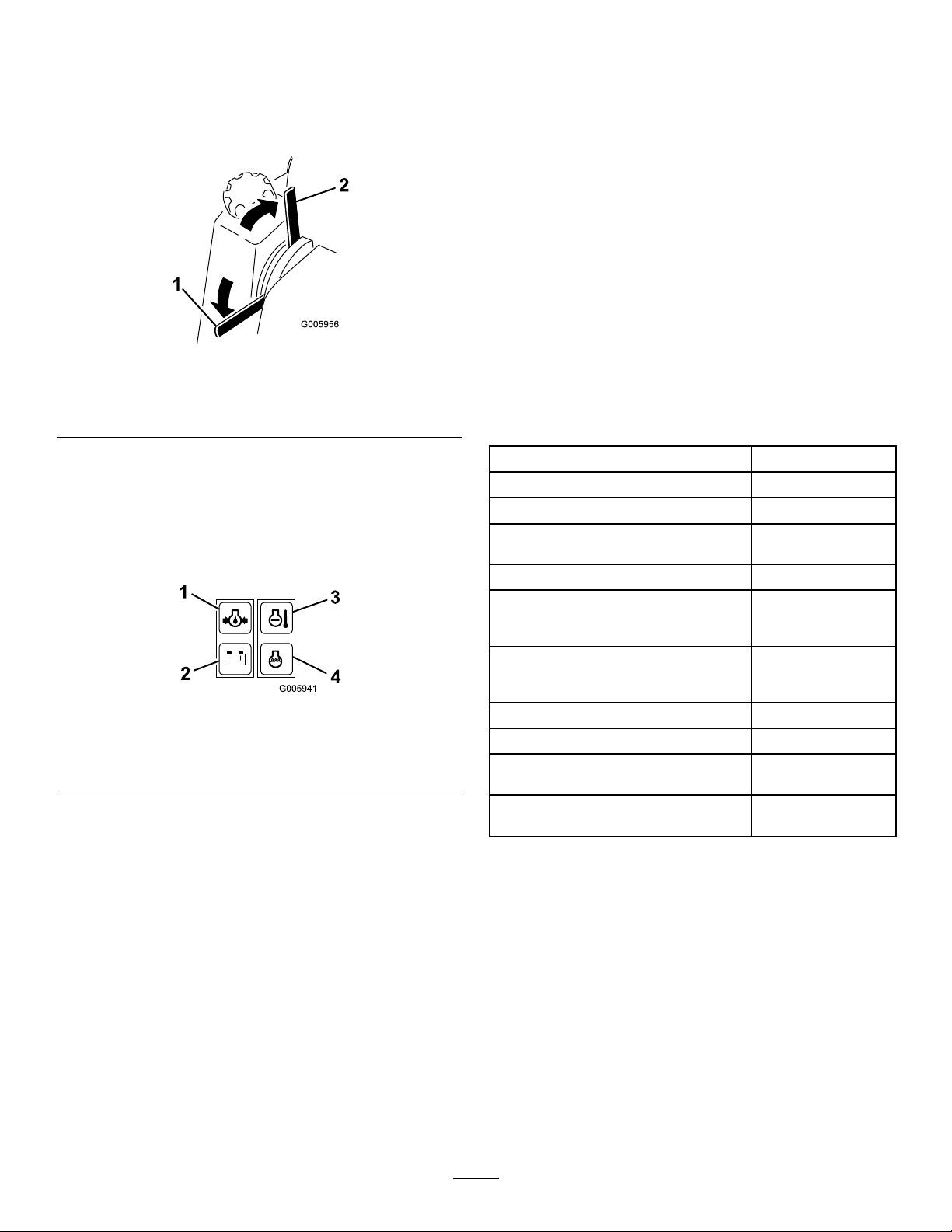

Parking-BrakeLever

•Toengagetheparkingbrake,rotatethelever

down(Figure9).

•Toreleasetheparkingbrake,rotatetheleverup

(Figure9).

Figure9

1.Parking-brake

lever—engaged

2.Parking-brake

lever—disengaged

•BatteryLight

Thislightisonforafewsecondswheneveryou

starttheengine.Ifthebatterylightisonwhile

theengineisrunning,thealternator,battery ,

orelectricalsystemisbroken.Contactyour

AuthorizedT oroDealerfordiagnosticsandrepair.

•Glow-PlugLight

ThislightisonwhenthekeyisturnedtoRUN

beforestartingtheengine.Theglow-pluglight

remainsonforupto10seconds,indicating

thattheglowplugsarewarmingtheengine.

Iftheglow-pluglightisonwhiletheengineis

running,theglowplugsarebroken.Contactyour

AuthorizedT oroDealerfordiagnosticsandrepair.

g005956

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

IndicatorLights

Theindicatorlightswarnyouinthecaseofasystem

malfunctionand,inthecaseoftheglow-pluglight,

indicatethattheglowplugsareon.Figure10

illustratesthe4indicatorlights.

Figure10

1.Oil-pressurelight

2.Batterylight

•Engine-TemperatureLight

Iftheengine-temperaturelightison,theengine

isoverheating.Shutofftheengineandallowthe

machinetocooldown.Checkthecoolantlevel

andthebeltstothefanandwaterpump.Fill

thecoolantasrequiredandreplaceanywornor

slippingbelts.Iftheproblempersists,contactyour

AuthorizedT oroDealerfordiagnosticsandrepair.

•Oil-PressureLight

Thislightisonforafewsecondswheneveryou

starttheengine.Iftheoil-pressurelightisonwhile

theengineisrunning,theengine-oilpressureis

low.Shutofftheengineandallowthemachine

tocooldown.Checktheoillevelandllthe

crankcasewithoilasneeded.Iftheproblem

persists,contactyourAuthorizedToroDealerfor

diagnosticsandrepair.

3.Engine-temperaturelight

4.Glow-pluglight

Width

Length

Height

Weight(withoutattachmentor

counterweight)

Weightofthecounterweight227kg(500lb)

Operatingcapacity—with74.8kg(165

lb)operator,thestandardbucket,and

withoutthecounterweight

Tippingcapacity—with74.8kg(165

lb)operator,thestandardbucket,and

g005941

withoutthecounterweight

Wheelbase

Dumpheight(withstandardbucket)120cm(47inches)

Reach—fullyraised(withstandard

bucket)

Heighttohingepin(narrowbucketin

standardposition)

103cm(41inches)

152cm(60inches)

125cm(49inches)

783kg(1,722lb)

227kg(500lb)

454kg(1,000lb)

71cm(28inches)

66cm(26inches)

168cm(66inches)

Attachments/Accessories

AselectionofT oroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.Toro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

14

Operation

BeforeOperation

BeforeOperationSafety

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageorrequirecertiedtrainingof

theoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetydecals.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Locatethepinch-pointareasmarkedonthe

machineandattachments;keepyourhandsand

feetawayfromtheseareas.

•Beforeoperatingthemachinewithanattachment,

ensurethattheattachmentisproperlyinstalled

andthatitisagenuineToroattachment.Readall

theattachmentmanuals.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsyouneedtoproperlyandsafely

performthejob.

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas;notethelocationofunmarkedobjectsand

structures,suchasundergroundstoragetanks,

wells,andsepticsystems.

AddingFuel

RecommendedFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatyoucanusewithin180daysto

ensurefuelfreshness.

Usesummer-gradedieselfuel(No.2-D)at

temperaturesabove-7°C(20°F)andwintergrade

(No.1-DorNo.1-D/2-Dblend)belowthat

temperature.Usingwinter-gradefuelatlower

temperaturesprovideslowerashpointandcoldow

characteristics,whicheasesstartingandreducesfuel

lterplugging.

Usingsummer-gradefuelabove-7°C(20°F)

contributestowardlongerfuelpumplifeandincreased

powercomparedtowinter-gradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Inspecttheareawhereyouwillusetheequipment

andremovealldebris.

•Ensurethattheareaisclearofbystandersbefore

operatingthemachine.Stopthemachineif

anyoneentersthearea.

FuelSafety

•Useextracarewhenhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaydegradeovertime.

•Fuellterpluggingmayoccurforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorformoreinformationon

biodiesel.

15

FillingtheFuelTank(s)

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit

(Figure11).

Figure11

AdjustingtheThigh Support

Toadjustthethighsupport(Figure12),loosen

theknobsandraiseorlowerthesupportpadto

thedesiredheight.Youcanalsoobtainadditional

adjustmentbylooseningthenutsecuringthepad

totheadjustmentplateandmovingtheplateupor

downasneeded.Tightenallfastenerssecurelywhen

nished.

g237886

1.Fuel-tankcap

4.Fillthetanktoabout2.5cm(1inch)belowthe

topofthetank,notthellerneck,withfuel.

Important:Thisspaceinthetankallows

fueltoexpand.Donotllthefueltank

completelyfull.

5.Installthefuel-tankcapsecurely,turningituntil

itclicks.

6.Wipeupanyspilledfuel.

PerformingDaily Maintenance

Beforestartingthemachineeachday,performthe

EachUse/DailyprocedureslistedintheMaintenance

(page24).

Important:Checkthehydraulic-uidlevel

andbleedthefuelsystembeforestartingthe

engineforthersttime;refertoCheckingthe

Hydraulic-FluidLevel(page36)andBleedingthe

FuelSystem(page31).

1.Thigh-supportbracket

2.Adjustmentplate

3.Thigh-supportpad

g006054

Figure12

4.Knobandatwasher

5.Carriagebolt

6.Locknutandatwasher

16

DuringOperation

DuringOperationSafety

GeneralSafety

•Donotcarryaloadwiththearmsraised.Always

carryloadsclosetotheground.

•Donotexceedtheratedoperatingcapacity,asthe

machinemaybecomeunstable,whichmayresult

inlossofcontrol.

•UseonlyToro-approvedattachmentsand

accessories.Attachmentscanchangethestability

andtheoperatingcharacteristicsofthemachine.

•Formachineswithaplatform:

–Lowertheloaderarmsbeforesteppingoffthe

platform.

–Donottrytostabilizethemachinebyputting

yourfootontheground.Ifyoulosecontrolof

themachine,stepofftheplatformandaway

fromthemachine.

–Donotplaceyourfeetundertheplatform.

–Donotmovethemachineunlessyouare

standingwithbothfeetontheplatformandyour

handsareholdingontothereferencebars.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Lookbehindanddownbeforebackingupto

ensurethatthepathisclear.

•Neverjerkthecontrols;useasteadymotion.

•Theowner/usercanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothingincludinggloves,eye

protection,longpants,substantialslip-resistant

footwear,andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotoperatethemachinewhenyouaretired,ill,

orundertheinuenceofalcoholordrugs.

•Nevercarrypassengersandkeeppetsand

bystandersawayfromthemachine

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

•Ensurethatallthedrivesareinneutralandengage

theparkingbrake(ifequipped)beforestartingthe

engine.Starttheengineonlyfromtheoperator's

position.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Watchfor

trafc.

•Stoptheattachmentwhenyouarenotworking.

•Stopthemachine,turnofftheengine,remove

thekey,andinspectthemachineifyoustrike

anobject.Makeanynecessaryrepairsbefore

resumingoperation.

•Neverrunanengineinanenclosedarea.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowertheloaderarmsanddisengagethe

auxiliaryhydraulics.

–Engagetheparkingbrake(ifequipped).

–Shutofftheengineandremovethekey.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Operatethemachineonlyinareaswherethereis

sufcientclearanceforyoutosafelymaneuver.

Beawareofobstaclesincloseproximitytoyou.

Failuretomaintainadequatedistancefromtrees,

walls,andotherbarriersmayresultininjuryasthe

machinebacksupduringoperationifyouarenot

attentivetothesurroundings.

•Checkforoverheadclearance(i.e.,electrical

wires,branches,anddoorways)beforedriving

underanyobjectsanddonotcontactthem.

•Donotoverlltheattachmentandalwayskeepthe

loadlevelwhenraisingtheloaderarms.Itemsin

theattachmentcouldfallandcauseinjury.

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.Anempty

bucketmakestherearofthemachinetheheavy

end,andafullbucketmakesthefrontofthe

machinetheheavyend.Mostotherattachments

makethefrontofmachinetheheavyend.

•Raisingtheloaderarmsonaslopeaffectsthe

stabilityofthemachine.Keeptheloaderarmsin

theloweredpositionwhenonslopes.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

17

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.T allgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,orbodiesofwater.The

machinecouldsuddenlyrolloverifawheelor

trackgoesovertheedgeortheedgecavesin.

Maintainasafedistancebetweenthemachine

andanyhazard.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

6.MovethethrottlelevertotheFASTsetting.

Important:Runningtheengineathigh

speedswhenthehydraulicsystemiscold

(i.e.,whentheairtemperatureisator

belowfreezing)coulddamagethehydraulic

system.Whenstartingtheengineincold

conditions,allowittoruninthemiddle

throttlepositionfor2to5minutesbefore

movingthethrottletotheFASTposition.

Note:Iftheoutdoortemperatureisbelow

freezing,storethemachineinagaragetokeep

itwarmerandtoaidinstarting.

DrivingtheMachine

Usethetractioncontrolstomovethemachine.The

fartheryoumovethetractioncontrolsinanydirection,

thefasterthemachinemovesinthatdirection.

Releasethetractioncontrolstostopthemachine.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Placethe

throttleleverintheFASTpositionforbestperformance.

Youcan,however,usethethrottlepositiontooperate

atslowerspeeds.

ShuttingOfftheEngine

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

StartingtheEngine

1.Standontheplatform.

2.Ensurethattheauxiliaryhydraulicsleverisin

theNEUTRALposition.

3.Movethethrottlelevermidwaybetweenthe

SLOWandFASTpositions.

4.Insertthekeyintothekeyswitchandturnitto

theRUNposition.

Note:Thebattery,oilpressure,andglow-plug

lightscomeon.

5.Whentheglow-pluglightturnsoff,turnthekey

totheSTARTposition.Whentheenginesstarts,

releasethekey.

Note:Awarmenginemaybestartedwithout

waitingforthelighttoturnoff.

Important:Donotengagethestarterfor

morethan10secondsatatime.Iftheengine

failstostart,wait30secondsforthestarter

tocooldownbetweenattempts.Failureto

followtheseinstructionscouldburnoutthe

startermotor.

2.Ensurethattheauxiliaryhydraulicsleverisin

theNEUTRALposition.

3.MovethethrottlelevertotheSLOWposition.

4.Iftheenginehasbeenworkinghardorishot,let

itidleforaminutebeforeturningthekeyswitch

totheOFFposition.

Note:Thishelpstocooltheenginebeforeyou

shutitoff.Inanemergency,youcanshutoff

theengineimmediately.

5.TurnthekeyswitchtotheOFFpositionand

removethekey.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

18

UsingAttachments

InstallinganAttachment

Important:UseonlyToro-approvedattachments.

Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthemachine.The

warrantyofthemachinemaybevoidedifyouuse

themachinewithunapprovedattachments.

Important:Beforeinstallingtheattachment,

ensurethatthemountplatesarefreeofanydirtor

debrisandthatthepinsrotatefreely.Ifthepins

donotrotatefreely,greasethem.

1.Positiontheattachmentonalevelsurfacewith

enoughspacebehindittoaccommodatethe

machine.

2.Starttheengine.

3.Tilttheattachmentmountplateforward.

4.Positionthemountplateintotheupperlipofthe

attachmentreceiverplate(Figure13).

g003711

Figure14

Figure13

1.Mountplate2.Receiverplate

5.Raisetheloaderarmswhiletiltingbackthe

mountplateatthesametime.

Important:Raisetheattachmentenoughto

clearthegroundandtiltthemountplateall

thewayback.

6.Shutofftheengineandremovethekey.

7.Engagethequick-attachpins,ensuringthatthey

arefullyseatedinthemountplate(Figure14).

1.Quick-attachpins

(engagedposition)

2.Disengagedposition

3.Engagedposition

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

g003710

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

Important:Ifthepinsdonotrotatetothe

engagedposition,themountplateisnot

fullyalignedwiththeholesintheattachment

receiverplate.Checkthereceiverplateand

cleanitifnecessary.

19

ConnectingtheHydraulicHoses

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury .Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponents,youmaybeburned.

7.Conrmthattheconnectionissecurebypulling

onthehoses.

RemovinganAttachment

1.Parkthemachineonalevelsurface.

2.Lowertheattachmenttotheground.

3.Shutofftheengineandremovethekey.

4.Disengagethequick-attachpinsbyturningthem

totheoutside.

5.Iftheattachmentuseshydraulics,movethe

auxiliary-hydraulicsleverforward,backward,

andbacktotheNEUTRALpositiontorelieve

pressureatthehydrauliccouplers.

6.Iftheattachmentuseshydraulics,slidethe

collarsbackonthehydrauliccouplersand

disconnectthem.

Important:Connecttheattachmenthoses

togethertopreventhydraulicsystem

contaminationduringstorage.

7.Installtheprotectivecoversontothehydraulic

couplersonthemachine.

8.Starttheengine,tiltthemountplateforward,and

backthemachineawayfromtheattachment.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

Iftheattachmentrequireshydraulicsforoperation,

connectthehydraulichosesasfollows:

1.Shutofftheengineandremovethekey.

2.Movetheauxiliary-hydraulicsleverforward,

backward,andbacktotheNEUTRALpositionto

relievepressureatthehydrauliccouplers.

3.Removetheprotectivecoversfromthehydraulic

connectorsonthemachine.

4.Ensurethatallforeignmatteriscleanedfrom

thehydraulicconnectors.

5.Pushtheattachmentmaleconnectorintothe

femaleconnectoronthemachine.

Note:Whenyouconnecttheattachmentmale

connectorrst,yourelieveanypressurebuilt

upintheattachment.

6.Pushtheattachmentfemaleconnectorontothe

maleconnectoronthemachine.

20

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleandebrisfromtheattachments,drives,

mufers,andenginetohelppreventres.Clean

upoilorfuelspills.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

Important:Donotexceed4.8km/h(3mph)

whentowing.

6.Afterrepairingthemachine,closethetowvalves

andtightenthejamnuts.

Important:Donotovertightenthetow

valves.

7.Replacetheplugs.

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Useafull-widthramp.Ensurethatthetrailer

ortruckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyouorbystandersavoidinjury.Refertoyour

localordinancesfortrailerandtie-downrequirements.

MovingaNon-Functioning Machine

Important:Donottoworpullthemachine

withoutrstopeningthetowvalves,oryouwill

damagethehydraulicsystem.

1.Shutofftheengineandremovethekey.

2.Removetheplugcoveringeachtowvalve

(Figure15).

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidentscausingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure16).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Ensurethatthelengthoframpisatleast4

timesaslongastheheightofthetraileror

truckbedtotheground.Thisensuresthat

rampangledoesnotexceed15degreeson

atground.

Figure15

3.Loosenthejamnutoneachtowvalve.

4.Turneachvalvecounterclockwise1turnwitha

hexwrenchtoopenthem.

5.Towthemachineasrequired.

g237902

21

oranon-load-carryingattachment(e.g.,

stumpgrinder),drivethemachineforward

uptheramp.

•Ifthemachinehasanemptyload-carrying

attachmentornoattachment,backthe

machineuptheramp.

Figure17

g237904

Figure16

1.Full-widthrampinstowed

position

2.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

3.H=heightofthetraileror

truckbedtotheground

4.Trailer

LoadingtheMachine

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

1.Machinewithfull

attachmentor

non-load-carrying

attachment—drivethe

g229507

machineforwardupthe

ramp.

2.Machinewithemptyor

noattachment—backthe

machineuptheramp.

6.Lowertheloaderarmsallthewaydown.

7.Shutofftheengine,removethekey,andengage

theparkingbrake.

8.Usethemetaltie-downloopsonthemachine

tosecurelyfastenthemachinetothetraileror

truckwithstraps,chains,cable,orropes(Figure

18).Refertolocalregulationsfortie-down

requirements.

•Loadandunloadthemachinewiththe

heavyenduptheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Lowertheramp(Figure16).

4.Lowertheloaderarms.

5.Loadthemachineontothetrailerwiththeheavy

enduptheramp,carryingloadslow(Figure17).

•Ifthemachinehasafullload-carrying

attachment(e.g.,bucketoradjustableforks)

g248506

Figure18

1.Tie-downloops

22

UnloadingtheMachine

1.Lowertheramp(Figure17).

2.Unloadthemachinefromthetrailerwiththe

heavyenduptheramp,carryingloadslow

(Figure19).

•Ifthemachinehasafullload-carrying

attachment(e.g.,bucketoradjustableforks)

oranon-load-carryingattachment(e.g.,

stumpgrinder),backitdowntheramp.

•Ifthemachinehasanemptyload-carrying

attachmentornoattachment,driveitforward

downtheramp.

Figure19

g237905

1.Machinewithfull

attachmentor

non-load-carrying

attachment—backthe

machinedowntheramp.

2.Machinewithemptyor

noattachment—drivethe

machineforwarddownthe

ramp.

LiftingtheMachine

Youcanliftthemachineusingthetie-down/liftloops

asliftpoints;refertoFigure18.

23

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every75hours

Every100hours

Every200hours

MaintenanceProcedure

•Torquethewheel-lugnuts.

•Replacethehydrauliclter.

•Changetheengineoilandlter.

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checktheengine-oillevel.

•Drainwaterfromthefuellter.

•Checkthetirepressure.

•Checkandcleantheradiatorscreen

•Checktheengine-coolantlevel.

•Testtheparkingbrake.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather ,andchemicaldeterioration.

•Checkthehydraulic-uidlevel.

•Changetheengineoilandlter(morefrequentlywhenoperatingconditionsare

extremelydustyorsandy).

•Checkthebatterycableconnections.

•Torquethewheel-lugnuts.

•Servicetheaircleaner.(Servicemorefrequentlyifconditionsareextremelydusty

orsandy.)

Every400hours

Every1,500hours

Yearly

Yearlyorbeforestorage

•Replacethehydrauliclter.

•Replaceallmovinghydraulichoses.

•Changethefuellter.

•Changetheenginecoolant.

•Changethehydraulicuid.

•Touchupchippedpaint.

Important:Refertoyourengineowner'smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

24

Pre-Maintenance

UsingtheCylinderLocks

Procedures

MaintenanceSafety

•Parkthemachineonalevelsurface,disengage

theauxiliaryhydraulics,lowertheattachment,

engagetheparkingbrake(ifequipped),shut

offtheengine,andremovethekey.Waitforall

movementtostopandallowthemachinetocool

beforeadjusting,cleaning,storing,orrepairingit.

•Cleanupoilorfuelspills.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthecomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatterybeforemakinganyrepairs;

refertoServicingtheBattery(page32).

•Keepyourhandsandfeetawayfromthemoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Donottamperwiththesafetydevices.

•UseonlyT oro-approvedattachments.

Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthemachine.Youmay

voidthewarrantyifyouusethemachinewith

unapprovedattachments.

WARNING

Theloaderarmsmaylowerwhenintheraised

position,crushinganyoneunderthem.

Installthecylinderlock(s)beforeperforming

maintenancethatrequiresraisedloaderarms.

InstallingtheCylinderLocks

1.Removetheattachment.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengineandremovethekey.

4.Positionacylinderlockovereachlift-cylinder

rod(Figure20).

g005162

Figure20

1.Cylinderlock4.Clevispin

2.Liftcylinder5.Lift-cylinderrod

3.Hairpincotter

5.Secureeachcylinderlockwithaclevispinand

cotterpin(Figure20).

6.Slowlylowertheloaderarmsuntilthecylinder

lockscontactthecylinderbodiesandrodends.

•UseonlygenuineT ororeplacementparts.

•Ifanymaintenanceorrepairrequirestheloader

armstobeintheraisedposition,securethearms

intheraisedpositionwiththehydraulic-cylinder

lock(s).

RemovingandStoringthe CylinderLocks

Important:Removethecylinderlocksfromthe

rodsandfullysecuretheminthestorageposition

beforeoperatingthemachine.

1.Starttheengine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengineandremovethekey.

4.Removetheclevispinandcotterpinsecuring

eachcylinderlock.

5.Removethecylinderlocks.

6.Lowertheloaderarms.

7.Installthecylinderlocksoverthehydraulic

hosesandsecurethemwiththeclevispinsand

cotterpins(Figure21).

25

Figure21

1.Hydraulichoses3.Hairpincotter

2.Cylinderlocks4.Clevispin

g005163

g005943

Figure22

1.Cover

5.Pullthecoveroffthemachine.

2.Lockingtab

AccessingInternal Components

WARNING

Openingorremovingcovers,hoods,and

screenswhiletheengineisrunningcould

allowyoutocontactmovingparts,seriously

injuringyou.

Beforeopeninganyofthecovers,hoods,and

screens,shutofftheengine,removethekey

fromthekeyswitch,andallowtheengineto

cool.

RemovingtheFront-AccessCover

1.Parkthemachineonalevelsurfaceandengage

theparkingbrake.

2.Raisetheloaderarmsandinstallthecylinder

locks.

Note:Ifyoumustremovethefront-access

coverwithoutraisingtheloaderarms,bevery

carefulnottodamagethecoverorhydraulic

hosesasyoumaneuverthecoveroutfrom

underthearms.

3.Shutofftheengineandremovethekey.

4.Releasethe2lockingtabs(Figure22,top,left

tabillustrated).

6.Whennished,replacethefront-accesscover

andsecureitwiththe2lockingtabs.

OpeningtheRear-AccessCover

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Releasethe2lockingtabsontopofthe

rear-accesscover(Figure23).

g005957

Figure23

1.Rear-accesscover3.Bolt

2.Lockingtabs

4.Removetheboltlocatednexttotherightlocking

tab(Figure23).

5.Graspingthehandle,pullthecoverupandback

toswingitopen(Figure23).

6.Whennished,closetherear-accesscoverby

swingingitupandseatingitinplace.

7.Secureitwiththe2lockingtabsandbolt.

26

Lubrication

EngineMaintenance

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily(Grease

immediatelyaftereverywashing.)

GreaseType:General-purposegrease

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

2.Shutofftheengineandremovethekey.

3.Cleanthegreasettingswitharag.

4.Connectagreaseguntoeachtting(Figure24

andFigure25).

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Keepyourhands,feet,face,clothing,andother

bodypartsawayfromthemuferandotherhot

surfaces.

ServicingtheAirCleaner

ServiceInterval:Every200hours—Servicetheair

cleaner.(Servicemorefrequentlyif

conditionsareextremelydustyor

sandy.)

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

2.Shutofftheengineandremovethekey.

3.Releasethelatchesontheaircleanerand

pulltheair-cleanercoverofftheair-lterbody

(Figure26).

Figure24

Figure25

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings(approximately3

pumps).

6.Wipeupanyexcessgrease.

g005945

g200767

Figure26

1.Latches

2.Air-cleanercover5.Dustcap

3.Air-lterbody

4.Squeezethedustcapsidestoopenitandknock

g004209

thedustout.

5.Cleantheinsideoftheair-cleanercoverwith

compressedairthatisunder205kPa(30psi).

4.Primarylter

Important:Donotusecompressedairon

theair-cleanerbody.

6.Gentlyslidethelteroutoftheair-lterbody

(Figure26).

27

Note:Avoidknockingthelterintothesideof

thebody.

Important:Donotattempttocleanthelter.

CheckingtheEngine-OilLevel

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

7.Inspectthenewlterfortears,anoilylm,or

damagetotherubberseal.Lookintothelter

whileshiningabrightlightontheoutsideofthe

lter;holesinthelterappearasbrightspots.

Ifthelterisdamaged,donotuseit.

8.Carefullyinstallthelter(Figure26).

Note:Ensurethatthelterisfullyseated

bypushingontheouterrimofthelterwhile

installingit.

Important:Donotpressonthesoftinside

areaofthelter.

9.Installtheair-cleanercoverwiththedustcap

orienteddownwardandsecurethelatches

(Figure26).

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Check

theengine-oillevel.

Aftertherst50hours—Changetheengineoil

andlter.

Every75hours—Changetheengineoiland

lter(morefrequentlywhenoperatingconditions

areextremelydustyorsandy).

Engine-OilSpecications

OilType:Detergentdieselengineoil(APIservice

CH-4,CI-4,orhigher)

CrankcaseCapacity:withlter,3.2L(0.84US

gallons)

Viscosity:Seethetablebelow.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Opentherear-accesscover.

4.Cleantheareaaroundtheoildipstick(Figure

28).

Figure28

1.Fillcap

2.Valvecover4.Metalend

5.Pulloutthedipstickandwipethemetalend

clean(Figure28).

6.Slidethedipstickfullyintothedipsticktube

(Figure28).

7.Pullthedipstickoutandlookatthemetalend.

8.Iftheoillevelislow,cleantheareaaroundthe

oil-llcapandremovethecap(Figure28).

9.Slowlypouronlyenoughoilintothevalvecover

toraisetheleveltotheuppermarkonthe

dipstick.

3.Oildipstick

Note:Usedieselengineoil,APIserviceCH-4,

CI-4,orhigher;refertoEngine-OilSpecications

(page28).

Important:Donotoverllthecrankcase

withoilbecauseitmaydamagetheengine.

g005936

Figure27

10.Replacethellcapanddipstick.

11.Closetherear-accesscover.

g238048

28

ChangingtheEngineOilandFilter

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsothatitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensurethatthe

oildrainscompletely.

3.Lowertheloaderarms,engagetheparking

brake,shutofftheengine,andremovethekey .

4.Placeapanundertheoil-draintube(Figure29).

Figure29

11.Applyathincoatofnewoiltotherubbergasket

onthereplacementlter(Figure30).

12.Installthereplacementoilltertothelter

adapter.Turntheoillterclockwiseuntilthe

rubbergasketcontactsthelteradapter,then

tightenthelteranadditional1/2turn(Figure

30).

13.Removethellcap(Figure28)andslowlypour

approximately80%ofthespeciedamountofoil

inthroughthevalvecover.

14.Checktheoillevel.

15.Slowlyaddadditionaloiltobringtheleveltothe

uppermarkonthedipstick.

16.Replacethellcap.

17.Closetherear-accesscover.

g005947

1.Clamp

2.Oil-draintube

3.Plug

5.Loosentheclampandremovetheplug(Figure

29).

6.Whentheoilhasdrainedcompletely ,replace

theplugandtightentheclamp.

Note:Disposeoftheusedoilatacertied

recyclingcenter.

7.Opentherear-accesscover.

8.Removetheoldlterandwipethelteradapter

(Figure30)gasketsurface.

Figure30

1.Oillter

2.Gasket

3.Adapter

9.Pournewoilofthepropertypeinthroughthe

centerholeofthelter.Stoppouringwhenthe

oilreachesthebottomofthethreads.

10.Allow1to2minutesfortheoiltobeabsorbed

byltermaterial,thenpourofftheexcessoil.

g000653

29

FuelSystem

ChangingtheFuelFilter

Maintenance

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Drainfuelfromthefueltankswhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanyfuelthatspills.

•Neversmokewhendrainingfuel,andstay

awayfromanopenameorwhereaspark

mayignitethefumes.

•RefertoFuelSafety(page15)fora

completelistoffuelrelatedprecautions.

DrainingWaterfromthe FuelFilter

ServiceInterval:Yearly

Important:Neverinstalladirtylter.

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Shutoffthefuelvalveonthebottomofthefuel

tank(Figure34).

4.Opentherear-accesscover.

5.Openthedrainvalve(Figure32)anddrainthe

fuelfromthefuellterintoasuitablecontainer

anddisposeofitproperly .

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Opentherear-accesscover.

4.Turnthedrainvalveuntilthewaterrunsoutof

thelter(Figure31).

Note:Thefuellterislocatednearthebottom

ofthefueltank.

Figure31

g005948

Figure32

1.Drainvalve

6.Removethefuellterwithalterwrench(Figure

32).

7.Cleanthemountingsurface.

8.Lubricatethegasketonthenewlterwithclean

engineoil.

9.Screwonthenewlterbyhanduntilthegasket

contactsthehousing,thentightenitanother1/2

turn.

10.Openthefuelvalveonthebottomofthefuel

tank(Figure34).

11.Bleedthefuelsystem;refertoBleedingtheFuel

System(page31).

12.Starttheengineandcheckforleaks.

g005935

2.Fuellter

1.Fuellter

5.Closethevalve.

6.Closetherear-accesscover.

2.Drainvalve

30

BleedingtheFuelSystem

DrainingtheFuelTank

Bleedtheairfromthefuelsysteminanyofthe

followingsituations:

•Initialstart-upofanewmachineoramachinethat

hasbeenstored

•Aftertheenginehasceasedrunningduetolack

offuel

•Aftermaintenancehasbeenperformedonthefuel

systemcomponents

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Opentherear-accesscover.

4.Placeadrainpanunderthefuelltertocatch

fuelspills.

5.Openthebleedscrewontopofthefuellterto

llthebowlwithfuel(Figure33).

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Shutoffthefuelvalveinthehosenearthe

bottomofthefueltank(Figure34).

g003795

Figure34

Figure33

1.Fuellter

6.Closethebleedscrewwhenfuelcomesoutin

asteadystream.

7.Onleftsideoftheengine,locatetheairventplug

ontopofthefuel-injectionpumpandconnecta

hosetoit,leadingtoadrainpan.

8.Opentheventplugandcranktheengineuntil

fuelcomesoutasteadystream.

9.Closetheventplug.

10.Closetherear-accesscover.

2.Bleedscrew

1.Fuelvalve(open)2.Fuelvalve(closed)

4.Opentherear-accesscover.

g005949

5.Loosenthehoseclampatthefuellterandslide

itupthefuellineawayfromthelter.

6.Pullthefuellineoffthefuellter,openthefuel

valve,andallowthefueltodrainintoafuelcan

ordrainpan.

7.Installthefuellineontothefuellter.

8.Slidethehoseclampclosetothefuellterto

securethefuelline.

9.Closetherear-accesscover.

10.Openthefuelvalveinthehosenearthebottom

ofthefueltankasillustratedinFigure34.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty .

31

ElectricalSystem

ServicingtheBattery

Maintenance

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

•Batteryacidispoisonousandcancauseburns.

Avoidcontactwithskin,eyes,andclothing.Protect

yourface,eyes,andclothingwhenworkingwitha

battery.

•Batterygasescanexplode.Keepcigarettes,

sparks,andamesawayfromthebattery.

ServiceInterval:Every75hours

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

4partswaterand1partbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoreduce

corrosion.

Specications:12V,450A(coldcranking)

RemovingtheBattery

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Removethebatterycover(Figure35)

Figure35

1.Batterycover5.Nut

2.Bolt6.Positivebatterycable

3.Battery7.Negativebatterycable

4.Bars8.Batterypad

4.Removethenutsandbarssecuringthebattery

(Figure35).

5.Disconnectthenegative(black)cabletothe

negative(-)batterypost(Figure35).

6.Disconnectthepositive(red)cabletothe

positive(+)batterypost(Figure35).

7.Liftthebatteryofftheplatform.

g230939

32

ChargingtheBattery

CleaningtheBattery

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespecially

importanttopreventbatterydamagewhenthe

temperatureisbelow0°C(32°F).

1.Removethebatteryfromthemachine;referto

RemovingtheBattery(page32).

2.Chargethebatteryfor10to15minutesat25to

30Aor30minutesat4to6A(Figure36).Do

notoverchargethebattery.

Figure36

1.Positivebatterypost

2.Negativebatterypost

3.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure36).

3.Red(+)chargerlead

4.Black(-)chargerlead

Note:Keeptheterminalsandtheentirebatterycase

clean,becauseadirtybatterydischargesslowly.

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

2.Shutofftheengineandremovethekey.

3.Removethebatteryfromthemachine;

RemovingtheBattery(page32).

4.Washtheentirecasewithasolutionofbaking

sodaandwater.

5.Rinsethebatterywithclearwater.

6.Coatthebatterypostsandcableconnectorswith

Grafo112X(skin-over)grease(T oroPartNo.

505-47)orpetroleumjellytopreventcorrosion.

7.Installthebattery;refertoInstallingtheBattery

(page33).

InstallingtheBattery

1.Installthebatteryontotheplatform(Figure35).

g003792

2.Securethebatteryinthechassiswiththebars

andnutsremovedpreviously(Figure35).

3.Usingthefastenerspreviouslyremoved,install

thepositive(red)batterycabletothepositive(+)

batteryterminal(Figure35).

4.Slidetheredterminalbootontothepositive

batterypost.

5.Usingthefastenerspreviouslyremoved,install

thenegative(black)batterycabletothenegative

(-)batteryterminal(Figure35).

6.Installthebatterycover(Figure35).

Important:Ensurethatthebatterycablesdonot

contactanysharpedgesoreachother.

ServicingaReplacementBattery

Theoriginalbatteryismaintenance-freeanddoesnot

requireservice.Forservicingareplacementbattery,

refertothebatterymanufacturer’sinstructions.

33

DriveSystem

CoolingSystem

Maintenance

CheckingtheTirePressure

ServiceInterval:Beforeeachuseordaily

Maintaintheairpressureinthetiresasspecied.

Checkthetireswhentheyarecoldtogetthemost

accuratereading.

Pressure:103to138kPa(15to20psi)

Note:Usealowertirepressure,103kPa(15psi),

whenoperatinginsandysoilconditionstoprovide

bettertractionintheloosesoil.

Maintenance

CoolingSystemSafety

•Swallowingenginecoolantcancausepoisoning;

keepoutofreachfromchildrenandpets.

•Dischargeofhot,pressurizedcoolantortouching

ahotradiatorandsurroundingpartscancause

severeburns.

–Alwaysallowtheenginetocoolatleast15

minutesbeforeremovingtheradiatorcap.

–Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

CleaningtheRadiator Screen

ServiceInterval:Beforeeachuseordaily

Removeanybuildupofgrass,dirtorotherdebrisfrom

theradiatorscreenwithcompressedair.

Figure37

1.Valvestem

CheckingtheWheel-Lug Nuts

ServiceInterval:Aftertherst8hours

Every100hours

Checkandtorquethewheellugnutsto68N∙m(50

ft-lb).

g003793

Checkingthe Engine-CoolantLevel

ServiceInterval:Beforeeachuseordaily

Thecoolingsystemislledwitha50/50solution

ofwaterandpermanentethyleneglycolantifreeze.

Checkthelevelofcoolantatthebeginningofeach

day,beforestartingtheengine.

DANGER

Therotatingshaftandfancancausepersonal

injury.

•Donotoperatethemachinewithoutthe

coversinplace.

•Keepyourngers,hands,andclothing

clearoftherotatingfananddriveshaft.

•Parkthemachineonalevelsurface,lower

theloaderarms,engagetheparkingbrake,

shutofftheengine,andremovethekey

fromthekeyswitchbeforeperforming

maintenance.

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,engagetheparkingbrake,and

shutofftheengine.

2.Removethekeyfromthekeyswitchandallow

theenginetocool.

34

3.Removetheradiatorcapandcheckthecoolant

level(Figure38).

Thecoolantshouldbeuptothellerneck.

Figure38

1.Radiatorcap

4.Ifthecoolantlevelislow,addcoolantuptothe

bottomofthellerneck.

Important:Donotoverlltheradiator.

5.Replacetheradiatorcap,ensuringthatitis

tightlysealed.

ChangingtheEngine

BrakeMaintenance

TestingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

1.Engagetheparking-brake;referto

Parking-BrakeLever(page14).

2.Starttheengine.

g005937

3.Slowlyattempttodrivethemachineforwardor

rearward.

4.Ifthemachinemoves,contactyourAuthorized

ServiceDealerforservice.

Coolant

ServiceInterval:Yearly

HaveanAuthorizedServiceDealerchangetheengine

coolantyearly.

Ifyouneedtoaddenginecoolant,refertoChecking

theEngine-CoolantLevel(page34).

35

HydraulicSystem

Maintenance

HydraulicSystemSafety

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

•Ensurethatallhydraulic-uidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

MaterialProperties

cStat40°C:55to62 Viscosity,ASTMD445

cStat100°C:9.1to9.8

Viscosityindex,ASTMD2270

PourPoint,ASTMD97-43to-37°C(-46to-35°F)

IndustryStandards

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25andVolvoWB-101/BM

140to152

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemuidisavailablein20

ml(2/3oz)bottles.Onebottleissufcientfor

15to22L(4to6USgallons)ofhydraulicuid.

OrderPartNo.44-2500fromyourAuthorizedToro

Dealer.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

HydraulicFluid

Specications

Every1,500hours/Every2years(whichever

comesrst)

HydraulicTankCapacity:56L(14.8USgallons)

Useonly1ofthefollowinguidsinthehydraulic

system:

•ToroPremiumTransmission/HydraulicTractor

Fluid(refertoyourAuthorizedServiceDealerfor

moreinformation)

•ToroPremiumAllSeasonHydraulicFluid

(refertoyourAuthorizedServiceDealerformore

information)

•IfeitheroftheaboveT orouidsarenotavailable,

youmayuseanotherUniversalTractorHydraulic

Fluid(UTHF),buttheymustbeonlyconventional,

petroleum-basedproducts.Thespecications

mustfallwithinthelistedrangeforallthefollowing

materialpropertiesandtheuidshouldmeet

thelistedindustrystandards.Checkwithyour

hydraulicuidsuppliertodetermineiftheuid

meetsthesespecications.

Checkingthe Hydraulic-FluidLevel

ServiceInterval:Every25hours

Checkthehydraulic-uidlevelbeforetheengineis

rststartedandafterevery25operatinghours.

RefertoCheckingtheHydraulic-FluidLevel(page36).

Important:Alwaysusethecorrecthydraulic

uid.Unspecieduidswilldamagethehydraulic

system.

1.Parkthemachineonalevelsurface,remove

anyattachment,engagetheparkingbrake(if

equipped),raisetheloaderarms,andinstallthe

cylinderlocks.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Removethehood/frontaccesscover.

4.Cleantheareaaroundthellerneckofthe

hydraulictank(Figure39).

5.Removetheller-neckcapandchecktheuid

levelonthedipstick(Figure39).

Theuidlevelshouldbebetweenthemarkson

thedipstick.

Note:T orowillnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souse

onlyproductsfromreputablemanufacturerswho

willstandbehindtheirrecommendations.

g005938

Figure39

1.Fillerneckcap2.Dipstick

36

6.Ifthelevelislow,addenoughuidtoraiseitto

theproperlevel.

7.Installtheller-neckcap.

8.Installthehood/frontaccesscover.

9.Removeandstorethecylinderlocksandlower

theloaderarms.

ReplacingtheHydraulic

10.Shutofftheengineandcheckforleaks.

11.Checktheuidlevelinthehydraulictank;refer

toCheckingtheHydraulic-FluidLevel(page36).

Adduidtoraisetheleveltomarkondipstick.

Donotoverllthetank.

12.Installthehood/frontaccesscover.

13.Removeandstorethecylinderlocksandlower

theloaderarms.

Filter

ServiceInterval:Aftertherst8hours

Every400hours

Important:Donotsubstituteanautomotiveoil

lterorseverehydraulicsystemdamagemay

result.

1.Parkthemachineonalevelsurface,remove

anyattachment,engagetheparkingbrake(if

equipped),raisetheloaderarms,andinstallthe

cylinderlocks.

2.Shutofftheengineandremovethekey.

3.Removethehood/frontaccesscover.

4.Placeadrainpanunderthelter.

5.Removetheoldlter(Figure40)andwipethe

surfaceofthelteradapterclean.

ChangingtheHydraulic Fluid

ServiceInterval:Yearly

1.Parkthemachineonalevelsurface,remove

anyattachment,engagetheparkingbrake(if

equipped),raisetheloaderarms,andinstallthe

cylinderlocks.

2.Shutofftheengineandremovethekey.

3.Removethehood/front-accesscover.

4.Placealargedrainpanunderthemachinethat

canholdatleastthehydraulic-tankcapacity.

5.Removethedrainplugfromthebottomofthe

hydraulictankandallowtheuidtocompletely

drainout.

6.Installthedrainplug.

7.Fillthehydraulictankwithhydraulicuid;refer

toHydraulicFluidSpecications(page36).

Note:Disposeofusedoilatacertiedrecycling

center.

Figure40

1.Hydrauliclter

2.Gasket

3.Filteradapter

6.Applyathincoathydraulicuidtotherubber

gasketonthereplacementlter(Figure40).

7.Installthereplacementhydrauliclterontothe

lteradapter(Figure40).Tightenitclockwise

untiltherubbergasketcontactsthelteradapter,

thentightenthelteranadditional1/2turn.

8.Cleanupanyspilleduid.

9.Starttheengineandletitrunforabout2minutes

topurgeairfromthesystem.

8.Installthehood/front-accesscover.

9.Removeandstorethecylinderlocksandlower

theloaderarms.

g003721

37

Cleaning

Storage

RemovingDebris

ServiceInterval:Beforeeachuseordaily

Important:Operatingtheenginewithblocked

screensand/orcoolingshroudsremovedwill

resultinenginedamageduetooverheating.

1.Parkthemachineonalevelsurface,raisethe

loaderarms,andinstallthecylinderlocks.

2.Shutofftheengineandremovethekey.

3.Removethefront-accesscover.

4.Cleananydebrisfromthegrill.

5.Opentherear-accesscover.

6.Wipeawaydebrisfromtheaircleaner.

7.Cleananydebrisbuildupontheenginewitha

brushorblower.

Important:Blowthedirtoutratherthan

washitout.Ifyouusewater,keepit

awayfromelectricalitemsandhydraulic

valves.Donotuseahigh-pressurewasher.

High-pressurewashingcandamagethe

electricalsystemandhydraulicvalvesor

depletegrease.

8.Replaceandsecurethefrontandrear-access

covers.

9.Removeandstorethecylinderlocksandlower

theloaderarms.

StorageSafety

•Allowthemachinetocoolbeforestoring.

•Donotstorethemachineorfuelnearames.

Storage

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Removedirtandgrimefromtheexternalpartsof

theentiremachine,especiallytheengine.Clean

dirtandchafffromtheradiator.

Important:Washthemachineusingmild

detergentandwater.Donotpressure-wash

themachine.Avoidexcessiveuseofwater,

especiallynearthecontrolpanel,engine,

hydraulicpumps,andmotors.

4.Servicetheaircleaner;refertoServicingtheAir

Cleaner(page27).

5.Greasethemachine;refertoGreasingthe

Machine(page27).

6.Drainwaterfromthefuellter;refertoDraining

WaterfromtheFuelFilter(page30).

7.Torquethewheellugnutsto68N∙m(50ft-lb).

8.Checkthehydraulicuidlevel;refertoChecking

theHydraulic-FluidLevel(page36).

9.Checkthetirepressure;refertoCheckingthe

TirePressure(page34).

10.Chargethebattery;refertotheChargingthe

Battery(page33).

11.Flushthefueltankwithfresh,cleandieselfuel.

12.Checkandtightenallfasteners.Repairor

replaceanyworn,damaged,ormissingparts.

13.Paintallscratchedorbaremetalsurfaceswith

paintavailablefromyourAuthorizedService

Dealer.

14.Checkantifreezeprotectionandlltheradiator

witha50/50solutionofwaterandpermanent

ethyleneglycolantifreeze.Refertoyourengine

owner’smanualorAuthorizedServiceDealerfor

detailsoncheckingandmaintainingthecooling

system.

15.Storethemachineinaclean,drygarageor

storagearea.Removethekeyfromthekey

switchandkeepitinamemorableplace.

16.Coverthemachinetoprotectitandkeepitclean.

Important:Whenremovingthemachinefrom

storage,chargethebattery;refertoChargingthe

Battery(page33).

38

Troubleshooting

Problem

Thestarterdoesnotcrank.