Page 1

FormNo.3358-183RevB

Dingo

®

320-DCompactUtility

Loader

ModelNo.22336—SerialNo.270000001andUp

Registeratwww.T oro.com.OriginalInstructions(EN)

Page 2

ThissparkignitionsystemcomplieswithCanadian

ICES-002.

Introduction

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comfor

productandaccessoryinformation,helpndinga

dealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

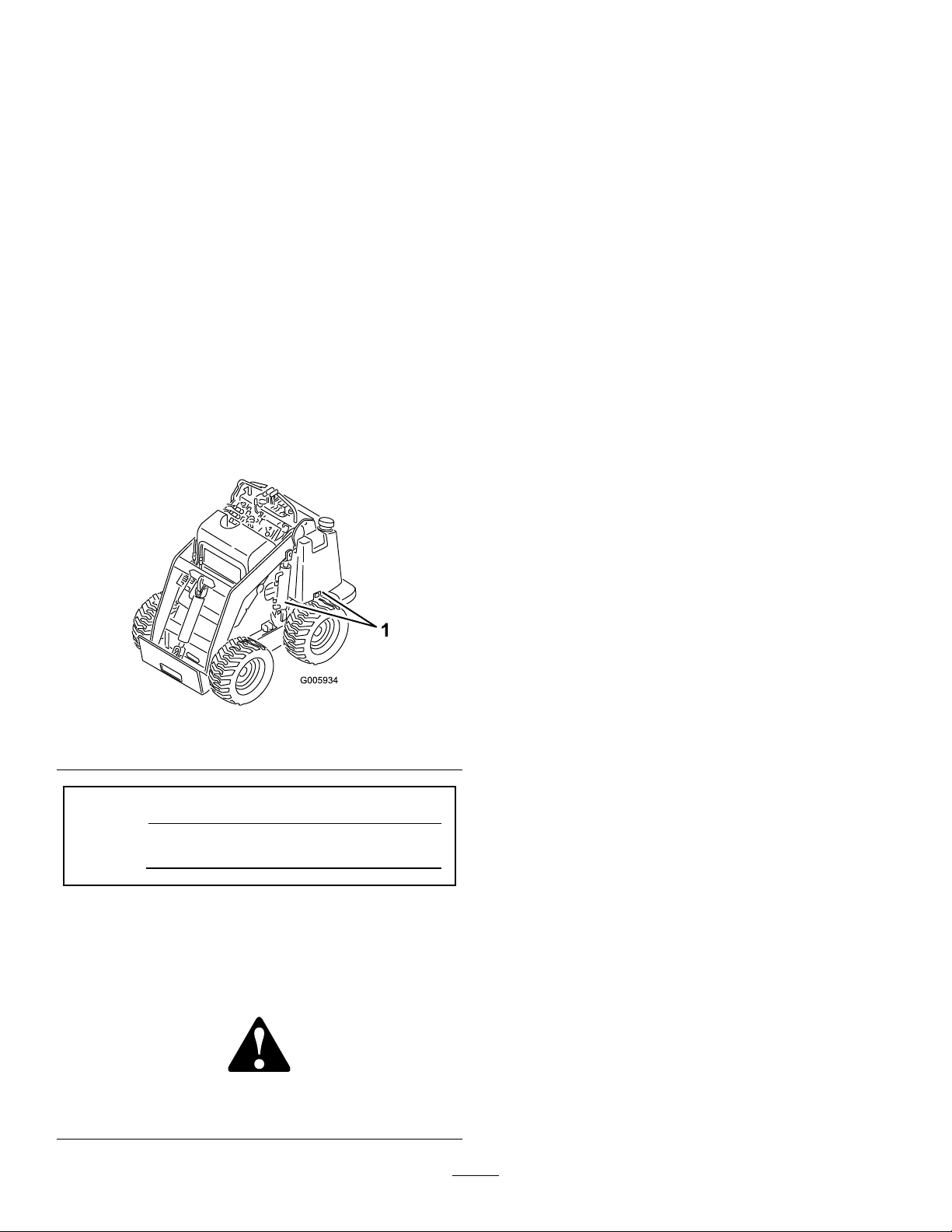

andserialnumbersofyourproductready .Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafetyalertsymbol

(Figure2),whichsignalsahazardthatmaycauseserious

injuryordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Contents

Introduction.................................................................2

Safety...........................................................................3

SafeOperatingPractices.......................................3

SoundPressure.....................................................6

SoundPower........................................................6

Vibration..............................................................6

SlopeChart..........................................................7

SafetyandInstructionalDecals.............................8

Setup..........................................................................11

1InstallingtheValveLever.................................11

2CheckingFluidLevels......................................11

3ActivatingtheBattery......................................11

ProductOverview......................................................14

Controls.............................................................14

Specications.....................................................17

Attachments/Accessories...................................17

StabilityData......................................................18

Operation...................................................................19

FillingtheFuelTank...........................................19

DrainingWaterfromtheFuelFilter.....................19

CheckingtheEngineOilLevel............................20

CheckingtheEngineCoolantLevel....................20

RemovingDebrisfromtheTraction

Unit................................................................21

CheckingtheHydraulicFluidLevel.....................21

TestingtheParkingBrake...................................21

CheckingtheTirePressure.................................22

StartingtheEngine.............................................22

DrivingtheTractionUnit...................................22

StoppingtheTractionUnit/Engine....................22

MovingaNon-functioningTraction

Unit................................................................23

UsingtheCylinderLocks....................................23

UsingAttachments.............................................24

SecuringtheTractionUnitforTransport.............25

AdjustingtheThighSupport...............................25

Maintenance...............................................................27

RecommendedMaintenanceSchedule(s)................27

PremaintenanceProcedures....................................28

OpeningtheAccessCovers................................28

Lubrication.............................................................29

GreasingtheTractionUnit.................................29

EngineMaintenance...............................................29

ServicingtheAirCleaner....................................29

ServicingtheEngineOil.....................................30

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

FuelSystemMaintenance.......................................31

ChangingtheFuelFilter.....................................31

BleedingtheFuelSystem....................................31

DrainingtheFuelTanks.....................................32

ElectricalSystemMaintenance................................33

ServicingtheBattery...........................................33

HydraulicSystemMaintenance...............................35

ReplacingtheHydraulicFilter.............................35

ChangingtheHydraulicFluid.............................35

CheckingtheHydraulicLines.............................35

Storage.......................................................................36

Troubleshooting.........................................................37

Schematics.................................................................40

Safety

Improperuseormaintenancebytheoperatoror

ownercanresultininjury.T oreducethepotential

forinjury,complywiththesesafetyinstructions

andalwayspayattentiontothesafetyalert

symbol

Danger

complywiththeinstructionmayresultinpersonal

injuryordeath.

,whichmeans:

—personalsafetyinstruction.Failureto

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Caution

,

W ar ning

,or

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator’sManualandothertraining

material.Iftheoperator(s)ormechanic(s)can

notreadEnglish,itistheowner’sresponsibilityto

explainthismaterialtothem.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateor

servicetheequipment.Localregulationsmayrestrict

theageoftheoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,

otherpeopleorproperty.

Preparation

•Evaluatetheterraintodeterminewhataccessories

andattachmentsareneededtoproperlyand

safelyperformthejob.Onlyuseaccessoriesand

attachmentsapprovedbythemanufacturer.

•Wearappropriateclothingincludinghardhat,

safetyglasses,longpants,safetyshoes,andhearing

protection.Longhair,looseclothingorjewelrymay

gettangledinmovingparts.

3

Page 4

•Inspecttheareawheretheequipmentistobeused

andremoveallobjectssuchasrocks,toys,andwire

whichcanbethrownbythemachine.

•Useextracarewhenhandlingfuels.Theyare

ammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethefuelcaporaddfuelwiththe

enginerunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperator’spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholes

andhiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingtheengine.Onlystartthe

enginefromtheoperator’sposition.

•Slowdownanduseextracareonhillsides.Besure

totravelintherecommendeddirectiononhillsides.

Turfconditionscanaffectthemachine’sstability.

•Slowdownandusecautionwhenmakingturnsand

whenchangingdirectionsonslopes.

•Neveroperatewiththeguardsnotsecurelyinplace.

Besureallinterlocksareattached,adjustedproperly,

andfunctioningproperty.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Stoponlevelground,lowerimplements,disengage

theauxiliaryhydraulics,engageparkingbrake,shut

offtheenginebeforeleavingtheoperator’ sposition

foranyreason.

•Keephandsandfeetawayfrommovingattachments.

•Lookbehindanddownbeforebackinguptobesure

ofaclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Readallattachmentmanuals.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthetractionunit.Stopthetractionunit

ifanyoneentersthearea.

•Neverleavearunningtractionunitunattended.

Alwayslowertheloaderarms,stoptheengine,set

theparkingbrake,andremovethekeybeforeleaving.

•Donotexceedtheratedoperatingcapacity,asthe

tractionunitmaybecomeunstablewhichmayresult

inlossofcontrol.

•Donotcarryaloadwiththearmsraised.Always

carryloadsclosetotheground.

•Donotoverloadtheattachmentandalwayskeep

theloadlevelwhenraisingtheloaderarms.Logs,

boards,andotheritemscouldrolldowntheloader

arms,injuringyou.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfrom

operation.Allowthemtocoolbeforeattemptingto

maintain,adjust,orservice.

•Checkforoverheadclearances(i.e.branches,

doorways,electricalwires)beforedrivingunderany

objectsanddonotcontactthem.

•Ensurethatyouoperatethetractionunitinareas

wheretherearenoobstaclesincloseproximitytothe

operator.Failuretomaintainadequatedistancefrom

trees,walls,andotherbarriersmayresultininjury

asthetractionunitbacksupduringoperationifthe

operatorisnotattentivetothesurroundings.Only

operatetheunitinareaswherethereissufcient

clearancefortheoperatortosafelymaneuverthe

product.

•Beforedigging,havetheareamarkedfor

undergroundutilities,anddonotdiginmarkedareas.

•Locatethepinchpointareasmarkedonthetraction

unitandattachmentsandkeephandsandfeetaway

fromtheseareas.

•Beforeoperatingthetractionunitwithan

attachment,ensurethattheattachmentisproperly

installed.

•Donotplaceyourfeetundertheplatform.

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryor

death.Allslopesrequireextracaution.

•Donotoperatethetractionunitonhillsidesor

slopesexceedingtheanglesrecommendedinthe

4

Page 5

StabilityDatasectioninSpecications,page17,and

thoseintheattachmentOperator’sManual.Seealso

theSlopeChart,page7.

•Operateupanddownslopeswiththeheavyend

ofthetractionunituphill.Weightdistribution

changes.Anemptybucketwillmaketherearof

thetractionunittheheavyend,andafullbucket

willmakethefrontofthetractionunittheheavy

end.Mostotherattachmentswillmakethefrontof

tractionunittheheavyend.

•Raisingtheloaderarmsonaslopewillaffectthe

stabilityofthemachine.Wheneverpossible,keepthe

loaderarmsintheloweredpositionwhenonslopes.

•Removinganattachmentonaslopewillmakethe

rearofthetractionunitheavy.RefertotheStability

DatasectioninSpecications,page17,todetermine

whethertheattachmentcanbesafelyremovedon

theslope.

•Removeobstaclessuchasrocks,treelimbs,etc.from

theworkarea.Watchforholes,ruts,orbumps,as

uneventerraincouldoverturnthetractionunit.Tall

grasscanhideobstacles.

•UseonlyToro-approvedattachments.Attachments

canchangethestabilityandtheoperating

characteristicsofthetractionunit.Warrantymaybe

voidedifusedwithunapprovedattachments.

•Keepallmovementsonslopesslowandgradual.Do

notmakesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthetraction

unitlosestraction,proceedslowly,straightdownthe

slope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthetractionunit

uphill.

•Donotoperateneardrop-offs,ditches,or

embankments.Thetractionunitcouldsuddenlyturn

overifawheelgoesovertheedgeofaclifforditch,

orifanedgecavesin.

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

•Donotparkthetractionunitonahillsideorslope

withoutloweringtheattachmenttothegroundand

chockingthewheels.

•Donottrytostabilizethetractionunitbyputting

yourfootontheground.

MaintenanceandStorage

•Disengagetheauxiliaryhydraulics,lowerthe

attachment,settheparkingbrake,stoptheengine,

andremovethekey.Waitforallmovementtostop

beforeadjusting,cleaning,orrepairing.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuel

spillage.

•Lettheenginecoolbeforestoringanddonotstore

nearame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallow

untrainedpersonneltoservicethemachine.

•Usejackstandstosupportcomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthe

positivelast.Reconnectpositiverstandnegative

last.

•Keephandsandfeetawayfrommovingparts.If

possible,donotmakeadjustmentswiththeengine

running.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.

Wearprotectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Ifanymaintenanceorrepairrequirestheloaderarms

tobeintheraisedposition,securethearmsinthe

raisedpositionwiththehydrauliccylinderlocks.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthetractionunitfreeofgrass,leaves,orother

debrisbuildup.Cleanupoilorfuelspillage.Allow

thetractionunittocoolbeforestoring.

•Useextracarewhenhandlingfuels.Theyare

ammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuelcaporaddfuelwhen

theengineisrunning.Allowtheenginetocool

beforerefueling.Donotsmoke.

–Neverrefuelthetractionunitindoors.

–Neverstorethetractionunitorfuelcontainer

insidewherethereisanopename,suchasnear

awaterheaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,

trunk,pickupbed,oranysurfaceotherthanthe

ground.

5

Page 6

–Keepcontainernozzleincontactwiththetank

duringlling.

•Stopandinspecttheequipmentifyoustrikean

object.Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineTororeplacementpartstoensure

thatoriginalstandardsaremaintained.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyour

face,eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks

andamesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthighpressurehydraulic

uid.Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.Hydraulicuidescaping

underpressurecanpenetrateskinandcauseinjury

requiringsurgerywithinafewhoursbyaqualied

surgeonorgangrenemayresult.

SoundPressure

Thisunithasamaximumsoundpressurelevelatthe

operator’searof97dBA,basedonmeasurementsof

identicalmachinesperEN11201.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof101

dBA,basedonmeasurementsofidenticalmachinesper

EN6395.

Vibration

Thisunitdoesnotexceedahand/armvibrationlevelof

0.5m/s

perEN1033.

Thisunitdoesnotexceedawholebodyvibration

levelof0.1m/s

machinesperEN1032.

2

,basedonmeasurementsofidenticalmachines

2

,basedonmeasurementsofidentical

6

Page 7

SlopeChart7SafetyandInstructionalDecals

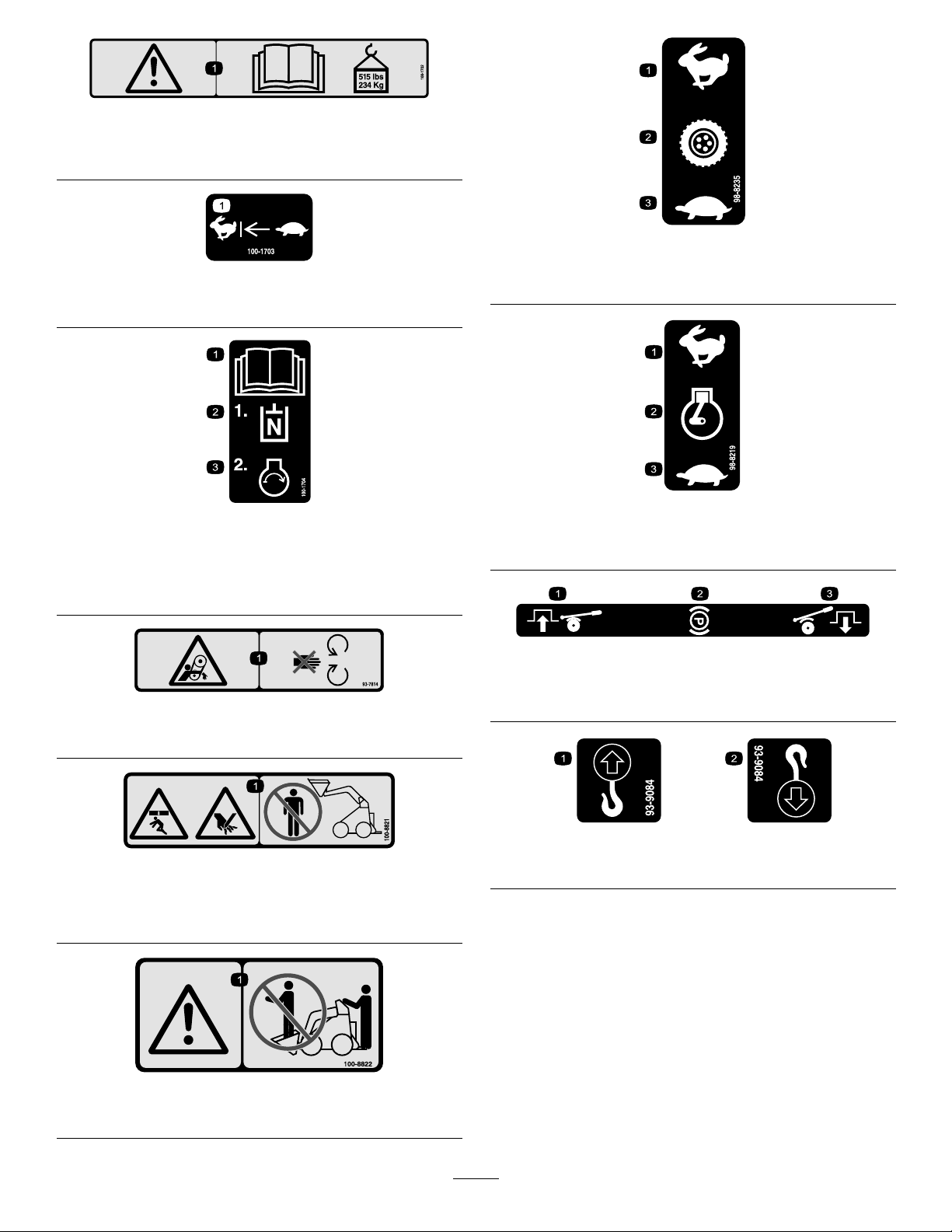

Page 8

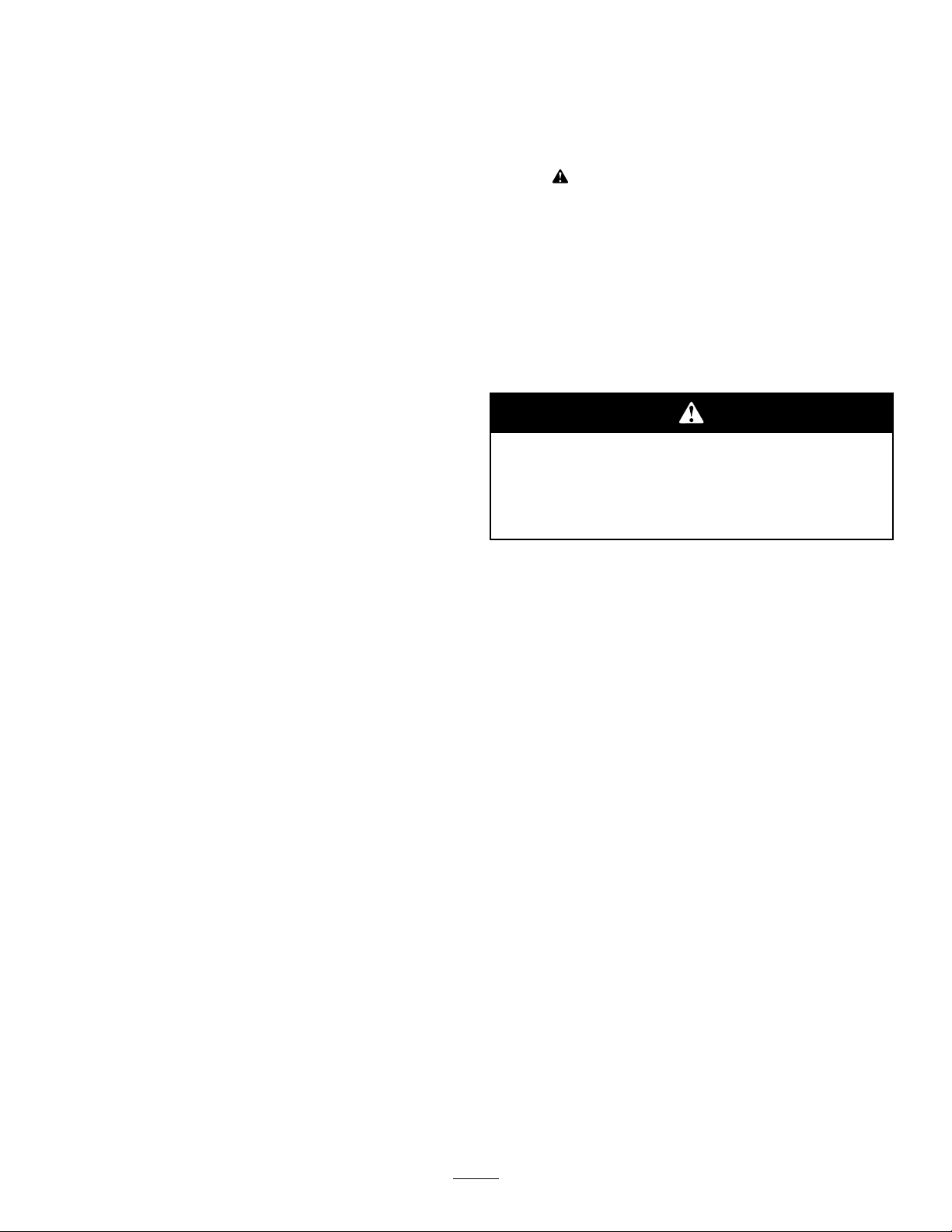

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

100-1701

1.Crushinghazard—installthecylinderlockandreadtheinstructionsbeforeservicingorperformingmaintenance.

2.Warning—removetheignitionkeyandlowertheloaderarmsbeforeleavingthemachine.

3.Cuttinghazardofhand—waitformovingpartstostop.

4.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistancefromthemachine.

5.Explosionandelectricalshockhazards—donotdiginareaswithburiedgasorelectricallines.

1.Warning—readthe

Operator’sManual.

2.Tippinghazard—donot

stepoffoperatorplatform

withloadraised,always

operatewiththeheavyend

ofthemachinepointed

uphill,carryloadslow,

maximumloadis515lbs

(234kg).

3.Armlift–down

4.Armlift—up

5.Wheeldrive—forward

6.Wheeldrive—reverse9.Engine—start

93-6680

108-9733

7.Buckettilt—down10.Engine—run

8.Buckettilt—up11.Engine—stop

93-6686

1.Hydraulicoil

2.ReadtheOperator’sManual.

8

Page 9

100-1702

1.Warning—readtheOperator’sManual;maximumload

ratingof515lb.(234Kg).

100-1703

1.Speedselector

1.Fast

2.Tractiondrive

98-8235

3.Slow

100-1704

1.ReadtheOperator’s

Manual.

2.Placetheauxiliary

hydraulicsinNeutral.

3.Starttheengine.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

100-8821

1.Crushinghazardandcuttinghazardofhand—stayasafe

distancefromthefrontofthetractionunitwhentheloader

armsareraised.

98-8219

1.Fast

2.Throttle

100-1692

1.Brakeengaged3.Brakedisengaged

2.Parkingbrake

93-9084

1.Liftpoint

3.Slow

2.Tie-downpoint

1.Warning—donotcarrypassengers.

100-8822

9

Page 10

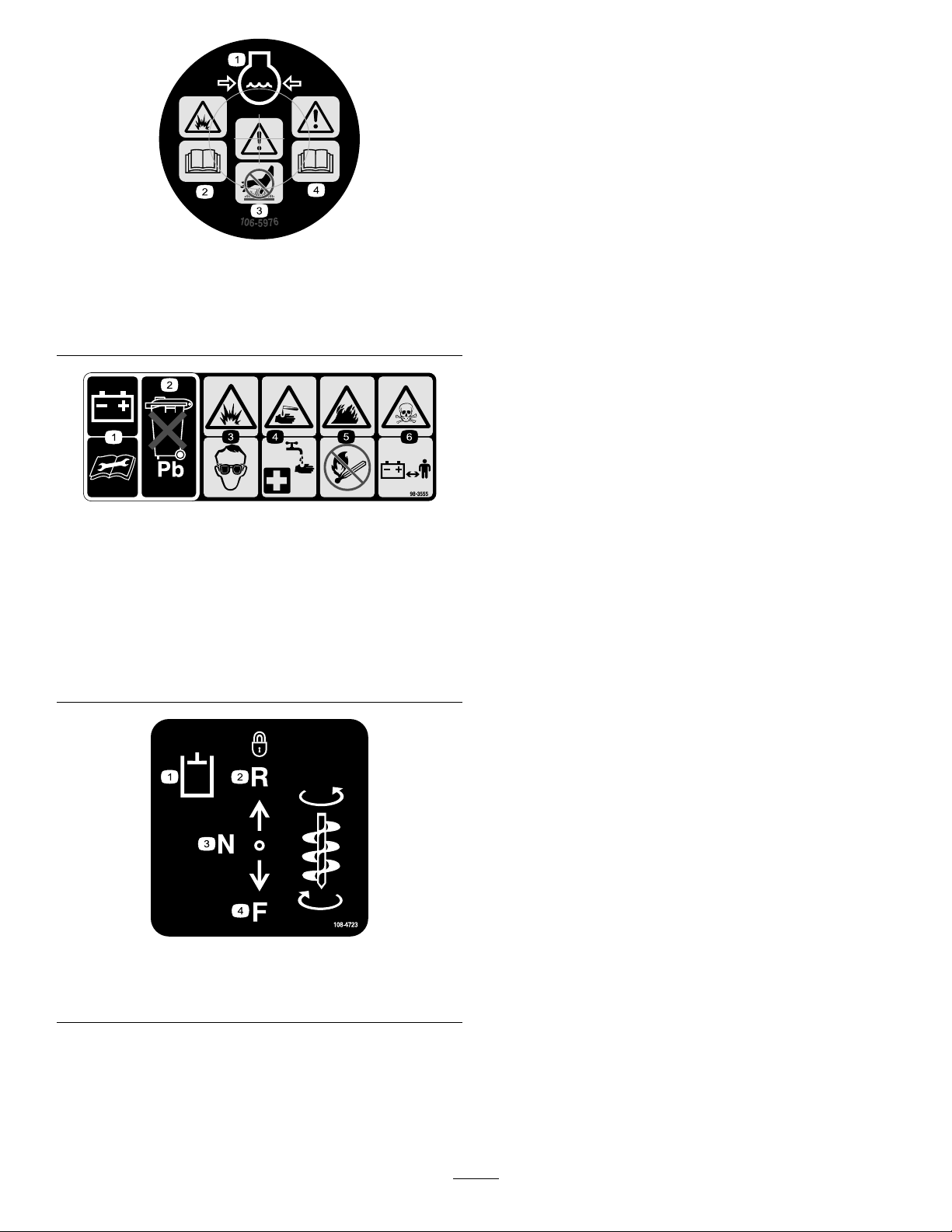

106-5976

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator’sManual.

3.Warning—donottouch

thehotsurface.

4.Warning—readthe

Operator’sManual.

98-3555

1.Readtheinstructionsbeforeservicingorperforming

maintenanceonthebattery.

2.Containslead;donotdiscard.

3.Explosionhazard—weareyeprotection.

4.Causticliquid/chemicalburnhazard—toperformrstaid,

ushwithwater.

5.Firehazard—nore,openames,orsmoking.

6.Poisonhazard—keepchildrenasafedistancefromthe

battery.

1.Auxiliaryhydraulics

2.Lockedreverse(detent)

108-4723

3.Neutral(off)

4.Forward

10

Page 11

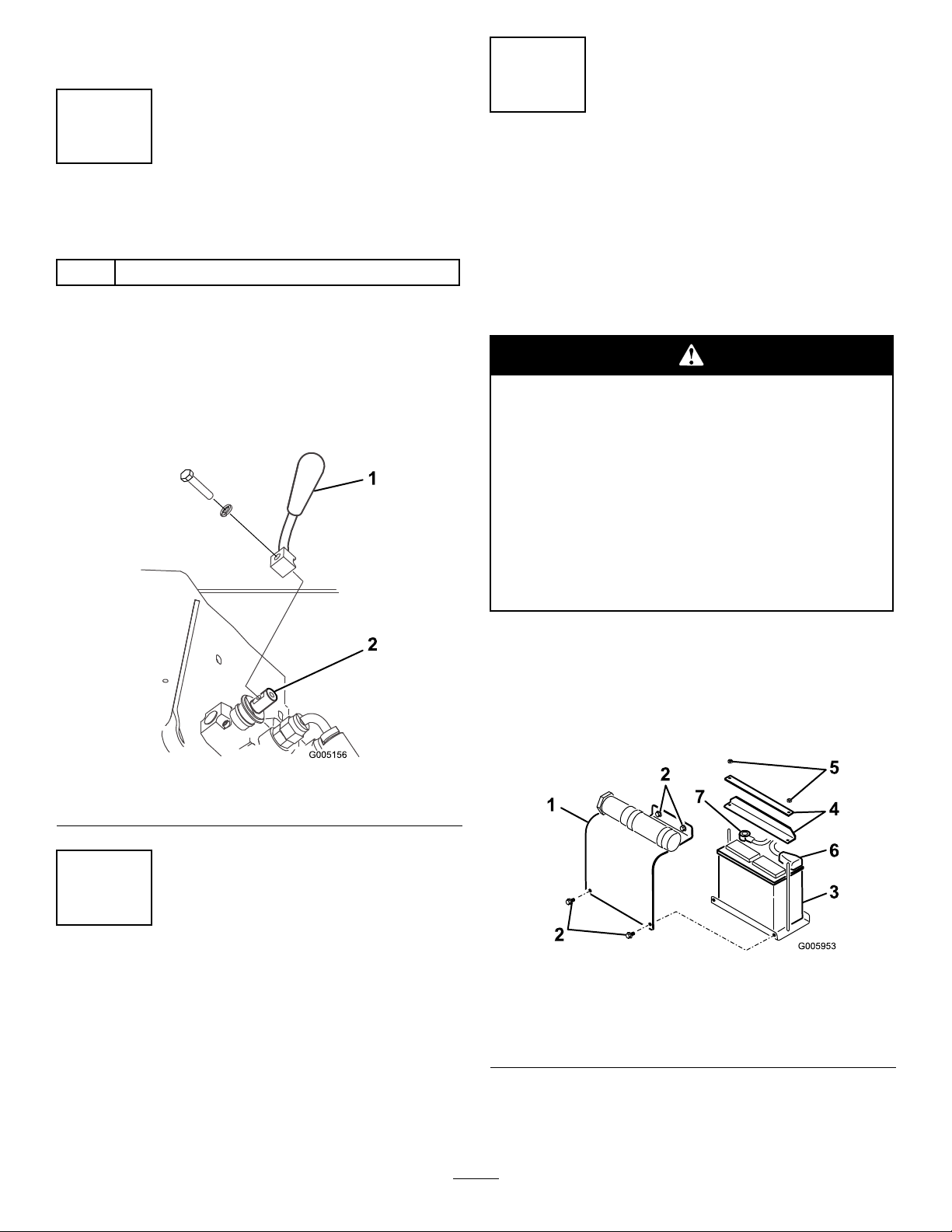

Setup

3

1

InstallingtheValveLever

Partsneededforthisprocedure:

1

Speedselectorvalvelever

Procedure

1.Removeanddiscardthenutsecuringtheboltand

lockwashertothespeedselectorlever.

2.Securethelevertothespeedselectorvalveusingthe

boltandlockwasherasillustratedinFigure3.

ActivatingtheBattery

NoPartsRequired

Procedure

Thetractionunitisshippedwithadrybattery.Youmust

purchasebulkelectrolytewith1.260specicgravity

fromalocalbatterysupplyoutlet.

Batteryterminalsormetaltoolscouldshort

againstmetalcomponents,causingsparks.

Sparkscancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,do

notallowthebatteryterminalstotouchany

metalpartsofthetractionunit.

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

tractionunit.

Figure3

1.Speedselectorvalvelever2.Speedselectorvalve

2

CheckingFluidLevels

NoPartsRequired

Procedure

Beforestartingtheengineforthersttime,checkthe

engineoil,hydraulicuid,andenginecoolantlevels.

RefertoOperationformoreinformation.

1.Parkthetractionunitonalevelsurface,raisethe

loaderarms,andinstallthecylinderlocks.

2.Stoptheengineandremovethekey.

3.Removethefourboltssecuringthebatterycover

andremovethecover(Figure4).

Figure4

1.Batterycover5.Nut

2.Bolt6.Positivecable

3.Battery7.Negativecable

4.Bars

4.Removethenutsandbarssecuringthebattery

(Figure4).

11

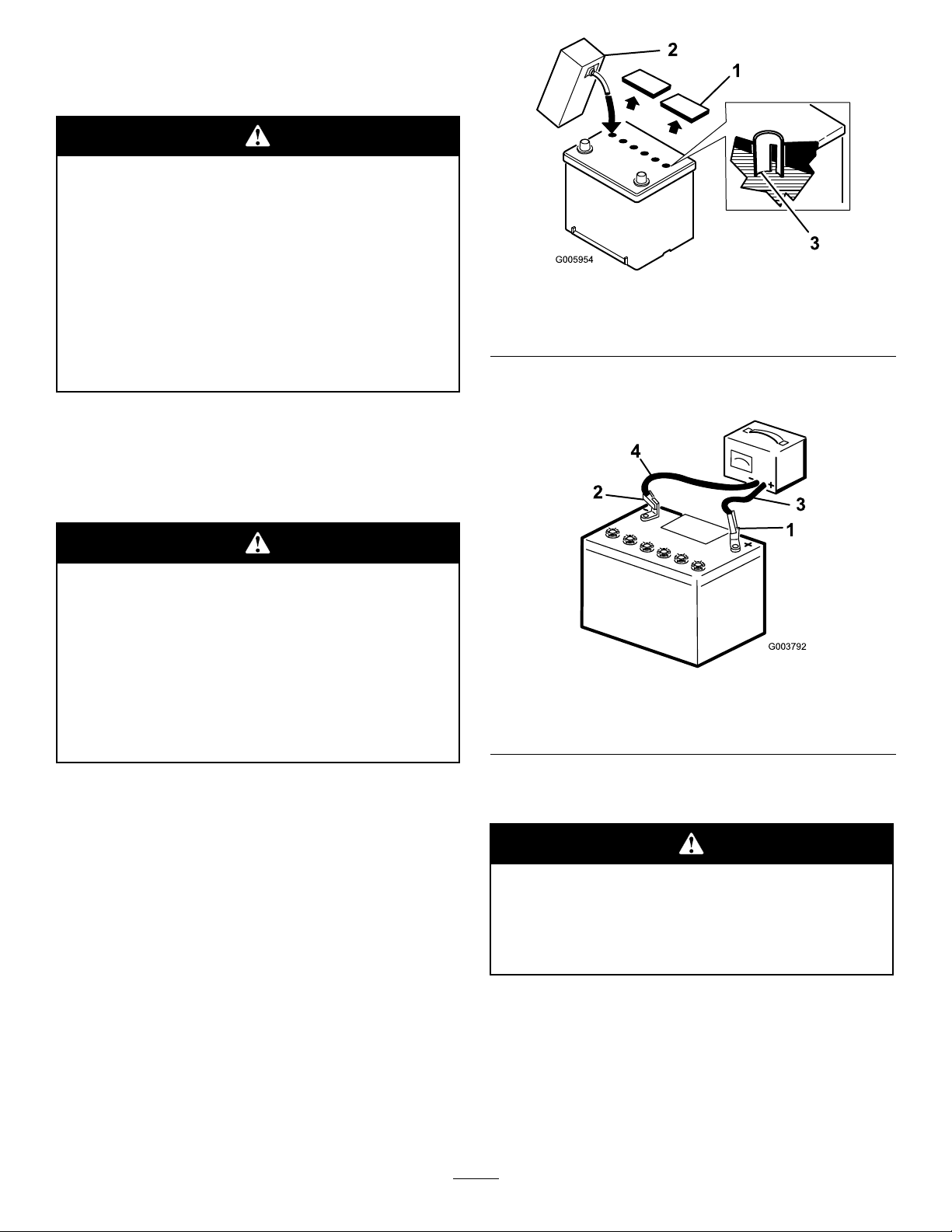

Page 12

5.Disconnectthenegative(black)cablefrom

1

2

3

4

G003792

thenegative(-)batterypost,ifitisn’talready

disconnected(Figure4).

Incorrectbatterycableroutingcoulddamage

thetractorandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

6.Disconnectthepositive(red)cablefromthepositive

(+)batterypost(Figure4).

7.Liftthebatteryoffoftheplatform.

8.Removethellercapsfromthebattery.

Figure5

1.Fillercaps

2.Electrolyte

3.Lowerpartofthetube

10.Leavethecoversoffandconnecta3to4amp

batterychargertothebatteryposts(Figure6).

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrobbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

9.Slowlypourelectrolyteintoeachcelluntilthe

electrolytelevelisuptothelowerpartofthetube

(Figure5).

Figure6

1.Positivepost

2.Negativepost

3.Chargerred(+)wire

4.Chargerblack(—)wire

11.Chargethebatteryatarateof4amperesorlessfor

4hours(12volts).

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

12.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(Figure6).

13.Slowlypourelectrolyteintoeachcelluntilthelevelis

onceagainuptotheupperlineonthebatterycase

(Figure5)andinstallthecovers.

14.Installthebatteryontotheplatform(Figure4).

12

Page 13

15.Securethebatteryinthechassiswiththebarsand

nutsremovedpreviously(Figure4).

16.Connectthepositive(red)cabletothepositive(+)

batterypost(Figure4).Slidetherubbercoverover

thebatterypost.

17.Connectthenegative(black)cabletothenegative

(-)batterypost(Figure4).

Important:Ensurethatthebatterycablesdo

notcontactanysharpedgesoreachother.

18.Installthebatterycover(Figure4).

13

Page 14

ProductOverview

G005939

1

2

3

4

5

20

17

6

18

7

8

13

14

15

12

11

21

9

18

16

4

14

19

10

22

G006057

631524

78

Figure7

1.Mountplate7.Wheel

2.Tiltcylinder

3.Auxiliaryhydrauliccouplers

4.Loaderarms

5.Frontaccesscover11.Engine17.Indicatorlights

6.Fueltank

8.Liftcylinder14.Liftpoints20.Radiatorllcap

9.Operatorplatform

10.Rearaccesscover(open)

12.Airlter

13.Controlpanel

15.Handle21.Thighsupport

16.Battery22.Flowdividercontrol

18.Towvalves

19.Parkingbrakelever

Controls

Becomefamiliarwithallthecontrols(Figure8)before

youstarttheengineandoperatethetractionunit.

1.Tractioncontrollevers

2.Attachmenttiltlever6.Throttlelever

3.Loaderarmlever7.Keyswitch

4.Auxiliaryhydraulicslever8.Hourmeter

KeySwitch

Thekeyswitch,usedtostartandstoptheengine,has

threepositions:off,run,andstart.

Figure8

5.Speedselectorlever

•Tostarttheengine,rotatethekeytotherunposition,

theglowpluglightwillcomeon.Whentheglow

pluglightturnsoff,turnthekeytothestartposition.

Releasethekeywhenenginestartsanditwillmove

automaticallytotherunposition.

•Tostoptheengine,rotatethekeytotheoffposition.

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeed

andrearwardtodecreasespeed.

TractionControlLevers

•Tomoveforward,movethetractioncontrollevers

forward.Tomoverearward,movethetraction

controlleversrearward.

•Togostraight,movebothtractioncontrollevers

equally.

•Toturn,movetheleverlocatedonthesideyou

wanttoturnbacktowardtheneutralpositionwhile

keepingtheotherleverengaged.

14

Page 15

Note:Thefartheryoumovethetractioncontrol

leversineitherdirection,thefasterthetractionunit

willmoveinthatdirection.

•Tosloworstop,movethetractioncontrollevers

toneutral.

AttachmentTiltLever

•Totilttheattachmentforward,slowlypushthe

attachmenttiltleverforward.

AuxiliaryHydraulicsLever

•Tooperateahydraulicattachmentinforward

direction,slowlypulltheauxiliaryhydraulicslever

upwardandthenrearward.

•Tooperateahydraulicattachmentinreverse

direction,slowlypulltheauxiliaryhydraulicslever

upwardandthenpushitforward.Thisisalsocalled

thedetentpositionbecauseitdoesnotrequire

operatorpresence.

•Totilttheattachmentrearward,slowlypullthe

attachmenttiltleverrearward.

LoaderArmLever

•Tolowertheloaderarms,slowlypushtheloader

armleverforward.

•Toraisetheloaderarms,slowlypulltheloaderarm

leverrearward.

LoaderValveLock

Theloadervalvelocksecurestheloaderarmand

attachmenttiltleverssothatyoucannotpushthem

forward.Thishelpstoensurethatnoonewill

accidentallylowertheloaderarmsduringmaintenance.

Securetheloaderarmswiththelockanytimeyouneed

tostopthemachinewiththeloaderarmsraised.

Tosetthelock,pullitbackandallthewaydownagainst

thelevers(Fig.13).

Note:Youwillneedtomovetheleversrearwardto

engageordisengagetheloadervalvelock.

SpeedSelectorLever

Ifyoumovethespeedselectorleverwhilethe

tractionunitisinmotion,thetractionunitwill

eitherstopsuddenlyoracceleratequickly.If

youoperatethetractionunitwiththespeed

selectorleverinanintermediateposition,the

tractionunitwilloperateerraticallyandmaybe

damaged.Y oucouldlosecontrolofthetraction

unitandinjurebystandersoryourself.

•Donotmovethespeedselectorleverwhen

thetractionunitisinmotion.

•Donotoperatethetractionunitwhen

thespeedselectorisinanyintermediate

position(i.e.,anypositionotherthanfully

forwardorfullyrearward).

•Movethespeedselectorlevertotheforwardposition

tosetthetractiondrive,loaderarms,andattachment

tilttohighspeedandtheauxiliaryhydraulicstolow

speed.

•Movethespeedselectorlevertotherearward

positiontosettheauxiliaryhydraulicstohighspeed

andthetractiondrive,loaderarms,andattachment

tilttolowspeed.

1.Loadervalvelock,

engaged

Figure9

2.Loadervalvelock,

disengaged

HourMeter

Thehourmeterdisplaysthenumberofhoursof

operationthathavebeenloggedonthetractionunit.

After50hoursandevery75hoursthereafter(thatisat

50,125,200,etc.)thehourmeterdisplaysSVConthe

lowerleftsideofthescreentoremindyoutochangethe

oilandperformtherequiredmaintenance.Afterevery

400hours(400,800,1200,etc.),thehourmeterdisplays

SVConthelowerrightsideofthescreentoremind

youtoperformthemaintenanceproceduresbasedona

400hourschedule.Thesereminderscomeonstarting

threehourspriortotheserviceintervaltimeandashat

regularintervalsforsixhours.

15

Page 16

FlowDividerControl

ParkingBrake

Thetractionunithydraulics(i.e.,thetractiondrive,

loaderarms,andattachmenttilt)workonaseparate

hydrauliccircuitfromtheauxiliaryhydraulicsfor

poweringattachments;however,thetwosystemsshare

thesamehydraulicpumps.Usingtheowdivider

control(Figure10),youcanvarythespeedofthe

tractionunithydraulicsbydivertinghydraulicowtothe

auxiliaryhydraulicscircuit.Theowdividerallowsyou

todividetheowofuidinvaryingdegreestoslowthe

tractionunit.Thus,themorehydraulicowyoudivert

totheauxiliaryhydraulics,theslowerthetractionunit

hydraulicswillmove.

Figure10

1.Flowdividercontrol4.10to11o’clockposition

2.Knob5.9o’clockposition

3.12o’clockposition

•Movetheowdividercontroltothetwelveo’clock

positiontoprovidemaximumspeedtothetraction

unithydraulics.

Thetractionunitisequippedwithaparkingbrake

(Figure11).Rotatethebrakeleverdownwardtosetthe

braketolocktherearwheelswheneverthetractionunit

willbestoppedonahillorleftunattended.Movethe

leverupbeforedrivingthetractionunit.

Figure11

1.Parkingbrakelever—On

position

2.Parkingbrakelever—Off

position

IndicatorLights

Theindicatorlightswarnyouinthecaseofasystem

malfunctionand,inthecaseoftheglowpluglight,

indicatethattheglowplugsareon.Figure12illustrates

thefourindicatorlights.

Usethissettingforfastoperationofthetractionunit.

•Movetheowdividercontrolbetweenthetwelve

o’clockandnineo’clockpositionstoslowthe

tractionunithydraulicsandnetunethespeed.

Useasettinginthisrangewithattachments

withhydraulicswhereyouneedtobothrunthe

attachmentandmovethetractionunithydraulics,

suchastheauger,boringunit,hydraulicblade,and

tiller.

•Movethecontroltothenineo’clockpositionto

transferallhydraulicowtotheauxiliaryhydraulics

oftheattachment.

Inthissetting,thetractionunithydraulicswillnot

work.Usethissettingwithhydraulicattachments

thatdonotrequiredthetractionunithydraulics.

Therearecurrentlynoattachmentsthatrequirethe

nineo’clockposition;however,thetrencherdoes

workbestifyousetitclosetonineo’clocksothat

thetractionunitwillcreepslowlywhentrenching.

Note:Theowdividercontrolcanbexedinplace

byturningtheknobonthecontrolclockwiseuntilit

contactsthedial(Figure10).

Figure12

1.Oilpressurelight

2.Batterylight

3.Enginetemperaturelight

4.Glowpluglight

•EngineTemperatureLight

Iftheenginetemperaturelightison,theengineis

overheating.Stoptheengineandallowthetraction

unittocooldown.Checkthecoolantlevelandthe

beltstothefanandwaterpump.Fillthecoolantas

requiredandreplaceanywornorslippingbelts.If

theproblempersists,contactyourAuthorizedToro

Dealerfordiagnosticsandrepair.

•OilPressureLight

Thislightisonforafewsecondswheneveryou

starttheengine.Iftheoilpressurelightisonwhile

theengineisrunning,theengineoilpressureislow .

Stoptheengineandallowthetractionunittocool

down.Checktheoillevelandllthecrankcasewith

16

Page 17

oilasneeded.Iftheproblempersists,contactyour

AuthorizedToroDealerfordiagnosticsandrepair.

•BatteryLight

Thislightisonforafewsecondswheneveryoustart

theengine.Ifthebatterylightisonwhiletheengine

isrunning,thealternator,battery,orelectricalsystem

Thislightisonwhenthekeyisturnedtorunbefore

startingtheengine.Theglowpluglightwillremain

onforupto10seconds,indicatingthattheglow

plugsarewarmingtheengine.Iftheglowpluglight

isonwhiletheengineisrunning,theglowplugsare

broken.ContactyourAuthorizedToroDealerfor

diagnosticsandrepair.

isbroken.ContactyourAuthorizedT oroDealerfor

diagnosticsandrepair.

•GlowPlugLight

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Width

Length

Height

Weight(withoutattachmentorcounterweight)1722lb(783kg)

Operatingcapacity(with200lboperator,thestandardbucket,andwithoutthecounterweight)524lb(238kg)

Tippingcapacity(with200lboperator,thestandardbucket,andwithoutthecounterweight)l048lb(476kg)

Wheelbase

Dumpheight(withstandardbucket)47inches(120cm)

Reach—fullyraised(withstandardbucket)26inches(66cm)

Heighttohingepin(narrowbucketinstandardposition)66inches(168cm)

40.5inches(103cm)

60inches(152cm)

49inches(125cm)

28inches(71cm)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesareavailableforusewiththemachinetoenhanceand

expanditscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww .T oro.comforalistof

allapprovedattachmentsandaccessories.

Important:UseonlyToroapprovedattachments.Otherattachmentsmaycreateanunsafeoperating

environmentordamagethetractionunit.

17

Page 18

StabilityData

Thefollowingtableslistthemaximumsloperecommendedforthetractionunitinthepositionslistedinthetables.

Slopesoverthelisteddegreemaycausethetractionunittobecomeunstable.Thedatainthetablesassumethatthe

loaderarmsarefullylowered;raisedarmsmayaffectthestability.

Ineachattachmentmanualisasetofthreestabilityratings,oneforeachhillposition.Todeterminethemaximum

slopeyoucantraversewiththeattachmentinstalled,ndthedegreeofslopethatcorrespondstothestabilityratings

oftheattachment.Example:IftheattachmenthasaFrontUphillratingofB,aRearUphillratingofD,anda

SideUphillratingofC,thenyoucoulddriveforwardupan18°slope,rearwardupa10°slope,orsidewaysona

14°slope,aslistedinthefollowingtable.

MaximumRecommendedSlopewhen

FrontUphillRearUphill

Conguration

Tractionunitwithoutattachment

Tractionunitwithcounterweight,withoutattachment

Tractionunitwithanattachmentratedwithoneofthefollowingstabilityratings

foreachslopeposition:*

A

B

C15°16°14°

D

E

7°20°17°

5°21°17°

25°25°20°

18°19°18°

10°10°9°

5°5°5°

Operatingwith:

SideUphill

18

Page 19

Operation

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Beforeoperating,checkthefuel,oil,andcoolantlevel;removedebrisfromthetractionunit;

testtheparkingbrake,andcheckthetirepressure.Also,ensurethattheareaisclearofpeopleanddebris.

Youshouldalsoknowandhavemarkedthelocationsofallutilitylines.

Youcouldfalloffoftheplatformandbeseriouslyinjuredduringoperation.

Donotmovethecontrolleversunlessyouarestandingwithbothfeetontheplatformandyourhands

areholdingthehandles.

FillingtheFuelTank

Theenginerunsonclean,freshdieselfuelwith

aminimumcetaneratingof40.Purchasefuelin

quantitiesthatcanbeusedwithin30daystoensure

fuelfreshness.

Usesummergradedieselfuel(No.2-D)attemperatures

above20°F(-7°C)andwintergradedieselfuel

(No.1-DorNo.1-D/2-Dblend)below20°F

(-7°C).Useofwintergradedieselfuelatlower

temperaturesprovideslowerashpointandpourpoint

characteristics,allowingeasierstartsandlesseningthe

chancesofchemicalseparationofthefuelduetolower

temperatures.

Useofsummergradedieselfuelabove20°F(-7°C)

willcontributetowardlongerlifeofthefuelpump

components.

Important:Donotusekeroseneorgasolinein

placeofdieselfuel.Failuretoobservethiscaution

willdamagetheengine.

1.Parkthetractionunitonalevelsurface,lowerthe

loaderarms,andstoptheengine.

2.Removethekeyandallowtheenginetocool.

3.Cleanaroundthefueltankcapandremovethecap.

4.Fillthetanktoaboutoneinchbelowthetopofthe

tank,notthellerneck,withdieselfuel.

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.A

reorexplosionfromfuelcanburnyouand

othersandcancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,

inanopenarea,whentheengineisoffand

iscold.Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomof

thellerneck.Thisemptyspaceinthetank

allowsthefueltoexpand.

•Neversmokewhenhandlingfuel,andstay

awayfromanopenameorwherefuel

fumesmaybeignitedbyaspark.

•Storefuelinaclean,safety-approved

containerandkeepthecapinplace.

5.Installthefueltankcap.Wipeupanyfuelthatmay

havespilled.

Note:Ifpossible,llthefueltankaftereachuse.This

willminimizepossiblebuildupofcondensationinside

thefueltank.

DrainingWaterfromtheFuel

Filter

ServiceInterval:Beforeeachuseordaily

Drainwaterorothercontaminantsfromthefuellter

daily.

1.Stoptheengineandremovethekey.

2.Opentherearaccesscover.

19

Page 20

3.Turnthedrainvalveuntilthewaterrunsoutofthe

G005936

4

123

lter(Figure13).

Note:Thefuellterislocatednearthebottom

ofthefueltank.

9.Slowlypouronlyenoughoil(dieselengineoil,API

serviceCH-4,CI-4,orhigher;refertoServicingthe

EngineOilinMaintenance)intothevalvecoverto

raisetheleveltotheuppermarkonthedipstick.

Important:Donotoverllthecrankcasewith

oilbecausetheenginemaybedamaged.

10.Replacethellercapanddipstick.

CheckingtheEngineCoolant

Level

ServiceInterval:Beforeeachuseordaily

Figure13

1.Fuellter

2.Drainvalve

4.Closethevalve.

5.Closetherearaccesscover.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthetractionunitonalevelsurface,lowerthe

loaderarms,andstoptheengine.

2.Removethekeyandallowtheenginetocool.

3.Opentherearaccesscover.

4.Cleanaroundtheoildipstick(Figure14).

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethyleneglycolantifreeze.Check

thelevelofcoolantatthebeginningofeachday,before

startingtheengine.

Iftheenginehasbeenrunning,thecoolant

intheradiatorwillbehotandpressurized.If

youremovethecap,itmaysprayout,causing

severeburns.

•Donotremovetheradiatorcaptocheck

coolantlevels.

•Donotremovetheradiatorcapwhenthe

engineishot.Allowtheenginetocoolforat

least15minutesoruntiltheradiatorcapis

coolenoughtotouchwithoutburningyour

hand.

1.Parkthetractionunitonalevelsurface,lowerthe

loaderarms,andstoptheengine.

Figure14

1.Fillercap

2.Valvecover4.Metalend

3.Oildipstick

5.Pulloutthedipstickandwipethemetalendclean

(Figure14).

6.Slidethedipstickfullyintothedipsticktube

(Figure14).

7.Pullthedipstickoutandlookatthemetalend.

8.Iftheoillevelislow ,cleanaroundtheoilllercap

andremovethecap(Figure14).

2.Removethekeyandallowtheenginetocool.

3.Removetheradiatorllercapandcheckthecoolant

level(Figure15).

Thecoolantshouldbeuptollerneck.

Figure15

1.Radiatorcap

4.Ifcoolantlevelislow ,addcoolantuptothebottom

ofthellerneck.

20

Page 21

Important:Donotoverlltheradiator.

4.Removethefrontaccesscover.

5.Replacetheradiatorllercap,ensuringthatitis

tightlysealed.

RemovingDebrisfromthe

TractionUnit

ServiceInterval:Beforeeachuseordaily

Important:Operatingtheenginewithablocked

radiator,willresultinenginedamagefrom

overheating.

1.Parkthetractionunitonalevelsurface,raisethe

loaderarms,andinstallthecylinderlocks.

2.Stoptheengineandremovethekey.

3.Removethefrontaccesscover.

4.Cleananydebrisfromthegrill.

5.Opentherearaccesscover.

6.Wipeawaydebrisfromtheaircleaner.

7.Cleananydebrisbuildupontheenginewithabrush

orblowerbeforeeachuse.

Important:Itispreferabletoblowdirtout,

ratherthanwashingitout.Ifwaterisused,

keepitawayfromelectricalitemsandhydraulic

valves.Donotuseahigh-pressurewasher.

High-pressurewashingcandamagethe

electricalsystemandhydraulicvalvesordeplete

grease.

8.Replaceandsecurethefrontandrearaccesscovers.

9.Removeandstorethecylinderlocksandlowerthe

loaderarms.

5.Cleantheareaaroundthellerneckofthehydraulic

tank(Figure16).

6.Removethecapfromthellerneckandcheckthe

uidlevelonthedipstick(Figure16).

Theuidlevelshouldbebetweenthemarksonthe

dipstick.

Figure16

1.Fillerneckcap2.Dipstick

7.Ifthelevelislow,addenoughuidtoraiseittothe

properlevel.

8.Installthecaponthellerneck.

9.Installthefrontaccesscover.

10.Removeandstorethecylinderlocksandlowerthe

loaderarms.

TestingtheParkingBrake

ServiceInterval:Beforeeachuseordaily

1.MovetheparkingbrakelevertotheOnposition

(Figure17).

CheckingtheHydraulicFluid

Level

ServiceInterval:Every25hours

Checkthehydraulicuidlevelbeforetheengineisrst

startedandafterevery25operatinghours.

HydraulicT ankCapacity:17.25USgallons(67l)

Use10W -30or15W-40detergent,dieselengineoil(API

serviceCH-4orhigher).

1.Removetheattachment,ifoneisinstalled.

2.Parkthetractionunitonalevelsurface,raisethe

loaderarms,andinstallthecylinderlocks.

3.Stoptheengine,removethekey ,andallowthe

enginetocool.

Figure17

1.Parkingbrakelever—On

position

2.Starttheengine.

3.Slowlyeasethetractiondriveleversforwardor

rearward.

4.Ifthetractionunitmoves,contactyourAuthorized

ToroDealerforservice.

21

2.Parkingbrakelever—Off

position

Page 22

CheckingtheTirePressure

1

G003793

ServiceInterval:Beforeeachuseordaily

Maintaintheairpressureinthetiresasspecied.Check

thetireswhentheyarecoldtogetthemostaccurate

reading.

Pressure:15-20psi(103-138kPa)

Note:Usealowertirepressure,15psi(103kPa),when

operatinginsandysoilconditionstoprovidebetter

tractionintheloosesoil.

freezingorlower),hydraulicsystemdamage

couldoccur.Whenstartingtheenginein

coldconditions,allowtheenginetorunin

themiddlethrottlepositionfor2to5minutes

beforemovingthethrottletofast(rabbit).

Note:Ifoutdoortemperatureisbelowfreezing,

storethetractionunitinagaragetokeepitwarmer

andaidinstarting.

DrivingtheTractionUnit

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Placethe

throttleleverinthefast(rabbit)positionforbest

performance.

Note:Thethrottlepositioncanbeutilizedtooperate

atslowerspeeds.

Todrivethetractionunit,completethefollowing

actionsasnecessary:

Figure18

1.Valvestem

StartingtheEngine

1.Standontheplatform.

2.Ensurethattheauxiliaryhydraulicsleverisin

neutral.

3.Movethethrottlelevermidwaybetweenslow

(turtle)andfast(rabbit)positions.

4.Insertthekeyintotheignitionandturnittothe

runposition.

Note:Thebattery,oilpressure,andglowplug

lightswillcomeon.

5.Whentheglowpluglightturnsoff,turnthekeyto

thestartposition.Whentheenginesstarts,release

thekey .

Note:Awarmenginemaybestartedwithout

waitingforthelighttoturnoff.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefails

tostart,allowa30secondcool-downperiod

betweenattempts.Failuretofollowthese

instructionscanburnoutthestartermotor.

6.Movethethrottlelevertodesiredsetting.

Important:Ifyouruntheengineathigh

speedswhenthehydraulicsystemiscold(i.e.,

whentheambientairtemperatureisnear

•Tomoveforward,movethetractioncontrollevers

forward.

•Tomoverearward,movethetractioncontrollevers

rearward.

•Togostraight,movebothtractioncontrollevers

equally.

•Toturn,movetheleverlocatedonthesideyou

wanttoturntowardtheneutralpositionwhile

keepingtheotherleverengaged.

•Tosloworstop,movethetractioncontrollevers

toneutral.

Note:Thefartheryoumovethetractioncontrollevers

ineitherdirection,thefasterthetractionunitwillmove

inthatdirection.

StoppingtheTraction

Unit/Engine

1.Movethetractioncontrolleverstoneutral.

2.Movethethrottlelevertotheslow(turtle)position.

3.Lowertheloaderarmstotheground.

4.Turntheignitionkeyoff.

Note:Iftheenginehasbeenworkinghardor

ishot,letitidleforaminutebeforeturningthe

ignitionkeyoff.Thishelpscooltheenginebefore

itisstopped.Inanemergency,theenginemaybe

stoppedimmediately .

5.Removethekey.

22

Page 23

Achildoruntrainedbystandercouldattemptto

operatethetractionunitandbeinjured.

Removethekeyfromtheswitchwhenleaving

thetractionunit,evenifjustforafewseconds.

MovingaNon-functioning

UsingtheCylinderLocks

Theloaderarmsmaylowerwhenintheraised

positioncrushinganyoneunderthem.

Installthecylinderlocksbeforeperforming

maintenancethatrequiresraisedloaderarms.

TractionUnit

Important:Donottoworpullthetraction

unitwithoutrstopeningthetowvalves,orthe

hydraulicsystemwillbedamaged.

1.Stoptheengine.

2.Removetheplugcoveringeachtowvalve,located

undereachfueltank(Figure19).

InstallingtheCylinderLocks

1.Starttheengine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Stoptheengine.

4.Positionaloaderarmcylinderlockovereachlift

cylinderrod(Figure20).

5.Secureeachloaderarmcylinderlockwithaclevis

pinandcotterpin(Figure20).

Figure20

1.Cylinderlock4.Clevispin

2.Liftcylinder5.Liftcylinderrod

3.Hairpincotter

Figure19

1.Towvalve2.Plug

3.Loosenthejamnutoneachtowvalve.

4.Turneachvalvecounterclockwiseoneturnwitha

hexwrenchtoopenthem.

5.Towthetractionunitasrequired.

Important:Donotexceed3mphwhentowing.

6.Whenyouhaverepairedthetractionunit,closethe

towvalvesandtightenthejamnuts.

Important:Donotovertightenthetowvalves.

7.Replacetheplugs.

6.Withtheengineoff,lowertheloaderarms.

Removing/StoringtheCylinderLock

1.Starttheengine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Stoptheengine.

4.Removetheclevispinandcotterpinsecuringeach

cylinderlock.

5.Removethecylinderlocks.

6.Lowertheloaderarms.

7.Installthecylinderlocksoverthehydraulichoses

andsecurethemwiththeclevispinsandcotterpins

(Figure21).

23

Page 24

Figure21

1.Hydraulichoses3.Hairpincotter

2.Cylinderlocks4.Clevispin

UsingAttachments

InstallinganAttachment

Important:UseonlyT oro-approvedattachments.

Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthetractionunit.The

warrantyofthetractionunitmaybevoidedifused

withunapprovedattachments.

Important:Theattachmentshouldberaised

enoughtocleartheground,andthemount

plateshouldbetiltedallthewayback.

6.Stoptheengine.

7.Engagethequickattachpins,ensuringthattheyare

fullyseatedinthemountplate(Figure23).

Important:Ifthepinsdonotrotatetothe

engagedposition,themountplateisnot

fullyalignedwiththeholesintheattachment

receiverplate.Checkthereceiverplateand

cleanitifnecessary.

Important:Beforeinstallingtheattachment,

ensurethatthemountplatesarefreeofanydirtor

debrisandthatthepinsrotatefreely.Ifthepinsdo

notrotatefreely,greasethem.

1.Positiontheattachmentonalevelsurfacewith

enoughspacebehindittoaccommodatethe

tractionunit.

2.Starttheengine.

3.Tilttheattachmentmountplateforward.

4.Positionmountplateintotheupperlipofthe

attachmentreceiverplate(Figure22).

Figure22

1.Mountplate2.Receiverplate

Figure23

1.Quickattachpins(shown

inengagedposition)

2.Disengagedposition

3.Engagedposition

Ifyoudonotfullyseatthequickattachpins

throughtheattachmentmountplate,the

attachmentcouldfalloffofthetractionunit,

crushingyouorbystanders.

Ensurethatyourquickattachpinsarefully

seatedintheattachmentmountplate.

5.Raisetheloaderarmswhiletiltingbackthemount

plateatthesametime.

24

Page 25

ConnectingtheHydraulicHoses

RemovinganAttachment

Iftheattachmentrequireshydraulicsforoperation,

connectthehydraulichosesasfollows:

1.Stoptheengine.

2.Movetheauxiliaryhydraulicsleverforward,

backward,andbacktoneutraltorelievepressure

atthehydrauliccouplers.

3.Movetheauxiliaryhydraulicsleverforwardintothe

detentposition.

4.Removetheprotectivecoversfromthehydraulic

couplersonthetractionunit.

5.Ensurethatallforeignmatteriscleanedfromthe

hydraulicconnectors.

6.Pushtheattachmentmaleconnectorintothefemale

connectoronthetractionunit.

Note:Whenyouconnecttheattachmentmale

connectorrst,youwillrelieveanypressurebuiltup

intheattachment.

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremovedwithin

afewhoursbyadoctorfamiliarwiththisform

ofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

Hydrauliccouplers,hydrauliclines/valves,and

hydraulicuidmaybehot.Ifyoucontacthot

componentsyoumaybeburned.

1.Lowertheattachmenttotheground.

2.Stoptheengine.

3.Disengagethequickattachpinsbyturningthem

totheoutside.

4.Iftheattachmentuseshydraulics,movetheauxiliary

hydraulicsleverforward,backward,andbackto

neutraltorelievepressureatthehydrauliccouplers.

5.Iftheattachmentuseshydraulics,slidethecollar

backonthehydrauliccouplersanddisconnectthem.

Important:Connecttheattachment

hosestogethertopreventhydraulicsystem

contaminationduringstorage.

6.Installtheprotectivecoversontothehydraulic

couplersonthetractionunit.

7.Starttheengine,tiltthemountplateforward,and

backthetractionunitawayfromtheattachment.

SecuringtheTractionUnitfor

Transport

Whentransportingthetractionunitonatrailer,always

usethefollowingprocedure:

Important:Donotoperateordrivethetraction

unitonroadways.

1.Lowertheloaderarms.

2.Stoptheengine.

3.Securethetractionunittothetrailerwithchainsor

strapsusingthetie-down/liftloops(Figure7)to

securetherearofthetractionunitandtheloader

arms/mountplatetosecurethefrontofthetraction

unit.

AdjustingtheThighSupport

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthetractionunittocoolbefore

touchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

7.Pushtheattachmentfemaleconnectorintothe

maleconnectoronthetractionunit.

8.Conrmthattheconnectionissecurebypulling

onthehoses.

9.Movetheauxiliaryhydraulicslevertoneutral.

Toadjustthethighsupport(Figure24),loosenthe

knobsandraiseorlowerthesupportpadtothedesired

height.Youcanalsoobtainadditionaladjustmentby

looseningthenutsecuringthepadtotheadjustment

plate,movingtheplateupordownasneeded.Tighten

allfastenerssecurelywhennished.

25

Page 26

G006054

3

2

1

4

5

6

1.Thighsupportbracket

2.Adjustmentplate

3.Thighsupportpad

Figure24

4.Knobandatwasher

5.Carriagebolt

6.Locknutandatwasher

26

Page 27

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every75hours

Every100hours

Every200hours

MaintenanceProcedure

•Replacethehydrauliclter.

•T orquethewheellugnutsto50ft-lb(68N⋅m).

•Changetheengineoilandlter.

•Drainwaterfromthefuellter.

•Checktheengineoillevel.

•Checktheenginecoolantlevel.

•Removedebrisfromthetractionunit.

•T esttheparkingbrake

•Checkthetirepressure.

•Greasethetractionunit.

•Checkforloosefasteners.

•Checkthehydraulicuidlevel.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Changetheengineoilandlter(morefrequentlywhenoperatingconditionsare

extremelydustyorsandy).

•Checkthebatteryelectrolytelevel.

•Checkthebatterycableconnections.

•T orquethewheellugnutsto50ft-lb(68N⋅m).

•Replacetheprimaryairlter.

Every400hours

Every600hours

Every1,500hours

Yearly

Yearlyorbeforestorage

Important:Refertoyour

•Replacethehydrauliclter.

•Replacethesafetyairlter.

•Replaceallmovinghydraulichoses.

•Changethefuellter.

•Changethehydraulicuid.

•T ouchupchippedpaint

Engine Operator’ s Man ual

foradditionalmaintenanceprocedures.

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewiresfromthesparkplugsbeforeyoudoany

maintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

27

Page 28

Premaintenance

Procedures

OpeningtheAccessCovers

RemovingtheFrontAccessCover

1.Raisetheloaderarmsandinstallthecylinderlocks.

Note:Inthecasethatyouneedtoremovethefront

accesscoverwithoutraisingtheloaderarms,bevery

carefulnottodamagethecoverorhydraulichoses

asyoumaneuverthecoveroutfromunderthearms.

2.Stoptheengineandremovethekey.

3.Releasethetwolockingtabs(Figure25,top,lefttab

illustrated).

Figure26

1.Rearaccesscover3.Bolt

2.Lockingtabs

3.Removetheboltlocatednexttotherightlocking

tab(Figure26).

4.Graspingthehandle,pullthecoverupandbackto

swingitopen(Figure26).

Figure25

4.Pullthecoveroffofthetractionunit.

5.Whennished,replacethefrontaccesscoverand

secureitwiththetwolockingtabs.

OpeningtheRearAccessCover

1.Stoptheengineandremovethekey.

2.Releasethetwolockingtabsontopoftherearaccess

cover(Figure26).

5.Whennished,closetherearaccesscoverby

swingingitupandseatingitinplace.

6.Secureitwiththetwolockingtabsandbolt.

28

Page 29

Lubrication

EngineMaintenance

GreasingtheTractionUnit

ServiceInterval:Beforeeachuseordaily

Greaseallpivotjointsevery8operatinghoursand

immediatelyaftereverywashing.

GreaseType:General-purposegrease.

1.Lowertheloaderarmsandstoptheengine.Remove

thekey .

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting(Figure27and

Figure28).

ServicingtheAirCleaner

PrimaryFilter:Replaceafterevery200operatinghours

ormoreoftenindustyconditions.

SafetyFilter:Replaceafterevery600operatinghours.

Note:Servicetheaircleanermorefrequentlyif

operatingconditionsareextremelydustyorsandy .

ReplacingtheFilters

ServiceInterval:Every200hours

Every600hours

1.Lowertheloaderarms,stoptheengine,andremove

thekey .

2.Opentherearaccesscover.

3.Releasethelatchesontheaircleanerandpulltheair

cleanercoveroffoftheaircleanerbody(Figure29).

Figure27

Figure28

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps).

5.Wipeupanyexcessgrease.

Figure29

1.Latches

2.Aircleanercover

3.Airlterbody

4.Squeezethedustcapsidestoopenitandknockthe

dustout.

5.Cleantheinsideoftheaircleanercoverwith

compressedair.

6.Gentlyslidetheprimarylteroutoftheaircleaner

body(Figure29).Avoidknockingthelterintothe

sideofthebody.

Important:Donotattempttocleantheprimary

lter.

7.Removethesafetylteronlyifyouintendtoreplace

it.

Important:Neverattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamagedandyoushouldreplaceboth

lters.

4.Primarylter

5.Safetylter

6.Dustcap

29

Page 30

8.Inspectthenewlter(s)fordamagebylookinginto

thelterwhileshiningabrightlightontheoutside

ofthelter.Holesinthelterwillappearasbright

spots.Inspecttheelementfortears,anoilylm,or

damagetotherubberseal.Ifthelterisdamaged

donotuseit.

9.Ifyouarereplacingthesafetylter,carefullyslide

thenewlterintothelterbody(Figure29).

Important:T opreventenginedamage,always

operatetheenginewithbothairltersandcover

installed.

10.Carefullyslidetheprimarylteroverthesafetylter

(Figure29).Ensurethatitisfullyseatedbypushing

ontheouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

11.Installtheaircleanercoverwiththesideindicatedas

UPfacingupandsecurethelatches(Figure29).

12.Closethehood.

ServicingtheEngineOil

Componentswillbehotifthetractionunithas

beenrunning.Ifyoutouchhotcomponentsyou

maybeburned.

Allowthetractionunittocoolbeforeperforming

maintenanceortouchingcomponentsunder

thehood.

4.Placeapanundertheoildraintube(Figure30).

Figure30

1.Clamp

2.Oildraintube

3.Plug

Changeoilandlteraftertherst50operatinghours

andthenevery75operatinghoursthereafter.

Note:Changeoilmorefrequentlywhenoperating

conditionsareextremelydustyorsandy .

OilType:Detergentdieselengineoil(APIservice

CH-4,CI-4orhigher)

CrankcaseCapacity:w/lter,0.84gal.(3.2l)

Viscosity:

•Fortemperaturesabove0°F(-18°C),use15W-40

(preferred)or10W-30.

•Fortemperaturesbelow32°F(0°C),use5W -30.

ChangingtheOilandFilter

ServiceInterval:Aftertherst50hours

Every75hours

1.Starttheengineandletitrunforveminutes.This

warmstheoilsoitdrainsbetter.

5.Loosentheclampandremovetheplug(Figure30).

6.Whentheoilhasdrainedcompletely,replacethe

plugandtightentheclamp.

Note:Disposeoftheusedoilatacertiedrecycling

center.

7.Opentherearaccesscover.

8.Removetheoldlterandwipethelteradapter

(Figure31)gasketsurface.

Figure31

1.Oillter

2.Gasket

3.Adapter

2.Parkthetractionunitsothatthedrainsideisslightly

lowerthantheoppositesidetoensurethattheoil

drainscompletely .

3.Lowertheloaderarms,chockthewheels,stopthe

engine,andremovethekey .

9.Pournewoilofthepropertypeinthroughthecenter

holeofthelter.Stoppouringwhentheoilreaches

thebottomofthethreads.

10.Allowaminuteortwofortheoiltobeabsorbedby

ltermaterial,thenpourofftheexcessoil.

30

Page 31

11.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter(Figure31).

12.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn(Figure31).

13.Removetheoilllcapandslowlypourapproximately

80%ofthespeciedamountofoilinthroughthe

valvecover.

14.Checktheoillevel;refertoCheckingtheOilLevel,

Operation,page19.

15.Slowlyaddadditionaloiltobringtheleveltothe

uppermarkonthedipstick.

16.Replacethellcap.

17.Closetherearaccesscover.

FuelSystem

Maintenance

ChangingtheFuelFilter

ServiceInterval:Yearly

Replacethefuellteryearly.

Important:Neverinstalladirtylter.

1.Lowertheloaderarms,stoptheengine,andremove

thekey .

2.Shutoffthefuelvalveonthebottomofthefuel

tank(Figure34).

3.Opentherearaccesscover.

4.Openthedrainvalve(Figure32)anddrainthefuel

fromthefuellterintoasuitablecontainerand

disposeofitproperly .

Figure32

1.Drainvalve

5.Removethefuellterwithalterwrench(Figure32).

6.Cleanthemountingsurface.

7.Lubricatethegasketonthenewlterwithclean

engineoil.Screwonthenewlterbyhanduntilthe

gasketcontactsthehousing.Thentightenitanother

1/2turn.

8.Openthefuelvalveonthebottomofthefueltank

(Figure34).

9.Bleedthefuelsystem;refertoBleedingtheFuel

System.

10.Starttheengineandcheckforleaks.

2.Fuellter

BleedingtheFuelSystem

Bleedtheairfromthefuelsysteminanyofthefollowing

situations:

•Initialstartupofanewtractionunitoratraction

unitthathasbeenstored.

31

Page 32

•Aftertheenginehasceasedrunningduetolackof

1

2

G003795

fuel.

2.Lowertheloaderarms,stoptheengine,andremove

thekey .

•Aftermaintenancehasbeenperformedonthefuel

systemcomponents.

1.Opentherearaccesscover.

2.Placeadrainpanunderthefuelltertocatchspills.

3.Openthebleedscrewontopofthefuelltertoll

thebowlwithfuel(Figure33).

Figure33

1.Fuellter

2.Bleedscrew

4.Closethebleedscrewwhenfuelcomesoutina

steadystream.

5.Onleftsideoftheengine,locatetheairventplugon

topofthefuelinjectionpumpandconnectahoseto

it,leadingtoadrainpan.

6.Opentheventplugandcranktheengineuntilfuel

comesoutasteadystream.

7.Closetheventplug.

8.Closetherearaccesscover.

DrainingtheFuelTanks

3.Shutoffthefuelvalveinthehosenearthebottom

ofthefueltank(Figure34).

Figure34

1.Fuelvalve,open2.Fuelvalve,closed

4.Opentherearaccesscover.

5.Loosenthehoseclampatthefuellterandslideit

upthefuellineawayfromthelter.

6.Pullthefuellineoffofthefuellter,openthefuel

valve,andallowthefueltodrainintoafuelcanor

drainpan.

7.Installthefuellineontothefuellter.

8.Slidethehoseclampclosetothefuelltertosecure

thefuelline.

9.Closetherearaccesscover.

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

•Drainfuelfromthefueltankswhenthe

engineiscold.Dothisoutdoorsinanopen

area.Wipeupanyfuelthatspills.

•Neversmokewhendrainingfuel,andstay

awayfromanopenameorwhereaspark

mayignitethefumes.

1.Parkthetractionunitonalevelsurface,toensure

thatthefueltanksdraincompletely.

10.Openthefuelvalvesinthehosesnearthebottomof

thefueltanksasillustratedinFigure34.

Note:Nowisthebesttimetoinstallanewfuellter

becausethefueltankisempty.

32

Page 33

ElectricalSystem

2

3

1

G003794

Maintenance

ServicingtheBattery

Checktheelectrolytelevelinthebatteryevery75hours.

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

fourpartswaterandonepartbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoreduce

corrosion.

Voltage:12v,450ColdCrankingAmps

Figure36

1.Fillercaps3.Lowerline

2.Upperline

CheckingtheElectrolyteLevel

ServiceInterval:Every75hours

Every75hours

1.Stoptheengineandremovethekey.

2.Removethebatterycover(Figure35).

Figure35

1.Batterycover5.Nut

2.Bolt6.Positivecable

3.Battery7.Negativecable

4.Bars

3.Lookatthesideofthebattery.Theelectrolytemust

beuptotheUpperline(Figure36).Donotallowthe

electrolytetofallbelowtheLowerline(Figure36).

4.Iftheelectrolyteislow ,addtherequiredamountof

distilledwater;refertoAddingWatertotheBattery.

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethetractionunit.Thisletsthewater

mixthoroughlywiththeelectrolytesolution.

Batteryelectrolytecontainssulfuricacidwhich

isadeadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontact

withskin,eyesorclothing.Wearsafety

glassestoshieldyoureyesandrubbergloves

toprotectyourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Removethenutsandbarssecuringthebattery

(Figure35).

2.Disconnectthenegative(black)cabletothenegative

(-)batterypost(Figure35).

33

Page 34

Incorrectbatterycableroutingcoulddamage

1

2

3

4

G003792

thetractorandcablescausingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative(black)

cable.

3.Disconnectthepositive(red)cabletothepositive

(+)batterypost(Figure35).

4.Liftthebatteryoffoftheplatform.

Important:Neverllthebatterywithdistilled

waterwhilethebatteryisinstalledinthetraction

unit.Electrolytecouldbespilledonotherparts

andcausecorrosion.

5.Cleanthetopofthebatterywithapapertowel.

6.Removethellercapsfromthebattery(Figure36).

7.Slowlypourdistilledwaterintoeachbatterycell

untiltheelectrolytelevelisuptotheUpperline

(Figure36)onthebatterycase.

2.Makesurethellercapsareinstalledinthebattery.

3.Chargethebatteryfor10to15minutesat25to30

ampsor30minutesat4to6amps(Figure37).Do

notoverchargethebattery.

Figure37

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthe

chargerleadsfromthebatteryposts(Figure37).

InstallingtheBattery

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

8.Waitvetotenminutesafterllingthebatterycells.

Adddistilledwater,ifnecessary,untiltheelectrolyte

levelisuptotheUpperline(Figure36)onthe

batterycase.

9.Installthebatteryllercaps.

ChargingtheBattery

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparks

andamesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespeciallyimportant

topreventbatterydamagewhenthetemperatureis

below32°F(0°C).

1.Checktheelectrolytelevel;refertoChecking

ElectrolyteLevel.

1.Installthebatteryontotheplatform(Figure35).

2.Securethebatteryinthechassiswiththebarsand

nutsremovedpreviously(Figure35).

3.Connectthepositive(red)cabletothepositive(+)

batterypost(Figure35).Slidetherubbercoverover

thebatterypost.

4.Connectthenegative(black)cabletothenegative(-)

batterypost(Figure35).

Important:Ensurethatthebatterycablesdo

notcontactanysharpedgesoreachother.

5.Installthebatterycover(Figure35).

34

Page 35

HydraulicSystem

Maintenance

ReplacingtheHydraulicFilter

ServiceInterval:Aftertherst8hours

Every400hours

Important:Donotsubstituteanautomotiveoil

lterorseverehydraulicsystemdamagemayresult.

Changethehydrauliclteraftertherst8operating

hoursandthenevery400operatinghoursthereafter.

1.Positiontractionunitonalevelsurface.

2.Raisetheloaderarmsandinstallthecylinderlocks,

stoptheengine,andremovethekey .

3.Removethefrontaccesscover.

4.Placeadrainpanunderthelter.

5.Removetheoldlter(Figure38)andwipethe

surfaceofthelteradaptergasketclean.

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremovedwithin

afewhoursbyadoctorfamiliarwiththisform

ofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

11.Checktheuidlevelinthehydraulictank(referto

CheckingtheHydraulicFluidinOperation,page19)

andadduidtoraisetheleveltomarkondipstick.

Donotoverllthetank.

12.Installthefrontaccesscover.

13.Removeandstorethecylinderlocksandlowerthe

loaderarms.

ChangingtheHydraulicFluid

Figure38

1.Hydrauliclter

6.Applyathincoathydraulicuidtotherubbergasket

onthereplacementlter(Figure38).

7.Installthereplacementhydrauliclterontothelter

adapter(Figure38).Tightenitclockwiseuntilthe

rubbergasketcontactsthelteradapter,thentighten

thelteranadditional1/2turn.

8.Cleanupanyspilleduid.

9.Starttheengineandletitrunforabouttwominutes

topurgeairfromthesystem.

10.Stoptheengineandcheckforleaks.

ServiceInterval:Yearly

Changethehydraulicuidyearly.

1.Positionthetractionunitonalevelsurface.

2.Raisetheloaderarmsandinstallthecylinderlocks.

3.Stoptheengineandremovethekey.

4.Removethefrontaccesscover.

5.Placealargedrainpanunderthetractionunitthat

canholdatleast17USgallons(67l).

6.Removethedrainplugfromthebottomofthe

hydraulictankandallowtheuidtocompletely

drainout.

7.Installthedrainplug.

8.Fillthehydraulictankwithapproximately15US

gallons(57L)of10W -30or15W -40detergent,diesel

engineoil(APIserviceCH-4orhigher);referto

CheckingHydraulicFluidinOperation,page19.

Note:Disposeofusedoilatacertiedrecycling

center.

9.Installthehood.

10.Removeandstorethecylinderlocksandlowerthe

loaderarms.

CheckingtheHydraulicLines

ServiceInterval:Every25hours

Every1,500hours

35

Page 36

Afterevery25operatinghours,checkthehydraulic

linesandhosesforleaks,loosettings,kinkedlines,

loosemountingsupports,wear,weather,andchemical

deterioration.Replaceallmovinghydraulichosesevery

1500hoursor2years,whichevercomesrst.Make

necessaryrepairsbeforeoperating.

Storage

1.Lowertheloaderarms,stoptheengine,andremove

thekey .

2.Removedirtandgrimefromtheexternalpartsof

theentiretractionunit,especiallytheengine.Clean

dirtandchafffromtheradiator.

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremovedwithin

afewhoursbyadoctorfamiliarwiththisform

ofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrompin

holeleaksornozzlesthatejecthighpressure

hydraulicuid.

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

Important:Youcanwashthetractionunit

withmilddetergentandwater.Donotpressure

washthetractionunit.Avoidexcessiveuseof

water,especiallynearthecontrolpanel,engine,

hydraulicpumps,andmotors.

3.Servicetheaircleaner;refertoServicingtheAir

Cleaner.

4.Greasethetractionunit;refertoGreasingthe

TractionUnit.

5.Drainwaterfromthefuellter;refertoDraining

WaterfromtheFuelFilter.

6.Torquethewheellugnutsto50ft-lb(68N⋅m).

7.Checkthehydraulicuidlevel;refertoCheckingthe

HydraulicFluidLevel.

8.Checkthetirepressure;refertoCheckingtheTire

Pressure.

9.Chargethebattery;refertotheServicingtheBattery.

10.Flushthefueltankwithfresh,cleandieselfuel.

11.Checkandtightenallbolts,nuts,andscrews.Repair

orreplaceanypartthatisdamagedordefective.

12.Paintallscratchedorbaremetalsurfaces.Paintis

availablefromyourAuthorizedServiceDealer.

13.Checkantifreezeprotectionandlltheradiatorwith

a50/50solutionofwaterandpermanentethylene

glycolantifreeze.RefertoyourEngineOwnersManual

orAuthorizedServiceDealerfordetailsonchecking

andmaintainingthecoolingsystem.

14.Storethetractionunitinaclean,drygarageor

storagearea.Removethekeyfromtheignition

switchandkeepitinamemorableplace.

15.Coverthetractionunittoprotectitandkeepitclean.

Important:Whenremovingthetractionunitfrom

storage,chargethebattery;refertoServicingthe

Battery.

36

Page 37

Troubleshooting

Problem

Thestarterdoesnotcrank

Theenginecranks,butwillnotstart.

PossibleCauseCorrectiveAction

1.Theelectricalconnectionsarecorroded

orloose.

2.Afuseisblownorloose.2.Correctorreplacethefuse.

3.Thebatteryisdischarged.

4.Therelayorswitchisdamaged.

5.Adamagedstarterorstartersolenoid.

6.Seizedinternalenginecomponents.6.ContactyourAuthorizedService

1.Incorrectstartingprocedure.

2.Thefueltankisempty.2.Fillwithfreshfuel.

3.Thefuelshut-offvalveisclosed.3.Openthefuelshut-offvalve.

4.Dirt,water,stalefuel,orincorrectfuel

isinthefuelsystem.

5.Cloggedfuelline.5.Cleanorreplace.

6.Thereisairinthefuel.6.Bleedthenozzlesandcheckforair

7.Inoperativeglowplugs.

8.Slowcrankingspeed.8.Checkthebattery,oilviscosity,and

9.Theaircleanerltersaredirty .9.Servicetheairlters.

10.Thefuellterisclogged.10.Replacethefuellter.

11.Improperfuelgradeforcoldweather

use.

12.Lowcompression.

13.Theinjectionnozzlesaredamaged.

14.Theinjectionpumptimingisincorrect.

15.Theinjectionpumpisbroken.

16.TheETRsolenoidisbroken.

1.Checktheelectricalconnectionsfor

goodcontact.

3.Chargethebatteryorreplaceit.

4.ContactyourAuthorizedService

Dealer.

5.ContactyourAuthorizedService

Dealer.

Dealer.

1.RefertoStartingandStoppingthe

Engine

4.Drainandushthefuelsystem;add

freshfuel.

leaksatthefuelhoseconnections

andttingsbetweenthefueltankand

engine.

7.Checkthefuse,glowplugs,andwiring.

startingmotor(contactyourAuthorized

ServiceDealer).

11.Drainthefuelsystemandreplacethe

fuellter.Addfreshfuelofpropergrade

forambienttemperatureconditions.

Youmayneedtowarmtheentire

tractionunit.

12.ContactyourAuthorizedService

Dealer.

13.ContactyourAuthorizedService

Dealer.

14.ContactyourAuthorizedService

Dealer.

15.ContactyourAuthorizedService

Dealer.

16.ContactyourAuthorizedService

Dealer.

Theenginestarts,butdoesnotkeep

running.

1.Thefueltankventisrestricted.1.Loosenthecap.Iftheenginerunswith

2.Dirtorwaterisinthefuelsystem.2.Drainandushthefuelsystem;add

3.Thefuellterisclogged.3.Replacethefuellter.

4.Thereisairinthefuel.4.Bleedthenozzlesandcheckforair

5.Improperfuelgradeforcoldweather

use.

thecaploosened,replacethecap.

freshfuel.

leaksatfuelhoseconnectionsand

ttingsbetweenthefueltankand

engine.

5.Drainthefuelsystemandreplacethe

fuellter.Addfreshfuelofpropergrade

forambienttemperatureconditions.

37

Page 38

Problem

6.Thesparkarrestorscreenisclogged.

7.Thefuelpumpisdamaged.7.ContactyourAuthorizedService

PossibleCauseCorrectiveAction

6.Cleanorreplacethesparkarrestor

screen.

Dealer.

Theengineruns,butknocksormisses.

Theenginewillnotidle.

1.Dirt,water,stalefuel,orincorrectfuel

isinthefuelsystem.

2.Engineoverheating.

3.Thereisairinthefuel.3.Bleednozzlesandcheckforairleaks

4.Theinjectionnozzlesaredamaged.

5.Lowcompression

6.Theinjectionpumptimingisincorrect.

7.Excessivecarbonbuild-up.

8.Internalwearordamage.

1.Thefueltankventisrestricted.1.Loosenthecap.Iftheenginerunswith

2.Dirt,water,stalefuel,orincorrectfuel

isinthefuelsystem.

3.Theaircleanerltersaredirty .3.Servicetheairlters.

4.Thefuellterisclogged.4.Replacethefuellter.

5.Thereisairinthefuel.5.Bleedthenozzlesandcheckforair

6.Thefuelpumpisdamaged.6.ContactyourAuthorizedService

7.Lowcompression

1.Drainandushthefuelsystem;add

freshfuel.

2.RefertoEngineOverheats.

atthefuelhoseconnectionsandttings

betweenthefueltankandengine.

4.ContactyourAuthorizedService

Dealer.

5.ContactyourAuthorizedService

Dealer.

6.ContactyourAuthorizedService

Dealer.

7.ContactyourAuthorizedService

Dealer.

8.ContactyourAuthorizedService

Dealer.

thecaploosened,replacethecap.

2.Drainandushthefuelsystem;add

freshfuel.

leaksatfuelhoseconnectionsand

ttingsbetweenthefueltankand

engine.

Dealer.

7.ContactyourAuthorizedService

Dealer.

Theengineoverheats.

1.Morecoolantisneeded.

2.Restrictedairowtotheradiator.

3.Thecrankcaseoillevelisincorrect.

4.Excessiveloading.4.Reduceload;uselowergroundspeed.

5.Incorrectfuelisinthefuelsystem.5.Drainandushthefuelsystem;add

6.Thethermostatisdamaged.

7.Thefanbeltislooseorbroken.7.ContactyourAuthorizedService

8.Injectiontimingisincorrect.

9.Coolantpumpisdamaged.9.ContactyourAuthorizedService

1.Checkandaddcoolant.

2.Inspectandcleantheradiatorscreen

witheveryuse.

3.Fillordraintothefullmark.

freshfuel.

6.ContactyourAuthorizedService

Dealer.

Dealer.

8.ContactyourAuthorizedService

Dealer.

Dealer.

38

Page 39

Problem

PossibleCauseCorrectiveAction