Page 1

FormNo.3413-874RevA

TX1000CompactToolCarrier

ModelNo.22327—SerialNo.400414000andUp

ModelNo.22327G—SerialNo.400414000andUp

ModelNo.22327HD—SerialNo.400414000andUp

ModelNo.22328—SerialNo.400414000andUp

ModelNo.22328HD—SerialNo.400414000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3413-874*A

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives;

fordetails,pleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Diggingintothemmay

causeashockoranexplosion.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUS,call811or

inAustralia,call1100forthenationwidemarking

service).

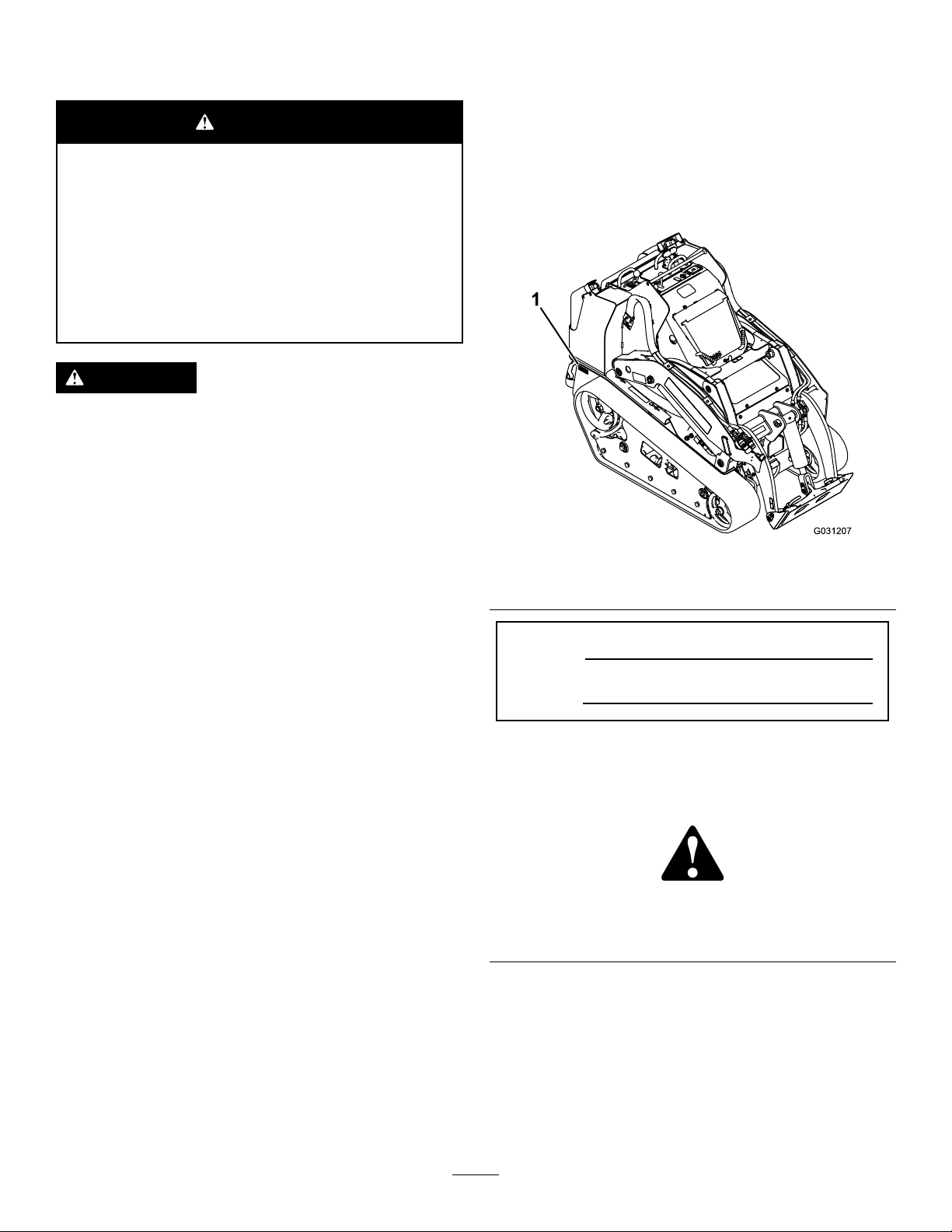

Wheneveryouneedservice,genuineT oroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

g031207

Figure1

1.Modelandserialnumberlocation

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineonany

forest-covered,brush-covered,orgrass-coveredlandunless

theengineisequippedwithasparkarrester,asdenedin

Section4442,maintainedineffectiveworkingorderorthe

engineisconstructed,equipped,andmaintainedforthe

preventionofre.

Theenclosedengineowner'smanualissuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EP A)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughtheengine

manufacturer.

Introduction

Thismachineisacompacttoolcarrierintendedtomove

variousearthandmaterialsforlandscapingandconstruction

work.Itisdesignedtooperateawidevarietyofattachments

eachofwhichperformaspecializedfunction.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

©2017—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

StabilityData..........................................................7

SlopeIndicator.......................................................8

SafetyandInstructionalDecals.................................9

ProductOverview.........................................................13

Controls...............................................................13

MessageDisplay.................................................16

Specications........................................................17

Attachments/Accessories........................................17

Operation....................................................................18

ThinkSafetyFirst...................................................18

AddingFuel...........................................................18

PerformingDailyMaintenance.................................19

StartingtheEngine.................................................20

DrivingtheMachine...............................................20

ShuttingOfftheEngine..........................................20

MovingaNon-FunctioningMachine.........................20

UsingAttachments.................................................21

TransportingtheMachine........................................23

LiftingtheMachine................................................24

Maintenance.................................................................25

RecommendedMaintenanceSchedule(s)......................25

Pre-MaintenanceProcedures......................................26

UsingtheCylinderLocks.........................................26

AccessingInternalComponents...............................27

Lubrication...............................................................29

GreasingtheMachine.............................................29

EngineMaintenance..................................................30

ServicingtheAirCleaner.........................................30

ServicingtheEngineOil..........................................31

FuelSystemMaintenance...........................................33

DrainingtheFuelFilter/WaterSeparator...................33

ReplacingtheFuelFilterCanisterandIn-Line

Filter.................................................................33

CheckingtheFuelLinesandConnections..................33

BleedingtheFuelSystem.........................................34

DrainingtheFuelTanks..........................................34

ElectricalSystemMaintenance....................................34

ServicingtheBattery...............................................34

ServicingtheFuses.................................................38

DriveSystemMaintenance.........................................39

ServicingtheTracks................................................39

CoolingSystemMaintenance......................................42

ServicingtheCoolingSystem...................................42

BrakeMaintenance....................................................43

TestingtheParkingBrake........................................43

BeltMaintenance......................................................43

CheckingtheAlternator/FanBeltTension.................43

ControlsSystemMaintenance.....................................44

AdjustingtheControls............................................44

HydraulicSystemMaintenance....................................44

HydraulicFluidSpecications..................................44

CheckingtheHydraulic-FluidLevel..........................45

ReplacingtheHydraulicFilter..................................46

ChangingtheHydraulicFluid...................................46

CheckingtheHydraulicLines...................................47

Cleaning...................................................................48

RemovingDebris...................................................48

CleaningtheChassis...............................................48

Storage........................................................................49

Troubleshooting...........................................................50

Schematics...................................................................54

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorlessgasthatisfatalifinhaled.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Diggingintothemmay

causeashockoranexplosion.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUS,call811or

inAustralia,call1100forthenationwidemarking

service).

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsyouneedtoproperlyandsafelyperformthe

job.Useonlytheaccessoriesandattachmentsthatare

approvedbythemanufacturer.

,which

—personalsafety

•Wearappropriateclothingincludinggloves,eye

protection,longpants,substantialslip-resistantfootwear,

andhearingprotection.Tiebacklonghairanddonot

wearjewelry.

•Inspecttheareawhereyouwillusetheequipmentand

removeallobjects,suchasrocks,toys,andwire,thatthe

machinecouldthrow.

•Useextracarewhenhandlingfuel.Fuelisammableand

itsvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuelcaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlesstheyare

functioningproperly.

Operation

•Neverrunanengineinanenclosedarea.

•Operatethemachineonlyingoodlight,keepingaway

fromholesandhiddenhazards.

•Ensurethatallthedrivesareinneutralandtheparking

brakeisengagedbeforestartingtheengine.Startthe

engineonlyfromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Ensureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthestabilityofthemachine.

•Slowdownandusecautionwhenmakingturns,crossing

roadsandsidewalks,andwhenchangingdirectionson

slopes.

•Neveroperatethemachinewithouttheguardssecurelyin

place.Ensurethatalltheinterlocksareattached,adjusted,

andfunctioningproperly.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Parkthemachineonalevelsurface,lowertheimplements,

disengagetheauxiliaryhydraulics,engagetheparking

brake,shutofftheengine,andremovethekeybefore

leavingtheoperator'spositionforanyreason.

•Keepyourhandsandfeetawayfromthemoving

attachments.

•Lookbehindanddownbeforebackinguptoensurethat

thepathisclear.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachinewhenyouaretired,ill,or

undertheinuenceofalcoholordrugs.

4

Page 5

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Readalltheattachmentmanuals.

•Ensurethattheareaisclearofpeoplebeforeoperating

themachine.Stopthemachineifanyoneentersthearea.

•Neverleavearunningmachineunattended.Alwayslower

theloaderarms,shutofftheengine,engagetheparking

brake,andremovethekeybeforeleaving.

•Donotexceedtheratedoperatingcapacity ,asthe

machinemaybecomeunstable,whichmayresultinloss

ofcontrol.

•Donotcarryaloadwiththearmsraised.Alwayscarry

loadsclosetotheground.

•Donotoverloadtheattachmentandalwayskeeptheload

levelwhenraisingtheloaderarms.Logs,boards,and

otheritemscouldrolldowntheloaderarms,injuringyou.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservicethemachine.

•Checkforoverheadclearances(i.e.,branches,doorways,

andelectricalwires)beforedrivingunderanyobjectsand

donotcontactthem.

•Operatethemachineinareaswheretherearenoobstacles

incloseproximitytoyou.Failuretomaintainadequate

distancefromtrees,walls,andotherbarriersmayresult

ininjuryasthemachinebacksupduringoperationif

youarenotattentivetothesurroundings.Operatethe

machineonlyinareaswherethereissufcientclearance

foryoutosafelymaneuver.

•Notethelocationofunmarkedobjectsandstructures,

suchasundergroundstoragetanks,wells,andseptic

systems.

•Locatethepinchpointareasmarkedonthemachineand

attachmentsandkeepyourhandsandfeetawayfrom

theseareas.

•Beforeoperatingthemachinewithanattachment,ensure

thattheattachmentisproperlyinstalledandthatitisa

genuineToroattachment.

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Donotoperatethemachineonhillsidesorslopes

exceedingtheanglesrecommendedonStabilityData

(page7),andthoseintheattachmentOperator'sManual.

SeealsotheSlopeIndicator(page8).

•Operatethemachineupanddownslopeswiththe

heavyendofthemachineuphill.Weightdistribution

changes.Anemptybucketmakestherearofthemachine

theheavyend,andafullbucketmakesthefrontofthe

machinetheheavyend.Mostotherattachmentsmakethe

frontofmachinetheheavyend.

•Raisingtheloaderarmsonaslopeaffectsthestabilityof

themachine.Wheneverpossible,keeptheloaderarmsin

theloweredpositionwhenonslopes.

•Donotremoveoraddattachmentsonaslope.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

workarea.Watchforholes,ruts,orbumps,asuneven

terraincouldoverturnthemachine.Tallgrasscanhide

obstacles.

•UseonlyToro-approvedattachments.Attachmentscan

changethestabilityandtheoperatingcharacteristicsof

themachine.Youmayvoidthewarrantyifyouusethe

machinewithunapprovedattachments.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthemachine

losestraction,proceedslowly,straightdowntheslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly

andkeeptheheavyendofthemachineuphill.

•Donotoperateneardrop-offs,ditches,orembankments.

Themachinecouldsuddenlyturnoverifatrackgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Usecautionwhenoperatingonwetgrass.Reduced

tractioncouldcausesliding.

•Donotparkthemachineonahillsideorslopewithout

loweringtheattachmenttotheground,engagingthe

parkingbrake(ifequipped),andchockingthetracks.

•Onmachineswithanoperatorplatform,donottryto

stabilizethemachinebyputtingyourfootontheground.

•Donotplaceyourfeetundertheplatform,ifequipped

onyourmachine.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

5

Page 6

MaintenanceandStorage

•Parkthemachineonalevelsurface,disengagethe

auxiliaryhydraulics,lowertheattachment,engagethe

parkingbrake(ifequippedonyourmachine),shutoff

theengine,andremovethekey .Waitforallmovement

tostopandallowthemachinetocoolbeforeadjusting,

cleaning,storing,orrepairingit.

•Cleandebrisfromtheattachments,drives,mufers,and

enginetohelppreventres.Wipeupanyspilledoilor

fuel.

•Allowtheenginetocoolbeforestoringanddonotstore

nearames.

•Neverallowuntrainedpersonneltoservicethemachine.

•Usejackstandstosupportthecomponentswhen

required.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Keepyourhandsandfeetawayfromthemovingparts.

Ifpossible,donotmakeadjustmentswiththeengine

running.

•Disconnectthebatterybeforemakinganyrepairs;refer

toUsingtheBattery-DisconnectSwitch(page35).

•Chargethebatteryinanopen,well-ventilatedarea,

awayfromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,and

amesawayfromthebattery.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Ifanymaintenanceorrepairrequirestheloaderarmsto

beintheraisedposition,securethearmsintheraised

positionwiththehydraulic-cylinderlock(s).

•Securetheloader-armvalvewiththeloader-valvelock(if

equippedonyourmachine)anytimeyouneedtostopthe

machinewiththeloaderarmsraised.

•Keepallnutsandboltstight.Keeptheequipmentin

goodcondition.

•Nevertamperwiththesafetydevices.

•Keepthemachinefreeofgrass,leaves,orotherdebris

buildup.Wipeupanyspilledoilorfuel.Allowthe

machinetocoolbeforestoring.

•Useextracarewhenhandlingfuel;itisammableandits

vaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuelcap(s)oraddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthemachineindoors.

–Neverstorethemachineorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Keepthecontainernozzleincontactwiththetank

duringlling.

–Donotstorefuelnearamesordrainindoors.

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforestarting.

•UseonlygenuineTororeplacementparts.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthigh-pressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithin

afewhoursbyaqualiedsurgeon;otherwise,gangrene

mayresult.

6

Page 7

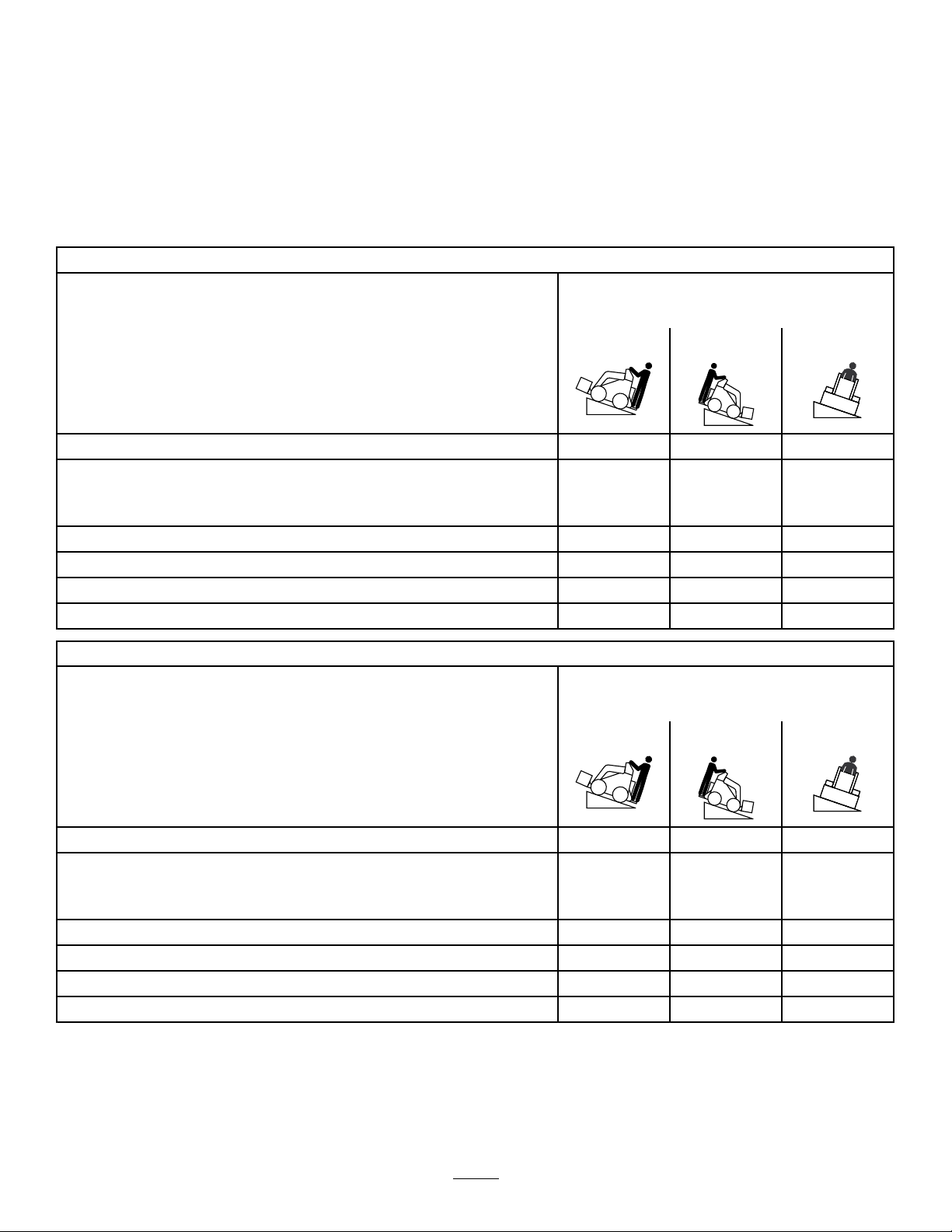

StabilityData

Thefollowingtableslistthemaximumsloperecommendedforthetractionunitinthepositionslistedinthetables.Slopesover

thelisteddegreemaycausethetractionunittobecomeunstable.Thedatainthetablesassumethattheloaderarmsarefully

lowered;raisedarmsmayaffectthestability.

Ineachattachmentmanualisasetof3stabilityratings,1foreachhillposition.Todeterminethemaximumslopeyoucan

traversewiththeattachmentinstalled,ndthedegreeofslopethatcorrespondstothestabilityratingsoftheattachment.

Example:IftheattachmentinstalledonaTXModel22327tractionunithasafrontuphillratingofB,aRearUphillratingof

D,andaSideUphillratingofC,thenyoucoulddriveforwardupa19°slope,rearwardupa11°slope,orsidewaysona11°

slope,aslistedinthefollowingtable.

Models22327,22327G,and22327HD

MaximumRecommendedSlopewhen

Operatingwith:

FrontUphillRearUphill

Conguration

Tractionunitwithoutattachment

Tractionunitwithanattachmentratedwith1ofthefollowingstabilityratingsfor

eachslopeposition:*

A

B

C16°17°11°

D

E

Model22328and22328HD

15°19°16°

25°25°20°

19°20°15°

14°11°8°

5°5°5°

MaximumRecommendedSlopewhen

Operatingwith:

FrontUphillRearUphill

SideUphill

SideUphill

Conguration

Tractionunitwithoutattachment

Tractionunitwithanattachmentratedwith1ofthefollowingstabilityratingsfor

eachslopeposition:*

A

B

C18°15°14°

D

E

16°19°19°

25°25°23°

21°19°18°

15°10°10°

5°5°5°

7

Page 8

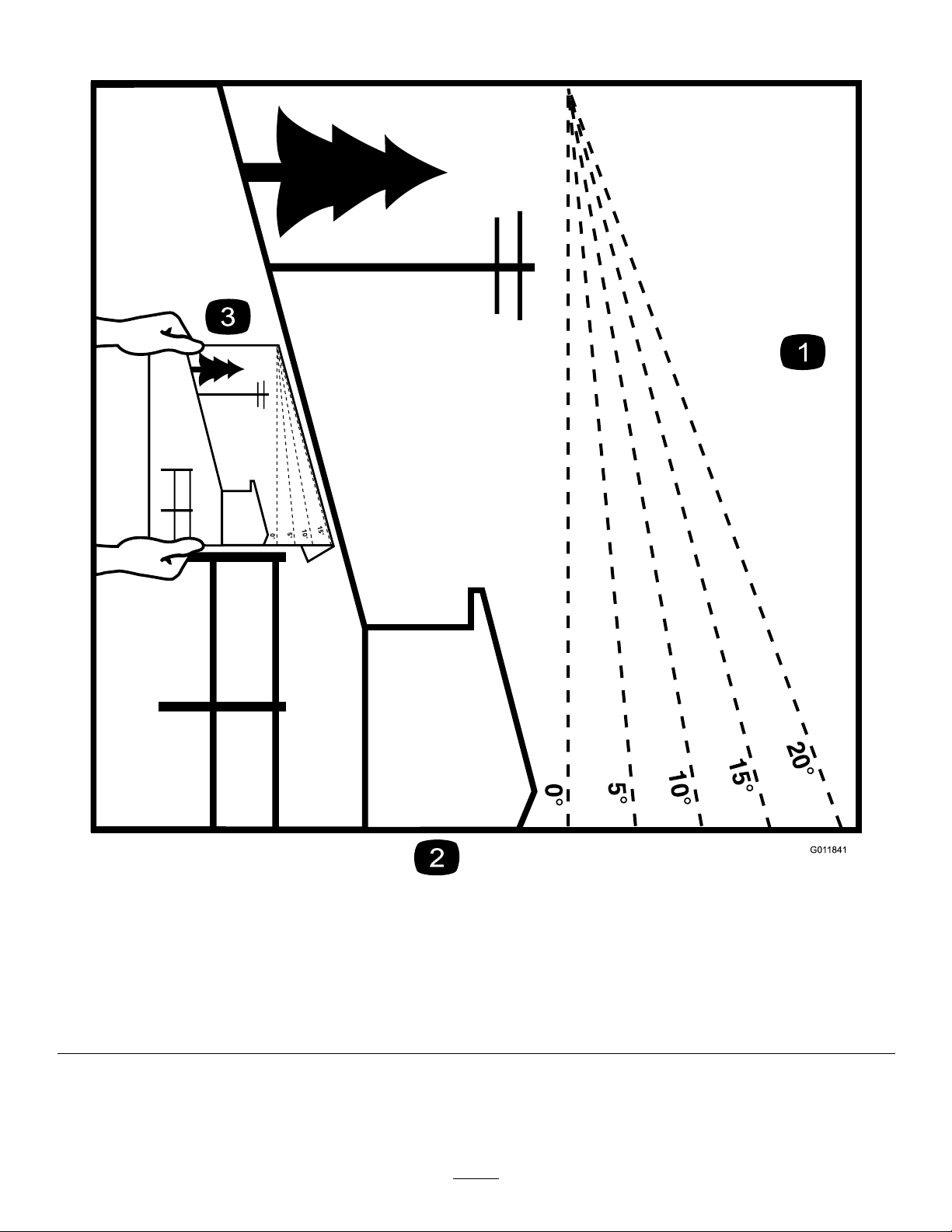

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Todeterminethemaximumslopeyoucansafelyoperatethemachineon,refertotheStabilityDatasection.Usetheslope

indicatortodeterminethedegreeofslopeofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthanthat

speciedintheStabilityDatasection.Foldalongtheappropriatelinetomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

8

g011841

Page 9

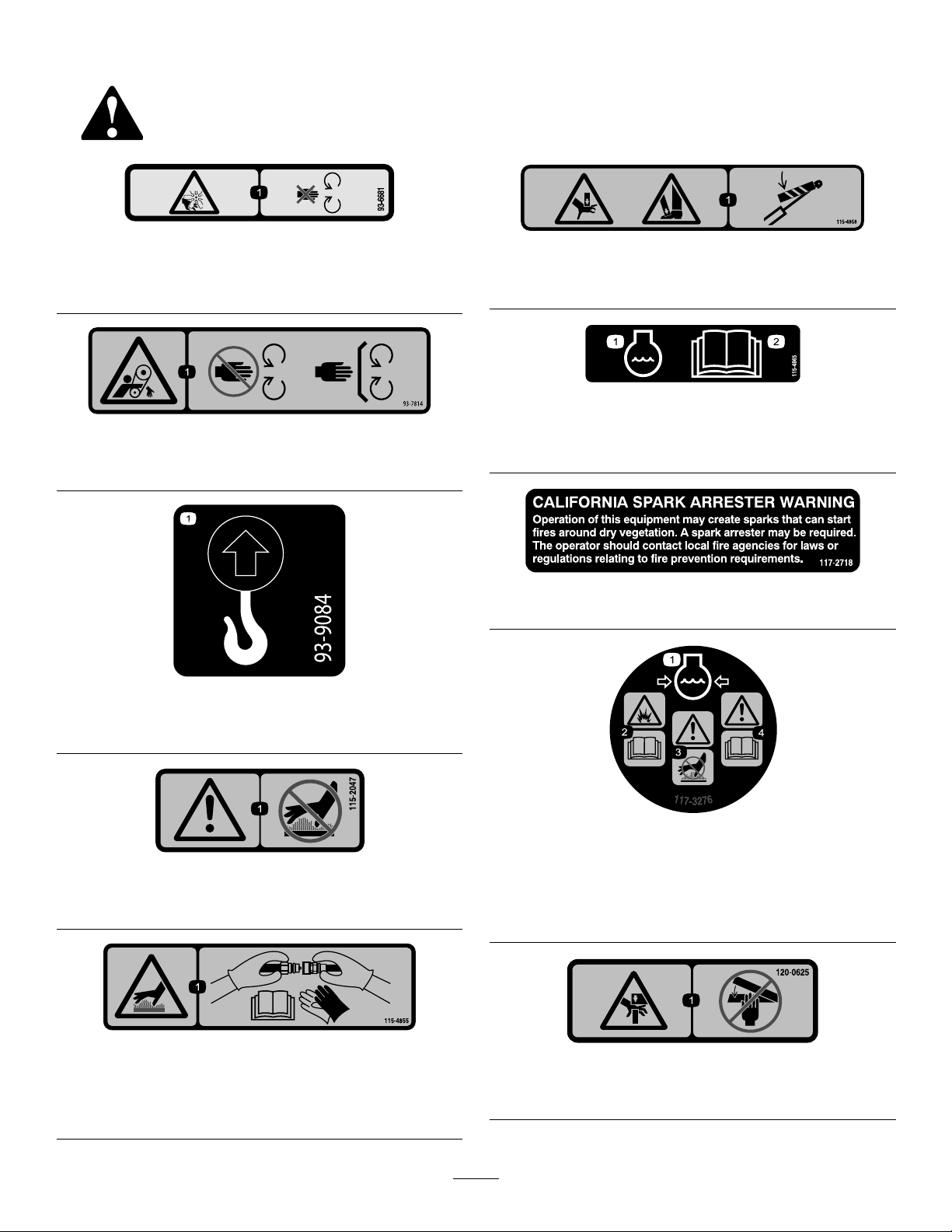

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedormissing.

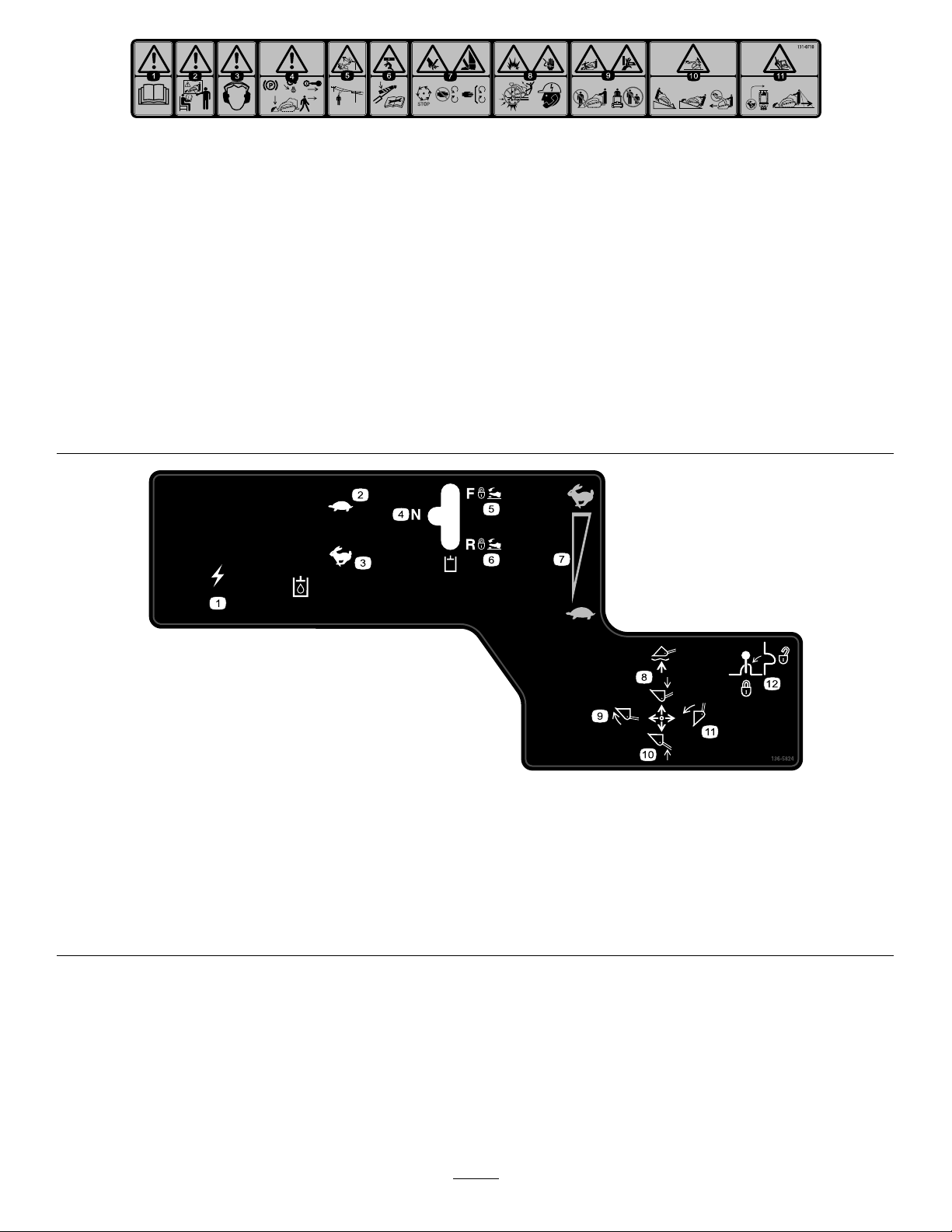

93-6681

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

decal93-6681

decal115-4858

115-4858

1.Crushinghazardofhandsorfeet—installthecylinderlock.

decal115-4865

115-4865

decal93-7814

1.Enginecoolant

2.ReadtheOperator's

Manual.

decal117-2718

117-2718

93-9084

1.Liftpoint/Tie-downpoint

115-2047

1.Warning—donottouchthehotsurface.

115-4855

1.Hotsurface/burnhazard—wearprotectivegloveswhen

handlingthehydrauliccouplersandreadtheOperator's

Manualforinformationonhandlinghydrauliccomponents.

decal93-9084

decal117-3276

117-3276

decal115-2047

decal115-4855

1.Enginecoolantunder

pressure

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

decal120-0625

120-0625

1.Pinchpoint,hand—keephandsaway.

9

Page 10

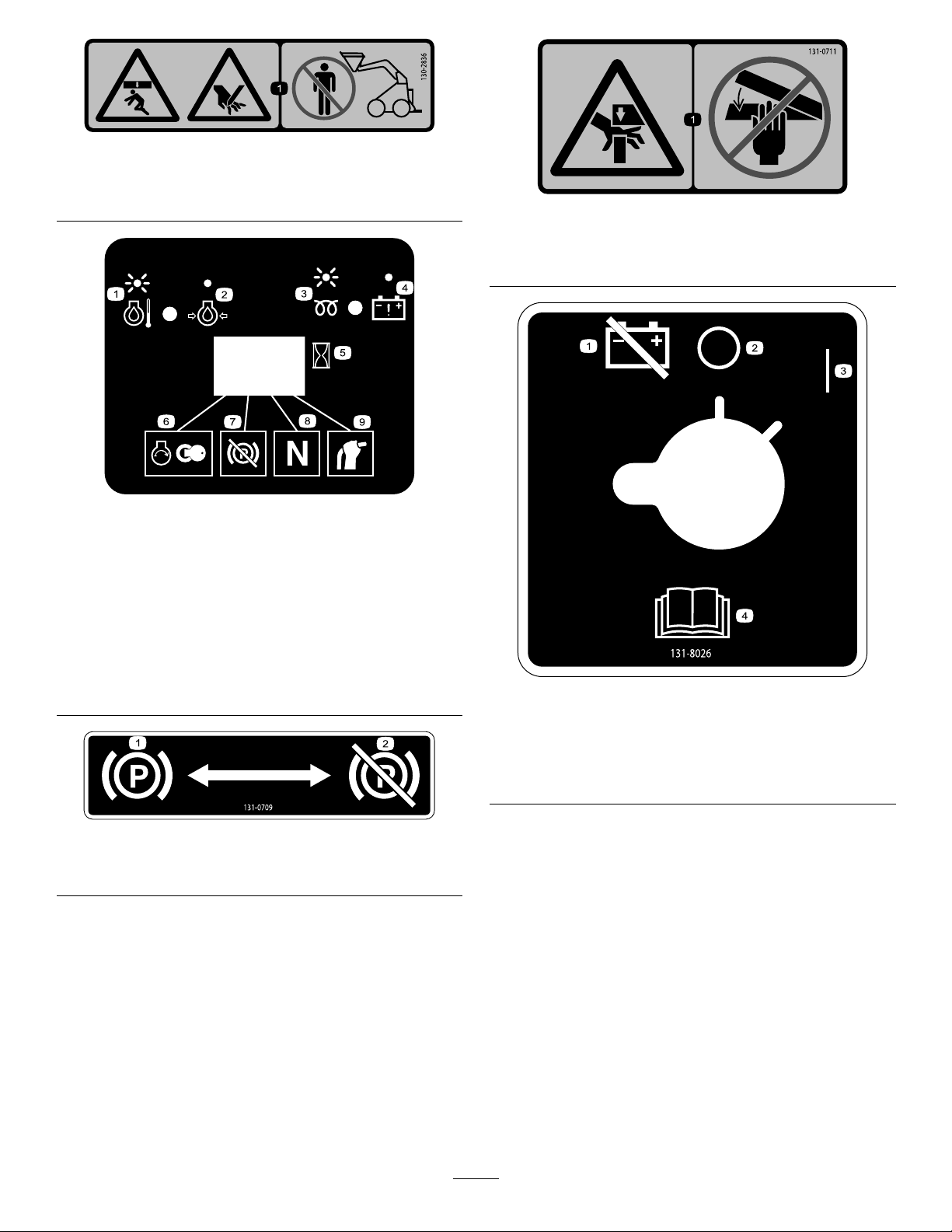

130-2836

1.Crushinghazard;cuttinghazard—keepawayfromthe

bucketandtheliftarm.

130-7637

decal130-2836

decal131-0711

131-0711

1.Crushinghazard—keepawayfrompinchpointsand

actuatingparts.

decal130-7637

1.Blinking

6.Enginestart

light—engine-coolant

temperature

2.Steadylight—engine-oil

7.Parkingbrakedisengaged

pressure

3.Blinkinglight—glowplug8.Tractionneutral

4.Steadylight—battery

9.Auxiliaryleverneutral

warning

5.Hourmeter

131-0709

1.Parkingbrake—engage2.Parkingbrake—disengage

decal131-8026

131-8026

1.Battery

power—disconnect

2.On4.ReadtheOperator's

decal131-0709

3.Off

Manual.

10

Page 11

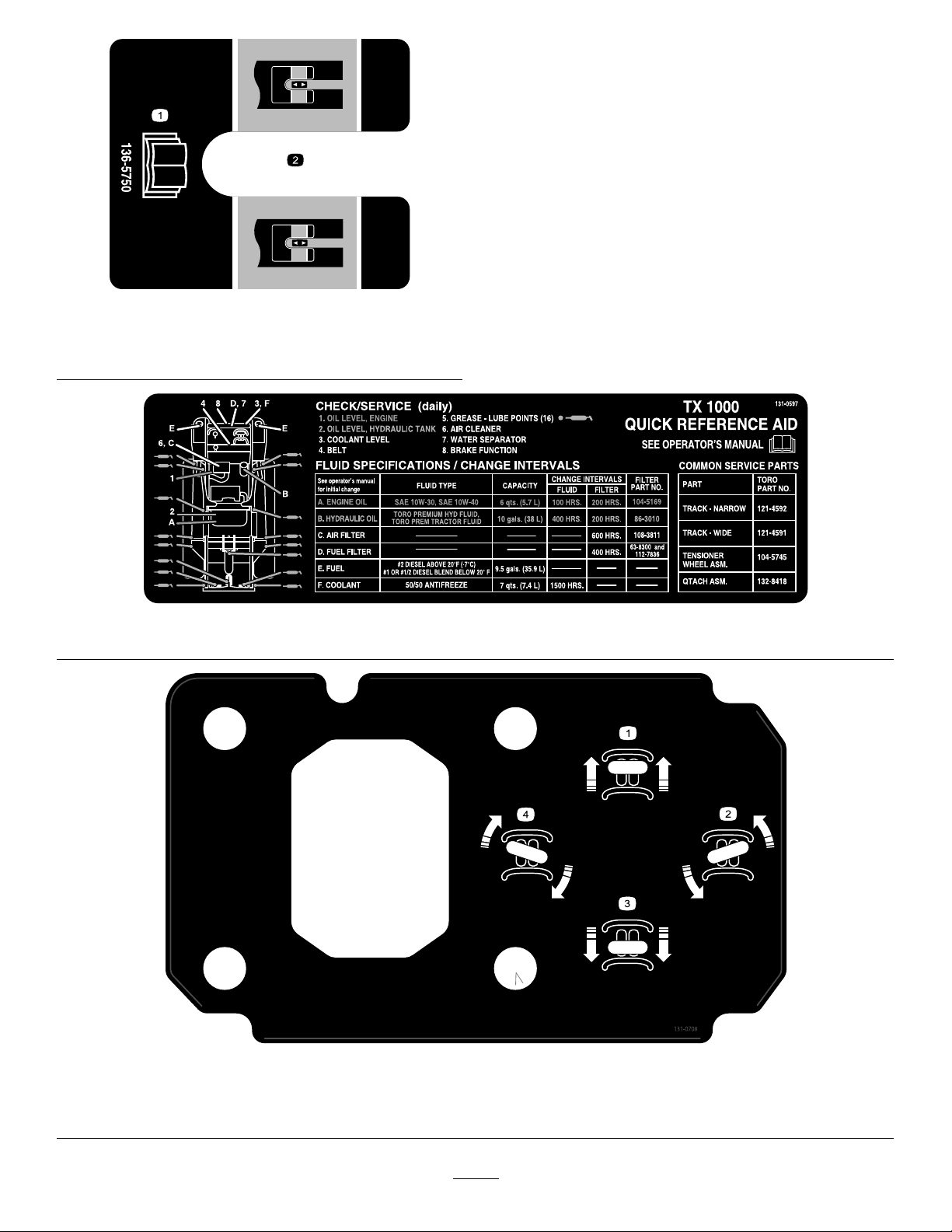

decal136-5750

136-5750

1.ReadtheOperator's

Manual.

2.Tensionblockguide

decal131-0597

131-0597

1.Moveforward

2.Turnright

decal131-0708

131-0708

3.Moverearward

4.Turnleft

11

Page 12

decal131-0710

131-0710

1.Warning—readtheOperator'sManual.7.Cutting/severinghazardofhandorfoot—waitforallmoving

partstostopbeforeservicing;keepawayfrommovingparts;

keepallguardsandshieldsinplace.

2.Warning—receivetrainingbeforeoperatingthemachine.

8.Explosionhazard;electrocutionhazard—callthelocalutilities

hotlinebeforebeginningworkinanarea.

3.Warning—wearhearingprotection.

9.Crushinghazard—keepawayfromthebucketwhenoperating

themachine;keepbystandersawayfromthemachine.

4.Warning—engagetheparkingbrake,lowerthebuckettothe

ground,shutofftheengine,andremovethekeyfromthe

ignitionbeforeleavingthemachine.

10.Tippinghazard—alwaysmoveupordownslopeswiththe

bucketlowered;neverdriveonaslopewiththebucketraised;

alwaysoperatewiththeheavyenduphill;alwayscarryloads

low;neverjerkthecontrollevers;useasteady,evenmotion.

5.Electrocutionhazard,powerlines—checkforpowerlinesin

theareabeforeusingthemachine.

11.Tippinghazard—donotmakefastturns;alwayscheckbehind

youbeforereversingthemachine.

6.Crushinghazard—keepawayfrompinchpoints;read

theOperator'sManualbeforeservicingorperforming

maintenance.

136-5824

1.Powersocket7.Enginespeed

2.Hydraulicuid—slow8.Lower/oattheattachment.

3.Hydraulicuid—fast9.Tilttheattachmentforward.

4.Hydraulicattachment—neutral10.Raisetheattachment.

5.Hydraulicattachment—forward

11.Tilttheattachmentrearward.

6.Hydraulicattachment—reverse12.Leverlock

12

decal136-5824

Page 13

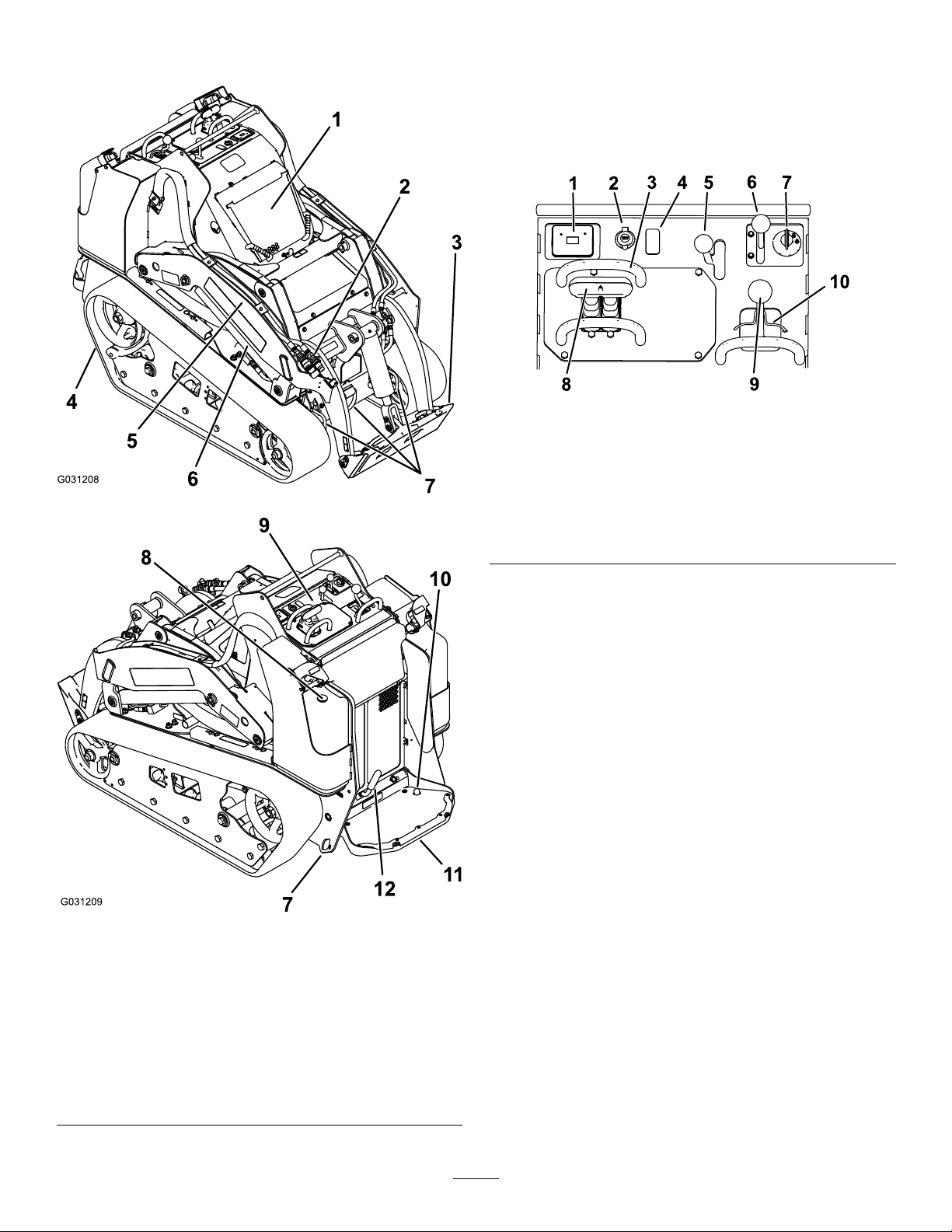

ProductOverview

Controls

Becomefamiliarwithallthecontrols(Figure5)beforeyou

starttheengineandoperatethetractionunit.

ControlPanel

g205233

Figure5

1.Messagedisplay6.Throttlelever

2.Powersocket7.Keyswitch

g031208

3.Referencebar

4.Plug

5.Auxiliaryhydraulicslever10.Loaderlock

8.Tractioncontrol

9.Loader-arm/attachment-tilt

lever

Figure4

1.Hood

2.Auxiliaryhydraulic

couplers

3.Mountplate

4.Track10.Auxiliaryhydraulicslock

5.Loaderarm

6.Liftcylinder

7.Tie-down/liftloop

8.Fuelgauge

9.Controlpanel

switch

11.Operatorplatform

12.Parkingbrake

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,has

3positions:OFF,RUN,andSTART.RefertoStartingthe

Engine(page20).

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeedand

rearwardtodecreasespeed.

ReferenceBar

Whendrivingthetractionunit,usethereferencebaras

ahandleandaleveragepointforcontrollingthetraction

g031209

controlandtheauxiliary-hydraulicslever.Toensuresmooth,

controlledoperation,donottakebothhandsoffthereference

barwhileoperatingthemachine.

13

Page 14

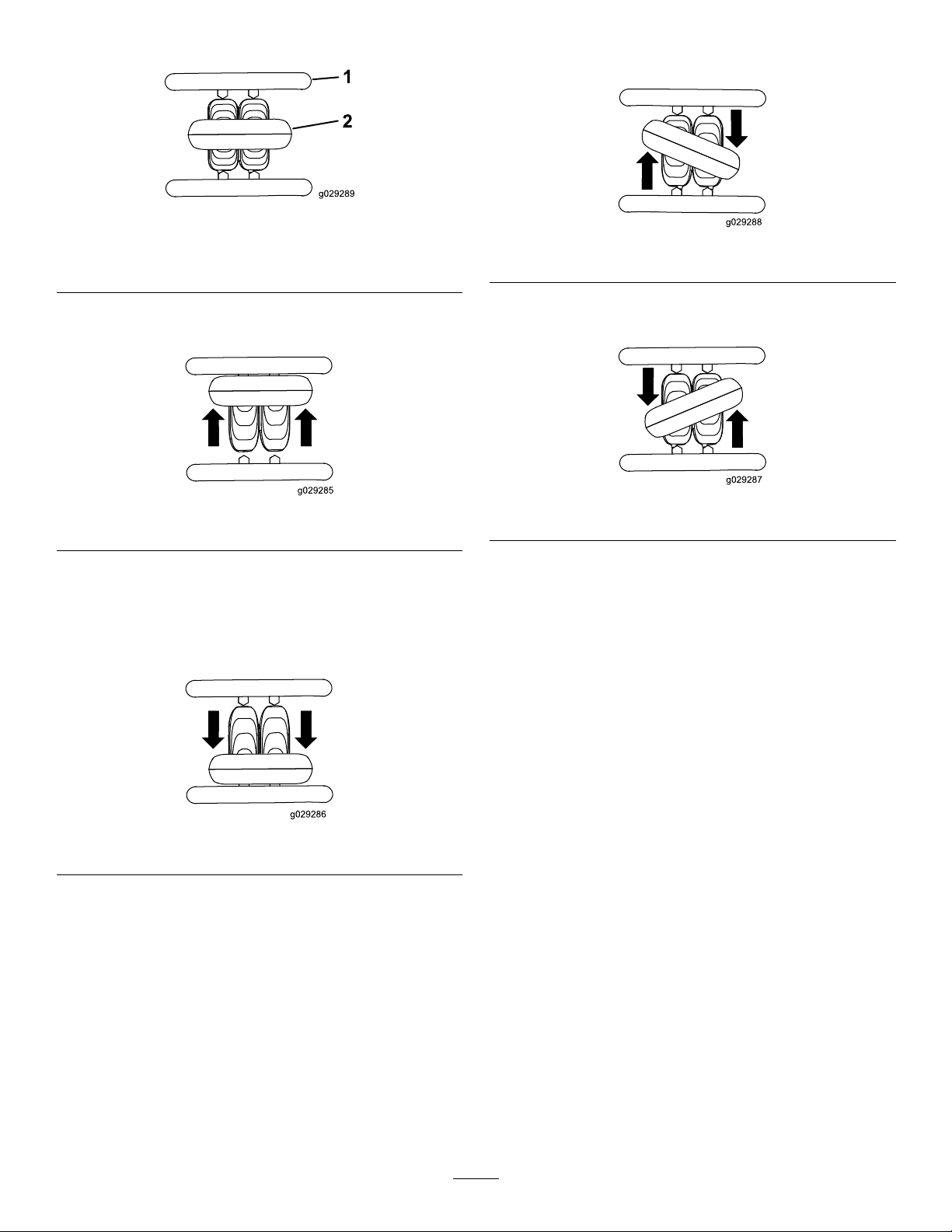

TractionControl

1.Referencebar

2.Tractioncontrol

Figure6

•Toturnright,rotatethetractioncontrolclockwise(Figure

9).

g029289

g029288

Figure9

•Tomoveforward,movethetractioncontrolforward

(Figure7).

Figure7

•Tomoverearward,movethetractioncontrolrearward

(Figure8).

Important:Whenreversing,lookbehindyoufor

obstructionsandkeepyourhandsonthereference

bar.

•Toturnleft,rotatethetractioncontrolcounterclockwise

(Figure10).

g029285

Figure10

g029287

•Tostopthemachine,releasethetractioncontrol(Figure

6).

Note:Thefartheryoumovethetractioncontrolinany

direction,thefasterthemachinemovesinthatdirection.

Figure8

g029286

14

Page 15

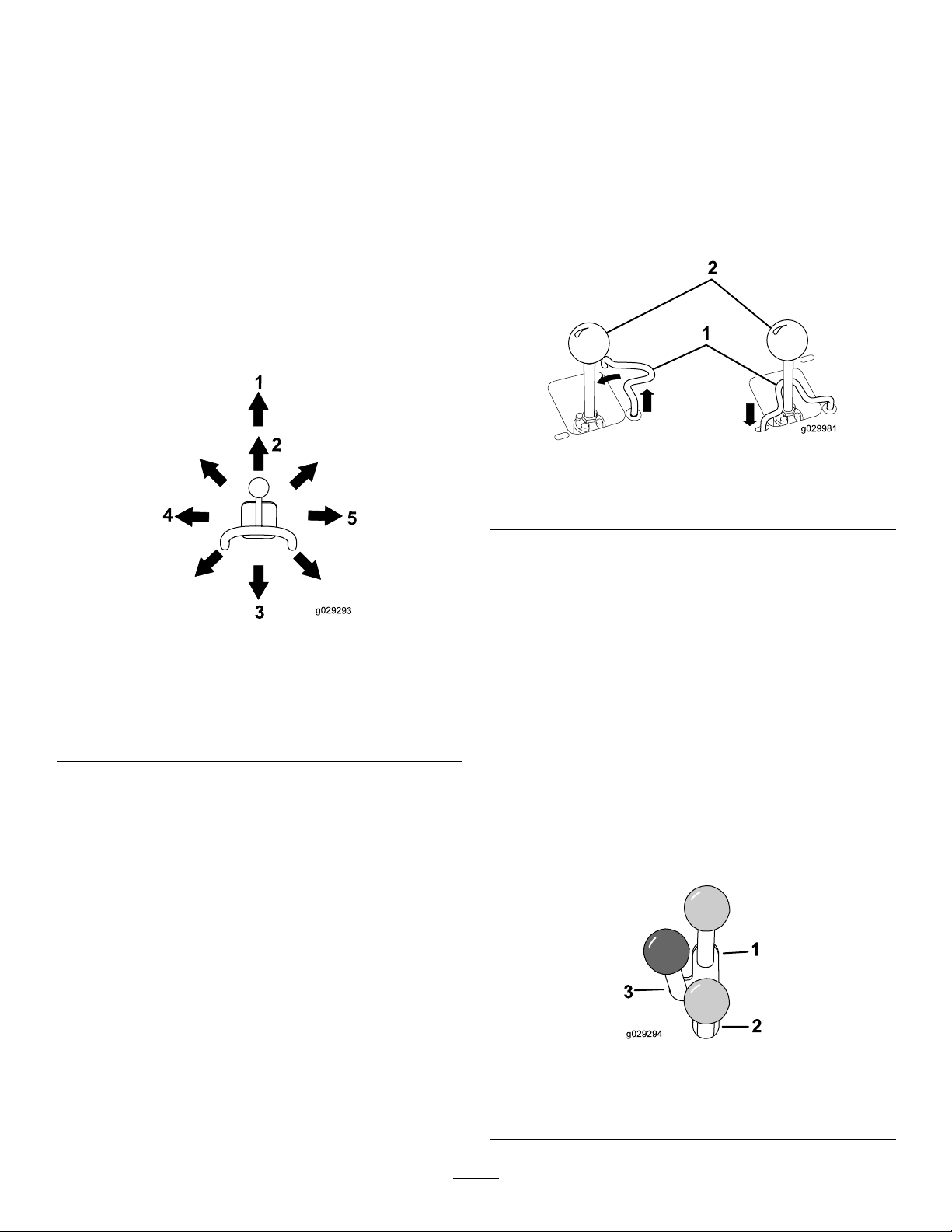

LoaderArm/Attachment-TiltLever

Loader-ValveLock

•Totilttheattachmentforward,slowlymovetheleverto

theright(Figure11).

•Totilttheattachmentrearward,slowlymovethelever

totheleft(Figure11).

•Tolowertheloaderarms,slowlymovetheleverforward

(Figure11).

•Toraisetheloaderarms,slowlymovetheleverrearward

(Figure11).

•Tolowertheloaderarmstoadetent(oat)position,push

theleverfullyforward(Figure11).

Note:Thisallowsattachmentssuchasthelevelerand

thehydraulicbladetofollowthecontoursoftheground

(i.e.,oat)whengrading.

Theloader-valvelocksecurestheloaderarm/attachment-tilt

leversothatyoucannotpushitforward.Thishelpsto

ensurethatnooneaccidentallylowerstheloaderarmsduring

maintenance.Securetheloaderarmswiththelockanytime

youneedtoshutoffthemachinewiththeloaderarmsraised.

Tosetthelock,liftuponitsothatitclearstheholein

thecontrolpanelandswingittotheleft,infrontofthe

loader-armlever,pushingitdownintothelockedposition

(Figure12).

Figure12

1.Loaderarm/attachment-tilt

lever

2.Loader-valvelock

g029981

Figure11

1.Detent(oat)position

2.Lowertheloaderarms.5.Tilttheattachment

3.Raisetheloaderarms.

4.Tilttheattachment

rearward.

forward.

Bymovingthelevertoanintermediateposition(e.g.,

forwardandleft),youcanmovetheloaderarmsandtiltthe

attachmentatthesametime.

Loader-Control-ReferenceBar

Theloader-control-referencebarhelpsstabilizeyourhand

g029293

whileoperatingtheloaderarm/attachment-tiltlever(Figure

4).

Auxiliary-HydraulicsLever

•Tooperateahydraulicattachmentintheforward

direction,movetheauxiliary-hydraulicsleverforward

(Figure13).

•Tooperateahydraulicattachmentinthereversedirection,

movetheauxiliary-hydraulicsleverrearward(Figure13).

Note:IfyoureleasetheleverwhileintheFORWARDor

REVERSEposition,theleverautomaticallyreturnstothe

NEUTRALposition(Figure13).

15

1.Forward-owhydraulics

2.Reverse-owhydraulics

g029294

Figure13

3.Neutral

Page 16

Auxiliary-Hydraulics-LockSwitch

MessageDisplay

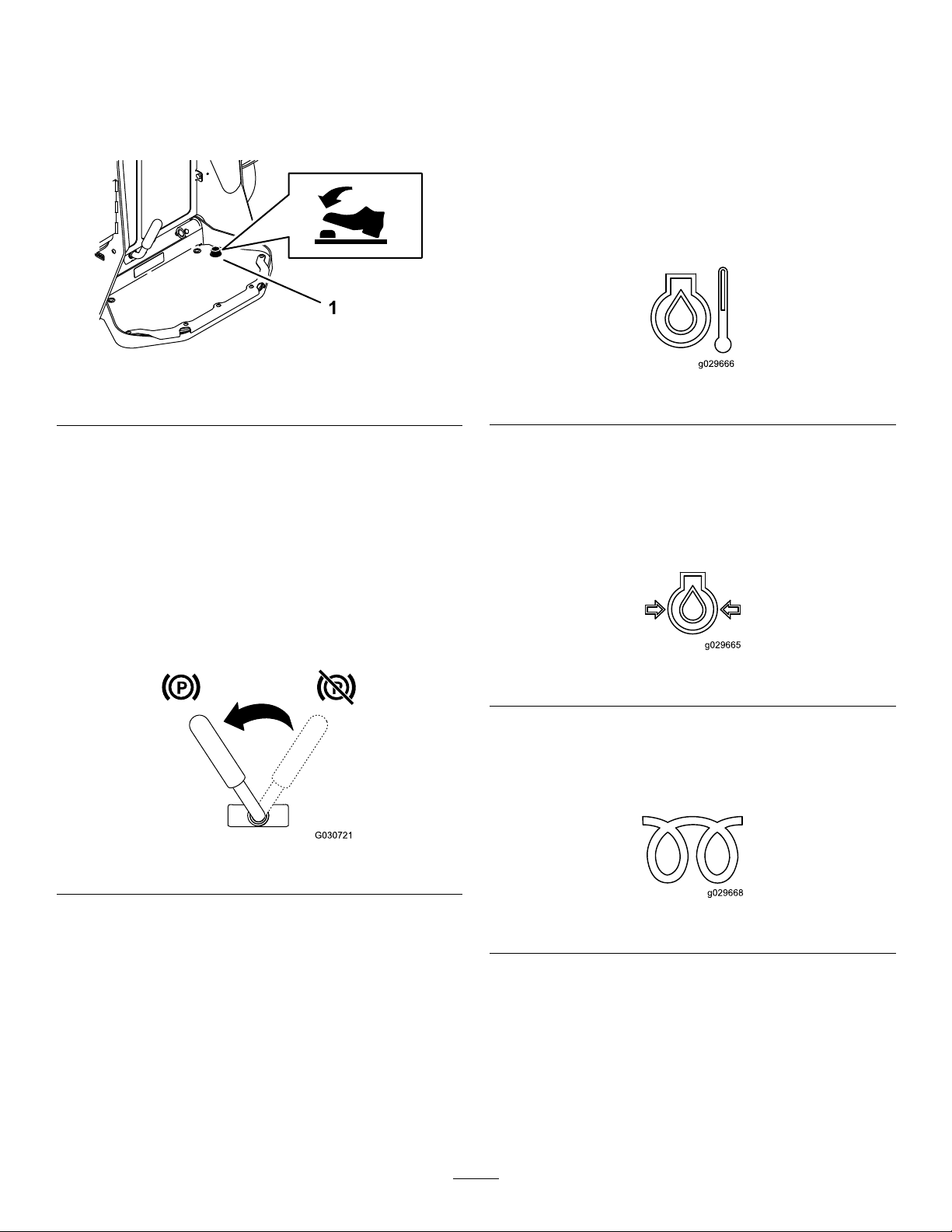

Useyourrightfoottopresstheauxiliary-hydraulics-lock

switchtolocktheauxiliary-hydraulicsleverintheFORW ARD

orREARWARDpositionandfreeyourhandforothercontrols

(Figure5).

Figure14

1.Auxiliary-hydraulics-lock

Parking-BrakeLever

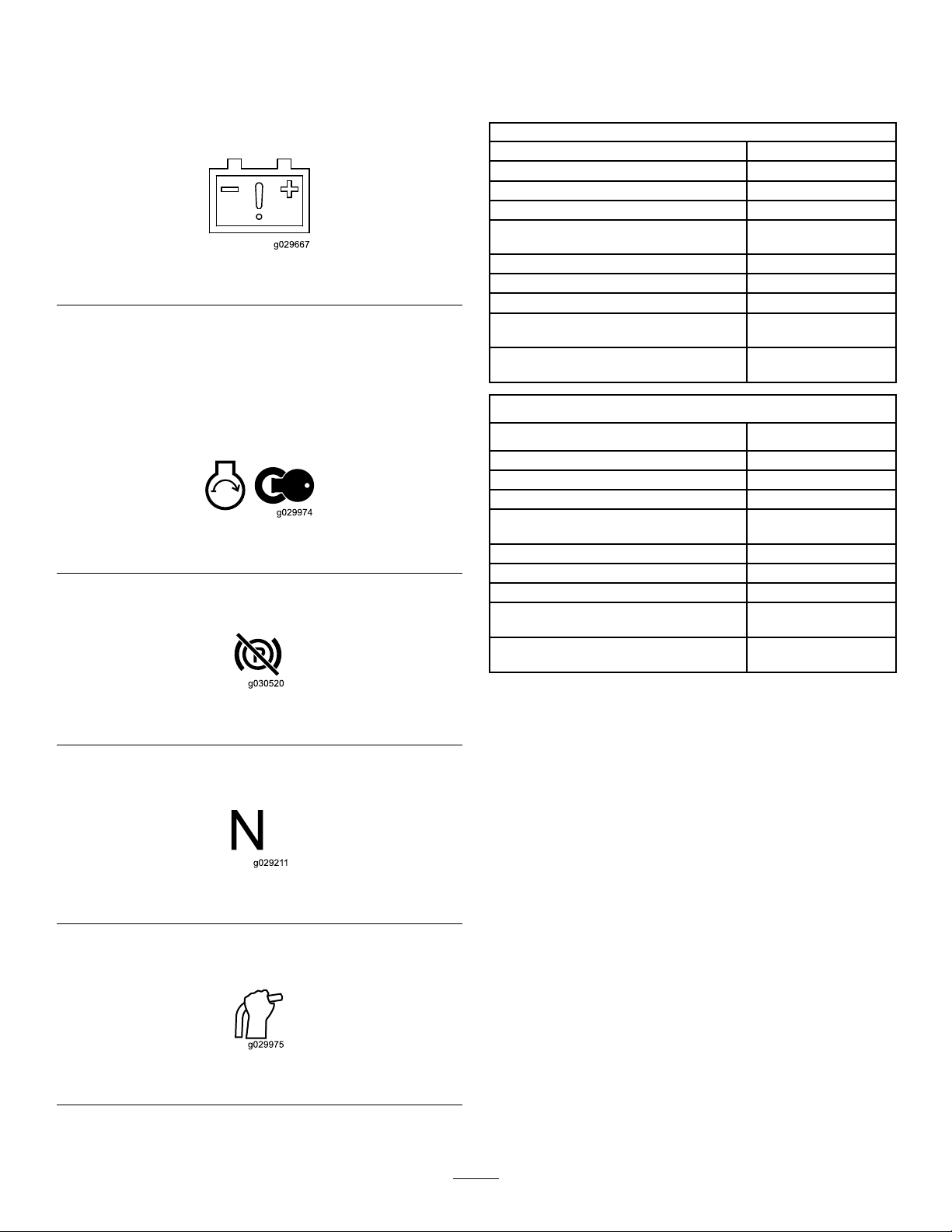

•Toengagetheparkingbrake,rotatethelevertoleft

(Figure15).

Note:Thetractionunitmayrollslightlybeforethe

brakesengageinthedrivesprocket.

Engine-Coolant-TemperatureLight

Iftheenginecoolantbecomestoohot,thelightontheleft

ashesandthehornsounds(Figure16).Ifthishappens,

disengagetheauxiliaryhydraulicsandletthemachinerunat

highidletoallowthecoolingsystemtocoolthemachine.

Checkthecoolantlevelwhentheenginehasfullycooled.

Important:Donotshutofftheengine,asthismay

causethemachinetooverheat.

g205234

g029666

Figure16

Engine-Oil-PressureLight

Iftheengine-oil-pressurebecomestoolow,thelightonthe

leftilluminatessteadily(Figure17).Ifthishappens,shutoff

theengineimmediatelyandchecktheoillevel.Ifitislow,add

oilandlookforpossibleleaks.

•Toreleasethebrake,rotatethebrakelevertotheright.

Note:Youmayneedtoadjustthetractioncontrolto

releasethebrakepinsandrotatethelever.

Figure15

FuelGauge

Thisgaugemeasurestheamountoffuelinthefueltank(s).

g029665

Figure17

Glow-PlugLight

Thelightontherightasheswhiletheglowplugsarecharged

andwarmingtheengine(Figure18).

g030721

g029668

Figure18

16

Page 17

Battery-ChargeLight

Ifthebatterychargebecomestoolow,thelightontheright

illuminatessteadily(Figure19).Ifthishappens,shutoffthe

engineandchargeorreplacethebattery.RefertoServicing

theBattery(page34).

Figure19

HourMeter

Thehourmeterdisplaysthenumberofhoursofoperation

thathavebeenloggedonthetractionunitandthefollowing

indicators:

•Enginestart—displayswhenyoustarttheengine

Figure20

•Parkingbrake—displayswhenyoudisengagetheparking

brake

Specications

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Model22327

Width

Length

Height

Weight

Operatingcapacity(withstandard

g029667

g029974

bucket)

Tippingcapacity(withstandardbucket)1296kg(2,857lb)

Wheelbase

Dumpheight(withstandardbucket)155cm(61inches)

Reach—fullyraised(withstandard

bucket)

Heighttohingepin(withstandard

bucketinhighestposition)

Model22328

Width

Length

Height

Weight

Operatingcapacity(withstandard

bucket)

Tippingcapacity(withstandardbucket)1296kg(2,857lb)

Wheelbase

Dumpheight(withstandardbucket)155cm(61inches)

Reach—fullyraised(withstandard

bucket)

Heighttohingepin(withstandard

bucketinhighestposition)

85cm(33inches)

256cm(101inches)

138cm(54inches)

1234kg(2,720lb)

454kg(1,000lb)

104cm(41inches)

62cm(25inches)

206cm(81inches)

103cm(41inches)

256cm(101inches)

138cm(54inches)

1297kg(2,860lb)

454kg(1,000lb)

104cm(41inches)

62cm(25inches)

206cm(81inches)

Figure21

•Tractionneutral—displayswhenthetractioncontrolis

intheNEUTRALposition

Figure22

•Auxiliaryleverneutral—displayswhentheauxiliarylever

isintheNEUTRALposition

Figure23

g030520

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Important:UseonlyToroapprovedattachments.

g029211

g029975

Otherattachmentsmaycreateanunsafeoperating

environmentordamagethetractionunit.

Tobestprotectyourinvestmentandmaintainoptimal

performanceofyourToroequipment,countonTorogenuine

parts.Whenitcomestoreliability,T orodeliversreplacement

partsdesignedtotheexactengineeringspecicationofour

equipment.Forpeaceofmind,insistonTorogenuineparts.

17

Page 18

Operation

G009027

1

2

AddingFuel

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Beforeoperating,checktheuidlevelsand

removedebrisfromthetractionunit.Also,ensurethat

theareaisclearofpeopleanddebris.Y oushouldalso

knowandhavemarkedthelocationsofalltheutility

lines.

ThinkSafetyFirst

Carefullyreadallsafetyinstructionsandsymbolsinthe

safetysection.Knowingthisinformationcouldhelpyouor

bystandersavoidinjury.

CAUTION

Thismachineproducessoundlevelsthatcancause

hearinglossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Useprotectiveequipmentforyoureyes,ears,hands,feet,

andhead.

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltanksoutdoors,inanopenarea,

whentheengineiscold.Wipeupanyfuelthat

spills.

•Neverllthefueltanksinsideanenclosed

trailer.

•Neversmokewhenhandlingfuelandstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleased,causingasparkthatcan

ignitethefuelvapors.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

Figure24

1.Weareyeprotection.2.Wearhearingprotection.

WARNING

Youcouldfallofftheplatformandbeseriously

injuredduringoperation.

Donotmovethemachineunlessyouarestanding

withbothfeetontheplatformandyourhandsare

holdingontothehandles.

•Alwaysplacefuelcontainersonthegroundaway

g009027

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbed,becauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer

ratherthanfromafuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

18

Page 19

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepyourfaceawayfromthenozzleandfuel

tankopening.

•Keepfuelawayfromyoureyesandskin.

FuelRecommendations

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatyoucanusewithin180daystoensurefuel

freshness.

Usesummer-gradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwintergrade(No.1-DorNo.

1-D/2-Dblend)belowthattemperature.Usingwinter-grade

fuelatlowertemperaturesprovideslowerashpointand

coldowcharacteristics,whicheasesstartingandreduces

fuellterplugging.

FillingtheFuelTanks

Fueltankcapacity:41L(11USgallons)

FillthefueltanksasshowninFigure25.

Note:Thefuel-tankcapsclickwhenyouclosethemsecurely.

Usethebracketstolockthefueltanks.

Usingsummer-gradefuelabove-7°C(20°F)contributes

towardlongerfuelpumplifeandincreasedpowercompared

towinter-gradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maydegradeovertime.

•Fuellterpluggingmayoccurforatimeafterconverting

tobiodieselblends.

g029669

Figure25

PerformingDaily Maintenance

Beforestartingthemachineeachday,performtheEach

Use/DailyprocedureslistedintheMaintenance(page25).

Important:Checkthehydraulic-uidlevelandbleed

thefuelsystembeforestartingtheenginefortherst

time;refertoCheckingtheHydraulic-FluidLevel(page

45)andBleedingtheFuelSystem(page34).

•Contactyourdistributorformoreinformationon

biodiesel.

19

Page 20

StartingtheEngine

ShuttingOfftheEngine

1.Ensurethattheauxiliary-hydraulicsleverand

traction-controlareintheNEUTRALposition.

2.MovethethrottlelevermidwaybetweentheSLOWand

FASTpositions.

3.InsertthekeyintothekeyswitchandturnittotheON

position.

4.Waitfortheglow-plugindicatorlighttostopblinking.

5.TurnthekeytotheSTARTposition.Whentheengines

starts,releasethekey.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefails

tostart,wait30secondsforthestartertocool

downbetweenattempts.Failuretofollowthese

instructionscouldburnoutthestartermotor.

6.Movethethrottlelevertothedesiredsetting.

Important:Runningtheengineathighspeeds

whenthehydraulicsystemiscold(i.e.,whenthe

airtemperatureisatorbelowfreezing)could

damagethehydraulicsystem.Whenstartingthe

engineincoldconditions,allowittoruninthe

middlethrottlepositionfor2to5minutesbefore

movingthethrottletotheFASTposition.

Note:Iftheoutdoortemperatureisbelowfreezing,

storethetractionunitinagaragetokeepitwarmer

andtoaidinstarting.

DrivingtheMachine

Usethetractioncontrolstomovethemachine.Thefarther

youmovethetractioncontrolsinanydirection,thefasterthe

machinemovesinthatdirection.Releasethetractioncontrols

tostopthemachine.

1.Parkthemachineonalevelsurface,engagetheparking

brake(ifequipped),andlowertheloaderarms.

2.Ensurethattheauxiliaryhydraulicsleverisinthe

NEUTRALposition.

3.MovethethrottlelevertotheSLOWposition.

4.Iftheenginehasbeenworkinghardorishot,letitidle

foraminutebeforeturningthekeyswitchtotheOFF

position.

Note:Thishelpstocooltheenginebeforeyoushut

itoff.Inanemergency,youcanshutofftheengine

immediately.

5.TurnthekeyswitchtotheOFFpositionandremove

thekey.

CAUTION

Achildoruntrainedbystandercouldattemptto

operatethetractionunitandbeinjured.

Removethekeyfromthekeyswitchwhenleaving

thetractionunit,evenifjustforafewseconds.

MovingaNon-Functioning Machine

Important:Donottoworpullthemachinewithoutrst

openingthetowvalves,oryouwilldamagethehydraulic

system.

1.Shutofftheengine.

2.Openthehoodandsecurethehoodprop.

3.Removethesidescreens;refertoRemovingtheSide

Screens(page28).

CAUTION

Whenreversing,youmaybackintostationary

objectsoroverbystandersandcauseserious

personalinjuryordeath.

Lookbehindyouforobstructionsorbystandersand

keepyourhandsonthereferencebar.

Thethrottlecontrolregulatestheenginespeedasmeasured

inrpm(revolutionsperminute).Placethethrottleleverinthe

FASTpositionforbestperformance.Youcan,however,use

thethrottlepositiontooperateatslowerspeeds.

4.Usingawrench,turnthetowvalvesonthehydraulic

pumpstwicecounterclockwise(Figure26).

20

Page 21

Figure26

UsingAttachments

InstallinganAttachment

Important:UseonlyToro-approvedattachments.

Attachmentscanchangethestabilityandtheoperating

characteristicsofthemachine.Thewarrantyofthe

g031210

g031211

machinemaybevoidedifyouusethemachinewith

unapprovedattachments.

Important:Beforeinstallingtheattachment,ensure

thatthemountplatesarefreeofanydirtordebrisand

thatthepinsrotatefreely.Ifthepinsdonotrotatefreely,

greasethem.

1.Positiontheattachmentonalevelsurfacewithenough

spacebehindittoaccommodatethemachine.

2.Starttheengine.

3.Tilttheattachmentmountplateforward.

4.Positionthemountplateintotheupperlipofthe

attachmentreceiverplate(Figure27).

1.Towvalve

5.Towthemachineasrequired.

6.Afterrepairingthemachine,closethetowvalvesbefore

operatingit.

g003710

Figure27

1.Mountplate2.Receiverplate

5.Raisetheloaderarmswhiletiltingbackthemountplate

atthesametime.

Important:Raisetheattachmentenoughtoclear

thegroundandtiltthemountplatealltheway

back.

6.Shutofftheengineandremovethekey.

7.Engagethequick-attachpins,ensuringthattheyare

fullyseatedinthemountplate(Figure28).

Important:Ifthepinsdonotrotatetothe

engagedposition,themountplateisnotfully

alignedwiththeholesintheattachmentreceiver

plate.Checkthereceiverplateandcleanitif

necessary.

21

Page 22

Figure28

1.Quick-attachpins

(engagedposition)

2.Disengagedposition

3.Engagedposition

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

ConnectingtheHydraulicHoses

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury;

otherwise,gangrenemayresult.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

CAUTION

Hydrauliccouplers,hydrauliclines/valves,and

hydraulicuidmaybehot.Ifyoucontacthot

components,youmaybeburned.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

Iftheattachmentrequireshydraulicsforoperation,connect

thehydraulichosesasfollows:

1.Shutofftheengineandremovethekey.

2.Movetheauxiliary-hydraulicsleverforward,backward,

andbacktotheNEUTRALpositiontorelievepressure

atthehydrauliccouplers.

3.Removetheprotectivecoversfromthehydraulic

connectorsonthemachine.

g003711

4.Ensurethatallforeignmatteriscleanedfromthe

hydraulicconnectors.

5.Pushtheattachmentmaleconnectorintothefemale

connectoronthemachine.

Note:Whenyouconnecttheattachmentmale

connectorrst,yourelieveanypressurebuiltupinthe

attachment.

6.Pushtheattachmentfemaleconnectorontothemale

connectoronthemachine.

7.Conrmthattheconnectionissecurebypullingon

thehoses.

RemovinganAttachment

1.Parkthemachineonalevelsurface.

2.Lowertheattachmenttotheground.

3.Shutofftheengineandremovethekey.

4.Disengagethequick-attachpinsbyturningthemto

theoutside.

5.Iftheattachmentuseshydraulics,movethe

auxiliary-hydraulicsleverforward,backward,andback

totheNEUTRALpositiontorelievepressureatthe

hydrauliccouplers.

6.Iftheattachmentuseshydraulics,slidethecollarsback

onthehydrauliccouplersanddisconnectthem.

Important:Connecttheattachmenthoses

togethertopreventhydraulicsystemcontamination

duringstorage.

7.Installtheprotectivecoversontothehydrauliccouplers

onthemachine.

8.Starttheengine,tiltthemountplateforward,andback

themachineawayfromtheattachment.

22

Page 23

TransportingtheMachine

g027996

5

1

2

6

Useaheavy-dutytrailerortrucktotransportthemachine.

Usefull-widthramps.Ensurethatthetrailerortruckhasall

thenecessarybrakes,lighting,andmarkingasrequiredbylaw.

Pleasecarefullyreadallthesafetyinstructions.Knowingthis

informationcouldhelpyou,yourfamily,pets,orbystanders

avoidinjury.Refertoyourlocalordinancesfortrailerand

tie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerousandcan

leadtoaccidentscausingpersonalinjury.

Donotdrivethemachineonapublicstreetor

roadway.

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath(Figure29).

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda15-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Ensurethatthelengthoframpisatleast4times

aslongastheheightofthetrailerortruckbedto

theground.Thisensuresthatrampangledoes

notexceed15degreesonatground.

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

15degrees

g027996

Figure29

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

23

Page 24

LoadingtheMachine

WARNING

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Loadandunloadthemachinewiththeheavy

enduptheramp.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

1.Ifusingatrailer,connectittothetowingvehicleand

connectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Lowertheramp,ensuringthattheanglebetweenthe

rampandthegrounddoesnotexceed15degrees

(Figure29).

4.Lowertheloaderarms.

5.Loadthemachineontothetrailerwiththeheavyend

uptheramp,carryingloadslow(Figure30).

•Ifthemachinehasafullload-carrying

attachment(e.g.,bucketoradjustableforks)ora

non-load-carryingattachment(e.g.,stumpgrinder),

drivethemachineforwarduptheramp.

•Ifthemachinehasanemptyload-carrying

attachmentornoattachment,backthemachine

uptheramp.

g031331

Figure31

1.Tie-downloops

UnloadingtheMachine

1.Lowertheramp,ensuringthattheanglebetweenthe

rampandthegrounddoesnotexceed15degrees

(Figure30).

2.Unloadthemachinefromthetrailerwiththeheavyend

uptheramp,carryingloadslow(Figure32).

•Ifthemachinehasafullload-carrying

attachment(e.g.,bucketoradjustableforks)ora

non-load-carryingattachment(e.g.,stumpgrinder),

backitdowntheramp.

•Ifthemachinehasanemptyload-carrying

attachmentornoattachment,driveitforward

downtheramp.

Figure30

1.Machinewithfull

attachmentor

non-load-carrying

attachment—drivethe

machineforwardupthe

ramp.

2.Machinewithemptyor

noattachment—backthe

machineuptheramp.

6.Lowertheloaderarmsallthewaydown.

7.Shutofftheengine,removethekey,andengagethe

parkingbrake.

8.Usethemetaltie-downloopsonthemachineto

securelyfastenthemachinetothetrailerortruckwith

straps,chains,cable,orropes(Figure31).Refertolocal

regulationsfortie-downrequirements.

g204458

g204457

1.Machinewithfull

attachmentor

non-load-carrying

attachment—backthe

machinedowntheramp.

Figure32

2.Machinewithemptyor

noattachment—drivethe

machineforwarddownthe

ramp.

LiftingtheMachine

Youcanliftthemachineusingthetie-down/liftloopsaslift

points;refertoFigure31.

24

Page 25

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

CAUTION

Ifyouleavethekeyinthekeyswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromthekeyswitchanddisconnectthewiresfromthesparkplugsbeforeyoudoany

maintenance.Setthewiresasidesothattheydonotaccidentallycontactthesparkplugs.

WARNING

Failuretoproperlymaintainthemachinecouldresultinprematurefailureofmachinesystems,causing

possibleharmtoyouorbystanders.

Keepthemachinewellmaintainedandingoodworkingorderasindicatedintheseinstructions.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every50hours

Every100hours

MaintenanceProcedure

•Replacethehydrauliclter.

•Changetheengineoilandlter.

•Checkandadjustthetracktension.

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checktheair-lter-serviceindicator.

•Checktheengine-oillevel.

•Drainwaterandothercontaminantsfromthefuellter/waterseparator.

•Cleanthetracks.

•Checkthetracksforexcessivewearandpropertension.

•Cleanthescreen,oilcooler,andfrontoftheradiator(moreoftenindirtyordusty

conditions).

•Checkthecoolantlevelintheexpansiontank.

•Testtheparkingbrake.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

•Removetheair-cleanercover,cleanoutdebris,andchecktheair-lter-service

indicator.

•Checkthehydraulic-uidlevel.

•Checkthebatterycondition.

•Changetheengineoil.(Servicemorefrequentlyifconditionsareextremelydusty

orsandy.)

•Checkandadjustthetracktension.

•Checkthecoolingsystemhoses.

•Checkthealternator/fanbelttension(refertotheengineowner’smanualfor

instructions).

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Checkfordirtbuildupinthechassis.

Every200hours

•Changetheoillter.(Servicemorefrequentlyifconditionsareextremelydusty

orsandy.)

•Replacethehydrauliclter.

25

Page 26

MaintenanceService

Every400hours

Interval

MaintenanceProcedure

•Replacethefuelltercanisterandin-linelter.

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Changethehydraulicuid.

Every500hours

Every1,500hours

Yearly

Yearlyorbeforestorage

Every2years

•Replacethealternator/fanbelt(refertotheengineowner’smanualforinstructions).

•Replaceallmovinghydraulichoses.

•Changetheenginecoolant(AuthorizedServiceDealeronly).

•Checkandadjustthetracktension.

•Touchupchippedpaint.

•Drainandcleanthefueltank(AuthorizedServiceDealeronly).

Pre-Maintenance

Procedures

UsingtheCylinderLocks

WARNING

Theloaderarmsmaylowerwhenintheraised

position,crushinganyoneunderthem.

Installthecylinderlock(s)beforeperforming

maintenancethatrequiresraisedloaderarms.

InstallingtheCylinderLocks

1.Removetheattachment.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengineandremovethekey.

4.Removethe2pinssecuringthecylinderlocktothe

postsonthesideofthemachine.

5.Slidethecylinderlockoverthelift-cylinderrod(Figure

33).

g031214

Figure33

1.Cylinderlock2.Lift-cylinderrod

6.Repeatstep4and5fortheothersideofthemachine.

7.Slowlylowertheloaderarmsuntilthecylinderlocks

contactthecylinderbodiesandrodends.

RemovingandStoringthe

CylinderLocks

Important:Removethecylinderlocksfromtherods

andfullysecuretheminthestoragepositionbefore

operatingthemachine.

1.Starttheengine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengineandremovethekey.

4.Removethepinssecuringthecylinderlocks.

5.Placethecylinderlocksonthepostsonthesidesofthe

machineandsecurewiththepins.

6.Lowertheloaderarms.

26

Page 27

AccessingInternal Components

WARNING

Openingorremovingcovers,hoods,andscreens

whiletheengineisrunningcouldallowyouto

contactmovingparts,seriouslyinjuringyou.

Beforeopeninganyofthecovers,hoods,and

screens,shutofftheengine,removethekeyfrom

thekeyswitch,andallowtheenginetocool.

ClosingtheHood

1.Liftuponthetabsecuringtheproprod(Figure35)

OpeningtheHood

1.Loosenthehood-lockingscrew(Figure34)

Figure34

1.Hood-lockingscrew3.Hood

2.Hood-latchlever

g031216

Figure35

1.Prop-rodtab

2.Lowerthehoodandsecureitbypushingdownonthe

frontofthehooduntilitlocksinplace.

3.Tightenthehood-lockingscrewtosecurethelatch

(Figure34).

OpeningtheRear-AccessCover

1.Removethefastener(Figure36).

g031215

2.Turnthehoodlatchclockwise(Figure34).

3.Liftuponthehandlesandswingthehoodup(Figure

34).

4.Securetheproprod.

g031217

Figure36

1.Fastener

2.Lifttherear-accesscoveruptoaccesstheinternal

components(Figure36).

3.Lowertherear-accesscoverandinstallthefastenerto

closethecover.

27

Page 28

RemovingtheSideScreens

RemovingtheFrontCover

1.Openthehoodandsecurethehoodprop.

2.Slidethesidescreens(Figure37)upandoutofthe

slotsinthefrontscreenandframe.

Figure37

Loaderarmsnotshownforclarity

1.Sidescreen

RemovingtheFrontScreen

1.Openthehoodandsecurethehoodprop.

1.Removethe2upperbolts(3/8x1inch),2washers,and

2lowerbolts(5/16x5/8inch)fromthefrontcover.

2.Removethefrontcover.

g030720

g204032

Figure39

1.Upperbolt—3/8x1inch

(2)

2.Frontcover

3.Washer(2)

4.Lowerbolt—5/16x5/8

inch(2)

2.Loosenthe2topboltsand2frontbolts.

Figure38

1.Bolt

g031218

3.Removethescreen.

28

Page 29

Lubrication

g031219

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily(Grease

immediatelyaftereverywashing.)

GreaseType:General-purposegrease.

1.Parkthemachineonalevelsurface,engagetheparking

brake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Cleanthegreasettingswitharag.

4.Connectagreaseguntoeachtting(Figure40,Figure

41,andFigure42).

Note:Raisetheloaderarmsbeforegreasingthe

ttingsinFigure42.

g004209

Figure41

g029953

Figure42

5.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps).

Figure40

6.Wipeupanyexcessgrease.

g031219

29

Page 30

EngineMaintenance

•Iftheserviceindicatorisclear,installtheair-cleaner

coverwiththedustcaporienteddownwardand

securethelatches(Figure43).

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checkthe

air-lter-serviceindicator.

Every25hours—Removetheair-cleanercover,clean

outdebris,andchecktheair-lter-serviceindicator.

ServicingtheAir-CleanerCover

andBody

Important:Replacetheair-cleanerlteronlywhenthe

serviceindicatorshowsred(Figure43).Changingthe

airlterbeforeitisnecessaryonlyincreasesthechance

ofdirtenteringtheenginewhenyouremovethelter.

1.Parkthemachineonalevelsurface,engagetheparking

brake(ifequipped),andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Openthehoodandsecuretheproprod(ifapplicable).

4.Checktheair-cleanerbodyfordamagethatcouldcause

anairleak.Checkthewholeintakesystemforleaks,

damage,orloosehoseclamps.

Replaceorrepairanydamagedcomponents.

5.Releasethelatchesontheaircleanerandpullthe

air-cleanercoverofftheair-cleanerbody(Figure43).

Important:Donotremovetheairlter.

•Iftheserviceindicatorisred,replacetheairlter

asdescribedinReplacingtheFilter(page30).

ReplacingtheFilter

Important:Topreventenginedamage,alwaysoperate

theenginewiththeairlterandcoverinstalled.

1.Gentlyslidethelteroutoftheair-cleanerbody

(Figure43).

Note:Avoidknockingthelterintothesideofthe

body.

Important:Donotattempttocleanthelter.

2.Inspectthenewlterfortears,anoilylm,ordamage

totherubberseal.Lookintothelterwhileshining

abrightlightontheoutsideofthelter;holesinthe

lterappearasbrightspots.

Ifthelterisdamaged,donotuseit.

3.Carefullyinstallthelter(Figure43).

Note:Ensurethatthelterisfullyseatedbypushing

ontheouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

4.Installtheair-cleanercoverwiththedustcaporiented

downwardandsecurethelatches(Figure43).

Figure43

1.Dustcap

2.Latch

3.Air-cleanercover

6.Squeezethedustcapsidestoopenitandknockthe

dustout.

7.Cleantheinsideoftheair-cleanercoverwith

compressedairthatisunder205kPa(30psi).

4.Primarylter

5.Air-lterbody

6.Serviceindicator

5.Closethehood.

g031236

8.Checktheserviceindicator.

30

Page 31

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Checkthe

engine-oillevel.

Aftertherst50hours—Changetheengineoiland

lter.

Every100hours—Changetheengineoil.(Service

morefrequentlyifconditionsareextremelydustyor

sandy.)

Every200hours—Changetheoillter.(Servicemore

frequentlyifconditionsareextremelydustyorsandy.)

OilT ype:Detergentdieselengineoil(APIserviceCH-4or

higher)

CrankcaseCapacity:withlter5.7L(1.5USgallons)

Viscosity:Seethetablebelow .

Figure44

g029940

Figure45

1.Oil-llcap2.Oildipstick

5.Checktheoilandaddadditionaloilasneeded(Figure

46).

Important:Donotoverllthecrankcasewithoil;

iftheoilinthecrankcaseistoohighandyourun

theengine,youmaydamagetheengine.

g001061

CheckingtheEngine-OilLevel

1.Parkthemachineonalevelsurface,engagetheparking

brake,andlowertheloaderarms.

2.Shutofftheengine,removethekey,andallowthe

enginetocool.

3.Openthehoodandsecuretheproprod.

4.Cleantheareaaroundtheoildipstickandoil-llcap

(Figure45).

g029301

Figure46

ChangingtheEngineOil

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsothatitdrainsbetter.

2.Parkthemachineonalevelsurface.

3.Raisetheloaderarmsandsecurewiththecylinder

locks;refertoInstallingtheCylinderLocks(page26).

31

Page 32

4.Engagetheparkingbrake,shutofftheengine,and

removethekey.

5.Draintheoilbeneaththeplatform(Figure47).

ChangingtheOilFilter

1.Raisetheloaderarmsandsecurewiththecylinder

locks;refertoInstallingtheCylinderLocks(page26).

CAUTION

Componentswillbehotifthemachinehas

beenrunning.Ifyoutouchhotcomponents,

youmaybeburned.

Usecaretoavoidtouchinghotcomponents

whilechangingtheoiland/orlter.

2.Engagetheparkingbrake,shutofftheengine,and

removethekey.

3.Removethefrontcover;refertoRemovingtheFront

Cover(page28).

4.Draintheoilfromtheengine;refertoChangingthe

EngineOil(page31).

5.Placeashallowpanorragundertheltertocatchoil.

6.Changetheoillter(Figure48).

g031212

Figure47

6.Removetheoil-llcapandslowlypourapproximately

80%ofthespeciedamountofoilinthroughthe

valvecover.

7.Checktheoillevel.

8.Slowlyaddadditionaloiltobringtheleveltotheupper

holeonthedipstick.

9.Replacethellcap.

g029749

Figure48

g029385

7.Removetheoil-llcapandslowlypourapproximately

80%ofthespeciedamountofoilinthroughthe

valvecover.

8.Checktheoillevel.

9.Slowlyaddadditionaloiltobringtheleveltotheupper

holeonthedipstick.

10.Replacethellcap.

11.Installthefrontcover;refertoRemovingtheFront

Cover(page28).

32

Page 33

FuelSystem

ReplacingtheFuelFilter

Maintenance

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

RefertoAddingFuel(page18)foracompletelistof

fuelrelatedprecautions.

DrainingtheFuel Filter/WaterSeparator

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,engagetheparking

brake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Opentherear-accesscover;refertoOpeningthe

Rear-AccessCover(page27).

4.Locatethefuellterontherearsideoftheengine

(Figure49)andplaceacleancontainerunderit.

CanisterandIn-LineFilter

ServiceInterval:Every400hours

1.Parkthemachineonalevelsurface,engagetheparking

brake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Opentherear-accesscover;refertoOpeningthe

Rear-AccessCover(page27).

4.Locatethefuelltersontherightsideoftheengine

(Figure49)andplaceacleancontainerunderit.

5.Cleantheareawheretheltercanistermounts(Figure

49).

6.Removetheltercanisterandcleanthemounting

surface(Figure49).

7.Lubricatethegasketonthenewltercanisterwith

cleanoil.

8.Fillthecanisterwithfuel.

9.Installtheltercanisterbyhanduntilthegasket

contactsthemountingsurface,thenrotateitan

additional1/2turn(Figure49).

10.Locatethein-lineltertotheleftofthefuellter

canister(Figure49)andnotethedirectionofow

arrowonthesideofthein-linelter.

Figure49

1.Hoseclamp

2.In-linelter

5.Loosenthedrainvalveonthebottomofthelter

canisterandallowthewatertodrain.

6.Whennished,tightenthedrainvalve.

7.Closetherear-accesscoverandsecurewiththefastener.

3.Fuel-ltercanister/water

separator

4.Drainvalve

11.Opentheclampsoneachendofthein-linelterand

slidethehosesoffit(Figure49).Discardthelter.

12.Slidethehosesovertheendofanewlter(Figure49),

ensuringthatthearrowonthelterispointingtoward

theengineorelectricfuelpump.

13.Securethehosestothelterwiththehoseclamps.

g029408

14.Closetherear-accesscoverandsecurewiththefastener.

CheckingtheFuelLines andConnections

ServiceInterval:Every400hours/Y early(whichevercomes

rst)

Inspectthefuellinesandconnectionsfordeterioration,

damage,orlooseconnections.Tightenanylooseconnections

andcontactyourAuthorizedServiceDealerforassistance

inxingdamagedfuellines.

33

Page 34

BleedingtheFuelSystem

ElectricalSystem

Youmustbleedthefuelsystembeforestartingtheengineif

anyofthefollowingsituationshaveoccurred:

•Initialstartupofanewmachine

•Theenginehasceasedrunningduetoalackoffuel.

•Maintenancehasbeenperformeduponfuel-system

components(e.g.,lterreplaced).

1.TurnthekeytotheRUNposition.

2.Letthefuelpumprunfor2minutespriortostarting

themachine.

DrainingtheFuelTanks

ServiceInterval:Every2years

HaveanAuthorizedServiceDealerdrainandcleanthefuel

tanks.

Maintenance

ServicingtheBattery

ServiceInterval:Every50hours

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Important:Beforeweldingonthemachine,disconnect

thenegativecablefromthebattery.

WARNING

Incorrectbatterycableroutingcoulddamagethe

machineandcables,causingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Alwaysdisconnectthenegative(black)cable

beforedisconnectingthepositive(red)cable.

•Alwaysconnectthepositive(red)cablebefore

connectingthenegative(black)cable.

WARNING

Batteryterminalsormetaltoolscouldshortagainst

metalcomponents,causingsparks.Sparkscan

causethebatterygassestoexplode,resultingin

personalinjury.

•Whenremovingorinstallingthebattery,donot

allowthebatteryterminalstotouchanymetal

partsofthetractionunit.

•Donotallowmetaltoolstoshortbetweenthe

batteryterminalsandmetalpartsofthetraction

unit.

34

Page 35

UsingtheBattery-Disconnect

Switch

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

1.Parkthemachineonalevelsurface,engagetheparking

brake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Openthehood,securetheproprod,andremovethe

leftsidescreen.

4.Turnthebattery-disconnectswitchtotheONorOFF

positiontoperformthefollowing:

•Toenergizethemachineelectrically,rotatethe

battery-disconnectswitchclockwisetotheON

position(Figure50).

•Tode-energizethemachineelectrically,rotatethe

battery-disconnectswitchcounterclockwisetothe

OFFposition(Figure50).

g033901

Figure50

1.Battery-disconnect

switch—OFFposition

2.Battery-disconnect

switch—ONposition

3.Jumppost

35

Page 36

RemovingtheBattery

1

2

3

4

G003792

1.Parkthemachineonalevelsurface,engagetheparkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.RemovethebatteryasshowninFigure51.

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged(1.265

specicgravity).Thisisespeciallyimportanttoprevent

batterydamagewhenthetemperatureisbelow0°C

(32°F).

1.Removethebatteryfromthemachine;referto

RemovingtheBattery(page36).

2.Chargethebatteryfor4to8hoursatarateof3to4A

(Figure52).Donotoverchargethebattery.

Figure51

Figure52

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

3.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure52).

g204573

g003792

36

Page 37

CleaningtheBattery

Note:Keeptheterminalsandtheentirebatterycaseclean,

becauseadirtybatterydischargesslowly.

1.Parkthemachineonalevelsurface,engagetheparking

brake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Removethebatteryfromthemachine;Removingthe

Battery(page36).

InstallingtheBattery

InstallthebatteryasshowninFigure53.

4.Washtheentirecasewithasolutionofbakingsoda

andwater.

5.Rinsethebatterywithclearwater.

6.CoatthebatterypostsandcableconnectorswithGrafo

112X(skin-over)grease(ToroPartNo.505-47)or

petroleumjellytopreventcorrosion.

7.Installthebattery;refertoInstallingtheBattery(page

37).

ServicingaReplacementBattery

Theoriginalbatteryismaintenance-freeanddoesnotrequire

service.Forservicingareplacementbattery,refertothe

batterymanufacturer’sinstructions.

g204572

Figure53

37

Page 38

Jump-StartingtheMachine

9.Installthecovertothejumppost.

WARNING

Contactwithhotsurfacesmaycausepersonal

injury.

Keephands,feet,face,clothingandotherbody

partsawaythemuferandotherhotsurfaces.

WARNING

Jump-startingthebatterycanproducegassesthat

canexplode.

Donotsmokenearthebattery,andkeepsparksand

amesawayfrombattery.

1.Openthehood,securetheproprod,andremovethe

leftsidescreen.

2.Removethecoverfromthejumppost(Figure54).

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorashort.Figure55

illustratesthefuseblockandidentiesthefusepositions.

g029409

Figure55

Figure54

1.Jumppost

3.Connectanendofthepositive(+)jumpercabletothe

jumppost(Figure54).

4.Connecttheotherendofthepositive(+)jumpercable

tothepositiveterminalofthebatteryintheother

machine.

5.Connectanendofthenegative(-)jumpercabletothe

negativepostofthebatteryintheothermachine.

1.Fuse(20A)3.Fuse(10A)

2.Fuse(15A)4.Fuse(7.5A)

Note:Ifthemachinedoesnotstart,eitherthemaincircuit

orthecontrolpanel/relayfusecouldbeblown.

Thereisalsoafuse(50A)locatedontherightsideofthe

machine.Raisetheloaderarms,installthecylinderlock,and

removetherightaccesscover.Thefuseislocatedjustinside

theframe.

g033902

6.Connecttheotherendofthenegative(-)jumpercable

toagroundpoint,suchasanunpaintedboltorchassis

member.

7.Starttheengineintheothermachine.Letitrunafew

minutes,thenstartyourengine.

8.Removethecablesinthereverseorderofconnection.

g205353

Figure56

1.Bolt3.Fuselocation

2.Rightaccesscover

38

Page 39

DriveSystem

Maintenance

ServicingtheTracks

ServiceInterval:Aftertherst50hours—Checkandadjust

thetracktension.

Beforeeachuseordaily—Cleanthetracks.

Beforeeachuseordaily—Checkthetracksfor

excessivewearandpropertension.

Every100hours—Checkandadjustthetracktension.

CleaningtheTracks

AdjustingtheTrackTension

Verifythatthetensionblockisalignedwiththegreenguide

onthedecalorthattheblockis1.3cm(1/2inch)awayfrom

therearofthetensiontubeslot(Figure58).Ifitisnot,adjust

thetracktensionusingthefollowingprocedure:

1.Parkthemachineonalevelsurfaceandengagethe

parkingbrake.

2.Withthebucketinstalledandpointingdown,lowerit

intothegroundsothatthefrontofthetractionunit

liftsoffthegroundafewcentimeters(inches).

3.Shutofftheengineandremovethekey.

4.Usingawaterhoseorpressurewasher,removedirt

fromeachtracksystem.

Important:Ensurethatyouusehigh-pressurewaterto

washonlythetrackarea.Donotuseahigh-pressure

washertocleantherestofthetractionunit.Donot

usehighpressurewaterbetweenthedrivesprocket

andthetractionunitoryoumaydamagethemotor

seals.High-pressurewashingcandamagetheelectrical

systemandhydraulicvalvesordepletegrease.

Important:Ensurethatyoufullycleantheroadwheels,

thefrontwheel,andthedrivesprocket(Figure57).The

roadwheelsshouldrotatefreelywhenclean.

g203962

Figure58

1.Greenguideondecal

2.Tensionblock

1.Parkthemachineonalevelsurface,engagetheparking

brake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Removethelockingboltandnut(Figure59).

g029758

Figure59

1.Tensiontube3.Tensioningscrew

2.Lockingbolt

Figure57

1.Track3.Drivesprocket

2.Frontwheel4.Roadwheel

4.Usinga1/2inchdriveratchet,turnthetensioning

screwcounter-clockwiseuntilthetensionblockaligns

withthegreenguideonthedecaloris1.3cm(1/2inch)

g029756

39

awayfromtherearofthetensiontubeslot(Figure58).

5.Aligntheclosestnotchinthetensionscrewtothe

locking-boltholeandsecurethescrewwiththelocking

boltandnut(Figure59).

6.Repeattheprocedurefortheothertrack.

Page 40

ReplacingNarrow-WidthTracks

Replacethetrackswhentheyarebadlyworn.

Note:Youhavenarrow-widthtracksifthetracksareless

than15.5cm(6inches)wide.

1.Parkthemachineonalevelsurface,engagetheparking

brake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Lift/supportthesideofthemachinethatyouwillwork

onsothatthetrackis7.6to10cm(3to4inches)off

theground.

4.Removethelockingboltandnut(Figure59).

5.Usinga1/2-inchdriveratchet,releasethedrivetension

byturningthetensioningscrewclockwise(Figure59

andFigure60).

12.Usinga1/2inchdriveratchet,turnthetensioning

screwcounter-clockwiseuntilthetensioningscrew

bottomsout(Figure61).

g203963

Figure61

1.Tensionnut2.T ensionscrew

13.Aligntheclosestnotchinthetensionscrewtothe

lockingboltholeandsecurethescrewwiththelocking

boltandnut.

Figure60

1.Drivesprocket5.Roadwheel

2.Track6.Pivottensioner

3.Frontwheel

4.Rearbolt

7.Ratchet(1/2inch)

6.Loosentherearbolt,nearthedrivewheel(Figure60).

Note:Thisenablesthedrivewheeltopivotforward

andreleasethetensionofthetrack.Ifitdoesnot

pivot,turnontheengineandbrieymovethetraction

controlforward.

7.Removethetrackatthetopofthefrontwheel,peeling

itoffthewheelwhilerotatingthetrackforward.

8.Whenthetrackisoffthefrontwheel,removeitfrom

thedrivesprocketandroadwheels(Figure60).

9.Beginningatthedrivesprocket,coilthenewtrack

aroundthesprocket,ensuringthatthelugsonthetrack

tbetweenthespacersonthesprocket(Figure60).

10.Pushthetrackunderandbetweentheroadwheels

(Figure60).

11.Startingatthebottomofthefrontwheel,installthe

trackaroundthewheelbyrotatingthetrackrearward

whilepushingthelugsintothewheel.

14.Torquetherearboltto108to122N∙m(80to90ft-lb).

15.Lowerthemachinetotheground.

16.Repeattheproceduretoreplacetheothertrack.

17.Drivethemachine,thenparkthemachineonalevel

surface,engagetheparkingbrake,shutofftheengine,

andremovethekey.

g029759

18.Verifythatthetensionscrewisbottomedout.

Note:Thetracktensionloosensaftersomeuse.

19.Adjustthetracktensionsothatthetensionblockaligns

withthegreenguideonthedecaloris1.3cm(1/2

inch)awayfromtherearofthetensiontubeslot;refer

toAdjustingtheTrackTension(page39).

40

Page 41

ReplacingWide-WidthTracks

Replacethetrackswhentheyarebadlyworn.

Note:Youhavewide-widthtracksifthetracksaremore

than23cm(9inches)wide.

1.Parkthemachineonalevelsurface,engagetheparking

brake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Lift/supportthesideoftheunittobeworkedonso

thatthetrackis7.6to10cm(3to4inches)offthe

ground.

4.Removethelockingboltandnut(Figure59).

5.Usinga1/2-inchdriveratchet,releasethedrivetension

byturningthetensioningscrewclockwise(Figure59

andFigure60).

14.Torquethenutto300ft-lb(407N∙m).

15.Turnthetensioningscrewcounter-clockwiseuntilthe

tensioningscrewbottomsout.

16.Aligntheclosestnotchinthetensionscrewtothe

lockingboltholeandsecurethescrewwiththelocking

boltandnut.

17.Torquetherearboltto108to122N∙m(80to90ft-lb).

18.Lowerthemachinetotheground.

19.Repeattheproceduretoreplacetheothertrack.

20.Drivethemachine,thenparkthemachineonalevel

surface,engagetheparkingbrake,shutofftheengine,

andremovethekey.

21.Verifythatthetensionscrewisbottomedout(Figure

61).

6.Loosentherearbolt,nearthedrivewheel(Figure60).

7.Removethenutsecuringtheouterfrontwheeland

removethewheel(Figure62).

Figure62

1.Nut

2.Washer4.Track

3.Outerfrontwheel

Note:Thetracktensionloosensaftersomeuse.

22.Adjustthetracktensionsothatthetensionblockaligns

withthegreenguideonthedecaloris1.3cm(1/2

inch)awayfromtherearofthetensiontubeslot;refer

toAdjustingtheTrackTension(page39).

g029760

8.Removethetrack(Figure62).

9.Pullthe2largewashersoutoftheouterwheels,1on

eachsideofeachwheel(Figure62).

10.Cleantheoldgreaseanddirtoutoftheareabetween

wherethewasherswereinstalledandthebearings