Page 1

FormNo.3420-641RevA

TX525CompactToolCarrier

ModelNo.22323—SerialNo.401800000andUp

ModelNo.22323G—SerialNo.401800000andUp

ModelNo.22324—SerialNo.401800000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3420-641*A

Page 2

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemical

orchemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

Introduction

Thismachineisacompacttoolcarrierintendedfor

useinvariousearthandmaterialsmovingactivitiesfor

landscapingandconstructionwork.Itisdesignedto

operateawidevarietyofattachmentseachofwhich

performaspecializedfunction.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

YoumaycontactTorodirectlyatwww.Toro.com

forproductsafetyandoperationtrainingmaterials,

accessoryinformation,helpndingadealer,orto

registeryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

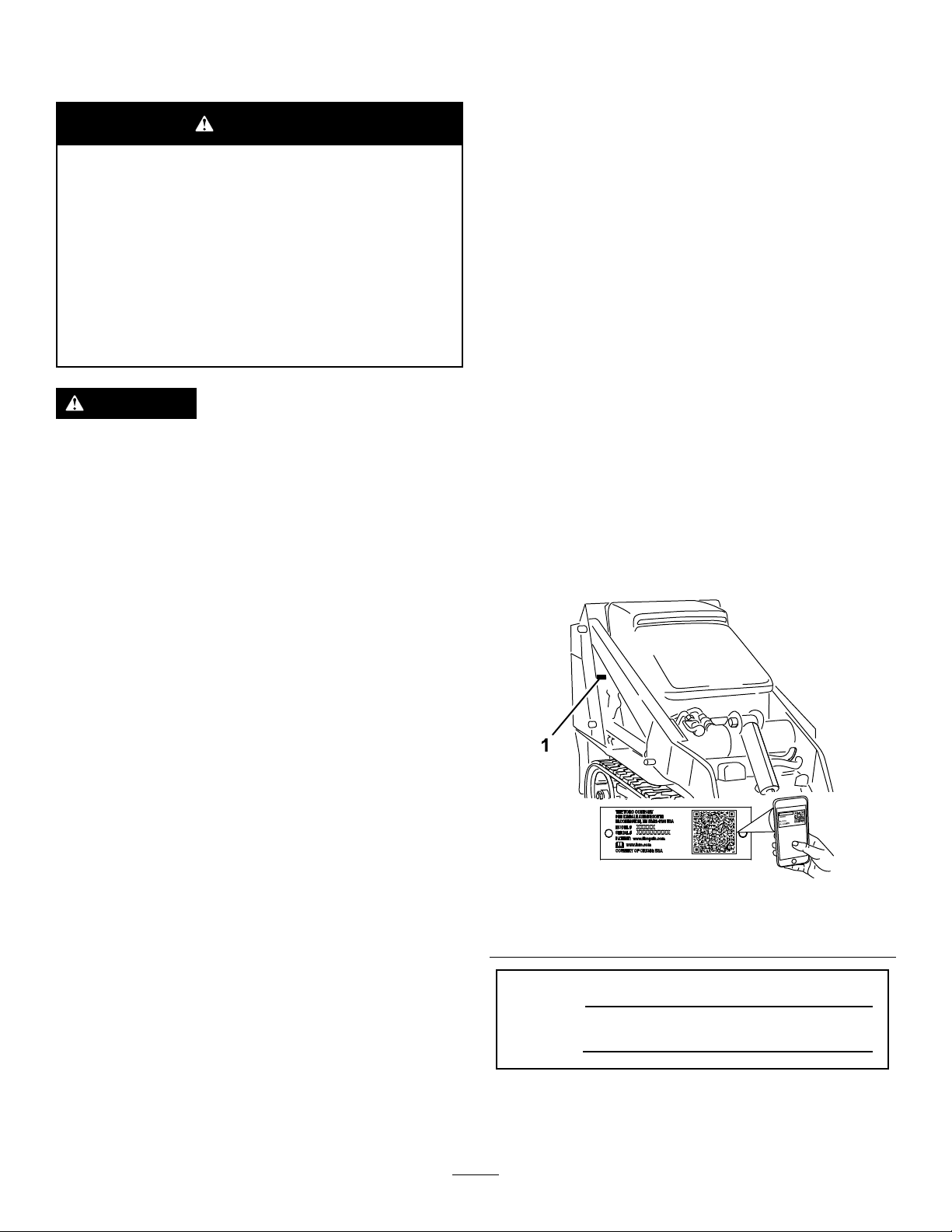

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

ItisaviolationofCaliforniaPublicResourceCode

Section4442or4443touseoroperatetheengineon

anyforest-covered,brush-covered,orgrass-covered

landunlesstheengineisequippedwithaspark

arrester,asdenedinSection4442,maintainedin

effectiveworkingorderortheengineisconstructed,

equipped,andmaintainedforthepreventionofre.

Theenclosedengineowner'smanualissupplied

forinformationregardingtheUSEnvironmental

ProtectionAgency(EPA)andtheCaliforniaEmission

ControlRegulationofemissionsystems,maintenance,

andwarranty.Replacementsmaybeorderedthrough

theenginemanufacturer.

g243442

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

©2018—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................5

ProductOverview.....................................................9

Controls.............................................................9

Specications..................................................13

Attachments/Accessories.................................13

BeforeOperation.................................................13

BeforeOperationSafety...................................13

AddingFuel......................................................14

PerformingDailyMaintenance..........................14

DuringOperation.................................................15

DuringOperationSafety...................................15

StartingtheEngine...........................................16

DrivingtheMachine..........................................16

ShuttingOfftheEngine.....................................16

UsingAttachments...........................................17

AfterOperation....................................................18

AfterOperationSafety......................................18

MovingaNon-FunctioningMachine..................18

TransportingtheMachine.................................19

LiftingtheMachine...........................................20

Maintenance...........................................................21

RecommendedMaintenanceSchedule(s)...........21

Pre-MaintenanceProcedures..............................22

MaintenanceSafety..........................................22

UsingtheCylinderLock....................................22

AccessingInternalComponents.......................23

Lubrication..........................................................25

GreasingtheMachine.......................................25

EngineMaintenance...........................................25

EngineSafety...................................................25

ServicingtheAirCleaner..................................25

ServicingtheEngineOil....................................26

FuelSystemMaintenance...................................28

CheckingtheFuelLinesand

Connections..................................................28

DrainingtheFuelFilter/WaterSeparator...........28

ReplacingtheFuelFilterCanisterand

In-LineFilter..................................................29

BleedingtheFuelSystem.................................29

DrainingtheFuelT ank(s)..................................30

ElectricalSystemMaintenance...........................30

ElectricalSystemSafety...................................30

ServicingtheBattery.........................................31

g000502

ServicingtheFuses..........................................33

DriveSystemMaintenance..................................34

ServicingtheTracks.........................................34

CoolingSystemMaintenance..............................37

CoolingSystemSafety.....................................37

ServicingtheCoolingSystem...........................37

BrakeMaintenance.............................................39

TestingtheParkingBrake.................................39

BeltMaintenance................................................39

CheckingtheConditionoftheHydraulic

PumpBelt.....................................................39

ControlsSystemMaintenance.............................40

AdjustingtheControls.......................................40

HydraulicSystemMaintenance...........................42

HydraulicSystemSafety...................................42

HydraulicFluidSpecications...........................42

CheckingtheHydraulic-FluidLevel...................42

ReplacingtheHydraulicFilter...........................43

ChangingtheHydraulicFluid............................44

Cleaning..............................................................45

RemovingDebris..............................................45

CleaningtheChassis........................................45

Storage...................................................................45

StorageSafety..................................................45

Storage.............................................................45

Troubleshooting......................................................46

Schematics.............................................................50

3

Page 4

Safety

GeneralSafety

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.Usingthisproductforpurposesother

thanitsintendedusecouldprovedangeroustoyou

andbystanders.

•Donotcarryaloadwiththearmsraised;always

carryloadsclosetotheground.

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphillandtheload

closetotheground.Weightdistributionchanges

withattachments.Anemptybucketmakesthe

rearofthemachinetheheavyend,andafull

bucketmakesthefrontofthemachinetheheavy

end.Mostotherattachmentsmakethefrontofthe

machinetheheavyend.

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingtheengine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandpetsasafedistanceaway

fromthemachine.

•Stopthemachine,shutofftheengine,andremove

thekeybeforeservicing,fueling,orunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalwayspay

attentiontothesafety-alertsymbol,whichmeans

Caution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

Youcanndadditionalsafetyinformationwhere

neededthroughoutthismanual.

4

Page 5

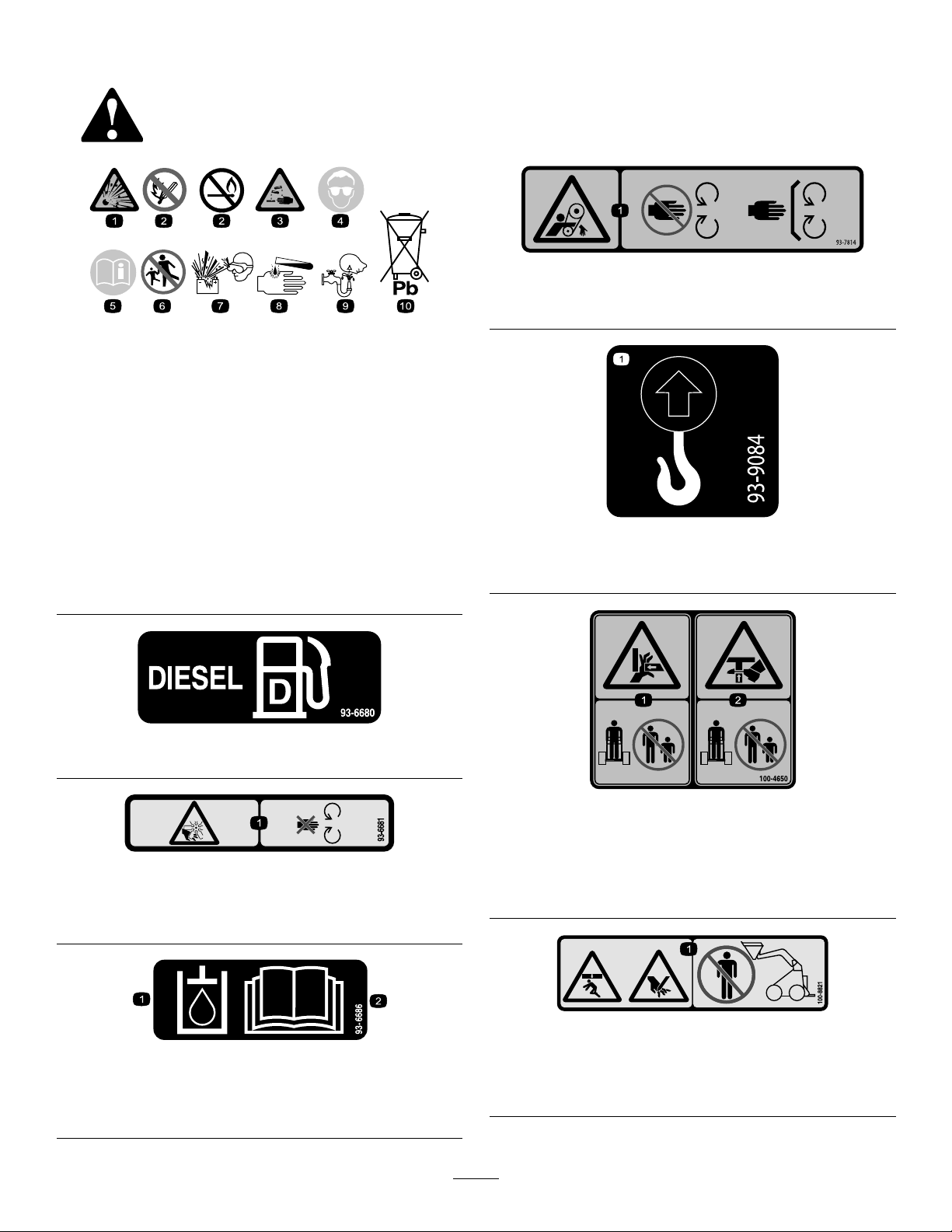

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

decal93-7814

93-7814

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard

93-6680

decalbatterysymbols

1.Entanglementhazard,belt—stayawayfrommovingparts.

decal93-9084

93-9084

1.Liftpoint/Tie-downpoint

decal93-6680

93-6681

1.Cutting/dismembermenthazard,fan—stayawayfrom

movingparts.

93-6686

1.Hydraulicuid

2.ReadtheOperator'sManual.

decal100-4650

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

decal93-6681

awayfromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

awayfromthemachine.

decal100-8821

decal93-6686

100-8821

1.Crushinghazardandcuttinghazardofhand—stayasafe

distanceawayfromthefrontofthetractionunitwhenthe

loaderarmsareraised.

5

Page 6

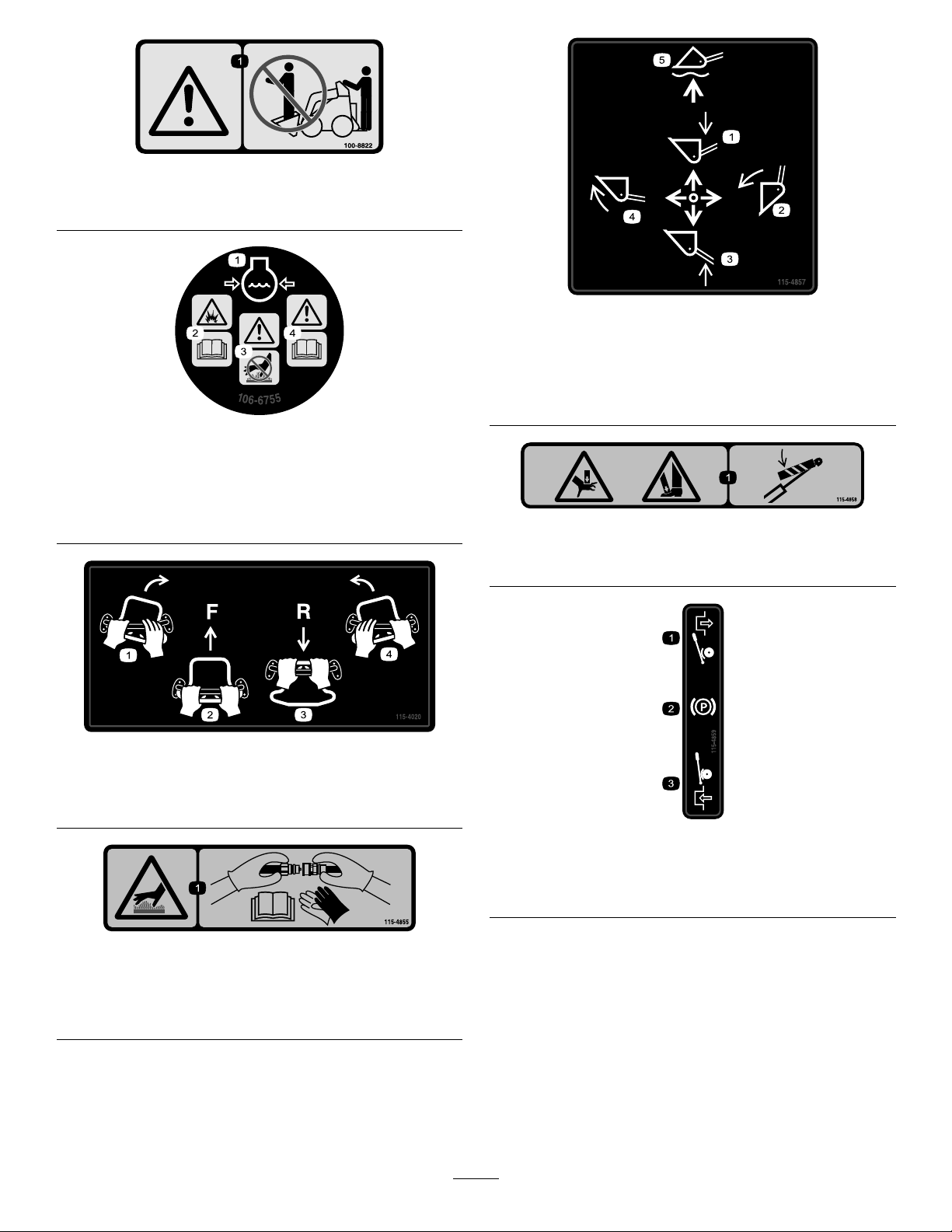

1.Warning—donotcarrypassengers.

decal100-8822

100-8822

decal115-4857

115-4857

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

115-4020

1.Turnright3.Reverse

2.Forward

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

4.Turnleft

1.Lowertheloaderarms.

4.Curlthebucket.

2.Dumpthebucket.5.Floatthebucketonthe

ground.

3.Raisetheloaderarms.

decal106-6755

decal115-4858

115-4858

1.Crushinghazardofhandsorfeet—installthecylinderlock.

decal115-4020

decal115-4859

115-4859

115-4855

1.Hotsurface/burnhazard—wearprotectivegloveswhen

handlingthehydrauliccouplersandreadtheOperator's

Manualforinformationonhandlinghydrauliccomponents.

1.Disengaged3.Engaged

2.Parkingbrake

decal115-4855

6

Page 7

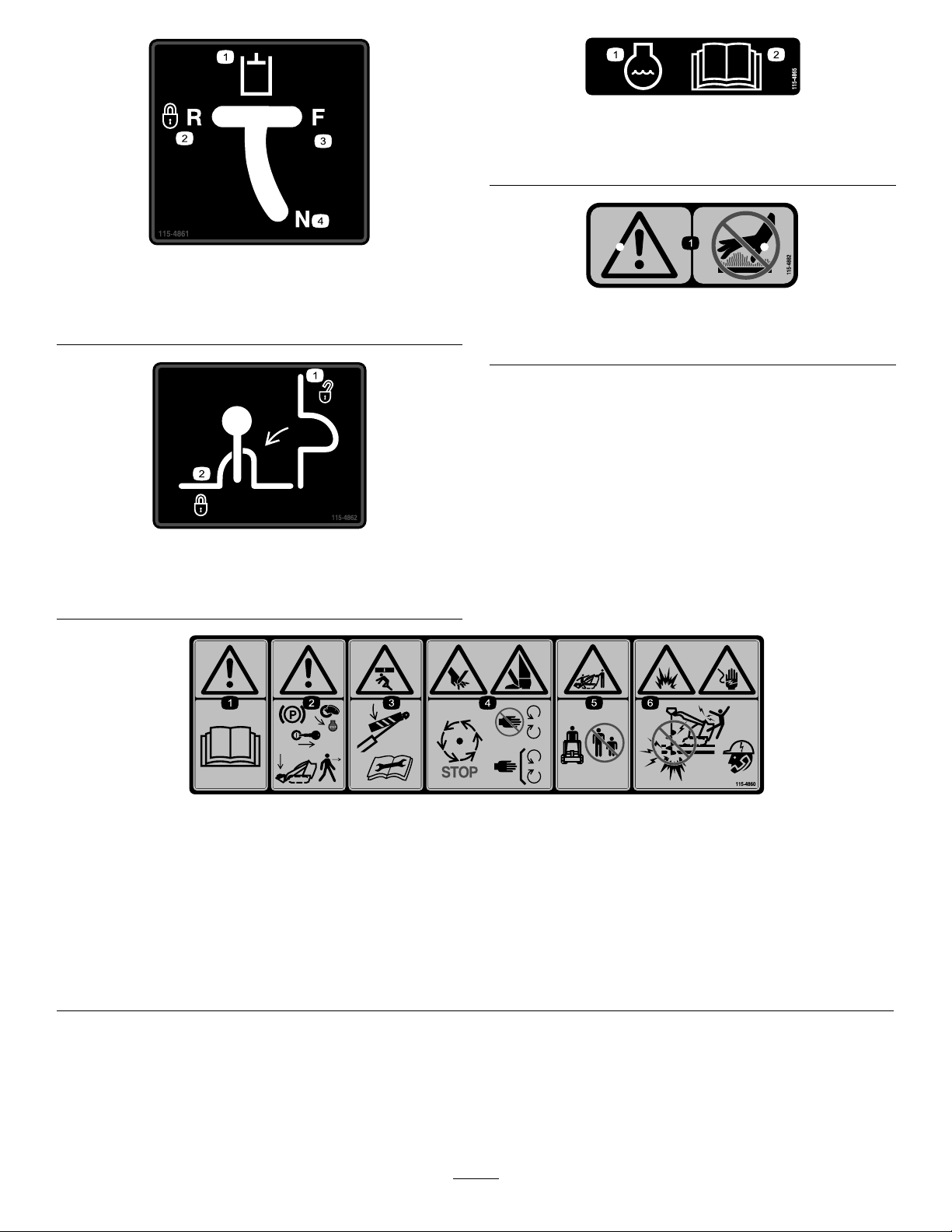

decal115-4865

115-4865

115-4861

1.Auxiliaryhydraulics3.Forward

2.Lockedreverse(detent)4.Neutral(off)

115-4862

1.Loader-valve

lock—unlocked

2.Loader-valvelock—locked

1.Enginecoolant

2.ReadtheOperator's

Manual.

decal115-4861

decal115-4882

115-4882

1.Warning—stayasafedistanceawayfromthehotsurfaces.

decal115-4862

115-4860

1.Warning—readtheOperator'sManual.

2.Warning—settheparkingbrake,shutofftheengine,removetheignitionkeyandlowertheloaderarmsbeforeleavingthemachine.

3.Crushinghazard—installthecylinderlockandreadtheinstructionsbeforeservicingorperformingmaintenance.

4.Cuttinghazardofhandsorfeet—waitforallmovingpartstostop;stayawayfrommovingparts;keepallguardsandshieldsin

place.

5.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistanceawayfromthemachine.

6.Explosionandelectricshockhazard—donotdiginareaswithburiedgasorelectricallines;contactlocalpowerorganizations

beforedigging.

7

decal115-4860

Page 8

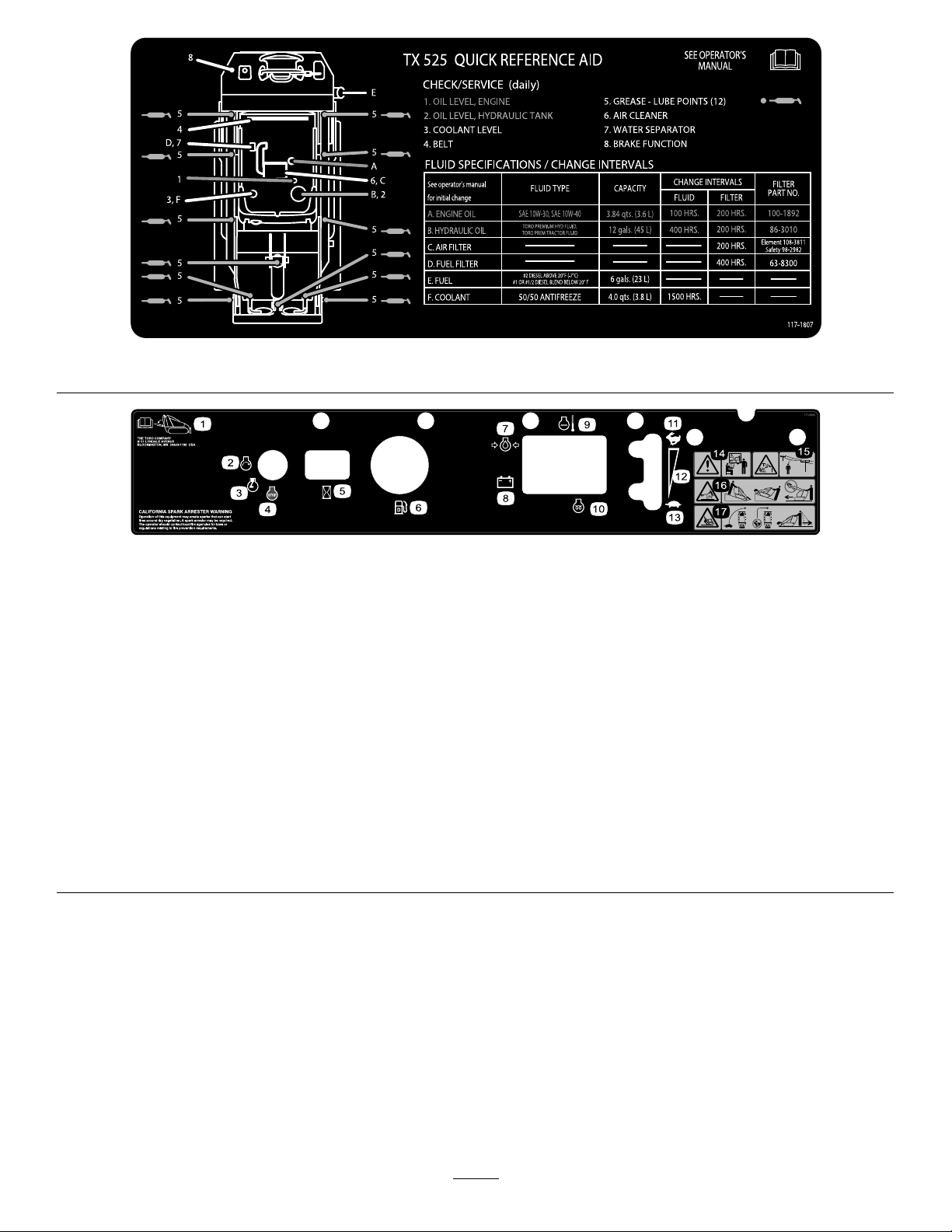

decal117-1807

117-1807

decal117-9905

117-9905

1.Operator'sManuallocation

2.Engine—start7.Engineoilpressure

3.Engine—run8.Battery

6.Fuelgauge—diesel1 1.Fast16.Tippinghazard—movethe

12.Continuousvariablesetting

13.Slow

4.Engine—stop9.Enginetemperature14.Warning—donotoperate

thismachineunlessyou

aretrained.

5.Hourmeter

10.Glowplug

15.Electricshockhazard,

overheadpowerlines—stay

awayfromoverheadpower

lines.

tractionunitwiththeheavy

enduphill;carryloadslow;

neverjerkthecontrols;use

asteady,evenmotion.

17.Tippinghazard—slowthe

tractionunitwhenturning,

donottravelfastwhen

turning,lookbehindand

downwhenreversing.

8

Page 9

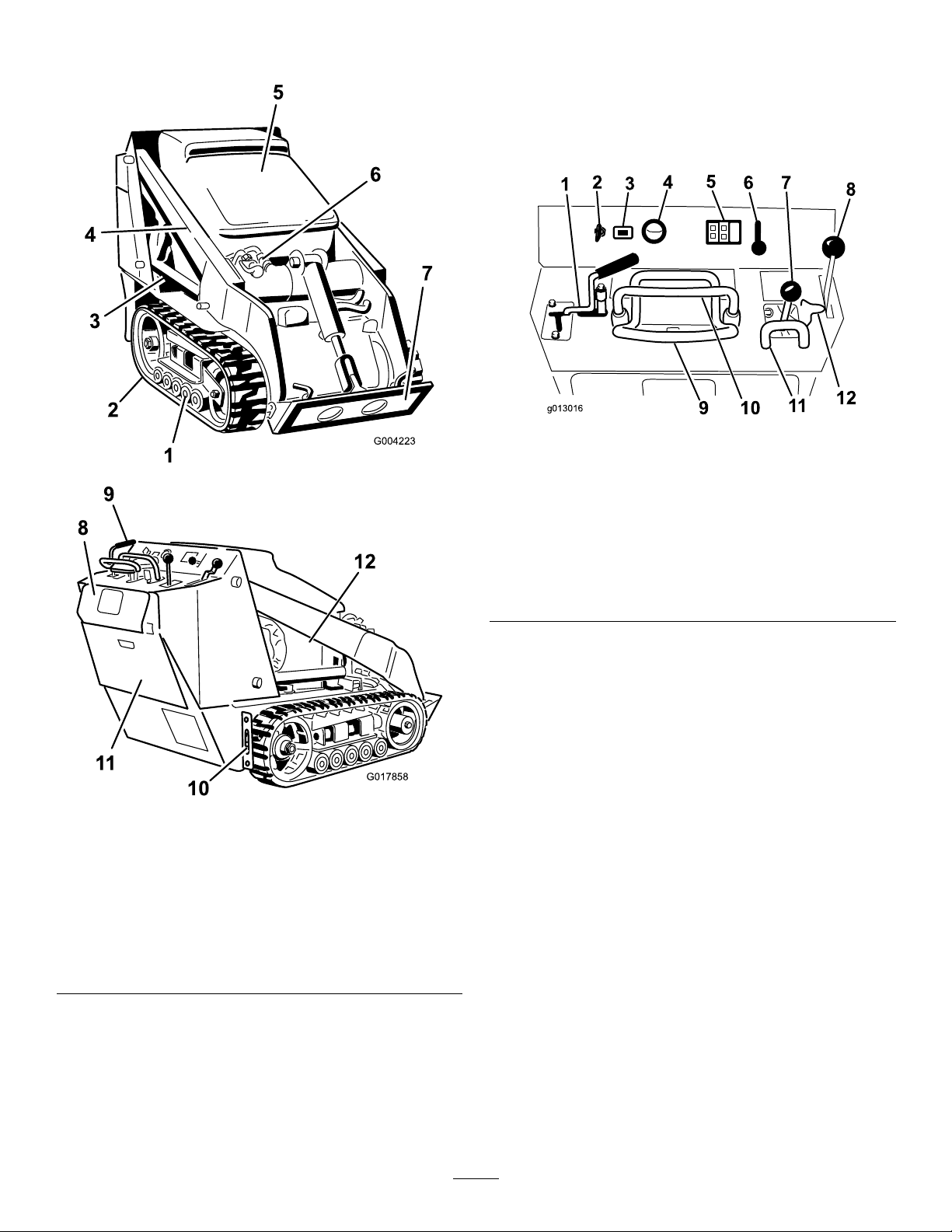

ProductOverview

Controls

Becomefamiliarwithallthecontrols(Figure4)before

youstarttheengineandoperatethetractionunit.

ControlPanel

g013016

Figure4

Figure3

1.Roadwheels7.Mountplate

2.Track

3.Liftcylinder9.Controlpanel

4.Loaderarms

5.Hood11.Rear-accesscover

6.Auxiliaryhydraulic

couplers

8.Reverse-safetyplate

10.Tie-down/liftloop

12.Sidepanelscreen

g004223

1.Auxiliaryhydraulicslever

2.Keyswitch8.Parking-brakelever

3.Hourmeter9.Tractioncontrol

4.Fuelgauge

5.Indicatorlightsand

glow-plugswitch

6.Throttlelever12.Loader-valvelock

7.Loader-arm/attachment-tilt

lever

10.Referencebar

11.Loader-control-reference

bar

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,

has3positions:OFF,RUN,andST ART.Referto

StartingtheEngine(page16).

g017858

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeed

andrearwardtodecreasespeed.

ReferenceBar

Whendrivingthetractionunit,usethereferencebar

asahandleandaleveragepointforcontrollingthe

tractioncontrolandtheauxiliary-hydraulicslever.T o

ensuresmooth,controlledoperation,donottake

bothhandsoffthereferencebarwhileoperatingthe

machine.

9

Page 10

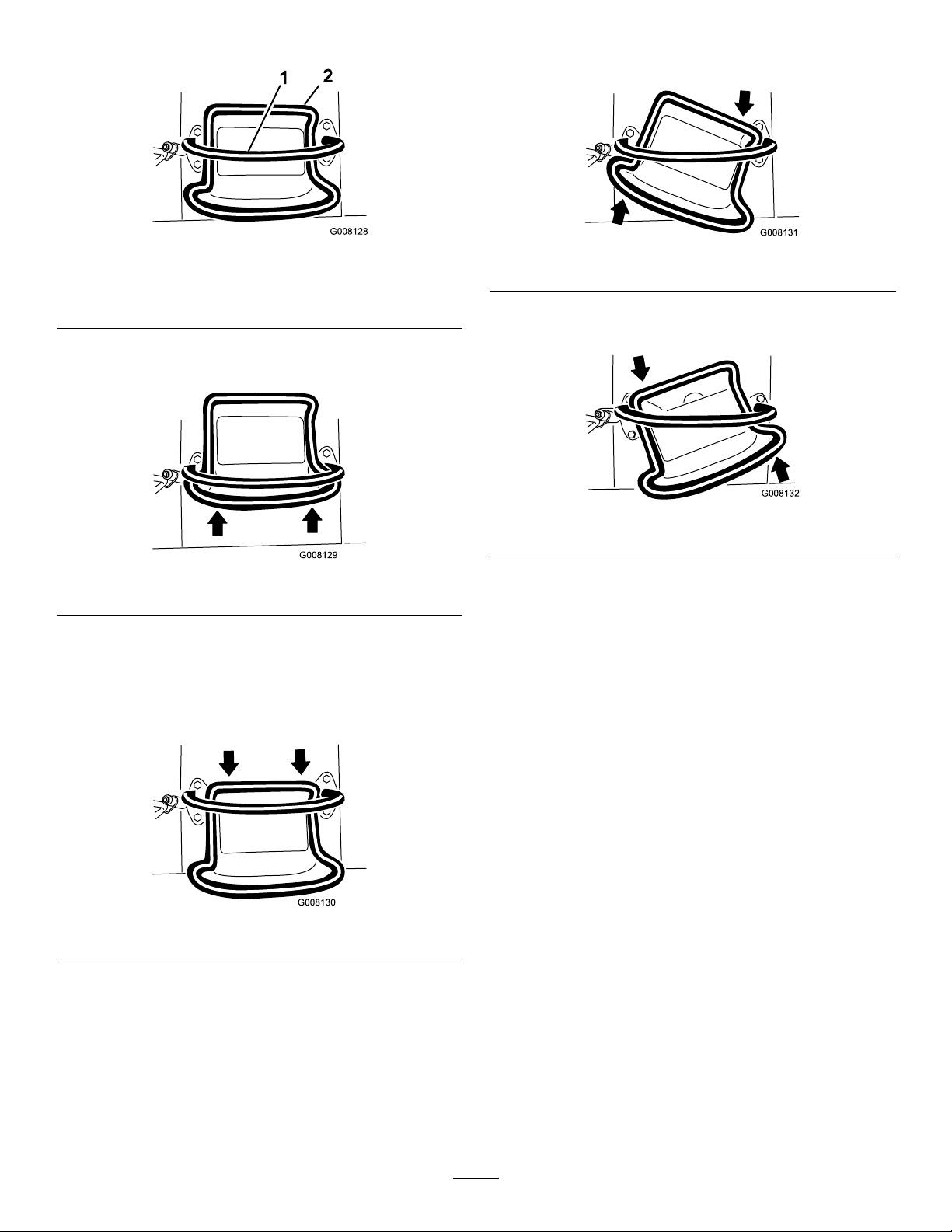

TractionControl

•Toturnright,rotatethetractioncontrolclockwise

(Figure8).

Figure5

1.Referencebar

2.Tractioncontrol

•Tomoveforward,movethetractioncontrolforward

(Figure6).

Figure6

•Tomoverearward,movethetractioncontrol

rearward(Figure7).

Important:Whenreversing,lookbehindyou

forobstructionsandkeepyourhandsonthe

referencebar.

g008128

Figure8

g008131

•Toturnleft,rotatethetractioncontrol

counterclockwise(Figure9).

g008132

Figure9

g008129

•Tostopthemachine,releasethetractioncontrol

(Figure5).

Note:Thefartheryoumovethetractioncontrolin

anydirection,thefasterthemachinemovesinthat

direction.

Figure7

g008130

10

Page 11

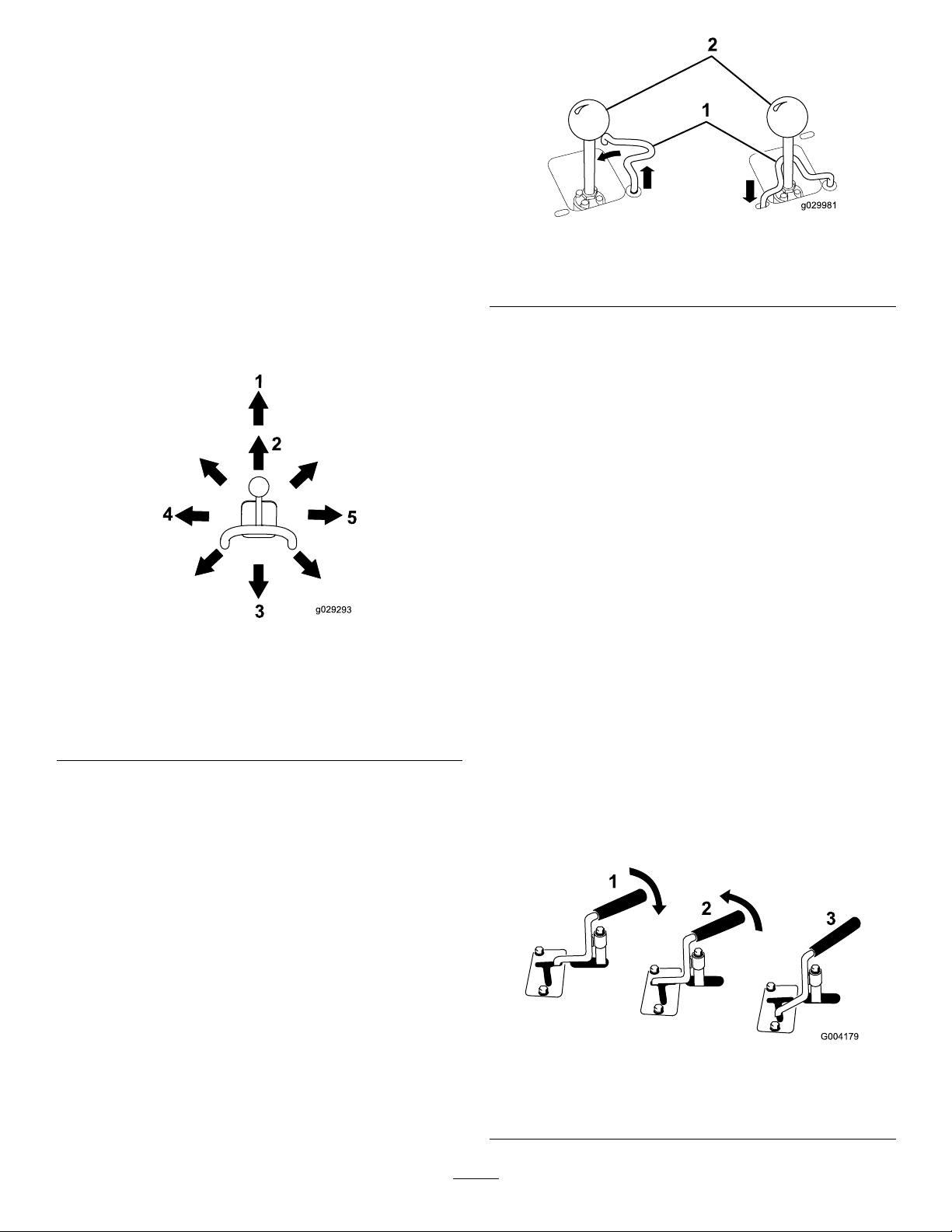

LoaderArm/Attachment-TiltLever

•Totilttheattachmentforward,slowlymovethe

levertotheright(Figure10).

•Totilttheattachmentrearward,slowlymovethe

levertotheleft(Figure10).

•Tolowertheloaderarms,slowlymovethelever

forward(Figure10).

•Toraisetheloaderarms,slowlymovethelever

rearward(Figure10).

•Tolowertheloaderarmstoadetent(oat)

position,pushtheleverfullyforward(Figure10).

Note:Thisallowsattachmentssuchastheleveler

andthehydraulicbladetofollowthecontoursof

theground(i.e.,oat)whengrading.

Figure10

1.Detent(oat)position

2.Lowertheloaderarms.5.Tilttheattachment

3.Raisetheloaderarms.

4.Tilttheattachment

rearward.

forward.

g029981

Figure11

1.Loaderarm/attachment-tilt

lever

2.Loader-valvelock

Loader-Control-ReferenceBar

Theloader-control-referencebarhelpsstabilizeyour

handwhileoperatingtheloaderarm/attachment-tilt

lever(Figure3).

HourMeter

Thehourmeterdisplaysthenumberofhoursof

operationthathavebeenloggedonthemachine.

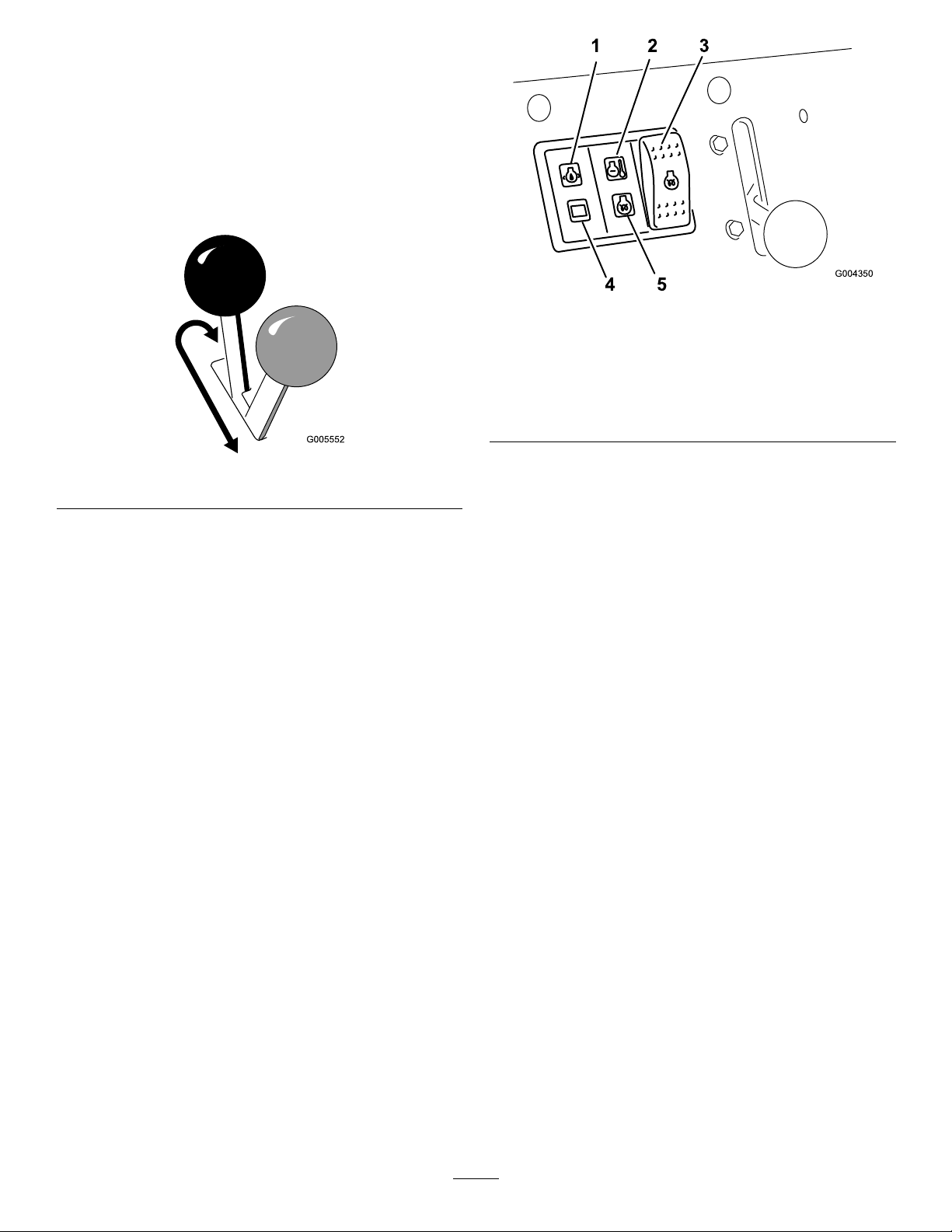

Auxiliary-HydraulicsLever

•Tooperateahydraulicattachmentintheforward

g029293

direction,rotatetheauxiliary-hydraulicslever

rearwardandpullitdowntothereferencebar

(Figure12,number1).

•Tooperateahydraulicattachmentinthereverse

direction,rotatetheauxiliary-hydraulicslever

rearward,thenmoveitleftintotheupperslot

(Figure12,number2).

Bymovingthelevertoanintermediateposition(e.g.,

forwardandleft),youcanmovetheloaderarmsand

tilttheattachmentatthesametime.

Loader-ValveLock

Theloader-valvelocksecurestheloader

arm/attachment-tiltleversothatyoucannotpushit

forward.Thishelpstoensurethatnooneaccidentally

lowerstheloaderarmsduringmaintenance.Secure

theloaderarmswiththelockanytimeyouneedto

shutoffthemachinewiththeloaderarmsraised.

Tosetthelock,liftuponitsothatitclearstheholein

thecontrolpanelandswingittotheleft,infrontof

theloader-armlever,pushingitdownintothelocked

position(Figure11).

Note:IfyoureleasetheleverwhileintheFORWARD

position,theleverautomaticallyreturnstothe

NEUTRALposition(Figure12,number3).Ifitisinthe

REVERSEposition,itremainsthereuntilyoupullitout

oftheslot.

Figure12

1.Forward-owhydraulics

2.Reverse-owhydraulics

11

3.Neutral

g004179

Page 12

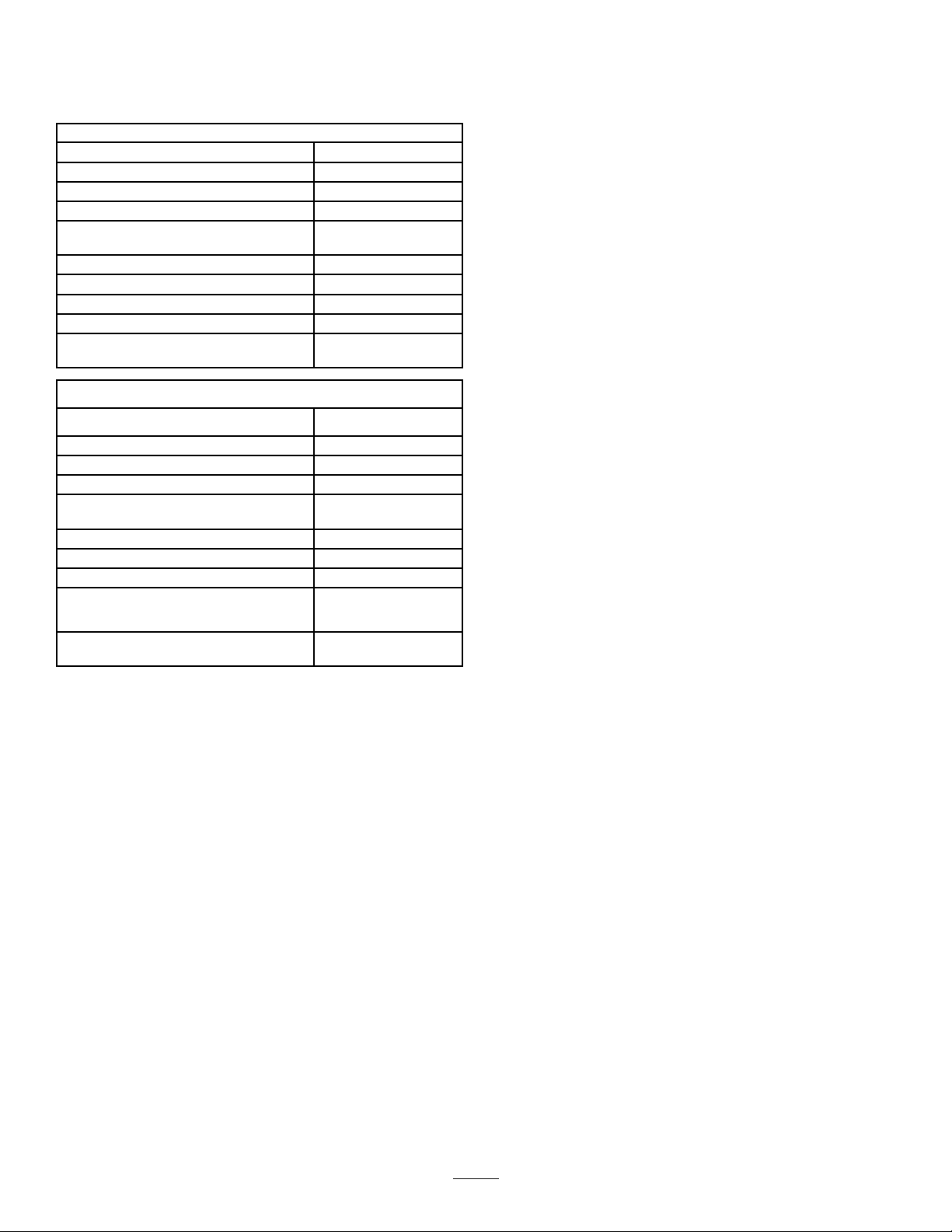

Parking-BrakeLever

•Toengagetheparkingbrake,pushthelever

forwardandtotheleftandthenpullitrearward

(Figure13).

Note:Thetractionunitmayrollslightlybeforethe

brakesengageinthedrivesprocket.

•Toreleasethebrake,pushtheleverforwardand

thenright,intothenotch(Figure13).

g004350

Figure14

Figure13

FuelGauge

Thisgaugemeasurestheamountoffuelinthefuel

tank(s).

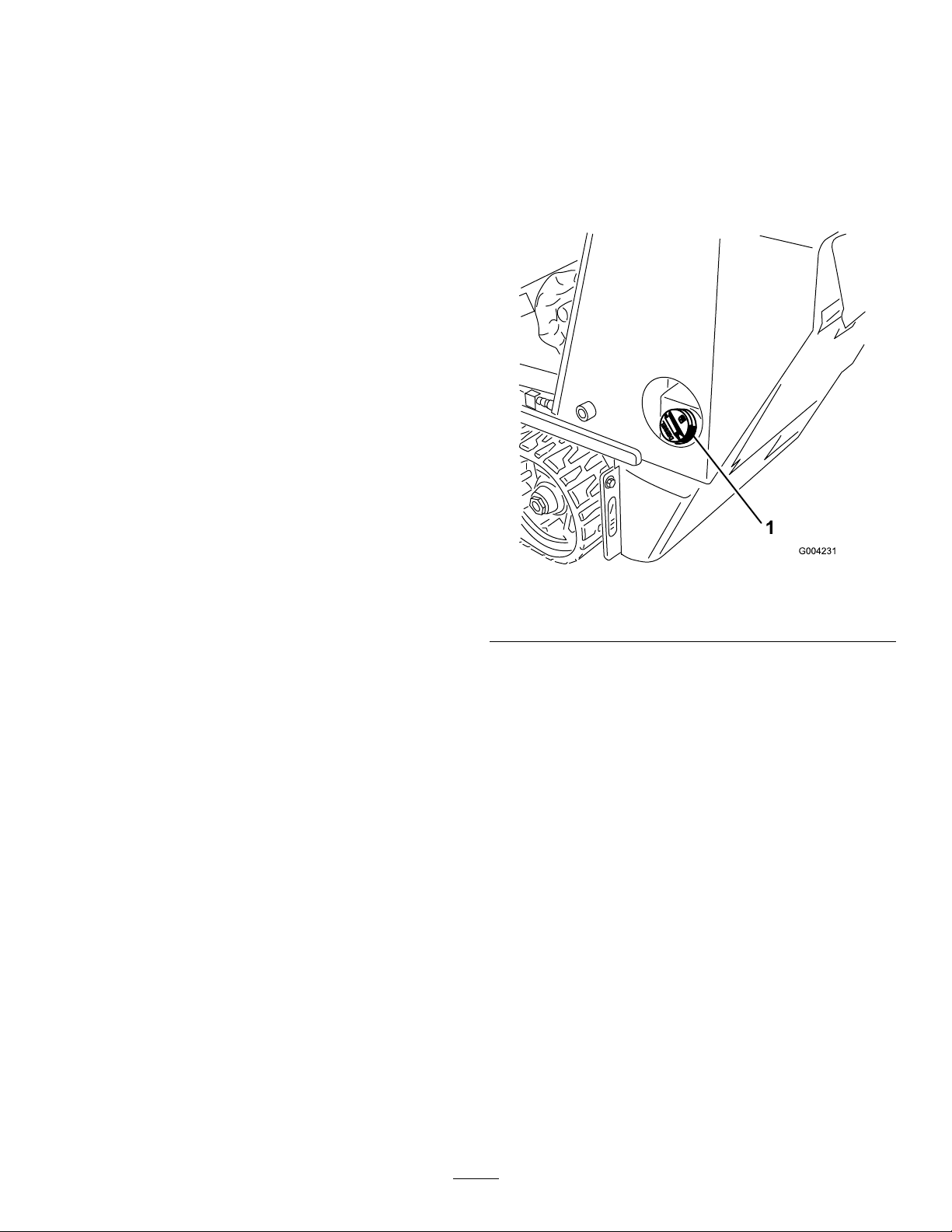

Engine-OilPressureLight

Iftheengine-oilpressuregetstoolow,thislight

illuminatesandanaudiblealarmsounds.Ifthis

happens,shutofftheengineimmediatelyandcheck

theoillevel.Ifitislow,addoilandlookforpossible

leaks.

1.Engine-oilpressurelight4.Battery-chargeindicator

2.Engine-coolant

temperaturelight

3.Glow-plugswitch

g005552

light

5.Glow-pluglight

Battery-ChargeIndicatorLight

Ifthebatterychargebecomestoolow,thislight

illuminatesandanaudiblealarmsounds.Ifthis

happens,shutofftheengineandchargeorreplace

thebattery.Checkthetensionofthealternatorbelt;

refertoyourengineowner’smanual.

Engine-CoolantTemperatureLight

Iftheenginecoolantgetstoohot,thislightilluminates

andanaudiblealarmsounds.Ifthishappens,shutoff

theengineandallowthetractionunittocool.Check

thecoolantlevelwhentheenginehasfullycooled.

Glow-PlugLight

Thislightilluminateswhiletheglowplugsarecharged

andwarmingtheengine.

Glow-PlugSwitch

Pressandholdthisswitchfor10secondstoactivate

theglowplugsbeforestartingtheengine.

12

Page 13

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Model22323

Width

Length

Height

Weight

Operatingcapacity(withstandard

bucket)

Tippingcapacity(withstandardbucket)717kg(1,580lb)

Wheelbase

Dumpheight(withnarrowbucket)119cm(47inches)

Reach—fullyraised(withnarrowbucket)55cm(22inches)

Heighttohingepin(narrowbucketin

highestposition)

Model22324

Width

Length

Height

Weight

Operatingcapacity(withstandard

bucket)

Tippingcapacity(withstandardbucket)717kg(1,580lb)

Wheelbase

Dumpheight(withnarrowbucket)119cm(47inches)

Reach—fullyraised(withnarrowbucket)55cm(22inches)

Heighttohingepin(narrowbucketin

highestposition)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachineto

enhanceandexpanditscapabilities.Contactyour

AuthorizedServiceDealerorDistributororgoto

www.T oro.comforalistofallapprovedattachments

andaccessories.

Important:UseonlyToroapprovedattachments.

Otherattachmentsmaycreateanunsafeoperating

environmentordamagethetractionunit.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineT oro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

86cm(34inches)

180cm(71inches)

117cm(46inches)

864kg(1,904lb)

251kg(553lb)

79cm(31inches)

168cm(66inches)

104cm(41inches)

180cm(71inches)

109cm(43inches)

913kg(2,013lb)

251kg(553lb)

79cm(31inches)

168cm(66inches)

Operation

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageorrequirecertiedtrainingof

theoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetydecals.

•Knowhowtostopthemachineandshutoffthe

enginequickly.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperatethemachineunlessthey

arefunctioningproperly.

•Locatethepinch-pointareasmarkedonthe

machineandattachments;keepyourhandsand

feetawayfromtheseareas.

•Beforeoperatingthemachinewithanattachment,

ensurethattheattachmentisproperlyinstalled

andthatitisagenuineT oroattachment.Readall

theattachmentmanuals.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsyouneedtoproperlyandsafely

performthejob.

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas;notethelocationofunmarkedobjectsand

structures,suchasundergroundstoragetanks,

wells,andsepticsystems.

•Inspecttheareawhereyouwillusetheequipment

andremovealldebris.

•Ensurethattheareaisclearofbystandersbefore

operatingthemachine.Stopthemachineif

anyoneentersthearea.

FuelSafety

•Useextracarewhenhandlingfuel.Itisammable

anditsvaporsareexplosive.

•Extinguishallcigarettes,cigars,pipes,andother

sourcesofignition.

•Useonlyanapprovedfuelcontainer.

•Donotremovethefuelcaporllthefueltank

whiletheengineisrunningorhot.

13

Page 14

•Donotaddordrainfuelinanenclosedspace.

•Donotstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheaterorotherappliance.

•Ifyouspillfuel,donotattempttostarttheengine;

avoidcreatinganysourceofignitionuntilthefuel

vaporshavedissipated.

AddingFuel

RecommendedFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswith

low(<500ppm)orultralow(<15ppm)sulfurcontent.

Theminimumcetaneratingshouldbe40.Purchase

fuelinquantitiesthatyoucanusewithin180daysto

ensurefuelfreshness.

Usesummer-gradedieselfuel(No.2-D)at

temperaturesabove-7°C(20°F)andwintergrade

(No.1-DorNo.1-D/2-Dblend)belowthat

temperature.Usingwinter-gradefuelatlower

temperaturesprovideslowerashpointandcoldow

characteristics,whicheasesstartingandreducesfuel

lterplugging.

FillingtheFuelTank(s)

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Cleanaroundthefuel-tankcapandremoveit

(Figure15).

Usingsummer-gradefuelabove-7°C(20°F)

contributestowardlongerfuelpumplifeandincreased

powercomparedtowinter-gradefuel.

Important:Donotusekeroseneorgasoline

insteadofdieselfuel.Failuretoobservethis

cautionwilldamagetheengine.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuel

ofuptoB20(20%biodiesel,80%petrodiesel).The

petrodieselportionshouldbeloworultralowsulfur.

Observethefollowingprecautions:

•Thebiodieselportionofthefuelmustmeet

specicationASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTM

D975orEN590.

•Paintedsurfacesmaybedamagedbybiodiesel

blends.

•UseB5(biodieselcontentof5%)orlesserblends

incoldweather.

•Monitorseals,hoses,gasketsincontactwithfuel

astheymaydegradeovertime.

•Fuellterpluggingmayoccurforatimeafter

convertingtobiodieselblends.

•Contactyourdistributorformoreinformationon

biodiesel.

g004231

Figure15

1.Fuel-tankcap

4.Fillthetanktoabout2.5cm(1inch)belowthe

topofthetank,notthellerneck,withfuel.

Important:Thisspaceinthetankallows

fueltoexpand.Donotllthefueltank

completelyfull.

5.Installthefuel-tankcapsecurely,turningituntil

itclicks.

6.Wipeupanyspilledfuel.

PerformingDaily Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedintheMaintenance

(page21).

Important:Checkthehydraulic-uidlevel

andbleedthefuelsystembeforestartingthe

engineforthersttime;refertoCheckingthe

Hydraulic-FluidLevel(page42)andBleedingthe

FuelSystem(page29).

14

Page 15

DuringOperation

DuringOperationSafety

GeneralSafety

•Donotcarryaloadwiththearmsraised.Always

carryloadsclosetotheground.

•Donotexceedtheratedoperatingcapacity,asthe

machinemaybecomeunstable,whichmayresult

inlossofcontrol.

•UseonlyToro-approvedattachmentsand

accessories.Attachmentscanchangethestability

andtheoperatingcharacteristicsofthemachine.

•Formachineswithaplatform:

–Donotstepofftheplatformwiththeloadraised.

–Ifyoulosecontrolofthemachine,stepoff

theplatformandawayfromthedirectionthe

machineismoving.

–Donottrytostabilizethemachinebyputting

yourfootontheground.

–Donotplaceyourfeetundertheplatform.

–Donotmovethemachineunlessyouare

standingwithbothfeetontheplatformand

yourhandsareholdingontothehandles.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Lookbehindanddownbeforebackingupto

ensurethatthepathisclear.

•Neverjerkthecontrols;useasteadymotion.

•Theowner/usercanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothingincludinggloves,eye

protection,longpants,substantialslip-resistant

footwear,andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotoperatethemachinewhenyouaretired,ill,

orundertheinuenceofalcoholordrugs.

•Nevercarrypassengersandkeeppetsand

bystandersawayfromthemachine

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

•Ensurethatallthedrivesareinneutralandengage

theparkingbrake(ifequipped)beforestartingthe

engine.Starttheengineonlyfromtheoperator's

position.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Watchfor

trafc.

•Stoptheattachmentwhenyouarenotworking.

•Stopthemachine,turnofftheengine,remove

thekey,andinspectthemachineifyoustrike

anobject.Makeanynecessaryrepairsbefore

resumingoperation.

•Neverrunanengineinanenclosedarea.

•Neverleavearunningmachineunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowertheloaderarmsanddisengagethe

auxiliaryhydraulics.

–Engagetheparkingbrake(ifequipped).

–Shutofftheengineandremovethekey .

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Operatethemachineonlyinareaswherethereis

sufcientclearanceforyoutosafelymaneuver.

Beawareofobstaclesincloseproximitytoyou.

Failuretomaintainadequatedistancefromtrees,

walls,andotherbarriersmayresultininjuryasthe

machinebacksupduringoperationifyouarenot

attentivetothesurroundings.

•Checkforoverheadclearance(i.e.,electrical

wires,branches,anddoorways)beforedriving

underanyobjectsanddonotcontactthem.

•Donotoverlltheattachmentandalwayskeepthe

loadlevelwhenraisingtheloaderarms.Itemsin

theattachmentcouldfallandcauseinjury.

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.Anempty

bucketmakestherearofthemachinetheheavy

end,andafullbucketmakesthefrontofthe

machinetheheavyend.Mostotherattachments

makethefrontofmachinetheheavyend.

•Raisingtheloaderarmsonaslopeaffectsthe

stabilityofthemachine.Keeptheloaderarmsin

theloweredpositionwhenonslopes.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

15

Page 16

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.Tallgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Donotoperatethemachineneardrop-offs,

ditches,embankments,orbodiesofwater.The

machinecouldsuddenlyrolloverifawheelor

trackgoesovertheedgeortheedgecavesin.

Maintainasafedistancebetweenthemachine

andanyhazard.

(i.e.,whentheairtemperatureisator

belowfreezing)coulddamagethehydraulic

system.Whenstartingtheengineincold

conditions,allowittoruninthemiddle

throttlepositionfor2to5minutesbefore

movingthethrottletotheFASTposition.

Note:Ifoutdoortemperatureisbelowfreezing,

storethetractionunitinagaragetokeepit

warmerandtoaidinstarting.

DrivingtheMachine

Usethetractioncontroltomovethemachine.The

fartheryoumovethetractioncontrolinanydirection,

thefasterthemachinemovesinthatdirection.

Releasethetractioncontroltostopthemachine.

Thethrottlecontrolregulatestheenginespeedas

measuredinrpm(revolutionsperminute).Placethe

throttleleverintheFASTpositionforbestperformance.

Youcan,however,usethethrottlepositiontooperate

atslowerspeeds.

ShuttingOfftheEngine

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

StartingtheEngine

1.Ensurethattheauxiliaryhydraulicsleverisin

theNEUTRALposition.

2.MovethethrottlelevermidwaybetweenSLOW

andFASTpositions.

3.Insertthekeyintothekeyswitchandturnitto

theRUNposition.

4.Presstheglow-plugswitchandholditfor10

seconds.

5.TurnthekeytotheST ARTposition.Whenthe

enginesstarts,releasethekey.

Important:Donotengagethestarterfor

morethan10secondsatatime.Iftheengine

failstostart,wait30secondsforthestarter

tocooldownbetweenattempts.Failureto

followtheseinstructionscouldburnoutthe

startermotor.

2.Ensurethattheauxiliaryhydraulicsleverisin

theNEUTRALposition.

3.MovethethrottlelevertotheSLOWposition.

4.Iftheenginehasbeenworkinghardorishot,let

itidleforaminutebeforeturningthekeyswitch

totheOFFposition.

Note:Thishelpstocooltheenginebeforeyou

shutitoff.Inanemergency ,youcanshutoff

theengineimmediately.

5.TurnthekeyswitchtotheOFFpositionand

removethekey.

CAUTION

Achildoruntrainedbystandercouldattempt

tooperatethetractionunitandbeinjured.

Removethekeyfromthekeyswitchwhen

leavingthetractionunit,evenifjustforafew

seconds.

6.MovethethrottlelevertotheFASTposition.

Important:Runningtheengineathigh

speedswhenthehydraulicsystemiscold

16

Page 17

UsingAttachments

InstallinganAttachment

Important:UseonlyToro-approvedattachments.

Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthemachine.The

warrantyofthemachinemaybevoidedifyouuse

themachinewithunapprovedattachments.

Important:Beforeinstallingtheattachment,

ensurethatthemountplatesarefreeofanydirtor

debrisandthatthepinsrotatefreely.Ifthepins

donotrotatefreely,greasethem.

1.Positiontheattachmentonalevelsurfacewith

enoughspacebehindittoaccommodatethe

machine.

2.Starttheengine.

3.Tilttheattachmentmountplateforward.

4.Positionthemountplateintotheupperlipofthe

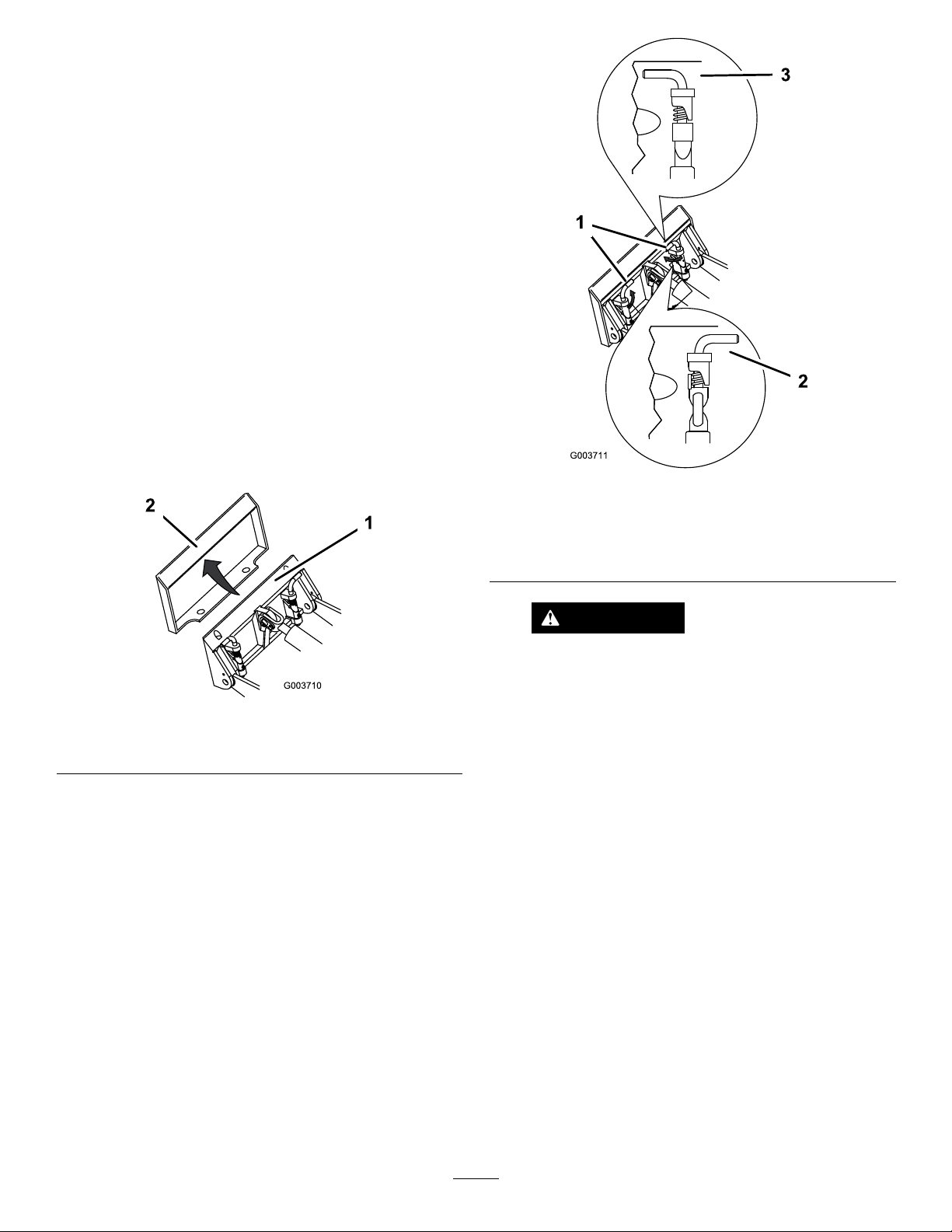

attachmentreceiverplate(Figure16).

g003711

Figure17

Figure16

1.Mountplate2.Receiverplate

5.Raisetheloaderarmswhiletiltingbackthe

mountplateatthesametime.

Important:Raisetheattachmentenoughto

clearthegroundandtiltthemountplateall

thewayback.

6.Shutofftheengineandremovethekey.

7.Engagethequick-attachpins,ensuringthatthey

arefullyseatedinthemountplate(Figure17).

1.Quick-attachpins

(engagedposition)

2.Disengagedposition

3.Engagedposition

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

g003710

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

Important:Ifthepinsdonotrotatetothe

engagedposition,themountplateisnot

fullyalignedwiththeholesintheattachment

receiverplate.Checkthereceiverplateand

cleanitifnecessary.

17

Page 18

ConnectingtheHydraulicHoses

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

RemovinganAttachment

1.Parkthemachineonalevelsurface.

2.Lowertheattachmenttotheground.

3.Shutofftheengineandremovethekey.

4.Disengagethequick-attachpinsbyturningthem

totheoutside.

5.Iftheattachmentuseshydraulics,movethe

auxiliary-hydraulicsleverforward,backward,

andbacktotheNEUTRALpositiontorelieve

pressureatthehydrauliccouplers.

6.Iftheattachmentuseshydraulics,slidethe

collarsbackonthehydrauliccouplersand

disconnectthem.

Important:Connecttheattachmenthoses

togethertopreventhydraulicsystem

contaminationduringstorage.

7.Installtheprotectivecoversontothehydraulic

couplersonthemachine.

8.Starttheengine,tiltthemountplateforward,and

backthemachineawayfromtheattachment.

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponents,youmaybeburned.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

Iftheattachmentrequireshydraulicsforoperation,

connectthehydraulichosesasfollows:

1.Shutofftheengineandremovethekey.

2.Movetheauxiliary-hydraulicsleverforward,

backward,andbacktotheNEUTRALpositionto

relievepressureatthehydrauliccouplers.

3.Removetheprotectivecoversfromthehydraulic

connectorsonthemachine.

4.Ensurethatallforeignmatteriscleanedfrom

thehydraulicconnectors.

5.Pushtheattachmentmaleconnectorintothe

femaleconnectoronthemachine.

Note:Whenyouconnecttheattachmentmale

connectorrst,yourelieveanypressurebuilt

upintheattachment.

6.Pushtheattachmentfemaleconnectorontothe

maleconnectoronthemachine.

7.Conrmthattheconnectionissecurebypulling

onthehoses.

AfterOperation

AfterOperationSafety

GeneralSafety

•Cleandebrisfromtheattachments,drives,

mufers,andenginetohelppreventres.Clean

upoilorfuelspills.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

MovingaNon-Functioning Machine

Important:Donottoworpullthemachine

withoutrstopeningthetowvalves,oryouwill

damagethehydraulicsystem.

1.Shutofftheengineandremovethekey.

2.Opentherear-accesscover.

3.Usingawrench,turnthetowvalvesonthe

hydraulicpumpstwicecounter-clockwise(Figure

18).

18

Page 19

Figure18

1.Lefttowvalve(righttrack)2.Righttowvalve(lefttrack)

4.Towthemachineasrequired.

5.Afterrepairingthemachine,closethetowvalves

beforeoperatingit.

SelectingaTrailer

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath(Figure19).

•Useonlyafull-widthramp;donotuse

individualrampsforeachsideofthe

machine.

•Ensurethatthelengthoframpisatleast4

timesaslongastheheightofthetraileror

truckbedtotheground.Thisensuresthat

rampangledoesnotexceed15degreeson

atground.

g004181

TransportingtheMachine

Useaheavy-dutytrailerortrucktotransportthe

machine.Useafull-widthramp.Ensurethatthetrailer

ortruckhasallthenecessarybrakes,lighting,and

markingasrequiredbylaw.Pleasecarefullyreadall

thesafetyinstructions.Knowingthisinformationcould

helpyouorbystandersavoidinjury.Refertoyour

localordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidentscausingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway.

1.Full-widthrampinstowed

position

2.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

g229507

Figure19

3.H=heightofthetraileror

truckbedtotheground

4.Trailer

19

Page 20

LoadingtheMachine

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Loadandunloadthemachinewiththe

heavyenduptheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

g243576

Figure21

1.Tie-downloops

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Lowertheramp(Figure19).

4.Lowertheloaderarms.

5.Loadthemachineontothetrailerwiththeheavy

enduptheramp,carryingloadslow(Figure20).

•Ifthemachinehasafullload-carrying

attachment(e.g.,bucketoradjustableforks)

oranon-load-carryingattachment(e.g.,

stumpgrinder),drivethemachineforward

uptheramp.

•Ifthemachinehasanemptyload-carrying

attachmentornoattachment,backthe

machineuptheramp.

Figure20

1.Machinewithfull

attachmentor

non-load-carrying

attachment—drivethe

machineforwardupthe

ramp.

2.Machinewithemptyor

noattachment—backthe

machineuptheramp.

UnloadingtheMachine

1.Lowertheramp(Figure20).

2.Unloadthemachinefromthetrailerwiththe

heavyenduptheramp,carryingloadslow

(Figure22).

•Ifthemachinehasafullload-carrying

attachment(e.g.,bucketoradjustableforks)

oranon-load-carryingattachment(e.g.,

stumpgrinder),backitdowntheramp.

•Ifthemachinehasanemptyload-carrying

attachmentornoattachment,driveitforward

downtheramp.

g204458

Figure22

g204457

1.Machinewithfull

attachmentor

non-load-carrying

attachment—backthe

machinedowntheramp.

2.Machinewithemptyor

noattachment—drivethe

machineforwarddownthe

ramp.

LiftingtheMachine

6.Lowertheloaderarmsallthewaydown.

7.Shutofftheengine,removethekey,andengage

theparkingbrake.

8.Usethemetaltie-downloopsonthemachine

tosecurelyfastenthemachinetothetraileror

truckwithstraps,chains,cable,orropes(Figure

21).Refertolocalregulationsfortie-down

requirements.

Youcanliftthemachineusingthetie-down/liftloops

asliftpoints;refertoFigure21.

20

Page 21

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every100hours

MaintenanceProcedure

•Replacethehydrauliclter.

•Changetheengineoilandlter.

•Checkandadjustthetracktension.

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checktheair-lter-serviceindicator.

•Checktheengine-oillevel.

•Drainwaterandothercontaminantsfromthefuellter/waterseparator.

•Cleanthetracks.

•Checkthetracksforexcessivewear(Ifthetracksareworn,replacethem).

•Cleanthescreen,oilcooler,andfrontoftheradiator(moreoftenindirtyordusty

conditions).

•Checkthecoolantlevelintheexpansiontank.

•Checkandcleantheradiatorscreen

•Testtheparkingbrake.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

•Removetheair-cleanercover,cleanoutdebris,andchecktheair-lter-service

indicator.

•Checkthehydraulic-uidlevel.

•Changetheengineoil.(Servicemorefrequentlyifconditionsareextremelydusty

orsandy.)

•Checkandadjustthetracktension.

•Checkthecoolingsystemhoses.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Checkfordirtbuildupinthechassis.

•Checkthealternator/fanbelttension(refertotheengineowner’smanualfor

instructions).

•Changetheoillter.(Servicemorefrequentlyifconditionsareextremelydusty

Every200hours

Every250hours

Every400hours

Every500hours

Every1,500hours

Yearly

Yearlyorbeforestorage

Every2years

orsandy.)

•Replacethehydrauliclter.

•Checkandgreasetheroadwheels.

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Replacethefuelltercanisterandin-linelter.

•Changethehydraulicuid.

•Replacethealternator/fanbelt(refertotheengineowner’smanualforinstructions).

•Replaceallmovinghydraulichoses.

•Changetheenginecoolant(AuthorizedServiceDealeronly).

•Checktheconditionofthehydraulicpumpbelt.

•Checkandadjustthetracktension.

•Touchupchippedpaint.

•Drainandcleanthefueltank(s)—AuthorizedServiceDealeronly .

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

21

Page 22

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

Pre-Maintenance

Procedures

MaintenanceSafety

•Parkthemachineonalevelsurface,disengage

theauxiliaryhydraulics,lowertheattachment,

engagetheparkingbrake(ifequipped),shut

offtheengine,andremovethekey .Waitforall

movementtostopandallowthemachinetocool

beforeadjusting,cleaning,storing,orrepairingit.

•Cleanupoilorfuelspills.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthecomponentswhen

required.

•Carefullyreleasepressurefromcomponentswith

storedenergy.

•Disconnectthebatterybeforemakinganyrepairs;

refertoServicingtheBattery(page31).

•Keepyourhandsandfeetawayfromthemoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Donottamperwiththesafetydevices.

•UseonlyToro-approvedattachments.

Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthemachine.Y oumay

voidthewarrantyifyouusethemachinewith

unapprovedattachments.

•UseonlygenuineTororeplacementparts.

•Ifanymaintenanceorrepairrequirestheloader

armstobeintheraisedposition,securethearms

intheraisedpositionwiththehydraulic-cylinder

lock(s).

InstallingtheCylinderLock

1.Removetheattachment.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengineandremovethekey.

4.Removethelynchpinsecuringthecylinderlock

totheloaderarm(Figure23).

Figure23

1.Cylinderlock

2.Liftcylinder

5.Lowerthecylinderlockoverthecylinderrodand

secureitwiththelynchpin(Figure23).

6.Slowlylowertheloaderarmsuntilthecylinder

lockcontactsthecylinderbodyandrodend.

3.Lynchpin

g004182

UsingtheCylinderLock

WARNING

Theloaderarmsmaylowerwhenintheraised

position,crushinganyoneunderthem.

Installthecylinderlock(s)beforeperforming

maintenancethatrequiresraisedloaderarms.

22

Page 23

RemovingandStoringthe CylinderLock

Important:Removethecylinderlockfromtherod

andfullysecureitinthestoragepositionbefore

operatingthemachine.

1.Starttheengine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengineandremovethekey.

4.Removethelynchpinsecuringthecylinderlock.

5.Rotatethecylinderlockuptotheloaderarm

andsecureitwiththelynchpin.

6.Lowertheloaderarms.

AccessingInternal Components

WARNING

Openingorremovingcovers,hoods,and

screenswhiletheengineisrunningcould

allowyoutocontactmovingparts,seriously

injuringyou.

Beforeopeninganyofthecovers,hoods,and

screens,shutofftheengine,removethekey

fromthekeyswitch,andallowtheengineto

cool.

OpeningtheHood

1.Loosenthehood-lockingscrew(Figure24)

Figure24

1.Hood3.Hood-lockingscrew

2.Hood-latchlever

2.Turnthehoodlatchclockwise(Figure24).

3.Swingthehoodup(Figure24).

23

g009691

Page 24

ClosingtheHood

ClosingtheRear-AccessCover

1.Liftuponthetabsecuringtheproprod(Figure

25)

Figure25

1.Prop-rodtab

2.Lowerthehoodandsecureitbypushingdown

onthefrontofthehooduntilitlocksinplace.

1.Movetherear-accesscoverinplaceoverthe

backofthemachine;ensurethatthetabsline

upintheslots.

2.Pushtheaccesscoverforward,liningupthe

hand-knobscrewswiththethreadedholesin

themachine.

3.Screwthehandknobstighttosecurethe

rear-accesscoverinplace.

RemovingtheSideScreens

1.Openthehood.

2.Slidethesidescreens(Figure27)upandoutof

theslotsinthefrontscreenandframe.

g007360

3.Tightenthehood-lockingscrewtosecurethe

latch(Figure24).

OpeningtheRear-AccessCover

1.Unscrewthe2handknobssecuringthe

rear-accesscovertothemachine(Figure26).

Figure26

1.Handknobs

2.Tilttherear-accesscoverdownandremoveto

accesstheinternalcomponents(Figure26).

g004352

Figure27

1.Sidescreen

InstallingtheSideScreens

Slidethesidescreensintoplaceintheslotsinthe

frontscreenandframe.

g244210

24

Page 25

Lubrication

EngineMaintenance

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily(Grease

immediatelyaftereverywashing.)

GreaseType:General-purposegrease.

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

2.Shutofftheengineandremovethekey.

3.Cleanthegreasettingswitharag.

4.Connectagreaseguntoeachtting(Figure28

andFigure29).

EngineSafety

•Shutofftheenginebeforecheckingtheoilor

addingoiltothecrankcase.

•Donotchangetheenginegovernorsettingor

overspeedtheengine.

•Keepyourhands,feet,face,clothing,andother

bodypartsawayfromthemuferandotherhot

surfaces.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Check

theair-lter-serviceindicator.

Every25hours—Removetheair-cleanercover,

cleanoutdebris,andchecktheair-lter-service

indicator.

ServicingtheAir-CleanerCover andBody

Important:Replacetheair-cleanerlteronly

whentheserviceindicatorshowsred(Figure30).

Changingtheairlterbeforeitisnecessaryonly

increasesthechanceofdirtenteringtheengine

whenyouremovethelter.

Figure28

Figure29

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings(approximately3

pumps).

6.Wipeupanyexcessgrease.

g004235

g004209

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

2.Shutofftheengineandremovethekey.

3.Openthehoodandsecuretheproprod(if

applicable).

4.Checktheair-cleanerbodyfordamagethat

couldcauseanairleak.Checkthewholeintake

systemforleaks,damage,orloosehoseclamps.

Replaceorrepairanydamagedcomponents.

5.Releasethelatchesontheaircleanerandpull

theair-cleanercoverofftheair-cleanerbody

(Figure30).

Important:Donotremovetheairlter.

25

Page 26

1.Dustcap

2.Latch

3.Air-cleanercover

Figure30

4.Primarylter

5.Air-lterbody

6.Serviceindicator

Important:Donotpressonthesoftinside

areaofthelter.

4.Installtheair-cleanercoverwiththedustcap

orienteddownwardandsecurethelatches

(Figure30).

5.Closethehood.

ServicingtheEngineOil

ServiceInterval:Beforeeachuseordaily—Check

theengine-oillevel.

g031236

Aftertherst50hours—Changetheengineoil

andlter.

Every100hours—Changetheengineoil.

(Servicemorefrequentlyifconditionsare

extremelydustyorsandy .)

6.Squeezethedustcapsidestoopenitandknock

thedustout.

7.Cleantheinsideoftheair-cleanercoverwith

compressedairthatisunder205kPa(30psi).

Important:Donotusecompressedairon

theair-cleanerbody.

8.Checktheserviceindicator.

•Iftheserviceindicatorisclear,installthe

air-cleanercoverwiththedustcaporiented

downwardandsecurethelatches(Figure

30).

•Iftheserviceindicatorisred,replacethe

airlterasdescribedinReplacingtheFilter

(page26).

ReplacingtheFilter

Important:Topreventenginedamage,always

operatetheenginewiththeairlterandcover

installed.

1.Gentlyslidethelteroutoftheair-cleanerbody

(Figure30).

Every200hours—Changetheoillter.(Service

morefrequentlyifconditionsareextremely

dustyorsandy.)

Engine-OilSpecications

OilType:Detergentdieselengineoil(APIservice

CH-4orhigher)

CrankcaseCapacity:withlter,3.7L(1.0USgallon)

Viscosity:Seetablebelow

Note:Avoidknockingthelterintothesideof

thebody.

Important:Donotattempttocleanthelter.

2.Inspectthenewlterfortears,anoilylm,or

damagetotherubberseal.Lookintothelter

whileshiningabrightlightontheoutsideofthe

lter;holesinthelterappearasbrightspots.

Ifthelterisdamaged,donotuseit.

3.Carefullyinstallthelter(Figure30).

Note:Ensurethatthelterisfullyseated

bypushingontheouterrimofthelterwhile

installingit.

g001061

Figure31

26

Page 27

CheckingtheEngine-OilLevel

ChangingtheEngineOil

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengine,removethekey,andallow

theenginetocool.

3.Openthehood.

4.Cleantheareaaroundtheoildipstick(Figure

32).

1.Starttheengineandletitrunfor5minutes.

Note:Thiswarmstheoilsothatitdrainsbetter.

2.Parkthemachinesothatthedrainsideisslightly

lowerthantheoppositesidetoensurethatthe

oildrainscompletely.

3.Lowertheloaderarms,engagetheparking

brake,shutofftheengine,andremovethekey.

4.Removethedrainplug(Figure33).

Figure32

1.Oildipstick2.Oil-llcap

5.Pulloutthedipstickandwipethemetalend

clean(Figure32).

6.Slidethedipstickfullyintothedipsticktube

(Figure32).

7.Pullthedipstickoutandlookatthemetalend.

8.Iftheoillevelislow(belowthebottomhole),

cleanaroundtheoil-llcapandremovethecap

(Figure32).

9.Slowlypouronlyenoughoilintothevalve

covertoraisetheleveltotheupperholeonthe

dipstick.

Important:Donotoverllthecrankcase

withoiltopreventdamagingtheengine.

10.Replacethellcapanddipstick.

11.Closethehood.

g004227

g004353

Figure33

1.Oildrainplug

5.Whentheoilhasdrainedcompletely ,replace

theplug.

Note:Disposeoftheusedoilatacertied

recyclingcenter.

6.Removethellcap(Figure32)andslowlypour

approximately80%ofthespeciedamountofoil

inthroughthevalvecover.

7.Checktheoillevel.

8.Slowlyaddadditionaloiltobringtheleveltothe

upperholeonthedipstick.

9.Replacethellcap.

27

Page 28

ChangingtheOilFilter

1.Draintheoilfromtheengine;refertoChanging

theEngineOil(page27).

FuelSystem

Maintenance

2.Whentheoilhasdrainedcompletely ,replace

theplug.

Note:Disposeoftheusedoilatacertied

recyclingcenter.

3.Placeashallowpanorragunderthelterto

catchoil.

4.Removetheoldlter(Figure34)andwipethe

surfaceofthelteradaptergasket.

DANGER

Incertainconditions,fuelisextremely

ammableandhighlyexplosive.Areor

explosionfromfuelcanburnyouandothers

andcandamageproperty.

RefertoFuelSafety(page13)foracomplete

listoffuelrelatedprecautions.

CheckingtheFuelLines andConnections

ServiceInterval:Every400hours/Yearly(whichever

comesrst)

Inspectthefuellinesandconnectionsfordeterioration,

damage,orlooseconnections.Tightenanyloose

connectionsandcontactyourAuthorizedService

Dealerforassistanceinxingdamagedfuellines.

DrainingtheFuel

Figure34

1.Oillter

5.Pournewoilofthepropertypethroughthe

centerholeofthelter.Stoppouringwhenthe

oilreachesthebottomofthethreads.

6.Allow1to2minutesfortheoiltobeabsorbed

byltermaterial,thenpourofftheexcessoil.

7.Applyathincoatofnewoiltotherubbergasket

onthereplacementlter.

8.Installthereplacementoilltertothelter

adapter.Turntheoillterclockwiseuntilthe

rubbergasketcontactsthelteradapter,then

tightenthelteranadditional1/2turn.

9.Removethellcap(Figure32)andslowlypour

approximately80%ofthespeciedamountofoil

inthroughthevalvecover.

Filter/WaterSeparator

ServiceInterval:Beforeeachuseordaily

g004354

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Locatethefuellterontherightsideofthe

engine(Figure35)andplaceacleancontainer

underit.

10.Checktheoillevel.

11.Slowlyaddadditionaloiltobringtheleveltothe

upperholeonthedipstick.

12.Replacethellcap.

28

Page 29

Figure35

1.Fuel-ltercanister/water

separator

2.Drainvalve

4.Loosenthedrainvalveonthebottomofthelter

canisterandallowthewatertodrain.

5.Whennished,tightenthedrainvalve.

3.Hoseclamps

4.In-linelter

10.Locatethein-lineltertotheleftofthefuellter

canister(Figure35)andnotethedirectionof

owarrowonthesideofthein-linelter.

11.Opentheclampsoneachendofthein-linelter

andslidethehosesoffit(Figure35).Discard

thelter.

12.Slidethehosesovertheendofanewlter

(Figure35),ensuringthatthearrowonthelter

ispointingtowardtheengineorelectricfuel

pump.

13.Securethehosestothelterwiththehose

clamps.

14.Closetherear-accesscoverandsecurewiththe

fastener(s).

BleedingtheFuelSystem

Youmustbleedthefuelsystembeforestartingthe

g009626

engineifanyofthefollowingsituationshaveoccurred:

•Initialstartupofanewmachine

•Theenginehasceasedrunningduetoalackof

fuel.

•Maintenancehasbeenperformedonfuelsystem

components(e.g.,lterreplaced).

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,andshutofftheengine.

2.Ensurethatthefueltankisatleasthalffull.

ReplacingtheFuelFilter CanisterandIn-LineFilter

ServiceInterval:Every400hours

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Opentherear-accesscover;refertoOpening

theRear-AccessCover(page24).

4.Locatethefuelltersontherightsideofthe

engine(Figure35)andplaceacleancontainer

underit.

5.Cleantheareawheretheltercanistermounts

(Figure35).

6.Removetheltercanisterandcleanthe

mountingsurface(Figure35).

7.Lubricatethegasketonthenewltercanister

withcleanoil.

8.Fillthecanisterwithfuel.

9.Installtheltercanisterbyhanduntilthegasket

contactsthemountingsurface,thenrotateitan

additional1/2turn(Figure35).

3.Openthehood.

4.Opentheair-bleedscrewonthefuel-injection

pump(Figure36).

g003880

Figure36

1.Air-bleedscrew

29

Page 30

5.TurnthekeyinthekeyswitchtotheONposition.

Theelectricfuelpumpbeginsoperation,thereby

forcingairoutaroundtheair-bleedscrew.Leave

thekeyintheONpositionuntilasolidstreamof

fuelowsoutaroundthescrew.

ElectricalSystem

Maintenance

6.TightenthescrewandturnthekeytotheOFF

position.

Note:Theengineshouldstartaftertheabove

bleedingproceduresarefollowed.However,ifengine

doesnotstart,airmaybetrappedbetweeninjection

pumpandinjectors;contactyourAuthorizedService

Dealer.

DrainingtheFuelTank(s)

ServiceInterval:Every2years

HaveanAuthorizedServiceDealerdrainandclean

thefueltank(s).

ElectricalSystemSafety

•Disconnectthebatterybeforerepairingthe

machine.Disconnectthenegativeterminalrst

andthepositivelast.Connectthepositiveterminal

rstandthenegativelast.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

•Batteryacidispoisonousandcancauseburns.

Avoidcontactwithskin,eyes,andclothing.Protect

yourface,eyes,andclothingwhenworkingwitha

battery.

•Batterygasescanexplode.Keepcigarettes,

sparks,andamesawayfromthebattery.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

30

Page 31

ServicingtheBattery

Alwayskeepthebatterycleanandfullycharged.Use

apapertoweltocleanthebatterycase.Ifthebattery

terminalsarecorroded,cleanthemwithasolutionof

4partswaterand1partbakingsoda.Applyalight

coatingofgreasetothebatteryterminalstoreduce

corrosion.

Specications:12V ,585A(coldcranking)

RemovingtheBattery

WARNING

Batteryterminalsormetaltoolscouldshort

againstmetalmachinecomponents,causing

sparks.Sparkscancausethebatterygasses

toexplode,resultinginpersonalinjury.

•Whenremovingorinstallingthebattery,

donotallowthebatteryterminalstotouch

anymetalpartsofthemachine.

g243600

Figure38

1.Positivecable4.Negativecable

2.Bar5.Battery

3.Boltandwasher

•Donotallowmetaltoolstoshortbetween

thebatteryterminalsandmetalpartsofthe

machine.

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

2.Shutofftheengineandremovethekey.

3.Opentherear-accesscover;refertoOpening

theRear-AccessCover(page24).

4.Removethebattery-accesspanel

6.Disconnectthenegative(black)groundcable

fromthebatterypost(Figure38).Retainthe

fasteners.

7.Slidetherubbercoveroffthepositive(red)

cable.

8.Disconnectthepositive(red)cablefromthe

batterypost(Figure38).Retainthefasteners.

9.Liftthebatteryoutofthechassis.

ChargingtheBattery

Important:Alwayskeepthebatteryfullycharged

(1.265specicgravity).Thisisespecially

importanttopreventbatterydamagewhenthe

temperatureisbelow0°C(32°F).

1.Removethebatteryfromthemachine;referto

RemovingtheBattery(page31).

2.Chargethebatteryfor10to15minutesat25to

30Aor30minutesat4to6A(Figure39).Do

notoverchargethebattery .

Figure37

1.Bolt(3)

5.Removethebolt,washer,andbarsecuringthe

battery(Figure38).

2.Battery-accesspanel

g244209

31

Page 32

1.Positivebatterypost

2.Negativebatterypost

Figure39

3.Red(+)chargerlead

4.Black(-)chargerlead

CleaningtheBattery

Note:Keeptheterminalsandtheentirebatterycase

clean,becauseadirtybatterydischargesslowly.

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

2.Shutofftheengineandremovethekey.

3.Removethebatteryfromthemachine;

RemovingtheBattery(page31).

4.Washtheentirecasewithasolutionofbaking

g003792

sodaandwater.

5.Rinsethebatterywithclearwater.

6.Coatthebatterypostsandcableconnectorswith

Grafo112X(skin-over)grease(T oroPartNo.

505-47)orpetroleumjellytopreventcorrosion.

3.Whenthebatteryisfullycharged,unplug

thechargerfromtheelectricaloutlet,then

disconnectthechargerleadsfromthebattery

posts(Figure39).

7.Installthebattery;refertoInstallingtheBattery

(page32).

InstallingtheBattery

1.Usingthefastenerspreviouslyremoved,install

thepositive(red)batterycabletothepositive(+)

batteryterminal(Figure38).

2.Slidetheredterminalbootontothepositive

batterypost.

3.Usingthefastenerspreviouslyremoved,install

thenegative(black)batterycabletothenegative

(-)batteryterminal(Figure38).

4.Securethebatteryusingthebar,bolt,and

washer(Figure38).

Important:Ensurethatthebatterycablesdo

notcontactanysharpedgesoreachother.

5.Installthebattery-accesspanel(Figure37).

6.Closetherear-accesscover;refertoClosingthe

Rear-AccessCover(page24).

ServicingaReplacementBattery

Theoriginalbatteryismaintenance-freeanddoesnot

requireservice.Forservicingareplacementbattery,

refertothebatterymanufacturer’sinstructions.

32

Page 33

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorashort.Figure

40illustratesthefuseblockandidentiesthefuse

positions.

g004984

Figure41

Figure40

1.Fuse(30A)3.Fuse(10A)

2.Empty

4.Openpositionforoptional

accessories

Note:Ifthemachinedoesnotstart,eitherthemain

circuitorcontrolpanel/relayfusecouldbeblown.

Toaccessthefuses,youmustremovethefusepanel,

asfollows:

1.Parkthemachineonalevelsurface,engage

theparkingbrake(ifequipped),andlowerthe

loaderarms.

2.Shutofftheengineandremovethekey.

3.Openthehood.

4.Pullthehairpincotterfromthebottomendofthe

hoodprop-rodandslidetheproprodoutofthe

retainingbracketsandtheprop-rodtab(Figure

41).

1.Prop-rodtab4.Retaining

2.Retainingbracket—top5.Hairpincotter

3.Prop-rod

bracket—bottom

5.Removethe4screwssecuringthefusepanel

andthenpullthepaneloutanduptoremove

g004355

it(Figure42).

1.Fusepanel

g004985

Figure42

2.Screw

6.Checkthefuses.

7.Installthefusepanelusingthe4screws

removedpreviously.

8.Installtheprop-rodintotheretainingbrackets

andprop-rodtabandsecureitwiththehairpin

cotter(Figure41).

33

9.Closethehood.

Page 34

DriveSystem

Maintenance

ServicingtheTracks

ServiceInterval:Aftertherst50hours—Checkand

adjustthetracktension.

Beforeeachuseordaily—Cleanthetracks.

Beforeeachuseordaily—Checkthetracksfor

excessivewear(Ifthetracksareworn,replace

them).

Every100hours—Checkandadjustthetrack

tension.

Every250hours/Y early(whichevercomes

rst)—Checkandgreasetheroadwheels.

g004200

Figure43

1.Track3.Roadwheels

2.Drivesprocket4.Tensionwheel

CleaningtheTracks

1.Parkthemachineonalevelsurfaceandengage

theparkingbrake.

2.Withthebucketinstalledandpointingdown,

loweritintothegroundsothatthefrontofthe

tractionunitliftsoffthegroundafewcentimeters

(inches).

3.Shutofftheengineandremovethekey.

4.Usingawaterhoseorpressurewasher,remove

dirtfromeachtracksystem.

Important:Ensurethatyouusehigh-pressure

watertowashonlythetrackarea.Donotuse

ahigh-pressurewashertocleantherestofthe

machine.Donotusehighpressurewaterbetween

thedrivesprocketandthemachineoryoumay

damagethemotorseals.High-pressurewashing

candamagetheelectricalsystemandhydraulic

valvesordepletegrease.

Important:Ensurethatyoufullycleantheroad

wheels,thetensionwheel,andthedrivesprocket

(Figure43).Theroadwheelsshouldrotatefreely

whenclean.

AdjustingtheTrackTension

Thereshouldbe7cm(2-3/4inches)betweenthe

tensionnutandthebackofthetensiontube(Figure

44).Ifnot,adjustthetracktensionusingthefollowing

procedure:

g004201

Figure44

1.7cm(2-3/4inches)

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Lift/supportthesideoftheunittobeworkedon

sothatthetrackisofftheground.

4.Removethelockingboltandnut(Figure45).

34

Page 35

Figure45

1.Lockingbolt3.Tensiontube

2.Tensioningscrew4.Tensionwheel

5.Usinga1/2-inchdriveratchet,turnthe

tensioningscrewcounterclockwiseuntilthe

distancebetweenthetensionnutandtheback

ofthetensiontube(Figure44)is7cm(2-3/4

inches).

6.Aligntheclosestnotchinthetensionscrewto

thelockingboltholeandsecurethescrewwith

thelockingboltandnut(Figure45).

7.Lowerthetractionunittotheground.

ReplacingtheTracks

ReplacingNarrow-WidthTracks

Whenthetracksarebadlyworn,replacethem.

Note:Y ouhavenarrow-widthtracksifthefront

tensionwheelsaremountedinsideaforkontheend

ofthetensiontube(Figure46).

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Lift/supportthesideoftheunittobeworkedon

sothatthetrackis8to10cm(3to4inches)

offtheground.

4.Removethelockingboltandnut(Figure45).

5.Usinga1/2-inchdriveratchet,releasethe

drivetensionbyturningthetensioningscrew

clockwise(Figure45andFigure46).

g004202

g004203

Figure46

1.Track5.Tracklug

2.Socketwrench(1/2inch)

3.Tensionwheel

4.Tensiontube8.Roadwheels

6.Drivesprocket

7.Sprocketcog

6.Pushthetensionwheeltowardtherearofthe

unittomovethetensiontubeagainsttheframe

(Figure46).

Ifitdoesnottouchtheframe,continueturning

thetensioningscrewuntilitdoes.

7.Beginremovingthetrackatthetopofthe

tensionwheel,peelingitoffthewheelwhile

rotatingthetrackforward.

8.Whenthetrackisoffthetensionwheel,remove

itfromthedrivesprocketandroadwheels

(Figure46).

9.Beginningatthedrivesprocket,coilthenew

trackaroundthesprocket,ensuringthatthelugs

onthetracktbetweenthecogsonthesprocket

(Figure46).

10.Pushthetrackunderandbetweentheroad

wheels(Figure46).

11.Startingatthebottomofthetensionwheel,

installthetrackaroundthewheelbyrotating

thetrackrearwardwhilepushingthelugsinto

thewheel.

12.Turnthetensioningscrewcounterclockwiseuntil

thedistancebetweenthetensionnutandthe

backofthetensiontube(Figure44)is7cm

(2-3/4inches).

13.Aligntheclosestnotchinthetensionscrewto

thelockingboltholeandsecurethescrewwith

thelockingboltandnut.

14.Lowerthetractionunittotheground.

35

Page 36

15.Repeatsteps3through14toreplacetheother

track.

ReplacingWide-WidthTracks

Whenthetracksarebadlyworn,replacethem.

Note:Y ouhavewide-widthtracksifthefronttension

wheelsaremountedonthesidesoftheendofthe

tensiontube(Figure47).

1.Parkthemachineonalevelsurface,engagethe

parkingbrake,andlowertheloaderarms.

2.Shutofftheengineandremovethekey.

3.Lift/supportthesideoftheunittobeworkedon

sothatthetrackis8to10cm(3to4inches)

offtheground.

4.Removethelockingboltandnut(Figure45).

5.Usinga1/2-inchdriveratchet,releasethe

drivetensionbyturningthetensioningscrew

clockwise(Figure45andFigure47).

9.Removethenutsecuringtheinnertension

wheelandremovethewheel(Figure47).

10.Pullthe4largewashersoutofthe2wheels,1

oneachsideofeachwheel.

11.Cleantheoldgreaseanddirtoutofthearea

betweenwherethewasherswereinstalledand

thebearingsinsidethewheels,thenllthisarea

oneachsideofeachwheelwithgrease.

12.Installthelargewashersonthewheelsoverthe

grease.

13.Installtheinnertensionwheelandsecureitwith

thenutremovedpreviously(Figure47).

14.T orquethenutto407N∙m(300ft-lb).

15.Installthenewtrack,ensuringthatthelugsin

thetracktbetweenthecogsinthemiddleof

thedrivesprocket(Figure47).

16.Installtheoutertensionwheelandsecureitwith

thenutremovedpreviously(Figure47).

17.T orquethenutto407N∙m(300ft-lb).

18.Turnthetensioningscrewcounterclockwiseuntil

thedistancebetweenthetensionnutandthe

backofthetensiontube(Figure44)is7cm

(2-3/4inches).

19.Aligntheclosestnotchinthetensionscrewto

thelockingboltholeandsecurethescrewwith

thelockingboltandnut.

20.Lowerthetractionunittotheground.

21.Repeatsteps3through20toreplacetheother

track.

Figure47

1.Track6.Tracklug

2.Socketwrench(1/2inch)

3.Tensionwheelnut

4.Outertensionwheel

5.Tensiontube10.Innertensionwheel

7.Drivesprocket

8.Sprocketcog

9.Roadwheels

6.Pushthetensionwheeltowardtherearofthe

unittomovethetensiontubeagainsttheframe

(Figure47).

Ifitdoesnottouchtheframe,continueturning

thetensioningscrewuntilitdoes.

7.Removethenutsecuringtheoutertension

wheelandremovethewheel(Figure47).

8.Removethetrack(Figure47).

MaintainingtheRoadWheels

1.Removethetracks;refertoReplacingthe

Tracks(page35).

2.Removethe4boltssecuringeachlowertrack

g004204

guidewhichcontainstheroadwheels,and

removethem(Figure48).

Figure48

1.Roadwheels

2.Lowertrackguide

3.Trackguidebolts(only2

g004205

shown)

36

Page 37

3.Removethesnapringandcapfromaroad

wheel(Figure49).

Figure49

1.Roadwheel4.Roadwheelcap

2.Gasket5.Snapring

3.Bolt6.Addgreaseunderthecap

CoolingSystem

Maintenance

CoolingSystemSafety

•Swallowingenginecoolantcancausepoisoning;

keepoutofreachfromchildrenandpets.

•Dischargeofhot,pressurizedcoolantortouching

ahotradiatorandsurroundingpartscancause

severeburns.

–Alwaysallowtheenginetocoolatleast15

g004206

ServicingtheCooling

minutesbeforeremovingtheradiatorcap.

–Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

4.Checkthegreaseunderthecapandaround

thegasket(Figure49).Ifitisdirty,gritty,or

depleted,cleanoutallofthegrease,replacethe

gasket,andaddnewgrease.

5.Ensurethattheroadwheelturnssmoothlyon

thebearing.Ifitisfrozen,replacetheroadwheel

asdescribedintheRoadWheelKitInstallation

InstructionsorcontactyourAuthorizedService

Dealerforrepair.

6.Placethegreasedroadwheelcapoverthebolt

head(Figure46).

7.Securetheroadwheelcapwiththesnapring

(Figure46).

8.Repeatsteps3through7fortheotherroad

wheels.

9.Installeachtrackguidetothetraction-unitframe

usingthefastenersyouremovedpreviously.

Torquetheboltsto91to112N∙m(67to83ft-lb).

10.Installthetracks;refertoReplacingtheTracks

(page35).

System

ServiceInterval:Beforeeachuseordaily—Clean

thescreen,oilcooler,andfrontof

theradiator(moreoftenindirtyor

dustyconditions).

Beforeeachuseordaily—Checkthecoolant

levelintheexpansiontank.

Every100hours—Checkthecoolingsystem

hoses.

Yearly—Changetheenginecoolant(Authorized

ServiceDealeronly).

DANGER

Therotatingshaftandfancancausepersonal

injury.

•Donotoperatethemachinewithoutthe

coversinplace.

•Keepyourngers,hands,andclothing

clearoftherotatingfananddriveshaft.

•Parkthemachineonalevelsurface,lower

theloaderarms,engagetheparkingbrake,

shutofftheengine,andremovethekey

fromthekeyswitchbeforeperforming

maintenance.

CleaningtheRadiatorScreen

ServiceInterval:Beforeeachuseordaily

Removeanybuildupofgrass,dirtorotherdebrisfrom

theradiatorscreenwithcompressedair.

37

Page 38

Checking,Adding,andBleeding theEngineCoolant

Thecoolingsystemislledwitha50/50solutionof

waterandpermanentethylene-glycolantifreeze.

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,engagetheparkingbrake,and

shutofftheengine.

2.Removethekeyfromthekeyswitchandallow

theenginetocool.

3.Checkthecoolantlevelofcoolantinthe

expansiontank(Figure50).

Thecoolantlevelshouldbeatorabovethemark

onthesideofthetank.

Figure50

1.Expansiontank2.Fullmark

g004230

Figure51

1.Expansiontank3.Topcoolant-bleedvalve

2.Coolant-llcapandller

neck

4.Frontcoolant-bleedvalve

B.Openthefrontandtopcoolant-bleedvalves

(Figure51).

C.Pourcoolantintothecoolant-llerneckuntil