Page 1

FormNo.3403-177RevB

G004222

TX525CompactToolCarrier

ModelNo.22323—SerialNo.315000001andUp

ModelNo.22323G—SerialNo.315000001andUp

ModelNo.22324—SerialNo.315000001andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3403-177*B

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thisproductcontainsachemicalorchemicals

knowntotheStateofCaliforniatocausecancer,

birthdefects,orreproductiveharm.

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineT orosparkarrestersareapprovedbytheUSDA

ForestryService.

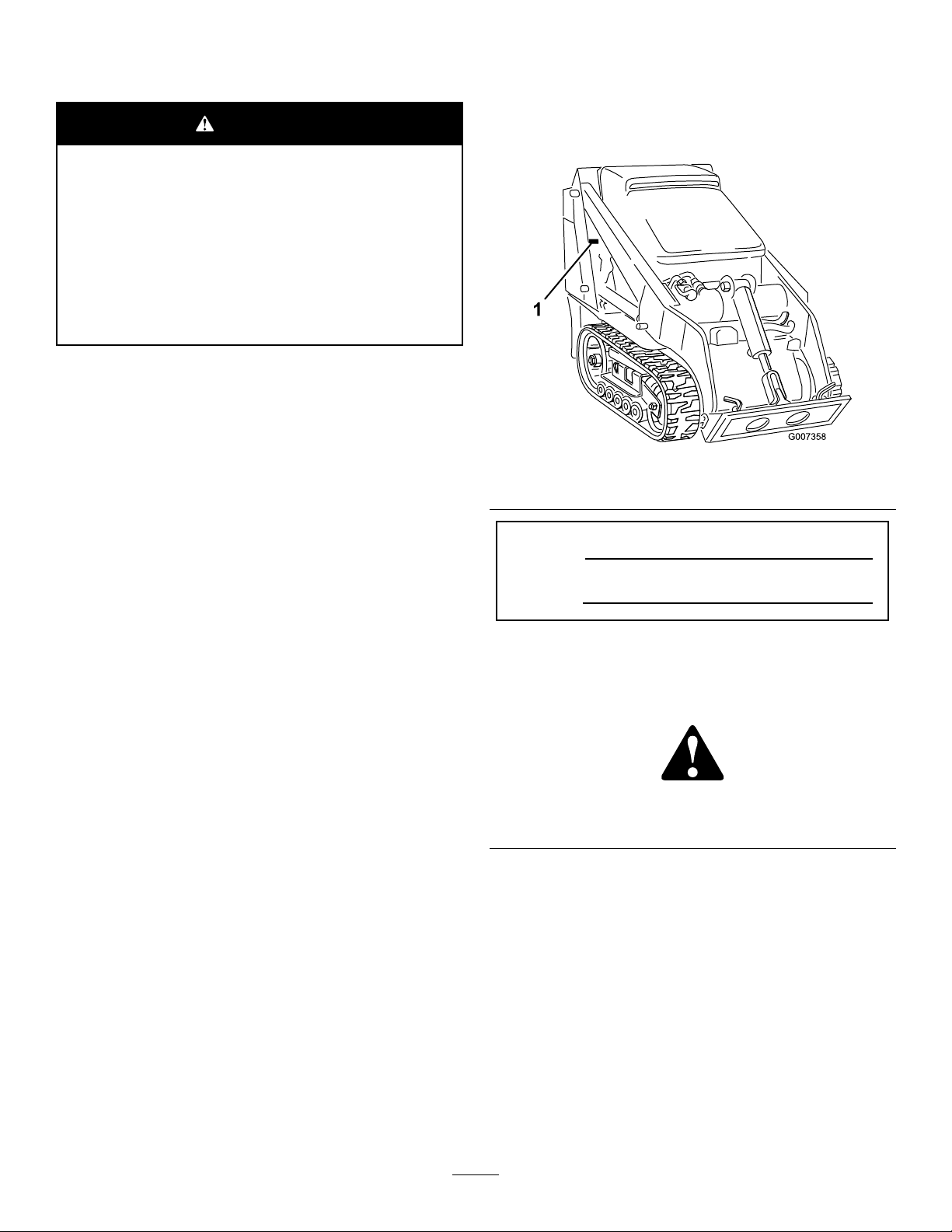

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready.Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Figure1

1.Modelandserialnumberlocation

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

Theenclosed

Engine Owner's Man ual

issuppliedfor

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Introduction

Thismachineisacompacttoolcarrierintendedforusein

variousearthandmaterialsmovingactivitiesforlandscaping

andconstructionwork.Itisdesignedtooperateawidevariety

ofattachmentseachofwhichperformaspecializedfunction.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafety-alertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2

1.Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely.

YoumaycontactTorodirectlyatwww .Toro.comforproduct

safetyandoperationtrainingmaterials,accessoryinformation,

helpndingadealer,ortoregisteryourproduct.

©2016—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Contents

Safety...........................................................................4

SafeOperatingPractices...........................................4

SoundPressureLevel...............................................6

SoundPower..........................................................6

VibrationLevel.......................................................6

StabilityData..........................................................7

SlopeIndicator.......................................................8

SafetyandInstructionalDecals.................................9

ProductOverview.........................................................13

Controls...............................................................13

Specications........................................................16

Attachments/Accessories........................................16

Operation....................................................................17

AddingFuel...........................................................17

FillingtheFuelTank...............................................17

CheckingtheEngine-OilLevel.................................18

CheckingtheHydraulicFluidLevel...........................19

Checking,Adding,andBleedingtheEngine

Coolant.............................................................20

BleedingtheFuelSystem.........................................21

StartingandShuttingOfftheEngine.........................21

StoppingtheTractionUnit......................................22

MovingaNon-FunctioningTractionUnit..................22

UsingtheCylinderLock..........................................22

UsingAttachments.................................................23

SecuringtheTractionUnitforTransport....................25

LiftingtheTractionUnit..........................................25

LoadingtheMachine..............................................25

Maintenance.................................................................27

RecommendedMaintenanceSchedule(s)......................27

PremaintenanceProcedures........................................28

OpeningtheHood.................................................28

ClosingtheHood...................................................28

OpeningtheRearAccessCover................................29

ClosingtheRearAccessCover.................................29

RemovingtheSideScreens......................................29

InstallingtheSideScreens........................................29

Lubrication...............................................................30

GreasingtheTractionUnit......................................30

EngineMaintenance..................................................30

ServicingtheAirCleaner.........................................30

ServicingtheEngineOil..........................................31

FuelSystemMaintenance...........................................33

CheckingtheFuelLinesandConnections..................33

DrainingtheFuelFilter/WaterSeparator...................33

ReplacingtheFuelFilterCanisterandIn-line

Filter.................................................................34

DrainingtheFuelTank...........................................34

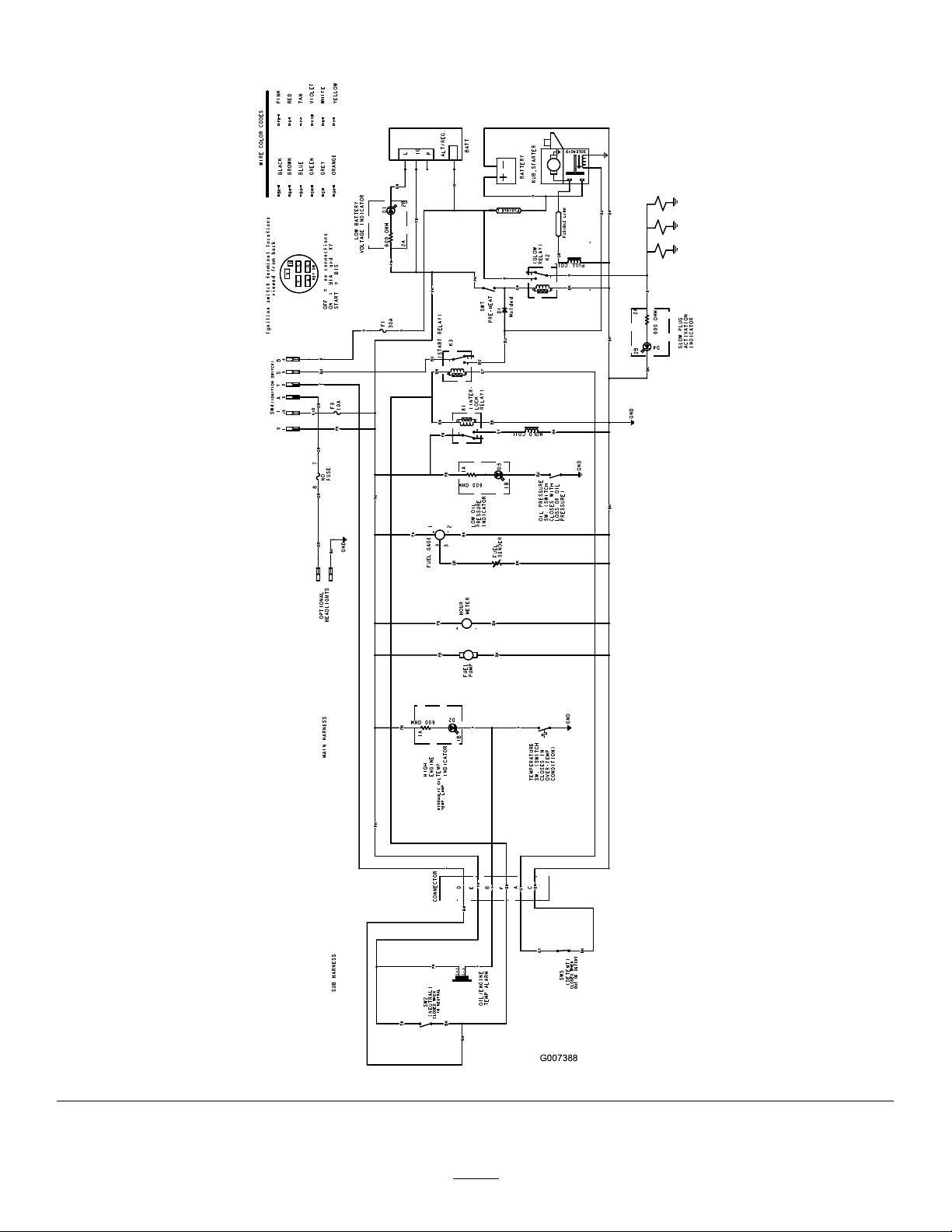

ElectricalSystemMaintenance....................................34

ServicingtheBattery...............................................34

DriveSystemMaintenance.........................................37

ServicingtheTracks................................................37

CoolingSystemMaintenance......................................40

ServicingtheCoolingSystem...................................40

BeltMaintenance......................................................41

CheckingtheConditionoftheHydraulicPump

Belt...................................................................41

CheckingtheAlternator/FanBeltTension.................41

ControlsSystemMaintenance.....................................41

AdjustingtheTractionControlAlignment.................41

AdjustingtheTractionControlNeutral

Position.............................................................42

AdjustingtheTrackingoftheTractionControl,

FullForwardPosition..........................................43

HydraulicSystemMaintenance....................................43

ReplacingtheHydraulicFilter..................................43

ChangingtheHydraulicFluid...................................44

CheckingtheHydraulicLines...................................45

Cleaning...................................................................46

RemovingDebrisfromtheTractionUnit...................46

CleaningtheChassis...............................................46

Storage........................................................................46

Troubleshooting...........................................................47

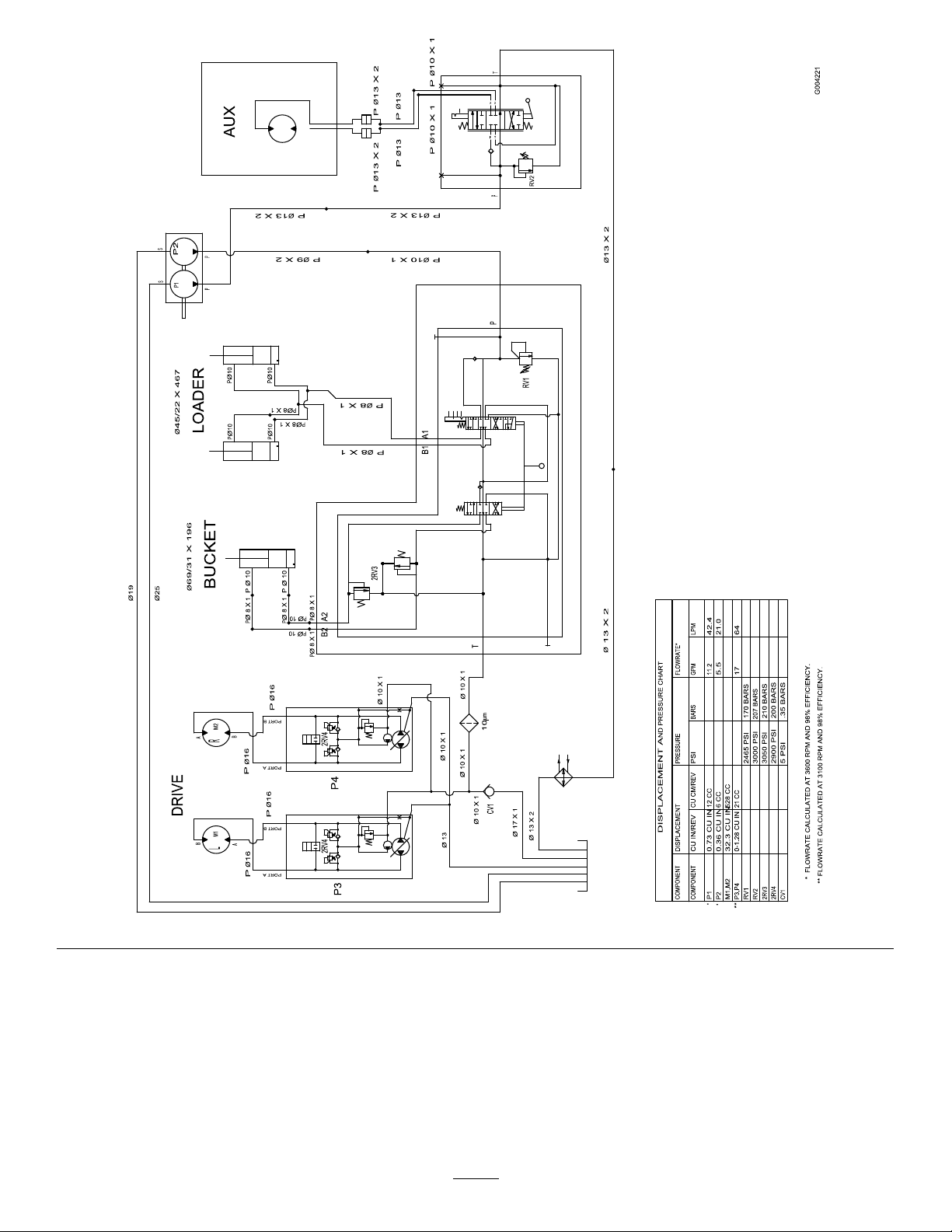

Schematics...................................................................51

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

Caution

,

W ar ning

,or

Danger

—personalsafety

•Wearappropriateclothingincludingsafetyglasses,long

pants,safetyshoes,andhearingprotection.Tiebacklong

hair.Donotwearjewelry.

•Inspecttheareawheretheequipmentistobeusedand

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

WARNING

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

•Becomefamiliarwiththesafeoperationoftheequipment,

operatorcontrols,andsafetysigns.

•Alloperatorsandmechanicsshouldbetrained.The

ownerisresponsiblefortrainingtheusers.

•Neverletchildrenoruntrainedpeopleoperateorservice

theequipment.Localregulationsmayrestricttheageof

theoperator.

•Theowner/usercanpreventandisresponsiblefor

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

Preparation

–Neverremovethefuelcaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingtheengine.Onlystarttheengine

fromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability .

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,lowerimplements,disengagethe

auxiliaryhydraulics,engageparkingbrake,shutoffthe

engine,andremovethekeybeforeleavingtheoperator's

positionforanyreason.

•Keephandsandfeetawayfrommovingattachments.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmay

occurifyoudigintothem.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,inAustralia,call1100

forthenationwidemarkingservice).

•Evaluatetheterraintodeterminewhataccessoriesand

attachmentsareneededtoproperlyandsafelyperform

thejob.Useonlyaccessoriesandattachmentsapproved

bythemanufacturer.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachinewhileill,tired,orunderthe

inuenceofalcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Readallattachmentmanuals.

4

Page 5

•Ensurethattheareaisclearofotherpeoplebefore

operatingthetractionunit.Stopthetractionunitif

anyoneentersthearea.

•Neverleavearunningtractionunitunattended.Always

lowertheloaderarms,shutofftheengine,settheparking

brake,andremovethekeybeforeleaving.

•Donotexceedtheratedoperatingcapacity,asthetraction

unitmaybecomeunstablewhichmayresultinlossof

control.

•Donotcarryaloadwiththearmsraised.Alwayscarry

loadsclosetotheground.

•Donotover-loadtheattachmentandalwayskeepthe

loadlevelwhenraisingtheloaderarms.Logs,boards,and

otheritemscouldrolldowntheloaderarms,injuringyou.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Checkforoverheadclearances(i.e.,branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Ensurethatyouoperatethetractionunitinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthetractionunit

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Beforedigging,havetheareamarkedforunderground

utilities,anddonotdiginmarkedareas.

•Locatethepinchpointareasmarkedonthetractionunit

andattachmentsandkeephandsandfeetawayfrom

theseareas.

•Beforeoperatingthetractionunitwithanattachment,

ensurethattheattachmentisproperlyinstalled.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

theheavyend,andafullbucketmakesthefrontofthe

tractionunittheheavyend.Mostotherattachmentsmake

thefrontoftractionunittheheavyend.

•Raisingtheloaderarmsonaslopeaffectsthestabilityof

themachine.Wheneverpossible,keeptheloaderarmsin

theloweredpositionwhenonslopes.

•Removinganattachmentonaslopemakestherearofthe

tractionunitheavy .RefertoStabilityData(page7),to

determinewhethertheattachmentcanbesafelyremoved

ontheslope.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

workarea.Watchforholes,ruts,orbumps,asuneven

terraincouldoverturnthetractionunit.Tallgrasscan

hideobstacles.

•UseonlyT oro-approvedattachments.Attachmentscan

changethestabilityandtheoperatingcharacteristicsof

thetractionunit.Warrantymaybevoidedifusedwith

unapprovedattachments.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthetractionunit

losestraction,proceedslowly,straightdowntheslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly

andkeeptheheavyendofthetractionunituphill.

•Donotoperateneardrop-offs,ditches,orembankments.

Thetractionunitcouldsuddenlyturnoverifatrackgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

•Donotparkthetractionunitonahillsideorslope

withoutloweringtheattachmenttotheground,setting

theparkingbrake,andchockingthetracks.

MaintenanceandStorage

•Disengagetheauxiliaryhydraulics,lowertheattachment,

settheparkingbrake,shutofftheengine,andremove

thekey.W aitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuelspills.

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Donotoperatethetractionunitonhillsidesorslopes

exceedingtheanglesrecommendedinStabilityData(page

7),andthoseintheattachmentOperator'sManual.Seealso

theSlopeIndicator(page8).

•Operateupanddownslopeswiththeheavyendof

thetractionunituphill.Weightdistributionchanges.

Anemptybucketmakestherearofthetractionunit

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatterybeforemakinganyrepairs.

Disconnectthenegativeterminalrstandthepositive

last.Connectpositiverstandnegativelast.

5

Page 6

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopen,well-ventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

SoundPressureLevel

SoundPressureLevelThisunithasasoundpressurelevelat

theoperator’ searof93dBA,whichincludesanUncertainty

Value(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN11201.

•Ifanymaintenanceorrepairrequirestheloaderarmsto

beintheraisedposition,securethearmsintheraised

positionwiththehydrauliccylinderlocks.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthetractionunitfreeofgrass,leaves,orotherdebris

buildup.Cleanupoilorfuelspills.Allowthetraction

unittocoolbeforestoring.

•Useextracarewhenhandlingfuels.Theyareammable

andvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethefuelcaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthetractionunitindoors.

–Neverstorethetractionunitorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pickupbed,oranysurfaceotherthantheground.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof101dBA,

whichincludesanUncertaintyV alue(K)of1dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO6395.

VibrationLevel

Measuredvibrationlevelforrighthand=1.5m/s

Measuredvibrationlevelforlefthand=1.3m/s

UncertaintyValue(K)=0.8m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

2

2

2

–Keepcontainernozzleincontactwiththetankduring

lling.

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforestarting.

•UseonlygenuineT ororeplacementpartstoensurethat

originalstandardsaremaintained.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparks,and

amesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthigh-pressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithin

afewhoursbyaqualiedsurgeonotherwisegangrene

mayresult.

6

Page 7

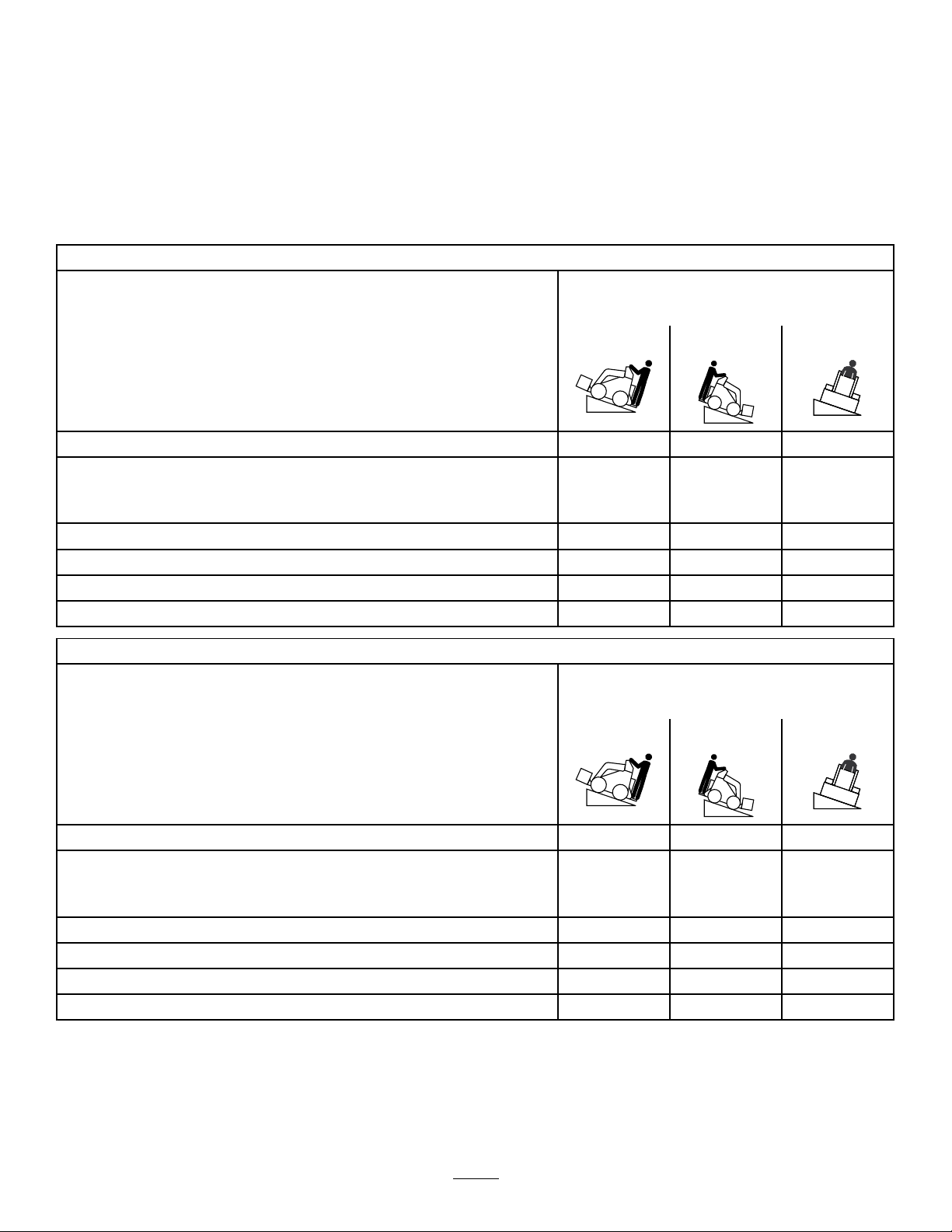

StabilityData

Thefollowingtableslistthemaximumsloperecommendedforthetractionunitinthepositionslistedinthetables.Slopesover

thelisteddegreemaycausethetractionunittobecomeunstable.Thedatainthetablesassumethattheloaderarmsarefully

lowered;raisedarmsmayaffectthestability.

Ineachattachmentmanualisasetof3stabilityratings,oneforeachhillposition.Todeterminethemaximumslopeyoucan

traversewiththeattachmentinstalled,ndthedegreeofslopethatcorrespondstothestabilityratingsoftheattachment.

Example:IftheattachmentinstalledonaTXmodel22323tractionunithasaFrontUphillratingofB,aRearUphillratingof

D,andaSideUphillratingofC,thenyoucoulddriveforwardupa19°slope,rearwardupa12°slope,orsidewaysona14°

slope,aslistedinthefollowingtable.

Model22323

MaximumRecommendedSlopewhen

Operatingwith:

FrontUphillRearUphill

Conguration

Tractionunitwithoutattachment

Tractionunitwithanattachmentratedwithoneofthefollowingstabilityratings

foreachslopeposition:*

A

B

C16°15°14°

D

E

Model22324

11°21°19°

25°25°20°

19°19°18°

10°12°9°

5°5°5°

MaximumRecommendedSlopewhen

Operatingwith:

FrontUphillRearUphill

SideUphill

SideUphill

Conguration

Tractionunitwithoutattachment

Tractionunitwithanattachmentratedwithoneofthefollowingstabilityratings

foreachslopeposition:*

A

B

C18°16°14°

D

E

12°19°21°

25°25°23°

22°22°20°

10°10°10°

5°5°5°

7

Page 8

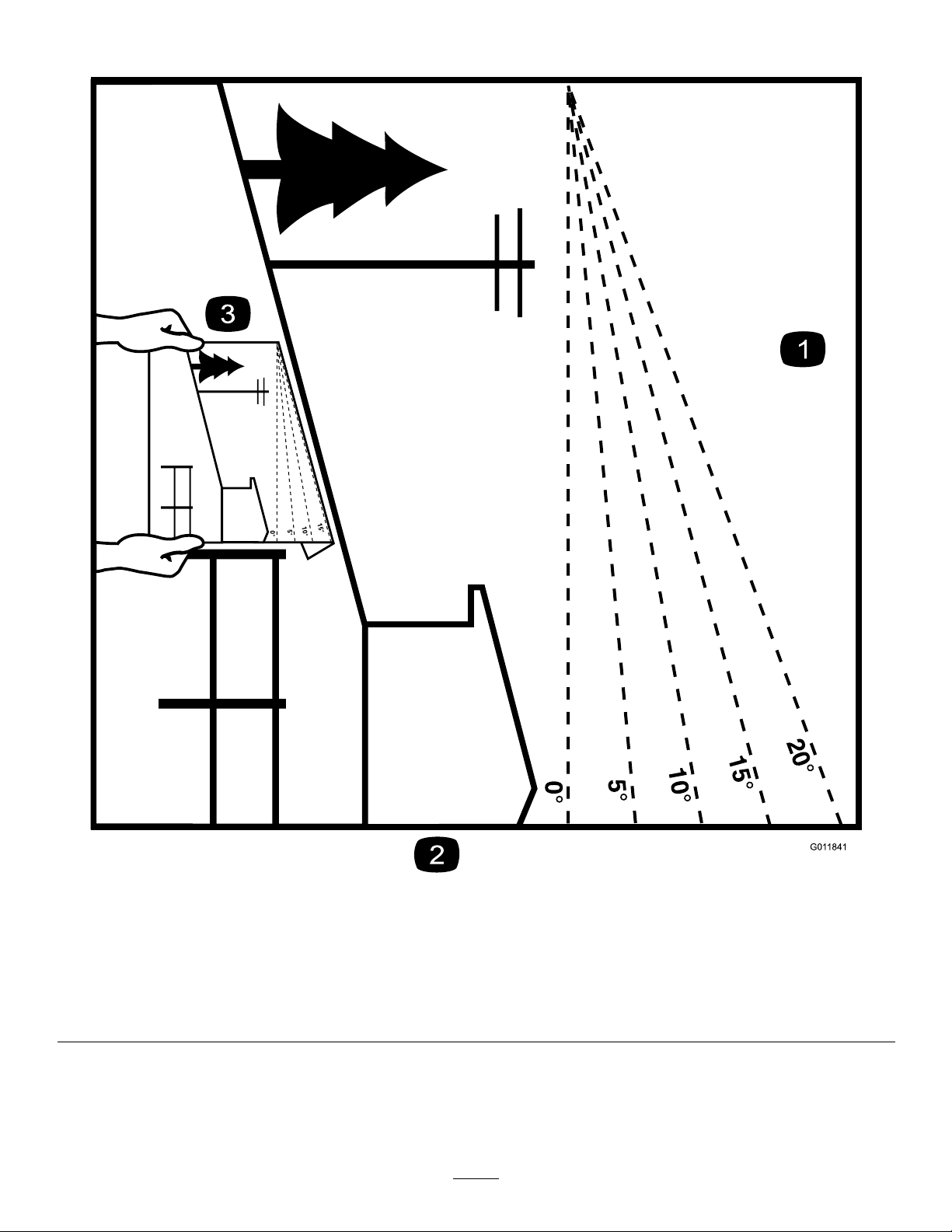

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Todeterminethemaximumslopeyoucansafelyoperatethemachineon,refertotheStabilityDatasection.Usetheslope

indicatortodeterminethedegreeofslopeofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthanthat

speciedintheStabilityDatasection.Foldalongtheappropriatelinetomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge

8

Page 9

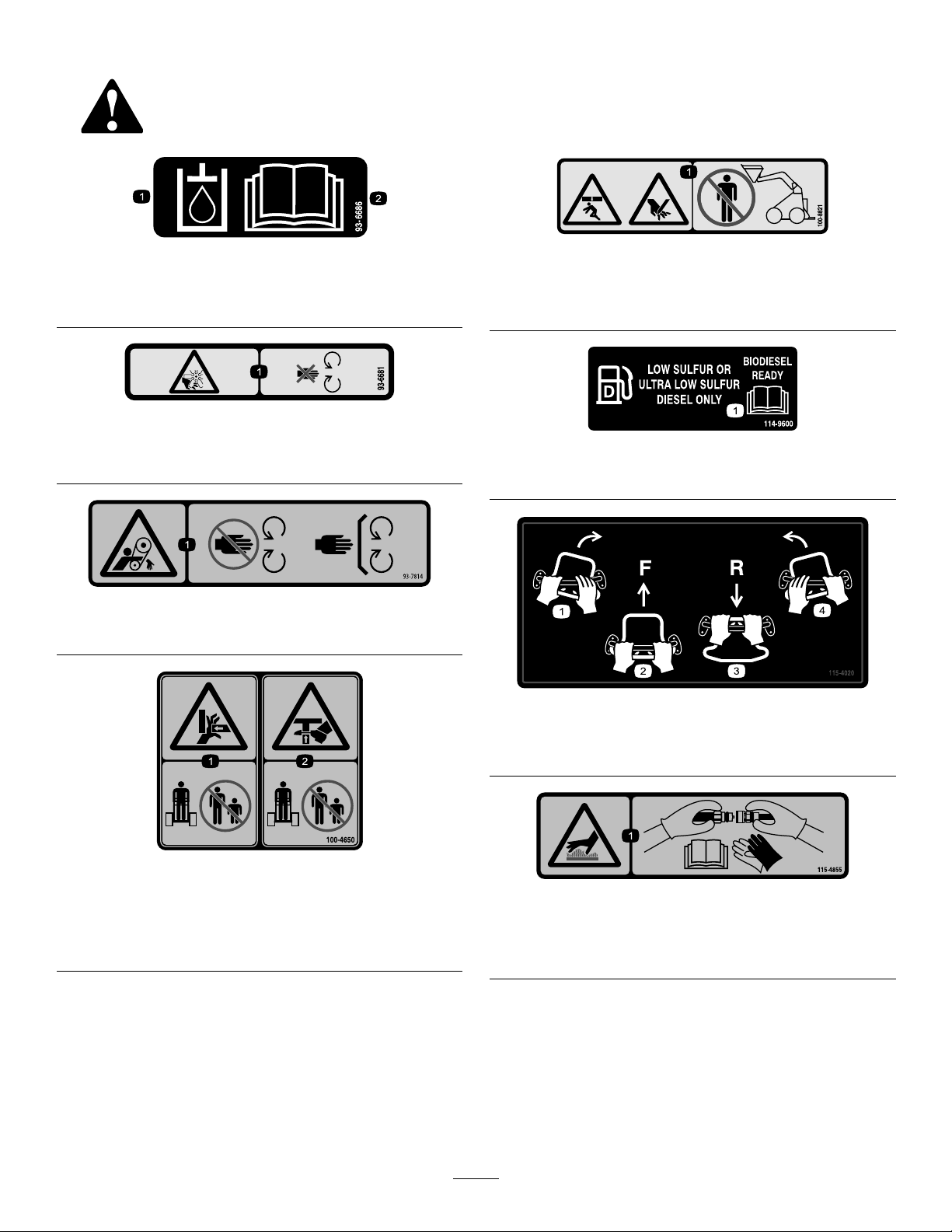

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6686

1.Hydraulicuid

2.ReadtheOperator'sManual.

93-6681

1.Cutting/dismemberment—hazard,fan-stayawayfrom

movingparts.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

100-8821

1.Crushinghazardandcuttinghazardofhand—stayasafe

distanceawayfromthefrontofthetractionunitwhenthe

loaderarmsareraised.

114-9600

1.ReadtheOperator'sManual.

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

awayfromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

awayfromthemachine.

115-4020

1.Turnright3.Reverse

2.Forward

4.Turnleft

115-4855

1.Hotsurface/burnhazard—wearprotectivegloveswhen

handlingthehydrauliccouplersandreadtheOperator's

Manualforinformationonhandlinghydrauliccomponents.

9

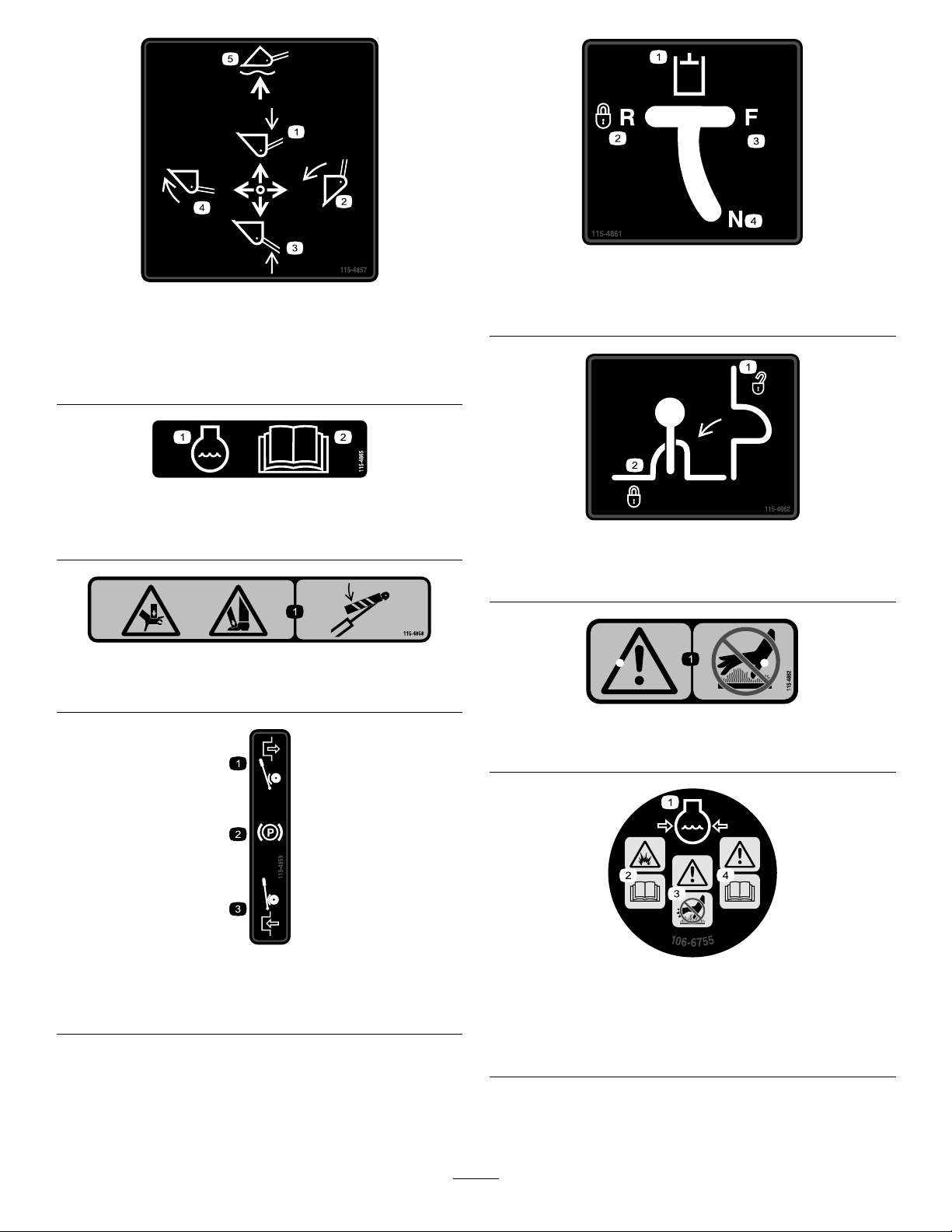

Page 10

115-4861

115-4857

1.Lowertheloaderarms.

2.Dumpthebucket.5.Floatthebucketonthe

3.Raisetheloaderarms.

4.Curlthebucket.

ground.

115-4865

1.Enginecoolant

2.ReadtheOperator's

Manual.

115-4858

1.Crushinghazardofhandsorfeet—installthecylinderlock.

1.Auxiliaryhydraulics3.Forward

2.Lockedreverse(detent)4.Neutral(off)

115-4862

1.Loader-valve

lock—unlocked

2.Loader-valvelock—locked

115-4882

1.Disengaged3.Engaged

2.Parkingbrake

1.Warning—stayasafedistanceawayfromthehotsurfaces.

115-4859

106-6755

1.Enginecoolantunder

pressure.

2.Explosionhazard—read

theOperator'sManual.

3.Warning—donottouchthe

hotsurface.

4.Warning—readthe

Operator'sManual.

10

Page 11

1.Liftpoint

93-9084

2.Tie-downpoint

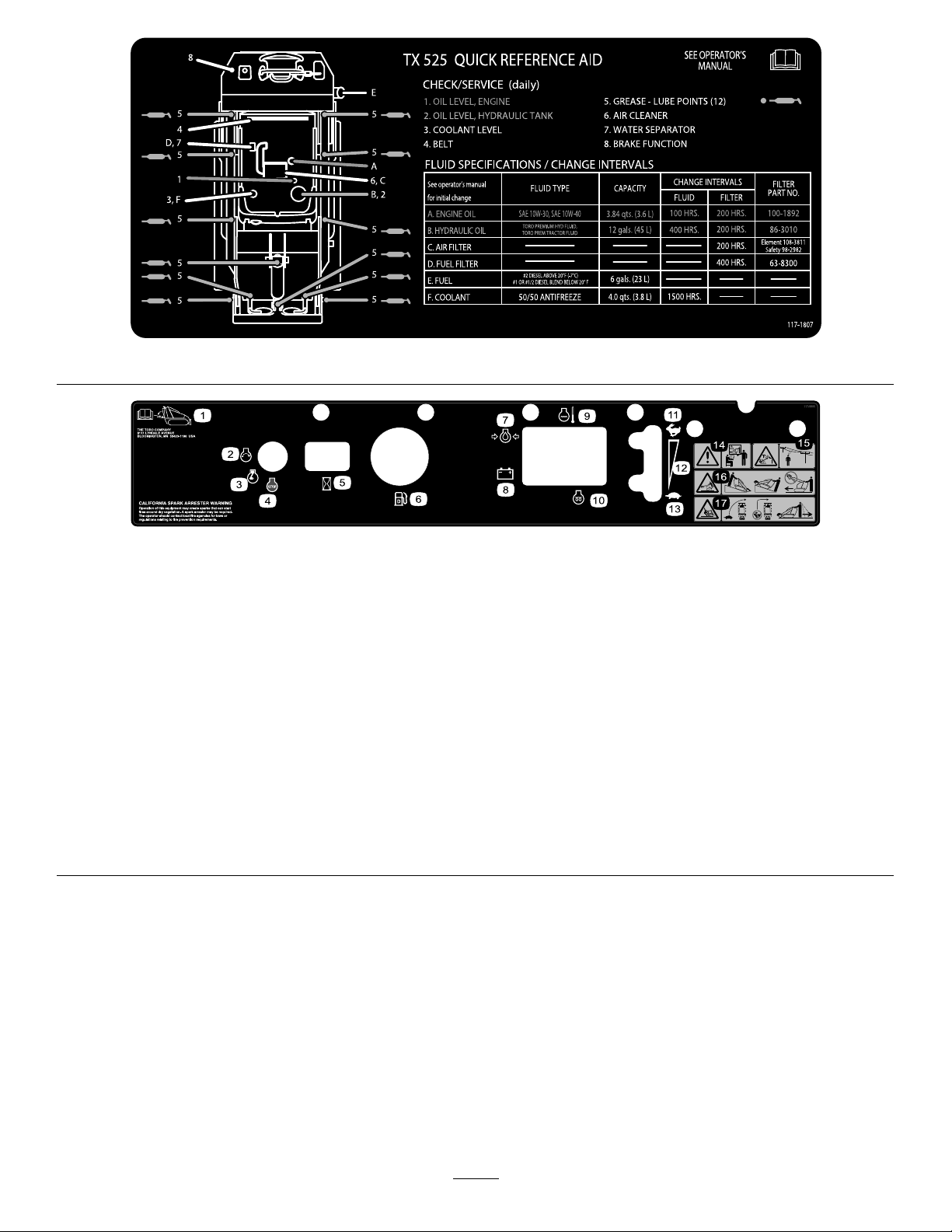

BatterySymbols

Someorallofthesesymbolsareonyourbattery .

1.Explosionhazard

2.Nore,opename,or

smoking

3.Causticliquid/chemical

burnhazard

4.Weareyeprotection.9.Flusheyesimmediately

5.ReadtheOperator's

Manual.

6.Keepbystandersasafe

distancefromthebattery.

7.Weareyeprotection;

explosivegasescan

causeblindnessandother

injuries.

8.Batteryacidcancause

blindnessorsevereburns.

withwaterandgetmedical

helpfast.

10.Containslead;donot

discard.

115-4860

1.Warning—readtheOperator'sManual.

2.Warning—settheparkingbrake,shutofftheengine,removetheignitionkeyandlowertheloaderarmsbeforeleavingthemachine.

3.Crushinghazard—installthecylinderlockandreadtheinstructionsbeforeservicingorperformingmaintenance.

4.Cuttinghazardofhandsorfeet—waitforallmovingpartstostop;stayawayfrommovingparts;keepallguardsandshieldsin

place.

5.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistanceawayfromthemachine.

6.Explosionandelectricshockhazard—donotdiginareaswithburiedgasorelectricallines;contactlocalpowerorganizations

beforedigging.

11

Page 12

117-1807

117-9905

1.Operator'sManuallocation

2.Engine—start7.Engineoilpressure

3.Engine—run8.Battery

4.Engine—stop9.Enginetemperature14.Warning—donotoperate

5.Hourmeter

6.Fuelgauge—diesel1 1.Fast16.Tippinghazard—movethe

12.Continuousvariablesetting

13.Slow

thismachineunlessyou

aretrained.

10.Glowplug

15.Electricshockhazard,

overheadpowerlines—stay

awayfromoverheadpower

lines.

tractionunitwiththeheavy

enduphill;carryloadslow;

neverjerkthecontrols;use

asteady,evenmotion.

17.Tippinghazard—slowthe

tractionunitwhenturning,

donottravelfastwhen

turning,lookbehindand

downwhenreversing.

12

Page 13

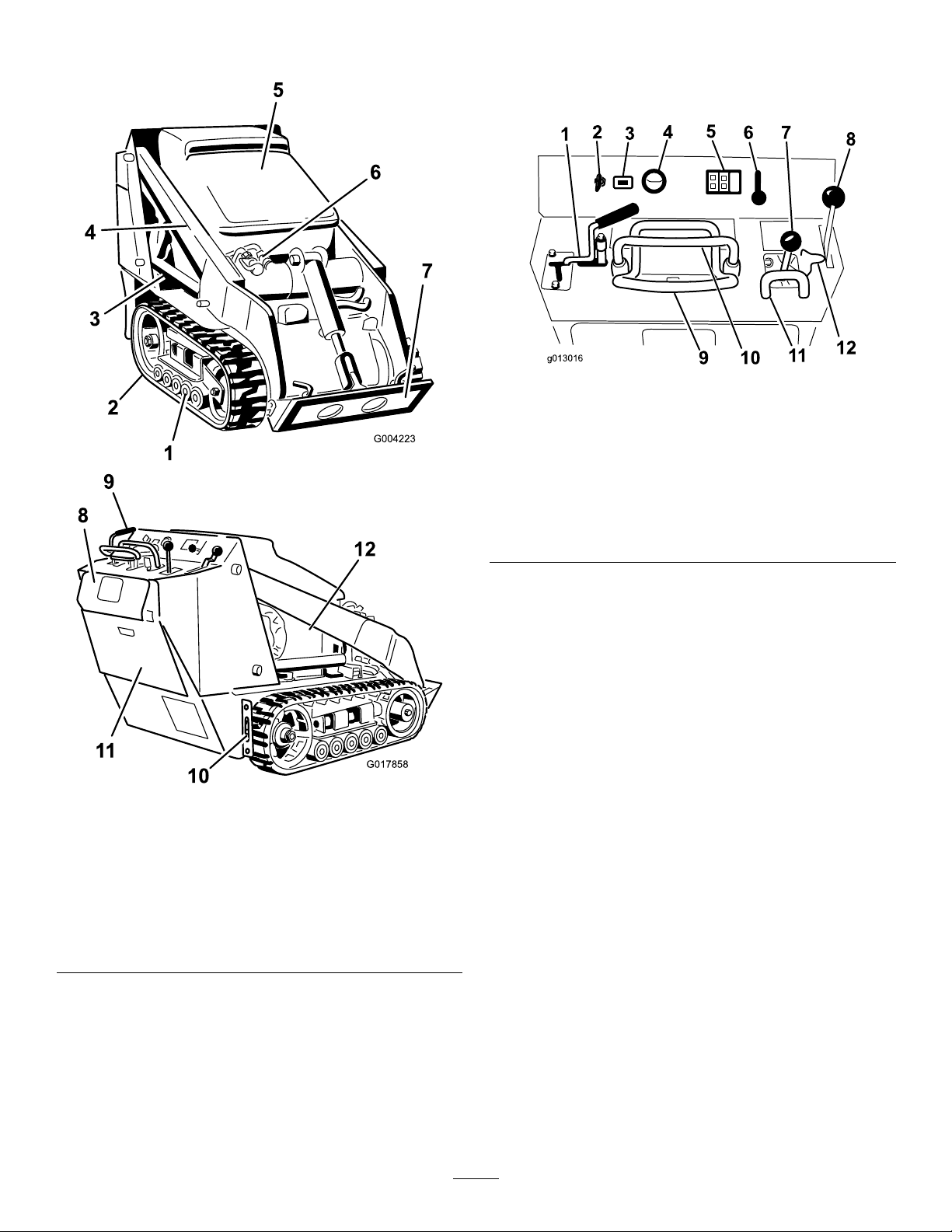

ProductOverview

12

G017858

1

2

3

4

5

6 7

8

12

11

109

g013016

Controls

Becomefamiliarwithallthecontrols(Figure5)beforeyou

starttheengineandoperatethetractionunit.

Figure5

Figure4

1.Roadwheels7.Mountplate

2.Track

3.Liftcylinder9.Controlpanel

4.Loaderarms

5.Hood11.Rearaccesscover

6.Auxiliary-hydraulic

couplers

8.Reversesafetyplate

10.Tie-down/liftloop

12.Sidepanelscreen

1.Auxiliary-hydraulicslever

2.Keyswitch8.Parking-brakelever

3.Hourmeter9.Tractioncontrol

4.Fuelgauge

5.Indicatorlightsandglow

plugswitch

6.Throttlelever12.Loader-valvelock

7.Loaderarm/attachmenttilt

lever

10.Referencebar

11.Loader-control-reference

bar

KeySwitch

Thekeyswitch,usedtostartandshutofftheengine,has3

positions:OFF,RUN,andSTART.

•Tostarttheengine,rotatethekeytotheRUNposition,

theglow-pluglightcomeson.Whentheglow-pluglight

turnsoff,turnthekeytotheSTARTposition.Release

thekeywhenenginestartsanditmovesautomatically

totheRUNposition.

•Toshutofftheengine,rotatethekeytotheOFFposition.

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeedand

rearwardtodecreasespeed.

ReferenceBar

Whendrivingthetractionunit,usethereferencebaras

ahandleandaleveragepointforcontrollingthetraction

controlandtheauxiliary-hydraulicslever.Toensuresmooth,

controlledoperation,donottakebothhandsoffthereference

barwhileoperatingthetractionunit.

13

Page 14

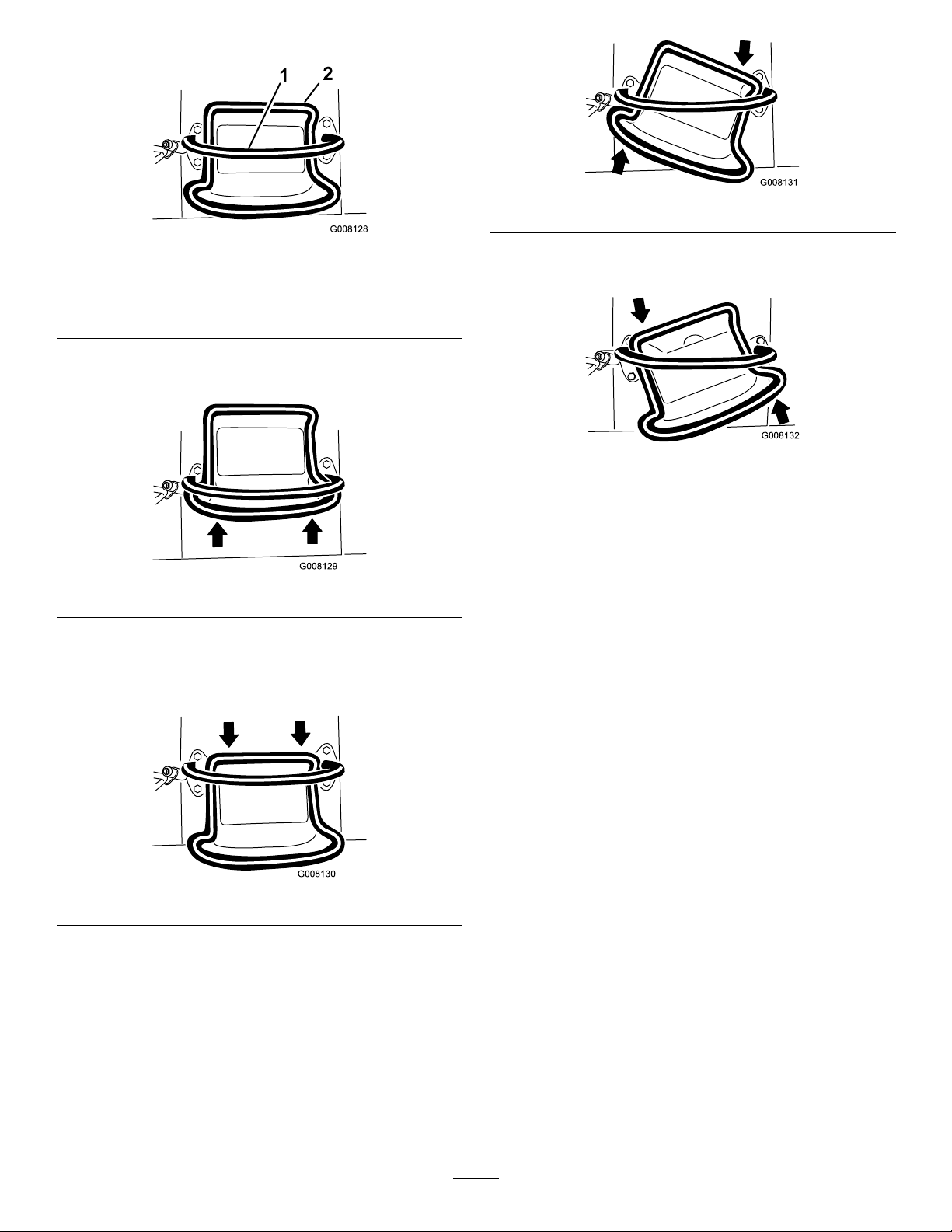

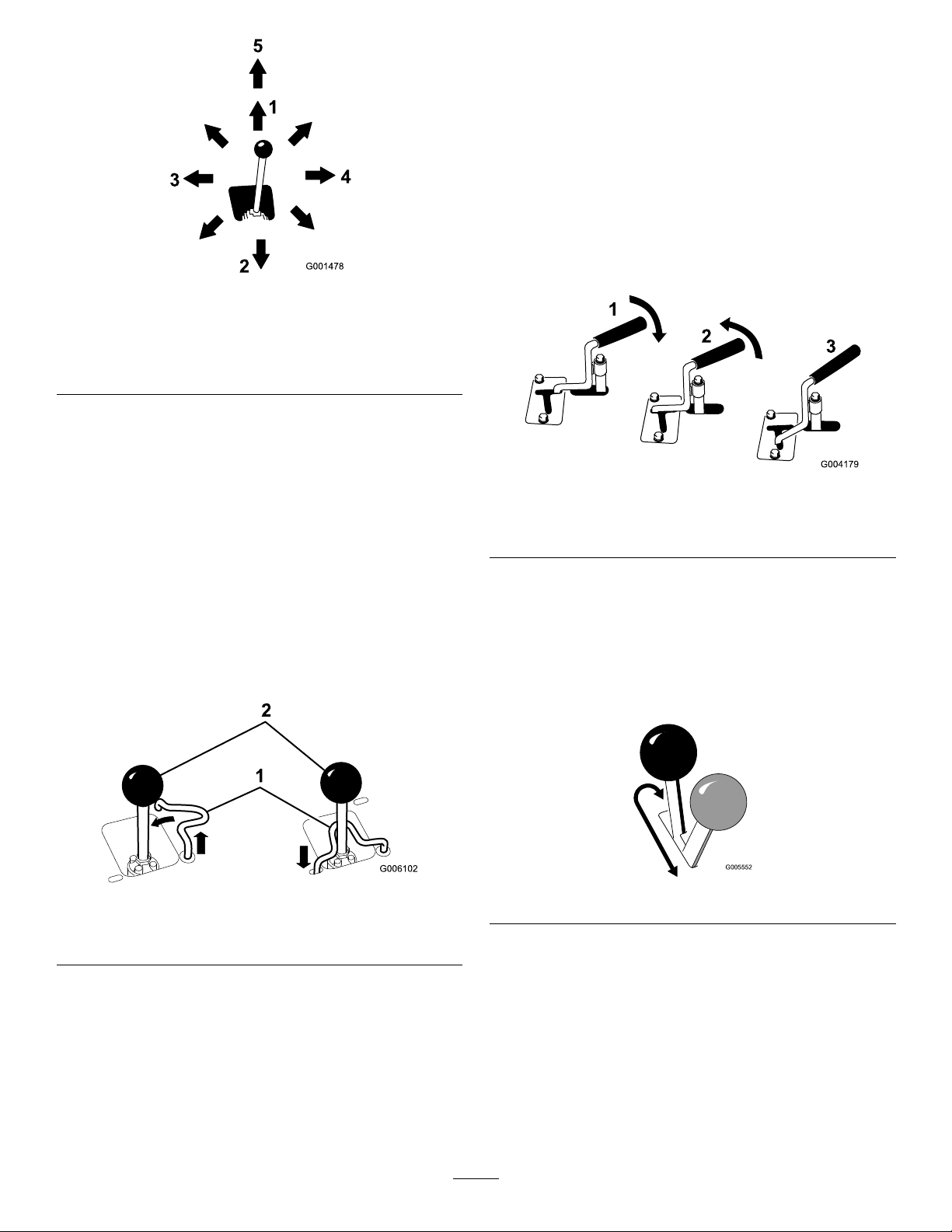

TractionControl

G008131

G008132

Figure9

Figure6

1.Referencebar(doesnotmovetogiveyouareferencepoint

andaxedhandletoholdwhileoperatingthetractionunit)

2.Tractioncontrol(movestocontrolthemachine)

•Tomoveforward,movethetractioncontrolforward

(Figure7).

Figure7

•Tomoverearward,movethetractioncontrolrearward

(Figure8).Whenreversing,lookbehindfor

obstructionsandkeepyourhandsonthereference

bar.

•Toturnleft,rotatethetractioncontrolcounterclockwise

(Figure10).

Figure10

•Tostop,releasethetractioncontrol(Figure6).

Note:Thefartheryoumovethetractioncontrolinany

direction,thefasterthemachinemovesinthatdirection.

LoaderArm/AttachmentTiltLever

Totilttheattachmentforward,slowlymovethelevertothe

right(Figure11).

Totilttheattachmentrearward,slowlymovethelevertothe

left(Figure11).

Figure8

•Toturnright,rotatethetractioncontrolclockwise(Figure

9).

Tolowertheloaderarms,slowlymovetheleverforward

(Figure11).

Toraisetheloaderarms,slowlymovetheleverrearward

(Figure11).

Youcanalsopushtheleverfullyforwardintoadetent

position(Figure11)toreleasetheloaderarmssothatthe

attachmentrestsontheground.Thisallowsattachmentssuch

asthelevelerandthehydraulicbladetofollowthecontours

oftheground(i.e.,oat)whengrading.

14

Page 15

Figure11

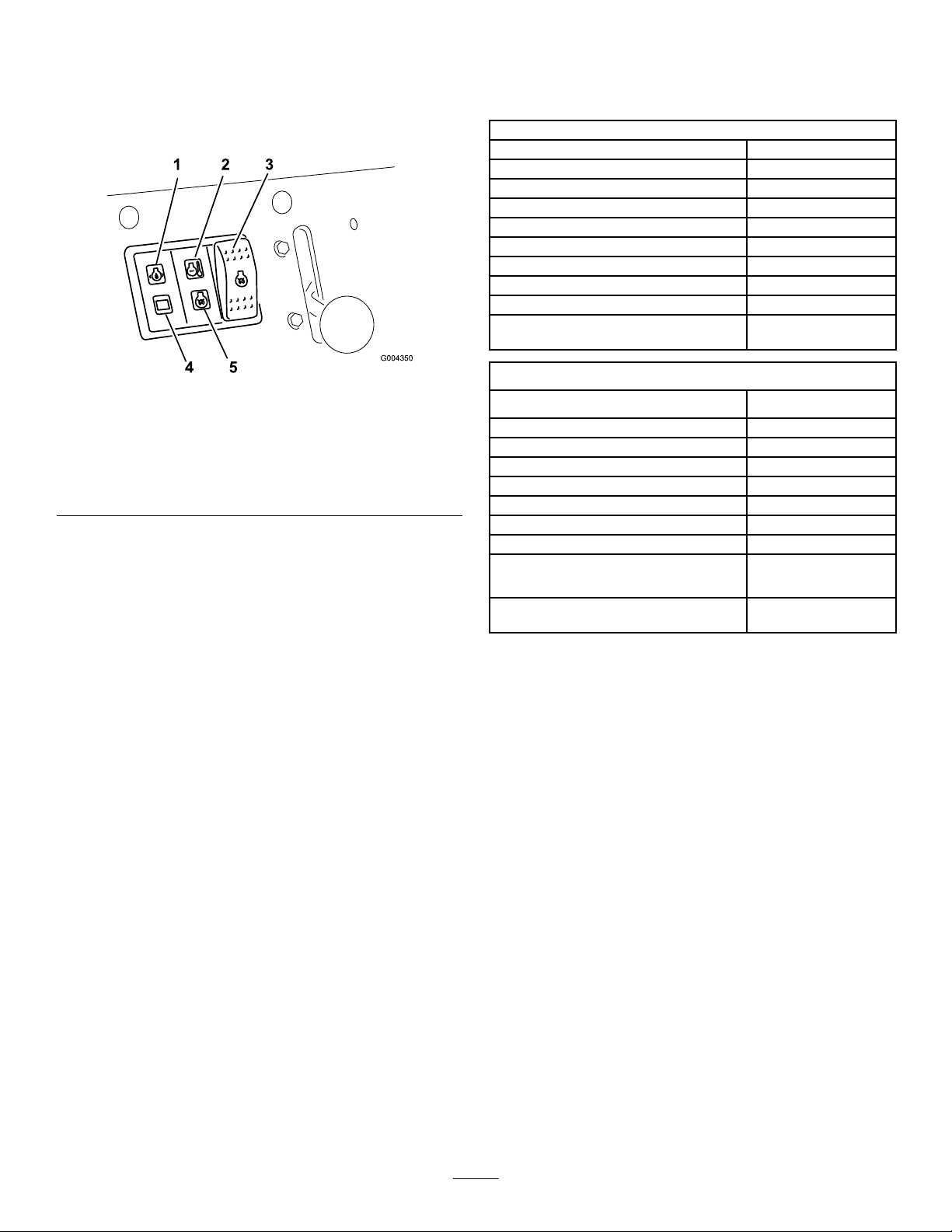

Auxiliary-HydraulicsLever

Tooperateahydraulicattachmentintheforwarddirection,

rotatetheauxiliary-hydraulicsleverrearwardandpullitdown

tothereferencebar(Figure13,number1).

Tooperateahydraulicattachmentinreversedirection,rotate

thehydraulicsleverrearward,thenmoveitleftintotheupper

slot(Figure13,number2).

Ifyoureleasetheleverwhileintheforwardposition,the

leverautomaticallyreturnstotheneutralposition(Figure13,

number3).Ifitisinthereverseposition,itremainsthere

untilyoupullitoutoftheslot.

1.Lowertheloaderarms

2.Raisetheloaderarms

3.Tilttheattachment

rearward

4.Tilttheattachmentforward

5.Detent(Float)position

Bymovingthelevertoanintermediateposition(suchas,

forwardandleft),youcanmovetheloaderarmsandtiltthe

attachmentatthesametime.

Loader-ValveLock

Theloader-valvelocksecurestheloaderarm/attachment

tiltleversothatyoucannotpushitforward.Thishelpsto

ensurethatnooneaccidentallylowerstheloaderarmsduring

maintenance.Securetheloaderarmswiththelockanytime

youneedtostopthemachinewiththeloaderarmsraised.

Tosetthelock,liftuponitsothatitclearstheholeinthe

controlpanelandswingittotheleftinfrontoftheloaderarm

lever,pushingitdownintothelockedposition(Figure12).

Figure13

1.Forward-owhydraulics

2.Reverse-owhydraulics

3.Neutral

Parking-BrakeLever

Tosettheparkingbrake,pushthebrakeleverforwardandto

theleftandthenpullitrearward(Figure14).

Note:Thetractionunitmayrollslightlybeforethebrakes

engageinthedrivesprocket.

Figure12

1.Loader-valvelock

2.Loaderarm/attachmenttilt

lever

Loader-Control-ReferenceBar

Theloader-control-referencebarhelpsstabilizeyourhand

whileoperatingtheloaderarm/attachmenttiltlever.

Figure14

Toreleasethebrake,pushtheleverforwardandthenright,

intothenotch.

FuelGauge

Thisgaugemeasurestheamountoffuelinthefueltank.

15

Page 16

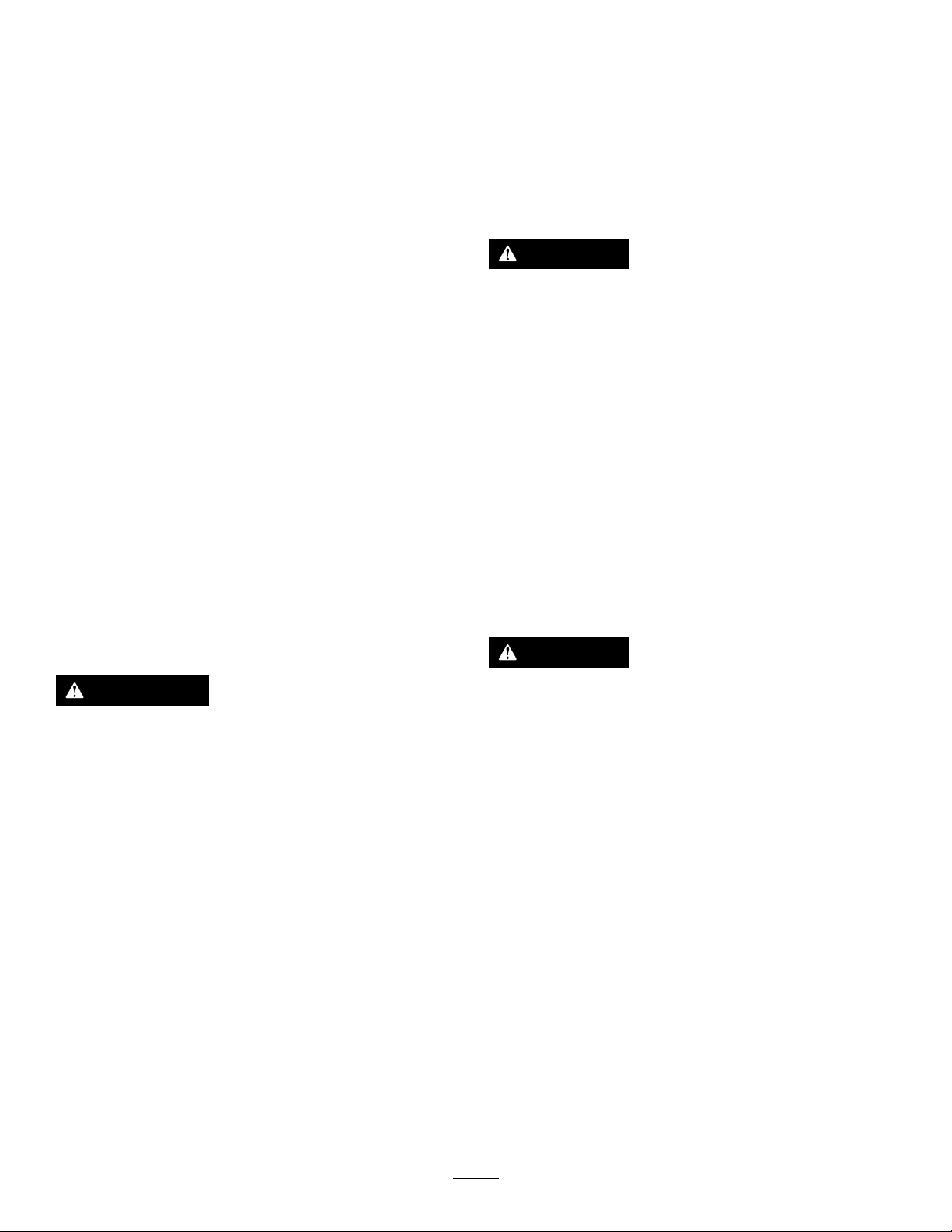

Engine-OilPressureLight

G004350

123

45

Specications

Iftheengine-oilpressuregetstoolow ,thislightilluminates

andanaudiblealarmsounds.Ifthishappens,shutoffthe

engineimmediatelyandchecktheoil.Iflow,addoiland/or

lookforpossibleleaks.

Figure15

1.Engine-oilpressurelight4.Batterychargeindicator

2.Engine-coolant

temperaturelight

3.Glow-plugswitch

light

5.Glow-pluglight

BatteryChargeIndicatorLight

Ifthebatterychargebecomestoolow,thislightilluminates

andanaudiblealarmsounds.Ifthishappens,shutoffthe

engineandchargeorreplacethebattery.Checkthetension

ofthealternatorbelt;refertoyourengineowner’smanual.

Note:Specicationsanddesignaresubjecttochange

withoutnotice.

Model22323

Width

Length

Height

Weight

Operatingcapacity251kg(553lb)

Tippingcapacity

Wheelbase

Dumpheight(withnarrowbucket)119cm(47inches)

Reach—fullyraised(withnarrowbucket)55cm(22inches)

Heighttohingepin(narrowbucketin

highestposition)

Model22324

Width

Length

Height

Weight

Operatingcapacity251kg(553lb)

Tippingcapacity

Wheelbase

Dumpheight(withnarrowbucket)119cm(47inches)

Reach—fullyraised(withnarrowbucket)55cm(22inches)

Heighttohingepin(narrowbucketin

highestposition)

86cm(34inches)

180cm(71inches)

117cm(46inches)

864kg(1904lb)

717kg(1,580lb)

79cm(31.2inches)

168cm(66inches)

104cm(41inches)

180cm(71inches)

109cm(43inches)

913kg(2,013lb)

717kg(1580lb)

79cm(31.2inches)

168cm(66inches)

EngineCoolantTemperatureLight

Iftheenginecoolantgetstoohot,thislightilluminatesand

anaudiblealarmsounds.Ifthishappens,shutofftheengine

andallowthetractionunittocool.Checkthecoolantlevel

whentheenginehasfullycooled.

Glow-PlugLight

Illuminateswhiletheglowplugsarechargedandwarming

theengine.

Glow-PlugSwitch

Pressandholdthisswitchfor10secondstoactivatetheglow

plugsbeforestartingtheengine.

HourMeter

Thehourmeterdisplaysthenumberofhoursofoperation

thathavebeenloggedonthetractionunit.

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesis

availableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealeror

Distributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Important:UseonlyToroapprovedattachments.

Otherattachmentsmaycreateanunsafeoperating

environmentordamagethetractionunit.

16

Page 17

Operation

•Monitorseals,hoses,gasketsincontactwithfuelasthey

maybedegradedovertime.

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Beforeoperating,checkthefuelandoil

level,andremovedebrisfromthetractionunit.Also,

ensurethattheareaisclearofpeopleanddebris.Y ou

shouldalsoknowandhavemarkedthelocationsofall

utilitylines.

AddingFuel

Useonlyclean,freshdieselfuelorbiodieselfuelswithlow

(<500ppm)orultralow(<15ppm)sulfurcontent.The

minimumcetaneratingshouldbe40.Purchasefuelin

quantitiesthatcanbeusedwithin180daystoensurefuel

freshness.

Fueltankcapacity:22L(5.85USgallons)

Usesummer-gradedieselfuel(No.2-D)attemperatures

above-7°C(20°F)andwinter-gradedieselfuel(No.1-D

orNo.1-D/2-Dblend)belowthattemperature.Useof

winter-gradefuelatlowertemperaturesprovideslowerash

pointandcoldowcharacteristicswhicheasesstartingand

reducesfuellterplugging.

Usingsummer-gradefuelabove-7°C(20°F)contributes

towardlongerfuelpumplifeandincreasedpowercompared

towinter-gradefuel.

Important:Donotusekeroseneorgasolineinsteadof

dieselfuel.Failuretoobservethiscautionwilldamage

theengine.

•Fuellterpluggingmaybeexpectedforatimeafter

convertingtobiodieselblendsd.

•Contactyourdistributorifyouwishformoreinformation

onbiodiesel.

FillingtheFuelTank

DANGER

Incertainconditions,fuelisextremelyammable

andhighlyexplosive.Areorexplosionfromfuel

canburnyouandothersandcandamageproperty.

•Fillthefueltankoutdoors,inanopenarea,when

theengineiscold.Wipeupanyfuelthatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinanapprovedcontainerandkeepit

outofthereachofchildren.Neverbuymore

thana30-daysupplyoffuel.

•Donotoperatewithouttheentireexhaust

systeminplaceandinproperworkingcondition.

DANGER

WARNING

Fuelisharmfulorfatalifswallowed.Long-term

exposuretovaporscancauseseriousinjuryand

illness.

•Avoidprolongedbreathingofvapors.

•Keepfaceawayfromnozzleandfueltankor

conditioneropening.

•Keepfuelawayfromeyesandskin.

BiodieselReady

Thismachinecanalsouseabiodieselblendedfuelofup

toB20(20%biodiesel,80%petrodiesel).Thepetrodiesel

portionshouldbeloworultralowsulfur.Observethe

followingprecautions:

•Thebiodieselportionofthefuelmustmeetspecication

ASTMD6751orEN14214.

•TheblendedfuelcompositionshouldmeetASTMD975

orEN590.

•Paintedsurfacesmaybedamagedbybiodieselblends.

•UseB5(biodieselcontentof5%)orlesserblendsincold

weather.

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethefuelvapors.Areorexplosionfrom

fuelcanburnyouandothersandcandamage

property.

•Alwaysplacefuelcontainersonthegroundaway

fromyourvehiclebeforelling.

•Donotllfuelcontainersinsideavehicleoron

atruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removeequipmentfromthe

truckortrailerandrefueltheequipmentwithits

wheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchequipment

onatruckortrailerfromaportablecontainer,

ratherthanfromafuel-dispensernozzle.

•Ifyoumustuseafuel-dispensernozzle,keepthe

nozzleincontactwiththerimofthefueltank

orcontaineropeningatalltimesuntilfuelingis

complete.

17

Page 18

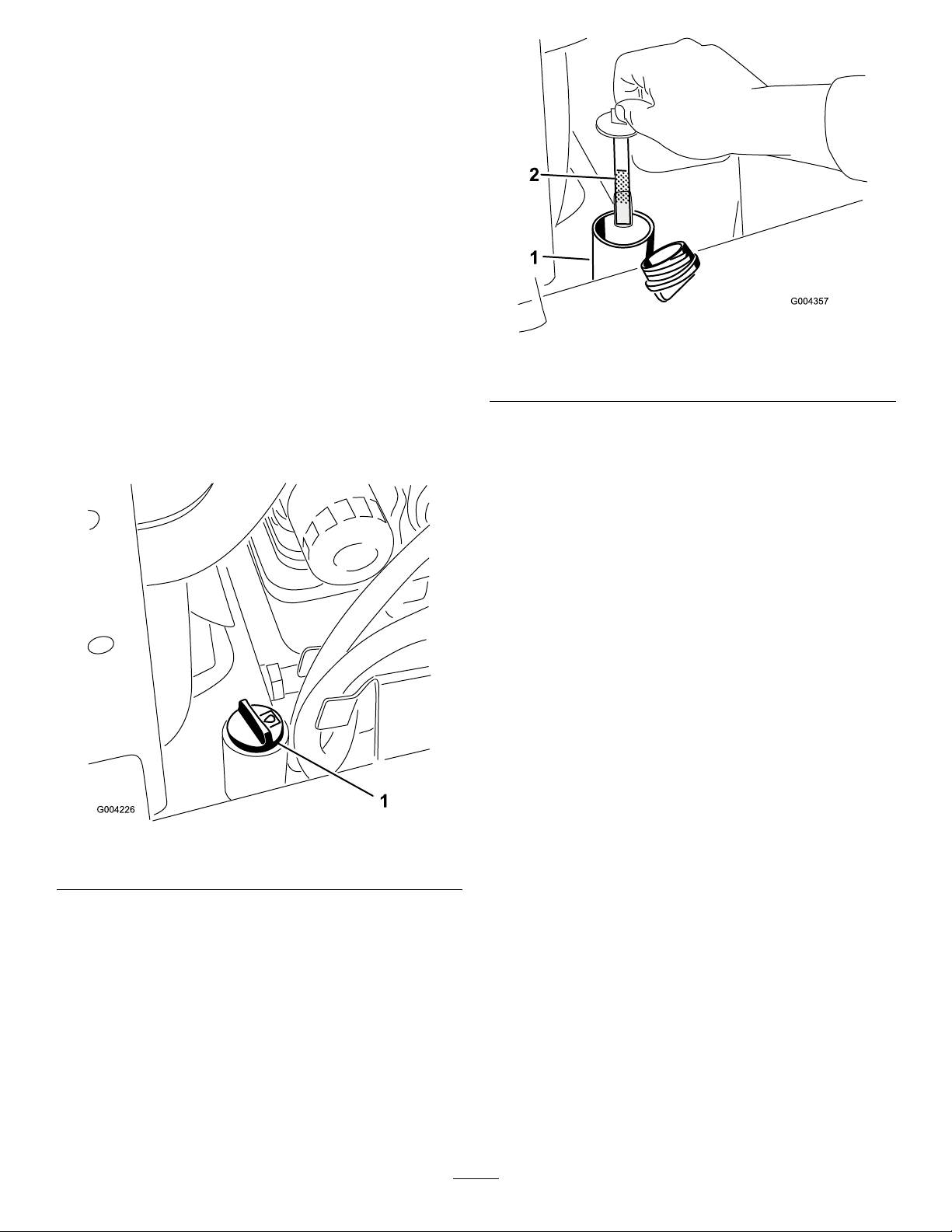

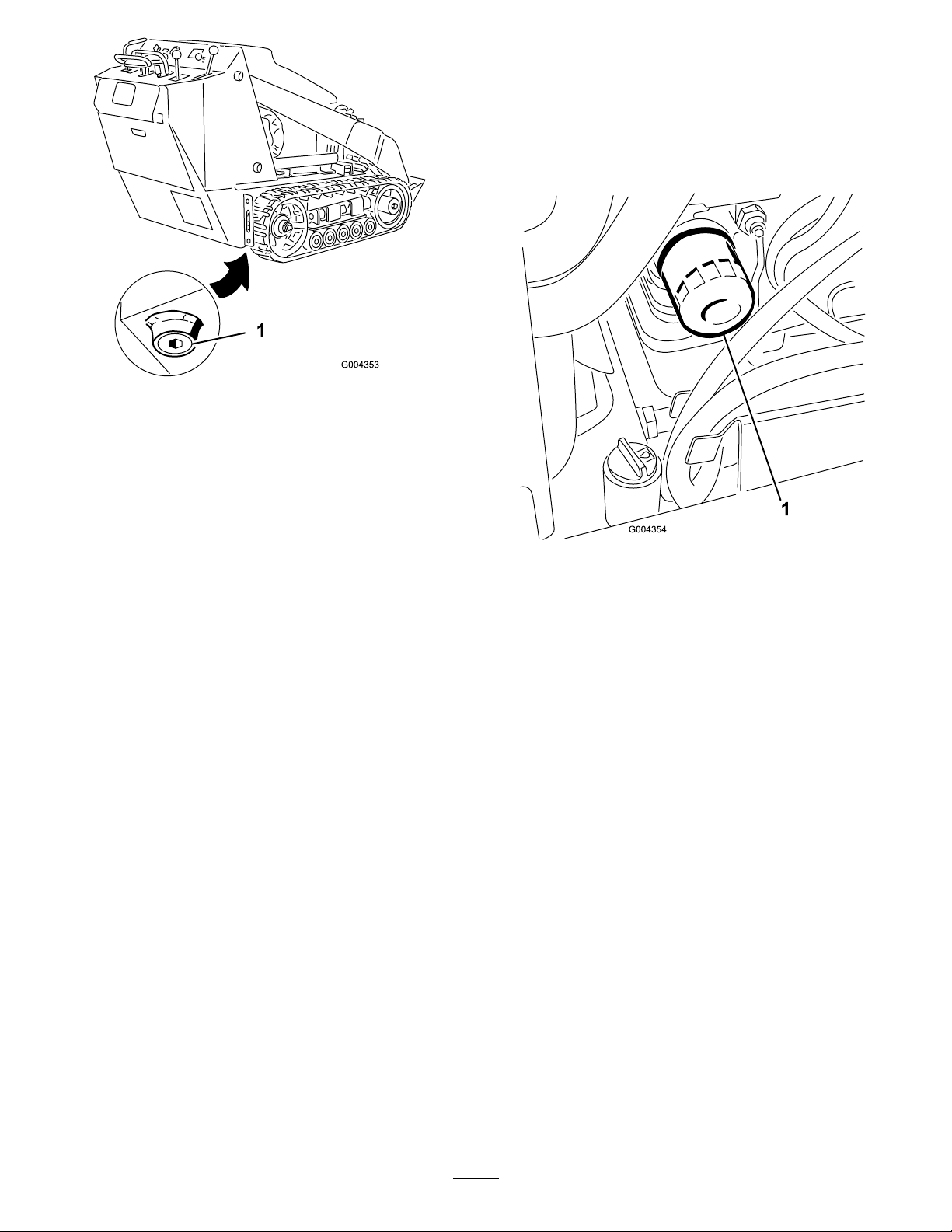

1.Removethefuel-tankcap(Figure16).

Figure16

1.Fuel-tankcap

2.Fillthetanktoabout2.5cm(1inch)belowthetopof

thetank,notthellerneck,withdieselfuel.

CheckingtheEngine-OilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthetractionunitonalevelsurface,lowerthe

loaderarms,andshutofftheengine.

2.Removethekeyandallowtheenginetocool.

3.Openthehood.

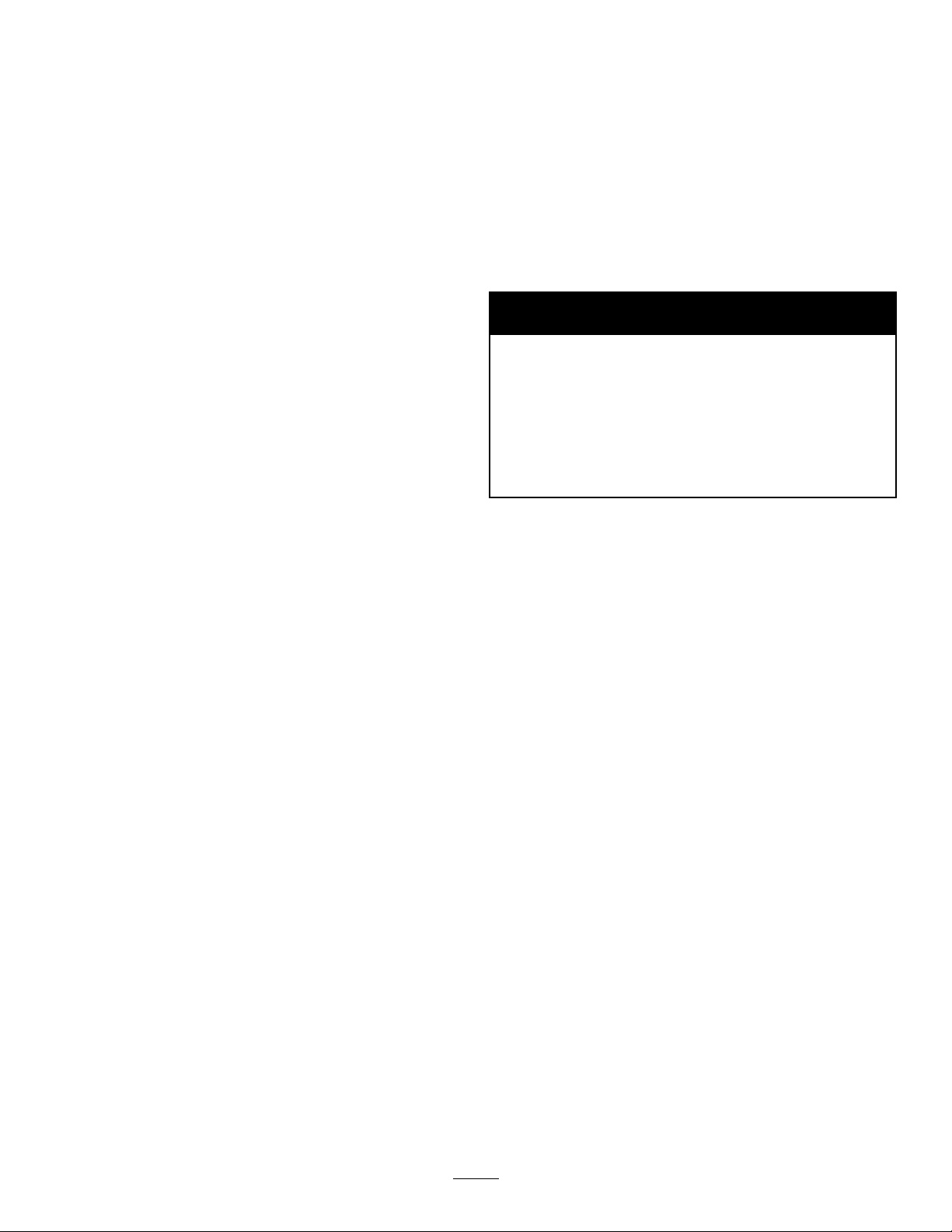

4.Cleanaroundtheoildipstick(Figure17).

3.Installthefuel-tankcap.

Figure17

1.Oildipstick2.Oil-llercap

5.Pulloutthedipstickandwipethemetalendclean

(Figure17).

6.Slidethedipstickfullyintothedipsticktube(Figure17).

7.Pullthedipstickoutandlookatthemetalend.

8.Iftheoillevelislow(belowthebottomhole),clean

aroundtheoil-llercapandremovethecap(Figure17).

9.Slowlypouronlyenoughoilintothevalvecoverto

raisetheleveltothetopholeonthedipstick.

Important:Donotoverllthecrankcasewithoil

becauseitmaydamagetheengine.

10.Replacethellercapanddipstick.

11.Closethehood.

18

Page 19

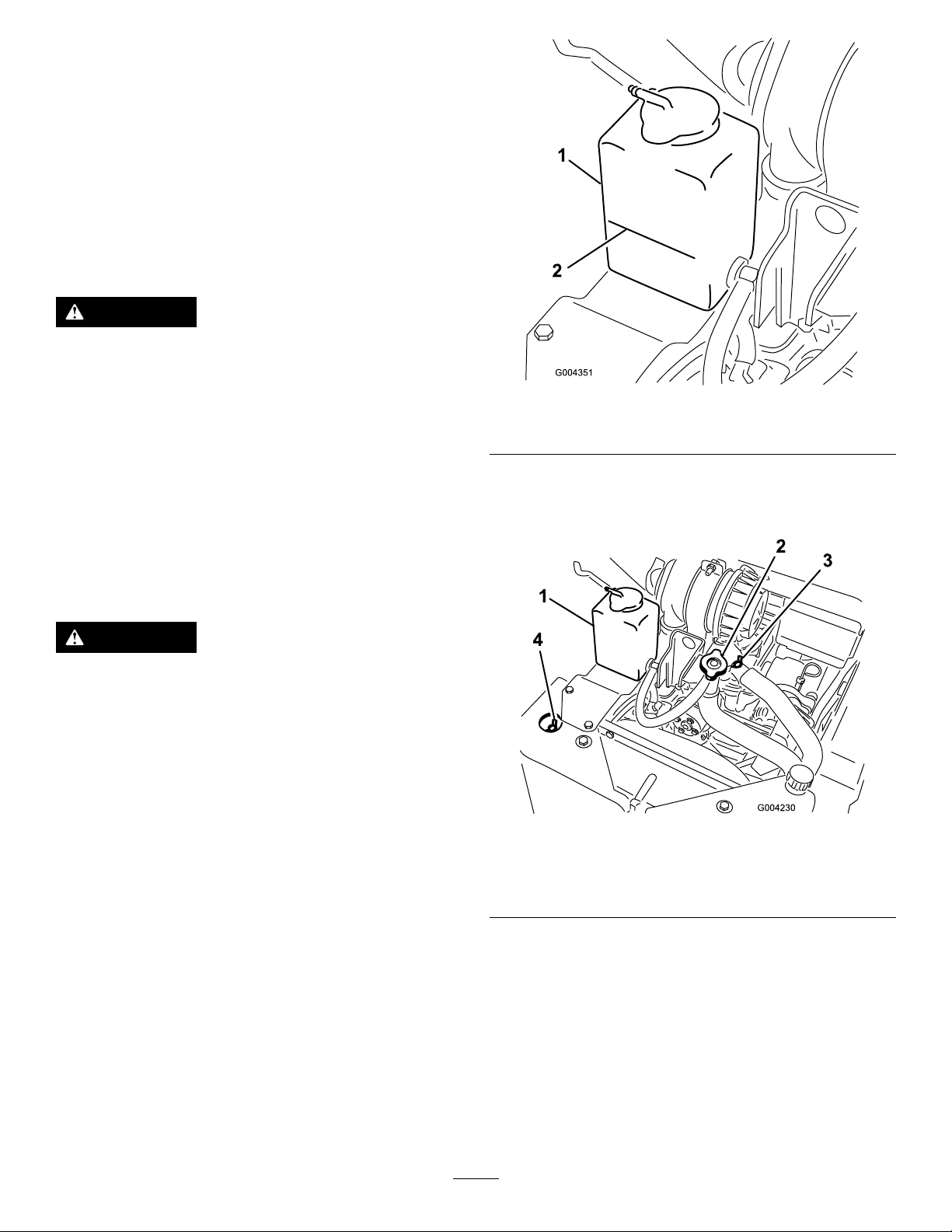

CheckingtheHydraulicFluid Level

ServiceInterval:Every25hours

HydraulicTankCapacity:45L(12USgallons)

RefertoChangingtheHydraulicFluid(page44)forhydraulic

uidspecications.

Important:Alwaysusethecorrecthydraulicuid.

Unspecieduidswilldamagethehydraulicsystem.

1.Removetheattachment,ifoneisinstalled;referto

RemovinganAttachment(page25).

2.Parkthetractionunitonalevelsurface,lowerthe

loaderarms,andfullyretractthetiltcylinder.

3.Shutofftheengine,removethekey,andallowthe

enginetocool.

Figure19

1.Fillerneck2.Dipstick

4.Openthehood.

5.Cleantheareaaroundthellerneckofthehydraulic

tank(Figure18).

Figure18

1.Hydraulicller-neckcap

7.Ifthelevelislow ,addenoughuidtoraiseittothe

properlevel.

8.Installthecaponthellerneck.

9.Closethehood.

6.Removethecapfromthellerneckandchecktheuid

levelonthedipstick(Figure19).

Note:Theuidlevelshouldbebetweenthemarks

onthedipstick.

19

Page 20

Checking,Adding,and BleedingtheEngineCoolant

ServiceInterval:Beforeeachuseordaily

Cleandebrisoffthescreen,oilcooler,andfrontofthe

radiatordailyandmoreoftenifconditionsareextremely

dustyanddirty

Thecoolingsystemislledwitha50/50solutionofwater

andpermanentethyleneglycolantifreeze.Checkthelevel

ofcoolantintheexpansiontankatthebeginningofeach

daybeforestartingtheengine.

DANGER

Iftheenginehasbeenrunning,thepressurized,hot

coolantcanescapeandcausesevereburns.

•Donotremovetheradiatorcapwhentheengine

ishot.Alwaysallowtheenginetocoolatleast

15minutesoruntiltheradiatorcapiscool

enoughtotouchwithoutburningyourhand

beforeremovingtheradiatorcap.

•Donottouchradiatorandsurroundingparts

thatarehot.

•Usearagwhenopeningtheradiatorcap,and

openthecapslowlytoallowsteamtoescape.

DANGER

Rotatingshaftandfancancausepersonalinjury.

•Donotoperatethemachinewithoutthecovers

inplace.

•Keepngers,handsandclothingclearof

rotatingfananddriveshaft.

•Parkthemachineonlevelground,lowerthe

loaderarms,settheparkingbrake,shutoff

theengine,andremovetheignitionkeybefore

performingmaintenance.

1.Checkthelevelofcoolantintheexpansiontank

(Figure20).

Thecoolantlevelshouldbeatorabovethemarkon

thesideofthetank.

Figure20

1.Expansiontank2.Fullmark

2.Ifthecoolantlevelislow ,completethefollowing

procedure:

A.Removethecoolant-llcap(Figure21).

Figure21

1.Expansiontank3.Topcoolant-bleedvalve

2.Coolant-llcapandller

neck

B.Openthefrontandtopcoolant-bleedvalves

(Figure21).

C.Pourcoolantintothecoolantllerneckuntil

thecoolantbeginstocomeoutofthefront

coolant-bleedvalve(Figure21).

D.Closethefrontcoolant-bleedvalve(Figure21).

E.Pourcoolantintothecoolantllerneckuntil

thecoolantbeginstocomeoutofthetop

coolant-bleedvalve(Figure21).

F.Closethetopcoolant-bleedvalve(Figure21).

4.Frontcoolant-bleedvalve

20

Page 21

G.Pourcoolantintothecoolantllerneckuntilthe

coolantlevelcomesintothellerneck(Figure21).

H.Installthecoolant-llcap(Figure21).

I.Addcoolantintotheexpansiontankuntilit

reachestheFulllineonthesideofthetank

(Figure21).

3.Installtheexpansiontankcap.

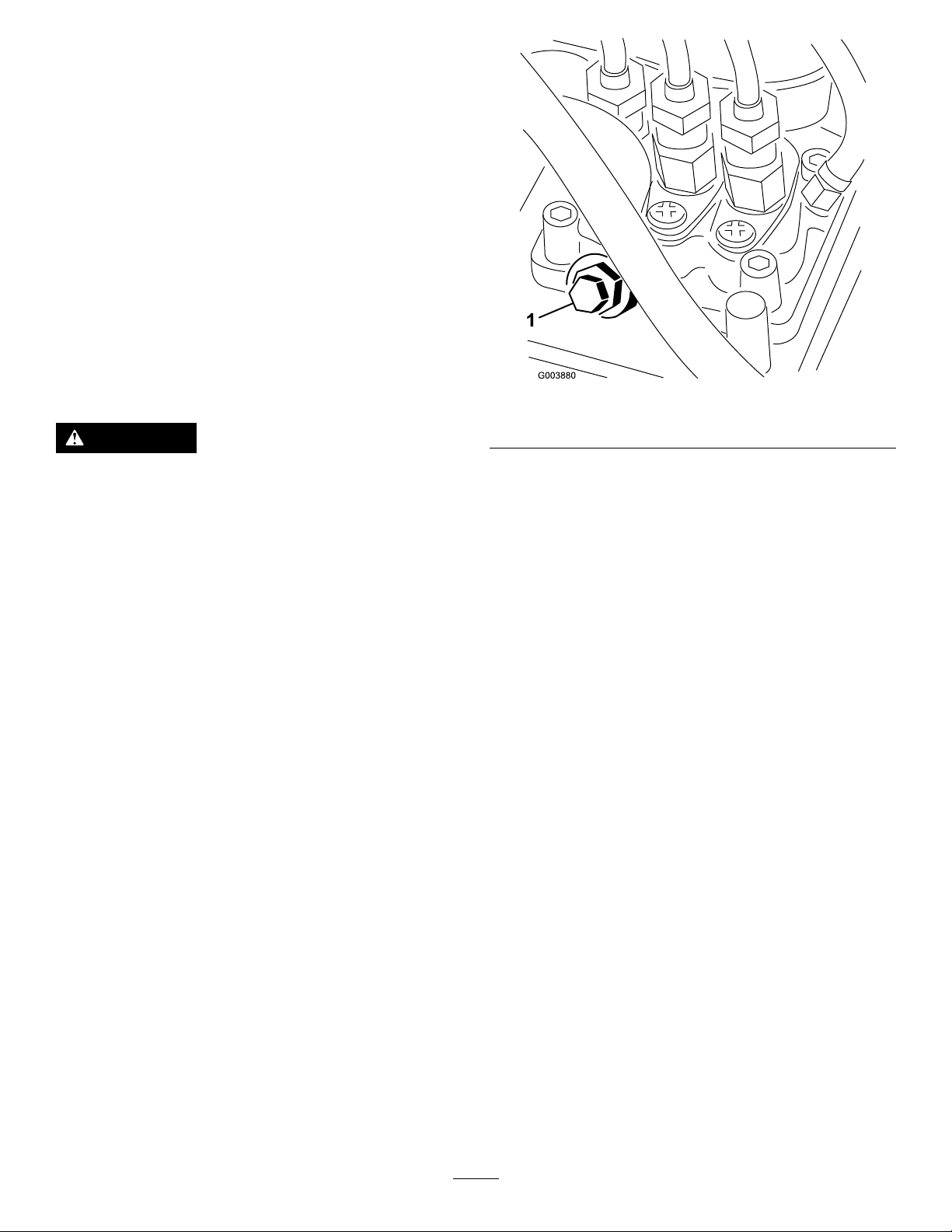

BleedingtheFuelSystem

Youmustbleedthefuelsystembeforestartingtheengineif

anyofthefollowingsituationshaveoccurred:

•Initialstartupofanewmachine.

•Enginehasceasedrunningduetolackoffuel.

•Maintenancehasbeenperformeduponfuelsystem

components(e.g.,lterreplaced).

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to1/2

in.(6to13mm)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

•Storefuelinaclean,safety-approvedcontainer

andkeepthecapinplace.

1.Ensurethatthefueltankisatleasthalffull.

2.Openthehood.

3.Opentheairbleedscrewonthefuel-injectionpump

(Figure22).

Figure22

1.Fuel-injectionpumpbleedscrew

4.TurnthekeyintheignitionswitchtotheONposition.

Theelectricfuelpumpwillbeginoperation,thereby

forcingairoutaroundtheairbleedscrew .Leavethe

keyintheONpositionuntilasolidstreamoffuelows

outaroundthescrew .

5.TightenthescrewandturnthekeytotheOFFposition.

Note:Normally,theengineshouldstartaftertheabove

bleedingproceduresarefollowed.However,ifenginedoes

notstart,airmaybetrappedbetweeninjectionpumpand

injectors;contactyourAuthorizedServiceDealer.

StartingandShuttingOffthe Engine

StartingtheEngine

1.Ensurethattheauxiliary-hydraulicsleverisinneutral.

2.MovethethrottlelevermidwaybetweenSLOW(turtle)

andFAST(rabbit)positions.

3.TurntheignitionkeytotheRUNposition.

4.Presstheglowplugswitchandholditfor10seconds.

5.TurntheignitionkeytotheSTARTposition.Whenthe

enginesstarts,releasethekey.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa30secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

6.Movethethrottlelevertodesiredsetting.

Important:Iftheengineisrunathighspeeds

whenthehydraulicsystemiscold(i.e.,whenthe

ambientairtemperatureisnearfreezingorlower),

21

Page 22

hydraulicsystemdamagecouldoccur.When

startingtheengineincoldconditions,allowthe

enginetoruninthemiddlethrottlepositionfor

2to5minutesbeforemovingthethrottletofast

(rabbit).

Note:Ifoutdoortemperatureisbelowfreezing,store

thetractionunitinagaragetokeepitwarmerandaid

instarting.

ShuttingOfftheEngine

1.MovethethrottlelevertotheSLOW(turtle)position.

2.Lowertheloaderarmstotheground.

3.Turntheignitionkeyoff.

Note:Iftheenginehasbeenworkinghardorishot,

letitidleforaminutebeforeturningtheignitionkey

off.Thishelpscooltheenginebeforeitisstopped.In

anemergency,youcanshutofftheengineimmediately.

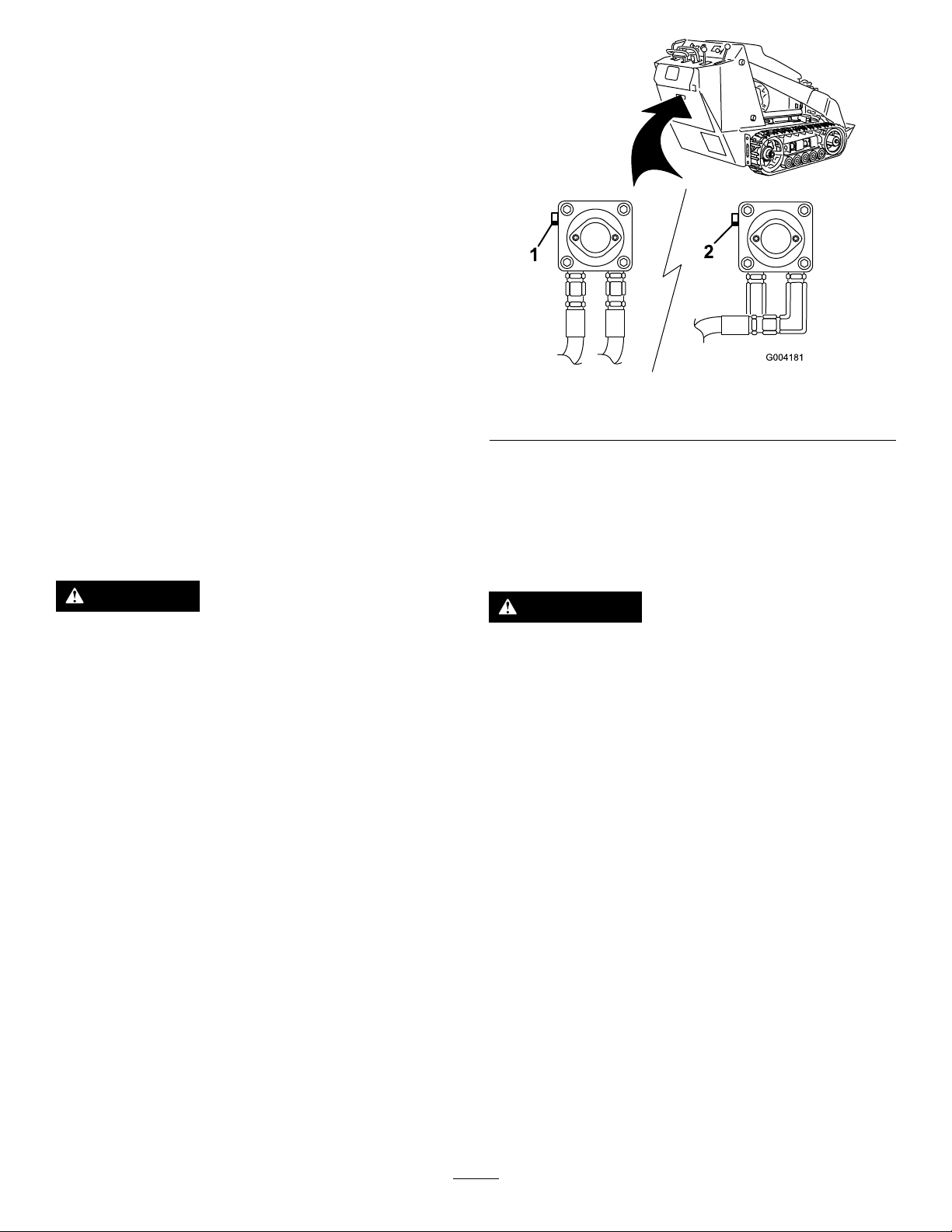

Figure23

1.Lefttowvalve(righttrack)2.Righttowvalve(lefttrack)

StoppingtheTractionUnit

Tostopthetractionunit,releasethetractioncontrol,move

thethrottlelevertoslow(turtle),lowerloaderarmstothe

ground,andshutofftheengine.Settheparkingbrakeand

removethekey .

CAUTION

Achildoruntrainedbystandercouldattemptto

operatethetractionunitandbeinjured.

Removethekeyfromtheswitchwhenleavingthe

tractionunit,evenifjustforafewseconds.

MovingaNon-Functioning TractionUnit

Important:Donottoworpullthetractionunitwithout

rstopeningthetowvalves,orthehydraulicsystemwill

bedamaged.

1.Shutofftheengine.

2.Opentherearaccesscover.

4.Towthetractionunitasrequired.

5.Whenthetractionunithasbeenrepaired,closethetow

valvesbeforeoperatingit.

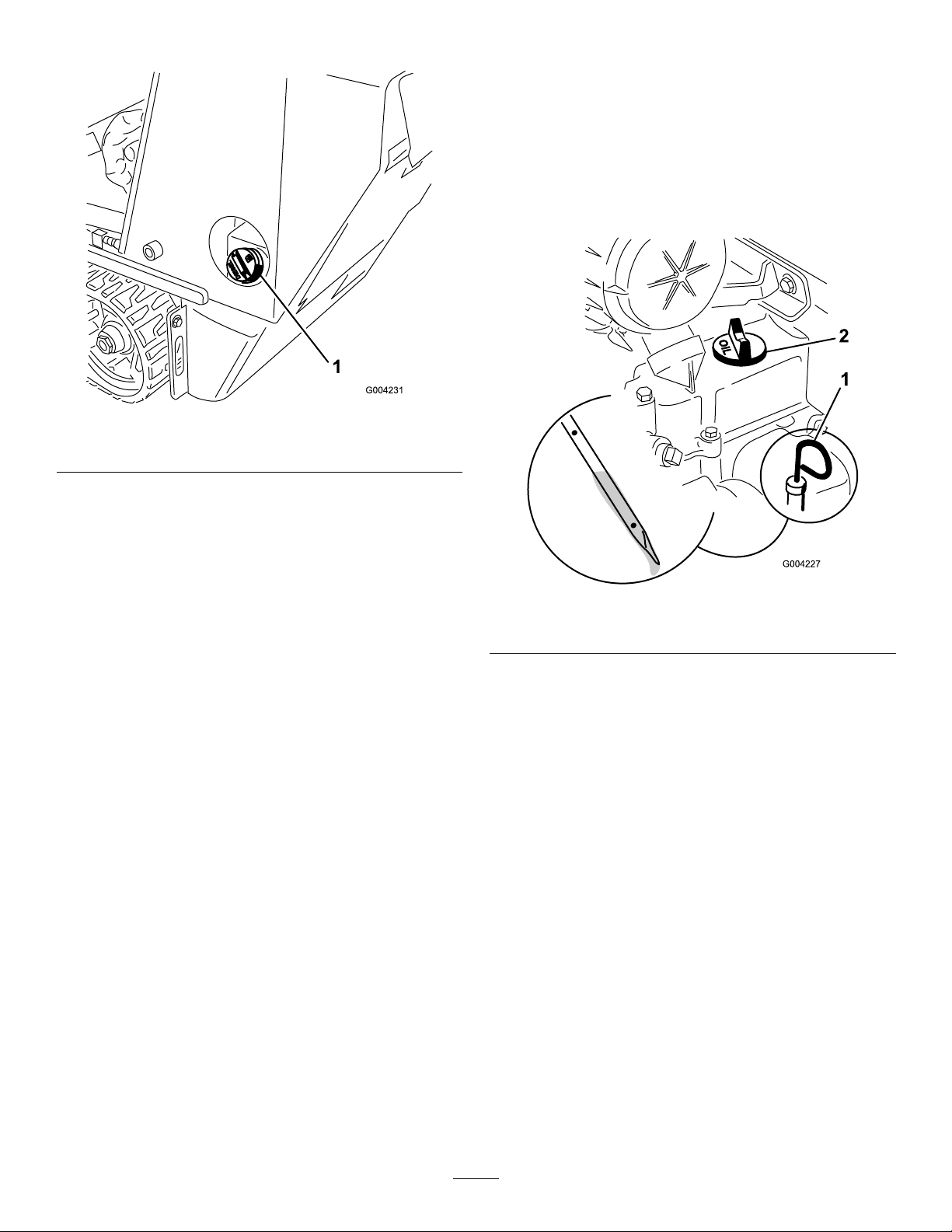

UsingtheCylinderLock

WARNING

Theloaderarmsmaylowerwhenintheraised

positioncrushinganyoneunderthem.

Installthecylinderlockbeforeperforming

maintenancethatrequiresraisedloaderarms.

InstallingtheCylinderLock

1.Removetheattachment.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengine.

4.Removethelynchpinsecuringthecylinderlocktothe

loaderarm(Figure24).

3.Usingawrench,turnthetowvalvesonthehydraulic

pumpstwicecounter-clockwise(Figure23).

22

Page 23

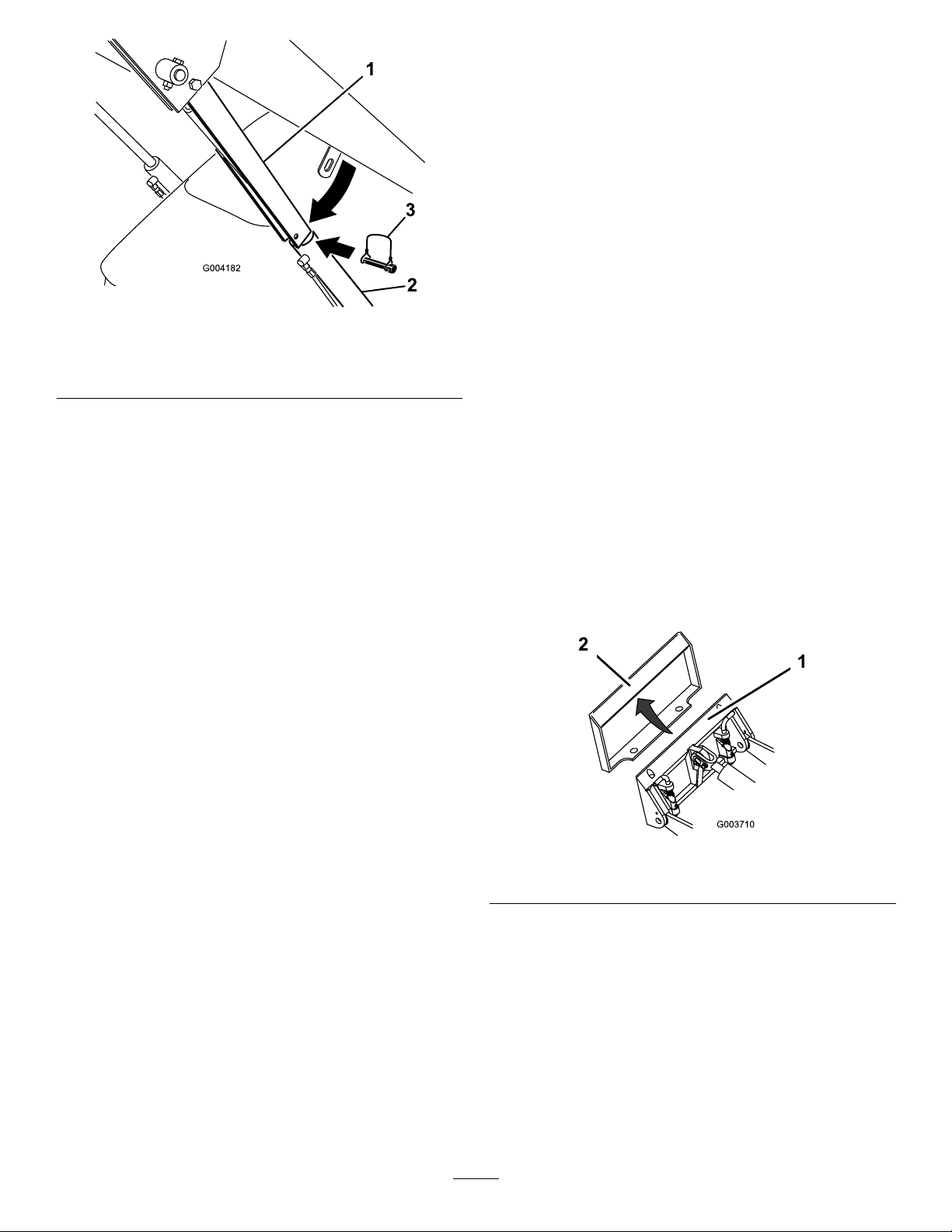

G004182

3

2

1

Figure24

1.Cylinderlock

2.Liftcylinder

5.Lowerthecylinderlockoverthecylinderrodand

secureitwiththelynchpin(Figure24).

6.Slowlylowertheloaderarmsuntilcylinderlock

contactsthecylinderbodyandrodend.

3.Lynchpin

UsingAttachments

Important:Ifyouareusinganattachmentwitha

serialnumberof200999999orearlier,themanualfor

theattachmentmaycontaininformationspecictothe

useoftheattachmentwithothertractionunits,suchas

settingsfortheowdividercontrolandspeedselector

leverandtheuseofacounterweightonthetractionunit.

ThesesystemsarebuiltintotheTX,andyoushould

ignoreanyreferencestothem.

InstallinganAttachment

Important:UseonlyToro-approvedattachments.

Attachmentscanchangethestabilityandtheoperating

characteristicsofthetractionunit.Thewarrantyofthe

tractionunitmaybevoidedifusedwithunapproved

attachments.

Important:Beforeinstallingtheattachment,ensure

thatthemountplatesarefreeofanydirtordebrisand

thatthepinsrotatefreely.Ifthepinsdonotrotatefreely,

greasethem.

1.Positiontheattachmentonalevelsurfacewithenough

spacebehindittoaccommodatethetractionunit.

Removing/StoringtheCylinderLock

Important:Ensurethatthecylinderlockisremoved

fromtherodandfullysecuredinthestorageposition

beforeoperatingthetractionunit.

1.Starttheengine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutofftheengine.

4.Removethelynchpinsecuringthecylinderlock.

5.Rotatethecylinderlockuptotheloaderarmand

secureitwiththelynchpin.

6.Lowertheloaderarms.

2.Starttheengine.

3.Tilttheattachmentmountplateforward.

4.Positionmountplateintotheupperlipofthe

attachmentreceiverplate(Figure25).

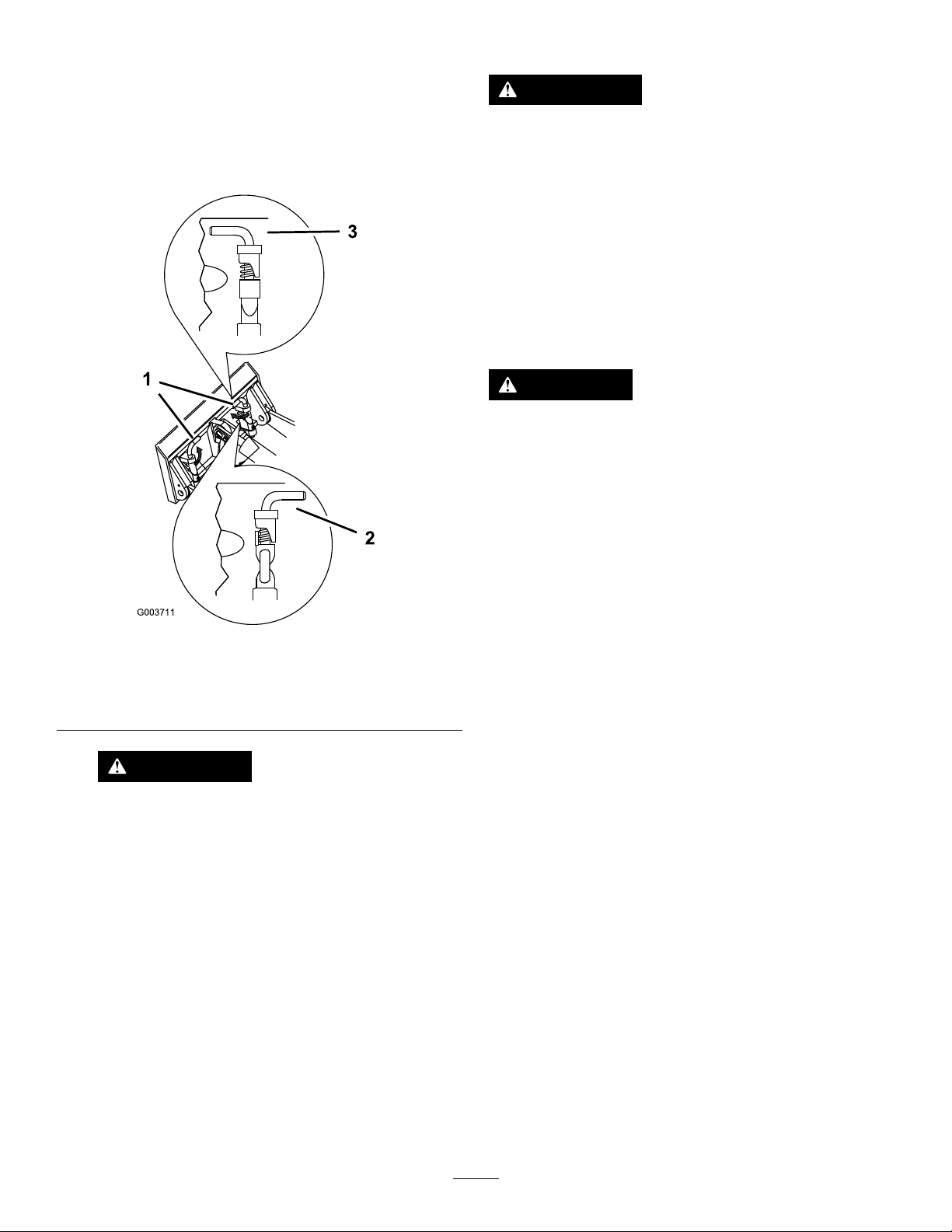

Figure25

1.Mountplate2.Receiverplate

5.Raisetheloaderarmswhiletiltingbackthemountplate

atthesametime.

Important:Theattachmentshouldberaised

enoughtocleartheground,andthemountplate

shouldbetiltedallthewayback.

6.Shutofftheengine.

23

Page 24

7.Engagethequick-attachpins,ensuringthattheyare

fullyseatedinthemountplate(Figure26).

ConnectingtheHydraulicHoses

Important:Ifthepinsdonotrotatetothe

engagedposition,themountplateisnotfully

alignedwiththeholesintheattachmentreceiver

plate.Checkthereceiverplateandcleanitif

necessary.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjectedinto

theskinmustbesurgicallyremovedwithinafew

hoursbyadoctorfamiliarwiththisformofinjury

otherwisegangrenemayresult.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressure

hydraulicuid.

•Usecardboardorpapertondhydraulicleaks;

neveruseyourhands.

CAUTION

Hydrauliccouplers,hydrauliclines/valves,and

hydraulicuidmaybehot.Ifyoucontacthot

components,youmaybeburned.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthetractionunittocoolbeforetouching

hydrauliccomponents.

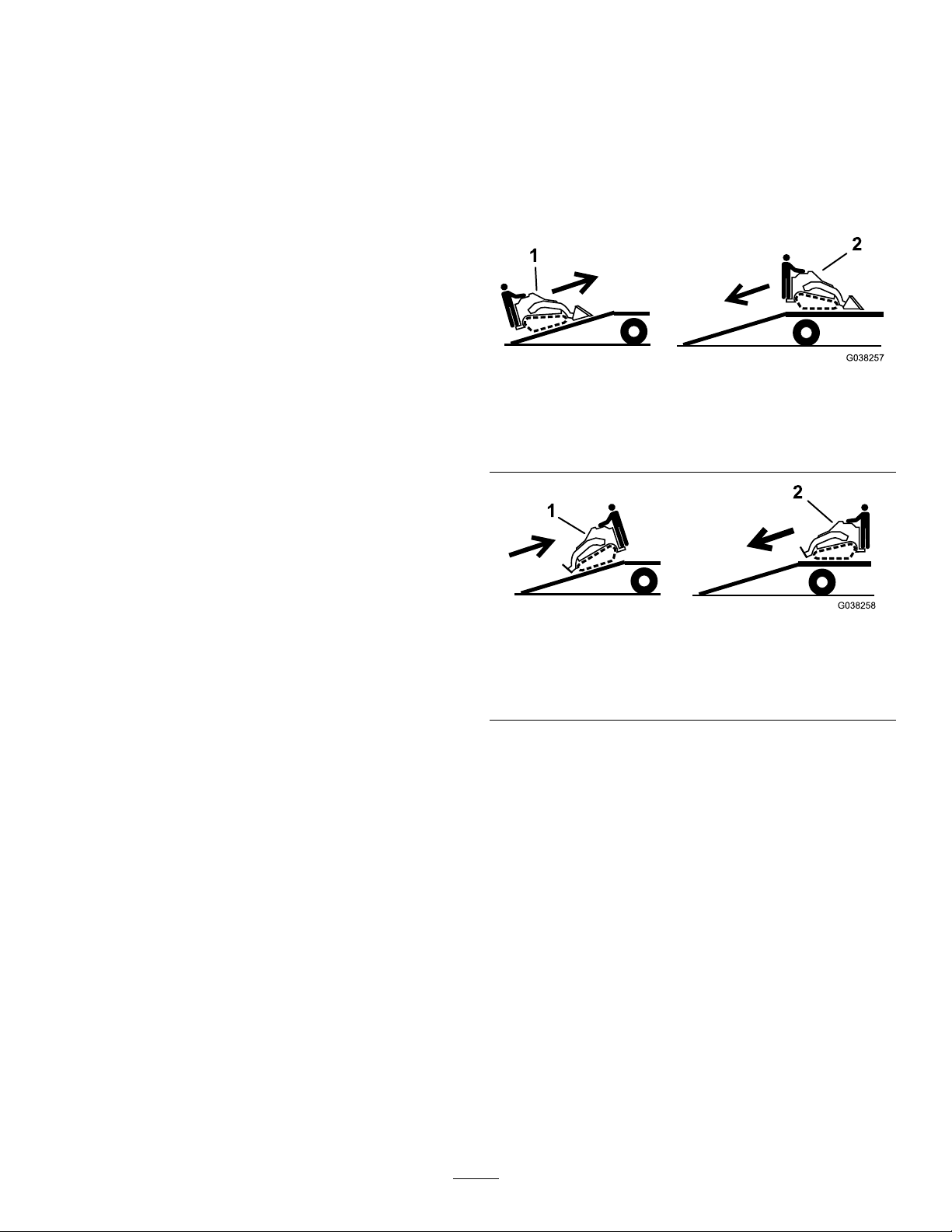

Figure26

1.Quick-attachpins(shown

inengagedposition)

2.Disengagedposition

3.Engagedposition

WARNING

Ifyoudonotfullyseatthequick-attachpins

throughtheattachmentmountplate,the

attachmentcouldfalloffthetractionunit,

crushingyouorbystanders.

Ensurethatyourquick-attachpinsarefully

seatedintheattachmentmountplate.

•Donottouchhydraulic-uidspills.

Iftheattachmentrequireshydraulicsforoperation,connect

thehydraulichosesasfollows:

1.Shutofftheengine.

2.Movetheauxiliary-hydraulicsleverforward,backward,

andbacktotheNEUTRALpositiontorelievepressure

atthehydrauliccouplers.

3.Movetheauxiliary-hydraulicsleverforwardintothe

DETENTposition.

4.Removetheprotectivecoversfromthehydraulic

couplersonthetractionunit.

5.Ensurethatallforeignmatteriscleanedfromthe

hydraulicconnectors.

6.Pushtheattachmentmaleconnectorintothefemale

connectoronthetractionunit.

Note:Whenyouconnecttheattachmentmale

connectorrst,youwillrelieveanypressurebuildupin

theattachment.

7.Pushtheattachmentfemaleconnectorintothemale

connectoronthetractionunit.

8.Conrmthattheconnectionissecurebypullingon

thehoses.

9.Movetheauxiliary-hydraulicslevertotheNEUTRAL

position.

24

Page 25

RemovinganAttachment

1.Lowertheattachmenttotheground.

2.Shutofftheengine.

3.Disengagethequick-attachpinsbyturningthemto

theoutside.

4.Iftheattachmentuseshydraulics,movethe

auxiliary-hydraulicsleverforward,backward,andback

totheNEUTRALpositiontorelievepressureatthe

hydrauliccouplers.

5.Iftheattachmentuseshydraulics,slidethecollarback

onthehydrauliccouplersanddisconnectthem.

Important:Connecttheattachmenthoses

togethertopreventhydraulicsystemcontamination

duringstorage.

6.Installtheprotectivecoversontothehydrauliccouplers

onthetractionunit.

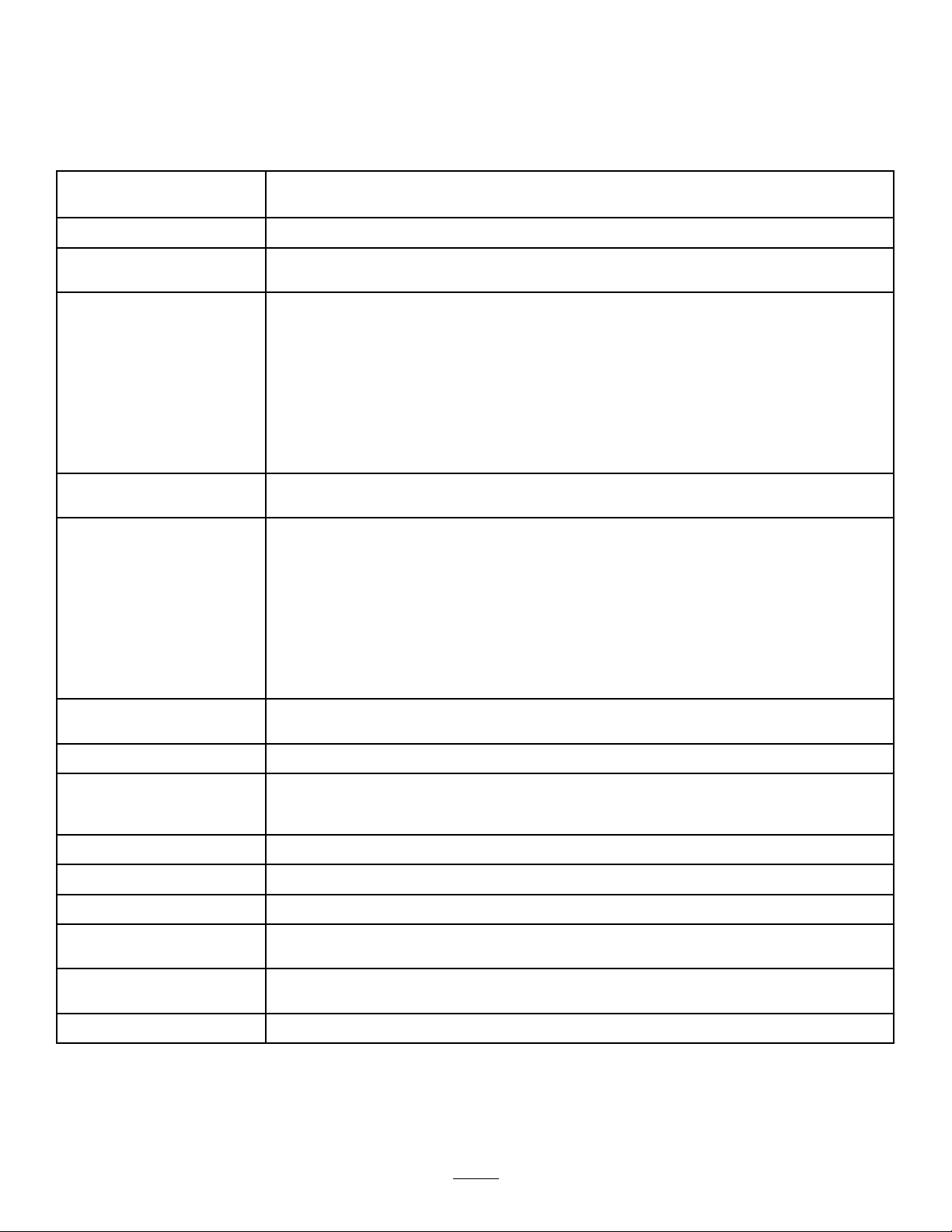

LoadingtheMachine

Useextremecautionwhenloadingortheunloadingmachine

ontoatraileroratruck.Useafull-widthrampthatiswider

thanthemachineforthisprocedure.Loadandunloadthe

machinewiththeheavyenduptheramp.Ifthemachinehas

anattachment,drivethemachineforwarduptherampand

backitdowntheramp(Figure27);ifthemachinedoesnot

haveanattachment,backthemachineuptherampanddrive

itforwarddowntheramp(Figure28).

Figure27

Machineswithanattachment

7.Starttheengine,tiltthemountplateforward,andback

thetractionunitawayfromtheattachment.

SecuringtheTractionUnitfor Transport

Whentransportingthetractionunitonatrailer,alwaysuse

thefollowingprocedure:

Important:Donotoperateordrivethetractionunit

onroadways.

1.Lowertheloaderarms,settheparkingbrake,andshut

offtheengine.

2.Securethetractionunittothetrailerwithchainsor

strapsusingthetie-down/liftloops(Figure4)tosecure

therearofthetractionunitandtheloaderarms/mount

platetosecurethefrontofthetractionunit.

LiftingtheTractionUnit

Youcanliftthetractionunitusingthetie-down/liftloopsas

liftpointsindicatedintheProductOverview(page13).

1.Drivethemachineforward

uptheramp.

Machineswithoutanattachment

1.Backthemachineupthe

ramp.

Important:Donotusenarrowindividualrampsfor

eachsideofthemachine.

Ensurethattherampislongenoughsothattheanglewith

thegrounddoesnotexceed17degrees(Figure29).Onat

ground,thisrequiresaramptobeatleast4timesaslongas

theheightofthetrailerortruckbedtotheground.Asteeper

anglemaycausemowercomponentstogetcaughtasthe

machinemovesfromtheramptothetrailerortruck.Steeper

anglesmayalsocausethemachinetotiporlosecontrol.If

youareloadingthemachineonornearaslope,positionthe

trailerortrucksothatitisonthedownsideoftheslopeand

therampextendsuptheslope.Thisminimizestheramp

angle.

2.Backthemachinedown

theramp.

Figure28

2.Drivethemachineforward

downtheramp.

25

Page 26

WARNING

g027996

5

1

2

6

Loadingamachineontoatrailerortruckincreases

thepossibilityoftip-overandcouldcauseserious

injuryordeath.

•Useextremecautionwhenoperatingamachine

onaramp.

•Useonlyafull-widthramp;donotuseindividual

rampsforeachsideofthemachine.

•Donotexceeda17-degreeanglebetweenthe

rampandthegroundorbetweentherampand

thetrailerortruck.

•Ensurethatthelengthoframpisatleast4times

aslongastheheightofthetrailerortruckbedto

theground.Thisensuresthatrampangledoes

notexceed17degreesonatground.

•Loadandunloadthemachinewiththeheavy

enduptheramp.

•Avoidsuddenaccelerationordecelerationwhile

drivingthemachineonarampasthiscould

causealossofcontroloratip-oversituation.

Figure29

1.Full-widthrampinstowed

position

2.Sideviewoffull-width

rampinloadingposition

3.Notgreaterthan

17degrees

4.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

5.H=heightofthetraileror

truckbedtotheground

6.Trailer

26

Page 27

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every100hours

MaintenanceProcedure

•Replacethehydrauliclter.

•Changetheengineoilandlter.

•Checkandadjustthetracktension.

•Checktheengine-oillevel.

•Checkthecoolingsystem.

•Greasethetractionunit.(Greaseimmediatelyaftereverywashing.)

•Checktheair-lterserviceindicator.

•Drainwaterandothercontaminantsfromthefuellter/waterseparator.

•Cleanthetracks.

•Checkthetracksforexcessivewear(Ifthetracksareworn,replacethem.)

•Cleantheradiator.

•Removedebrisfromthetractionunitandsidescreens.

•Checkforloosefasteners.

•Checkthehydraulicuidlevel.

•Removeair-cleanercover,cleanoutdebris,andchecktheair-lterserviceindicator.

•Changetheengineoil.

•Checkthebattery-electrolytelevel(replacementbatteryonly).

•Checkthebatterycableconnections.

•Checkandadjustthetracktension.

•Checkthecoolingsystemhoses.

•Checkthealternator/fanbelttension(refertotheengineowner’smanualfor

instructions).

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Checkfordirtbuild-upinthechassis.

Every200hours

Every250hours

Every400hours

Every500hours

Every600hours

Every1,500hours

Yearly

Yearlyorbeforestorage

Every2years

•Changetheoillter.

•Replacethehydrauliclter.

•Checkandgreasetheroadwheels.

•Checkthefuellinesandconnectionsfordeterioration,damage,orlooseconnections.

•Replacethefuelltercanisterandin-linelter.

•Changethehydraulicuid.

•Replacethealternator/fanbelt(refertotheengineowner’smanualforinstructions).

•Replacethesafetyairlter.

•Replaceallmovinghydraulichoses.

•Changetheenginecoolant(AuthorizedServiceDealeronly).

•Checktheconditionofthehydraulicpumpbelt.

•Checkandadjustthetracktension.

•T ouchupchippedpaint.

•Drainandcleanthefueltank(AuthorizedServiceDealeronly).

Important:Refertoyourengineowner’smanualforadditionalmaintenanceprocedures.

27

Page 28

CAUTION

3

G009691

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionbeforeyoudoanymaintenance.

Premaintenance

Procedures

Beforeopeninganyofthecovers,shutofftheengineand

removethekey.Allowtheenginetocoolbeforeopening

anycovers

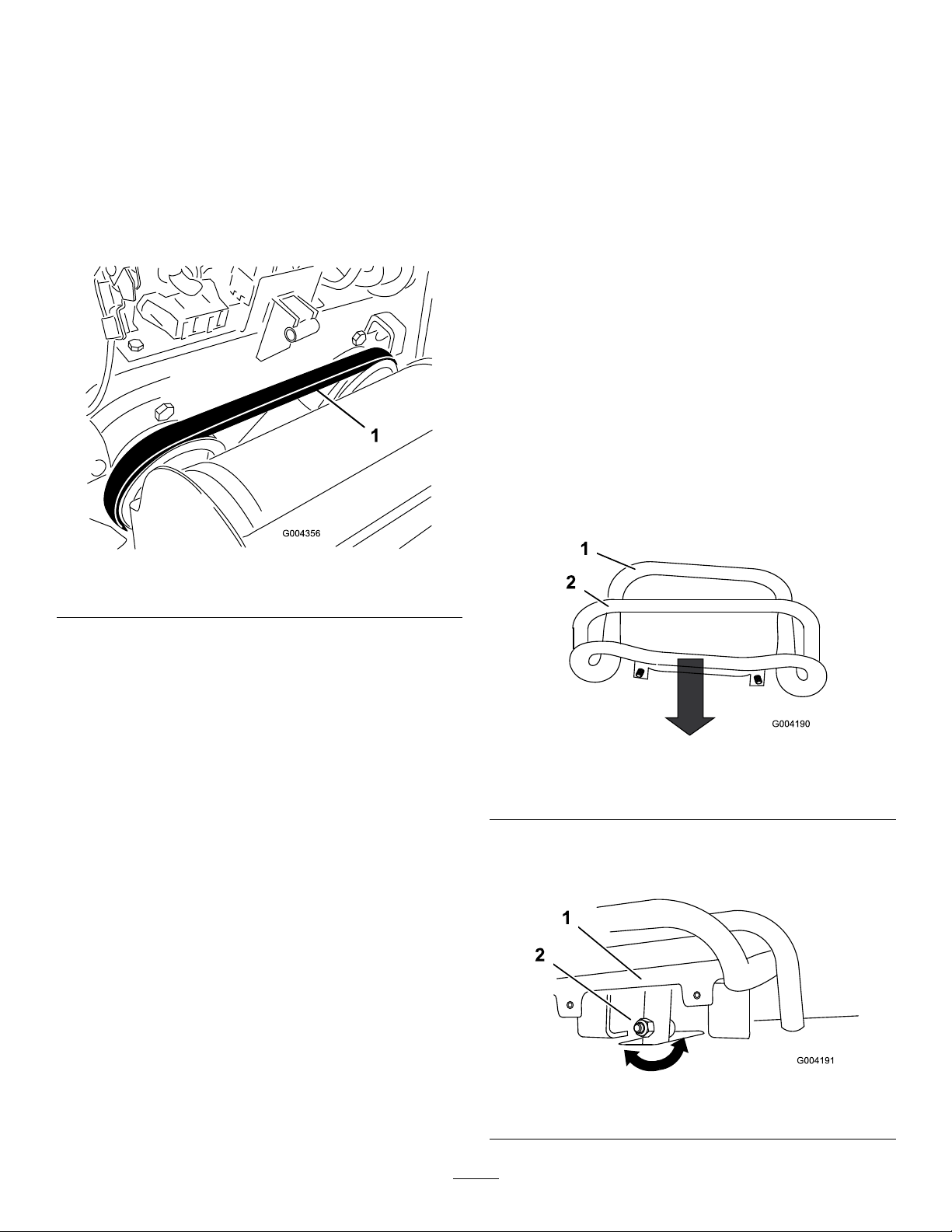

OpeningtheHood

1.Loosenthehood-lockingscrew(Figure30)

ClosingtheHood

1.Liftuponthetabsecuringtheprop-rod(Figure31)

Figure31

1.Prop-rodtab

2.Lowerthehoodandsecureitbypushingdownonthe

frontofthehooduntilitlocksinplace.

Figure30

1.Hood3.Hood-lockingscrew

2.Hood-latchlever

2.Turnthehoodlatchclockwise(Figure30).

3.Swingthehoodup(Figure30).

3.Tightenthehood-lockingscrewtosecurethelatch

(Figure30).

28

Page 29

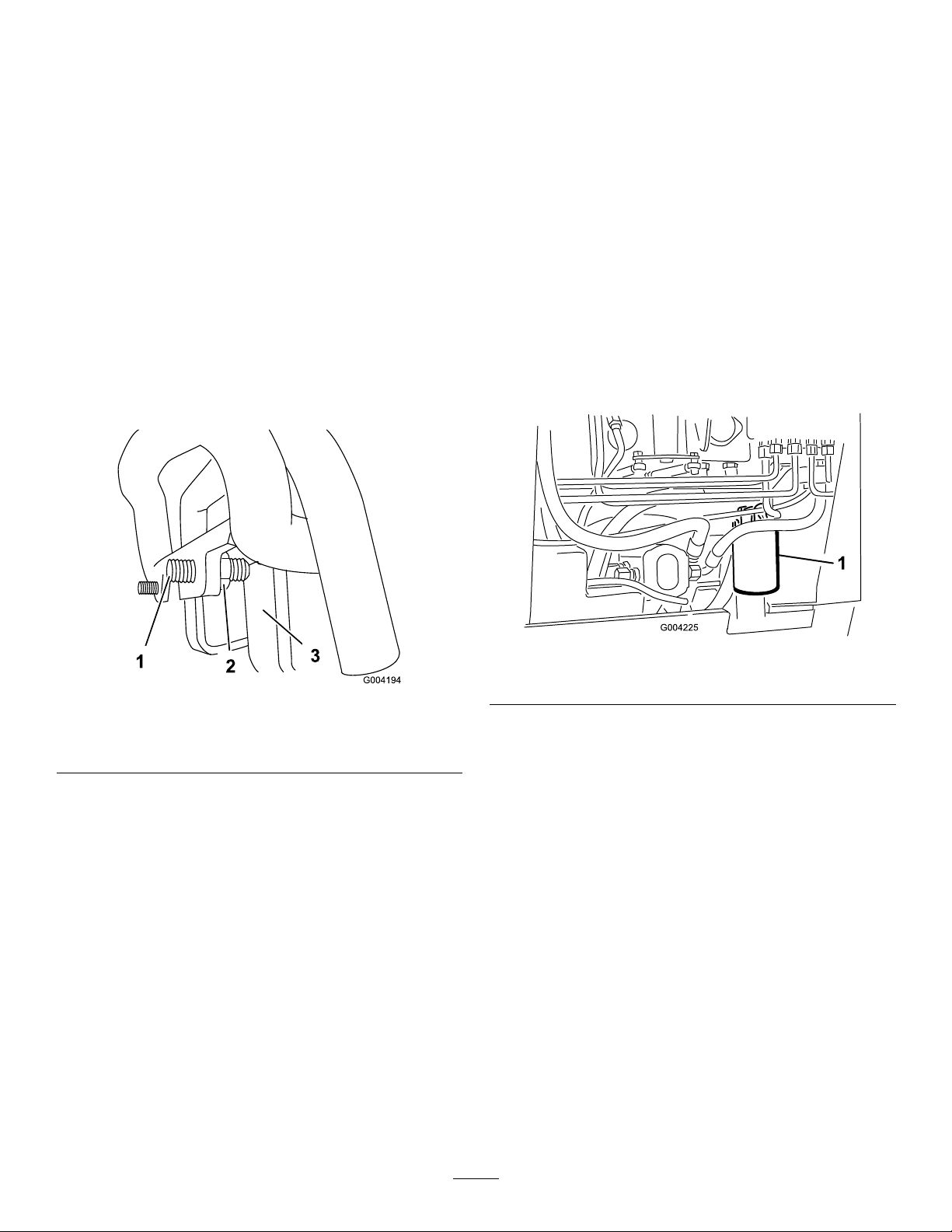

OpeningtheRearAccess

RemovingtheSideScreens

Cover

1.Unscrewthe2handknobssecuringtherearaccess

covertothemachine(Figure32).

Figure32

1.Handknobs

2.Tilttherearaccesscoverdownandremovetoaccess

theinternalcomponents(Figure32).

ClosingtheRearAccessCover

1.Openthehood.

2.Slidethesidescreens(Figure33)upandoutofthe

slotsinthefrontscreenandframe.

Figure33

1.Sidescreen

1.Movetherearaccesscoverinplaceoverthebackof

thetractionunitmakingsurethatthetabslineupin

theslots.

2.Pushtheaccesscoverforward,liningupthehand-knob

screwswiththethreadedholesinthemachine.

3.Screwthehandknobstighttosecuretherearaccess

coverinplace.

InstallingtheSideScreens

Slidethesidescreensintoplaceintheslotsinthefrontscreen

andframe.

29

Page 30

Lubrication

g034220

EngineMaintenance

GreasingtheTractionUnit

ServiceInterval:Beforeeachuseordaily(Grease

immediatelyaftereverywashing.)

GreaseType:General-purposegrease.

1.Lowertheloaderarmsandshutofftheengine.

Removethekey.

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting(Figure34and

Figure35).

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checkthe

air-lterserviceindicator.

Every25hours—Removeair-cleanercover,cleanout

debris,andchecktheair-lterserviceindicator.

Every600hours—Replacethesafetyairlter.

ServicingtheAir-CleanerCoverand

Body

Important:Servicetheaircleanerlteronlywhenthe

serviceindicatorshowsred(Figure36).Changingthe

airlterbeforeitisnecessaryonlyincreasesthechance

ofdirtenteringtheenginewhenthelterisremoved.

1.Lowertheloaderarms,shutofftheengine,andremove

thekey.

2.Openthehood.

3.Checktheair-cleanerbodyfordamage,whichcould

causeanairleak..Checkthewholeintakesystemfor

leaks,damage,orloosehoseclamps.Replaceofrepair

anddamagedcomponents.

Figure34

Figure35

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps).

5.Wipeupanyexcessgrease.

4.Releasethelatchesontheaircleanerandpullthe

air-cleanercoverofftheair-cleanerbody(Figure36).

Important:Donotremovetheairlters.

Figure36

1.Air-lterserviceindicator

2.Airlterbody

3.Primarylter

5.Squeezethedustcapsidestoopenitandknockthe

dustout.

6.Cleantheinsideoftheair-cleanercoverwith

compressedair.

7.Checktheair-lterserviceindicator.

4.Air-cleanercover

5.Latches

6.Dustcap

•Iftheserviceindicatorisclear,cleananydebris

fromcoverandinstallcover.

30

Page 31

Ensurethatthecoverisseatedcorrectlyandseals

withtheair-cleanerbody.

•Iftheserviceindicatorisred,replacetheairlter

asdescribedinReplacingtheFilters(page31).

ServicingtheEngineOil

ServiceInterval:Aftertherst50hours—Changethe

engineoilandlter.

Every100hours—Changetheengineoil.

ReplacingtheFilters

1.Gentlyslidetheprimarylteroutoftheair-cleaner

body(Figure36).Avoidknockingthelterintothe

sideofthebody .

Important:Donotattempttocleantheprimary

lter.

2.Inspectthenewlter(s)fordamagebylookingintothe

lterwhileshiningabrightlightontheoutsideofthe

lter.Holesinthelterappearasbrightspots.Inspect

theelementfortears,anoilylm,ordamagetothe

rubberseal.Ifthelterisdamageddonotuseit.

3.Carefullyslidetheprimarylterintothelterbody

(Figure36).Ensurethatitisfullyseatedbypushingon

theouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

4.Installtheair-cleanercoverwiththesideindicatedas

UPfacingupandsecurethelatches(Figure36).

5.Closethehood.

Every200hours—Changetheoillter.

OilT ype:Detergentdieselengineoil(APIserviceCH-4or

higher)

CrankcaseCapacity:withlter,3.7L(0.98USgallons)

Viscosity:Seetablebelow

Figure37

ChangingtheOil

1.Starttheengineandletitrunfor5minutes.This

warmstheoilsothatitdrainsbetter.

2.Parkthetractionunitsothatthedrainsideisslightly

lowerthantheoppositesidetoensurethattheoil

drainscompletely.

3.Lowertheloaderarms,settheparkingbrake,shutoff

theengine,andremovethekey .

CAUTION

Componentswillbehotifthetractionunithas

beenrunning.Ifyoutouchhotcomponents,

youmaybeburned.

Allowthetractionunittocoolbefore

performingmaintenanceortouching

componentsunderthehood.

4.Removethedrainplug(Figure38).

31

Page 32

Figure38

1.Oildrainplug

5.Whentheoilhasdrainedcompletely ,replacetheplug.

Note:Disposeoftheusedoilatacertiedrecycling

center.

ChangingtheOilFilter

1.Draintheoilfromtheengine;refertoChangingthe

Oil(page31).

2.Placeashallowpanorragundertheltertocatchoil.

3.Removetheoldlter(Figure39)andwipethesurface

ofthelteradaptergasket.

6.Removetheoilllcapandslowlypourapproximately

80%ofthespeciedamountofoilinthroughthe

valvecover.

7.Checktheoillevel;refertoCheckingtheEngine-Oil

Level(page18).

8.Slowlyaddadditionaloiltobringtheleveltotheupper

holeonthedipstick.

9.Replacethellcap.

Figure39

1.Oillter

4.Pournewoilofthepropertypethroughthecenter

holeofthelter.Stoppouringwhentheoilreaches

thebottomofthethreads.

5.Allowaminuteortwofortheoiltobeabsorbedby

ltermaterial,thenpourofftheexcessoil.

6.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter.

7.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn.

8.Fillthecrankcasewiththepropertypeofnewoil;refer

toChangingtheOil(page31).

32

Page 33

FuelSystem

Maintenance

DANGER

Undercertainconditions,dieselfuelandfuel

vaporsarehighlyammableandexplosive.Are

orexplosionfromfuelcanburnyouandothersand

cancausepropertydamage.

•Useafunnelandllthefueltankoutdoors,in

anopenarea,whentheengineisoffandiscold.

Wipeupanyfuelthatspills.

•Donotllthefueltankcompletelyfull.Add

fueltothefueltankuntilthelevelis1/4to1/2

in.(6to13mm)belowthebottomoftheller

neck.Thisemptyspaceinthetankallowsthe

fueltoexpand.

•Neversmokewhenhandlingfuel,andstayaway

fromanopenameorwherefuelfumesmaybe

ignitedbyaspark.

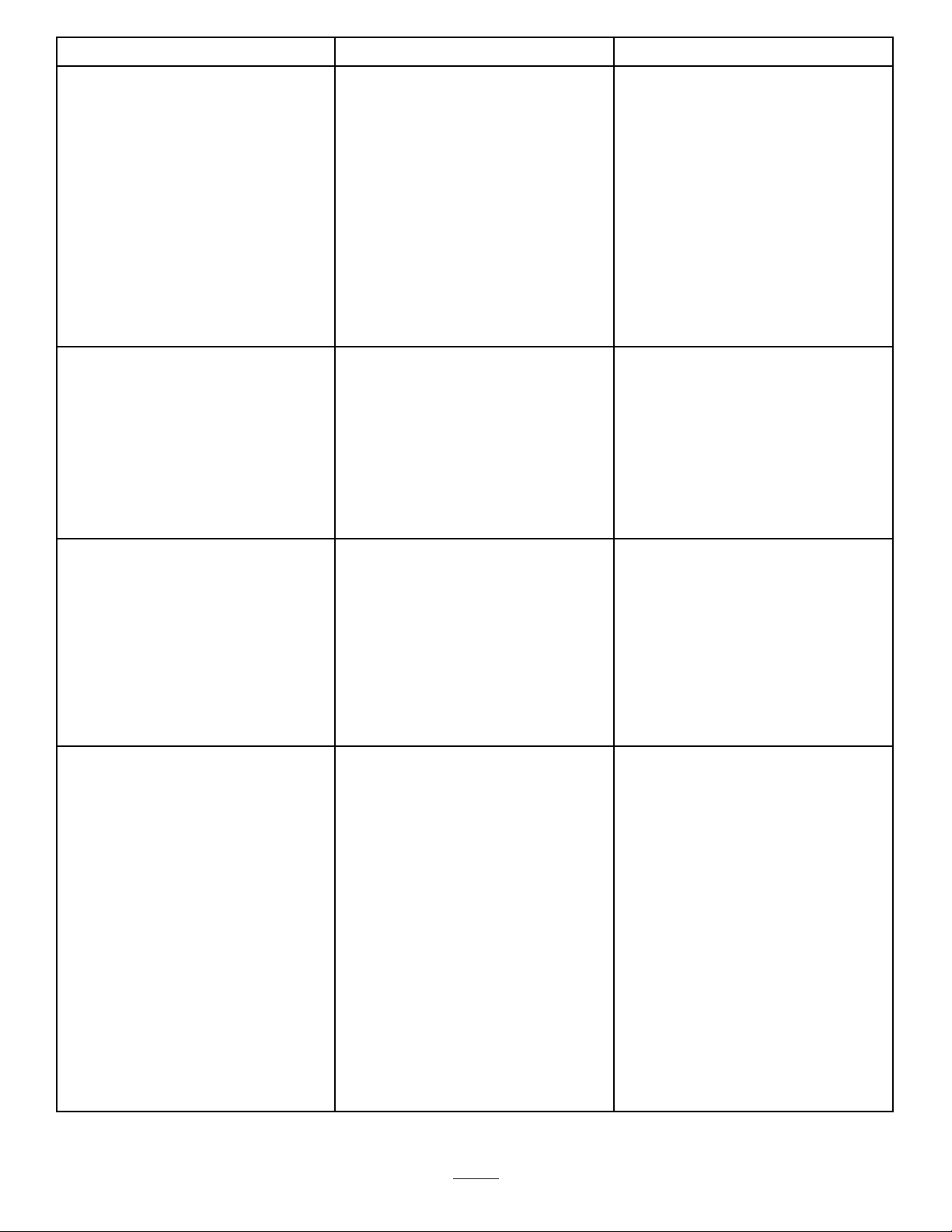

DrainingtheFuelFilter/Water Separator

ServiceInterval:Beforeeachuseordaily

1.Locatethefuellterontherightsideoftheengine

(Figure40)andplaceacleancontainerunderit.

•Storefuelinaclean,approvedcontainerand

keepthecapinplace.

CheckingtheFuelLinesand Connections

ServiceInterval:Every400hours/Y early(whichevercomes

rst)

Inspectthefuellinesandconnectionsfordeterioration,

damage,orlooseconnections.Tightenanylooseconnections

andcontactyourAuthorizedServiceDealerforassistance

inxingdamagedfuellines.

Figure40

1.Fuelltercanister/water

separator

2.Drainvalve

2.Loosenthedrainvalveonthebottomofthelter

canisterandallowthewatertodrain.

3.Whennished,tightenthedrainvalve.

3.Hoseclamps

4.In-linelter

33

Page 34

ReplacingtheFuelFilter CanisterandIn-lineFilter

ServiceInterval:Every400hours

ElectricalSystem

Maintenance

1.Locatethefuelltersontherightsideoftheengine

(Figure40)andplaceacleancontainerunderit.

2.Cleantheareawheretheltercanistermounts(Figure

40).

3.Removetheltercanisterandcleanthemounting

surface(Figure40).

4.Lubricatethegasketonthenewltercanisterwith

cleanoil.

5.Installtheltercanisterbyhanduntilthegasket

contactsthemountingsurface,thenrotateitan

additional1/2turn(Figure40).

6.Locatethein-linelterbehindthefuelltercanister

(Figure40)andnotethedirectionofowarrowon

thesideofthein-linelter.

7.Opentheclampsoneachendofthein-linelterand

slidethehosesoffit(Figure40).Discardthelter.

8.Slidethehosesovertheendofanewlter(Figure40),

ensuringthatthearrowonthelterispointinginthe

samedirectionasthearrowontheoldlter.

9.Securethehoseswiththehoseclamps.

ServicingtheBattery

ServiceInterval:Every100hours—Checkthe

battery-electrolytelevel(replacement

batteryonly).

Every100hours—Checkthebatterycable

connections.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Important:Thefollowingproceduresapplywhen

servicinga(dry)batterythathasreplacedtheoriginal

battery.Theoriginal(wet)batterydoesnotrequire

service.

DrainingtheFuelTank

ServiceInterval:Every2years

HaveanAuthorizedServiceDealerdrainandcleanthefuel

tank.

Alwayskeepthebatterycleanandfullycharged.Useapaper

toweltocleanthebatterycase.Ifthebatteryterminalsare

corroded,cleanthemwithasolutionof4partswaterand

1partbakingsoda.Applyalightcoatingofgreasetothe

batteryterminalstoreducecorrosion.

Voltage:12V ,585A(coldcranking)

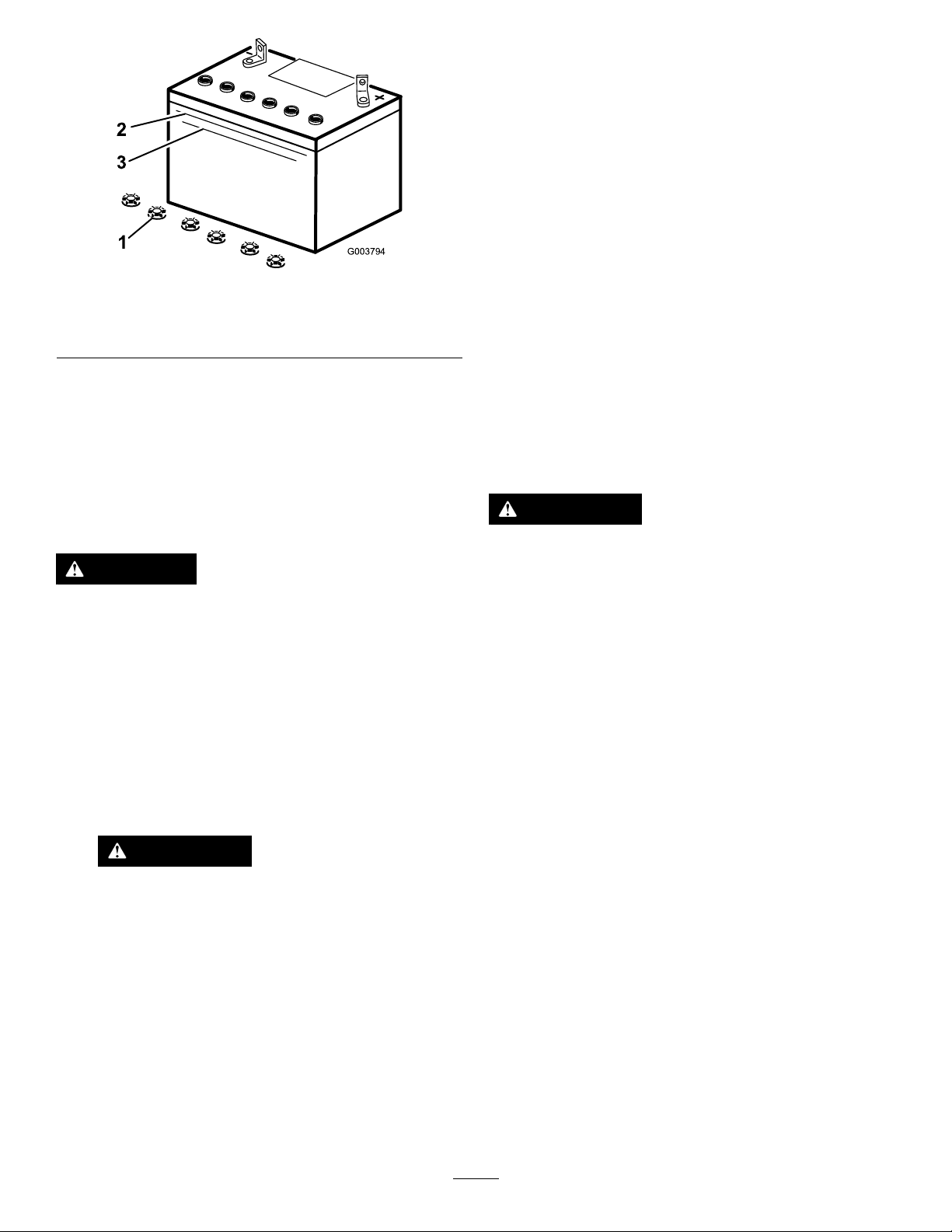

CheckingtheElectrolyteLevel

1.Shutofftheengineandremovethekey.

2.Lookatthesideofthebattery.Theelectrolytemust

beuptotheUpperline(Figure41).Donotallowthe

electrolytetofallbelowtheLowerline(Figure41).

34

Page 35

2

3

1

G003794

Figure41

1.Fillercaps3.Lowerline

2.Upperline

3.Iftheelectrolyteislow ,addtherequiredamountof

distilledwater;refertoAddingWatertotheBattery

(page35).

3.Removethebatteryfromthetractionunit.

Important:Neverllthebatterywithdistilled

waterwhilethebatteryisinstalledinthetraction

unit.Electrolytecouldbespilledonotherparts

andcausecorrosion.

4.Cleanthetopofthebatterywithapapertowel.

5.Removethellercapsfromthebattery(Figure41).

6.Slowlypourdistilledwaterintoeachbatterycelluntil

theelectrolytelevelisuptotheUpperline(Figure41)

onthebatterycase.

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

7.Wait5to10minutesafterllingthebatterycells.Add

distilledwater,ifnecessary,untiltheelectrolytelevelis

uptotheUpperline(Figure41)onthebatterycase.

8.Installthebatteryllercaps.

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethetractionunit.Thisletsthewatermix

thoroughlywiththeelectrolytesolution.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Disconnectthenegative(black)cablefromthenegative

(-)batterypost.

WARNING

Incorrectbatterycableroutingcoulddamage

thetractorandcables,causingsparks.Sparks

cancausethebatterygassestoexplode,

resultinginpersonalinjury.

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged(1.265

specicgravity).Thisisespeciallyimportanttoprevent

batterydamagewhenthetemperatureisbelow0°C

(32°F).

1.Checktheelectrolytelevel;refertoCheckingthe

ElectrolyteLevel(page34).

2.Makesurethatthellercapsareinstalledinthebattery.

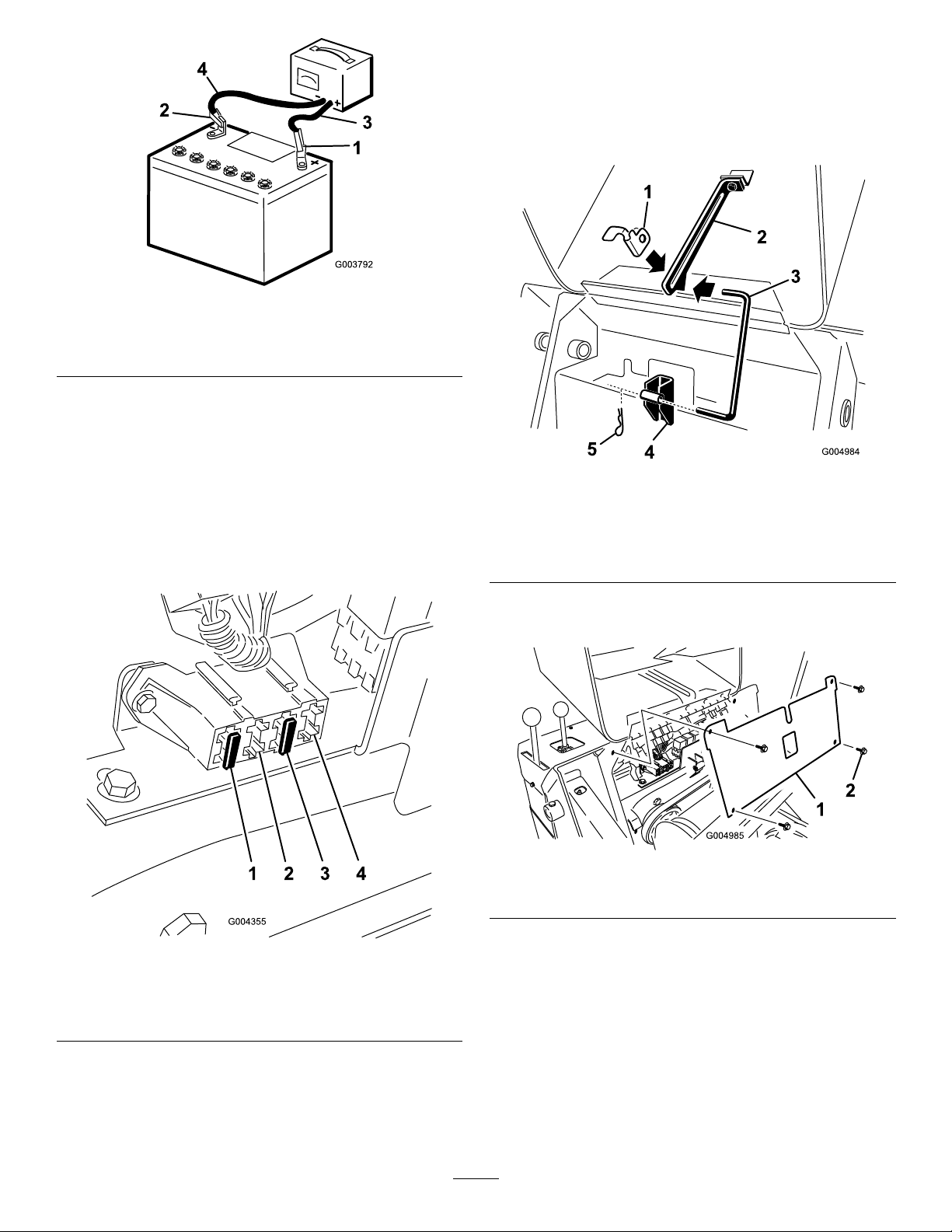

3.Chargethebatteryfor10to15minutesat25to30Aor

30minutesat4to6A(Figure42).Donotovercharge

thebattery.

•Alwaysdisconnectthenegative(black)

batterycablebeforedisconnectingthe

positive(red)cable.

•Alwaysconnectthepositive(red)battery

cablebeforeconnectingthenegative

(black)cable.

2.Disconnectthepositive(red)cablefromthepositive

(+)batterypost.

35

Page 36

1

2

3

4

G003792

Figure42

1.Shutofftheengineandremovethekey.

2.Raisethehood.

3.Pullthehairpincotterfromthebottomendofthe

hoodprop-rodandslidetheproprodoutofthe

retainingbracketsandtheprop-rodtab(Figure44).

1.Positivebatterypost

2.Negativebatterypost

3.Red(+)chargerlead

4.Black(-)chargerlead

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure42).

ServicingtheFuses

Theelectricalsystemisprotectedbyfuses.Itrequires

nomaintenance;however,ifafuseblows,checkthe

component/circuitforamalfunctionorashort.Figure43

illustratesthefuseblockandidentiesthefusepositions.

Figure44

1.Prop-rodtab4.Retaining

bracket—bottom

2.Retainingbracket—top5.Hairpincotter

3.Prop-rod

4.Removethe4screwssecuringthefusepanelandthen

pullthepaneloutanduptoremoveit(Figure45).

Figure43

1.Fuse(30A)3.Fuse(10A)

2.Empty

Note:Ifthetractionunitdoesnotstart,eitherthemain

circuitorcontrolpanel/relayfusecouldbeblown.

4.Openpositionforoptional

accessories

Toaccessthefuses,youmustremovethefusepanel,as

follows:

Figure45

1.Fusepanel

2.Screw

5.Checkthefuses.

6.Installthefusepanelusingthe4screwsremoved

previously.

7.Installtheprop-rodintotheretainingbracketsand

prop-rodtabandsecureitwiththehairpincotter

(Figure44).

8.Closethehood.

36

Page 37

DriveSystem

Maintenance

ServicingtheTracks

ServiceInterval:Aftertherst50hours—Checkandadjust

thetracktension.

Beforeeachuseordaily—Cleanthetracks.

Beforeeachuseordaily—Checkthetracksfor

excessivewear(Ifthetracksareworn,replacethem.)

Every100hours—Checkandadjustthetracktension.

Every250hours/Yearly(whichevercomes

rst)—Checkandgreasetheroadwheels.

CleaningtheTracks

1.Withabucketontheloaderarms,lowerthebucketto

thegroundsothatthefrontofthetractionunitliftsoff

thegroundafewinches.

2.Shutofftheengine,andremovethekey .

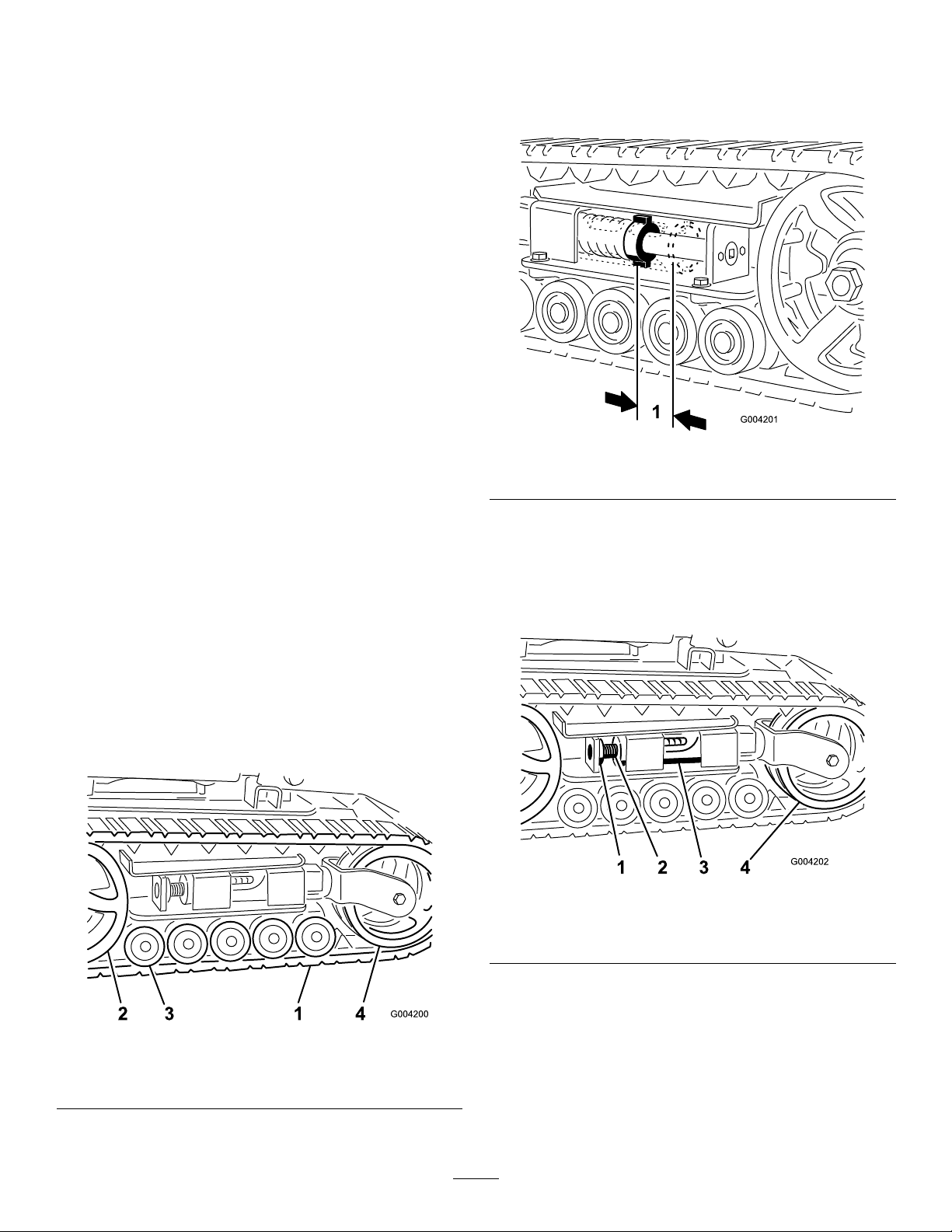

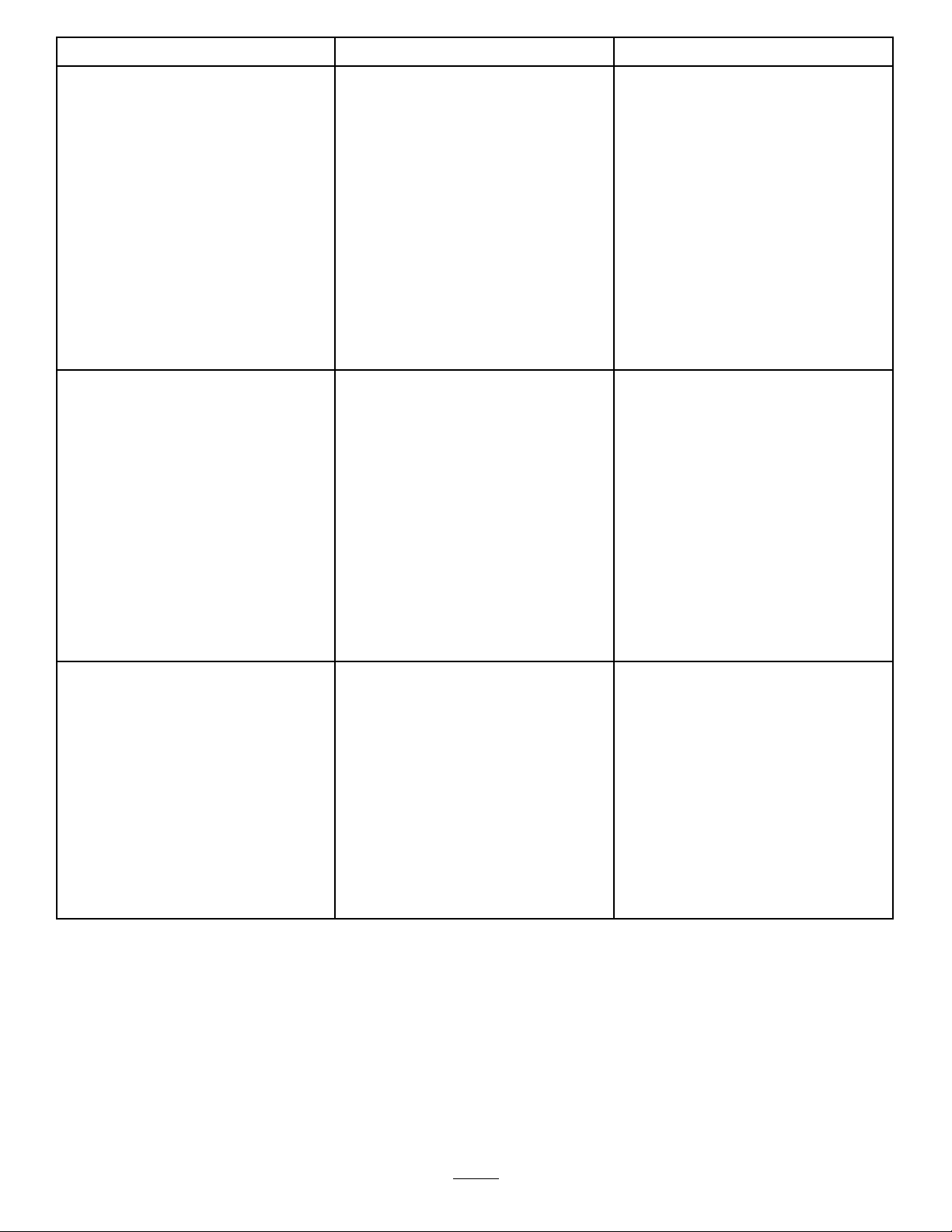

AdjustingtheTrackTension

Thereshouldbe7cm(2-3/4inches)betweenthetensionnut

andthebackofthetensiontube(Figure47).Ifnot,adjust

thetracktensionusingthefollowingprocedure:

Figure47

1.7cm(2-3/4inches)

3.Usingawaterhoseorpressurewasher,removedirt

fromeachtracksystem.

Important:Ensurethatyouusehigh-pressurewaterto

washonlythetrackarea.Donotuseahigh-pressure

washertocleantherestofthetractionunit.Donot

usehighpressurewaterbetweenthedrivesprocket

andthetractionunitoryoumaydamagethemotor

seals.High-pressurewashingcandamagetheelectrical

systemandhydraulicvalvesordepletegrease.

Important:Ensurethatyoufullycleantheroadwheels,

thetensionwheel,andthedrivesprocket(Figure46).

Theroadwheelsshouldrotatefreelywhenclean.

1.Lowertheloaderarms,shutofftheengine,andremove

thekey.

2.Lift/supportthesideoftheunittobeworkedonso

thatthetrackisofftheground.

3.Removethelockingboltandnut(Figure48).

Figure48

1.Lockingbolt3.T ensiontube

2.Tensioningscrew4.Tensionwheel

Figure46

1.Track3.Roadwheels

2.Drivesprocket4.Tensionwheel

4.Usinga1/2inchdrivesocket(Figure49),turnthe

tensioningscrewcounter-clockwiseuntilthedistance

betweenthetensionnutandthebackofthetension

tube(Figure47)is7cm(2-3/4inches).

5.Aligntheclosestnotchinthetensionscrewtothe

lockingboltholeandsecurethescrewwiththelocking

boltandnut(Figure48).

6.Lowerthetractionunittotheground.

37

Page 38

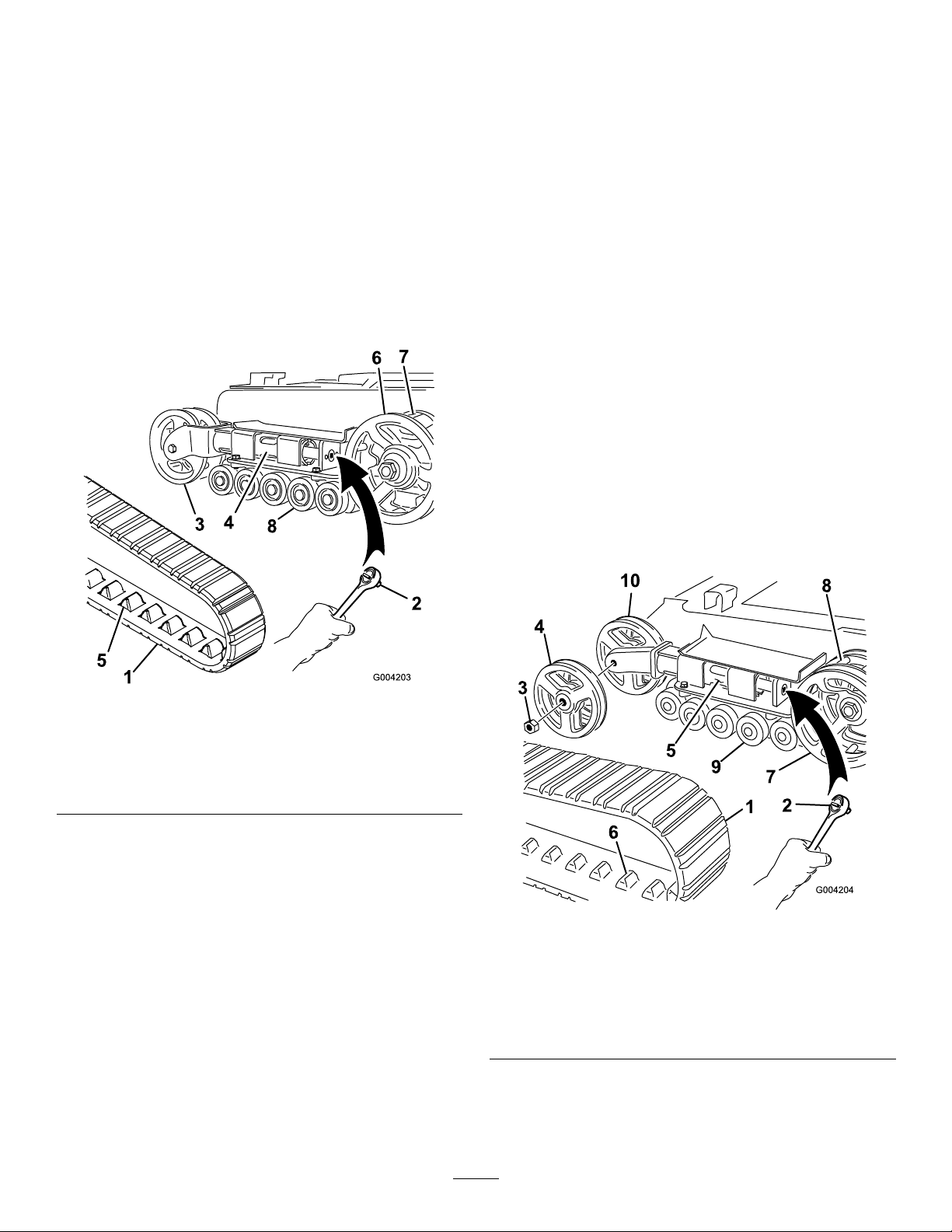

ReplacingtheTracks

Model22323

Whenthetracksarebadlyworn,replacethem.

1.Lowertheloaderarms,shutofftheengine,andremove

thekey.

2.Lift/supportthesideoftheunittobeworkedonso

thatthetrackis7.6to10cm(3to4inches)offthe

ground.

3.Removethelockingboltandnut(Figure48).

4.Usinga1/2inchdrivesocket,releasethedrivetension

byturningthetensioningscrewclockwise(Figure48

andFigure49).

10.Startingatthebottomofthetensionwheel,installthe

trackaroundthewheelbyrotatingthetrackrearward

whilepushingthelugsintothewheel.

11.Turnthetensioningscrewcounter-clockwiseuntilthe

distancebetweenthetensionnutandthebackofthe

forktube(Figure47)is7cm(2-3/4inches).

12.Aligntheclosestnotchinthetensionscrewtothe

lockingboltholeandsecurethescrewwiththelocking

boltandnut.

13.Lowerthetractionunittotheground.

14.Repeatsteps2through13toreplacetheothertrack.

Model22324

Whenthetracksarebadlyworn,replacethem.

1.Lowertheloaderarms,shutofftheengine,andremove

thekey.

2.Lift/supportthesideoftheunittobeworkedonso

thatthetrackis7.6to10cm(3to4inches)offthe

ground.

3.Removethelockingboltandnut(Figure48).

Figure49

1.Track5.Tracklug

2.1/2inchsocket

3.Tensionwheel

4.Forktube8.Roadwheels

6.Drivesprocket

7.Sprocketspacer

5.Pushthetensionwheeltowardtherearoftheunit

tomovetheforktubeagainsttheframe(Figure49).

(Ifitdoesnottouchtheframe,continueturningthe

tensioningscrewuntilitdoes.)

6.Beginremovingthetrackatthetopofthetension

wheel,peelingitoffthewheelwhilerotatingthetrack

forward.

7.Whenthetrackisoffthetensionwheel,removeitfrom

thedrivesprocketandroadwheels(Figure49).

8.Beginningatthedrivesprocket,coilthenewtrack

aroundthesprocket,ensuringthatthelugsonthetrack

tbetweenthespacersonthesprocket(Figure49).

9.Pushthetrackunderandbetweentheroadwheels

(Figure49).

4.Usinga1/2inchdrivesocket,releasethedrivetension

byturningthetensioningscrewclockwise(Figure48

andFigure50).

Figure50

1.Track6.Tracklug

2.1/2inchsocket

3.Tensionwheelnut

4.Outertensionwheel

5.Forktube10.Innertensionwheel

7.Drivesprocket

8.Sprocketspacer

9.Roadwheels

5.Pushthetensionwheeltowardtherearoftheunitto

movethetensiontubeagainsttheframe(Figure50).

38

Page 39

(Ifitdoesnottouchtheframe,continueturningthe

tensioningscrewuntilitdoes.)

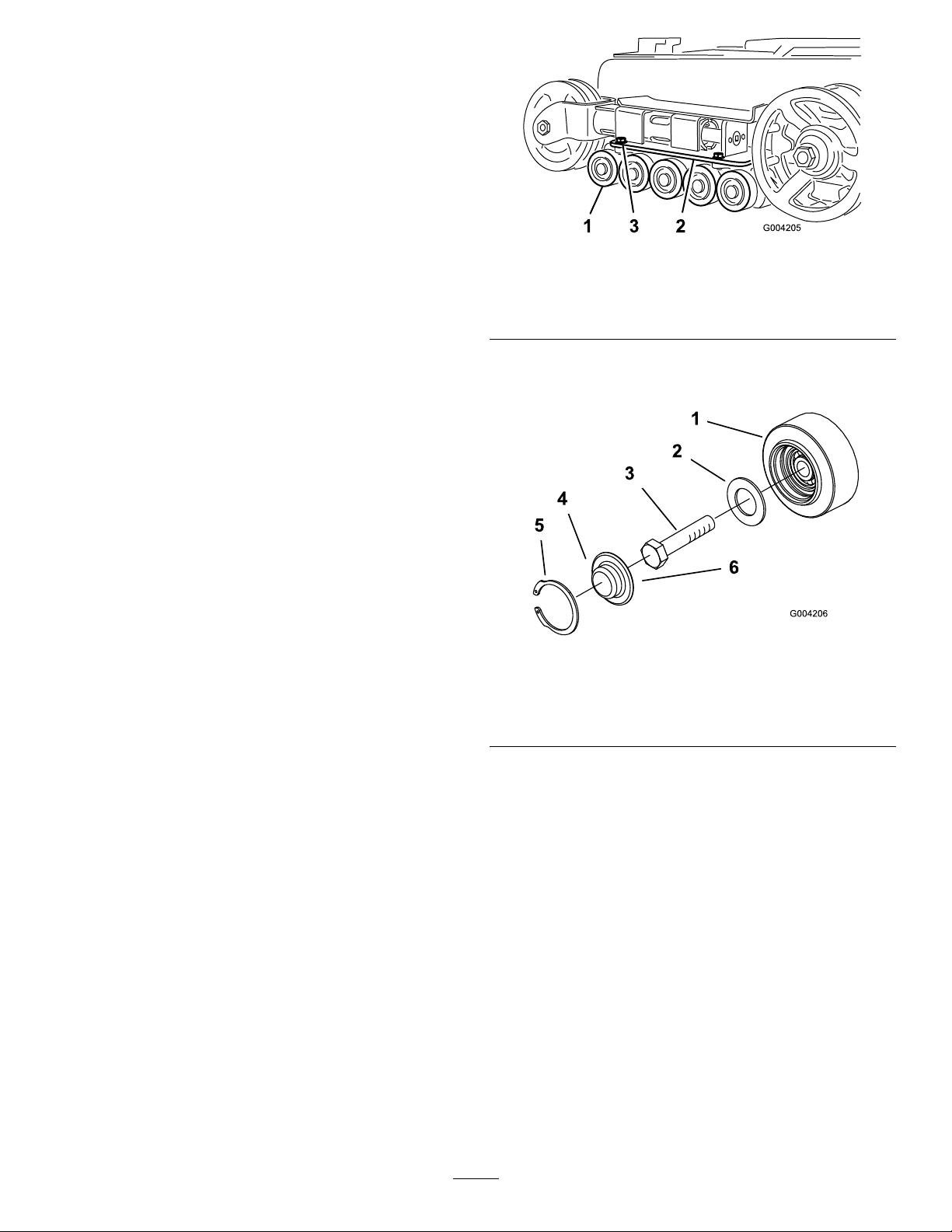

6.Removethenutsecuringtheoutertensionwheeland

removethewheel(Figure50).

7.Removethetrack(Figure50).

8.Removethenutsecuringtheinnertensionwheeland

removethewheel(Figure50).

9.Pullthe4largewashersoutofthe2wheels,1oneach

sideofeachwheel.

10.Cleantheoldgreaseanddirtoutoftheareabetween

wherethewasherswereinstalledandthebearings

insidethewheels,thenllthisareaoneachsideof

eachwheelwithgrease.

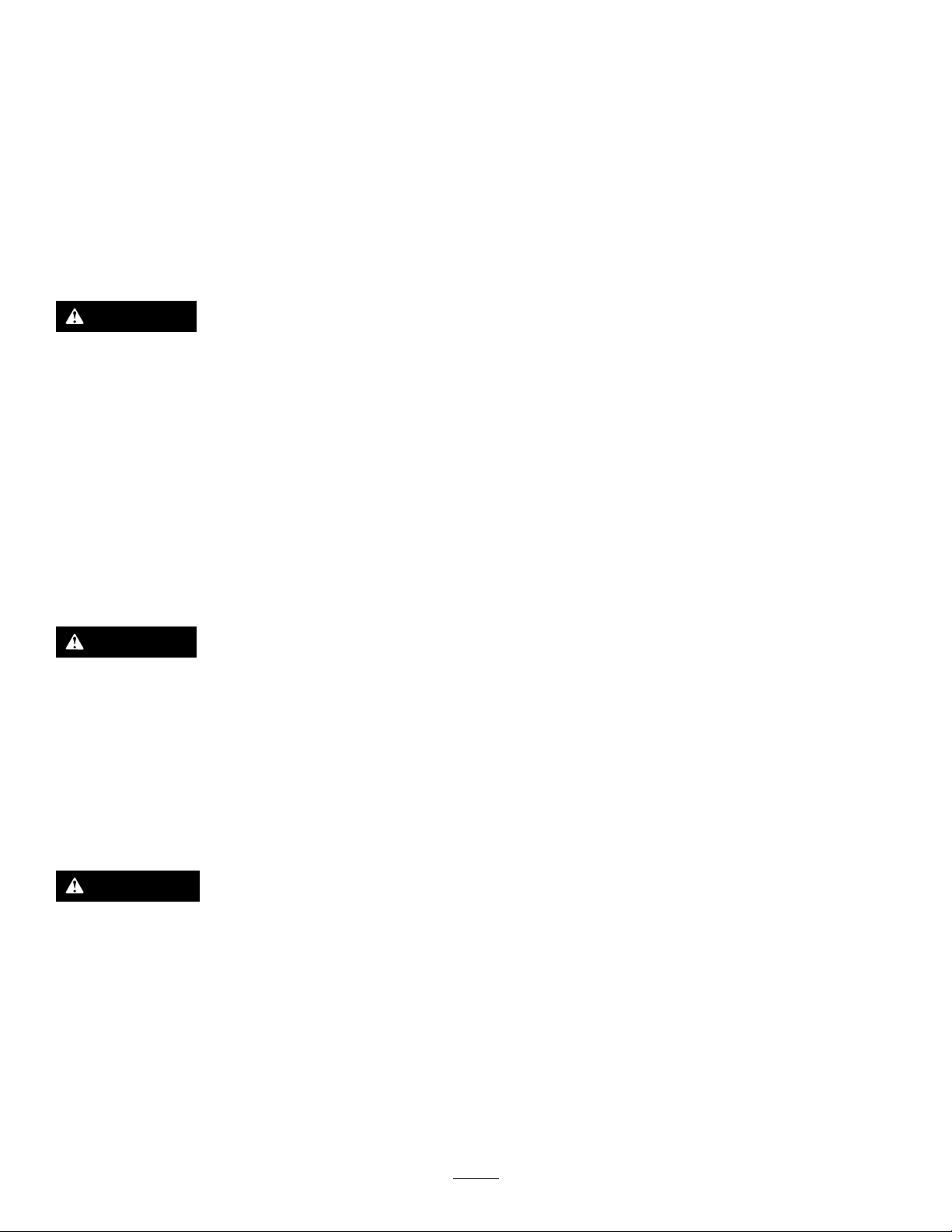

1.Roadwheels

2.Lowertrackguide

Figure51

3.Trackguidebolts(only2

shown)

11.Installthelargewashersonthewheelsoverthegrease.

12.Installtheinnertensionwheelandsecureitwiththe

nutremovedpreviously(Figure50).

13.Torquethenutto407N∙m(300ft-lb).

14.Installthenewtrack,ensuringthatthelugsinthe

tracktbetweenthespacersinthemiddleofthedrive

sprocket(Figure50).

15.Installtheoutertensionwheelandsecureitwiththe

nutremovedpreviously(Figure50).

16.Torquethenutto407N∙m(300ft-lb).

17.Turnthetensioningscrewcounter-clockwiseuntilthe

distancebetweenthetensionnutandthebackofthe