Page 1

FormNo.3373-546RevB

TX427CompactUtilityLoader

ModelNo.22321—SerialNo.312000201andUp

ModelNo.22321G—SerialNo.312000201andUp

ModelNo.22322—SerialNo.312000201andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3373-546*B

Page 2

ThisproductcomplieswithallrelevantEuropeandirectives,

fordetailspleaseseetheseparateproductspecicDeclaration

ofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Theengineexhaustfromthisproduct

containschemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

DANGER

Theremaybeburiedpower,gas,and/ortelephone

linesintheworkarea.Shockorexplosionmay

occurifyoudigintothem.

Havethepropertyorworkareamarkedforburied

linesanddonotdiginmarkedareas.Contactyour

localmarkingserviceorutilitycompanytohavethe

propertymarked(forexample,intheUnitedStates,

call811forthenationwidemarkingservice).

Introduction

Thismachineisacompactutilityloaderintendedforusein

variousearthandmaterialsmovingactivitiesforlandscaping

andconstructionwork.Itisdesignedtooperateawidevariety

ofattachmentseachofwhichperformaspecializedfunction.

Readthisinformationcarefullytolearnhowtooperateand

maintainyourproductproperlyandtoavoidinjuryand

productdamage.Youareresponsibleforoperatingthe

productproperlyandsafely .

YoumaycontactTorodirectlyatwww .Toro.comforproduct

andaccessoryinformation,helpndingadealer,ortoregister

yourproduct.

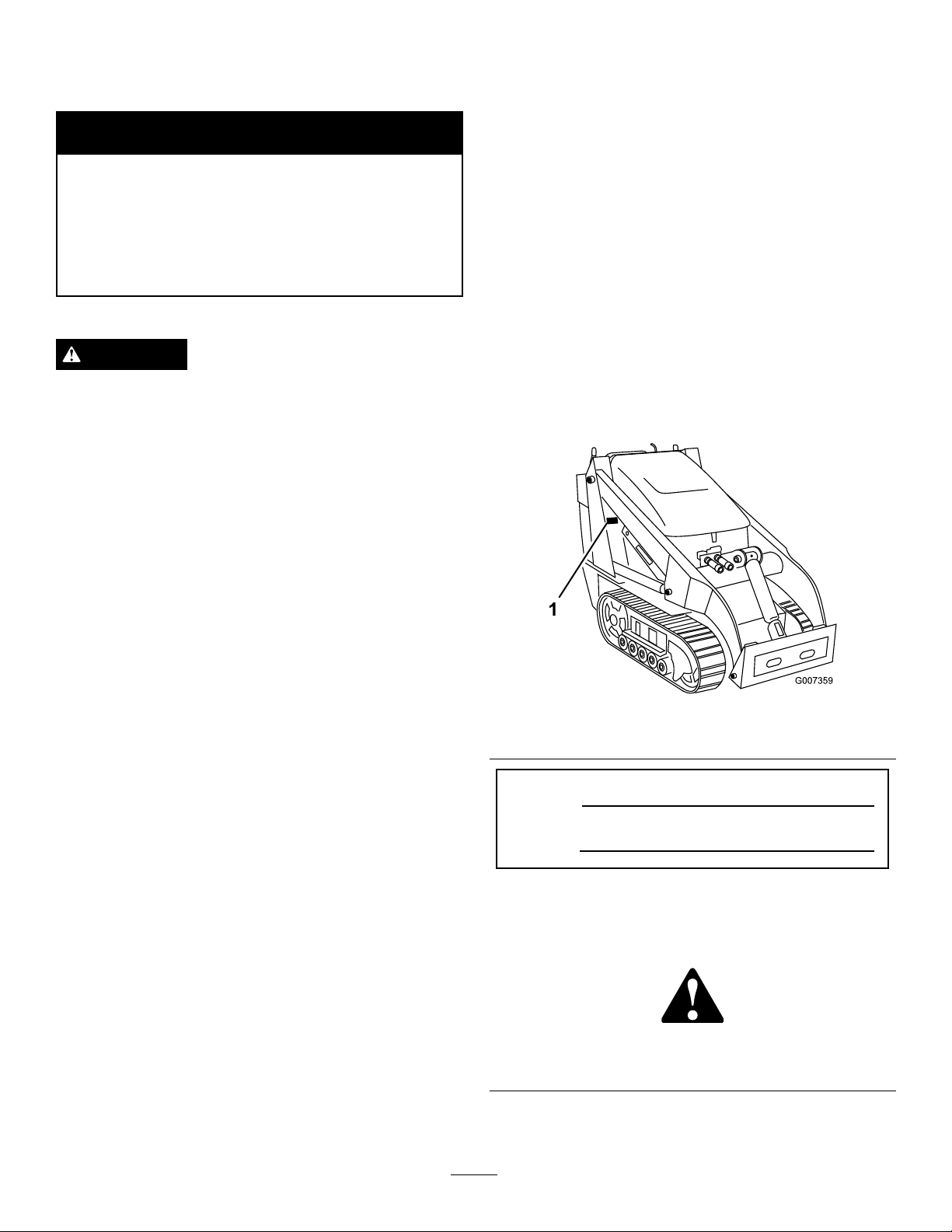

Wheneveryouneedservice,genuineToroparts,oradditional

information,contactanAuthorizedServiceDealerorToro

CustomerServiceandhavethemodelandserialnumbersof

yourproductready .Figure1identiesthelocationofthe

modelandserialnumbersontheproduct.Writethenumbers

inthespaceprovided.

Becauseinsomeareastherearelocal,state,orfederal

regulationsrequiringthatasparkarresterbeusedonthe

engineofthismachine,asparkarresterisavailableas

anoption.Ifyourequireasparkarrester,contactyour

AuthorizedToroServiceDealer.

GenuineTorosparkarrestersareapprovedbytheUSDA

ForestryService.

Important:ItisaviolationofCaliforniaPublic

ResourceCodeSection4442touseoroperatetheengine

onanyforest-covered,brush-covered,orgrass-covered

landwithoutasparkarrestermufermaintainedin

workingorder,ortheengineconstricted,equipped,and

maintainedforthepreventionofre.Otherstatesor

federalareasmayhavesimilarlaws.

ThissparkignitionsystemcomplieswithCanadianICES-002.

Theenclosed

informationregardingtheUSEnvironmentalProtection

Agency(EPA)andtheCaliforniaEmissionControl

Regulationofemissionsystems,maintenance,and

warranty.Replacementsmaybeorderedthroughthe

enginemanufacturer.

Engine Owner's Man ual

issuppliedfor

Figure1

1.Modelandserialnumberlocation

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(

whichsignalsahazardthatmaycauseseriousinjuryordeath

ifyoudonotfollowtherecommendedprecautions.

Figure2),

©2012—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Figure2

1.Safetyalertsymbol

Thismanualuses2otherwordstohighlightinformation.

Importantcallsattentiontospecialmechanicalinformation

Contactusatwww.T oro.com.

2

PrintedintheUSA.

AllRightsReserved

Page 3

andNoteemphasizesgeneralinformationworthyofspecial

attention.

Contents

Introduction..................................................................2

Safety...........................................................................4

SafeOperatingPractices...........................................4

SoundPressureLevel...............................................6

SoundPower..........................................................6

VibrationLevel.......................................................6

StabilityData..........................................................7

SlopeIndicator.......................................................8

SafetyandInstructionalDecals.................................9

ProductOverview.........................................................13

Controls...............................................................13

Specications........................................................16

Attachments/Accessories........................................16

Operation....................................................................17

AddingFuel...........................................................17

CheckingtheEngineOilLevel.................................18

CheckingtheHydraulicFluidLevel...........................18

StartingandStoppingtheEngine..............................19

StoppingtheTractionUnit......................................19

MovingaNon-functioningTractionUnit...................19

UsingtheCylinderLock..........................................20

UsingAttachments.................................................20

SecuringtheTractionUnitforTransport....................22

LiftingtheTractionUnit..........................................22

Maintenance.................................................................23

RecommendedMaintenanceSchedule(s)......................23

PremaintenanceProcedures........................................24

OpeningtheHood.................................................24

ClosingtheHood...................................................24

OpeningtheRearAccessCover................................24

ClosingtheRearAccessCover.................................25

RemovingtheSideScreens......................................25

InstallingtheSideScreens........................................25

RemovingtheFrontScreen......................................25

Lubrication...............................................................26

GreasingtheTractionUnit......................................26

EngineMaintenance..................................................27

ServicingtheAirCleaner.........................................27

ServicingtheCarbonCanister..................................27

ServicingtheEngineOil..........................................28

ServicingtheSparkPlugs.........................................29

FuelSystemMaintenance...........................................30

ChangingtheFuelFilter..........................................30

DrainingtheFuelTank...........................................31

ElectricalSystemMaintenance....................................31

ServicingtheBattery...............................................31

DriveSystemMaintenance.........................................33

ServicingtheTracks................................................33

BeltMaintenance......................................................36

Inspecting/ReplacingtheDriveBelt.........................36

ControlsSystemMaintenance.....................................37

AdjustingtheTractionControlAlignment.................37

AdjustingtheTractionControlNeutral

Position.............................................................38

AdjustingtheTrackingoftheTractionControl,

FullForwardPosition..........................................38

HydraulicSystemMaintenance....................................39

ReplacingtheHydraulicFilter..................................39

ChangingtheHydraulicFluid...................................40

CheckingtheHydraulicLines...................................41

Cleaning...................................................................42

RemovingDebrisfromtheTractionUnit...................42

CleaningtheChassis...............................................42

Storage........................................................................44

Troubleshooting...........................................................45

Schematics...................................................................46

3

Page 4

Safety

Improperuseormaintenancebytheoperatororowner

canresultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafetyalertsymbol,which

means:

instruction.Failuretocomplywiththeinstructionmay

resultinpersonalinjuryordeath.

SafeOperatingPractices

Thisproductiscapableofamputatinghandsandfeet.Always

followallsafetyinstructionstoavoidseriousinjuryordeath.

Engineexhaustcontainscarbonmonoxide,an

odorless,deadlypoisonthatcankillyou.

Donotruntheengineindoorsorinanenclosed

area.

Training

•ReadtheOperator'sManualandothertrainingmaterial.If

•Becomefamiliarwiththesafeoperationoftheequipment,

•Alloperatorsandmechanicsshouldbetrained.The

•Neverletchildrenoruntrainedpeopleoperateorservice

•Theowner/usercanpreventandisresponsiblefor

Preparation

•Evaluatetheterraintodeterminewhataccessoriesand

•Wearappropriateclothingincludinghardhat,safety

•Inspecttheareawheretheequipmentistobeusedand

•Useextracarewhenhandlinggasolineandotherfuels.

Caution

,

W ar ning

,or

Danger

—personalsafety

WARNING

theoperator(s)ormechanic(s)cannotreadEnglish,itis

theowner'sresponsibilitytoexplainthismaterialtothem.

operatorcontrols,andsafetysigns.

ownerisresponsiblefortrainingtheusers.

theequipment.Localregulationsmayrestricttheageof

theoperator.

accidentsorinjuriesoccurringtohimselforherself,other

peopleorproperty.

attachmentsareneededtoproperlyandsafelyperform

thejob.Onlyuseaccessoriesandattachmentsapproved

bythemanufacturer.

glasses,longpants,safetyshoes,andhearingprotection.

Longhair,looseclothingorjewelrymaygettangledin

movingparts.

removeallobjectssuchasrocks,toys,andwirewhichcan

bethrownbythemachine.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer

–Neverremovethegascaporaddfuelwiththeengine

running.Allowtheenginetocoolbeforerefueling.

Donotsmoke.

–Neverrefuelordrainthemachineindoors.

•Checkthattheoperator'spresencecontrols,safety

switches,andshieldsareattachedandfunctioning

properly.Donotoperateunlesstheyarefunctioning

properly.

Operation

•Neverrunanengineinanenclosedarea.

•Onlyoperateingoodlight,keepingawayfromholesand

hiddenhazards.

•Besurealldrivesareinneutralandparkingbrakeis

engagedbeforestartingtheengine.Onlystarttheengine

fromtheoperator'sposition.

•Slowdownanduseextracareonhillsides.Besureto

travelintherecommendeddirectiononhillsides.Turf

conditionscanaffectthemachine'sstability.

•Slowdownandusecautionwhenmakingturnsandwhen

changingdirectionsonslopes.

•Neveroperatewiththeguardsnotsecurelyinplace.Be

sureallinterlocksareattached,adjustedproperly,and

functioningproperty.

•Donotchangetheenginegovernorsettingoroverspeed

theengine.

•Stoponlevelground,lowerimplements,disengagethe

auxiliaryhydraulics,engageparkingbrake,shutoffthe

enginebeforeleavingtheoperator'spositionforany

reason.

•Keephandsandfeetawayfrommovingattachments.

•Lookbehindanddownbeforebackinguptobesureof

aclearpath.

•Nevercarrypassengersandkeeppetsandbystanders

away.

•Slowdownandusecautionwhenmakingturnsand

crossingroadsandsidewalks.

•Donotoperatethemachineundertheinuenceof

alcoholordrugs.

•Usecarewhenloadingorunloadingthemachineintoa

trailerortruck.

•Usecarewhenapproachingblindcorners,shrubs,trees,

orotherobjectsthatmayobscurevision.

•Readallattachmentmanuals.

•Ensurethattheareaisclearofotherpeoplebefore

operatingthetractionunit.Stopthetractionunitif

anyoneentersthearea.

•Neverleavearunningtractionunitunattended.Always

lowertheloaderarms,stoptheengine,settheparking

brake,andremovethekeybeforeleaving.

•Donotexceedtheratedoperatingcapacity,asthetraction

unitmaybecomeunstablewhichmayresultinlossof

control.

•Donotcarryaloadwiththearmsraised.Alwayscarry

loadsclosetotheground.

4

Page 5

•Donotover-loadtheattachmentandalwayskeepthe

loadlevelwhenraisingtheloaderarms.Logs,boards,and

otheritemscouldrolldowntheloaderarms,injuringyou.

•Neverjerkthecontrols;useasteadymotion.

•Watchfortrafcwhenoperatingnearorcrossing

roadways.

•Donottouchpartswhichmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,adjust,

orservice.

•Checkforoverheadclearances(i.e.branches,doorways,

electricalwires)beforedrivingunderanyobjectsanddo

notcontactthem.

•Ensurethatyouoperatethetractionunitinareaswhere

therearenoobstaclesincloseproximitytotheoperator.

Failuretomaintainadequatedistancefromtrees,walls,

andotherbarriersmayresultininjuryasthetractionunit

backsupduringoperationiftheoperatorisnotattentive

tothesurroundings.Onlyoperatetheunitinareaswhere

thereissufcientclearancefortheoperatortosafely

maneuvertheproduct.

•Beforedigging,havetheareamarkedforunderground

utilities,anddonotdiginmarkedareas.

•Locatethepinchpointareasmarkedonthetractionunit

andattachmentsandkeephandsandfeetawayfrom

theseareas.

•Beforeoperatingthetractionunitwithanattachment,

ensurethattheattachmentisproperlyinstalled.

•Lightningcancausesevereinjuryordeath.Iflightning

isseenorthunderisheardinthearea,donotoperate

themachine;seekshelter.

SlopeOperation

Slopesareamajorfactorrelatedtoloss-of-controland

tip-overaccidents,whichcanresultinsevereinjuryordeath.

Allslopesrequireextracaution.

•Donotoperatethetractionunitonhillsidesorslopes

exceedingtheanglesrecommendedintheStabilityData

sectionandthoseintheattachmentOperator'sManual.See

alsothe

•Operateupanddownslopeswiththeheavyendof

thetractionunituphill.Weightdistributionchanges.

Anemptybucketwillmaketherearofthetractionunit

theheavyend,andafullbucketwillmakethefrontofthe

tractionunittheheavyend.Mostotherattachmentswill

makethefrontoftractionunittheheavyend.

•Raisingtheloaderarmsonaslopewillaffectthestability

ofthemachine.Wheneverpossible,keeptheloaderarms

intheloweredpositionwhenonslopes.

•Removinganattachmentonaslopewillmaketherearof

thetractionunitheavy.Referto

determinewhethertheattachmentcanbesafelyremoved

ontheslope.

•Removeobstaclessuchasrocks,treelimbs,etc.fromthe

workarea.Watchforholes,ruts,orbumps,asuneven

SlopeIndicator(page8).

StabilityData(page7)to

terraincouldoverturnthetractionunit.Tallgrasscan

hideobstacles.

•UseonlyToro-approvedattachments.Attachmentscan

changethestabilityandtheoperatingcharacteristicsof

thetractionunit.Warrantymaybevoidedifusedwith

unapprovedattachments.

•Keepallmovementsonslopesslowandgradual.Donot

makesuddenchangesinspeedordirection.

•Avoidstartingorstoppingonaslope.Ifthetractionunit

losestraction,proceedslowly,straightdowntheslope.

•Avoidturningonslopes.Ifyoumustturn,turnslowly

andkeeptheheavyendofthetractionunituphill.

•Donotoperateneardrop-offs,ditches,orembankments.

Thetractionunitcouldsuddenlyturnoverifatrackgoes

overtheedgeofaclifforditch,orifanedgecavesin.

•Donotoperateonwetgrass.Reducedtractioncould

causesliding.

•Donotparkthetractionunitonahillsideorslope

withoutloweringtheattachmenttotheground,setting

theparkingbrake,andchockingthetracks.

MaintenanceandStorage

•Disengagetheauxiliaryhydraulics,lowertheattachment,

settheparkingbrake,stoptheengine,andremovethe

key.Waitforallmovementtostopbeforeadjusting,

cleaning,orrepairing.

•Cleandebrisfromattachments,drives,mufers,and

enginetohelppreventres.Cleanupoilorfuelspillage.

•Lettheenginecoolbeforestoringanddonotstorenear

ame.

•Donotstorefuelnearamesordrainindoors.

•Parkthemachineonlevelground.Neverallowuntrained

personneltoservicethemachine.

•Usejackstandstosupportcomponentswhenrequired.

•Carefullyreleasepressurefromcomponentswithstored

energy.

•Disconnectthebatteryorremovethesparkplugwires

beforemakinganyrepairs.Disconnectthenegative

terminalrstandthepositivelast.Reconnectpositive

rstandnegativelast.

•Keephandsandfeetawayfrommovingparts.Ifpossible,

donotmakeadjustmentswiththeenginerunning.

•Chargebatteriesinanopenwellventilatedarea,away

fromsparkandames.Unplugthechargerbefore

connectingordisconnectingitfromthebattery.Wear

protectiveclothinganduseinsulatedtools.

•Keepallpartsingoodworkingconditionandallhardware

tightened.Replaceallwornordamageddecals.

•Ifanymaintenanceorrepairrequirestheloaderarmsto

beintheraisedposition,securethearmsintheraised

positionwiththehydrauliccylinderlock.

5

Page 6

•Securetheloaderarmvalvewiththeloadervalvelock

anytimeyouneedtostopthemachinewiththeloader

armsraised.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO6395.

•Keepnutsandboltstight.Keepequipmentingood

condition.

•Nevertamperwithsafetydevices.

•Keepthetractionunitfreeofgrass,leaves,orotherdebris

build-up.Cleanupoilorfuelspillage.Allowthetraction

unittocoolbeforestoring.

•Useextracarewhenhandlinggasolineandotherfuels.

Theyareammableandvaporsareexplosive.

–Useonlyanapprovedcontainer.

–Neverremovethegascaporaddfuelwhenthe

engineisrunning.Allowtheenginetocoolbefore

refueling.Donotsmoke.

–Neverrefuelthetractionunitindoors.

–Neverstorethetractionunitorfuelcontainerinside

wherethereisanopename,suchasnearawater

heaterorfurnace.

–Neverllacontainerwhileitisinsideavehicle,trunk,

pick-upbed,oranysurfaceotherthantheground.

–Keepcontainernozzleincontactwiththetankduring

lling.

VibrationLevel

Measuredvibrationlevelforrighthand=1.1m/s

Measuredvibrationlevelforlefthand=1.1m/s

UncertaintyValue(K)=0.6m/s

Measuredvaluesweredeterminedaccordingtotheprocedures

outlinedinENISO20643.

2

2

2

•Stopandinspecttheequipmentifyoustrikeanobject.

Makeanynecessaryrepairsbeforerestarting.

•UseonlygenuineTororeplacementpartstoensurethat

originalstandardsaremaintained.

•Batteryacidispoisonousandcancauseburns.Avoid

contactwithskin,eyes,andclothing.Protectyourface,

eyes,andclothingwhenworkingwithabattery.

•Batterygasescanexplode.Keepcigarettes,sparksand

amesawayfromthebattery.

•Keepyourbodyandhandsawayfrompinholeleaks

ornozzlesthatejecthighpressurehydraulicuid.Use

cardboardorpapertondhydraulicleaks;neveruse

yourhands.Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjuryrequiringsurgerywithina

fewhoursbyaqualiedsurgeonorgangrenemayresult.

SoundPressureLevel

SoundPressureLevelThisunithasasoundpressurelevelat

theoperator’searof90dBA,whichincludesanUncertainty

Value(K)of1dBA.

Soundpressurelevelwasdeterminedaccordingtothe

proceduresoutlinedinEN11201.

SoundPower

Thisunithasaguaranteedsoundpowerlevelof103dBA,

whichincludesanUncertaintyValue(K)of1dBA.

6

Page 7

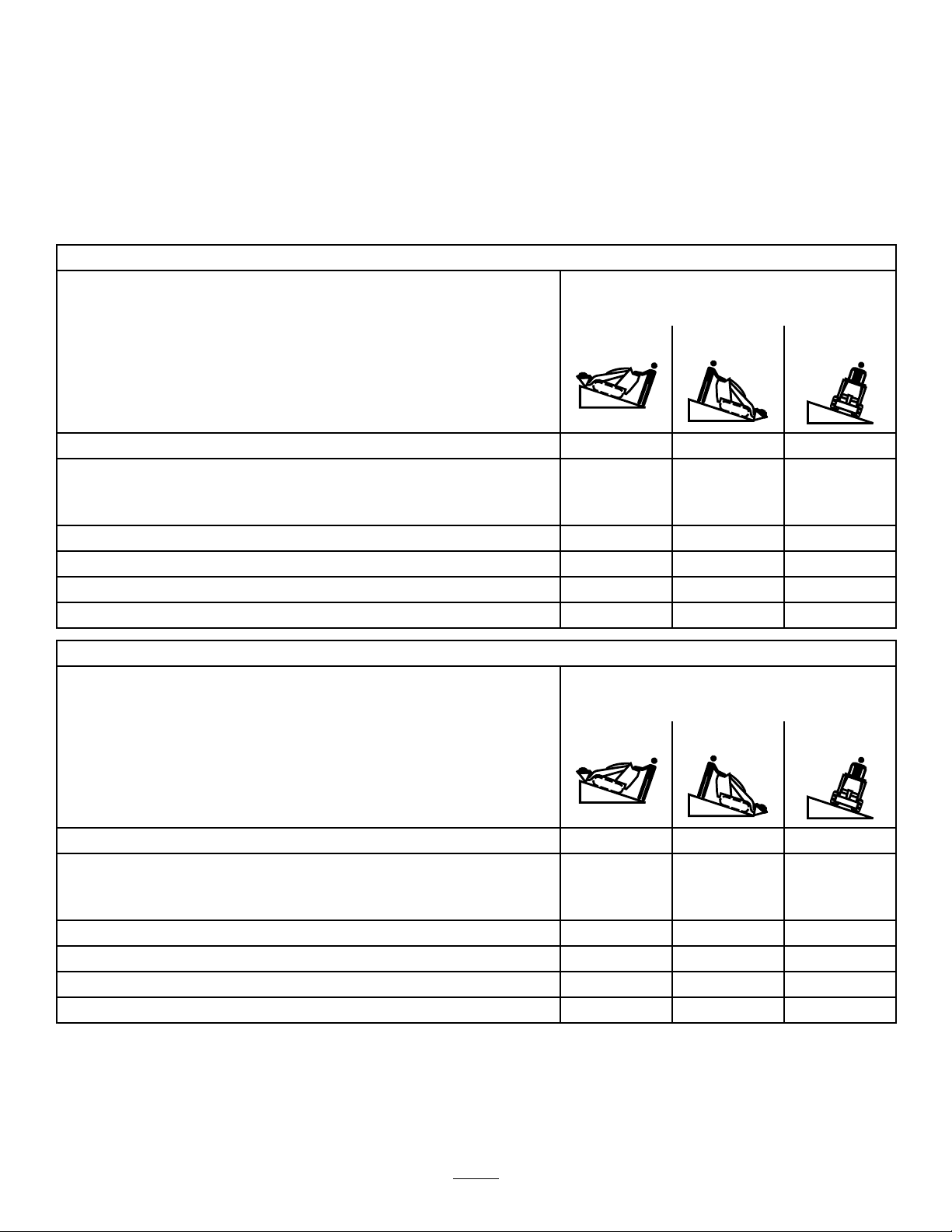

StabilityData

Thefollowingtableslistthemaximumsloperecommendedforthetractionunitinthepositionslistedinthetables.Slopesover

thelisteddegreemaycausethetractionunittobecomeunstable.Thedatainthetablesassumethattheloaderarmsarefully

lowered;raisedarmsmayaffectthestability .

Ineachattachmentmanualisasetofthreestabilityratings,oneforeachhillposition.Todeterminethemaximumslopeyou

cantraversewiththeattachmentinstalled,ndthedegreeofslopethatcorrespondstothestabilityratingsoftheattachment.

Example:IftheattachmentinstalledonaTX427tractionunithasaFrontUphillratingofB,aRearUphillratingofD ,anda

SideUphillratingofC,thenyoucoulddriveforwardupa20°slope,rearwardupa12°slope,orsidewaysona14°slope,as

listedinthefollowingtablefortheTX427tractionunit.

Model22321and22321G

MaximumRecommendedSlopewhen

Operatingwith:

FrontUphillRearUphill

Conguration

Tractionunitwithoutattachment

Tractionunitwithanattachmentratedwithoneofthefollowingstabilityratings

foreachslopeposition:*

A

B

C17°17°14°

D

E

Model22322

11°21°19°

25°25°20°

20°20°18°

10°12°9°

5°5°5°

MaximumRecommendedSlopewhen

Operatingwith:

FrontUphillRearUphill

SideUphill

SideUphill

Conguration

Tractionunitwithoutattachment

Tractionunitwithanattachmentratedwithoneofthefollowingstabilityratings

foreachslopeposition:*

A

B

C18°16°16°

D

E

12°20°23°

25°25°25°

22°22°22°

10°10°10°

5°5°5°

7

Page 8

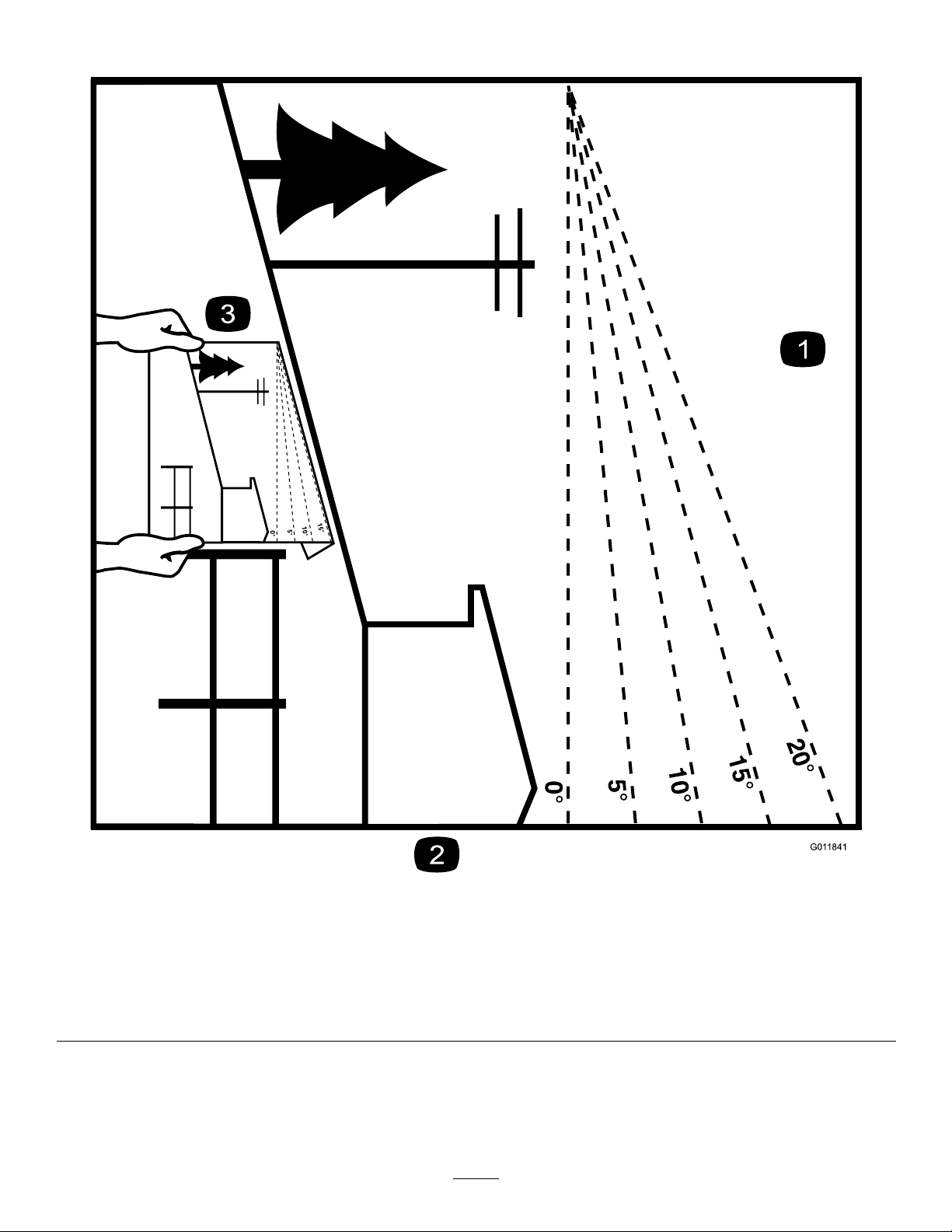

SlopeIndicator

G011841

Figure3

Thispagemaybecopiedforpersonaluse.

1.Todeterminethemaximumslopeyoucansafelyoperatethemachineon,refertotheStabilityDatasection.Usetheslope

indicatortodeterminethedegreeofslopeofhillsbeforeoperating.Donotoperatethismachineonaslopegreaterthanthat

speciedintheStabilityDatasection.Foldalongtheappropriatelinetomatchtherecommendedslope.

2.Alignthisedgewithaverticalsurface,atree,building,fencepole,etc.

3.Exampleofhowtocompareslopewithfoldededge.

8

Page 9

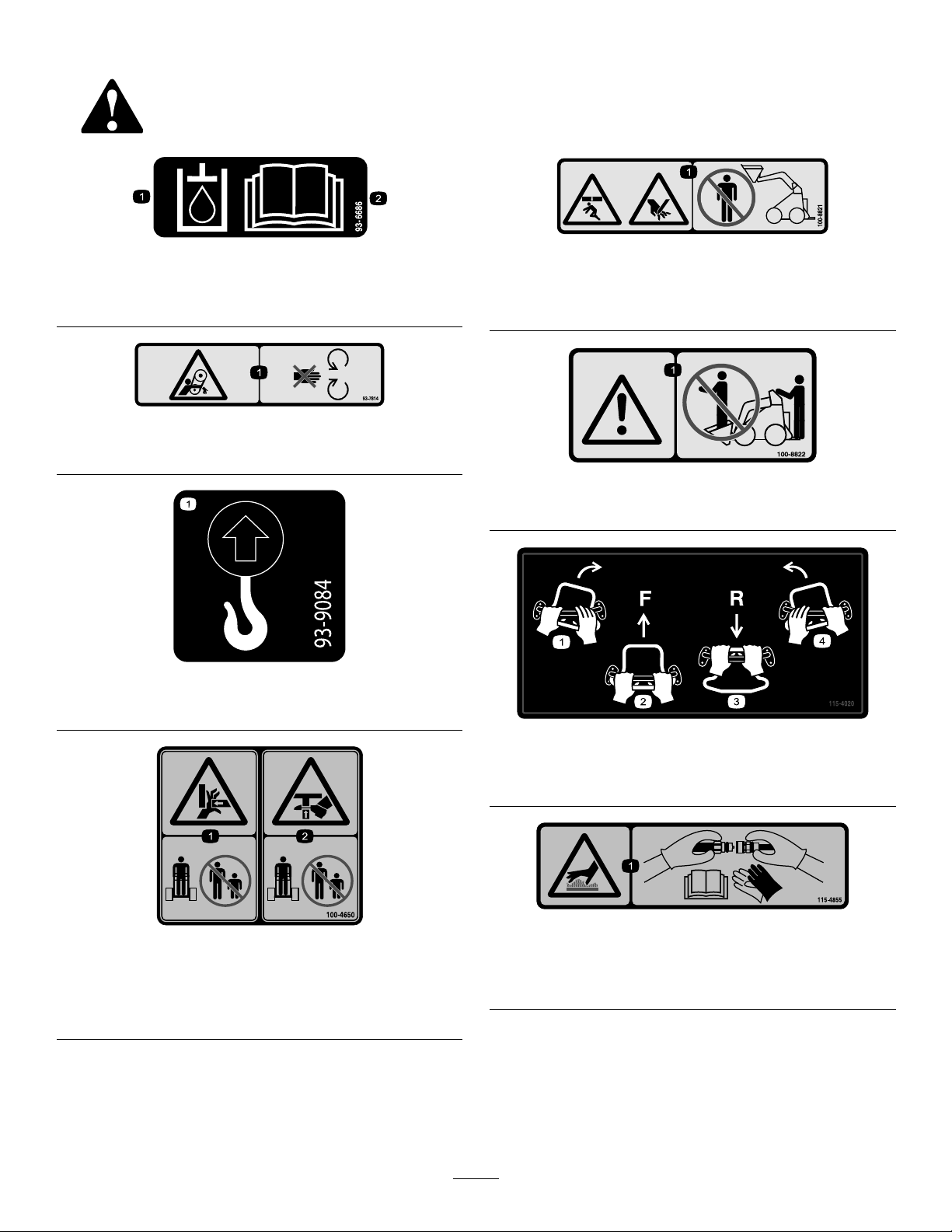

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaofpotential

danger.Replaceanydecalthatisdamagedorlost.

93-6686

1.Hydraulicoil

2.ReadtheOperator'sManual.

93-7814

1.Entanglementhazard,belt—stayawayfrommovingparts.

93-9084

100-8821

1.Crushinghazardandcuttinghazardofhand—stayasafe

distancefromthefrontofthetractionunitwhentheloader

armsareraised.

100-8822

1.Warning—donotcarrypassengers.

1.Liftpoint

2.Tie-downpoint

100-4650

1.Crushinghazardofhand—keepbystandersasafedistance

fromthemachine.

2.Crushinghazardoffoot—keepbystandersasafedistance

fromthemachine.

115-4020

1.Turnright3.Reverse

2.Forward

4.Turnleft

115-4855

1.Hotsurface/burnhazard—wearprotectivegloveswhen

handlingthehydrauliccouplersandreadtheOperator's

Manualforinformationonhandlinghydrauliccomponents.

9

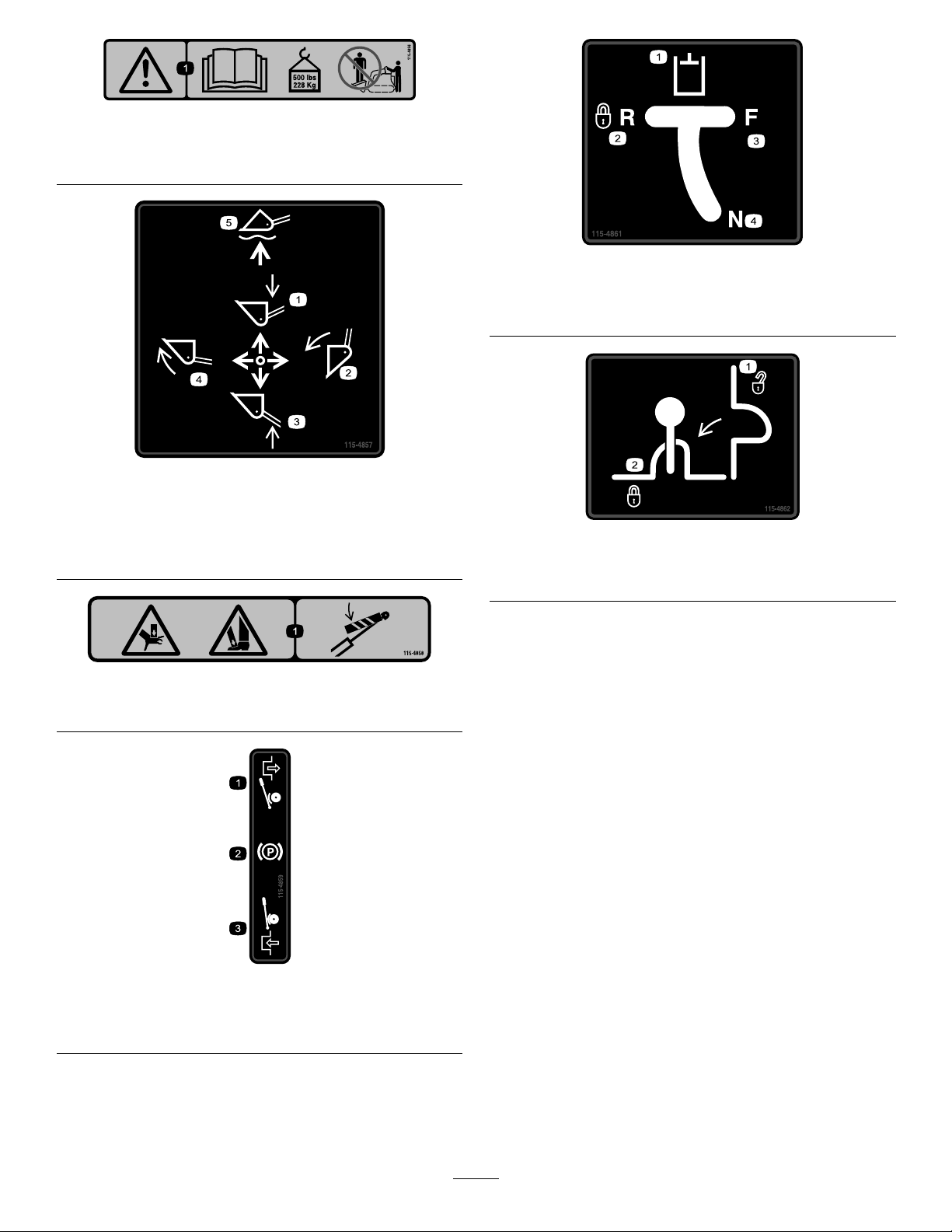

Page 10

115-4856

1.Warning—readtheOperator'sManual;maximumload

ratingof500lb(228Kg);noriders.

115-4857

115-4861

1.Auxiliaryhydraulics3.Forward

2.Lockedreverse(detent)4.Neutral(off)

1.Lowertheloaderarms.

2.Dumpthebucket.5.Floatthebucketonthe

3.Raisetheloaderarms.

4.Curlthebucket.

ground.

115-4858

1.Crushinghazardofhandsorfeet—installthecylinderlock.

1.Loadervalvelock,

unlocked

115-4862

2.Loadervalvelock,locked

1.Disengaged3.Engaged

2.Parkingbrake

115-4859

10

Page 11

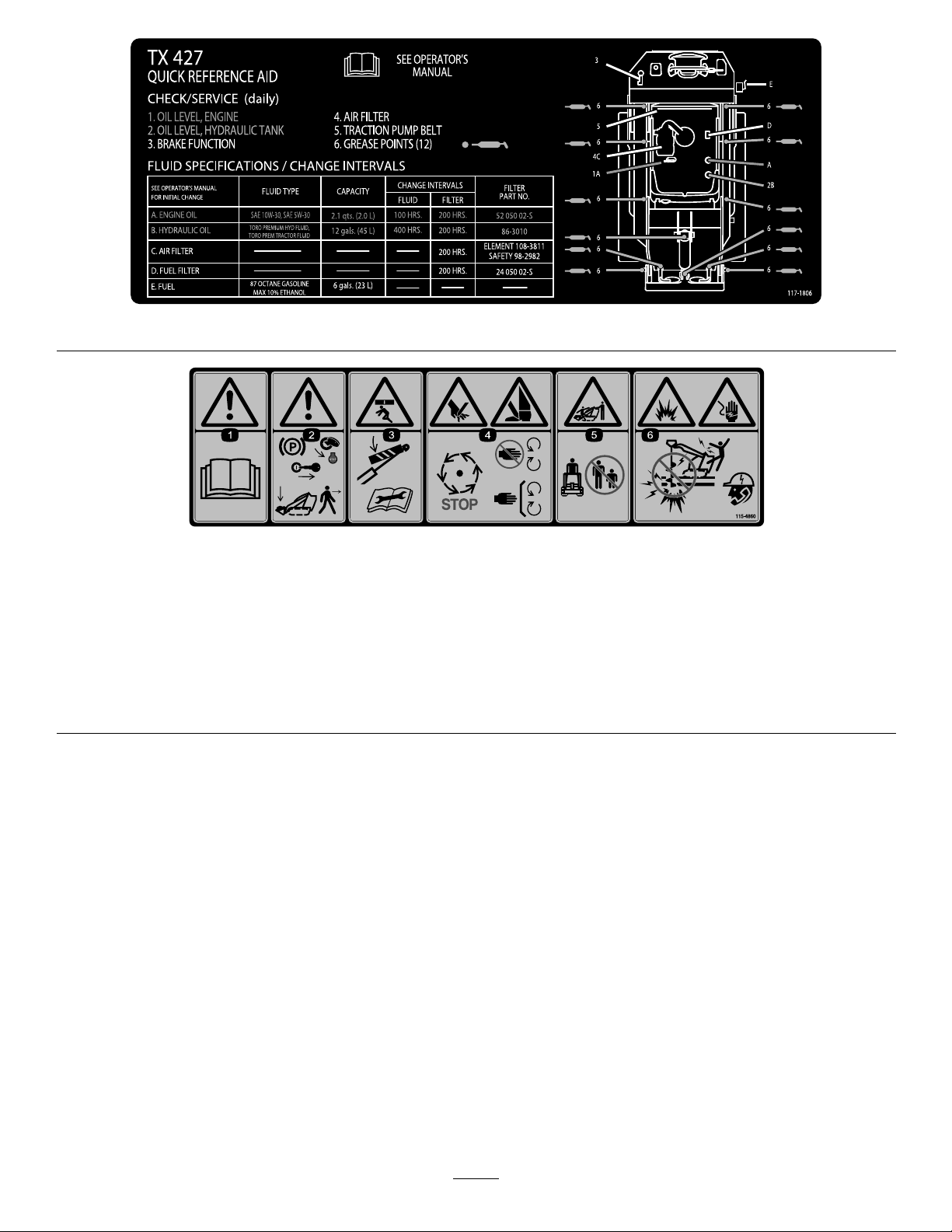

117–1806

115-4860

1.Warning—readtheOperator'sManual.

2.Warning—settheparkingbrake,stoptheengine,removetheignitionkeyandlowertheloaderarmsbeforeleavingthemachine.

3.Crushinghazard—installthecylinderlockandreadtheinstructionsbeforeservicingorperformingmaintenance.

4.Cuttinghazardofhandsorfeet—waitforallmovingpartstostop;stayawayfrommovingparts;keepallguardsandshieldsin

place.

5.Crushing/dismembermenthazardofbystanders—keepbystandersasafedistancefromthemachine.

6.Explosionandelectricshockhazard—donotdiginareaswithburiedgasorelectricallines;contactlocalpowerorganizations

beforedigging.

11

Page 12

117-4045

1.ReadtheOperator'sManual,located

insidetherearaccesscover.

2.Fast

3.Continuousvariablesetting

4.Slow

5.Throttle11.Hourmeter17.Tippinghazard—movethetractionunit

6.On

7.Choke

8.Off

9.Fuel15.Warning—donotoperatethismachine

10.Hydraulicoiltemperature16.Electricshockhazard,overheadpower

12.Engine—start18.Tippinghazard—slowthetractionunit

13.Engine—run

14.Engine—stop

unlessyouaretrained.

lines—stayawayfromoverheadpower

lines.

withtheheavyenduphill;donottravel

withtheloaderarmsraised.

whenturning,donottravelfastwhen

turning,lookbehindanddownwhen

reversing.

12

Page 13

ProductOverview

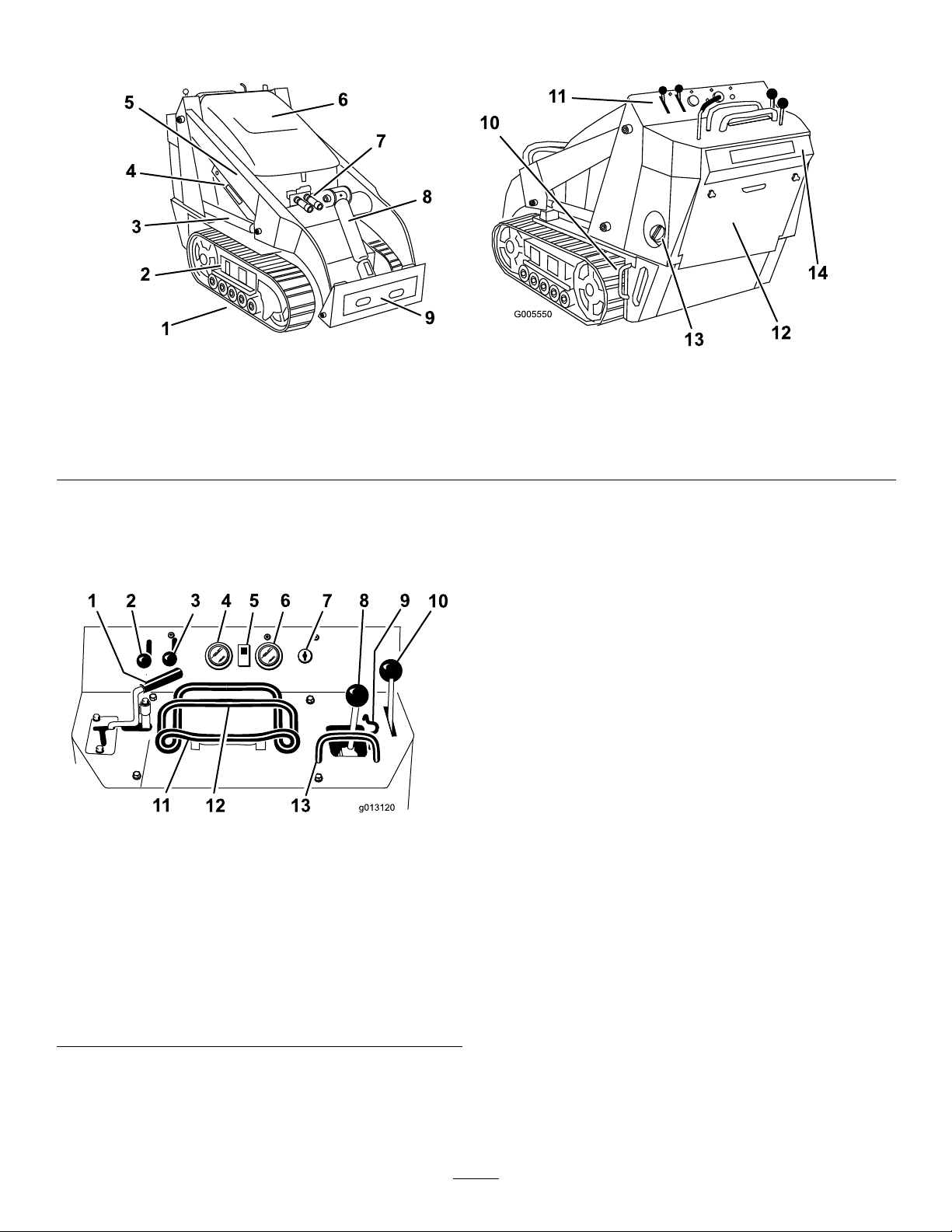

Figure4

1.Track5.Loaderarms9.Mountplate13.Fueltank

2.Trackadjustmentchamber6.Hood

3.Liftcylinder

4.Cylinderlock

7.Auxiliaryhydrauliccouplers

8.Tiltcylinder12.Rearaccesscover

10.Tie-down/liftloop14.Reversesafetyplate

11.Controlpanel

Controls

Becomefamiliarwithallthecontrols(Figure5)beforeyou

starttheengineandoperatethetractionunit.

Figure5

1.Auxiliaryhydraulicslever

2.Throttlelever9.Loadervalvelock

3.Chokelever

4.Fuelgauge11.Tractioncontrol

5.Hydraulicoiltemperature

light

6.Hourmeter/tachometer13.Loadercontrolreference

7.Keyswitch

8.Loaderarm/attachmenttilt

lever

10.Parkingbrakelever

12.Referencebar

bar

Tostarttheengine,rotatethekeytothestartposition.Release

thekeywhenenginestartsanditwillmoveautomaticallyto

therunposition.

Tostoptheengine,rotatethekeytotheoffposition.

ThrottleLever

Movethecontrolforwardtoincreasetheenginespeedand

rearwardtodecreasespeed.

ChokeLever

Beforestartingacoldengine,movethechokeleverforward.

Aftertheenginestarts,regulatethechoketokeeptheengine

runningsmoothly.Assoonaspossible,movethechokelever

allthewayrearward.

Note:Awarmenginerequireslittleornochoking.

ReferenceBar

Whendrivingthetractionunit,usethereferencebaras

ahandleandaleveragepointforcontrollingthetraction

controlandtheauxiliaryhydraulicslever.Toensuresmooth,

controlledoperation,donottakebothhandsoffofthe

referencebarwhileoperatingthetractionunit.

KeySwitch

Thekeyswitch,usedtostartandstoptheengine,hasthree

positions:off,run,andstart.

13

Page 14

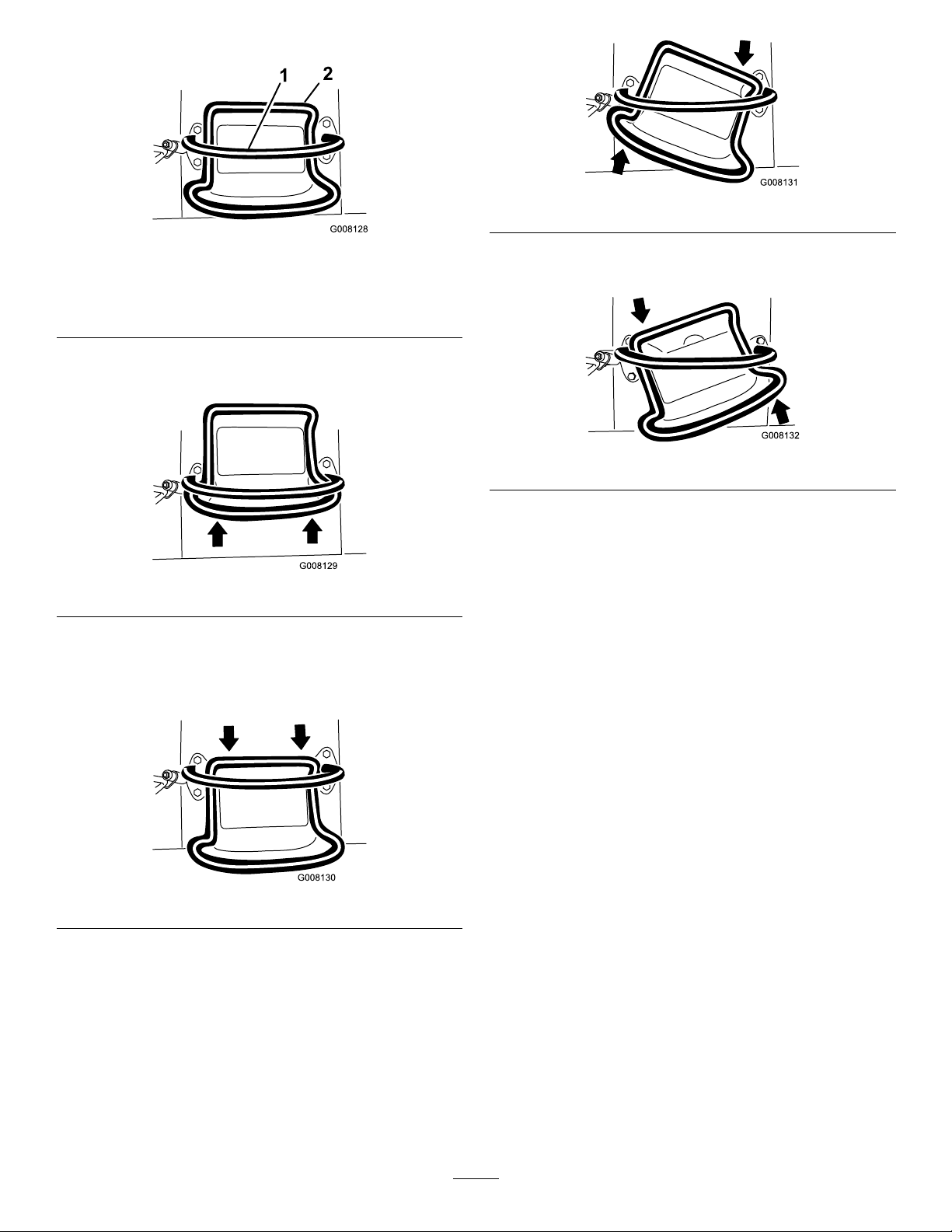

TractionControl

G008131

G008132

Figure9

Figure6

1.Referencebar(doesnotmovetogiveyouareferencepoint

andaxedhandletoholdwhileoperatingthetractionunit)

2.Tractioncontrol(movestocontrolthemachine)

•Tomoveforward,movethetractioncontrolforward

(Figure7).

Figure7

•Tomoverearward,movethetractioncontrolrearward

(Figure8).Whenreversing,lookbehindfor

obstructionsandkeepyourhandsonthereference

bar(Figure7).

•Toturnleft,rotatethetractioncontrolcounterclockwise

(Figure10).

Figure10

•Tostop,releasethetractioncontrol(Figure6).

Note:Thefartheryoumovethetractioncontrolinany

direction,thefasterthemachinewillmoveinthatdirection.

LoaderArm/AttachmentTiltLever

Totilttheattachmentforward,slowlymovethelevertothe

right(Figure11).

Totilttheattachmentrearward,slowlymovethelevertothe

left(Figure11).

Figure8

•Toturnright,rotatethetractioncontrolclockwise

(Figure9).

Tolowertheloaderarms,slowlymovetheleverforward

(Figure11).

Toraisetheloaderarms,slowlymovetheleverrearward

(Figure11).

Youcanalsopushtheleverfullyforwardintoadetent

position(Figure11)toreleasetheloaderarmssothatthe

attachmentrestsontheground.Thisallowsattachmentssuch

asthelevelerandthehydraulicbladetofollowthecontours

oftheground(i.e.,oat)whengrading.

14

Page 15

Figure11

AuxiliaryHydraulicsLever

Tooperateahydraulicattachmentintheforwarddirection,

rotatetheauxiliaryhydraulicsleverrearwardandpullitdown

tothereferencebar(Figure13,number1).

Tooperateahydraulicattachmentinreversedirection,rotate

thehydraulicsleverrearward,thenmoveitleftintotheupper

slot(Figure13,number2).

Ifyoureleasetheleverwhileintheforwardposition,thelever

willautomaticallyreturntotheneutralposition(Figure13,

number3).Ifitisinthereverseposition,itwillremainthere

untilyoupullitoutoftheslot.

1.Lowertheloaderarms

2.Raisetheloaderarms

3.Tilttheattachment

rearward

4.Tilttheattachmentforward

5.Detent(Float)position

Bymovingthelevertoanintermediateposition(suchas,

forwardandleft),youcanmovetheloaderarmsandtiltthe

attachmentatthesametime.

LoaderValveLock

Theloadervalvelocksecurestheloaderarm/attachmenttilt

leversothatyoucannotpushitforward.Thishelpstoensure

thatnoonewillaccidentallylowertheloaderarmsduring

maintenance.Securetheloaderarmswiththelockanytime

youneedtostopthemachinewiththeloaderarmsraised.

Tosetthelock,liftuponitsoitclearstheholeinthecontrol

panelandswingittotheleftinfrontoftheloaderarmlever,

pushingitdownintothelockedposition(Figure12).

Figure13

1.Forwardowhydraulics

2.Reverseowhydraulics

3.Neutral

ParkingBrakeLever

Tosettheparkingbrake,pushthebrakeleverforwardandto

theleftandthenpullitrearward(Figure14).

Note:Thetractionunitmayrollslightlybeforethebrakes

engageinthedrivesprocket.

Figure12

1.Loadervalvelock

2.Loaderarm/attachmenttilt

lever

LoaderControlReferenceBar

Theloadercontrolreferencebarhelpsstabilizeyourhand

whileoperatingtheloaderarm/attachmenttiltlever.

Figure14

Toreleasethebrake,pushtheleverforwardandthenright,

intothenotch.

FuelGauge

Thisgaugemeasurestheamountoffuelinthefueltank.

15

Page 16

HydraulicOilTemperatureLight

After50hoursandthenevery100hoursthereafter(that

isat150,250,350,etc.)thescreendisplaysCHGOILto

Ifthehydraulicoilgetstoohot,thislightilluminatesandan

audiblealarmsounds.Ifthishappens,stoptheengineand

allowthetractionunittocool.

remindyoutochangetheengineoil.Afterevery100hours,

thescreendisplaysSVCtoremindyoutoperformtheother

maintenanceproceduresbasedona100,200,or400hour

schedule.Thesereminderscomeonstartingthreehoursprior

HourMeter/Tachometer

totheserviceintervaltimeandashatregularintervalsfor

sixhours.

Whentheengineisoff,thehourmeter/tachometerdisplays

thenumberofhoursofoperationthathavebeenloggedon

thetractionunit.Whentheengineisrunning,itdisplaysthe

speedoftheengineinrevolutionsperminute(rpm).

Specications

Note:Specicationsanddesignaresubjecttochangewithoutnotice.

Model22321and22321G

Width

Length

Height

Weight

Operatingcapacity500lb(227Kg)

Tippingcapacity

Wheelbase

Dumpheight(withnarrowbucket)47inches(1 19cm)

Reach—fullyraised(withnarrowbucket)22inches(55cm)

Heighttohingepin(narrowbucketinhighestposition)66inches(168cm)

34inches(86cm)

71inches(180cm)

46inches(1 17cm)

1880lb(853Kg)

1480lb(671Kg)

31.2inches(79cm)

Model22322

Width

Length

Height

Weight

Operatingcapacity500lb(227Kg)

Tippingcapacity

Wheelbase

Dumpheight(withnarrowbucket)47inches(1 19cm)

Reach—fullyraised(withnarrowbucket)22inches(55cm)

Heighttohingepin(narrowbucketinhighestposition)66inches(168cm)

41inches(104cm)

71inches(180cm)

46inches(1 17cm)

2075lb(941Kg)

1427lb(647Kg)

31.2inches(79cm)

Attachments/Accessories

AselectionofToroapprovedattachmentsandaccessoriesareavailableforusewiththemachinetoenhanceandexpand

itscapabilities.ContactyourAuthorizedServiceDealerorDistributororgotowww .Toro.comforalistofallapproved

attachmentsandaccessories.

Important:UseonlyT oroapprovedattachments.Otherattachmentsmaycreateanunsafeoperatingenvironment

ordamagethetractionunit.

16

Page 17

Operation

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Important:Beforeoperating,checkthefuelandoil

level,andremovedebrisfromthetractionunit.Also,

ensurethattheareaisclearofpeopleanddebris.You

shouldalsoknowandhavemarkedthelocationsofall

utilitylines.

AddingFuel

•Forbestresults,useonlyclean,fresh,unleadedgasoline

withanoctaneratingof87orhigher((R+M)/2rating

method).

•Oxygenatedfuelwithupto10%ethanolor15%MTBE

byvolumeisacceptable.

•DoNotuseethanolblendsofgasoline(suchasE15

orE85)withmorethan10%ethanolbyvolume.

Performanceproblemsand/orenginedamagemayresult

whichmaynotbecoveredunderwarranty.

•DoNotusegasolinecontainingmethanol.

•DoNotstorefueleitherinthefueltankorfuelcontainers

overthewinterunlessafuelstabilizerisused.

•DoNotaddoiltogasoline.

DANGER

Incertainconditionsduringfueling,static

electricitycanbereleasedcausingasparkwhich

canignitethegasolinevapors.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Alwaysplacegasolinecontainersontheground

awayfromyourvehiclebeforelling.

•Donotllgasolinecontainersinsideavehicleor

onatruckortrailerbedbecauseinteriorcarpets

orplastictruckbedlinersmayinsulatethe

containerandslowthelossofanystaticcharge.

•Whenpractical,removegas-poweredequipment

fromthetruckortrailerandrefueltheequipment

withitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuch

equipmentonatruckortrailerfromaportable

container,ratherthanfromagasolinedispenser

nozzle.

•Ifagasolinedispensernozzlemustbeused,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,

whentheengineiscold.Wipeupanygasoline

thatspills.

•Neverllthefueltankinsideanenclosedtrailer.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis1/4to

1/2inch(6to13mm)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

gasolinetoexpand.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwheregasoline

fumesmaybeignitedbyaspark.

•Storegasolineinanapprovedcontainerand

keepitoutofthereachofchildren.Neverbuy

morethana30-daysupplyofgasoline.

•Donotoperatewithoutentireexhaustsystemin

placeandinproperworkingcondition.

UsingStabilizer/Conditioner

Useafuelstabilizer/conditionerinthetractionunitto

providethefollowingbenets:

•Keepsgasolinefreshduringstorageof90daysorless.

Forlongerstorageitisrecommendedthatthefueltank

bedrained.

•Cleanstheenginewhileitruns

•Eliminatesgum-likevarnishbuildupinthefuelsystem,

whichcauseshardstarting

Important:Donotusefueladditivescontaining

methanolorethanol.

Addthecorrectamountofgasstabilizer/conditionertothe

gas.

Note:Afuelstabilizer/conditionerismosteffectivewhen

mixedwithfreshgasoline.Tominimizethechanceofvarnish

depositsinthefuelsystem,usefuelstabilizeratalltimes.

FillingtheFuelTank

1.Parkthetractionunitonalevelsurface,lowerthe

loaderarms,andstoptheengine.

2.Removethekeyandallowtheenginetocool.

3.Cleanaroundthefueltankcapandremoveit.

17

Page 18

Note:Thecapistetheredtothefueltank.

4.Addunleadedgasolinetothefueltank,untilthelevelis

justbelowthebottomofthellerneck.

Important:Donotoverllthecrankcasewithoil

becausetheenginemaybedamaged.

10.Replacethellercapanddipstick.

Important:Thisspaceinthetankallowsgasoline

toexpand.Donotllthefueltankcompletelyfull.

5.Installthefueltankcapsecurely,turningituntilitclicks.

6.Wipeupanygasolinethatmayhavespilled.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Parkthetractionunitonalevelsurface,lowerthe

loaderarms,andstoptheengine.

2.Removethekeyandallowtheenginetocool.

3.Openthehood.

4.Cleanaroundtheoildipstick(

Figure15).

11.Closethehood.

CheckingtheHydraulicFluid Level

ServiceInterval:Every25hours

HydraulicTankCapacity:12USgallons(45.4l)

RefertoChangingtheHydraulicFluid(page40)forhydraulic

uidspecications.

Important:Alwaysusethecorrecthydraulicuid.

Unspecieduidswilldamagethehydraulicsystem.

1.Removetheattachment,ifone

isinstalled;refertoRemovingan

AttachmentRemovinganAttachment(page21).

2.Parkthetractionunitonalevelsurface,lowerthe

loaderarms,andfullyretractthetiltcylinder.

3.Stoptheengine,removethekey,andallowtheengine

tocool.

4.Openthehoodandremovetheleftsidescreen.

Figure15

1.Oildipstick

5.Pulloutthedipstickandwipethemetalendclean

(

Figure15).

6.Slidethedipstickfullyintothedipsticktube(Figure15).

7.Pullthedipstickoutandlookatthemetalend.

8.Iftheoillevelislow ,cleanaroundtheoilllercapand

removethecap(Figure16).

2.Metalend

5.Cleantheareaaroundthellerneckofthehydraulic

Figure17).

tank(

6.Removethecapfromthellerneckandchecktheuid

levelonthedipstick(Figure17).

Theuidlevelshouldbebetweenthemarksonthe

dipstick.

Figure17

1.Fillerneckcap2.Dipstick

Figure16

1.Fillercap2.Valvecover

9.Slowlypouronlyenoughoilintothevalvecoverto

raisetheleveltotheF(full)mark.

7.Ifthelevelislow,addenoughuidtoraiseittothe

properlevel.

8.Installthecaponthellerneck.

9.Replacetheleftsidescreenandclosethehood.

18

Page 19

StartingandStoppingthe

StoppingtheTractionUnit

Engine

StartingtheEngine

1.Ensurethattheauxiliaryhydraulicsleverisinneutral.

2.MovethechokeleverforwardtotheOnpositionifyou

arestartingacoldengine.

3.Movethethrottlelevermidwaybetweenslow(turtle)

andfast(rabbit)positions.

Note:Awarmorhotenginemaynotrequirechoking.

4.Turntheignitionkeytothestartposition.Whenthe

enginesstarts,releasethekey.

Important:Donotengagethestarterformore

than10secondsatatime.Iftheenginefailsto

start,allowa30secondcool-downperiodbetween

attempts.Failuretofollowtheseinstructionscan

burnoutthestartermotor.

5.Aftertheenginestarts,graduallymovethechoke

leverbacktotheOffposition.Iftheenginestallsor

hesitates,pullthechokeoutagainuntiltheengine

warmsup.

6.Movethethrottlelevertodesiredsetting.

Tostopthetractionunit,releasethetractioncontrol,move

thethrottlelevertoslow(turtle),lowerloaderarmstothe

ground,andstoptheengine.Settheparkingbrakeand

removethekey .

CAUTION

Achildoruntrainedbystandercouldattemptto

operatethetractionunitandbeinjured.

Removethekeyfromtheswitchwhenleavingthe

tractionunit,evenifjustforafewseconds.

MovingaNon-functioning TractionUnit

Important:Donottoworpullthetractionunitwithout

rstopeningthetowvalves,orthehydraulicsystemwill

bedamaged.

1.Stoptheengine.

2.Opentherearaccesscover.

3.Usingawrench,turnthetowvalvesonthehydraulic

pumpstwicecounter-clockwise(Figure18).

Important:Iftheengineisrunathighspeeds

whenthehydraulicsystemiscold(i.e.,whenthe

ambientairtemperatureisnearfreezingorlower),

hydraulicsystemdamagecouldoccur.When

startingtheengineincoldconditions,allowthe

enginetoruninthemiddlethrottlepositionfor

2to5minutesbeforemovingthethrottletofast

(rabbit).

Note:Ifoutdoortemperatureisbelowfreezing,store

thetractionunitinagaragetokeepitwarmerandaid

instarting.

StoppingtheEngine

1.Movethethrottlelever3/4ofthewaytotheFast

position.

2.Lowertheloaderarmstotheground.

3.Turntheignitionkeyoff.

Note:Ifyousetthethrottlelowerthanhalfwayto

fast,theenginewillcontinuetorunforonesecond

afterturningthekeytotheOffposition,preventinga

loudafterrebang.

Note:Iftheenginehasbeenworkinghardorishot,

letitrunforaminutebeforeturningtheignitionkey

off.Thishelpscooltheenginebeforeitisstopped.In

anemergency,theenginemaybestoppedimmediately.

Figure18

1.Lefttowvalve(righttrack)2.Righttowvalve(lefttrack)

4.Towthetractionunitasrequired.

5.Whenthetractionunithasbeenrepaired,closethetow

valvesbeforeoperatingit.

19

Page 20

UsingtheCylinderLock

G004182

3

2

1

UsingAttachments

WARNING

Theloaderarmsmaylowerwhenintheraised

positioncrushinganyoneunderthem.

Installthecylinderlockbeforeperforming

maintenancethatrequiresraisedloaderarms.

InstallingtheCylinderLock

1.Removetheattachment.

2.Raisetheloaderarmstothefullyraisedposition.

3.Stoptheengine.

4.Removethelynchpinsecuringthecylinderlocktothe

loaderarm(Figure19).

Important:Ifyouareusinganattachmentwithaserial

numberof200999999orearlier,themanualforthe

attachmentmaycontaininformationspecictotheuse

oftheattachmentwithothertractionunitmodels,such

assettingsfortheowdividercontrolandspeedselector

leverandtheuseofacounterweightonthetractionunit.

ThesesystemsarebuiltintotheTX,andyoushould

ignoreanyreferencestothem.

InstallinganAttachment

Important:UseonlyToro-approvedattachments.

Attachmentscanchangethestabilityandtheoperating

characteristicsofthetractionunit.Thewarrantyofthe

tractionunitmaybevoidedifusedwithunapproved

attachments.

Important:Beforeinstallingtheattachment,ensure

thatthemountplatesarefreeofanydirtordebrisand

thatthepinsrotatefreely.Ifthepinsdonotrotatefreely,

greasethem.

1.Positiontheattachmentonalevelsurfacewithenough

spacebehindittoaccommodatethetractionunit.

2.Starttheengine.

Figure19

1.Cylinderlock

2.Liftcylinder

5.Lowerthecylinderlockoverthecylinderrodand

secureitwiththelynchpin(Figure19).

6.Slowlylowertheloaderarmsuntilcylinderlock

contactsthecylinderbodyandrodend.

3.Lynchpin

Removing/StoringtheCylinderLock

Important:Ensurethatthecylinderlockisremoved

fromtherodandfullysecuredinthestorageposition

beforeoperatingthetractionunit.

1.Starttheengine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Stoptheengine.

4.Removethelynchpinsecuringthecylinderlock.

5.Rotatethecylinderlockuptotheloaderarmand

secureitwiththelynchpin.

6.Lowertheloaderarms.

3.Tilttheattachmentmountplateforward.

4.Positionmountplateintotheupperlipofthe

attachmentreceiverplate(

Figure20

1.Mountplate2.Receiverplate

5.Raisetheloaderarmswhiletiltingbackthemountplate

atthesametime.

Important:Theattachmentshouldberaised

enoughtocleartheground,andthemountplate

shouldbetiltedallthewayback.

6.Stoptheengine.

7.Engagethequickattachpins,ensuringthattheyare

fullyseatedinthemountplate(

Important:Ifthepinsdonotrotatetothe

engagedposition,themountplateisnotfully

Figure20).

Figure21).

20

Page 21

alignedwiththeholesintheattachmentreceiver

plate.Checkthereceiverplateandcleanitif

necessary.

6.Pushtheattachmentmaleconnectorintothefemale

connectoronthetractionunit.

Note:Whenyouconnecttheattachmentmale

connectorrst,youwillrelieveanypressurebuiltupin

theattachment.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjuryorgangrenemayresult.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthatejecthigh

pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks,neveruseyourhands.

CAUTION

Figure21

1.Quickattachpins(shown

inengagedposition)

2.Disengagedposition

3.Engagedposition

WARNING

Ifyoudonotfullyseatthequickattachpins

throughtheattachmentmountplate,the

attachmentcouldfalloffofthetractionunit,

crushingyouorbystanders.

Ensurethatyourquickattachpinsarefully

seatedintheattachmentmountplate.

ConnectingtheHydraulicHoses

Iftheattachmentrequireshydraulicsforoperation,connect

thehydraulichosesasfollows:

1.Stoptheengine.

2.Movetheauxiliaryhydraulicsleverforward,backward,

andbacktoneutraltorelievepressureatthehydraulic

couplers.

3.Movetheauxiliaryhydraulicsleverintothereverse

position.

4.Removetheprotectivecoversfromthehydraulic

couplersonthetractionunit.

5.Ensurethatallforeignmatteriscleanedfromthe

hydraulicconnectors.

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponentsyoumaybeburned.

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthetractionunittocoolbefore

touchinghydrauliccomponents.

•Donottouchhydraulicuidspills.

7.Pushtheattachmentfemaleconnectorintothemale

connectoronthetractionunit.

8.Conrmthattheconnectionissecurebypullingon

thehoses.

9.Movetheauxiliaryhydraulicslevertoneutral.

RemovinganAttachment

1.Lowertheattachmenttotheground.

2.Stoptheengine.

3.Disengagethequickattachpinsbyturningthemto

theoutside.

4.Iftheattachmentuseshydraulics,movetheauxiliary

hydraulicsleverforward,backward,andbacktoneutral

torelievepressureatthehydrauliccouplers.

5.Iftheattachmentuseshydraulics,slidethecollarback

onthehydrauliccouplersanddisconnectthem.

Important:Connecttheattachment

hosestogethertopreventhydraulicsystem

contaminationduringstorage.

21

Page 22

6.Installtheprotectivecoversontothehydrauliccouplers

onthetractionunit.

7.Starttheengine,tiltthemountplateforward,andback

thetractionunitawayfromtheattachment.

SecuringtheTractionUnitfor Transport

Whentransportingthetractionunitonatrailer,alwaysuse

thefollowingprocedure:

Important:Donotoperateordrivethetractionunit

onroadways.

1.Lowertheloaderarms.

2.Stoptheengine.

3.Securethetractionunittothetrailerwithchainsor

strapsusingthetie-down/liftloops(

therearofthetractionunitandtheloaderarms/mount

platetosecurethefrontofthetractionunit.

Figure4)tosecure

LiftingtheTractionUnit

Youcanliftthetractionunitusingthetie-down/liftloops

asliftpoints(Figure4).

22

Page 23

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Aftertherst50hours

Beforeeachuseordaily

Every25hours

Every100hours

Every200hours

MaintenanceProcedure

•Replacethehydrauliclter.

•Changetheengineoilandlter.

•Checkandadjustthetracktension.

•Checktheengineoillevel.

•Greasethetractionunit.(Greaseimmediatelyaftereverywashing.)

•Checktheairlterserviceindicator.

•Cleanthetracks.

•Checkthetracksforexcessivewear(Ifthetracksareworn,replacethem.)

•Removedebrisfromthetractionunit.

•Checkforloosefasteners.

•Checkthehydraulicuidlevel.

•Removeaircleanercover,cleanoutdebris,andchecktheairlterserviceindicator.

•Inspectthedrivebeltforwearordamage.

•Changetheengineoil.

•Checkthebatteryelectrolytelevel(replacementbatteryonly).

•Checkthebatterycableconnections.

•Checkandadjustthetracktension.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Checkfordirtbuild-upinthechassis.

•Replacethecarboncanisterairlter(Servicemorefrequentlyifconditionsare

extremelydustyorsandy).

•Replacethecarboncanisterpurge-linelter(Servicemorefrequentlywhenusing

thevibratoryplowattachment).

•Changetheoillter.

•Checkthesparkplugs.

•Changethefuellter.

•Replacethedrivebelt.

•Replacethehydrauliclter.

Every250hours

Every400hours

Every600hours

Every1,500hours

Yearlyorbeforestorage

Important:Refertoyour

•Checkandgreasetheroadwheels.

•Changethehydraulicuid.

•Replacethesafetyairlter.

•Replaceallmovinghydraulichoses.

•Checkandadjustthetracktension.

•T ouchupchippedpaint

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

Note:After50hoursandthenevery100hoursthereafter(thatisat150,250,350,etc.)thehourmeterdisplaysCHGOIL

toremindyoutochangetheengineoil.Afterevery100hours,thescreendisplaysSVCtoremindyoutoperformtheother

maintenanceproceduresbasedona100,200,or400hourschedule.Thesereminderscomeonstartingthreehourspriortothe

serviceintervaltimeandashatregularintervalsforsixhours.

23

Page 24

CAUTION

3

G009691

Ifyouleavethekeyintheignitionswitch,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Removethekeyfromtheignitionanddisconnectthewirefromthesparkplugbeforeyoudoany

maintenance.Setthewireasidesothatitdoesnotaccidentallycontactthesparkplug.

Premaintenance

Procedures

Beforeopeninganyofthecovers,stoptheengineandremove

thekey .Allowtheenginetocoolbeforeopeninganycovers

Important:Ifyouwillbetiltingthemachinemorethan

25degrees,clampofftheventhoseonthetopofthefuel

tank(

Figure59)topreventfuelfromfoulingthecarbon

canister.

Figure23

OpeningtheHood

1.Loosenthehoodlockingscrew(Figure22)

Figure22

1.Proprod3.Hood

2.Bracket4.Proprodholder

ClosingtheHood

1.Pulltheproprodoutofthebracketonthehoodand

loweritintoitsholder.

2.Lowerthehoodandsecureitbypushingdownonthe

frontofthehooduntilitlocksinplace.

3.Tightenthehoodlockingscrewtosecurethelatch

(Figure22).

OpeningtheRearAccess Cover

1.Unscrewthe2handknobssecuringtherearaccess

covertothemachine(Figure24).

1.Hood3.Hoodlockingscrew

2.Leverhoodlatch

2.Turnthehoodlatchclockwise(Figure22).

3.Swingthehoodup(Figure22).

4.Swingtheproprodupandsecureitinthebracketon

thehood(Figure23).

Figure24

1.Handknob

2.Tilttherearaccesscoverdownandremovetoaccess

theinternalcomponents(Figure24).

24

Page 25

ClosingtheRearAccessCover

g013122

5

1.Movetherearaccesscoverinplaceoverthebackofthe

tractionunitmakingsurethetabslineupintheslots.

2.Pushtheaccesscoverforward,liningupthehandknob

screwswiththethreadedholesinthemachine.

3.Screwthehandknobstighttosecuretherearaccess

coverinplace.

RemovingtheSideScreens

1.Openthehood.

2.Slidethesidescreens(Figure25)upandoutofthe

slotsinthefrontscreenandframe.

Figure26

Figure25

1.Sidescreen

InstallingtheSideScreens

Slidethesidescreensintoplaceintheslotsinthefrontscreen

andframe.

RemovingtheFrontScreen

CAUTION

1.Frontweight

2.Bolts5.Rearweight

3.Slopedplate

3.Removethecarriageboltsandnutssecuringthesloped

plate(Figure26).

4.Lifttheslopedplateupandoffofthetractionunit.

5.Removethe4boltssecuringthefrontscreentothe

tractionunitframe(Figure27).

4.Carriagebolts

Iftheenginehasbeenrunningtheheatshieldwill

beveryhotandcouldburnyou.

Allowthetractionunitcoolcompletelybefore

touchingtheheatshield.

1.Openthehoodandremovebothsidescreens.

2.Loosentheboltssecuringtheweights(

Figure26).

Figure27

1.Frontscreen

6.Removetheshoulderboltsandnutssecuringtheoil

coolertothetopofthefrontscreen(Figure28).

25

2.Bolts(leftsideboltnot

shown)

Page 26

Figure28

1.Nut3.Frontscreen

2.Oilcooler4.Shoulderbolts

7.Removethefrontscreen.

8.Whennished,installthefrontscreenwiththe4bolts

removedpreviously .

9.Installtheoilcoolertothefrontscreenwiththe4

shoulderboltsandnutsremovedpreviously.

Lubrication

GreasingtheTractionUnit

ServiceInterval:Beforeeachuseordaily(Grease

immediatelyaftereverywashing.)

GreaseType:General-purposegrease.

1.Lowertheloaderarmsandstoptheengine.Remove

thekey.

2.Cleanthegreasettingswitharag.

3.Connectagreaseguntoeachtting(Figure29).

10.Slidetheslopedplatebetweentheframeandthe

weightsandsecureittothefrontscreengrillusingthe

carriageboltsandnutsremovedpreviously(Figure26).

11.Tightentheboltssecuringthefrontweights(Figure26).

12.Installthesidescreensandclosethehood.

Figure29

4.Pumpgreaseintothettingsuntilgreasebeginsto

oozeoutofthebearings(approximately3pumps).

5.Wipeupanyexcessgrease.

26

Page 27

EngineMaintenance

G009742

7

1

2

3

4

5

6

•Iftheserviceindicatorisclear,cleananydebris

fromcoverandinstallcover.

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily—Checktheair

lterserviceindicator.

Every25hours—Removeaircleaner

cover,cleanoutdebris,andchecktheair

lterserviceindicator.

Every600hours—Replacethesafetyair

lter.

ServicingtheAirCleanerCoverand

Body

Important:Servicetheaircleanerlteronlywhenthe

serviceindicatorshowsred(Figure30).Changingthe

airlterbeforeitisnecessaryonlyincreasesthechance

ofdirtenteringtheenginewhenthelterisremoved.

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Openthehood.

3.Checktheaircleanerbodyfordamagewhichcould

causeanairleak..Checkthewholeintakesystemfor

leaks,damage,orloosehoseclamps.Replaceofrepair

anddamagedcomponents.

4.Releasethelatchesontheaircleanerandpulltheair

cleanercoveroffoftheaircleanerbody(

Important:Donotremovetheairlters.

Figure30).

Ensurethatthecoverisseatedcorrectlyandseals

withtheaircleanerbody.

•Iftheserviceindicatorisred,replacetheairlter

asdescribedinReplacingtheFilters.

ReplacingtheFilters

1.Gentlyslidetheprimarylteroutoftheaircleaner

body(Figure30).Avoidknockingthelterintothe

sideofthebody.

Important:Donotattempttocleantheprimary

lter.

2.Removethesafetylteronlyifyouintendtoreplaceit.

Important:Neverattempttocleanthesafety

lter.Ifthesafetylterisdirty,thentheprimary

lterisdamagedandyoushouldreplaceboth

lters.

3.Inspectthenewlter(s)fordamagebylookinginto

thelterwhileshiningabrightlightontheoutsideof

thelter.Holesinthelterwillappearasbrightspots.

Inspecttheelementfortears,anoilylm,ordamageto

therubberseal.Ifthelterisdamageddonotuseit.

4.Ifyouarereplacingthesafetylter,carefullyslidethe

newlterintothelterbody(Figure30).

Important:Topreventenginedamage,always

operatetheenginewithbothairltersandcover

installed.

Figure30

5.Latches

6.Aircleanercover

7.Dustcap

1.Airlterserviceindicator

2.Safetylter

3.Airlterbody

4.Primarylter

5.Squeezethedustcapsidestoopenitandknockthe

dustout.

6.Cleantheinsideoftheaircleanercoverwith

compressedair.

7.Checktheairlterserviceindicator.

5.Carefullyslidetheprimarylteroverthesafetylter

(Figure30).Ensurethatitisfullyseatedbypushingon

theouterrimofthelterwhileinstallingit.

Important:Donotpressonthesoftinsidearea

ofthelter.

6.Installtheaircleanercoverwiththesideindicatedas

UPfacingupandsecurethelatches(

7.Closethehood.

Figure30).

ServicingtheCarbonCanister

ReplacingtheCarbonCanisterAirFilter

ServiceInterval:Every200hours—Replacethecarbon

canisterairlter(Servicemorefrequently

ifconditionsareextremelydustyor

sandy).

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Removetherearaccesscover;see

OpeningtheRearAccessCover(page24).

3.Removeanddiscardtheairlter(Figure31).

27

Page 28

1

2

3

4

5

6

G018430

Figure31

G005564

ServicingtheEngineOil

ServiceInterval:Aftertherst50hours

Every100hours—Changetheengineoil.

Every200hours—Changetheoillter.

Note:Changeoilandltermorefrequentlywhenoperating

conditionsareextremelydustyorsandy.

OilType:Detergentoil(APIserviceSG,SH,SJ,orhigher)

CrankcaseCapacity:w/lter,2.1qt.(2l)

Viscosity:Seetablebelow

1.Hoseclamp

2.Hosetocarboncanister

3.Carboncanister

4.Installanewlterontothecarboncanister(Figure31).

5.Installtherearaccesscover;see

ClosingtheRearAccessCover(page25).

4.Airlter

5.Purge-linelter

6.Rearaccessdoor

ReplacingtheCarbonCanister

Purge-lineFilter

ServiceInterval:Every200hours—Replacethecarbon

canisterpurge-linelter(Servicemore

frequentlywhenusingthevibratoryplow

attachment).

Note:Checkthepurge-linelteroccasionallyfordirt.Ifthe

lterappearstobedirty,replaceit.

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Removetherearaccesscover;see

OpeningtheRearAccessCover(page24).

3.Movethespring-typehoseclampsonbothsidesofthe

carboncanisterpurge-linelterawayfromthelter

(Figure31).

4.Removeanddiscardthepurge-linelter(Figure31).

5.Installanewlterintothehosewiththearrowon

thelterpointingawayfromthecarboncanisterand

secureitwiththehoseclamps(Figure31).

6.Installtherearaccesscover;see

ClosingtheRearAccessCover(page25).

Figure32

ChangingtheOil

1.Starttheengineandletitrunforveminutes.This

warmstheoilsoitdrainsbetter.

2.Parkthetractionunitsothatthedrainsideisslightly

lowerthantheoppositesidetoensurethattheoil

drainscompletely.

3.Lowertheloaderarms,settheparkingbrake,stopthe

engine,andremovethekey.

CAUTION

Componentswillbehotifthetractionunithas

beenrunning.Ifyoutouchhotcomponents

youmaybeburned.

Allowthetractionunittocoolbefore

performingmaintenanceortouching

componentsunderthehood.

4.Removethedrainplug(Figure33).

28

Page 29

Figure33

1.Oildrainvalve

5.Whentheoilhasdrainedcompletely,replacetheplug.

Note:Disposeoftheusedoilatacertiedrecycling

center.

6.Removetheoilllcapandslowlypourapproximately

80%ofthespeciedamountofoilinthroughthe

valvecover.

7.Checktheoillevel;referto

CheckingtheEngineOilLevel(page18).

ChangingtheOilFilter

1.Draintheoilfromtheengine;referto

ChangingtheOil(page28).

2.Placeashallowpanorragundertheltertocatchoil.

3.Removetheoldlter(Figure34)andwipethesurface

ofthelteradaptergasket.

Figure34

1.Oillter

8.SlowlyaddadditionaloiltobringtheleveltotheF

(full)markonthedipstick.

9.Replacethellcap.

4.Pournewoilofthepropertypethroughthecenter

holeofthelter.Stoppouringwhentheoilreaches

thebottomofthethreads.

5.Allowaminuteortwofortheoiltobeabsorbedby

ltermaterial,thenpourofftheexcessoil.

6.Applyathincoatofnewoiltotherubbergasketon

thereplacementlter.

7.Installthereplacementoilltertothelteradapter.

Turntheoillterclockwiseuntiltherubbergasket

contactsthelteradapter,thentightenthelteran

additional1/2turn.

8.Fillthecrankcasewiththepropertypeofnewoil;refer

to

ChangingtheOil(page28).

ServicingtheSparkPlugs

ServiceInterval:Every200hours—Checkthesparkplugs.

Ensurethattheairgapbetweenthecenterandsideelectrodes

iscorrectbeforeinstallingeachsparkplug.Useasparkplug

wrenchforremovingandinstallingthesparkplugsanda

gappingtool/feelergaugetocheckandadjusttheairgap.

Installnewsparkplugsifnecessary.

Type:ChampionPlatinum3071,RC12YC,orequivalent.Air

Gap:0.03inch(0.75mm)

RemovingtheSparkPlugs

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Openthehood.

3.Pullthewiresoffofthesparkplugs(

29

Figure35).

Page 30

Figure35

1.Sparkplugwire2.Sparkplug

4.Cleanaroundthesparkplugs.

5.Removebothsparkplugsandmetalwashers.

CheckingtheSparkPlugs

1.Lookatthecenterofbothsparkplugs(Figure36).If

youseelightbrownorgrayontheinsulator,theengine

isoperatingproperly.Ablackcoatingontheinsulator

usuallymeanstheaircleanerisdirty.

FuelSystem

Maintenance

ChangingtheFuelFilter

ServiceInterval:Every200hours/Yearly(whichevercomes

rst)

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Openthehoodandremovetheleftsidescreen.

3.Loosenthetankcaptorelievepressure.

4.Clampthefuellinesonbothsidesofthefuellter

Figure37).

(

Important:Nevercleanthesparkplugs.Always

replacethesparkplugswhentheyhaveablack

coating,wornelectrodes,anoilylm,orcracks.

Figure36

1.Centerelectrodeinsulator3.Airgap(nottoscale)

2.Sideelectrode

2.Checkthegapbetweenthecenterandsideelectrodes

(Figure36).

3.Bendthesideelectrode(Figure36)ifthegapisnot

correct.

Figure37

1.Filter2.Hoseclamp

5.Squeezetheendsofthehoseclampstogetherandslide

themawayfromthelter(Figure37).

6.Placeadrainpanunderthefuellinestocatchanyleaks,

thenremovethelterfromthefuellines.

7.Slidethefuellinesonthenewfuellterttings,

ensuringthatthearrowonthelterpointsawayfrom

thefuellinecomingfromthefueltankandtowardthe

linegoingtothefuelpump.

Important:Neverinstalladirtylter.

8.Movethehoseclampsclosetothelter.

9.Removetheclampblockingfuelowandopenthe

fuelvalves.

10.Securethetankcap.

11.Replacethesidescreenandclosethehood.

InstallingtheSparkPlugs

1.Threadthesparkplugsintothesparkplugholes.

2.Tightenthesparkplugsto20ft-lb(27N-m).

3.Pushthewiresontothesparkplugs(Figure35).

4.Closethehood.

30

Page 31

DrainingtheFuelTank

ElectricalSystem

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Draingasolinefromthefueltankwhenthe

engineiscold.Dothisoutdoorsinanopenarea.

Wipeupanygasolinethatspills.

•Neversmokewhendraininggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Syphonthegasolinefromthetankusingapumptype

syphon.

Note:Nowisthebesttimetoinstallanewfuellterbecause

thefueltankisempty .

Maintenance

ServicingtheBattery

ServiceInterval:Every100hours—Checkthebattery

electrolytelevel(replacementbattery

only).

Every100hours—Checkthebattery

cableconnections.

WARNING

CALIFORNIA

Proposition65Warning

Batteryposts,terminals,andrelated

accessoriescontainleadandleadcompounds,

chemicalsknowntotheStateofCalifornia

tocausecancerandreproductiveharm.

Washhandsafterhandling.

Important:Thefollowingproceduresapplywhen

servicinga(dry)batterythathasreplacedtheoriginal

battery.Theoriginal(wet)batterydoesnotrequire

service.

Alwayskeepthebatterycleanandfullycharged.Useapaper

toweltocleanthebatterycase.Ifthebatteryterminalsare

corroded,cleanthemwithasolutionoffourpartswaterand

onepartbakingsoda.Applyalightcoatingofgreasetothe

batteryterminalstoreducecorrosion.

Voltage:12v ,585ColdCrankingAmps

CheckingtheElectrolyteLevel

1.Stoptheengineandremovethekey.

2.Removethe4boltssecuringthebatterycoverand

removeitfromoverthebattery.

3.Lookatthesideofthebattery.Theelectrolytemust

beuptotheUpperline(

electrolytetofallbelowtheLowerline(

Figure38).Donotallowthe

Figure38).

31

Page 32

2

3

1

G003794

levelisuptotheUpperline(

1

2

3

4

G003792

case.

6.Installthebatteryllercaps.

Figure38)onthebattery

ChargingtheBattery

WARNING

Chargingthebatteryproducesgassesthatcan

explode.

Figure38

1.Fillercaps3.Lowerline

2.Upperline

4.Iftheelectrolyteislow ,addtherequired

amountofdistilledwater;referto

AddingWatertotheBattery(page32).

AddingWatertotheBattery

Thebesttimetoadddistilledwatertothebatteryisjust

beforeyouoperatethetractionunit.Thisletsthewatermix

thoroughlywiththeelectrolytesolution.

DANGER

Batteryelectrolytecontainssulfuricacidwhichisa

deadlypoisonandcausessevereburns.

•Donotdrinkelectrolyteandavoidcontactwith

skin,eyesorclothing.Wearsafetyglassesto

shieldyoureyesandrubberglovestoprotect

yourhands.

Neversmokenearthebatteryandkeepsparksand

amesawayfrombattery.

Important:Alwayskeepthebatteryfullycharged(1.265

specicgravity).Thisisespeciallyimportanttoprevent

batterydamagewhenthetemperatureisbelow32°F

(0°C).

1.Checktheelectrolytelevel;referto

CheckingtheElectrolyteLevel(page31).

2.Makesurethellercapsareinstalledinthebattery.

3.Chargethebatteryfor10to15minutesat25to30

ampsor30minutesat4to6amps(Figure39).Do

notoverchargethebattery.

•Fillthebatterywherecleanwaterisalways

availableforushingtheskin.

1.Removethebatteryfromthetractionunit.

Important:Neverllthebatterywithdistilled

waterwhilethebatteryisinstalledinthetraction

unit.Electrolytecouldbespilledonotherparts

andcausecorrosion.

2.Cleanthetopofthebatterywithapapertowel.

3.Removethellercapsfromthebattery(

4.Slowlypourdistilledwaterintoeachbatterycelluntil

theelectrolytelevelisuptotheUpperline(Figure38)

onthebatterycase.

Important:Donotoverllthebatterybecause

electrolyte(sulfuricacid)cancausesevere

corrosionanddamagetothechassis.

5.Waitvetotenminutesafterllingthebatterycells.

Adddistilledwater,ifnecessary,untiltheelectrolyte

Figure38).

1.Positivebatterypost

2.Negativebatterypost

4.Whenthebatteryisfullycharged,unplugthecharger

fromtheelectricaloutlet,thendisconnectthecharger

leadsfromthebatteryposts(Figure39).

5.Replacethebatterycover.

32

Figure39

3.Red(+)chargerlead

4.Black(-)chargerlead

Page 33

DriveSystem

Maintenance

ServicingtheTracks

ServiceInterval:Aftertherst50hours—Checkandadjust

thetracktension.

Beforeeachuseordaily—Cleanthe

tracks.

Beforeeachuseordaily—Checkthe

tracksforexcessivewear(Ifthetracks

areworn,replacethem.)

Every100hours—Checkandadjustthe

tracktension.

Every250hours/Yearly(whichever

comesrst)—Checkandgreasetheroad

wheels.

CleaningtheTracks

1.Withabucketontheloaderarms,lowerthebucketto

thegroundsothatthefrontofthetractionunitliftsoff

ofthegroundafewinches.

2.Stoptheengine,andremovethekey.

3.Usingawaterhoseorpressurewasher,removedirt

fromeachtracksystem.

Important:Ensurethatyouusehigh-pressure

watertowashonlythetrackarea.Donotusea

high-pressurewashertocleantherestofthetraction

unit.High-pressurewashingcandamagetheelectrical

systemandhydraulicvalvesordepletegrease.

AdjustingtheTrackTension

Thereshouldbe2-3/4inches(7cm)betweenthetensionnut

andthebackofthetensiontube(Figure41).Ifnot,adjust

thetracktensionusingthefollowingprocedure:

Figure41

1.2-3/4inches(7cm)

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Lift/supportthesideoftheunittobeworkedonso

thatthetrackisoffoftheground.

3.Removethelockingboltandnut(Figure42).

Important:Ensurethatyoufullycleantheroadwheels,

thetensionwheel,andthedrivesprocket(Figure40).

Theroadwheelsshouldrotatefreelywhenclean.

Figure40

1.Track3.Roadwheels

2.Drivesprocket4.T ensionwheel

Figure42

1.Lockingbolt3.Tensiontube

2.Tensioningscrew4.Tensionwheel

4.Usinga1/2inchdrivesocketwrench(Figure43),

turnthetensioningscrewcounter-clockwiseuntilthe

distancebetweenthetensionnutandthebackofthe

tensiontube(Figure41)is2-3/4inches(7cm).

5.Aligntheclosestnotchinthetensionscrewtothe

lockingboltholeandsecurethescrewwiththelocking

boltandnut(

6.Lowerthetractionunittotheground.

33

Figure42).

Page 34

ReplacingtheTracks(Models22321

and22321G)

Whenthetracksarebadlyworn,replacethem.

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Lift/supportthesideoftheunittobeworkedonso

thatthetrackis3to4inches(7.6to10cm)offofthe

ground.

3.Removethelockingboltandnut(Figure42).

4.Usinga1/2inchdrivesocketwrench,releasethedrive

tensionbyturningthetensioningscrewclockwise

(Figure42andFigure43).

11.Turnthetensioningscrewcounter-clockwiseuntilthe

distancebetweenthetensionnutandthebackofthe

tensiontube(Figure41)is2-3/4inches(7cm).

12.Aligntheclosestnotchinthetensionscrewtothe

lockingboltholeandsecurethescrewwiththelocking

boltandnut.

13.Lowerthetractionunittotheground.

14.Repeatsteps2through13toreplacetheothertrack.

ReplacingtheTracks(Model22322)

Whenthetracksarebadlyworn,replacethem.

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Lift/supportthesideoftheunittobeworkedonso

thatthetrackis3to4inches(7.6to10cm)offofthe

ground.

3.Removethelockingboltandnut(Figure42).

4.Usinga1/2inchdrivesocketwrench,releasethedrive

tensionbyturningthetensioningscrewclockwise

(Figure42andFigure44).

Figure43

1.Track5.Tracklug

2.1/2inchsocketwrench

3.Tensionwheel

4.Tensiontube8.Roadwheels

6.Drivesprocket

7.Sprocketcog

5.Pushthetensionwheeltowardtherearoftheunitto

movethetensiontubeagainsttheframe(

Figure43).

(Ifitdoesnottouchtheframe,continueturningthe

tensioningscrewuntilitdoes.)

6.Beginremovingthetrackatthetopofthetension

wheel,peelingitoffofthewheelwhilerotatingthe

trackforwards.

7.Whenthetrackisoffofthetensionwheel,removeit

fromthedrivesprocketandroadwheels(Figure43).

8.Beginningatthedrivesprocket,coilthenewtrack

aroundthesprocket,ensuringthatthelugsonthetrack

tbetweenthecogsonthesprocket(Figure43).

9.Pushthetrackunderandbetweentheroadwheels

(

Figure43).

10.Startingatthebottomofthetensionwheel,installthe

trackaroundthewheelbyrotatingthetrackrearward

whilepushingthelugsintothewheel.

Figure44

1.Track6.Tracklug

2.1/2inchsocketwrench

3.Tensionwheelnut

4.Outertensionwheel

5.Tensiontube10.Innertensionwheel

7.Drivesprocket

8.Sprocketcog

9.Roadwheels

5.Pushthetensionwheeltowardtherearoftheunitto

movethetensiontubeagainsttheframe(Figure44).

(Ifitdoesnottouchtheframe,continueturningthe

tensioningscrewuntilitdoes.)

6.Removethenutsecuringtheoutertensionwheeland

removethewheel(

Figure44).

7.Removethetrack(Figure44).

34

Page 35

8.Removethenutsecuringtheinnertensionwheeland

removethewheel(Figure44).

9.Pullthe4largewashersoutofthe2wheels,1oneach

sideofeachwheel.

10.Cleantheoldgreaseanddirtoutoftheareabetween

wherethewasherswereinstalledandthebearings

insidethewheels,thenllthisareaoneachsideof

eachwheelwithgrease.

11.Installthelargewashersonthewheelsoverthegrease.

12.Installtheinnertensionwheelandsecureitwiththe

nutremovedpreviously(

Figure44).

13.Torquethenutto300ft-lb(407N-m).

14.Installthenewtrack,ensuringthatthelugsinthetrack

tbetweenthecogsinthemiddleofthedrivesprocket

(Figure44).

Figure46

1.Roadwheel4.Roadwheelcap

2.Gasket5.Snapring

3.Bolt6.Addgreaseunderthecap

15.Installtheoutertensionwheelandsecureitwiththe

nutremovedpreviously(Figure44).

16.Torquethenutto300ft-lb(407N-m).

17.Turnthetensioningscrewcounter-clockwiseuntilthe

distancebetweenthetensionnutandthebackofthe

tensiontube(

Figure41)is2-3/4inches(7cm).

18.Aligntheclosestnotchinthetensionscrewtothe

lockingboltholeandsecurethescrewwiththelocking

boltandnut.

19.Repeatsteps2through18toreplacetheothertrack.

20.Lowerthetractionunittotheground.

MaintainingtheRoadWheels

1.Removethetracks;refertoReplacingtheTracks.

2.Removethe4boltssecuringeachlowertrackguide

whichcontainstheroadwheels,andremovethem

(Figure45).

4.Checkthegreaseunderthecapandaroundthegasket

(Figure46).Ifitisdirty,gritty,ordepleted,cleanoutall

ofthegrease,replacethegasket,andaddnewgrease.

5.Ensurethattheroadwheelturnssmoothlyonthe

bearing.Ifitisfrozen,replacetheroadwheelas

describedintheRoadWheelKitInstallationInstructionsor

contactyourAuthorizedServiceDealerforrepair.

6.Placethegreasedroadwheelcapoverthebolthead

(Figure46).

7.Securetheroadwheelcapwiththesnapring

(Figure46).

8.Repeatsteps3through7fortheotherroadwheels.

9.Installeachtrackguidetothetractionunitframeusing

thefastenersyouremovedpreviously.Torquethebolts

to67to83ft-lb(91to112N-m).

10.Installthetracks;refertoReplacingtheTracks.

Figure45

1.Roadwheels

2.Lowertrackguide

3.Trackguidebolts(onlytwo

shown)

3.Removethesnapringandcapfromaroadwheel

(

Figure46).

35

Page 36

BeltMaintenance

Inspecting/ReplacingtheDrive Belt

ServiceInterval:Every25hours—Inspectthedrivebeltfor

wearordamage.

Every200hours—Replacethedrivebelt.

Replacethebeltifyoundanysignsofwear,cracks,or

damageorafter200operatinghours,whichevercomesrst.

Toreplacethedrivebelt,completethefollowingprocedure:

Note:Tocompletethisprocedure,youwillneedasturdy

metalhooktodisconnecttheidlerpulleyspring,suchasthe

SpringRemovalTool(T oropartnumber92–5771)available

fororderfromyouAuthorizedServiceDealer.

1.Lowertheloaderarms,stoptheengine,andremove

thekey.

2.Openthehood.

3.Connectthehookonthespringremovaltooltothe

hookontheidlerpulleyspring,anddisconnectthe

springfromthestudasillustratedin

Figure47.

Figure47

1.Springremovaltool

2.Drivebelt

3.Idlerpulleyspring(spring

covernotshown)

4.Removetheidlerpulleyspringfromtheidlerpulley

assembly(Figure48).

4.Idlerpulley

5.Engine(see-throughfor

illustrativepurposes)

36

Page 37

Figure48

Springcovernotshown

1.Idlerpulleyassembly2.Drivebeltrouting

5.Removethebeltfromthethreepulleys(Figure49).

ControlsSystem

Maintenance

Thefactoryadjuststhecontrolsbeforeshippingthetraction

unit.However,aftermanyhoursofuse,youmayneedto

adjustthetractioncontrolalignment,theneutralpositionof

thetractioncontrol,andthetrackingofthetractioncontrol

inthefullforwardposition.

Important:Toadjustthecontrolsproperly,complete

eachprocedureintheorderlisted.

AdjustingtheTractionControl Alignment

Ifthetractioncontrolbardoesnotrestushandsquare

withthereferencebarwheninthefullbackwardposition,

immediatelycompletethefollowingprocedure:

1.Parkthetractionunitonaatsurfaceandlowerthe

loaderarm.

2.Stoptheengineandremovethekey.

3.Pullstraightbackonthetractioncontrolsothefront

ofthecontrolcontactsthereferencebar(

Figure50).

Figure49

Springcovernotshown

6.Installanewdrivebeltaroundthethreepulleys

(Figure48).

7.Installtheendoftheidlerpulleyspringtothearmon

theidlerpulleyassembly .

Important:Ifyouhaveremovedthespringcover,

ensuretoinstallitoverthespringatthistime.

8.Usingthespringremovaltool,pulltheidlerspring

hookupandaroundthestudonthetractionunit,

pullingtheidlerpulleytight.

9.Removethespringremovaltoolfromthespringand

closethehood.

Figure50

1.Frontofthecontrol,outof

alignment

4.Ifthefrontofthetractioncontroldoesnotrestsquare

andushwiththereferencebar,loosentheangenut

andboltinthestemofthetractioncontrol(Figure51).

1.Tractioncontrol

2.Referencebar

Figure51

2.Stem,boltandnut

37

Page 38

5.Adjustthetractioncontrolsothatitrestsushagainst

g013014

1

2

thereferencebarwhenitispulledstraightback

(Figure51andFigure52).

Figure52

WARNING

Whenthetractionunitisrunning,youcould

becaughtandinjuredinmovingpartsor

burnedonhotsurfaces.

Stayawayfrompinchpoints,movingparts,

andhotsurfaceswhenadjustingtherunning

tractionunit.

5.Ifthelefttrackmoves,lengthenorshortentheright

tractionroduntilthetrackstopsmoving.

6.Iftherighttrackmoves,lengthenorshortentheleft

tractionroduntilthetrackstopsmoving.