Page 1

Dingo 222

Traction Unit

Model Number 22304—990001 & Up

FORM NO. 3323-287

Operator’s Manual

Domestic English (EN)

Page 2

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied

with your new product, so feel free to contact your

local Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

product. The two numbers are stamped into a plate

mounted on left rear side of frame.

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

Read this manual carefully to learn how to operate

and maintain your product correctly. Reading this

manual will help you and others avoid personal injury

and damage to the product. Although we design,

produce and market safe, state-of-the-art products,

you are responsible for using the product properly

and safely. You are also responsible for training

persons, who you allow to use the product, about safe

operation.

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

The left and right side of the machine is determined

by standing on the platform in the normal operator’s

position.

The engine exhaust from this product

contains chemicals known to the State of

California to cause cancer, birth defects,

The Toro Company – 1999

All Rights Reserved

or other reproductive harm.

Page 3

Contents

Page

Safety 2.

Assembly 8

Specifications 11

Before Operating 13

Operation 17

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 2

Slope Chart 6

Safety and Instruction Decals 7

Loose Parts 8

Installing the Valve Lever 8

Activating the Battery 8

General Specifications 11

Attachments 11

Stability Data 12

Adding Fuel 13

Using Stabilizer/Conditioner 14

Checking the Oil Level 14

Removing Debris from the Traction Unit 15

Checking the Hydraulic Fluid 15

Tire Pressure 16

Controls 17

Starting and Stopping the Engine 19

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . .

. . . . . . . . . . . . . . .

.

. . . . . . . . . .

. . . . . . .

Page

Driving Forward or Backward 20

Stopping the Traction Unit 20

Moving a Non Functioning Traction Unit 20

Using the Cylinder Locks 21

Attachments 21

Securing the Traction Unit for Transport 23

Maintenance 24

Service Interval Chart 24

Servicing the Air Cleaner 25

Servicing the Engine Oil 26

Servicing the Spark Plugs 28

Greasing and Lubrication 29

Replacing the Fuel Filter 30

Draining the Fuel Tank 30

Servicing the Hydraulic System 31

Servicing the Traction Drive Chains 32

Servicing the Battery 33

Cleaning and Storage 34

Troubleshooting 36

Warranty

. . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . .

.

. . . . . . . . . . . . .

. .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . .

. . . . .

Back Cover

1

Page 4

Safety

Improper use or maintenance by the operator or

owner can result in injury. To reduce the potential

for injury, comply with these safety instructions

and always pay attention to the safety alert

symbol, which means CAUTION, WARNING, or

DANGER—“personal safety instruction.” Failure

to comply with the instruction may result in

personal injury or death.

Safe

This product is capable of amputating hands and feet.

Always follow all safety instructions to avoid serious

injury or death.

Operating Practices

POTENTIAL HAZARD

• Engine exhaust contains carbon monoxide,

which is an odorless, deadly poison.

WHAT CAN HAPPEN

• Carbon monoxide can kill you and is also

known to the State of California to cause

birth defects.

HOW TO AV

OID THE HAZARD

• Do not run engine indoors or in an enclosed

area.

General Operation

• Read, understand, and follow all instructions in

the operator’s manual, in the video, and on the

traction unit before starting. Also, read all

attachment manuals where supplied

• Allow only responsible adults who are familiar

with the instructions to operate the traction unit.

• Do not operate the traction unit or attachments

while wearing sandals, tennis shoes, sneakers, or

shorts. Always wear long pants and substantial

shoes. W

hearing protection, and a hard hat are advisable

and may be required by some local ordinances

and insurance regulations.

• Ensure that the area is clear of other people

before operating the traction unit. Stop the

traction unit if anyone enters the area.

• Never carry passengers on attachments or on the

traction unit.

• Always look down and behind before and while

backing.

• Do not place your feet under the platform.

• Slow down before turning. Sharp turns on any

terrain may cause loss of control.

earing safety glasses, safety shoes,

Because in some areas there are local, state, or federal

regulations requiring that a spark-arrester be used on

engines, a spark-arrester is available as an option for

the traction unit. If a spark-arrester is required,

contact your Toro dealer. Genuine Toro approved

spark-arresters are approved by the USDA Forestry

Service. It is a violation of the State of California

PRC Section 4442 to use or operate the engine on any

forest-covered, brush-covered, or grass-covered land,

unless the engine is equipped with a spark-arrester,

maintained in working order, or the engine is

constricted, equipped, and maintained for the

prevention of fire.

2

• Never leave a running traction unit unattended.

Always lower the loader arms, stop the engine,

and remove the key before dismounting.

• Do not exceed the rated operating capacity, as

the traction unit may become unstable which

may result in loss of control.

• Do not carry a load with the arms raised. Always

carry loads close to the ground. Do not step off

of the platform with the load raised.

Page 5

Safety

• Do not over-load the attachment and always

keep the load level when raising the loader arms.

Logs, boards, and other items could roll down

the loader arms, injuring you.

• Never jerk the control levers; use a steady

motion.

• Keep your hands, feet, hair, and loose clothing

away from any moving parts.

• Operate only in daylight or good artificial light.

• Do not operate the traction unit while under the

influence of alcohol or drugs.

• Watch for traffic when operating near or crossing

roadways.

• Use extra care when loading or unloading the

traction unit onto a trailer or truck.

• Do not touch parts which may be hot from

operation. Allow them to cool before attempting

to maintain, adjust, or service.

• Raising the loader arms on a slope will affect the

stability of the machine. Whenever possible,

keep the loader arms in the lowered position

when on slopes.

• Removing an attachment on a slope will make

the rear of the traction unit heavy. Refer to the

Stability Data section, page 12, to determine

whether the attachment can be safely removed

on the slope.

• Remove obstacles such as rocks, tree limbs, etc.

from the work area. Watch for holes, ruts, or

bumps, as uneven terrain could overturn the

traction unit. T

all grass can hide obstacles.

• Use slow speed on slopes. Before starting the

engine, put the pump selector lever in the slow

(turtle) position so that you will not have to stop

or shift while on the slope.

• Follow the recommendations in the attachment

manuals for the use of counterweights to

improve stability.

• Locate and mark underground utilities before

digging to avoid the risk of electrical shock or

explosion. Do not dig in marked areas.

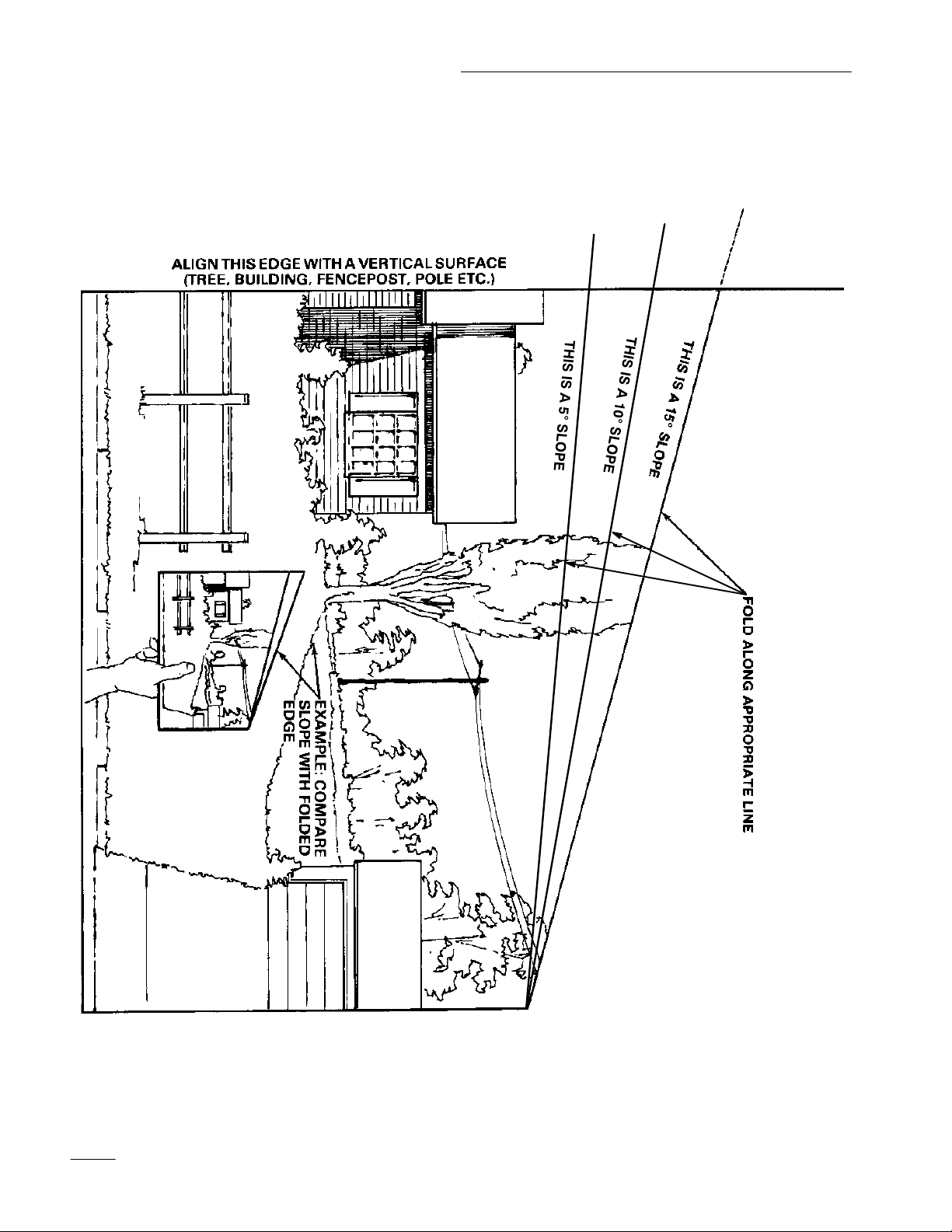

Slope Operation

Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. All slopes require extra caution.

• Do not operate the traction unit on hillsides or

slopes exceeding the angles recommended in the

Stability Data section, page 12, and those in the

attachment operator’s manual. See also the

slope chart on page 6.

• Operate up and down slopes with the heavy

end of the traction unit uphill. Weight

distribution changes. An empty bucket will make

the rear of the traction unit the heavy end, and a

full bucket will make the front of the traction

unit the heavy end. Most other attachments will

make the front of traction unit the heavy end.

• Use only Toro approved attachments.

Attachments can change the stability and the

operating characteristics of the traction unit.

Warranty may be voided if used with

unapproved attachments.

• Keep all movements on slopes slow and gradual.

Do not make sudden changes in speed or

direction.

• Avoid starting or stopping on a slope. If tires

lose traction, proceed slowly, straight down the

slope.

• Check for overhead clearances (i.e. branches,

doorways, electrical wires) before driving under

any objects and do not contact them.

• Avoid turning on slopes. If you must turn, turn

slowly and keep the heavy end of the traction

unit uphill.

• Do not operate near drop-offs, ditches, or

embankments. The traction unit could suddenly

turn over if a wheel goes over the edge of a cliff

or ditch, or if an edge caves in.

3

Page 6

Safety

• Do not operate on wet grass. Reduced traction

could cause sliding.

• Do not park the traction unit on a hillside or

slope without lowering the attachment to the

ground and chocking the wheels.

• Do not try to stabilize the traction unit by putting

your foot on the ground.

Children

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the traction unit and the work activity.

Never assume that children will remain where you

last saw them.

• Keep children out of the work area and under the

watchful care of another responsible adult.

• Be alert and turn the traction unit off if children

enter the area.

• Before and while backing, look behind and down

for small children.

• Keep nuts and bolts tight. Keep equipment in

good condition.

• Never tamper with safety devices. Check safety

systems for proper operation before each use.

• Keep the traction unit free of grass, leaves, or

other debris build-up. Clean up oil or fuel

spillage. Allow the traction unit to cool before

storing.

• Use extra care when handling gasoline and other

fuels. They are flammable and vapors are

explosive.

• Use only an approved container.

• Never remove the gas cap or add fuel when

the engine is running. Allow the engine to

cool before refueling. Do not smoke.

• Never refuel the traction unit indoors.

• Never store the traction unit or fuel

container inside where there is an open

flame, such as near a water heater or

furnace.

• Never carry children. They may fall off and be

seriously injured or interfere with safe traction

unit operation.

• Never allow children to operate the traction unit.

• Use extra care when approaching blind corners,

shrubs, trees, the end of a fence, or other objects

that may obscure vision.

Service

• Stop the engine and disconnect the spark plug

wires before performing any service, repairs,

maintenance, or adjustments.

• If any maintenance or repair requires the loader

arms to be in the raised position, secure the arms

in the raised position with the hydraulic cylinder

locks included with traction unit.

• Never run a traction unit inside a closed area.

• Never fill a container while it is inside a

vehicle, trunk, pick–up bed, or any surface

other than the ground.

• Keep container nozzle in contact with the

tank during filling.

• Stop and inspect the equipment if you strike an

object. Make any necessary repairs before

restarting.

• Use only genuine replacement parts to ensure

that original standards are maintained.

• Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes, and clothing.

Protect your face, eyes, and clothing when

working with a battery.

• Battery gases can explode. Keep cigarettes,

sparks and flames away from the battery.

4

Page 7

• Keep your body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid. Use cardboard or paper to find

hydraulic leaks. Hydraulic fluid escaping under

pressure can penetrate skin and cause injury

requiring surgery within a few hours by a

qualified surgeon or gangrene may result.

Safety

5

Page 8

Safety

Slope

Read all safety instructions on pages 2–4.

Chart

6

Page 9

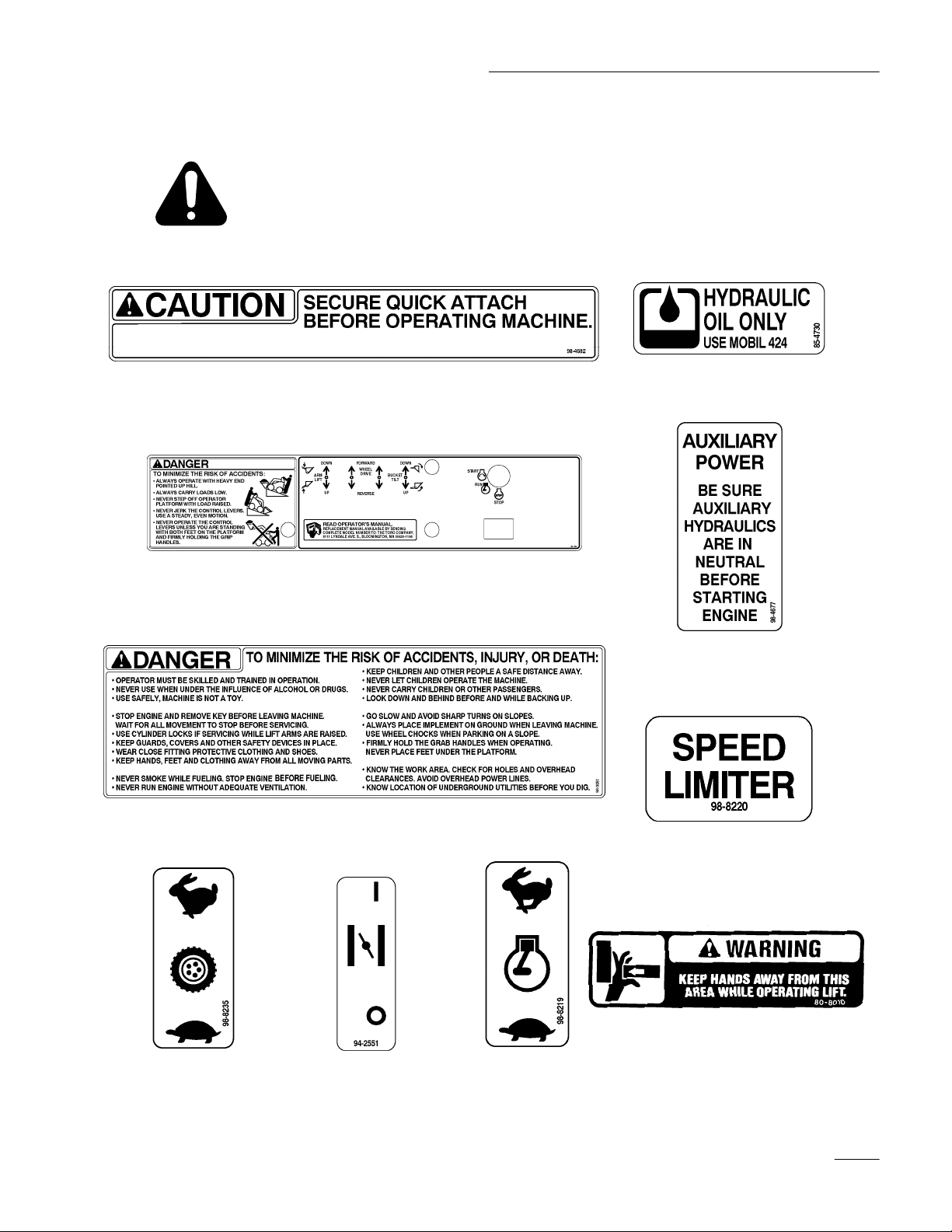

Safety

Safety

RATED

and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

OPERA

TING CAP

On Loader Cross Bar

(Part No. 98–4682)

(Part No. 99–1385)

ACITY 515 LBS.

On Control Panel

Near Oil Fill

(Part No. 85–4730)

Inside Left Loader Arm (1)

On Front Control Panel

(Part No. 98–8235)

(Part No. 98–9051)

On

Control Panel

(Part No. 94–2551)

On Control Panel

(Part No. 98–8219)

On Front Control Panel

(Part No. 98–4677)

On Front Control Panel

(Part No. 98–8220)

On Both Sides of Frame and

Loader, and on Top of Loader

Arms (6)

(Part No. 80–8010)

7

Page 10

Assembly

Loose

Parts

Note: Use the chart below to verify all parts have been shipped.

DESCRIPTION QTY. USE

V

alve Lever

Key 2

Oil filter

Chain link

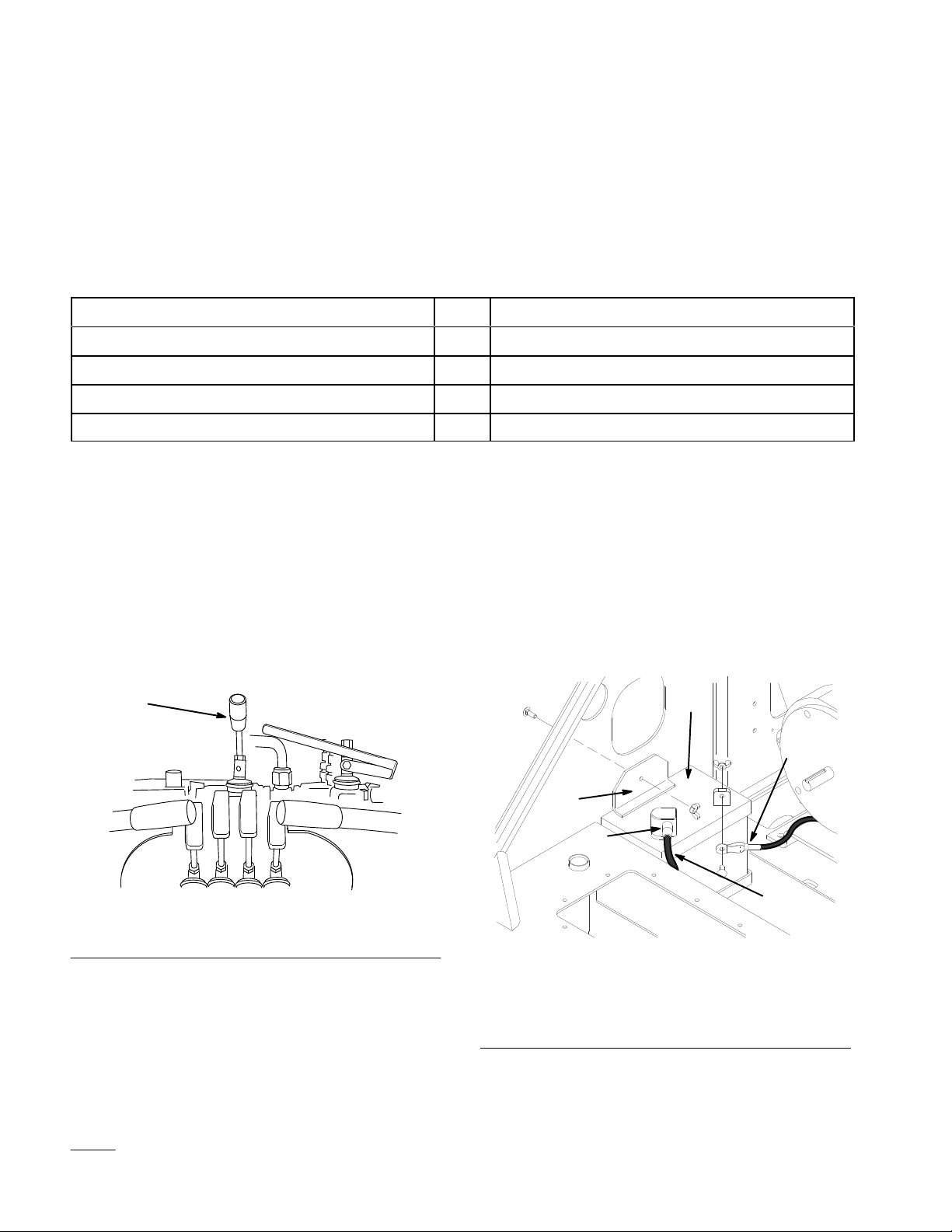

Installing

the V

alve Lever

1. Thread the lever into the pump selector valve

(Fig. 1).

1

1

2

Install valve lever

Start the engine

Break–in oil change

Spare parts

Activating

the Battery

The traction unit is shipped with a dry battery.

Purchase bulk electrolyte with 1.260 specific gravity

from a local battery supply outlet.

Note: The lever should be installed with the

bend toward the operator.

1. Remove the wing nut and bolt securing the

battery clamp and strip (under the clamp) and

2. Tighten the jam nut on the lever to lock it in

remove the clamp and strip (Fig. 2).

position.

1. Pump

1

selector lever

Figure 1

m–3883

1. Battery

2. Battery

3.

Positive cable

2

clamp

4

Figure 2

1

4.

Rubber cover

5.

Negative cable

5

3

m–3953

8

Page 11

Assembly

2. Gently push the hydraulic hoses aside and lift

the battery out of the chassis.

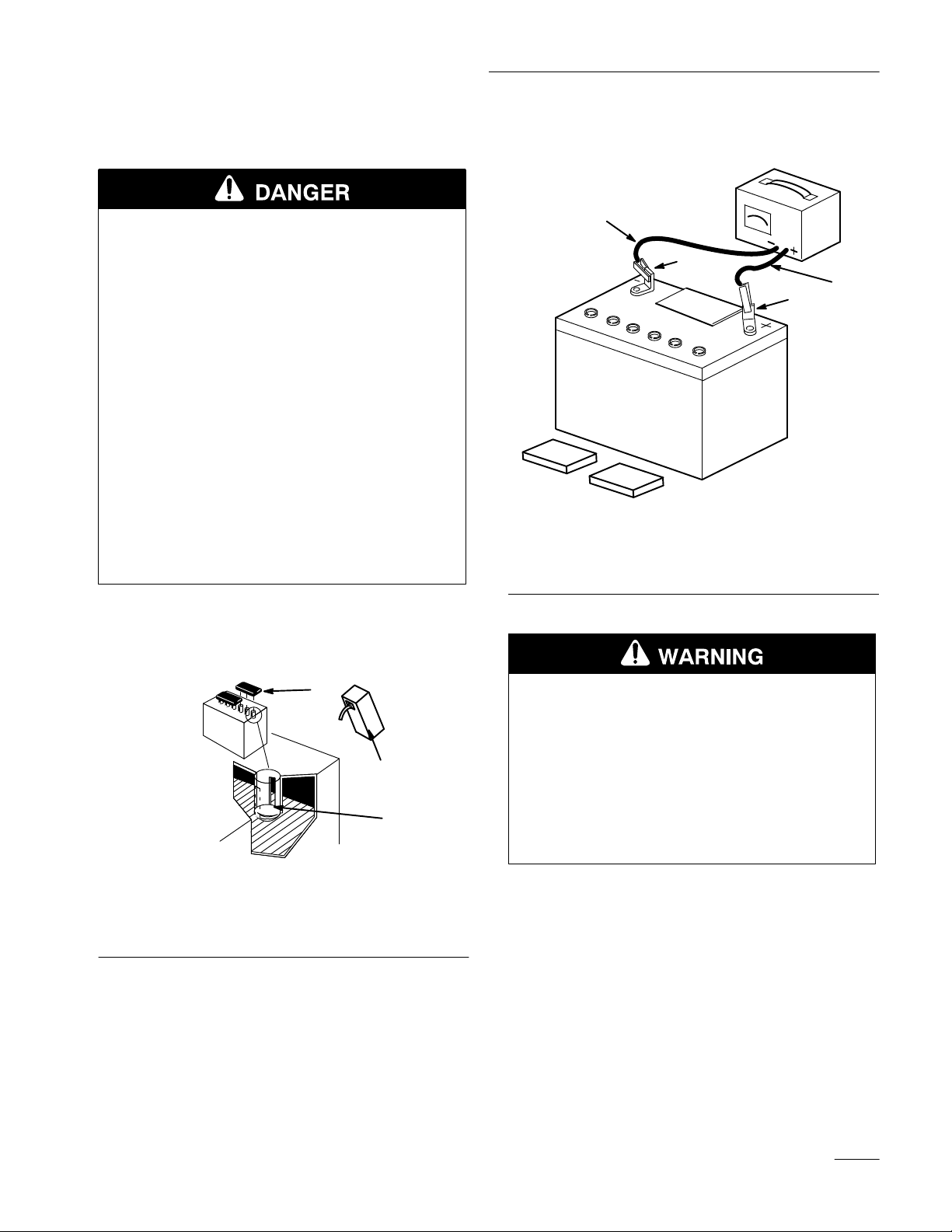

POTENTIAL HAZARD

• Battery electrolyte contains sulfuric acid

which is a deadly poison and it causes

severe burns.

WHAT CAN HAPPEN

• If you drink electrolyte you could die or if it

gets onto your skin you will be burned.

HOW TO AV

OID THE HAZARD

• Do not drink electrolyte and avoid contact

with skin, eyes or clothing. Wear safety

glasses to shield your eyes and rubber

gloves to protect your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

5. Charge the battery at a rate of 4 amperes or less

for 4 hours (12 volts).

4

2

3

1

1254

Figure 4

1. Positive

2.

post

Negative post

3.

Charger red (+) wire

4.

Charger black (–) wire

3. Remove filler caps from the battery. Slowly pour

electrolyte into each cell until the electrolyte

level is up to the lower part of the tube (Fig. 3).

1

2

3

1262

Figure 3

1. Filler

2. Electrolyte

caps

Lower part of the tube

3.

4. Leave the covers off and connect a 3 to 4 amp

battery charger to the battery posts (Fig. 4).

POTENTIAL

• Charging battery pr

HAZARD

oduces gasses.

WHAT CAN HAPPEN

• Battery gasses can explode.

HOW TO AV

OID THE HAZARD

• Keep cigarettes, sparks and flames away

from battery.

6. When the battery is fully charged, disconnect the

charger from the electrical outlet and from the

negative and positive battery posts (Fig. 4).

7. Slowly pour electrolyte into each cell until the

level is once again up to the upper line on the

battery case (Fig. 3) and install covers.

9

Page 12

Assembly

8. Install the battery into the chassis (Fig. 2).

9. Secure the battery in the chassis with the battery

clamp, strip, and wing nut (Fig. 2).

10. Using the bolt and wing nut supplied with the

battery, connect the positive (red) cable to the

positive (+) battery post (Fig. 2). Slide the

rubber cover over the battery post.

11. Using the bolt and wing nut supplied with the

battery, connect the negative (black) cable to the

negative (–) battery post (Fig. 2).

Note: Ensure that the battery cables do not

contact any sharp edges or each other.

10

Page 13

Specifications

General

Overall width 40.5 inches (103 cm)

Overall length 60.0 inches (152 cm)

Overall height 49.0 inches (125 cm)

Weight 1565 lbs (710kg)

Rated operating capacity 515 lbs (234 kg)

(with 200 lb operator)

Tipping capacity l030lbs (467kg)

(with 200 lb operator)

Wheelbase 28.5 inches (72 cm)

Dump height 48.75 inches (124 cm)

(with std. bucket)

Reach – fully raised 26.0

(with std. bucket)

Specifications

inches

(66 cm)

Attachments

Many attachments are available for use with the

traction unit. These attachments allow you to

perform many different functions with the traction

unit such as hauling materials, digging holes, grading,

and more. Contact your Toro dealer for a list of all

approved Dingo attachments and accessories.

IMPORTANT: Use only Toro approved

attachments.

Height to hinge pin 66.0 inches (168 cm)

(std bucket in highest position)

Note: Specifications and design are subject to

change without notice.

11

Page 14

Check Before Operating

Stability

Data

The following table lists the maximum slope recommended for the traction unit in the positions listed in the

table. Slopes over the listed degree may cause the traction unit to become unstable. The data in the table

assumes that the loader arms are fully lowered and that the factory installed tires are on the traction unit, inflated

to the recommended pressure; raised arms and other tire types or pressure may affect the stability.

Maximum Recommended Slope

when Operating with:

Front Uphill

Configuration

T

raction unit without attachment

T

raction unit with counterweight, without attachment

T

raction unit with an attachment rated with one of the following

stability ratings for each slope position:*

A 25° 25° 20°

B 18° 19° 17°

8° 20° 17°

5° 21° 17°

Rear Uphill

Side Uphill

C 15° 16° 14°

D 10° 10° 9°

E 5° 5° 5°

* In each attachment manual is a set of three stability ratings, one for each hill position. To determine the

maximum slope you can traverse with the attachment installed, find the degree of slope that corresponds to the

stabilities ratings of the attachment.

Example: If the attachment installed on the traction unit has a Front Uphill rating of B, a Rear Uphill rating of

D, and a Side Uphill rating of C, then you could drive forward up a 18

° slope, rearward up a 10° slope, or

sideways on a 14° slope, as listed in the above table.

12

Page 15

Before Operating

Before operating, check the fuel and oil level, remove

debris from the traction unit, and check the tire

pressure. Also, ensure that the area is clear of people

and debris. You should also know and have marked

the locations of all utility lines.

Adding

Fuel

POTENTIAL HAZARD

• When fueling, under certain circumstances,

a static charge can develop, igniting the

gasoline.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

POTENTIAL

HAZARD

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AV

OID THE HAZARD

• Fill the fuel tank outdoors, in an open area,

when the engine is cold. Wipe up any

gasoline that spills.

• Do not fill the fuel tank completely full.

Add gasoline to the fuel tank until the level

is 1/4” to 1/2” (6 mm to 13 mm) below the

bottom of the filler neck. This empty space

in the tank allows gasoline to expand.

• Never smoke when handling gasoline, and

stay away from an open flame or where

gasoline fumes may be ignited by a spark.

• Store gasoline in an approved container

and keep it out of the reach of children.

Never buy more than a 30-day supply of

gasoline.

HOW TO AV

OID THE HAZARD

• Always place gasoline containers on the

ground away from your vehicle before

filling.

• Do not fill gasoline containers inside a

vehicle or on a truck or trailer bed because

interior carpets or plastic truck bed liners

may insulate the container and slow the

loss of any static charge.

• When practical, r

equipment from the truck or trailer and

refuel the equipment with its wheels on the

ground.

emove gas–power

ed

• If this is not possible, then refuel such

equipment on a truck or trailer from a

portable container, rather than from a

gasoline dispenser nozzle.

• If a gasoline dispenser nozzle must be used,

keep the nozzle in contact with the rim of

the fuel tank or container opening at all

times until fueling is complete.

Use unleaded regular gasoline (85 pump octane

minimum). Leaded regular gasoline may be used if

unleaded regular is not available.

IMPORTANT: Never use methanol, gasoline

containing methanol, or gasohol containing

more than 10% ethanol because the fuel

system could be damaged. Do not mix oil with

gasoline.

13

Page 16

Check Before Operating

Filling the Fuel Tank

1. Park the traction unit on a level surface, lower

the loader arms, and stop the engine.

2. Remove the key and allow the engine to cool.

3. Clean around the fuel tank cap and remove it.

4. Add unleaded regular gasoline to each fuel tank,

until the level is 1/4 to 1/2 inch (6 mm to

13 mm) below the bottom of each filler neck.

IMPORTANT: This space in the tank allows

gasoline to expand. Do not fill the fuel tank

completely full.

5. Install the fuel tank cap securely. Wipe up any

gasoline that may have spilled.

Using

Use a fuel stabilizer/conditioner in the fuel tank to

provide the following benefits:

Stabilizer/Conditioner

Checking

the Oil Level

1. Park the traction unit on a level surface, lower

the loader arms, and stop the engine.

2. Remove the key and allow the engine to cool.

3. Clean around the oil dipstick (Fig. 5).

4. Pull out the dipstick and wipe the metal end

clean (Fig. 5).

5. Slide the dipstick fully into the dipstick tube

(Fig. 5).

6. Pull the dipstick out and look at the metal end.

7. If the oil level is low, clean around the oil filler

cap and remove the cap (Fig. 5).

8. Slowly pour only enough oil into the valve cover

to raise the level to the F (full) mark.

IMPORTANT: Do not overfill the crankcase

with oil because the engine may be damaged.

• Keeps gasoline fresh during storage of 90 days

or less. For longer storage, drain the fuel tank.

• Cleans the engine while it runs.

• Eliminates gum-like varnish buildup in the fuel

system, which causes hard starting.

IMPORTANT: Do not use fuel additives

containing methanol or ethanol.

Add the correct amount of gas stabilizer/conditioner

to the gas.

Note: A fuel stabilizer/conditioner is most

effective when mixed with fresh

gasoline. To minimize the chance of

varnish deposits in the fuel system, use

fuel stabilizer at all times.

9. Replace the filler cap and dipstick.

4

2

3

m–3873 m–3219

1. Oil

dipstick

2.

Filler cap

1

Figure 5

3. V

4.

alve cover

Metal end

14

Page 17

Check Before Operating

Removing

T

raction Unit

IMPORTANT: Operating the engine with a

blocked grass scr

fins, and/or cooling shrouds removed, will

result in engine damage from overheating.

1. Park the traction unit on a level surface, raise the

loader arms, and install the cylinder locks; refer

to Using the Cylinder Locks, page 21.

2. Stop the engine and remove the key.

3. Clean any debris from the grill before each use

and/or during use, if required.

4. Wipe away debris from the air cleaner before

each use and/or during use, and empty the

pre-cleaner jar, if required.

5. Clean any debris build-up on the engine with a

brush or blower before each use.

Debris from the

een, dirty or plugged cooling

Use only Group 1 ISO type 46/68 anti–wear

hydraulic fluids, recommended for ambient

temperatures consistently below 100 F, such as Toro

Hy-Pro, Mobil Fluid 424, or other equivalent fluid.

IMPORTANT: Use only the group 1 ISO type

46/68 anti-wear hydraulic fluids. Other fluids

could cause system damage.

1. Remove the attachment, if one is installed; refer

to Removing an Attachment, page 23.

2. Park the traction unit on a level surface, lower

the loader arms, stop the engine, and remove the

key.

3. Clean the area around the filler neck of the

hydraulic tank (Fig. 6).

4. Remove the cap from the filler neck and check

the fluid level on the dipstick (Fig. 6).

The fluid level should be at the mark on the

dipstick.

IMPORTANT: It is preferable to blow dirt

out, rather than washing it out. If water is

used, keep it away from electrical items and

hydraulic valves. Do not use a high-pressure

washer. High-pressure washing can damage

the electrical system and hydraulic valves or

deplete grease.

6. Remove and store the cylinder locks (refer to

Using the Cylinder Locks, page 21), and lower

the loader arms.

Checking

Check the hydraulic fluid level before the engine is

first started and after every 25 operating hours.

Hydraulic Tank Capacity: 17.25 gal. (67 l)

the Hydraulic Fluid

1

2

m–4392

Figure 6

1. Filler

5. If the level is low, add enough fluid to raise it to

6. Install the cap on the filler neck.

neck cap

the proper level.

2. Dipstick

15

Page 18

Check Before Operating

Tire

Pressure

Maintain the air pressure in the tires as specified.

Check the tires when they are cold to get the most

accurate reading.

Pressure: 20–30 psi

Note: Use a lower tire pressure (20 psi) when

operating in sandy soil conditions to

provide better traction in the loose soil.

1

m–1872

Figure 7

1. Valve

stem

16

Page 19

Operation

To stop the engine, rotate the key to the off position.

POTENTIAL

HAZARD

• Operator could fall off platform.

WHAT CAN HAPPEN

• Operator could be seriously injured.

HOW TO AV

• Do not move any of the contr

unless standing with both feet on the

platform and hands holding the hand grips.

OID THE HAZARD

ol levers

Controls

Become familiar with all the controls (Fig. 8) before

you start the engine and operate the traction unit.

5

1

3

2

4

Throttle Lever

Move the control forward to increase the engine

speed and rearward to decrease speed.

Choke Lever

Before starting a cold engine, move the choke lever

fully forward. After the engine starts, regulate the

choke to keep the engine running smoothly. As soon

as possible, move the choke lever rearward as far as

possible. A warm engine requires little or no choking.

Traction Control Levers

To move forward, move the traction control levers

forward. To move rearward, move the traction control

levers rearward.

To go straight, move both traction control levers

equally.

6

1. Traction

2.

3.

4.

control levers

Attachment tilt lever

Loader arm lever

Auxiliary hydraulics lever

Figure 8

8

5.

Pump selector lever

6.

Throttle lever

7.

Choke lever

8.

Key switch

m–4388

7

Key Switch

The key switch, used to start and stop the engine, has

three positions: off, run, and start.

To start the engine, rotate the key to the start position.

Release the key when engine starts and it will move

automatically to the run position.

To turn, move the lever located on the side you want

to turn back toward the neutral position while keeping

the other lever engaged.

The farther you move the traction control levers in

either direction, the faster the traction unit will move

in that direction.

To slow or stop, move the traction control levers to

neutral.

Attachment Tilt Lever

To tilt the attachment forward, slowly push the

attachment tilt lever forward.

To tilt the attachment rearward, slowly pull the

attachment tilt lever rearward.

17

Page 20

Operation

Loader Arm Lever

To lower the loader arms, slowly push the loader arm

lever forward.

To raise the loader arms, slowly pull the loader arm

lever rearward.

Auxiliary Hydraulics Lever

To operate a hydraulic attachment in forward

direction, slowly pull the auxiliary hydraulics lever

rearward.

To operate a hydraulic attachment in reverse

direction, slowly push the auxiliary hydraulics lever

forward.

Pump Selector Lever

Move the pump selector lever to the fast (rabbit)

position to set the traction drive, loader arms, and

attachment tilt to high speed and the auxiliary

hydraulics to low speed.

Move the pump selector lever to the slow (turtle)

position to set the auxiliary hydraulics to high speed

and the traction drive, loader arms, and attachment tilt

to low speed.

POTENTIAL HAZARD

• If the pump selector lever is moved while

the traction unit is in motion, the traction

unit will either stop suddenly or accelerate

quickly.

• If the traction unit is operated with the

pump selector lever in an intermediate

position, the traction unit will operate

erratically and may be damaged.

WHAT CAN HAPPEN

• You could be thrown forward or

backwards, resulting in injury.

• If the traction unit accelerates quickly, you

could lose control of the traction unit and

injure bystanders or yourself.

• You could lose control of the traction unit,

severely injuring yourself or others.

• The traction unit could be damaged.

HOW TO AV

OID THE HAZARD

• Do not move the pump selector lever when

the traction unit is in motion.

• Do not operate the traction unit when the

speed selector is in any intermediate

position (i.e., any position other than fully

forward or fully rearward).

18

Flow Divider Control

The traction unit hydraulics (i.e., the traction drive,

loader arms, and attachment tilt) work on a separate

hydraulic circuit from the auxiliary hydraulics for

powering attachments; however, the two systems

share the same hydraulic pumps. Using the flow

divider control (Fig. 9), you can vary the speed of the

traction unit hydraulics by diverting hydraulic flow to

the auxiliary hydraulics circuit. The flow divider

allows you to divide the flow of fluid in varying

degrees to slow the traction unit. Thus, the more

hydraulic flow you divert to the auxiliary hydraulics,

the slower the traction unit hydraulics will move.

Page 21

Operation

1

2

5

3

4

Figure 9

1. Flow

2. Knob

3.

divider control

12 o’clock position

4.

10 to 1

1 o’clock position

5.

9 o’clock position

• Move the flow divider control to the

twelve–o’clock position to provide maximum

speed to the traction unit hydraulics.

Use this setting for fast operation of the traction

unit.

• Move the flow divider control between the

twelve–o’clock and nine–o’clock positions to

slow the traction unit hydraulics and fine tune

the speed.

Use a setting in this range with attachments with

hydraulics where you need to both run the

attachment and move the traction unit

hydraulics, such as the auger, boring unit,

hydraulic blade, and tiller.

• Move the control to the nine–o’clock position to

transfer all hydraulic flow to the auxiliary

hydraulics of the attachment.

Starting

and Stopping the

Engine

Starting the Engine

1. Stand on the platform.

2. Move the auxiliary hydraulics valve lever to

neutral.

3. Move the throttle lever midway between slow

(turtle) and fast (rabbit) positions.

4. Move the choke lever fully forward before

starting a cold engine.

Note: A warm or hot engine may not require

choking.

5. Turn the ignition key to the start position. When

the engines starts, release the key.

IMPORTANT: Do not engage the starter for

more than 10 seconds at a time. If the engine

fails to start, allow a 30 second cool-down

period between attempts. Failure to follow

these instructions can burn out the starter

motor.

6. After the engine starts, gradually move the choke

to rearward. If the engine stalls or hesitates,

move the choke forward again until the engine

warms up.

In this setting, the traction unit hydraulics will

not work. Use this setting with hydraulic

attachments that do not required the traction unit

hydraulics. There are currently no attachments

that require the nine–o’clock position; however,

the trencher does work best if you set it close to

nine–o’clock so that the traction unit will creep

slowly when trenching.

Note: The flow divider control can be fixed

in place by turning the knob on the

control clockwise until it contacts the

dial (Fig. 9).

7. Move the throttle lever to desired setting.

IMPORTANT: If you run the engine at high

speeds when the hydraulic system is cold (i.e.,

when the ambient air temperature is around

freezing or lower), you could damage the

hydraulic system. When starting the engine

in cold conditions, allow the engine to run in

the middle throttle position for 2 to 5 minutes

before moving the throttle to fast (rabbit).

19

Page 22

Operation

Stopping the Engine

1. Move the throttle lever to the slow (turtle)

position.

2. Lower the loader arms to the ground.

3. Turn the ignition key off.

Note: If the engine has been working hard or

is hot, let it idle for a minute before

turning the ignition key off. This helps

cool the engine before it is stopped. In

an emergency, the engine may be

stopped immediately

Driving

The throttle control regulates the engine speed as

measured in rpm (revolutions per minute). Place the

throttle lever in the fast (rabbit) position for best

performance.

Forward or Backward

.

Stopping

To stop the traction unit, move the traction control

levers to neutral and the throttle lever to slow (turtle),

lower loader arms to the ground, and turn the ignition

key off to stop the engine. Remove the key.

POTENTIAL HAZARD

the T

raction Unit

• Someone could move or attempt to operate

the traction unit while it is unattended.

WHAT CAN HAPPEN

• Children or bystanders may be injured if

they use the traction unit.

HOW TO AV

•

Always r

leaving the traction unit, even if just for a

few seconds.

OID THE HAZARD

emove the ignition key when

Note: Throttle position can be utilized to

operate at slower speeds.

To drive the traction unit, complete the following

actions as necessary:

• To move forward, move the traction control

levers forward.

• To move rearward, move the traction control

levers rearward.

• To go straight, move both traction control levers

equally.

• To turn, move the lever located on the side you

want to turn toward the neutral position while

keeping the other lever engaged.

• To slow or stop, move the traction control levers

to neutral.

Note: The farther you move the traction

control levers in either direction, the

faster the traction unit will move in

that direction.

Moving

T

raction Unit

IMPORTANT: Never tow or pull the traction

unit. Rotating the wheels manually will cause

damage to the hydraulic wheel motors.

1. Stop the engine.

2. Lift the traction unit off the ground, using the

two lift points (Fig. 10) and move onto a trailer.

1

1. Lift

points

a Non Functioning

m–4389

Figure 10

1

20

Page 23

Operation

Using

POTENTIAL

the Cylinder Locks

HAZARD

• The loader arms may lower when in the

raised position.

WHAT CAN HAPPEN

• Anyone under the loader arms may be

injured or crushed.

HOW TO AV

OID THE HAZARD

• Always install the cylinder locks when

doing maintenance that requir

loader arms.

es raised

Installing the Cylinder Locks

1. Start the engine.

7. Slowly lower the loader arms until cylinder

locks contact the cylinder body and rod end.

8. Stop the engine.

Removing/Storing the Cylinder Locks

1. Start the engine.

2. Raise the loader arms to the fully raised position.

3. Stop the engine.

4. Remove the clevis pin and cotter pin securing

each cylinder lock.

5. Remove the cylinder locks.

6. Lower the loader arms.

7. Install the cylinder locks over the hydraulic

hoses and secure them with the clevis pins and

cotter pins (Fig. 12).

2. Raise the loader arms to the fully raised position.

3. Stop the engine.

4. Position a loader arm cylinder lock over each lift

cylinder rod (Fig. 11).

5. Secure each loader arm cylinder lock with a

clevis pin and cotter pin (Fig. 11).

5

1

4.

Clevis pin

5.

Lift cylinder rod

4

m–4398

1. Cylinder

2.

Lift cylinder

3.

Hairpin cotter

1

3

2

Figure 1

lock

6. Start the engine.

3

1. Hydraulic

2.

Cylinder locks

1

2

hoses

2

Figure 12

3.

4.

1

Hairpin cotter

Clevis pin

Attachments

Connecting an Attachment

IMPORTANT: Use only Toro approved

attachments. Attachments can change the

stability and the operating characteristics of

4

m–4397

21

Page 24

Operation

the traction unit. The warranty of the traction

unit may be voided if used with unapproved

attachments.

IMPORTANT: Before installing the

attachment, ensure that the mount plates are

free of any dirt or debris.

1. Position the attachment on a level surface with

enough space behind it to accommodate the

traction unit.

2. Move the pump control lever to the turtle

position.

3. Start the engine.

4. Slowly push the attachment tilt lever forward to

tilt the attachment mount plate forward.

5. Position mount plate into the upper lip of the

attachment receiver plate (Fig. 13).

1

2

m–4055

Figure 13

1. Mount

plate

2.

Receiver plate

6. Raise the loader arms while tilting back the

mount plate at the same time.

1

m–4056

Figure 14

1. Quick

attach pins (shown in engaged position)

Connecting the Hydraulic Hoses

If the attachment requires hydraulics for operation,

connect the hydraulic hoses as follows:

1. Stop the engine.

2. Move the auxiliary hydraulics lever forward,

backward, and back to neutral to relieve pressure

at the hydraulic couplers.

IMPORTANT: Ensure that all foreign matter

is cleaned from the hydraulic connections

before making connections.

3. Remove the protective covers from the hydraulic

couplers on the traction unit. Connect the covers

together to prevent contamination during

operation.

4. Slide the collars back on the hydraulic couplers

and connect the attachment couplers to the

traction unit couplers.

IMPORTANT: The attachment should be

raised enough to clear the ground, and the

mount plate should be tilted all the way back.

7. Stop the engine.

8. Engage the quick attach pins (Fig. 14).

22

Page 25

Operation

POTENTIAL HAZARD

• Hydraulic fluid escaping under pressure

can penetrate skin and cause injury.

WHAT CAN HAPPEN

• Fluid accidentally injected into the skin

must be surgically removed within a few

hours by a doctor familiar with this form of

injury or gangrene may result.

HOW TO AV

OID THE HAZARD

• Keep body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic

leaks, never use your hands.

5. Confirm that the connection is secure by pulling

on the hoses.

Securing

the T

raction Unit for

Transport

IMPORTANT: Do not operate or drive the

traction unit on roadways.

IMPORTANT: When transporting the

traction unit on a trailer, always use the

following procedure:

1. Lower the loader arms.

2. Stop the engine.

3. Secure the traction unit to the trailer with chains

or straps using the operator platform support

openings to secure the rear of the traction unit

and the loader arms/mount plate to secure the

front of the traction unit.

Removing an Attachment

1. Lower the attachment to the ground

2. Stop the engine.

3. Disengage the quick attach pins by turning them

to the outside.

4. If the attachment uses hydraulics, move the

auxiliary hydraulics lever forward, backward,

and back to neutral to relieve pressure at the

hydraulic couplers.

5. If the attachment uses hydraulics, slide the

collars back on the hydraulic couplers and

disconnect them.

6. Connect the attachment hoses together to prevent

hydraulic system contamination during storage.

7. Install the protective covers onto the hydraulic

couplers on the traction unit.

8. Start the engine, tilt the mount plate forward,

and back the traction unit away from the

attachment.

23

Page 26

Maintenance

Service

Service

Hydraulic Fluid–check level

Hydraulic Fluid–change

Hydraulic Filter–change

Engine Oil—check level

Engine Oil—change

Engine Oil Filter–change (200

hours or every other oil

change)

Wheel Nuts–tighten

T

raction Drive Chain—lubricate

Chassis—grease

Foam Air Filter—clean

Paper Air Filter—replace

Spark Plug(s)—check

Engine RPM (idle & full

throttle)—check

Gasoline—drain

Hydraulic lines–check

Battery–check electrolyte

Battery–charge, disconnect

cables

Fuel Filter—replace

T

ires—check pressure

Check/tighten all fasteners

Chipped Surfaces—paint

1

More

Interval Chart

Operation

1

1

2

1

3

3

often in dusty

, dirty conditions, 2 Immediately

Each

Use8Hours25Hours50Hours

Initial X

Initial X

X

Initial X

Initial

X

X

X

1

Initial X

X

3

3

X X

after

every washing, 3 Storage Service

100

Hours

X

X

X

200

Hours

X

X

X

400

Hours

X

X

Yearly

X

X

24

Page 27

Maintenance

POTENTIAL

HAZARD

• If you leave the key in the ignition switch, someone could start the engine.

WHAT CAN HAPPEN

• Accidental starting of the engine could seriously injure you or other bystanders.

HOW TO AV

OID THE HAZARD

• Remove the key from the ignition switch and and disconnect negative battery cable

from battery before you do any maintenance.

Servicing

the Air Cleaner

Foam Element: Clean and oil after every 25 operating

hours.

Paper Element: Replace after every 100 operating

hours.

Note: Service the air cleaner more frequently

(every few hours) if operating

conditions are extremely dusty or

sandy.

Removing the Foam and Paper Elements

1. Lower the loader arms, stop the engine, and

remove the key.

1. Wingnut

2. Air

cleaner cover

3.

Cover nut

4. Cover

1

3

5

7

Figure 15

Foam element

5.

6.

Paper element

7.

Rubber seal

8.

Air cleaner base

2

4

6

8

m–3866

2. Clean around the air cleaner to prevent dirt from

getting into the engine and causing damage.

3. Unscrew the wingnut and remove the air cleaner

cover (Fig. 15).

4. Carefully slide the foam element off the paper

element (Fig. 15).

5. Unscrew the cover nut and remove the cover and

paper element (Fig. 15).

6. Inspect the paper element for dirt, tears, an oily

film, and/or damage to the rubber seal. If it is

dirty or damaged, discard it and obtain a new

replacement.

IMPORTANT: Do not attempt to clean the

paper element.

25

Page 28

Maintenance

Cleaning the Foam Element

1. Wash the foam element in liquid soap and warm

water. When the element is clean, rinse it

thoroughly.

2. Dry the element by squeezing it in a clean cloth

(do not wring).

3. Put one or two ounces of oil on the element

(Fig. 16). Squeeze the element to distribute the

oil.

IMPORTANT: Replace the foam element if it

is torn or worn.

2

1

m–1213

Figure 16

1. Foam

element

2. Oil

Servicing

the Engine Oil

Change oil after the first 25 operating hours and then

every 100 operating hours thereafter.

Note: Change oil more frequently when

operating conditions are extremely

dusty or sandy.

Oil Type: Detergent oil (API service SG or SH)

Crankcase Capacity: w/filter, 2.1 qt. (2 l)

Viscosity: See table below

USE THESE SAE VISCOSITY OILS

10W–30, 10W–40

5W–20, 5W–30

–20 0 20

°

F

–30°–20 –10

C

40 60

32

01020

80 100

30 40

Installing the Foam and Paper Elements

IMPORTANT: To prevent engine damage,

always operate the engine with the complete

foam and paper air cleaner assembly

installed.

1. Carefully slide the foam element onto the paper

air cleaner element (Fig. 15).

2. Place the air cleaner assembly onto the air

cleaner base (Fig. 15).

3. Install the air cleaner cover and secure with

cover nut (Fig. 15).

26

Page 29

Changing/Draining Oil

1. Start the engine and let it run five minutes. This

warms the oil so it drains better.

2. Park the traction unit so that the drain side is

slightly lower than the opposite side to ensure

that the oil drains completely.

3. Lower the loader arms, chock the wheels, stop

the engine, and remove the key.

POTENTIAL HAZARD

• Components will be hot if the traction unit

has been running.

WHAT CAN HAPPEN

• Touching hot components can cause burns.

HOW TO AV

OID THE HAZARD

• Allow the traction unit to cool before

performing maintenance or any touching

components.

Maintenance

1

1. Oil

Figure 17

drain valve

m–3216

6. Remove the oil fill cap and slowly pour

approximately 80% of the specified amount of

oil in through the valve cover.

7. Check the oil level; refer to Checking Oil Level,

page 14.

8. Slowly add additional oil to bring the oil level to

the full mark on the dipstick.

4. Place one end of a hose on the drain valve and

the other end in a pan. Open the drain valve by

turning it counter–clockwise, pulling out as you

turn it (Fig. 17).

5. When oil has drained completely, close the drain

valve and remove the hose.

Note: Dispose of the used oil at a certified

recycling center.

9. Replace the fill cap.

27

Page 30

Maintenance

Changing the Oil Filter

Replace the oil filter every 200 hours or every other

oil change.

Note: Change the oil filter more frequently

when operating conditions are

extremely dusty or sandy.

1. Drain the oil from the engine; refer to

Changing/Draining Oil, page 27.

2. Remove the old filter and wipe the filter adapter

(Fig. 18) gasket surface.

3. Apply a thin coat of new oil to the rubber gasket

on the replacement filter (Fig. 18).

3

Servicing

the Spark Plugs

Check the spark plugs after every 200 operating

hours. Ensure that the air gap between the center and

side electrodes is correct before installing each spark

plug. Use a spark plug wrench for removing and

installing the spark plugs and a gapping tool/feeler

gauge to check and adjust the air gap. Install new

spark plugs if necessary.

Type: Champion RC12YC (or equivalent) Air Gap:

0.030 in. (0.76 mm)

Removing the Spark Plugs

1. Lower the loader arms, stop the engine, and

remove the key.

2. Pull the wires off of the spark plugs (Fig. 19).

3. Clean around the spark plugs to prevent dirt

from falling into the engine and potentially

causing damage.

1. Oil

filter

2. Gasket

1

Figure 18

2

3. Adapter

m–1256

4. Install the replacement oil filter on the filter

adapter. Turn the oil filter clockwise until the

rubber gasket contacts the filter adapter, then

tighten the filter an additional 1/2 turn (Fig. 18).

5. Fill the crankcase with the proper type of new

oil; refer to Changing/Draining Oil, page 27.

4. Remove the spark plugs and metal washers.

1

2

Figure 19

1. Spark

plug wire

2.

Spark plug

m–3876

28

Page 31

Maintenance

Checking the Spark Plugs

1. Look at the center of the spark plugs (Fig. 20). If

you see light brown or gray on the insulator, the

engine is operating properly. A black coating on

the insulator usually means the air cleaner is

dirty.

IMPORTANT: Replace the spark plugs when

they have a black coating, worn electrodes, an

oily film, or cracks. Do not attempt to clean a

spark plug.

2. Check the gap between the center and side

electrodes (Fig. 20). Bend the side electrode

(Fig. 20) if the gap is not correct.

2

1

3

0.030

in.

(0.76 mm)

Greasing

and Lubrication

Grease all pivot joints every 8 operating hours and

immediately after every washing. Lubricate the drive

chain every 50 operating hours.

Greasing the Traction Unit

Grease Type: General-purpose grease.

1. Lower the loader arms, stop the engine, and

remove the key.

2. Clean the grease fittings with a rag.

3. Connect a grease gun to each fitting in turn.

4. Pump grease into the fittings until it begins to

ooze out of the bearings.

5. Wipe up any excess grease.

m–3215

1. Center

2.

Side electrode

Figure

electrode insulator

20

3.

Air gap (not to scale)

Installing the Spark Plugs

1. Install the spark plugs.

2. Tighten the spark plugs to 20 ft-lb (27 N.m).

3. Push the wires onto the spark plugs (Fig. 19).

Lubricating Traction Drive Chain

1. Lower the loader arms, stop the engine, and

remove the key.

2. Apply a general purpose oil (10W30) onto upper

and lower chain spans.

3. Start the traction unit and slowly move it

forward to expose un–lubed upper and lower

chain spans.

4. Stop the engine and remove the key.

5. Apply oil to newly exposed un–lubed chain

spans.

29

Page 32

Maintenance

Replacing

Replace the fuel filter after every 200 operating hours

or yearly, whichever occurs first.

the Fuel Filter

Replacing the Fuel Filter

Do not re-install a dirty filter.

1. Lower the loader arms, stop the engine, and

remove the key.

2. Shut off the fuel valve on the bottom of the fuel

tank.

3. Clamp fuel line between fuel tank and fuel filter

to block fuel flow.

4. Squeeze the ends of the hose clamps together

and slide them away from the filter (Fig. 21).

5. Place a drain pan under the fuel lines to catch

any leeks, then remove the filter from the fuel

lines.

Draining

POTENTIAL

the Fuel T

HAZARD

ank

• In certain conditions gasoline is extremely

flammable and highly explosive.

WHAT CAN HAPPEN

• A fire or explosion from gasoline can burn

you, others, and cause property damage.

HOW TO AV

OID THE HAZARD

• Drain gasoline from the fuel tank when the

engine is cold. Do this outdoors in an open

area. Wipe up any gasoline that spills.

• Never drain gasoline near an open flame or

where gasoline fumes may be ignited by a

spark.

• Never smoke while handling fuel.

1. Park the traction unit on a level surface, to

ensure that fuel tank drains completely.

6. Install a new filter and move the hose clamps

close to the filter.

7. Remove clamp blocking fuel flow and open the

fuel valve.

1

2

m–3217

Figure 21

1. Filter 2. Hose

clamp

2. Lower the loader arms, stop the engine, and

remove the key.

3. Shut off the fuel valve on the bottom of the fuel

tank.

4. Loosen the hose clamp at the fuel filter and slide

it up the fuel line away from the fuel filter.

5. Pull the fuel line off fuel filter, open the fuel

valve, and allow gasoline to drain into a gas can

or drain pan.

Note: Now is the best time to install a new

fuel filter because the fuel tank is

empty.

6. Install the fuel line onto the fuel filter. Slide the

hose clamp close to the fuel filter to secure the

fuel line.

7. Open the fuel valve on the bottom of the fuel

tank.

30

Page 33

Maintenance

Servicing

the Hydraulic

System

Replacing the Hydraulic Filter

Change the hydraulic filter:

• After the first 8 operating hours.

• After every 200 operating hours.

1. Park the traction unit on a level surface, to

ensure that fuel tank drains completely.

2. Place drain pan under filter, remove the old

filter, and wipe the filter adapter gasket surface

clean.

3. Apply a thin coat hydro fluid to the rubber

gasket on the replacement filter (Fig. 22).

4. Install a replacement hydraulic filter onto the

filter adapter. Tighten it clockwise until the

rubber gasket contacts the filter adapter, then

tighten the filter an additional 1/2 turn (Fig. 22).

IMPORTANT: Do not substitute an

automotive oil filter or severe hydraulic

system damage may result.

1

6. Start the engine and let run for about two

minutes to purge air from the system.

7. Stop the engine and check for leaks.

8. Check the fluid level in the hydraulic tank and

add enough oil to raise the level to mark on

dipstick.

Changing the Hydraulic Fluid

Change the hydraulic fluid:

• After the first 8 operating hours.

• After every 400 operating hours.

1. Park the traction unit on a level surface.

2. Place a large drain pan under the traction unit

that can hold at least 17 gal. (67 l).

3. Remove the drain plug from the bottom of the

hydraulic tank and allow the fluid to completely

drain out.

4. Install the drain plug.

5. Fill the hydraulic tank with approximately 15

gal. (57 L) of Toro Hy-Pro, Mobil Fluid 424, or

equivalent (refer to Checking Hydraulic Fluid on

page 15).

2

3

Figure 22

1. Hydraulic

2. Gasket

5. Clean up any spilled fluid.

filter

3. Adapter

IMPORTANT: Do not substitute automotive

oil or severe hydraulic system damage may

result.

Note: Dispose of used oil at a certified

recycling center.

Checking Hydraulic Lines

After every 100 operating hours, check the hydraulic

lines and hoses for leaks, loose fittings, kinked lines,

loose mounting supports, wear, weather and chemical

deterioration. Replace all moving hydraulic hoses

every 1500 hours or 2 years, whichever comes first.

Make necessary repairs before operating.

31

Page 34

Maintenance

POTENTIAL HAZARD

• Hydraulic fluid escaping under pressure

can penetrate skin and cause injury.

WHAT CAN HAPPEN

• Fluid accidentally injected into the skin

must be surgically removed within a few

hours by a doctor familiar with this form of

injury or gangrene may result.

3. Turn the front wheel forward on one side of the

traction unit until the top span of the drive chain

is tight.

4. Measure the distance between the bottom of the

chain guard and the lower chain span (Fig. 23).

If the slack in the chain is not within 1–1/2 to

2–1/2 inches (3.8 to 6.35 cm), adjust the tension

(refer to Adjusting the Tension).

HOW TO AV

OID THE HAZARD

• Keep body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid.

• Use cardboard or paper to find hydraulic

leaks, never use your hands.

Servicing

the T

raction Drive

Chains

Checking the Tension

Check the drive chain tension before using the

traction unit for the first time and every 50 hours of

use thereafter.

The drive chains should have about 1–1/2 to 2–1/2

inches (3.8 to 6.35 cm) of slack between the bottom

of the chain guard and the bottom chain span when

the top chain span is pulled tight. Use the following

procedure to check the tension:

1. With the bucket installed, lower it into the

ground until the front tires are off of the ground.

3

1

2

1. Chain

2.

guard

Bottom span of the chain

Figure 23

3.

1–1/2” to 2–1/2”

m–3962

5. Repeat steps 3 and 4 for the other drive chain.

6. Start the engine and raise the bucket to return the

front wheels to the ground.

Adjusting the Tension

1. With the bucket installed, lower it into the

ground until the front tires are off of the ground.

2. Stop the engine and remove the key.

2. Stop the engine and remove the key.

32

3. Loosen the nuts securing the axle retaining

bracket (Fig. 24).

Page 35

Maintenance

4. Loosen the jam nut on the chain tensioning bolt

and loosen the bolt (Fig. 24).

1

2

3

m–3963

1. Axle

2. Nut

retaining bracket

Figure 24

3.

4.

4

Chain tensioning bolt

Jam nut

5. Turn the front wheel on one side of the traction

unit until the upper span of the drive chain is

tight.

6. Adjust the chain tensioning bolt until the

distance between the bottom of the chain guard

and the lower chain span is within 1–1/2 to

2–1/2 inches (3.8 to 6.35 cm) (Fig. 23).

a solution of four parts water and one part baking

soda. Apply a light coating of grease to the battery

terminals to reduce corrosion.

Voltage: 12 v, 380 Cold Cranking Amps

Checking the Electrolyte Level

1. Clean the top of the battery with a paper towel.

2. Lift off the filler caps (Fig. 25).

3. Check the electrolyte level. The electrolyte

should be up to the lower part of the tube

(Fig. 25). Do not allow the electrolyte to get

below the top of the plates (Fig. 25).

4. If the electrolyte is low, add distilled water to

each cell until the level is up to the lower part of

the tube (Fig. 25).

IMPORTANT: Do not overfill the battery

because electr

sever

e corr

olyte (sulfuric acid) can cause

osion and damage to the chassis.

1

7. Position the axle retaining bracket tight against

the axle and the frame, then tighten the jam nut

on the bolt to secure it in place (Fig. 24) and

torque the nut to 30 ft-lbs (40.7 N⋅m).

8. Tighten the nuts securing the axle retaining

bracket and torque them to 90 ft-lbs (122 N⋅m).

9. Repeat steps 3 through 8 for the other drive

chain.

10. Start the engine and raise the bucket to return the

front wheels to the ground.

Servicing

the Battery

Check the electrolyte level in the battery every 100

hours. Always keep the battery clean and fully

charged. Use a paper towel to clean the battery case.

If the battery terminals are corroded, clean them with

1. Filler

2.

caps

Lower part of tube

2

Figure 25

3. Plates

3

5. Press the filler caps onto the battery.

Charging the Battery

IMPORTANT: Keep the battery fully charged

(1.260 specific gravity). This is especially

important to prevent battery damage when

the temperature is below 32°F (0°C).

1. Check the electrolyte level; refer to Checking

Electrolyte Level, page 33.

1262

33

Page 36

Maintenance

2. Remove the filler caps from the battery and

connect a 3 to 4 amp battery charger to the

battery posts.

3. Charge the battery at a rate of 4 amperes or less

for 4 hours (12 volts). Do not overcharge the

battery.

POTENTIAL HAZARD

• Charging the battery pr

WHAT CAN HAPPEN

oduces gasses.

• Battery gasses can explode.

HOW TO AV

OID THE HAZARD

• Keep cigarettes, sparks and flames away

from battery.

4. Install the filler caps after the battery is fully

charged.

3. Service the air cleaner; refer to Servicing the Air

Cleaner, page 25.

4. Grease the traction unit; refer to Greasing and

Lubrication, page 29.

5. Change the engine oil; refer to Servicing the

Engine Oil, page 26.

6. Remove the spark plugs and check their

condition; refer to Servicing the Spark Plugs,

page 28.

7. With the spark plugs removed from the engine,

pour two tablespoons of engine oil into the spark

plug holes.

8. Use the starter to crank the engine and distribute

the oil inside the cylinder.

9. Install the spark plugs, but do not install the

wires on the spark plugs.

10. Check the tire pressure; refer to Tire Pressure,

page 16.

Cleaning

1. Lower the loader arms, stop the engine, and

remove the key.

2. Remove dirt and grime from the external parts of

the entire traction unit, especially the engine.

Clean dirt and chaff from the outside of the

engine’s cylinder head fins and blower housing.

IMPORTANT: You can wash the traction unit

with mild detergent and water. Do not

pressure wash the traction unit. Avoid

excessive use of water

control panel, engine, hydraulic pumps and

motors.

and Storage

, especially near the

11. Charge the battery; refer to Servicing the Battery

page 33.

12. For storage over 30 days, prepare the traction

unit as follows.

A. Add a petroleum based

stabilizer/conditioner to fuel in the tank.

Follow mixing instructions from stabilizer

manufacturer. (1 oz. per gallon). Do not use

an alcohol based stabilizer (ethanol or

methanol).

Note: A fuel stabilizer/conditioner is most

effective when mixed with fresh

gasoline and used at all times.

34

Page 37

B. Run the engine to distribute conditioned

fuel through the fuel system (5 minutes).

C. Stop the engine, allow it to cool and drain

the fuel tank; refer to Draining Fuel Tank,

page 30.

D. Restart the engine and run it until it stops.

E. Choke the engine.

F. Start and run the engine until it will not

start again.

G. Dispose of fuel properly. Recycle as per

local codes.

IMPORTANT: Do not store

stabilizer/conditioned gasoline over 90 days.

13. Check and tighten all bolts, nuts, and screws.

Repair or replace any part that is damaged or

missing.

Maintenance

14. Paint all scratched or bare metal surfaces. Paint

is available from your Authorized Service

Dealer.

15. Store the traction unit in a clean, dry garage or

storage area. Remove the key from the ignition

switch and keep it in a memorable place. Cover

the traction unit to protect it and keep it clean.

35

Page 38

Troubleshooting

g,,

gp

g

PROBLEM

Starter does not crank

Engine will not start, starts hard, or

fails to keep running.

POSSIBLE CAUSES

1.

Auxiliary hydraulics lever is

not in neutral position.

2.

Battery is dead.

3.

Electrical connections are

corroded or loose.

4.

Relay or switch is defective.

1.

Fuel tank is empty

2.

Choke is not ON.

3.

Air cleaner is dirty

4.

Spark plug wires is loose or

disconnected.

5.

Spark plugs are pitted, fouled,

or gap is incorrect.

6.

Dirt in fuel filter

7.

Dirt, water

fuel system.

, or stale fuel is in

. 1.

. 3.

. 6.

CORRECTIVE ACTION

1.

Move lever to neutral

position.

2.

Charge the battery

3.

Check electrical connections

for good contact.

4.

Contact Authorized Service

Dealer.

Fill fuel tank with gasoline.

2.

Move choke lever to ON.

Clean or replace air cleaner

element.

4.

Install wires on spark plug.

5.

Install new

spark plugs.

Replace fuel filter

7.

Contact Authorized Service

Dealer.

, correctly gapped

.

.

Engine loses power

Engine overheats.

Abnormal vibration.

.

1.

Engine load is excessive.

2.

Air cleaner is dirty

3.

Oil level in crankcase is low

4.

Cooling fins and air passages

under engine blower housing

are plugged.

5.

Spark plugs are pitted, fouled,

or gap is incorrect.

6.

Dirt in fuel filter

7.

Dirt, water

fuel system.

1.

Engine load is excessive.

2.

Oil level in crankcase is low

3.

Cooling fins and air passages

under engine blower housing

are plugged.

1.

Engine mounting bolts are

loose.

, or stale fuel is in

. 2.

. 6.

. 3.

. 2.

1.

Reduce ground speed.

Clean air cleaner element.

Add oil to crankcase.

4.

Remove obstruction from

cooling fins and air passages.

5.

Install new

spark plugs.

Replace fuel filter

7.

Contact Authorized Service

Dealer.

1.

Reduce ground speed.

Add oil to crankcase.

3.

Remove obstruction from

cooling fins and air passages.

1. T

ighten engine mounting

bolts.

, correctly gapped

.

36

Page 39

Troubleshooting

PROBLEM

Machine does not drive.

When at rest, loader arms creep

downward more than 3” per hour

(less than 3” an hour is normal for

this machine).*

When at rest, loader arms settle

downward 2” quickly and then

stop.*

POSSIBLE CAUSES

1.

Flow divider valve lever is in

9 o’clock position.

2.

Hydro fluid level low

3. T

raction pump drive coupler

is loose or broken.

4.

Pump and/or wheel motor is

defective or damaged.

5.

Control valve is defective or

damaged.

6.

Relief valve is defective or

damaged.

1. V

alve spool leakage

1.

Cylinder seals are leaking

2.

Cylinder rephase valve is

leaking

CORRECTIVE ACTION

1.

Move lever to the 12 to 10

o’clock position.

.

2.

Add hydro fluid to reservoir

3.

Contact Service Dealer

4.

Contact Service Dealer

Contact Service Dealer

5.

6.

Contact Service Dealer

1.

Contact Service Dealer

1.

Replace seals.

2.

Contact Service Dealer

.

.

.

.

.

.

.

* Tested with warm oil and no more than 515 lbs in the bucket. Measure the downward drop at the attachment

lock pins on the back of the mount plate.

37

Page 40

T

The Toro Company warrants your Toro SiteWorkT Systems Product (“Product”) to be free from defects in

materials

repair

on

or workmanship for the period of time listed below

the Product at no cost to you including diagnosis, labor

. Where a warrantable condition exists, T

, parts, and transportation. This warranty begins

the date the Product is delivered to the original retail purchaser

oro will

.

Warranty

Owner

Responsibilities:

As the Product owner, you are responsible for required

maintenance and adjustments stated in your Owner’s

Manual. Failure to perform required maintenance and

adjustments can be grounds for disallowing a warranty

claim.

Instructions for Obtaining W

You

are responsible for notifying the T

Distributor

from whom you purchased the Product as soon as you

believe

If you need help locating a Toro SiteWorkT Systems

Distributor or Authorized Dealer, or if you have questions

regarding

contact us at:

Maintenance

Parts

(“Maintenance

up

or Authorized T

a warrantable condition exists.

your warranty rights or

oro LCE Division

T

811

1 L

yndale A

Minneapolis, MN, 55420–1

elephone: (612) 888–8801

T

Facsimile: (612) 887–8258

Parts:

scheduled for replacement as required

Parts”), are warranted

to the scheduled replacement time for that part.

Duration: One year or 500 operational hours, whichever occurs first.

arranty Service:

oro SiteW

venue South

oro SiteW

orkT

responsibilities, you may

196

for the period of time

ork Systems

Systems

maintenance

Dealer

Items/Conditions Not Covered:

Not

all product failures or malfunctions that occur during the

warranty period are defects in materials or workmanship.

The