Toro 22303TE Operator's Manual

Form No. 3323-446

Dingo

320-D

Traction Unit

Model Number 22303TE—990001 & Up

Operator’s Manual

International English (GB)

Introduction

Thank you for purchasing a Toro product.

All of us at Toro want you to be completely satisfied

with your new product, so feel free to contact your

local Authorized Service Dealer for help with service,

genuine replacement parts, or other information you

may require.

Whenever you contact your Authorized Service

Dealer or the factory, always know the model and

serial numbers of your product. These numbers will

help the Service Dealer or Service Representative

provide exact information about your specific

product. The two numbers are stamped into a plate

mounted on the left rear side of the frame.

For your convenience, write the product model and

serial numbers in the space below.

Model No:

Serial No.

Read this manual carefully to learn how to operate

and maintain your product correctly. Reading this

manual will help you and others avoid personal injury

and damage to the product. Although we design,

produce and market safe, state-of-the-art products,

you are responsible for using the product properly

and safely. You are also responsible for training

persons, who you allow to use the product, about safe

operation.

The warning system in this manual identifies

potential hazards and has special safety messages that

help you and others avoid personal injury, even death.

DANGER, WARNING and CAUTION are signal

words used to identify the level of hazard. However,

regardless of the hazard, be extremely careful.

DANGER signals an extreme hazard that will cause

serious injury or death if the recommended

precautions are not followed.

WARNING signals a hazard that may cause serious

injury or death if the recommended precautions are

not followed.

CAUTION signals a hazard that may cause minor or

moderate injury if the recommended precautions are

not followed.

The Toro Company – 1999

8111 Lyndale Ave. South

Bloomington, MN 55420–1196

Two other words are also used to highlight

information. “Important” calls attention to special

mechanical information and “Note” emphasizes

general information worthy of special attention.

The left and right side of the machine is determined

by standing on the platform in the normal operator’s

position.

All Rights Reserved

Printed in the USA

Contents

Page

Safety 2.

Assembly 8

Specifications 11

Before Operating 13

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Safe Operating Practices 2

Sound Pressure Level 4

Sound Power Level 4

Vibration Level 4

Slope Chart 5

Safety and Instruction Decals 6

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Loose Parts 8

Installing the Valve Lever 8

Activating the Battery 8

. . . . . . . . . . . . . . . . . . . . . . . . . . .

Attachments 11

Stability Data 12

Adding Fuel 13

Draining Water from the Fuel Filter 14

Checking the Oil Level 14

Checking the Cooling System 15

Removing Debris from the Traction Unit 15

Checking the Hydraulic Fluid 16

Tire pressure 16

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . . .

. . . . .

. . . . . . . . . . . . . . .

. . . . . . . . . .

.

. . . . . . . . . .

Page

Operation 18

Maintenance 27

Troubleshooting 38

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Traction Unit Overview 18

Controls 19

Indicator Lights 21

Starting and Stopping the Engine 22

Driving Forward or Backward 22

Stopping the Traction Unit 23

Moving a Non-functioning Traction Unit 23

Using the Cylinder Locks 23

Installing and Removing Attachments 24

Securing the Traction Unit for Transport 26

Service Interval Chart 27

Testing the Parking Brake 28

Opening the Access Covers28. . . . . . . . . . . .

Servicing the Air Cleaner 29

Servicing the Engine Oil 30

Greasing the Traction Unit 31

Changing the Fuel Filter 32

Bleeding the Fuel System 33

Draining the Fuel Tank 33

Servicing the Hydraulic System 34

Servicing the Battery 35

Cleaning and Storage 36

. . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . .

. . . . . . . . . .

. . . . . . . . . . . . .

.

. . . . . . . . . . . . .

. . . .

. .

. . . . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . .

. . . . . . . . . . . . .

. . . . . . . . . . . . . . .

. . . . . . . . .

. . . . . . . . . . . . . . . . .

. . . . . . . . . . . . . . . . .

1

Safety

Improper use or maintenance by the operator or

owner can result in injury. To reduce the potential

for injury, comply with these safety instructions

and always pay attention to the safety alert

symbol, which means CAUTION, WARNING, or

DANGER—“personal safety instruction.” Failure

to comply with the instruction may result in

personal injury or death.

Safe

This product is capable of amputating hands and feet.

Always follow all safety instructions to avoid serious

injury or death.

Operating Practices

General Operation

• Read, understand, and follow all instructions in

the operator’s manual and on the traction unit

before starting. Also, read all attachment

manuals where supplied

• Allow only responsible adults who are familiar

with the instructions to operate the traction unit.

• Slow down before turning. Sharp turns on any

terrain may cause loss of control.

• Never leave a running traction unit unattended.

Always lower the loader arms, stop the engine,

and remove the key before dismounting.

• Do not exceed the rated operating capacity, as

the traction unit may become unstable which

may result in loss of control.

• Do not carry a load with the arms raised. Always

carry loads close to the ground. Do not step off

of the platform with the load raised.

• Do not over-load the attachment and always

keep the load level when raising the loader arms.

Logs, boards, and other items could roll down

the loader arms, injuring you.

• Never jerk the control levers; use a steady

motion.

• Keep your hands, feet, hair, and loose clothing

away from any moving parts.

• Operate only in daylight or good artificial light.

•

Always wear long pants and substantial shoes.

Wearing safety glasses, safety shoes, hearing

protection, and a hard hat are advisable and may

be required by some local ordinances and

insurance regulations.

• Ensure that the area is clear of other people

before operating the traction unit. Stop the

traction unit if anyone enters the area.

• Never carry passengers on attachments or on the

traction unit.

• Always look down and behind before and while

backing.

• Do not place your feet under the platform.

2

• Do not operate the traction unit while under the

influence of alcohol or drugs.

• Watch for traffic when operating near or crossing

roadways.

• Use extra care when loading or unloading the

traction unit onto a trailer or truck.

• Do not touch parts which may be hot from

operation. Allow them to cool before attempting

to maintain, adjust, or service.

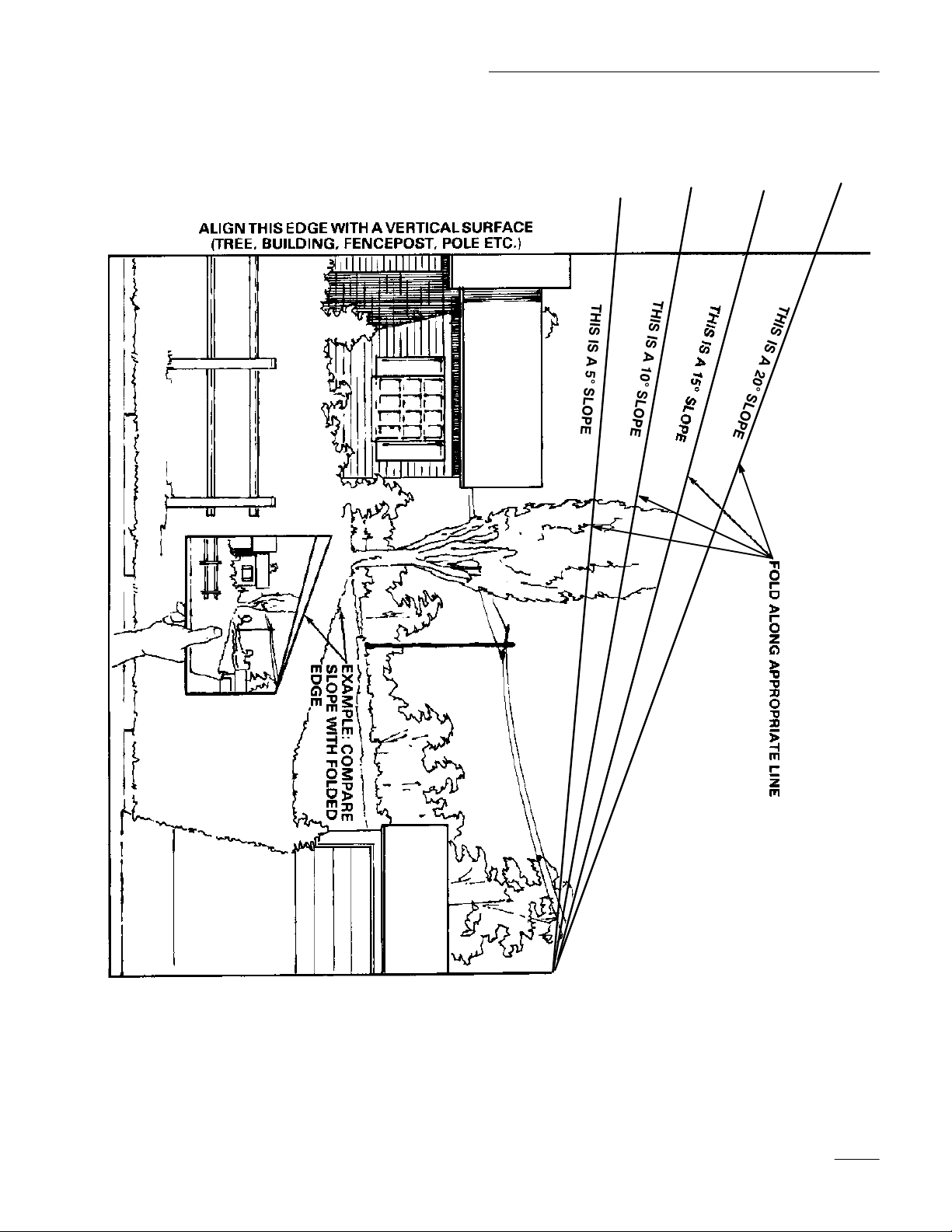

Slope Operation

Slopes are a major factor related to loss-of-control

and tip-over accidents, which can result in severe

injury or death. All slopes require extra caution.

Safety

• Do not operate the traction unit on hillsides or

slopes exceeding the angles recommended in the

Stability Data section, page 12, and those in the

attachment operator’s manual. See also the

slope chart on page 5.

• Operate up and down slopes with the heavy

end of the traction unit uphill. Weight

distribution changes. An empty bucket will make

the rear of the traction unit the heavy end, and a

full bucket will make the front of the traction

unit the heavy end. Most other attachments will

make the front of traction unit the heavy end.

• Raising the loader arms on a slope will affect the

stability of the machine. Whenever possible,

keep the loader arms in the lowered position

when on slopes.

• Removing an attachment on a slope will make

the rear of the traction unit heavy. Refer to the

Stability Data section, page 12, to determine

whether the attachment can be safely removed

on the slope.

• Remove obstacles such as rocks, tree limbs, etc.

from the work area. Watch for holes, ruts, or

bumps, as uneven terrain could overturn the

traction unit. T

all grass can hide obstacles.

• Use slow speed on slopes. Before starting the

engine, put the pump selector lever in the slow

(turtle) position so that you will not have to stop

or shift while on the slope.

• Avoid starting or stopping on a slope. If tires

lose traction, proceed slowly, straight down the

slope.

• Check for overhead clearances (i.e. branches,

doorways, electrical wires) before driving under

any objects and do not contact them.

• Avoid turning on slopes. If you must turn, turn

slowly and keep the heavy end of the traction

unit uphill.

• Do not operate near drop-offs, ditches, or

embankments. The traction unit could suddenly

turn over if a wheel goes over the edge of a cliff

or ditch, or if an edge caves in.

• Do not operate on wet grass. Reduced traction

could cause sliding.

• Do not park the traction unit on a hillside or

slope without lowering the attachment to the

ground and chocking the wheels.

• Do not try to stabilize the traction unit by putting

your foot on the ground.

Children

Tragic accidents can occur if the operator is not alert

to the presence of children. Children are often

attracted to the traction unit and the work activity.

Never assume that children will remain where you

last saw them.

• Follow the recommendations in the attachment

manuals for the use of counterweights to

improve stability.

• Use only Toro approved attachments.

Attachments can change the stability and the

operating characteristics of the traction unit.

Warranty may be voided if used with

unapproved attachments.

• Keep all movements on slopes slow and gradual.

Do not make sudden changes in speed or

direction.

• Keep children out of the work area and under the

watchful care of another responsible adult.

• Be alert and turn the traction unit off if children

enter the area.

• Before and while backing, look behind and down

for small children.

• Never carry children. They may fall off and be

seriously injured or interfere with safe traction

unit operation.

• Never allow children to operate the traction unit.

3

Safety

• Use extra care when approaching blind corners,

shrubs, trees, the end of a fence, or other objects

that may obscure vision.

Service

• Stop the engine before performing any service,

repairs, maintenance, or adjustments.

• If any maintenance or repair requires the loader

arms to be in the raised position, secure the arms

in the raised position with the hydraulic cylinder

locks included with traction unit.

• Never run a traction unit inside a closed area.

• Keep nuts and bolts tight. Keep equipment in

good condition.

• Never tamper with safety devices. Check safety

systems for proper operation before each use.

• Keep the traction unit free of grass, leaves, or

other debris build-up. Clean up oil or fuel

spillage. Allow the traction unit to cool before

storing.

• Use extra care when handling fuel. It is

flammable and vapors are explosive.

• Stop and inspect the equipment if you strike an

object. Make any necessary repairs before

restarting.

• Use only genuine replacement parts to ensure

that original standards are maintained.

• Battery acid is poisonous and can cause burns.

Avoid contact with skin, eyes, and clothing.

Protect your face, eyes, and clothing when

working with a battery.

• Battery gases can explode. Keep cigarettes,

sparks and flames away from the battery.

• Keep your body and hands away from pin hole

leaks or nozzles that eject high pressure

hydraulic fluid. Use cardboard or paper to find

hydraulic leaks. Hydraulic fluid escaping under

pressure can penetrate skin and cause injury

requiring surgery within a few hours by a

qualified surgeon or gangrene may result.

Sound

This unit has a sound pressure at the operator’s ear of

97 dB(A), based on measurements of identical

machines per Directive 81/1051/EEC.

Pressure Level

• Use only an approved container.

• Never remove the fuel cap or add fuel when

the engine is running. Allow the engine to

cool before refueling. Do not smoke.

• Never refuel the traction unit indoors.

• Never store the traction unit or fuel

container inside where there is an open

flame, such as near a water heater or

furnace.

• Never fill a container while it is inside a

vehicle, trunk, pick–up bed, or any surface

other than the ground.

• Keep container nozzle in contact with the

tank during filling.

Sound

This unit has a sound power level of 105 LwA, based

on measurements of identical machines per Directive

84/538/EEC.

Vibration

This unit has a maximum hand-arm vibration level of

0.5 m/s2 and whole–body vibration level of 0.1 m/s

based on measurements of identical machines per EN

1033 and EN 1032.

Power Level

Level

2

4

Safety

Slope

Chart

5

Safety

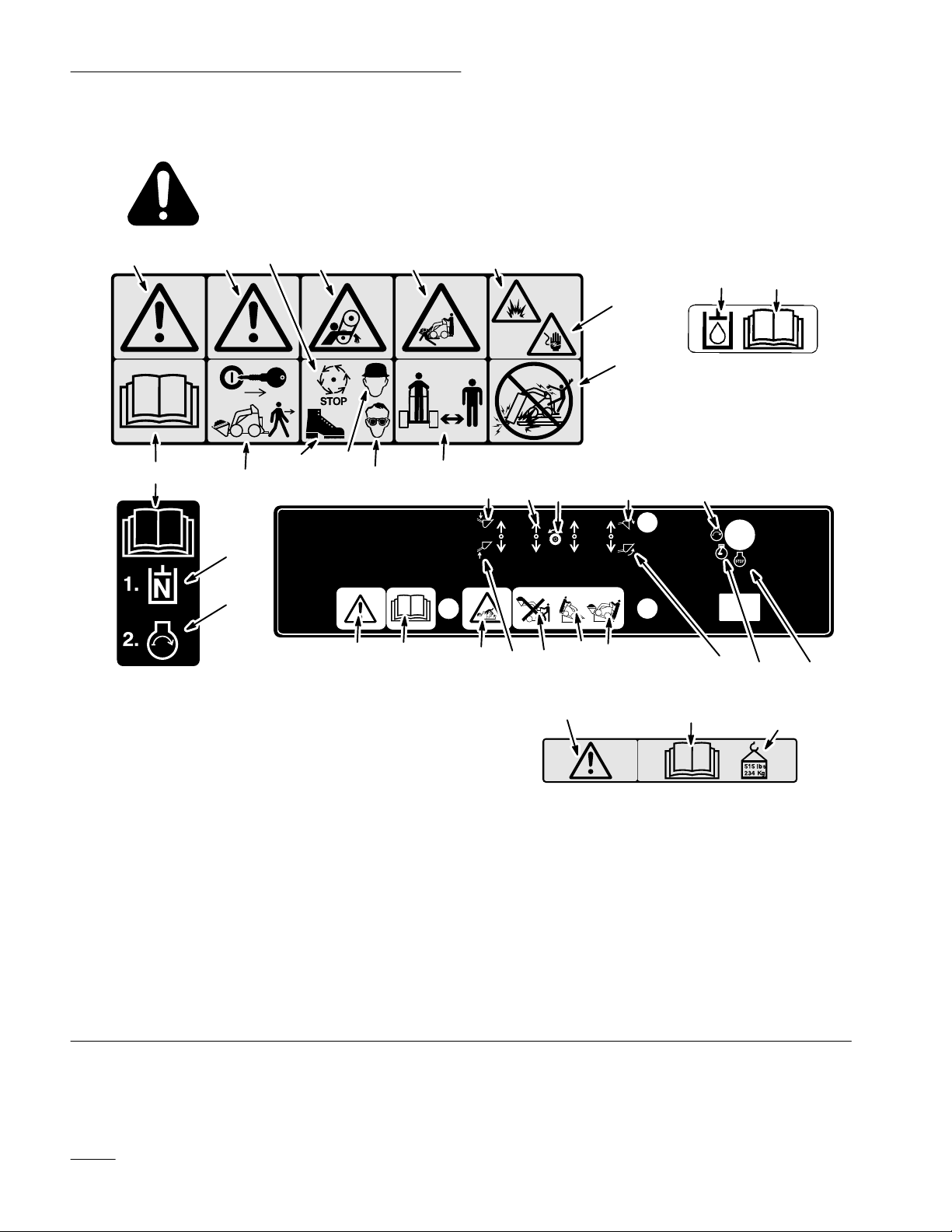

Safety and Instruction Decals

Safety decals and instructions are easily visible to the operator and are located near

any area of potential danger. Replace any decal that is damaged or lost.

1

2

# 100–1704

1 3 4 5

9

10

8

11

12

13

18

19

# 100–1706

1 2

20

26

2

6

7

# 93–6686

# 100–1701

22

17

19

2

25

D

C

28 29

27

16

1514

321

F

R

21

23

24

1

1. Safety

2.

3.

4.

5.

6.

7.

8.

alert symbol

Read the operator’s manual

Entanglement hazard

Crushing hazard

Explosion hazard

Electric shock hazard

Do not dig in areas with

buried gas or power lines

Shut of

f engine and remove

key before leaving the

operator’

s position

6

9. W

ait for moving parts to stop

10. W

ear protective foot wear

11. W

ear a protective hard hat

12. W

ear eye protection

13.

Keep bystanders away from

the work area

14.

Lower attachment

15.

Lever movement indicator

16. T

raction drive

Figure 1

17. T

18.

19.

20. T

21.

22.

# 100–1702

ilt attachment down

Shift the auxiliary hydraulics

lever into neutral

Start the engine

ipping hazard–exceeding

rated load capacity can

cause instability

Keep a full load uphill

Keep an empty load downhill

23.

Do not step of

operator platform with a

raised load

24.

Raise attachment

25. T

ilt attachment up

26.

Hydraulic oil only

27.

Maximum load capacity

28.

Run the engine

29.

Stop the engine

f of the

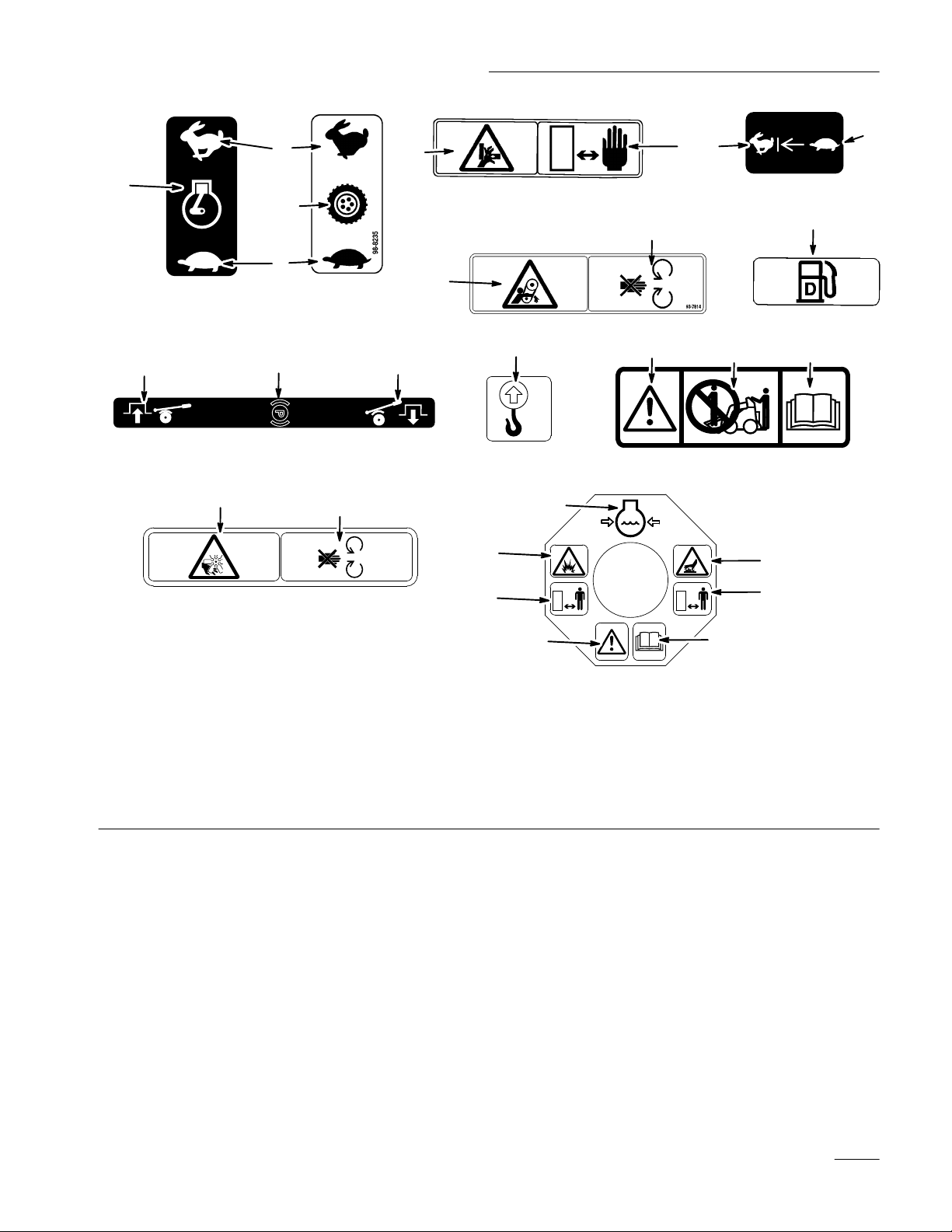

Safety

16

# 98–8219

14

# 100–1692

17

1

2

3

# 98–8235

9

5

4

# 93–9367

7

1

#

100–1703

8

3

6

# 93–7814

10

15

# 93–9084

7

18

11

12 13

# 99–3088

# 93–6680

# 93-7840

19

21

1. Fast

2. Traction

3. Slow

4.

5.

drive

Pinch point–crushing of

fingers or hands

Keep hands away

# 93–6681

6.

7. Stay

8. Use

9.

10.

11.

Entanglement hazard

away

from moving parts

only diesel fuel

Parking brake

Lift Point

Safety alert symbol

20

Figure 2

12.

13.

14.

15.

16.

17.

11

No riders

Read the operator’s manual

Brake on

Brake of

f

Engine speed

Cutting hazard—moving fan

20

13

18.

Coolant under pressure

19.

Explosive hazard—Coolant

is pressurized when hot

20.

Stay away and do not open

when hot

21.

Burn hazard—Radiator and

coolant gets very hot.

7

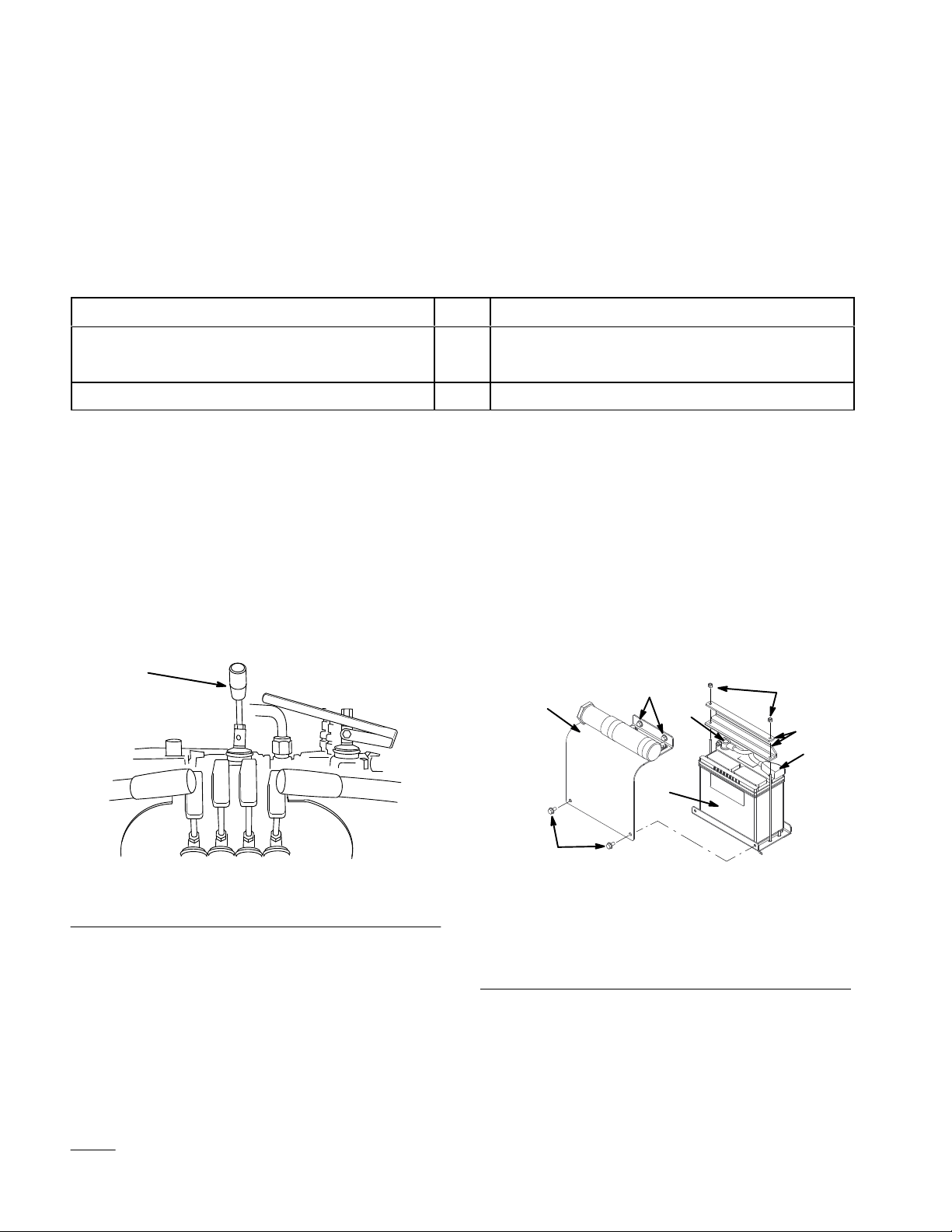

Assembly

Loose

Parts

Note: Use the chart below to verify that all parts have been shipped.

DESCRIPTION QTY. USE

T

raction Unit

V

alve Lever

Key 2

Installing

the V

alve Lever

1. Thread the lever into the pump selector valve

(Fig. 3).

1

1

Install valve lever

Start engine

Activating

the Battery

The traction unit is shipped with a dry battery. Bulk

electrolyte with 1.260 specific gravity must be

purchased from a local battery supply outlet.

Note: The lever should be installed with the

bend toward the operator.

1. Remove the four bolts securing the battery cover

and remove the cover (Fig. 4)

2. Tighten the jam nut on the lever to lock it in

position.

2. Remove the nuts and bars securing the battery

(Fig. 4).

1

1

2

7

5

4

6

1. Pump

8

selector lever

Figure 3

m–3883

1. Battery

2. Bolt

3. Battery

4. Bars

2

cover

3

Figure 4

5. Nut

6.

Positive cable

7.

Negative cable

m–4391

3. Lift the battery off of its platform.

Assembly

4

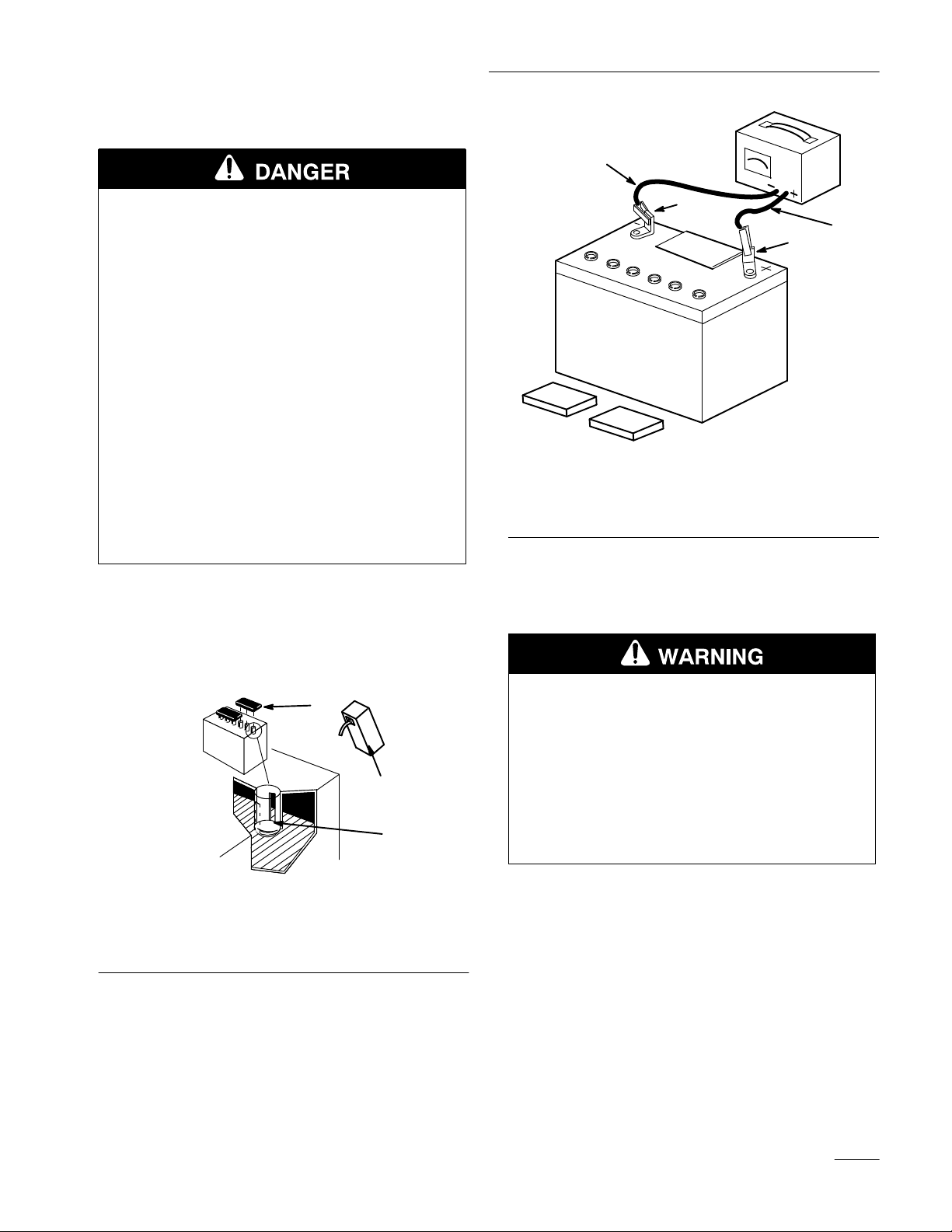

POTENTIAL HAZARD

• Battery electrolyte contains sulfuric acid

which is a deadly poison and it causes

severe burns.

WHAT CAN HAPPEN

• If you drink electrolyte you could die, or if

it gets onto your skin you will be burned.

HOW TO AV

OID THE HAZARD

• Do not drink electrolyte and avoid contact

with skin, eyes or clothing. Wear safety

glasses to shield your eyes and rubber

gloves to protect your hands.

• Fill the battery where clean water is always

available for flushing the skin.

• Follow all instructions and comply with all

safety messages on the electrolyte container.

4. Remove the filler caps from the battery.

5. Slowly pour electrolyte into each cell until the

electrolyte level is up to the lower part of the

tube (Fig. 5).

2

3

1

1254

Figure 6

1. Positive

2.

post

Negative post

3.

Charger red (+) wire

4.

Charger black (–) wire

7. Charge the battery at a rate of 4 amperes or less

for 4 hours (12 volts).

1

2

3

1262

Figure 5

1. Filler

2. Electrolyte

caps

Lower part of the tube

3.

6. Leave the covers off and connect a 3 to 4 amp

battery charger to the battery posts (Fig. 6).

POTENTIAL HAZARD

• Charging the battery pr

oduces gasses.

WHAT CAN HAPPEN

• Battery gasses can explode.

HOW TO AV

OID THE HAZARD

• Keep cigarettes, sparks, and flames away

from the battery.

8. When the battery is fully charged, disconnect the

charger from the electrical outlet and from the

negative and positive battery posts (Fig. 6).

9. Slowly pour electrolyte into each cell until the

level is once again up to the upper line on the

battery case (Fig. 5) and install the covers.

9

Assembly

10. Install the battery onto its platform (Fig. 4).

11. Secure the battery in the chassis with the bars

and nuts removed previously (Fig. 4).

12. Connect the positive (red) cable to the

positive (+) battery post (Fig. 4). Slide the

rubber cover over the battery post.

13. Connect the negative (black) cable to the

negative (–) battery post (Fig. 4).

Note: Ensure that the battery cables do not

contact any sharp edges or each other.

14. Install the battery cover (Fig. 4).

10

Specifications

Note: Specifications and design are subject to change without notice.

Width

Length

Height

Weight

Operating capacity (with a 200 lb operator)

T

ipping capacity (with a 200 lb operator)

Wheelbase

Dump height (with standard bucket)

Reach—fully raised (with the standard bucket)

Height to hinge pin (with the standard bucket fully raised)

Attachments

Many attachments are available for use with the

traction unit. These attachments allow you to to

perform many different functions with the traction

unit such as hauling materials, digging holes, grading,

and more. Contact your Toro dealer for a list of all

approved SiteW

accessories.

ork Systems attachments and

40.5 inches (103 cm)

60 inches (152 cm)

49 inches (125 cm)

1722 lbs (781 Kg)

515 lbs (234 Kg)

1030 lbs (467 Kg)

28 inches (71 cm)

48.75 inches (124 cm)

26 inches (66 cm)

66 inches (168 cm)

IMPORTANT: Use only Toro approved

attachments.

11

Check Before Operating

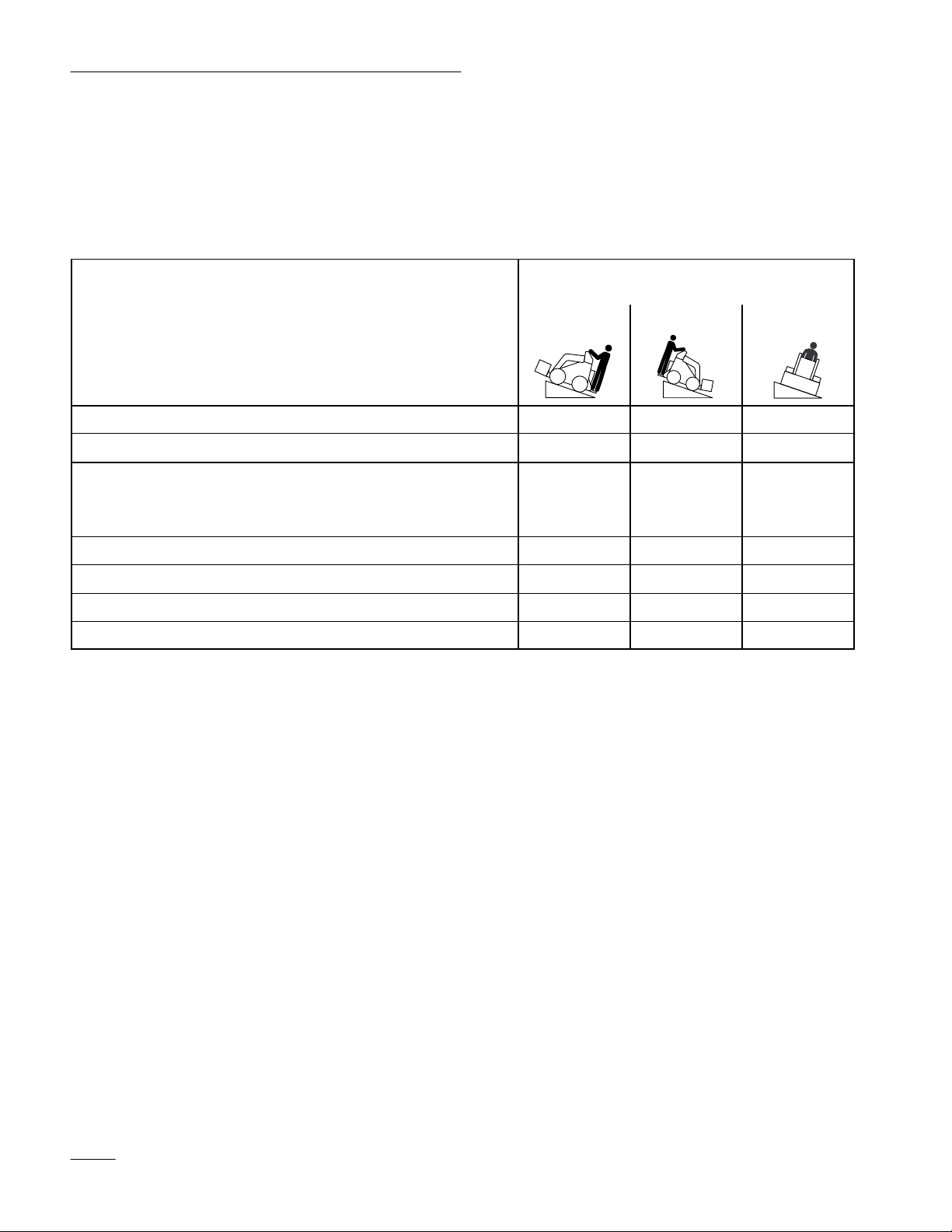

Stability

Data

The following table lists the maximum slope recommended for the traction unit in the positions listed in the

table. Slopes over the listed degree may cause the traction unit to become unstable. The data in the table

assumes that the loader arms are fully lowered and that the factory installed tires are on the traction unit, inflated

to the recommended pressure; raised arms and other tire types or pressure may affect the stability.

Maximum Recommended Slope

when Operating with:

Front Uphill

Configuration

T

raction unit without attachment

T

raction unit with counterweight, without attachment

T

raction unit with an attachment rated with one of the following

stability ratings for each slope position:*

A 25° 25° 20°

B 18° 19° 18°

7° 20° 17°

5° 21° 17°

Rear Uphill

Side Uphill

C 15° 16° 14°

D 10° 10° 9°

E 5° 5° 5°

* In each attachment manual is a set of three stability ratings, one for each hill position. To determine the

maximum slope you can traverse with the attachment installed, find the degree of slope that corresponds to the

stabilities ratings of the attachment.

Example: If the attachment installed on the traction unit has a Front Uphill rating of B, a Rear Uphill rating of

D, and a Side Uphill rating of C, then you could drive forward up a 18

° slope, rearward up a 10° slope, or

sideways on a 14° slope, as listed in the above table.

12

Loading...

Loading...