FormNo.3442-386RevB

e-Dingo500CompactToolCarrier

ModelNo.22218—SerialNo.407100000andUp

ModelNo.22218G—SerialNo.400000000andUp

Registeratwww.T oro.com.

OriginalInstructions(EN)

*3442-386*

ThisproductcomplieswithallrelevantEuropean

directives;fordetails,pleaseseetheseparateproduct

specicDeclarationofConformity(DOC)sheet.

WARNING

CALIFORNIA

Proposition65Warning

Thepowercordonthisproductcontains

lead,achemicalknowntotheState

ofCaliforniatocausebirthdefects

orotherreproductiveharm.Wash

handsafterhandling.

Batteryposts,terminals,andrelated

accessoriescontainleadandlead

compounds,chemicalsknownto

theStateofCaliforniatocause

cancerandreproductiveharm.Wash

handsafterhandling.

Useofthisproductmaycauseexposure

tochemicalsknowntotheStateof

Californiatocausecancer,birthdefects,

orotherreproductiveharm.

Important:Withyourmobiledevice,youcan

scantheQRcodeontheserialnumberdecal(if

equipped)toaccesswarranty,parts,andother

productinformation.

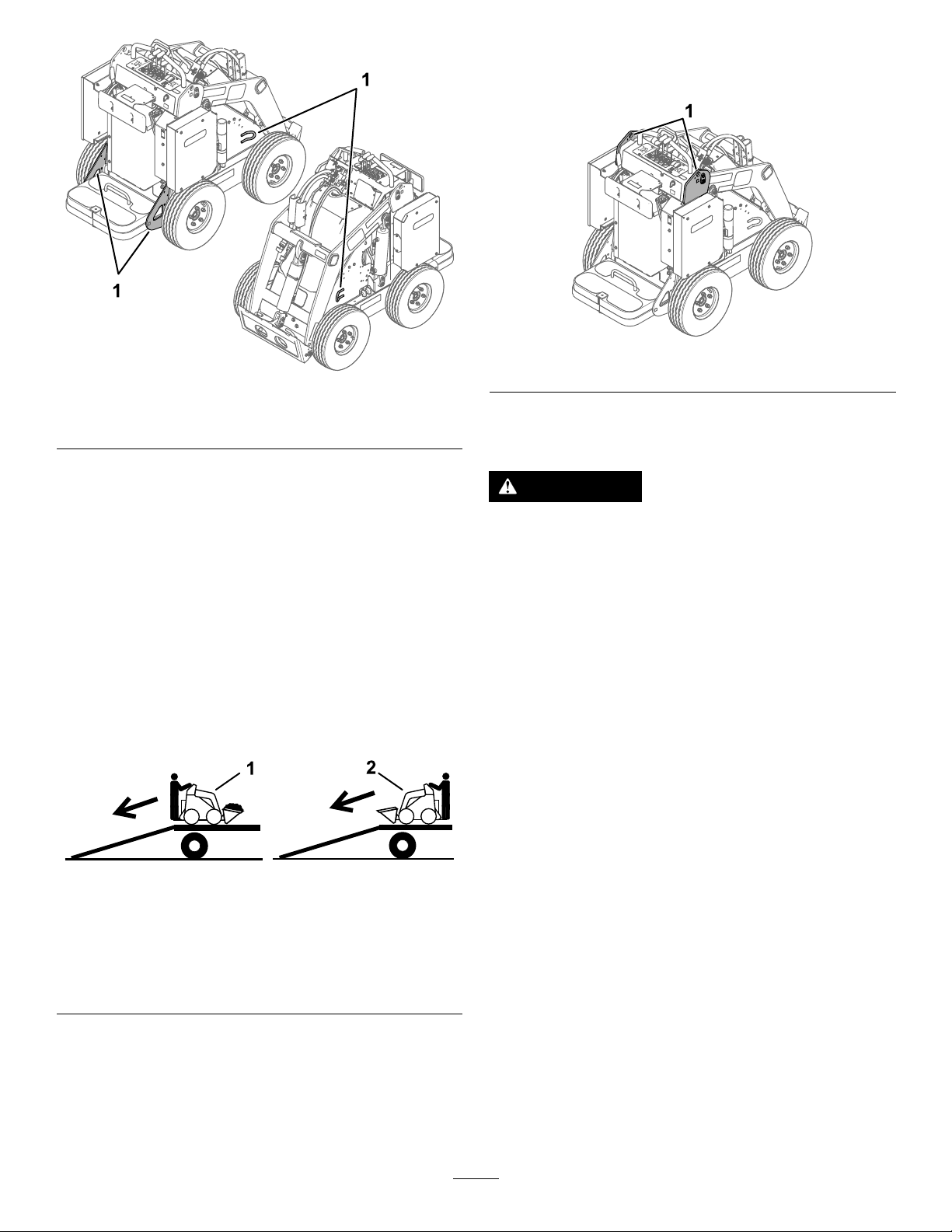

g311261

Figure1

1.Modelandserialnumberlocation

Introduction

Thismachineisacompacttoolcarrierintendedfor

useinvariousearthandmaterialsmovingactivitiesfor

landscapingandconstructionwork.Itisdesignedto

operateawidevarietyofattachments,eachofwhich

performsaspecializedfunction.Usingthisproduct

forpurposesotherthanitsintendedusecouldprove

dangeroustoyouandbystanders.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoid

injuryandproductdamage.Youareresponsiblefor

operatingtheproductproperlyandsafely .

Visitwww.T oro.comforproductsafetyandoperation

trainingmaterials,accessoryinformation,helpnding

adealer,ortoregisteryourproduct.

Wheneveryouneedservice,genuineToroparts,or

additionalinformation,contactanAuthorizedService

DealerorToroCustomerServiceandhavethemodel

andserialnumbersofyourproductready.Figure1

identiesthelocationofthemodelandserialnumbers

ontheproduct.Writethenumbersinthespace

provided.

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

©2021—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafetyandInstructionalDecals..........................4

Setup........................................................................8

1CheckingtheHydraulicFluidLevel..................8

2ChargingtheBatteries.....................................8

ProductOverview.....................................................9

Controls.............................................................9

InfoCenterDisplay........................................10

Specications..................................................13

Attachments/Accessories.................................13

BeforeOperation.................................................13

BeforeOperationSafety...................................13

PerformingDailyMaintenance..........................14

AdjustingtheThighSupport..............................14

DuringOperation.................................................14

DuringOperationSafety...................................14

StartingtheMachine.........................................16

DrivingtheMachine..........................................16

PowerSaveMode............................................16

ShuttingOfftheMachine..................................16

UsingAttachments...........................................16

UsingtheInfoCenter.........................................18

AfterOperation....................................................19

AfterOperationSafety......................................19

MovingaNon-FunctioningMachine..................21

HaulingtheMachine.........................................21

LiftingtheMachine...........................................23

MaintainingtheBatteries..................................23

TransportingtheBatteries.................................24

UsingtheBatteryCharger................................24

Maintenance...........................................................27

MaintenanceSafety..........................................27

RecommendedMaintenanceSchedule(s)...........27

Pre-MaintenanceProcedures..............................28

UsingtheCylinderLocks..................................28

AccessingInternalComponents.......................29

DisconnectingtheMainPower..........................30

Lubrication..........................................................31

GreasingtheMachine.......................................31

ElectricalSystemMaintenance...........................32

ElectricalSystemSafety...................................32

DisconnectingorConnectingPowertothe

Machine........................................................32

ReplacingtheStaticStrap................................32

ServicingtheBatteries......................................32

MaintainingtheBatteryCharger.......................32

ServicingtheFuse............................................33

DriveSystemMaintenance..................................33

CheckingtheTireTreads..................................33

CheckingtheWheel-LugNuts..........................33

BrakeMaintenance.............................................34

TestingtheParkingBrake.................................34

HydraulicSystemMaintenance...........................34

HydraulicSystemSafety...................................34

RelievingHydraulicPressure............................34

HydraulicFluidSpecications...........................35

CheckingtheHydraulic-FluidLevel...................35

ReplacingtheHydraulicFilter...........................36

ChangingtheHydraulicFluid............................36

Cleaning..............................................................37

RemovingDebris..............................................37

WashingtheMachine.......................................37

Storage...................................................................37

StorageSafety..................................................37

StoringtheMachine..........................................37

BatteryStorageRequirements.........................38

Troubleshooting......................................................39

3

Safety

bucketmakesthefrontofthemachinetheheavy

end.Mostotherattachmentsmakethefrontofthe

machinetheheavyend.

GeneralSafety

DANGER

Theremaybeburiedutilitylinesinthework

area.Diggingintothemmaycauseashock

oranexplosion.

Havethepropertyorworkareamarkedfor

buriedlinesanddonotdiginmarkedareas.

Contactyourlocalmarkingserviceorutility

companytohavethepropertymarked(for

example,intheUS,call811orinAustralia,

call1100forthenationwidemarkingservice).

Alwaysfollowallsafetyinstructionstoavoidserious

injuryordeath.Usingthisproductforpurposesother

thanitsintendedusecouldprovedangeroustoyou

andbystanders.

•Donotcarryaloadwiththearmsraised;always

carryloadsclosetotheground.

•Slopesareamajorfactorrelatedtoloss-of-control

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphillandtheload

closetotheground.Weightdistributionchanges

withattachments.Anemptybucketmakesthe

rearofthemachinetheheavyend,andafull

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas.

•ReadandunderstandthecontentofthisOperator’s

Manualbeforestartingthemachine.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Neverallowchildrenoruntrainedpeopleto

operatethemachine.

•Keepyourhandsandfeetawayfromthemoving

componentsandattachments.

•Donotoperatethemachinewithouttheguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepbystandersandchildrenoutoftheoperating

area.

•Stopthemachine,shutoffthemachine,and

removethekeybeforeservicingorunclogging

themachine.

Improperlyusingormaintainingthismachinecan

resultininjury.T oreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

,which

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyarea

ofpotentialdanger.Replaceanydecalthatisdamagedormissing.

93-6686

1.Hydraulicuid2.ReadtheOperator's

Manual.

decal93-6686

decal93-9084

93-9084

1.Liftpoint/Tie-downpoint

4

1.Warning—wearhearingprotection.

decal98-4387

98-4387

decal132-9051

132-9051

1.Tie-downpoint

decal133-8061

133-8061

108-4723

1.Auxiliaryhydraulics

2.Lockedreverse(detent)

3.Neutral(off)

4.Forward

130-2836

1.Crushinghazardfromabove;cuttinghazardofthe

hand—keepawayfromtheattachmentandtheliftarm.

130-2837

decal108-4723

decal137-9712

137-9712

1.Warning—readthe

Operator’sManual.

2.Warning—keepat

temperaturesbelow65°C

(149°F).

decal130-2836

decal130-2837

3.Explosionhazard—donot

openthebattery;donot

useadamagedbattery.

4.Warning—readthe

Operator’sManual

forbatterycharging

information.

1.Warning—donotcarrypassengersinthebucket.

5

decal139-7709

139-7709

1.Waterlevel2.Attention—readthe

Operator’sManual.

decal139-7707

139-7707

1.Parking

2.Parkingbrake—engaged

139-7717

decal139-7717

brake—disengaged

decal139-7718

139-7718

1.Warning—Disconnectthepower,stopthemachine,read

theOperator’sManual.

139-7708

1.Crushinghazardfromabove,fallingload—ensurethatthe

quick-attachleversarelocked.

decal139-7708

decal139-7721

139-7721

1.Warning—readtheOperator’sManualbeforeperforming

batterymaintenance;donotoperatethemachinewhen

thebatterychargerisconnected;disconnectthebattery

chargerbeforeoperatingthemachine.

6

139-7738

> -5° C

> 23° F

139-7738

1.Keepthebatteryattemperaturesabove-5°C(23°F);

readtheOperator’sManual;slidethecoverupandpivotit

sidewaystoaccessthebatterychargingport,donotuse

awrench.

decal139-8343

139-8343

1.RecyclableLithium-Ion3.Electricshockhazard

2.Donotdiscardimproperly.4.Firehazard

decal139-7738

decal137-9713

137-9713

1.Warning—readtheOperator'sManual.5.Explosionhazard—avoidsparks;nore,openames,or

2.Warning—keepoutoftherainandotherwetconditions.6.Asphyxiationhazard,poisonousfumesortoxicgases—donot

3.Warning—donottouchthehotsurface.7.Electricshockhazard—donotperformmaintenanceonthe

4.Warning—donotopenthebattery;donotuseadamaged

battery.

smoking.

chargethebatteryinanenclosedspace.

battery.

139-7660

1.Warning—readtheOperator’sManual.

2.Warning—alloperatorsshouldbetrainedbeforeoperating

themachine.

3.Warning—keepbystandersaway.

4.Tippinghazard—donotdrivethemachinewiththeload

raised;positiontheheavyendofthemachineuphillwhen

drivingonaslope.

5.Lowertheattachment.

6.Raisetheattachment.

7.Tractioncontrols

8.Tilttheattachmentdown.

9.Titletheattachmentup.

10.Ecomode—On

11.Ecomode—Off

12.InchMode—On

13.InchMode—Off

14.On

15.Off

decal139-7660

7

Setup

1

CheckingtheHydraulic

FluidLevel

NoPartsRequired

Procedure

Beforestartingthemachineforthersttime,check

thehydraulic-uidlevel;refertoCheckingthe

Hydraulic-FluidLevel(page35).

2

ChargingtheBatteries

NoPartsRequired

Procedure

Chargethebatteries;refertoChargingtheBatteries

(page25).

8

ProductOverview

g281979

Figure3

1.Attachmentmountplate

2.Tiltcylinder6.Batterybox

3.Auxiliaryhydrauliccouplers

4.Loaderarms8.Wheel12.Parking-brakelever

5.Cylinderlock

7.Liftcylinder1 1.Controlpanel15.Operatorplatform

Controls

ControlPanel

9.Handle13.Thighsupport

10.Liftpoint14.Counterweight

KeySwitch

Thekeyswitchhas2positions:ONandOFF(Figure

4).

Usethekeyswitchtostartorshutoffthemachine;

refertoStartingtheMachine(page16)andShutting

OfftheMachine(page16).

Traction-ControlLevers

•Tomoveforward,movethetraction-controllevers

forward.

•Tomoverearward,movethetraction-controllevers

rearward.

•Toturn,movetheleverlocatedonthesideyou

g281978

Figure4

wanttoturnbacktowardtheNEUTRALposition

whilekeepingtheotherleverengaged.

1.InfoCenter

2.Loader-armlever6.Keyswitch

3.Traction-controllevers7.Eco-modeswitch

4.Attachment-tiltlever8.Inch-modeswitch

5.Auxiliary-hydraulicslever

Note:Thefartheryoumovethetraction-control

leversineitherdirection,thefasterthemachine

movesinthatdirection.

•Tosloworstop,movethetraction-controllevers

totheNEUTRALposition.

Attachment-TiltLever

•Totilttheattachmentforward,slowlypushthe

attachment-tiltleverforward.

•Totilttheattachmentrearward,slowlypullthe

attachment-tiltleverrearward.

9

Loader-ArmLever

Inch-ModeSwitch

•Tolowertheloaderarms,slowlypushthe

loader-armleverforward.

•Toraisetheloaderarms,slowlypulltheloader-arm

leverrearward.

Auxiliary-HydraulicsLever

•Tooperateahydraulicattachmentintheforward

direction,slowlypulltheauxiliary-hydraulicslever

outandthenpulldown.

•Tooperateahydraulicattachmentinthereverse

direction,slowlypulltheauxiliary-hydraulicslever

outandthenpushitupward.Thisisalsocalled

theDETENTpositionbecauseitdoesnotrequire

operatorpresence.

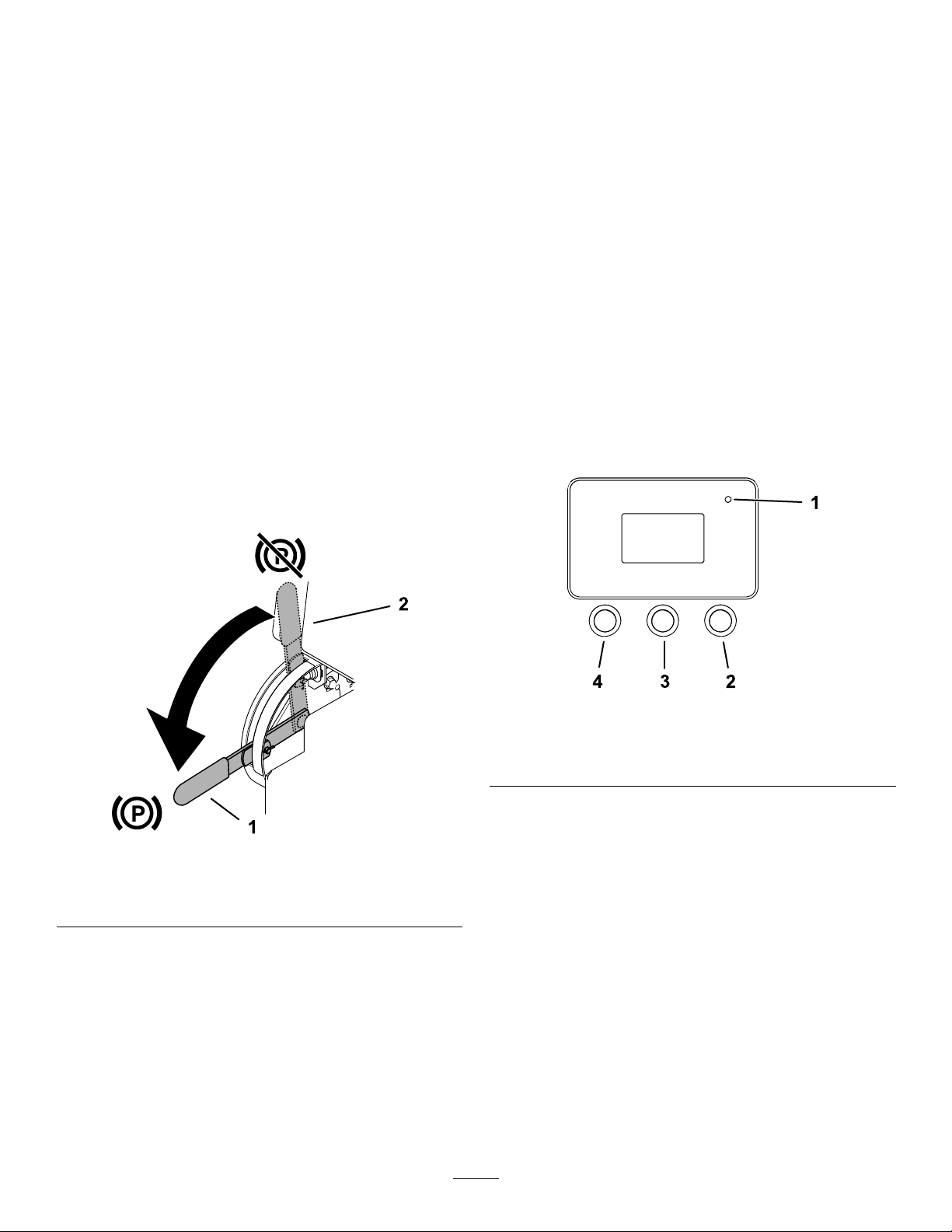

Parking-BrakeLever

•Toengagetheparkingbrake,rotatethelever

down(Figure5).

•Toreleasetheparkingbrake,rotatetheleverup

(Figure5).

PresstheswitchtotheONpositiontoactivateInch

Mode.UseInchModetoslowthespeedofthe

machinewheninstallingorremovingattachments,

makingsmalladjustmentswiththemachine,and

turningcorners.

Note:InchModeoverridesanycurrentsettings(e.g.,

Ecomode,attachmentmodes).Themachinewill

returntothosesettingswhenInchModeisoff.

InfoCenterDisplay

TheInfoCenterLCDdisplayshowsinformationabout

yourmachine,suchastheoperatingstatus,various

diagnosticsandotherinformationaboutthemachine

(Figure6).Thereisasplashscreenandmain

informationscreenoftheInfoCenter.Youcanswitch

betweenthesplashscreenandmaininformation

screenatanytimebypressinganyoftheInfoCenter

buttonsandthenselectingtheappropriatedirectional

arrow.

Figure5

1.Parking-brake

lever—engaged

2.Parking-brake

lever—disengaged

Eco-ModeSwitch

PresstheswitchtotheONpositiontoactivateEco

Mode.UseEcoModetoreducethemotorspeedand

reducebatteryconsumption.

g264015

Figure6

1.Indicatorlight3.Middlebutton

2.Rightbutton

4.Leftbutton

•LeftButton,MenuAccess/BackButton—pressthis

g303557

buttontoaccesstheInfoCentermenus.Youcan

useittoexitanymenuthatyouarecurrentlyusing.

•MiddleButton—usethisbuttontoscrolldown

menus.

•RightButton—usethisbuttontoopenamenu

wherearightarrowindicatesadditionalcontent.

Note:Thepurposeofeachbuttonmaychange

dependingonwhatisrequiredatthetime.Each

buttonislabeledwithanicondisplayingitscurrent

function.

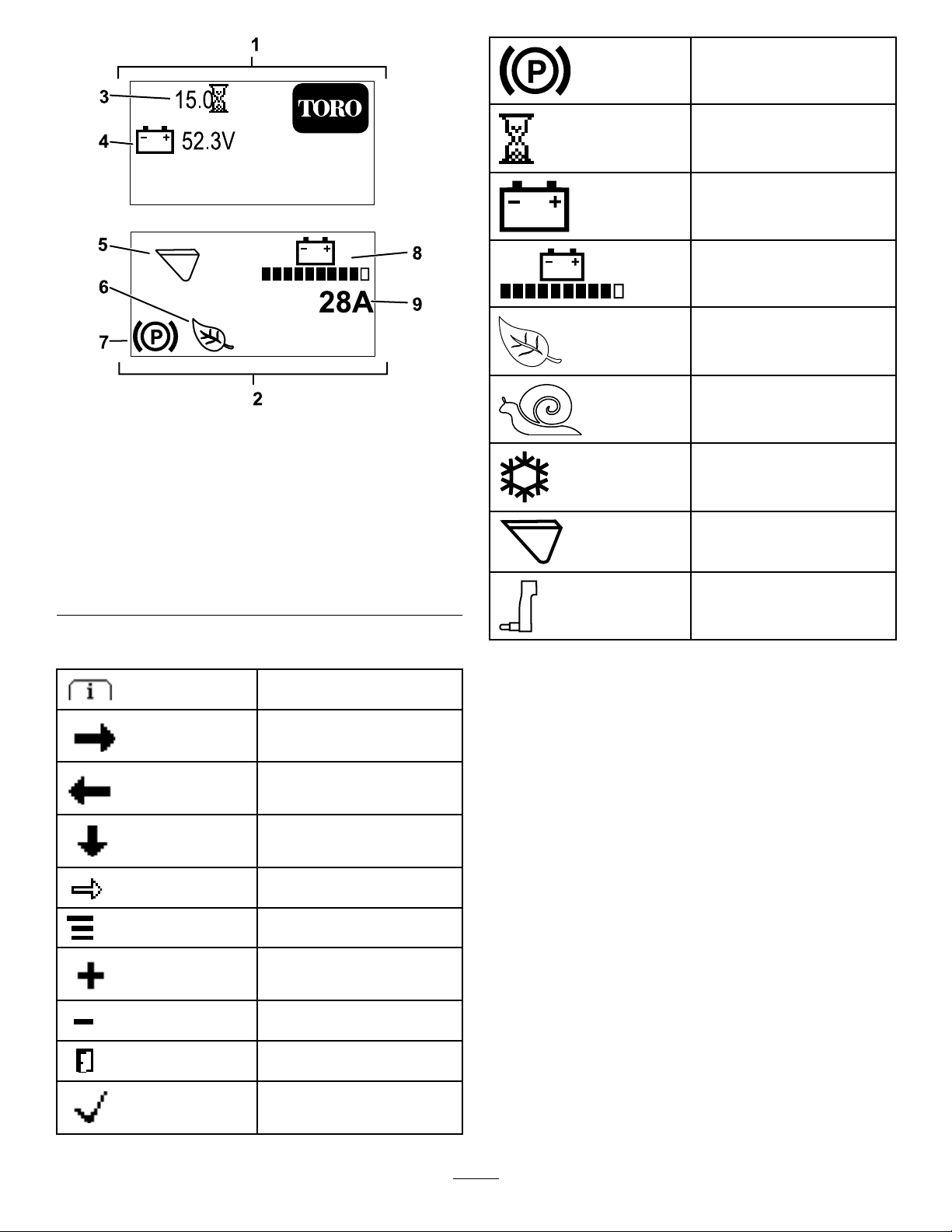

Figure7showswhatyoumayseeontheInfoCenter

whenyourunthemachine.Thesplashscreen

displaysforafewsecondsafteryouturnthekeyto

theONpositionthentherunscreendisplays.

10

Parkingbrakeisengaged.

Hourmeter

Batteryvoltage

Batterycharge—eachsolidbar

representsthechargein10%

increments.

EcoModeison.

Figure7

1.Splashscreen

2.Runscreen7.Parkingbrakeisengaged.

3.Hoursoperated8.Batterycharge

4.Batteryvoltage9.Instantaneousmachine

5.Attachmentmode(Bucket

Modeshown)

6.EcoorInchModeison

(EcoModeshown).

amperage

InfoCenterIconDescriptions

Menuaccess

Next

Previous

Scrolldown

g315353

InchModeison.

Coldstart

BucketModeison.

HammerModeison.

Enter

Changetheattachmentmode.

Increase

Decrease

Exitmenu

CheckPINentry

11

InfoCenterMenus

Service

ToaccesstheInfoCentermenusystem,pressthe

menuaccessbuttonwhileatthemainscreen.

Thiswillbringyoutothemainmenu.Refertothe

followingtablesforasynopsisoftheoptionsavailable

fromthemenus:

MainMenu

MenuItemDescription

Faults

ServiceTheServicemenucontains

DiagnosticsTheDiagnosticsmenu

SettingsTheSettingsmenuallows

AboutTheAboutmenuliststhe

TheFAULTSmenucontains

alistoftherecentmachine

faults.RefertotheService

ManualoryourAuthorized

ServiceDealerformore

informationontheF AULTS

menu.

informationonthemachine

suchashoursofuseandother

similarnumbers.

displaysthestateofeach

machineswitch,sensorand

controloutput.Y oucanuse

thistotroubleshootcertain

issuesasitwillquicklytellyou

whichmachinecontrolsareon

andwhichareoff.

youtocustomizeandmodify

congurationvariablesonthe

InfoCenterdisplay.

modelnumber,serialnumber,

andsoftwareversionofyour

machine.

Faults

MenuItemDescription

CurrentListsthetotalnumberof

LastIndicatesthelastkey-onhour

First

OccurrencesIndicatesthenumberoffault

key-onhours(i.e.,hoursthat

thekeyhasbeenintheON

position).

thatthefaultoccurredon.

Indicatestherstkey-onhour

thatthefaultoccurredon.

occurrences.

MenuItemDescription

Hours

CountsListsthenumberoftimesthe

Liststhetotalnumberofhours

thatthekey,motor,andEco

Modehavebeenonandthe

tractioncontrolshavebeen

engaged.

motorhasbeenstartedand

theamperagehoursforthe

battery.

Diagnostics

MenuItemDescription

BatteryIndicatestheinputsand

MotorcontrolIndicatestheinputsand

outputsforthebattery .Inputs

includethecurrentbattery

voltage;outputsincludethe

batterycurrentandpercentage

stateofcharge.

outputsforthemotorcontrol.

Inputsincludekeyrun,

neutral,parkingbrake,

auxiliary,Inch,Ecomode,

andraise/lower;usethese

tocheckinputfeedbackon

themachine.Outputsinclude

motorspeed(inrpm),phase

current,DCcurrent,controller

temperature,andmotor

temperature.

Settings

MenuItemDescription

Language

Backlight

ContrastControlsthecontrastofthe

ProtectedMenusAllowsyoutoaccess

Controlsthelanguageused

ontheInfoCenter.

Controlsthebrightnessofthe

LCDdisplay

LCDdisplay.

protectedmenusbyinputting

apasscode.

About

MenuItemDescription

Model

SerialListstheserialnumberofthe

S/WRevListsthesoftwarerevisionof

MotorCtrlSWListsthesoftwarerevisionof

BatterySWListsthesoftwarerevisionof

Liststhemodelnumberofthe

machine

machine

themastercontroller .

themotorcontrol.

thebattery.

12

Specications

Note:Specicationsanddesignaresubjectto

changewithoutnotice.

Width

Length

Height

Weight(withoutattachment)938kg(2,068lb)

Ratedoperatingcapacity—with74.8

kg(165lb)operatorandthestandard

bucket

Tippingcapacity—with74.8kg(165lb)

operatorandthestandardbucket

Wheelbase

Dumpheight(withstandardbucket)120cm(47inches)

Reach—fullyraised(withstandard

bucket)

Heighttohingepin(narrowbucketin

standardposition)

Attachments/Accessories

AselectionofToroapprovedattachmentsand

accessoriesisavailableforusewiththemachine

toenhanceandexpanditscapabilities.Contact

yourAuthorizedServiceDealerorauthorizedT oro

distributororgotowww.T oro.comforalistofall

approvedattachmentsandaccessories.

Toensureoptimumperformanceandcontinuedsafety

certicationofthemachine,useonlygenuineToro

replacementpartsandaccessories.Replacement

partsandaccessoriesmadebyothermanufacturers

couldbedangerous,andsuchusecouldvoidthe

productwarranty.

89cm(35inches)

152cm(62inches)

125cm(49inches)

234kg(515lb)

590kg(1,300lb)

71cm(28inches)

71cm(28inches)

168cm(66inches)

Operation

BeforeOperation

BeforeOperationSafety

GeneralSafety

•Neverallowchildrenoruntrainedpeopleto

operateorservicethemachine.Localregulations

mayrestricttheageorrequirecertiedtrainingof

theoperator.Theownerisresponsiblefortraining

alloperatorsandmechanics.

•Becomefamiliarwiththesafeoperationofthe

equipment,operatorcontrols,andsafetydecals.

•Alwaysengagetheparkingbrake,shutoffthe

machine,removethekey,waitforallmoving

partstostop,andallowthemachinetocool

beforeadjusting,servicing,cleaning,orstoring

themachine.

•Knowhowtostopthemachineandshutoffthe

machinequickly.

•Checkthatthesafetyswitchesandshieldsare

attachedandfunctioningproperly.Donotoperate

themachineunlesstheyarefunctioningproperly .

•Locatethepinch-pointareasmarkedonthe

machineandattachments;keepyourhandsand

feetawayfromtheseareas.

•Beforeoperatingthemachinewithanattachment,

ensurethattheattachmentisproperlyinstalled

andthatitisagenuineT oroattachment.Readall

theattachmentmanuals.

•Evaluatetheterraintodeterminewhataccessories

andattachmentsyouneedtoproperlyandsafely

performthejob.

•Havethepropertyorworkareamarkedforburied

linesandotherobjects,anddonotdiginmarked

areas;notethelocationofunmarkedobjectsand

structures,suchasundergroundstoragetanks,

wells,andsepticsystems.

•Inspecttheareawhereyouwillusetheequipment

forunevensurfacesorhiddenhazards.

•Ensurethattheareaisclearofbystandersbefore

operatingthemachine.Stopthemachineifa

bystanderentersthearea.

13

PerformingDaily

Maintenance

Beforestartingthemachineeachday ,performthe

EachUse/DailyprocedureslistedinMaintenance

(page27).

AdjustingtheThigh

Support

Toadjustthethighsupport(Figure8),loosenthe

knobsandraiseorlowerthesupportpadtothe

desiredheight.Y oucanalsoobtainadditional

adjustmentbylooseningthenutsecuringthepad

totheadjustmentplateandmovingtheplateupor

downasneeded.Tightenallfastenerssecurelywhen

nished.

Figure8

1.Thigh-supportbracket

2.Adjustmentplate

3.Thigh-supportpad

4.Knobandatwasher

5.Carriagebolt

6.Locknutandatwasher

DuringOperation

DuringOperationSafety

GeneralSafety

•Donotcarryaloadwiththearmsraised.Always

carryloadsclosetotheground.

•Donotexceedtheratedoperatingcapacity,asthe

machinemaybecomeunstable,whichmayresult

inlossofcontrol.

•UseonlyT oro-approvedattachmentsand

accessories.Attachmentscanchangethestability

andtheoperatingcharacteristicsofthemachine.

•Formachineswithaplatform:

–Lowertheloaderarmsbeforesteppingoffthe

platform.

–Donottrytostabilizethemachinebyputting

yourfootontheground.Ifyoulosecontrolof

themachine,stepofftheplatformandaway

fromthemachine.

–Donotplaceyourfeetundertheplatform.

–Donotmovethemachineunlessyouare

standingwithbothfeetontheplatformandyour

handsareholdingontothereferencebars.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

g006054

•Lookbehindanddownbeforebackingupto

ensurethatthepathisclear.

•Neverjerkthecontrols;useasteadymotion.

•Theowner/usercanpreventandisresponsible

foraccidentsthatmaycausepersonalinjuryor

propertydamage.

•Wearappropriateclothingincludinggloves,eye

protection,longpants,substantialslip-resistant

footwear,andhearingprotection.Tiebacklong

hairanddonotwearlooseclothingorloose

jewelry.

•Donotoperatethemachinewhenyouaretired,ill,

orundertheinuenceofalcoholordrugs.

•Nevercarrypassengersandkeeppetsand

bystandersawayfromthemachine.

•Operatethemachineonlyingoodlight,keeping

awayfromholesandhiddenhazards.

•Ensurethatallthedrivesareinneutralbefore

startingthemachine.Startthemachineonlyfrom

theoperator'sposition.

•Usecarewhenapproachingblindcorners,shrubs,

trees,orotherobjectsthatmayobscurevision.

14

•Slowdownandusecautionwhenmakingturns

andcrossingroadsandsidewalks.Watchfor

trafc.

•Stoptheattachmentwhenyouarenotworking.

•Stopthemachine,shutoffthemachine,remove

thekey,andinspectthemachineifyoustrike

anobject.Makeanynecessaryrepairsbefore

resumingoperation.

•Neverleaveamachineonwhenunattended.

•Beforeleavingtheoperatingposition,dothe

following:

–Parkthemachineonalevelsurface.

–Lowertheloaderarmsanddisengagethe

auxiliaryhydraulics.

–Shutoffthemachineandremovethekey.

•Donotoperatethemachinewhenthereistherisk

oflightning.

•Operatethemachineonlyinareaswherethereis

sufcientclearanceforyoutosafelymaneuver.

Beawareofobstaclesincloseproximitytoyou.

Failuretomaintainadequatedistancefromtrees,

walls,andotherbarriersmayresultininjuryasthe

machinebacksupduringoperationifyouarenot

attentivetothesurroundings.

•Checkforoverheadclearance(i.e.,electrical

wires,branches,ceilings,anddoorways)before

drivingunderanyobjectsanddonotcontactthem.

•Donotoverlltheattachmentandalwayskeepthe

loadlevelwhenraisingtheloaderarms.Itemsin

theattachmentcouldfallandcauseinjury.

SlopeSafety

•Operatethemachineupanddownslopeswith

theheavyendofthemachineuphill.Weight

distributionchangeswithattachments.Anempty

bucketmakestherearofthemachinetheheavy

end,andafullbucketmakesthefrontofthe

machinetheheavyend.Mostotherattachments

makethefrontofmachinetheheavyend.

•Slowdownanduseextracareonhillsides.Ground

conditionscanaffectthestabilityofthemachine.

•Avoidstartingorstoppingonaslope.Ifthe

machinelosestraction,proceedslowly,straight

downtheslope.

•Avoidturningonslopes.Ifyoumustturn,turn

slowlyandkeeptheheavyendofthemachine

uphill.

•Keepallmovementsonslopesslowandgradual.

Donotmakesuddenchangesinspeedor

direction.

•Ifyoufeeluneasyoperatingthemachineona

slope,donotdoit.

•Watchforholes,ruts,orbumps,asuneventerrain

couldoverturnthemachine.T allgrasscanhide

obstacles.

•Usecautionwhenoperatingonwetsurfaces.

Reducedtractioncouldcausesliding.

•Evaluatetheareatoensurethatthegroundis

stableenoughtosupportthemachine.

•Usecautionwhenoperatingthemachinenearthe

following:

–Drop-offs

–Ditches

–Embankments

–Bodiesofwater

Themachinecouldsuddenlyrolloverifatrack

goesovertheedgeortheedgecavesin.Maintain

asafedistancebetweenthemachineandany

hazard.

•Donotremoveoraddattachmentsonaslope.

•Donotparkthemachineonahillsideorslope.

•Raisingtheloaderarmsonaslopeaffectsthe

stabilityofthemachine.Keeptheloaderarmsin

theloweredpositionwhenonslopes.

•Slopesareamajorfactorrelatedtolossofcontrol

andtip-overaccidents,whichcanresultinsevere

injuryordeath.Operatingthemachineonany

slopeoruneventerrainrequiresextracaution.

•Establishyourownproceduresandrulesfor

operatingonslopes.Theseproceduresmust

includesurveyingthesitetodeterminewhich

slopesaresafeformachineoperation.Always

usecommonsenseandgoodjudgmentwhen

performingthissurvey.

15

StartingtheMachine

ShuttingOfftheMachine

1.Standontheplatform.

2.Ensurethattheparkingbrakeisengagedandall

4leversareintheNEUTRALposition.

3.Insertthekeyintothekeyswitchandturnitto

theONposition.

Note:Themachinemayhavedifcultystartingunder

severecoldconditions.Whenstartingacoldmachine,

keepthemachineabove-18°C(0°F).

Note:Whenthemachinetemperatureisbelow-1°C

(30°F),thecold-startsymbol(Figure9)willappear

ontheInfoCenterwhilethemotorincreasesspeed

for2minutes.Duringthistime,donotmovethe

tractioncontrolswhiletheparkingbrakeisengaged;

otherwise,themotorshutsoffandthe2minutes

resets.Thecold-startsymboldisappearswhenthe

motorreachesfullspeed.

Figure9

DrivingtheMachine

Usethetractioncontrolstomovethemachine.The

fartheryoumovethetractioncontrolsinanydirection,

thefasterthemachinemovesinthatdirection.

Releasethetractioncontrolstostopthemachine.

PowerSaveMode

Whenthemachineidles,itwillgointoapowersaver

modeaftersometime.

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,andengagetheparkingbrake.

2.Ensurethattheauxiliaryhydraulicsleverisin

theNEUTRALposition.

3.TurnthekeyswitchtotheOFFpositionand

removethekey.

CAUTION

Childrenorbystandersmaybeinjuredifthey

moveorattempttooperatethemachinewhile

itisunattended.

Alwaysremovethekeyandengagethe

parkingbrakewhenleavingthemachine

unattended.

UsingAttachments

g304012

InstallinganAttachment

Important:UseonlyToro-approvedattachments.

Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthemachine.The

warrantyofthemachinemaybevoidedifyouuse

themachinewithunapprovedattachments.

Important:Beforeinstallingtheattachment,

ensurethatthemountplatesarefreeofanydirtor

debrisandthatthepinsrotatefreely.Ifthepins

donotrotatefreely,greasethem.

1.Positiontheattachmentonalevelsurfacewith

enoughspacebehindittoaccommodatethe

machine.

2.Startthemachine.

3.Tilttheattachmentmountplateforward.

PowerSave1

Afteridling5to7seconds,themotorspeed

decreases.T oresumenormaloperationspeed,move

atractionlever,attachment-tiltlever,orloader-arm

lever.

PowerSave2

Afteridling30seconds,themotorshutsoff.T o

resumeoperation,rapidlymoveatractionlevertwice.

PowerSave3

Afteridling5minutes,themachineshutsoff.To

resumeoperation,turnthekeytotheOFFposition,

engagetheparkingbrake,andturnthekeytoON

position.

4.Positionthemountplateintotheupperlipofthe

attachmentreceiverplate(Figure10).

g003710

Figure10

1.Mountplate2.Receiverplate

16

5.Raisetheloaderarmswhiletiltingbackthe

mountplateatthesametime.

ConnectingtheHydraulicHoses

Important:Raisetheattachmentenoughto

clearthegroundandtiltthemountplateall

thewayback.

6.Shutoffthemachineandremovethekey.

7.Engagethequick-attachpins,ensuringthatthey

arefullyseatedinthemountplate(Figure11).

Important:Ifthepinsdonotrotatetothe

engagedposition,themountplateisnot

fullyalignedwiththeholesintheattachment

receiverplate.Checkthereceiverplateand

cleanitifnecessary.

WARNING

Ifyoudonotfullyseatthequick-attach

pinsthroughtheattachmentmountplate,

theattachmentcouldfalloffthemachine,

crushingyouorbystanders.

Ensurethatthequick-attachpinsarefully

seatedintheattachmentmountplate.

WARNING

Hydraulicuidescapingunderpressurecan

penetrateskinandcauseinjury.Fluidinjected

intotheskinmustbesurgicallyremoved

withinafewhoursbyadoctorfamiliarwith

thisformofinjury;otherwise,gangrenemay

result.

•Ensurethatallhydraulic-uidhoses

andlinesareingoodconditionandall

hydraulicconnectionsandttingsaretight

beforeapplyingpressuretothehydraulic

system.

•Keepyourbodyandhandsawayfrom

pinholeleaksornozzlesthateject

high-pressurehydraulicuid.

•Usecardboardorpapertondhydraulic

leaks;neveruseyourhands.

CAUTION

Hydrauliccouplers,hydrauliclines/valves,

andhydraulicuidmaybehot.Ifyoucontact

hotcomponents,youmaybeburned.

1.Quick-attachpins

(engagedposition)

2.Disengagedposition

Figure11

3.Engagedposition

g003711

•Weargloveswhenoperatingthehydraulic

couplers.

•Allowthemachinetocoolbeforetouching

hydrauliccomponents.

•Donottouchhydraulicuidspills.

Iftheattachmentrequireshydraulicsforoperation,

connectthehydraulichosesasfollows:

1.Shutoffthemachineandremovethekey.

2.Movetheauxiliary-hydraulicsleverforward,

backward,andbacktotheNEUTRALpositionto

relievepressureatthehydrauliccouplers.

3.Removetheprotectivecoversfromthehydraulic

connectorsonthemachine.

4.Ensurethatallforeignmatteriscleanedfrom

thehydraulicconnectors.

5.Pushtheattachmentmaleconnectorintothe

femaleconnectoronthemachine.

Note:Whenyouconnecttheattachmentmale

connectorrst,yourelieveanypressurebuilt

upintheattachment.

6.Pushtheattachmentfemaleconnectorontothe

maleconnectoronthemachine.

7.Conrmthattheconnectionissecurebypulling

onthehoses.

17

RemovinganAttachment

AccessingProtectedMenus

1.Parkthemachineonalevelsurface.

2.Lowertheattachmenttotheground.

3.Shutoffthemachineandremovethekey.

4.Disengagethequick-attachpinsbyturningthem

totheoutside.

5.Iftheattachmentuseshydraulics,movethe

auxiliary-hydraulicsleverforward,backward,

andbacktotheNEUTRALpositiontorelieve

pressureatthehydrauliccouplers.

6.Iftheattachmentuseshydraulics,slidethe

collarsbackonthehydrauliccouplersand

disconnectthem.

Important:Connecttheattachmenthoses

togethertopreventhydraulicsystem

contaminationduringstorage.

7.Installtheprotectivecoversontothehydraulic

couplersonthemachine.

8.Startthemachine,tiltthemountplateforward,

andbackthemachineawayfromtheattachment.

Note:ThefactorydefaultPINcodeforyoumachine

iseither0000or1234.

IfyouchangedthePINcodeandforgotthecode,

contactyourAuthorizedServiceDealerforassistance.

1.FromtheMAINMENU,usethecenterbuttonto

scrolldowntotheSETTINGSMENUandpressthe

rightbutton(Figure13).

g264775

Figure13

2.IntheSETTINGSMENU,usethecenterbuttonto

scrolldowntothePROTECTEDMENUandpress

therightbutton(Figure14A).

UsingtheInfoCenter

ChangingtheAttachmentMode

1.FromtheRunscreen,pressthemiddlebuttonto

accesstheAttachmentChangescreen.

2.Pressthemiddleorrightbuttontoswitch

betweenHammerorBucketmode.

Note:TurnonEcomodewhenusingHammer

mode.HammerMode,whenusedwithEco

mode,slowsthemotorspeed(inrpm)toreduce

energyconsumptionwhenusingattachments.

BucketMode

3.PresstheleftbuttontoreturntotheRunscreen.

1.Currentattachmentmode

2.Changeattachmentmode

maintainsthemotorspeed.

Figure12

3.ReturntoRunscreen

g264249

Figure14

3.ToenterthePINcode,pressthecenterbutton

g304809

untilthecorrectrstdigitappears,thenpress

therightbuttontomoveontothenextdigit

(Figure14BandFigure14C).Repeatthisstep

untilthelastdigitisenteredandpresstheright

buttononcemore.

4.PressthemiddlebuttontoenterthePINcode

(Figure14D).

18

Note:IftheInfoCenteracceptsthePINcode

andtheprotectedmenuisunlocked,theword

“PIN”displaysintheupperrightcornerofthe

screen.

Youcanviewandchangethesettingsinthe

PROTECTEDMENU.OnceyouaccessthePROTECTED

MENU,scrolldowntoPROTECTSETTINGSoption.

Usetherightbuttontochangethesetting.Setting

theProtectSettingstoOFFallowsyoutoviewand

changethesettingsinthePROTECTEDMENUwithout

enteringthePINcode.SettingtheProtectSettings

toONhidestheprotectedoptionsandrequiresyou

toenterthePINcodetochangethesettinginthe

PROTECTEDMENU.

AfterOperation

AfterOperationSafety

GeneralSafety

•Shutoffthemachine,removethekey ,waitforall

movementtostop,andallowthemachinetocool

beforeadjusting,cleaning,storing,orservicingit.

•Cleandebrisfromtheattachmentsanddrivesto

helppreventres.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.

•Donottouchpartsthatmaybehotfromoperation.

Allowthemtocoolbeforeattemptingtomaintain,

adjust,orservicethemachine.

•Usecarewhenloadingorunloadingthemachine

intoatrailerortruck.

BatteryandChargerSafety

General

•Improperlyusingormaintainingthebattery

chargercouldresultininjury.T oreducethis

potential,complywiththeallsafetyinstructions.

•Useonlythesuppliedchargerforbatterycharging.

•Conrmthevoltagethatisavailableinyour

countrybeforeusingthecharger.

•ForconnectiontoasupplynotintheUS,

useanattachmentplugadapteroftheproper

congurationforthepoweroutlet,ifneeded.

•Donotgetthechargerwet;keepitprotectedfrom

rainandsnow.

•Ariskofre,electricshock,orinjurymayresult

fromusinganaccessorynotrecommendedor

soldbyToro.

•Toreduceriskofabatteryexplosion,followthese

instructionsandtheinstructionsforanyequipment

thatyouintendtousenearthecharger.

•Donotopenbatteries.

•Intheeventthatabatteryleaks,avoidcontact

withtheliquid.Ifyouaccidentlycomeintocontact

withtheliquid,ushwithwaterandseekmedical

help.Liquidejectedfromthebatterymaycause

irritationorburns.

•RefertoanAuthorizedServiceDealertoservice

orreplaceabattery.

Training

•Neverallowchildrenoruntrainedpeopleto

operateorservicethecharger.Localregulations

mayrestricttheageoftheoperator.Theowner

19

isresponsiblefortrainingalloperatorsand

mechanics.

•Read,understand,andfollowallinstructionson

thechargerandinthemanualbeforeoperating

thecharger.Befamiliarwiththeproperuseofthe

charger.

MaintenanceandStorage

•Storethechargerindoorsinadry,secureplace

thatisoutofthereachofunauthorizedusers.

•Donotdisassemblethecharger.T akethecharger

toanAuthorizedServiceDealerwhenserviceor

repairisrequired.

Preparation

•Keepbystandersandchildrenawaywhile

charging.

•Wearappropriateclothingwhilecharging,

includingeyeprotection;longpants;and

substantial,slip-resistantfootwear.

•Shutoffthemachineandwait5secondsuntilthe

machinehascompletelypowereddownbefore

charging.Failuretodothismaycausearcing.

•Ensurethattheareaiswellventilatedwhile

charging.

•Readandfollowallprecautionsforcharging.

•Thechargerisforuseonlyonnominal120and

240VACcircuits,andisequippedwithagrounding

plugfor120V ACoperation.Forusewith240V

circuits,contactyourAuthorizedServiceDealer

forthecorrectpowercord.

Operation

•Donotabusethecord.Donotcarrythecharger

bythecordoryankonthepowersupplycordto

disconnectthechargerfromthereceptacle.Keep

thecordfromheat,oil,andsharpedges.

•Unplugthepowercordfromtheoutletbefore

startinganymaintenanceorcleaningtoreduce

riskofelectricshock.

•Maintainorreplacesafetyandinstructionlabels

asneeded.

•Donotoperatethechargerwithadamaged

cordorplug.Replaceadamagedcordorplug

immediately.

•Ifthechargerhasreceivedanimpact,been

dropped,orotherwisedamaged,donotuseit;

takeittoanAuthorizedServiceDealer.

•Connectthechargerdirectlytoagrounding

(3-prong)receptacle.Donotusethechargeron

anungroundedoutlet,evenwithanadaptor.

•Donotaltertheprovidedpowercordorplug.

•Avoiddroppingametaltoolnearorontoabattery;

itmightcauseasparkorshort-circuitanelectrical

partthatcouldleadtoanexplosion.

•Removemetalitemssuchasrings,bracelets,

necklaces,andwatcheswhenworkingwitha

lithium-ionbattery.Alithium-ionbatterycan

produceenoughcurrenttocauseasevereburn.

•Neveroperatethechargerwithoutgoodvisibility

orlight.

•Useanappropriateextensioncord.

•Ifthepowersupplycordisdamagedwhileitis

pluggedin,disconnectthecordfromthewall

receptacleandcontactanAuthorizedService

Dealerforareplacement.

•Unplugthechargerfromtheelectricaloutletwhen

notinuse,beforemovingittoanotherlocation,or

priortoservicingit.

20

MovingaNon-Functioning

Machine

Important:Donottoworpullthemachine

withoutrstopeningthetowvalves,oryouwill

damagethehydraulicsystem.

1.Shutoffthemachineandremovethekey.

2.Removetheplugcoveringeachtowvalve

(Figure15).

3.Loosenthejamnutoneachtowvalve.

g304100

Figure16

1.Towvalve

4.Turneachvalvecounterclockwise1turnwitha

hexwrenchtoopenthem.

5.Towthemachineasrequired.

Important:Donotexceed4.8km/h(3mph)

whentowing.

6.Afterrepairingthemachine,closethetowvalves

andtightenthejamnuts.

Important:Donotovertightenthetow

valves.

7.Replacetheplugs.

g304099

Figure15

1.Plug

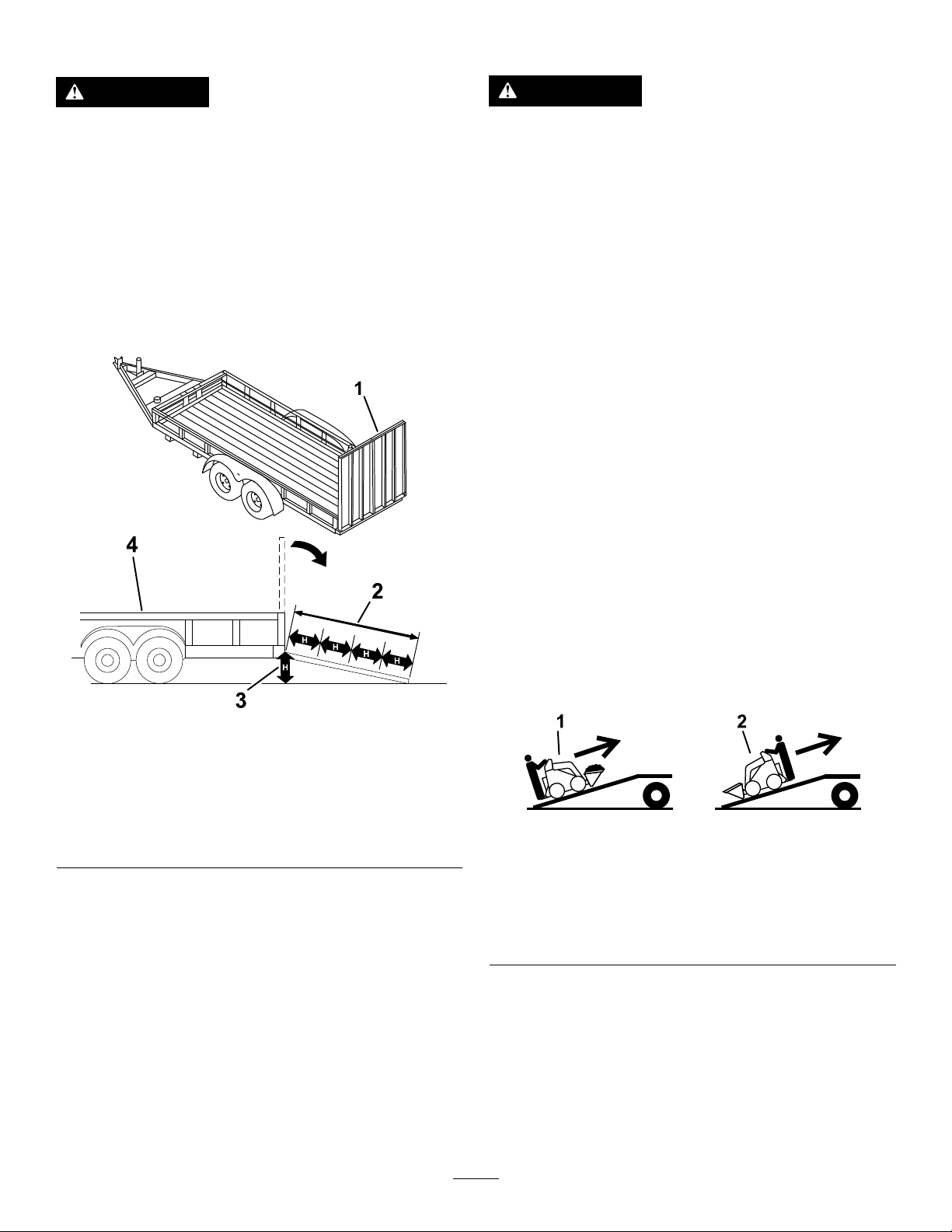

HaulingtheMachine

Useaheavy-dutytrailerortrucktohaulthemachine.

Useafull-widthramp.Ensurethatthetrailerortruck

hasallthenecessarybrakes,lighting,andmarkingas

requiredbylaw.Pleasecarefullyreadallthesafety

instructions.Knowingthisinformationcouldhelp

youorbystandersavoidinjury.Refertoyourlocal

ordinancesfortrailerandtie-downrequirements.

WARNING

Drivingonthestreetorroadwaywithout

turnsignals,lights,reectivemarkings,ora

slow-moving-vehicleemblemisdangerous

andcanleadtoaccidentscausingpersonal

injury.

Donotdrivethemachineonapublicstreet

orroadway .

21

SelectingaTrailer

LoadingtheMachine

WARNING

Loadingorunloadingamachineontoatrailer

ortruckincreasesthepossibilityoftip-over

andcouldcauseseriousinjuryordeath

(Figure17).

•Useonlyfull-widthramps.

•Ensurethatthelengthoframpisatleast4

timesaslongastheheightofthetraileror

truckbedtotheground.Thisensuresthat

rampangledoesnotexceed15degreeson

atground.

Figure17

WARNING

Loadingamachineontoatrailerortruck

increasesthepossibilityoftip-overandcould

causeseriousinjuryordeath.

•Useextremecautionwhenoperatinga

machineonaramp.

•Loadandunloadthemachinewiththe

heavyenduptheramp.

•Avoidsuddenaccelerationordeceleration

whiledrivingthemachineonarampas

thiscouldcausealossofcontrolora

tip-oversituation.

1.Ifusingatrailer,connectittothetowingvehicle

andconnectthesafetychains.

2.Ifapplicable,connectthetrailerbrakes.

3.Lowertheramp(s).

4.Lowertheloaderarms.

5.Loadthemachineontothetrailerwiththeheavy

enduptheramp,carryingloadslow(Figure18).

•Ifthemachinehasafullload-bearing

attachment(e.g.,bucket)ora

non-load-bearingattachment(e.g.,

trencher),drivethemachineforwardupthe

ramp.

•Ifthemachinehasanemptyload-bearing

attachmentornoattachment,backthe

machineuptheramp.

g229507

1.Full-widthramp(s)in

stowedposition

2.Rampisatleast4times

aslongastheheightof

thetrailerortruckbedto

theground

3.H=heightofthetraileror

truckbedtotheground

4.Trailer

Figure18

1.Machinewithfull

attachmentor

non-load-bearing

attachment—drivethe

machineforwardupthe

ramp(s).

6.Lowertheloaderarmsallthewaydown.

7.Engagetheparkingbrake,shutoffthemachine,

andremovethekey.

8.Usethemetaltie-downloopsonthemachine

tosecurelyfastenthemachinetothetraileror

truckwithstraps,chains,cable,orropes(Figure

19).Refertolocalregulationsfortie-down

requirements.

22

g237904

2.Machinewithemptyor

noattachment—backthe

machineuptheramp(s).

1.Tie-downloops

LiftingtheMachine

Liftthemachineusingtheliftpoints(Figure19).

g305397

Figure21

g304319

Figure19

MaintainingtheBatteries

UnloadingtheMachine

1.Lowertheramp(s).

2.Unloadthemachinefromthetrailerwiththe

heavyenduptheramp,carryingloadslow

(Figure20).

•Ifthemachinehasafullload-bearing

attachment(e.g.,bucket)ora

non-load-bearingattachment(e.g.,

trencher),backitdowntheramp.

•Ifthemachinehasanemptyload-bearing

attachmentornoattachment,driveitforward

downtheramp.

Figure20

1.Machinewithfull

attachmentor

non-load-bearing

attachment—backthe

machinedownthe

ramp(s).

2.Machinewithemptyor

noattachment—drivethe

machineforwarddownthe

ramp(s).

WARNING

Thebatteriescontainshighvoltage,which

couldburnorelectrocuteyou.

•Donotattempttoopenthebatteries.

•Useextremecarewhenhandlingabattery

withacrackedcase.

•Useonlythechargerdesignedforthe

batteries.

Thelithium-ionbatteriesholdasufcientchargeto

performintendedworkduringitslifespan.Astime

goesby,thetotalamountofworkthatthebatteries

areabletocompleteonasinglechargegradually

diminishes.

Note:Y ourresultsmayvarydependingonthe

distanceyouneedtotransportthemachine,the

undulationsthatyoutravelacross,andotherfactors

asdiscussedinthissection.

g237905

Toachievemaximumlifeandusefromyourbatteries,

followtheseguidelines:

•Donotopenthebattery.Therearenouser

serviceablepartsinside.Ifyouopenthepack,

youwillvoidyourwarranty.Thebatteriesare

protectedbytamper-alertingdevices.

•Store/parkthemachineinaclean,drygarageor

storagearea,awayfromdirectsunlightand

heatsources.Donotstoreitinalocationwhere

thetemperaturedropsbelow-30°C(-22°F)or

risesabove60°C(140°F).Temperaturesoutside

ofthisrangewilldamageyourbatteries.High

temperaturesduringstorage,especiallyatahigh

stateofcharge,reducesthelifeofthebatteries.

23

•Whenstoringthemachineformorethan10days,

ensurethatthemachineisinacoollocation,out

ofsunlight,andatleast50%charged.

•Ifyouareoperatingthemachineinhotconditions

orinsunlight,thebatterymayoverheat.Ifthis

happens,ahigh-temperaturealertwillappear

ontheInfoCenter.Inthiscondition,themachine

slowsdown.

Immediatelydrivethemachinetoacoollocation

outofthesun,turnoffthemachine,andallowthe

batteriestocoolfullybeforeresumingoperation.

•IfyourmachineisequippedwiththeLightKit,shut

offthelightswhentheyarenotinuse.

TransportingtheBatteries

UsingtheBatteryCharger

RefertoFigure22foranoverviewofthe

battery-chargerdisplaysandcords.

TheUSDepartmentofTransportationand

internationaltransportationauthoritiesrequirethat

lithiumionbatteriesbetransportedusingspecial

packagingandonlybetransportedbycarrierscertied

tohaulthem.IntheUS,youareallowedtotransport

abatterywhenitisinstalledonthemachineas

batterypoweredequipment,withsomeregulatory

requirements.ContacttheUSDepartmentof

Transportationortheappropriategovernmentbodyin

yourcountryfordetailedregulationsontransportation

ofyourbatteriesorthemachinewiththebatteries

equipped.

ContactyourAuthorizedServiceDealerforwaysto

shipordisposeofthebatteries.

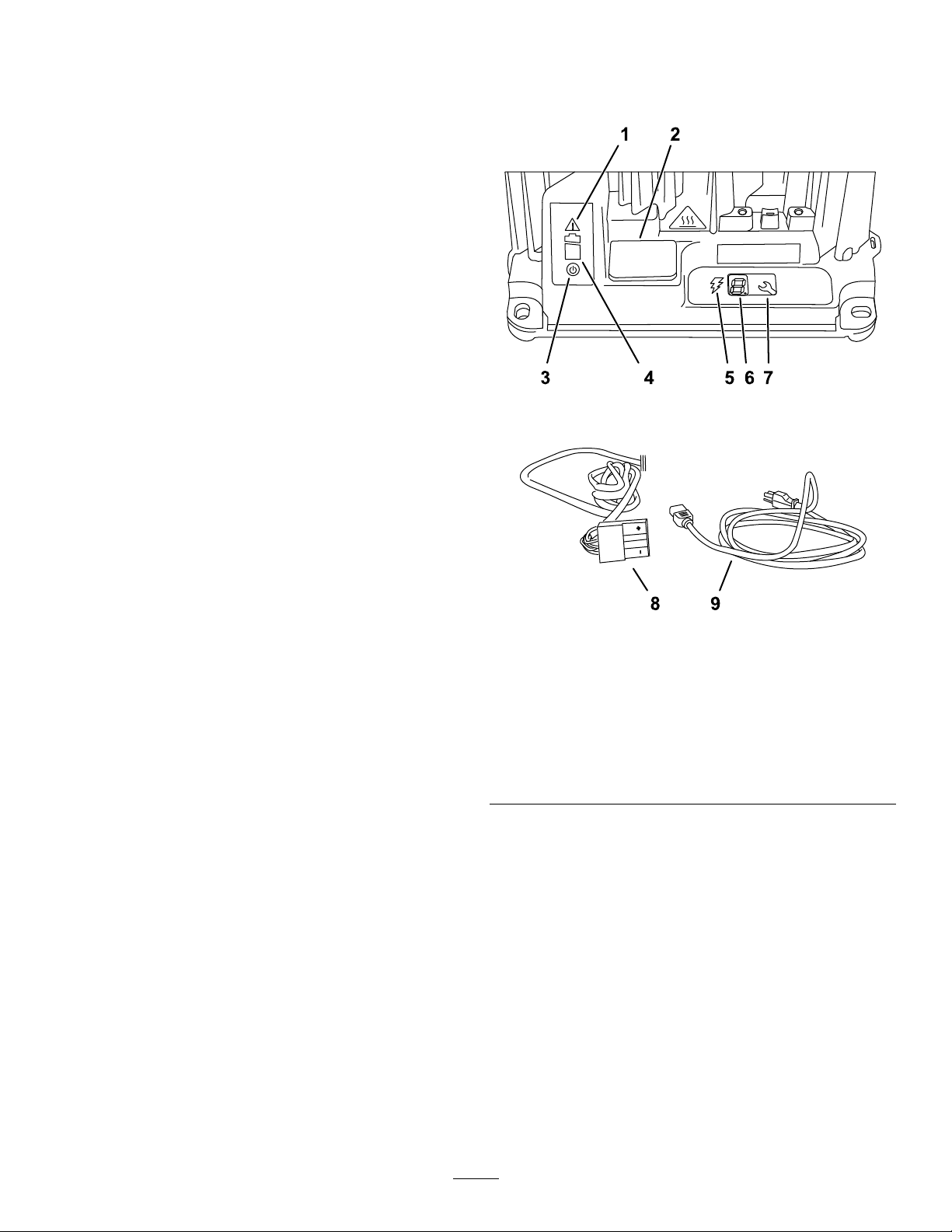

Figure22

1.Errorindicatorlight

2.USBportcover7.Selectbutton

3.ACPowerindicatorlight8.Outputconnectorandcord

4.Battery-chargingindicator

light

5.Charging-outputindicator

light

6.LCDdisplay

9.Power-supplycord

g251620

g251632

24

ConnectingtoaPowerSource

ChargingtheBatteries

Toreducetheriskofelectricshock,thischargerhasa

3-pronggroundedplug(typeB).Iftheplugdoesnot

tintothewallreceptacle,othergroundedplugtypes

areavailable;contactanAuthorizedServiceDealer.

Donotchangethechargerorthepower-supply-cord

pluginanyway.

DANGER

Contactwithwaterwhilechargingthe

machinecouldcauseelectricshock,causing

injuryordeath.

Donothandletheplugorthechargerwithwet

handsorwhilestandinginwater.

Important:Checkthepowersupplycord

periodicallyforholesorcracksintheinsulation.

Donotuseadamagedcord.Donotrunthecord

throughstandingwaterorwetgrass.

1.Insertthechargerplugonthepower-supply

cordintothematchinginputpowersocketon

thecharger.

WARNING

Adamagedchargercordcancausean

electricalshockorare.

Important:Chargethebatteriesonlyin

temperaturesthatarewithintherecommended

range;refertothefollowingtableforthe

recommendedrange:

RecommendedTemperatureRangefor

Charging

Chargingrange0°to45°C(32°to113°F)

Low-temperaturecharging

range(ReducedCurrent)

High-temperaturecharging

range(ReducedCurrent)

Ifthetemperatureisbelow-5°C(23°F),thebatteries

willnotcharge.Ifthetemperaturerisesabove-5°C

(23°F),unplugthechargerandplugitinagainto

chargethebatteries.

1.Parkthemachineinthedesignatedlocationfor

charging.

2.Engagetheparkingbrake.

3.Shutoffthemachineandremovethekey.

4.Ensurethattheconnectorsarefreeofdustand

debris.

5.Connectthechargerpowercordtoapower

source;refertoConnectingtoaPowerSource

(page25).

-5°to0°C(23°to32°F)

45°to60°C(113°to140°F)

Thoroughlyinspectthepowersupply

cordbeforeusingthecharger.Ifthecord

isdamaged,donotoperatethecharger

untilyouobtainareplacement.

2.Insertthewallplugendofthepowersupplycord

intoagroundedelectricaloutlet.

6.Slidethechargercoverupandpivotitoutofthe

way(Figure23).

g304908

Figure23

1.Chargercover

25

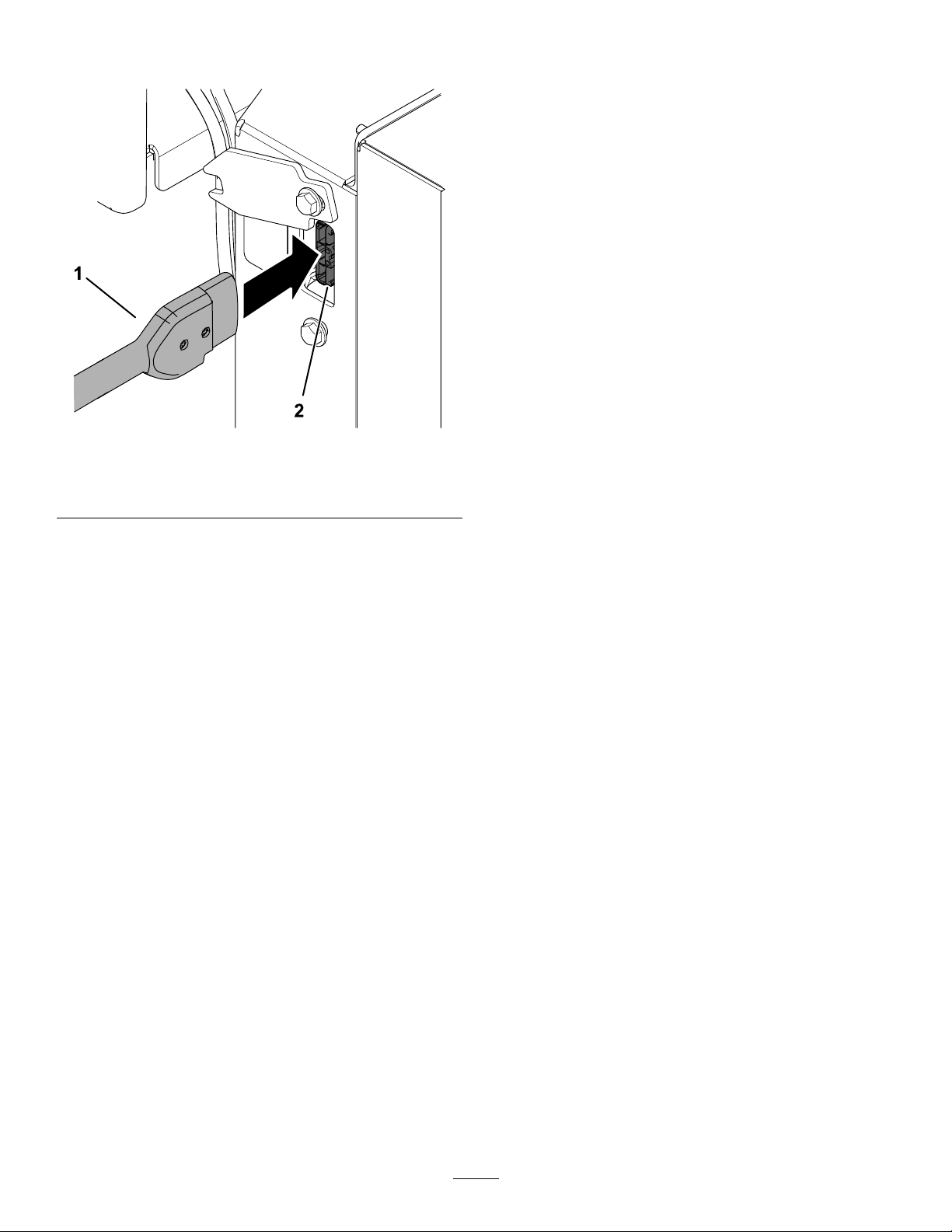

7.Plugthecharger-outputconnectorintothe

chargerconnectoronthemachine.

Figure24

MonitoringtheChargingProcess

andTroubleshooting

Note:TheLCDstatusdisplaydisplaysmessages

duringthecourseofcharging.Mostareroutine.

Ifthereisafault,theerrorindicatorlightwillash

amberorasolid,lightred.Anerrormessagewill

appearintheInfoCenter1digitatatime,startingwith

theletterEorF(e.g.,E-0-1-1).

Tocorrectanerror,refertoTroubleshooting(page39).

Ifnoneofthesesolutionscorrecttheissue,contactan

AuthorizedServiceDealer.

CompletingtheChargingProcess

Whenchargingiscomplete,thebattery-charging

indicatorlight(Figure22)showssolidgreenand

themachineInfoCenterdisplays10solidbars.

g306958

Disconnectthechargerconnectorfromthemachine

connector.

1.Charger-outputconnector

8.Observethechargertoensurethatthebatteries

arecharging.

2.Machinecharger

connector

Note:Thebattery-chargingindicatorlight

shouldashandthecharging-outputindicator

lightshouldilluminate.

Themachineamperage,displayedonthe

InfoCenter,increaseswhilethebatteriescharge.

Iftheamperageremainsat0,thebatteriesare

notcharging.

9.Disconnectthechargerwhenthemachine

reachesasufcientlevel;refertoCompleting

theChargingProcess(page26).

10.Pivotthechargercoverinplaceandslideit

downoverthelowerbolt(Figure23).

26

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

MaintenanceSafety

CAUTION

Ifyouleavethekeyintheswitch,someonecouldaccidentlystarttheengineandseriously

injureyouorotherbystanders.

Removethekeyfromtheswitchbeforeyouperformanymaintenance.

•Parkthemachineonalevelsurface,disengage

theauxiliaryhydraulics,lowertheattachment,

engagetheparkingbrake,shutoffthemachine,

andremovethekey.Waitforallmovementtostop

andallowthemachinetocoolbeforeadjusting,

cleaning,storing,orrepairingit.

•Donotallowuntrainedpersonneltoservicethe

machine.

•Usejackstandstosupportthecomponentswhen

required.

•Carefullyreleasepressurefromcomponents

withstoredenergy;refertoRelievingHydraulic

Pressure(page34).

•Disconnectthebatterybeforemakinganyrepairs;

refertoDisconnectingorConnectingPowertothe

Machine(page32).

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

MaintenanceProcedure

•Keepyourhandsandfeetawayfromthemoving

parts.Ifpossible,donotmakeadjustmentswith

theenginerunning.

•Keepallpartsingoodworkingconditionandall

hardwaretightened.Replaceallwornordamaged

decals.

•Donottamperwiththesafetydevices.

•UseonlyT oro-approvedattachments.

Attachmentscanchangethestabilityandthe

operatingcharacteristicsofthemachine.Youmay

voidthewarrantyifyouusethemachinewith

unapprovedattachments.

•UseonlygenuineTororeplacementparts.

•Ifanymaintenanceorrepairrequirestheloader

armstobeintheraisedposition,securethearms

intheraisedpositionwiththehydraulic-cylinder

lock(s).

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every100hours

Every400hours

Every1,500hoursor

2years,whichever

comesrst

•T orquethewheel-lugnuts.

•Replacethehydrauliclter.

•Greasethemachine.(Greaseimmediatelyaftereverywashing.)

•Checkthestaticstrap;replaceitifwornormissing.

•Checkthetiretreads.

•T esttheparkingbrake.

•Removedebrisfromthemachine.

•Checkforloosefasteners.

•Checkthehydrauliclinesforleaks,loosettings,kinkedlines,loosemounting

supports,wear,weather,andchemicaldeterioration.

•Checkthehydraulic-uidlevel.

•T orquethewheel-lugnuts.

•Replacethehydrauliclter.

•Replaceallmovinghydraulichoses.

27

MaintenanceService

Interval

MaintenanceProcedure

Yearly

Yearlyorbeforestorage

•Changethehydraulicuid.

•T ouchupchippedpaint.

Pre-Maintenance

Procedures

UsingtheCylinderLocks

WARNING

Theloaderarmsmaylowerwhenintheraised

position,crushinganyoneunderthem.

Installthecylinderlock(s)beforeperforming

maintenancethatrequiresraisedloaderarms.

InstallingtheCylinderLocks

1.Removetheattachment.

2.Raisetheloaderarmstothefullyraisedposition.

RemovingandStoringthe

CylinderLocks

Important:Removethecylinderlocksfromthe

rodsandfullysecuretheminthestorageposition

beforeoperatingthemachine.

1.Startthemachine.

2.Raisetheloaderarmstothefullyraisedposition.

3.Shutoffthemachineandremovethekey.

4.Removetheclevispinandcotterpinsecuring

eachcylinderlock.

5.Removethecylinderlocks.

6.Lowertheloaderarms.

7.Installthecylinderlocksoverthehydraulic

hosesandsecurethemwiththeclevispinsand

cotterpins(Figure26).

3.Shutoffthemachineandremovethekey.

4.Positionacylinderlockovereachlift-cylinder

rod(Figure25).

Figure25

1.Cylinderlock4.Clevispin

2.Liftcylinder5.Lift-cylinderrod

3.Hairpincotter

5.Secureeachcylinderlockwithaclevispinand

cotterpin(Figure25).

6.Slowlylowertheloaderarmsuntilthecylinder

lockscontactthecylinderbodiesandrodends.

g005162

1.Hydraulichoses3.Hairpincotter

2.Cylinderlocks4.Clevispin

Figure26

g319295

28

AccessingInternal

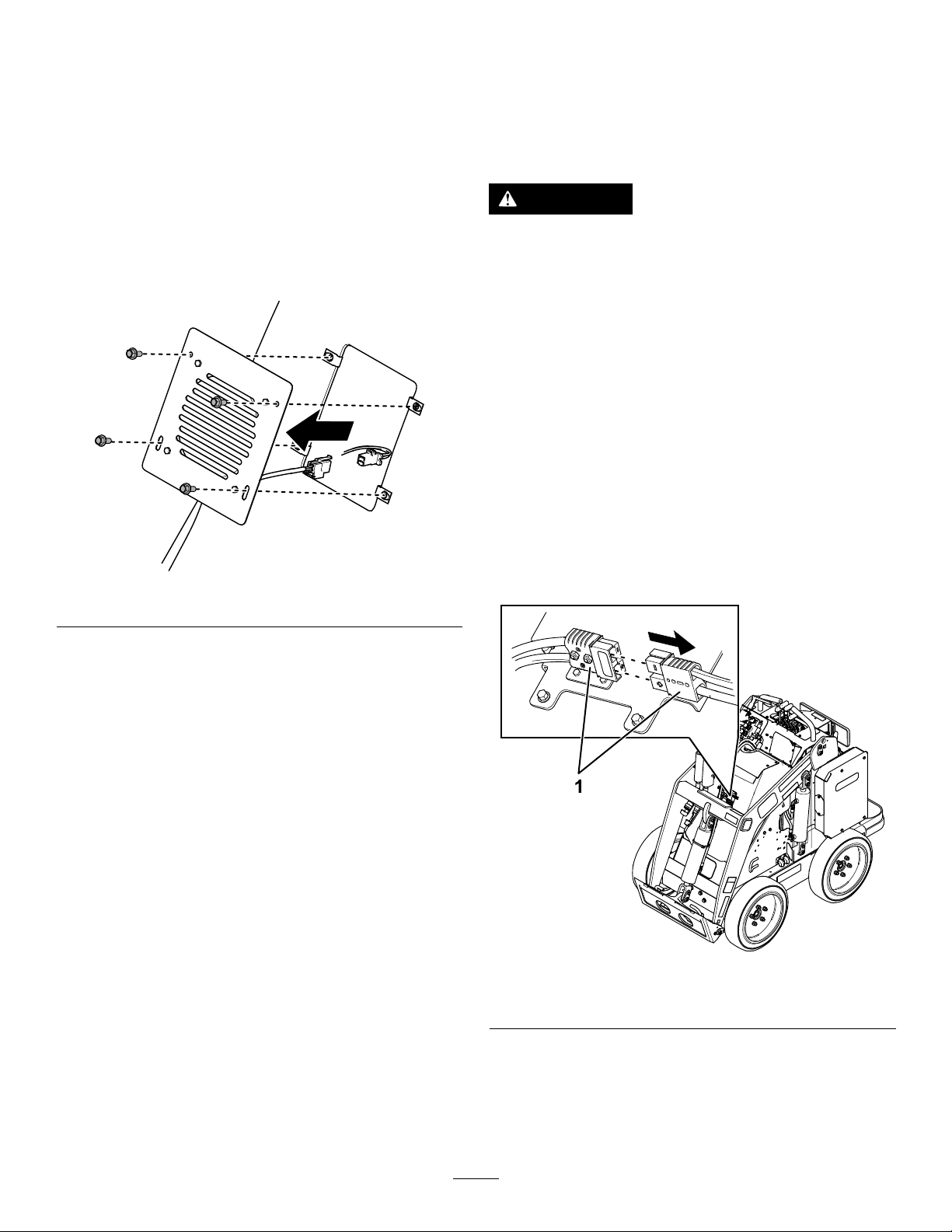

RemovingtheHood

Components

WARNING

Openingorremovingcovers,hoods,and

screenswhilethemachineisrunningcould

allowyoutocontactmovingparts,seriously

injuringyou.

Beforeopeninganyofthecovers,hoods,and

screens,shutoffthemachine,removethekey

fromthekeyswitch,andallowthemachine

tocool.

WARNING

Therotatingfancancausepersonalinjury.

•Donotoperatethemachinewithoutguards

inplace.

•Keepyourngers,hands,andclothing

clearoftherotatingfan.

Note:Ifyouneedtoaccessthemain-power

connectorsorfusebutcannotsafelyraisetheloader

armstoremovethehood,refertoRemovingtheFront

Cover(page30)foraccess.

1.Parkthemachineonalevelsurface.

2.Raisetheloaderarmsandinstallthecylinder

locks.

Note:Ifyoucannotraisetheloaderarmsusing

themachinepower,pulltheloader-armlever

rearwardanduseahoisttolifttheloaderarms.

3.Shutoffthemachine,removethekey,andwait

formovingpartstostop.

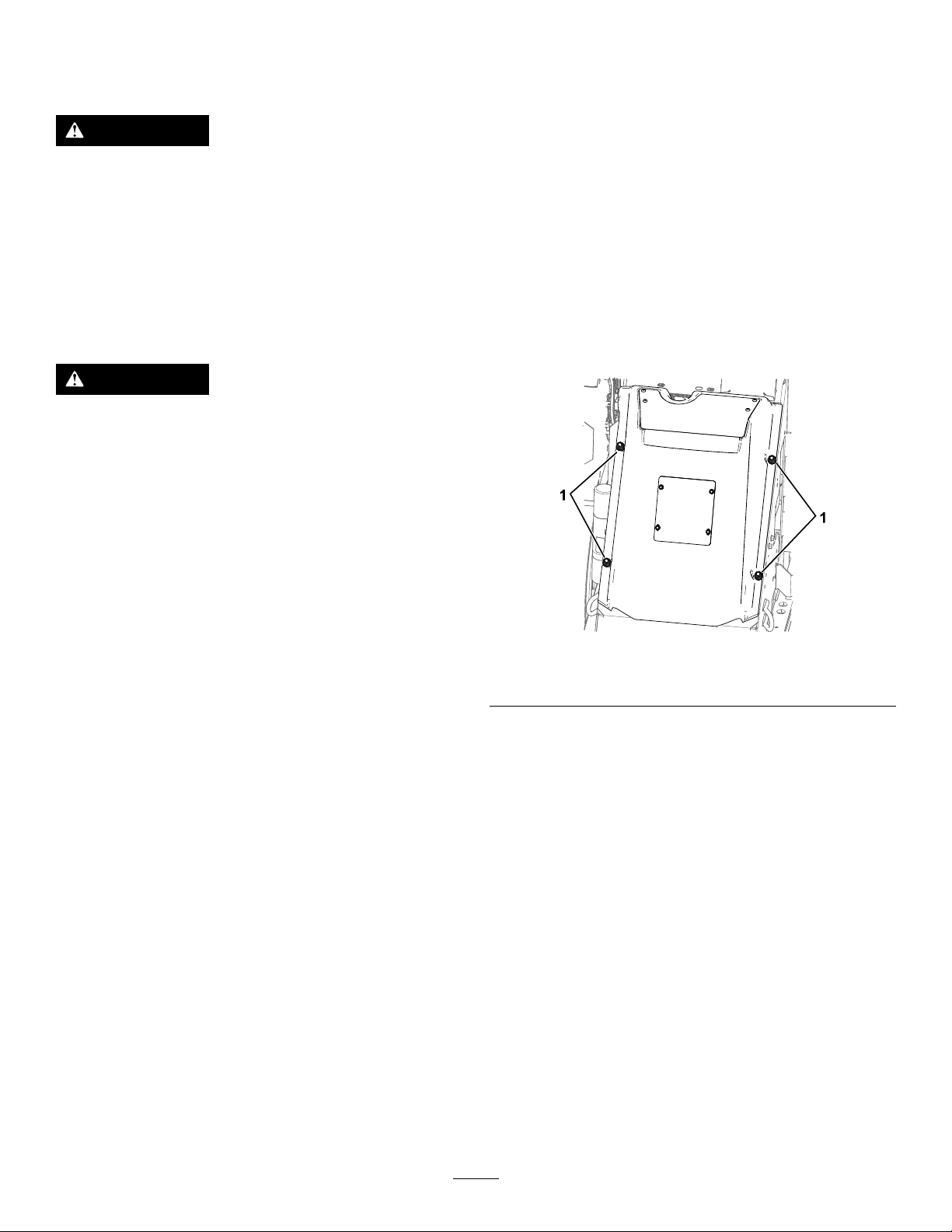

4.Loosenthe4nutssecuringthehood.

•Shutoffthemachineandremovethekey

beforeperformingmaintenance.

g304438

Figure27

1.Nuts

5.Liftthehoodandunplugthefan.

6.Pullthehoodoffthemachine.

29

RemovingtheFrontCover

DisconnectingtheMain

Important:Removethefrontcovertoaccess

themain-powerconnectorsandfuseonlywhen

youareunabletosafelyraisetheloaderarmsto

removethehood.

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,andengagetheparkingbrake.

2.Shutoffthemachine,removethekey,andwait

formovingpartstostop.

3.Removethe4boltssecuringthefrontcover,

removethecover,andunplugthefan.

Power

Beforeyouservicethemachine,disconnectthe

machinefromthepowersupplybyseparatingthe

main-powerconnectors(Figure29).

CAUTION

Ifyoudonotdisconnectthepowertothe

machine,someonecouldaccidentallyturnon

themachine,causingseriousbodilyinjury.

Alwaysseparatetheconnectorsbefore

workingonthemachine.

1.Parkthemachineonalevelsurface.

2.Raisetheloaderarmsandinstallthecylinder

locks.

3.Shutoffthemachineandremovethekey.

4.Removethehood;refertoRemovingtheHood

(page29).

5.Separatethe2powerconnectors(Figure29).

Figure28

6.Makeanyrepairs.

g356986

7.Plugtheconnectorstogetherbeforeoperating

themachine.

g304040

Figure29

1.Main-powerconnectors

30

Lubrication

GreasingtheMachine

ServiceInterval:Beforeeachuseordaily(Grease

immediatelyaftereverywashing.)

GreaseType:General-purposegrease

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,andengagetheparkingbrake.

2.Shutoffthemachineandremovethekey.

3.Cleanthegreasettingswitharag.

g004209

Figure31

4.Connectagreaseguntoeachtting(Figure30

andFigure31).

5.Pumpgreaseintothettingsuntilgreasebegins

tooozeoutofthebearings(approximately3

pumps).

6.Wipeupanyexcessgrease.

Figure30

g304444

31

ElectricalSystem

ServicingtheBatteries

Maintenance

ElectricalSystemSafety

•Disconnectthemain-powerconnectorsbefore

repairingthemachine.

•Chargethebatteryinanopen,well-ventilated

area,awayfromsparksandames.Unplugthe

chargerbeforeconnectingordisconnectingthe

battery.Wearprotectiveclothinganduseinsulated

tools.

Disconnectingor

ConnectingPowerto

theMachine

Themain-powerconnectorsprovidepowerfrom

thebatteriestothemachine.Disconnectthepower

byseparatingtheconnectors;connectthepower

byinstallingtheconnectorstogether.Referto

DisconnectingtheMainPower(page30).

ReplacingtheStaticStrap

ServiceInterval:Beforeeachuseordaily—Check

thestaticstrap;replaceitifwornor

missing.

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,andengagetheparkingbrake.

2.Shutoffthemachineandremovethekey.

3.Undertheplatform,replacethestaticstrapas

showninFigure32.

Note:Themachineisequippedwith7lithium-ion

batteries.

Ifyouattempttoopenthemaincompartmentof

abattery,youwillvoidyourwarranty.Ifabattery

requiresservice,contactyourAuthorizedService

Dealerforassistance.

Disposeoforrecyclelithium-ionbatteriesin

accordancewithlocalandfederalregulations.

MaintainingtheBattery

Charger

Important:Allelectricalrepairsshouldbe

performedbyanAuthorizedServiceDealeronly .

Theoperatorcanperformverylittlemaintenanceother

thanprotectingthechargerfromdamageandweather.

MaintainingtheBattery-Charger

Cords

•Cleanthecordswithaslightlydampclothafter

eachuse.

•Coilthecordswhennotinuse.

•Periodicallyexaminethecordsfordamage,and

replacethemwhennecessarywithToro-approved

parts.

CleaningtheBattery-ChargerCase

Cleanthecasewithaslightlydampclothaftereach

use.

Figure32

1.Nut3.Washer

2.Staticstrap

g315429

4.Bolt

32

ServicingtheFuse

1.Parkthemachineonalevelsurface.

2.Raisetheloaderarmsandinstallthecylinder

locks.

3.Shutoffthemachineandremovethekey.

DriveSystem

Maintenance

CheckingtheTireTreads

4.Removethehood;refertoRemovingtheHood

(page29).

5.Disconnectthemainpowertothemachine;

refertoDisconnectingorConnectingPowerto

theMachine(page32).

6.Locatethefuseandreplaceit(Figure33).

Figure33

ServiceInterval:Beforeeachuseordaily

Checkthetiretreadsforwear.Replacethetireswhen

thetreadsarewornandshallow.

CheckingtheWheel-Lug

Nuts

ServiceInterval:Aftertherst8hours

Every100hours

Checkandtorquethewheellugnutsto68N∙m(50

ft-lb).

g304512

7.Torquethenutsto12to18N∙m(9to13ft-lb).

8.Connectthemain-powerconnectors.

9.Installthefrontcover.

33

BrakeMaintenance

TestingtheParkingBrake

HydraulicSystem

Maintenance

ServiceInterval:Beforeeachuseordaily

1.Engagetheparking-brake;referto

Parking-BrakeLever(page10).

2.Startthemachine.

3.Slowlyattempttodrivethemachineforwardor

rearward.

Note:Themachinemaymovesomebeforethe

parkingbrakelocksinplace.

4.Ifthemachinemoveswithouttheparkingbrake

lockinginplace,contactyourAuthorizedService

Dealerforservice.

HydraulicSystemSafety

•Seekimmediatemedicalattentionifuidisinjected

intoskin.Injecteduidmustbesurgicallyremoved

withinafewhoursbyadoctor.

•Ensurethatallhydraulic-uidhosesandlinesare

ingoodconditionandallhydraulicconnections

andttingsaretightbeforeapplyingpressureto

thehydraulicsystem.

•Keepyourbodyandhandsawayfrompinhole

leaksornozzlesthatejecthigh-pressurehydraulic

uid.

•Usecardboardorpapertondhydraulicleaks.

•Safelyrelieveallpressureinthehydraulicsystem

beforeperforminganyworkonthehydraulic

system.

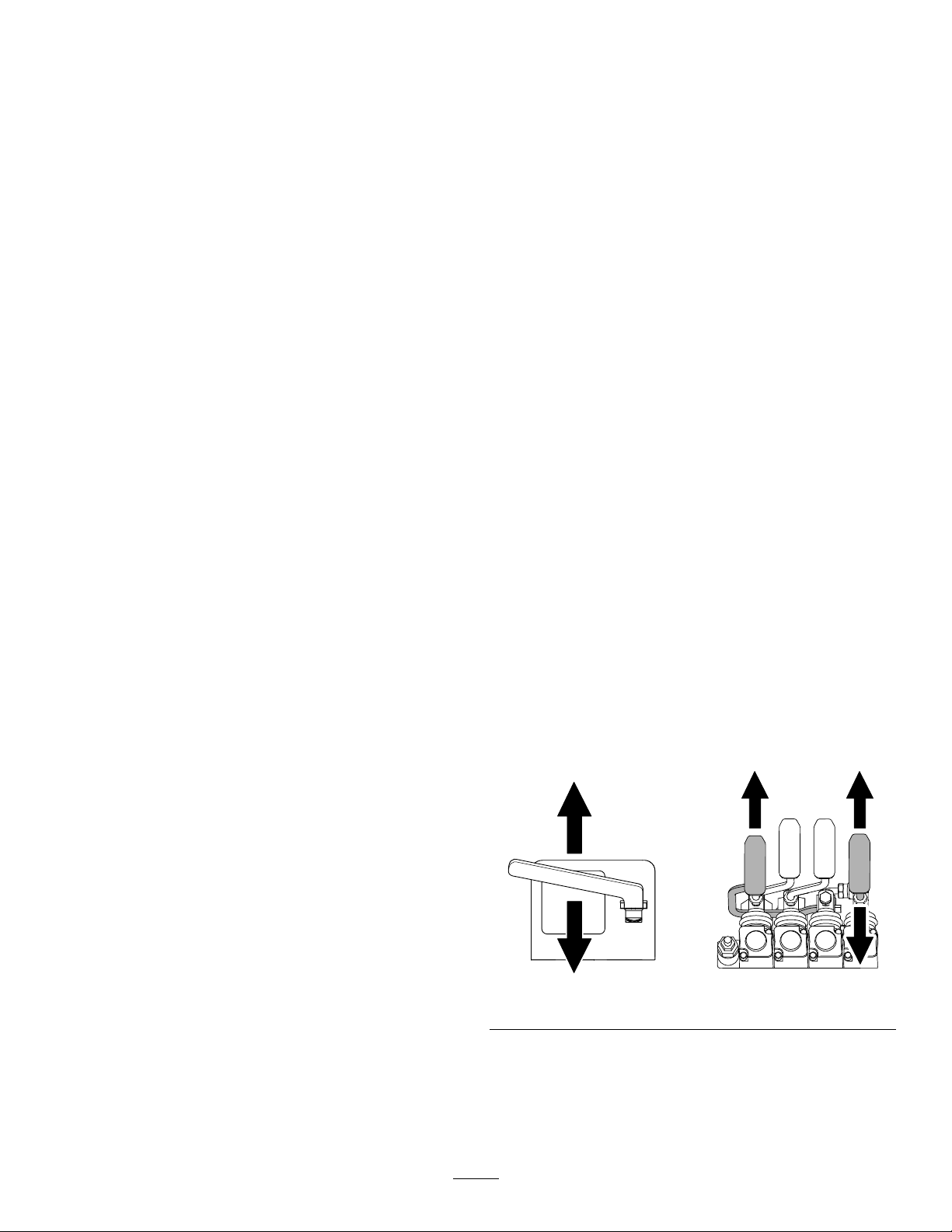

RelievingHydraulic

Pressure

Torelievehydraulicpressurewhilethemachineison,

disengagetheauxiliaryhydraulicsandfullylowerthe

loaderarms.

Torelievethepressurewhilethemachineisoff,move

theauxiliary-hydraulicsleverbetweentheforwardand

reverseowpositionstorelieveauxiliaryhydraulic

pressure,movetheattachment-tiltleverforwardand

rearward,andmovetheloader-armleverforwardto

lowertheloaderarms(Figure34).

Figure34

g281214

34

HydraulicFluid

Checkingthe

Specications

HydraulicTankCapacity:56L(14.8USgallons)

Useonly1ofthefollowinguidsinthehydraulic

system:

•ToroPremiumTransmission/HydraulicTractor

Fluid(refertoyourAuthorizedServiceDealerfor

moreinformation)

•ToroPXExtendedLifeHydraulicFluid(refer

toyourAuthorizedServiceDealerformore

information)

•IfeitheroftheaboveT orouidsarenotavailable,

youmayuseanotherUniversalTractorHydraulic

Fluid(UTHF),buttheymustbeonlyconventional,

petroleum-basedproducts.Thespecications

mustfallwithinthelistedrangeforallthefollowing

materialpropertiesandtheuidshouldmeet

thelistedindustrystandards.Checkwithyour

hydraulicuidsuppliertodetermineiftheuid

meetsthesespecications.

Note:T orowillnotassumeresponsibilityfor

damagecausedbyimpropersubstitutions,souse

onlyproductsfromreputablemanufacturerswho

willstandbehindtheirrecommendations.

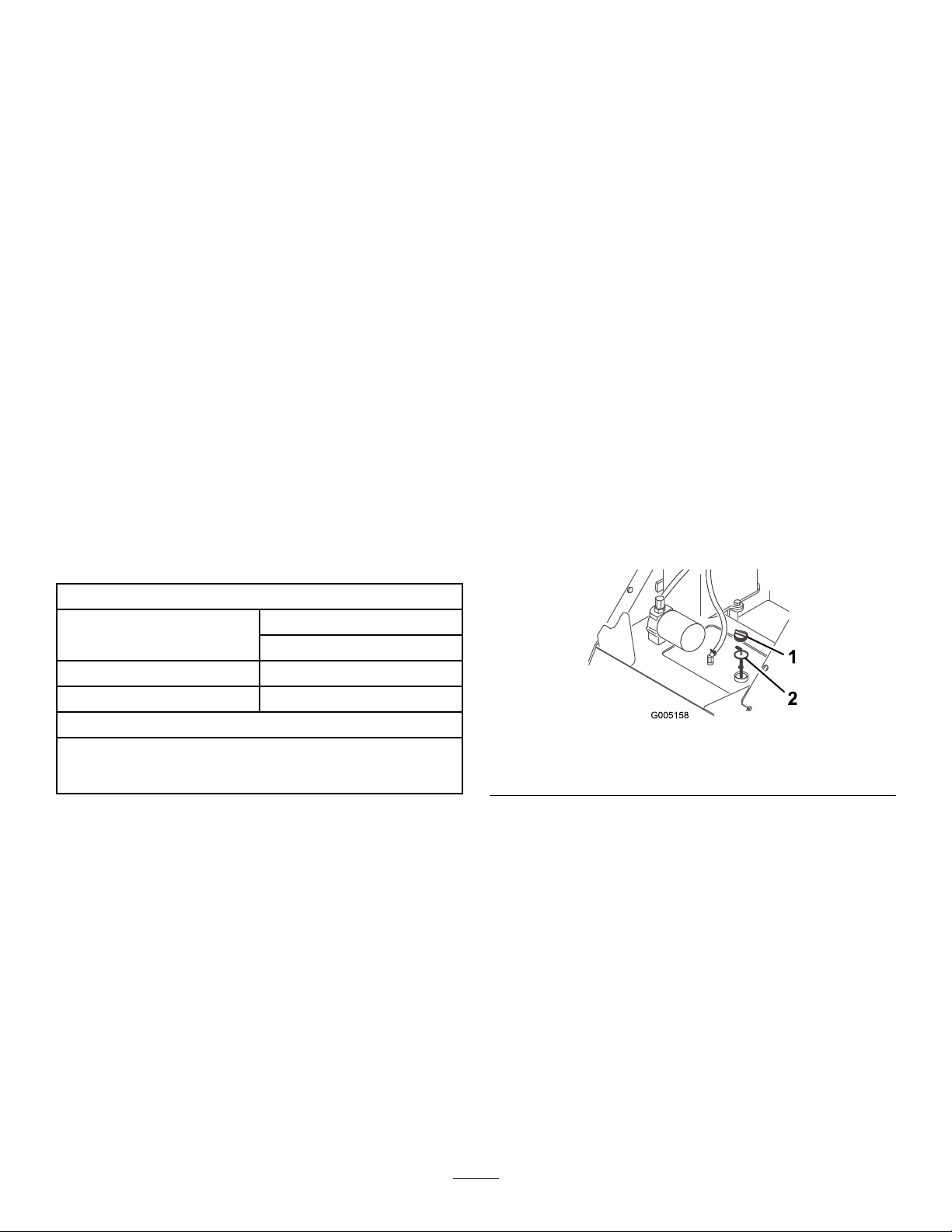

Hydraulic-FluidLevel

ServiceInterval:Every25hours

Checkthehydraulic-uidlevelbeforethemachineis

rststartedandafterevery25operatinghours.

RefertoHydraulicFluidSpecications(page35).

Important:Alwaysusethecorrecthydraulic

uid.Unspecieduidswilldamagethehydraulic

system.

1.Parkthemachineonalevelsurface,remove

anyattachment,engagetheparkingbrake,raise

theloaderarms,andinstallthecylinderlocks.

2.Shutoffthemachine,removethekey,andallow

themachinetocool.

3.Removethehood/frontaccesscover.

4.Cleantheareaaroundthellerneckofthe

hydraulictank(Figure35).

5.Removetheller-neckcapandchecktheuid

levelonthedipstick(Figure35).

Theuidlevelshouldbebetweenthemarkson

thedipstick.

MaterialProperties

cStat40°C:55to62 Viscosity,ASTMD445

cStat100°C:9.1to9.8

Viscosityindex,ASTMD2270

PourPoint,ASTMD97-43to-37°C(-46to-35°F)

IndustryStandards

APIGL-4,AGCOPoweruid821XL,FordNewHolland

FNHA-2-C-201.00,KubotaUDT ,JohnDeereJ20C,Vickers

35VQ25andVolvoWB-101/BM

140to152

Note:Manyhydraulicuidsarealmostcolorless,

makingitdifculttospotleaks.Areddyeadditive

forthehydraulicsystemuidisavailablein20ml

(0.67oz)bottles.Onebottleissufcientfor15to

22L(4to6USgallons)ofhydraulicuid.Order

PartNo.44-2500fromyourAuthorizedService

Dealer.

g005158

Figure35

1.Fillerneckcap2.Dipstick

6.Ifthelevelislow,addenoughuidtoraiseitto

theproperlevel.

7.Installtheller-neckcap.

8.Installthehood/frontaccesscover.

9.Removeandstorethecylinderlocksandlower

theloaderarms.

35

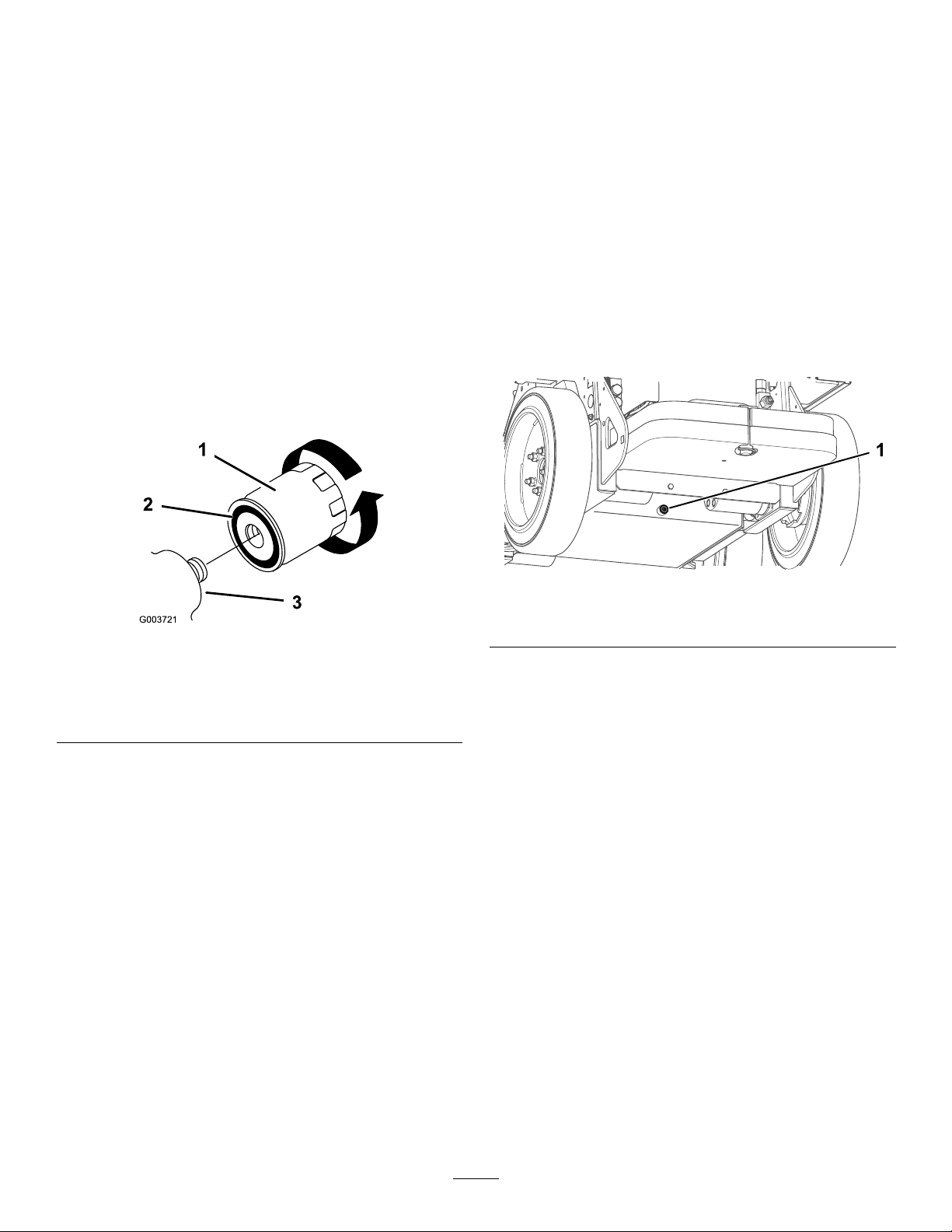

ReplacingtheHydraulic

ChangingtheHydraulic

Filter

ServiceInterval:Aftertherst8hours

Every400hours

Important:Donotsubstituteanautomotiveoil

lter;otherwise,severehydraulicsystemdamage

mayresult.

1.Parkthemachineonalevelsurface,remove

anyattachment,engagetheparkingbrake,raise

theloaderarms,andinstallthecylinderlocks.

2.Shutoffthemachineandremovethekey.

3.Removethehood.

4.Placeadrainpanunderthelter.

5.Removetheoldlter(Figure36)andwipethe

surfaceofthelteradapterclean.

Fluid

ServiceInterval:Yearly

1.Parkthemachineonalevelsurface,remove

anyattachment,engagetheparkingbrake,raise

theloaderarms,andinstallthecylinderlocks.

2.Shutoffthemachineandremovethekey.

3.Removethehood.

4.Placealargedrainpanunderthemachinethat

canholdatleast61L(16USgallons).

5.Removethedrainplugfromthebottomofthe

hydraulictankandallowtheuidtocompletely

drainout(Figure37).

Figure36

1.Hydrauliclter

2.Gasket

3.Filteradapter

6.Applyathincoathydraulicuidtotherubber

gasketonthereplacementlter(Figure36).

7.Installthereplacementhydrauliclterontothe

lteradapter(Figure36).Tightenitclockwise

untiltherubbergasketcontactsthelteradapter,

thentightenthelteranadditional1/2turn.

8.Cleanupanyspilleduid.

9.Startthemachineandletitrunforabout2

minutestopurgeairfromthesystem.

10.Shutoffthemachineandcheckforleaks.

11.Checktheuidlevelinthehydraulictank;refer

toCheckingtheHydraulic-FluidLevel(page35).

Adduidtoraisetheleveltomarkondipstick.

Donotoverllthetank.

g305431

Figure37

g003721

1.Drainplug

6.Installthedrainplug.

7.Fillthehydraulictankwithhydraulicuid;refer

toHydraulicFluidSpecications(page35).

Note:Disposeofuseduidatacertied

recyclingcenter.

8.Installthehood.

9.Removeandstorethecylinderlocksandlower

theloaderarms.

12.Installthehood.

13.Removeandstorethecylinderlocksandlower

theloaderarms.

36

Cleaning

Storage

RemovingDebris

ServiceInterval:Beforeeachuseordaily

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,andengagetheparkingbrake.

2.Shutoffthemachineandremovethekey.

3.Cleananydebrisfromthemachine.

Important:Blowthedirtoutratherthan

washitout.Ifyouusewater,keepitaway

fromelectricalitemsandhydraulicvalves.

Cleanelectricalconnectorsusing

compressedair;donotusecontactcleaner.

4.Removeandstorethecylinderlocksandlower

theloaderarms.

WashingtheMachine

Whenpressurewashingthemachine,dothefollowing:

•Wearappropriatepersonalprotectiveequipment

forthepressurewasher.

•Keepallguardsinplaceonthemachine.

•Avoidsprayingatelectroniccomponents.

•Avoidsprayingatedgesofdecals.

•Spraytheexteriorofthemachineonly .Donot

spraydirectlyintoopeningsinthemachine.

•Sprayonlythedirtypartsofthemachine.

•Usea40-degreeorlargerspraynozzle.40-degree

nozzlesareusuallywhite.

•Keepthetipofthepressurewasheratleast61cm

(2ft)awayfromthesurfacebeingwashed.

•Useonlypressurewasherswithpressurebelow

13790kpa(2000psi)andowbelow7.6L(2US

gallons)perminute.

•Replacedamagedorpeelingdecals.

StorageSafety

•Shutoffthemachine,removethekey ,waitforall

movingpartstostop,andallowthemachineto

coolbeforestoringit.

•Donotstorethemachinenearames.

StoringtheMachine

1.Parkthemachineonalevelsurface,lowerthe

loaderarms,andengagetheparkingbrake.

2.Shutoffthemachineandremovethekey.

3.Removedirtandgrimefromtheexternalparts

oftheentiremachine.

Important:Washthemachineusingmild

detergentandwater.Avoidexcessiveuse

ofwater,especiallynearthecontrolpanel,

hydraulicpumps,andmotors.

4.Greasethemachine;refertoGreasingthe

Machine(page31).

5.Torquethewheellugnuts;refertoCheckingthe

Wheel-LugNuts(page33).

6.Checkthehydraulicuidlevel;refertoChecking

theHydraulic-FluidLevel(page35).

7.Checkandtightenallfasteners.Repairor

replaceanyworn,damaged,ormissingparts.

8.Paintallscratchedorbaremetalsurfaceswith

paintavailablefromyourAuthorizedService

Dealer.

9.Storethemachineinaclean,drygarageor

storagearea.Removethekeyfromthekey

switchandkeepitinamemorableplace.

10.Forprolongedstorage,followthebattery

storagerequirements;refertoBatteryStorage

Requirements(page38).

11.Coverthemachinetoprotectitandkeepitclean.

•Greaseallgreasepointsafterwashing;referto

GreasingtheMachine(page31).

37

BatteryStorage

Requirements

Note:Y oudonotneedtoremovethebatteriesfrom

themachineforstorage.

Fortemperaturerequirementsforstorage,refertothe

followingtable:

TemperatureRequirementsforStorage

StorageConditions

Normalstorageconditions

Extremeheat—1monthor

less

Extremecold—3monthsor

less

TemperatureRequirement

-20°to45°C(-12°to1 13°F)

45°to60°C(113°to140°F)

-30°to-20°C(-22°to-12°F)

Important:Temperaturesoutsideofthisrange

willdamageyourbatteries.

Thetemperatureatwhichthebatteriesarestored

affectstheirlong-termlife.Storageforlong

periodsoftimeatextremetemperatureswill

reducethebatterylife.Storethemachineinthe

normalstorageconditionsindicatedinthetable

above.

•Beforeyoustorethemachine,chargeordischarge

thebatteriesbetween40%to60%(50.7Vto

52.1V).

Note:A50%chargeisoptimaltoensurea

maximumbatterylife.Whenthebatteriesare

chargedto100%beforestorage,thebatterylife

shortens.

Ifyouanticipatethatthemachinewillbestored

foralongerperiodoftime,chargethebatteries

toaround60%.

•Forevery6monthsofstorage,checkthe

battery-chargelevelandensurethatitisbetween

40%and60%.Ifthechargeisbelow40%,charge

thebatteriesbetween40%to60%.

•Afterchargingthebatteries,disconnectthebattery

chargerfrompower.

•Ifyouleavethechargeronthemachine,itshutsoff

afterthebatteriesarefullychargedanddoesnot

turnbackonunlessthechargerisdisconnected

andreconnected.

38

Troubleshooting

MachineTroubleshooting

Problem

Themachinedoesnotdrive.

Whenatrest,theloaderarmslowermore

than7.6cm(3inches)perhour(lessthan

7.6cmor3inchesanhourisnormalfor

themachine).

Whenatrest,theloaderarmslower5cm

(2inches)quicklyandthenstop.

Themachinedoesnotcharge.

Themachinedoesnotstartimmediately

aftershuttingitoff.

Themachinedoesnotresumeoperation

afteridling.

Battery-ChargerErrorCodes

Problem

PossibleCauseCorrectiveAction

1.Theparkingbrakeisengaged.1.Disengagetheparkingbrake.

2.Thehydraulic-uidlevelislow.2.Addhydraulicuidtothereservoir.

3.Thehydraulicsystemisdamaged.

1.Thevalvespoolisleaking.

1.Thecylindersealsareleaking.1.Replacetheseals.

1.Thetemperatureisabove60°C(1 13°F)

orbelow-5°C(23°F).

1.Themachinedidnotpowerdown

completely.

1.ThemachineisinPowerSaveMode.

PossibleCauseCorrectiveAction

3.ContactyourAuthorizedService

Dealer.

1.ContactyourAuthorizedService

Dealer.

1.Chargethemachineinconditions

between-5°C(23°F)and60°C(113°F).

1.Allowthemachinetocompletelypower

downbeforestartingitagain.

1.Rapidlymoveatractionlevertwiceor

shutoffandstartthemachineagain.

CodeE-0-0-1,orE-0-4-7

CodeE-0-0-41.BMSorbatteryfaultdetected1.ContactanAuthorizedServiceDealer.

CodeE-0-0-7

CodeE-0-1-2

CodeE-0-2-31.HighACvoltageerror(>270VAC)1.ConnectchargertoanACsourcethat

CodeE-0-2-41.Chargerfailedtoinitialize

CodeE-0-2-51.LowACvoltageoscillationerror

1.Batteryhighvoltage1.Ensurethatthebatteryvoltageis

correctandthecableconnectionsare

secure;ensurethatthebatteryisin

goodcondition.

1.Batteryamphourlimitexceeded1.Possiblecausesincludepoorbattery

health,verydeeplydischargedbattery,

poorlyconnectedbattery ,and/or

highparasiticloadsonbatterywhile

charging.Possiblesolutions:Replace

batteries.Disconnectparasiticloads.

Thiserrorwillclearoncethechargeris

resetbycyclingDC.

1.Reversepolarityerror1.Thebatteryisconnectedtothecharger

incorrectly.Ensurethatthebattery

connectionsaresecure.

providesstableACbetween85-270

VAC/45-65Hz.

1.Thechargerhasfailedtoturnon

properly.DisconnecttheACinputand

batteryconnectionfor30seconds

beforeretrying.

1.TheACsourceisunstable.Could

becausedbyundersizedgenerator

orseverelyundersizedinputcables.

ConnectchargertoanACsourcethat

providesstableACbetween85-270

VAC/45-65Hz.

39

Problem

PossibleCauseCorrectiveAction

CodeE-0-3-71.Re-programmingfailed1.Softwareupgradefailureorscript

CodeE-0-2-9,E-0-3-0,E-0-3-2,E-0-4-6,

orE-0-6-0

1.Communicationerrorwithbattery1.Ensurethattheconnectionofthe

operationfailure.Ensurethatthenew

softwareiscorrect.

signalwirestothebatteryissecure.

Battery-ChargerFaultCodes

Problem

F-0-0-1,F-0-0-2,F-0-0-3,F-0-0-4,

F-0-0-5,F-0-0-6,orF-0-0-7

1.Internalchargerfault1.RemovetheACconnectionand

PossibleCauseCorrectiveAction

batteryconnectionforaminimumof

30secondsandretry.Ifitfailsagain,

pleasecontactanAuthorizedService

Dealer.

40

Notes:

Notes:

EEA/UKPrivacyNotice

Toro’sUseofYourPersonalInformation

TheT oroCompany(“T oro”)respectsyourprivacy .Whenyoupurchaseourproducts,wemaycollectcertainpersonalinformationaboutyou,eitherdirectly

fromyouorthroughyourlocalT orocompanyordealer.T orousesthisinformationtofullcontractualobligations-suchastoregisteryourwarranty,

processyourwarrantyclaimortocontactyouintheeventofaproductrecall-andforlegitimatebusinesspurposes-suchastogaugecustomer

satisfaction,improveourproductsorprovideyouwithproductinformationwhichmaybeofinterest.T oromayshareyourinformationwithoursubsidiaries,