Page 1

FormNo.3364-357RevB

66cmHeavy-DutyRearBagger

LawnMower

ModelNo.22203TE—SerialNo.312000001andUp

ToregisteryourproductordownloadanOperator'sManualorPartsCatalogatnocharge,gotowww.T oro.com.OriginalInstructions(EN)

Page 2

ThisproductcomplieswithallrelevantEuropean

G018480

1

directives.Fordetails,seetheseparateproductspecic

DeclarationofConformity(DOC)sheet.

Formodelswithstatedenginehorsepower,thegross

horsepoweroftheenginewaslaboratoryratedbythe

enginemanufacturerinaccordancewithSAEJ1940.

Asconguredtomeetsafety,emission,andoperating

requirements,theactualenginehorsepoweronthisclass

oflawnmowerwillbesignicantlylower.

Donottamperwiththeenginecontrolsoralterthe

governorspeed;doingsomaycreateanunsafecondition

resultinginpersonalinjury.

Introduction

ModelNo.

SerialNo.

Thismanualidentiespotentialhazardsandhassafety

messagesidentiedbythesafetyalertsymbol(Figure2),

whichsignalsahazardthatmaycauseseriousinjury

ordeathifyoudonotfollowtherecommended

precautions.

Figure2

1.Safetyalertsymbol

Thisrotary-blade,walk-behindlawnmoweris

intendedtobeusedbyresidentialhomeowners

orprofessional,hiredoperators.Itisdesigned

primarilyforcuttinggrassonwell-maintainedlawns

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

onresidentialorcommercialproperties.Itisnot

designedforcuttingbrushorforagriculturaluses.

Readthisinformationcarefullytolearnhowtooperate

andmaintainyourproductproperlyandtoavoidinjury

andproductdamage.Youareresponsibleforoperating

theproductproperlyandsafely.

YoumaycontactTorodirectlyatwww .T oro.comfor

productandaccessoryinformation,helpndingadealer,

ortoregisteryourproduct.

Contents

Introduction.................................................................2

Safety...........................................................................3

GeneralSafety......................................................3

SoundPressure.....................................................5

SoundPower........................................................5

Vibration,Hand/arm...........................................5

SafetyandInstructionalDecals.............................5

Wheneveryouneedservice,genuineToroparts,

oradditionalinformation,contactanAuthorized

ServiceDealerorToroCustomerServiceandhave

themodelandserialnumbersofyourproductready .

Figure1identiesthelocationofthemodelandserial

numbersontheproduct.Writethenumbersinthe

spaceprovided.

Setup...........................................................................7

1InstallingtheHandle..........................................7

2FillingtheEngineCrankcasewith

Oil....................................................................7

ProductOverview........................................................8

Controls...............................................................8

Operation.....................................................................9

CheckingtheEngineOilLevel..............................9

FillingtheFuelTank.............................................9

StartingtheEngine.............................................11

StoppingtheEngine...........................................11

OperatingtheBlade............................................11

OperatingtheTractionDrive..............................12

CheckingtheBlade-BrakeClutch........................12

AdjustingtheCuttingHeight..............................13

UsingtheGrassBag...........................................14

OperatingTips...................................................14

Figure1

1.Modelandserialnumberlocation

Maintenance...............................................................16

RecommendedMaintenanceSchedule(s)................16

PremaintenanceProcedures....................................17

PreparingforMaintenance.................................17

©2012—TheT oro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Contactusatwww.Toro.com.

2

PrintedintheUSA

AllRightsReserved

Page 3

Lubrication.............................................................17

LubricatingthePivotArms.................................17

LubricatingtheGearCase...................................17

EngineMaintenance...............................................18

ServicingtheAirFilter........................................18

ChangingtheEngineOil....................................19

ServicingtheSparkPlug.....................................20

FuelSystemMaintenance.......................................21

EmptyingtheFuelTank.....................................21

CleaningtheFuelFilter.......................................21

DriveSystemMaintenance.....................................21

AdjustingtheSelf-propelDrive...........................21

ControlsSystemMaintenance.................................22

AdjustingtheBlade-BrakeCable.........................22

BladeMaintenance.................................................22

MaintainingtheCuttingBlade.............................22

Cleaning.................................................................24

CleaningundertheBeltCover.............................24

CleaningundertheHousing................................24

CleaningtheDischargeTunnel...........................24

Storage.......................................................................25

PreparingtheFuelSystem...................................25

PreparingtheEngine..........................................25

PreparingtheRestoftheMachine.......................25

RemovingtheMachinefromStorage..................25

Troubleshooting.........................................................26

Safety

Improperlyusingormaintainingthismachinecan

resultininjury .Toreducethepotentialforinjury,

complywiththesesafetyinstructions.

Torodesignedandtestedthismachineforreasonably

safeservice;however,failuretocomplywiththe

followinginstructionsmayresultinpersonalinjury.

Toensuremaximumsafety,bestperformance,and

togainknowledgeofthemachine,itisessential

thatyouandanyotheroperatorofthemachineread

andunderstandthecontentsofthismanualbefore

theengineiseverstarted.Payparticularattention

tothesafetyalertsymbol(

Caution,Warning,orDanger—“personalsafety

instruction.”Readandunderstandtheinstruction

becauseithastodowithsafety .Failuretocomply

withtheinstructionmayresultinpersonalinjury.

GeneralSafety

Thefollowinginstructionshavebeenadaptedfromthe

ISOstandard5395.

Thiscuttingmachineiscapableofamputatinghands

andfeetandofthrowingobjects.Failuretoobserve

thefollowingsafetyinstructionscouldresultinserious

injuryordeath.

Figure2)whichmeans

Training

•Readtheinstructionscarefully.Befamiliarwiththe

controlsandtheproperuseofthemachine.

•Neverallowchildrenorpeopleunfamiliarwiththese

instructionstousethemachine.Localregulations

canrestricttheageoftheoperator.

•Keepinmindthattheoperatororuserisresponsible

foraccidentsorhazardsoccurringtootherpeopleor

theirproperty.

•Understandexplanationsforallpictogramsusedon

themachineorintheinstructions.

Gasoline

WARNING—Gasolineishighlyammable.Takethe

followingprecautions:

•Storefuelincontainersspecicallydesignedforthis

purpose.

•Refueloutdoorsonlyanddonotsmokewhile

refueling.

•Addfuelbeforestartingtheengine.Neverremove

thecapofthefueltankoraddgasolinewhilethe

engineisrunningorwhentheengineishot.

3

Page 4

•Ifgasolineisspilled,donotattempttostartthe

enginebutmovethemachineawayfromthearea

ofspillageandavoidcreatinganysourceofignition

untilgasolinevaporshavedissipated.

•Replaceallfueltankandcontainercapssecurely.

Preparation

•Whilemowing,alwayswearsubstantialfootwearand

longtrousers.Donotoperatethemachinewhen

barefootorwearingopensandals.

•Thoroughlyinspecttheareawherethemachineisto

beusedandremoveallstones,sticks,wires,bones

andotherforeignobjects.

•Beforeusing,alwaysvisuallyinspecttoseethat

guards,andsafetydevices,suchasdeectorsand/or

grasscatchers,areinplaceandworkingcorrectly.

•Beforeusing,alwaysvisuallyinspecttoseethatthe

blades,bladebolts,andcutterassemblyarenotworn

ordamaged.Replacewornordamagedbladesand

boltsinsetstopreservebalance.

Starting

•Disengageallbladeanddriveclutches,andshiftinto

neutralbeforestartingtheengine.

•Donottiltthemachinewhenstartingtheengine

orswitchingonthemotor,unlessthemachinehas

tobetiltedforstarting.Inthiscase,donottiltit

morethanabsolutelynecessary,andliftonlythepart

whichisawayfromtheoperator.

•Starttheengineorswitchonthemotorcarefully

accordingtoinstructionsandwithfeetwellaway

fromtheblade(s)andnotinfrontofthedischarge

chute.

Operation

•Nevermowwhilepeople,especiallychildren,orpets

arenearby .

•Mowonlyindaylightoringoodarticiallight.

•Avoidoperatingthemachineinwetgrass,where

feasible.

•Stayalertforholesintheterrainandotherhidden

hazards.

•Donotputhandsorfeetnearorunderrotatingparts.

Keepclearofthedischargeopeningatalltimes.

•Neverpickuporcarryamachinewhiletheengine

isrunning.

•Useextremecautionwhenreversingorpullinga

pedestrian-controlledmachinetowardyou.

•Walk,neverrun.

•Slopes:

–Donotmowexcessivelysteepslopes.

–Exerciseextremecautionwhenmowingon

slopes.

–Mowacrossthefaceofslopes,neverupand

down,andexerciseextremecautionwhen

changingdirectiononslopes.

–Alwaysbesureofyourfootingonslopes.

•Uselowthrottlesettingswhenengagingthe

traction-clutch,especiallyinhighgears.Reduce

speedonslopesandinsharpturnstoprevent

overturningorlossofcontrol.

•Stopthebladeifthemachinehastobetiltedfor

transportationwhencrossingsurfacesotherthan

grassandwhentransportingthemachinetoand

fromtheareatobemowed.

•Donotoperatetheengineinaconnedspacewhere

dangerouscarbonmonoxidefumescancollect.

•Stoptheengine

–wheneveryouleavethemachine;

–beforerefueling;

–beforeremovingthegrasscatcher;or

–beforemakingheightadjustmentunless

adjustmentcanbemadefromtheoperator's

position.

•Stoptheengineanddisconnectthespark-plugwire

–beforeclearingblockagesoruncloggingchute;

–beforechecking,cleaningorworkingonthe

machine;

–afterstrikingaforeignobject,inspectthe

machinefordamageandmakerepairsbefore

startingandoperatingthemachine;or

–ifthemachinestartstovibrateabnormally(check

immediately).

•Reducethethrottlesettingduringengineshutdown,

andclosethefuelvalveattheconclusionofmowing.

•Watchoutfortrafcwhencrossingornearroadways.

MaintenanceandStorage

•Keepallnuts,boltsandscrewstighttobesurethe

machineisinsafeworkingcondition.

•Donotusepressurecleaningequipmentonthe

machine.

•Neverstorethemachinewithgasolineinthefuel

tankorinsideabuildingwherefumescanreachan

openameorspark.

4

Page 5

•Allowtheenginetocoolbeforestoringthemachine

inanyenclosure.

•Toreducearehazard,keeptheengine,silencer,

batterycompartment,andgasolinestoragefreeof

grass,leaves,orexcessivegrease.

•Checkgrasscatchercomponentsandthe

dischargeguardfrequently ,andreplacethemwith

manufacturer'srecommendedparts,whennecessary.

•Replacewornordamagedpartsforsafety .

•Replacefaultysilencers.

•Ifthefueltankmustbedrained,dothisoutdoors.

•Donotchangetheenginegovernorsettingsor

overspeedtheengine.Operatinganengineat

excessivespeedcanincreasethehazardofpersonal

injury.

•Becarefulwhileworkingonthemachinetoprevent

entrapmentofngersbetweenmovingbladesand

xedparts.

•Toensurethebestperformanceandsafety ,

purchaseonlygenuineT ororeplacementparts

andaccessories.Donotuse

will-t

partsand

accessories;theymaycauseasafetyhazard.

SoundPressure

Thismachinehasamaximumsoundpressurelevelatthe

operator’searof87dBA,whichincludesanUncertainty

Value(K)of1dBA.Thesoundpressurelevelwas

determinedaccordingtheproceduresoutlinedinEN

836andISO11201.

SoundPower

Thismachinehasaguaranteedsoundpowerlevelof98

dBA,whichincludesanUncertaintyValue(K)of1dBA.

Thesoundpowerlevelwasdeterminedaccordingtothe

proceduresoutlinedinISO11094.

Vibration,Hand/arm

Measuredvibrationlevelforthelefthand=2.3m/s

Measuredvibrationlevelfortherighthand=2.5m/s

UncertaintyValue(K)=1.3m/s

Themeasuredvaluesweredeterminedaccordingtothe

proceduresoutlinedinEN836.

2

2

2

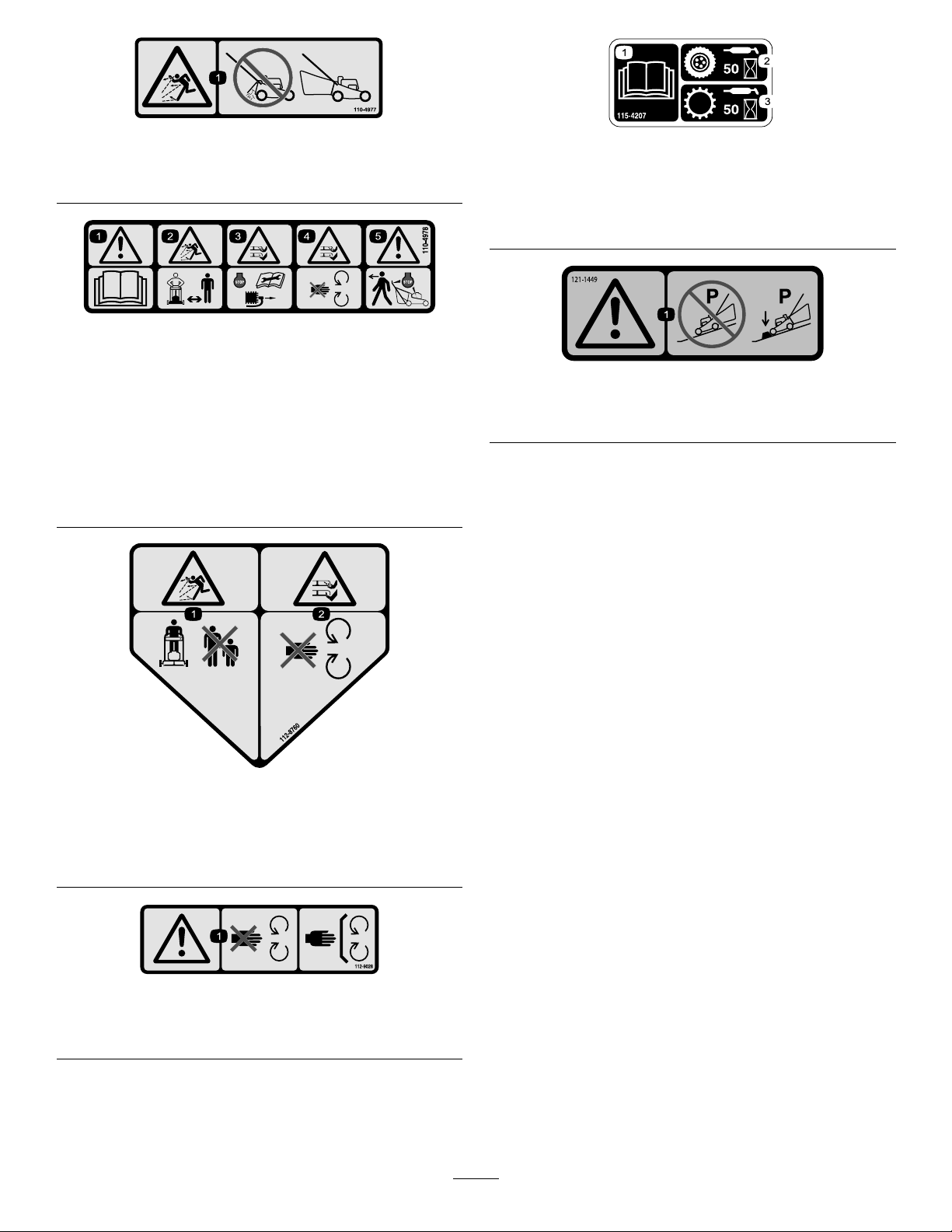

SafetyandInstructionalDecals

Safetydecalsandinstructionsareeasilyvisibletotheoperatorandarelocatednearanyareaof

potentialdanger.Replaceanydecalthatisdamagedorlost.

Manufacturer'sMark

1.Indicatesthebladeisidentiedasapartfromtheoriginal

machinemanufacturer.

98-4387

1.Warning—wearhearingprotection.

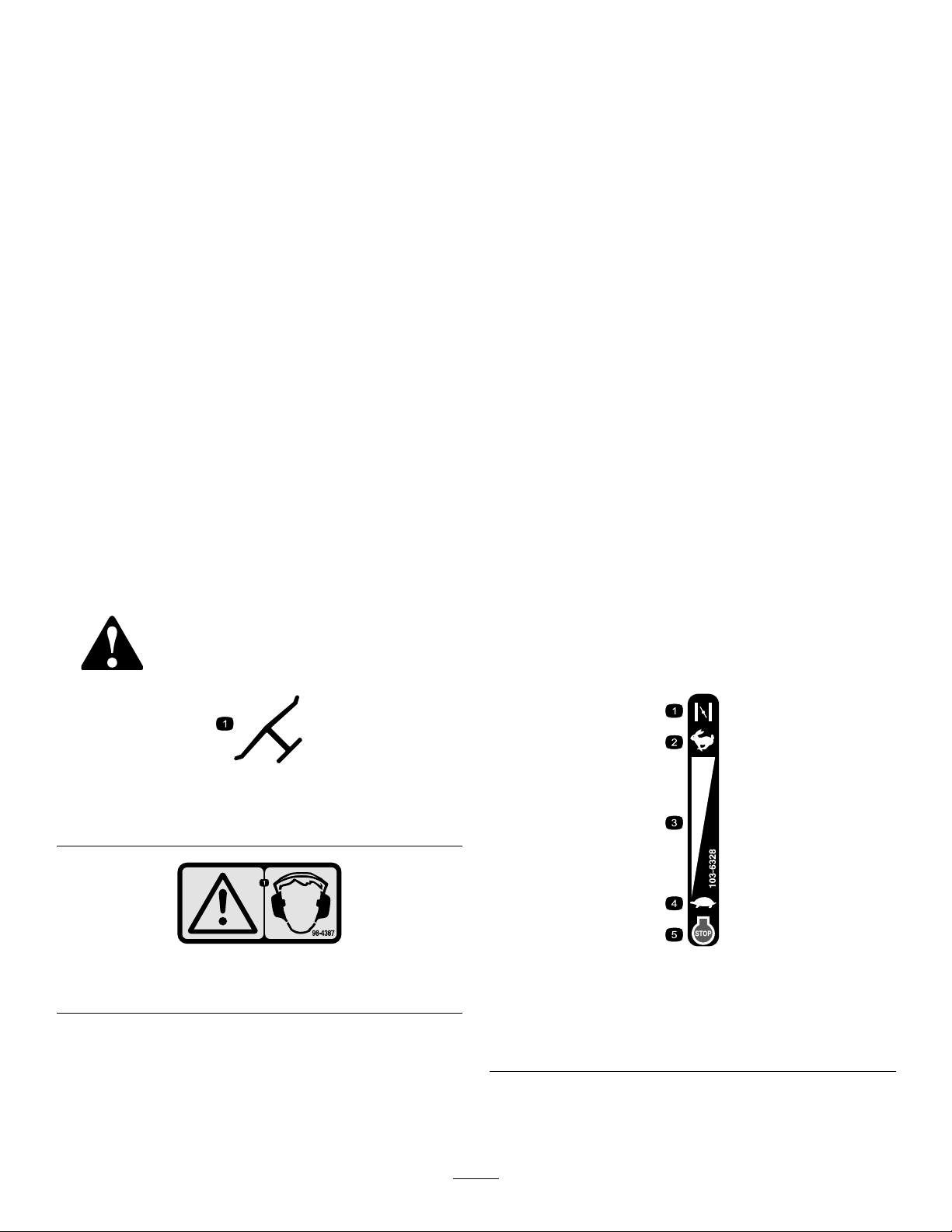

103-6328

1.Choke4.Slow

2.Fast5.Engine—stop

3.Continuousvariable

setting

5

Page 6

110-4977

1.Thrownobjecthazard—donotoperatethemachinewithout

abaginplace.

110-4978

1.Warning—readtheOperator'sManual.

2.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

3.Cutting,dismembermenthazardofhandorfoot—stopthe

engineandremovethesparkplugwirebeforeperforming

anymaintenanceonthemachine.

4.Cutting,dismembermenthazardofhandorfoot—stayaway

frommovingparts.

5.Warning—stoptheenginebeforeleavingthemachine.

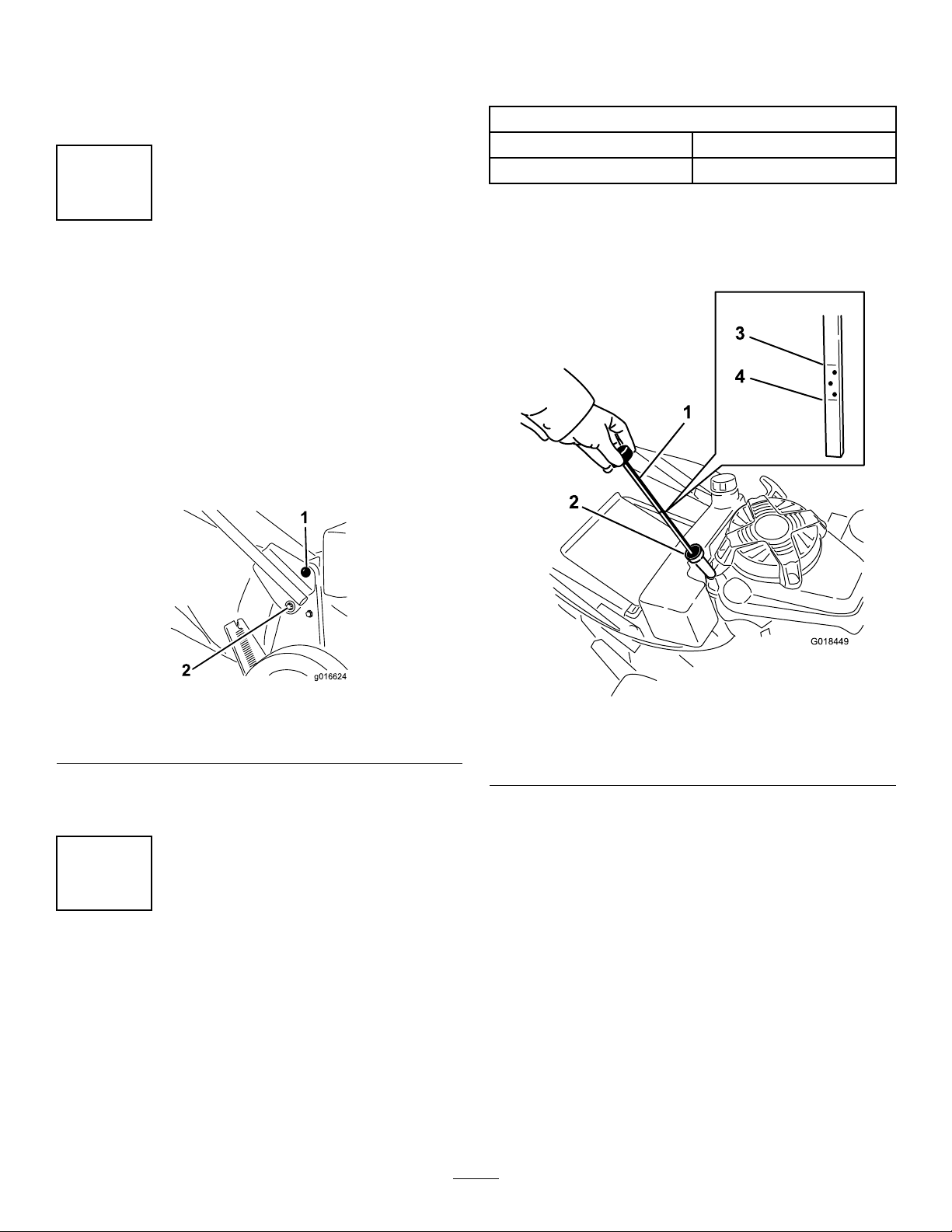

115-4207

1.ReadtheOperators

Manual.

2.Lubricatethedrivewheel

pivotarmsevery50hours.

3.Lubricatethetransmission

every50hours.

121–1449

1.Warning—donotparkonslopesunlesswheelsarechocked

orblocked.

112-8760

1.Thrownobjecthazard—keepbystandersasafedistance

fromthemachine.

2.Cutting/dismembermentofhandorfoot—stayawayfrom

movingparts.

112-9028

1.Warning—stayawayfrommovingparts;keepallguardsin

place.

6

Page 7

Setup

1

2

g016624

G018449

4

Note:Determinetheleftandrightsidesofthemachine

fromthenormaloperatingposition.

Useonlyhigh-qualitySAE30orSAE10W30weight

detergentoilthathastheAmericanPetroleumInstitute

(API)serviceclassicationSF,SG,SH,orSJ .

OilCapacityoftheEngine

Withoillter0.89liters(30ounces)

Withoutoillter0.70liters(24ounces)

1

InstallingtheHandle

NoPartsRequired

Procedure

1.Removethehandlefastenersfromtheleftandright

sidesofthemachinehousing.

2.Removethefastenersfromthehandlebracketson

theleftandrightbottomendsofthehandle.

3.Rotatethehandlebackintoitsoperatingposition

andinstallthefastenersasshown(Figure3).

Note:Whenthecrankcaseisempty ,pourabout3/4

oftheoilcapacityoftheengine(withoillter)into

theoil-llhole(Figure4),thenperformthefollowing

procedure:

Figure3

1.Carriageboltandanged

hexnut

4.Usethecabletiesprovidedtosecurethecontrol

cablestothehandle.

2.Hex-headbolt,washer,

andnut

2

FillingtheEngineCrankcase

withOil

NoPartsRequired

Procedure

Important:Thismachine

intheengine.Youmustlltheenginecrankcase

withoilbeforestartingtheengine.

does not

comewithoil

Figure4

1.Dipstick3.Fullmark

2.Oil-llhole

1.Movethemachinetoalevelsurface.

2.Cleanaroundthedipstick.

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,butdonot

screwitin.

6.Removethedipstickagainandreadtheoillevelon

thedipstick(Figure4).

A.IftheoillevelreadingisbelowtheAddmark

onthedipstick,slowlypouroilintotheoil-ll

holetoraisetheoilleveltotheFullmarkonthe

dipstick,thenrepeatsteps4through6.

B.IftheoillevelreadingisabovetheFullmark

onthedipstick,draintheexcessoiluntilthe

4.Addmark

7

Page 8

oillevelonthedipstickreadsFull;referto

DrainingtheEngineOil(page19).

C.IftheoillevelreadingisapproximatelyattheFull

mark,insertthedipstickintothellerneckand

turnthecapclockwisebyhanduntilitistight.

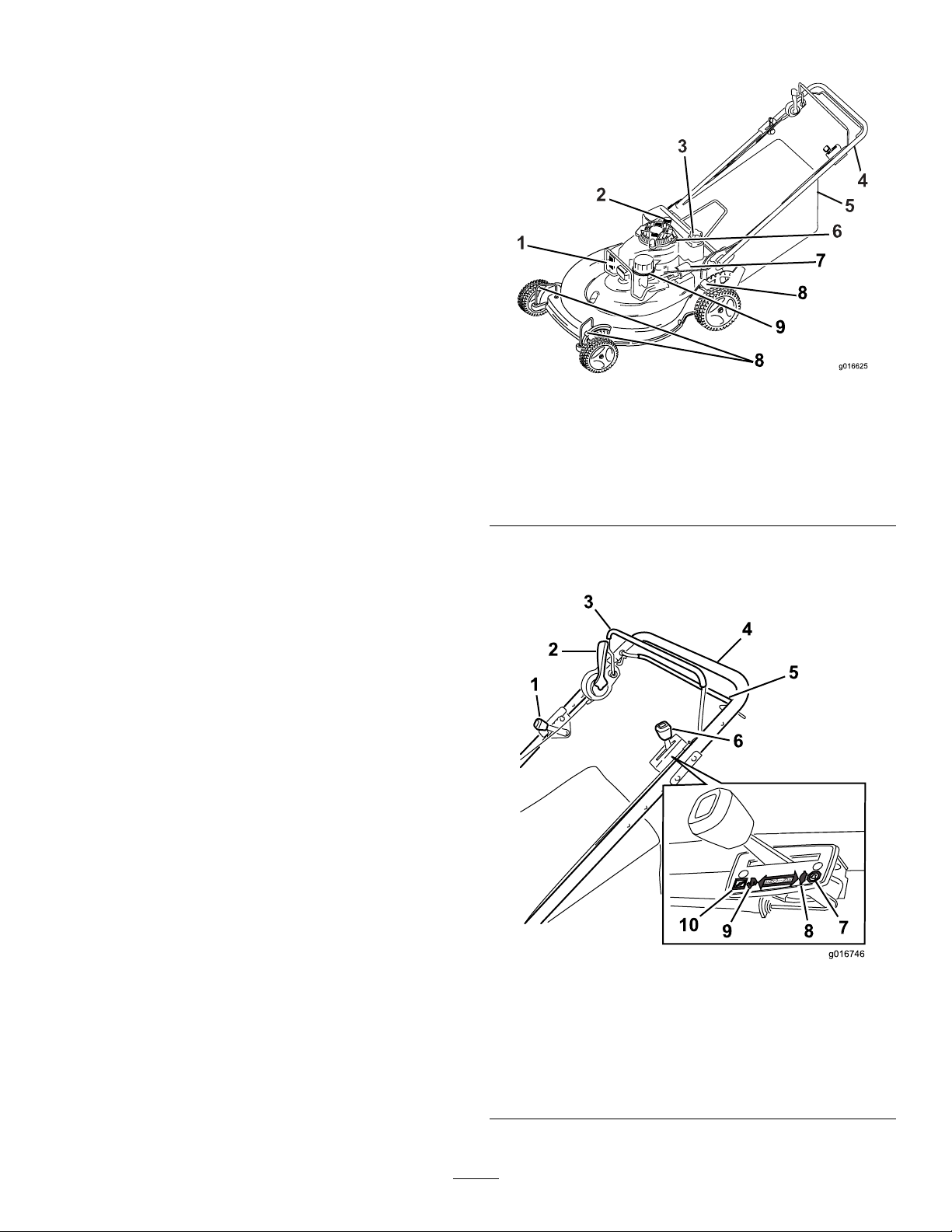

ProductOverview

Figure5

1.Sparkplug

2.Oilll/dipstick7.Oillter

3.Fuel-tankcap

4.Handle

5.Grassbag

Controls

6.Recoil-starterhandle

8.Cutting-heightlever(3)

9.Airlter

1.Ground-speed-control

lever

2.Blade-controllever

3.Blade-controlbar

4.Handle9.Fast

5.Traction-controlbar

8

Figure6

6.Throttle-controllever

7.Stop

8.Slow

10.Choke

Page 9

Operation

G018449

4

Note:Determinetheleftandrightsidesofthe

machinefromthenormaloperatingposition.

Eachtimebeforeyoumow ,ensurethattheself-propel

drive,theblade-controlbar,andblade-controllever

operateproperly.Whenyoureleasetheblade-control

bar,thebladeandself-propeldriveshouldstop.Ifthey

donot,contactanAuthorizedServiceDealer.

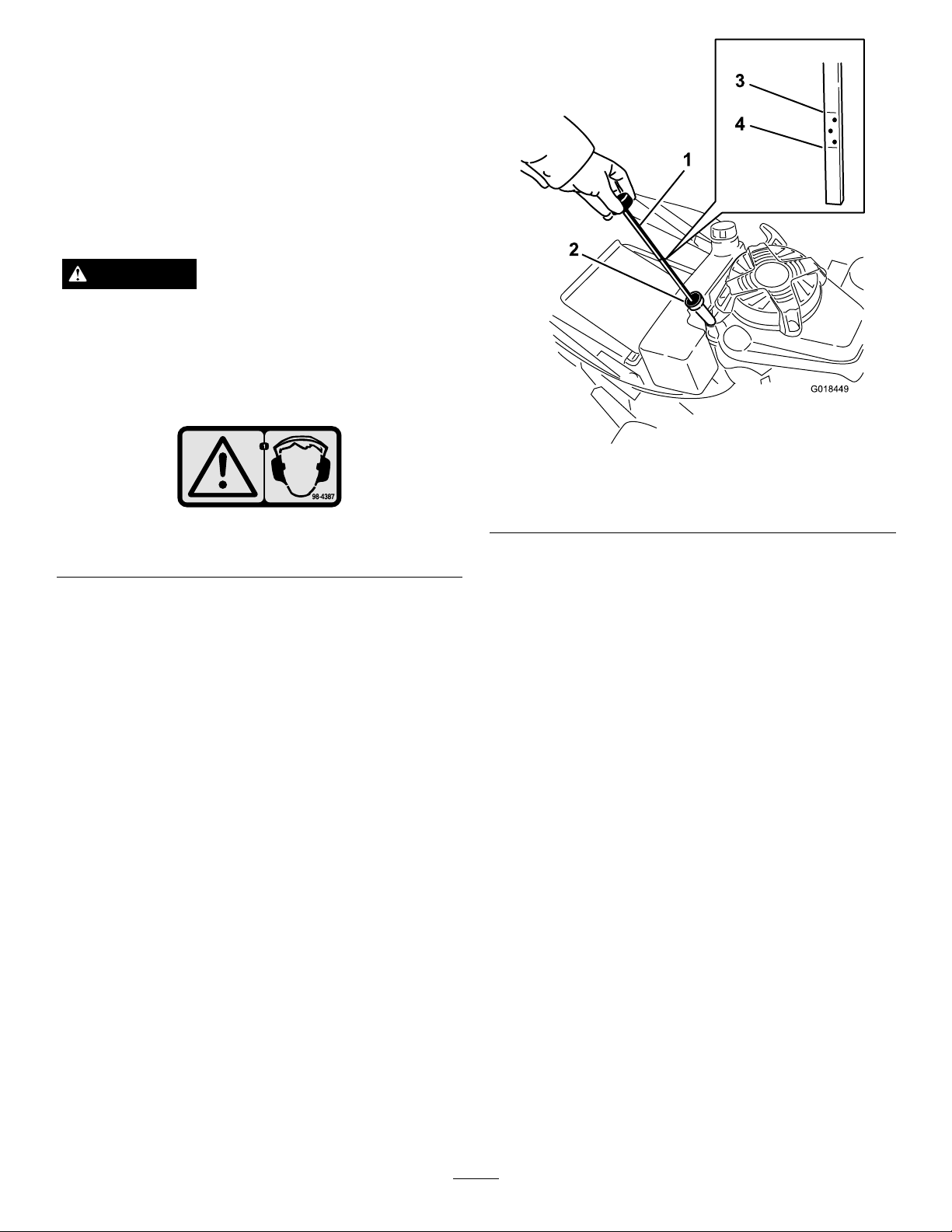

CAUTION

Thismachineproducessoundlevelsinexcessof

85dBAattheoperator'searandcancausehearing

lossthroughextendedperiodsofexposure.

Wearhearingprotectionwhenoperatingthis

machine.

Figure7

Figure8

1.Dipstick3.Fullmark

2.Oil-llhole

4.Addmark

1.Warning—wearhearingprotection.

CheckingtheEngineOilLevel

ServiceInterval:Beforeeachuseordaily

1.Movethemachinetoalevelsurface.

2.Cleanaroundthedipstick(

Figure8).

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,butdonot

screwitin.

6.Removethedipstickandreadtheoillevelonthe

dipstick(Figure8).

A.IftheoillevelreadingisbelowtheAddmark

onthedipstick,slowlypouroilintotheoil-ll

holetoraisetheoilleveltotheFullmarkonthe

dipstick,thenrepeatsteps

B.IftheoillevelreadingisabovetheFullmark

onthedipstick,draintheexcessoiluntilthe

oillevelonthedipstickreadsFull;referto

DrainingtheEngineOil(page19).

C.Iftheoillevelreadingisapproximatelyatthe

Fullmark,insertthedipstickintothellerneck

andturnthecapclockwisebyhanduntilitis

tight.

4through6.

FillingtheFuelTank

Forbestresults,useclean,fresh,lead-freegasolinewith

anoctaneratingof87orhigher.Toensurefreshness,

purchaseonlytheamountofgasolinethatyouexpectto

usein30days.Usingunleadedgasolineresultsinfewer

combustiondepositsandlongerenginelife.Youmay

useleadedgasolineifunleadedgasolineisnotavailable.

9

Page 10

Important:Donotaddoiltothegasoline.

G018470

Important:Donotusemethanol,gasoline

containingmethanol,gasoholcontainingmore

than10%ethanol,premiumgasoline,orwhitegas.

Usingthesefuelscandamagetheengine'sfuel

system.

Important:Donotusegasolinethathasbeen

storedlongerthan30days.

DANGER

Incertainconditions,gasolineisextremely

ammableandhighlyexplosive.Areorexplosion

fromgasolinecanburnyouandothersandcan

damageproperty.

•Fillthefueltankoutdoors,inanopenarea,and

whentheengineiscold.Wipeupanygasoline

thatspills.

•Donotllthefueltankcompletelyfull.Add

gasolinetothefueltankuntilthelevelis6to13

mm(1/4to1/2inch)belowthebottomofthe

llerneck.Thisemptyspaceinthetankallows

thegasolinetoexpand.

DANGER

Whenfueling,undercertaincircumstances,astatic

chargecandevelop,ignitingthegasoline.Areor

explosionfromgasolinecanburnyouandothers

anddamageproperty.

•Alwaysplacegasolinecontainersontheground

andawayfromyourvehiclebeforelling .

•Donotllgasolinecontainersinsideavehicle

oronatruckortrailerbedbecauseinterior

carpetsorplastictruckbedlinersmayinsulate

thecontainerandslowthelossofanystatic

charge.

•Whenpractical,removegasoline-powered

machinefromthetruckortrailerandrefuelthe

machinewithitswheelsontheground.

•Ifthisisnotpossible,thenrefuelsuchmachine

onatruckortrailerfromaportablecontainer,

notfromagasolinedispensernozzle.

•Ifyoumustuseagasolinedispensernozzle,

keepthenozzleincontactwiththerimofthe

fueltankorcontaineropeningatalltimesuntil

fuelingiscomplete.

•Neversmokewhenhandlinggasoline,andstay

awayfromanopenameorwhereasparkmay

ignitethegasolinefumes.

•Storegasolineinanapprovedfuelcontainer

andkeepitoutofthereachofchildren.

•Neverbuymorethana30-daysupplyof

gasoline.

Important:Toreducestartingproblems,add

fuelstabilizertothefuelallseason,mixingitwith

gasolinelessthan30daysold.

Important:Donotusefueladditivesotherthan

afuelstabilizer/conditioner.Donotusefuel

stabilizerswithanalcoholbasesuchasethanol,

methanol,orisopropanol.

1.Cleanaroundthefuel-tankcap(Figure9).

Figure9

1.Fuel-tankcap

2.Removethecapfromthetank.

10

Page 11

3.Fillthefueltankwithunleadedgasolinetowithin

G018450

1

6to13mm(1/4to1/2inch)fromthetopofthe

tank.Donotllintothellerneckbecausethe

gasolinemusthaveroomtoexpand.

4.Installthefuel-tankcapandwipeupanyspilled

gasoline.

4.Movetheground-speed-controllevertotheNeutral

(N)position.

5.Pullthestarterhandlelightlyuntilyoufeel

resistance,thenpullitsharply.

6.Whentheenginestarts,movethethrottleandset

theground-speedcontrolasdesired.

StartingtheEngine

1.Connectthewiretothesparkplug(Figure10).

Figure10

1.Spark-plugwire

StoppingtheEngine

1.MovethethrottlecontroltotheStopposition.

2.Disconnectthewirefromthesparkplugifyoudo

notusethemachineorleaveitunattended.

OperatingtheBlade

EngagingtheBlade

ServiceInterval:Beforeeachuseordaily

Note:Whenyoustarttheengine,thebladedoesnot

turn;youmustengagethebladetomow .

1.Pulltheblade-controlbartothehandleandhold

Figure12).

it(

2.Openthefuelvalve(Figure11).

Figure11

1.Fuelvalve

2.Oillter

3.MovethethrottlecontrollevertotheChoke

position(Figure6).

Note:Youdonotneedtousethechokewhenthe

engineiswarm.

Figure12

1.Blade-controlbar

2.Movetheblade-controlleverfullyforwarduntilthe

bladeisengaged(Figure13).

11

Page 12

Figure13

DisengagingtheBlade

Releasetheblade-controlbar.

2.Movetheground-speed-controllevertothedesired

gearposition.

3.Squeezethetraction-controlbaragainstthehandle

Figure15).

(

Figure15

DisengagingtheTractionDrive

Releasethetraction-controlbar.

Important:Whenyoureleasetheblade-control

bar,thebladeshouldstopwithin3seconds.Ifit

doesnotstopproperly,stopusingyourmachine

immediatelyandcontactanAuthorizedService

Dealer.

OperatingtheTractionDrive

EngagingtheTractionDrive

1.Releasethetraction-controlbar(Figure14).

CheckingtheBlade-Brake

Clutch

Checktheblade-controlbarandtheblade-controllever

beforeeachusetoensurethattheblade-brakeclutch

systemisoperatingproperly.Youcanusethegrassbag

totesttheblade-brakeclutchmechanism:

1.Installtheemptygrassbagonthemachine;referto

InstallingtheGrassBag(page14).

2.Starttheengine.

3.Engagetheblade.

Note:Thegrassbagshouldinate.

4.Releasetheblade-controlbar.

Note:Ifthebagdoesnotimmediatelydeate,

itindicatesthatthebladeisstillrotating.The

blade-brakeclutchmechanismmaybedeteriorating,

and,ifignored,couldresultinanunsafeoperating

condition.Havethemachineinspectedandserviced

byanAuthorizedServiceDealer.

Figure14

1.Traction-controlbar2.Throttle

12

Page 13

DANGER

Iftheblade-brakeclutchsystemisnotworking,

thebladewillcontinuetorotatewhenyourelease

theblade-controlbar.Youcouldcomeintocontact

withblade,causingseriousinjury.

•Ensurethatthebladebrakeclutchworks

properlybeforeeachuse.

•Neveruseamachineequippedwitha

blade-brakeclutchthathasaninoperative

safetysystem.

•Ifthesafetysystemonyourmachinedoes

notoperateproperly,takeittoanAuthorized

ServiceDealerforrepair.

AdjustingtheCuttingHeight

Figure16

1.Cutting-heightlever(atthehighestsetting)

2.Cutting-heightlever(atthelowestsetting)

Thefrontwheelsareadjustedindividuallywitha

cutting-heightlever(Figure16).Therearwheelsare

adjustedtogetherwithacutting-heightleverlocated

abovetheleftrearwheel(Figure17).

Cuttingheightsare25mm(1inch),38mm

(1-1/2inches),51mm(2inches),64mm(2-1/2inches),

76mm(3inches),and89mm(3-1/2inches),and102

mm(4inches).

Note:Adjustallthewheelstothesamecuttingheight

setting.

DANGER

Adjustingthecutting-heightleverscouldbring

yourhandsintocontactwithamovingbladeand

resultinseriousinjury.

•Stoptheengineandwaitforallmovementto

stopbeforeadjustingthecuttingheight.

•Donotputyourngersunderthehousing

whenadjustingthecuttingheight.

2.Releasethecutting-heightleverandseatitsecurely

inthenotch.

AdjustingtheRearCuttingHeight

1.Pulltherearcutting-heightleveroutandmoveitto

thedesiredsetting(Figure17).

AdjustingtheFrontCuttingHeight

1.Pulleachofthecutting-heightleverstowardthe

wheel(Figure16)andmoveittothedesiredsetting.

Figure17

1.Cutting-heightlever(atthehighestsetting)

2.Cutting-heightlever(atthelowestsetting)

2.Releasetheleverandseatitsecurelyinthedesired

notch.

13

Page 14

UsingtheGrassBag

MowingwiththeGrassBag

InstallingtheGrassBag

1.Releaseboththeblade-controlbarandthe

traction-controlbarandwaitforallmovingparts

tostop.

2.Raiseandholdupthereardoor(

Figure18

1.Reardoor2.Bag-supporttabs

3.Setthebagframeonthebag-supporttabs

Figure18).

(

4.Lowerthereardoorontothebag.

Figure18).

RemovingtheGrassBag

WARNING

Aworngrassbagcouldallowsmallstones

andothersimilardebristobethrowninthe

operator'sorbystander'sdirectionandresultin

seriouspersonalinjuryordeathtotheoperatoror

bystanders.

Checkthegrassbagfrequently.Ifitisdamaged,

installanewT ororeplacementbag.

OperatingTips

GeneralMowingTips

•Cleartheareaofloosesticks,branches,stones,wire,

twine,andotherdebristhatthebladecouldhit.

•Avoidstrikingsolidobjectswiththeblade.Never

deliberatelymowoveranythingotherthangrassor

fallenleaves.

•Ifthemachinestrikesanobjectorstartstovibrate,

immediatelystoptheengine,disconnectthewire

fromthesparkplug,andexaminethemachinefor

damage.

•Forbestperformance,installanewToroblade

beforethecuttingseasonbegins.Maintainasharp

bladethroughoutthecuttingseasonbyperiodically

lingdownnicksontheblade.Whennecessary,

replacethewornbladewithanoriginalToro

replacementblade.

•Keeptheengineingoodrunningcondition.

•Setthethrottlecontrollevertothefastestposition

forthebestcuttingresults.

Toremovethebag,reversethestepsabove.

DANGER

Themachinecanthrowgrassclippingsand

otherobjectsthroughanopendischargetunnel.

Objectsthrownwithenoughforcecouldcause

seriouspersonalinjuryordeathtotheoperatoror

bystander.

Donotoperatethemachinewithoutagrassbag

installed.

WARNING

Operatingamachinewithitsenginerunning

ataspeedgreaterthanthehighestfactory

settingcancausethemachinetothrowapart

ofthebladeorengineintotheoperator'sor

bystander'sareaandresultinseriouspersonal

injuryordeath.

–Donotchangetheenginetorunfasterthan

highestspeedsetbythefactory.

–Ifyoususpectthattheenginespeedisfaster

thannormal,contactanAuthorizedService

Dealer.

•Cleanunderthemachinehousingaftereachuse;

refertoCleaningundertheHousing(page24).

•Cleantheairlterfrequently.V erydryconditions

ormulchingstirsupmoreclippingsanddust,which

clogstheairlterandreducesengineperformance.

14

Page 15

CuttingGrass

•Cutonlyaboutathirdofthegrassbladeatatime.

•Whencuttinggrassover15cm(6inches)tall,mow

atthehighestcutting-heightsettingandwalkslower;

thenmowagainatalowersettingforthebestlawn

appearance.Ifthegrassistoolong,themachine

mayplugandcausetheenginetostall.

•Grassgrowsatdifferentratesatdifferenttimesof

theyear.Inthesummerheat,itisbesttocutgrass

attheheight-of-cutsettingsrangingfrom64mm

(2-1/2inches)to89mm(3-1/2inches).Donotcut

below51mm(2inches)unlessthegrassissparseor

itislatefallwhengrassgrowthbeginstoslowdown.

•Mowonlydrygrassorleaves.Wetgrassand

leavestendtoclumpontheyardandcancausethe

machinetogetpluggeduportheenginetostall.

WARNING

Wetgrassorleavescancauseseriousinjuryif

youslipandcontacttheblade.Mowonlyindry

conditions.

•Alternatethemowingdirection.Thishelpsdisperse

theclippingsoverthelawnforevenfertilization.

•Ifthenishedlawnappearanceisunsatisfactory,try

oneormoreofthefollowing:

–Sharpenorreplacetheblade.

–Walkataslowerpacewhilemowing.

–Raisethecuttingheightonyourmachine.

–Overlapcuttingswathsinsteadofcuttingafull

swathwitheachpass.

–Setthecuttingheightonthefrontwheels1

notchlowerthanthecuttingheightoftherear

wheels.

–Cutthegrassmorefrequently .

CuttingLeaves

•Aftercuttingthelawnwithleafcover,ensurethatat

leasthalfofthelawnshowsthroughthecutleaves.

Youmayneedtomakemorethanonepassover

theleaves.

•Forlightleafcoverage,setallthewheelsatthesame

cutting-heightsetting.

•Iftherearemorethan13cm(5inches)ofleaveson

thelawn,setthefrontcuttingheight1or2notches

higherthantherearcuttingheight.Thismakesit

easiertofeedtheleavesunderthemachinehousing.

•Slowdownyourmowingspeedifthemachinedoes

notcuttheleavesnelyenough.

15

Page 16

Maintenance

Note:Determinetheleftandrightsidesofthemachinefromthenormaloperatingposition.

RecommendedMaintenanceSchedule(s)

MaintenanceService

Interval

Aftertherst8hours

Beforeeachuseordaily

Every25hours

Every50hours

Every75hours

Every100hours

MaintenanceProcedure

•Changetheengineoil.

•Checktheengineoillevel.

•Ensurethatthebladestopswithin3secondsafterreleasingtheblade-controlbar.

•Checktheaircleaner.

•Checktheblade-brakecableadjustmentandadjustthecable,ifnecessary .

•Checkthebladeforwearordamage.

•Checkthebladeandtheenginemountingfastenersandtightenthemiftheyare

loose.

•Cleanunderthemachinehousing.

•Cleanthedischargetunnel.

•Cleanthefoampre-lter.

•Lubricatethepivotarms.

•Lubricatethegearcase.

•Changetheengineoilwithoutchangingtheoillter(moreoftenindustyconditions).

•Checkforleaksinthefuelsystemand/oradeterioratingfuelhose;replaceparts

ifnecessary.

•Sharpenorreplacetheblade;maintainitmorefrequentlyiftheedgedullsquicklyin

roughorinsandyconditions.

•Cleanunderthebeltcover.

•Adjusttheself-propeldrivesystem.

•Changetheoilandoillter(moreoftenindustyconditions).

•Checkthesparkplugandreplaceitifnecessary.

•Cleanthefuellterelement.

•Adjusttheblade-brakecable.

Every300hours

Yearly

Yearlyorbeforestorage

Important:Refertoyour

•Replacethepaperlter(morefrequentlyindustyconditions).

•Emptythefueltankbeforerepairsasdirected.

•Changetheengineoil.

•Changetheoillter.

•Cleanthefuellter.

•Lubricatethepivotarms.

•Emptythefueltank.

•Preparetheengineforstorage.

Engine Operator's Man ual

foradditionalmaintenanceprocedures.

CAUTION

Ifyouleavethewireonthesparkplug,someonecouldaccidentlystarttheengineandseriouslyinjure

youorotherbystanders.

Disconnectthewirefromthesparkplugbeforeyoudoanymaintenance.Setthewireasidesothatitdoes

notaccidentlycontactthesparkplug.

16

Page 17

Premaintenance

G018450

1

Lubrication

Procedures

LubricatingthePivotArms

PreparingforMaintenance

1.Movethemachinetoalevelsurface.

2.Stoptheengineandwaitforallmovingpartstostop.

3.Disconnectthewirefromthesparkplug,andsecure

thewiresoitcannotcomeincontactwiththespark

Figure19).

plug(

ServiceInterval:Every50hours

Yearlyorbeforestorage

1.Referto

2.Movetherearcutting-heightleverstothecenter

setting.

3.Drainthegasolinefromthefueltank;referto

EmptyingtheFuelTank(page21).

4.Tipthemachineontoitsrightsidewiththeairlter

up.

5.Wipethegreasettingswithacleanrag(Figure20).

Note:Thegreasettingsarelocatedneartherear

wheels.

PreparingforMaintenance(page17).

Figure19

1.Spark-plugwire

WARNING

Tippingthemachinemaycausethefueltoleak

fromthecarburetororthefueltank.Gasoline

isextremelyammable,highlyexplosive,and,

undercertainconditions,cancausepersonal

injuryorpropertydamage.

Avoidfuelspillsbydrainingthegasolinetoan

acceptablelevelwiththefuelvalve;neversiphon.

4.Ifyoumusttipthemachineandthereisfuel

inthefueltank,emptythefueltank;referto

EmptyingtheFuelTank(page21).

Note:Ifpossible,waittoperformmaintenance

untilthefueltankisnearlyemptyfromrunningthe

machineduringnormaloperation.

Figure20

6.Attachagreasegunnozzleontoeachttingand

gentlyapply2or3pumpsof#2multi-purpose

lithium-basedgrease.

Important:Excessivegreasepressuremay

damagetheseals.

7.Returnthemachinetoitsoperatingposition.

8.Connectthewiretothesparkplug.

LubricatingtheGearCase

ServiceInterval:Every50hours

1.Installagreasegunontothettinglocatedunder

thefueltank(

Figure21).

17

Page 18

g013799

1

Figure21

1.Installagreasegunhere.

2.Gentlyapplyoneto2pumpsof#2multipurpose

lithium-basedgrease.

EngineMaintenance

ServicingtheAirFilter

ServiceInterval:Beforeeachuseordaily

Every25hours—Cleanthefoam

pre-lter.

Every300hours—Replacethepaper

lter(morefrequentlyindusty

conditions).

Important:Donotoperatetheenginewithoutthe

airlterassembly;extremeenginedamagewill

occur.

1.Wipeawayalldirtanddebrisfromaroundtheair

ltercoverandbase(

Figure22).

Figure22

1.Cover3.Paperlter

2.Foampre-lter4.Airlterbase

2.Twistthecovercounterclockwiseandremoveit.

3.Removethepaperlterwiththefoampre-lter;

refertoFigure22.

4.Removethefoampre-lterfromaroundthepaper

lter;discardthepaperlter.

Important:Donottrytocleanapaperlter.

5.Carefullywipeawayanydirtordebrisfromthe

insideofboththecoverandthebase.

Important:Donotallowdirtordebristoenter

theengine.

6.Washthefoampre-lterwithamilddetergentand

water,thenblotitdry.

7.Saturatethefoampre-lterwithcleanengineoil,

thengentlysqueezeit(donottwistit)toremove

theexcessoil.

18

Page 19

8.Wrapthefoampre-lteraroundanewpaperlter;

setthemonthebase.

9.Installtheairltercoverandtwistitclockwiseuntil

itlocksinplace.

7.Ifyouarenotchangingtheoillterthistime,

connectthewiretothesparkplug.

8.Recycletheusedoilaccordingtolocalcodes.

ChangingtheOilFilter

ChangingtheEngineOil

DrainingtheEngineOil

ServiceInterval:Aftertherst8hours

Every50hours

Yearly

1.Runtheenginetowarmtheengineoil.

Note:Warmoilowsbetterandcarriesmore

contaminants.

2.Referto

3.Slideahoseovertheoil-drainvalve,asshownin

Figure23.

PreparingforMaintenance(page17).

ServiceInterval:Every100hours

Yearly

Note:Replacethelterwitheveryotheroilchange.

1.Draintheengineoilfromtheengine;referto

DrainingtheEngineOil(page19).

2.Placearagundertheoilltertocatchanyoilthat

mayleakoutasyouremovethelter.

3.Removetheoillter.

WARNING

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury.

Avoidcontactingthehotengineoilwhenyou

drainit.

4.Coatthegasketonthenewoillterwithalittleoil

ontheendofyournger;referto(Figure24).

Figure23

1.Oil-drainvalve2.Oillter

4.Placeanoildrainpanunderthedrainhose.

5.Openthedrainvalveandallowtheoiltodraininto

thepan.

Note:Slightlytipthemachineontoitsleftsideto

drainasmuchoilaspossible.

WARNING

Oilmaybehotaftertheenginehasbeenrun,

andcontactwithhotoilcancausesevere

personalinjury.

Avoidcontactingthehotengineoilwhenyou

drainit.

6.Afterdrainingtheoil,closetheoil-drainvalveand

removethedrainhose.

Figure24

1.Gasket

5.Threadthenewlterontothepostuntilitseats

againsttheengine,thenhandtightenitanadditional

2/3ofaturn.

6.Filltheenginewithoil;referto

FillingtheEnginewithOil(page20).

7.Connectthewiretothesparkplug.

8.Runtheengineforabout3minutes.

9.Stoptheengine,waitforallmovingpartstostop,

andcheckforanyoilleakagearoundthelter.

10.Checktheengineoillevel;referto

CheckingtheEngineOilLevel(page9).

11.Recycletheusedoillteraccordingtolocalcodes.

19

Page 20

FillingtheEnginewithOil

G018449

4

Important:Thismachine

intheengine.Youmustlltheenginecrankcase

withoilbeforestartingtheengine.

Useonlyhigh-qualitySAE30orSAE10W30weight

detergentoilthathastheAmericanPetroleumInstitute

(API)serviceclassicationSF,SG,SH,orSJ .

OilCapacityoftheEngine

Withoillter0.89liters(30ounces)

Withoutoillter0.70liters(24ounces)

does not

comewithoil

A.IftheoillevelreadingisbelowtheAddmark

onthedipstick,slowlypouroilintotheoil-ll

holetoraisetheoilleveltotheFullmarkonthe

dipstick,thenrepeatsteps

4through6.

B.IftheoillevelreadingisabovetheFullmark

onthedipstick,draintheexcessoiluntilthe

oillevelonthedipstickreadsFull;referto

DrainingtheEngineOil(page19).

C.IftheoillevelreadingisapproximatelyattheFull

mark,insertthedipstickintothellerneckand

turnthecapclockwisebyhanduntilitistight.

Note:Whenthecrankcaseisempty ,pourabout3/4

oftheoilcapacityoftheengine(withoillter)into

theoil-llhole(

Figure25),thenperformthefollowing

procedure:

ServicingtheSparkPlug

ServiceInterval:Every100hours

UseanNGKBPR5ESsparkplugorequivalent.

1.RefertoPreparingforMaintenance(page17).

2.Cleanaroundthesparkplug.

3.Removethesparkplugfromthecylinderhead.

Important:Replaceacracked,fouled,or

dirtysparkplug.Donotcleantheelectrodes

becausegritenteringthecylindercandamage

theengine.

4.Setthegapontheplugto0.030in.(0.76mm)

Figure26)

(

Figure25

1.Dipstick3.Fullmark

2.Oil-llhole

1.Movethemachinetoalevelsurface.

4.Addmark

2.Cleanaroundthedipstick.

3.Removethedipstickbyrotatingthecap

counterclockwiseandpullingitout.

4.Wipethedipstickcleanwithacleancloth.

5.Insertthedipstickintothellerneck,butdonot

screwitin.

6.Removethedipstickandreadtheoillevelonthe

dipstick(Figure25).

Figure26

1.Centerelectrodeinsulator

2.Sideelectrode

3.Airgap(nottoscale)

5.Installthesparkplug.

6.Torquetheplugto17ft-lb(23N-m).

7.Connectthewiretothesparkplug.

20

Page 21

FuelSystem

DriveSystem

Maintenance

EmptyingtheFuelTank

ServiceInterval:Every50hours

Every300hours

1.Referto

2.Waitfortheenginetocooldown.

Note:Draingasolinefromacoldengineonly .

3.Closethefuelvalve(

4.Disconnectthefuellinebylooseningthetubeclamp

atthecarburetorandputtingthelooseendofthe

fuellineintoanapprovedfuelcontainer.

5.Openthefuelvalveanddrainthefuelcompletely

fromthetankandfuelline.

6.Closethefuelvalve.

7.Connectthelooseendofthefuellinetothe

carburetorandsecureitwithatubeclamp.

PreparingforMaintenance(page17).

Figure11).

Maintenance

AdjustingtheSelf-propelDrive

ServiceInterval:Every75hours

Ifthemachinedoesnotself-propelorhasatendency

tocreepforwardwhenthetraction-controlbarismore

than38mm(1-1/2inches)fromthehandle,adjustthe

self-propeldrive.

1.Ifthemachinedoesnotself-propel,rotatethe

transmission-cablenutsclockwise1/2turntotighten

thebelt(

Figure27).

8.Connectthewiretothesparkplug.

9.Disposeofthecollectedfuelaccordingtolocal

regulations.

CleaningtheFuelFilter

ServiceInterval:Yearly

Every100hours

Thefuellter(screen)elementislocatedinsidethefuel

tank.

1.Drainthegasolinefromthefueltank;referto

EmptyingtheFuelTank(page21).

2.Drainthegasolinecompletelyfromthetankand

fuelline.

3.Removethefueltankfromthemachine.

4.Closethefuelvalve.

5.Cleanthelterbypouringasmallamountofclean

gasolineinthefueltank,movingthefuelaround

insidethetank,andaddingittothecollected

gasoline.

Figure27

1.Transmission-cablenuts

2.Ifthemachinecreepsforward,rotatethe

transmission-cablenuts1/2turncounterclockwise

toloosenthebelt(Figure27).

3.Ifthemachinedoesnotdriveupslopes,youmay

needtoincreasethebelttensionbyrotatingthe

transmission-cablenutsclockwise.

6.Installthefueltankandthefuelline.

21

Page 22

ControlsSystem

Maintenance

BladeMaintenance

MaintainingtheCuttingBlade

AdjustingtheBlade-Brake

Cable

ServiceInterval:Beforeeachuseordaily

Every100hours

Wheneveryouinstallanewblade-brakecableassembly

orreplacethebelt,adjusttheblade-brakecable.

1.Referto

2.Removethebeltcover.

3.Loosentheblade-brake-cablenutsuntilthe

brake-cableconduitslides(Figure28).

PreparingforMaintenance(page17).

Alwaysmowwithasharpblade.Asharpbladecuts

cleanlyandwithouttearingorshreddingthegrassblades.

1.Stoptheengineandwaitforallmovingpartstostop.

2.Disconnectthewirefromthesparkplug(

3.Drainthegasolinefromthefueltank;referto

EmptyingtheFuelTankandCleaningtheFuelFilter.

4.Tipthemachineontoitsrightside(

Figure10).

Figure29).

Figure28

1.Blade-brake-cablenuts

2.Brake-cableconduit

4.Pullthecabletotheremovetheslack,butdonot

puttensiononthespring.

5.Tightentheblade-brake-cablenuttolockthe

adjustmentinplace.

6.Checktheadjustmentbyactivatingthebladebrake

clutch.

Note:Thedistancefromtheendofthebrake-cable

conduittotheboltthatanchorsthespringshould

measure11.4cm(4-1/2inches).RefertoFigure28.

3.4-1/2inches(11.4cm)

Figure29

1.Bladebolt3.Anti-scalpcup

2.Washer4.Blade

InspectingtheBlade

ServiceInterval:Beforeeachuseordaily

Beforeeachuseordaily

Every50hours

Carefullyexaminethebladeforsharpnessandwear,

especiallywheretheatandthecurvedpartsmeet

Figure30A).Becausesandandabrasivematerialcan

(

wearawaythemetalthatconnectstheatandcurved

partsoftheblade,checkthebladebeforeusingthe

machine.Ifyounoticeaslotorwear(

Figure30C),replacetheblade;refertoRemovingthe

Blade.

Figure30Band

7.Installthebeltcover.

8.Connectthewiretothesparkplug.

22

Page 23

Figure30

1.Sail

2.Flatpartoftheblade4.Slotformed

3.Wear

BalancingtheBlade

1.Checkthebalanceofthebladebyplacingthecenter

holeofthebladeoveranailorscrewdrivershank

clampedhorizontallyinavise(

Figure32

Figure32).

Note:Forthebestperformance,installanewblade

beforethecuttingseasonbegins.Duringtheyear,le

downanysmallnickstomaintainthecuttingedge.

DANGER

Awornordamagedbladecanbreak,andapiece

ofthebladecouldbethrownintotheoperator's

orbystander'sarea,resultinginseriouspersonal

injuryordeath.

•Inspectthebladeperiodicallyforwearor

damage.

•Replaceawornordamagedblade.

RemovingtheBlade

Grasptheendofthebladeusingaragorathickly

paddedglove.Removethebladebolt,washer,anti-scalp

cup,andblade(Figure29).

SharpeningtheBlade

Note:Youcanalsocheckthebalanceusinga

commerciallymanufacturedbladebalancer.

2.Ifeitherendofthebladerotatesdownward,lethat

end(notthecuttingedgeortheendnearthecutting

edge).Thebladeisproperlybalancedwhenneither

enddrops.

InstallingtheBlade

1.Installasharp,balancedToroblade,thewasher,

anti-scalpcup,andbladenuts.

Note:Thesailoftheblademustpointtowardthe

topofthemowerhousingforproperinstallation.

Torquethebladeboltto102to115N-m(75to85

ft-lb).

2.Returnthemachinetoitsoperatingposition.

3.Closethefuelvalveandllthefueltankwith

gasoline.

4.Connectthewiretothesparkplug.

Filethetopsideofthebladetomaintainitsoriginal

cuttingangle(Figure31A)andinnercuttingedgeradius

(Figure31B).Thebladewillremainbalancedifyou

removethesameamountofmaterialfrombothcutting

edges.

Figure31

1.Sharpenatthisangleonly.

2.Maintaintheoriginalradius

here.

23

Page 24

Cleaning

G018483

CleaningundertheBeltCover

ServiceInterval:Every50hours

1.Referto

2.Pushdownandforwardonthefrontofthebelt

covertounlatchitfromthefrontmountingscrew

(Figure33).

PreparingforMaintenance(page17).

Note:Thebladewilldrawinwaterandwashout

clippings.Letthewaterrununtilyounolongersee

clippingsbeingwashedoutfromunderthehousing.

4.Disengagetheblade,stoptheengineandwaitfor

allmovingpartstostop.

5.Turnoffthewater.

6.Startthemachineandletitrunforafewminutes

todryoutthemoistureonthemachineandits

components.

ScrapingMethod

Ifwashingdoesnotremovealldebrisfromunderthe

machine,scrapeitclean.

Figure33

3.Pushdownonthebeltcoveroneachsideofthe

engineandliftthecoveroffthemachine.

4.Brushoutthedebrisaroundthebeltarea.

5.Installthebeltcover.

6.Connectthewiretothesparkplug.

CleaningundertheHousing

Toensurethebestperformance,keeptheundersideof

themachinehousingclean.

WashingMethod

ServiceInterval:Beforeeachuseordaily

1.Referto

2.Tipthemachineontoitsrightside.

3.Removethedirtandgrassclippingswithahardwood

scraper.Avoidburrsandsharpedges.

4.Returnthemachinetoitsoperatingposition.

5.Connectthewiretothesparkplug.

PreparingforMaintenance(page17).

CleaningtheDischargeTunnel

ServiceInterval:Beforeeachuseordaily

Cleanthedischargetunnelaftereachuse.

Ensurethatthedischargetunneldoorclosessecurely

whenyouremovethebag.Ifthedebrispreventsthe

dischargedoorfromclosingsecurely ,cleantheinsideof

thedischargetunnelandthedoorthoroughly.

1.Positionthemachineonaatconcreteorasphalt

surfacenearagardenhose.

2.Starttheengine.

3.Holdtherunninggardenhoseathandleleveland

directthewatertoowonthegroundjustinfront

oftherightrearwheel(

1.Rightrearwheel

Figure34).

Figure34

24

Page 25

Storage

Topreparethemachineforoff-seasonstorage,perform

therecommendedmaintenanceprocedures.Referto

Maintenance.

2.Cleananydirtandchafffromtheengine,cooling

ns,andrecoil-startervents.

3.Removegrassclippings,dirt,andgrimefromthe

externalpartsoftheengine,theshrouding,andthe

topofthemachinehousing.

Storethemachineinacool,clean,dryplace.Coverthe

machinetokeepitcleanandprotected.

PreparingtheFuelSystem

ServiceInterval:Yearlyorbeforestorage

WARNING

Gasolinecanvaporizeifyoustoreitoverlong

periodsoftimeandexplodeifitcomesintocontact

withanopename.

•Donotstoregasolineoverlongperiodsoftime.

•Donotstorethemachinewithgasolineinthe

fueltankorthecarburetorinanenclosurewith

anopename.(Forexample,afurnaceora

waterheaterpilotlight.)

•Allowtheenginetocoolbeforestoringitinany

enclosure.

Emptythefueltankwhenmowingthelasttimebefore

storingthemachine.

1.Runthemachineuntiltheenginestopsfromrunning

outoffuel.

2.Primetheengineandstartitagain.

3.Allowtheenginetorununtilitstops.Whenyoucan

nolongerstarttheengine,itissufcientlydry.

4.Cleanunderthebeltcover;referto

CleaningundertheBeltCover(page24).

5.Checktheconditionoftheblade;referto

MaintainingtheCuttingBlade(page22).

6.Servicetheairlter;referto

ServicingtheAirFilter(page18).

7.Lubricatethepivotarms;referto

LubricatingthePivotArms(page17).

8.Tightenallnuts,bolts,andscrews.

9.Touchupallrustedorchippedpaintsurfaceswith

paintavailablefromanAuthorizedServiceDealer.

RemovingtheMachinefrom

Storage

1.Checkandtightenallfasteners.

2.Removethesparkplugandspintheenginerapidly

usingthestartertoblowexcessoilfrominsidethe

engine.

3.Inspectandinstallthesparkplugasdescribedin

ServicingtheSparkPlug(page20).

4.Performanyneededmaintenanceprocedures;refer

tothechaptertitledMaintenance(page16).

5.Fillthefuelinthefueltankwithfreshgasoline.

PreparingtheEngine

ServiceInterval:Yearlyorbeforestorage

1.Whiletheengineisstillwarm,changetheoil;refer

toChangingtheEngineOil(page19).

2.Removethesparkplug.

3.Usinganoilcan,addaboutonetablespoonofoilto

theinsideoftheenginethroughthespark-plughole.

4.Slowlyrotatetheengineseveraltimes,usingthe

starterrope,todistributetheoil.

5.Installthesparkplugbutdonotconnectthewireto

thesparkplug.

PreparingtheRestofthe

Machine

1.Cleanunderthemowerhousing;referto

CleaningundertheHousing(page24).

6.Checktheengineoillevelandllasneeded;referto

CheckingtheEngineOilLevel(page9).

7.Connectthewiretothesparkplug.

25

Page 26

Troubleshooting

Problem

Theenginedoesnotstart

Theenginestartshardorlosespower

PossibleCauseCorrectiveAction

1.Thewireisnotconnectedtothespark

plug.

2.ThethrottleleverisnotintheChoke

position.

3.Thefuelcapventholeisplugged.3.Cleanthefuelcapventholeorreplace

4.Thesparkplugispitted,fouled,orthe

gapisincorrect.

5.Thefueltankisemptyorthefuel

systemcontainsstalefuel.

1.Thefuelcapventholeisplugged.1.Cleanthefuelcapventholeorreplace

2.Theairlterelementisdirtyandis

restrictingtheairow .

3.Theundersideofthemachinecontains

clippingsanddebris.

4.Thesparkplugispitted,fouled,orthe

gapisincorrect.

5.Theengineoillevelistoolow,toohigh,

orexcessivelydirty.

6.Thefueltankcontainsstalefuel.6.Drainandllthefueltankwithfresh

1.Connectthewiretothesparkplug.

2.MovethethrottlelevertotheChoke

position.

thefuelcap.

4.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

5.Drainand/orllthefueltankwith

freshgasoline.Iftheproblempersists,

contactanAuthorizedServiceDealer.

thefuelcap.

2.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

3.Cleanunderthemachine.

4.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

5.Checktheengineoil.Changetheoilif

itisdirty;addordraintheoiltoadjust

theoilleveltotheFullmarkonthe

dipstick.

gasoline.

Theenginerunsrough

Themachineorenginevibrates

excessively

Thereisanunevencuttingpattern

Themachinedoesnotself-propel

1.ThethrottleleverisnotintheFast

position.

2.Thewireisnotconnectedtothespark

plug.

3.Theairlterelementisdirtyandis

restrictingtheairow .

4.Thesparkplugispitted,fouled,orthe

gapisincorrect.

1.Theundersideofthemachinehousing

containsclippingsanddebris.

2.Theenginemountingboltsareloose.2.Tightentheenginemountingbolts.

3.Theblademountingnutsareloose.3.Tightentheblademountingnuts.

4.Thebladeisbentorisoutofbalance.4.Balancetheblade.Ifthebladeisbent,

1.Youaremowinginthesamepattern

repeatedly.

2.All4wheelsarenotatthesameheight.

3.Theundersideofthemachinehousing

containsclippingsanddebris.

4.Thebladeisdull.

1.Thereisdebrisunderthebeltcover.

2.Theself-propeldrivecableisoutof

adjustmentorisdamaged.

1.MovethethrottlelevertotheFast

position.

2.Connectthewiretothesparkplug.

3.Cleantheairlterpre-cleanerand/or

replacethepaperairlter.

4.Checkthesparkplugandadjustthe

gapifnecessary.Replacethespark

plugifitispitted,fouled,orcracked.

1.Cleanunderthemachinehousing.

replaceit.

1.Changethemowingpattern.

2.Setall4wheelstothesameheight.

3.Cleanunderthemachinehousing.

4.Sharpenandbalancetheblade.

1.Cleanthedebrisfromunderthebelt

cover.

2.Adjusttheself-propeldrivecable.

Replacethecableifnecessary.

26

Page 27

IntlDistList

Distributor:

AtlantisSuveSulamaSisstemleriLt

BalamaPrimaEngineeringEquip.HongKong85221552163

B-RayCorporation

CascoSalesCompany

CeresS.A.CostaRica

CSSCTurfEquipment(pvt)Ltd.SriLanka

CyrilJohnston&Co.

EquiverMexico525553995444

FemcoS.A.Guatemala

G.Y .K.CompanyLtd.

GeomechanikiofAthensGreece

GuandongGoldenStarChina

HakoGroundandGardenSweden

HakoGroundandGarden

HayterLimited(U.K.)

HydroturfInt.CoDubai

HydroturfEgyptLLC

IbeaS.P.A.

IrriamcPortugal351212388260

IrrigationProductsInt'lPvtLtd.India862283960789

JeanHeybroekb.v .Netherlands3130639461 1

MaquiverS.A.Colombia

MaruyamaMfg.Co.Inc.

MetraKft

Mountelda.s.CzechRepublic

MunditolS.A.

OslingerTurfEquipmentSA

OyHakoGroundandGardenAb

ParklandProductsLtd.NewZealand6433493760

Prochaska&Cie

RTCohen2004Ltd.

Riversa

ScSvendCarlsenA/S

SolvertS.A.S.

SpyprosStavrinidesLimitedCyprus

SurgeSystemsIndiaLimited

T-MarktLogisticsLtd.Hungary3626525500

ToroAustraliaAustralia61395807355

ToroEuropeNVBelgium3214562960

Country:

Turkey902163448674

Korea82325512076

PuertoRico7877888383

NorthernIreland442890813121

Japan81726325861

Norway4722907760

UnitedKingdom441279723444

UnitedArabEmirates97143479479

Egypt2025194308

Italy390331853611

Japan81332522285

Hungary3613263880

Argentina541148219999

Ecuador59342396970

Finland35898700733

Austria4312785100

Israel97298617979

Spain

Denmark4566109200

France33130817700

India911292299901

PhoneNumber:

5062391 138

94112746100

5024423277

30109350054

862087651338

4635100000

5712364079

420255704220

34952837500

35722434131

374-0269RevC

Page 28

TheT oroWarranty

ConditionsandProductsCovered

TheToroCompanyanditsafliate,ToroWarrantyCompany,pursuantto

anagreementbetweenthem,jointlypromisetotheoriginalpurchaser*

torepairtheToroProductslistedbelowifdefectiveinmaterialsor

workmanship.

Thefollowingtimeperiodsapplyfromthedateofpurchase:

ProductsWarrantyPeriod

WalkPowerMowers

•CastDeck

5yearsResidentialUse

45DaysCommercialUse

•Engine

5yearsGTSPromise

Seeenginemanufacturer'swarranty

•SteelDeck

2yearsResidentialUse

45DaysCommercialUse

•Engine

2yearsGTSPromise

Seeenginemanufacturer'swarranty

ElectricHandHeldProducts2yearlimitedwarranty

Snowthrowers

•SingleStage

2yearsResidentialUse

45DaysCommercialUse

•TwoStage

2yearsResidentialUse

45DaysCommercialUse

•Electric2yearsResidentialUse

AllRide-OnUnitsBelow

•Engine

Seeenginemanufacturer'swarranty

1yearPartsonly

•Attachments1year

RearEngineRiders2yearsResidentialUse

90DaysCommercialUse

Lawn&GardenTractors

2yearsResidentialUse

90DaysCommercialUse

TimeCutterZMowers

3yearsResidentialUse

30DaysCommercialUse

TITANMowers3yearsor240hours

•Frame

Lifetime(originalowneronly)

TITANMXMowers3yearsor400hours

•Frame

ZMasterMowers—2000Series

•Frame

Lifetime(originalowneronly)

5yearsor1200hours

Lifetime(originalowneronly)

2

2

2

2

2

2

2

2

3

4

3

4

3

4

OwnerResponsibilities

YoumustmaintainyourT oroProductbyfollowingthemaintenance

proceduresdescribedintheOperator'sManual.Suchroutine

maintenance,whetherperformedbyadealerorbyyou,isatyourexpense.

InstructionsforObtainingWarrantyService

IfyouthinkthatyourT oroProductcontainsadefectinmaterialsor

workmanship,followthisprocedure:

1.Contactyoursellertoarrangeserviceoftheproduct.Ifforanyreason

itisimpossibleforyoutocontactyourseller,youmaycontactany

ToroAuthorizedDistributortoarrangeservice.

1

2.Bringtheproductandyourproofofpurchase(salesreceipt)tothe

ServiceDealer.IfforanyreasonyouaredissatisedwiththeService

Dealer’sanalysisorwiththeassistanceprovided,contactusat:

1

CustomerCareDepartment,RLCDivision

TheT oroCompany

811 1LyndaleAvenueSouth

Bloomington,MN55420-1196

Manager:T echnicalProductSupport:001–952–887–8248

SeeattachedDistributorList

ItemsandConditionsNotCovered

1

Thisexpresswarrantydoesnotcoverthefollowing:

•Costofregularmaintenanceserviceorwearparts,suchasblades,

rotorblades(paddles),scraperblades,belts,fuel,lubricants,oil

changes,sparkplugs,cable/linkageorbrakeadjustments

•Anyproductorpartwhichhasbeenalteredormisusedandrequires

replacementorrepairduetoaccidentsorlackofpropermaintenance

•Repairsnecessaryduetofailuretousefreshfuel(lessthanone

monthold),orfailuretoproperlypreparetheunitpriortoanyperiod

ofnon-useoveronemonth

•Engineandtransmission.Thesearecoveredbytheappropriate

manufacturer’sguaranteeswithseparatetermsandconditions

Allrepairscoveredbythesewarrantiesmustbeperformedbyan

AuthorizedToroServiceDealerusingT oroapprovedreplacementparts.

*OriginalPurchasermeansthepersonwhooriginallypurchasedtheT oroProduct.

1

SomeenginesusedonT oroProductsarewarrantedbytheenginemanufacturer.

2

Residentialusemeansuseoftheproductonthesamelotasyourhome.Useatmorethanone

locationisconsideredcommercialuseandthecommercialusewarrantywouldapply.

3

Whicheveroccursrst.

4

LifetimeFrameWarranty-Ifthemainframe,consistingofthepartsweldedtogethertoformthe

tractorstructurethatothercomponentssuchastheenginearesecuredto,cracksorbreaksin

normaluse,itwillberepairedorreplaced,atT oro'soption,underwarrantyatnocostforparts

andlabor.Framefailureduetomisuseorabuseandfailureorrepairrequiredduetorustor

corrosionarenotcovered.

Thiswarrantyincludesthecostofpartsandlabor,butyoumustpay

transportationcosts.

Warrantymaybedeniedifthehourmeterisdisconnected,altered,or

showssignsofbeingtamperedwith.

GeneralConditions

Thepurchaseriscoveredbythenationallawsofeachcountry.Therights

towhichthepurchaserisentitledwiththesupportoftheselawsarenot

restrictedbythiswarranty.

374-0268RevC

Loading...

Loading...