Page 1

LAWN-BOY V-ENGINE SERVICE MANUAL

Table of Contents – Page 1 of 2

REFERENCE SECTION

SAFETY

SPECIFICATIONS - ENGINE SPECIFICATIONS

SPECIFICATIONS - ENGINE FASTENER TORQUE REQUIREMENTS

SPECIFICATIONS - CARBURETOR SPECIFICATIONS (WALBRO LMR-16)

SPECIAL TOOL REQUIREMENTS

TROUBLESHOOTING

MAINTENANCE

SECTION 1 WALBRO LMR-16 CARBURETOR

LMR-16 CARBURETOR - IDENTIFICATION

LMR-16 CARBURETOR - THEORY OF OPERATION

LMR-16 CARBURETOR - GOVERNOR THEORY

LMR-16 CARBURETOR - REMOVAL

LMR-16 CARBURETOR - DISASSEMBLY

LMR-16 CARBURETOR - CLEANING AND INSPECTION

LMR-16 CARBURETOR - ASSEMBLY

LMR-16 CARBURETOR - PRESETTING THE GOVERNOR

LMR-16 CARBURETOR - ASSEMBLING AIR BOX TO CARBURETOR

LMR-16 CARBURETOR - INSTALLATION

LMR-16 CARBURETOR - FINAL CHECK

LMR-16 CARBURETOR - CHOKE ADJUSTMENT

LMR-16 CARBURETOR - SERVICING THE AIR FILTER

LMR-16 CARBURETOR-TROUBLESHOOTING

SECTION 2 PRIMER START CARBURETOR

PRIMER START CARBURETOR - IDENTIFICATION

PRIMER START CARBURETOR - THEORY OF OPERATION

PRIMER START CARBURETOR - GOVERNOR THEORY

PRIMER START CARBURETOR - REMOVAL

PRIMER START CARBURETOR - DISASSEMBLY

PRIMER START CARBURETOR - CLEANING AND INSPECTION

PRIMER START CARBURETOR - ASSEMBLY

PRIMER START CARBURETOR - INSTALLATION

PRIMER START CARBURETOR - PRESETTING THE GOVERNOR

PRIMER START CARBURETOR - FINAL CHECK

PRIMER START CARBURETOR - SERVICING THE AIR FILTER

PRIMER START CARBURETOR TROUBLESHOOTING

ENGINE STARTS HARD

ENGINE RUNS RICH

ENGINE RUNS LEAN

FUEL LEAKS FROM CARBURETOR

Page 2

LAWN-BOY V-ENGINE SERVICE MANUAL

Table of Contents – Page 2 of 2

SECTION 3 FUEL SYSTEM

FUEL SYSTEM - OPERATION

FUEL SYSTEM - CAP SERVICE

FUEL SYSTEM - TANK REMOVAL

FUEL SYSTEM - CLEANING

FUEL SYSTEM - TANK INSTALLATION

SECTION 4 IGNITION SYSTEM

IGNITION SYSTEM - TROUBLESHOOTING

IGNITION SYSTEM - SPARK PLUG OPERATION

IGNITION SYSTEM - SPARK PLUG SERVICE

IGNITION SYSTEM - CD PACK OPERATION

IGNITION SYSTEM - CD PACK AIR GAP ADJUSTMENT

IGNITION SYSTEM - CD PACK REMOVAL/INSTALLATION

IGNITION SYSTEM - FLYWHEEL OPERATION

IGNITION SYSTEM FLYWHEEL REMOVAL

IGNITION SYSTEM - FLYWHEEL INSTALLATION

SECTION 5 REWIND STARTER

REWIND STARTER - OPERATION

REWIND STARTER - REMOVAL AND DISASSEMBLY

REWIND STARTER - REASSEMBLY

SECTION 6 ENGINE

ENGINE - DESCRIPTION

ENGINE - THEORY OF OPERATION

ENGINE - SERVICE TIPS

ENGINE - REMOVAL

ENGINE - DISASSEMBLY

ENGINE - INSPECTION AND REPAIR

ENGINE - REED VALVE SERVICE

ENGINE - REASSEMBLY

SECTION 7 PIVOTING ZONE START BRAKE

INTRODUCTION

PIVOTING ZONE START BRAKE - OPERATION

PIVOTING ZONE START BRAKE - DISASSEMBLY

PIVOTING ZONE START BRAKE - ASSEMBLY

APPENDIX A

Page 3

V-Engine

Page 4

Reference Section

TABLE

OF

CONTENTS

Service Section

Safety Information

Engine Specifications 10

Engine Fastener Torque Requirements 11

Carburetor Specifications 12

Special Tool Requirements 13

Troubleshooting 14

Maintenance 19

Recommended Maintenance Schedule 19

Air Filter 19

Spark Plug 20

Cleaning the Exhaust System 21

9

Section 1 LMR-16

Identification 25

Theory of Operation 25

Governor Theory 25

Removal 26

Disassembly 27

Cleaning and Inspection 27

Assembly 28

Presetting the Governor 29

Assembling Air Box to Carburetor 29

Installation 30

Final Check 30

Choke Adjustment 30

Servicing the Air Filter

Carburetor

30

V-Engine

Troubleshooting 31

3

Table

of

Contents

Page 5

Service Section (cont'd)

TABLE

OF

CONTENTS

Section

2

Primer Start Carburetor

Identification 32

of

Theory

Governor The0

Removal 33

Disassembly 34

Cleaning and Inspection 34

Assembly 34

Installation 35

Presetting the Governor 35

Final Check 35

Servicing the Air Filter 36

Troubleshooting 36

Operation 32

ry

32

Section 3

Section 4

Fuel System

Operation 37

Cap Service 37

Tank Removal 38

Cleaning 38

installation

Tank

Ignition System

Troubleshooting 39

Spark Plug

Operation 39

Service 39

38

V-Engine

Table

of

Contents

Page 6

Service Section (cont’d)

Section 4 (cont’d)

CD Pack

Flywheel

TABLE

Operation 40

Air Gap Adjustment 41

Removal Installation 41

Operation 41

Removal 41

Installation 42

OF

CONTENTS

Section

Section 6

5

Rewind Starter

Operation 43

Removal and Disassembly 43

Reassembly 44

Engine

Description

Theory

Service Tips

Removal ..............................................................................................................

Disassembly ........................................................................................................

of

Operation ............................................................................................

........................................................................................................

Inspection and Repair

Reed Valve Service

..............................................................................

..................................................................................

.........................................................

Reassembly .........................................................................................................

V-Engine Table

of

Contents

Page 7

Service Section (cont’d)

TABLE

OF

CONTENTS

Section

Appendix A

7

Pivoting Zone Start Brake

Introduction

Operation

Disassembly 53

Assembly

Exploded View Diagrams A-1

53

53

54

Table

of

Contents

6

V-Engine

Page 8

SAFETY INFORMATION

This safety symbol means WARNING or PERSONAL SAFETY INSTRUCTION read the instruction

because it has to do with your safety. Failure to comply with the instruction may result in personal injury

or even death.

This manual is intended as a service and repair manual only. The safety instructions provided herein are for troubleshooting, service and repair of the engine only. The individual Operator’s manual will contain safety information

V

on the complete product powered by the

through:

Lawn-Boy Corporation

Publications Department

8111

Lyndale Avenue South

MN

Bloomington,

55430

engine. Operator’s manuals with complete instructions are available

U.S.A.

SAFETY TIPS

Avoid unexpected starting of engine

Always turn

spark plug wire before attempting cleaning, adjustment or repair.

Avoid lacerations and amputations

Stay clear of all moving parts whenever the engine is

running. Treat all normally moving parts as

were moving whenever the engine

the potential to start.

Avoid burns

Do

not touch the engine while it is running or shortly

after it has been running.

Avoid Falls

Do not operate the powered product on slippery surfaces or

Avoid fires

Wipe up any spilled fuel or oil immediately.

off

the powered product and disconnect

if

footing is questionable.

if

they

is

running or has

Avoid asphyxiation

Never operate an engine in a confined area without

proper ventilation.

Avoid fires and explosions

Use a container designed for gasoline. Avoid spilling

fuel and never smoke while working with any type of

fuel.

Avoid accidental misuse of fuel

Always stole fuel in a properly labeled container

designed for gasoline.

Avoid injury due to inferior parts

Use only Lawn-Boy@ original parts to ensure that

important safety criteria are met.

Avoid

Always clear the area of bystanders before starting or

testing powered equipment.

Avoid injury due

Always clear the area of sticks, rocks or any other

debris that could be picked up and thrown by the

powered equipment.

injury to bystanders

to

projectiles

Reference Section

9

Safety Information

Page 9

Engine Specifications

Bore 2.3810 2.3800 (60.477 85.852 mm)

Stroke 1.7520 1.7497” (44.501 44.442 mm)

Connecting rod length 3.00 (76.2 mm)

Wrist pin diameter

Wrist pin offset

Crankpin diameter

Top and bottom main bearings Dia: Top: .875” (22.23 mm) Bottom:1.125” (28.58 mm)

Displacement

Horsepower

Compression ratio 5.91:l (Range of 5.151 6.668:l)

Carburetor ‘93 models

Carburetor ‘94 models up)

Fuel required

Recommended oil

Fuel tank capacity

Ignition type

CD Pack air gap

Spark timing

.5000”

.070

.742” (18.85 mm)

7.78 cu in (127.51 cc)

4.5

Dual circuit Walbro, float type,’ with fixed main jet

Single-circuit Lawn-Boy with fixed main jet, float type, with primer

32:l premix unleaded regular (87 octane 2-cycle oil

Lawn-Boy Ashless 2-cycle oil

1.5 quarts

Solid state CD Pack, magneto type

.010 (.25 mm)

2’ 8’ BTDC (Cranking); 22’ 28’ (Running)

(12.7 mm)

(1.78 mm) toward major thrust side

__-

--_-

Spark plug air gap Champion RJ12C .035 (.889 mm)

Starting system

Governor Air vane

Governed engine speed

Idle speed

Air cleaner

Choke

Fuel filter

Piston Permanent mold, high silicon aluminum

Piston rings Cast iron, semi-keystone top ring

Rope rewind

3050+/- 100 RPM

2200 2800 RPM

Oiled, foam type

Manual, butterfly type (Walbro only)

ln-tank and in-carburetor

10

Reference Section

Page 10

SPECIFICATIONS

Engine Fastener Torque Requirements

Torque

(cont'd)

45 50

375 425

5

60 70

45

90 110

105 115

300 350

15 25

150 190

140 200

10 13

65 75

58 70

60 70

150 200

65.15

7

in

55 in

ft

Ibs

in

Ibs

(.5 .8 N-m)

in

Ibs

Ibs

in

Ibs

in

in

in

Ibs

in

in

in

Ibs

in

Ibs

in

Ibs

in

Ibs

in

in

Ibs

(60 67 N-m)

lbs

(42 47 N-m)

(6.7 7.8 N-m)

(5.0 6.1 N-m)

(10 12 N-m)

Ibs

(12 13 N-m)

Ibs

(34 39 N-m)

(1.7 2.8 N-m)

Ibs

(17 22 N-m)

Ibs

(16 22 N-m)

(1.1 1.5 N-m)

(7.3 8.4 N-m)

(6.5 7.8 N-m)

_I

(6.7 7.8 N-m)

Ibs

(17 23 N-m)

(7.3 8.4 N-m)

-__I_-----~-

* Use thread-locking compound

Reference Section

11

Specifications

Page 11

SPECIFICATIONS

Carburetor Specifications (Walbro LMR-16)

Carburetor Specifications (Primer Start)

(cont’d)

12

Reference Section

Page 12

SPECIAL TOOL REQUIREMENTS

V-Engine

DESCRIPTION

V

Engine Tool Kit 612490

Air Gap Gauge 604659

Piston Stop 61 21 03

Crankshaft Gauge 609968

Piston Ring Compressor 609967

E-12

Where

Note:

If

to

The tools included in this kit are also found in the D and F Engine Tool Kit (part number 683625.)

you already own that kit, you do not need to purchase any additional special tools.

Tool

Torx

Socket Purchase

Purchase:

Requirements

Includes tools shown below necessary to service

Sets .010” gap between flywheel and coil.

Prevents piston from traveling over TDC. Use when servicing flywheel

or installing piston.

Sets correct gap on crankshaft support.

Compresses rings into piston grooves during installation of piston.

Use to remove upper and lower crankshaft seals.

Use to properly position upper and lower crankshaft seals.

Use to remove crankcase fasteners.

Locally

Order through Lawn-Boy parts department as you would any other part.

__-

.-

V

Engine.

Reference Section

13

Special Tools

Page 13

Contents

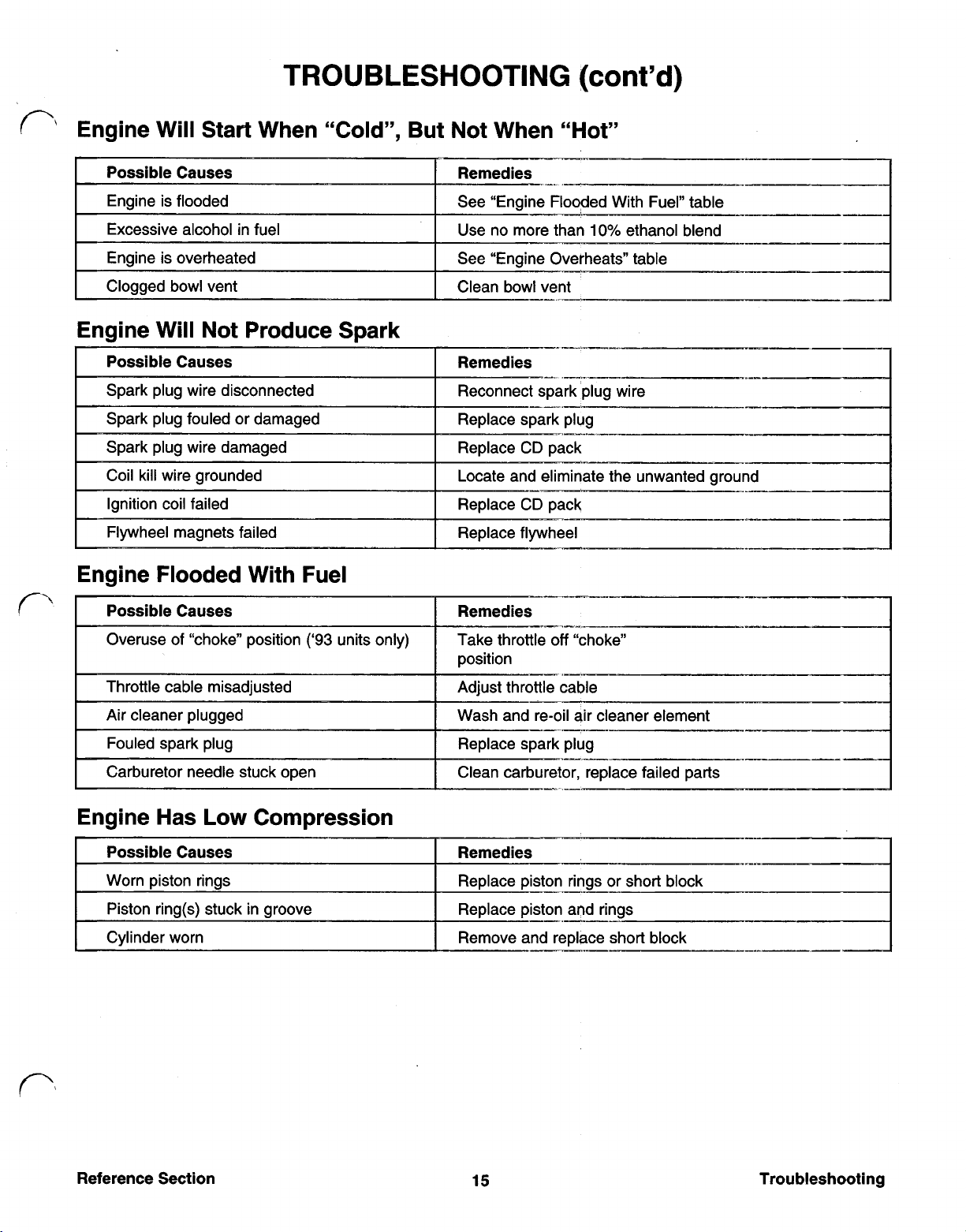

TROUBLESHOOTING

Engine Will Not Start When “Cold

Engine Will Start When “Cold But Not When “Hot”

Engine Will Not Produce Spark

Engine Flooded With Fuel

Engine Has Low Compression

Engine Lacks Power

Engine Surges

Engine Backfires

Engine Overheats

Engine Vibrates Excessively

Engine Crankshaft Will Not Turn

Engine Produces Mechanical Knocking Sound

Engine Pre-Ignites

Engine Smokes Excessively

Engine Stalls

Spark Plug Fouled

......................................................

14

15

15

15

15

16

16

16

I6

16

17

17

17

17

.I8

18

Engine Will Not Start When “Cold”

Engine flooded with fuel See “Engine Flooded With Fuel” table

Reed valves not closed Replace reed valves

ank with clean, fresh,

re-oil air cleaner element

ve and replace the spark plug

I

Not Produce Spark” table

blade

_I_~

I

Troubleshooting

14

Reference Section

Page 14

TROUBLESHOOTING

Engine Will Start When “Cold”, But Not When “Hot”

e Flooded With Fuel” table

Engine Will Not Produce Spark

Possible Causes

I

Coil kill wire grounded

Locate and eliminate the unwanted ground

(cont’d)

---~--

Engine Flooded With Fuel

I

Possible Causes Remedies

Overuse of “choke” position

Throttle cable misadjusted Adjust throttle cable

Air cleaner plugged

Fouled spark plug

Carburetor needle stuck open Clean carburetor, replace failed parts

Engine Has

Possible Causes

Worn piston rings

Low

Compression

(‘93

units only)

off

Take throttle

position

Wash and re-oil air cleaner element

Replace spark plug

Remedies

Replace piston rings or short block

Replace piston and rings Piston ring(s) stuck in groove

Remove and replace short block Cylinder worn

“choke”

-_-.-

I

I

Reference Section

15

Troubleshooting

Page 15

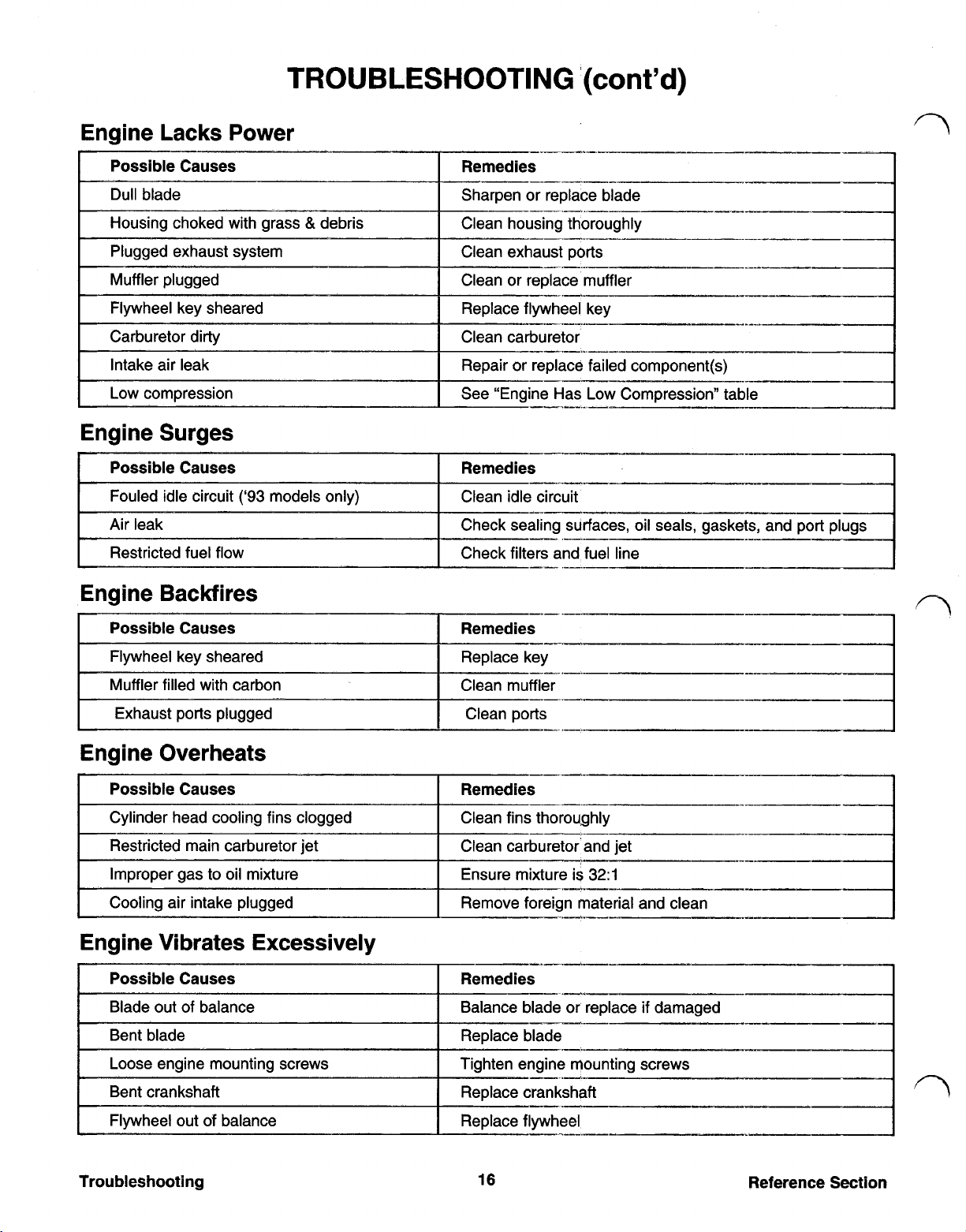

Engine Surges

TROUBLESHOOTING

‘(cont’d)

Possible Causes

Fouled idle circuit

Air leak

Restricted fuel flow

(‘93

models only)

Engine Backfires

Possible Causes Remedies

I

Flywheel key sheared

Muffler filled with carbon

Exhaust ports plugged

Engine Overheats

Possible Causes

Cylinder head cooling fins clogged

Restricted main carburetor jet

Improper gas to oil mixture

Cooling air intake plugged

Remedies

Clean idle circuit

Check sealing surfaces, oil seals, gaskets, and

Check filters and fuel line

Replace key

Clean muffler

Clean ports

Remedies

Clean fins thoroughly

Clean carburetor’ and jet

Ensure mixture is

Remove foreign material and clean

32:l

Engine Vibrates Excessively

Possible Causes

Blade out of balance

Bent blade Replace blade

Loose engine mounting screws

Bent crankshaft

Flywheel out

Troubleshooting

of

balance

Remedies

Balance blade or replace

Tighten engine mounting screws

Replace crankshaft

Replace flywheel

16

-.--_-

if

damaged

Reference Section

Page 16

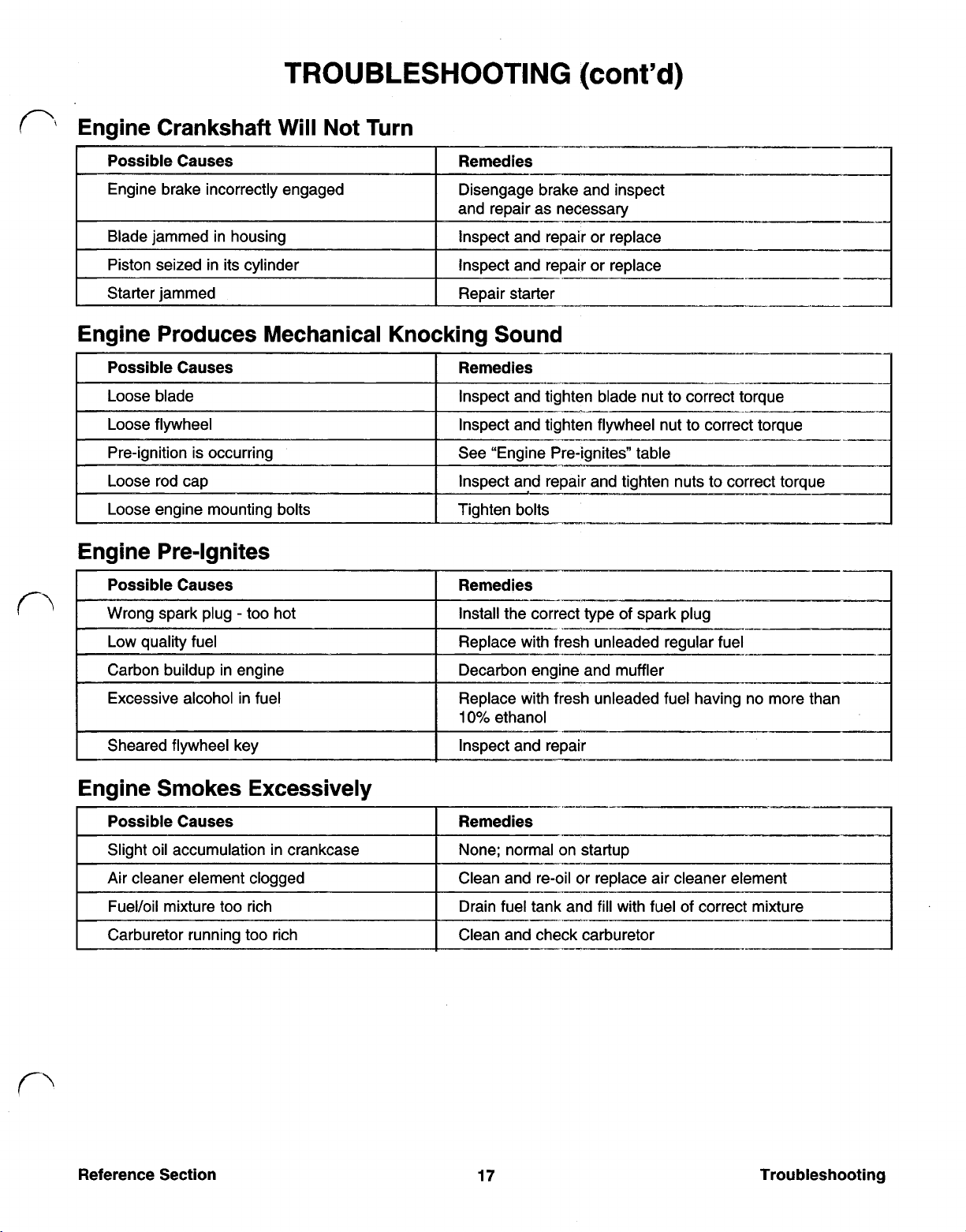

TROUBLESHOOTING

(cont’d)

Engine Crankshaft Will

Possible Causes Remedies

Engine brake incorrectly engaged

Blade jammed in housing

Piston seized in its cylinder

Starter jammed

Not

Turn

Disengage brake and inspect

and repair as necessary

Inspect and repair or replace

Inspect and repair or replace

Repair starter

Engine Produces Mechanical Knocking Sound

Possible Causes Remedies

Engine Pre-Ignites

Possible Causes Remedies

Wrong spark plug too hot Install the correct type of spark plug

I

I

Replace with fresh unleaded regular fuel

Excessive alcohol in fuel

Sheared flywheel key Inspect and repair

Decarbon engine and muffler

Replace with fresh unleaded fuel having no more than

10%

_I-..

ethanol

Engine Smokes Excessively

Possible Causes Remedies

Slight oil accumulation in crankcase

Fuel/Oil mixture too rich Drain fuel tank and fill with fuel of correct mixture

Carburetor running too rich

None; normal on startup

Clean and re-oil or replace air cleaner element Air cleaner element clogged

Clean and check carburetor

_-

I

I

I

Reference Section

17

Troubleshooting

Page 17

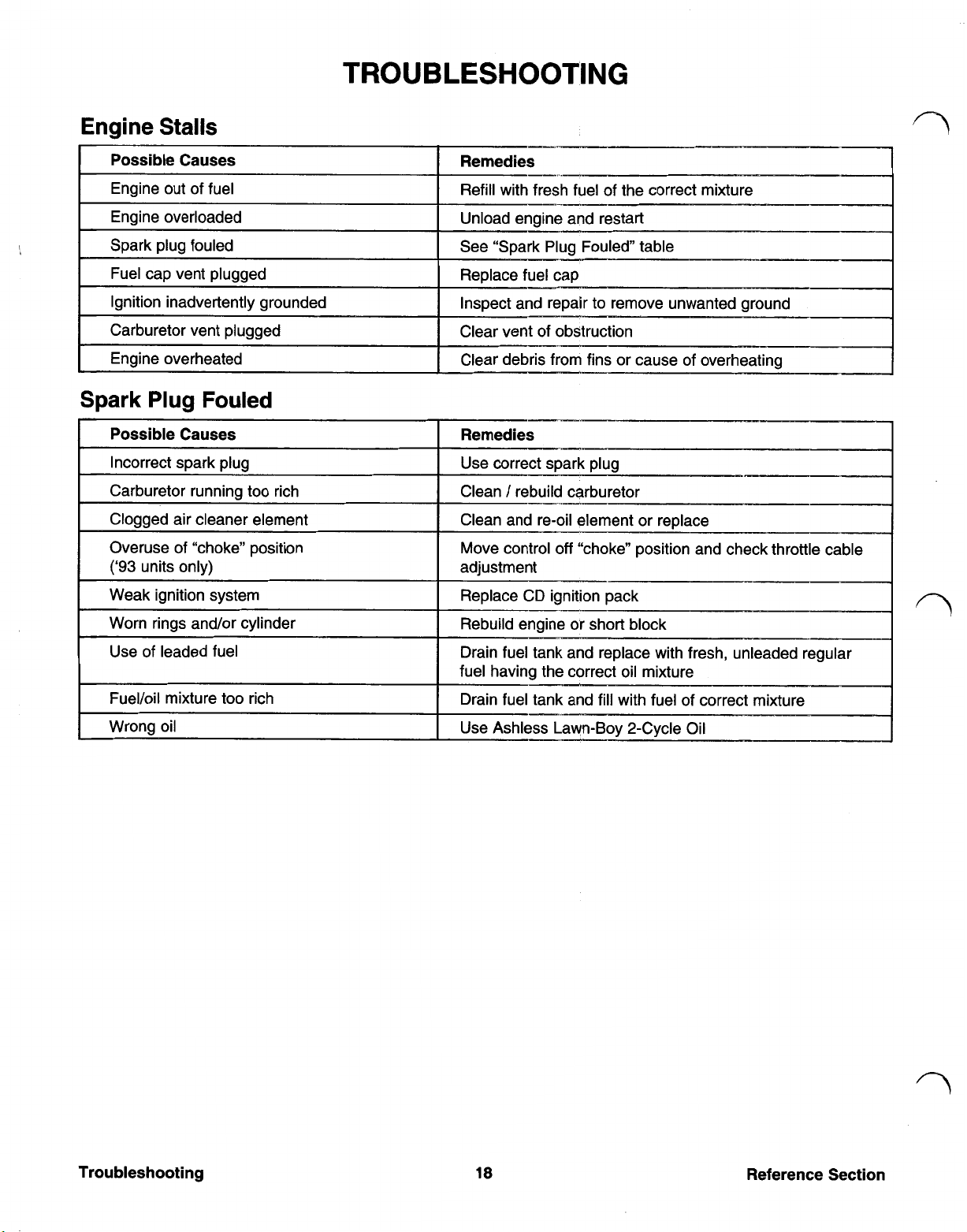

Engine

Stalls

Spark

Use

Plug

of

leaded fuel resh, unleaded regular

Fouled

Page 18

Recommeded Maintenance Schedule

25

50

100

Hours Air Filter

Hours

Hours

Blade Brake

I

Exhaust Ports

I

I

Cooling System

Check blade and engine mounting

f

bolts and screws tight to ensure safe operation.

replace.

Check for leakage and/or deterioration

Air

Filter

Once every season, or every

filter housing and element.

25

hours, clean the air

Do

so

more frequently

under dusty conditions.

Notes:

in place. Doing

Do not operate the engine without the air filter

so

may damage the engine or cause

excessive engine wear.

Figure 1 shows the

‘93

carburetor;

‘94

models have

an additional wire clamp to release.

1.

To remove air filter, snap cover latch open,

swing to side and unhook. Remove the cover

and air filter

(Figure

1).

Filter

Cover

Figure

1

Reference Section

19

Maintenance

Page 19

MAINTENANCE

(cont’d)

Air Filter

2.

3.

(cont’d)

Wash air filter in laundry detergent.

Squeeze filter to remove excess liquid and blot

dry with a paper towel or rag

Figure

Apply one tablespoon of SAE

filter

(Figure

distributed evenly throughout filter. Blot lightly

with paper towel to remove excess oil.

3).

Lightly squeeze filter until oil is

2

(Figure

30

oil to the air

2).

Spark

A spark plug that is dirty, pitted, carbon covered or

has worn electrodes may cause hard starting and

poor operation.

Clean or replace spark plug once a season or every

25 hours, whichever occurs first. Use Champion

RJ12C,

Remove spark plug and clean with a wire brush,

removing carbon buildup. DO NOT SANDBLAST.

Check condition of plug for cracks, damaged or worn

electrodes. Replace

1.

Plug

or

equivalent.

if

necessary.

Set spark plug gap at

See

Figure

,035

(.85

4.

in.

mm)

0.035

inch (.85mm).

Replace filter with cleanest side facing

carburetor.

Note:

is not puckered (allowing direct passage of air and dir

to carburetor).

Be sure filter is properly seated in air box and

Figure

3

Figure

2. Install spark plug finger tight, then torque to

ft

180 in Ibs (15

Ibs)

Figure

4

(20 N-m_

5

Figure

5.

Maintenance

20

Reference Section

Page 20

MAINTENANCE

Cleaning The Exhaust System

Warning:

accidentally starting the engine.

1.

I

Disconnect the spark plug wire to prevent

Using a 1/2 drive with a 15/16 socket, remove

the blade nut that secures both the mulch fan

and blade to the engine. Use heavy duty gloves

to hold the blade while removing the nut

(Figure

6).

Figure

6

(cont'd)

4.

Remove the three bolts to remove the muffler

cover. Drop the cover down to inspect the

condition of the exhaust ports, etc.

(Figure

5.

Pull the starter rope until the piston covers the

exhaust ports

a

3/8”

8).

(Figure

(9

mm) wooden dowel.

9).

Clean them with

2.

Using a soft hammer, gently tap the blade drive

it

to remove

(Figure

3.

If

necessary, clean the small louvers in the

muffler cover; they must be open.

from the shaft of the engine

7).

Figure

7

Ports

Figure 9

Reassembling Exhaust System

1. Insert three bolts into the muffler cover and

90

tighten to a torque of 150-1

7-22

(1

2.

Re-install the blade drive, beveled edge towards

the engine to match its shaft angle.

3.

Re-install the blade and mulch fan with the

15/16" nut. Be sure the small circular bosses on

the blade drive collar match the holes in the

(Figure

N-m)

blade. Tighten the nut to 50

6).

in Ibs

ft

Ibs

(68

N-m)

Reference Section

21

Maintenance

Page 21

SECTION

1

WALBRO

LMR-16

CARBURETOR

LMR-16 Carburetor Identification

The LMR-16 carburetor can be identified by its

aluminum body. Walbro (the manufacturer's name) is

also stamped on the side of the body. These

carburetor's were used on 1993 models.

LMR-16 Carburetor Theory of Operation

As

the crankshaft rotates, the piston moves back and

forth in the cylinder, alternately creating a pressure or

a partial vacuum in the crankcase

When a vacuum is created by upward piston

movement, the reed valve opens and air rushes

through the carburetor throat. The carburetor throat is

a venturi tube (large at each end but with a smaller

center passage). When the air rushes through this

tube, air pressure at the center of the passage

lowered.

(Figure

10).

is

LMR-16 Carburetor Governor Theory

The shaft of the governor air vane is attached to the

throttle disc of the carburetor

by the rotating flywheel, attempts to close the throttle.

The governor spring resists this force and attempts to

open the throttle. The balance between these two

forces is the governed engine speed. Spring tension

may be changed via an adjustable collar which

50

75

produces a

each adjustment "click"

RPM

so

that air flow, created

change in engine speed for

(Figure

12).

Figure

By inserting a tube from the carburetor float bowl into

the venturi

venturi draws fuel through the tube. The fuel/oil mix is

then picked up by, and mixed with, the moving air.

This fuel/oil/air mixture enters the crankcase through

the reed valves

operation of the engine as long as fuel is supplied

to it.

(Figure

(Figure

11).

10

lower air pressure at the

10)

thereby sustaining

Figure

12

Service Section

Venturi

Effect

Figure

11

25

Carburetor

Page 22

LMR-16

1.

2.

3.

4.

5.

6.

Carburetor Removal

Disconnect spark plug wire.

Remove Fuel Tank (See page 38).

Open and remove air cleaner cover and air filter

element.

Detach carburetor from engine by removing

mounting bolts. Remove and discard the

small carburetor gaskets. Save the carburetor

heat shield.

Disconnect the fuel line.

Pull the carburetor assembly down and away

from the engine such that the air vane clears the

hole in the shroud base

(Figure 13).

two

two

7.

Remove the throttle cable screw and nut and

disconnect the cable from the control lever

(Figure 14).

Figure 14

Figure 13

CAUTION:

damage to the governor spring.

8. Hold the carburetor in one hand and

cleaner box

choke shaft. Rotate the carburetor

counterclockwise and remove the spring from

the control lever.

Be careful in the next step to prevent

so

that the control lever clears the

lift

the air

Page 23

LMR-16 Carburetor Disassembly

.l.

Remove the in-line filter from the fuel inlet.

2.

Remove the screw holding the air vane to the

throttle shaft. Remove the air vane collar and

governor spring and remove the throttle valve

screw, plate and shaft

(Figure 15).

Figure 15

Remove the idle adjustment needle and spring.

Remove the bowl retaining bolt and gasket, the

bowl and the bowl gasket.

Remove the float shaft, float and inlet needle.

Remove the fuel inlet (Viton) seat using a short

piece of wire or a shot of compressed air.

Using an awl, pierce the Welch plug, then

so

carefully remove it

holes are exposed

that the idle progression

(Figure 17).

3.

Gently bend spread the slot in the choke shaft

and remove the choke plate using pliers. Lift

the choke shaft and spring from the carburetor

(Figure 16).

Figure 16

Figure 17

LMR-16 Carburetor Cleaning and

Inspection

Thoroughly clean all the carburetor parts and inspect

them for wear. Wash the jets and passages and blow

dry with compressed air immediately.

CAUTION:

in the carburetor.

Note:

sealer, use a spray cleaner to clean external surfaces.

Immersing the entire carburetor in a cleaning solution

will remove the seal coating.

Never enlarge or restrict any passageway

Since this carburetor has a special external

Service Section

27

Carburetor

Page 24

LMR-16

1.

2.

Carburetor Assembly

Install Welch plug using a blunt tool having the

same diameter as the Welch plug.

Install the fuel inlet valve seat: coat the seat with

oil and install it grooved side down

(Figure 18).

INSTALL

5.

Place bowl onto the carburetor body and install

the bowl retaining bolt and gasket

(Figure 20).

n

Figure 18

3.

Place the inlet needle on the float and install it

on

carburetor. Push the float pin into the

carburetor body through the float hinge

(Figure 19).

Note:

The float is not adjustable

necessary to check float height. However,

always make sure that no liquid is inside the float

before reinstalling.

so

it is not

Figure

Install idle needle and spring. Turn in until the

needle seats lightly then back it out

a turn.

Install the choke shaft and spring as shown

(Figure 21).

Figure 21

Make sure the opening on the choke plate

8.

faces left.

20

5/8

3/4

of

Figure 19

4.

Position the bowl gasket on the top edge of the

carburetor body.

Carburetor

28

Push the choke plate into the shaft

9.

Figure 22

(Figure 22)

CHOKE

Service Section

Page 25

LMR-16 Carburetor Assembly (cont’d)

10. Place a drop of Loctite on the screw and install

the throttle shaft and valve with the valve hole to

the left

(Figure 23).

LMR-16 Carburetor Presetting the

Governor

1. Hold the carburetor with the mounting flange

facing you and the throttle wide open.

2.

Preset the governor by turning the collar

3-4

the window on the collar is

of the pulse hole.

clicks to the right

so

that

Figure 23

1 1. Place the governor spring into the collar and

place the collar and spring onto the throttle shaft.

so

Position the collar

that the window is in line

LMR-16 Carburetor Assembling Air

to Carburetor

1. Hook the end

control lever and move the air box

counterclockwise.

2. Lift the control lever over the choke shaft and

place on the front

the post on the lever activates the choke.

3.

Install the carburetor mounting bolts

of

the governor spring into the

of the carburetor. Make sure

?

Figure 26

(Figure 26).

Box

4.

Place one carburetor-to-crankcase gasket onto

the carburetor for mounting bolts.

Figure 24

with the pulse hole

12. Install the air vane and screw

Service Section 29 Carburetor

(Figure 24).

Figure 25

AIR

VANE

(Figure 25).

5.

Install the heat shield as shown

Figure

(Figure 27).

27

Page 26

LMR-16 Carburetor Assembly (cont’d)

LMR-16 Carburetory Choke Adjustment

6. Install the remaining carburetor gasket; make

sure all pulse holes are aligned.

7.

Hook the control cable into the control lever and

fasten the cable to the air box.

LMR-16 Carburetor Installation

1.

While holding the carburetor and parts together,

turn the assembly and guide the air vane into the

opening in the shroud base

2. Install the bolts finger tight.

3. Pull the carburetor to the left and push the air

box to the right. Tighten the bolts and torque to

45

55

in Ibs (5.1 6.2 N-m)

4.

Check that the choke moves freely.

5.

Install a cleaned and re-oiled element into the air

box and install the air box cover.

(Figure

13).

LMR-16 Carburetor Final Check

The ‘93 Lawn-Boy LMR carburetor used in the

V

Engine has an all metal housing with a mechanical

choke, an adjustable idle mixture, a fixed main jet and

a fixed float.

1. Move throttle control to “choke” position.

2. Look into the carburetor and be sure the choke

is closed. Tighten the hex screw and nut on the

black plastic cable holder to keep the cable in

place.

3.

Install the in-line fuel filter and attach the fuel line

to the carburetor fitting.

LMR-16 Carburetor Servicing the Air Filter

To remove the air filter, at the left side, snap the

cover latch open, swing it to the right and

unhook it. Remove the cover and air filter

element

(Figure

28).

Perform the following preliminary checks to eliminate

some of the possibilities that may contribute to

carburetor malfunction:

Ignition system ensure that all components

1.

are adjusted to specs and are the correct

components.

Fuel tank and in-line filters must not be

2.

plugged.

Fuel cap vent hole must not be plugged.

3.

Air filter must be clean and oiled.

4.

Crankcase seal Crankcase seals must be

5.

installed properly and in good condition;

torque value on the bolts must be correct.

Carburetor flange gaskets and heat shield

6.

must be installed correctly (pulse holes must

be aligned).

Exhaust ports must not be restricted.

7.

Fuel mixture must be new and not of

8.

unknown quantities, not old, etc.

Governor air vane must move freely.

9.

Figure

28

Clean and re-oil the air filter element according

to the procedure in Maintenance, pages 19

20.

and

CAUTION:

element or with a dry element; engine life will be

shortened.

Do not operate the engine without a filter

Page 27

Engine Starts Hard

LMR-16 CARBURETOR-TROUBLESHOOTING

Engine Runs

Dirty air cleaner

I

Dirt in carburetor Clean carburetor

Engine Runs Lean

Carburetor bolts not tight Tighten bolts to 45 55 in Ibs (5.1

Improper carburetor

adjustment

I

Dirt in idle mixture pocket Remove Welch plug and clean

Restricted filter(s)

Welch plug leaking

Engine Surges

Rich

I

Clean

or

replace air filter element

Adjust to 5/8 to 3/4 turn open

Clean filter(s)

Seal all Welch plugs

6.2

N-m)

I

I

Fuel Leaks From Carburetor

Dirt under inlet needle

Bowl vent plugged Remove bowl and clean with compressed air

Float leaking (heavy) Replace float

Float stuck

(gummed carburetor)

Service Section

carburetor and crankcase

Remove inlet needle, clean or replace seat

Remove bowl and clean carburetor

31

I

I

Carburetor

Page 28

SECTION

2

PRIMER START CARBURETOR

Primer Start Carburetor Identification

The primer start carburetor is easily identified by its

primer and its black plastic body. It is different from

earlier Lawn-Boy plastic body carburetors because it

does not have the adjustable needle behind the air-

1994

vane governor. This carburetor is found on

newer V-Engines.

and

Primer Start Carburetor Theory

of Operation

As

the crankshaft rotates, the piston in a vertically

mounted engine moves back and forth in cylinder,

alternately creating a pressure or a partial vacuum in

the crankcase (Figure

When a vacuum is created by upward piston

movement, the reed valve opens and air rushes

through the carburetor throat. The carburetor throat is

a venturi tube (large at each end but with a smaller

center passage). When air rushes through this tube,

air pressure at the center of the passage is lowered.

29).

By inserting a tube from the carburetor float bowl into

30),

the venturi (Figure

venturi draws fuel through the tube. The fuel/oil mix is

then picked up by, and mixed with, the moving air.

This fuel/oil/air mixture enters the crankcase through

the reed valves,(Figure

operation of the engine as long as fuel is supplied to

it.

I

lower air pressure at the

29)

thereby sustaining

Venturi

Effect

Figure

30

Primer Start Carburetor Governor Theory

The shaft of the governor air vane is attached to the

throttle disc of the carburetor

by the rotating flywheel, attempts to close the throttle.

The governor spring resists this force and attempts to

open the throttle. The balance between these two

forces is the governed engine speed. Spring tension

may be changed via an adjustable collar which

50

75

produces a

each adjustment "click" it is moved

RPM

so

that air flow, created

change in engine speed for

(see

Figure

31).

1

Figure

29

-ADJUSTABLE

I

Figure

31

Page 29

Primer Start Carburetor Removal

1.

Disconnect spark plug wire.

2.

Remove fuel line and drain; remove the fuel tank

(see page 38).

3. Open and remove air cleaner cover and air filter

element. Remove the

covering the mounting screws.

4.

Detach carburetor from engine by removing two

mounting screws. Discard the

carburetor gaskets on either side of the

carburetor shield. Keep the heat shield for later

installation.

5.

Disconnect the fuel line and the primer tube from

the carburetor fittings

two

plastic plugs

two

(Figure 32).

smaller

6.

Pull the carburetor assembly down and away

from the engine such that the air vane governor

clears the hole in the shroud mounting base.

7.

Remove the throttle cable screw and nut from

the throttle cable mounting bracket.

CAUTION:

Be careful in the next step to avoid

damage to the delicate governor spring.

8. Slide the white plastic control lever to either end

it

of its adjustment and snap

to the locked

position to help restrict its movement while you

disconnect the throttle cable from the control

(Figure 34).

lever

CONTROL LEVER

Figure 32

Figure 34

Service Section 33 Carburetor

Page 30

Primer Start Carburetor Dissassembly

1.

At the throat of the carburetor, using a needle

nose pliers, gently pull the throttle plate out of

the air vane assembly shaft

the orientation of the small protrusions on the

throttle plate as you pull it out. The single

protrusion should be on your left; next to the hole

9

at the

o’clock position).

(Figure

35).

Notice

5.

Remove the fuel filter from the fuel nozzle.

6. Remove the float hinge pin, the inlet valve

needle assembly (with its clip) and the float

(Figure

7. Inspect the float for cracks or deterioration of the

cork.

8.

Remove the brass inlet fuel valve seat and

discard it

9.

Remove the nozzle and the high speed jet from

the nozzle.

36).

Discard the needle and clip.

(Figure

36).

Primer Start Carburetor Cleaning and

1. With the carburetor completely disassembled,

thoroughly clean all parts in a parts cleaning

solution and inspect for wear or deterioration.

Blow dry all carburetor passages with

compressed air. Use a spray cleaner only to

clean external surfaces.

Figure

3. Hold the governor collar on the carburetor and

lift the air vane/throttle shaft out of the

carburetor. Lift the collar and spring up,

detaching the spring from the speed control

lever.

4.

Turn the carburetor over and remove

the four bowl retaining screws, the

bowl gasket and the bowl

Discard the bowl gasket.

Gasket

Fuel

(main jet)

35

(Figure

fuel

36).

CAUTION:

restrict any passageway in the carburetor.

2.

Always check the carburetor mounting flange

and the fuel bowl mounting flange to be sure

they are flush.

If

tag wire

is

used, never enlarge or

Primer Start Carburetor Assembly

1.

Install the high speed jet into the fuel nozzle

(Figure

2.

Turn the carburetor over and install the nozzle

assembly into the carburetor body.

3.

Install a new brass inlet fuel valve seat.

4.

Install a new inlet valve needle and clip on the

float.

Install the float assembly with a new float hinge

5.

pin in the bottom of the carburetor. Ensure that

the hinge pin is positioned properly to keep the

float level. The float should be free to move up

and down easily in the carburetor body.

6.

Adjust float

flange (gasket not in place) to top of float.

36).

so

height is 7/16 to 15/32 from bowl

Carburetor

Figure

36

34

7.

Install the fuel filter over the fuel nozzle.

Service Section

Page 31

Primer Start Carburetor Assembly (cont’d)

8.

Install a new fuel bowl gasket and the fuel bowl

with the four bowl retaining screws.

9. Hook the governor spring into the bottom of the

governor collar.

10. Holding the spring in the collar, hook the other

end of the spring into the speed control arm.

Place the collar and spring over the carburetor

fitting.

11. Install the air vane and throttle shaft into the

carburetor body by very carefully pushing the

shaft through the collar into the carburetor body.

12. Push the throttle plate into the throttle shaft.

(Figure 37)

(The plate only inserts one way).

Primer Start Carburetor Installation

Install new gaskets and the heat shield (removed

1.

in a previous procedure) on the carburetor. The

air cleaner element and its cover should not be

in place at this time.

Guide the air vane through the opening in the

2.

shroud base from the bottom of the base and

attach the carburetor to the engine with

mounting screws. Tighten them to a torque of

45-55 in Ibs (5.1 6.2 N-m) Replace the cap

plugs.

Insert the bent wire

3.

vertical tab of the speed control lever. Set the

throttle to fast and the speed control lever

the throttle plate

4.

Install the fuel line and primer tube on the

appropriate carburetor fittings.

Check that the choke/air vane assembly

5.

moves freely.

Install the air filter element and cover.

6.

of

the throttle cable into the

is

sprung to the full open position.

two

so

that

Primer Start Carburetor Presetting the

Governor

Note:

approximately 50-75 RPMs.

Each “click” of the governor collar represents

1.

Turn the collar clockwise to increase spring

tension (and engine RPMs) or counterclockwise

to decrease spring tension and RPMs

(Figure 37).

4

clicks clockwise.

2. Use a tachometer to check engine speed;

normal setting is 3050 150 RPM.

Preset the governor collar 3 or

Figure 37

Primer Start Carburetor Final Check

The Primer Start carburetor used in V Engines has

an all Minlon housing with a fixed high speed jet and

an adjustable float.

Perform the following preliminary checks to eliminate

some of the possibilities that may contribute to

carburetor malfunction:

Ignition system

1.

are adjusted to specs and are the correct

components.

Fuel tank filter

2.

Fuel cap vent

3.

4.

Air filter

Crankcase seal

5.

installed properly and in good condition; torque

value on the bolts must be correct.

Carburetor flange gaskets and heat shield

6.

must be installed correctly.

must be clean and oiled.

ensure that all components

must not be plugged.

hole must not be plugged.

Crankcase seals must be

Exhaust ports

7.

Fuel

8.

9.

Service Section 35 Carburetor

mixture must be new, not unknown, etc.

Governor air vane

must not be restricted.

must move freely.

Page 32

Primer Start Carburetor Servicing the

Air Filter

1.

To remove the air filter, at the left side unsnap

the wire holder from the cover, and then unsnap

the cover from the clear plastic shell. Remove

the cover and air filter element

2. Clean and re-oil the air filter element according

to the procedure in Maintenance, pages

and 20.

(Figure

38).

19

CAUTION:

filter element or with a dry element; engine life

will be shortened.

Do

not operate the engine without a

PRIMER START CARBURETOR TROUBLESHOOTING

Engine Starts Hard

r replace as necessary

air cleaner element and carburetor

Tighten bolts to

--

realign gaskets and tighten

45

55

~I___-._

in Ibs

Figure

(5.1

38

6.2 N-m)

Engine Runs Lean

Fuel Leaks From Carburetor

5

55

Ibs

(5.1

6.2 N-m)

bowl and clean with compressed

Remove bowl and clean carburetor

Page 33

FUEL SYSTEM

Fuel System Operation

The V Engine uses a 1.5 quart plastic fuel tank

(Figure

filter screen. The filter is chemically welded in the

bottom

tank is mounted above the level of the carburetor and

uses gravity to supply fuel through a

mm) rubber hose to the carburetor. The fuel hose is

friction-fitted to the tank outlet at one end and to the

carburetor at the other end.

The fuel tank is vented through an opening in the fuel

cap. The fuel opening on the tank is

diameter and is opposite the fuel outlet, helping to

prevent damage to the filter screen by funnels and

gasoline filler spouts that may be inserted into the fuel

tank during refueling. The placement of the cap also

prevents interference with the starting rope in Zone

Start applications.

39) with a non-replaceable

of

the tank over a sediment reservoir. The

Figure

39

75

micron in-tank

.25”

I.D.

1.75”

(45

(6.35

mm)

Fuel System Cap Service

1.

The fuel cap may not be disassembled; however,

the vent opening on the cap and inner sealing

disc should be kept free of debris.

2.

The ventilating ability of the cap may be tested

by filling the cap with water and observing the

flow of water out of the vent opening in the top of

If

the cap.

opening may be plugged or restricted.

3.

If the fuel cap will not vent properly, replace the

entire cap assembly.

water does not drain, the vent

Figure

40

The fuel cap is a four piece design

an inner sealing disc that is vented to a baffle

assembly in the body of the cap. The baffle assembly

allows expansion in the tank without the

Atmospheric pressure is allowed into the tank from an

opening in the cap to allow gravity to feed fuel to the

(If

carburetor.

entire assembly must be replaced.)

Service Section

an individual part of the cap fails, the

(Figure

loss

40)

of fuel.

with

37

Fuel System

Page 34

Fuel System Tank Removal

1.

Disassemble the starter rope

(Figure 41)

starter rope knot and release the rope. (The

plastic rope stop prevents the rope from

rewinding completing into the starter).

Note:

crimp the fuel hose and use a forceps to remove

the fuel hose from the carburetor

sufficiently to untie (or cut) the

Figure 41

To remove the fuel tank, you may either

OR

You may reach under the edge of the fuel tank

to pull the hose off the tank outlet, but

be ready to catch the fuel that will drain out of

the tank.

If

you use this method, you must have a

container large enough to hold the amount of

fuel in the tank.

CAUTION:

in a container designed for gasoline and

Avoid fire and explosion. Store fuel

smoke while working around gasoline.

Release the clamping pliers and drain the fuel

into a container designed to receive gasoline.

If

2.

you removed the fuel line from the tank outlet,

catch the fuel as it drains out of the tank outlet.

Set the fuel aside and away from the immediate

working area.

“T”

handle

you

never

must

3.

Using

a

#

T25 TORX driver, remove the three

screws with captive washers and spacers that

secure the fuel tank to the shroud assembly

(Figure 42)

Figure 42

Fuel System Cleaning

1.

Take the fuel tank to an appropriate area and

wash the tank in clean solvent intended for

cleaning engine parts.

2. Back wash the filter screen by directing cleaning

solvent, under moderate pressure, through the

sediment reservoir and screen, opposite the

direction of fuel flow.

3.

Wash the tank again with clean solvent.

4.

Clean or replace the fuel hose.

Fuel System Tank Installation

1.

Fasten the tank to the engine with the three

screws with captive washers and spacers.

2.

Connect the fuel line.

Page 35

SECTION

4

Ignition System Troubleshooting

Check the ignition system in the following order:

Spark plug (connection & wire, condition)

CD Pack (air gap, connections or spark)

Flywheel (key and magnets)

Use the following table to aid in diagnosing the

problem.

IGNITION SYSTEM

Problem

Misfiring, no firing,

engine surges, engine dies

(Note: these symptoms

may also be caused by

fuel symptom problems).

Possible Cause

Spark plug or lead wire loose

Spark plug in poor condition

CD Pack air gap wrong

CD Pack high tension lead loose

CD Pack leads loose or dirty

CD Pack defective

Flywheel key damaged or sheared

Flywheel magnets demagnetized

or weak

Ignition System Spark Plug Operation

The spark plug ignites the oil-fuel mixture by

producing a spark just before the piston reaches top

dead center (TDC). A spark plug is typically

constructed as shown in

Figure

43.

Suggested Remedy

Tighten plug to specifications

Adjust (see CD Pack - Service in this section).

Secure with

Replace flywheel.

GE

silicon sealant.

I

Ignition System Spark Plug Service

1.

Check spark plug with chart in this subsection

and replace, following specifications given on

this page.

CAUTION:

2.

Clean with a wire brush, removing the carbon

buildup. Check conditions of the plug for

cracking or damage. Replace as necessary.

Service Section

Do not clean plug with a sand blaster.

Gap at

.89

mm

(.35")

39

Figure 43

Ignition System

Page 36

Ignition System

CD

Pack

Operation

The V Engine uses a solid state ignition module to

generate an electrical pulse for the spark plug. The

term “solid state” is a broad term applied to any

electrical system which uses electronic components

such as diodes, transistors, silicon controlled rectifiers,

etc., that take the place of one or more of the older

standard mechanical ignition components.

Electronic components are very small, have no

moving parts, require no mechanical adjustments, and

are not affected by wear as are mechanical devices.

They deliver uniform performance throughout

component life under adverse operating conditions,

so

can be hermetically sealed

that they are unaffected

by dust, dirt, oil or moisture.

is

The Capacitive Discharge (CD) system

breakerless,

and contains electronic components that replace

mechanical points and related accessories (such as a

breaker cam, spark advance assembly, etc).

Figure 44

the

V

shows the location of the CD Pack used in

Engine.

When the SCR

is

triggered or “fires”, up to

200

volts

DC, stored in the capacitor, travels to the spark coil.

Here it is stepped up to as much as

25,000

volts and

is discharged across the electrodes of the spark plug

(Figure 46).

SPARK PLUG

Figure 46

At slower speeds, the flywheel magnet induces a

smaller charge in the trigger coil. This action triggers

the silicon controlled rectifier (SCR) enabling easier

5

starting in a “retarded firing position” about

before top dead center (BTDC)

(Figure 47).

degrees

Figure 44

As the flywheel magnet passes the CD Pack, an AC

voltage is induced into the charge coil. This AC

voltage is converted by a rectifier into a DC signal

which is then stored in a capacitor

(Figure 45).

POLE SHOE.

LEG

LEG

SHOE

Figure 47

At

At faster speeds (about

800

RPM),

the flywheel

magnets induce a large enough charge in the trigger

coil to trigger the SCR in the “advanced firing position’’

25

(about

degrees BTDC)

(Figure 48).

Ignition System

Figure 45

40

CRANKSHAFT

25.”

BTDC

AT

Figure 48

Service Section

Page 37

Ignition System CD Pack

Air

Gap Adjustment

1.

Rotate flywheel until the magnets are directly

adjacent to the CD Pack as shown in

Figure 49

2.

Adjust gap by loosening screws, inserting Lawn

Boy gauge (p/n 604659) or a piece of

stock and tightening screws.

Figure 49.

.010

shim

Ignition System Flywheel Operation

The flywheel is connected directly to the Crankshaft

(secured by a flywheel key and nut) and turns at the

same speed as the crankshaft. Two permanent

magnets, imbedded in the flywheel, rotate past the coil

in the CD Pack to begin the generation of electricity.

Imbedded in the opposite side of the flywheel are

steel counterweights which offset the weight of the

magnets. These counterweights are not magnetic.

Ignition System Flywheel Removal

1.

Remove spark plug and install piston stop

(p/n,677389)

(Figure 51).

Ignition System CD Pack

Removal/Installation

1.

Disconnect leads and remove mounting screws.

2.

Remove screws, replace CD Pack and set gap

1

as outlined in step

100

torque of

in. Ibs

above. Tighten screws to a

(1 1

N-m)

(Figure

Figure 50

Figure 51

50).

Service Section 41 Ignition System

Page 38

2. Remove shroud and fuel hoses.

3. Remove flywheel nut.

4. Remove flywheel by pulling up on edge of

flywheel while striking wide fin of flywheel with

a soft hammer

(Figure 52).

Figure 52

4. Torque flywheel nut

Ibs (43 47 N-m)

(Figure 54)

Figure 54

to 375-425 in

5. Remove key and check its condition.

6.

Replace crankshaft and/or flywheel

distorted or cracked.

7.

Check flywheel for wear and flywheel magnets

for strength.

if

keyway is

Ignition System Flywheel Installation

1.

Make sure flywheel keyway is absolutely clean.

2.

Make sure key is installed correctly

3. Locate keyway cutout in flywheel over key

and shaft.

MAKE

SURE

IS

INSTALLED

CORRECTLY

KEY

(Figure

53).

RIGHT WRONG

Ignition System

Figure

53

42 Service Section

Page 39

SECTION

5

REWIND

Rewind Starter Operation

The rewind starter operates through a retainer/friction

two

disc that causes

the center of the rewind starter and engage the inside

of the starter hub on the flywheel. The engagement

dogs move into contact with the starter hub when the

rewind rope is pulled. When the engine starts, the

speed of the engine exceeds the speed of the rewind

starter and forces the starter dogs back into the center

of the rewind mechanism, disengaging them from the

starter hub.

engagement dogs to extend from

Rewind Starter Removal and

Disassembly

Note:

to the shroud.

1.

2.

The rewind starter assembly housing is riveted

Remove the fuel tank.

Remove the four screws that secure the shroud

to the shroud base

front screw is a

5/16

are

3/8

hex.

(Figure 55).

hex while the other three

Note that the

STARTER

Figure 56

5.

Remove the

springs Take note of the positioning of the

springs for correct installation later.

(Figure 56).

6.

Completely extend the rewind rope of the starter

and hold the reel in place. Untie the knot in the

end of the rope, withdraw the rope and slowly

allow the reel to unwind to a relaxed state.

two

starter engagement dogs and

Figure 55

3.

To service and/or replace the starter

engagement dogs and springs, turn the shroud

over to gain access to the starter mechanism.

4.

Use a

No.

1

Phillips screwdriver to remove the

Phillips-head shoulder screw from the center of

the rewind mechanism and lift the retainer plate

from the starter.

7.

Remove the reel from the rewind housing. The

is

rewind spring

fall out or be released suddenly

careful The rewind spring is not serviceable.

the spring has failed, an entirely new spring and

reel assembly must be used for repair.

captured in the reel and will not

if

you are

If

Service Section

43

Rewind Starter

Page 40

Rewind Starter Reassembly

1.

Lubricate the center post

with a small amount

2.

Place the reel assembly on the center post of the

rewind starter and turn the reel counterclockwise

until the hook on the reel spring engages the

spring retainer on the center post

(Figure

57).

of

the rewind starter

of

general purpose grease.

of

the starter.

4.

Install the retaining plate and Phillips shoulder

screw. Tighten the screw to a torque

(3.7 N-m)

(Figure

59).

of

33 in Ibs

Figure

3. Install the engagement dog springs and the

center spring as shown in

57

Figure

58.

Figure

CAUTION:

performing procedures of the next step.

5.

Pretension the spring by turning the pulley

plate counterclockwise

through the guide, then the reel.

6.

Tie a single knot in the end

singe the end with a lighter to prevent the

knotted end of the rope from fraying

Figure

Wear gloves for protection while

60).

59

5

turns. Insert the rope

of

the rope; then

(see

Figure

58

44

Figure

60

Service Section

Page 41

Rewind Starter Reassembly (cont'd)

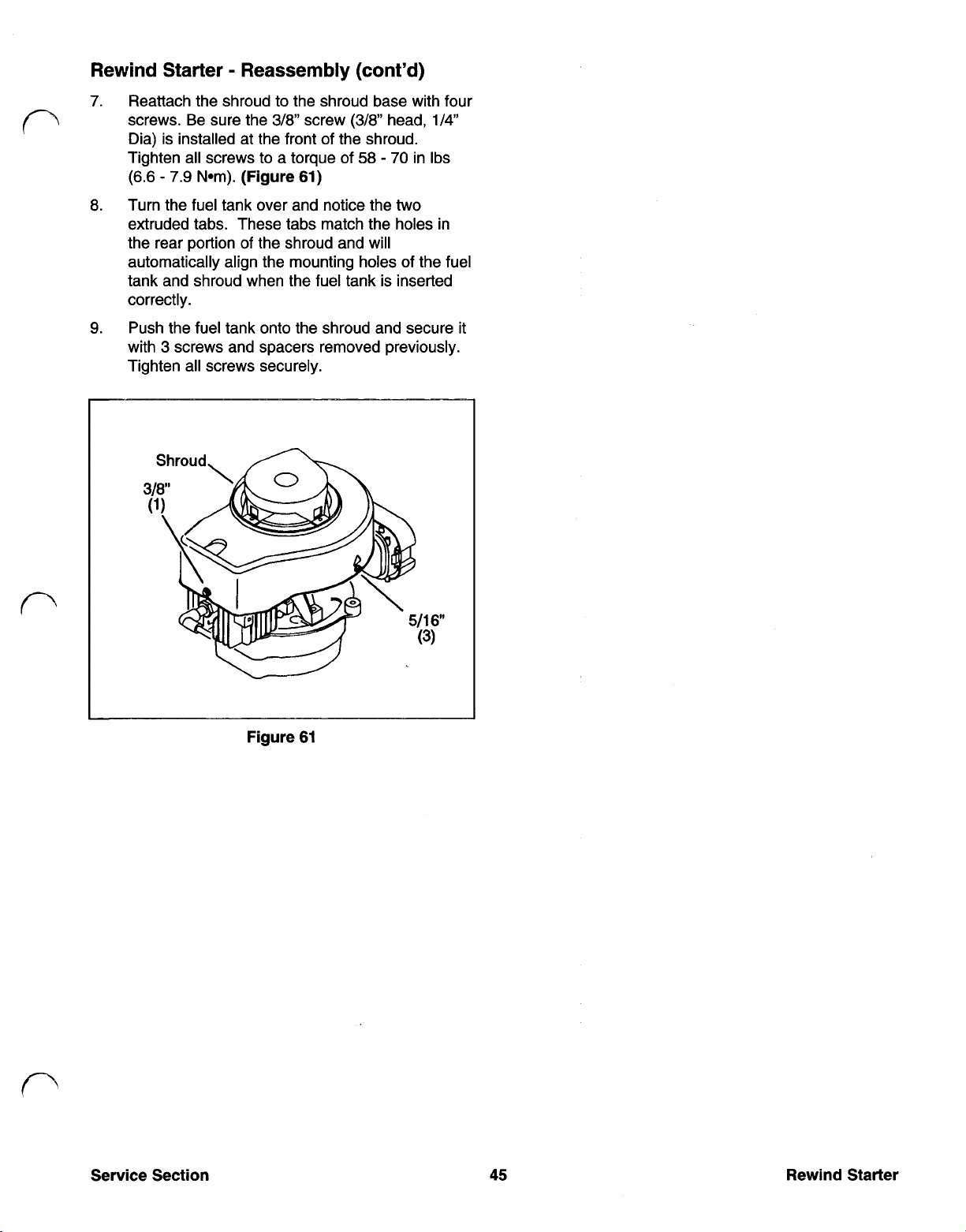

7. Reattach the shroud to the shroud base with four

3/8

screw

(3/8”

58

head,

70

in Ibs

two

screws. Be sure the

Dia) is installed at the front of the shroud.

Tighten all screws to a torque

(6.6 7.9 N-m)

8.

Turn the fuel tank over and notice the

extruded tabs. These tabs match the holes in

the rear portion of the shroud and will

automatically align the mounting holes of the fuel

tank and shroud when the fuel tank is inserted

correctly.

9. Push the fuel tank onto the shroud and secure it

3

with

Tighten all screws securely.

screws and spacers removed previously.

Shroud,

(Figure 61)

of

1/4"

Figure 61

Service Section

45

Rewind Starter

Page 42

SECTION

6

ENGINE

Engine Description

Two-cycle engines have special advantages which

make their use more practical in certain applications.

Two cycle engines are lightweight with an excellent

power-to-weight ratio and can be operated in any

position. They are also notably easy

service because of their uncomplicated design. The

V

Lawn-Boy Two-cycle

rotary motors is a reed valve design. This design

name describes the path of the fuel/air mixture into

the cylinder/crankcase and combustion chamber, and

the exhausting of spent gases.

Engine Theory

Two two-cycle (or two-stroke) engine is one of the

simplest and most efficient power systems ever

developed.

Figures 62 and 63

the engine during one full crankshaft revolution. Fuel

intake, fuel ignition and the exhaust of burned gases

all take place during a single 360-degree rotation of

the crankshaft.

Reed

Engine used on Lawn-Boy

of

Operation

below show what happens inside

to maintain and

first stroke

The movement of the piston towards the spark plug

also has an important effect in the crankcase. Once

the transfer port is sealed, the crankcase is under

vacuum. This action pulls the reed valve open and

draws in a fresh charge of air/fuel mixture.

Just before the piston reaches top dead center (TDC),

the spark plug fires. When the engine is functioning

properly, the air/fuel mixture ignites, causing a burn

that occurs evenly through the power stroke.

compression ratio is too high, the air/fuel mixture

actually explodes, which can be heard and is

identified as detonation). The burn continues as the

piston changes direction and begins its travel towards

the crankcase.

When the piston opens the exhaust port, high-

pressure exhaust gases exit the exhaust port. Further

movement of the piston towards the crankcase

uncovers the transfer port which allows a fresh charge

of oil/fuel mixture to enter the combustion chamber.

As

the exhaust gases continue to exit the exhaust port

the engine is readied for another cycle.

The 2-cycle engine

the correct oil/fuel mixture is maintained in the fuel

tank. Oil suspended in the fuel vapor adheres to all

moving parts, keeping them continually coated,

I

regardless of operating angle.

second (or power) stroke

is

always well lubricated as long a

Figure 63

of

a 2-cycle engine.

(If

the

illustrates the

I

Figure 62

Beginning at a point where the top of the piston is just

below the exhaust port, the piston moves forward

As

toward the crankcase.

uncovered, the air/fuel mixture stored in the

pressurized crankcase is forced into the combustion

chamber.

The crankshaft continues its rotation and the piston

begins its travel toward the spark plug.

the piston seals off the transfer port first, then the

exhaust port. When both ports are sealed, the

remaining travel compresses the air/fuel mixture to

prepare it for ignition. The travel of piston towards the

spark plug is called the compression stroke

(Figure 62).

the transfer port is

As

it moves,

Figure 63

Second

Stroke

Engine

46

Service Section

Page 43

Engine Service Tips

The numbers in parentheses in the discussions that

A.

follow refer to the exploded views in Appendix

major items are:

Cylinder/Crankcase Halves (21, page A-2).

1.

two

The

be mixed. Check cleaning and assembly N-m)

procedures under Engine Disassembly in this

subsection. Be sure to use Loctite 515 on the

mating surfaces. Torque the four washer-head

screws that secure the

in Ibs (12 13 N-m)

halves are a matched pair and cannot tightened to a torque of

two

halves to 105 11

The

5

7.

Carburetor Gaskets (24, page A-4).

Carburetor gaskets (24) on either side of the

carburetor shield (1) may be leaking or damaged

causing air leaks into the engine (may cause

power fluctuations). Ensure that air

cleaner/carburetor mounting screws

45

55

in Ibs

(6)

(5.0

are

6.1

Engine Removal

Prior to disassembling the engine and prior to further

troubleshooting a malfunction, separate it from the

mower as follows:

Oil Seals (3, page A-2).

2.

leaky or damaged oil seals

Core Plugs

3.

damaged or leaky plugs (four locations). will keep the rope from rewinding completely into

Muffler Baffle

4.

be cleaned every

carbon from clogging exhaust system

power

piston scoring).

5.

Muffler Plate Screws (2, page A-3).

may have loosened due to vibration. They

should be tightened to a torque of 140 200 in

(16

Ibs

6.

Exhaust ports

as necessary

(1

page A-2).

(1

50

loss)

and from entering engine (causing

22 N-m)

should be inspected and cleaned

(Figure 64).

Visually inspect for 1. Disconnect the spark plug wire.

(two

locations).

Visually inspect for knot in the starter rope. (The plastic rope stop

page A-3).

hours (maximum) to keep 3. Remove the fuel tank (page 38).

This item should

Screws

2. Disassemble the

4.

5.

6.

'T

starter handle to untie the

the starter).

Remove the shroud (page 43); starter comes

off

with shroud.

Remove the flywheel (page 41).

Remove the remaining bolts securing the shroud

base to the crankshaft halves

(Figure 65).

Ports

I I

Figure 64

Service Section 47 Engine

Figure 65

Page 44

Engine

5.

Removal

Remove brake plate assembly by removing one

10

mm shoulder screw and one 3/8 washer-

head screw. Place the assembly on the mower

deck and disconnect the ground wire (that goes

to the CD Pack).

(cont’d)

(Figure 66).

9. On self-propelled models only, remove the 5/16

screw to remove the belt drive cover. Remove

3/8”

two

drive guide bracket to the drive unit

67

(belt will stay with the engine as cover is

removed).

screws with spacers that secure the belt

(Figures

&

68).

Remove the drive belt from the pulley

Figure 66

7.

Remove the CD Pack (page 41).

Note:

carburetors have an additional wire holder that

must be released to remove the air cleaner

element. Mounting screws are identical.

8.

Snap open the air cleaner cover (catch on left,

hinge on right) and remove the air filter element.

Remove the

to the engine. Disconnect the fuel line from the

carburetor. Separate the carburetor from the

engine with controls attached and set it on the

mower deck.

Step 8 covers ‘93 carburetors; ‘94

two

screws securing the carburetor

Figure 67

Page 45

Engine Removal (cont’d)

10.

Remove the spark plug and install piston stop

(p/n 677389) in the spark plug hole.

1 1. Remove the 15/16 blade nut that secures the

blade and mulch fan to the engine shaft. Use

heavy duty gloves to hold the blade while

removing the nut.

2.

Remove the entire crankshaft assembly and

discard the oil seals (3, page A-2).

3. Carefully remove the

screws

rod cap and the split bearing liner. The needle

roller bearings are under the split bearing liner

(Figure 70).

(9,

page A-2) to remove the connecting

HSH

(hex, sockethead) cap

Notes:

material in the blade nut, use a new nut after the

fourth time it has been removed and re-installed.

Since the engine shaft and blade collar protrude

beyond the bottom of the muffler cover, have a

couple of short lengths (about 1

set about four inches apart to set the engine

after removing

12. Under the mower deck, remove the three 1/2”

bolts that secure the engine to the mower deck

and

the deck and set it on the 2 x

arrangement).

Due to the nature of the self-locking

ft

ea) of 2 x 4‘s

it

in the next step.

lift

the engine (with drive belt) up and out

4‘s

(or equivalent

on

of

Engine Disassembly

Note:

engine disassembly in the following paragraphs, the

engine exploded view is shown on page A-2.

Numbers used in the text refer to that view.

1. Remove the four crankcase cap screws with a

In addition to the figures supplementing the

E-12

Torx No.

using a screwdriver

socket and separate the halves

(Figure

69).

Figure 70

Remove the piston and rod assembly; separate

if

the assembly

pliers (p/n 303857) on the retaining ring (16).

Use wrist pin knock out tool (p/n 602884) to

punch out wrist pin (17).

necessary, using a compression

(Figure 71).

Figure 71

Figure

Service Section

69

49

Engine

Page 46

Engine Inspection and Repair

Engine Reed Valve Service

Check bearings for wear and freedom of

if

movement: replace

Check rings for sticking, remove and check rings

for wear or damage; replace rings

questionable.

Check all parts for wear or damage and replace

if

questionable.

Clean crankcase surfaces with Gel Seal and

Gasket Remover

questionable.

if

(Figure 72).

These assemblies

enter the crankcase

trap fuel mixtures in the crankcase on power strokes.

1.

Check clearance between tip

replace reeds

(.4 mm).

CAUTION:

reeds.

(Figure 73)

on

compression strokes and to

Figure 73

if

clearance is more than

Do not use compressed air to clean

permit fuel mixtures to

of

reed and plate;

.015

Figure 72

5.

Check that the ring end gap is between

.016

with

.030

and

6. Replace core plugs (1)

Lock (p/n 682301) on outside surfaces and

special tool (p/n 609904) for installation.

CAUTION:

with a drill bit. An enlarged hole will reduce

compression and engine efficiency.

Do

as the wear limit.

if

leaking, using Screw

not attempt to clean any hole

.006

2.

Clean reeds carefully, by hand, using carburetor

solvent.

3.

When replacing reeds, install smooth edge down

(Figure 74)

of

screws.

and use Loctite 271 on threads

Figure 74

Page 47

Engine Reassembly

1. Secure wrist pin using snap ring. Make sure

square edge of snap ring faces out and ring

opening faces up (toward top of piston)

(Figure

75).

SNAP

RING

6. Oil parts and use piston stop (p/n 677389) and

ring’compressor (p/n 609967) to install piston

with “BTM” mark facing down toward exhaust

ports

Note:

(Figure

77).

Letters “BTM” were omitted on some

engines. However, the small “rectangle” should

still be visible through ports.

Figure

75

2. Install pressure back piston ring in top groove

with bevel facing up; stagger ring gaps.

CAUTION:

Use piston stop to prevent top ring

from falling into cylinder and causing damage.

3. Assemble rod cap. Ensure that dovetail ends of

liners are matched. Install new needles

p/n 68391 1.

Note:

One side of the paper is sticky; remove

paper carefully while installing needle bearings.

There should be 32 needle bearings on the

lower connecting rod.

4.

Lubricate and assemble bearings (lettered side

out) to Crankshaft and install crankshaft.

5.

Install rod cap; ensure that mating marks are

aligned. Clean old screws thoroughly and apply

Loctite 271

(Figure

76).

Torque to 70 in-lbs

(7.8 N-m)

7. Apply Loctite

51

5

Figure

77

gasket maker very thinly to

the crankcase cover sealing surface, being

careful not

(Figure

to get sealant on bearings or seals

78).

Figure

78

ALIGNMENT

Service Section

MARKS

Figure

76

51

Engine

Page 48

8.

Carefully align the

two

crankcase halves using

the alignment pin and its matching hole; press

two

the

halves together

(Figure

79).

Reinstalling External Components

10. Reattach the flywheel brake system.

11. Install new

oil

seals.

12. Install shroud base.

13. Clean crankshaft and flywheel hub and install

flywheel (see page 42).

Figure

9.

Tighten the hex washer head screws to a total of

110 in Ibs (12.5 N-m)

(2.26 N-m) increments

that the crankshaft turns freely

79

tightening only20 in lbs

at

a

time

while checking

(Figure

INCREMENTS

80).

14. Install

carburetor

and governor assembly (see

page 30 for '93 models, page 35 for '94 models).

15. Install starter and shroud assembly and starter

handle (see page 45).

16. Reconnect fuel lines and electrical system leads.

17. Test run engine.

Engine

Figure

80

52

Service Section

Page 49

Introduction

In 1982 the federal government mandated that all

25”

consumer walk behind mowers with a cut of

cm) or less be equipped with safety devices. There

are two primary criteria which these devices must

meet:

1.

A

two-step operation must be performed in order

to start the blade rotating.

2. The blade must come to a stop within three

seconds of the operator leaving the operator’s

position.

One of the ways the Lawn Boy Corporation met these

requirements was with the “zone start system.” This

system utilizes a kill switch and a brake which stops

the engine when the operator releases the blade

control bail

engagement criteria is met by requiring the operator to

pull the bail to the handle first, then pull the recoil rope

from the operator’s position.

(Figure 81).

The two-step blade

(63.5

The switch is closed when the blade control bail is in

the “at rest” (vertical) position

the bail to the main mower handle opens the switch.

Switch leads are connected to the primary side of the

coil and to ground. When the switch is closed, the

electronic ignition module is bypassed

cannot interrupt primary current flow. This action

prevents the coil from producing the high voltage

necessary to generate spark. When the switch is

open, the ignition coil produces spark.

Stopping the engine and blade is accomplished by

means of a brake that is applied to the bottom of the

flywheel. The brake spring is in the “braked position

when the blade control bail is in the “at rest” or vertical

position. When the blade control bail is lowered to the

mower handle the brake is retracted from the under

side of the flywheel to allow the engine to run.

(Figure 81).

so

that it

Lowering

Pivoting Zone Start Brake Disassembly

See

Figure 82;

disassembly continued next page.

43

Figure 81

Pivoting Zone Start Brake Operation

The pivoting style zone brake system has two main

functions. The first function of the system is to stop

the production of spark and the second is to stop the

engine and the blade.

Stopping spark production is controlled by a switch.

Service Section

53

Figure 82

1

Ground strap stop

2 Self-tapping screw

3

Brake switch lead wire

4

Ground strap

5

Insulation strap

6 Plastic rivet (self expanding) (2)

7

Shoulder screw (10 mm)

8 Brake plate assembly

9 Screw

10 Brake mounting plate

Pivoting Zone Start Brake

Page 50

Pivoting Zone Start Brake Disassembly

(cont'd)

Note:

procedures refer to Figure 82 on previous page.

1.

2. To reduce the pressure

3.

Numbers in parentheses in the following

If

the engine and blade are taking more than

seconds to stop when the blade control bail is

released

wear and replace

brake pad and the brake plate are replaceable