Page 1

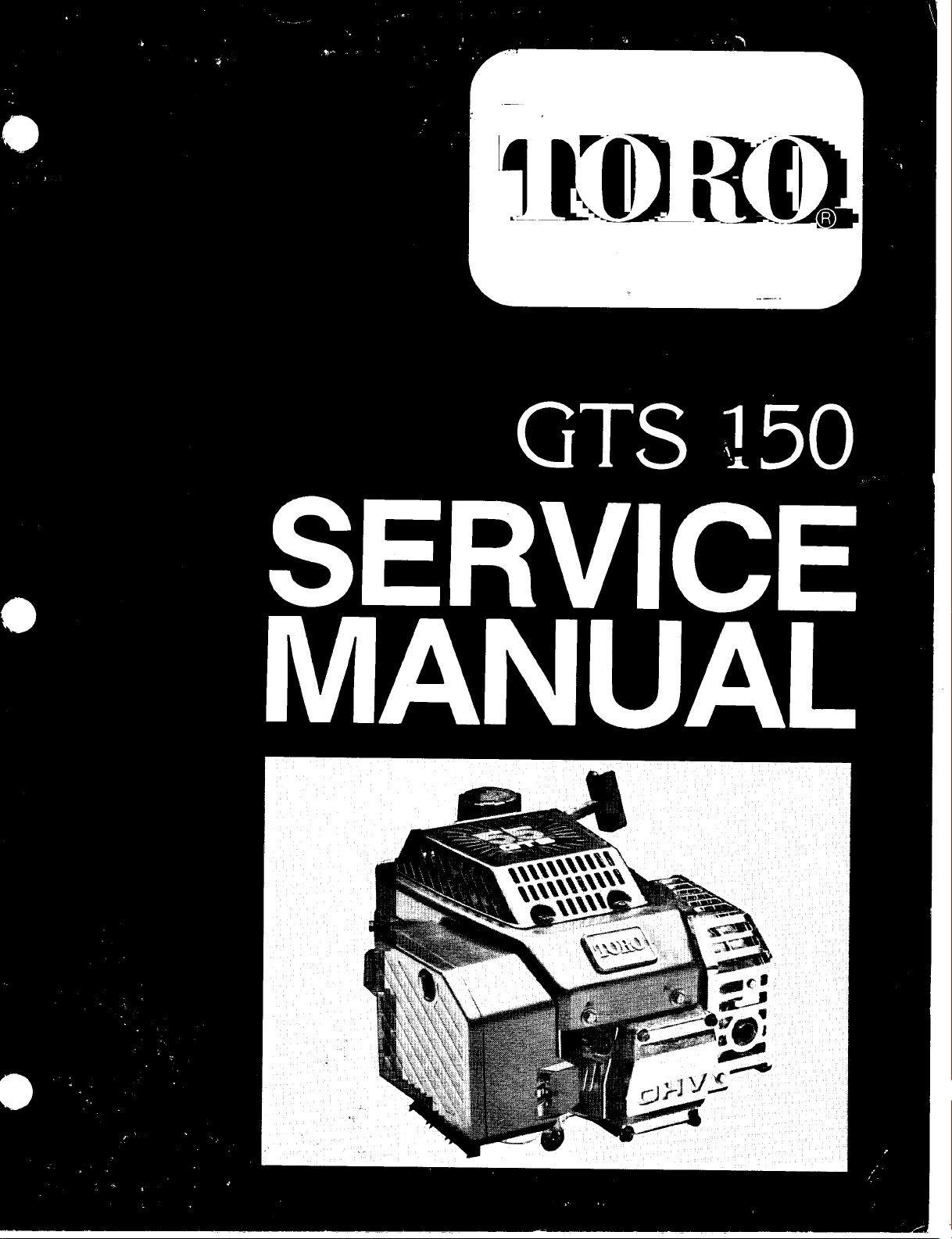

OHV GTS 150 ENGINE SERVICE MANUAL

Table Of Contents – Page 1 of 4

PREFACE

SAFETY INFORMATION

SAFETY TIPS

SPECIFICATIONS

GTS 150 ENGINE SPECIFICATION

GTS 150 CARBURETOR SPECIFICATIONS

GTS 150 FASTENER TORQUES

TOOL REQUIREMENTS

TROUBLESHOOTING

ENGINE DOES NOT START WHEN "COLD"

ENGINE WILL START "COLD", BUT WILL NOT START "HOT"

ENGINE DOES NOT PRODUCE SPARK

ENGINE HAS LOW COMPRESSION

ENGINE FLOODED WITH FUEL

ENGINE LACKS POWER

BENT PUSH ROD

ENGINE SURGING

ENGINE BACK FIRES

ENGINE AFTER FIRES

ENGINE OVERHEATS

ENGINE VIBRATES EXCESSIVELY

ENGINE CRANKSHAFT WILL NOT TURN

ENGINE PRODUCES MECHANICAL KNOCKING SOUND

PRE-IGNITION

ENGINE SMOKES EXCE SSI VE L Y

ENGINE STALLS

SPARK PLUG FOULED

GTS 150 MAINTENANCE

SERVICING AIR CLEANER

REPLACING THE SPARK PLUG

REMOVING GASOLINE FROM THE FUEL TANK

CHANGING CRANKCASE OIL

CARBURETOR - ADJUSTMENT

COMPRESSION - MEASUREMENT

THROTTLE - ADJUSTMENT

CLEAN THE ENGINE AND RECOIL STARTER

CLEAN THE COOLING SYSTEM

PREPARING THE ENGINE FOR STORAGE

Page 2

OHV GTS 150 ENGINE SERVICE MANUAL

Table Of Contents – Page 2 of 4

SECTION I CARBURETOR

CARBURETOR DESCRIPTION

CARBURETOR THEORY AND OPERATION

CARBURETOR - REMOVAL

CARBURETOR - PRESSURE TESTING

CARBURETOR - DISASSEMBLY

CARBURETOR - CLEANING AND SERVICE

CARBURETOR - ASSEMBLY

CARBURETOR - ADJUSTMENT

SECTION 2 FUEL SYSTEM

FUEL TANK - OPERATION

FUEL TANK - REMOVAL

FUEL TANK AND FILTER - CLEANING

FUEL CAP - OPERATION

FUEL CAP - SERVICE

FUEL HOSE - REMOVAL

FUEL HOSE - INSTALLATION

SECTION 3 IGNITION

OPERATION

IGNITION OPERATION - FLYWHEEL

IGNITION OPERATION - IGNITION ARMATURE COIL

IGNITION OPERATION - SPARK PLUG

ARMATURE COIL WIRING - OPERATION

AIR GAP - ADJUSTMENT

IGNITION ARMATURE COIL - REMOVAL

IGNITION ARMATURE COIL - TESTING

IGNITION ARMATURE COIL - INSTALLATION

SECTION 4 REWIND STARTER

REWIND STARTER - OPERATION

REWIND STARTER- DISASSEMBLY

REWIND STARTER - ASSEMBLY

REWIND STARTER - INSTALLATION

Page 3

OHV GTS 150 ENGINE SERVICE MANUAL

Table Of Contents – Page 3 of 4

SECTION 5 ENGINE

ENGINE - OPERATION

INTAKE STROKE

COMPRESSION STROKE

POWER STROKE

EXHAUST STROKE

ENGINE DISASSEMBLY

AIR CLEANER - OPERATION

AIR CLEANER - REMOVAL

REWIND STARTER. OPERATION

REWIND STARTER - REMOVAL

BLOWER SHROUD - REMOVAL

MUFFLER SHROUD - REMOVAL

FLYWHEEL BRAKE - OPERATION (IF INSTALLED)

FLYWHEEL BRAKE - REMOVAL (IF INSTALLED)

FUEL TANK - OPERATION

FUEL TANK - REMOVAL

MUFFLER - OPERATION

MUFFLER - REMOVAL

DIPSTICK AND OIL FILL TUBE - REMOVAL

CARBURETOR - OPERATION

CARBURETOR - REMOVAL

IGNITION COIL - OPERATION

IGNITION COIL - REMOVAL

THROTTLE BRACKET - REMOVAL

ALTERNATOR - OPERATION

ALTERNATOR - REMOVAL (IF INSTALLED)

FLYWHEEL - REMOVAL

ELECTRIC STARTER - OPERATION

ELECTRIC STARTER. REMOVAL (IF INSTALLED)

THROTTLE CONTROL LEVER AND LINK ROD - REMOVAL

VALVE COVER- REMOVAL

HEAD ASSEMBLY - REMOVAL

HEAD - DISASSEMBLY

VALVES AND SEATS - RECONDITIONING

BREATHER - OPERATION

BREATHER - REMOVAL

OIL PUMP - OPERATION

OIL PUMP - REMOVAL

SUMP - REMOVAL

GOVERNOR AND SPLASHER - OPER ATION

GOVERNOR AND SPLASHER - REMOVAL

CAMSHAFT - OPERATION

CAMSHAFT- REMOVAL

COMPRESSION RELEASE - OPERATION

COMPRESSION RELEASE - REMOVAL

CRANKSHAFT- REMOVAL

PISTON AND CONNECTING ROD - OPERATION

Page 4

OHV GTS 150 ENGINE SERVICE MANUAL

Table Of Contents – Page 4 of 4

SECTION 5 ENGINE - continued

PISTON AND CONNECTING ROD - REMOVAL

PISTON RINGS - REMOVAL

PISTON PIN - REMOVAL

GOVERNOR ARM - REMOVAL

ENGINE ASSEMBLY

PISTON PIN - INSTALLATION

PISTON RING - INSTALLATION

PISTON - INSTALLATION

CRANKSHAFT - INSTALLATION

GOVERNOR SHAFT - INSTALLATION

CAM FOLLOWERS - INSTALLATION

CAMSHAFT - INSTALLATION

GOVERNOR/SPLASHER- INSTALLAT ION

SUMP - INSTALLATION

0IL PUMP - INSTALLATION

BREATHER - INSTALLATION

HEAD - ASSEMBLY

PUSH RODS - INSTALLATION

HEAD - INSTALLATION

VALVE CLEARANCE - ADJU ST MENT

VALVE COVER - INSTALLATION

THROTTLE BRACKET - INSTALLATION

GOVERNOR CONTROL LEVER AND LINK ROD - INSTALLATION

CARBURETOR - INSTALLATION

GOVERNOR - ADJUSTMENT

ELECTRIC STARTER - INSTALLATION

FLYWHEEL - INSTALLATION

ALTERNATOR - INSTALLATION

IGNITION ARMATURE COIL - INSTALLATION

FLYWHEEL BRAKE - INSTALLATION (IF REQUIRED)

MUFFLER - INSTALLATION

MUFFLER SHROUD - INSTALLATION

DIPSTICK TUBE - INSTALLATION

FUEL TANK - INSTALLATION

BLOWER SHROUD - INSTALLATION

REWIND STARTER- INSTALLATION

AIR CLEANER - INSTALLATION

SPARK PLUG - INSTALLATION

ACKNOWLEDGEMENT

Page 5

Page 6

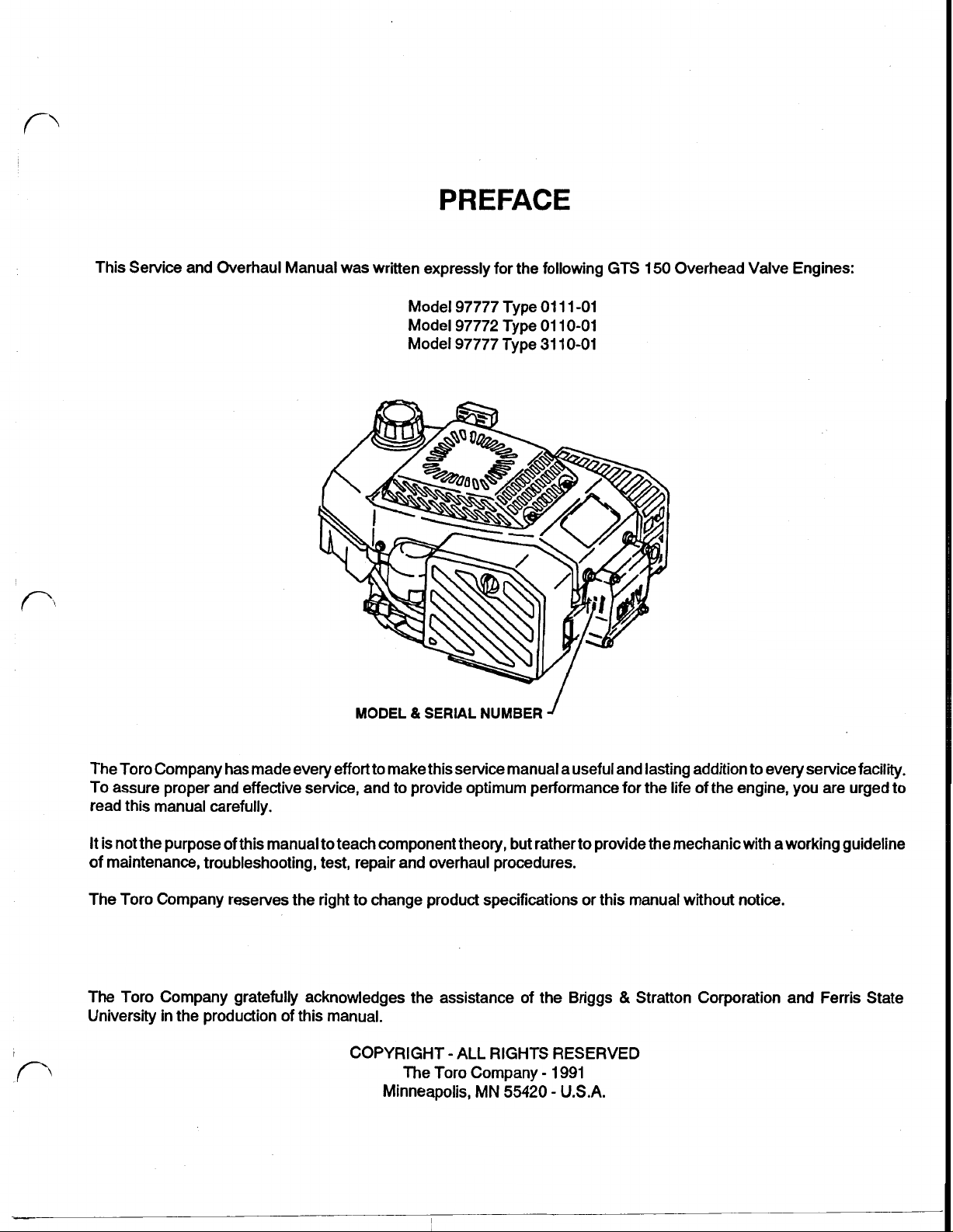

PREFACE

This Service and Overhaul Manual was written expressly for the following GTS

Model 97777 Type

Model 97772 Type

Model 97777 Type

MODEL & SERIAL NUMBER

01

01

31

11

-01

10-01

10-01

150

Overhead Valve Engines:

The Toro Company has made every effort to make this service manual a useful and lasting addition to every service facility.

To assure proper and effective service, and to provide optimum performance for the life of the engine, you are urged to

read this manual carefully.

It is not the purpose of this manual to teach component theory, but rather to provide the mechanic with a working guideline

of maintenance, troubleshooting, test, repair and overhaul procedures.

The Toro Company reserves the right to change product specifications or this manual without notice.

&

The Toro Company gratefully acknowledges the assistance of the Briggs

University in the production of this manual.

I

COPYRIGHT - ALL RIGHTS RESERVED

Minneapolis,

The Toro Company

MN

55420

-

1991

-

U.S.A.

Stratton Corporation and Ferris State

Page 7

Reference Information

TABLE

OF

CONTENTS

Service Procedures

Section

1

Carburetor

Safety Information

Specifications

Tool Requirements

Troubleshooting.,

Maintenance

description

operation

removal

pressure testing

disassembly

cleaning and service

assembly

..................................................................................................................

....................................................................................................................

......................................................................................................................

...................................................................................................................

..............................................................................................

.............................................................................................................

.....................................................................................................

........................................................................................................

...............................................................................................................

..........................................................................................................

................................................................................................................

Page

10

15

19

19

20

21

21

...................................................................................................

21

22

6

7

9

adjustment

Section 2 Fuel System

fuel tank

fuel cap

fuel hose

Section 3 Ignition System

Ignition operation

..................................................................................................................

operation

removal

cleaning

operation

service

removal

installation

flywheel

armature coil

..............................................................................................................

22

...........................................................................................................

............................................................................................................

............................................................................................................

...........................................................................................................

............................................................................................................

........................................................................................................

........................................................................................................

.............................................................................................................

.....................................................................................................

23

23

23

23

23

23

23

25

25

25

Table of Contents

.-

....

-.

GTS

2

...

150

Page 8

Service Procedures (cont’d)

TABLE

OF

CONTENTS

Section

Section

Section

3

Ignition System (cont’d)

spark plug

armature coil wiring

air gap adjustment

removal

testing

installation

4

Rewind Starter

operation

disassembly

assembly

installation

5 Engine

operation

disassembly

..........................................................................................................

......................................................................................................................

........................................................................................................................

..................................................................................................................

....................................................................................................................

....................................................................................................................

..................................................................................................................

....................................................................................................................

Page

....................................................................................................

.....................................................................................................

...............................................................................................................

...............................................................................................................

25

26

26

26

26

26

27

27

28

28

29

30

air cleaner

rewind starter

blower shroud

muffler shroud

flywheel brake

fuel tank

muffler

oil fill tube

carburetor

ignition coil

throttle bracket

alternator

flywheel

electric starter

throttle control lever

head components

valves and seats reconditioning

........................................................................................................

....................................................................................................

...................................................................................................

..................................................................................................

..................................................................................................

...........................................................................................................

..............................................................................................................

..........................................................................................................

.........................................................................................................

........................................................................................................

..................................................................................................

..........................................................................................................

.............................................................................................................

...................................................................................................

...........................................................................................

..............................................................................................

.......................................................................

30

30

30

30

31

31

31

31

32

32

32

33

33

33

34

34

35

GTS

150

breather

............................................................................................................

36

..

3

Table

of

Contents

Page 9

Service Procedures (cont’d)

TABLE

OF

CONTENTS

Section

5 Engine (cont’d)

oil pump

sump

governor and splasher

cam shaft and cam followers

compression release

crankshaft

piston and connecting rod

piston rings and pin

governor arm

assembly

piston pin and rings

piston

crankshaft

governor shaft

cam followers

....................................................................................................

.................................................................................................................

.......................................................................................

.............................................................................

.........................................................................................

.........................................................................................................

.................................................................................

...........................................................................................

.....................................................................................................

...........................................................................................

...............................................................................................................

.........................................................................................................

..................................................................................................

...................................................................................................

Page

36

36

37

37

37

38

38

39

39

40

40

40

41

41

cam

shaft

..........................................................................................................

governor and splasher

sump

.................................................................................................................

oil pump

breather

head

push rods

valves

valve clearance adjustment

throttle bracket

governor control lever

carburetor

governor adjustment

electric starter

flywheel

alternator

ignition armature coil

............................................................................................................

............................................................................................................

..................................................................................................................

.........................................................................................................

...............................................................................................................

..................................................................................................

.........................................................................................................

...................................................................................................

.............................................................................................................

...........................................................................................................

.......................................................................................

...............................................................................

........................................................................................

..........................................................................................

.........................................................................................

41

41

41

42

42

42

42

43

43

43

43

44

44

44

45

45

45

.....

Table

of

Contents

~

4

GTS

150

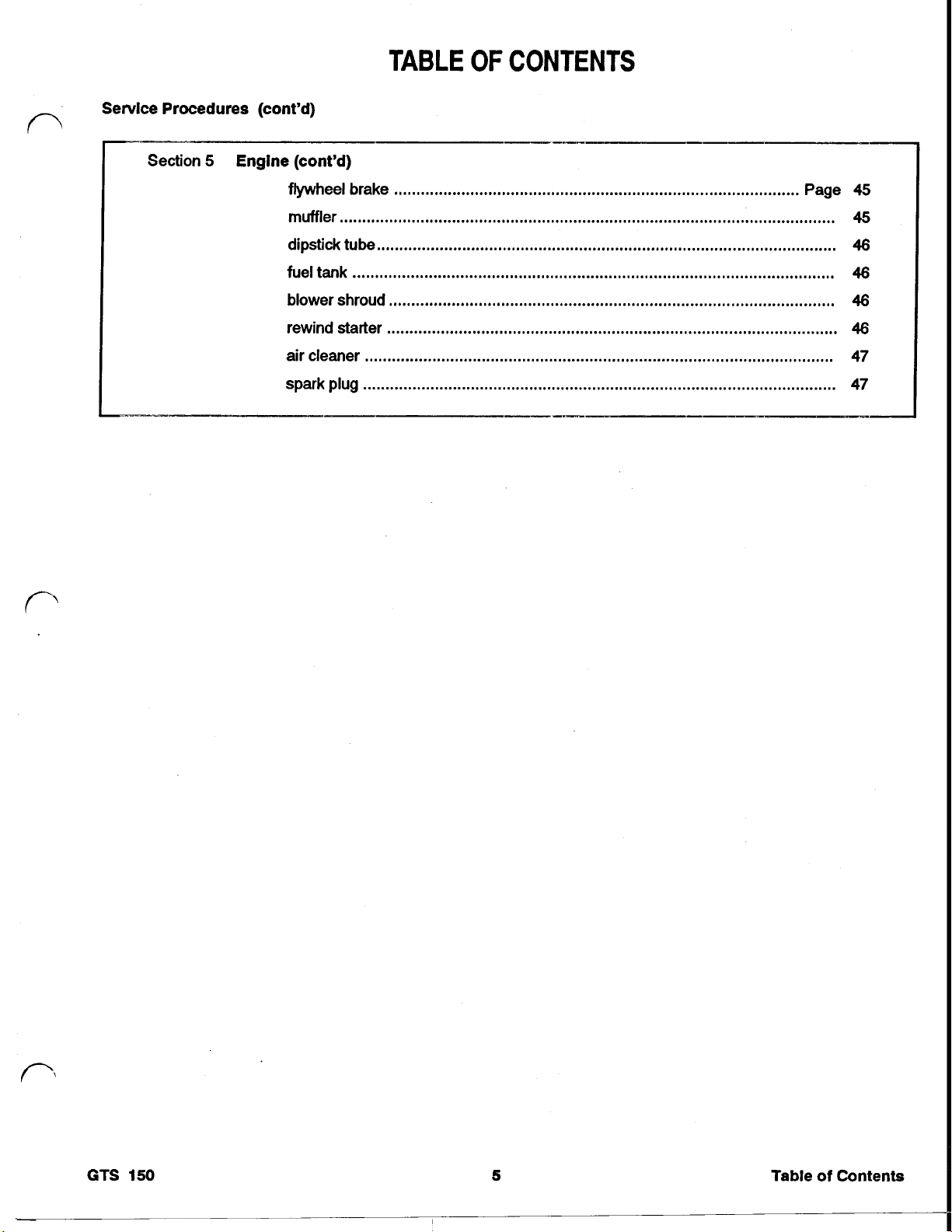

Page 10

TABLE

OF

CONTENTS

Service Procedures

(cont'd)

flywheel brake

muffler

dipstick tube

fuel tank

blower shroud

rewind starter

air cleaner

spark plug

..........................................................................................

..............................................................................................................

......................................................................................................

...........................................................................................................

...................................................................................................

....................................................................................................

........................................................................................................

.........................................................................................................

Page 45

45

46

46

46

46

47

47

GTS

150

5

Table

of

Contents

Page 11

SAFETY INFORMATION

This safety symbol means

WARNING or CAUTION,

PERSONAL

TION Read the instruction

because

Failure to comply with the

instruction may result in personal injury or

death.

SAFETY

it

has to do wlth safety.

INSTRUC-

SAFETY

This manual is intended as a service and repair

manual only. The safety instructions provided in

this manual are for the troubleshooting and service

of the engine only. The individual Operator's

will contain safety information on the operation of

the complete product powered by the

engine. Operator's manuals with complete operational safety instructions are available through:

The Toro Company

Publications Department

8111

Lyndale Avenue South

MN

Minneapolis,

55430

U.S.A.

Manual

GTS

150

TIPS

Avoid lacerations and amputations ...

Stay clear of all moving parts whenever the engine is

running. Treat

were moving whenever the engine is running or has

the potential to start.

Avoid burns...

Do

not touch the engine while running or shortly after

running.

Avoid fails. ...

Do

not operate the mower on slippery surfaces or

footing is questionable.

Avoid fires and falls...

Wipe up any spilled fuel or

Avoid asphyxiation

Never operate

proper ventilation.

Avoid eye injuries

Wear eye protection when working with springs or

cables and when running engine.

Avoid unexpected starting of engine

Always turn

before attempting any cleaning, adjustment or repair.

all

normally moving parts as

oil.

....

an

engine in a confined area without

....

...

off

key and disconnect spark plug wire

if

they

if

Avoid fires and explosions

Use a container designed for gasoline. Avoid spilling gasoline and never smoke while working around

gasoline.

Avoid accidental misuse of fuel.

Always store fuel

that is designed for gasoline.

Avoid injury due to inferior parts

Use only Toro original parts to insure that important

safety criteria are met.

Avoid injury to bystanders

Always clear the area of bystanders before starting

a

or testing

Avoid injury due to projectiles

Always clear the area to be mowed of sticks, rocks

and other debris that could be picked up and thrown

by the mower.

lawn mower.

in

a properly labeled container

...

..

...

...

...

Safety information

6

GTS

150

Page 12

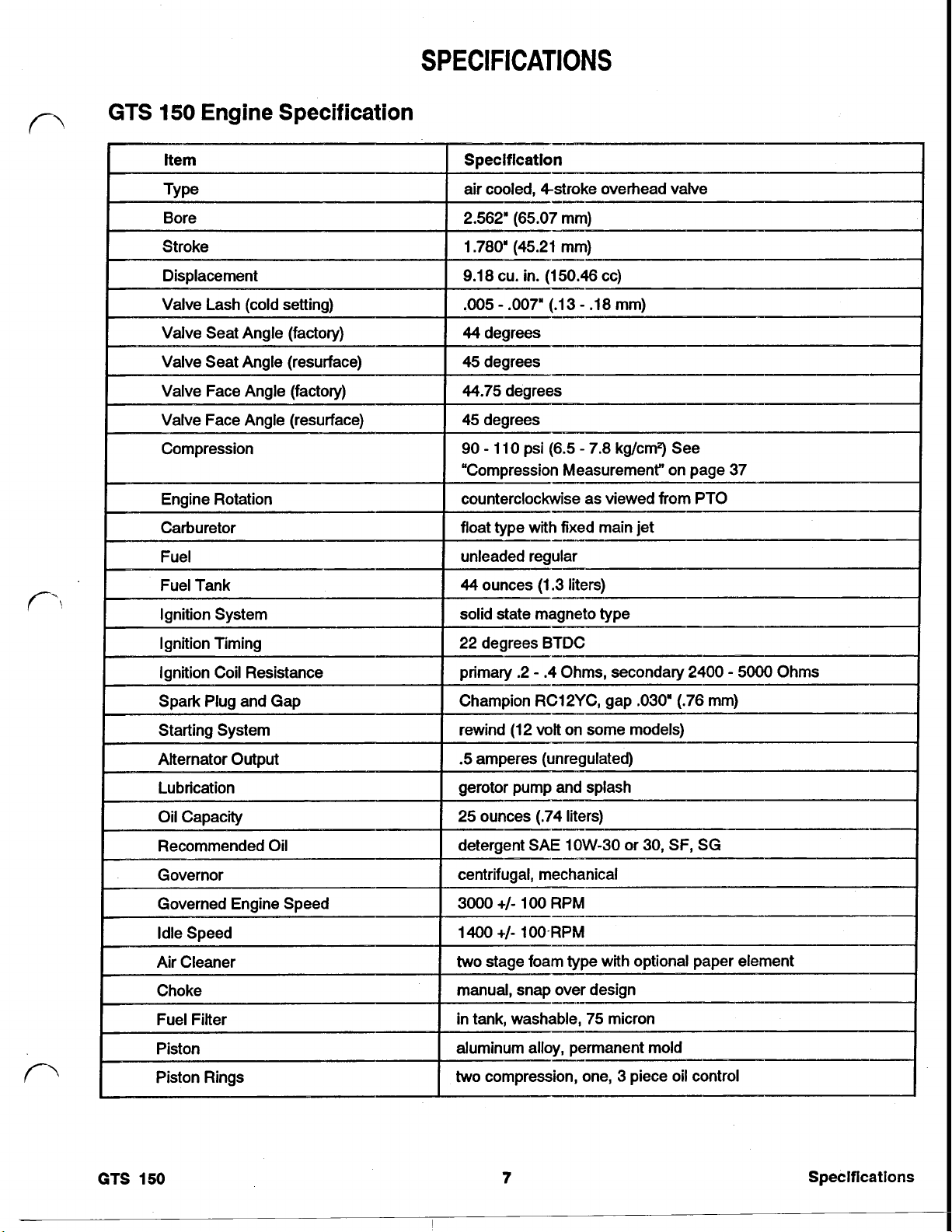

SPECIFICATIONS

GTS

I

150

Engine Specification

Engine Rotation

Carburetor float type with fixed main jet

Fuel

led, llstroke overhead valve

Measurement on page 37

counterclockwise as viewed from PTO

unleaded regular

I

Recommended Oil

44

ounces (1.3 liters)

solid state magneto type

22 degrees BTDC

primary .2

Champion RC12YC, gap .030" (.76 mm)

rewind (1 2

detergent SAE 1OW-30 or 30, SF,

two

stage foam type with optional paper element

manual, snap over design

in

tank, washable, 75 micron

.4

Ohms, secondary

_-

volt

on some models)

2400

SG

-

5000

Ohms

GTS

Piston aluminum alloy, permanent mold

Piston Rings

150

I

two

compression,

7

one, 3 piece oil control

Specifications

Page 13

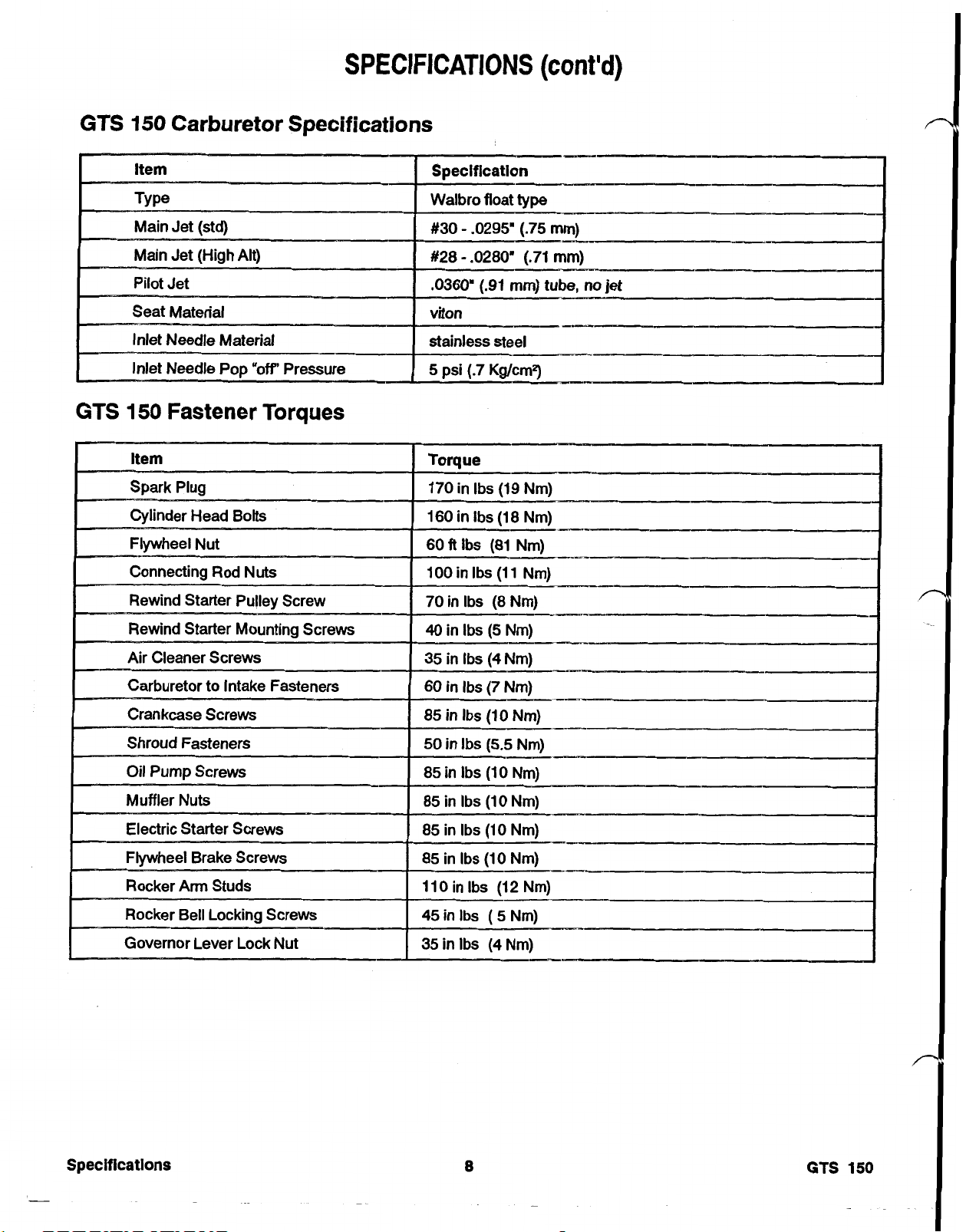

SPECIFICATIONS

(cont'd)

GTS

GTS

150

Carburetor Specifications

150

Fastener Torques

Specifications

-

a

GTS

150

Page 14

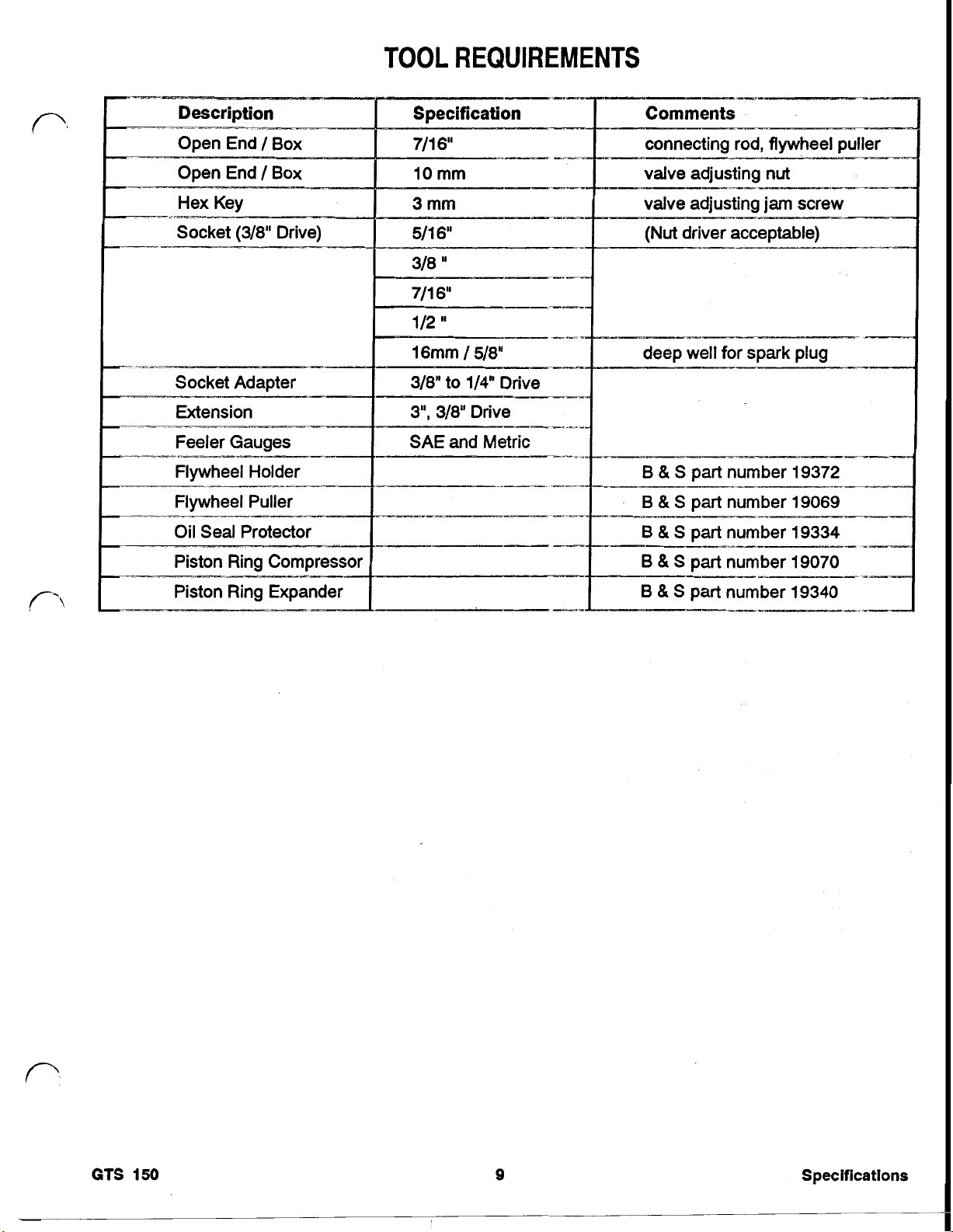

TOOL REQUIREMENTS

Comments

--

_-

----_.I

connecting rod, flywheel puller

valve adjusting

-

valve adjusting

(Nut

driver acceptable)

I-p

deep well for spark plug

_-_s_

B

&

B

6

6

B

&

&

&

&

S

S

S

S

S

-___ti--

11_1--____---

_.____I_____..^_______I-

I

I

nut

_--__

jam

I_--^

____~rmY___

screw

-.

----

part number 19372

part number 19069

part number 19334

part number 19070

part number 19340

~._-

.-

-~

-p_-

-~

--

.I

-

GTS

150

9

Specifications

Page 15

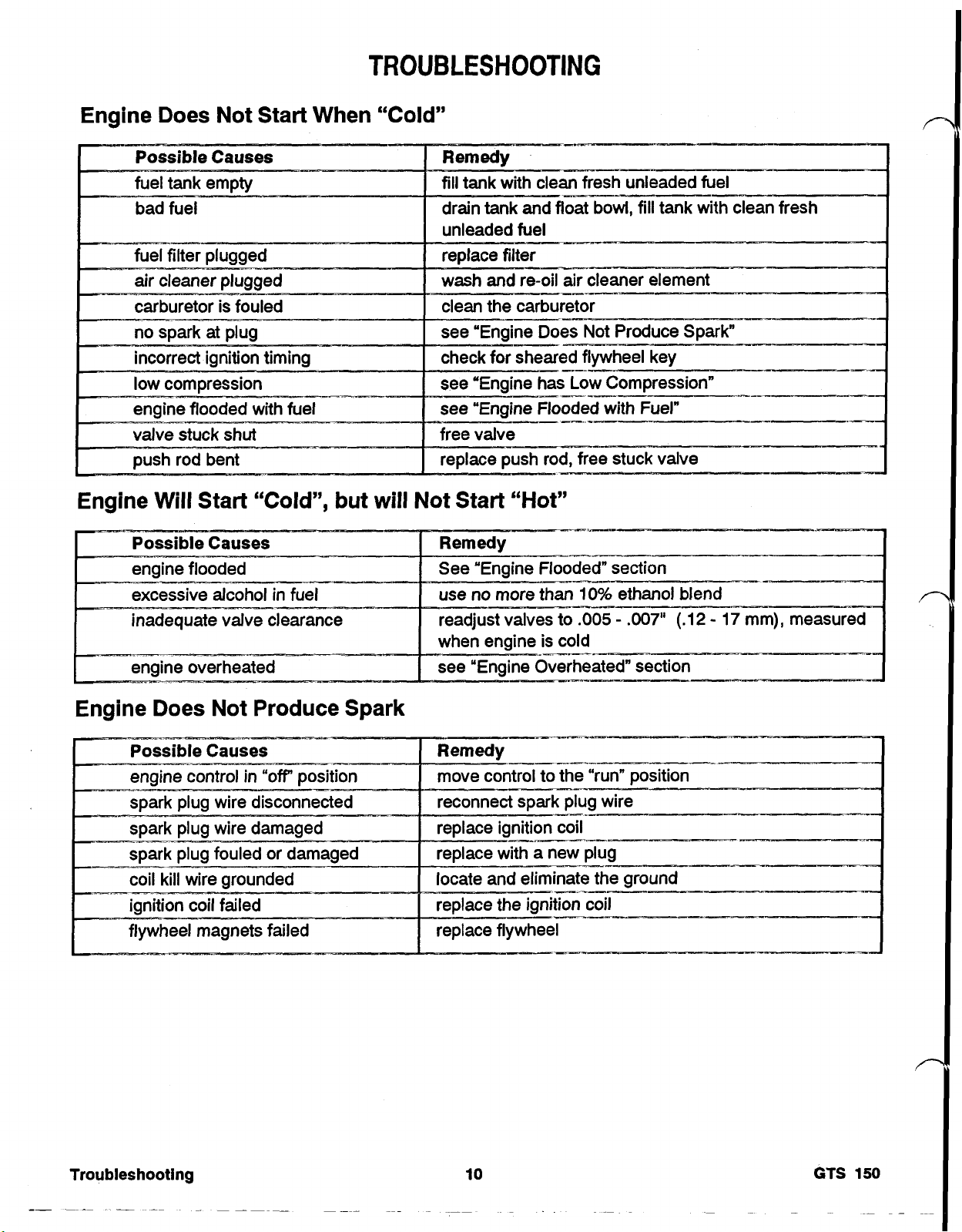

TROUBLESHOOTING

Engine Does Not Start When

Engine Will Start “Cold”, but will Not Start

“Cold”

“Hot”

inadequate valve clearance readjust valves

Engine Does Not Produce Spark

to

.005

-

.007” (.12

-

17 mm), measured

GTS

150

Page 16

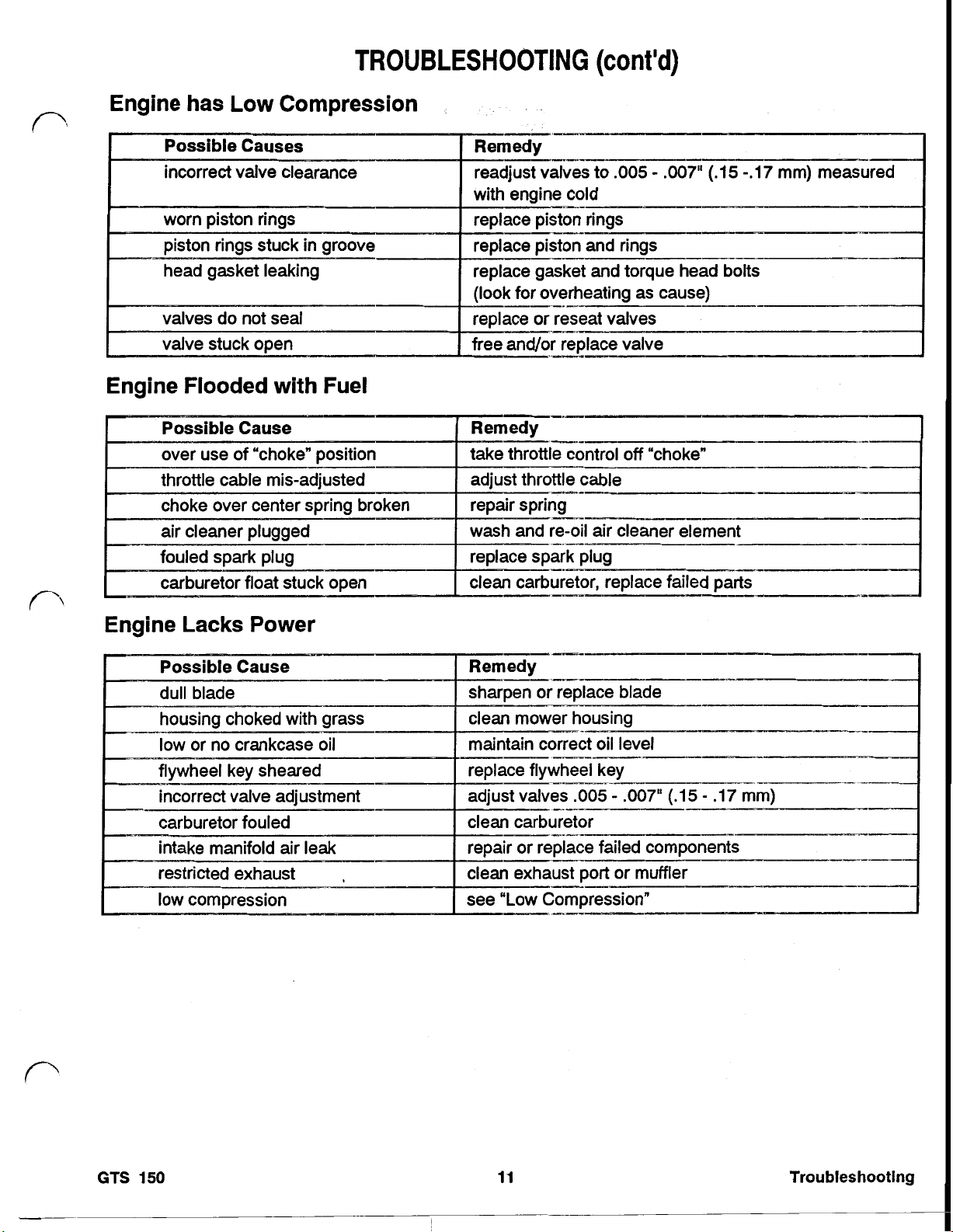

Engine has Low Compression

TROUBLESHOOTING

(cont'd)

incorrect valve clearance readjust valves

Engine Flooded with Fuel

with engine cold

carburetor replace failed parts

to

.005

-

.007" (.15-.17 mm) measured

--

Engine Lacks Power

GTS

150

11

Troubleshooting

Page 17

TROUBLESHOOTING

(cont’d)

Bent Push

Rod

Engine Surging

Engine Back Fires

Engine After Fires

Engine Overheats

Engine Vibrates Excessively

.

out

of

balance-blade

Trouble shooting

12

GTS

150

Page 18

TROUBLESHOOTING

(cont'd)

Engine Crankshaft Will

Not

Turn

Engine Produces Mechanical Knocking Sound

Pre-Ignition

Engine Smokes Excessively

. .

with fresh unleaded regular fuel with no more

--_-

GTS

150

13

Troubleshooting

Page 19

TROUBLESHOOTING

(cont’d)

Engine

Spark

Stalls

Plug Fouled

Page 20

GTS

150

MAINTENANCE

Servicing

Normally, clean the air cleaner after every

hours. More frequent cleaning is required when the mower

is operated in dusty or dirty conditions.

1. Stop the engine, allow

spark plug wire. Remove the key from the key switch

on electric start models.

2.

Rotate the knob securing the air cleaner cover to the

engine until the cover can be removed. Clean the

cover thoroughly. See Figure 1.

Air

Cleaner

25

operating

it

to cool and disconnect the

Replacing the Spark Plug

Use a Champion RC12YC spark plug or equivalent. The

correct air gap is

25

every

1.

operating hours and check its condition.

Stop the engine, allow it to cool and disconnect the

spark plug wire. See Figure

the switch on electric start models.

.030"

(.76mm). Remove the plug after

2.

Remove the key from

Figure

3.

If the outside of the foam element is dirty, remove it

from the air cleaner body and clean it thoroughly. See

Figure

A.

6.

C. Saturate the element with

4.

Reinstall the foam element and air cleaner cover. Do

not operate the engine without the air cleaner element

as extreme engine wear and damage will likely result.

A.

1.

Wash the foam element in a solution of liquid soap

and warm water. Squeeze the element to remove

dirt, but do not twist as the foam may tear. Rinse

thoroughly in clear water.

Dry the element by wrapping

Squeeze the rag and

SAE

1

OW

30

engine oil. Squeeze the element to

remove excess oil and to distribute the oil thor-

A

oughly.

Paper elements are available for use in extremely

dirty conditions. Toro part number 77-901

damp element is desirable.

1

foam

element to dry.

5

teaspoons

it

in

a clean rag.

(25

ml) of

0.

1.

Static Gard

2.

Air Cleaner Code Numbers

3.

Carburetor

4.

Spark

2.

Clean around the spark plug and use a

remove the plug from the cylinder head. Replace a

cracked, fouled, or dirty spark plug. Do not sand blast,

scrape, or clean electrodes as engine damage could

result from grit entering the cylinder.

3.

Set the air gap at

the correctly gapped spark plug and gasket seal.

Tighten the plug to

Plug

.030"

14

5.

Model,

6.

Muffler

7.

Muffler Guard

(0.76 mm) , See Figure

ft Ibs (1 9 N-m)

(.76MM)

Type

518"

and

socket to

3.

Install

1

GTS

150

15

Figure

3

Maintenance

Page 21

Removing Gasoline from the Fuel Tank

1.

Stop the engine, allow it to cool and disconnect the

spark plug wire. Remove the key switch on electric

start models.

2.

Remove the cap from the fuel tank and use a pump

type siphon to transfer fuel into a clean gas can

container designed to hold gasoline. Note: this is the

only fuel removal procedure that should be used for

general maintenance.

Changing Crankcase Oil

2

Change the oil after the first

25

every

more contaminants than cold oil, run the engine for a

minute period before draining the oil.

1.

hours. Since warm oil will drain better and carry

Stop the engine, allow it to cool and disconnect the

spark plug wire. See Figure

operating hours and after

4.

or

5

5.

When the oil is drained, return the mower to its upright

position and add fresh oil to the engine. Refer to

"Filling the Crankcase with Oil" on pagexx. The crank-

25

oz

(.74

case capacity is

the crankcase may retain a small amount of oil, reducing the amount required to bring the oil level back to

normal.

Carburetor -Adjustment

1

.

Turn the idle mixture screw clockwise until

NOT FORCE.

2.

Turn the idle mixture screw counterclockwise

turns. This will permit the engine to start and final

adjustment can be made with the engine running.

3.

Start the engine and allow

4.

While the engine is running, move the speed control

lever to the fast position until the hole "A"

lever aligns with the hole

6.

See Figure

the holes

Use a

in

position.

liters). When changing oil,

it

seats.

it

to warm up.

in

the throttle

in

the throttle control bracket.

1/8"

(3

mm) diameter pin to hold

DO

1-1/2

Figure

2.

Remove the' gasoline from the fuel tank: refer to

"Removing Gasoline" on page

3.

Remove the dipstick from the oil

drain pan next to the left side of the mower.

4.

Tip the mower on its left side, allowing the oil to drain

into the drain pan. See Figure

4

23.

fill

tube and place a

5.

ALIGNED

HOLES

'A'

Figure

5.

Adjust the high speed screw on the throttle control

a

3000,

1/8"

(3

bracket to obtain

6.

Remove the pin and move the speed control lever to

the slow or idle position, until hole

control lever aligns with the hole

bracket.

holes in alignment.

7.

Adjust the idle speed stop screw to

Figure

Use

7.

6

100

RPM.

“B”

in the throttle

in

the throttle control

mm) diameter pin to hold the

1700,

100.

See

Figure

5

16

Page 22

IDLE

TOP

SPEED

MIXTURE

NO

LOAD

SCREW

1.

Stop the engine, allow

it

to cool and disconnect

spark plug wire. Remove the key on electric

models.

2.

Move the throttle control to the "Fast" position.

3.

Loosen the cable clamp screw until the throttle cable

sheath can slide

4.

Move the throttle cable left or right until holes in the

in

its

clamp.

throttle lever and throttle bracket align. See Figure

THROTTLE

BRACKET

the

start

8

Figure

7

8. Turn the idle mixture screw slowly, clockwise (lean

mixture) until the speed just begins to slow down.

Then, turn the idle mixture screw slowly counterclock-

in

wise (rich mixture) until the engine increases

speed

and then just starts to slow down. Turn the screw to a

if

midpoint position between rich and lean. Note:

the

speed exceeds 1900 RPM during this adjustment,

7

repeat step

and 8. If the engine does not accelerate

properly, re-adjust the idle mixture screw approximately 1/8 of a turn counterclockwise to richen the

mixture.

9. Remove the aligning pin and re-adjust the idle speed

stop screw to 1400 100 RPM.

IO.

Re-check the high speed setting.

-

Compression

Measurement

Engine compression can vary depending on the technique

and compression gauge used to make the measurement.

5.

6.

7.

The compression values given in the specification section

are a reference point only. We recommend the individual

8. Connect the spark plug wire.

dealer establish compression values based on new product using his or her own technique and compression

Clean the Engine and Recoil Starter

gauge.

Accumulated yard debris and dirt can cause overheating

1. Remove the spark plug and install a compression

gauge that threads into the spark plug opening.

2.

Pull the starter rope rapidly to achieve a momentary

500

engine speed of over

RPM. This will cause the

and malfunction of control linkages. Before every mowing

the muffler area, throttle linkage and air intake screens

should be cleaned of debris.

1. Stop the engine, allow it to cool and disconnect the

compression release mechanism to allow the intake

valve to completely close.

3.

Pull the starter rope repeatedly until there is no further

2.

rise in the compression value.

Throttle -Adjustment

Throttle control adjustment may be required

if

the engine

3.

does not start, stop or run at the correct speed. Whenever

a new throttle control cable is installed, the throttle must be

adjusted.

HOLES

'A'

CABLE

CLAMP

SCREW

Insert a

1/8"

CABLE

(3

mm) pin

Figure

8

in

the aligned holes to hold the

throttle lever in position.

Pull the throttle cable slightly to remove any slack and

tighten the cable clamp screw to lock the adjustmen

in

place.

Remove the 1/8"

control back to the

(3

mm) pin and bring the throttle

off

position.

spark plug wire. Remove the key on electric starl

models.

Remove dirt and debris with a cloth, brush or

pressure

(30

psi,

200

kPa or less) air. When using

compressed air be sure to wear safety glasses

low

to

prevent eye injury from airborne debris.

A forceful stream of water is not recommended

as

it

could cause contamination of the fuel system.

GTS

150

17

Malntenance

Page 23

Clean the Cooling

Every25 hours, or every cutting season, the engine blower

housing must be removed and the cooling fins cleaned.

Failure to clean the cooling system may lead to engine

overheating and severe engine damage.

1.

Stop the engine, allow

spark plug wire. Remove the key

models.

2. Remove the four

retain the blower housing to the engine.

3.

Remove the gas cap and lift the blower housing and

recoil starter assembly away from the engine to expose the cooling fins. Replace the gas cap.

4. Remove dirt and debris with a cloth, brush or low

pressure,

compressed air be sure to wear safety glasses to

prevent eye injury from airborne debris. See Figure

System

it

to cool and disconnect the

on

electric start

3/8"

hex, washer head screws that

30

psi (200 kPa) or less, air. When using

9.

Fuel can be left

as Toro's Stabilizer/Conditioner is added to the gasoline

and

Toro's Stabilizer/Conditioner is petroleum distillate based.

The Toro Company does not recommend stabilizers with

-an alcohol base, such

alcohol.

Under normal conditions, all fuel additives remain effective

in

1.

2.

3.

4.

in

the fuel tank only

run

through the engine before storage.

as

ethanol, methanol or isopropyl

fuel for

6-8

months.

Remove the spark plug and pour

(30

ml) of

SAE

30

oil into the spark plug hole

cylinder. Pull the starter rope slowly to coat the inside

of the cylinder. Install the spark plug and tighten

to 14 ftIb (19Nm). Do not connect the spark plug wire.

Clean dirt and chaff from the cylinder, cylinder head

fins, and blower housing. Also remove grass clippings,

dirt and grime from the external parts of the engine,

shrouding and top of the mower housing.

Clean the air cleaner: refer to the Maintenance Sec-

tion on Servicing the Air Cleaner on page

Change the engine oil: refer to the Maintenance

Section on Changing the Engine Oil on page 16.

if

a fuel additive such

two

tablespoons

in

15.

the

5.

Tighten all nuts,

6.

Store the engine

engine to keep

W

Figure

5.

Remove the gas cap and install the blower housing.

Replace the gas cap. Install the four

head screws that retain the blower housing. Tighten

50

the screws to

Preparing the Engine for Storage

For long termstorage, either remove gasoline

tank and carburetor as described on page 16 or add a fuel

stabilizer to the gasoline. If the gasoline has been removed

from the fuel tank, start the engine and allow it to idle until

all the fuel is consumed and the engine stops. Repeat the

starting procedure

line is removed from the engine. If gasoline is not removed

from the carburetor

deposits will form and cause starting problems and/or poor

engine operation.

in Ibs (5.6 N-m)

two

more times to assure all the gaso-

in

this manner, gum-like varnish

9

3/8"

hex, washer

from

the

fuel

bolts

and fasteners.

in

a clean, dry place. Cover the

it

clean and protected.

18

GTS

150

Page 24

SECTION 1 CARBURETOR

Carburetor Description

The carburetor used on the

GTS

150 is a dual circuit (pilot

and main), float bowl design with fixed main jet, fixed

nonremovable pilot jet and an adjustable pilot circuit

mixture screw. The carburetor is fitted with a standard

number

30

(.0295") main jet.

A

high attitude main jet

number 28 (.0280") is also available. The carburetor is

fitted with a stainless steel inlet needle and a replaceable

inlet seat. The throttle and choke shaft are equipped with

dust seals.

Carburetor

Theory

The carburetor receives fuel from the tank and mixes

and Operation

it

with air in the right proportions to provide a highly combustible mixture to the engine.

As

the piston moves down on the intake stroke, a partial

vacuum is created within the cylinder, causing the greater

atmospheric pressure to force air to flow through the

carburetor into the cylinder. The velocity of the air

creases as

it

flows through the carburetor venturi and the

air pressure is reduced at this point to less than atmospheric pressure. The differences of pressure in the venturi

of the carburetor causes atmospheric pressure to push

raw fuel from the float bowl into the air stream where it

breaks up into a fine spray, or becomes atomized, and

mixes with the air stream. See Figure 10.

in-

Fuel atomization becomes more efficient due to heat, once

the engine has reached normal operating temperature.

a result, the engine does not require the rich mixture it did

for starting and the choke plate must be moved to the open

position. The engine speed is now regulated by the throttle

plate. In no load condition, a small portion of the fuel may

be drawn from the main discharge tube, however the

primary fuel supply is drawn from the pilot circuit. Air

passing through the pilot jet from the pilot air fitting draws

fuel

pre-mixes with the incoming air and is discharged into the

VENTURI

carburetor bore where the fuel becomes atomized. See

Figure 12.

PILOT

SYSTEM

COLD START

Figure

out

of the pilot jet orifice from the float bowl. This fuel

11

As

--

CARBURETOR

BORE

TO

FLOAT BOWL

When starting the engine, an extra rich mixture is required.

The choke plate is closed by the operator to provide an

approximate 8:l (approximately six times richer than

normal) ratio of fuel to air for this rich mixture. Closing the

choke plate further reduces the air pressure area in the

venturi to increase the fuel drawn into the carburetor bore.

In this condition, fuel is drawn from the float bowl through

the pilot system ports as well as the main discharge tube

to achieve the proper starting mixture. See Figure 11.

GTS

150

ENGINE

19

''LOT

I

Figure

PILOT

12

JET

I

PILOT

AIR

FITTING

Carburetor

Page 25

As the throttle plate is opened to compensate for engine

load, the main discharge tube becomes the main source of

fuel. Opening the' throttle plate increases the flow of air

through the venturi and strengthens the low pressure area

at the main discharge tube. Fuel discharge increases at

the main discharge tube as it decreases from the pilot

system. Air is drawn from the air correction jet, through

holes along the length of the main discharge tube. This

it

pre-mixes air with the fuel before

bore for more efficient atomizing of the fuel. See Figure

SYSTEM

enters the carburetor

13.

3.

Disconnect the choke over-center spring. Note the

position of the spring for correct assembly. See

Figure

15.

Figure

Carburetor

1.

Remove the fuel from the tank as described in the

Maintenance Section on page

2.

Remove the three

screws retaining the air cleaner to the carburetor.

Take care not to lose the cork gasket that seals

between the air cleaner body and the carburetor. See

Figure

Removal

5/16"

14.

13

16.

hex, washer head shoulder

Figure

4.

Remove the

retain the carburetor, the insulator gasket, and engine

block. See Figure

two

3/8"

16.

15

hex, washer head screws that

Figure

14

20

Figure

5.

Have a rag ready to absorb a small amount of spilled

gasoline. Pull the carburetor away from the engine.

Twist

the carburetor to unhook the carburetor from the

governor link rod. As the carburetor is tilted, fuel that

is

in the fuel bowl may leak

6.

Hold the carburetor over a drain pan and use a

wrench to loosen the bowl nut. Allow the remaining

in

the bowl to drain into the pan. Tighten the bowl

fuel

nut.

16

out

the bowl vent tube.

GTS

1/2”

150

Page 26

Carburetor

1.

Turn the carburetor upside down.

2.

Connect a pressure tester to the inlet fitting on the

carburetor. See Figure

3.

Pump the pressure to the inlet needle "pop

sure,

4.

The inlet needle should

down to zero, the inlet needle is not seating indicating

that carburetor service is required.

Carburetor Disassembly

5

psi

Pressure.

Figure

(.3

kglcm

Testing

17.

17

2).

seal.

off

If the pressure leaks

pres-

IDLE

STOP

SCREW

IDLE

MIXTURE

SCREW

.-

Figure

5.

Thethrottle plate is retained with one screw. When the

plate is removed the throttle shaft may be withdrawn

from the body of the carburetor.

6.

The choke plate is retained in a slot

an

with

pulling

shaft may then be removed from the body of the

carburetor.

7.

If the carburetor vent passage is open

sary to remove the welch plug that covers the vent

opening

area that does not have a filter screen or other

cleanable device.

interference

it

out

of the slot with a pair

in

the bowl

fit.

19

in

the choke shaft

The plate may be removed by

of

pliers. The choke

it

is not neces-

of

the carburetor. This is a vent

1.

Remove the bowl nut, bowl and gasket.

2.

Use a

9/16"

wrench to remove the main jet and float

stop disc. See Figure

3.

Remove the float hinge pin, float and inlet needle.

4.

Remove the idle mixture screw and spring and the idle

stop screw and spring. See Figure

18.

Figure

18

19.

8.

Remove the pilot circuit welch plug from the side of the

carburetor. Pierce the plug with a small chisel or

pointed device and pry the plug out of the body of the

carburetor.

9.

The viton, fuel inlet seat may be removed by pulling the

of

seat out

crochet hook.

Carburetor Cleaning and

I.

CAUTION:

use with chemicals and wear eye protection when

working with carburetor cleaning materials. Work only

in

well ventilated areas free from sparks or flames.

Make sure you follow all manufacturers recommendations on the use of their cleaning products.

2.

The carburetor

in carburetor cleaner, however; after the soak, each

passage and component in the carburetor should be

washed with a pressurized carburetor cleaning agent.

Soak tanks may not

cleaner will remove any residue.

3.

Direct the pressurized cleaner through all openings

and passages

or air flow.

the body

of

the carburetor with a number

Service

Wear gloves that are suitable for

body

and components may be soaked

be

clean and the pressurized

in

the opposite direction of normal fuel

5

GTS

150

21

Carburetor

Page 27

4.

Use extreme care with mechanical cleaning devices:

i.e. wires, probes, tip cleaners, etc. Mechanical cleaning may damage or enlarge critically sized carburetor

components and passages.

Carburetor - Assembly

1,

Install a new welch plug in the pilot circuit opening on

1/8”

(3

the body of the carburetor. Use a

punch to dimple and seal the welch plug

the carburetor.

2.

Install the throttle shaft dust seal and throttle shaft in

the body of the carburetor.

3.

Use red, number

screw and install the throttle plate. Allow the specified

amount of time for the Loctite to cure before operating

the engine.

4.

Place a dust seal on the choke shaft and insert the

choke shaft in the body of the carburetor.

5.

While looking at the choke end of the carburetor,

position the choke shaft with the over-center spring

slot toward the right side

6.

Insert the choke plate

slot of the choke shaft. The choke should fully close

90

with a

degree clockwise turn of the shaft.

271

Loctite

(R)

on the throttle plate

of

the carburetor.

so

the plate is captured in the

mm) pin

in

the body of

10.

Install the needle on the float. Put the float and needle

in

position and insert the hinge pin.

1I.

Install the float stop disc and

12.

Install the bowl gasket and the

13.

Install the bowl nut.

the

fuel

main jet.

bowl.

Carburetor -Adjustment

See “Carburetor - Adjustment"

on page

16.

in

the Maintenance Section

7.

Install the idle stop screw. Adjustment of the screw

should be performed when the engine is running. Idle

1700

speed should beset to

carburetor adjustment procedure.

8.

Install the idle mixture screw; nominally set at

1-1/2 turns open. See Figure

IDLE

MIXTURE

SCREW

RPM. See page

20.

16

for the

1

to

9.

Install a new viton seat. Insert the seat with a

mm) pin punch. The flat end of the inlet needlewill also

in

work to push the seat

damage the point end of the needle.

place. Take care not to

Carburetor

1/8"

(3

22

GTS

150

Page 28

SECTION

2

FUEL

SYSTEM

FUEL

Fuel lank Operation

The GTS150 uses a 1.6 quart (1.5 liters) plastic fuel tank

with a non-replaceable75micron in-tankfilterscreen. The

filter is welded in the bottom of the tank over a sediment

reservoir. The tank is mounted above the level of the

carburetor and uses gravity to supply fuel through a .25'

I.D. (6.35 mm) rubber hose to the carburetor. The fuel tank

is vented through an opening in the fuel cap. The fuel hose

is retained to the tank and the carburetor with spring type

hose clamps. The fuel opening on the tank is 1.75" (45

mm) in diameter and is opposite the fuel outlet helping to

prevent damage to the filter screen by funnels and gasoline filler spouts. The placement of the cap also prevents

interference with the starting rope

Fuel lank Removal

1. Crimp the fuel hose with a pair of locking pliers to

2. Remove the hose clamp on the carburetor end of the

3.

4. Remove the four 3/8" hex, washer head screws that

5. Remove the gasoline tank cap and remove the blower

6.

TANK

in

Zone

Start

applications.

prevent fuel flow.

hose.

CAUTION:

in a container designed for gasoline and never smoke

while working around gasoline. Release the clamping

pliers and drain the fuel into a container designed to

receive gasoline.

retain the blower housing to the engine. It is not

necessary to remove the recoil starter.

housing.

Remove the

retain the fuel tank to the fuel tank bracket.

Avoid fire and explosion. Store fuel

two

3/8" hex, washer head screws that

into the tank from an opening in the cap to allow gravity to

feed fuel to the carburetor.

Fuel Cap Service

1.

The fuel cap may not

vent opening on the cap and inner sealing disc should

be kept free of debris.

2. Theventilating ability of the cap may be tested by filling

the cap with water and observing the flow

of the vent opening

the

not drain,

3.

If the cap will not vent properly,

Fuel Hose - Removal

1.

CAUTION:

fuel

in

smoke while working around gasoline.

2. Remove the air cleaner cover and foam element.

3.

Remove the three 5/16" hex, washer head shoulder

screws that retain the air cleaner body to the engine.

4. Pull the air cleaner body away from the engine. Take

care not to lose the cork gasket between the air

cleaner and the carburetor. Take note of the position

of the breather hose on the back of the air cleaner and

the location of its' connection to the breathervent tube.

5.

Disconnect the fuel hose from the carburetor by

squeezing the spring type hose clamp with a pair of

pliers.

6.

Drain the fuel into a container designed for gasoline.

7.

Remove the fuel hose from the fitting on the bottom of

the gasoline tank.

Fuel Hose - Installation

vent

a container designed for gasoline and never

be

disassembled, however, the

of

water out

in

the side of the cap. If water does

opening may

Avoid fire and explosions. Store

be

plugged

it

should be replaced.

or

restricted

Fuel lank and Filter Cleanlng

1. Wash the tank in clean solvent designed for cleaning

engine parts.

2. Back wash the filter screen by directing cleaning

vent, under pressure, through the sediment reservoir

and screen, opposite fuel flow direction.

3. Wash the tank again with clean solvent.

4. Clean or replace the fuel hose.

Fuel Cap Operation

The fuel cap is a three piece design with an inner sealing

disc that is vented to a baffle assembly in the body of the

cap. The baffle assembly acts to allow expansion in the

loss

tank without

GTS150

of fuel. Atmospheric pressure is allowed

sol-

23

Make certain the fuel hose is clean. Even

1.

hose is new, run clean solvent through the inside of the

hose prior to installation.

a

Install

2.

end of the fuel hose. Install the hose on the outlet pipe

of the fuel tank. Secure the fuel hose with the hose

clamp.

Install the other end of the fuel hose to the inlet pipe on

3.

the carburetor and secure it with the remaining hose

clamp.

Install the body of the air cleaner.

4.

IMPORTANT:

on the back of the air cleaner body mates with the

spring type hose clamp

Take care that the breather vent hose

2"

(5 cm) from each

Fuel

if

the fuel

System

Page 29

breather vent tube. Leakage

to enter the air cleaner on the carburetor side

filter element.

5.

Make sure the cork gasket is between the air cleaner

body and the carburetor. Install the three

washer head shoulder screws.

6.

Make sure the air cleaner element is properly cleaned

and oiled, see Maintenance Section on page

install the element.

7.

Install the air cleaner cover and tighten the thumb

screw.

in

this area will allow dirt

5/16"

of

15

the

hex,

and

GTS150

Page 30

operation

SECTION 3 IGNITION

The firing of the spark plug at the proper time

culmination of a number of components working together.

These components on the GTS 150 are:

Flywheel

Ignition armature coil

Spark plug

Armature coil wiring

The following describes the function of each of the above

components.

Ignition

The flywheel is connected directly to the crankshaft and

turns at the same speed

the flywheel are three magnets. These magnets rotate

past the coil to generate electricity.

Imbedded in the opposite side of the flywheel are steel

counterweights which offset the weight of the three magnets. These counterweights are not magnetic.

Ignition Operation

The ignition armature coil is actually a transformer.

positioned close to the flywheel to allow the magnetic field

of the flywheel magnets to cut through the wire coils of the

armature coil to generate electricity. See Figure 21.

Operation - Flywheel

as

the crankshaft. Imbedded in

-

Ignition

Armature Coil

IGNITION

COIL

is

It

the

is

the voltage at point

tor

to flow through the collector, emitter circuit of TR2 than it

With the base current for TRI diverted, TR1 turns

opening the armature coil primary circuit. Remember, the

current flowing through resistor

small and can not support the magnetic field created

primary winding. When the circuit through TR1 opens, the

magneticfield in the primary winding collapses, generating

an extremely high voltage in the secondary winding,

enough voltage to cause a spark at the spark plug.

Figure

Lowvoltage is produced in the primary coil of the armature

coil which causes a very small current to flow through

"R"

resistor

current will cause the transistor to "turn on" creating a low

resistance path through the collector, emitter circuit of the

transistor

As the magnets continue to cut through the coils of the

primary winding the primary voltage will increase.

voltage also develops across the voltage divider network

created by resistors R1

resistance path for the base current flowing through resis-

"R".

is

through the base, emitter circuit of TR1.

to the base of transistor TR1. This small base

as

shown by the dotted line.

,

R2. At a precisely timed moment,

"A"

In fact, when this occurs,

22

This

turns TR2 "on" creating a low

it

is easier for the current

"off,

"R"

and TR2 is extremely

in

the

Figure

Complete operation of the ignition circuit is described with

reference to Figure 22.

GTS

150

21

Ignition Operation Spark Plug

The spark plug is used to ignite the air-fuel mixture by

producing a spark just before the piston reaches top dead

as

center. A spark plug is typically constructed

Figure

23.

25

shown

Ignition

in

Page 31

INSULATOR

5.

Tighten the

the armature coil to

6.

Remove the gas cap and replace the blower shroud.

The blower shroud fasteners are tightened to

(5.6Nm).

7.

Install the gas cap.

Ignition Armature Coil Removal

1.

Remove the gas cap.

5/16"

hex, washer head screws retaining

45

in

Ibs

(5Nm).

50

in

Ibs

E

a

Figure

There are two critical areas important to proper spark plug

function. The first is that the electrodes are properly

gapped and are clean. This ensures that a strong spark will

it

be present and that

gap or fouling can delay firing enough to cause a

power or stalling. Correct gap is

The other important area is the insulator. The insulator

prevents arcing from taking place in another area of the

plug, away from the electrodes. Because of the extremely

high voltage present, even a slight crack or fouling of the

head insulator can result in arcing and a malfunction of the

Plug-

Armature Coil Wiring - Operation

The armature coil has two external wires. One wire is the

high voltage spark plug wire and the other wire is the

primary grounding or engine kill wire. The free end of the

kill wire is terminated at the throttle bracket kill terminal.

There are two ground terminals that connect to the frame

of the armature coil and through the armature coil frame to

the block of the engine.

occurs at the proper time. Excessive

23

.030" (.76

CHAMPION

RC12YC

.OW"

(.76

mm).

mm)

loss

of

4.

5.

6.

Ignition Armature Coil Testing

Use an approved tester to test armature coils. Coil specifications are supplied by the tester manufacturer or can be

found in Briggs and Stratton form

Book

1.

2.

CAUTION:

gas tank. Do not smoke or allow open flames around

gasoline. Gasoline fumes are explosive.

2.

Remove the four

retain the blower housing.

3.

Remove the blower housing and replace the gas cap

on the fuel tank.

Disconnect the armature coil secondary ground wire

(igniton kill wire) from the grounding terminal on the

throttle control bracket.

Unplug the spark plug wire.

Remove the

retain the armature coil. The armature coil may now be

removed from the engine.

for Testing Briggs Stratton Ignition Coils."

The primary coil should have

tance. The secondary coil should have

ohms of resistance.

Primary resistance is measured between the kill wire

and ground. Because the primary resistance

small the resistance measurement will more realistically be used for disclosing either short circuits or,

more likely, open circuits

two

extreme care

3/8"

hex, washer head screws that

5/16"

hex, washer head screws that

in

if

there is fuel in the

MS-7862,

.2

to

.4

ohms of resis-

2400

the primary winding.

"Instruction

to

5000

is

so

Air Gap Adjustment

1.

Remove the gas cap.

Use extreme care if there is fuel in the

Do

gas tank.

gasoline. Gasoline fumes are explosive.

2.

Remove the four

retain the blower housing.

3.

Remove the blower housing and replace the gas cap

on the fuel tank.

4.

Loosen the two screws that retain the ignition armature coil. Use a feeler gauge to set the air gap between

the flywheel and ignition armature coil to

(.20

-

.30

Ignition

not smoke or allow open flames around

3/8"

hex, washer head screws that

.008

-

.012."

mm)

3.

Secondary resistance is measured between the spark

plug wire and ground.

Ignition Armature Coil Installation

I.

26

Lightly tighten the

armature coil. Use a feeler gauge to set the air gap

between the flywheel and ignition armature coil to

-

.012."

(.20

2.

Tighten the

the armature coil to

3.

Remove the gas cap and install the blower shroud.

The blower shroud fasteners are tightened to

(5.6Nm).

4.

Install the gas cap.

two

screws that retain the ignition

.30

mm)

5/16"

hex, washer head screws retaining

45

in

.~

Ibs (5Nm).

50

GTS

.008

in

Ibs

150

Page 32

SECTION

4

REWIND STARTER

Rewind Starter Operation

The rewind starter operates through a retainer/friction disc

that causes

center of the rewind starter and engage the inside of the

starter cup on the flywheel. The engagement dogs move

into contact with the starter cup when the rewind rope is

pulled. When the engine starts, the speed of the engine

exceeds the speed of the rewind starter and forces the

starter dogs back into the center of the rewind mechanism,

disengaging them from the starter cup.

Rewind Starter Disassembly

1.

Remove the four

retain the rewind starter assembly to the engine.

2.

Remove the alignment pin from the Phillips head

screw in the center

Figure

24.

two

engagement dogs to extend from the

5/16"

hex, washer head screws that

of

the rewind mechanism. See

4.

Remove the

of the positioning of the springsfor correct installation.

See Figure

5.

Completely extend the rewind rope and hold the reel

in

place. Untie the knot

the rope and slowly allow the reel to unwind to a

relaxed state.

two

ratchet dogs and springs. Take note

26.

Figure

26

in

the end of the rope, withdraw

Figure

3.

Remove the Phillips head screw from the center of the

rewind mechanism and

starter. See Figure

25.

24

lift

the friction plate from the

6.

Remove the reel from the rewind housing. The rewind

spring is captured

suddenly released.

able. If the spring has failed, an entire spring and reel

assembly must

in

the reel and will not fall

The

rewind spring is not service-

be

used for repair. See Figure

Figure

27

out

or

27.

be

GTS

150

Figure

25

27

Rewind

Starter

Page 33

Rewind Starter Assembly

1.

Lubricate the center post of the rewind starter with a

small amount of general purpose grease.

2.

Place the reel assembly on the center post

rewind starter and turn the reel counterclockwise until

the hook on the reel spring engages the spring retainer

on the center post of the starter. See Figure

of

28.

the

4.

Install the friction disc retainer and retaining screw.

See Figure

30.

SCREW

Figure

3.

Install the dog springs and the brake spring as shown

in Figure

29.

Figure

28

29

I

5.

Drive the aligning roll pin into the center of the retaining screw and slide the plastic sleeve over the pin. See

Figure

Rewind Starter Installation

1.

Install the rewind starter on the blower housing, cen-

tering the aligning pin in the opening

crankshaft.

31.

Figure

Figure

30

31

in

the end of the

Rewind Starter

28

2.

Install the four

screws and tighten to

5/16"

hex, washer head retaining

40

in

Ibs

(4.5Nm).

GTS150

Page 34

SECTION 5 ENGINE

Engine - Operation

Intake Stroke

The GTS

The running engine begins with the first of four strokes

being the intake stroke. The piston moves from Top Dead

Center (TDC) to Bottom Dead Center (BDC) with the

intake valve opening

as the piston reaches BDC. While the piston is moving

toward BDC with the intake valve open, a partial vacuum

is created in the cylinder. Air and fuel will enter the cylinder

under atmospheric pressure as long as the intake valve is

open and the piston is moving toward BDC. See Figure

150

is a four stoke cycle, over head valve engine.

as

the piston leaves TDC and closing

32.

Power Stroke

When the piston comes close to TDC the mixture is ignited

by the spark plug and the third stroke begins. The expand-

ing combustion gases push the piston down

creating the power stroke, both the intake and exhaust

valves are still closed

at

this time. See Figure

Figure

34

in

the cylinder

34.

Figure

Compression Stroke

The second stroke (compression) begins

leaves BDC and moves toward TDC. Both the intake and

exhaust valves are closed at this time. As the piston

moves, the air/fuel mixture is compressed

See Figure 33.

32

as

the piston

in

the cylinder.

Exhaust Stroke

The fourth stroke (exhaust) begins as the piston reached

As

BDC and the exhaust valve opens.

TDC

toward

engine. See Figure 35.

the piston forces the exhaust gases from the

the piston moves

GTS

150

Figure

33

29

Figure

35

Engine

Page 35

Engine Dissassembly

Rewlnd Starter Operation

See Section 4 Rewind Starter on page

Air Cleaner Operation

Combustion air comes from the fan blades on the flywheel

air

(the flywheel also provides cooling

moves into the air cleaner body through

an

blower housing and

cleaner. The air has to make

then another right angle

the oiled foam element, Heavier particles will not

to make the turn into the foam element and will fall, or

be blown

Note that an optional paper air cleaner element is available

for this engine.

out

the opening

opening in the upper

a

right angle turn down and

turn

through plastic ribs to enter

in

the bottom of the air cleaner.

for the engine). Air

an

opening

body

in

the

of the air

be

able

will

Rewind Starter Removal

1.

Air Cleaner Removal

1. Loosen (counterclockwise rotation) the thumb screw

retaining the air cleaner cover, and remove the cover

of

from the body

the air cleaner. See Figure

36.

27.

Remove the four 5/16" hex, washer head screws

retaining the recoil starter to the blower housing. See

Figure

38.

Figure

38

Figure

2.

Remove the foam filter element. See Figure 36.

3.

Remove the three 5/16" hex, washer head shoulder

screws retaining the air cleaner body to the carburetor

and throttle bracket.

4.

Pull the air cleaner body away from the engine and at

the same time pull the breather hose

Do

vent tube.

cleaner body and the carburetor. See Figure

not lose the cork gasket between the air

36

off

the breather

37.

2.

Lift

the starter away from the blower shroud.

Blower Shroud Removal

1. Remove the four

retaining the blower shroud.

2.

Lift

the blower shroud

3/8"

hex, washer head cap screws

off

Muffler Shroud Removal

1. Remove

the back of the muffler shroud.

2.

Remove

the muffler shroud. See Figure

two

3/8" hex, washer bead cap screws from

two

5/16" hex, cap screws from the front of

the engine. See Figure

39.

38.

AIR

RETAINING

SCREWS

Figure

37

Figure

39

GTS

150

Page 36

Flywheel Brake Operation

Zone start mowers are fitted with a flywheel brake that kills

the ignition and stops

is a spring loaded lever that when released causes a brake

shoe to rub against the flywheel in a self energizing

manner. An arm on the brake lever at the same time

touches a contact point that is part of the ignition kill wire

terminal. This will ground the kill wire to prevent spark. To

start the engine, the brake cable

electrical contact and pull the brake shoe away from the

flywheel.

Flywheel Brake Removal (if Installed)

1.

Unload the spring with a spring hook.

2.

Remove the cable.

3.

Disconnect the ignition kill wire.

4.

Remove the two

retain the brake assembly to the block of the engine.

See Figure

the

5/16"

40.

(if

installed)

rotation of the engine. The brake

is

pulled to both open

hex, washer head screws that

Muffler Operation

The muffler quiets exhaust noise by slowing the escape of

combustion gases while at the same time preventing

excessive back pressure. The muffler is of a dual chamber

design with the exhaust being discharged into the first

chamber and then through a series of holes into the

second chamber where the exhaust is discharged to the

atmosphere.

Muffler Removal

1.

Remove the

that retain the exhaust pipe to the engine.

2.

Remove the single

that retains the muffler bracket to the block of the

engine. See Figure

two

3/8"

hex, washer head cap screws

3/8"

hex, washer head cap screw

41.

Figure

Fuel lank Operation

See Section

Fuel lank Removal

Crimp the fuel hose with a pair of locking pliers.

2.

Remove the hose clamp on the carburetor end of the

hose.

CAUTI0N

in a container designed for gasoline and never smoke

while working around gasoline.

3.

Release the clamping pliers and drain the fuel into a

container designed to receive gasoline.

4.

Remove the two

(1-1/4"

2

on Fuel System, page

:

A

Avoid fire and explosion, store fuel

3/8"

long) retaining the fuel tank to the engine.

40

23.

hex, washer head screws

Figure

3.

Remove and discard the gasket between the exhaust

pipe and the engine.

Fill

Dipstick and Oil

Remove the two

retain the dipstick tube.

2.

Withdraw the tube from the block of the engine. The

tube is sealed with an

lube Removal

3/8'

41

hex, washer head screws that

"0"

ring. See Figure

42.

5.

The

75

micron fuel filter screen is an integral part of the

fuel tank and is not removable.

GTS

150

31

Figure

42

Engine

Page 37

Carburetor - Operation

See Section

Carburetor - Removal

1.

Note the position of the choke over-center spring

before removal. This will aid proper reinstallation. The

long hook end of the spring is attached to the carburetor shaft. Unhookthe choke over-center spring. See

Figure

1

-

Carburetor, page

43.

Figure

19.

43

lgnltion

1.

2.

3.

Coil

-

Removal

Note the routing of the ignition ground (kill) wire, this

will make reinstallation easier. Disconnect the ignition

ground wire from the terminal on the back of the

throttle bracket. See Figure

Disconnect the ignition coil high tension wire from the

spark plug.

Remove the

ignition coil. The coil may now be lifted away from the

engine. See Figure

two

5/16"

46.

45.

hex head screws retaining the

2.

Remove the

screws that retain the carburetor. See Figure

3.

During removal, rotate the body

unhook the throttle lever from the governor control

rod.

4.

The insulator/gasket may now be removed.

Ignition Coil

two

-

Operation

3/8”

hex, washer head shoulder

CARBURETOR

GASKET

Figure

44

of

the carburetor and

44.

IGNITION

Figure

Throttle Bracket - Removal

1.

Remove the

retain the front blower shroud bracket.

2.

Remove the

retain the throttle bracket to the engine block. See

Figure

47.

two

two

3/8"

3/8"

46

hex, washer head screws that

hex, washer head screws that

KILL

See Section

Engine

3

-

Ignition, page

25.

32

GTS

150

Page 38

Alternator Operation

2.

Remove the alternator.

Flywheel Removal

1.

Remove the

15/16"

starter cup. See Figure

hex

nut

retaining the flywheel

50.

The alternator is a single coil employing

1/2

wave rectification through the use of a diode built into the body

alternator. The alternator also uses a capacitor in parallel

with the output for electrical filtration. The diode can be

checked with a ohmmeter by alternately placing the posi-

tive and negative leads on the connections

See Figure

and block

,

Alternator Removal

1.

Remove the

retaining the alternator. See Figure

in

ALTERNATOR.

ASSEMBLY

.

.

48.

The diode should conduct in one direction

the other.

.

two

ALTERNATE

Figure

(if

5/16"

48

installed)

hex, washer head cap screws

+/-

49.

.

to

the diode.

of

the