Page 1

OHV GTS 140 ENGINE SERVICE MANUAL

Table of Contents – Page 1 of 3

PREFACE

1. GENE RAL INFORMATION

SAFETY INSTRUCTIONS

GENERAL SERVICE SAFETY INSTRUCTIONS

MODEL AND SERIAL NUMBERS

SPECIFICATIONS

SERVICE DATA

CARBURETOR

FASTENER TORQUE SPECIFICATION

SPECIAL TOOLS

2. MAINTENANCE

AIR CLEANER

CHANGING OIL

SPARK PLUG

VALVE LASH

GOVERNOR AND THROTTLE LINKAGE

IGNITION

FUEL SYSTEM

CARBURETOR

STORAGE

3. TROUBLESHOOTING AND TEST PROCEDURES

TROUBLESHOOTING CHART

CARBURETOR

REMOVAL--CARBURETOR

SERVICE--CARBURETOR

REASSEMBLY--CARBURETOR

GAS CAP

DISASSEMBLY

SERVICE

REASSEMBLY

FUEL TANK AND FILTER

DISASSEMBLY

SERVICE

REASSEMBLY

IGNITION

TESTING SPARK INTENSITY

TESTING KILL SWITCH OPERATION

BBC AND COMMERCIAL KILL SYSTE MS

ZONE START APPLICATIONS

REMOVAL--IGNITION

INSTALLATION--IGNITION

ELECTRIC STARTER AND ALTERN ATOR

Page 2

OHV GTS 140 ENGINE SERVICE MANUAL

Table of Contents – Page 2 of 3

3. TROUBLESHOOTING AND TEST PROCEDURES - Continued

TESTING--ELECTRIC STARTER

IF THE MOTOR TURNS:

IF THE MOTOR DOES NOT TURN:

TESTING--ALTERNATOR

REMOVAL--ELECTRIC STARTER

INSTALLATION--ELECTRIC STARTER

REMOVAL--ALTERNATOR

INSTALLATION--ALTERNATOR

RECOIL STARTER

REMOVAL AND DISASSEMBLY--RECOIL START ER

REPAIR--RECOIL STARTER

ROPE REPLACEMENT

SPRING REPLACEMENT

REASSEMBLY

4. ENGINE DISASSEMBLY, INSPECTION AND REASSEMBLY

DISASSEMBLY

RECOIL STARTER

FUEL TANK

AIR CLEANER

COOLING SHROUDS

MUFFLER

ELECTRIC STARTER

ALTERNATOR

IGNITION COIL

OIL FILL TUBE

THROTTLE CONTROL AND CARBURETOR

FLYWHEEL

BREATHER

CYLINDER HEAD ASSEMBLY

VALVES

OIL PUMP

CRANKCASE

GOVERNOR ASSEMBLY

CAMSHAFT

COMPRESSION RELEASE

PISTON AND CONNECTING ROD

INSPECTION AND RECONDITIONING

CRANKSHAFT

CONNECTING ROD

PISTON

CYLINDER

PISTON RINGS

VALVES

Page 3

OHV GTS 140 ENGINE SERVICE MANUAL

Table of Contents – Page 3 of 3

4. ENGINE DISASSEMBLY, INSPECTION AND REASSEMBLY - Continued

REASSEMBLY

PISTON, RINGS AND CONNECTING ROD

CAMSHAFT AND FOLLOWERS

GOVERNOR ASSEMBLY

CRANKCASE

OIL PUMP

VALVES

CYLINDER HEAD ASSEMBLY

BREATHER

FLYWHEEL

THROTTLE CONTROL AND CARBURETOR

OIL FILL TUBE

IGNITION COIL

ALTERNATOR COIL AND STARTER MOTOR

MUFFLER

MUFFLER AND COOLING SHROUD

AIR CLEANER

FUEL TANK

RECOIL STARTER

Page 4

Page 5

PREFACE

This Service and Overhaul Manual was written expressly for the TOR0

model VMFS and VMG6 Overhead Valve Engine.

The Toro Company has made every effort to make this service manual a

useful and lasting addition to every service facility. To assure proper and

effective service, and to provide optimum performance for the life of the

engine, you are urged to read this manual carefully.

It is not the purpose of this manual to teach component theory, but rather to

provide the mechanic with a working guideline of maintenance,

troubleshooting, test, repair and overhaul procedures.

The Tor0 Company reserves the right to change product specifications or

this manual without notice.

The Toro Company gratefully acknowledges the assistance of the Suzuki

Motor Company in the production of this manual.

COPYRIGHT

The

MINNEAPOLIS, MN

Toro

ALL

RIGHTS

Company

55420

RESERVED

1986

-

U.S.A.

Page 6

TABLE

1

GENERAL INFORMATION PAGE

Safety Instructions 1

General Service Safety Instructions 1

Model and Serial Numbers

Specifications 2

Service Data 3

Special Tools

2

MAINTENANCE

Air Cleaner

Consumer Air Cleaner Maintenance

Commercial Air Cleaner Maintenance

Changing Oil 7

Spark Plug 7

ValveLash 7

Governor and Throttle Linkage 7

Ignition 8

Fuel System 8

Carburetor 9

Storage 9

3

TROUBLESHOOTING AND TEST PROCEDURES

Preliminary Troubleshooting 10

Troubleshooting Chart 11

Carburetor 12

Removal 12

Service 13

Reassembly 13

Gas Cap 14

Disassembly 14

Service 14

Reassembly 14

Fuel Tank

Disassembly 14

Service 14

Reassembly 15

Ignition 15

Testing 15

Removal 16

Installation 17

Electric Starter

Testing Starter 17

Testing Alternator 18

Removal Starter 18

Installation Starter 18

Removal Alternator 19

Installation Alternator 19

Recoil Starter 19

Removal and Disassembly 19

Repair 21

Reassembly 21

&

Filter 14

&

Alternator 17

OF

CONTENTS

1

5

6

6

6

4

ENGINE DISASSEMBLY. INSPECTION AND REASSEMBLY

Disassembly 22

Recoil Starter 22

Fuel Tank 22

Aircleaner 22

Cooling Shrouds 22

L--

Page 7

Muffler

Electric Starter

Alternator

Ignition Coil

Oil Fill Tube 22

Throttle Control and Carburetor 23

Flywheel 23

Breather 23

Cylinder Head Assembly 24

Valves 25

Oil Pump 25

Crankcase 26

Governor Assembly 26

Camshaft 26

Compression Release 27

Piston and Connecting Rod 27

Inspection and Reconditioning 28

Crankshaft 28

Connecting Rod 28

Piston 29

Cylinder 29

Piston Rings 29

Valves 29

Reassembly 31

Piston. Rings and Connecting Rod 31

Camshaft and Followers 32

Governor Assembly 32

Crankcase 32

Oil Pump 32

Valves 33

Cylinder Head Assembly 33

Breather 34

Flywheel 34

Throttle Control and Carburetor 34

Oil Fill Tube 35

Ignition Coil 35

Alternator Coil and Starter Motor 35

Muffler 35

Muffler and Cooling Shroud 36

Air Cleaner 36

Fuel Tank 36

Recoil Starter 36

Page 8

SAFETY INSTRUCTIONS

A

PERSONALSAFETY INSTRUCTION

Read the instruction because

do with safety. Failure to comply with

the instruction may result in personal

injury.

This manual is intended to be a service and

repair manual only. The safety instructions

provided in this manual are for the trouble-

shooting and service of the product only.

Individual owners manuals will contain safety

information for the operation of products that

are fitted with the engine described in this

manual.

Operators manuals with complete operational

safety instructions are available through:

The Toro Company

Publications Department

81 11 Lyndale Avenue South

Minneapolis, MN 55420 U.S.A.

Be sure to include the model and serial number

of your machine.

If

you have any questions concerning this

Repair Manual, please contact:

The Tor0 Company

Service Department

81 11 Lyndale Avenue South

Minneapolis,

GENERAL SERVICE SAFETY INSTRUCTIONS

1.

Use extreme care when handling any gasoline and oil that may be in the engine.

Gasoline and oil are flammable and should

not be exposed to flame or spark. Do not

smoke while handling any fuel or oil.

2. Drain and/or store gasoline and oil only in

approved containers.

3.

Wipe up any spilled gasoline or oil.

4. Do not run an engine in a confined area

without adequate ventilation. Exhaust

fumes are hazardous and could possibly be

deadly.

5.

Disconnect and ground the spark plug high

tension wire before performing any engine

service. This will prevent accidental starting

of the engine.

6.

If the engine must be kept running to

perform maintenance

This safety symbol means

WARNING or CAUTION-

it

has to

MN

55420 U.S.A.

or

making adjust-

ments, keep clear of the PTO shaft, cutting

blades and other moving parts.

7.

Do

not overspeed the engine by changing

the governor settings. Maximum engine

speed with no load is listed in the engine

specifications on page

8. The engine must be stopped before checking the oil or adding oil to the crankcase.

9.

Do

not touch the engine muffler or guard

while the engine is running or soon after it

has stopped. These areas could be hot

enough to cause a burn.

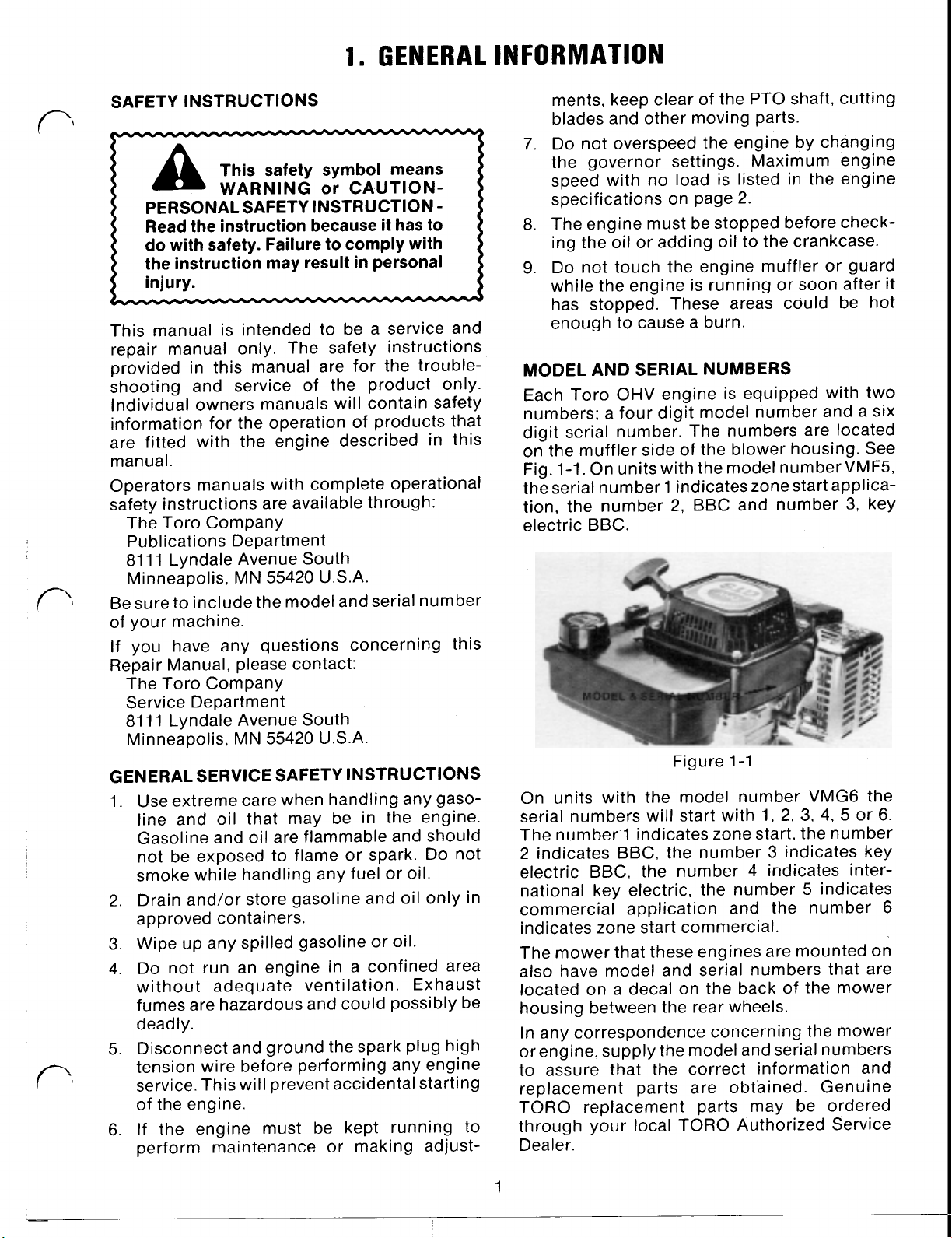

MODEL AND SERIAL NUMBERS

Each Toro OHV engine is equipped with two

numbers: a four digit model number and a six

digit serial number. The numbers are located

on the muffler side of the blower housing. See

Fig. 1-1. On units with the model number VMF5,

the serial number 1 indicates zone start application, the number

electric BBC.

On units with the model number VMG6 the

serial numbers will start with 1,

The number.1 indicates zone start, the number

2 indicates BBC, the number

electric BBC, the number 4 indicates international key electric, the number

commercial application and the number

indicates zone start commercial.

The mower that these engines are mounted on

also have model and serial numbers that are

located on a decal on the back of the mower

housing between the rear wheels.

In any correspondence concerning the mower

or engine, supply the model and serial numbers

to assure that the correct information and

replacement parts are obtained. Genuine

TORO replacement parts may be ordered

through your local TORO Authorized Service

Dealer.

2,

Figure 1-1

2.

BBC and number

2,

3,

3

indicates key

5

3,

key

4, 5 or 6.

indicates

6

1

Page 9

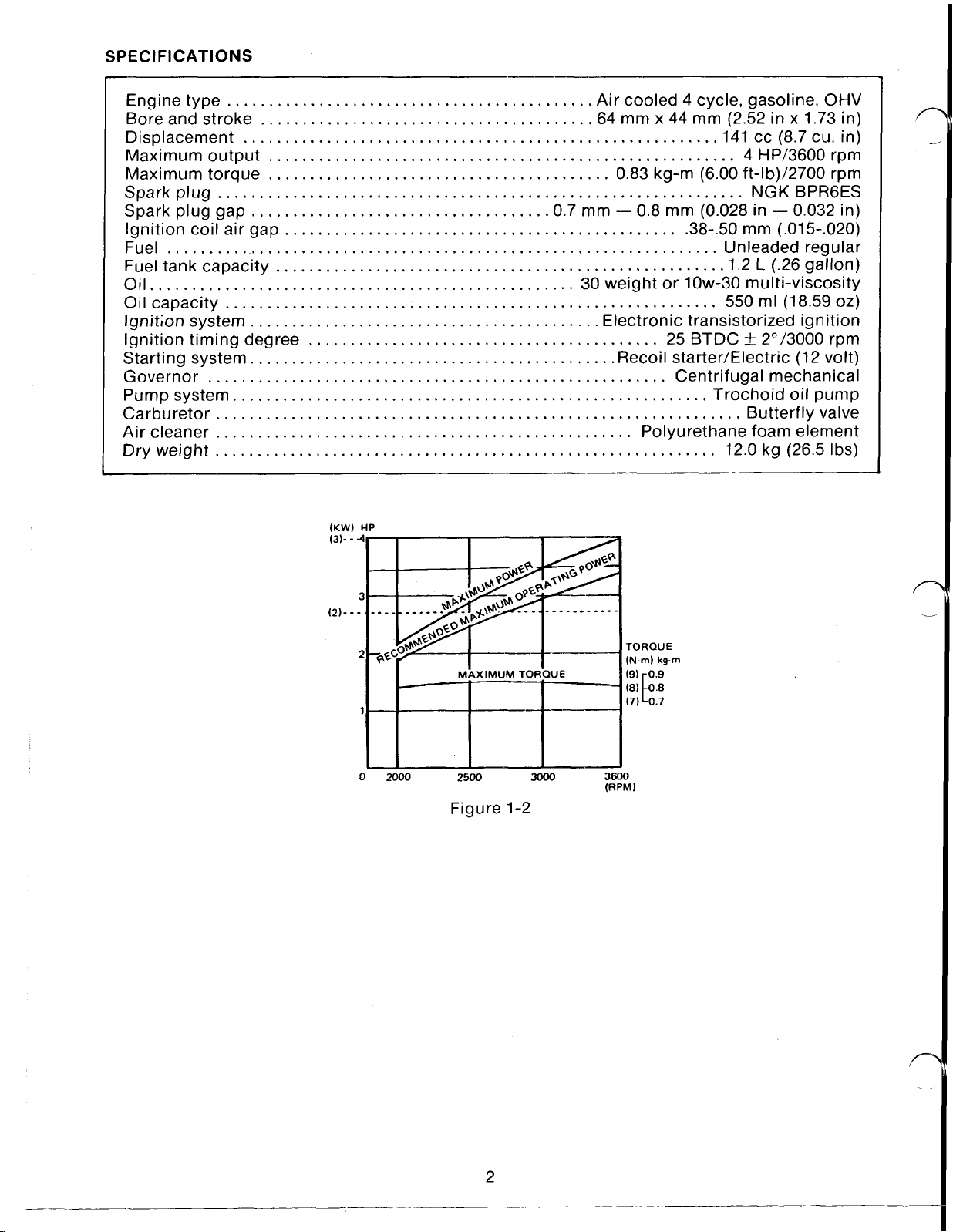

SPECIFICATIONS

Engine type Air cooled 4 cycle, gasoline,

Bore and stroke .64 mm

x

44 mm (2.52 in x 1.73 in)

OHV

Displacement 141 cc (8.7 cu. in)

Maximum output 4 HP/3600 rpm

Maximum torque 0.83 kg-m (6.00 ft-lb)/2700 rpm

Spark plug NGK BPR6ES

Spark plug gap .0.7 mm 0.8 mm (0.028 in 0.032 in)

Ignition coil air gap.. .38-50 mm (.015-,020)

Fuel Unleaded regular

Fuel tank capacity .1.2

Oil..

Oil capacity

30

weight or low-30 multi-viscosity

L

550

ml (18.59

(.26 gallon)

0Z)

Ignition system Electronic transistorized ignition

Ignition timing degree 25 BTDC rpm

Starting system. .Recoil starter/Electric (12 volt)

Governor Centrifugal mechanical

Pump system.. Trochoid oil pump

Carburetor Butterfly valve

Air cleaner Polyurethane foam element

Dry weight 12.0 kg (26.5 Ibs)

(KW)

HP

3

2

0

2000

2500

Figure 1-2

3000

3600

RPM)

TORQUE

(Nm)

kgrn

2

Page 10

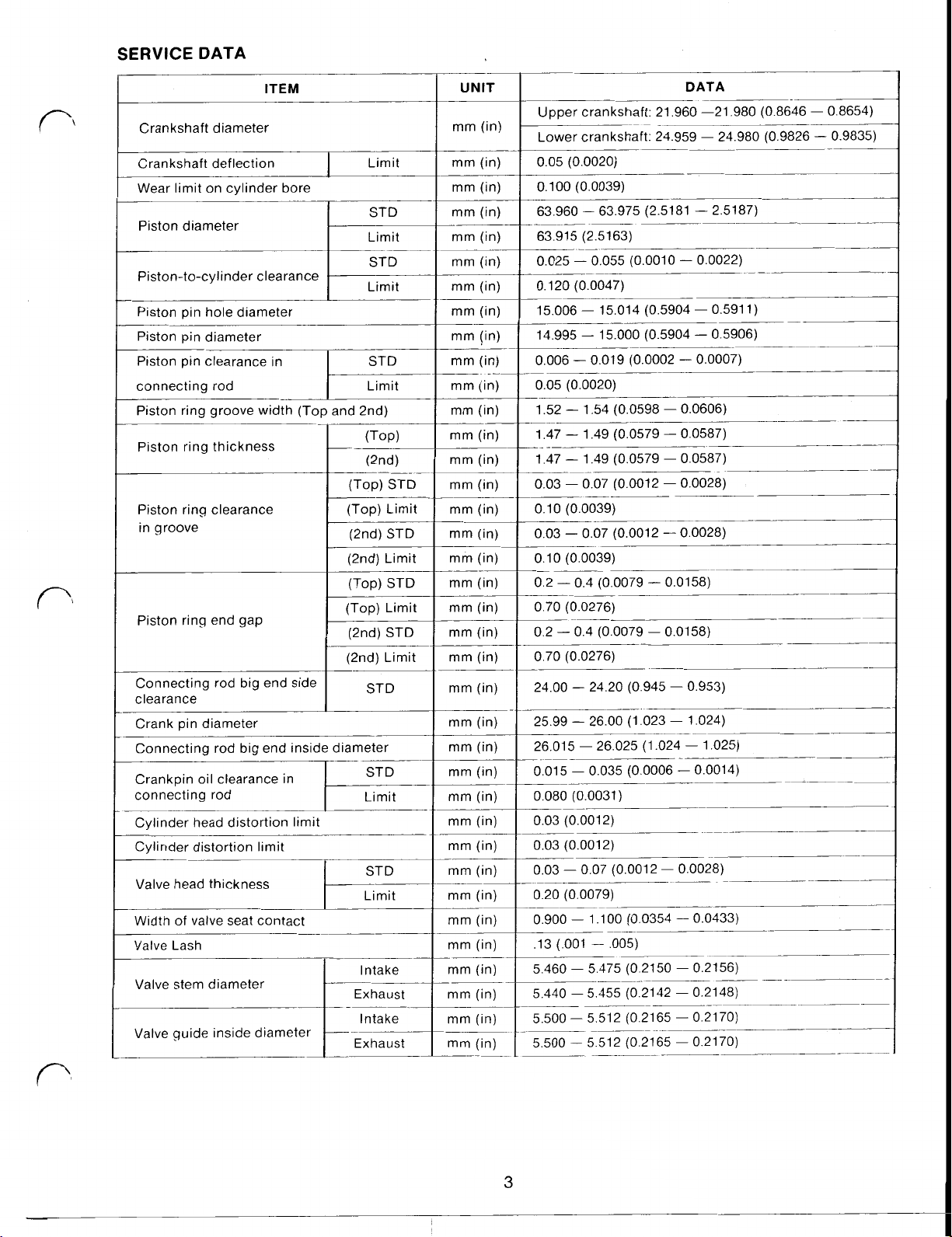

SERVICE

DATA

ITEM

Crankshaft diameter

Crankshaft deflection Limit

Wear limit on cylinder bore

Piston diameter

Piston-to-cylinder clearance

Piston pin hole diameter

Piston pin diameter

Piston pin clearance in

connecting rod Limit

Piston ring groove width (Top and 2nd)

Piston ring thickness

(Top) STD

_____-

Piston ring clearance

in groove

Piston ring end gap

Connecting rod big end side

clearance

Crank pin diameter

Connecting rod big end inside diameter

Crankpin oil clearance in

connecting rod Limit

__-

Cylinder head distortion limit

Cylinder distortion limit

Valve head thickness

Width of valve seat contact

Valve Lash

Valve stem diameter

Valve guide inside diameter

(Top) Limit

(2nd) STD

(2nd) Limit

(Top) STD

(Top) Limit

(2nd) STD

(2nd) Limit

I

Intake

_-

Exhaust

Intake

Exhaust-

STD

Limit

STD

Limit

(TOP)

(2nd)

ST D

STD

___-

STD

UNIT

mm (in!

____-

mm (in)

mm (in)

mm (in)

____-

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

~-

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

~-

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

____-

mm (in)

mm (in)

mm (in)

mm

(in)

DATA

Upper crankshaft: 21.960 -21.980 (0.8646 0.8654)

Lower crankshaft: 24.959 24.980 (0.9826 0.9835)

0.05

(0.0020)

0.100 (0.0039)

63.960 63.975 (2.5181 2.5187)

63.915 (2.5163)

0.055

0.025

0.120 (0.0047)

15.006 15.014 (0.5904 0.591 1)

14.995 15.000 (0.5904 0.5906)

0.006 0.019 (0.0002

0.05

(0.0020)

1.52 1.54 (0.0598 0.0606)

1.47 1.49 (0.0579 0.0587)

1.47 1.49 (0.0579 0.0587)

0.03 0.07 (0.0012 0.0028)

0.10 (0.0039)

0.03 0.07 (0.0012 0.0028)

0.10 (0.0039)

0.2 0.4 (0.0079 0.0158)

0.70 (0.0276)

0.2 0.4 (0.0079

0.70 (0.0276)

24.00 24.20 (0.945 0.953)

25.99 26.00 (1.023 1.024)

26.015 26.025 (1.024 1.025)

0.01

5

0.080 (0.0031)

0.03 (0.0012)

0.03 (0.0012)

0.03

0.07

0.20 (0.0079)

0.900 1.1

.13 (.001

5.460 5.475 (0.2150 0.2156)

5.440 5.455 (0.2142 0.2148)

5.500

5.500

(0.0010 0.0022)

0.0007)

0.0158)

0.035 (0.0006 0.0014)

(0.001 2 0.0028)

00

(0.0354 0.0433)

,005)

5.512 (0.2165 0.2170)

5.51 2 (0.21 65 0.21 70)

3

Page 11

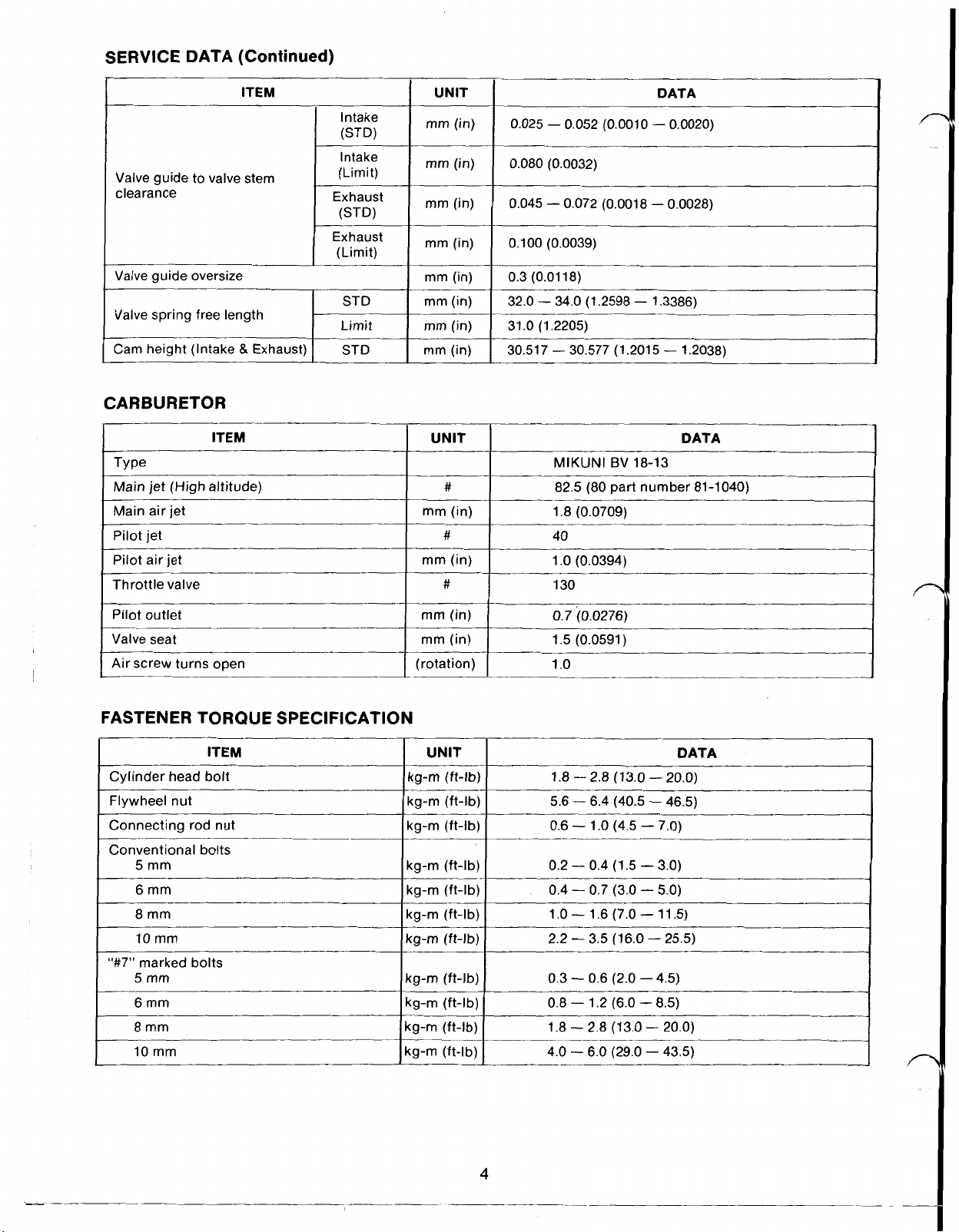

SERVICE DATA (Continued)

ITEM

Intake

(STD)

Intake

Valve guide

clearance Exhaust

Valve guide oversize

Valve spring free length

to

valve stem

(Limit)

(STD)

Exhaust

(Limit)

Limit

CARBURETOR

ITEM

TYPE

Main jet (High altitude)

Main air jet

Pilot jet

Throttle valve

UNIT

mm(in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

mm (in)

0.025 0.052 (0.0010 0.0020)

0.080 (0.0032)

0.045 0.072 (0.0018 0.0028)

0.100 (0.0039)

0.3

(0.01 18)

32.0 34.0 (1.2598 1.3386)

.O

(1.2205)

31

30.51 7 30.577 (1.201

UNIT

#

mm (in)

#

mm (in) Pilot air jet

#

MlKUNl BV

82.5 (80

part number

1.8 (0.0709)

40

1

.O

(0.0394)

130

DATA

5

18-13

1.2038)

DATA

81-1040)

Pilot outlet

Valve seat

Air screw turns open

FASTENER TORQUE SPECIFICATION

ITEM

Cylinder head bolt

Flywheel nut

Connecting

Conventional bolts

5

6

8

10

"#7"

marked bolts

5

6

8

10

mm

mm

mm

mm

mm

mm

mm

mm

rod

nut

kg-m (ft-lb:

kg-m (ft-lb:

kg-m (ft-lb:

kg-m (ft-lb)

kg-m (ft-lb)

kg-m (ft-lb)

kg-m (ft-lb)

kg-m (ft-lb)

kg-m (ft-lb)

kg-m (ft-lb)

kg-m (ft-lb)

mm (in)

mm (in)

(rotation)

UNIT

0.7

(0.0276)l

1.5 (0.0591)

1

.o

DATA

1.8 2.8 (13.0 20.0)

5.6 6.4

0.6 1

0.2 0.4 (1.5

0.4 0.7 (3.0

1

.O

2.2

(40.5

.O

(4.5

1.6

(7.0

3.5

(16.0 25.5)

46.5)

7.0)

3.0)

5.0)

11.5)

0.3 0.6 (2.0 4.5)

0.8 1.2 (6.0

8.5)

1.8 2.8 (13.0 20.0)

4.0 6.0 (29.0 43.5)

I

I

4

Page 12

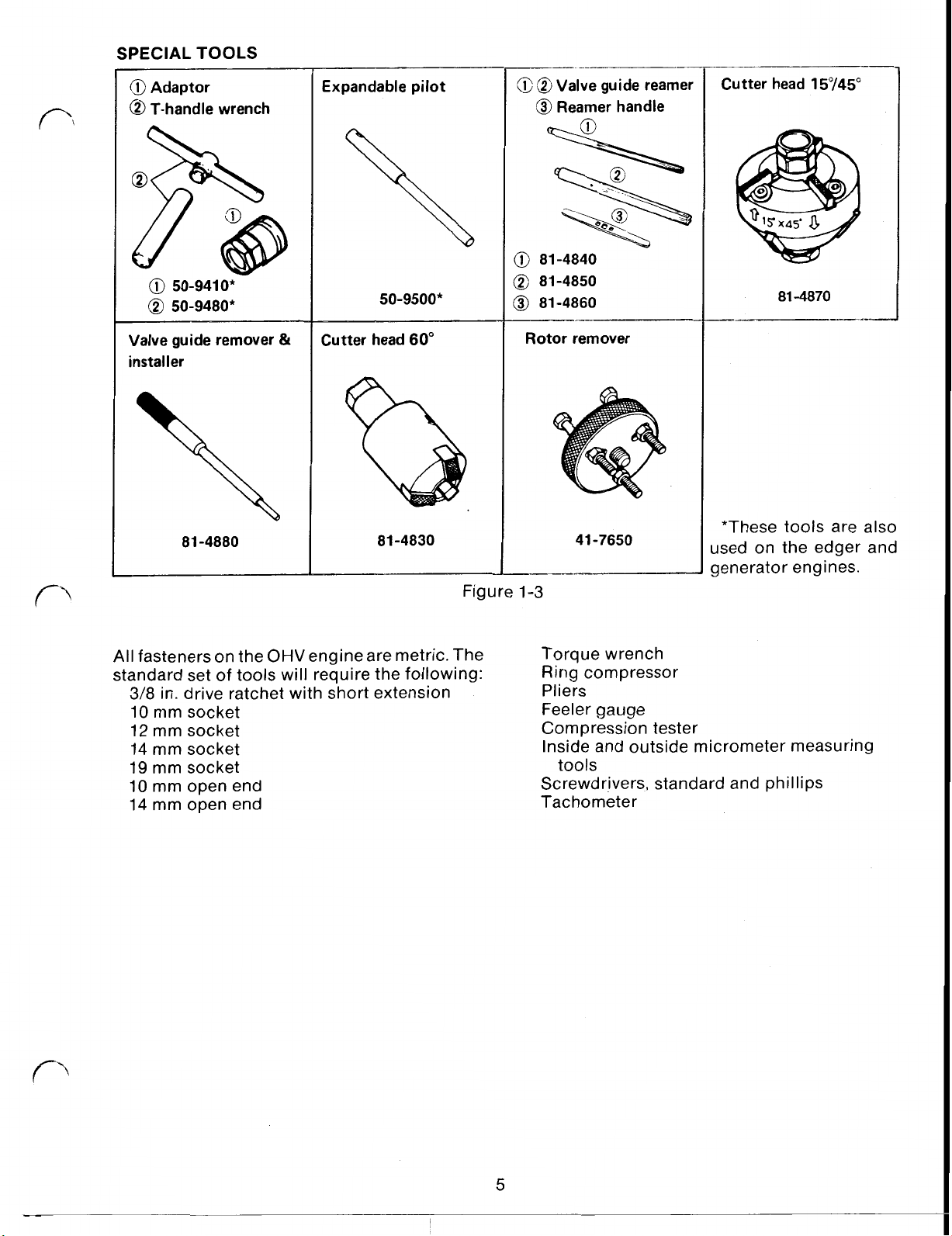

SPECIAL TOOLS

@

Adaptor

T-handle wrench

50-9410*

50-9480*

Valve guide remover

installer

81 -4880

Expandable pilot

Cutter

&

50-9500*

head

60"

81 -4830

Figure

Valve guide reamer

Reamer handle

A

81-4840

81-4850

81-4860

Rotor remover

41 -7650

1-3

Cutter

head

81

-4870

*These tools are also

used on the edger and

generator engines.

I

All

fasteners on the

standard set

3/8

in. drive ratchet with short extension

10

mm socket

12

mm socket

14

mm socket

19

mm socket

10

mm open end

14

mm open end

OHV

engine are metric. The

of

tools will require the following:

Torque wrench

Ring compressor

Pliers

Feeler gauge

Compression tester

Inside and outside micrometer measuring

tools

Screwdrivers, standard and phillips

Tachometer

5

Page 13

2.

MAINTENANCE

AIR CLEANER

The consumer air cleaner should be serviced

every

air cleaner is of a two part design: the foam

pre-cleaner should be serviced every 25 hours

and the paper element every

frequent service for both air cleaners may be

required in dusty or dirty conditions.

Consumer Air Cleaner Maintenance

1.

2. Clean loose debris from the air cleaner

3.

25

hours of engine use. The commercial

50

hours. More

Stop the engine and pull the high tension

wire off the spark plug.

body.

Push

in

the locking tabs and lift off the air

2-1.

cleaner cover. See Fig.

Clean the cover.

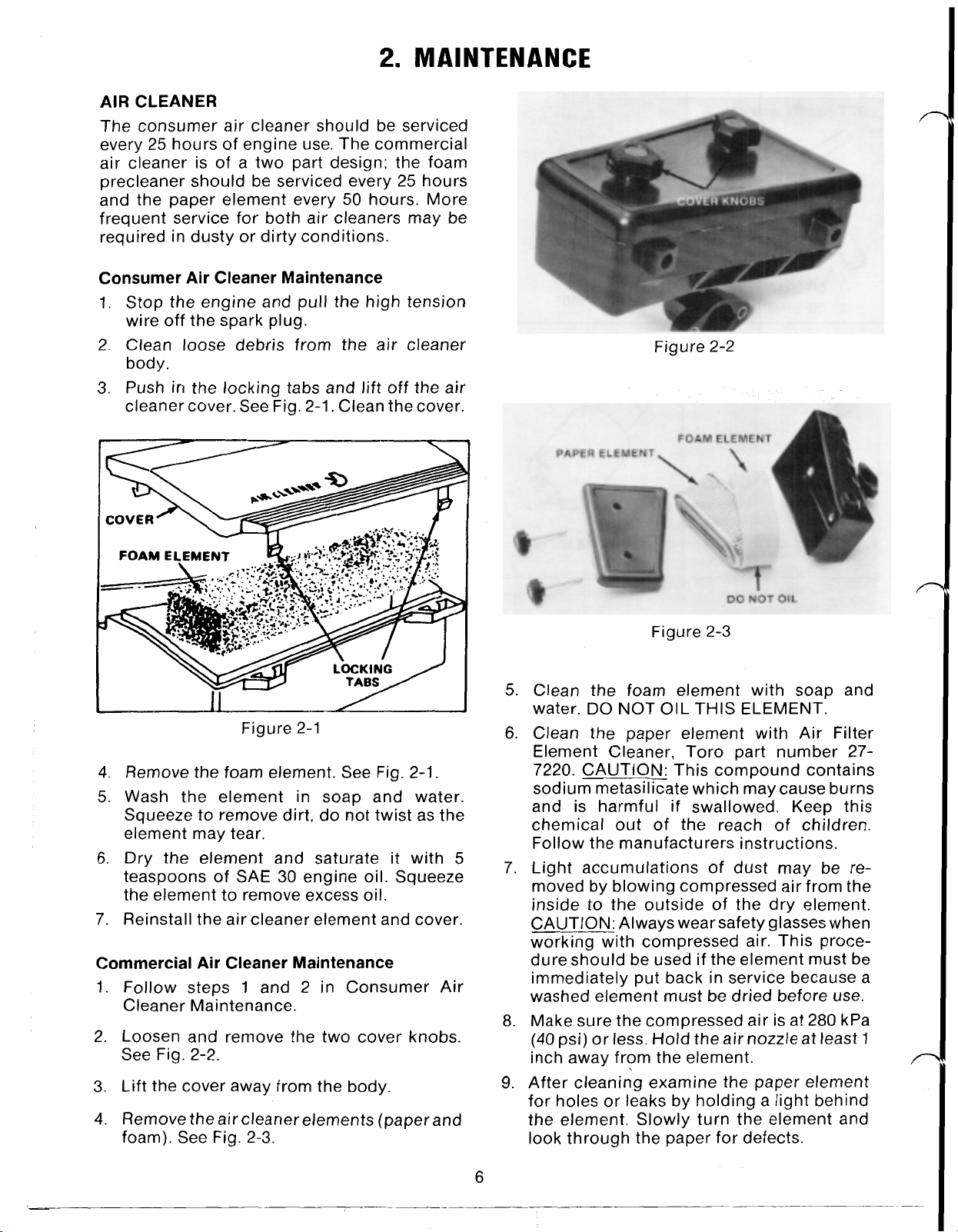

Figure 2-2

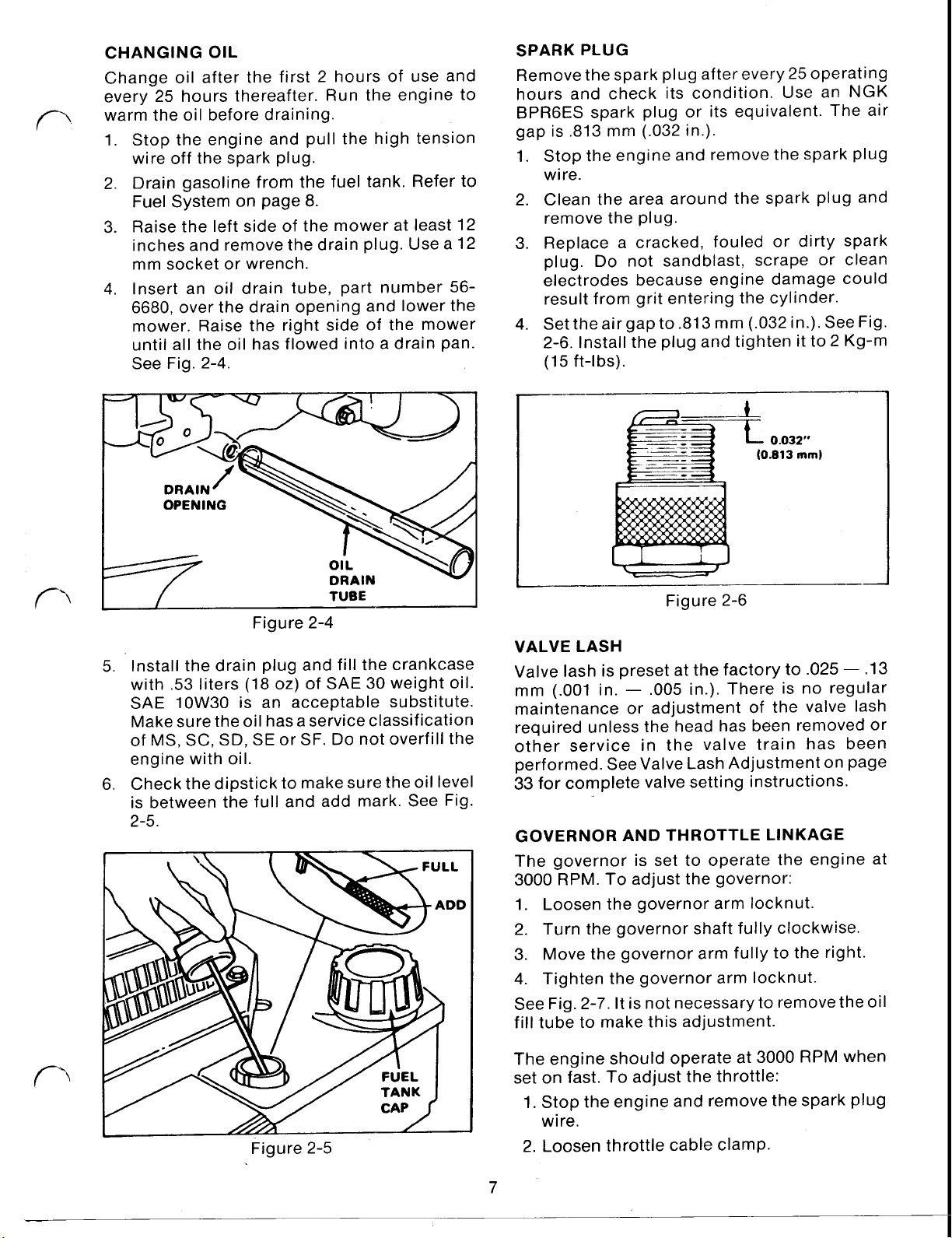

PAPER ELEMENT

Figure 2-1

4.

Remove the foam element. See Fig.

5.

Wash the element in soap and water.

Squeeze

element may tear.

6.

Dry the element and saturate it with

teaspoons of SAE

the element

7. Reinstall the air cleaner element and cover.

Commercial Air Cleaner Maintenance

1.

Follow steps

Cleaner Maintenance.

2. Loosen and remove the two cover knobs.

See Fig. 2-2.

3.

Lift the cover away from the body.

4.

Remove the air cleaner elements (paper and

foam). See Fig. 2-3.

to

remove dirt, do not twist as the

30

engine oil. Squeeze

to

remove excess oil.

1

and 2

in

Consumer Air

2-1.

5

Figure

5.

Clean the foam element with soap and

DO

water.

6.

Clean the paper element with Air Filter

Element Cleaner, Toro part number 27-

7220. CAUTION: This compound contains

sodium metasilicate which may cause burns

and is harmful

chemical

Follow the manufacturers instructions.

7.

Light accumulations

moved by blowing compressed air from the

inside

CAUTION: Always wear safety glasses when

working with compressed air. This procedure should be used if the element must be

immediately put back in service because a

washed element must be dried before use.

Make sure the compressed air is at 280 kPa

8.

(40 psi) or less. Hold the air nozzle at least

inch away from the element.

After cleaning examine the paper element

9.

for holes or leaks by holding a light behind

the element. Slowly turn the element and

look through the paper for defects.

NOT

out

of the reach

to

the outside of the dry element.

2-3

OIL

THIS

if

swallowed. Keep this

ELEMENT.

of

dust may be re-

of

children.

1

6

Page 14

CHANGING OIL

2

Change oil after the first

hours of use and

every 25 hours thereafter. Run the engine to

warm the oil before draining.

1. Stop the engine and pull the high tension

wire off the spark plug.

2. Drain gasoline from the fuel tank. Refer

Fuel System on page

8.

to

3. Raise the left side of the mower at least 12

inches and remove the drain plug. Use a 12

mm socket or wrench.

4. Insert an oil drain tube, part number 56-

6680, over the drain opening and lower the

mower. Raise the right side of the mower

until all the oil has flowed into a drain pan.

See Fig. 2-4.

SPARK PLUG

Remove the spark plug after every

25

operating

hours and check its condition. Use an NGK

BPR6ES spark plug or its equivalent. The air

gap is ,813 mm (.032 in.).

1. Stop the engine and remove the spark plug

wire.

2. Clean the area around the spark plug and

remove the plug.

3.

Replace a cracked, fouled or dirty spark

Do

plug.

not sandblast, scrape or clean

electrodes because engine damage could

result from grit entering the cylinder.

4.

Set the air gap to .813 mm (.032 in.). See Fig.

2-6. Install the plug and tighten it to

(1

5

ft-l bs).

0.032"

(0.813

mm)

2

Kg-m

I

01

L

DRAIN

I

TUBE

Figure 2-4

5.

Install the drain plug and fill the crankcase

with .53 liters (18 oz) of SAE

30

weight oil.

SAE 10W30 is an acceptable substitute.

Make sure the oil has a service classification

of

MS,

SC,

SD,

SE or SF.

Do

not overfill the

engine with oil.

6. Check the dipstick to make sure the oil level

is between the full and add mark. See Fig.

2-5.

I

Figure 2-6

VALVE LASH

Valve lash is preset at the factory to

mm (.001 in.

.005

in.). There is no regular

.025

maintenance or adjustment of the valve lash

required unless the head has been removed or

other service in the valve train has been

performed. See Valve Lash Adjustment on page

33

for complete valve setting instructions.

GOVERNOR AND THROTTLE LINKAGE

The governor is set to operate the engine at

3000

RPM. To adjust the governor:

1. Loosen the governor arm locknut.

2. Turn the governor shaft fully clockwise.

3.

Move the governor arm fully to the right.

4. Tighten the governor arm locknut.

See Fig. 2-7. It is not necessary to remove the

fill tube to make this adjustment.

.13

oil

Figure 2-5

The engine should operate at 3000 RPM when

set on fast. To adjust the throttle:

1.

Stop the engine and remove the spark plug

wire.

2. Loosen throttle cable clamp.

7

Page 15

Figure 2-7

3.

Align the holes

throttle lever.

4.

Insert a tight fitting pin; e.g. 1/8 in. drill bit.

5.

Move the throttle control on the handle

“fast” and tighten the cable clamp screw.

6.

Back out the upper screw until only a few

threads remain in the throttle lever.

7.

Install the plug wire and start the engine.

8. Using

engine speed

9.

Now turn the upper screw until it

contacts the throttle lever tang (a maximum

gap of ,020 in. is acceptable).

10.

Remove the alignment pin.

11.

On BBC engines, set the throttle control on

the handle in the “stop” position. Bend the

grounding tang until

throttle lever. See Fig. 2-8.

only

in

the throttle bracket and

the lower screw, adjust the

to

3000 RPM.

just

barely

it

just contacts the

to

IGNITION

The

OHV

engine uses a solid state ignition

system with timing fixed at

2

degrees at 3000 RPM. Ignition timing is not

adjustable. However, ignition timing may

change

flywheel key has sheared. The engine may

continue

formance. Under these conditions the timing

will advance, making starting and running

difficult. The coil

mm (.015 in.).

FUEL SYSTEM

The fuel tank has a capacity of 1.21

should be drained of fuel before changing oil

and at the end of each season. To drain the fuel:

1.

2. Use a pump or syphon to transfer the

!

CAUTION: Gasoline is highly flammable, handle

flame or spark while handling gasoline.

The fuel system is equipped with an 84 micron

in-line fuel filter. See Fig. 2-9.

occurs, this filter should be examined for

contamination. There is no “in tank” filter on

this engine.

if

a blade impact has occurred and the

to

run with a degradation

to

flywheel air gap is set at .38

Pull off the spark plug wire

gasoline into a clean gasoline container.

CAUTION: Gasoline

flammable, handle

Do

not smoke

spark while handling gasoline.

it

carefully.

or

allow any open flame or

Do

not smoke or allow any open

25

degrees BTDC

L

(44

is

highly

it

carefully.

If

poor running

in

oz)

per-

and

Governor and throttle adjustments should be

made on an as needed basis only.

Throttle

Control

Figure 2-8

Assembly

Figure

The fuel tank cap should be periodically

examined for proper venting. The cap is fitted

with a sealing disc but cannot be disassembled.

See Fig

2-10.

2-9

Page 16

CARBURETOR

The

OHV

engine is equipped with a Mikuni

BV

18-1 3 float bowl type Carburetor. The standard

main jet is a number 82.5. This number is

stamped in the base of the jet. The only

adjustment on the carburetor is the pilot system

pilot screw. The pilot screw should be set one

turn open. See. Fig. 2-1

1.

This will have the

most effect at idle or low speed with no load on

the engine.

PILOT

ONE

SCREW

TURN

OPEN

inlet needle with a

stainless

steel tip. The needle

is replaceable.

The carburetor is also fitted with a bowl drain

screw that can be used to drain fuel out of the

bowl after the tank is drained. See Fig. 2-12.

Open the screw and drain the fuel into a

suitable container.

Figure 2-12

STORAGE

To insure long engine life and easy engine

starting, it is important to follow these storage

procedures at the end

1.

Drain gasoline from the tank. Refer to Fuel

System

2.

Drain gasoline from the carburetor bowl.

Refer

3.

Drain the engine oil; refer

on

on

page

to

Carburetor Maintenance above.

page

7.

of

each season:

8.

to

Changing Oil

PlLO

Figure 2-1 1

The carburetor on theVMF5 model uses a brass

fuel inlet seat (not replaceable) and an inlet

needle with a Viton tip. The needle is replace-

able. The carburetor on the

VMG6

model uses a

Viton fuel inlet seat (not replaceable) and an

9

4.

Remove the spark plug and pour

spoons of

SAE 30

or 1OW-30 oil into the

cylinder. Pull the starter rope slowly to coat

the inside

of

the cylinder. Install the spark

plug and tighten it to 2.0 kg-m (15 ft-lbs).

5.

Service the air cleaner; refer to Air Cleaner

Maintenance on page

6.

Clean dirt from all areas of the engine.

7.

Tighten all nuts, bolts and screws.

8.

Refill the crankcase with oil; refer to

Changing Oil on page

6.

7.

2

table-

Page 17

3.

TROUBLESHOOTING AND TEST PROCEDURES

This section has been divided into the troubleshooting and service of individual systems.

To

determine what system needs to be evaluated, some preliminary troubleshooting is necessary.

These are checks that can be made with little or no disassembly and would normally be made with

the customer or owner present.

The following form is useful in documenting engine conditions during preliminary troubleshooting:

PRELIMINARY TROUBLESHOOTING

PRODUCT

MODEL/SERIAL

ENGINE MODEL

ENGINE SERIAL

DISTRIBUTORp- DEALER NAME

EVALUATOR DEALER CONTACT/PHONE

PRE-EVALUATION INFORMATION

Purchase Date Date Failed How Used? Residential Commercial

Fuel Mix: Ratio OiVBrand Gasoline/Brand

to

Symptoms Prior

Failure?

~___.-

CUSTOMER NAME

ADDRESS

PHONE

Engine Compressions? N/A---. PSI ___Compression Specification

VISUAL ANALYSIS

COOLING FINS: CARBURETOR: FUEL CAP: MUFFLER/EXHAUST PORTS:

Clean Clean- Vented Clean-- CarbonedObstructed Contaminated Clogged CRANKCASE: Clean

AIR CLEANER ASM: Comments Distorted Contaminated Burned-

Clean FUEL FILTER: SPARK PLUG: Clean- METAL DISCOLORATION?

Dirty Clean Carboned Fouled- NO---.-Damaged Clogged Type Yes

PSI

10

Page 18

TROUBLESHOOTING

CHART

The information gathered in preliminary troubleshooting can now be used with the following

troubleshooting chart to determine individual systems

PROBLEM

Engine does not St;

Engine starts hard

or loses power.

Engine operates

eratically.

Engine idles poorly.

Engine skips at

high speed.

Engine overheats.

1.

2.

3.

4.

5.

6.

7.

8.

9. Valves not closing.

1.

2.

3.

1.

2.

3.

1.

2.

3.

4.

~ ~~

1.

1.

2.

3.

4.

POSSIBLE CAUSES

~____________.

Throttle not in CHOKE position.

Gas tank is empty.

Air cleaner element is

dirty.

Spark plug is loose.

Spark plug wire is loose or

disconnected from spark plug.

Spark plug gap is incorrect.

Spark plug is defective

Carburetor is flooded with gasoline.

Dirt, water or stale gas in fuel tank

Vent hole in fuel tank cap is plugged.

Air cleaner is dirty.

Spark plug is defective.

Spark plug gapped incorrectly.

Air cleaner is dirty.

~

Air cleaner is dirty.

Oil level in crankcase is low.

Air slots in engine shroud are plugged.

Cooling fins and air passages under

engine blower housing are plugged.

Air gap between electrodes of spark

plug

is too close.

Cooling air flow is restricted

Oil

level in crankcase is low.

Incorrect spark plug.

Low oil level.

to

be serviced.

_.___~~___~___

~____

~-

1.

2.

3.

4.

5.

6.

7.

8. Remove air cleaner element and pull

9. Check valve lash. See page

1.

2.

3.

_____~____--~-___

1.

2.

3.

____

1.

2.

3.

4.

and air passages.

1.

Set air gap

See page

_~___

1.

Remove any obstruction from

shroud, blower housing, air passages,

and cooling fins on engine.

2.

Add

3.

Install new, correctly gapped plug.

See page

1.

Change or add oil. Inspect for engine

damage. See page

CORRECTIVE ACTION

Move throttle to CHOKE.

Fill fuel tank with gasoline.

Clean air cleaner element.

See page

Tighten spark plug to proper

specification. See page

Install spark plug wire on spark plug.

Set air gap to proper specification.

See page

Install new, correctly gapped plug.

See page

starter rope continuously until

carburetor clears itself and engine

starts. When engine starts, stop it and

install air cleaner element. See

page

Drain gas and clean fuel tank. Fill

tank with clean, fresh gasoline. See

page

Clean or replace fuel tank cap. See

page 8-9.

Clean the air cleaner element. See

page

Install new, correctly gapped plug.

See page

Set air gap to proper specification.

See page

Clean the air cleaner element. See

page

Clean the air cleaner element. See

page

Add

Remove obstruction from slots.

Remove obstruction from cooling fins

6.

7.

7.

6.

8.

6.

7.

7.

6.

6.

oil

to crankcase. See page

to

proper specification.

7.

_~

oil

to crankcase. See page

7.

__

7.

7.

____~___

______

33.

7.

slots

7.

in

11

Page 19

CARBURETOR

Removal

1.

System page 8. The fuel tank is held in place

with two screws and is removed by pulling it

straight up. Drain the carburetor fuel bowl

and disconnect the fuel hose from the

carburetor. See Fig.

-

Carburetor

Drain and remove the fuel tank; refer to Fuel

3-1.

Figure 3-1

rod

to

allow it to be unhooked after the

carburetor has been removed.

Figure 3-3

5.

The bowl of the carburetor may be removed

by unscrewing the retaining nut on the

bottom of the bowl. See Fig. 3-4. The float

and spacer (that limits float drop) are visible

in this photograph.

2. Remove the single screw retaining the air

cleaner and dipstick tube and the two nuts

retaining the air cleaner to the carburetor.

See Fig.

the carburetor. Remove the breather hose

from the fitting on the air cleaner.

3. Lift the choke rod off the Carburetor. The

rod has a

the body of the air cleaner. See Fig. 3-3.

Please note the position of the gasket

between the air cleaner and carburetor. The

raised rib on the metal gasket should face

the air cleaner.

4.

The carburetor may be pulled off the studs.

There is enough travel in the throttle control

3-2.

Pull the air cleaner away from

Figure 3-2

90"

bend as it is held

in

place by

Figure 3-4

6.

The standard main jet is a #82.5 and is

equipped with a spacer/washer. The float

and inlet needle may be removed by pulling

out the float hinge pin. See Fig. 3-5. Please

of

note: one end

slightly. The pin must be removed from this

end.

INLET NEEDLE

the hinge pin is flattened

Figure 3-5

Page 20

7. The pilot jet may be removed next. The pilot

jet is a

#40

and can be cleaned or replaced.

Fuel flows through the small opening in the

end of the jet and air enters through the

holes in the side. The opening on the top

has no function as it is plugged.

The pilot screw controls air in the pilot

circuit. It should be open one full turn. See

Fig. 3-6.

Figure 3-6

8.

Carburetor disassembly is completed by

removing the choke and throttle shafts and

is

the main nozzle. The bowl gasket

also

replaceable and should be removed prior to

service or cleaning of the carburetor. See

Fig. 3-7. To withdraw the choke and throttle

shaft, the choke and throttle plates must be

removed. Each plate is retained with two

screws.

Service Carburetor

The metallic body of the carburetor may be

cleaned in carburetor cleaner. Plastic parts may

be damaged by some carburetor cleaners.

Carburetor passages may be cleaned out with

compressed air.

CAUTION!

safety glasses when

compressed air.

Be sure

to

using

wear

Replace any components that show wear or

damage. The inlet needle is replaceable but the

seat is not.

If

it is suspected that the seat is leaking, the

carburetor can be pressure tested after it has

been cleaned. Use Toro pressure tester, number 41-7910. If the seat is good, it will hold

kg/cm2 (7 psi) for at least

10

seconds. This

.5

procedure should be completed with the car-

buretor turned upside down

the needle closed. See Fig. 3-8.

so

the float holds

If

the pressure

leaks down, replace the needle and try the test

again.

If

the carburetor fails again, the seat is

bad and the carburetor must be replaced.

Figure 3-7

Throttle Shaft

Gasket

Nozzle

Figure 3-8

Reassembly Carburetor

1. Install the choke and throttle shafts. Check

Fig. 3-3 and 3-7 for proper orientation of the

shafts.

2. Install the choke and throttle plates. Use a

thread locking compound such as Loctite

271 on the screws.

3. Replace the main nozzle and bowl gasket.

4. Install the pilot jet and pilot screw. See Fig.

3-6. The pilot screw should be one turn open.

5.

Hook

the inlet needle into the float and

secure the float and needle in place with the

hinge pin. See Fig. 3-9.

13

Page 21

Figure 3-9

Figure

3-11

6. Remount the bowl and gasket.

7.

Mount the gaskets and spacer on the studs.

The correct sequence is described in Fig.

3-10.

Figure 3-10

8.

Hook the throttle control rod and spring into

the governor arm and throttle, then mount

the carburetor on the studs.

9.

Remount the air cleaner. Make sure to

install the spacer washer on the screw that

retains the air cleaner and oil fill tube. Refer

to Fig. 3-2.

10. Install the fuel tank and reconnect the fuel

hose. Be sure to route the fuel hose behind

the governor arm.

GAS CAP

Disassembly

1.

The gas cap used on the OHV engine is a

two piece design, however; no disassembly

is recommended. The inner sealing disc is

riveted into the plastic cap. See Fig. 3-1

1.

Service

1.

The tank should provide a free gravity flow

is

8.

84

higher

micron

of fuel to the carburetor (the tank

than the carburetor).

not evident (the engine is starving for fuel)

loosen the cap and see if fuel flow is

re-established.

If

2.

Reassembly

1.

2.

FUEL TANK AND FILTER

Disassembly

2. Disconnect the fuel hose at the carburetor.

3. Wipe up any fuel that may have drained out

Service

1.

2. This is the only fuel filter in the system and

3. If the fuel tank is dirty or contaminated,

the fuel flow improves, the cap is not

venting. Examine the vent hole in the

sealing disc and the cap to make sure they

are unobstructed.

Make sure the vent opening in the sealing

disc is turned 90 degrees from the vent

opening in the cap.

Remount the cap.

1.

Drain the fuel tank with a siphon pump.

Make sure you transfer the fuel to an

approved container.

Refer to Fig. 3-1.

of the hose when disconnected.

If

the fuel filter is plugged, clogged or dirty,

replace it. See Fig. 2-9 on page

must be replaced with the same

filter. Part number 56-6360.

wash the tank in parts cleaning solvent and

dry completely.

If

a free flow of fuel is

Page 22

Reassembly

1. Install a new filter, if necessary.

2. Mount the fuel tank using two spacers and

two screws.

3. Route the fuel hose behind the governor

arm.

4. Connect the hose to the carburetor.

IGNITION

Testing Spark Intensity

The ignition system can be checked for spark

intensity using a spark tester, part number

41

-7890.

1. Pull off the plug connector and remove the

spark plug.

2.

Inspect the plug for wear, carbon deposits

and damage. Replace the plug if damaged,

burnt or fouled.

3. Check for the correct plug gap and adjust, if

.7

necessary, to

in.).

4. Attach the spark tester and set the tester

gap to 4.2 mm (.166 in). (4 turns counterclockwise from the closed position.)

5.

Pull the starter and observe for spark.

6.

If

the spark is evident, the ignition system is

operating properly.

proceed to testing kill switch operation.

Testing Kill Switch Operation

There are two ignition kill systems, one for zone

start, and one for BBC and commercial applications. Both systems depend on a lever

contacting a grounding tang to ground the

ignition and stop the engine.

BBC

and Commercial

1. Make sure the kill wire is properly connected to the grounding tang on the throttle

control. See Fig. 3-12.

.8 mm (.028 in. .032

If

Kill

no spark

Systems

is

evident,

2.

3. In the “off” position, the throttle lever should

When the throttle control is in the “run”

position, the throttle lever should move

away from the ground tang. See Fig. 3-13.

In this position, the ground tang should not

have continuity to ground. This can be

tested by disconnecting the kill wire and

testing the tang with

the volt-ohmmeter on RX1 with one probe

on the tang and one probe on ground. There

should be a reading

continuity).

contact the ground tang. This will ground

the ignition and stop the engine. See Fig.

4.

3-1

a

volt-ohmmeter. Place

of

infinity (no-

Figure 3-1

2

Zone Start Applications

1.

Make sure the engine kill wire is connected

to the ground tang. See Fig. 3-15.

15

Figure 3-14

Page 23

Figure 3-15

2. With the control bail tensioned (run position), the brake pad is pulled away from the

flywheel and the brake lever is rotated away

from the ground tang. See Fig. 3-16. The

ground tang should not have continuity to

ground. This can be tested by disconnecting the kill wire and testing the tang to

ground continuity with a volt-ohmmeter.

Removal

1.

Drain the fuel tank. Refer

Ignition

to

Fuel System on

page 8.

2.

Remove the air cleaner assembly. Refer to

Air Cleaner Removal on page 12.

3. Remove the shrouding, including one screw

retaining the muffler guard. See Fig. 3-18.

Note: It is not necessary to remove the recoil

starter unless it is to be serviced.

Figure 3-18

Figure 3-16

3. With the control bail in the “off” or “stop”

position, the brake pad is against the fly-

wheel and the brake lever is contacting the

ground tang. This will ground the ignition

and stop the engine. See Fig.

3-17.

4.

The ignition coil may now be removed from

its mounting bosses. Be sure to unplug the

kill wire. See Fig. 3-19.

Figure 3-19

5.

If removal of the throttle bracket is

sary, remove the two fasteners shown

3-20.

I

neces-

in Fig.

Figure

3-17

Figure 3-20

Page 24

6.

If

removal of the brake assembly and switch

is necessary, remove the two retaining

screws. See Fig. 3-21.

Figure 3-21

Installation Ignition

1. Mount the brake assembly or throttle

assembly.

2.

Install the ignition coil. Mount a wire re-

tainer on either the right or left side of the

coil, depending on the brake system used.

Refer to Fig. 3-19.

3. Establish an air gap of .38

-.020) between the flywheel and ignition

coil. Use a feeler gauge or spacer of appro-

priate thickness. Tighten the ignition coil

fasteners.

4.

Reinstall all shrouding. Note:

the screw for the oil

5.

Mount the air cleaner assembly. Install the

long screw and spacer washers through the

air cleaner and dip-stick tube at this time.

Refer to Fig. 3-2.

6.

Mount the fuel tank. Route the fuel hose

behind the governor arm.

ELECTRIC STARTER AND ALTERNATOR

The electric starter used on the OHV engine

operates on 12 volts DC and is controlled by a

start switch and ignition kill switch. The battery

is under continuous charge with a 300 ma

alternator. See Fig. 3-22 for the OHV electric

start wiring schematic.

Testing Electric Starter

The starter motor fails to turn:

1. Check the battery, make sure it is connected

and fully charged. If the motor still does not

turn, go to step two.

fill

tube at this time.

.50

mm (.015

Do

not install

3. Apply 12 volts direct to the starter motor

If

1. Check the starter switch. Use a volt ohm-

2. Check the battery ground to the engine.

3. Check the wire connectors at the battery

If

1. Verify that the engine

2. Replace the motor as the internal com-

Figure 3-22

2. Remove the spark plug wire and disconnect

the starter motor plug.

terminals. See Fig. 3-23.

Figure 3-23

the motor turns:

meter. There should be continuity through

the switch in the “start” mode.

There should be continuity between the

negative battery terminal and the body

the engine.

and starter motor.

the motor does not turn:

is

not seized.

engine

ponents are not replaceable.

is

free go to step “2”.

If

of

the

17

Page 25

Testing Alternator

Battery does not charge during mower

operation:

1.

Check battery connections and alternator

connections to make sure they are complete

and secure. Check the connection points at

the battery, alternator wire, key switch and

all ground connections.

2. Measure the alternator output with the

engine at 3000 RPM. With the battery

connected, alternator output should be 13.2

volts DC. The voltage can be measured

between the red wire on the key switch and

the black ground wire.

3.

If

the measured voltage is 12 volts or less, it

indicates the alternator may not be charging.

Go

to step four.

4.

Complete a resistance test on the alternator

coil. This test may be completed without

removing the coil from the engine.

measurements are taken between the output wire and ground. Disconnect the wire

for these tests. For clarity, the coil has been

removed in the following figures.

5.

The alternator coil is equipped with a diode

assembly that will rectify the alternator

output. See Fig. 3-24.

All

Figure 3-25

7.

Reverse the leads and complete the test.

The measurement is 707 ohms. The meter

was on the 2000 ohm scale and the reading

is .707 or 707 ohms. See Fig. 3-26.

n

Figure 3-24

6. Check the diode and coil assembly with a

volt-ohmmeter. The meter in Fig. 3-25

indicates a resistance of infinity when a

numeral one appears to the left of the

decimal point. The measurement should be

infinity when the positive probe of the meter

is placed on the output wire. See Fig. 3-25.

The negative probe

ground terminal of the alternator coil.

is

connected to the

Figure 3-26

Removal Electric Starter

1.

Pull the spark plug wire off the spark plug.

2. Unplug the starter connector.

3.

Unscrew the two mounting screws as shown

in

Fig. 3-32.

4.

It

is not necessary to take shrouding off the

engine to remove the starter.

5.

The serviceable components on the starter

are shown in Fig. 3-27.

6.

The pinion is serviceable by removing the

retainer clip and then lifting the components

off the starter motor shaft.

Installation Electric Starter

1. Coat the starter motor worm shaft and pinion

teeth with a light coat of molybdenum di-

sulfide lubricant, Toro part number 505-37.

2. Assemble the starter motor components

shown

3. Install the starter motor and torque the

fasteners to 2.2 3.5 kg-m (16-25 ft-lb).

(Make sure you don’t pinch the alternator

wire under the starter motor.)

in

Fig. 3-27.

as

Page 26

Retainer

Pinion

Stop

Pinion

Figure 3-27

Removal Alternator

2,

1. Follow steps 1,

3 under Removal

Ignition on page 16.

2. Remove the two screws retaining the alternator to the engine block.

3. Pull the alternator wire and rubber grommet

out of the block.

Installation Alternator

1. Install the alternator and secure with two

fasteners. The screws should be tightened

to 1.0 1.6 kg-m (7-11 ft-lbs). Route the

wire and grommet through the opening in

the engine block. See Fig. 3-28.

RECOIL

All

STARTER

OHV

engines, including electric start, are

equipped with recoil starters. Recoil starter

service is performed as follows:

Removal and Disassembly

Recoil

Starter

1. Remove the four screws retaining the starter

to the blower housing. See Fig. 3-29. Note

the orientation

of

the recoil rope for proper

reassembly.

Figure 3-29

2. Turn the starter over and unwind the starter

rope to release spring tension on the starter

pulley. See step 1, 2, 3 on Rope Replacement, page

21.

Carefully remove the recoil

assembly retaining nut. The nut is under a

slight amount of spring pressure. Slowly

back off the nut until the spring pressure is

released. See Fig. 3-30.

Figure 3-30

3. Lift off the friction plate and expose the

starter pawl guide. See Fig. 3-31. Note how

the guide is installed and remove it.

Figure 3-28

2. Take care that the alternator wire does not

become pinched behind the starter motor.

3. Reinstall all shrouding, air cleaner and fuel

tank. Follow steps

Installation Ignition.

6 on page

17

on

Figure 3-31

4,

5,

19

I

Page 27

4. The friction spring is directly underneath

the starter pawl guide. The starter pawl is

also visible. See Fig. 3-32. Remove the

friction spring.

Figure 3-32

5.

Remove the shaft spacer. See. Fig. 3-33.

Figure 3-35

8.

The detensioned recoil spring will be captured in the bottom of the recoil pulley.

Carefully lift the pulley and recoil spring

free of the recoil housing. See Fig. 3-36.

Figure 3-33

6. Remove the nylon washer that is installed

under the spacer and spring. See Fig. 3-34.

Lift the starter pawl off at this time.

Figure 3-34

7.

The starter pawl pivots on the pin shown in

Fig. 3-35. Remove the pin.

Figure 3-36

9.

Turn the pulley over and examine the con-

dition of the recoil spring. It should be

as

retained in the pulley

On reassembly, the loop end of the spring

must be caught on the lip

recoil assembly.

Figure 3-37

seen in Fig.

of

the hub in the

3-37.

Page 28

Repair Recoil Starter

The most likely components on the recoil

starter to require repair are the coil spring and

starter rope.

‘A

when working with the recoil spring. If

the spring

could result.

Rope Replacement

1.

Rope replacement may be accomplished

without disassembly of the starter. First take

the starter off the engine.

2.

If

the pulley spring has not be detensioned,

withdraw about one foot of rope and while

holding the pulley in place, unwind the

remaining rope on the pulley.

3. Slowly release the rope until the pulley

spring fully relaxes. IMPORTANT.

turn the pulley any further in the clockwise

direction or the spring will unhook from the

center hub.

will turn freely in the counter-clockwise

direction without an increase in spring

tension. To correct, the pulley must be

removed and the spring re-hooked.

4. Untie the knot in the rope and replace with

new. The rope is 4mm (5/32 in.) in diameter

and 175cm (70 in.) long.

5.

Wrap the new rope around the pulley in a

counter-clockwise direction. See Fig.

6.

When the rope is fully wound on the pulley,

extend about two feet of rope, hold the

pulley in place and take two additional

wraps of rope around the pulley in a

counter-clockwise direction. This will preload the spring.

CAUTION:

glasses and use extreme care

is

suddenly released, injury

If

thespring un-hooks the pulley

Wear safety

Do

3-36.

not

7. Re-install the recoil starter.

Spring Replacement

1.

Follow steps one through nine under

“Recoil Starter Removal and Disassembly”

on page

2. Carefully remove the broken spring to

prevent rapid expansion of the spring.

CAUTION: Wear safety glasses and use

extreme care to prevent injury.

3. The replacement spring is provided with a

wire retainer to hold it together.

4. Place the spring in the pulley and release

from its retainer.

5.

The spring should be installed in the pulley

as shown in Fig. 3-37.

6.

If

the spring has expanded outside the

pulley, it can be reinstalled by first placing

the hook end into the pulley. See Fig. 3-37.

7. Wind the spring into the pulley in a counterclockwise direction from the outside until

the spring is fully retained.

8.

Place the pulley in the recoil housing and

turn it slowly in a counter-clockwise direction, with a slight down pressure, until the

pulley drops down indicating the spring is

hooked on the center hub.

Reassembly

1.

Install the pawl-pivot pin. See Fig. 3-35.

2. Install the nylon washer, starter pawl and

spacer. See Figs. 3-34, 3-33.

3. Install the friction spring and pawl guide.

See Figs. 3-32, 3-31.

4.

Install the friction disc and mounting nut.

Use a thread locker on the nut: e.g. Loctite

242. See Fig. 3-30.

5.

Install the recoil rope. Refer to steps

Rope Replacement on page 21.

19.

5

&

6

it

of

21

Page 29

4.

ENGINE DISASSEMBLY, INSPECTION AND REASSEMBLY

DISASSEMBLY

Recoil Starter

1.

Remove the four screws retaining the

starter.

If

the recoil starter must be disassembled,

2.

to

refer

on page 19-20.

Fuel Tank

1.

Drain the tank per instructions on page

2.

Drain the carburetor per instructions on

page 9.

3. Disconnect the fuel hose.

4. Remove the two screws retaining the fuel

tank.

5.

Lift the fuel tank off the engine.

Air

Cleaner

1.

Remove the air cleaner assembly. Refer to

steps one and two of Carburetor Service on

page 12.

Cooling Shrouds

1.

Remove the three screws retaining the

engine top cover.

2.

Remove the three screws retaining the

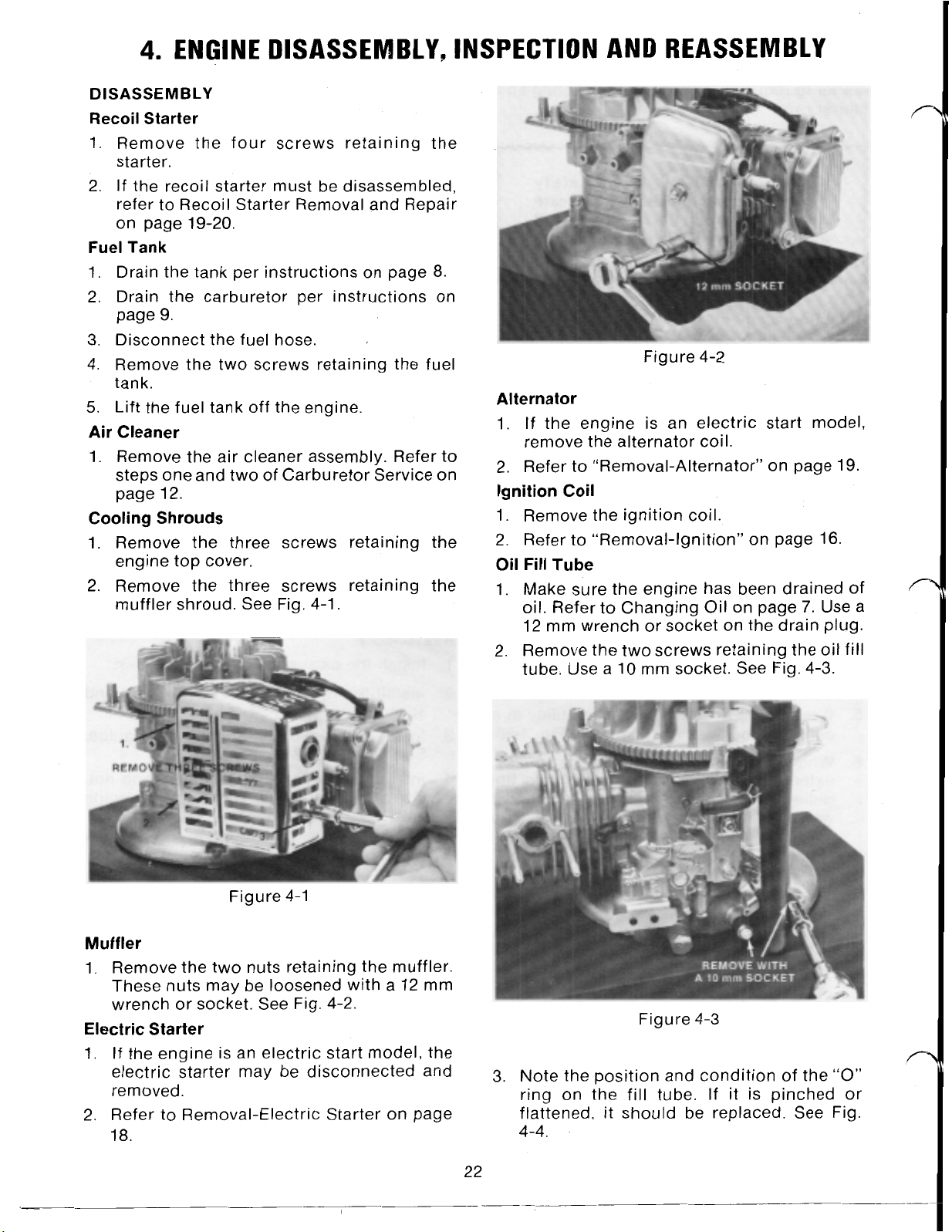

muffler shroud. See Fig. 4-1.

Recoil Starter Removal and Repair

8.

Figure 4-2

Alternator

1.

If

the engine is an electric start model,

remove the alternator coil.

2. Refer

Ignition Coil

1.

Remove the ignition coil.

2. Refer

Oil Fill Tube

1. Make sure the engine has been drained of

oil. Refer

12 mm wrench

2. Remove the two screws retaining the oil fill

tube. Use a

to

“Removal-Alternator” on page 19.

to

“Removal-Ignition” on page

to

Changing Oil on page

or

socket

10

mm socket. See Fig. 4-3.

on

the drain plug.

7.

16.

Use a

Figure 4-1

Muffler

1.

Remove the two nuts retaining the muffler.

These nuts may be loosened with a 12 mm

wrench or socket. See Fig. 4-2.

Electric Starter

1.

If

the engine is an electric start model, the

electric starter may be disconnected and

removed.

2. Refer to Removal-Electric Starter on page

18.

Figure 4-3

3. Note the position and condition of the

ring on the fill tube.

flattened, it should be replaced. See Fig.

4-4.

If

it is pinched or

“0”

Page 30

Figure 4-4

Throttle Control and Carburetor

1.

Refer to “Removal-Carburetor’’ on page

2.

Refer to disassembly steps

12-13

if further carburetor service is necessary.

5,6,7,8

on page

Flywheel

1.

Use a screwdriver through the starter cup to

hold the flywheel in place.

2.

Use a

19

mm socket to remove the flywheel

nut. See Fig. 4-5.

12.

5.

Examine the condition of the flywheel taper,

keyway and crankshaft key and taper. See

Fig. 4-7.

Figure 4-7

Breather

1. Remove the two screws retaining the breather assembly cover. Use a 10 mm socket or

wrench. See Fig. 4-8.

Figure 4-5

3.

After the flywheel nut is removed, unscrew

the three fasteners retaining the starter cup.

4.

Mount flywheel puller#41-7650 and remove

the flywheel. Insert the screws for the puller

into the same holes used by the starter cup

retaining screws. See Fig. 4-6.

Figure 4-6

Figure 4-8

2.

Under the cover will be a gasket, a reed plate

and another gasket.

Figure 4-9

23

Page 31

3. The reed retainer and reed must be mounted

“up” as seen in Fig. 4-9.

Cylinder Head Assembly

1. Remove the four screws retaining the valve

cover. See Fig. 4-10. Don’t lose the washers

under each screw.

Figure 4-10

2. If the head assembly is to be completely

torn down, remove each valve rocker arm.

This step is not essential to the removal of

the cylinder head. Hold the adjusting nut

with a 14 mm wrench and loosen the jam nut

with a 10 mm wrench. See Fig. 4-1 1. Remove

the nuts, rocker arms and push rods.

HEAD

Figure 4-12

GASKET

Figure

4-11

3. Remove the four head bolts. Use a 12 mm

socket with a short extension. Two of the

head bolts are under the valve cover. See

Fig. 4-12.

4. Pull the head away from the engine block.

Do

not lose the two aligning pins. The head

gasket will fit only one way over these pins.

See Fig. 4-13.

24

Figure 4-13

5.

Lubricating oil flows into the

through the passages shown

head assembly

I

in Fig. 4-14.

Figure 4-14

6.

Lubricating oil flows back to the crankcase

through the passages shown in Fig. 4-15.

Page 32

Figure 4-15

Oil

Pump

1. Turn the engine upside down and remove

the three screws retaining the oil pump

cover. Use a 10 mm wrench or socket. See

Fig. 4-18.

PCOVER

Valves

1. The valve keepers may be removed by hand.

Support the bottom of the valve with your

fingers and push down and back with your

thumbs on the keeper. See Fig. 4-16.

Figure 4-16

2.

The valves may now be withdrawn from the

head. The valve springs and keepers are

identical and interchangeable. See Fig.

4-1

7.

Figure 4-18

2.

Remove the oil pump cover and examine the

condition of the

“0”

ring. The oil pump is a

two-piece gerotor type oil pump driven by

the camshaft. See Fig. 4-19.

Figure 4-19

3.

When removing the gerotor set, note the

orientation of the parts

so

they may be

reassembled in the same order.

Oil is drawn out of the crankcase through

4-20

the opening toward the top in Fig.

and

discharged through the opening in the

bottom and up through the center of the

camshaft.

Figure 4-17

Figure 4-20

25

Page 33

Crankcase

1.

Remove the seven screws retaining the

sump assembly to the block. When the

is

sump

not

pulled off the crankshaft, take care

to

cut the seal. See Fig. 4-21.

Figure 4-21

2. Turn the sump over and examine the

governor assembly. Make sure the governor

plunger has not dropped into the block of

the engine as the plunger is loose on its

shaft. See Fig. 4-22.

2. Note the position of the two thrust washers.

Refer to Fig. 4-23. One washer is located

under the plunger and one is located under

the governor assembly.

Camshaft

1.

The camshaft drives both the governor and

the oil pump. Refer to Fig. 4-22.

2. The witness marks on the cam gear and

crank gear can be seen in Fig. 4-24. These

to

marks must be matched

establish correct

valve timing.

Figure 4-24

3. The cam gear may now be removed from the

crankcase. Note the oil pump drive pin in

the end of the shaft. See Fig. 4-25.

Figure 4-22

Governor Assembly

1.

To

disassemble the governor, pry up between the governor and the sump of the

engine with a flat bladed screwdriver. See

Fig. 4-23. The governor is held on its shaft

with a nylon shoulder. There are no retain-

ing rings.

Figure 4-23

Figure 4-25

4. With the camshaft removed, the cam followers are exposed. See Fig. 4-26.

e

WASHER

Figure 4-26

Page 34

5.

Pull the cam followers out of the engine.

New parts are identical and may be placed

in either opening. Used parts should be

installed in the original holes to maintain

wear patterns.

Figure 4-27

6.

If

necessary, the governor shaft may be

removed by unseating the retaining ring

and pulling the shaft out of the block. See

Fig. 4-28. There are no seals or

“0”

the block or on the shaft.

rings in

Figure 4-29

I’

FLYWEIGHT

Figure 4-28

Compression Release

1. The compression release assembly is designed to hold the exhaust valve off its seat

during start up. This is accomplished by an

additional lobe on the back side of the

exhaust cam that is activated by a flyweight

assembly. The compression release is

shown in Fig. 4-29 as it would be during

cranking or starting.

2. When the engine speed increases, the

flyweight will move in the direction of the

arrow in Fig. 4-30. This will cause the lobe to

rotate exposing its flat edge to the exhaust

cam. This will allow the exhaust valve to

fully close at operating speed. See Fig. 4-30.

3. The flyweight spring is the only replaceable

part. Refer to Fig. 4-30.

FLYWEIGHT MOVEMENT

Figure 4-30

Piston and Connecting Rod

1.

To

remove the connecting rod, straighten

the tabs on the locking plate and remove the

rod cap nuts. See Fig. 4-31.

Figure 4-31

27

Page 35

2. The piston and crankshaft may now be

removed from the cylinder. See Fig. 4-32.

lower diameter of the crankshaft is 24.959

24.980 (.9826 .9835).

Rod

Journal

Diameter

25.99-26mm (1.023-1.024 in.)

Figure 4-34

Figure 4-32

3. Remove the piston rings. The bottom ring is

for oil control, the second ring is cast iron

for quick seating and the top ring is chrome

plated for long wear.

4. The rings are marked with the letter

The

“N”

should face up on correct installa-

tion. See Fig. 4-33.

Figure 4-33

“N”.

Connecting

1.

Measure the inside diameter of the connecting rod crankshaft bearing. The diam-

eter should be 26.105 26.025 mm (1.024

1.025 in.) See Fig. 4-35.

26.015-26.025

1.024-1.025

2. Measure the inside diameter

necting rod piston pin bearing. The diameter should be 14.989 14.981 mm (5901

Rod

Connecting

Crankshaft Bearing

mm

in.

,590 in.) See Fig. 4-36.

3;

Figure 4-35

of

Rod

the con-

INSPECTION AND RECONDITIONING

Crankshaft

1. Inspect for a bent crankshaft. The limit on

crankshaft deflection (1/2

cated run-out on a dial indicator) is

(.002 in).

2. Measure the diameter of the crankshaft rod

journal. The journal diameter should be

25.99 26.00 mm. (1.023 1.024 in.) See

Fig. 4-34.

3. The upper diameter of the crankshaft is

21.960 21.980 mm (.8646 .8654). The

of

a total indi-

.05

mm

14.981-14.989 (.590- -.5901 in.)

Piston Pin Bearing

Diameter

Figure 4-36

28

Page 36

Piston

of

1. Measure the outside diameter

The piston should measure 63.960 63.975

mm (2.5181 2.5187 in.).

measures less than 63.915 mm (2.5163 in.)

replace it. See Fig. 4-37.

Piston Diameter

the piston.

If

the piston

Cylinder Bore

Measurement

Figure 4-39

The amount of wear is the difference between the largest and smallest measurements.

3. The wear limit is .1 mm (.0039 in.).

c

63.960-63.975 mm (2.5181-2.5187)

14

mm

(0.55

in)

Figure 4-37

2. Measure the piston pin diameter. The pin

should measure 14.995 15.00 mm (5904

5906 in.) See Fig. 4-38.

Piston Pin Diameter

14.995-15.00 mm (S904-.5906 in.)

Figure 4-38

3. The clearance between the piston pin and

connecting rod bearing should be .006

.019 mm (.0002 ,0007 in.). The wear limit

is

.05

mm (.002 in.). Both the connecting rod

and piston pin must be replaced if the wear

limit is exceeded.

Cylinder

(2.52

1. Diameter of the cylinder is 64 mm

Cylinder bore condition is determined by

establishing the total cylinder bore wear.

2. Take a total of 6 cylinder measurements as

shown in Fig. 4-39. Take two measurements

A,

B.

each at point

C.

in.).

Piston Rings

1. Measure the piston ring clearance in the

piston ring groove. See Fig. 4-40.

Clearance .03-.07 mm (.0012-.0028 in.)

Wear Limit .1 mm (.0039 in.)

Piston Ring Clearance in Groove

-03-.07 mm (.0012-.0028 in.)

Figure 4-40

2. Measure the piston ring end gap where

cylinder wear is at a minimum. This will be

about 3 mm (1/8 in.) from the upper edge of

the cylinder. The end gap measured with a

feeler gauge is .20-.40 mm (.0079-,0158 in.).

The limit is .7 mm (.027 in.).

Valves

1. Measure the valve stem diameter. See Fig.

4-41.

Intake Valve 5.460-5.475 mm

(.2150-.2156 in.)

Exhaust Valve- 5.440-5.455 mm

(.2142-,2148 in.)

2.

Use a small bore gauge and a micrometer to

measure the valve guide

Intake & Exhaust- 5.500-5.512 mm

I.D.

(.2165-,2170 in.)

29

Page 37

Valve Stem Diameter

Valve Seat Angles

Exhaust 5.440-5.455 (.2142-.2148 in.)

Figure 4-41

to

3. Calculate the valve stem

valve guide

clearance wear limit. Subtract the valve

I.D.

stem diameter from the valve guide

If

these limits are exceeded, the valves and

valve guides must be replaced.

Intake clearance limit

.08

mm

(.0032 in.)

Exhaust clearance limit ,100 mm

(.0039 in

See Valve Guide Replacement on page

.)

30.

4. Valve seat contact is determined by coating

the valve seat with Prussian Blue. Install the

valve and rotate it in its seat. The width of

the contact area for both intake and exhaust

is shown in Fig. 4-42.

Intake and Exhaust Valve Contact Area

,800-1

.OO

mm (.0315-.0394 in.)

The pattern must be a continuous ring

If

without break.

the pattern is not within

specification, the valve seat must be reconditioned

15”

45’

60”

Figure 4-43

A. Install the pilot shaft in the valve guide.

6.

Insert the 45 degree cutter and connect

the “T” handle.

to

C. Cut the seat

45 degrees with one or

two turns of the cutter.

D.

Coat the seat with Prussian Blue and

measure the contact area on the valve

face. Refer

E.

If

the position of the contact area is low,

to

step

#4

on page

30.

see Fig. 4-44A. cut the seat with the 60

degree cutter

to

raise the contact area.

F. If the contact area is high, see Fig. 4-

446, cut the seat using the 15 degree

cutter

to

lower the contact area.

I

“B”

Valve Seat Contact Pattern

.800-1.00 mm (.0315-.0394 in.)

Figure 4-42

5.

Recondition the valve seat. Three cuts are

required to properly recondition the valve

seat. See Fig. 4-43.

The special

“T” handle wrench

Adaptor

Expandable

60

Degree Cutter

tools

required are as follows:

50-9480

50-941

Pilot

50-9500

81-4830

0

15/45 Degree Cutter 81-4370

Figure

6. Valve Guide Replacement

The valve guides are shrink-fit in place. Use

the following procedures

ment valve guides.

A. Use valve guide installer and remover,

part number 81-4880,

valve guide out of the head of the engine.

Insert the remover from the combustion

chamber side of the head.

B.

Ream the hole with a valve guide reamer,

part number 81-4850. Turn the reamer

with

handle. part number 81-4860. The

30

4-44

(HIGH)

A

&

B

to

install replace-

to

drive the old

Page 38

diameter of the hole after reaming will be

9.300-9.315mm (.3661-.3667 in.) on both

intake and exhaust.

C.

Use the valve guide installer, part number 81-4880, to drive in the new oversize

valve guides. part number 81-3830. Drive

the guides in from the valve cover side of

the head. When properly installed, there

27.5

will be

mm (1.08 in.) clearance

between the end of the valve guide and

the gasket surface of the head. See Fig.

4-45.

Replacement

Guides

27.5

mm

(1.08

in)

Fig u re 4-45

2.

The letter

“N”

on

each piston ring should

face toward the top of the piston.

3.

Before installing the piston, check the

on

match marks

will ensure correct installation.

the arrow

on

the rod cap and rod. This

Also

the connecting rod, this should

point to the push rod side of the engine on

installation. See Fig. 4-47.

note

D.

Check the

the diameter

I.D.

of

the new guidesagainst

of

the valve systems.

If

clearance is too small:

intake guide

less than

.025

mm (.001 in.)

exhaust guide

less than ,045 mm (.0017 in.).

you must ream the guide with valve

guide reamer, part number

41-4840.

This

will enlarge the valve guide diameter to

5.5

mm (.2165 in.)

REASSEMBLY

Piston, Rings and Connecting Rod

1. Use a ring expander to install three piston

rings. The top ring is chrome plated, the

second ring is plain iron and the third is an

oil control ring. See Fig. 4-46.

the

Figure 4-47

4.

Lubricate the crankshaft with

30

weight oil

and slide it into the ball bearing. Take care

not to damage the seal. Lubricate the piston

and install it with a piston ring compressor.

See Fig. 4-48.

Figure 4-46

31

Figure 4-48

5.

The arrow

on

the face of the piston should

point the same direction as the arrow on the

connecting rod toward the push rods.

See Fig. 4-49.

Page 39

Figure 4-49

Camshaft and Followers

1. Install the cam followers. They are both the

same, it makes no difference in which of the

two openings they are installed. Oil before

you insert them. See Fig.

4-50.

Governor Assembly

1.

Lubricate and install the thrust washer on

the flyweight shaft. Lubricate and install the

flyweight assembly. Push it down on the

shaft until it snaps in place.

2.

Place a small amount of grease on the

governor plunger and thrust washer. Install

them on the flyweight shaft. See Fig. 4-52.

Figure 4-50

2.

If

the governor arm has been removed,

lubricate it and install it at this time.

3.

Lubricate and install the camshaft. Make

sure the timing marks on the cam gear and

crankshaft gear are in line. See Fig. 4-51.

Figure 4-51

Figure 4-52

Crankcase

1. Place a new gasket on the block assembly.

2.

Put a piece of protective tape over the

crankshaft keyway; lubricate the shaft.

3.

Install the sump assembly on the block. You

may have to turn the crankshaft slightly to

get the camshaft gear and governor gear to

Do

engage.

not force the fit as damage to

the nylon governor gear may occur. Take

care that the governor plunger does not

drop into the block assembly.

4. Tighten the seven sump screws to .4-.7 kg-m

Oil

(3.0-5.0

Pump

ft-lbs).

1. Lubricate and install the center drive gear of

the gerotor set. You may have to turn the

gear to get it to properly engage with the

drive pin on the camshaft.

2.

Lubricate and install the outer gear of the

gerotor set. Put the gears back into the

engine the same way they came out. This

will maintain any wear pattern that may

have developed in the gear set. See Fig.

4-53.

3.

Install the

the three screws to

ft-I

bs).

“0”

ring and cover plate. Torque

.4-.7

kg-m

(3.0-5.0

32

Page 40

Figure 4-53

Valves

1. Lubricate the valve stems and install the

valves in the head.

2.

The valve heads are marked intake and

exhaust. The intake valve is mounted in the

large diameter opening and the exhaust

valve is mounted in the small diameter

opening.

valves in the wrong opening but they will not

seal.

3. Install the valve springs and keepers. The

keepers and springs are the same on intake

and exhaust. See Fig. 4-54. Hold the head of

the valve in place and push down with your

thumbs to install the keepers.

NOTE:

It is possible to insert the

4. Insert the four head bolts and torque to 1.8

-2.8 kg-m (13

5.

Install the two push rods they are

interchangeable.

6.

Install the rocker arms they are also

interchangeable.

7.

Install the adjusting nuts and jam nuts.

8.