Page 1

RESIDENTIAL PRODUCTS

WALK BEHIND MOWER

ENGINE SERVICE MANUAL

2012 and Prior LC1P65FA (159cc)

Page 2

About this Manual

This service manual was written expressly for Toro service technicians. The Toro Company

has made every effort to make the information in this manual complete and correct. Basic shop

safety knowledge and mechanical/electrical skills are assumed. The Table of Contents lists the

systems and the related topics covered in this manual. An electronic version of this service

manual is available on the Toro Dealer Portal. We are hopeful that you will find this manual a

valuable addition to your service shop. If you have any questions or comments regarding this

manual, please contact us at the following address:

The Toro Company

Residential and Landscape Contractor Service Training Department

8111 Lyndale Avenue South

Bloomington, MN 55420

Page 3

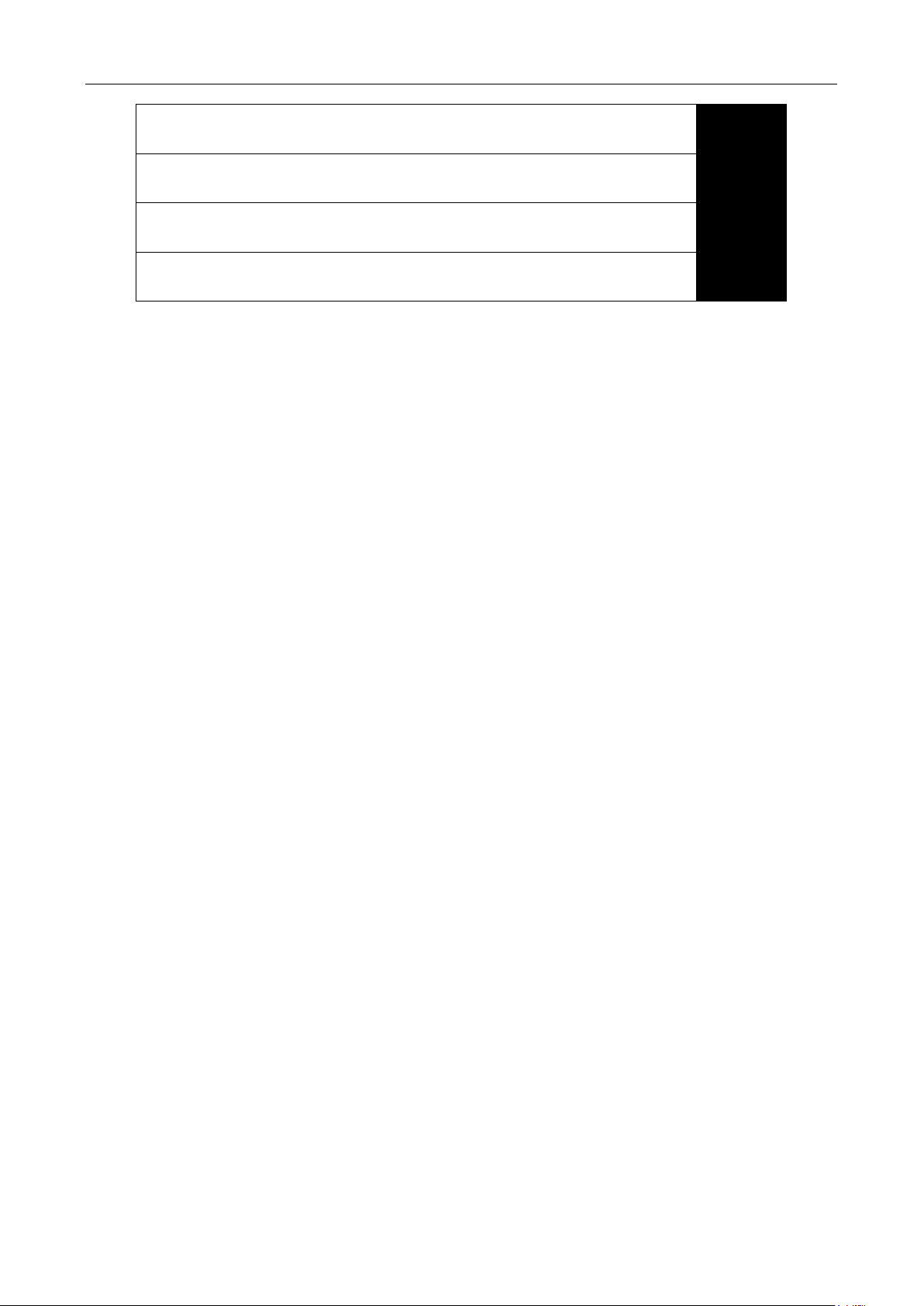

Chapter 1 – General Service Information

1

Chapter 2 - Engine Service / Maintenance

2

Chapter 3 - Engine Disassembly and Service

3

Chapter 4 - Electrical

4

Page 4

NOTES:

Page 5

1

Chapter 1 – General Service Information

Safety 2

Service Rules 3

Engine Model / Serial Number Location 3

Engine Fastener Torque Specification 4

General Specifications 4

Engine Specifications 5

Troubleshooting 6

1

Page 6

Safety

Safety Information

This symbol means WARNING or PERSONAL SAFETY INSTRUCTION – read the instruction because it has

to do with your safety. Failure to comply with the instruction may result in personal injury or even death.

This manual is intended as a service and repair manual only. The safety instructions provided herein are for

troubleshooting, service, and repair of the Toro engine. The Toro mower and operator’s manuals contain

safety information and operating tips for safe operating practices.

Avoid Unexpected Engine Start - Turn off engine and disconnect the spark plug before servicing engine.

Avoid Lacerations and Amputations - Stay clear of all moving parts while the engine is running.

Avoid Burns - Do not touch the engine, muffler, or other components which may increase in temperature

during operation, while the unit is running or shortly after it has been running.

Avoid Fires and Explosions - Avoid spilling fuel and never smoke while working with any type of fuel or

lubricant. Wipe up any spilled fuel or oil immediately. Never remove the fuel cap or add fuel when the engine

is running. Always use approved, labeled containers for storing or transporting fuel and lubricants.

Avoid Asphyxiation - Never operate an engine in a confined area without proper ventilation.

Avoid Injury From Batteries - Battery acid is poisonous and can cause burns. Avoid contact with skin, eyes,

and clothing. Battery gases can explode. Keep cigarettes, sparks, and flames away from the battery.

Avoid Injury Due To Inferior Parts - Use only original equipment parts to ensure that important safety

criteria are met.

Avoid Injury To Bystanders - Always clear the area of bystanders before starting or testing power

equipment.

Avoid Injury Due To Projectiles - Always clear the area of sticks, rocks, or any other debris that could be

picked up and thrown by the power equipment.

Avoid Modifications - Never alter or modify any part unless it is a factory approved procedure.

2

Page 7

Service Rules

1. Only use genuine Toro parts and lubrication products.

2. Always install new gaskets, O-rings and seals when assembling engine.

3. Always torque fasteners to specification and in sequence.

4. Always lubricate friction components with clean engine oil or engine assembly lube

when assembling engine.

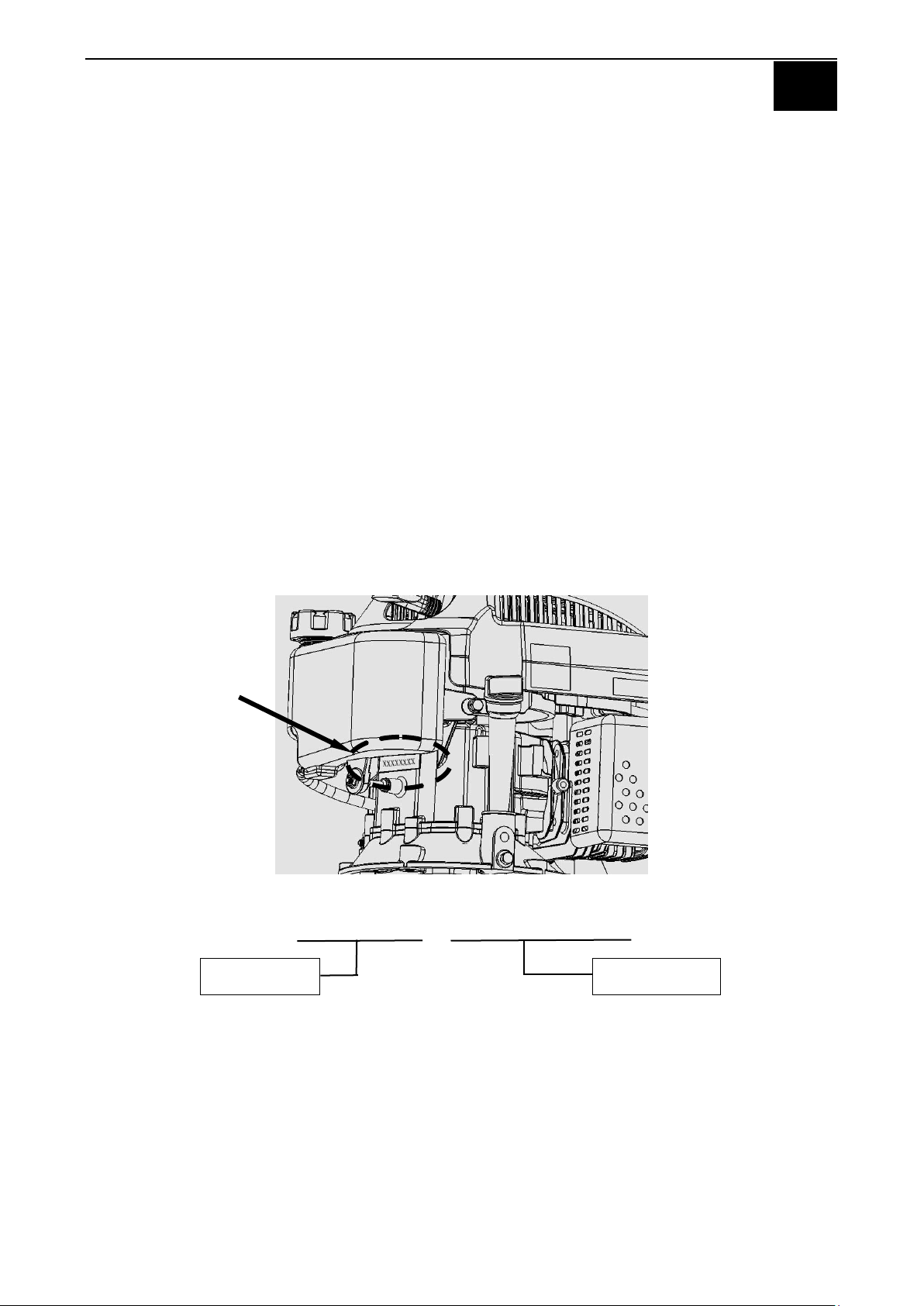

Engine Model and

Serial Numbers

Engine Model

Serial Number

1

Engine Model / Serial Number Location

The engine model and serial number are stamped into the crankcase, near the fuel tank.

XXX-XXXX XXXXXXXXXXX

3

Page 8

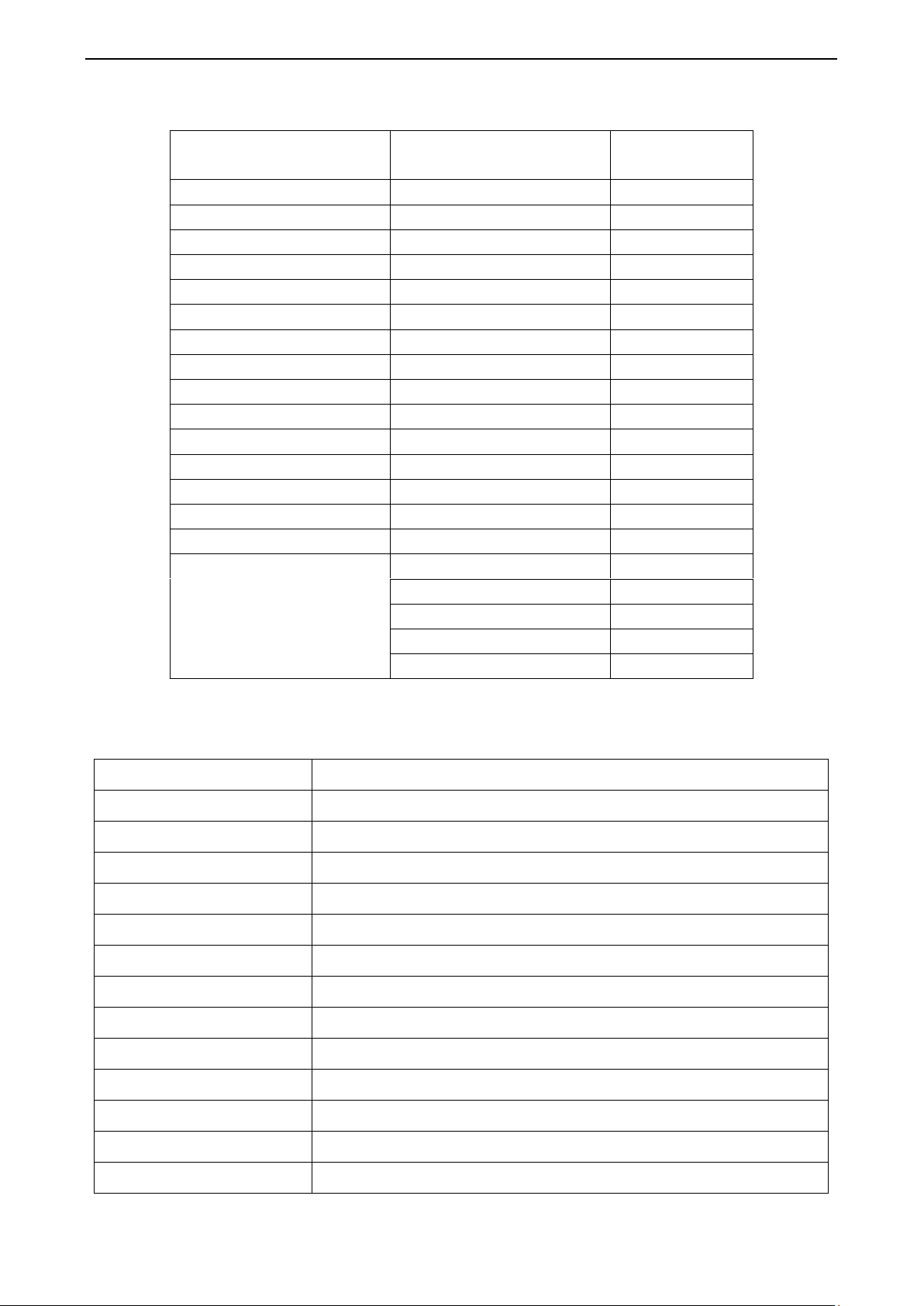

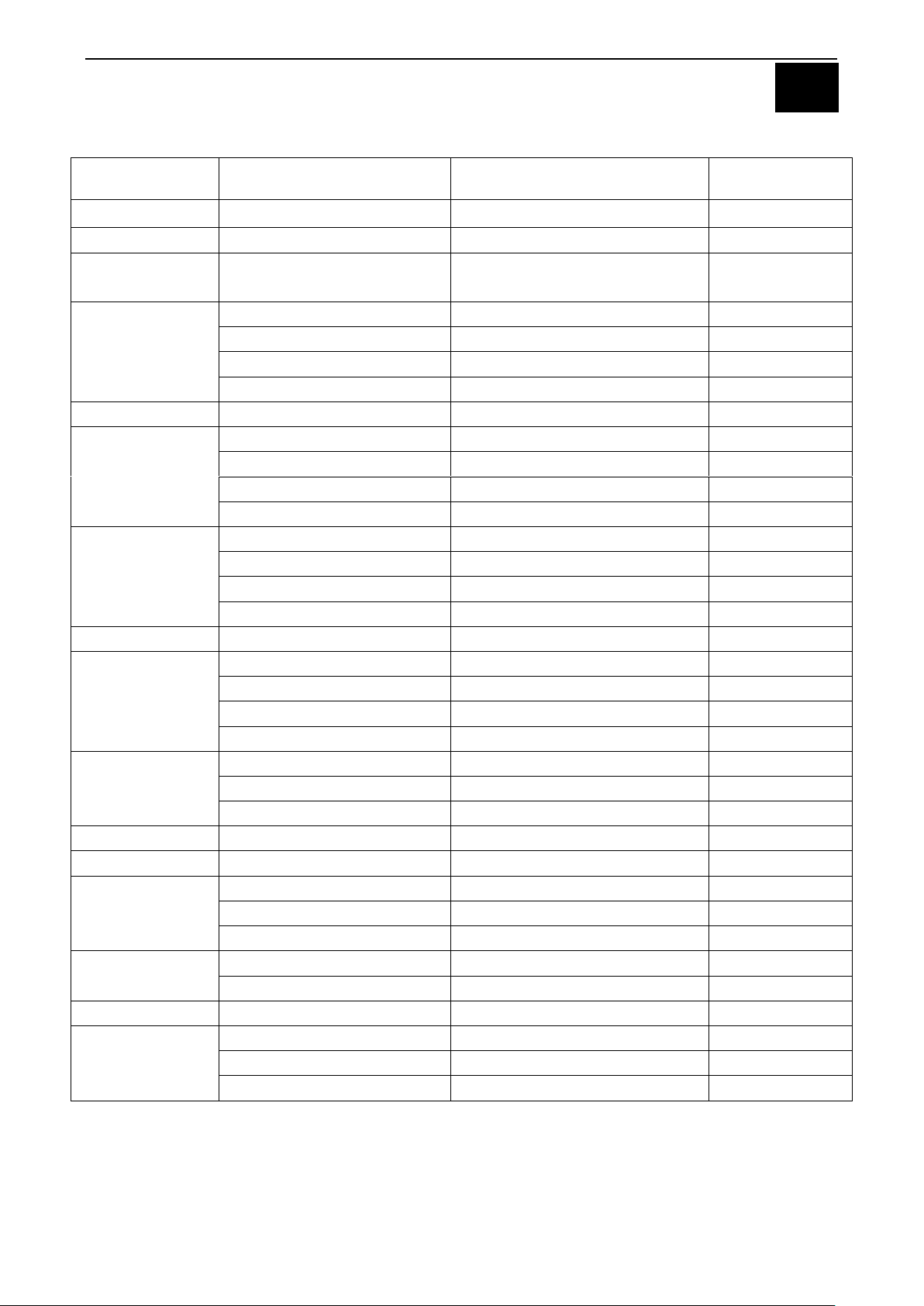

Item

Fastener Size

Torque

Specification

Cylinder Head Bolts

M8

25 ft-lbs (34 Nm)

Connecting Rod Bolts

M7

9.5 ft-lbs (13 Nm)

Flywheel Nut

M14

62.5 ft-lbs (85 Nm)

Valve Adjust Lock Nut

M6

10 ft-lbs (14 Nm)

Pivot Arm Pivot Stud

M8

22 ft-lbs (30 Nm)

Crankcase Cover Bolt

M6

7.5 ft-lbs (10 Nm)

Muffler Nuts

M6

7.5 ft-lbs (10 Nm)

Air Cleaner Nuts

M6

6 ft-lbs (8 Nm)

Recoil (Fan Shroud) Nut

M6

6 ft-lbs (8 Nm)

Oil Drain Bolt

M10

15.5 ft-lbs (21 Nm)

Fuel Tank Bolts / Nuts

M6

7.5 ft-lbs (10 Nm)

Governor Arm Pinch Nut

M6

7.5 ft-lbs (10 Nm)

Spark Plug

-

22 ft-lbs (30 Nm)

Ignition and Charge Coil Bolts

M6

7.5 ft-lbs (10 Nm)

Electric Starter Motor Bolts

M6

7.5 ft-lbs (10 Nm)

Standard Torque Values

M5 Bolt / Nut

4.5 ft-lbs (6 Nm)

M6 Bolt / Nut

7.5 ft-lbs (10 Nm)

M8 Bolt / Nut

19 ft-lbs (26 Nm)

M10 Bolt / Nut

28 ft-lbs (38 Nm)

M12 Bolt / Nut

41 ft-lbs (55 Nm)

Model

1P65FA

Type

Single cylinder, 4-Stroke, Forced Air Cooling, OHV

Bore x Stroke (mm)

65×48

Displacement (cc)

159

Compression Ratio

8 :1

Lubrication

Splash

Starting

Recoil and Electric Start

Rotation

Counter-Clockwise (From P.T.O. Side)

Ignition System

Transistorized Magneto Ignition

Air Cleaner

Foam & Paper

Fuel Type

Unleaded Gasoline, 87 Octane

Oil Capacity

Max. Fill: 20 oz (0.59 l)

Dimensions (L×W×H)

371×338×356 (mm)

Dry Weight

26.4 lbs (12 kg)

Engine Fastener Torque Specifications

General Specifications

4

Page 9

Engine Specifications

Part

Item

Standard

Service Limit

Engine

Operating RPM

2900 – 3100 RPM

-

Cylinder Head

Warpage

-

0.00393” (0.10 mm)

Cylinder

Sleeve Taper / Out of Round

(Inside Diameter)

2.559” (65.0 mm)

2.566” (65.165 mm)

Piston

Skirt Outside Diameter

2.558” (64.985 mm)

2.553” (64.845 mm)

Cylinder Clearance

0.00059 - 0.00196” (0.015-0.05 mm)

0.00472” (0.12 mm)

Piston Pin Bore Inside Diameter

0.5118” (13.002 mm)

0.5137” (13.048 mm)

Piston Pin Clearance

0.00007- 0.0005” (0.002-0.014 mm)

.00314“ (0.08 mm)

Piston Pin

Outside Diameter

0.5118” (13.0 mm)

0.51” (12.954 mm)

Piston Rings

Ring To Groove (Top and Middle)

0.00059 - 0.00177” (0.015-0.045 mm)

0.0059” (0.15 mm)

End Gap (Top and Middle)

0.0078 - 0.0157” (0.2-0.4 mm)

0.0393” (1.0 mm)

Width (Top and Middle)

0.059” (1.5 mm)

0.0539” (1.37 mm)

Width (Oil Ring)

0.0984” (2.5 mm)

0.0933” (2.37 mm)

Connecting Rod

Small End Inside Diameter

0.5125” (13.02 mm)

0.5145” (13.07 mm)

Big End Inside Diameter

1.0244” (26.02 mm)

1.0263” (26.07 mm)

Big End Oil Clearance

0.00157 - 0.00248” (0.04-0.063 mm)

0.0047” (0.12 mm)

Big End Side Clearance

0.00393 - 0.02755” (0.1-0.7 mm)

0.0433” (1.1 mm)

Crankshaft

Crackpin Outside Diameter

1.0228” (25.98 mm)

1.0204” (25.92 mm)

Valve

Clearance (cold) (Intake)

0.0039” (0.10 mm)

-

Clearance (cold) (Exhaust)

0.0059” (0.15 mm)

-

Stem Diameter (Intake)

0.2157” (5.48 mm)

0.2093” (5.318 mm)

Stem Diameter (Exhaust)

0.2141” (5.44 mm)

0.2076” (5.275 mm)

Valve Guides

Inside Diameter (Intake, Exhaust)

0.2165” (5.50 mm)

0.2193” (5.572 mm)

Stem to Guide Clearance (Intake)

.00039” - 0.0013” (0.01-0.034 mm)

.00393” (0.10 mm)

Stem to Guide Clearance (Exhaust)

0.0019 - 0.0027” (0.05-0.070 mm)

0.0047” (0.12 mm)

Valve Seat

Seat Width

0.0314” (0.8 mm)

0.0787” (2.0 mm)

Valve Spring

Free Length

1.2007” (30.5 mm)

1.1417” (29.0 mm)

Camshaft

Height (Intake)

1.0905” (27.7 mm)

1.0807” (27.45 mm)

Height (Exhaust)

1.0925“ (27.75 mm)

1.0826” (27.50 mm)

Journal (Bearing)

0.5505” (13.984 mm)

0.5478“ (13.916 mm)

Crankcase Cover

Camshaft Hole Diameter

0.5511” (14.0 mm)

0.553” (14.048 mm)

Crankshaft Hole Diameter

1.0” (25.4 mm)

1.00472” (25.52 mm)

Spark Plug

Gap

0.0275 - 0.0314” (0.7-0.8 mm)

-

Ignition Coil

Resistance (Primary)

1.1-1.6 Ω

-

Resistance (Secondary)

10.5 KΩ +/- 15%

-

Gap to Flywheel

.01” (0.254 mm)

-

1

NOTE: The only internal parts available for this engine are gaskets and seals.

5

Page 10

Troubleshooting

Hard Starting / Poor Running

- Incorrect Fuel (Level, Age, Octane, Ethanol Content)

- Fuel System Contamination and / or Carburetor Debris

- Incorrect Oil Level

- Spark Plug (Incorrect Gap, Fouled, Loose or Faulty)

- Air Filter Restriction

- Air Intake System Leaks

- Ignition Coil to Flywheel Gap Incorrect

- Weak / No Spark

- Auto Choke System (Improper Function)

- Choke / Air Vane Linkage

- Operating RPM Incorrect

- Governor Adjustment Incorrect

- Engine Valve Clearance out of Specification

- Low Compression or Excessive Leakdown

Overheating

- Incorrect Oil Level

- Cylinder Head Gasket Leak

- Debris Build-Up Restricting Air Flow

6

Page 11

2

Chapter 2 - Engine Service / Maintenance

Engine Oil Change Procedure 8

Air Cleaner Service 9

Spark Plug Service 10

Valve Clearance Inspection and Adjustment 11

Engine Governor – Zero Point Setting 11

Fuel Filter Replacement 12

Auto Choke System / Function 13

Auto Choke System View 14

7

Page 12

Engine Oil Change Procedure

1. Run engine to warm engine oil.

2. Remove spark plug cap from the spark plug.

NOTE: Ensure fuel system contains no fuel to prevent leakage when the mower is tipped onto its side.

3. Remove the dipstick.

4. Tip the mower onto side with the dipstick on the downward side. Drain the used oil through the oil fill tube

into a suitable container.

5. Return the mower to the operating position.

6. Add oil through the dipstick tube. Wipe the dipstick clean and insert it into the dipstick tube to check the oil

level.

NOTE: DO NOT screw the dipstick into the dipstick tube to check the oil level

NOTE: DO NOT overfill the engine oil

7. Fully Install the dipstick and hand tighten it securely.

8. Properly dispose of the used engine oil.

Engine Oil Capacity:

Max. Fill: 20 oz (0.59 l)

Engine Oil Type:

SAE 30 or 10W-30 detergent oil. API classification of SF,SG, SH, SJ, SL, or higher.

8

Page 13

2

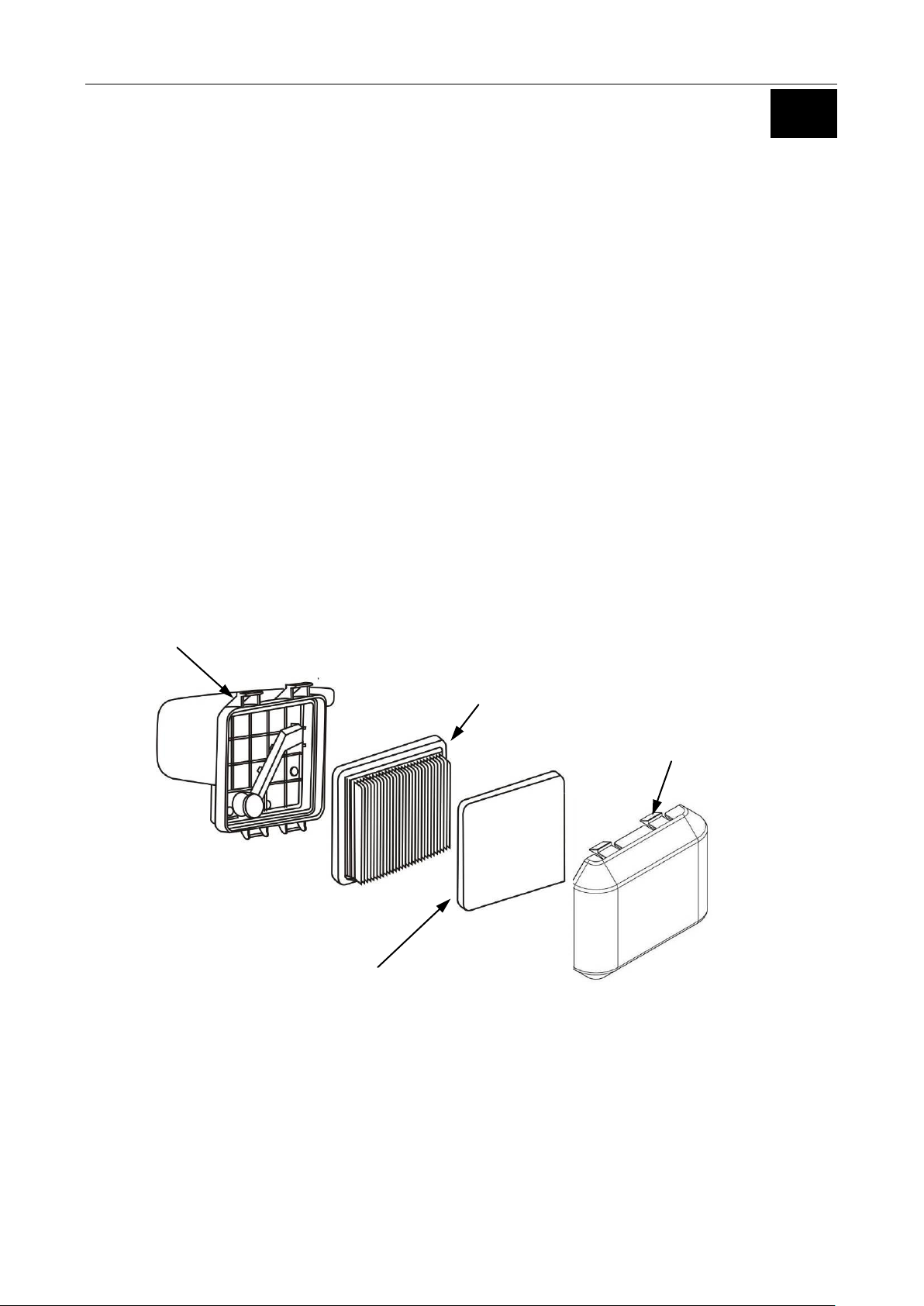

Paper Element

Air Cleaner Base

Air Cleaner

Cover

Foam Element

Air Cleaner Service

1. Press the upper latch tabs and rotate the top of the cover outward to open and remove the cover.

2. Remove the paper air filter and the foam pre-filter.

3. Inspect the foam pre-filter, and replace it if damaged or excessively dirty.

4. Inspect the paper air filter.

NOTE: If the paper air filter is excessively dirty, damaged or is wet with oil or fuel, replace it.

5. Remove dirt from the air cleaner body and cover using a moist rag. Do not wipe dirt into the air duct.

6. If the foam pre-filter is reusable, clean it with warm soapy water. Thoroughly rinse and dry foam element.

7. Insert the foam pre-filter and the paper air filter into the air cleaner

8. Properly Install the cover and verify cover latch tabs are fully engaged.

9

Page 14

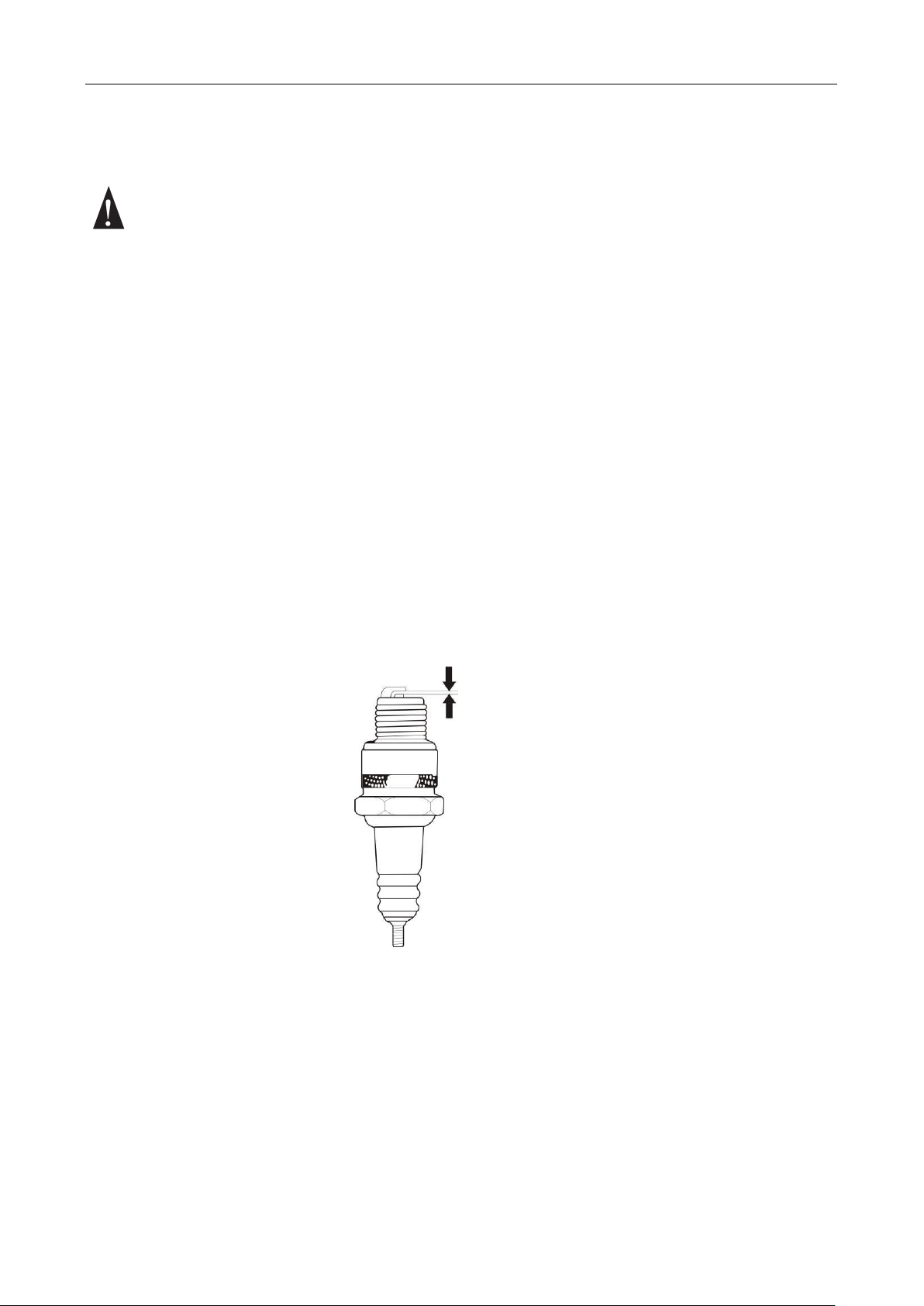

0.0275 - 0.0314”

(0.7-0.8 mm)

Spark Plug Service

NOTE: Spark plugs of the wrong size or incorrect heat range can cause severe engine damage.

High Voltage Ignition Systems can be Dangerous - Use Caution when Servicing Ignition Systems

1. Disconnect the spark plug cap and thoroughly clean the spark plug area.

2. Remove the spark plug from the engine.

3. Inspect the spark plug for excessively worn electrodes, chips or cracks in the insulator, or excessive

deposits.

4. Measure the electrode gap and adjust if necessary. Spark Plug Gap: 0.0275 - 0.0314” (0.7-0.8 mm)

5. Install spark plug and torque to specification - 22 ft-lbs (30 Nm).

6. Fully install the spark plug cap on the plug.

10

Page 15

2

Governor Arm

Shaft

Pinch Bolt Nut

Governor Arm

Valve Clearance Inspection and Adjustment

NOTE: Valve clearance inspection and adjustment must be done with the engine cold.

1. Rotate engine to TDC (top-dead-center) of the

compression stroke.

2. Remove the valve cover. Be sure both valves are

completely closed and the decompression arm is not

holding the valve open.

3. Measure the clearance between the rocker

arm and the valve stem with a feeler gauge.

Intake: 0.0039” (0.10 mm)

Exhaust: 0.0059” (0.15 mm)

4. To adjust valve clearance:

- Hold the rocker arm pivot and loosen the pivot lock

nut.

- Turn the rocker arm pivot to obtain the specified

clearance.

- Hold the rocker arm pivot and tighten the pivot lock nut to specification - 11 ft-lbs (15 Nm).

5. Recheck the clearance and readjust if necessary.

6. Inspect the valve cover gasket and replace if necessary. Install the valve cover and torque fasteners to

specification - 7.5 ft-lbs (10 Nm).

Engine Governor – Zero Point Setting

1. Loosen but do not remove the governor

arm pinch bolt and nut.

2. Move the governor arm to fully open

the throttle valve. Firmly hold

the governor arm in this position.

3. Rotate the governor arm shaft fully

clockwise and secure it in this position

with a pair of pliers.

4. Tighten the governor arm pinch bolt and nut to Specification - 7.5 ft-lbs (10 Nm).

5. Verify that the governor arm and throttle valve move freely. Verify engine RPM is within specification.

11

Page 16

Fuel Filter

A

Fuel Filter and Hose Replacement

- Fuel is Extremely Flammable - Use Extreme Caution When Servicing the Fuel System

1. Drain the fuel tank into an approved container.

NOTE: Ensure fuel system contains no fuel to prevent leak when the fuel filter is replaced.

2. If necessary, remove air filter cover and base as outlined in this manual.

3. Release the fuel filter / fuel hose clamps (A) and slide them away from fittings.

4. Remove the fuel filter / fuel hose asm. from the engine.

5. Install new fuel filter / hose asm. and hose clamps (A).

6. Re-fill tank with fresh fuel.

7. Verify hose routing and check for leaks.

8. Properly dispose of any unused fuel.

9. Reinstall air filter cover and base as outlined in this manual.

12

Page 17

1

2

2

Auto Choke System / Function

A. Governor Rod - Connected to the governor system

which controls the angle of the throttle plate and sets

engine operating RPM.

B. Thermal Spring Rod - Connected to the thermal

spring, which mounts on the muffler. The thermal spring

adjusts the choke plate angle as the engine temperature

changes.

C. Air Vane Rod - Connected to the air vane in the

blower housing which will fully open the choke plate at

full operating RPM at any engine temperature.

COLD START - Picture 1 illustrates the choke plate

position while starting a cold engine. The thermal spring

is cold, keeping the choke closed. The air vane is

inactive because the engine is not running.

HOT START - Picture 2 illustrates the maximum amount

the thermal spring can open the choke plate while the

engine is hot and not running.

FULL RPM - Picture 3 illustrates the maximum amount

the air vane can open the choke plate. When engine

RPM decreases, the choke will close, however if the

engine is hot, the thermal spring will prevent the choke

from fully closing.

13

Page 18

Auto Choke System View

Thermal Spring Asm.

(Mounts onto Muffler)

Thermal Spring

Choke Linkage

Choke Rod Lock

Air Vane

Choke Linkage

Air Vane

Washer

Screw

Image for Reference Only

14

Page 19

3

Chapter 3 - Engine Disassembly and Service

Engine Service – Upper End 16-26

Air Cleaner and Muffler Exploded View 16

Recoil Starter and Engine Cover Exploded View 17-18

Carburetor and Linkage Exploded View 19-20

Flywheel and Breather Exploded View and Service Info 21

Cylinder Head Exploded View and Service Info 22

Intake and Exhaust Valve Exploded View and Service Info 23

Valve Spring / Valve Seat / Cylinder Head Specifications 24

Valve Stem / Valve Guide Specifications 25

Valve Seat Reconditioning 26

Engine Service – Lower End 27-36

Crankcase / Governor Exploded View and Information 27-28

Crankshaft / Piston / Camshaft Exploded View and Info 29

Piston / Connecting Rod Exploded View and Information 30

Valve Timing 31

Crankshaft Bearing / Piston / Cylinder Specifications 32

Piston / Piston Ring Specifications 33

Piston Ring / Connecting Rod Specifications 34

Crankshaft Specifications 35

Camshaft Specifications 36

NOTE: The only internal parts available for this engine are gaskets and seals.

15

Page 20

Nut

Muffler

Shield

Muffler

Breather Tube

Exhaust

Gasket

Primer Asm

(International Only)

Air Cleaner Base

Intake Gasket

Cover

Foam

Element

Paper

Element

Nut

Engine Service – Upper End

Air Cleaner and Muffler Exploded View

16

Page 21

Recoil Asm.

Nut

Fuel Cap Asm

Nut

Bolt

Washer

Fuel Tank

Bolt

Fuel Hose

Fuel Filter

Fuel Hose

Clamp

Screw

Engine Cover

3

Recoil Starter and Engine Cover Exploded View

17

Page 22

Set Screw

Ratchet Guide

Spring

Ratchet

Spring

Reel

Spring

Bushing

Recoil Asm. Cover

18

Page 23

3

Governor

Arm

Governor

Spring

Governor

Pinch Bolt

Throttle Return

Spring

Governor

Rod

Control Asm.

Bracket

Gasket

Insulator /

Heat Shield

Spacer

Gasket

Carburetor and Linkage Exploded View

19

Page 24

Carburetor Exploded View

Throttle Valve Asm.

Pilot Jet

O Ring

Float Valve Asm

Float

Main Jet and

Nozzle

Throttle Stop

Screw

Float Bowl

Float Bowl

Mounting Bolt

and Gasket

Drain Plug

and Gasket

20

Page 25

3

Key

Brake / Switch

Asm.

Flywheel Nut

63 ft-lbs (85 Nm)

Breather

Cover

Breather

Gasket

6 ft-lbs (8Nm)

Breather

Valve

7.5 ft-lbs (10Nm)

Shield

Flywheel and Breather Exploded View and Service Info

21

Page 26

Spark Plug

22 ft-lbs (36 Nm)

Cylinder Head Gasket

Valve Cover

7.5 ft-lbs

(10 Nm)

Valve Cover Gasket

Cylinder Head Bolt Torque Sequence:

1. Initially Torque the (4) Cylinder Head Bolts in a Crisscross Pattern to 10 ft-lbs (14 Nm).

2. Evenly Torque the (4) Cylinder Head Bolts in a Crisscross Pattern to 25 ft-lbs (34 Nm).

Cylinder Head Exploded View and Service Information

22

Page 27

3

Lock Nut

11 ft-lbs (15 Nm)

Rocker Arm Pivot

Rocker Arm

Rocker Arm Pivot Stud

22 ft-lbs (30 Nm)

Push Rods

Intake Valve

Exhaust Valve

Valve Spring

Valve Spring

Retainer

Push Rod

Guide

Intake and Exhaust Valve Exploded View and Service Information

23

Page 28

Standard

Service Limit

1.2007” (30.5 mm)

1.1417” (29.0 mm)

Standard

Service limit

0.0314” (0.8 mm)

0.0787” (2.0 mm)

Service Limit

0.00393” (0.10 mm)

STRAIGHT EDGE

FEELER GAUGE

Valve Spring Free Length Specification

NOTE: If this measurement is out of specification, complete engine

replacement is required. The only internal parts available for this engine are gaskets and seals.

Valve Seat Width Inspection

Remove carbon deposits from the combustion chamber. Inspect the valve

seats for pitting or other damage.

Valve Seat Width Specification:

Cylinder Head Warp Inspection

- Remove carbon deposits from the combustion

chamber.

- Clean off any gasket material from the

cylinder head surface.

- Check the spark plug hole and valve areas for cracks.

- Check the cylinder head for warpage with a straight

edge and a feeler gauge as shown.

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

24

Page 29

Standard

Service Limit

Intake

0.2157” (5.48 mm)

0.2093” (5.318 mm)

Exhaust

0.2141” (5.44 mm)

0.0047” (0.12 mm)

Standard

Service limit

0.2165” (5.50 mm)

0.2193” (5.572 mm)

Standard

Service limit

Intake

.00039” - 0.0013”

(0.01-0.034 mm)

.00393”

(0.10 mm)

Exhaust

0.0019 - 0.0027”

(0.05-0.070 mm)

0.0047”

(0.12 mm)

3

Valve Stem Inspection

Inspect each valve for face irregularities, bending

or abnormal wear.

Valve Stem Diameter Specification

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

Valve Guide Inspection

Ream the exhaust valve guide to remove any carbon deposits before

measuring.

Valve Guide ID Specification:

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

Valve Stem to Guide Clearance

Subtract each valve stem OD from the corresponding guide ID to

obtain the guide-to-stem clearance.

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

25

Page 30

Standard

Service Limit

0.0314”

(0.8 mm)

0.0787”

(2.0 mm)

CONTACT TOO LOW

CONTACT TOO HIGH

Valve Seat Reconditioning

1. Thoroughly clean the combustion chamber and valve seats to remove carbon deposits.

2. Apply a light coat of Prussian Blue or erasable felt-tipped marker ink to the valve faces.

3. Properly install valves, springs and keepers. Manually open the valves, then and snap them closed

against their seats several times. Be sure the valves do not rotate on the seat. Remove the valve

assemblies. The transferred marking compound will show any area of the seat that is not concentric.

4. Use a 45°cutter to remove enough material to produce a smooth and concentric seat. Follow the valve

seat cutter manufacture’s instructions. Turn the cutter clockwise, never counterclockwise. Continue to

turn the cutter as you lift it from the valve seat.

5. Use a 30°~32° and 60° cutter to narrow and adjust the valve seat so that it contacts the middle of the

valve face. The 30°~32° cutter removes material from the top edge. The 60° cutter removes material from

the bottom edge. Be sure that the width of the finished valve seat is within specification.

6. Lap valves in accordance with valve lapping kit instructions.

7. Clean valve and seat of all lapping compound.

Valve Seat Width

.

26

Page 31

3

Aux. Oil Drain

15.5 ft-lbs (21 Nm)

Sealing Washer

7.5 ft-lbs (10 Nm)

Governor

Holder

Gasket

Pin

Weight

Washer

Slider

Clip

Washer

Shaft

Governor

Holder

Governor Asm.

Rubber Oil

Baffle

Engine Service – Lower End

Crankcase / Governor Exploded View and Service Information

Governor Exploded Views

27

Page 32

Crankcase Exploded View

Oil Seal

Crankcase /

Sump Cover

Crankcase / Sump Cover Bolt

Torque Sequence

7.5 ft-lbs (10 Nm)

1 2 3 4 5

6

7

Sump Cover Gasket

Oil Dip Stick

O Ring

Governor Arm Shaft

Governor Oil Seal

Governor Lock Pin

Oil Seal

28

Page 33

3

Crankshaft

Thrust Washer

Connecting Rod

Bolts

9.5 ft-lbs (13 Nm)

Bearing

Piston Asm.

Connecting Rod

Connecting Rod Cap

Valve Tappets

Cam Shaft

Oil Seal

Crankshaft / Piston / Camshaft Exploded View and Service Info

29

Page 34

Piston Connecting Rod Exploded View and Service Information

Assembly:

Install Rings with Orientation Mark “UP”

Stagger the piston ring gap as shown:

Top Ring

Second Ring

Oil Ring

Piston

Mark

Top Ring

Second Ring

Oil Ring

Check, refer to

Piston Pin

Piston Pin Circlip:

Install the circlip gap in the

12:00 Position (circlip gap

facing up)

Connecting Rod Orientation

Align Long end of connecting rod

with piston orientation “triangle”

CLIP

CUT-OUT

30

Page 35

3

Timing Marks

Crankshaft

Camshaft

Valve Timing

Crankshaft Bearing Free Play

1. Clean the bearing in solvent and dry it.

2. Spin the bearing by hand and check for play.

Replace the bearing if it is noisy or has excessive free play.

31

Page 36

Crankshaft Bearing Free Play

Standard

Service Limit

0.5118”

(13.0 mm)

0.51”

(12.954 mm)

Standard

Service Limit

2.559”

(65.0 mm)

2.566”

(65.165 mm)

1. Clean the bearing in solvent and dry it.

2. Spin the bearing by hand and check for play.

Piston Pin Outside Diameter

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

Cylinder Taper and Out of Round

Inspect cylinder for taper and out of round with a bore gauge.

Measure in two different directions, front to back and side to side, on

three different levels (½”down from the top, middle and ½” up from the

bottom).

Cylinder Taper and Out of Round Specifications

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

32

Page 37

Standard

Service Limit

2.558”

(64.985 mm)

2.553”

(64.845 mm)

Standard

Service Limit

0.00059 - 0.00196”

(0.015-0.05 mm)

0.00472”

(0.12 mm)

Standard

Service Limit

Top/

Middle

0.00059 - 0.00177”

(0.015-0.045 mm)

0.0059”

(0.15 mm)

Standard

Service Limit

Top/

Middle

0.059”

(1.5 mm)

0.0539”

(1.37 mm)

Piston Skirt Outside Diameter

Measure the piston skirt outside diameter 10mm from the skirt base and

90°to piston pin hole.

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

Piston to Cylinder Clearance Specification

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

Piston Ring to Groove Clearance

NOTE: If this measurement is out of specification, complete engine

replacement is required. The only internal parts available for this engine are gaskets and seals.

Piston Ring Width

NOTE: If this measurement is out of specification, complete engine

replacement is required. The only internal parts available for this engine

are gaskets and seals.

33

Page 38

Standard

Service Limit

0.0078 - 0.0157”

(0.2-0.4 mm)

0.0393”

(1.0 mm)

Standard

Service Limit

0.5125”

(13.02 mm)

0.5145”

(13.07 mm)

Standard

Service Limit

1.0244”

(26.02 mm)

1.0263”

(26.07 mm)

Piston Ring End Gap

Use the piston to position the rings squarely 1” down from the

top of the cylinder.

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

Connecting Rod Small End ID

NOTE: If this measurement is out of specification, complete engine replacement

is required. The only internal parts available for this engine are gaskets and

seals.

Connecting Rod Big End ID

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

34

Page 39

Standard

Service Limit

1.0228”

(25.98 mm)

1.0204”

(25.92 mm)

Standard

Service Limit

0.00393 - 0.02755”

(0.1-0.7 mm)

0.0433”

(1.1 mm)

Standard

Service Limit

0.0015 – 0.0024”

(0.040-0.063 mm)

0.0047”

(0.120 mm)

Crankshaft pin OD

NOTE: If this measurement is out of specification, complete engine

replacement is required. The only internal parts available for this engine

are gaskets and seals.

Connecting Rod Big End Side Clearance

NOTE: If this measurement is out of specification, complete engine

replacement is required. The only internal parts available for this

engine are gaskets and seals.

Connecting Rod Big End Oil Clearance

1. Clean oil from the crankshaft and connecting rod.

2. Use plastic gauge style measuring tool in accordance to the

manufactures instructions to measure the oil clearance.

Connecting Rod Bolt Torque: 9.5 ft-lbs (13 Nm)

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

35

Page 40

Standard

Service Limit

Intake

1.0905”

(27.7 mm)

1.0807”

(27.45 mm)

Exhaust

1.0925“

(27.75 mm)

1.0826”

(27.50 mm)

Standard

Service Limit

0.5505”

(13.984 mm)

0.5478”

(13.916 mm)

Camshaft Lobe Specifications

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

Camshaft Journal OD

Check the camshaft bearing journal for scoring, wear or damage.

NOTE: Verify that the decompression mechanism moves freely.

NOTE: If this measurement is out of specification, complete engine replacement is required.

The only internal parts available for this engine are gaskets and seals.

36

Page 41

4

Chapter 4 – Electrical System Information

Ignition / Charge Coil Gap Adjustment 38

Ignition Coil Resistance Inspection 38

Spark Testing 39

Electrical System Wiring 40

37

Page 42

Ignition / Charge Coil Gap

.01” (0.254 mm)

A - Primary Coil Resistance

1.1-1.6 Ω

B - Secondary Coil Resistance

10.5 KΩ +/- 15%

A

B

Ignition / Charge Coil Gap Adjustment

High Voltage Ignition Systems can be Dangerous - Use Caution when Servicing Ignition

Systems

1. Install the coil and lightly tighten the mounting bolts.

2. Rotate engine so the coil is aligned with the magnet portion of the flywheel.

3. Insert the feeler gauge between the flywheel and coil.

4. Adjust the coil gap at both side of the coil.

5. Torque the coil mounting bolts to specification – 7.5 ft-lbs (10 Nm).

Ignition Coil Resistance Inspection

Primary Coil

Place Ohm meter leads between the harness connection

lead and the exposed metal coil leg.

Secondary Coil

Place Ohm meter leads between exposed metal coil leg

and the spark plug terminal connection.

38

Page 43

Spark Plug

4

Spark Testing

- Fuel is Extremely Flammable - Use Extreme Caution When Servicing the Fuel System

- High Voltage Ignition Systems can be Dangerous - Use Caution when Servicing Ignition Systems

1. Safely drain the fuel system and store fuel in an approved container.

2. Remove spark plug boot from the spark plug.

3. Remove the spark plug from the engine.

4. Connect the negative (-) electrode of the spark plug (threaded area) to ground (cylinder head cover).

5. Crank the engine and view the electrode gap. Spark should be present when engine is turning over.

6. Reinstall the spark plug and torque to specification - 22 ft-lbs (30 Nm).

7. Properly install the spark plug boot.

39

Page 44

E D B A C G F

F

Electrical System Wiring (Electric Start Shown)

A Ignition Coil

B Starter Motor

C Alternator

D Brake / Kill Switch

E Starter Interlock Switch

F To Chassis Harness

G To Ground

40

Page 45

NOTES:

41

Page 46

RESIDENTIAL PRODUCTS

Form Number: 492-9231

42

Loading...

Loading...