Page 1

KAWASAKI FC150V ENGINE MANUAL

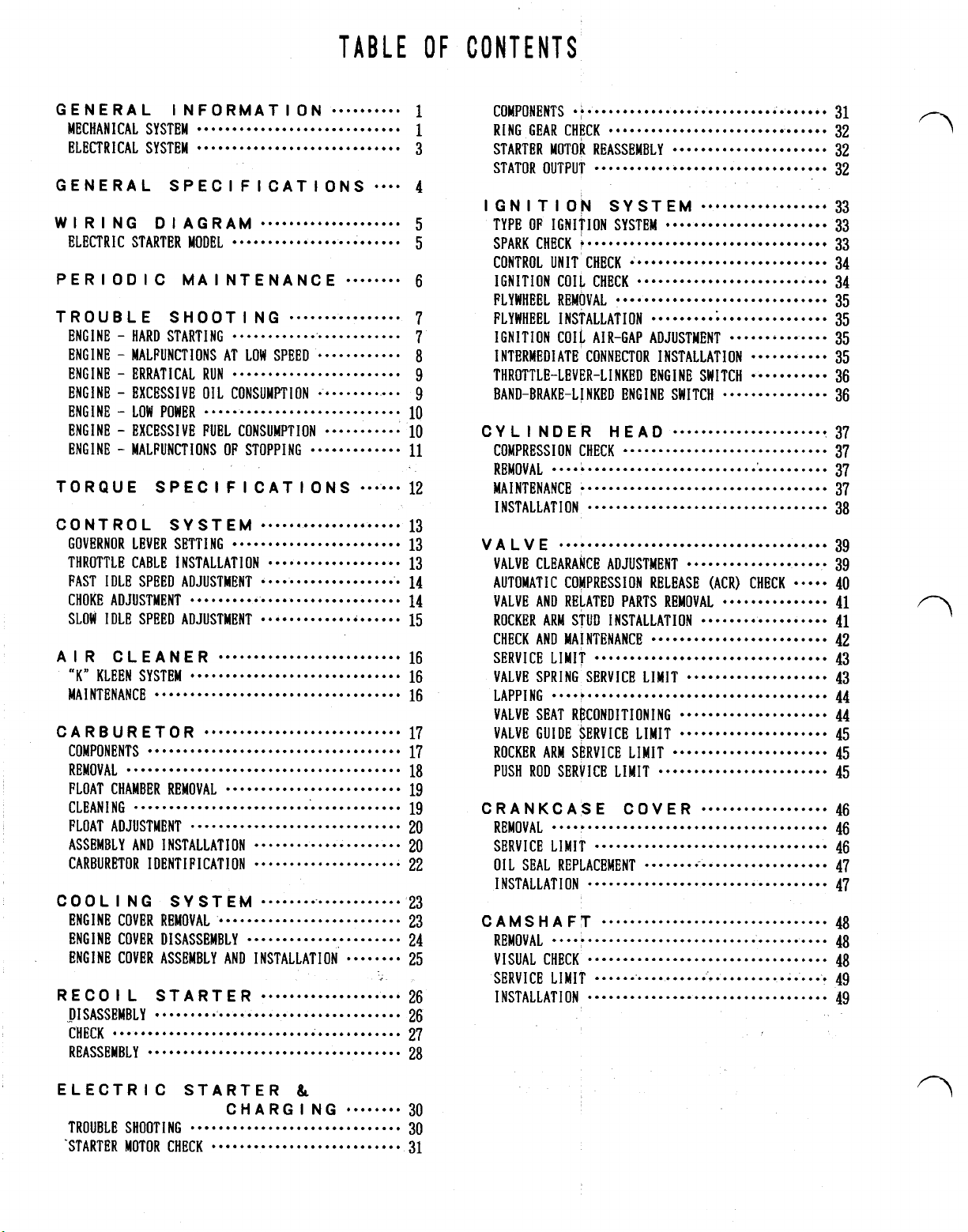

Table of Contents – Page 1 of 3

GENERAL INFORMATION

MECHANICAL SYSTEM

ELECTRICAL SYSTEM

GENERAL SPECIFICATIONS

WIRING DIAGRAM

ELECTRIC STARTER MODEL

PERIODIC MAINTENANCE

TROUBLE SHOOTING

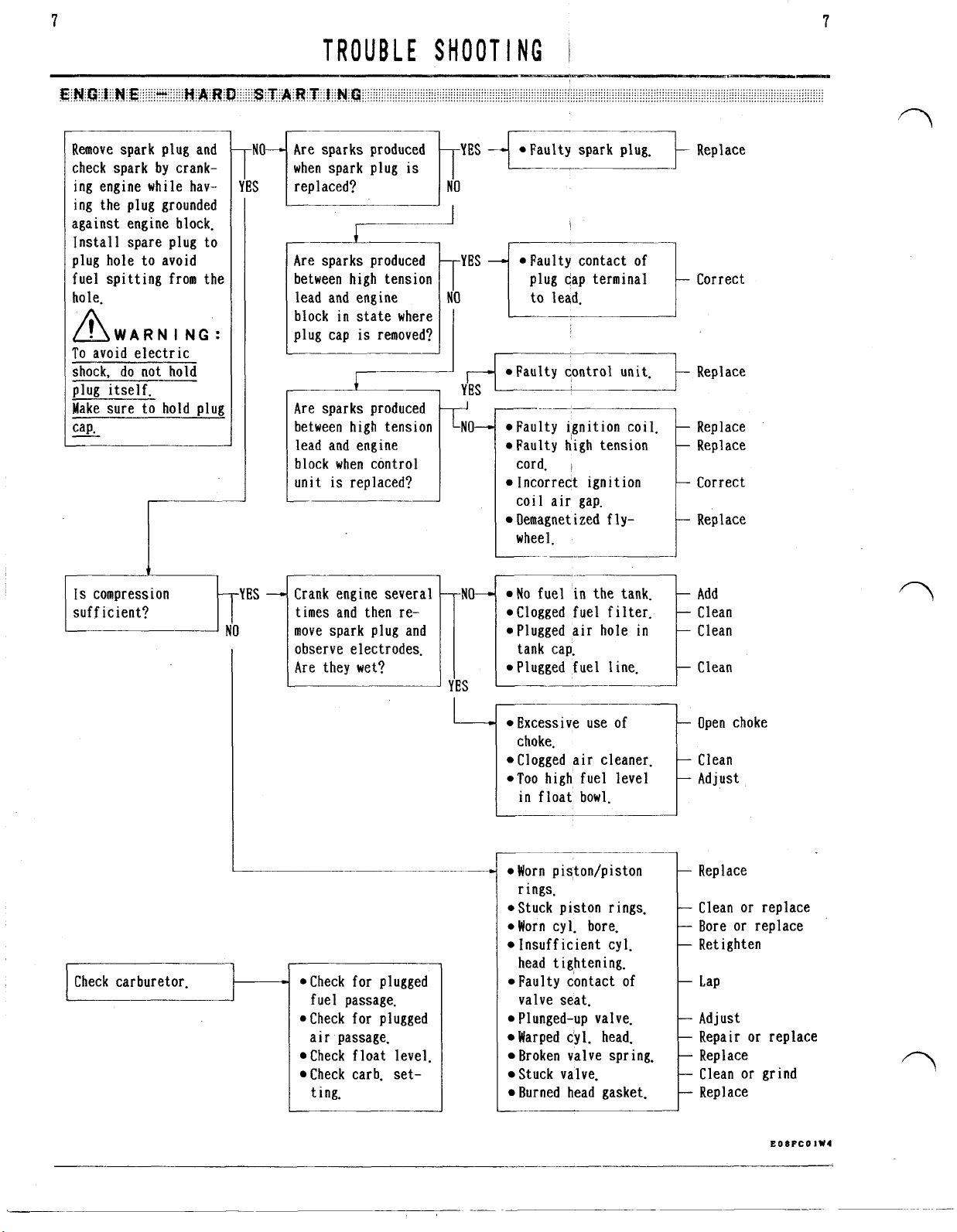

ENGINE - HARD STARTING

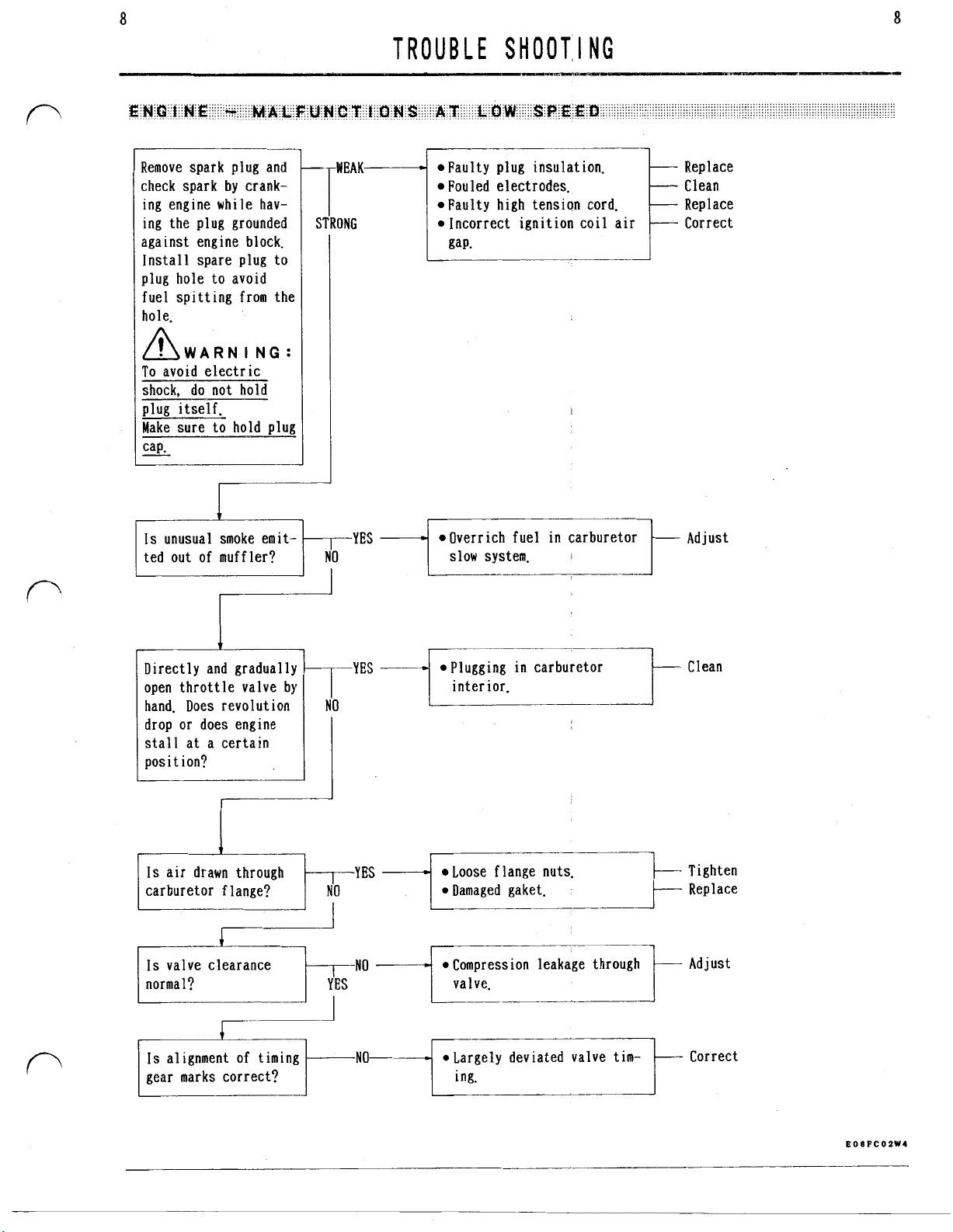

ENGINE - MALFUNCTIONS AT LOW SPEED

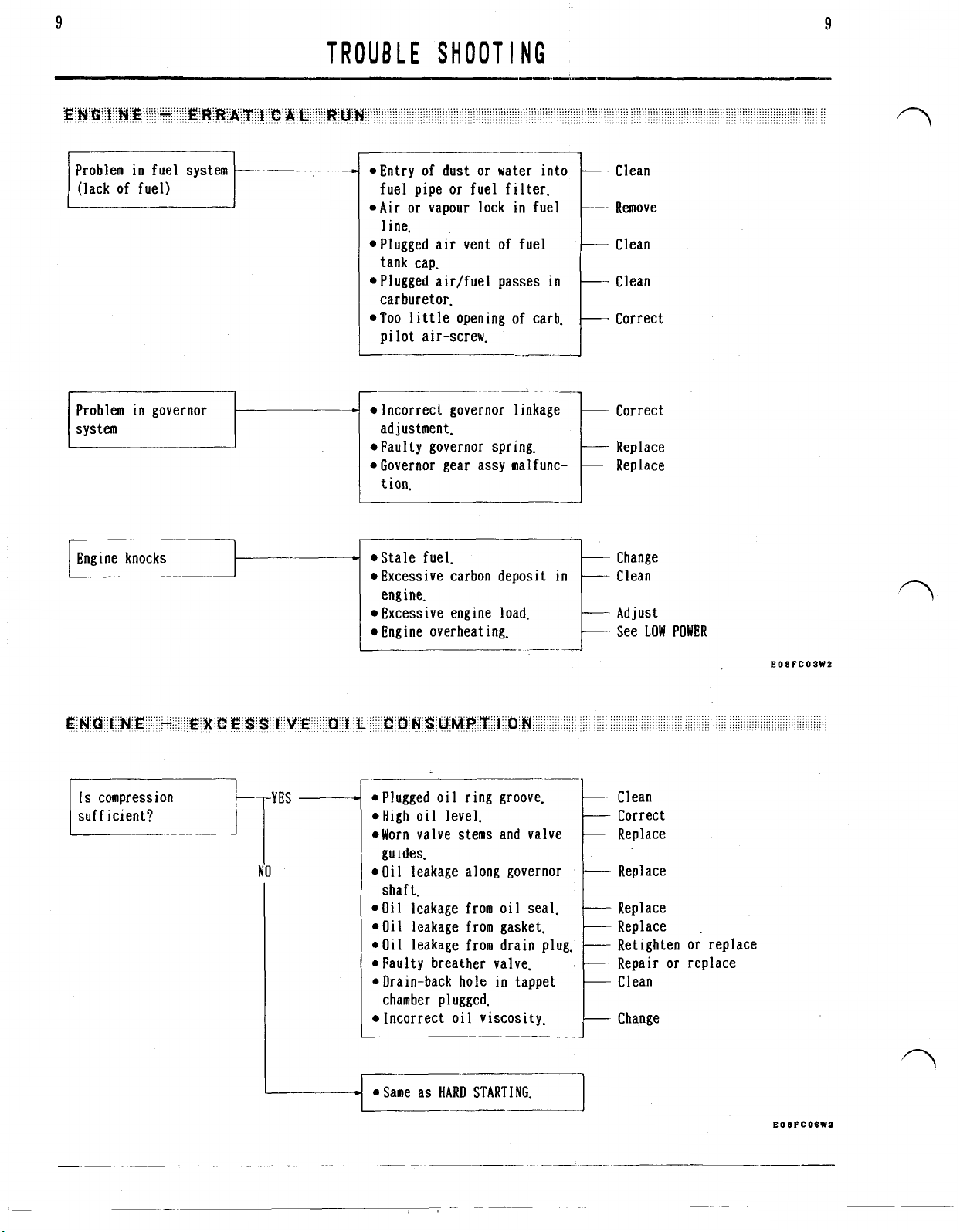

ENGINE - ERRATICAL RUN

ENGINE - EXCESSIVE OIL CONSUMPTION

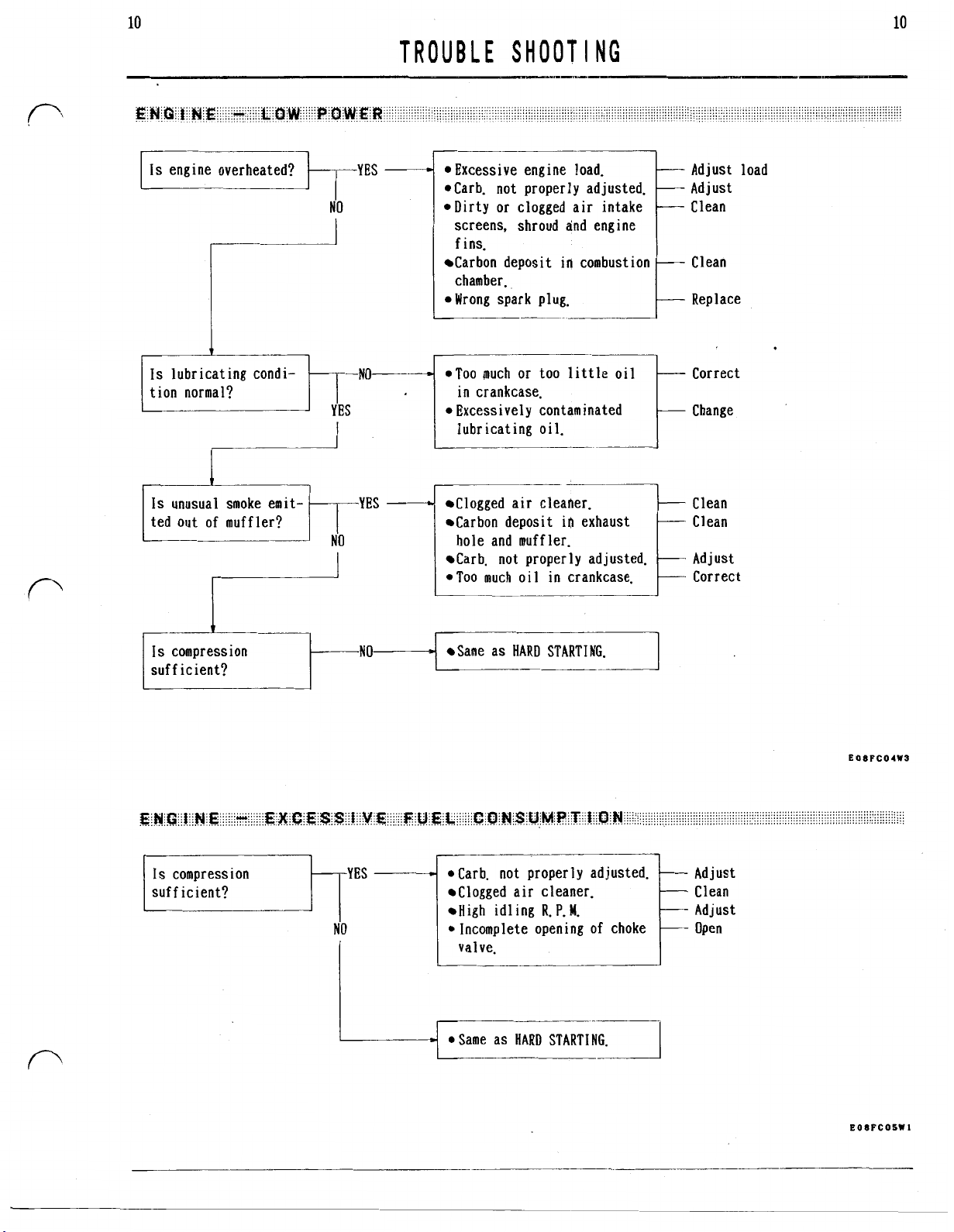

ENGINE - LOW POWER

ENGINE - EXCESSIVE FUEL CONSUMPTION

ENGINE - MALFUNCTIONS OF STOPPING

TORQUE SPECIFICATIONS

CONTROL SYSTEM

GOVERNOR LEVER SETTING

THROTTLE CABLE INSTALLATION

FAST IDLE SPEED ADJUSTMENT

CHOKE ADJUSTMENT

SLOW IDLE SPEED ADJUSTMENT

AIR CLEANER

"K" KLEEN SYSTEM

MAINTENANCE

CARBURETOR

COMPONENTS

REMOVAL

FLOAT CHAMBER REMOVAL

CLEANING

FLOAT ADJUSTMENT

ASSEMBLY AND INSTALLATION

CARBURETOR IDENTIFICATION

COOLING SYSTEM

ENGINE COVER REMOVAL

ENGINE COVER DISASSEMBLY

ENGINE COVER ASSEMBLY AND INSTALLATION

RECOIL STARTER

DISASSEMBLY

CHECK

REASSEMBLY

Page 2

KAWASAKI FC150V ENGINE MANUAL

Table of Contents – Page 2 of 3

ELECTRIC STARTER & CHARGING

TROUBLE SHOOTING

STARTER MOTOR CHECK

COMPONENTS

RING GEAR CHECK

STARTER MOTOR REASSEMBLY

STATOR OUTPUT

IGNITION SYSTEM

TYPE OF IGNITION SYSTEM

SPARK CHECK

CONTROL UNIT CHECK

IGNITION COIL CHECK

FLYWHEEL REMOVAL

FLYWHEEL INSTALLATION

IGNITION COIL AIR-GAP ADJUSTMENT

INTERMEDIATE CONNECTOR INSTALLATION

THROTTLE-LEVER-LINKED ENGINE SWITCH

BAND-BRAKE-LINKED ENGINE SWITCH

CYLINDER HEAD

COMPRESSION CHECK

REMOVAL

MAINTENANCE

INSTALLATION

VALVE

VALVE CLEARANCE ADJUSTMENT

AUTOMATIC COMPRESSION RELEASE (ACR) CHECK

VALVE AND RELATED PARTS REMOVAL

ROCKER ARM STUD INSTALLATION

CHECK AND MAINTENANCE

SERVICE LIMIT

VALVE SPRING SERVICE LIMIT

LAPPING

VALVE SEAT RECONDITIONING

VALVE GUIDE SERVICE LIMIT

ROCKER ARM SERVICE LIMIT

PUSH ROD SERVICE LIMIT

CRANKCASE COVER

REMOVAL

SERVICE LIMIT

OIL SEAL REPLACEMENT

INSTALLATION

Page 3

KAWASAKI FC150V ENGINE MANUAL

Table of Contents – Page 3 of 3

CAMSHAFT

REMOVAL

VISUAL CHECK

SERVICE LIMIT

INSTALLATION

PISTON & CON-ROD

REMOVAL

PISTON AND PISTON RING VISUAL CHECK

PISTON CLEANING

PISTON SERVICE LIMIT

PISTON PIN SERVICE LIMIT

PISTON RING SERVICE LIMIT

PISTON RING INSTALLATION

CON-ROD VISUAL CHECK

CON-ROD SERVICE LIMIT

PISTON AND CON-ROD ASSEMBLY

PISTON/CON-ROD ASSY INSTALLATION

CRANKSHAFT

VISUAL CHECK

SERVICE LIMIT

INSTALLATION

CRANK PIN RE-GRINDING

GOVERNOR

GOVERNOR GEAR CHECK AND REMOVAL

GOVERNOR GEAR INSTALLATION

GOVERNOR SHAFT INSTALLATION

LUBRICATING SYSTEM

ENGINE OIL

OIL SLINGER CHECK

BREATHER SYSTEM

BREATHER REED VALVE CHECK

CYLINDER/CRANKCASE

CYLINDER SERVICE LIMIT

CYLINDER BORE RE-SIZING

BALL BEARING CHECK

BALL BEARING REPLACEMENT

OIL SEAL REPLACEMENT

CAMSHAFT BEARING SERVICE LIMIT

BAND BRAKE

BAND BRAKE MECHANISM

BRAKE SHOE REPLACEMENT

BRAKE CABLE ADJUSTMENT

Page 4

4=stroke

air-cooled

gasoline

engine

WORKSHOP

MANUAL

Page 5

FOREWORD

This manual

nics in a properly equipped

In order to perform the work efficiently and to

avoid costly mistakes, read the text thoroughly,

familiarize yourself with the procedures before

starting work, and then do the work carefully in a

clean area. Whenever special tools

specified. do not use makeshift tools

Precision measurements can only be made if the proper instruments are used, and the use of substitute

tools may adversely affect safe operation.

Whenever you see these

T

I

0

Always follow safe operation and maintenance pract ices.

A

ual and on the equipment. When you see this symbol,

read the message that follows very carefully to

avoid fire, personal injury,

C

A

UT

or

procedures to avoid equipment damage

t ion.

N

0

T E :

interest for more efficient

is

designed for

N

symbols, heed their instructions!

W

A

R N I N

tifies important safety messages in this man-

I 0 N

Indicates message

G

:

:

This

identifies special instructions

use by trained mechashop.

or

equipments are

or

equipment.

W

A

R N I N

This safety alert symbol iden-

or

or

and convenient operat ion.

G

AND

C

A

U

loss

of life.

or

destruc-

points of particular

The term "Replace" and some abbreviations are used

as follows:

Replace

MIN

MAX

Assy

STD

PTO

Approx.

Carb.

Con-rod

Cyl.

Dia.

All

may be reproduced, stored in a retrieval system,

or

tronic mechanical photocopying, recording

wise. without the prior written permission of Engine

Division/Kawasaki Heavy Industries, Ltd.

ty can be accepted for any inaccuracies

in this publication, although every possible care

has been taken to make it as complete and accurate

as possible.

ject to change without prior notice

Illustrations in this publication are intended for

reference use only and may not depict actual model

component parts.

=

Usually means replace with a new part

=

Minimum

=

Maximum

=

Assembly

=

Standard

=

Power take off

=

Approximately (Approximate)

=

Carburetor

=

Connecting rod

=

Cylinder

=

Diameter

rights reserved.

transmitted in any form

All

procedures and specifications sub-

NO

part of this publication

or

by any means, elec-

or

other-

No

liabili-

or

omissions

or

obligation.

EOOFCOIW9

SAFETY

WA

R

W

A

R N I N

mable and can be explosive under certain con- sembly operations on the equipment with the

A

ditions. Stop the engine. Do not smoke. Make sure electric starter, disconnect the negative

the area

of flame

a pilot light.

the spark plug wire from the spark

accidental starting.

A

in servicing the product.

is

or

W A R

equipment, always stop the engine and remove

WARN I NG

or

a piece of thick cloth from edges and heat

G

:

Gasoline

is

extremely flam-

__--

well ventilated and free from any source lead from the battery to avoid the possibility of

sparks; this includes any appliance with accidentally cranking the engine while partially

disassembled.

N I N G

When servicing the engine

or

A

plug

to avoid

:

Protect your hands with gloves

in a clean. dry environment with dry hands. For maximum shock hazard protection, connect the equipment

ground terminal to an earth ground.

N I N G

W

A

R N I N G

when working on the electrical equipment. Work

:

Before performing any disas-

:

Always minimize shock hazards

EO1FC1W1

Page 6

TABLE

OF

CONTENTS

Page 7

PI STON

PI STON

PI STON

PI STON

1

STON

P

PI STON

GOVERNOR

GOVERNOR GEAR CHECK AND REMOVAL

GOVERNOR GEAR INSTALLATION

GOVERNOR SHAFT INSTALLATION

60

60

60

60

Page 8

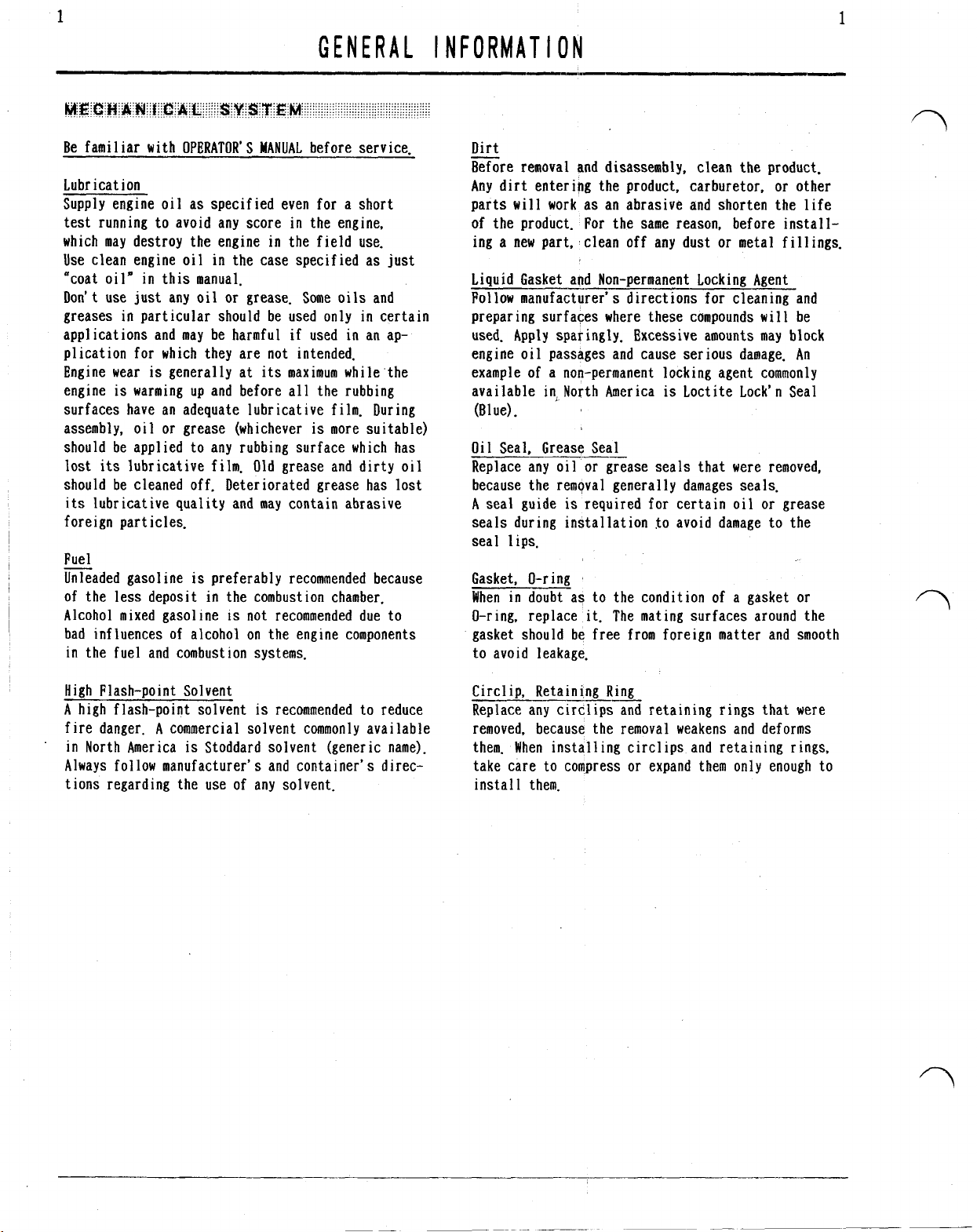

1

1

GENERAL

Be famil iar with OPERATOR’

Lubrication

Supply engine oil as specified even for a short

test running to avoid any score

which may destroy the engine in the field use.

Use clean engine oil in the case specified as just

“coat oil” in this manual.

Don’ t use just any

greases

applications and may be harmful if used in an application for which they are not intended.

Engine wear

engine

surfaces have an adequate lubricative film. During

assembly, oil or grease (whichever

should be applied to any rubbing surface which has

lost its lubricative film. Old grease and dirty oil

should be cleaned off. Deteriorated grease has lost

its

foreign particles.

Fuel

Unleaded gasoline

of the less deposit in the combustion chamber.

Alcohol mixed gasoline

bad influences

in the fuel and combustion systems.

in

particular should be used only

is

is

warming up and before all the rubbing

lubricative quality and may contain abrasive

oil

generally at

is

of

alcohol on the engine components

S

MANUAL before service.

in

the engine,

or grease. Some

its

maximum while.the

preferably recommended because

is

not recommended due to

oils

and

in

certain

is

more suitable)

I

NFORMAT

Dirt

Before removal and disassembly, clean the product.

Any dirt entering the product, carburetor, or other

parts will work as an abrasive and shorten the life

of the product. For the same reason, before install-

ing

a

Liquid Gasket and Non-permanent Locking Agent

Follow manufacturer’s directions for cleaning and

preparing surfaces where these compounds wi

used. Apply sparingly. Excessive amounts may block

engine oil passages and cause serious damage. An

example of a non-permanent locking agent commonly

available in

(Blue).

Oil Seal, Grease Seal

Replace any oil or grease seals that were removed,

because the removal generally damages seals.

A seal guide

seals during installation

seal lips.

Gasket, 0-r

When

O-ring, replace

gasket should be free from foreign matter and smooth

to avoid leakage.

I

ON

new part,

in

doubt as to the condition of a gasket or

’

clean off any dust

North

America

is

required for certain oil or grease

ing

it.

The mating surfaces around the

or

metal fillings.

11

be

is

Loctite Lock’n Seal

to

avoid damage to the

High Flash-point Solvent

A

high flash-point solvent

fire danger.

in

North America

Always follow manufacturer’s and container’s directions regarding the use of any solvent.

A

commercial solvent commonly available

is

Stoddard solvent (generic name).

is

recommended to reduce

Circl ip, Retaini,ng Ring

Replace any circlips and retaining rings that were

removed, because the removal weakens and deforms

them. When installing circlips and retaining rings,

take care to compress or expand them only enough to

install them.

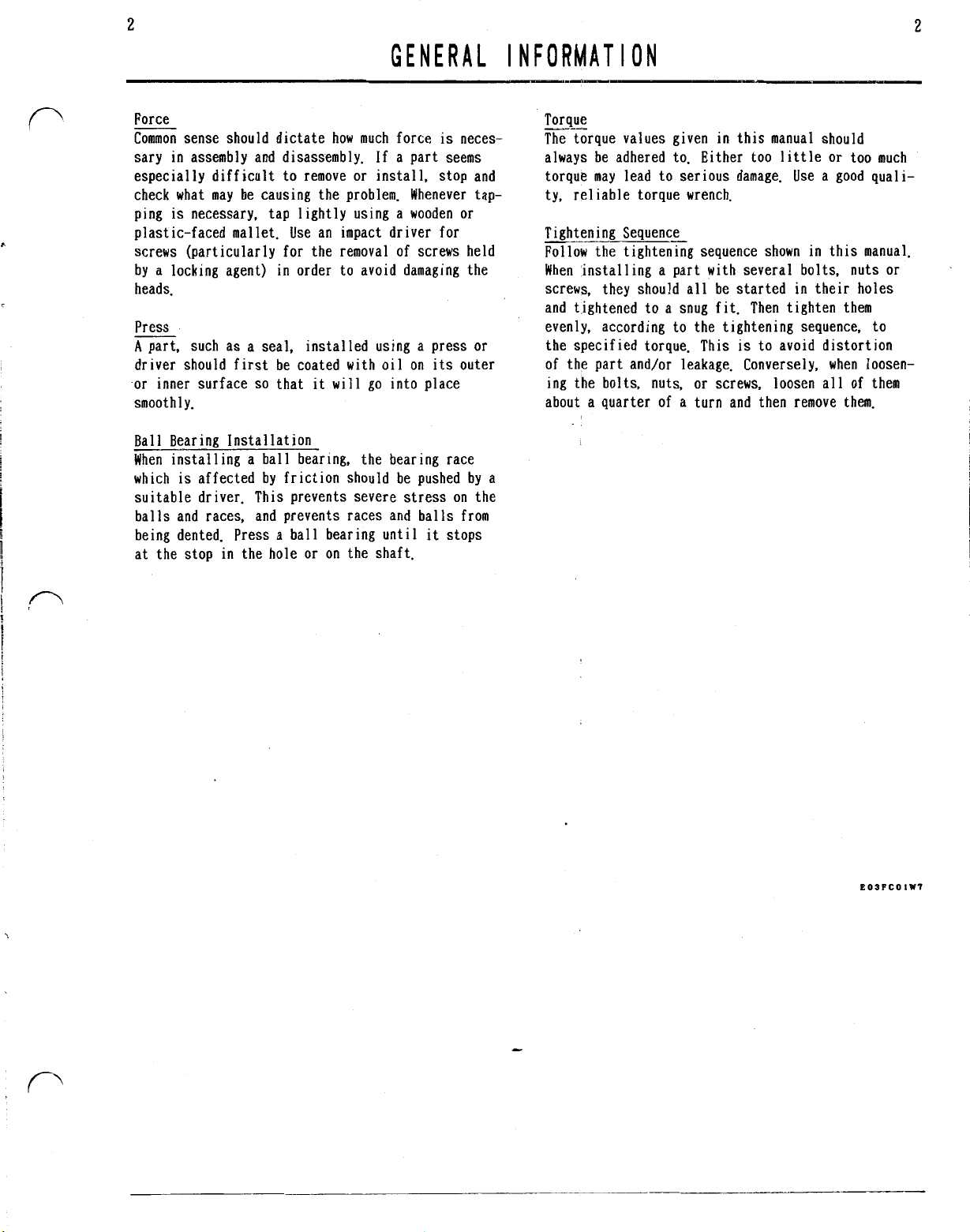

Page 9

2

2

GENERAL

Force

Common sense should dictate how much force

sary in assembly and disassembly.

especially difficult to remove

check what may be causing the problem. Whenever tapping

is

necessary, tap lightly using a wooden or

plastic-faced mallet. Use an impact driver for

screws (particularly for the removal of screws held

by a locking agent) in order to avoid damaging the

heads.

Press

A

part, such as a seal, installed using a press or

driver should first be coated with oil on

.or inner surface

smoothly.

Ball Bearing Installation

When installing a ball bearing, the bearing race

which

is

affected by friction should be pushed by a

suitable driver. This prevents severe stress on the

balls and races, and prevents races and balls from

being dented. Press a ball bearing until it stops

at the stop

so

that

it

in

the hole or on the shaft.

If

or

install, stop and

will go into place

is

neces-

a part seems

its

outer

I

NFORMAT

Torque

The torque values given

always be adhered to. Either too little or too much

torque may lead to serious damage. Use a good quality, reliable torque wrench.

Tightening Sequence

follow

When installing a part with several bolts, nuts or

screws, they should all be started in their holes

and tightened to

evenly, according to the tightening sequence, to

the specified torque.

of the part and/or leakage. Conversely, when loosen-

ing the bolts, nuts,

about a quarter of a turn and then remove them.

I

ON

the

tightening sequence shown

a

snug fit. Then tighten them

in

this manual should

in

this manual.

This

is

to avoid distortion

or

screws, loosen all of them

EOSPCOIW7

Page 10

3

3

GENERAL

No

Shock

The electrical parts should never be sharply struck,

with a hammer, or dropped on a hard surface. Such

a shock to the parts may damage them.

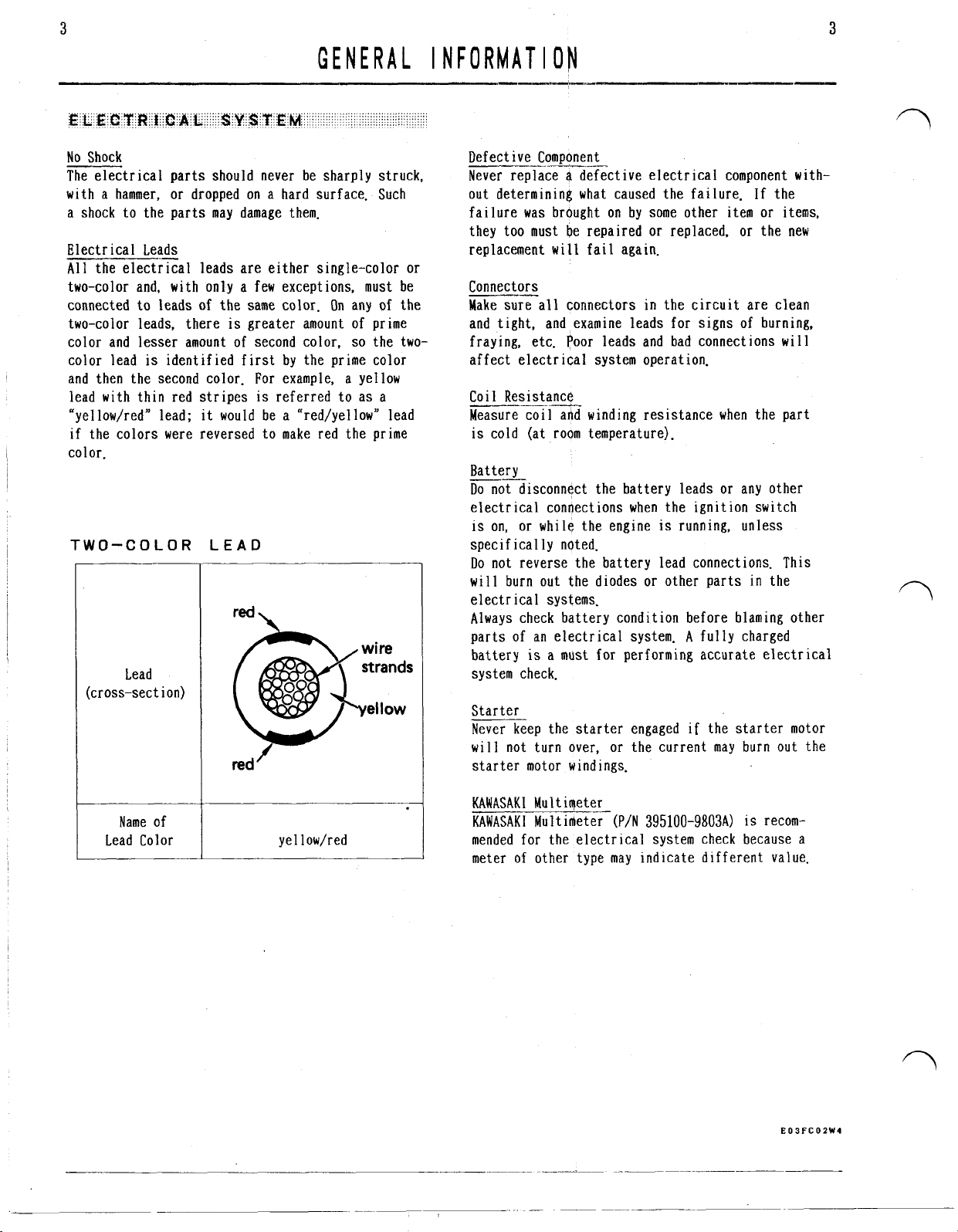

Electrical Leads

All

the electrical leads are either single-color or

two-color and,

connected to leads of the same color. On any of the

two-color leads, there

color and lesser amount of second color,

color lead

and then the second color. For example, a yellow

lead with thin red stripes

“yellow/red” lead;

if the colors were reversed to make red the prime

color.

TWO-COLOR

(cross-sect ion)

with

only a few exceptions,

is

greater amount of prime

is

identified first by the prime color

is

referred to as a

it

would be a “red/yellow” lead

LEAD

must

so

the two-

red

Lead

red’

I

NFORMAT

Defective Component

Never replace

out determining what caused the failure. If the

failure was brought on by some other item or items,

they too must be repaired or replaced, or the new

replacement

be

Connectors

~-

Make sure all connectors in the circuit are clean

and tight, and examine leads for signs of burning,

fraying, etc. Poor leads and bad connections will

affect electrical system operation.

Coil Resistance

Measure coil add winding resistance when the part

is

cold (at room temperature).

Battery

~-

Do

not disconnect the battery leads or any other

electrical connections when the ignition switch

is

on, or while the engine

specifically noted.

Do

not reverse the battery lead connections.

will burn out the diodes or other parts

electrical systems.

Always check battery condition before blaming other

parts of an electrical system.

battery

system check.

Starter

Never keep the starter engaged if the starter motor

will not

starter motor windings.

I

ON

a

will

is

a must for performing accurate electrical

turn

over, or the current may burn out the

defective electrical component with-

fail again.

is

running, unless

This

in

the

A

fully charged

Name of

Lead Color

ye

1

1

ow/red

KAWASAKI

KAWASAKI

mended for the electrical system check because a

meter of other type may indicate different value.

MultimeterMultimeter

(P/N

395100-9803A)

is

recom-

Page 11

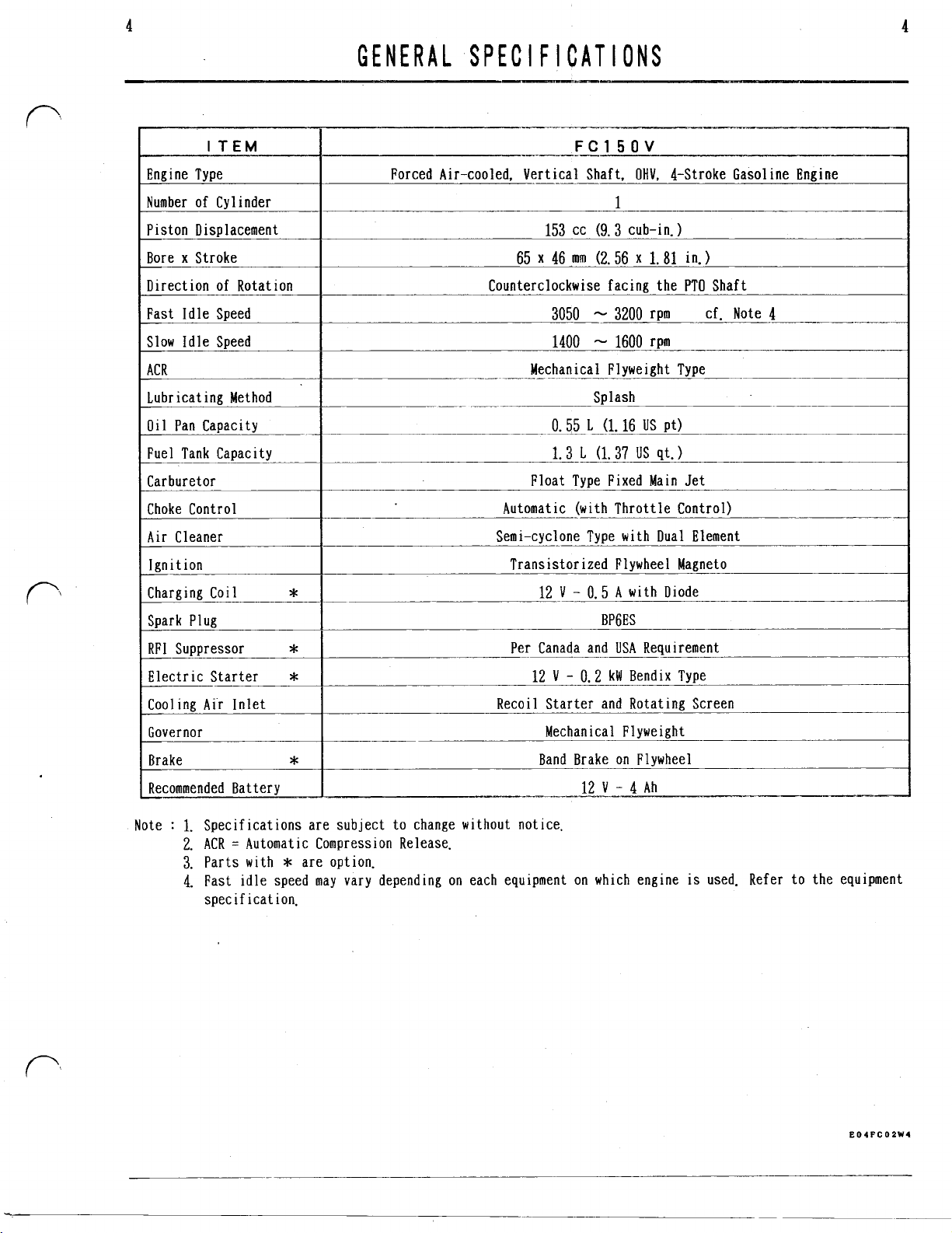

4

4

Number of Cylinder

Oil

Pan Capacity

GENERAL SPEC

I F I

CAT

I

ONS

~__=.-

Automatic (with Throttle Control)

FC15OV

1

3200

rpm cf. Note

Mechanical Flyweight Type

0.55

L

(1.16

US

Pt)

1.

3

g.

37

us

qt.

4

Note

:

one Type with Dual Element

ransistorized Flywheel Magneto

V

0.5

A

with Diode

Per Canada and USA Requirement

12

V

0.2

kW

Bendix Type

Mechanical Flyweight

Band Brake on Flywheel

1.

Specifications are subject to change without notice.

2.

ACR = Automatic Compression Release.

3.

Parts with * are option.

is

4.

Fast idle speed may vary depending on each equipment on which eng

specification.

ine

used. Refer to the equ

ipment

Page 12

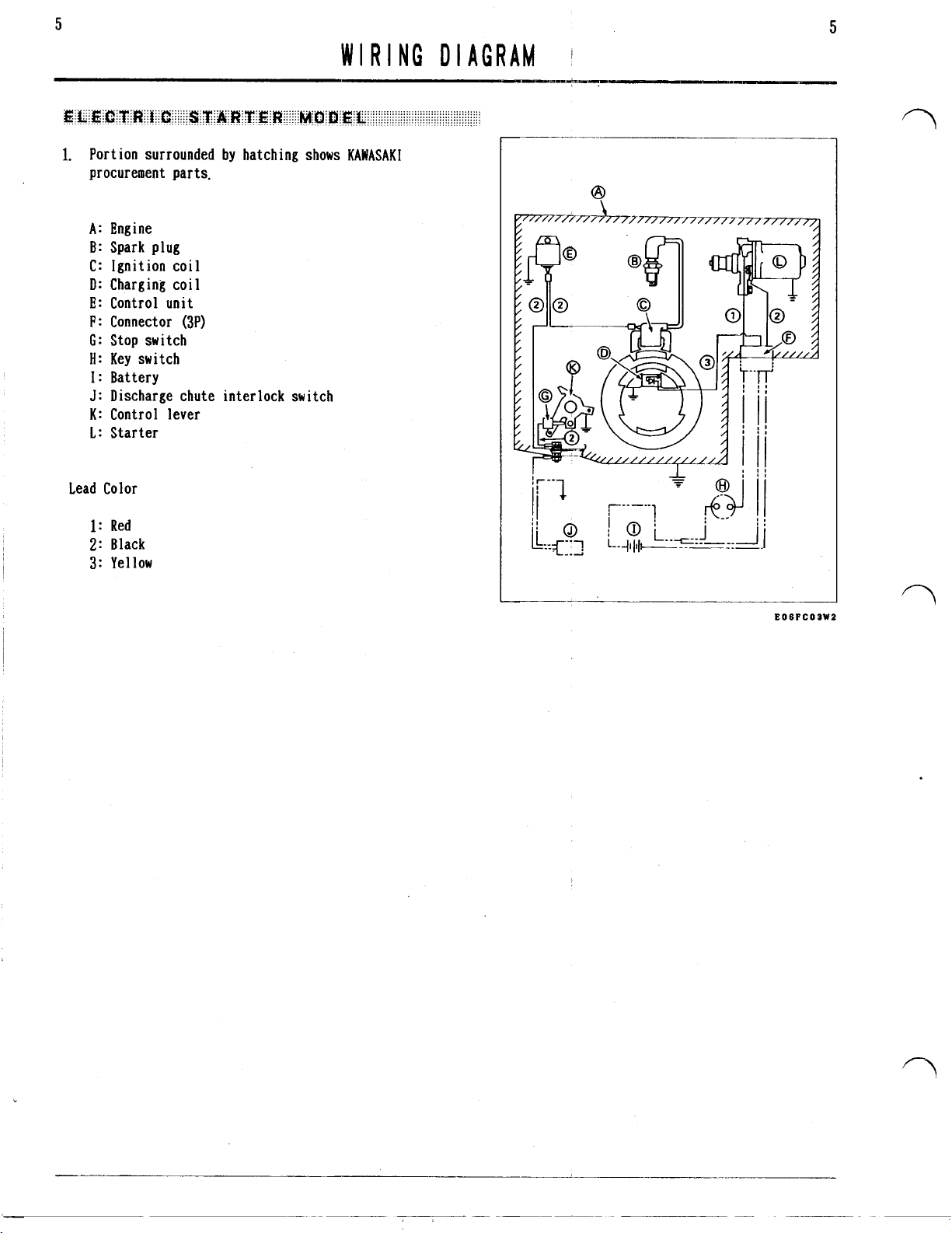

5

5

1.

Portion surrounded

procurement parts.

A:

Engine

B:

Spark plug

C: Ignition coil

D:

Charging coil

E:

Control unit

P:

Connector

G:

Stop switch

H:

Key switch

I:

Battery

J:

Discharge chute interlock switch

K:

Control lever

1:

Starter

Lead Color

by

(3P)

WIRING DIAGRAM

hatching shows

KAWASAKI

1

E.

1:

Red

2:

Black

3:

Yellow

E06PC09W2

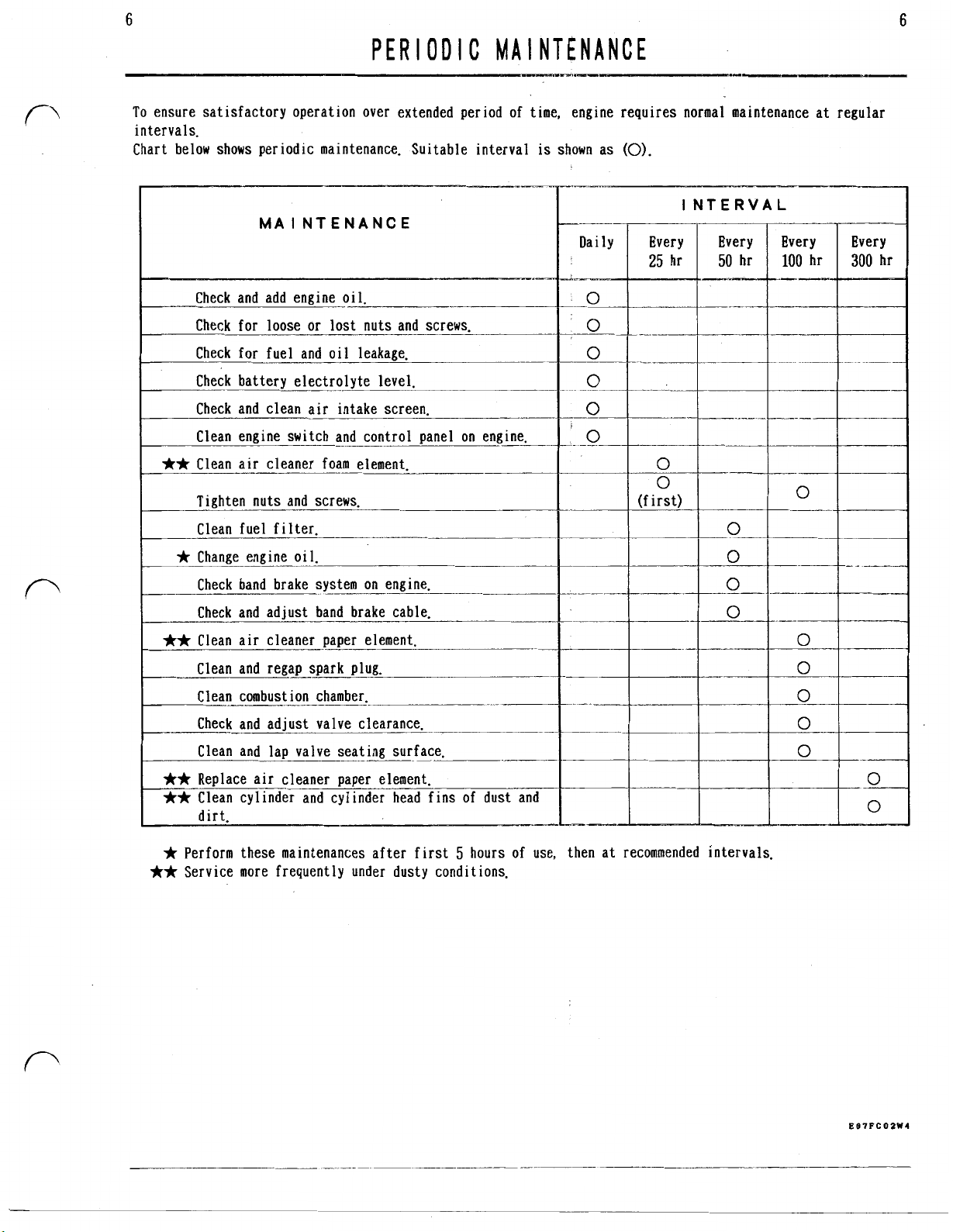

Page 13

6

PER

I

OD

I

C

MA

I

NTENANCE

To ensure satisfactory operation over extended period of time, engine requires normal maintenance at regular

intervals.

Chart below shows periodic maintenance. Suitable interval

MAINTENANCE

is

shown as

Daily

(0).

Every

25

I

NTERVAL

Every

hr

50

Every

100

hr

Every

300

6

Check and add engine oi

Check for loose

Check for fuel and oil leakage.

Check battery electrolyte level.

Check and clean air intake screen.

Clean engine switch and control panel on engine.

**

Clean air cleaner foam element.

Tighten nuts and screws.

Clean fuel filter.

*

Change engine oil.

Check band brake system on engine.

Check and adjust band brake cable.

**

Clean air cleaner paper element.

Clean and regap spark plug.

Clean combustion chamber.

Check and adjust valve clearance.

or

1.

lost nuts and screws

(first)

Clean and lap valve seating surface.

**

Replace air cleaner paper element.

**

Clean cylinder and cylinder head fins of dust and

Ir Perform these maintenances after first

**

Service more frequently under dusty conditions.

5

hours of use, then at recommended intervals.

Page 14

7

7

I

Remove spark plug and

check spark by crank-

ing engine while having the plug grounded

against engine block.

Install spare plug to

plug hole to avoid

fuel spitting

ha le.

Make sure to hold plug

from

YES

the

Are sparks produced

when spark plug

lead and engine

block

plug cap

Are sparks produced

between high tension

lead and engine

block when control

unit

TROUBLE

in

state where

is

removed?

is

replaced?

SHOOTING

is

elty

I

spark plug. Replace

plug cap terminal Correct

Faulty high tension Rep1 ace

Incorrect ignition Correct

Is

compression

sufficient?

Check carburetor.

Demagnetized fly- Rep ace

Rep lace

I.---

Crank engine several

times and then remove spark plug and

observe electrodes.

Are they wet?

’

YES

*No

fuel in the tank.

*Clogged fuel filter. Clean

.Plugged air hole in Clean

tank cap.

*Plugged fuel line. Clean

Excessive use of

Clogged air cleaner.

*Too

high fuel level

in float bowl.

Open choke

Clean

Adjust

~_-

Worn piston/piston

ings.

*Stuck piston rings.

Worn cyl. bore.

Insufficient cyl.

head tightening.

I-

*Check for plugged

fuel passage.

.Check

for

plugged

air passage,

Check float level.

Check carb. set-

t

ing.

*Faulty contact of Lap

valve seat.

Plunged-up valve.

Warped cyl. head.

Broken valve spring. Replace

Stuck valve. Clean

Burned head gasket.

Replace

Clean

or

replace

Bore

or

replace

Retighten

Adjust

Repair

Replace

or

replace

or

grind

EOOPCOIW4

Page 15

8

8

I

Remove spark plug and

check spark by crank-

ing engine while having the plug grounded

against engine block.

Install spare plug to

plug hole to avoid

fuel spitting from the

hole.

To avoid electric

shock, do not hold

plug itself.

Make sure to hold plug

cap.

STRONG Incorrect ignition coil air Correct

TROUBLE

Faulty plug insulation.

Fouled electrodes.

*Faulty high tension cord. Rep

SHOOT,I

NG

1

ace

Is

unusual smoke emit-

ted out of muffler?

Directly and gradually

open throttle valve by

hand. Does revolution

drop or does engine

stall at a certain

position?

Is

air drawn through

carburetor flange?

Is

valve clearance Compression leakage through

NO

YES

NO

*

Overrich fuel

slow system.

I

*Plugging in carburetor

interior.

Loose flange nuts. Tighten

Damaged gaket. Replace

in

carburetor Adjust

Clean

Is

alignment

of

timing

EOBPCOZW4

Page 16

9

9

Problem

system

in

governor

TROUBLE

.Entry of dust

fuel pipe

.Air

1

ine.

*Plugged air vent of fuel Clean

tank cap.

*Plugged air/fuel passes in Clean

carburetor.

.Too

pilot air-screw.

Incorrect governor linkage Correct

adjustment.

Faulty governor spring. Rep 1 ace

Governor gear assy malfunc- Replace

t

ion.

SHOOT

or

or

vapour lock in fuel Remove

little opening of carb. Correct

I

NG

or

fuel filter.

Engine knocks

NO

Stale fuel.

Excessive carbon deposit

engine.

Excessive engine load.

Engine overheating. See LOW

.Plugged oil ring groove. C 1 ean

.High

oil

level. Correct

.Worn valve stems and valve Replace

guides.

.Oil

leakage along governor Rep1 ace

shaft.

.Oil leakage from oil seal.

*Oil

leakage from gasket.

.Oil leakage from drain plug. Retighten

Faulty breather valve. Repair

.Drain-back hole

chamber plugged.

Incorrect oil viscosity. Change

in

in

tappet

Change

Clean

Adjust

POWER

1

ace

Rep

Replace

or

Clean

or

replace

replace

Same as

HARD

STARTING.

I

EOIFCOBV?

Page 17

10

10

Is

unusual

ted out of

TROUBLE

~Carb. not properly adjusted. Adjust

*Dirty or clogged air intake Clean

screens, shroud and engine

fins.

Carbon deposit

chamber.

*Wrong spark plug. Rep

NO--

I

*Too much or too little oil Correct

in crankcase.

Excessively contaminated Change

lubricating oil.

Clogged air cleaner. Clean

Carbon deposit

hole and muffler.

Carb. not properly adjusted. Adjust

SHOOT

I

NG

in

combust ion Clean

I

io

exhaust Clean

Adjust load

1

ace

Correct

Same as

sufficient?

sufficient?

Is

compress ion *Carb. not properly adjusted. Adjust

Clogged air cleaner. Clean

High id1 ing

Incomplete opening

valve.

HARD

STARTING.

R.

P.M.

___-

of

choke Open

Adjust

EOBFCO4W3

Page 18

11

11

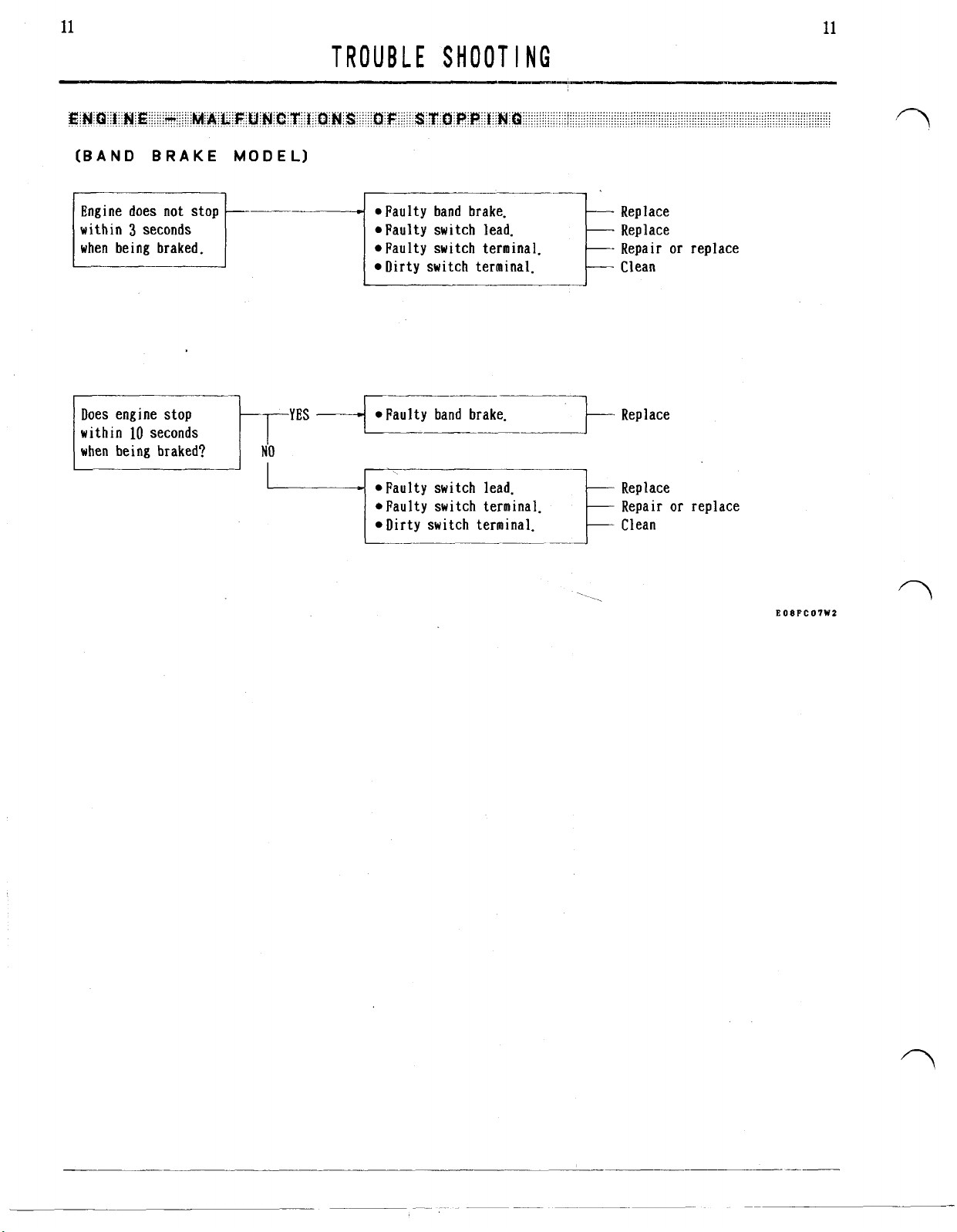

TROUBLE

(BAND BRAKE MODEL)

Engine does not stop

3

within

when being braked.

I

Does engine stop -+Faulty band brake.

within

when being braked?

seconds

10

seconds

I

*Faulty band brake.

.Faulty switch lead.

Faulty switch terminal.

Dirty switch terminal. Clean

Faulty switch lead. Replace

*Faulty switch terminal.

Dirty switch terminal. Clean

SHOOT

I

NG

Rep

1

ace

1

ace

Rep

Repair or replace

Rep

1

ace

Repair or replace

E08PC07W2

Page 19

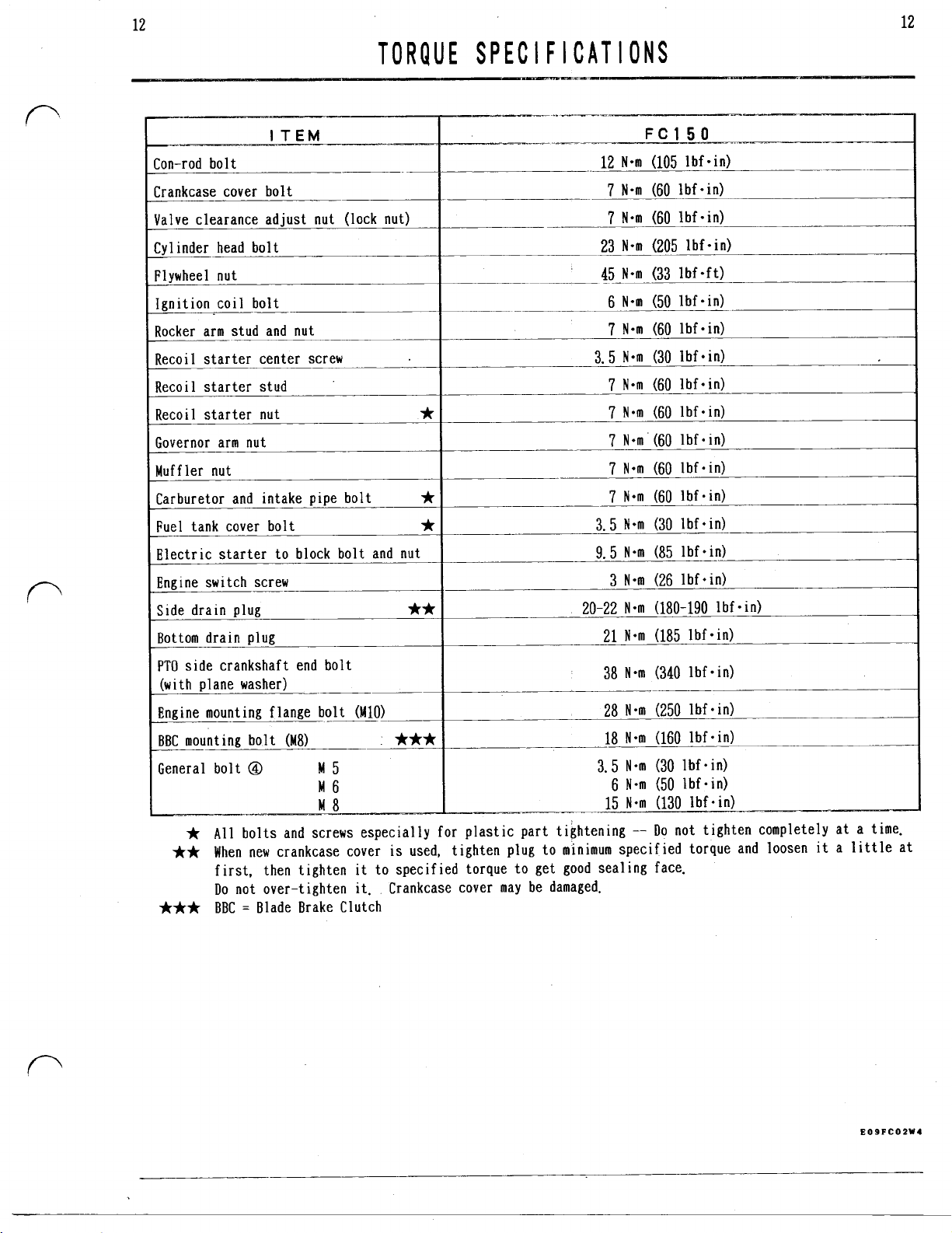

12

12

I

Governor arm nut

TORQUE

SPEC

I

F

I

CAT

I

ONS

12

N-m

7

N.m

7

N-m

23

N-m

45

N-m

6

N-m

7

N-m

3.5

N-m

7

N-m

7

N-m

7

N.m.(60 lbf-in

7

N-m

7

N-m

FC150

(105

lbf-in

(60

lbf-in

(60

lbf-in)

(205

lbf-in)

(33

lbf -ft)

(50

lbf-in)

(60

lbf-in)

(30

lbf-in)

(60

lbf-in)

(60

lbf-in)

(60

lbf-in)

(60

lbf-in)

__.___..___

3.5

N.m

(30

9.5

N-m

(85

3

N-m

(26

20-22

N-m

Side drain plug

21

(with plane washer)

Engine mounting flange bolt

BBC mounting bolt (M8)

General bolt

(M10)

38

28

18

3.5

15

j,

All bolts and screws especially for plastic part tightening

**

***

When new crankcase cover

first, then tighten it to specified torque to get good sealing face.

Do

not over-tighten it. Crankcase cover may be damaged.

BBC = Blade Brake Clutch

is

used, tighten plug to minimum specified torque and loosen it a little at

(180-190

N-m

(185

N-m

(340

N-m(250 lbf-in

N-m

(160

N-m

(30

6

N-m

(50

N-m

(130

Do

lbf-in

lbf .in)

lbf-in

lbf-in)

lbf-in)

lbf-in)

lbf-in

lbf-in)

Ibf-in)

lbf-in

not tighten completely at a time.

E09FCOZW4

Page 20

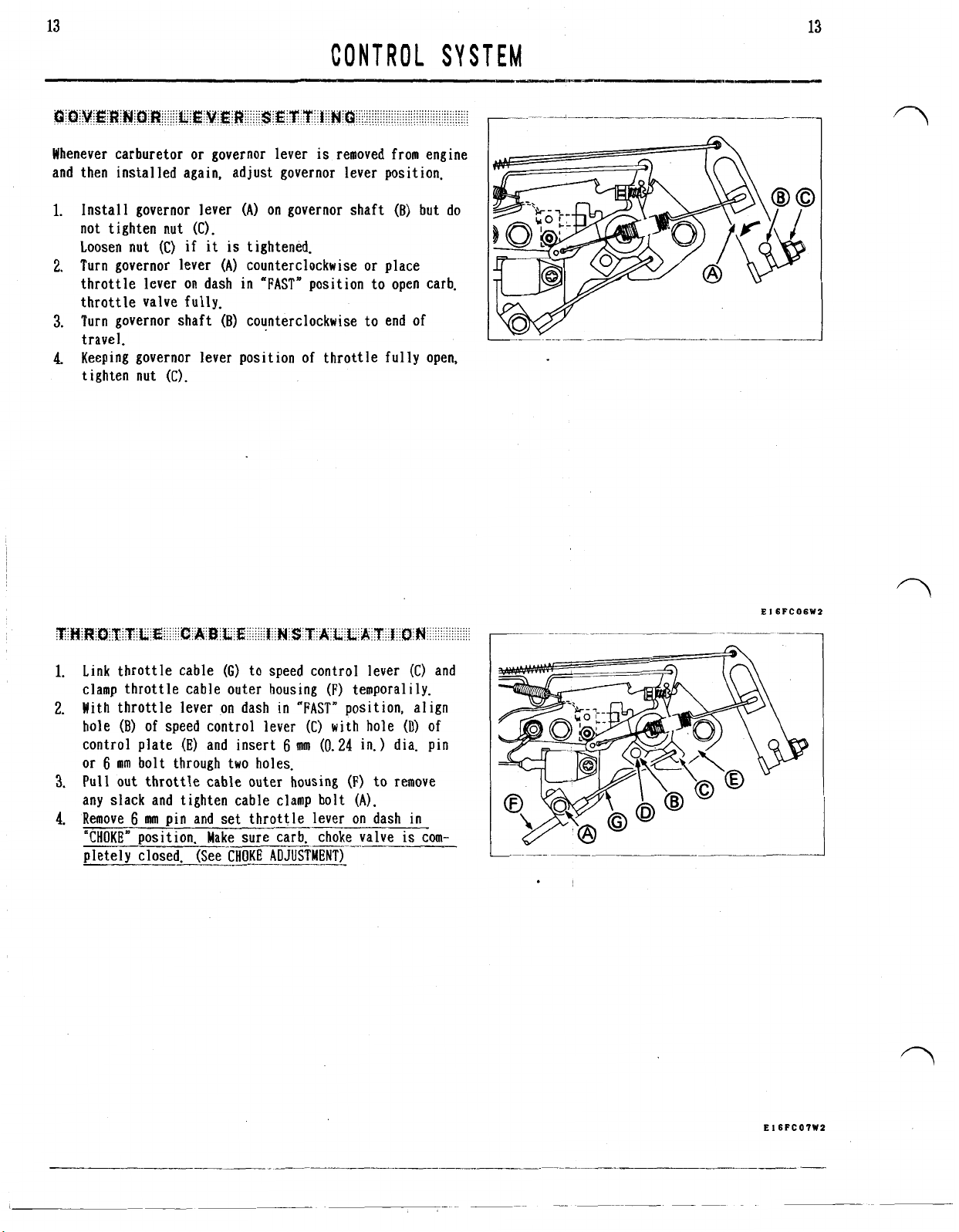

13

13

Whenever carburetor

or

governor lever

CONTROL

is

removed from engine

SYSTEM

and then installed again. adjust governor lever position.

Install governor lever

on governor shaft

(B)

but do

(A)

not tighten nut (C).

(C)

Loosen nut

Turn governor lever

throttle lever on dash in

if it is tightened.

(A)

counterclockwise

"FAST*

position to open carb.

or

place

throttle valve fully.

Turn governor shaft

(B)

counterclockwise to end

of

travel.

Keeping governor lever position of throttle fully open,

tighten nut

(C).

Link throttle cable

clamp throttle cable outer housing

(G)

to speed control lever

(F)

temporalily.

(C)

and

With throttle lever on dash in "FAST" position, align

hole

(B)

of

speed control lever

control plate

or

6

mm bolt through two holes.

Pull

out throttle cable outer housing

(E)

and insert 6 mm

any slack and tighten cable clamp bolt

(C)

with hole

(0.24

in.) dia. pin

(F)

to remove

(A).

(D)

of

Remove 6 mm pin and set throttle lever on dash in

is

"CHOKE* position. Make sure carb. choke valve

~~

corn-

pletely closed. (See CHOKE ADJUSTMENT)

E

I6FCO6W2

E

16FCO?W2

Page 21

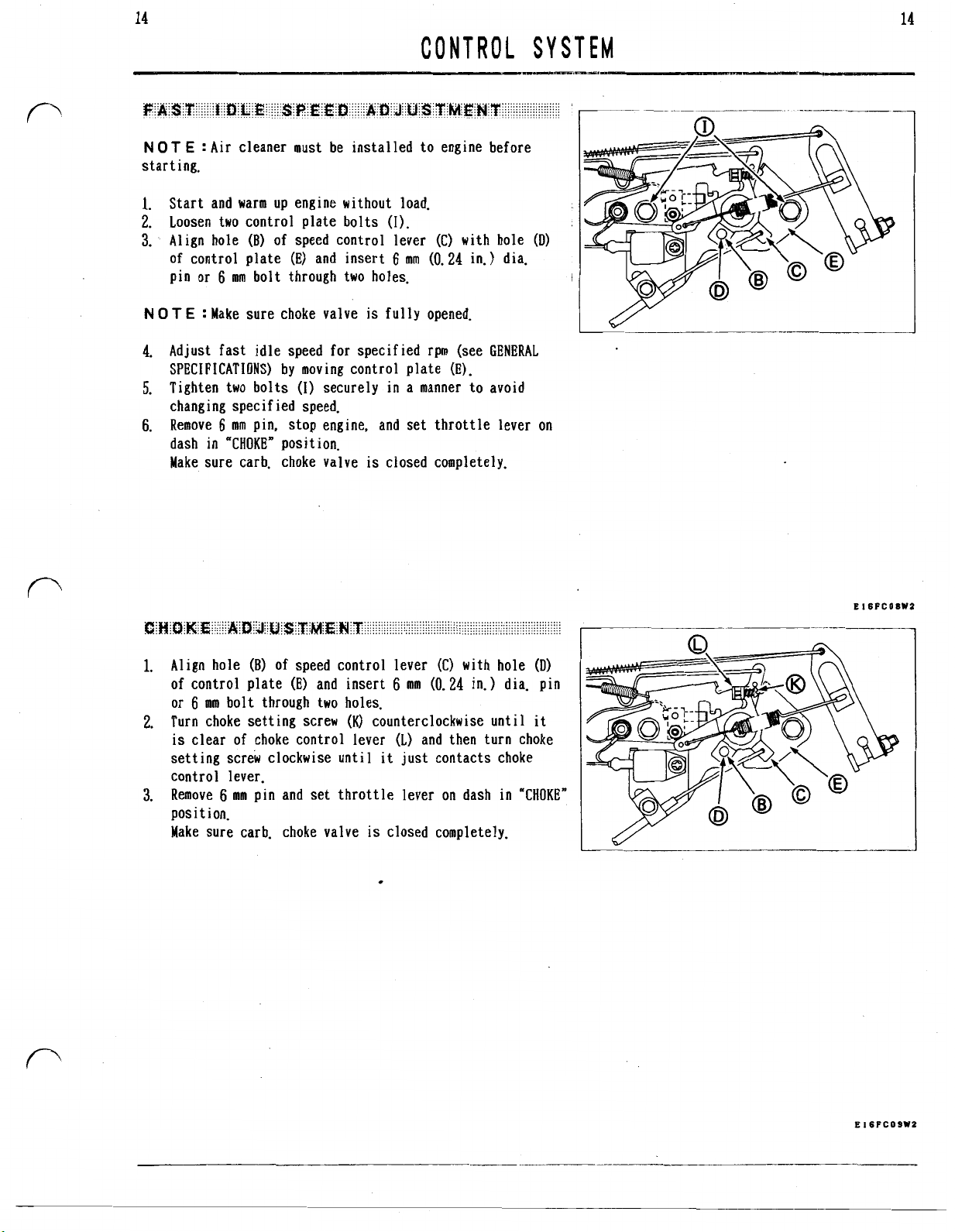

14

14

CONTROL

NOT

E

:

Air cleaner must be installed to engine before

starting.

1.

Start and warm up engine without load.

2.

Loosen two control plate bolts

3.

Align hole

of control plate (E) and insert 6 mm

pin or

NOT

E

4.

Adjust fast idle speed for specified rpm (see GENERAL

SPECIFICATIONS) by moving control plate (E).

5.

Tighten two bolts

changing specified speed.

6.

Remove 6 mm pin, stop engine, and set throttle lever on

dash in "CHOKE" position.

Make sure carb. choke valve

(B)

of

speed control lever (C) with hole

6

mm bolt through two holes.

:

Make sure choke valve

(I)

securely in a manner to avoid

(I).

(0.24

in.) dia.

is

fully opened.

is

closed completely.

SYSTEM

(I))

!

1.

Align hole

of control plate

or

6

2.

Turn choke setting screw

is

clear of choke control lever

setting screw clockwise until it just contacts choke

control lever.

3.

Remove 6 mm pin and set throttle lever on dash

posit ion.

Make sure carb. choke valve

(B)

of

speed control lever (C) with hole

(E)

and insert

mm bolt through two holes.

6

mm

(0.24

in.) dia. pin

(K)

counterclockwise until it

(1)

and then turn choke

is

closed completely.

(D)

in

"CHOKE"

E16PCOSWZ

Page 22

15

15

CONTROL

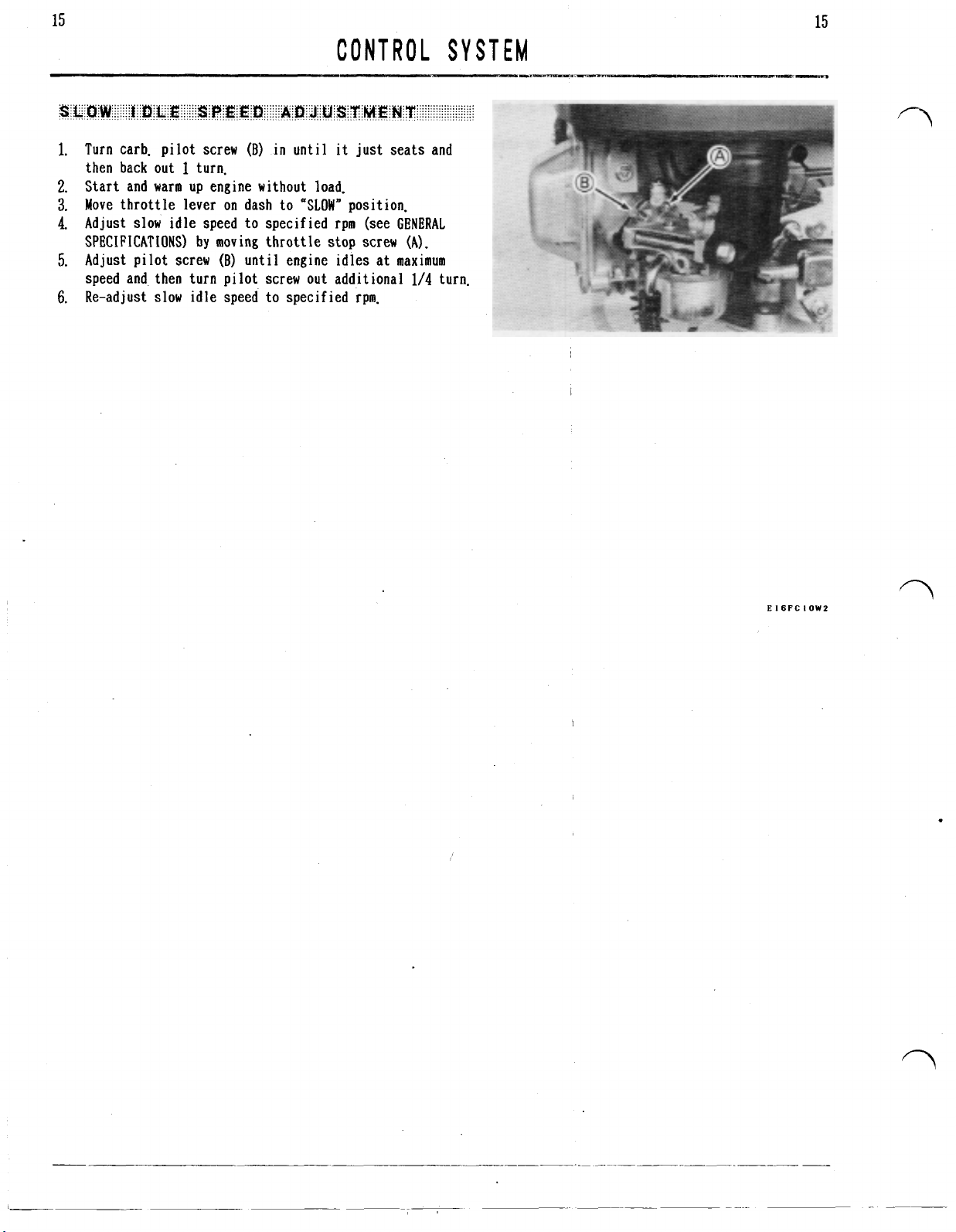

1.

Turn carb. pilot screw

then back out

2.

Start and warm up engine without load.

3.

Move throttle lever on dash to "SLOW" position.

4.

Adjust slow idle speed to specified rpm (see GENERAL

SPECIFICATIONS) by moving throttle stop screw (A).

5.

Adjust pilot screw

speed and then turn pilot screw out additional

6.

Re-adjust slow idle speed to specified rpm.

1

turn.

(B)

in until it just seats and

(B)

until engine idles at maximum

SYSTEM

1/4

turn.

E

I6FC

I

OW2

Page 23

16

16

AIR

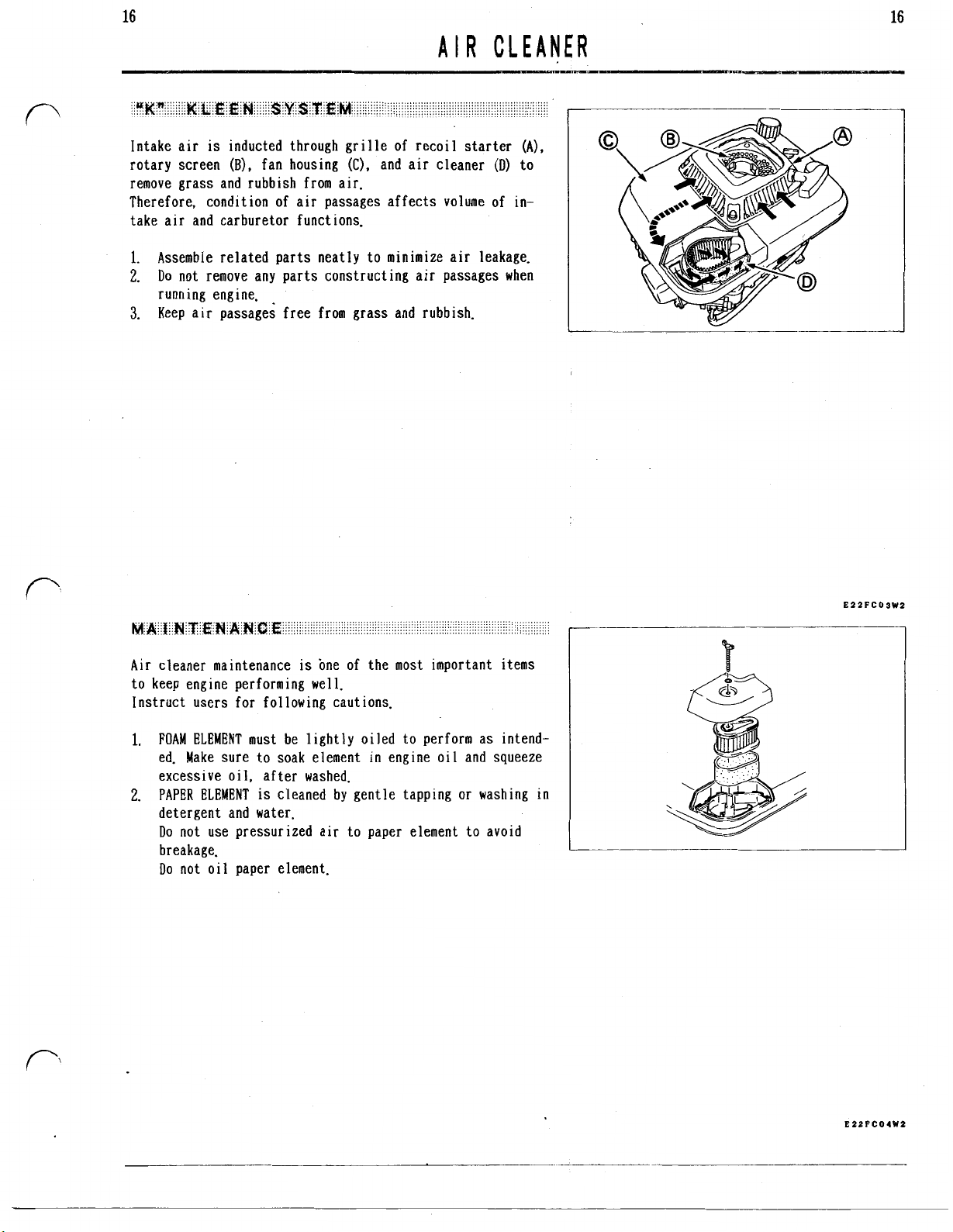

1.

Assemble related parts neatly to minimize air leakage.

2.

Do

not remove any parts constructing air passages when

running engine.

3.

Keep air passages free from grass and rubbish.

CLEANER

Air cleaner maintenance

to keep engine performing well.

Instruct users for following cautions.

1.

FOAM

ELEMENT

ed. Make sure to soak element

excessive oil, after washed.

2.

PAPER

ELEMENT

detergent and water.

Do

not use pressurized air to paper element to avoid

breakage.

Do

not oil paper element.

must be lightly oiled to perform as intend-

is

one of the most important items

in

engine oil and squeeze

is

cleaned by gentle tapping

or

washing in

E22FC03W2

E22FCO4W2

Page 24

17

17

CARBURETOR

This carburetor

(idle mixture) and fixed main jet.

NOT

E

:

conf igulation.

is

float type with adjustable pilot screw

Refer to each parts catalog for detailed parts

10

E24FC08WS

Page 25

18

W A R

N I

N

G

:

Gasoline

Avoid fires due to smoking or careless practices.

1.

Shut fuel valve.

2.

Drain fuel from float chamber.

3.

Disconnect fuel line

fuel line opening immediately

into suitable container.

4.

Disconnect breather tube

5.

Disconnect adaptor

6.

Remove bolts

c

A

UT

0

N

:

Do not lose collars in intake pipe bolt

holes.

(D)

(E).

is

extremely flammable.

(C)

from carburetor. Plug the

or

drain fuel

(A)

from intake pipe

from intake pipe

CARBURETOR

in

the line

(B).

(B).

18

Unhook throttle rod

7.

(GI.

lever

Unhook choke rod

8.

lever

(J).

(E)

and rod spring

(H)

and choke rod spring

(F)

from throttle

(I)

from choke

E24FCOSW3

Page 26

19

19

CARBURETOR

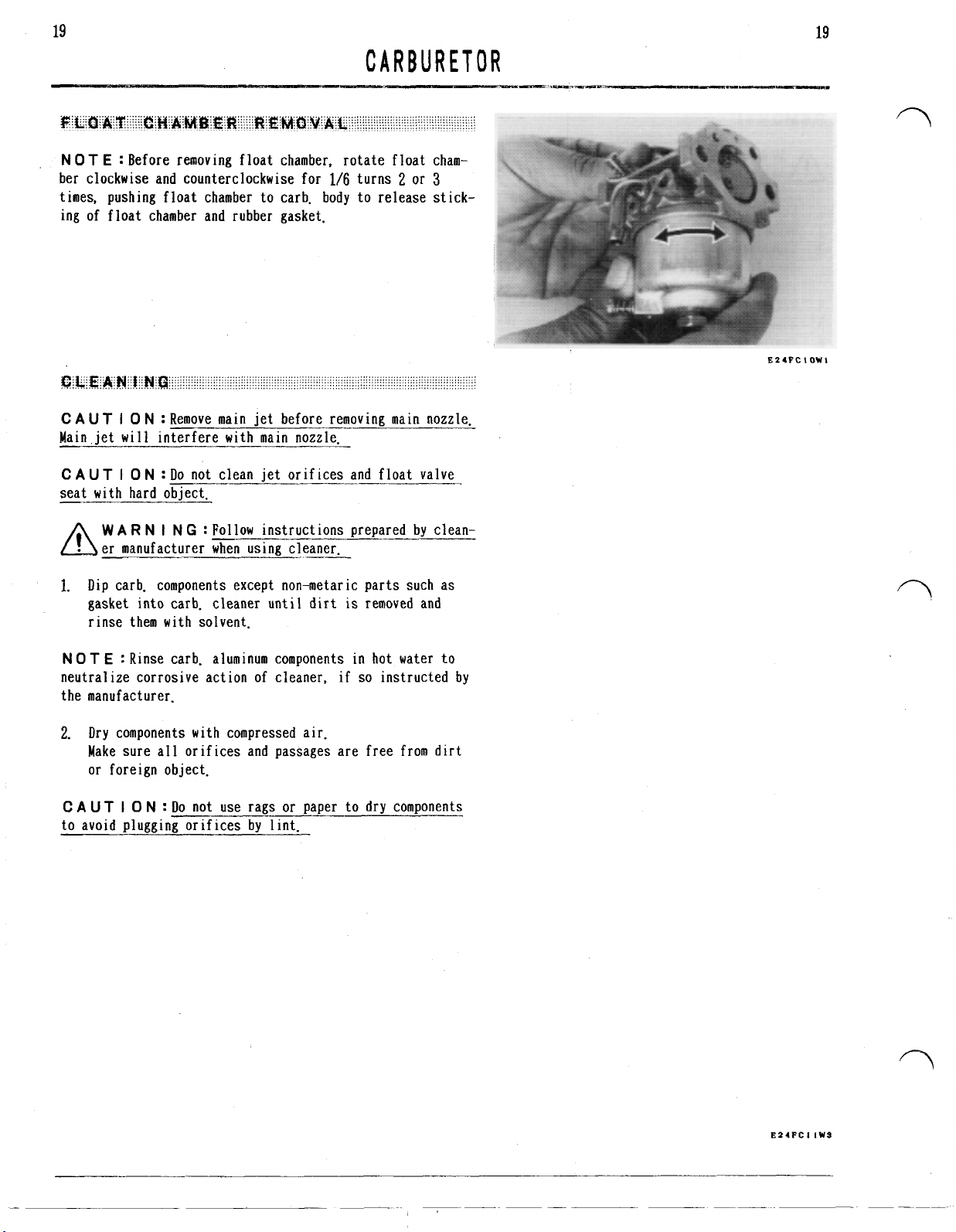

N 0 T E :

ber clockwise and counterclockwise for

Before removing float chamber, rotate float cham-

1/6

turns 2 or

3

times, pushing float chamber to carb. body to release stick-

ing

of

float chamber and rubber gasket.

C

A

UT

I

0

N

:

Remove main jet before removing main nozzle.

Main iet will interfere with main nozzle

C

A

UT

I

0

N

:

Do not clean jet orif ices and float valve

seat with hard object.

W

A

R

N I N

G

:

Follow instructions prepared by clean-

er manufacturer when using cleaner.

1.

Dip

carb. components except non-metaric parts such as

is

gasket into carb. cleaner until dirt

removed and

rinse them with solvent.

E24FCIOWI

NOT

E

:

Rinse carb. aluminum components

neutralize corrosive action of cleaner, if

in

hot water to

so

instructed by

the manufacturer.

2.

Dry components with compressed air.

Make sure all orifices and passages are free from dirt

or foreign object.

C

A

U

T I 0 N

:

Do

not use rags or paper to dry components

to avoid plugging orif ices by lint.

E24FCI

1W3

Page 27

20

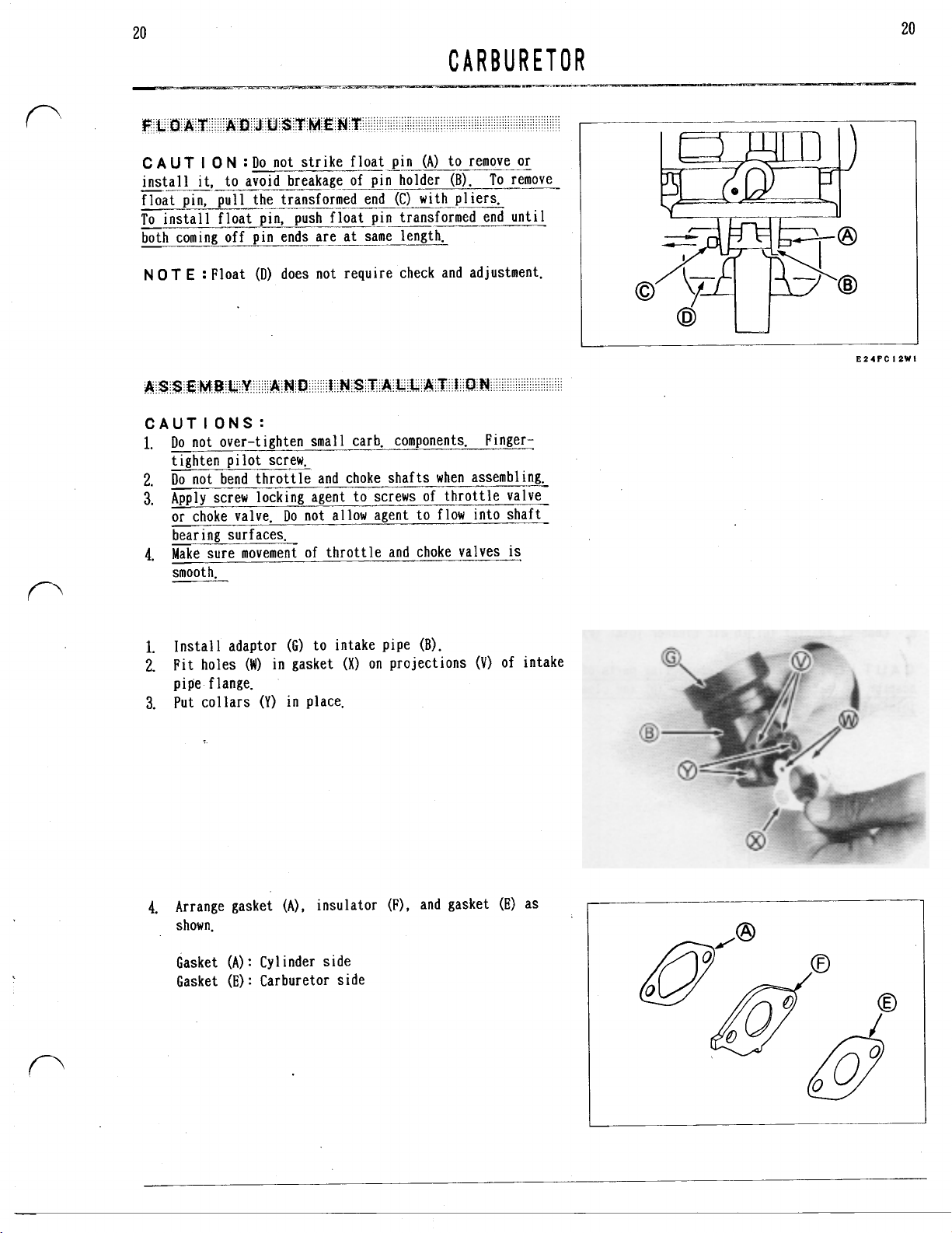

C A UT

install

I

0 N :

Do

not strike float pin

it,

to avoid breakage of pin holder

(A)

to remove or

(B).

To

remove

float pin, pull the transformed end (C) with pliers.

To

install float pin, push float pin transformed end until

both coming off pin ends are at same length.

NOT

E

:

Float

(D)

does not require check and adjustment.

I I

CAUT I

1.

ONS:

Do

not over-tighten small carb. components. Finger:

tighten pilot screw.

2.

Do

not bend throttle and choke shafts when assembling.

3.

Apply screw locking agent to screws of throttle valve

Do

or choke valve.

not allow agent to flow into shaft

bearing surf aces.

4.

Make sure movement of throttle and choke valves

is

smooth.

EZIFCIZWI

1.

Install adaptor (G) to intake pipe

2.

Fit holes

(W)

in gasket

(X)

on projections

pipe flange.

3.

Put collars

4.

Arrange gasket

(Y)

in place.

(A).

insulator

shown.

Gasket

Gasket

(A)

:

Cylinder side

(E):

Carburetor side

(B).

(F),

and gasket

(V)

of intake

(E)

as

Page 28

21

21

CARBURETOR

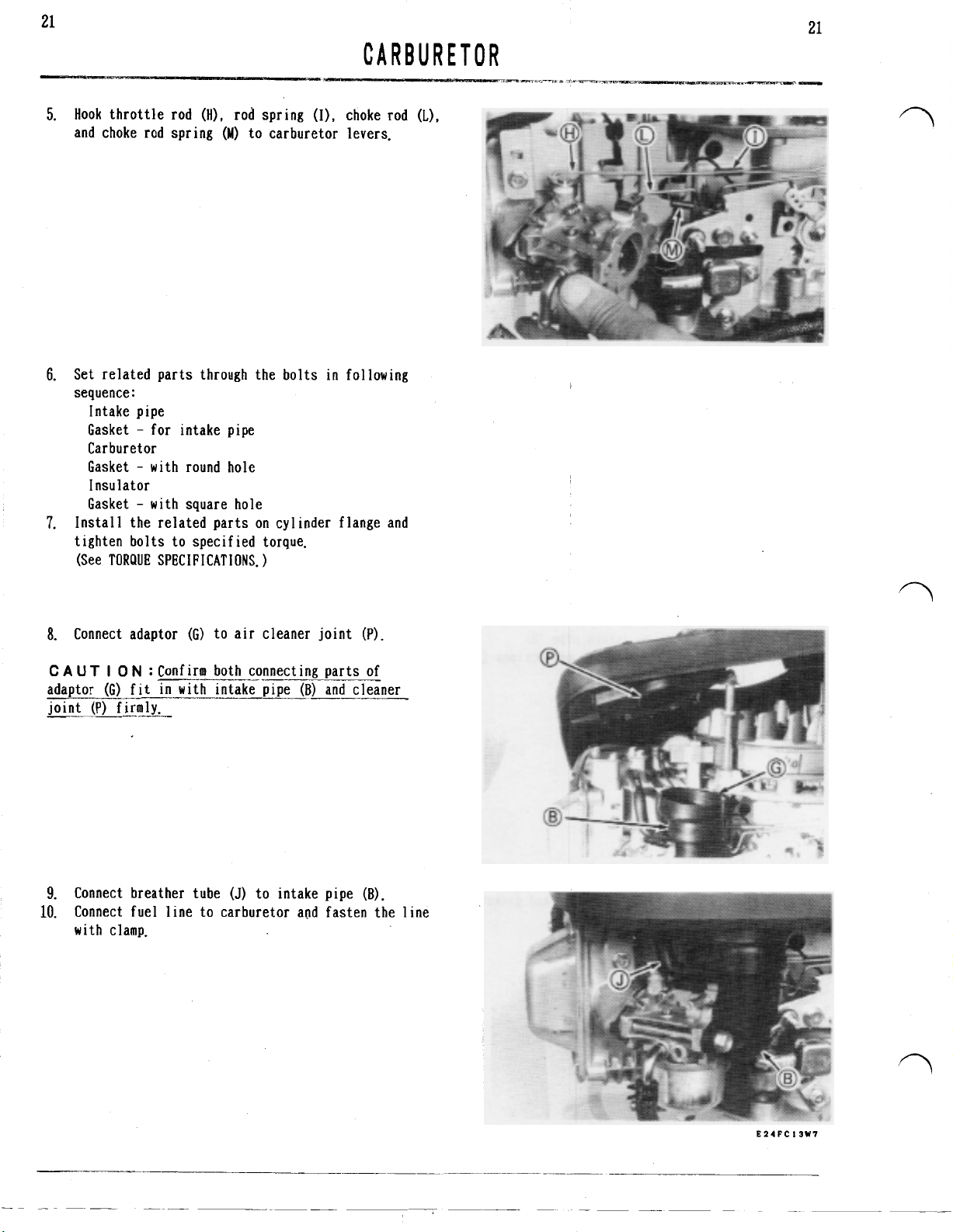

Hook throttle rod

5.

and choke rod spring

6.

Set related parts through the bolts

sequence

7.

Install the related parts on cylinder flange and

tighten bolts to specified torque.

(See TORQUE SPECIFICATIONS.)

:

Intake pipe

Gasket for intake pipe

Carburetor

Gasket with round hole

Insulator

Gasket with square hole

(HI,

rod spring

(M)

to carburetor

(I).

choke rod

levers.

in

following

(L),

8.

Connect adaptor (G) to air cleaner joint (P).

C A UT

adaptor

joint (P) firmly.

9.

10.

I 0 N

:

Confirm both connecting parts of

(G)

fit in with intake pipe

Connect breather tube

Connect fuel line to carburetor and fasten the line

with clamp.

(J)

(B)

and cleaner

to intake pipe

(B).

Page 29

22

22

CARBURETOR

315510 6100C 5510C

15001 2541 12541

EZIPAOTWI

Page 30

23

23

COOL

W

A R N

I

N

G

:

Gasoline

Avoid fires due to smoking

Engine cover

fuel valve, and fuel tank cover,

1.

Shut fuel valve

carburetor inlet.

2.

Open fuel valve and drain fuel into suitable container,

3.

Remove recoil starter.

CAUT I ON:

4.

Remove oil filler cap

5.

Disconnect fuel line

is

removed together with fuel tank, tank cap,

(A)

and disconnect fuel line

Do not lose washers

is

extremely flammable.

or

careless practices,

(C)

(E).

(F)

from fuel valve (A).

and collars (D).

I

NG

(B)

from

SYSTEM

W A R

N I N G :

avold engine starting.

6.

Loosen flywheel nut (G) by turning

Use air impact wrench to avoid flywheel retation.

7.

Remove flywheel nut (G). washer

(I).

8.

Slightly lifting up engine cover, disconnect intake

pipe adoptor

9.

Remove engine cover assy.

10.

Remove oil filler

Remove plug cap from spark plug to

it

counterclockwise.

(H),

and starting pulley

(J)

from air cleaner outlet

(1).

(K).

E26FCOZW4

Page 31

24

1. Remove fuel tank cap (D).

2. Pull fuel valve knob (B)

COOLING SYSTEM

off from valve shaft (E)

: : :

: : : : :

.::,

24

N 0 T E : Knob (B) is install

ed on valve shaft (E) w i

fit.

3.

Disconnect fuel line

(F)

fiom fuel tank (C).

4. Remove fuel strainer (I) from fuel tank (C).

5.

Remove fuel tank cover (G).

t

h snap

l

J

I

/;;\A---

w

I

1

C AUT I ON : Do not lose collars

6.

Remove fuel valve (A).

C

A UT

I 0 N : Do not disassemble fuel valve (A).

(If).

t

E2SFC03W3

,

Page 32

COOLING SYSTEM

Assembly and installation are reverse of disassembly and

removal.

1.

2.

3.

4.

5.

6.

7.

Note following points.

Apply locking agent on thread

when

replace stud for

engine cover mounting.

Align notch (A) of oil filler with projection

(B)

filler port.

Make sure O-ring (C) is in place.

Coat a light film of oil on O-ring and install oil

filler.

Tighten screws in crisscross sequence and evenly

specified torque.

Do not tighten screw completely at a time.

Holding pulley, torque flywheel

nut

as specified

TORQUE SPECIFICATIONS.

Connect air cleaner outlet

(0)

and intake pipe adaptor

(E) firmly.

of

to

in

25

:‘:’

:::::

.::::

,jjjj

: :

EZSFCO4W2

Page 33

26 26

RECO

C

A

UT

I 0 N

:

Do

not wedge rope between reel and case.

1.

Pull

handle

Then hold rope in place with locking pliers or knot

2.

Pull

knot in handle

W

A R N I N

avoid injury.

3.

While carefully holding reel

locking pliers or untie knot.

4.

Unwind spring tension slowly.

NOT

E

:

1

through 4 are not necessary except when rope and/or

handle are changed. Instead of the steps, unwind spring

tension keeping rope in notch

out

about

250

mm

(10

in).

(B)

out and untie

G

:

Wear gloves during disassembling to

(C)

and case

As

for recoil starter with extended rope, steps

(E)

of reel.

I L STARTER

(A).

it.

(D),

remove

5.

Remove screw

6.

Remove retainer

7.

Before removing pawl

pawl, then remove pawl and spring

i

(F)

and washer

(H)

with circlip

(J),

(G).

(I)

carefully.

make sure position of the

(K).

Page 34

27

27

W

A R N I

RECO

N

G

:

When removing reel (C), be careful

I L 'STARTER

that recoil spring under the reel does not fly loose

and causes injury. The spring

NOT

E

:

There should be no spring tension on reel when

removing reel. If tension

is

under great pressure.

is

felt, push reel back into

place and gently "wiggle" it until reel can be easily

removed.

8.

Rotate reel

(C)

one-quarter turn clockwise from rest

position where no tension can be felt. Then, slowly

lift reel straight up out of case.

W A R

N I N

G

:

Be careful that recoil spring

(M)

does not fly loose from reel (C) and causes injury.

The

9.

If

is

under great pressure:

recoil spring

(M)

must be removed from reel (C), hold

the reel with spring side downward in suitable container

and tap reel to remove recoil spring.

1.

Dip

metal parts in bath of high flash-point solvent, if

necessary.

C

A

UT

I

0

N

:

Do not clean any non-metalic parts

in

solvent. They may be damaged by the solvent.

2.

Check starter pawl for chips

3.

Check starter rope for excessive wear

4.

Check springs for break, rust, distortion,

i

t

ion.

cond

If

damage

WAR

is

found, replace the part.

N 1 N

G

:

Do not throw away recoil spring as

or

excessive wear.

or

fraying.

or

weakened

installed in reel. Recoil spring may fly loose from

reel and cause injury.

E27FAO2W2

Page 35

28

28

RECO

W

A R N I

!

installation to avoid injury. The recoil spring must

be assembled with great pressure.

1.

Coat grease for high temperature application on recoil

spring

2.

Set recoil spring

(C)

catches

3.

Wind recoil spring

4.

Make sure that gap between spring hook

of reel boss

If not, make the gap by bending spring end with long

nose pl ier.

N

G':

Wear gloves during recoil spring

_._-

(A)

and sliding surfaces.

(A)

in reel

hook

(D)

in

reel.

(A)

into reel

(F)

is

2 4 mm

(B)

so

(B)

(0.08

that spring end

counterclockwise.

0.16

I

L

(E)

and outside

in.).

STARTER

(M)

If rope

5.

3.5

(G)

is

unwound from reel

turns

counterclockwise facing pawl groove

(B),

wind rope

in

(H).

reel

Page 36

29

29

RECO

7.

Install spring

groove.

8.

Install retainer

NOT

E

:

Apply locking agent on screw

C

A U T I 0

tightening may disturb movement

9.

Tighten screw

SPECIFICATIONS.)

N

(J)

and pawl

(M),

(K)

into the respective

covering pawl with

"R*

(N).

:

Do

not over tighten screw

of

pawl.

(N)

to specified torque. (See TORQUE

(N).

Over

I

L

STARTER

side groove.

11.

Pull

rope out of case and install handle.

12.

Check movement

13.

Pull

rope out to the end.

out to the end

preloading

clockwise, keeping rope

then check the condition again.

of

pawl, pulling and returning rope.

If

rope can not be pulled

or

can not be rewound when released,

is

too much. Rotate reel

(G)

in

notch

(B)

1

turn

(0)

of reel, and

Page 37

30

30

ELECTRIC

1.

Disconnect spark plug cap, and ground the cap

terminal. test. Do not touch any rotating parts

2.

Turn key switch to "ON" position and check

condition.

(STARTER DOES NOT ROTATE)

I--

Does pinion rotate?

""-I

(STARTER

ROTATES

BUT

SLOW)

STARTER

I--

@Weak or faulty battery.

@Faulty leads or connection.

*Faulty key switch.

0

Faulty starter motor.

k

W

and equipment during test.

C

A

UT

"OFF", disconnect negative lead from battery as

soon as possible.

CHARGl

A R N I N G :

NG

Engine may be cranked in this

-_-

I

0 N :

If

starter does not stop by key switch

Charge

Repair or replace

Repair or replace

Repair or replace

or

replace

of

engine

and well charged?

(STARTER ROTATES

(STARTER DOES NOT STOP

BUT

CAN

IN

NOT

CRANK

NO

KEY

SWITCH "OFF")

NO

ENGINE)

harge or replace

@Faulty leads or connection.

0

Faulty starter motor.

0

Faulty engine.

*Worn pinion or ring gear.

0

Incorrect starter alignment. Correct

0

Faulty key switch.

+Repair or replace

Repair or replace

Repair or replace

Repair or replace

Repair or replace

Correct

Repair or replace

Page 38

31

31

ELECTRIC STARTER

WA

R N I

N

G

:

Disconnect negative

(+)

then positive

1.

Disconnect battery before removing electric starter from

lead to prevent spark at terminal.'-'

(-)

lead first and

&

CHARGl NG

engine to avoid accidental running of starter in handl-

i

ng.

2.

Remove electric starter from engine.

W A

R N I

N

G

:

The test room must be free from any

flammable object. Keep away your body from pinion.

CA

UT

I

O

N

:

Be careful not to deform electric starter

I-

body by holding.

Hold electric starter with vice.

Connect cable

Connect jumper cable

(A)

with positive

(B)

with negative

(+)

battery terminal.

(-)

battery

terminal.

Touch starter body with the other end of jumper cable

(B)

intermittently (within one second).

or

If pinion does not turn, repair

replace starter motor.

E28FC22W2

1

C

A

U

T

I

0

N

:

Because of difficulty

further disassembling

is

not

recommended.

in

reassembling,

8

5

E28FC23W2

Page 39

32

32

ELECTRIC STARTER

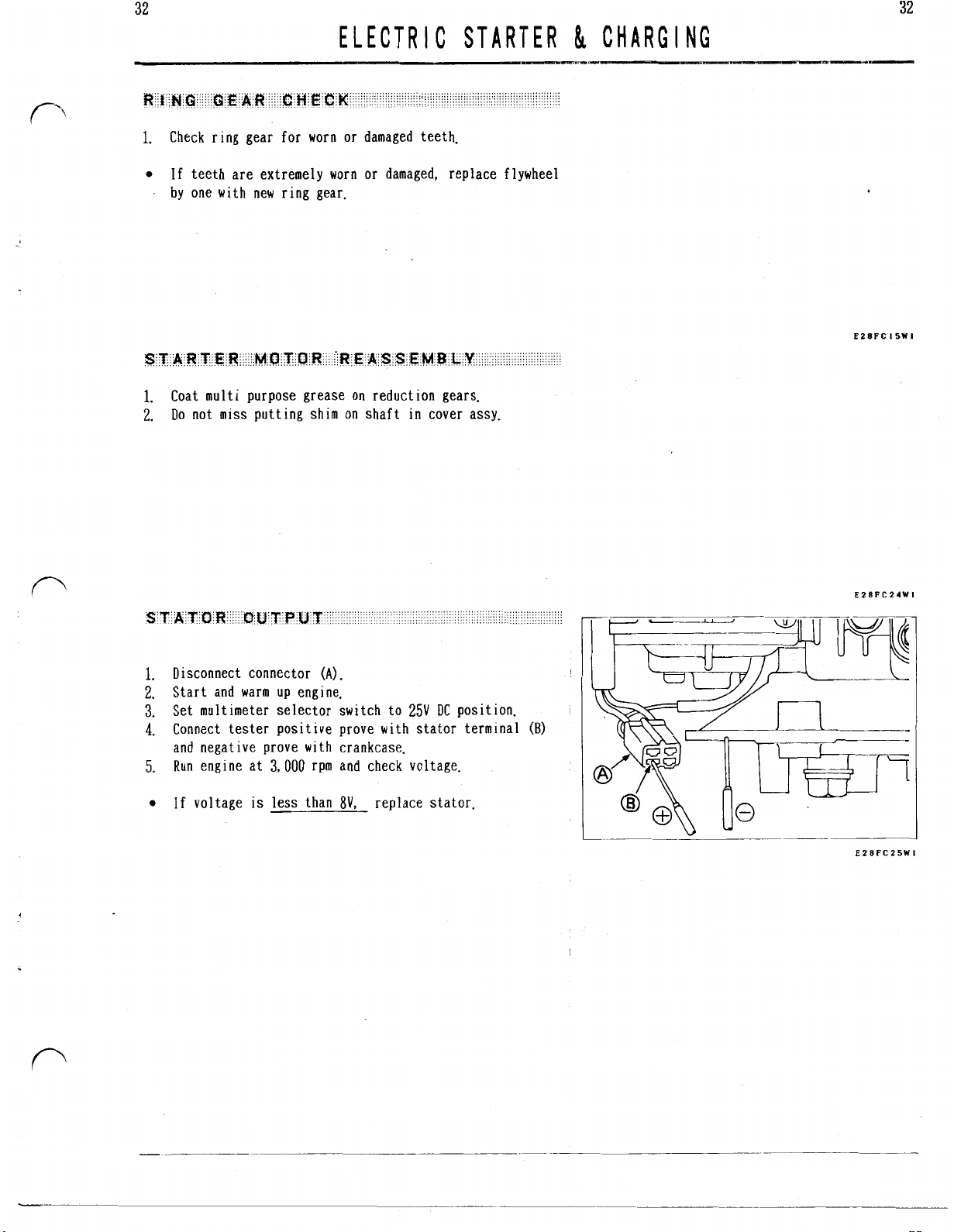

1.

Coat multi purpose grease on reduction gears.

2.

Do

not miss putting

shim

on shaft

in

cover assy.

&

CHARGl NG

E28FC15WI

1.

Disconnect connector

2.

Start and warm up engine.

3.

Set multimeter selector switch to

4.

Connect tester positive prove with stator term

and negative prove with crankcase.

5.

Run

engine at

If voltage

3,000

is

less than

(A).

2!jV

DC

rpm and check voltage.

8V,

replace stator.

ion.

posit

inal

(B)

E28FC24WI

E28FC25WI

Page 40

I

GN

I T I

ON

SYSTEM

33

Transistor controlled ignition system

engines and this system consists of following components.

1.

Ignition coil

2.

Control

3.

Flywheel (with permanent magnet)

These components do not mechanically contact and periodic

maintenance

I,:

CU: Control unit

R,

R2:

unit

is

not required.

Primary coil

Secondary coil

:

Control resistor

Control resistor

is

used for these

TR,

:

Transistor

TR2:

Transistor

F

:

Flywheel

SP

:

Spark plug

SW

:

Engine switch

To check ignition system, check spark as follows;

1.

Remove spark plug and connect plug cap with the removed

spark plug.

2.

Install spare plug

from hole.

W

A R N I N G :

cap, but not spark plug.

3.

Keeping contact with spark plug metal part (not center

electrode) and engine block, crank engine.

C

A

UT

I

0

N

:

Do

cleaner.

e

If

no

or

very weak spark

and regap

try engine cranking again.

If spark

with new spark plug.

it

is

not improved by cleaning, try checking again

to

plug hole to avoid fuel spitting

To

avoid electric shock, hold plug

not clean spark plug with bead

is

observed, clean spark plug

to

0.7

0.8

mm

(0.028

0.031

or

in.

sand

and

E30FCOIW2

If

spark

is

not improved yet, check ignition system.

E30FCOBW2

Page 41

34

I

GN

1.

Set multimeter selector switch to

2.

Check resistance between terminal

R

x

(A)

and case

IT

I

ON

SYSTEM

position.

(B).

34

If resistance

unit.

C A U T I 0 N

I

.CONTROL UN IT RES I STANCE

Case

N 0 T

E

:

This check may not cover every defect.

is

out of specified value, replace control

:

Do

not use Megger.

Terminal

(B)

(A)

Case

(B)

E30FCOSW2

r

1.

Check resistance between the points as specified.

2.

If resistance

ignition coil.

IGNITION COIL RESISTANCE

Primary

coil

Secondary

1

coi

is

out

of

specified value, replace

Connect ion

Primary terminal

and Core (C)

Plug lead

and Core (C)

(A)

(B)

Resistance

0.67

(R

x

6.0

(R

x

Range)

Range)

EBOFC

I

OW2

Page 42

35

35

IGNITION

1.

Remove starting pulley and engine cover assy. (See

GINE COVER REMOVAL.

2.

Avoiding flow-out of engine oil, place engine on bench

so

that flywheel faces sideward.

3.

Put soft metal piece on shaft end to avoid demage and

strike metal piece sharply until flywheel comes loose.

1.

Before installing flywheel, remove grease and oil from

taper part of crankshaft and taper hole of flywheel.

2.

Make sure key

3.

Torque

nut

as specified

(See ENGINE COVER ASSEMBLY AND INSTALLATION.

)

is

in

place when installing flywheel.

in

TORQUE SPECIFICATIONS.

SYSTEM

EN-

ESOFCIIWI

If ignition coil

installing coil.

1.

Insert

(A) between coil legs (B) and flywheel ‘rim

2.

Pushing coil to flywheel, tighten coil mounting screws

firmly.

Intermediate connector installation

Be careful of terminal direction.

A:

Nut

B:

Control

C: Stop switch terminal

D:

Nut

E: Washer

0.3

is

removed or replaced, adjust AIR-GAP in

mm

(0.012

in.)

feeler gauge or solid sheet

(c).

is

as shown.

F:

Insulator

unit

terminal G: Control plate

H:

Insulator

I:

Bolt

E30FCIZWI

E30FC I3Wl

Page 43

36

I

GN

I T I

ON

SYSTEM

36

Engine switch linked with throttle lever

trol pannel of engine and operated as follows:

1.

When control lever

idle, or choke, control lever

(B).

tang

2.

When control lever

tion, the lever contacts with engine switch tang

grounds ignition circuit.

C

AUT

I

0

N

:

Check and clean engine switch tang area to

keep good contact.

3.

Engine switch installation

Control lever

Switch tang

Nut

Washer

Control plate

Insulator

G:

Insulator

H:

Bolt

(A)

(A)

is

positioned at slow idle, fast

is

is

pulled beyond slow idle posi-

is

as shown,

is

equipped on con-

far from engine switch

(B)

and

ESOFC

l5W2

is

Engine switch linked with band brake

case side and operated as follows:

1.

When brake control lever on equipment

position, control cable

(B)

shoe

tang

2.

When brake control lever on equipment

position, control cable

shoe

tang

C

A

UT

keep good contact.

NOT

throttle-lever-linked engine switch.

from flywheel and to release engine switch

(F)

from lever

(B)

to contact flywheel and to make engine switch

(F)

contact with lever

I 0 N

:

Check and clean engine switch tang area to

E

:Switch configulation

(A).

(D)

pulls lever

(D)

releases lever

(A).

is

equipped on crank-

is

moved to start

(A)

to release

is

moved to stop

(A)

to force

the same as that of

E30FC16W2

Page 44

31

CYL

I

NDER HEAD

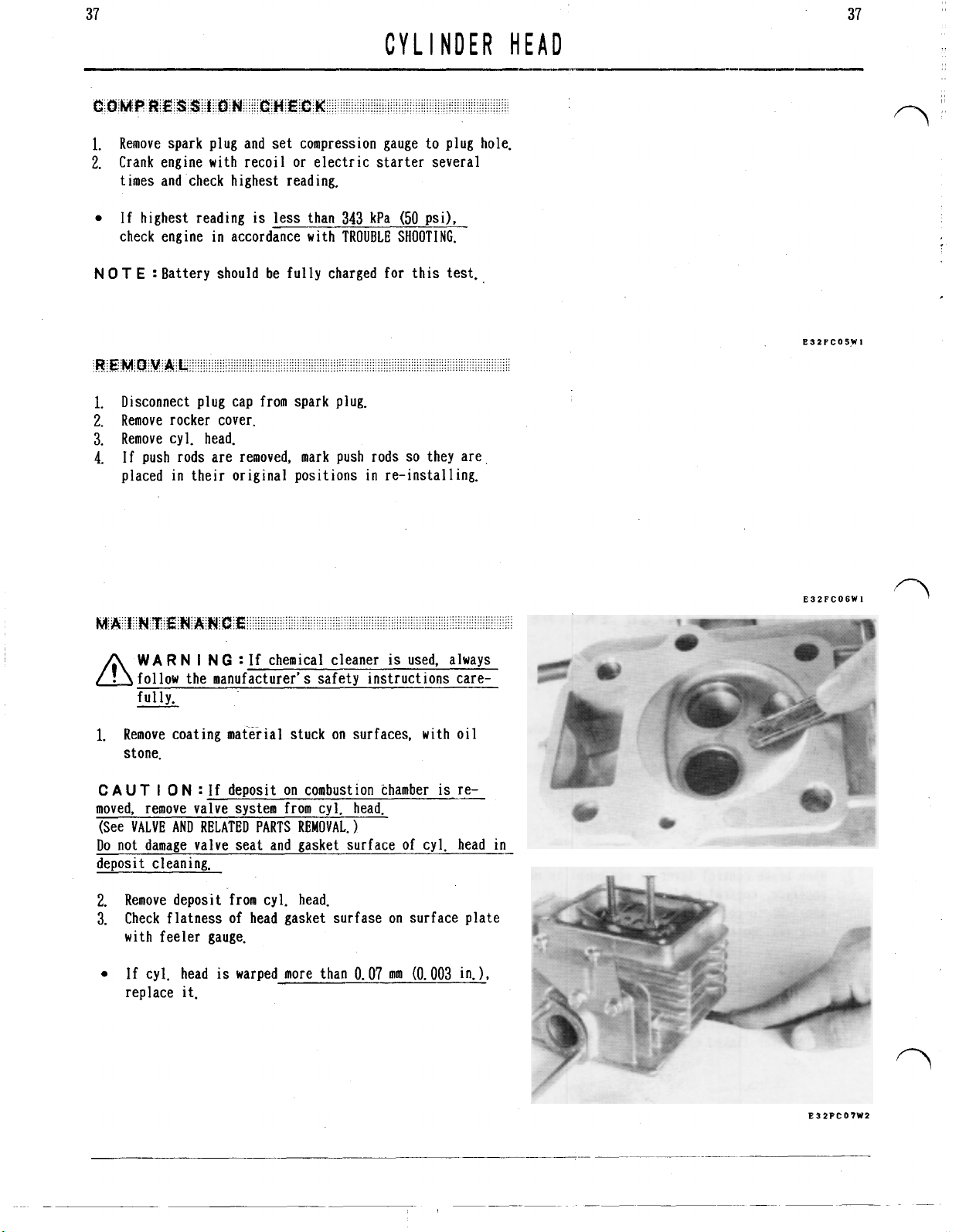

1.

Remove spark plug and set compression gauge to plug hole.

2.

Crank engine with recoil or electric starter several

times and check highest reading.

is

less

than

343

kPa

(50

If highest reading

in

check engine

NOT

E

:

Battery should be fully charged for this test.

1.

Disconnect plug cap from spark plug.

2.

Remove rocker cover.

3.

Remove cyl. head.

4.

If push rods are removed, mark push rods

placed in their original positions in re-installing.

accordance with TROUBLE SHOOTING.

psi),

so

they are

37

E32FCOSWI

W

A

R

N

I N

G

:

If chemical cleaner

follow the manufacturer's safety instructions carefully.

1.

Remove coating material stuck

stone.

C

A

UT

I

0

N

:

If deposit on combustion chamber

moved, remove valve system from cyl, head.

(See

VALVE

AND

RELATED

Do not damage valve seat and gasket surface of cyl. head in

deposit cleaning.

Remove deposit from cyl. head.

2.

Check flatness of head gasket surfase on surface plate

3.

with feeler gauge.

If cyl. head

replace it.

PARTS

is

warped more than

on

REMOVAL.)

is

used, always

surfaces, with oil

is

re-

0.07

mm

(0.003

in.),

E32FC06WI

Page 45

38

CVL

I

NDER

C

AUT

I

0 N :

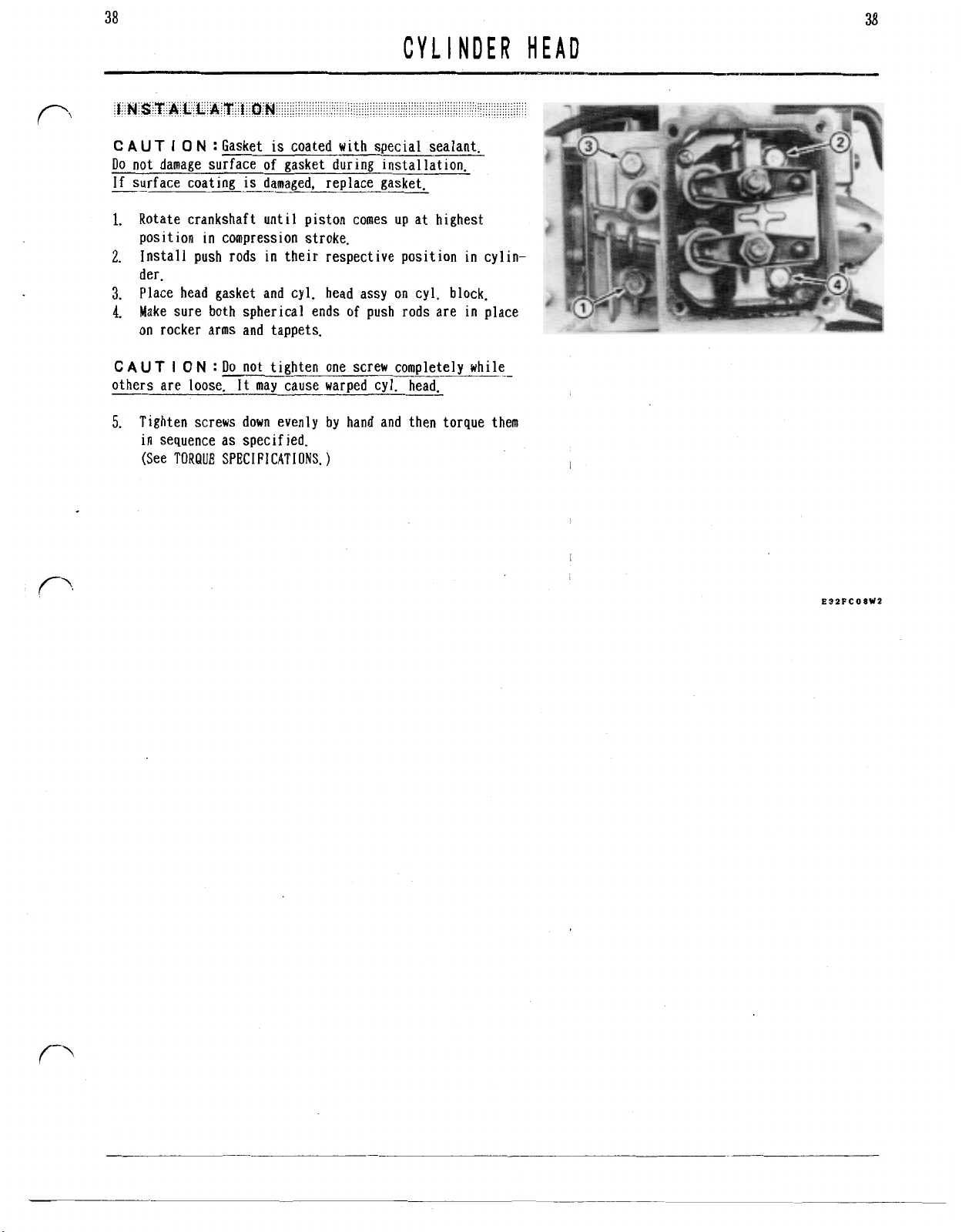

Gasket

Do

not damage surface of gasket during installation.

If surface coating

1.

Rotate crankshaft until piston comes up at highest

position in compression stroke.

2.

Install push rods in their respective position

der.

3.

Place head gasket and cyl. head assy on cyl. block.

4.

Make sure both spherical ends of push rods are

on rocker arms and tappets.

is

coated with special sealant.

is

damaged, replace gasket.

in

in

HEAD

cylin-

place

38

CAUT I

others are loose.

5.

0

N

:

Do

not tighten one screw completely while

It

may cause warped cy]. head.

Tighten screws down evenly by hand and then torque them

in

sequence as specified.

(See TORQUE SPECIFICATIONS.

E32FCOSW2

Page 46

39

39

VALVE

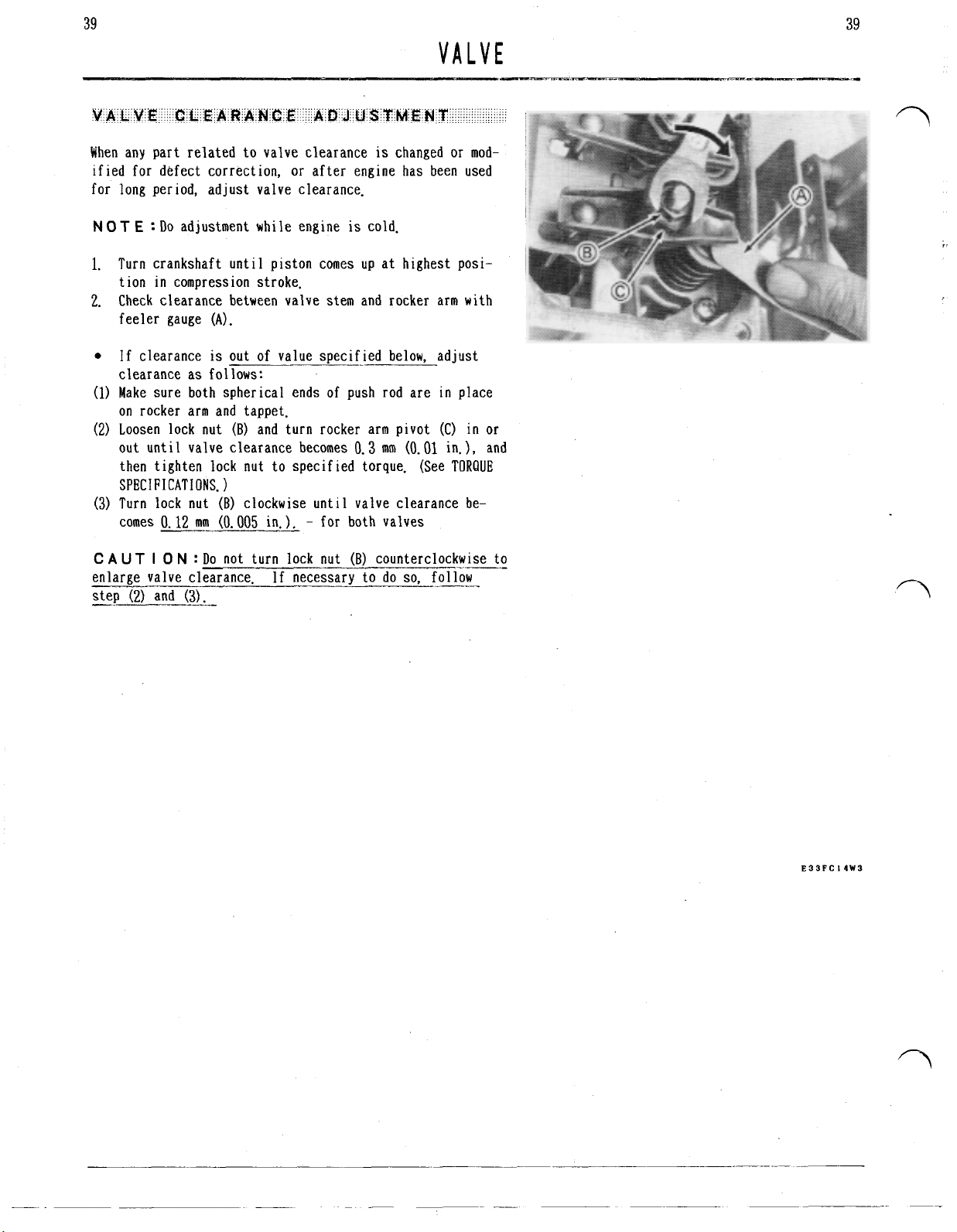

When any part related to valve clearance

ified for defect correction,

or

after engine has been used

is

changed or mod-

for long period, adjust valve clearance.

NOT

E

:

Do

adjustment while engine

1.

Turn

crankshaft

in

tion

2.

Check clearance between valve stem and rocker arm with

compression stroke.

feeler gauge

If clearance

until

(A).

is

out

piston comes

of

value specified below, adjust

is

cold.

up

at highest posi-

clearance as follows:

(1)

Make sure both spherical ends of

push

rod are

in

place

on rocker arm and tappet.

(2)

Loosen lock nut

out until valve clearance becomes

then tighten lock

(B)

and turn rocker arm pivot (C)

0.3

mm

(0.01

nut

to specified torque. (See TORQUE

in

or

in.), and

SPECIFICATIONS.

(3)

Turn lock

comes

C

A

UT

enlarge valve clearance If necessary to do

0.12

I

0

nut

(B)

clockwise

mm

N

:

Do

(0.005

in.). for both valves

not turn lock nut

until

valve clearance be-

(B)

counterclockwise to

so.

follow

E33FC

I4W3

Page 47

40

VALVE

is

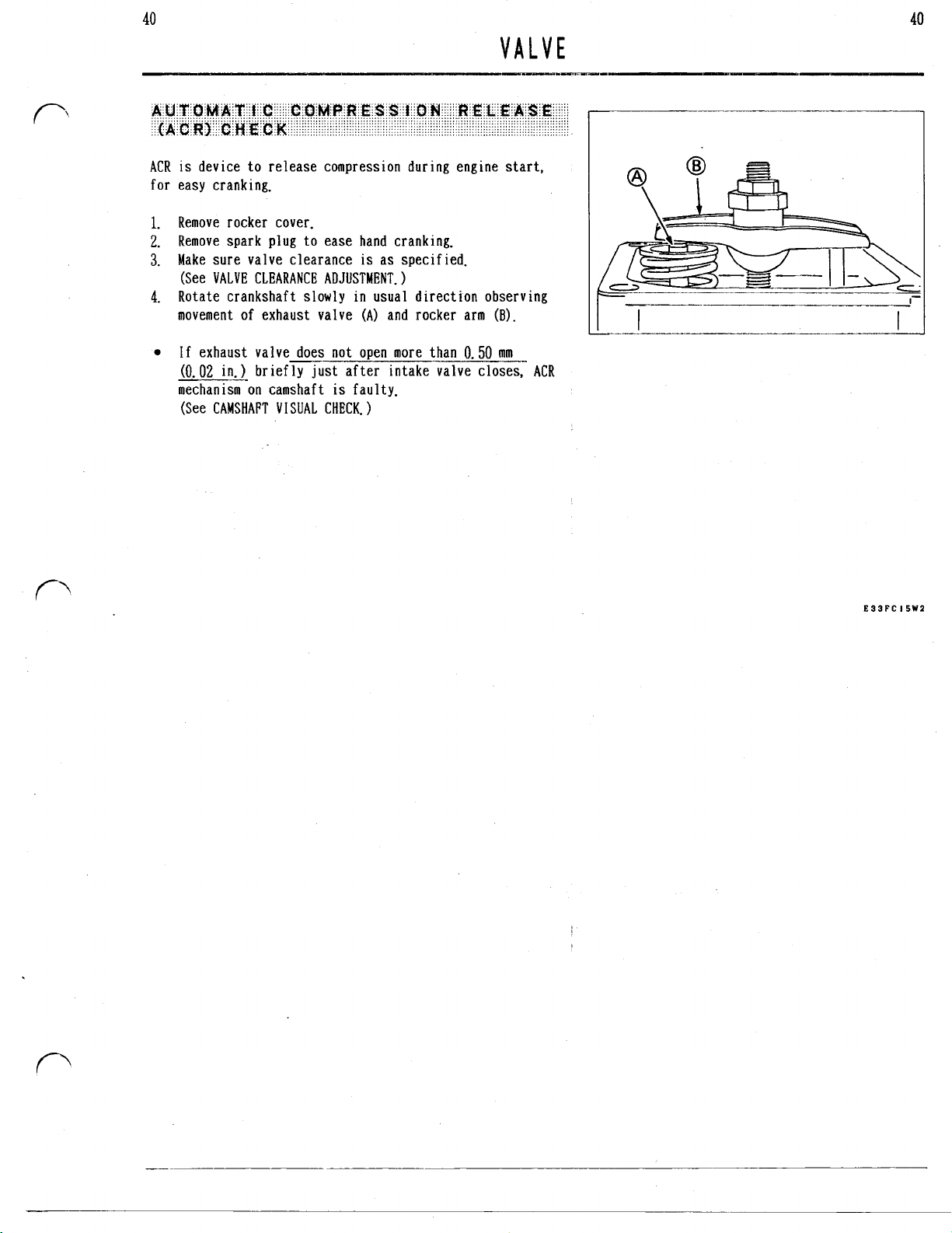

ACR

for

1.

2.

3.

4.

device to release compression during engine start,

easy cranking.

Remove rocker cover.

Remove spark plug to ease hand cranking.

Make sure valve clearance

(See VALVE CLEARANCE ADJUSTMENT.

Rotate crankshaft slowly in usual direction observing

movement of exhaust valve

is

as specified.

(A)

and rocker arm

(B).

40

If exhaust valve does not open more than

(0.02

in.)

briefly

mechanism on camshaft

(See CAMSHAFT VISUAL CHECK.

just

after intake valve closes.

is

faulty.

0.50

mm

ACR

E33FC15WZ

Page 48

41

NOT

E

:

Mark push rods

original positions in re-installing.

1.

Remove push rods.

2.

Unscrew lock nuts

rocker arms (C).

3.

Place screw head of valve spring compressor

valve head and

and retainer

4.

Compress spring and remove retainer

pliers.

5.

Remove compressor and valve spring.

(F).

so

they are placed in their

(A)

and pivots

SI

ip jaw of compressor between spring

(B),

and then remove

(F)

with needle nose

VALVE

(D)

on the

(E)

41

NOT

E

:

Before pulling valve out of guide

burrs

from valve stem, and oil to stem to avoid damaging

valve guide.

When re-installing

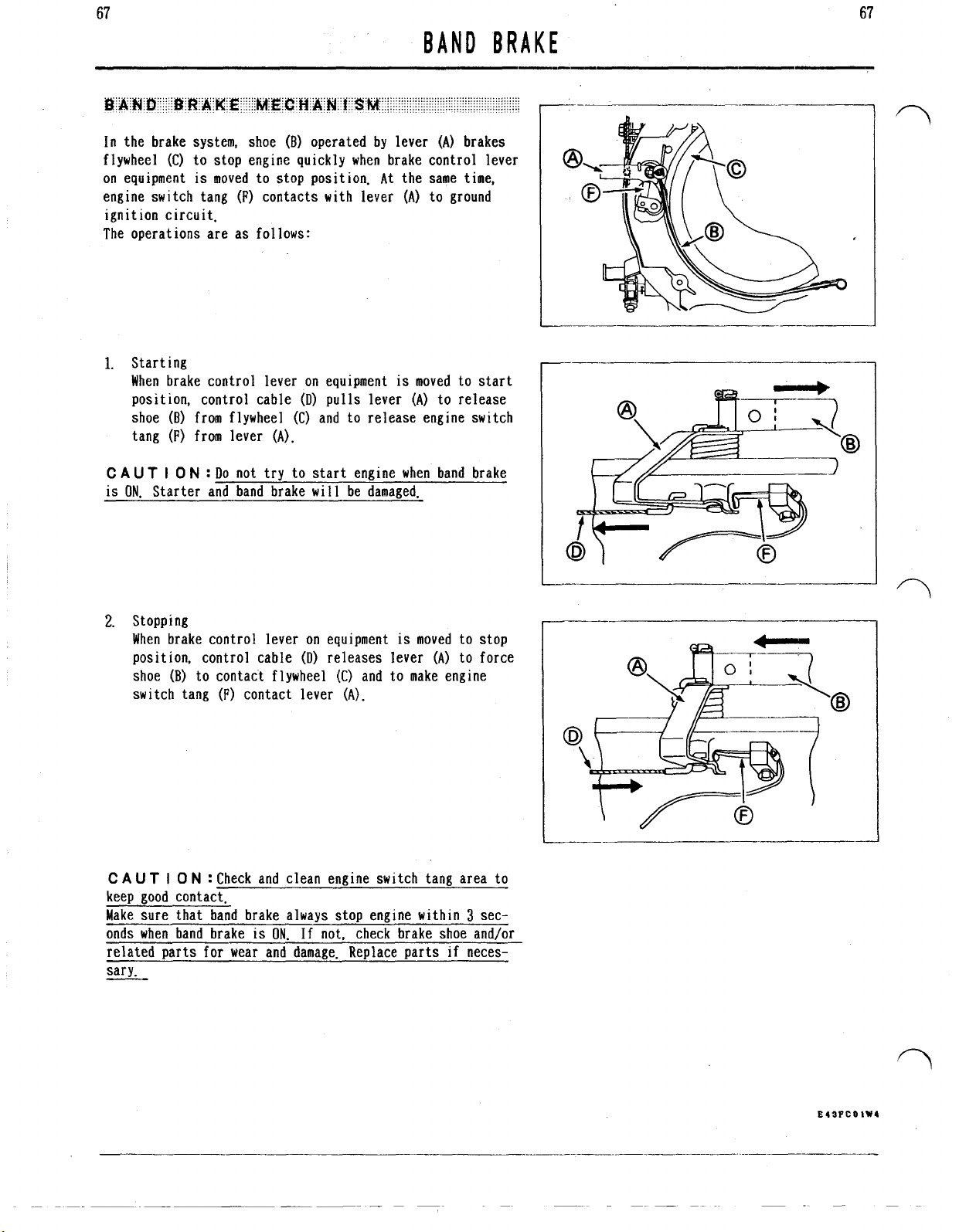

ing agent on thread and tighten to specified torque. (See

TORQUE

SPECIFICATIONS.

or

replacing rocker arm stud, apply lock-

)

(G),

remove all

E33FC16W3

Page 49

42

1.

Check valve head for excessive deposit and gas leakage.

2.

Remove carbon from valve head with wi-re brush.

3.

Check valve head for warped face

margine

If valve head has above defect, replace valve,

N

0

T

and deposit triggers gas leakage causing valve defects.

Therefore unleaded gasoline

4.

Check valve stem for sticking, gummy deposit, discoloration at area covered by valve guide, and excessive

corrosion.

5.

Remove carbon from valve stem as well as head.

If valve stem

smoothly in guide, replace valve.

(B)

of less than

E

:

Excessive deposit

is

worn excessively or does not move

0.5

is

is

(A)

dent on face and

mm

(0.020

caused by leaded gasoline,

recommended.

in.).

42

N 0 T

E

:

Sticking and discolorat ion are caused by over

heating of engine, or gas leakage from valve face. Therefore

such causes must be corrected as well as valve maintenance.

Gummy deposit

system and use fresh gasoline. Remove gasoline from fuel

system before long storage.

6.

Check valve stem for worn stem end.

7.

Grind worn stem end (C,D) squarely to stem shaft with

valve lapping guide

If length from stem end to groove

(0.15

is

caused by old or stale gasoline. Clean fuel

(E)

and oil stone

in.) after grinding, replace valve.

(F).

is

less than

3.8

mm

I

\

E33FC

I7W4

Page 50

43

1.

Check diameter

guide at several points with micrometer.

If

diameter

of

valve stem in area covered

is

less than

MIN.

replace valve.

VALVE

by

valve

43

VALVE STEM DIA.

2.

Check bend of valve stem at center part with

(A)

and dial indicator

If bend (dial gauge reading) of valve stem

0.03

mm

C

AUT

face.

(0.0012

I

0

N

If

valve face

in.

:

Do

not try to grind or recondition valve

is

worn or damaged, replace

MIN

(B).

replace valve.

V

blocks

is

more than

it.

E33FC

I8W2

1.

Check valve spring for any damage and replace it if

necessary.

2.

Check free length of valve spring with vernier calipers.

If length

spring.

is

less than

for

both springs

31.5

mm

(1.240

in.), replace

E33FC

I9WI

Page 51

44

VALVE

If valve does not contact all way around with seat, lap

valve into seat.

1.

Coat fine lapping compound sparingly on valve face.

2.

Rotate valve in circular motion with valve lapper (A).

N 0 T

E

:

Lapping mark should appear on or near center of

va

1

ve face.

3.

Check valve every

until uniform ring appears on valve seat all way around.

4.

After lapping, wash parts

Dry parts thoroughly.

8

to

10

strokes and continue lapping

in

solvent to remove compound.

44

Reface valve seat with

1.

enough material to make smooth and concentric seat.

Use

30°

2.

(0.021

A

Make a

3.

at edge of seat.

Coat marker and check contact of valve face and seat.

4.

Contact should be at center part of valve face as shown

and all way around.

Lap valve into seat. (See LAPPING.)

5.

cutter to narrow seat width to

0.046

in.

:

Seat width

light

pass with

1.

45’

cutter, removing only

0.53

45’

cutter to remove any burr

1.16

E33FC2OW2

mm

E33FC2lW2

Page 52

45

1.

Use valve guide cleaner to clean

2.

Check inside diameter of valve gu

i

nside of valve guides.

11

de at several points

with inside micrometer.

45

VALVE

If diameter

VALVE

Intake

Exhaust

is

more than

GUIDE

MAX,

rep

ace cyl. head.

INSIDE

5.550

5.560

mm

mm

D

(0.2185

(0.2189

I

A.

MAX

in.

in.

E33FC22W2

(A

with push rod),

(B

th valve stem), and (C

wi

with pivot).

If necessary, replace rocker

1.

Check bend of push rod at center part with

(A)

and dial indicator

If bend (dial gauge reading)

(0.024

in.),

replace push rod.

(B).

arm.

is

more than

V

blocks

0.6

mm

E33FC23WI

E33FC24WI

Page 53

46

CRANKCASE COVER

W

A R N

I

N

G

:

Be careful not to burn yourself by

oil.

1.

Drain engine

2.

Remove rust and burr from edge

3.

Loosen screws, and tap parts near dowel alternately with

soft mallet.

1.

Check inside diameter

points with inside micrometer.

oil

to suitable container.

of

PTO

of

PTO

bearing

shaft step.

(A)

at several

46

E34PCOIWI

If diameter

is

more than

25.100

mm

(0.9882

place crankcase cover.

2.

Check inside di-ameter

of

camshaft bearing

several points with inside micrometer.

If

diameter

is

more than

14.070

mm

(0.5539

place crankcase cover.

.in.), re-

(B)

at

in.), re-

E34FCO6W2

Page 54

47

47

CRANKCASE

0

1

':L

SEAL

If

oil leakage through oil seal

damaged, replace oil seal.

1.

Remove oil seal by tapping

punch.

2.

Placing spring held seal lip

into

housing

with

housing end (C).

3.

Before final assembly, pack some amount of grease for

high

temperature application into space between seal

(A:)

and dust 1 ip

REPLACEMENT

is

observed or seal lip

it

out with screw driver or

(A)

inside, push oil seal

until

seal outside surface becomes flush

(B).

COVER

is

1

ip

Clean gasket surface and place new gasket on crankcase.

1.

Pack grease into oil seal. (See

2.

Coat a light film

3.

Make sure governor weights are closed.

4.

Make sure governor gear

5.

with

cam gear when installing crankcase cover.

of

oil on bearings.

is

OIL

SEAL

REPLACEMENT.)

properly aligned to mesh

Do

not

force cover into position.

Install crankcase cover and tighten bolts down evenly

6.

by hand. Tighten bolts

in

the sequence as shown and

to

the specified torque. (See TORQUE SPECIFICATIONS.)

Do

not tighten one bolt completely before the others.

It

may cause warped crankcase cover.

is

When new crankcase cover

7.

drain plug

(A)

must be performed carefully. (See NOTE

used, tightening of side

in TORQUE SPECIFICATIONS.)

E34FC04W2

E34FCO7W2

Page 55

48

CAMSHAFT

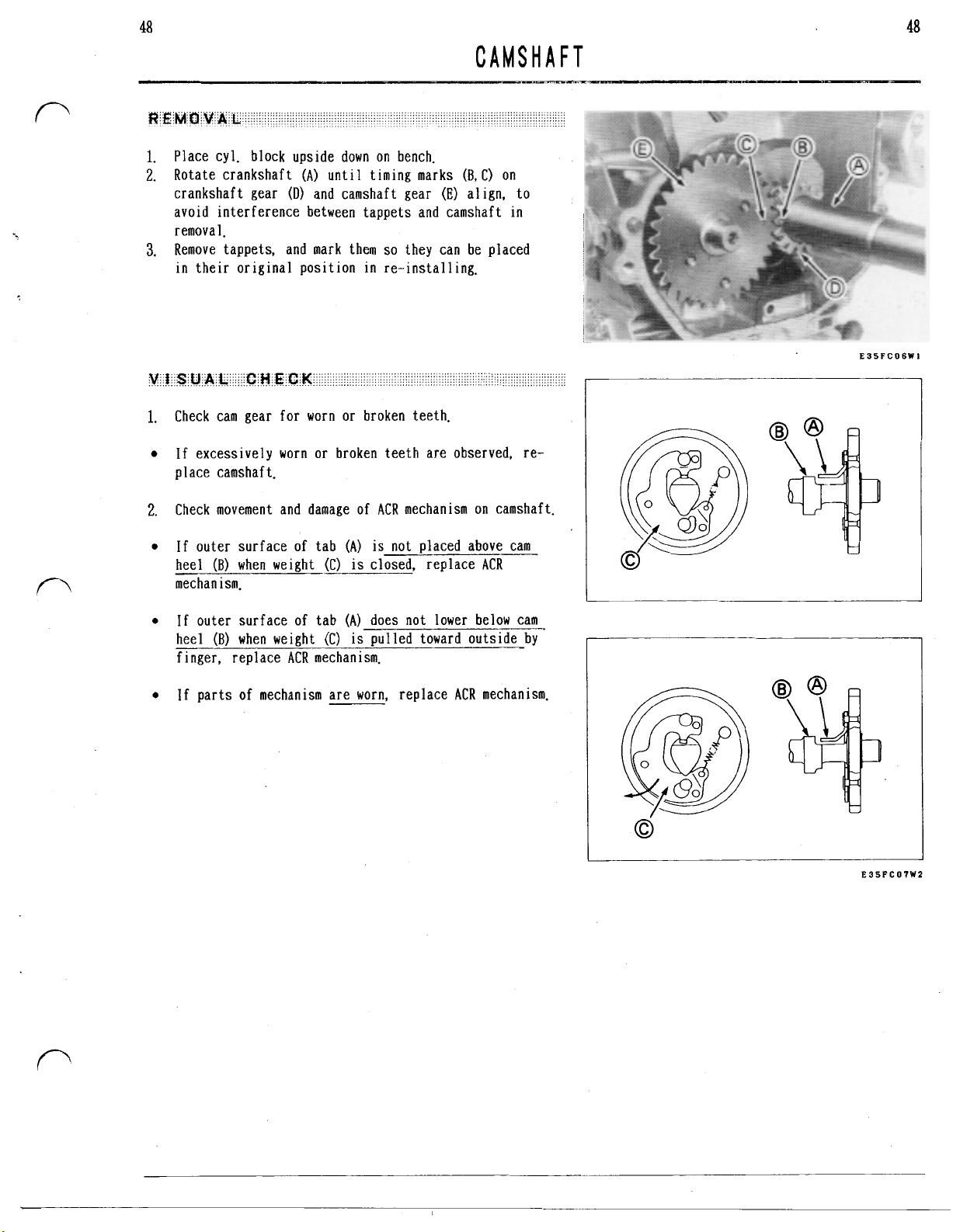

1.

Place cyl. block upside down on bench.

2.

Rotate crankshaft

crankshaft gear

avoid interference between tappets and camshaft

removal.

3.

Remove tappets, and mark them

in

their original position

Check cam gear for worn or broken teeth.

If excessively worn or broken teeth are observed, re-

place camshaft.

(A)

until timing marks

(D)

and camshaft gear

so

they can be placed

in

re-installing.

(B,

C) on

(E)

align, to

in

48

E35FC06WI

Check movement and damage of ACR mechanism on camshaft.

(A)

is

If outer surface of tab

heel

(B)

when weight (C)

mechanism.

If

outer surface of tab

(B)

heel

finger, replace ACR mechanism.

If parts of mechanism are worn, replace ACR mechanism.

when weight (C)

not placed above cam

is

closed, replace ACR

(A)

does not lower below cam

is

pulled toward outside by

E35PCO'IWZ

Page 56

49

CAMSHAFT

2.

Check cam lobe height with vernier calipers,

49

If lobe height

replace camshaft.

1.

Place cyl. block upside down

2.

Install tappets in their respective positions and push

them all the way into guide to avoid interference with

camshaft in assembling.

3.

Rotate crankshaft

4.

Aligning timing marks

into crankcase.

is

less

until

than

22.80

on

piston

(A)

and

mm

(0.898

bench.

is

at highest position.

(B),

install camshaft

in.).

E35FC08W2

E35FCOSWI

Page 57

50

PI

STON

C

A

UT

I 0

N

:

Remove any carbon or ridge at top of cyl.

bore to avoid piston ring breakage in. removing.

4t

CON-ROD

50

Rotate crankshaft

1.

Loosen con-rod bolts and remove con-rod cap.

2.

Push piston and con-rod out through top of cylinder.

3.

Remove piston from con-rod.

4.

Remove piston rings from piston with ring expander

5.

(A)

to expose con-rod bolts

(B).

(C).

E36FCIZW2

Page 58

51

PI

STON

Appearance of piston and piston rings shows condition of

engine

piston and/or piston rings and remove cause of such

damage.

in

running. If excessive damage

is

observed, replace

&

51

CON-ROD

Rings of wrong size

1.

will

I

2.

e

3.

e

4.

e

not fit

consumption and excessive blowby.

Check ring end gap and arrange end gap as shown in

PISTON RING INSTALLATION.

Scuffing

when friction and/or combustion temperature are unusually high.

Check and clean cooling system.

Check and correct quality and level of oil.

Check and adjust fuel and combustion systems.

Engine running at abnormally high temperature may cause

varnish, lacquer,

grooves making rings stick.

Apply same treatment as above

Vertical scratches across piston rings are due to

abrasive

been left in engine during overhaul, or may be loose

lead and carbon deposit.

Check air cleaner and clean

Check any air intake through abnormal route.

Clean engine inside and change oil.

to

or

scoring of both rings and piston occurs

in

engine. Abrasive may be airborne, may have

or

rings having improper end gap

shape of cylinder.

or

carbon deposit formed

This

causes high oil

2.

or

replace damaged one.

in

piston ring

(A)

Scratches across oil side rails

5.

in

engine oil, and other rings will also be worn

this

condition causing high oil consumption, increased

in

deposit

e

Clean engine inside and change oil.

combustion chamber, and ring sticking.

are due to abrasive

in

Page 59

52

PI

STON

C

A

UT

I 0 N

:

Do

not use caustic cleaning solution

brush to clean piston.

1.

Remove all deposits from piston.

2.

Clean carbon from piston ring grooves with ring groove

is

cleaner. If cleaning tool

ton ring breaking into suitable size.

3.

Make sure oil return passages in ring groove are open.

not available. use old pis-

&

CON-ROD

or

wire

52

1.

Check clearance between ring groove and ring using

new ring and feeler gauge.

If clearance

piston. for top and second rings

2.

Check inside diameter of piston pin hole at several

points with inside micrometer.

If diameter

replace piston.

is

more than

is

more than

0.10

15.050

mm

(0.004

mm

(0.5925

in.), replace

in.),.

E36FC 13W

I

E36FC

E36FC

I4W2

I

SW

I

Page 60

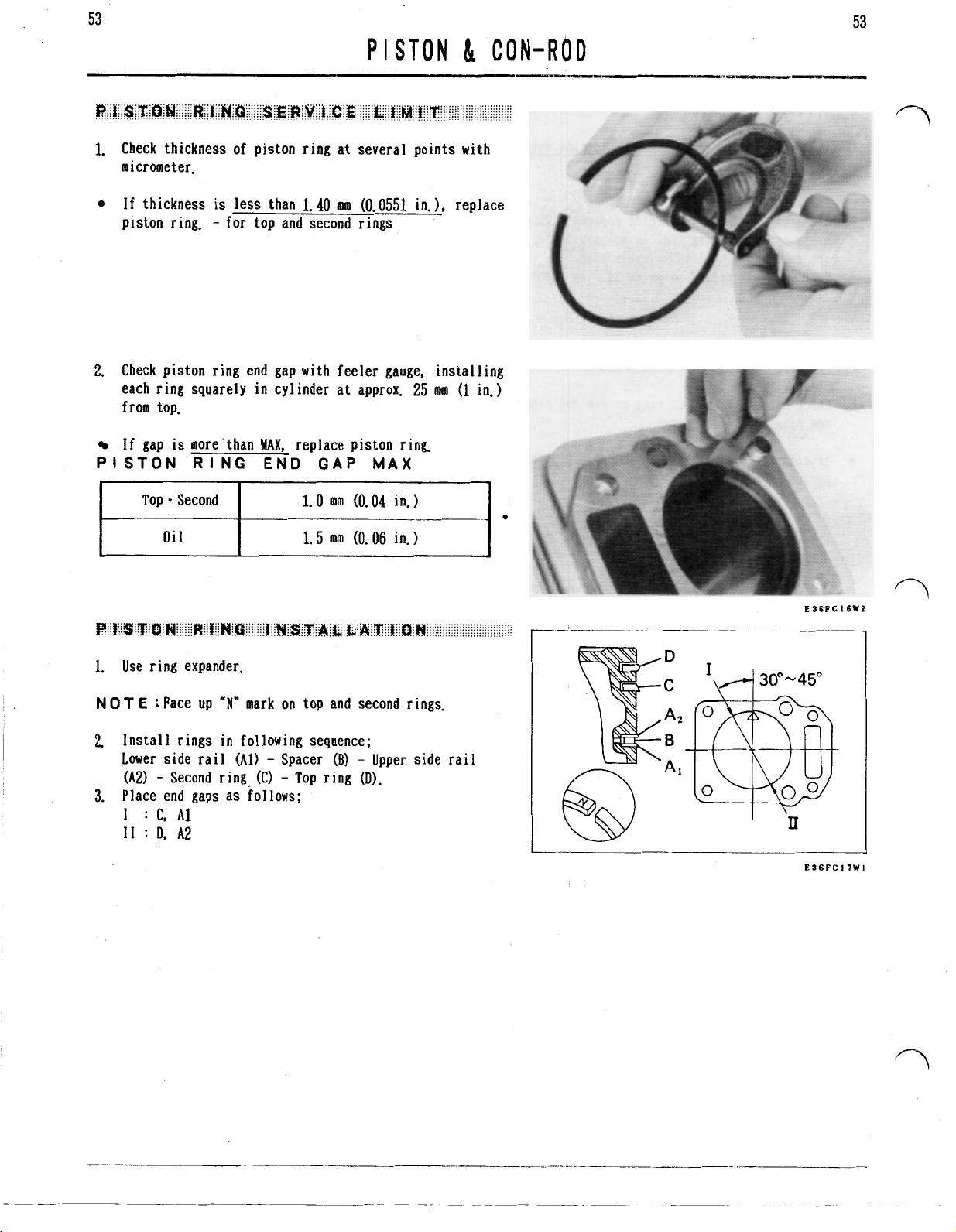

53

PI

STON & CON-ROD

1.

Check thickness of piston ring at several points with

micrometer.

If

thickness

piston ring. for top and second rings

2.

Check piston ring end gap with feeler gauge, insta

each ring squarely in cylinder at approx.

from top.

is

less than

1.40

am

(0.0551

in.), replace

.11

ing

25

mm

(1

in.)

53

If gap

PISTON

1.

Use ring expander.

N 0 T

2.

lnstall rings in following sequence;

Lower side rail

(A21

Place end gaps as follows

3.

1

11

is

more-than

RING

Top Second

E

:

Face up

Second ring (C)

:

C.

A1

:

D,

A2

MAX,

replace piston ring.

END

“N”

mark on top and second rings.

(Al)

GAP

1.0

mm

1.5

mm

Spacer

(B)

Top ring

MAX

(0.04

(0.06

Upper side rail

(D).

.

in.

in.

E36PC

I6W2

E36FCl7WI

Page 61

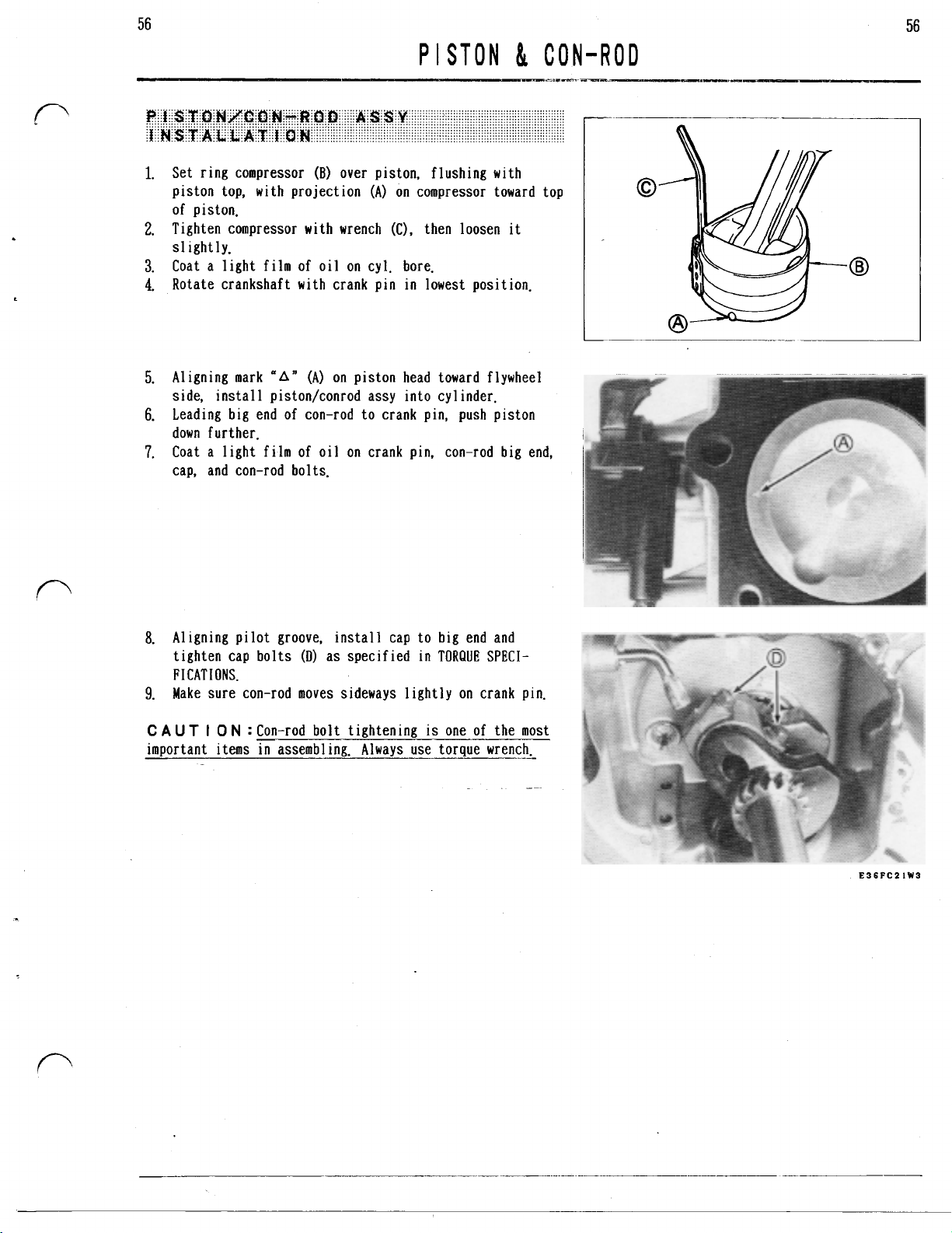

54

PI

STON

Check con-rod especially big end for wearing, scratching,

scoring, and/or discoloring.

Abnormal wearing and scratching are caused by foreign

particle(s) in oil.

Clean engine inside and change oil.

Check air cleaner. and clean

If con-rod and/or crankshaft are used again, remove

ridges on their surface carefully.

or

replace damaged one.

&

CON-ROD

54

Scoring and discoloring are symptom of

and/or over heating.

is

If crankpin surface

replace con-rod and crankshaft.

Check and clean cooling system.

Check quality of oil and maintenance method with.user.

C

A

UT

I 0 N

: